Patents

Literature

124results about How to "Eliminate hidden dangers of insecurity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

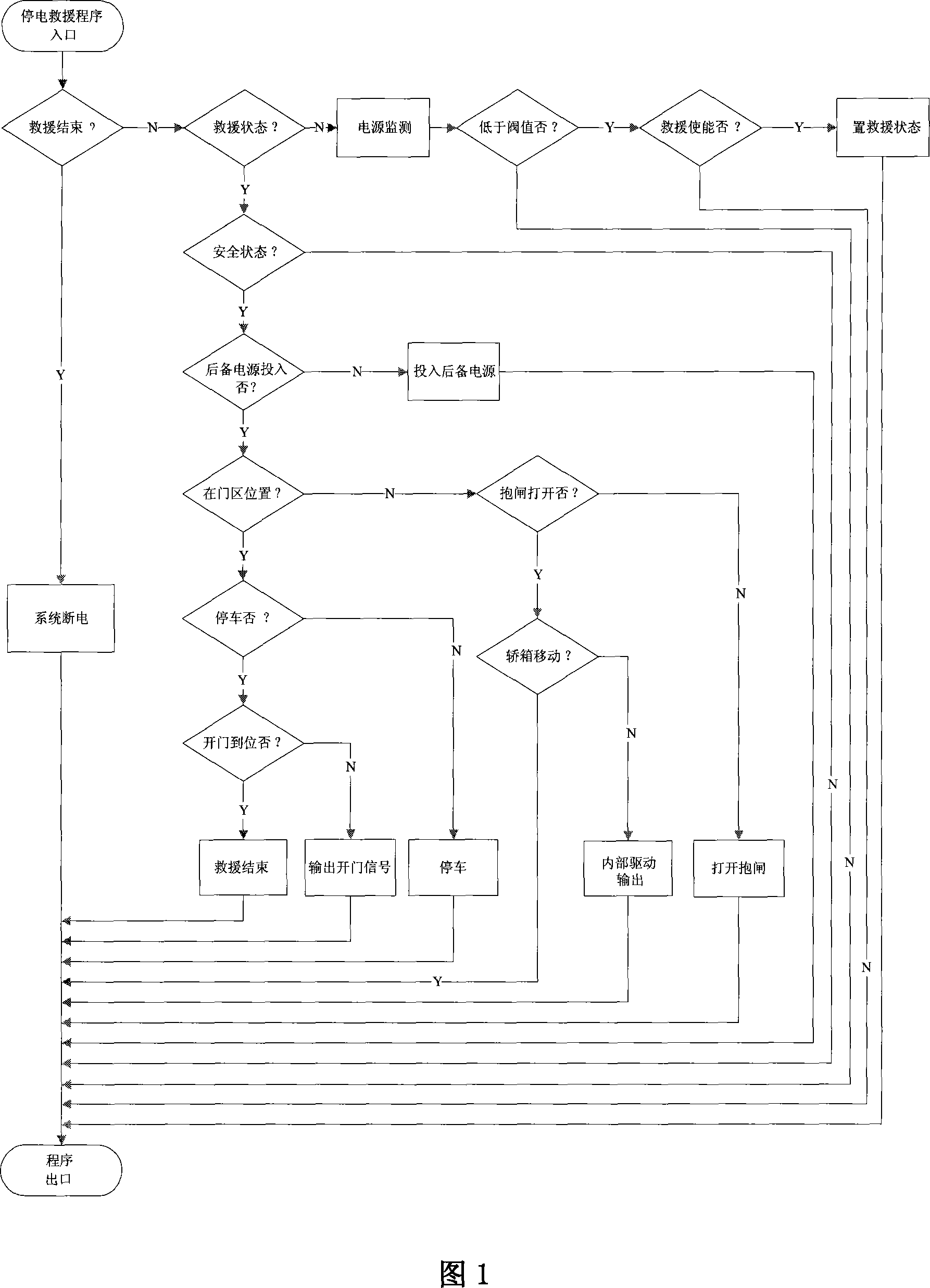

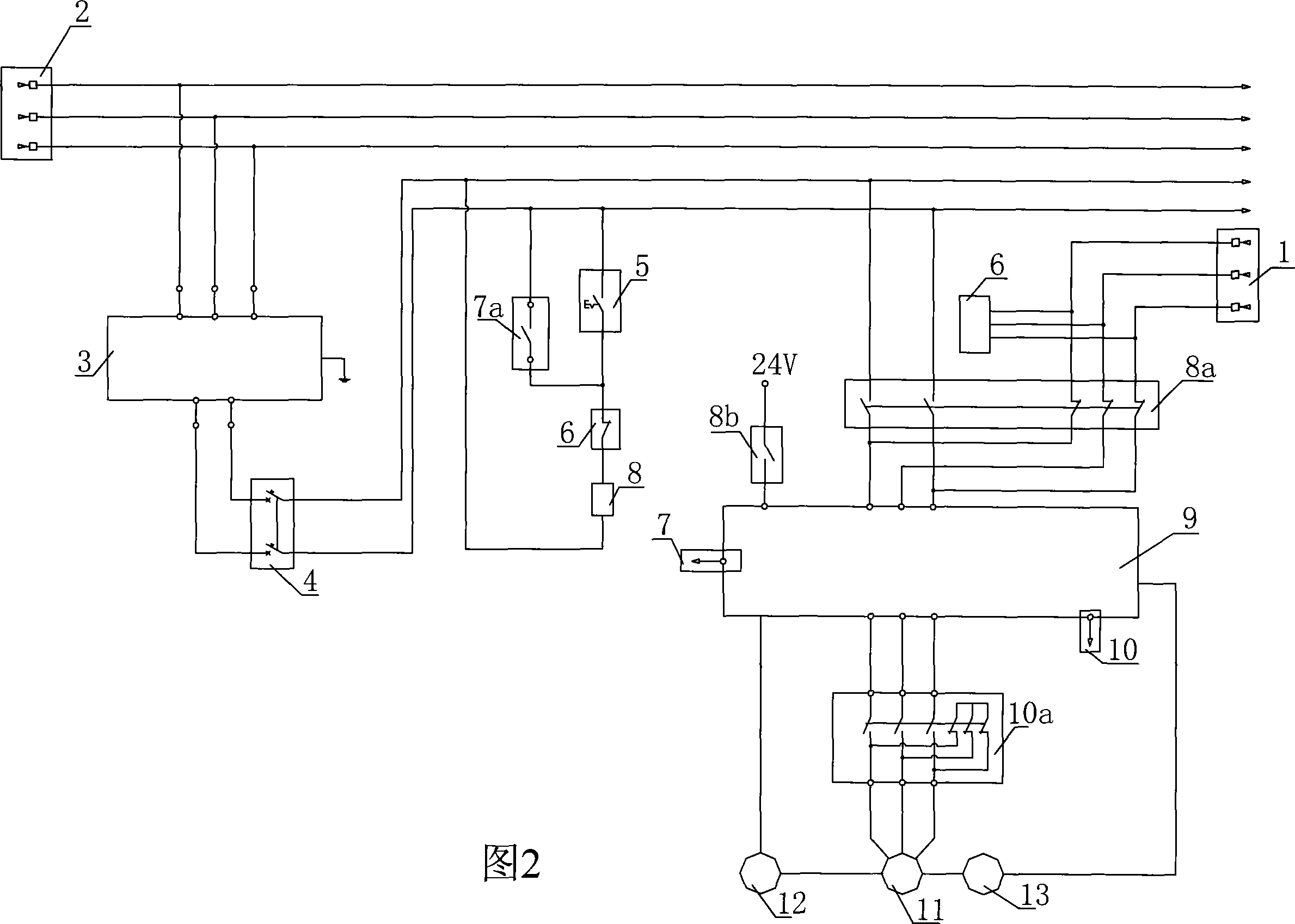

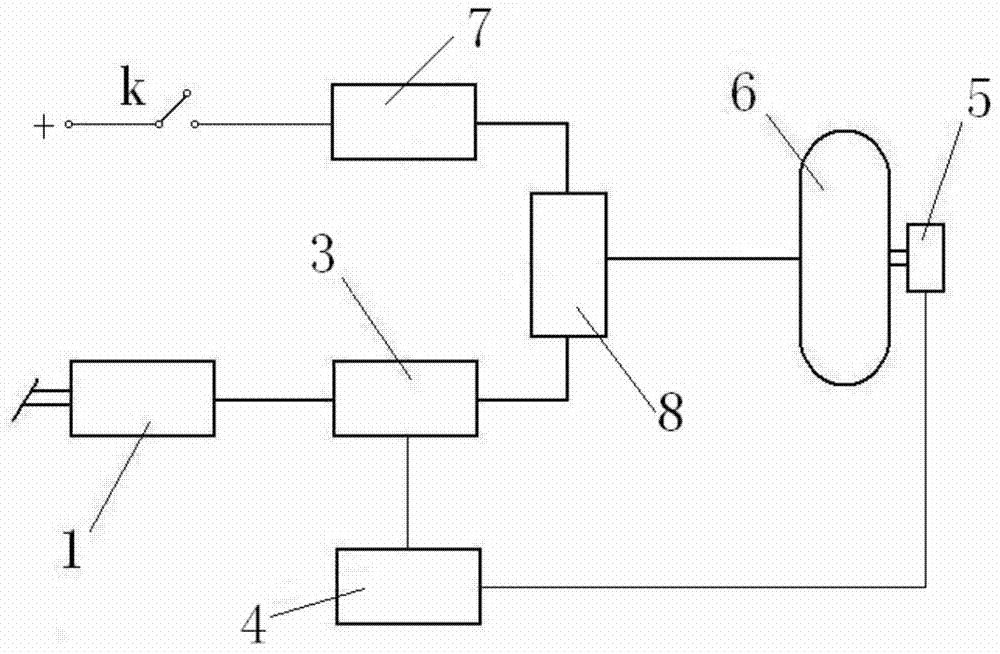

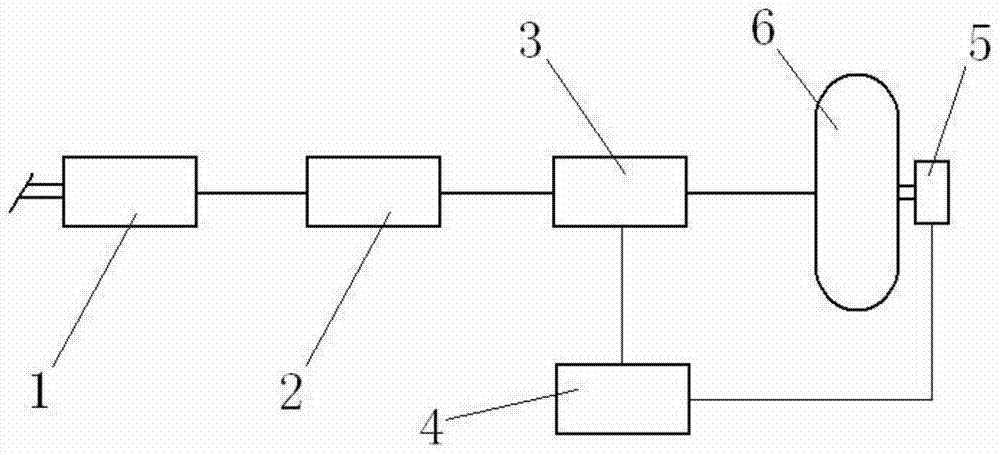

Power failure rescue method for sync motor driven lift

The power failure rescue method for sync motor driven lift includes: detecting power source with a power source detector, entering to the power failure mode by means of program or peripheral switch setting after detecting power failure, switching to the spare power source for providing the controller with power source while short-circuiting the winding of the sync motor with an interlocking contactor; entering to the power failure rescue function and blocking outer power source; performing corresponding operations of loosening mechanical brake for the cage to move slowly to the heaver side until reaching to the door opening area and opening the door. The present invention can disperse passengers safely from lift in the case of power failure.

Owner:SJEC CORP

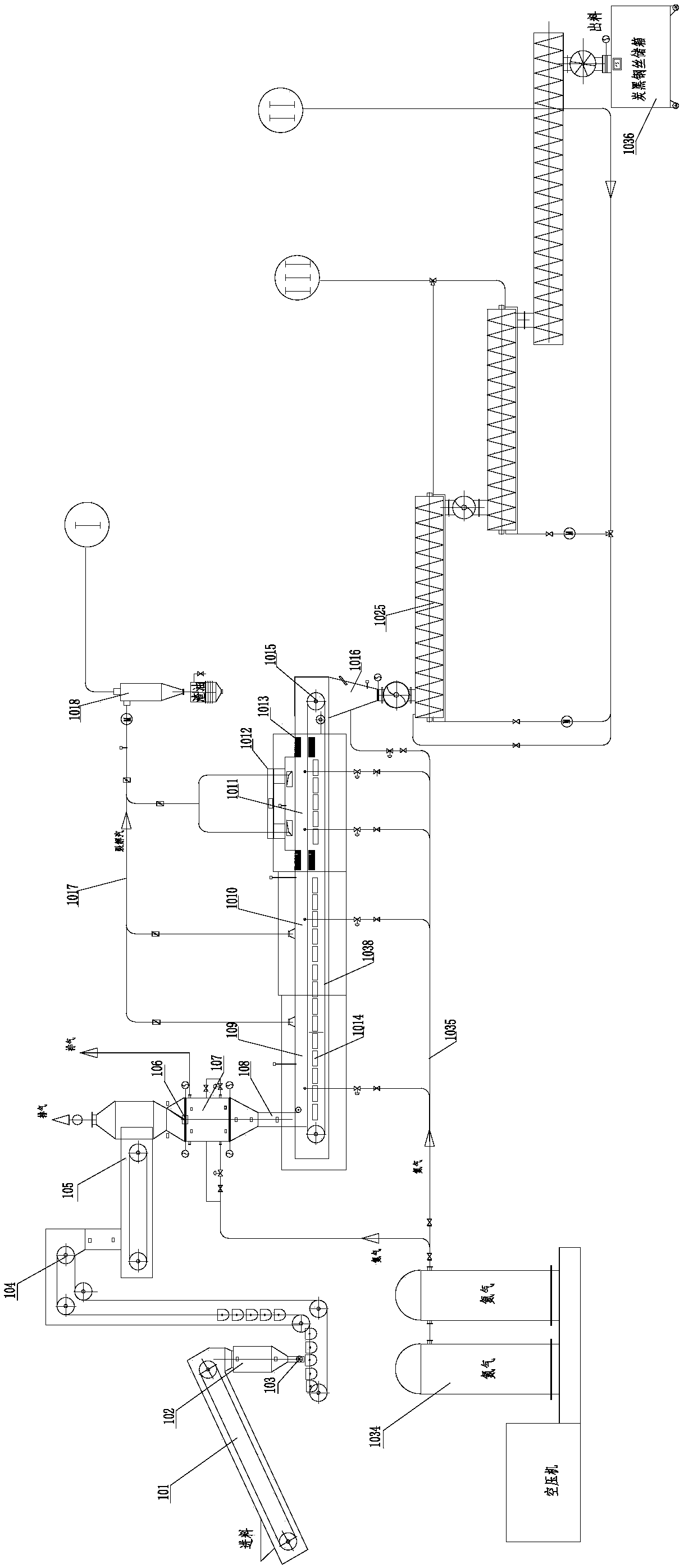

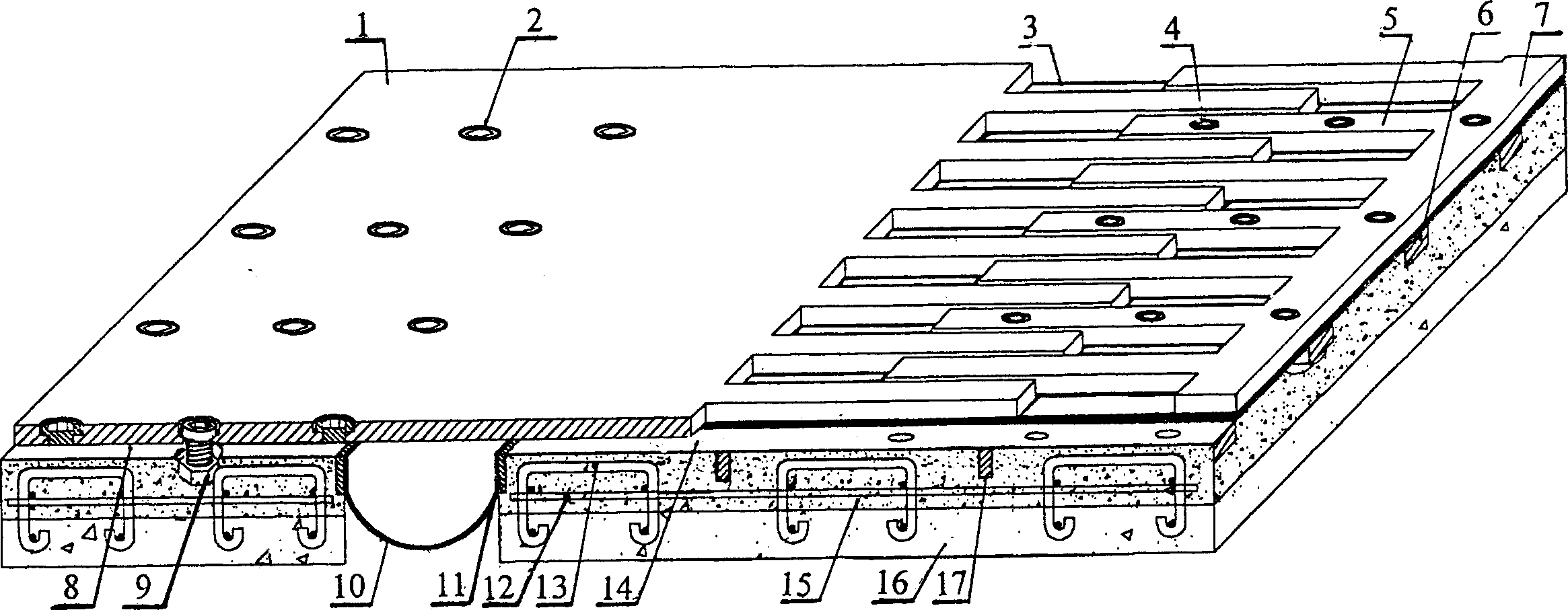

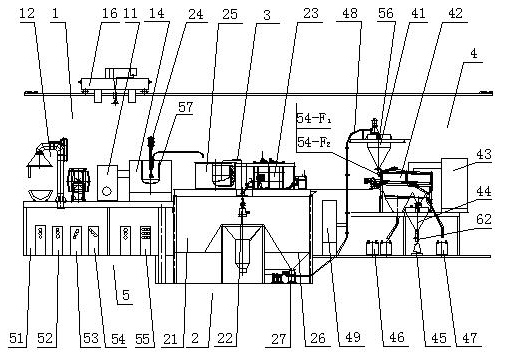

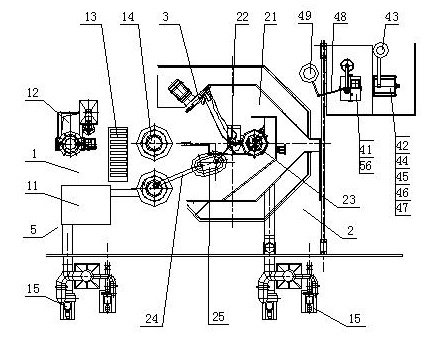

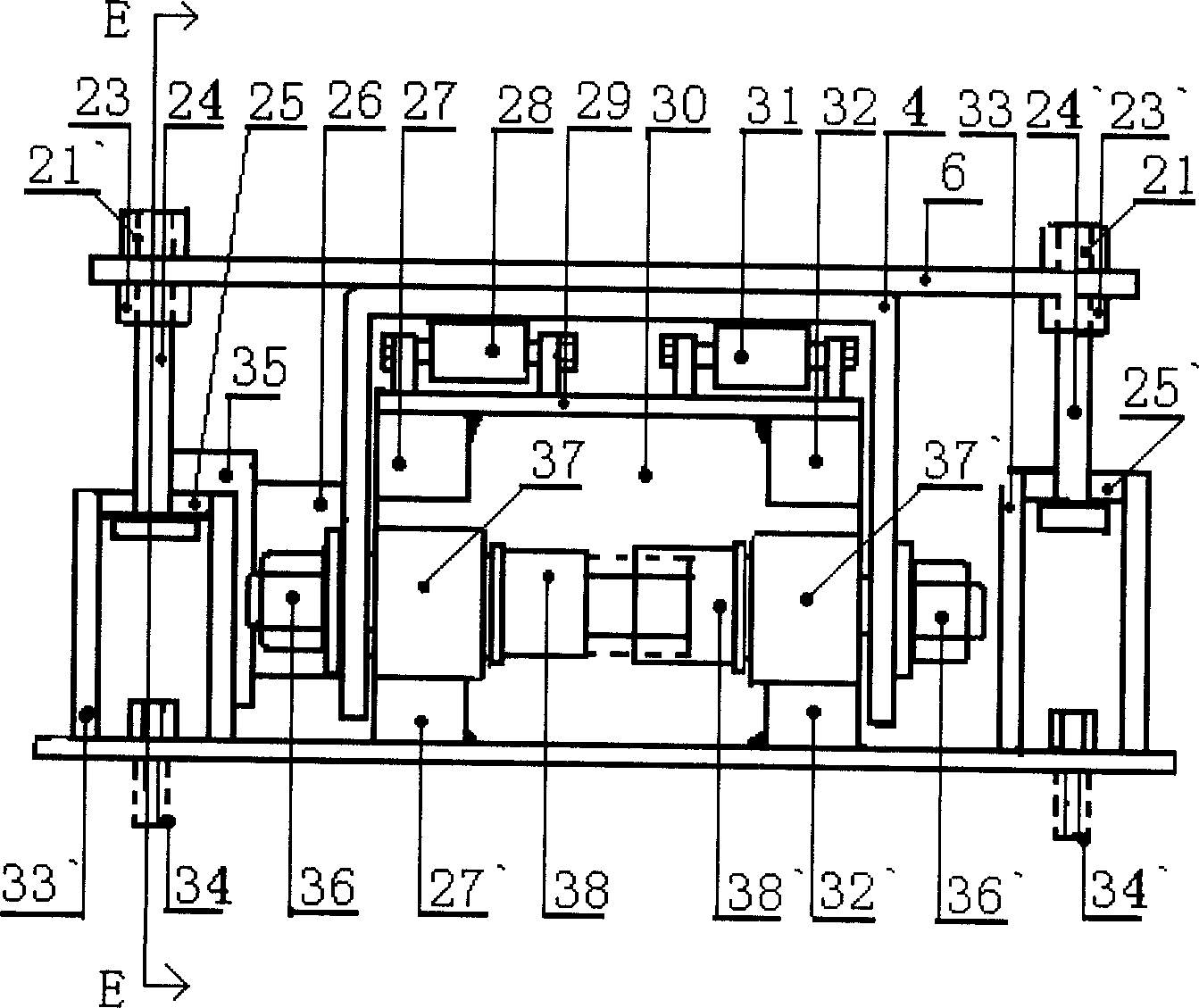

Efficient fully-automatic semi-finished stewed noodle production line

ActiveCN105053104AGood kneading qualityFully automatedMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsReciprocating motionTransverse fracture

The invention discloses an efficient fully-automatic semi-finished stewed noodle production line. The front end of the longitudinal fracture conveying device of the novel double-head fully-automatic cycle dough kneading machine of the production line is provided with a first pair of dough kneading rollers, a longitudinal fracture synchronizing wheel is arranged above the longitudinal fracture conveying device, two sides of the longitudinal fracture conveying device are provided with longitudinal fracture rotating plates inwardly continuously folding to central portions, a longitudinal fracture burdening pressure roller is arranged above the longitudinal fracture conveying device, the rear end of the longitudinal fracture conveying device is provided with a second pair of dough kneading rollers, the second pair of the dough kneading rollers is provided with an obliquely arranged conveying device, a guiding plate is arranged behind the second pair of the dough kneading rollers, the frame of the machine is provided with a transverse fracture one-layer conveying device capable of moving back and forth, a transverse fracture two-layer conveying device is arranged directly below the transverse fracture one-layer conveying device, and the rear end of the transverse fracture two-layer conveying device is connected with the first pair of tough kneading rollers. Dough from the dough kneading machine is automatically sent to the double-head fully-automatic cycle dough kneading machine and is automatically kneaded in a cycle manner in the double-head fully-automatic cycle dough kneading machine, and the kneaded dough is automatically sent to a semi-finished stewed noodle forming machine to realize fully-automatic production of semi-finished stewed noodles.

