Carbon aerogel with ultra-high linear sensitivity and preparation and application thereof in sensor

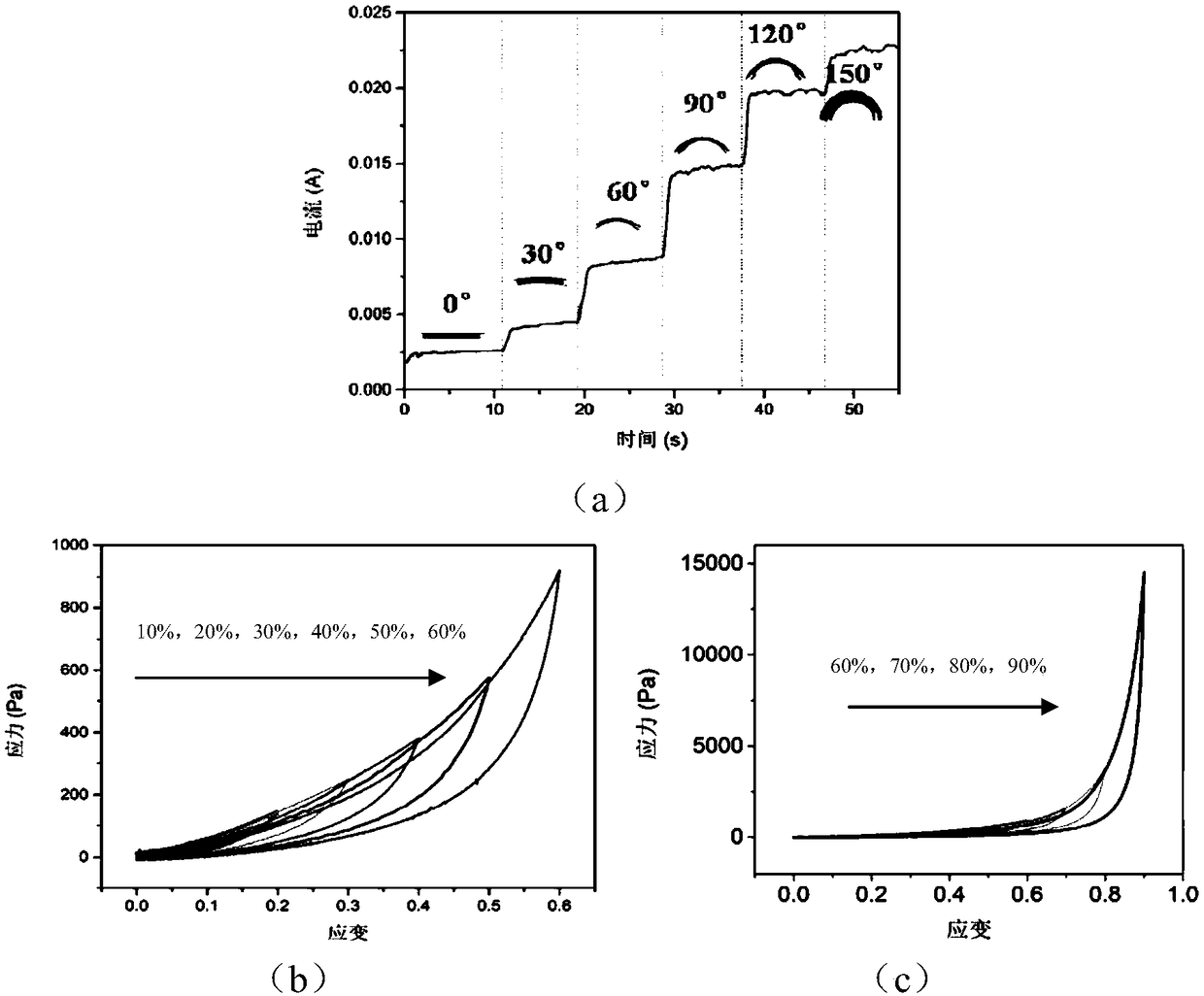

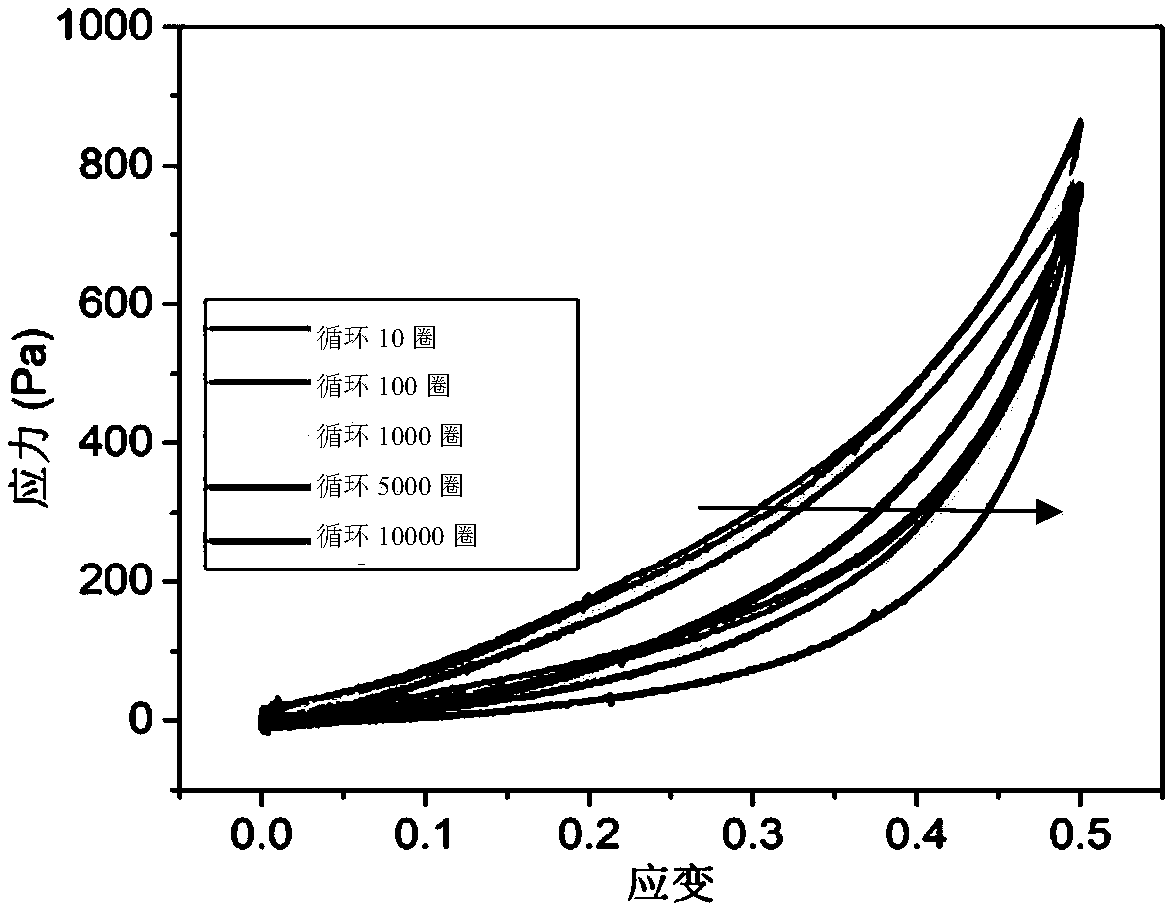

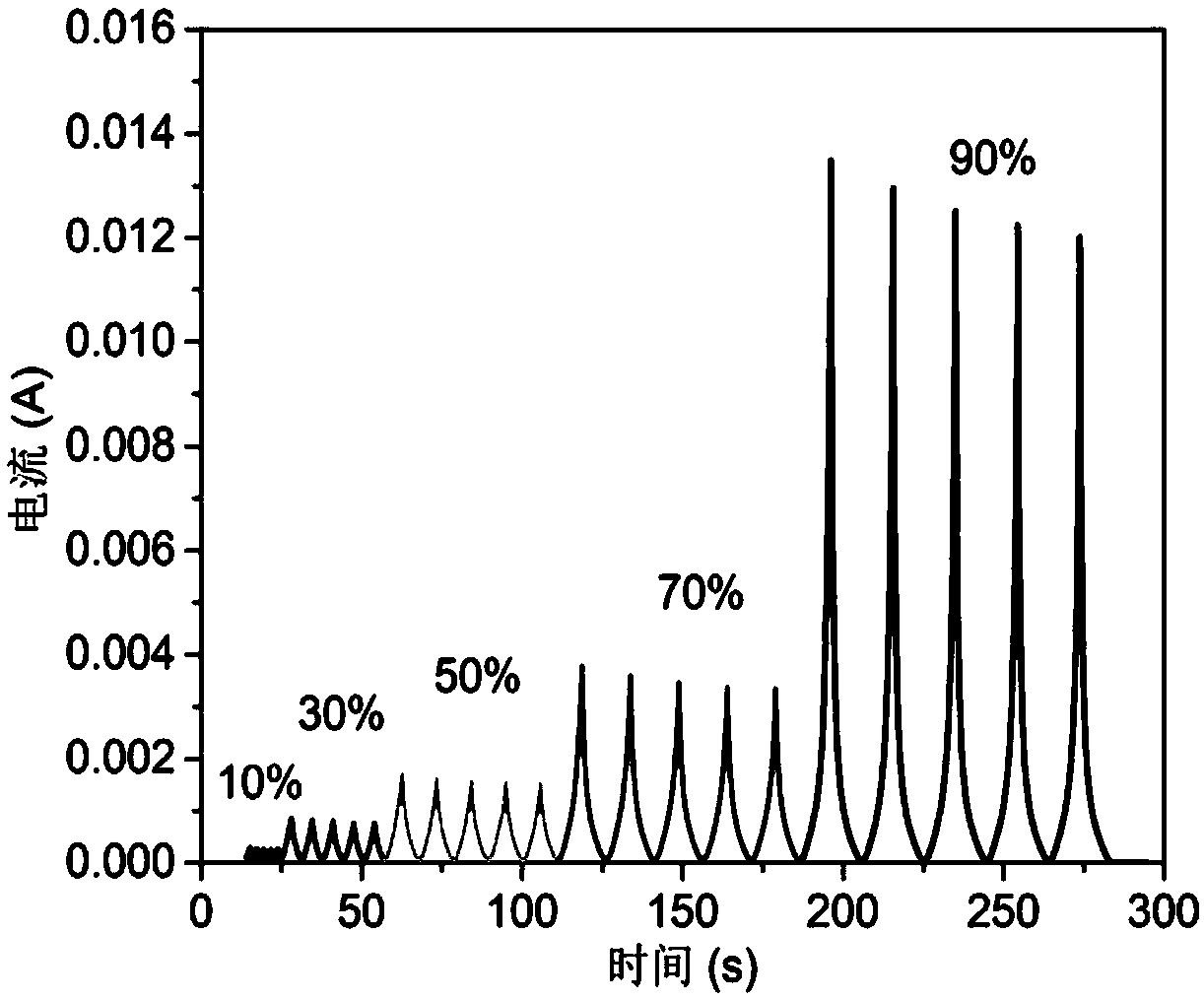

A carbon aerogel and sensitivity technology, applied in the field of carbon aerogel and its preparation, can solve the problems of large recognition stress and difficulty in realizing sensitive sensing, and achieve ultra-high sensitivity, excellent cycle stability, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) MXene (Ti 3 C 2 ) material was added into ultrapure water or deionized water, and then ultrasonic stripped and dispersed for 2 hours to obtain a 0.05wt% MXene suspension;

[0036] (2) adding nano-microcrystalline cellulose equivalent to 3 times the quality of MXene into the MXene suspension obtained in step (1), ultrasonically again for 0.5 hour, to obtain MXene / nano-crystalline cellulose suspension;

[0037] (3) Put the above-mentioned MXene / nanocrystalline cellulose suspension in a plastic box, tie the box to the outer wall of the metal box, pour liquid nitrogen into the metal box for freezing (you can freeze it, 15 minutes), and wait for the solution Freeze-drying (-52°C, 24h) after complete freezing to prepare MXene / nanocrystalline cellulose composite airgel;

