Patents

Literature

1752 results about "Enzyme method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

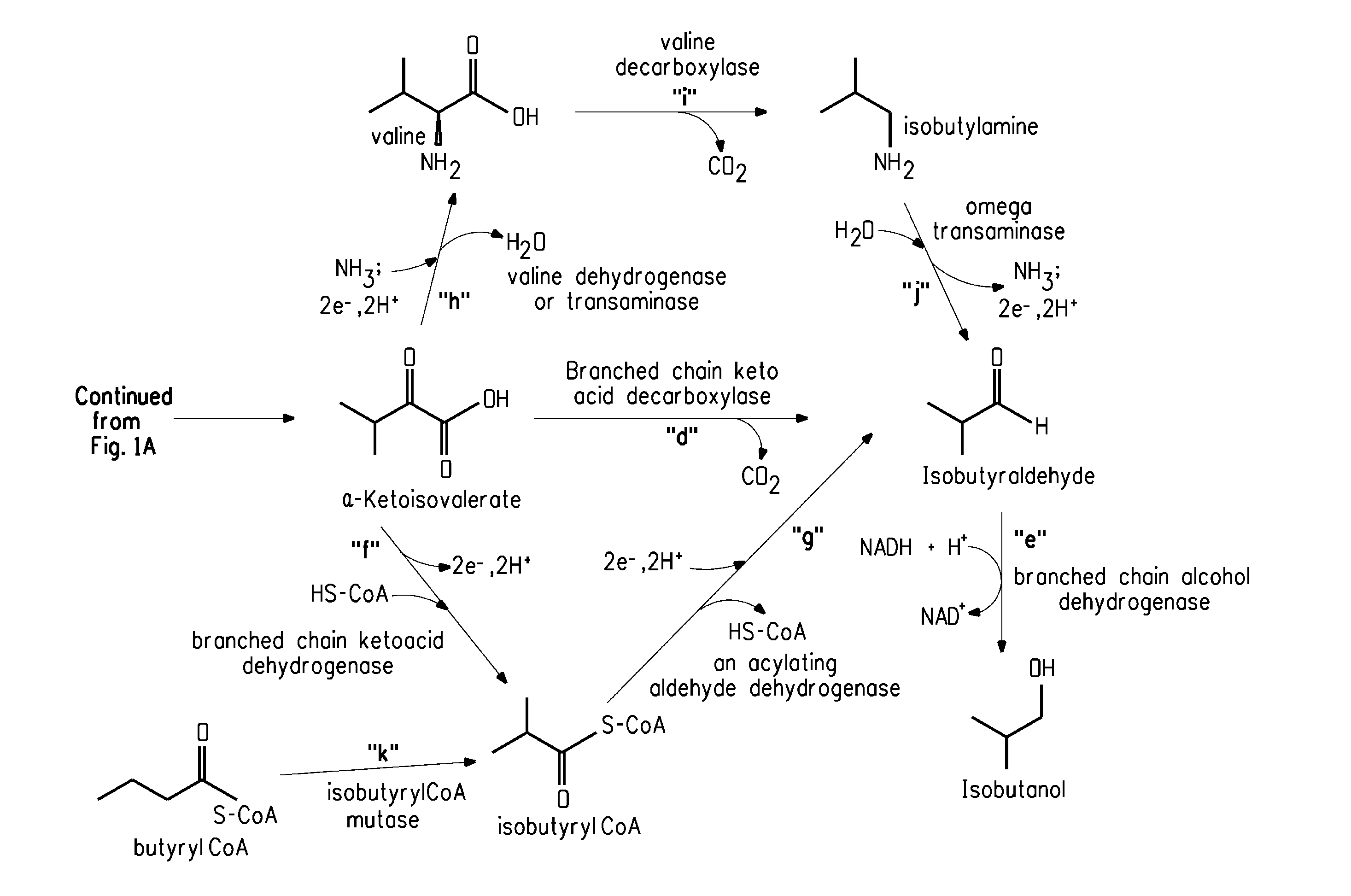

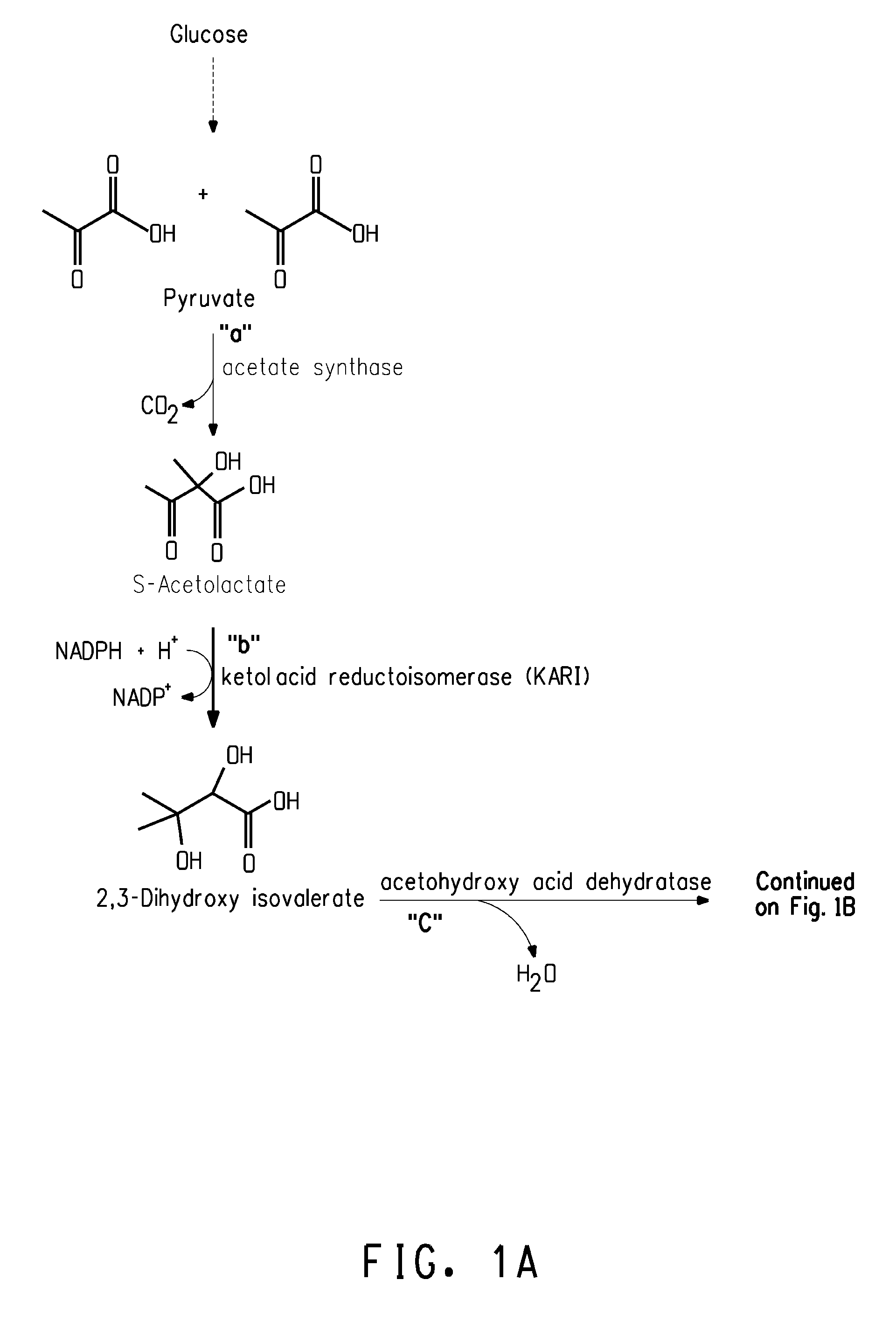

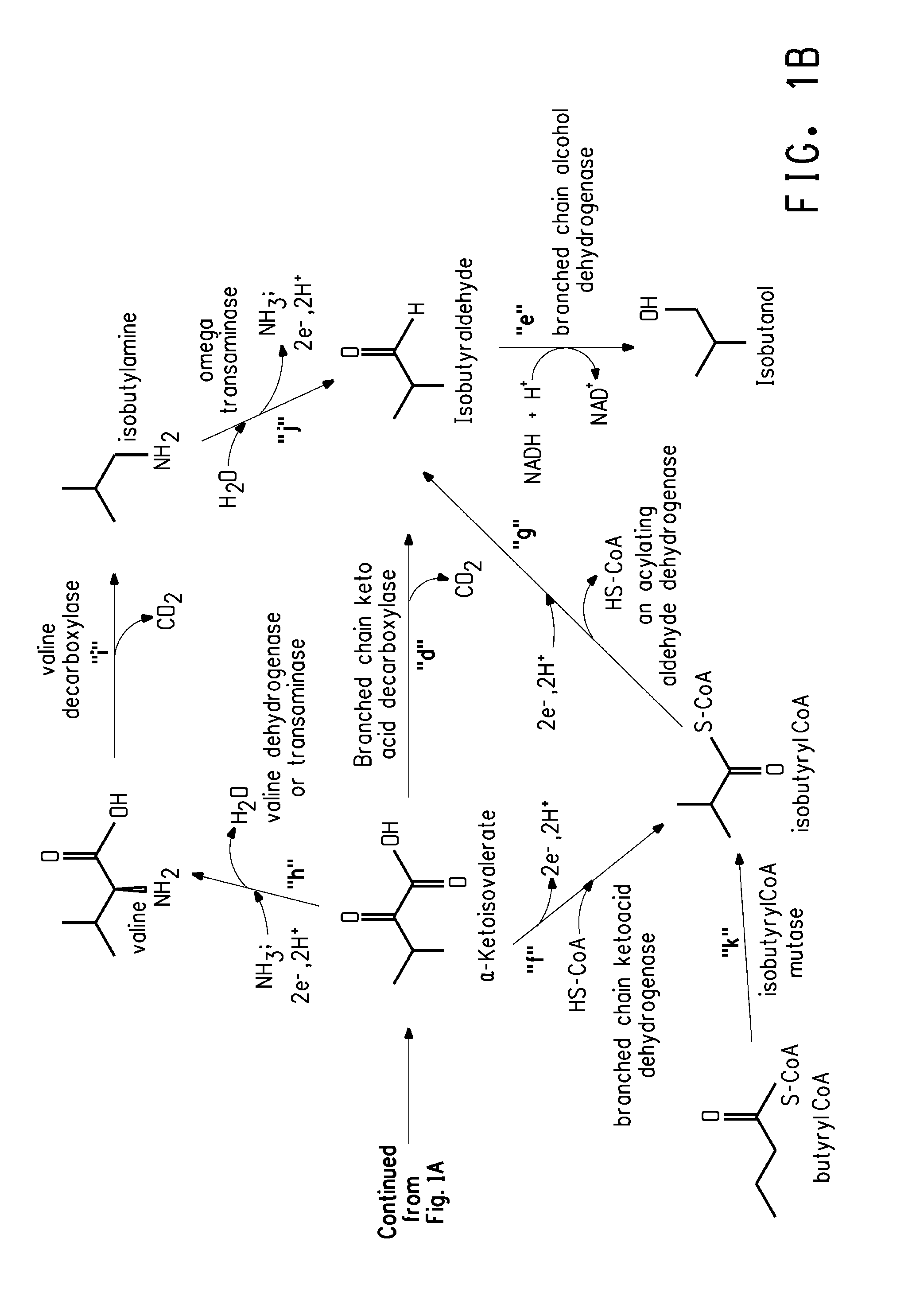

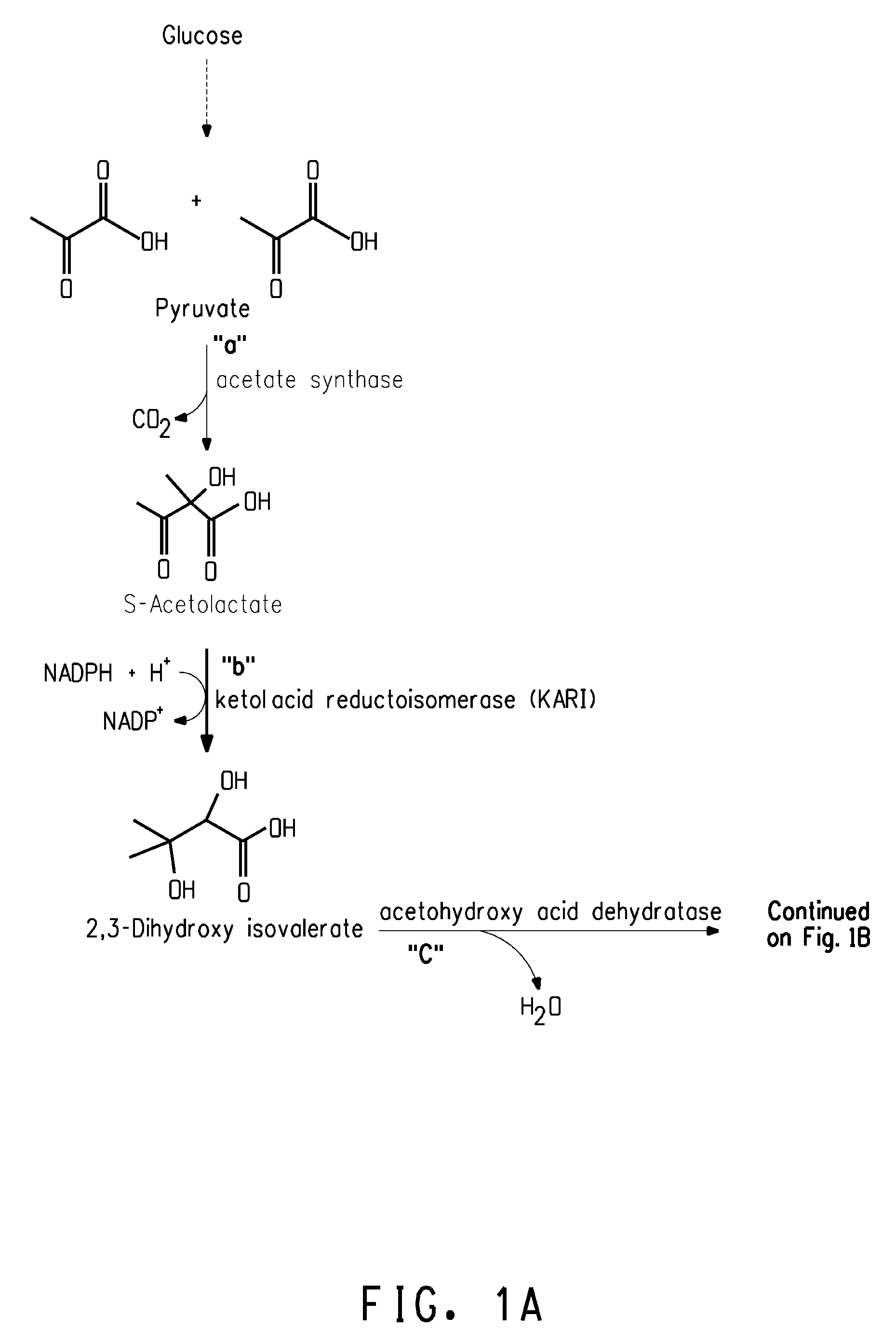

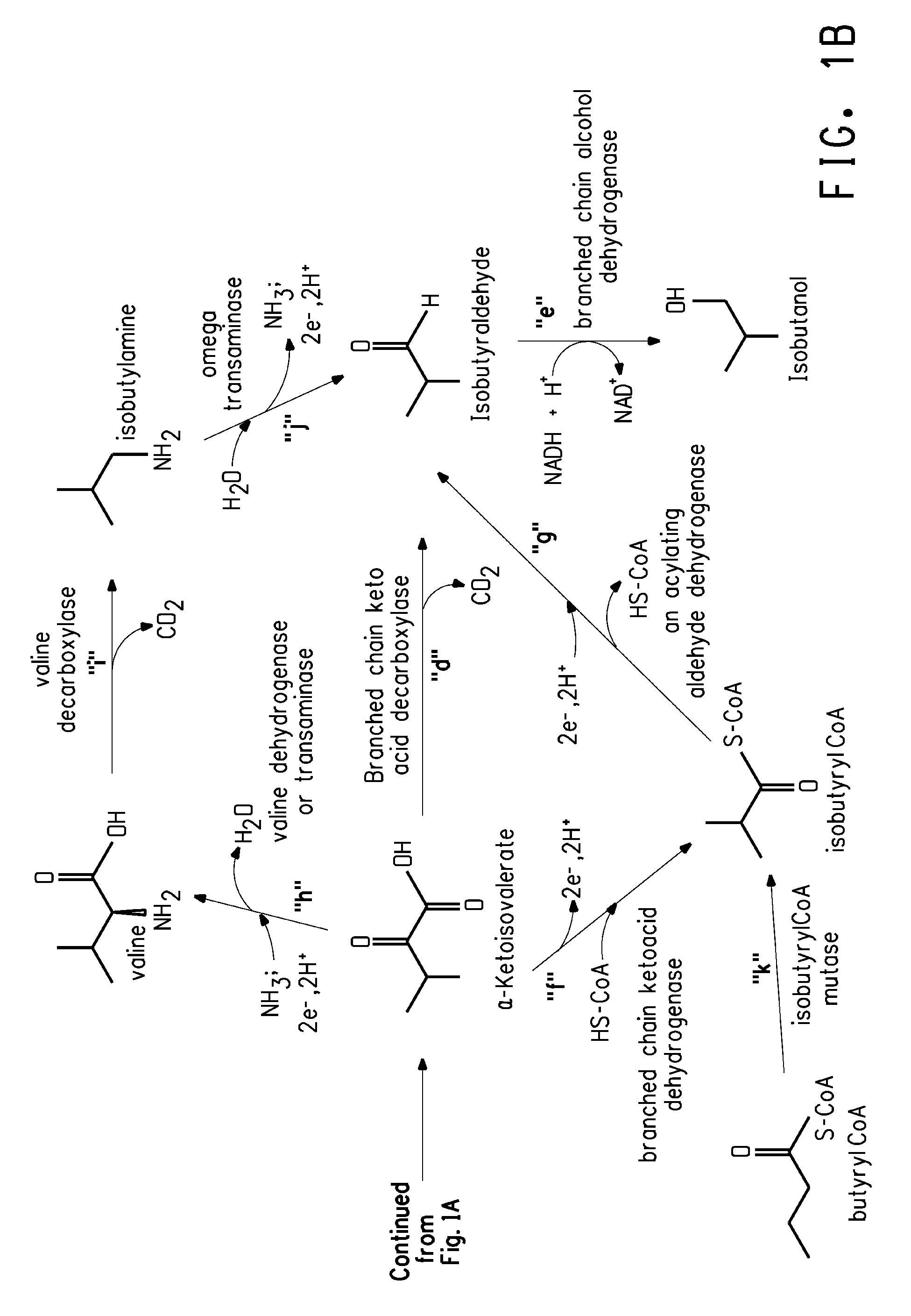

Fermentive production of isobutanol using highly active ketol-acid reductoisomerase enzymes

Methods for the fermentative production of isobutanol is provided by the fermentative growth of a recombinant microorganism expressing a highly active ketol-acid reductoisomerase enzyme in addition to other enzymes required for conversion of glucose to isobutanol.

Owner:GEVO INC

Fermentive production of isobutanol using highly active ketol-acid reductoisomerase enzymes

Methods for the fermentative production of isobutanol is provided by the fermentative growth of a recombinant microorganism expressing a highly active ketol-acid reductoisomerase enzyme in addition to other enzymes required for conversion of glucose to isobutanol.

Owner:GEVO INC

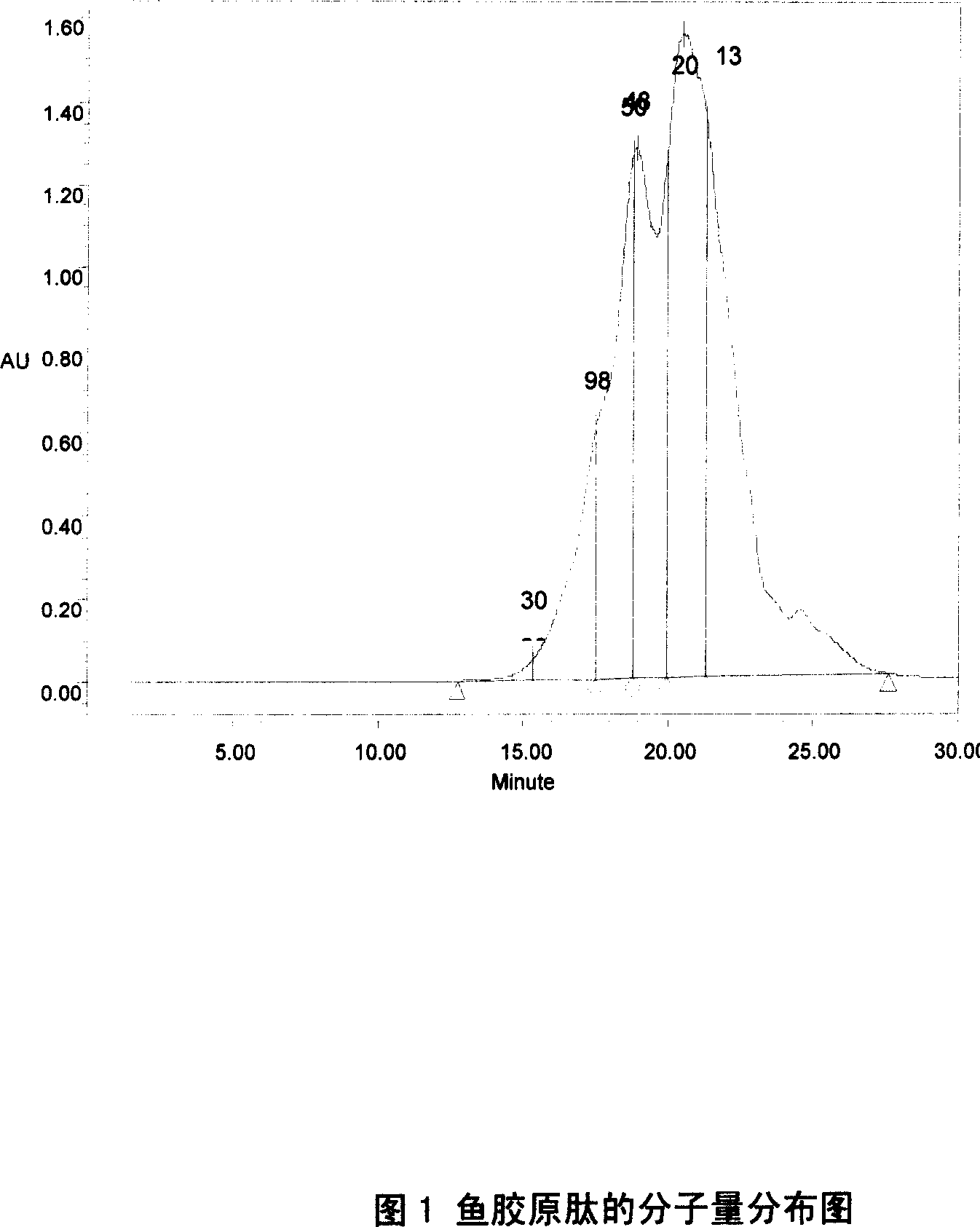

Industry method of producing fish collagen peptide from fish skin and bone by an enzyme method

ActiveCN101061827ASimple processShorten the production cycleAnimal proteins working-upComplex proteinFish products

The invention discloses a special method to extract collagen from fish peel and bone with complex prolease, which comprises the following steps: choosing salmon, AnKang fish peel and processing waste of fish product as raw material; unfreezing; washing; scaling off; degreasing; grinding; enzymolyzing; separating; de-oiling; ultra filtering; condensing; spray-drying; getting the product. This invention possesses simple craft and short production circle.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD +1

