Patents

Literature

50 results about "Filler network" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene/carbon nano tube hybridized filler network enhanced rubber material and preparation method thereof

ActiveCN105131359AGood mechanical propertiesImprove fatigue resistanceRubber materialCarbon nanotube

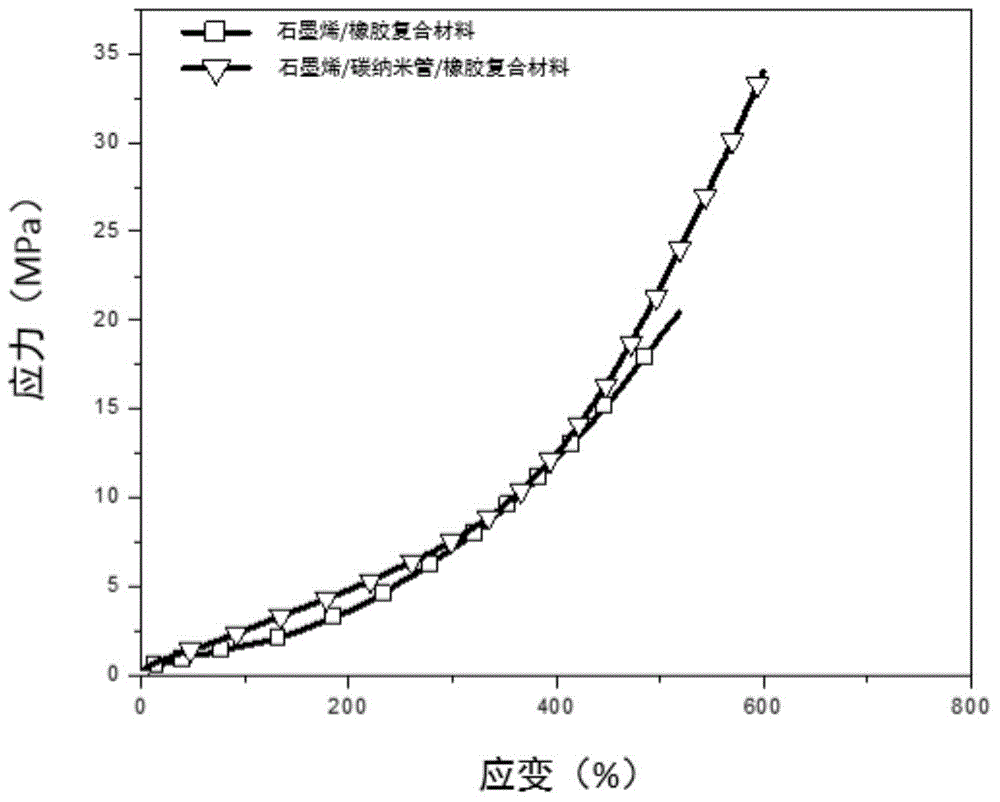

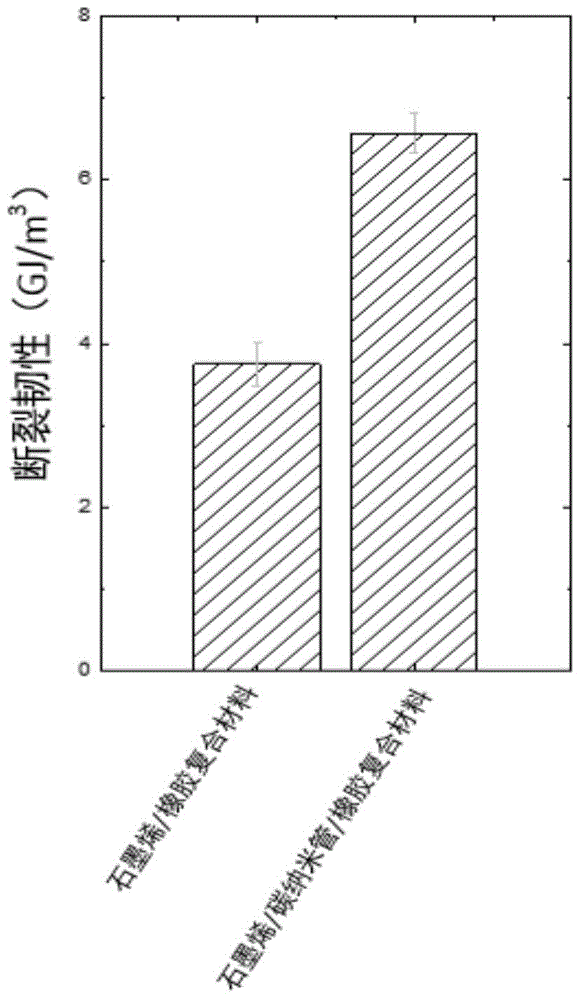

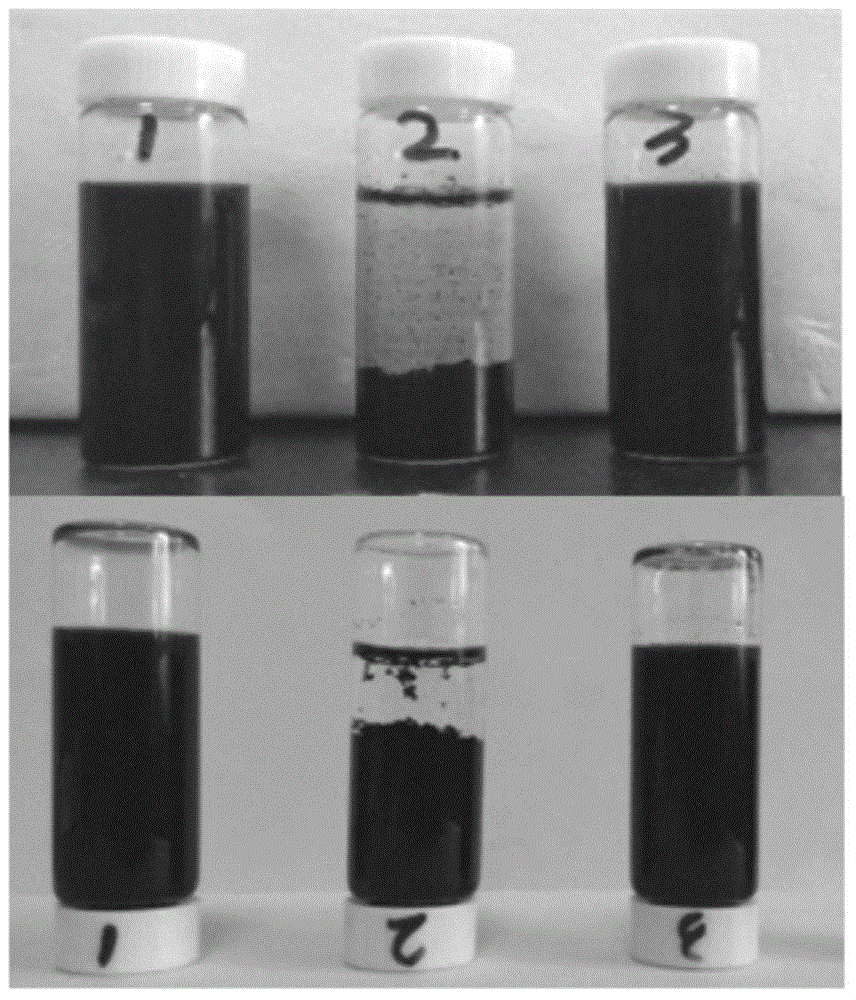

The invention discloses a graphene / carbon nano tube hybridized filler network enhanced rubber material and a preparation method thereof. According to the rubber material, graphene and carbon nano tubes are taken as filler, a hybridized filler network is formed in a rubber material matrix, wherein 100 parts by mass of the rubber material matrix are adopted, and 0.1-20 parts by mass of graphene and the carbon nano tubes are adopted. The rubber material is prepared according to steps as follows: oxidized graphene and the carbon nano tubes are added to water, and a hybridized suspension liquid is prepared; the prepared hybridized suspension liquid is added to an emulsion of the rubber material matrix and mixed, a demulsifier is added for demulsification, an oxidized graphene / carbon nano tube / rubber particle suspension liquid is prepared, then, a reducing agent is added for a reduction reaction, solid-liquid separation is performed after sufficient reaction, an obtained solid phase is washed and dried, and the rubber material is prepared. The graphene and the carbon nano tubes form the hybridized filler network in the rubber material and have an energy dissipation function, so that the rubber material has excellent mechanical property, fatigue resistance, crack growth resistance and conductive property.

Owner:SICHUAN UNIV

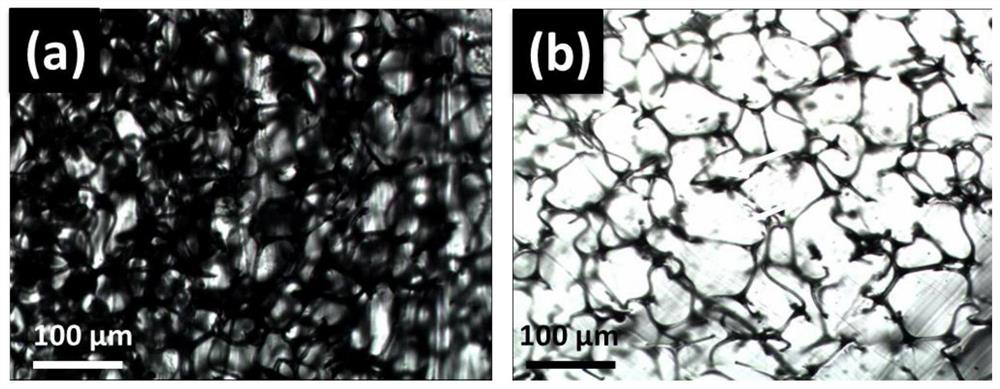

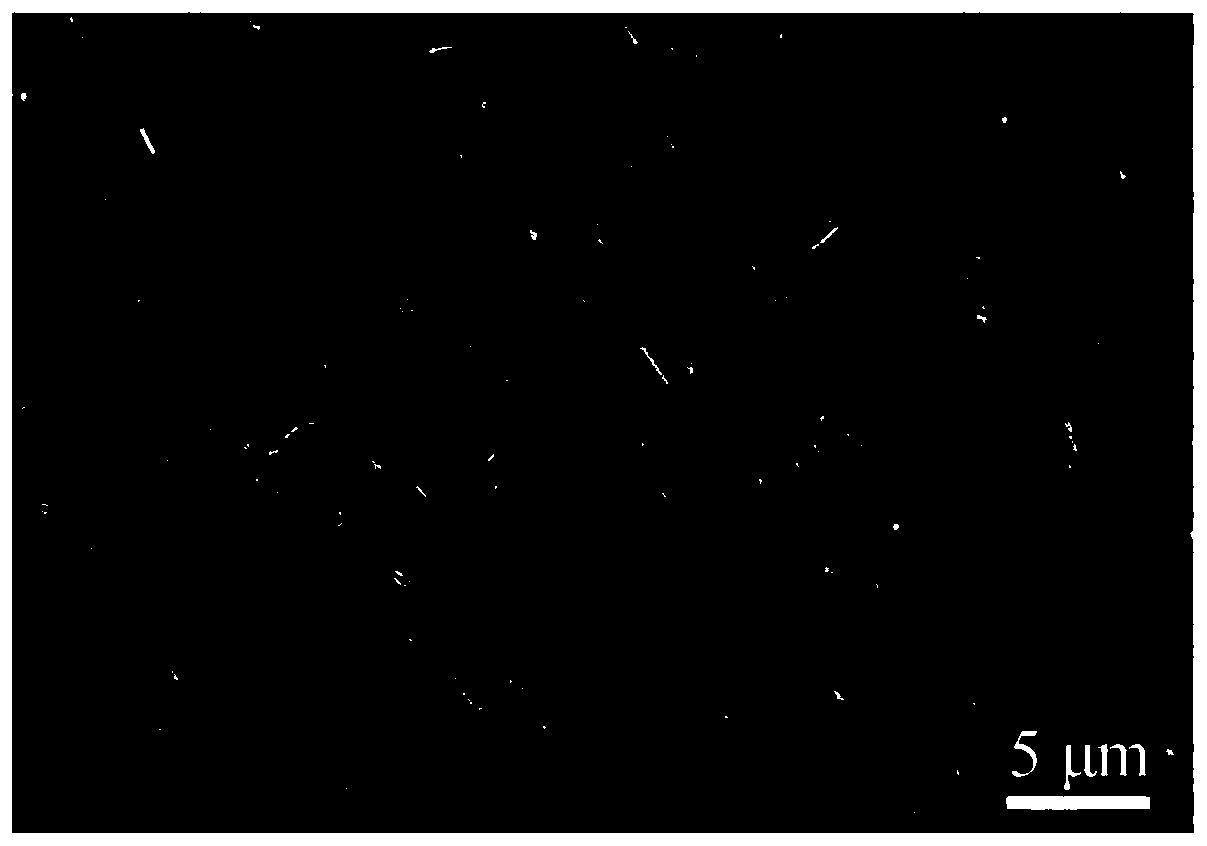

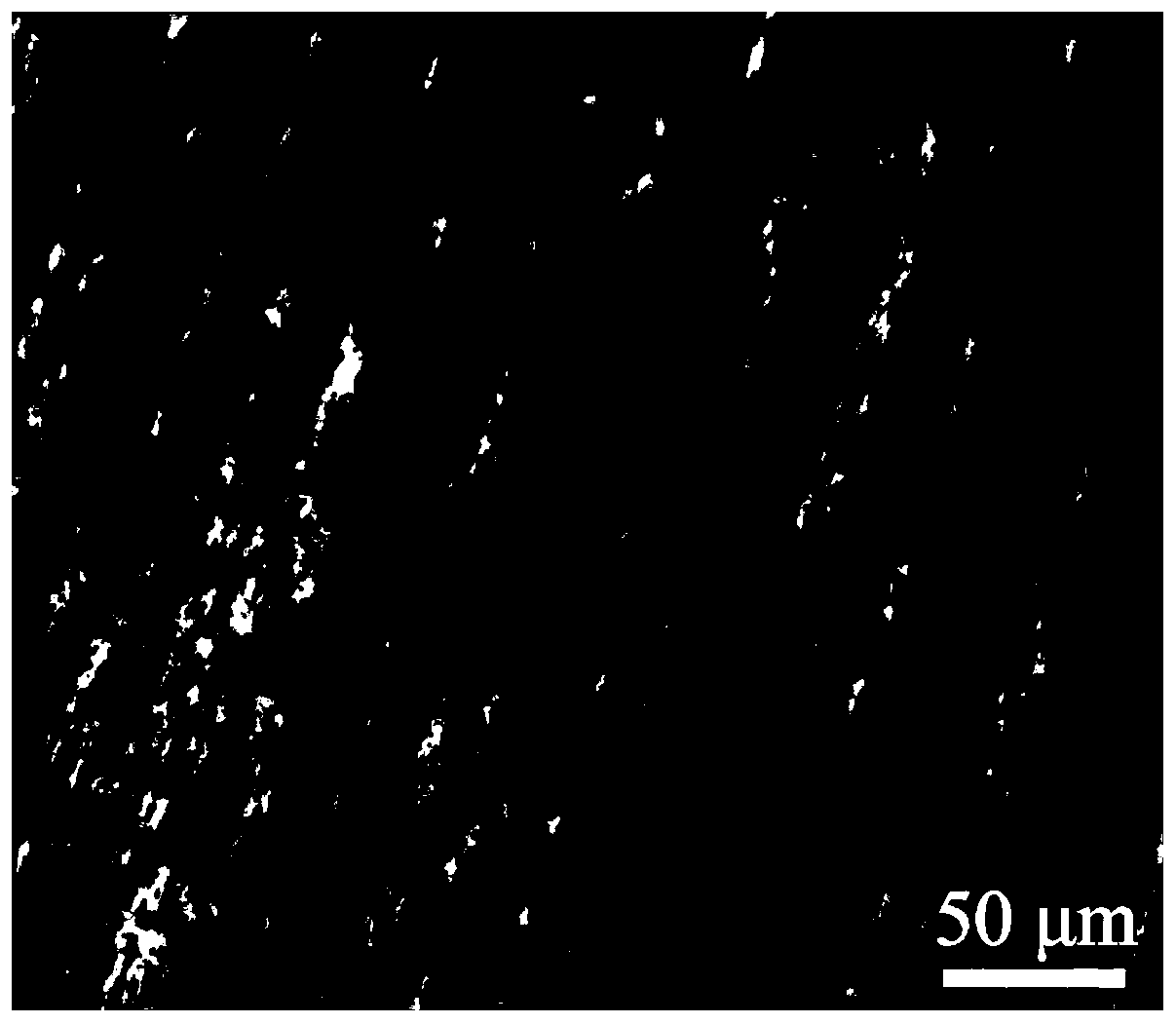

Visual fluorescence labeling technology of silicone rubber filler network structure

InactiveCN106525786AAchieve fluorescent labelingRealize visualizationFluorescence/phosphorescencePolymer scienceFluorescence

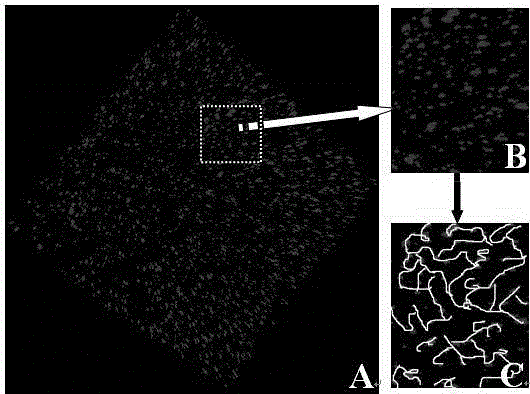

The invention relates to fluorescence labeling of a silicone rubber filler network, and a visual fluorescence labeling technology thereof. The technology comprises the following steps: first taking homemade rare earth doped silicon dioxide fluorescent powder as the filler by use of an applied patented method of the research group, preparing a silicon rubber composite material with a fluorescence function by use of banburying, vulcanizing and other rubber composite material processing technologies, thereby realizing the fluorescence labeling of the silicon rubber filler network; rapidly scanning the silicon rubber composite material with the fluorescence function point by point, line by line and face by face by use of a laser scanning confocal microscope testing technology to obtain continuous optical sections, and then acquiring a real three-dimensional structure of the silicon rubber filler network by use of a three-dimensional reconstruction computer image processing technology. The visualization of the silicone rubber filler network is realized so as to simply, conveniently, directly and veritably observe the filler network structure and the change process thereof; the technology lays the foundation for developing the research on the structure change and the mechanical property relation of the silicon rubber filler network, and revealing the distortion, damage, reconstruction and the like structure evolution processes of the silicon rubber filler network and the action mechanism of the structure evolution processes to the mechanical property.

