Patents

Literature

12937results about How to "Improve resource utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Data storage method, device and system and management server

InactiveUS20100268908A1Increase load on and instabilityLow utilization ratioError detection/correctionMemory adressing/allocation/relocationInstabilityResource utilization

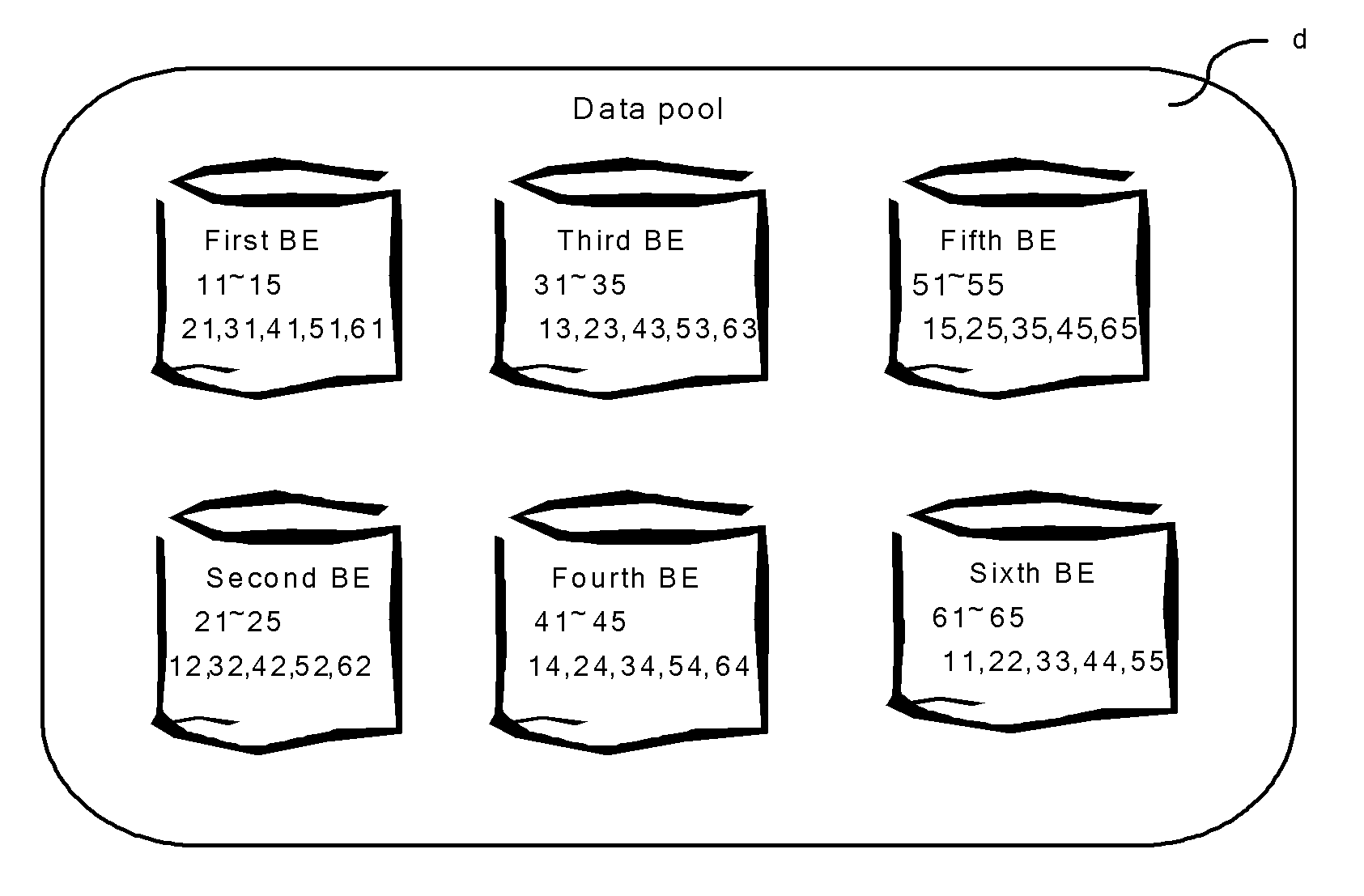

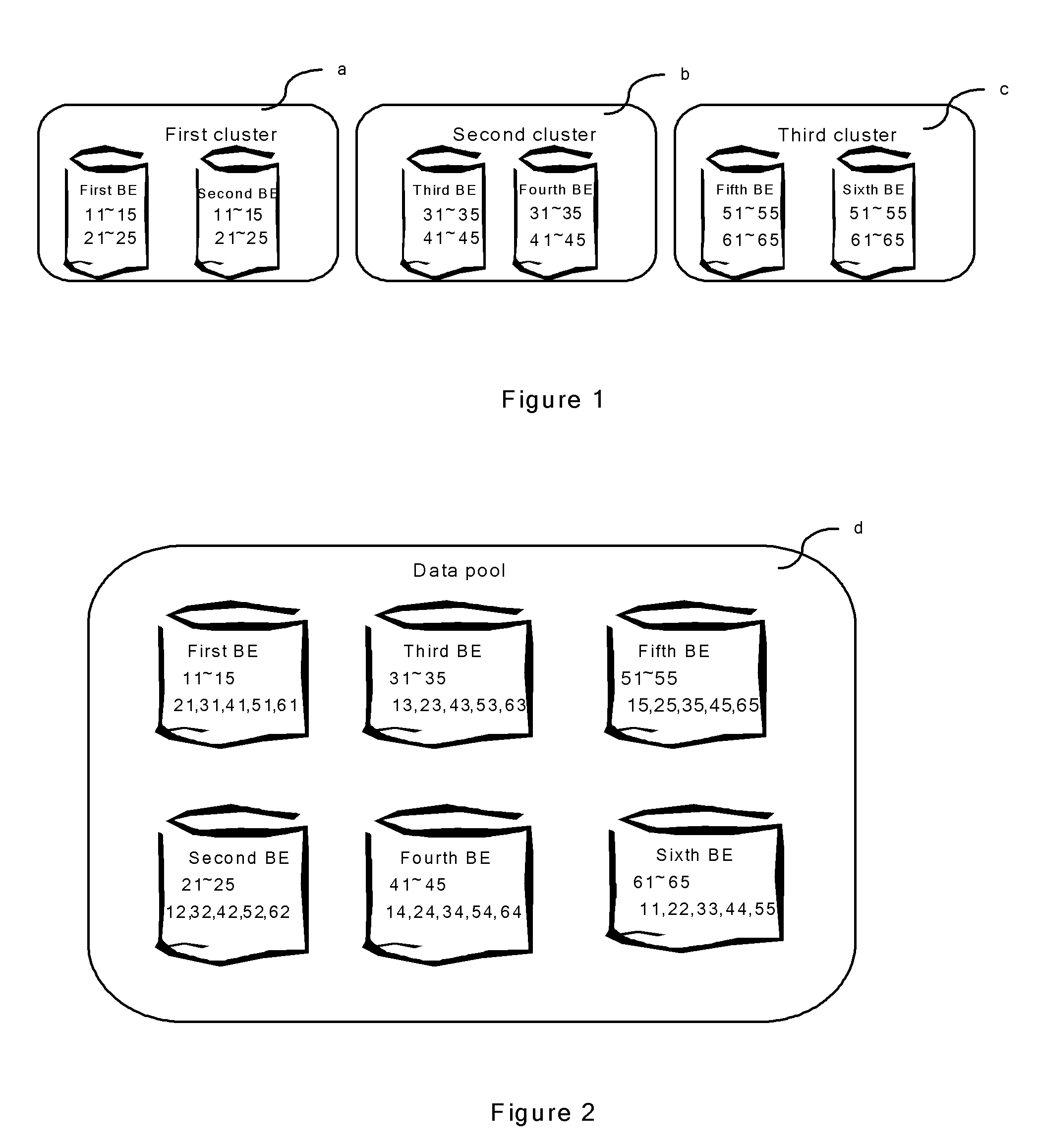

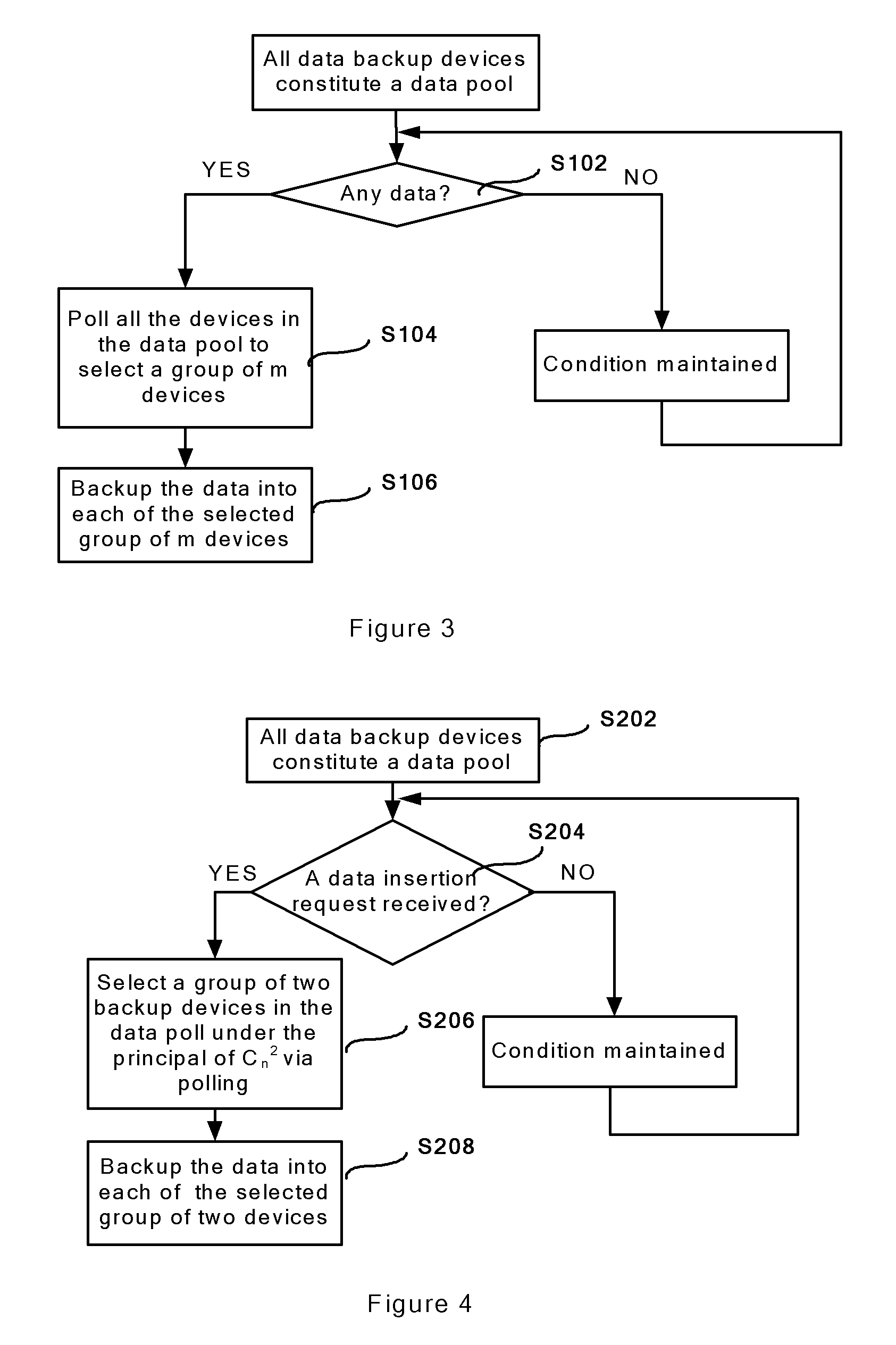

The present invention relates to a data storage method, device and system and a management server. The data storage method includes: constituting a data pool from all of n data storage devices; when there is data for storage, polling all the devices in the data pool to select a group of m devices, and storing the data onto each of the selected group of m devices, where m is larger than one and smaller than n. The embodiments of the invention can address the problems of an existing data storage approach that a failing node causes an increased load on and instability of another node and that each node in the existing data storage approach has a low utilization ratio and poor predictability, so as to achieve uniform loads on the devices and high reliability of the nodes despite any failing node and improve the resource utilization ratio and predictability of the nodes.

Owner:CHINA MOBILE COMM GRP CO LTD

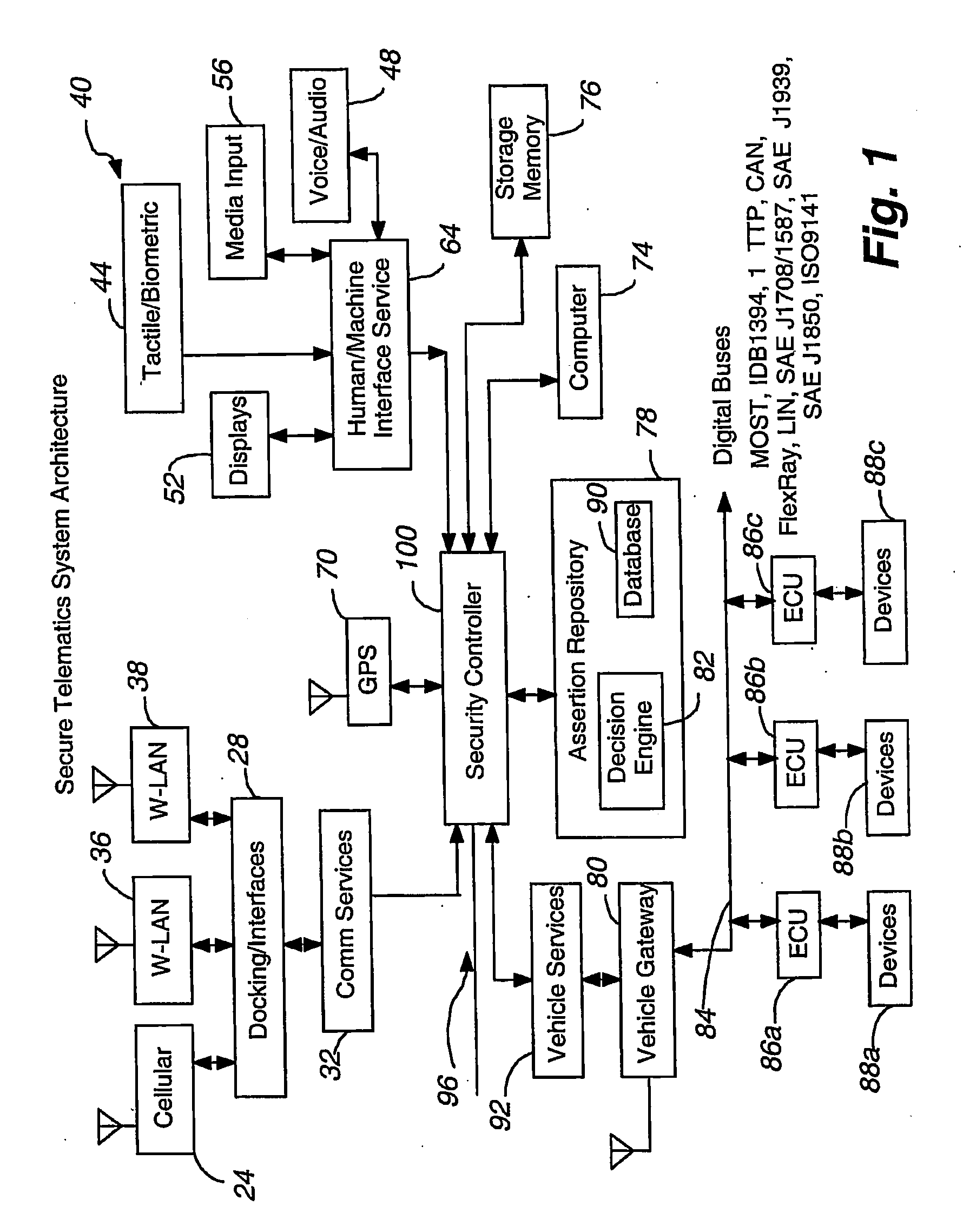

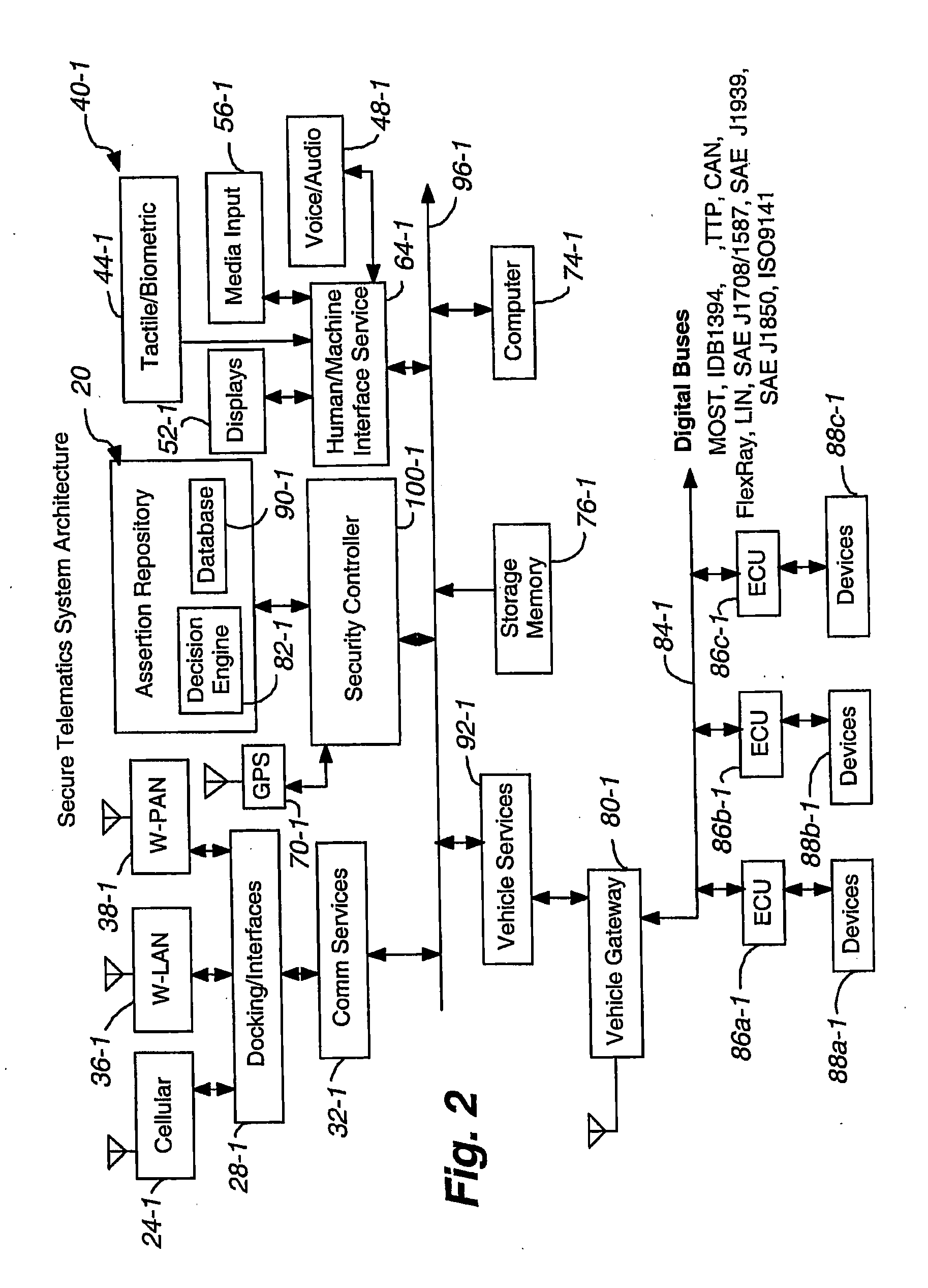

Secure telematics

InactiveUS20080148374A1Expands telematics usageImprove integrityVehicle testingRegistering/indicating working of vehiclesComputer networkService provision

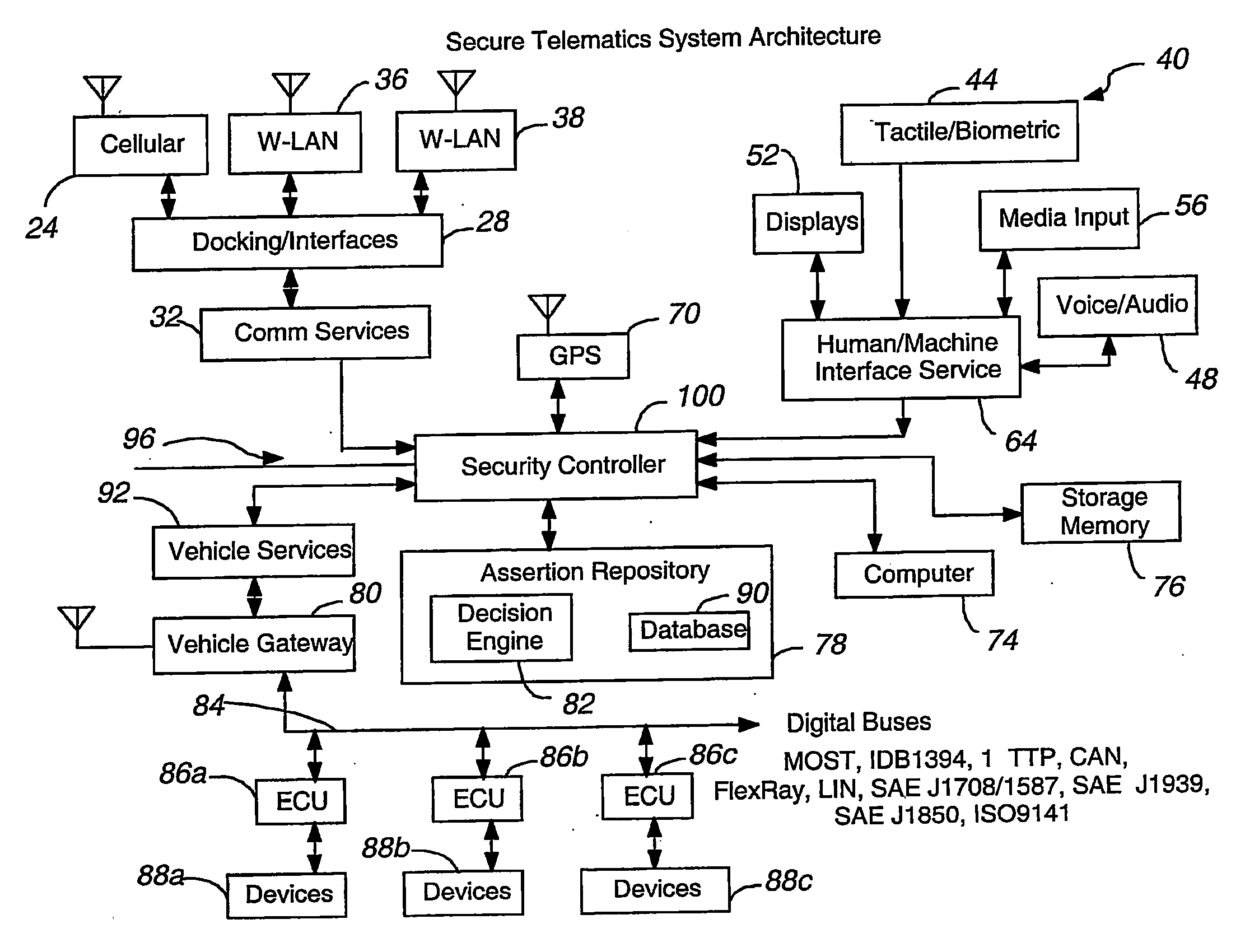

A telematics system that includes a security controller is provided. The security controller is responsible for ensuring secure access to and controlled use of resources in the vehicle. The security measures relied on by the security controller can be based on digital certificates that grant rights to certificate holders, e.g., application developers. In the case in which applications are to be used with vehicle resources, procedures are implemented to make sure that certified applications do not jeopardize vehicle resources' security and vehicle users' safety. Relationships among interested entities are established to promote and support secure vehicle resource access and usage. The entities can include vehicle makers, communication service providers, communication apparatus vendors, vehicle subsystem suppliers, application developers, as well as vehicle owners / users. At least some of the entities can be members of a federation established to enhance and facilitate secure access and usage of vehicle resources.

