Sealer, members covered with sprayed coatings, and bearings

A technology for coating components and treating agents, which is applied in the directions of fusion spraying, metal material coating process, coating, etc., can solve the problems of difficulty in maintaining environmental occlusion, poor adhesion of substrates, complicated devices, etc., and achieves permeability. Excellent, improved adhesion, effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 5 and comparative example 1~ comparative example 7

[0112] Materials used in Table 1 are shown below.

[0113] (1) Glycidyl ether compound or cycloaliphatic diepoxy compound

[0114] (1-1) Trimethylolpropane triglycidyl ether: manufactured by Nagase Chemtex Co., Ltd., Denakol EX-321L, viscosity: 500 mPa·s (25° C.)

[0115] (1-2) Phenylene diglycidyl ether: manufactured by Nagase Chemtex Co., Ltd., denacol EX-201L, viscosity: 240 mPa·s (25° C.)

[0116] (1-3) Alkylene diglycidyl ether: Japan Epikisilesin Co., Ltd. product, YED216M, viscosity: 15 mPa·s (25° C.)

[0117] (1-4) Alkylene monoglycidyl ether: Japan Epikisilesin Co., Ltd. product, YED111E, viscosity: 7 mPa·s (25° C.)

[0118] (1-5) Cyclic aliphatic diepoxy compound: manufactured by Daicel Chemical Industry Co., Ltd., Celocide 3000, viscosity: 10 mPa·s (25° C.)

[0119] (2) epoxy resin

[0120] (2-1) Bisphenol F-type epoxy resin: made by Japan Epikisilesin Co., Ltd., Epico-ro 806, viscosity: 2000 mPa·s (25° C.)

[0121] (3) curing agent, curing accelerator

[0122...

Embodiment 6~ Embodiment 8 and comparative example 8~ comparative example 10

[0150] The components shown in Table 2 were fully stirred and mixed at room temperature, and left to stand for 30 minutes in order to eliminate air bubbles in the mixture to obtain a sealing treatment agent. In addition, the material used in Table 2 corresponds to the material used in Table 1 mentioned above. The specific gravity before and after curing was measured for the obtained sealing agent, and the sealing agent was evaluated by the density ratio before and after curing of the sealing agent. The results are listed in Table 2 together.

[0151]

[0152] Before calculation, the density of the uncured sealing agent is measured according to the measurement method in the specific gravity cup method described in JIS K6833 "Test method for solvent-free liquid resin for electrical insulation", and the obtained specific gravity is taken as the density before curing (unit: g / cm 3 ). On the other hand, about 20 g is weighed in a clean PP container (capacity 30 ml) free of fo...