Owner:SOUTHWEAT UNIV OF SCI & TECH

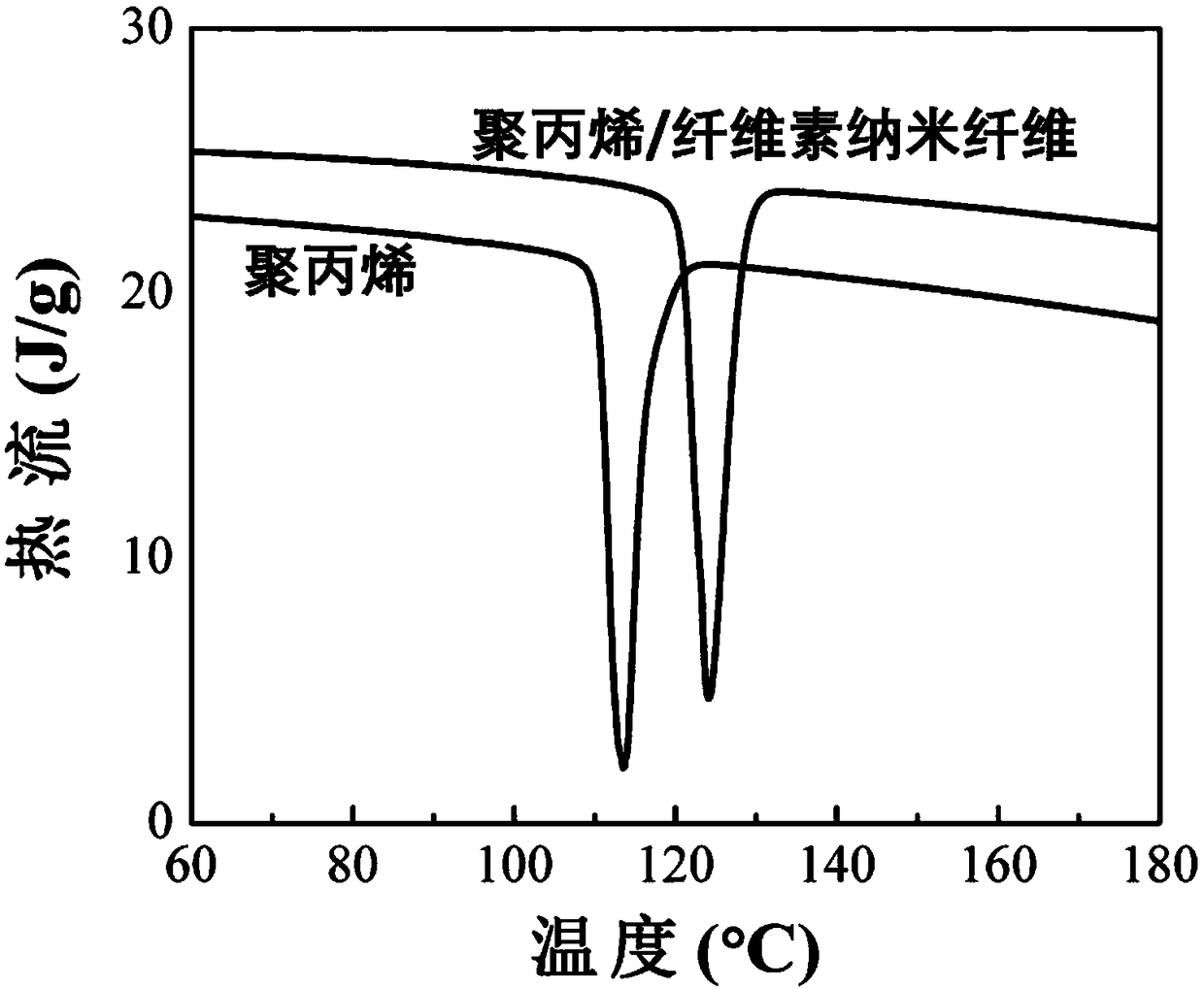

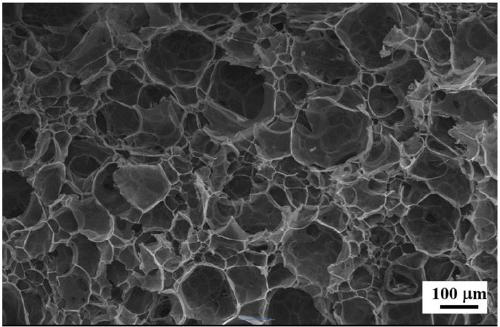

Nano cellulose reinforced polypropylene foam material and preparation method thereof

The invention discloses a nano cellulose reinforced polypropylene foam material and a preparation method thereof. The nano cellulose reinforced polypropylene foam material is prepared from, by weight,88-97.8 parts of polypropylene, 2-10 parts of cellulose, 0.2-2 parts of a compatibilizer and supercritical fluid 1-10% of the weight of polypropylene. By adoption of maleic anhydride grafted polypropylene as the compatibilizer for improving an interface of polypropylene and nano cellulose, high strength and high modulus of a composite material are achieved; further, the nano cellulose forms a filler network in polypropylene to improve polypropylene melt strength and can also serve as a polypropylene crystal nucleating agent to improve polypropylene foaming capacity. A polypropylene / nano cellulose composite material is prepared according to an extrusion blending method, and technical simplicity and suitableness for large-batch industrial production are realized.

Owner:合肥华聚微科新材料有限责任公司

Functionalized boron nitride nanosheet/MXene/polybenzimidazole high-thermal-conductivity composite film and preparation method thereof

ActiveCN112552681AEliminate adverse effects such as low flexibilityImprove mechanical propertiesBoron nitrideElectronics

The invention belongs to the technical field of composite materials, and provides a functionalized boron nitride nanosheet / MXene / polybenzimidazole high-thermal-conductivity composite film and a preparation method thereof. The preparation method includes the steps: firstly, dispersing amino-functionalized boron nitride nanosheets and MXene nanosheets in a dispersing agent, obtaining a mixed solution after mixing, then adding polybenzimidazole into the mixed solution, to obtain a functionalized boron nitride nanosheet / MXene / polybenzimidazole blended solution, and carrying out suction filtrationon the mixed solution to obtain the composite film. A three-dimensional structure of a polybenzimidazole polymer is utilized, so that modified boron nitride and MXene with electronegativity are subjected to electrostatic self-assembly, and the self-supporting film taking polybenzimidazole as a framework and taking functionalized boron nitride nanosheets and MXene as mixed fillers is formed. The filling network formed by the synergistic effect of the boron nitride nanosheets and Ti3C2Tx bridging effectively reduces the interface thermal resistance, and endows the composite film with excellent heat-conducting property. The method is simple and effective, and the prepared high-thermal-conductivity film has a wide application prospect in the fields of energy, electronics and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

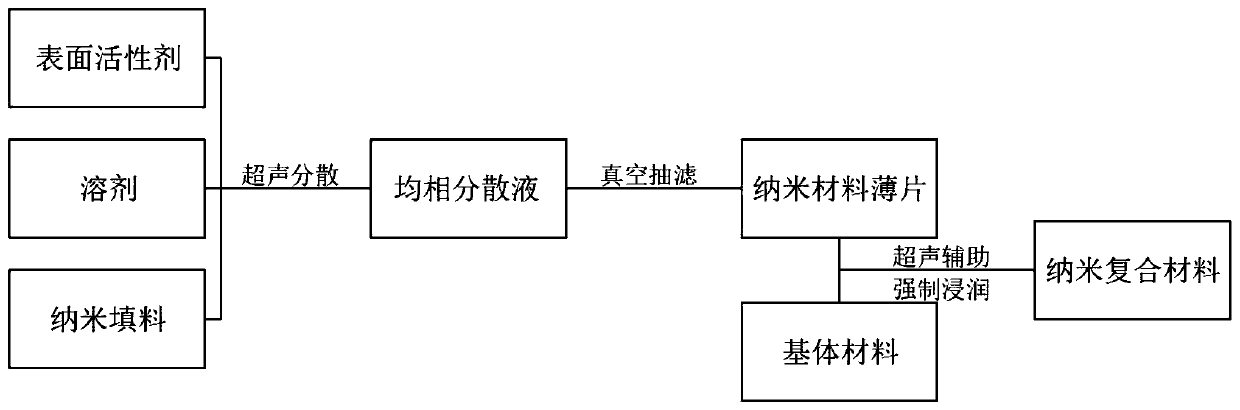

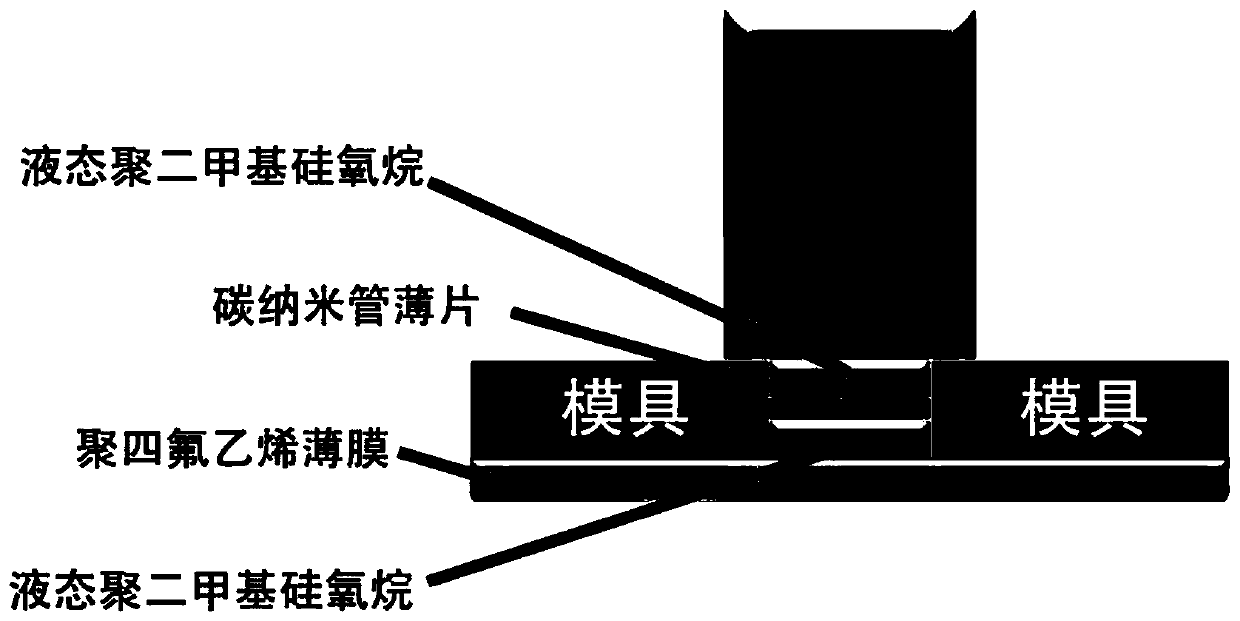

Method for preparing polymer nanocomposite through ultrasonic-assisted forced infiltration

InactiveCN111267372AOvercoming the barrier of surface tensionImprove mechanical propertiesCoatingsConvertersPolymer science

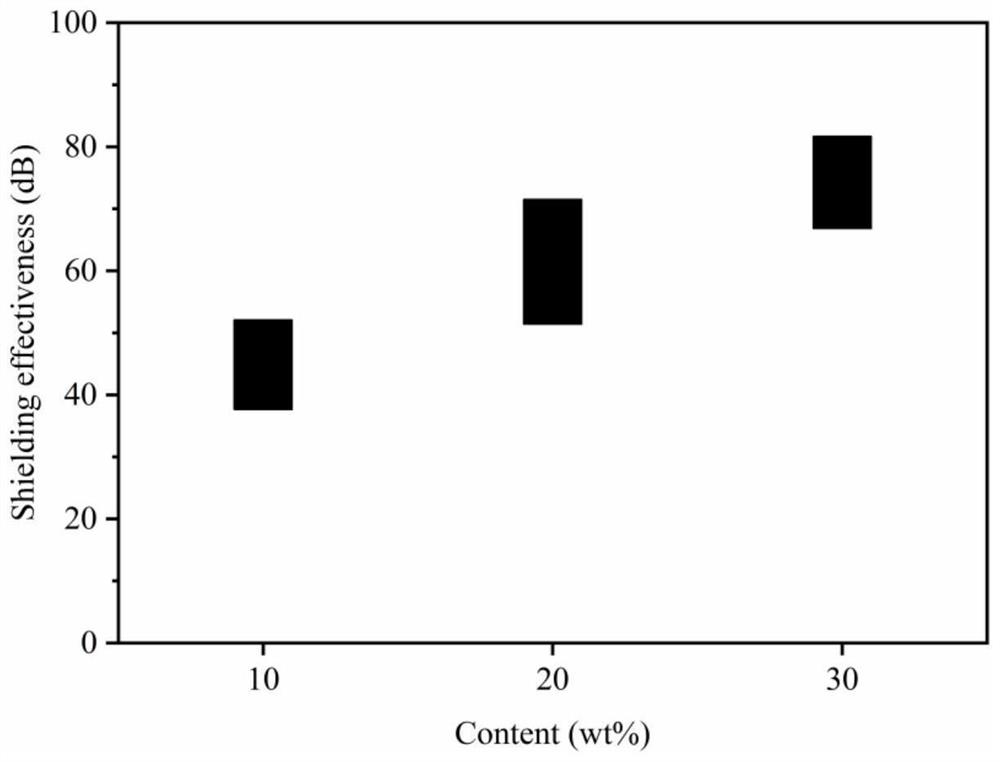

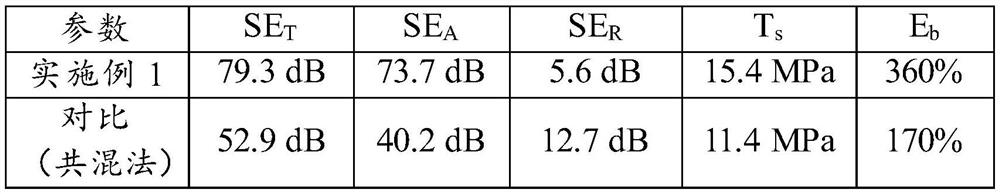

The invention provides a method for preparing a polymer nanocomposite through ultrasonic-assisted forced infiltration. The method comprises the following steps of: preparing homogeneous dispersion liquid through ultrasonic dispersion; preparing nanomaterial flakes through vacuum filtration; preparing the polymer nanocomposite through ultrasonic-assisted forced infiltration; and performing heat preservation solidification or cooling setting on the polymer nanocomposite prepared in step III. According to the method, nano-filler networks which are tightly stacked are prepared firstly to overcomethe obstacle of surface tension; and a high-viscosity polymer matrix material is forcibly infiltrated into the filler networks to prepare the nanocomposite product with nano-fillers uniformly dispersed in the polymer matrix, and meanwhile ensure that the complete nano-filler networks exist in the product. The polymer nanocomposite shows excellent mechanical properties, electrical / thermal conductivity, electromagnetic shielding properties, dielectric properties, and the like. Therefore, the polymer nanocomposite prepared by the method can be applied to devices or systems such as flexible sensors, thermal interface materials, dielectric elastomers, and light-to-heat converters.

Owner:BEIJING UNIV OF CHEM TECH

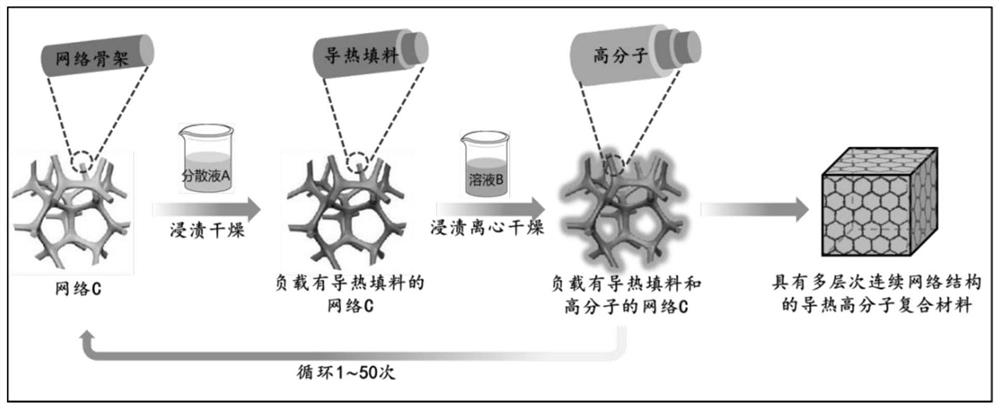

Heat-conducting polymer composite material with multi-layer continuous network structure and preparation method

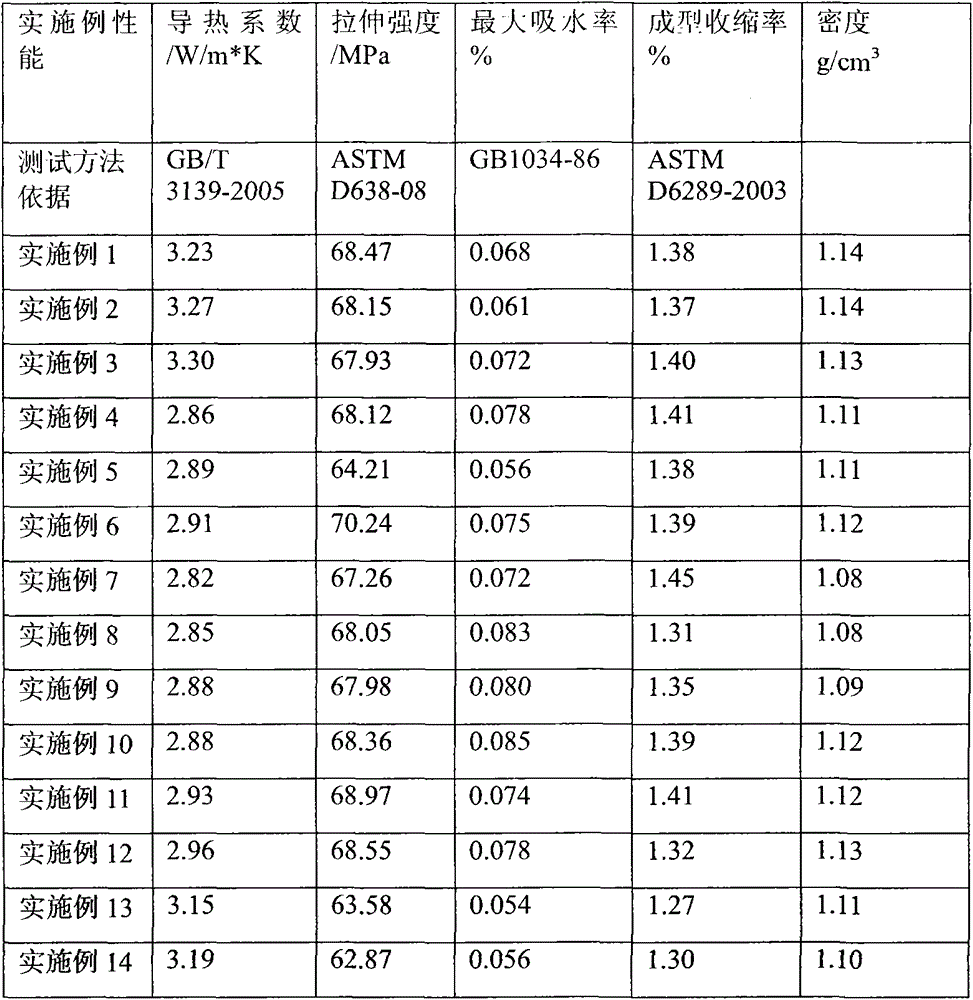

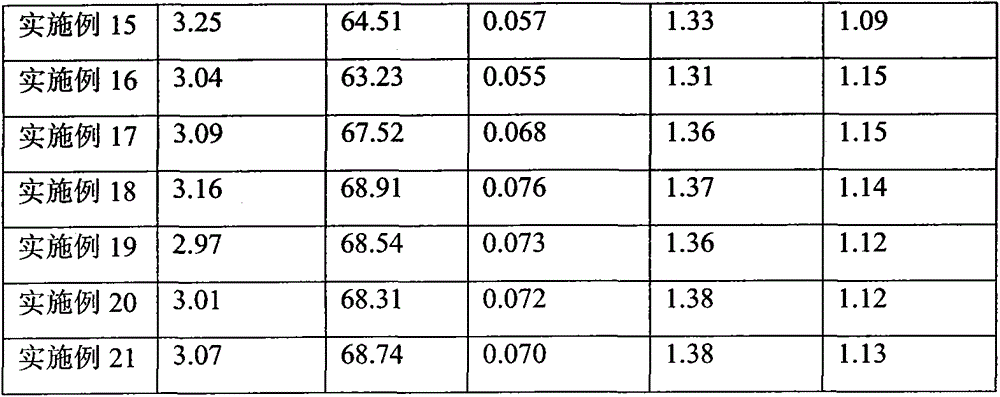

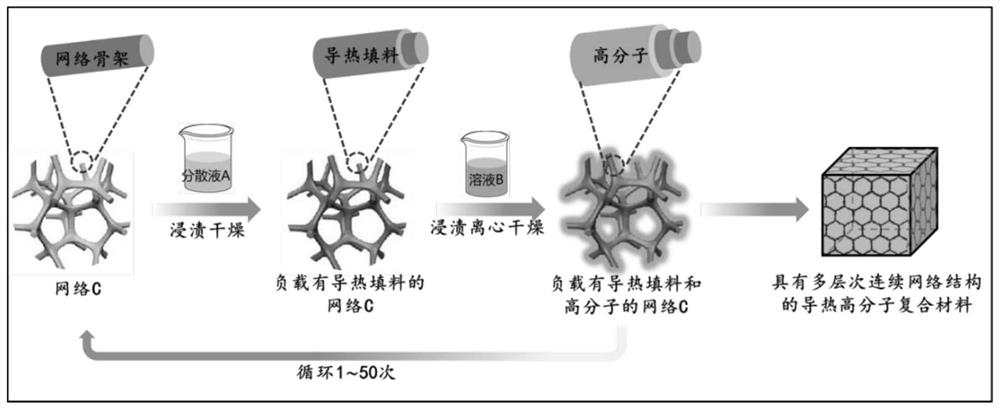

ActiveCN112574468ASmall average distanceRaw materials are easy to obtainHeat-exchange elementsNetwork structureMacromolecule

