Nitrogen doping carbonized bacterial cellulose/graphene/platinum composite nanomaterial and preparation method thereof

A technology of composite nanomaterials and bacterial cellulose, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor conductivity and poor conductivity of graphene oxide, and achieve easy Effects of immobilization, improvement of catalytic performance, and improvement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

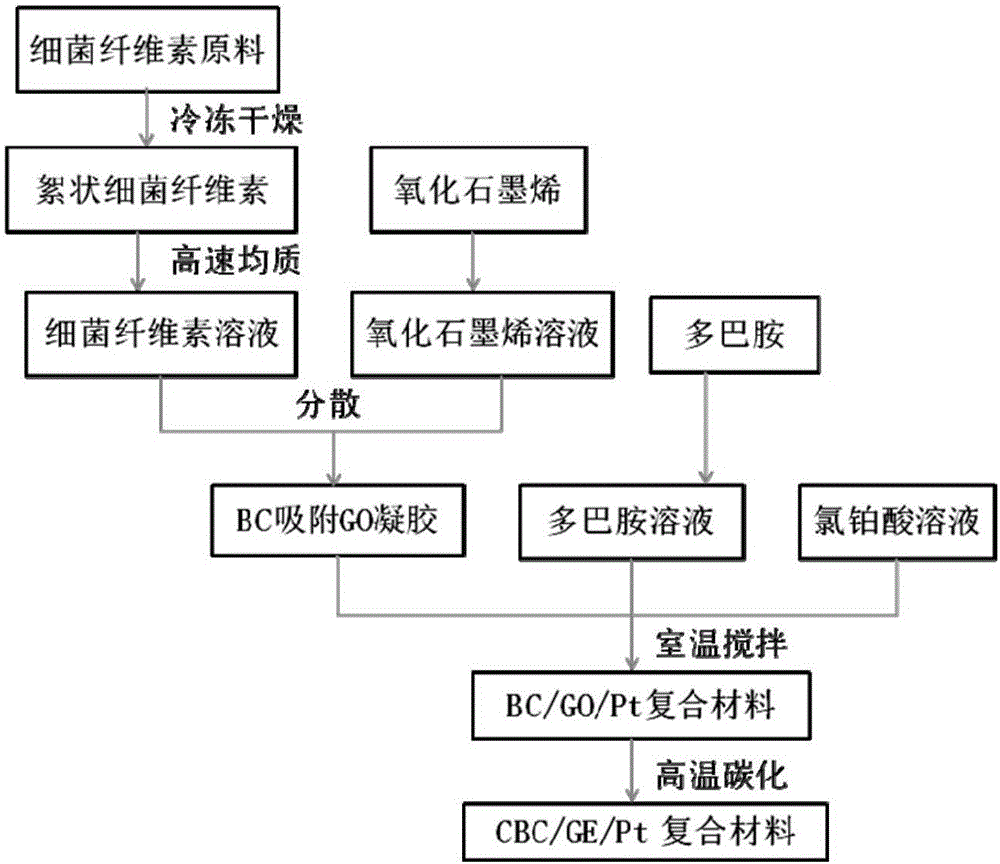

[0024] A kind of preparation method of nitrogen-doped carbonized bacterial cellulose / graphene / platinum composite nanomaterial of the present invention, flow chart is as follows figure 1 shown, including the following steps:

[0025] The first step: take the flocculent bacterial cellulose statically fermented by Acetobacter xylinum, and use 0.1% to 4% NaOH and 0.1% to 4% H 2 o 2 Treat at 60-90°C for 1-5 hours. Rinse with continuous flowing tap water (obtain pure flocculent bacterial cellulose raw material). Place the treated flocculent bacterial cellulose in a freeze dryer to freeze-dry at a temperature of -47 to -54°C for 10 to 24 hours, and use it in a vacuum bag;

[0026] The second step: disperse the graphene oxide prepared by the improved Hummers method in water, and disperse it with 100W ultrasonic to form a uniform graphene oxide suspension; use the prepared flocculent bacterial cellulose with a high-speed homogenizer at a speed of 15000r / min Homogenize for 30 minute...