Owner:王朝民

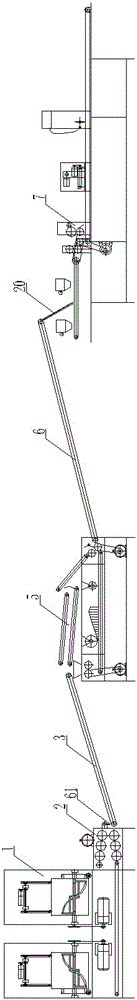

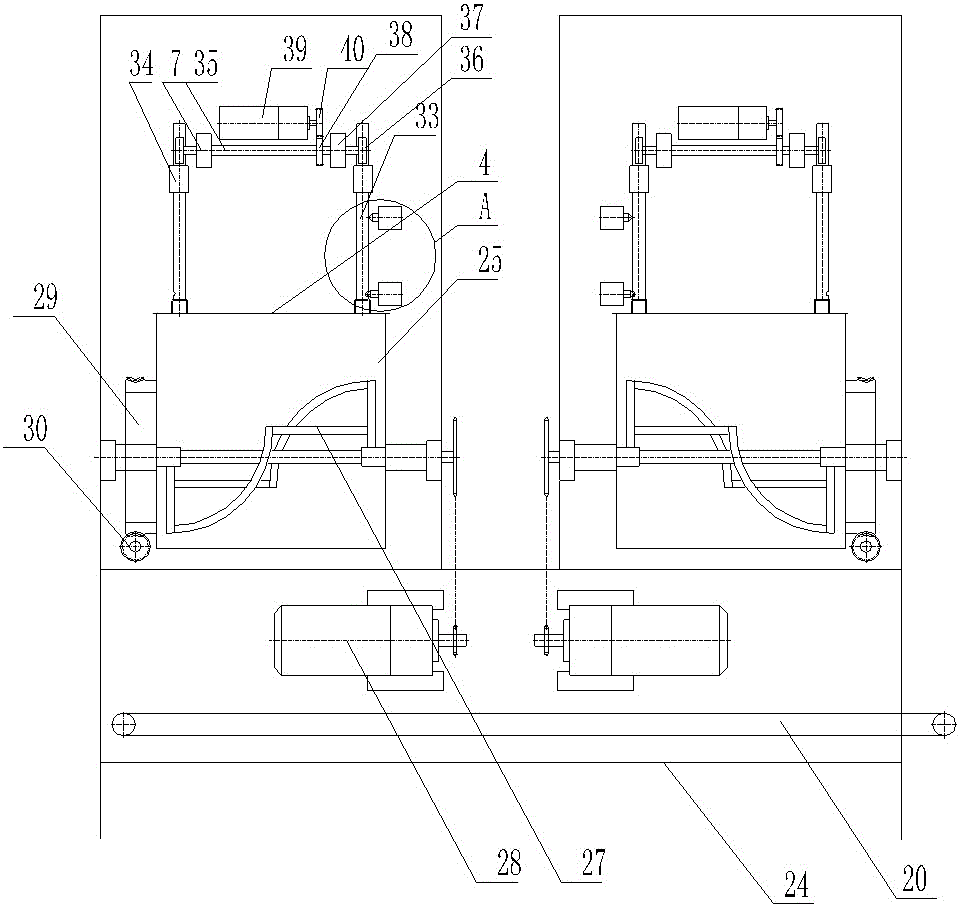

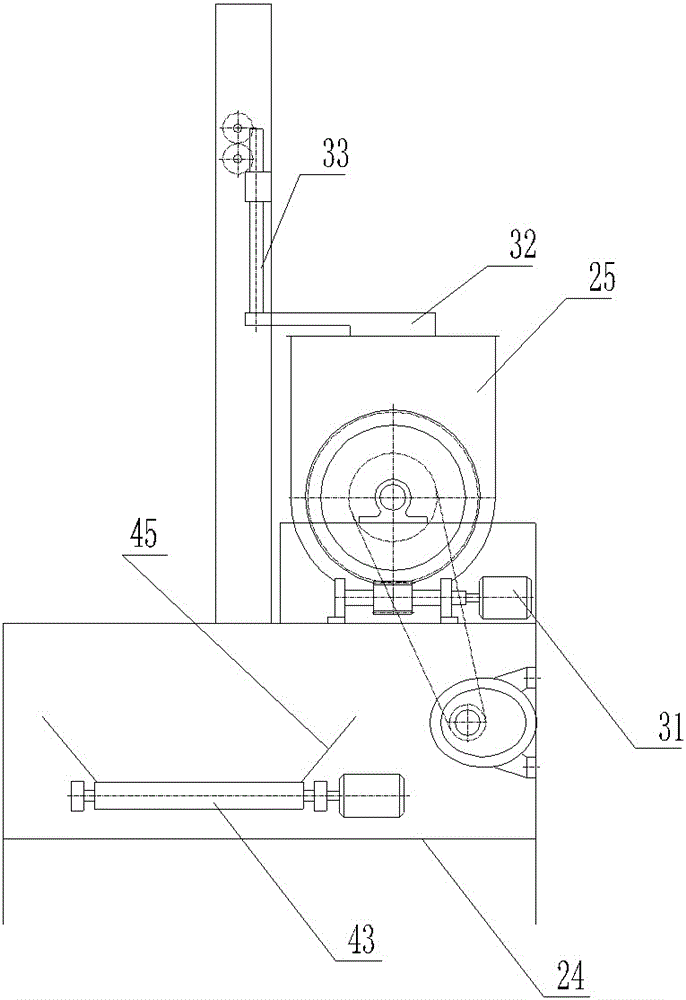

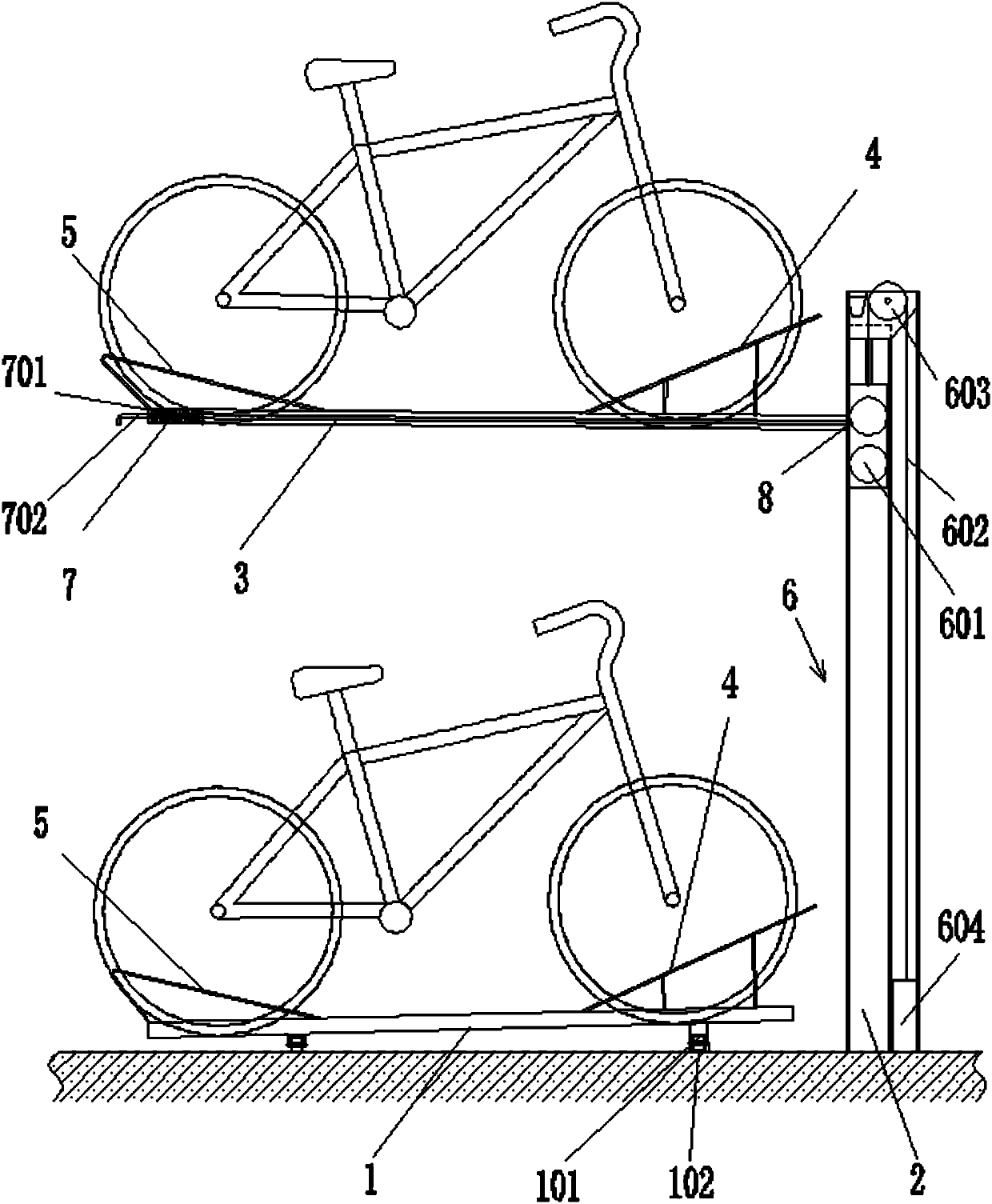

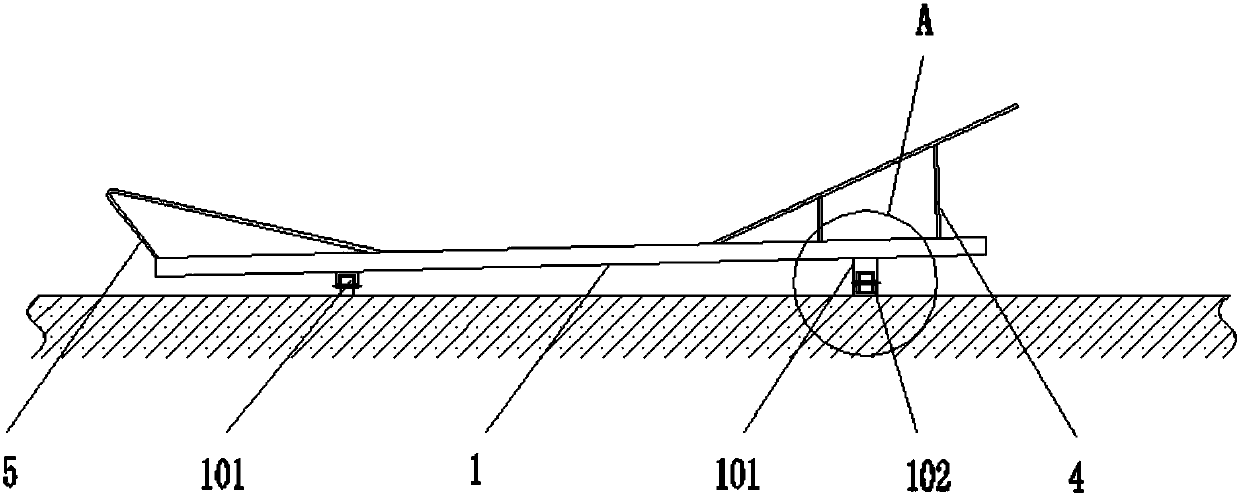

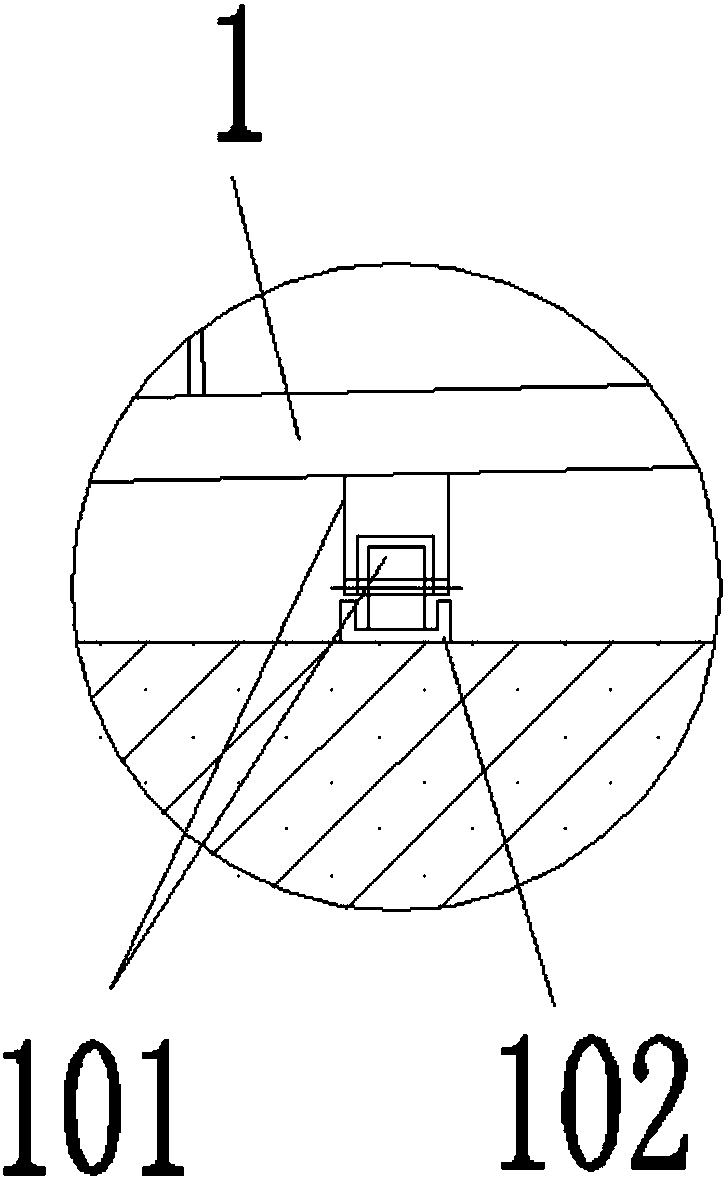

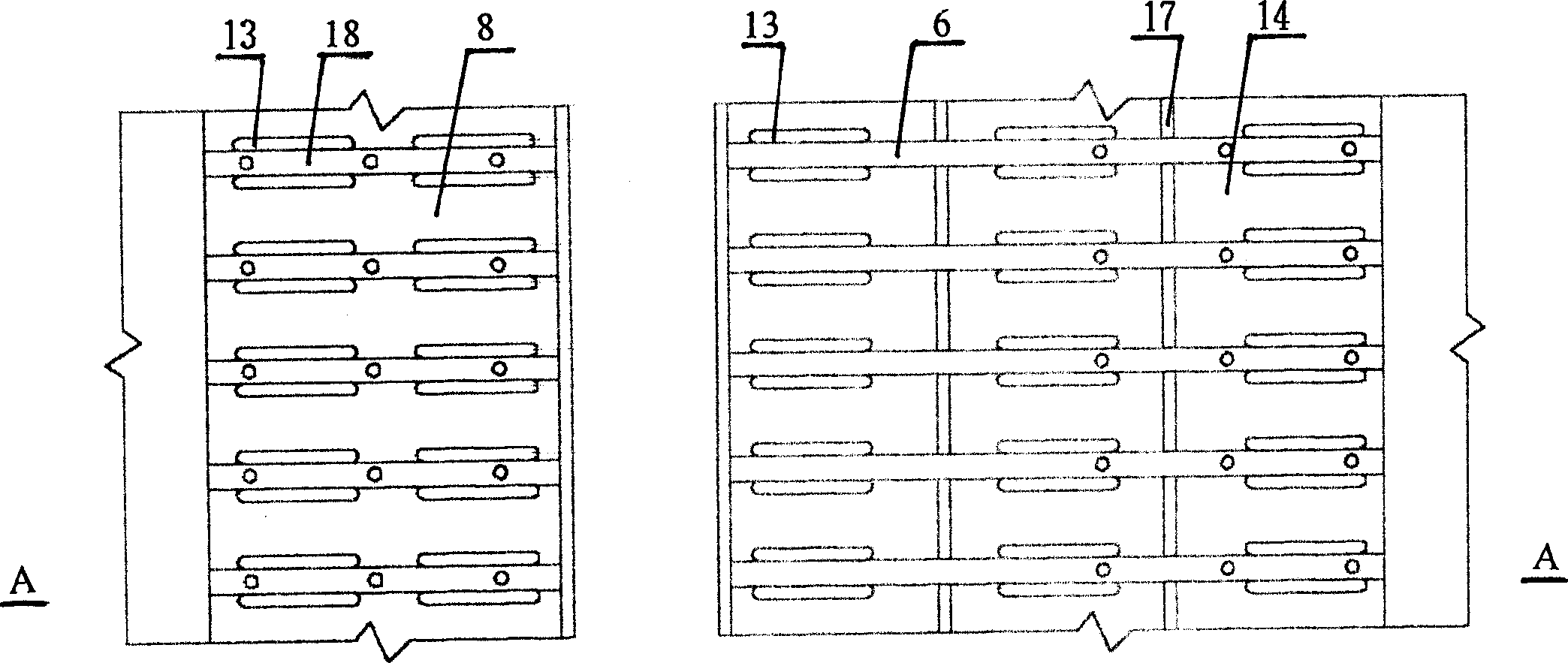

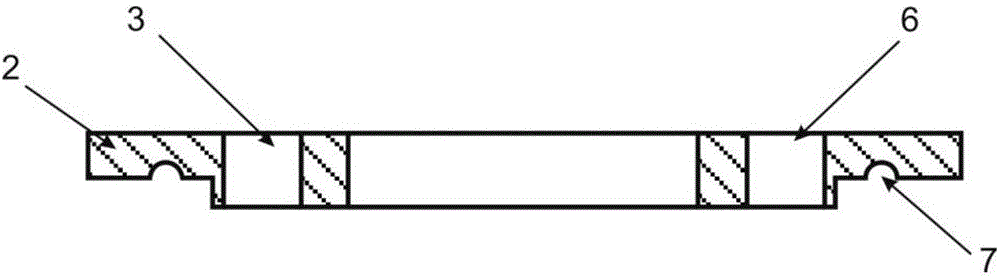

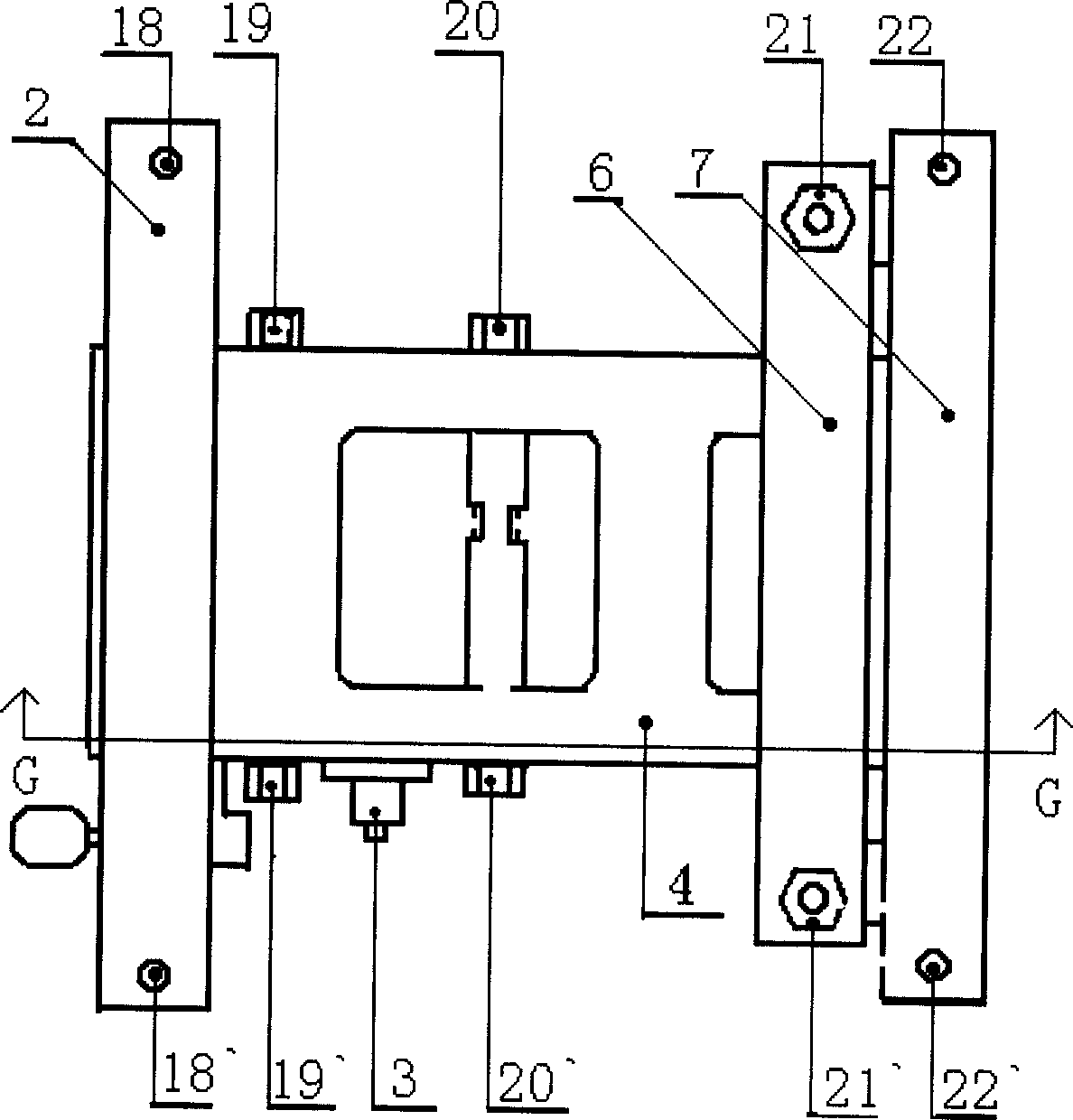

Double-layer mechanical type stereoscopic bicycle parking equipment

The invention provides double-layer mechanical type stereoscopic bicycle parking equipment which comprises an upper-layer parking shelf, a lower-layer parking shelf and a vertical bracket, wherein thefront and rear wheels of a single bicycle which is inserted into the two parking shelves are constrained by using frame type front and rear wheel fixing brackets in a two-point front and rear supportmanner on the two parking shelves respectively; the frame type front and rear wheel fixing brackets are fixedly connected with support racks; the parking density of one layer of bicycles on the lower-layer parking shelf is adjusted through roller devices and sliding tracks at the bottom of the lower-layer parking shelf; lifting of the upper-layer parking shelf along a vertical bracket is completed on the upper-layer parking shelf through a pulley pack sliding block lifting system which is arranged inside the vertical bracket and is based on a pure mechanical structure consisting of moving andfixed pulleys; and the positions of the shelves are locked by inserting one end of a spring cotter device which is mounted inwards in the length direction of a lifting support rack into a positioningcutter hole formed in the vertical bracket. The pure mechanical pulley pack lifting system of the equipment is easy and smooth to operate, bicycles on an upper layer can be parked safely without jumping, and the equipment is concise and simple in overall structure and easy to implement and has the optimal cost performance when being compared with other similar equipment in the market.

