Self burring device for gear hobbing machine

A gear hobbing machine and deburring technology, which is applied to gear teeth, mechanical equipment, components with teeth, etc., can solve the problems of large chamfering cutter chamfering grinding wheel loss of gear hobbing machines, easy hand injury, etc., to eliminate unsafe hidden dangers , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

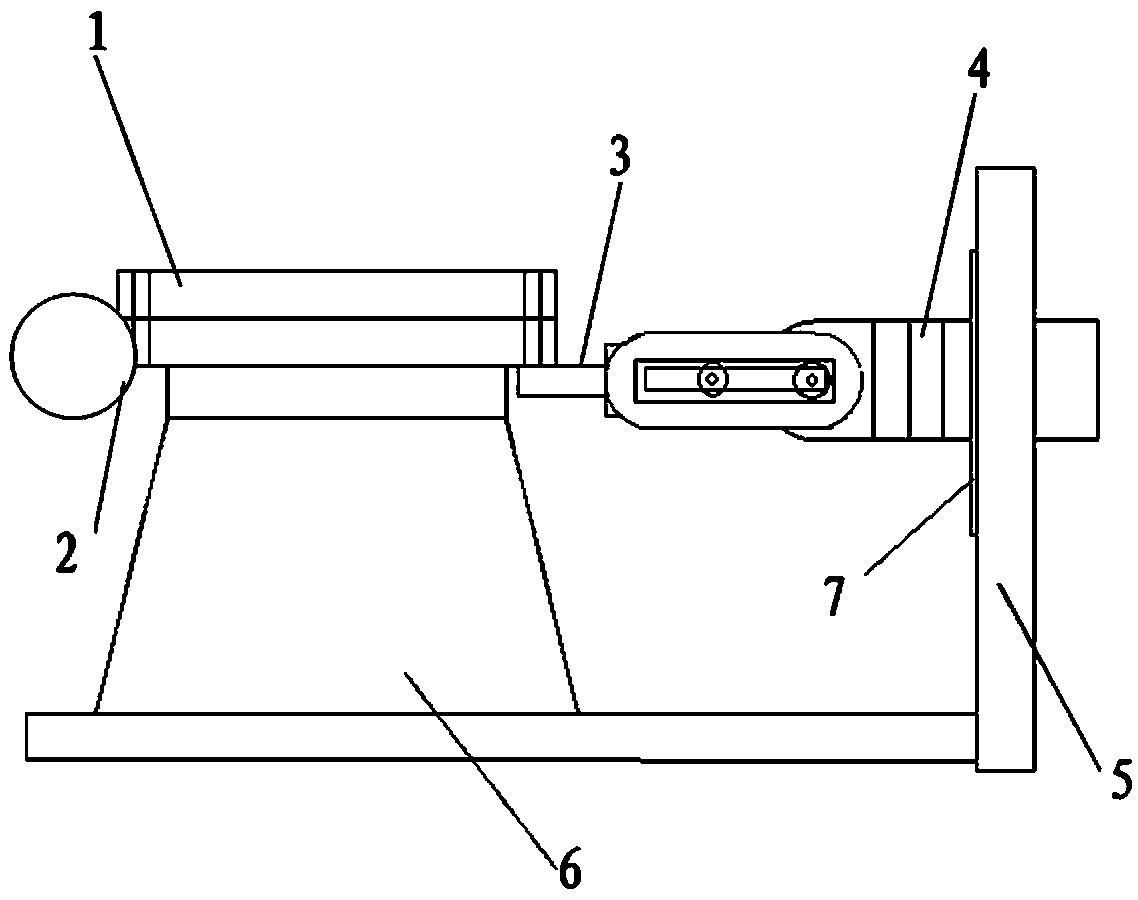

[0008] figure 1 As shown, it is a gear hobbing machine self-deburring device, which includes a gear hobbing machine table 6 with a gear hob 2 at the front, a column 5 at the rear of the gear hobbing machine table 6, and a rail 7 on the column 5 , the track 7 is provided with a self-deburring device 4 that can move up and down, the front end of the self-deburring device 4 is provided with a white steel knife 3, and the working surface of the white steel knife 3 is arranged on the working surface of the gear hobbing machine. The ends of the workpiece 1 on the stage 6 correspond. Wherein, the hardness of the white steel knife 3 is selected as HRC66. In this way, the deburring effect of the workpiece is better. In the present invention, the white steel knife in the self-deburring device is used to scrape off the flanging burrs which are continuously generated during gear hobbing, thereby eliminating unsafe hidden dangers and reducing production costs.

[0009] The above descrip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com