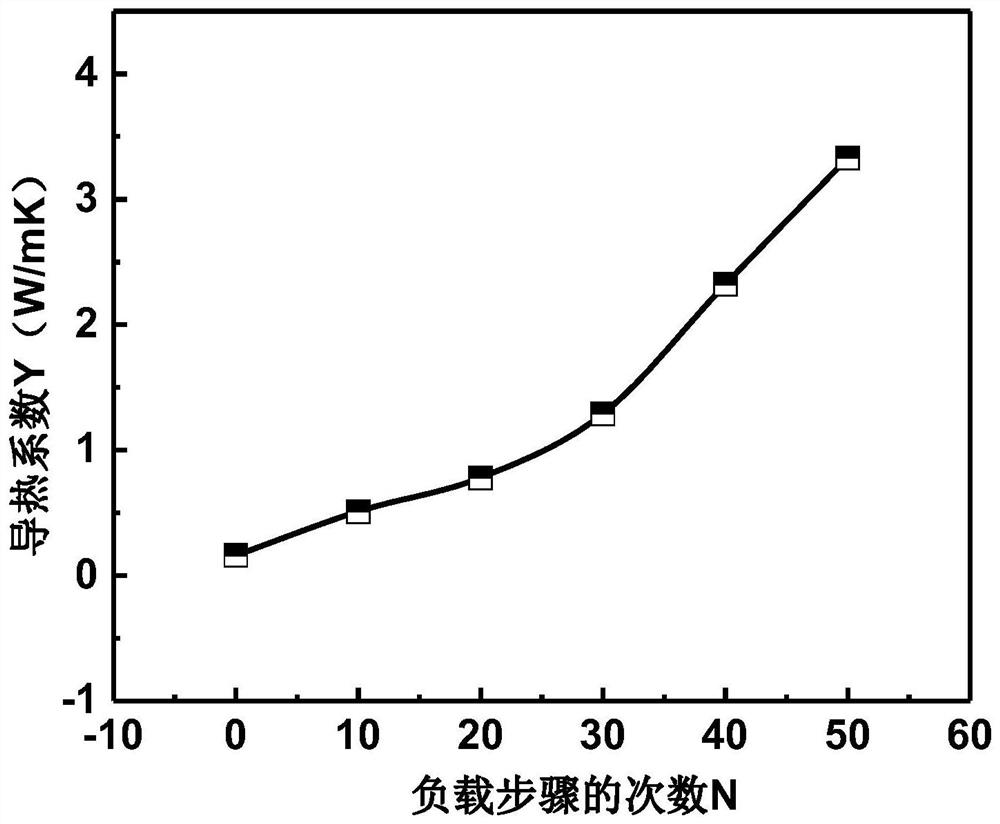

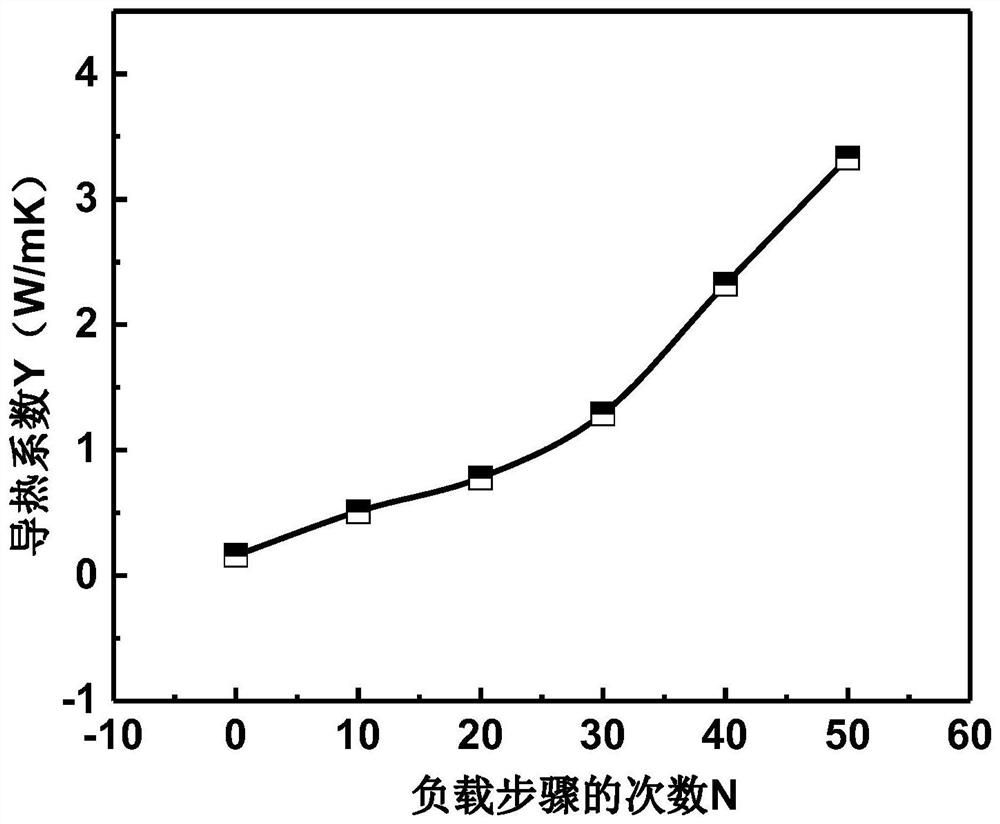

The invention discloses a heat-conducting polymer composite material with multi-layer continuous network structure and a preparation method. The preparation method comprises the following steps: preparing a network C, and loading the network C for 2-50 times, wherein each loading method comprises the following steps: immersing the network C in a dispersion liquid A, taking out the network C, drying the network C at 20-200 DEG C to obtain a network C loaded with a heat-conducting filler, immersing the network C loaded with the heat-conducting filler in a solution B, taking out the network C, conducting drying at 20-320 DEG C for 30-300 min, so as to obtain the heat-conducting polymer composite material. According to the preparation method disclosed by the invention, the required raw materials are simple and easy to obtain, the heat-conducting filler can form a multi-layer three-dimensional continuous heat-conducting network through a simple impregnation process, and the heat-conductingpolymer composite materials with different heat-conducting properties can be obtained by controlling the loading times. The average distance between the polymer matrix of the obtained heat-conductingpolymer composite material and the heat-conducting filler network is relatively small, and the heat conductivity coefficient is relatively high.

Owner:济南英维新材料科技合伙企业(有限合伙)

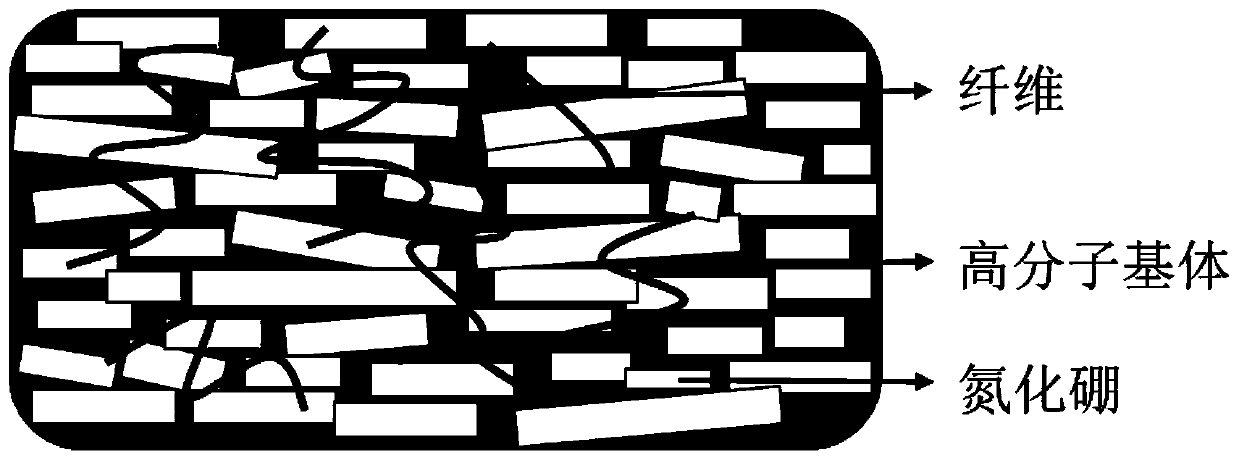

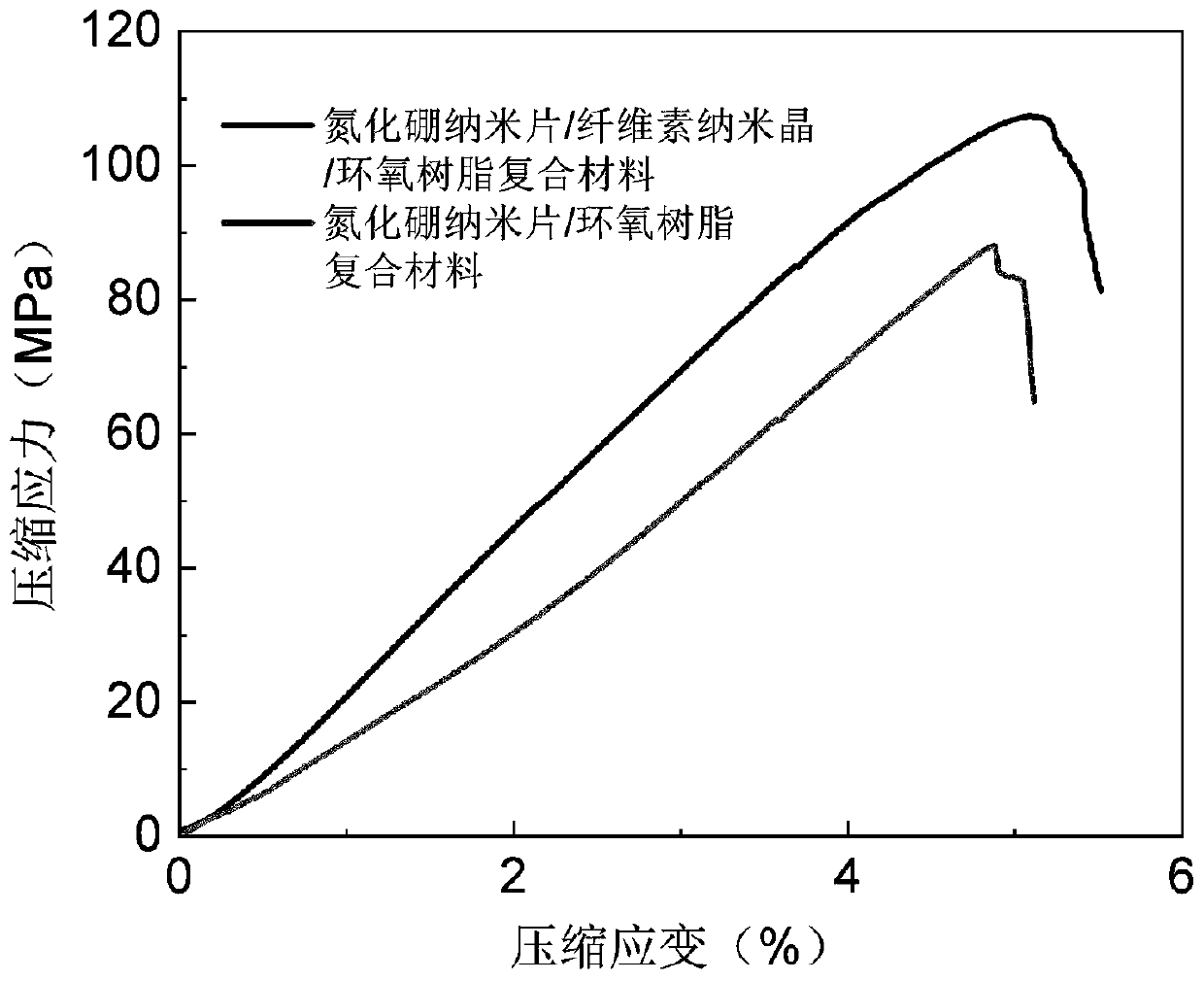

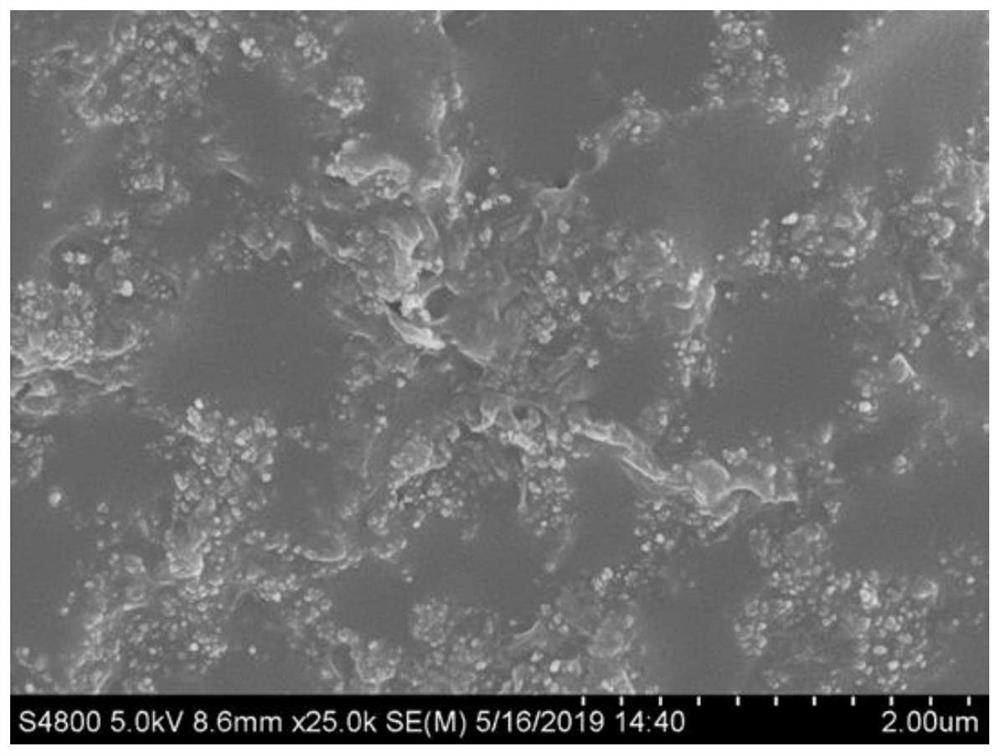

High-filling-capacity hexagonal boron nitride nanosheet/fiber/polymer blocky composite material and preparation method thereof

ActiveCN111423698AHigh mechanical strengthLower interface thermal resistanceGrain treatmentsFiberHexagonal boron nitride

The invention relates to a high-filling-capacity hexagonal boron nitride nanosheet / fiber / polymer blocky composite material and a preparation method thereof. The high-filling-capacity hexagonal boron nitride nanosheet / fiber / polymer blocky composite material comprises hexagonal boron nitride nanosheets, fibers and a polymer matrix, the fibers are connected with the hexagonal boron nitride nanosheetsin different laminated layers to form a hexagonal boron nitride nanosheet-fiber hybrid filler network; and the sum of the hexagonal boron nitride nanosheet and the fiber accounts for 65-80% of the total mass of the material. By constructing a high-proportion filled hexagonal boron nitride nanosheet / fiber three-dimensional network in a polymer matrix, the composite material has good processabilityand excellent mechanical properties.

Owner:HEBEI UNIV OF TECH

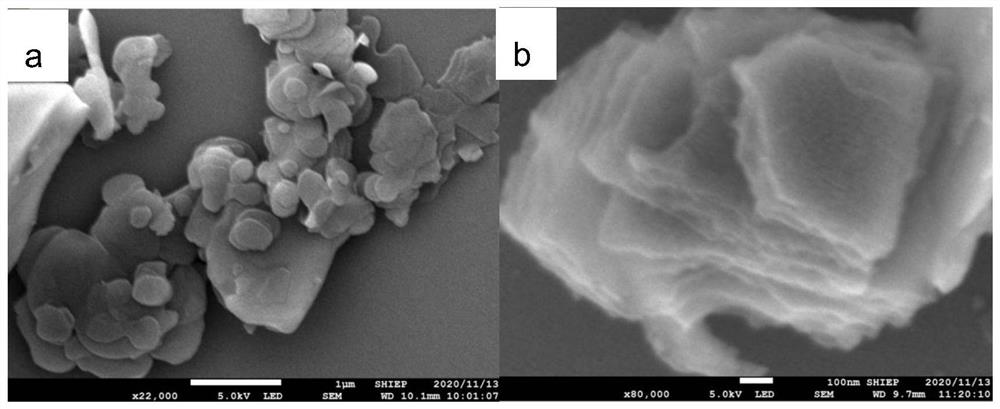

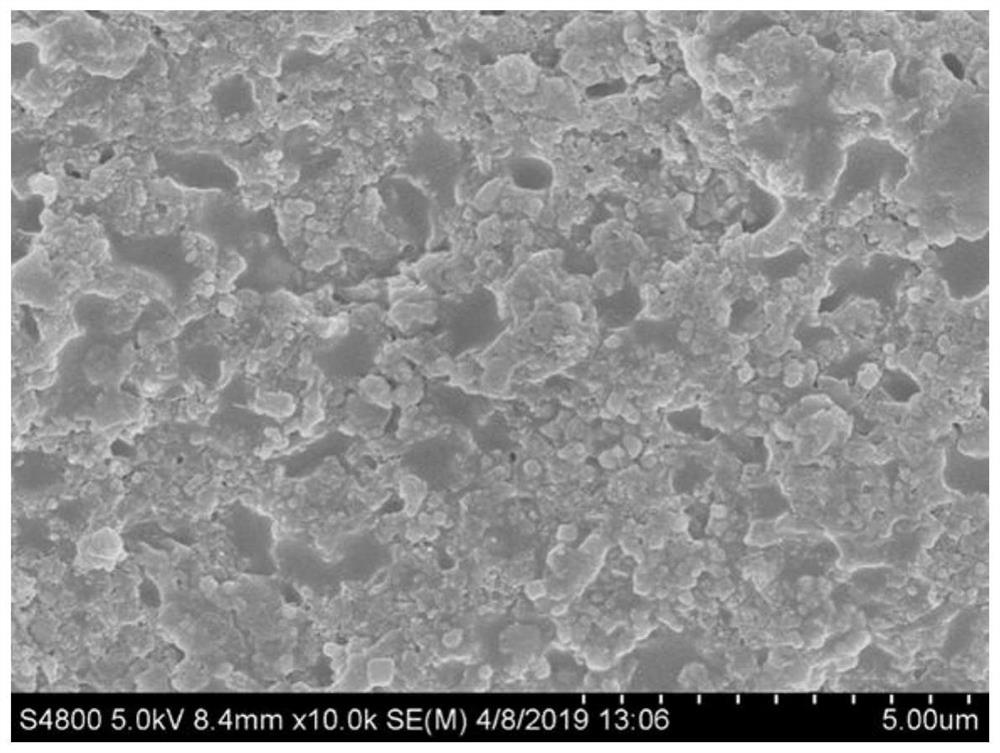

High-thermal-conductivity rubber nano composite material and preparation method thereof

ActiveCN112442217AHigh thermal conductivityMild method conditionsChemical industryHeat-exchange elementsLatex particleNanocomposite

The invention discloses a high-thermal-conductivity rubber nano composite material and a preparation method thereof. The composite material is prepared from the following raw materials: 100 parts by weight of rubber latex; 0.5-20 parts by weight of a graphene oxide aqueous dispersion; 5-500 parts by weight of a nano heat-conducting filler; 1-40 parts by weight of a reducing agent; 0.01-10 parts byweight of an emulsifier; and 0.1-5 parts by weight of a vulcanizing agent. According to the invention, the nano heat-conducting filler and the rubber latex particles are guided to forma three-dimensional network through graphene oxide gelation, and then the high-thermal-conductivity rubber composite material internally containing the three-dimensional filler network is prepared through hot pressing of the network, so that the heat-conducting property is greatly improved.