Owner:BAOJI SIDA AUTOMOBILE GRP

Metal surface rust protection solution

InactiveCN102994995AGood anti-rust functionImprove bindingMetallic material coating processesLiquid wasteSodium phosphates

Owner:杨恒春

Airplane hydraulic brake system

InactiveCN104773287AReduce workloadEliminate hidden dangers of insecurityBraking action transmissionAircraft brake actuating mechanismsEngineering principlesControl engineering

An airplane hydraulic brake system comprises a hydraulic brake valve, a liquid-controlled conversion valve, an electro-hydraulic servo valve, an anti-slide control box and a speed sensor. The liquid-controlled conversion valve is mounted on a downstream hydraulic pipeline of the hydraulic brake valve, the electro-hydraulic servo valve is mounted on a downstream hydraulic pipeline of the liquid-controlled conversion valve, an electrical interface of the electro-hydraulic servo valve is electrically connected with the anti-slide control box through a shielding insulation wire, an oil inlet of the electro-hydraulic servo valve is in pipeline connection with an oil outlet of the liquid-controlled conversion valve, a brake opening of the electro-hydraulic servo valve is in pipeline connection with an oil inlet of a brake device of a brake airplane wheel, and an oil returning opening of the electro-hydraulic servo valve is in pipeline connection with an airplane oil returning pipeline through a hydraulic filler neck and a guide pipe. The airplane hydraulic brake system can meet the ever-growing airplane take-off line brake requirement, is reasonable in structure, easy and convenient to implement, and beneficial for reducing of burdens of a driver, conforms to the man-machine engineering principle and meanwhile the accident potentials caused by false-operation switching on of a take-off line brake switch are eliminated.

Owner:XIAN AVIATION BRAKE TECH

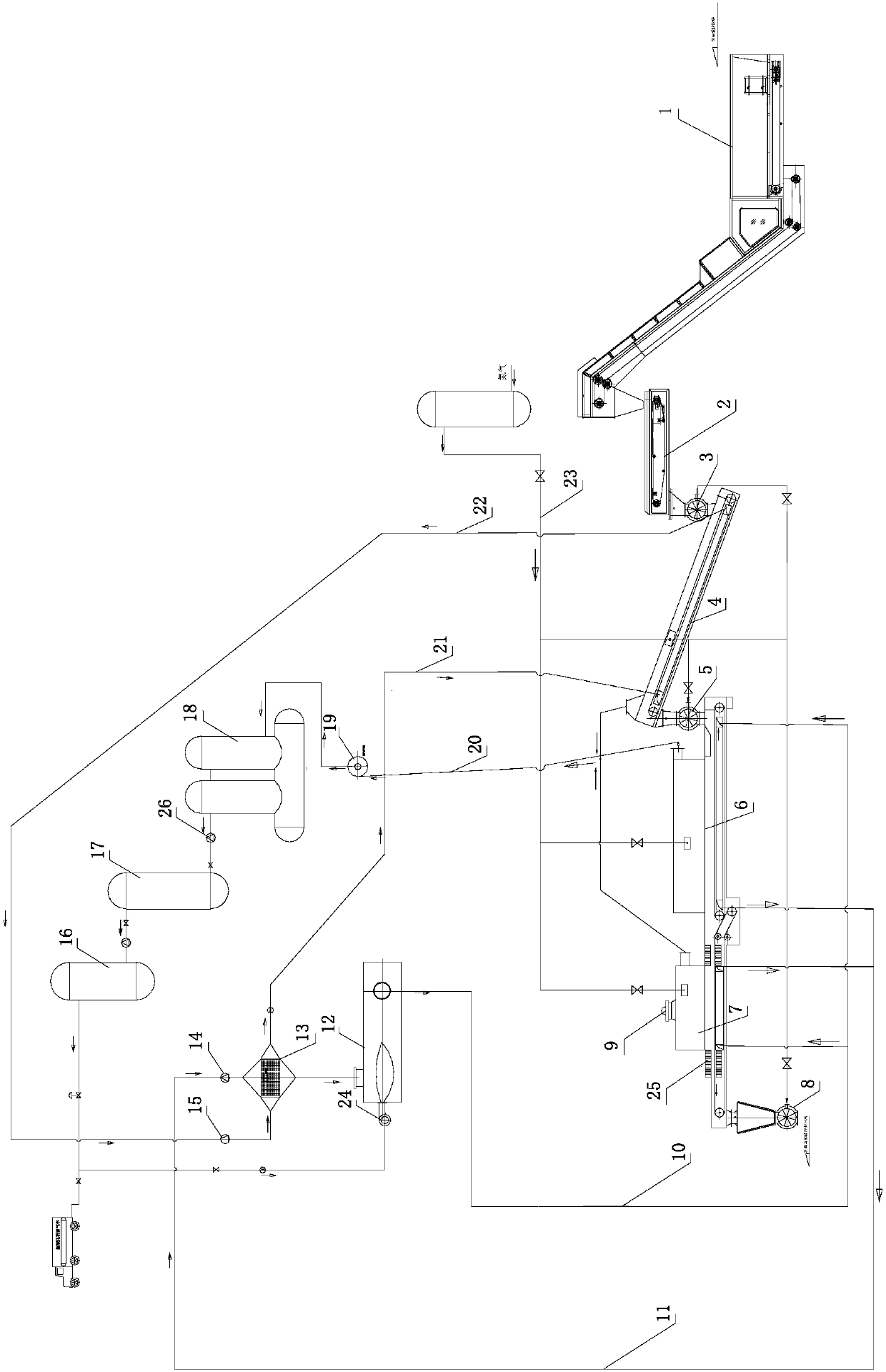

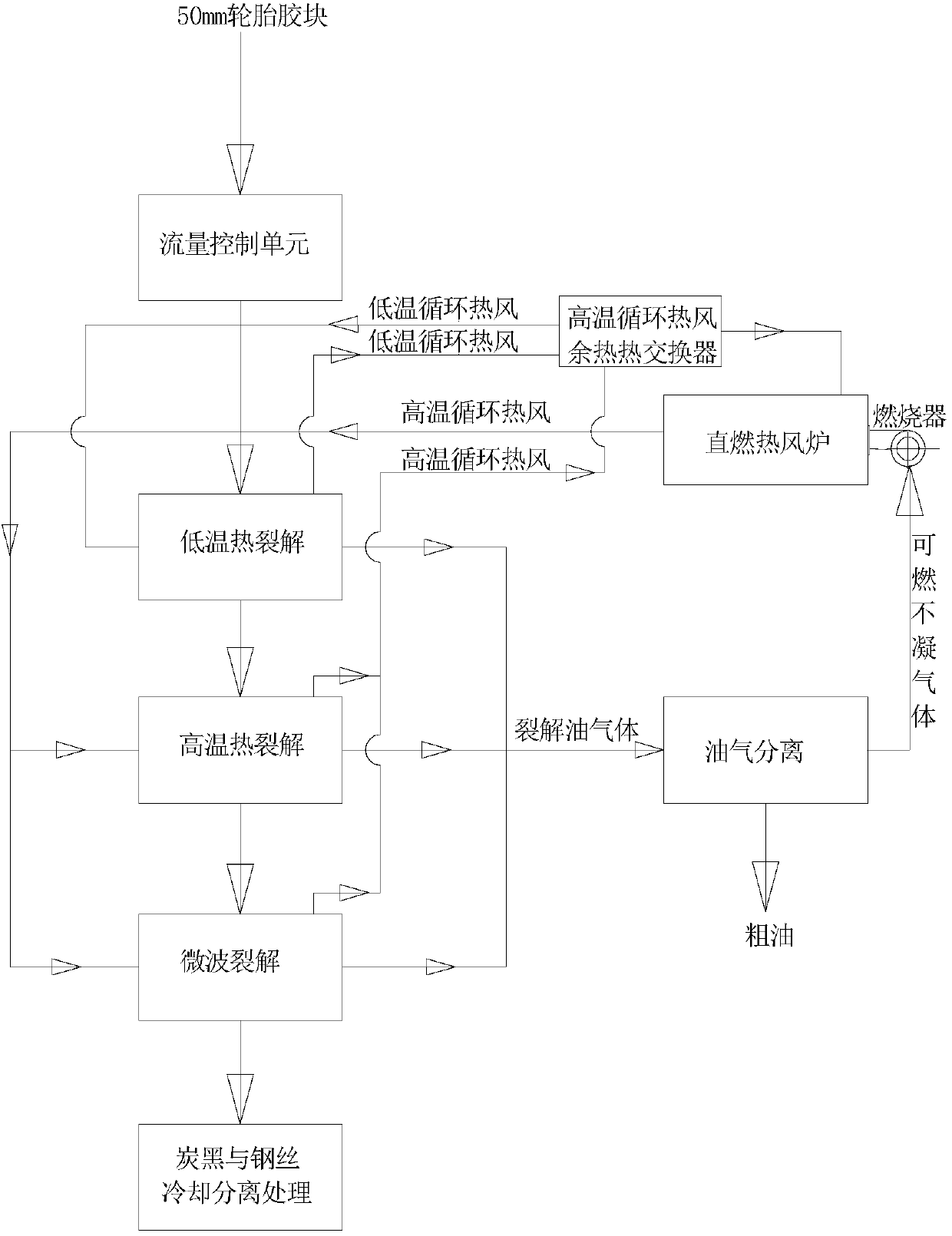

Method and system for cracking waste rubber

PendingCN108018062ARapid lysisReduce energy consumptionPigmenting treatmentTransportation and packagingMicrowaveWaste rubber

The invention provides a method and a system for cracking waste rubber. The waste rubber is sequentially sent to a low-temperature thermal cracking chamber, a high-temperature thermal cracking chamberand a microwave cracking chamber which respectively have an oxygen-free or oxygen-deficient environment, wherein thermal cracking of the waste rubber in the low-temperature thermal cracking chamber is carried out in a 200-400 DEG C environment, thermal cracking in the high-temperature thermal cracking chamber is carried out in a 500-800 DEG C environment, and microwave cracking in the microwave cracking chamber is carried out in a 500-800 DEG C environment; a cracking oil gas generated in the cracking process is continuously discharged from the low-temperature thermal cracking chamber, the high-temperature thermal cracking chamber and the microwave cracking chamber; and solids generated in the cracking process are recovered. The method and the system can effectively reduce the energy consumption in the cracking process and improve the cracking efficiency of the waste tire and the quality of cracked carbon black.

Owner:江苏林达智思环保科技有限公司

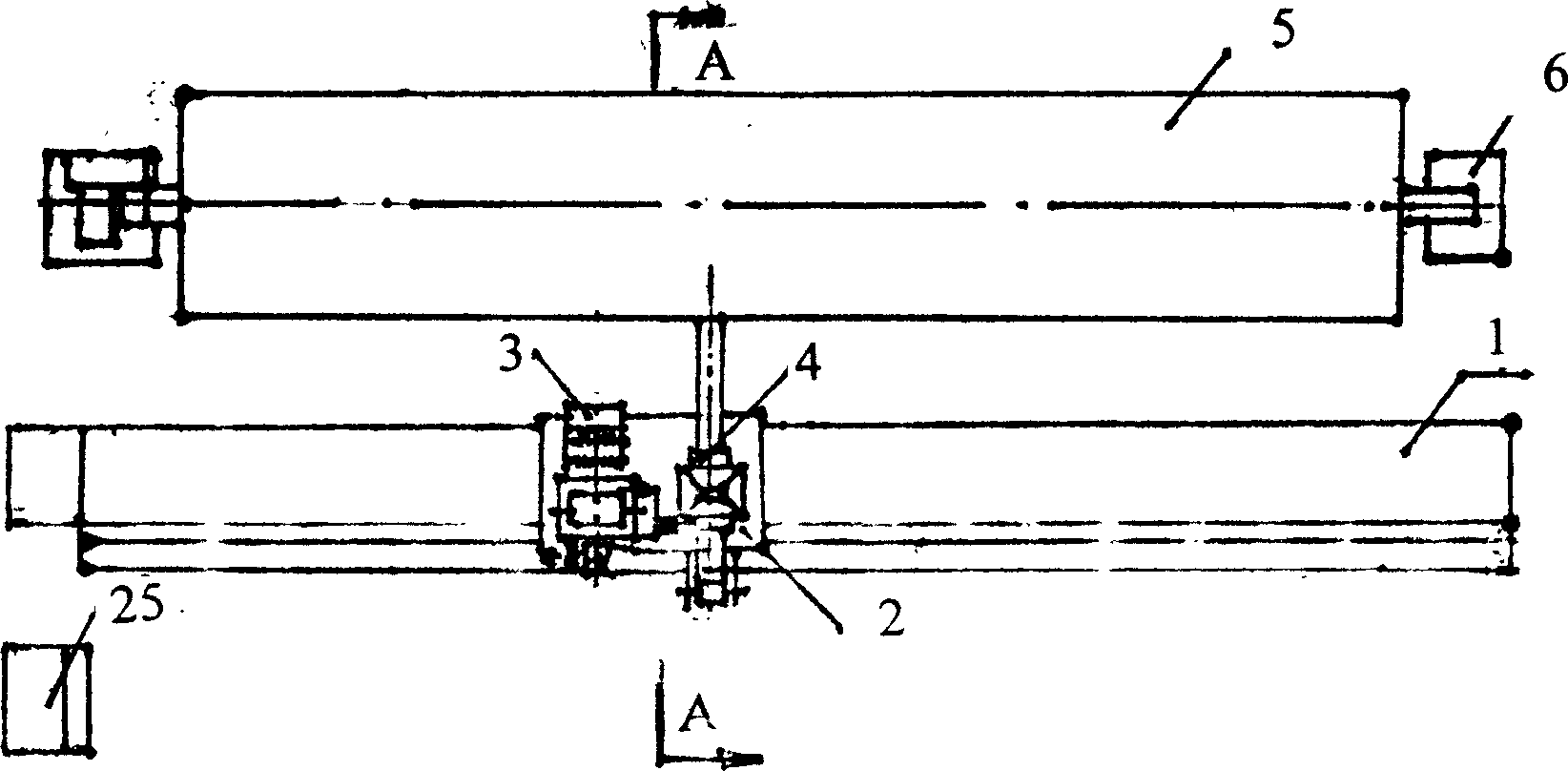

Making apparatus and method for wet type sanding and enwinding glass fibre reinforced plastic pipe from underside

The present invention relates to an equipment for making GFRP pipe by adopting wet sand-adding lower-winding process and method thereof. Said equipment is mainly formed from working table, running carriage, winding system, sand-adding system, mould and mould-supporting frame. Said invention also provides their connection arrangement and working mode. Said invented winding and sand-adding processes can be implemented under the GFRP pipe, and adopts wet sand-adding process so as to reduce dust pollution, and can raise working efficiency.

Owner:天津市天联滨海复合材料有限公司

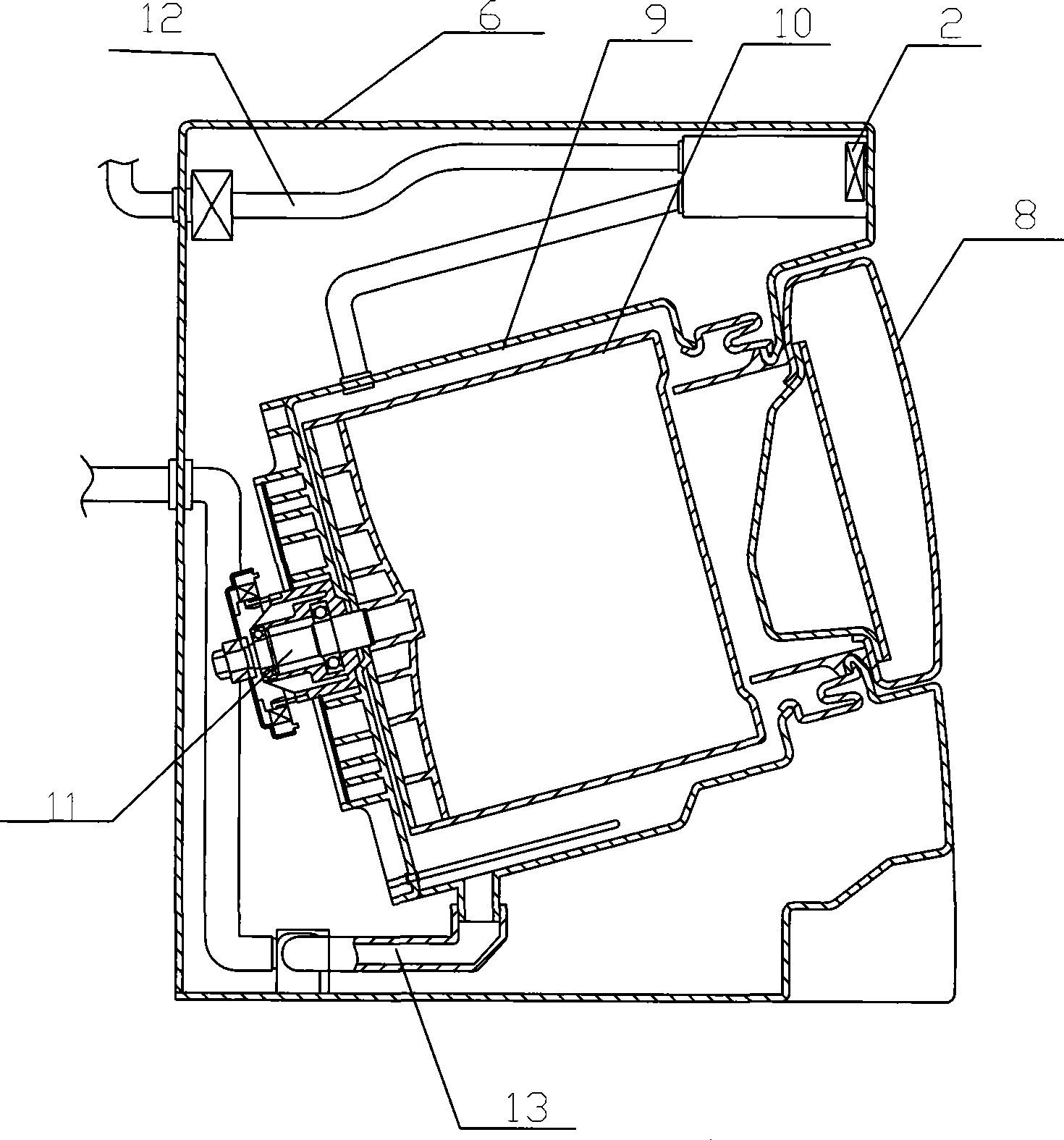

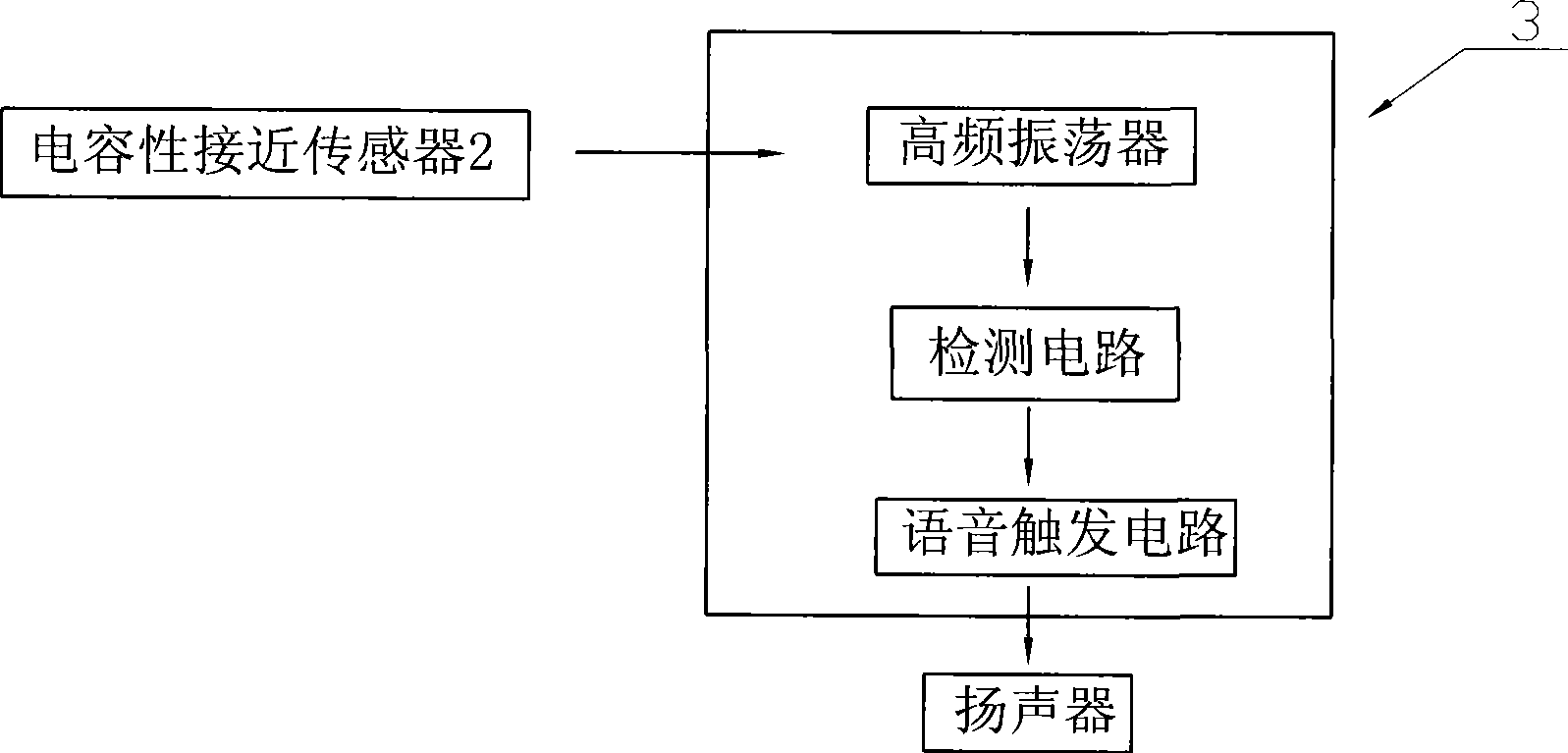

Detection prompting method and system for washing machine

ActiveCN101469504AEasy to useEliminate hidden dangers of insecurityOther washing machinesTextiles and paperCapacitanceProximity sensor

