Mycose separation and purification method

A technology for separation and purification of trehalose, applied in the field of separation and purification of trehalose, can solve problems such as unsuitable industrial production, and achieve the effects of low cost, less trehalose loss, and high separation and purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

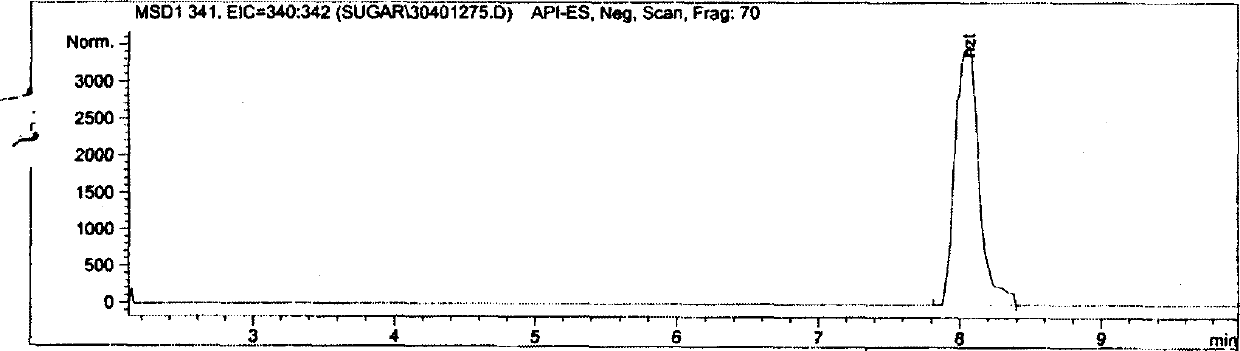

Image

Examples

Embodiment Construction

[0030] A method for separating and purifying trehalose, including the following steps:

[0031] a. Provide the enzyme reaction solution obtained by the enzyme conversion method to produce trehalose and pass it:

[0032] The enzyme reaction solution can be made of starch, starch hydrolysate (maize starch hydrolysate), malto-oligosaccharides, maltose, etc., through enzymes (malto-oligosaccharyl trehalose synthase MTSasc and malto-oligosaccharyl trehalose hydrolase MTHase and The enzyme reaction solution obtained by the action of Trehalose synthase, etc.). After determination, the trehalose content of the enzyme reaction solution accounts for about 60% of the total sugar content. The enzyme reaction solution is passivated at 100°C for 10 minutes to make the enzyme in the reaction solution Denaturation of similar and heat-insensitive proteins;

[0033] b. Glucoamylase hydrolysis reaction:

[0034] According to the sugar content in the enzyme reaction solution and the conversion rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com