Patents

Literature

267 results about "Particulate suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

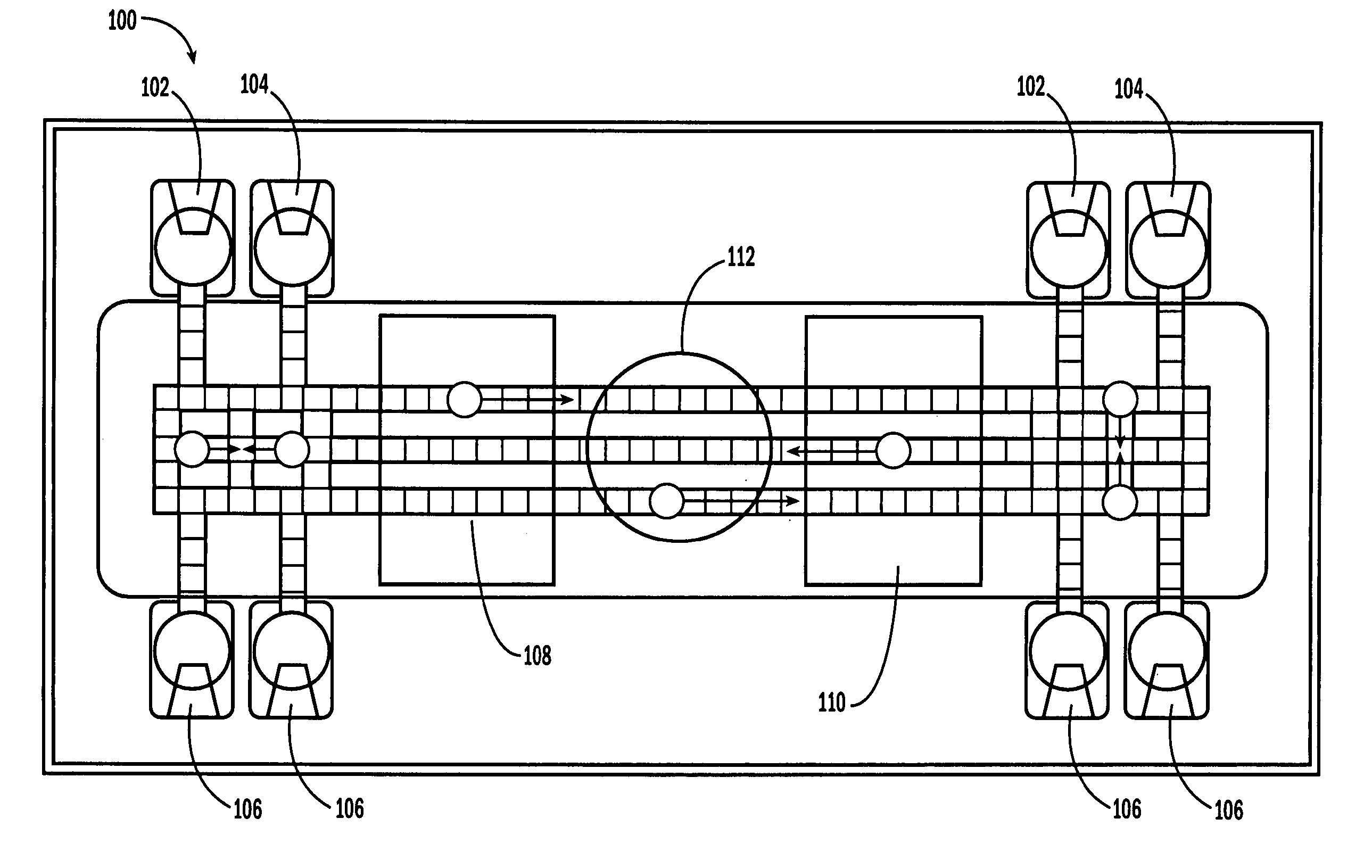

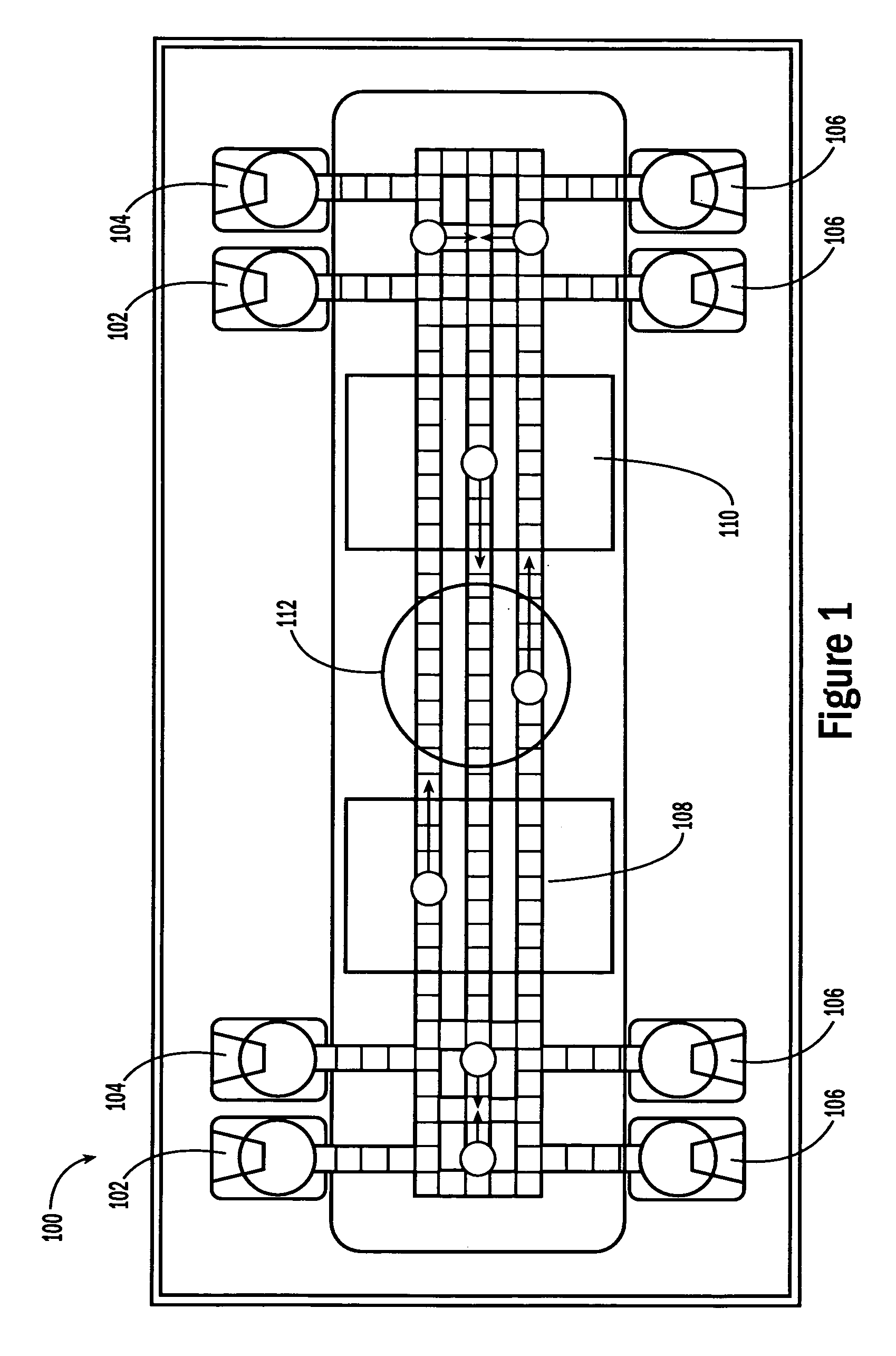

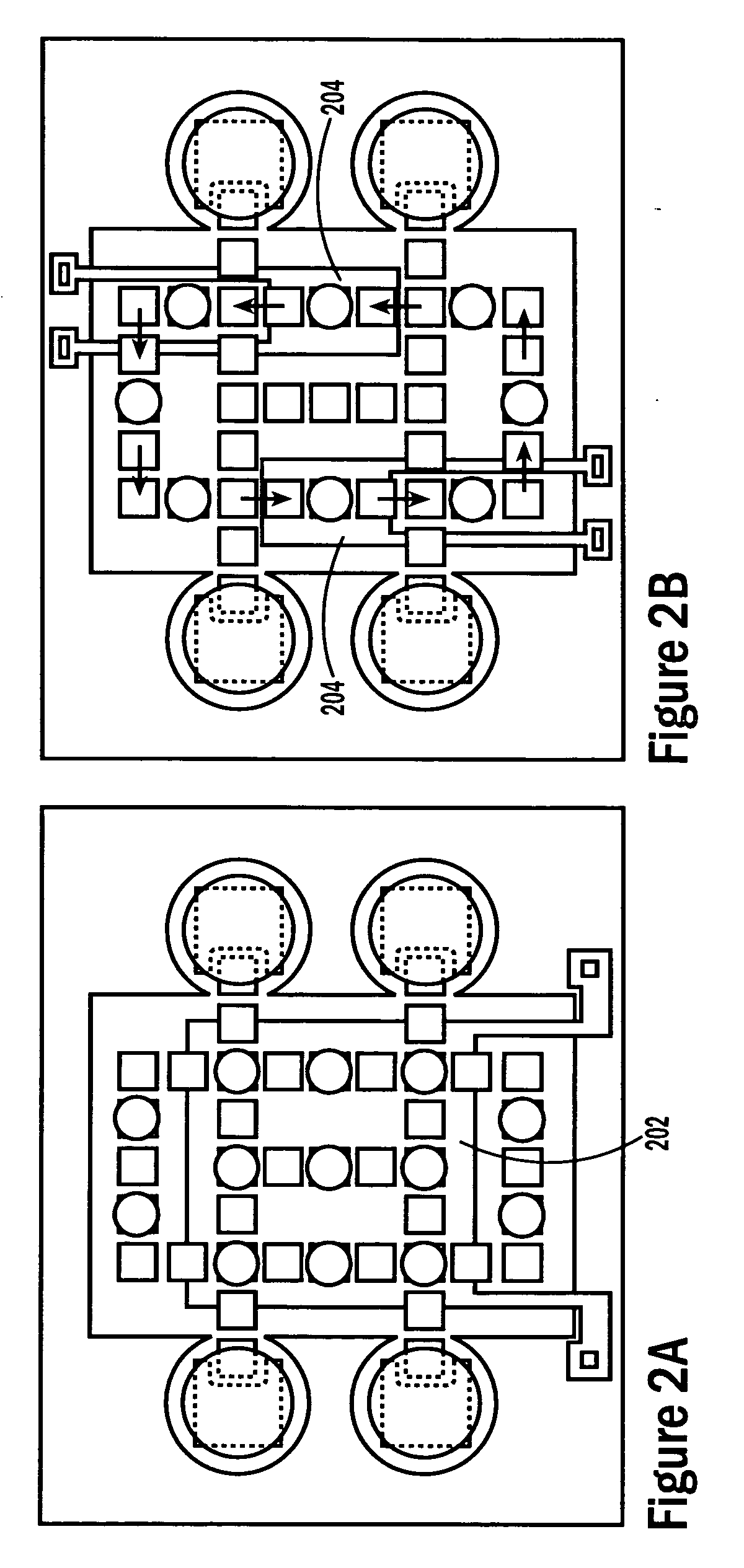

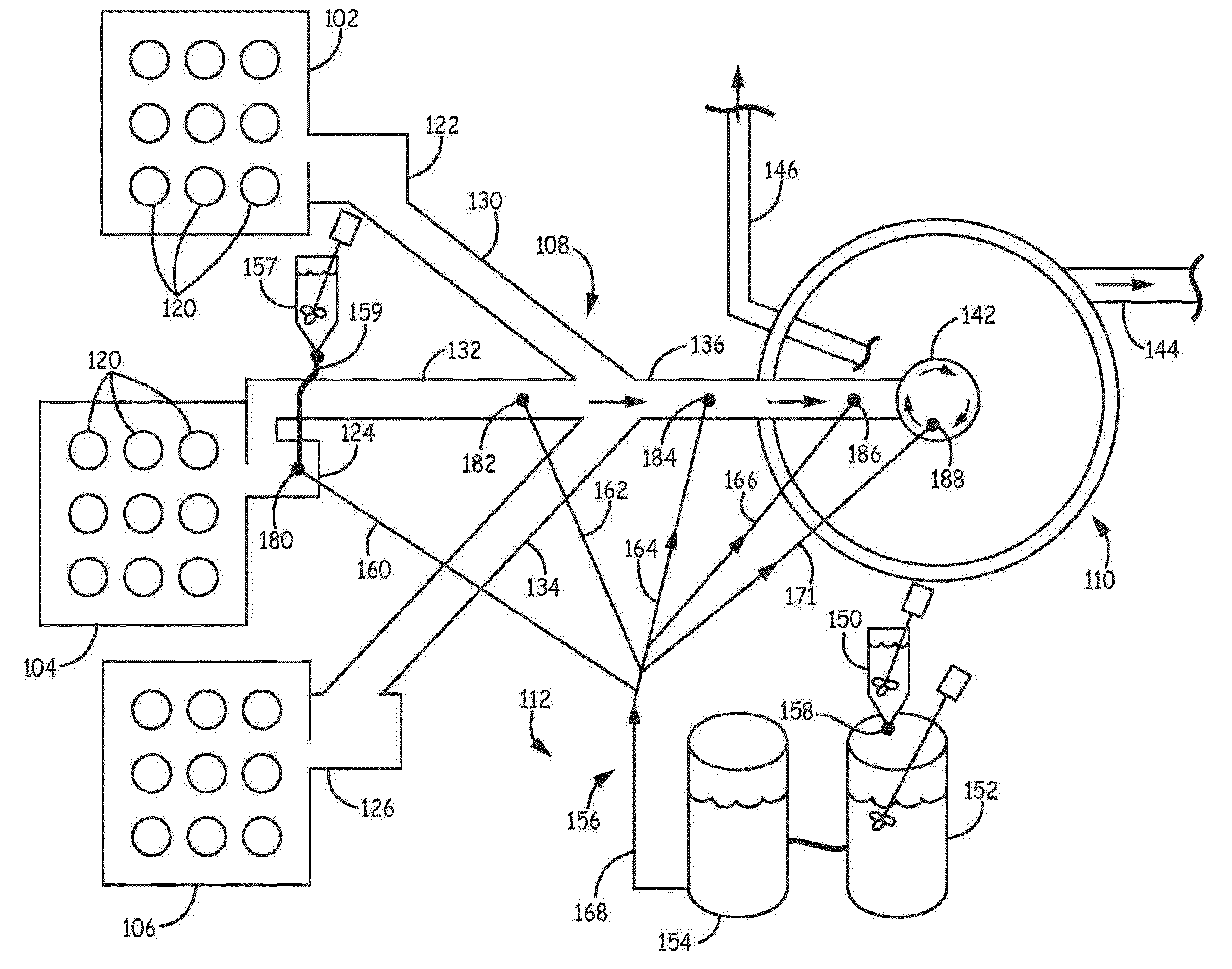

Droplet-based particle sorting

InactiveUS20080053205A1Large facilityEasy to testSludge treatmentVolume/mass flow measurementChemical physicsParticle sorting

Owner:ADVANCED LIQUID LOGIC

Droplet-based particle sorting

InactiveUS7901947B2Reduces and eliminates build-upImprove efficiencySludge treatmentVolume/mass flow measurementChemical physicsParticle sorting

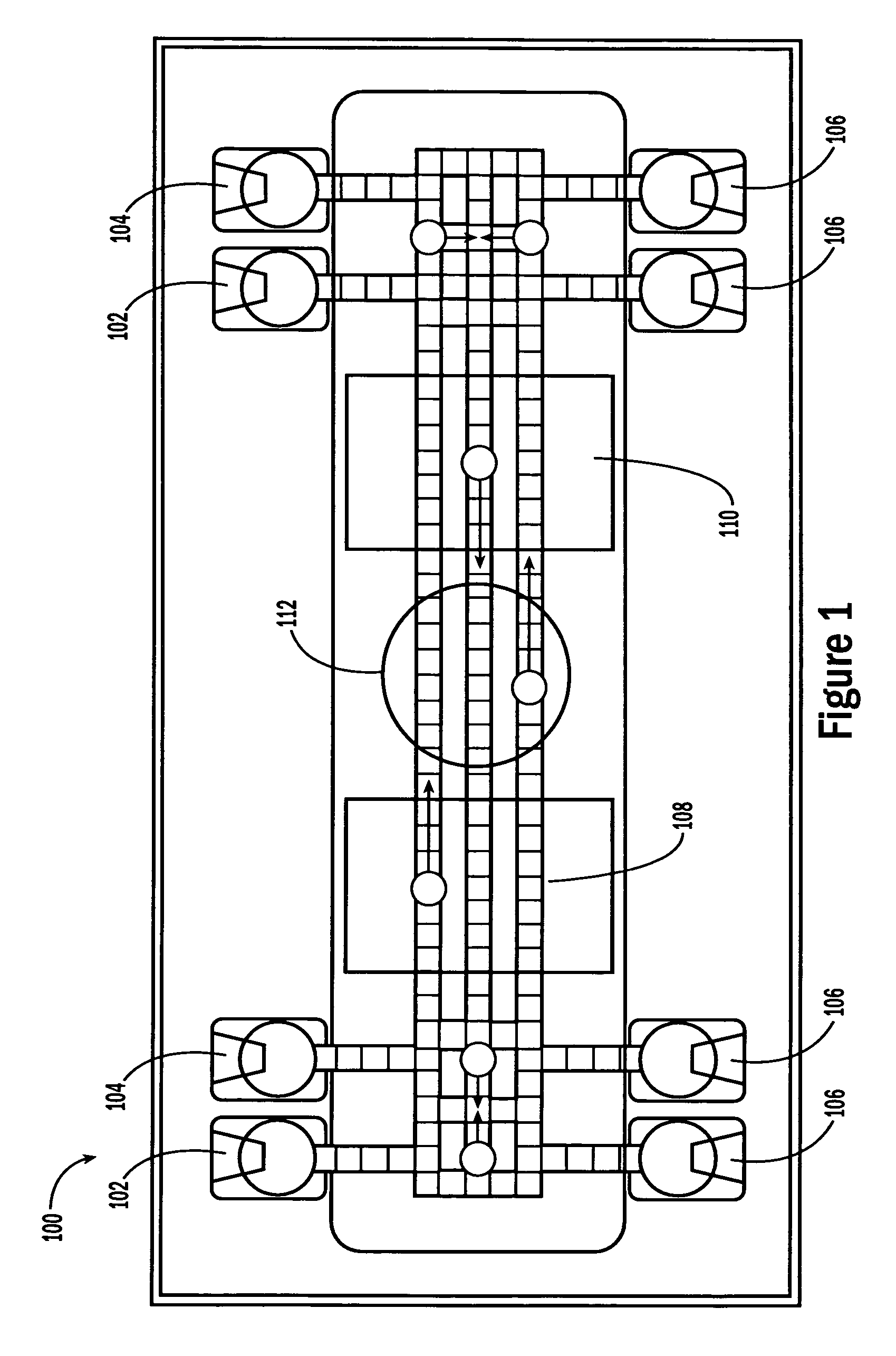

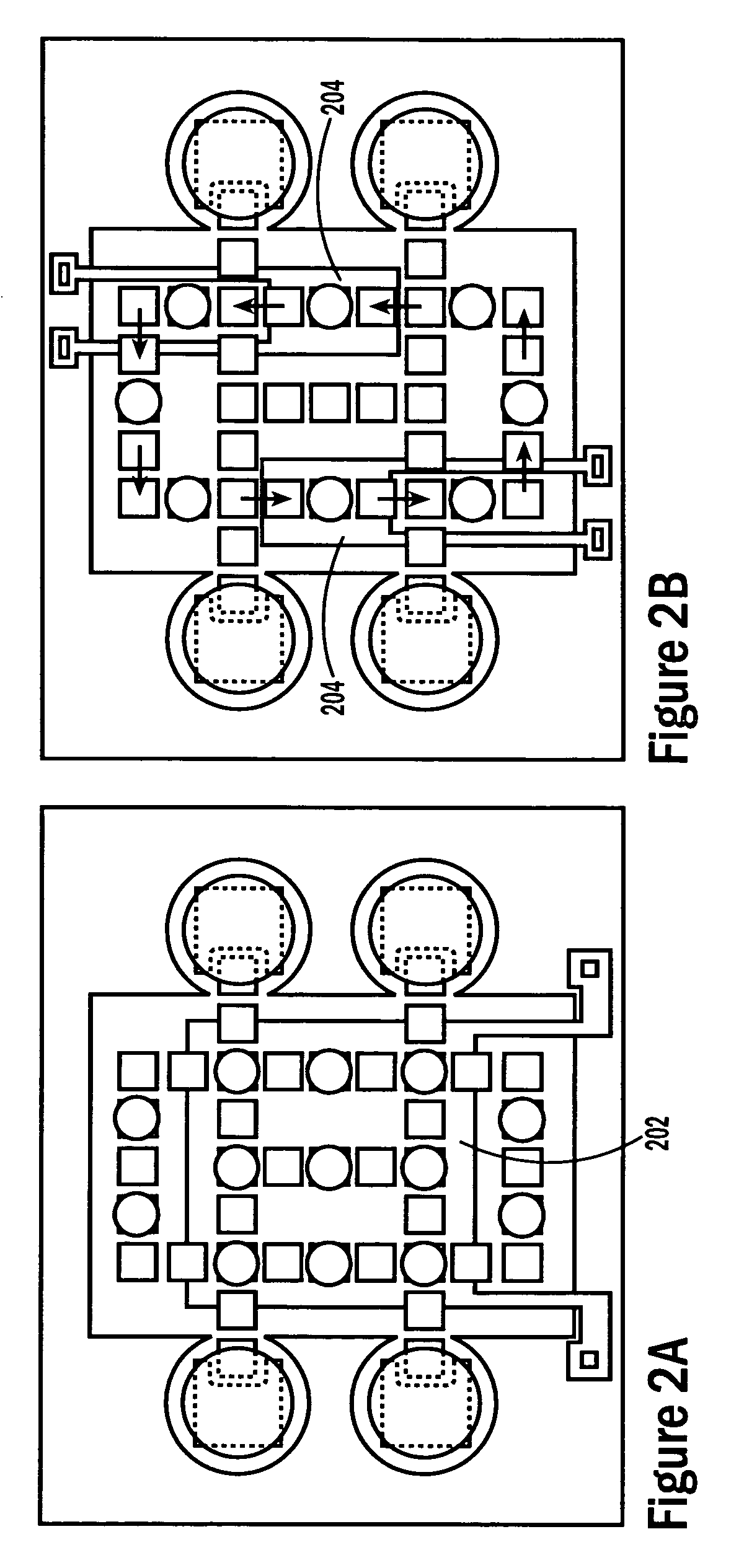

The present invention relates to droplet-based particle sorting. According to one embodiment, a droplet microactuator is provided and includes: (a) a suspension of particles; and (b) electrodes arranged for conducting droplet operations using droplets comprising particles. A method of transporting a particle is also provided, wherein the method includes providing a droplet comprising the particle and transporting the droplet on a droplet microactuator.

Owner:ADVANCED LIQUID LOGIC

Pneumatic valve interface for use in microfluidic structures

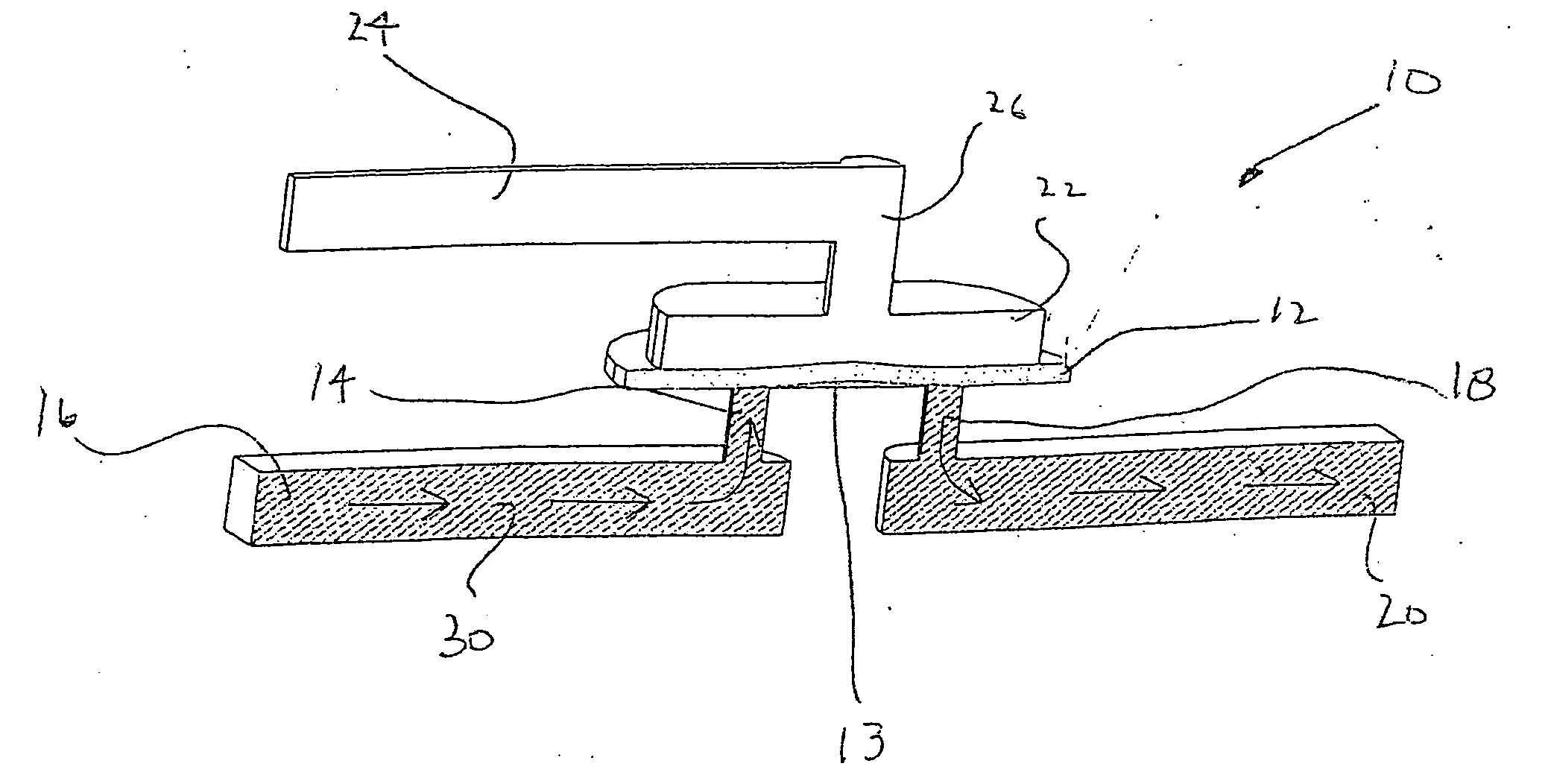

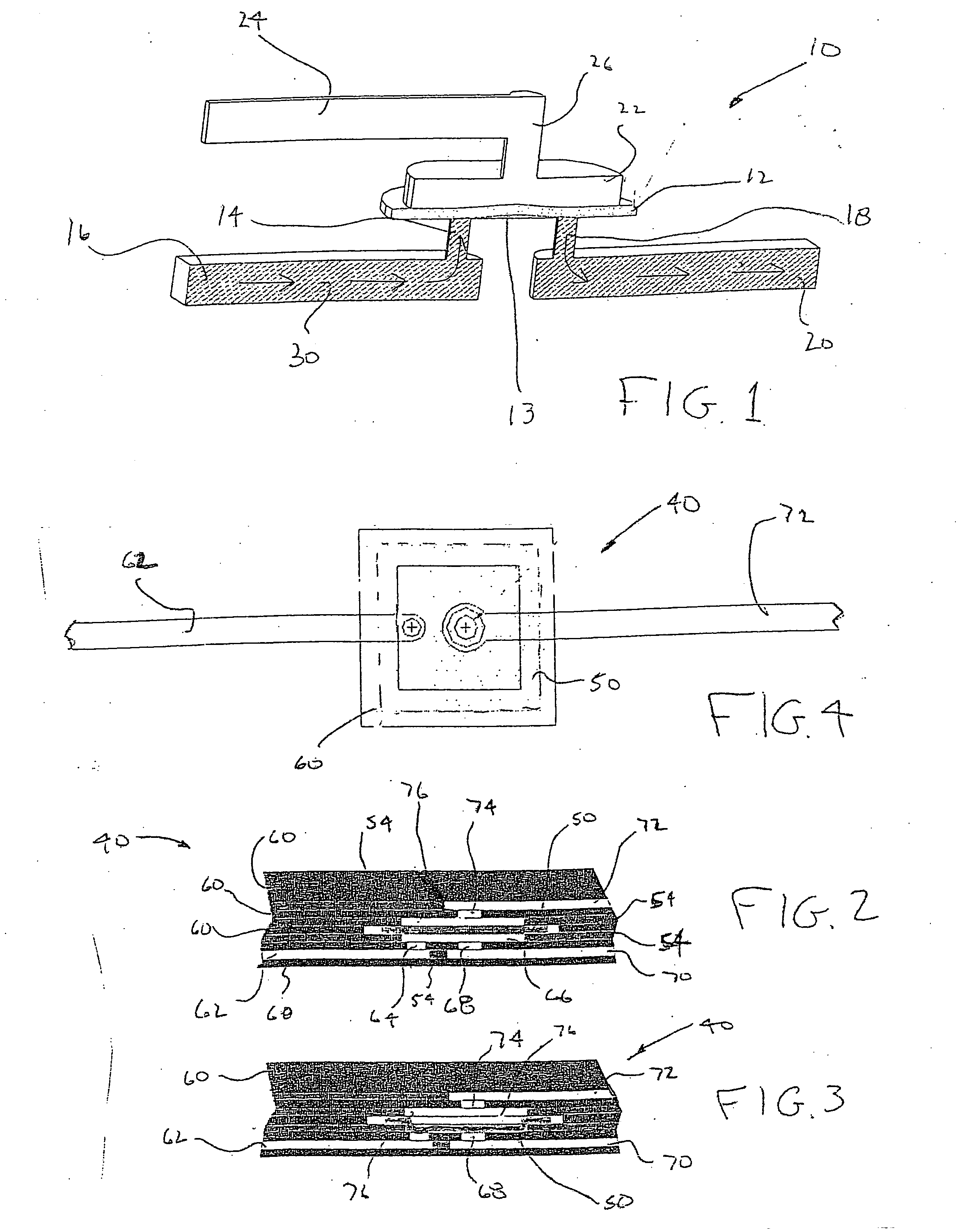

A pneumatic valve for use in laminated plastic microfluidic structures. This zero or low dead volume valve allows flow through microfluidic channels for use in mixing, dilution, particulate suspension and other techniques necessary for flow control in analytical devices.

