High-humidity-resistant insulating sheath material for transformer and preparation method thereof

An insulating sheath and high-humidity-resistant technology, applied in the field of sealing materials, can solve problems such as economic losses, leakage, and power outages, and achieve the effects of improving high-humidity resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

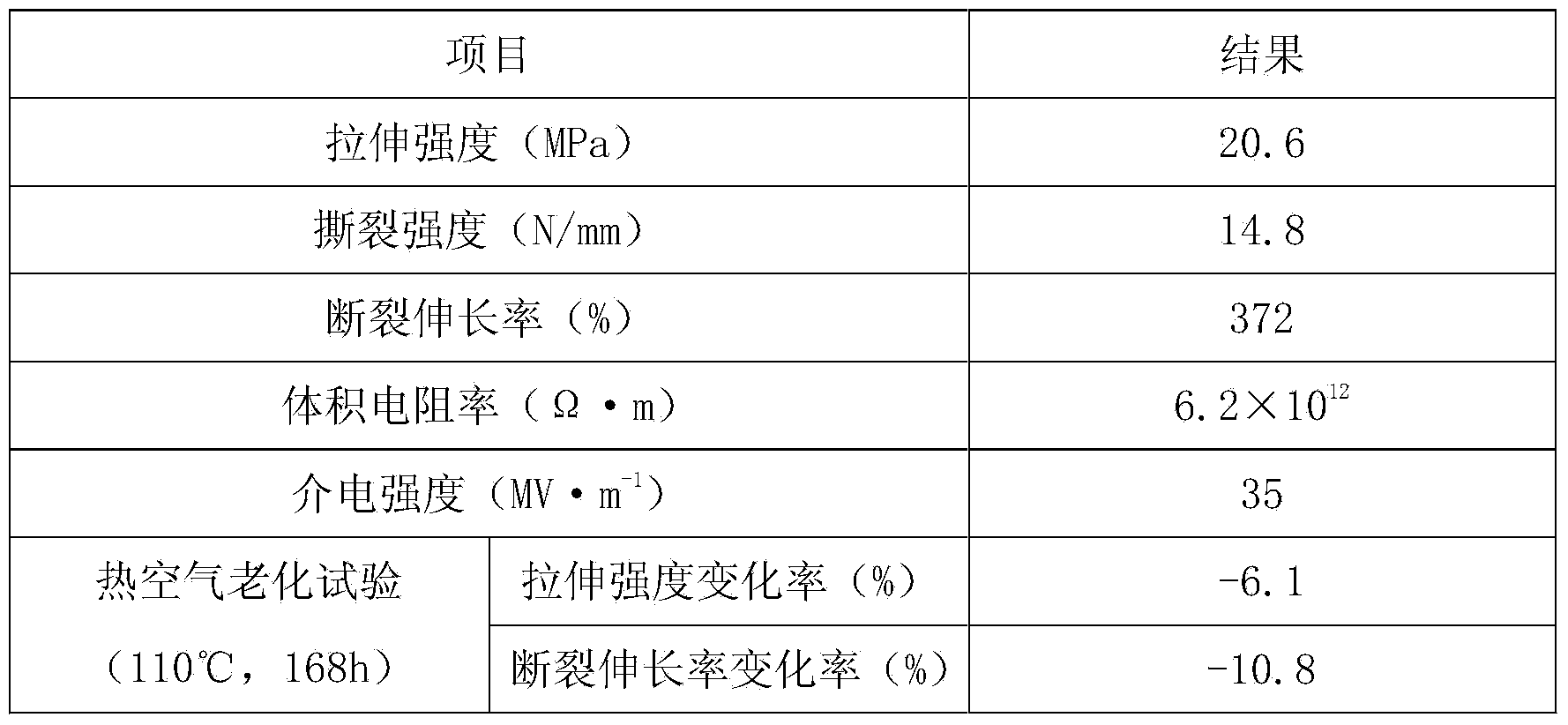

Examples

Embodiment Construction

[0012] A high-humidity resistant insulating sheath material for transformers, which is made of the following raw materials (kg): tetrapropylene fluorine rubber (aflas100H) 90, EPDM rubber (Germany LANXESS 3950) 30, nitrile rubber (N240S ) 15, zinc oxide 4, magnesium oxide 3, stearic acid 1.5, dibutyltin dilaurate 2, palm wax 3, carbon black N99025, dibutyl phthalate 12, paraffin oil 8, aluminum silicate 20, nano Diatomite 15, composite filler 6, diphenylmethane bismaleimide 2, insoluble sulfur 4, accelerator TETD1, anti-aging agent 40101.5, antioxidant 47201.5;

[0013] The preparation method of the composite filler is as follows: a. Weigh bauxite, sepiolite, illite and kaolin in a weight ratio of 7:5:4:1 and mix them evenly, calcinate at 530°C for 2h, cool to normal temperature and put Stir in 15% sulfuric acid solution at 1500rpm for 2 hours, filter, wash until neutral, dry, pulverize, and pass through a 400 mesh sieve; b. Add water to the sieved powder and stir to make a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com