Patents

Literature

509 results about "Viton" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Viton is a brand of FKM, a synthetic rubber and fluoropolymer elastomer commonly used in O-rings, chemical-resistant gloves, and other molded or extruded goods. The name is a registered trademark of The Chemours Company.

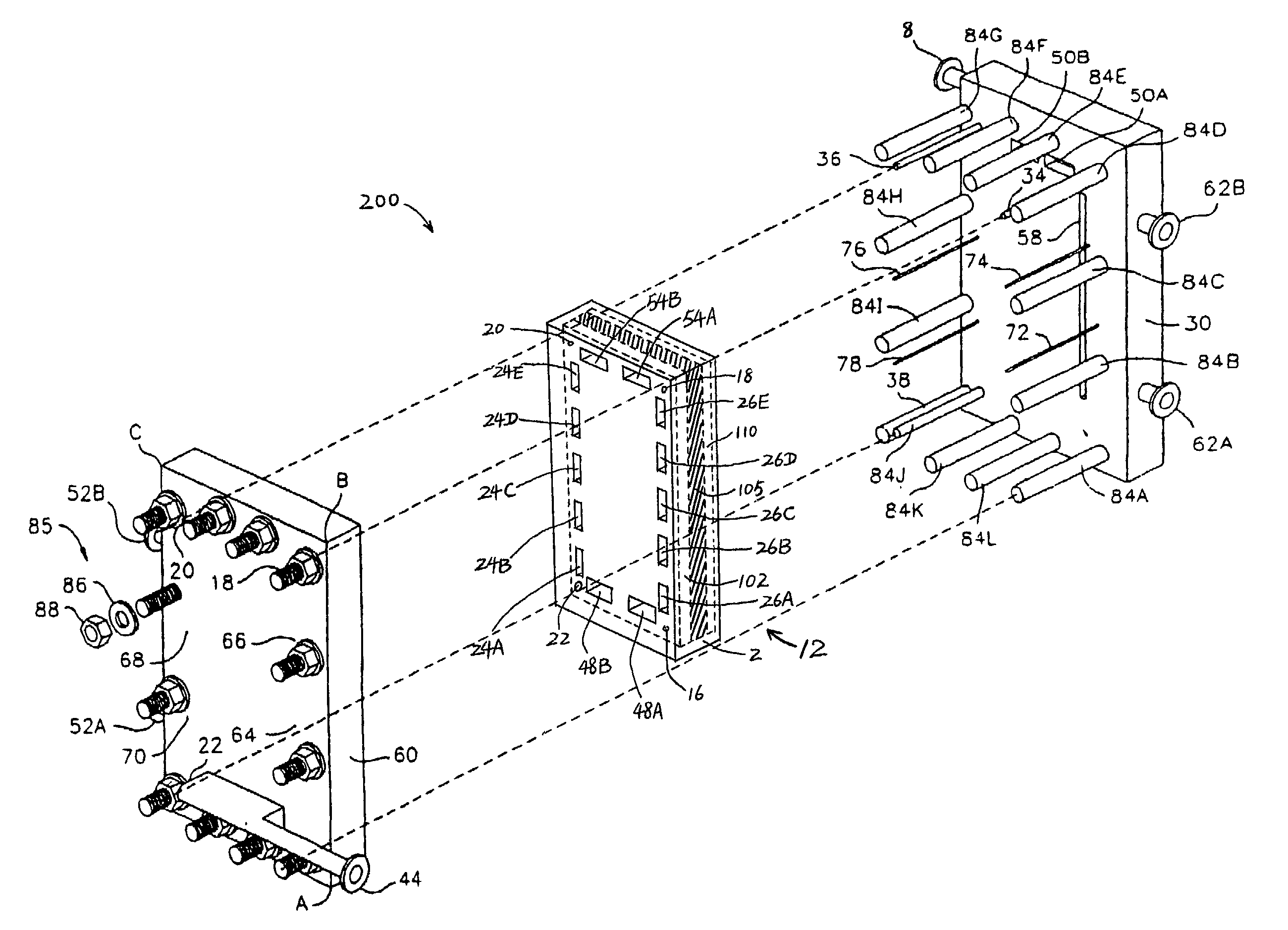

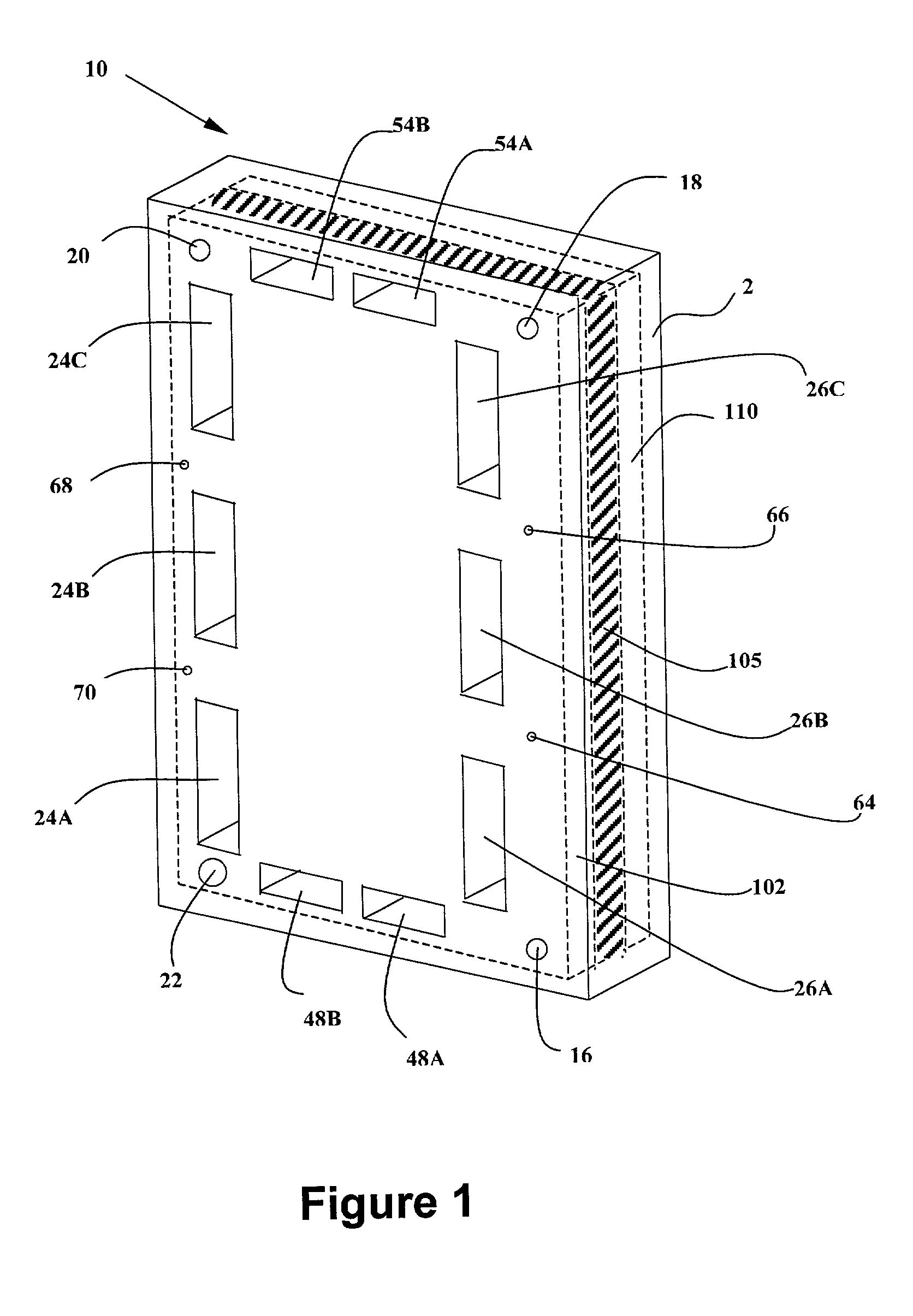

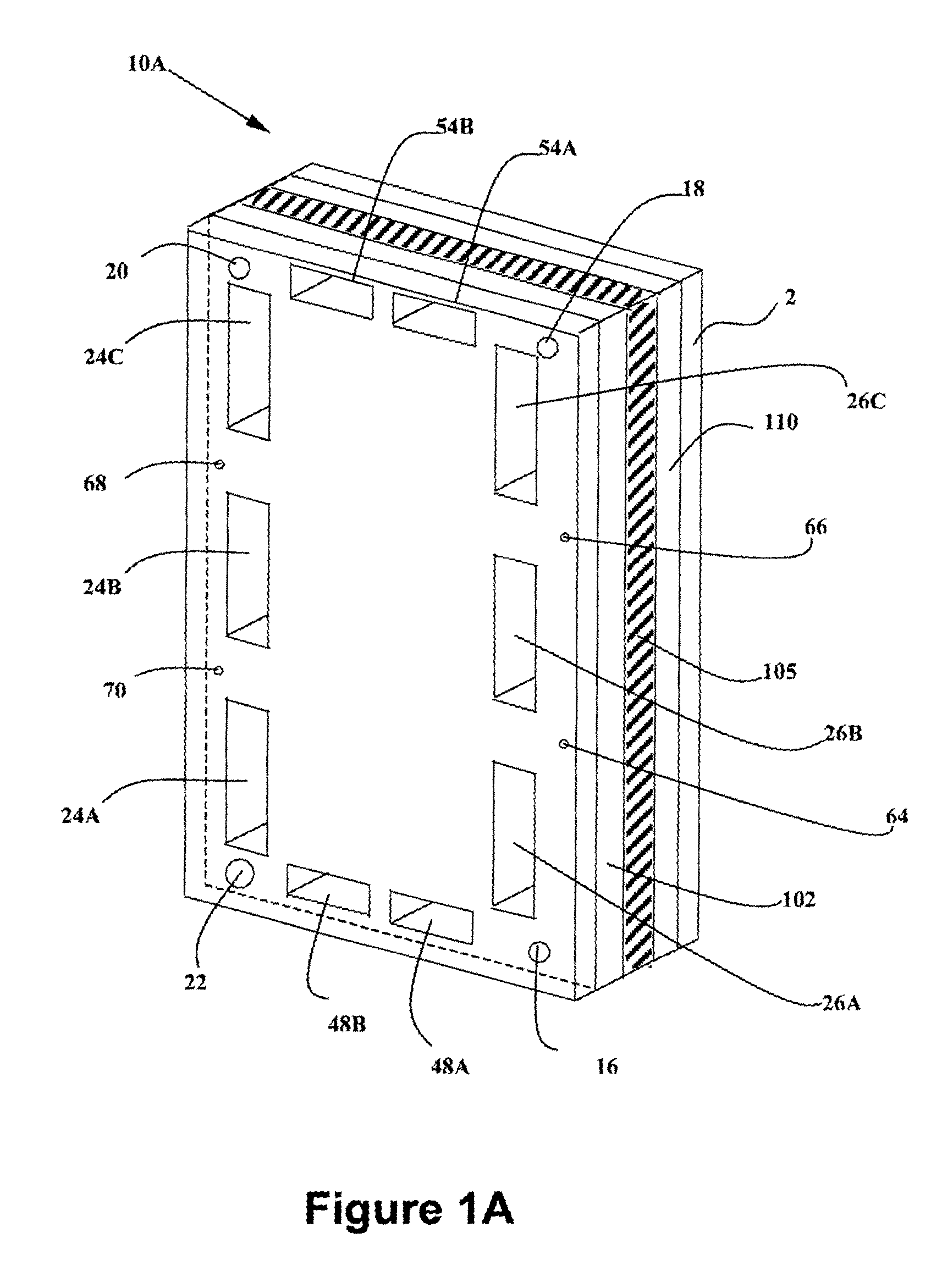

Integral gasketed filtration cassette article and method of making the same

InactiveUS20020139741A1Simple and efficient and economicalLow costSemi-permeable membranesFiltration separationEpoxyPolyester

An integral gasketed filtration cassette structure of a type comprising a filtration cassette fully or partially overcoated by a gasket layer, forming a fluid-tight seal between the filtration cassette and the filtration cassette holder to which the filtration cassette is to be affixed. The filtration cassette comprises filter sheets arranged in a multilaminate, peripherally bonded array, wherein the filter sheets alternate with permeate and retentate sheets. The gasket layer comprises an elastomeric material with suitable hardness and temperature resistance for sealing, such as silicone, ethylenepropylenedienemonomer (EPDM), viton, polyurethane, polypropylene, polyethylene, polyvinylchloride, polyester, epoxy, ethylvinylacetate, bunnas, and styrene butadiene. The filtration cassettes and filter of the invention may be advantageously employed for dewatering of aqueous biomass suspensions, desalting of proteins, removal of secreted metabolites from cellular suspensions, and the like.

Owner:KOPF HENRY III

Raw paper of high-performance environment-friendly paper based friction material and manufacturing method of friction plate

ActiveCN101805589AGood physical and mechanical propertiesIncrease coefficient of frictionOther chemical processesNon-macromolecular organic additionAdhesiveStatic friction

The invention discloses raw paper of a high-performance environment-friendly paper based friction material and a manufacturing method of a friction plate. The high-performance environment-friendly paper based friction material is characterized by comprising the following components in percentage by weight: a substrate comprises 7-15% of carbon fiber, 5-10% of chopped aramid fiber, 5-10% of aramidpulp and 9-30% of bamboo fiber pulp; a friction agent comprises 10-20% of kieselguhr and 8-12% of cashew nut shell powder; a frictional property regulator adopts 2-4% of rubber particles, 5-10% of calcium carbonate and 10-15% of flake graphite; and a forming adhesive comprises 1-2% of fluororubber, 3-15% of silicone resin and 3-15% of phenolic resin. The invention fully forms the materials of thefriction material into a whole by changing the traditional impregnation process, effectively improves the physical and mechanical properties of the friction plate, improves the friction factors, regulates the dynamic and static friction ratio factors, and reduces the abrasion ratio of the friction plate.