The invention relates to a detection prompt method and system for a washing machine, wherein a capacitive proximity sensor is installed inside the washing machine. When people get closed to the washing machine, capacitance value of the capacitor changes, then a high frequency oscillator and a detection circuit in a control unit detects the capacitance value change so as to determine whether people has got closed, and a loudspeaker is conducted, a prompt description is sent to user. The control unit further comprises a voice trigger circuit for sending out different voice prompt description to users according to program of the washing machine operation. The capacitive proximity sensor is disposed 0.5 meter above the bottom of the washing machine; at least one capacitive proximity sensor is disposed on the front or the lateral surface of the washing machine. The invention is capable of sensing distance between a person and the washing machine, carrying out proper voice prompt according to a washing machine program when a user get closed, facilitating using by users, and eliminating unsafe hidden trouble in the mean time.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

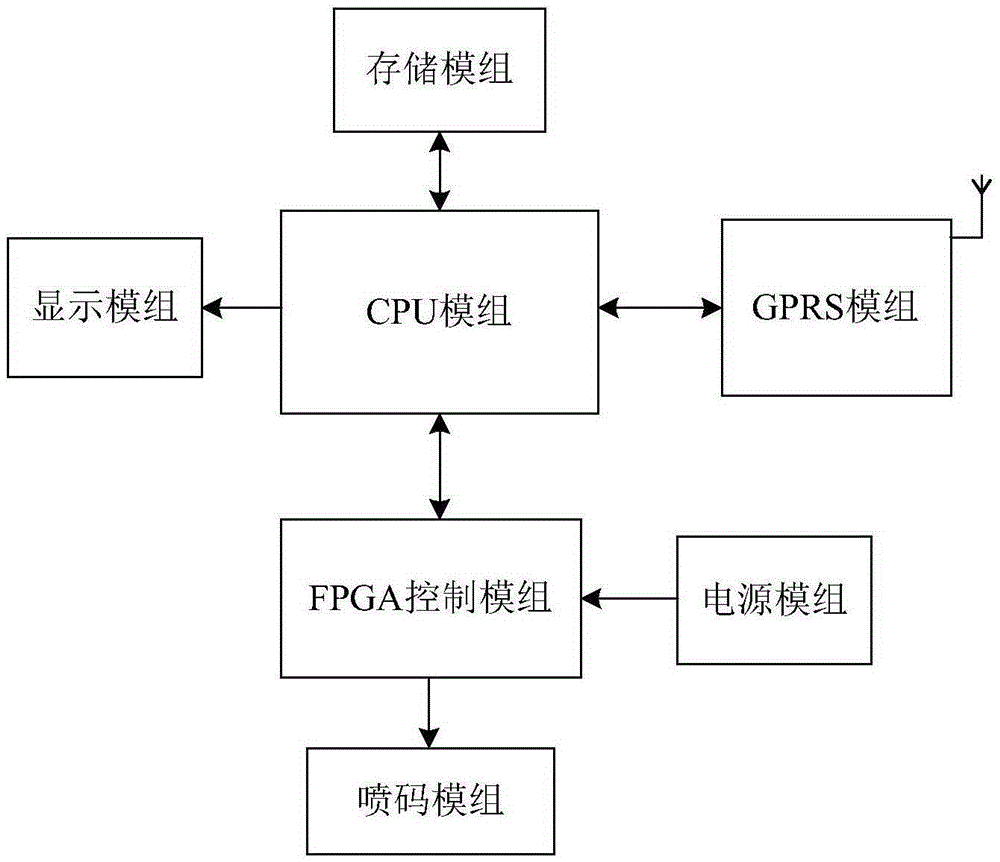

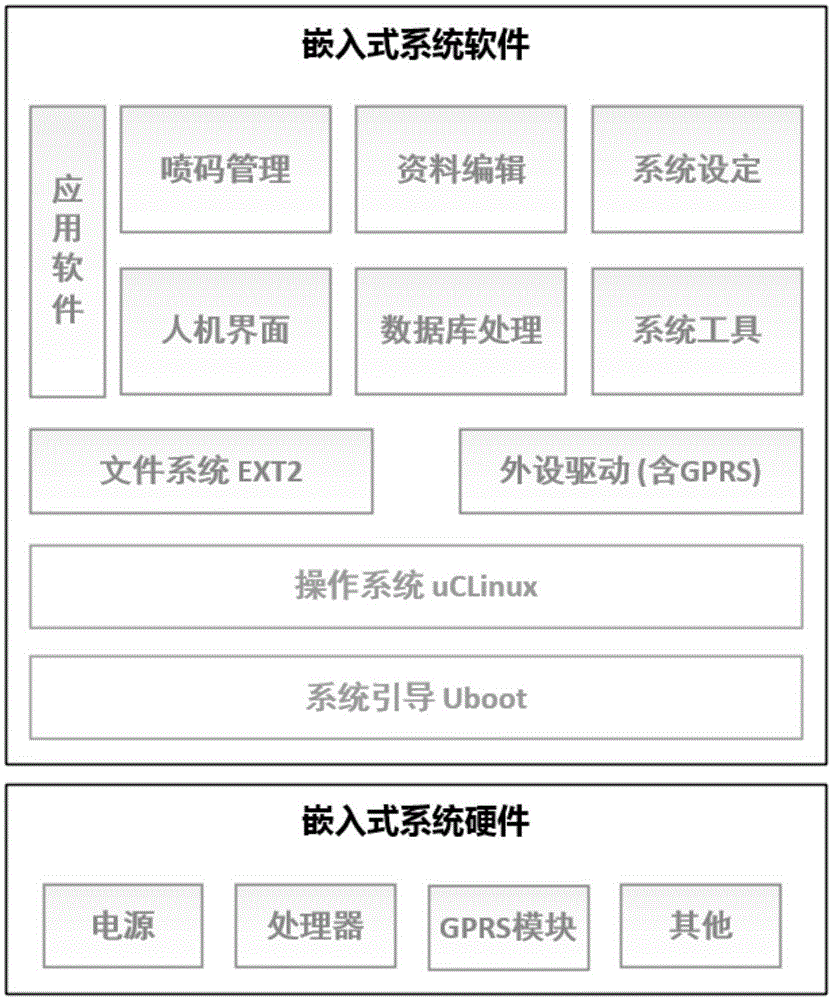

Ink-jet machine achieving remote real-time code ink jetting based on GPRS

InactiveCN105346249AReduce interactionEnsure personal safetyOther printing apparatusHardware structureOperational system

The invention discloses an ink-jet machine achieving remote real-time code ink jetting based on a GPRS. The ink-jet machine is composed of a hardware structure and a software structure. The hardware structure is composed of a CPU module, a GPRS module, an FPGA control module, a code ink jetting module, a power module, a storage module and a display module, wherein the GPRS module and the FPGA control module are connected with the CPU module, the code ink jetting module and the power module are connected with the FPGA control module, and the storage module and the display module are connected with the CPU module. The software structure is composed of a system guiding part, a Linux operating system, a file system, a peripheral driver and application software. The ink-jet machine can be remotely controlled to perform code ink jetting in real time, and meanwhile the ink-jet machine has the beneficial effects that cost is low, implementation is easy, and the body health of workers is facilitated.

Owner:SOJET ELECTRONICS XIAMEN

Method for extraction of heparin sodium and co-production of polypeptide protein powder and amino acid protein powder by utilizing porcine and bovine lungs

ActiveCN103951768APreserve integrityEliminate hidden dangers of insecurityPeptide preparation methodsFermentationEconomic benefitsWastewater

The invention discloses a method for extraction of heparin sodium and co-production of polypeptide protein powder and amino acid protein powder by utilizing porcine and bovine lungs, belonging to the technical field of manufacturing of biomedicines. The method adopts the steps of (1) pulping; (2) salt solution; (3) enzymolysis; (4) precipitation and adsorption; (5) elution and drying; (6) preparation of the polypeptide protein powder; (7) preparation of the amino acid protein powder. The method disclosed by the invention has the advantages of reasonable process design, no emission of waste gas, waste water and waste residue and no environmental pollution and is suitable for large-scale production; waste liquid and the waste residue produced in the production process are recycled and turned into treasure, so that economic benefits are improved; the operation is simple, the production period is short, the production yield is high and the method is suitable for popularization and application.

Owner:GUIZHOU HUIJING BIOTECH

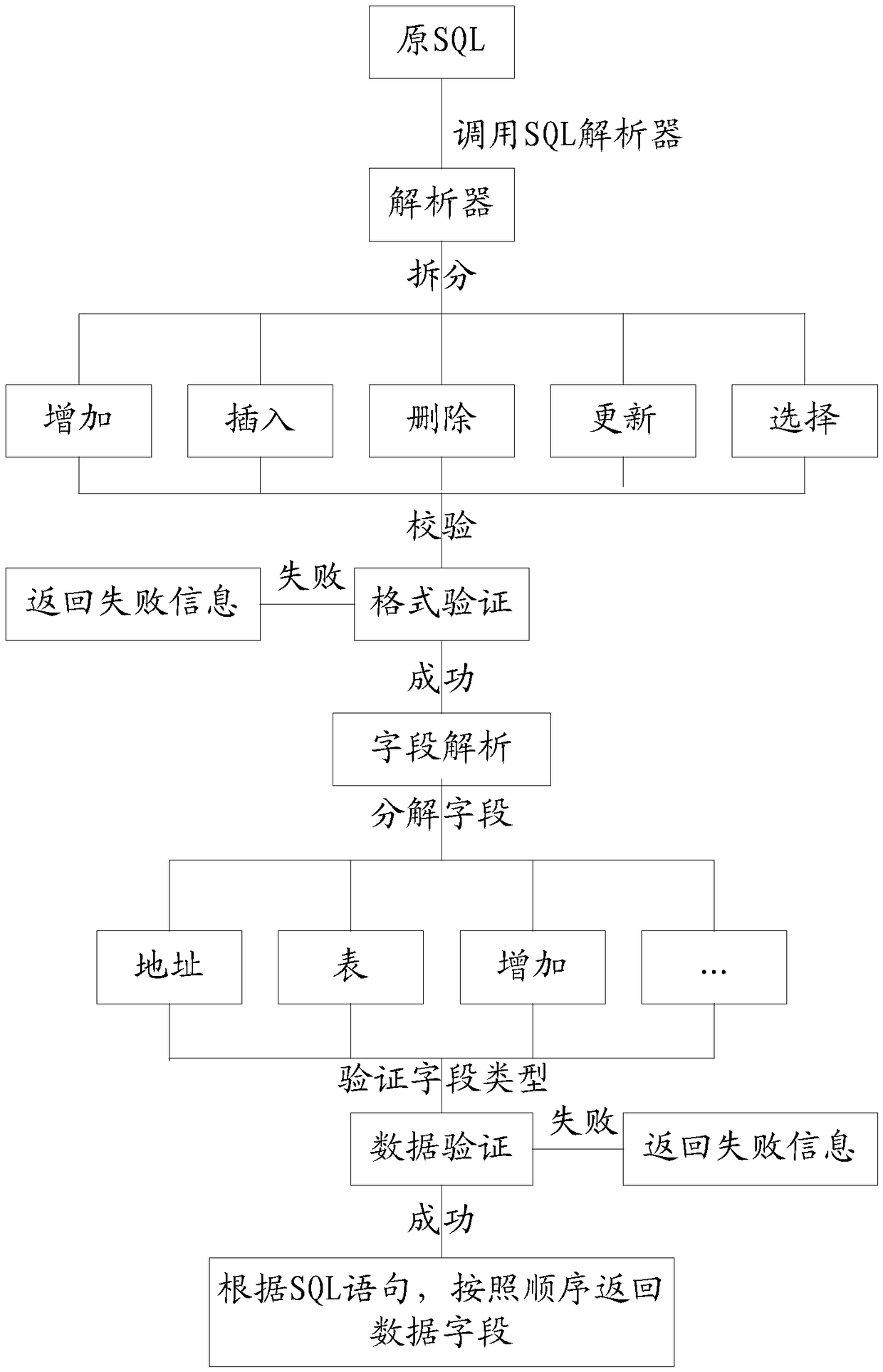

SQL parsing method based on regular and string cutting

ActiveCN109033410AReduce use costEliminate hidden dangers of insecuritySpecial data processing applicationsParsingSQL

The invention discloses a SQL parsing method based on regularity and character string cutting, which relates to the technical field of SQL database. By splitting the original SQL statement into keywords, type format validation and field resolution, you can get a generic SQL statement, support for compatibility with all database operations, therefore, it reduces the developer's use cost of SQL. Inaddition, by parsing SQL statements to get table and table field structure, we can create our own database model (modeling) according to the parsed field information, so as to remove the hidden dangers of foreign databases such as IOE.

Owner:韩雪松 +1

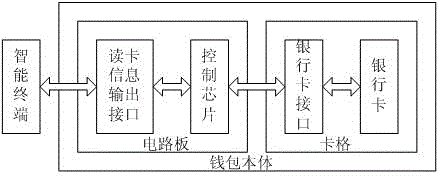

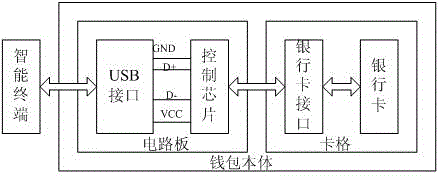

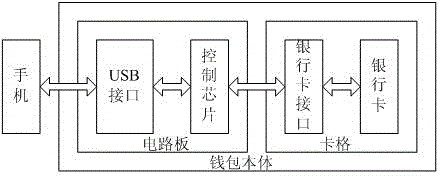

Smart wallet and payment method

InactiveCN104820923AGuaranteed normal operationEliminate hidden dangers of insecurityPursesMoney bagsPaymentComputer module

The invention relates to a smart wallet and a payment method. The smart wallet includes a wallet body provided with card grids for insertion of bank cards, a circuit board and a card reading module are also arranged on the wallet body, the card reading module includes a control chip arranged on the circuit board and a card reading information output interface, and bank card interfaces arranged in the card grids, and the control chip is connected with the card reading information output interface and a bank card interface and reads information of a bank card through the card reading information output interface and outputs to an intelligent terminal. The payment method provides a method of using an intelligent terminal to read a bank card in the smart wallet, and adopts bank regulations to complete payment. According to the smart wallet provided by the invention, read-write of the bank card inserted in the wallet is realized by use of a special card reader arranged in the wallet, thereby ensuring that the card of a user is operated in the card reader of the user himself, and eliminating a hidden danger of being unsafe.

Owner:SHENZHEN TAOTAOGU INFORMATION TECH

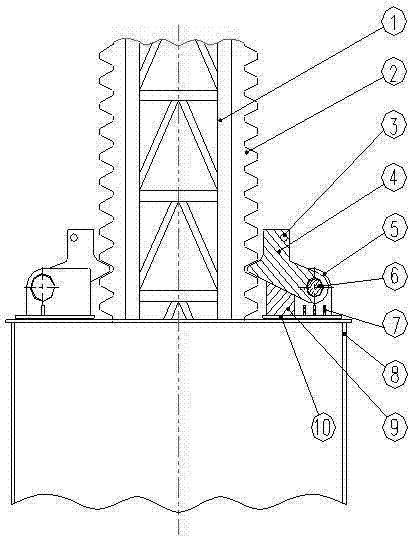

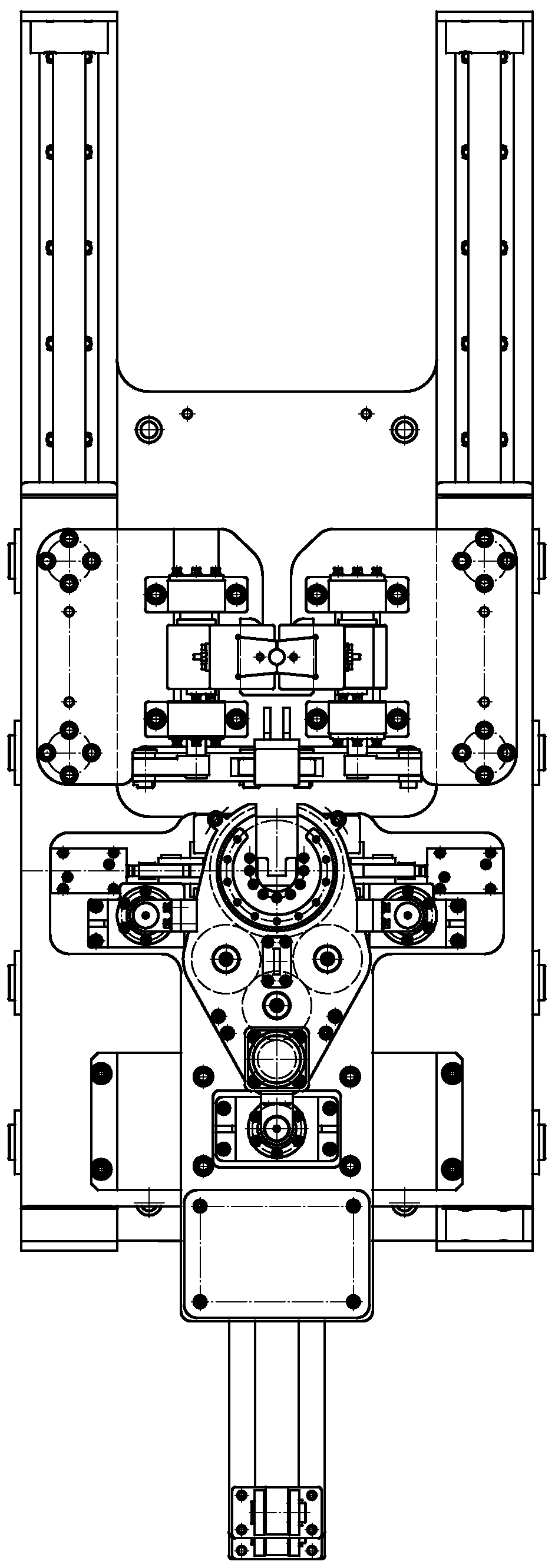

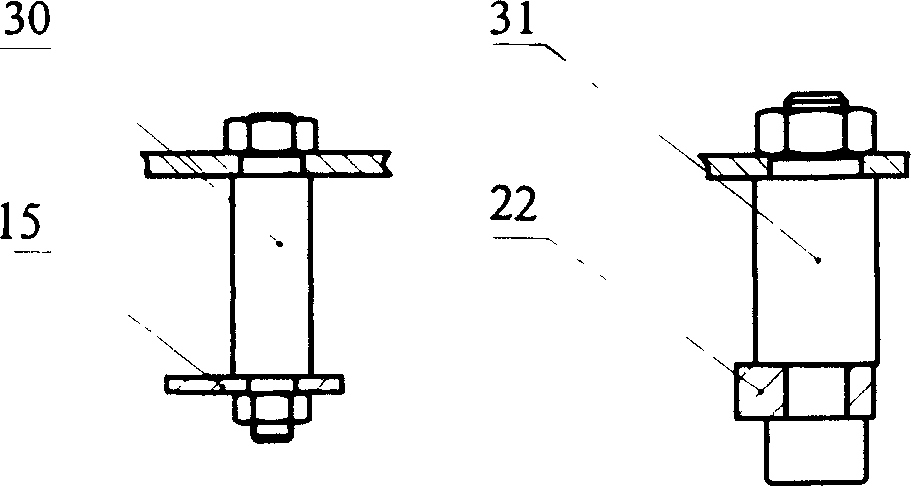

Lifting rack random locking mechanism of truss pile leg platform

InactiveCN104743471AEliminate the phenomenon of sliding pilesEliminate hidden dangers of insecurityLifting framesLocking mechanismEngineering

The invention discloses a lifting rack random locking mechanism of a truss pile leg platform. A rack is arranged on a platform lifting pile; a pawl machine is arranged on the rack of the platform lifting pile; and a pawl shape is arranged at the front end of the pawl machine, and is engaged to the rack. The pawl machine is fixed on a pile area; a pawl pin shaft is arranged at the back end of the pawl machine; a hole is formed in a pin shaft main force board; and the pawl pin shaft penetrates through the hole of the main force plate. The mechanism mainly adopts the hinge type pawl machine, the stressed pile support, the random locking and the force hole control mechanism, and is mounted at the top of the platform pile area; the variable load of the platform vibration is increased or decreased; and the hinge type pawl machine can be firmly buckled on the rack, so that the working gesture tends to an ideal state, and the pile slip phenomenon generated by the platform can be thoroughly prevented. The mechanism needs no auxiliary driving power, is compact in structure, small in volume, convenient to operate and strong in practicability, and can improve the platform operation safety.

