Graphene/carbon nano tube hybridized filler network enhanced rubber material and preparation method thereof

A technology of carbon nanotubes and reinforced rubber, which is applied in the field of rubber materials, can solve problems such as high cost, poor dispersion, and obvious agglomeration, and achieve good mechanical properties, increase production costs, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

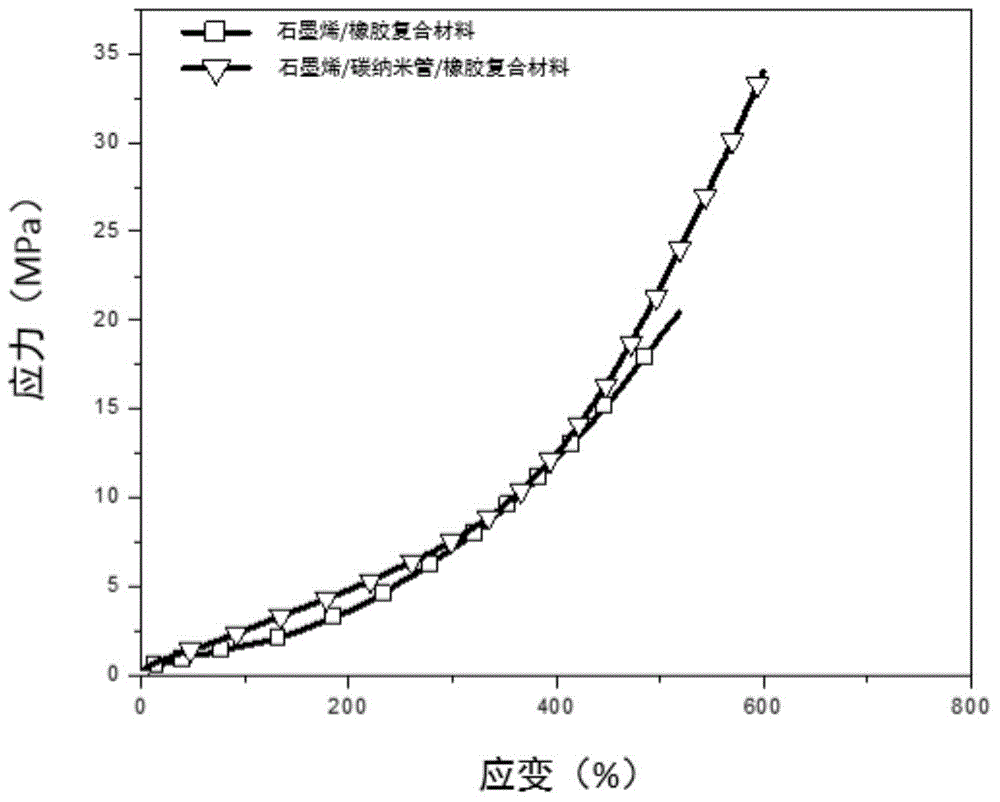

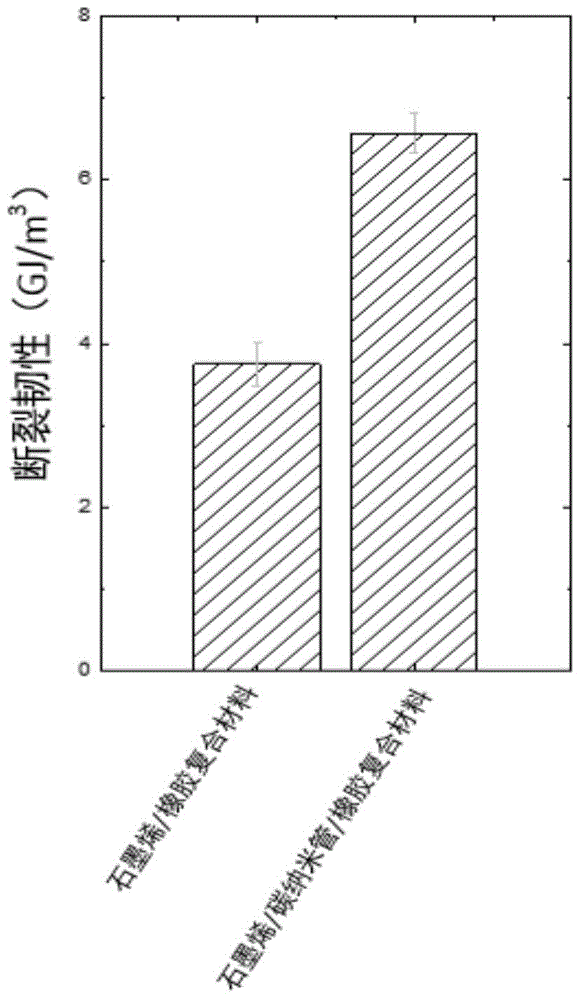

Embodiment 1

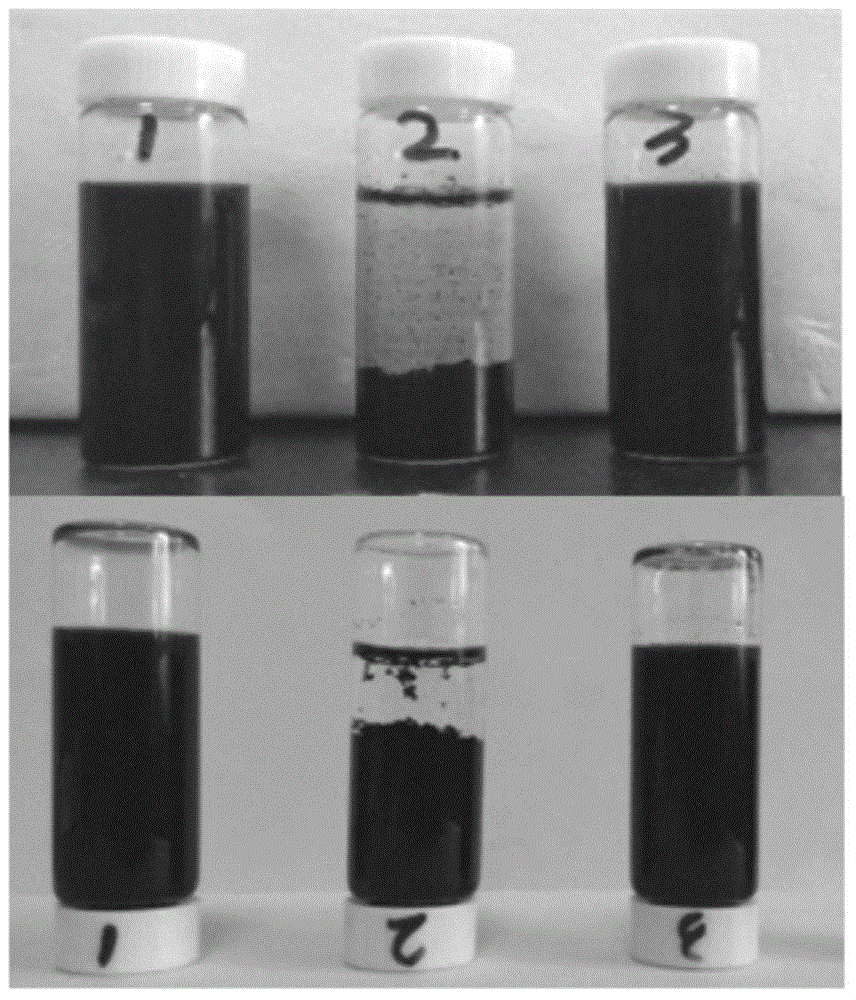

[0028] Add 0.5g of graphene oxide and 1g of multi-walled carbon nanotubes into 100g of water, and disperse ultrasonically for 1 hour to obtain a graphene oxide / carbon nanotube hybrid suspension, and then add the hybrid suspension to 200g of natural In the latex, stir mechanically for 30 minutes, add 50g of sodium chloride solution with a mass concentration of 20%, to obtain a suspension of graphene oxide / carbon nanotubes / natural rubber particles, add 2g of sodium borohydride to reduce graphene oxide, and the reduction time is 24 Hours, the reduction temperature is 50°C. The reduced product was filtered, washed with water 10 times, and dried to a constant weight to obtain a graphene / carbon nanotube / natural rubber nanocomposite material. The composite material is formed by traditional rubber vulcanization method, and the tensile strength of the obtained sheet is 35MPa, the elongation at break is 600%, the fracture toughness is 7GJ, and the tear energy is 1600J / m 2 The crack gro...

Embodiment 2