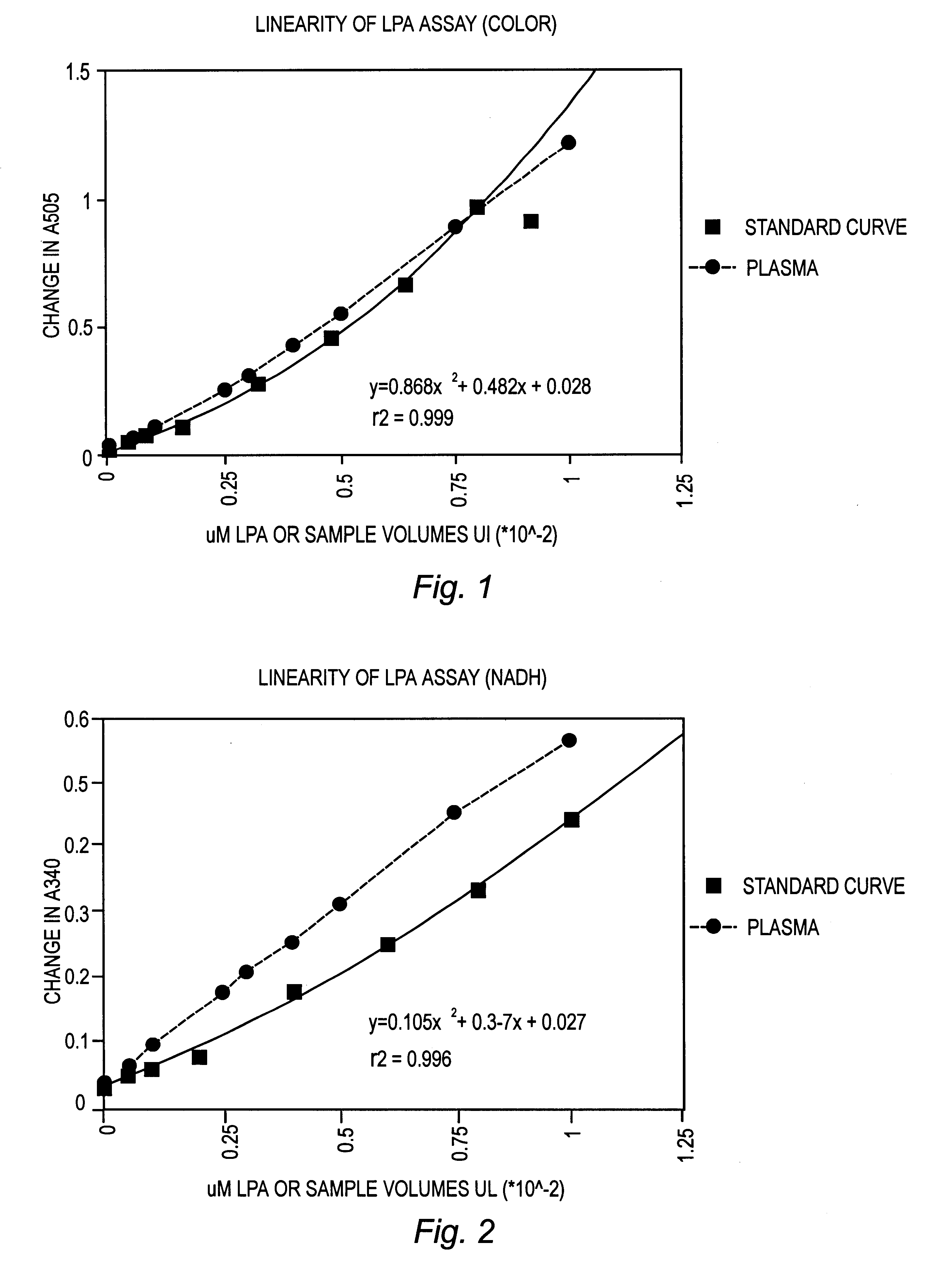

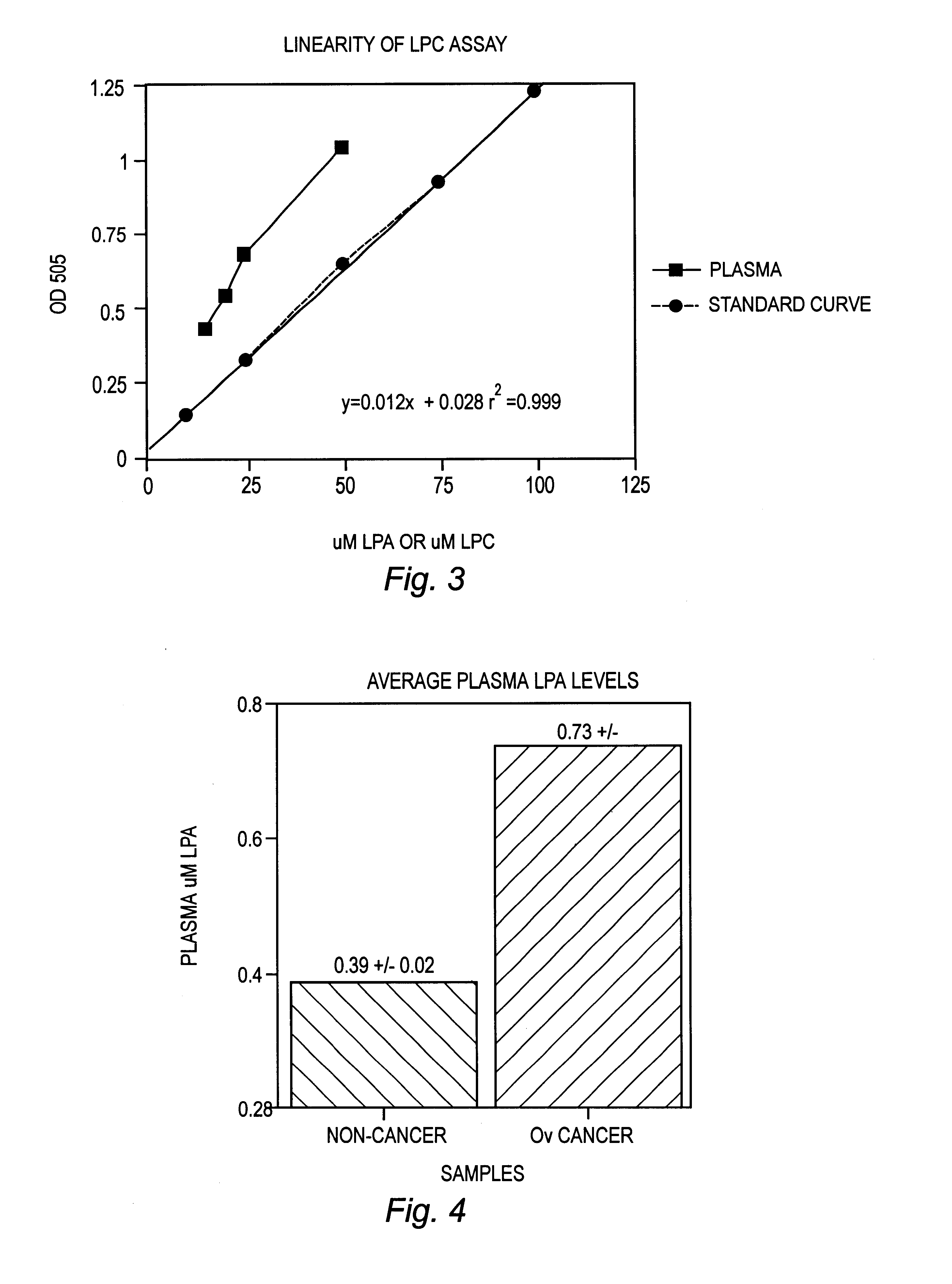

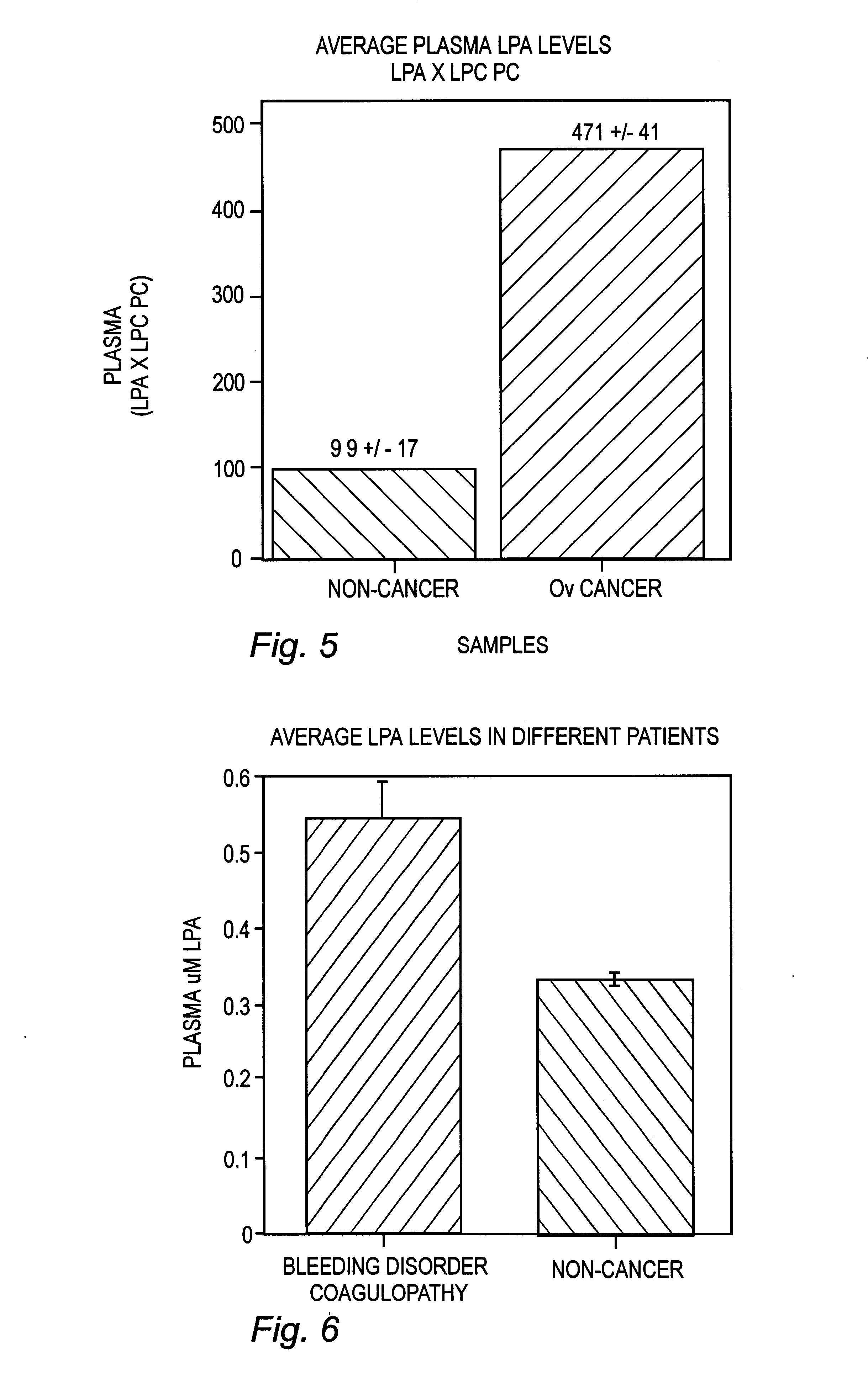

Enzyme method for detecting lysophospholipids and phospholipids and for detecting and correlating conditions associated with altered levels of lysophospholipids

InactiveUS6248553B1Enhanced signalMicrobiological testing/measurementBiological material analysisBody fluidBiology

The present invention is an enzymatic method and diagnostic kits for detecting and quantifying the presence of one or more lysophospholids in a sample of bodily fluid taken from a test subject. The method uses enzymes in a two step assay and may be used to detect disease conditions associated with altered levels of lysophospholipids and to correlate such conditions with altered levels of lysophospholipids.

Owner:APOLLO ENDOSURGERY INC

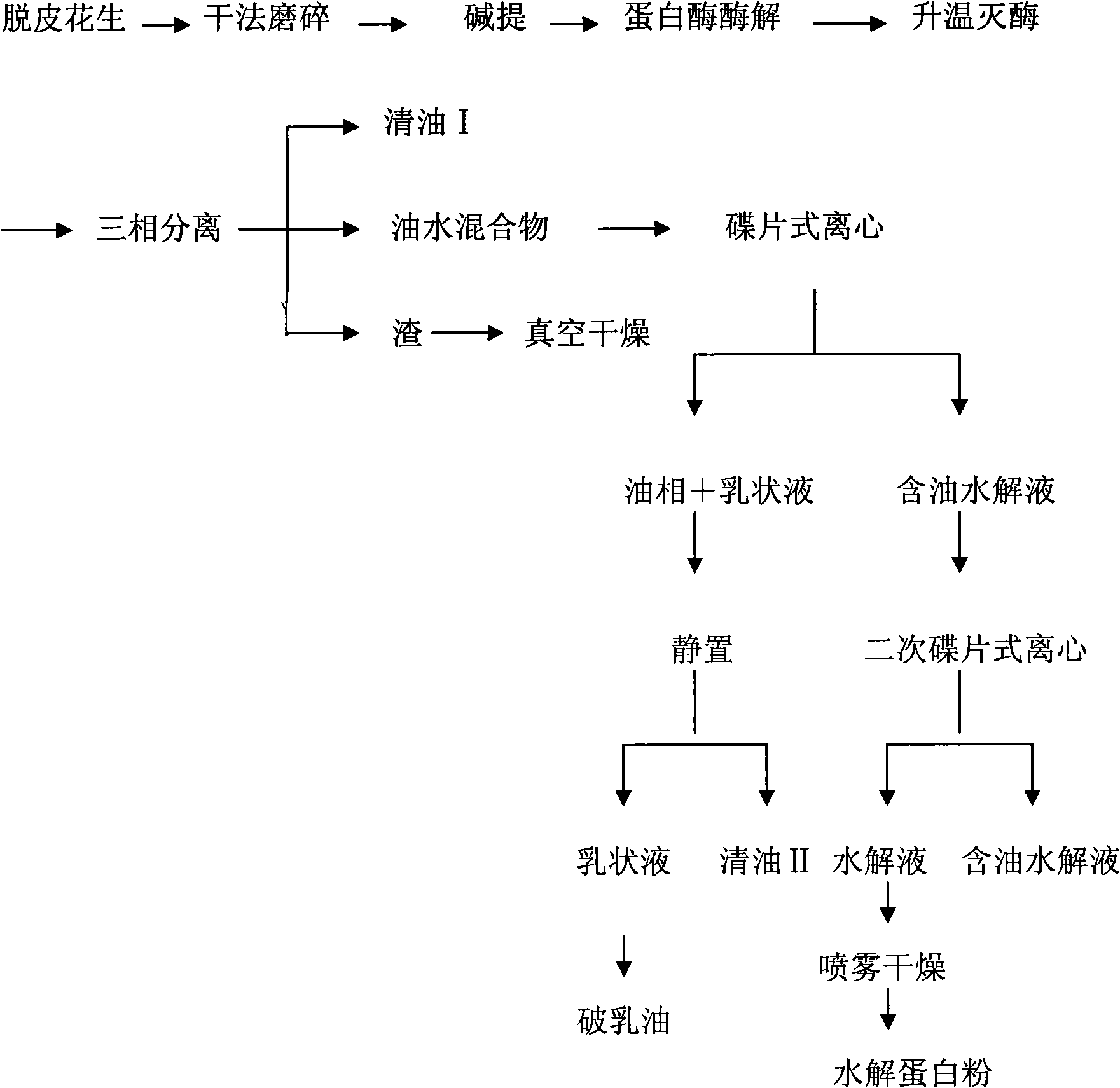

Medium test method for extracting oil and protolysate from peanut with water-enzyme method

InactiveCN101401658AHas a physiologically active functionProtein composition from vegetable seedsEdible oils/fatsHydrolysateInsoluble residue

The invention provides an intermediate test method for extracting oil and hydrolyzed protein from peanut by a water enzyme method, which belongs to the technical field of the application of biological technique in food industry. In the method, the peanut is used as a raw material, single alkali protease is used for enzymolysis, a three-phase separator is used to separate oil, oil-water mixture and insoluble residue simultaneously, a disc-type centrifuge is used to further separate the oil-water mixture so as to obtain emulsion and hydrolysate, wherein the emulsion is subjected to freezing, thawing and emulsion breaking to obtain emulsion breaking oil, and the hydrolysate is subjected to spray drying to obtain peanut hydrolyzed protein powder. The invention provides a better process for industrializing the method of extracting oil and hydrolyzed protein by the water enzyme method, and has the advantages of simple technological line and high utilization rate of products.

Owner:JIANGNAN UNIV

Natural tea essence prepared by using tea and preparation method thereof

ActiveCN101928639AFavorable for free precipitationEasily damagedEssential-oils/perfumesPectinaseWater vapor

