Patents

Literature

296results about How to "Accelerated vulcanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

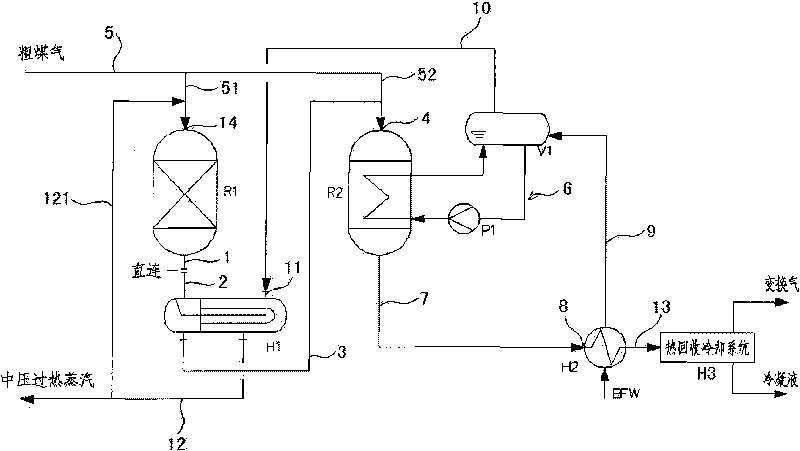

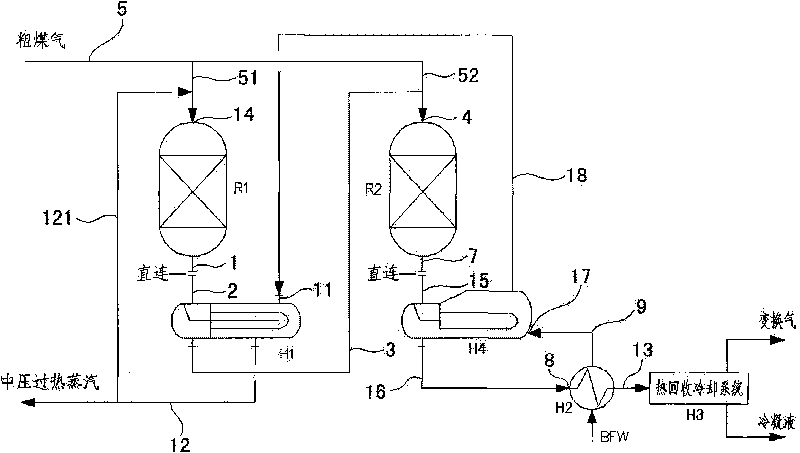

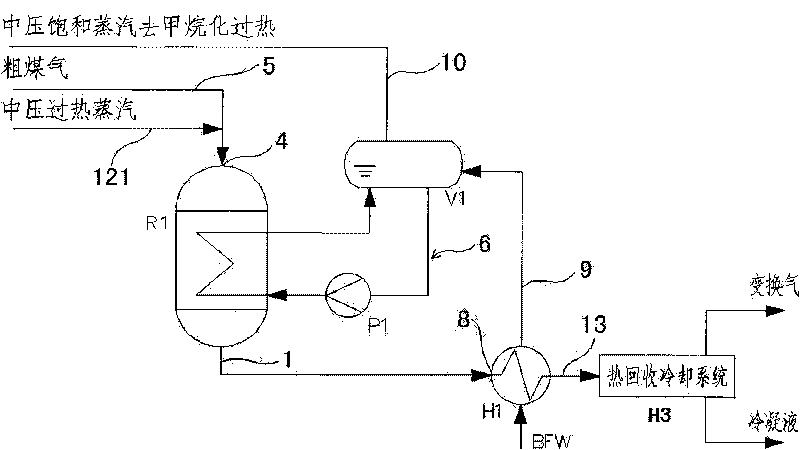

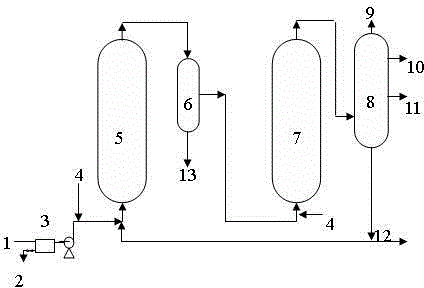

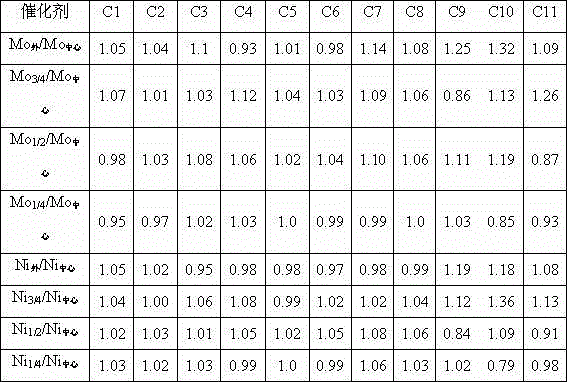

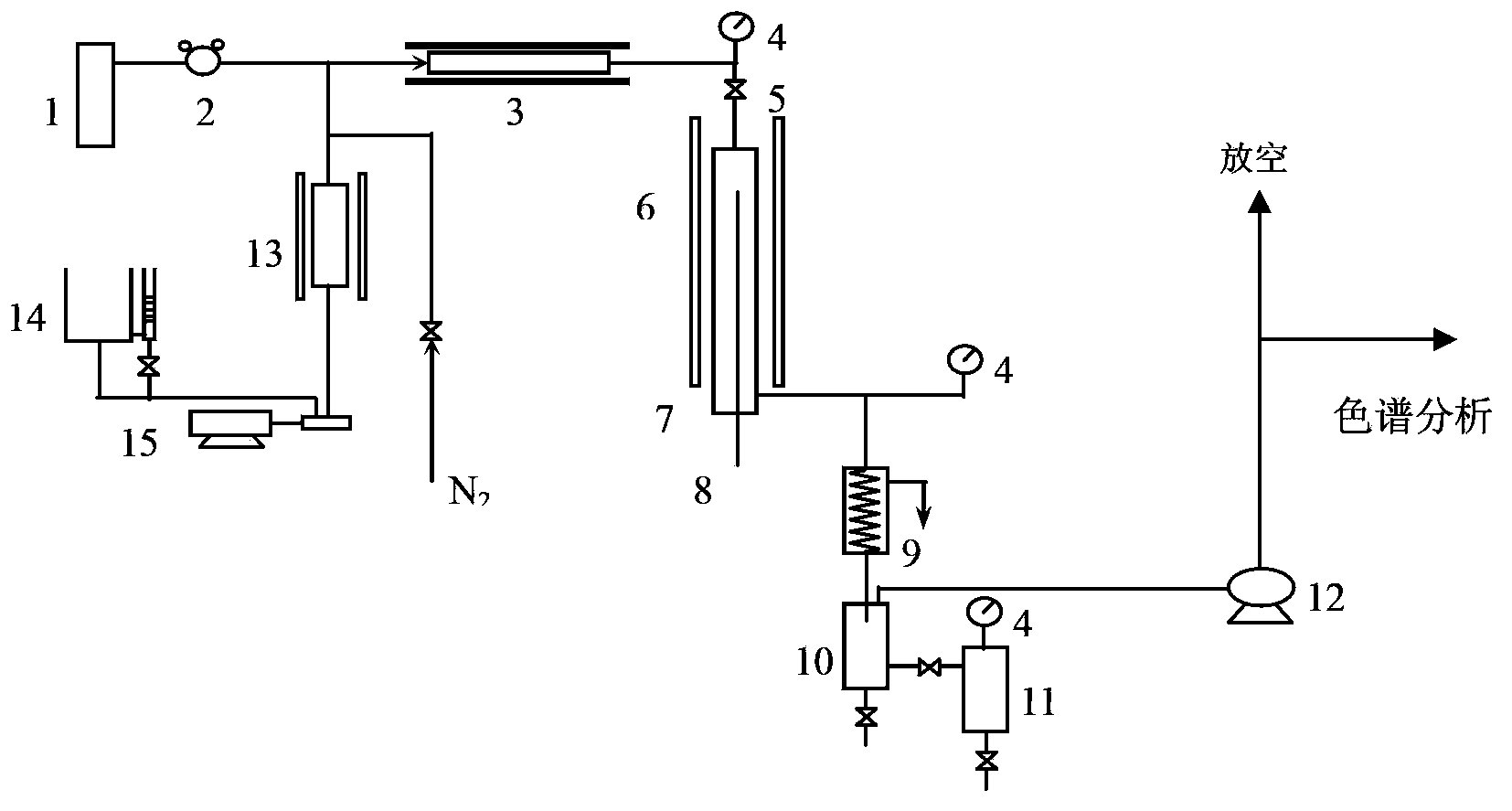

Shunting-type isothermal sulfur-tolerant conversion process and equipment thereof

ActiveCN101704513ASatisfy conversion rate requirementsMeet the requirements of adiabatic conversion control temperature riseHydrogenChemical industryShunt typesSulfur

The invention discloses a shunting-type isothermal sulfur-tolerant conversion process. The process comprises the following steps: shunting raw coal gas from exterior into at least two parts; leading overheat stream in the first part of the raw coal gas to increase the temperature to 200-300 DEG C; and then entering a first-stage conversion reaction step to carry out a conversion reaction and generate first conversion gas; and conveying the other part of the raw coal gas to next-stage conversion reaction step to carry out a conversion reaction. The catalyst bed of a shift converter has the advantages of stable temperature, simple control, convenient operation and low output CO content. The invention has the advantages of short conversion flows, few equipment, reduced resistance, great byproduct stream amount, high overheat temperature, stream pressure and heat recovery rate, and the like, thereby achieving the aims of reducing conversion stages, equipment number and resistance fall, decreasing investment, having great byproduct stream amount and high overheat temperature, stream pressure and heat recovery rate, reducing conversion stream consumption and outward wastewater discharge, protecting the environment and easily maximizing the device equipment. The invention also discloses shunting-type isothermal sulfur-tolerant conversion equipment used by the process.

Owner:SHANGHAI INT ENG CONSULTING

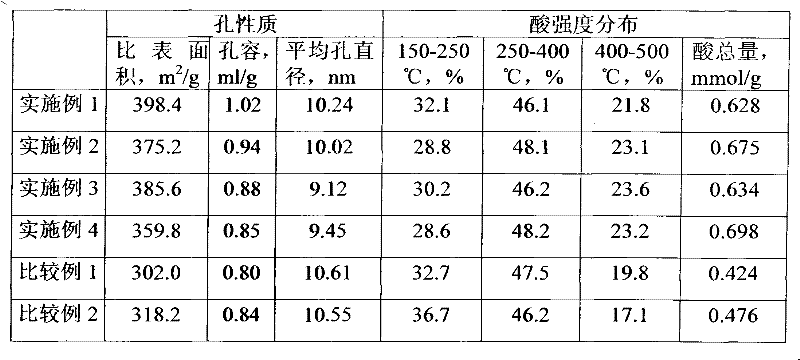

Preparation method for composite oxide carrier

ActiveCN102451765AGood dispersionLarge specific surface areaCatalyst carriersRefining to eliminate hetero atomsAluminium hydroxideAqueous solution

The present invention discloses a preparation method for a composite oxide carrier. According to the method of the present invention, a composite oxide dry glue is prepared by the following steps, wherein the steps comprise: firstly preparing an aluminum hydroxide wet filter cake and an aqueous solution containing an IVB group metal complex; adding the wet filter cake to the complex solution, andstrongly stirring; carrying out filtering and drying to obtain the composite oxide dry glue. With the composite oxide dry glue prepared by the method, most of the IVB group metal oxide can be distributed on the surface of aluminum oxide so as to reduce the influence on the pore structure of the aluminum oxide, improve the assistant catalysis effect of the IVB group metal oxide, and improve the pore structure and the surface performance of the composite oxide carrier. In addition, with the present invention, the sulfurization performance of the catalyst adopting the composite oxide carrier as the carrier can be improved, and the loaded active metal is easy to reduce.