Owner:陕西帕若德新材料科技有限公司

Fluoropolymer organic lining anticorrosive material for chimney, flue and other pipelines and containers and construction method thereof

ActiveCN101891993AImprove temperature resistanceImprove acid resistanceBio-packagingLarge containersVulcanizationAdhesive

The invention provides an anticorrosive material for a chimney, a flue and other containers and pipelines and an anticorrosive construction process. The construction method of the anticorrosive material comprises the following steps: using crude rubber with higher fluorine content as a raw material, then adding curing agent, stabilizer, special stuffing and other components, and mixing to form precuring gross rubber; dissolving the rubber by using low-molecular weight esters and ketones as the solvent to form a putty type rubber paste; and finally, adding special additives, uniformly mixing, coating to the inner walls of a chimney, a flue and a chemical container, and curing into the polymerized fluororubber organic lining under the room-temperature condition. The material can be independently used as the anticorrosive material, and can also be used for protecting common foam glass bricks (ceramic bricks) and adhesive for anticorrosive purpose in the domestic chimney (flue) at present. The invention well solves the technical problems of fluororubber room-temperature curing and difficult anticorrosive construction, can be used in a high-temperature environment of more than 230 DEG C, and can endure high-concentration sulfuric acid, nitric acid, hydrochloric acid, phosphoric acid, hydrofluoric acid, corresponding salts and a mixture thereof. The anticorrosive lining material is economically affordable, has extremely high comprehensive anticorrosive properties such as temperature resistance, acid resistance and the like, and is applicable to the anticorrosive treatment of a cured chimney.

Owner:重庆大众防腐股份有限公司

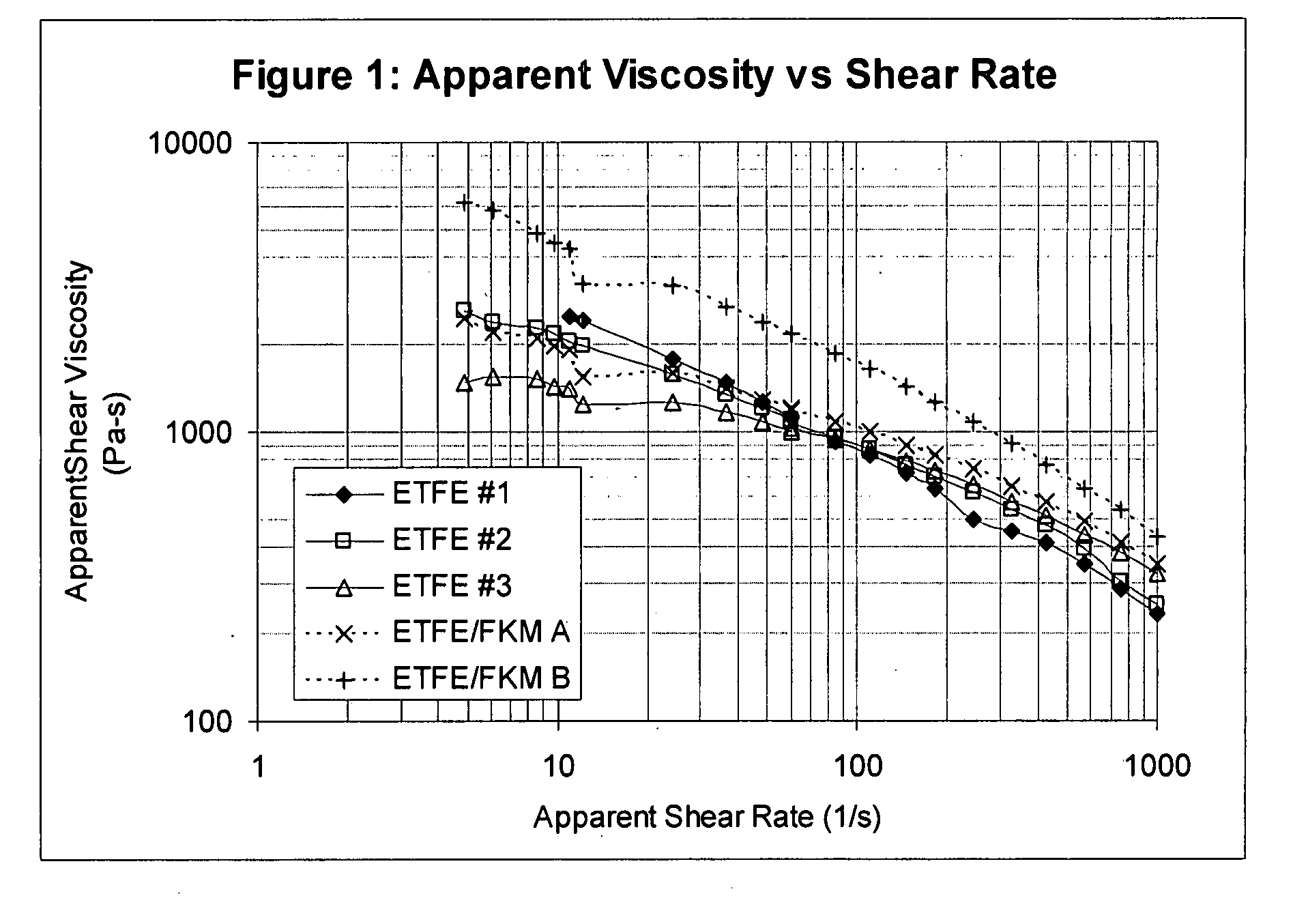

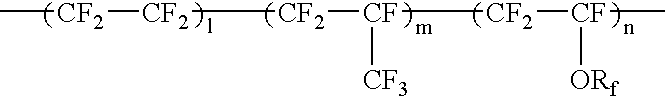

Thermoplastic Polymer Composition

InactiveUS20090011164A1Excellent formabilityMaintain good propertiesBottlesSynthetic resin layered productsPolymer scienceThermoplastic elastomer

An object of the present invention is to provide a thermoplastic polymer composition which is flexible and capable of melt-molding and has excellent heat resistance, chemical resistance and oil resistance. The thermoplastic polymer composition comprises 10 to 95% by weight of a fluororesin (A) and 90 to 5% by weight of a crosslinked fluororubber (B), in which the fluororubber (A) comprises a fluorine-containing ethylenic polymer (a) having a melting point of 120° to 330° C. and the crosslinked fluororubber (B) is obtained by cross-linking dynamically at least one kind of fluororubber (b-1) or a fluorine-containing thermoplastic elastomer (b-2) in the presence of the fluororubber (A) and a crosslinking agent (C) under melting condition.

Owner:DAIKIN IND LTD

Thermoplastic, moldable polymer composition and dynamic vulcanizates thereof

InactiveUS20080032080A1Good chemical resistanceExcellent fuel barrier propertyEngine sealsOther chemical processesTetrafluoroethylenePolymer science

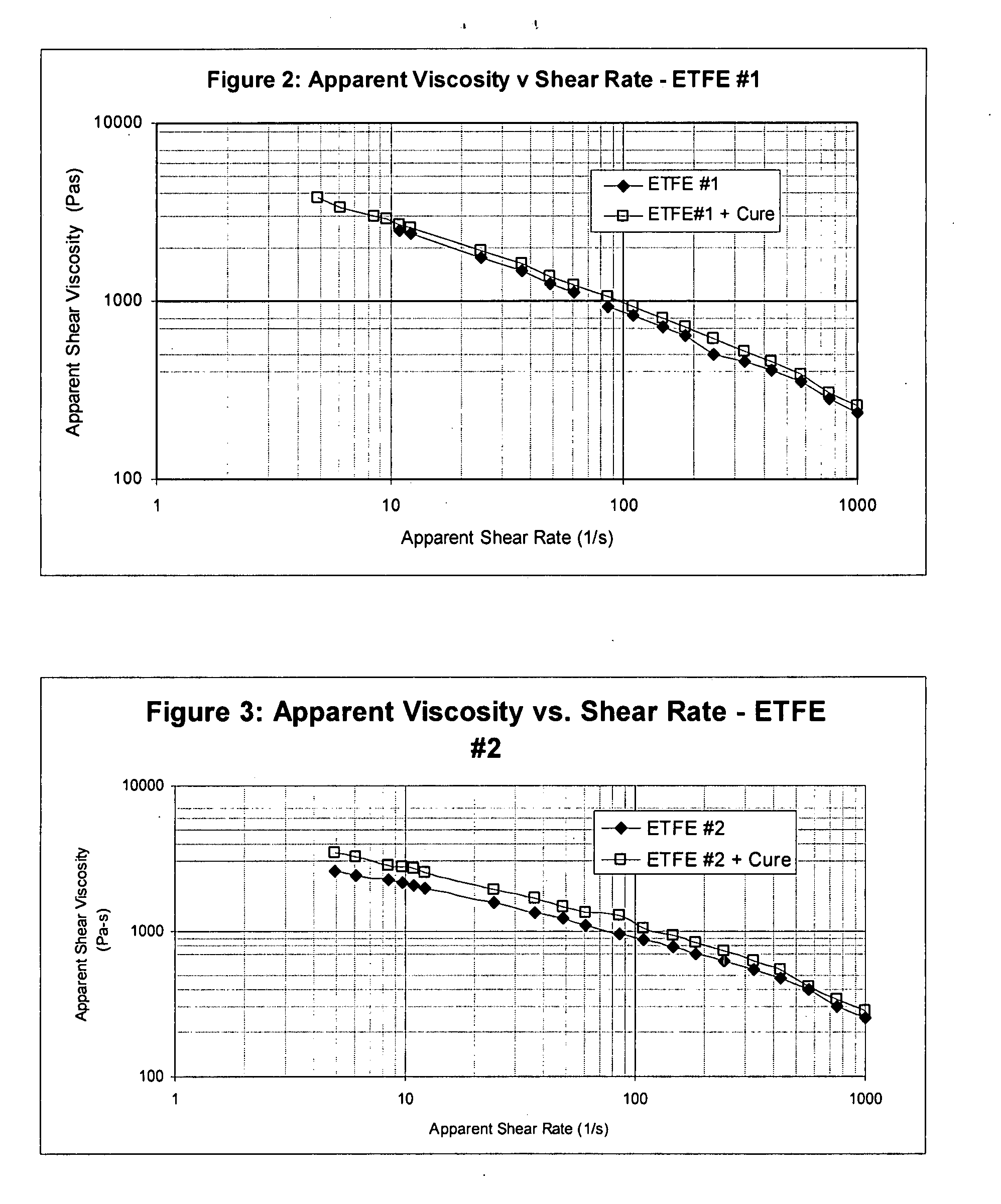

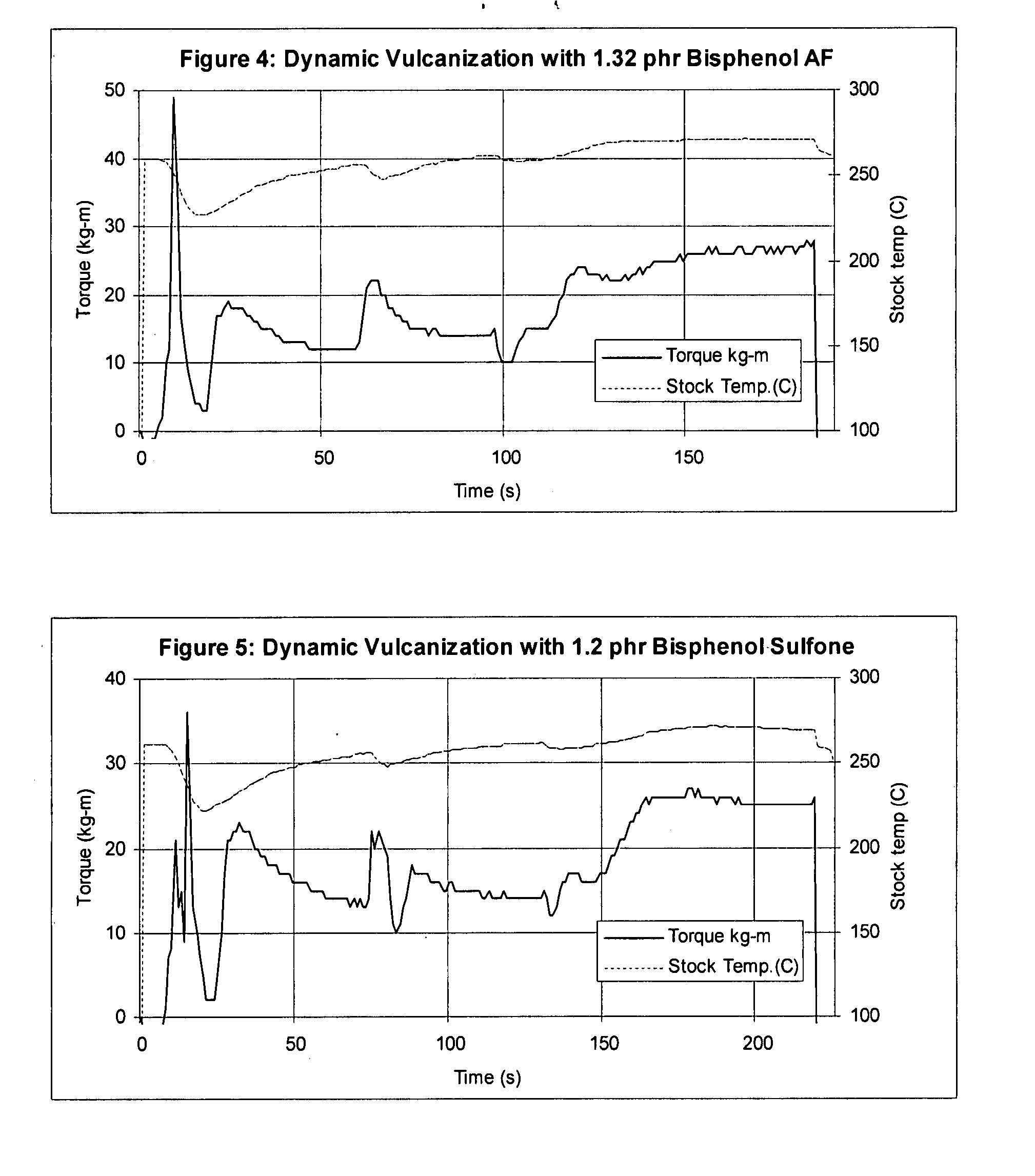

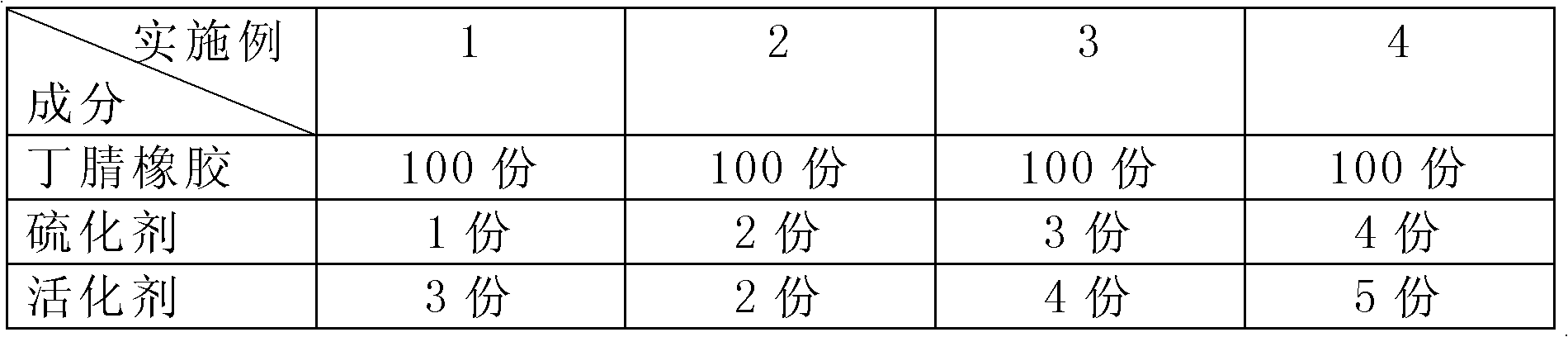

A thermoplastic, moldable, millable, extrudable composition of matter involving at least three polymeric components: a fluoroelastomer, an ETFE (ethylene / tetrafluoroethylene alternating copolymer, which may optionally contain one or more comonomers in minor amounts to alter crystallinity and melting temperature) fluoroplastic, and a block fluoropolymer containing at least one fluoroelastomer block and at least one ETFE block. The fluoroelastomer component and optionally the fluoroelastomer portion of the block fluoropolymer are crosslinked in a dynamic vulcanization process. Also disclosed are multilayer articles in which the aforesaid fluoro-TPV is adhered to an ETFE plastic layer. These bonded multilayer objects may include injection-molded parts that are either co-injected with both ETFE and fluoro-TPV layers, or insert molding jobs in which a previously molded ETFE insert is placed into a mold and surrounded by fluoro-TPV; and also multilayer co-extruded products such as hoses in which a fluoro-TPV layer is extruded against an ETFE layer.