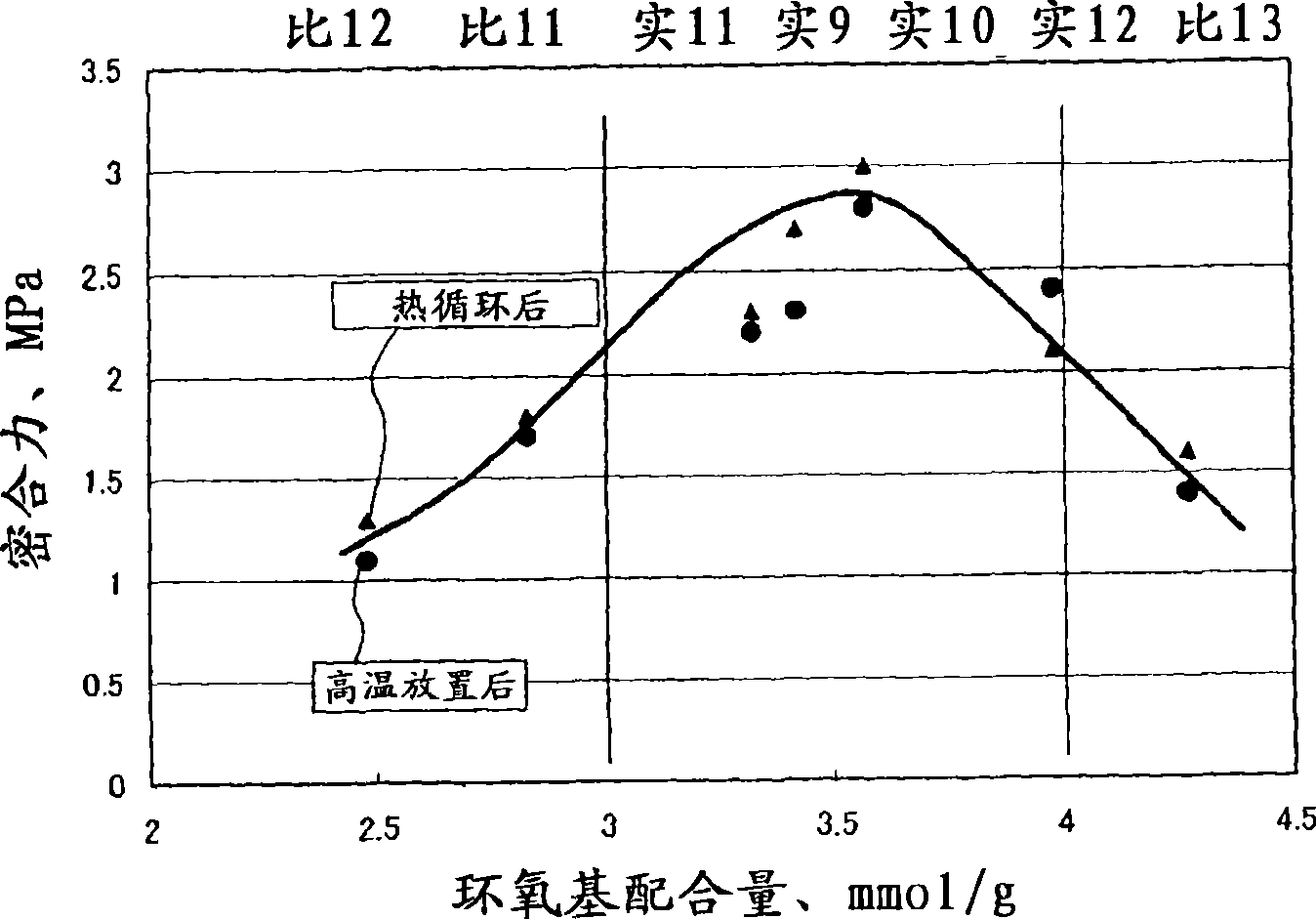

Embodiment 9~ Embodiment 12 and comparative example 11~ comparative example 13

[0173] The components shown in Table 3 were sufficiently stirred and mixed at room temperature, and left to stand for 30 minutes in order to eliminate air bubbles in the mixture to obtain a sealing treatment agent. Note that the materials used in Table 3 correspond to the materials used in Table 1 above.

[0174]

