Patents

Literature

431results about How to "Easy to soak" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Negative electrode active substance of lithium ionic cell and preparing method thereof, negative electrode and cell

InactiveCN101425580AImprove ionic conductivityWeak electronic conductivityElectrode manufacturing processesSecondary cellsOxideLithium electrode

The invention relates to a cathode active substance of a lithium ion battery. The cathode active substance contains carbon material and metal oxide; the metal oxide is clad on the surface of the carbon material and adopts one or some of s IIA, IIIA, IB, IB, IIIB and IVB metal oxides in an element periodic table. The battery prepared and obtained by the cathode active substance has good safe performance and electrical chemical property.

Owner:BYD CO LTD

Low-viscosity epoxy resin system for resin transfer molding and preparation and using method thereof

The invention relates to a low-viscosity epoxy resin system for resin transfer molding and a preparation and using method thereof. The epoxy resin system consists of a component A and a component B, wherein in the component A, the weight ratio of epoxy resin to reactive diluent to antifoaming agent is 55-90: 10-45: 0.05-1; and the weight ratio of the component B (curing agent) to the component A is 100: 10-30. The preparation and using method comprises the following steps of: mixing and stirring the components A and B of the epoxy resin system uniformly in a ratio, pumping vacuum and removing bubbles at room temperature, and finally heating the components for 6 hours at the temperature of 80 DEG C to obtain a casting. The epoxy resin system can improve the gelling time and viscosity, meanwhile keeps good mechanical property and thermal property, and can be used for manufacturing large-sized composite structural members of automobiles, ships, wind-power blades, aerospace and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

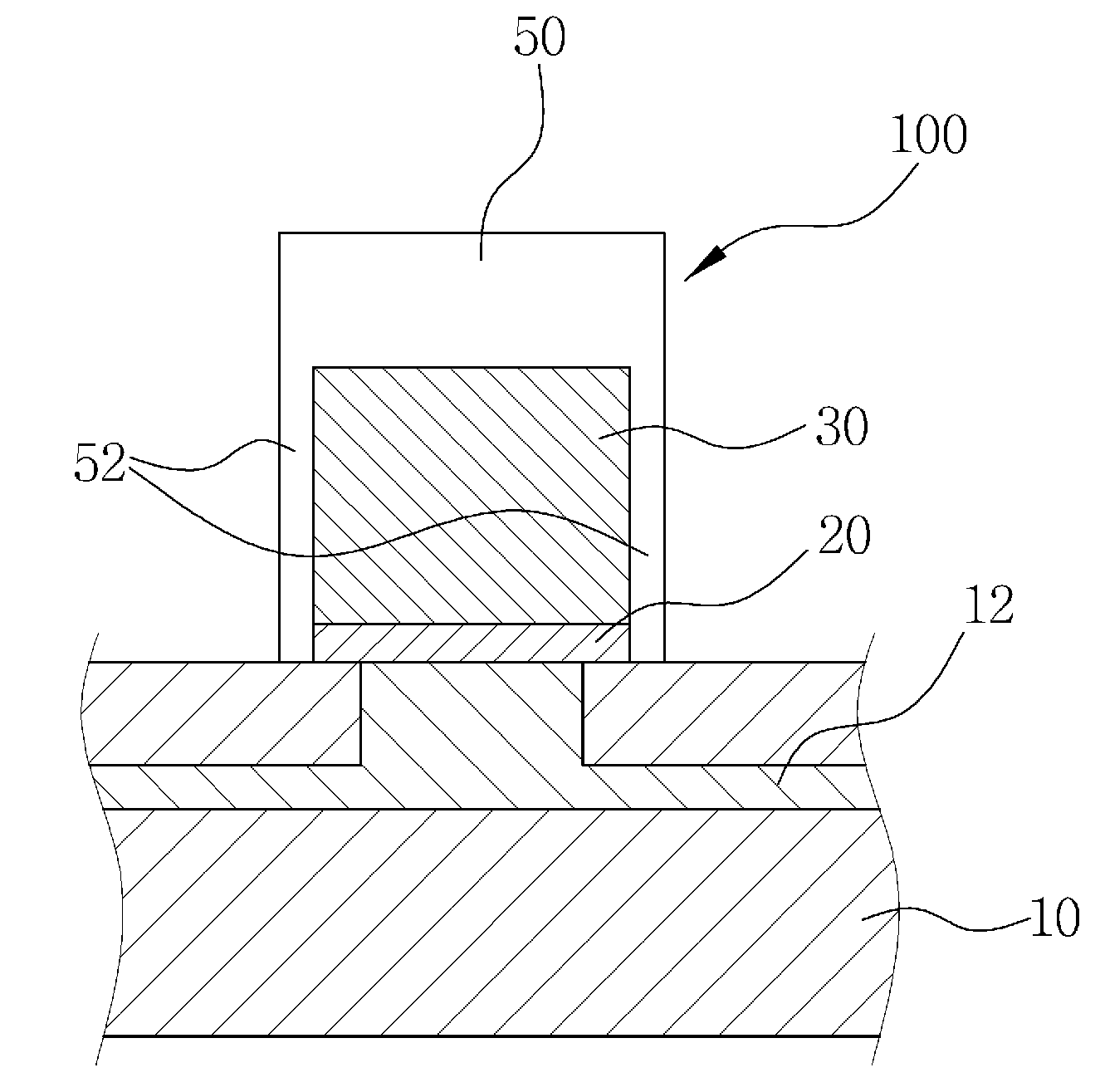

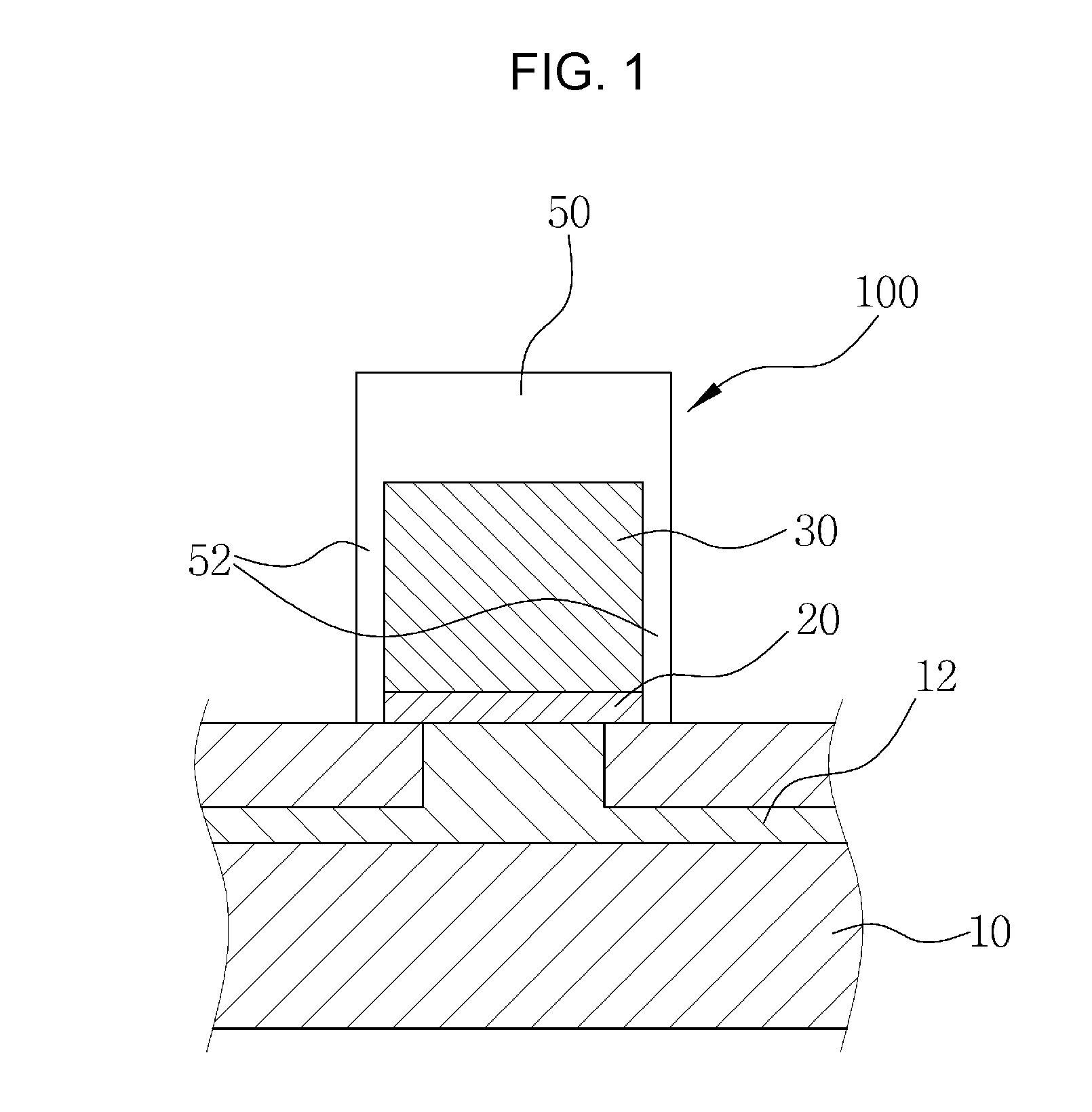

Copper pillar tin bump on semiconductor chip and method of forming the same

InactiveUS20090127708A1High-density packagingHigh densitySemiconductor/solid-state device detailsSolid-state devicesResistSemiconductor chip

Copper pillar tin bump on semiconductor chip comprises a copper layer composed on chip and a tin layer entirely wrapping whole outer surface of said copper layer. A method for forming of the copper pillar tin bump on semiconductor chip comprises: composing the first copper layer on said chip; applying photoresist to said first copper layer, exposing and developing a part of said photoresist, composing the copper pillar layer at the developed part of photoresist, composing the upper tin layer, removing said photoresist, removing said the first copper layer except disposing place of copper pillar layer, composing side tin layer. The minute pattern makes it possible to form a high density packaging by reducing a pitch of copper pillar tin bump. Signal delay can be reduced by low electric resistance, and underfill can be easily soaked.

Owner:HWABEAK ENG

Special water-based cutting fluid for diamond wire saw

The invention relates to a special water-based cutting fluid for diamond wire saw comprising the following components in percentage by weight: 0.01% of dispersing agent, 0.01-3% of wetting agent, 0.05% of defoaming agent, 0.01% of corrosion inhibitor, 0.01% of chelating agent, 0.01% of bactericide, 0.01% of penetrating agent and the balance of water. The invention has the advantages of extremely lower viscosity, good cooling property and good chip suspension and diffusivity; in addition, silicon grains of chip grains can be greatly wetted, the diamond wire saw is cleaned clearly, has low foaminess, is not sensitive to metal ions and can not be combusted. The special water-based cutting fluid disclosed by the invention is stable during use at high temperature and has longer service life and higher cutting efficiency; and in addition, the cutting fluid left on the silicon chips is easy to be removed, and the recovery of silicon powder turns to be very easy.

Owner:JIANGSU KAIXING PLASTICS

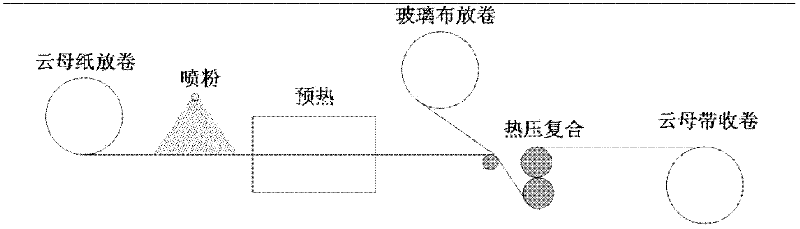

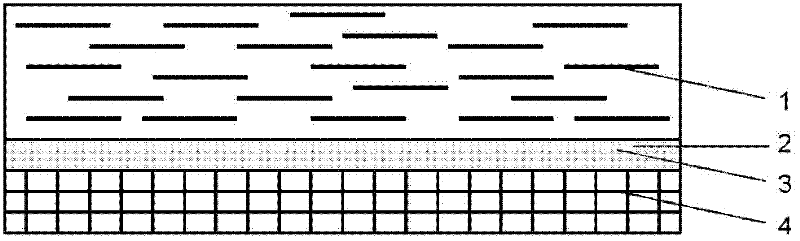

Preparation method of high-permeability mica tape

ActiveCN102412041ALong-term softnessWon't penetrateInsulatorsNatural mineral layered productsEngineeringSolvent

The invention discloses a preparation method of a high-permeability mica tape. The high-permeability mica tape comprises: a mica paper layer (1) and a reinforcement material layer (4). The high-permeability mica tape is characterized in that: an adhesive layer (2) is sprayed between the mica paper layer (1) and the reinforcement material layer (4); the mica paper layer (1) is mica paper possessing the high permeability; the adhesive layer (2) is a solventless powdered resin which forms point distribution and a large amount of pore channels (3) exist between the pointlike resin. The method comprises the following steps: (1) respectively rewinding the mica paper and the reinforcement material and spraying the solventless adhesive resin powder on the mica paper; (2) after the mica paper sprayed with the adhesive resin powder is preheated, performing hot pressing and compositing, winding and cutting to the mica paper and the reinforcement material so as to obtain the high-permeability mica tape. The prepared mica tape possesses the high permeability. Adhesive contents are small. Flexibility is good. A caking property of the reinforcement material and the mica paper is good. The mica tape can be stored for a long time, can not harden and can not be crisp. A winding technology is good and the mica tape has many other advantages. The mica tape is suitable for insulation processing of various kinds of motors or electric appliance products and especially suitable for a large high-voltage generator set, whose voltage range is 13.8-27Kv. The mica tape is suitable for a main insulation VPI processing technology of a coil (stator bar) with a unilateral insulation thickness of 4-8mm. Soakage time can be shortened.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

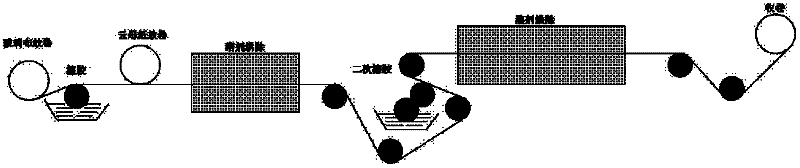

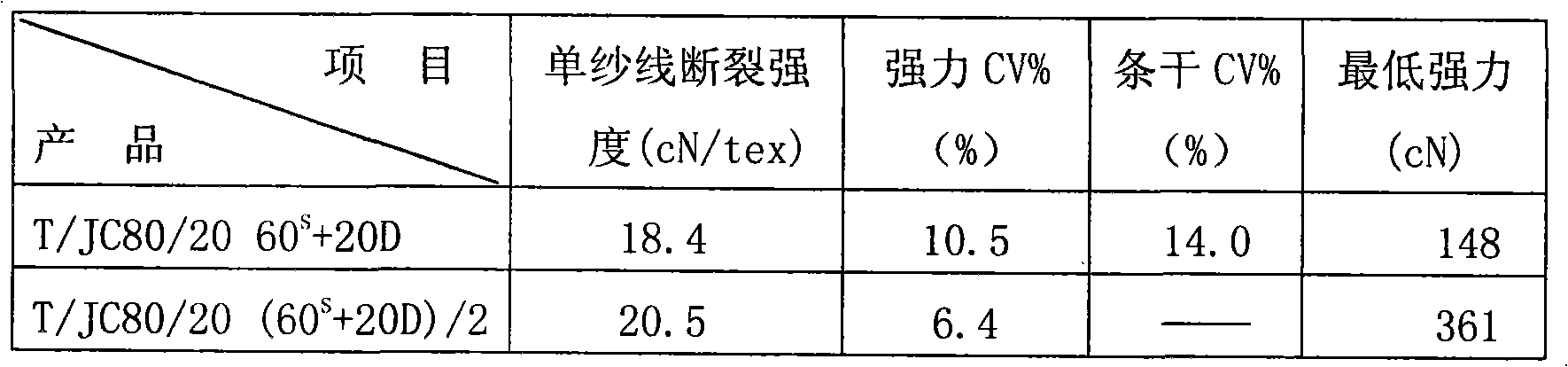

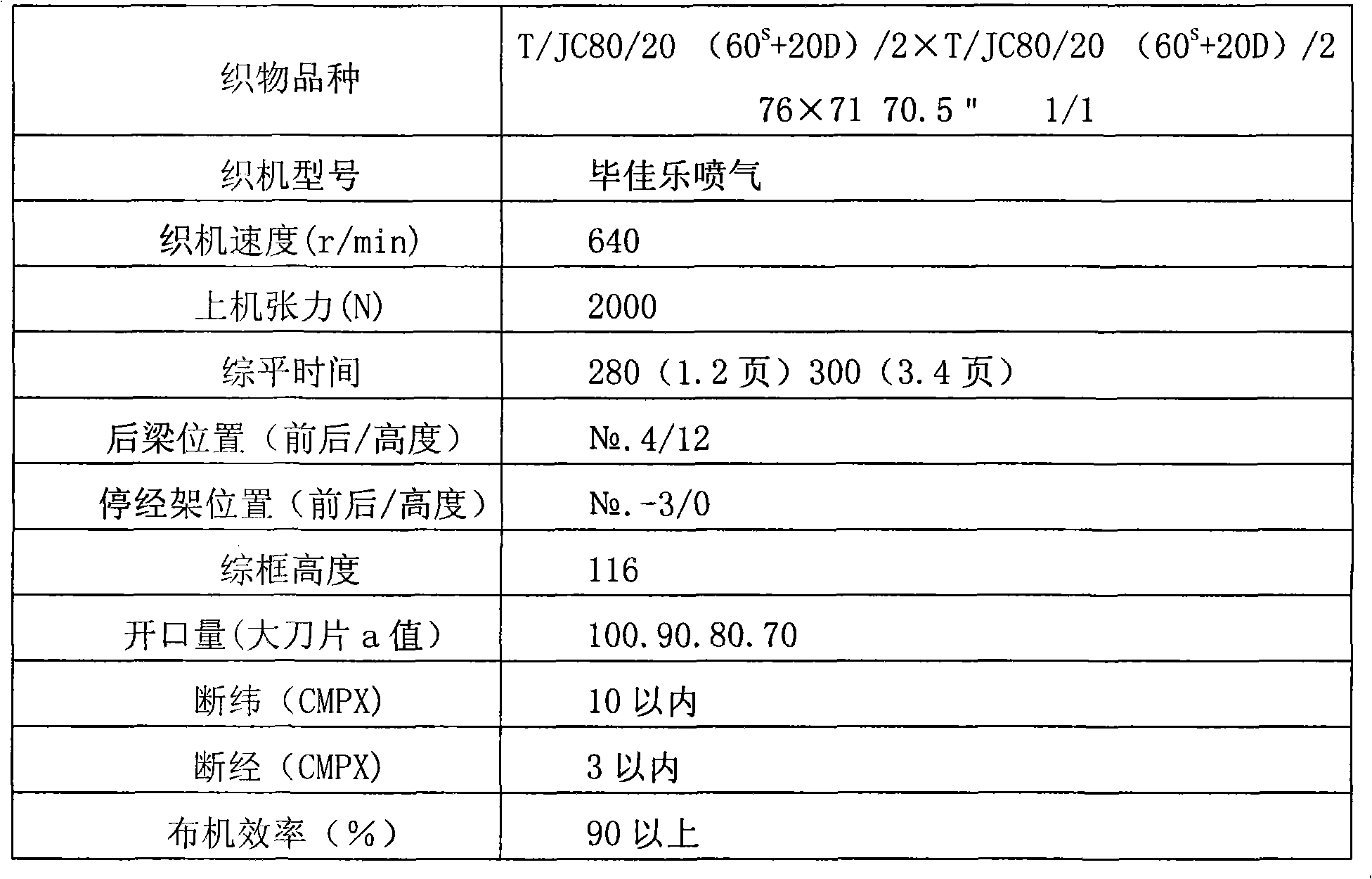

Production method of moisture-absorbing and sweat-discharging fabric

InactiveCN101962850AGood moisture absorption and quick drying effectSkinnyFibre cleaning/opening machinesWoven fabricsBreaking strengthPolyester

The invention relates to a production method of a moisture-absorbing and sweat-discharging fabric. In the method, the moisture-absorbing and sweat-discharging fabric is produced by using 80 percent of honeycomb moisture-absorbing and quick-drying fibers and 20 percent of cotton fibers as coating fibers and 20D common polyester filaments as core yarns. The method comprises the following steps: subjecting moisture-absorbing and sweat-discharging fibers to cotton opening and cleaning, cotton carding and primary combination, subjecting cotton fibers to cotton opening and cleaning, cotton carding and fine carding, and combining the moisture-absorbing and sweat-discharging fibers and cotton fibers primarily; combining secondarily; spinning a coarse yarn; spinning a fine yarn; winding single yarn; twisting; yarn strand winding; and producing T / JC80 / 20(60s+20D) single yarnbs and T / JC80 / 20(60S+20D) / 2 yarn stands, wherein the breaking strengths of the single yarn and the yarn strand are 18.4cN / tex and 20.5cN / tex respectively, the strength CV values of the single yarn and the yarn strand are 10.5 percent and 6.4 percent respectively, the lowest strength of the single yarn and the yarn strand are 148cN and 361cN respectively, and the yarn levelness of the T / JC80 / 20(60S+20D) single yarn is 14.0 percent; and weaving the yarn and yarn stand by warping, sizing, denting, weaving, finishing and producing a T / JC80 / 20(60s+20D) / 2*T / JC80 / 20(60s+20D) / 2 76*71 70.5''1 / 1. In the invention, the fabric produced by reasonable cotton cleaning and carding processes and proper sizing and weaving processes and by combining two combined yarns has high moisture-absorbing and rapid-drying effects and offers an excellent skinny effect.