Owner:CYBERCAR INC

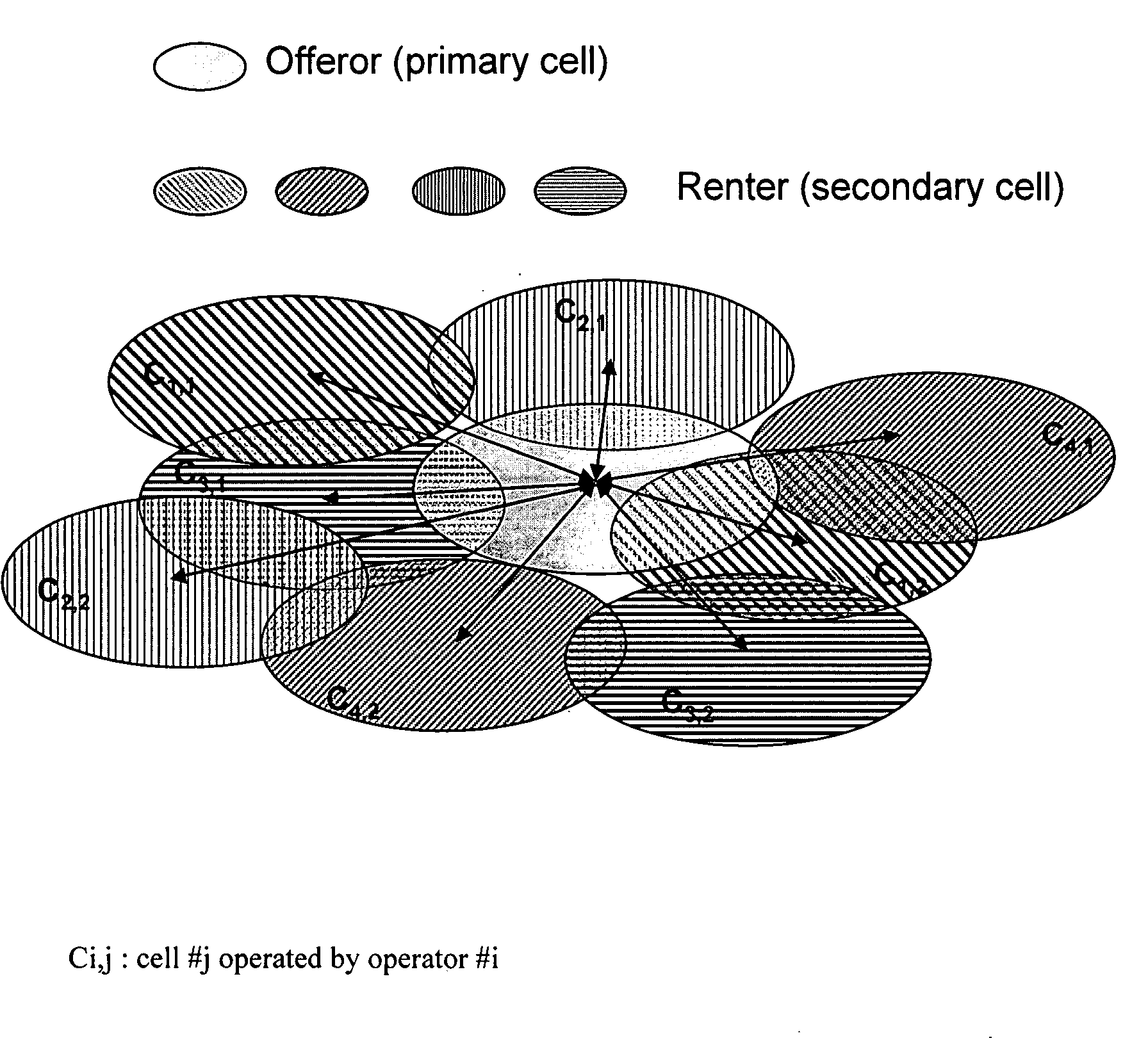

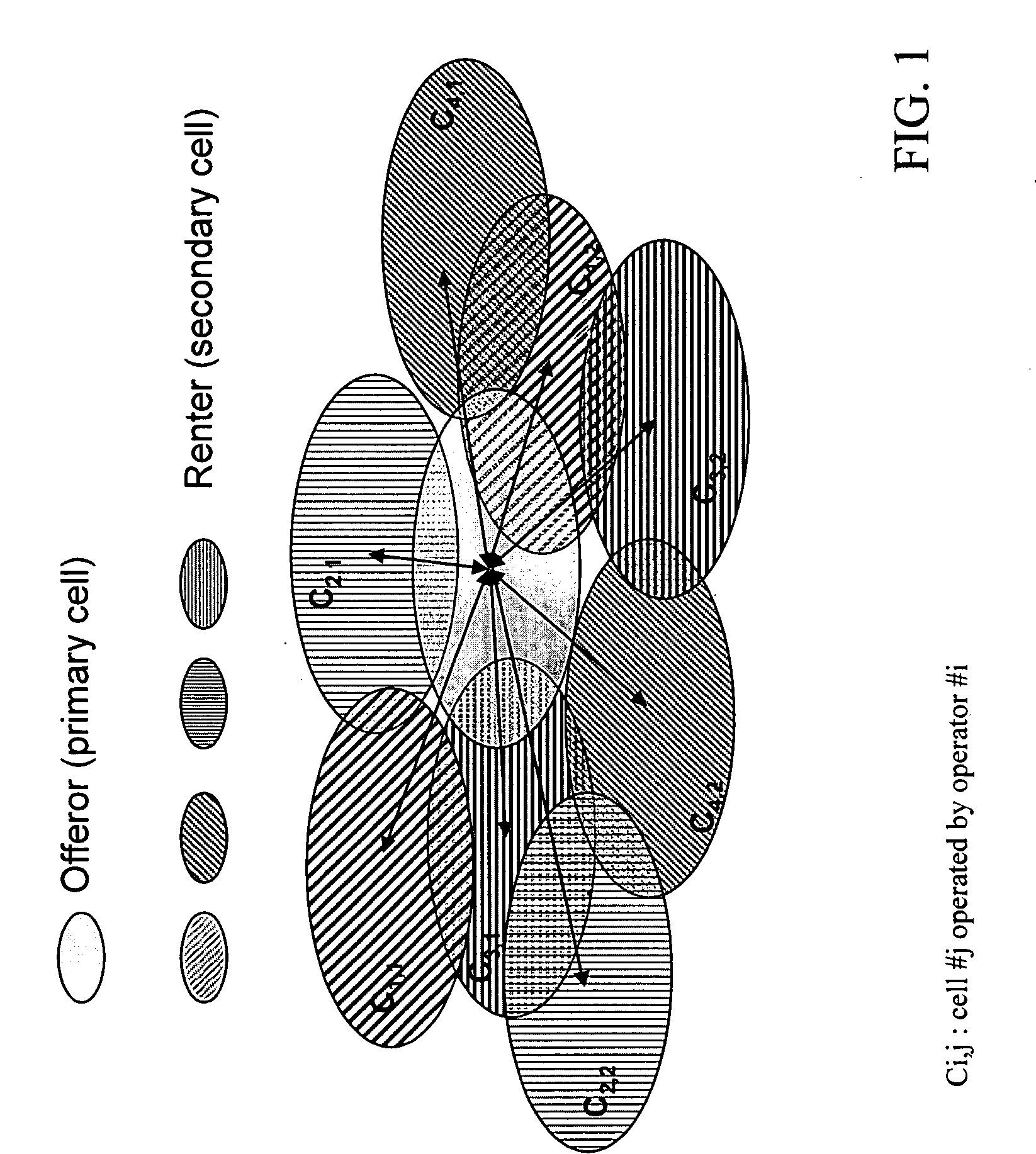

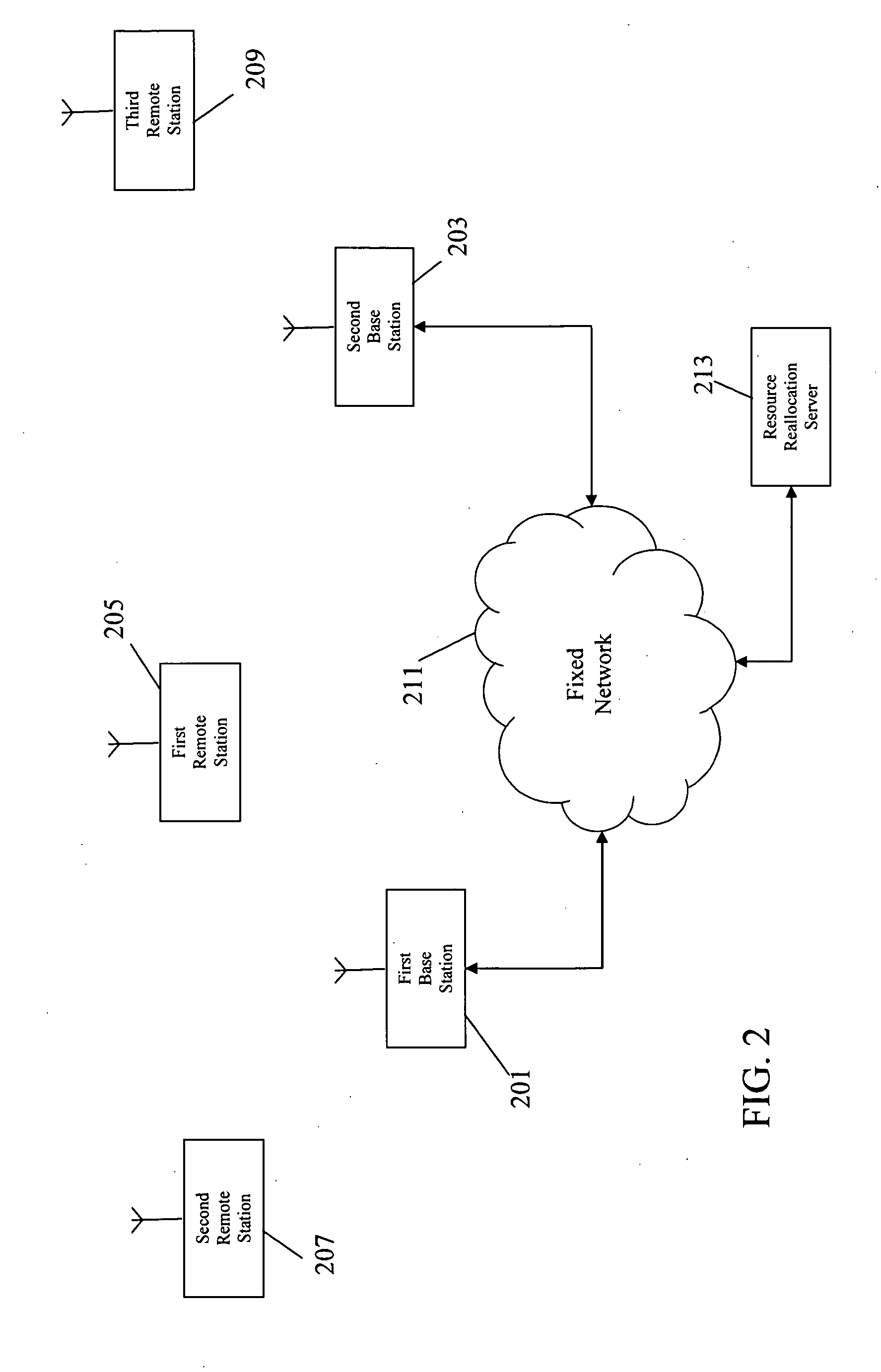

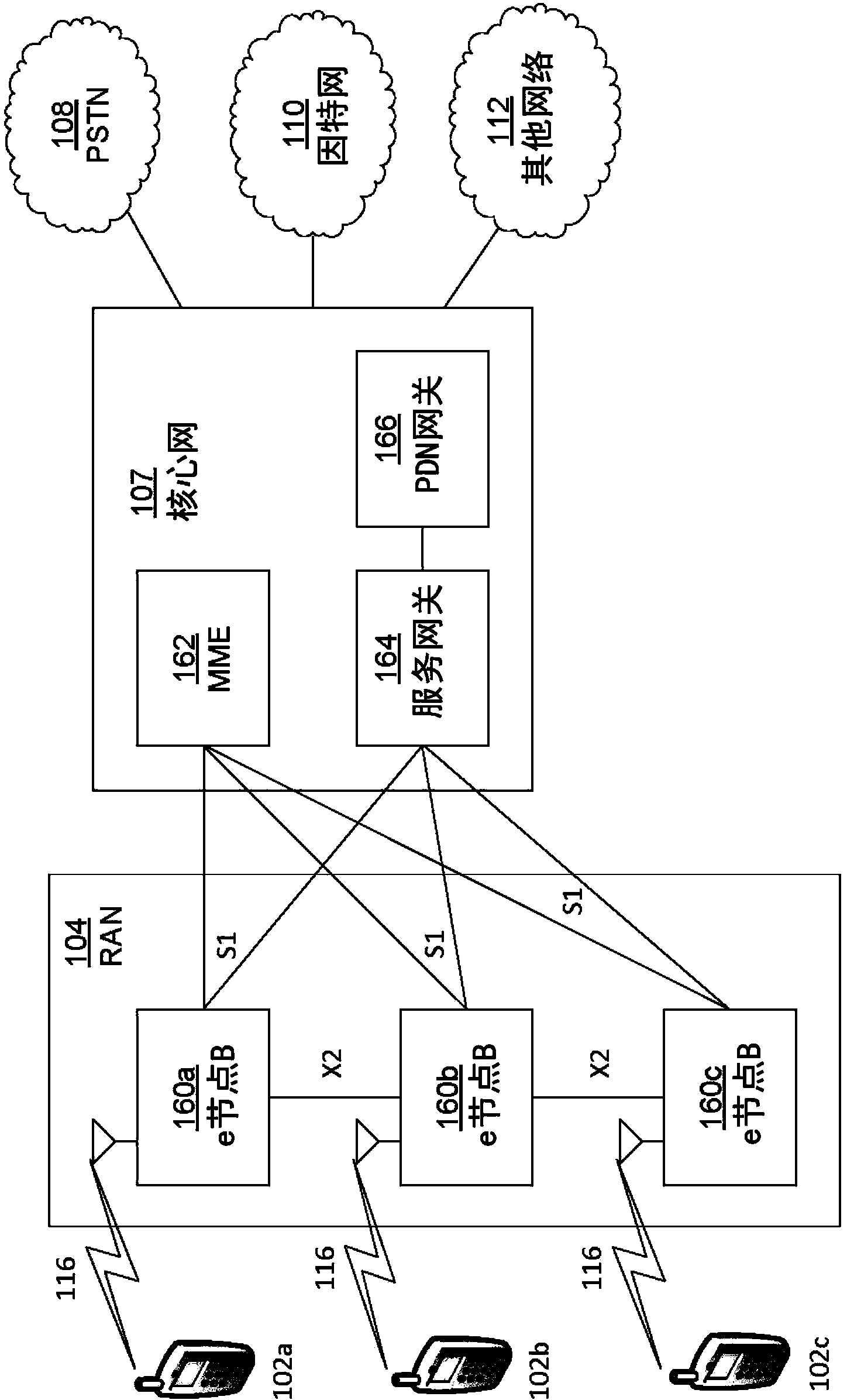

Resource exchange discovery in a cellular communication system

ActiveUS20090161614A1Efficient disseminationEasy to useConnection managementWireless commuication servicesAir interfaceStructure of Management Information

A cellular communication system comprises a set of base stations (201,203) which transmit downlink resource exchange discovery messages to remote terminals in resource allocations of a Media Access Control, MAC, frame structure. The discovery messages may indicate that a base station has resource available for reallocation to another base station or that a base station is seeking resource to be allocated from another base station. A remote terminal (205) comprises a receiver (401, 403) which receives a first message of the downlink resource exchange discovery messages from at least a first base station (201). A discovery message transmit processor (407) generates a second message, which is an uplink resource exchange message comprising resource exchange data determined from the first message, and transmits this to a second base station (203). The second base station (203) then initiates a temporary air interface resource reallocation with the first base station in response to receiving the second message.

Owner:MOTOROLA SOLUTIONS INC

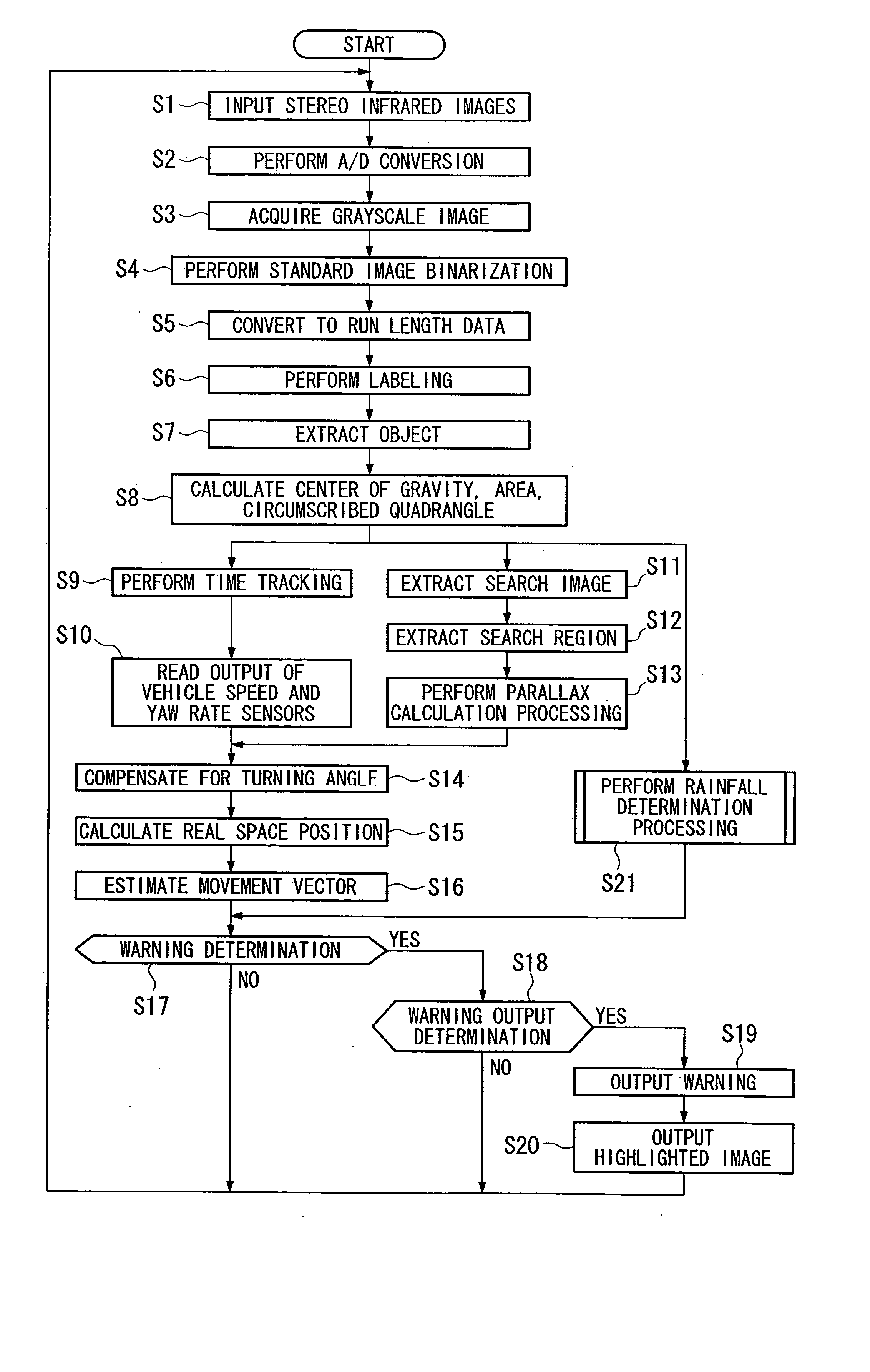

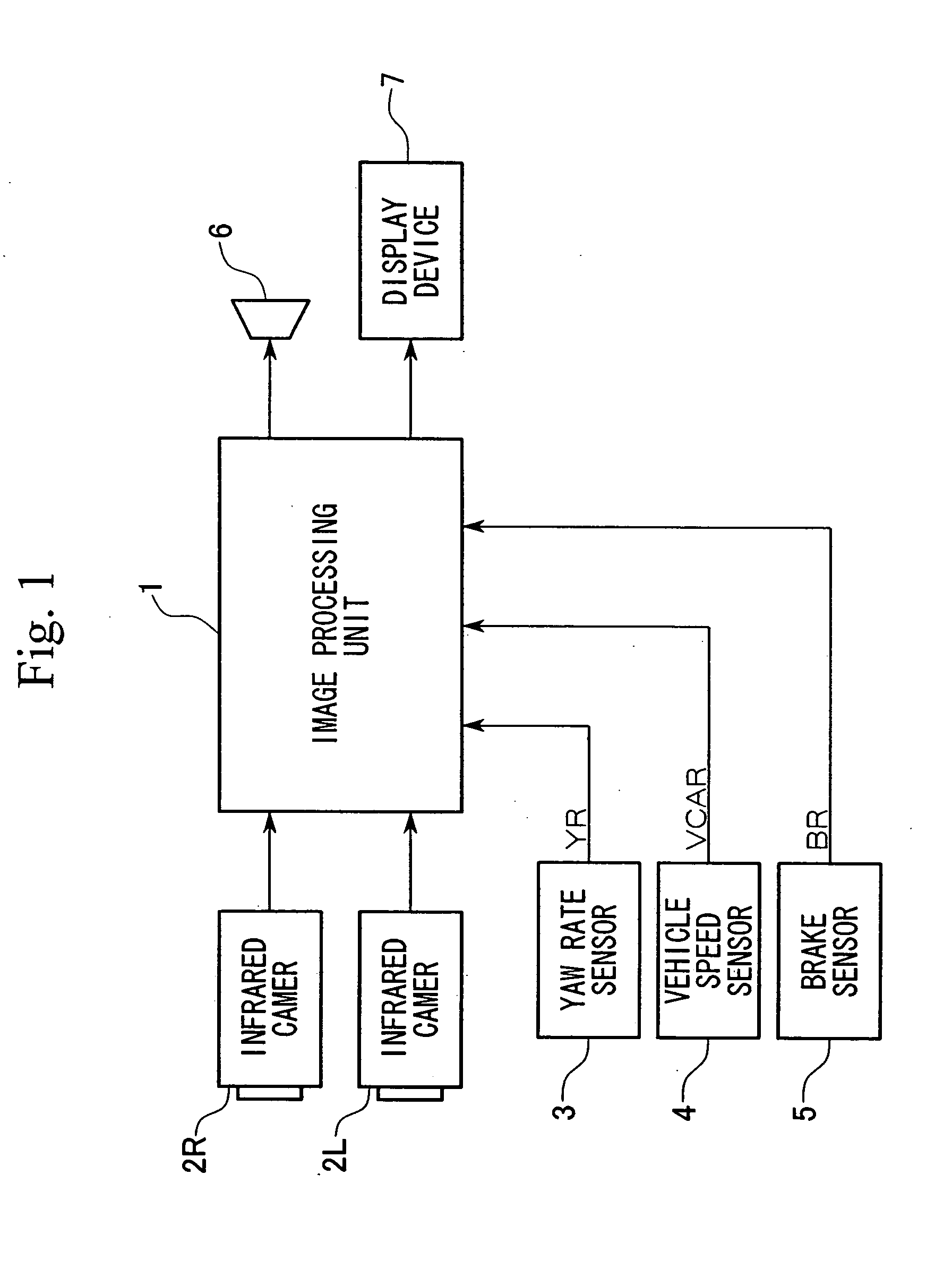

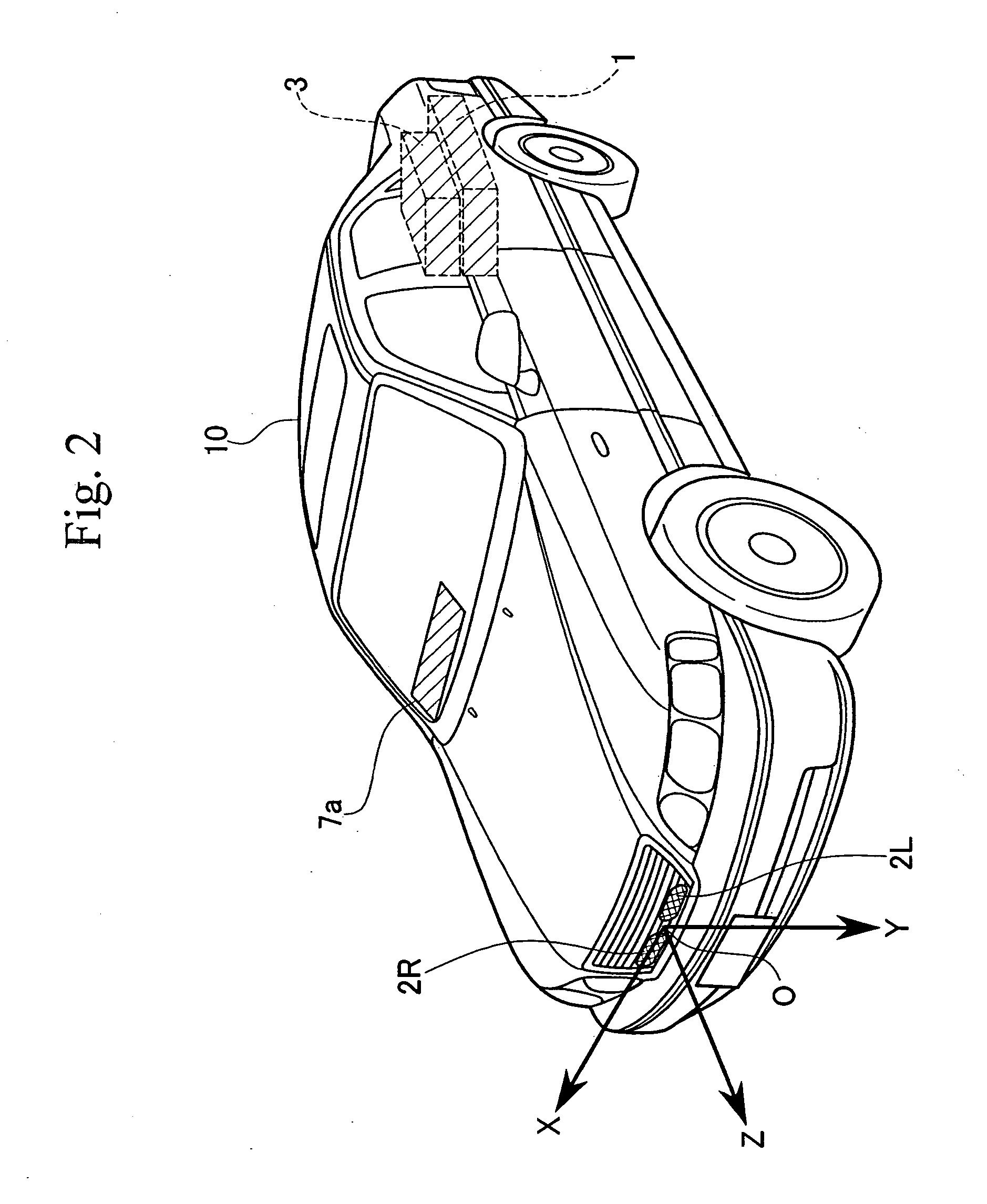

Vehicle environment monitoring device

ActiveUS20050063565A1Improve resource utilizationAccurate judgmentImage enhancementImage analysisHeight differenceState of the Environment

A vehicle environment monitoring device identifies objects from an image taken by an infrared camera. Object extraction from images is performed in accordance with the state of the environment as determined by measurements extracted from the images as follows: N1 binarized objects are extracted from a single frame. Height of a grayscale objects corresponding to one of the binarized objects are calculated. If a ratio of the number of binarized objects C, where the absolute value of the height difference is less than the predetermined value ΔH, to the total number N1 of binarized objects, is greater than a predetermined value X1, the image frame is determined to be rainfall-affected. If the ratio is less than the predetermined value X1, the image frame is determined to be a normal frame. A warning is provided if it is determined that the object is a pedestrian and if a collision is likely.

Owner:ARRIVER SOFTWARE AB

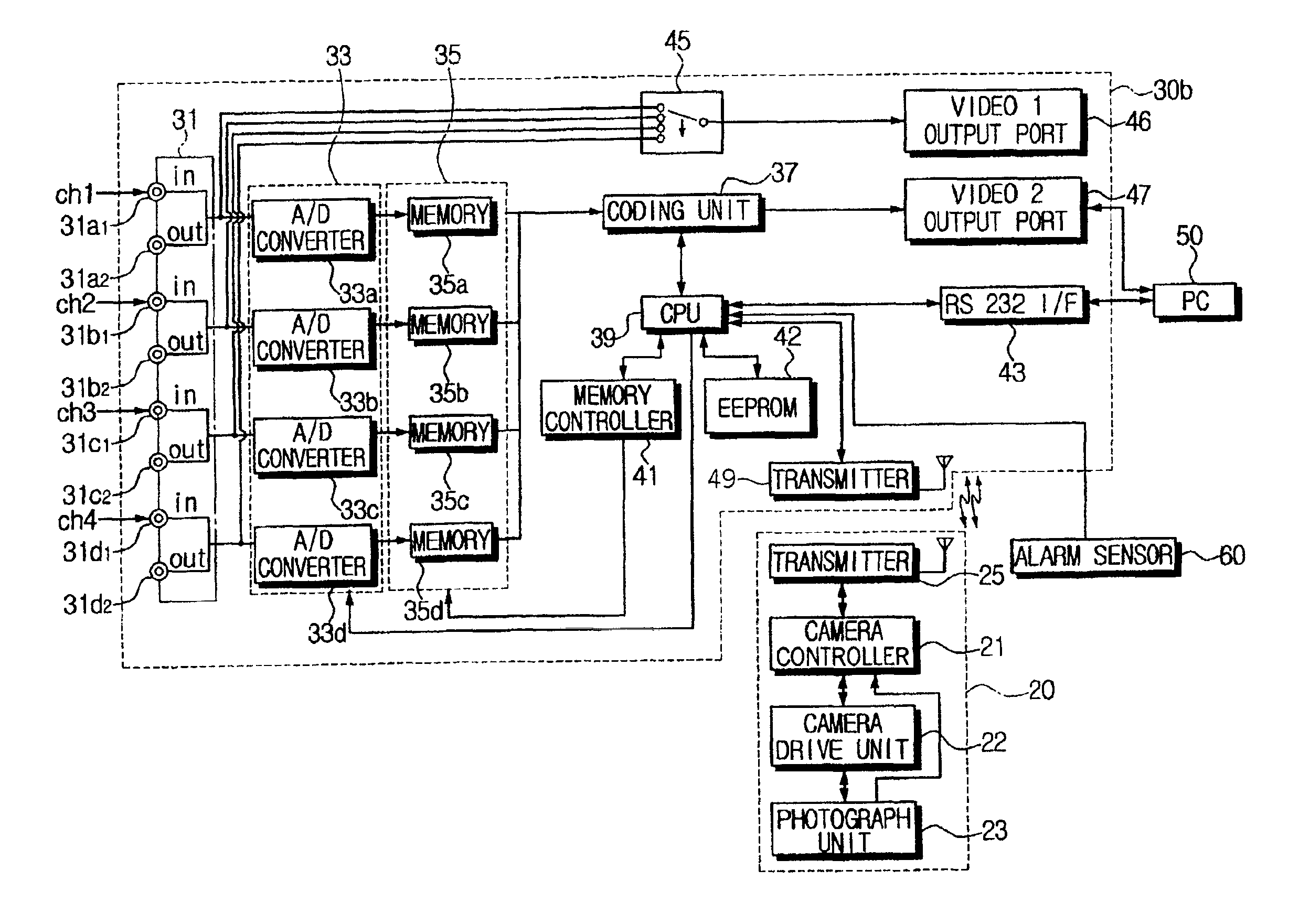

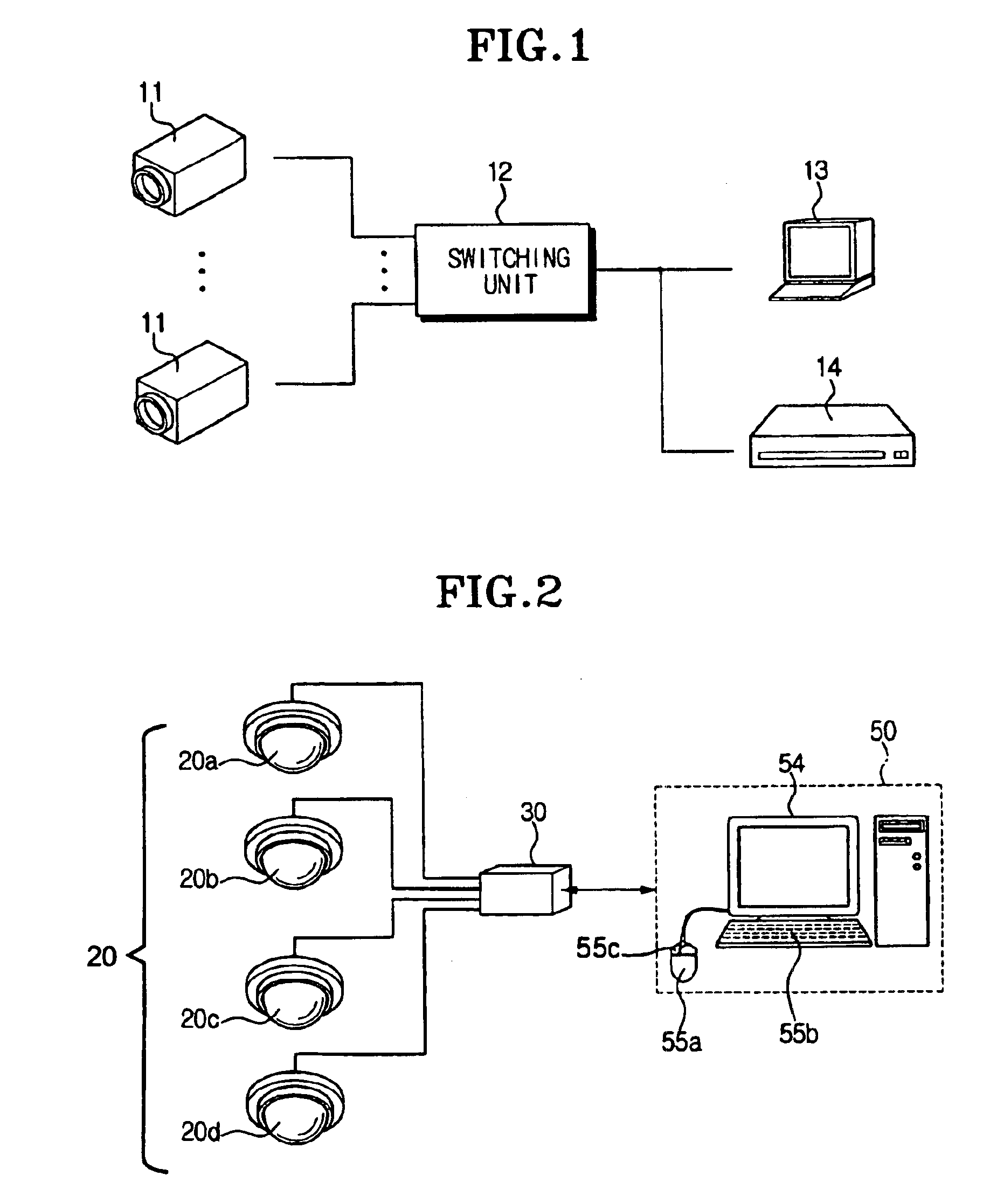

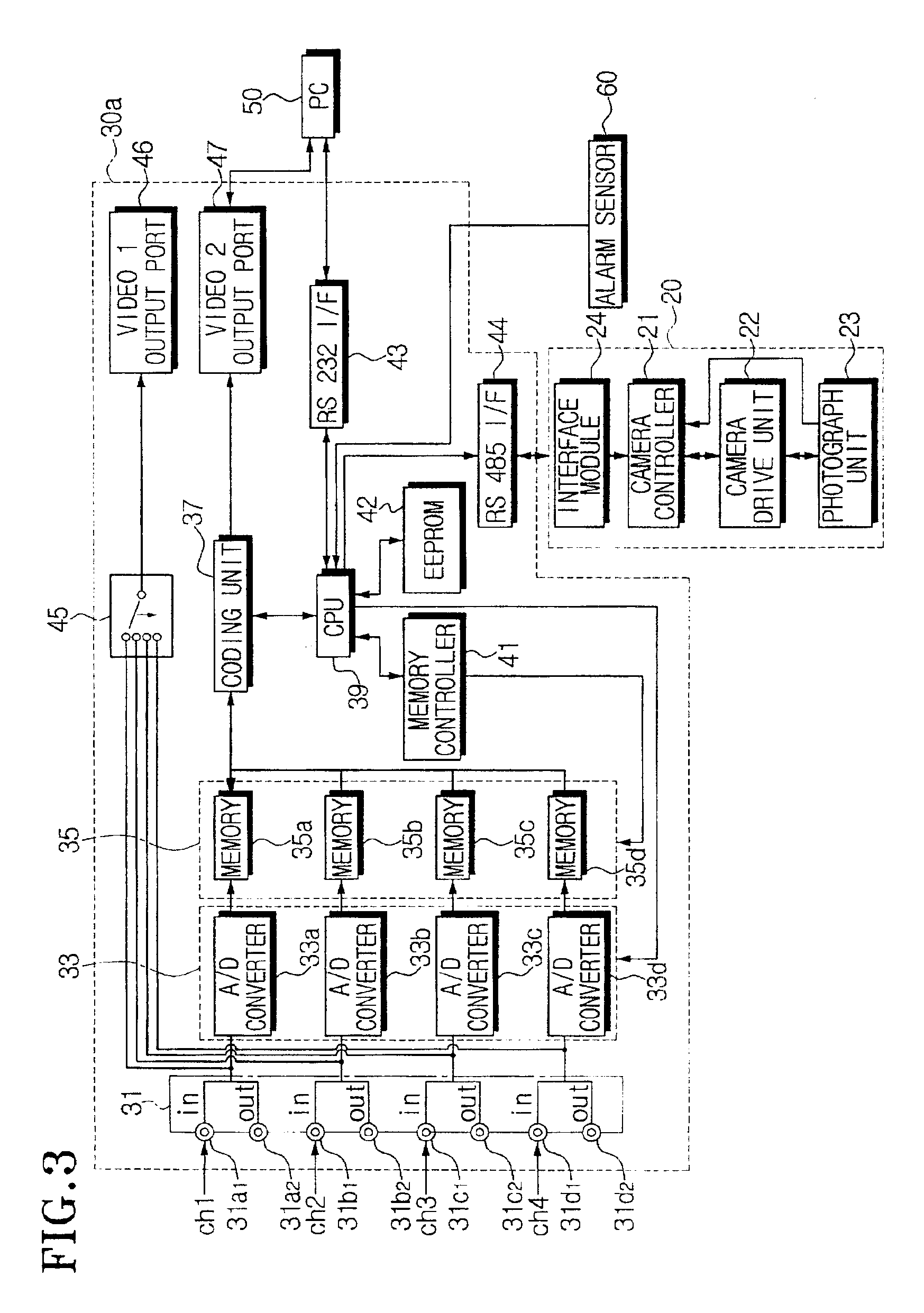

Multichannel image processor and security system employing the same

InactiveUS6956477B2Improve resource utilizationReduce space constraintsColor television detailsClosed circuit television systemsCommunication interfaceComputer graphics (images)

