Method and equipment for using condensed water of new steam stripped under high pressure

A technology of high-pressure dissolution and condensate water, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of difficult continuous and stable operation of production, perforation or cracks of heating tube bundles, pressure imbalance, etc., to eliminate unsafe hidden dangers and eliminate defects Consequences, the effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

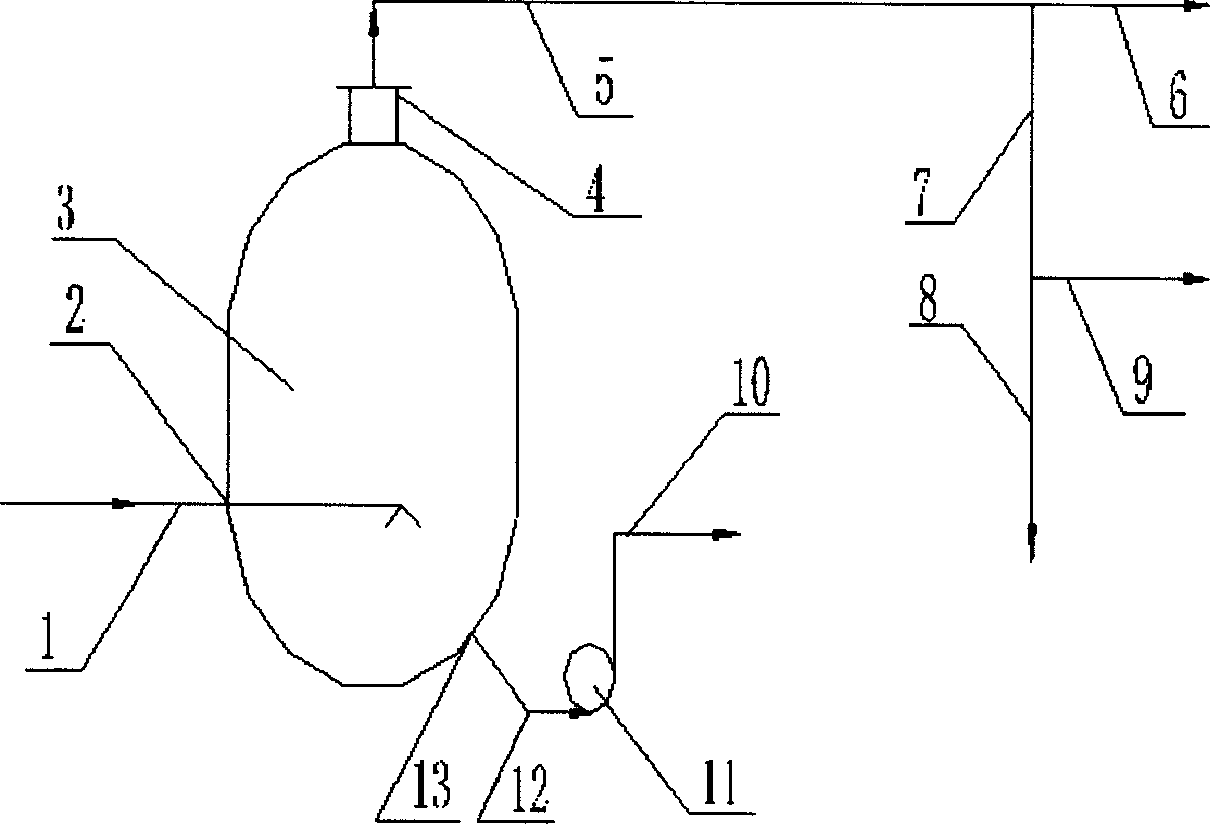

[0011] Embodiment of the present invention: According to the amount of fresh steam for high-pressure stripping and the usage of each steam point, design the condensate tank and various pipelines, and determine the model and specification of the pump. An inlet 2, an exhaust nozzle 4 and an outlet 13 are made on the condensate tank 3, and the pipe 1 is extended from the inlet 2 into the inside of the condensate tank 3, and it is firmly connected at the inlet 2, and one end of the pipe 12 is connected to the outlet 13 connection, the other end is connected to the inlet of pump 11, the outlet of pump 11 is connected to pipeline 10, the exhaust nozzle 4 is connected to main pipe 5, main pipe 5 is connected to branch pipe 6 and branch pipe 7, and branch pipe 7 is connected to branch pipe 8 and branch pipe 9 .

[0012] When working, after the high-pressure stripping new steam condensate is throttled and decompressed into the condensate tank, a large amount of secondary steam generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com