Patents

Literature

97 results about "Water fraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water associated fraction. The water associated fraction (WAF), sometimes termed the water-soluble fraction (W.S.F.), is the solution of low molecular mass hydrocarbons naturally released from petroleum hydrocarbon mixtures in contact with water.

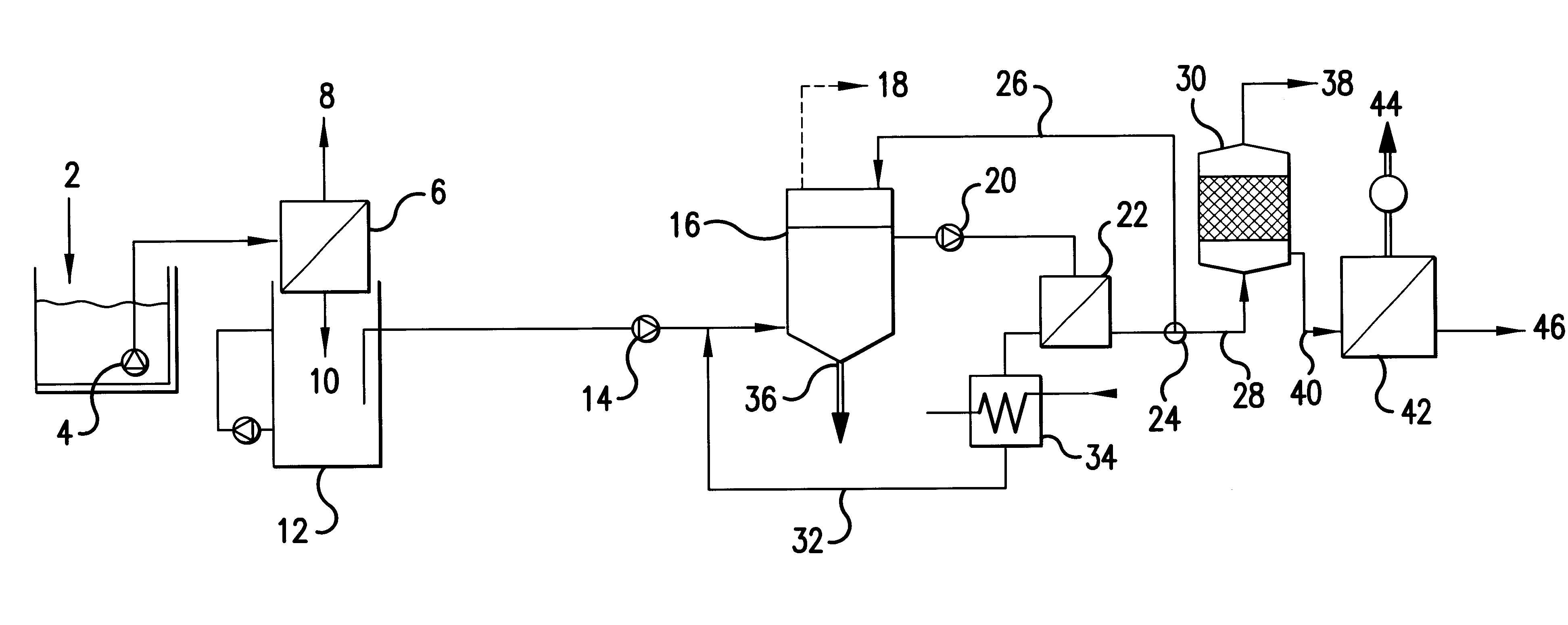

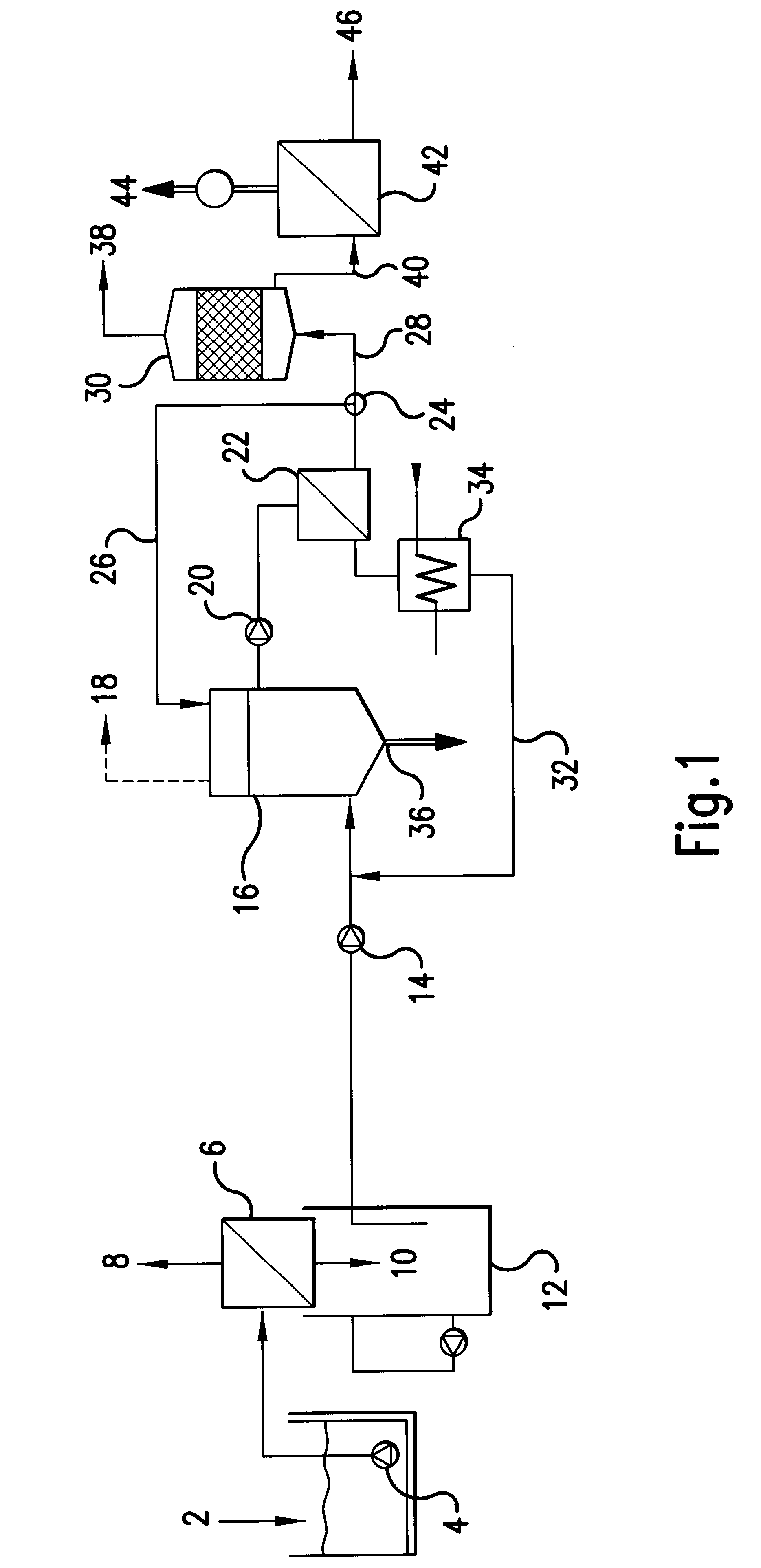

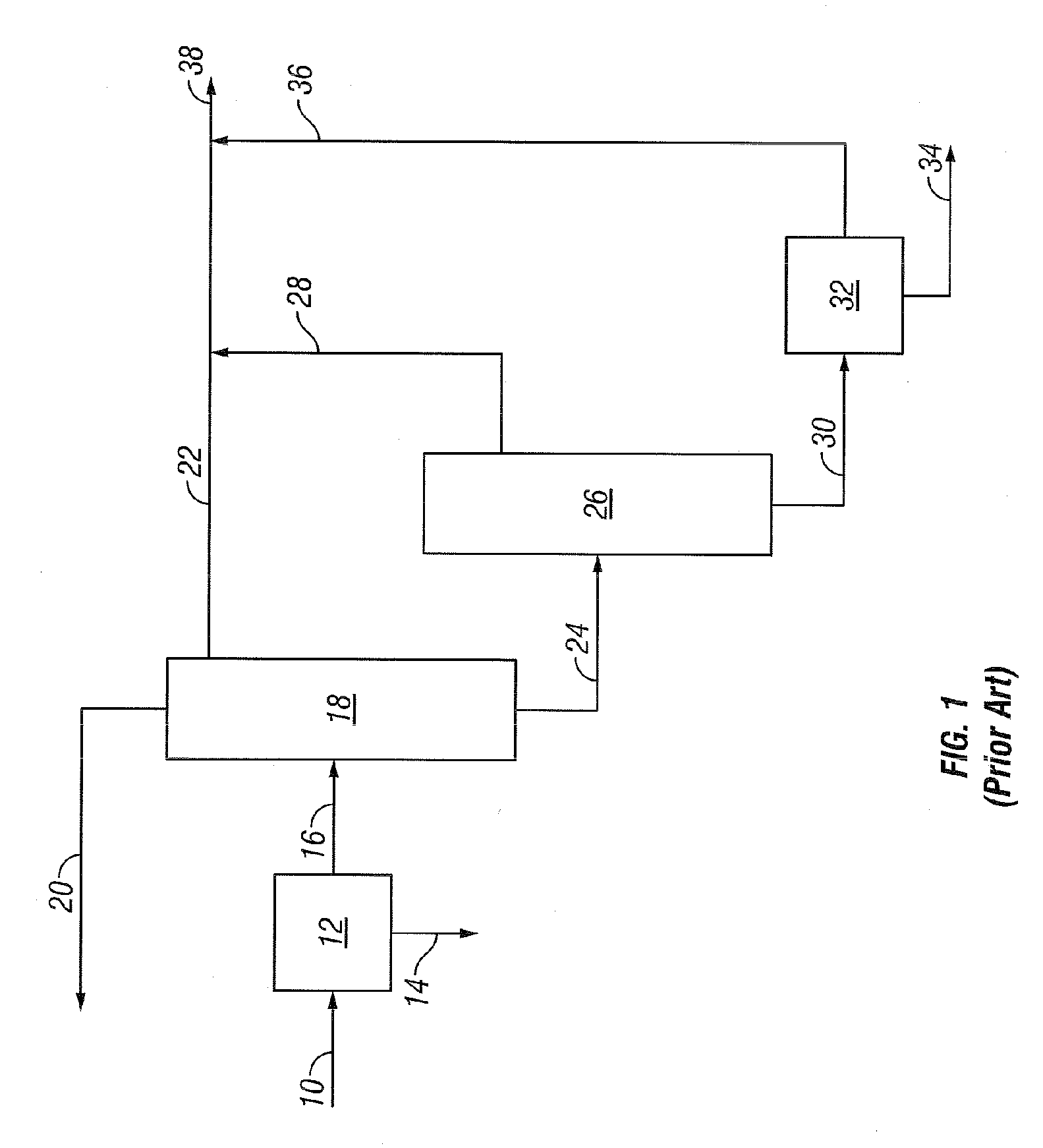

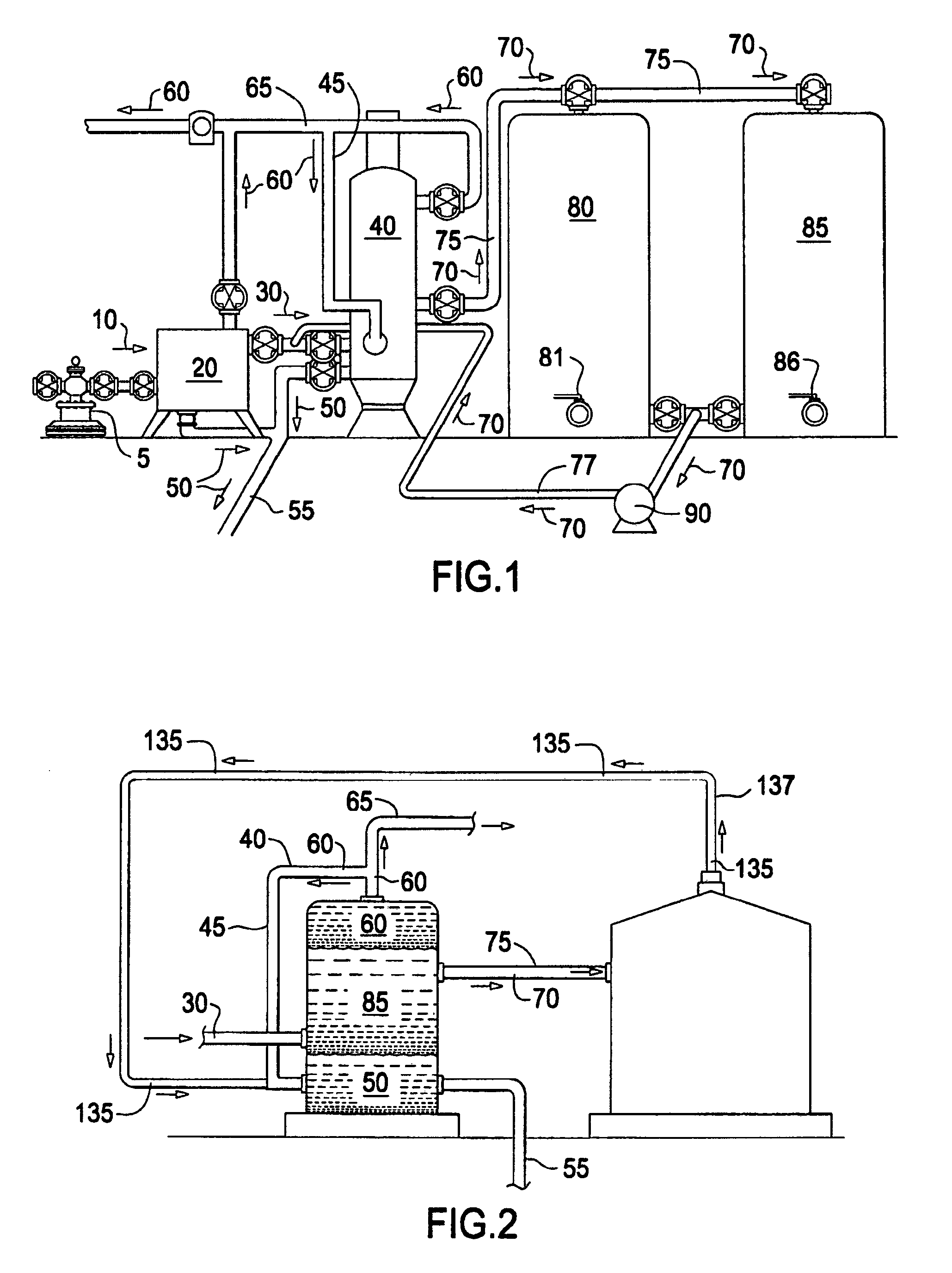

Method and plant for the treatment of liquid organic waste

InactiveUS6368849B1Increase profitReduce environmental impactBioreactor/fermenter combinationsBio-organic fraction processingFiberUltrafiltration

A method and plant for the treatment of an organic waste material in liquid form, e.g. liquid manure from livestock, the method comprising filtering fibres and particles from the liquid, subjecting the liquid to anaerobic fermentation in a biogas reactor, separating a substantially sterile and particle-free permeate stream from the biogas reactor, e.g. using ultrafiltration, subjecting the permeate stream to treatment with an ammonia stripper at an elevated temperature and preferably at reduced pressure to remove substantially all ammonia and carbon dioxide and to result in an ammonia fraction and a nutrient salt fraction, and separating the nutrient salt fraction into a fertiliser concentrate fraction and a water fraction, e.g. using reverse osmosis. The end products of the method are clean water, ammonia concentrate, fertiliser concentrate containing salts of P and K, compost and high-quality biogas with a high methane content.