Owner:HANWHA TECHWIN CO LTD

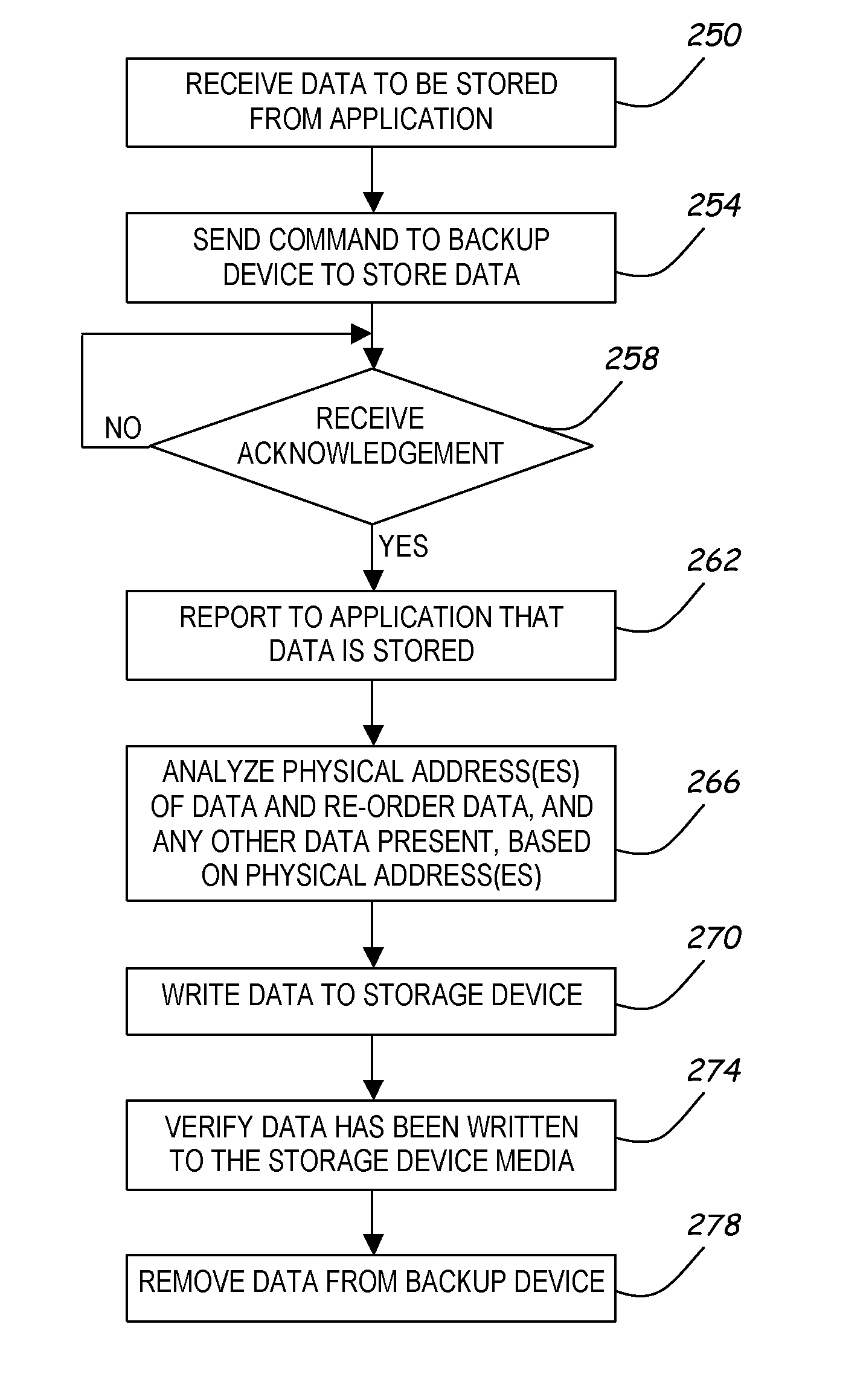

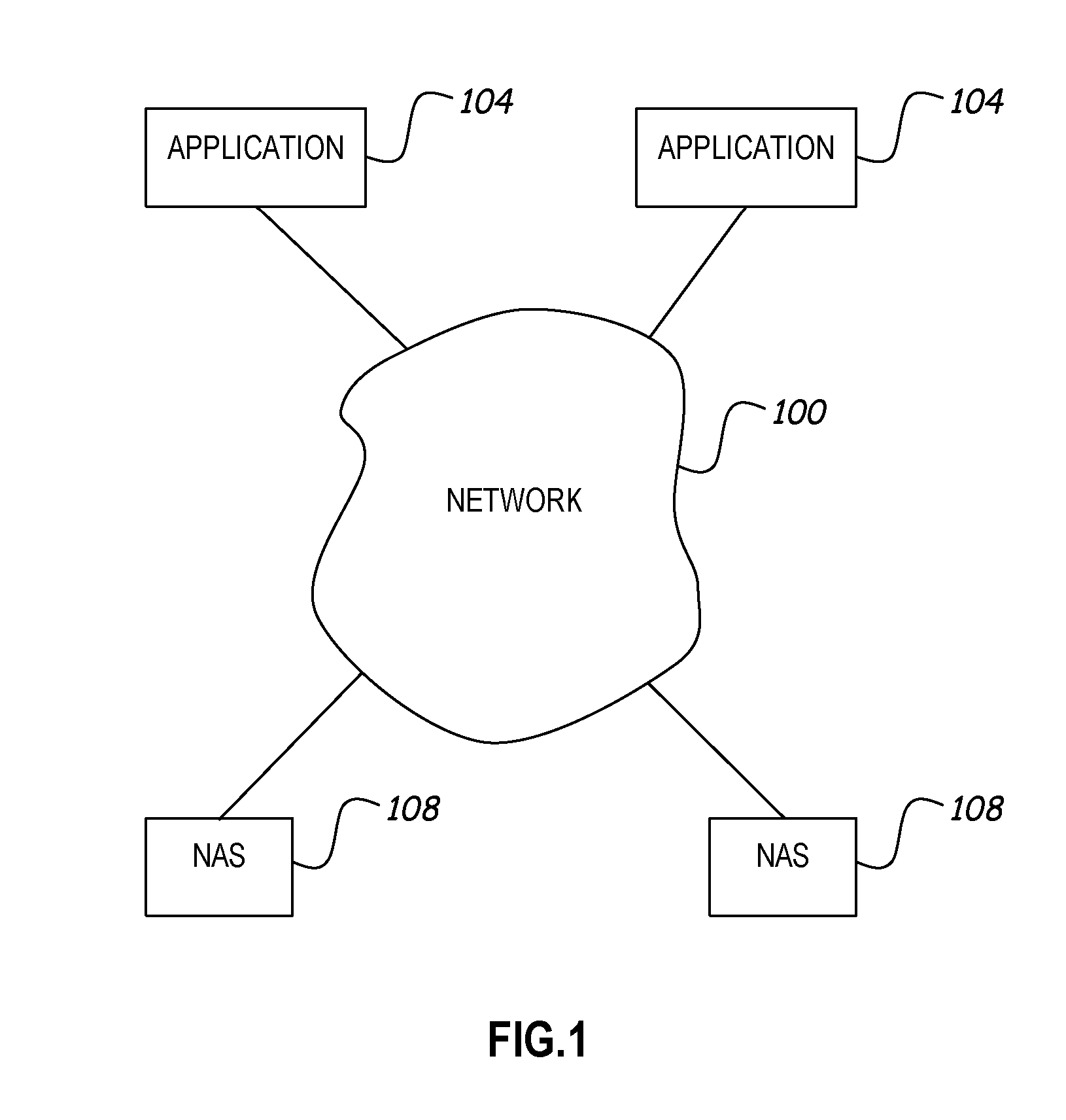

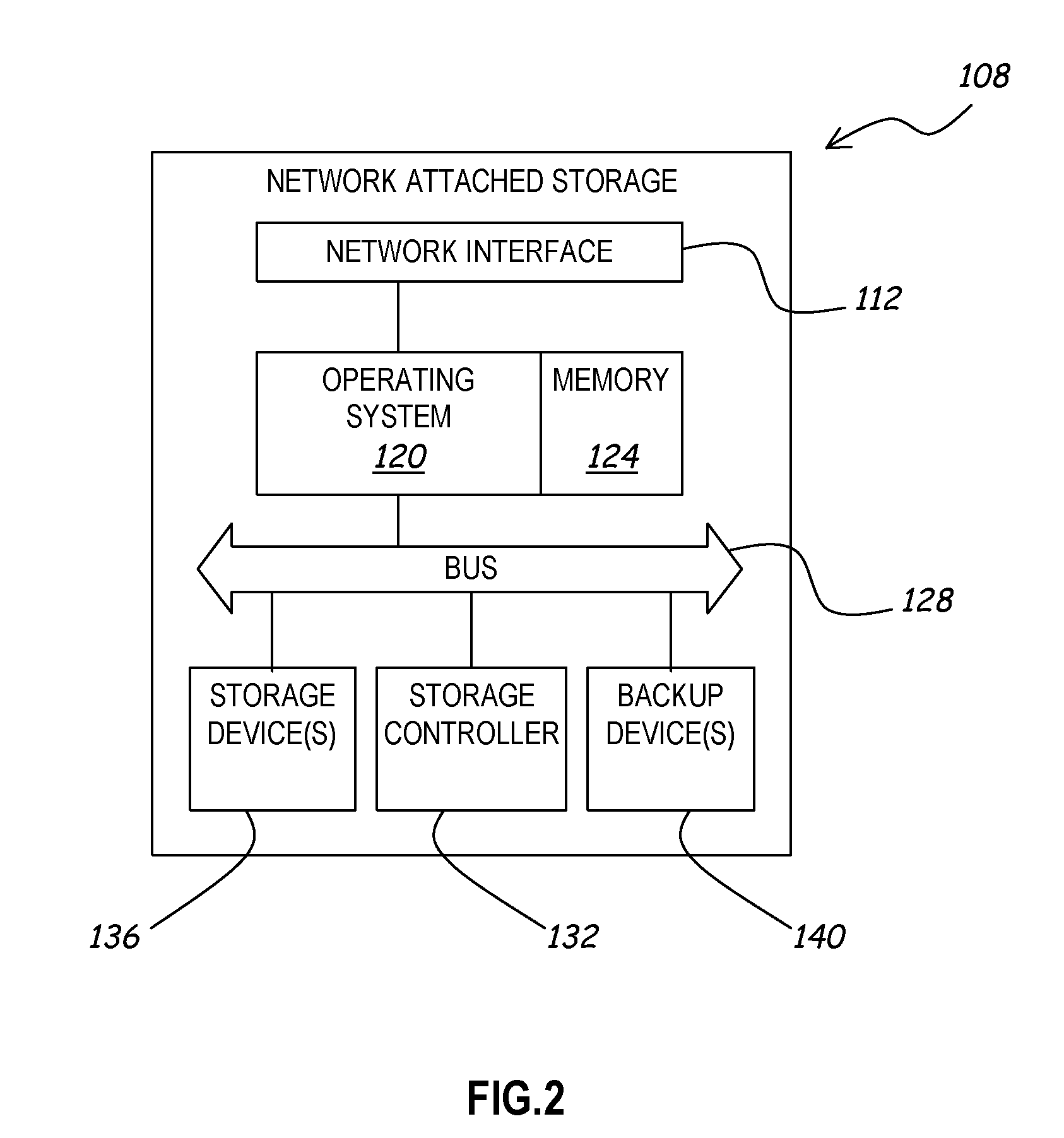

Non-Volatile Memory Backup for Network Storage System

InactiveUS20060080515A1Improve resource utilizationImprove efficiencyError detection/correctionMemory systemsStandby powerData storing

A data storage system including a primary data storage device and a backup data storage device stores data with enhanced performance. The primary data storage device has a primary data storage device memory for holding data, and the backup data storage device has a backup volatile memory, a backup non-volatile memory, and a processor. The backup storage device processor causes a copy of data provided to the primary data storage device to be provided to the backup data storage device volatile memory, and in the event of a power interruption moves the data from the backup volatile memory to the backup non-volatile memory. In such a manner, data stored at the backup data storage device is not lost in the event of a power interruption. The backup data storage device further includes a backup power source such as a capacitor, a battery, or any other suitable power source, and upon detection of a power interruption, switches to the backup power source and receives power from the backup power source while moving the data from the backup volatile memory to the backup non-volatile memory.

Owner:HEWLETT PACKARD DEV CO LP

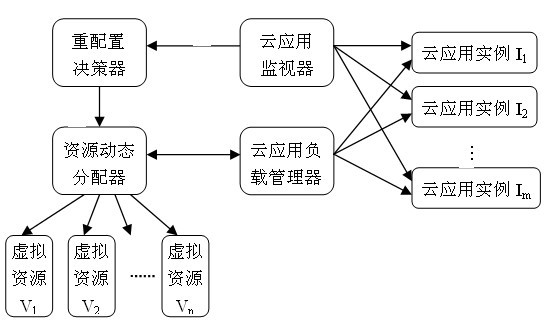

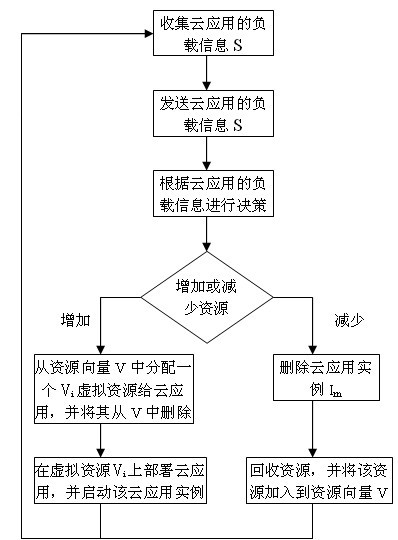

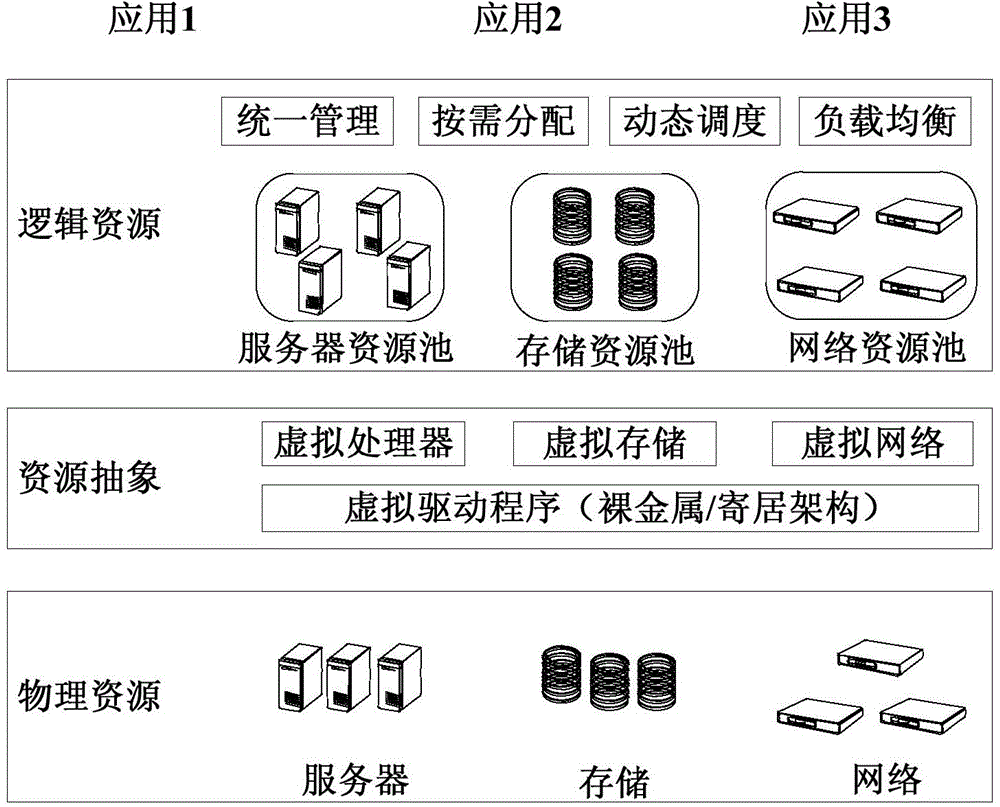

Cloud computing resource scheduling method based on dynamic reconfiguration virtual resources

InactiveCN101938416ADynamic Allocation OptimizationMeeting the Need for Dynamic ScalabilityData switching networksCurrent loadDecision taking

The invention relates to a cloud computing resource scheduling method based on dynamic reconfiguration virtual resources. The method comprises the steps of: using cloud application load information collected by a cloud application monitor as a basis; making a dynamic decision based on the load capacity of the virtual resources for running cloud application and the current load of the cloud application; and dynamically reconfiguring virtual resources for cloud application based on the decision result. Dynamic adjustment of resources is realized by a method for reconfiguring virtual resources for cloud application, without needing dynamic redistribution of physical resources or stopping executing cloud application. The method can dynamically reconfigure the virtual resources according to the load variation of the cloud application, optimize allocation of the cloud computing resources, realize effective use of the cloud computing resources, and meet the requirements on dynamic scalability of cloud application. In addition, the method can avoid waste of the cloud computing resources, and save the cost for using resources for cloud application users.

Owner:SOUTH CHINA UNIV OF TECH

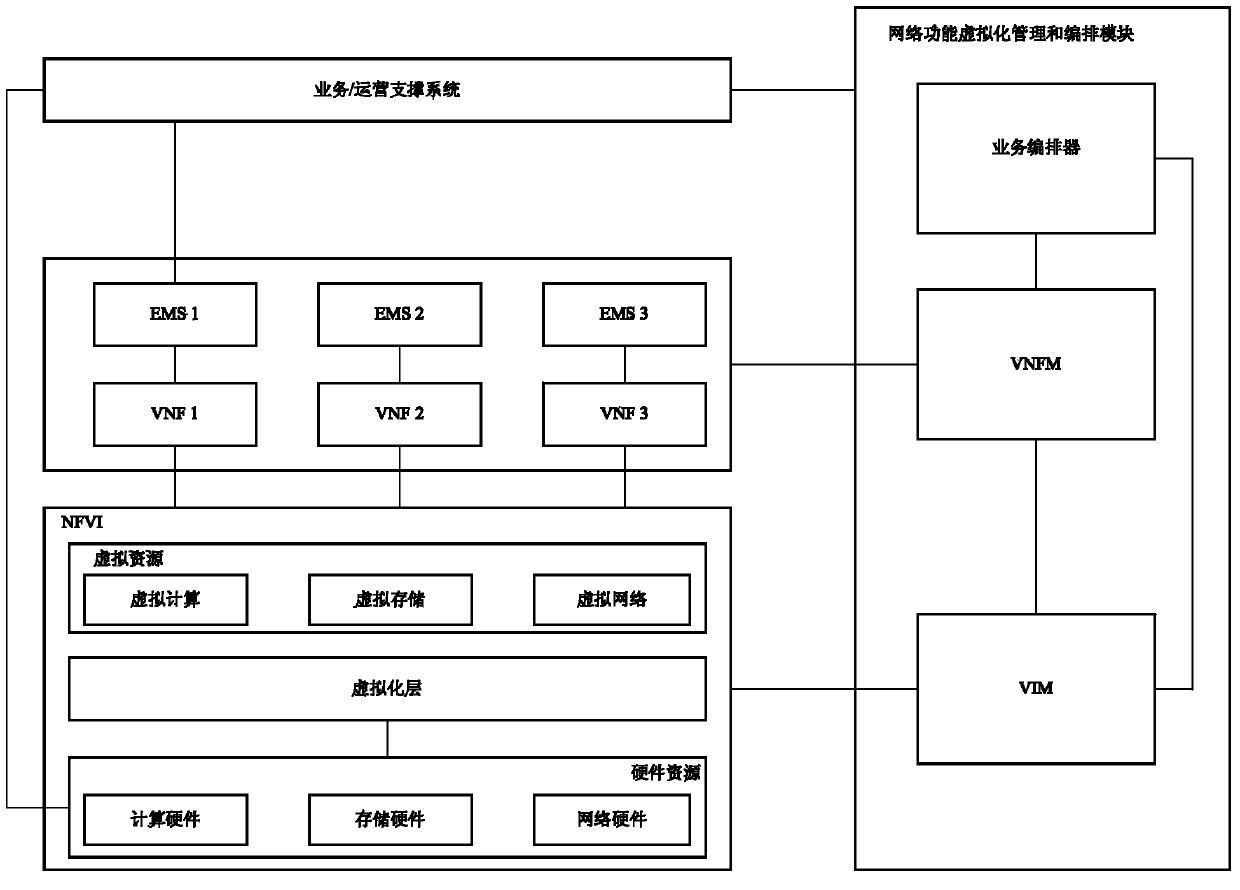

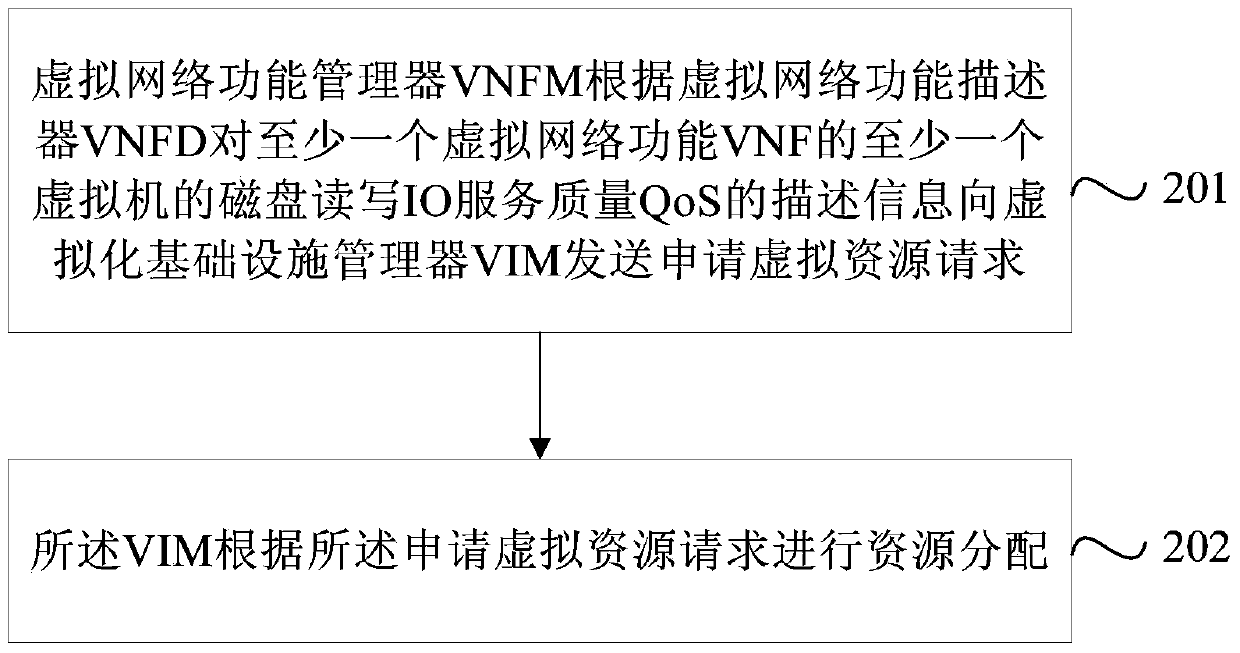

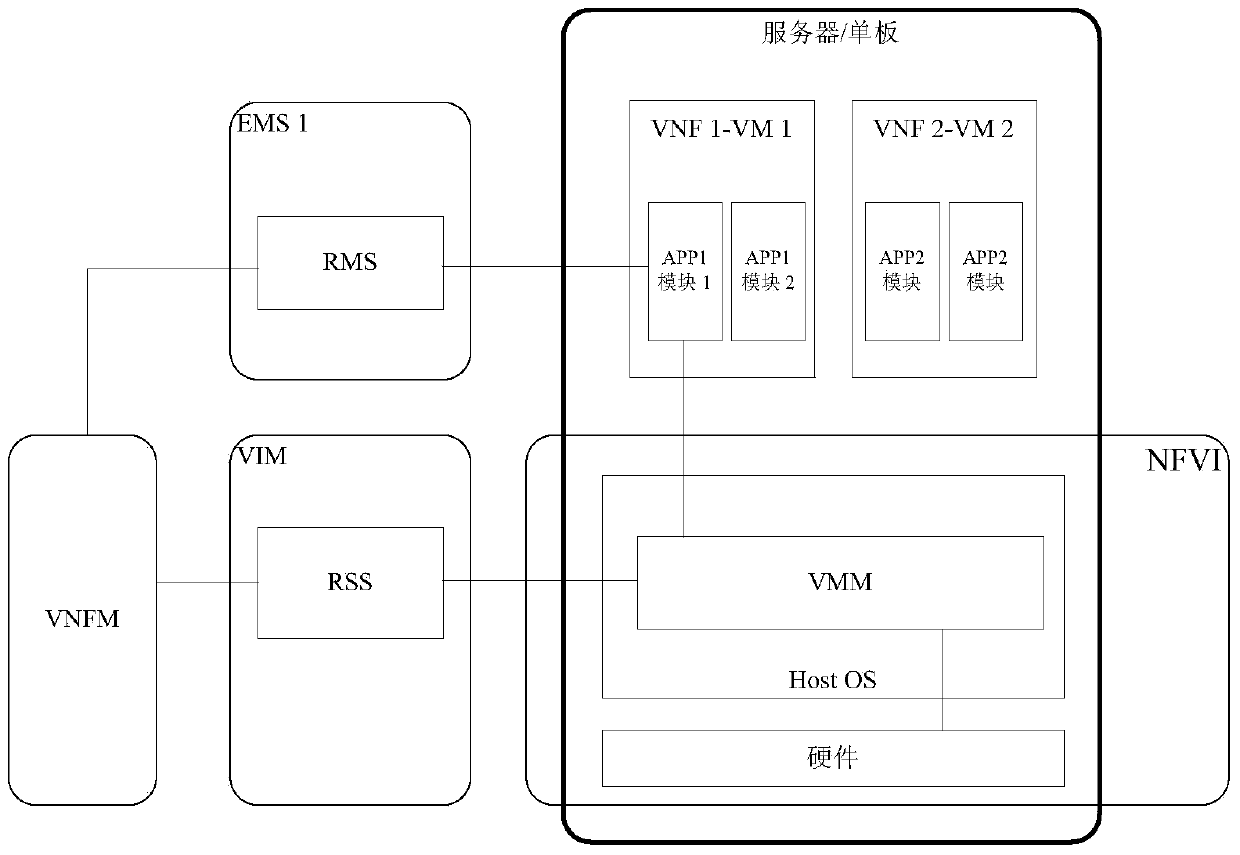

Method and device for distributing virtual resources based on disk IO

ActiveCN104050045AReasonable deploymentEfficient use ofInput/output to record carriersResource allocationResource informationResource utilization

The embodiment of the invention provides a method and device for distributing virtual resources based on disk IO. The method includes the steps that a VNFM is used for sending a request for applying for the virtual resources to a VIM according to information for describing QoS of disk read-write IO of at least one virtual machine with at least one VNF by a VNFD, wherein the description information includes resource information of QoS of the disk IO of at least one virtual machine in the regular service execution process and resource information of QoS of the disk IO in the burst traffic process. The request for applying for the virtual resources includes the description information. Furthermore, the VIM conducts resource distribution according to the request for applying for the virtual resources, services can be more reasonably deployed and can more effectively utilize physical resources, and therefore the overall resource utilization rate of a system is increased.

Owner:HUAWEI TECH CO LTD

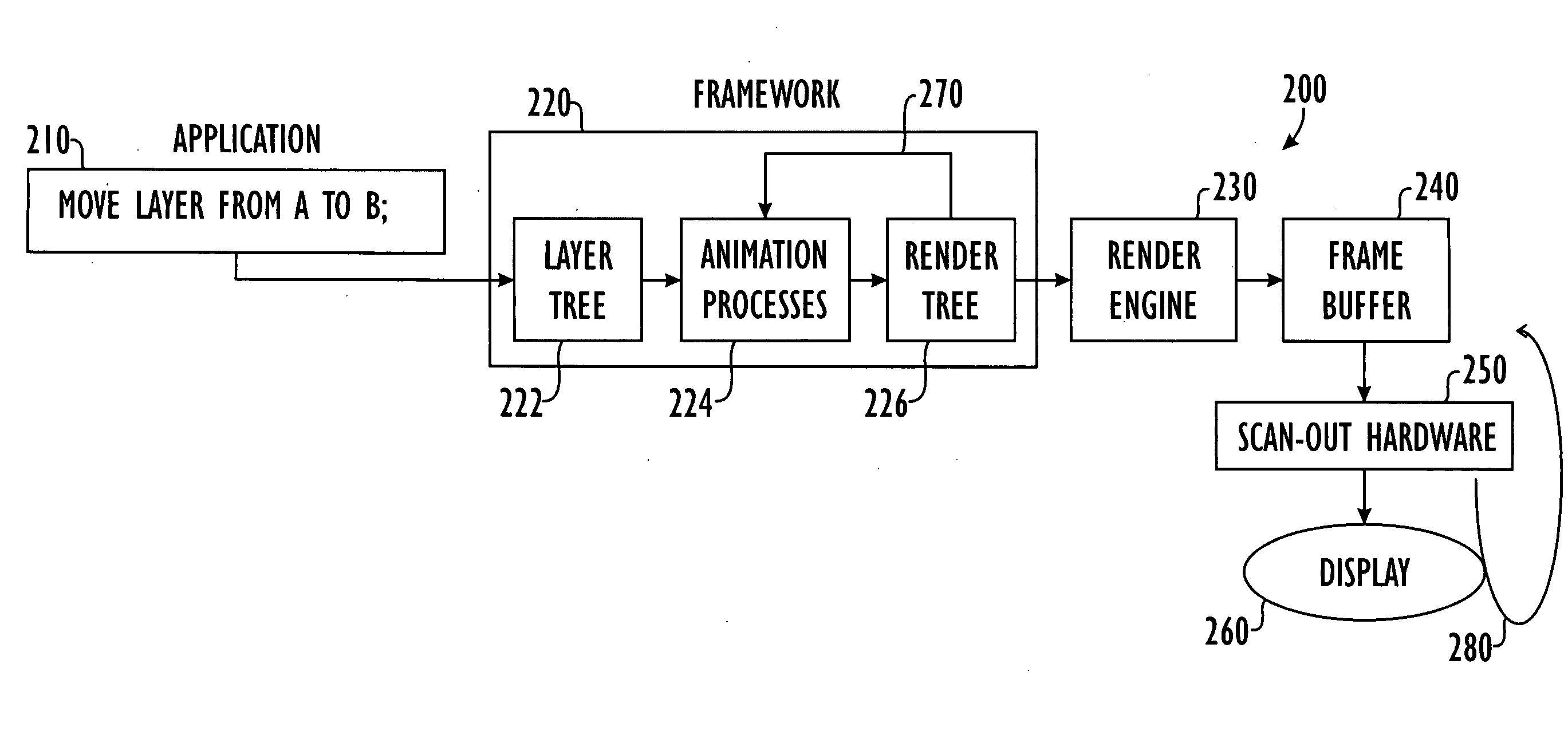

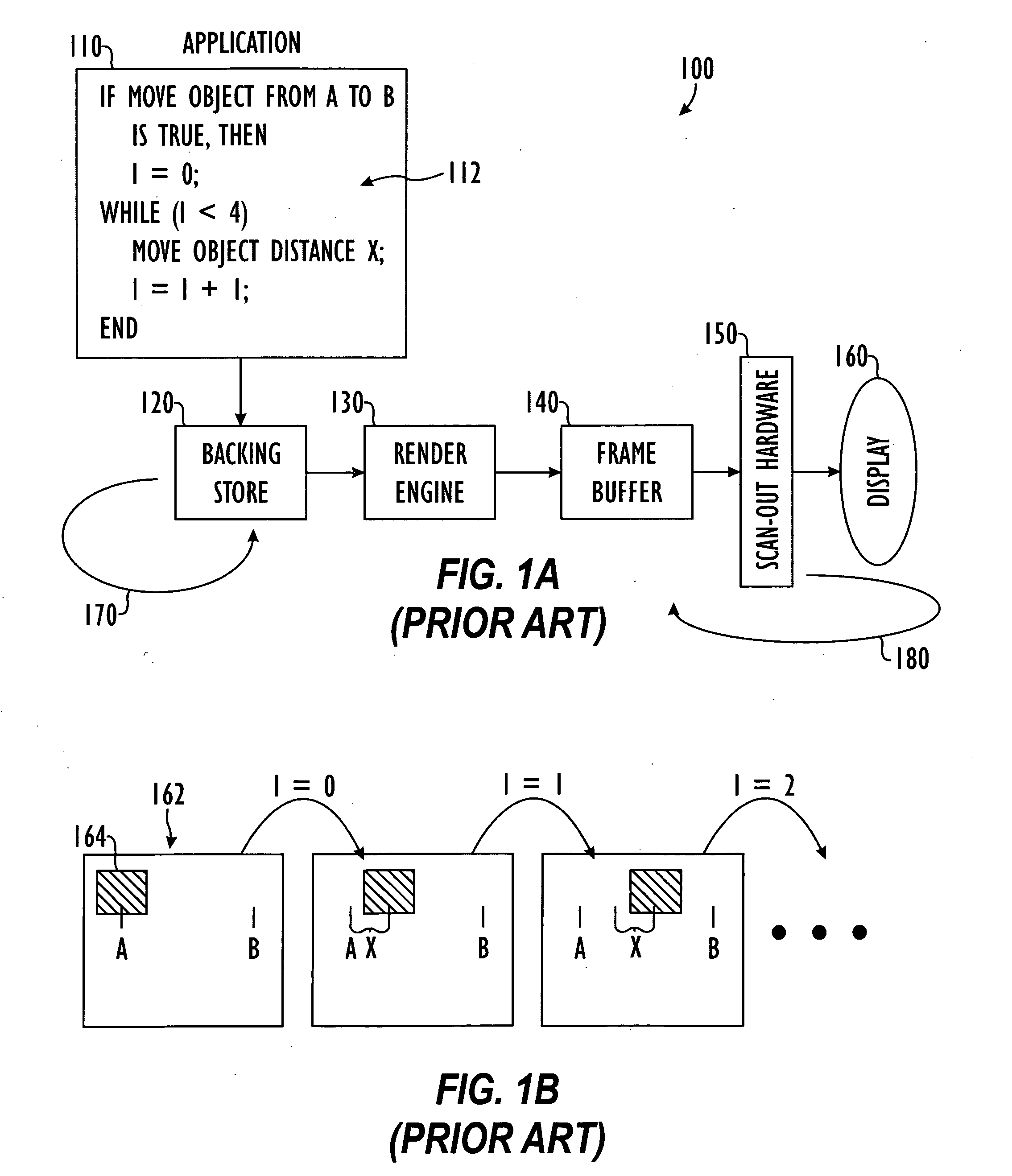

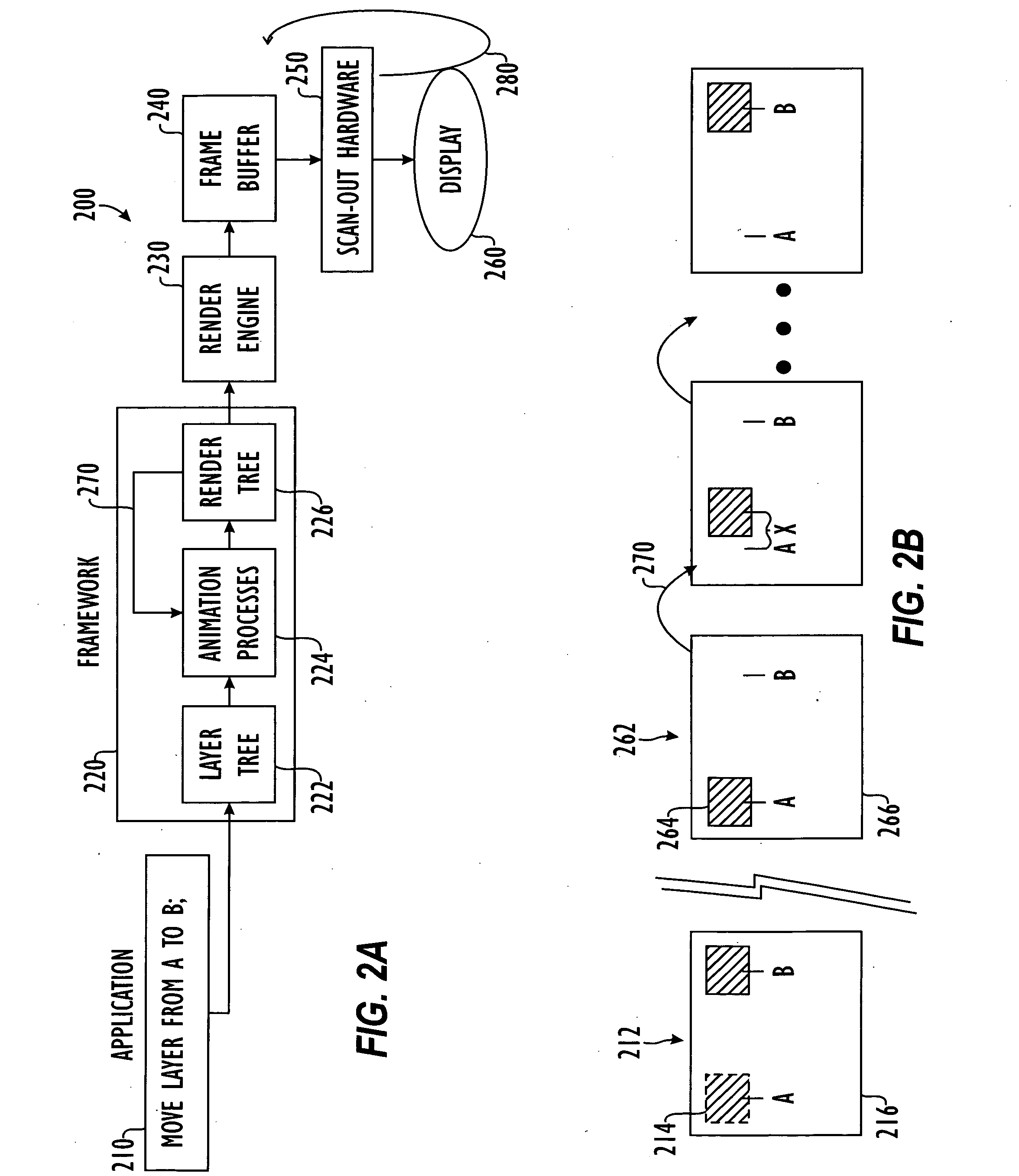

Framework for graphics animation and compositing operations

ActiveUS20080034292A1Improve resource utilizationAnimationProcessor architectures/configurationGraphicsVisibility

A framework for performing graphics animation and compositing operations has a layer tree for interfacing with the application and a render tree for interfacing with a render engine. Layers in the layer tree can be content, windows, views, video, images, text, media, or any other type of object for a user interface of an application. The application commits change to the state of the layers of the layer tree. The application does not need to include explicit code for animating the changes to the layers. Instead, an animation is determined for animating the change in state. In determining the animation, the framework can define a set of predetermined animations based on motion, visibility, and transition. The determined animation is explicitly applied to the affected layers in the render tree. A render engine renders from the render tree into a frame buffer for display on the computer system. Those portions of the render tree that have changed relative to prior versions can be tracked to improve resource management.

