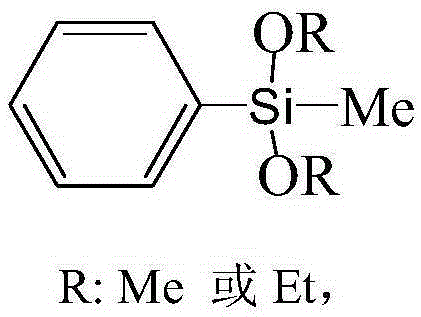

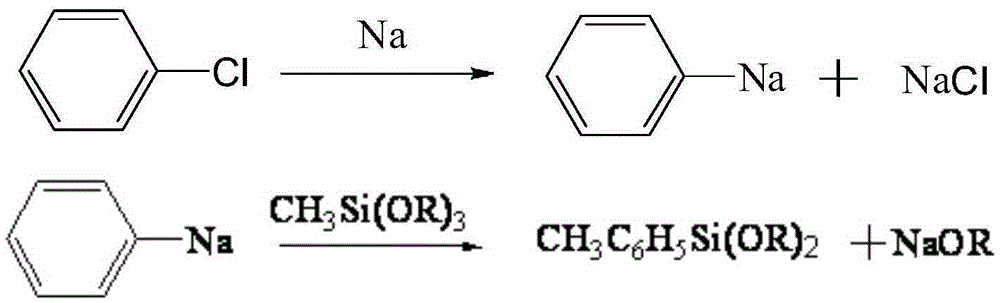

Nucleophilic method used for preparing phenylmethyldialkoxysilanes

A technology of methyl phenyl dialkoxy silane and methyl trialkoxy silane is applied in the synthesis field of organosilicon compounds, which can solve the problem of difficult separation of by-products and target monomers, extremely high requirements for drying of instruments and equipment, and metal Problems such as troublesome handling of halogen salts, to achieve the effect of enhancing rapid progress and offensive capabilities, eliminating unsafe hidden dangers, and mild and controllable production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A nucleophilic method for preparing methylphenyldialkoxysilane includes the following steps:

[0044] (1) Under the protection of nitrogen, add 23g of sodium block to 69g of toluene, then add 0.33g of paraffin, and heat to 99°C to prepare a metal sodium particle suspension;

[0045] (2) Add the metal sodium particle suspension to the mixture of 62.5g chlorobenzene and 227g methyltrimethoxysilane, then add 0.32g 15-crown-5, and react for 2h at 38°C to stop the reaction. The reaction mixture was filtered and rectified under reduced pressure to obtain methylphenyldimethoxysilane with a yield of 87%.

Embodiment 2

[0047] A nucleophilic method for preparing methylphenyldialkoxysilane includes the following steps:

[0048] (1) Under the protection of nitrogen, add 23 g of sodium block to 115 g of toluene, then add 0.35 g of oleic acid, and heat to 102° C. to prepare a metal sodium particle suspension;

[0049] (2) Add the metal sodium particle suspension to the mixture of 59.2g chlorobenzene and 358.5g methyltrimethoxysilane, then add 0.45g 15-crown-5, and react for 7h at 44℃, stop the reaction After the reaction mixture is filtered, it is rectified under reduced pressure to obtain methylphenyldimethoxysilane with a yield of 67%.

Embodiment 3

[0051] A nucleophilic method for preparing methylphenyldialkoxysilane includes the following steps:

[0052] (1) Under the protection of nitrogen, add 23g of sodium block to 138g of toluene, then add 0.31g of oleic acid, and heat to 104°C to prepare a metal sodium particle suspension;

[0053] (2) Add the metal sodium particle suspension to the mixture of 56.25g of chlorobenzene and 408.66g of methyltrimethoxysilane, then add 0.45g of 15-crown-5, and react for 5h at 52°C to stop the reaction After the reaction mixture is filtered, it is rectified under reduced pressure to obtain methylphenyldimethoxysilane with a yield of 67%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com