Patents

Literature

72 results about "Degree of reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In turbomachinery, Degree of reaction or reaction ratio (R) is defined as the ratio of the static pressure drop in the rotor to the static pressure drop in the stage or as the ratio of static enthalpy drop in the rotor to the static enthalpy drop in the stage. Degree of reaction (R) is an important factor in designing the blades of a turbine, compressors, pumps and other turbo-machinery. It also tells about the efficiency of machine and is used for proper selection of a machine for a required purpose.

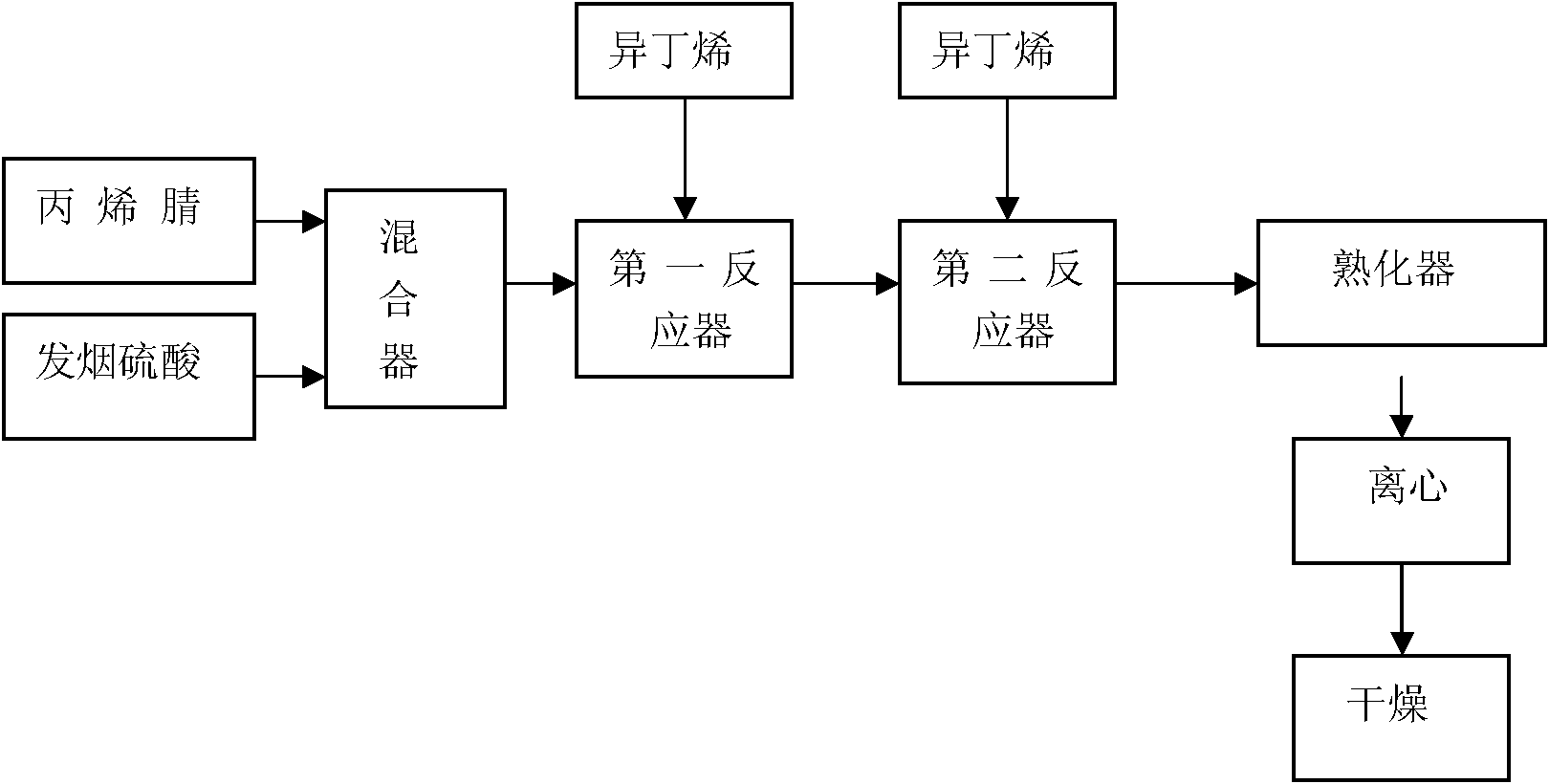

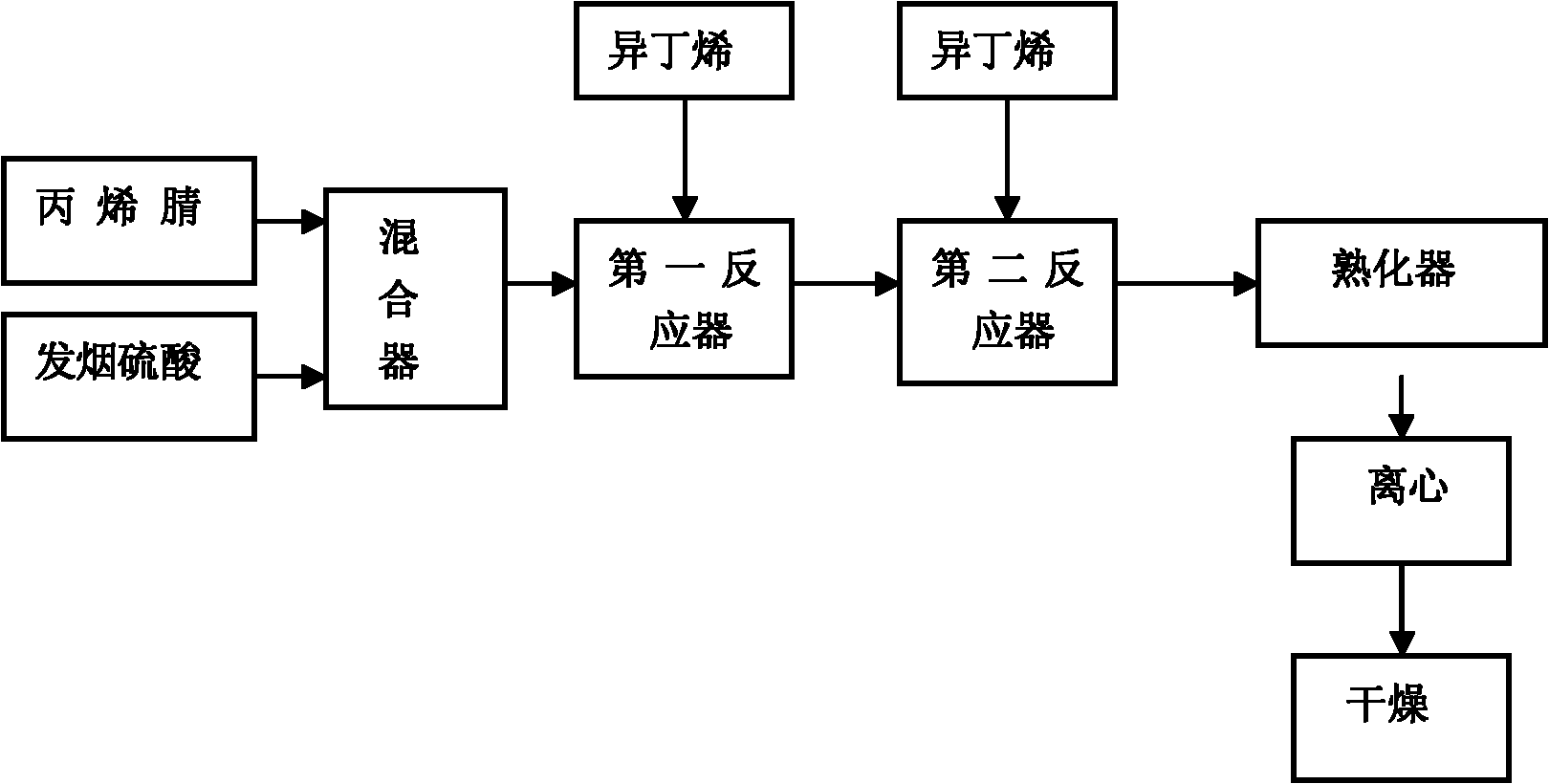

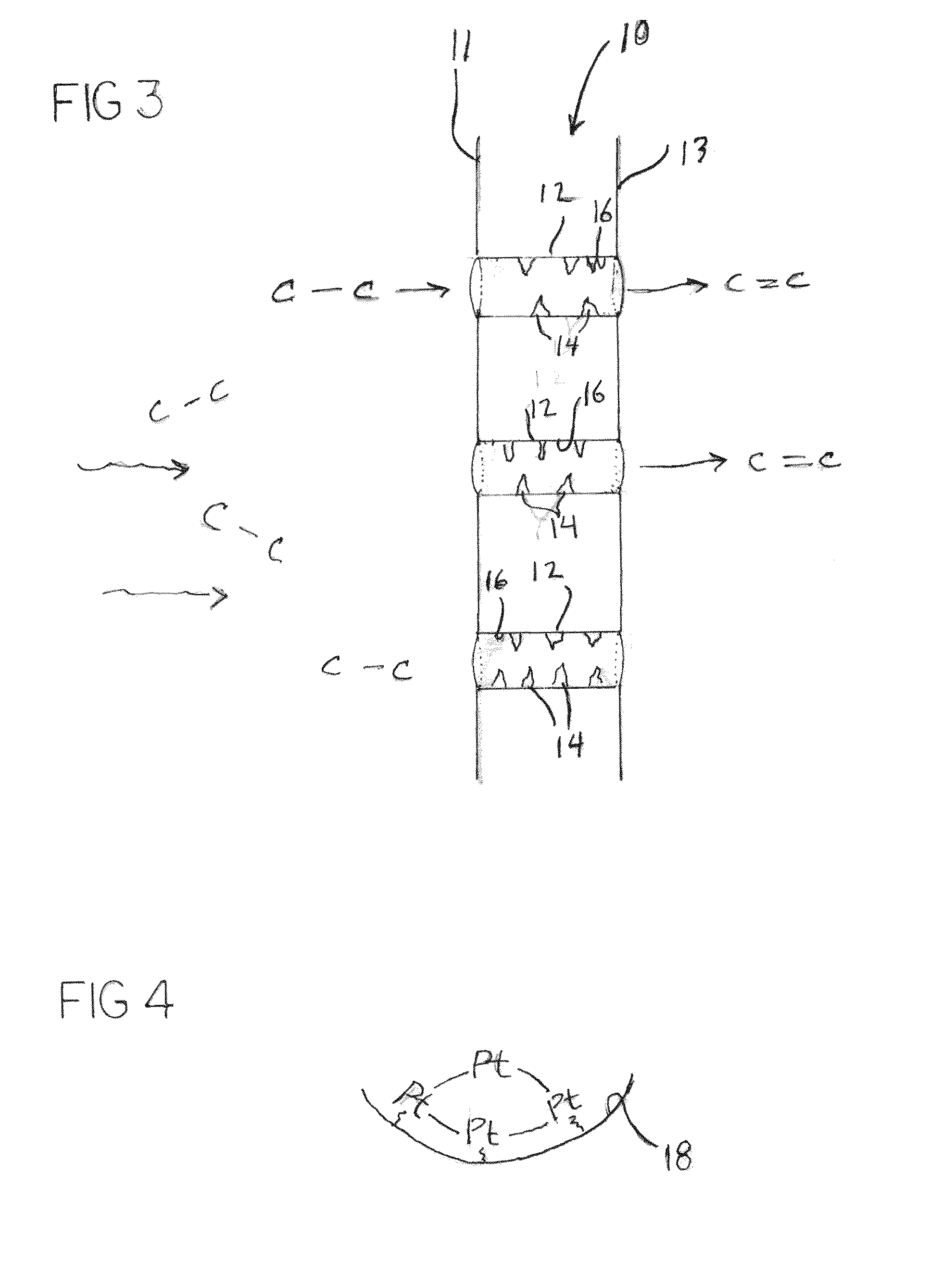

Synthesis process for 2-acrylamido-2-methyl propane sulfonic acid through continuous method

InactiveCN102351744AStable ratioStrong reaction stabilitySulfonic acid preparationFirst-order reactionAcrylonitrile