Owner:APPLE INC

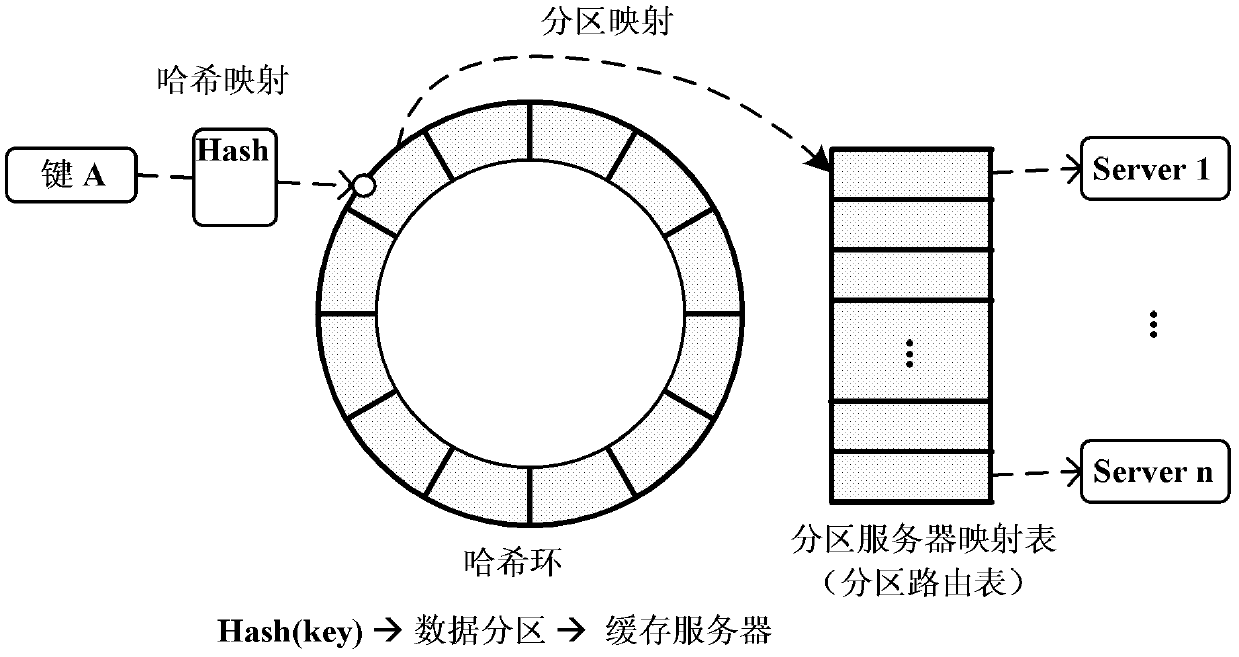

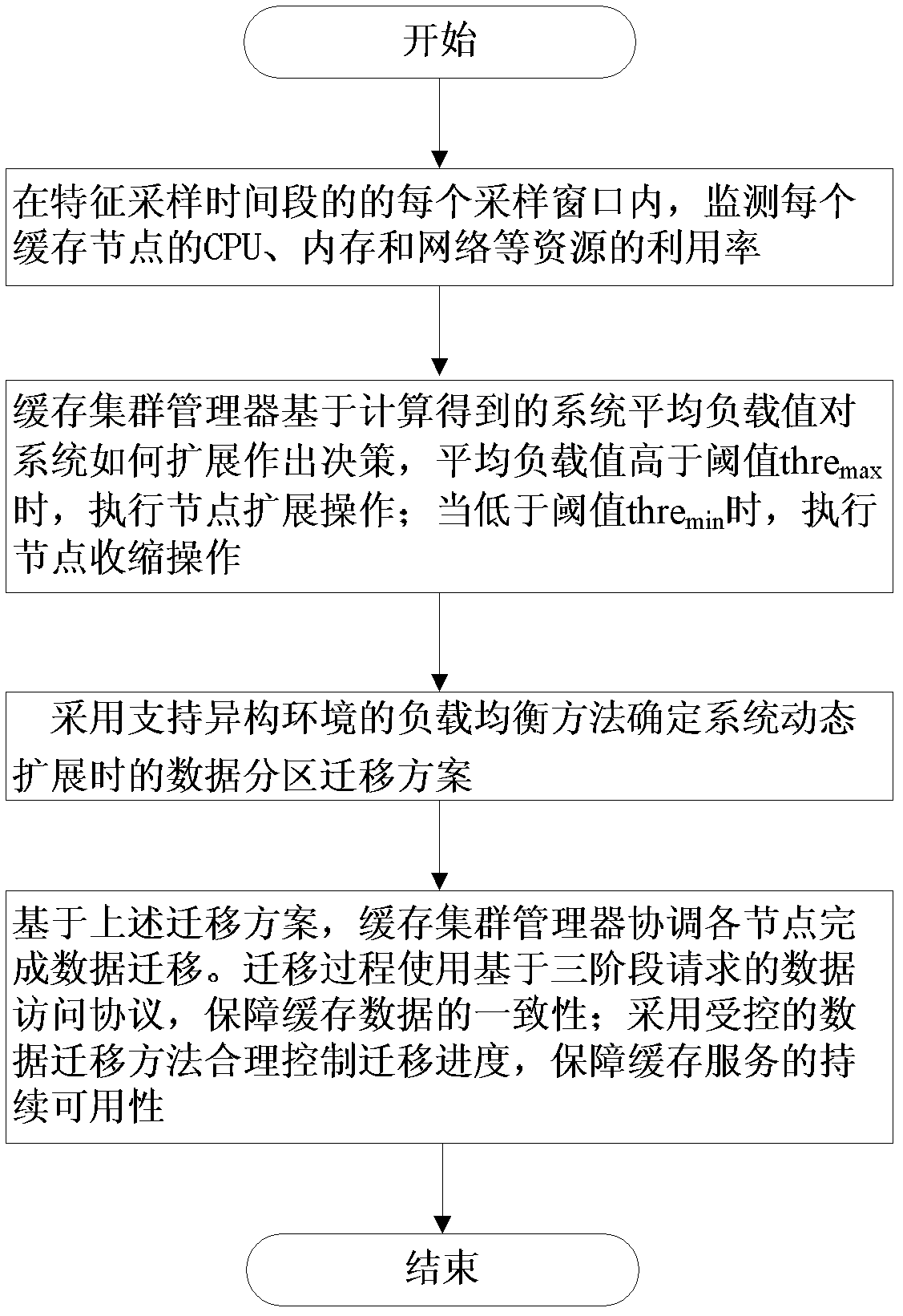

Distributed type dynamic cache expanding method and system supporting load balancing

InactiveCN102244685AReduce overheadImprove performanceData switching networksTraffic capacityCache server

The invention discloses a distributed type dynamic cache expanding method and system supporting load balancing, which belong to the technical field of software. The method comprises steps of: 1) monitoring respective resource utilization rate at regular intervals by each cache server; 2) calculating respective weighing load value Li according to the current monitored resource utilization rate, and sending the weighting load value Li to a cache clustering manager by each cache server; 3) calculating current average load value of a distributed cache system by the cache clustering manager according to the weighting load value Li, and executing expansion operation when the current average load value is higher than a threshold thremax; and executing shrink operation when the current average load value is lower than a set threshold thremin. The system comprises the cache servers, a cache client side and the cache clustering manager, wherein the cache servers are connected with the cache client side and the cache clustering manager through the network. The invention ensures the uniform distribution of the network flow among the cache nodes, optimizes the utilization rate of system resources, and solves the problems of ensuring data consistency and continuous availability of services.

Owner:济南君安泰投资集团有限公司

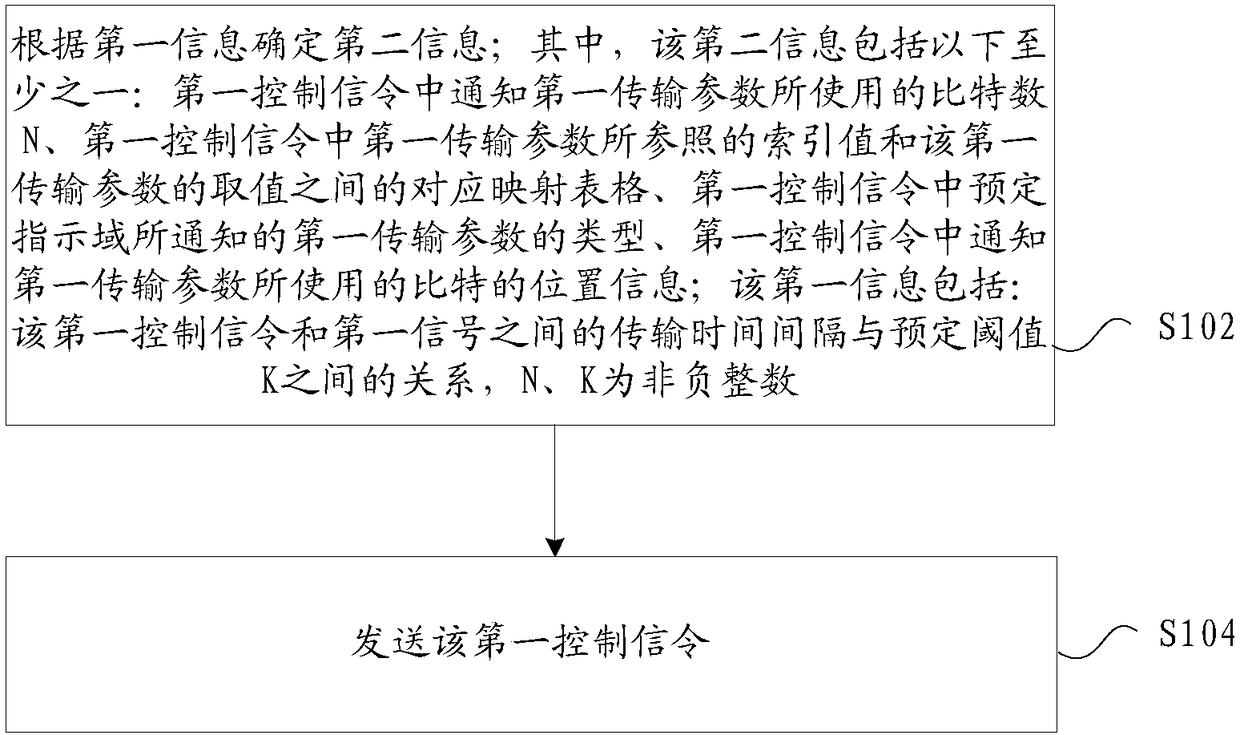

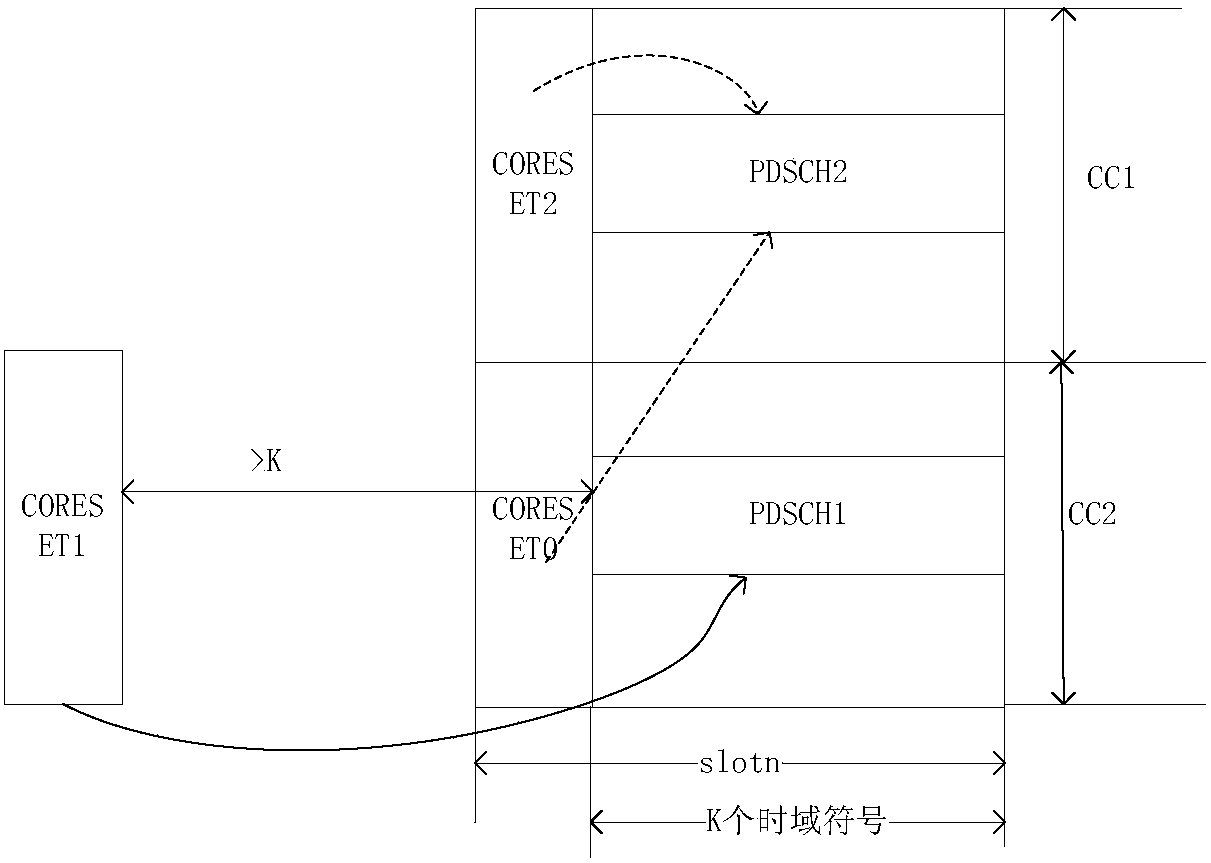

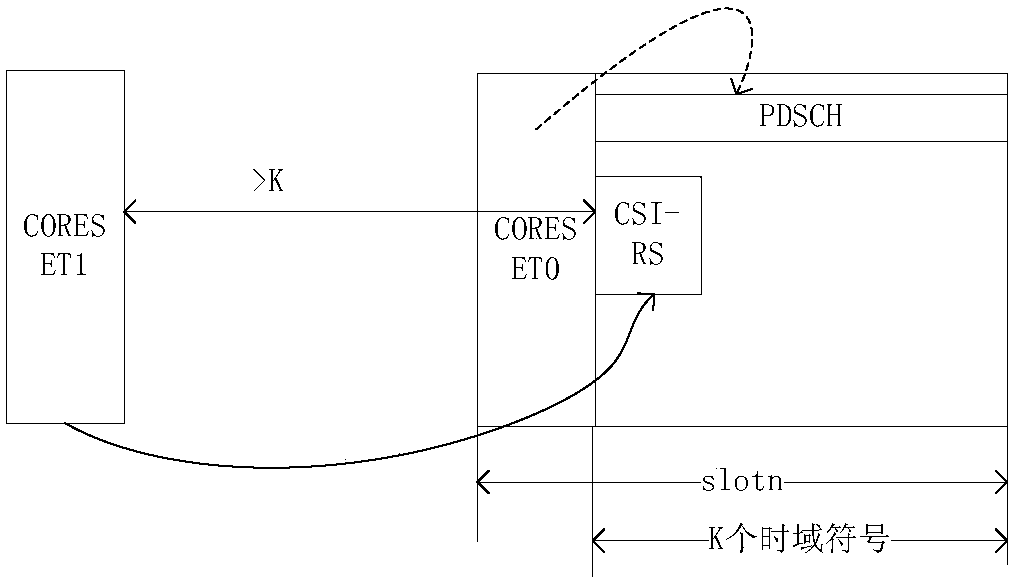

Sending and receiving method and apparatus of control signaling, and information determining method and apparatus

PendingCN108199819ASolve low resource utilizationImprove resource utilizationTransmission path divisionSignal allocationReal-time computingResource utilization

The invention provides a sending and receiving method and apparatus of control signaling, and an information determining method and apparatus. The method comprises the following steps: determining second information according to first information, wherein the second information comprises at least one of: the number of bits used in first control signaling to notify a first transmission parameter, an index value referred by the first transmission parameter in the first control signaling, a corresponding mapping table between the values of the first transmission parameter, the type of the first transmission parameter notified in a predetermined indication domain in the first control signaling, and location information of the bit used for notifying the first transmission parameter in the firstcontrol signaling; the first information comprises a transmission time interval between the first control signaling and a first signal and a relationship between predetermined thresholds K, and N andK are non-negative integers; and sending the first control signaling. Therefore, the problem of low resource utilization rate because the bit domains of the notification beams in the physical layer dynamic control signaling are not fully utilized in related art is solved.

Owner:ZTE CORP

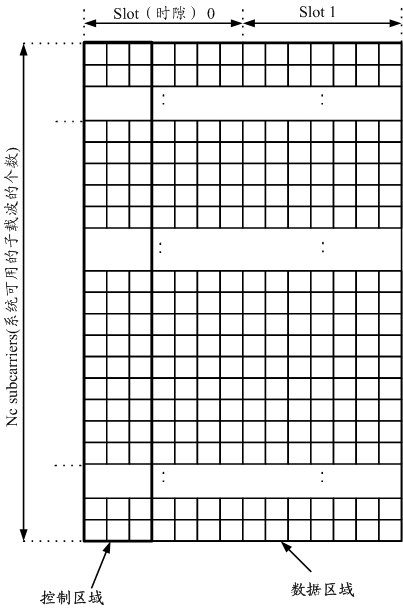

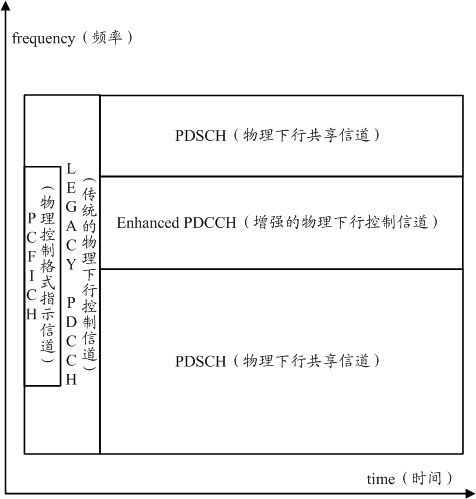

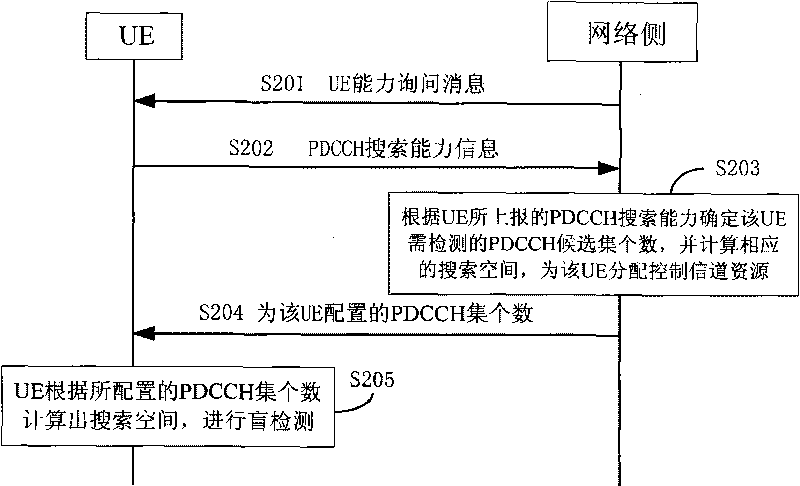

Method for receiving and transmitting information on physical downlink control channel and equipment thereof

InactiveCN102170703AImprove resource utilizationIncrease capacityWireless communicationControl channelUser equipment

The invention discloses a method for receiving and transmitting information on a physical downlink control channel and equipment thereof. The method comprises the following steps: the resource position of an enhanced physical downlink control channel cluster is indicated to user equipment by a base station; scheduling information is transmitted to the user equipment on the resource position of a physical downlink control channel cluster by the base station; the resource position of the enhanced physical downlink control channel cluster is determined by the user equipment according to the indication of the base station; and blind check carried out on the resource position of the enhanced physical downlink control channel cluster by the user equipment to receive the scheduling information transmitted by the base station to the user equipment. The invention can effectively provide the capacity of the physical downlink control channel, simultaneously, can effectively improve the utilization rate of the resource of the enhanced physical downlink control channel.

Owner:CHINA ACAD OF TELECOMM TECH

Gravel attapulgite flower ceramsite

ActiveCN102503372BHigh strengthLower sintering temperatureCeramic materials productionCeramicwarePhysical chemistryMaterials science

The invention discloses gravel attapulgite flower ceramsite. The key point of the technical scheme is that the gravel attapulgite flower ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, kieselguhr tailing powder and rice husk powder.t. The gravel attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, baking, cooling, smashing, sieving and packaging. The gravel attapulgite flower ceramsite is an irregularly-shaped granule, and has a rough and porous surface, light weight, high strength and high water absorption. The gravel attapulgite flower ceramsite can be soaked in water without being cracked and release nutrition required by flowers continuously and slowly. The gravel attapulgite flower ceramsite is produced by utilizing the sludge and tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the gravel attapulgite flower ceramsite is suitable for planting the flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Spherical attapulgite flower ceramsite

ActiveCN102503539AReduce manufacturing costHigh strengthCeramic materials productionCeramicwareMetallurgyBentonite powder

The invention discloses spherical attapulgite flower ceramsite. The key points of the technical scheme are that the spherical attapulgite flower ceramsite consists of high-adhesion attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, diatomite tailing powder and rice husk powder. The spherical attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, roasting, cooling, screening and packaging. The spherical attapulgite flower ceramsite has a rough and porous surface, is light in weight, high in strength and water absorption rate, can be immersed in water throughout the year without cracking and can continuously and slowly release nutrition required by flowers. Moreover, the spherical attapulgite flower ceramsite is produced by comprehensively utilizing the sludge and tailings, so that the resource utilization rate is improved, waste is turned into wealth, and environment is protected. Besides, the cylindrical attapulgite flower ceramsite is applicable to cultivation of various flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

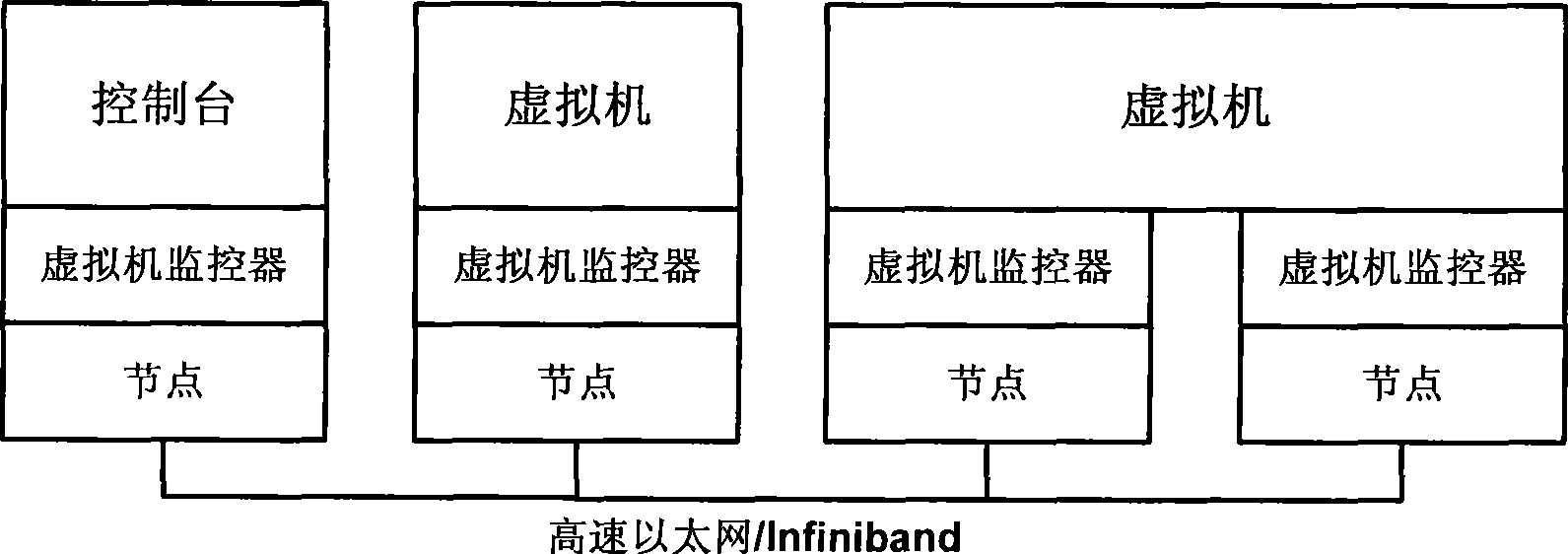

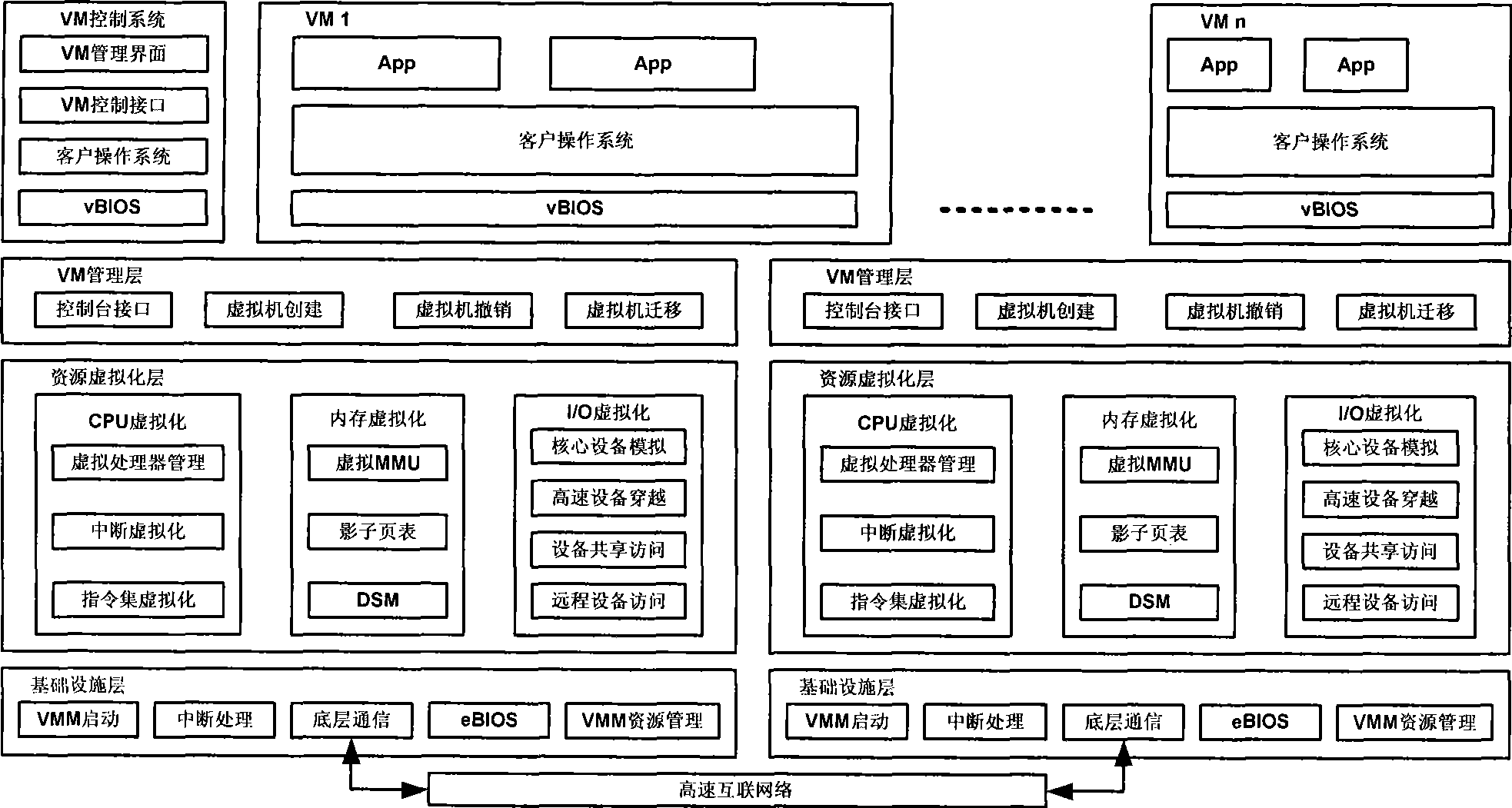

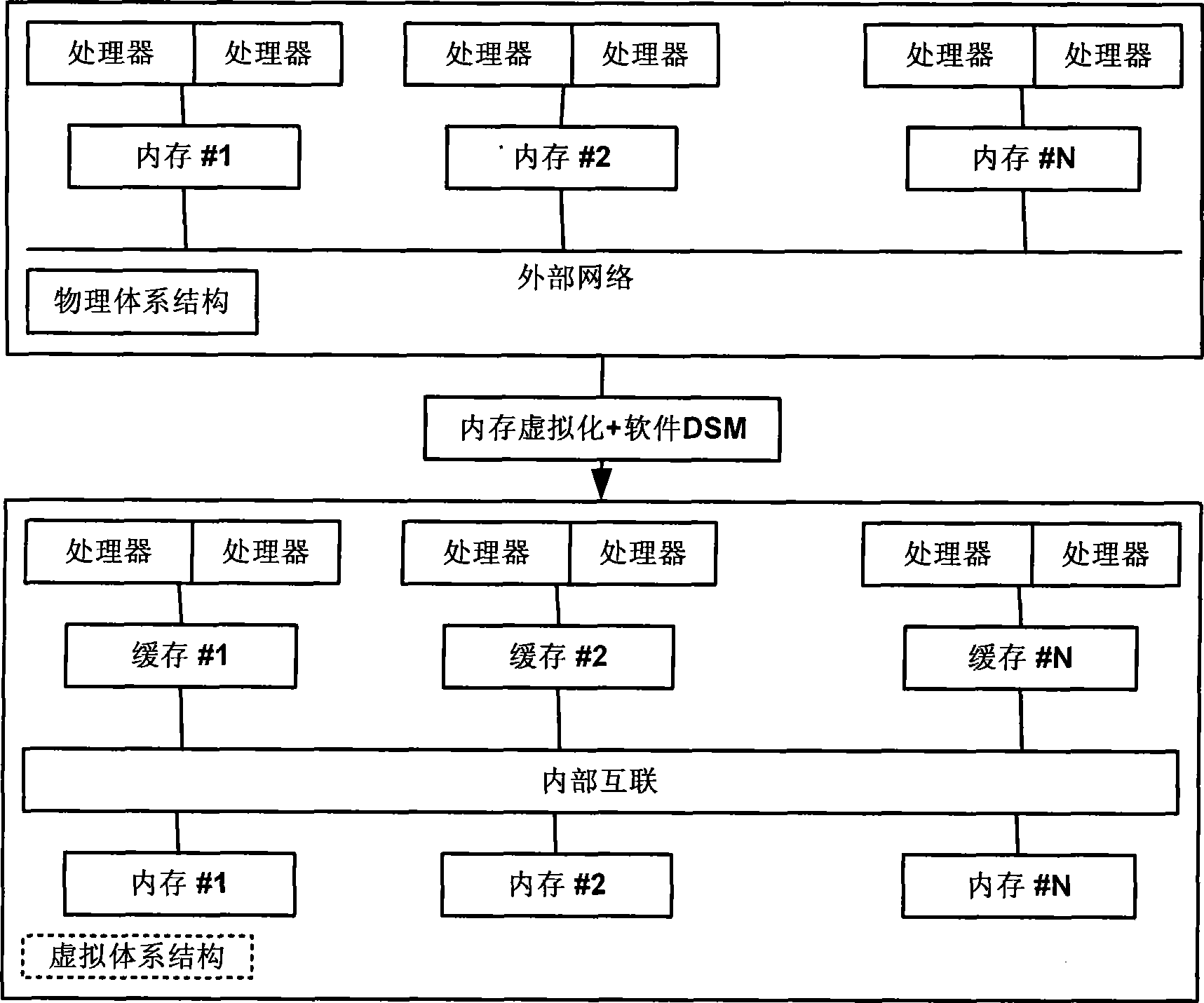

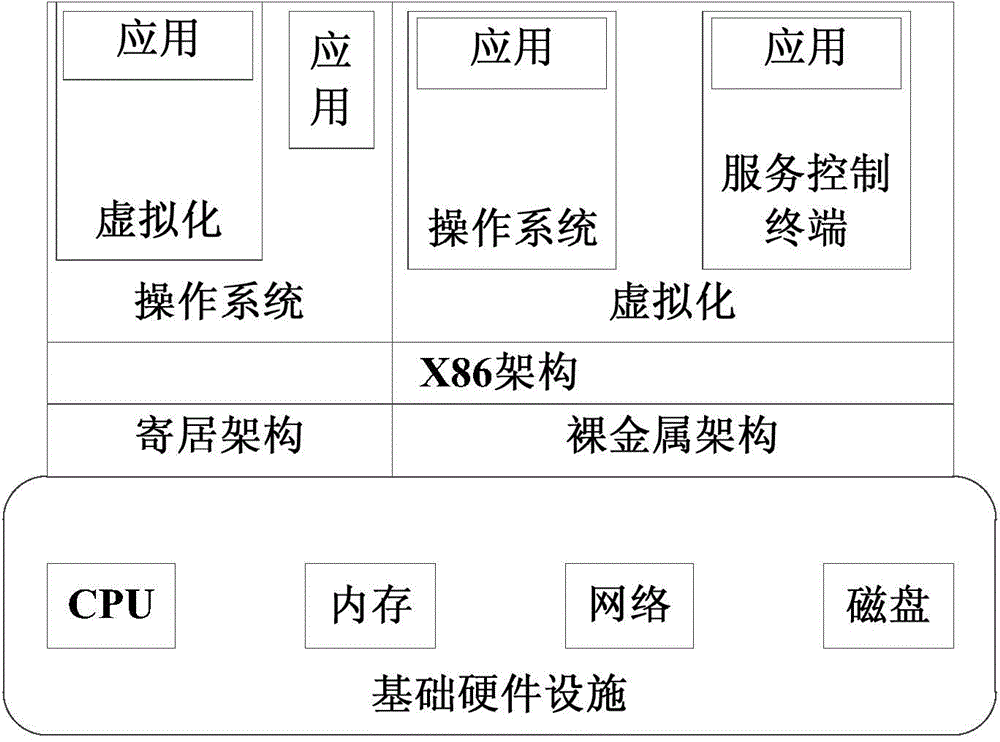

Construct method of distributed virtual machine monitor system

InactiveCN101398768AAchieve perceptionAchieve integrationSoftware simulation/interpretation/emulationVirtualizationOperational system

The invention provides a building method for a distribution virtual machine monitor system which adopts the most advanced virtualization technology for deploying and building the distribution virtual machine monitor system DVMM on a plurality of physical nodes above hardware and below an operation system, integrates and virtualizes the resources of a plurality of computers into virtual resources through the DVMM for centralized and united management. According to the application demands, the method can integrate the resources of a plurality of machines into a virtual machine provided with a single system mapping for a user to use so as to meet the resource demand of super application; besides, the method can build a plurality of virtual machines on one machine, thereby integrating a plurality of applications of small scales on one machine for improving the operating factors of the resources; therefore, the building method can fully utilize the existing resources for meeting the demands of various applications and has a broad application prospect as well as generates a remarkable economic benefit.