Owner:DAIKIN AMERICA INC

Leather cup rubber for laundry machine and preparation method thereof

The invention discloses leather cup rubber for a laundry machine. The leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of chlorosulfonated polyethylene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorine rubber, 3-5 parts of natural rubber, 20-30 parts of high abrasion furnace black N330, 10-15 parts of modified white carbon black, 3-4 parts of zirconia, 8-10 parts of modified wood ash, 4-6 parts of attapulgite, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of isocyanate, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BZ, 1-2 parts of stearic acid, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of polyethylene wax, 1-2 parts of antioxidant DSTP, 1-2 parts of anti-aging agent NBC, 2-3 parts of gamma-methacryloxypropyl trimethoxysilane and 16-18 parts of triethyl citrate. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

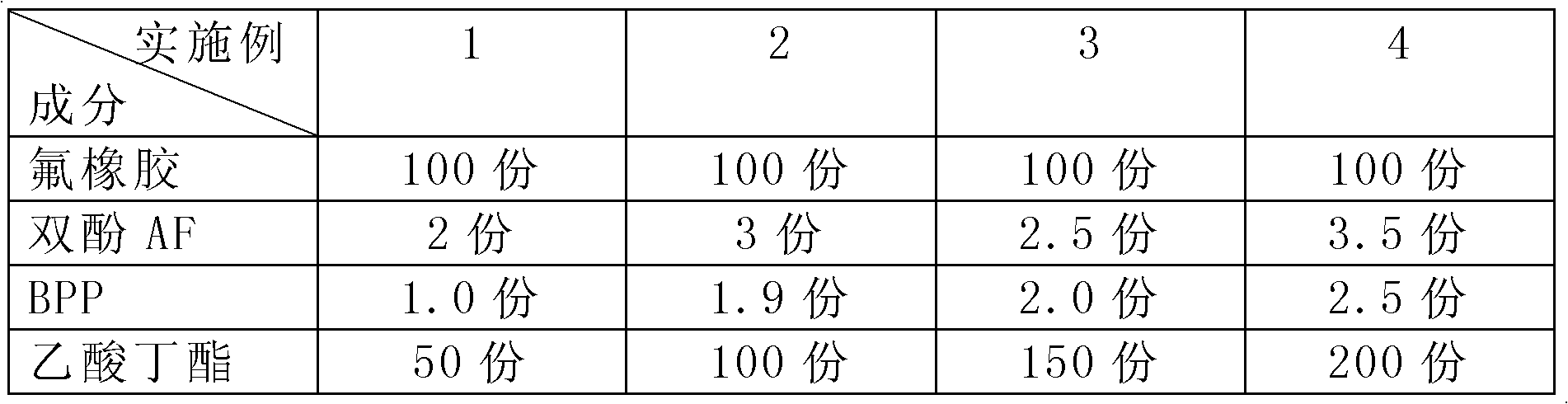

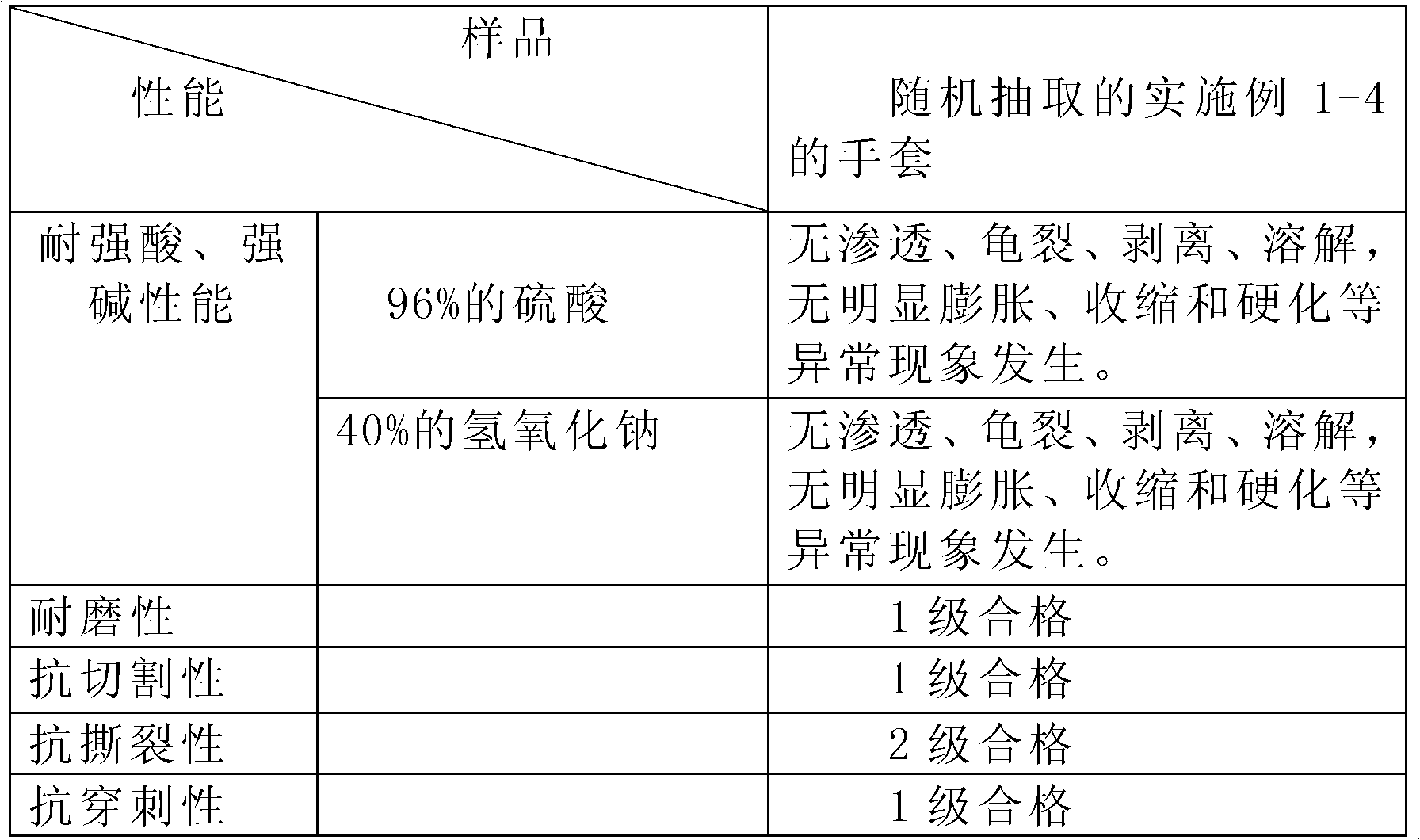

Fluorine/butadiene rubber composite glove and manufacturing method thereof

The invention relates to a fluorine / butadiene rubber composite glove and a manufacturing method thereof, belonging to the technical field of labour protection appliances. The glove comprises a fiber glove lining, the surface of the fiber glove lining is coated with a butyronitrile emulsion layer, the surface of the butyronitrile emulsion layer is coated with a fluorine rubber layer, and fluorine rubber particles are sprayed on the surface of the fluorine rubber layer, wherein the butyronitrile emulsion layer comprises the components such as butyronitrile rubber, a vulcanizer and an activator,and the fluorine rubber cement comprises the components of the fluorine rubber, the vulcanizer, a vulcanization accelerator and an ester solvent. The method for manufacturing the glove comprises three steps burdening, soaking cement and pouring cement. The glove and the manufacturing method in the invention have the following advantages: the performances of resistances to chemicals, strong acid, strong alkali and corrosion are achieved, and the cost is lower; and meanwhile, the method for manufacturing the glove adopts a flow line production manner during the production process, the product process is simple, the cost is lowers, and the glove is applicable to large-scale industrialized production.