Owner:CHINA PETROLEUM & CHEM CORP +1

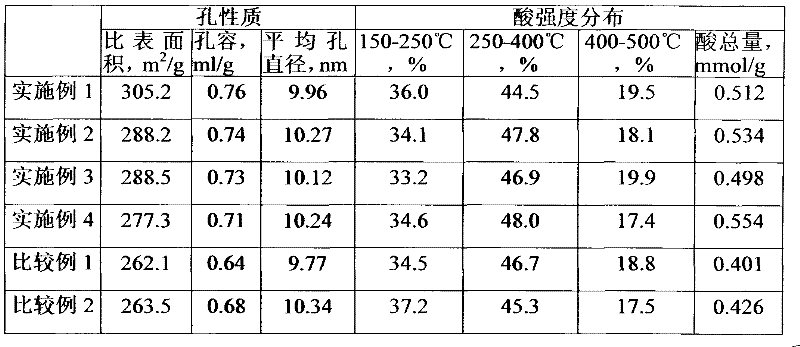

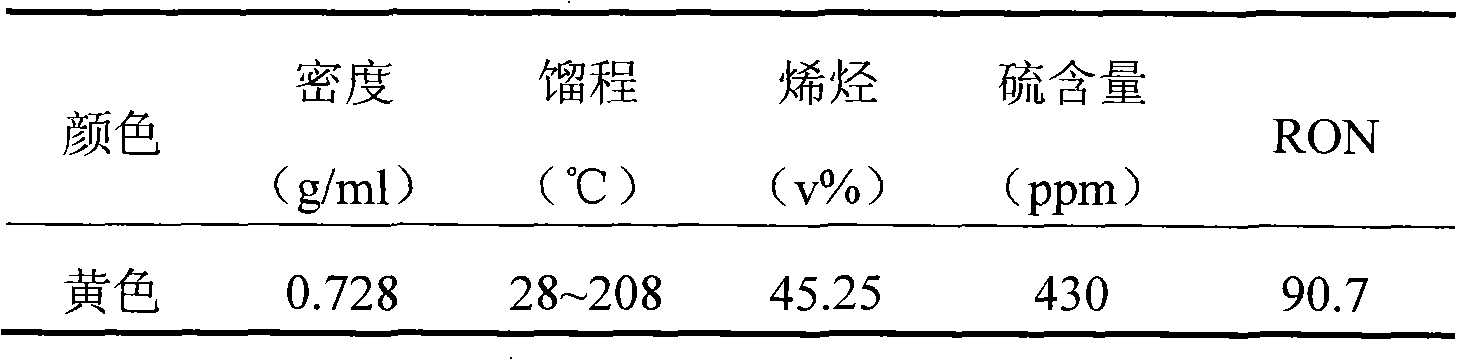

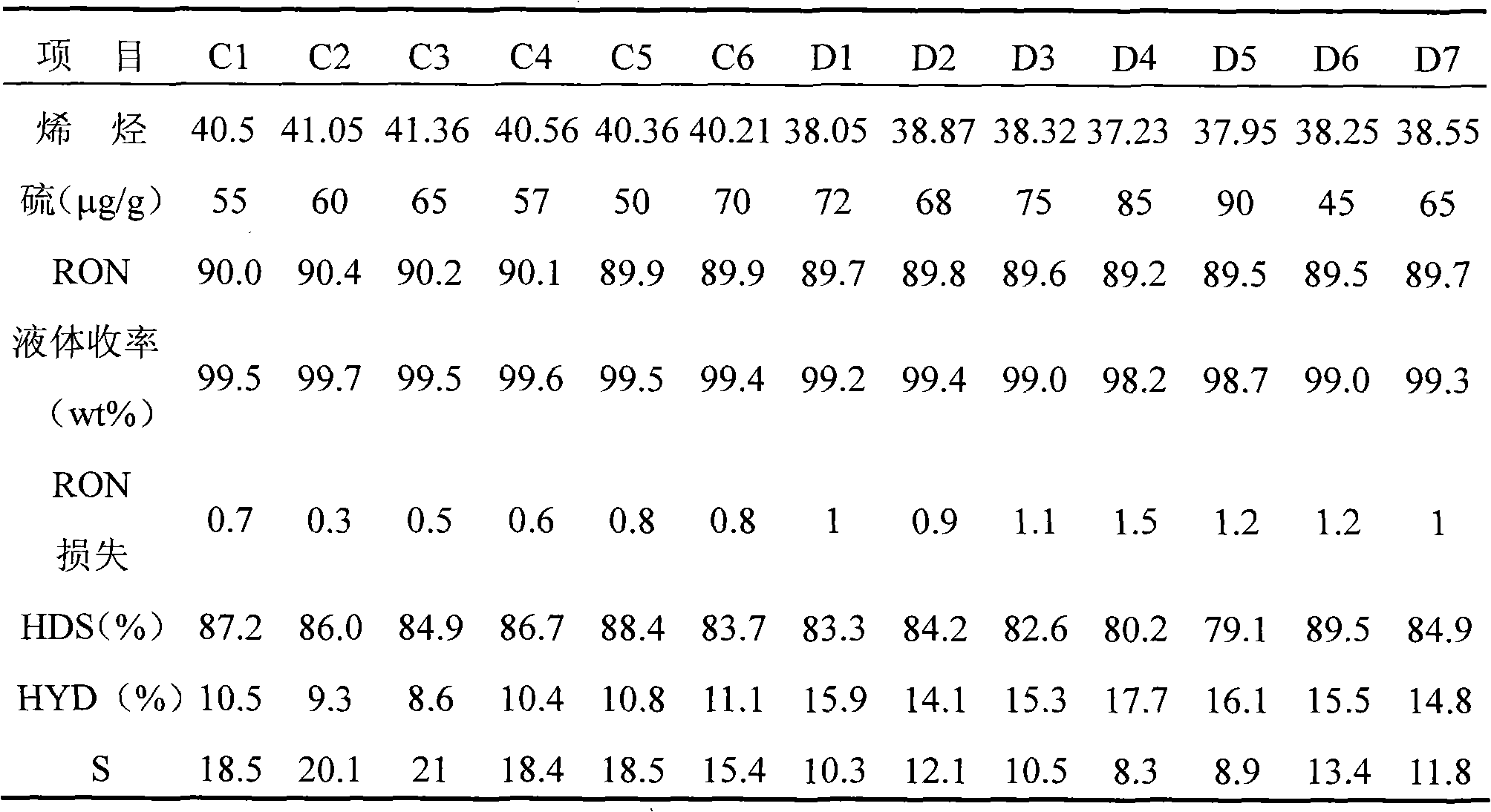

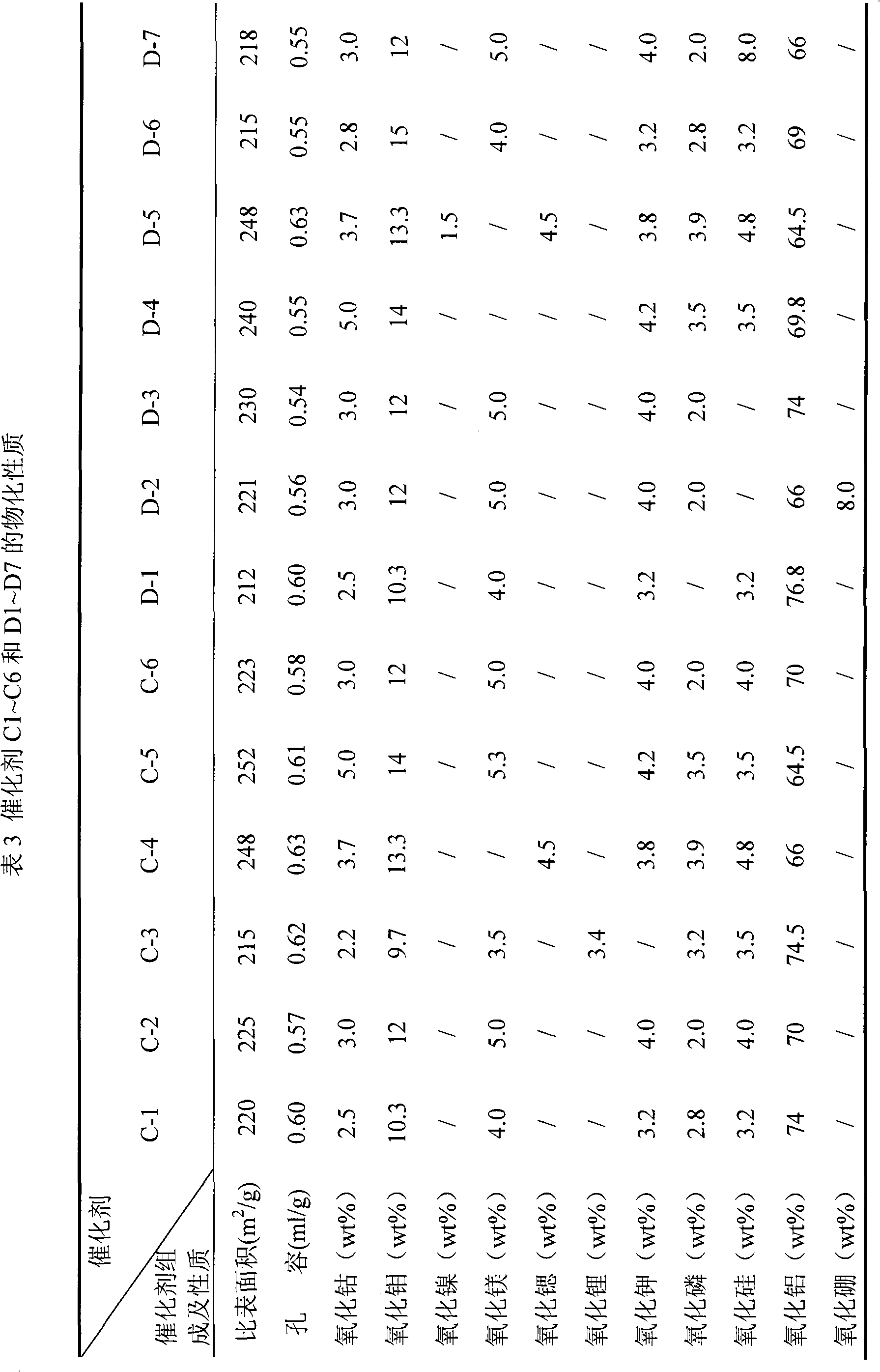

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN102335612AReduce acid strengthEnhance the interaction strengthMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

The invention relates to a selective hydrodesulfurization catalyst contains cobalt and molybdenum as active components. The selective hydrodesulfurization catalyst is characterized in that silicon oxide and aluminum oxide are used as carriers of the catalyst; based on the total weight of 100%, the catalyst comprises 2-6wt% of cobalt oxide, 9-15 wt% of molybdenum oxide, 2-8wt% of alkaline earth metal oxide, 2-6wt% of phosphorus oxide, 3-5wt% of alkali metal oxide, 2-6wt% of silicon oxide and 54-80 wt% of aluminum oxide; and the catalyst has the specific surface area of 200-300m<2> / g and the pore volume of 0.5-0.7mL / g. The catalyst has high hydrogenation activity and selectivity, good stability, low research octane number loss and high liquid yield. The catalyst is suitable for selective hydrodesulfrization of low-quality gasoline and is particularly suitable for selective hydrodesulfrization of low-quality FCC (Family Car China) gasoline.

Owner:PETROCHINA CO LTD

Preparation method of high-activity hydrodemetalization catalyst for residuum

ActiveCN103785400AEasy to vulcanizeEnhanced demetallization activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereChemistry

The invention discloses a preparation method of high-activity hydrodemetalization catalyst for residuum. The method comprises the following steps: (1) dipping a formed alumina carrier with polyol and / or monosaccharide aqueous solution, and conducting hydrothermal carbonization treatment in a sealed container after dipping; (2) drying the alumina carrier subjected to hydrothermal carbonization treatment in the step (1), loading active components Mo and Ni, and then drying again; and (3) roasting the alumina loaded with active components obtained in the step (2) in nitrogen atmosphere, and then roasting in the air atmosphere to finally prepare the hydrodemetalization catalyst for residuum. The active components of the catalyst prepared by the method distributes uniformly on the carrier, have weak interaction with the carrier, and are easy for full sulfuration, so as to significantly improve the metal removal and desulfurization activity of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

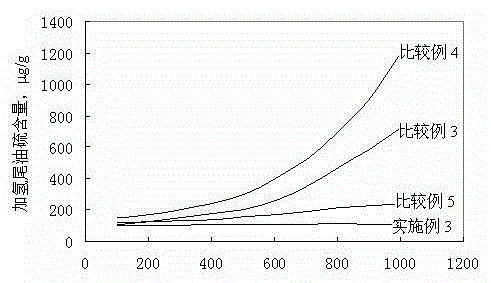

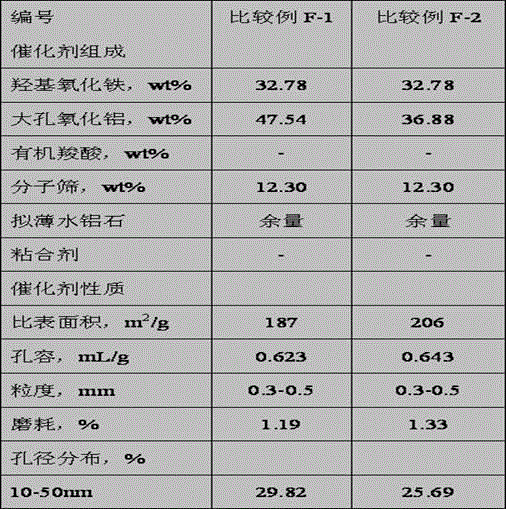

Method for hydrogenation of coal tar via fluidized bed

ActiveCN104593060AConsistent activityEasy to removeTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a method for hydrogenation of coal tar via a fluidized bed. The method comprises the following steps: subjecting a coal tar raw material to hydro-upgrading; carrying out separation to remove water; and then carrying out hydrorefining and fractionation so as to obtain a gasoline fraction, a diesel fraction and hydrogenation tail oil. A hydro-upgrading catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina, a molecular sieve and pseudo-boehmite; and a hydrofining catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina and a binder. The method provided by the invention adopts cheap iron oxyhydroxide as an active metal component, the hydro-upgrading catalyst and the hydro-refining catalyst are graded, so cost is low. According to the invention, moderate cracking of coal tar is carried out before refining of coal tar, so impurities in coal tar are effectively removed, product distribution and product quality are adjusted, and the running period of a device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

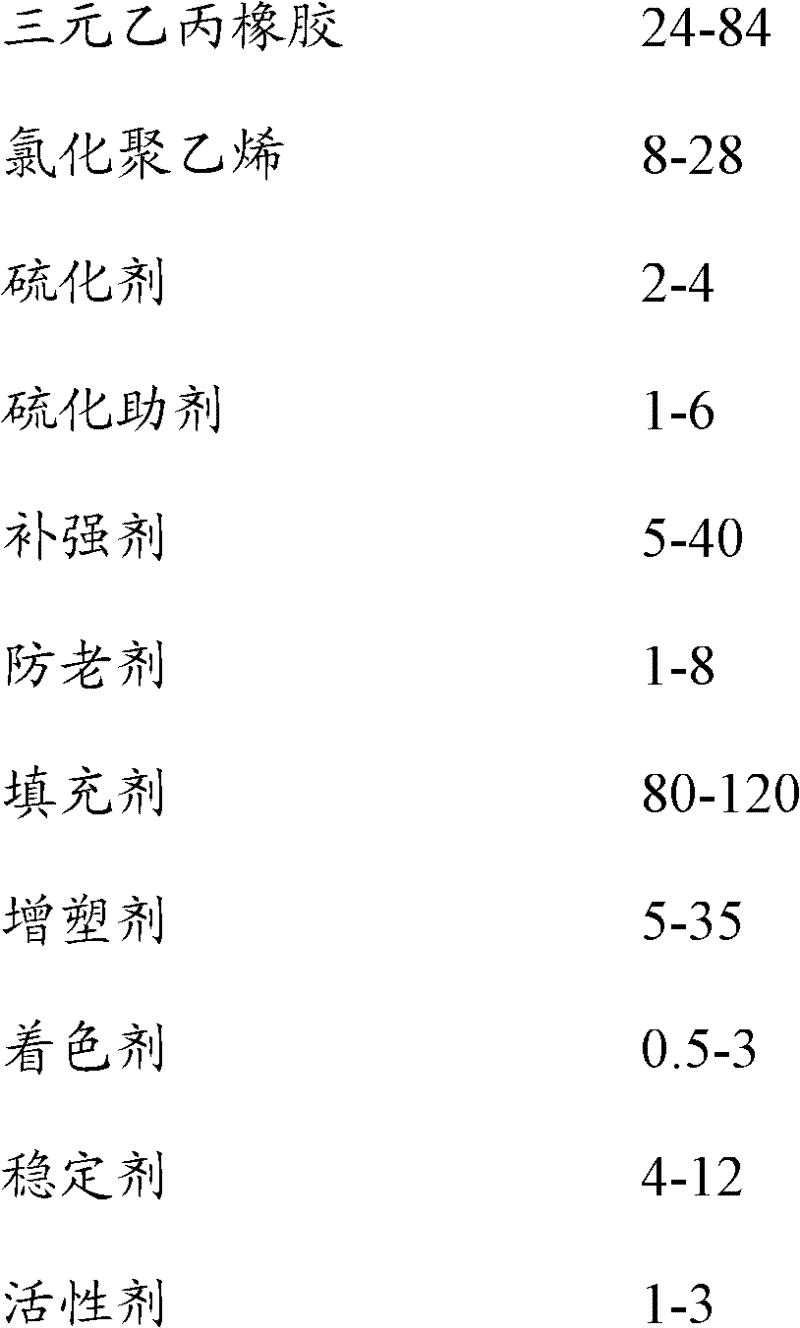

Rubber insulating glue for mine cables

InactiveCN102417663AAccelerated vulcanizationHigh activityPlastic/resin/waxes insulatorsVulcanizationPolymer science

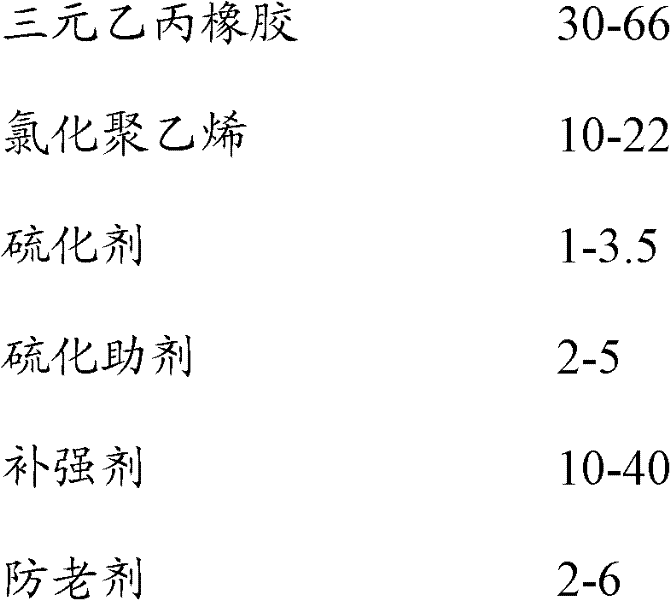

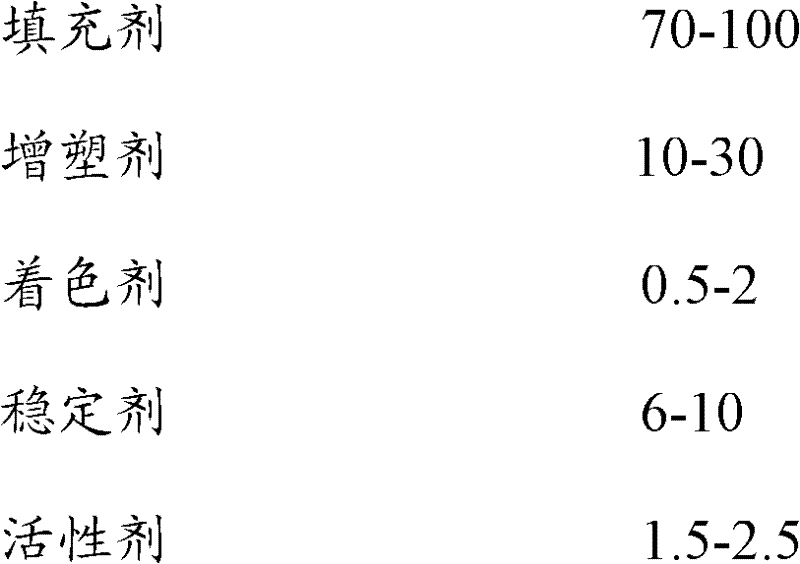

The invention relates to rubber insulating glue for mine cables. Raw materials for the glue comprise, by weight, 24 to 84 of ethylene-propylene terpolymer rubber, 8 to 28 of chlorinated polyethylene, 2 to 4 of a vulcanizing agent, 1 to 6 of a vulcanization aid, 5 to 40 of a strengthening agent, 1 to 8 of an anti-aging agent, 80 to 120 of a filling agent, 5 to 35 of a plasticizer, 0.5 to 3 of a coloring agent, 4 to 12 of a stabilizing agent and 1 to 3 of an active agent, wherein, the mass ratio of ethylene-propylene terpolymer rubber to chlorinated polyethylene is 3:1. According to the invention, chlorinated polyethylene is employed to substitute a part of ethylene-propylene terpolymer rubber, a formula for the raw materials is properly adjusted, and therefore, the prepared rubber insulating glue for mine cables shows the advantage of reduced utilization cost under the prerequisite that the glue meets utilization requirements for mine cables.