Owner:CHINA PETROCHEMICAL CORP +1

Anti-rust liquor and processing method therefor

The invention relates to antirust fluid. The invention also relates to a processing method of the antirust fluid. The antirust fluid made by the method is provided with obvious antirust function and has light even no pollution to the environment. The antirust fluid is generated mainly from the action of alkcnyl succinic acid and monoethanolamine. The mole ratio of alkcnyl succinic acid to monoethanolamine is 0.5-1 to 1. The main components of the antirust fluid are alkcnyl succinic acid dodecenylbutadioic, water and monoethanolamine.

Owner:马国伟 +1

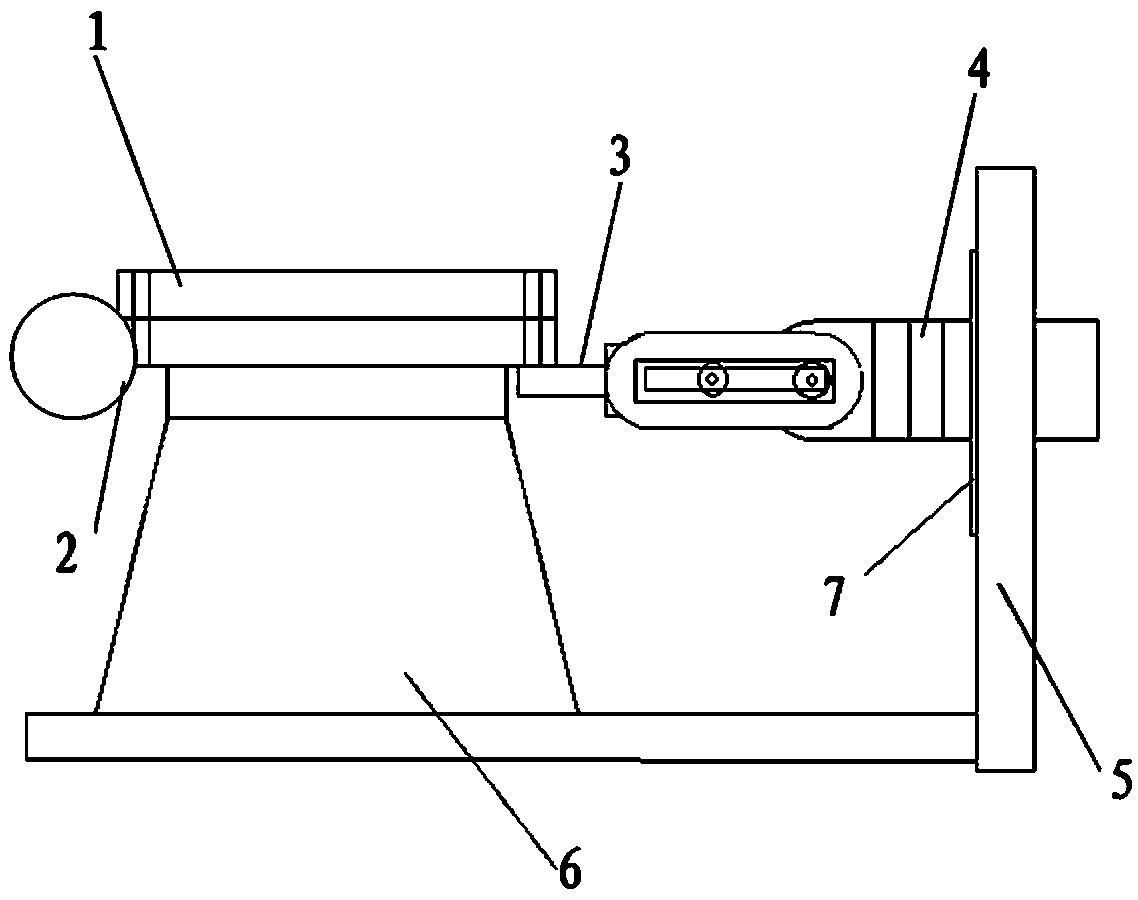

Self burring device for gear hobbing machine

InactiveCN103737120AEliminate hidden dangers of insecurityReduce manufacturing costGear teethHobbingEngineering

The invention discloses a self burring device for a gear hobbing machine. The self burring device comprises a gear hobbing machine working table. A gear hob is arranged on the front portion of the gear hobbing machine working table. A column is arranged on the rear portion of the gear hobbing machine working table, a track is arranged on the column, the self burring device capable of moving vertically is arranged on the track, a white steel knife is arranged at the front end of the self burring device, and the working face of the white steel knife corresponds to the end portion of a workpiece arranged on the gear hobbing machine working table. By means of rotating of the gear hobbing machine in the workpiece machining process, the white steel knife arranged in the self burring device scrapes the flanging and burrs generated continuously during hobbing, safety hazards are removed, and production cost is reduced.

Owner:LIUZHOU ZHENGLING GROUP

Pumping rod power clamp device

PendingCN110173223AHigh degree of mechanizationReduce labor intensityDrilling rodsDrilling casingsEngineeringUltimate tensile strength

The invention discloses a pumping rod power clamp device which comprises a pumping rod bottom plate, a pumping rod power clamp, a pumping rod slip and a pumping rod power clamp base. The lower portionof the pumping rod power clamp base is connected with one end of the pumping rod bottom plate. The upper portion of the pumping rod power clamp base is connected with the pumping rod power clamp. Thepumping rod slip is connected with one end of the pumping rod bottom plate, the lower portion of the pumping rod bottom plate is connected with an oil well platform, and the pumping rod is supportedon the pumping rod slip. The pumping rod power clamp device is high in mechanical degree, a mechanical and power mechanism can be provided, the power clamp completes screwing and unscrewing work of apumping rod, the phenomenon that the power clamp needs to be manually operated to complete the screwing and unscrewing work of the pumping rod in a poor working condition outdoors is avoided, the labor intensity of operators is relieved, the work efficiency is improved, potential safety hazards existing in field operation are eliminated, and the safe and efficient work requirement of modern oil well work can be met.

Owner:SENIOR AI EQUIP CO LTD

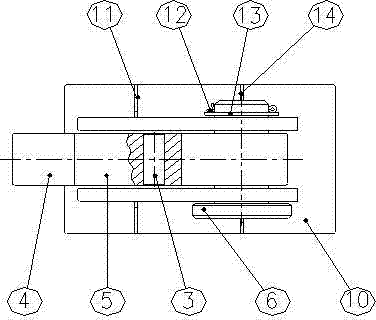

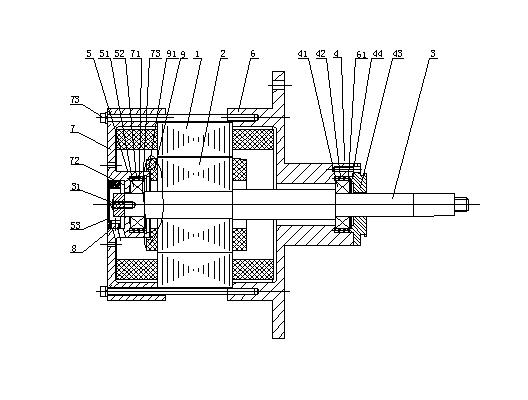

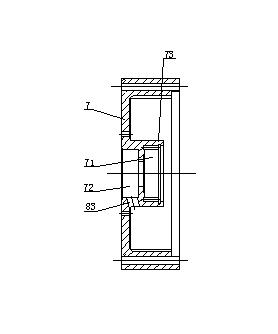

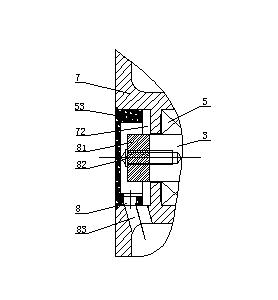

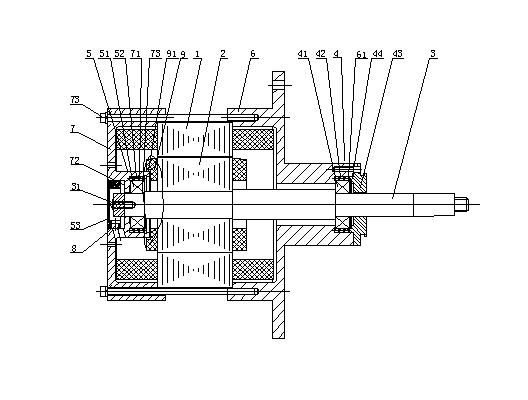

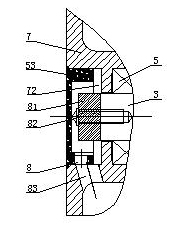

Speed measurement control device for motor

InactiveCN102075036ASolve the problem of no self-contained speed measuring deviceImprove motor functionManufacturing dynamo-electric machinesStructural associationElastic componentControl theory

The invention discloses a speed measurement control device for a motor. The speed measurement control device comprises a motor main shaft inserted in a stator iron core and a rotor iron core, wherein the motor main shaft is fixed in an upper end cover and a lower end cover of the motor through an upper bearing device and a lower bearing device respectively; the upper bearing device comprises an upper end cover bearing fixed on the main shaft; the upper end cover bearing is arranged in a concave platform of the upper end cover of the motor; an upper bearing elastic component is radially arranged on the upper end cover bearing in the concave platform; an upper sealing cover plate is axially arranged on the upper bearing elastic component; the lower bearing device comprises a lower end coverbearing fixed on the main shaft; the lower end cover bearing is arranged in an inner concave platform of the lower end cover of the motor; a lower bearing elastic component is radially arranged on the lower end cover bearing in the inner concave platform; a lower sealing cover plate is arranged in an outer concave platform of the lower end cover of the motor; and signal converters are arranged incavities of the lower sealing cover plate and the outer concave platform. The scheme provided by the invention overcomes the defect that the motor application is limited because the conventional motor is not provided with the speed measurement control device and the like; besides, the speed measurement control device is suitable for various control motors.

Owner:胡磊

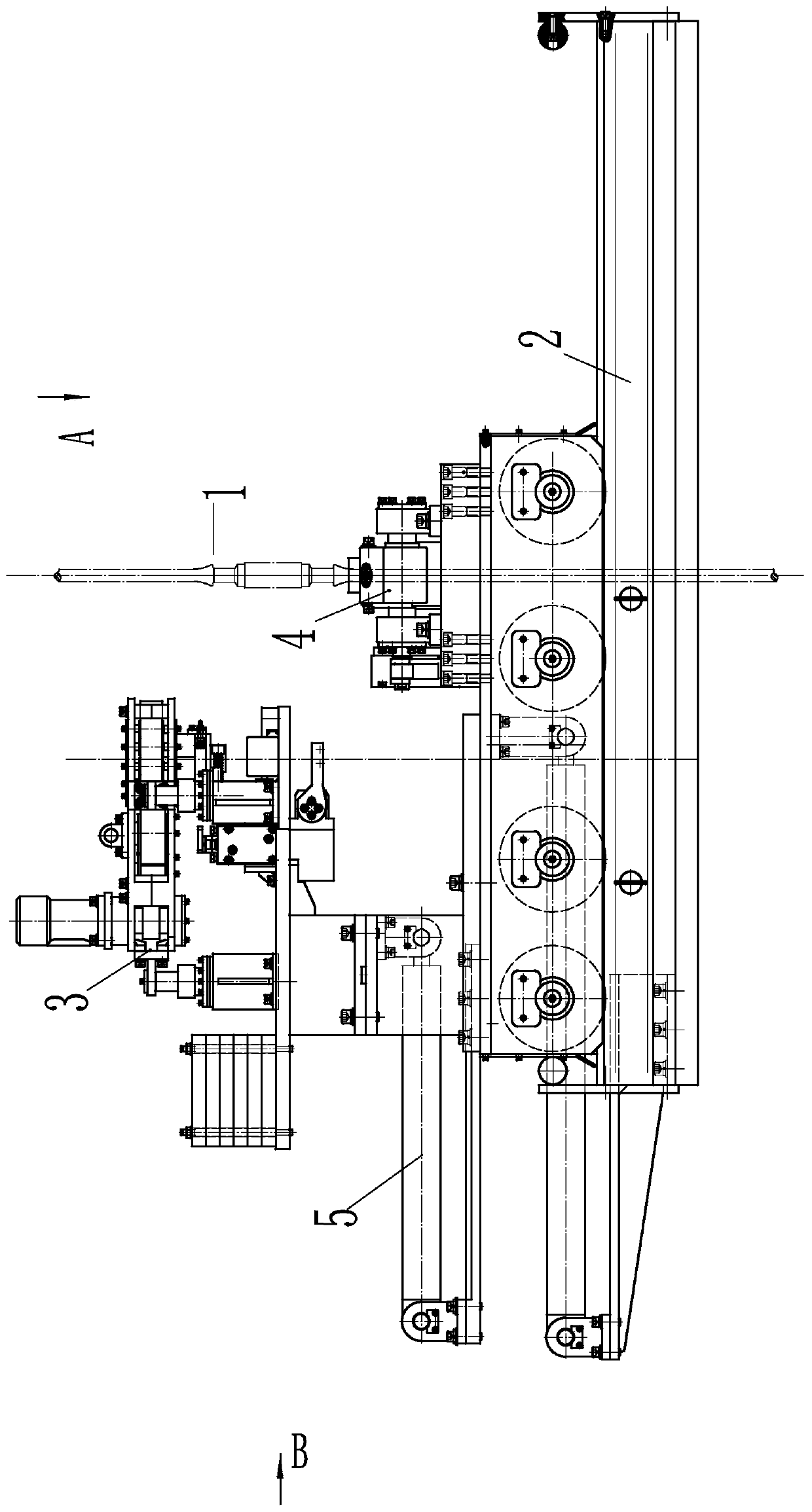

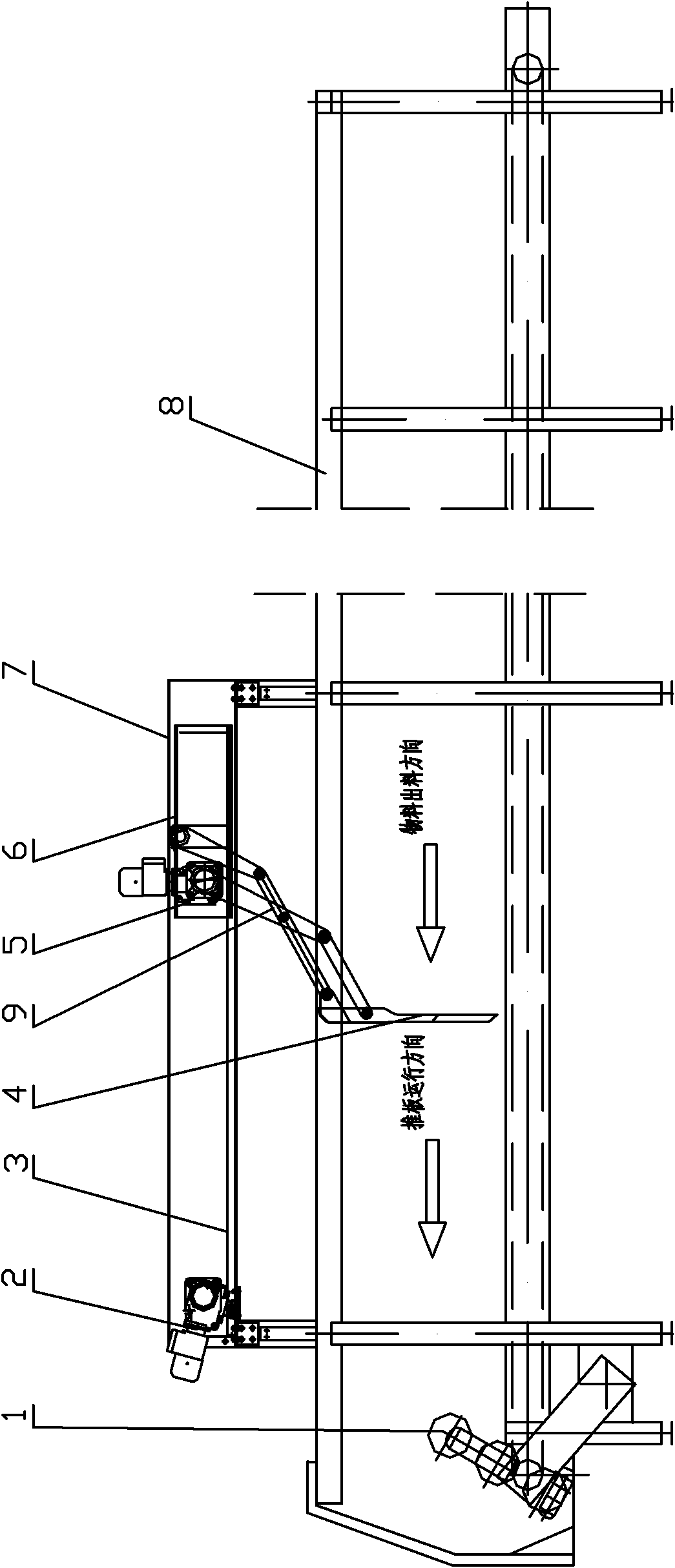

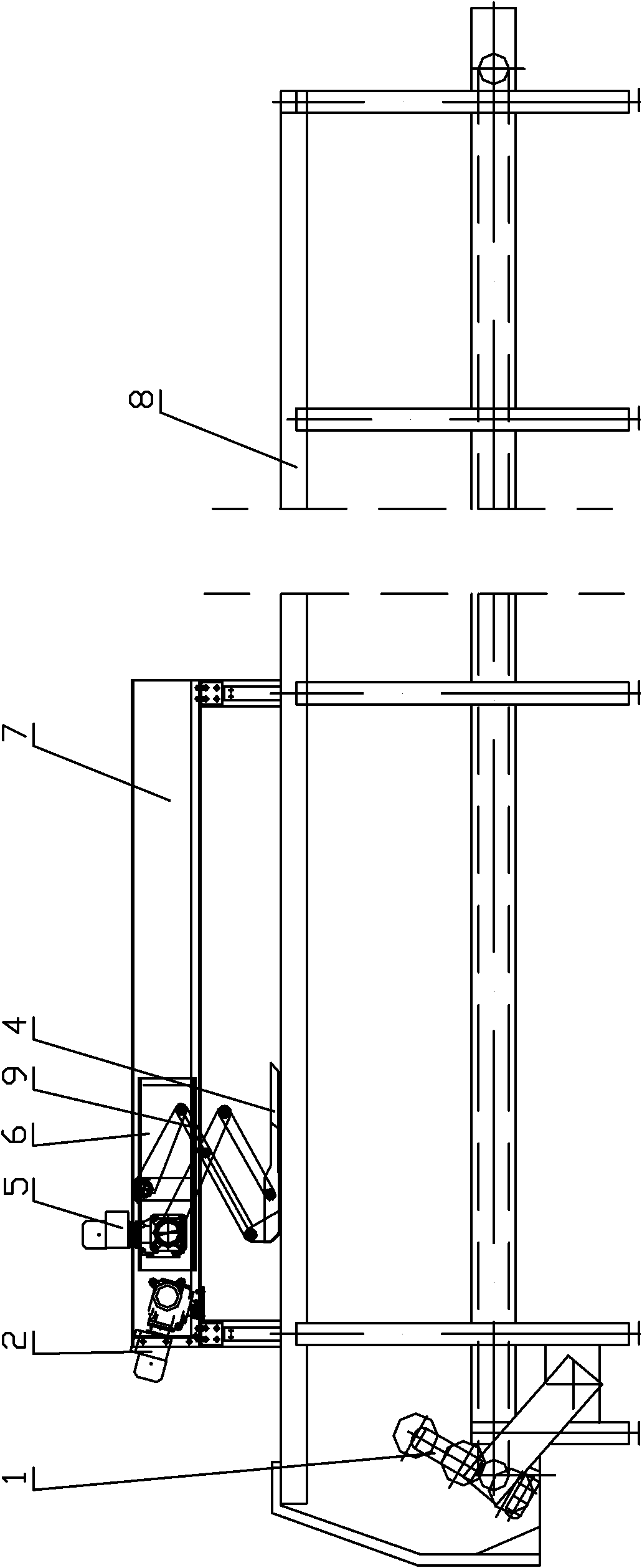

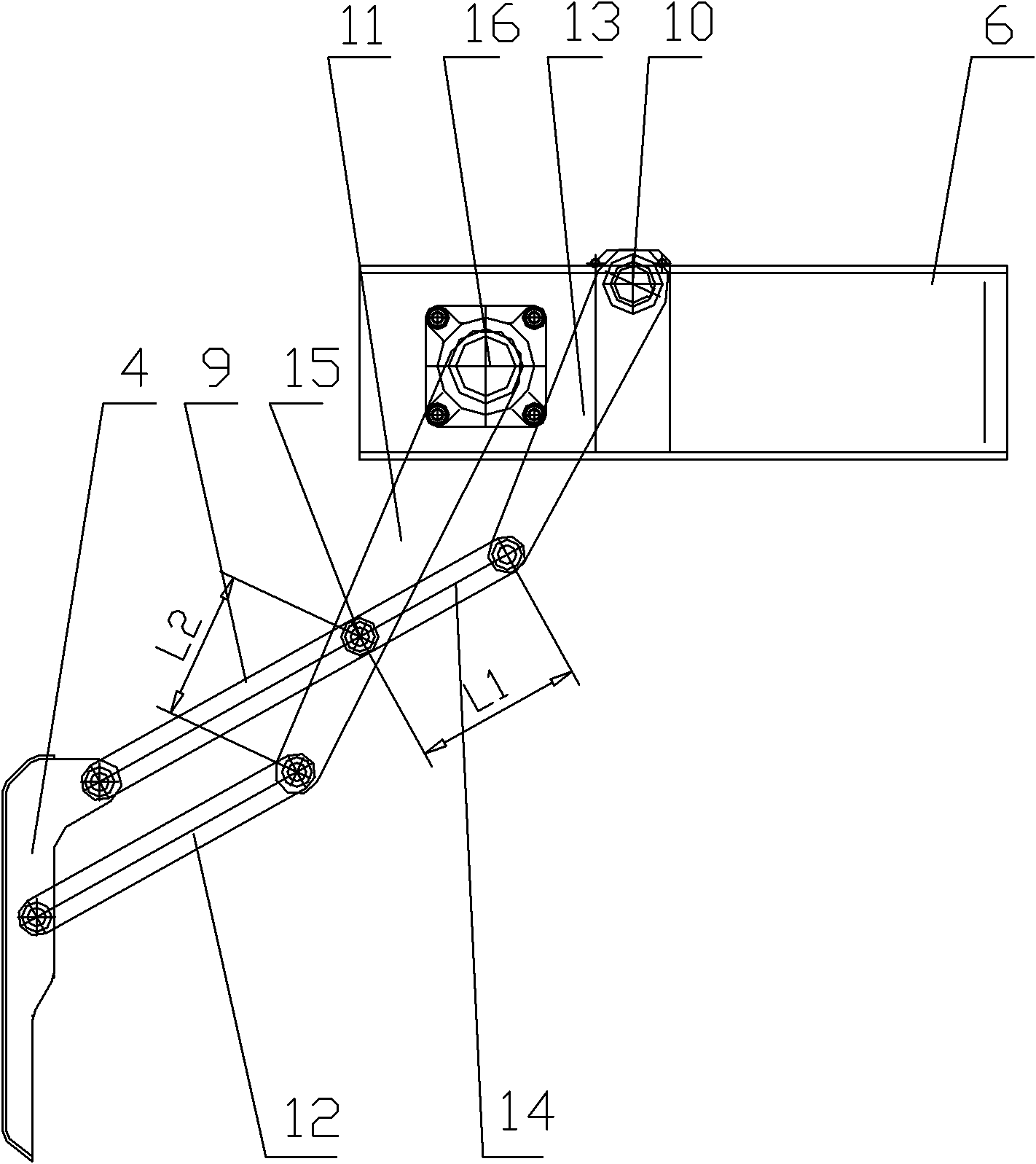

Device for pushing and feeding tail materials in silo

The invention discloses a device for pushing and feeding tail materials in a silo, belonging to the technological field of cigarette machinery. A frame is arranged on two wallboards at two sides of the head portion of the silo. Slide rails are arranged at the bottom of the frame; the material pushing device is sleeved on the slide rails, front ends of the slide rails are equipped with a reciprocating running motor; the reciprocating running motor is in connection with the material pushing device through a toothed driving chain; a turnover motor and an upper connecting shaft are arranged in the material pushing device; a driving transmission shaft on the turnover motor and the upper connecting shaft penetrate through the top of the silo and are connected with four connecting rod-hinge-push slab mechanisms at two sides of the silo; a push slab of each four-connecting rod hinge push-slab mechanism has an area equal to the sectional area of the silo. The device provided by the invention is reasonable in design, is ingenious in structure, is flexible in operation and is convenient in use, solves the problem of unstable tail materials and eliminates hidden safety troubles in the production process.