Owner:GR BIOTECH

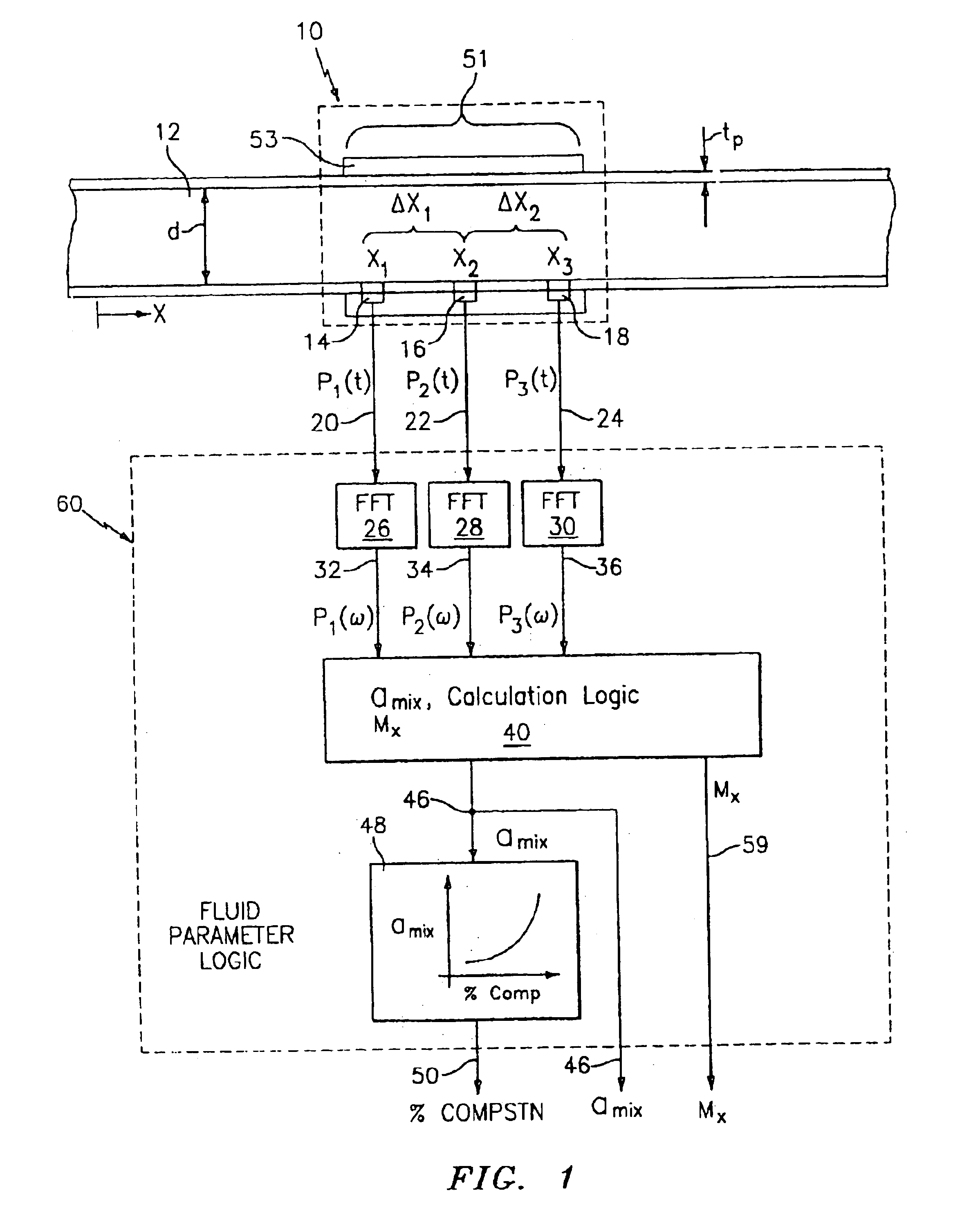

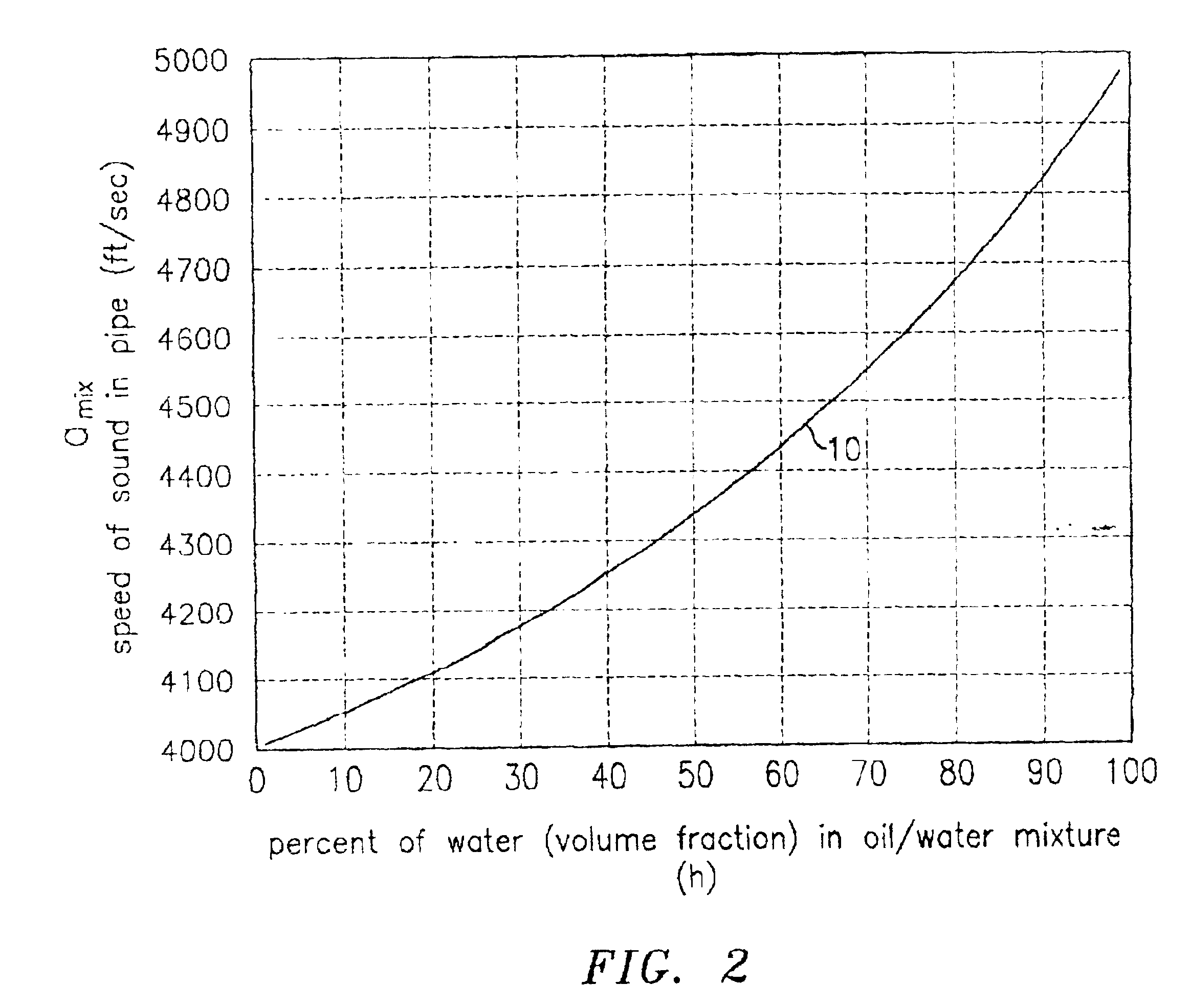

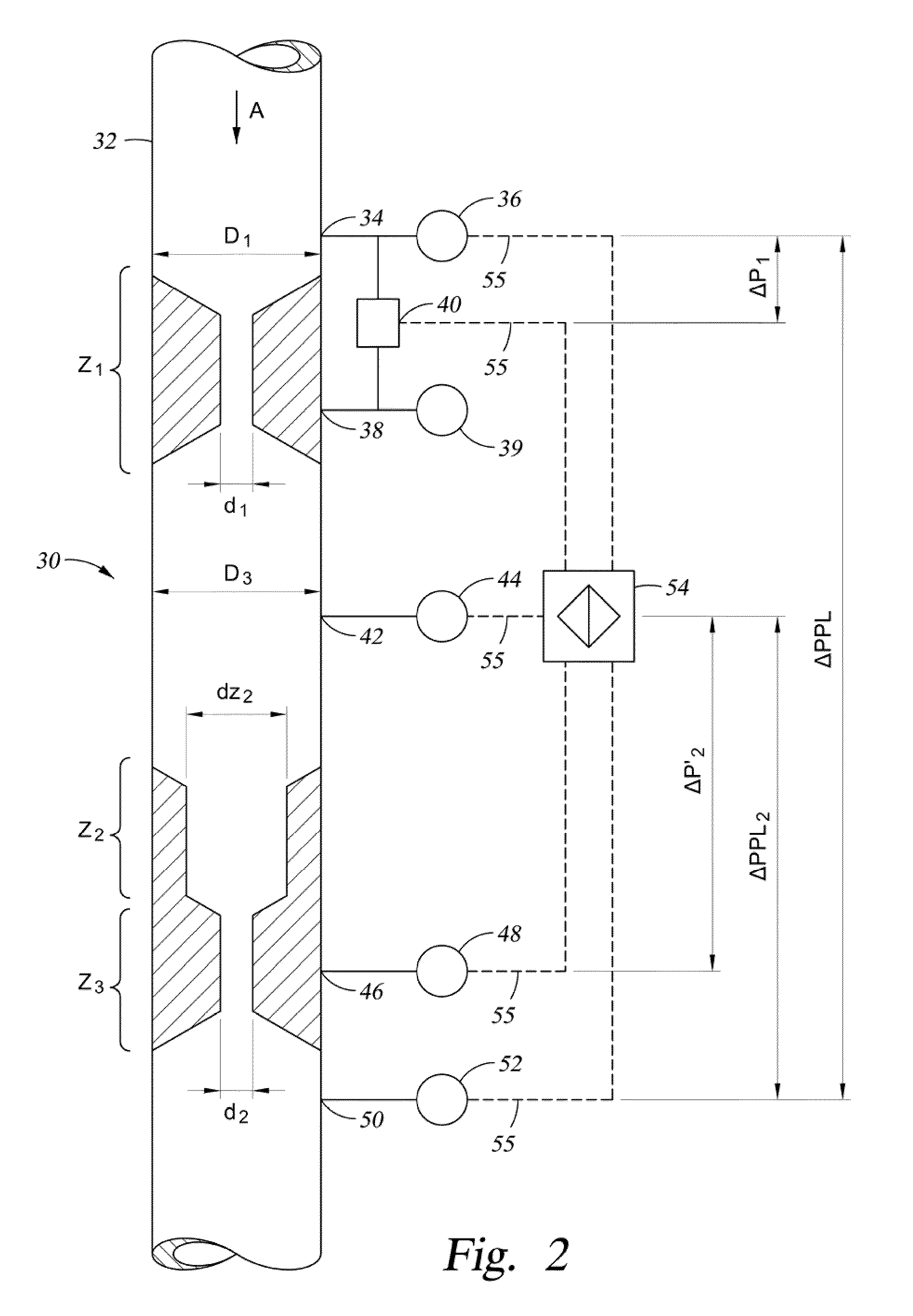

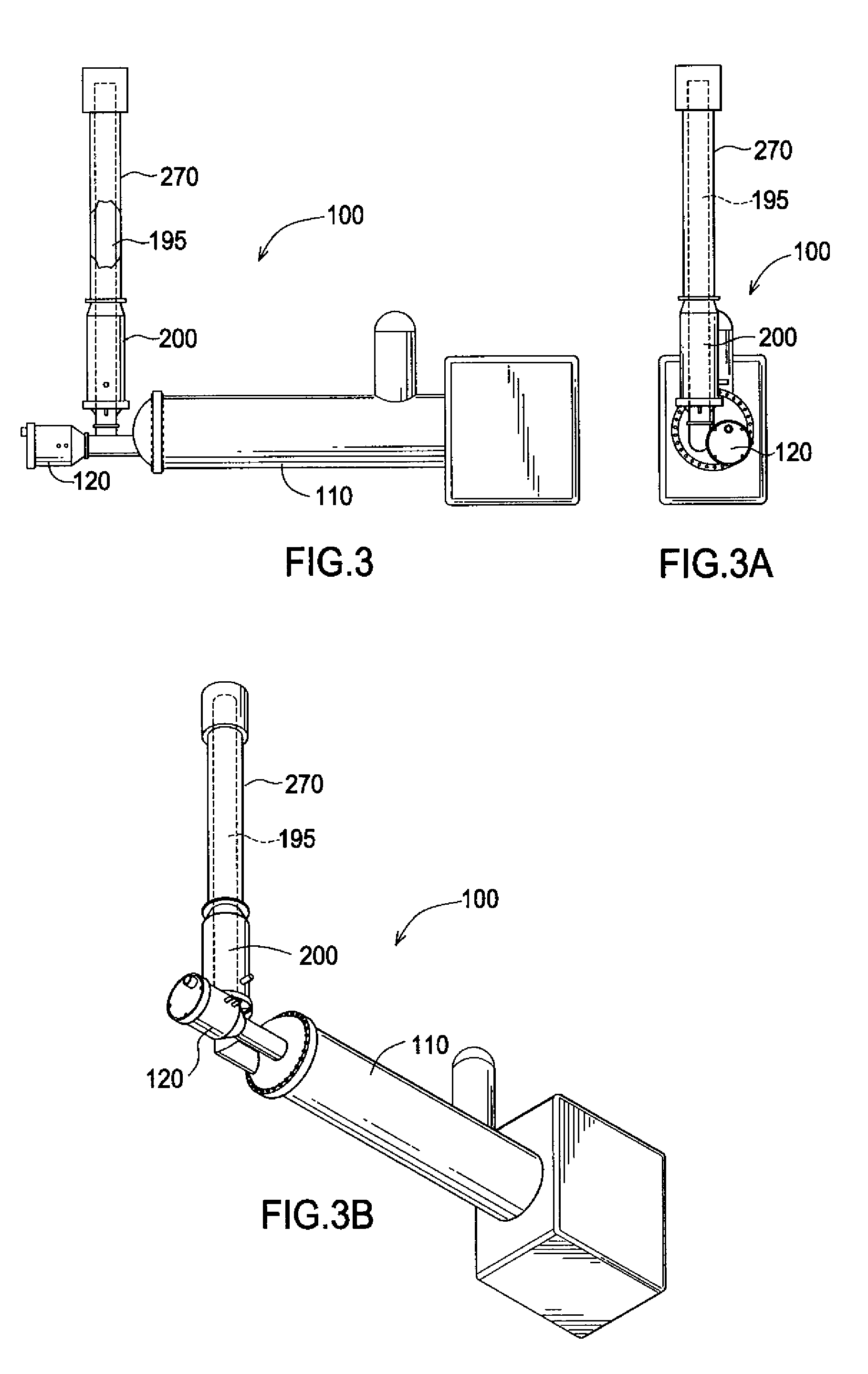

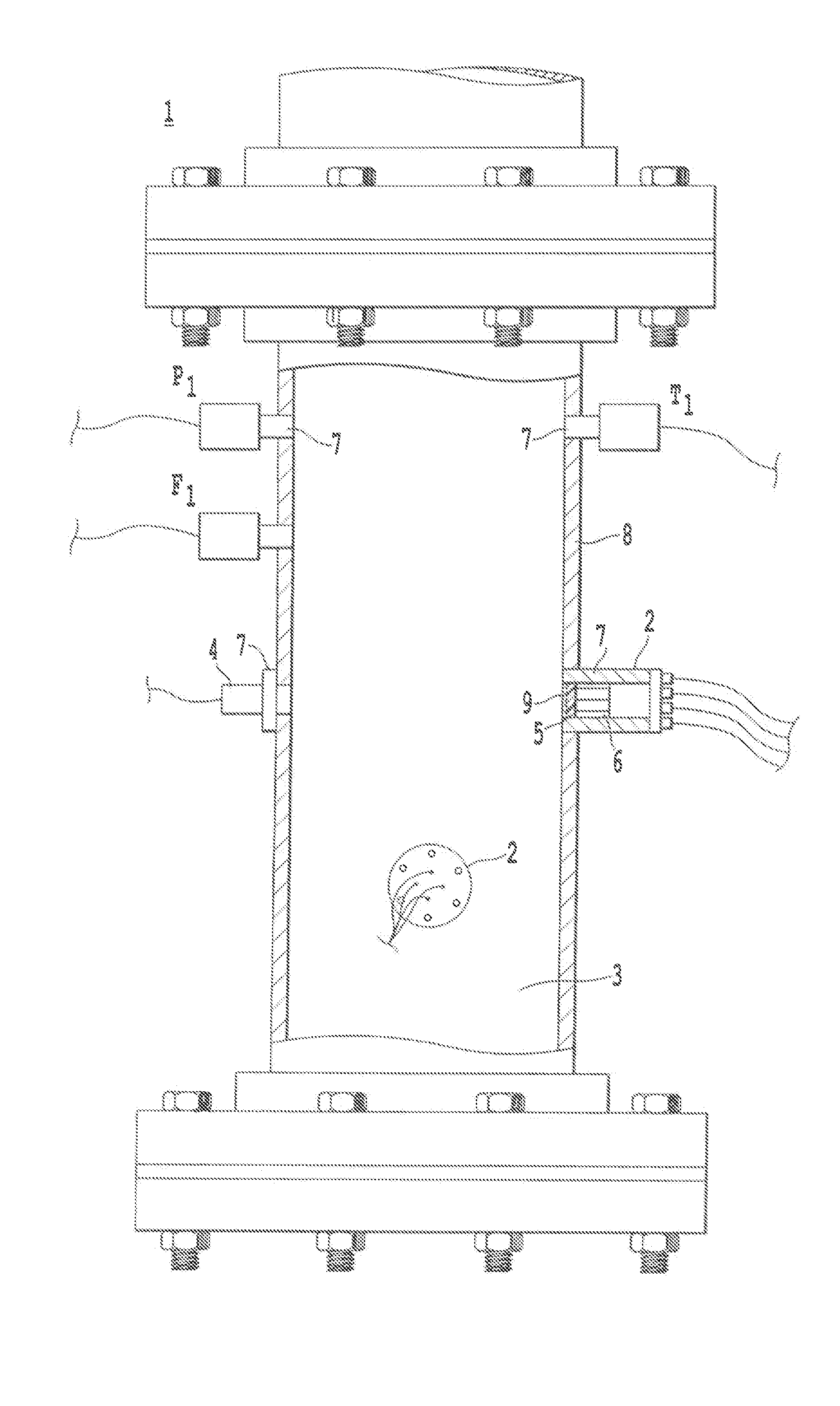

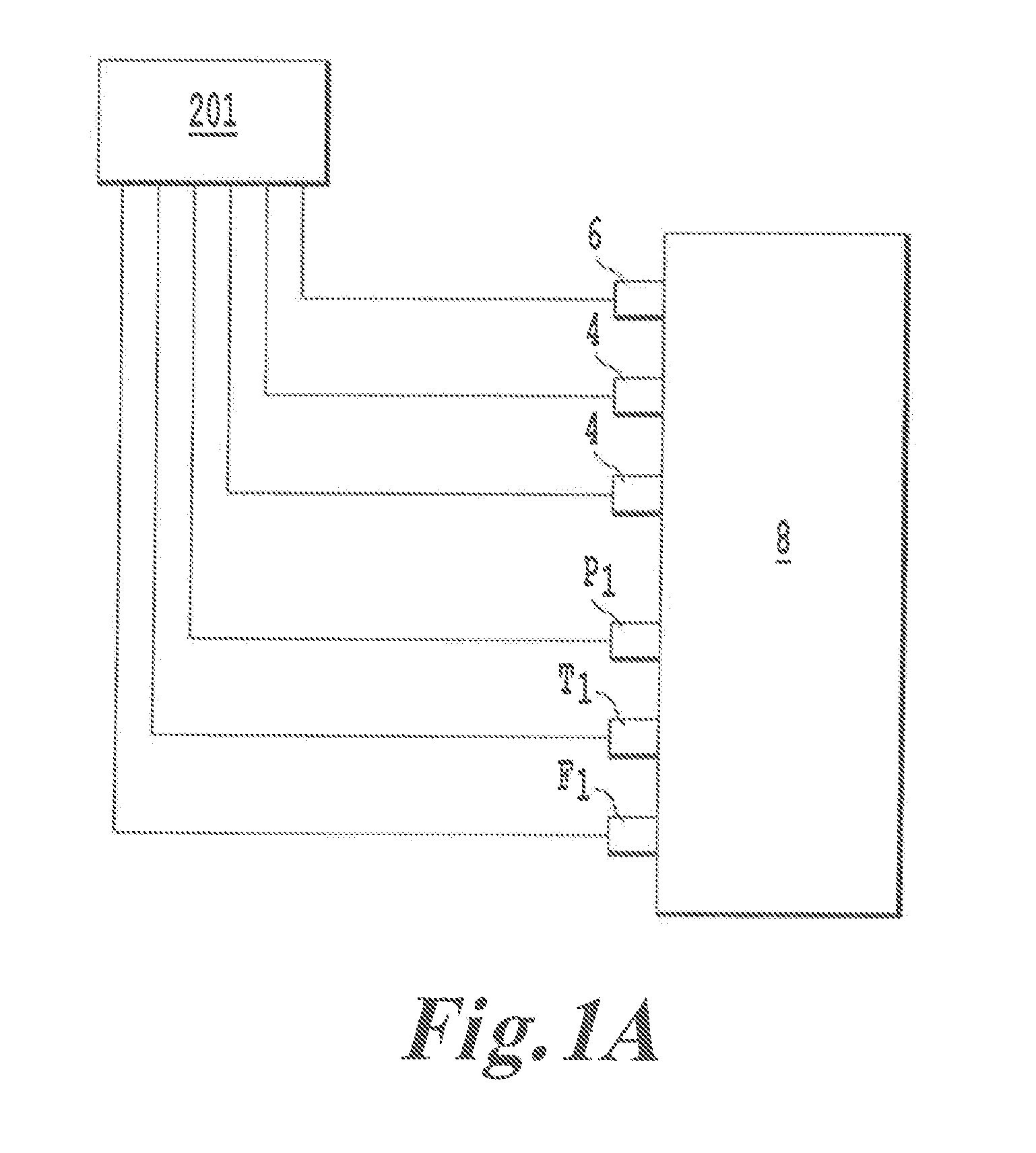

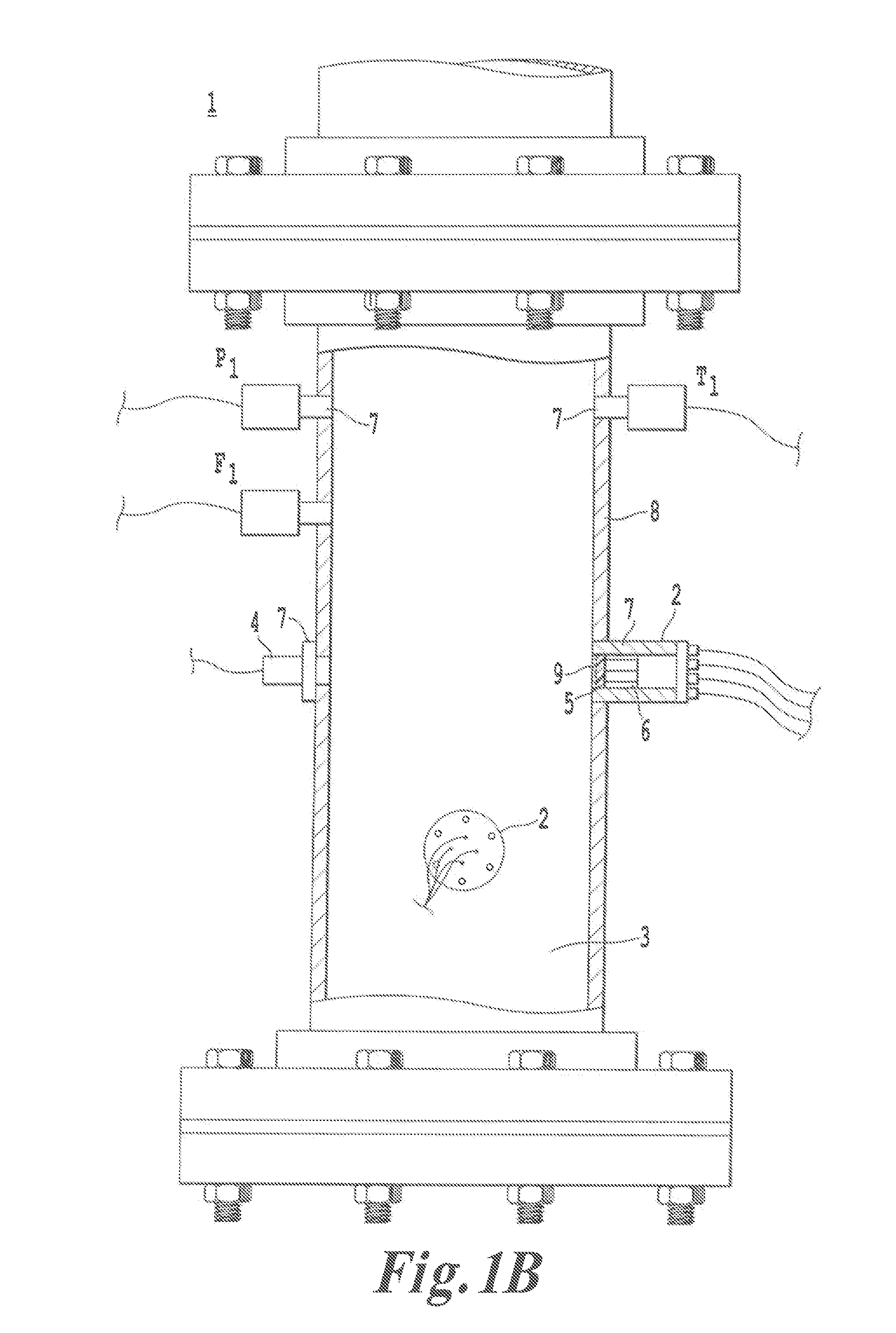

Fluid parameter measurement in pipes using acoustic pressures

InactiveUS6862920B2Less sensitive to static shifts (or errors) in sensingImprove measurement reliabilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringWater fraction

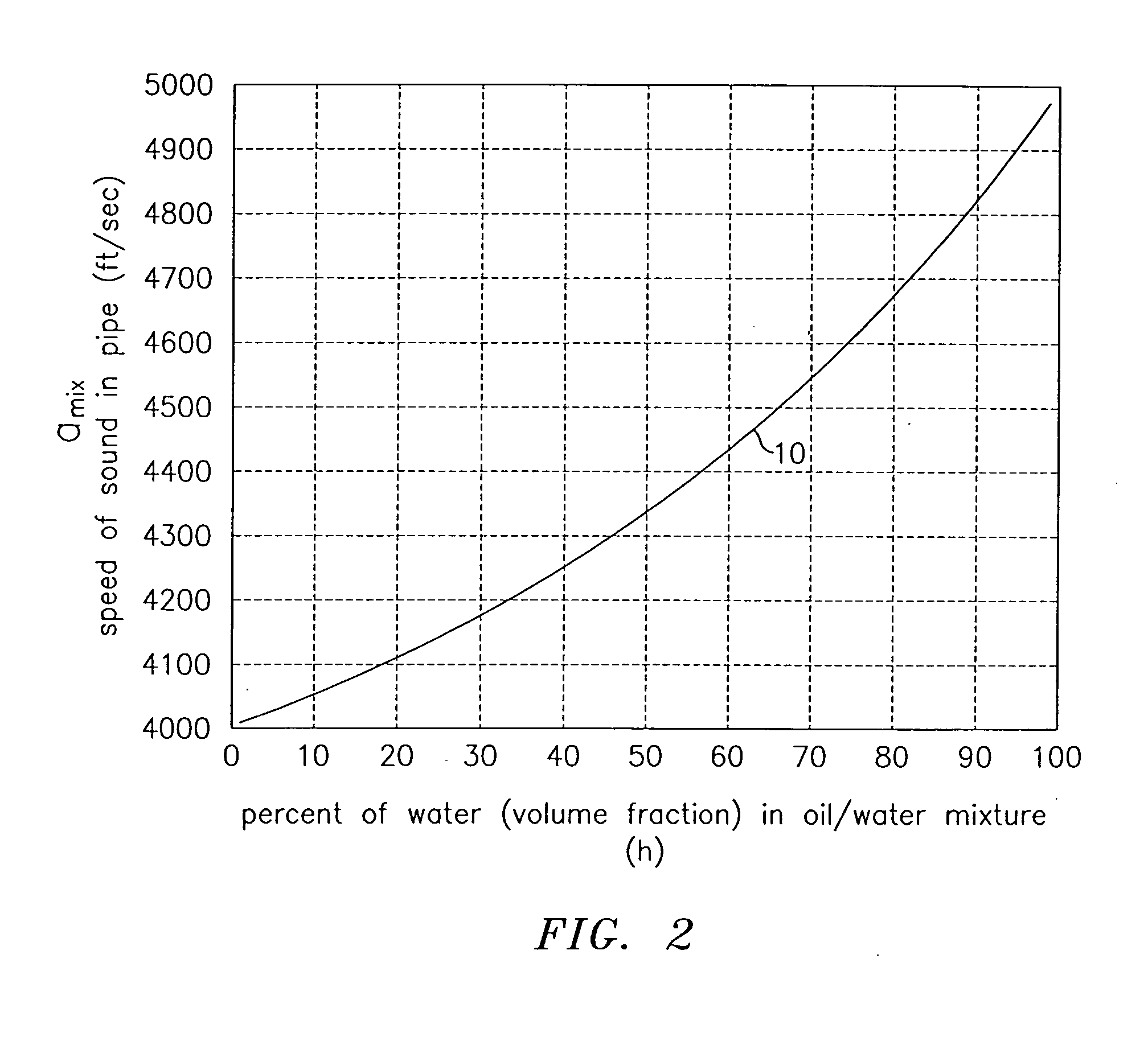

At least one parameter of at least one fluid in a pipe is measured using a spatial array of acoustic pressure sensors placed at predetermined axial locations along the pipe 12. The pressure sensors provide acoustic pressure signals, which are provided to a signal processing system that determines the speed of sound amix of the fluid (or mixture) in the pipe 12 using acoustic spatial array signal processing techniques. Numerous spatial array processing techniques may be employed to determine the speed of sound amix. The speed of sound amix is provided to another logic system that calculates the percent composition of the mixture, e.g., water fraction, or any other parameter of the mixture or fluid which is related to the sound speed amix. The signal processing system may also determine the Mach number Mx of the fluid. The acoustic pressure signals measured are lower frequency (and longer wavelength) signals than those used for ultrasonic flow meters, and thus are more tolerant to inhomogeneities in the flow. No external source is required and thus may operate using passive listening. The invention will work with arbitrary sensor spacing and with as few as two sensors if certain information is known about the acoustic properties of the system.

Owner:WEATHERFORD TECH HLDG LLC

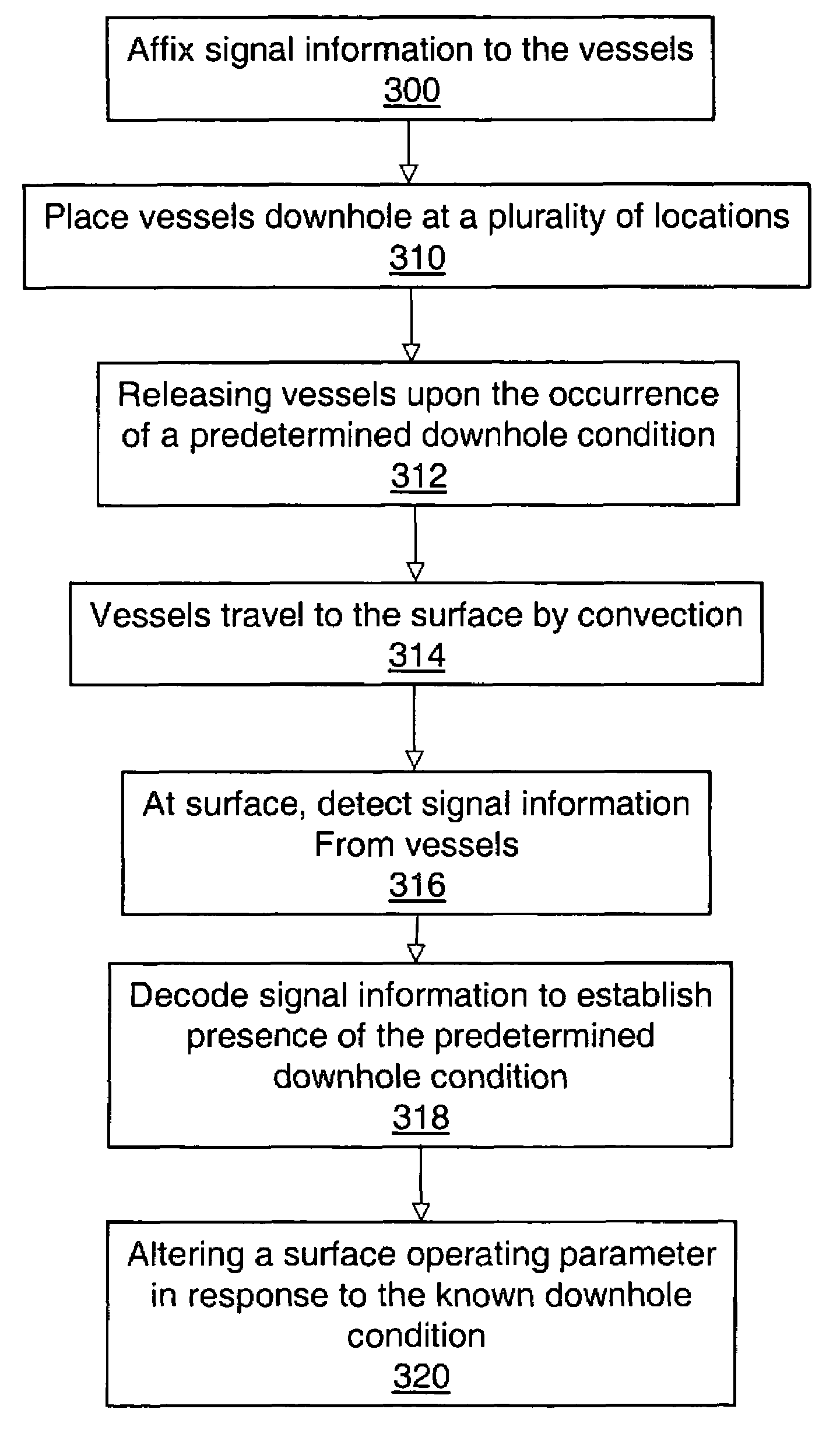

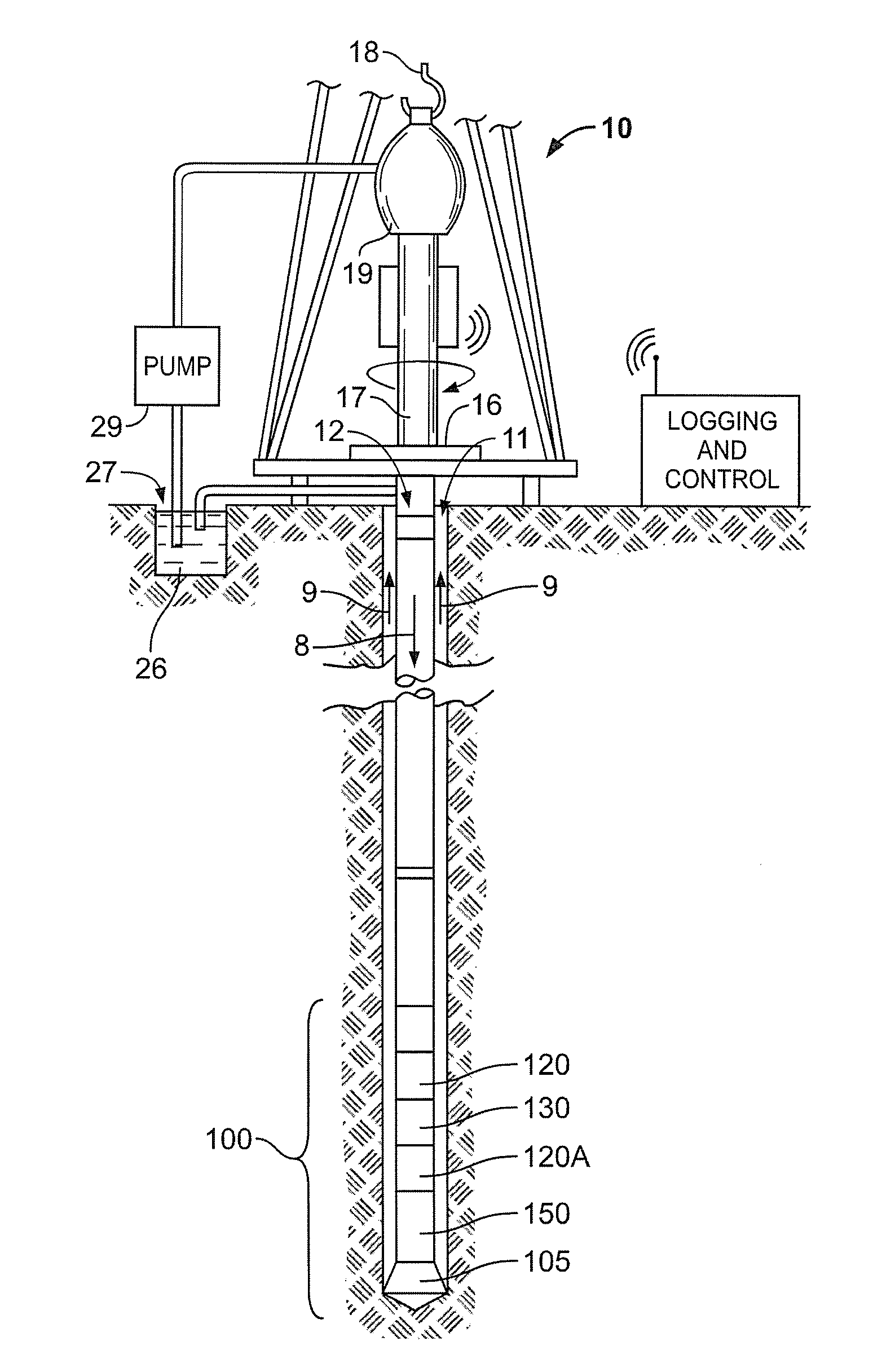

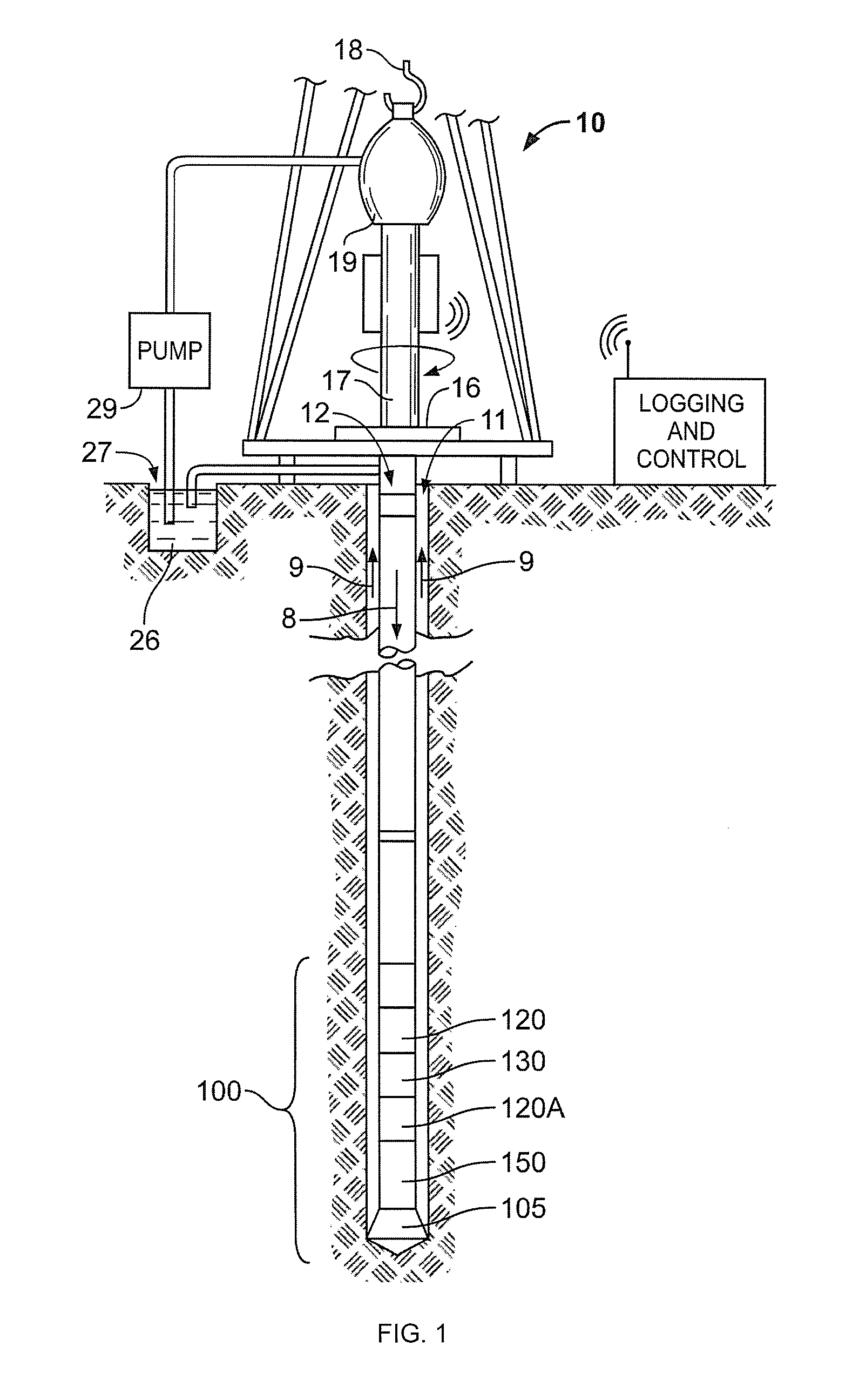

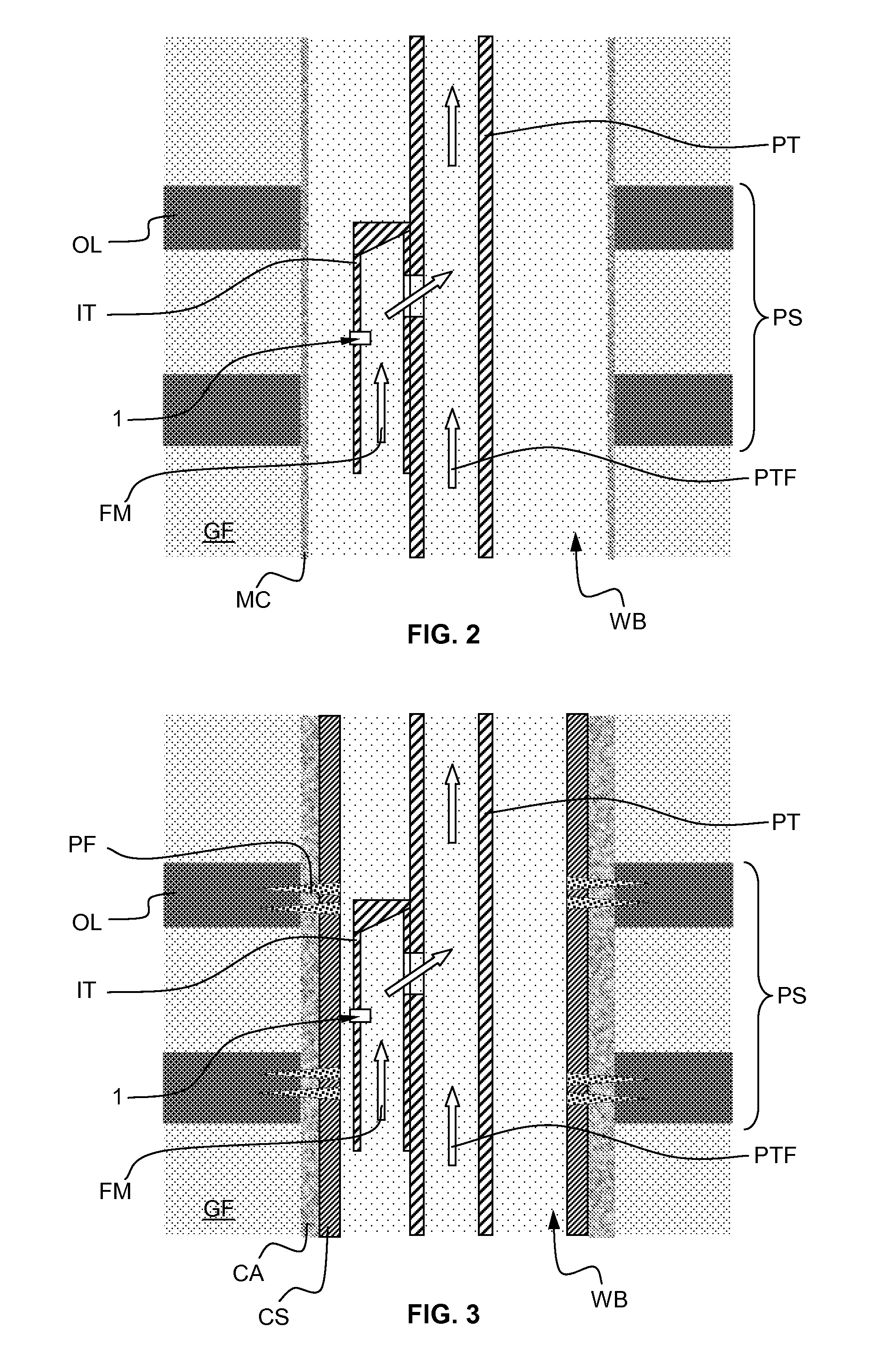

System and method for wellbore communication

InactiveUS6993432B2Simple and robustElectric/magnetic detection for well-loggingSurveyMarine engineeringMechanical wear

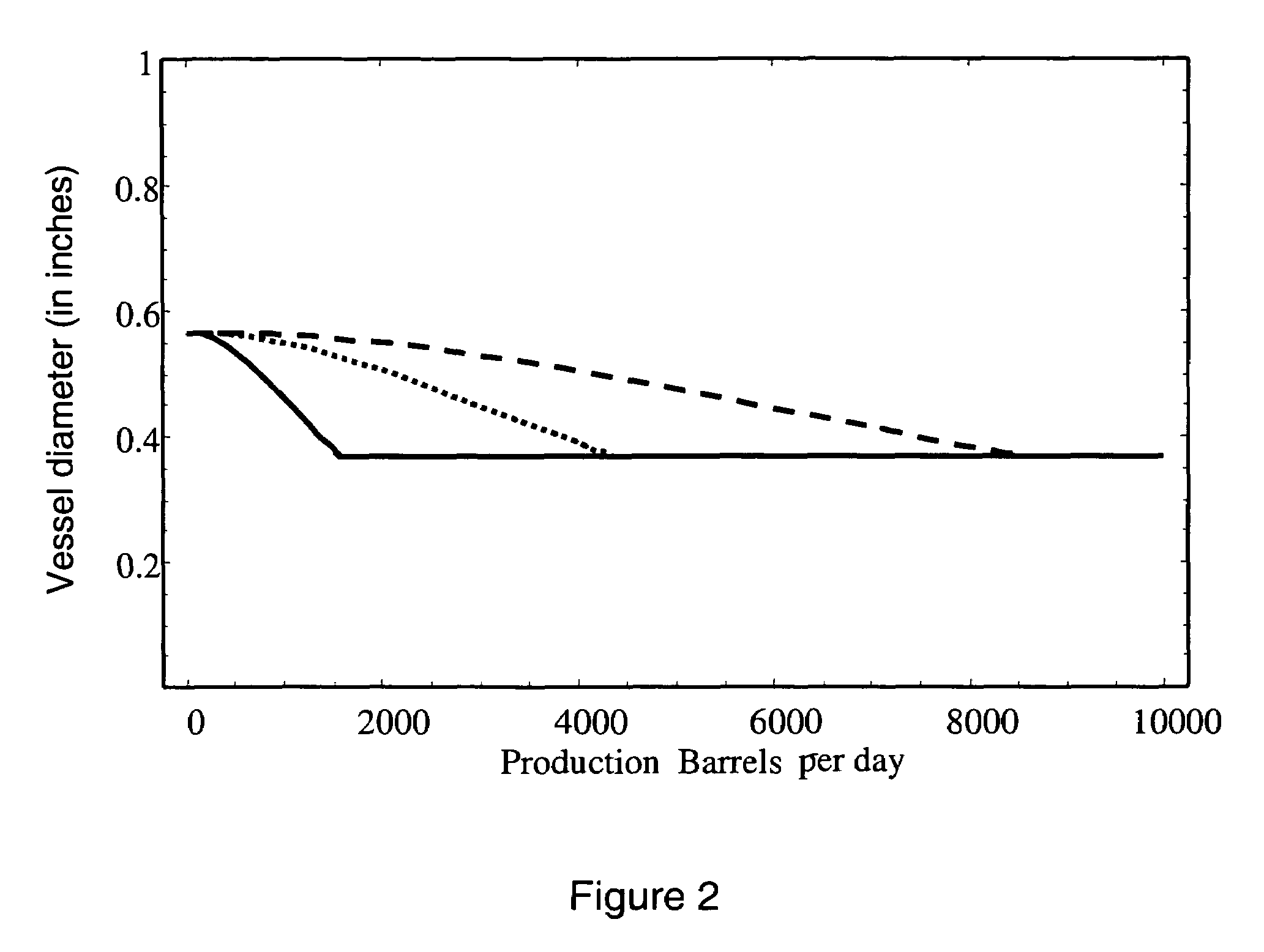

A method and system is disclosed for communicating information from a downhole location to the surface including a plurality of releasable vessels containing predetermined signal information affixed to the vessels prior to placement of the vessels downhole and indicative of the presence of at least one of three or more predetermined downhole conditions and a sensing and releasing system that senses the occurrence of the downhole condition, such as a simple threshold, and release the vessels in response to the sensing. The predetermined downhole condition can be characteristic of the fluid being produced in the borehole, such as water fraction, a certain level of mechanical wear or damage to downhole equipment such as bit wear, or the firing a one or more charges on a wireline deployed perforation tool.