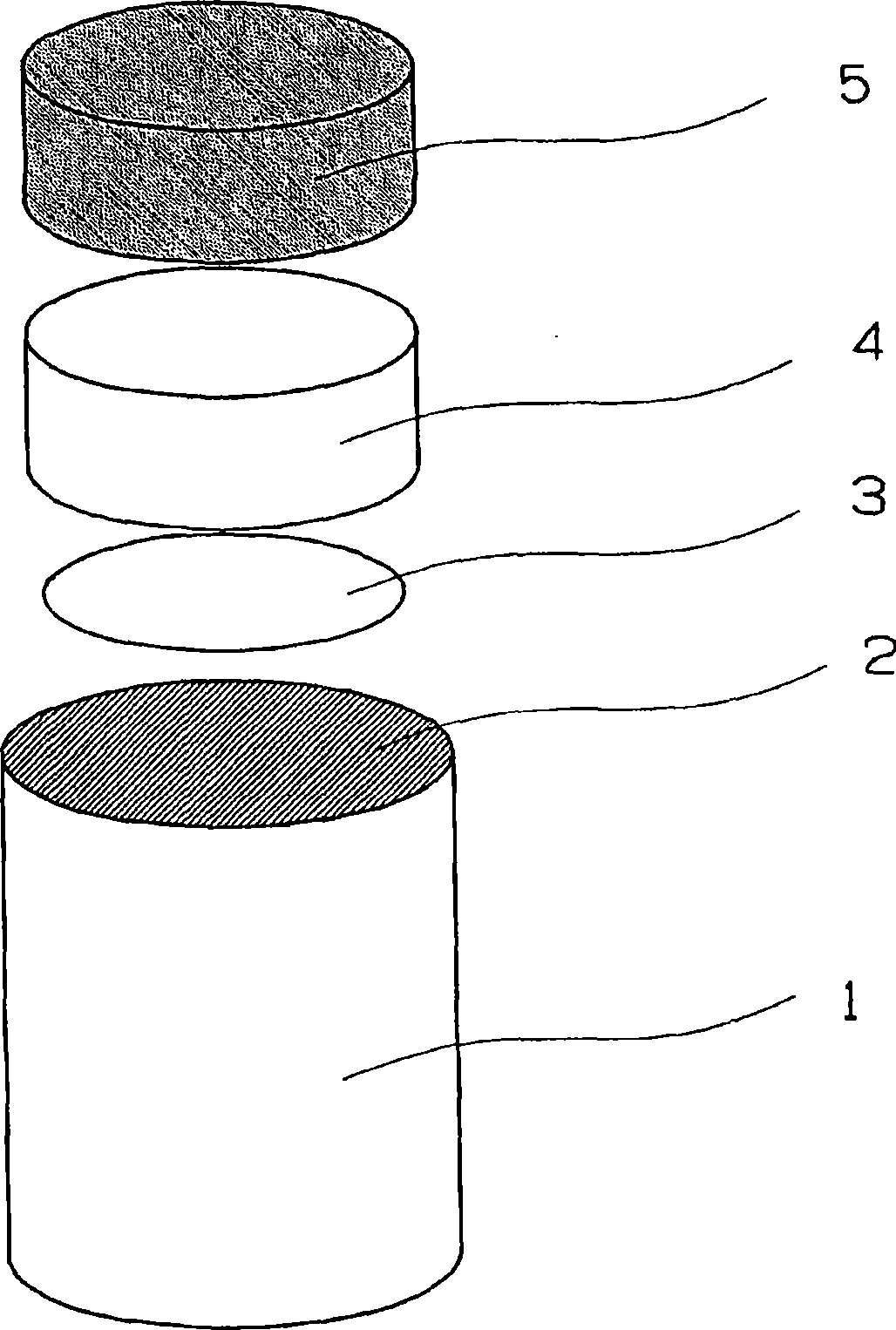

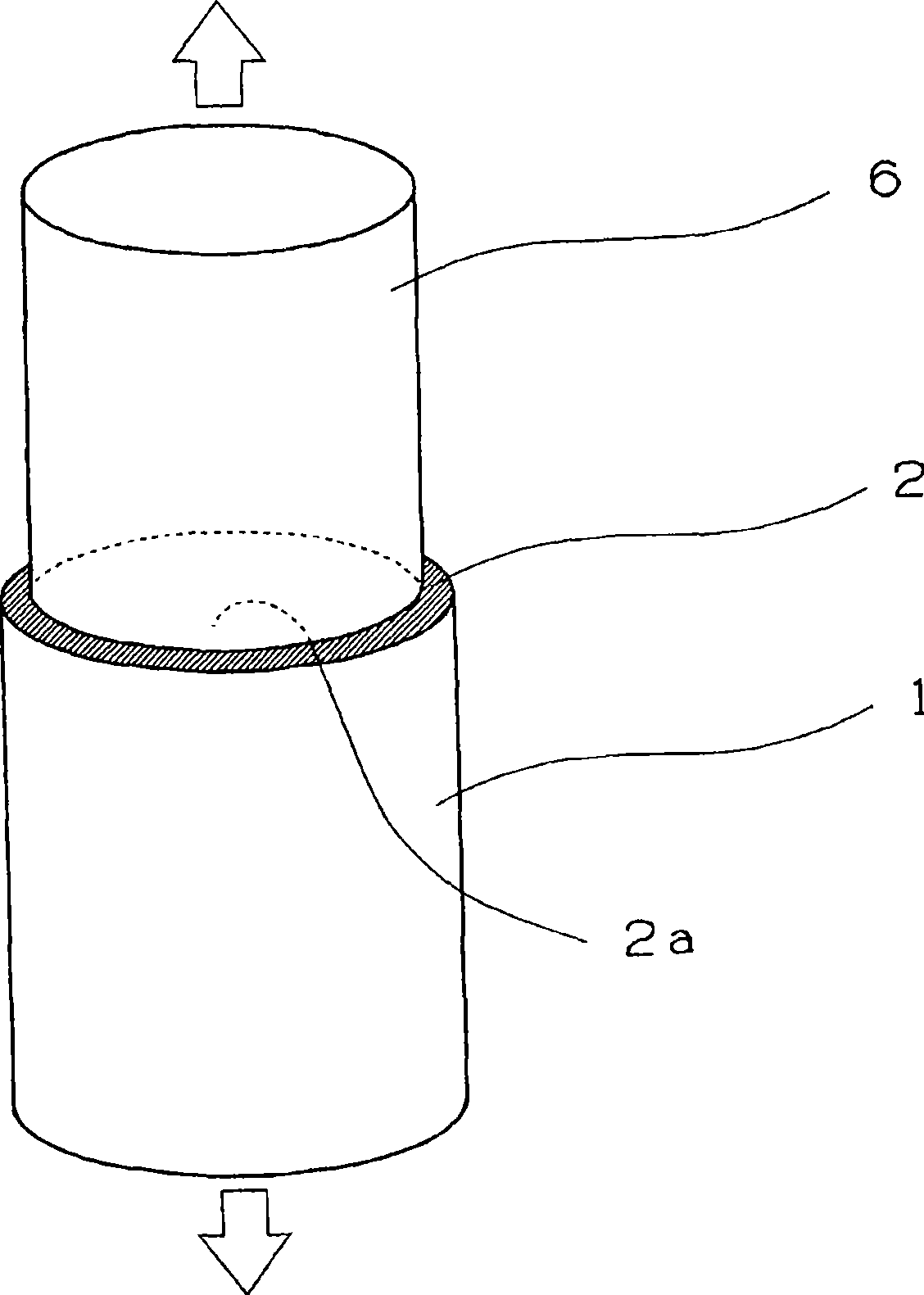

[0175] Next, a test piece made of SUJ2 of ф20 mm×25 mm was prepared, and an alumina ceramic sprayed film with a film thickness of 400 μm was formed on the cylindrical end surface by the atmospheric plasma spraying method.

[0176] The sealing agent shown in Table 3 was applied to the surface of the thermal sprayed surface under a room temperature atmosphere using a polyamide brush, and left to stand for 30 minutes. Thereafter, the sealing treatment agent-coated test piece was produced in a state in which the excess sealing treatment agent of the surface-adhered components was scraped off with a polyethylene spatula. Thereafter, these coated test pieces were pre-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com