Owner:JIHUA 3509 TEXTILE

High copolymer pulp components for composite inorganic nanoparticles

The invention discloses a component of copolymer using in complex inorganic nanoparticles and relates to the pulp and sizing production and process technology of spinning warp sizing and paper-making glue processes. The said copolymer is a kind of ionic acrylic polymers and it is made of ionic monomers, hydrophilic monomers, acrylate monomers and few other monomers by free radical copolymerization reaction, or is made of polyacrylamide as the raw material by macromolecular chemical reaction. The said copolymer is used to prepare a new slurry component which substantial replaces PVA in the spinning warp sizing and paper-making glue processes. The said slurry contains of the mixture in a proportion of 0.1-50 % of copolymer, 0.1-50 % inorganic nanoparticles and residual water.

Owner:XUZHOU CITY ZHONGHENG FINE CHEM TECH

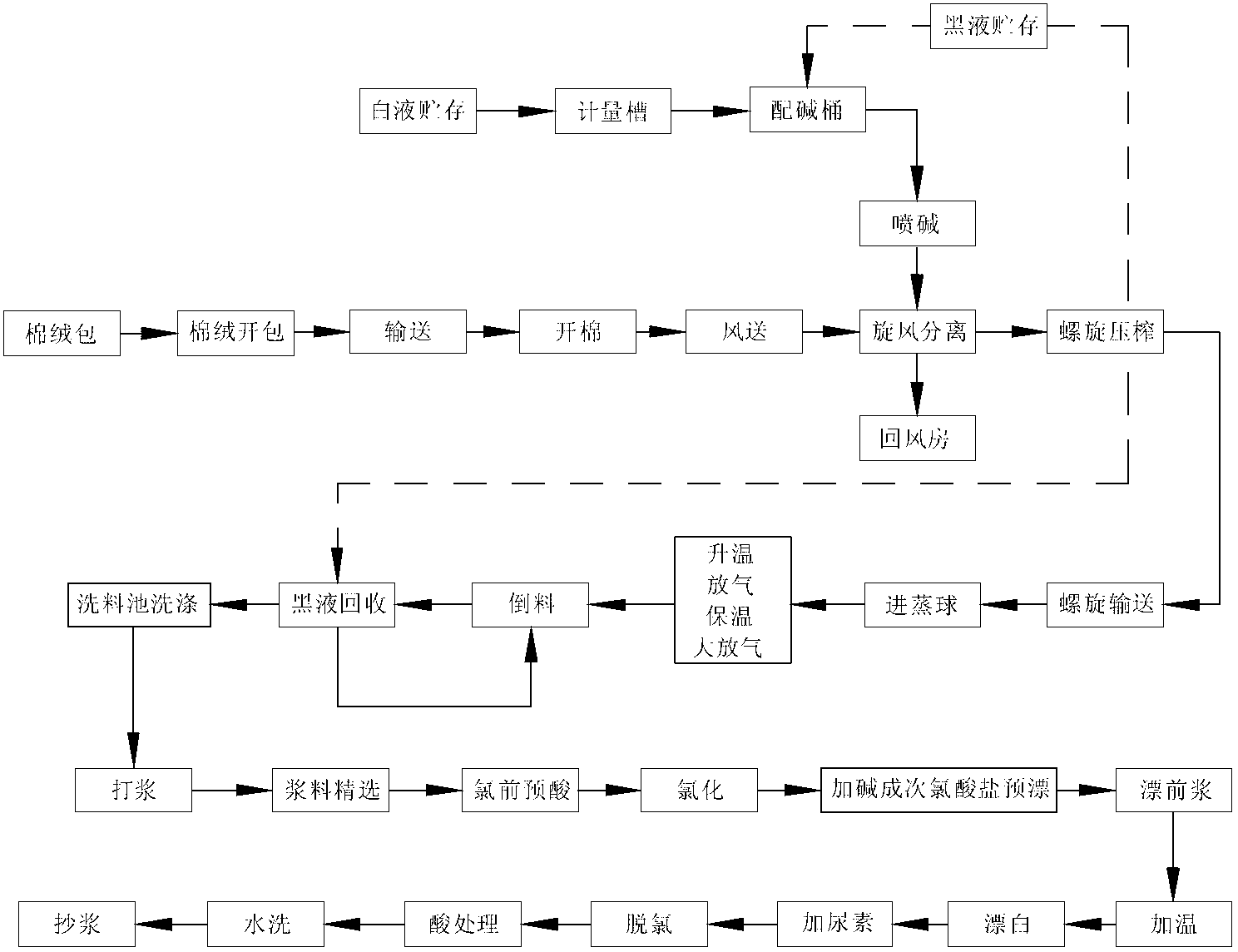

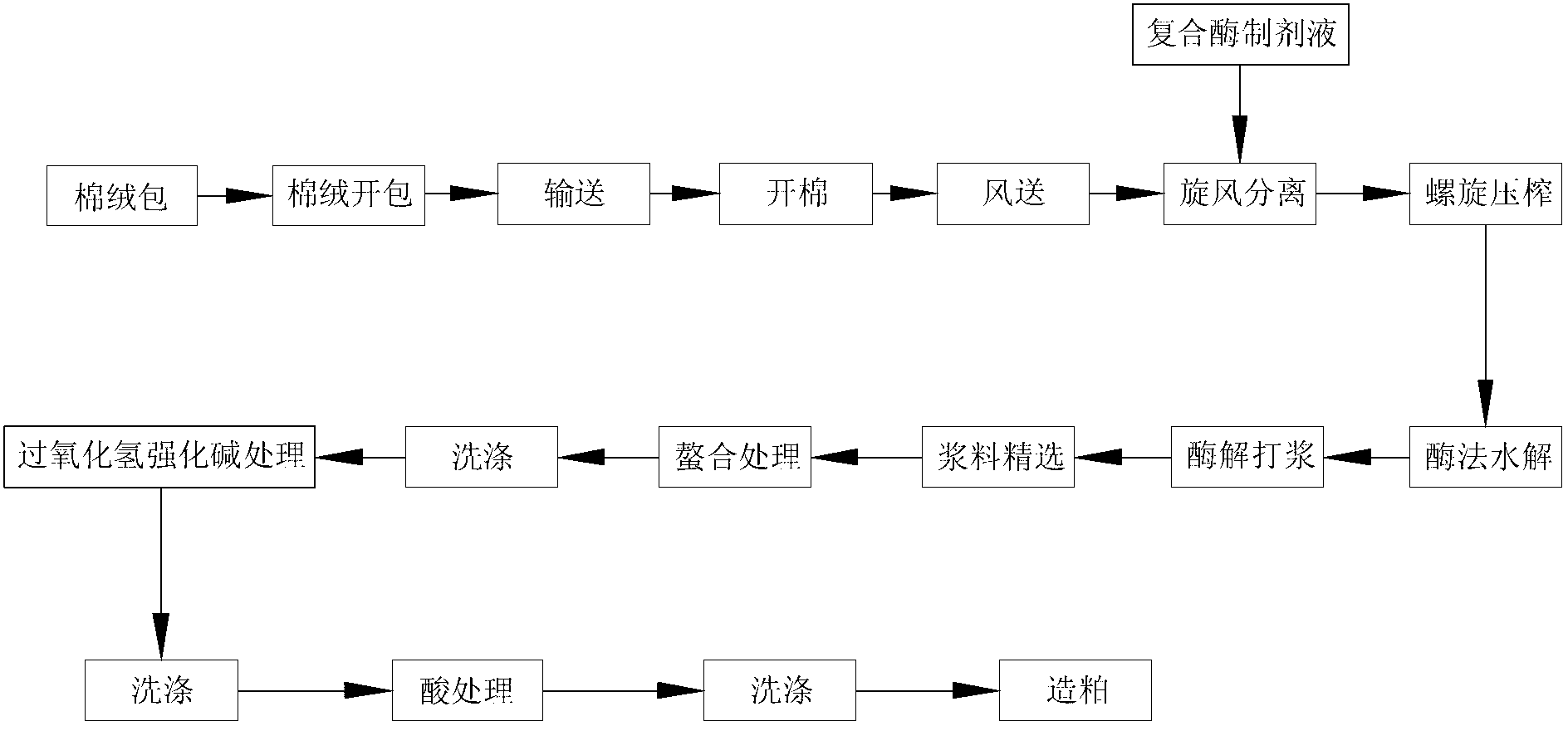

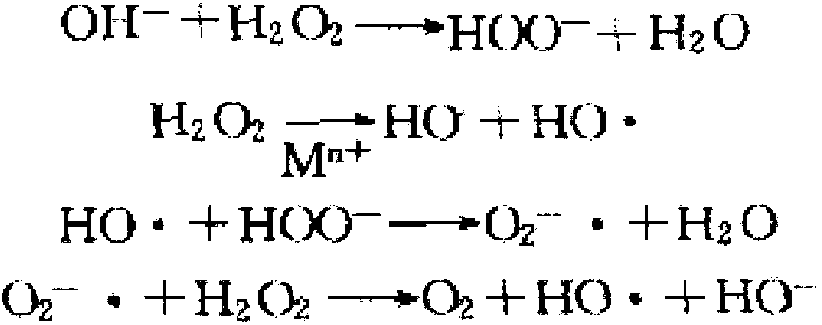

Complex enzyme preparation and technique for preparing dissolving pulp by using same

ActiveCN103061181ALoose structureEnhancement and effectPaper material treatmentChemical oxygen demandCellulose fiber

The invention relates to the technical field of production of regenerated cellulose fiber, in particular discloses a complex enzyme preparation applied in the preparation of dissolving pulp and a technique for preparing the dissolving pulp by using the enzyme preparation. The complex enzyme preparation is divided into a complex enzyme preparation I and a complex enzyme preparation II, wherein the complex enzyme preparation I mainly consists of feruloyl esterase, lipase and the like; and the complex enzyme preparation II mainly consists of xylanase, cellulase and the like. The complex enzyme preparation is applied in the technique for purifying alpha-cellulose and preparing the dissolving pulp; and the technique comprises the following steps of impurity removal for raw materials, enzyme method pretreatment, enzymolysis pulping, chelation treatment, alkali hydroxyl active oxygen cooking, acid treatment, washing, sand removal and pulp mixing. The method has the simple preparation technique, and adopts the complex enzyme preparation to treat the raw material pulp so as to effectively remove lignin, hemicellulose, pectin substance and waxiness and to reduce the degree of polymerization of the alpha-cellulose; the energy consumption is low under the normal pressure condition; the COD (Chemical Oxygen Demand) value of the pulping waste water is low; the yield of the dissolving pulp is high; the alpha-cellulose has high content and uniform degree of polymerization; and the production requirements of viscose can be satisfied.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

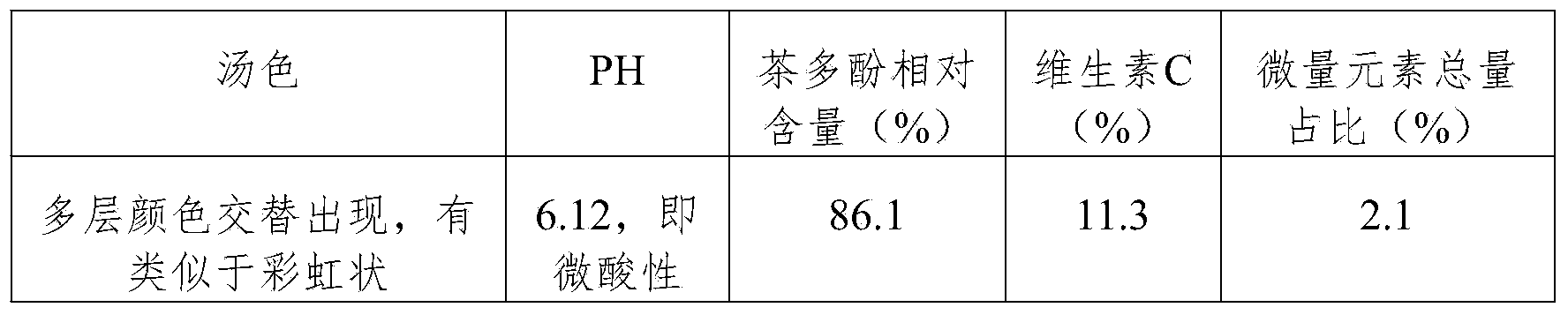

Health compound tea and preparation method thereof

ActiveCN104222378AHigh in nutrientsGood for healthPre-extraction tea treatmentLiquid glucoseAcetic acid

The invention relates to the technical field of health tea, and particularly relates to health compound tea and a preparation method thereof. by reasonably matching raw materials of the health compound tea and properly treating all raw materials in a preparation process, unnecessary parts are removed, necessary parts in all raw materials are extracted; by regulating white wine, liquid glucose, acetic acid and enzyme and accurately controlling a process sequence and process parameters in a regulating process, the prepared health compound tea is remarkable in health effect, good in taste, and rich in nutrients; a synergistic effect is formed between the raw materials, thus the nutrients of the tea are increased, and the health effect is promoted.

Owner:GUIZHOU FENGGANG XIANRENLING ZINC & SELENIUM ORGANIC TEA IND

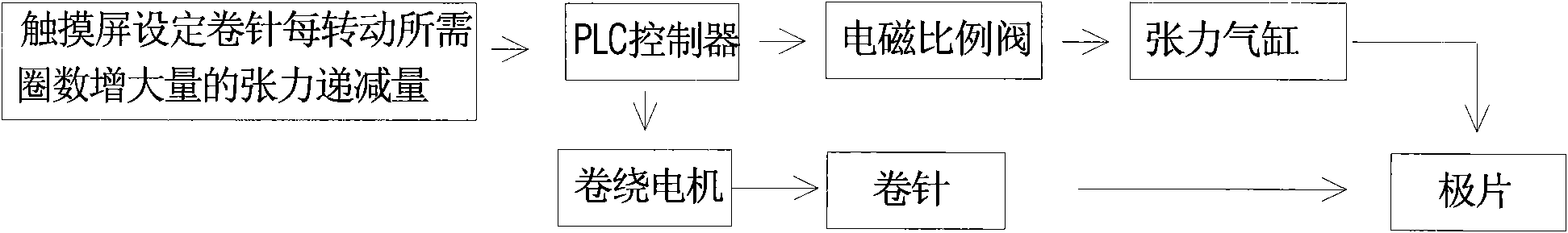

Cylindrical secondary battery bare electric core winding variable-tension control method

InactiveCN101567467AShorten injection timeShorten the production cycleFinal product manufactureSecondary cellsControl systemElectric machine

The invention provides a cylindrical secondary battery bare electric core winding variable-tension control method. An electric core winding variable-tension control comprises an indirect tension detection unit, a PLC controller, a tension cylinder for pushing the tension bar, and a winding electric machine for driving the rotation of the coiling needle and the PLC controller controls the winding electric machine to drive the winding needle to realize the unwinding tension control based on the detection information of the indirect tension detection unit and the air pressure in the tension cylinder is controlled by an electromagnetic proportioning valve for supplying gas into the tension cylinder. During winding the battery electric core, the PLC controller gradually controls the electromagnetic proportioning valve and reduces the air pressure in the tension cylinder based on the calculated winding cylinder number and the increase of the coiling needle according to the pole piece tension variance. The control method effectively solves the problems that the electric core is too tight due to the cylindrical electric core constant-tension winding and then the battery production efficiency is reduced, thereby ensuring that the electric core whole winding is tight inside and loose outside during winding process, in favor of electrolyte permeation and the charging time in the battery production procedure is obviously reduced.

Owner:GEESUN AUTOMATION TECH

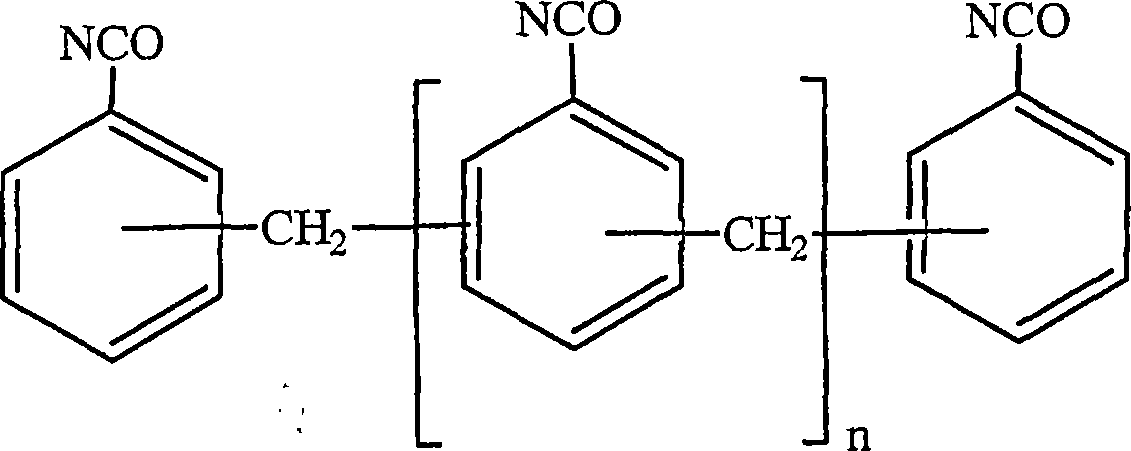

Laminating adhesive, laminate including the same, and method of making a laminate

InactiveCN101014637AReduced shelf lifeFast curingPolyureas/polyurethane adhesivesSynthetic resin layered productsMeth-Adhesive

Disclosed is a method of making a laminate that includes a) preparing an adhesive composition, where the preparing includes combining a first part that includes (meth)acrylate functional, polyisocyanate prepolymer, and polyisocyanate monomer, the first part including at least 10 % by weight isocyanate functional groups, and a second part that includes polyol, at least one of the first part and the second part includes photoinitiator, b) coating a first flexible substrate with the adhesive composition, c) exposing the adhesive composition to radiation to partially cure the adhesive composition, and d) contacting the adhesive composition with a second flexible substrate.