Owner:PERKINELMER HEALTH SCIENCES INC

Method and apparatus for sensing and characterizing particles

InactiveUS6111398AIndividual particle analysisParticle suspension analysisLiquid mediumHigh resistivity

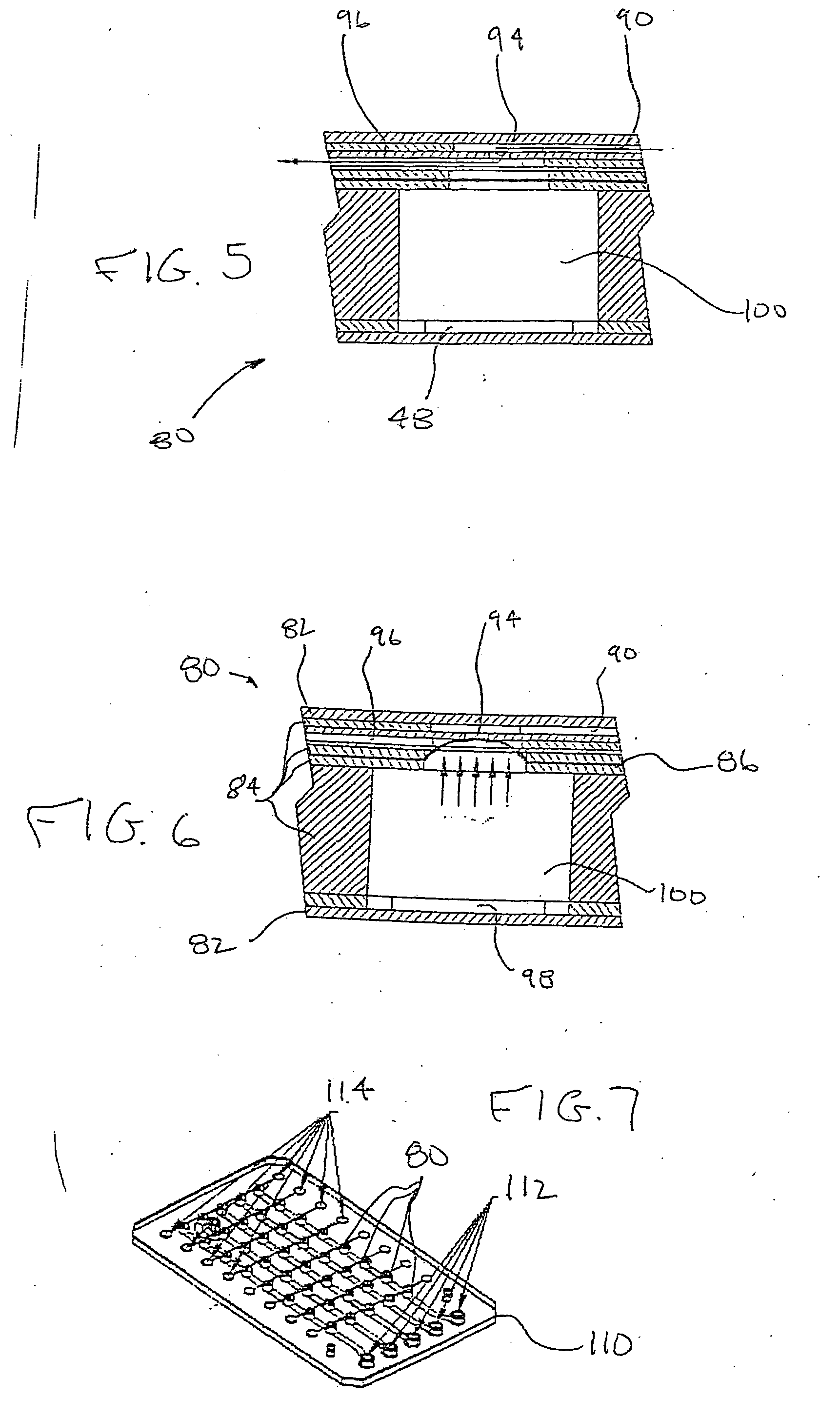

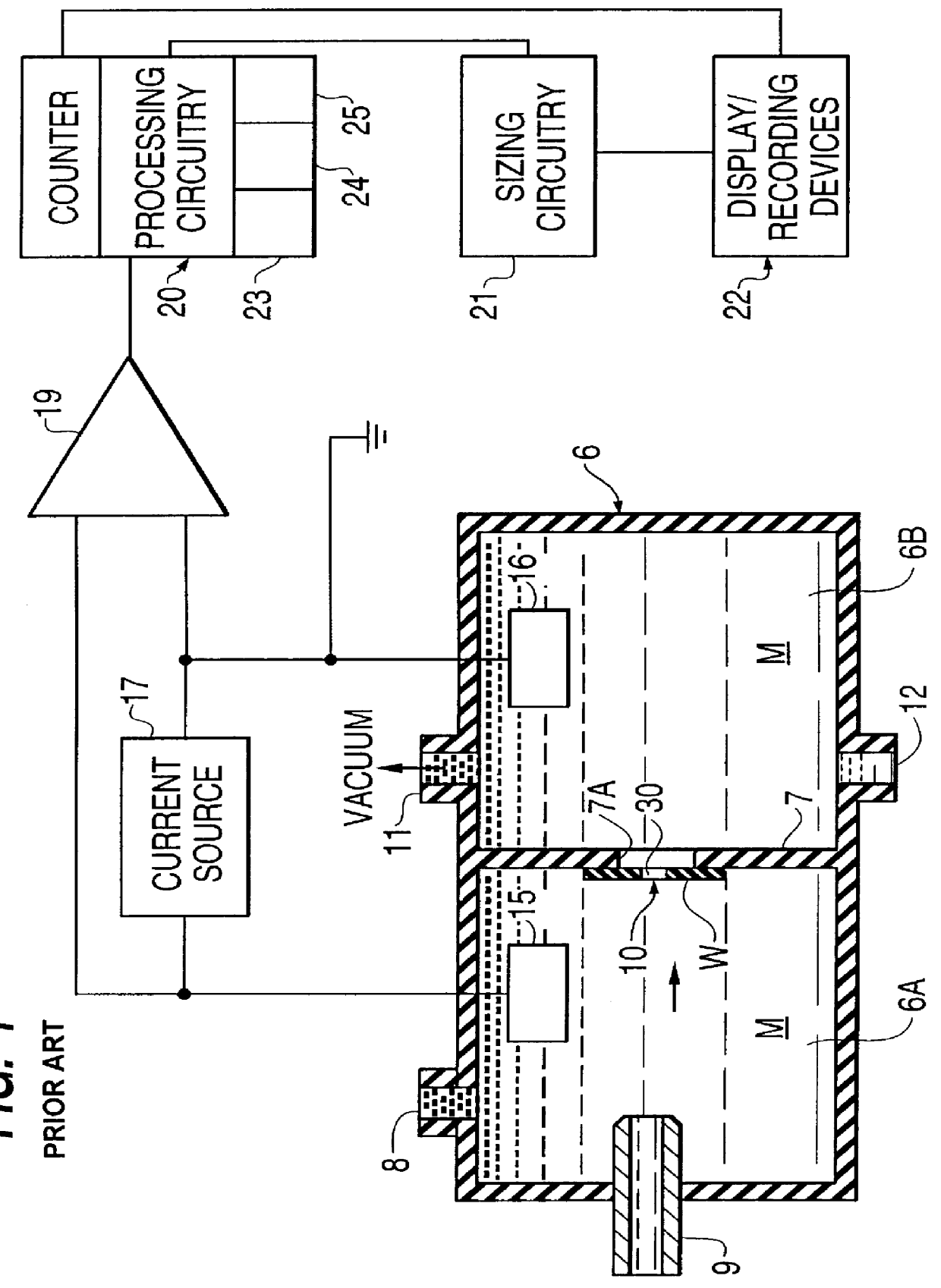

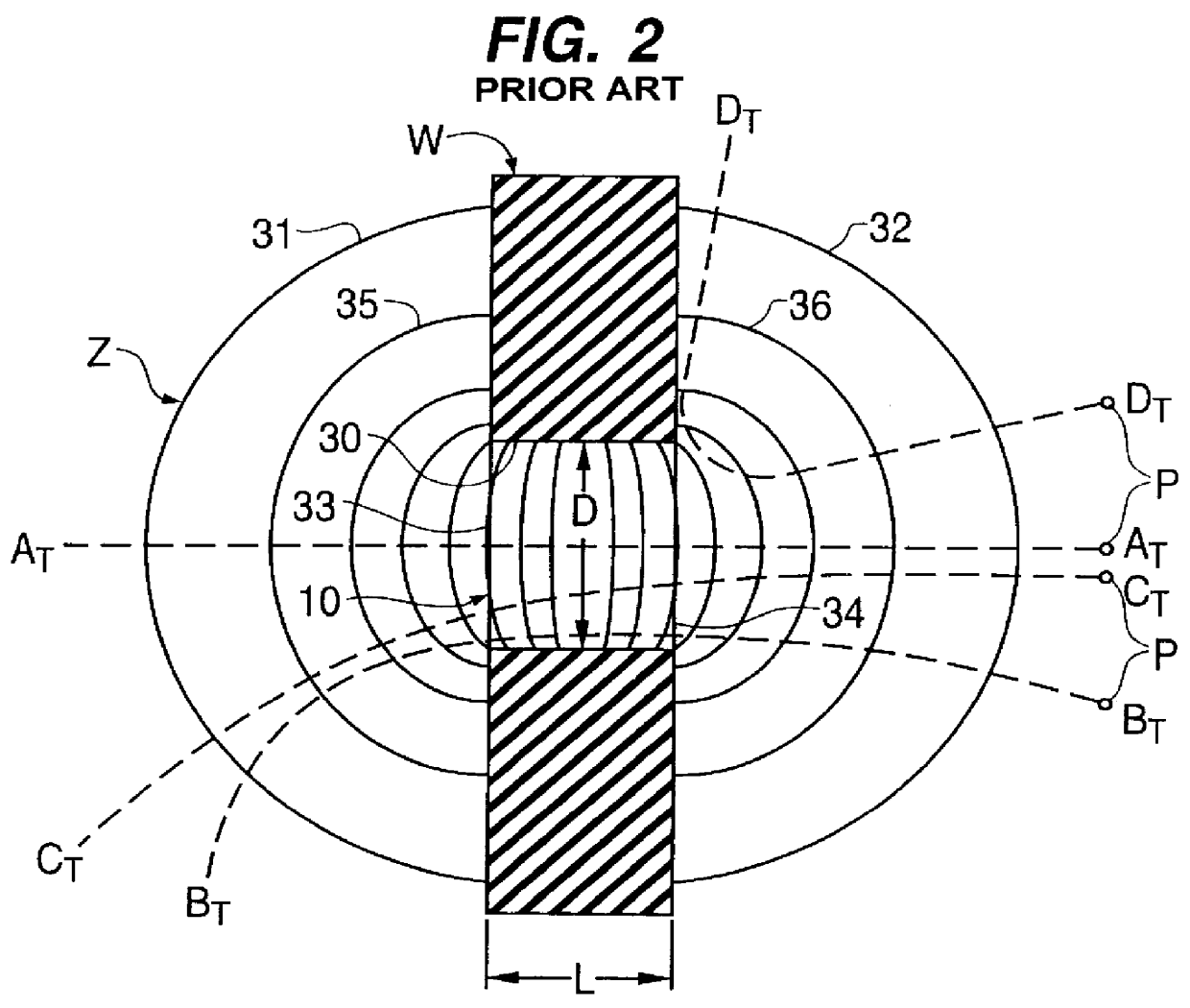

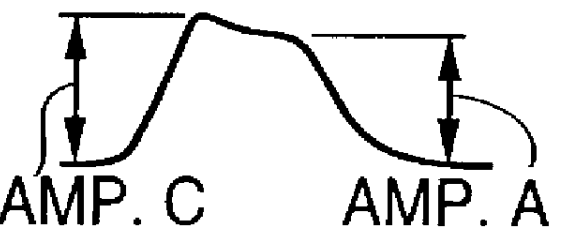

Apparatus for sensing and characterizing particles (e.g., blood cells or ceramic powders) suspended in a liquid medium comprises a conduit through which the particle suspension is caused to pass simultaneously with an electrical current. According to the invention, the interior wall of the conduit effectively varies in resistivity along the length of the conduit to define a delimited central region of high electrical resistivity which is smoothly contiguous on its opposing boundaries to uninsulated distal elements of lesser electrical resistivity. The delimited central region of the conduit functions as a Coulter volumeter conduit. The uninsulated distal elements of the conduit are made to have a dimension along the conduit wall which is at least equal to the axial extent of the effective ambit electric fields of a traditional Coulter volumeter conduit having a cross-sectional geometry identical to that of the delimited central region of high resistivity in the improved volumeter conduit. According to a preferred embodiment of the invention, the delimited central region of the improved volumeter conduit is defined by a traditional Coulter conduit wafer, i.e., a dielectric wafer containing a central circular conduit, and the distal elements of lesser resistivity are defined by uninsulated, electrically conductive, circular collars attached to opposite sides of the conduit wafer. The conduit in the conduit wafer and the openings in the conductive collars collectively form a hydrodynamically smooth volumeter conduit, in which the electric and hydrodynamic fields of the traditional volumeter conduit are advantageously amended in the manner above noted.

Owner:COULTER INTERNATIONAL CORPORATION

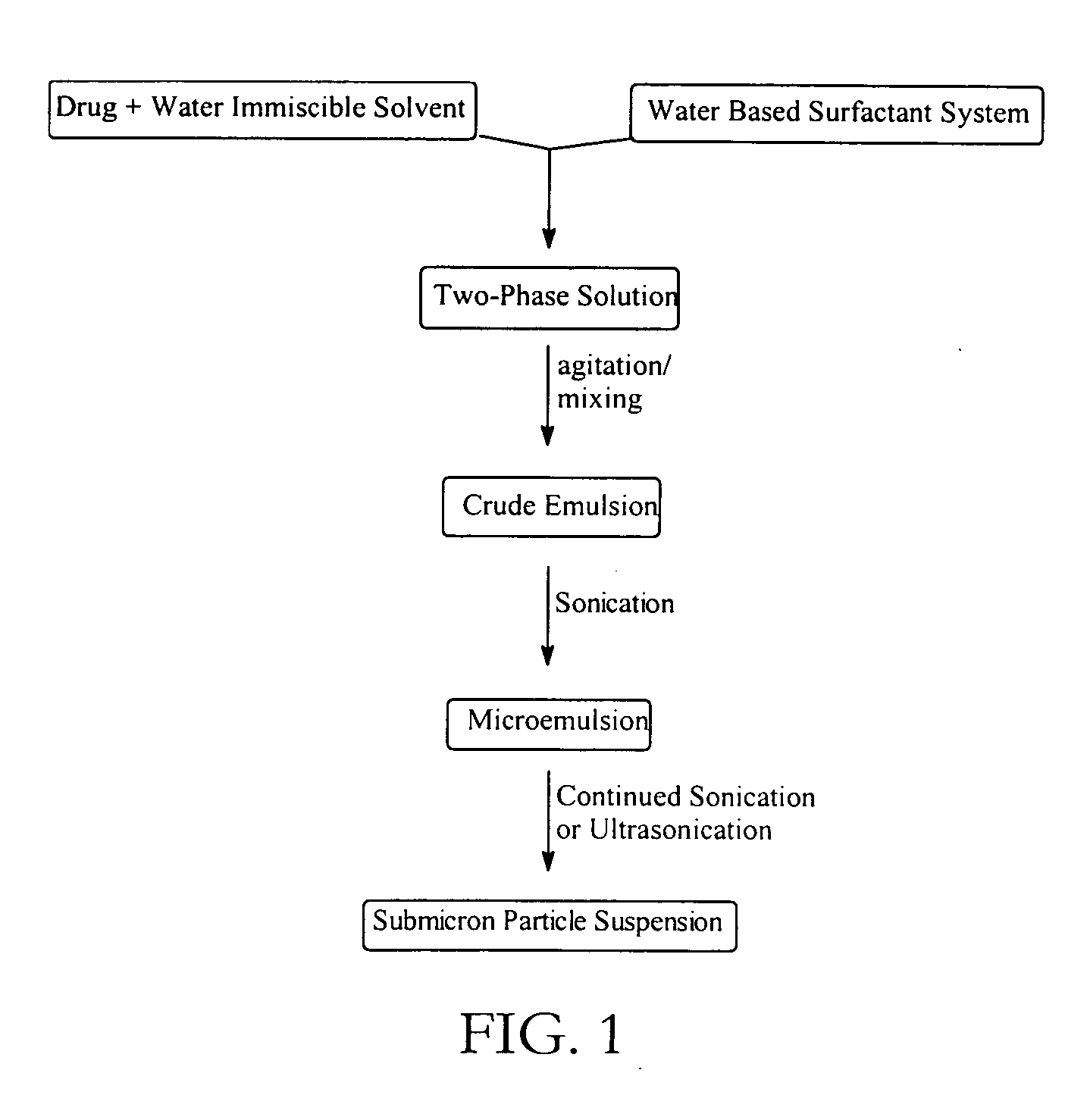

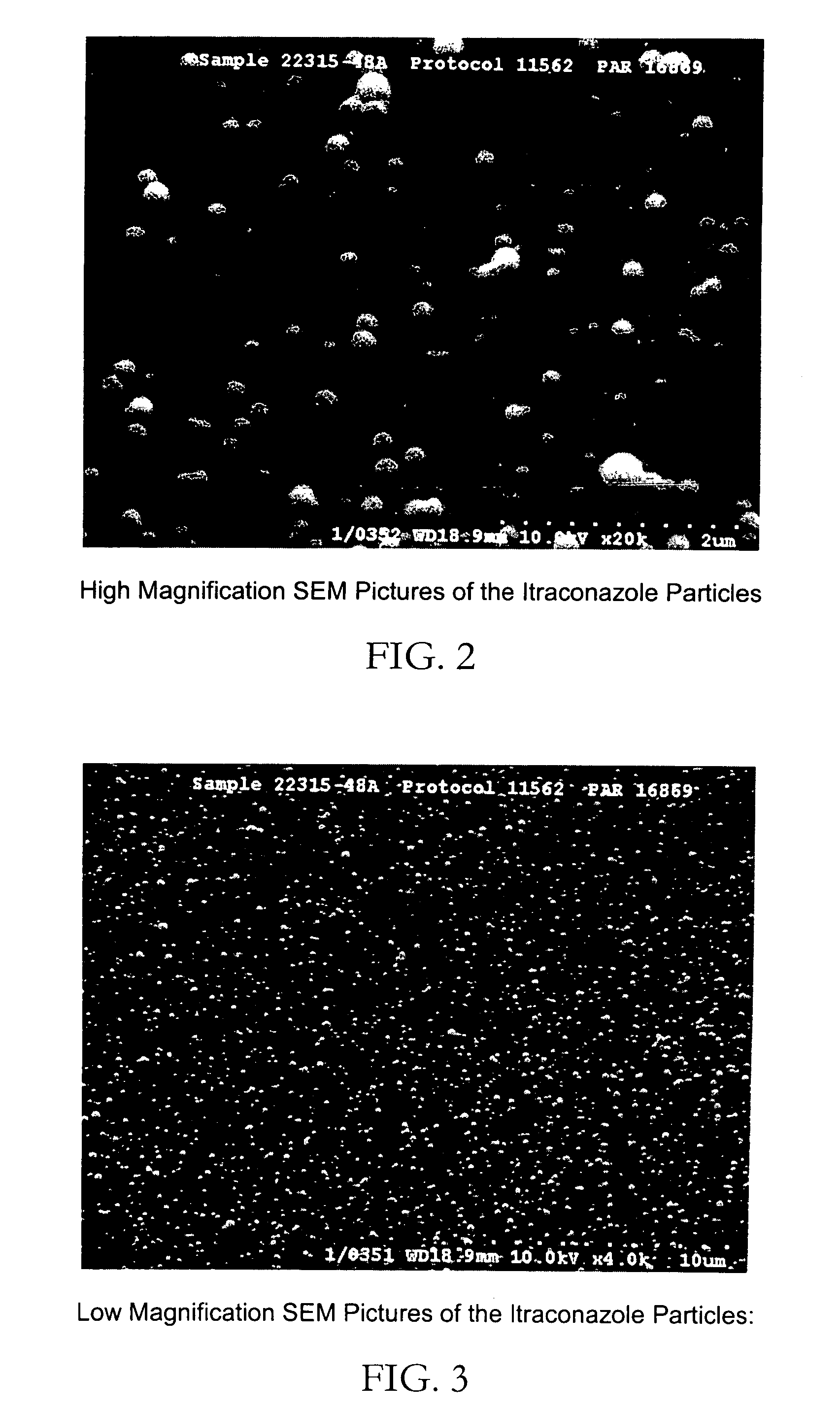

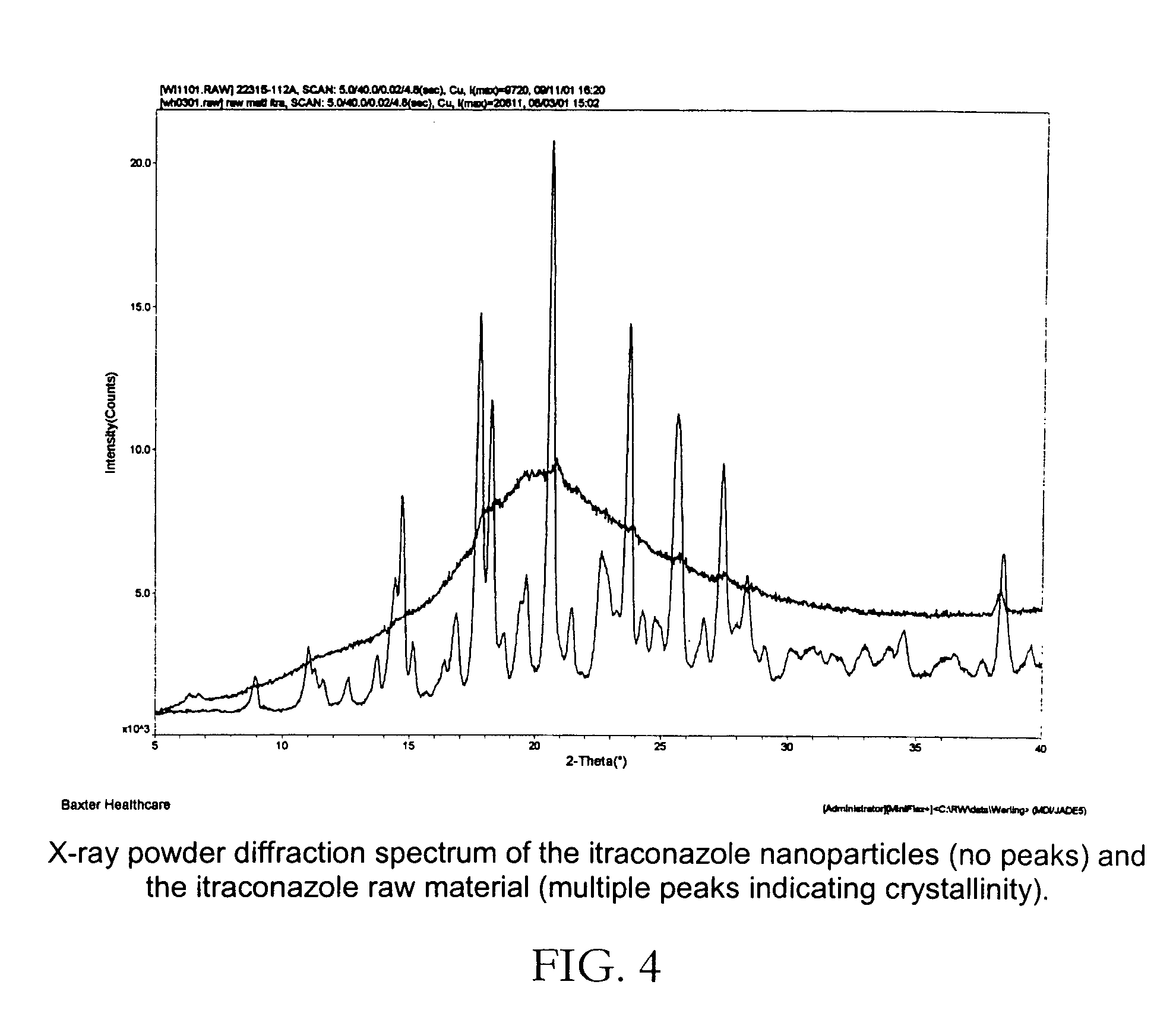

Preparation of submicron solid particle suspensions by sonication of multiphase systems

The present invention provides a method for preparing submicron-sized particles. The method includes the steps of: (1) providing a multiphase system having an organic phase and an aqueous phase, the organic phase having a pharmaceutically effective compound therein; and (2) sonicating the system to evaporate a portion of the organic phase to cause precipitation of the compound in the aqueous phase and having an average effective particle size of less than about 2 m.

Owner:BAXTER INT INC

Injection vehicle for polymer-based formulations

InactiveUS7582311B1Increase dosePowder deliveryOrganic active ingredientsParticulatesPharmaceutical formulation

The invention provides injection vehicles suitable for administering particulate suspensions, such as polymer-based formulations, as well as associated pharmaceutical formulations, articles of manufacture, and kits. Other aspects of the invention included methods for producing and administering pharmaceutical formulations. The injection vehicles of the invention are superior to conventional injection vehicles in that they include a pseudoplastic composition that improves injectability, which facilitates delivery of the desired dose. The injection vehicles of the invention also allow the use of smaller-bore needles than are usually necessary to inject polymer-based formulations, reducing the pain associated with injection of such formulations.

Owner:GENENTECH INC

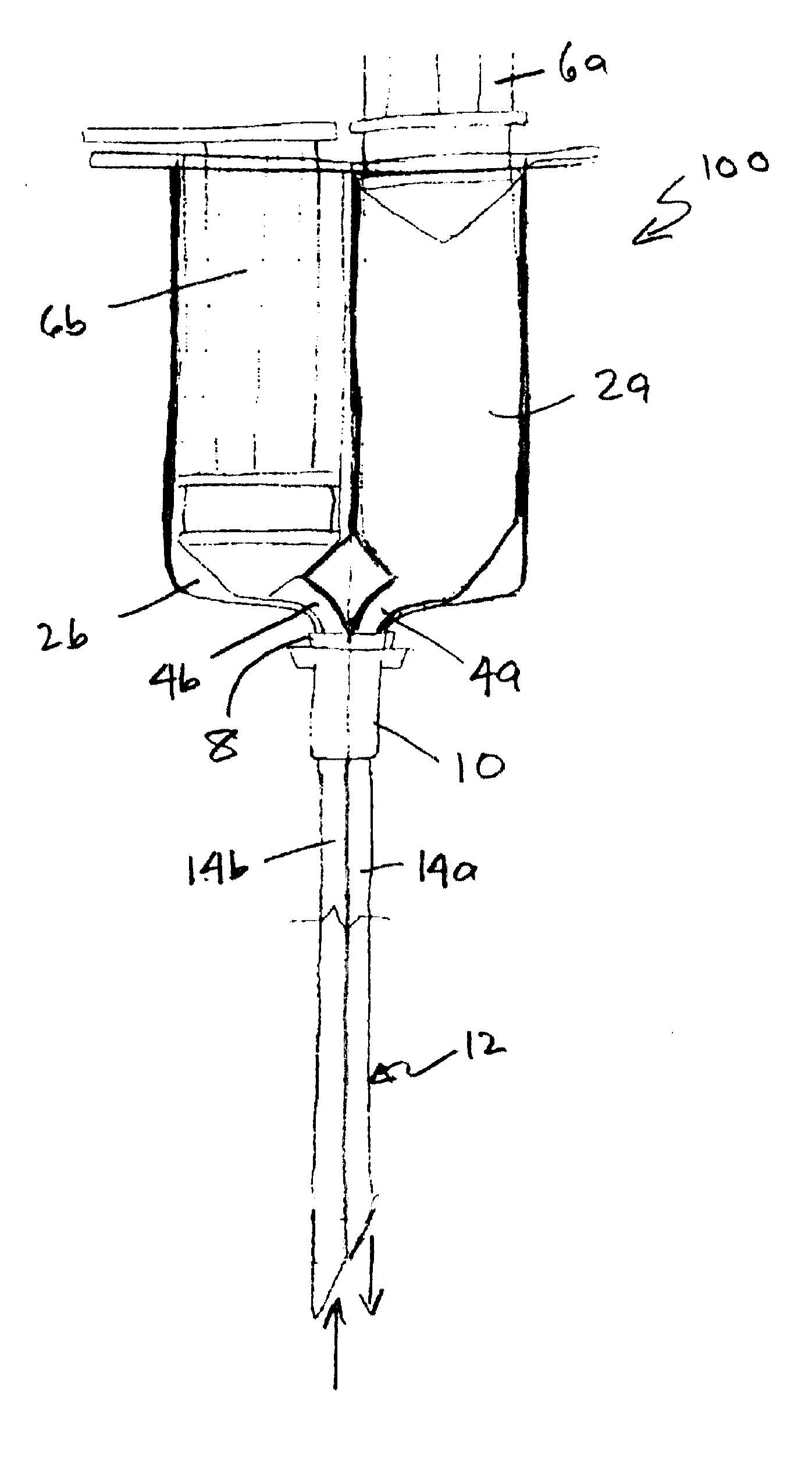

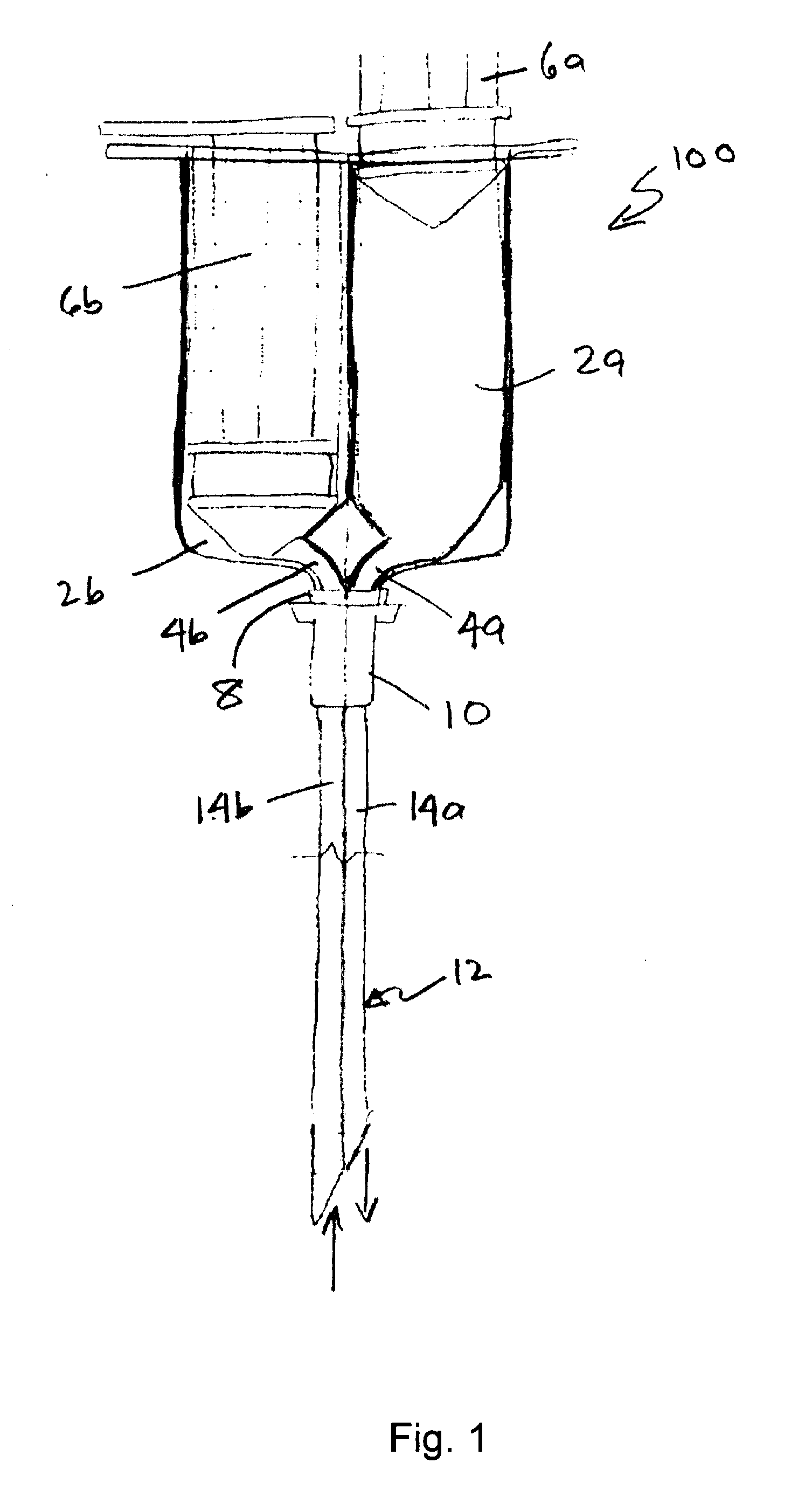

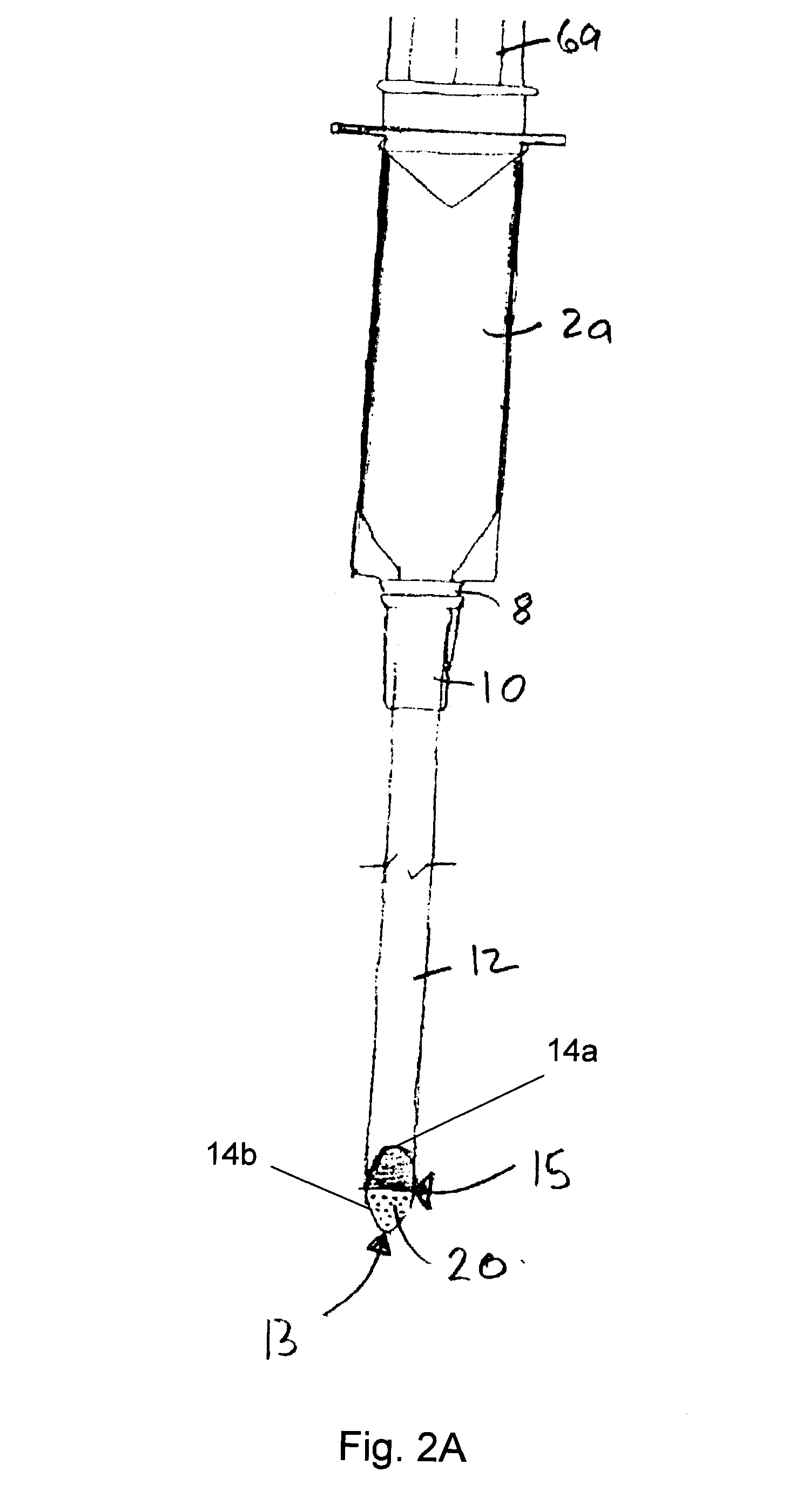

Microparticle delivery syringe and needle for placing particle suspensions and removing vehicle fluid

A syringe having two or more chambers having a needle defining two or more lumens for injecting a microparticle suspension into a desired space, the lumens being in fluid communication with respective chambers. One of the chambers has the microparticle suspension disposed therein while the other chamber is empty. The lumen in fluid communication with the empty chamber has a filter element disposed therein such that the suspension fluid may be withdrawn from the space into the empty chamber without withdrawing the microparticles.

Owner:WARSAW ORTHOPEDIC INC

Method for producing polymer-particle composites

InactiveUS6881448B1Uniform packingHigh densityDiffusing elementsPretreated surfacesParticle densitySolvent

An objective of the invention is to provide a method for producing a polymer-particle composite by which a polymer-particle composite having a desired particle density and a desired film thickness can be produced conveniently without allowing the particle to be aggregated in the polymeric matrix. To accomplish the objective described above, the present invention provides a method for producing a polymer-particle composite comprising a step of forming a polymer-containing layer mainly consisting of a polymeric material and a step of bringing a particle suspension containing the particle suspended in a solvent capable of swelling the polymeric material into contact with the polymer-containing layer.