Owner:ANHUI LAND GRP

Preparation method of hydrogenation catlayst

ActiveCN101279291AEasy to useInhibit aggregationOrganic-compounds/hydrides/coordination-complexes catalystsRefining to eliminate hetero atomsPorous catalystSulfur

The present invention relates to a preparation method for a hydrotreating catalyst, which induces organic additives before, in the middle of or after inducing the active metal components on a porous catalyst carrier; wherein, at least one organic additive is an organic additive containing sulfur; then carries out one or a plurality of drying steps after inducing the active metals or the organic additives with a drying temperature lower than 300 DEG C but without baking processes in the preparation process of the catalyst. The use property of the hydrotreating catalyst prepared by the method of the present invention can be further improved and the method can be applied to various hydrotreating catalyst processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

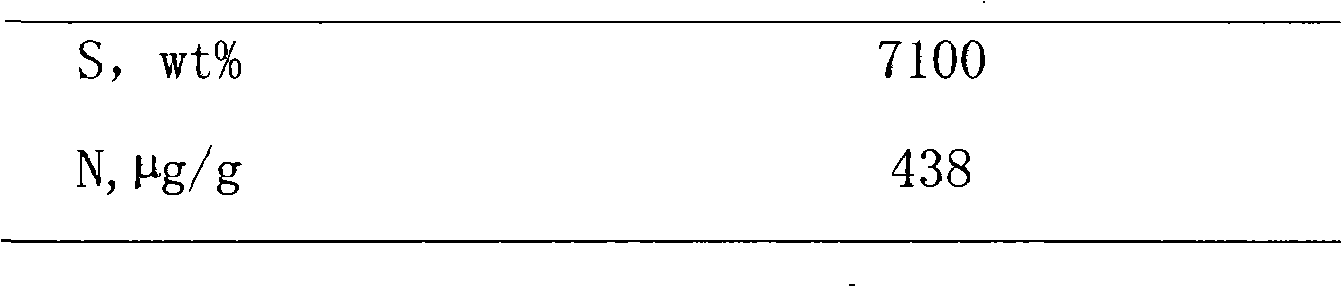

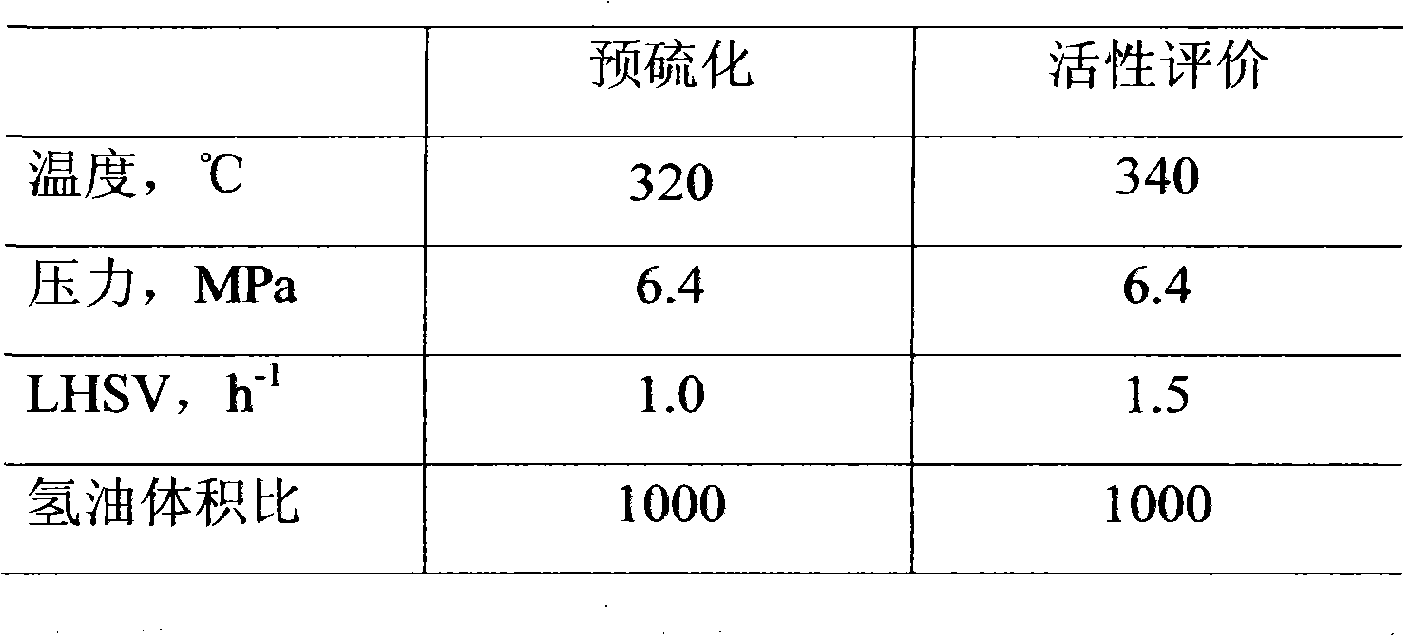

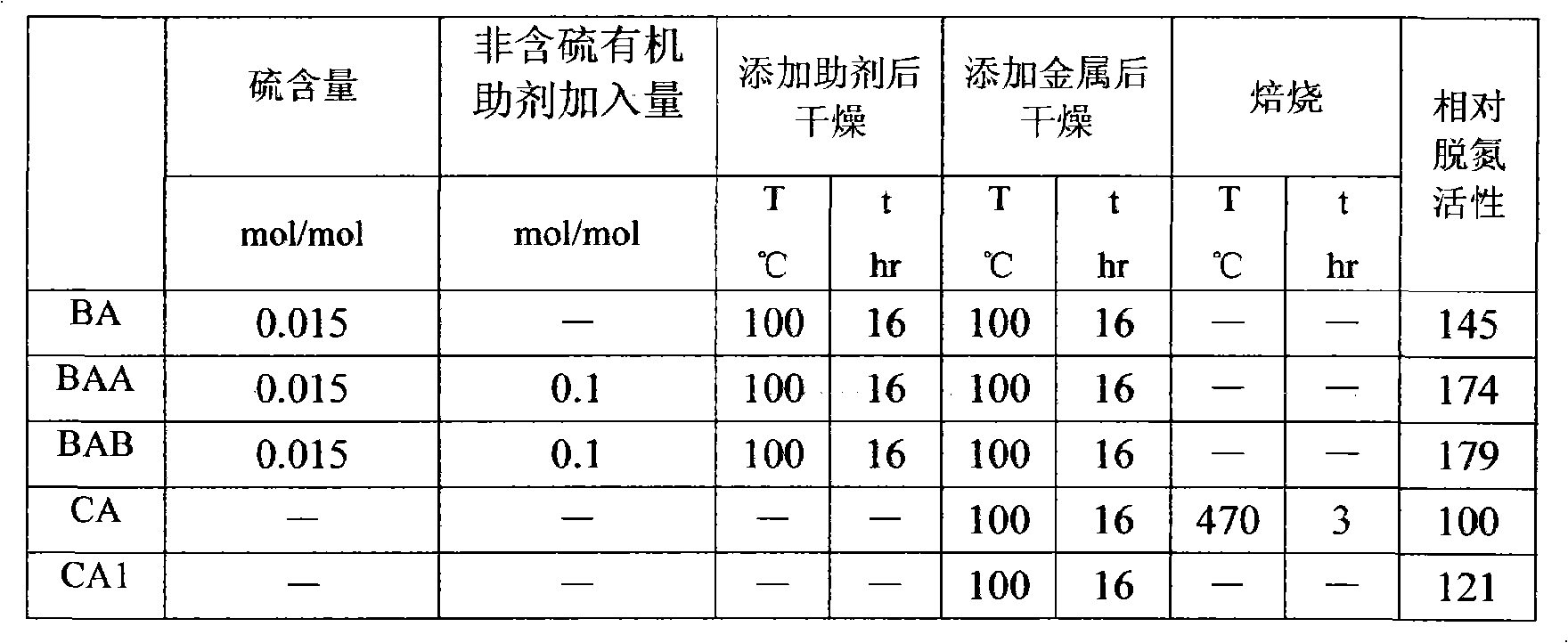

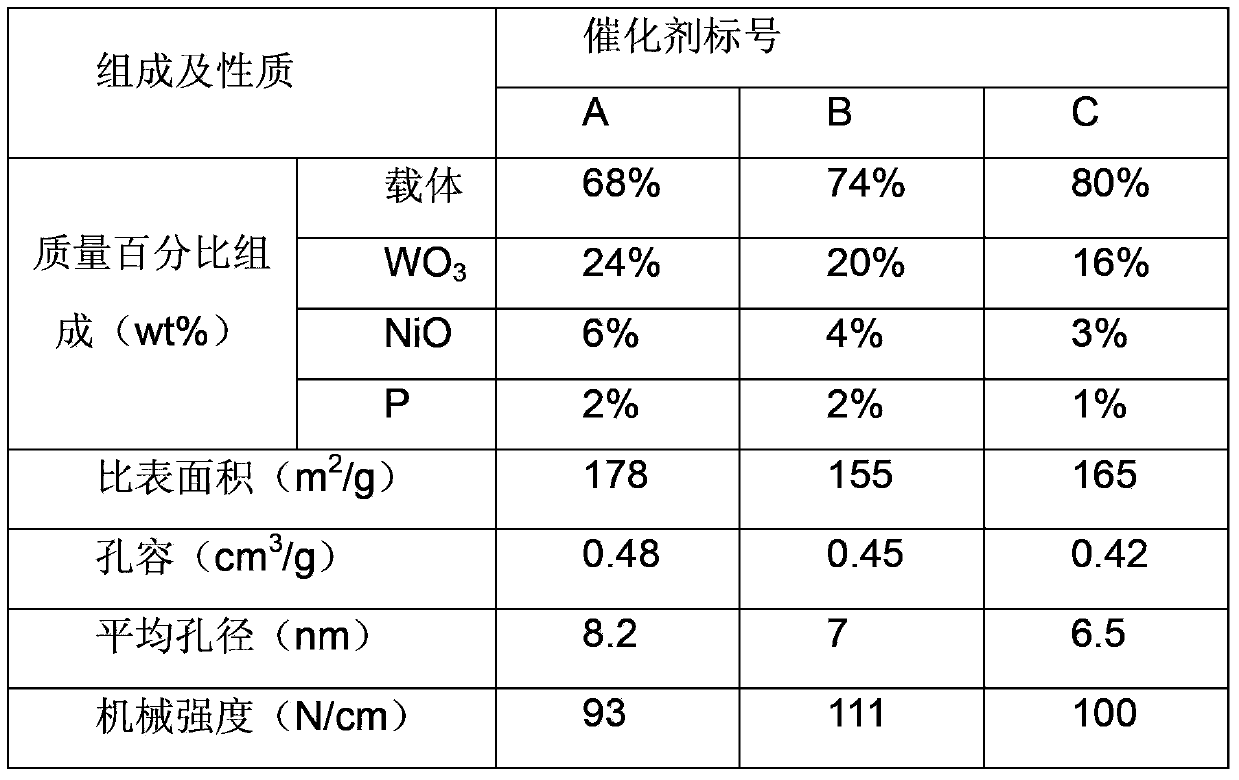

Hydro-denitrification catalyst for coal tar and preparation method thereof

ActiveCN103386321AHigh activityReduce carbon depositionMolecular sieve catalystsMolecular sieveActivated carbon

The invention discloses a hydro-denitrification catalyst for coal tar and a preparation method thereof. The catalyst is composed of an active component, an additive and a carrier, wherein the active component is composed of tungsten trioxide and nickel oxide, and through taking the total mass of the catalyst as a benchmark, the content of the tungsten trioxide accounts for 16-24 wt % of the catalyst, and the content of the nickel oxide accounts for 3-6 wt % of the catalyst; the additive is phosphorus, through taking the total mass of the catalyst as a benchmark, and in terms of an elementary substance, the phosphorus accounts for 1-2 wt % of the catalyst; through taking the total mass of the catalyst as a benchmark, and in terms of a carrier dry basis, the carrier accounts for 68-80 wt % of the catalyst; and the carrier is composed of activated carbon, alumina and a H beta molecular sieve, wherein the activated carbon accounts for 10-31 wt % of the carrier, the alumina accounts for 53-82 wt % of the carrier, and the H beta molecular sieve accounts for 8-16 wt % of the carrier. The catalyst disclosed by the invention is easy to vulcanize and relatively high in activity; and a pore structure of the activated carbon is adjustable, so that the conversion of colloid components and the removal of nitrogen impurities in coal tar are facilitated, thereby slowing the carbon deposition of the catalyst. Compared with conventional catalysts, the prepared catalyst has more excellent hydro-denitrification performance.

Owner:SHAANXI COAL & CHEM TECH INST

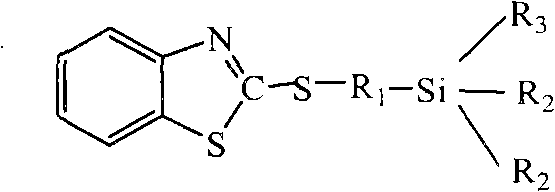

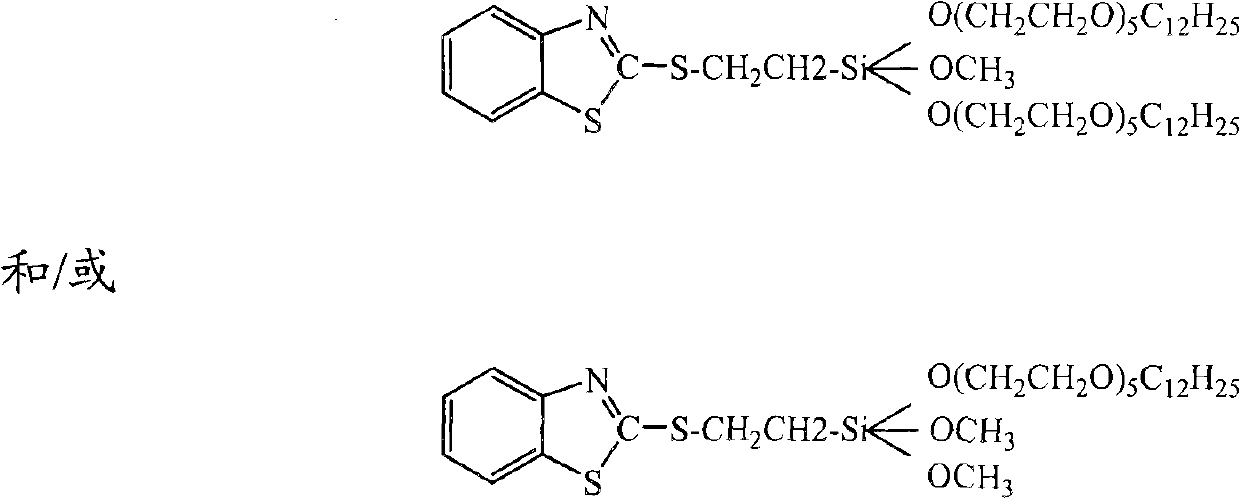

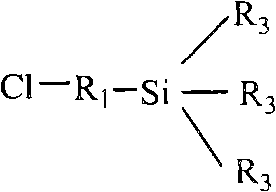

Low-volatility benzothiazolyl mercaptosilanes and preparation method thereof

ActiveCN102344462AImprove bindingImprove mechanical propertiesGroup 4/14 element organic compoundsRubber materialPolymer science

The invention discloses a low-volatility benzothiazolyl mercaptosilane and a preparation method thereof. A molecular structural formula of the low-volatility benzothiazolyl mercaptosilane is shown in the patent specification. The preparation method of the low-volatility benzothiazolyl mercaptosilane comprises the following steps that 1, a polyether and a chloroalkyl silane undergo a reaction at a temperature of 30 to 180 DEG C in the presence of one or more catalysts; and R3-H is separated from the reaction products so that a silane semi-finished product is obtained; and 2, 2-mercaptobenzothiazole is added into an organic solvent; and one or more alkalis and semi-finished silane are added into the 2-mercaptobenzothiazole solution to undergo a reaction with stirring at a temperature of 20 to 120 DEG C in a nitrogen atmosphere for 0.5 to 24 hours; the reaction products are subjected to filtration, washing and reduced pressure distillation to produce a brown-red liquid desired product. The low-volatility benzothiazolyl mercaptosilane can release a small quantity of alcohols, can improve reinforcing effects, mechanical properties and dynamic mechanical properties of vulcanized rubbers, and rolling resistance and wet skid resistance of tread rubber, has long scorch time and fast sulfuration speed, and can improve greatly sulfuration performances of rubber materials.

Owner:JIANGSU QIXIANG HIGH NEW MATERIAL

Hydrotreating catalyst preparation method

ActiveCN109718797AImprove responseFacilitated DiffusionMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsActivated carbonMicrowave

The invention discloses a hydrotreating catalyst preparation method, which comprises: crushing a wood raw material into wood chips, carrying out mixing kneading on the wood chips and pseudo-boehmite,and carrying out extruding molding; carrying out microwave pretreatment on the molded material, and carrying out carbonization treatment under an inert protective gas atmosphere; carrying out high temperature activation on the carbonized material, wherein the activation atmosphere is an alkaline gas atmosphere; and impregnating the carbon-containing alumina carrier obtained after the high temperature activation with a solution containing an active metal component, drying, and calcining to prepare the hydrotreating catalyst. According to the present invention, with the preparation method, the relationship between the active carbon and the alumina in the catalyst is effectively regulated, the acidity of the surface of the catalyst carrier is improved, and the prepared catalyst has good porestructure and good surface property, and has high hydrodemetallization efficiency, high desulfurization efficiency and high deasphalting efficiency in residue oil hydrotreating.

Owner:CHINA PETROLEUM & CHEM CORP +1

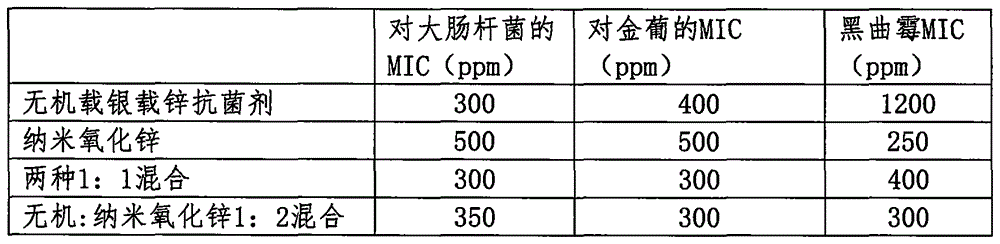

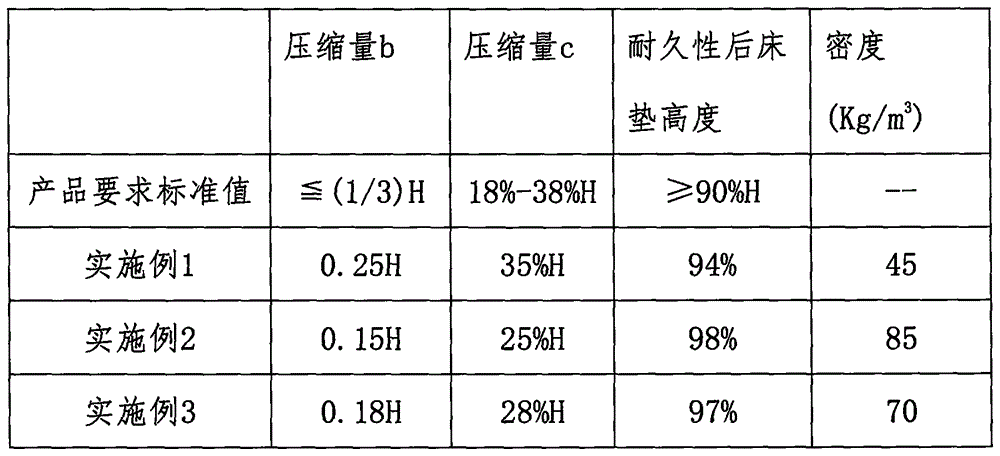

Antibacterial and mildewproof latex foam material and preparation method thereof

The invention provides an antibacterial and mildewproof latex foam material and a preparation method thereof. The foaming material comprises, by weight, 100 parts of latex (based on dry weight), 0.58 parts of potassium hydroxide, 2-5 parts of potassium vegetable oleate, 1-2 parts of potassium ricinate, 4-6 parts of sulfur, 1-2 parts of an antiager, 1-2 parts of sodium silicofluoride, 1-1.5 parts of bentonite, 4-6 parts of a vulcanization accelerator nanometer zinc oxide, and 0.5-1 part of an inorganic silver-carrying zinc-carrying antibacterial agent. The preparation method comprises removing ammonia, stirring ingredients, aging the mixture, and carrying out foaming, material filling, setting, vulcanization, cleaning and drying setting. The antimicrobial efficiency of the antibacterial and mildewproof latex foam material is 99% or more. The anti-mildew performance of the antibacterial and mildewproof latex foam material reaches the level 0-1. The elasticity, rebound resilience, strength and hardness of the foam material are excellent.