Owner:HB FULLER CO

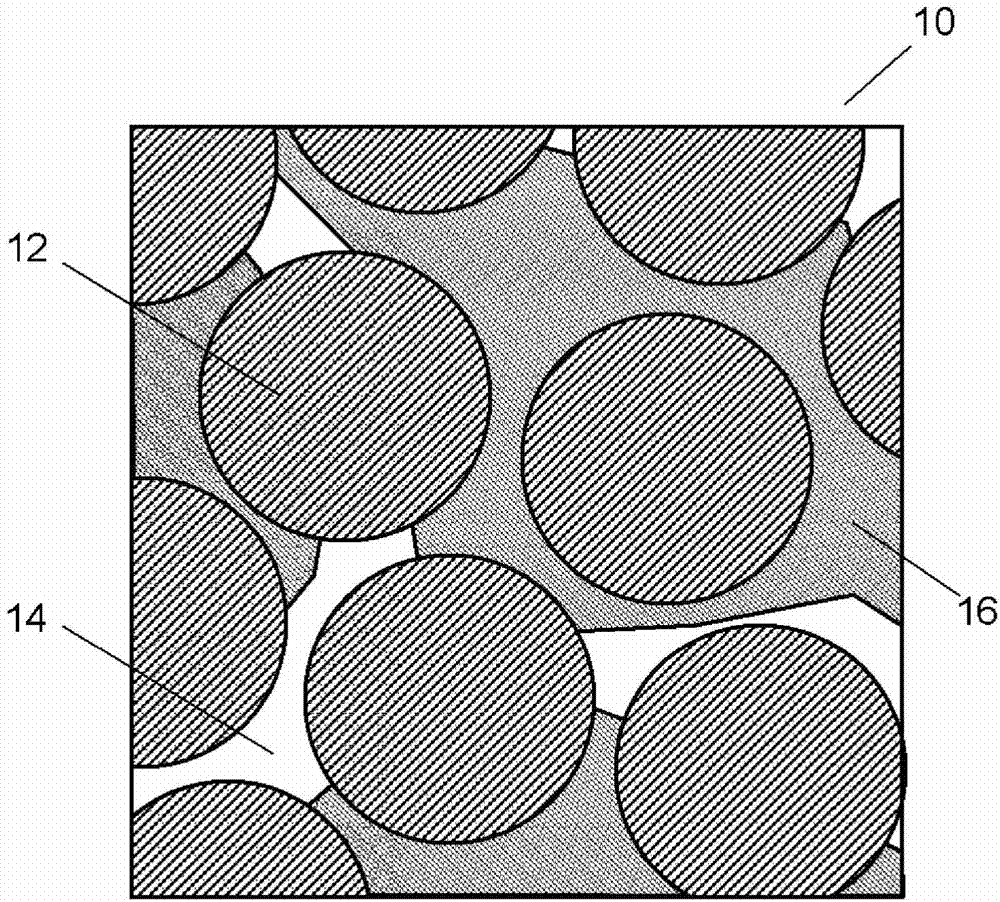

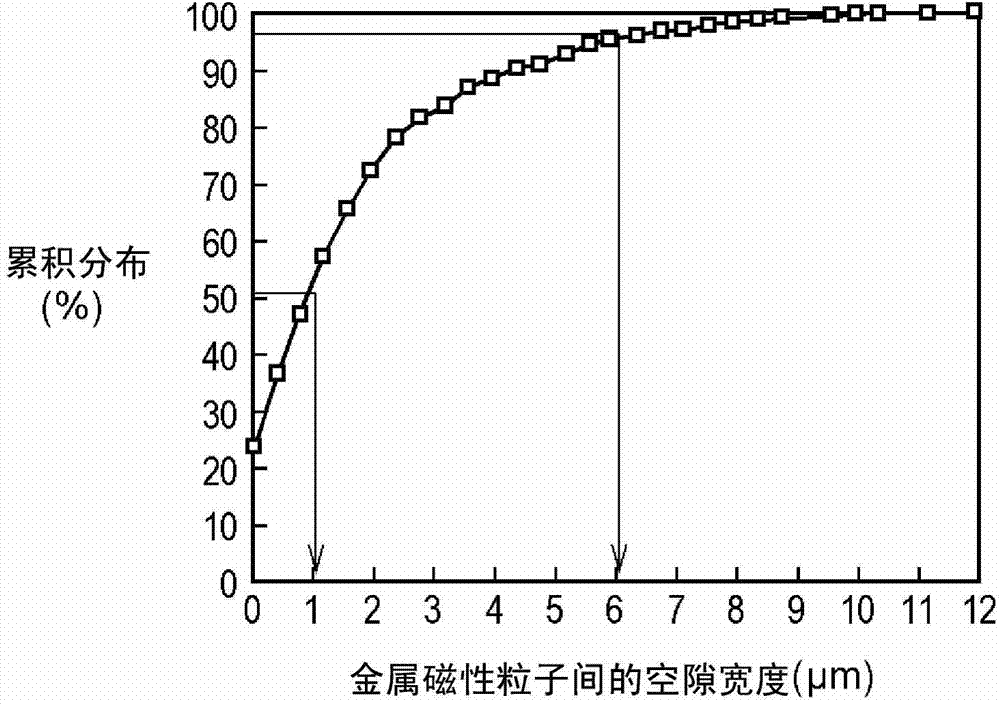

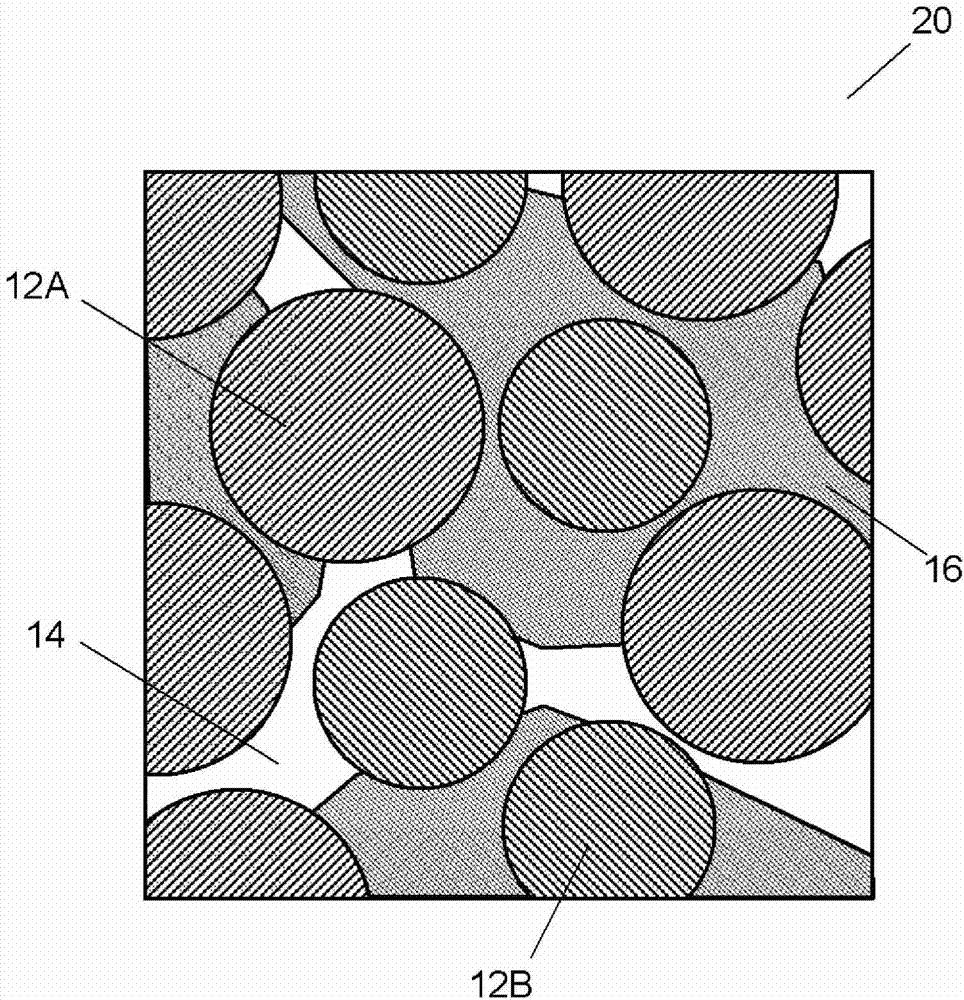

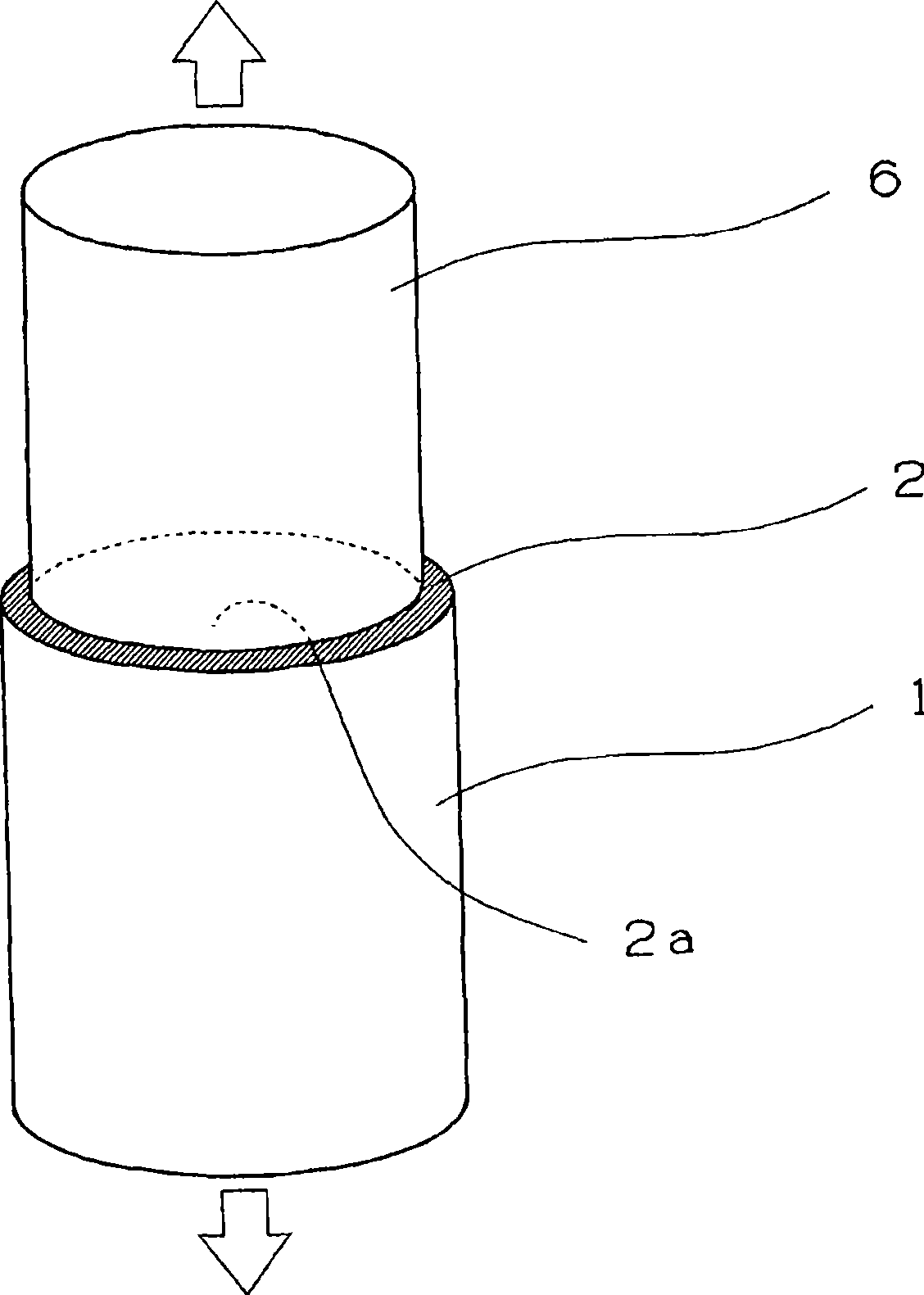

Composite magnetic body and method for manufacturing same

ActiveCN104756203AHigh mechanical strengthHigh insulation resistanceTransportation and packagingMetal-working apparatusMicroparticleMetal

A composite magnetic body includes a metal magnetic powder formed of a plurality of metal magnetic particles and an insulating material which is impregnated into at least some spaces among a plurality of metal magnetic microparticles. In a cumulative distribution curve for the width of spaces between the metal magnetic particles, the width of spaces forming 50% of the cumulative distribution is 3 µm or less, and the width of spaces forming 95% of the cumulative distribution is 4 µm or more.

Owner:PANASONIC INTPROP MANAGEMENT CO LTD

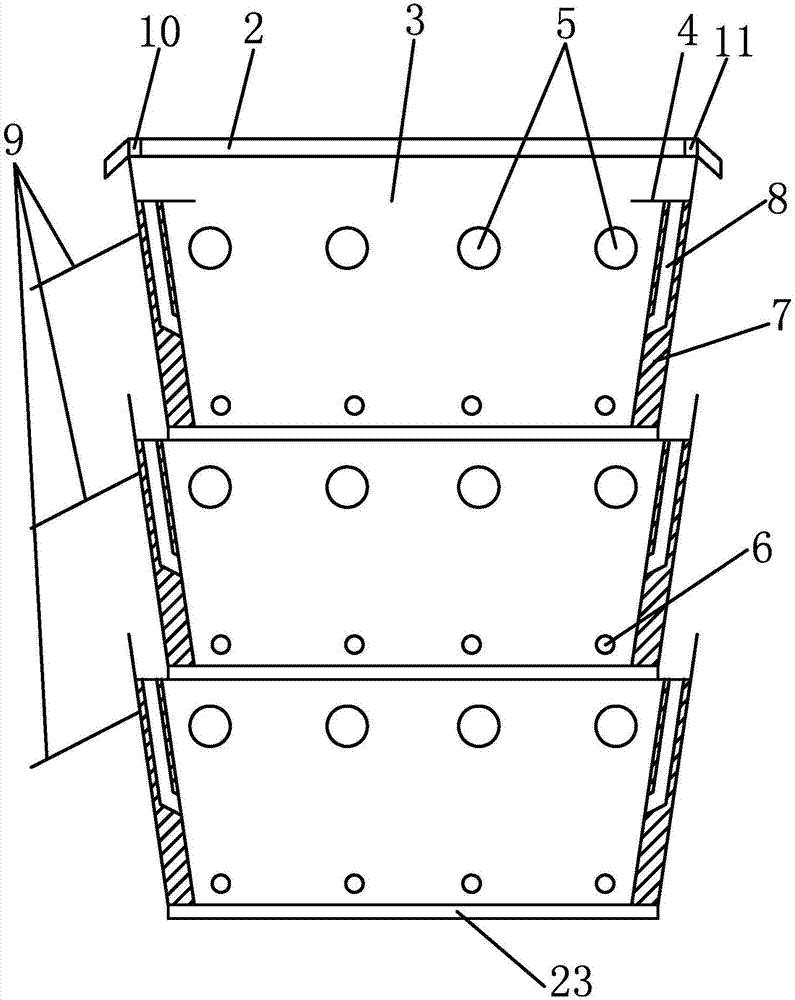

Plant cultivation device

ActiveCN107094529AGood insulationSmall footprintWatering devicesPressurised distribution of liquid fertiliserFertilizerWater diversion

The invention provides a plant cultivation device. The plant cultivation device comprises a base, wherein a plurality of planting pots are arranged on the base, each planting pot comprises a plurality of unit pots which are superposed sequentially from bottom to top, a pot cover is arranged at the top of the corresponding superposed unit pots in a covering manner, each unit pot is a cubical pot body with a tapering inclination angle, the specification of a top opening of each cubical pot body is greater than that of a pot bottom of each cubical pot body, each cubical pot body has a semitransparent circumferential wall, an annular supporting edge is arranged at the inner circumferential side of each semitransparent circumferential wall, a plurality of ventilation holes are formed in the upper part of each semitransparent circumferential wall, a plurality of drainage holes are formed in the lower part of each semitransparent circumferential wall, a plurality of supporting columns are arranged at the inner side of each semitransparent circumferential wall in an integrated manner, water diversion passages are formed in the supporting columns, a window is formed in one side wall of each semitransparent circumferential wall, and a window plate is hinged to each window; and a watering hole and a charging hole are further formed in each pot cover. According to the plant cultivation device, the floor area is saved, water and fertilizers are efficiently utilized, heat and moisture are preserved, and lighting is guaranteed.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

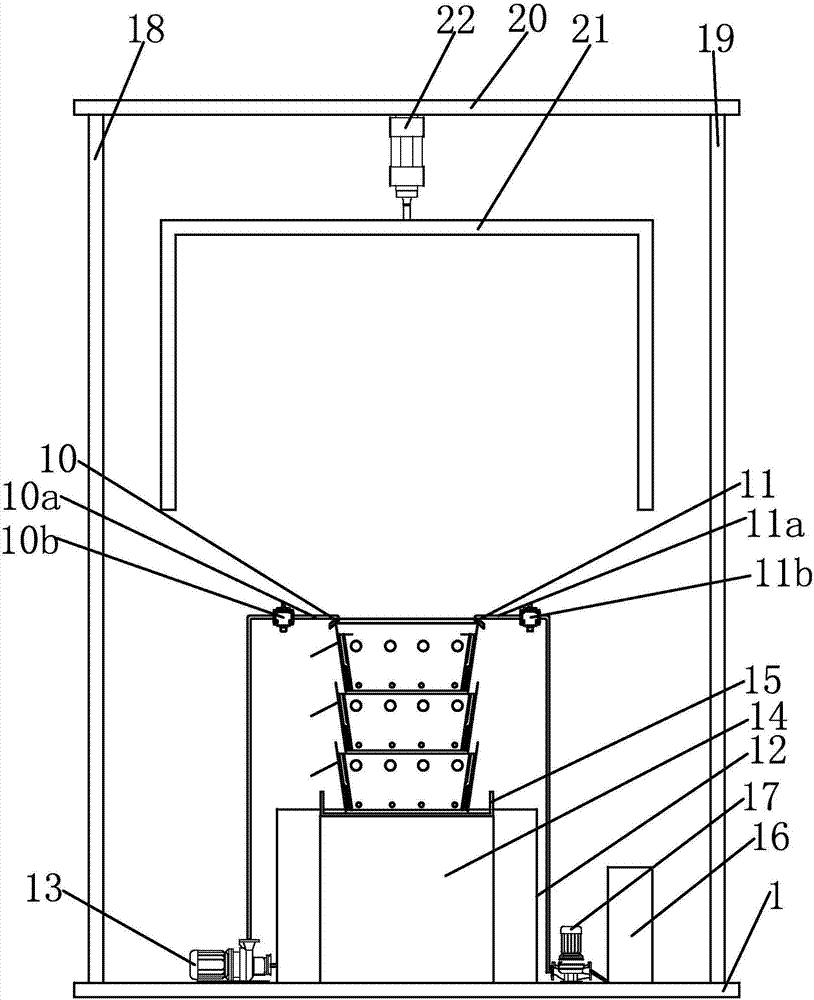

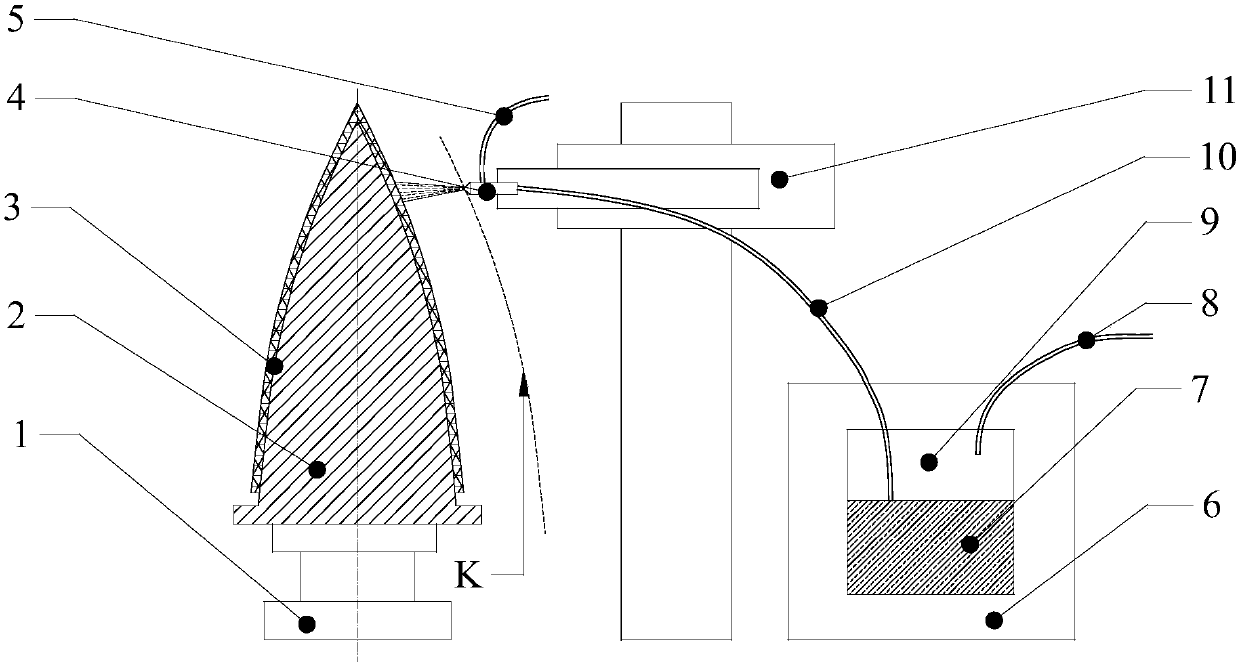

Jet molding device and method for resin based composite antenna housing

InactiveCN107891616AGood material uniformityImprove molding quality and pass rateDomestic articlesAirflowEngineering

The invention discloses a jet molding device for a resin based composite antenna housing. The jet molding device comprises a male mold, a reinforced fiber fabric, a rotating turntable, a jet device, atwo-dimensional moving device and a resin generation device, wherein the male mold is sleeved with the reinforced fiber fabric; the rotating turntable is arranged below the male mold and used for driving the male mold and the reinforced fiber fabric to rotate around respective vertical axes; the jet device is used for atomizing resin and jetting the resin into the reinforced fiber fabric; the two-dimensional moving device is connected with the jet device and used for driving the jet device to conduct two-dimensional movement along the offset curve of the outline of the male mold; and the resin generation device is connected with the jet device and used for heating the resin and conveying the resin to the jet device. The resin is jet to the reinforced fiber fabric through high-pressure airflow, the resin more easily permeates into the fabric, and the material uniformity is better. The jet molding process can be directly monitored through naked eyes and other means, defects existing inthe molding process can be treated in real time, and thus the molding quality and the percent of pass are improved.