The invention relates to a natural tea essence prepared by using tea and a preparation method thereof. The tea is taken as a raw material; high-purity natural tea essences with different tea aroma characteristics are prepared through compound enzymolysis, releasing, steam distillation under reduced pressure, cold trap recycling, low temperature freezing concentration, centrifugal oil-water separation, and trace moisture adsorption by using anhydrous sodium sulfate; and the compound enzymolysis and the releasing are realized by adding pectinase, cellulase or pectinase and cellulose complex enzyme, and beta-glucosidase. In the preparation method, a pectinase and cellulose complex enzyme method is adopted for enzymolysis to facilitate cracking cell walls of the tea so as to facilitate liberation and separation of aroma components from the tea, and improve the yield of the essence; therefore, the method is a method for industrially producing the natural tea essence which is energy-saving, low in cost, environmentally friendly and high in efficiency.

Owner:ZUNYI LUSHENG HEALTH SOURCE & TECH DEV

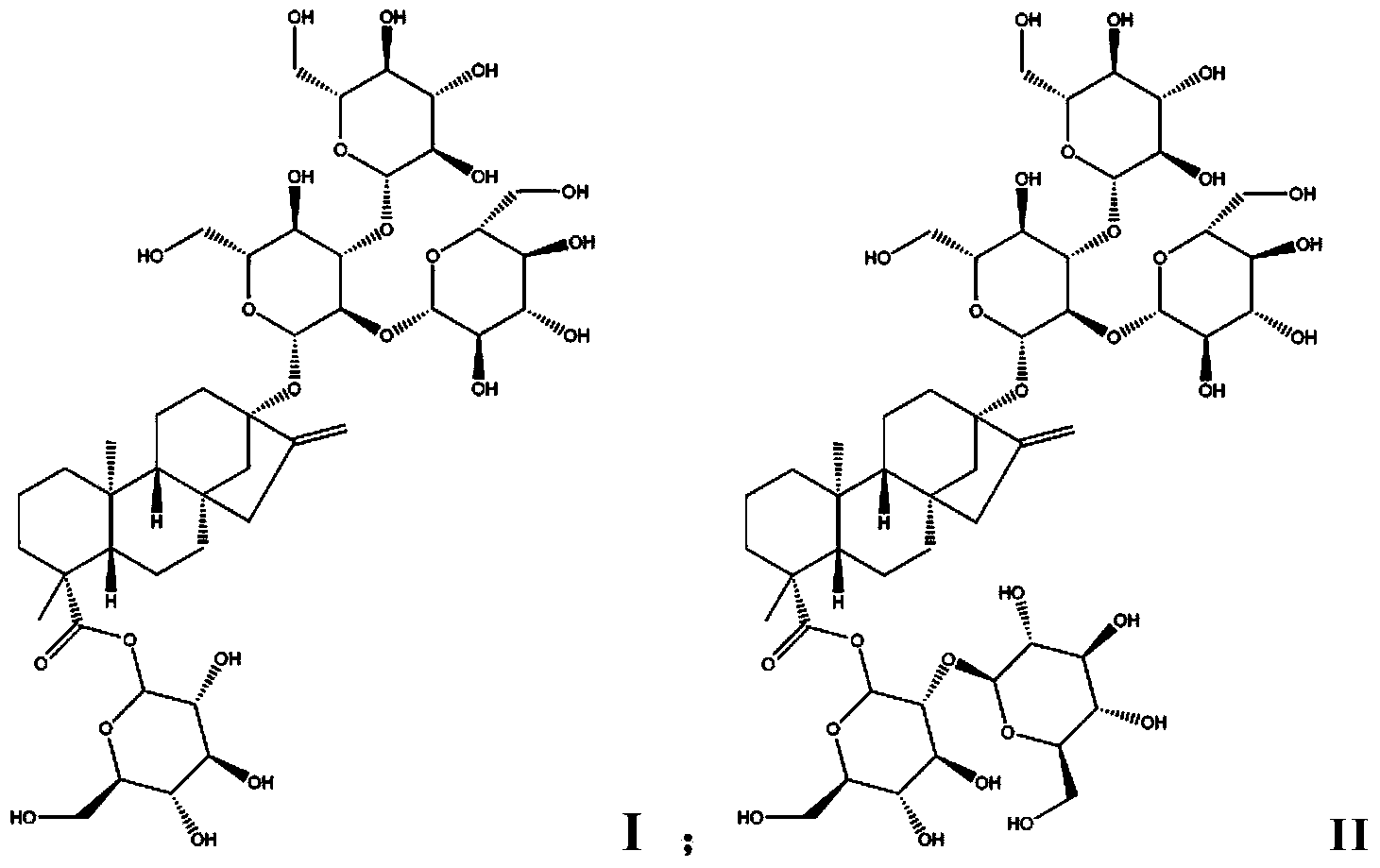

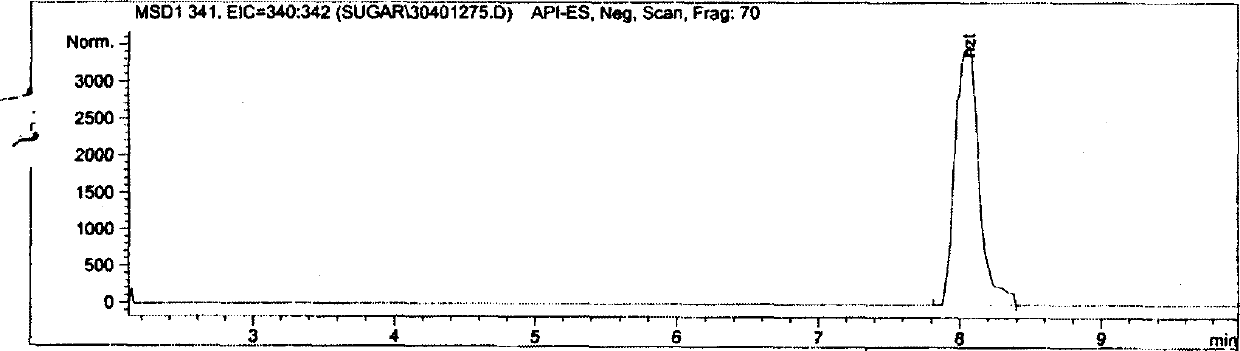

Method for preparing rebaudioside M through enzyme method

ActiveCN103757074AImprove conversion rateHigh purityFermentationSucrose synthetaseUdp glucosyltransferase

The invention relates to a method for preparing rebaudioside M through an enzyme method. According to the method, rebaudioside A or rebaudioside D is used as a substrate, and the substrate reacts to generate the rebaudioside M in the presence of sucrose and UDP under the catalytic action of a mixture of UDP-glucosyltransferase and sucrose synthetase or recombinant cells containing the UDP-glucosyltransferase and the sucrose synthetase, wherein the reaction is performed in a water-phase system having a pH value of 5.0-9.0 at 20-60 DEG C. The method for preparing rebaudioside M through an enzyme method has important application value; and compared with the existing technology of extracting rebaudioside M from stevia rebaudian leaves, the method provided by the invention obviously shortens the production cycle, improves the productivity and lowers the cost, and can provide products having higher purity. Thus, the method can be used in the food and beverage industry in a more economical manner.