Owner:3M INNOVATIVE PROPERTIES CO +1

Method of using triaxial magnetic fields for making particle structures

A method of producing three-dimensional particle structures with enhanced magnetic susceptibility in three dimensions by applying a triaxial energetic field to a magnetic particle suspension and subsequently stabilizing said particle structure. Combinations of direct current and alternating current fields in three dimensions produce particle gel structures, honeycomb structures, and foam-like structures.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

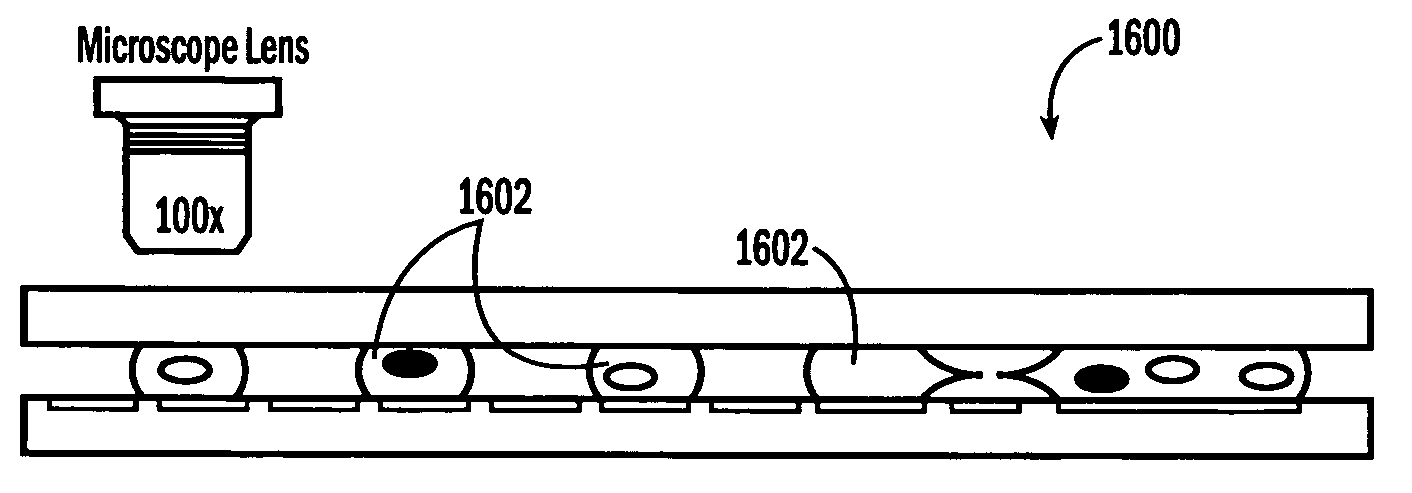

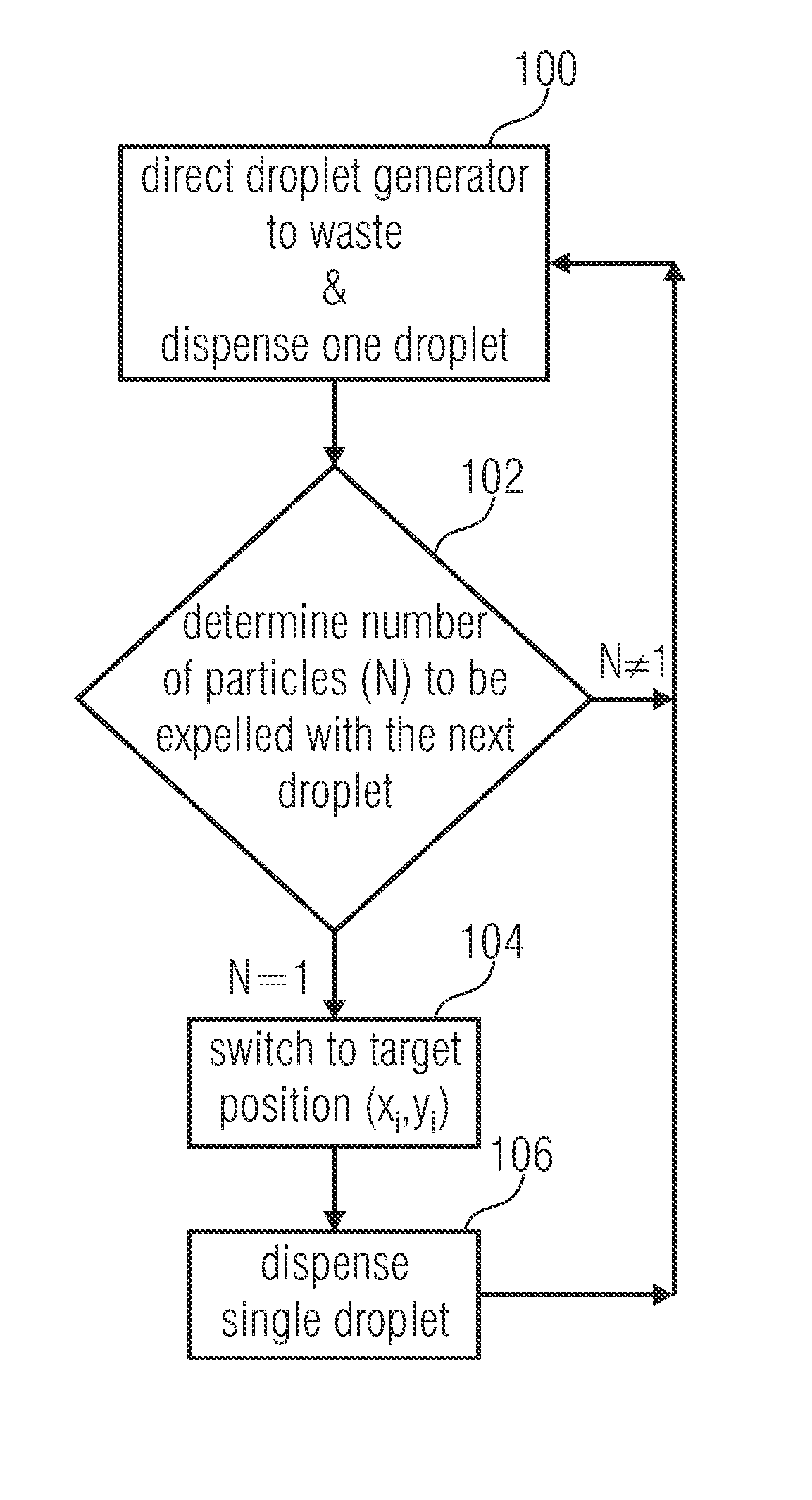

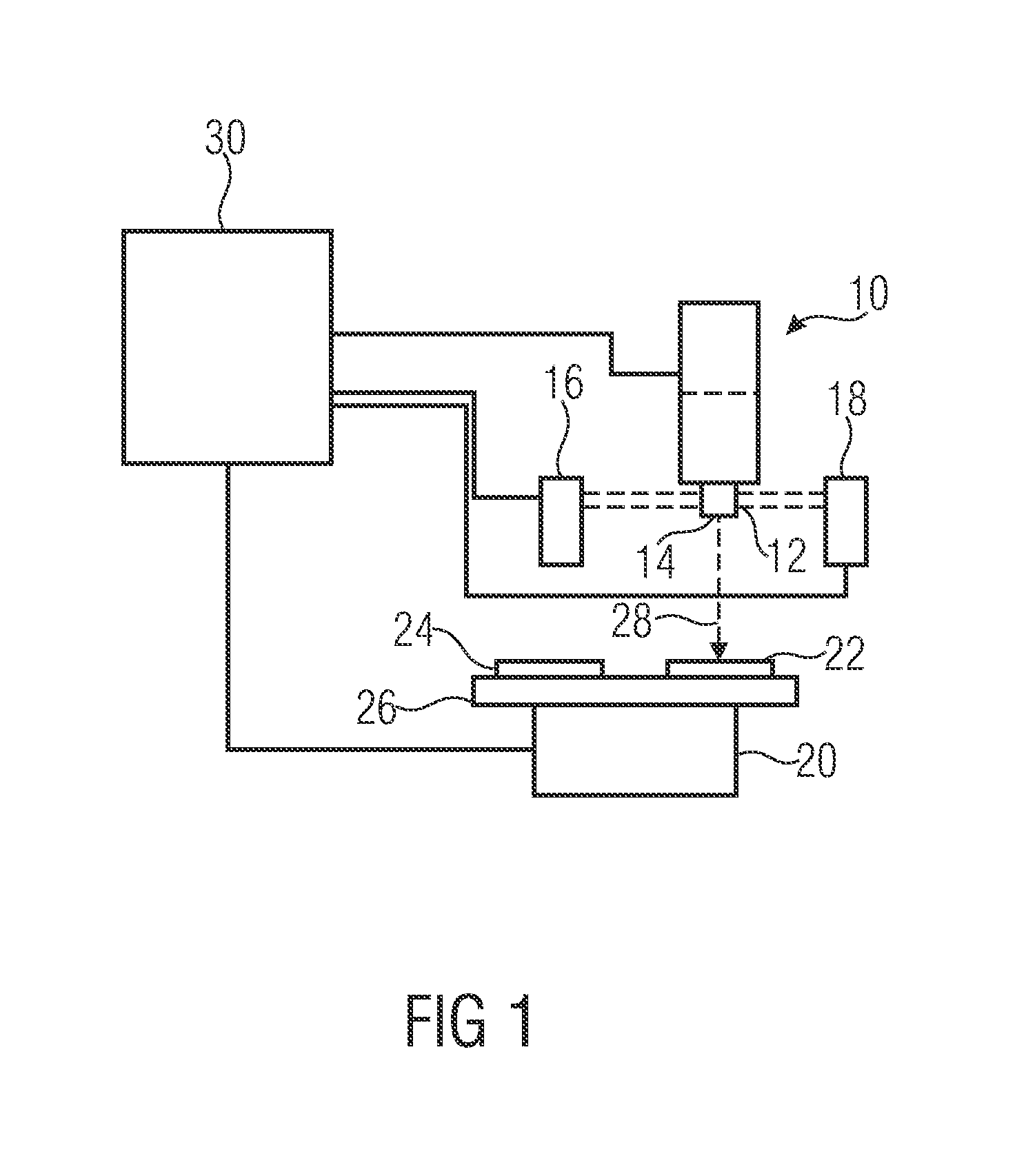

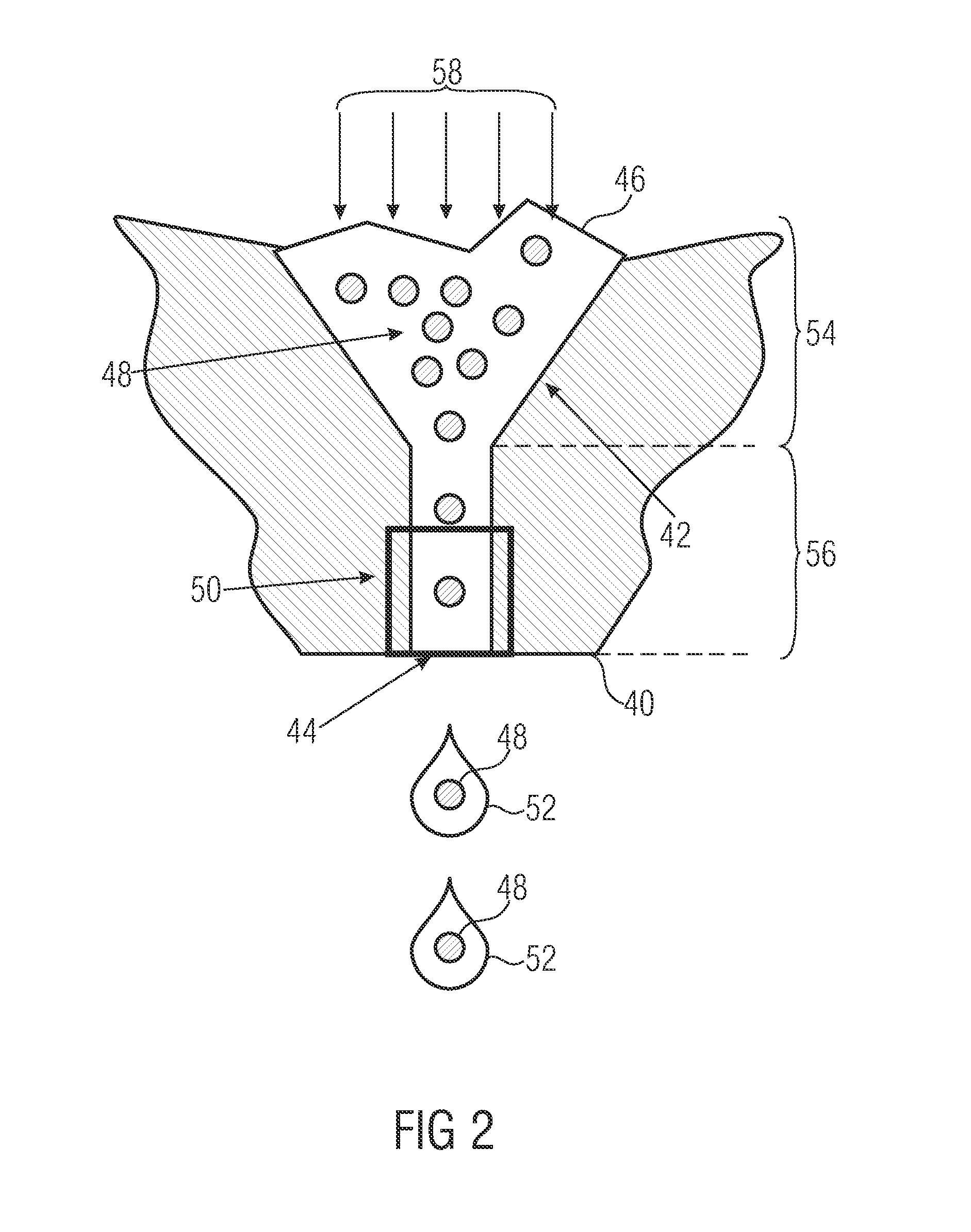

Apparatus and method for dispensing cells or particles confined in a free flying droplet

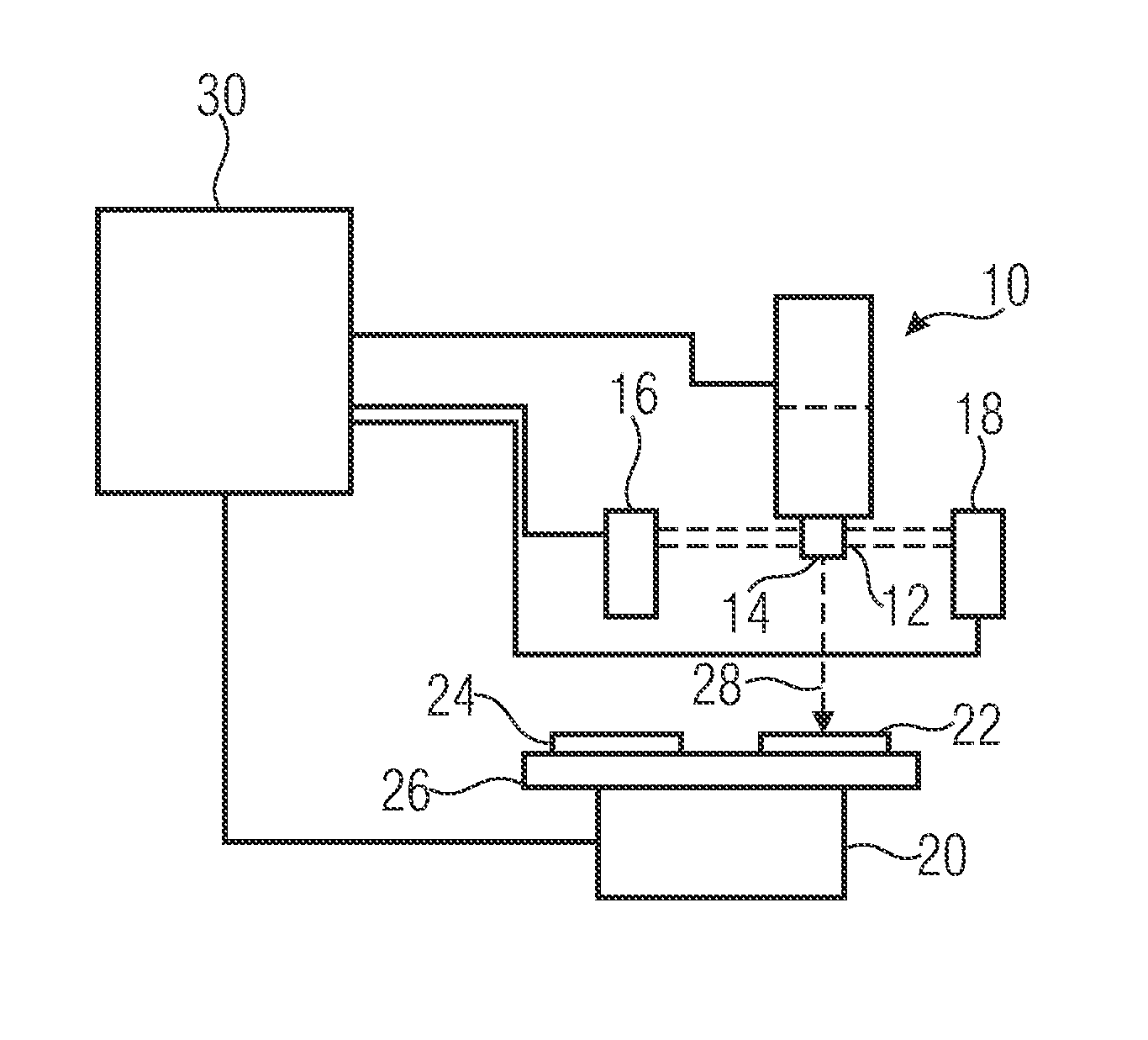

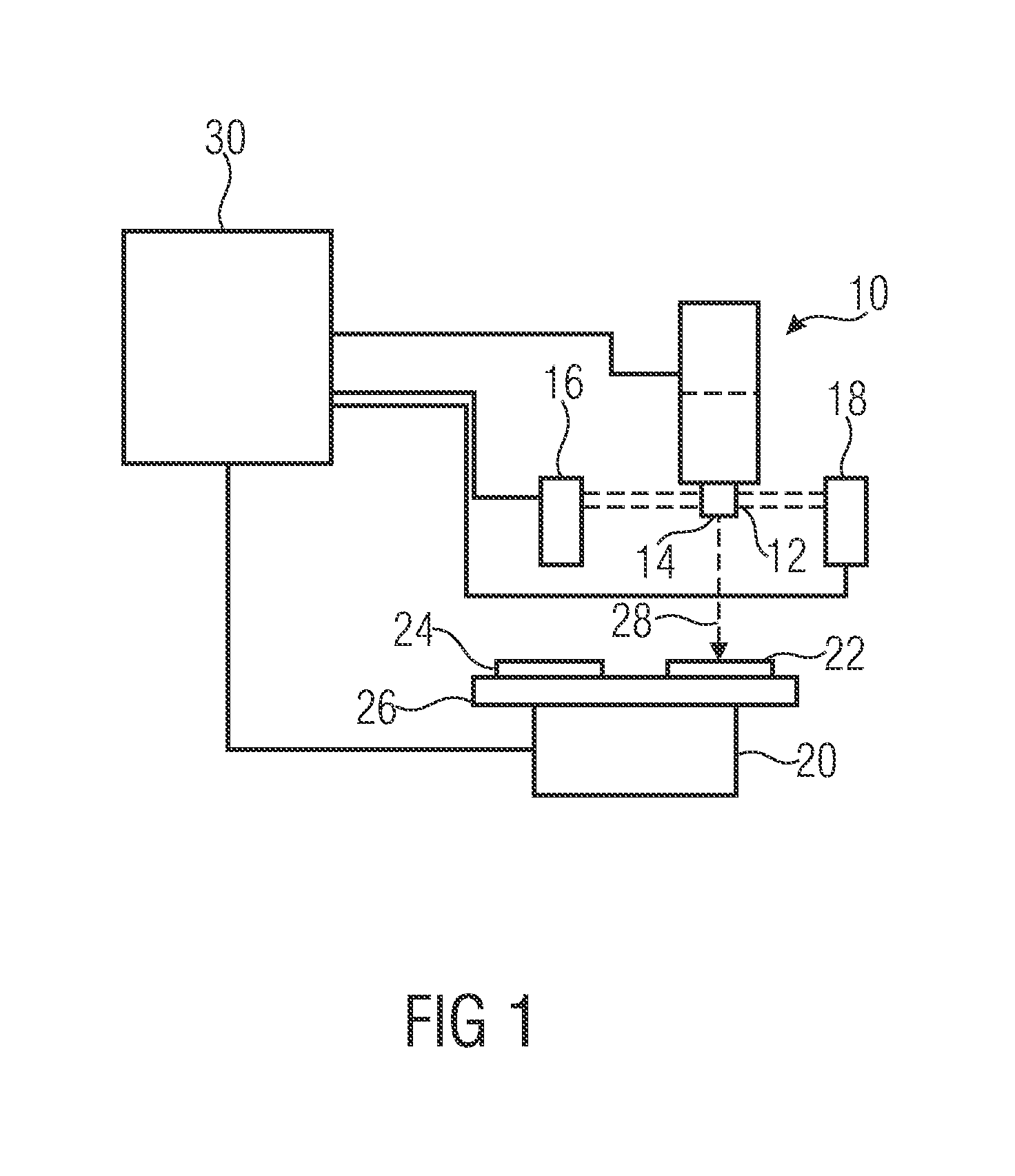

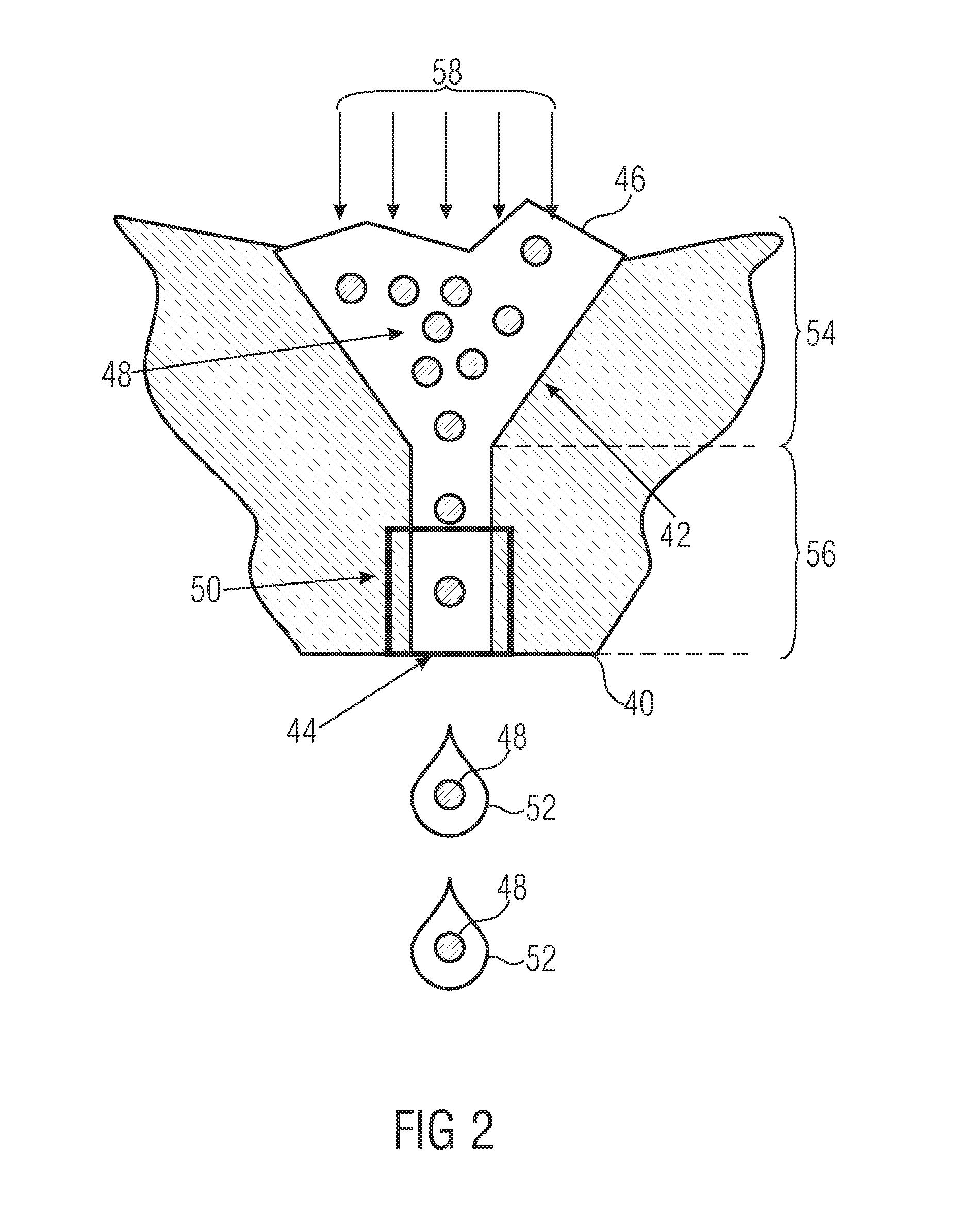

ActiveUS20130095469A1Improve reliabilityReliable distributionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringOn cells

An apparatus for dispensing one or more cells or particles confined in a free flying droplet has a droplet generating device configured to eject out of an orifice a free flying droplet of a suspension of cells or particles. The droplet generating device has a branch-less one-way channel having the orifice at one end thereof. A device for detecting information on cells or particles located in an observation volume of the suspension within the branch-less one-way channel is provided. An ejected droplet is directed to a first position or a second position depending on the detected information.

Owner:CYTENA GMBH

Injection vehicle for polymer-based formulations

InactiveUS7651703B2Increase dosePowder deliveryOrganic active ingredientsParticulatesPharmaceutical formulation

The invention provides injection vehicles suitable for administering particulate suspensions, such as polymer-based formulations, as well as associated pharmaceutical formulations, articles of manufacture, and kits. Other aspects of the invention included methods for producing and administering pharmaceutical formulations. The injection vehicles of the invention are superior to conventional injection vehicles in that they include a pseudoplastic composition that improves injectability, which facilitates delivery of the desired dose. The injection vehicles of the invention also allow the use of smaller-bore needles than are usually necessary to inject polymer-based formulations, reducing the pain associated with injection of such formulations.

Owner:GENENTECH INC

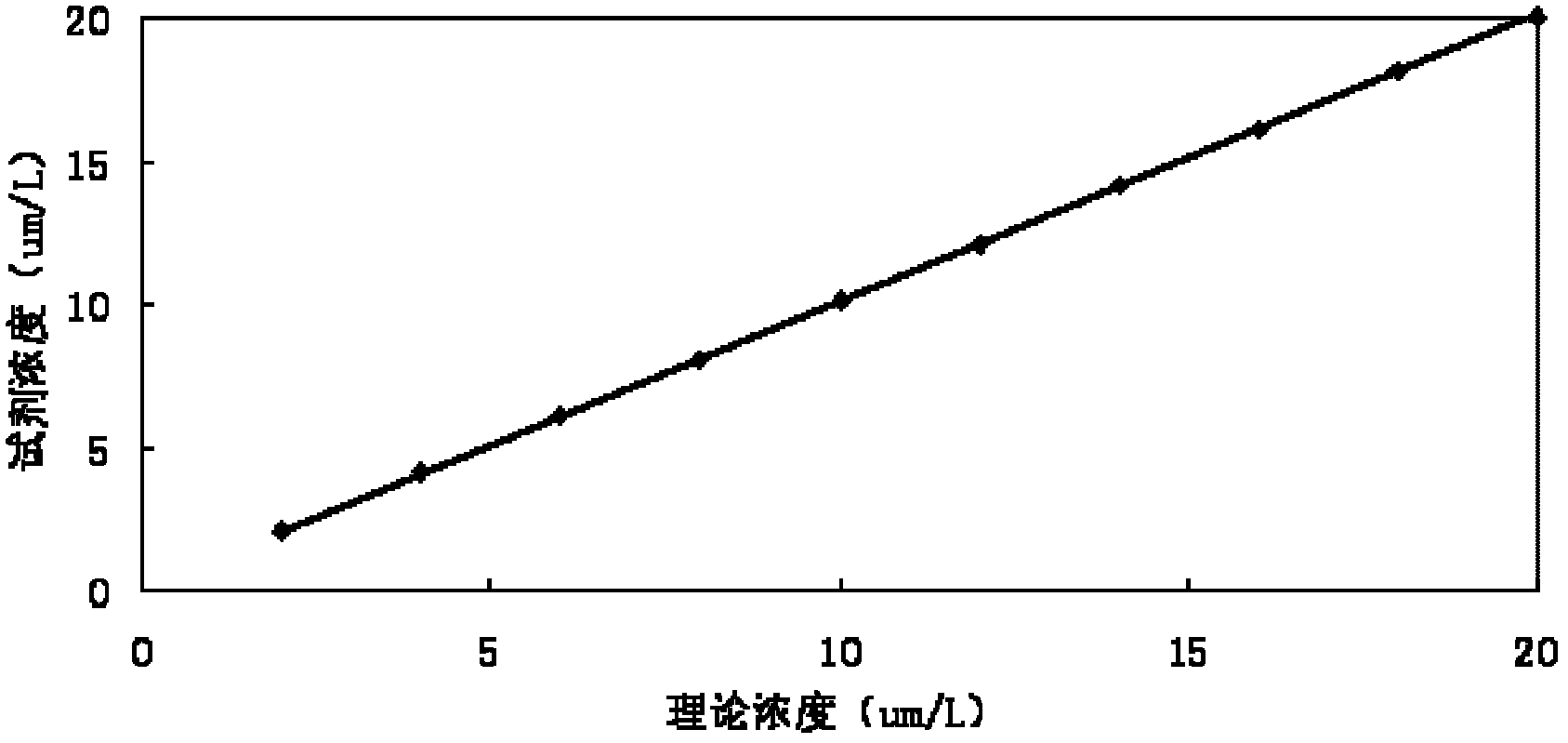

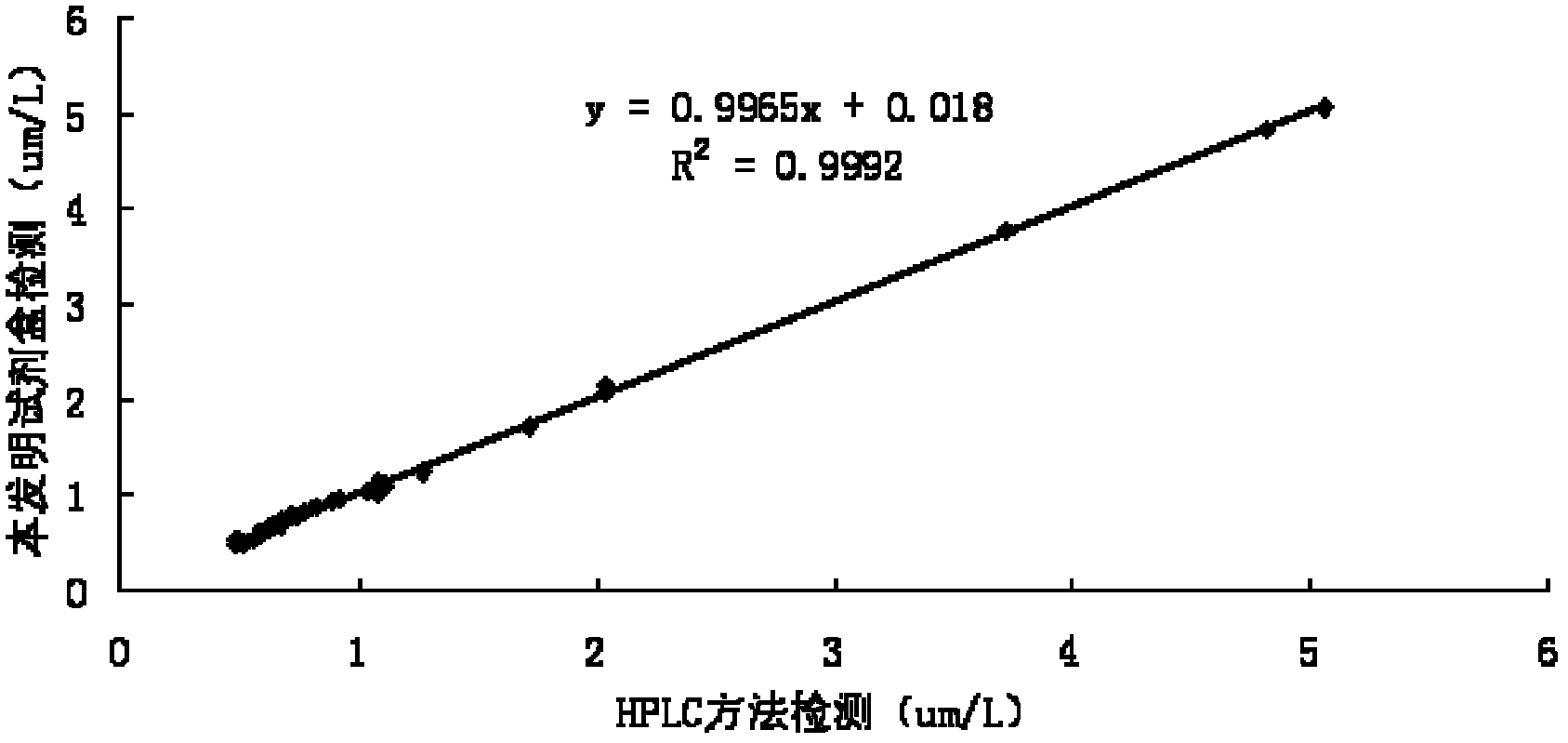

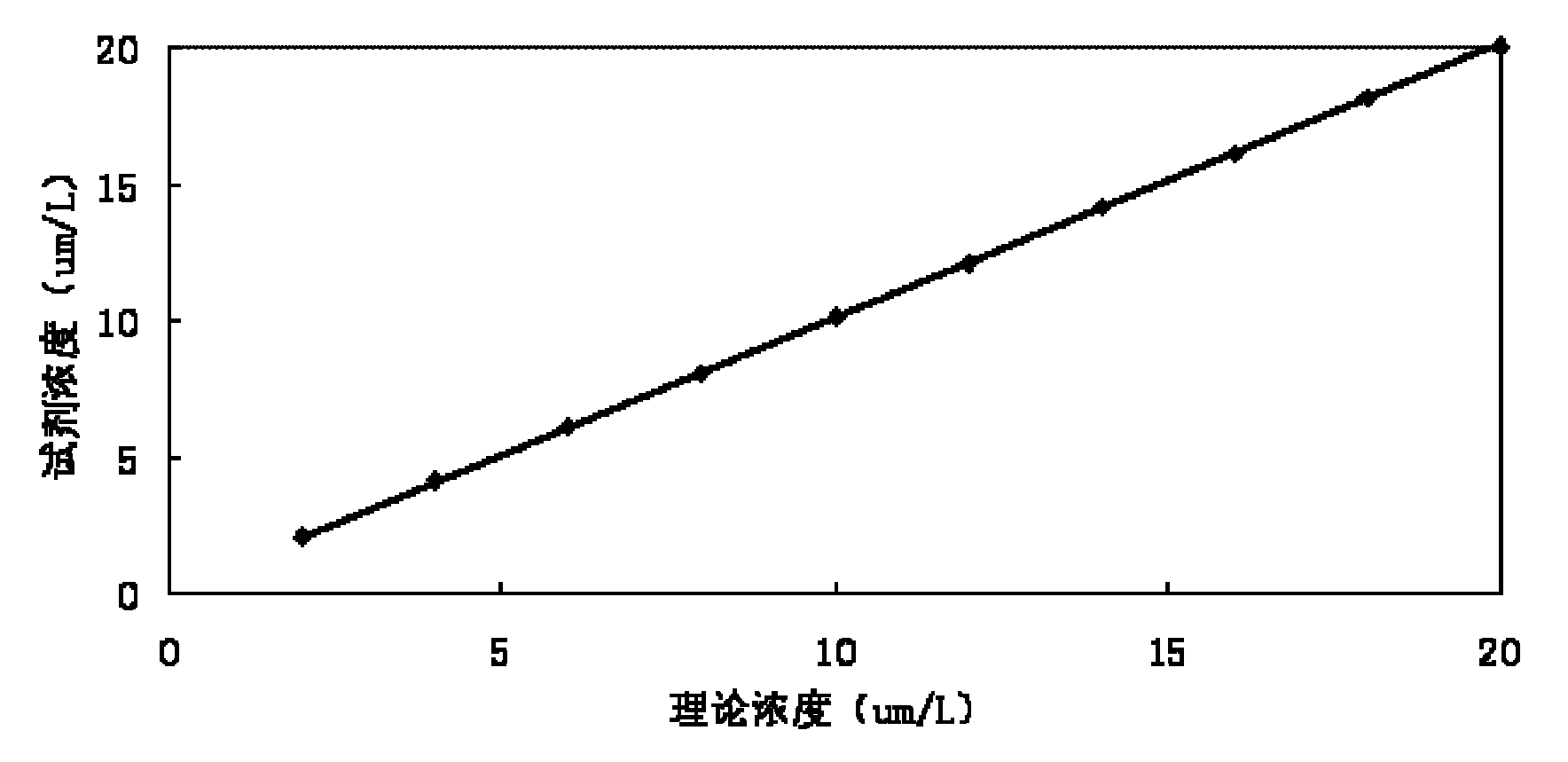

Latex enhanced immunoturbidimetry kit for detection of asymmetric dimethylarginine content

ActiveCN102628868AThe detection process is fastHigh detection specificityBiological testingCompetitive bindingLatex particle

The invention relates to a latex enhanced immunoturbidimetry kit for the detection of asymmetric dimethylarginine content. Specifically, the invention relates to a latex enhanced immunoturbidimetry kit for the detection of asymmetric dimethylarginine (ADMA) content in human blood samples. The kit comprises a mouse anti-human monoclonal antibody solution, an ADMA-human Serum albumin complex crosslinked latex particle expansion and an ADMA calibrator. According to the method, by the utilization of competitive binding of free ADMA in blood and ADMA crosslinked on the surface of latex particles to ADMA monoclonal antibody, turbidity formed by the reaction between the ADMA-crosslinked latex particles and ADMA monoclonal antibody is reduced. Therefore, the content of ADMA is detected through the reduction degree of turbidity. The kit provided by the invention can be applied in a biochemical analyzer commonly-used in clinic, is convenient and rapid to operate and has strong specificity. Both sensitivity and detection range of the kit can satisfy clinic application needs.