Embodiment 1

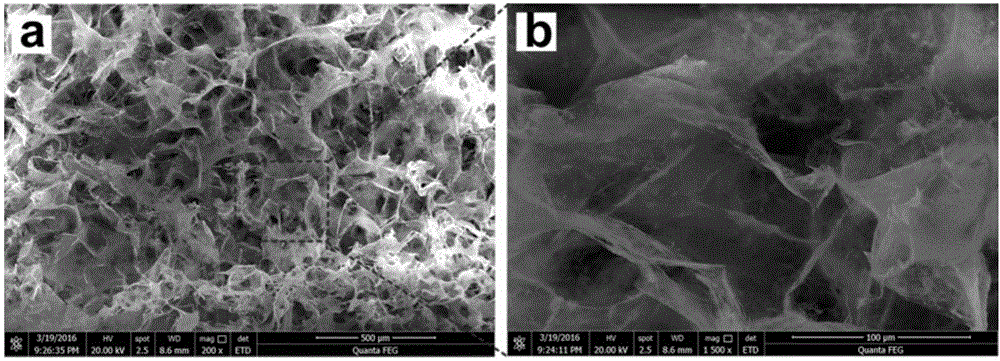

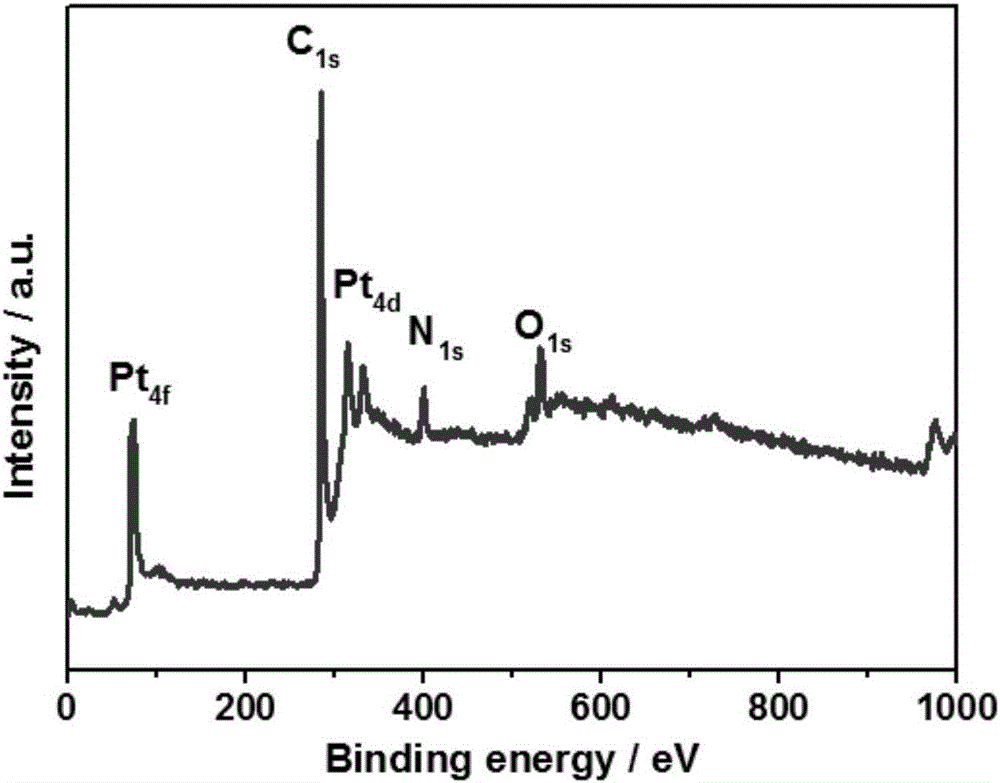

[0031] The flocculent bacterial cellulose statically fermented by Acetobacter xylinum was treated with 0.1% NaOH and 0.1% H 2 o 2Treat it in a water bath at 90°C for 3 hours, take it out and wash it with tap water until neutral, place it in a freeze dryer to dry for 24 hours, take it out and use a high-speed homogenizer at a speed of 15000r / min to homogenize the bacterial cellulose for 30 minutes to obtain a uniform bacterial cellulose solution , then add 10mL graphene oxide suspension, 20°C, 100W ultrasonic to make it evenly dispersed, then add dopamine solution, mechanically stir at 25°C-30°C for 2h, add chloroplatinic acid solution, continue stirring for 4h; The product was filtered, washed with deionized water to neutrality, and then freeze-dried for 24 hours to obtain the bacterial cellulose / graphene oxide / platinum precursor composite material. Raise the temperature to 400°C, keep it warm for 1 hour, raise the temperature to 800°C, keep the temperature for 2 hours, and c...

Embodiment 2

[0034] The flocculent bacterial cellulose statically fermented by Acetobacter xylinum was treated with 0.2% NaOH and 0.2% H 2 o 2 Treat it in a water bath at 80°C for 2 hours, take it out and wash it with tap water until neutral, place it in a freeze dryer to dry for 20 hours, take it out and homogenize the bacterial cellulose with a high-speed homogenizer at a speed of 10,000r / min for 30 minutes to obtain a uniform bacterial cellulose solution , then add 10mL graphene oxide suspension, 20°C, 100W ultrasonic to make it evenly dispersed, then add dopamine solution, mechanically stir at 25°C-30°C for 2h, add chloroplatinic acid solution, continue stirring for 4h; The product was filtered, washed with deionized water to neutrality, and then freeze-dried for 24 hours to obtain the bacterial cellulose / graphene oxide / platinum precursor composite material. Raise the temperature to 400°C, keep it warm for 1 hour, raise the temperature to 900°C, keep the temperature for 2 hours, and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com