Owner:PEPSICO INC

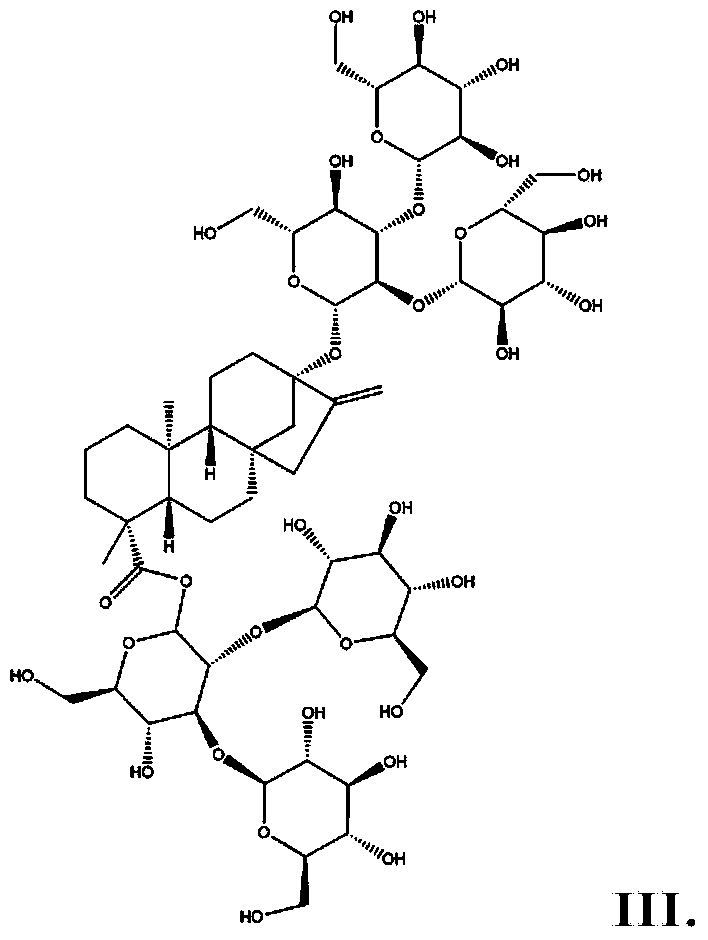

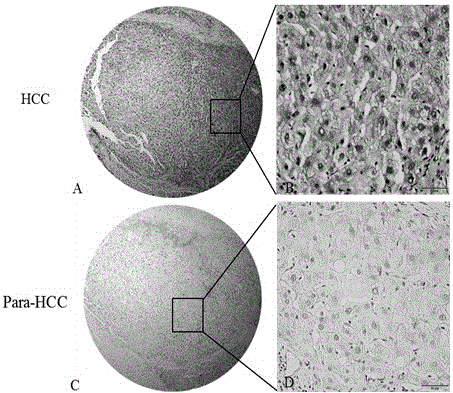

Process of knocking out Wnt3a gene and verification method thereof

InactiveCN106434752AHigh targeting accuracyShort experiment cycleFermentationVector-based foreign material introductionValidation methodsWNT3A gene

The invention discloses a process of knocking out Wnt3a gene and a verification method thereof. The knockout and verification of Wnt3a gene are finished through the following steps: establishment of a Cas9 lentiviral vector for Wnt3a gene, culture and passage of HepG2 cell, lentivirus infection and screening of target cell, verification of gene knockout efficiency through a mispairing enzyme method, cell protein analysis and cell proliferation detection by a CCK-8 method. The invention has the following advantages: the Wnt3a gene is knocked out by establishing a Cas9 double-vector lentivirus system for the first time; Crispr / Cas9 is a technology for accurately editing specific site of the genome of any species, and the cell-level single gene or multiple genes can be knocked out by the technology; compared with other gene editing technologies, the method has the advantages that the targeting accuracy is higher; only if the RNA target sequence is completely matched with the genome sequence, can the Cas9 cut the DNA and realize simultaneous knockout of multiple sites of the target gene; and moreover, the experimental period of vector establishment is short, the time and the cost are remarkably saved, and species limit is avoided.

Owner:AFFILIATED HOSPITAL OF NANTONG UNIV

Two-step enzyme measuring method and measuring reagent for creatinine in blood serum

ActiveCN102721684AAvoid accuracyDensity avoidanceMaterial analysis by observing effect on chemical indicatorCreatinine risePeroxidase

The invention discloses a two-step enzyme measuring method and measuring reagents for creatinine in blood serum. The hydrogen peroxide generated by endogenous creatine is eliminated by utilizing catalase in a reagent 1 of the creatinine measuring reagents, and the catalase in the reagent 1 is suppressed by utilizing the catalase in a reagent 2 of the creatinine measuring reagents, so that the creatinine content in a sample is measured. The invention has the advantages that the phenomenon that the cost is increased because of oxidizing hydrogen peroxide by the catalase, so that the detection result is low in accuracy and precision is avoided.

Owner:NINGBO MEDICAL SYSTEM BIOTECHNOLOGY CO LTD

Method for preparing ganoderma spore oil

ActiveCN1883590AFunction increaseEnhance immune functionMetabolism disorderDigestive systemSporeCentrifugation

The invention relates to a process for preparing glossy ganoderma spore oil by using lucid ganoderma spore powder and glossy ganoderma as the raw material, which comprises enzyme method wall-breaking, wet method palletizing, supercritical CO2 extracting, finally carrying out centrifugation.

Owner:GUANGDONG YUEWEI EDIBLE FUNGI TECH +1

Method for extracting mulberry cyanidin

ActiveCN102212053AHigh puritySimple processOrganic chemistryNatural dyesUltrafiltrationMacroporous resin

The invention relates to a method for extracting cyaniding and belongs to the technical field of extracting natural medicaments. The method adopts the process of ultrasonic-assisted enzyme method extraction, flocculation, ultrafiltration, macroporous resin adsorption, nanofiltration condensation, spray drying and high-purity cyaniding. Compared with the traditional processes, the method has the advantages of overcoming the defects in the traditional processes, effectively improving the yield and the quality of the product, greatly lowering the consumption and the loss of the organic solvents,reducing energy consumption, lowering production cost, having practicability and progress and reaching the domestic leading level.

Owner:湖州柳荫生物科技有限公司

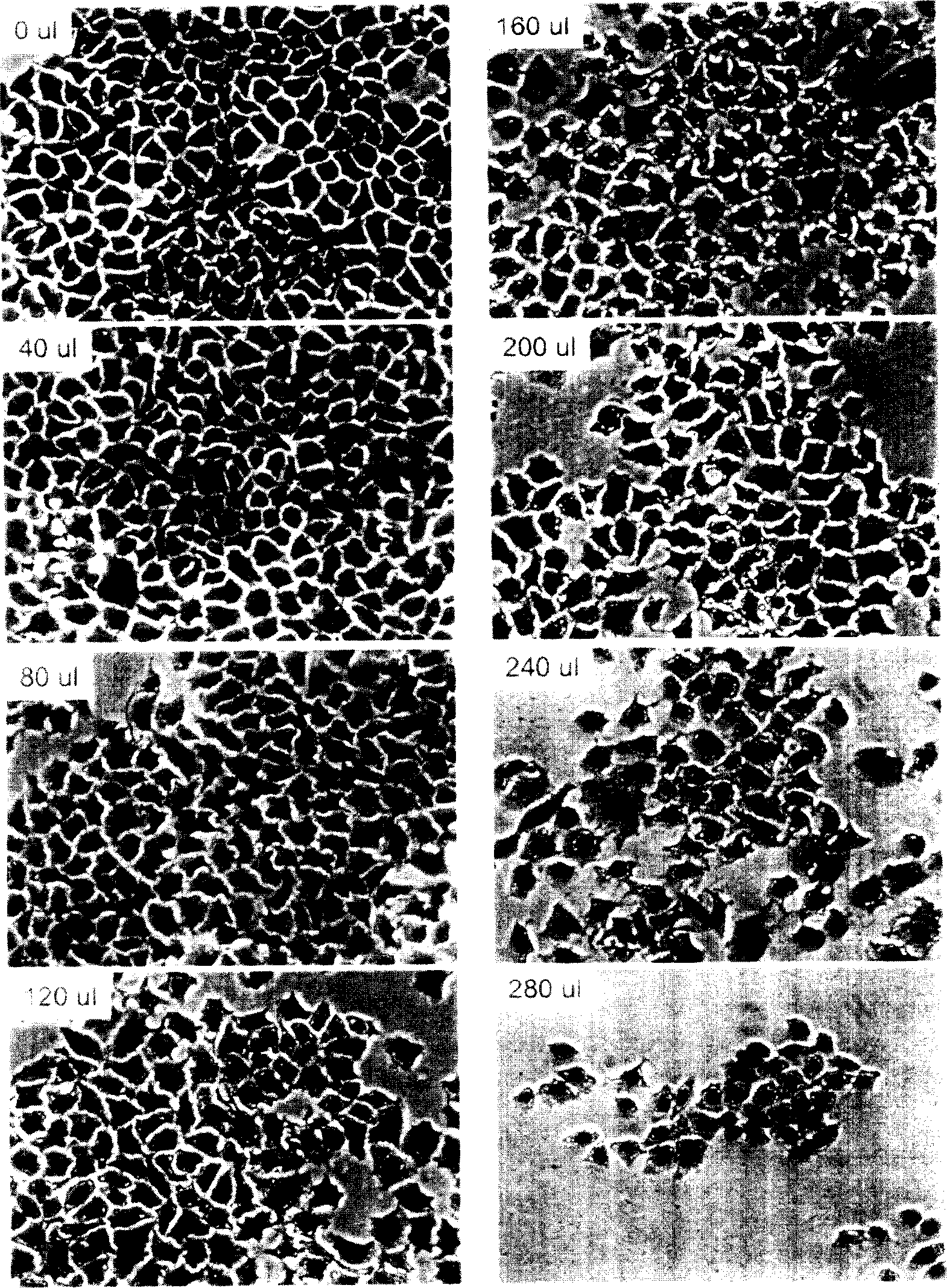

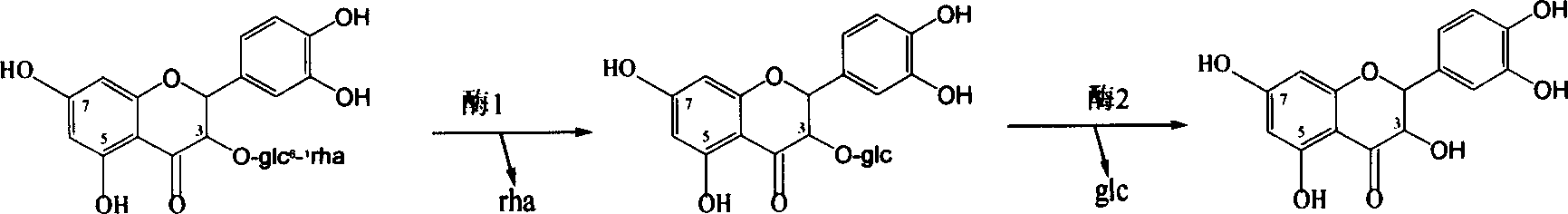

Method for preparing isoquercetin and quercetin by enzymatic method and hydrolyzing rutin

The method for preparing isoquercetin and quercetin by adopting enzyme method to hydrolyze rutin glycosyl includes the following steps: using the enzyme capable of hydrolyzing rutin glycosyl, mixing said enzyme, rutin, buffer solution and ethyl alcohol and making them produce reaction for 2-24 hr. and its reaction temp. is 15-70 deg.C, pH value is 4-8, rutin concentration is 0.1-10% and ethyl alcohol concentration is 0-35%, so that the isoquercetin and quercetin can be extracted, and the purity of said invented products is greater than 90%.

Owner:SUNFLOWER PHARM GRP (TIANJIN) DRUG RES INST CO LTD

Method for preparing porous starch through enzyme method in high temperature

A process for preparing the porous starch by high-temp enzyme method includes such steps as proportionally mixing starch with water, regulating pH=1.5-12.5, adding the cross-linking agent with multiple function groups, stirring while reacting to obtain cross-linked starch, regulating pH=6-7, dewatering, washing, drying to obtain powdered cross-linked starch, regulating concentration of emulsion, adding amylase, enzymolyzing, regulating pH=6-7, filtering, washing, centrifugal dewatering, pulverizing filtered cake, and drying to obtain porous starch.

Owner:SOUTH CHINA UNIV OF TECH

Method for extracting polysaccharide from cordyceps militaris medium

ActiveCN102731666AReasonable workmanshipEffective extraction methodMetabolism disorderAntipyreticTrypsinPrecipitation

The invention discloses a method for extracting polysaccharide from a cordyceps militaris medium. The cordyceps militaris is crushed and mixed with water, is extracted in an enzyme liquor and an alkali liquor under 30 DEG C to 80 DEG C, and an obtained solution is centrifugalized. An insoluble substance is extracted repeatedly, and supernatants are combined. Amylase enzymolysis is performed on the obtained product under 50 DEG C to 75 DEG C. After centrifugation, a supernatant is condensed to be with a sugar content of 1.5 percent to 3.0 percent. The supernatant is added with ethanol and alcohol precipitation is performed on the obtained product under 0 DEG C to 4 DEG C, a product is obtained by drying the obtained product after centrifugation. After deproteinization and dialysis, crude cordyceps polysaccharide is obtained. A single enzyme method, a double enzyme method, a compound enzyme method and a supersonic wave enzyme method can be adopted, and protease, trypsin, etc. can be adopted. The method optimizes the technology route for extracting the cordyceps polysaccharide, enhances an obtaining rate and an extraction efficiency of the cordyceps polysaccharide. Extraction, separation and purification of the cordyceps polysaccharide are carried out effectively. The method provides a solution approach for the utilization of agricultural wastes, and provides a technology base for further exploitation of the cordyceps polysaccharide.