Owner:福家汇(北京)电子商务有限公司

Method for preparing residual oil hydro-demetallization catalyst

ActiveCN104549328AEvenly distributedIncrease contentCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPolyol

The invention discloses a method for preparing a residual oil hydro-demetallization catalyst. The method comprises the following steps: (1) utilizing a polyhydric alcohol and / or a monosaccharide water solution for impregnation of an alumina carrier, carrying out hydrothermal carbonization treatment in a sealed vessel after the impregnation, and carrying out drying; (2) utilizing hydrogen peroxide for surface modification treatment of the alumina carrier which is hydrothermally carbonized in step (1), carrying out drying, loading the modified alumina carrier with active constituents, and carrying out drying again; (3) utilizing the alumina carrier which is loaded with the active constituents in step (2) for calcination in a nitrogen atmosphere or an inertia atmosphere, and then for calcination again in an oxygen-containing atmosphere to obtain the residual oil hydro-demetallization catalyst. The prepared residual oil hydro-demetallization catalyst is characterized in that the functions of the active constituents and a carrier are relatively poor, and the active constituents are uniformly distributed on the carrier, so that the active constituents are easy to vulcanize, and the demetallization activity and the desulfurization activity of the residual oil hydro-demetallization catalyst are obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-strength heat-resistant modified silicon rubber power cable sheath material

InactiveCN104292836AHigh strengthImprove heat resistanceRubber insulatorsInsulated cablesPolymer scienceBenzoyl peroxide

The invention discloses a high-strength heat-resistant modified silicon rubber power cable sheath material which is prepared from the following raw materials in parts by weight: silicone rubber, fluorine rubber, nano calcium carbonate, modified silica, potassium titanate whiskers, aluminum hydroxide, ferric oxide, tin oxide, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, methyltris(methylethylketoximino)silane, benzoyl peroxide, hydroxyl silicone oil, an amino silane coupling agent, dibutyltin dilaurate, magnesium oxide, a hydroxy stearic acid, an accelerant, an antiager, and a plasticizer. The high-strength heat-resistant modified silicon rubber power cable sheath material disclosed by the invention is high in strength and good in heat resistance, and a cable sheath prepared by using the high-strength heat-resistant modified silicon rubber power cable sheath material is good in comprehensive performance and long in service life.

Owner:ANHUI CONSTANT CRYSTAL CABLE GROUP

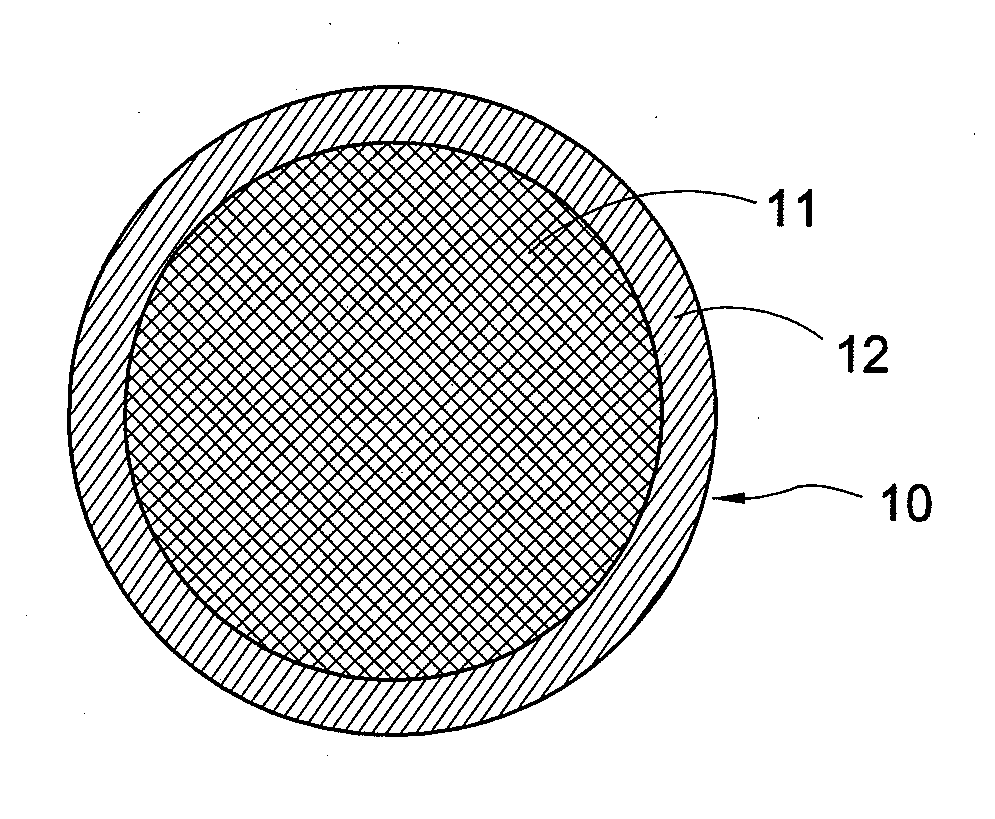

Low-temperature-resistant and abrasion-resistant cable

InactiveCN105038257AChanging the crystallization temperatureLower crystallization temperatureRubber insulatorsInsulated cablesPhosphorous acidMelamine phosphate

The invention discloses a low-temperature-resistant and abrasion-resistant cable. The low-temperature-resistant and abrasion-resistant cable comprises a conductive cable core, an inner protective cover and an outer protective cover. The conductive cable core is wrapped by the inner protective cover, and the inner protective cover is wrapped by the outer protective cover. The outer protective cover comprises polymethylvinylphenylsiloxane gum, hydrogenated butadiene-acrylonitrile rubber, solution polymerized styrene-butadiene rubber, methyl fluorine silicone oil, epoxidized soybean oil, dioctyl nylon acid ester, fumed silica, micro gelating capsule red phosphorus, melamine phosphate, dicumyl peroxide, vinyltriethoxysilane, zinc oxide, Ca / Zn compound stabilizer, TX-1 type rare-earth stabilizer, magnesium stearate, antioxygen 1076, phosphorous acid trioctyl ester and silicone powder. The low-temperature-resistant and abrasion-resistant cable is good in low temperature resistance and high in tenacity and abrasion resistance.

Owner:ANHUI RUIKAN SCI CABLE

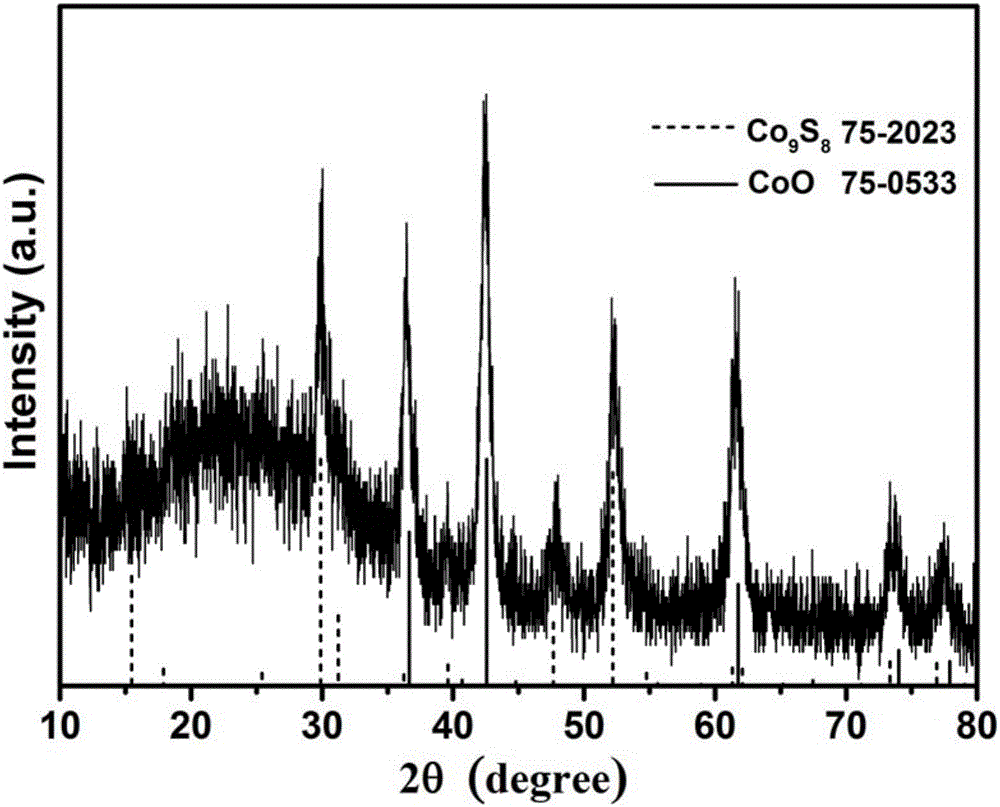

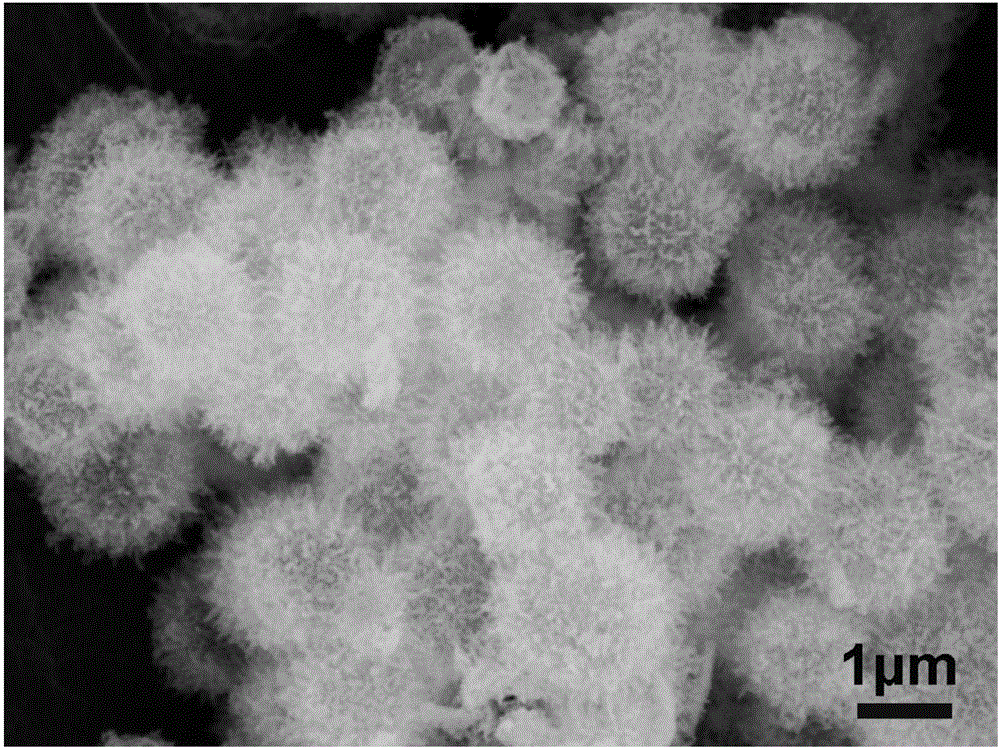

Hollow micro-sphere possessing multilayer cobaltous sulfide/cobaltous oxide shell and preparation method and application thereof

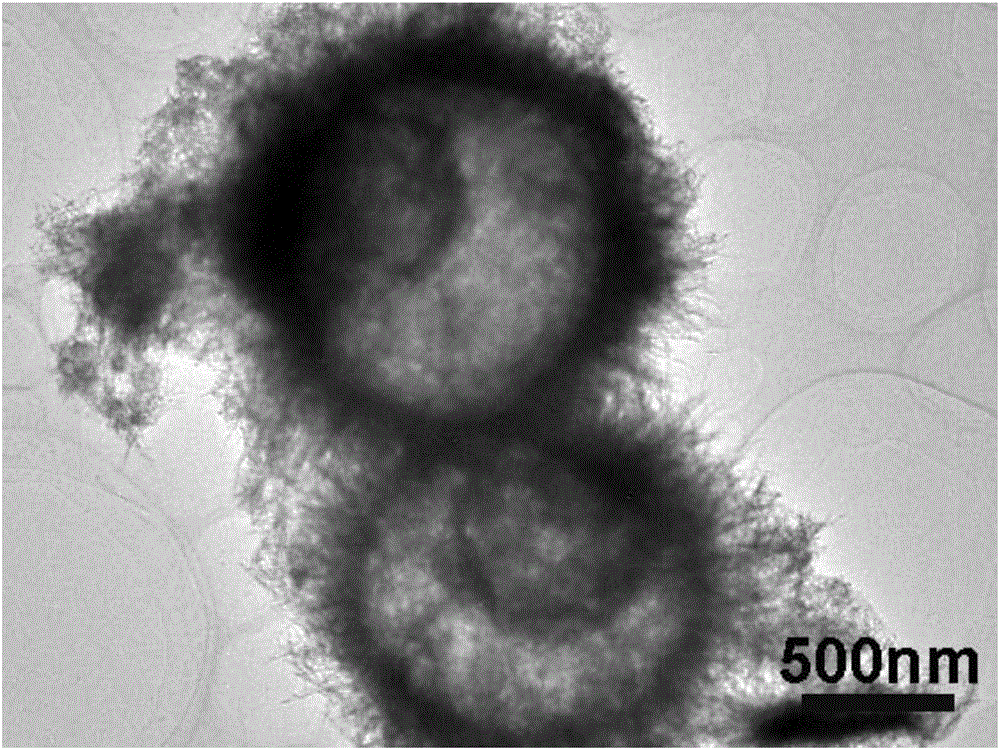

InactiveCN106298255AGood size controlLow priceHybrid capacitor electrodesMicroballoon preparationDispersityNanowire

The present invention discloses a hollow micro-sphere possessing a multilayer cobaltous sulfide / cobaltous oxide shell and a preparation method and an application thereof. The preparation method comprises the steps of firstly adopting a low temperature solution precipitation method to grow a Co2CO3(OH)2 nanowire on the surface of a carbon sphere, calcining in the air to obtain the hollow micro-sphere possessing the multilayer Co3O4 shell, and then vulcanizing the Co3O4 micro-sphere in a tube furnace to obtain the complete hollow micro-sphere possessing the multilayer cobaltous sulfide / cobaltous oxide shell. According to the present invention, the obtained powder is good in dispersity and uniform in size and has the controllable particle size, the reaction repeatability is high, and the preparation cost is low.

