Interface supramolecular reinforced nano composite material and preparation method thereof

A nanocomposite material and supramolecular technology, applied in the field of interfacial supramolecule reinforced nanocomposite materials and its preparation, can solve the problems of lack of interface design, material processability and mechanical properties decline, hindering the practical application of materials, etc., to achieve the benefit of large Effects of large-scale application, reduction of preparation cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] TA-WS 2 Preparation of nanosheet dispersion: 240 mg of tungsten disulfide (WS 2 ) powder, 120 mg of tannic acid (TA) were added to 120 mL of deionized water, and then ultrasonicated for 2 h with an ultrasonic pulverizer at 300 W. Finally, centrifuge at 6000rpm for 15 minutes and take the supernatant to remove unstripped WS 2 , collecting WS stable in TA solution 2 nanosheets, prepared TA-WS 2 nanosheet dispersion.

[0030] TA-WS 2 / PU composite preparation: First, TA-WS 2 Nanosheet dispersion (72g, 0.1wt%) was added to polyurethane latex (1g, 60wt%), and stirred for 30 minutes. Next, the mixed TA-WS 2 / PU latex is vacuum filtered through a polypropylene filter membrane with a pore size of 0.22 μm to obtain TA-WS 2 / PU film, TA-WS 2 / PU membrane attached to the filter membrane. The formed film was dried in air at room temperature for 4 hours, and then peeled off from the polypropylene filter membrane to obtain WS 2 / PU composite material.

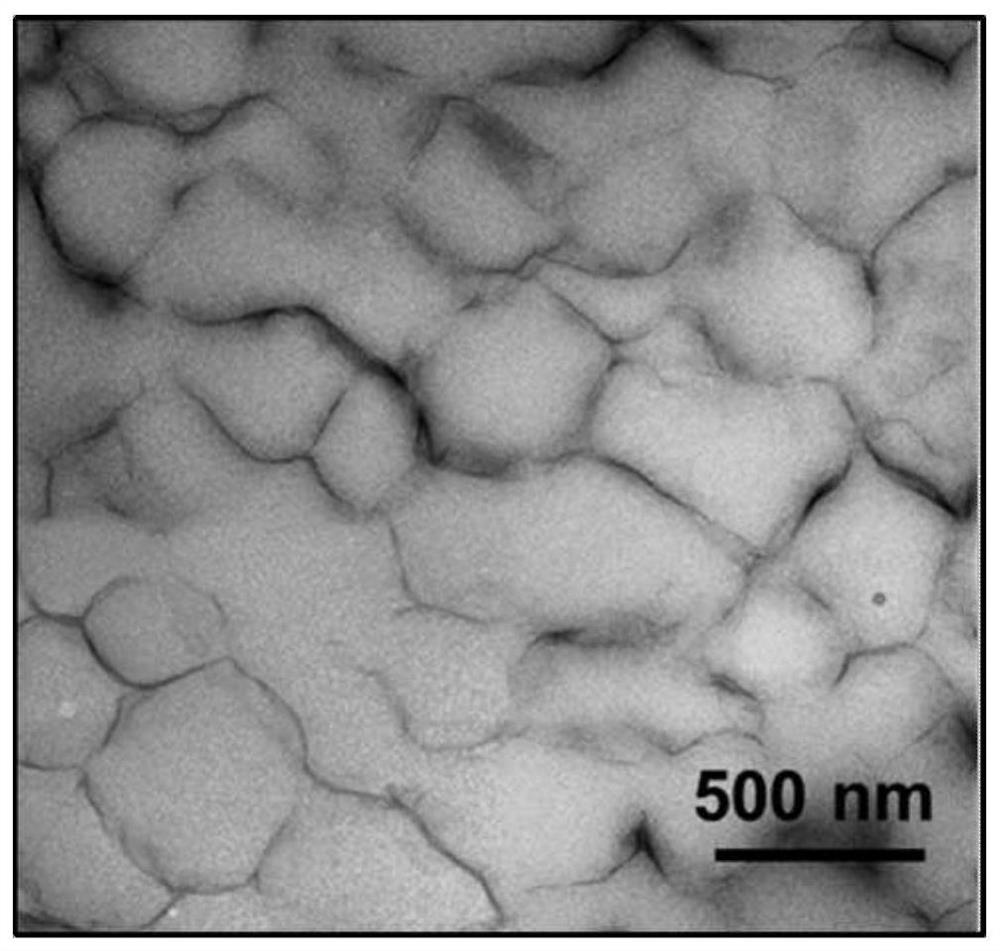

[0031] The transmi...

Embodiment 2

[0033] Preparation of polydopamine@halloysite nano-hybrid dispersion: mix dopamine (1.0g) in 100ml, 0.5w% halloysite suspension dispersion, add appropriate amount of NH 3 ·H 2 O (28%). Thereafter, the solution was reacted for 2 hours under vigorous stirring. Rinse several times with deionized water to obtain polydopamine@haloysite nanohybrid dispersion.

[0034] Preparation of photothermal nanocomposites: Add epoxidized natural rubber (1.7g, 35wt%) and polydopamine @ halloysite suspension (12g, solid content: 0.5wt%) under strong stirring conditions, ultrasonic 5min, preparation Supramolecular reinforced nanocomposite latex was obtained. The obtained composite latex was dropped into a polytetrafluoroethylene mold, and baked in an oven at 65°C for 4 hours to obtain a nanocomposite material reinforced by multiple hydrogen bonds at the interface.

Embodiment 3

[0036] Fe 3+ -Preparation of GO nanosheet dispersion: graphene (GO) nanosheets were prepared according to the modified Hummer method. Graphite powder (3.0g, 1wt%), FeCl 3 (2g) and KMnO 4 (18.0g, 6wt%) mixed and slowly added concentrated H2 SO 4 / H 3 PO 4 (360:40 v / v) mixture. The obtained blend was then heated to 50 °C and stirred for 12 h. Afterwards, the blend was cooled to room temperature and kept at 30% H 2 o 2 (3 mL) in an ice bath. The resulting product was purified by repeated centrifugation and dialysis in deionized water.

[0037] Preparation of GA-ENR emulsion: 2.5 g of gelatin (GA) was dissolved in 97.5 mL of deionized water to obtain a GA solution (1 wt%). In addition, 21.2 g of epoxidized natural rubber (ENR) latex was added to 12.8 g of GA solution and vigorously stirred at room temperature for 10 min to prepare GA-ENR emulsion.

[0038] Preparation of nanocomposites: 84.21 g of Fe intercalated 3+ The GO dispersion was mixed with GA-ENR latex, stirre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com