Owner:BEIJING UNIV OF CHEM TECH

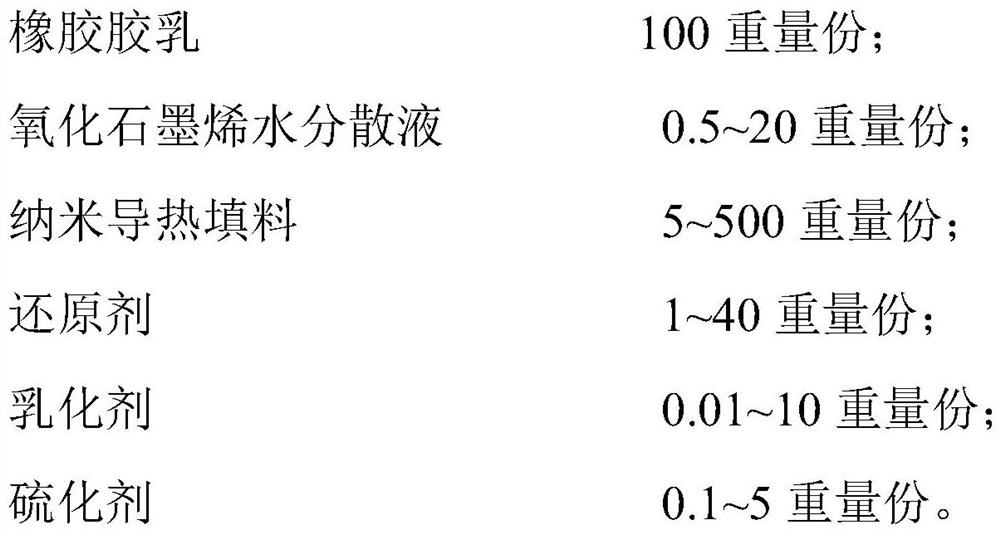

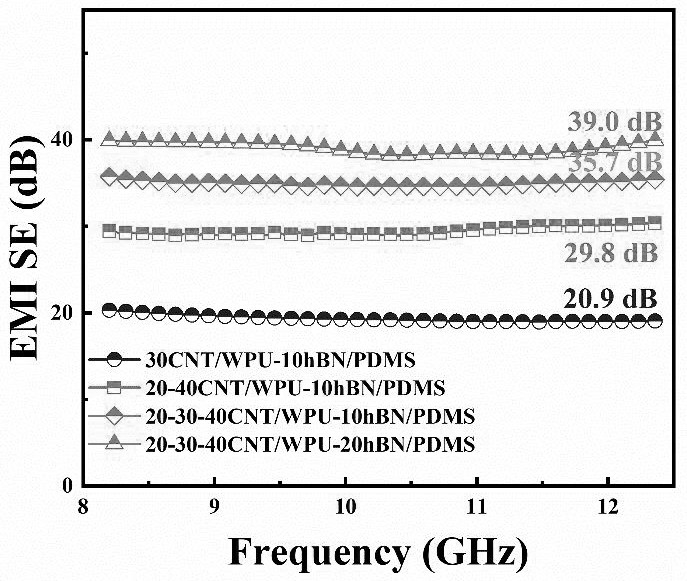

Low-reflection and high-absorption electromagnetic shielding polymer composite material with gradient electric conduction-uniform heat conduction dual-functional network

ActiveCN112831185AImprove thermal conductivityReduce scatterMaterial nanotechnologyShielding materialsHexagonal boron nitrideBoron nitride

The invention belongs to the technical field of functional composite materials, and particularly relates to a low-reflection and high-absorption electromagnetic shielding polymer composite material with a gradient electric conduction-uniform heat conduction dual-function network structure and a preparation method of the low-reflection and high-absorption electromagnetic shielding polymer composite material. The composite material comprises a gradient conductive carbon nanotube network with a vertical orientation foam structure, and a uniformly heat-conducting hexagonal boron nitride / carbon nanotube functional network jointly constructed by a uniformly dispersed hexagonal boron nitride filler network constructed by blending and pouring processes in carbon nanotube foam and a gradient carbon nanotube network. Conductive carbon nanotube foam is successfully compounded with high-thermal-conductivity but insulating boron nitride, the low-reflection and high-absorption characteristics of the electromagnetic shielding composite material are realized through gradient prefabricated network structure control, and hexagonal boron nitride is directionally arranged under the effect of volume limitation by constructing an oriented foam structure prefabricated network, so that the optimal optimization of the heat-conducting property of the composite material is realized, and the goal of simultaneously optimizing the low-reflection and high-absorption properties and the heat-conducting property of the electromagnetic shielding composite material is finally realized.

Owner:ZHONGBEI UNIV +1

Biodegradable polymer composite with high thermal conductivity and preparation method thereof

The invention discloses a biodegradable polymer composite with high thermal conductivity. The biodegradable polymer composite comprises heat-conducting nanofiller and a biodegradable polymer with a shape memory characteristic, wherein the heat-conducting nanofiller is arranged in the biodegradable polymer in order. The heat-conducting nanofiller without chemical modification is mixed with the biodegradable polymer, by use of the shape memory characteristic of the polymer, the heat-conducting nanofiller is arranged in order by stretch induced self-assembly, meanwhile, the heat-conducting nanofiller arranged in order is used as a physical crosslinking site to maintain the orientation state of the material, after the obtained material is heated secondarily, the filler still keeps high orientation, a constructed orientated structure facilitates lap joint of an ordered filler network with a small quantity of heat-conducting nanofiller, so that the production cost is reduced, the material density is reduced, the strength and ductility of the material are enhanced, and the thermal conductivity of the material is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

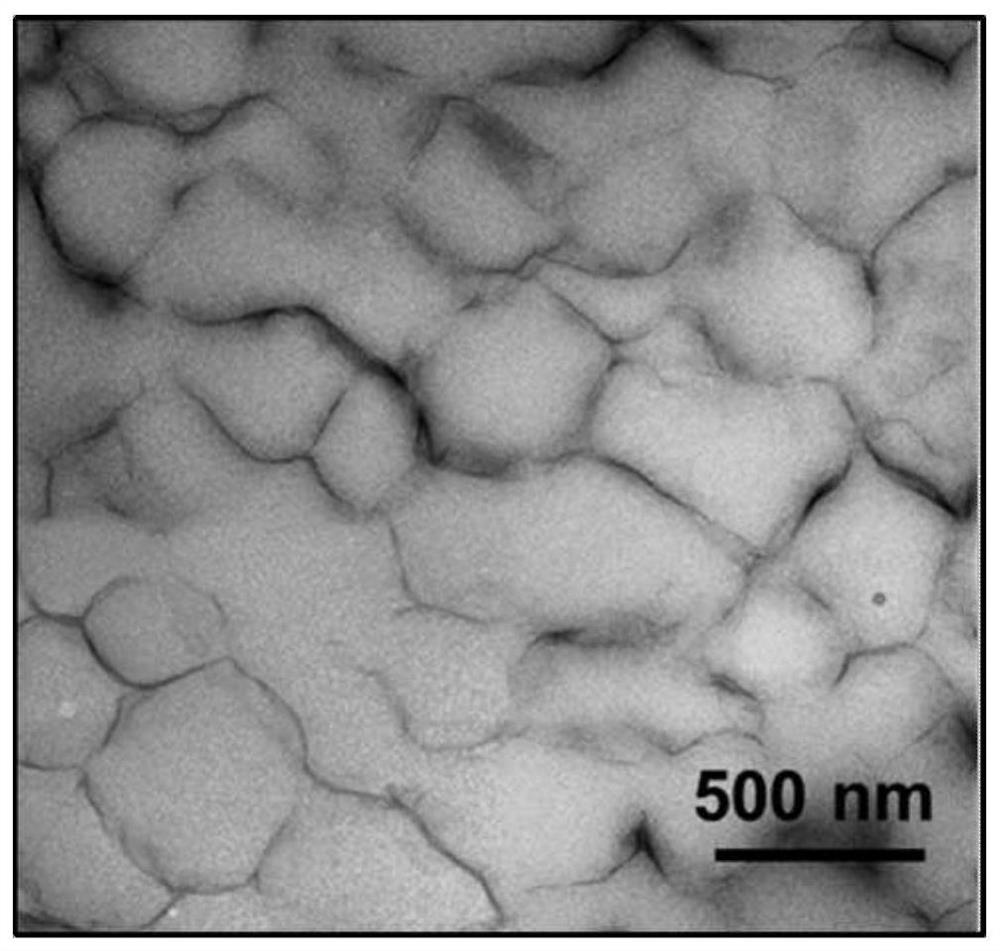

Interface supramolecular reinforced nano composite material and preparation method thereof

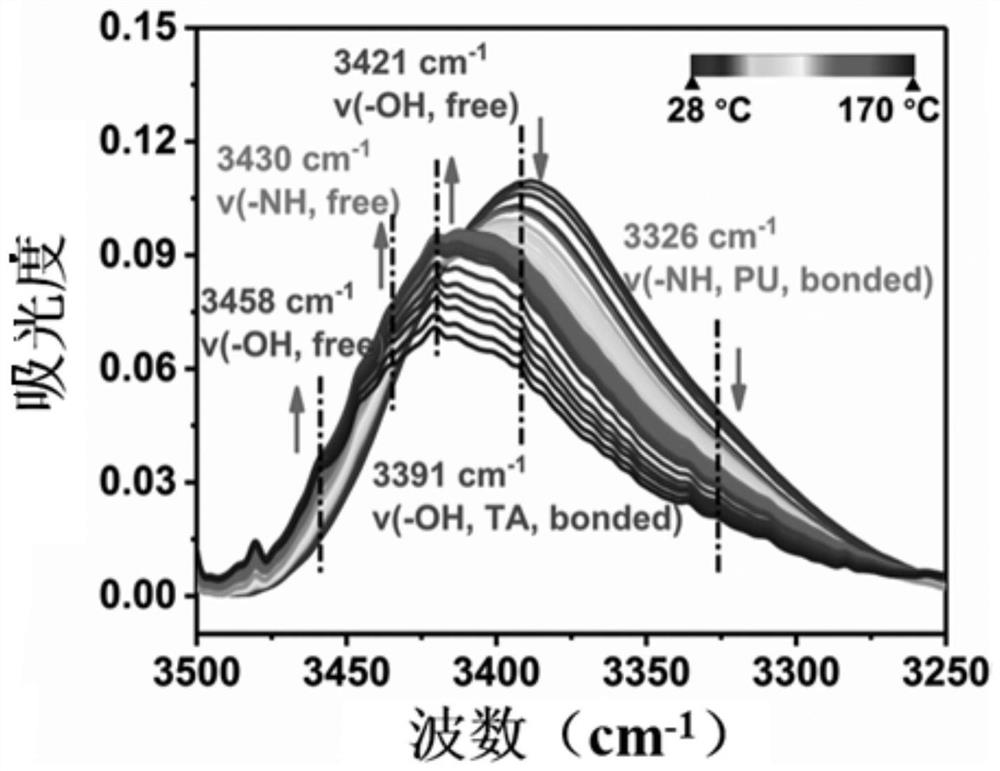

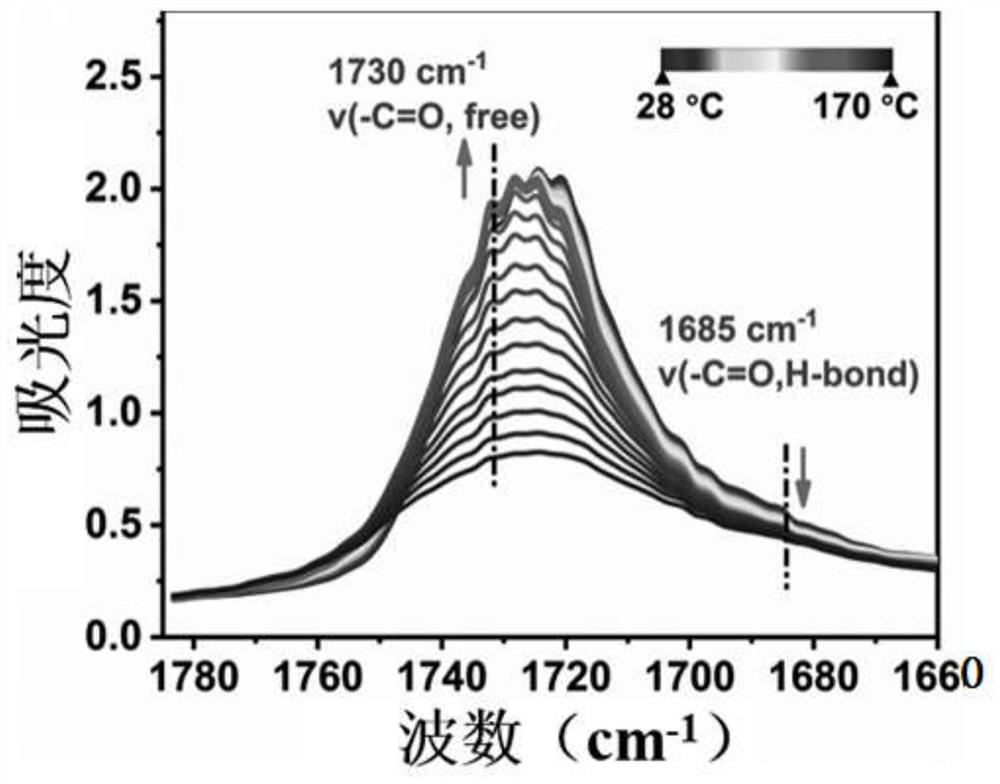

InactiveCN112375369AUnique three-dimensional nano-filler network structureEasy to preparePolyphenolNanocomposite

The invention discloses an interface supramolecular reinforced nano composite material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing a nano-filler dispersion liquid, and stably dispersing a nano-filler; (2) adding polyphenol and analogues thereof to modify the surface of the nano-filler; (3) carrying out ultrasonic dispersion mixing on the surface-modified nano-filler dispersion liquid obtained in the step (2) and latex emulsion according to a weight ratio, or subjecting the modified filler and latex to double-roller / banburying extrusionmelting processing dispersion; and (4) injecting the mixed latex obtained in the step (3) into a mold, and conducting drying and molding in a 60 DEG C blast oven. The preparation method is simple, andthe obtained material has a unique three-dimensional nano-filler network structure, so that the rigid filler and the flexible polymer matrix have good interface bonding and an interface phase with acertain thickness, crack propagation can be stopped when the material is damaged, a large amount of impact energy is consumed, and borne external force is transmitted, so that the purposes of strengthening and toughening are achieved.

Owner:SICHUAN UNIV

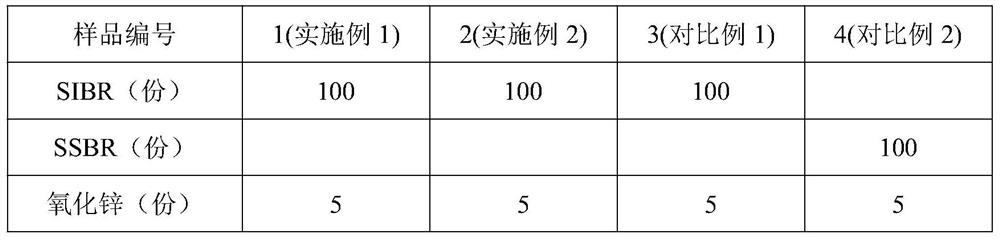

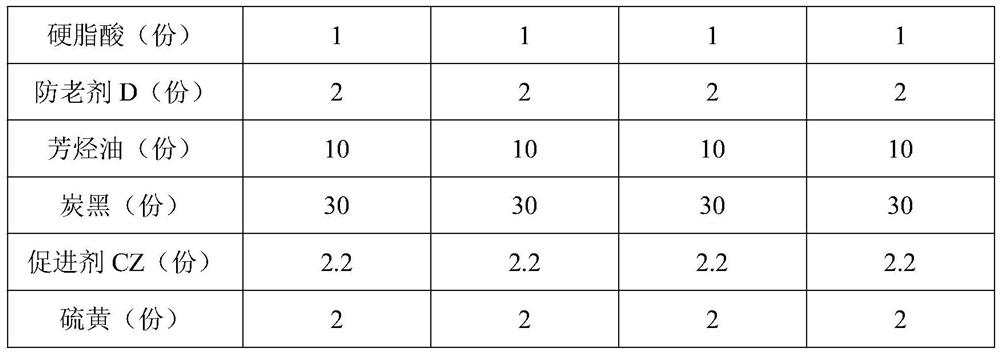

SIBR integrated rubber containing amino group, integrated rubber composite material and preparation method thereof

ActiveCN112920355AImprove performanceLimit motion friction heatSpecial tyresRubber materialPolymer science

The invention relates to SIBR integrated rubber containing an amino group, an integrated rubber composite material and a preparation method thereof. The SIBR integrated rubber is a quadripolymer of styrene, isoprene, butadiene and an amino group-containing monomer 1,1-diphenylethylene derivative initiated by alkyl lithium, and a polymer chain contains not less than 3 amino functionalized diphenylethylene derivative units. Amino on the introduced diphenylethylene derivative and hydroxyl on the surface of reinforcing filler carbon black or white carbon black can form a strong filler network locally on the rubber material in the form of ionic bonds or hydrogen bonds, meanwhile, introduction of an amino functional group can passivate the movement ability of a rubber molecular chain so as to limit movement friction heat generation of a macromolecular chain end, finally, the purposes of reducing internal friction heat generation of the tire and improving the reinforcing effect of the carbon black and the white carbon black are achieved, and the rubber composite material is endowed with the properties of high modulus and low energy consumption. The SIBR integrated rubber is simple and easy to implement, low in cost, easy to industrialize and wide in application range, and has good economic benefits and social effects.

