Hollow microspheres with multilayer nickelous sulfide shells, preparation method and application thereof

A technology of micron spheres and nickel sulfide, applied in the direction of nickel sulfide, hybrid capacitor electrodes, etc., can solve the problem of less nickel sulfide materials, and achieve the effect of low price, wide source, and simple vulcanization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

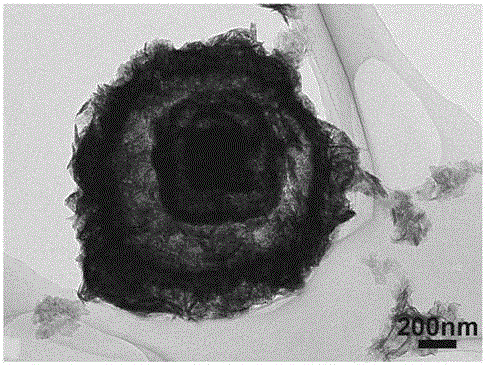

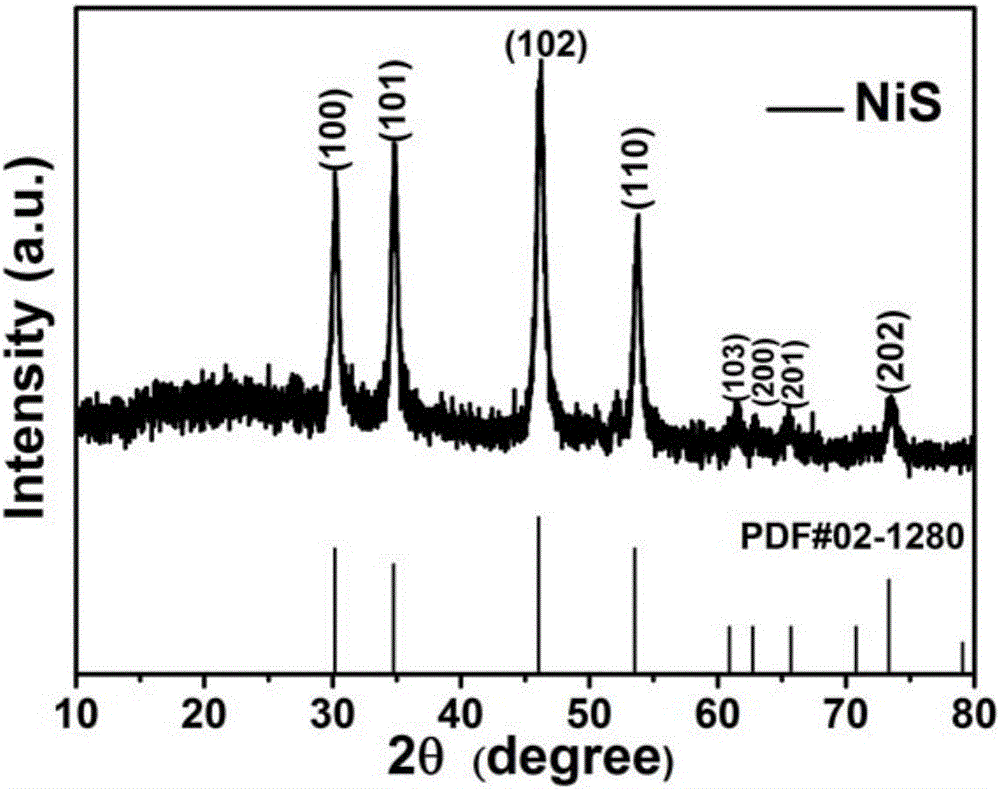

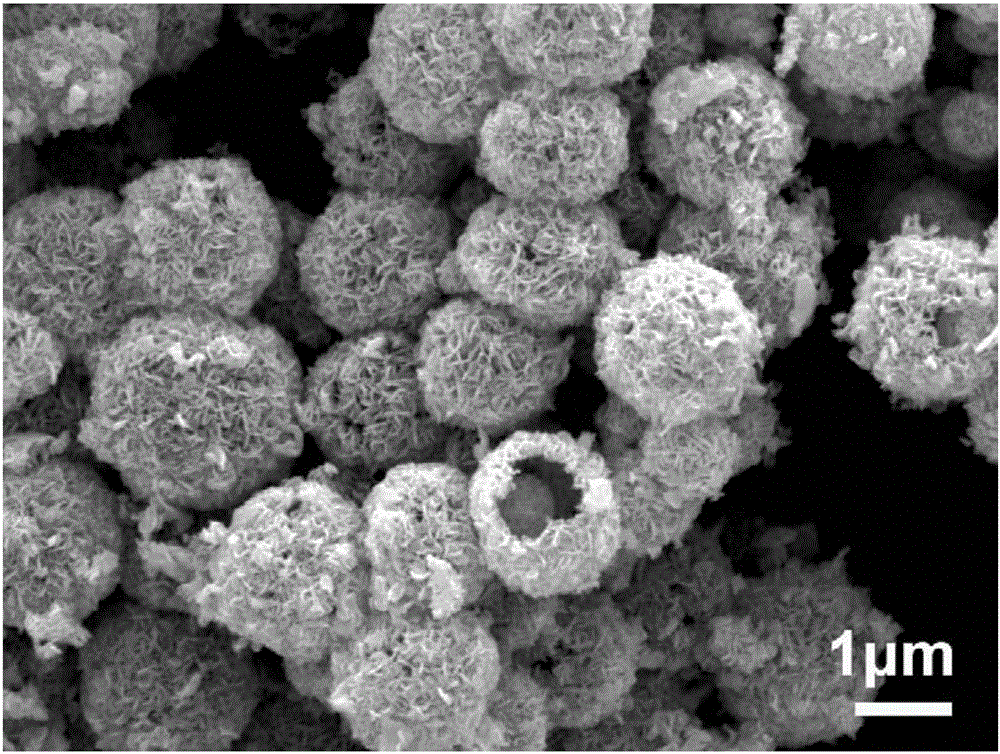

[0030] 50 mg of carbon spheres with a diameter of 1 μm were ultrasonically dispersed in a mixed solution of 100 ml of water and ethanol (volume ratio 1:1), 0.2 g of nickel nitrate and 1 g of urea were added and mixed evenly, the mixed solution was stirred at 80 °C for 12 h, and the obtained product was centrifuged. It was separated and washed with deionized water and ethanol, and then dried in an incubator at 60 °C for 12 h. The obtained powder was heat-treated in air at 450 °C for 2 h, and the heating rate was 3 °C / min. The obtained nickel oxide hollow structure microspheres were mixed with sulfur powder (the Ni / S molar ratio was 1:1), transferred to a tube furnace, and calcined at 400 °C for 4 h in an argon atmosphere, that is, the hollow shell of multi-layer nickel sulfide shell. Microspheres. The prepared nickel sulfide material is uniformly mixed according to 80wt.%, acetylene black 10wt.% and FVDF10wt.% to make a slurry, which is uniformly coated on a nickel mesh (1*2cm...

Embodiment 2