Owner:台州达顿安防科技有限公司

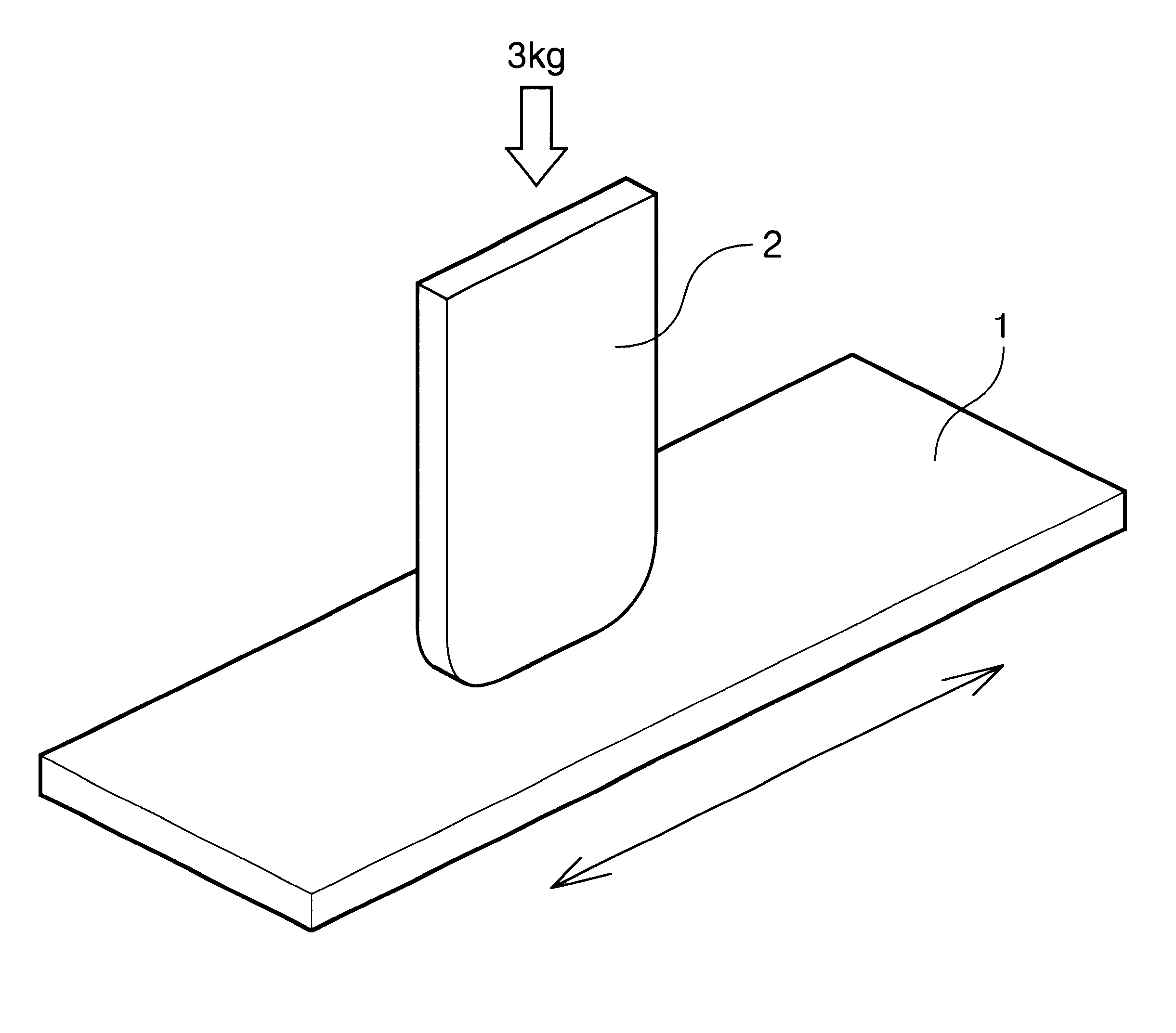

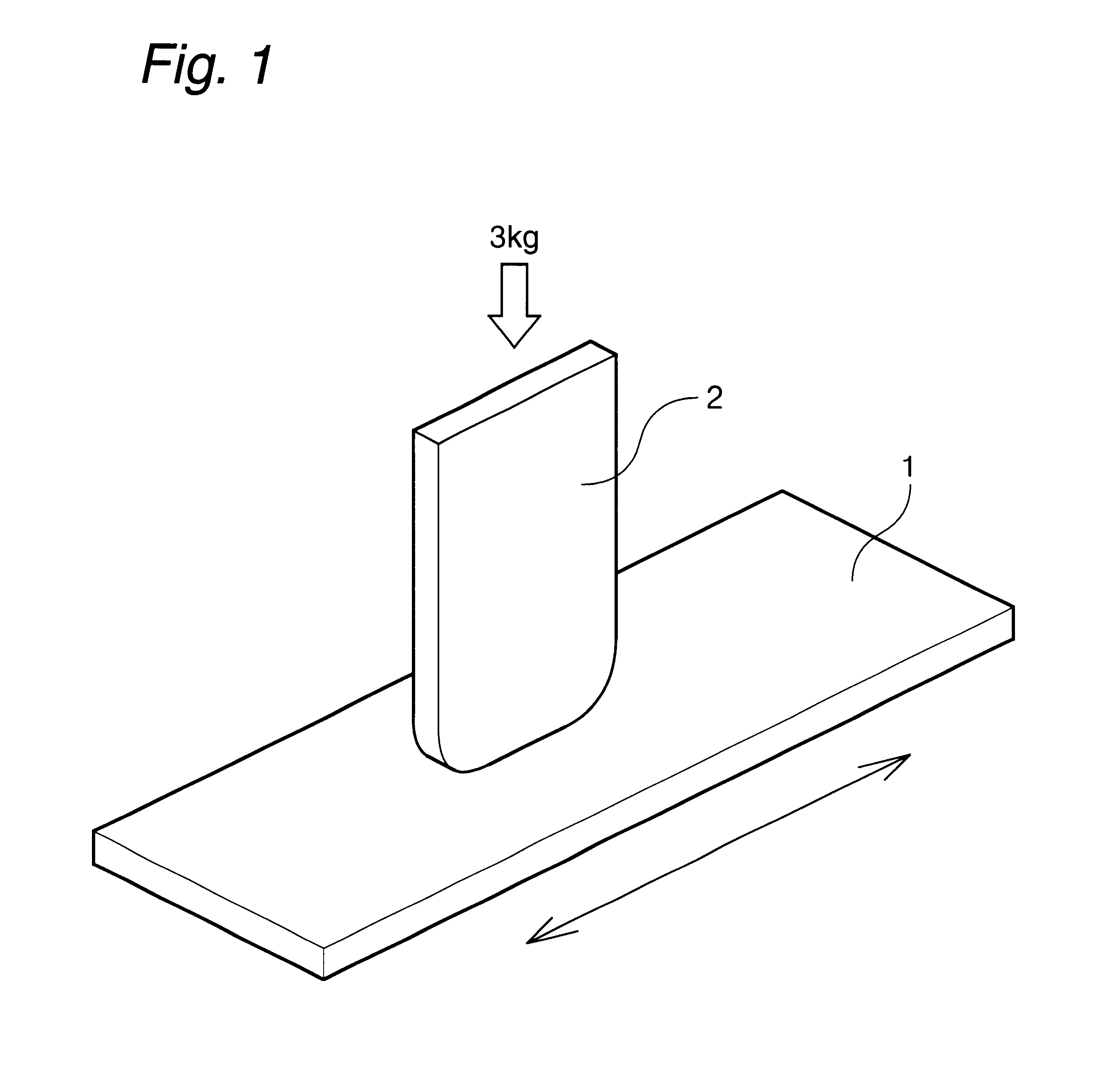

Method for producing low friction fluorine rubber crosslinked body

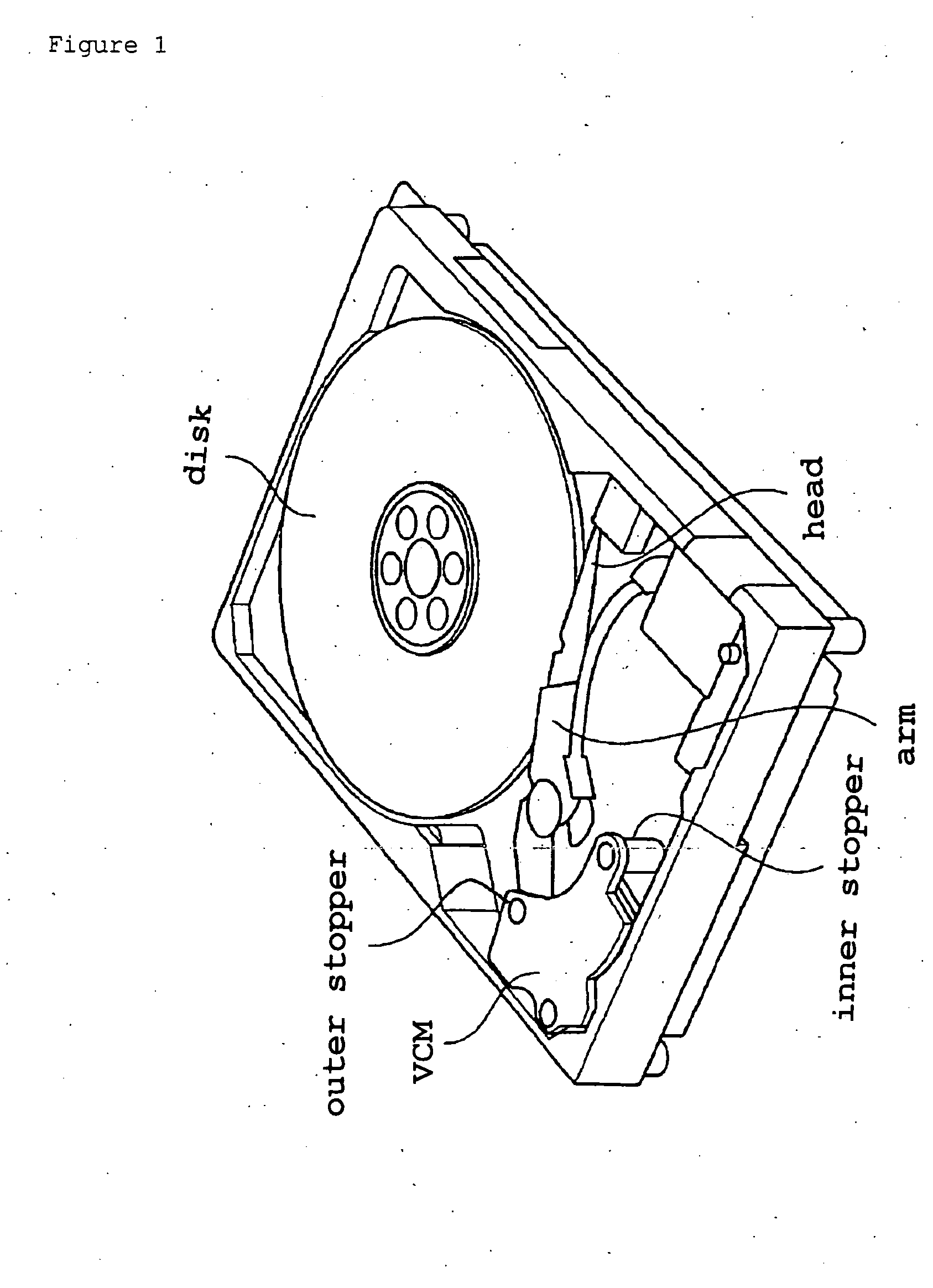

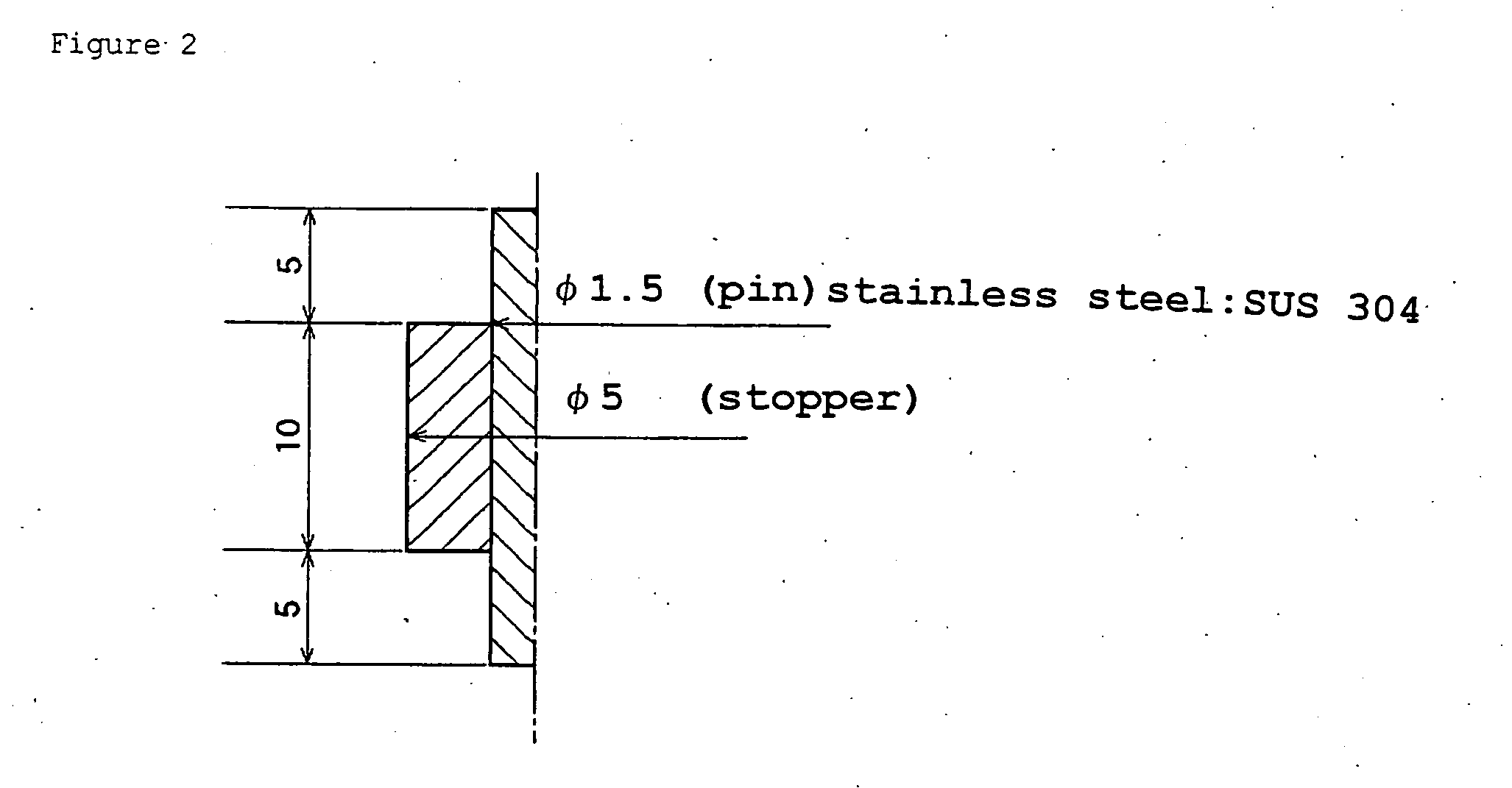

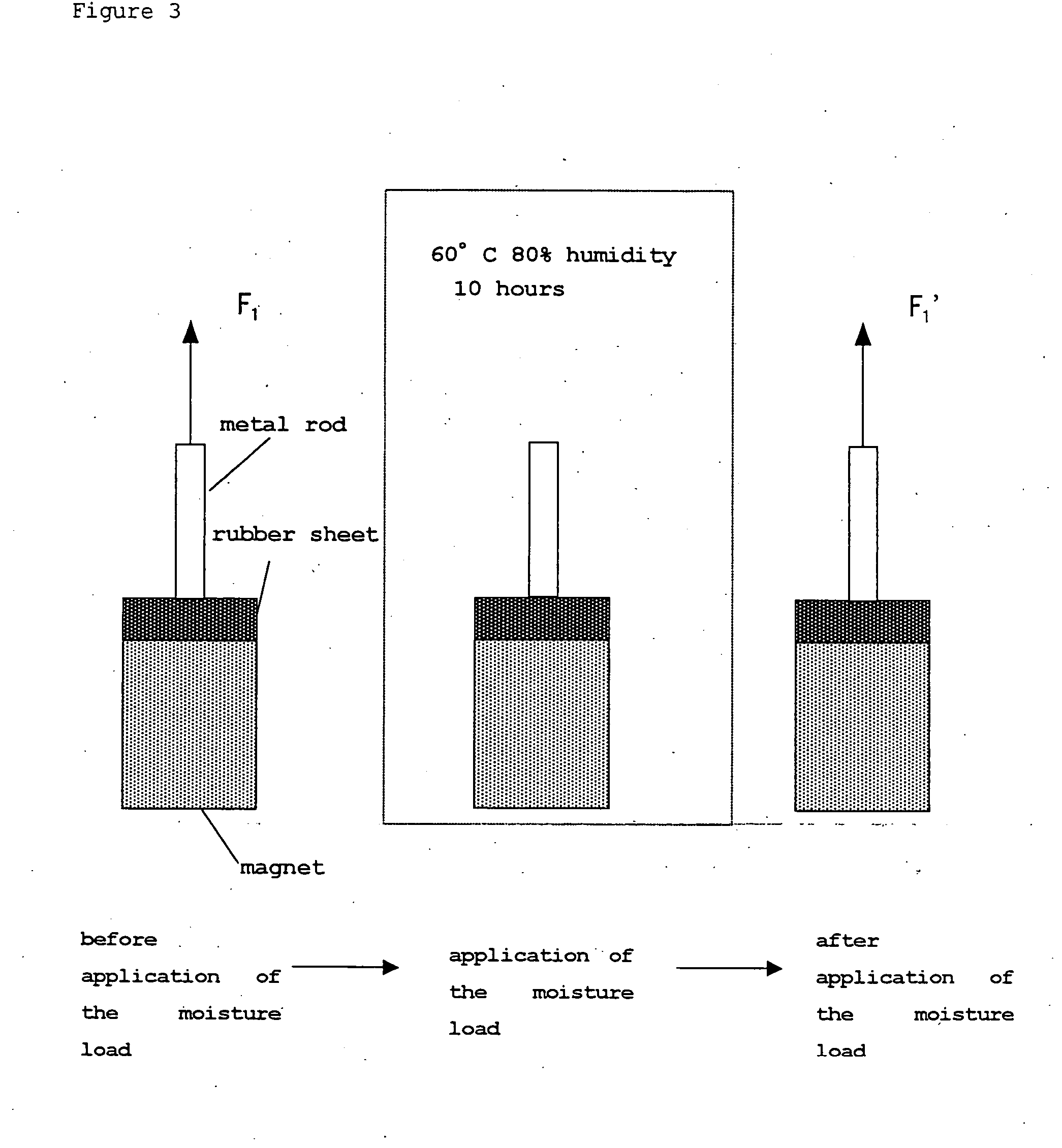

A fluororubber composition includes a polyol-crosslinkable fluororubber, a crosslinking accelerator, a polyol crosslinking agent and calcium hydroxide, with the crosslinking accelerator having a specific weight ratio relative to the polyol crosslinking agent, and is heat treated under specific conditions to give a low-friction fluororubber crosslinked product that is well balanced and excellent in properties such as low frictional properties, low tackiness and low resilience properties and that is favorably employed as rubber vibration insulators and impact-absorbing stoppers represented by HDD stoppers.

