Method for producing hollow noodles

A hollow noodle, rice noodle technology, applied in food preparation, food coating, dough extruder, etc., to achieve the effects of excellent process performance, easy infiltration, and improved viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

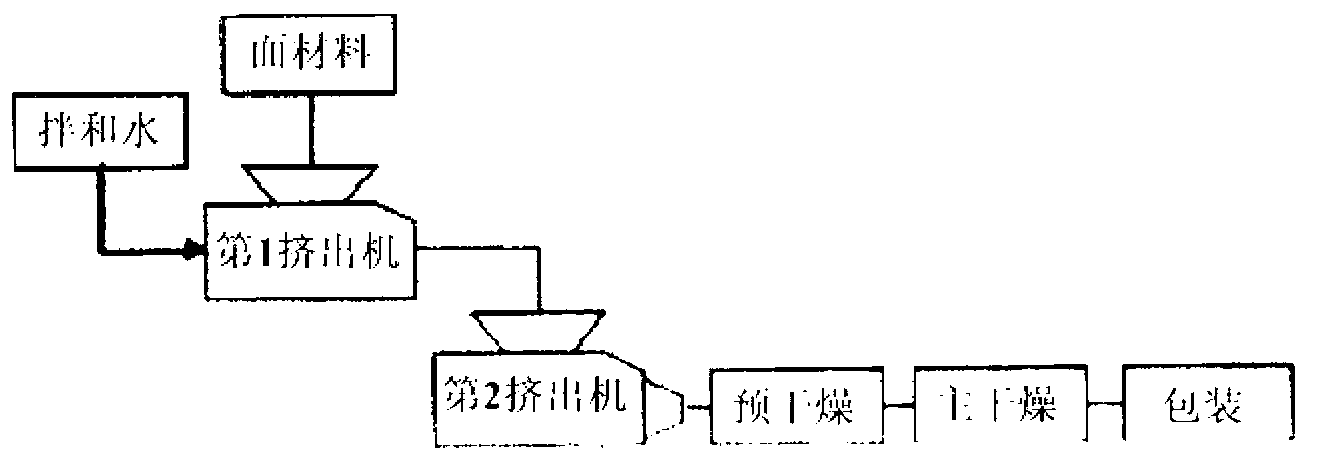

Method used

Image

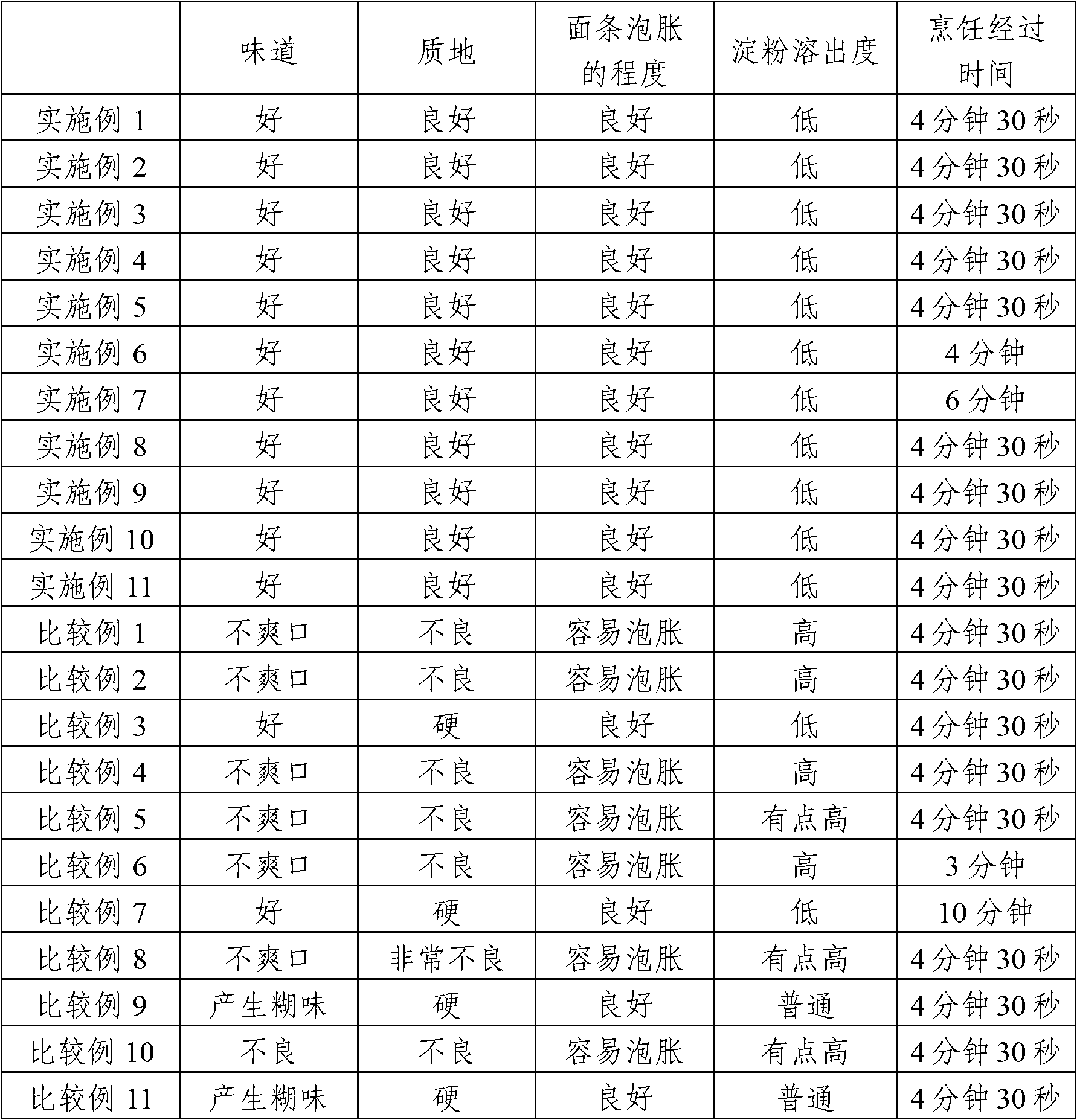

Examples

Embodiment 1

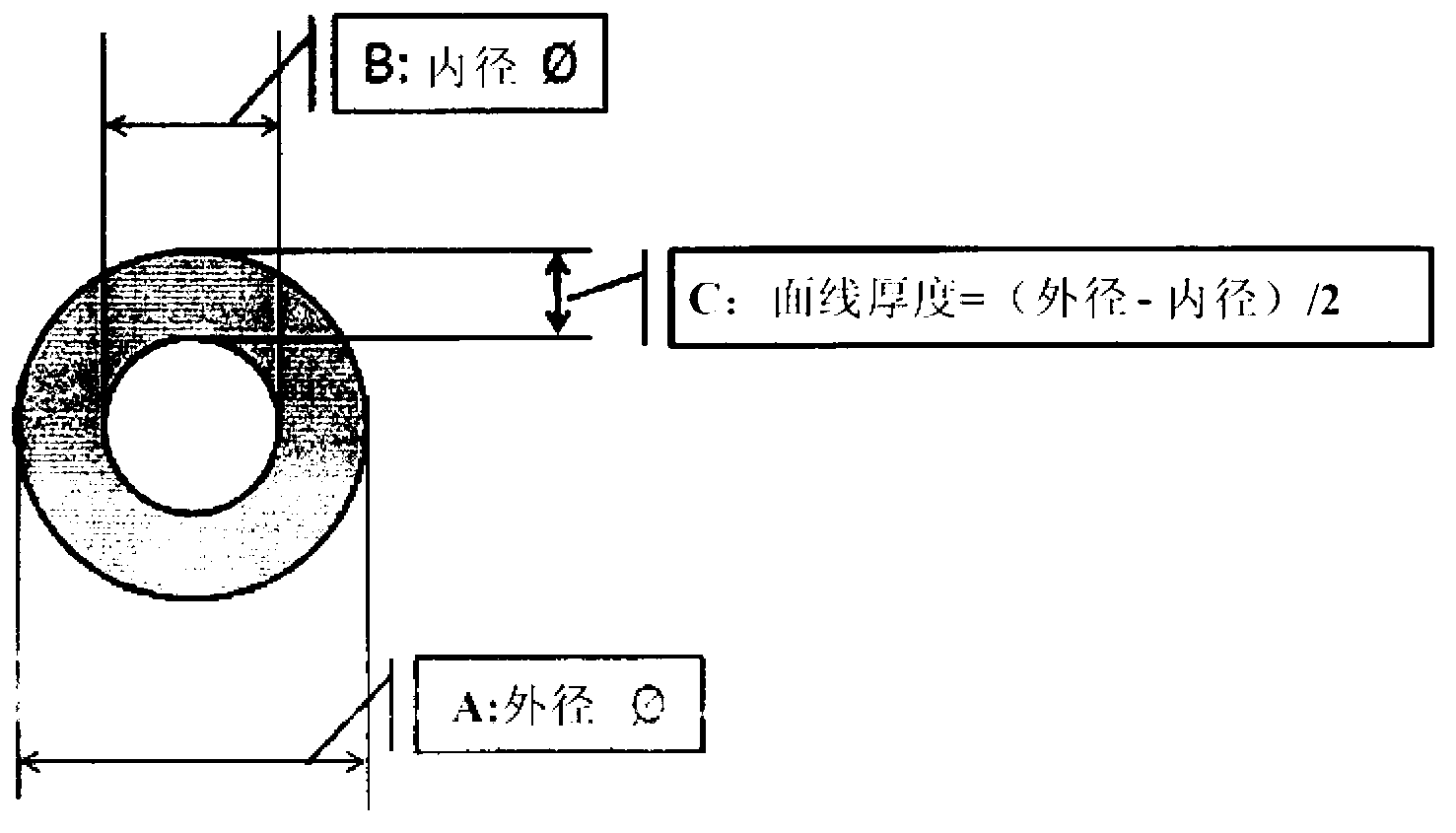

[0067] 100 parts by weight of rice noodles are put into a mixer as a noodle material, and 35 parts by weight of mixing water are added to 100 parts by weight of rice noodles. With respect to 100 parts by weight of noodle materials, 3 parts by weight of refined salt, 1.2 parts by weight of kelp extract, 3 parts by weight of rice bran flavor liquid, and water were mixed in mixing water. Put the noodle material and mixing water into the mixer, mix and gelatinize at 110°C, then cut the gelatinized mixture into the specified weight, and transfer it to the pneumatic device (Air Shift). In the extruder, the outer diameter / inner diameter combination of the hollow face is the outer diameter 2.0mm, inner diameter And by extruding at a thickness of 0.5mm, the sticking of the extruded surface is suppressed to the maximum and it is cut. Adjust the air (Air) injection pressure to disperse the cut hollow surface evenly, and make it produce the largest pores, so that the formed surface do...

Embodiment 2

[0069] Hollow noodles were prepared in the same manner as in Example 1, except that 1.0 parts by weight of the kelp extract was added to 100 parts by weight of rice noodles.

Embodiment 3

[0071] Hollow noodles were prepared in the same manner as in Example 1, except that 1.5 parts by weight of the kelp extract was added to 100 parts by weight of rice noodles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com