Owner:SCHLUMBERGER TECH CORP

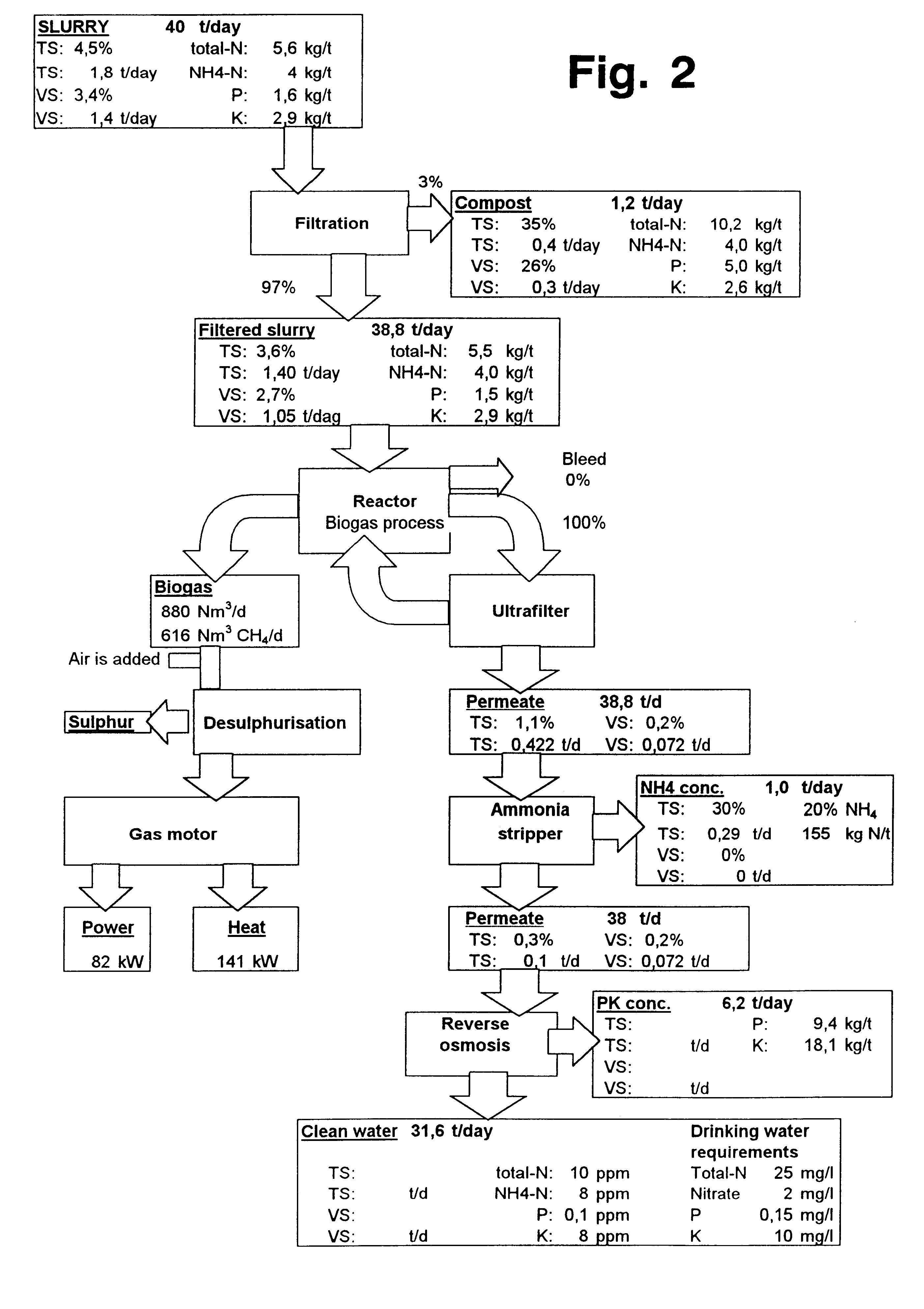

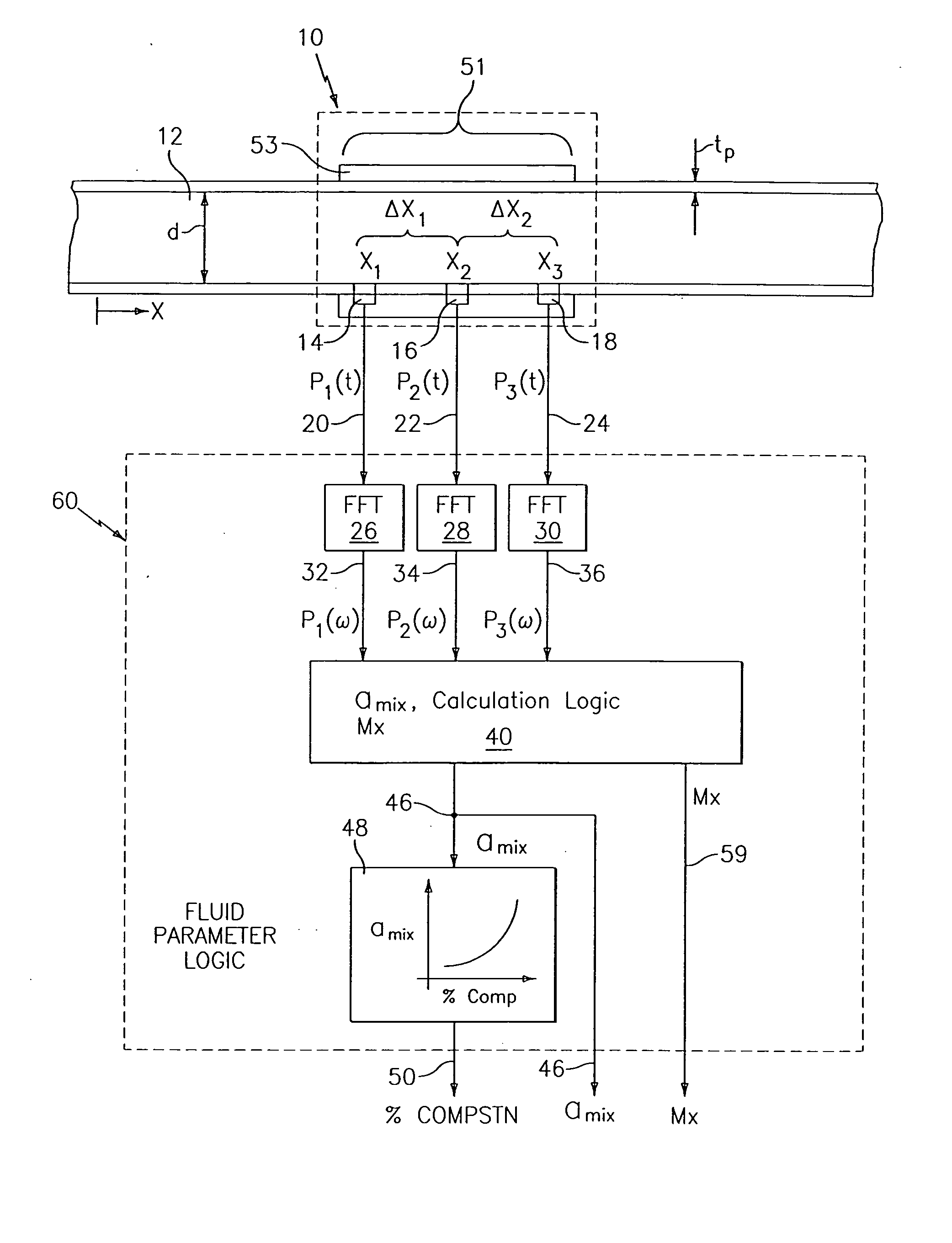

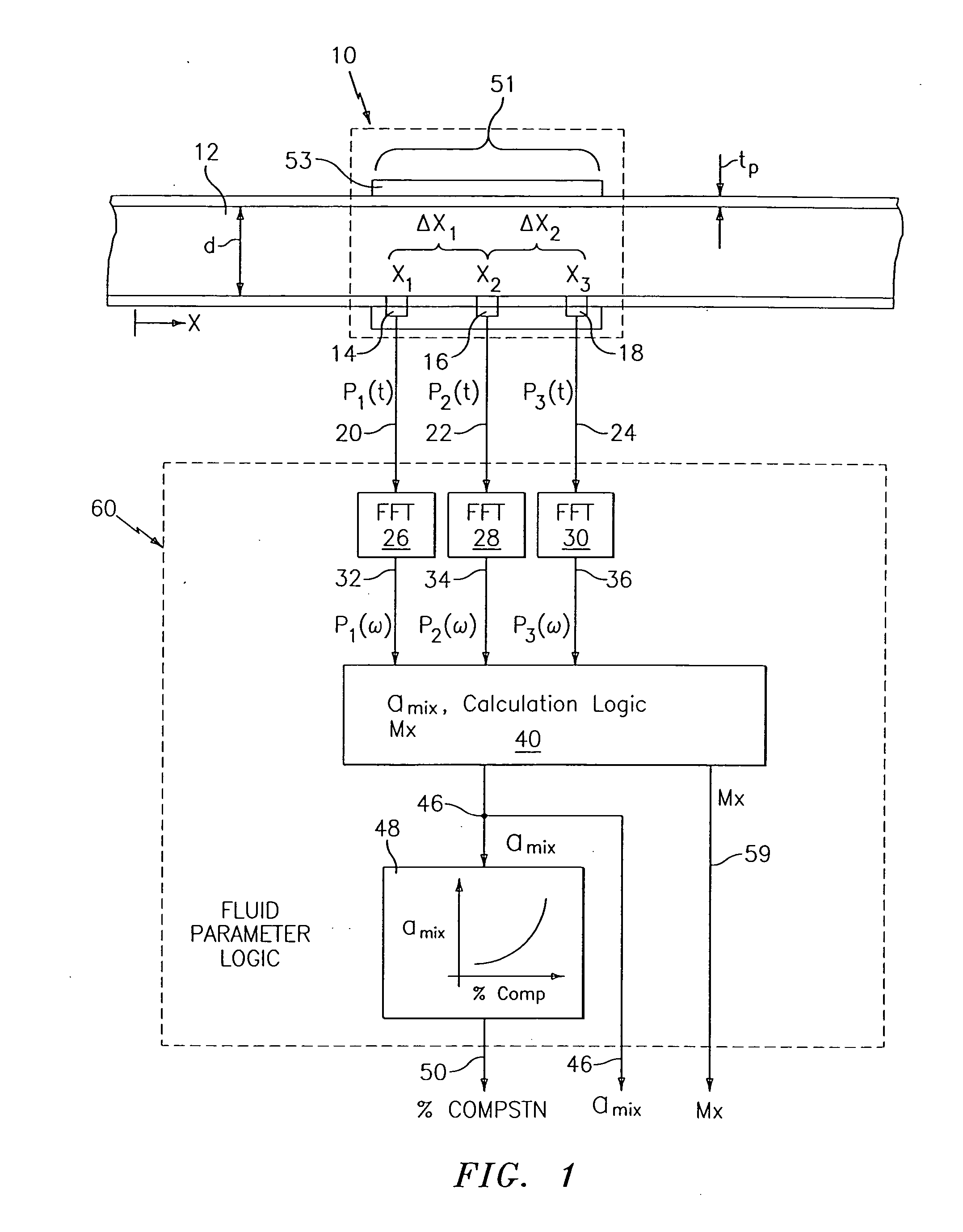

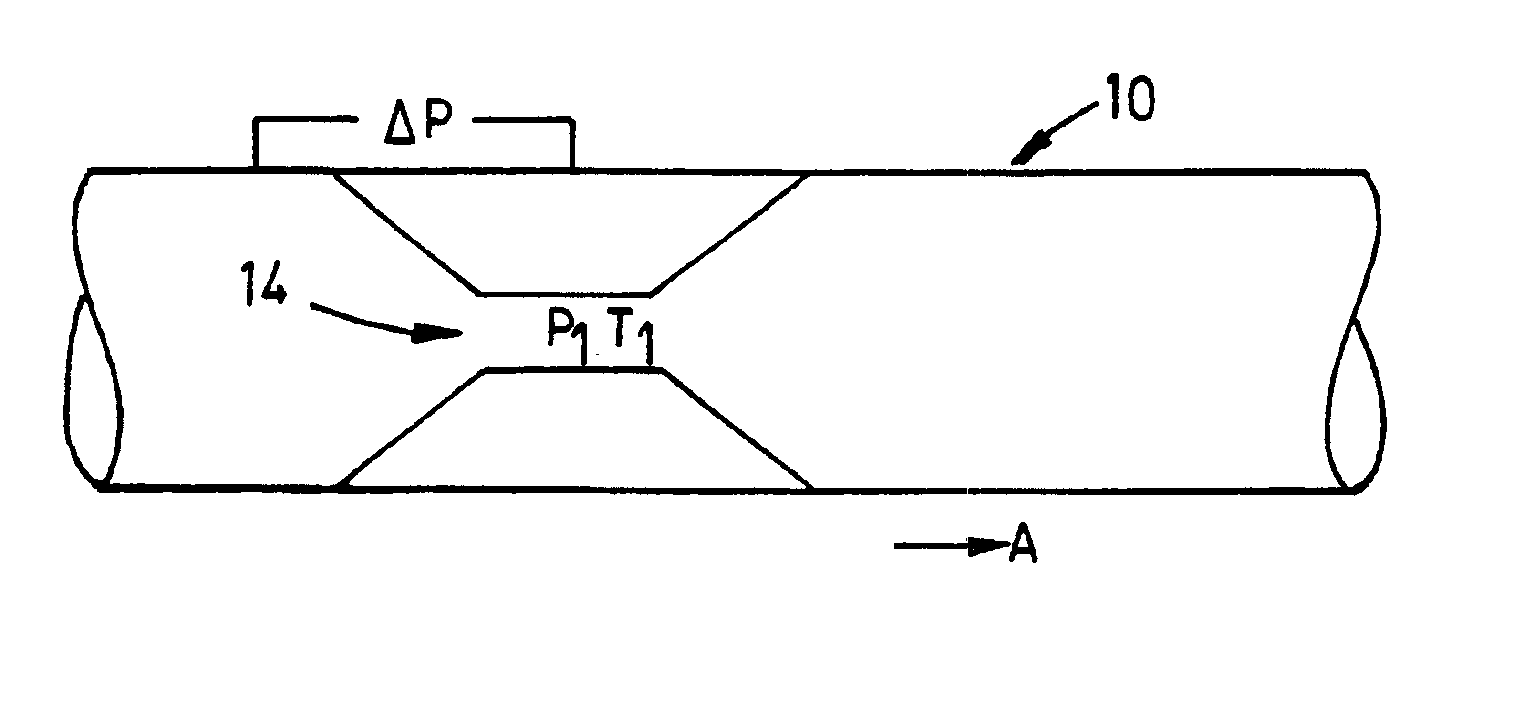

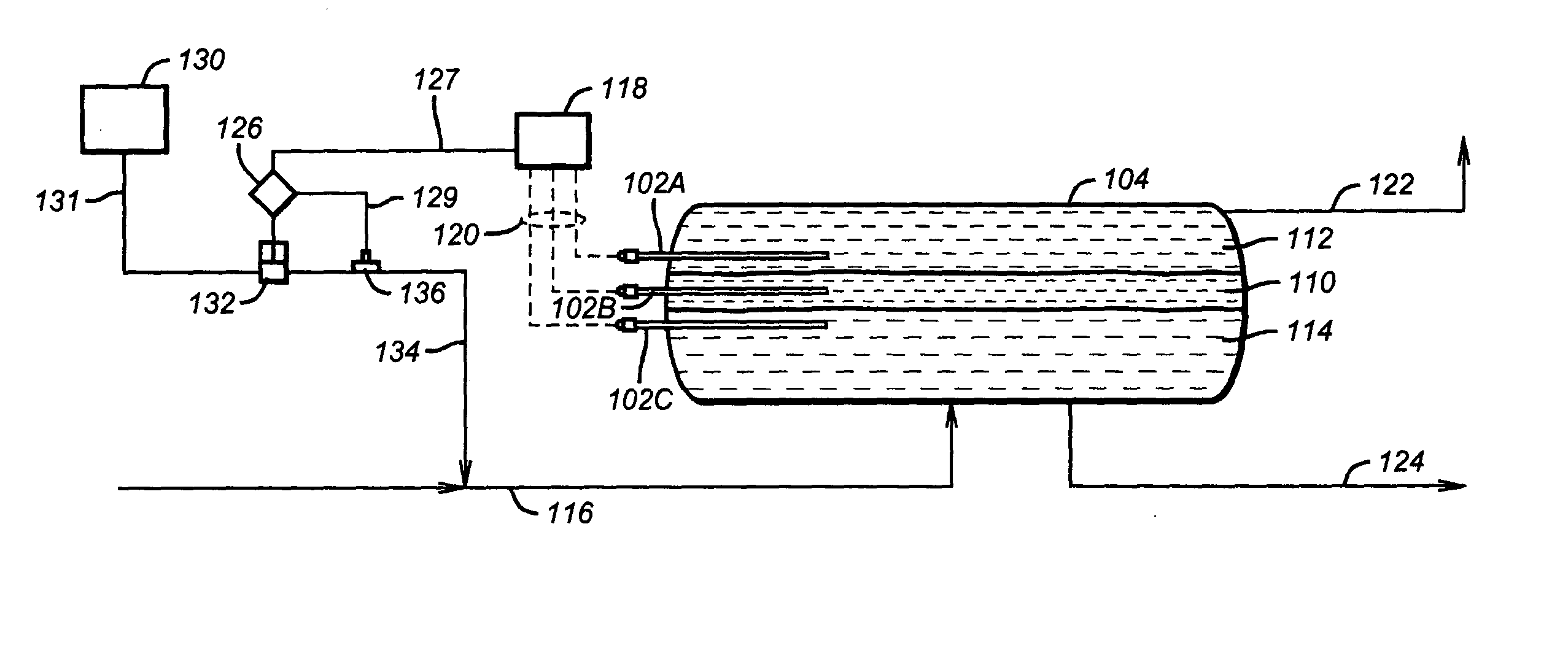

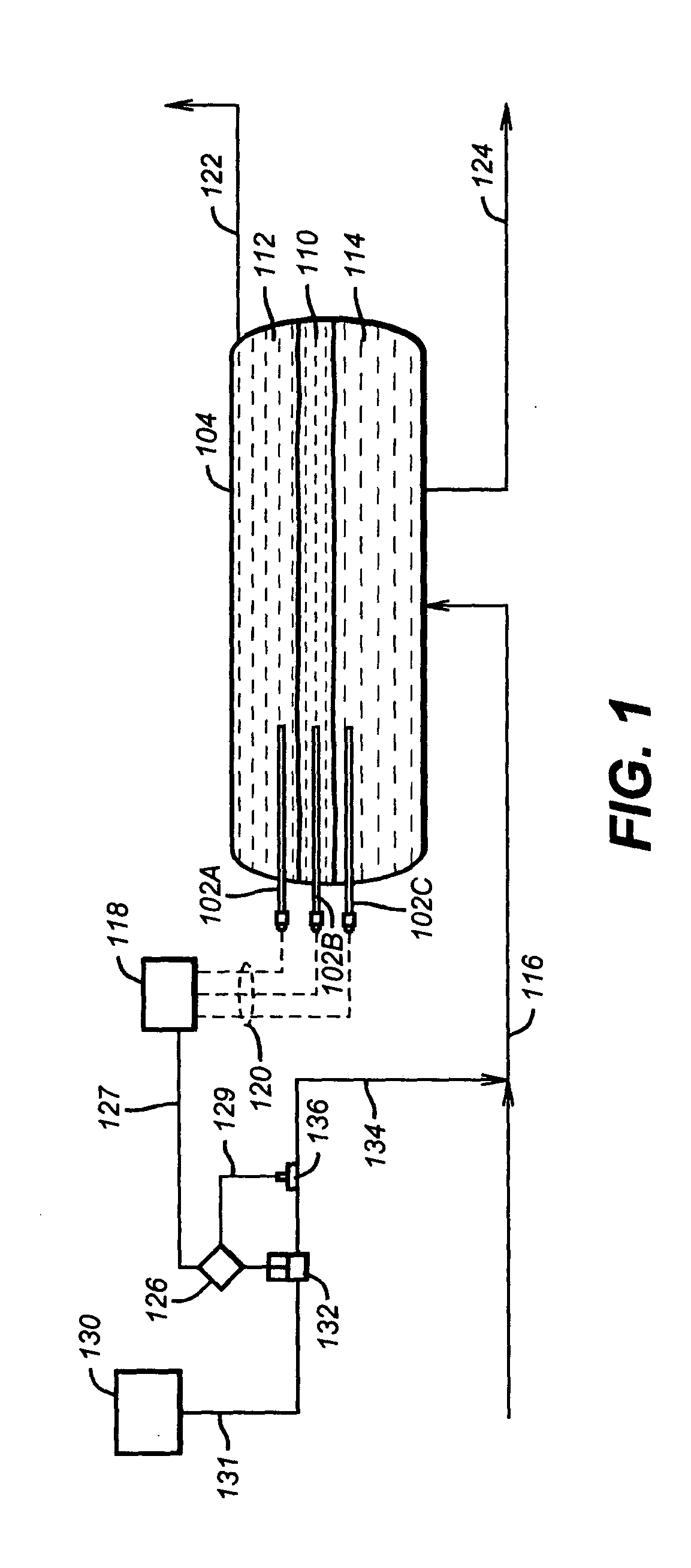

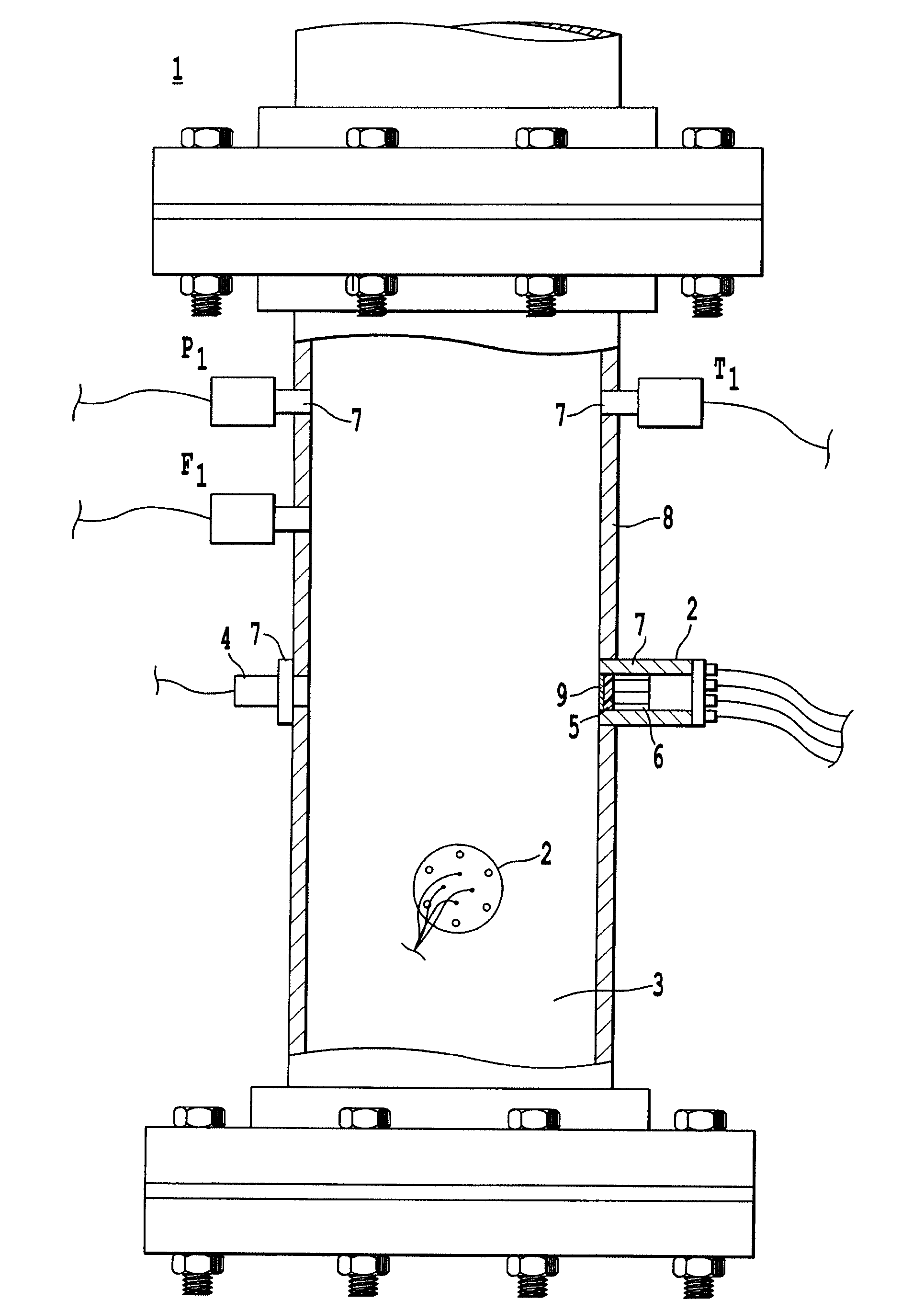

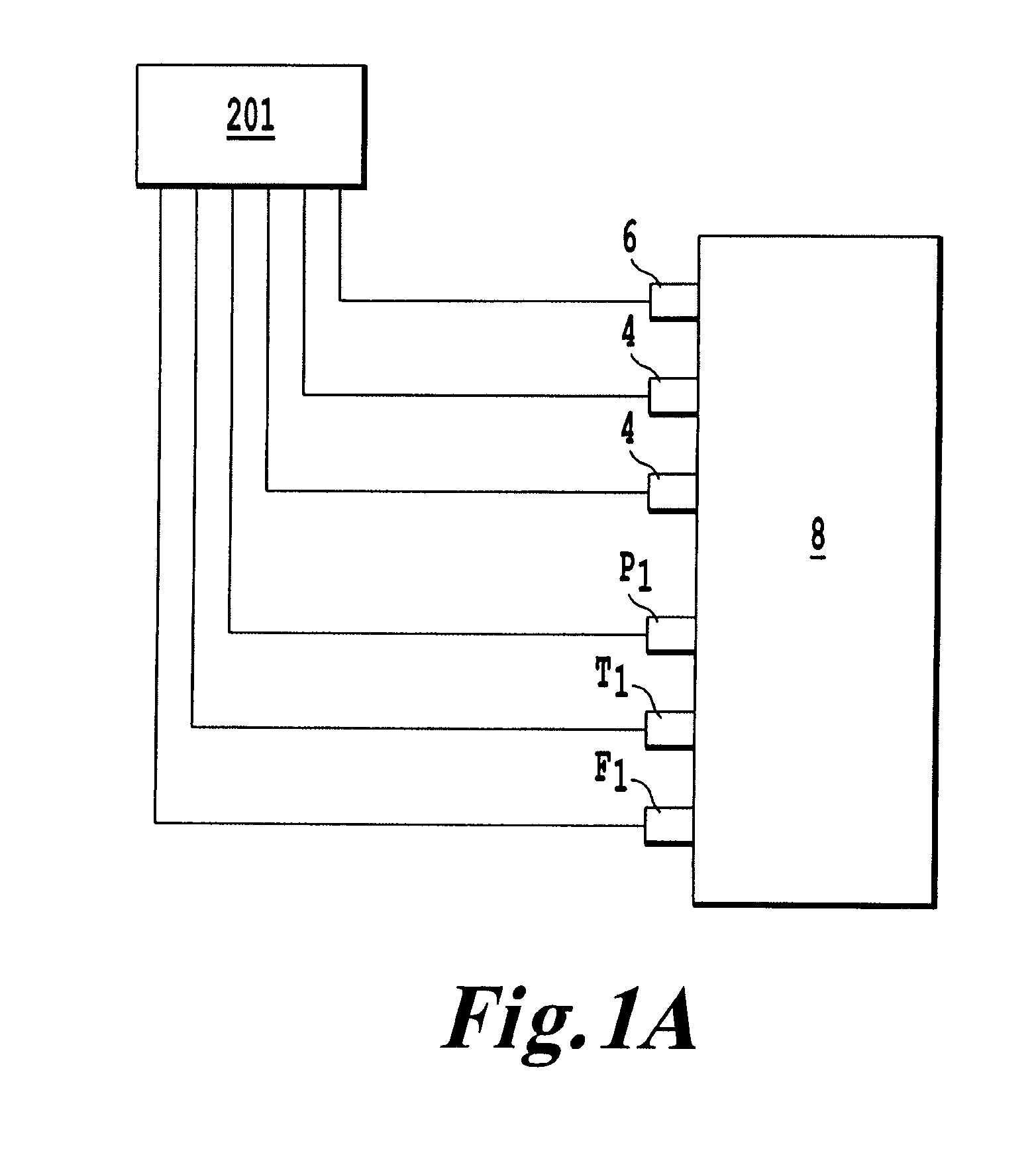

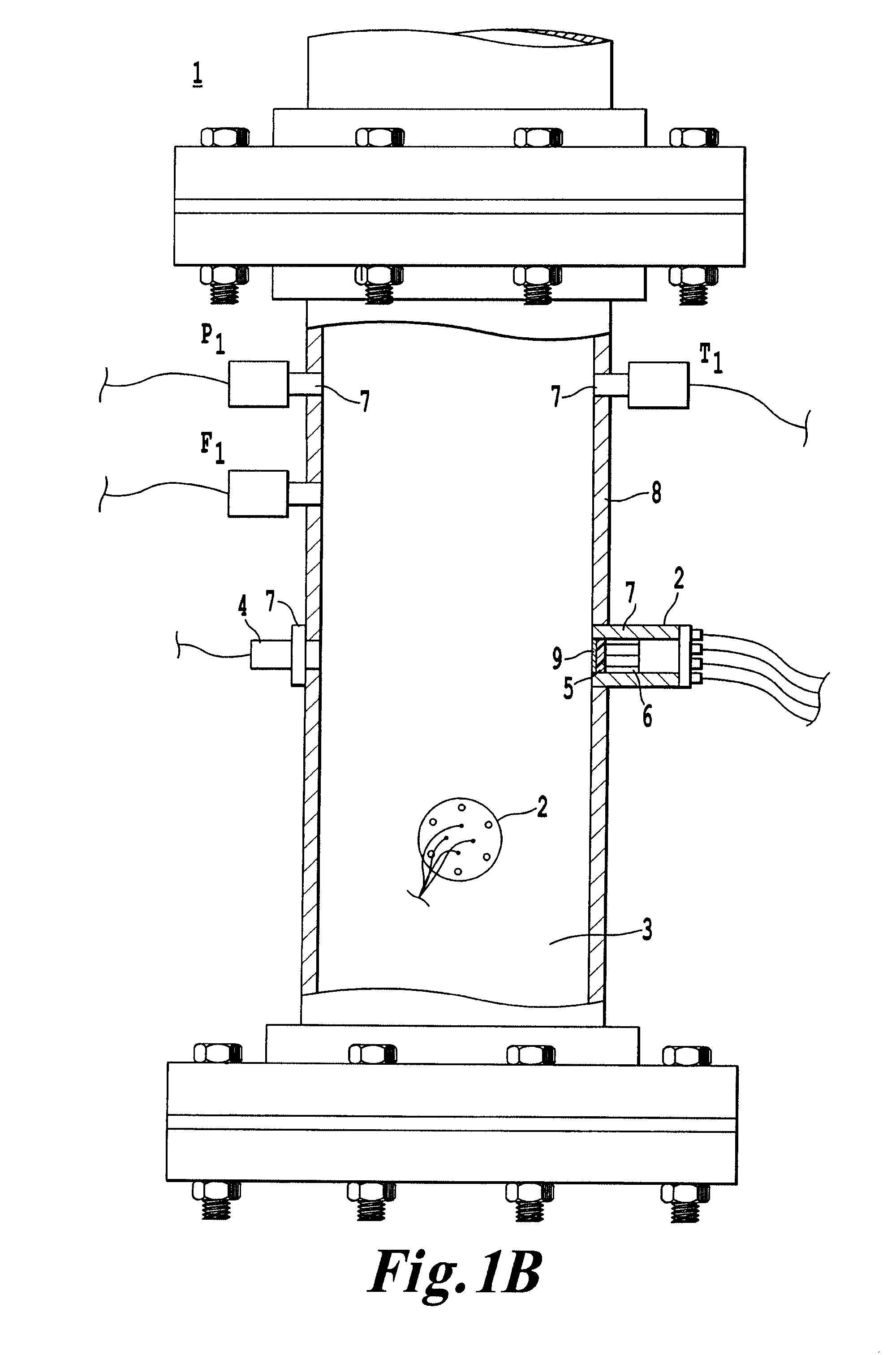

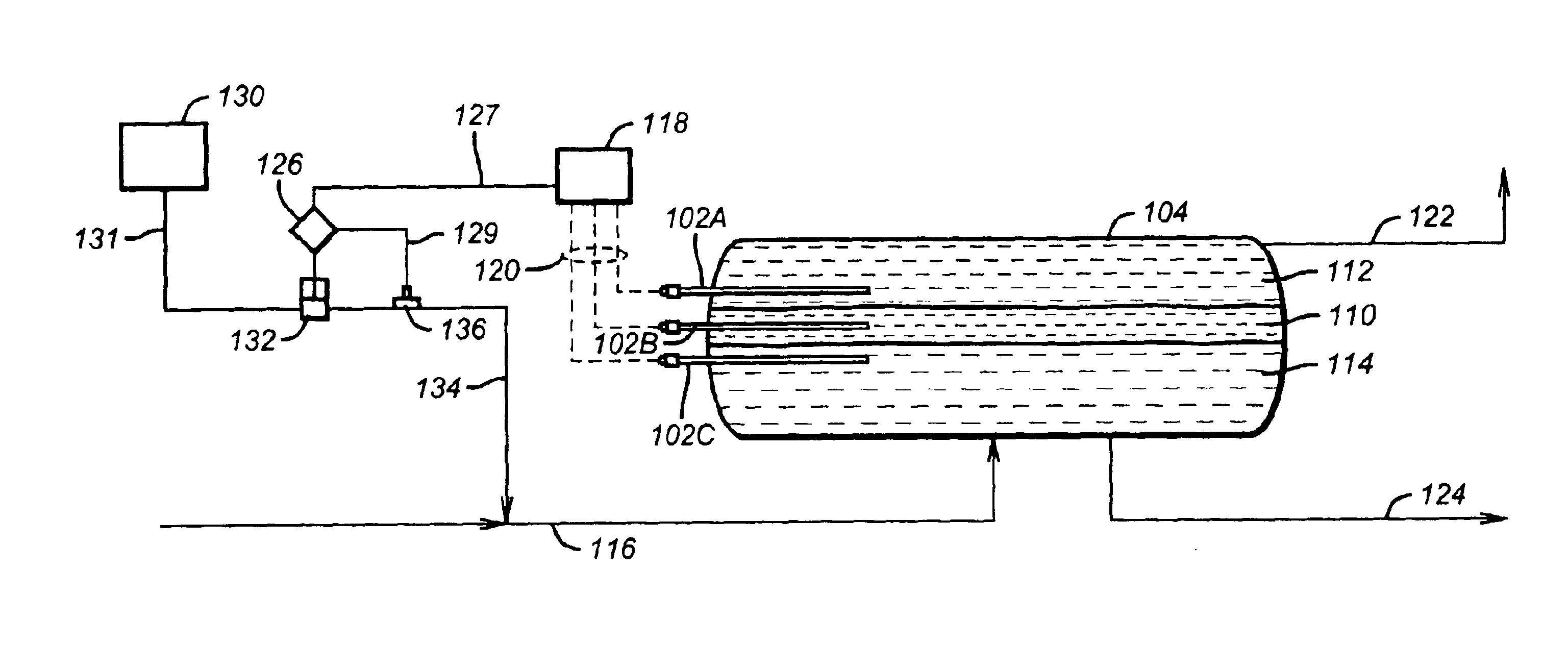

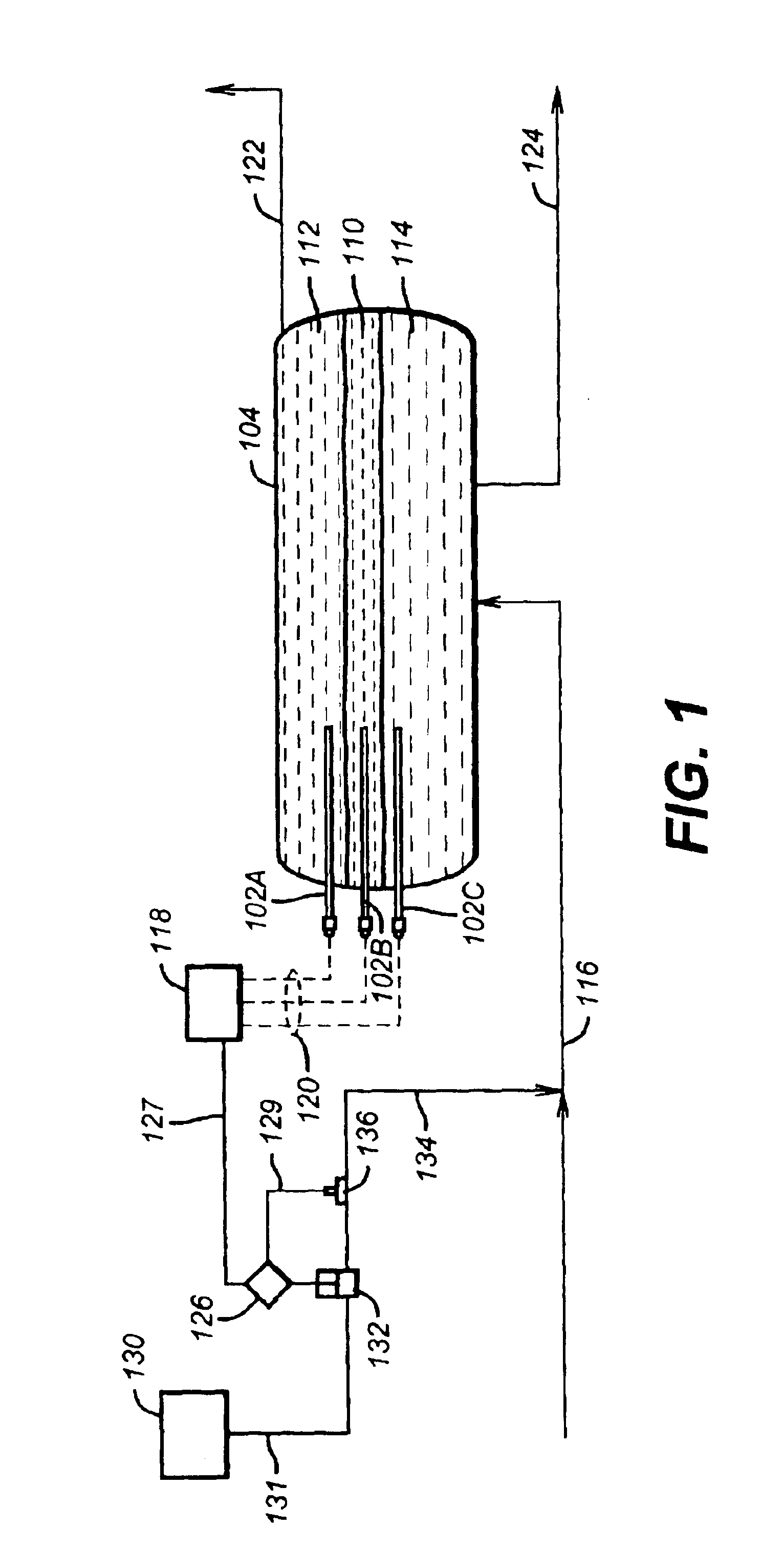

Fluid parameter measurement for industrial sensing applications using acoustic pressures

InactiveUS20050000289A1Less sensitiveImprove measurement reliabilityVibration measurement in solidsVibration measurement in fluidEngineeringOpto electronic

In industrial sensing applications at least one parameter of at least one fluid in a pipe 12 is measured using a spatial array of acoustic pressure sensors 14,16,18 placed at predetermined axial locations x1, x2, x3 along the pipe 12. The pressure sensors 14,16,18 provide acoustic pressure signals P1(t), P2(t), P3(t) on lines 20,22,24 which are provided to signal processing logic 60 which determines the speed of sound amix of the fluid (or mixture) in the pipe 12 using acoustic spatial array signal processing techniques with the direction of propagation of the acoustic signals along the longitudinal axis of the pipe 12. Numerous spatial array-processing techniques may be employed to determine the speed of sound amix. The speed of sound amix is provided to logic 48, which calculates the percent composition of the mixture, e.g., water fraction, or any other parameter of the mixture, or fluid, which is related to the sound speed amix. The logic 60 may also determine the Mach number Mx of the fluid. The acoustic pressure signals P1(t), P2(t), P3(t) measured are lower frequency (and longer wavelength) signals than those used for ultrasonic flow meters, and thus is more tolerant to inhomogeneities in the flow. No external source is required and thus may operate using passive listening. The invention will work with arbitrary sensor spacing and with as few as two sensors if certain information is known about the acoustic properties of the system. The sensor may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