Owner:DALIAN POLYTECHNIC UNIVERSITY

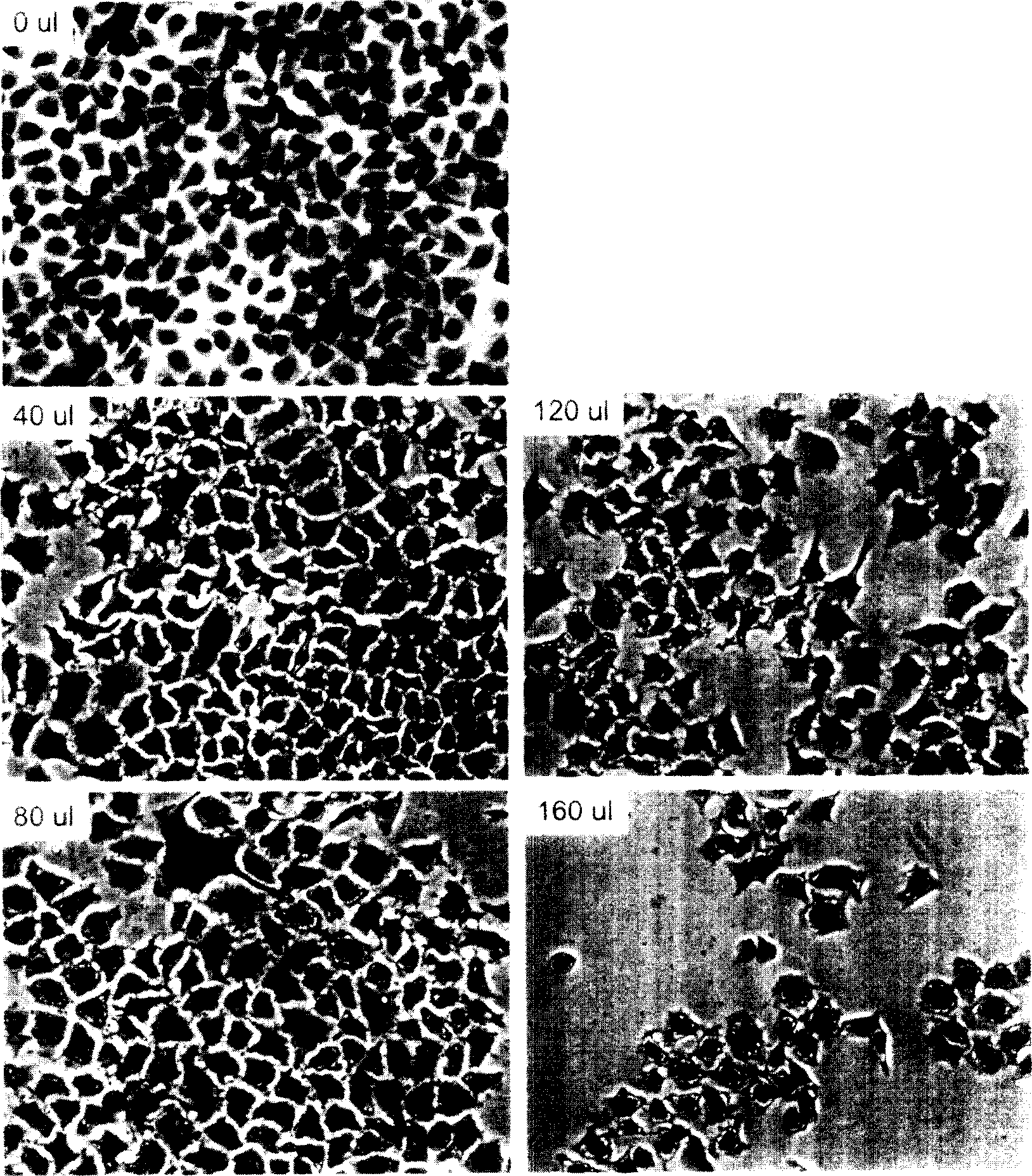

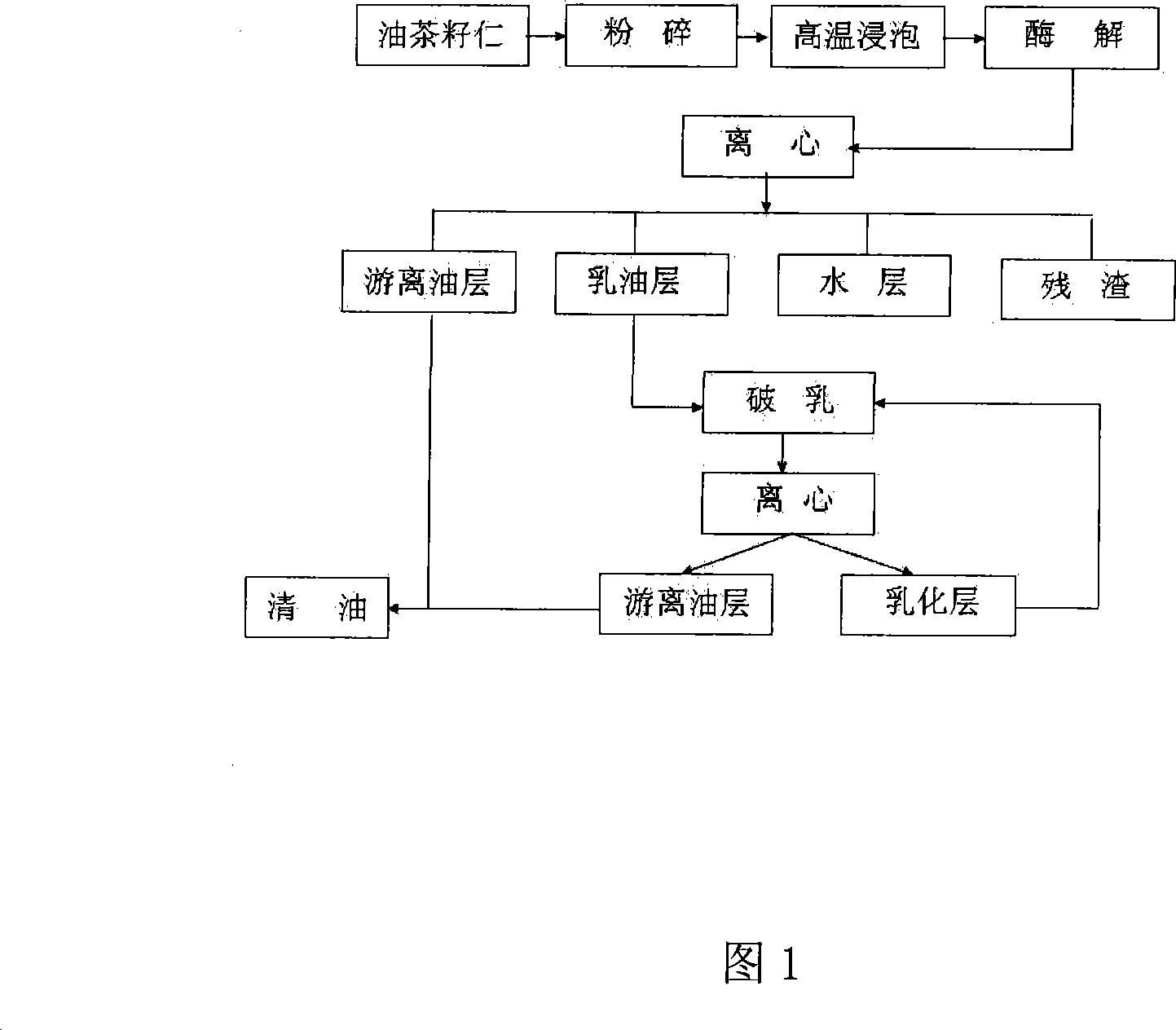

Technique for extracting grease from oil-tea camellia seed by enzyme method

InactiveCN101235399AReduce emulsificationReduce foaming and other problemsFermentationCamellia oleiferaDry weight

The invention relates to an enzymatical extraction process of oil in tea seed oil kernel, which comprises the following steps: firstly, utilizing dried tea seed oil kernel to be raw material, immersing in water in high temperature after disintegrating, stirring in uniform speed under 70-100 DEG C, secondly, enzyme hydrolyzing, adding acid protease which is 0.02-1% dry weight of disintegration samples or mixed enzyme of acid protease / cellulose in 45-55 DEG C to stir in uniform speed, and enzymatic hydrolysis for 2-4 hours, thirdly, separation emulsion breaking processing, directly separating out primary free boiled oil after enzymolysis liquid is centrifuged, getting secondary free boiled oil through centrifuging after missible oil demulsifies, combining the primary free boiled oil and the secondary free boiled oil, and getting the total boiled oil. The invention has the advantages that first, the invention reduces the problem of emulsification, foaming and the like which are faced when a grinding method is utilized to destroy cell structures, second, the invention prevents various enzymes in cells from degrading oil, which has high oil extraction rate to a further disintegrated function to tea seed oil kernel cell, third, the invention increases the treatment to missible oil, which increases free boiled oil yield through demulsifying, centrifuging, stewing to layer and the other modes.

Owner:江西春源绿色食品有限公司

Preparation method of instant oat flour

InactiveCN104642910AModerate tastePreserve soluble nutrientsFood preparationCelluloseAdditive ingredient

The invention discloses a preparation method of instant oat flour and relates to a preparation method of oat flour. The preparation method comprises the following steps: baking, cleaning, soaking, steaming and cooling oats, serving as raw materials, sequentially; glue milling the oats after pretreatment to prepare oat pulp, carrying out enzymatic hydrolysis, heating, boiling, and killing enzyme; and cooling an enzymolysis liquid, glue milling, homogenizing, drying, sterilizing and packaging a finished product. According to the preparation method disclosed by the invention, with the oats as the raw materials, by virtue of pretreatment, enzymatic hydrolysis technological treatment and spray drying, the instant oat flour which can keep multiple nutritional components and fragrance of oat is prepared; the prepared instant oat flour is moderate in taste, has self flavor of oat, keeps the soluble nutritional components in the oats, is also capable of providing extra plant proteins, fats and soluble dietary fibers and can be directly used for preparing an oat beverage; as macromolecular substances including starch, cellulose and proteins in the oats are hydrolyzed by virtue of an enzyme method, the viscosity of the starch of the oats is lowered, and the problems of water separating, gelation, precipitation and the like caused when the oats are applied to beverages are solved.

Owner:厦门北大泰普食品科技有限公司

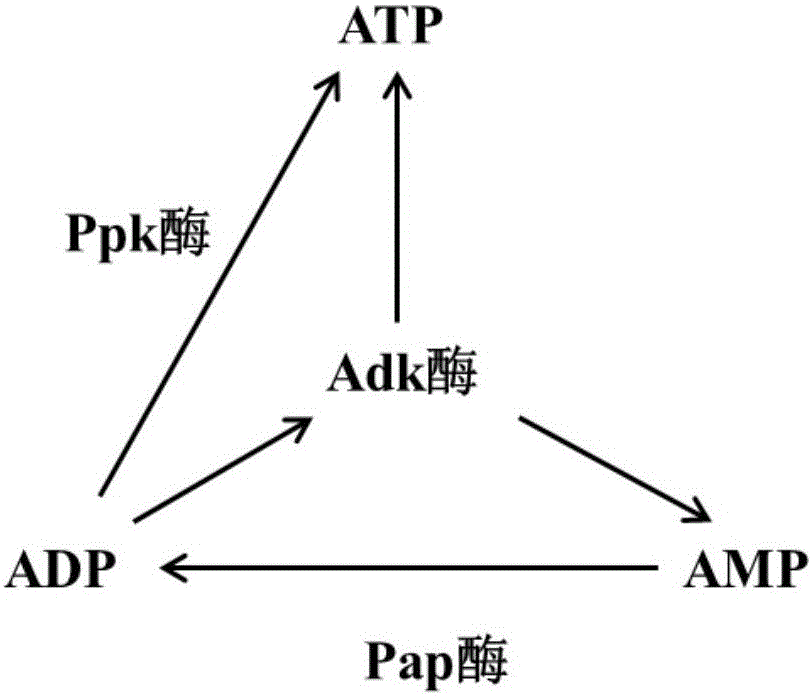

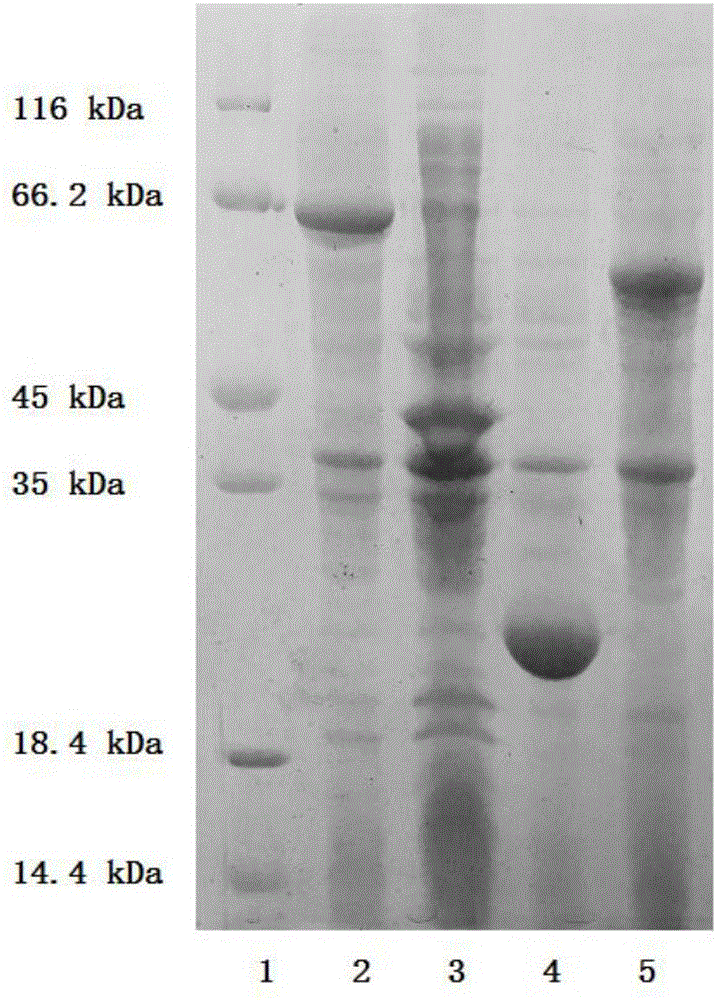

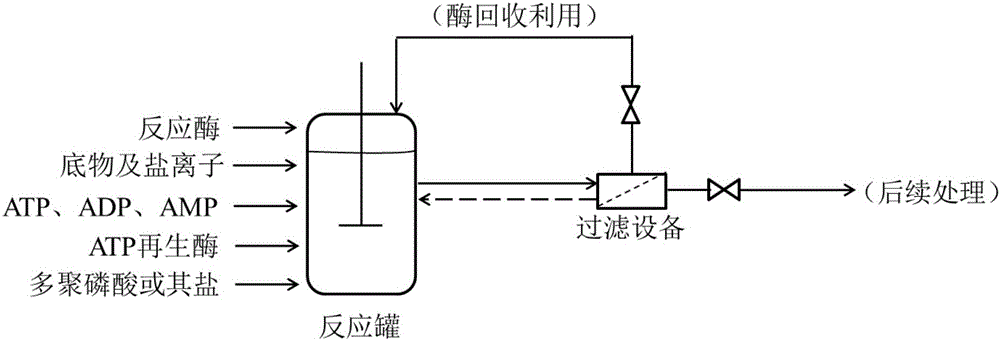

Method for regenerating ATP (adenosine triphosphate) by enzyme process and application thereof

InactiveCN105861598AReduce usagePromote regenerationTransferasesFermentationPhosphoric acidEnzyme catalysis

The invention discloses a method for regenerating ATP by enzymatic method, which comprises the following steps: (1) preparing and obtaining ATP regenerating enzyme; (2) regenerating ATP in reaction liquid; (3) separating products and ATP regenerating enzyme. According to the method for regenerating ATP of the present invention, it has the following beneficial effects: (1) adopt three kinds of ATP regenerating enzymes of novel Ppk, Adk and Pap, the ATP consumed in the enzymatic reaction can be recycled and regenerated, greatly reducing the amount of ATP used, regenerated The process is simple and efficient, the reaction is easy to control, and the stability is high. (2) The substrate polyphosphoric acid or its salt to be added to the reaction is cheap and less polluting. (3) The enzymatic reaction does not need to add expensive ATP to start the reaction, add ADP or cheap AMP. (4) ATP regenerating enzyme recovery system was established, which is suitable for large-scale industrial production.

Owner:SHENZHEN GSH BIO TECH CO LTD

Synchronous aqueous enzymatic ultrasonic extraction for walnut oil and walnut protein peptide

InactiveCN101280327AQuality improvementMild treatment conditionsCheese manufactureVegetable proteins working-upOil phaseDietary fibre

The invention relates to an enzyme method ultrasonic extraction method of walnut oil and walnut protein, which belongs to the food and the functional food field. Water is added into walnut kernel or walnut powder to be grinded into paste, protease or compound protease are added into to be performed hydrolization, and simultaneously ultrasonic processing is performed, then the walnut kernel or walnut powder is agitated to perform enzymatic extraction, and then centrifugal separation oil phase, protein peptide oil water phase and residual solid phase are performed; walnut oil is acquired by refining the obtained oil phase, which meets the requirements of green foods; the protein peptide aqueous solution can be directly used to produce degreased walnut protein nutrient milk, or to prepare walnut antioxidation peptide after performed nanofiltration, which is used in health products, food additives, cosmetics or daily chemical articles, or to produce nutrient condensed milk after being performed low temperature concentrating, or to produce walnut protein nutrition powder after performed spray drying; the solid phase residue is prepared into diet fiber food after being dried and grinded into powder; walnut nutrient protein peptide products can be obtained through performing vacuum concentration and spray drying to walnut protein peptide extracting solution containing nutrient content.

Owner:KUNMING UNIV OF SCI & TECH

Pulping and papermaking process through multiple-composition biological enzyme method

InactiveCN102345244AReduce consumptionImprove product qualityNon-fibrous pulp additionPaper/cardboardBlack liquorWastewater

The invention discloses a pulping and papermaking process through a multiple-composition biological enzyme method. The method is a biopulping method, which adopts a production process for preparing paper pulp through pulping and fermenting by using a multiple-composition biological enzyme method (phanerochaete, phanerochaete chrysosporium, xylanase, glucoamylase, yeast), adopts agricultural straws, rice and wheat straws, cotton stalks, rape stalks, reeds, bamboo, wood and the like as main raw materials, and comprises treatments of glass cutting, impurity removing, puffing, fermenting through multiple-composition biological enzyme, pulp washing, pulp selecting, defibrination and separation to form the pulp. According to the present invention, no black liquid is generated during the pulping process, the water from fermenting and pulping is recycled so as to achieve zero discharge of wastewater.

