Method for preparing ganoderma spore oil

A technology of Ganoderma lucidum spore oil and Ganoderma lucidum spore powder, which is applied in the biological field and can solve problems affecting the quality of spore oil and reducing physiological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: the preparation method 1 of whole Ganoderma lucidum spore oil

[0055] (1) Enzymatic wall breaking. Mix 50% Ganoderma lucidum spores, 30% Ganoderma lucidum powder, 10% millet, and 10% sorghum (soak millet and sorghum overnight and wash), add 1.2 times pure water, mix well, adjust the pH to 5.5 with HCl, and then autoclave it The pot is sterilized by 0.15MP pressure for 2 hours. After cooling, operate in a sterile room, insert red Ganoderma lucidum strains, and cultivate at 30°C. 20 days after the mycelium of Ganoderma lucidum is covered with the culture material, the culture product is taken out, dried, and pulverized by a ball mill for 10 minutes.

[0056] (2) Granulation. Using pure water as a wetting agent, a one-step granulator is used to granulate the spores of Ganoderma lucidum after enzymatically breaking the wall. The drying temperature is controlled at 40° C. and the drying time is 2.5 hours to obtain 20-mesh granules with a moisture content of...

Embodiment 2

[0059] Embodiment 2: the preparation method 2 of whole Ganoderma lucidum spore oil