Owner:HUAWEI TECH CO LTD

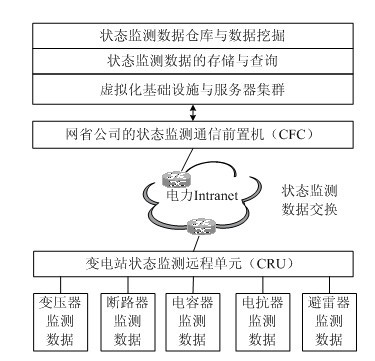

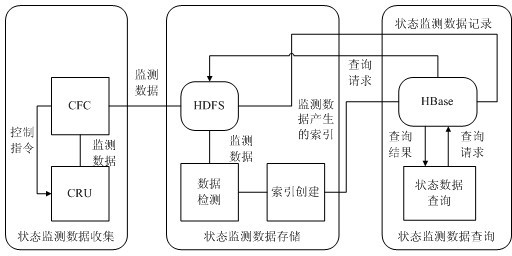

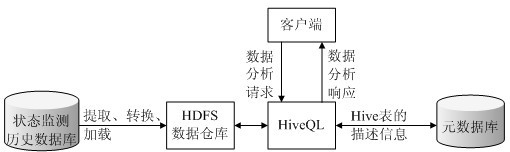

Distributed storage and parallel mining method for state monitoring data

InactiveCN102685221AEnsure operabilityReduce construction costsData switching networksService modelData warehouse

A distributed storage and parallel mining method for state monitoring data includes the steps: defining function service models of a remote substation state monitoring unit and a state monitoring communication front-end processor by means of Web service description language, and exchanging the state monitoring data of electric power equipment in an electric power wide area network environment by a simple object access protocol; storing large-scale state monitoring data redundancy in a distributed file system, creating an index table for a state monitoring data file, inserting the index table into a large-scale structural data table and querying the state monitoring data according to a query request; and generating basic data and multi-dimensional analytical data by extracting, converting and loading to built a data warehouse, and parallelly executing association rules, classification and clustered data mining algorithm by means of MapReduce task decomposition and result summary. The distributed storage and parallel mining method can be used for effectively realizing distributed data exchange, redundant storage and rapid parallel processing for state monitoring information of the mass electric power equipment in an intelligent power network environment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

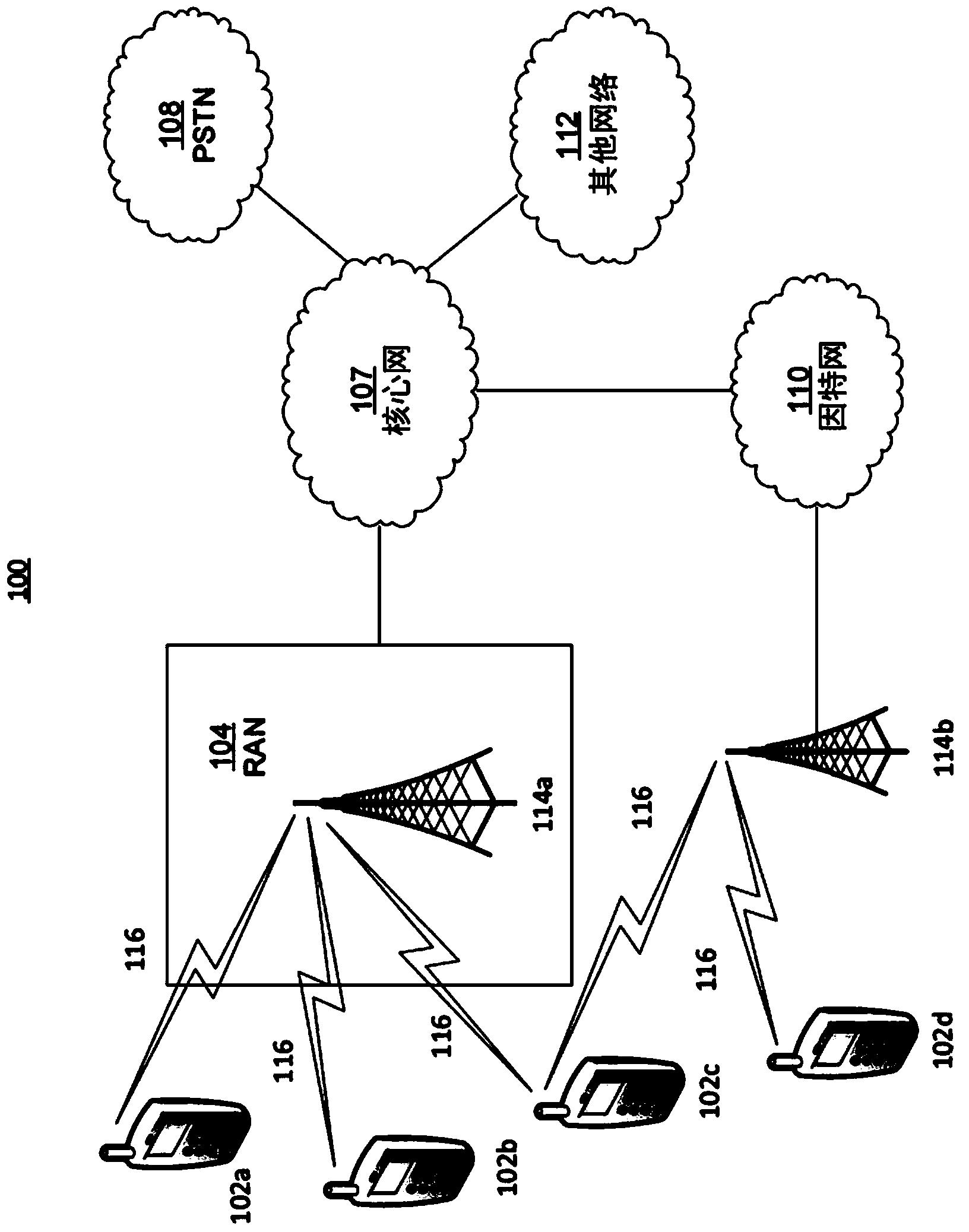

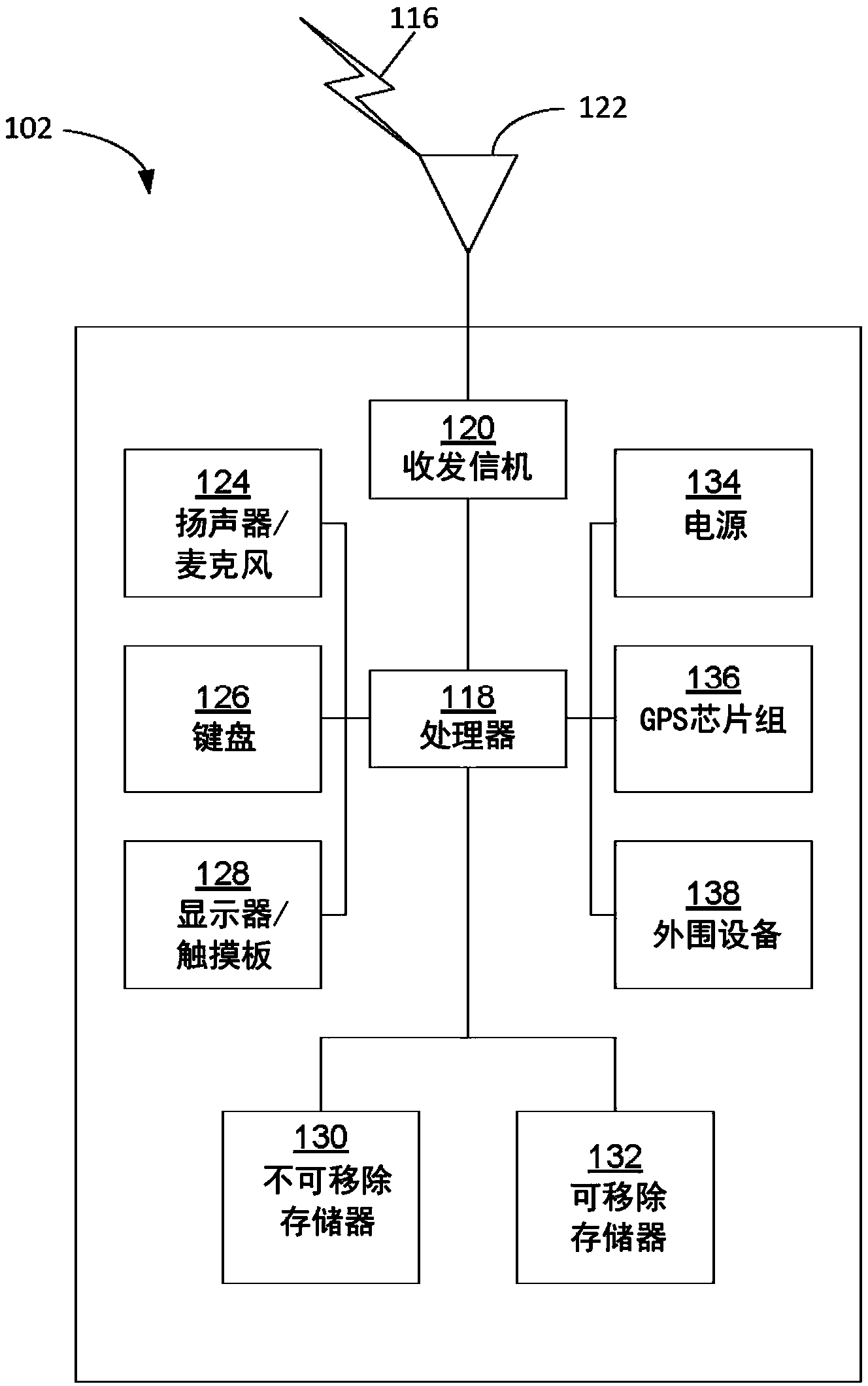

Systems and methods for improved uplink coverage

ActiveCN104254995AImprove resource utilizationError prevention/detection by using return channelTransmission path divisionComputer scienceSignal design

Systems and method are specified to improve the reception of UL transmission, for example in power or coverage limited situations. A WTRU may modify procedures to increase the available signal energy for reception at an eNB and / or to make more efficient use of the available signal energy at the receiver for processing UL transmissions. Example methods for increasing UL link coverage may include modifying HARQ timing (e.g., shorter HARQ), using longer TTIs, use of dedicated PUSCH allocations, use of new PUSCH modulations, enhanced reference signal design, UL macro diversity reception for PUSCH, utilizing protocol reduction techniques, ensuring in-order packet delivery, and / or utilizing a configuration for coverage limited / power limited modes of operation. The proposed methods may be applied individually or in any combination.

Owner:INTERDIGITAL PATENT HLDG INC

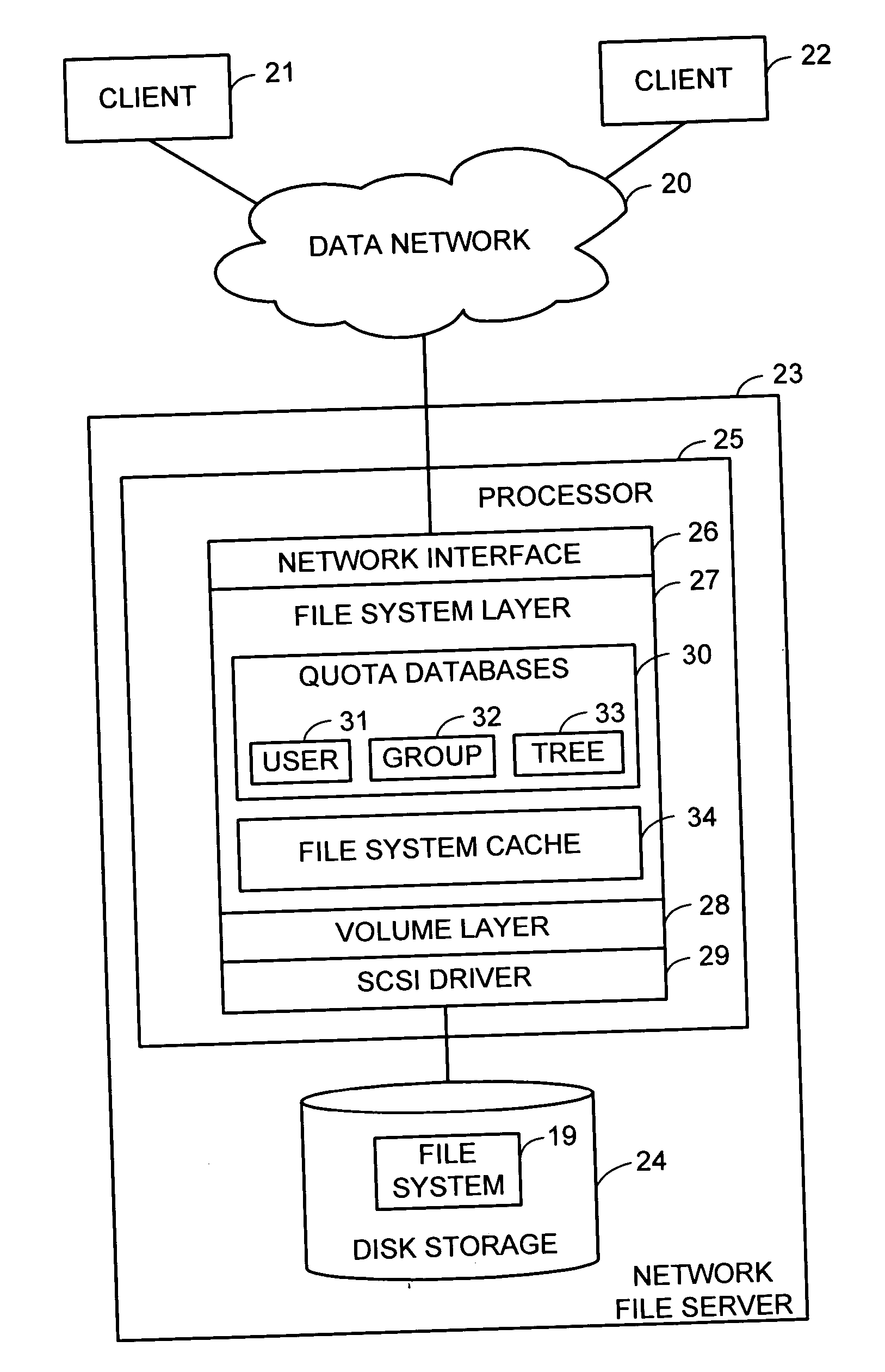

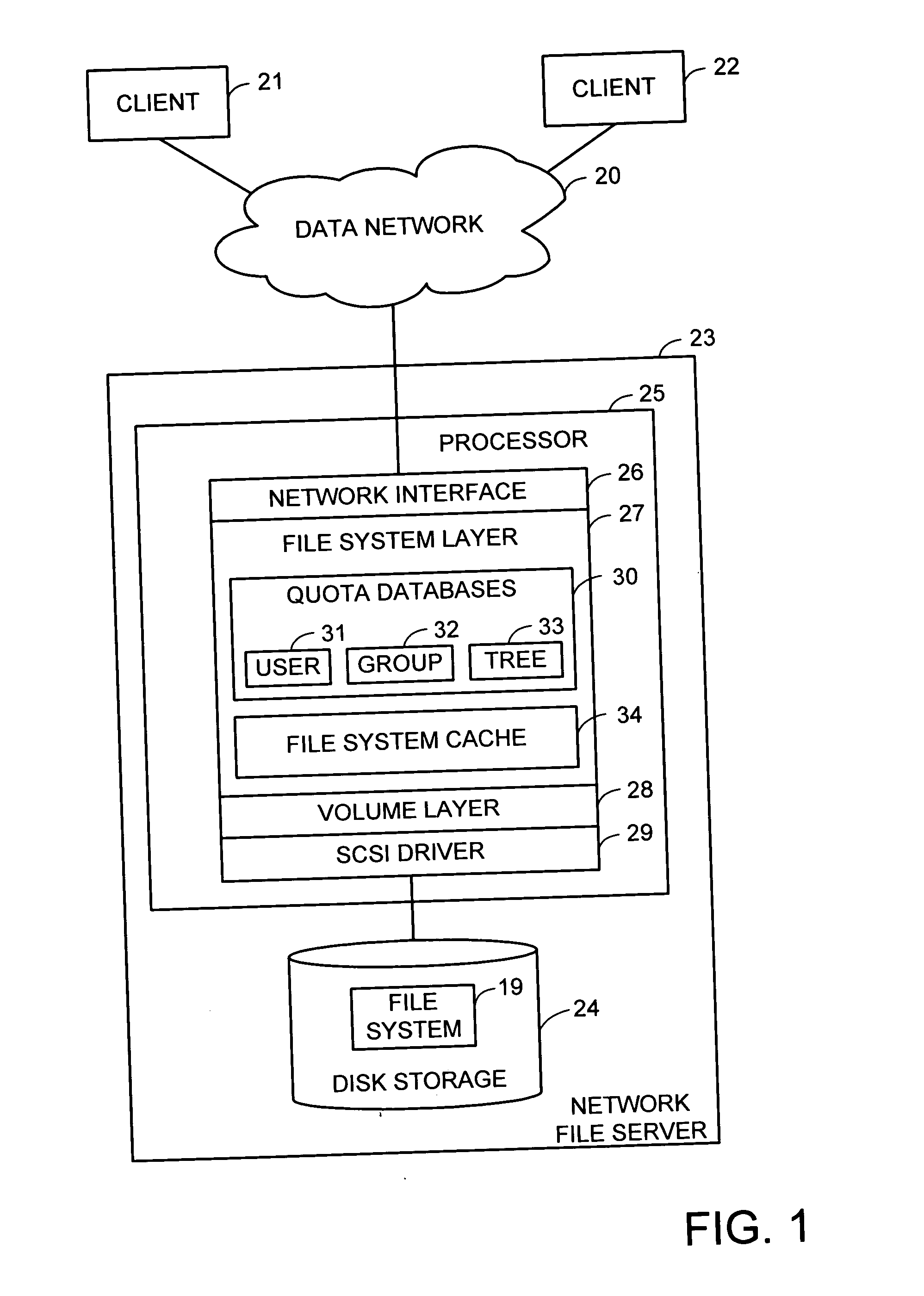

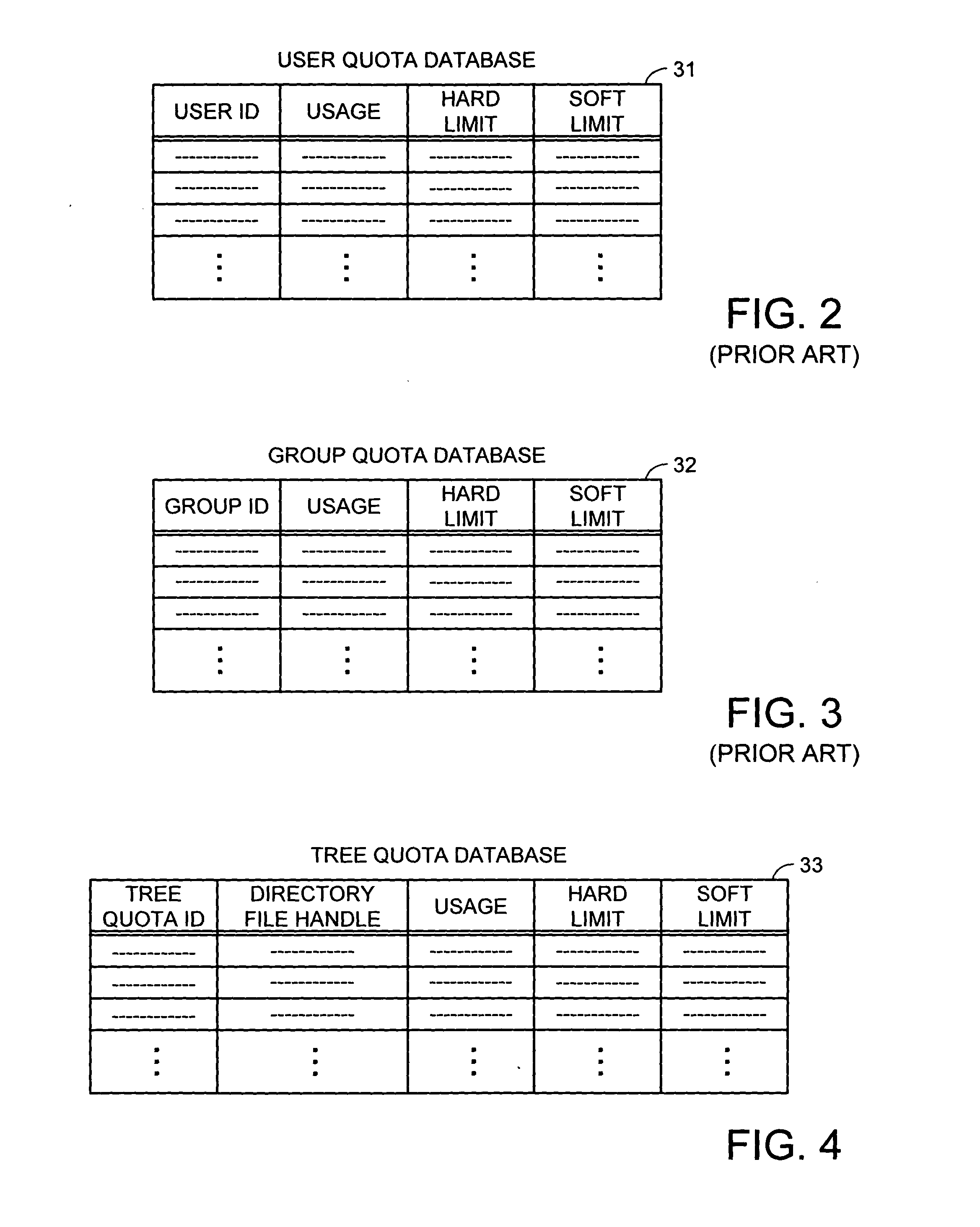

Using a file for associating the file with a tree quota in a file server

ActiveUS20050050107A1Improve resource utilizationSpecial data processing applicationsMemory systemsClient-sideFile server

To avoid the need for storing a tree quota identifier attribute for every file in a quota tree, a tree quota identifier is included in the file handle returned by the file server to a client in response to a directory lookup request. The file server discovers that the file is in a quota tree when searching along a path specified by the file pathname and finding a directory having a tree quota identifier. The file server responds to a client request for changing the storage resources used by the file by inspecting the file handle and upon finding the tree quota identifier in the file handle, using the tree quota identifier to index a tree quota database to find usage and limits for the tree quota. The file server checks the limits against any increase in the storage resources for the file, and updates the usage.

Owner:EMC IP HLDG CO LLC

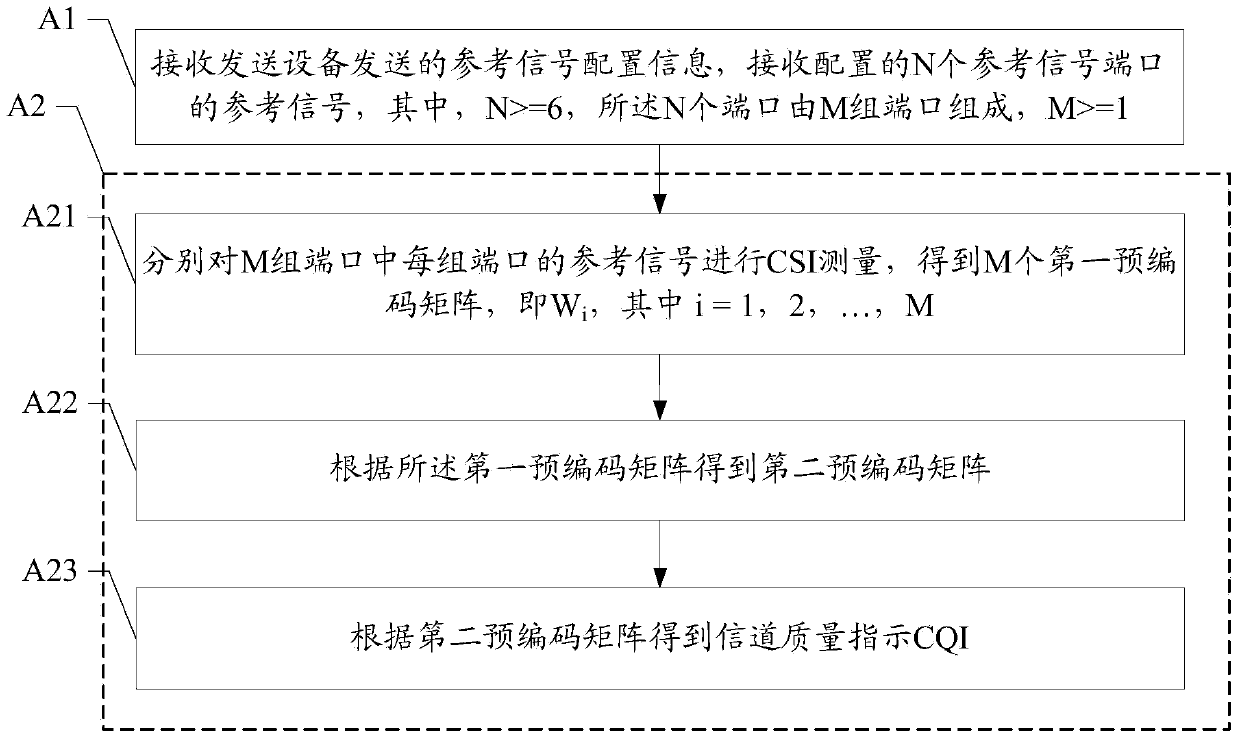

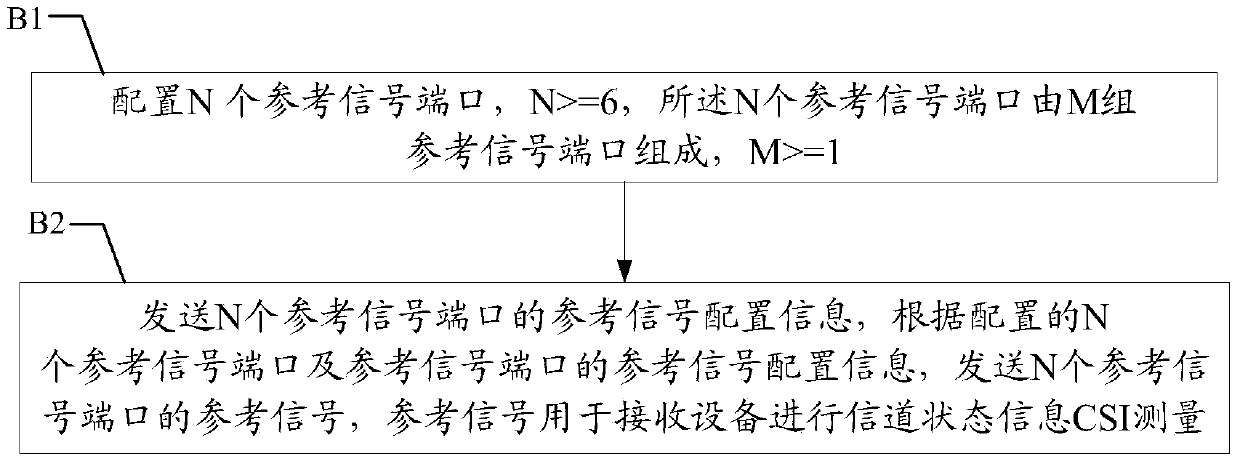

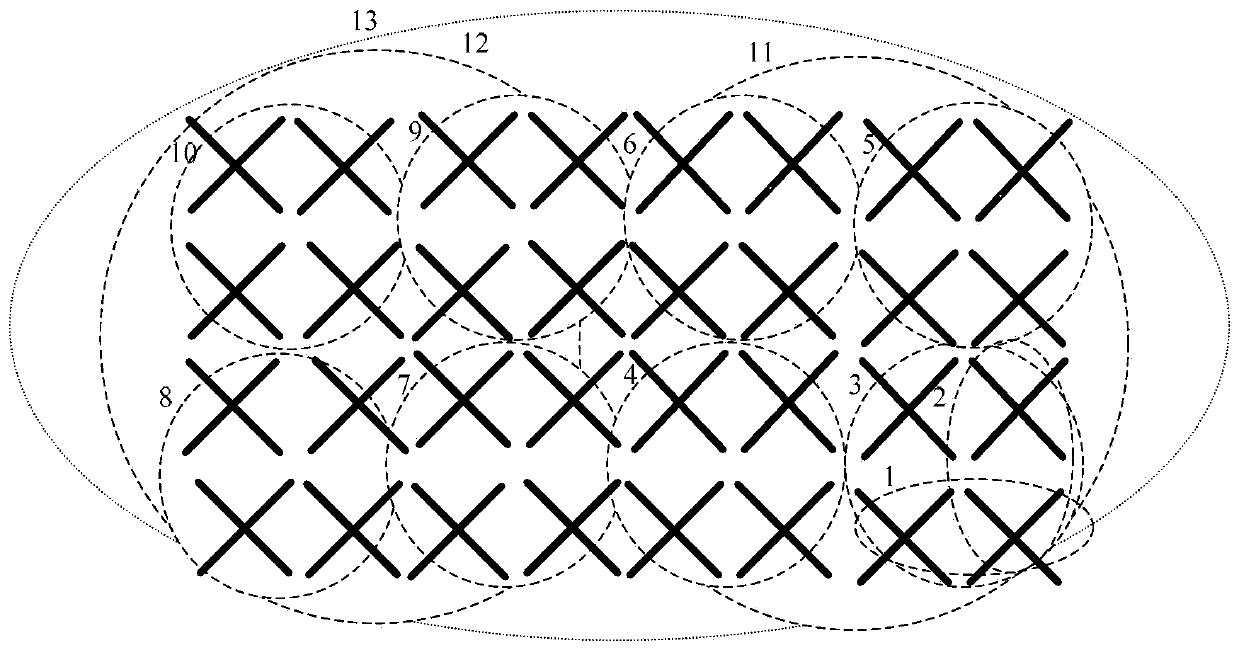

Method and device for measuring CSI (Channel State Information) as well as reference signal sending method and device

ActiveCN103746779AReduce overheadImprove resource utilizationError detection/prevention using signal quality detectorRadio transmissionChannel state informationComputer science

The invention provides a method and a device for measuring CSI (Channel State Information) as well as a reference signal sending method and a reference signal sending device. The method comprises the following steps: receiving reference signal allocation information sent by sending equipment and allocated reference signals of N reference signal ports; measuring CSI on the basis of the allocated reference signals of the N reference signal ports, wherein N is greater than or equal to 6, and the N reference signal ports consist of M groups of reference signal ports, wherein M is greater than or equal to 1. The step of measuring the CSI on the basis of the reference signals of the N reference signal ports comprises the following steps: measuring the CSI of the reference signals of each group of ports among the M groups of reference signal ports so as to obtain M first precoding matrixes, namely Wi, wherein i is equal to 1,2,...,M; obtaining a second precoding matrix W: W=W1*W2*...*WM according to the first precoding matrixes; obtaining a CQI (Channel Quality Indicator) according to the second precoding matrix. According to the scheme, measurement on the CSI is realized.