Owner:王凤忠

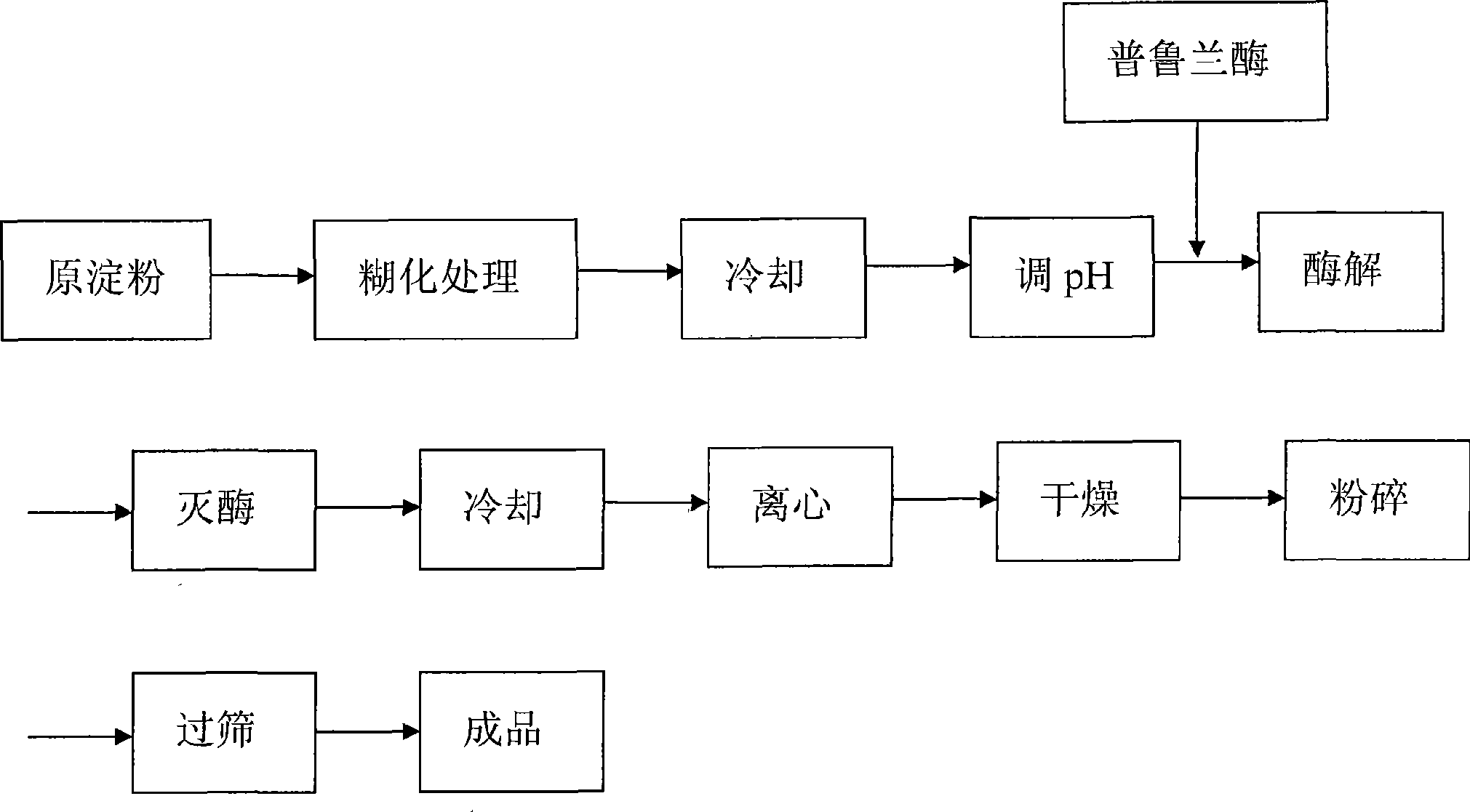

Preparation method of slowly digestive starch

The invention provides a preparation method of slowly digestive starch by utilizing Pullulanase to modify and process raw starch by an enzyme method, changing the particle structure of the starch, enabling molecular chains of the starch to realign and recombine, controlling action conditions to damage amorphous structure and adjust crystal structure and further changing crystallization conditions so that the crystallinity of the starch is improved and can be controlled. The method comprises the following steps: preparing the raw starch, adding the Pullulanase to be enzymatically hydrolyzed, sterilized, cooled, refrigerated, baked, pulverized, screened, and the like. The invention provides an enzymatic preparation technology for a novel functional food raw material-slowly digestive starch and can be used in raw starch and modified starch enterprises, and the slowly digestive starch and slowly digestive starch products, which are produced by the technology, can be applied to the food industry and the medicine industry.

Owner:HARBIN UNIV OF COMMERCE

Method for preparing paper pulp by using biological enzyme

InactiveCN102978986AEasy to handleReduce energy consumptionCellulose material pulpingState of artFermentation

The invention relates to a preparation method of paper pulp, and further relates to a method for preparing the paper pulp through a biological enzyme method. The technical scheme is that the method comprises the following steps of: one, segment cutting; two, puffing; three, heat preservation fermentation; four, shoving; five, pulp washing; six, pulp selecting, wherein screened out coarse residues are put into the step three for fermentation again; seven, pulp grinding; and eight, screening, wherein the screened out pulp residues are put into the step seven for pulp grinding again. Compared with the prior art, the method has the advantages that the pulping and papermaking through the biological enzyme method has the characteristics of 'three highs and three lows' compared with the conventional process technology.