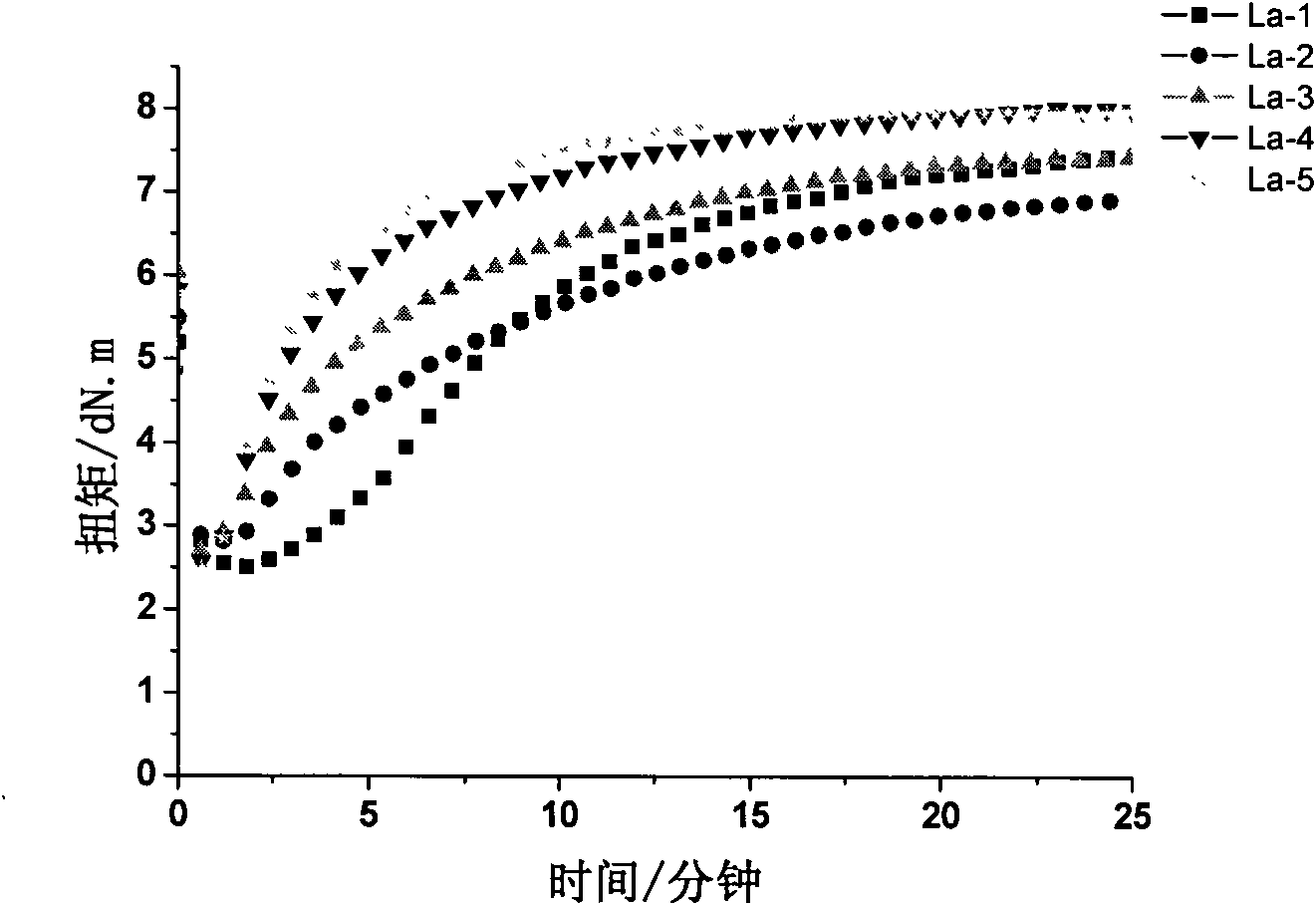

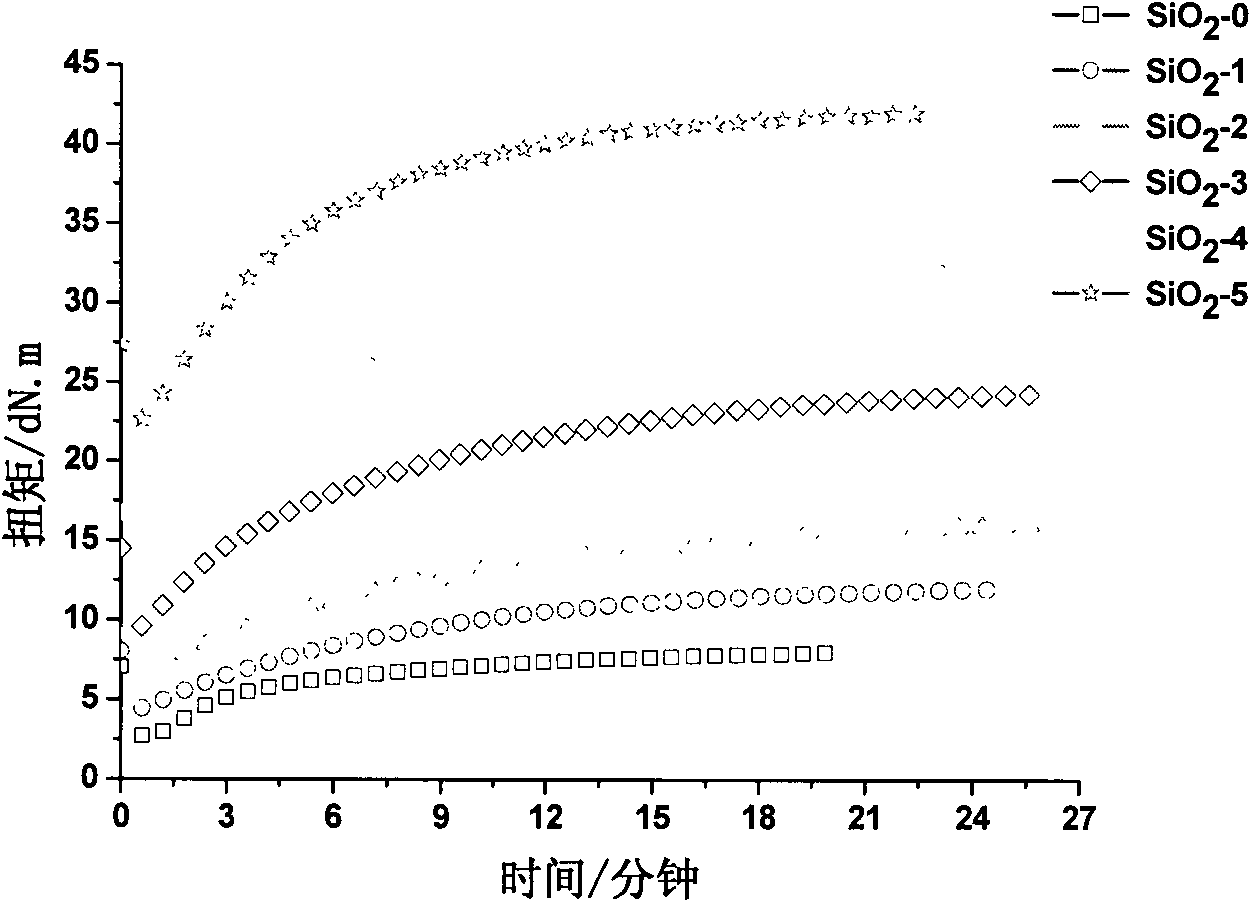

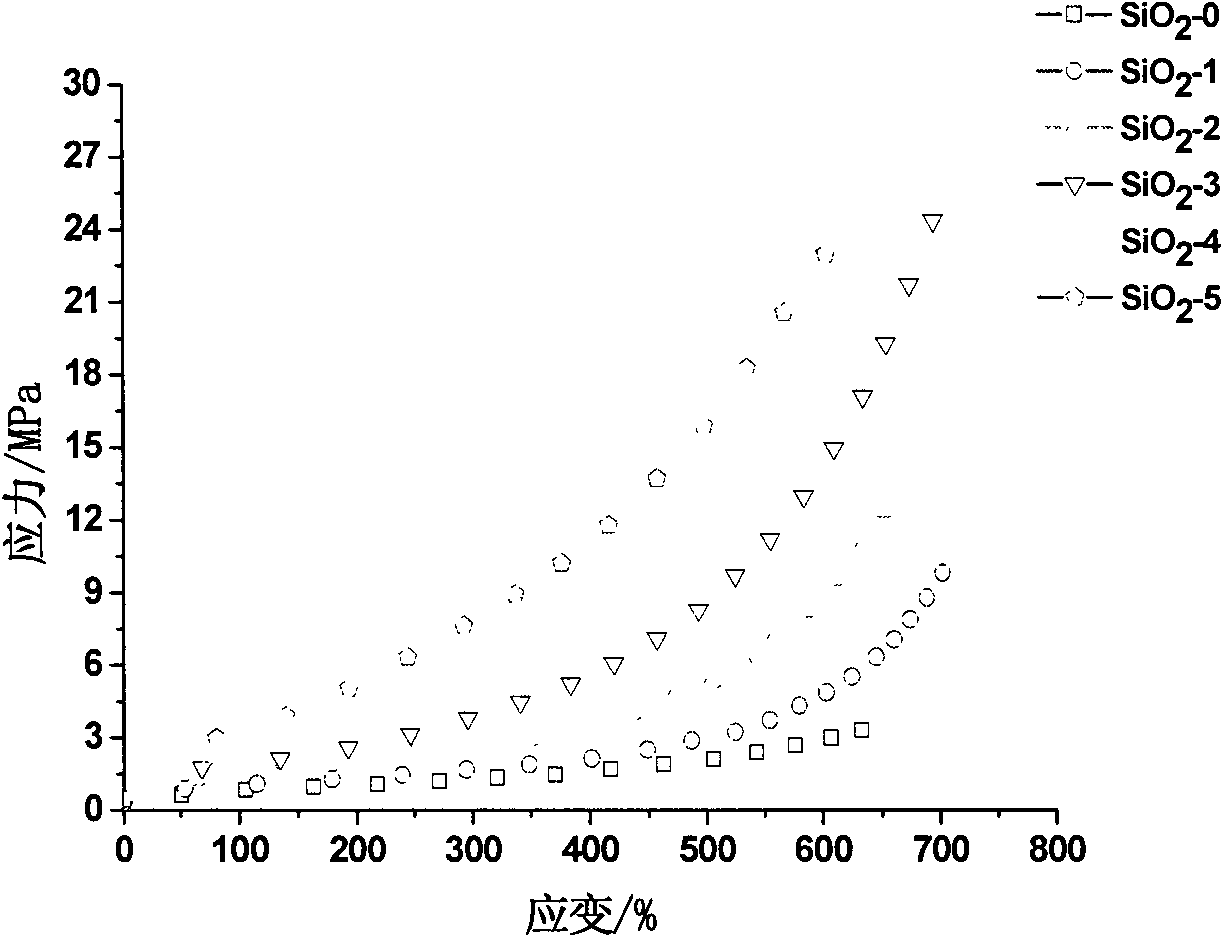

Rare earth rubber vulcanization accelerator, and preparation method and application thereof

ActiveCN101962452ASignificant vulcanization acceleration effectAccelerated vulcanization acceleration effectOrganic chemistryRare-earth elementVulcanization

The invention discloses a rare earth rubber vulcanization accelerator, and a preparation method and application thereof. The accelerator is prepared by compounding rare earth ions and carboxylic acid substituted dithiocarbamate, wherein the rare earth ions may be one or the mixture of more than one of 14 rare earth elements, except promethium which is a radioactive element, with the atomic numbers of 57 to 71 in the periodic table of elements. The rare earth vulcanization accelerator of the invention is added into a rubber formula without adding the vulcanization active agents of stearic acid and zinc oxide to achieve good vulcanization effect and prepare a rubber composite material with high comprehensive mechanical properties which are remarkably superior to those of the accelerator zinc diethyl dithiocarbamate (ZDC) commonly used in industry at present in the same proportion, is a carbamate rare earth compound of primary amine, does not produce nitrite in a vulcanization process, and is environmentally-friendly.

Owner:SOUTH CHINA UNIV OF TECH

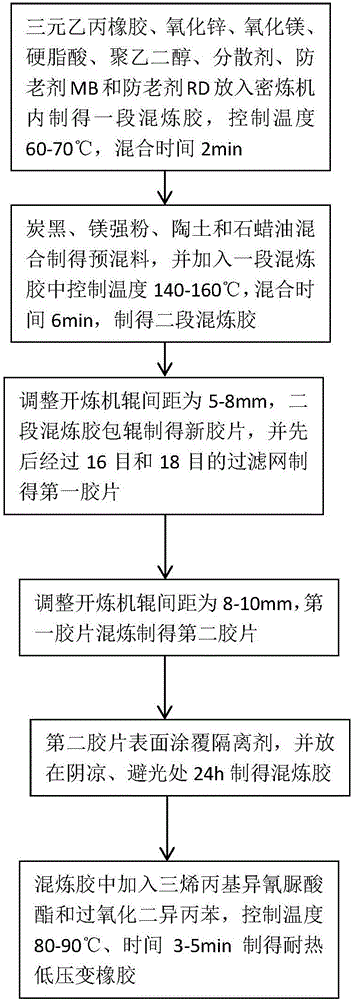

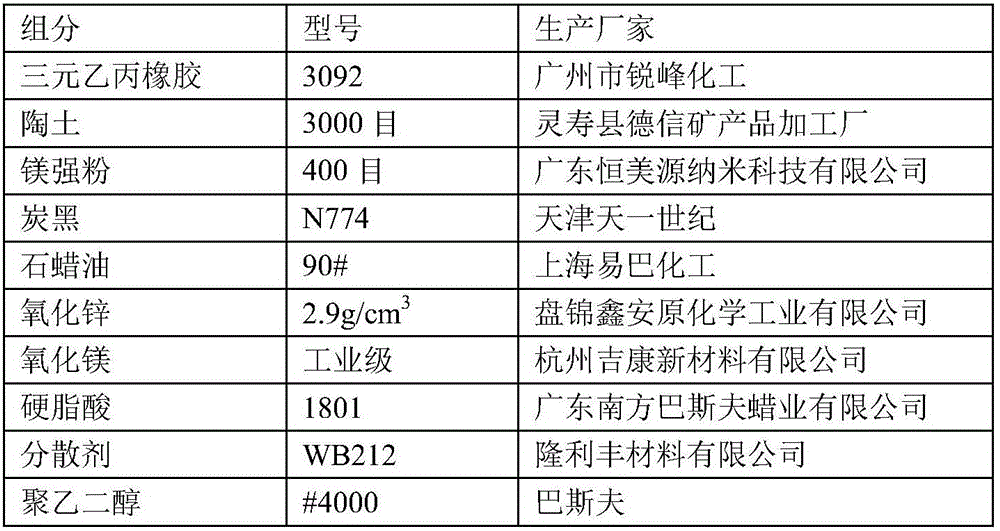

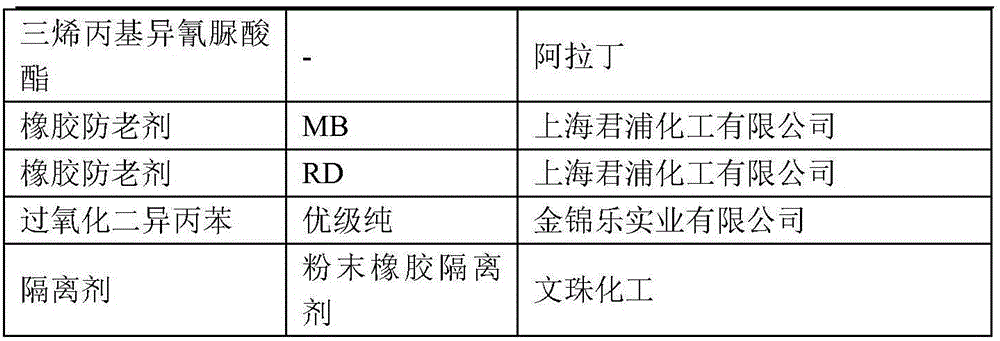

Heat-resistant low-pressure-change rubber and preparation method thereof

The invention relates to heat-resistant low-pressure-change rubber which is prepared from the following components in parts by weight: 100 parts of ethylene propylene terpolymer, 40 to 80 parts of argil, 40 to 80 parts of strong magnesium powder, 30 to 50 parts of carbon black, 20 to 30 parts of paraffin oil, 5 to 8 parts of zinc oxide, 10 to 15 parts of magnesium oxide, 1 to 3 parts of stearic acid, 2 to 4 parts of a dispersing agent, 2 to 4 parts of polyethylene glycol, 1 to 3 parts of triallyl isocyanurate, 3 to 6 parts of an anti-aging agent, 5 to 10 parts of a vulcanizing agent, wherein the vulcanizing agent is dicumyl peroxide. The ethylene propylene terpolymer is cooperated with a preparation process, so that rubber which can resist high temperature of 150 DEG C for a long time and is relatively low in permanent set at break can be prepared.