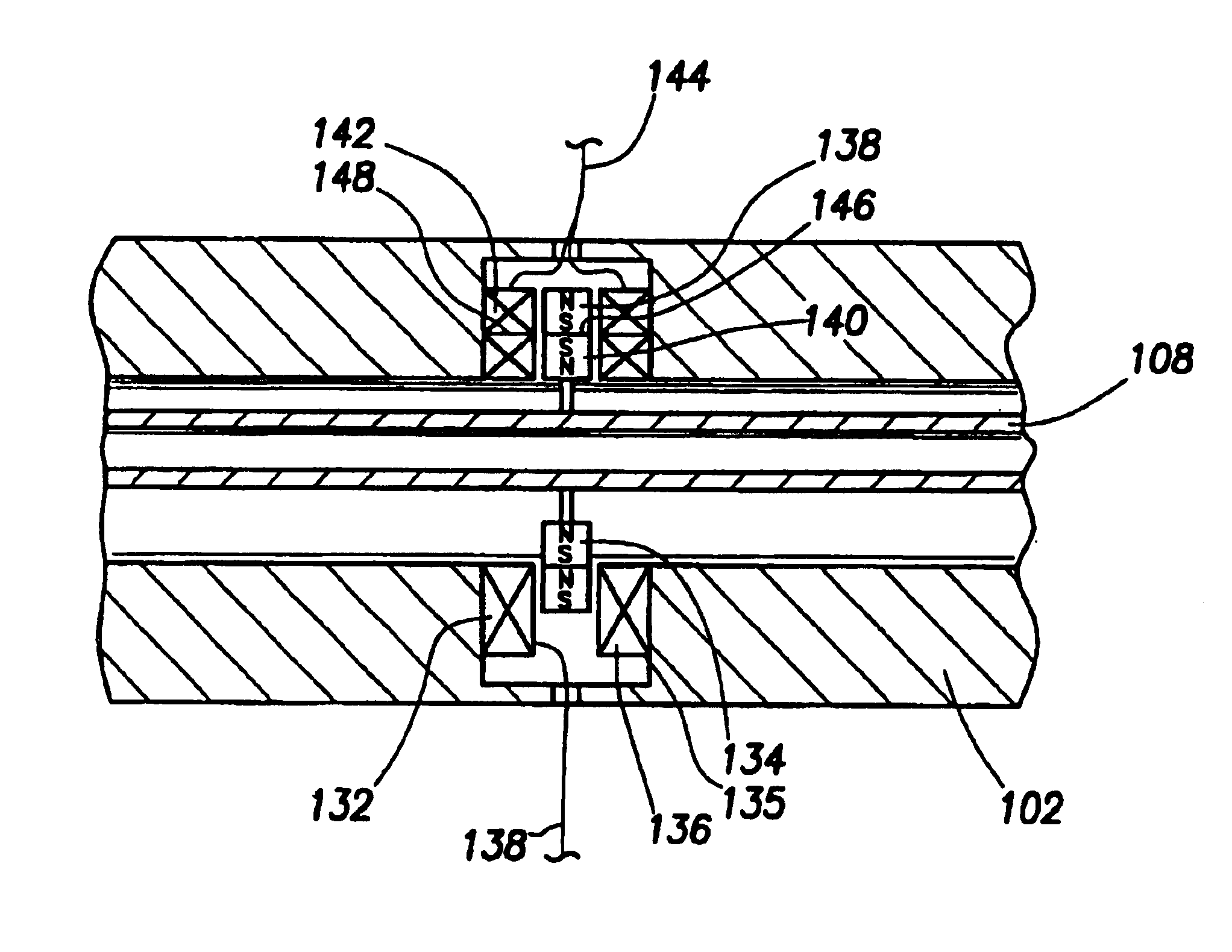

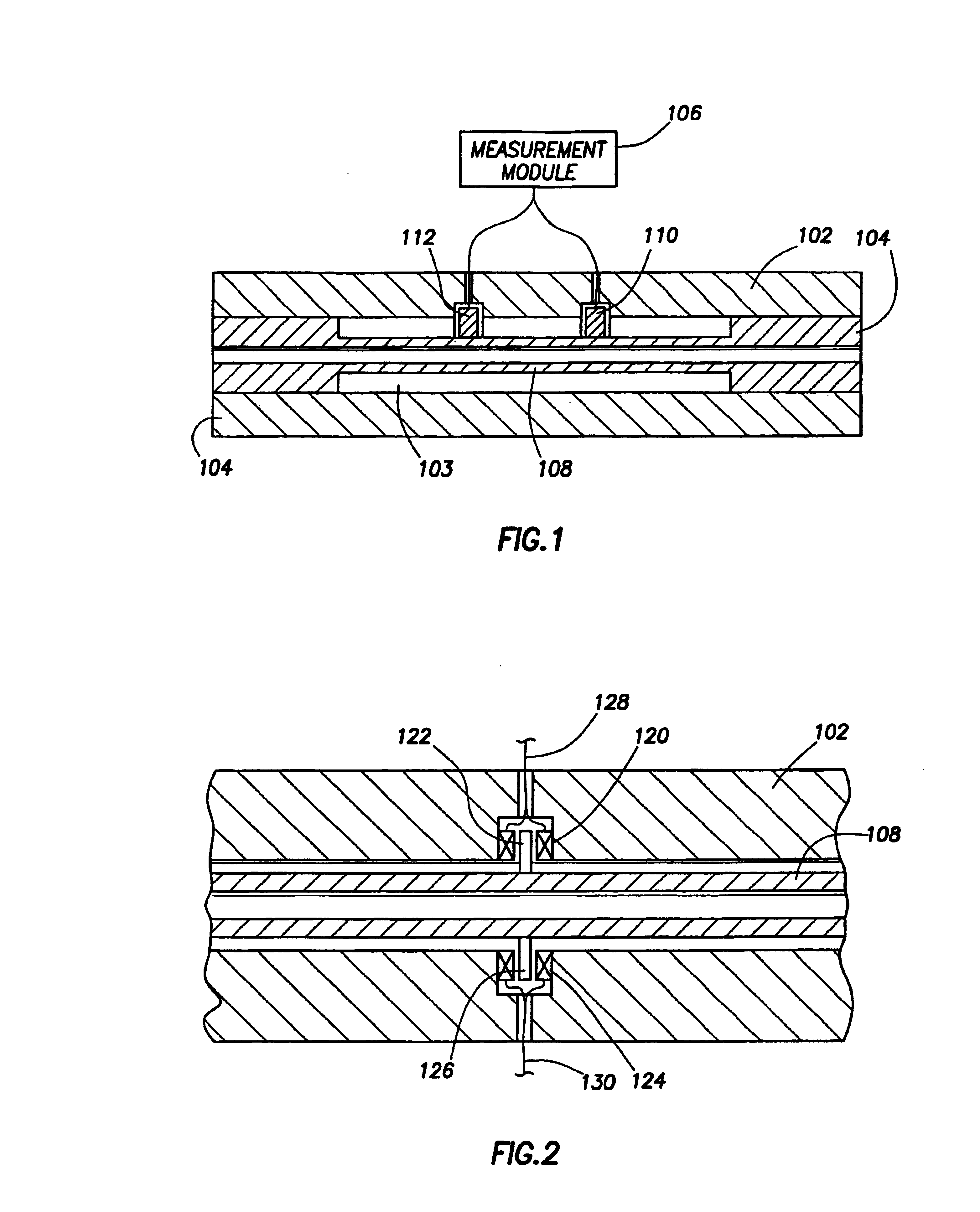

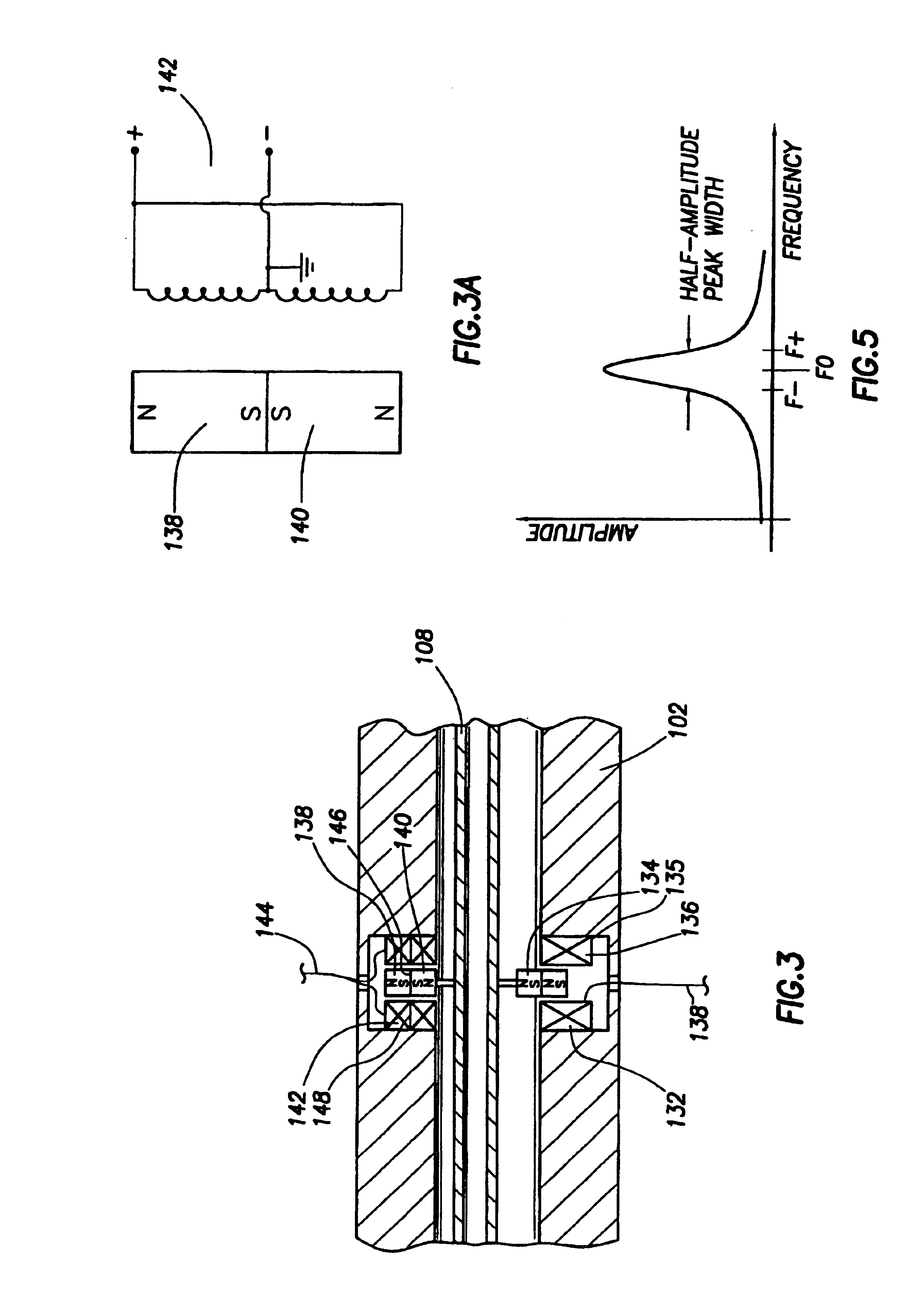

Single tube densitometer

InactiveUS6912904B2Improve accuracyImprove reliabilityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement deviceComputer module

A measurement device is provided that determines fluid properties from vibration frequencies of a sample cavity. In one embodiment, the measurement device includes a sample flow tube, vibration source and detector mounted on the tube, and a measurement module. The sample flow tube receives a flow of sample fluid for characterization. The measurement module employs the vibration sources to generate vibrations in the tube. The measurement module combines the signals from the vibration detector on the tube to determine properties of the sample fluid, such as density, viscosity, compressibility, water fraction, and bubble size. The measurement module may further detect certain flow patterns such as slug flow, for example. To measure the sample fluid density, the measurement module determines the resonant frequency of the sample flow tube. The density can then be calculated according to a formula that compensates for the temperature and pressure of the system.

Owner:HALLIBURTON ENERGY SERVICES INC

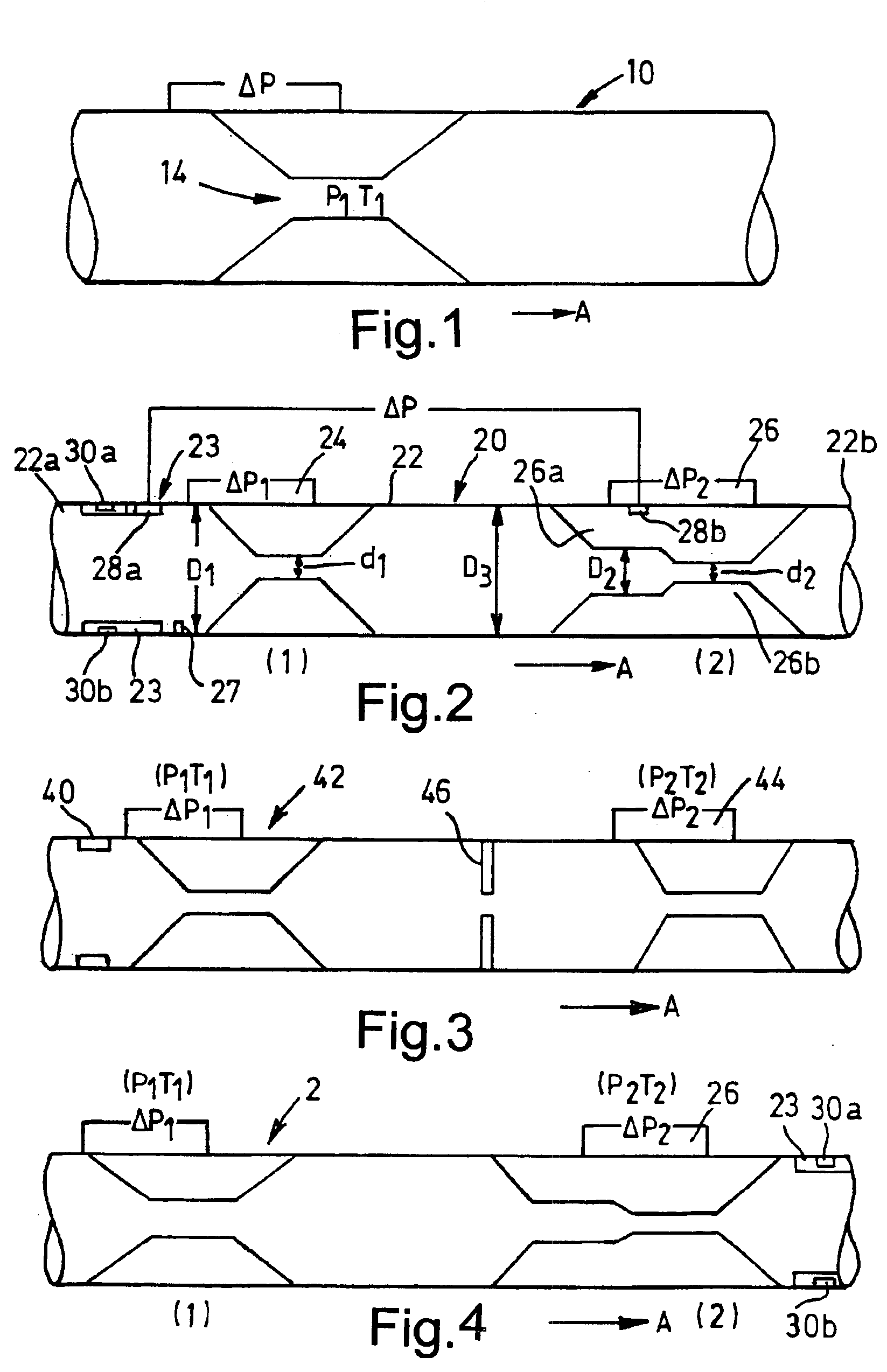

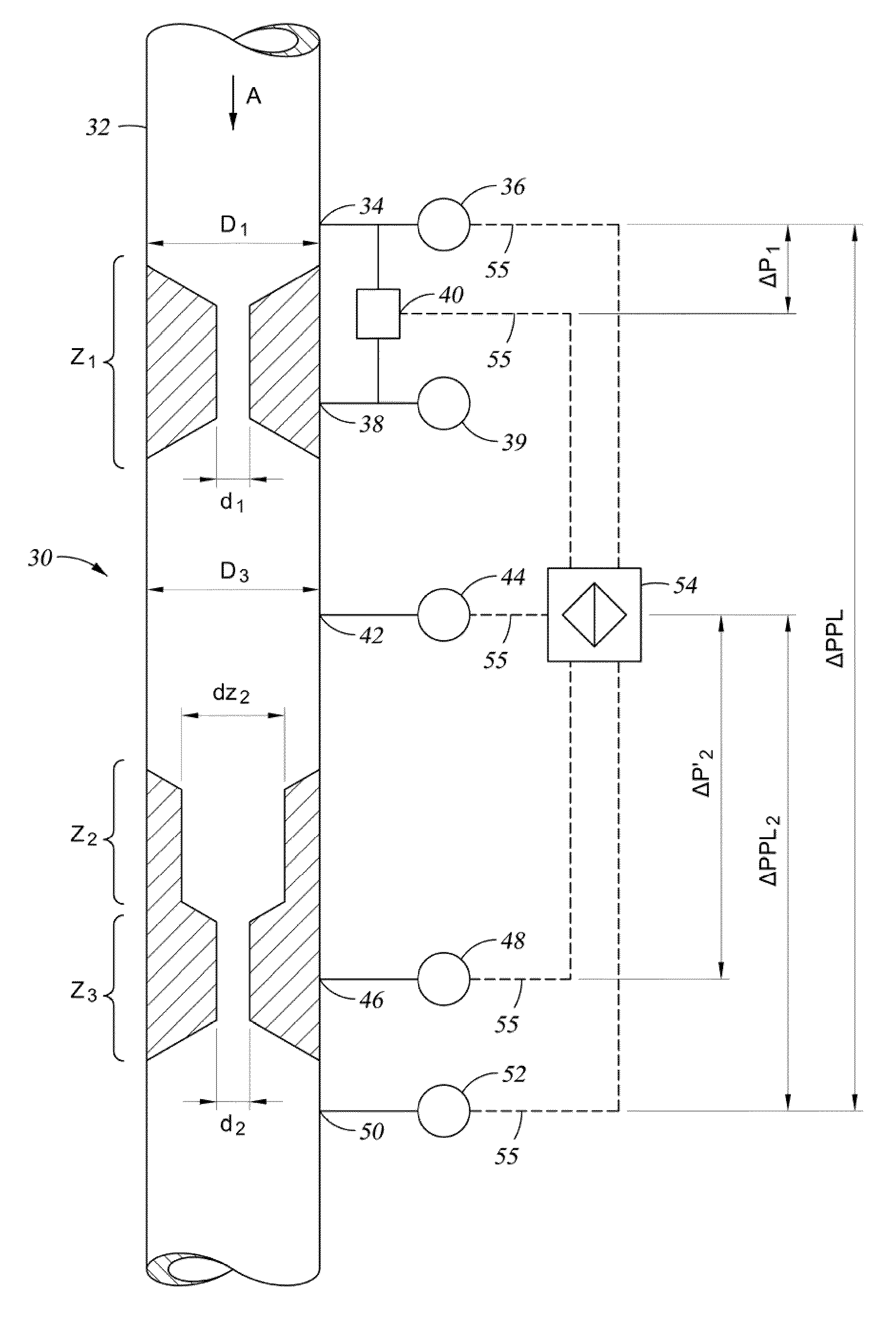

Multiphase flow meter using multiple pressure differentials

InactiveUS6935189B2Improve compression performanceMeasure can be takenVolume/mass flow by differential pressureEngineeringWater fraction

A flowmeter, and a method of, measuring the flow of a multi-phase fluid is described. The flowmeter has a first pressure sensor located in a conduit for measuring a first pressure differential at a first location and a second response sensor spaced along the conduit for measuring a second pressure differential at a second location. The flowmeter includes pressure drop creation means for causing a drop in fluid pressure between the first and second locations, and a water fraction meter upstream of the first location or downstream of the second location for measuring the fraction of water in the multi-phase fluid. Various embodiments of the invention are described and in a preferred arrangement the first and second pressure measuring means are venturi flowmeters.

Owner:EUROPEAN SPACE AGENCY +1

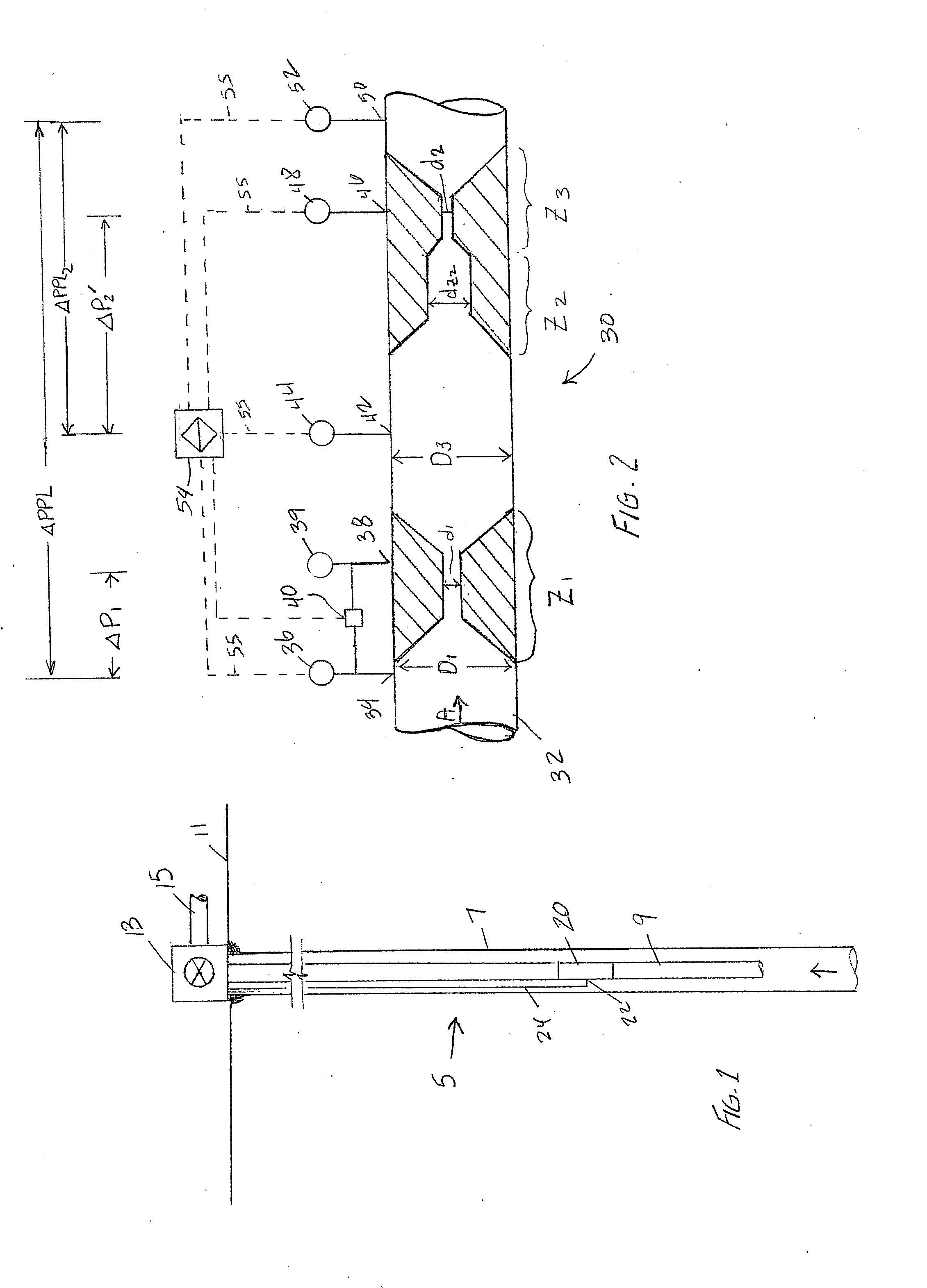

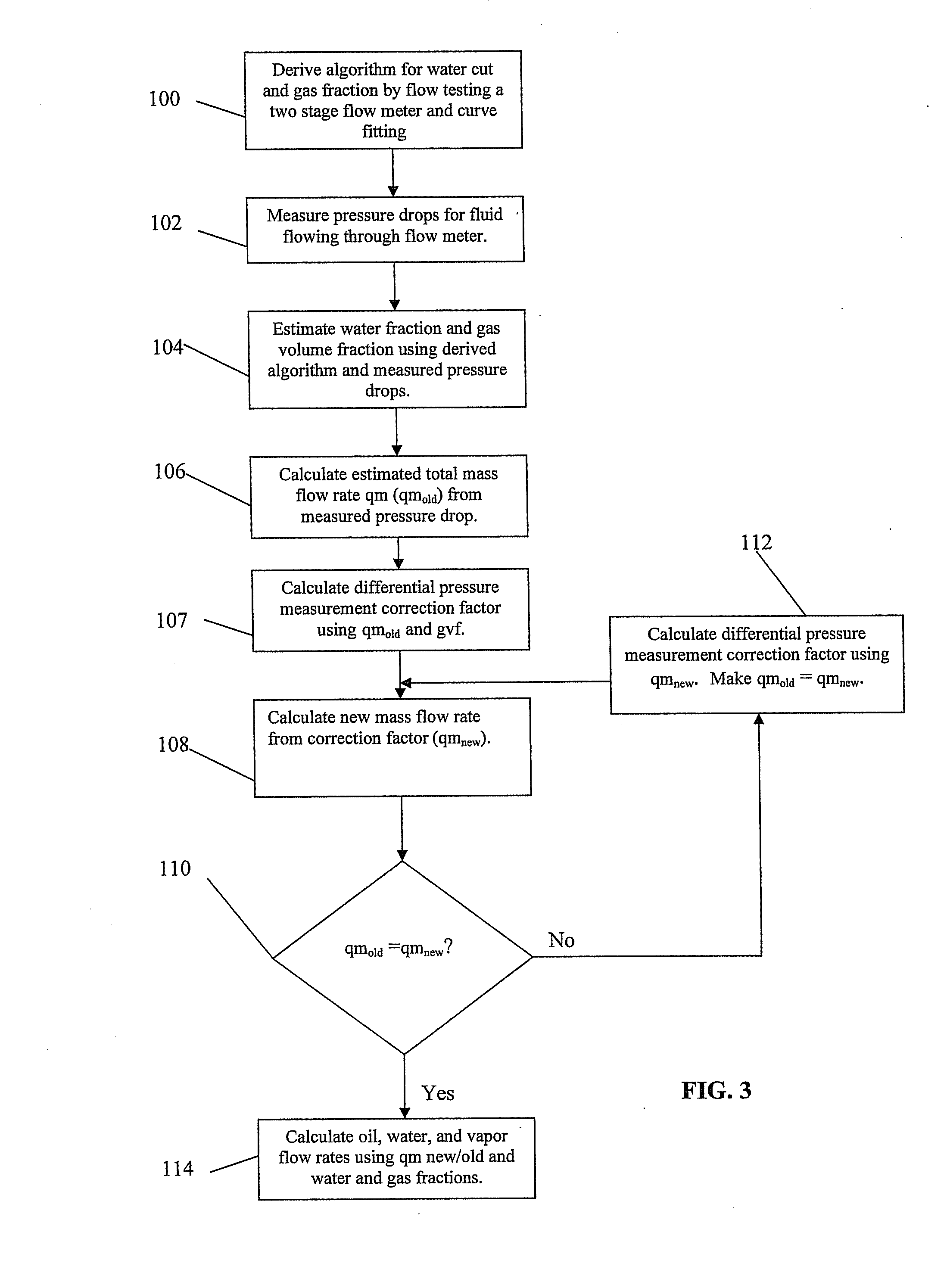

Method of measuring multiphase flow

Multi-phase flow is estimated in a flow meter having a first and a second stage by empirically deriving an algorithm for the water and gas fractions, measuring pressures within the flow meter, and estimating a total mass flow rate based on the measured pressures. A corrected total mass flow rate is calculated using a liquid / gas slip correction technique. The oil fraction can be determined from the corrected total mass flow rate and gas and water fractions.

Owner:BAKER HUGHES INC

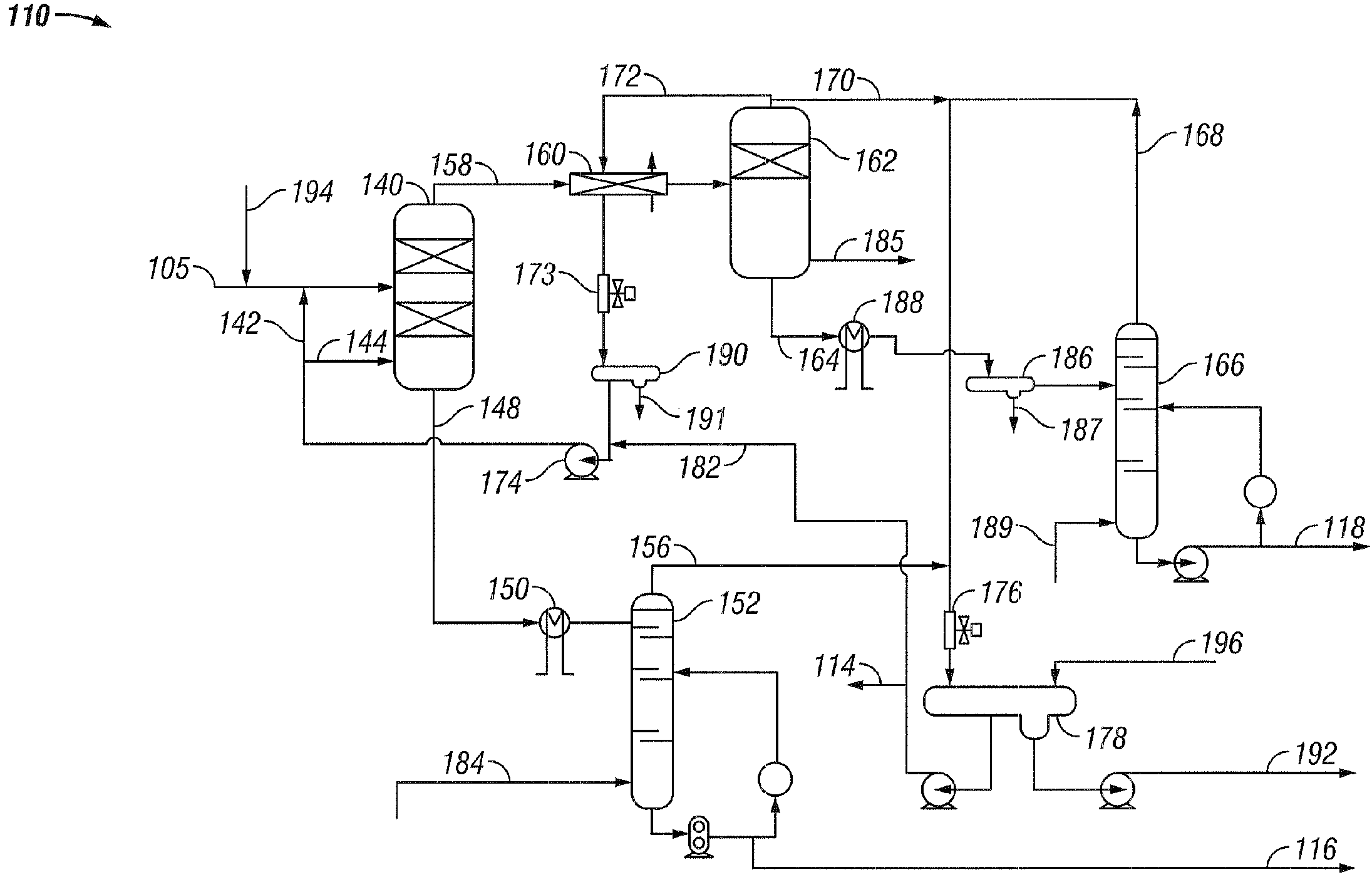

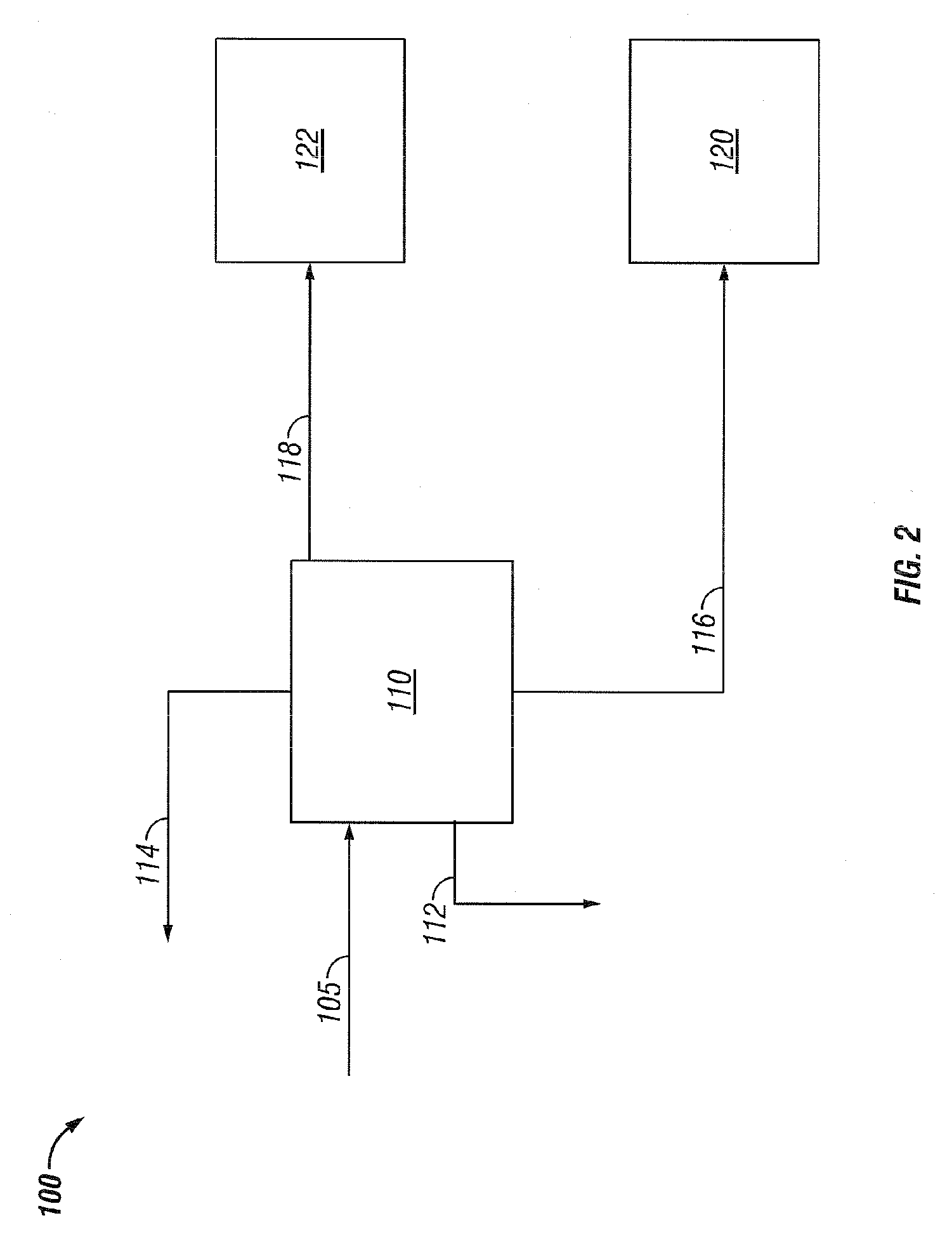

Bitumen production-upgrade with common or different solvents

ActiveUS7749378B2Reduce capital investmentReduce operating expensesWorking-up pitch/asphalt/bitumen by selective extractionRefining by water treatmentDiluentWater fraction

Disclosed is a process for the upgrading of heavy oils and bitumens, where the total feed to the process can include heavy oil or bitumen, water, and diluent. The process can include the steps of solvent deasphalting 110 the total feed 105 to recover an asphaltene fraction 116, a deasphalted oil fraction 118 essentially free of asphaltenes, a water fraction 112, and a solvent fraction 114. The process allows removal of salts from the heavy oils and bitumens either into the aqueous products or with the asphaltene product.

Owner:KELLOGG BROWN & ROOT LLC

Method of treatment of vegetable matter with ultrasonic energy

InactiveUS20060110503A1Producing viscosityIncrease contentMilk preservationDough treatmentVegetable matterCavitation

A method for modifying the viscosity of pureed vegetable matter, said method including the step of applying relatively low-frequency ultrasonic energy (having a frequency in the range from about 16 kHz to 100 kHz) to said puree via a sonotrode in a manner such that cavitation of a water fraction in said puree is induced, and the cellular structure and cell wall material of the vegetable matter are degraded, thereby to increase the viscosity of said puree.

Owner:MARS INC

Bitumen Production-Upgrade with Common or Different Solvents

ActiveUS20060283776A1Reduce operating expensesOperational reliability is increasedWorking-up pitch/asphalt/bitumen by selective extractionRefining by water treatmentDiluentFuel oil

Disclosed is a process for the upgrading of heavy oils and bitumens, where the total feed to the process can include heavy oil or bitumen, water, and diluent. The process can include the steps of solvent deasphalting 110 the total feed 105 to recover an asphaltene fraction 116, a deasphalted oil fraction 118 essentially free of asphaltenes, a water fraction 112, and a solvent fraction 114. The process allows removal of salts from the heavy oils and bitumens either into the aqueous products or with the asphaltene product.