Owner:DALIAN UNIV OF TECH

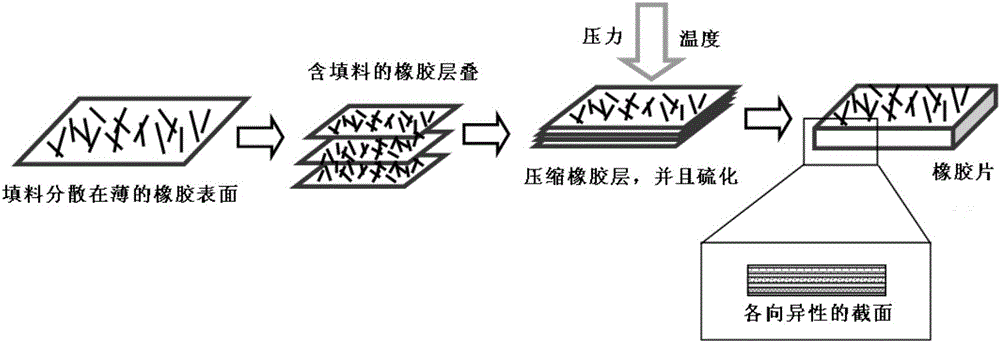

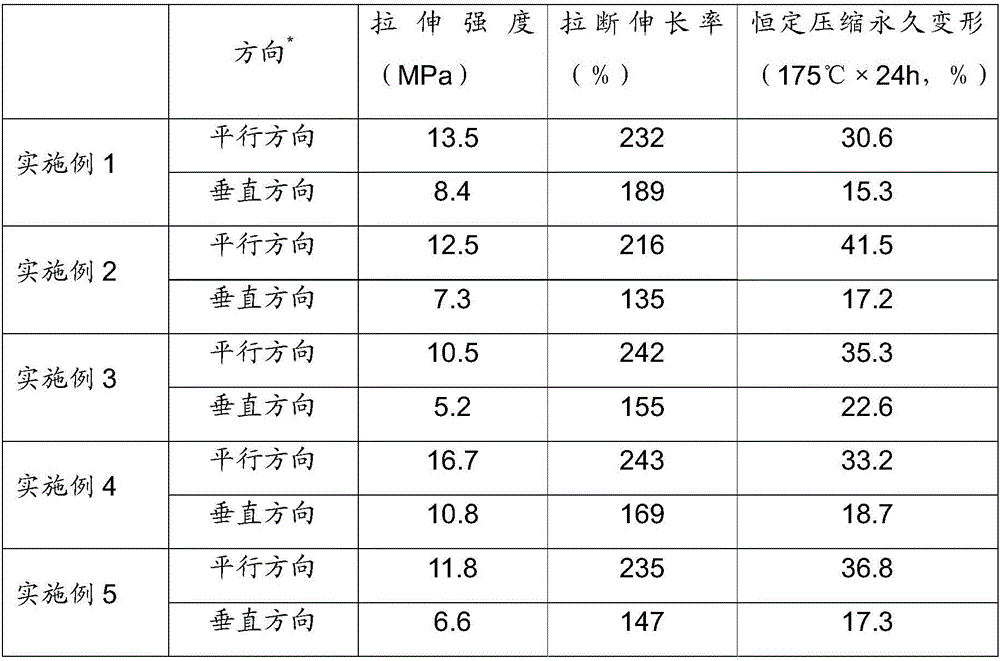

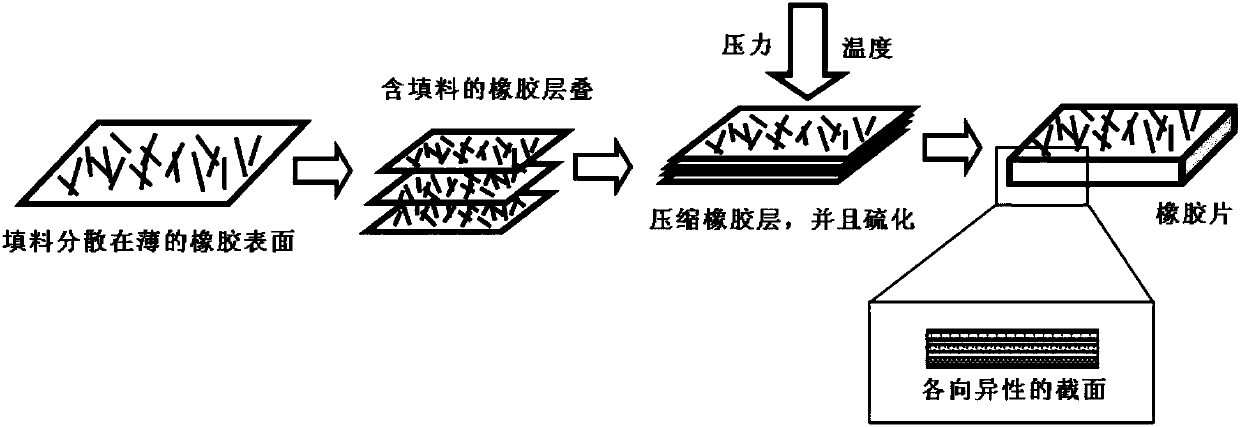

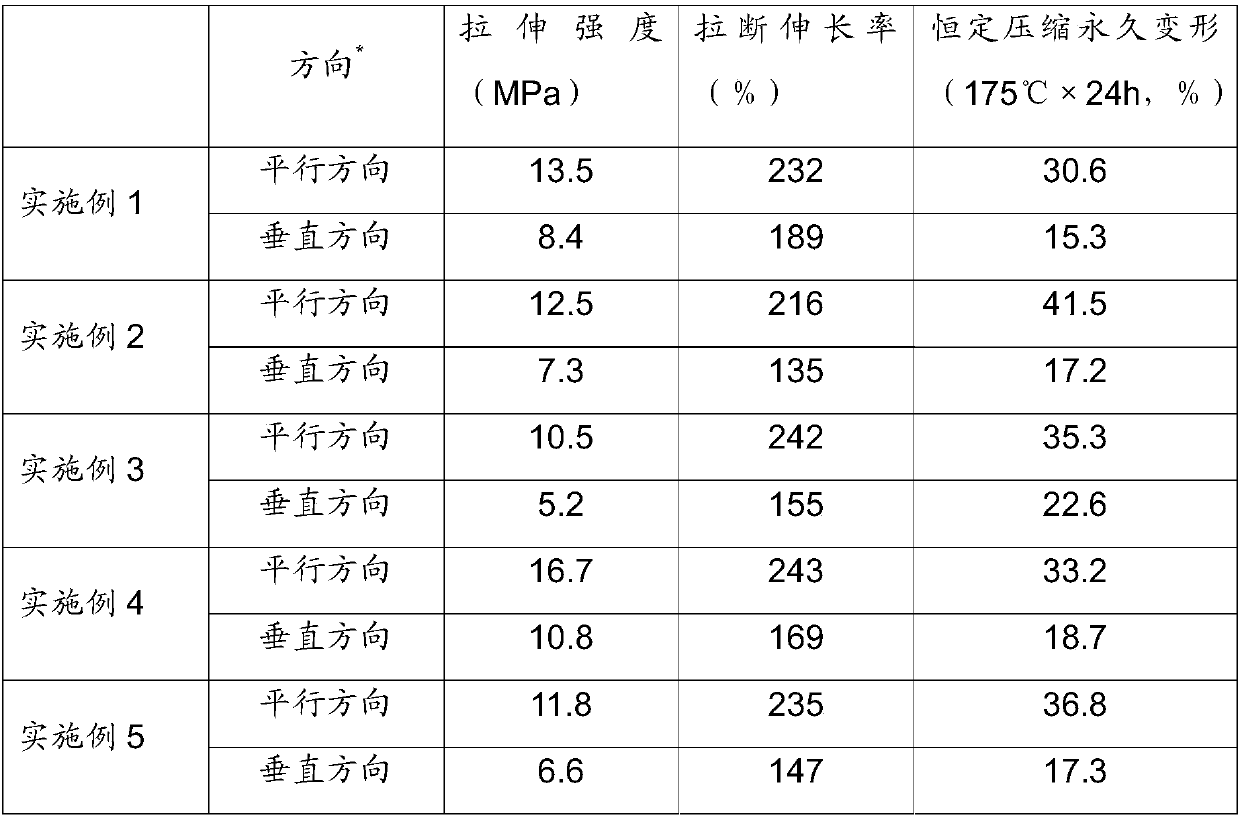

Method for preparing multilayer filler/fluoroether rubber composition through layering method

The invention relates to a method for preparing a multilayer filler / fluoroether rubber composition through a layering method. The method includes the steps that filler such as carbon black and carbon nanotubes is dispersed on the surfaces of rubber thin films through a direct dispersion method or jet dispersion method; and the rubber thin films containing the filler are compounded layer by layer and then pressurized and vulcanized to obtain a fluoroether rubber material with a multilayer structure. According to the method, the filler / fluoroether rubber composition which is prepared by compounding a single-filler network structure into the multilayer structure with different dimensions or distribution characteristics through a special process method brings excellent performance in all directions into play, has excellent tensile strength, elongation at break and medium resistance, is suitable for being used in sealed environments, and further improves reliability of sealing structures.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

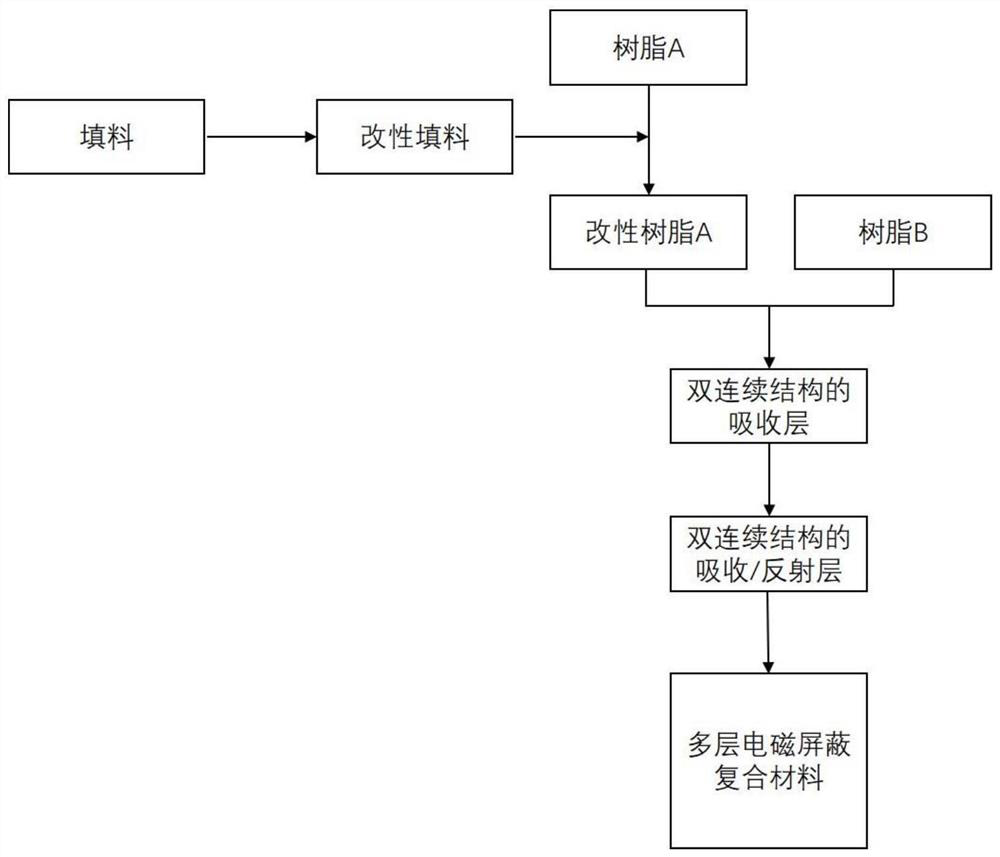

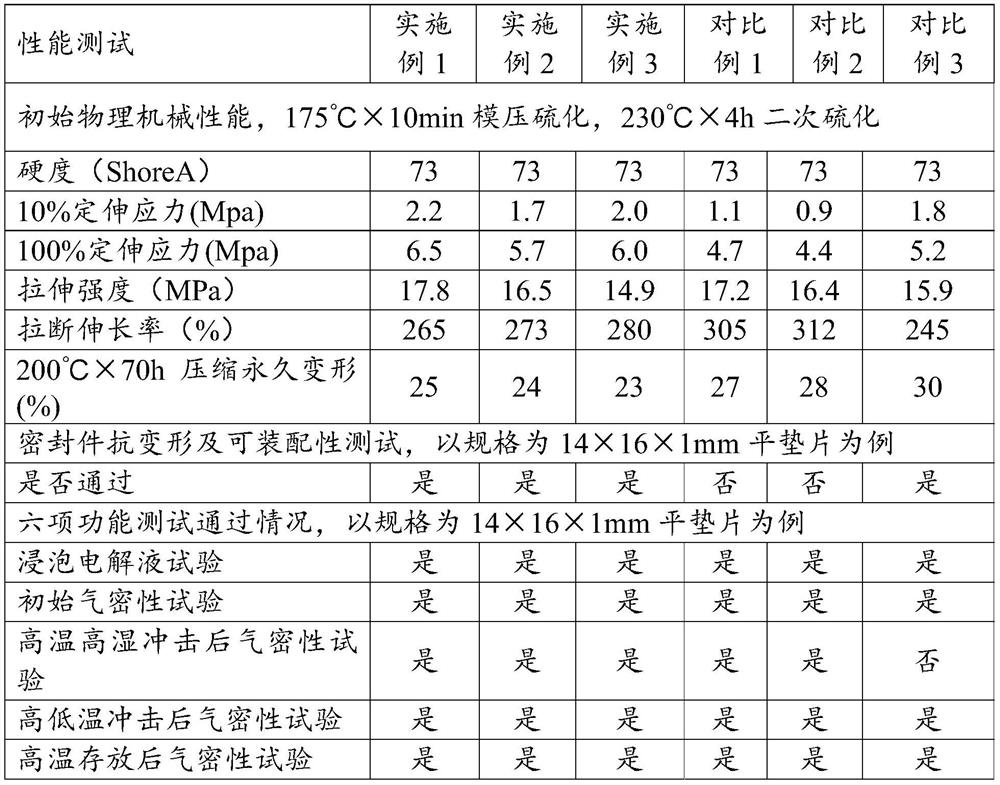

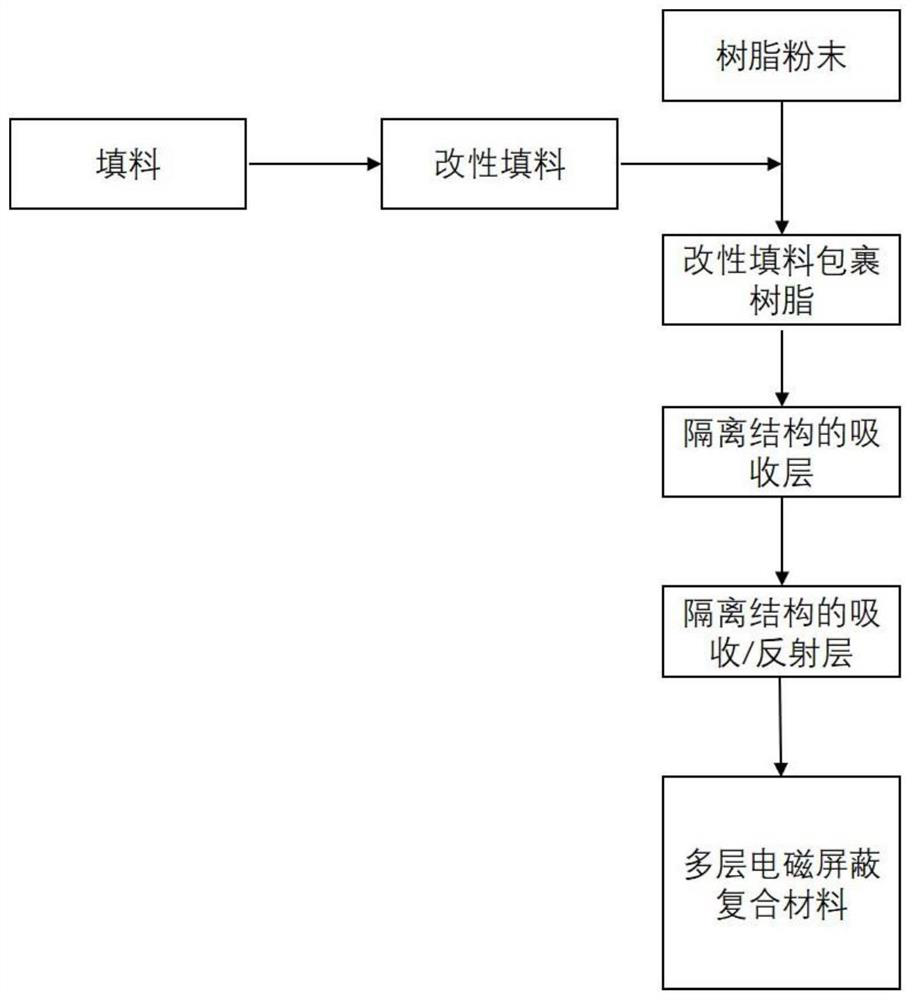

Multilayer electromagnetic shielding composite material based on bicontinuous structure and preparation method and application thereof

ActiveCN112743945AImprove electromagnetic shielding performanceImprove mechanical propertiesMagnetic/electric field screeningSynthetic resin layered productsMetal nanowiresReflective layer

The invention provides an electromagnetic shielding composite material. The electromagnetic shielding composite material comprises an absorbing layer and a reflecting layer compounded on the absorbing layer, the absorbing layer comprises a modified resin layer with a bicontinuous structure; and the reflecting layer comprises a metal nanowire film layer. According to the electromagnetic shielding composite material, the specific layer material is adopted, the absorption layer is of the special bicontinuous structure, the absorption layer-reflection layer stacked structure is combined, and the electromagnetic shielding composite material with the specific structure and composition is obtained. The composite material has the advantages of high electromagnetic shielding effectiveness, low electromagnetic wave reflection, excellent mechanical property and the like, the special bicontinuous structure of the absorption layer can promote mutual lap joint of fillers in the absorption layer to form a filler network, the shielding efficiency of the absorption layer is further improved, and reflection of the composite material to electromagnetic waves is further reduced. The composite material can replace a traditional electromagnetic shielding composite material to be applied to the fields of emerging 5G communication and aerospace.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method and equipment for evaluating dispersion degree of white carbon black in rubber material and computer readable carrier medium

ActiveCN113884664AEasy to adjustImprove performanceFlow propertiesMaterial testing goodsRubber materialPolymer science

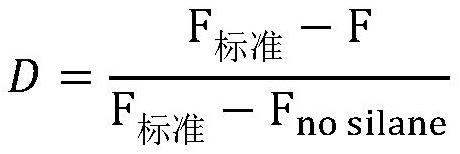

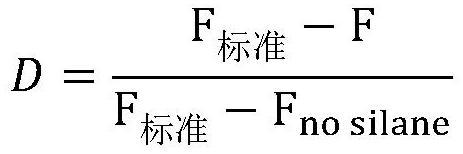

The invention relates to the technical field of detection of rubber materials in the tire industry, and in particular relates to a method and equipment for evaluating the dispersion degree of white carbon black in a rubber material and a computer readable carrier medium. The invention relates to the method for evaluating the dispersion degree of white carbon black in the rubber material. The method comprises the following steps: 1) acquiring a flow value F, a flow value F standard and a flow value Fno silane; 2) based on the dispersion degree of the white carbon black of the flow value, calculating the dispersion degree D according to a formula. The smaller the dispersity D is, the better the dispersion of the surface white carbon black is. According to the invention, the flow value of the rubber material is tested through the rubber material flow analyzer so as to evaluate the agglomeration degree of the filler network in the white carbon black formula so as to evaluate the white carbon black dispersion degree, and the method has characteristics of quantification, simple operation and strong reproducibility. The method can be used for evaluating the advantages and disadvantages of different types of white carbon black, and can also be used for guiding the process adjustment and performance optimization of a white carbon black formula.