Owner:HUBEI CHINA TOBACCO IND

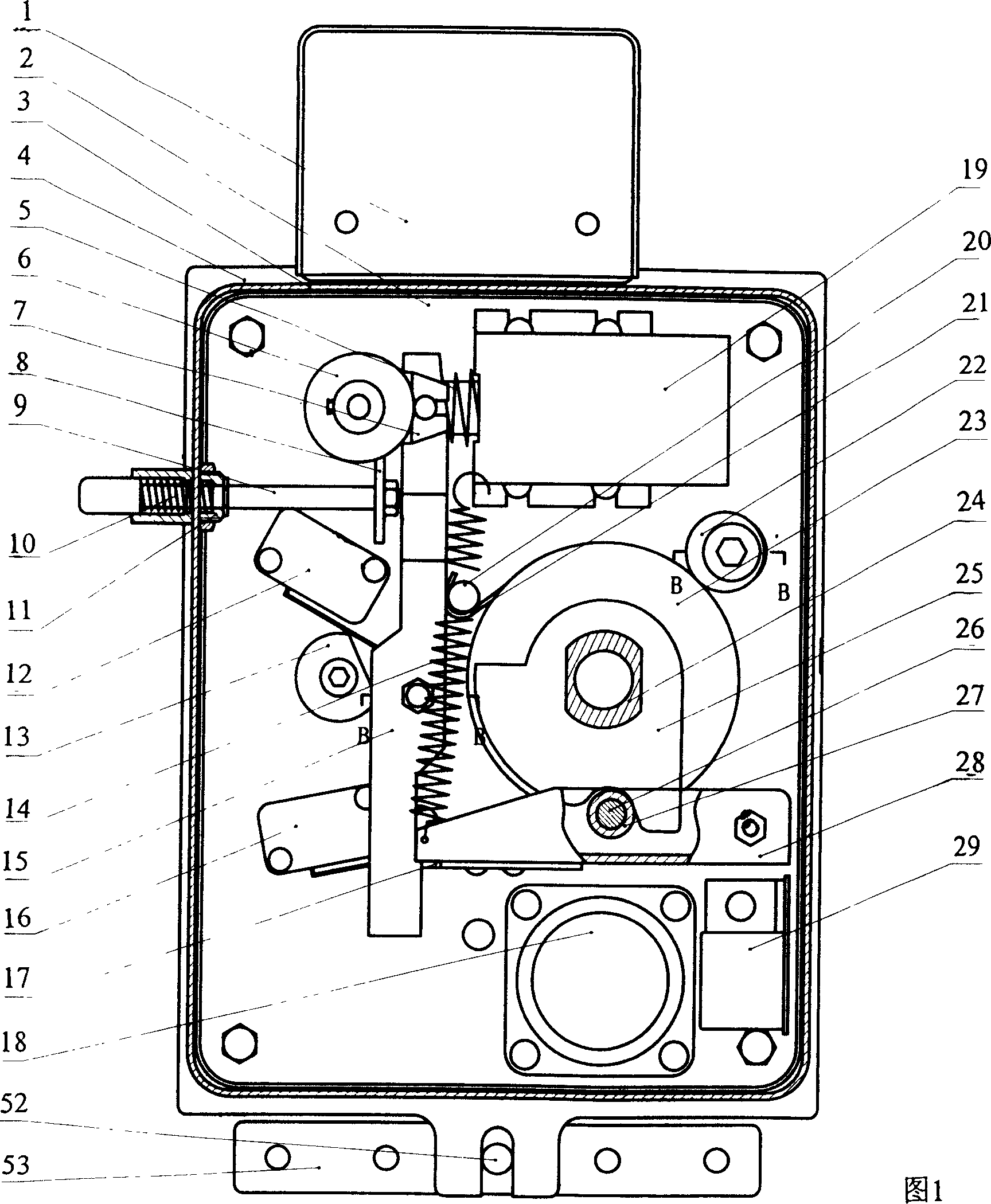

Automatic actuating mechanism for extinguishing and smoke exhausting valve

A full-automatic executing mechanism for opening or closing the fire-proofing smoke exhaust valve is based on geardrive. It features that a drive mechanism is fixed to output axle, the output gear is matched with a output movable wheel in slide mode, the output gear is engaged with the gear train engaged with the gear on the motor shaft, and said output movable wheel is engaged with the sectoriral gear on mainshaft.

Owner:王兆君

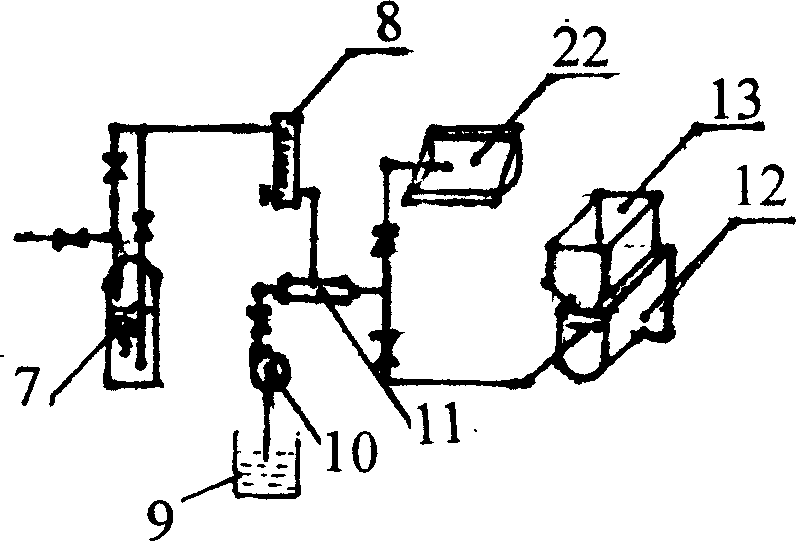

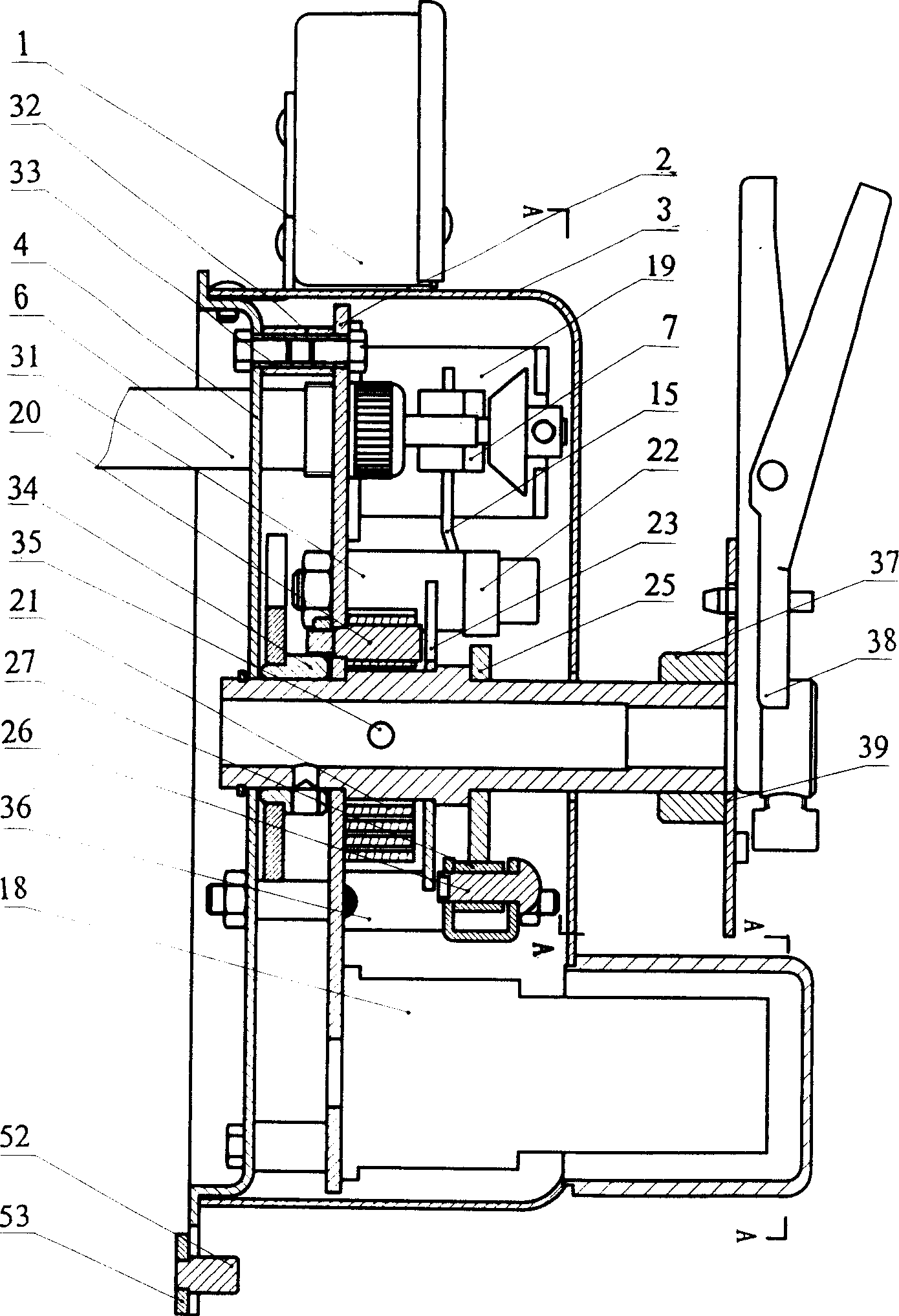

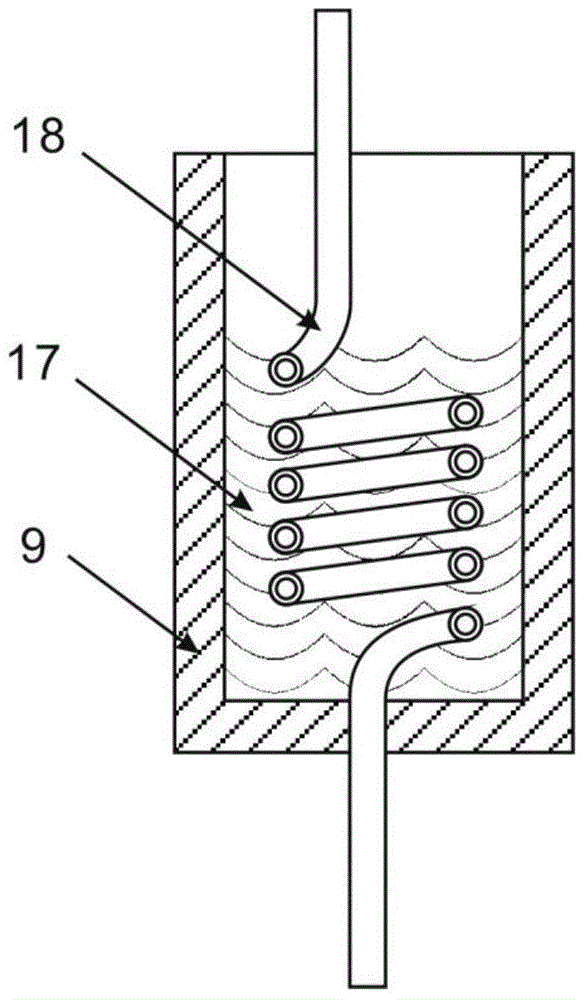

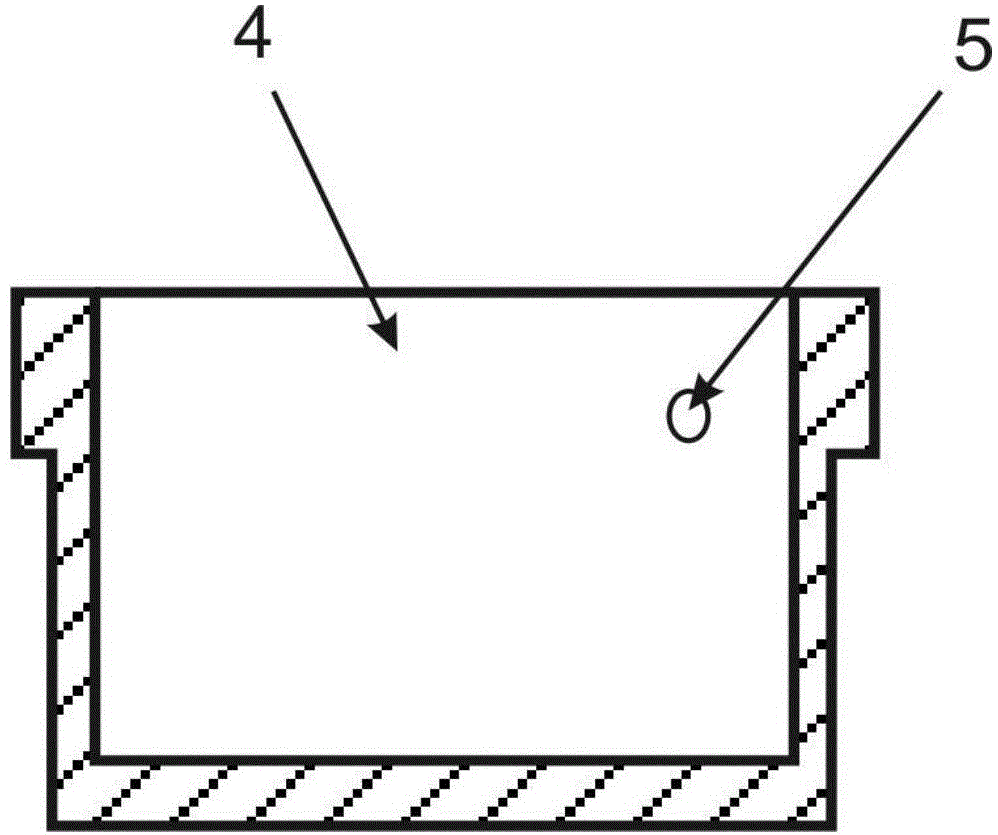

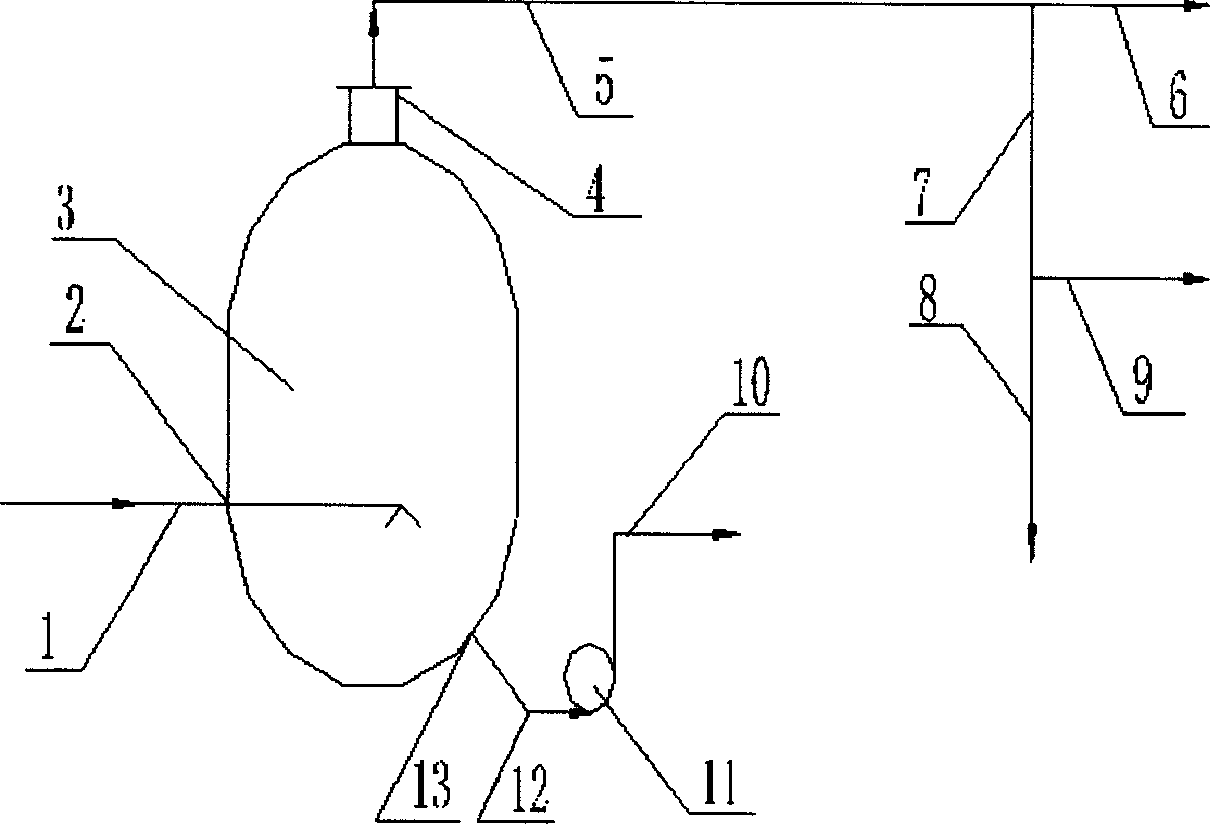

Diamond anvil cell pressing machine trace gas liquefying plant

InactiveCN104819889AImprove the environmentEliminate hidden dangers of insecurityPreparing sample for investigationProduct gasEngineering

The invention belongs to the technical field of gas trace liquefying encapsulation in a diamond anvil cell pressing machine and relates to a diamond anvil cell pressing machine trace gas liquefying plant. The diamond anvil cell pressing machine trace gas liquefying plant comprises a cavity outer sleeve (1), an upper cover (2) and a low-temperature chamber (4), wherein the low-temperature chamber (4) is mounted in an opening in the middle of the upper cover (2); the upper cover (2) is provided with a liquid nitrogen inlet (3) and a liquid nitrogen outlet (6); the space enclosed by the outer sleeve (1), the upper cover (2) and the low-temperature chamber (4) is a liquid nitrogen chamber (8); the diamond anvil cell pressing machine is disposed in the low-temperature chamber (4), and a gas inlet (5) is formed in the lateral side of the low-temperature chamber (4) and can be communicated with a sample chamber in the diamond anvil cell pressing machine. The diamond anvil cell pressing machine trace gas liquefying plant has the advantages that the liquid nitrogen is used to cool the low-temperature chamber (4) and the diamond anvil cell pressing machine, and when temperature reaches the liquefying temperature of encapsulation gases, the gases are injected into the sample chamber; liquefied gases are saved greatly as compared with the prior art, and potential safety hazards of inflammable and explosive gases can be eliminated.