Owner:KELLOGG BROWN & ROOT LLC

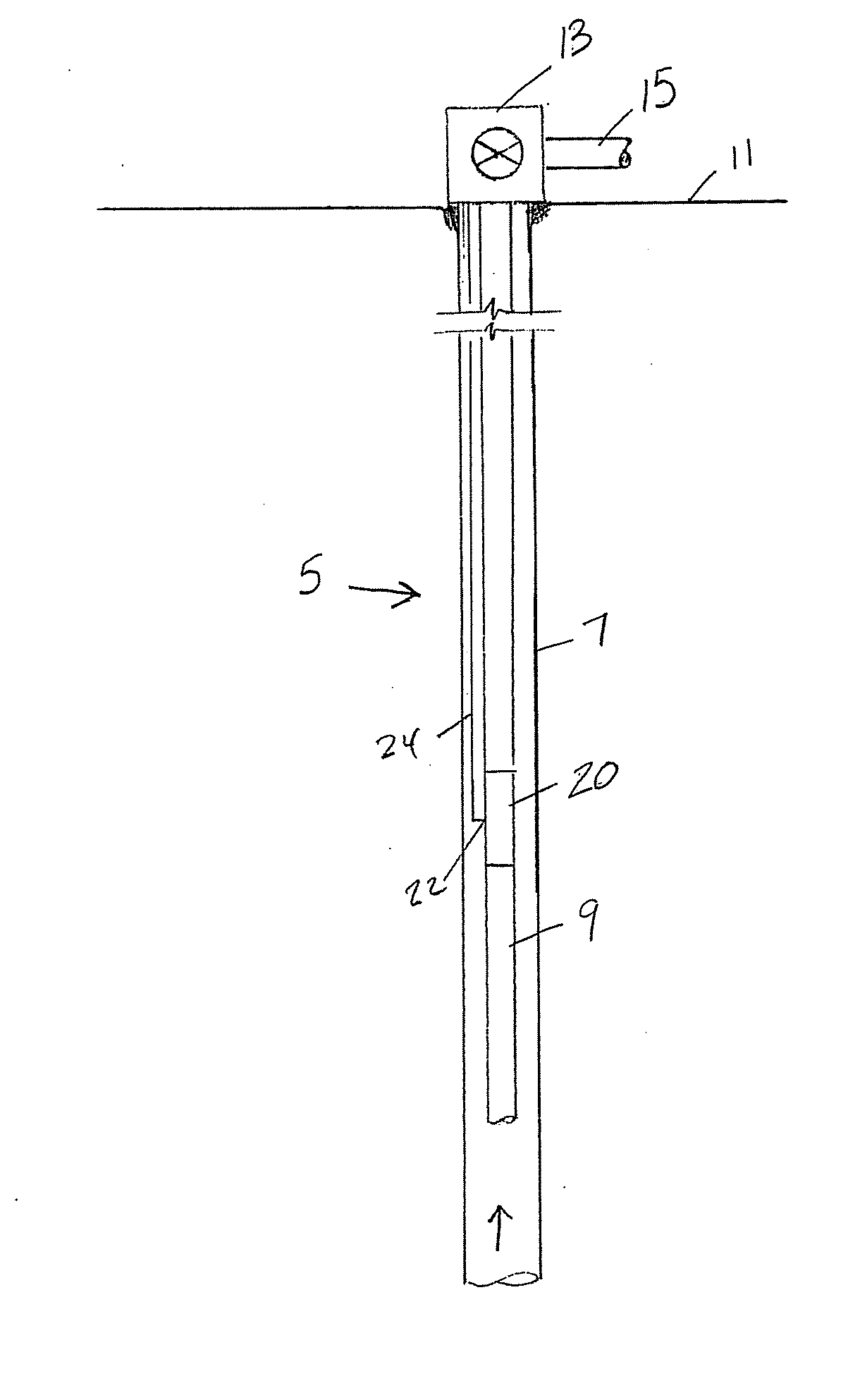

Method of measuring multiphase flow using a multi-stage flow meter

ActiveUS7707897B2Volume flow measuring devicesVolume/mass flow by differential pressureWater fractionCorrection technique

Multi-phase flow is estimated in a flow meter having a first and a second stage by empirically deriving an algorithm for the water and gas fractions, measuring pressures within the flow meter, and estimating a total mass flow rate based on the measured pressures. A corrected total mass flow rate is calculated using a liquid / gas slip correction technique. The oil fraction can be determined from the corrected total mass flow rate and gas and water fractions.

Owner:BAKER HUGHES INC

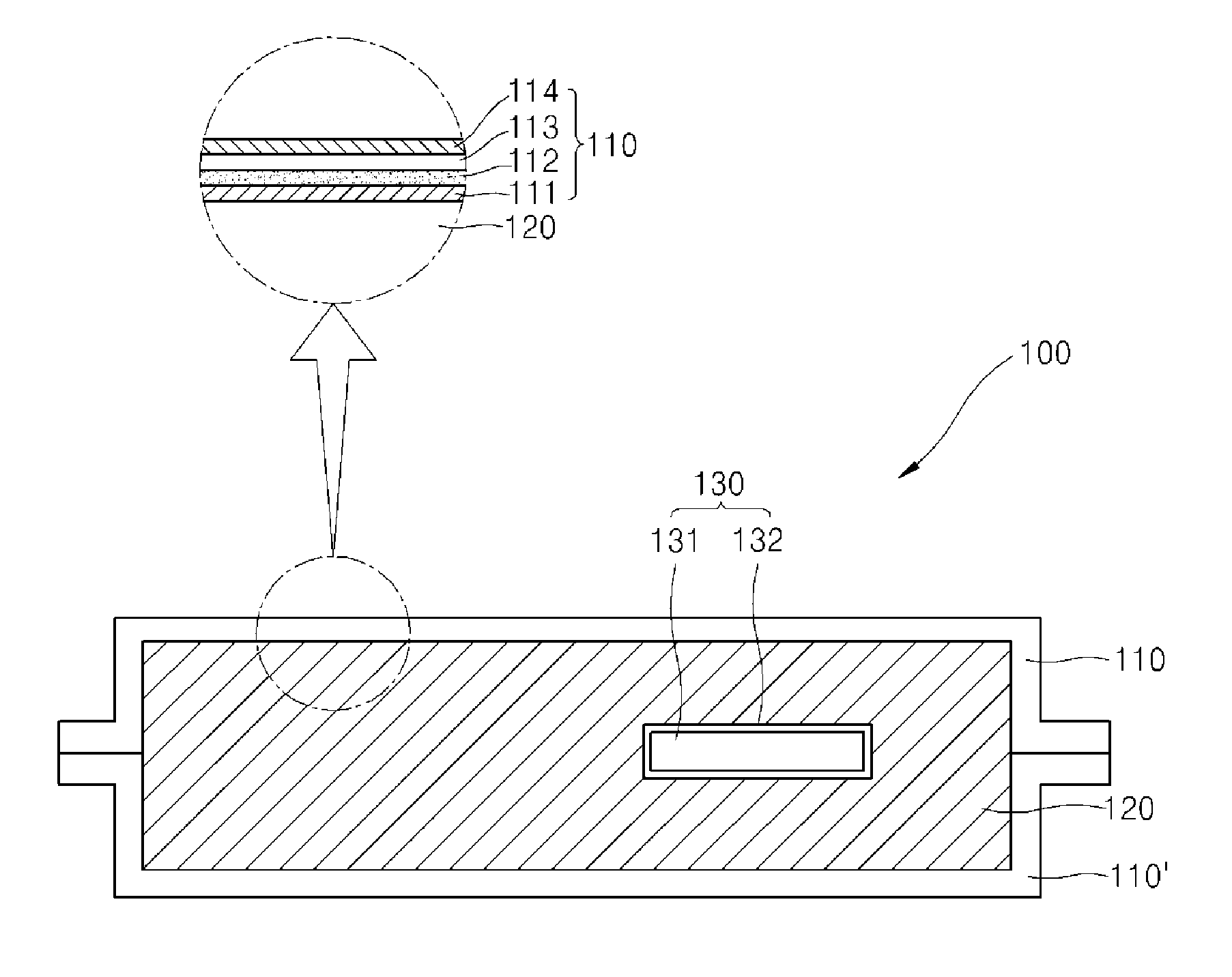

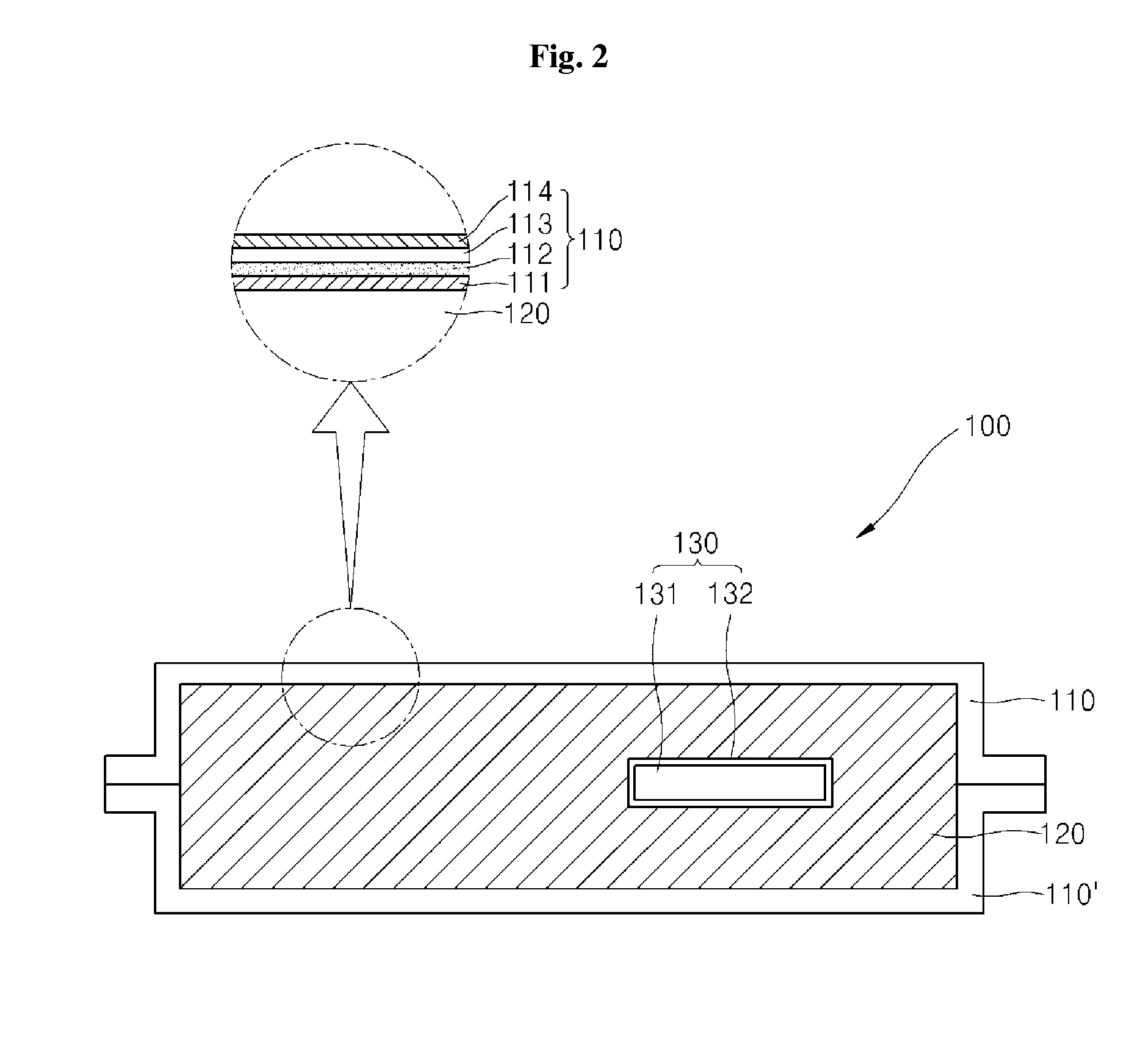

Vacuum thermal insulation material equipped with a getter material for water-fraction and gas adsorption, and production method therefor

ActiveUS20140178626A1Increased durabilityPromote absorptionLamination ancillary operationsThermal insulationThermal insulationNonwoven fabric

Owner:ES GLOBAL CO LTD

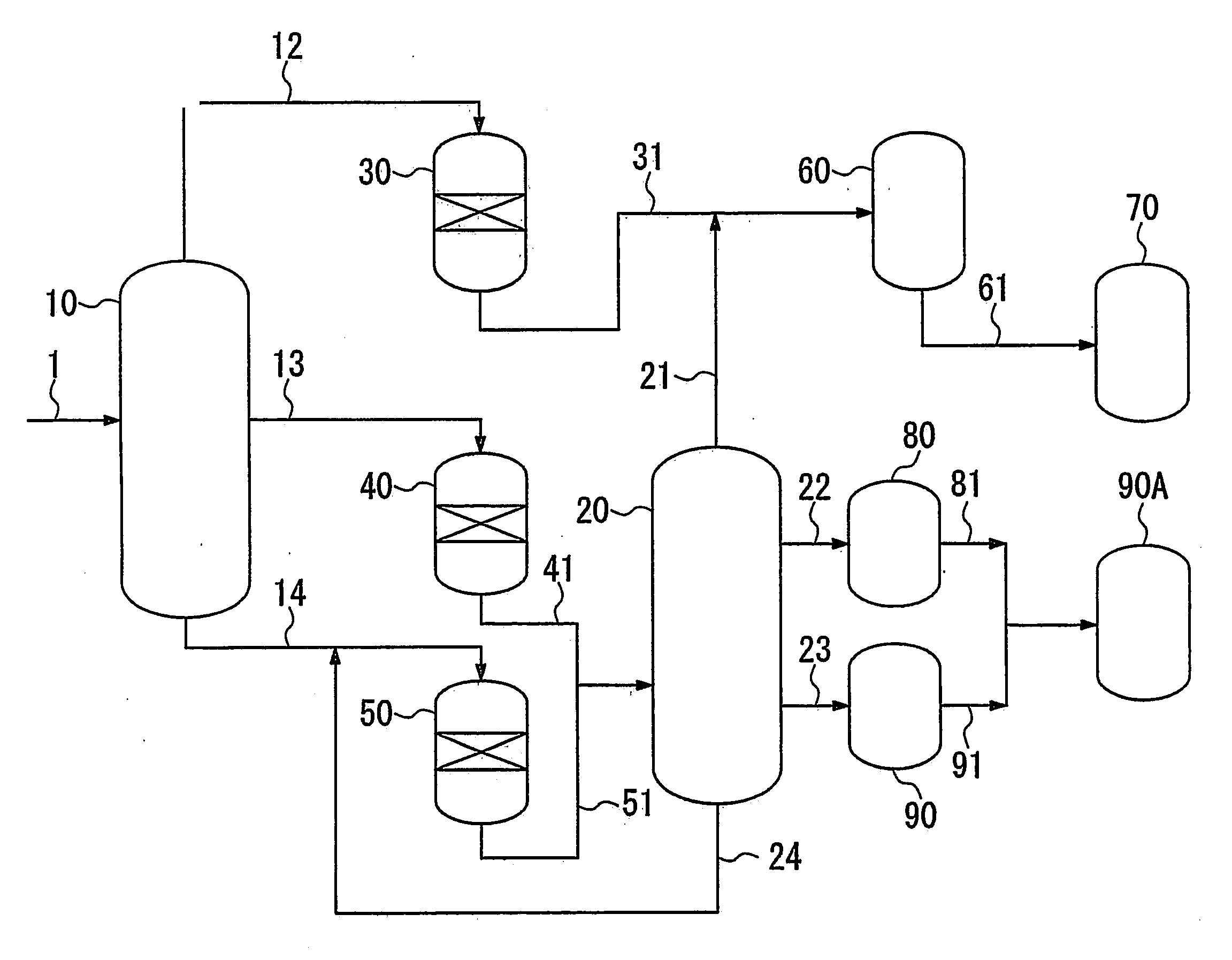

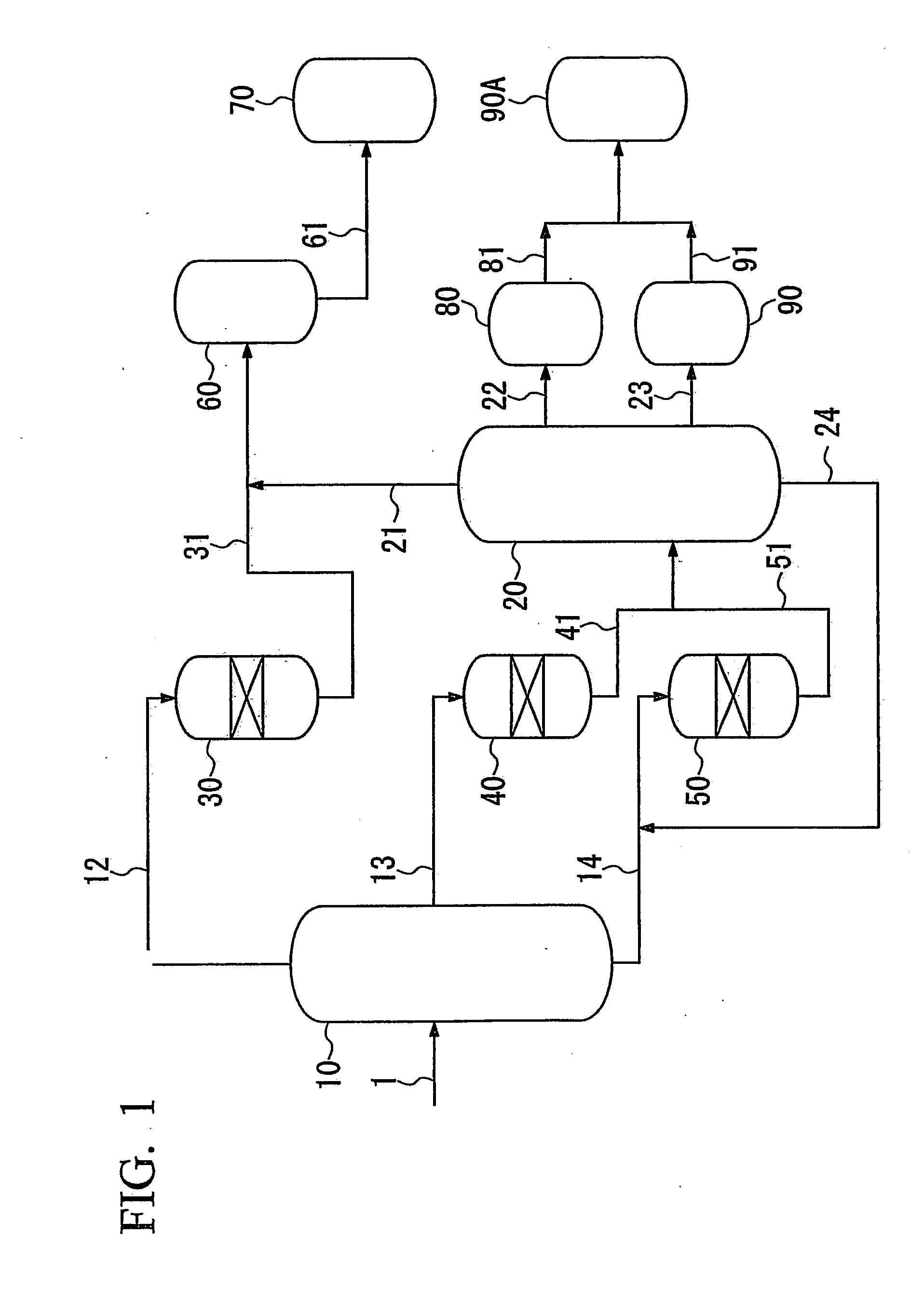

Method of manufacturing diesel fuel

InactiveUS20100300933A1Narrower boiling rangePrediction is simpleRefining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsWaxKerosene

Provided is A method of manufacturing diesel fuel, including: fractionating in a first fractionator a synthetic oil obtained by Fisher-Tropsch synthesis into at least two fractions of a middle fraction, and a wax fraction containing a wax component heavier than the middle fraction; hydroisomerizing the middle fraction by bringing the middle fraction into contact with a hydroisomerizing catalyst to produce a hydroisomerized middle fraction; hydrocracking the wax fraction by bringing the wax fraction into contact with a hydrocracking catalyst to produce a wax decomposition compound; fractionating in a second fractionator a mixture of the hydroisomerized middle fraction and the hydrocracked wax fraction into at least two fractions including a kerosene fraction and a gas oil fraction; and mixing the at least two fractions at a predetermined blend ratio to produce a diesel fuel having a kinematic viscosity at 30° C. of 2.5 mm2 / s or more and a pour point of −7.5° C. or less.

Owner:JAPAN OIL GAS & METALS NAT CORP +5

Real-time on-line sensing and control of emulsions in formation fluids

ActiveUS20050018176A1Efficient demulsificationReduce presencePhase-affecting property measurementsScattering properties measurementsEmulsionEngineering

Real time determination of the presence of emulsion in a formation fluid is accomplished using an optical probe, preferably an attenuated total reflectance probe. The determination can then be used to appropriately increase, decrease or leave unchanged the use of demulsification additives or other means to control emulsion formation. The method is particularly useful for free water knock-out separations, where a plurality of probes can be used to distinguish the location and / or volume of emulsion, or “rag”, layer and thereby to facilitate decantation of relatively pure oil and water fractions. It can also be effectively used in pipelines, and can optionally determine the degree of emulsification and trends toward emulsification or demulsification.

Owner:BAKER HUGHES INC

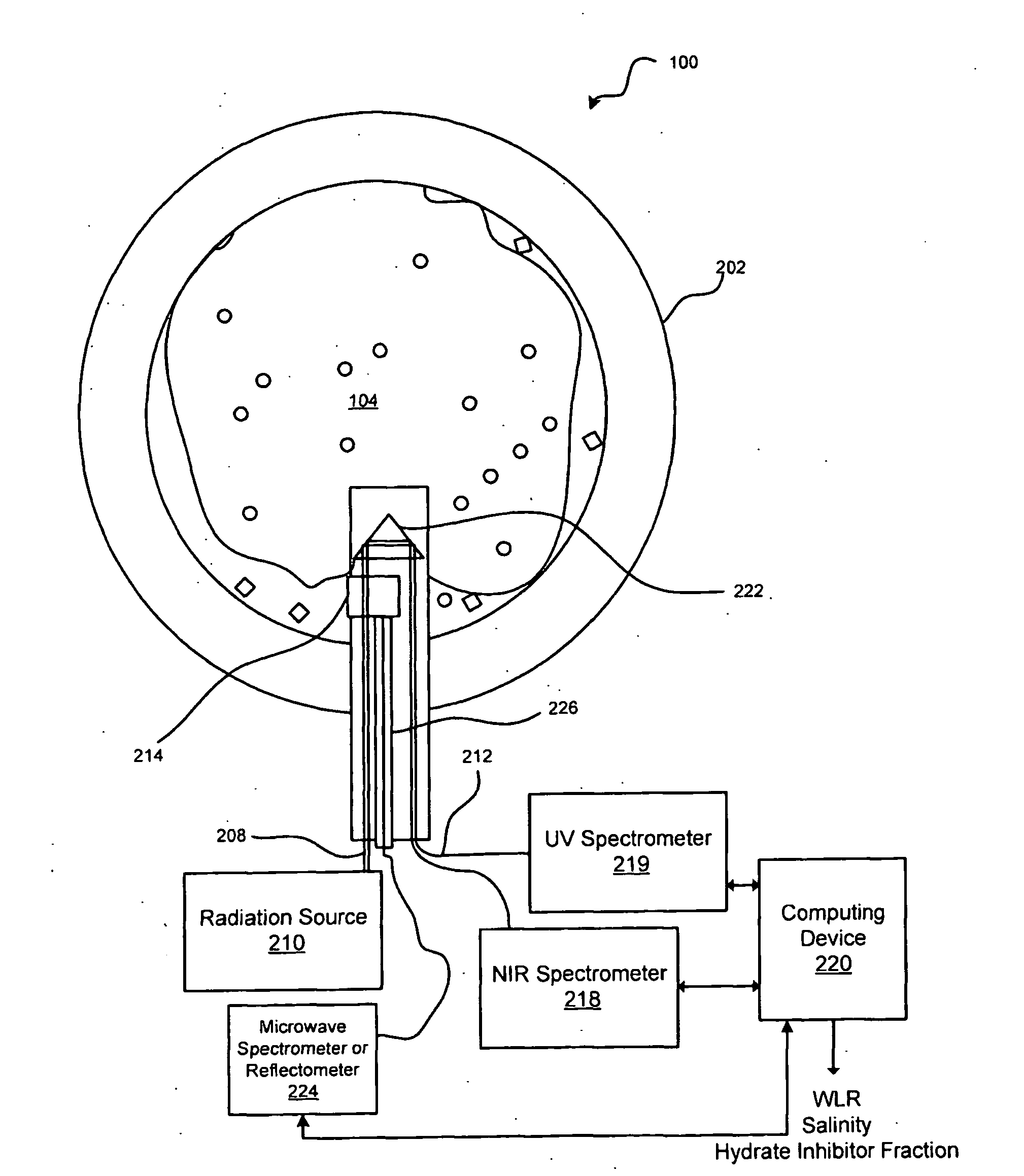

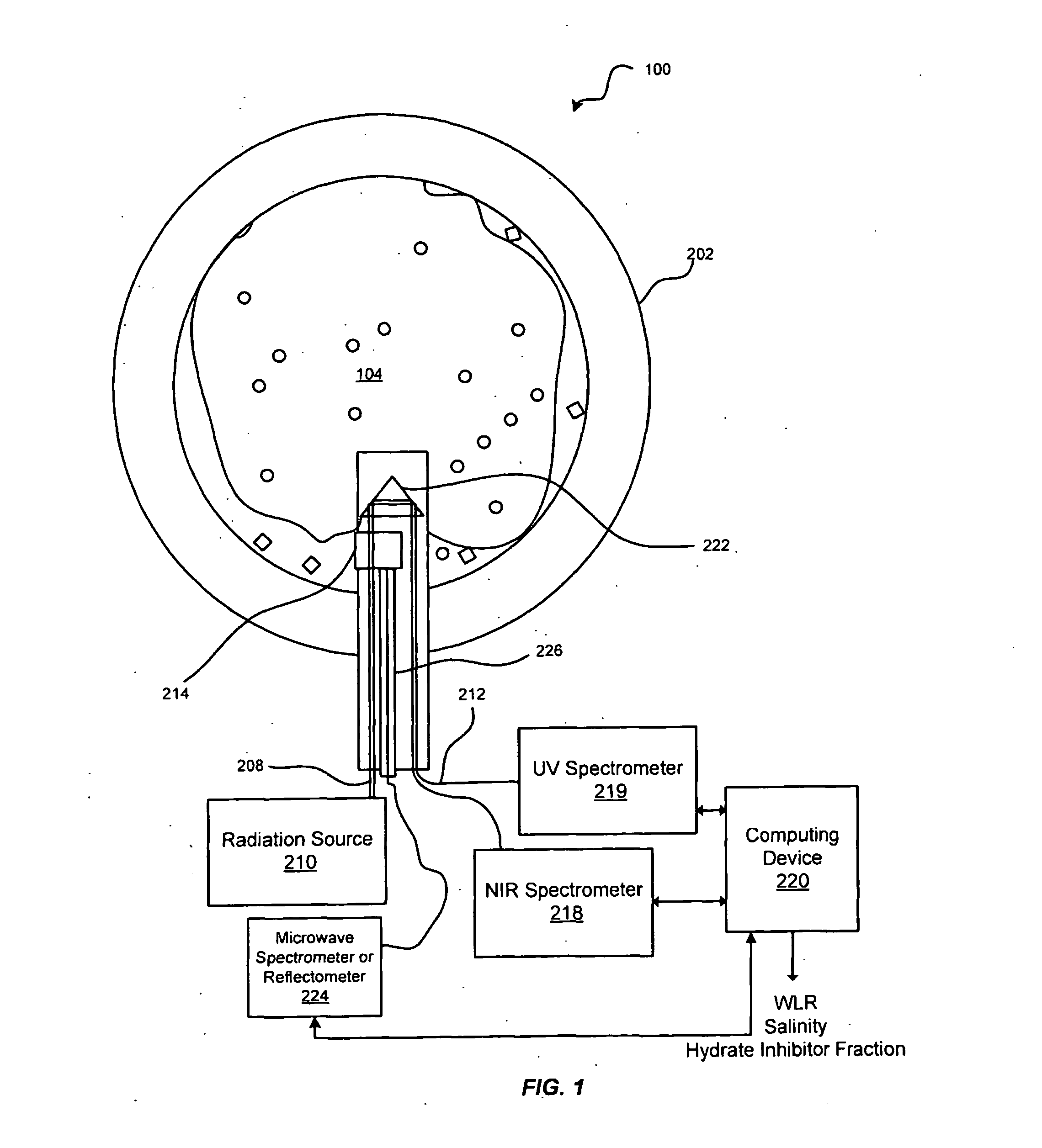

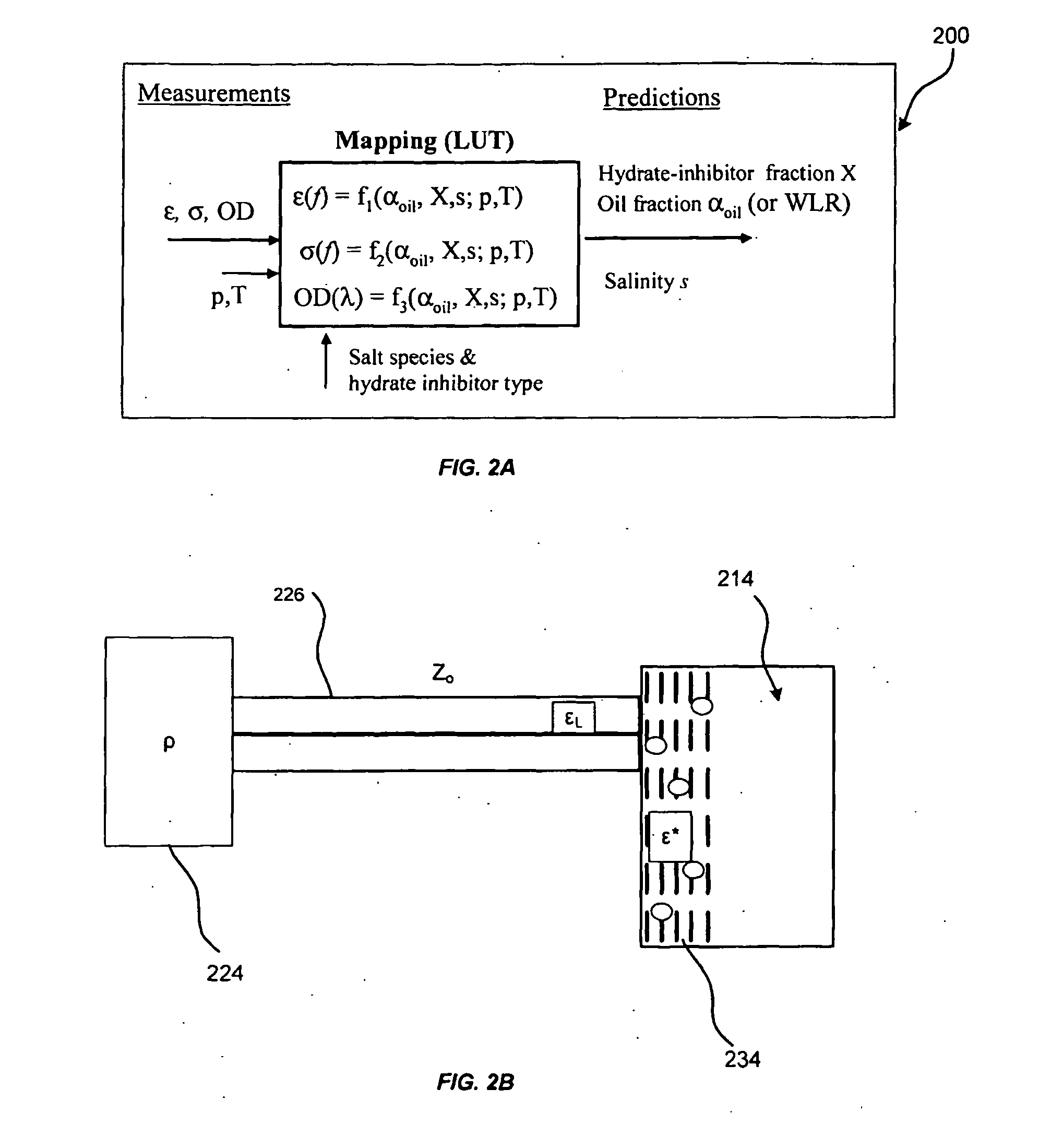

Immersion probe for multi-phase flow assurance

ActiveUS20130009048A1Preventing hydrate formationReduce excessElectric/magnetic detection for well-loggingRadiation pyrometryWater flowWater fraction

An immersion probe is described that includes sensing elements that allow for hydrate inhibitor dosage to be more efficiently provided into gas and / or oil wells. The immersion probe allows for detection of first appearance of water in a multiphase flow in a well, measuring the amount of inhibitor in water within the well, determining an accurate water-cut, and measuring other property such as water salinity. Accordingly, with the known water-cut, salinity and the water flow rate inferred from the inhibitor injection flow rate and inhibitor-in-water fraction, a correct dosage of the inhibitor can be injected to the well in order to prevent hydrate formation, while reducing overdosing. Water flow rate may also be inferred from an independently measured liquid flow rate and the immersion-probe measured water cut.

Owner:SCHLUMBERGER TECH CORP

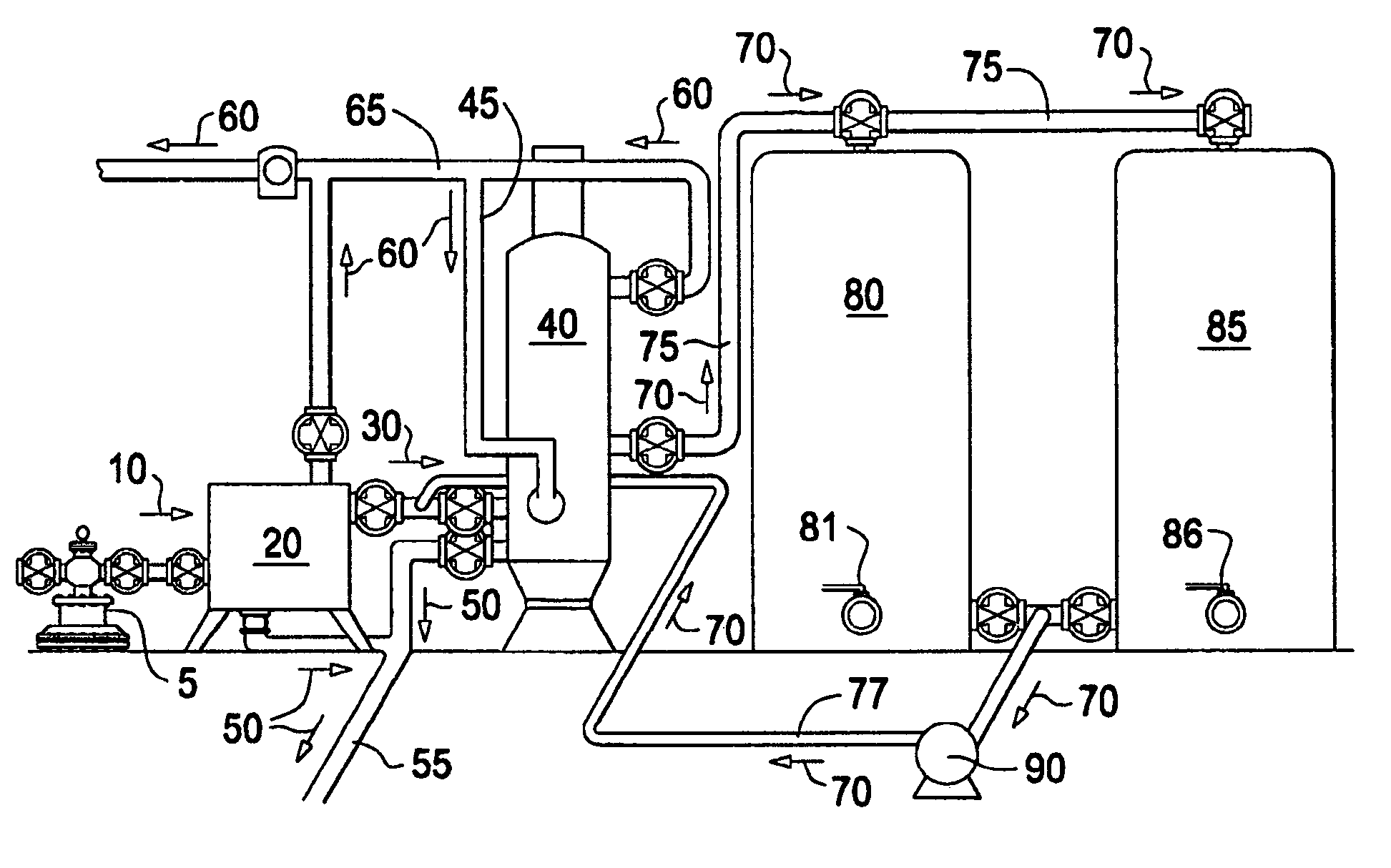

Method and apparatus to reduce a venting of raw natural gas emissions

InactiveUS7520743B1Facilitate phase separationEfficient separationFluid removalWater/sewage treatment by heatingCombustorExhaust fumes

With the disclosed device, some or all of the available oil tank vent gas in a production system can be utilized to augment the primary fuel gas needed by a heater treater unit to separate the gas, oil, and water fractions from raw natural gas extracted at the wellhead. Augmenting the primary fuel gas with vent gas reduces the demand for primary fuel gas, which thereby increases the amount of gas traversing a meter. The disclosed device also provides for an auxiliary burner unit that can directly address any available oil tank vent gas that is not utilized to augment fuel gas as waste gas. A method and apparatus for reducing the venting of raw natural gas emissions from an oil storage tank is described.