Owner:SHANGHAI HUAWEI TECH CO LTD

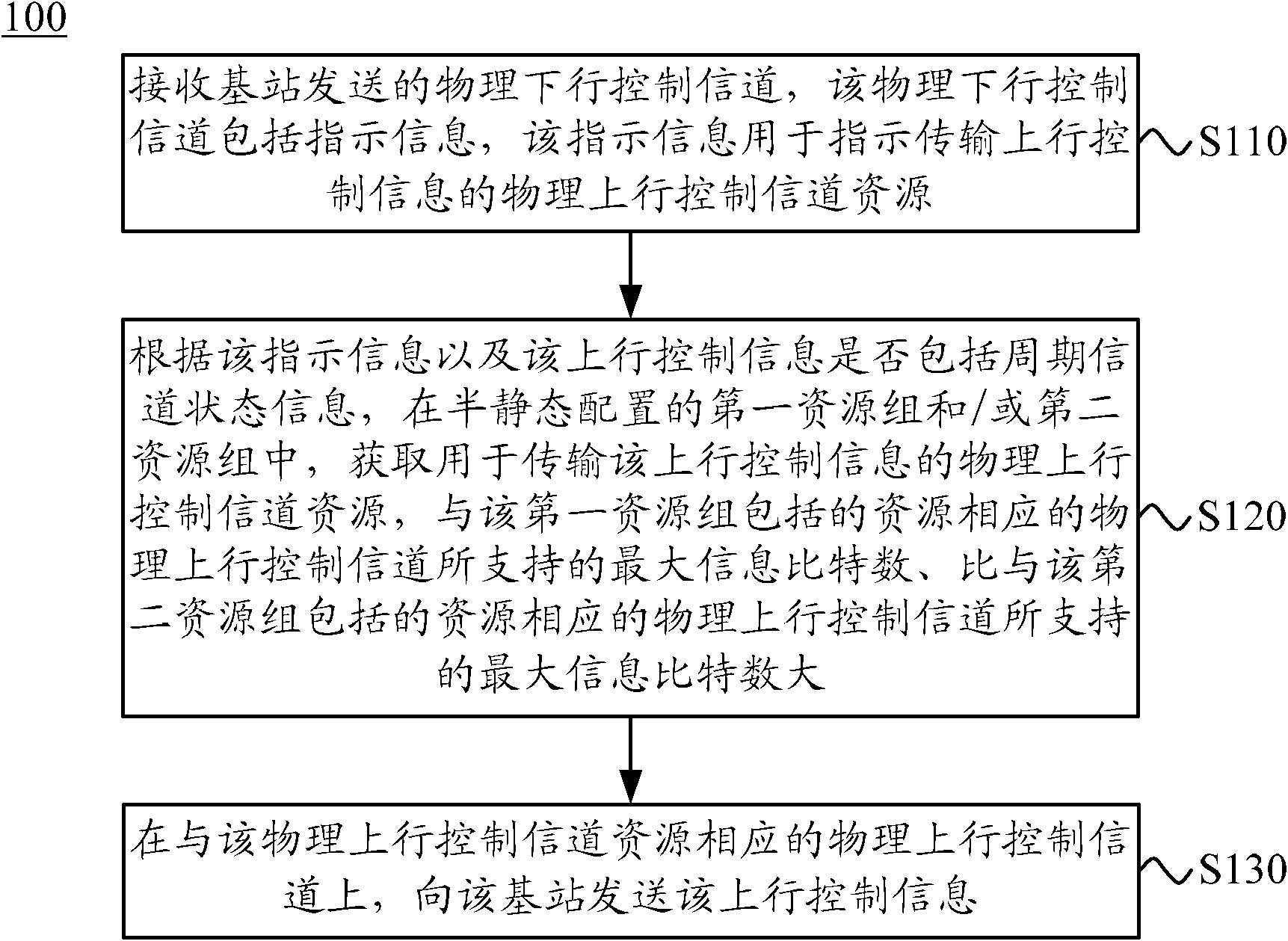

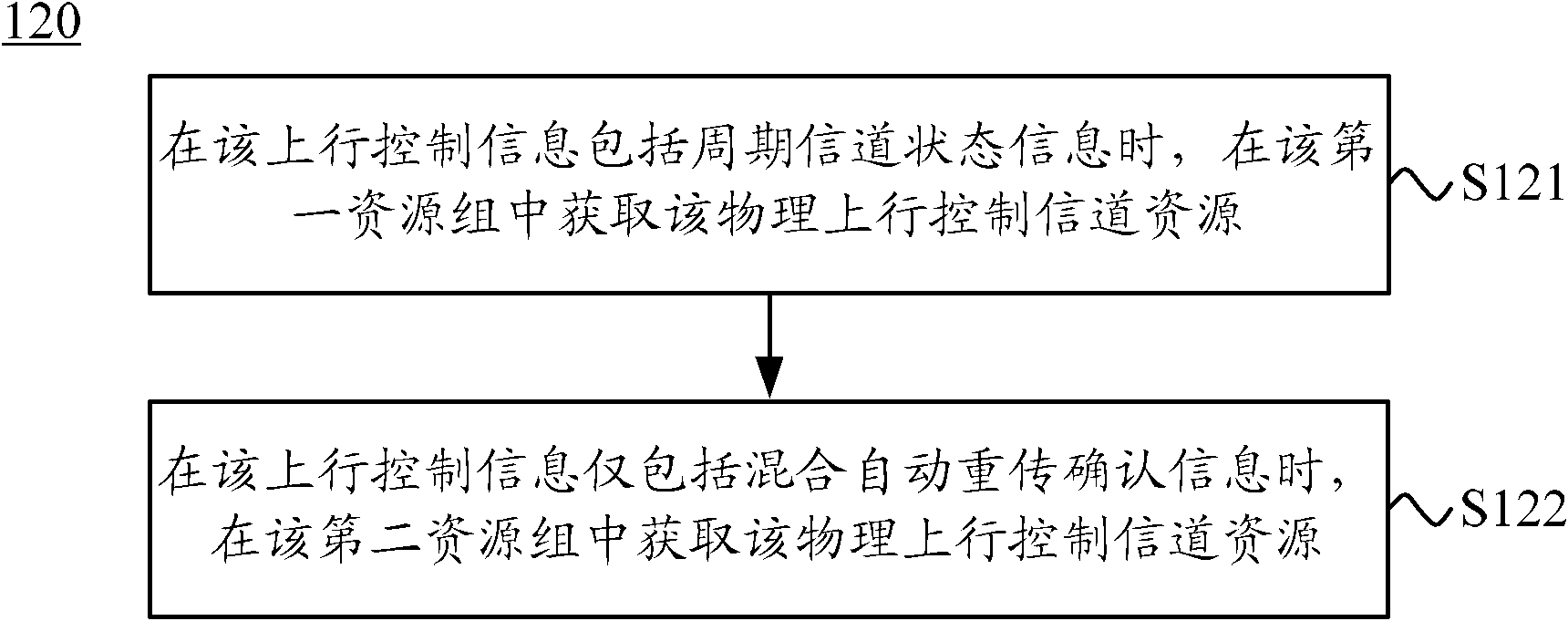

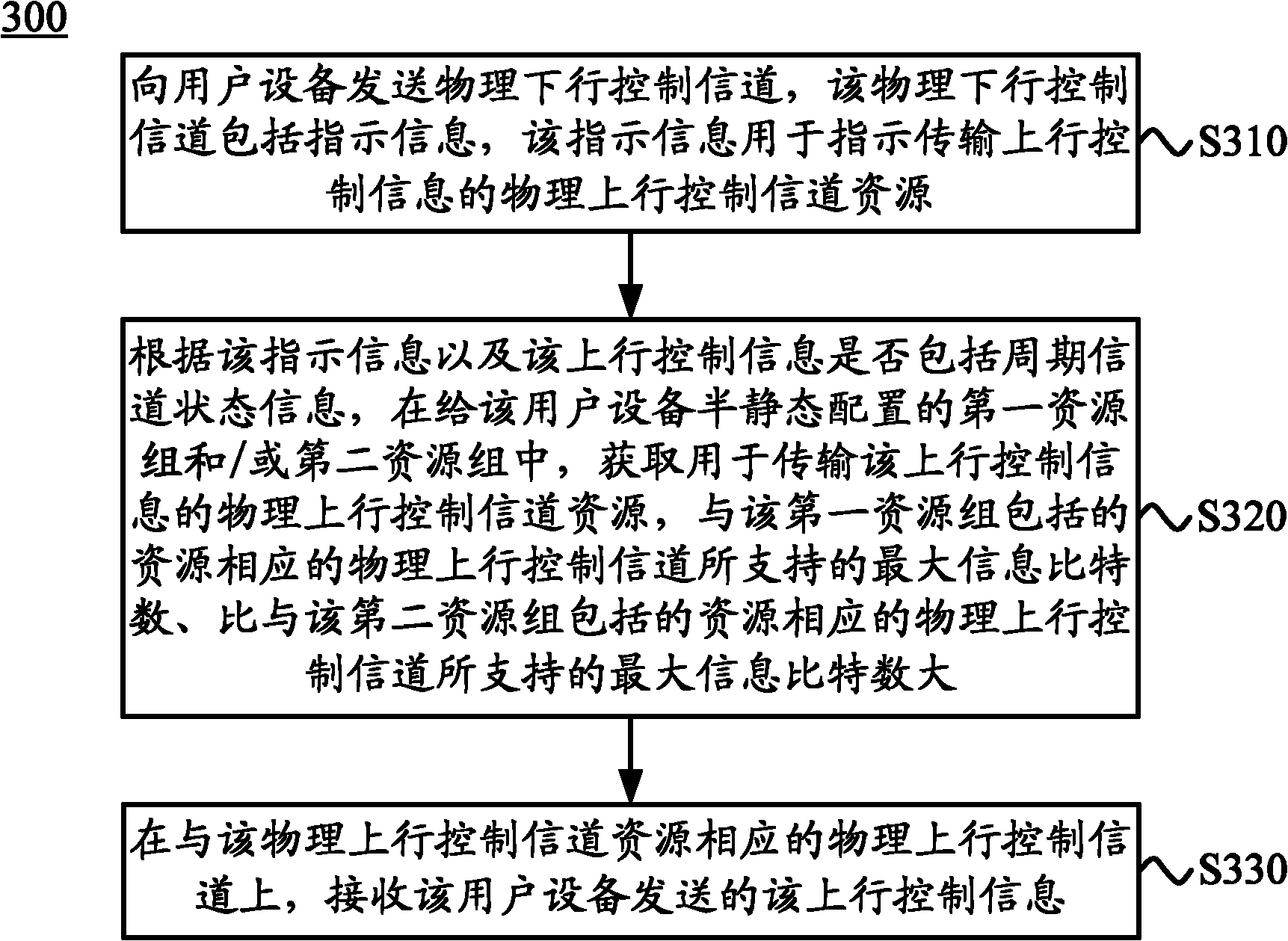

Method, user equipment and base station for transmitting uplink control information

ActiveCN103209483AReduce resource overheadImprove resource utilizationError prevention/detection by using return channelNetwork traffic/resource managementChannel state informationTelecommunications

The invention discloses a method, user equipment and a base station for transmitting uplink control information. The method comprises receiving a physical downlink control channel sent from the base station, wherein the physical downlink control channel comprises indication information used for indicating physical uplink control channel resources used for transmitting the uplink control information; acquiring the physical uplink control channel resources used for transmitting the uplink control information in a first resource group and or a second resource group which are configured in a semi-static state according to whether period channel state information included in the indication information and the uplink control information or not; and sending the uplink control information to the base station on a physical uplink control channel corresponding to the physical uplink control channel resources. The method, the user equipment and the base station for transmitting the uplink control information can transmit the uplink control information, reduce resource expenses of the physical uplink control channel in transmission of the uplink control information and improve the resource utilization rate.

Owner:HUAWEI TECH CO LTD

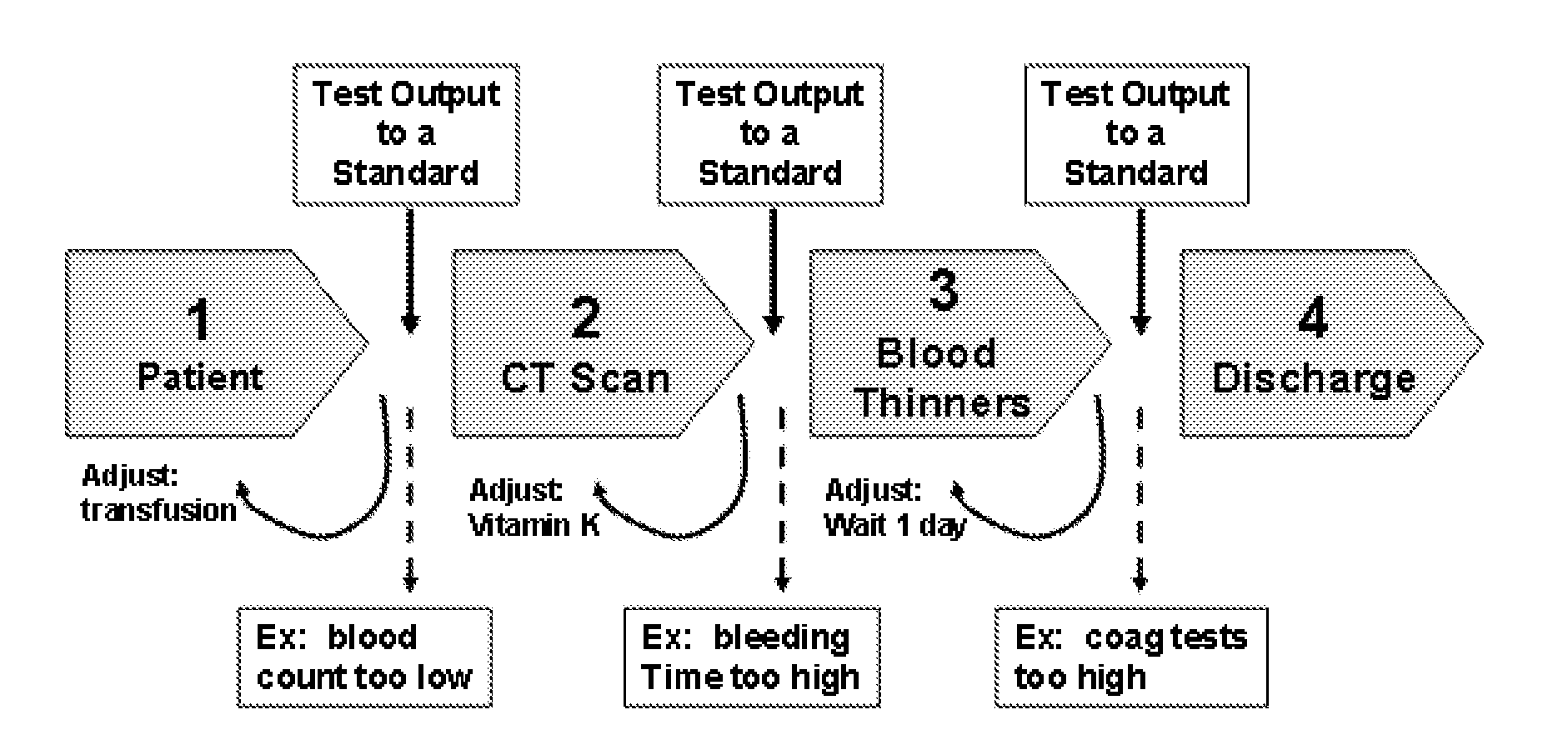

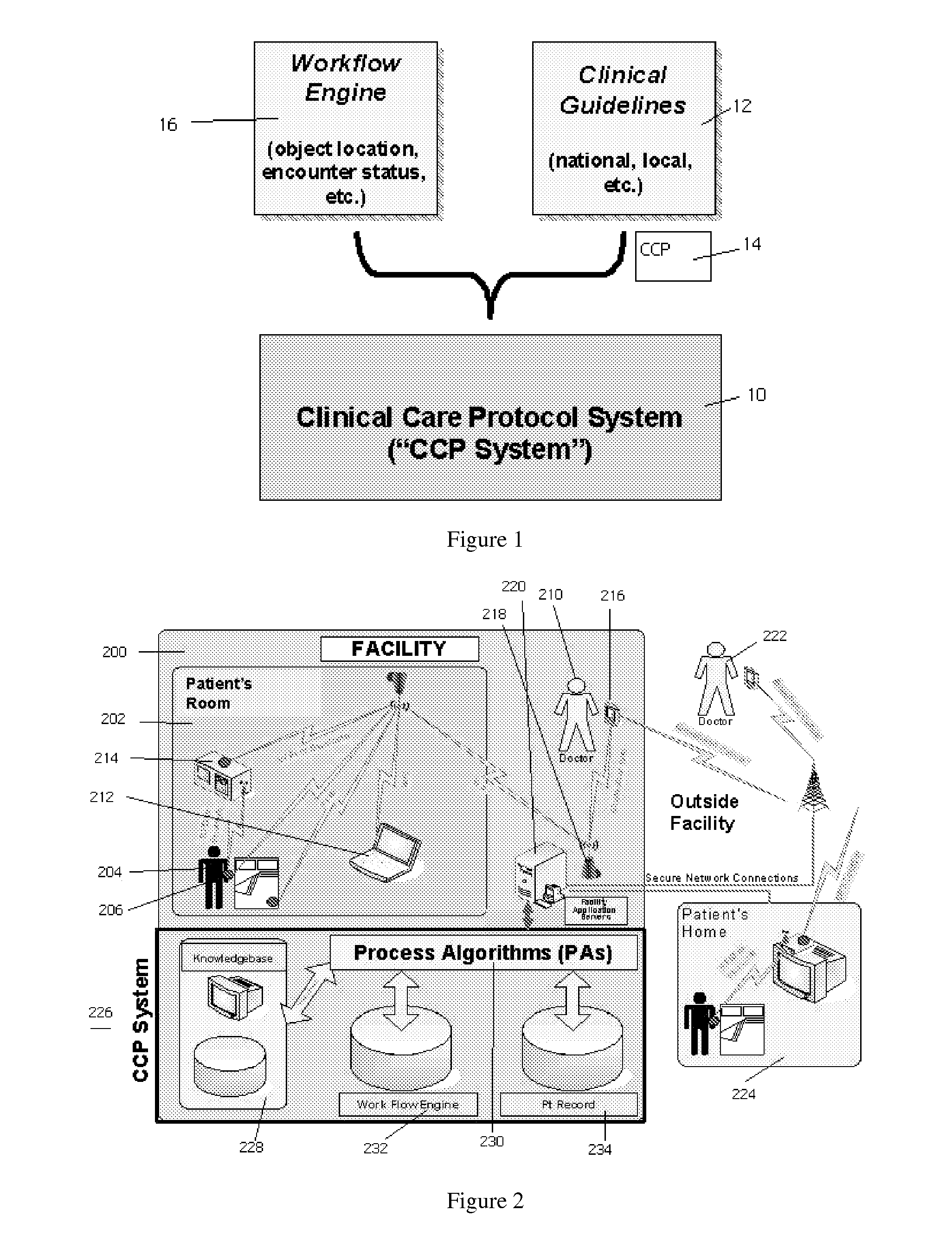

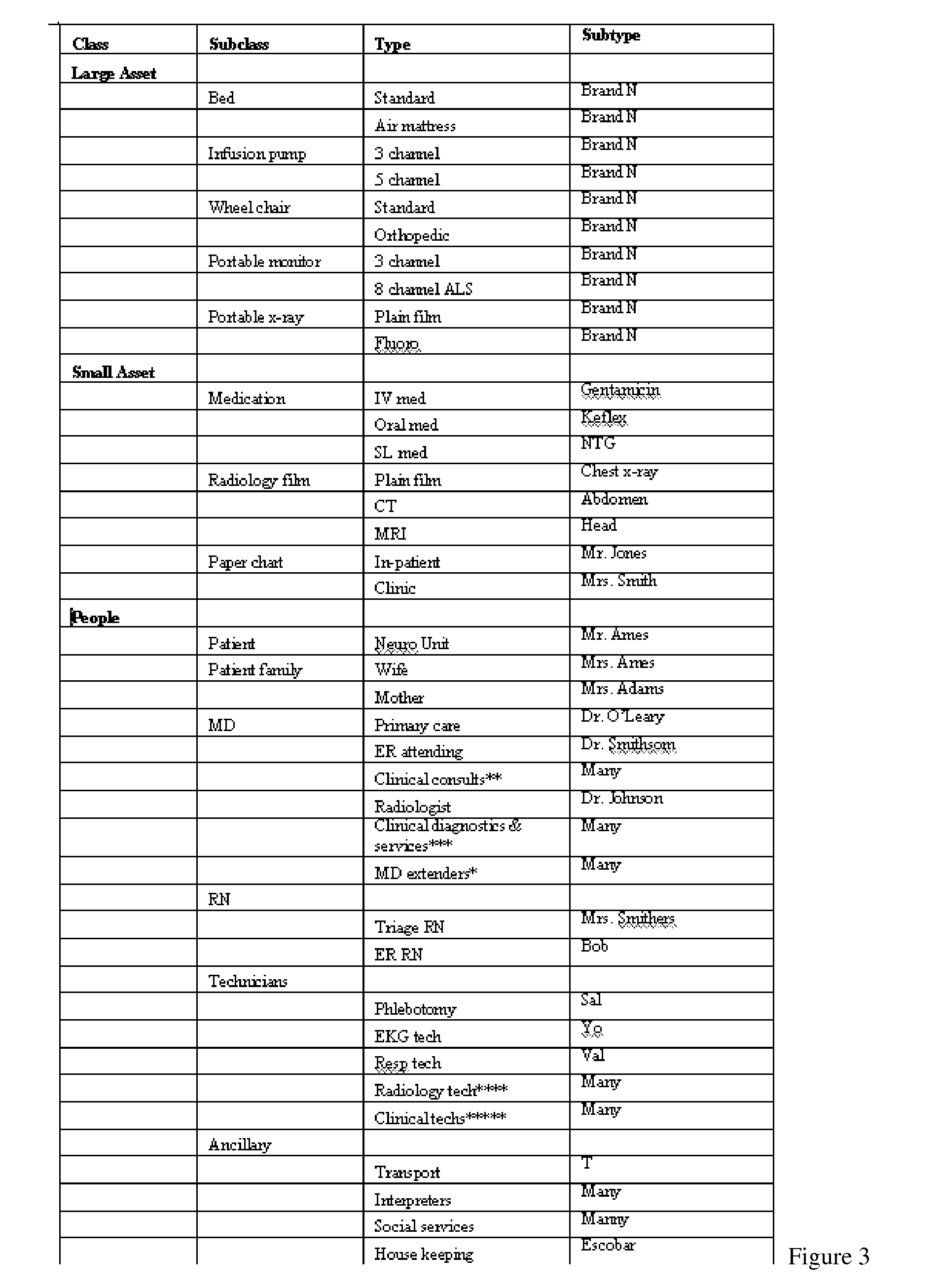

Method and system for providing clinical care

InactiveUS20070185739A1Improve implementation of and adherenceRaise the possibilityData processing applicationsMedical automated diagnosisGuidelineClinical care

The present invention describes a method that is operative within a clinical environment in which real-time locations of personnel and resources are tracked. The method begins in association with entry of a patient into the clinical environment, such as when a patient is in transit, or has been admitted, to an emergency room or to a hospital. In response, a given care guideline is identified. Using the care guideline, a set of one or more process rules, and information associated with at least one “encounter,” the system generates a patient-specific care protocol; the protocol includes a set of steps through which the patient is expected to proceed while in the clinical environment. An encounter occurs when two or more of objects (e.g., the patient, clinical personnel, and a clinical resource) are in a given physical proximity for a given time period at determined by the at least one process rule. According to the method, at least one event that occurs during at least a first step of the patient-specific care protocol is then monitored. Using information generated by the monitoring step and at least one process rule, the system then determines whether the patient moves to a next step in the patient-specific care protocol.

Owner:CLINILOGIX

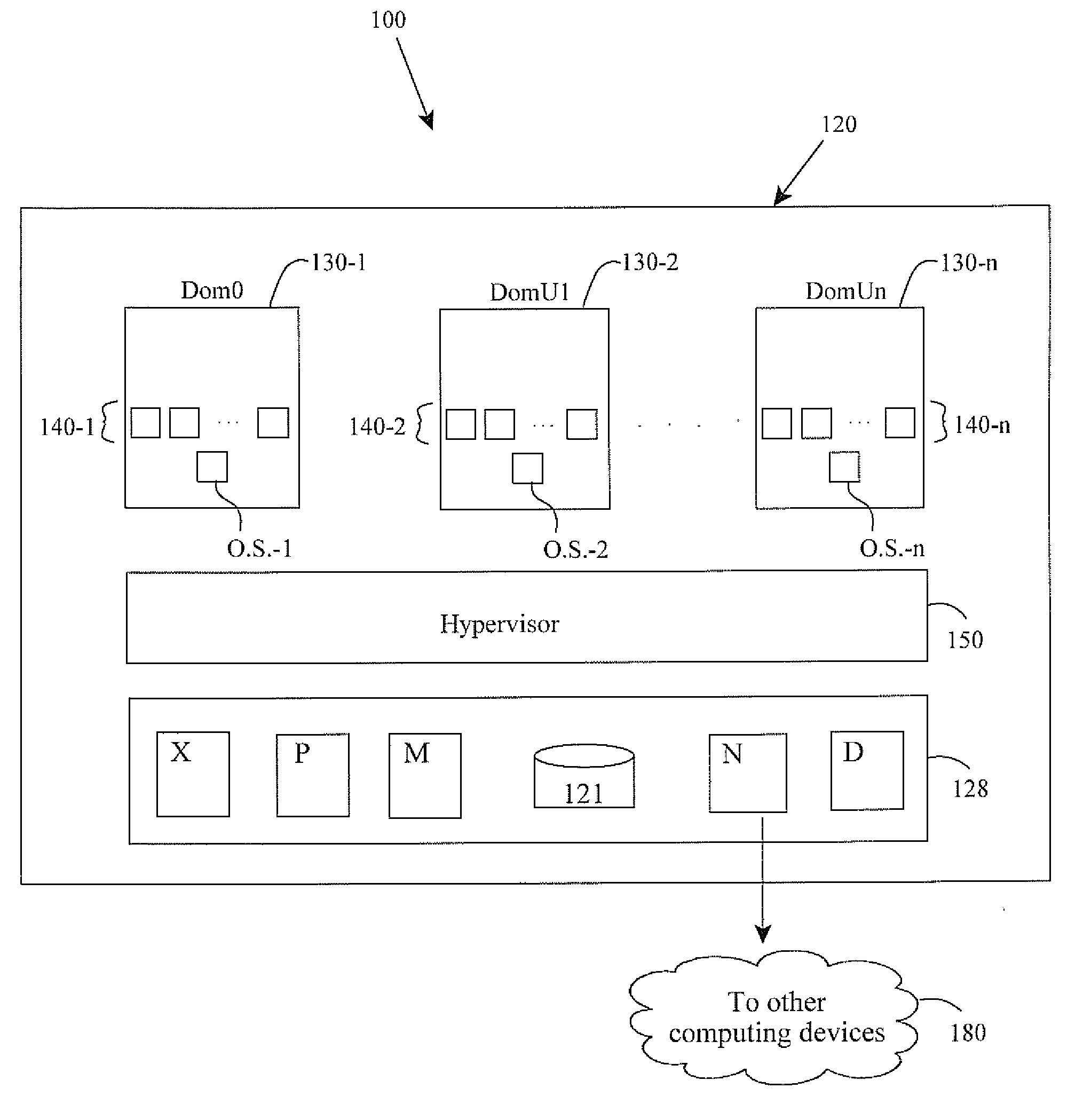

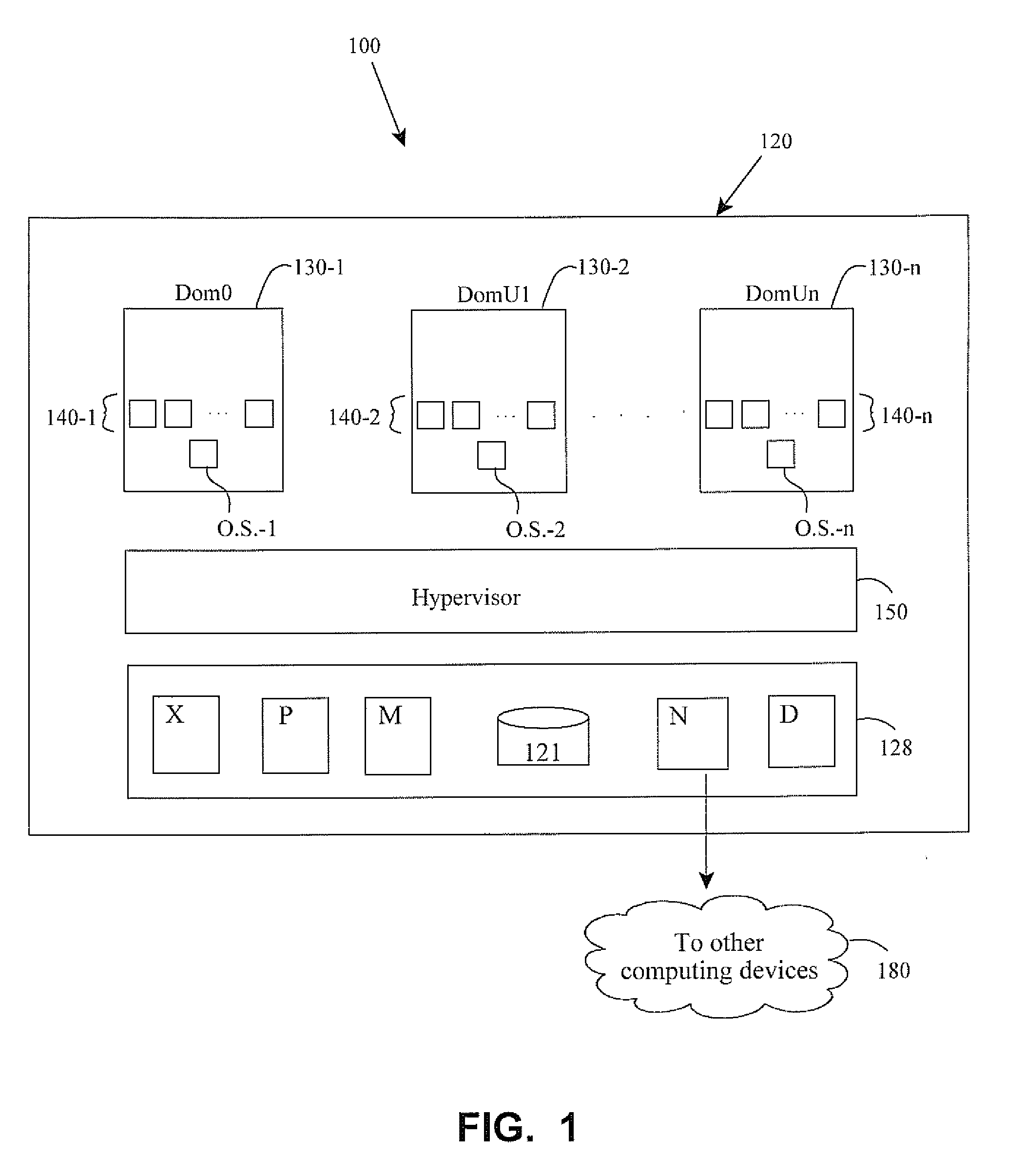

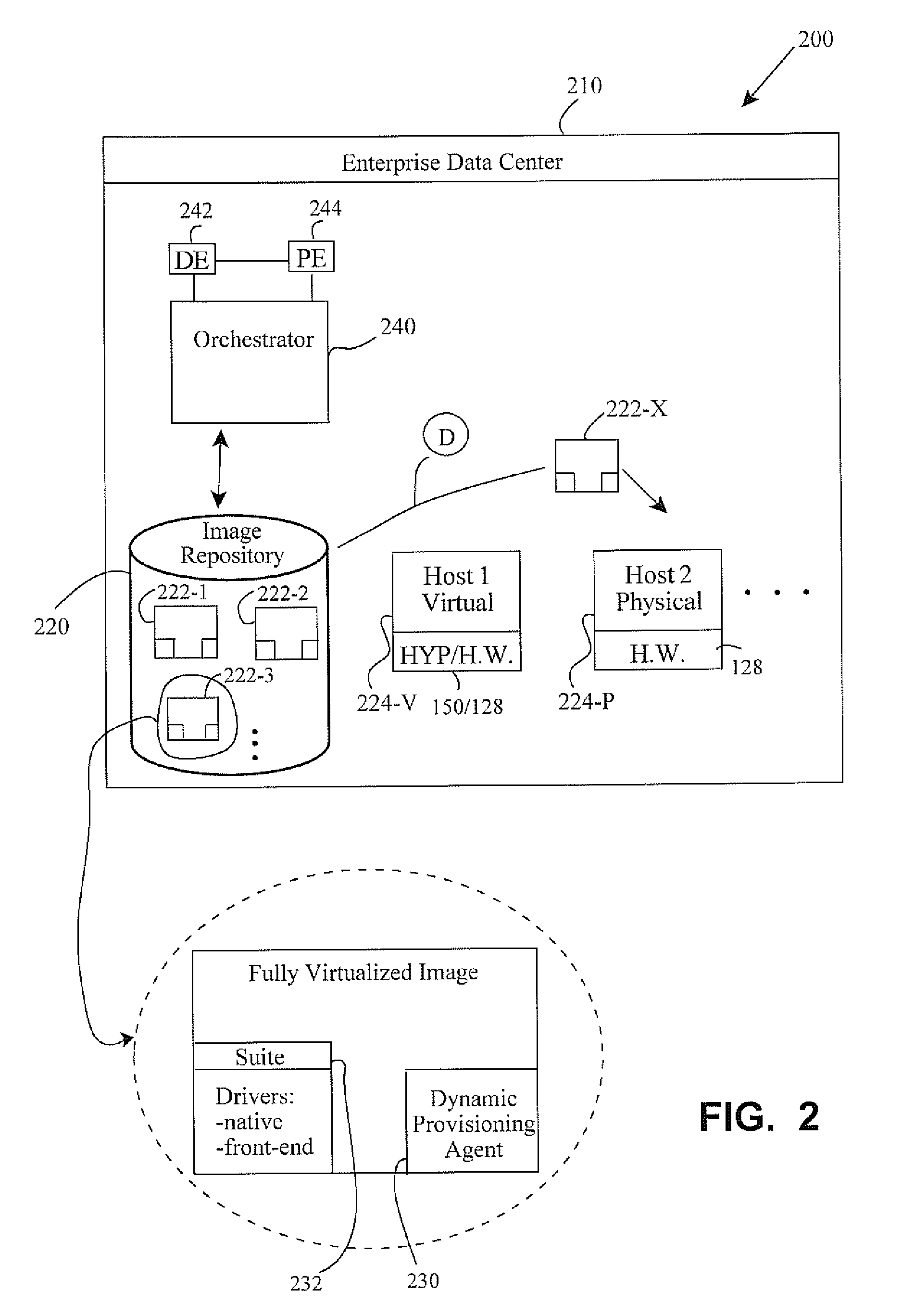

Workload management for heterogeneous hosts in a computing system environment

ActiveUS20110035754A1Improve performanceImprove resource utilizationMultiprogramming arrangementsMemory systemsData centerComputing systems

Methods and apparatus involve managing workload migration to host devices in a data center having heterogeneously arranged computing platforms. Fully virtualized images include drivers compatible with varieties of host devices. The images also include an agent that detects a platform type of a specific host device upon deployment. If the specific host is a physical platform type, the agent provisions native drivers. If the specific host is a virtual platform type, the agent also detects a hypervisor. The agent then provisions front-end drivers that are most compatible with the detected hypervisor. Upon decommissioning of the image, the image is returned to its pristine state and saved for later re-use. In other embodiments, detection methods of the agent are disclosed as are computing systems, data centers, and computer program products, to name a few.