Owner:JILIN UNIV

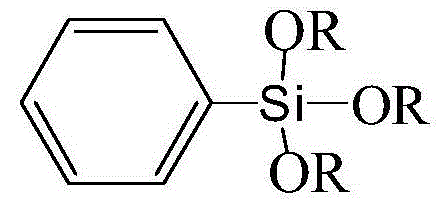

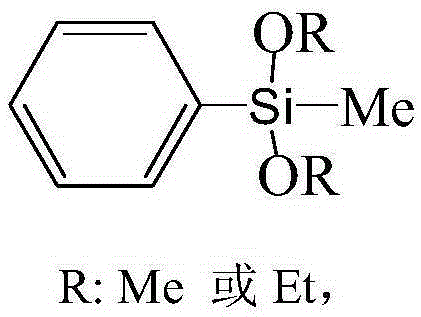

Method for preparing phenyl trialkyl alkoxy silane by nucleophilic method

InactiveCN104926858AEvenly dispersedLarge specific surface areaGroup 4/14 element organic compoundsBenzeneSilanes

The invention belongs to the technical field of synthesis of organosilicon compound and particularly relates to a method for preparing phenyl trialkyl alkoxy silane by a nucleophilic method. Under inertia gas protection, the method includes adding sodium into methylbenzene and dispersant, heating and preparing metal sodium metallic particle suspension; adding metal sodium metallic particle suspension into mixed liquid of halogeno benzene and tetraalkoxy silane, then adding reaction accelerant, rectifying to obtain phenyl trialkyl alkoxy silane products after reaction mixture is subjected to solid-liquid separation; or adding halogeno benzene into the metal sodium metallic particle suspension to react to prepare phenyl alkali metal sodium salt suspension, adding the phenyl alkali metal sodium salt suspension into mixed liquid of tetraalkoxy silane and reaction accelerant, and rectifying to obtain phenyl trialkyl alkoxy silane products after reaction mixture is subjected to solid-liquid separation. The preparation conditions of normal pressure, low temperature, simple operation, mildness and controllability are achieved and industrialization is facilitated.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

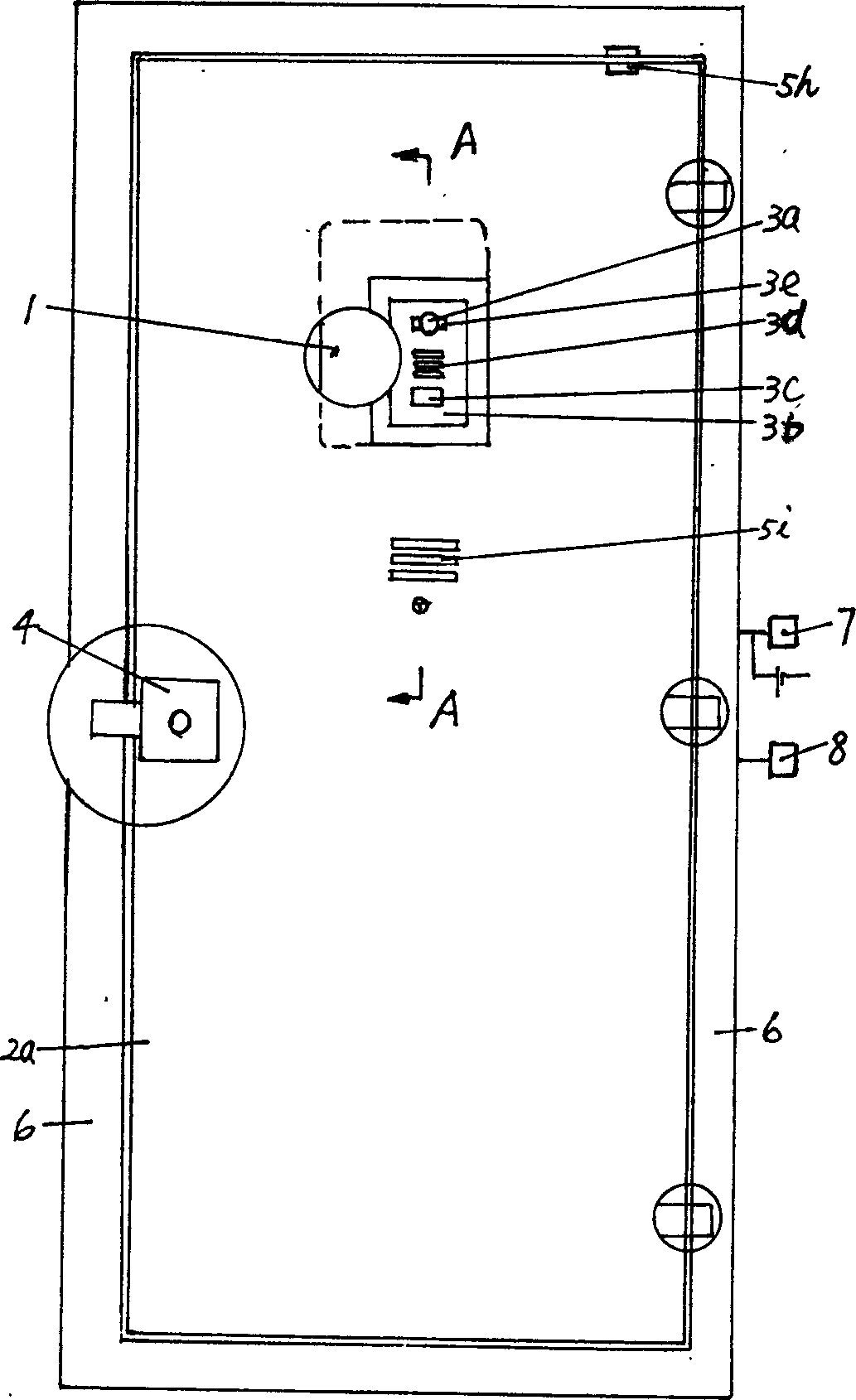

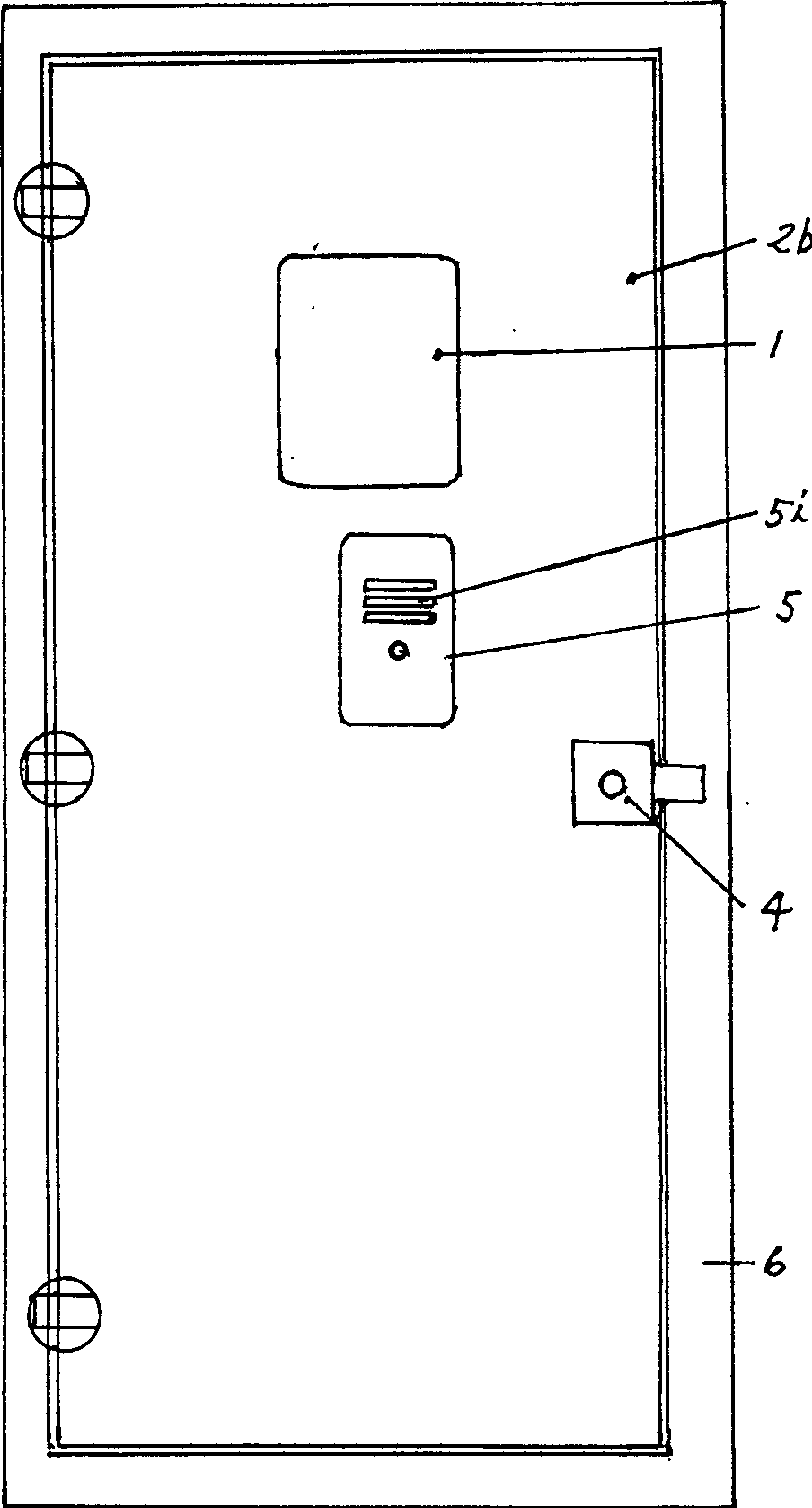

Anti-theft door with intelligent alarm and visible intercom functions

InactiveCN1464167AReasonable structural designCompact structureBurglar alarm by openingBurglary protectionInfraredKey pressing

The anti-theft door with intelligent alarm and visual intercom includes door, peephole for camera, infrared emitting hole, loudspeaker hole, key hole, talking hole, door lock, doorway telephone set and visual indoor telephone set. The doorway telephone set has video camera stylus connected to the key circuit board, loudspeaker, eletrect, key and LED; the visual indoor telephone set has main circuit board, unlocking button, monitoring button, display button, power supply circuit and microphone. The present invention features the alarm on the door with loudspeaker, keyboard, pick-up, alarm main circuit board with microprocessor and digital recorder, door magnet, motor and remote controller. The present invention can perform visual intercom, convenient opening of door, intelligent alarming and unattended anti-theft.

Owner:BOND GRP CO LTD

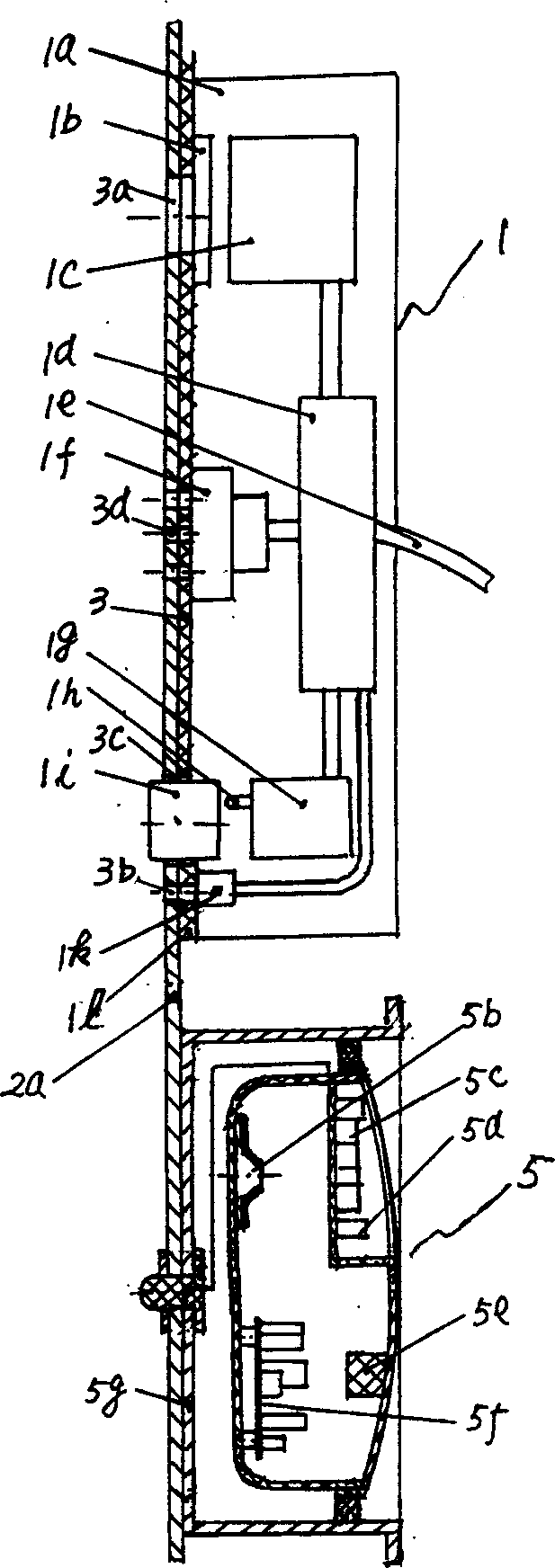

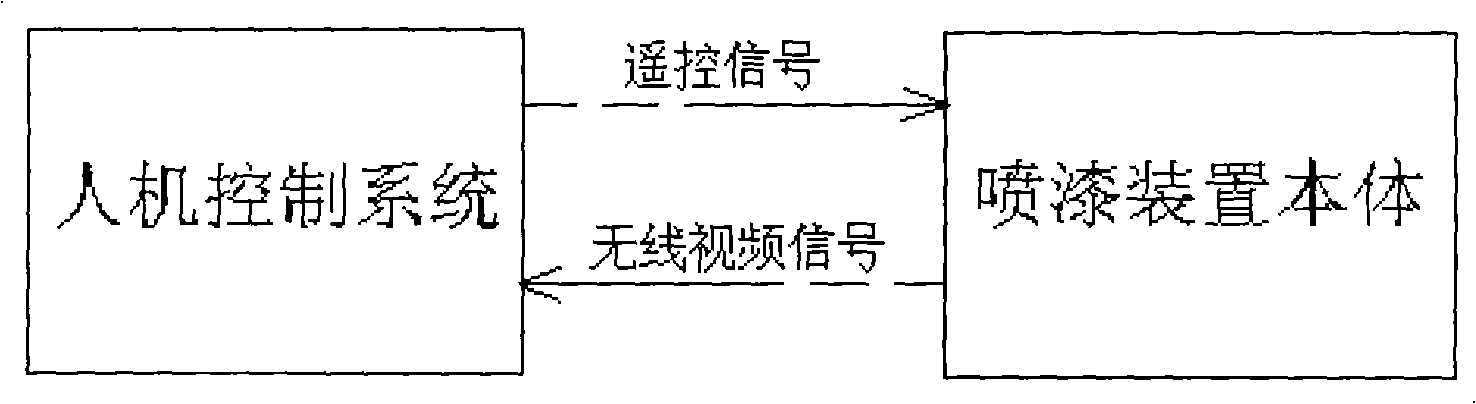

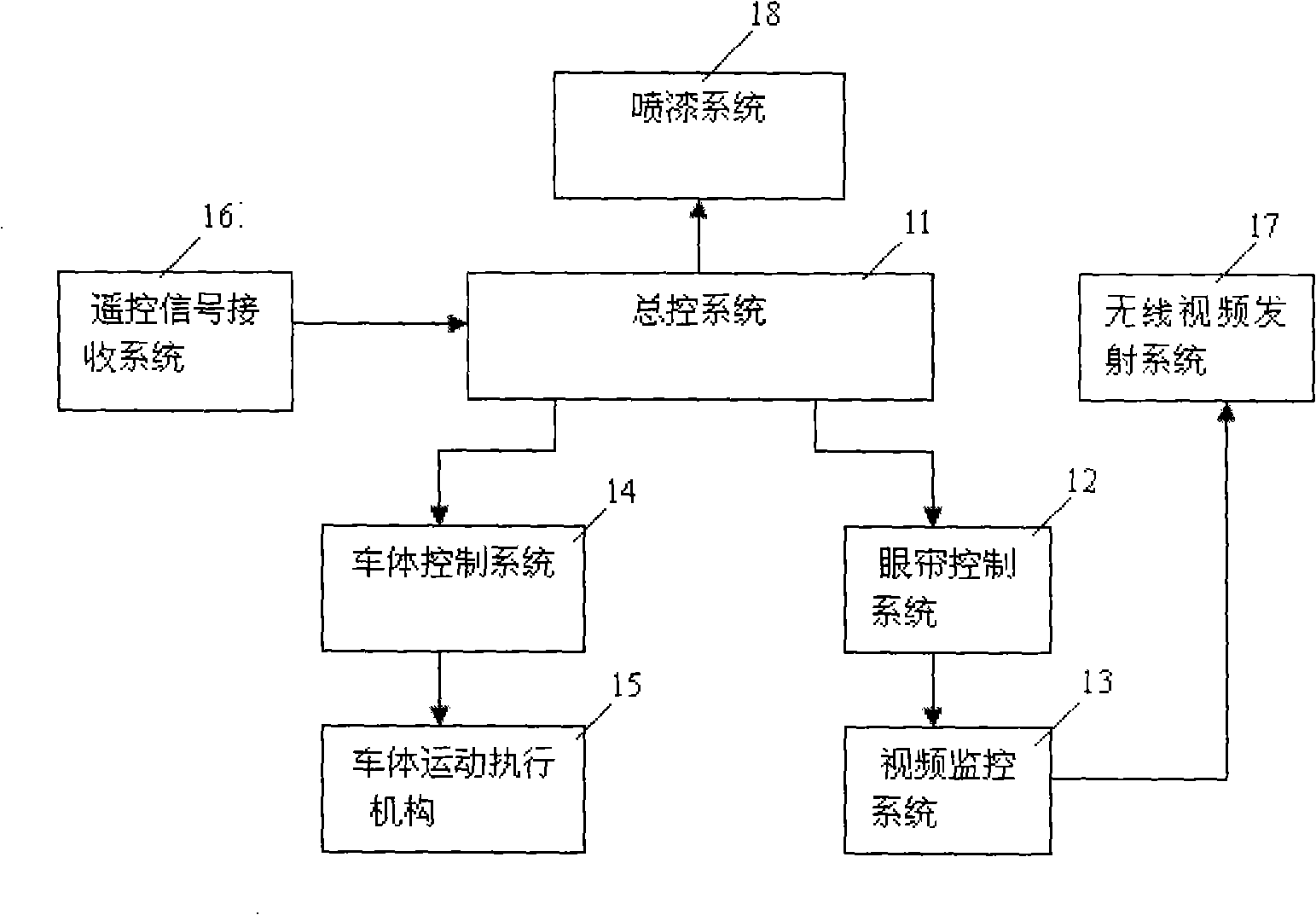

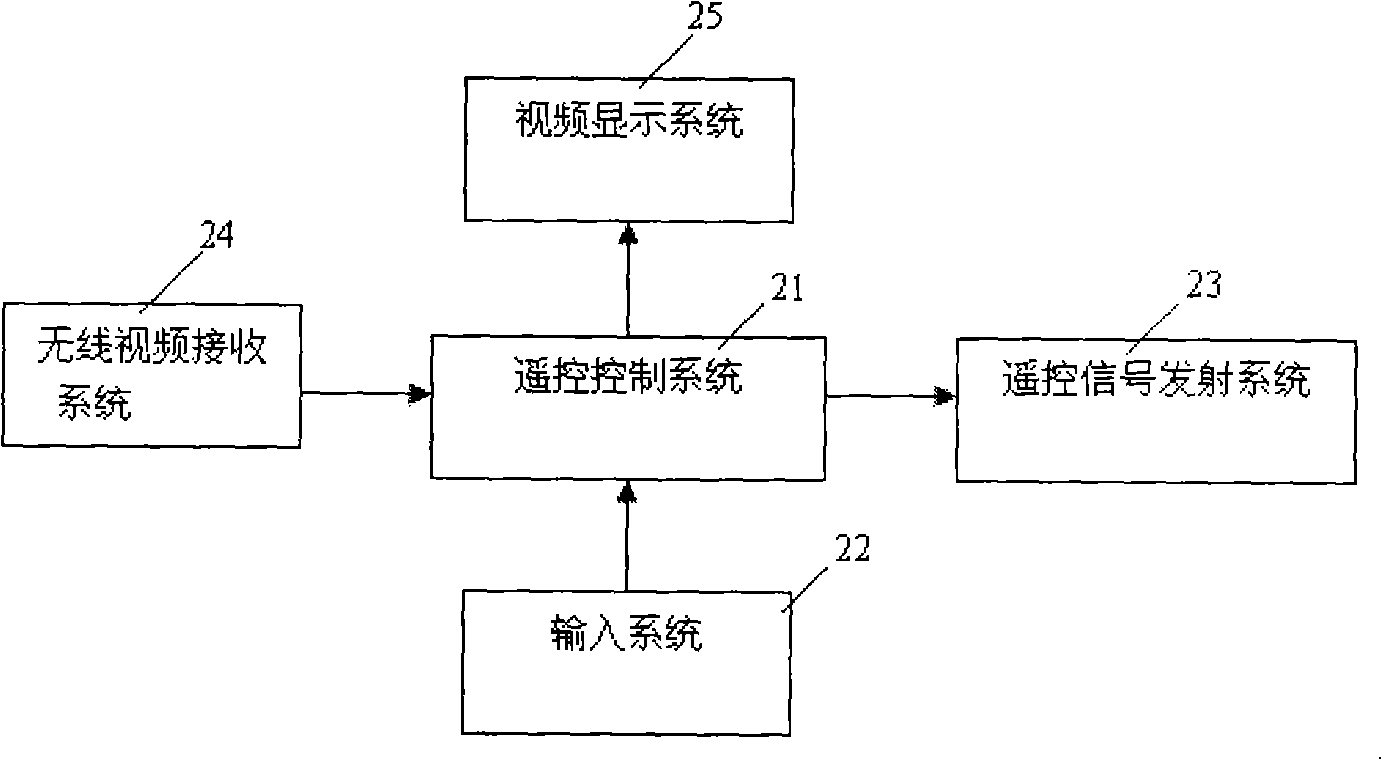

Intelligent type motorcar chassis lacquer spraying arrangement

InactiveCN101284264ARealize automatic controlReduce labor intensityLiquid surface applicatorsCoatingsVideo monitoringComputer control system

The invention relates to a spray painting device. The invention discloses an intelligent automotive chassis spray painting device. The spray painting device comprises: a spray painting device body and a human-computer control system, wherein the human-computer control system communicates with the spray painting device by a remote control signal, and the spray painting device body is transferred to the human-computer control system by a wireless video signal. The spray painting device is used for the spray painting work of an automotive chassis, which can realize the automatic control and the automatic spray painting. When in spray painting, people do not need to enter the bottom part of an automobile, thus reducing the labor intensity and eliminating the unsafe hidden danger. At the same time, the spray painting device is provided with a video monitoring system, which can ensure the spray painting quality of the automotive chassis under the situation of automatic control.