Owner:ZHONGCE RUBBER GRP CO LTD

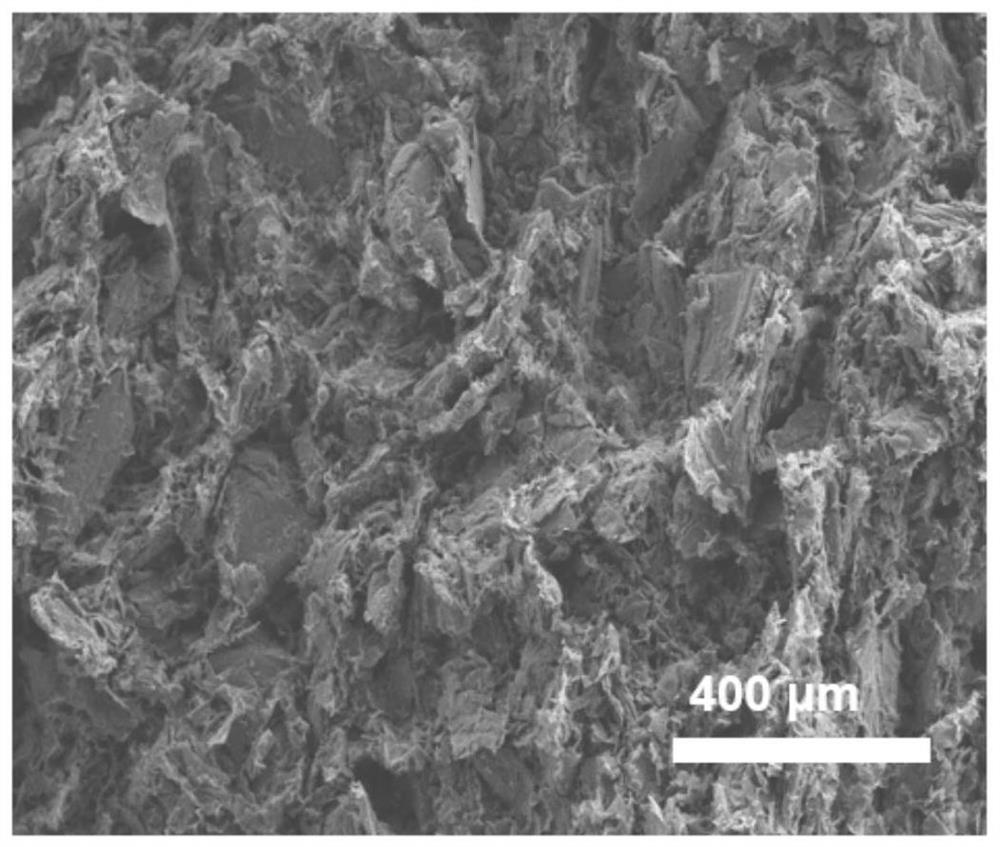

Preparation method of vertically-oriented three-dimensional expanded graphite heat conductor and reinforced heat-conducting polymer-based composite material thereof

The invention discloses a preparation method of a vertically-oriented three-dimensional expanded graphite heat conductor and a reinforced heat-conducting polymer-based composite material thereof, and relates to a vertically-oriented three-dimensional expanded graphite heat conductor and a preparation method thereof, and application of the vertically-oriented three-dimensional expanded graphite heat conductor to improve the heat conductivity of polymer matrix composite materials. The vertically-oriented three-dimensional expanded graphite heat conductor has a continuous vertically-oriented three-dimensional filler network structure and is composed of flaky expanded graphite and reduced graphene oxide, wherein the reduced graphene oxide serves as a framework material for supporting the expanded graphite to form a three-dimensional structure. The invention provides a polymer-based composite material reinforced by adopting the vertically-oriented three-dimensional expanded graphite heat conductor, wherein the vertically-orientedthree-dimensional expanded graphite heat conductor is used as a continuous phonon transmission skeleton for efficiently improving the heat-conducting property of the polymer-based composite material, the longitudinal heat-conducting property of the heat-conducting polymer-based composite material can reach 10-40W / (m.K).

Owner:EAST CHINA UNIV OF SCI & TECH +1

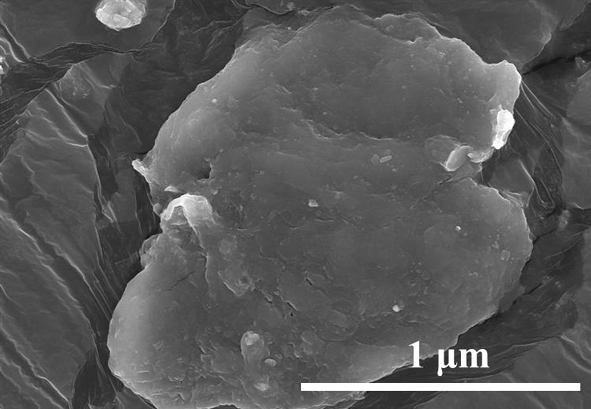

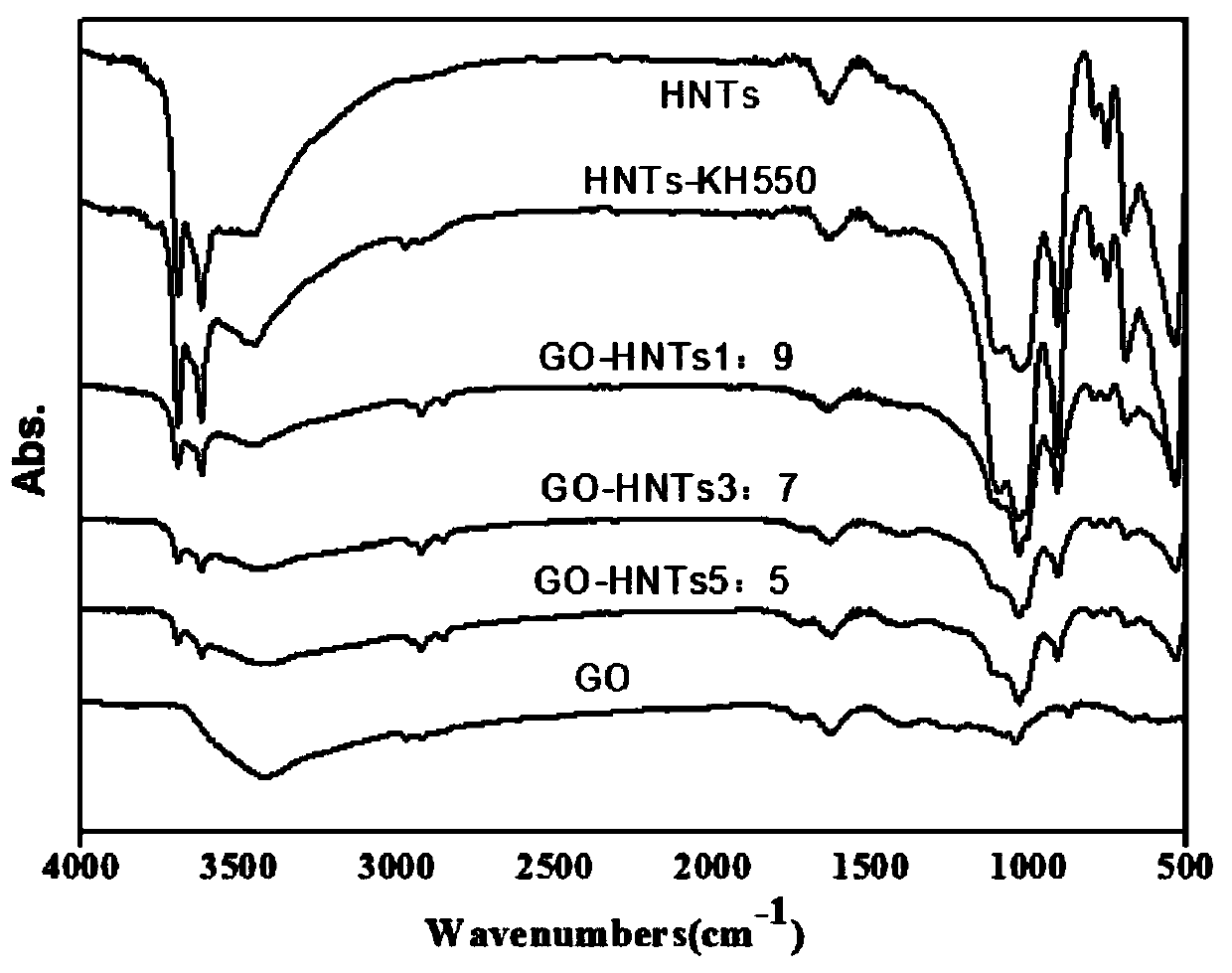

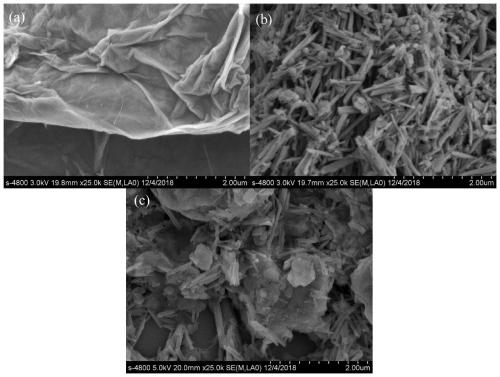

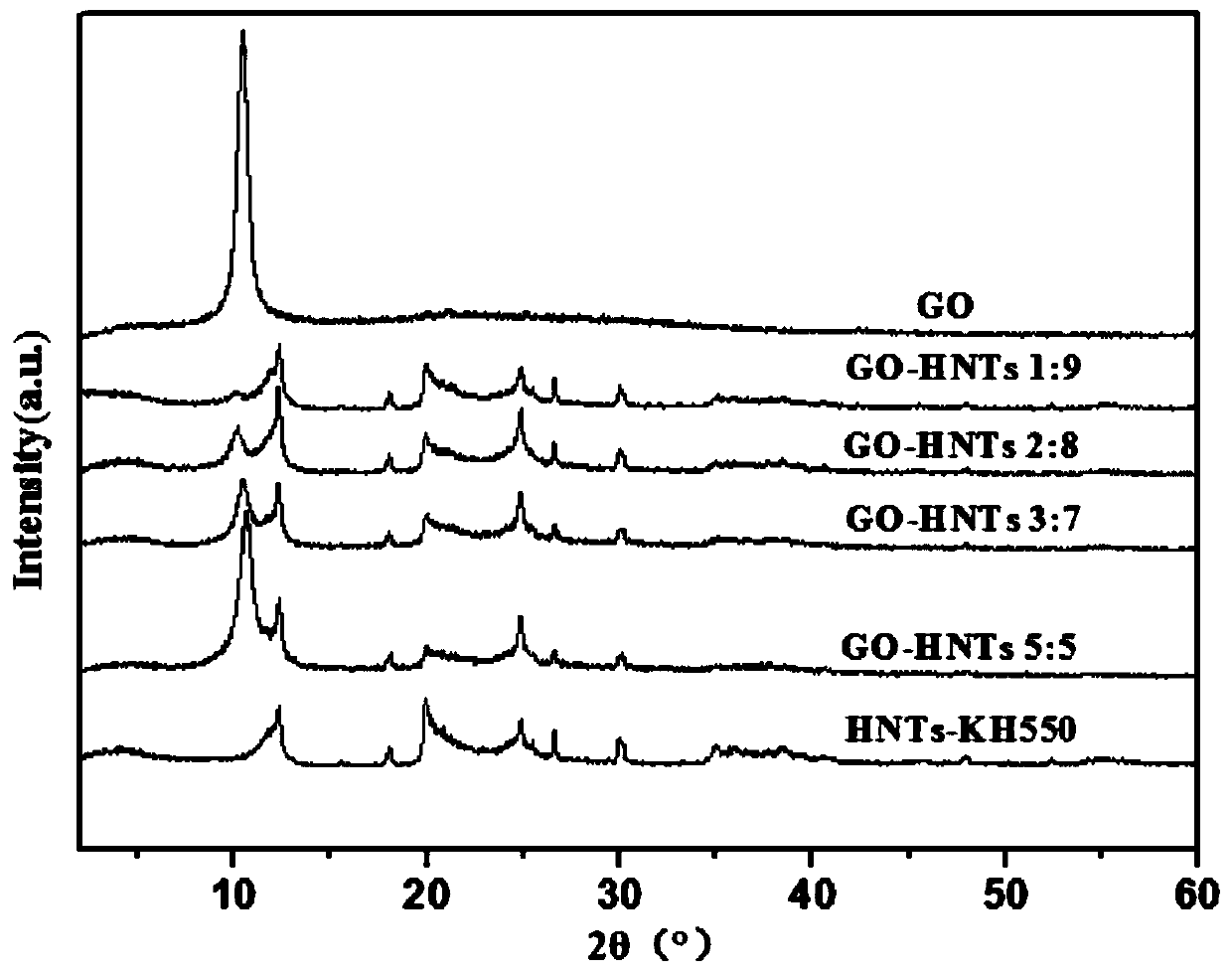

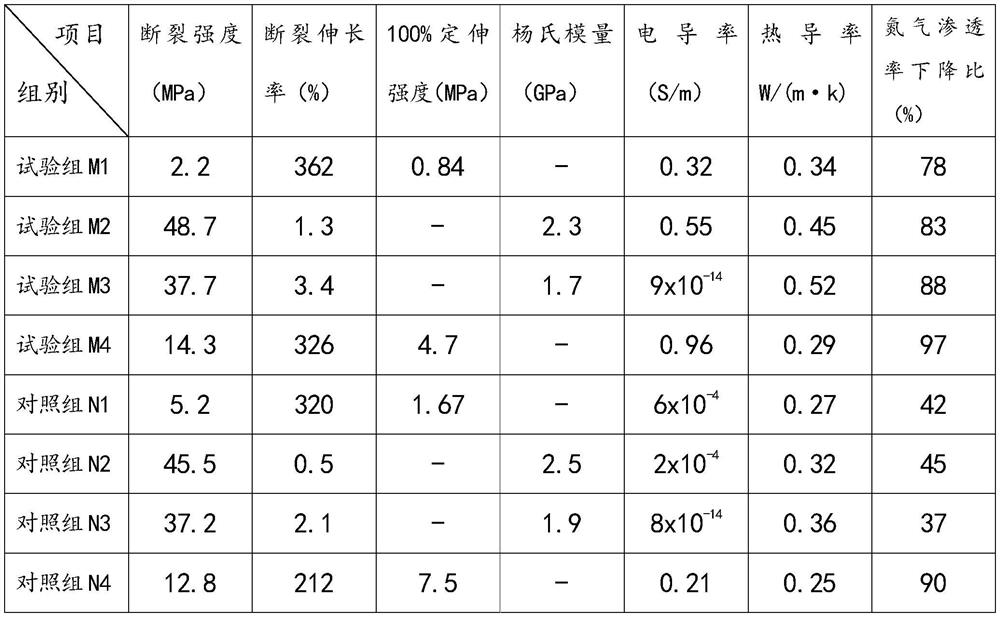

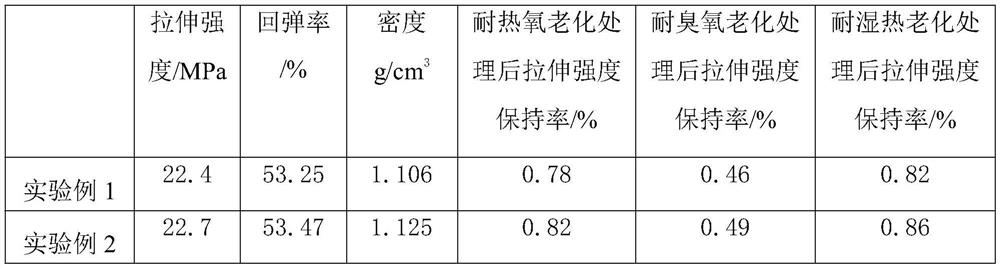

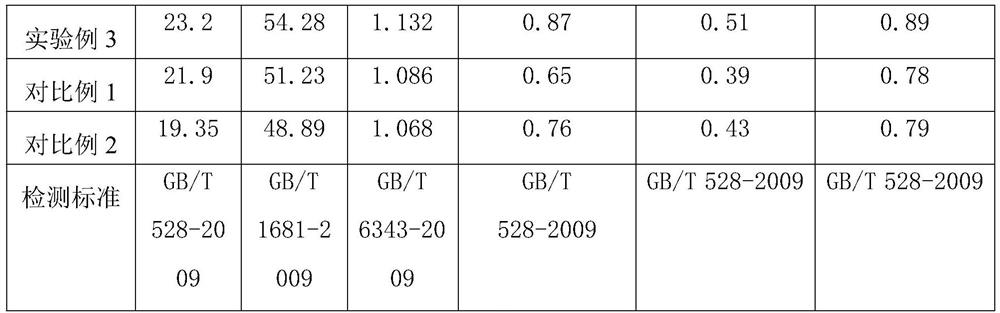

Graphene oxide loaded halloysite modified styrene-butadiene rubber and preparation method thereof

The invention disclose graphene oxide loaded halloysite modified styrene-butadiene rubber and a preparation method thereof. Graphene oxide loaded halloysite with a modified filler is added into the styrene-butadiene rubber for improving the mechanical properties of the styrene-butadiene rubber. Graphene oxide loaded halloysite uses graphene oxide as a carrier, and one-dimensional halloysite nanomaterials are tightly attached to the graphene oxide. According to the graphene oxide loaded halloysite modified styrene-butadiene rubber and the preparation method thereof, the styrene-butadiene rubberis modified through the graphene oxide loaded halloysite, the one-dimensional halloysite and the two-dimensional graphene oxide cooperate with each other, so that the agglomeration problem of a single nano material in the rubber is solved, and a strong interaction force between the one-dimensional halloysite and the two-dimensional graphene oxide enables the effect of mutual promotion and dispersion to be more obvious, a filler network structure is formed in a matrix, and the mechanical property of the styrene-butadiene rubber is obviously improved.