Owner:NOK CORP

Seal ring rubber material and mixing method thereof

InactiveCN102010553AAvoid bloomingPrevent blooming and scorching of rubberEngine sealsRubber materialCalcium hydroxide

The invention relates to a seal ring rubber material and a mixing method thereof. The mixing method comprises the following steps: carrying out crude rubber laminating and roller covering: adding 1-1.5 parts of aflux-42 serving as a processing agent and 1.5-2 parts of TM-80 serving as a mould release agent into 100 parts of fluororubber serving as crude rubber; mixing the above components of the rubber material for about 1 minute at the roller temperature of 40-45 DEG C, and adding 4-6 parts of activated magnesia serving as an acceptor; evenly mixing, adding 30-40 parts of a reinforcing agent which contains aramid pulp fiber; evenly mixing once again, adding 1-1.5 parts of bisphenol AF serving as a vulcanizing agent and 1-0.5 part of tert-butyl peroxypivalate (BPP) serving as an accelerator; and finally adding 5-7 parts of calcium hydroxide, packaging into a cornucopla for three or four times after all compounding ingredients are consumed up under the roller temperature of below 55 DEG C, adjusting the roller distance to be less than 0.55mm, rolling the dropped rubber for five or six times, and discharging. The seal ring rubber material has the advantages of rapid vulcanization speed of fluororubber, high production efficiency and low rejection rate.

Owner:广东天诚密封件股份有限公司

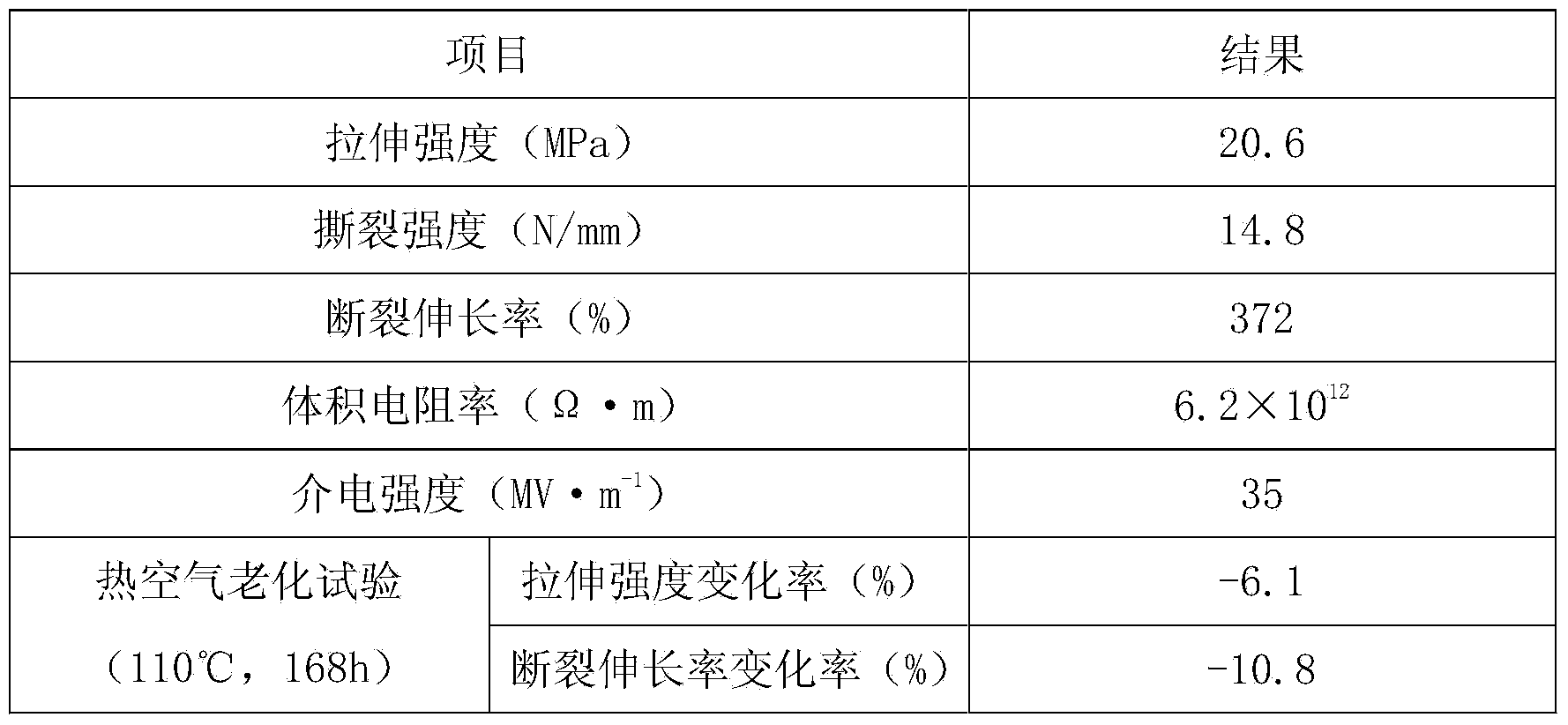

Silicone rubber insulating fluororubber cable material and preparation method thereof

The invention discloses a silicone rubber insulating fluororubber cable material and a preparation method thereof. The silicone rubber insulating fluororubber cable material comprises the following raw materials in parts by weight: 90-100 parts of methyl vinyl silicone rubber, 20-30 parts of magnesium hydroxide, 40-60 parts of SBS (Styrene Butadiene styrene), 50-60 parts of ethylene-vinyl acetate copolymer, 20-30 parts of polytetrafluoroethylene, 1-4 parts of precipitated white carbon black, 60-80 parts of light calcium carbonate, 2-4 parts of 2,4-dichlorobenzoyl, 3-5 parts of accelerant DM, 3-6 parts of 2-thiolbenzimidazole, 1-3 parts of cross-linking agent TAC, 2-4 parts of calcium stearate, 2-4 parts of antioxidant DSTP, 1-5 parts of stearoyl-rac-glycerol, 2-5 parts of stearic acid and 10-20 parts of ammonium polyphosphate. According to the invention, the preparation method is simple, the electric performance is superior, the formula of the raw materials is rational, and the prepared cable material is environment-friendly, has the advantages of softness, wear resistance, watertightness and the like, and passes the A-level fire resistance test in China.

Owner:安徽华海特种电缆集团有限公司

Fluorine rubber-fluorosilicone rubber blend and preparation method thereof

The invention belongs to the technical field of materials and relates to a rubber blending modification technology. Due to the introduction of vinyl-terminated poly(trifluoropropyl) siloxane to the main chain of fluorine rubber, the compatibility of fluorine rubber and fluorosilicone rubber can be improved, and due to the reduction of the viscosity difference between fluorine rubber and fluorosilicone rubber, the blending uniformity of fluorine rubber and fluorosilicone rubber can be improved. A fluorine rubber and fluorosilicone rubber blend provided by the invention at least comprises main rubber consisting of fluorine rubber and fluorosilicone rubber, a compatibilizer and a fluorine rubber viscosity modifier, wherein the fluorine rubber accounts for 10-50% in the main rubber, the compatibilizer is fluorine rubber grafted vinyl-terminated poly(trifluoropropyl)siloxane, the use amount of the compatibilizer is 2-20% of that of the main rubber, and the use amount of the fluorine rubber viscosity modifier is 30-45% of that of fluorine rubber. The fluorine rubber and fluorosilicone rubber blend is prepared by adopting a high-temperature vacuum blending process, has good high-temperature resistance and good medium resistance and low compression set, can be applied to the technical field of processing of sealing products and damping parts and can be particularly applied to the fields with oil resistance.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

High lubricity, multi-layer polyolefin laminate

InactiveUS6706385B1Easy to slideImprove wear resistanceEngine sealsSynthetic resin layered productsPolymer sciencePolyolefin

The laminate of the invention comprises a sliding member of a resin composition and a Substrate layer of a thermoplastic olefin elastomer (A), and is obtained by co-extruding: the resin composition which is obtained by melt kneading a thermoplastic olefin elastomer (A), an ultra-high-molecular weight polyolefin (except a powder thereof having a particle diameter of 1 to 100 mum) having an intrinsic viscosity, as measured in a decalin solvent at 135° C., of 1 to 40 dl / g, an inorganic or organic filler powder, and optionally, a polyolefin resin, an organopolysiloxane, a fatty acid amide and a fluororubber in a twin-screw extruder, and the thermoplastic olefin elastomer (A). The laminate has excellent sliding properties with window glass and excellent abrasion resistance. Moreover, the laminate can be produced by a simple process because it requires no adhesive, and the laminate has great bonding strength between the substrate layer and the sliding member layer.

Owner:MITSUI CHEM INC

High temperature steam and oil resistant fluororubber pad

ActiveCN1702112AGuaranteed low temperature resistanceMeet the use requirementsHeating oilEngineering

The invention relates to a thermostable viton gasket, which is mainly used as sealing element in plate exchanger using high temperature steam and heating oil. The viton gasket comprises 70-75 wt% of F26 ready-mixed glue and 25-30 wt% of HNBR ready-mixed glue. Said F26 ready-mixed glue comprises 100 wt% of 26-style rubber, 2-2.2 wt% of hexaflurate bisphenol A and so on. HNBR ready-mixed glue comprises 100 wt% of hydrogenated rubber, 48-52 wt% of black pigment and so on. The invention can resist high temperature steam and oil.

Owner:蒋惠成

Technology for producing new viton coating metal sealing gasket for internal combustion engine use

InactiveCN101067403AThe process formula is reasonableSimple processSealing arrangements for enginesMachines/enginesSilanesEngineering

The preparation process of the metal sealing filling piece with the fluorine rubber coat used in gas engine is provided in invention. The coat is made up of the 100 parts of the 26 type fluorine raw rubber, 250-350 parts of the mixing solvent, the 25-35 parts of the carbon black, 1.5-3 parts of the KH-560 silane resin acceptor, 30-50 parts of the 3# vulcanized agent, 5-15 parts of the MgO, 3-7 parts of the phenyl-methyl polysiloxane resin and 3-7 parts of Supramoly. The advantage of the invention is: (1) the process batch formula is proper and the dope has good flow level; (2) it needn't the bottom coating; (3) it can use the flame plating or screen printing process to operate on the fluorine rubber.

Owner:NANCHANG UNIV

Fluororubber composition and molding articles

The invention discloses a fluororubber rubber composition and moulding product, which comprises the following parts: 100wt% fluororubber, 5-50wt% non-metal whisker and 0. 1-5wt% surface activator. The invention possesses high stretching strength and modulus, which improves heat resistance and abrasion resistance.

Owner:上海道氟实业有限公司

Oil resistant rubber material and preparation method thereof

The invention provides an oil resistant rubber material. The oil resistant rubber material comprises the following components in parts by weight: 60-70 parts of butadiene-acrylonitrile rubber, 25-35 parts of fluororubber, 5-10 parts of dioctyl tin maleate, 2-3 parts of glass fibers, 1-2 parts of stearic acid, 0.5-0.8 part of light calcium carbonate, 3-5 parts of magnesium dimethacrylate, 2-3 parts of drying oil alkyd resin, 1-2 parts of paraffin, 3-5 parts of dilauryl thiodipropionate, 1-2 parts of diacetyl peroxide, 0.8-1.2 parts of zinc oxide, 8-10 parts of aluminium oxide, 6-8 parts of white carbon black, 0.8-1.5 parts of anti-aging agent and 1-3 parts of sulfur. The invention also provides a preparation method of the oil resistant rubber material. The oil resistant rubber material has good sealability, high temperature resistance and oil resistance and is suitable for sealing automobile gearboxes.

Owner:LIUZHOU YINGHANG AUTO PARTS

High-humidity-resistant insulating sheath material for transformer and preparation method thereof

The invention discloses a high-humidity-resistant insulating sheath material for a transformer and a preparation method thereof. The sheath material is prepared from the following raw materials in parts by weight: 80-100 parts of tetrafluoroethylene-propylene rubber, 25-35 parts of ethylene-propylene-diene monomer, 10-15 parts of nitrile rubber, 3-6 parts of zinc oxide, 2-4 parts of magnesium oxide, 1-2 parts of stearic acid, 1.5-2.5 parts of dibutyltin dilaurate, 2-4 parts of palm wax, 20-30 parts of carbon black N990, 10-15 parts of dibutyl phthalate, 5-10 parts of paraffin oil, 15-25 parts of alumina silicate, 10-15 parts of nanometer diatomite, 4-8 parts of a composite filling material, 2-3 parts of bismaleimide, 3-5 parts of insoluble sulphur, 1-1.5 parts of promoter TETD, 1-2 parts of antiager 4010 and 1-2 parts of an antioxidant. The sheath material of the invention employs the rubber main material with relatively good ozone resistance, and also employs the antioxidant, the composite filling material and the like with good ozone resistance in the formula, so that the sheath material is improved in high humidity resistance and ozone resistance while the good insulating performance and the physical mechanical properties of the sheath material are guaranteed.

Owner:ANHUI KELIN ELECTRONICS

Fluorine-containing elastomer and composition thereof for crosslinking

To provide a novel crosslinking system of fluorine-containing elastomer giving a crosslinked product particularly having improved mechanical strength and compression set at high temperature. A fluorine-containing rubber composition comprising a fluorine-containing elastomer having carboxyl group and / or alkoxycarbonyl group at an end of a trunk chain and / or branched chain as a crosslinkable group.

Owner:DAIKIN IND LTD

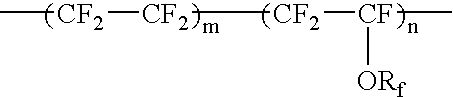

Fluorine-containing rubber composition

InactiveUS6503986B1Enhanced radiationHigh transparencyOther chemical processesSemiconductor/solid-state device detailsPolymer scienceMulti segment

To provide a fluorine-containing rubber composition comprising (a-1) a non-perfluoro fluorine-containing rubber and (b-1) a fluorine-containing multi-segment polymer comprising an elastomeric fluorine-containing polymer chain segment and non-elastomeric fluorine-containing polymer chain segment, in which structural units of each of the elastomeric fluorine-containing polymer chain segment and the non-elastomeric fluorine-containing polymer chain segment comprise not less than 90% by mole of a perhalo olefin unit. The fluorine-containing rubber composition is capable of providing a clean sealing material for semi-conductor production apparatuses without using a filler.

