CO sulfur tolerant shift catalyst in cobalt-molybdenum system and preparation method

A sulfur-resistant conversion and catalyst technology, which is applied in the direction of catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor stability, short service life, easy deactivation, etc., achieve outstanding results and improve activity Stability, vulcanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of Al-Ti-based surface layer magnesium aluminum spinel

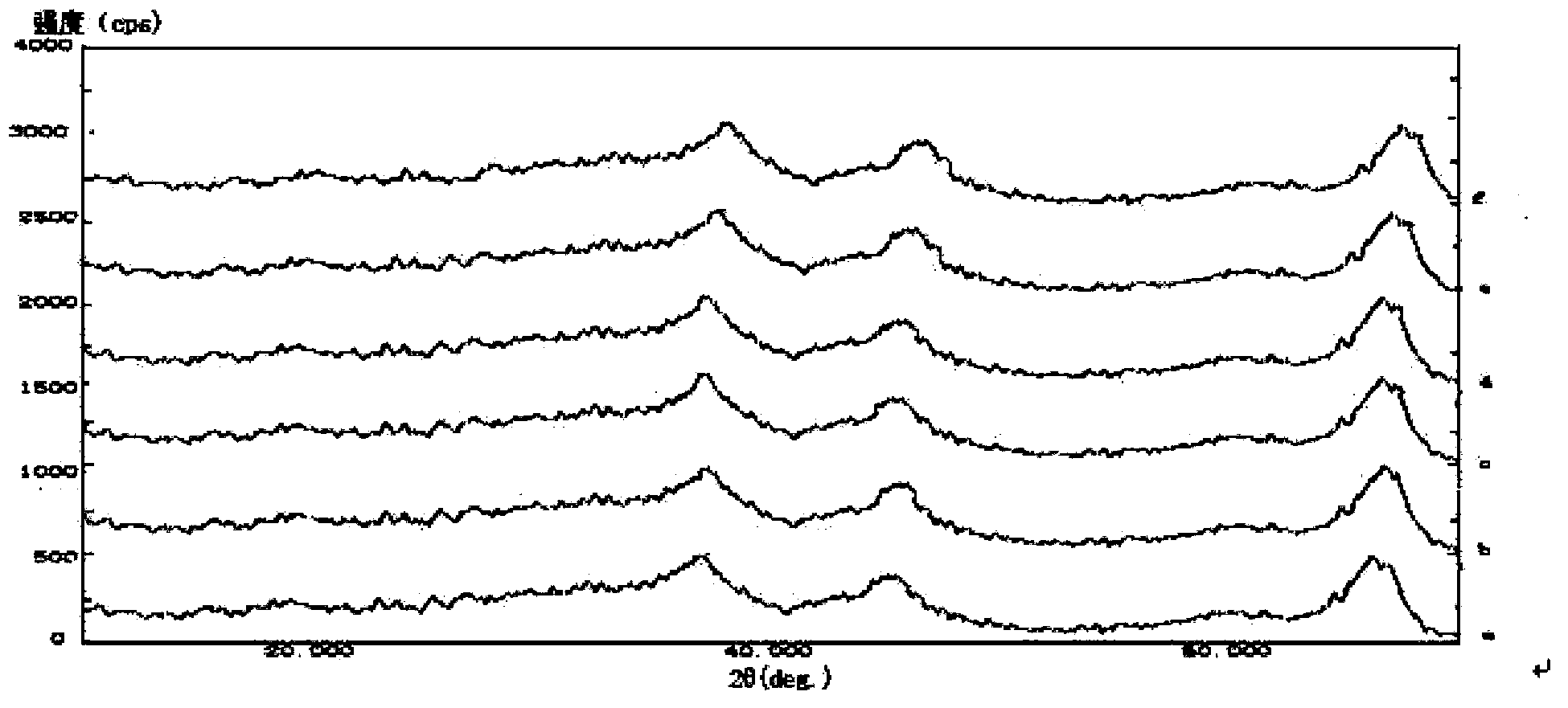

[0035] Buy industrial product spherical alumina carrier with a specific surface of 260m 2 / g, the specific pore volume is 0.44ml / g, the strength is 96N / particle, the water absorption rate is 70%, and the bulk density is 0.60g / ml. The carrier was analyzed by X-ray diffractometer, and the main component of the carrier was γ-Al 2 o 3 . Prepare 90g TiO 2 / L TiCl 4 Acetone solution 70ml, impregnated with 100g of the above-mentioned alumina carrier, placed in the air and fully hydrolyzed, washed to no Cl - , dried at 120°C for 6h, and calcined at 550°C for 3h to obtain an aluminum-titanium composite carrier. Dissolve 100g of magnesium nitrate crystals in 50ml of water, heat to 60°C until the crystals are completely dissolved, impregnate 100g of aluminum-titanium composite carrier with this solution, dry at 120°C for 8 hours, and roast at 600°C for 3 hours to obtain the surface magnesium alum...

Embodiment 2

[0036] Example 2: Preparation of Al-Ti-based surface-layer magnesium-aluminum spinel

[0037] Use the alumina support in embodiment 1, prepare 37gTiO 2 / L TiCl 4 Acetone solution 70ml, impregnated with 100g of the above-mentioned alumina carrier, placed in the air and fully hydrolyzed, washed to no Cl - , dried at 100°C for 8h, and calcined at 500°C for 3h to obtain an aluminum-titanium composite carrier. Dissolve 300g of magnesium nitrate crystals in 60ml of water, heat to 60°C until the crystals are completely dissolved, impregnate 100g of the above-mentioned aluminum-titanium composite carrier with this solution, dry at 100°C for 10 hours, and roast at 750°C for 3 hours to obtain a surface-layer magnesium-aluminum spinel carrier. Carrier composition: TiO 2 : 2%, MgO: 20%, the balance is Al 2 o 3 ;Strength: 136N / piece; Water absorption: 50%; Number Z02.

Embodiment 3

[0038] Example 3: Preparation of Al-Ti-based surface-layer magnesium-aluminum spinel

[0039] Use the alumina carrier in embodiment 1, prepare 70gTiO 2 / L TiCl 4 Acetone solution 70ml, impregnated with 100g of the above-mentioned alumina carrier, placed in the air and fully hydrolyzed, washed to no Cl - , dried at 120°C for 10h, and calcined at 500°C for 3h to obtain an aluminum-titanium composite carrier. Dissolve 25g of magnesium nitrate crystals in 20ml of water, heat to 60°C until the crystals are completely dissolved, impregnate 100g of the above-mentioned aluminum-titanium composite carrier with this solution, dry at 80°C for 12 hours, and roast at 700°C for 3 hours to obtain a surface-layer magnesium-aluminum spinel carrier. Carrier composition: TiO 2 : 4.5%, MgO: 3%, the balance is Al 2 o 3 ;Strength: 97N / piece; Water absorption: 58%; Number Z03.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com