[0032] 50 mg of carbon spheres with a diameter of 1 μm were ultrasonically dispersed in 100 ml of a mixed solution of water and ethanol (volume ratio 2:1), 0.3 g of nickel sulfate and 1 g of urea were added to mix well, the mixed solution was stirred at 100 ° C for 12 h, and the resulting product was centrifuged. It was separated and washed with deionized water and ethanol, and then dried in an incubator at 60 °C for 12 h. The obtained powder was heat-treated in air at 450 °C for 2 h, and the heating rate was 3 °C / min. The obtained hollow-structured nickel oxide microspheres were mixed with sulfur powder (Ni / S molar ratio of 1:2), transferred to a tube furnace, and calcined at 400 °C for 4 h in an argon atmosphere, that is, a hollow core with a multi-layer nickel sulfide shell. Microspheres.

Embodiment 3

[0034] 50 mg of carbon spheres with a diameter of 1 μm were ultrasonically dispersed in 100 ml of a mixed solution of water and methanol (volume ratio 1:1), 0.2 g of nickel nitrate and 1 g of urea were added, and the mixture was evenly mixed. It was separated and washed with deionized water and ethanol, and then dried in an incubator at 60 °C for 12 h. The obtained powder was heat-treated in air at 500 °C for 2 h, and the heating rate was 3 °C / min. The obtained nickel oxide hollow microspheres were mixed with thiourea (the molar ratio of Ni / S was 1:2), transferred to a tube furnace, and calcined at 400 °C for 4 h in an argon atmosphere to obtain a hollow multi-layer nickel sulfide shell. Microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com