Negative electrode active substance of lithium ionic cell and preparing method thereof, negative electrode and cell

A negative electrode active material and lithium-ion battery technology, applied in the direction of active material electrodes, electrode manufacturing, battery electrodes, etc., can solve the problems of poor safety performance of lithium-ion batteries, achieve the effect of improving safety performance and preventing thermal diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

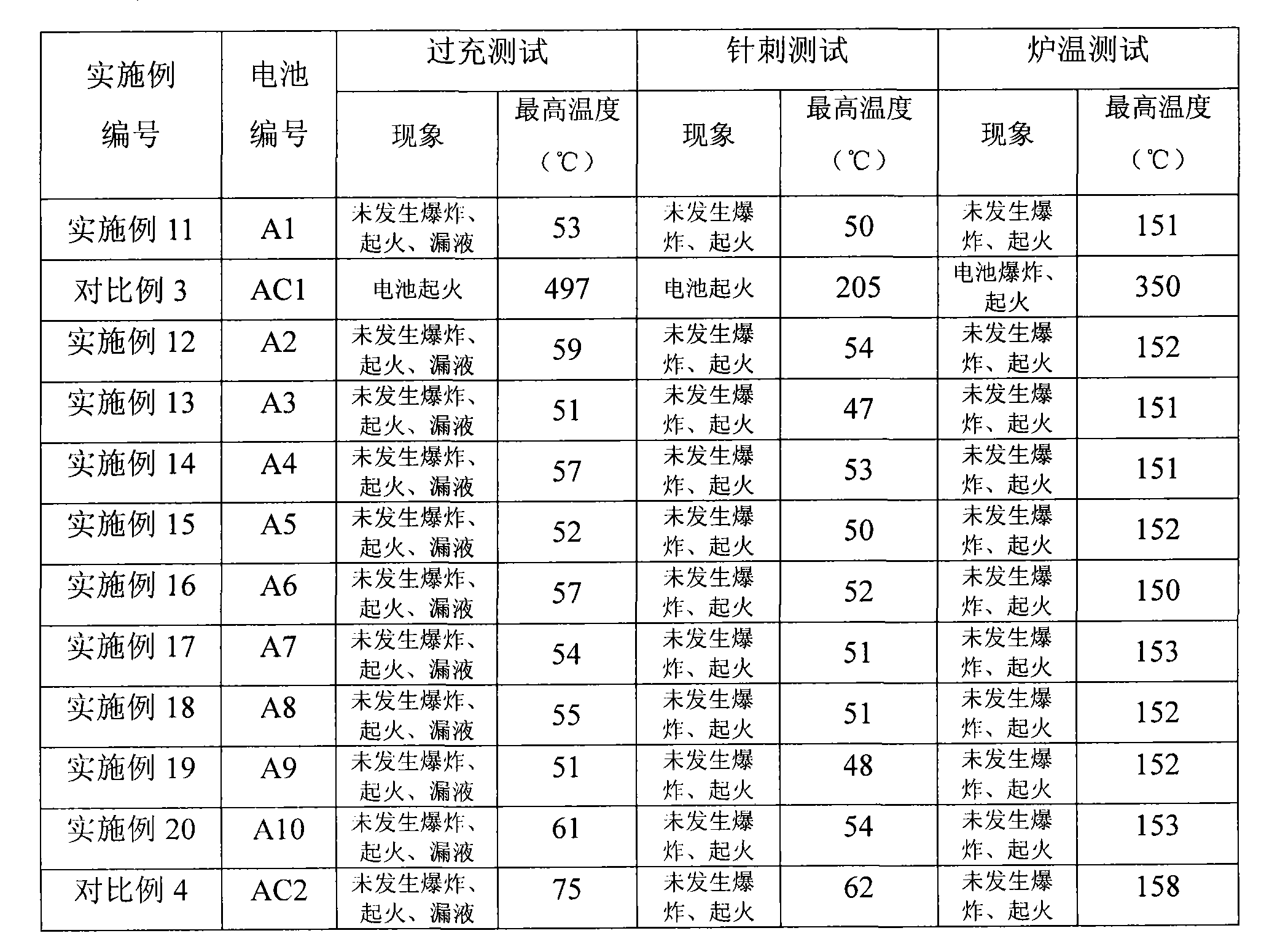

Examples

preparation example Construction

[0030] The preparation method of the negative electrode includes coating and / or filling the slurry containing the negative electrode active material, the negative electrode binder and the solvent on the current collector, drying, and calendering, wherein the binder is enol group polymerized things. Wherein, the solvent can be selected from N-methylpyrrolidone (NMP), dimethylformamide (DMF), diethylformamide (DEF), dimethylsulfoxide (DMSO), tetrahydrofuran (THF) and One or more of water and alcohols. The amount of the solvent can make the paste have viscosity and fluidity, and can be coated on the current collector. Generally, based on the weight of the negative electrode active material, the solvent is used in an amount of 100-150% by weight. Wherein, the methods and conditions of drying and calendering are well known to those skilled in the art.

[0031] The lithium ion battery provided by the present invention includes a pole core and a non-aqueous electrolyte, the pole c...

Embodiment 1

[0044] This example illustrates the preparation of the negative electrode active material provided by the present invention, as well as the negative electrode and the battery.

[0045] (1) Preparation of negative electrode active material

[0046] Al(NO 3 ) 3 Mix with absolute ethanol (alcohol) to obtain a concentration of 1.86% by weight of Al(NO 3 ) 3 solution, and the carbon material graphite and the above Al(NO 3 ) 3 solution mixing, the graphite and Al(NO 3 ) 3 Al(NO 3 ) 3 The weight ratio is 100:1.25. After drying at 80°C, put it into a high-temperature furnace at 400°C for sintering for 4 hours to obtain graphite coated with alumina on the surface. Based on the total amount of the negative electrode active material, the content of the carbon material graphite is 99.70% by weight, and the content of aluminum oxide is 0.30% by weight.

[0047] (2) Preparation of negative electrode

[0048] 100 parts by weight of the negative electrode active material obtained i...

Embodiment 2

[0056] This example illustrates the preparation of the negative electrode active material provided by the present invention, as well as the negative electrode and the battery.

[0057] Prepare negative electrode active material, negative electrode and lithium ion battery according to the method for embodiment 1, difference is, in the preparation process of negative electrode active material, described carbon material graphite and Al(NO 3 ) 3 The weight ratio is 100:0.8. In the obtained negative electrode active material, based on the total amount of the negative electrode active material, the content of carbon material graphite is 99.80% by weight, and the content of aluminum oxide is 0.20% by weight. Lithium-ion battery A2 was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com