Owner:TIANJIN ZHIZHAN SCI & TECH

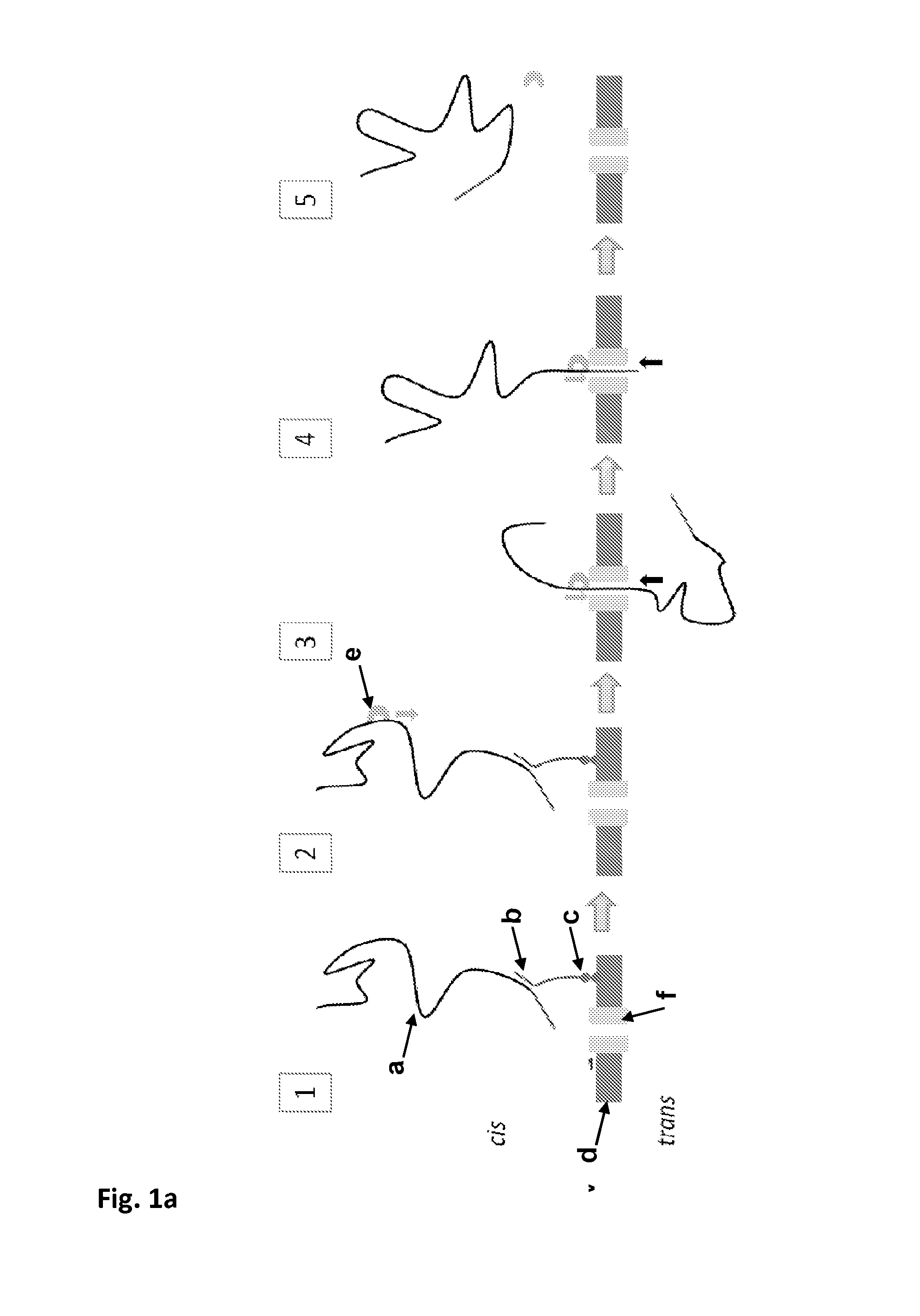

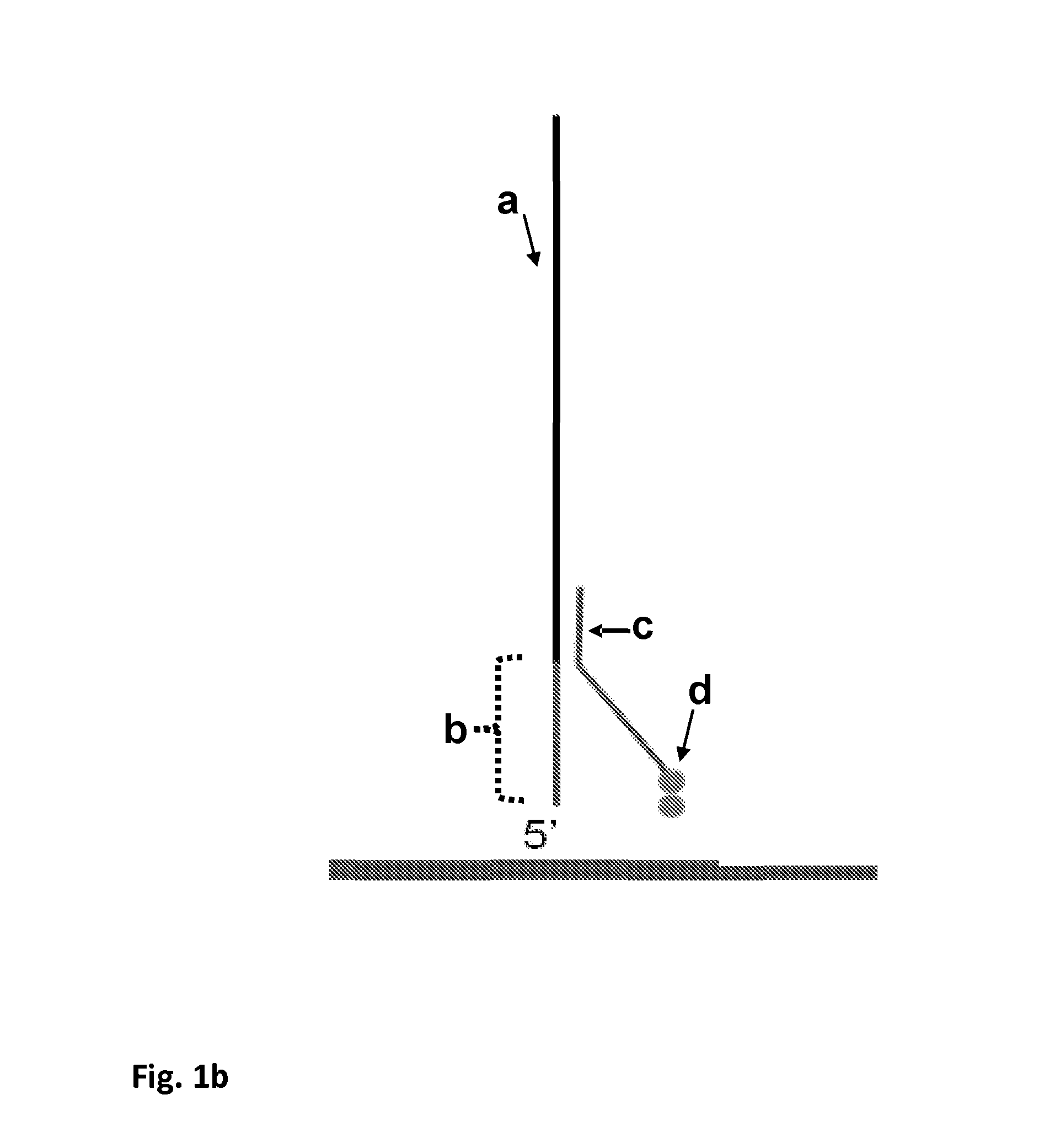

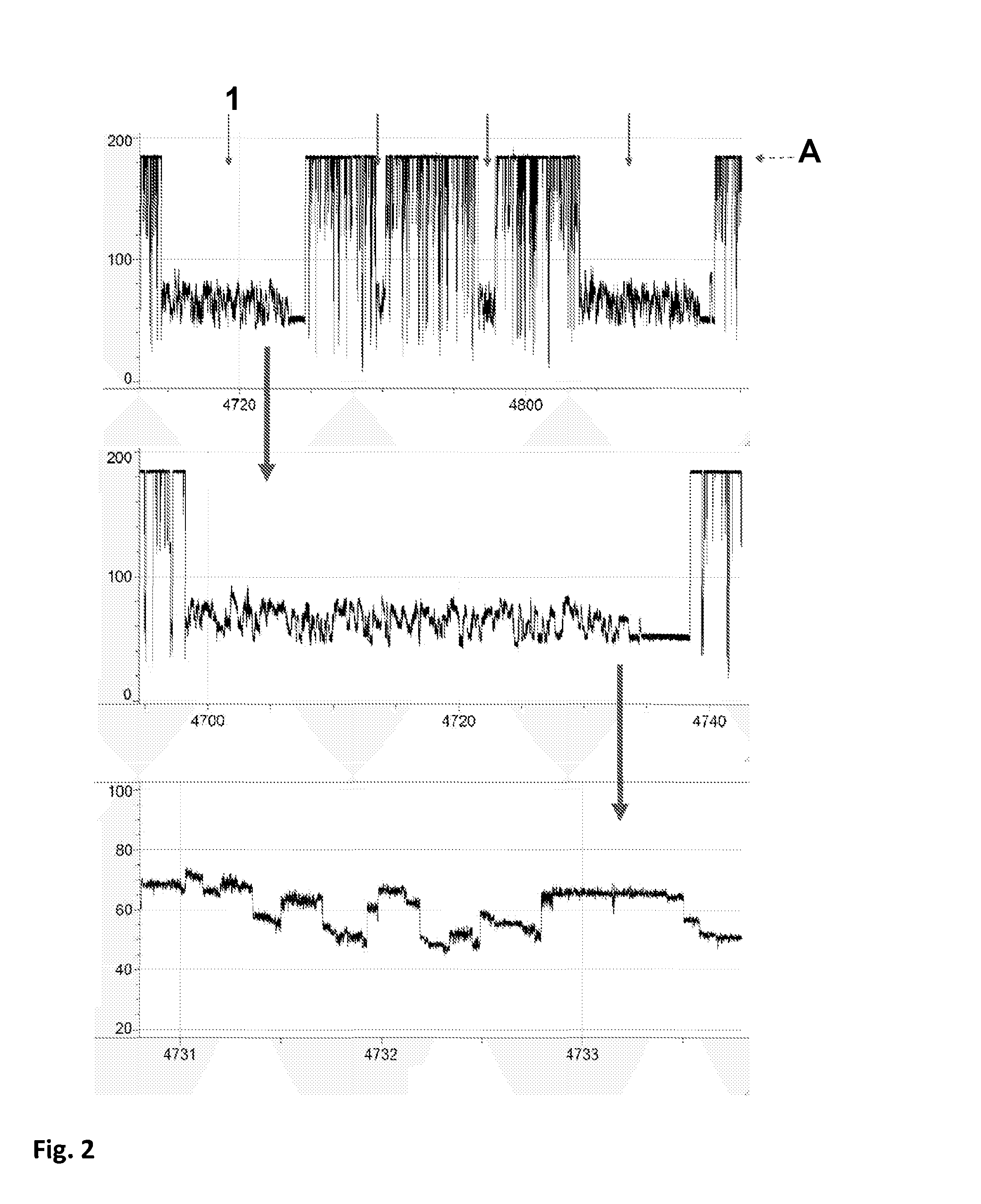

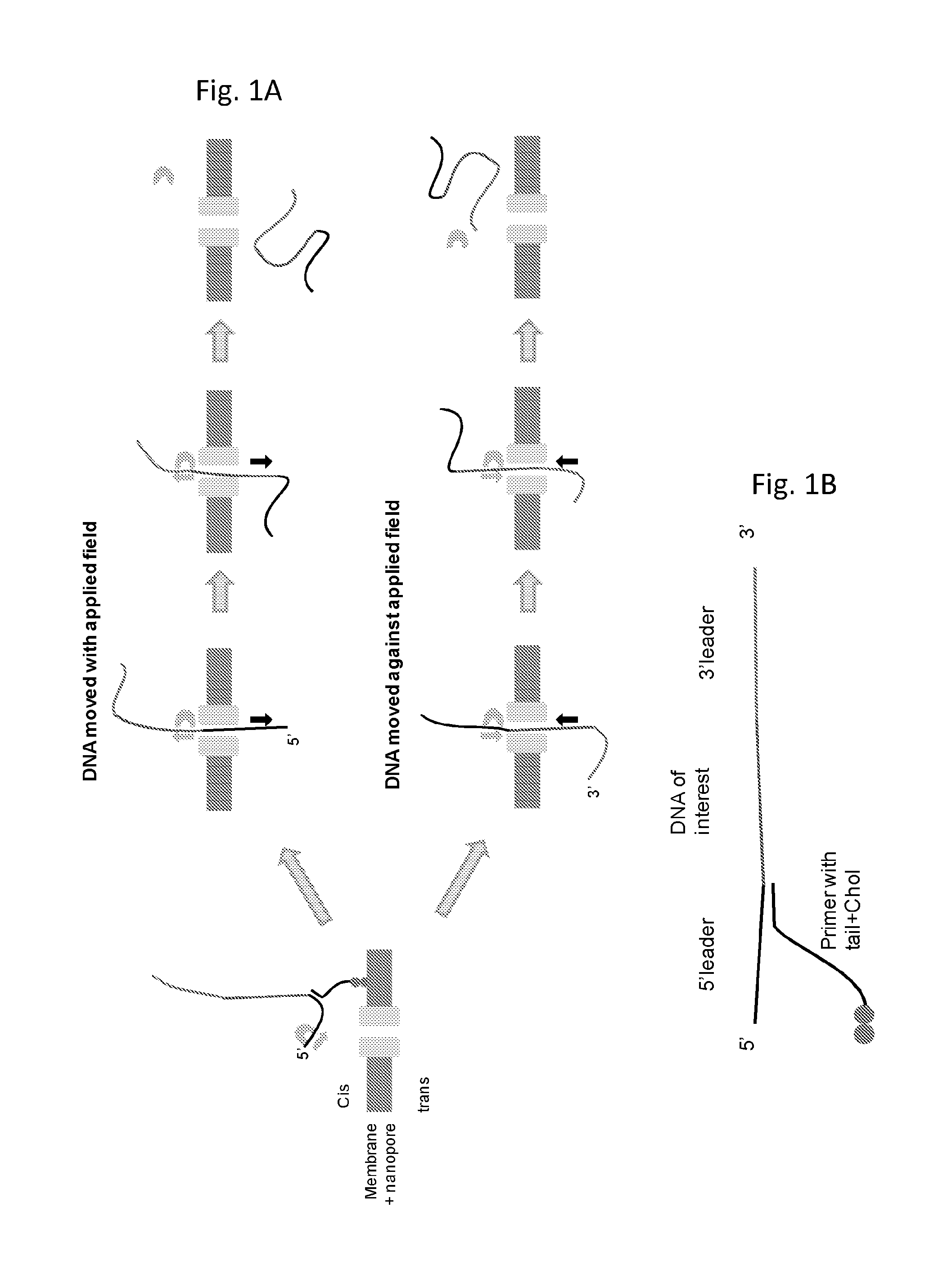

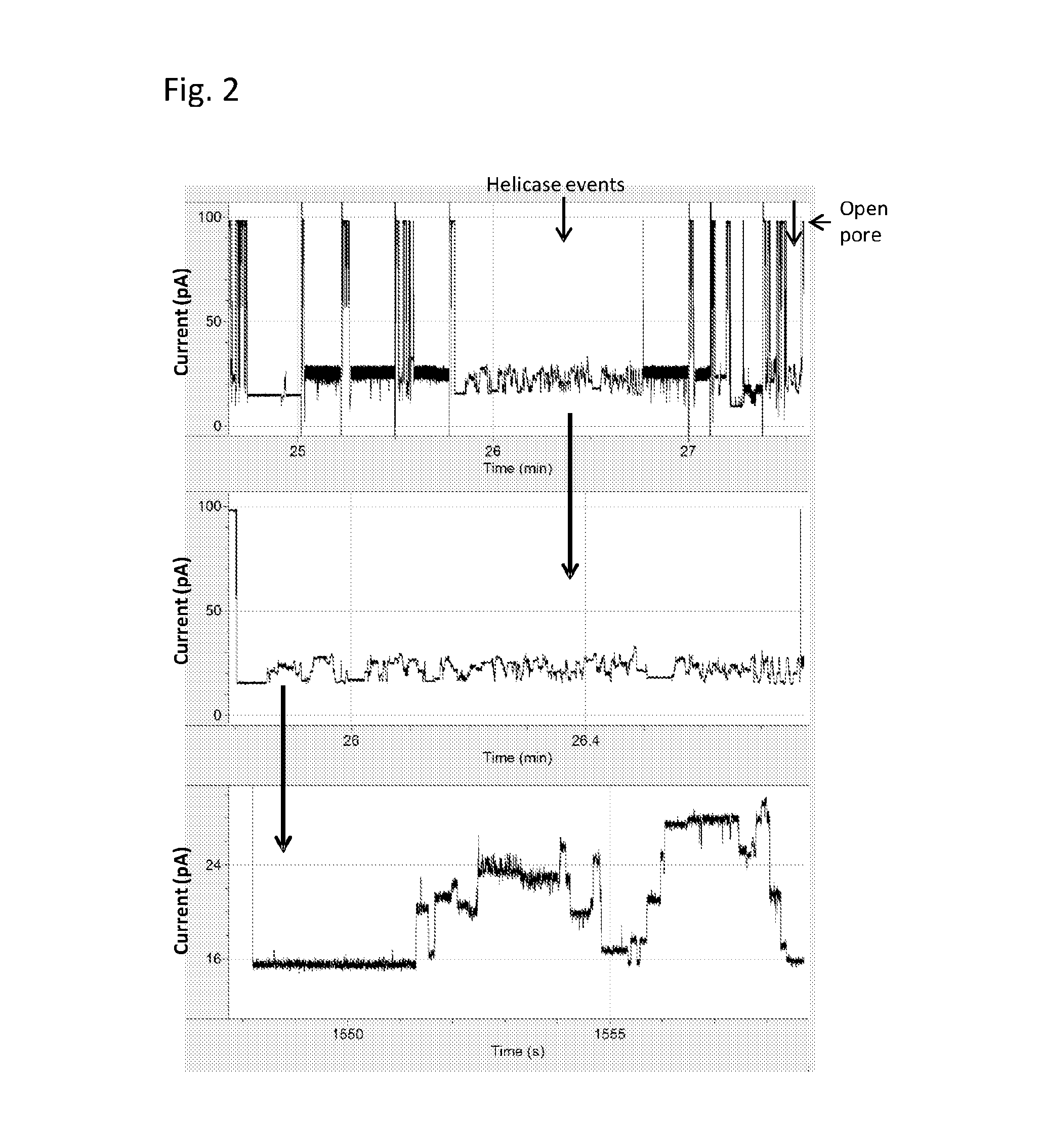

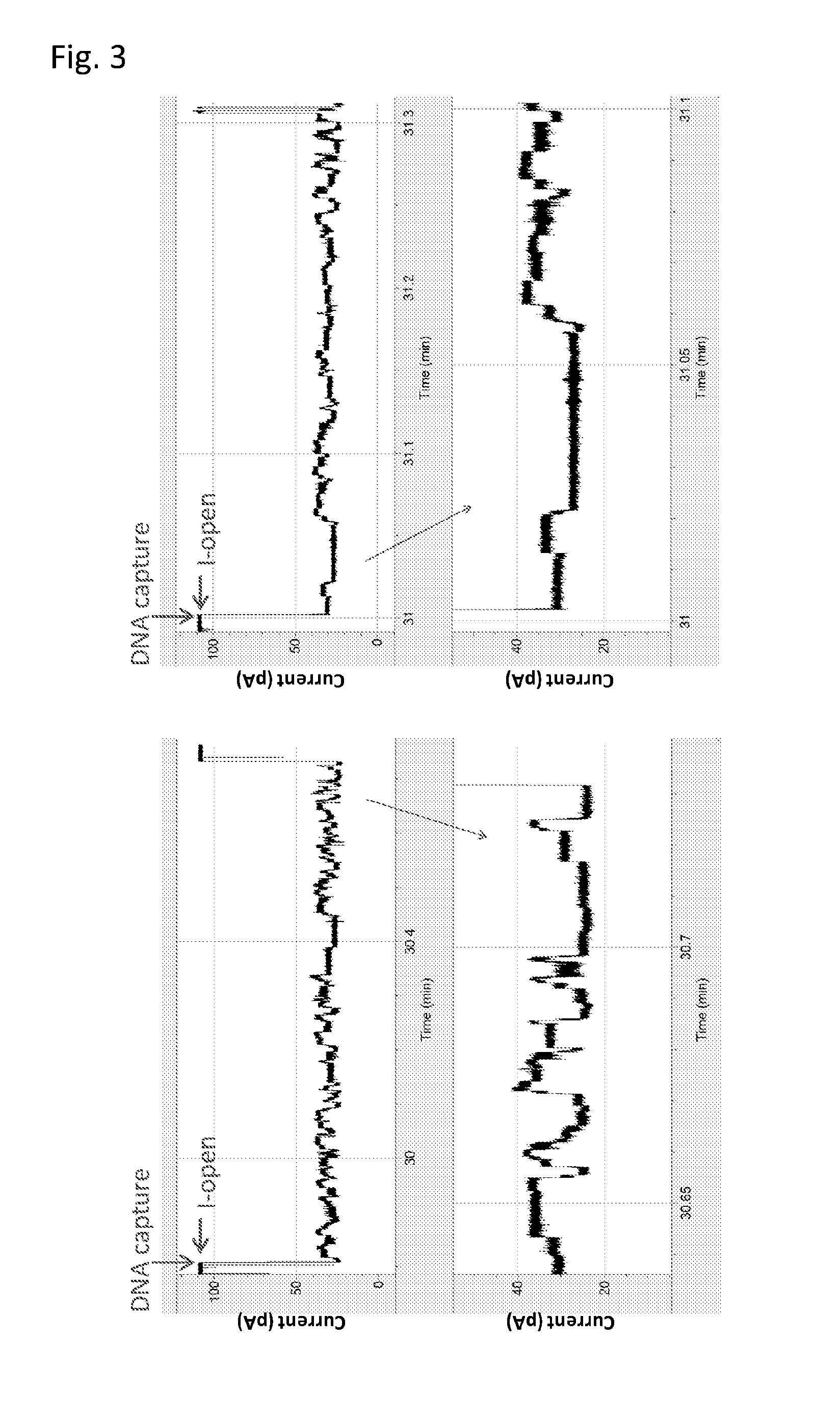

Enzyme method

ActiveUS20140255921A1Improve featuresBioreactor/fermenter combinationsBiological substance pretreatmentsNucleotideMolecular motor

The invention relates to a new method of characterising a target polynucleotide. The method uses a pore and a Hel308 helicase or amolecular motor which is capable of binding to the target polynucleotide at an internal nucleotide. The helicase or molecular motor controls the movement of the target polynucleotide through the pore.

Owner:OXFORD NANOPORE TECH LTD

Enzyme method for detecting disease conditions by measuring lysophosphatidic acid

InactiveUS6255063B1Reduce background concentrationMicrobiological testing/measurementBiological material analysisAssayLysophosphatidic acid

The present invention is an enzymatic method and diagnostic kits for detecting and quantifying the presence of one or more lysophospholids in a sample of bodily fluid taken from a test subject. The method uses enzymes in a two step assay and may be used to detect disease conditions associated with altered levels of lysophospholipids and to correlate such conditions with altered levels of lysophospholipids.