Owner:SHANGHAI RADIO EQUIP RES INST

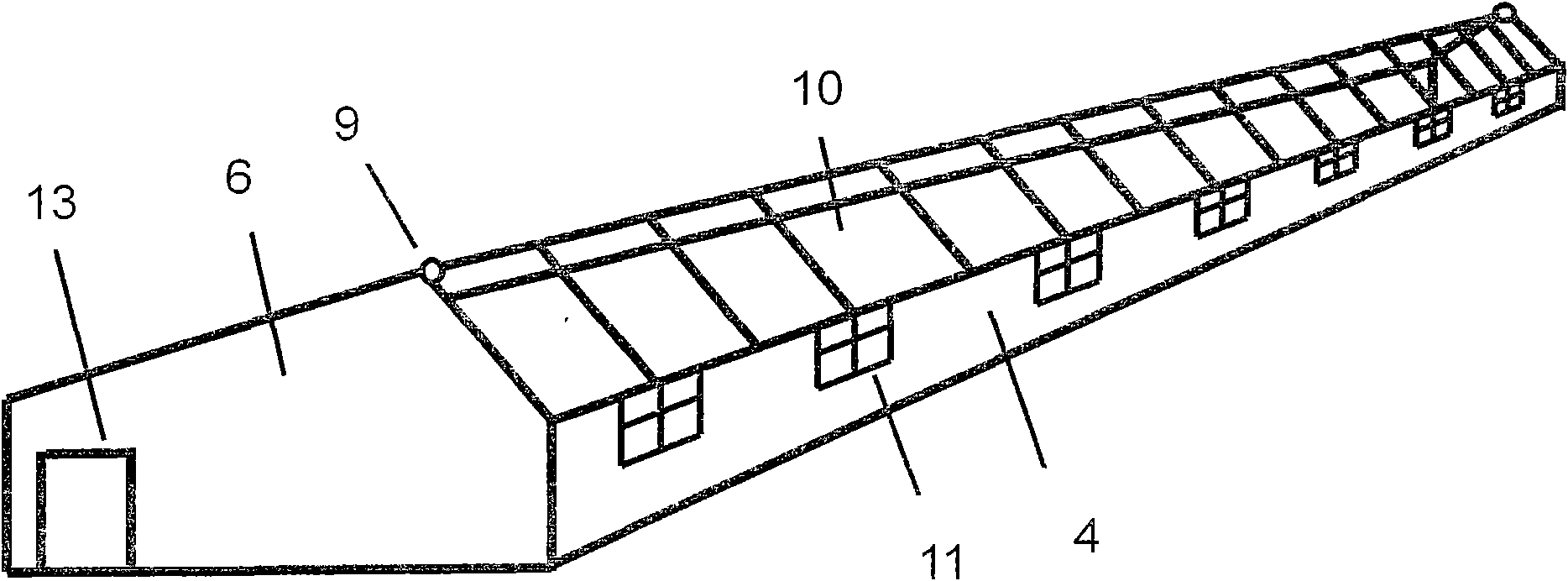

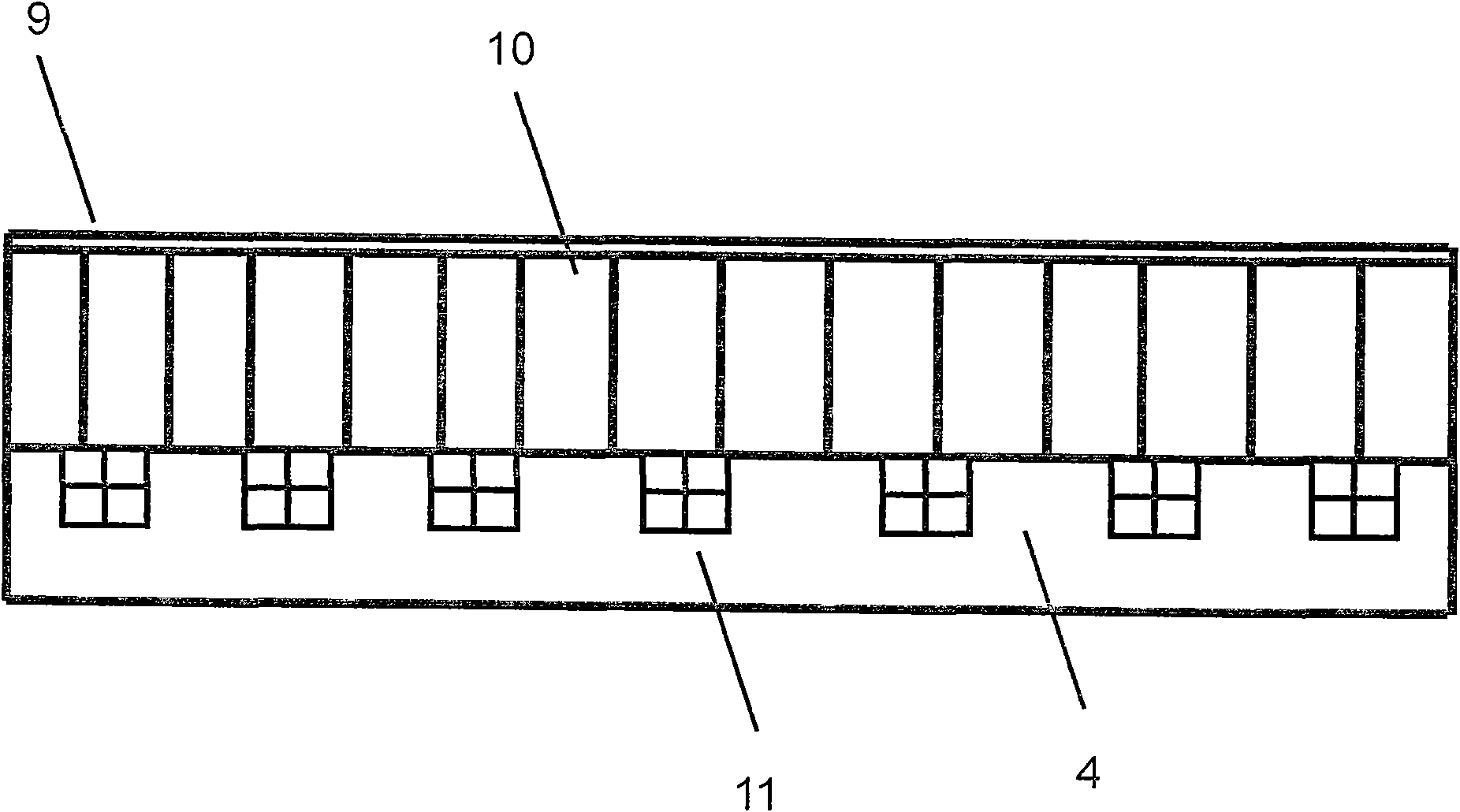

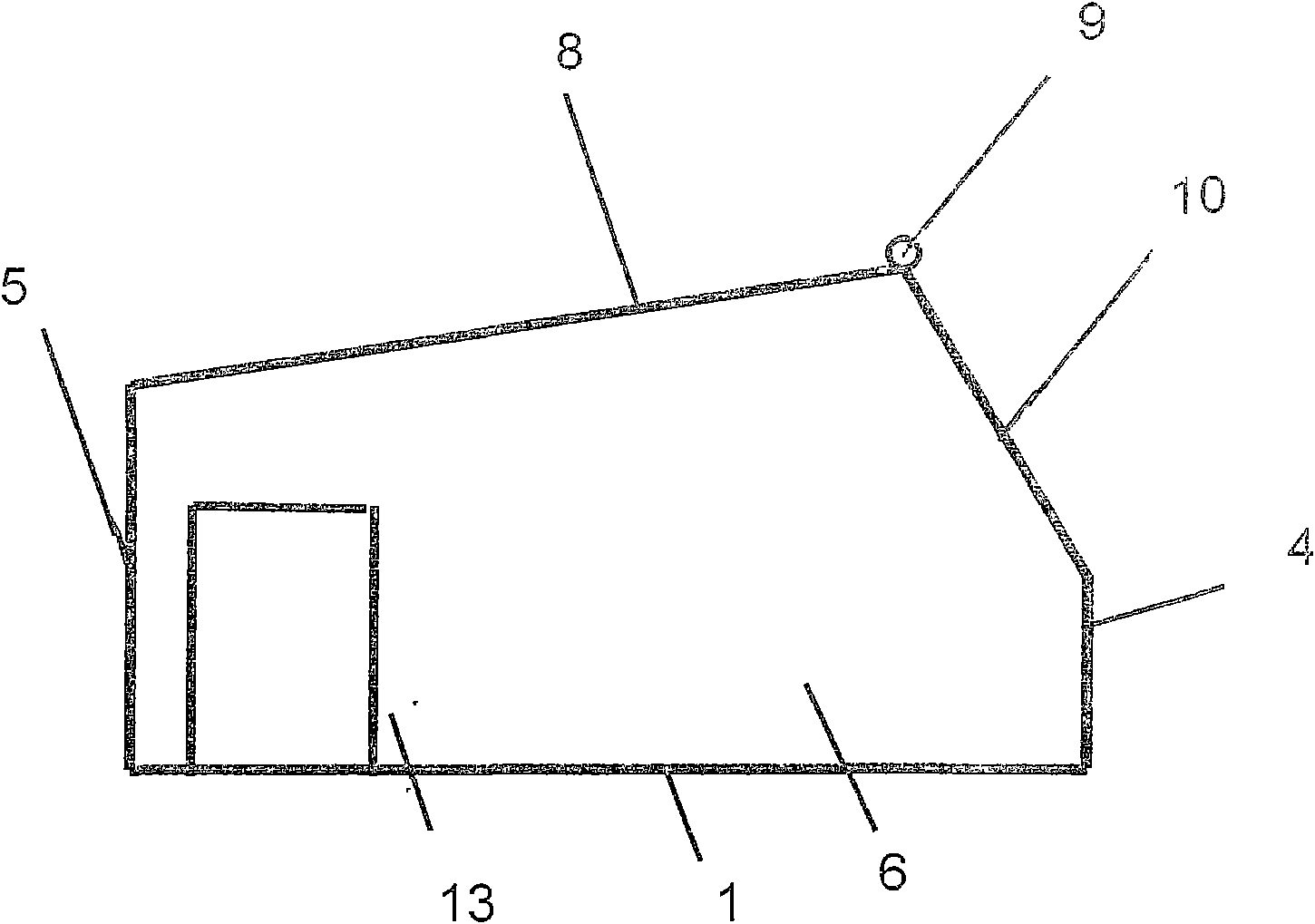

Energy-saving and emission-reducing sow gestation hut in the north

The invention relates to an energy-saving and emission-reducing sow gestation hut in the north. The sow hut is encircled by a south wall, a north wall, a west side wall and an east side wall. An automatic roller shutter is placed at the junction of a sloping roof and a ridge of a sunshine glass plate ceiling; the sunshine glass plate ceiling is located on the sunshine glass plate ceiling, and the sloping ceiling is located on the north wall; the south wall is provided with a window, the west side wall is provided with a west side door, and the east side wall is provided with an east side door; the ground is provided with a pit, a slotted floor is covered on the pit, and a limit fence crosses over the slotted floor; and the pit is provided with a drainage sewer, and the drainage sewer is covered by a drainage cover. The invention utilizes the structure characteristics that the sunshine can transmit the glass, and the automatic roller shutter is placed at the junction of the ceiling and the ridge so that the hut can keep the temperature, and is ventilated and is dry; and the ground is provided with the pit and the slotted floor is covered on the pitch, thereby the problems of large discharge capacity, bad environment and moisture of the hut and odor caused by accumulated excrement are solved.

Owner:GANSU AGRI UNIV

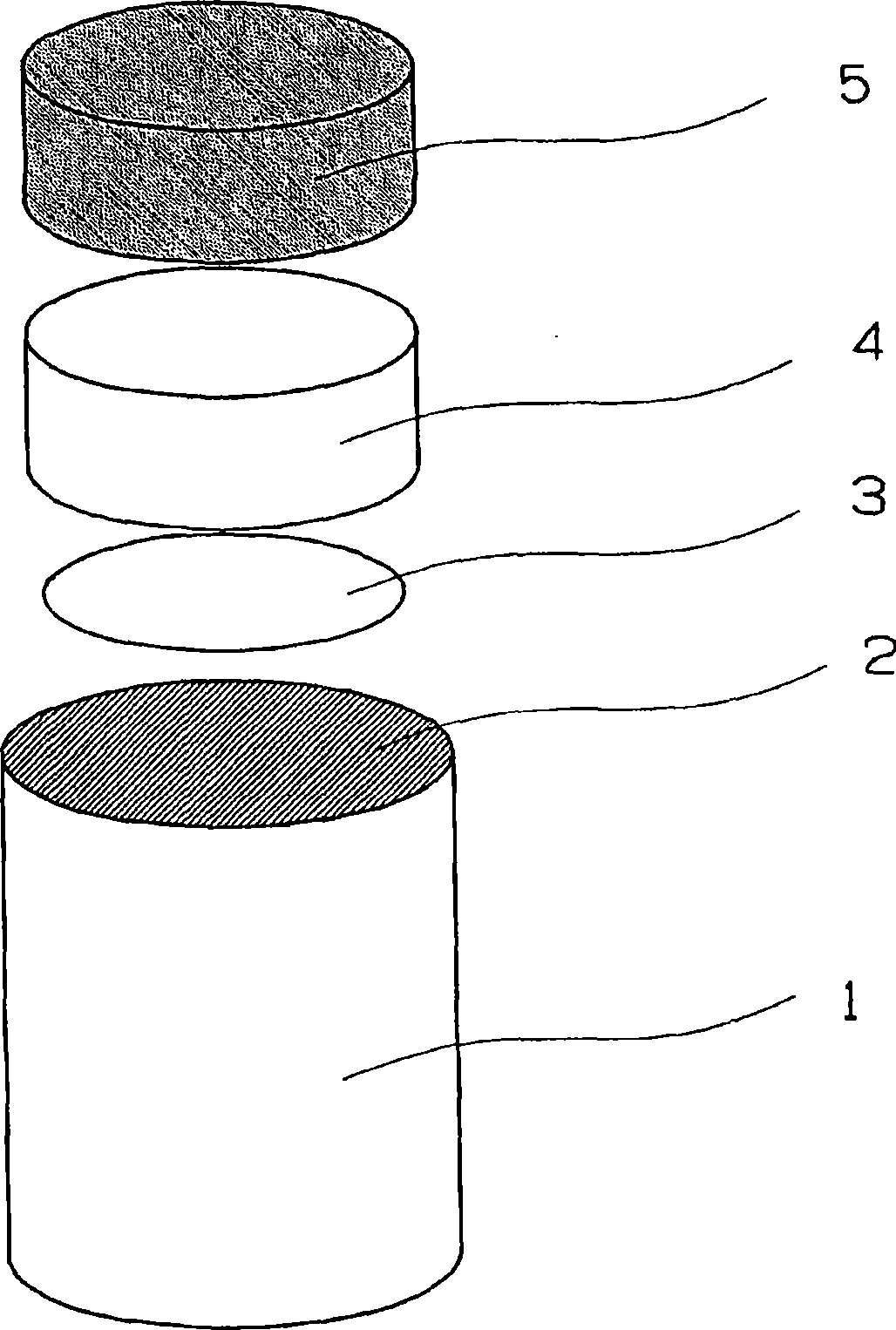

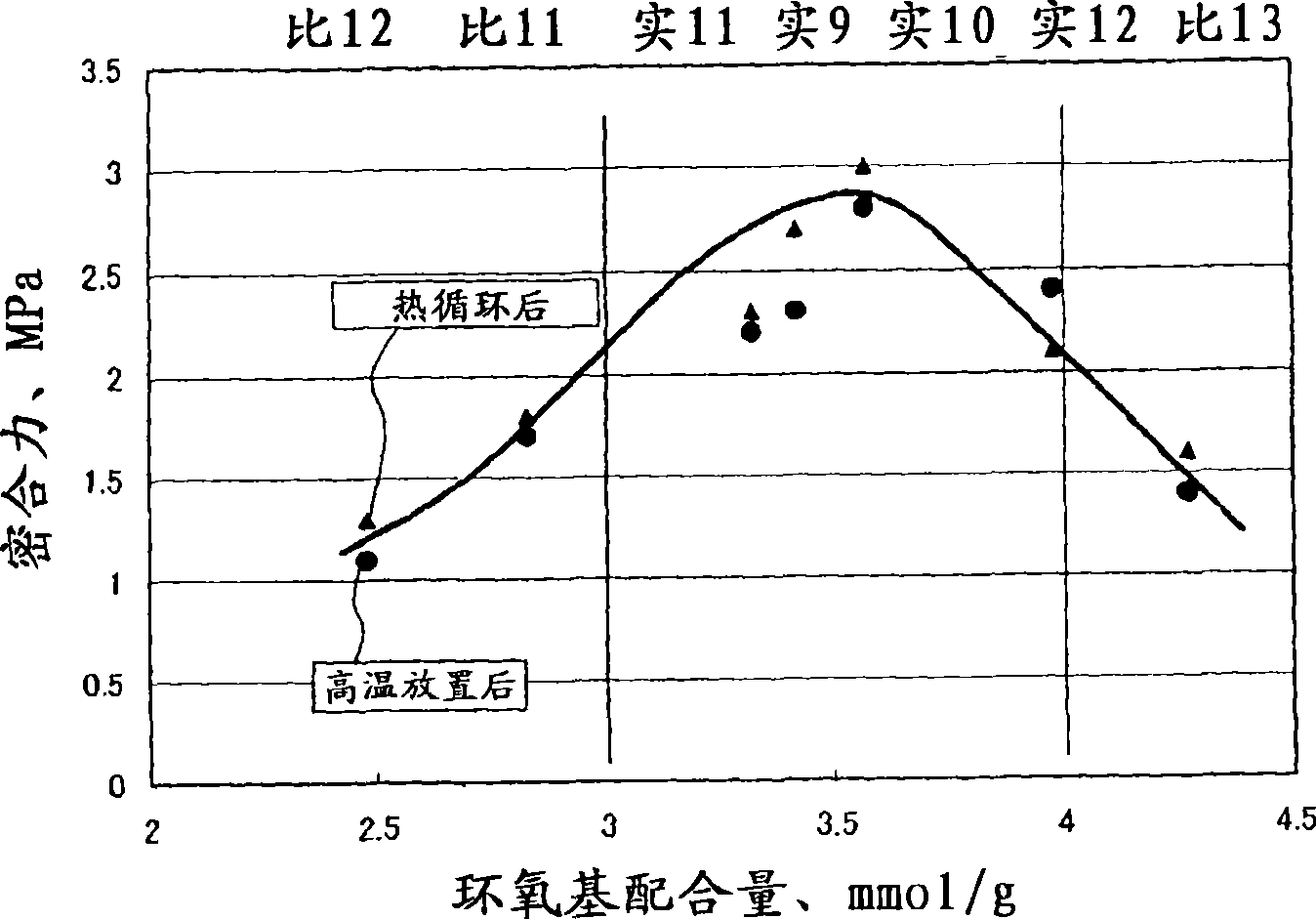

Sealer, members covered with sprayed coatings, and bearings

ActiveCN101421436AInhibitionPossibility of avoiding deterioration of sealing propertiesMolten spray coatingEpoxyEther

The present invention provides a pore-sealing agent and a member of coating a spray deposit. The pore-sealing agent is excellent in permeability into pores (gaps) of a spray deposit and can be favorably filled thereinto and is capable of sealing pores until a state in which gaps in a spray deposit material are substantially entirely filled is obtained. The pore-sealing agent contains an epoxy group-containing component and a hardener and does not contain a polymerizable vinyl group-containing solvent. The epoxy group-containing component is a mixture containing a polyglycidyl ether compound in which the number of epoxy groups contained in one molecule is not less than three as an essential component thereof and in addition, an alkylenediglycidyl ether compound or a cyclic aliphatic diepoxy compound, both of which contain two epoxy groups in one molecule thereof. Excluding the hardener, the mixing ratio of the polyglycidyl ether compound to the epoxy group-containing component of the mixture is 10 to 95 wt%.