Owner:北京华通橡塑制品有限公司

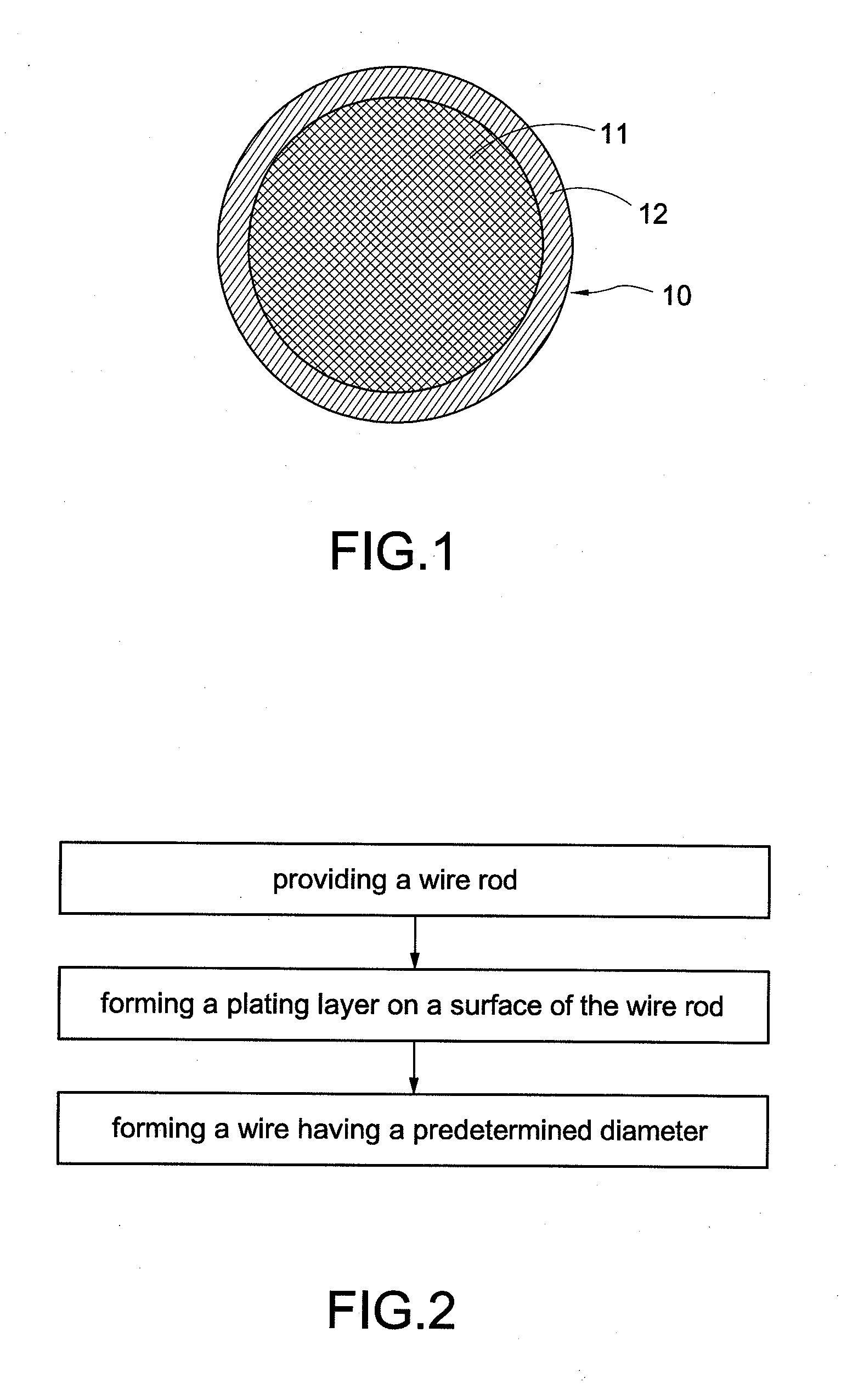

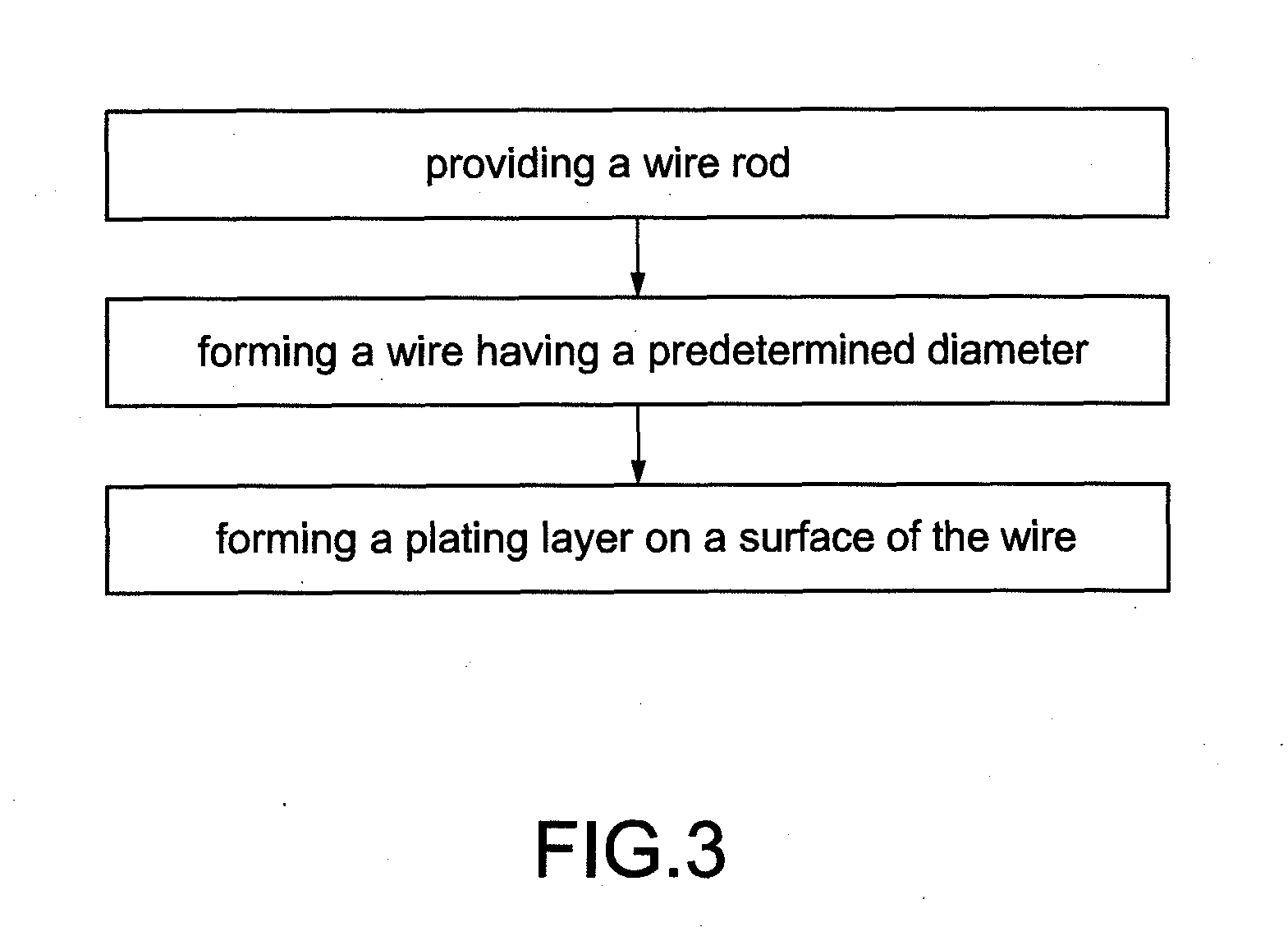

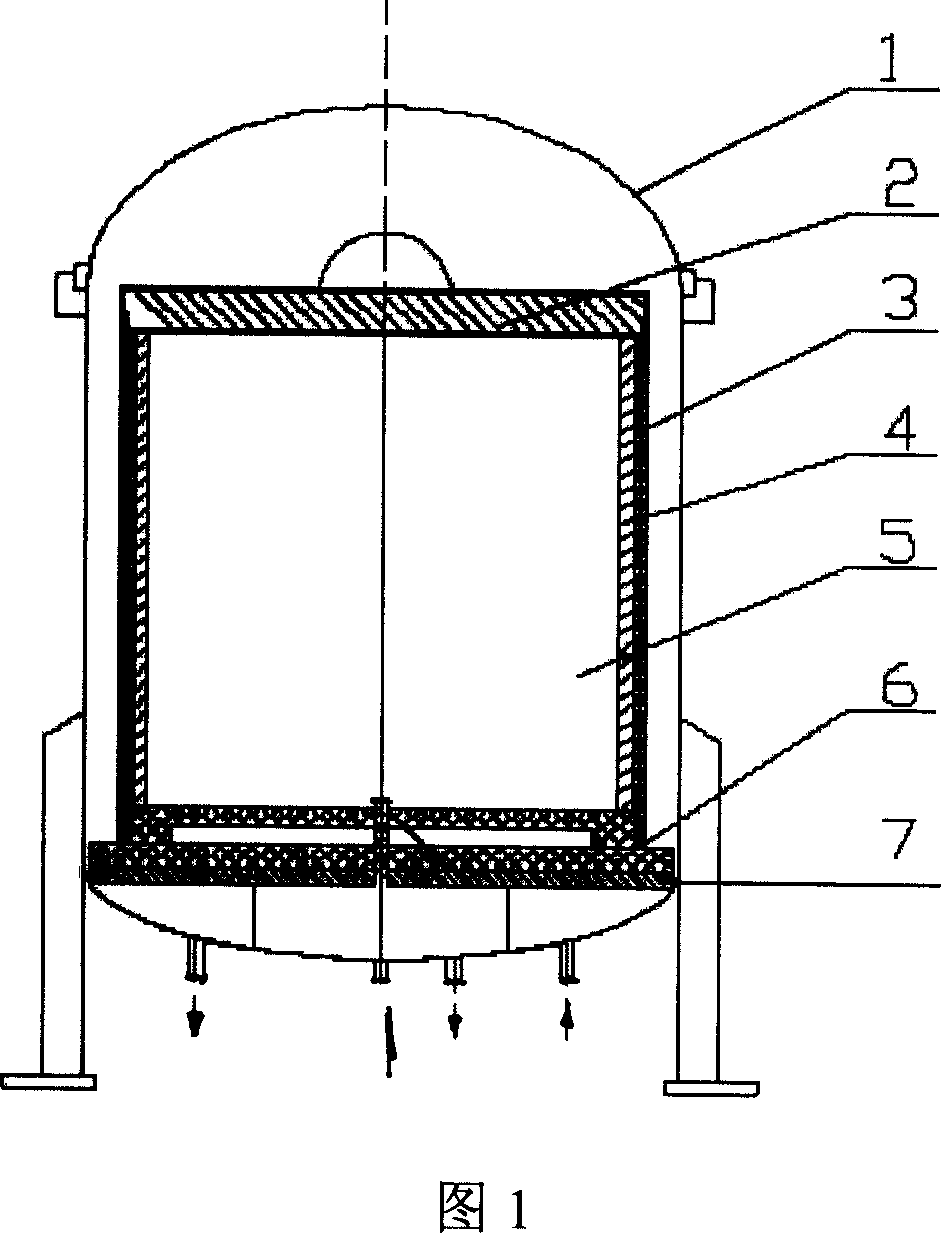

Composite wire of silver-palladium alloy coated with metallic thin film and method thereof

InactiveUS20130233593A1Improve conductivityImprove ductilityNon-insulated conductorsSolid-state devicesWire rodAlloy

Owner:WIRE TECH +1

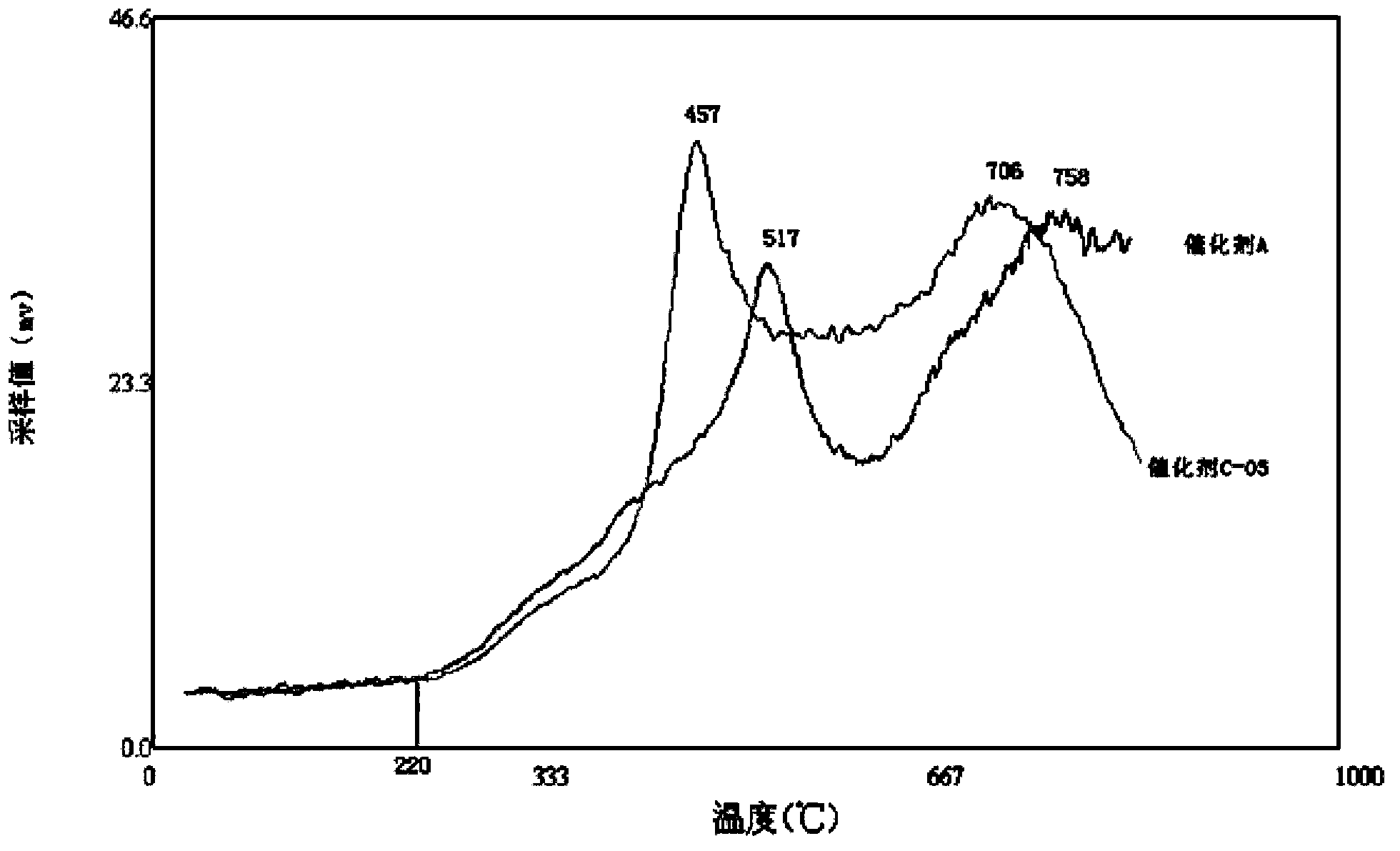

Method for circularly and rapidly pre-vulcanizing sulfur tolerant shift catalyst and carrying out segmental pre-vulcanizing by utilizing sulfur tolerant shift catalyst

ActiveCN103657741AThe vulcanization method is simpleHeating up fastCatalyst activation/preparationSocial benefitsVulcanization

The invention relates to a segmental pre-vulcanizing method of a sulfur tolerant shift catalyst in a multi-segment conversion process, particularly relates to a method for rapidly pre-vulcanizing cobalt-molybdenum-series sulfur tolerant shift catalysts and belongs to the technical field of pretreatment of the sulfur tolerant shift catalyst. According to the method, aiming at the situations of the temperature raising and the slow vulcanizing speed caused due to insufficient vulcanizing conditions, a segmental vulcanizing method is utilized, namely the rapid pre-vulcanizing of a first-segment furnace is reinforced to raise the temperature of a subsequent second-segment furnace; first-segment vulcanizing conditions are reinforced to guarantee the vulcanization of the catalyst so as to realize the rapid, efficient and complete vulcanization, meanwhile, the temperature of a subsequent second-segment bed is raised by high-temperature vulcanized gas in a rapid vulcanizing process, and the subsequent working segments are similarly processed, so that the vulcanizing and temperature raising time is greatly shortened, and the vulcanizing cost is lowered; by utilizing a circular vulcanizing manner, the emptying quantity is few, the overtemperature is avoided, the vulcanizing process is convenient and safe, the pollution is light, and the method has remarkable economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP

Synthetic rubber for nylon curtain wire on inner layer of tire

The invention relates to a synthetic rubber for a nylon curtain wire on an inner layer of a tire in the field of synthetic rubber. The technical proposal is as follows: the synthetic rubber includes the following raw materials according to the parts by weight: 90 of natural rubber, 8-12 of butadiene-styrene rubber, 40-60 of fine reclaimed rubber, 3-5 of zinc oxide, 2-3.5 of stearic acid, 3-5 of antioxidant, 1.5-3 of tackifying resin, 1.5-3 of homogenizing agent, 1-3 of plasticizer, 1.5-2.2 of silane coupling agent, 30-40 of high-abrasion furnace black, 6-8 of silica hydrated, 7.5-8.5 of aromatic oil, 2-3 of sulfur, 1-2 of vulcanization accelerator and 0.1-0.25 of antiscorcher. The invention adopts a silica hydrated and Si-69 balance vulcanization system so as to avoid over-vulcanization and then to greatly improve the whole performance of the tire. The formulation involves a great amount of fine reclaimed rubber to replace the natural rubber, thereby not only saving the cost and resources but also improving the milling and rolling property of the inner layer curtain wire rubber.

Owner:SHANDONG HENGYU RUBBER CO LTD

Solvent-resistant corrosion-resistant rubber and preparation method thereof

The invention discloses a solvent-resistant and corrosion-resistant rubber and a preparation method thereof. The solvent-resistant and corrosion-resistant rubber consists of the following parts by mass: 30-50 parts of natural rubber, 20-30 parts of nitrile rubber, and 20-30 parts of fluorosilicone rubber 30 parts, 3-7 parts of active zinc oxide, 3-9 parts of PE wax, 4-10 parts of n-butyl methacrylate, 3-8 parts of epoxy resin, 0.3-1.2 parts of anti-aging agent, 1-part of resorcinol 3 parts, polytetrafluoroethylene 6‑10 parts, coumarone resin 2‑5 parts, stearic acid 3‑6 parts, white carbon black 8‑15 parts, sulfur 10‑15 parts, accelerator AM‑2 3‑ 5 parts, 0.1-0.3 parts of anti-scorch agent CTP, the present invention is prepared by two-stage mixing method. The solvent-resistant and corrosion-resistant rubber of the invention has good resistance to organic solvents, strong acid and alkali resistance, corrosion resistance, excellent wear resistance and high temperature resistance, simple preparation, low cost and certain promotion value.

Owner:安徽省含山县锦华氧化锌厂

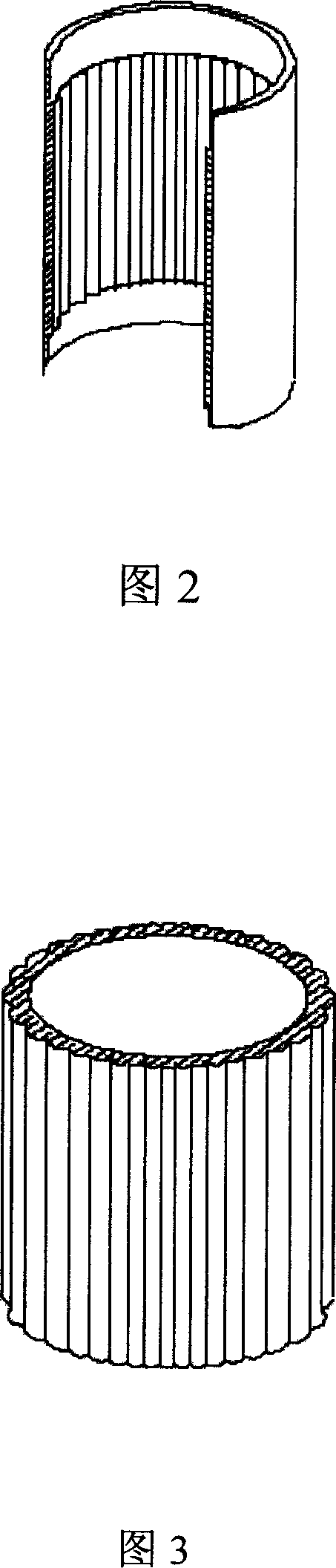

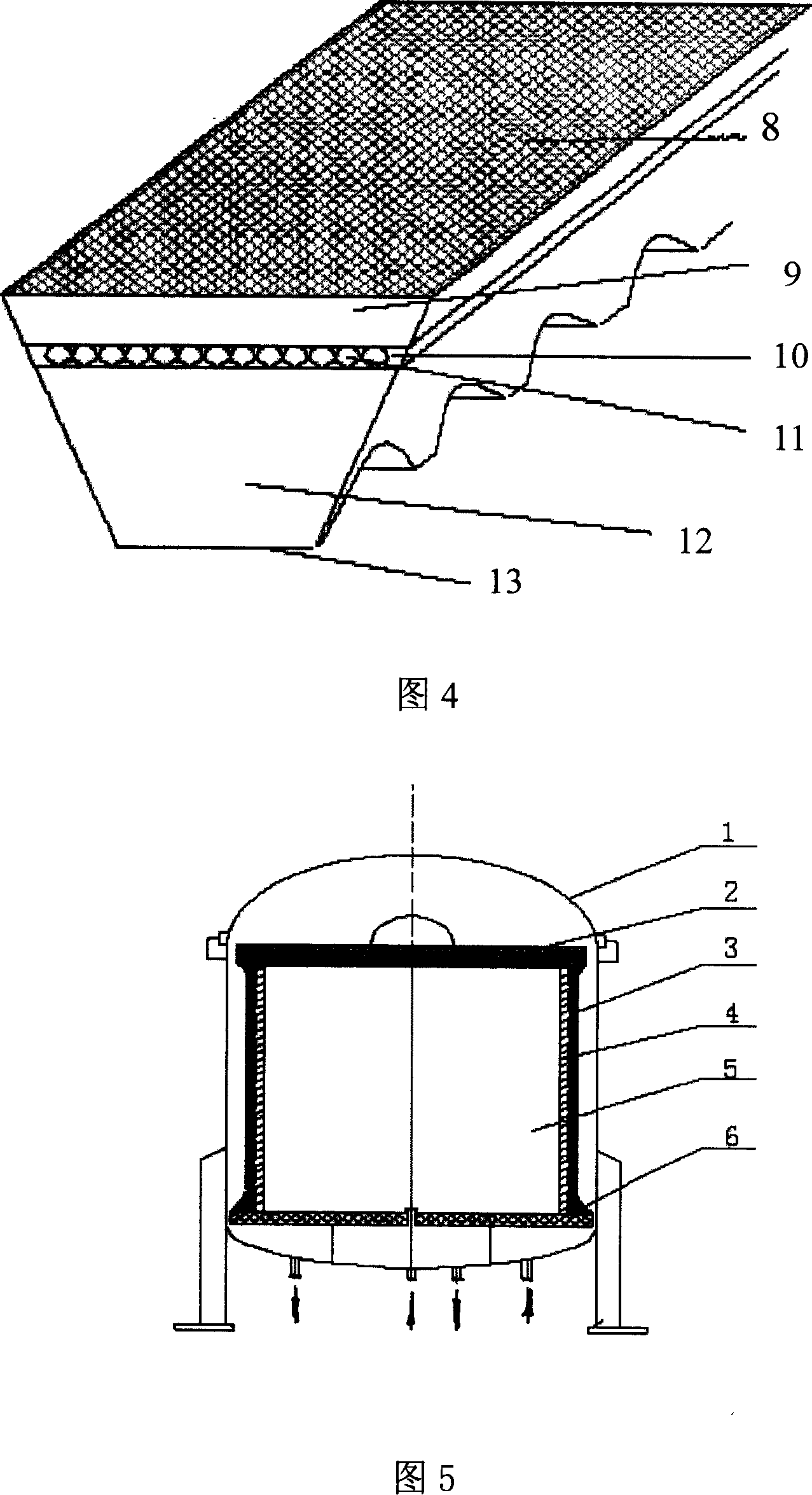

Reverse-forming sulfuration method for sealed type tooth-shaped edge V tape of rubber lagging