[0038] (4) The composite airgel was placed in a tube furnace, and the temperature was raised to 600°C at a rate of 3°C / min in a nitrogen atmosphere and kept for 4 hours to obtain an elastic carbon aerog...

Embodiment 2

[0042] (1) MXene (Ti 3 C 2 ) into ultrapure water or deionized water, and then ultrasonic stripping and dispersion for 1 hour to obtain a MXene suspension with a concentration of 0.1wt%;

[0043] (2) adding nano-microcrystalline cellulose equivalent to 5 times of MXene quality into step (1) gained MXene suspension, ultrasonication for 1 hour again, to obtain MXene / nano-microcrystalline cellulose suspension;

[0044] (3) Put the above-mentioned MXene / nanocrystalline cellulose suspension in a plastic box, tie the box to the outer wall of the metal box, pour liquid nitrogen into the metal box for freezing (you can freeze it, 15 minutes), and wait for the solution Freeze-drying (-52°C, 24h) after complete freezing to prepare MXene / nanocrystalline cellulose composite airgel;

[0045] (4) The obtained composite airgel was placed in a tube furnace, and the temperature was raised to 700° C. at a rate of 5° C. / min in a nitrogen atmosphere and kept for 2 hours to obtain an elastic car...

Embodiment 3

[0050] (1) MXene (Ti 3 C 2 ) into ultrapure water or deionized water, and then ultrasonic stripping and dispersion for 4 hours to obtain a MXene suspension with a concentration of 1 wt %;

[0051] (2) adding nano-microcrystalline cellulose equivalent to 4 times of MXene quality into step (1) gained MXene suspension, ultrasonic again for 3 hours, to obtain MXene / nano-microcrystalline cellulose suspension;

[0052] (3) Put the above-mentioned MXene / nanocrystalline cellulose suspension in a plastic box, tie the box to the outer wall of the metal box, pour liquid nitrogen into the metal box for freezing (you can freeze it, 15 minutes), and wait for the solution Freeze-drying (-52°C, 24h) after complete freezing to prepare MXene / nanocrystalline cellulose composite airgel;

[0053] (4) The obtained composite airgel was placed in a tube furnace, and the temperature was raised to 700° C. at a rate of 5° C. / min in a nitrogen atmosphere and kept for 2 hours to obtain an elastic carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com