Owner:ANHUI UNIVERSITY

Cross-linked polymer composite material with isolation filler network structure and preparation method of cross-linked polymer composite material

ActiveCN112745544AImprove conductivityImprove barrier propertiesCompression moldingCrosslinked polymers

The invention belongs to the field of high polymer materials, and discloses a cross-linked polymer composite material with an isolation network structure and a preparation method of the cross-linked polymer composite material. The cross-linked polymer composite material with the isolation network structure is obtained by introducing an exchange bond into a cross-linked polymer, mixing the cross-linked polymer with a filler and carrying out compression molding. The obtained cross-linked polymer composite material has high mechanical properties and conductivity. The preparation method is suitable for preparing the cross-linked polymer composite material, and is particularly suitable for preparing the cross-linked polymer composite material with the isolation network structure.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of oil-resistant non-slip sole

The invention relates to the technical field of sole preparation, in particular to a preparation method of an oil-resistant non-slip sole. Nitrile rubber, butadiene rubber, epichlorohydrin rubber, white carbon black, DOPT oil, zinc oxide, modified halloysite micro powder, diethylene glycol, stearic acid, a plasticizer and the like are used as raw materials for preparing the oil-resistant non-slip sole. The nitrile rubber, the butadiene rubber, the epichlorohydrin rubber, the white carbon black, the zinc oxide and other raw materials cooperate with one another, so that the oil resistance and the slip resistance of the sole prepared by the invention are effectively ensured; the white carbon black and the modified halloysite micro powder interact to form a special double-filler network, so that the dispersion uniformity of the white carbon black and the modified halloysite micro powder in a mixed material system is promoted to a certain extent, and the mechanical property of the sole is effectively improved; and in addition, the modified halloysite micro powder and the zinc oxide cooperate with each other, so that the anti-aging performance of the prepared sole is further improved, and the service life of the prepared oil-resistant anti-slip sole is effectively prolonged.

Owner:莆田鸿途鞋塑有限公司

Preparation method for rubber composite material

The invention discloses a preparation method for a rubber composite material, and belongs to the field of the material preparation. The preparation method comprises the following steps: weighing silica slurry, preparing suspension, stirring and pre-dispersing; dropwise adding a coupling agent in a room temperature, and adding silica; stirring and enabling the coupling agent to be adequately and uniformly mixed with the silica suspension, preparing activation modified silica suspension; preparing white carbon black by the same method; adjusting a pH value of a modified silica suspension or modified white carbon black dispersion system, and weighing natural latex and adding to the dispersion system, stirring and dispersing by using an electric stirrer; co-coagulating by using calcium chloride solution, performing crepe, pelletizing to obtain a silica or white carbon black filled natural rubber master batch; and mixing the white carbon black / natural rubber master batch and the silica / natural rubber master batch according to a matching ratio. After the silica is added, a filler network of a white carbon black / silica filling rubber material is more uniform, and rolling resistance is reduced; hardness of vulcanized rubber is slightly reduced, stress at definite elongation, tensile strength, tear strength and elongation at break are increased, and physical properties are improved.

Owner:惠明伟

A functionalized boron nitride nanosheet/mxene/polybenzimidazole composite film with high thermal conductivity and preparation method

ActiveCN112552681BImprove mechanical propertiesLower interface thermal resistanceThin membraneBoron nitride

The invention belongs to the technical field of composite materials, and provides a functionalized boron nitride nanosheet / MXene / polybenzimidazole high thermal conductivity composite film and a preparation method. Disperse in a dispersant, mix to obtain a mixed solution, then add polybenzimidazole to the mixed solution to obtain a functionalized boron nitride nanosheet / MXene / polybenzimidazole blend, and filter the blend to obtain a composite film . The invention utilizes the three-dimensional structure of the polybenzimidazole polymer to make the modified boron nitride and the MXene with electronegativity undergo electrostatic self-assembly to form the polybenzimidazole as the skeleton, the functionalized boron nitride nanosheets and the MXene as the Self-supporting films of mixed fillers. Boron nitride nanosheets and Ti 3 C 2 The filled network formed by the synergistic effect of Tx bridging effectively reduces the interfacial thermal resistance and endows the composite film with excellent thermal conductivity. The method is simple and effective, and the prepared high thermal conductivity film has wide application prospects in the fields of energy, electronics and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

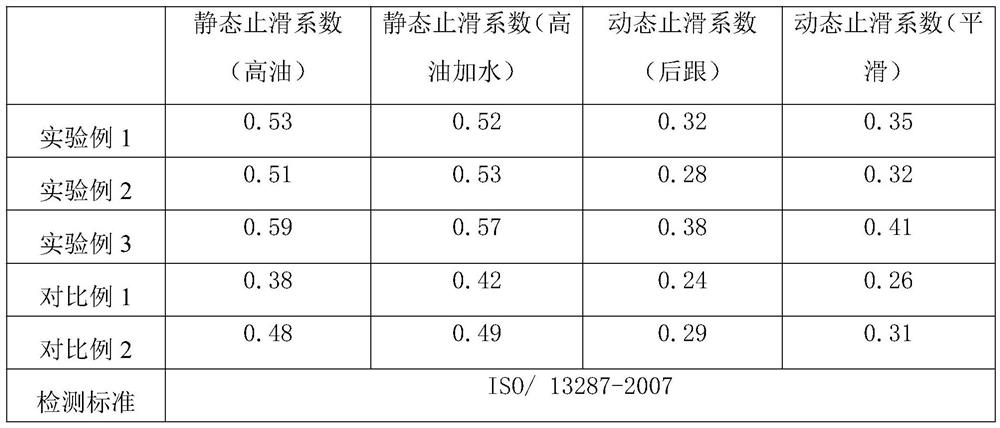

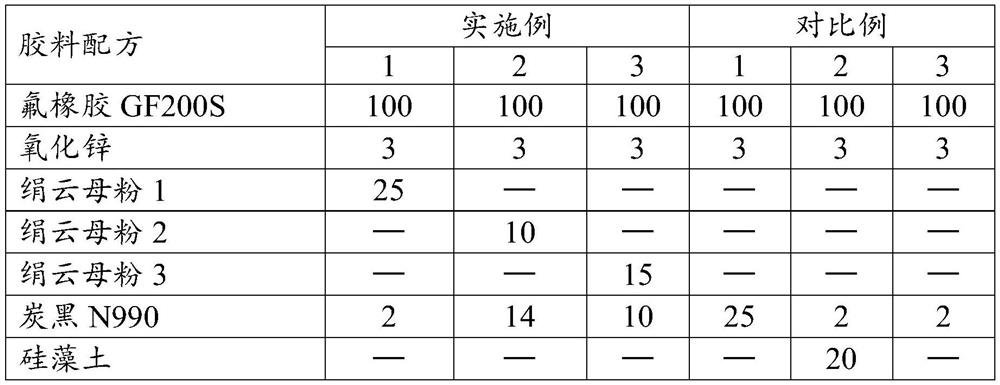

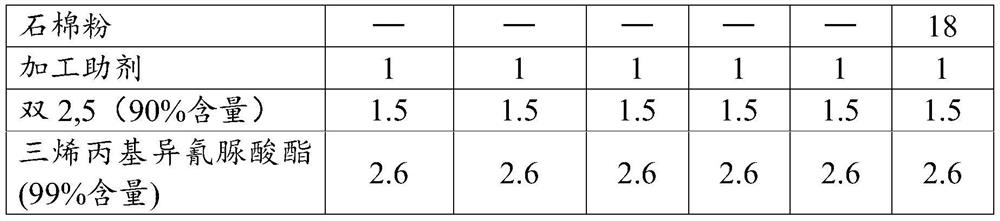

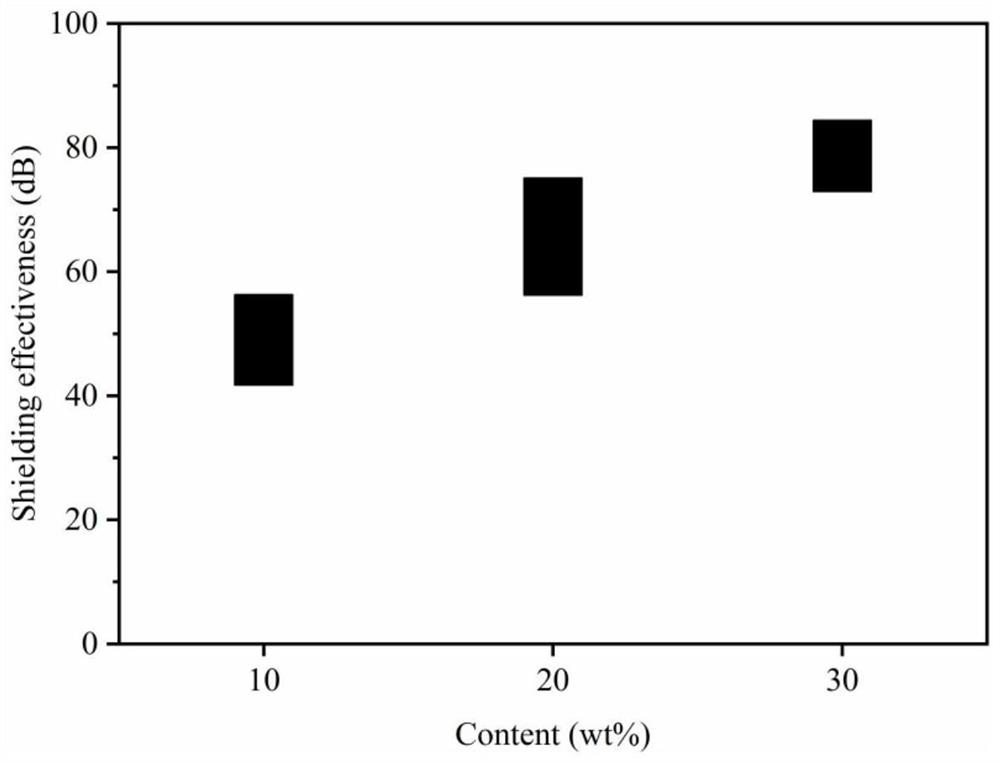

Anti-deformation fluororubber as well as preparation method and application thereof

The invention discloses anti-deformation fluororubber as well as a preparation method and application thereof, and belongs to the technical field of rubber and plastic sealing. The anti-deformation fluororubber comprises the following preparation raw materials in parts by weight: 100 parts of fluoroperoxide rubber, 3 parts of metal oxide, 0-20 parts of a first filler, 10-25 parts of a second filler, 0-3 parts of a processing aid, 1.0-3.0 parts of peroxide and 2.4-3.0 parts of a cross-linking agent, wherein the second filler is a layered filler. Through adjustment of a filler network, the fluororubber is filled with the layered filler with good rigidity and high radius-thickness ratio, so that the deformation-resistant fluororubber obtains excellent dimensional stability under the synergistic supporting action of a cross-linked network and the filler network, and is suitable for thin products within 1mm; therefore, the deformation capability of thin products in the online assembly, storage and transportation processes is solved, and meanwhile, six function tests required by the power battery sealing element can be met.

Owner:GUANGZHOU MECHANICAL ENG RES INST +2

A kind of multi-layer electromagnetic shielding composite material based on isolation structure and its preparation method and application

ActiveCN112848586BImprove electromagnetic shielding performanceImprove mechanical propertiesMagnetic/electric field screeningSynthetic resin layered productsMetal nanowiresReflective layer

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

High-thermal-conductivity electromagnetic shielding polyether-ether-ketone composite material with isolation structure as well as preparation method and application thereof

ActiveCN113337077AImprove conductivityImprove thermal conductivityPoly ether ether ketoneCarbon nanotube

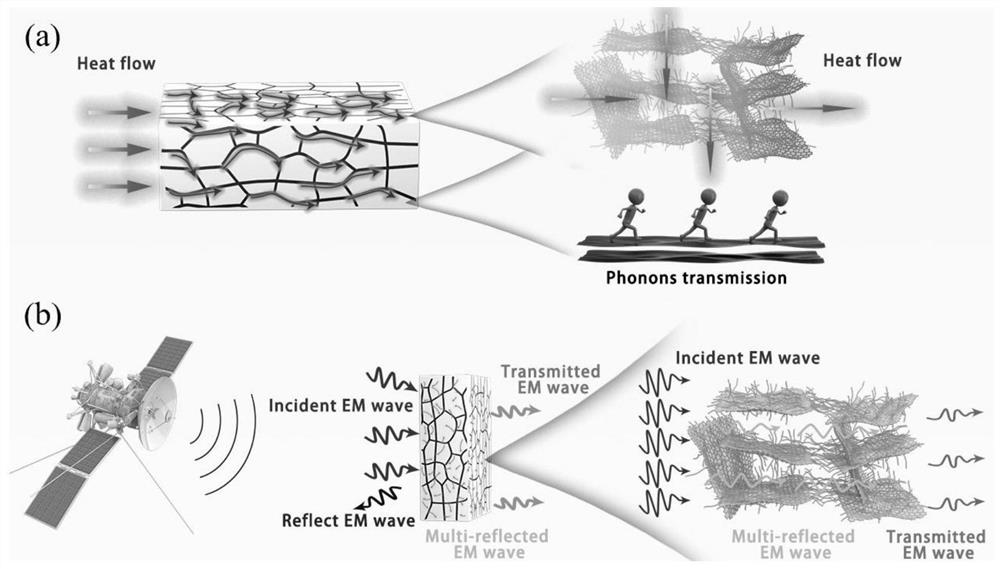

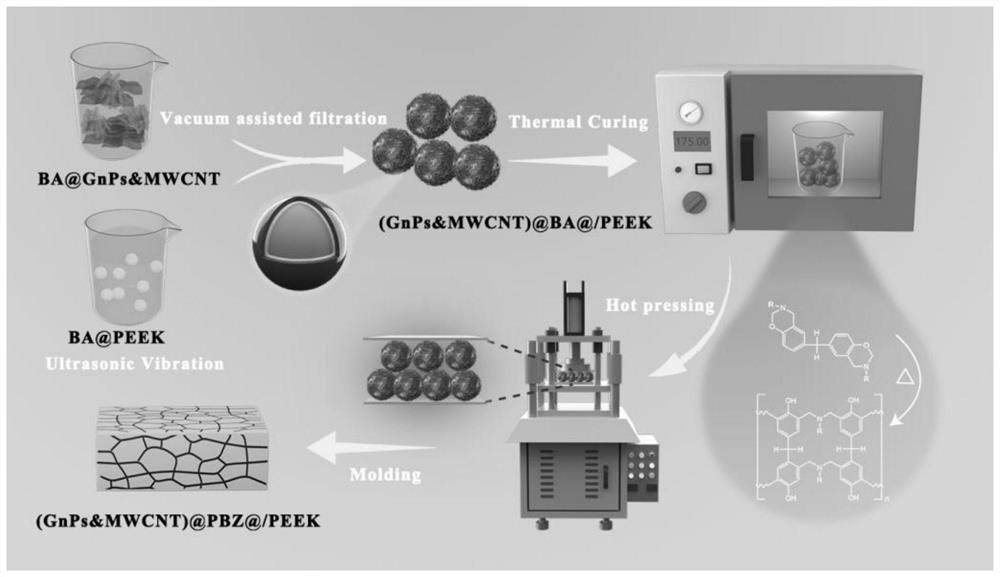

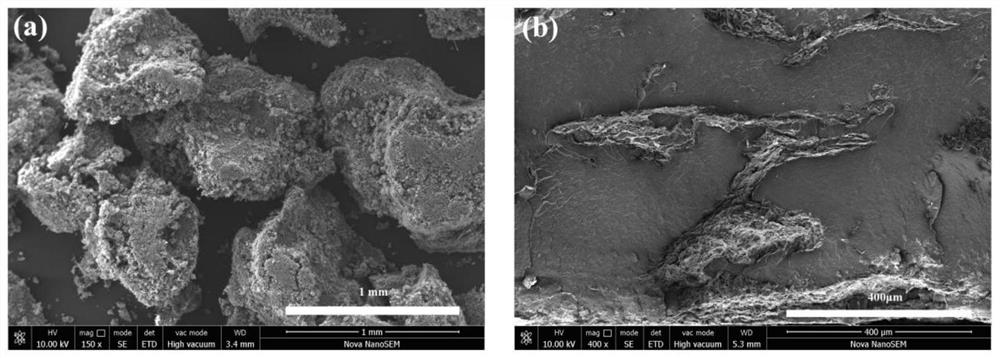

The invention provides a high-thermal-conductivity electromagnetic shielding polyether-ether-ketone composite material with an isolation structure and a preparation method and application thereof, and belongs to the technical field of composite materials. According to the invention, the carbon nanotubes and the graphene are used as synergistic mixed fillers, so the contact area between the fillers is increased, establishment of a filler network is facilitated, and the transmission effectiveness is improved; polybenzoxazine with a hydrogen bond effect is introduced to modify and compound the polyether-ether-ketone and the mixed filler to obtain the polyether-ether-ketone composite particle with the mixed filler as a skin layer, the polybenzoxazine as an adhesion layer and the polyether-ether-ketone particle as a core. And the high-thermal-conductivity electromagnetic shielding polyether-ether-ketone composite material with the isolation structure is obtained through cross-linking solidification and melting hot pressing. The polyetheretherketone is modified by the benzoxazine polymer layer, an isolation structure is constructed, a stable and efficient heat-conducting and electric-conducting transmission network is formed, the interface compatibility of the filler and the polymer is improved, the interface thermal resistance is reduced, and the material has good heat-conducting and electromagnetic shielding performance.

Owner:JILIN UNIV

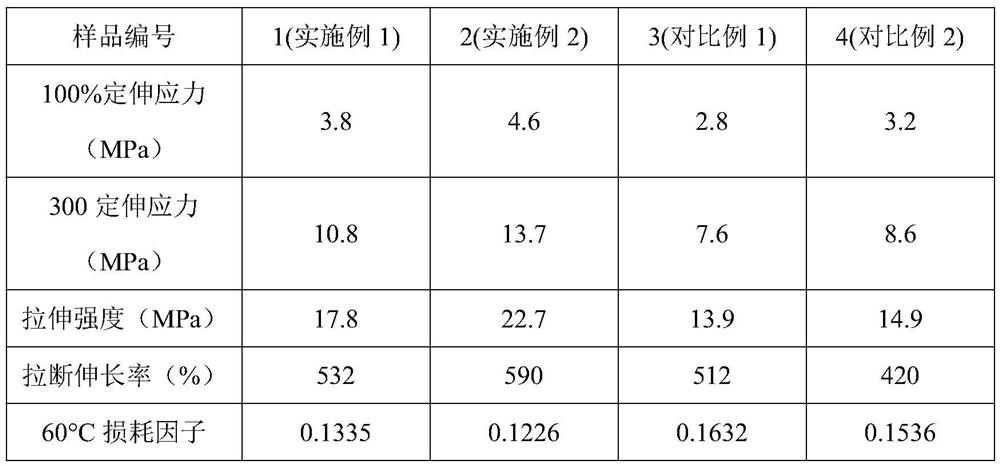

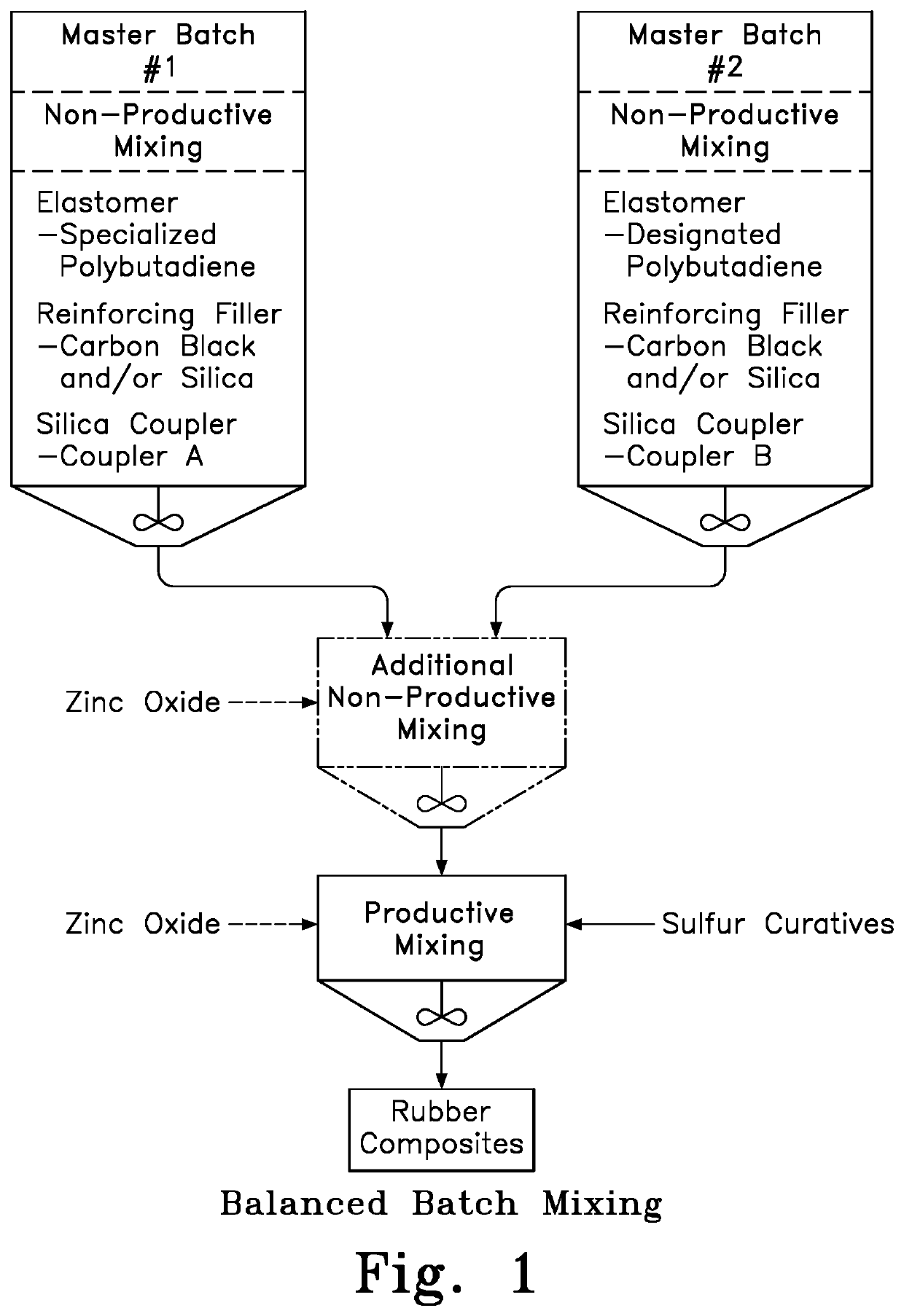

Rubber composition containing dual polybutadiene elastomers with balanced filler reinforcement network, preparation and tire with component

ActiveUS20200247981A1Less internal heat generationImprove rolling resistanceSpecial tyresTyre tread bands/patternsElastomerPolymer science

The invention relates to preparation of a rubber composition which contains polybutadiene elastomers with balanced reinforcing filler network, rubber composition prepared thereby and tire with at least one component comprised of such rubber composition.