Owner:NTN CORP

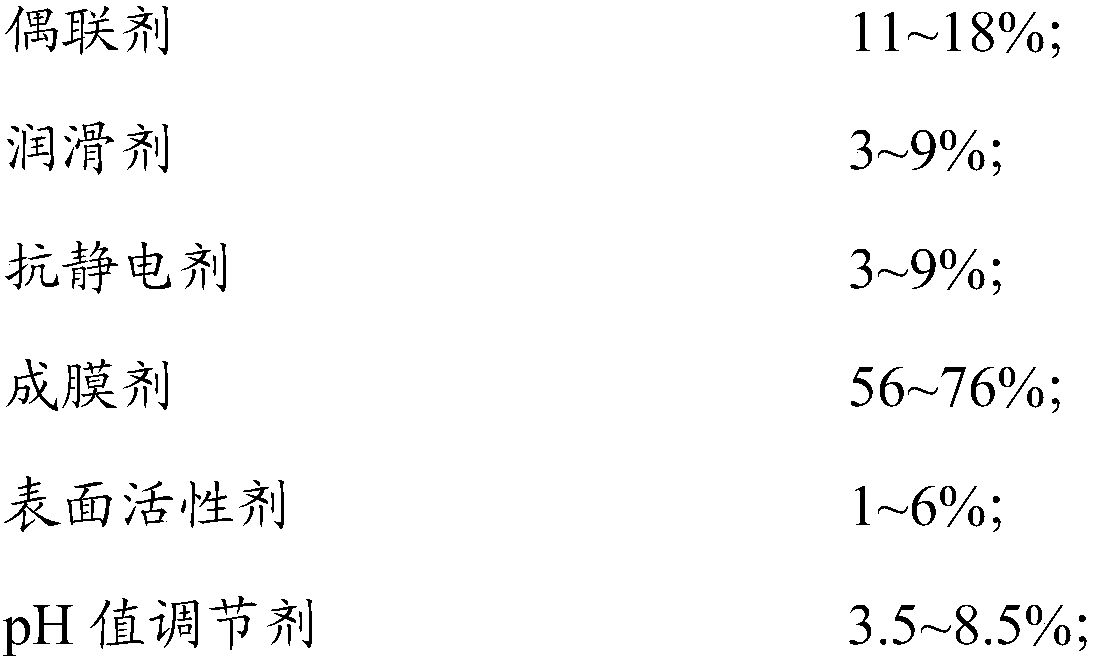

Glass fiber stranded twistless rough yarn impregnating compound, and preparation method, product and application thereof

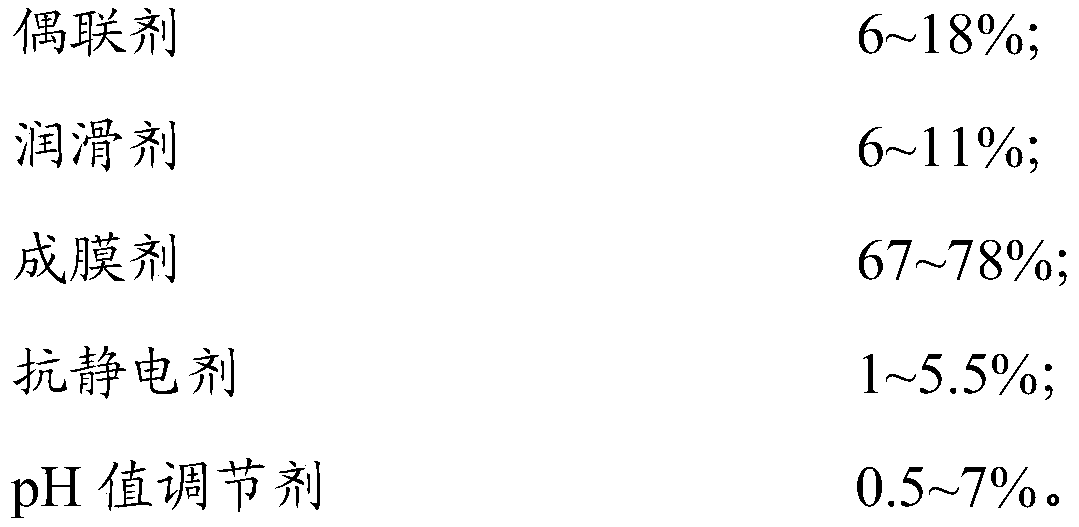

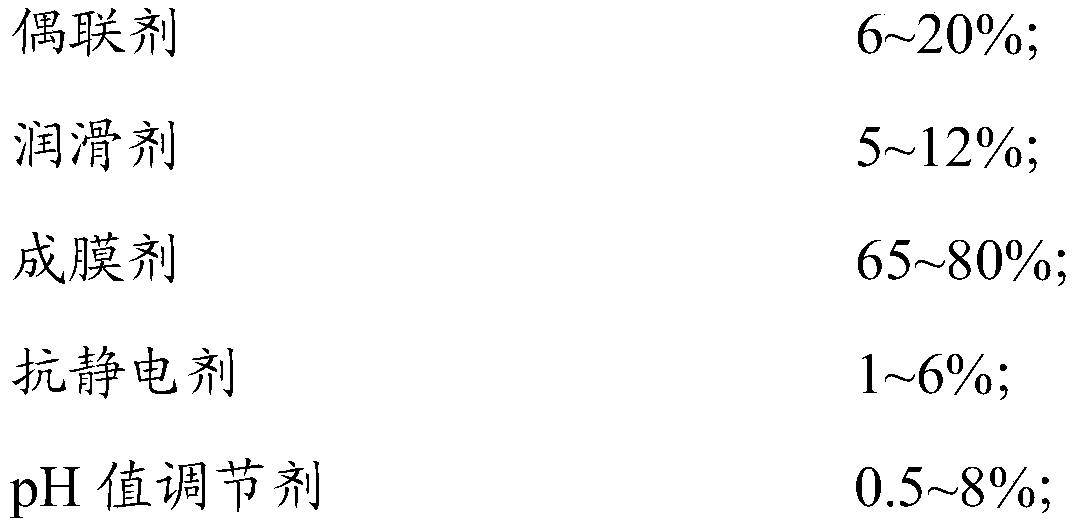

The invention discloses a glass fiber stranded twistless rough yarn impregnating compound. The solid mass of the impregnating compound accounts for 6-14% of the total mass of the impregnating compound; the impregnating compound comprises the following components in percentage by solid mass: 6-20% of a coupling agent, 5-12% of a lubricant, 65-80% of a film-forming agent, 1-6% of an antistatic agentand 0.5-8% of a pH value regulator, wherein the film-forming agent is formed by mixing at least three of an epoxy modified polyester resin emulsion, water-soluble epoxy resin, a bisphenol A epoxy resin emulsion and a polyurethane resin emulsion. Glass fiber yarns produced by coating with the impregnating compound is good in compatibility with target resin, namely polyester resin, and good in permeability, the mechanical property of a product can be high, and the mechanical property index requirements of pultrusion profiles and winding pressure containers are met.

Owner:JUSHI GRP CO

Method for processing duck wheat coarse grain food

InactiveCN1561798ANutrient lossNo relapseFood shapingFood preparationPolygonum fagopyrumFood material

A food is prepared from the flour of tartarian buckwheat through stirring, laying asid for a certain time, granulating, rounding, steaming, sprayinkg atomized water, dispersing, steaming, baking at 90-110 deg.C for quick dewatering, and cooling.

Owner:GUIYANG GAOXIN YINGNA TECH DEV

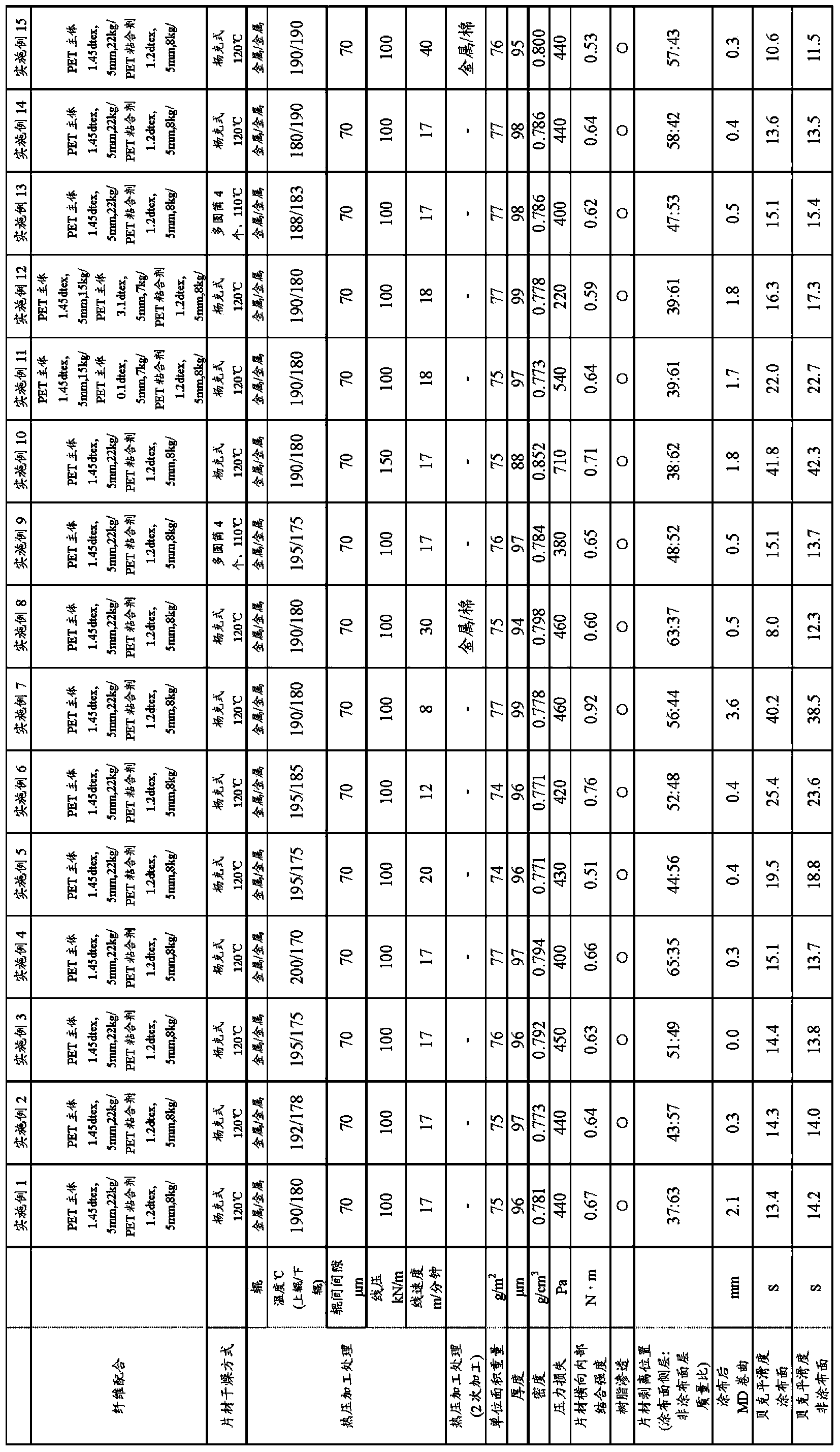

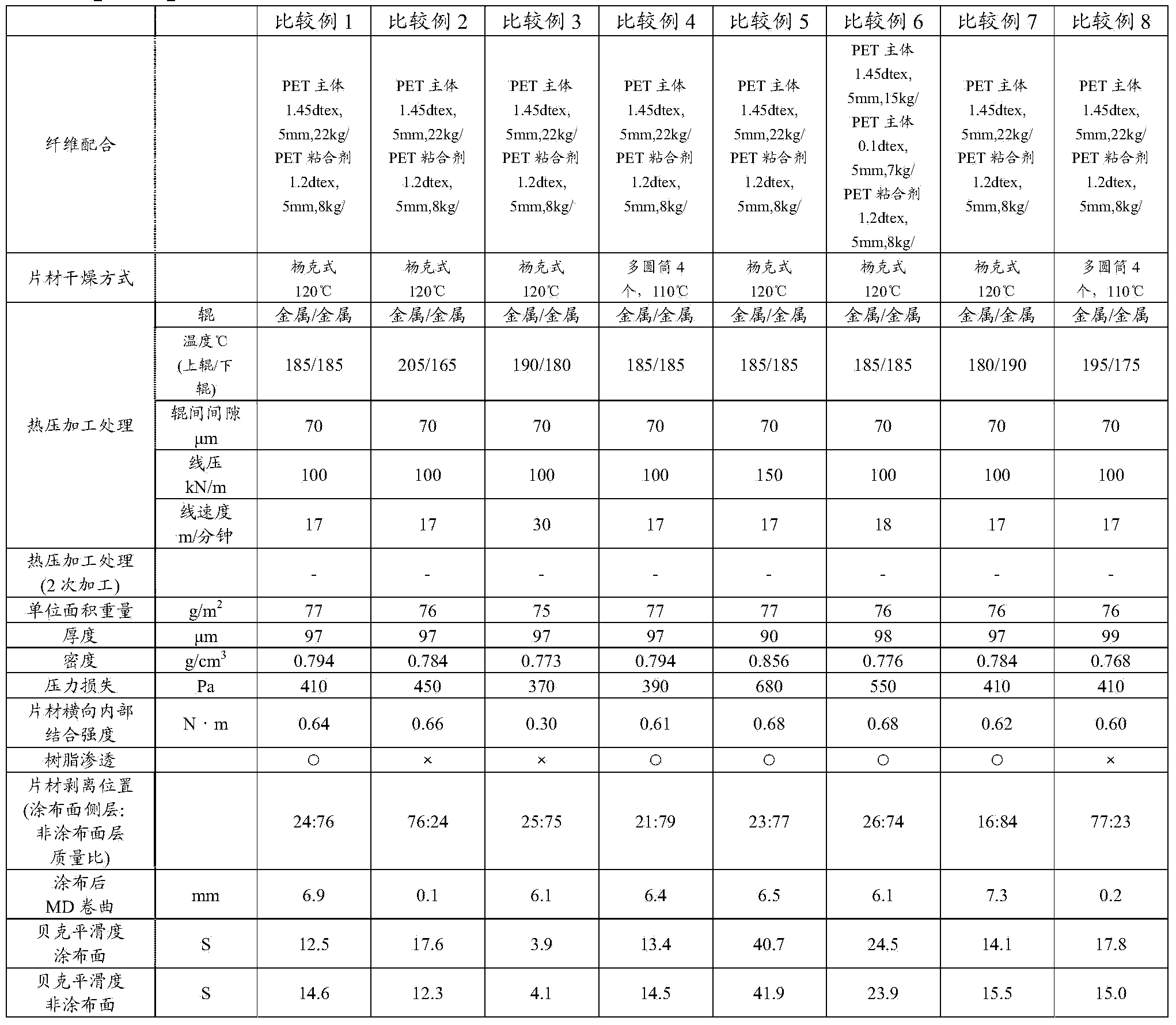

Nonwoven fabric for semipermeable membrane supporting body and method for manufacturing same

ActiveCN104125857AEasy to soakAvoid curlSemi-permeable membranesMembranesSemipermeable membraneNonwoven fabric

The present invention addresses the problem of providing a nonwoven fabric for a semipermeable membrane supporting body which shows a good MD curl when a semipermeable membrane coating solution is applied to the supporting body (nonwoven fabric) and cured, and a method for manufacturing the same. The nonwoven fabric for a semipermeable membrane supporting body according to the present invention is a nonwoven fabric which comprises an organic synthetic fiber as the main component and on one surface of which a semipermeable membrane is to be supported, characterized in that, when the nonwoven fabric to be coated with the semipermeable membrane is separated into two layers along the thickness direction thereof to give a layer on the side of the surface to be coated with the semipermeable membrane and the other layer on the side of the surface not to be coated with the semipermeable membrane, the ratio of the layer on the side of the surface to be coated with the semipermeable membrane is 35-70 mass% inclusive relative to the sum of the layer on the side of the surface to be coated with the semipermeable membrane and the layer on the side of the surface not to be coated with the semipermeable membrane.

Owner:HOKUETSU KK

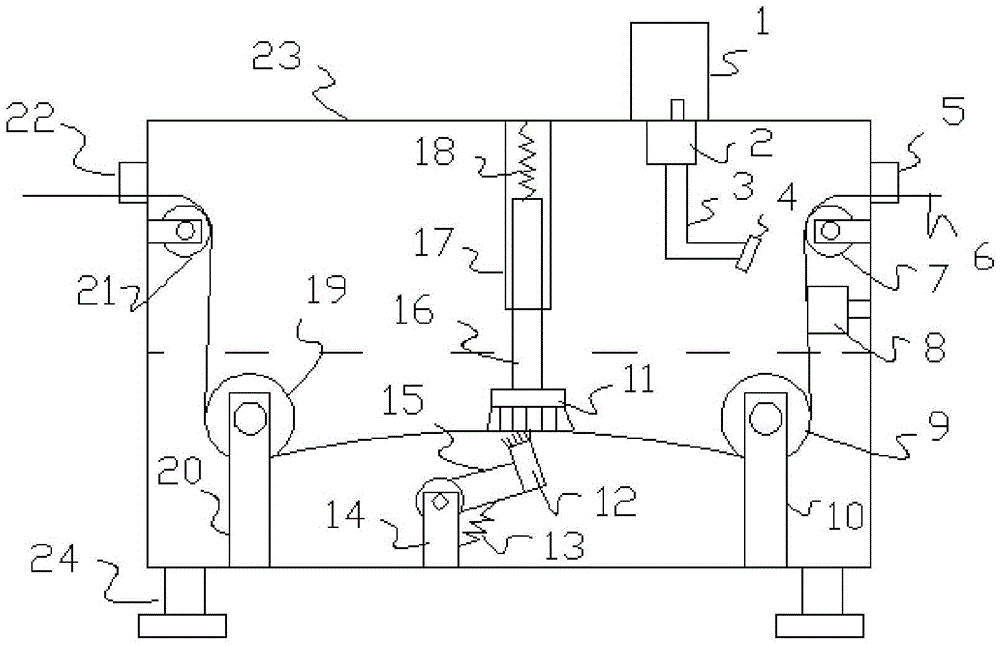

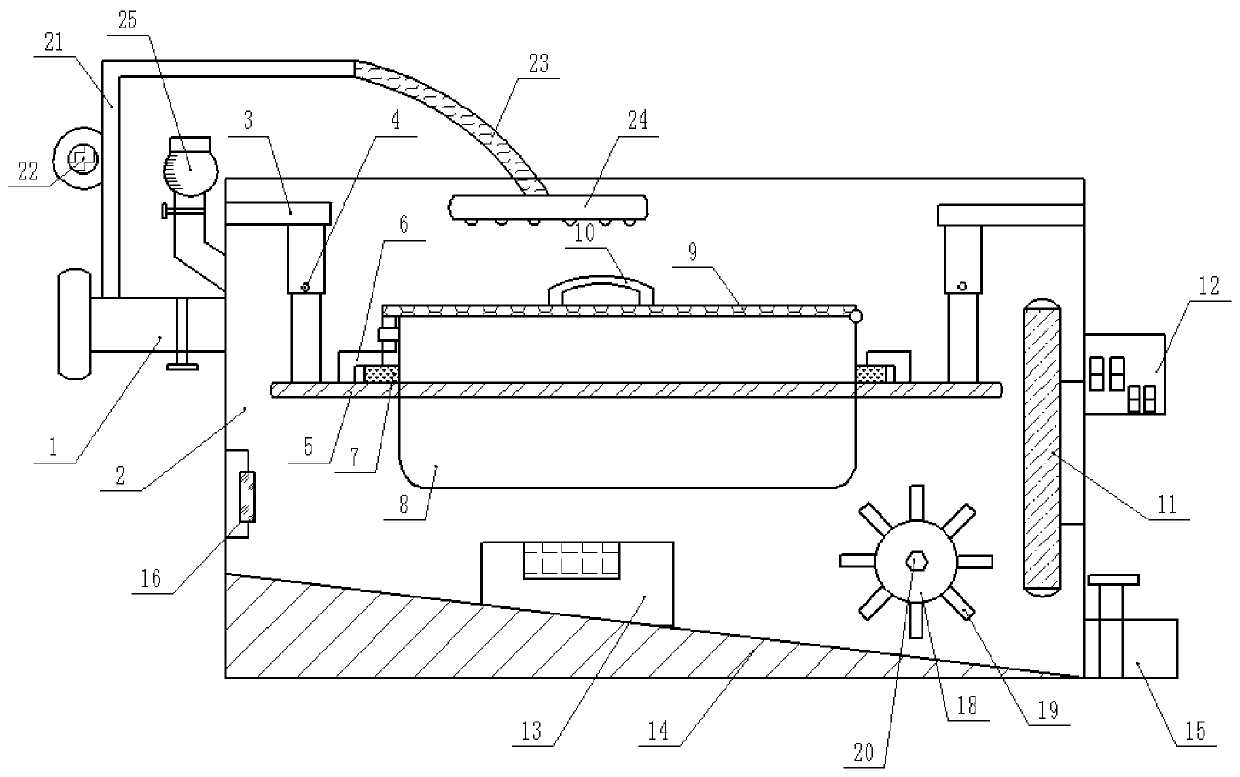

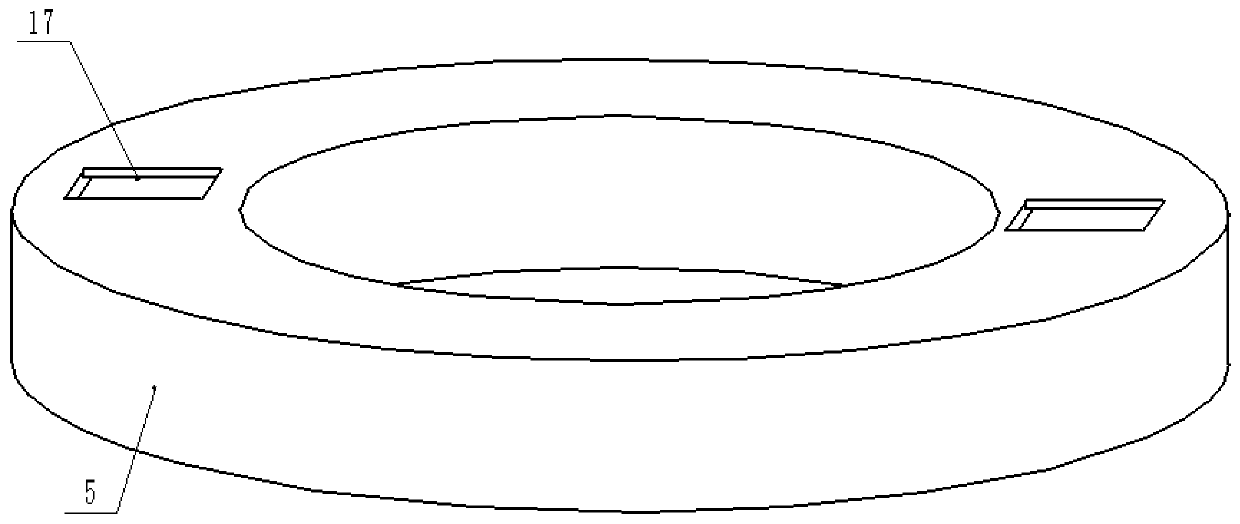

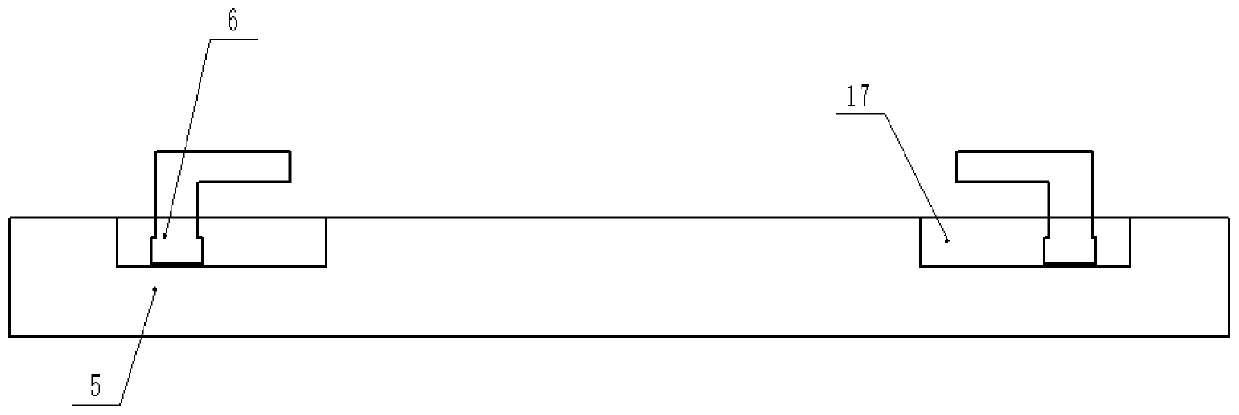

Woven cloth flushing device

ActiveCN105544127APlay a guiding roleEasy to soakMechanical cleaningSucessive textile treatmentsEngineeringMechanical engineering

The invention relates to the field of spinning, in particular to a woven cloth flushing device. By means of the flushing device, soaking and flushing can be conducted at the same time, and meanwhile deformation of woven fabric can be prevented and the product quality can be easily kept. The woven cloth flushing device structurally comprises a box body. A feed port and a discharge port are formed in the left end and the right end of the box body respectively. A feed guide wheel is arranged on the portion, below the feed port, on the inner wall of the box body. A discharge guide wheel is arranged on the portion, below the discharge port, on the inner wall of the box body. A first guide wheel and a second guide wheel are fixedly arranged on the two sides of the bottom in the box body respectively. A support is arranged between the first guide wheel and the second guide wheel. A supporting rod is hinged to the top of the support. A first brush is arranged at the tail end of the supporting rod. A first spring is arranged between the supporting rod and the support. The woven cloth flushing device is easy to operate, convenient to use and suitable for washing various types of woven cloth.