Owner:DAIKIN IND LTD

Leather cup rubber material for brake of automobile and preparation method thereof

The invention discloses a leather cup rubber material for a brake of an automobile. The leather cup rubber material is prepared from the following raw materials in parts by weight: 40-50 parts of nitrile rubber, 20-30 parts of chlorosulfonated polyethylene rubber, 10-30 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorine rubber, 3-5 parts of natural rubber, 30-40 parts of high abrasion furnace black N330, 15-20 parts of modified white carbon black, 3-4 parts of graphite, 8-10 parts of modified wood ash, 4-6 parts of vermiculite, 4-6 parts of quartz sand, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of sulfur, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BPP, 1-2 parts of stearic acid, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of lignite wax, 1-2 parts of antioxidant DSTP, 1-2 parts of anti-aging agent RD, 2-3 parts of phenyl triethoxysilane and 16-18 parts of acetyl triethyl citrate. The rubber material disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber material can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

Mixture for automobile high-speed rotation oil seals

InactiveCN104327429APhysical and mechanical properties unchangedOptimize the formula systemCalcium silicatePolymer science

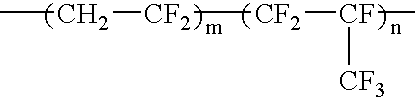

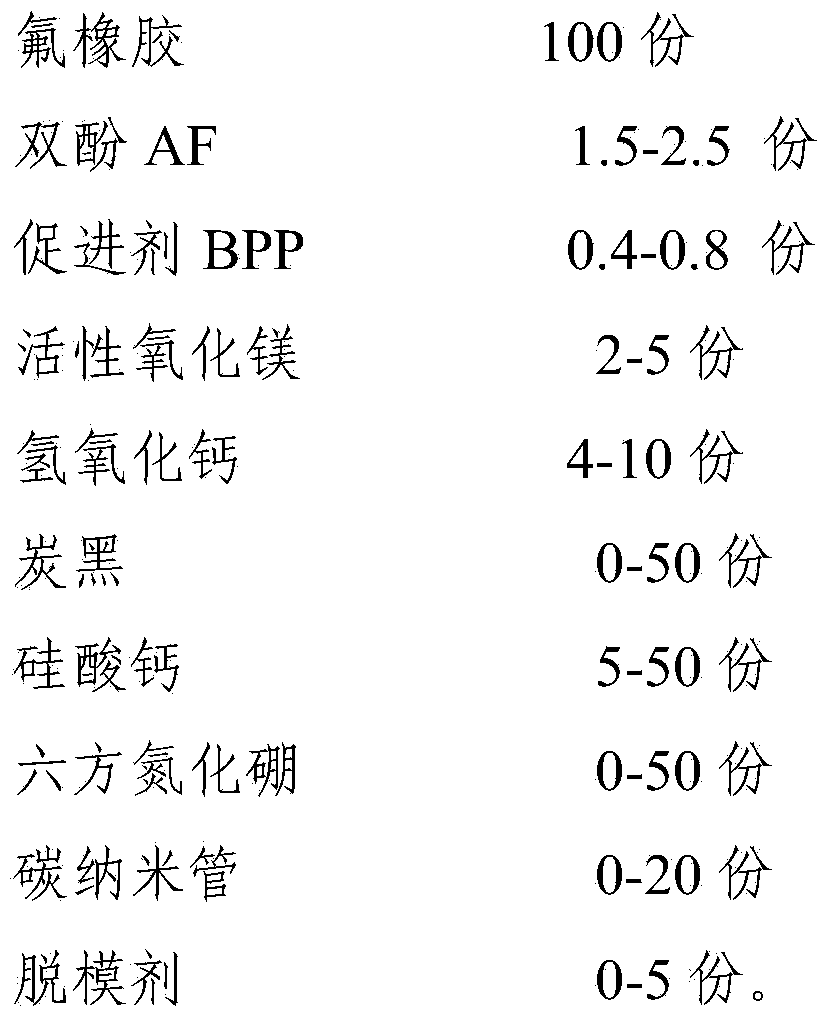

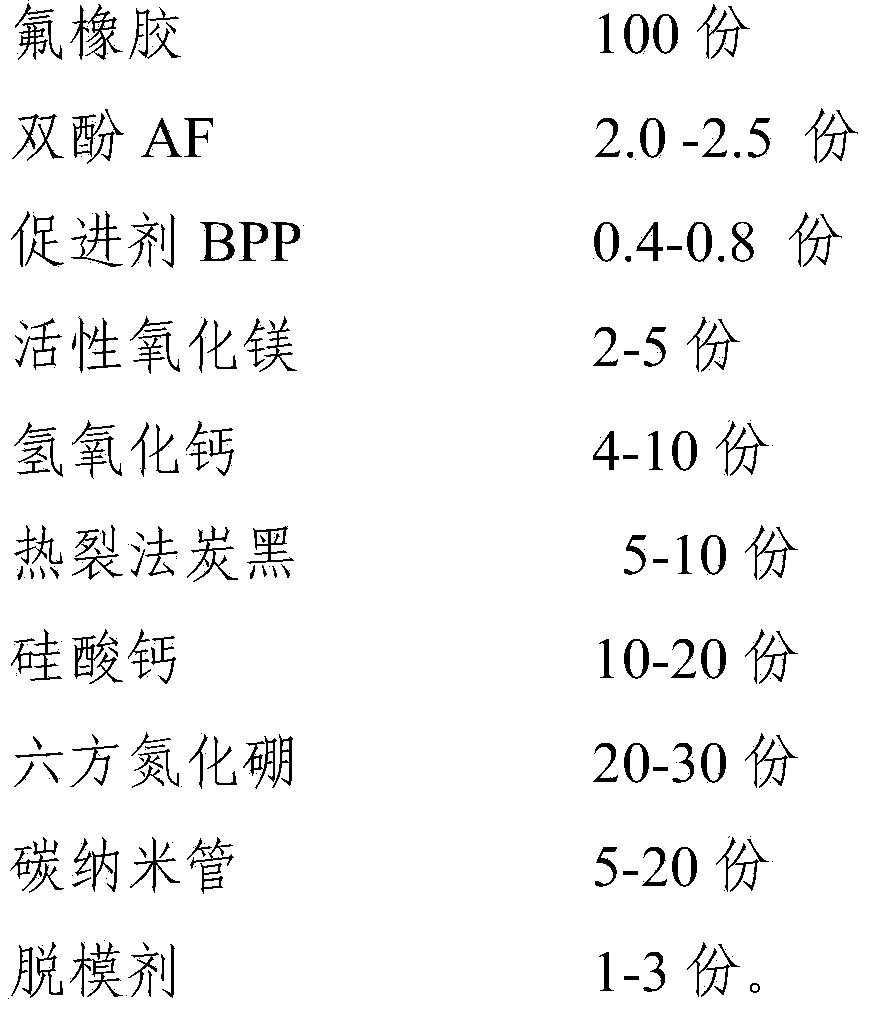

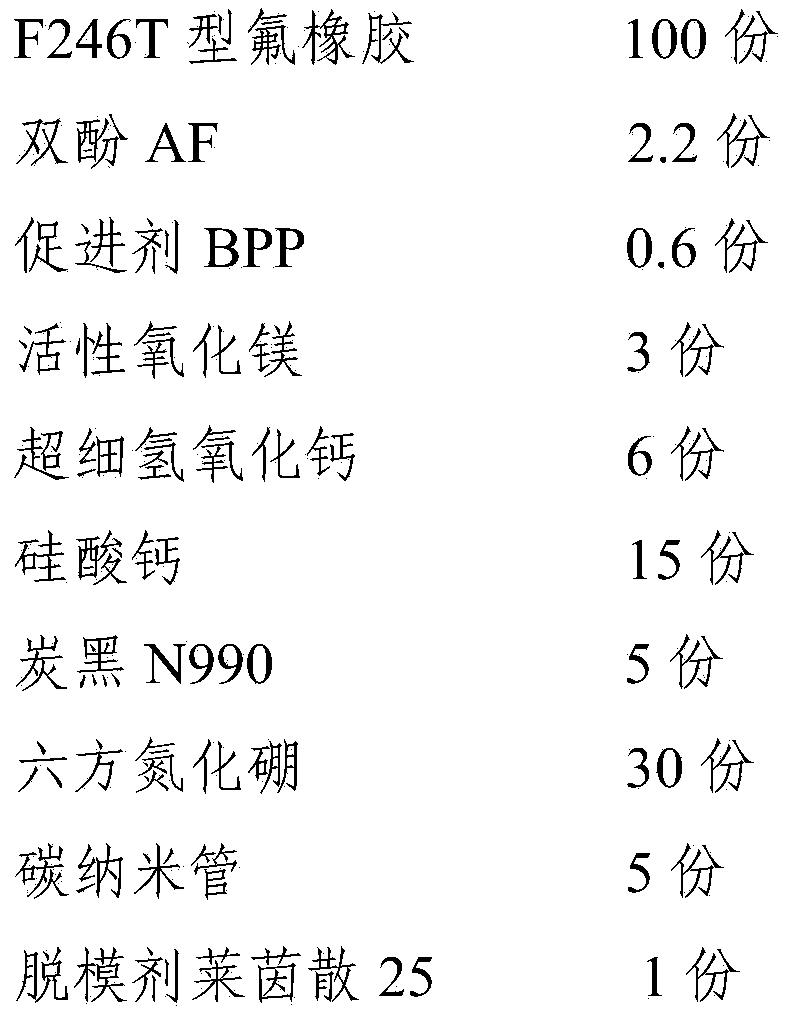

The invention belongs to the field of organic compound processing, and provides a mixture for automobile high-speed rotation oil seals, which is prepared from the following components in parts by weight: 100 parts of fluororubber, 1.5-2.5 parts of bisphenol AF, 0.4-0.8 part of accelerator BPP, 2-5 parts of active magnesium oxide, 4-10 parts of calcium hydroxide, 0-50 parts of carbon black, 5-50 parts of calcium silicate, 0-50 parts of hexagonal boron nitride, 0-20 parts of carbon nanotube and 1-3 parts of mold release agent. By adopting the fluororubber F246 (the Mooney viscosity is 100-150) as the base unvulcanized rubber and optimizing the formula system, the physical and mechanical properties of the vulcanized fluororubber of the original formula are basically unchanged. The two different types of heat-conducting fillers are compounded to enhance the heat conductivity coefficient of the compounded rubber under the synergic actions, and the heat-conducting property of the vulcanized rubber product for manufacturing is obviously enhanced.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Turbine booster hose of fluorine rubber, oil-resisting silicon rubber and silicon rubber and its production