Owner:刘雨盈

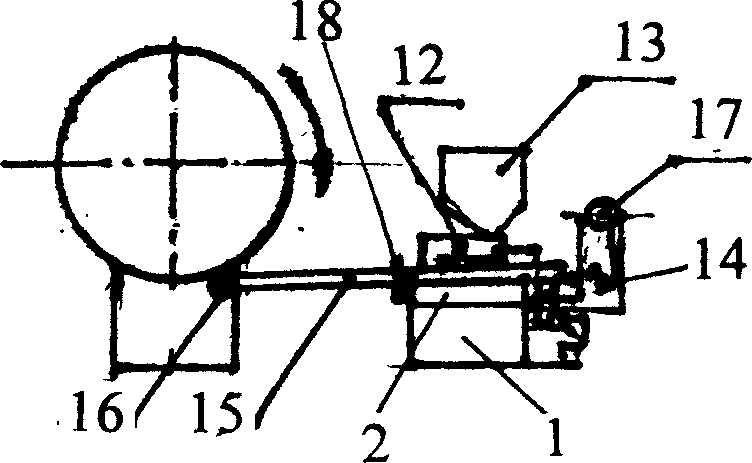

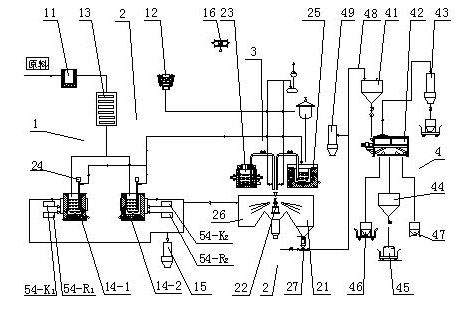

Magnesium, magnesium alloy and wastes thereof based production line for producing particle magnesium desulfurizing agent/particle magnesium alloy desulfurizing agent

InactiveCN101974665ASolve comprehensive problems such as increased use costsSimple structureGas emission reductionSiphonAutomatic control

The invention relates to a magnesium, magnesium alloy and wastes thereof based production line for producing a particle magnesium desulfurizing agent / particle magnesium alloy desulfurizing agent, adopting the technical scheme which comprises a raw material preheating and refining system, a granulating and injecting system, a vacuum siphon system, a sieving and finished product processing system and an automatic control and operation system. The production line overcomes the defects of high energy consumption, serious environmental pollution, dangers caused by easy incontrollable operation of a material carrying tank, poor safety and product consistency and low repeatability due to the adoption of a crucible electric furnace as well as the defects of serious waste of a magnesium resource, high maintenance cost of equipment, overhigh reject ratio and the like by mechanically cutting and clamping magnesium ingots / magnesium alloy in the traditional particle magnesium / particle magnesium alloy production equipment using a fusion method, thereby solving the comprehensive problems of improved using cost and the like. The production line is suitable for producing molten iron preprocessing desulfurizing agent, molten steel deep-desulfurizing agent and cast iron mixed modifier in steel smelting as well as magnesium / magnesium alloy desulfurizing agent for producing Fe-Si-Mg and Fe-Si-Ca intermediate alloy in silicon iron fusion.

Owner:HUNAN S R M SCI & TECH

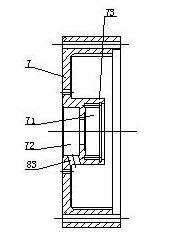

Bearing buffer unit for motor

InactiveCN102097884AIncreased resistance to cushioningImprove compliance rateSupports/enclosures/casingsMechanical engineeringStator

The invention provides a bearing buffer unit for a motor, comprising motor spindles, wherein the motor spindles pass through the centers of a stator core and a rotor core, and are respectively fixed in the upper end cap and the lower end cap of a motor by an upper bearing device and a lower bearing device; the upper bearing device comprises upper end cap bearings which are fixed at the spindles; the upper end cap bearings are arranged in a concave platform of the upper end cap of the motor; the upper end cap bearings in the concave platform are respectively provided with an upper bearing elastic element in a radial direction; each upper bearing elastic element is provided with an upper sealing cover plate in an axial direction; the lower bearing device comprises lower end cap bearings which are fixed at the spindles; the lower end cap bearings are arranged in an inner concave platform of the lower end cap of the motor; each lower end cap bearing in the inner concave platform is provided with a lower bearing elastic element in a radial direction; and lower sealing cover plates are arranged in an outer concave platform of the lower end cap of the motor. The above technical scheme isused to overcome the defects that bearings for an existing motor are easily extruded mutually and damaged at the joints of the spindles and the end caps due to high-speed running, heat emission, parking, cooling, deformation and the like, the tail ends of the spindles of the motor are exposed and the like. The bearing buffer unit is used for controlling motors in different freezing operating rooms.

Owner:胡磊

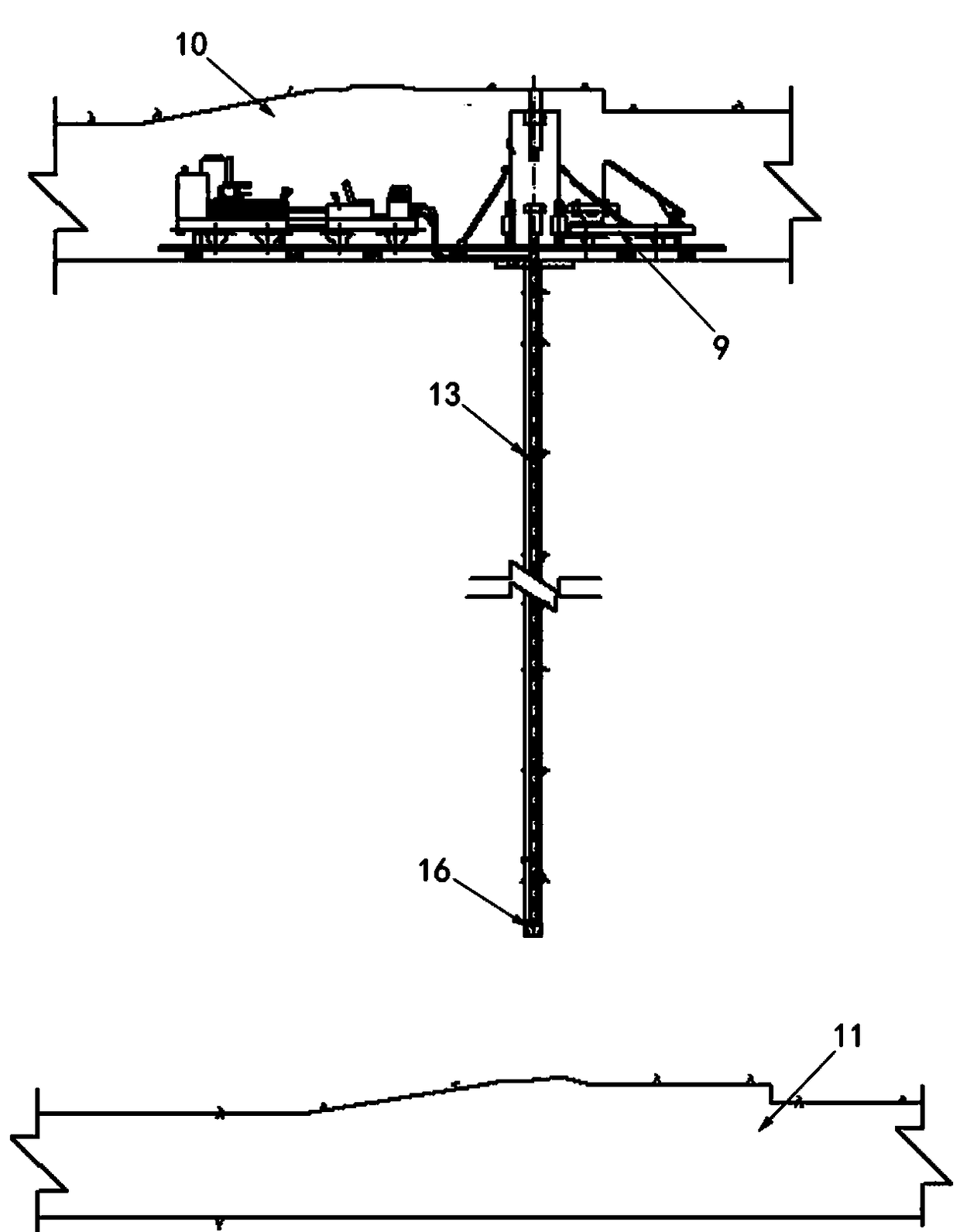

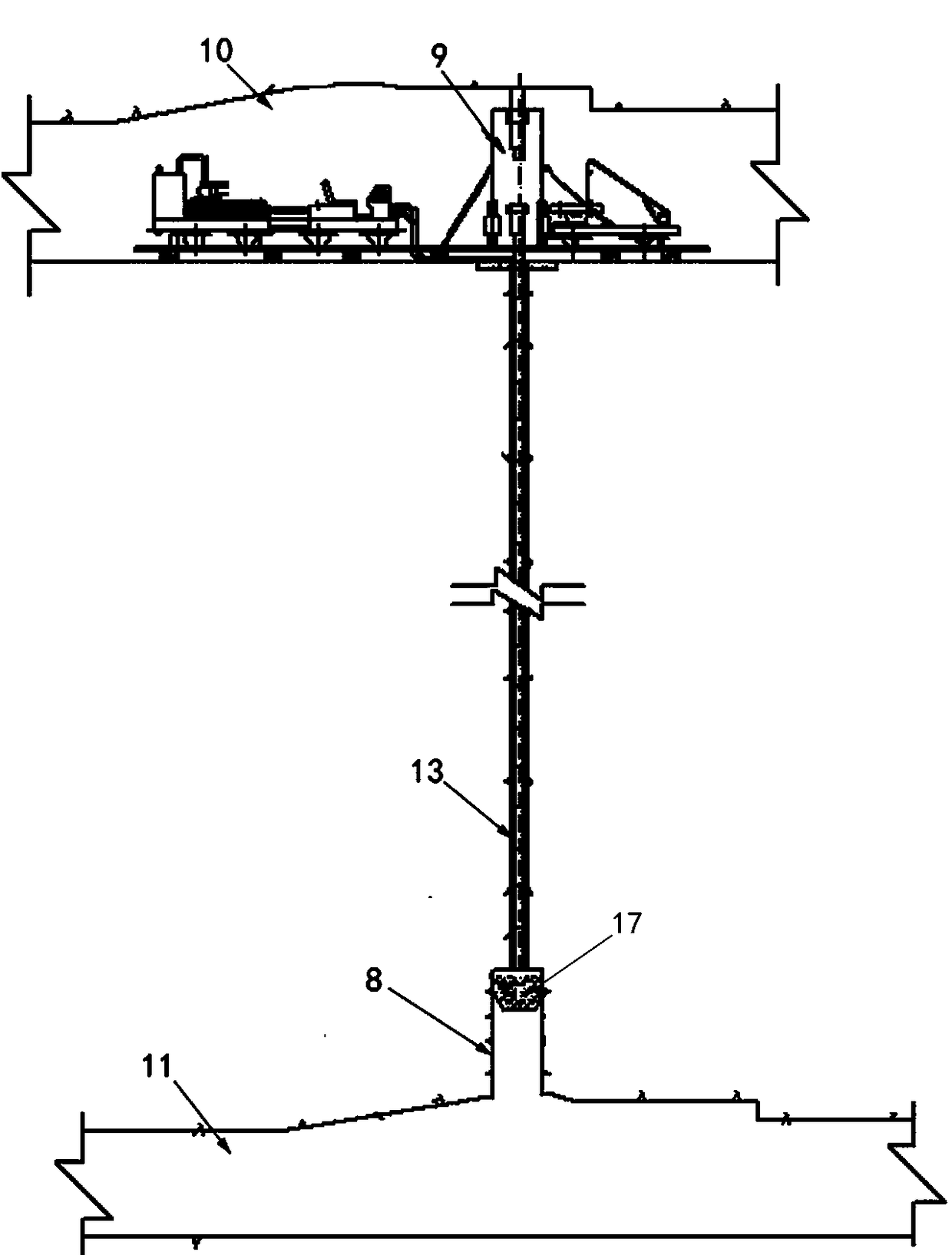

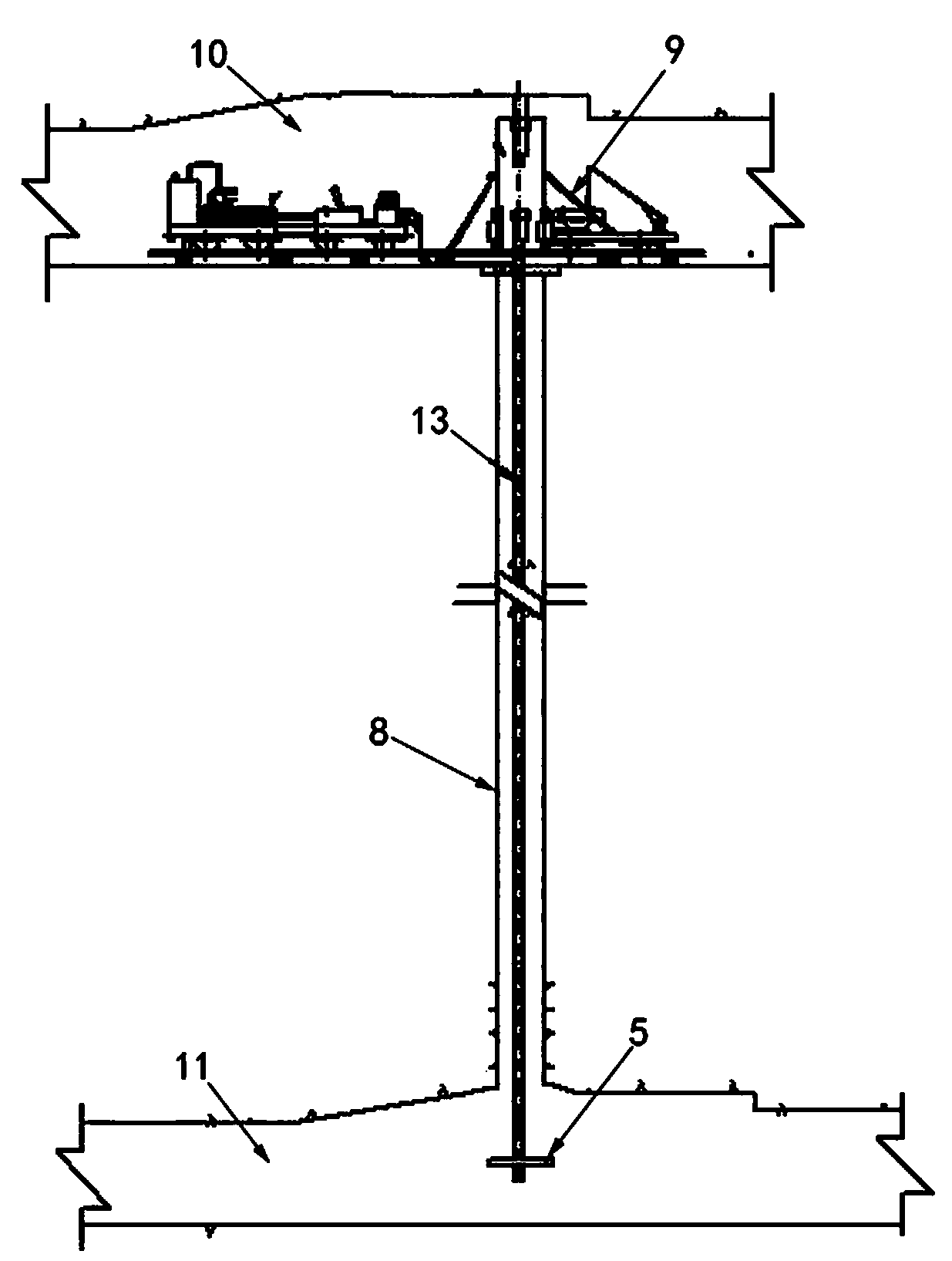

Construction method for utilizing raise-boring machine to mount vertical shaft gas pipe

ActiveCN108626482AEliminate hidden dangers of insecurityEfficient constructionPipe laying and repairGas removalSocial benefitsEconomic benefits

The invention relates to the field of vertical shaft gas pipe installation, in particular to a construction method for utilizing a raise-boring machine to mount a vertical shaft gas pipe. The construction method comprises the following steps: 1, excavating a vertical shaft; 2, mounting a gas pipe; and 3, pouring concrete to reinforce a pipe. With adoption of the construction method for utilizing the raise-boring machine to mount the vertical shaft gas pipe, the potential safety hazard caused by pipeline installation in an oblique lane and a drift is eliminated, fast efficient construction is realized, good reputation is gained, and high social benefit is created. The construction method for utilizing the raise-boring machine to mount the vertical shaft gas pipe is also suitable for installation of other mine types and other pipelines and can generate huge economic benefit.

Owner:XISHAN COAL ELECTRICITY CONSTR ENG GRP CO LTD

Nucleophilic method used for preparing phenylmethyldialkoxysilanes

InactiveCN105254659AEnhanced rapid progress and offensive capabilitiesSmooth responseGroup 4/14 element organic compoundsBenzeneAlkali metal

The invention relates to a nucleophilic method used for preparing phenylmethyldialkoxysilanes. The nucleophilic method comprises following steps: 1) under protection of insert gas, metallic sodium is cut into small pieces and is added into an organic solvent, a dispersing agent is added, and an obtained solution is heated so as to obtain a brightly silvery sodium particle suspension; and 2) the brightly silvery sodium particle suspension is added into a mixed solution of halogeno benzene and methyl trialkoxysilane, and a reaction accelerator is added so as to obtain a phenylmethyldialkoxysilane product, or halogeno benzene is added into the brightly silvery sodium particle suspension so as to obtain a phenyl alkali metal sodium suspension, and the phenyl alkali metal sodium suspension is added into a mixed solution of methyl trialkoxysilane and the reaction accelerator so as to obtain the phenylmethyldialkoxysilane product. Operation of the nucleophilic method is carried out under normal pressure; the nucleophilic method is mild and controllable; phenylmethyldialkoxysilane can be obtained with high yield; and the nucleophilic method is suitable for industrialized and large-scale production.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

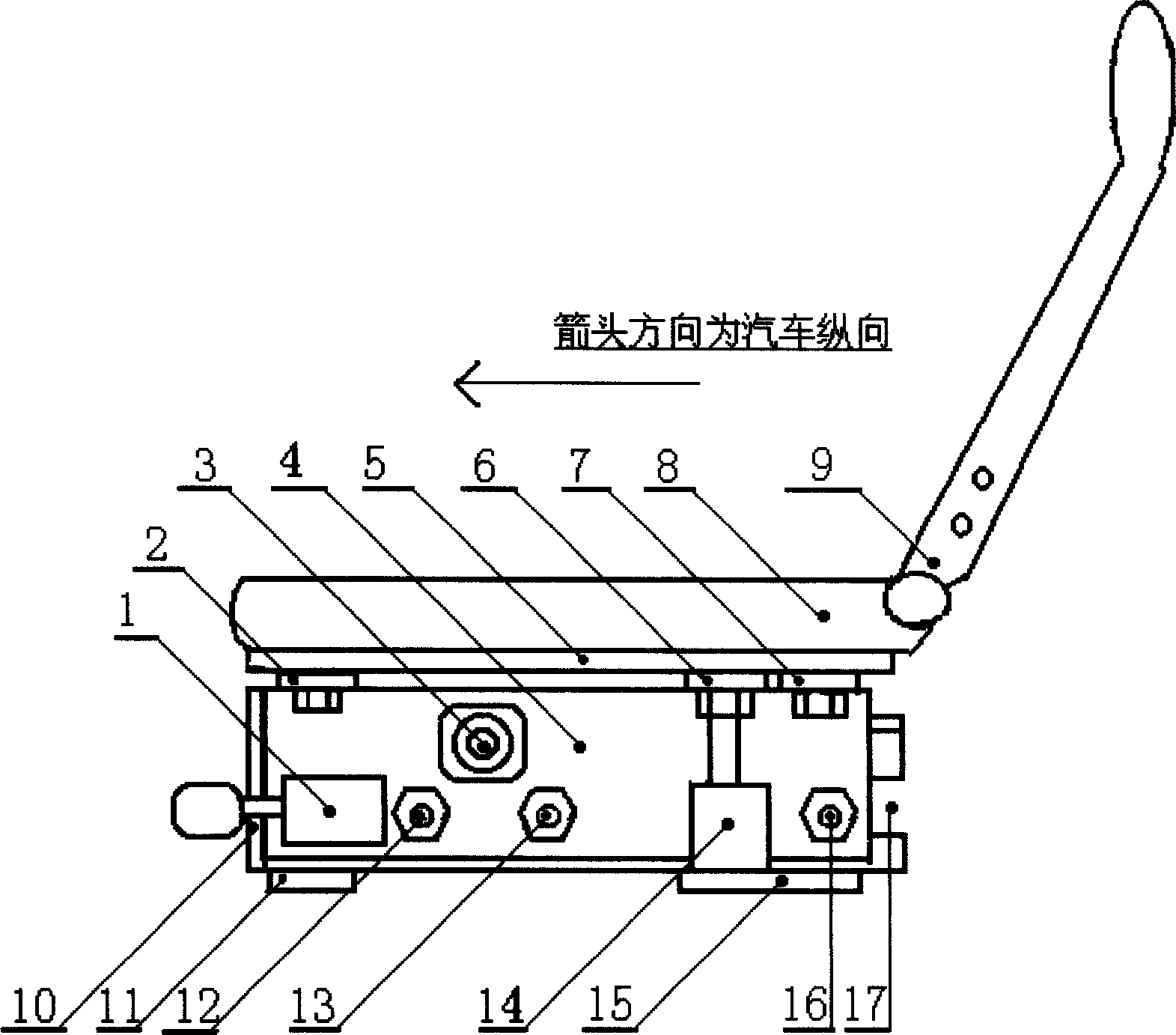

Special front row chair for small vehicle

The special front row chair for small vehicle has one control system to control the chair by means of the inertia force installed below the chair track, one bounce preventer operating in pressing in mode, and one movable frame with rollers mounted on the fixing frame comprising two parallel tracks on the floor and one energy absorber. In emergency, the energy absorber absorbs and converts the kinetic energy of the chair, the control system operates, the locked chair and the rider move backwards and the chair is locked with the bounce preventer to protect the ride.

Owner:刘熙

Method and equipment for using condensed water of new steam stripped under high pressure

InactiveCN1872690AEliminate bad consequencesEliminate hidden dangers of insecurityAluminium oxides/hydroxidesResource utilizationEngineering

This invention discloses a device for utilizing high-pressure stripped steam condensate. The device comprises a condensate channel, a water inlet, an air outlet, an exit, a pump and pipelines. When the steam enters the condensate channel, a large amount of gas is produced, part of which can be provided to thermal water stations and thermal water channels, and the rest can be provided to steam stations. The condensate is discharged through the condensate channel by the pump. The device has such advantages as balanced pressure, high resource utility and high safety, and can be used in aluminumoxide production.

Owner:GUIYANG AL-MG DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com