Owner:苏州卓米纺织科技有限公司

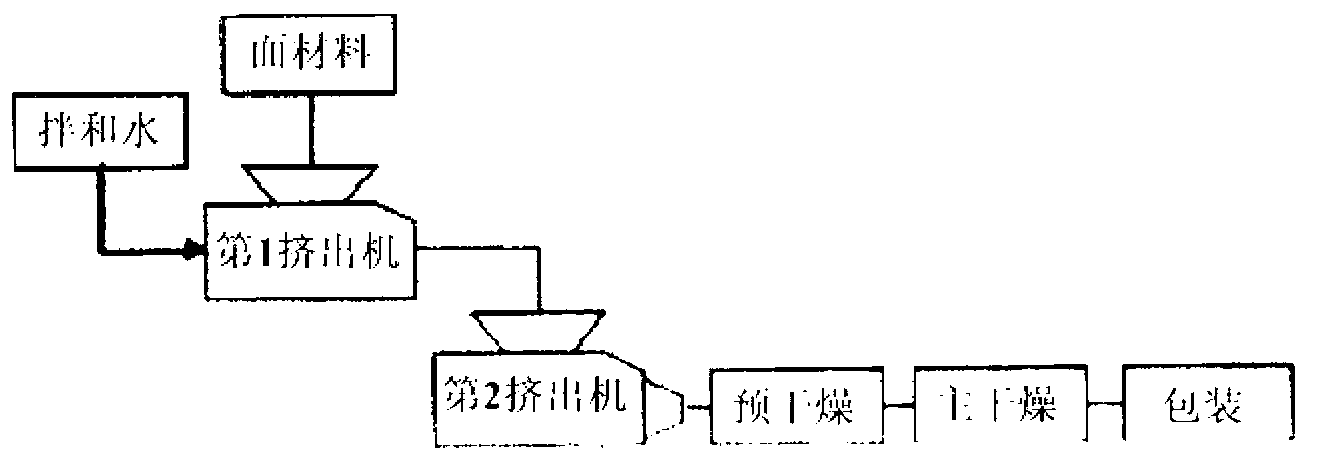

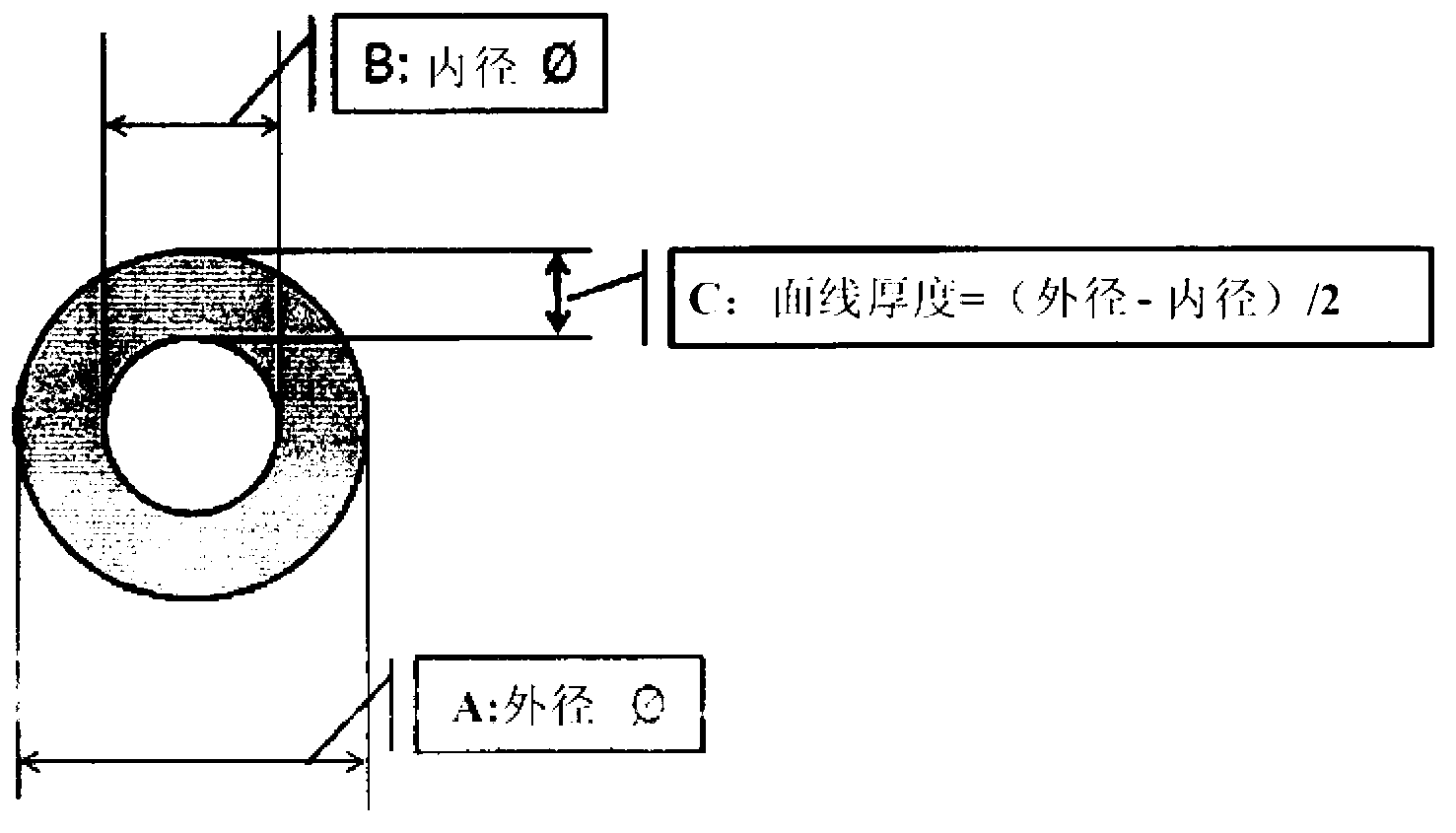

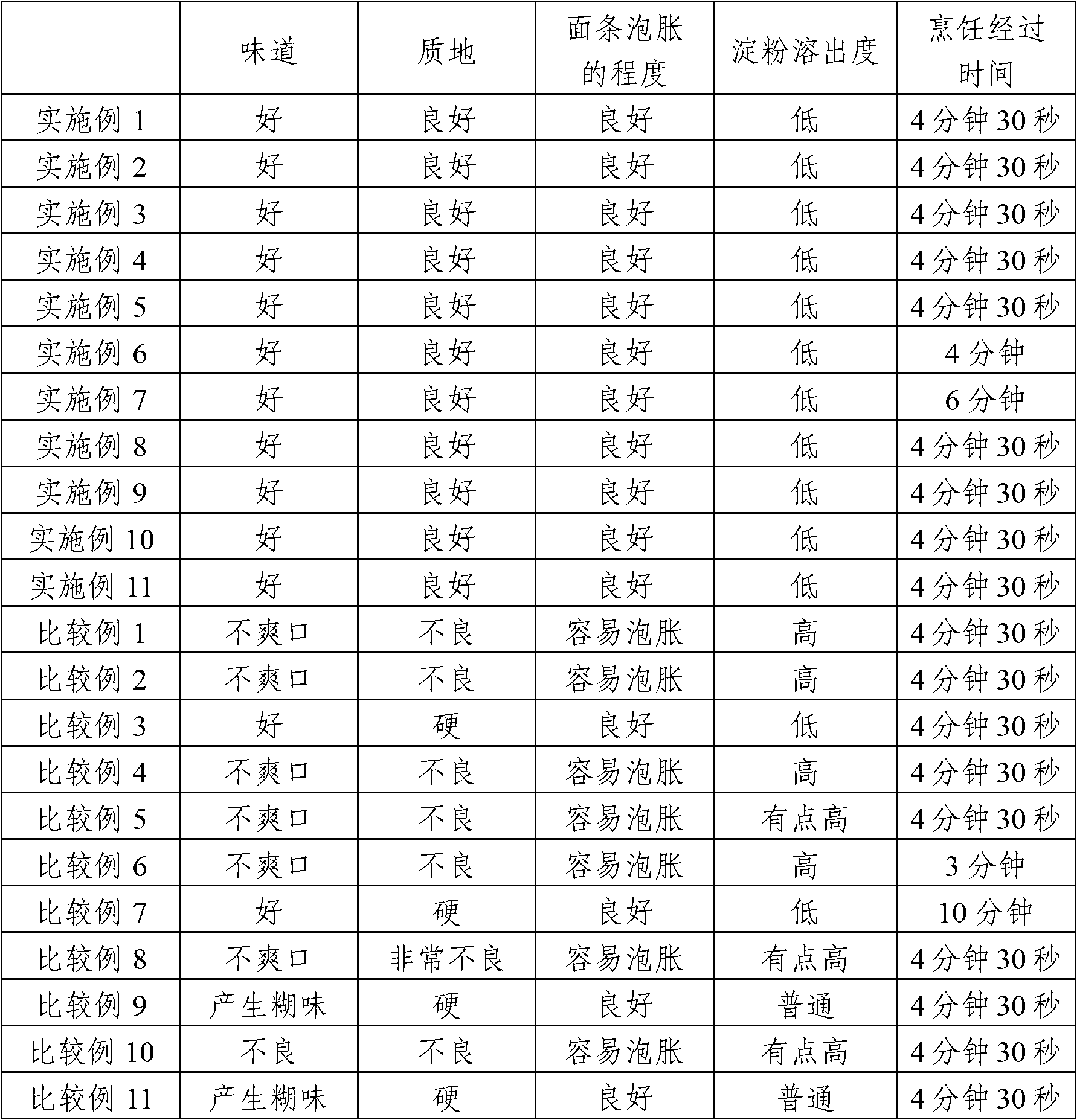

Method for producing hollow noodles

ActiveCN102781242AGreat tasteReduce cooking timeFood coatingDough extruding machinesEvaporationWater fraction

The present invention relates to a method for producing hollow noodles, and more specifically to one in which a gelatinized doughy substance is passed through a die designed to form a hollow area, such that the noodles which have passed through in this way have a tubular hollow area on the inside and hence it is possible to produce noodles which have a dramatically reduced cooking time and readily allow juices and sauces to penetrate inside the noodle during cooking and so enhance the taste. Further, it is possible to produce noodles in which the formation of the hollow causes the noodle surface area to be increased, and, as a result, there is rapid evaporation of the water fraction on the surface of the noodle which is being gelatinized and injected, and hence noodle stickiness is dramatically improved and consequently noodle sticking is reduced.

Owner:NONG SHIM

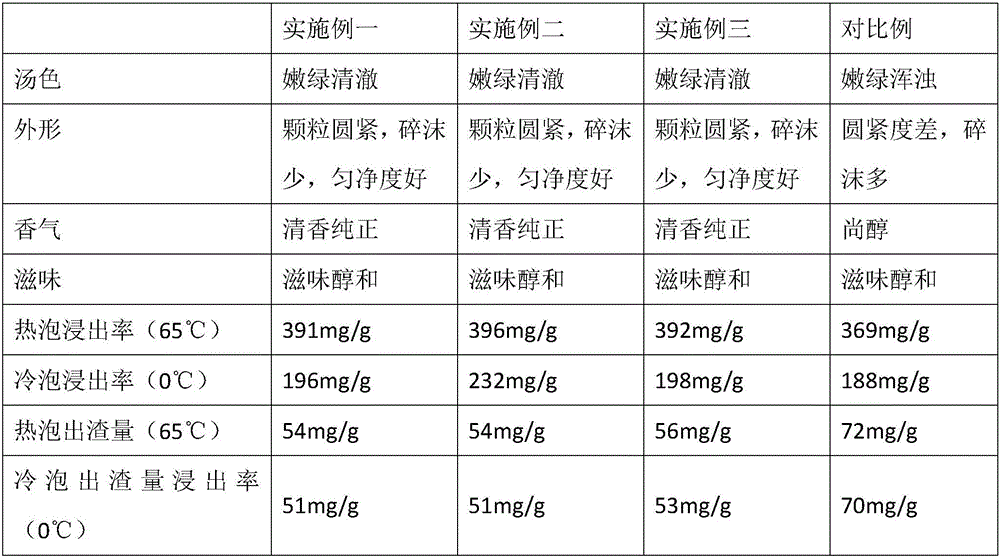

Easy-to-brew granulated green tea processing technology

InactiveCN106212748AImprove leaching rateIncrease the amount of slagPre-extraction tea treatmentRetention timeSlag

The invention discloses an easy-to-brew granulated green tea processing technology. The processing technology comprises the steps of fixation, rolling, rolling and cutting and drying; before fixation is conducted, needle-punched hole punching is conducted on picked tea leaves through a needle plate; after rolling and cutting are conducted, formed granulated green tea is subjected to expanding treatment and pressure-releasing freezing treatment; for expansion, the granulated green tea is put into an expanding machine, the control temperature ranges from 50 DEG C to 80 DEG C, the pressure ranges from 0.2 MPa to 0.4 MPa, and the retention time ranges from 5 min to 25 min; for pressure-releasing freezing, after expanding treatment is completed, a pressure releasing system is opened, the pressure is instantly released to 0.01 MPa to 0.08 MPa, when pressure releasing is conducted, the temperature is rapidly decreased to -10 DEG C to 4 DEG C, and the retention time ranges from 5 min to 25 min; in the drying process, the room temperature is kept, and air-drying is conducted on the granulated green tea. The granulated green tea obtained through the processing technology is high in leaching rate, low in slag quantity and high in tea quality.

Owner:务川自治县万壶香茶业有限公司

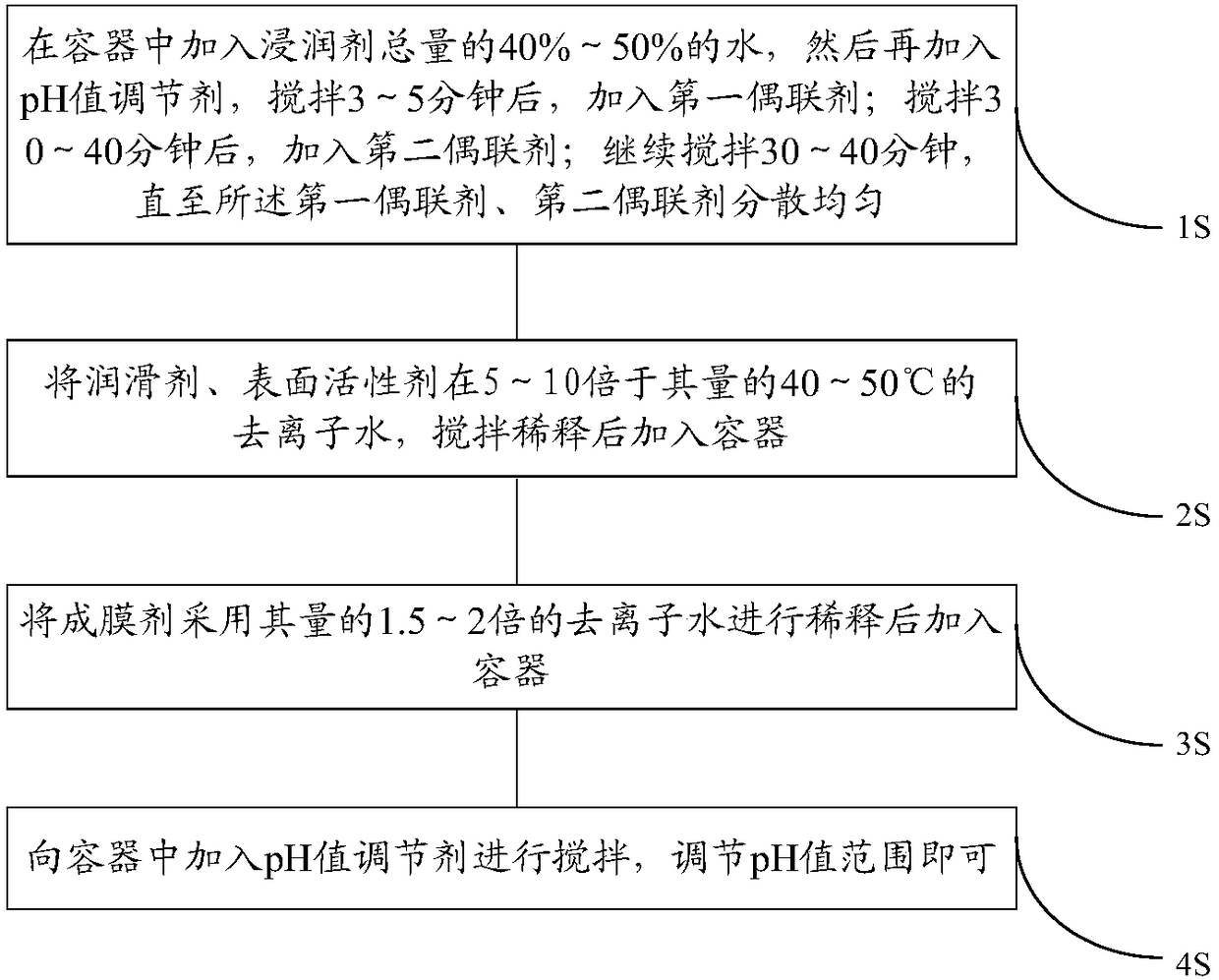

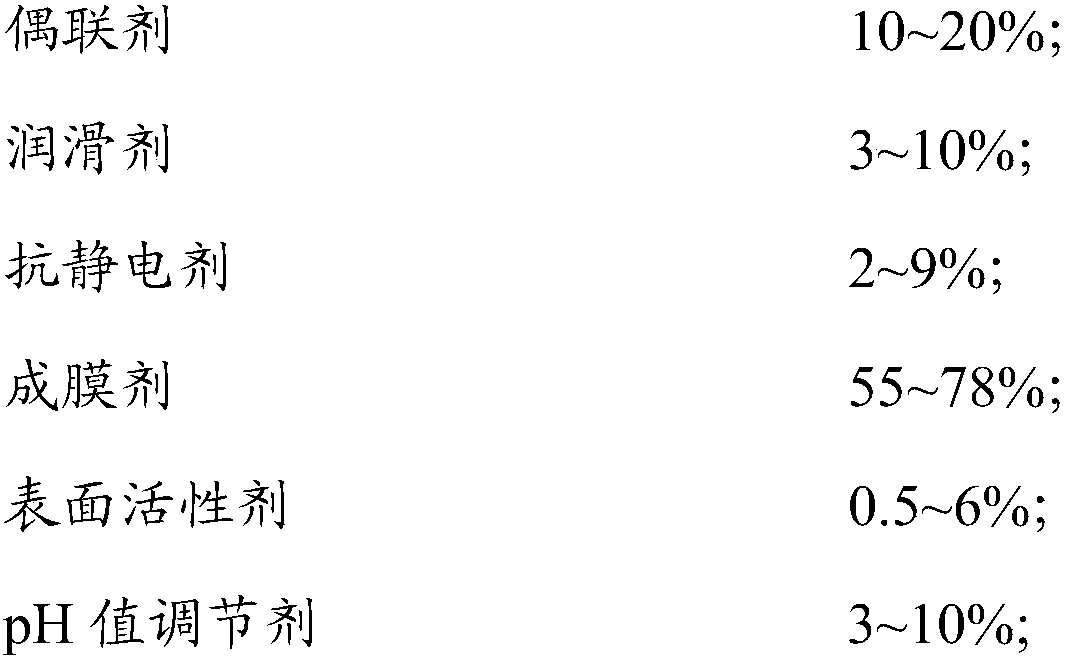

Direct yarn impregnating compound for insulator as well as preparation method and application thereof

The invention provides a direct yarn impregnating compound for an insulator. According to the impregnating compound, the percentage of solid mass of each component in solid mass of the impregnating compound is as follows: 10 to 20 percent of a coupling agent, 3 to 10 percent of lubricant, 2 to 9 percent of antistatic agent, 55 to 78 percent of film forming agent, 0.5 to 6 percent of surfactant and3 to 10 percent of pH (Potential of Hydrogen) value regulator; the film forming agent is prepared from a first film forming agent and a second film forming agent; the first film forming agent is selected from one of water-soluble epoxy resin emulsion, bisphenol A type epoxy resin emulsion and bisphenol F type epoxy resin emulsion; the second film forming agent adopts the bisphenol F type epoxy resin emulsion; the mass ratio of the two film forming agents ranges from (1 to 4) to (1 to 0.6). Direct yarns produced by the impregnating compound have good compatibility and impregnation with targetresin, i.e., epoxy resin; a product has high mechanical properties and good electrical insulating performance, and requirements of standards are met.