Owner:CHEM APPL & ENG

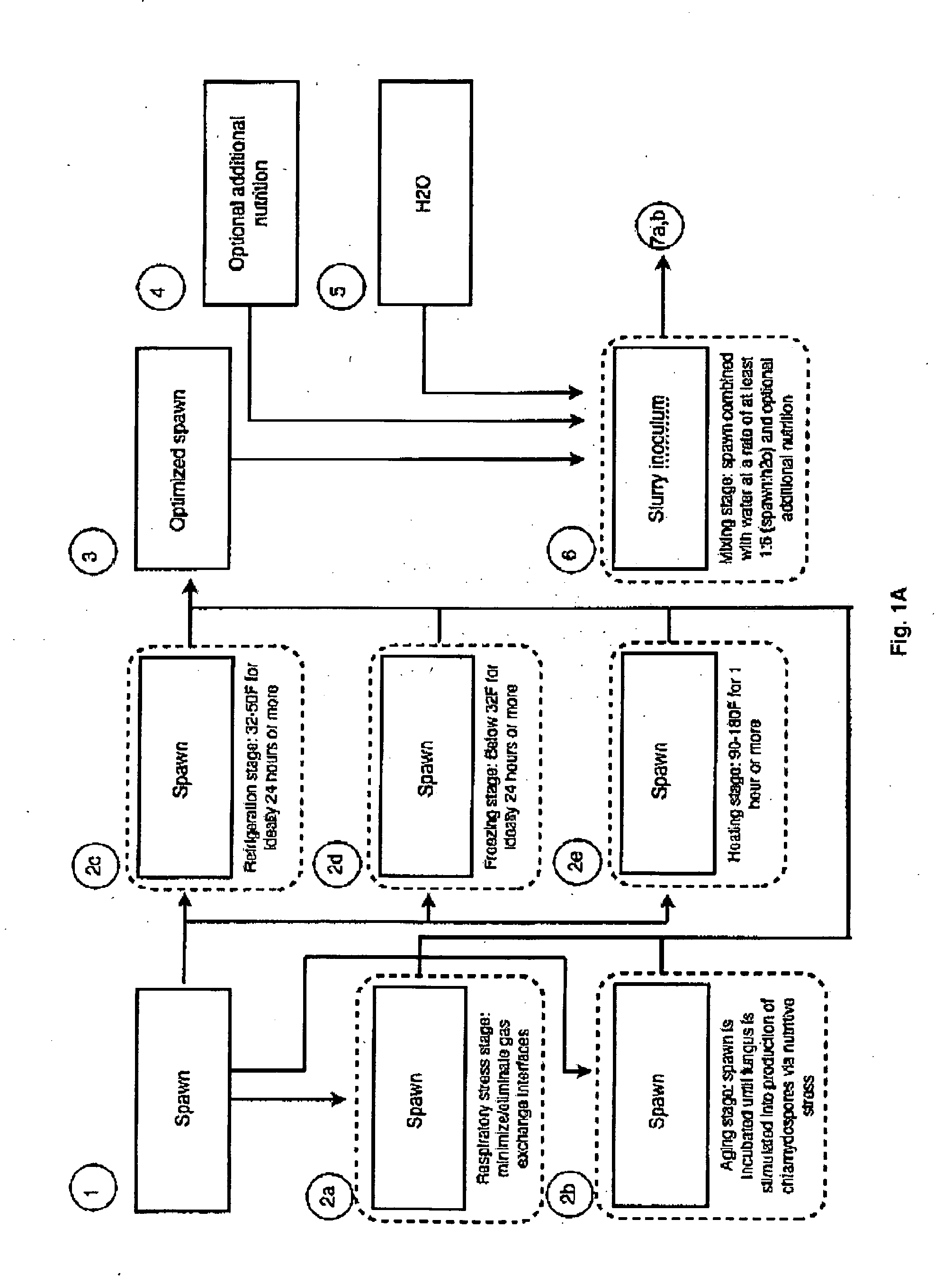

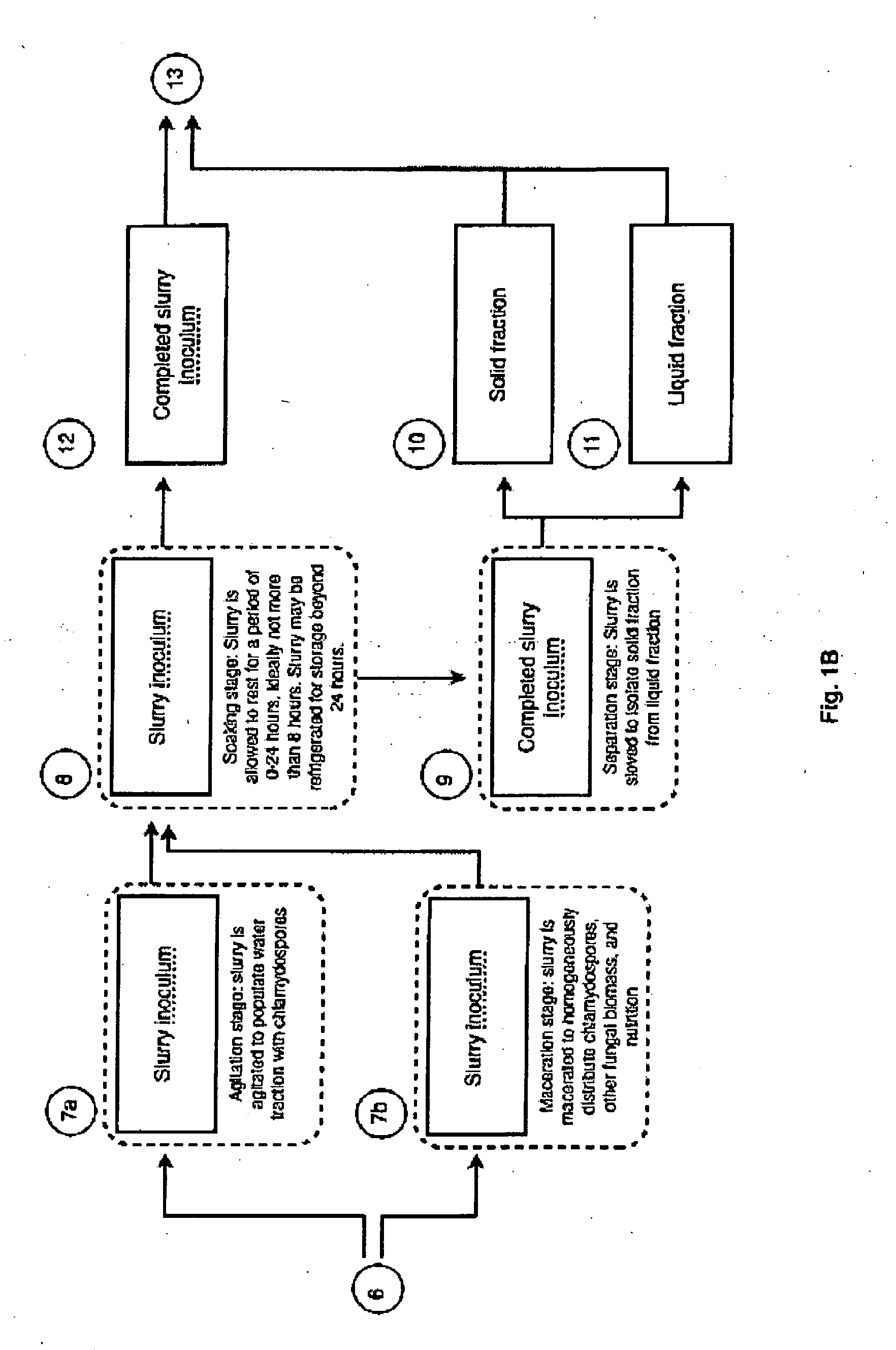

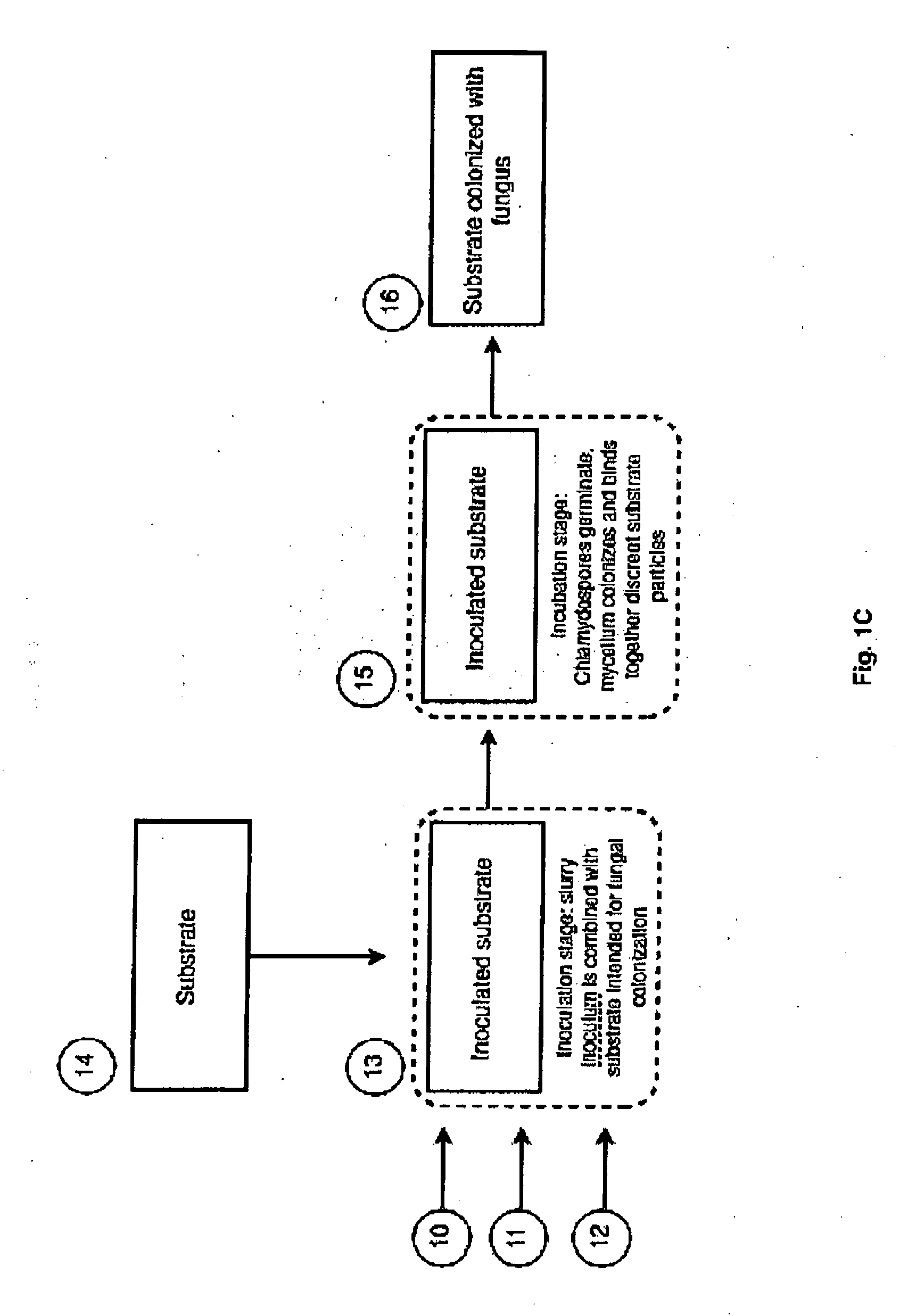

Process for the Production and Utilization of Chlamydospore Rich Slurry Inoculum

The process for the production of a chlamydospore rich slurry inoculum begins with a substrate colonized with a desired Basidiomycete fungus capable of producing chlamydospores during vegetative growth. The colonized substrate is treated to increase the chlamydospore production and content in said spawn and thereafter combined with water at rate of at least 1:6 spawn:water to obtain a slurry inoculum. The inoculum may then be agitated to populate a water fraction with chlamydospores or macerated to homogenously distribute the chlamydospores. Soaking of the agitated / macerated inoculum for a time sufficient to further stimulate production of chlamydospores via water shock and obtain a chlamydospore rich slurry

Owner:ECOVATIVE DESIGN LLC

Ultrasound multiphase fraction meter and method for determining phase fractions in a multiphase fluid

InactiveUS20090025460A1Analysing fluids using sonic/ultrasonic/infrasonic wavesVolume/mass flow measurementUltrasound attenuationWater fraction

Owner:SAUDI ARABIAN OIL CO +1

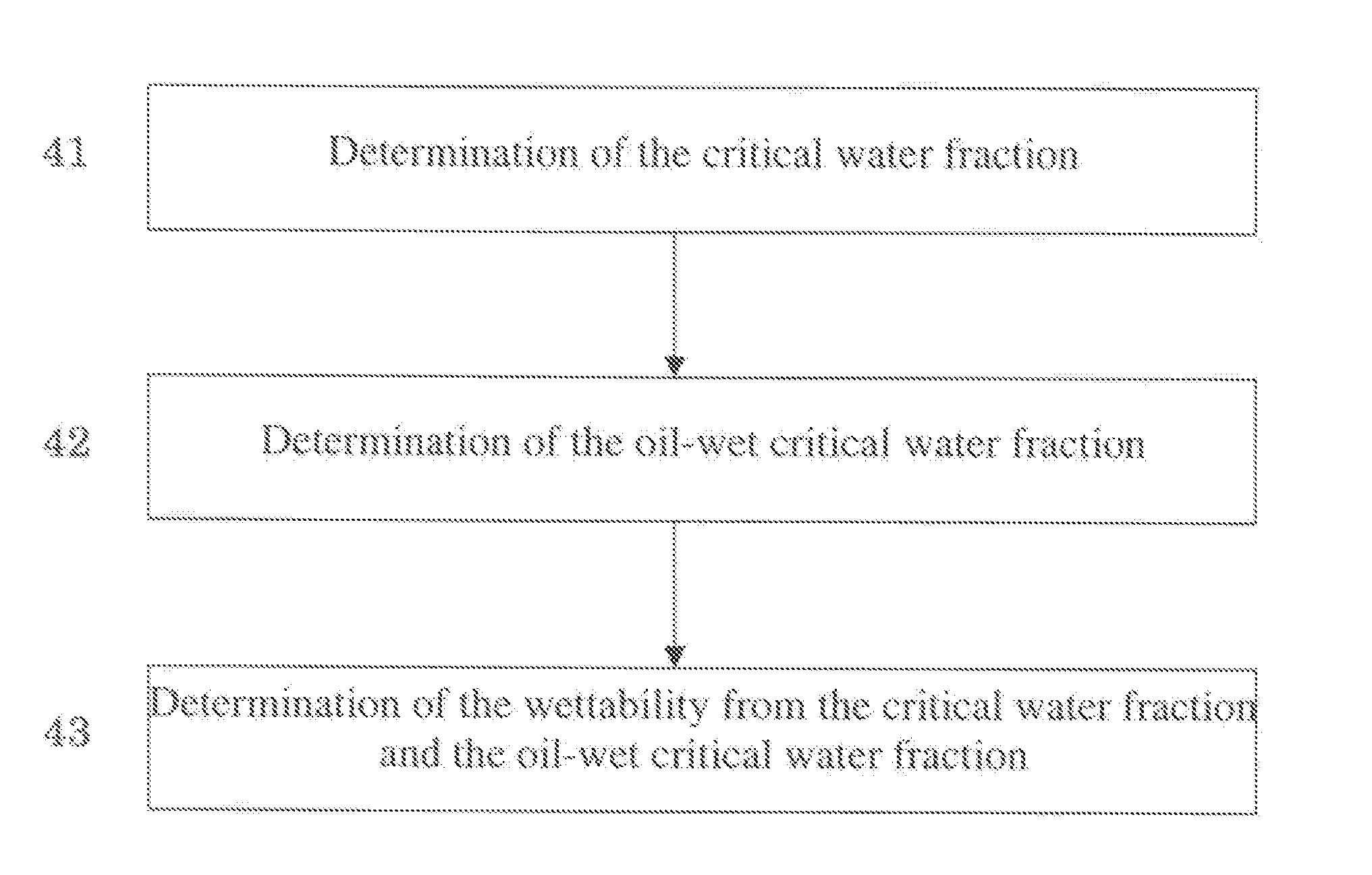

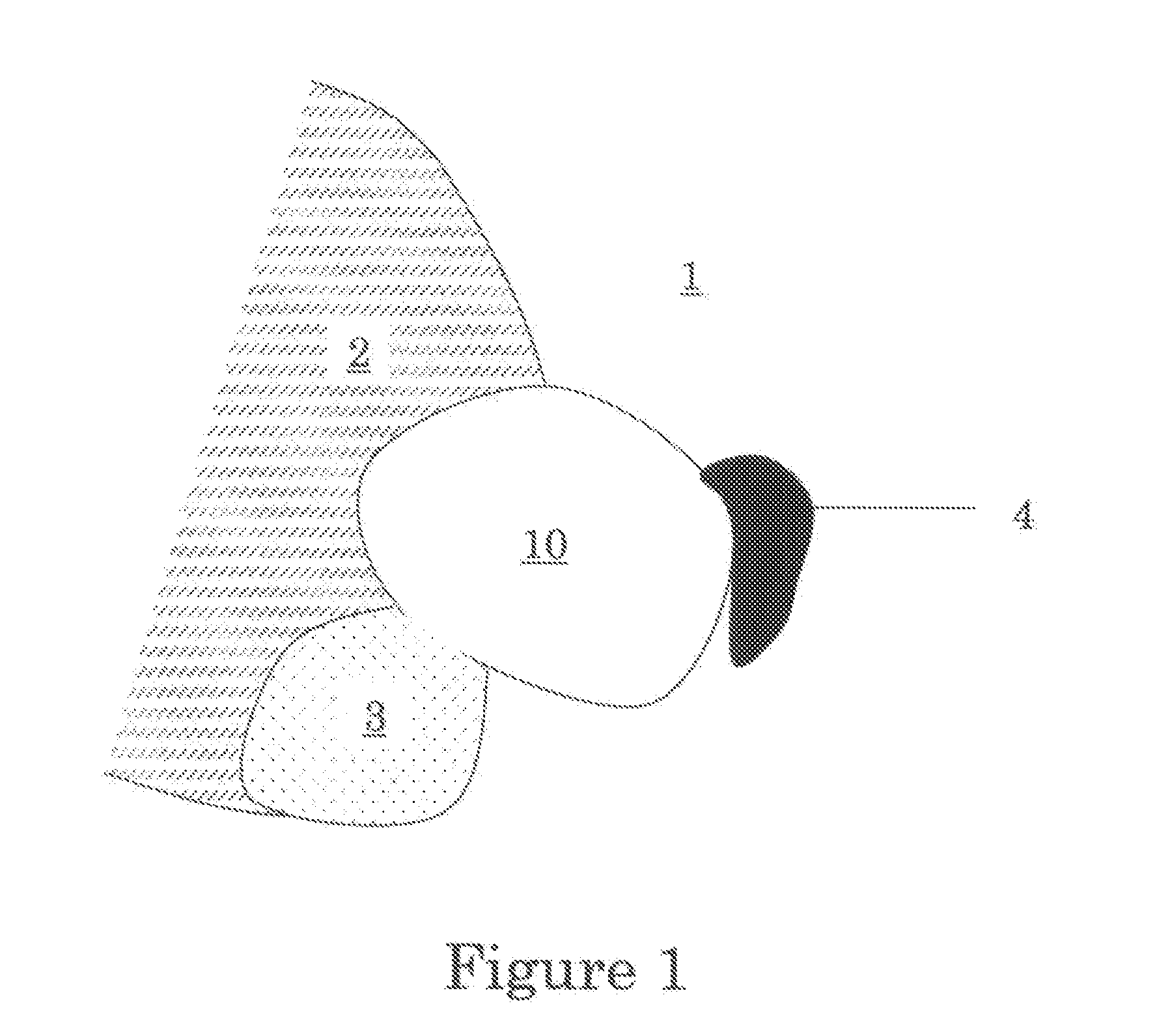

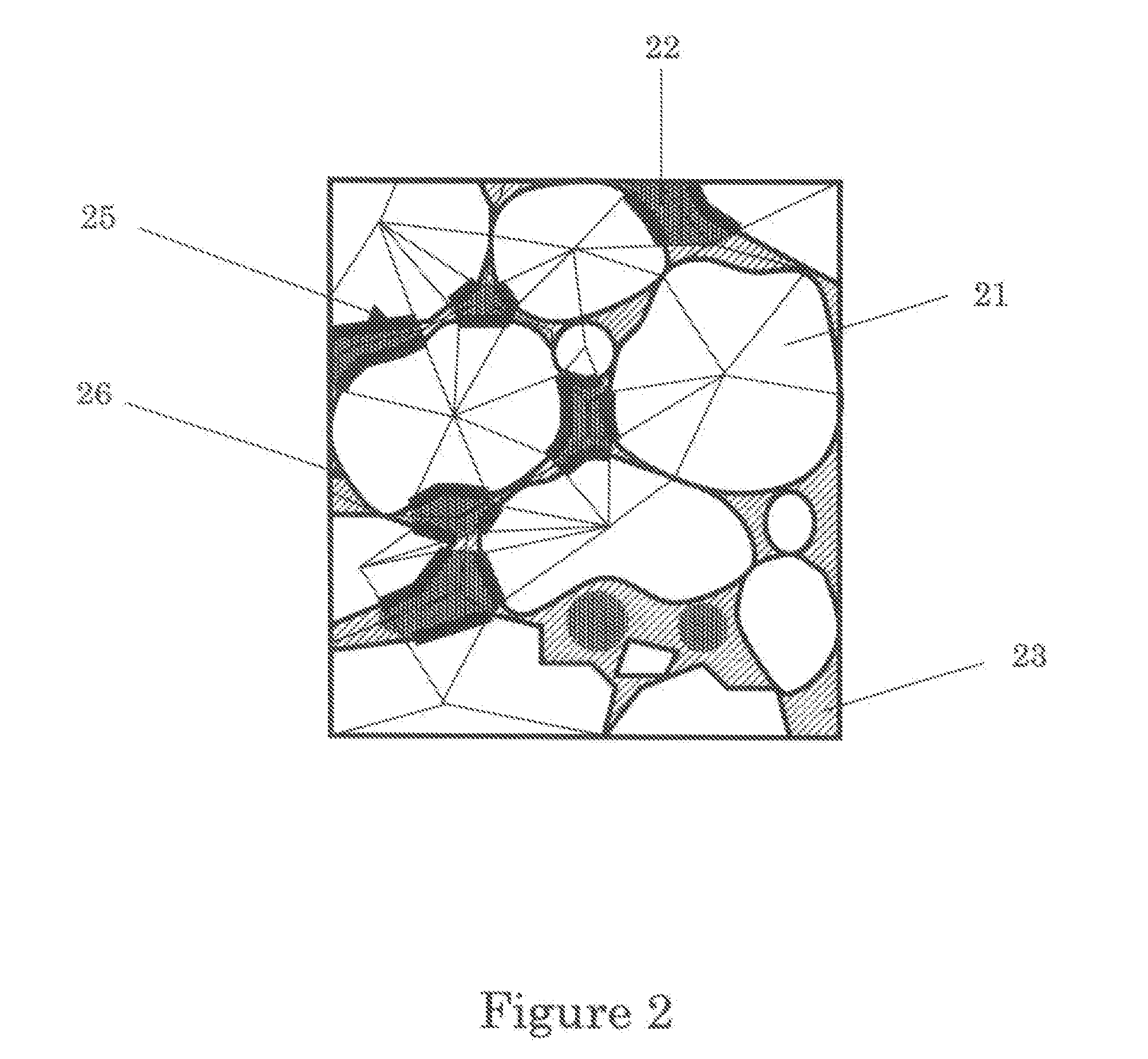

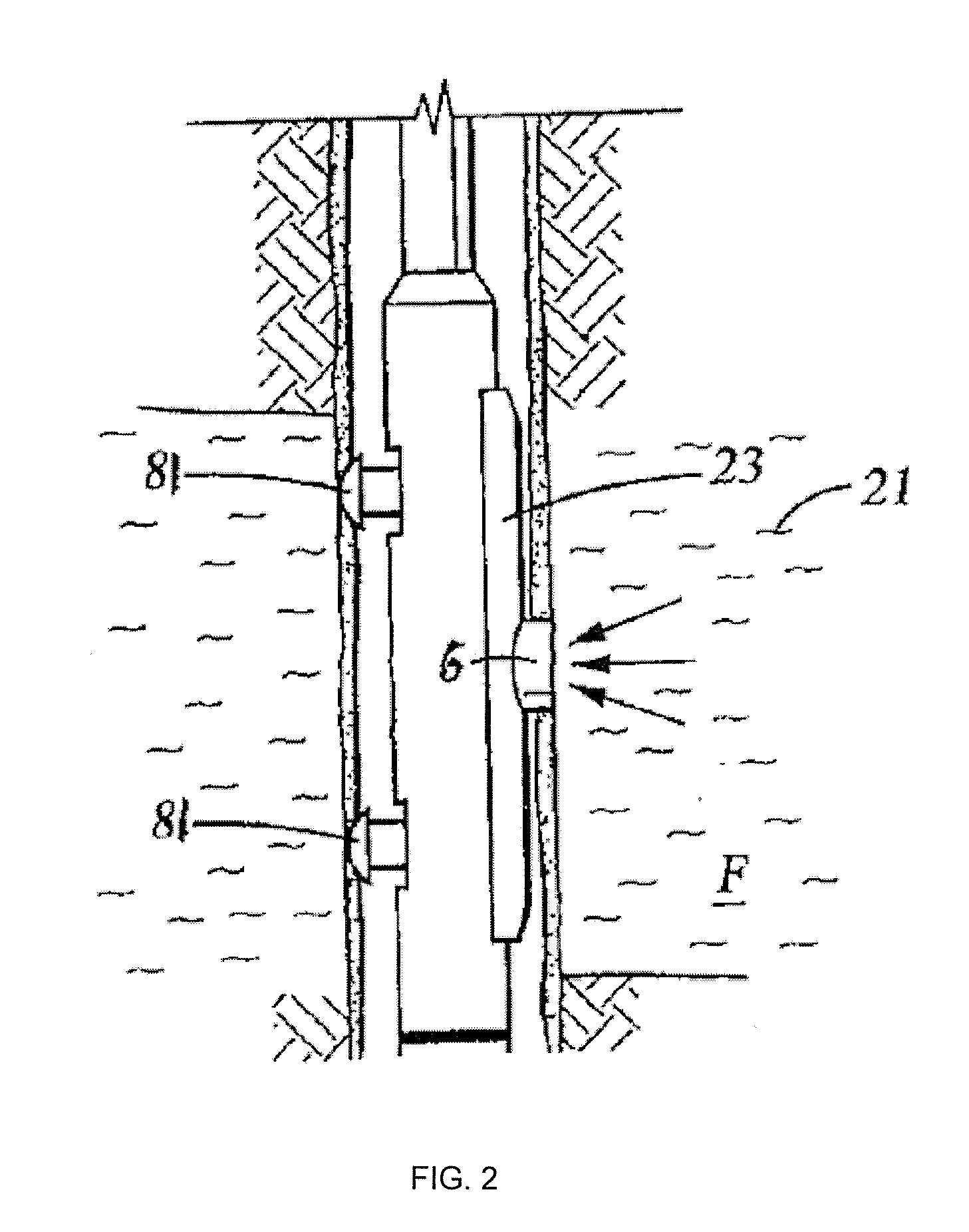

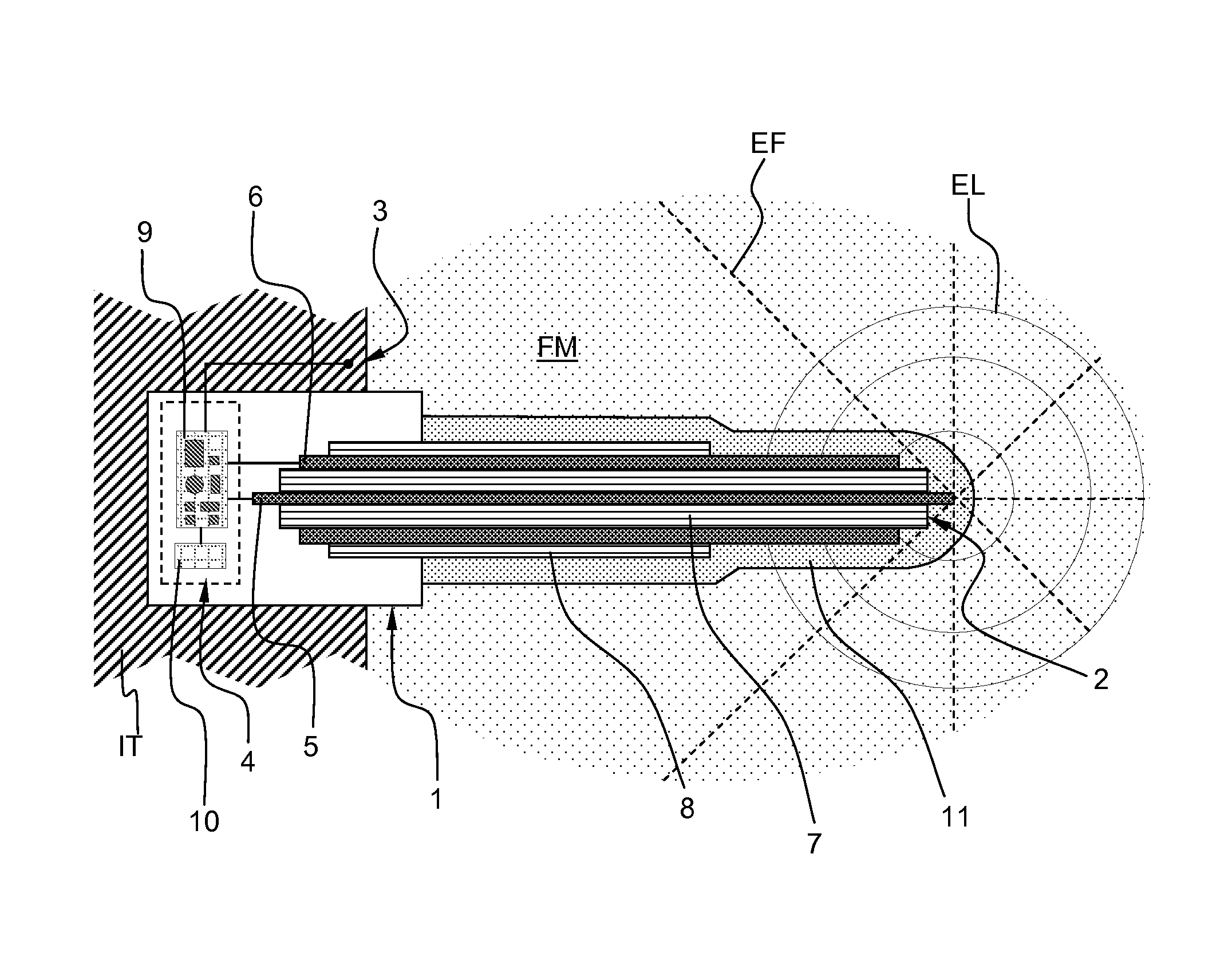

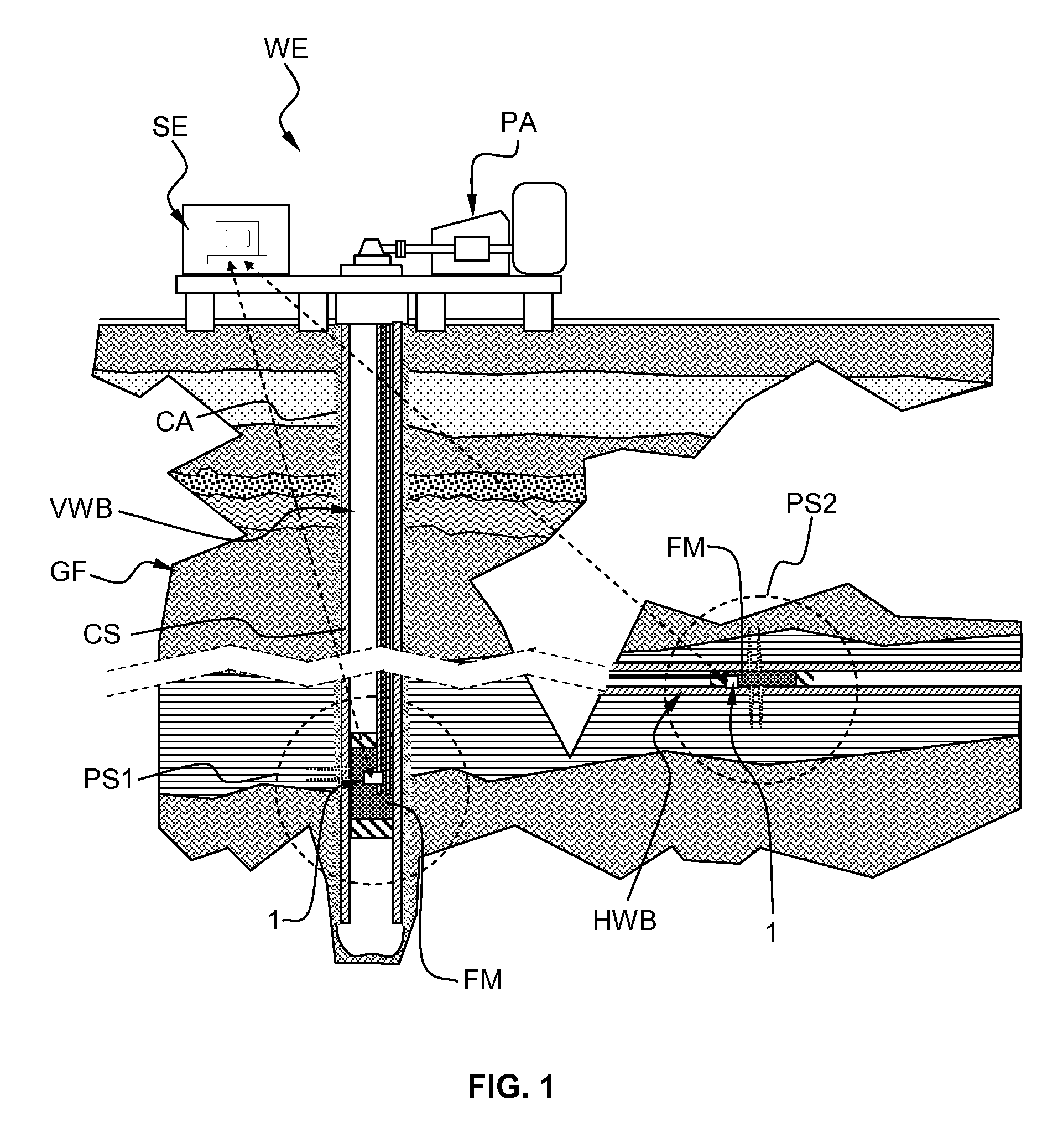

Method and Apparatus for Measuring the Wettability of Geological Formations

InactiveUS20070112518A1Electric/magnetic detection for well-loggingSeismology for water-loggingHydrologyWater fraction

The invention discloses a method for determining the wettability of an underground formation traversed by a borehole, the method comprising: determining the critical water fraction of the underground formation; determining the critical water fraction of the underground formation taken entirely oil-wet, which is called the oil-wet critical water fraction; and combining the critical water fraction and the oil-wet critical water fraction in order to determine the wettability of the underground formation. The invention also discloses the related apparatus for performing downhole measurement of the wettability of an underground formation traversed by a borehole, the apparatus having a longitudinal axis and being lowered in the borehole along the longitudinal axis, the apparatus comprising: a first sensor for measuring the water saturation of the underground formation; a second sensor for measuring the resistivity of the underground formation; and first and second sensors being located substantially at the same position along the longitudinal axis of the apparatus, and first and second sensors measuring a same location of the underground formation; and the apparatus; determines the critical water fraction of the underground formation from the water saturation and the resistivity; determines the oil-wet critical water fraction of the underground formation; and deduces the wettability of the underground formation from the critical water fraction and oil-wet critical water fraction.