Owner:SUSE LLC

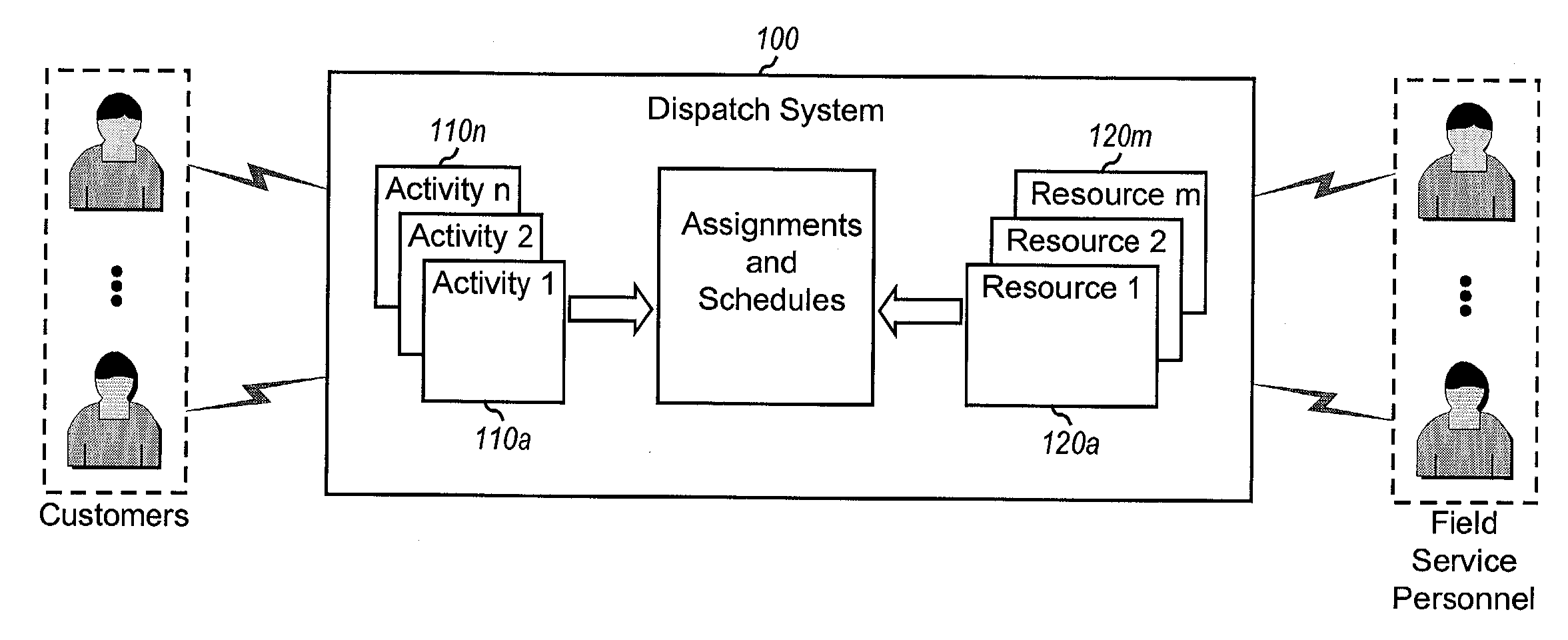

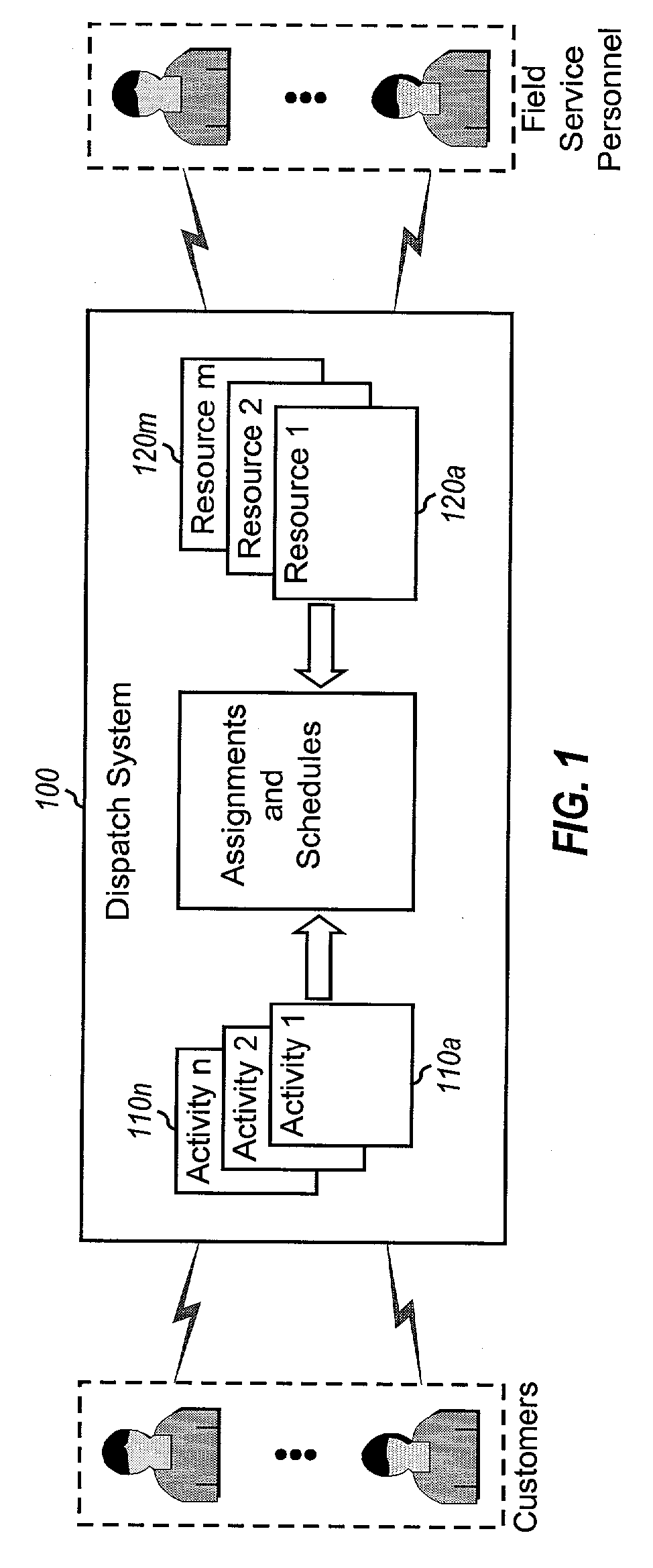

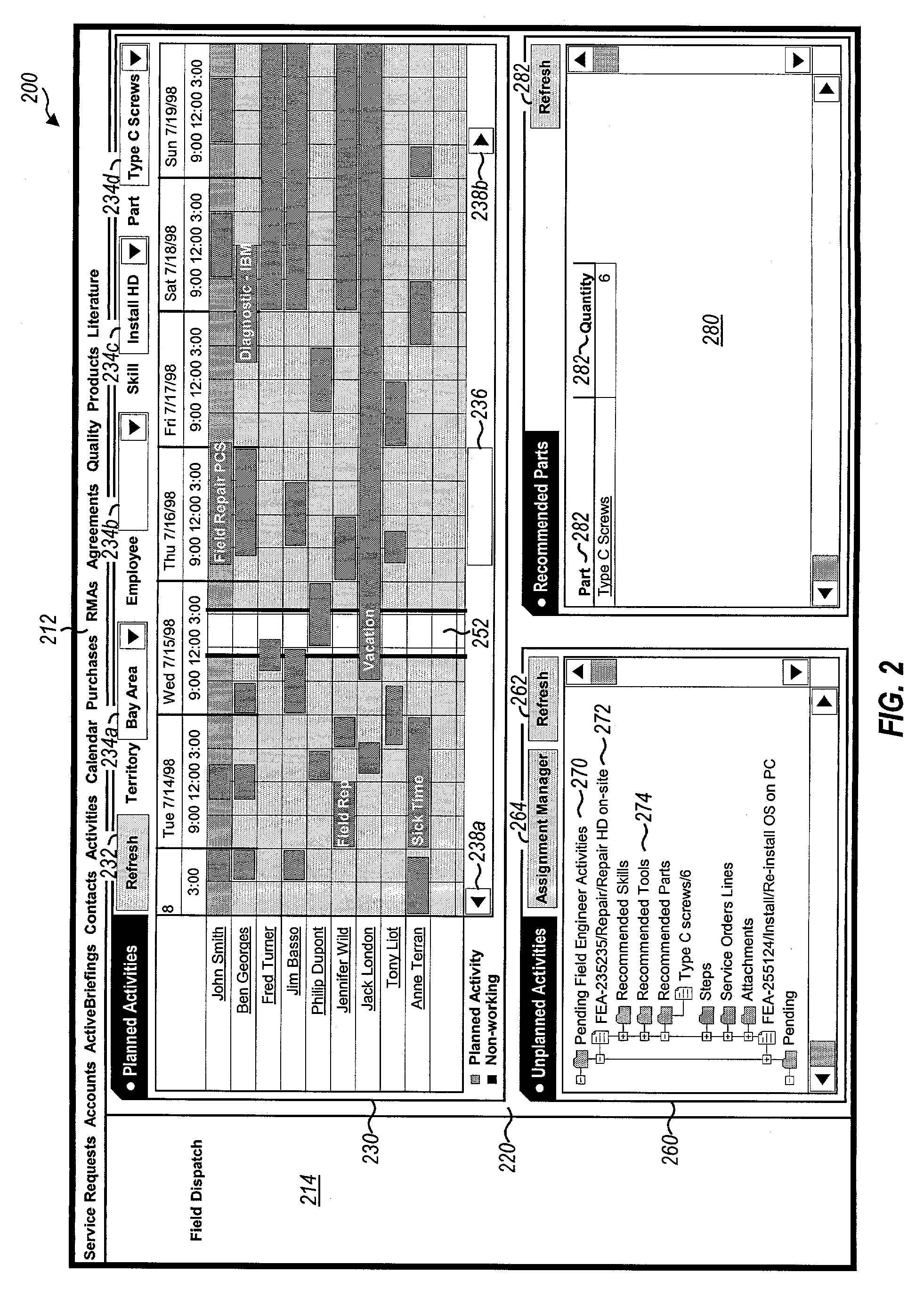

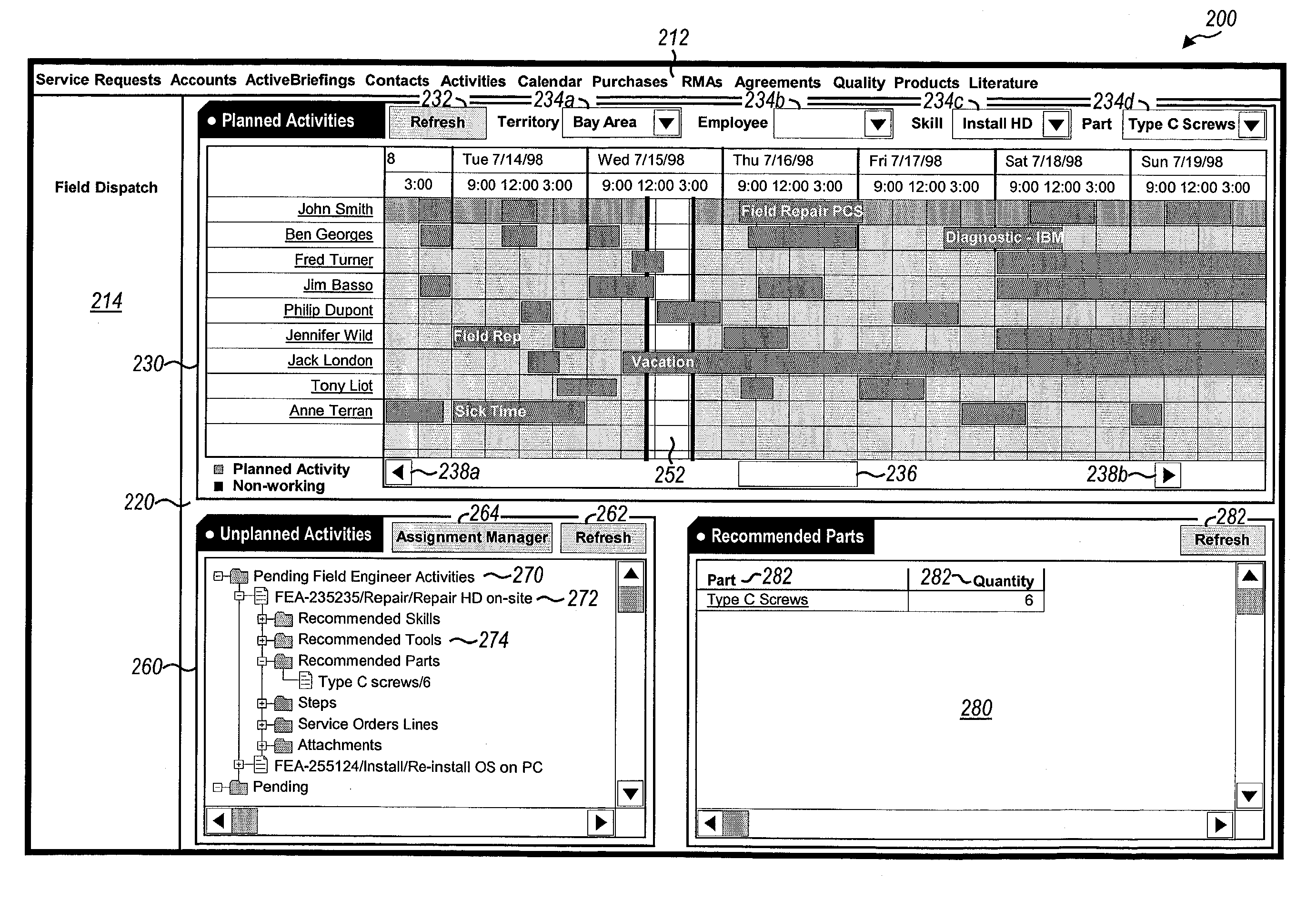

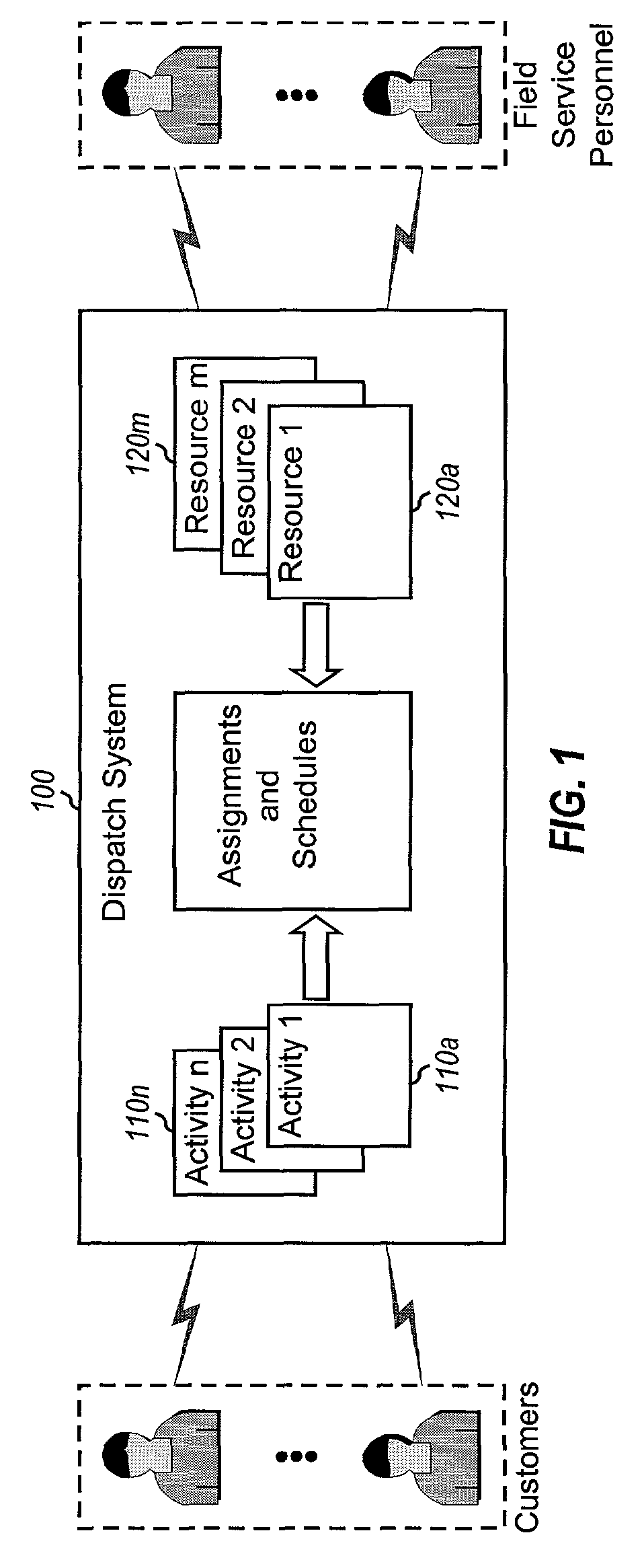

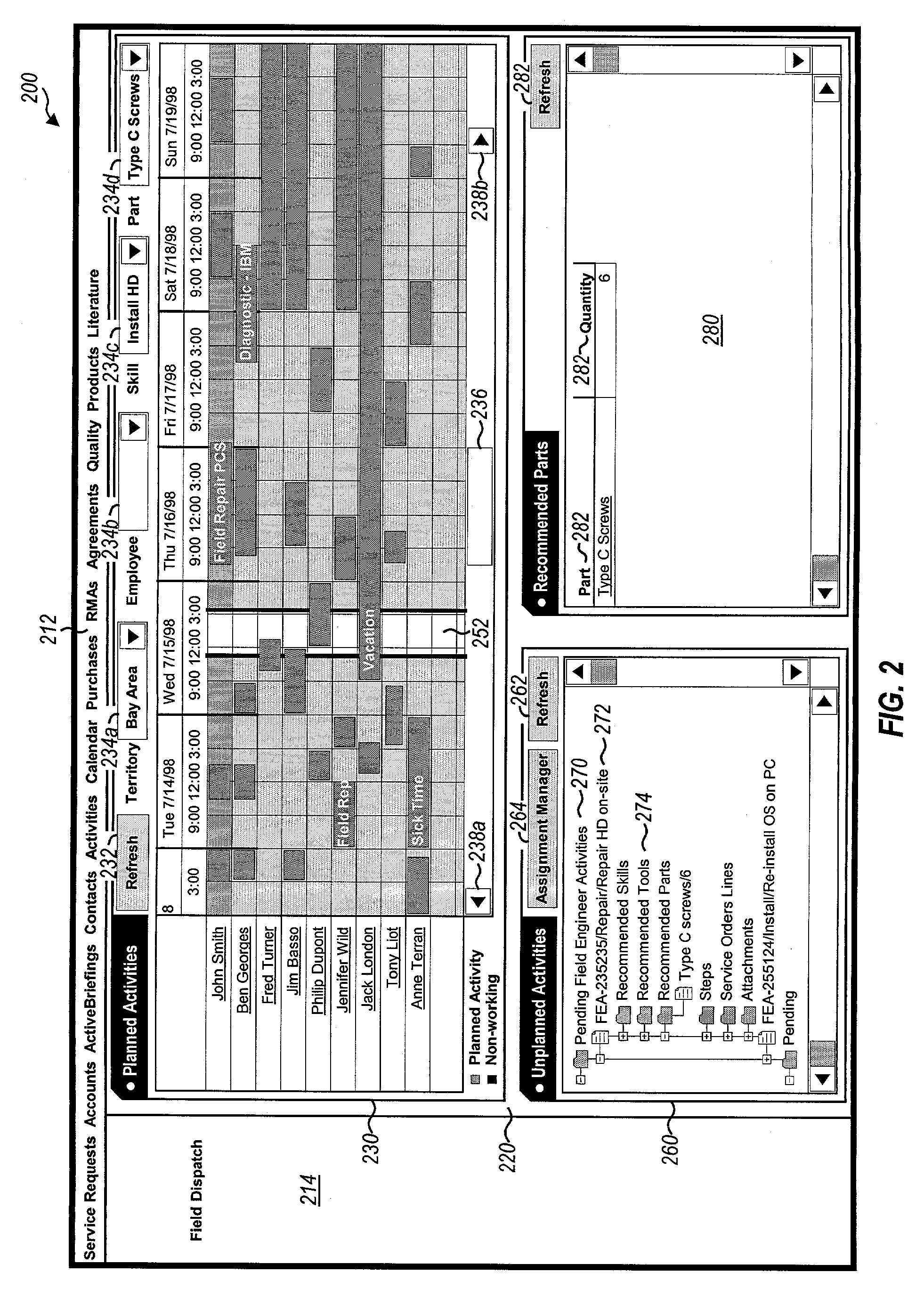

System and method for assigning and scheduling activities

InactiveUS20070219842A1Improve resource utilizationEfficient executionDigital computer detailsResourcesProgram planningComputer science

Techniques to facilitate assignment and scheduling of activities. In accordance with a method, a chart showing a calendar of schedule for a number of available resources is provided in a first frame (or window) in a user interface menu, and a number of objects representative of a number of unplanned activities are provided in a second frame. A selection for an unplanned activity in the second frame (or a planned activity in the first frame) is received and, in response, selected ones of a number of objects in the chart are highlighted based on the selected activity. A request to assign the selected activity to a selected resource and to schedule the selected activity for a particular time duration is thereafter received. The requested assignment and scheduling may be accepted or rejected based on the requirements of the selected activity and the capabilities of the selected resource.

Owner:SIEBEL SYST INC

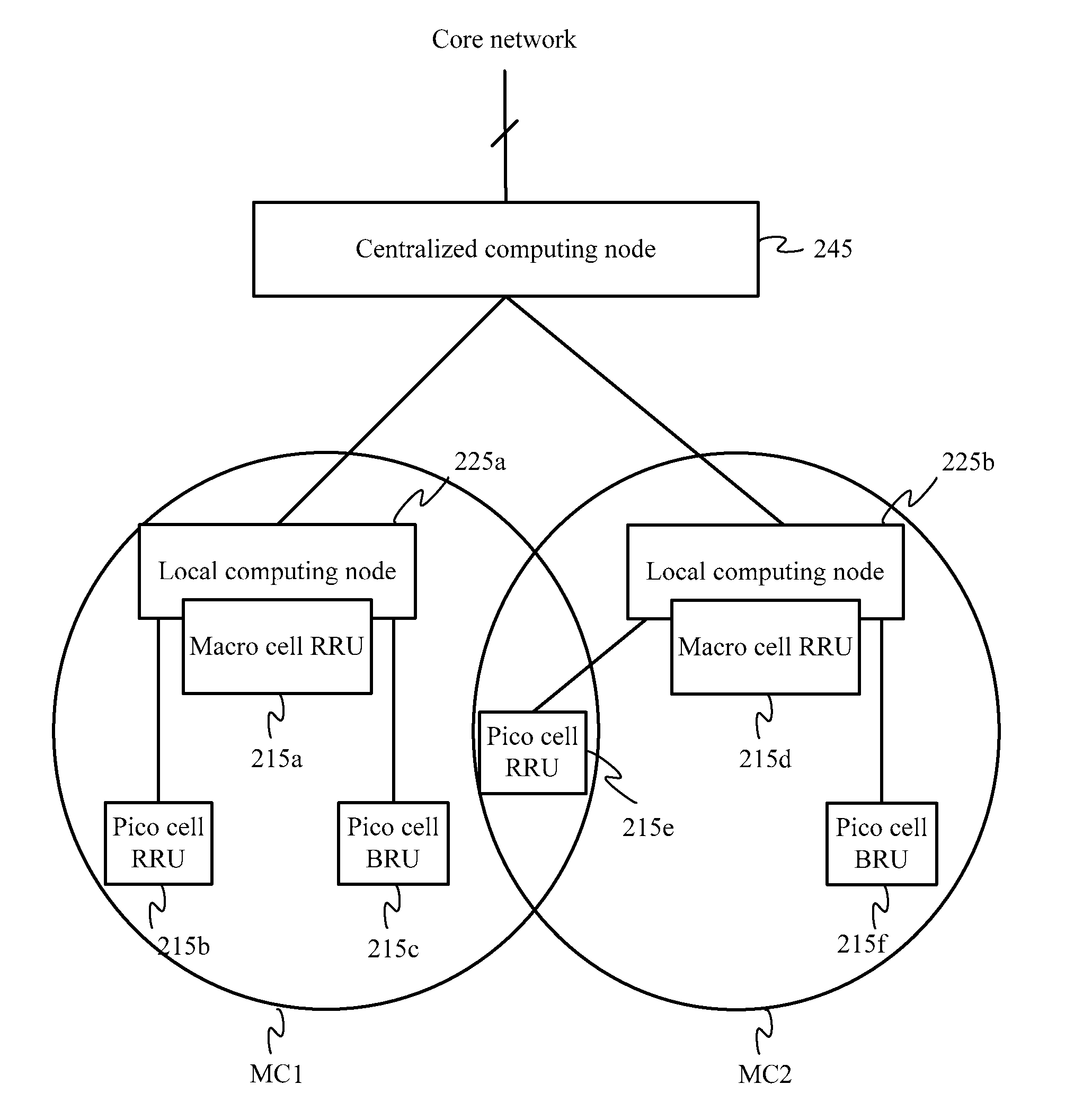

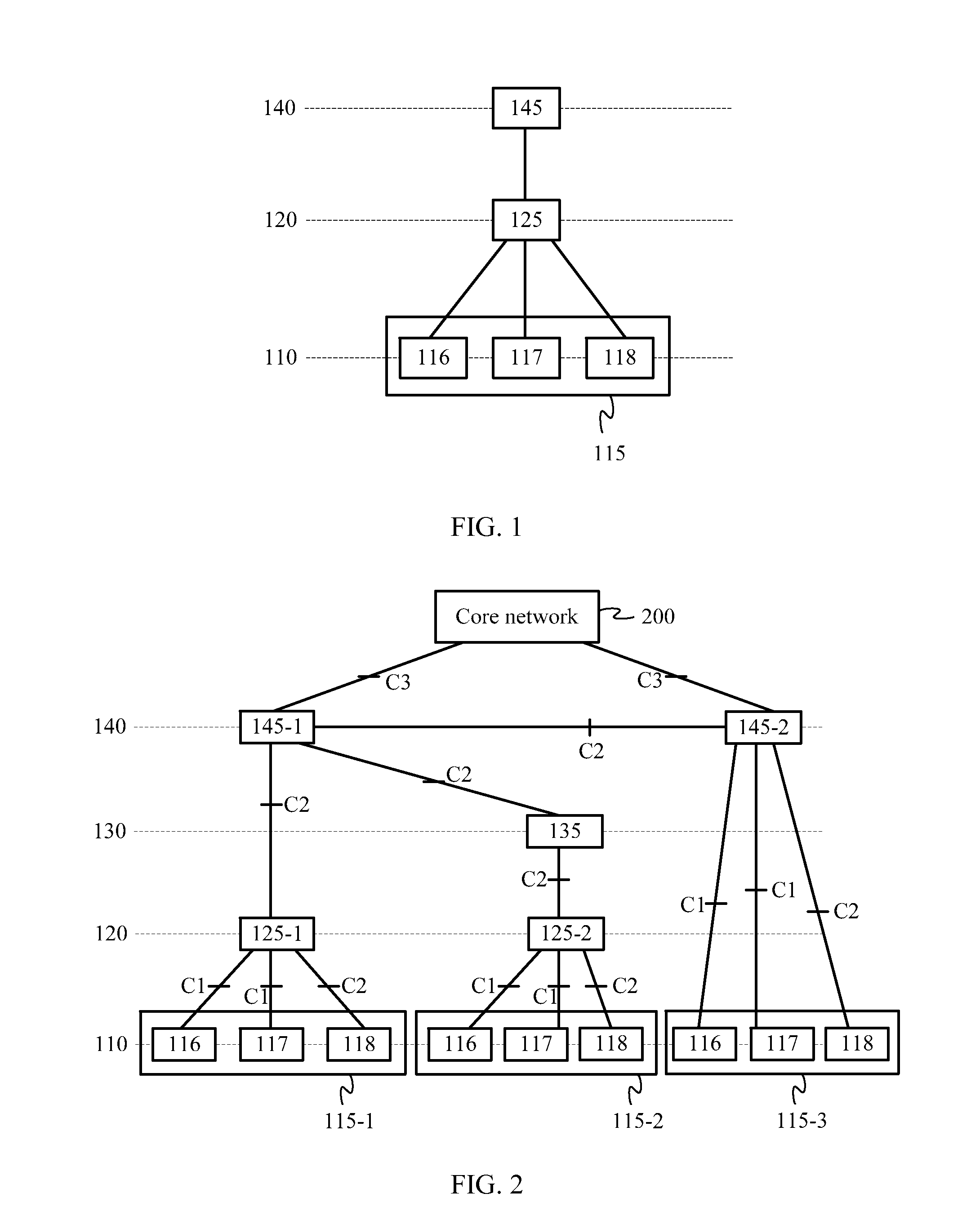

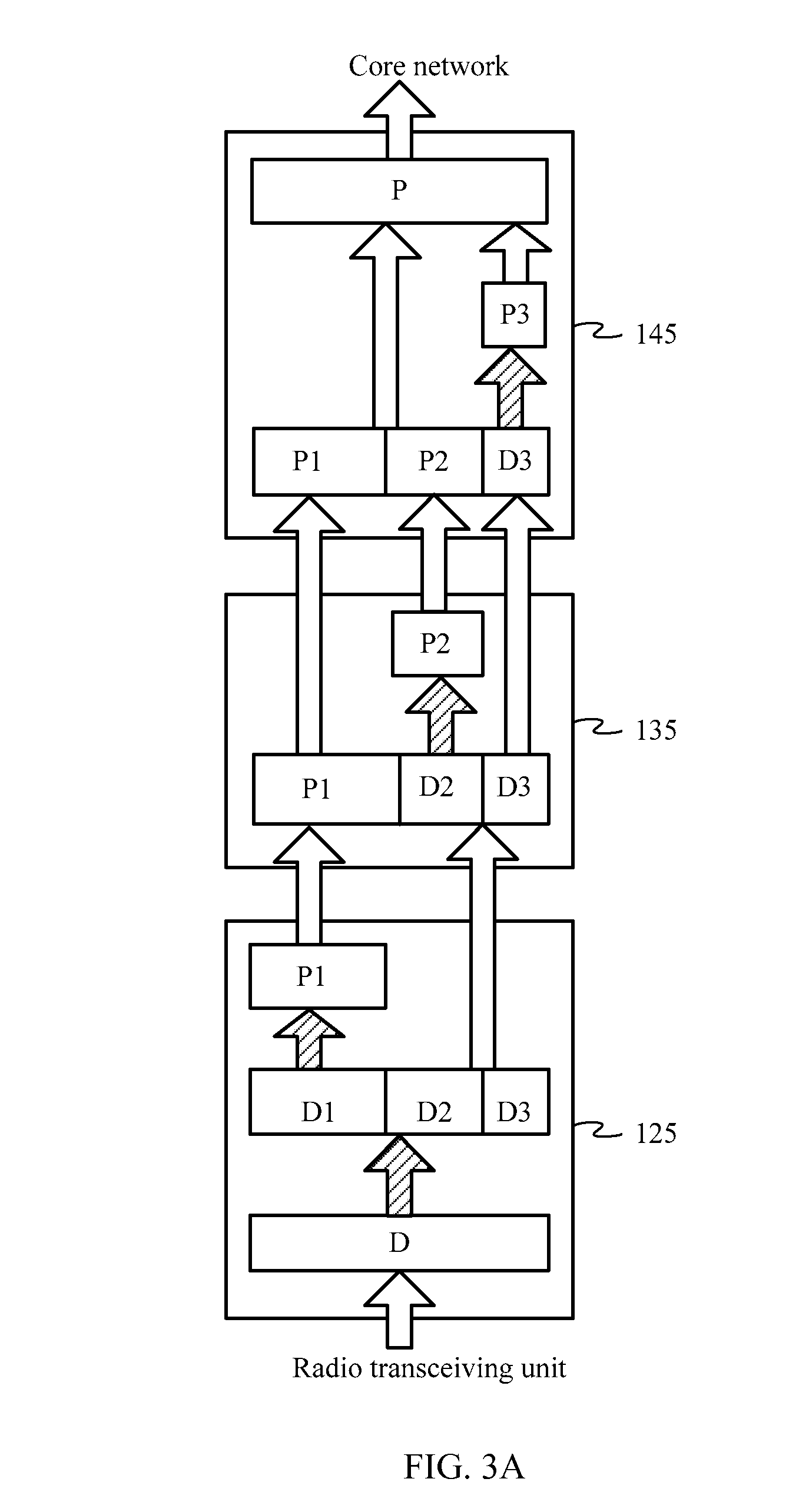

Communication system and management method thereof

ActiveUS20130017852A1Save network bandwidthIncrease profitRadio transmissionWireless commuication servicesCommunications systemCentralized computing

Embodiments of the present invention provide a communication system and management method thereof. The communication system includes: a radio transceiving layer, including a radio transceiving node combination, where the radio transceiving node combination includes at least one type of the following: a macro cell RRU, a Pico cell RRU, and a Pico cell BRU; a local computing layer, including a local computing node, connected to a radio transceiving node in one or multiple neighboring radio transceiving node combinations and configured to execute all communication processing or a first part of communication processing of a cell corresponding to the local computing node; a centralized computing layer, including a centralized computing node, connected to the local computing node in the local computing layer and configured to execute a second part of communication processing, where the all communication processing includes the first part and second part of communication processing.