Owner:BEIJING STRONG BIOTECH INC

Latent self-repair microcapsule and preparation method thereof

ActiveCN102604469AAfter solving the inflow crackSolve catalystCoatingsMicroballoon preparationVacuum dryingChemistry

The invention belongs to the technical field of preparation of a microcapsule, and relates to a latent self-repair microcapsule for an organic coating and a preparation method of the latent self-repair microcapsule. The method comprises the steps of feeding urea and formaldehyde mixed solution into a four-mouth flask, adjusting the pH value to 7.5-11.8 with triethanolamine, and ensuring that the temperature is slowly increased for reaction for 3 hours, so as to produce viscous transparent water-soluble urea-formaldehyde prepolymer solution; sufficiently mixing a capsule-core epoxy resin, a capsule-core diluting agent, and a capsule-core latent curing modifier proportionally, adding distilled water, stirring, adding an emulsifying agent, emulsifying for 10-20min in a high-speed emulsifyingmachine, so as to form O / W type emulsion, mixing the urea-formaldehyde prepolymer solution and the emulsified liquid and sufficiently stirring to disperse in an aqueous medium, adjusting the pH valueto 1.0 to 5.0, centrifugating the particle suspension after curing at a controlled temperature for 3 hours, performing flushing for a plurality of times, and then performing vacuum drying to obtain the microcapsule. The method has the advantages that the technology is simple, the condition is easy to control, the preparation cost is low, the product quality is good, the repair effect is good, themanpower and cost are saved, and the method is environment-friendly.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

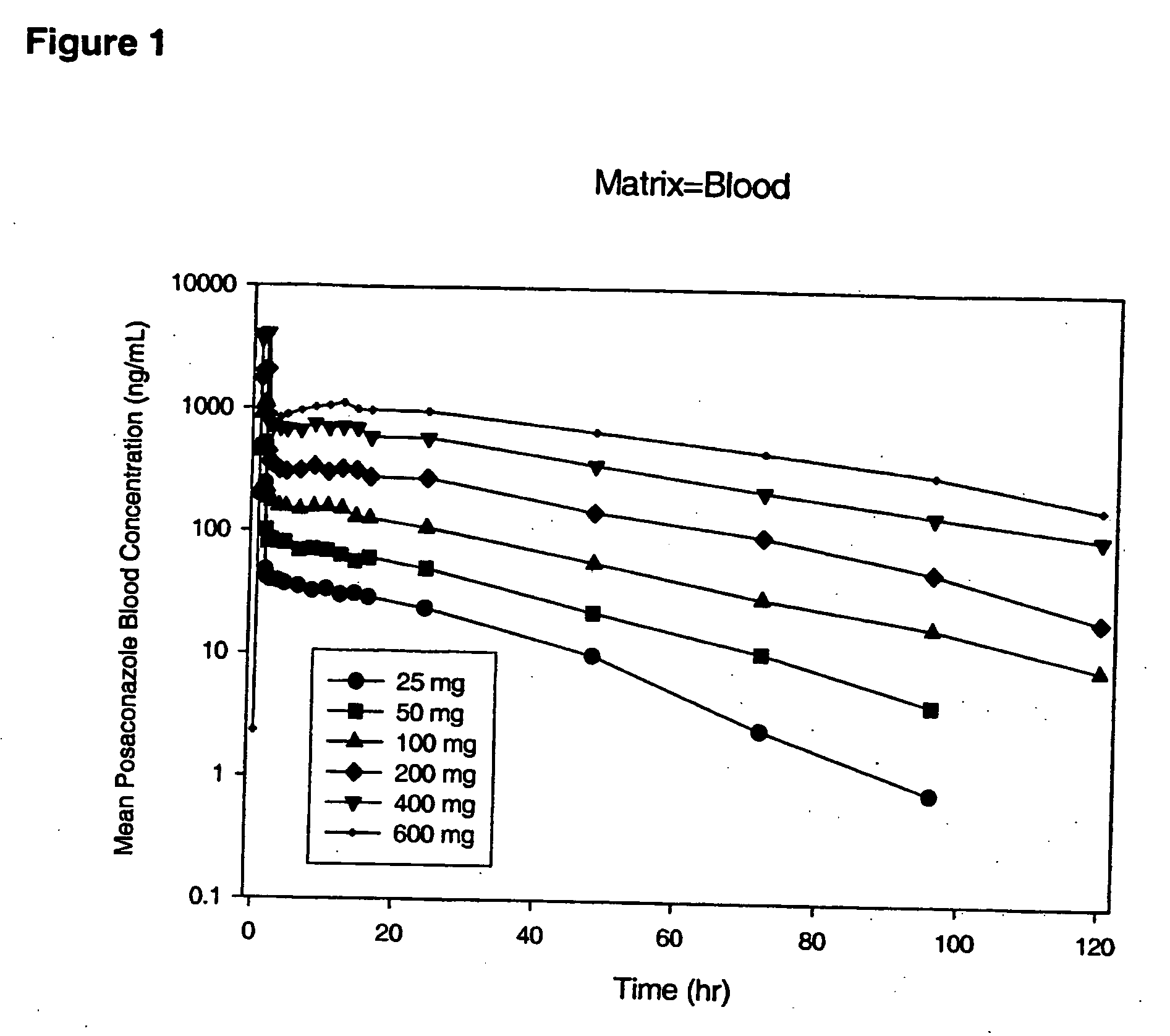

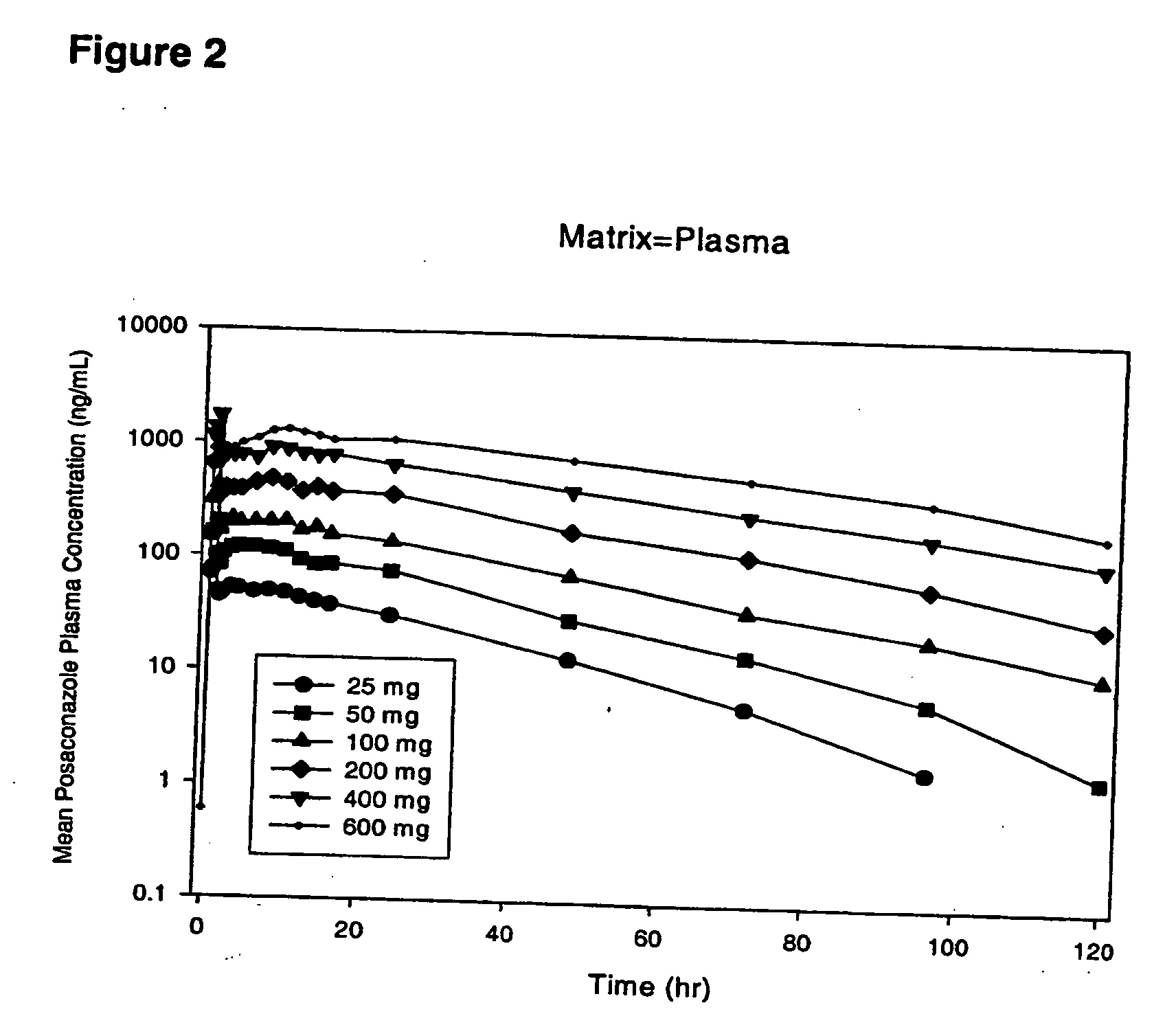

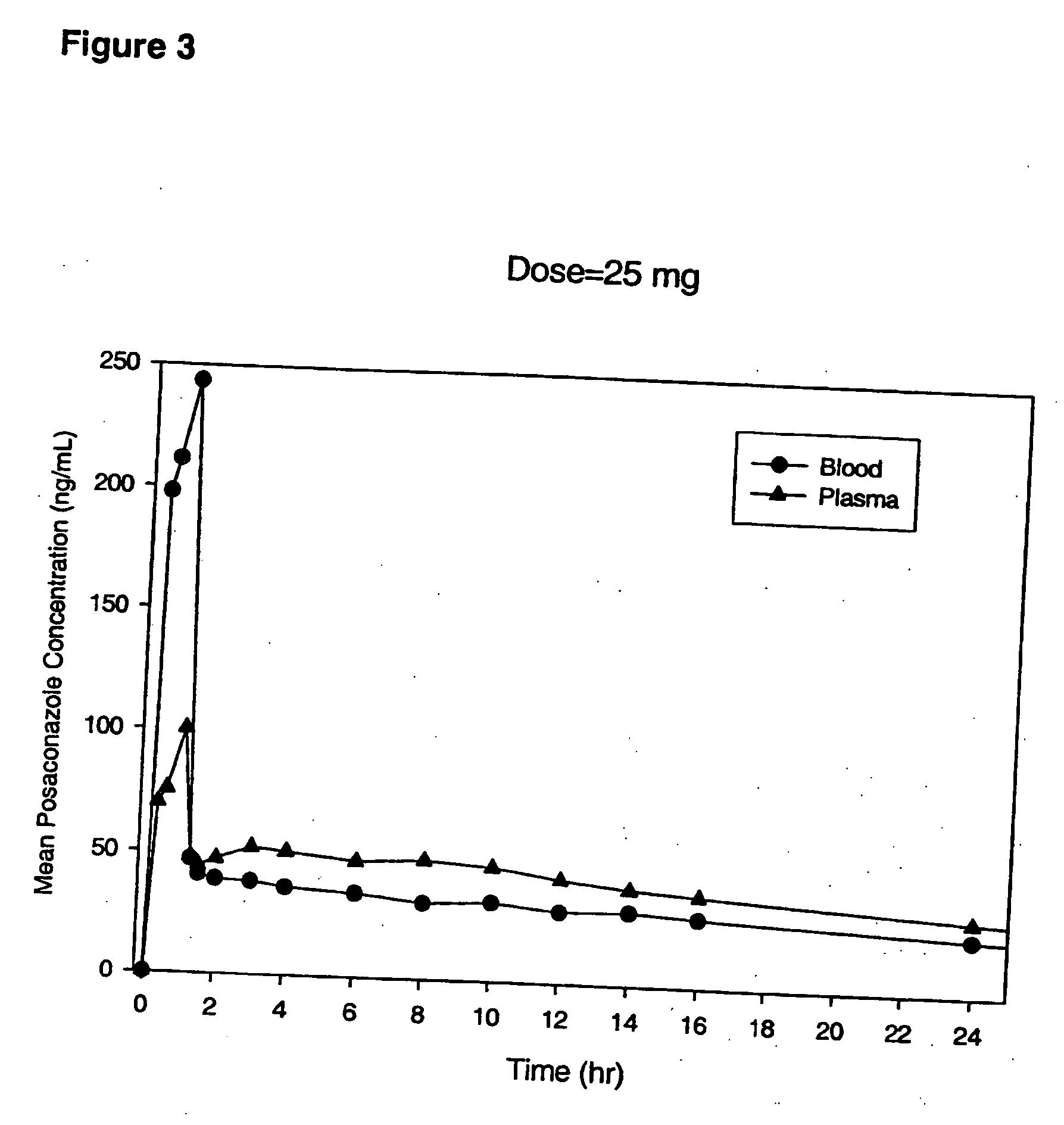

Particulate-stabilized injectable pharmaceutical compositions of Posaconazole

InactiveUS20060160823A1Reduce autoclave-induced particle size growthPromote growthOrganic active ingredientsAntimycoticsParticulatesAdditive ingredient

The present invention provides formulations useful for treating infections, in particular, formulations that include the active pharmaceutical ingredient Posaconazole in an injectable suspension of particles that is stable when subjected to terminal sterilization. Preferred median particle sizes of between 1.5 and 3.0 microns are found to result in superior pharmacokinetic characteristics, such as those displayed below.

Owner:SCHERING CORP

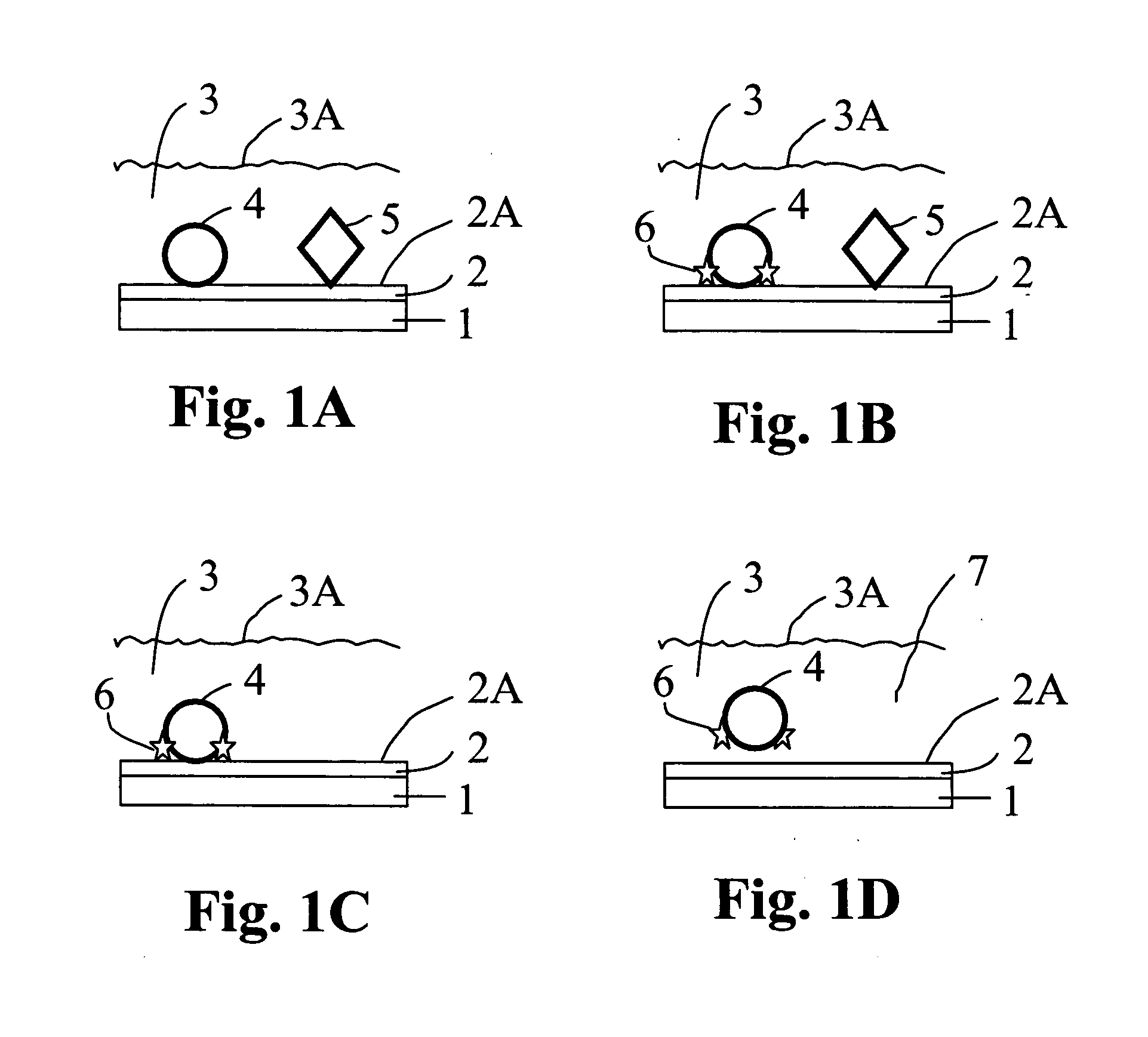

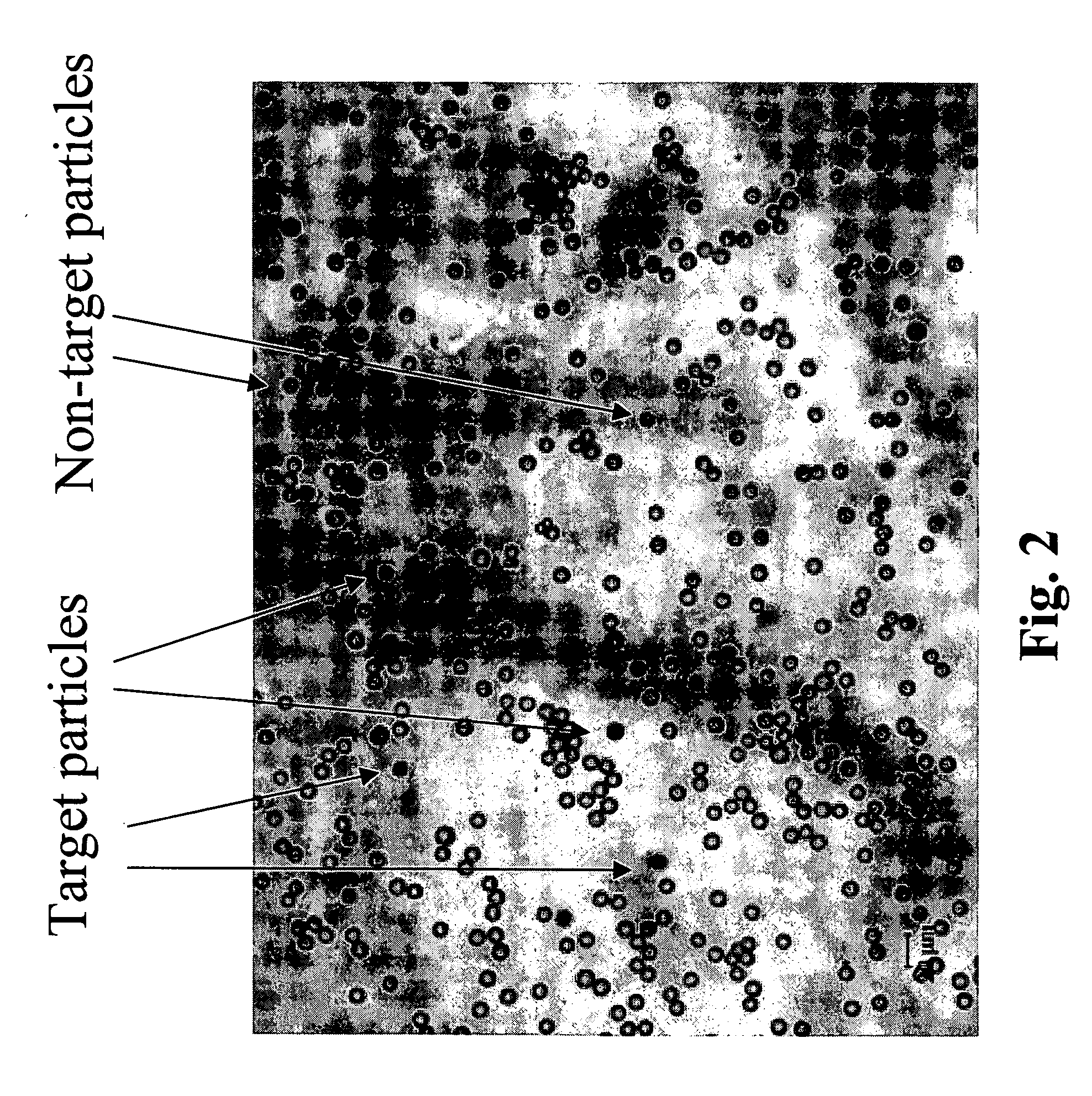

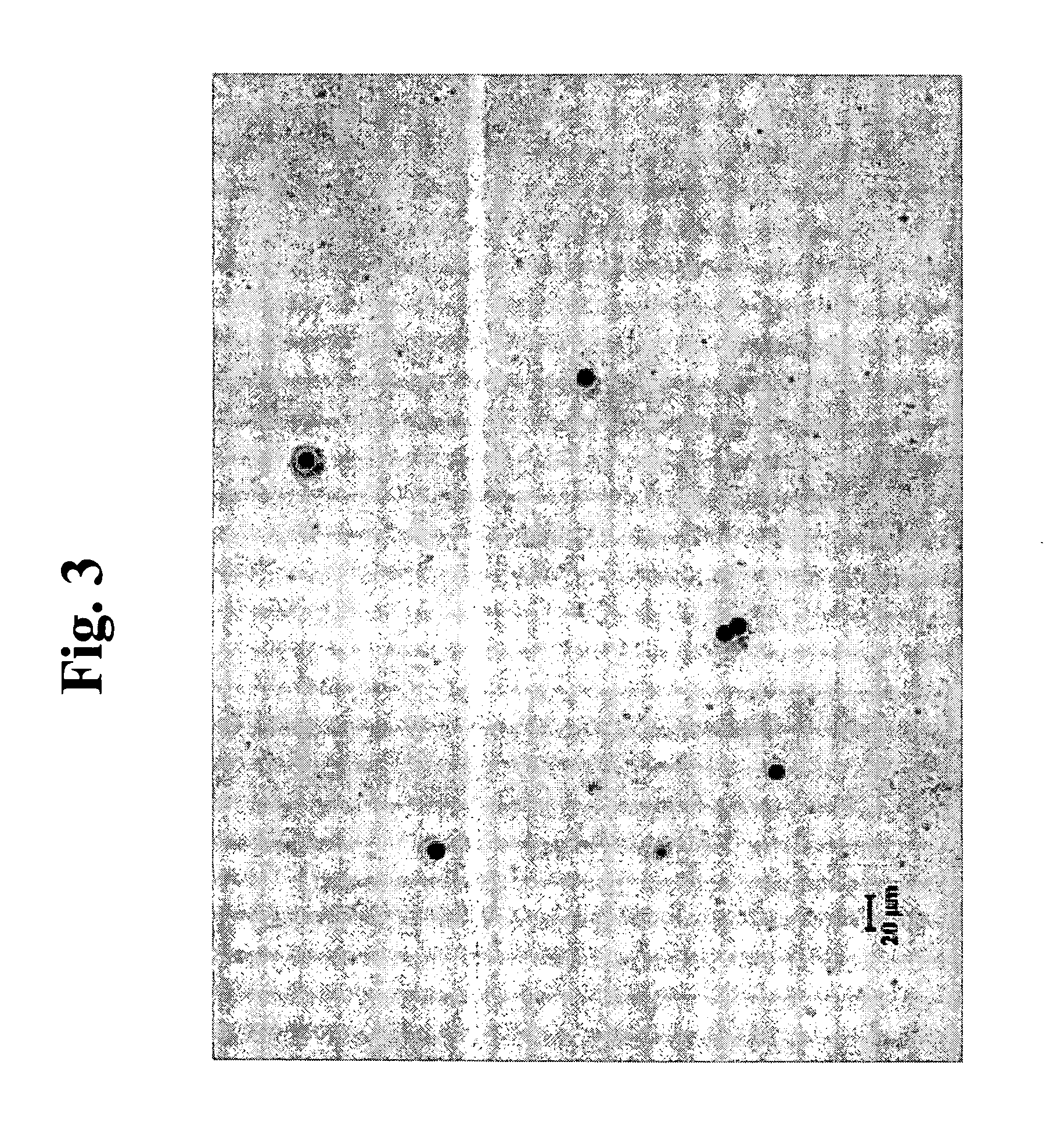

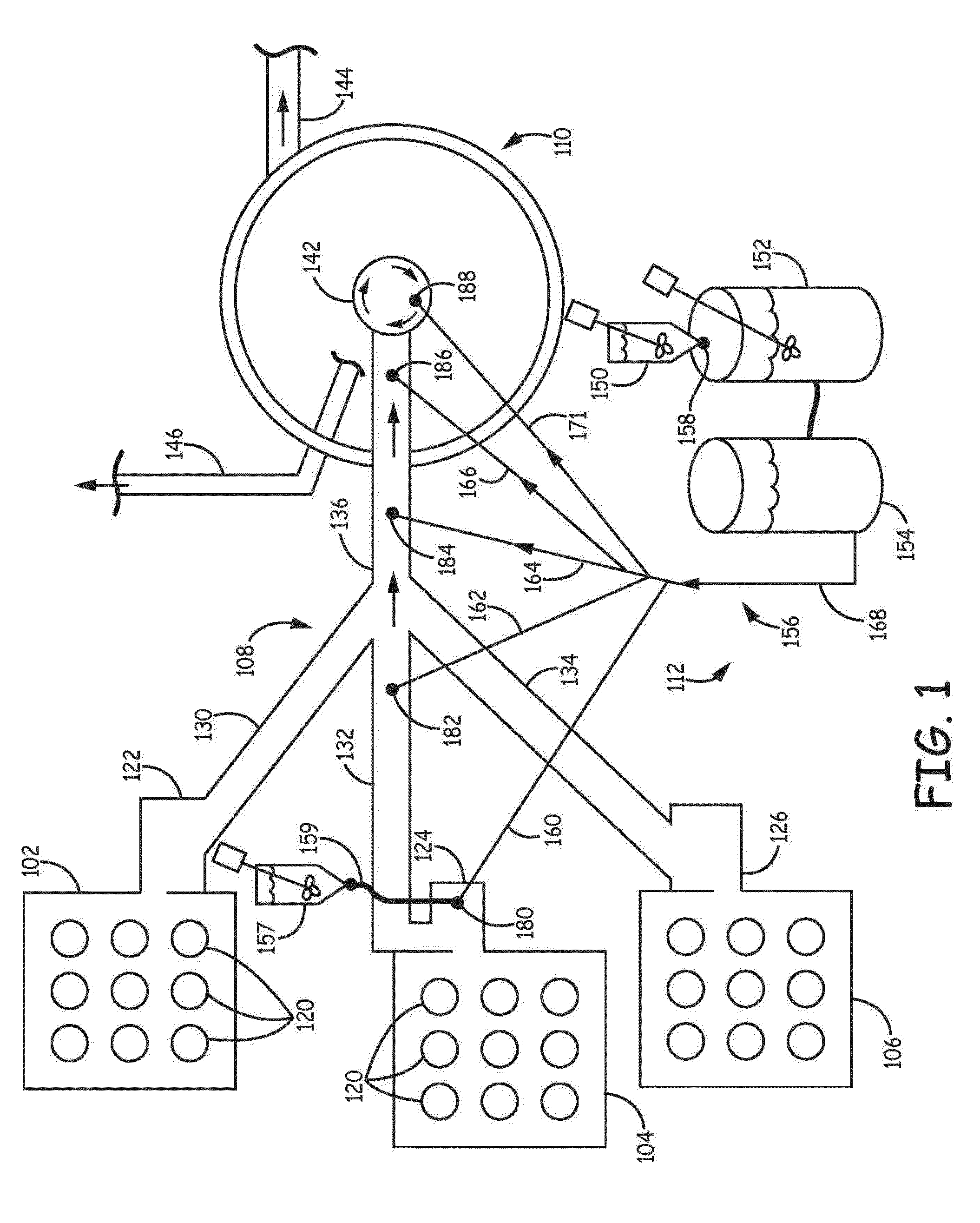

Method and system for sorting and separating particles

The present invention relates to a method of particle separation comprising preparing a suspension of particles containing at least one recognizable target particle in a suspending solution, labeling the target particle with a conjugate marker, wherein the conjugate marker comprises at least one recognition unit for the recognizable target particle and at least one peroxidase enzyme, contacting a gelatin surface with the suspending solution, adding developer to the suspending solution in contact with the gelatin surface and in the presence of phenol to attach the target particle to the gelatin surface, and washing the gelatin surface to remove unattached particles. The method may also include detecting the presence of the target particle on the gelatin surface as well as detaching and recovering the attached particles after removal of the non-target particles.