It relates to the glue sleeve seal teeth shape reversed V shape forming sulfuration. It makes belt blank at the inner mold, installs the round cylinder glue sleeve with teeth on the surface inside and smooth surface inside both ends on the glue sleeve base and fastened with shrouding rings, putting them into sulfur can, hanging belt blank into glue sleeve, covering the top cap and the cap of the sulfur can, sequentially opening the outside pressure and inner pressure steam for sulfuration, stripping the belt blank round cylinder with vertical rack outside and the cutting belt blank round cylinder, getting many teeth shape cutting V belt. It solves the sealing issue at both ends of the glue sleeve, eliminating the bubbling stratification defect of the product, increasing effective cutting 2-4 lines, reducing material consumption and cost.

Owner:ZHEJIANG ZIJINGANG RUBBER BELT

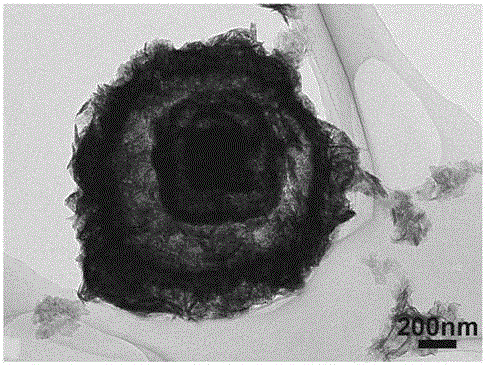

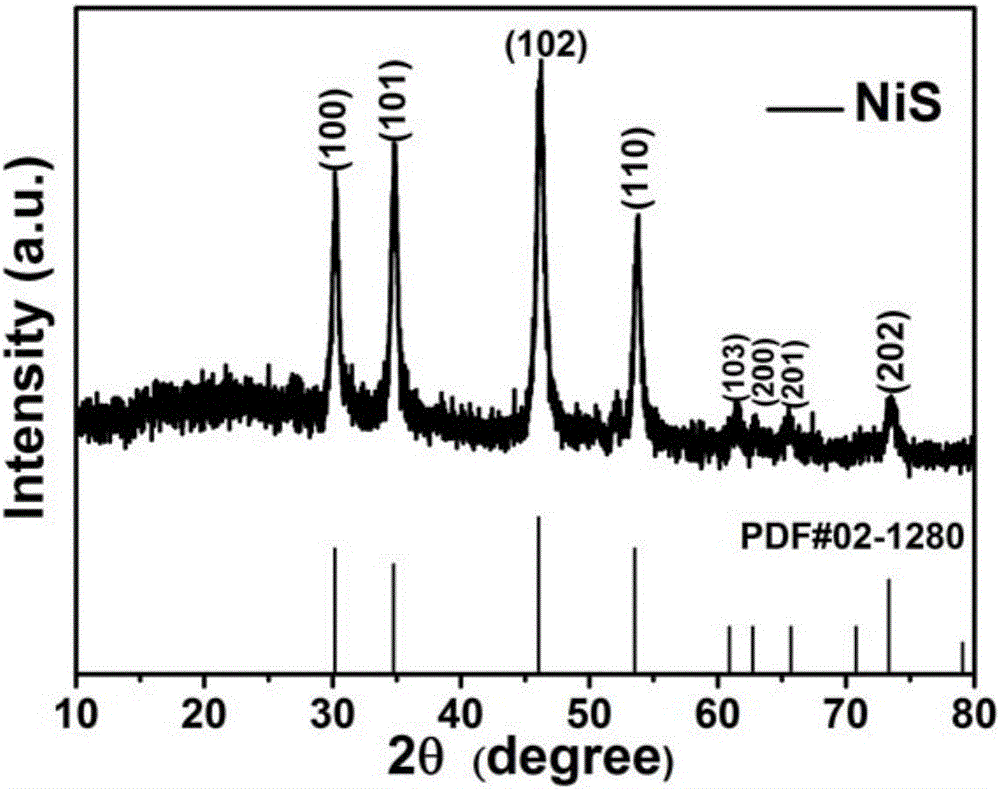

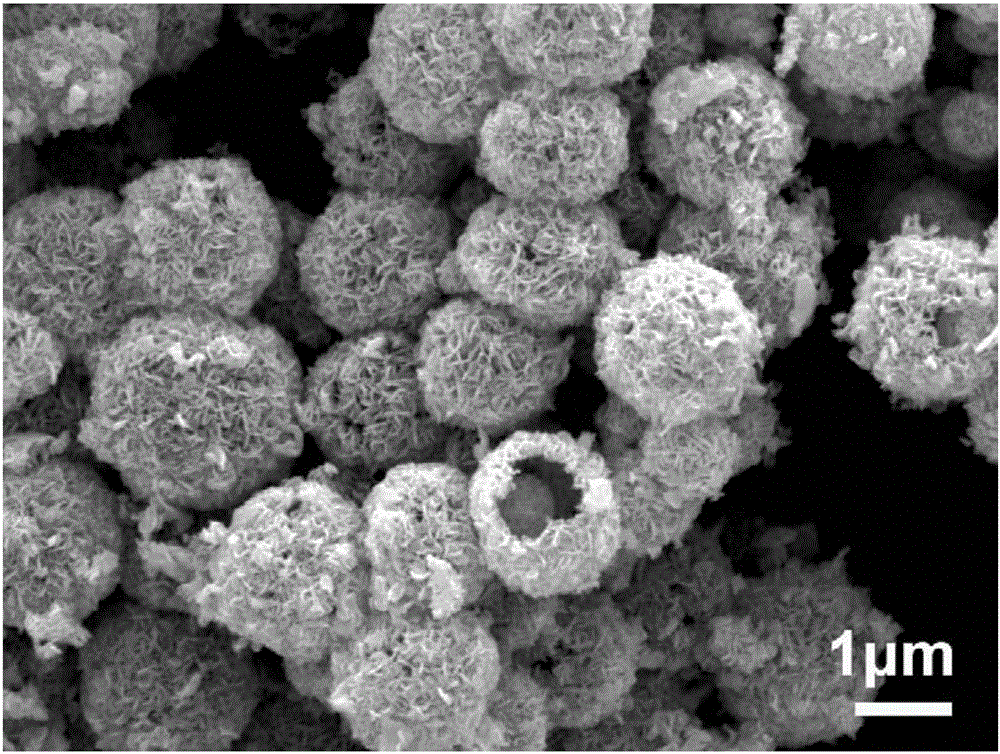

Hollow microspheres with multilayer nickelous sulfide shells, preparation method and application thereof

InactiveCN106277078AShape is easy to controlLow priceHybrid capacitor electrodesNickel sulfidesMicrosphereTube furnace

The invention discloses hollow microspheres with multilayer nickelous sulfide shells, a preparation method and application thereof. The preparation method comprises the following steps: growing a nickel precursor on the carbon sphere surfaces by low-temperature solution precipitation, calcining in air to obtain the hollow microspheres with multilayer nickel oxide shells, and vulcanizing the nickel oxide microspheres in a pipe furnace to obtain the complete hollow microspheres with multilayer nickelous sulfide shells. The unique multilayer-shell hollow structure is beneficial to effective infiltration of the electrolyte, and the electrolyte can sufficiently contact the active substances, thereby enhancing the electrochemical properties of the material. The supercapacitor electrode material prepared from the multilayer-shell hollow nickelous sulfide microspheres has the advantages of favorable electrochemical properties, simple technique and mild conditions.

Owner:CENT SOUTH UNIV

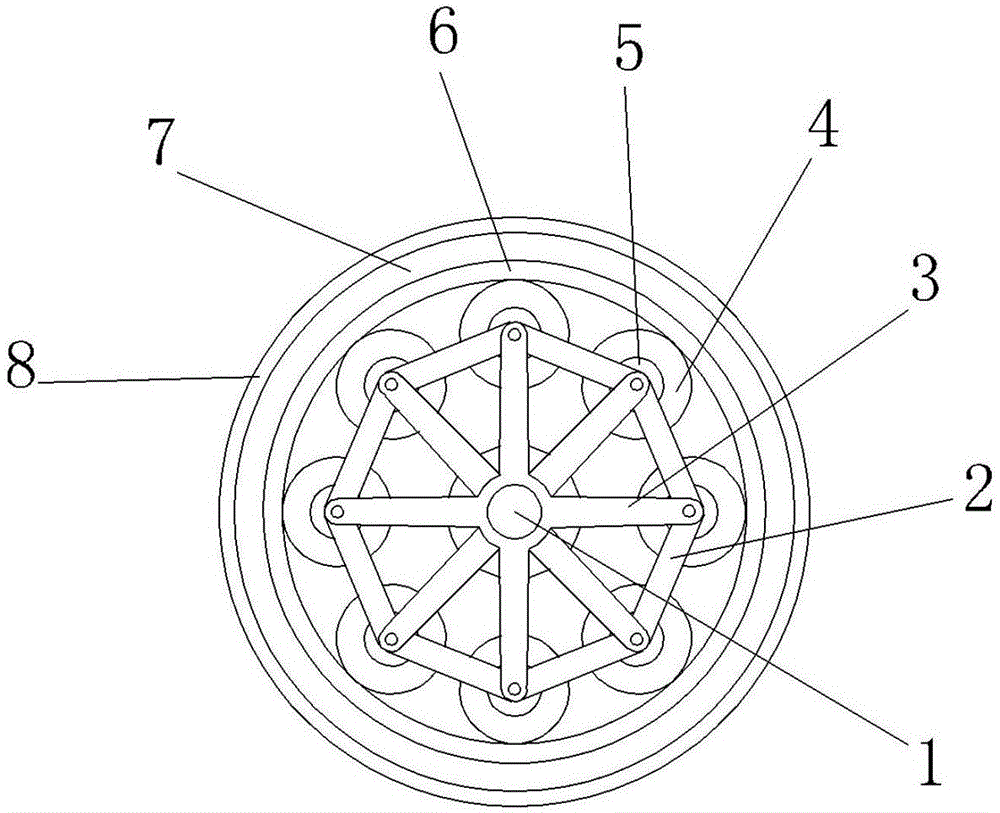

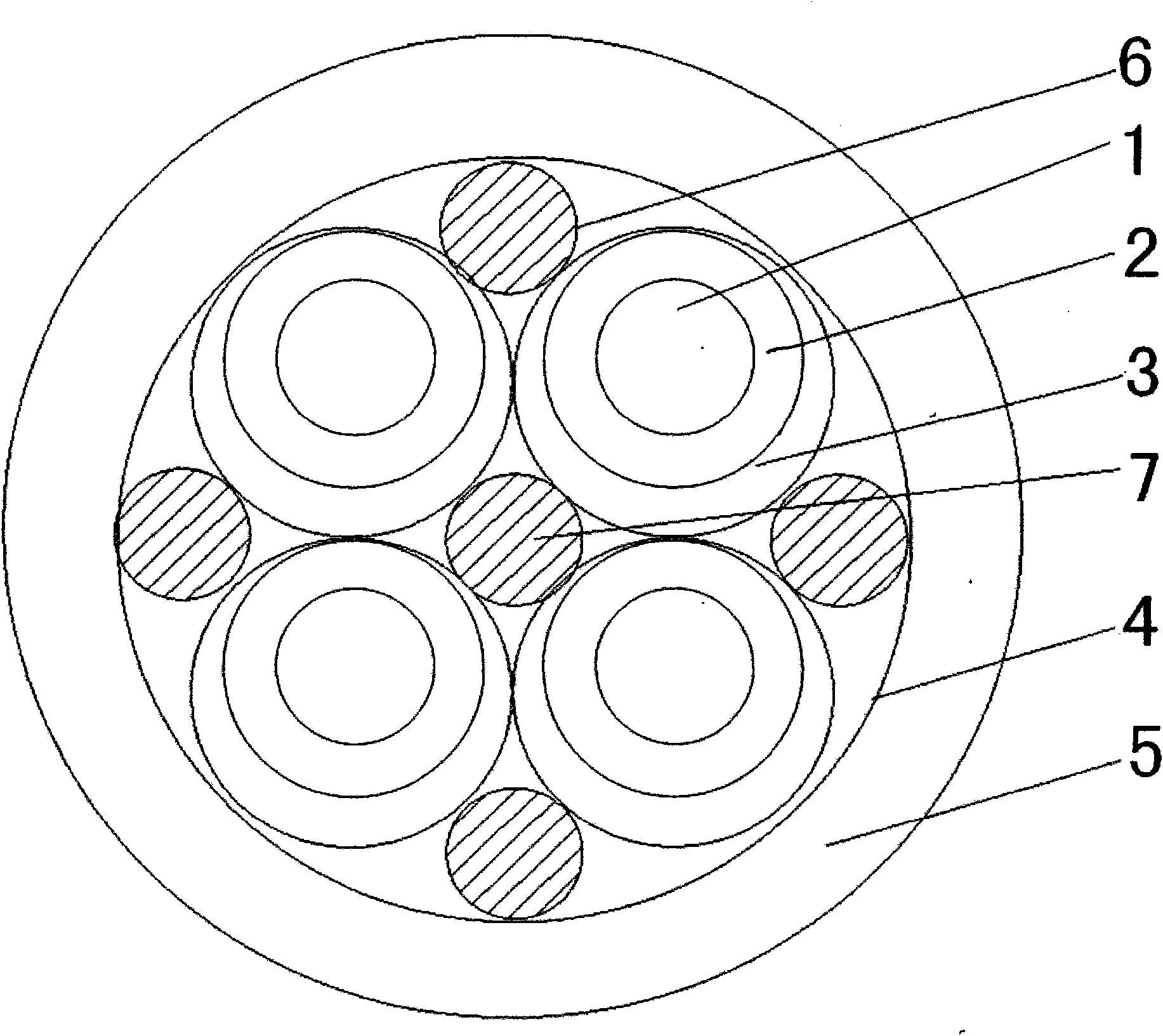

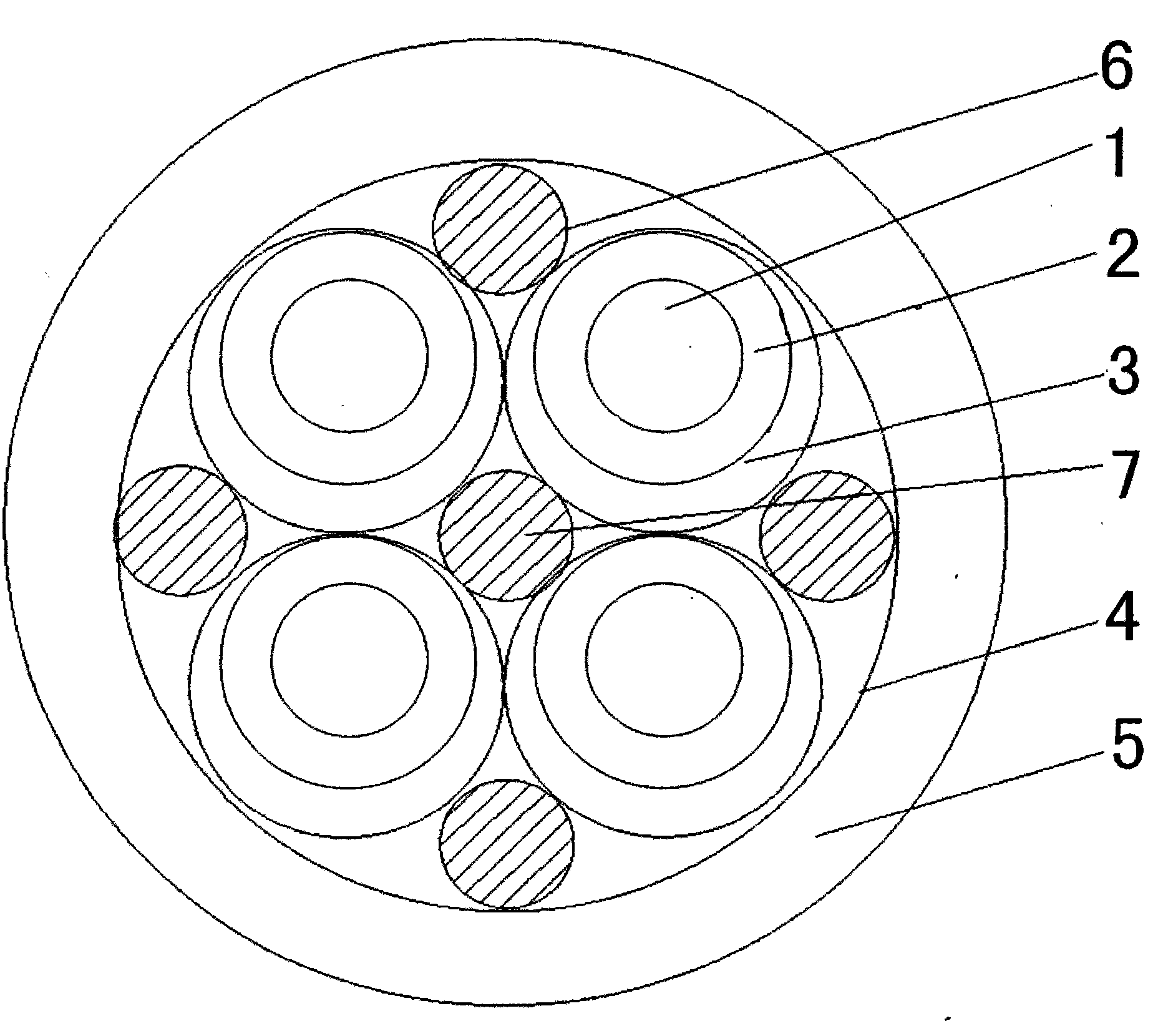

Mining anti-extrusion high-wear-resistance cable

InactiveCN105111538AEasy to fixImprove stabilityRubber insulatorsClimate change adaptationAntioxidantEngineering