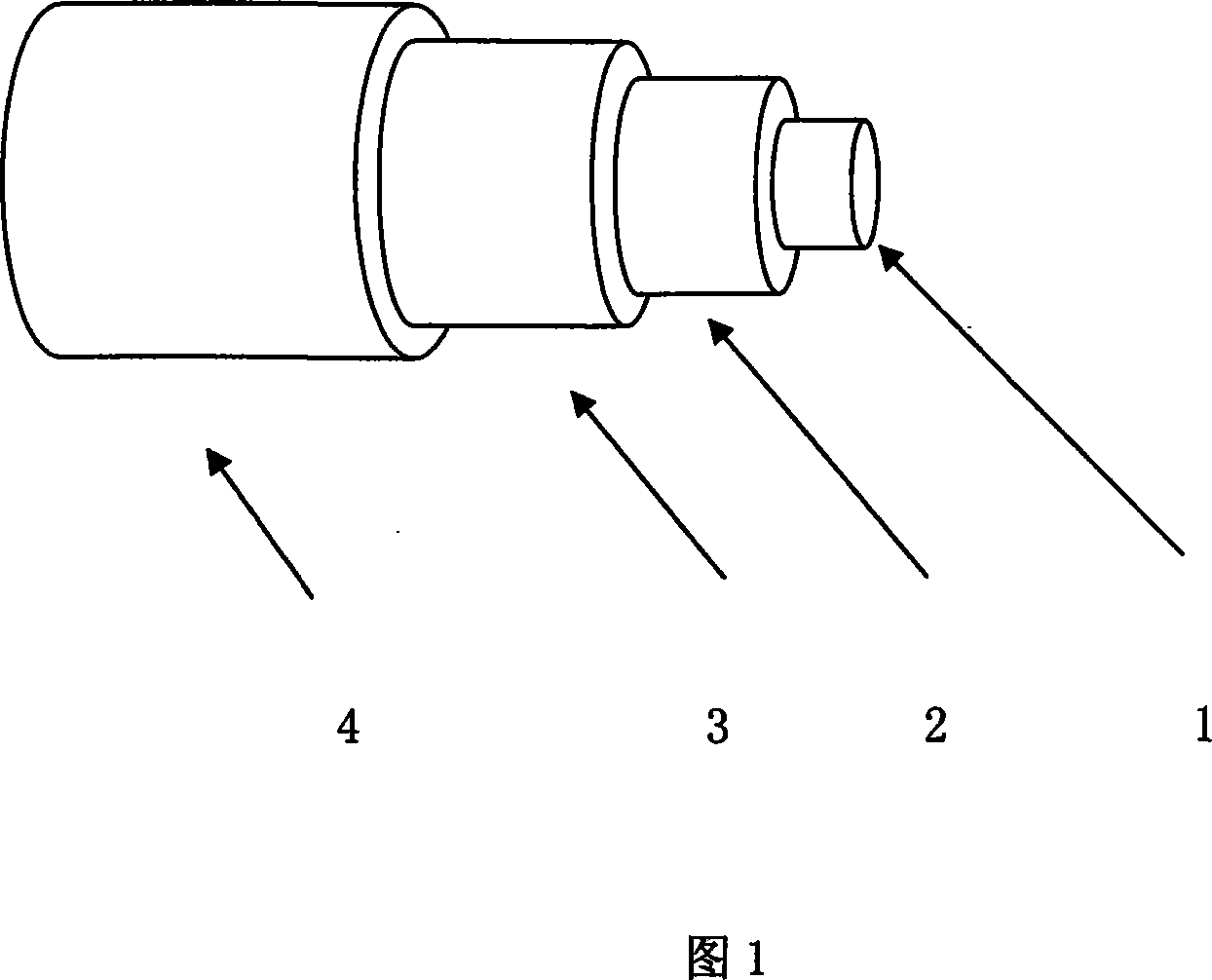

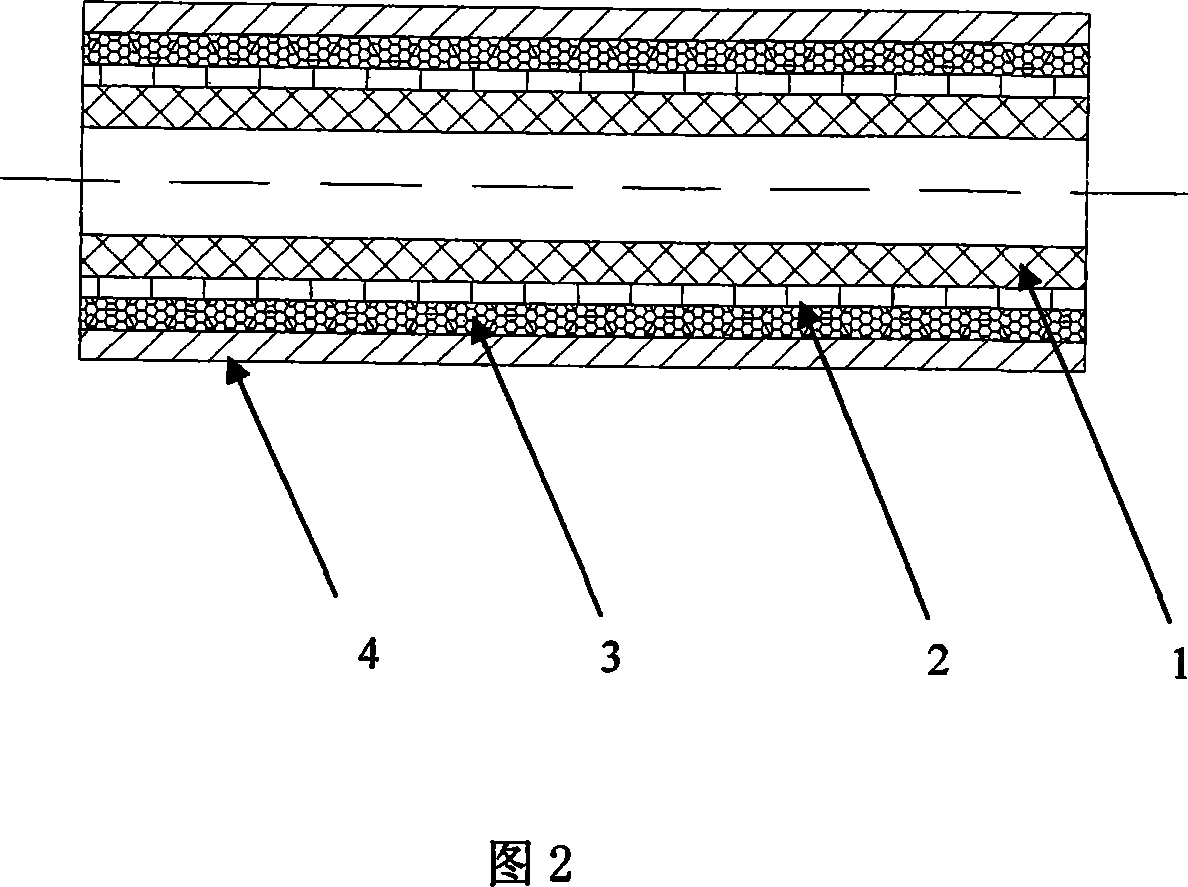

The invention discloses an extrusion production, the fluorine rubber inner layer (1), resistance oil silicone rubber middle (2), kevlar line (3) and the outer layer of silicone rubber (4) composed of automobile turbocharged hose, broke the previous three-layer structure of the turbocharged, four- layer structure used, and uses advanced extrusion technology, braided hose to a molding process, the turbocharged hose reached appearance no impurities, without defects, flat and smooth. Not only increase production efficiency, but also through our compound formula, the structure of several aspects of research and development, so that the hose can meet the performance requirements of use, the hose improve the oil resistance, high temperature resistant, resistant infiltration, and improve the bursting pressure, the hose of the service life is extension.

Owner:TIANJIN PENGYI GRP CO LTD

Leather cup rubber material for brake of automobile and preparation method thereof

Owner:WUHU HENGKUN AUTO PARTS

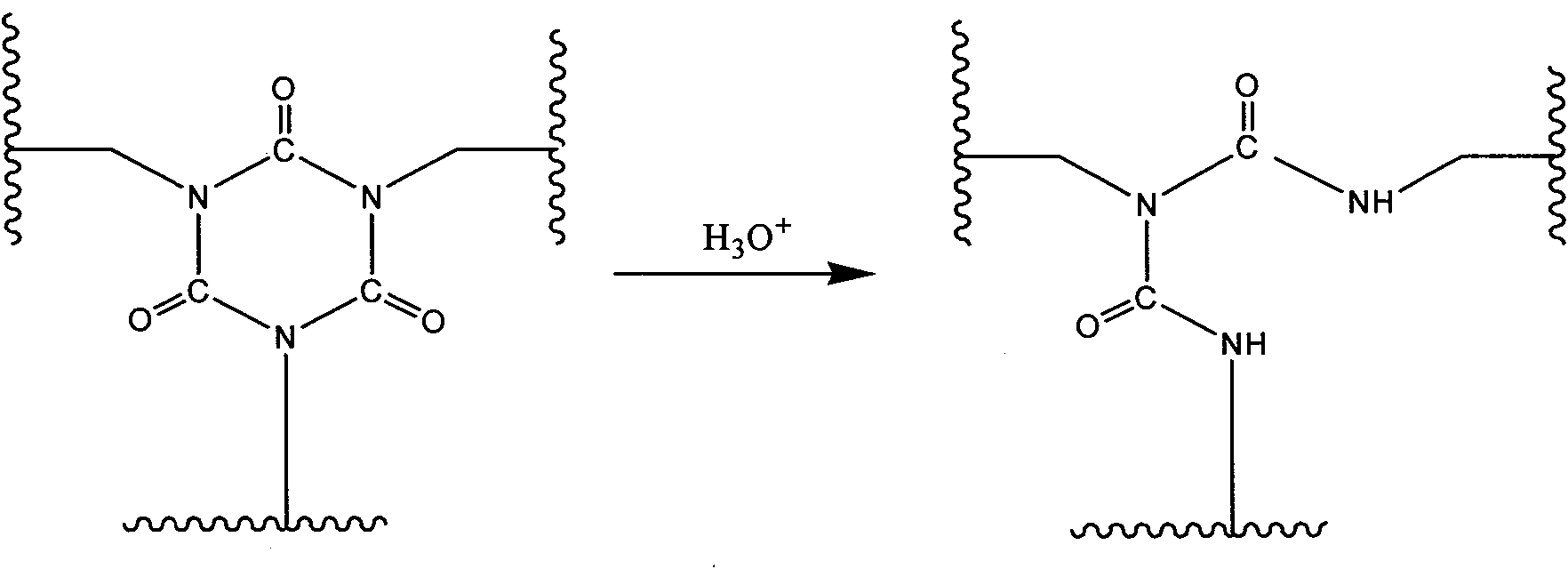

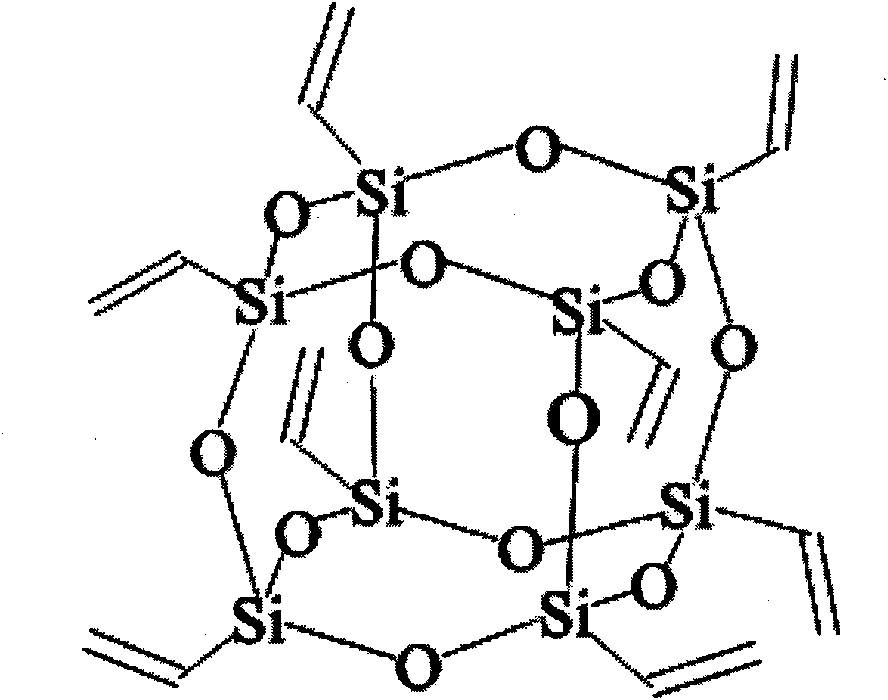

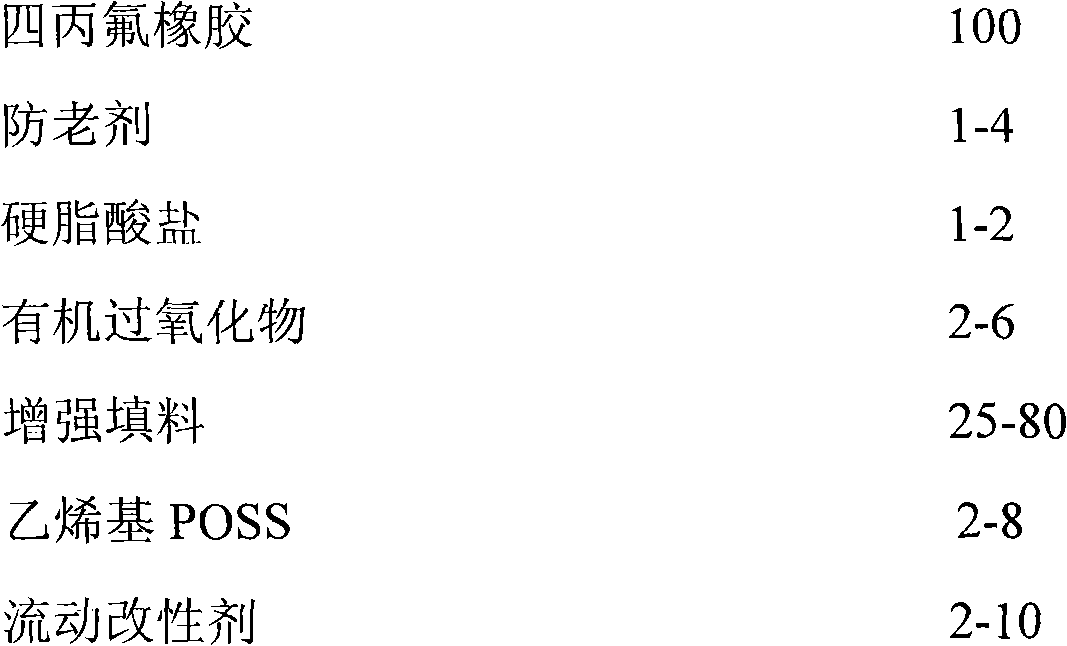

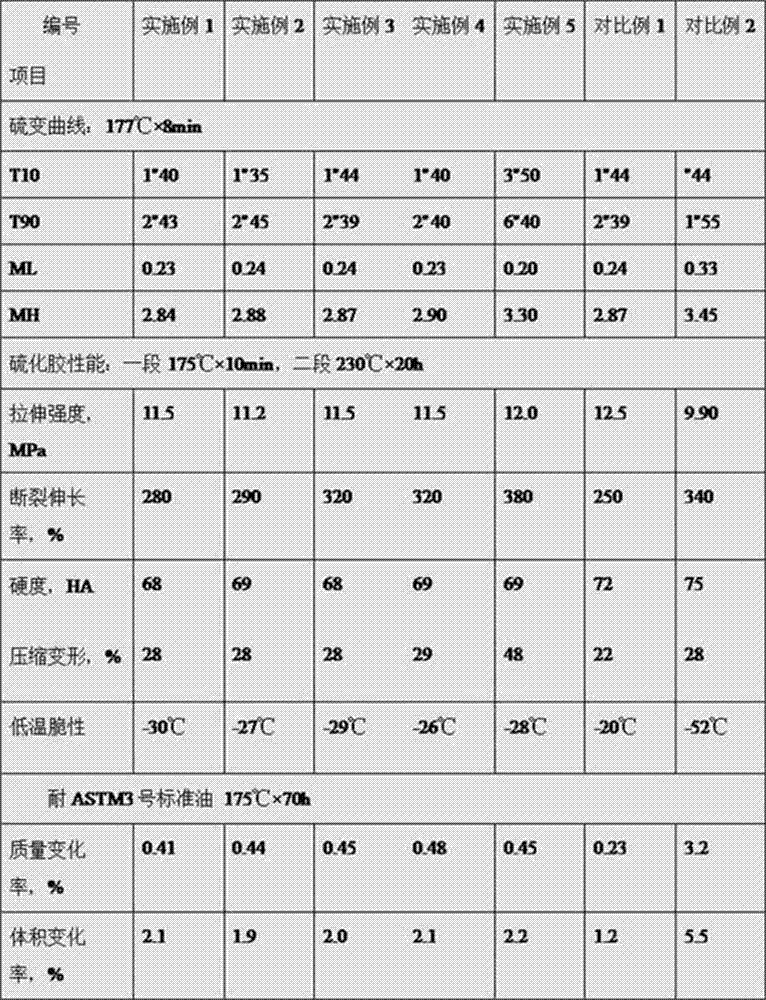

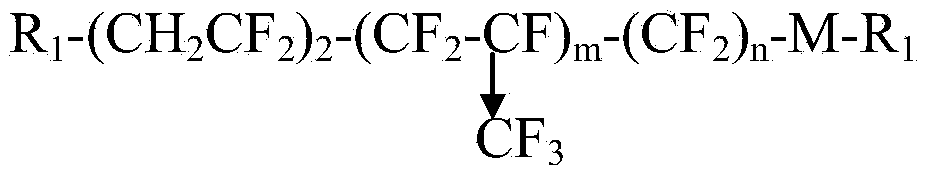

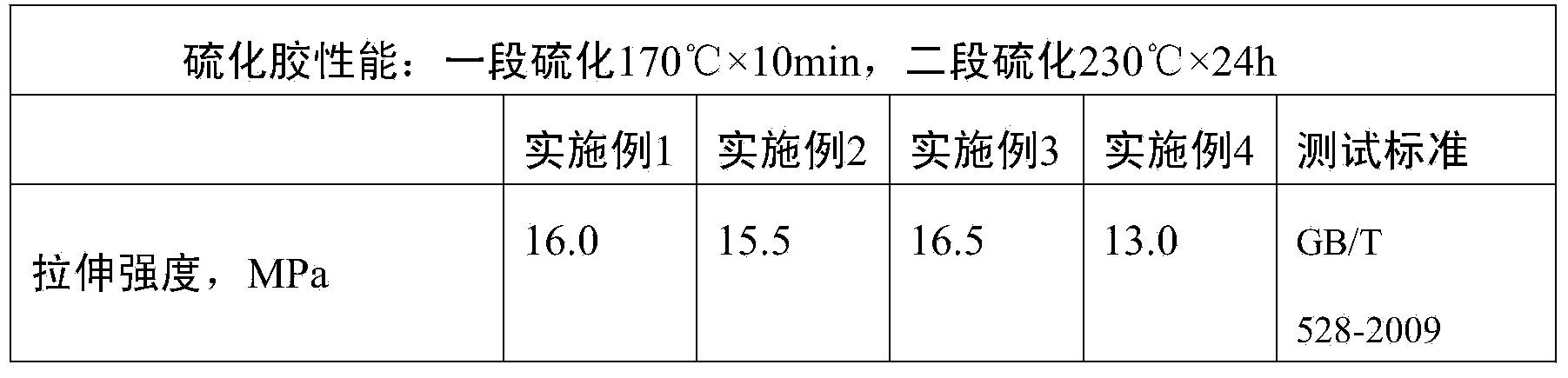

Acidproof, alkali-proof and hydrogen-sulphide-corrosion-resistant aflas composite