Owner:CARESTREAM HEALTH INC

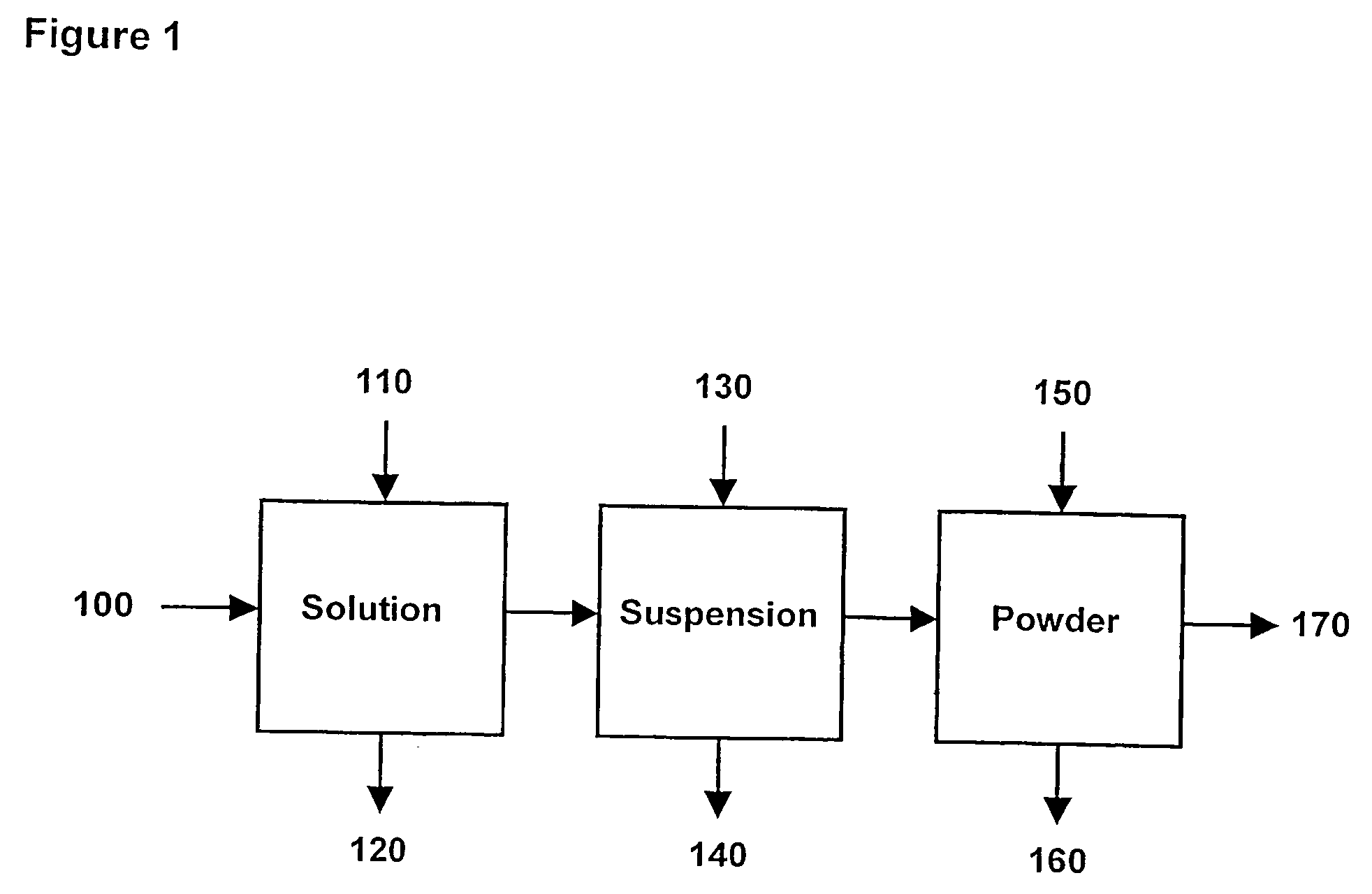

Process of forming and modifying particles and compositions produced thereby

Owner:NANOSHIFT LLC

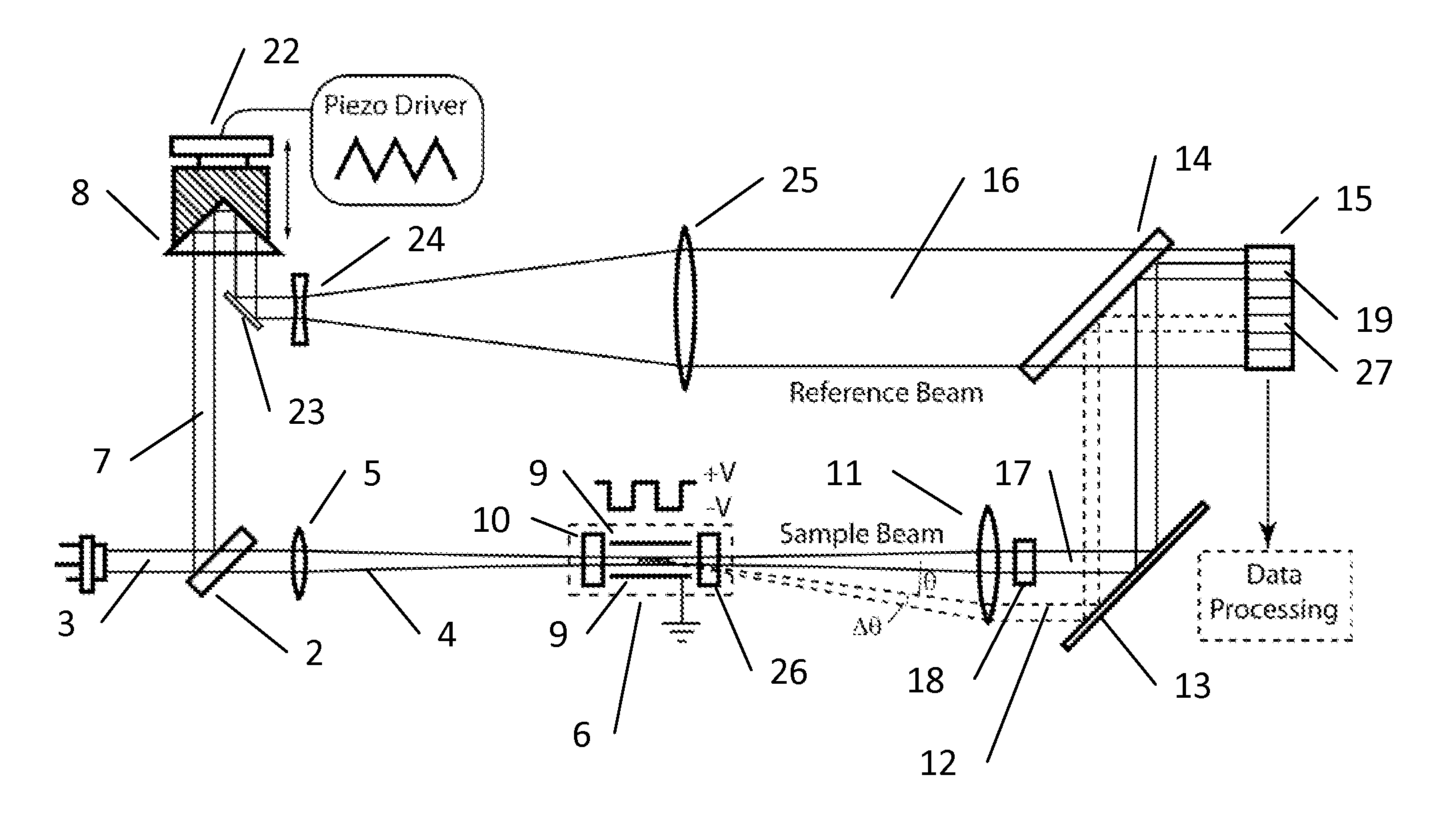

Method and apparatus to measure particle mobility in solution

ActiveUS20110210002A1Reduce harmMinimizing electrochemical degradationSludge treatmentVolume/mass flow measurementPhotodetectorFree solution

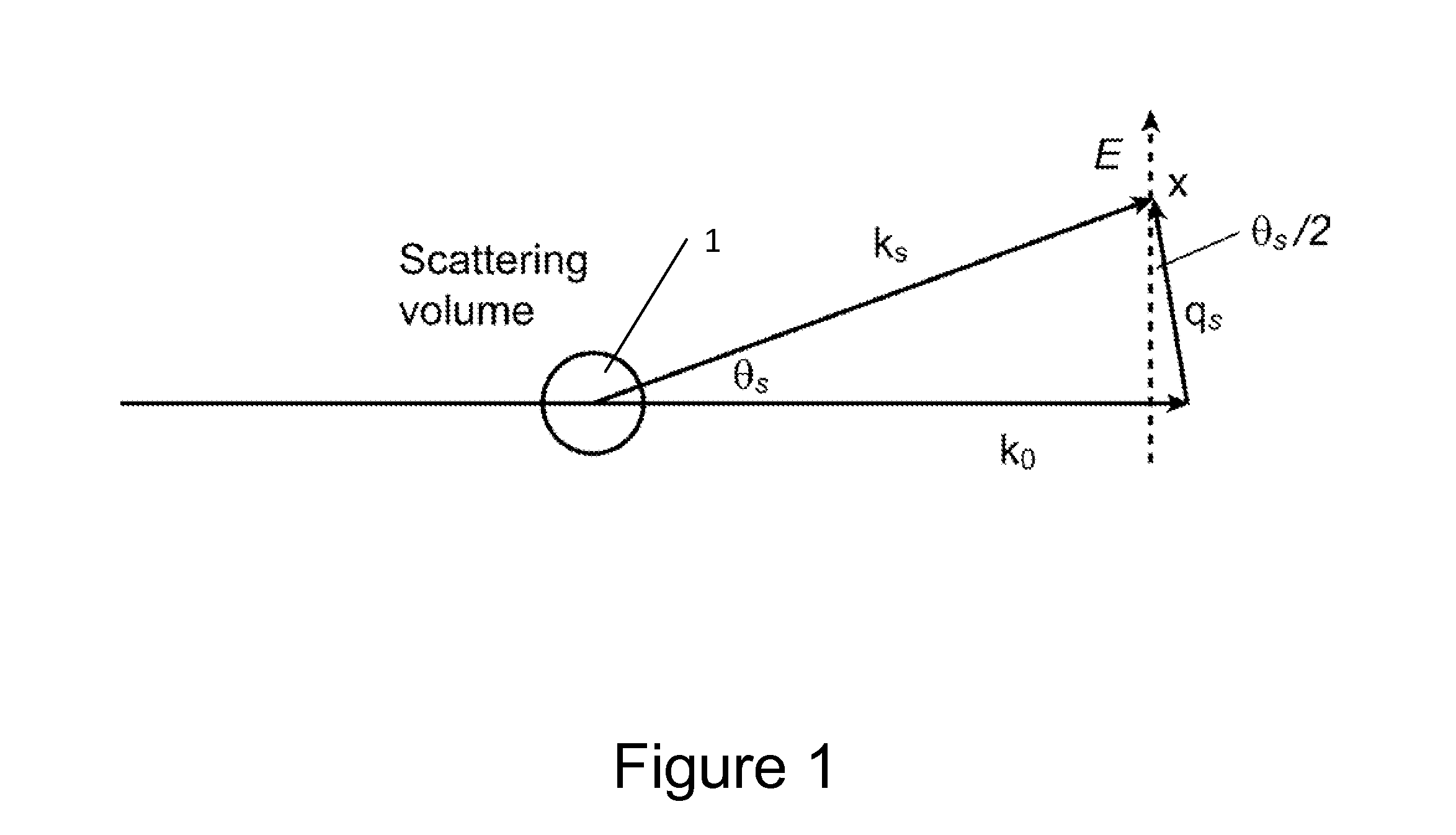

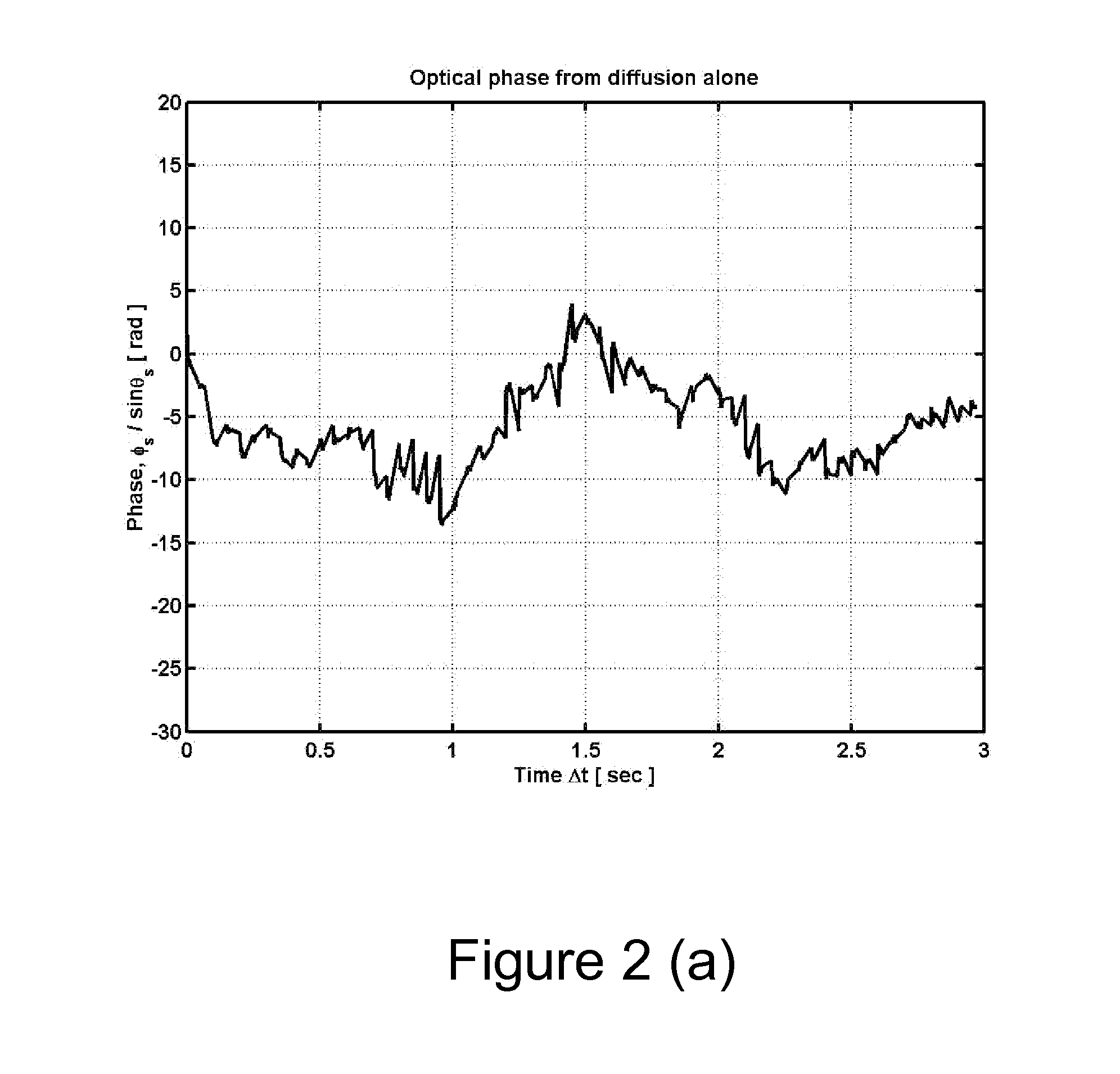

A method and apparatus is disclosed for measurement of the electrophoretic mobility of particles and molecules in solution. A sample of particles is placed in a cell containing two electrodes that apply an alternating electric field. A monochromatic light beam passes through the sample. Light scattered by the particles, along with the unscattered beam, is collected and collimated as it exits the cell. This beam is combined in free space with a phase modulated reference beam. The interference forms a frequency modulated speckle pattern, which is detected by a photodetector array. Each array element collects a narrow range of well-defined scattering angles. The signal from each is demodulated to extract the optical phase information providing a first-principle measurement of the electrophoretic mobility of the scattering particles. Each detector element provides a simultaneous independent measurement. This inherent parallelism drastically increases the amount of information available in a given time. The resulting increased sensitivity extends the mobility measurement to particles below one nanometer, reduces the required concentration and electric field compared to previous methods. This minimizes damage to fragile samples, increases the electrode useful life, and reduces joule heating. Electrophoretic mobility is a critically important parameter for predicting the stability of nanoparticle suspensions and pharmaceutical formulations such as protein therapeutics. This invention enables reliable free-solution phase measurement of these samples.

Owner:WYATT TECH

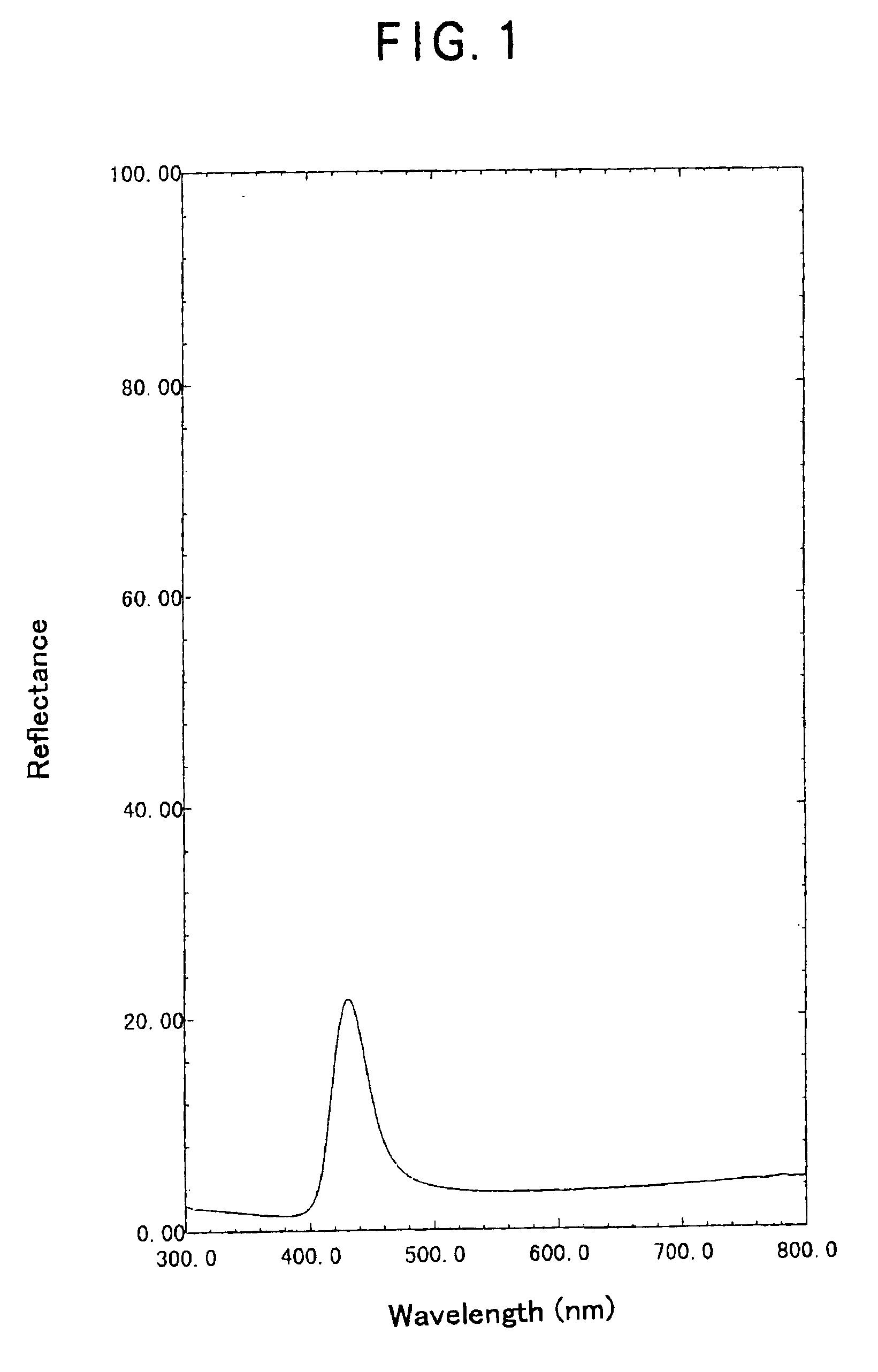

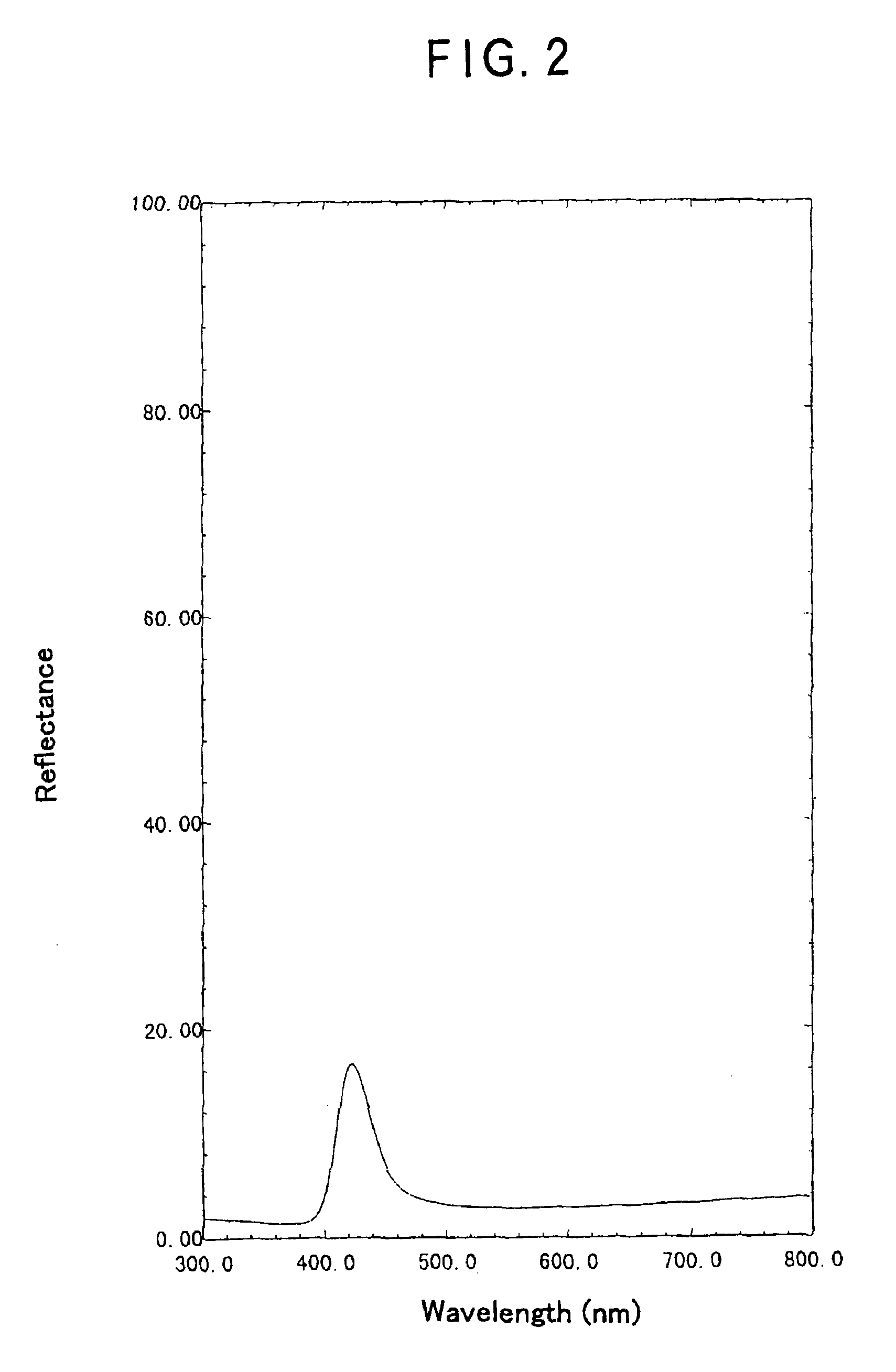

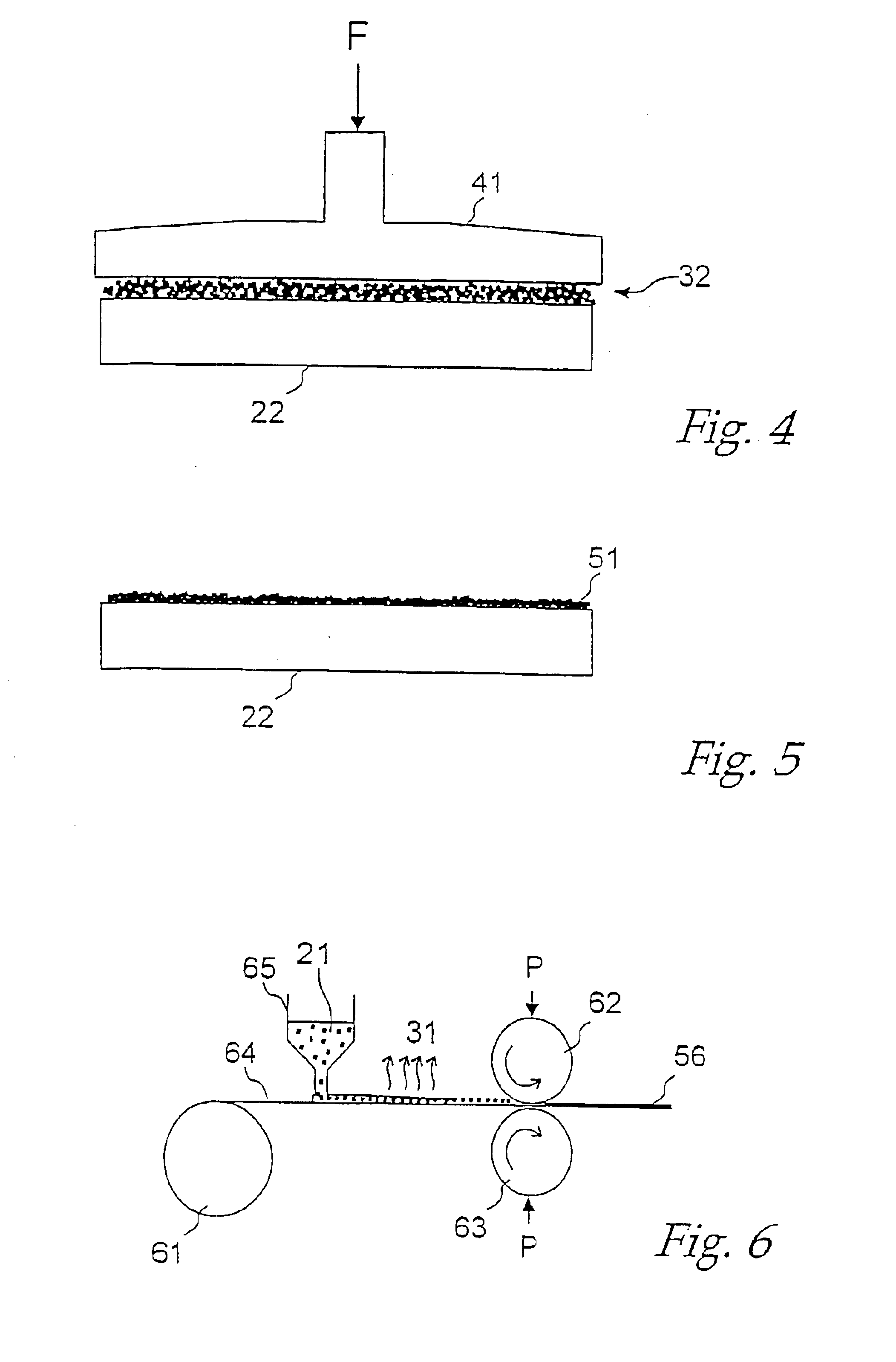

Method for manufacturing nanostructured thin film electrodes

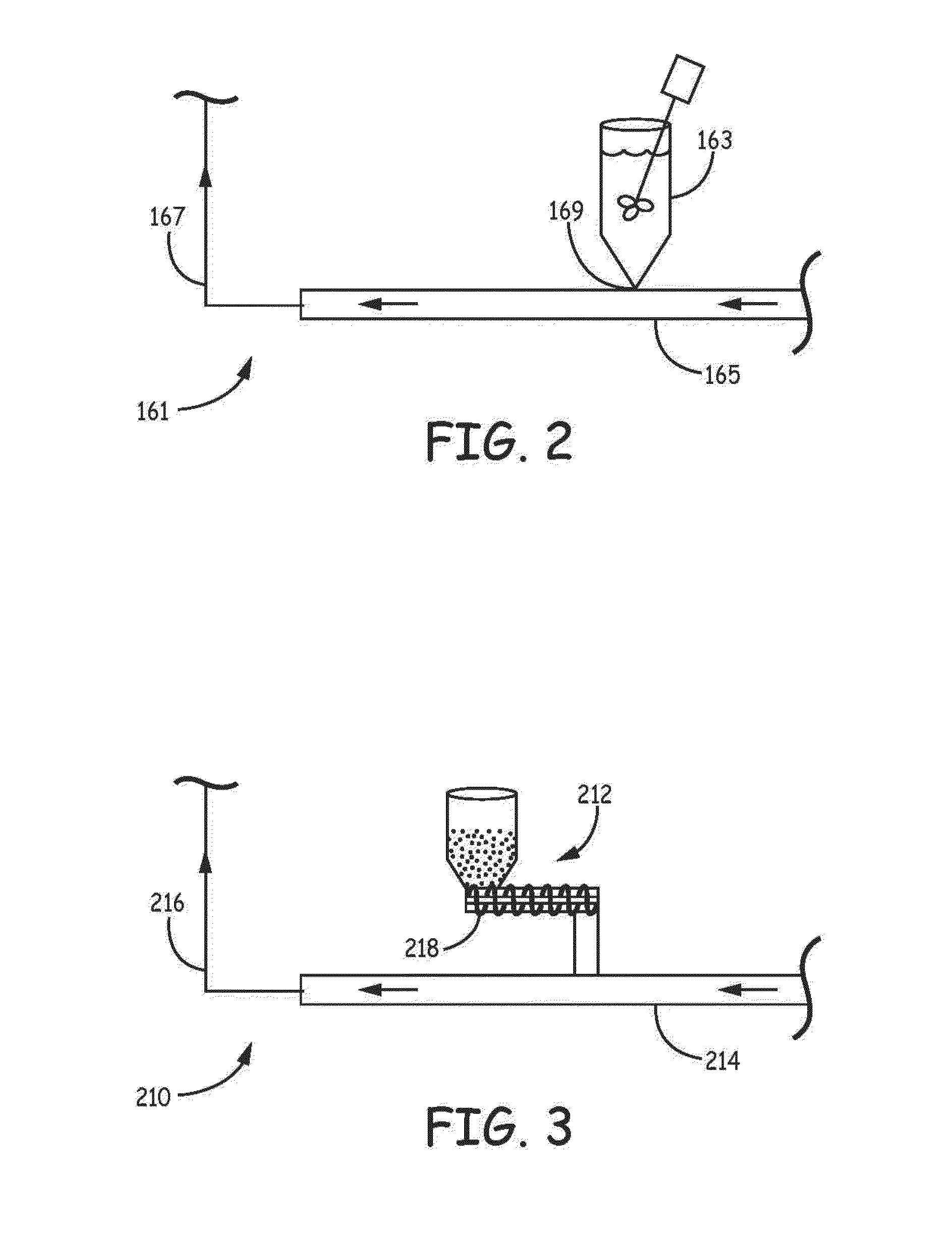

InactiveUS6881604B2Short processing timeLight-sensitive devicesCell electrodesEvaporationSuspending Agents

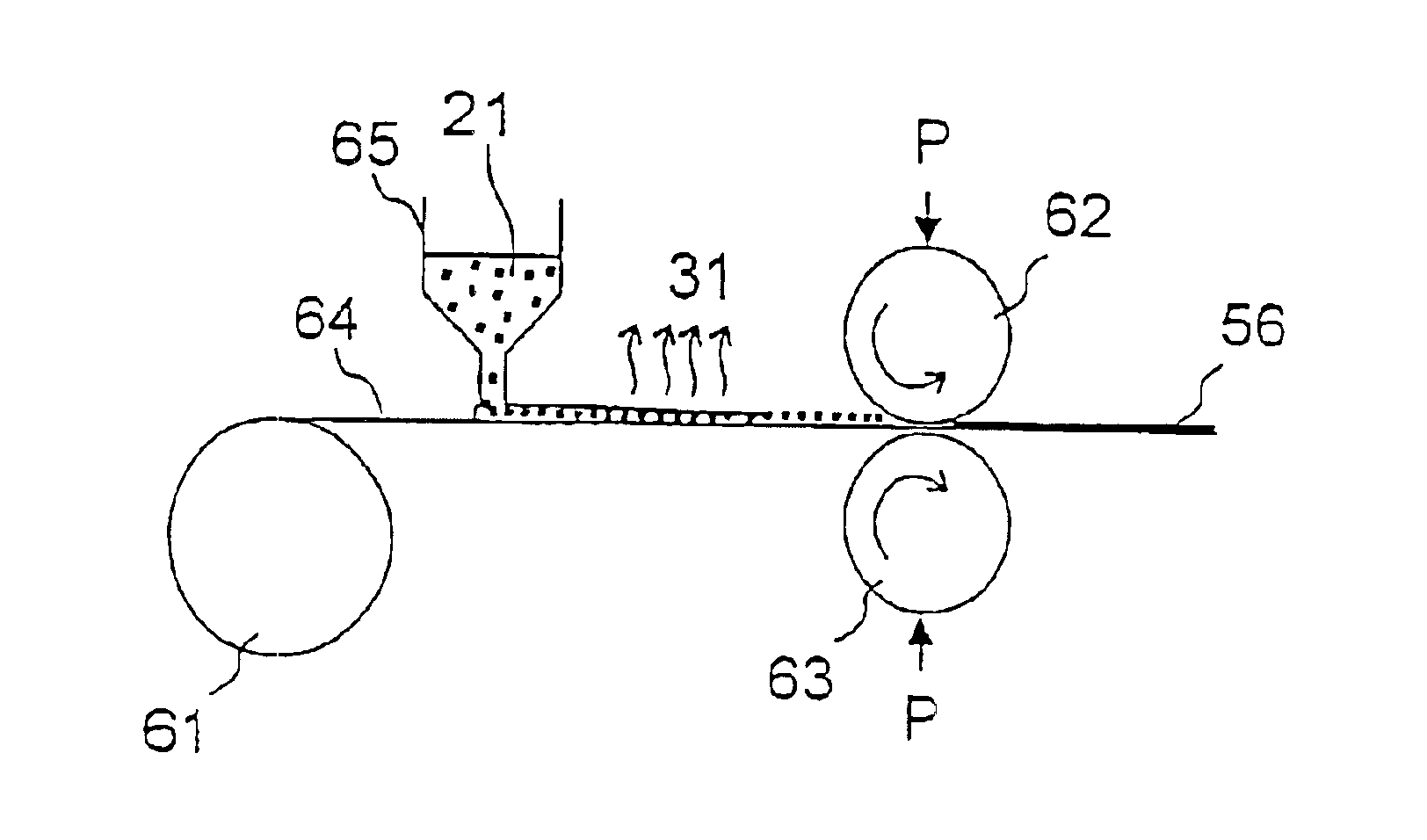

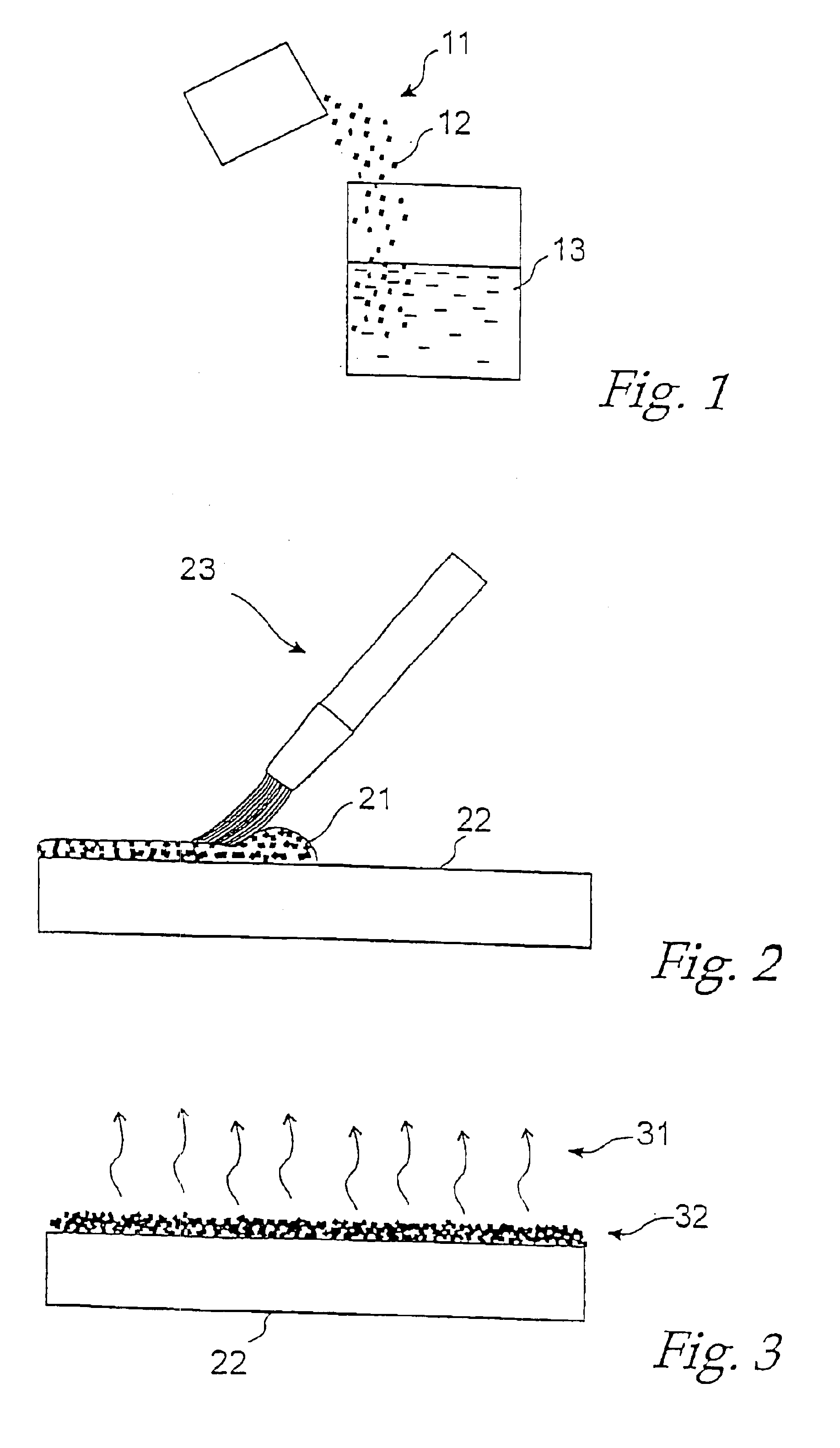

A method for a binder-free manufacturing a nanostructured porous film, e.g. for use in solar cells, includes the steps of preparing a suspension of semi-conducting nanometer-sized particles in a volatile suspending agent (21), depositing the particle suspension on a conducting substrate, removing the suspending agent by evaporation (31), thereby leaving a particle layer on said substrate and compressing (P) the deposited particle layer for mechanical and electrical interconnection.