Owner:HUAWEI TECH CO LTD

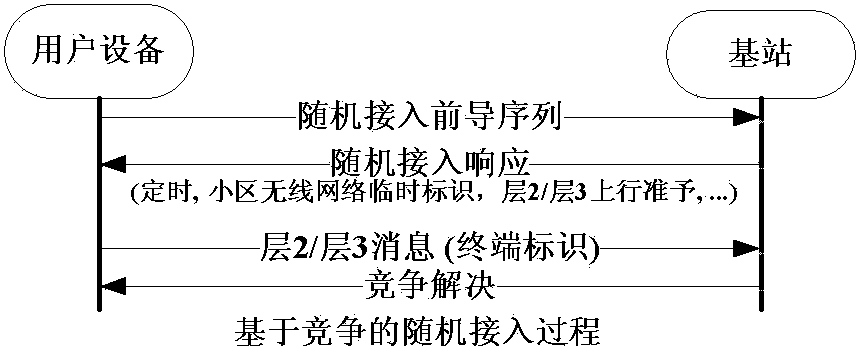

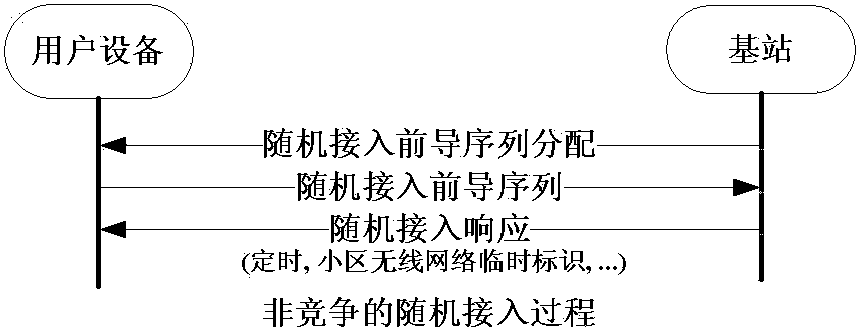

Physical random access channel sending and receiving methods, base station and user equipment

ActiveCN104254135AImprove resource utilizationImproved Spectrum/Energy EfficiencyPower managementNetwork traffic/resource managementFrequency spectrumResource utilization

The invention provides a method executed by a base station. The method comprises the following steps that: physical random access channel (PRACH) configuration parameters for user equipment are generated and transmitted; a random preamble sequence and corresponding PRACH resource sets sent by the user equipment are detected, so that the type and / or coverage enhancement level of the user equipment can be determined; and random access responses can be generated based on the type and / or coverage enhancement level of the user equipment. The invention also provides a method executed by the user equipment, a corresponding base station and user equipment. With the methods, base station and user equipment of the invention adopted, the resource utilization rate of LTE supported MTC user equipment can be improved, and frequency spectrum and energy efficiency can be improved, and time and frequency resource conflict between cells can be reduced.

Owner:SHARP KK

System and method for assigning and scheduling activities

InactiveUS7788598B2Quickly and easily and accurately assign and scheduleImprove resource utilizationResourcesInput/output processes for data processingComputer scienceUser interface

Techniques to facilitate assignment and scheduling of activities. In accordance with a method, a chart showing a calendar of schedule for a number of available resources is provided in a first frame (or window) in a user interface menu, and a number of objects representative of a number of unplanned activities are provided in a second frame. A selection for an unplanned activity in the second frame (or a planned activity in the first frame) is received and, in response, selected ones of a number of objects in the chart are highlighted based on the selected activity. A request to assign the selected activity to a selected resource and to schedule the selected activity for a particular time duration is thereafter received. The requested assignment and scheduling may be accepted or rejected based on the requirements of the selected activity and the capabilities of the selected resource.

Owner:SIEBEL SYST INC

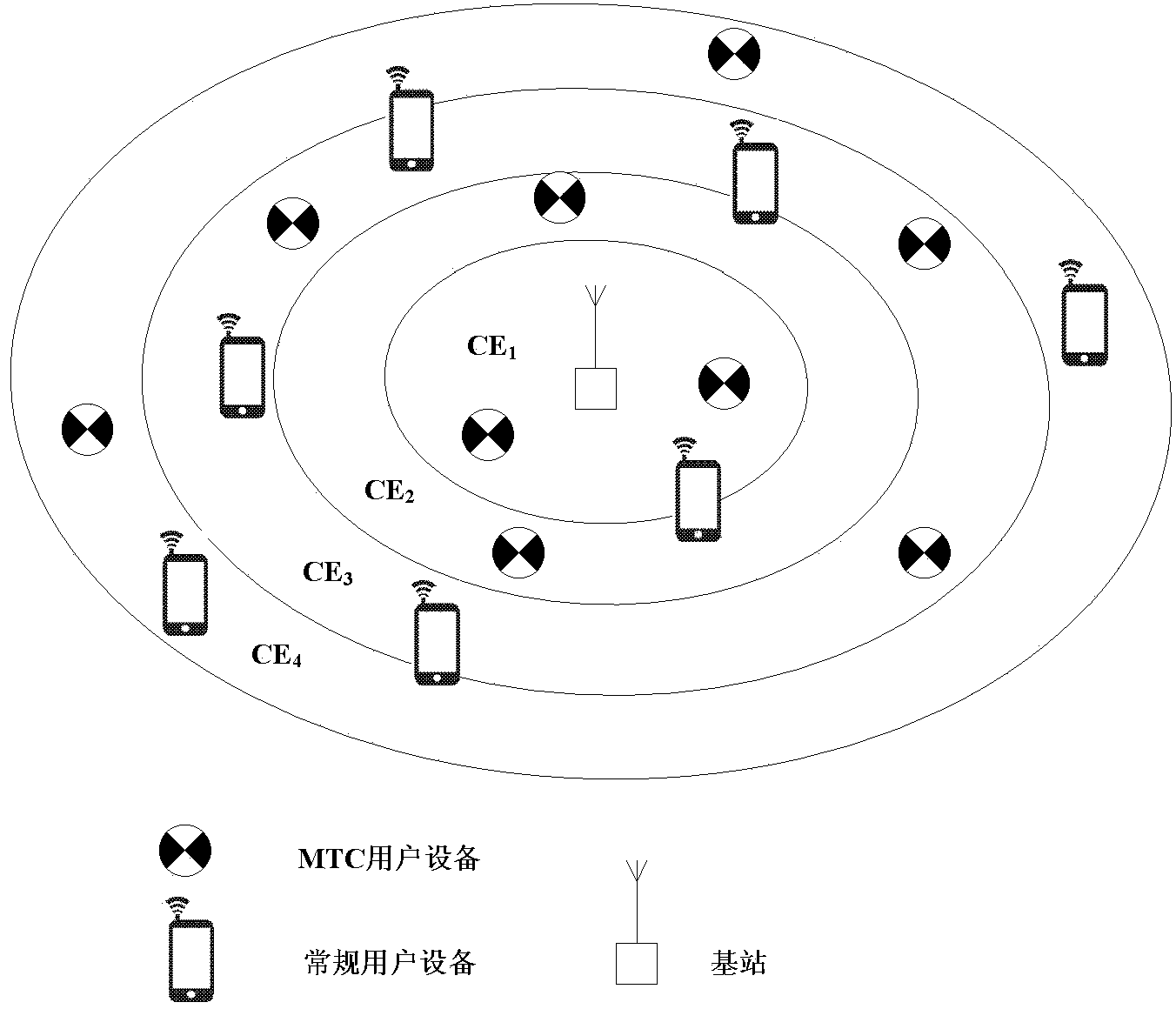

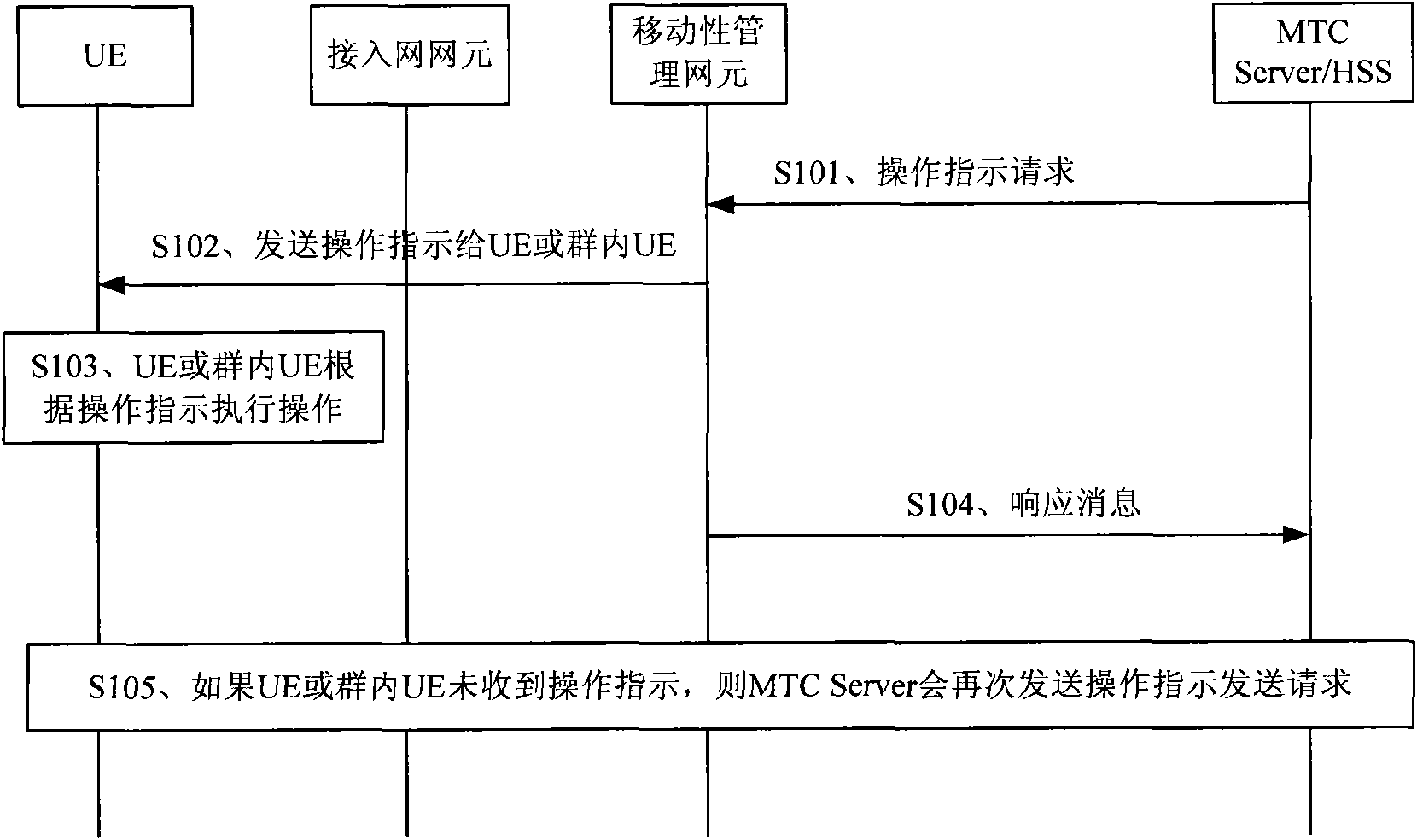

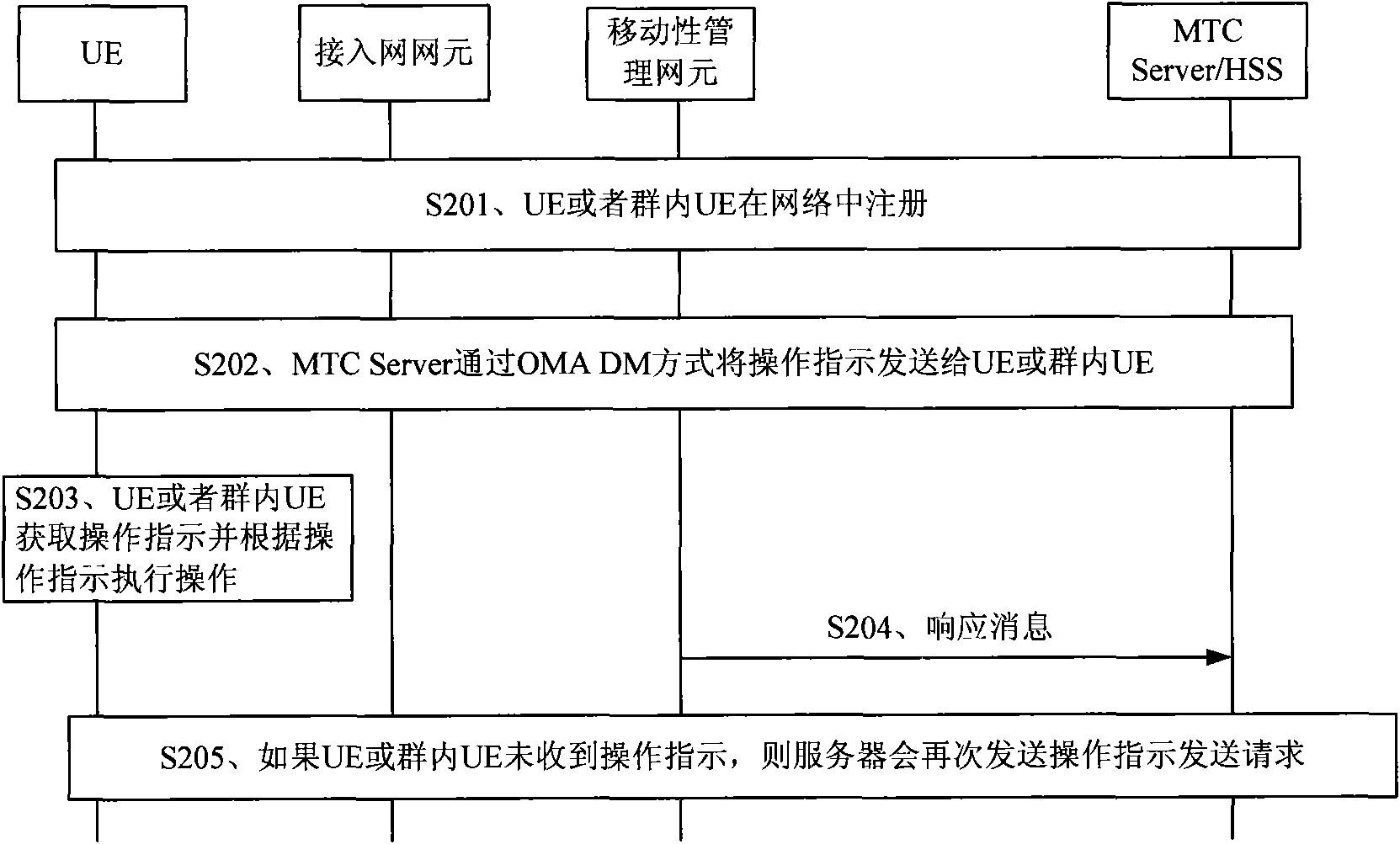

M2M user equipment as well as operation control method and system thereof

InactiveCN101959133AImprove resource utilizationReduce shockBroadcast service distributionWireless commuication servicesControl systemBusiness data

The embodiment of the invention discloses an operation control method for a M2M user equipment applied in machine to machine, which comprises the steps of: receiving information including operation instructions and sent from a network side, wherein the operation instructions comprise at least one of the instructions of indicating a user equipment UE or a group UE to register, activating signed data and transmitting business data; and operating the user equipment UE or the group UE according to the received operation instruction. The embodiment of the invention also provides corresponding user equipment, a corresponding server and a corresponding control system. In the embodiment of the invention, the user equipment is controlled by the network side to perform operation, the UE can be indicated to register, activate the signed data or transmit the business data at any time, the UE or the group UE can be in a dormant state or the state of going to register, and the impact and the influence from a large number of user equipment UE on the network side can be reduced so as to greatly improve the utilization ratio of network resources, meet the current M2M application and provide convenient and effective services for operators and users.

Owner:HUAWEI TECH CO LTD

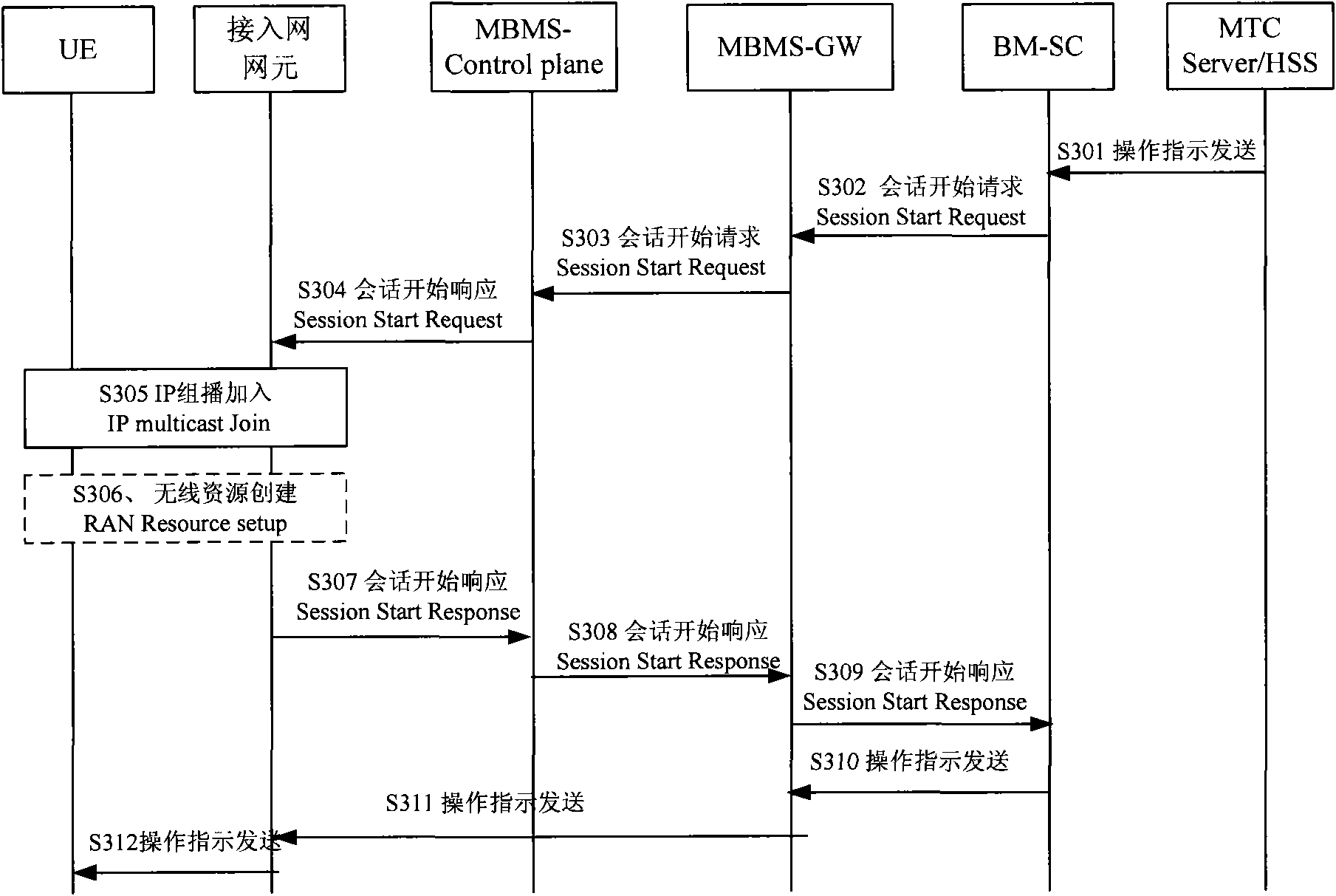

Operation management method of electric power system cloud simulation platform

ActiveCN104463492AAchieve integrationImplement storage service managementResourcesResource Management SystemElectric power system

The invention provides an operation management method of an electric power system cloud simulation platform. The electric power system cloud simulation platform comprises a cloud simulation resource management system and a cloud simulation application supporting system. The method comprises the following steps that the cloud simulation resource management system is constructed; the cloud simulation application supporting system is constructed; the safety of the electric power system cloud simulation platform is determined; operation management of the electric power system cloud simulation platform is carried out. Cloud simulation analytical calculation application is achieved, multiple users can carry out currents, transient stability, small interference, short-circuit currents and other simulation calculation functions on one or more sets of data according to the permission in the mode of facing network services, and the limitation that services and data of standalone version software cannot be shared in large-scale interconnected power grid analytical calculation is eliminated.

Owner:STATE GRID CORP OF CHINA +2

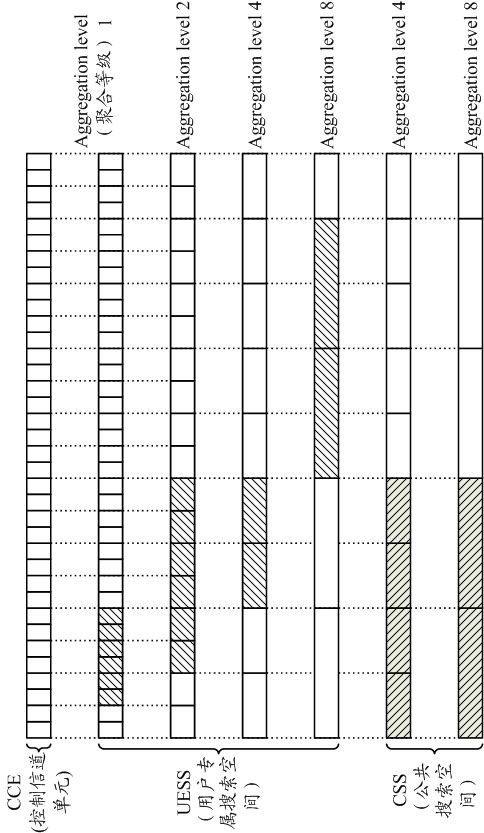

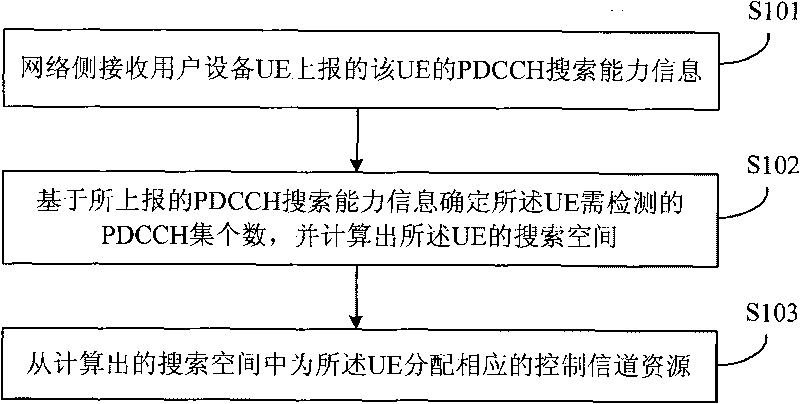

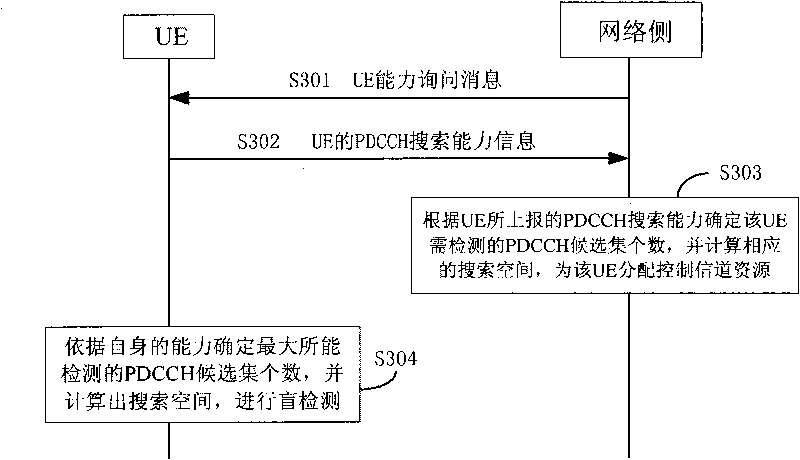

Method and device for optimizing search space of user equipment

ActiveCN101699901AImprove resource utilizationConducive to saving electricityEnergy efficient ICTAssess restrictionResource utilizationTerminal equipment

The embodiment of the invention discloses a method for optimizing the search space of user equipment, which comprises the following steps: receiving the search capability information of a physical downlink control channel (PDCCH) of the user equipment (UE), which is reported by the UE; based on the search capability information of the PDCCH, which is reported by the UE, determining the number of candidate sets of the PDCCH of the UE, which needs to be detected; and according to the number of the candidate sets of the PDCCH, calculating the search space of the UE. The embodiment of the invention also provides a corresponding device for optimizing the search space of the UE, and user terminal equipment. The scheme provided by the embodiment of the invention can increase the success ratio of resource allocation of the PDCCH and increase the search efficiency of the UE, thereby increasing the resource utilization ratio of the PDCCH and being beneficial to power saving of the UE.

Owner:SHANGHAI HUAWEI TECH CO LTD

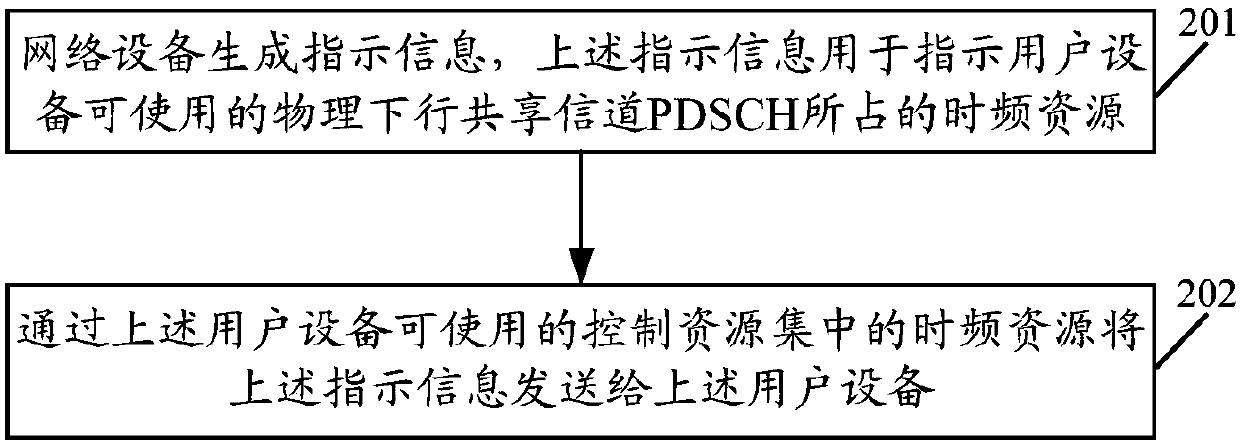

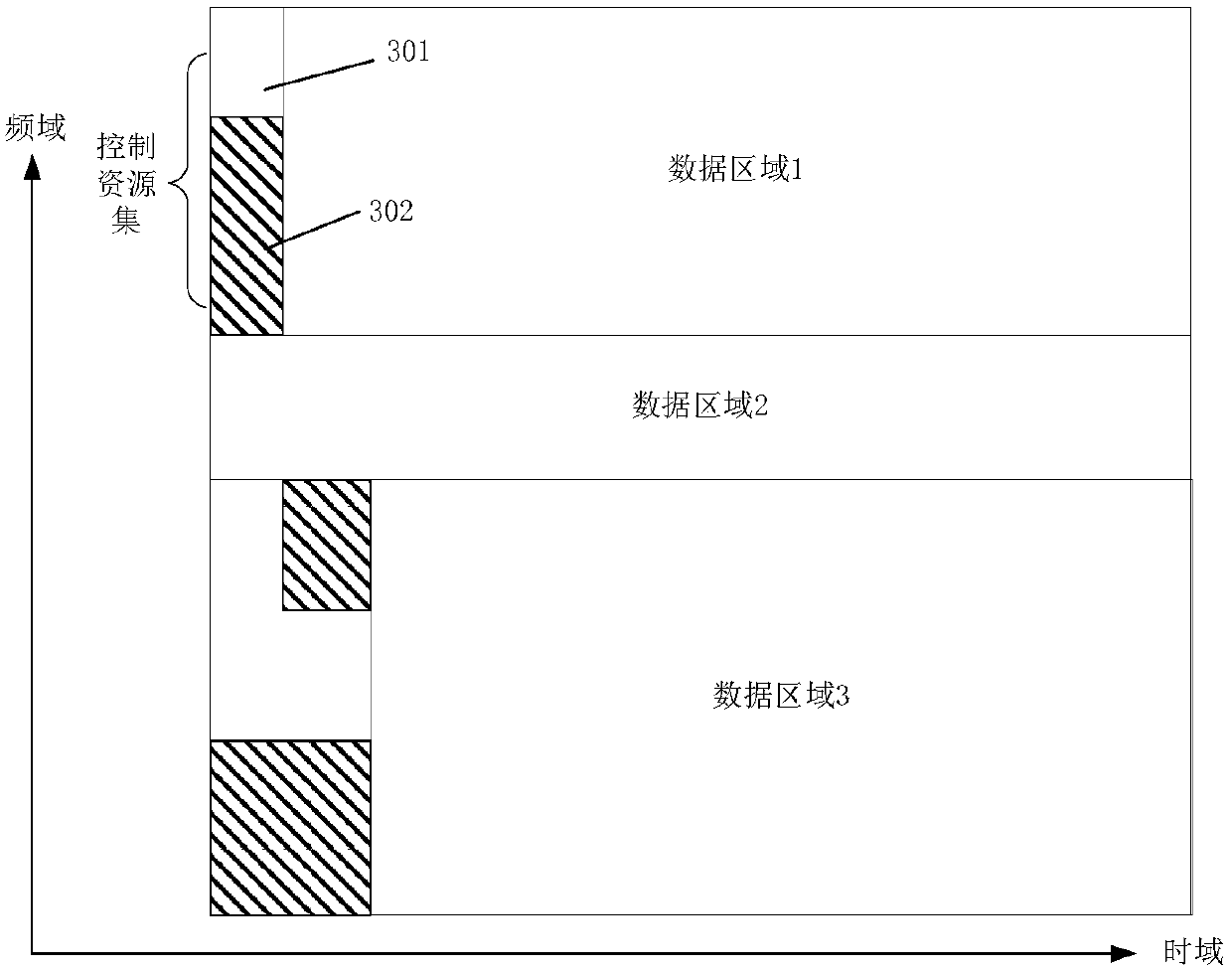

Resource indicating method, relevant equipment and communication system

InactiveCN107659994AFair useImprove resource utilizationWireless communicationCommunications systemResource utilization

The embodiment of the invention discloses a resource indicating method, relevant equipment and a communication system. The resource indicating method can comprise the following steps: generating indication information by network equipment, wherein the indication information is used for indicating time frequency resources occupied by a physical downlink shared channel (PDSCH) available for user equipment; and transmitting the indication information to the user equipment through time frequency resources in a control resource set available for the user equipment. Through adoption of the resourceindicating method, the relevant equipment and the communication system in the embodiment of the invention, the problem concerned with information indication for the user equipment when downlink control information or downlink data information is transmitted by means of the time frequency resources in the control resource set is solved, and the resource utilization ratio is increased.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com