The invention discloses a mining anti-extrusion high-wear-resistance cable comprising a supporting core, a connecting ring, a supporting rod, a cable core, multiple axes, an insulating layer, a jacket layer, an armored layer and a filling body, wherein the jacket layer comprises the following raw materials in parts by weight: 90 parts of butadiene-nitrile rubber, 45 parts of chloroprene rubber, 40 parts of ethylene propylene diene rubber, 35 parts of chlorinated polyethylene, 19 parts of maleic anhydride grafted EVA (ethylene vinyl acetate copolymer), 7.5 parts of zinc oxide, 3 parts of chlorinated paraffin, 5.5 parts of calcium stearate, 7.5 parts of white carbon black, 10 parts of talc powder, 9 parts of active kaolin, 5 parts of antimony trioxide, 4.5 parts of triphenyl phosphite, 4 parts of magnesium hydroxide, 4.5 parts of aluminum oxide, 5.5 parts of an anti-aging agent RD, 3.5 parts of an N,N'-di-sec-butyl-p-phenylenediamine antioxidant, 4 parts of a curing agent DTDM and 5.5 parts of a curing agent PDM. The cable is excellent in extrusion resistance and wear resistance.

Owner:ANHUI MENTOR CABLE GROUP

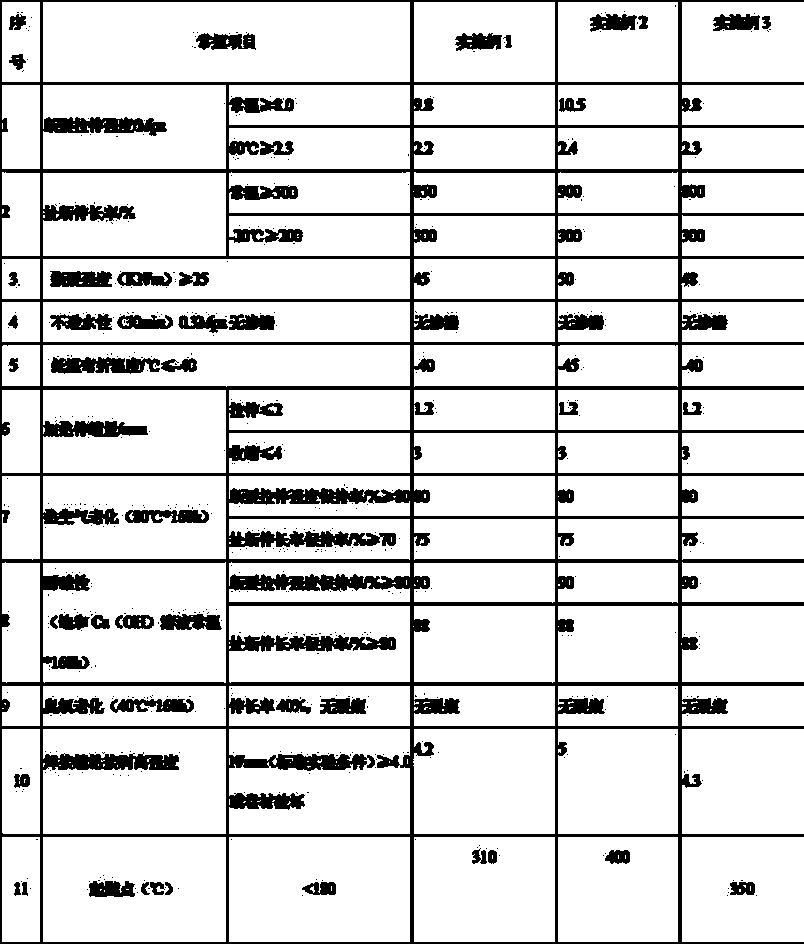

Ethylene-propylene-diene monomer rubber waterproof roll and production method thereof

The invention discloses an ethylene-propylene-diene monomer rubber waterproof roll. The ethylene-propylene-diene monomer rubber waterproof roll is prepared from the following raw materials in parts by weight: ethylene-propylene-diene monomer rubber, DOP (Dioctyl-Phthalate) thermal welding agent, carbon black, light calcium carbonate, stearic acid, zinc oxide, rubber accelerator, sulfur, processing oil, fire-retardant plasticizer, chlorinated polyethylene (CPE), white carbon black and rubber accelerator tetramethyl thiuram disulfide (TMTD). A production method of the ethylene-propylene-diene monomer rubber waterproof roll comprises the steps of banburying, filtering, compounding, thermal cracking, calendering, rolling, vulcanization and packaging. The ethylene-propylene-diene monomer rubber waterproof roll produced by the method has good ageing resistance, small possibility of cracking and good waterproof effect and has an inflaming retarding function, the initiation temperature exceeds 300 DEG C, and the ethylene-propylene-diene monomer rubber waterproof roll has no water-permeating phenomenon through permeable experiments.

Owner:WEIFANG ZHENGTAI WATERPROOF MATERIAL

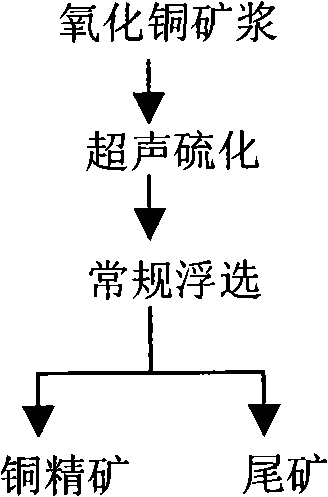

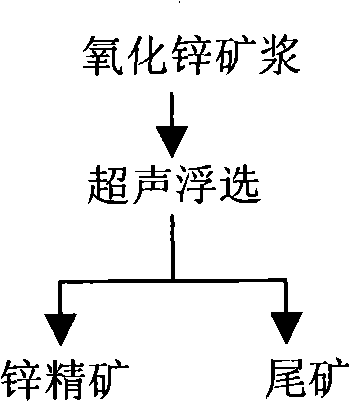

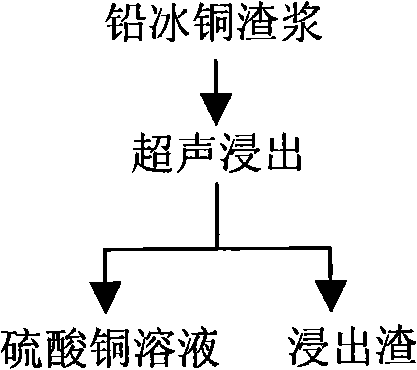

Method and technique for eliminating particle surface envelope in solution with ultrasound wave, and uses

InactiveCN101293194AImprove purification efficiencyAccelerated vulcanizationEnergy based chemical/physical/physico-chemical processesSonicationUltrasound wave

The present invention provides a method which utilizes ultrasonic to remove the surface cladding of particles, in particular to a method which utilizes ultrasonic to strike particles in a solution and remove the surface cladding of particles so as to expose the surface of particles. The ultrasonic is 15 to 200 kHz in frequency and 0.5 to 200w / cm< 2 > in acoustic intensity. The surface cladding of particles comprises the self surface cladding of particles and newly generated surface cladding of particles in the solution. The uses of the method include ultrasonic sulfuration process, ultrasonic floatation process, ultrasonic dipping process and ultrasonic purification process.

Owner:株洲市兴民科技有限公司

Heavy oil hydrogenation catalyst and preparation method thereof

ActiveCN104069884AHigh crystallinityGood channel connectivityCatalyst carriersMolecular sieve catalystsMolecular sieveTungsten

The invention provides a heavy oil hydrogenation catalyst and a preparation method thereof. The preparation method comprises the following steps: introducing a phosphorus source in the preparation process of a Y molecular sieve to obtain a phosphorus-containing NaY molecular sieve; converting the phosphorus-containing NaY molecular sieve into a phosphorus-containing hydrogen-type Y molecular sieve; preparing a solution from a titanium precursor and an aluminum precursor; adding the phosphorus-containing hydrogen-type Y molecular sieve, and hydrolyzing the solution to obtain a micro-pore / meso-pore oxide composite carrier; adding cobalt salt or nickel salt into the solution for preparing the micro-pore / meso-pore oxide composite carrier, and hydrolyzing the solution to obtain a metal-modified micro-pore / meso-pore oxide composite carrier; dropwise adding a solution of active components of nickel-tungsten or nickel-molybdenum into the metal-modified micro-pore / meso-pore oxide composite carrier; and immersing, drying and roasting to obtain the heavy oil hydrogenation catalyst. The catalyst provided by the invention can meet requirements on diffusion, hydrogenolysis and hydrogenation reaction of heavy oil macro-molecules, and is excellent in hydrogenation-denitrification activity on heavy oil.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Radiation-resistant and flame-retardant nuclear power station cable insulating material and preparation method thereof

InactiveCN104672629AEvenly dispersedImprove radiation resistanceRubber insulatorsNuclear powerRare earth

The invention discloses a radiation-resistant and flame-retardant nuclear power station cable insulating material. The radiation-resistant and flame-retardant nuclear power station cable insulating material comprises the following raw materials in parts by weight: 90-100 parts of an ethylene-propylene-diene monomer, 30-40 parts of neoprene, 50-60 parts of ABS resin, 20-30 parts of an ethylene-tetrafluoroethylene copolymer, 15-25 parts of barium sulfate, 10-15 parts of lead oxide, 20-25 parts of rare earth oxide, 10-20 parts of silicon nitride, 20-25 parts of nanotalcum powder, 15-25 parts of hard pottery clay, 20-30 parts of nanomagnesium hydroxide, 1-1.5 parts of a zircoaluminate coupling agent TL-5, 4-8 parts of 1, 1, 3, 3-tetramethylbutyl hydroperoxide, 0.5-1.1 parts of sulphur powder, 0.8-1.2 parts of an assistant crosslinking agent TAIC, 0.4-0.8 part of an assistant crosslinking agent HVA-2, 2-4 parts of sodium crotonate, 4-6 parts of magnesium oxide, 2-5 parts of triphenyl phosphate, 3-6 parts of zinc stearate and 3-4 parts of an antiager. The invention further discloses a preparation method of the radiation-resistant and flame-retardant nuclear power station cable insulating material.

Owner:ANHUI SPECIAL CABLE GRP

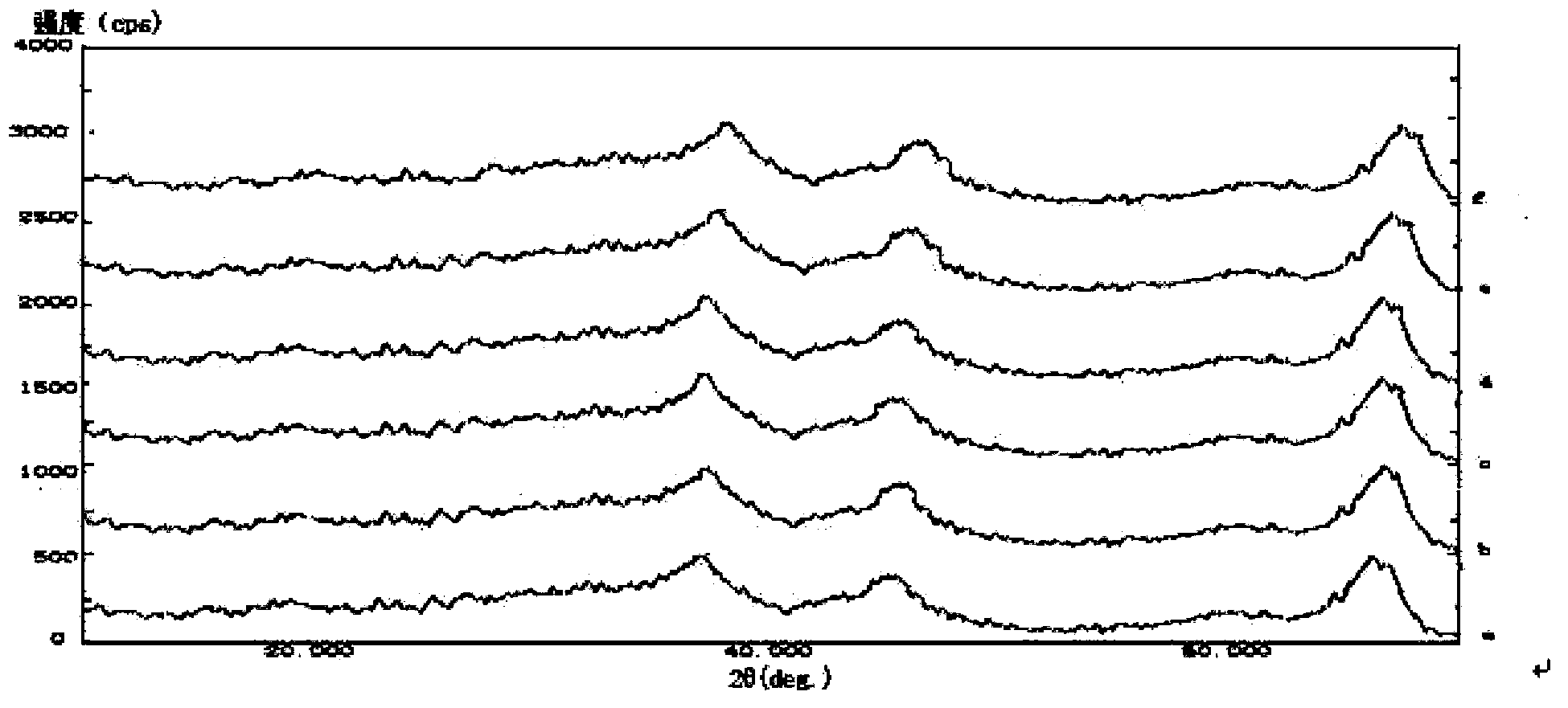

CO sulfur tolerant shift catalyst in cobalt-molybdenum system and preparation method

ActiveCN103447049APromote reductionAccelerated vulcanizationHydrogenCatalyst carriersCobaltChemistry

The invention provides a CO sulfur tolerant shift catalyst in a cobalt-molybdenum system. The CO sulfur tolerant shift catalyst comprises a carrier and active components, wherein the carrier is aluminium-titanium-based surficial magnesium-aluminium spinel; the active components are cobalt and molybdenum. The catalyst is ball-shaped. A preparation method comprises the following steps: introducing titanium on aluminium oxide to prepare the aluminium-titanium composite carrier; uniformly introducing magnesium on the aluminium-titanium composite carrier, and carrying out roasting and phase inversion to form the aluminium-titanium-based surficial magnesium-aluminium spinel; introducing the active components into the aluminium-titanium-based surficial magnesium-aluminium spinel to prepare the catalyst. The CO sulfur tolerant shift catalyst provided by the invention has the advantages that the low-temperature activity and the low-sulfur activity are good, the stability is strong, the adaptability to the demanding conversion condition of synthesized gas with high CO content (more than or equal to 60%) is stronger, the difficulties of poor stability, easy inactivity and short service life when the existing industrial catalyst is used for shifting of the synthesized gas with high CO content as a shifting or pre-shifting catalyst are solved, and the application range of the traditional CO sulfur tolerant shift catalyst is greatly expanded.

Owner:SHANDONG QILU KELI CHEMICAL RESEARCH INSTITUTE CO LTD

Silicone rubber insulating fire-resisting flexible cable

InactiveCN101847461AImprove insulation performanceImprove stabilityFlexible cablesFlexible conductorsFire retardantMetal

The invention aims to provide a silicone rubber insulating fire-resisting flexible cable and can effectively solve the problems that a control cable in the prior art has a high halogen content, is inflammable, generates toxic gas after combustion, and the like. The invention relates to a silicone rubber insulating cladding high temperature resisting flexible cable which comprises an inner core and a cable outer layer clad outside the inner core, wherein the inside of the inner core comprises a conductor wire core, an insulating layer and a fire-resisting layer from inside to outside in sequence; the inside of the cable outer layer comprises a fire-retardant tape and a cladding layer from inside to outside in sequence; and a flame-retardant filler is arranged in a gap between the cable outer layer and the inner core. The invention can realize fire resistance of the cable mainly by cladding mica on the surface of a silicone rubber insulated wire core, and can achieve the effects of fire resistance and flame retardant by using filling materials, tapes, cladding materials and metal materials which are not inflammable or have flame-retardant performance.

Owner:上海索谷电缆集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com