Owner:SCHLUMBERGER TECH CORP

Real-time on-line sensing and control of emulsions in formation fluids

InactiveUS6927846B2Reduce presenceSmooth connectionPhase-affecting property measurementsScattering properties measurementsEmulsionWater fraction

Real time determination of the presence of emulsion in a formation fluid is accomplished using an optical probe, preferably an attenuated total reflectance probe. The determination can then be used to appropriately increase, decrease or leave unchanged the use of demulsification additives or other means to control emulsion formation. The method is particularly useful for free water knock-out separations, where a plurality of probes can be used to distinguish the location and / or volume of emulsion, or “rag”, layer and thereby to facilitate decantation of relatively pure oil and water fractions. It can also be effectively used in pipelines, and can optionally determine the degree of emulsification and trends toward emulsification or demulsification.

Owner:BAKER HUGHES HLDG LLC

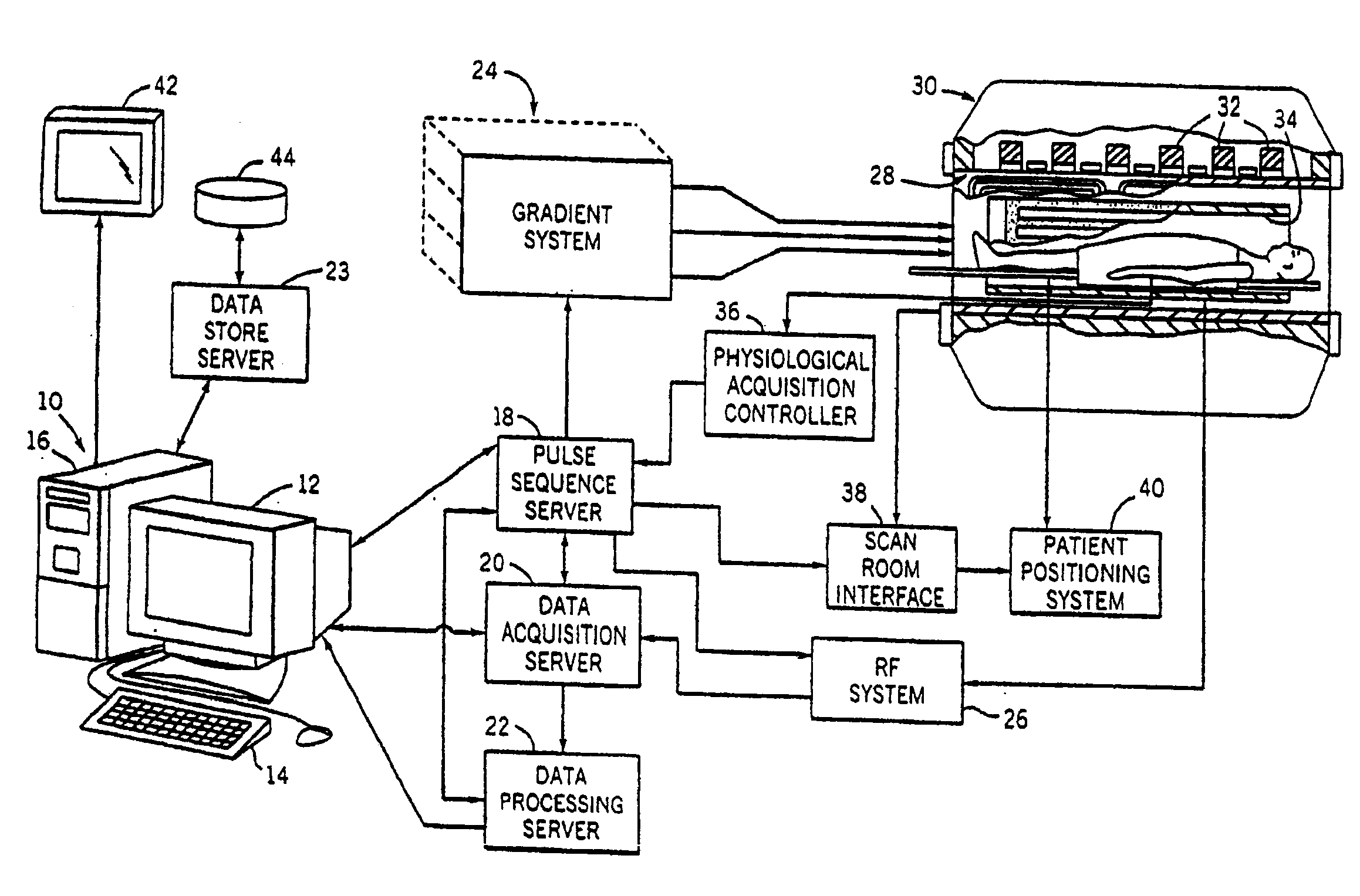

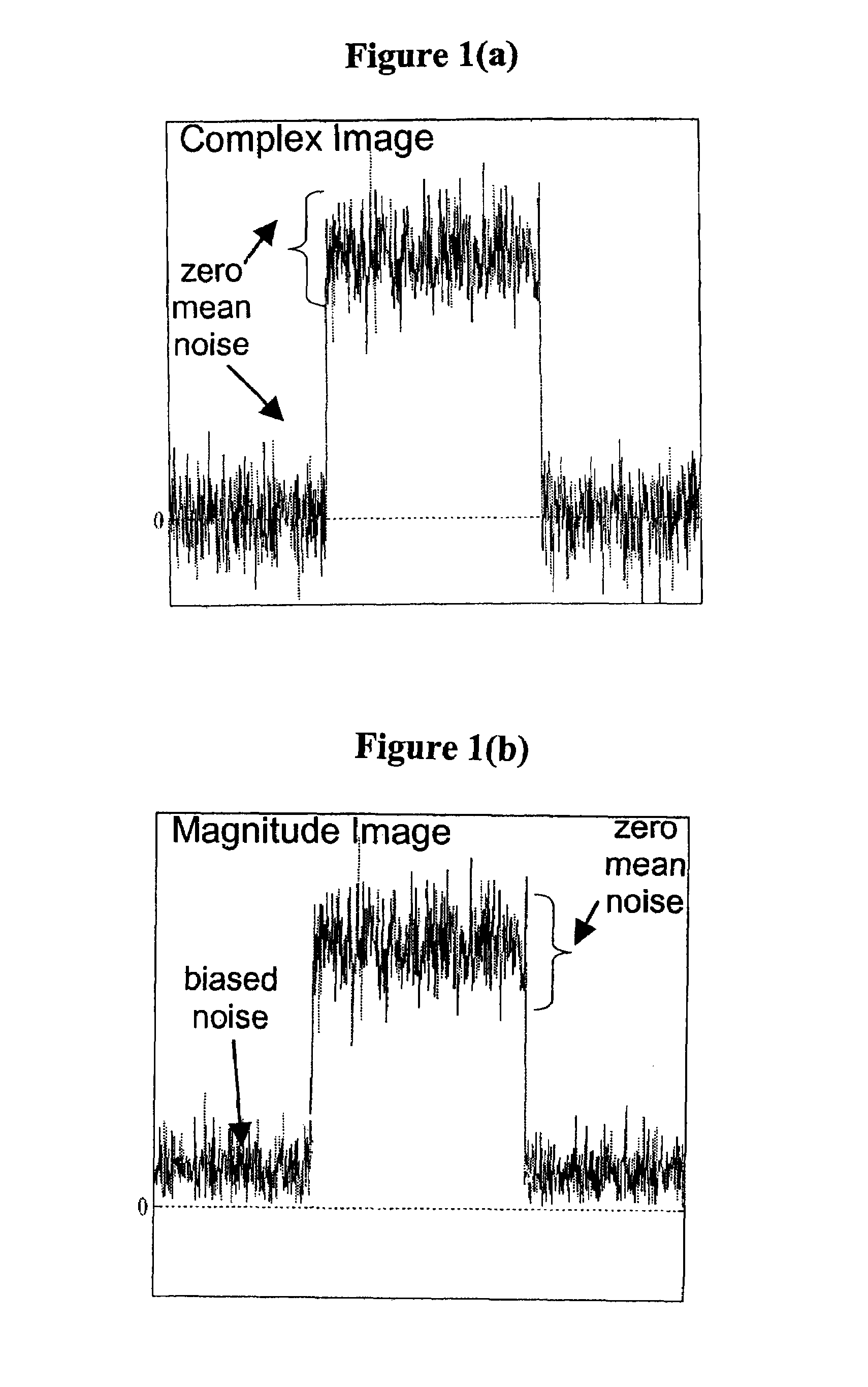

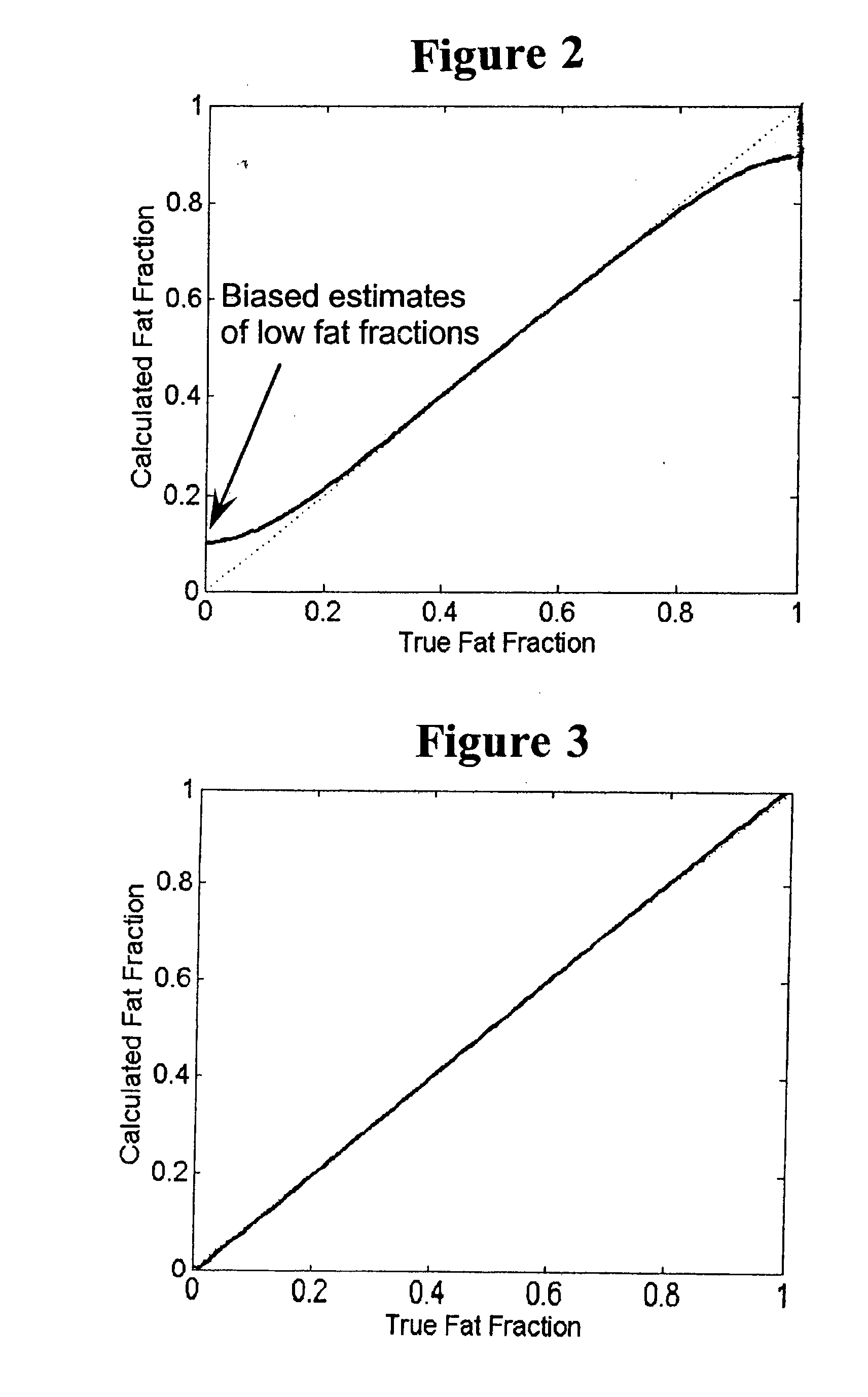

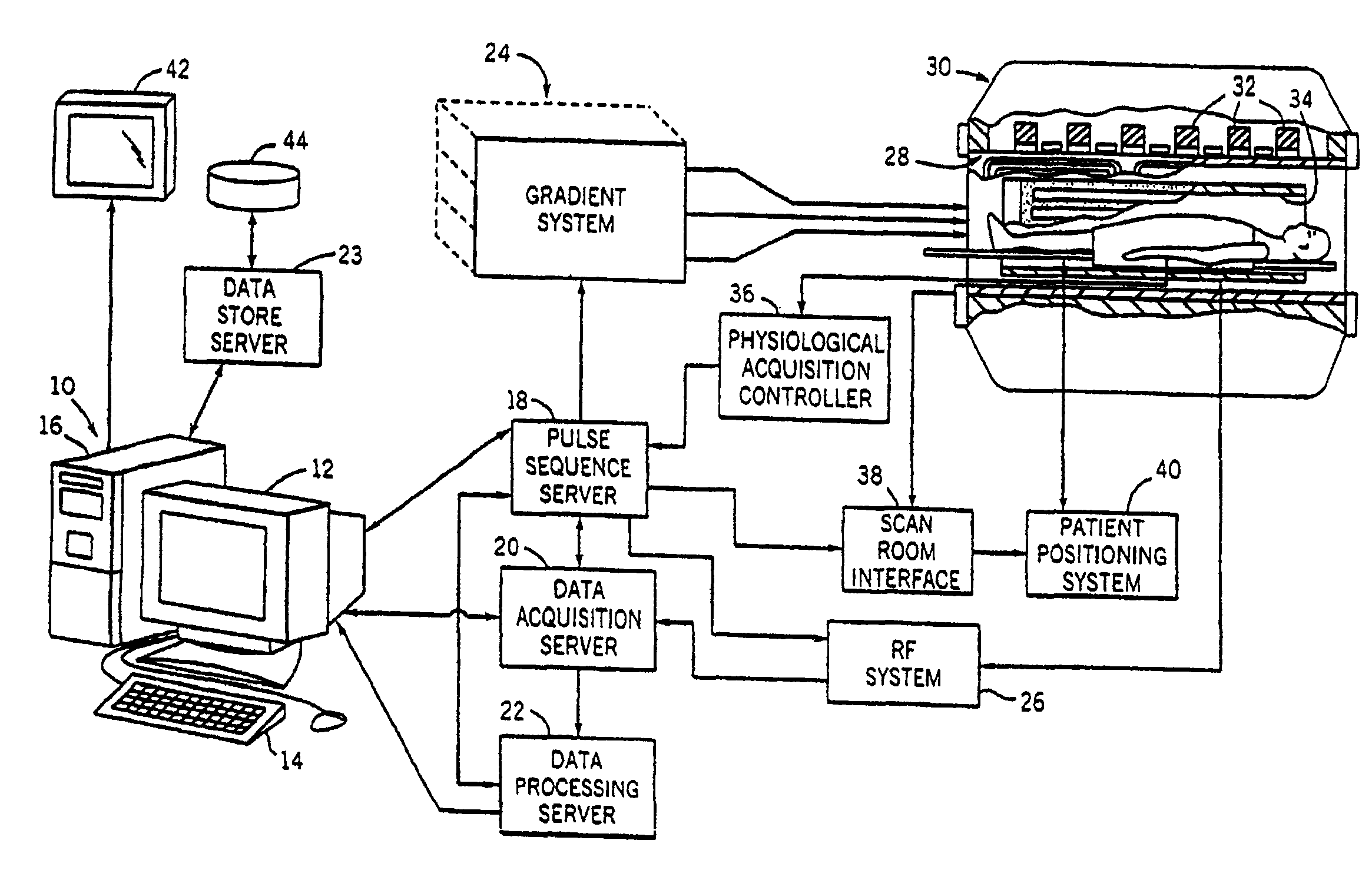

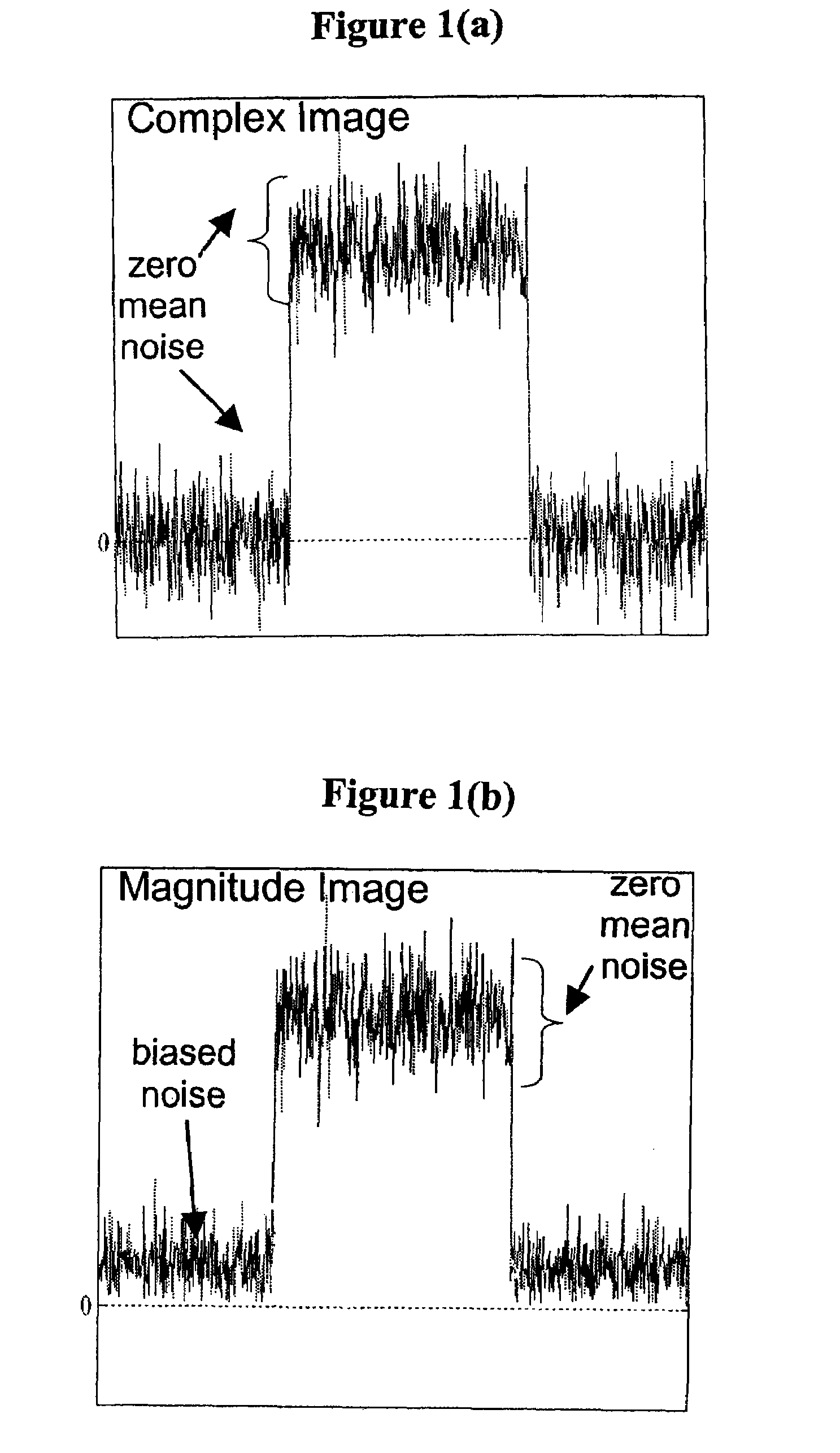

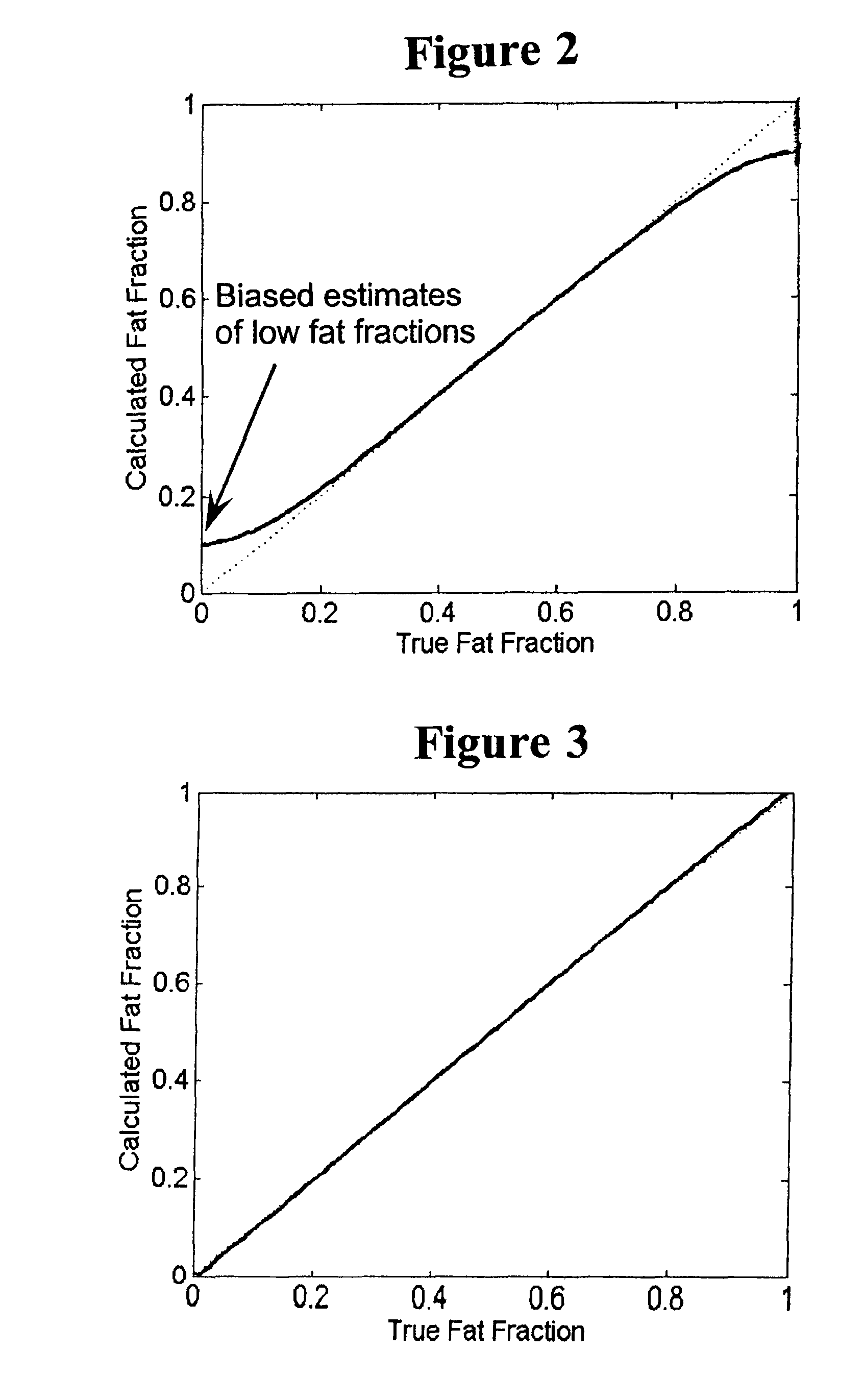

Methods for fat quantification with correction for noise bias

ActiveUS20090112081A1Accurate calculationImprove image signal-to-noise ratioMagnetic measurementsDiagnostic recording/measuringData setVoxel

Methods are disclosed for calculating a fat fraction corrected for noise bias of one or more voxels of interest using a magnetic resonance imaging (MRI) system. A plurality of image data sets are obtained each corresponding to NMR k-space data acquired using a pulse sequence with an individual associated echo time tn. A system of linear equations is formed relating image signal values to a desired decomposed calculated data vector having a component such as a water and fat combination having zero mean noise, or having a real fat component and a real water component. A fat fraction is calculated from at least one component of the decomposed calculated data vector. In another embodiment, the system of linear equations is normalized and can directly estimate a fat fraction or a water fraction having reduced noise bias.

Owner:GENERAL ELECTRIC CO +1

Ultrasound multiphase fraction meter and method for determining phase fractions in a multiphase fluid

ActiveUS20100274503A1Material analysis using sonic/ultrasonic/infrasonic wavesVolume meteringUltrasound attenuationWater fraction

An apparatus and method to determine fractions of various phases in a multiphase fluid. The apparatus includes main body including an interior configured receive a multiphase fluid and an exterior. The apparatus senses fluid pressure of multiphase fluid received in the interior and senses a fluid temperature of the multiphase fluid. The apparatus transmits an ultrasonic wave into the fluid and detects the transmitted wave to determine its velocity and attenuation. The apparatus may adjust the determined velocity and attenuation based on the temperature and pressure of the fluid to compensate for a difference between the sensed temperature and pressure and a standard temperature and pressure. The apparatus determines a gas fraction, water fraction, and a non-water fluid fraction of the multiphase fluid based on the sensed fluid pressure, the sensed fluid temperature, and the velocity and attenuation of the ultrasonic wave in the multiphase fluid.

Owner:MULTIPHASE FLOW INT +1

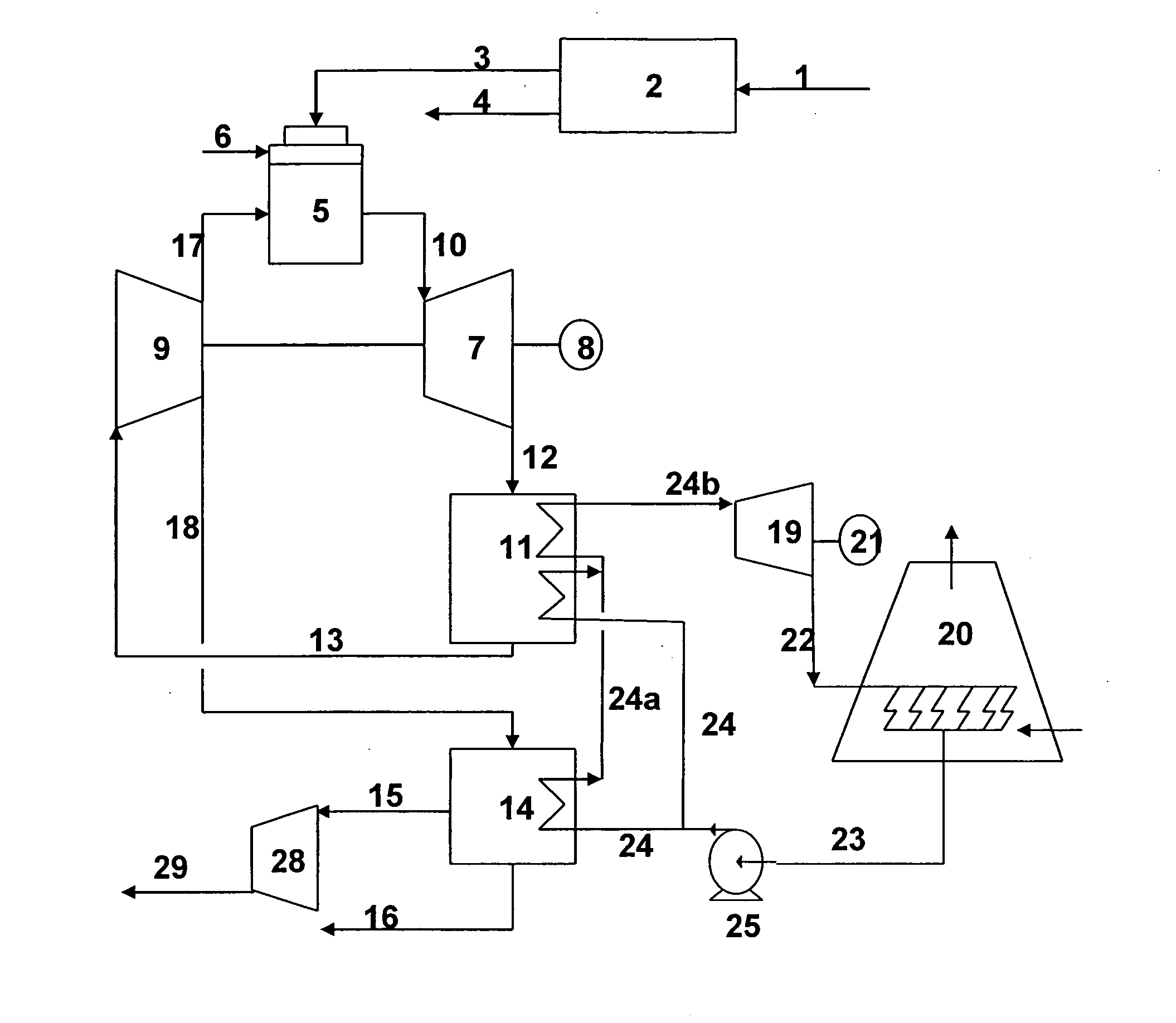

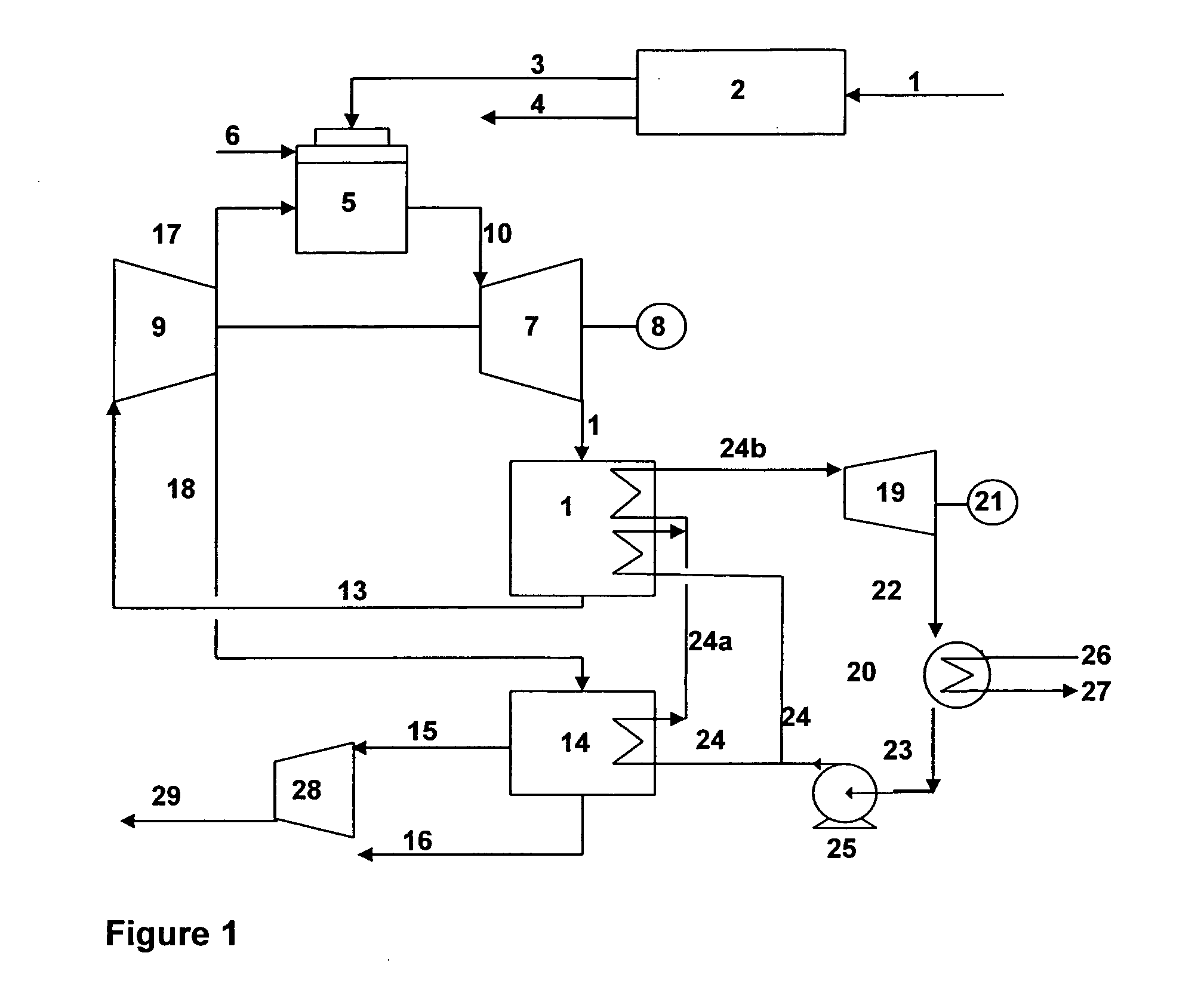

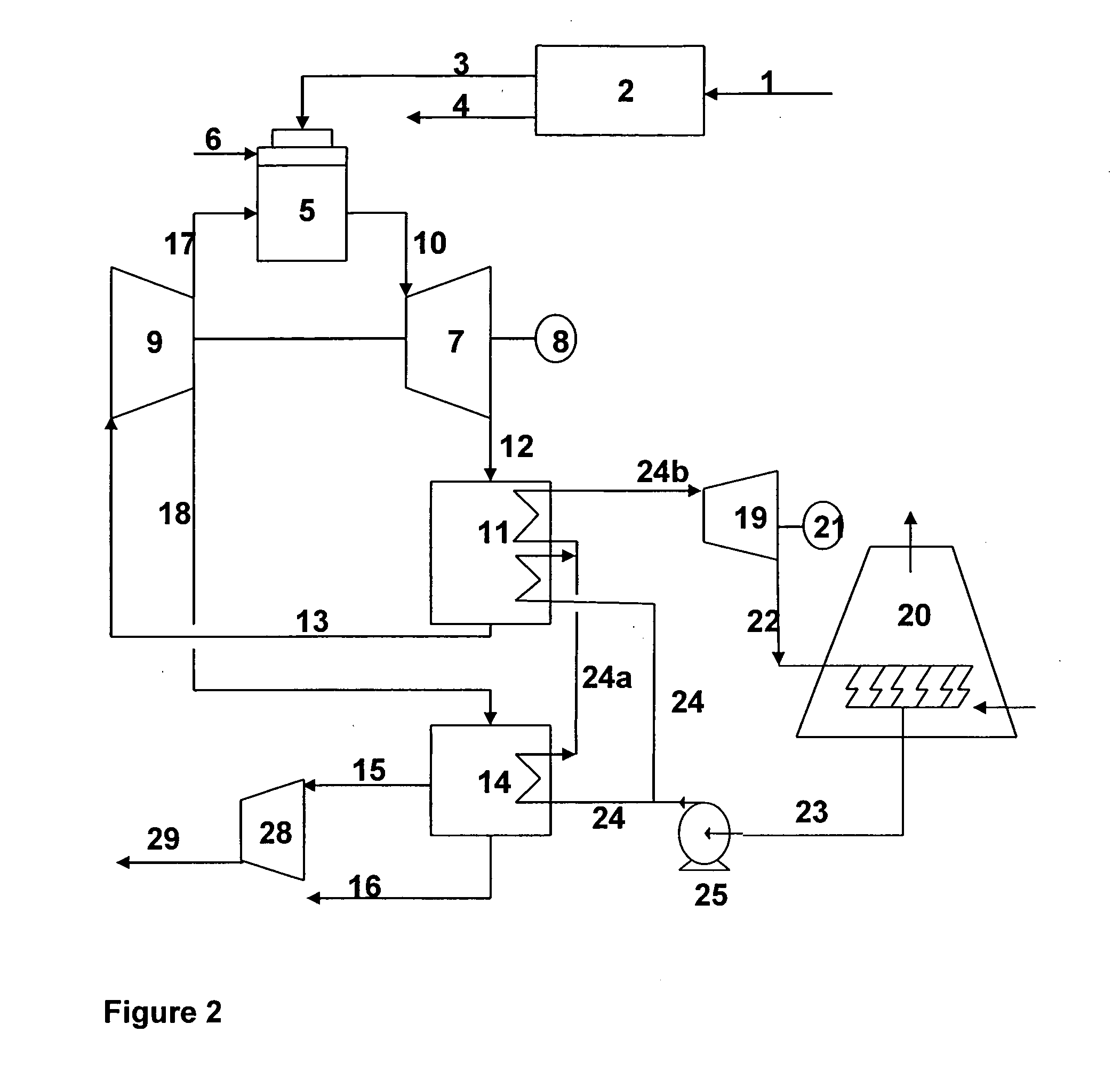

Method and plant for combined production of electric energy and water

InactiveUS20110042968A1Gas turbine plantsIndirect carbon-dioxide mitigationSteam condensationWater production

This invention relates to a method and plant for combined electric energy and water production, where the method comprises feeding substantially pure oxygen and a hydrocarbon fuel in a stochiometric ratio to a combustor (5), combusting the oxygen and hydrocarbon feed for forming an exhaust gas at comparatively high temperature and pressure, passing the exhaust gas at high temperature and pressure to an expander (7) that runs an electric generator (8) and an exhaust gas compressor (9), passing the exhaust gass exiting the expander to an exhaust gas cooler (11) which cools the gas to a temperature above the steam condensation temperature, passing the exhaust gas exiting the exhaust gas cooler to the exhaust gas compressor for pressurising, and passing the pressurised exhaust gas to an exhaust gas condenser (14) where the exhaust gas is condensed and thus separated into a substantially pure water fraction and a gaseous CO.