Owner:THE GOODYEAR TIRE & RUBBER CO

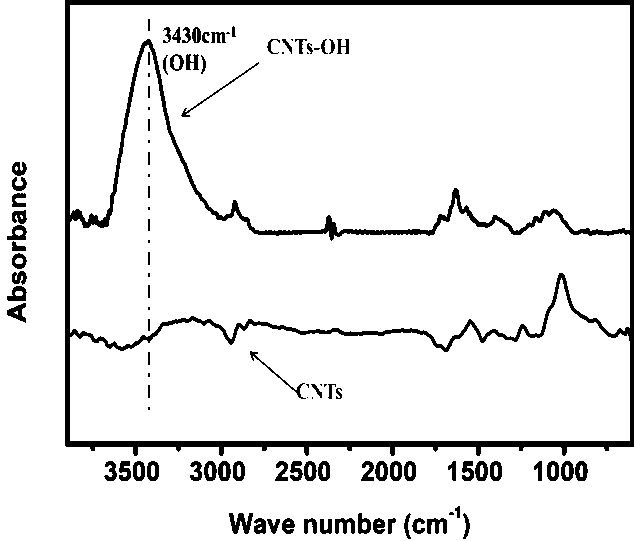

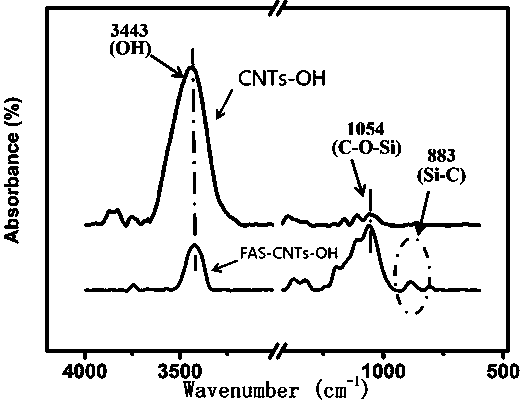

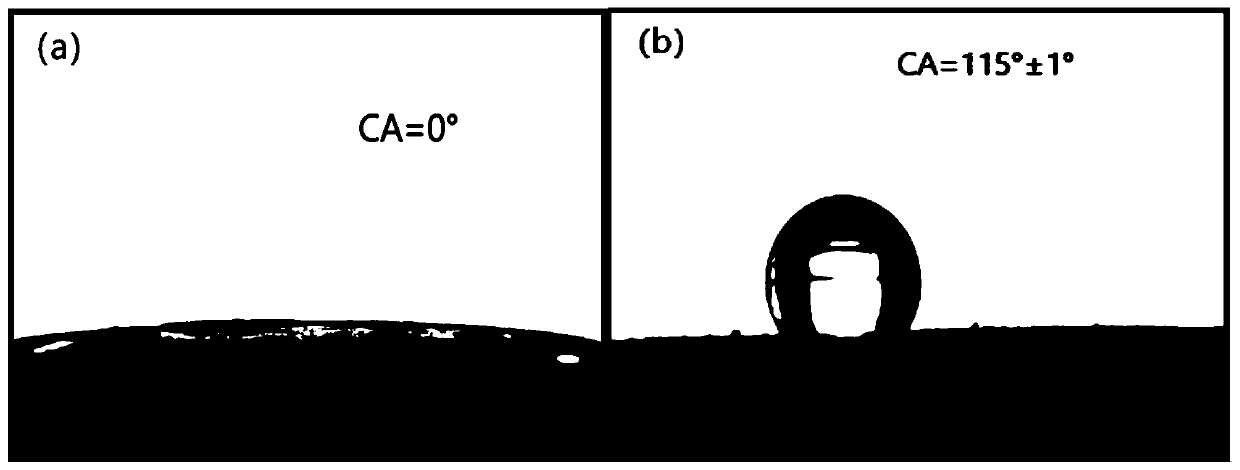

Method for functional modification of carbon nanotubes (CNTs) applicable to composite rubber system

InactiveCN111187449AEasy to operateNo reduction in lengthPigment treatment with organosilicon compoundsRubber materialPolymer science

The invention provides a method for functional modification of CNTs applicable to a composite rubber system. The method comprises the following steps: treating CNTs by using a covalent bond modification method, i.e., a hydrogen peroxide (H2O2) oxidation method so as to form hydroxyl functional groups on the surfaces of CNTs through oxidation; and then subjecting a silane coupling agent, i.e., (heptadecafluoro-1,1,2,2-tetradecyl)trimethoxysilane (CF3(CF2)7CH2CH2Si(OC2H5)3) (AC-FAS) and the hydroxyl groups on the surface of the CNTs to a dehydration condensation reaction so as to successfully introduce the silane coupling agent to the surfaces of the CNTs. A contact angle test result shows that the surfaces of the CNTs functionalized by the method are changed from hydrophilicity to hydrophobicity, so the compatibility of the CNTs with a rubber matrix is effectively improved. A carbon black / carbon nanotube composite rubber material prepared from 5 phr of the functionalized carbon nanotubes has excellent mechanical properties, and the heat-conducting property of the carbon black / carbon nanotube composite rubber material can be improved by 11.9%. The dispersibility of the CNTs and the compatibility between the CNTs and the matrix are well improved; the dispersion of the CNTs effectively promotes the dispersion of the carbon black; and the two fillers, namely the CNTs and the carbonblack, construct a good filler network in the rubber matrix. The functional modification method provided by the invention effectively solves problems in application of the carbon nanotubes to rubber.

Owner:QINGDAO UNIV OF SCI & TECH

Heat-conducting gel and preparation method thereof

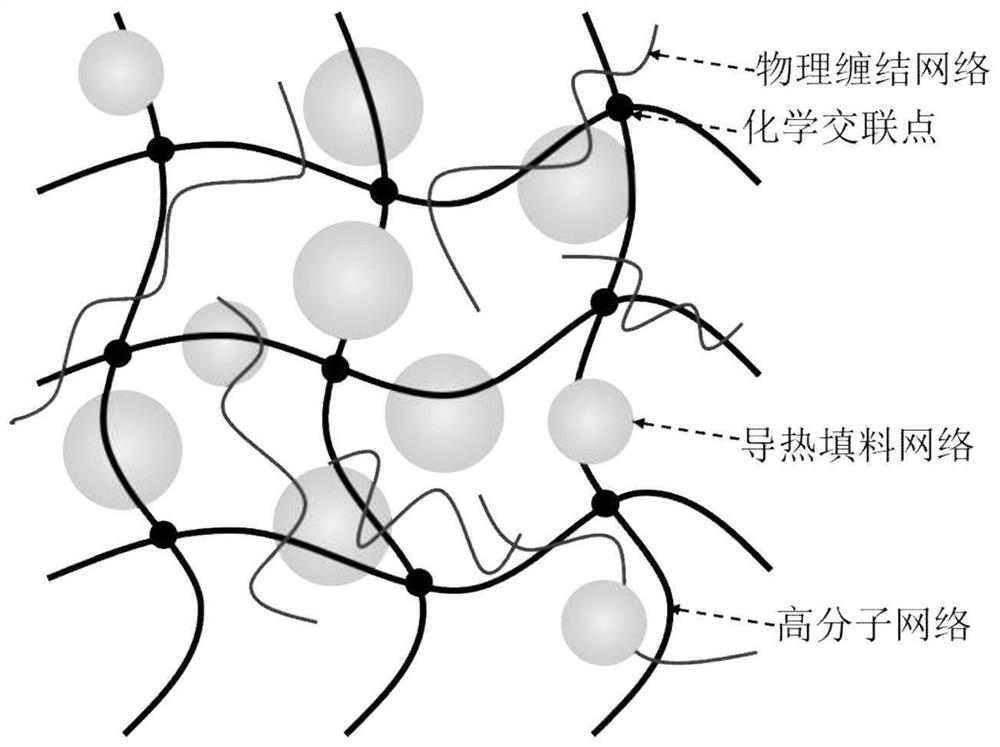

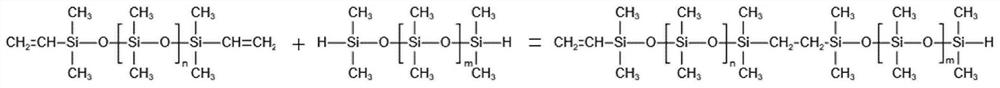

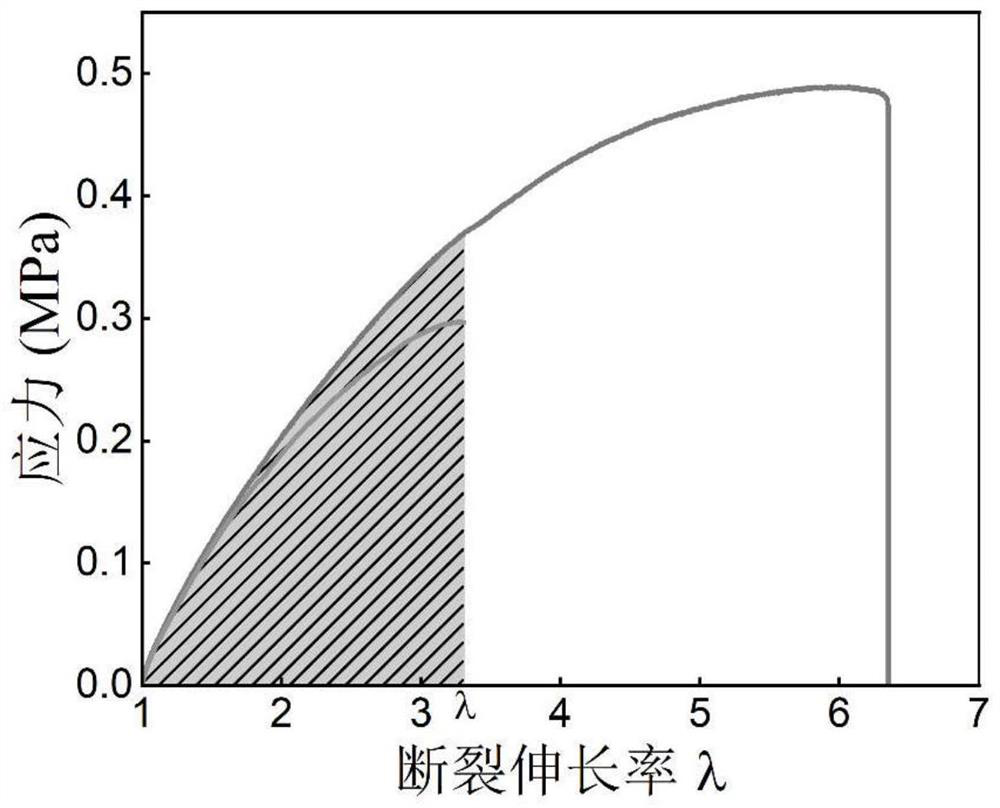

ActiveCN114292521AImprove toughnessImprove thermal conductivityHeat-exchange elementsElastomerPolymer science

The invention discloses heat-conducting gel and a preparation method thereof. The heat-conducting gel comprises the following raw material components in parts by mass: 1-20 parts of side chain vinyl silicone oil; 1-20 parts by mass of double-end hydrogen-containing silicone oil; 1-20 parts by mass of double-end vinyl silicone oil; 0.01 to 1.0 part by mass of a catalyst; 0.001 to 0.5 part by mass of an inhibitor; and 60-90 parts by mass of a heat-conducting filler. Starting from the design of a heat-conducting gel molecular chain structure, a large number of molecular chain physical entanglement networks, chemical cross-linked networks and heat-conducting filler networks are introduced into an organic silicon elastomer, and the characteristic that physical entanglement points slide along with molecular chains through external force is utilized, so that the ultrahigh toughness (200-8000J / m < 2 >) of the organic silicon thermal interface material is realized; the high thermal conductivity (0.5-8.0 W / mK) and the low contact thermal resistance (2.00-0.05 DEG C * cm < 2 > / W) of the organic silicon thermal interface material are realized at the same time by utilizing a thermal conduction path formed by the interaction between the thermal conduction filler and molecular chain entanglement.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS +1

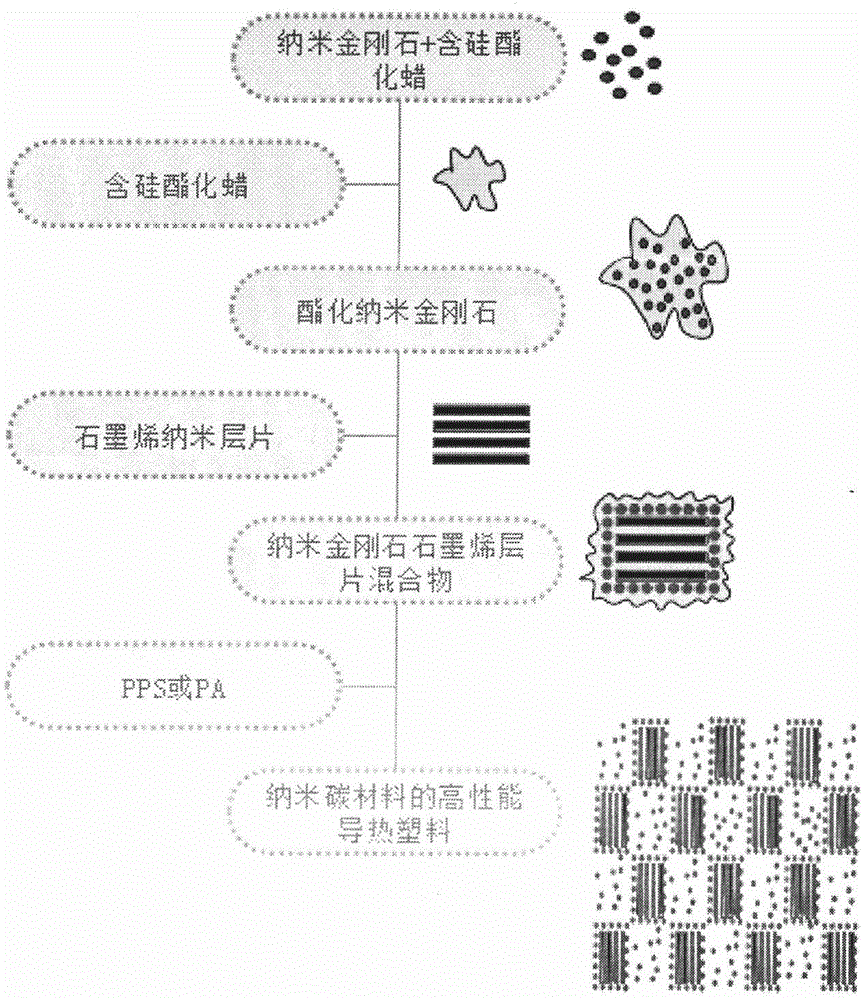

Nanocarbon material-based high-performance heat conducting material and preparation method thereof

InactiveCN104448817AHigh thermal conductivityGood dispersionHeat-exchange elementsPolymer scienceHeat conducting

The invention discloses a nanocarbon material-based high-performance heat conducting material and a preparation method thereof. The preparation method comprises the following steps: mixing nanodiamond with graphine nanoply as a heat conducting filler, pretreating the heat conducting filler, constructing a filler network by utilizing the esterified nanodiamond coated graphine nanoply mixture in a polymer matrix, performing 'forced parallel connection' to form mutual contact and further form a heat conducting channel so as to realize better dispersion of the nanodiamond and graphine nanoply in a composite material. Heat conducting powder enters into the polymer matrix in a dispersing manner to forcibly form a mutually connected heat conducting channel network, heat is efficiently conducted through the shaking transfer of the heat conducting filler, the formed heat conducting network does not pass through the hollow part and is guided out directly from the heat conducting powder, so that the heat conducting efficiency is greatly improved. The prepared high heat conducting material can be used for forming heat radiation parts of various electrical appliances and automobiles, and has larger practical application values.

Owner:广州索润科技股份有限公司

Thermally conductive polymer composite material with multi-level continuous network structure and preparation method

ActiveCN112574468BSmall average distanceRaw materials are easy to obtainHeat-exchange elementsConductive polymer compositeNetwork structure

Owner:济南英维新材料科技合伙企业(有限合伙)

A method for preparing multi-layer filler/fluoroether rubber composition by lamination method

The invention relates to a method for preparing a multilayer filler / fluoroether rubber composition through a layering method. The method includes the steps that filler such as carbon black and carbon nanotubes is dispersed on the surfaces of rubber thin films through a direct dispersion method or jet dispersion method; and the rubber thin films containing the filler are compounded layer by layer and then pressurized and vulcanized to obtain a fluoroether rubber material with a multilayer structure. According to the method, the filler / fluoroether rubber composition which is prepared by compounding a single-filler network structure into the multilayer structure with different dimensions or distribution characteristics through a special process method brings excellent performance in all directions into play, has excellent tensile strength, elongation at break and medium resistance, is suitable for being used in sealed environments, and further improves reliability of sealing structures.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com