Owner:APOLLO ENDOSURGERY INC

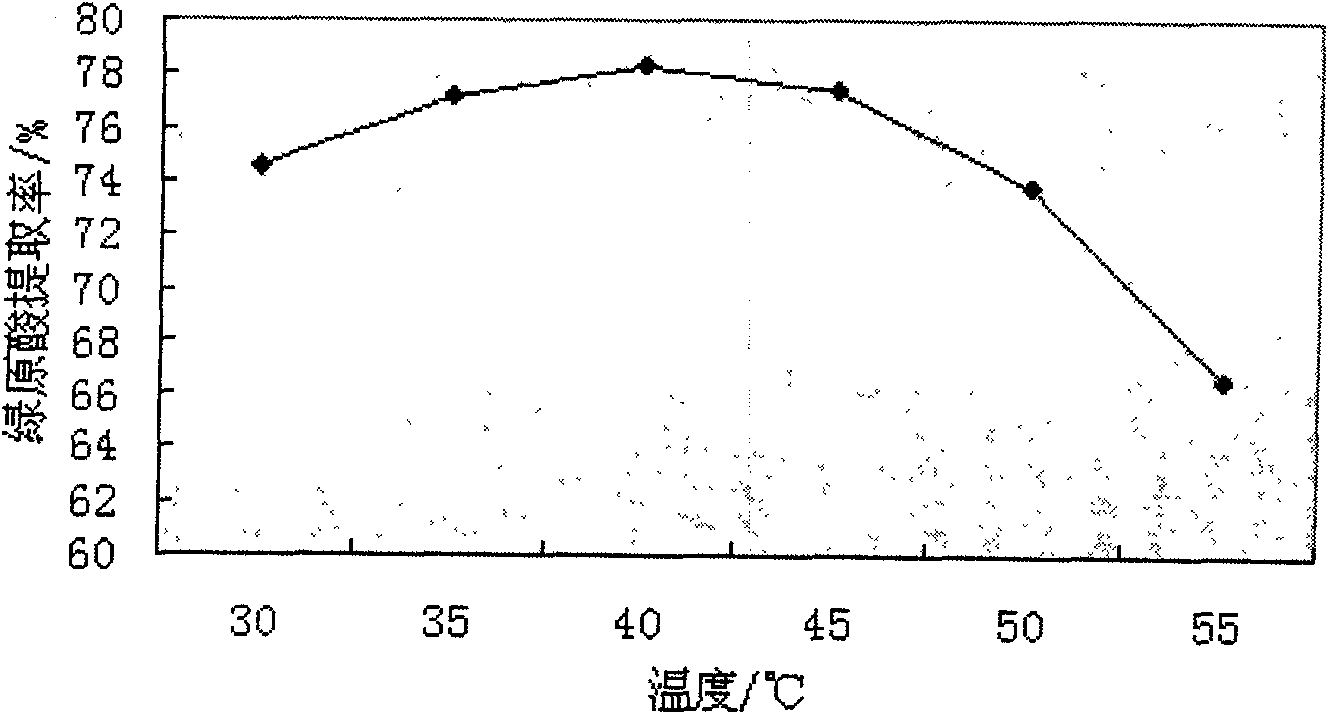

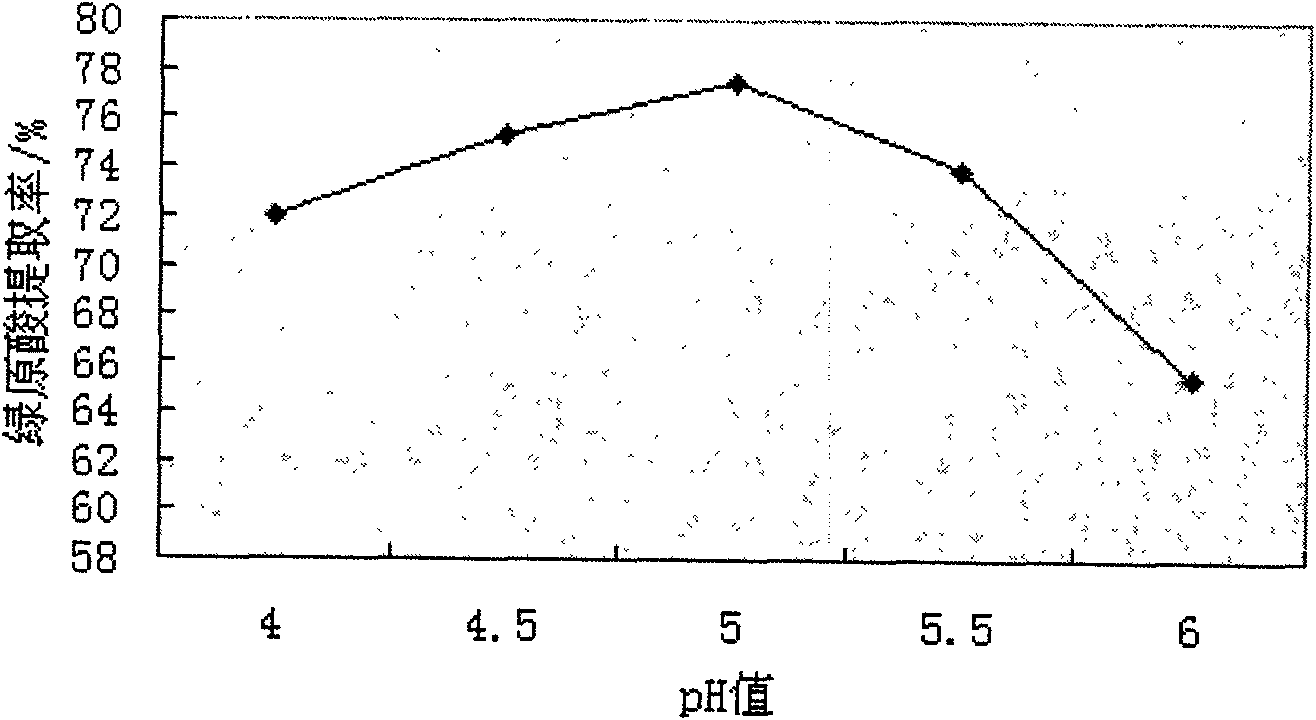

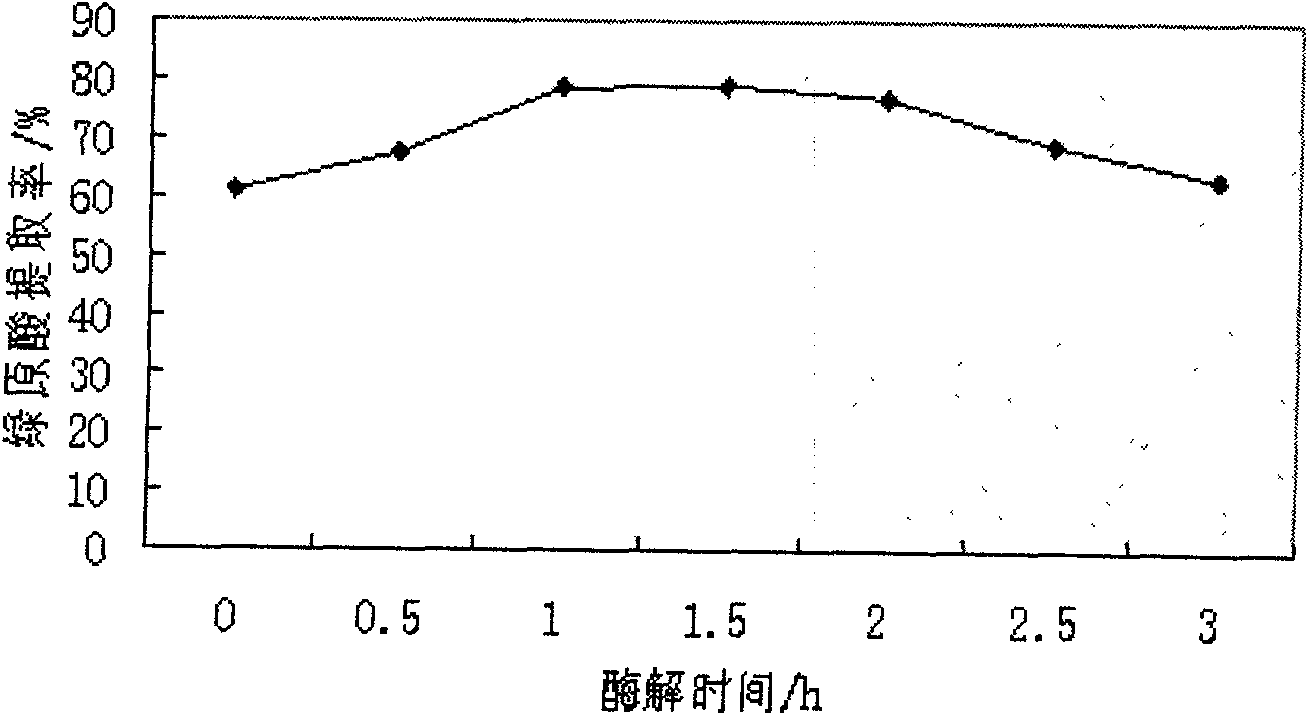

Method for extracting chlorogenic acid from honeysuckle by using compound enzyme method

InactiveCN101830804AGood process repeatabilityThe result is stableCarboxylic acid esters separation/purificationPectinaseChlorogenic acid

The invention relates to a method for extracting chlorogenic acid from honeysuckle by using a compound enzyme method and researches a novel process for extracting a main medicinal effective component of the chlorogenic acid from the honeysuckle by a cellulose and pectinase compounding enzyme method. Through a single factor experiment and an orthogonal test, optimal process conditions for extracting the chlorogenic acid from the honeysuckle by using the compound enzyme method can be optimized: the enzymolysis temperature is 45DEG C, the pH is 4.5, the compound ratio of the cellulose to the pectinase is 1.0:0.3 and the enzymolysis time is 1.5 hours. The test result shows that the process repeatability is favorable and the result is stable. The extraction rate of the chlorogenic acid extracted from the honeysuckle by using the compound enzyme method can reach 83.06 percent which is improved by 16.93 percent in comparison with the extraction rate of the chlorogenic acid extracted by using a water extraction process.

Owner:ZHONGXIN PHARMA FACTORY OF TIANJIN ZHONGXIN PHARMA GROUP

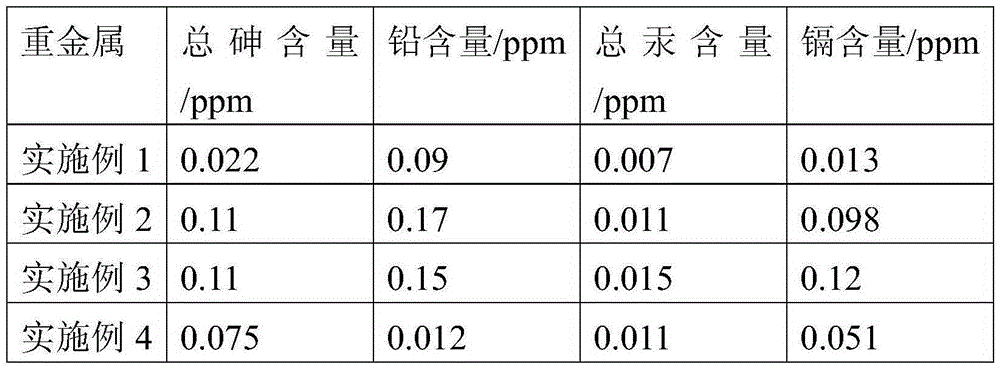

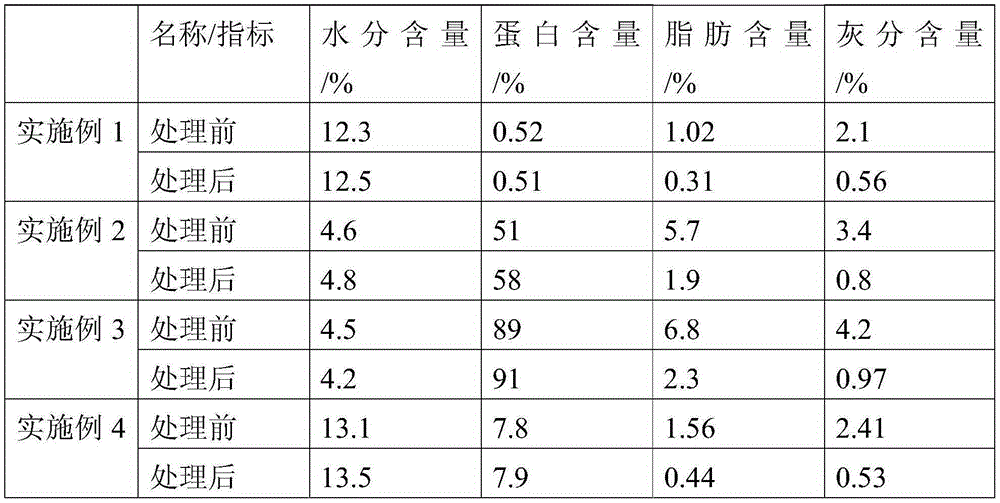

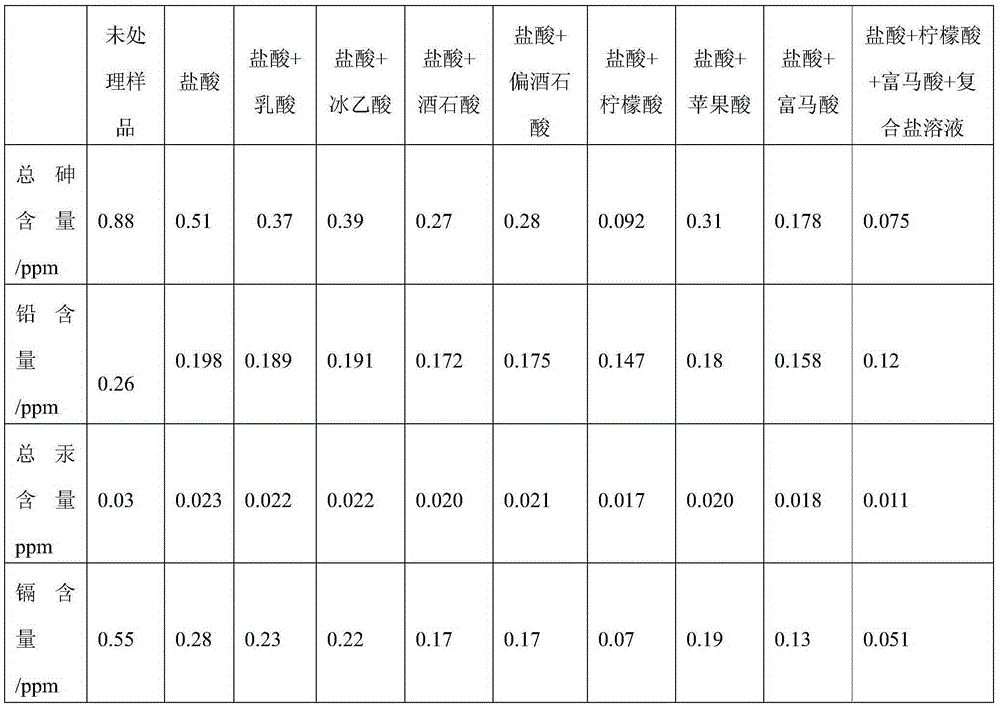

Preparation method of rice products with low content of heavy metal

ActiveCN105410598AImprove plasticityImprove water holding capacityFood scienceRice proteinRotational flow

The invention discloses a preparation method of rice products with a low content of heavy metal. The method comprises the following steps of performing pulp mixing, performing enzymolysis, performing complexing, performing washing separation and performing drying treatment on rice flour or rice protein flour, so that the rice flour or the rice protein flour with a low content of metal is finally prepared. According to the method disclosed by the invention, an enzyme method and a chemical method are used, so that the heavy metal in the rice flour or the rice protein flour is dissociated out in a complexing manner; then solid-liquid separation is performed by a physical method of the stepwise gradient separation of rotational flow, so that the purpose of reducing the content of the heavy metal in the rice flour or the rice protein flour is realized, and a deeply processed product, namely the rice flour or the rice protein flour, with high quality and high added value is prepared. The method is simple to operate and low in cost.

Owner:JIANGNAN UNIV

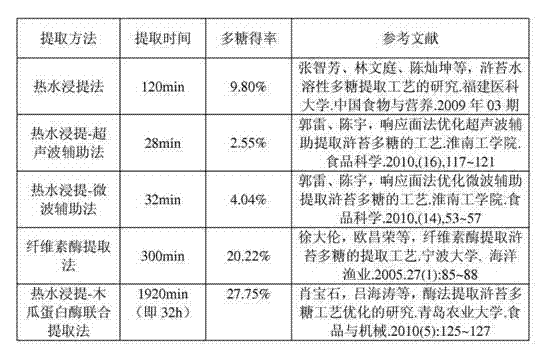

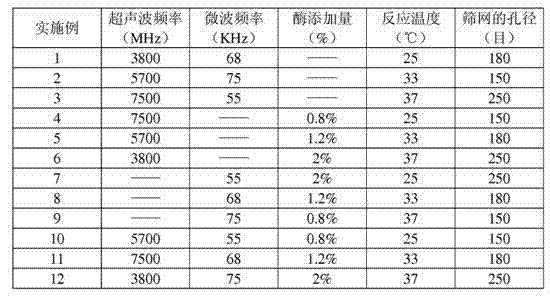

Extracting process for efficiently extracting polysaccharide of enteromorpha

The invention provides an extracting process for efficiently extracting polysaccharide of enteromorpha. In a process of adding water to extract, the polysaccharide of enteromorpha is extracted by at least two of a microwave method, an ultrasonic method and an enzyme method, wherein in the ultrasonic method, the ultrasonic frequency is 3800 MHz-7500MHz, the extracting time is one minute to three minutes, and the pH value is 5.0-5.5; in the microwave method, the microwave frequency is 55kHz-75kHz, the extracting time is one minute to three minutes and the pH value is 5.0-5.5; in the enzyme method, the adding amount of the enzyme is 0.8%-2%, the pH value is 5.0-6.0, the treatment time is 1.5hours-2hours and the reaction temperature is 25 DEG C to 37 DEG C; and in a solid-liquid separating step, the slag of the extracted liquid is removed by adopting a screen cloth of 150-250 meshes. According to the extracting process disclosed by the invention, the polysaccharide of enteromorpha can be extracted within a short time.

Owner:FUJIAN HAIXING HEALTH FOOD

Method for protease-method wool felt-proofing treatment by using ultrasonic technology

InactiveCN103924439AHelps catalyze hydrolysisReduce processing timeBiochemical fibre treatmentUltrasonic/sonic fibre treatmentEngineeringUltrasonic technology

The invention discloses a method for protease-method wool felt-proofing treatment by using an ultrasonic technology, belongs to the application technical filed of wool fabric dyeing and finishing in the wool manufacturing industry and aims at solving the problems that the treating time is long, the felt-proofing rate is high and the fiber damage is large in a single protease method so as to realize the effect of optimizing wool fiber / wool top / wool fabric biological enzyme-method felt-proofing finishing. The felt proofing can be performed on wool under an ultrasonic condition, the protease catalytic hydrolysis speed is increased, the shedding off of a wool scale layer is accelerated, the protease method treating time is shortened, and the degradation of the protease to the inferiors of fibers is reduced. The synergistic effect of ultrasonic waves and the protease can replace a conventional chlorination method or single protease method felt-proofing method, so that the felt-proofing performance of wool fabrics is improved.

Owner:JIANGNAN UNIV

Enzyme method

ActiveUS20140335512A1High salt concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsDNA unwinding enzymeHelicase

The invention relates to a new method of characterising a target polynucleotide. The method uses a pore and a RecD helicase. The helicase controls the movement of the target polynucleotide through the pore.

Owner:OXFORD NANOPORE TECH LTD

Method for preparing n-3PUFA ocean glycerin ester by enzymatical process

A method for preparing n-3PUFA marine glyceride through adopting enzyme method includes following steps: refined fish oil is made into n-3PUFA condensate through saponification, acidification and urea adduct method; lipase catalyzes the synthesis reaction between n-3PUFA and glycerol; n-3PUFA marine glyceride is extracted and separated; moreover, n-3PUFA is effectively concentrated in glyceride to be made into functional products which can prevent and cure cardiovascular diseases and nourish the brain and improve intelligence. The raw material of the invention, n-3PUFA, is extracted from natural fish oil, thereby being safe and effective; during production, nitrogen protection is adopted without adding synthetic antioxidant, thereby effectively preventing oxidation of n-3PUFA; with scientific and reasonable technique, the invention completes synthesis by means of biological enzyme method along with high esterification degree of reaction, higher utilization rate of raw material and easily controlled reaction process; therefore, the invention has wide market prospect.

Owner:GUANGDONG OCEAN UNIVERSITY

Mycose separation and purification method

InactiveCN1807465ACorrosion and color retentionReduce manufacturing costPurification methodsIon exchange

The invention discloses a Process for the purification and separation of trehalose, containing enzymolysis reaction which adds saccharify enzyme in enzyme reaction liquor which is getted from the produced trehalose by enzymic conversion method and inoculating 3-10wt% Saccharomyces cerevisiae in saccharify enzyme enzymolysis liquor, fermenting and culturing in the condition of 25-30deg C and pH 5. 5-7. 5, then getting trehalose pure product after centrifuging, hyperfiltration, ion-exchange, condensation, crystallization and desiccation. Comparing with prevenient activated charcoal column chromatography and organolite process, this invention using two-stage remove mixed sugar of enzymolysis liquor, detecting the getted trehalose pure product by HPLC, its purity is as high as 98. 0%. at the same time, this invention has the advantage of high detaching and purifying efficiency, few lose of trehalose, low cost, simple technology and so on, bringing active impel on predigesting productive technology, improving production and reducing production costs of trehalose's produce by enzyme method.

Owner:胡耀辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com