Profile controlling and flooding composition for high-temperature oil reservoirs with high salinity

A high-temperature, high-salt, composition technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of low oil displacement efficiency, poor temperature and salt resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

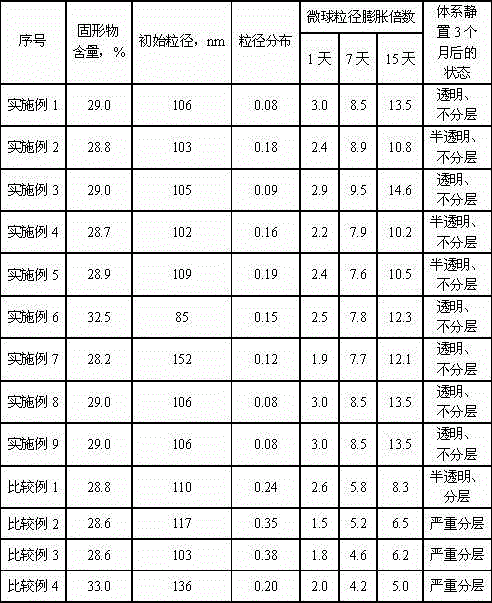

Examples

Embodiment 1

[0054] The polymer microemulsion of the present embodiment is prepared by polymerizing a reverse phase microemulsion under the action of a redox composite initiator; the reverse phase microemulsion comprises the following components in parts by weight:

[0055] a) 50 parts of oil-soluble solvent; oil-soluble solvent is white oil;

[0056] b) 15 parts of emulsifier; the HLB value of the emulsifier is 6.7 (from Span 80 (that is, sorbitan monooleate) HLB value is 4.3; Tween 20 (polyoxyethylene (20EO) sorbitan monolauryl Ester) mixed with HLB value 16.7);

[0057] c) 30 parts of water-soluble monomer A; water-soluble monomer A is composed of 18 parts of acrylamide, 6 parts of sodium acrylate and 6 parts of 2-acrylamido-2-methylpropanesulfonate sodium;

[0058] d) 6 parts of temperature-resistant and salt-resistant monomers; the temperature-resistant and salt-resistant monomers are selected from oil-soluble temperature-resistant and salt-resistant monomers: octadecyl methacrylate;...

Embodiment 2

[0122] The polymer microemulsion of the present embodiment is prepared by polymerizing a reverse phase microemulsion under the action of a redox composite initiator; the reverse phase microemulsion comprises the following components in parts by weight:

[0123] a) 50 parts of oil-soluble solvent; oil-soluble solvent is white oil;

[0124] b) 15 parts of emulsifier; the emulsifier HLB is 6.7 Span 40;

[0125] c) 30 parts of water-soluble monomer A; water-soluble monomer A is composed of 18 parts of acrylamide, 6 parts of sodium acrylate and 6 parts of 2-acrylamido-2-methylpropanesulfonate sodium;

[0126] d) 6 parts of temperature-resistant and salt-resistant monomers; the temperature-resistant and salt-resistant monomers are selected from oil-soluble temperature-resistant and salt-resistant monomers: octadecyl methacrylate;

[0127] e) 24 parts of water;

[0128] Wherein, the composite initiator, in terms of the above-mentioned total monomer weight percent, comprises the fol...

Embodiment 3

[0145] The polymer microemulsion of the present embodiment is prepared by polymerizing a reverse phase microemulsion under the action of a redox composite initiator; the reverse phase microemulsion comprises the following components in parts by weight:

[0146] a) 50 parts of oil-soluble solvent; oil-soluble solvent is white oil;

[0147] b) 15 parts of emulsifier; the HLB value of the emulsifier is 6.7 (from Span 80 (that is, sorbitan monooleate) HLB value is 4.3; Tween 20 (polyoxyethylene (20EO) sorbitan monolauryl Ester) mixed with HLB value 16.7);

[0148] c) 30 parts of water-soluble monomer A; water-soluble monomer A is composed of 18 parts of acrylamide, 6 parts of sodium acrylate and 6 parts of 2-acrylamido-2-methylpropanesulfonate sodium;

[0149] d) 6 parts of temperature-resistant and salt-resistant monomers; the temperature-resistant and salt-resistant monomers are selected from oil-soluble temperature-resistant and salt-resistant monomers: octadecyl methacrylate;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com