Owner:FORSKARPATENT I UPPSALA

Apparatus and method for dispensing cells or particles confined in a free flying droplet

ActiveUS8834793B2Improve reliabilityReliable distributionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringOn cells

Owner:CYTENA GMBH

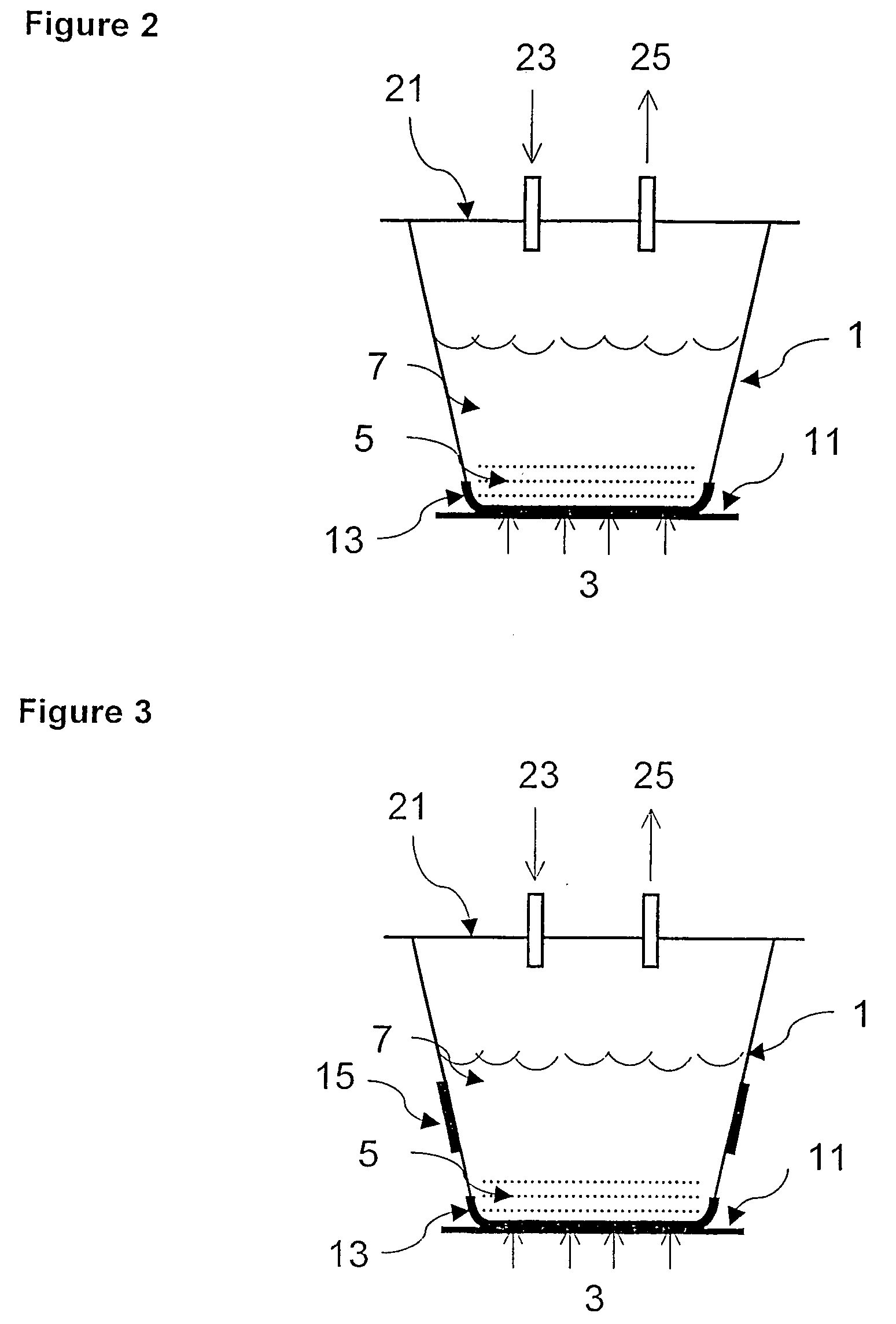

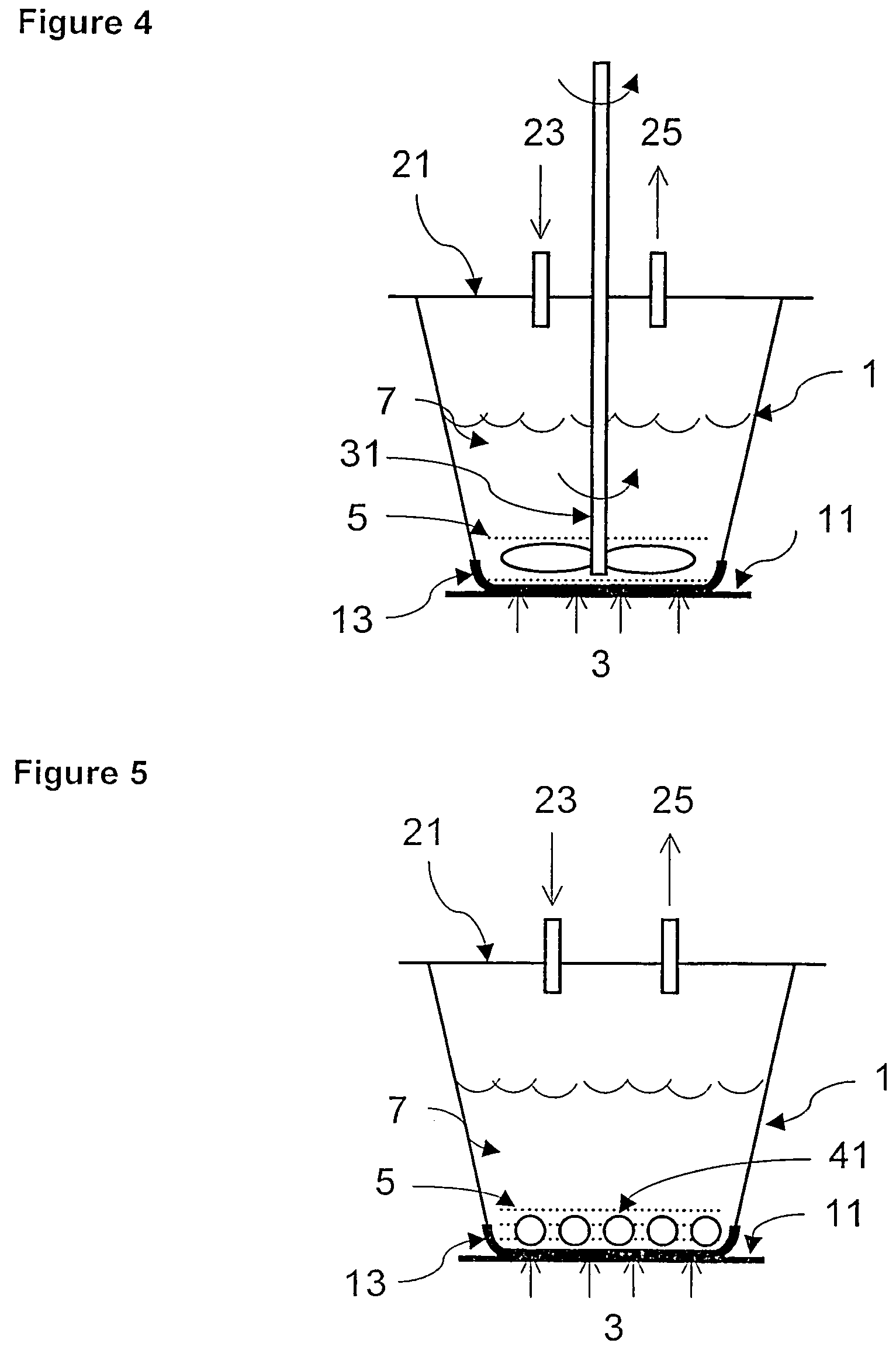

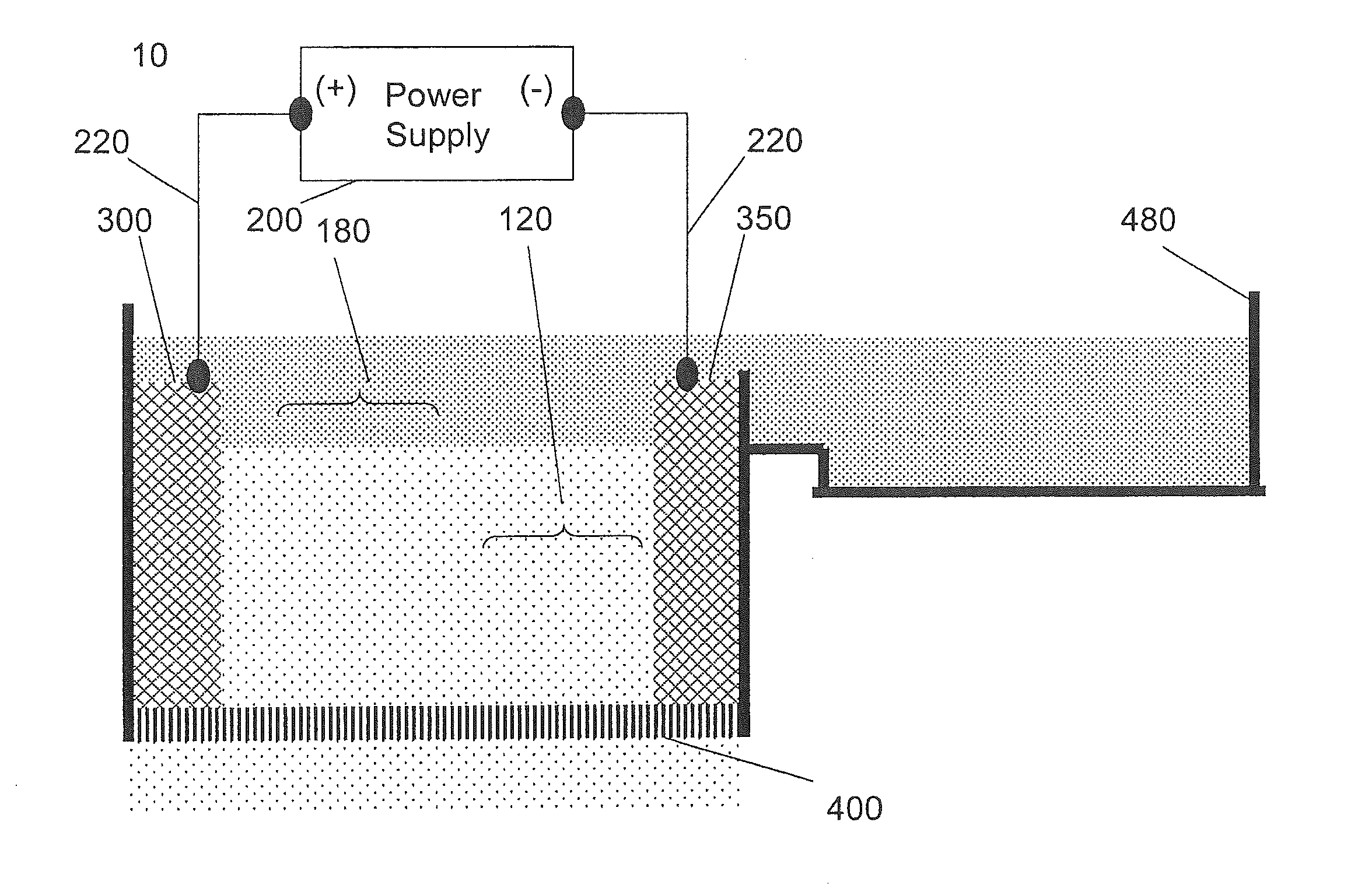

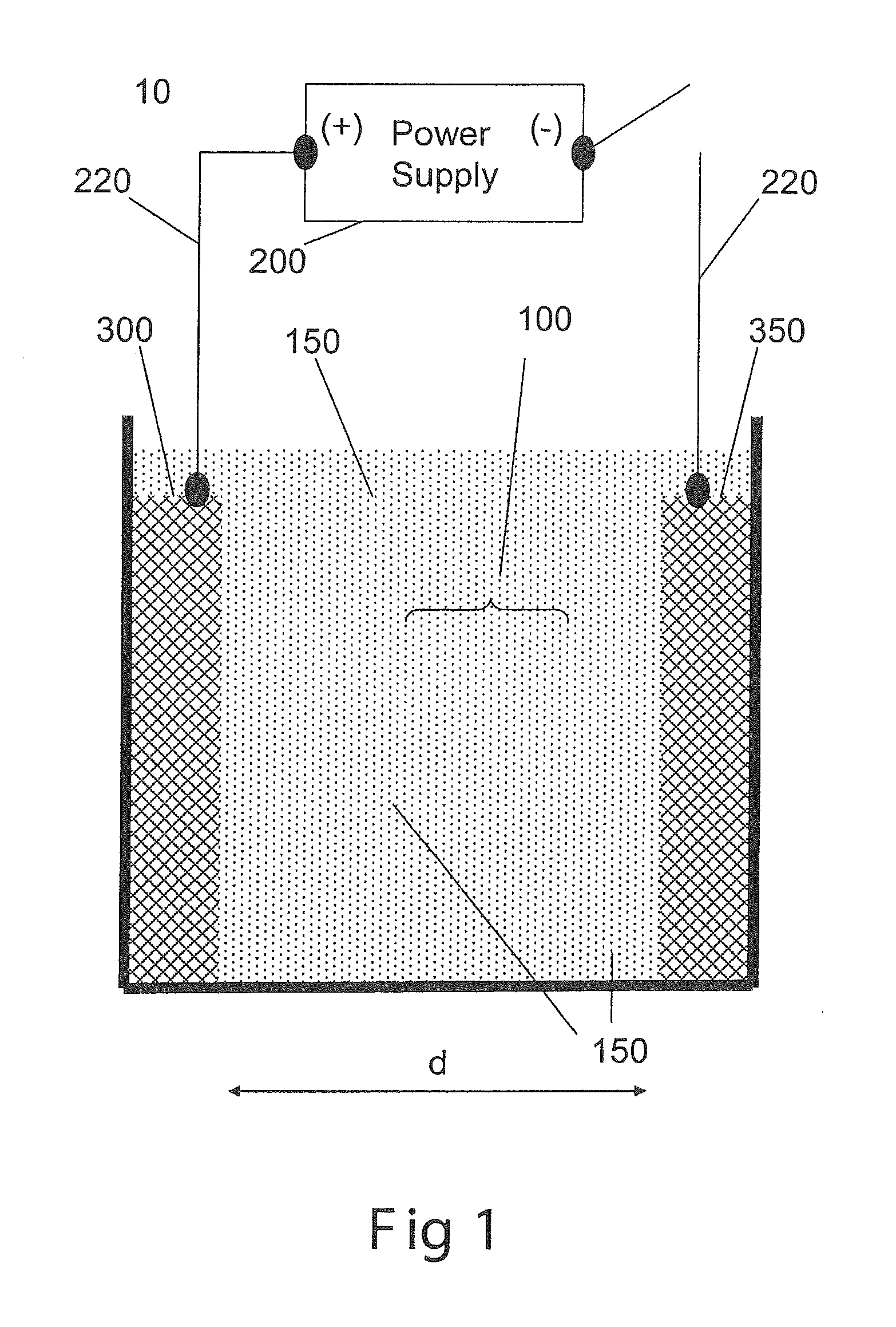

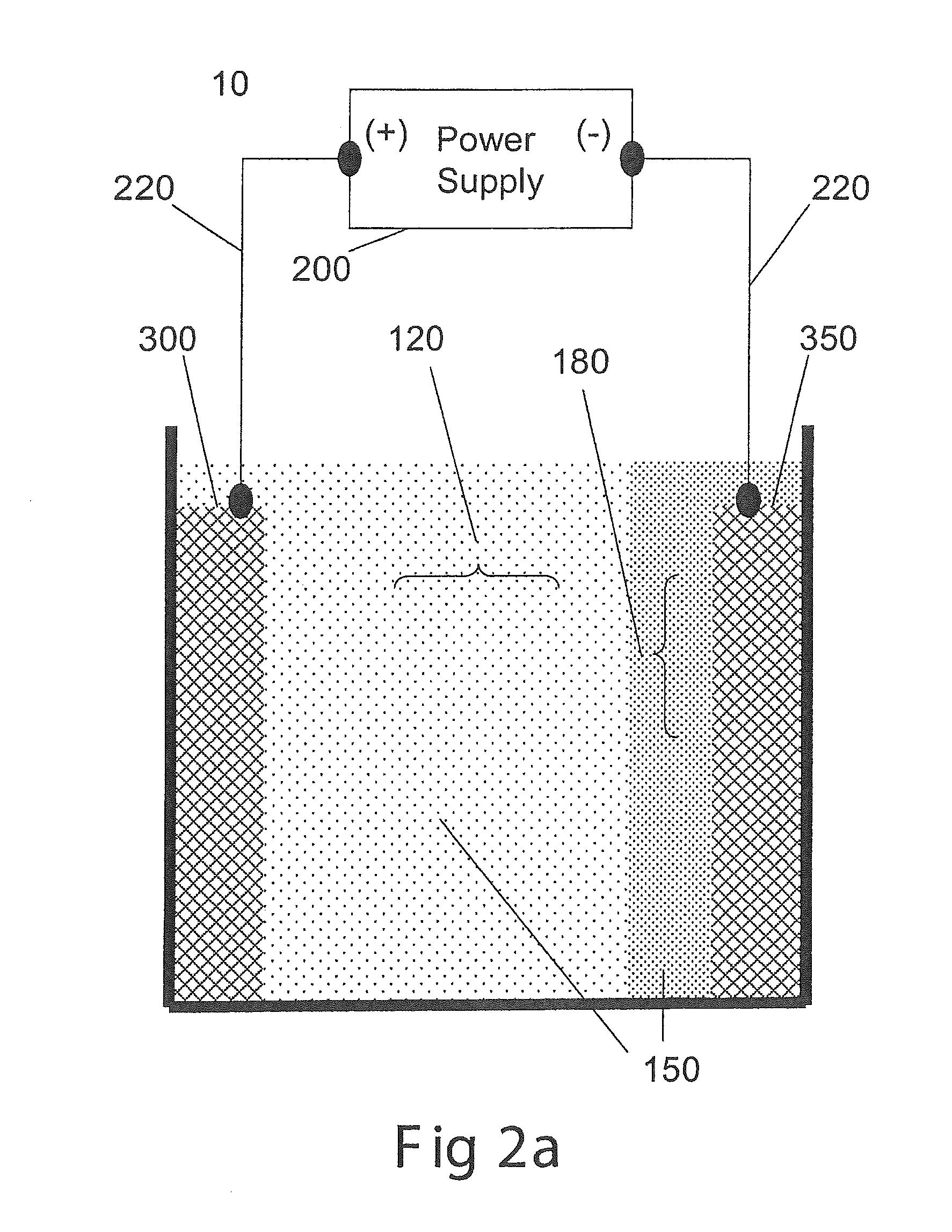

Electrolytic system and method for filtering an aqueous particulate suspension

ActiveUS20120091000A1Clogging of filter is minimized and eliminatedSludge treatmentVolume/mass flow measurementSuspended particlesFiltration

An electrolytic filtration method and apparatus for the concentration and collection of suspended particulates from aqueous solutions is disclosed. The electrolytic cell contains at least an anode and a cathode, and in one embodiment contains a plurality of anodes and cathodes. The electrolytic cell also contains a filter, and in one embodiment the filter is a moving belt filter. While not bound by theory, the electrolytic filtration method and apparatus is based on the electrophoretic movement of algae particles suspended in an aqueous solution away from the filter under the influence of an electric field. In one embodiment the electric field is a pulsed waveform with unidirectional voltage or current pulses. In another embodiment, the electric field is a pulsed waveform with bidirectional voltage or current pulses.

Owner:PHYSICAL SCI +1

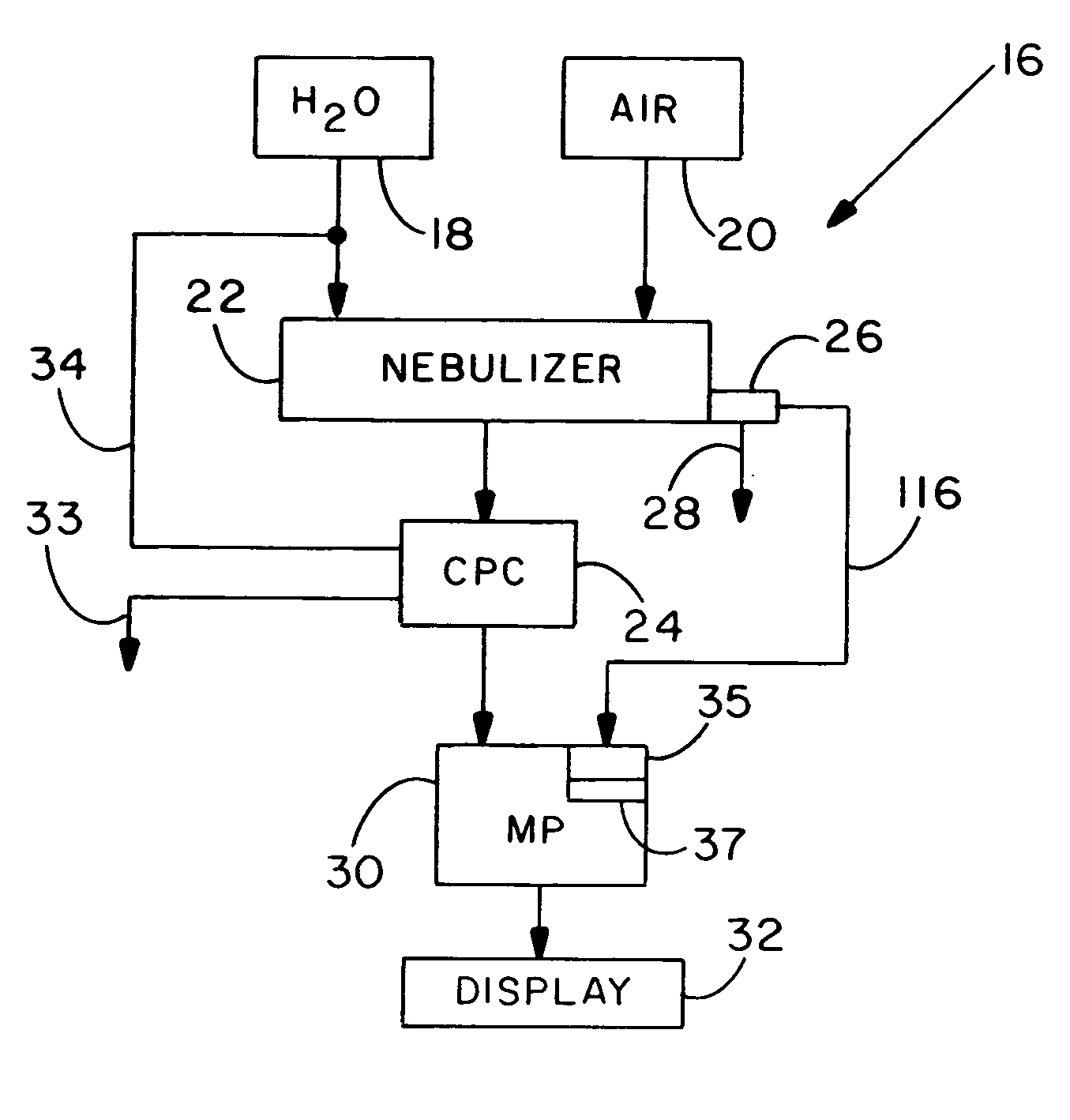

System for Measuring Non-Volatile Residue in Ultra Pure Water

ActiveUS20080144003A1Reduce water pressureAvoid residueSamplingComponent separationWastewaterWater flow

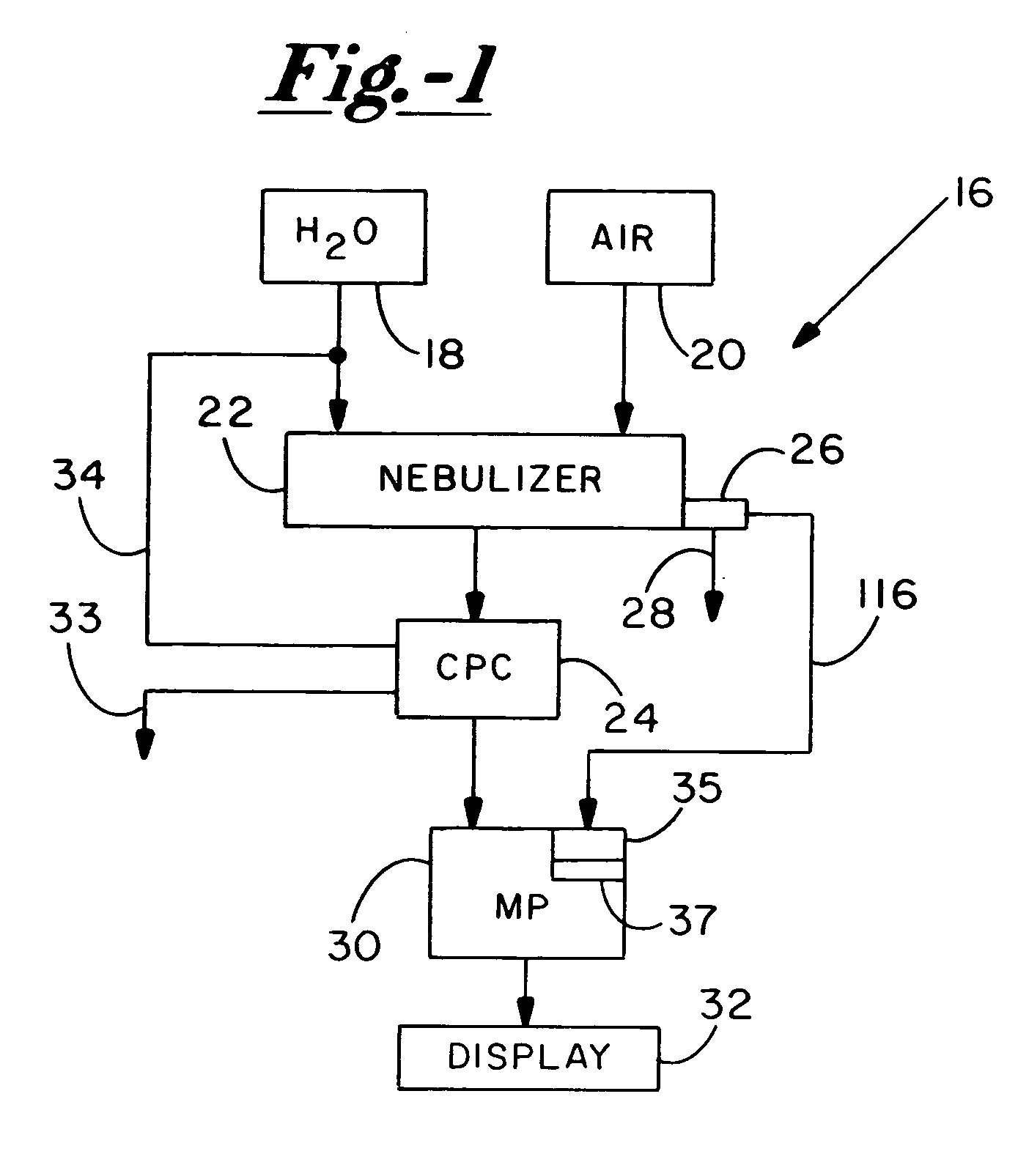

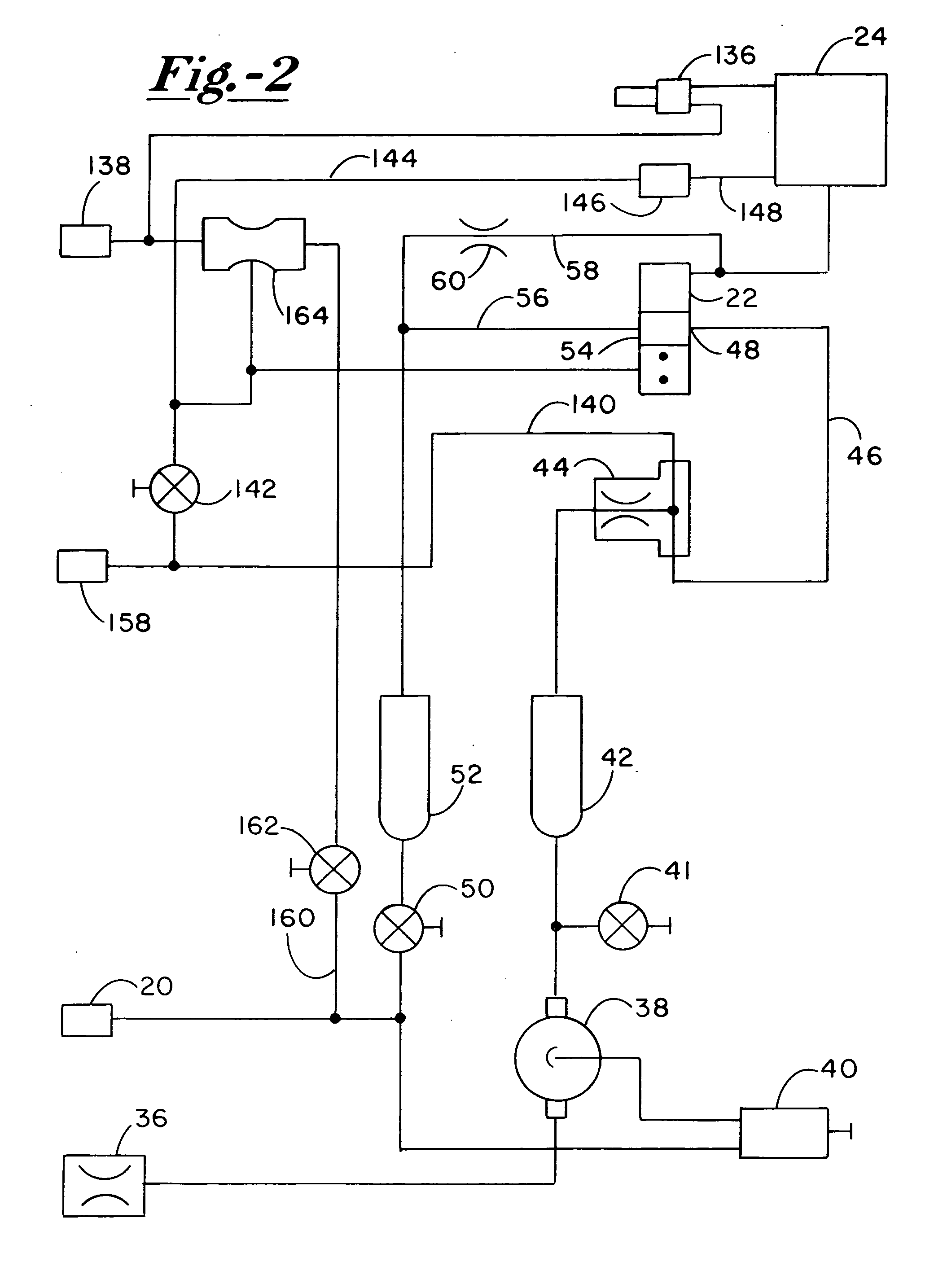

A system for monitoring non-volatile residue concentrations in ultra pure water includes a nebulizer for generating an aerosol composed of multiple water droplets, a heating element changing the aerosol to a suspension of residue particles, and a condensation particle counter to supersaturate the dried aerosol to cause droplet growth through condensation of a liquid onto the particles. The nebulizer incorporates a flow dividing structure that divides exiting waste water into a series of droplets. The droplets are counted to directly indicate a waste water flow rate and indirectly indicate an input flow rate of water supplied to the nebulizer. The condensation particle counter employs water as the condensing medium, avoiding the need for undesirable chemical formulations and enabling use of the ultra pure water itself as the condensing medium.