Owner:NEBB TECH

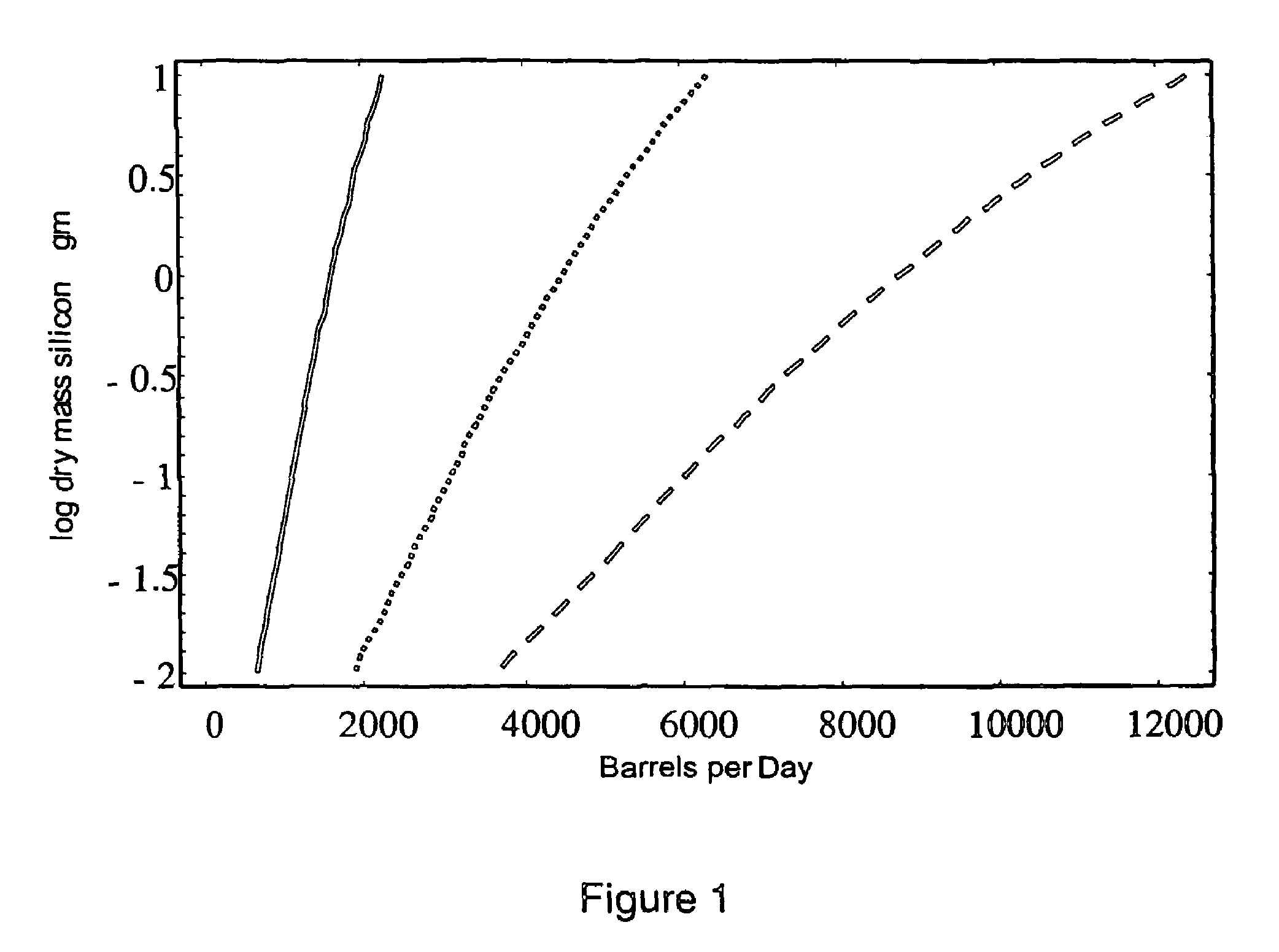

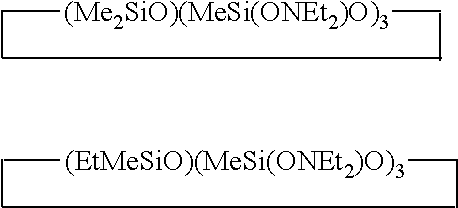

Oil-In-Water Silicone Emulsion Composition

InactiveUS20110319557A1Satisfaction intensitySatisfactory rubbery elasticityTransportation and packagingMixingColloidal silicaSilicon dioxide

An oil-in-water silicone emulsion composition comprising (A) 100 mass parts of a polyorganosiloxane that contains in each molecule at least two groups selected from the group consisting of the silicon-bonded hydroxyl group, silicon-bonded alkoxy groups, and silicon-bonded alkoxyalkoxy groups, (B) 0.1 to 200 mass parts of a colloidal silica, (C) 0.1 to 100 mass parts of an aminoxy group-containing organosilicon compound that contains at least three silicon-bonded aminoxy groups in each molecule, (D) 0.1 to 50 mass parts of a surfactant, and (E) 10 to 200 mass parts water. Such oil-in-water silicone emulsion composition that contains little low molecular weight silicone can form, even without the use of a tin catalyst, a cured film that exhibits a satisfactory strength and a satisfactory adherence to substrate, through the removal of the water fraction.

Owner:DOW CORNING TORAY CO LTD

Methods and Apparatus for Determining A Viscosity of Oil in A Mixture

Methods and apparatus for determining a viscosity of oil in a mixture are disclosed herein. An example method includes determining water fractions of a mixture flowing into a downhole tool and determining viscosities of the mixture. The mixture includes water and oil. The example method also includes determining a viscosity of the oil based on the water fractions and the viscosities.

Owner:SCHLUMBERGER TECH CORP

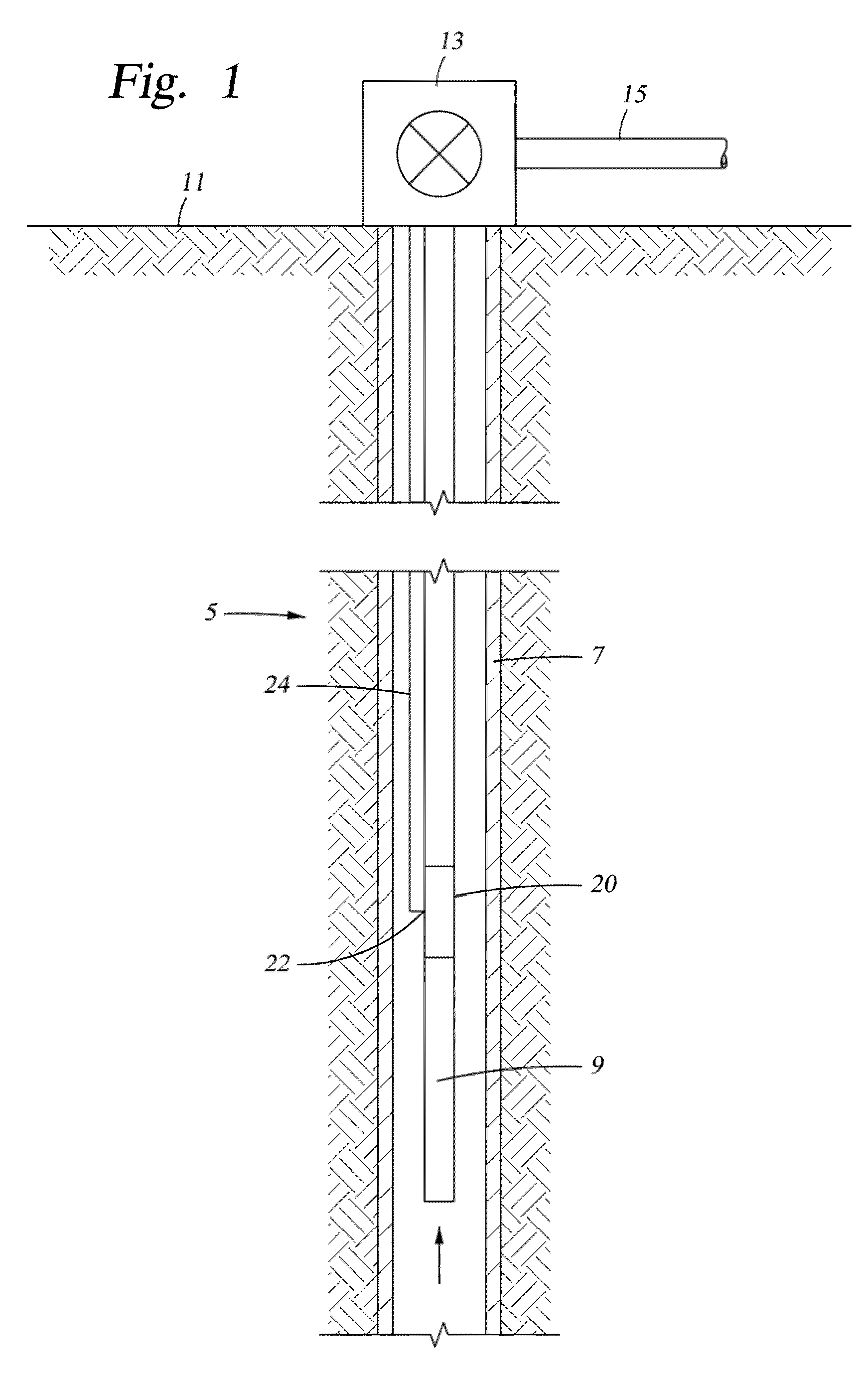

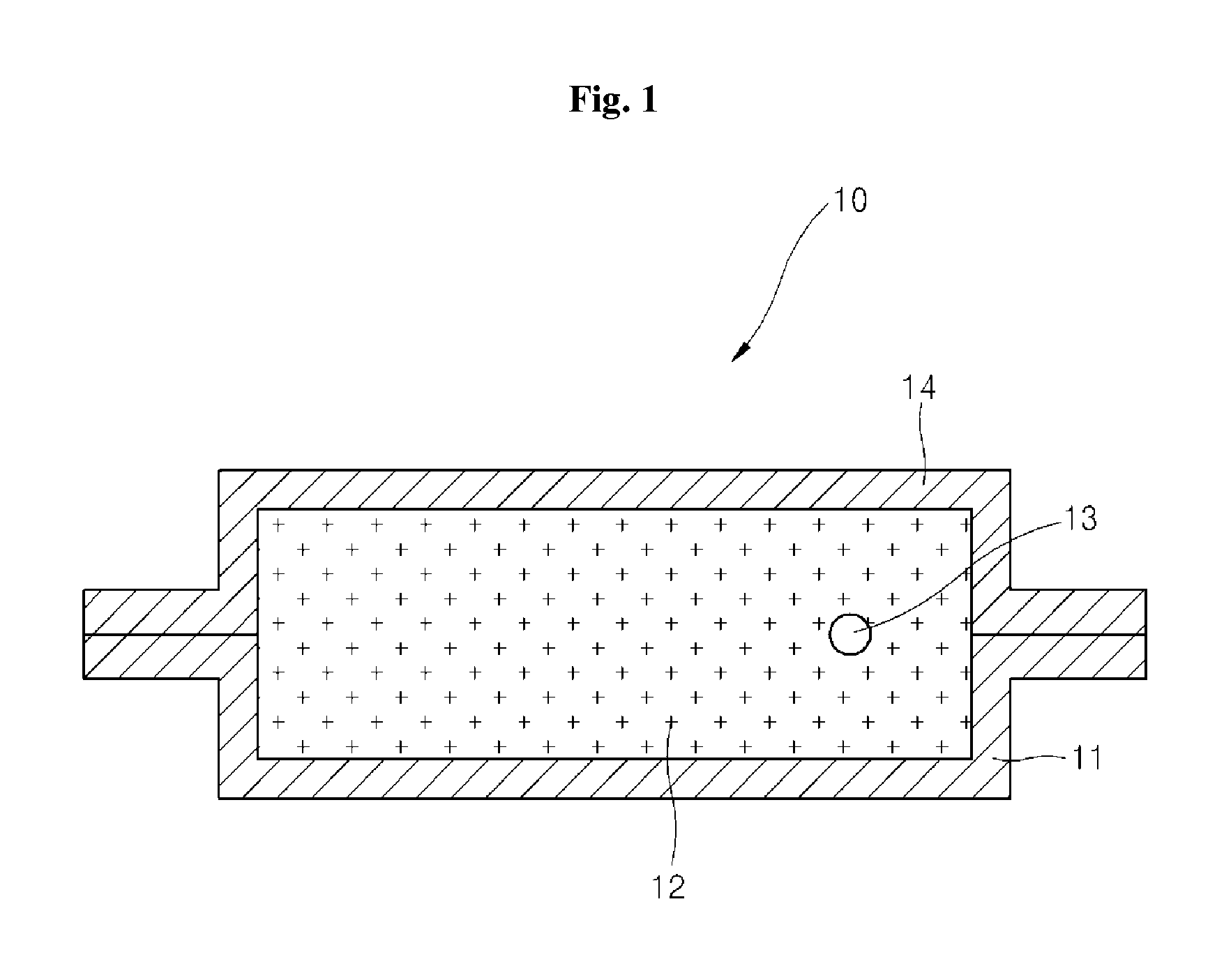

Water fraction measuring sensor and method having capacitance module

A sensor for measuring water fraction in a fluid mixture flowing in a conductive tubing within a borehole. The sensor comprises: an active probe, a reference probe, and an electronic unit. The active probe includes a first electrode and a second electrode isolated from each other by a first insulating layer, the first and second electrodes are preferably in contact with the fluid mixture. The reference probe is formed from an internal wall of the conductive tubing contacting the fluid mixture and isolated from the reference probe by a second insulating layer. The electronic unit is coupled to the first and second electrodes, and to the reference probe, the electronic unit preferably includes a capacitance module for measuring a capacitance between the active probe and the reference probe.

Owner:SCHLUMBERGER TECH CORP

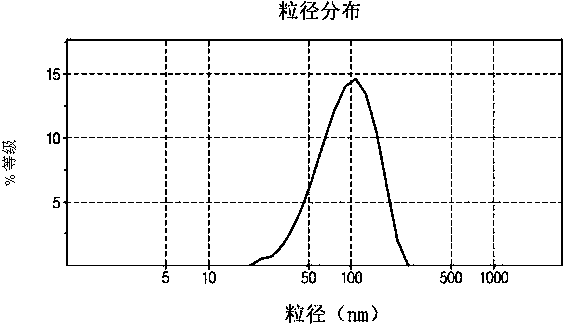

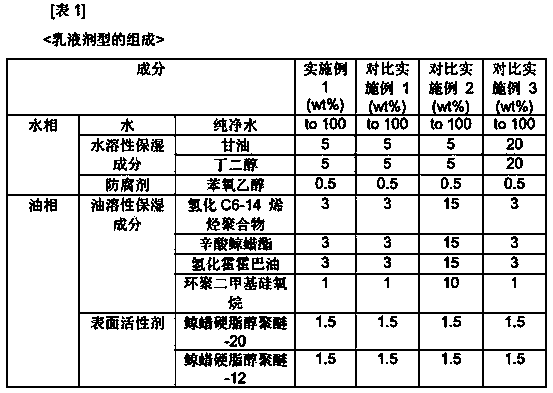

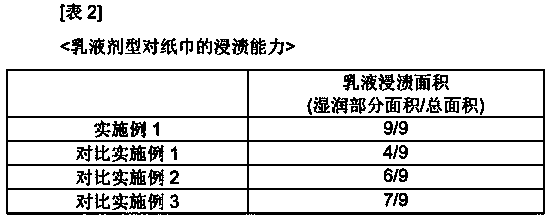

Cosmetic tissue comprising microemulsion particles, and production method for same and method of using same

InactiveCN104024523ACosmetic effectiveReduce churnCosmetic preparationsToilet preparationsWater fractionMicroemulsion

The present invention relates to a cosmetic tissue comprising microemulsion particles, and to a production method for same and method of using same. The present invention provides a cosmetic tissue to which is securely attached a dried composition comprising microemulsion particles of no more than 5,000 nm. Also, the present invention provides a production method for cosmetic tissue comprising: a first step of obtaining a composition comprising microemulsion particles of no more than 5,000 nm; a second step of coating the composition onto a tissue substrate; and a third step of drying the composition, and the present invention provides a method of using same. According to the present invention, after the skin has been cleaned, removal of the remaining water fraction and coating of a dermatological beauty composition are carried out in one go, thereby allowing easy-to-use and effective cosmetic enhancement to the skin.

Owner:AMOREPACIFIC CORP

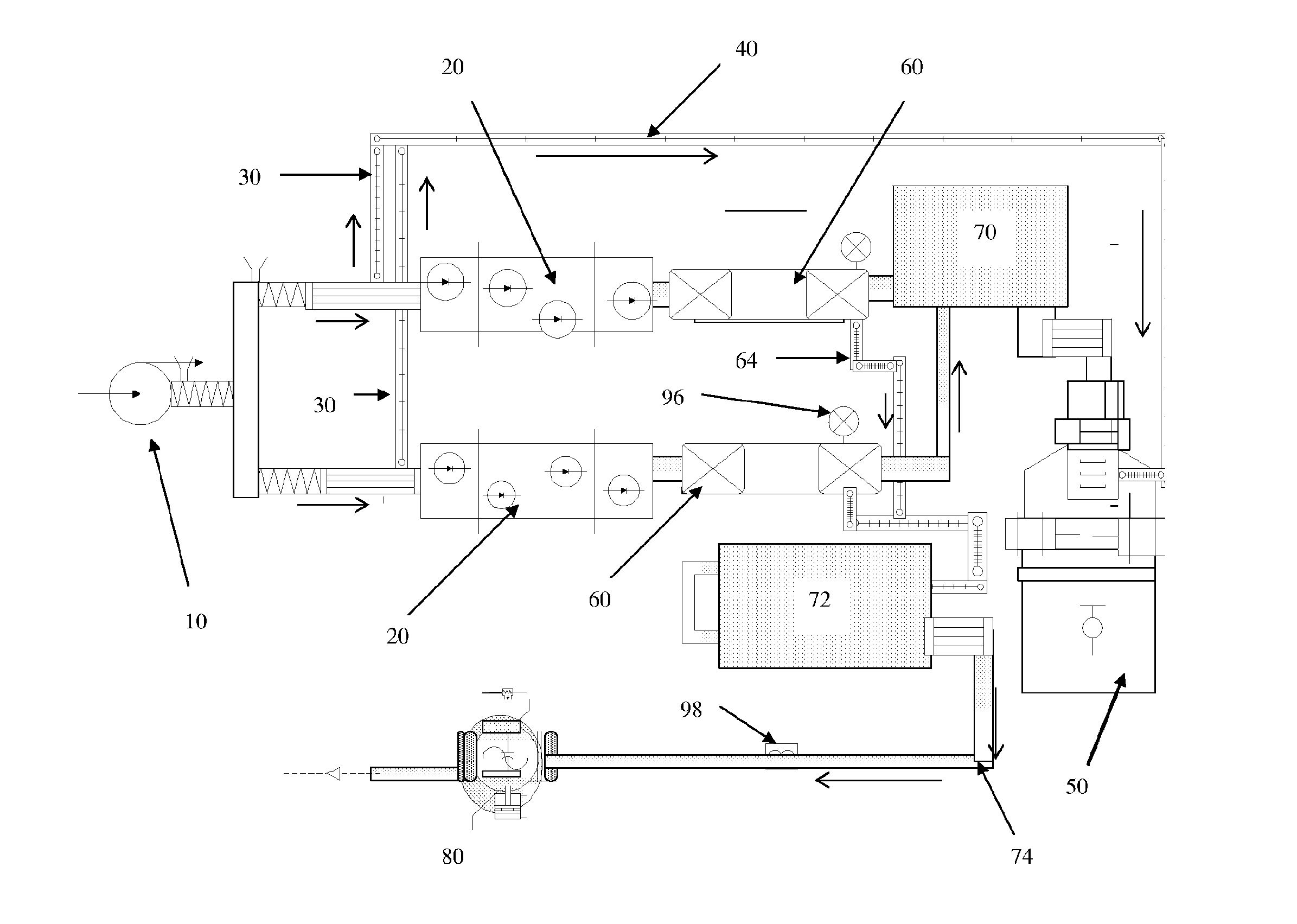

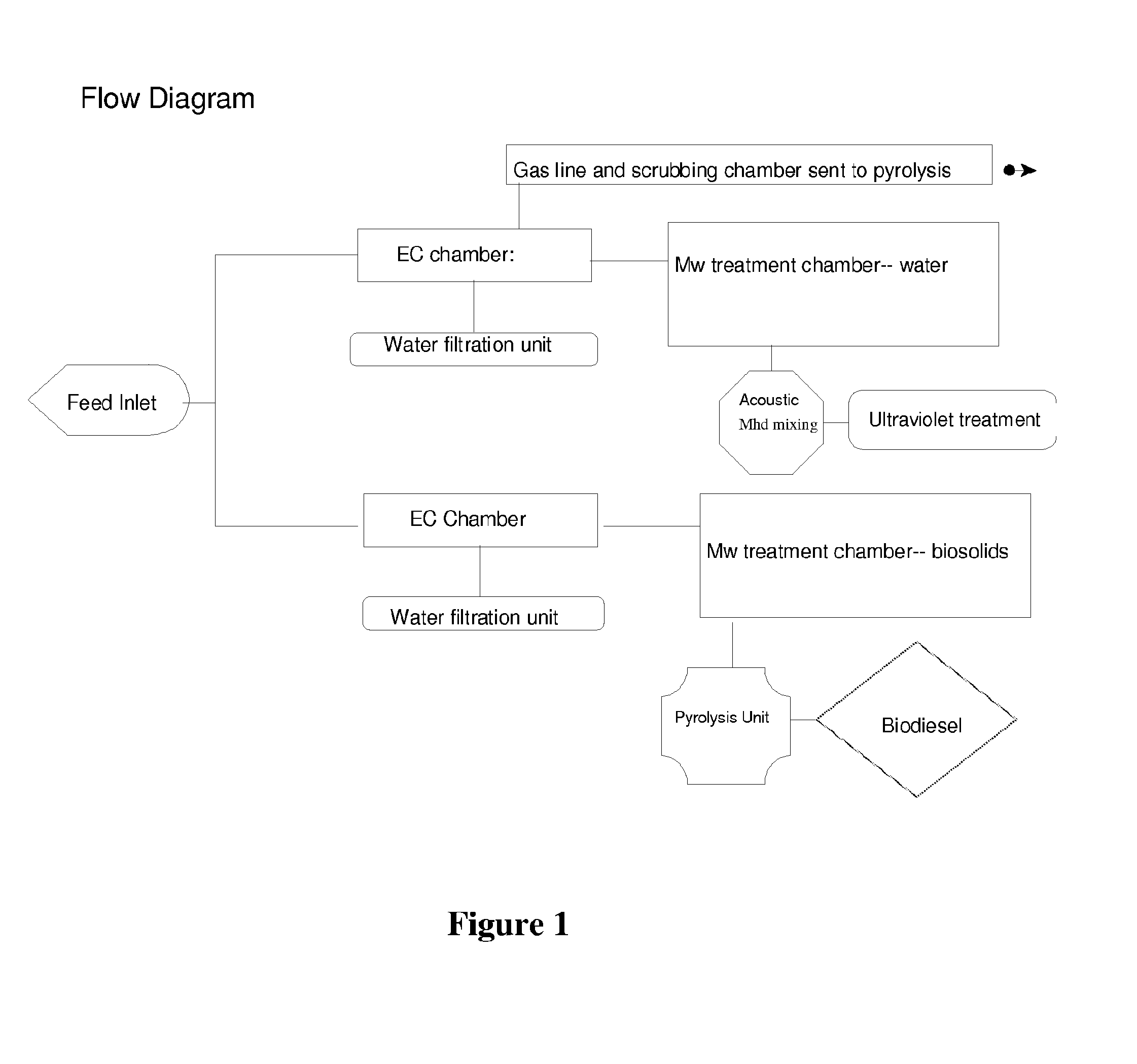

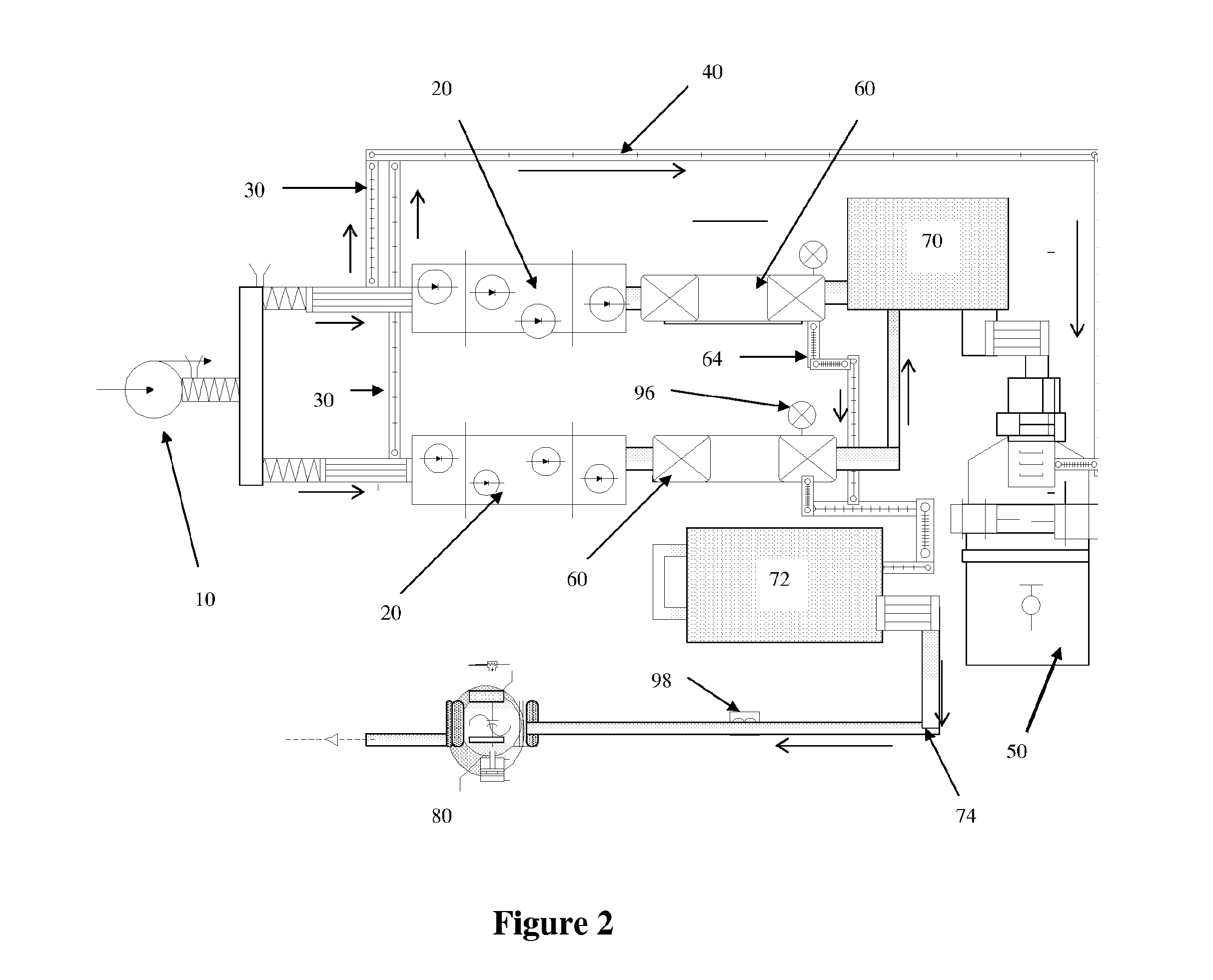

Method and system for harvesting water, energy and biofuel

InactiveUS20120111800A1Liquid degasificationWaste water treatment from animal husbandryPotable waterBiofuel

A method for harvesting potable water and energy from waste that comprises the steps of collecting the waste, separating the waste into a water fraction, a solid fraction, and a gas fraction, sterilizing the water fraction, converting the solid fraction into an energy resource; and scrubbing the gas fraction.

Owner:COLLINS CAROL ANN

Methods for fat quantification with correction for noise bias

ActiveUS8000769B2Improve image signal-to-noise ratioExcessive signal averagingMagnetic measurementsDiagnostic recording/measuringData setVoxel

Methods are disclosed for calculating a fat fraction corrected for noise bias of one or more voxels of interest using a magnetic resonance imaging (MRI) system. A plurality of image data sets are obtained each corresponding to NMR k-space data acquired using a pulse sequence with an individual associated echo time tn. A system of linear equations is formed relating image signal values to a desired decomposed calculated data vector having a component such as a water and fat combination having zero mean noise, or having a real fat component and a real water component. A fat fraction is calculated from at least one component of the decomposed calculated data vector. In another embodiment, the system of linear equations is normalized and can directly estimate a fat fraction or a water fraction having reduced noise bias.

Owner:GENERAL ELECTRIC CO +1

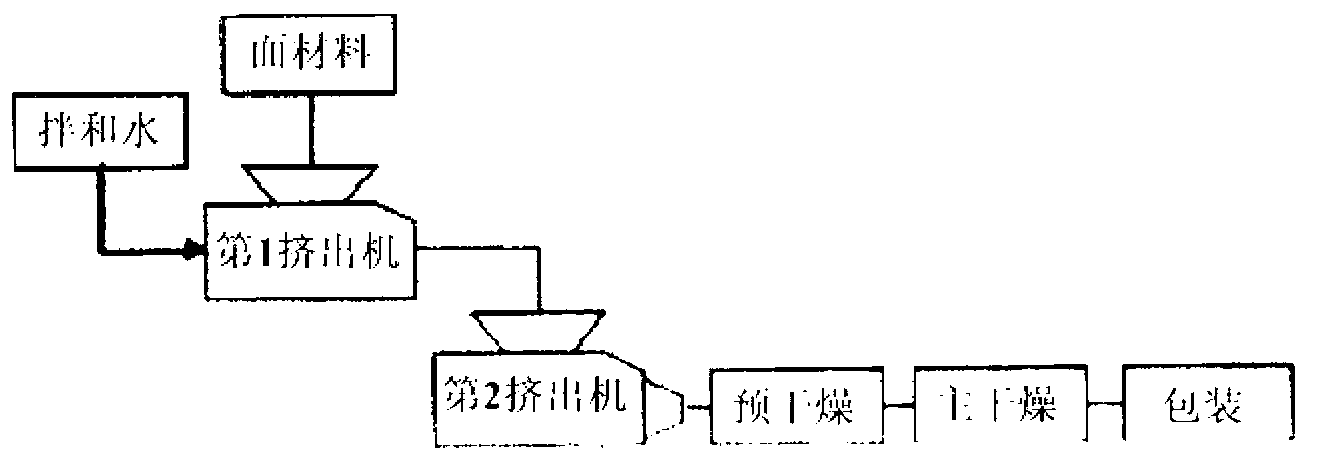

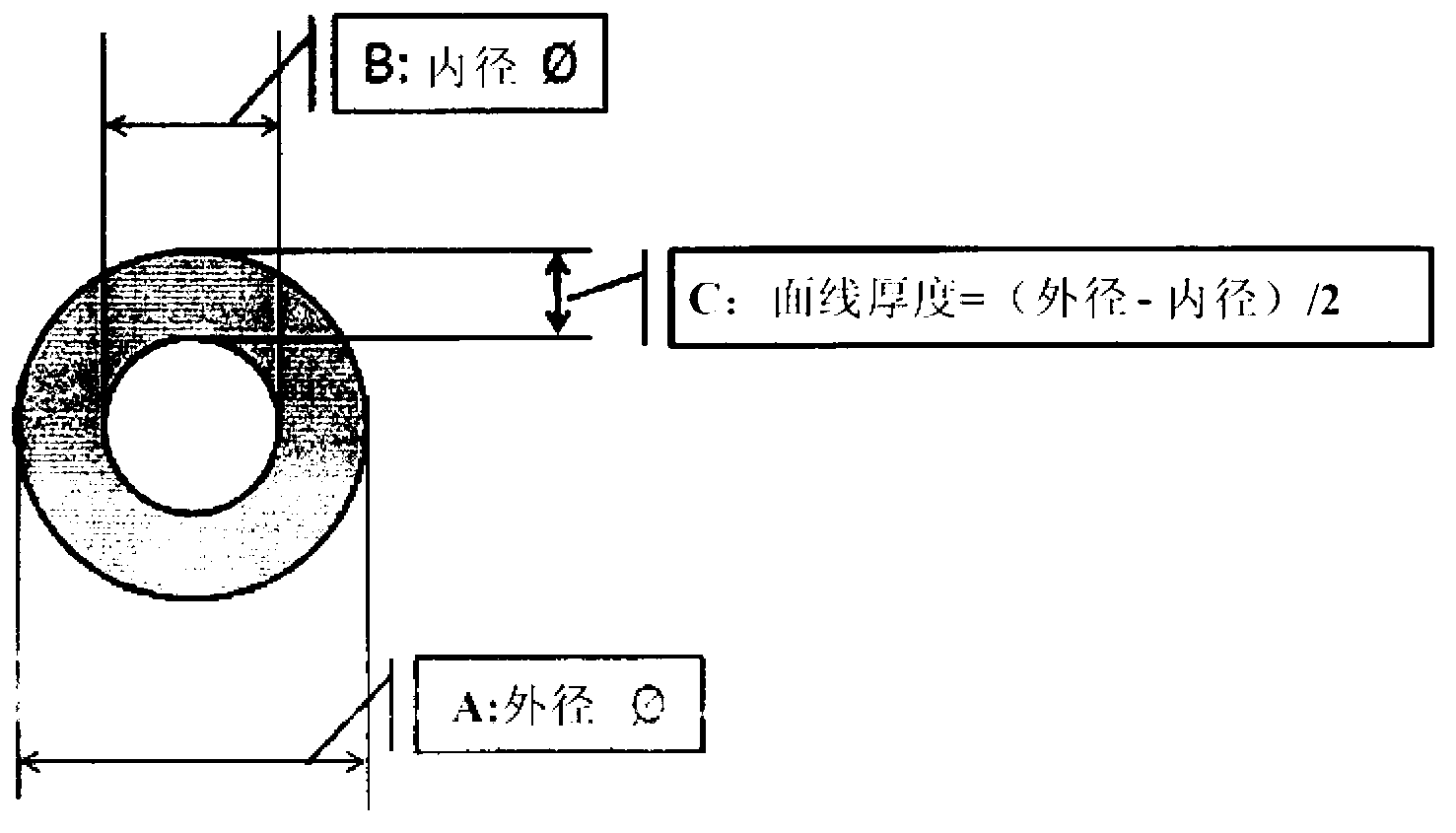

Method for producing hollow noodles

ActiveCN102781242AGreat tasteReduce cooking timeFood coatingDough extruding machinesEvaporationWater fraction

The present invention relates to a method for producing hollow noodles, and more specifically to one in which a gelatinized doughy substance is passed through a die designed to form a hollow area, such that the noodles which have passed through in this way have a tubular hollow area on the inside and hence it is possible to produce noodles which have a dramatically reduced cooking time and readily allow juices and sauces to penetrate inside the noodle during cooking and so enhance the taste. Further, it is possible to produce noodles in which the formation of the hollow causes the noodle surface area to be increased, and, as a result, there is rapid evaporation of the water fraction on the surface of the noodle which is being gelatinized and injected, and hence noodle stickiness is dramatically improved and consequently noodle sticking is reduced.

Owner:NONG SHIM

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com