Owner:JUSHI GRP CO

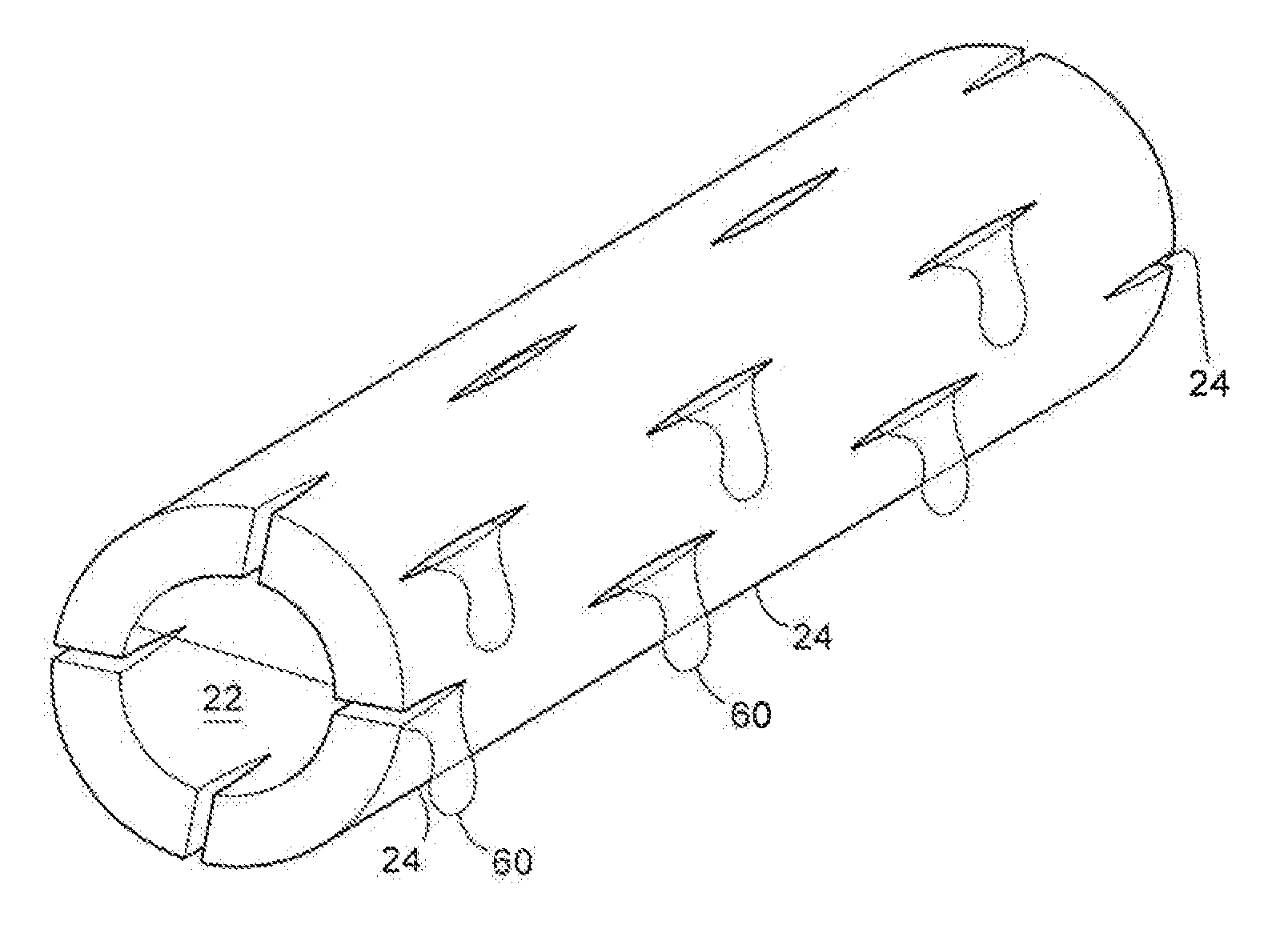

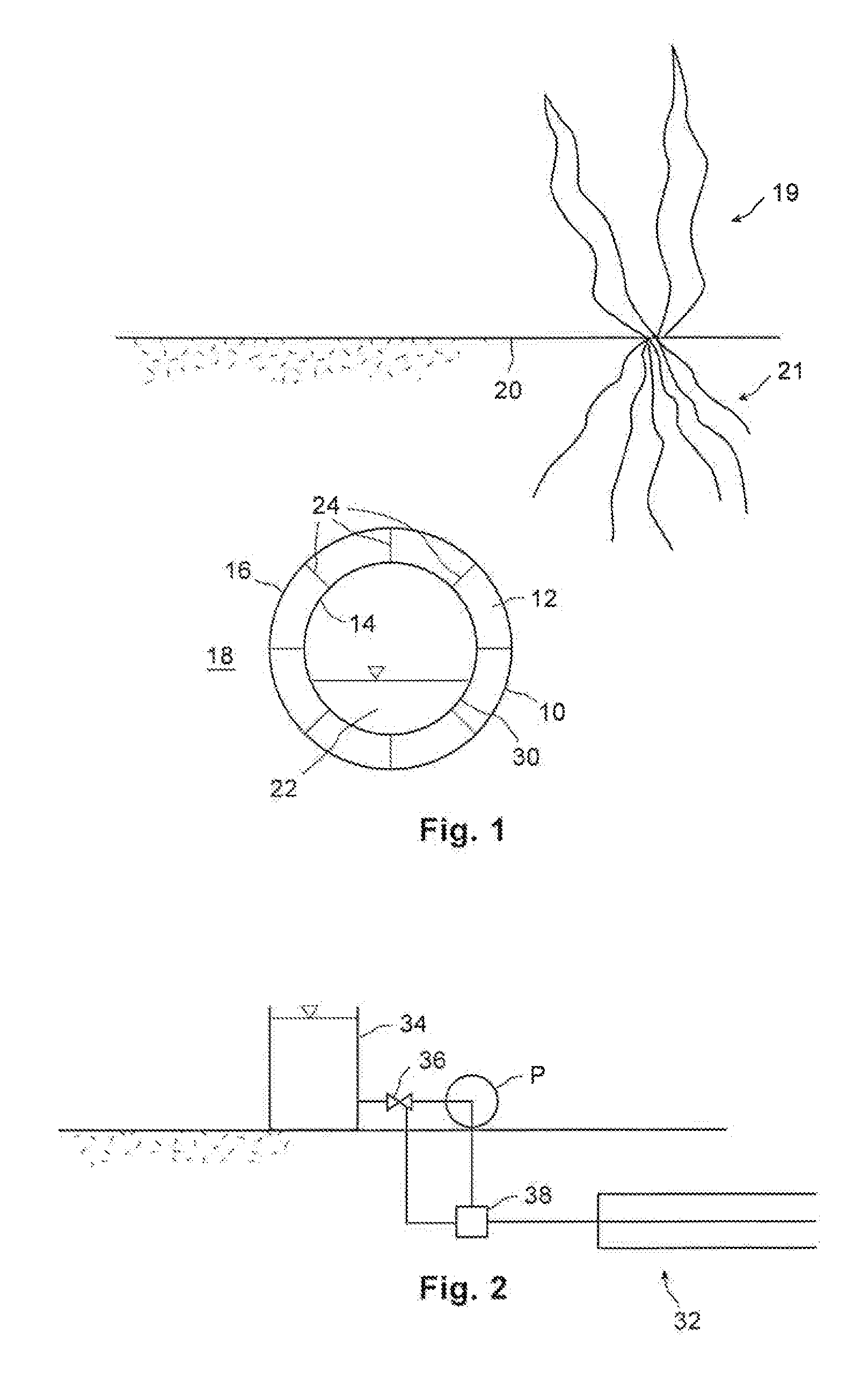

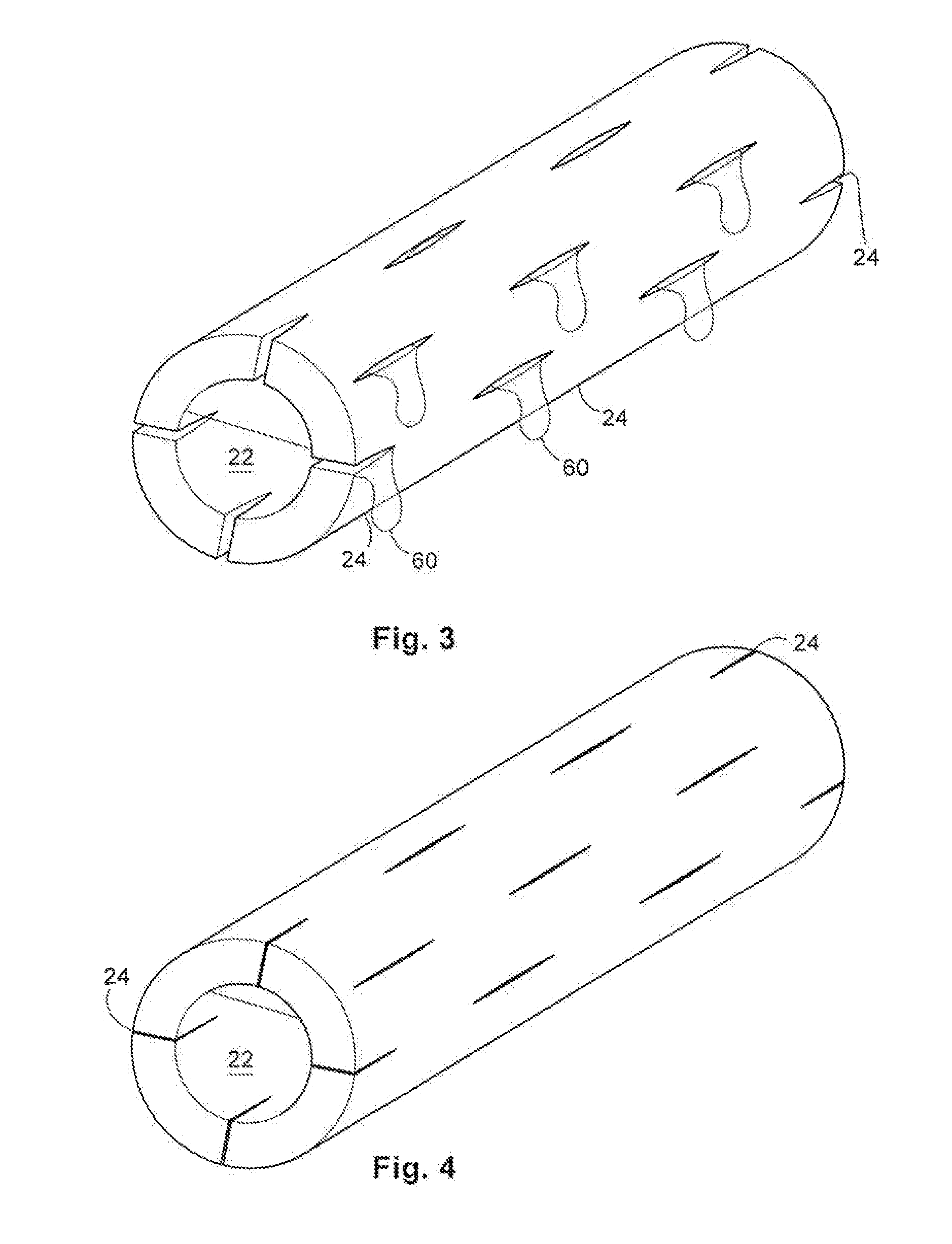

Moisture responsive irrigation method and apparatus

An irrigation device comprising a moisture responsive barrier is provided. At least a portion of the barrier has perforations, at least some of the perforations are associated with a water swellable material. The perforations are configured to open as the water swellable material loses moisture and dries out and are configured to close as said water swellable material is exposed to and absorbs water, such as during a watering step. According to another aspect the irrigation method includes the steps of positioning a perforated barrier between a source of irrigation water and an area to be irrigated, wherein the perforations are associated with a water swellable material; exposing the water swellable material to water to cause the water swellable material to swell to close the perforations; and permitting the water swellable material to dry, to open the perforations, whereby the opening and closing of the perforations regulates the amount of irrigation water being applied across the barrier in the irrigation method.

Owner:CANPLAS INDS

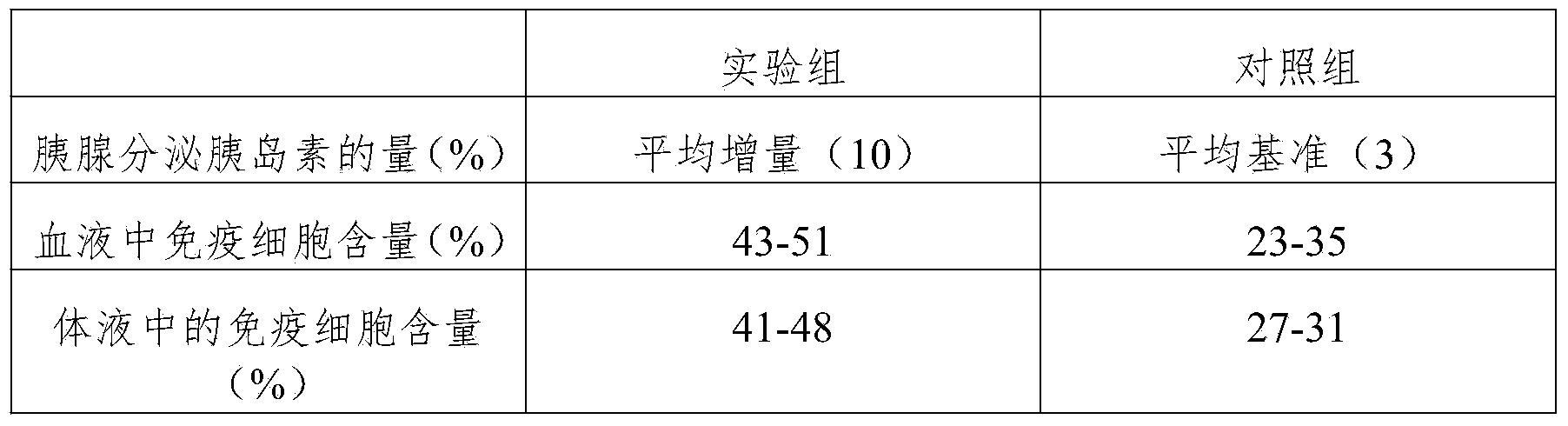

No mark gene deletion deoxidated mutant strain of wild Manhu bacteria and its use

InactiveCN1644680AImprove immunityGood control effectAntibacterial agentsBacteriaVibrio anguillarumFish farming

A bacterin for fish farming is used to treat vibriosis with reduced toxicity. The vaccine is mainly formed by no marker gene deletion strains with toxicity reduced. It is effective for cross immunization of Rongzao vibrios. The vaccine made from it can effectively be used to prevent testing fishes from diseases caused by vibriosis.

Owner:SHANGHAI HAOSI MARINE BIOTECHNOLOGY CO LTD

Seed soaking device for agricultural seedling culture

The invention discloses a seed soaking device for agricultural seedling culture, and belongs to the field of agriculture. The seed soaking device comprises a seed soaking box, a water inlet pipe is arranged on the side wall of the seed soaking box, a telescopic rod is arranged on the lower surface of a horizontal plate, the bottom end of the telescopic rod is connected with a fixed circular ring,a seed soaking mesh basket is detachably arranged on the fixed circular ring, an ultraviolet sterilizing lamp is mounted on the inner wall of the seed soaking box, an inclined guide plate is arrangedat the bottom end of the seed soaking box, a water discharging pipe is arranged at the lowest end of the inclined guide plate, a heater is mounted on the inclined guide plate, a pesticide adding pipeis arranged on the seed soaking box, one end of a spraying pipe is connected with the water inlet pipe, a plastic hose is arranged at the other end of the spraying pipe, and a spraying disk is arranged on the plastic hose. According to the seed soaking device, agricultural seeds are soaked underwater and cannot be floated on the water surface, proper water temperature and water flowing are ensuredin the seed soaking process, seed soaking efficiency and effect is improved, breeding and propagating of harmful bacteria on the seeds are avoided, eggs on the seeds are killed, safe seedling cultureof the seeds can be ensured, the germination rate of the seeds is increased, and growth of the seeds is facilitated.