Owner:FLUID MEASUREMENT TECH

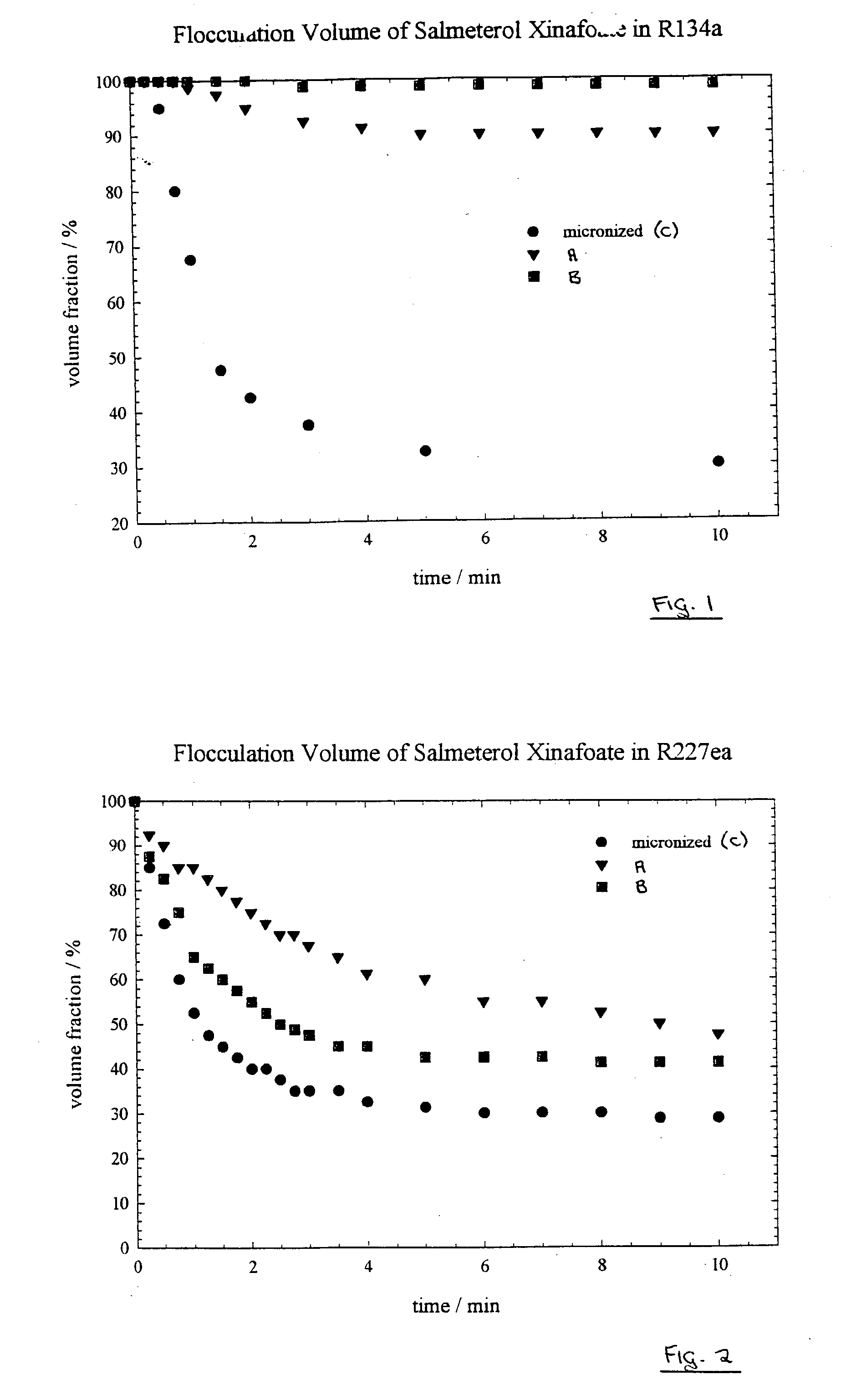

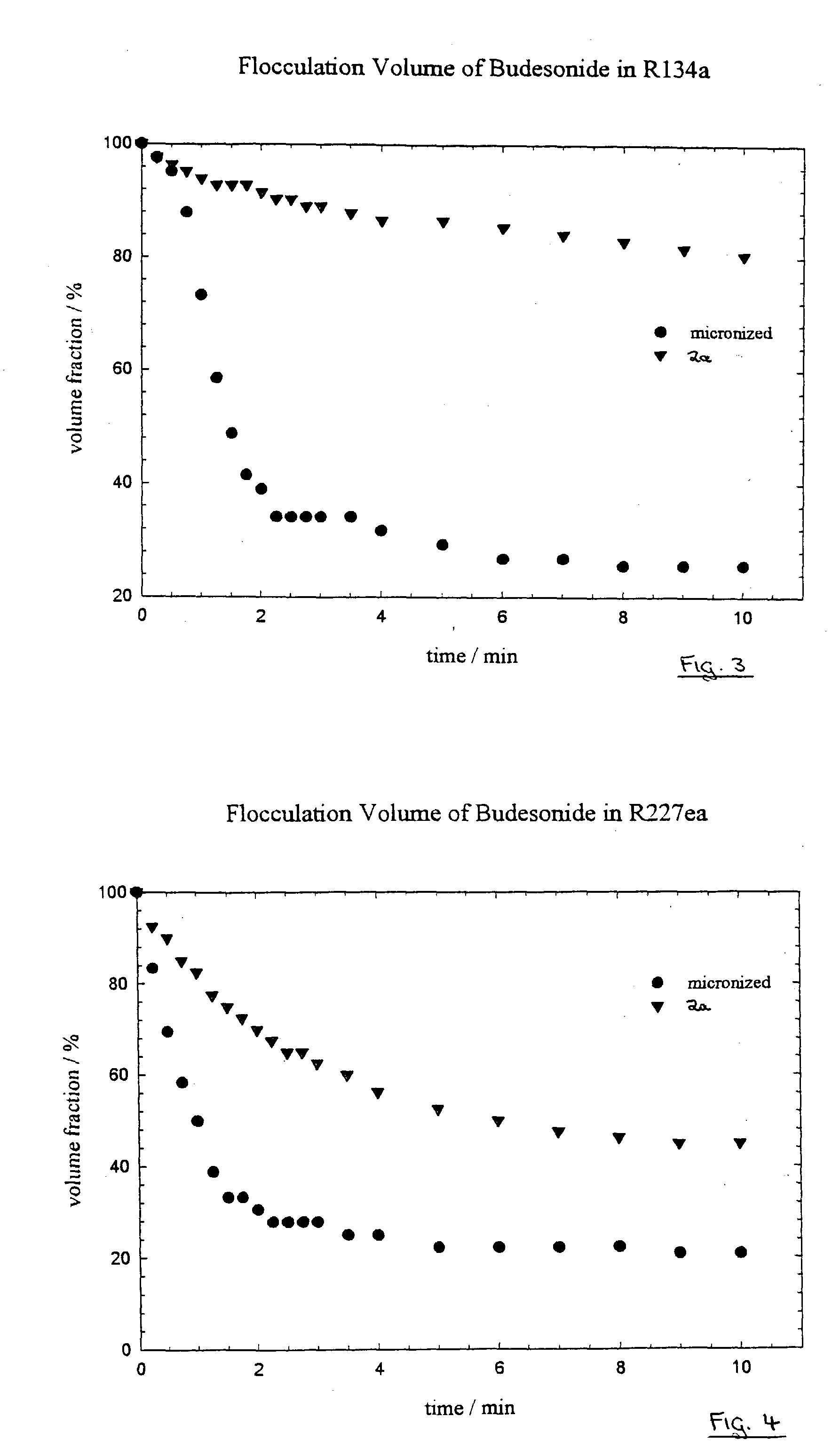

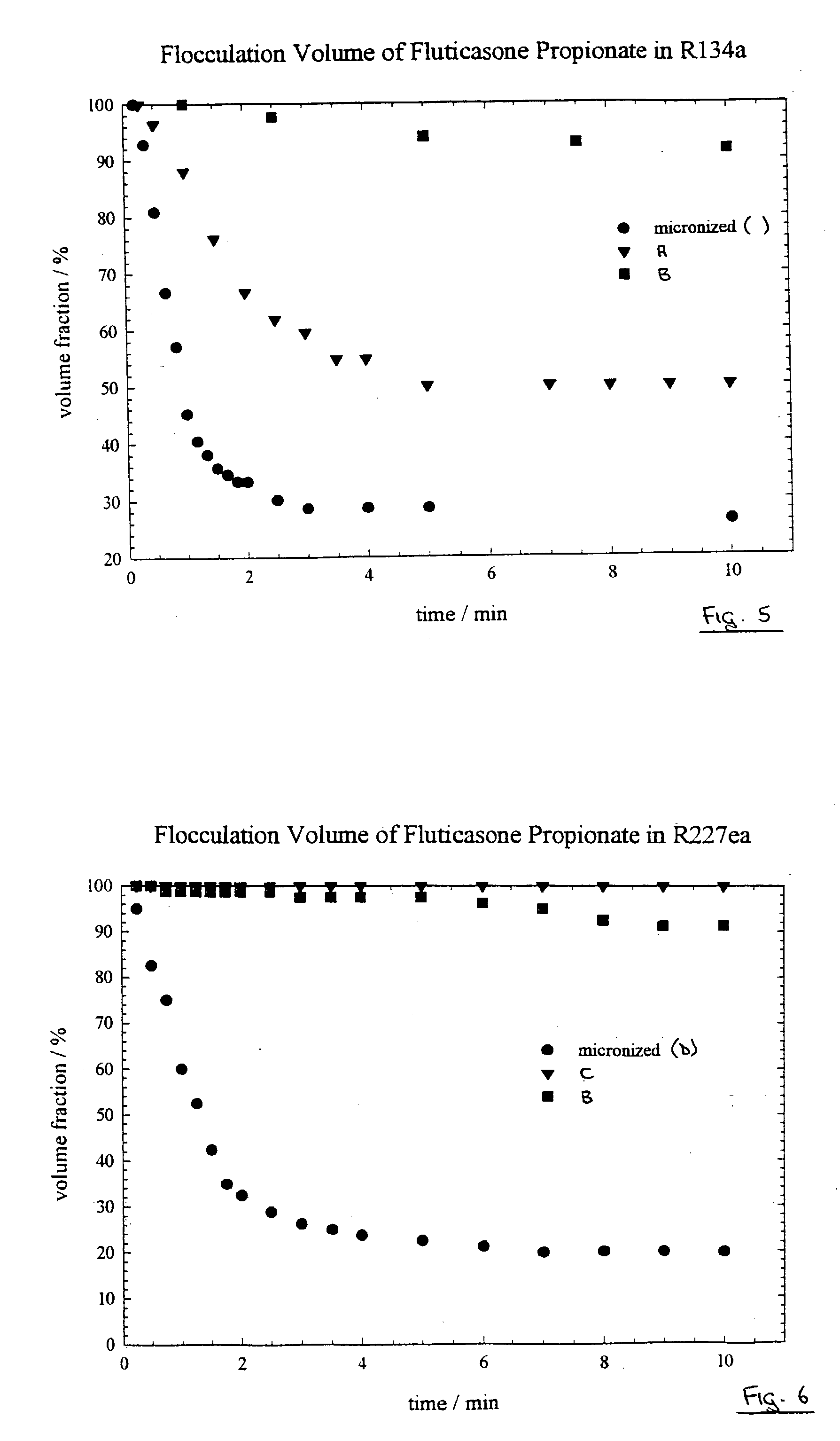

Particulate materials

The present invention relates to active substances in particulate form, to methods for preparing them, to formulations containing them and to uses of such substances and formulations. A preferred embodiment is directed to particulate suspensions having improved flocculation behaviour in a suspension vehicle, such as a hydrofluoroalkane propellant used in metered dose inhalers.

Owner:NEKTAR THERAPEUTICS INC

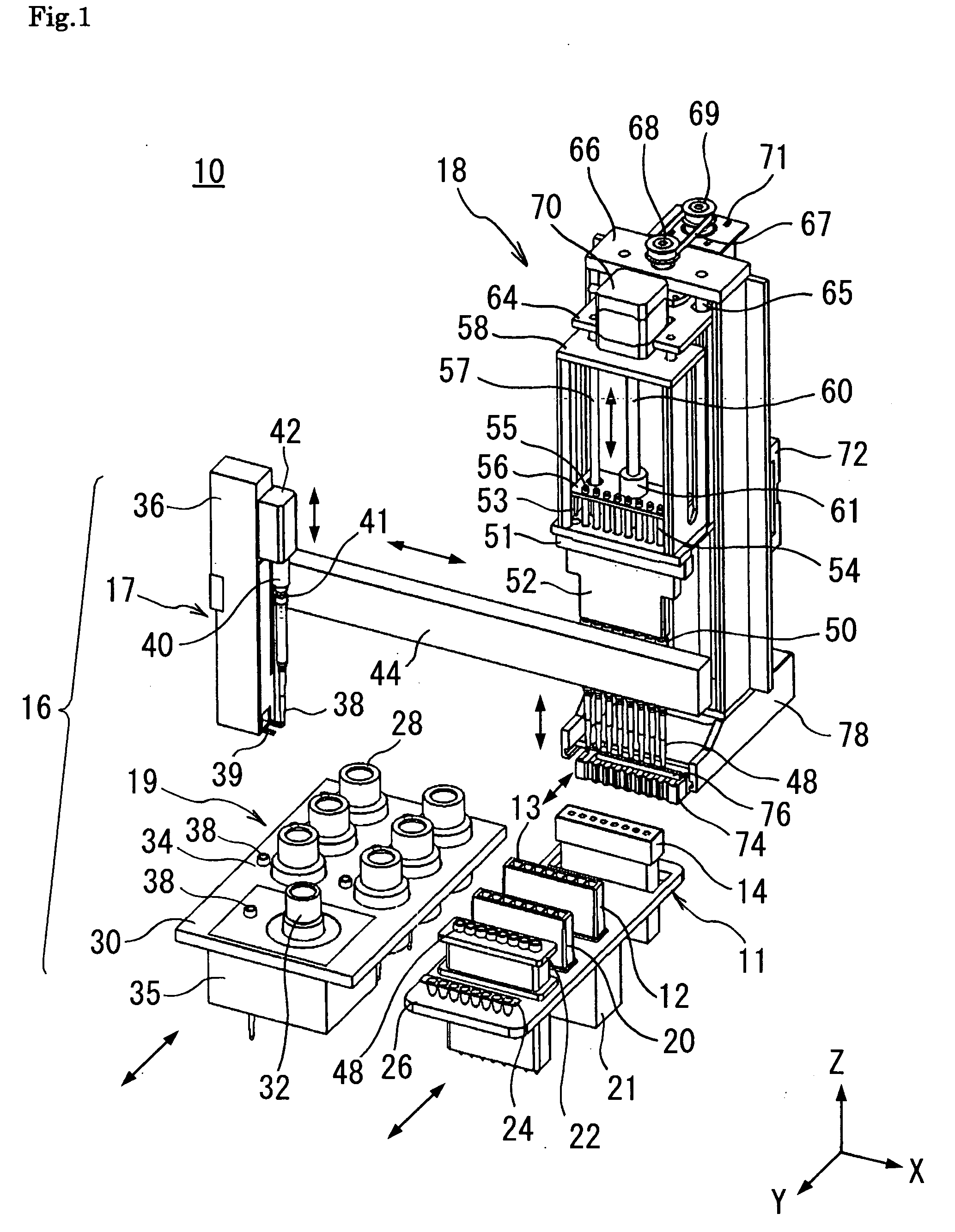

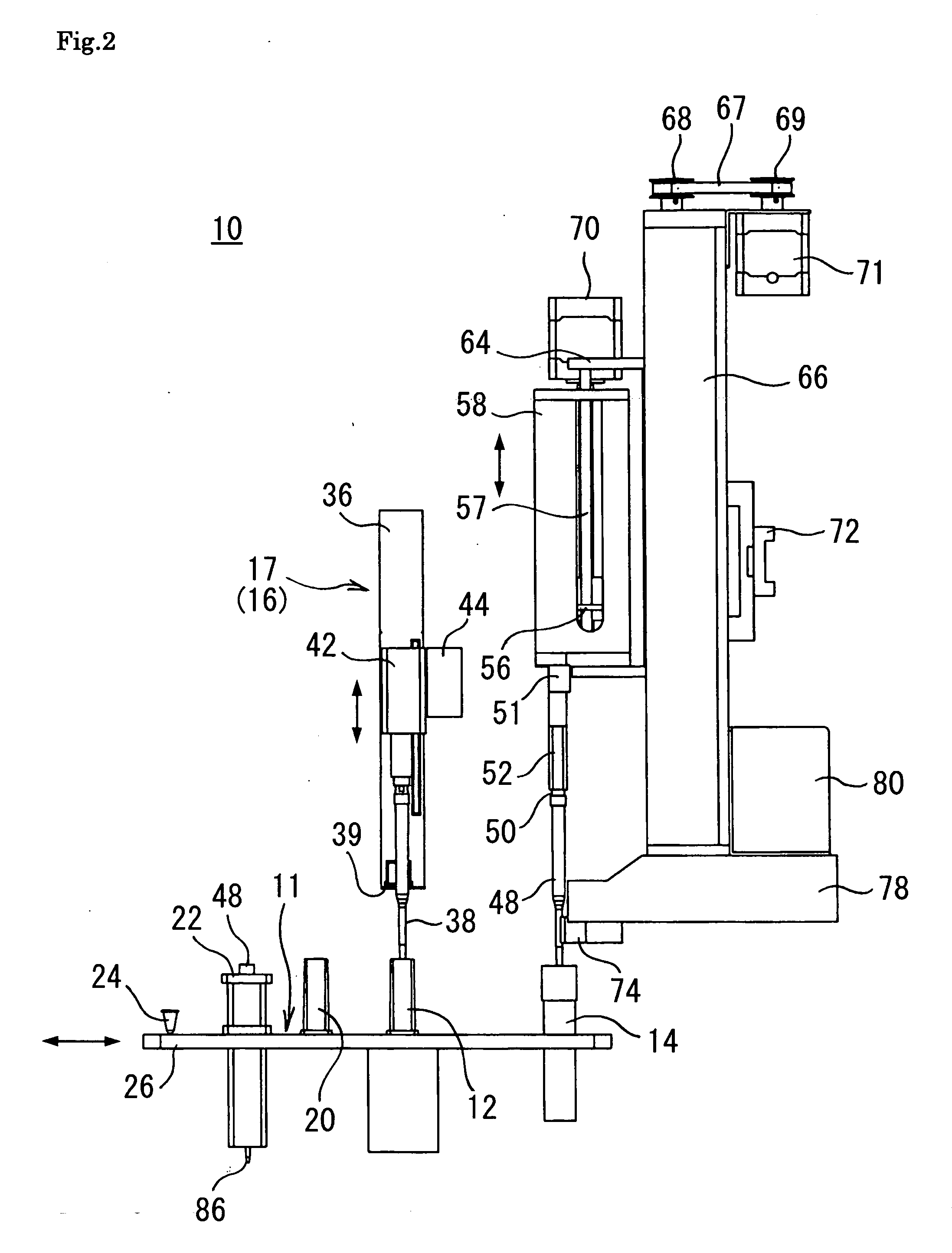

Magnetic particle parallel processing apparatus permitting repeated use of container and method of magnetic particle parallel processing permitting repeated use of container

InactiveUS20100137165A1Easy to handleWorking area can be savedWithdrawing sample devicesWater/sewage treatment by magnetic/electric fieldsEngineeringParallel processing

To provide a magnetic particle parallel processing apparatus permitting repeated use of a container, and a method of magnetic particle parallel processing permitting repeated use of a container, with which the rate of repeated use of a container is enhanced to thereby achieve a saving in the working space and a saving in the working time. The apparatus comprises: at least one reaction container; a liquid disposal tank; a reagent etc. feeder with at least one flow channel for feeding at least one type of liquid selected from the group consisting of two or more types of solutions and a magnetic particle suspension according to the processing content, at a given amount and at a given timing, to the reaction container; and a magnetic separator which has at least one processing nozzle with a distal end insertable into the reaction container and the liquid disposal tank, for sucking and discharging a liquid through the distal end, and which also has a magnetic means capable of applying a magnetic field to the interior of the distal end to thereby attract magnetic particles contained in the liquid inside the distal end to the inner wall thereof to effect separation of the magnetic particles, and canceling the magnetic field to thereby release the attracted magnetic particles and re-suspend the same in a liquid.

Owner:UNIVERSAL BIO RESEARCH CO LTD

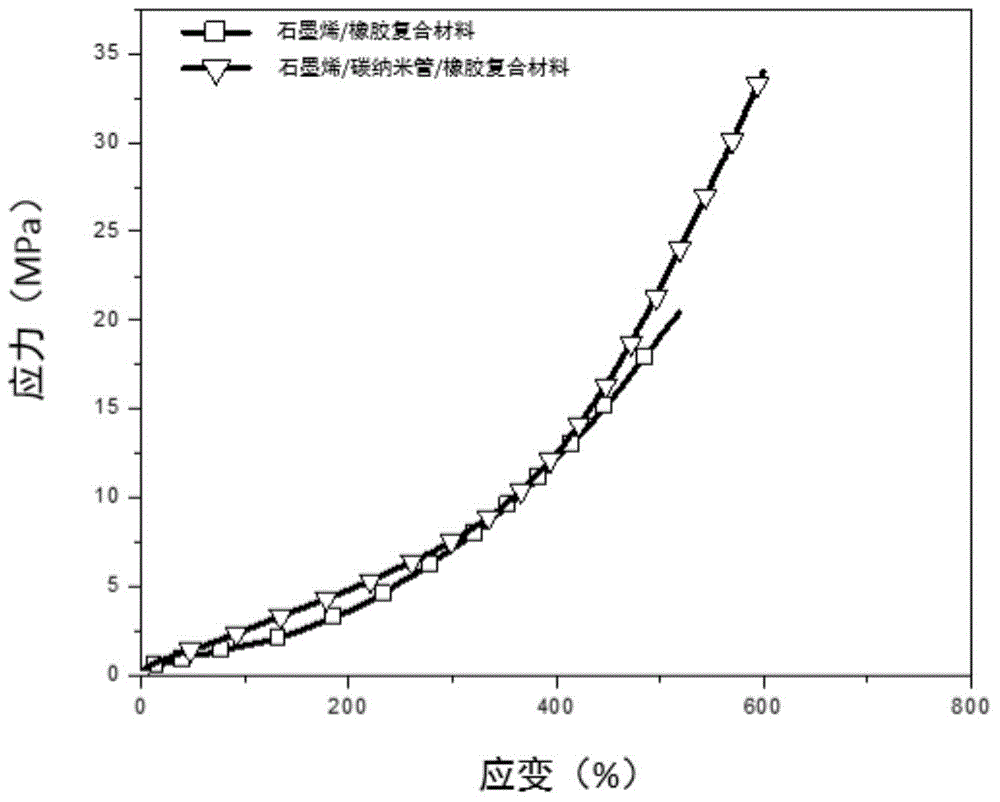

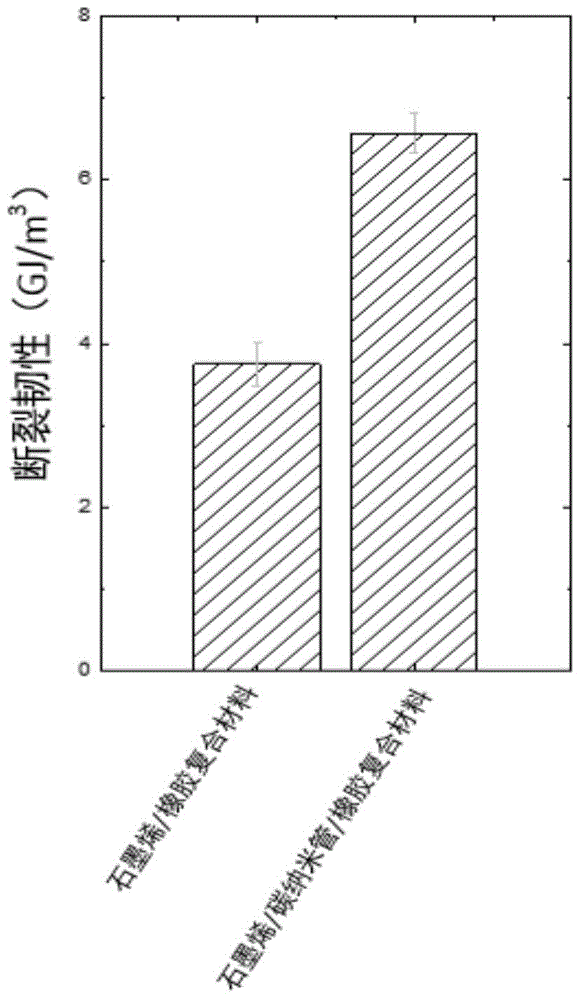

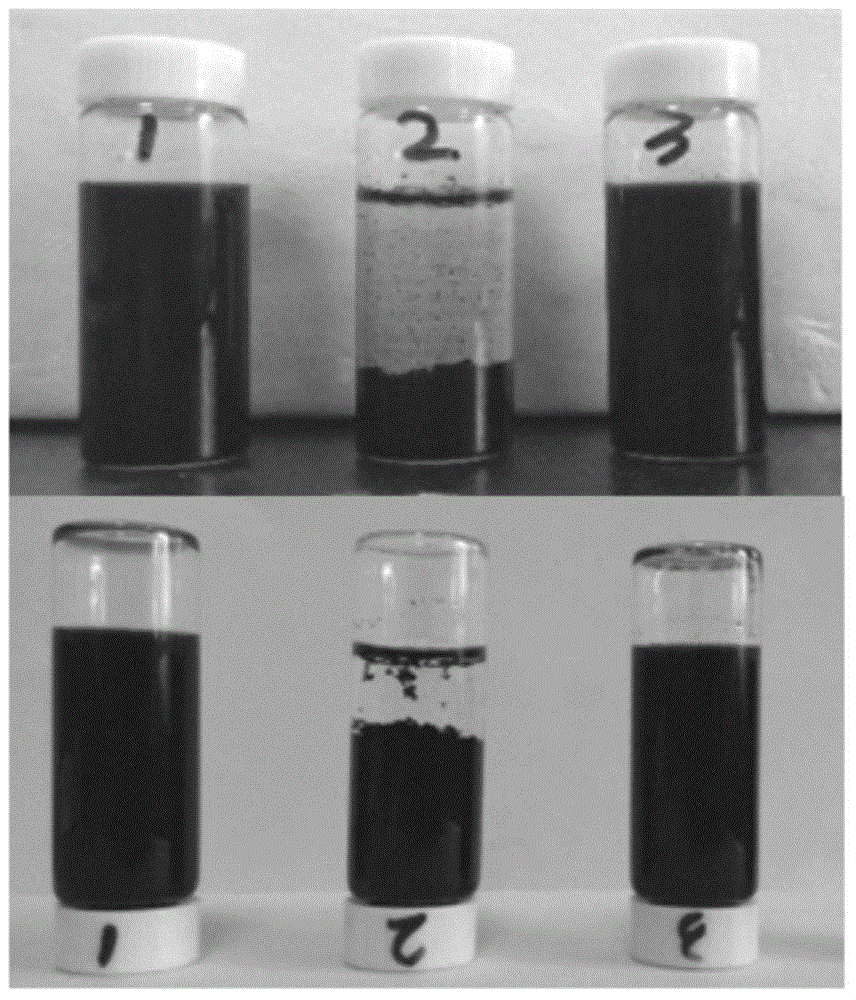

Graphene/carbon nano tube hybridized filler network enhanced rubber material and preparation method thereof

ActiveCN105131359AGood mechanical propertiesImprove fatigue resistanceRubber materialCarbon nanotube

The invention discloses a graphene / carbon nano tube hybridized filler network enhanced rubber material and a preparation method thereof. According to the rubber material, graphene and carbon nano tubes are taken as filler, a hybridized filler network is formed in a rubber material matrix, wherein 100 parts by mass of the rubber material matrix are adopted, and 0.1-20 parts by mass of graphene and the carbon nano tubes are adopted. The rubber material is prepared according to steps as follows: oxidized graphene and the carbon nano tubes are added to water, and a hybridized suspension liquid is prepared; the prepared hybridized suspension liquid is added to an emulsion of the rubber material matrix and mixed, a demulsifier is added for demulsification, an oxidized graphene / carbon nano tube / rubber particle suspension liquid is prepared, then, a reducing agent is added for a reduction reaction, solid-liquid separation is performed after sufficient reaction, an obtained solid phase is washed and dried, and the rubber material is prepared. The graphene and the carbon nano tubes form the hybridized filler network in the rubber material and have an energy dissipation function, so that the rubber material has excellent mechanical property, fatigue resistance, crack growth resistance and conductive property.

Owner:SICHUAN UNIV

Particle suspensions of flocculating polymer powders and powder flocculant polymer blends

Powder blends are described comprising blends of particulate water soluble high molecular weight polymer flocculants. The polymer flocculants can include polyethylene oxide, polyacrylamide, copolymers thereof and combinations thereof. The powder blends allows the use of fine powders while reducing potential air quality and safety issues. The powder blends can be used for waste water purification, fiber dewatering, and the like. The powder blends can be diluted by a water dilution flow prior to entering a waste water stream.

Owner:PSMG

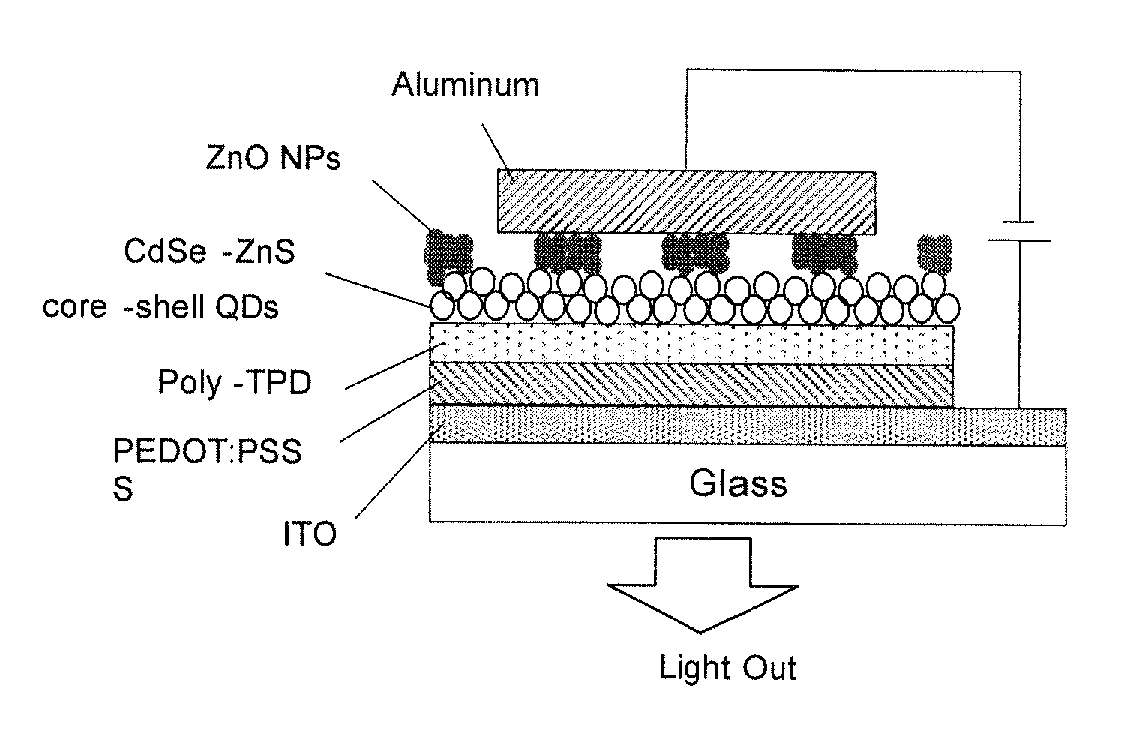

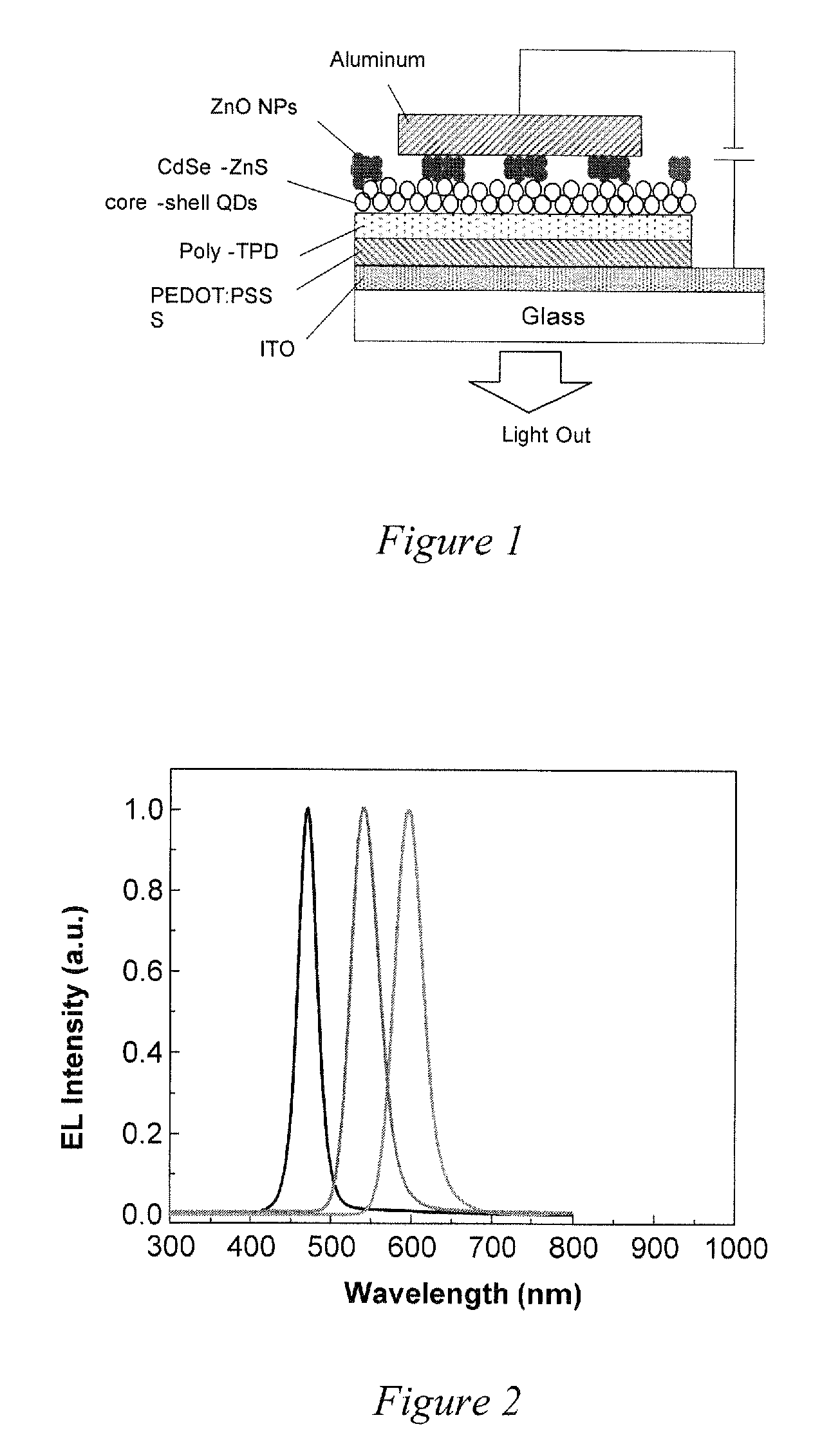

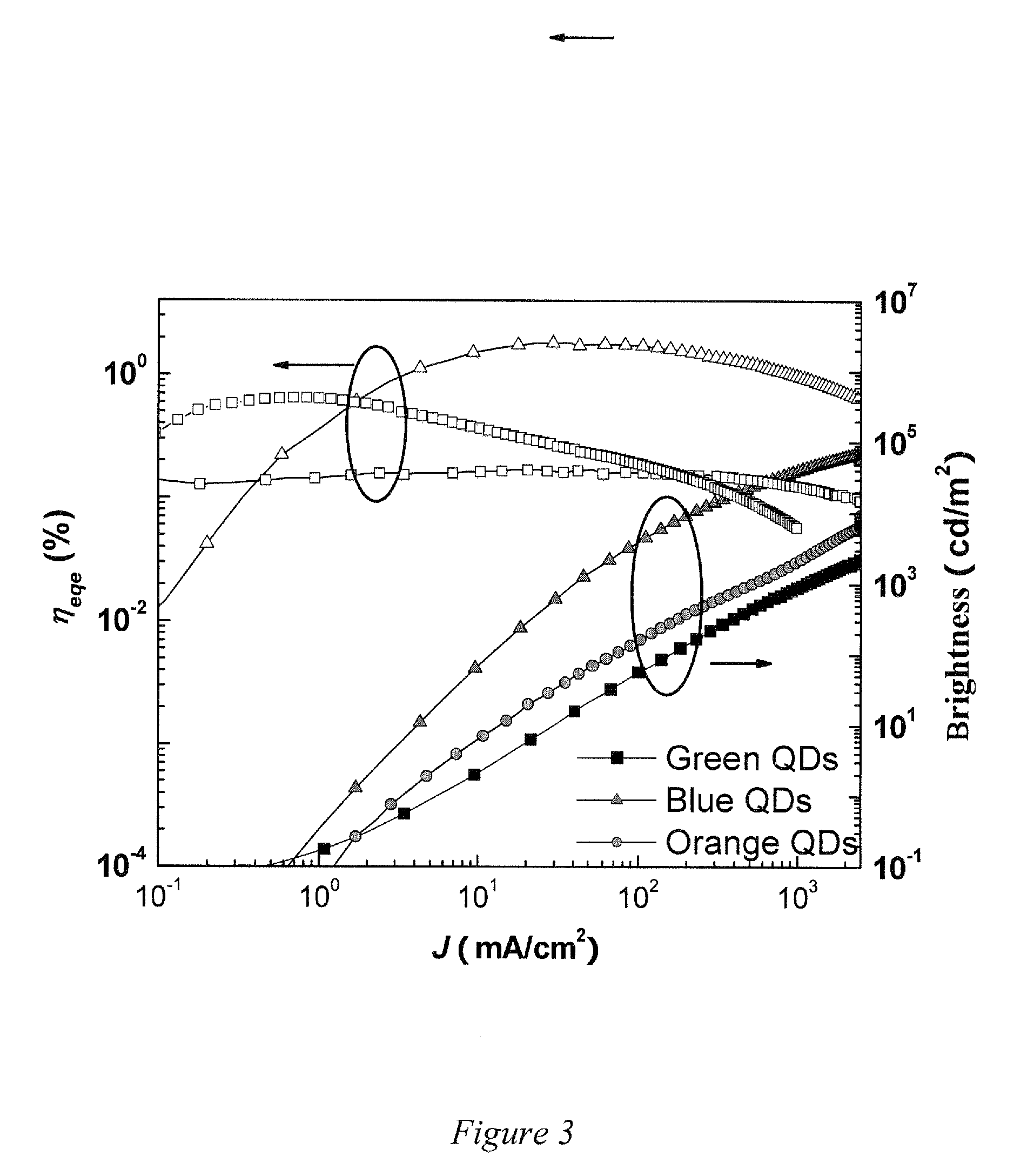

Stable and all solution processable quantum dot light-emitting diodes

InactiveUS9054330B2Electroluminescent light sourcesSolid-state devicesSUSPENDING VEHICLEChemical reaction