The invention relates to an acidproof, alkali-proof and hydrogen-sulphide-corrosion-resistant aflas composite. In the composite, aflas serves as main material, organic peroxide serves as a cross linking agent, vinyl polyphenyl silsesquioxane serves as an assistant cross-linking agent, hard carbon black serves as an enhanced filler, and resin serves as a flow modifier. The composite can be used for preparing rubber products used in an acid or alkali environment, especially in the hydrogen sulfide environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Plastic based foam metalizing method

The invention provides a method for metalizing plastic base foam, which relates to a coat made of organic materials. The method is achieved through the following steps: plastic base foam is submerged in low temperature heat curing polymer silver paste or the low temperature heat curing polymer silver paste is sprayed to the plastic base foam so that the fiber of the plastic base foam is attached with a conducting layer; the plastic base foam and the low temperature heat curing polymer silver paste are thermally cured for thirty to sixty minutes at the temperature of 120 DEG C to 180 DEG C, thus forming a foam metalized layer. The silver paste consists of 30 to 60 percent of silver powder, and 70 to 40 percent of organic carriers. The silver powder is flaky silver powder. The organic carriers consist of 5 to 15 percent of viton resin, 1 percent of an adhesion accelerant N742, 5 to 15 percent of dibutyl phthalate and 69 to 89 percent of butyl acetate. By adopting the method for metalizing plastic base foam provided by the invention, the foam plastic can be metalized well inside; after the metalized foam plastic is electroplated, the plastic base foam can be manufactured into foamed metal grid plates which are capable of carrying current and become foam base lead-acid accumulator plate grid electrodes.

Owner:陈群星

Fluorine-containing elastomer with excellent low temperature and liquid resistance and preparation method thereof

InactiveCN104774411ALiquid resistance effects are minimizedAdvantages Good performanceAlkaneCalcium hydroxide

The invention discloses a fluorine-containing elastomer with excellent low temperature and liquid resistance and a preparation method thereof. The elastomer is prepared by thermally kneading and mixing the following components in parts by weight: 100 parts of fluororubber, 0-30 parts of acid absorbent, 0-35 parts of calcium hydroxide, 0-50 parts of reinforcing filler, 0-10 parts of plasticizer, 0.5-5 parts of vulcanizing agent, 0-5 parts of organic wax, 0.2-2 parts of accelerant, 1-30 parts of fluorosilicone alkane ester and 1-10 parts of multifunctional additive LCA. The fluorine-containing elastomer and the preparation method, which are provided by the invention, have the beneficial effects that the preparation method is simple and practicable and is lower in production cost; by adding fluorosilane ester to the components of the fluorine-containing elastomer and simultaneously matching fluorosilane ester with the multifunctional additive LCA, the low temperature brittleness temperature of an existing fluororubber compound is better decreased (Tg of the fluorine-containing elastomer can be reduced by about 5-10 DEG C) after the existing fluororubber compound undergoes primary or secondary vulcanization; meanwhile, the effects on the liquid resistance of the fluororubber are very small, so that the fluororubber can be more widely applied.

Owner:江苏千富之丰科技有限公司

Modified fluororubber rubber compound and preparation method thereof

ActiveCN103772859AImprove physical performanceReduced low temperature performanceAviationVulcanization

The invention provides a modified fluororubber rubber compound and a preparation method thereof. The fluororubber takes modified binary fluororubber as a raw material; meanwhile, two vulcanization agent manners including a bisphenol vulcanization system and a peroxide vulcanization system are combined to carry out vulcanization; an auxiliary agent is increased and matched, and is mixed with the material to prepare the modified fluororubber rubber compound. The modified fluororubber rubber compound has excellent high heat resistance, cold resistance, low permeability and fuel oil resistance, and is applicable to industries including aerospace, aviation, cars, metallurgy, petrochemical engineering, electronics and the like; the performance on a sealing application is not too low and a problem caused by that an application environment is changed is not caused; the modified fluororubber rubber compound can be used as the first choice of a sealing material.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Rubber material for prestressing jack sealing ring and preparation method for rubber material

The invention discloses a rubber material for a prestressing jack sealing ring. The rubber material is formed by mixing a rubber material A and a rubber material B in an equal ratio, wherein the rubber material A consists of the following raw materials in part by weight: 95 to 105 parts of polyurethane rubber, 7 to 9 parts of silicone rubber, 4 to 6 parts of fluororubber, 3 to 4 parts of ethylenepropylene rubber, 0.7 to 0.9 part of natural rubber, 0.3 to 0.5 part of sulfur, 0.4 to 0.6 part of zinc oxide, 0.3 to 0.5 part of stearic acid, 1 to 2 parts of antioxidant 4010NA, 3 to 4 parts of paraffin, 62 to 65 parts of highly wear-resistant carbon black N330, 18 to 22 parts of dioctyl phthalate (DOP), 25 to 35 parts of aluminum hydroxide and 1 to 2 parts of accelerator PZ; and the rubber material B consists of the following raw materials in part by weight: 82 to 87 parts of unary homopolymer of chlorohydrin rubber, 12 to 18 parts of copolymer of chlorohydrin rubber, 1 to 2 parts of zinc stearate, 1 to 3 parts of antioxidant RD, 0.4 to 0.6 part of gum-easy T-78, 1 to 2 parts of rhein wax, 45 to 55 parts of carbon black, 10 to 14 parts of barium sulfate, 5 to 8 parts of DOP, 4 to 6 parts of lead trioxide, 0.4 to 0.6 part of sulfur and 1 to 2 parts of accelerator Na-22. The sealing ring prepared from the rubber material has high oil resistance, heat resistance, air tightness, flame retardance and tear resistance and is low in material cost.

Owner:HEFEI SHICHUAN ENG MACHINERY

Automobile fuel oil evaporative rubber tube with composite structure and manufacturing method for automobile fuel oil evaporative rubber tube

InactiveCN102418817AImprove high temperature resistanceGood medium corrosion resistanceFlexible pipesCalcium hydroxideVulcanization

The invention discloses an automobile fuel oil evaporative rubber tube with a composite structure and a manufacturing method for the automobile fuel oil evaporative rubber tube. The rubber pipe consists of an inner tube rubber layer made of fluororubber containing a bisphenol vulcanizer, magnesium oxide, calcium hydroxide, carbon black and a promoter and an outer tube rubber layer made of epichloro-hydrin rubber containing a vulcanizer, the carbon black, a plasticizer, the magnesium oxide and an anti-aging agent, and the inner tube rubber layer and the outer tube rubber layer are glued integrally and extruded in a composite mode by a composite extruding machine. The manufacturing method comprises the following steps of: mixing sizing materials of an inner tube and an outer tube in an internal mixer, passing through an open mill thinly, extruding a rubber tube blank from the composite extruding machine in a composite mode, cutting under the condition of a fixed length, vulcanizing by an evaporative cylinder, performing two-section vulcanization, cutting a head under the condition of the fixed length, and cleaning to obtain the evaporative rubber tube. The manufacturing method has an advanced process and high production efficiency and is low is manufacturing cost; and a finished product is low in fuel oil permeability, resistant to heat, aging and negative pressure and environment-friendly, and can meet the requirements of vehicular assembly.

Owner:宁波丰茂汽车零部件有限公司

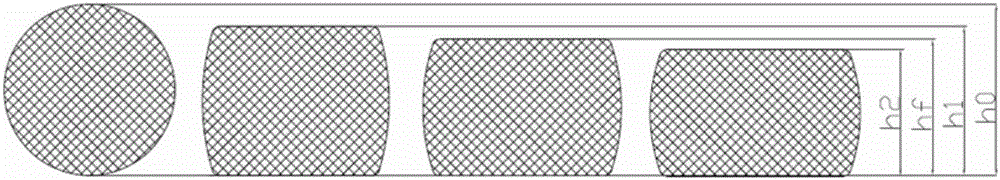

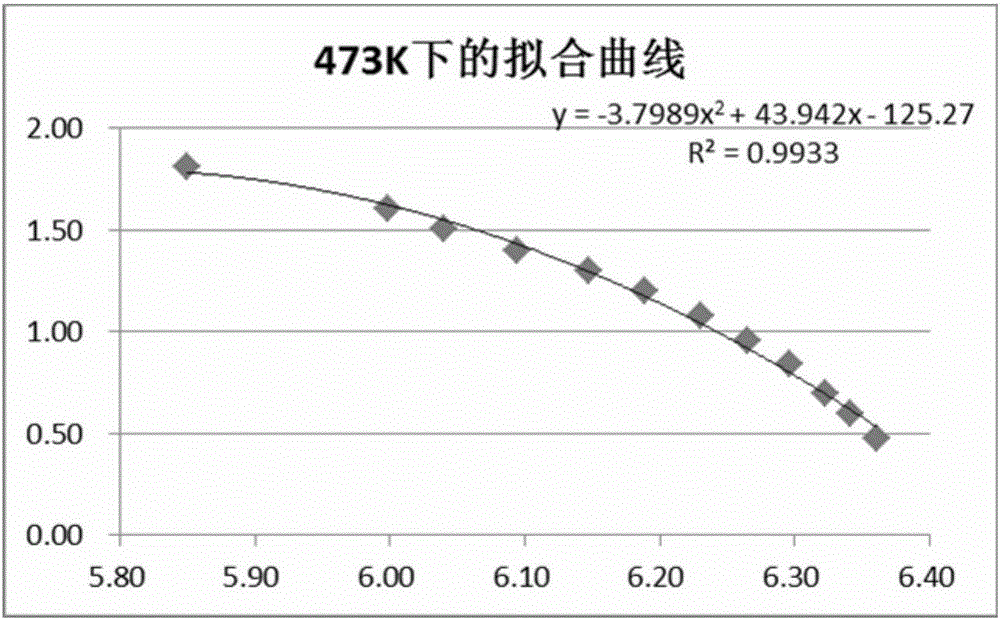

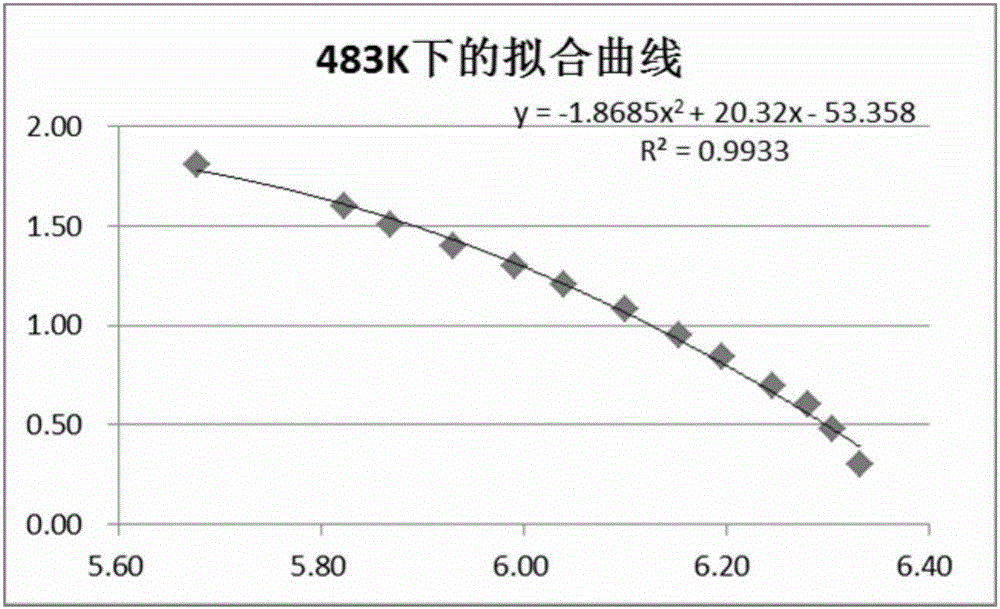

Static seal fluorubber O-shaped ring service life prediction method

ActiveCN105352815AIncrease credibilityMaterial strength using tensile/compressive forcesResidual service lifeTest sample

The invention belongs to the technical field of rubber material life prediction, and discloses a static seal fluorubber O-shaped ring service life prediction method. The method comprises the following steps: performing an accelerated ageing test on an O-shaped ring sample by employing a compression clamp at different temperature, respectively obtaining a relation curve of recovery height and time logarithm; selecting a height value of a test terminal point and substituting the height value into a relation to obtain a corresponding time logarithm lgt; performing linear fitting on lgt and 1 / T to obtain a relation in a specification, and examining t to obtain a lower limit of a confidence interval. A prediction formula of the remaining life under operating temperature TW is shown in the specification. By using the O-shaped ring from disassembly under actual working conditions as the test sample, real compression ratio for arranging grooves is taken as test compression ratio, through fitting of a regression equation and parameter examination and determination of a y0 confidence interval, the lower limit of the confidence interval is used for predicting the service life, credibility of the life prediction result is higher, and the method has an engineering application value.

Owner:广州国机密封科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com