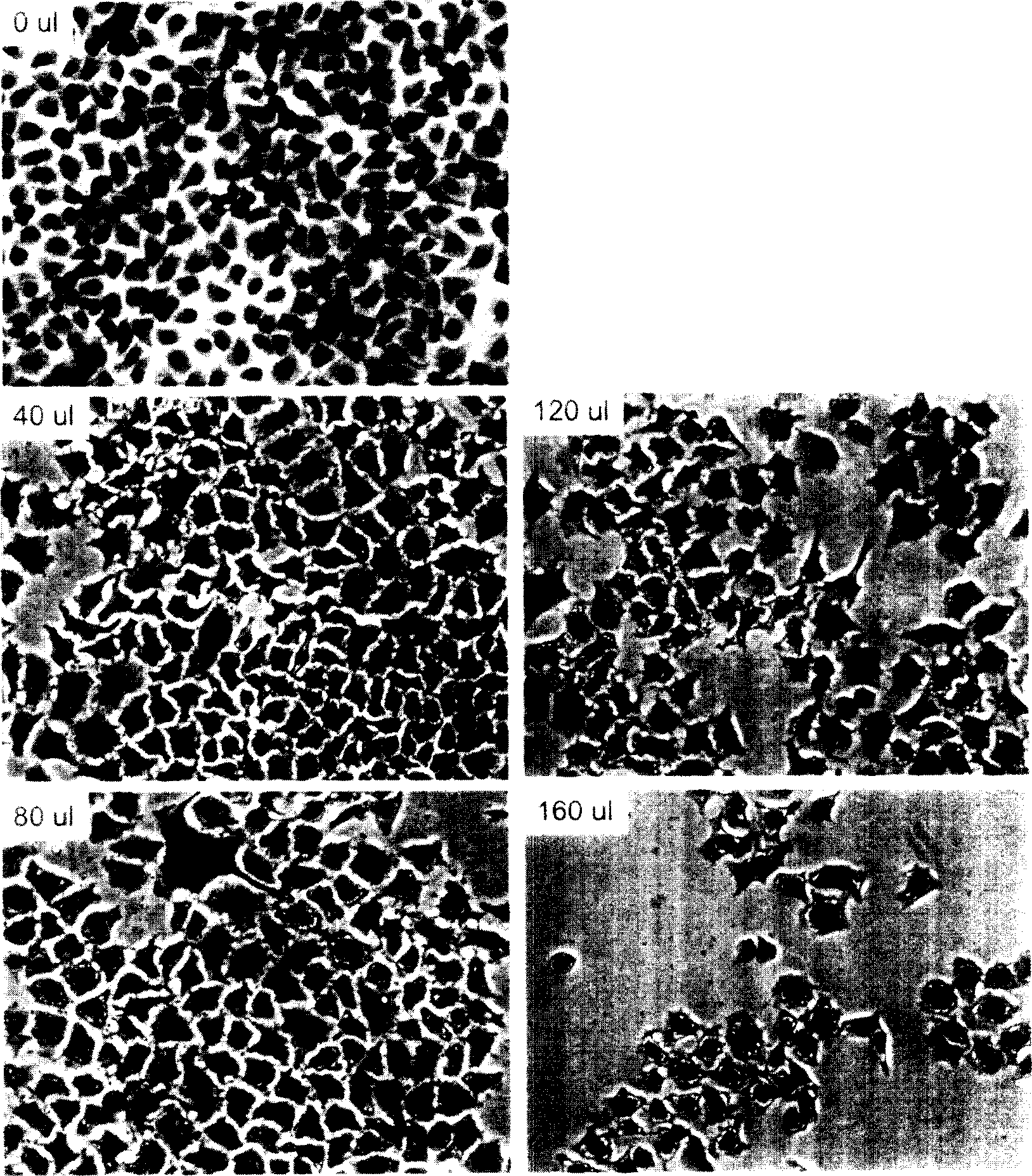

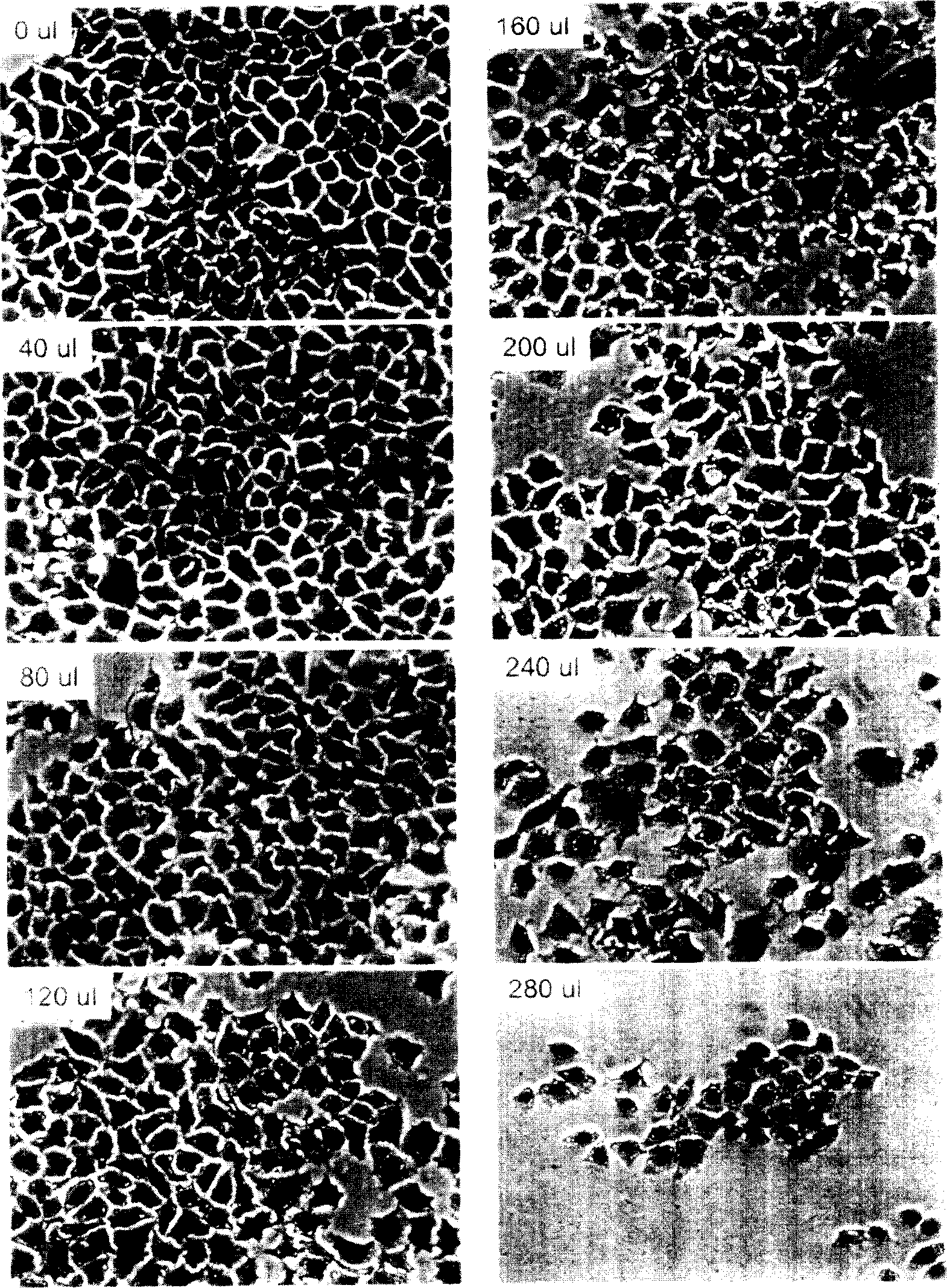

[0060] (1) Enzymatic wall breaking process. 70% Ganoderma lucidum spores, 20% Ganoderma lucidum powder, 5% millet (soaked overnight, washed), 2% CaCO by weight 3 , 2.5% sucrose, 0.5% B complex vitamins 1 Mix, add 1.2 times pure water, mix evenly, adjust the pH to 5.5 with HCl, and then sterilize with a pressure of 0.15MP in an autoclave for 2 hours. After cooling, operate in a sterile room, insert red Ganoderma lucidum strains, and cultivate at 25°C. 40 days after the hyphae of Ganoderma lucidum were covered with the culture material, the culture product was taken out, dried, ground and kneaded for 10 minutes, counted by a blood cell counting board under a microscope, and the wall breaking rate was over 95%.

[0061] (2) Granulation. Using pure water as a wetting agent, the ganoderma lucidum spores after enzymatic wall breaking were granulated with a wet granulator, the drying temperature ...

Embodiment 3

[0064] Embodiment 3: the preparation method 3 of whole Ganoderma lucidum spore oil

[0065](1) Enzyme breaking of Ganoderma lucidum spores. Mix 90% Ganoderma lucidum spores and 10% Ganoderma lucidum powder, add 1.2 times pure water, mix evenly, and sterilize in an autoclave at 0.15 MP for 2 hours. After cooling, operate in a sterile room, insert the ganoderma lucidum granule strain, and cultivate it at 20°C. After the mycelium of Ganoderma lucidum is covered with the culture material, the culture product is taken out, dried and pulverized by a ball mill for 20 minutes.

[0066] (2) Granulation. Using pure water as a wetting agent, the ganoderma lucidum spores after enzymatically broken walls were granulated with a wet granulator at a drying temperature of 45°C and a drying time of 2 hours to obtain 20-mesh granules with a moisture content of less than 5%.

[0067] (3) Supercritical CO 2 extraction. Put the granulated Ganoderma lucidum spores into supercritical CO 2 In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com