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Dispersible concentrate lipospheres for delivery of active agents

A formulation containing one or more lipophilic agents, methods of making and using the formulation are described herein. The formulation is formed by adding a pre-suspension concentrate composition to an aqueous medium. Upon contact with the aqueous medium, a solid nanoparticle suspension spontaneously forms. The resulting formulation is in the form of a microemulsion. The concentrate contains an amphiphilic solvent, a pharmaceutically acceptable solid carrier such as a solid fatty acid or ester, a surfactant, and an agent. Preferably the concentrate contains a combination of a surfactant with a high hydrophilic / lipophilic balance (HLB) of at least about 8 and a surfactant with a low HLB of less than about 5. The agent is preferably a lipophilic drug and other lipophilic ingredient, such as vitamins. The composition is suitable for use in medical and non-medical applications. The microemuslions described herein have increased stability was compared to the prior art.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

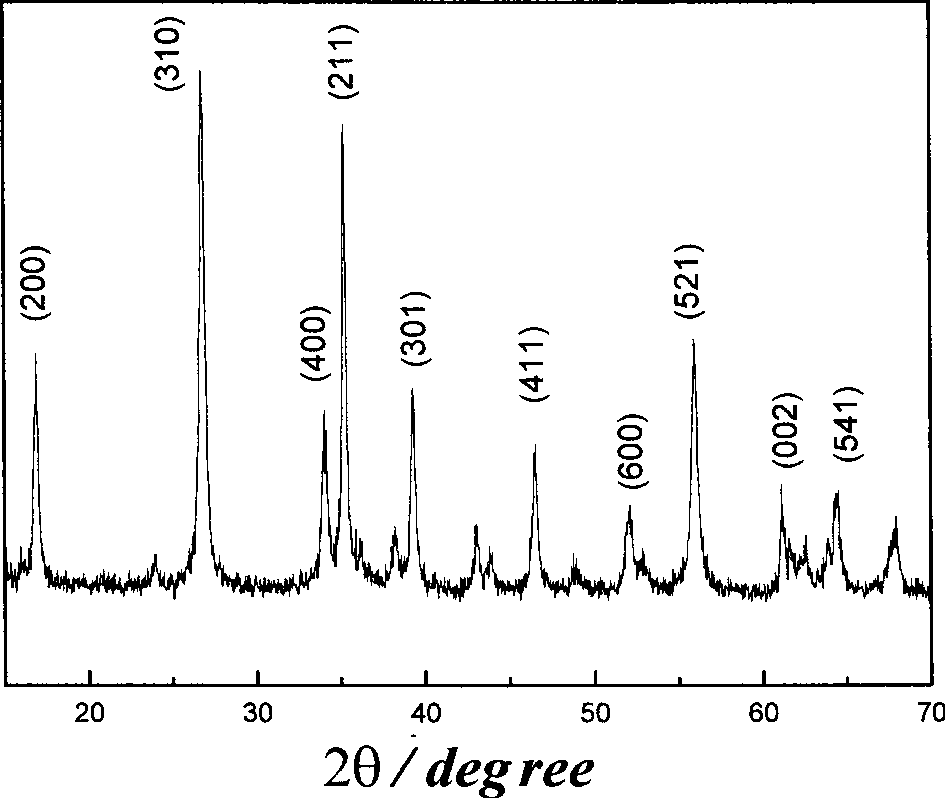

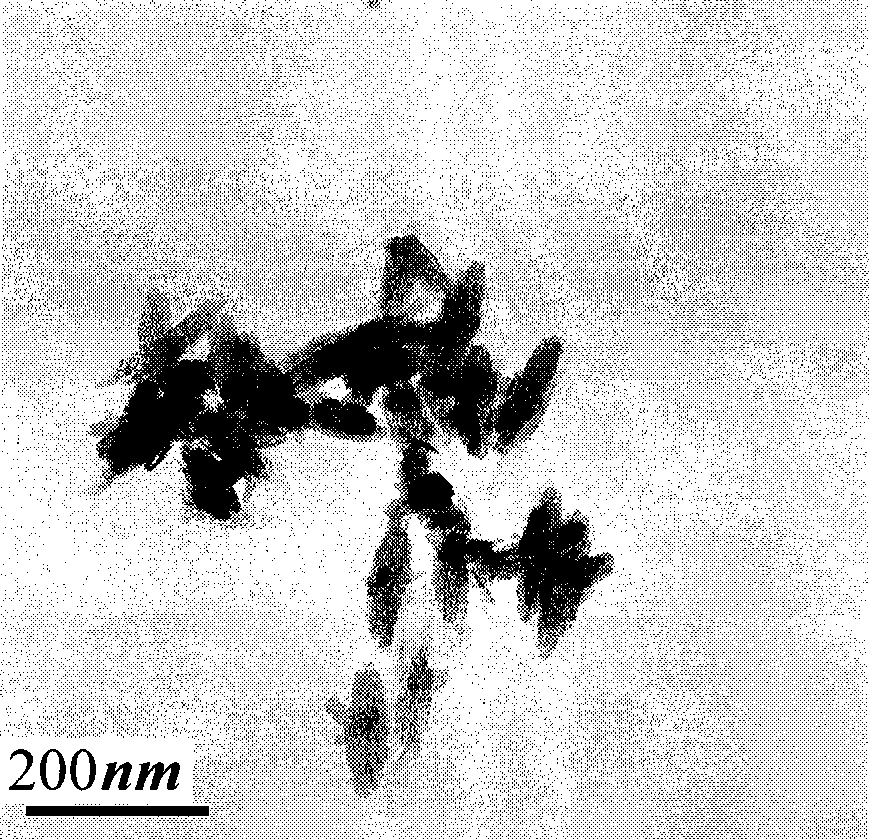

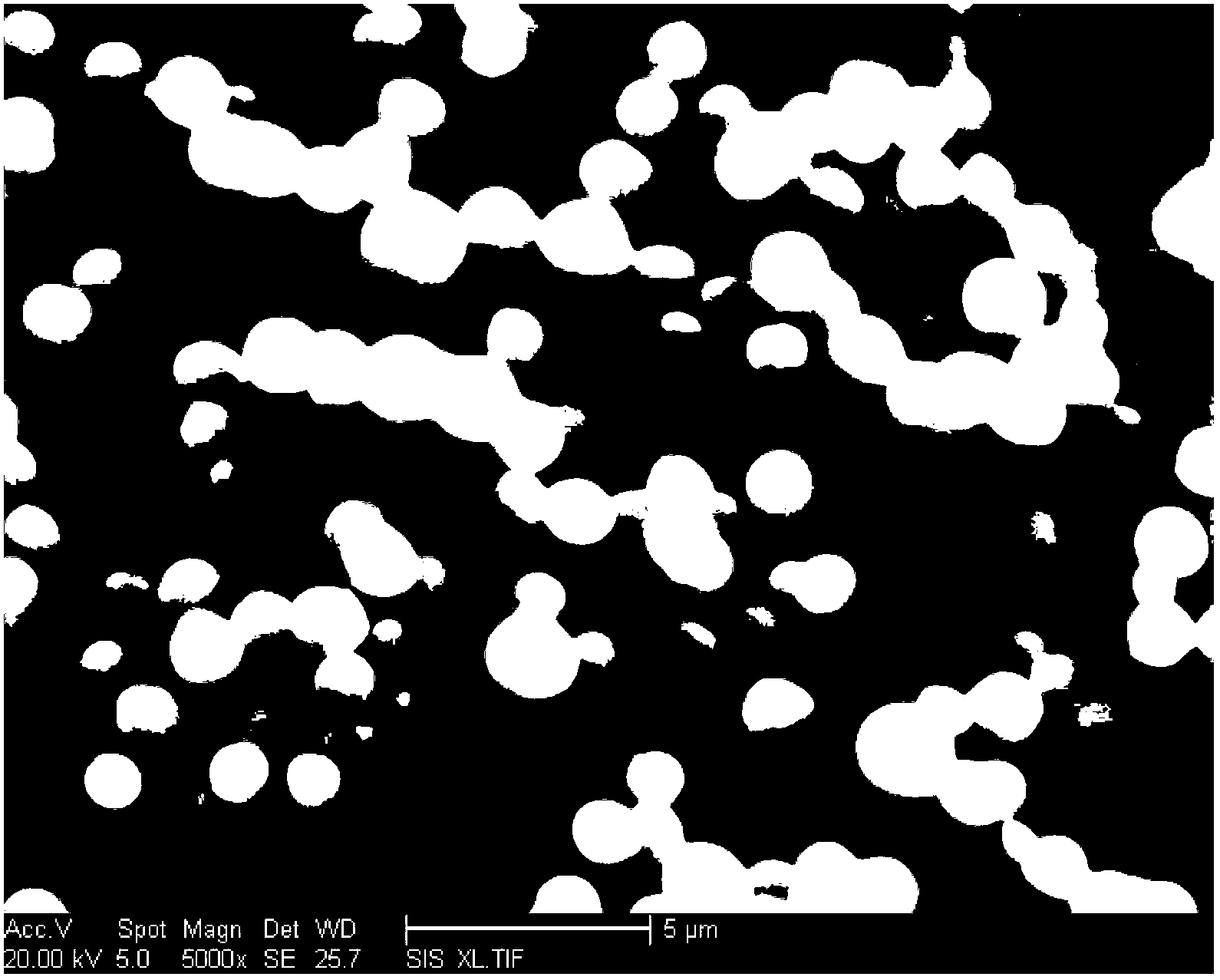

Method for preparing beta-FeOOH nano granule suspension solution

InactiveCN101423256AEvenly dispersedImprove stabilityIron oxides/hydroxidesNanoparticleEnhanced heat transfer

The invention discloses a Beta-FeOOH nanoparticle suspension preparation method, relating to a preparation method of an enhanced heat transfer medium, in particular to a stable Beta-FeOOH nanoparticle suspension. The method comprises the steps as follows: firstly, the aqueous solution of ferric trichloride and urea is prepared, wherein, the mass ratio of the ferric trichloride and the urea is 6:1; and then the aqueous solution is added into an airtight PTFE reactor, reacted at the temperature of 80 plus or minus 2 DEG C till the end, and naturally cooled to room temperature, so that the Beta-FeOOH nanoparticle suspension is obtained. The method adds no stabilizing agent, and the produced Beta-FeOOH is small in size and good in uniformity and stability. The method has the advantages of small number of production equipment, simple operating steps, low cost, and requires no additives except raw materials, thus being suitable for industrial production.

Owner:YANGZHOU UNIV

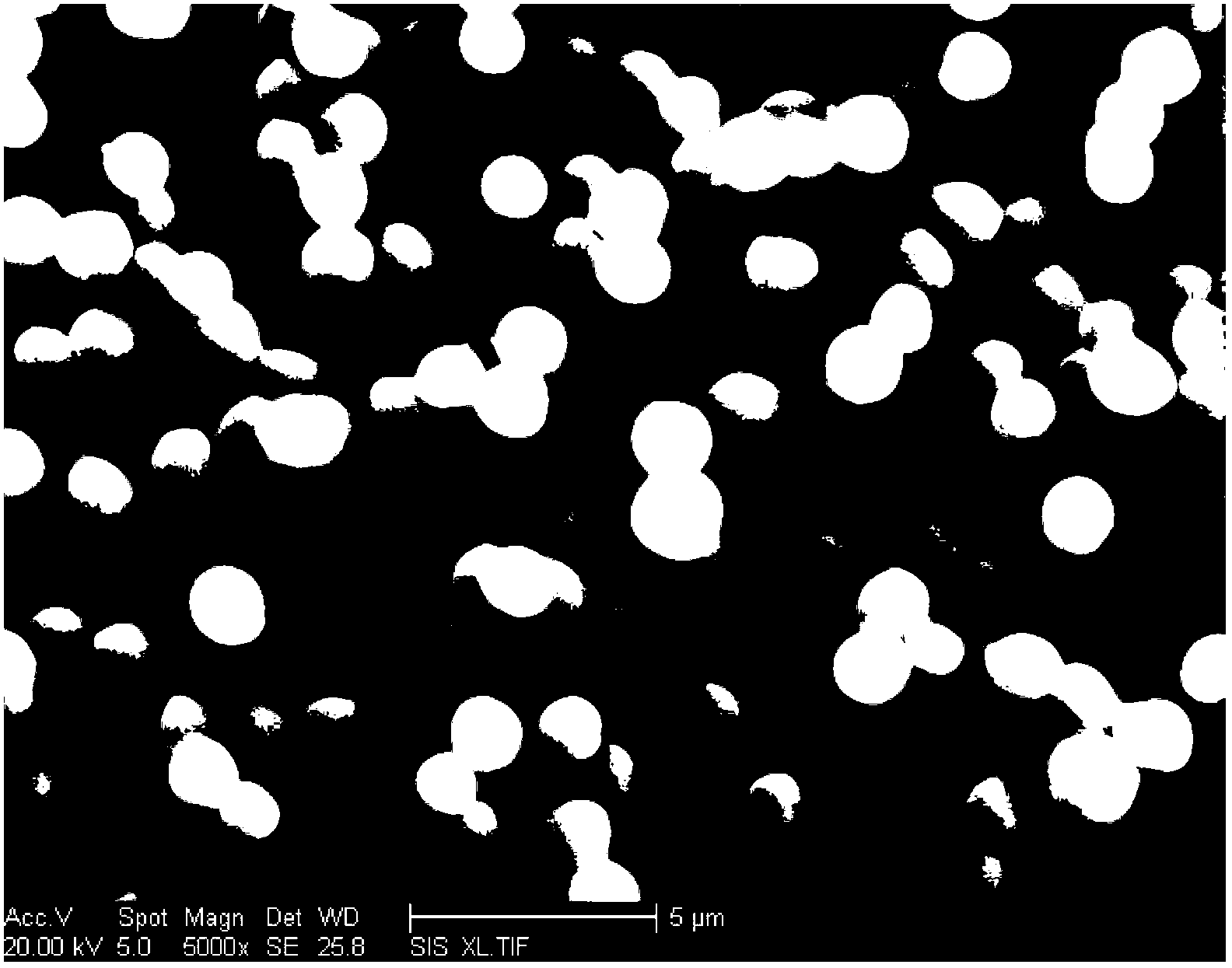

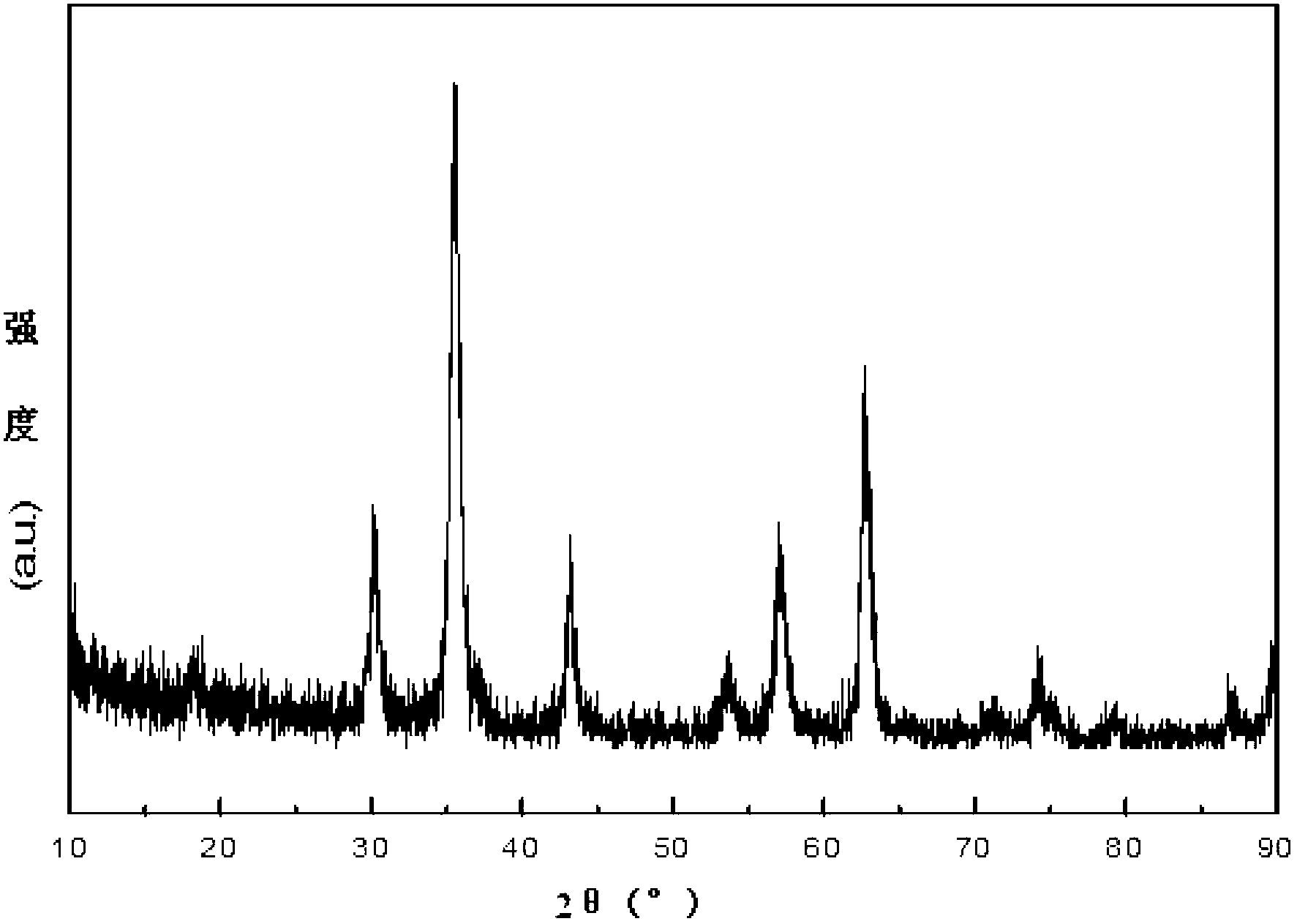

Preparation method of electromagnetic composite hollow microspheres

InactiveCN103157412ANot easy to fall offInhibit sheddingInorganic material magnetismMicroballoon preparationMicrospherePhotonics

The invention provides a preparation method of electromagnetic composite hollow microspheres, relates to a preparation method of a composite hollow material and aims to solve the problems of poor conductivity, high density and high falling possibility of magnetic particles of the existing composite hollow material. The preparation method comprises the following steps: 1, preparing polystyrene microspheres; 2, dispersing the polystyrene microspheres in concentrated sulfuric acid, and sulfonating; 3, preparing a magnetic Fe3O4 nano particle suspension; 4, adding the sulfonic-group-containing SPS microspheres and the Fe3O4 nano particle suspension into a water solution; 5, adding ethanol and ammonia water, and dropwisely adding ethyl orthosilicate; 6, adding into a PVP-containing ethanol solution, and stirring; and 7, mixing an aniline solution with the PVP modified magnetic microspheres, dropwisely adding ammonium persulfate, drying, adding N,N-dimethylformamide, and soaking. For the prepared hollow microspheres, the conductivity is 0.01-1.0 S / cm, the density is low, and the magnetic particles are less prone to fall; and the hollow microspheres are mainly used in the fields of light-weight electromagnetic materials, photonic crystals, wave-absorbing materials and the like.

Owner:HARBIN INST OF TECH

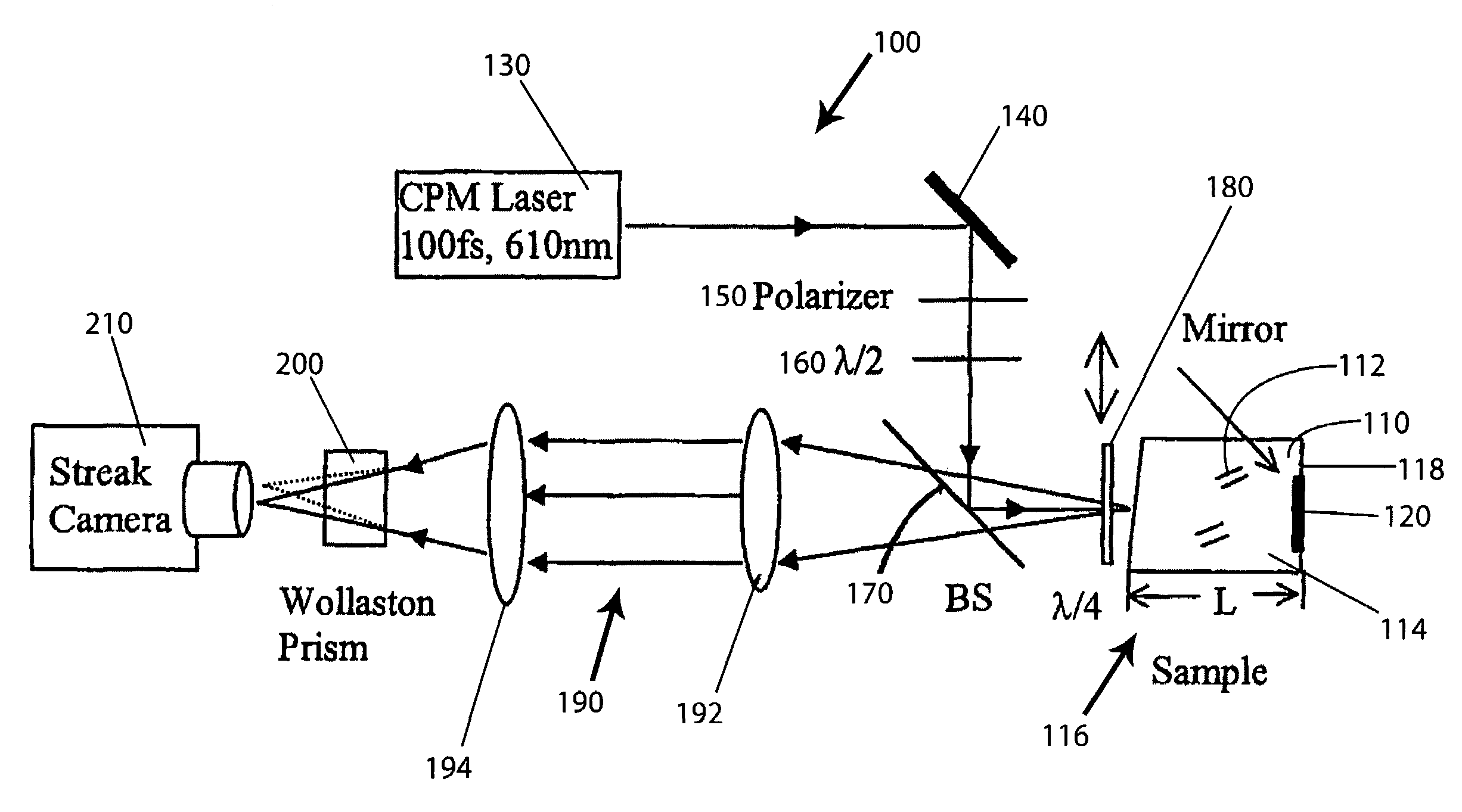

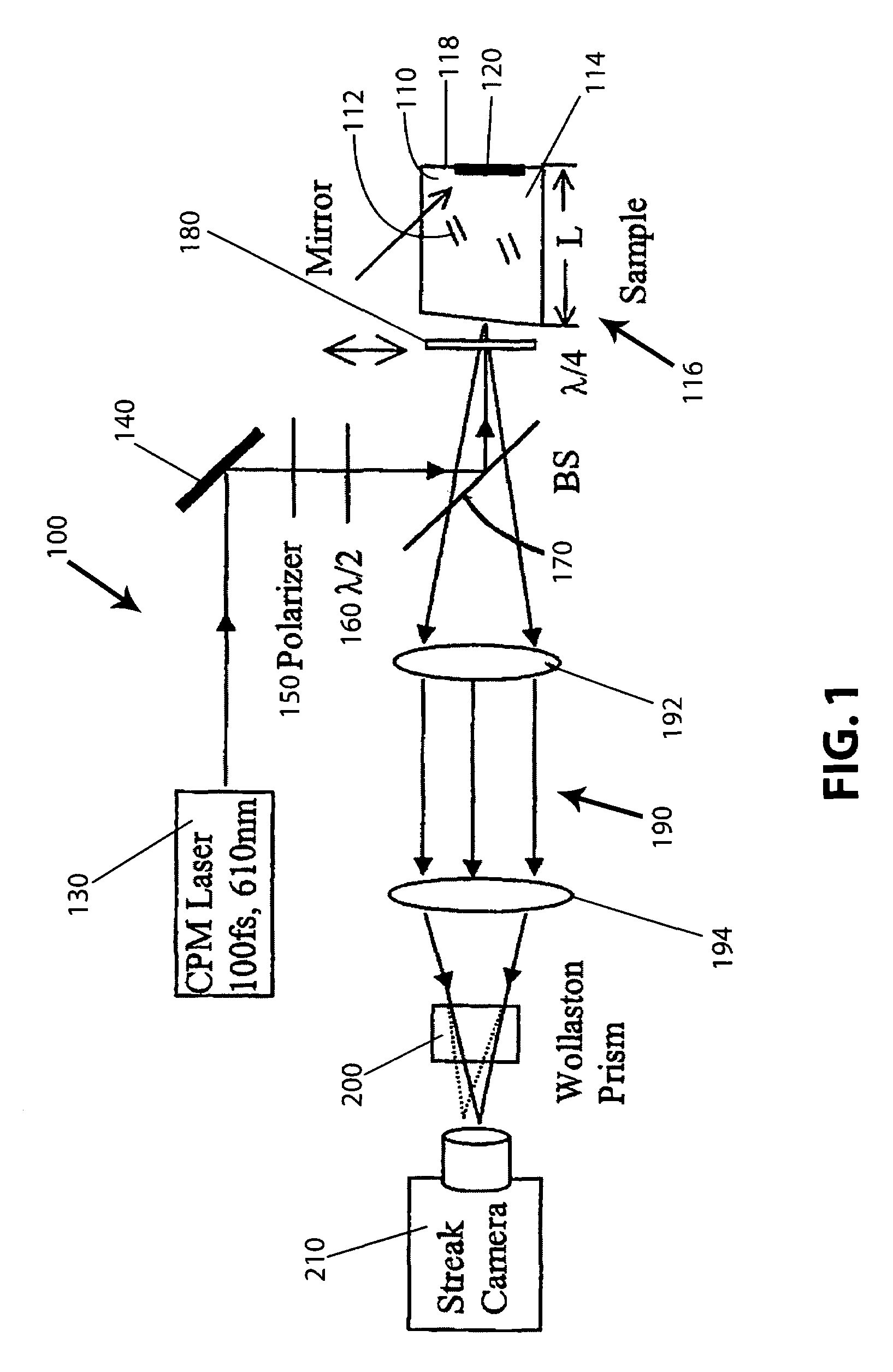

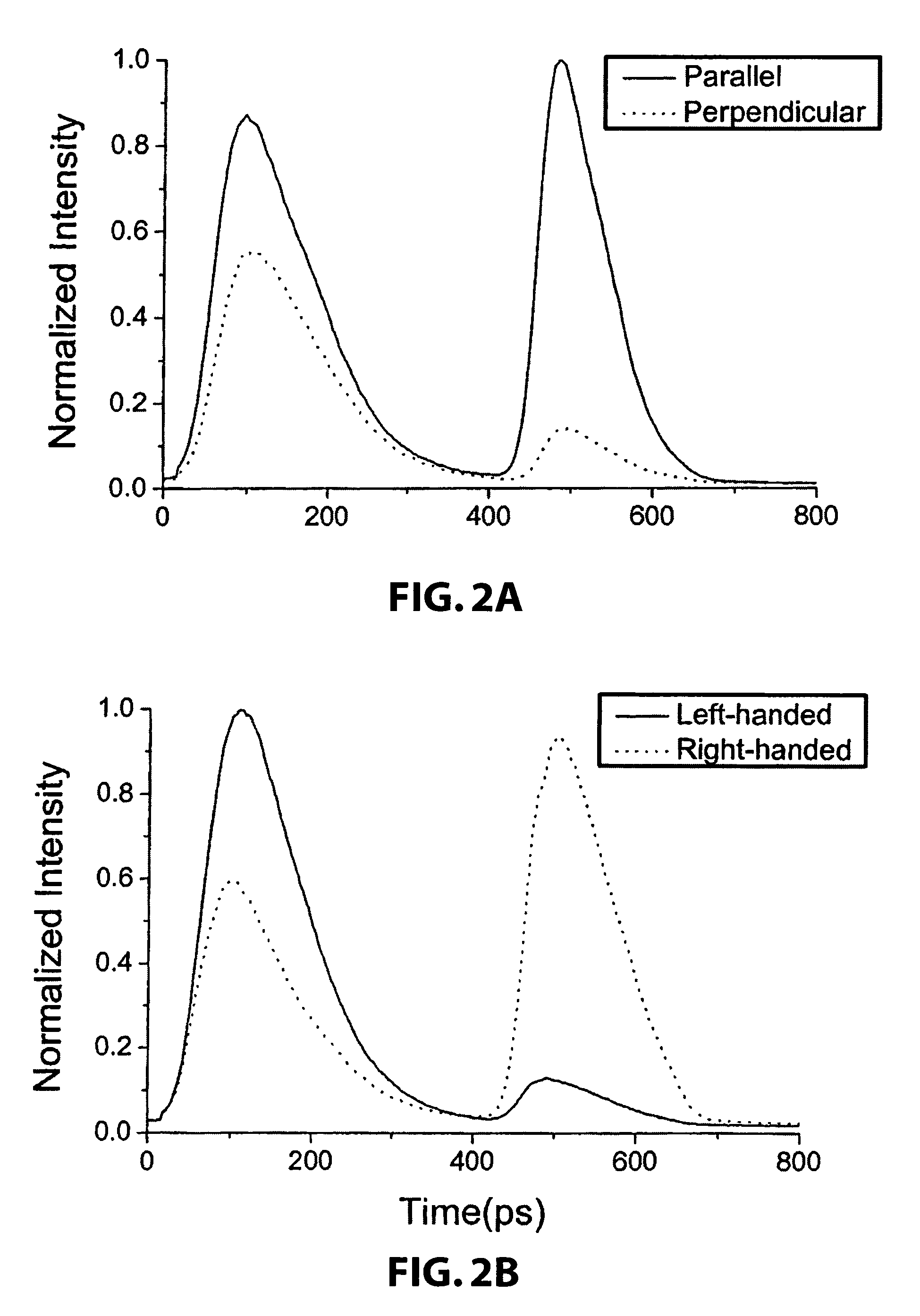

Imaging systems and methods to improve backscattering imaging using circular polarization memory

InactiveUS7515265B2Improve image contrastSamplingPolarisation-affecting propertiesRed blood cellImage contrast

An optical technique to improve the imaging of a target inside suspensions of scattering particles includes the illumination of the scattering particles with circularly polarized light. The backscattered light from the host medium preserves the helicity of incident light, while the backscattered light reflected from the target is predominated with light of opposite helicity. Based on the observed helicity difference in the emerging light that originated at the target and that backscattered from the medium, the present optical technique improves the image contrast using circular polarization. This approach makes use of polarization memory which leads to the reflected light from the target accompanied by weak diffusive backscattered light. Using the present technique, improved imaging of the artery wall is achieved and plaque composition can be assessed through a blood field associated with the artery. The scattering from the particles, such as red blood cells, in the blood is reduced due to polarization memory. The present invention can be also applied to other biomedical application, as well as image targets through adverse environmental conditions, such as fog, clouds, smoke, murky water, etc.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com