Anti-deformation fluororubber as well as preparation method and application thereof

A fluororubber and anti-deformation technology, applied in the field of anti-deformation fluororubber and its preparation, can solve the problems of inability to meet the continuous working life of 15 years, inability to adapt to a wide range of compression deformation capacity, and decrease in glue content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1~3

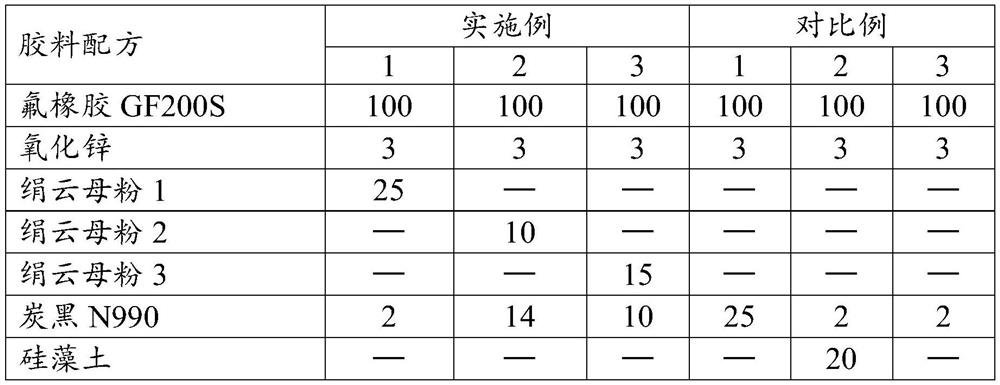

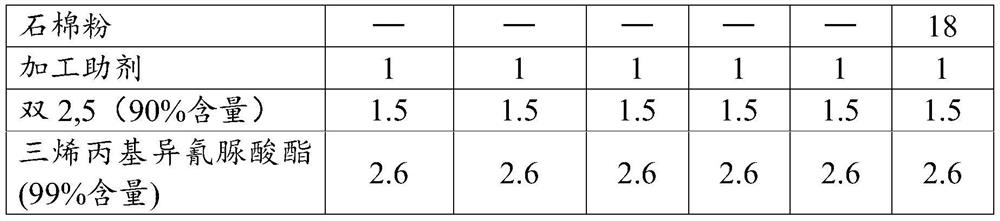

[0028] See Table 1 for the raw material formulations of the anti-deformation fluororubbers described in Examples 1-3 and Comparative Examples 1-3.

Embodiment 1~3 and comparative example 1~3

[0029] The preparation method of the anti-deformation fluororubber described in Examples 1-3 and Comparative Examples 1-3 comprises the following steps:

[0030] (1) Add fluoroperoxide rubber, zinc oxide, filler, layered filler, processing aid, peroxide and part of crosslinking agent into an open mill and mix to obtain a semi-finished product;

[0031] (2) Mold and vulcanize the semi-finished product in a flat vulcanizing machine with a temperature of 170°C and a vulcanization pressure of 15MPa for 10 minutes. After removing the flash, put it into an oven at a temperature of 230°C for secondary vulcanization for 4 hours, clean, pack and store , to obtain the anti-deformation fluororubber.

[0032] The raw material formula / weight part of anti-deformation fluororubber described in Table 1 embodiment 1~3 and comparative example 1~3

[0033]

[0034]

[0035] Remarks: sericite powder 1 diameter-thickness ratio > 70, particle size 800 mesh; sericite powder 2 diameter-thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com