Owner:山东鲁寿种业有限公司

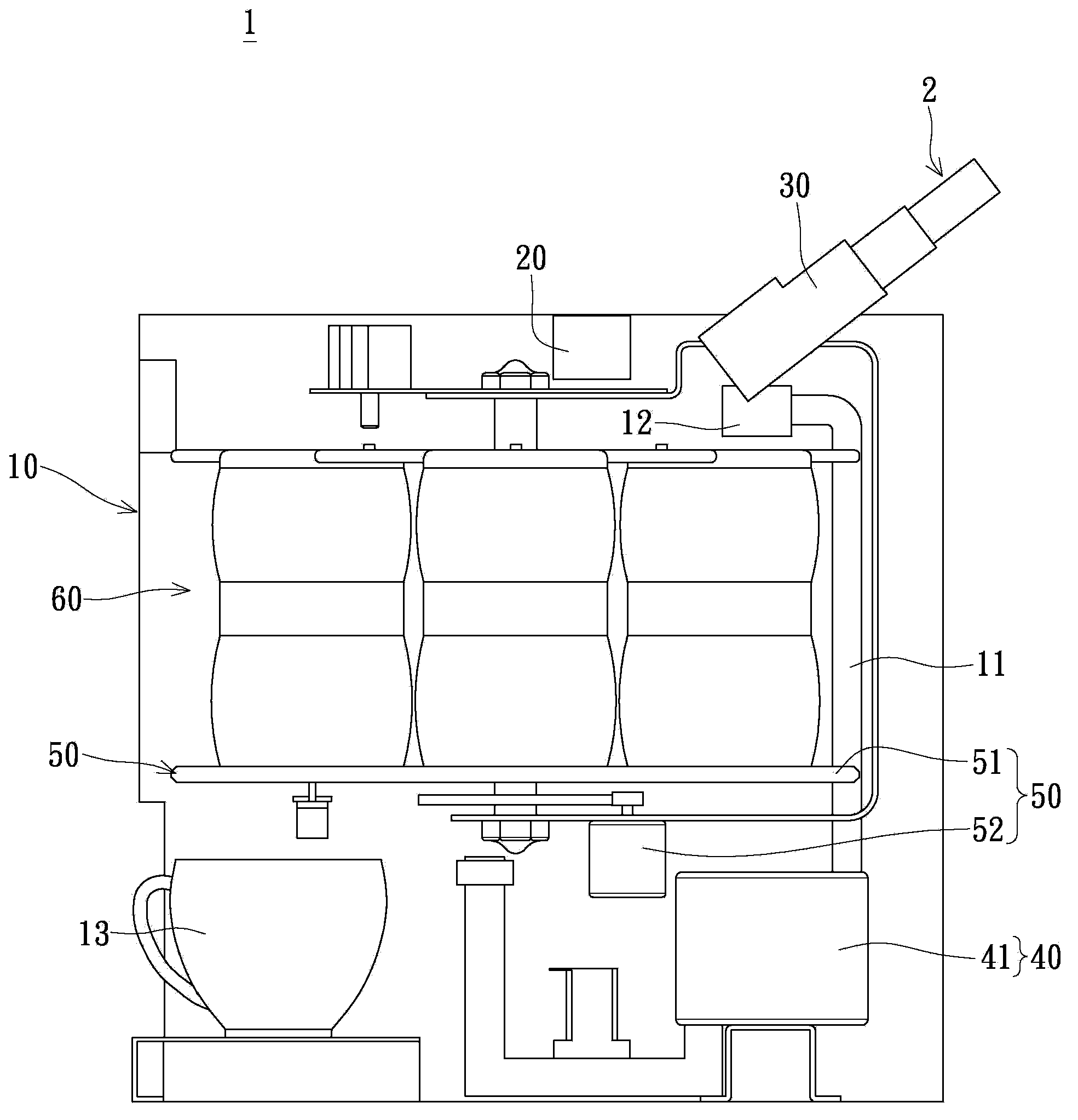

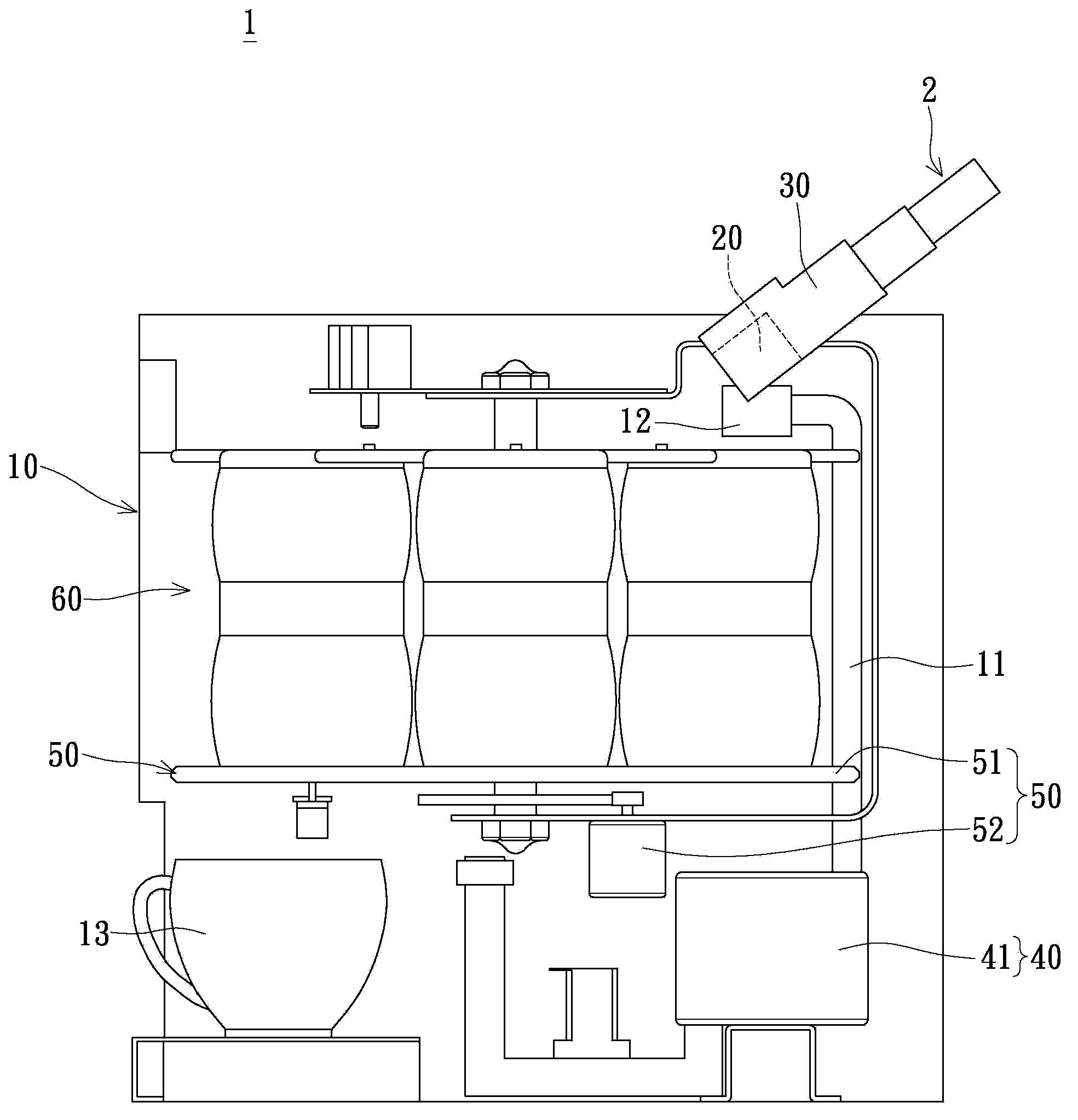

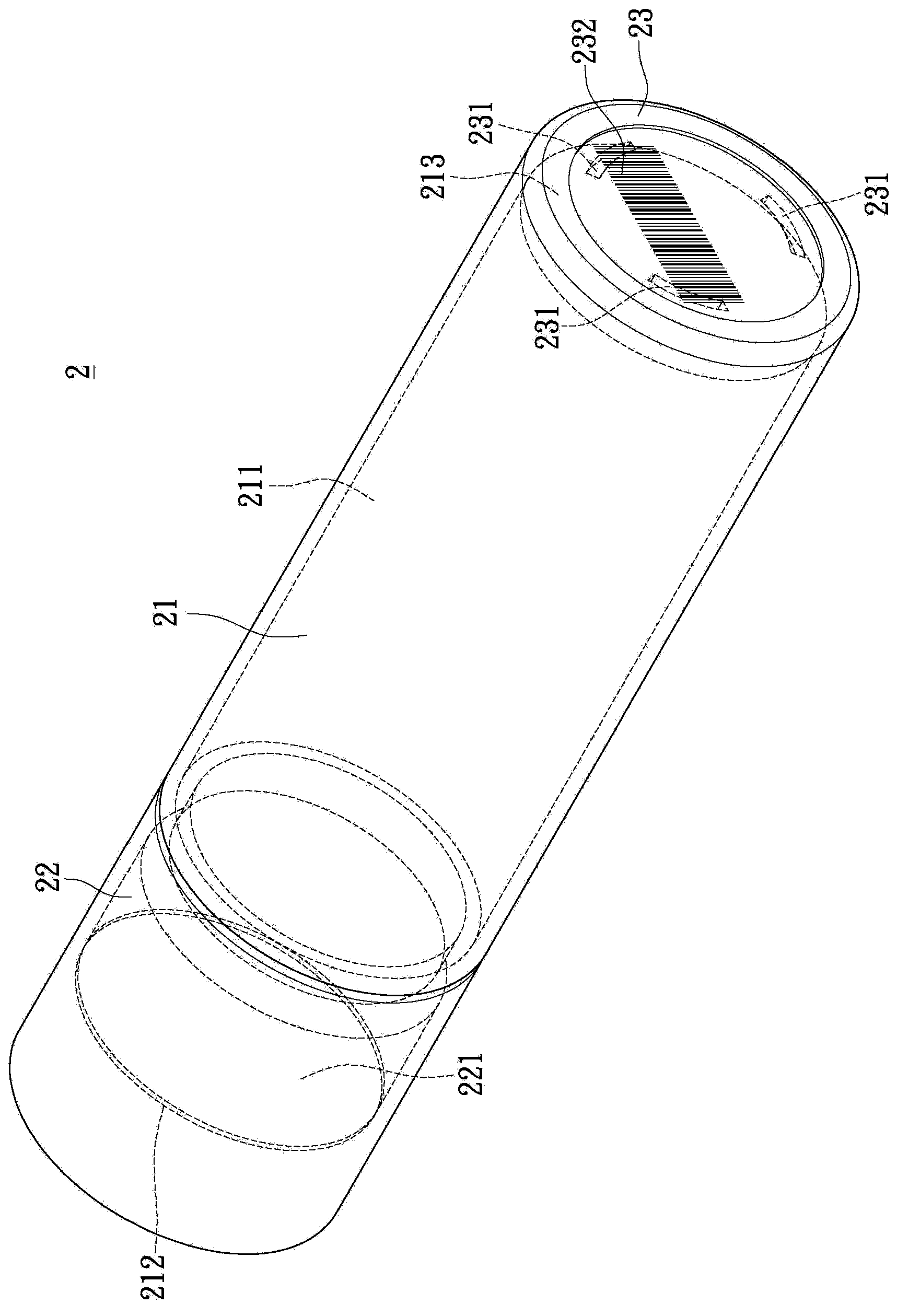

Drink brewing machine

The invention provides a drink brewing machine which is mainly applicable to drink brewing with complex processes. The drink brewing machine comprises a machine body, an identification unit, a control unit, a feeding unit, a temperature control unit, an adjustment unit and a plurality of brewing units. Raw materials to be brewed are filled inside a raw material brewing packaging device with an identification code, after the raw material are arranged in the feeding unit, the identification unit is used for reading the identification code, the control unit generates a brewing control signal according to the identification code, the other main power supply elements open a close cover of the raw material brewing packaging device, move and select the brewing units, and control water temperature and soak time according to the brewing control signal so as to obtain drinks meeting specific brewing raw material characteristics.

Owner:TEATASTER INT

Environment-friendly antibacterial rubber for automobile interior and exterior decoration and preparation method thereof

The invention relates to the technical field of function materials four automobile interior and exterior decoration, in particular to environment-friendly antibacterial rubber for automobile interior and exterior decoration and a preparation method of the rubber. The rubber is mainly prepared by the following raw materials in parts by weight: 90-110 parts of a rubber matrix, 1.5-3 parts of a promoting agent, 10-15 parts of stearic acid, 7-10 parts of paraffin, 20-50 parts of a reinforcing agent, 0.5-1.5 parts of soap, 1-3 parts of an anti-aging agent, 20-30 parts of a flame retardant, 0.5-1 part of a vulcanizing agent, 2-6 parts of nano zinc oxide, 2-6 parts of nano silver oxide, 0.5-1 part of N-(trichloromethyl sulfur) phthalimide, 0.5-1 part of polyhexamethyleneguanidine phosphate, 20-25 parts of nano chitosan, 10-15 parts of nano titania and 90-110 parts of a dispersing agent. All the raw materials have a synergistic effect, and the environment-friendly antibacterial rubber has obvious antibacterial property, air purification performance and anti-fouling self-cleaning performance and simultaneously has mechanical strength and environmental protection performance meeting the requirements of materials for automobile interior and exterior decoration.

Owner:HENAN HENGFA RUBBER & PLASTIC

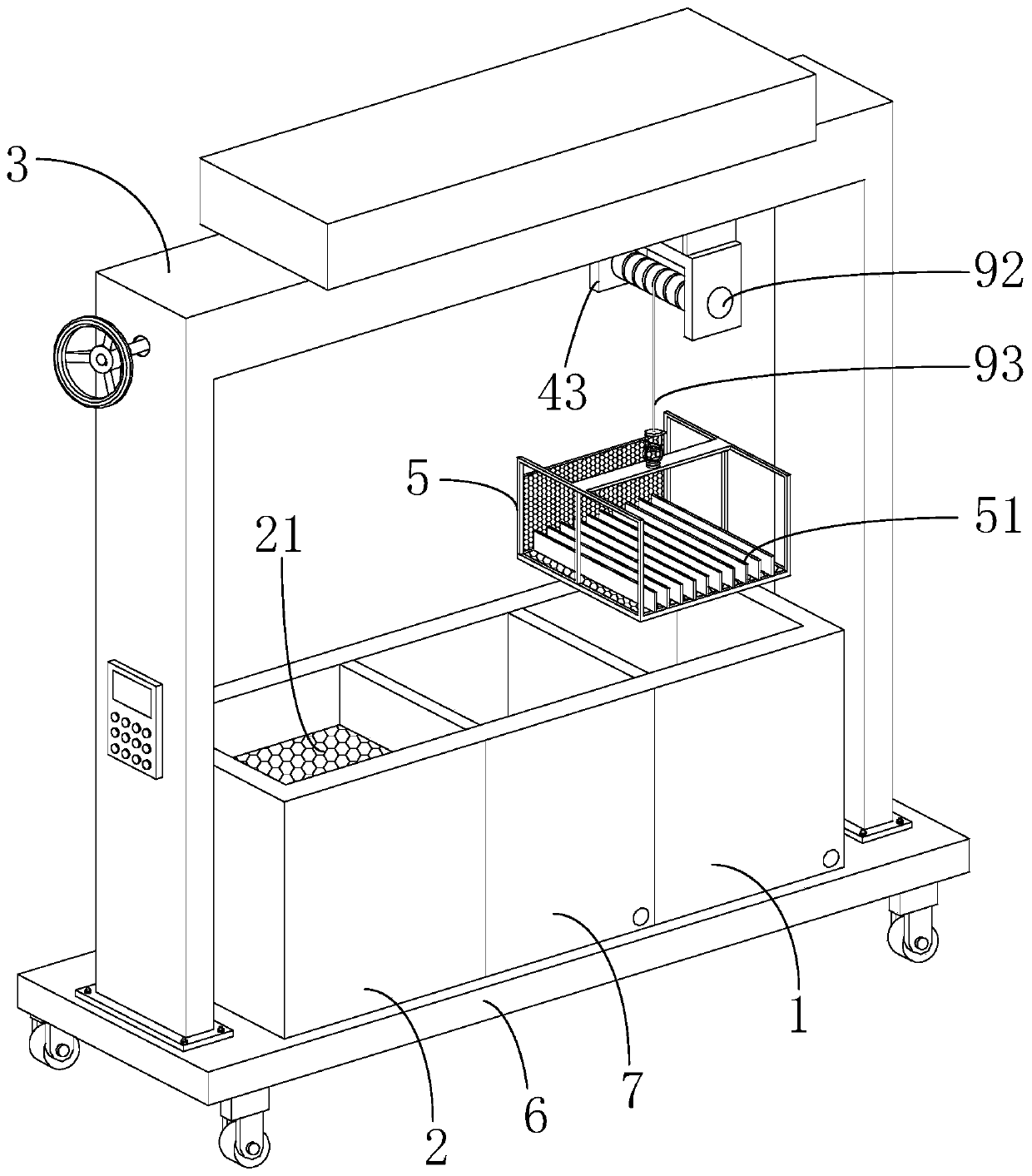

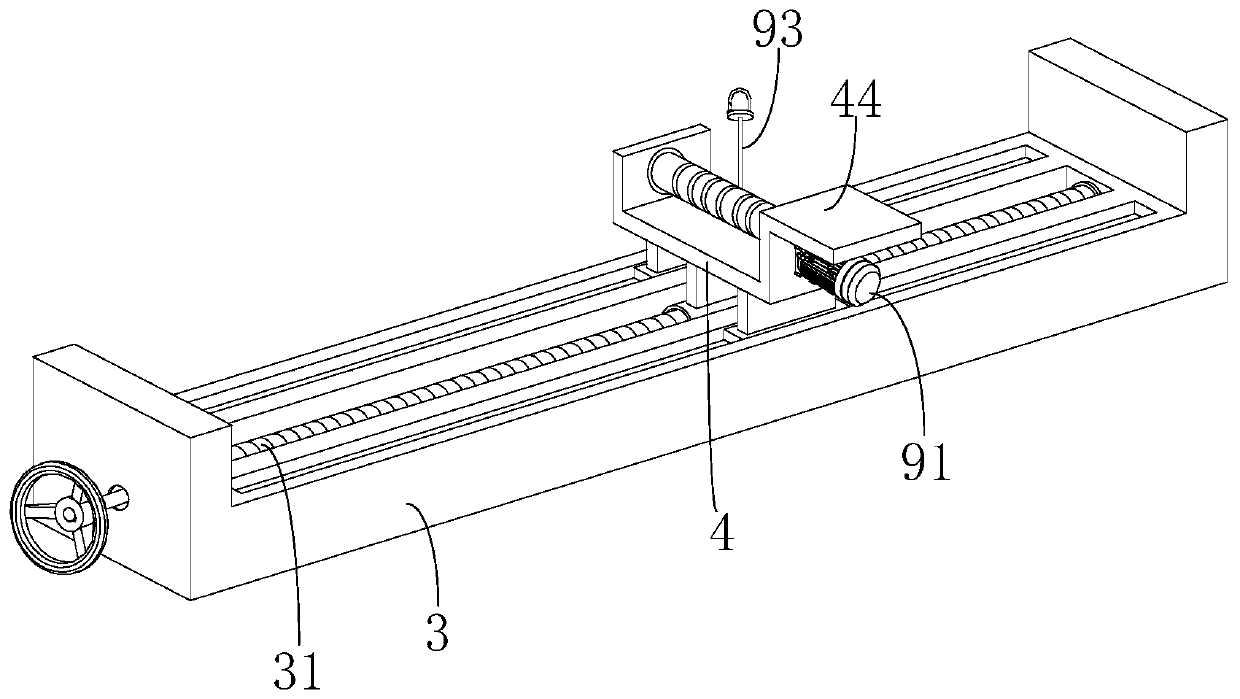

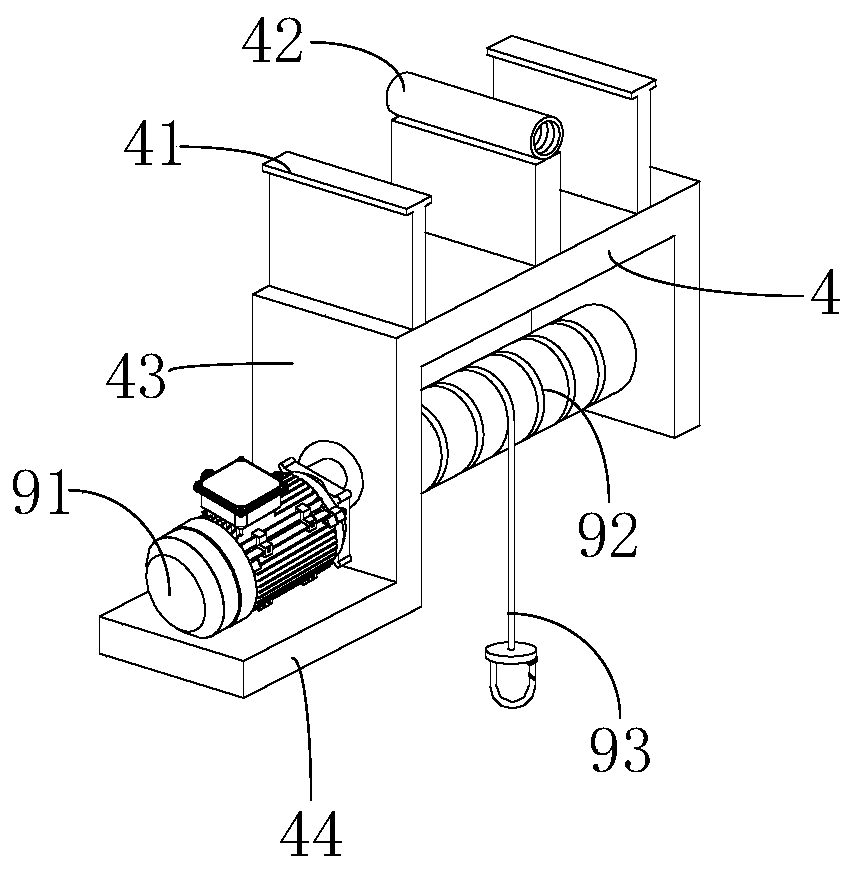

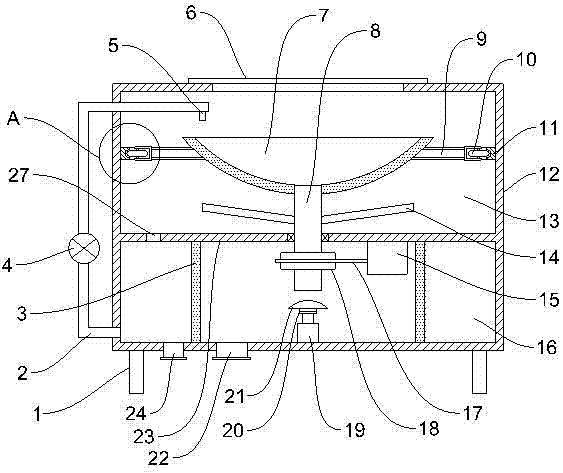

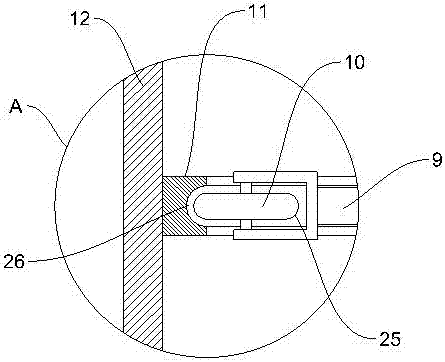

Tile soaking equipment and tile soaking method

PendingCN110485680AQuick and easy soakingReduce labor inputBuilding constructionsMechanical engineeringBuilding construction

The invention provides tile soaking equipment and a tile soaking method. The equipment comprises a soaking cylinder, a supporting cross beam erected above the soaking cylinder, a sliding part installed on the supporting cross beam in a sliding manner, a material frame used for loading tiles, and an air drying cylinder, wherein the material frame is installed on the sliding part in a liftable manner through a lifting mechanism, the air drying cylinder and the soaking cylinder are arranged below a guide groove side by side, and a supporting frame is arranged in the air drying cylinder. The equipment solves the problems that during traditional tile construction, personnel need to carry in or out pieces of tiles with time and labor consumed, and the construction efficiency is low.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Rust prevention soaking device for automotive part

InactiveCN107321561AImprove stabilityFully soakedLiquid surface applicatorsCoatingsEngineeringPiston rod

The invention discloses an anti-rust soaking device for auto parts, which comprises a box body, a transverse partition is arranged on the inner side of the box body, a fittings placement frame is arranged in the soaking chamber, and a supporting cylinder is connected in the middle of the bottom of the fittings placement frame , the upper side of the diaphragm is installed with stirring blades on the support tube, the lower side of the diaphragm is installed with a pulley on the support tube, the pulley is connected with the drive motor through the transmission belt, and the bottom of the separation chamber is equipped with a telescopic cylinder. The piston rod of the cylinder is connected with a plug through the rotation of the rotating body. There is also a filter plate on the outside of the separation chamber, and a return pipe connected to the bottom of the separation chamber is provided on the side of the box. The other end of the pipe extends to the top of the accessory placement frame, and a spray head is installed at the end of the pipe. The invention has a novel structure, is convenient to use, has better antirust oil immersion effect on auto parts, and is easy to remove impurities and is beneficial to popularization.

Owner:韩祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com