[0032] Add 1g of graphene oxide and 5g of multi-walled carbon nanotubes into 100g of water, and ultrasonically disperse for 2 hours to obtain a graphene oxide / carbon nanotube hybrid suspension, and then add 1000g of styrene-butadiene with a solid content of 10% to the hybrid suspension In the latex, stir mechanically for 5 hours, add 100g of calcium chloride solution with a mass concentration of 10%, to obtain a suspension of graphene oxide / carbon nanotubes / styrene-butadiene rubber particles, add 5g of hydrazine hydrate to reduce graphene oxide, and the reduction time is 5 hours, the reduction temperature is 100°C. The reduced product was filtered, washed 20 times with water, and dried to a constant weight to obtain a graphene / carbon nanotube / styrene-butadiene rubber nanocomposite material. The composite material is formed by the traditional rubber vulcanization method, and the energy dissipation capacity of the sheet stretched to 400% strain is 12MJ / m 3 , Fracture toughness ...

Embodiment 3

[0036] Add 2.5g of graphene oxide and 5g of multi-walled carbon nanotubes into 100g of water, and ultrasonically disperse for 2 hours to obtain a graphene oxide / carbon nanotube hybrid suspension, and then add the hybrid suspension to 100g of polycarbonate with a solid content of 50%. In the ethyl acrylate emulsion, mechanically stirred for 10 minutes, adding 10 g of aluminum chloride solution with a mass concentration of 20%, to obtain a suspension of graphene oxide / carbon nanotubes / polyethyl acrylate particles, adding 20 g of vitamin C to reduce graphene oxide, The reduction time is 24 hours, and the reduction temperature is 50°C. The reduced product was filtered, washed with water for 5 times, and dried to a constant weight to obtain a graphene / carbon nanotube / polyethylacrylate nanocomposite material. The composite material is molded by traditional rubber vulcanization method, and the conductivity of the prepared sheet is 10S / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com