The invention discloses a synthesis process for 2-acrylamido-2-methyl propane sulfonic acid through a continuous method. The synthesis process comprises the following steps of: continuously and uniformly mixing acrylonitrile and fuming sulfuric acid at the temperature of 10-12 DEG C; performing first order reaction and second order reaction at the temperature of 20-45 DEG C under a condition of introducing vaporized isobutene; and slaking, centrifuging and drying to continuously produce the 2-acrylamido-2-methyl propane sulfonic acid product. By designing unique first order reaction, second order reaction and slaking flow, completeness degree of reaction of the material is guaranteed, the product yield and the quality stability are improved, and the reaction period is greatly shortened. The synthesis process has the advantages of scientific and rational flow design, practicability, product yield of over 96 percent and liquid phase detection purity of over 96 percent.

Owner:WEIFANG QUANXIN CHEM

Method for preparing n-3PUFA ocean glycerin ester by enzymatical process

A method for preparing n-3PUFA marine glyceride through adopting enzyme method includes following steps: refined fish oil is made into n-3PUFA condensate through saponification, acidification and urea adduct method; lipase catalyzes the synthesis reaction between n-3PUFA and glycerol; n-3PUFA marine glyceride is extracted and separated; moreover, n-3PUFA is effectively concentrated in glyceride to be made into functional products which can prevent and cure cardiovascular diseases and nourish the brain and improve intelligence. The raw material of the invention, n-3PUFA, is extracted from natural fish oil, thereby being safe and effective; during production, nitrogen protection is adopted without adding synthetic antioxidant, thereby effectively preventing oxidation of n-3PUFA; with scientific and reasonable technique, the invention completes synthesis by means of biological enzyme method along with high esterification degree of reaction, higher utilization rate of raw material and easily controlled reaction process; therefore, the invention has wide market prospect.

Owner:GUANGDONG OCEAN UNIVERSITY

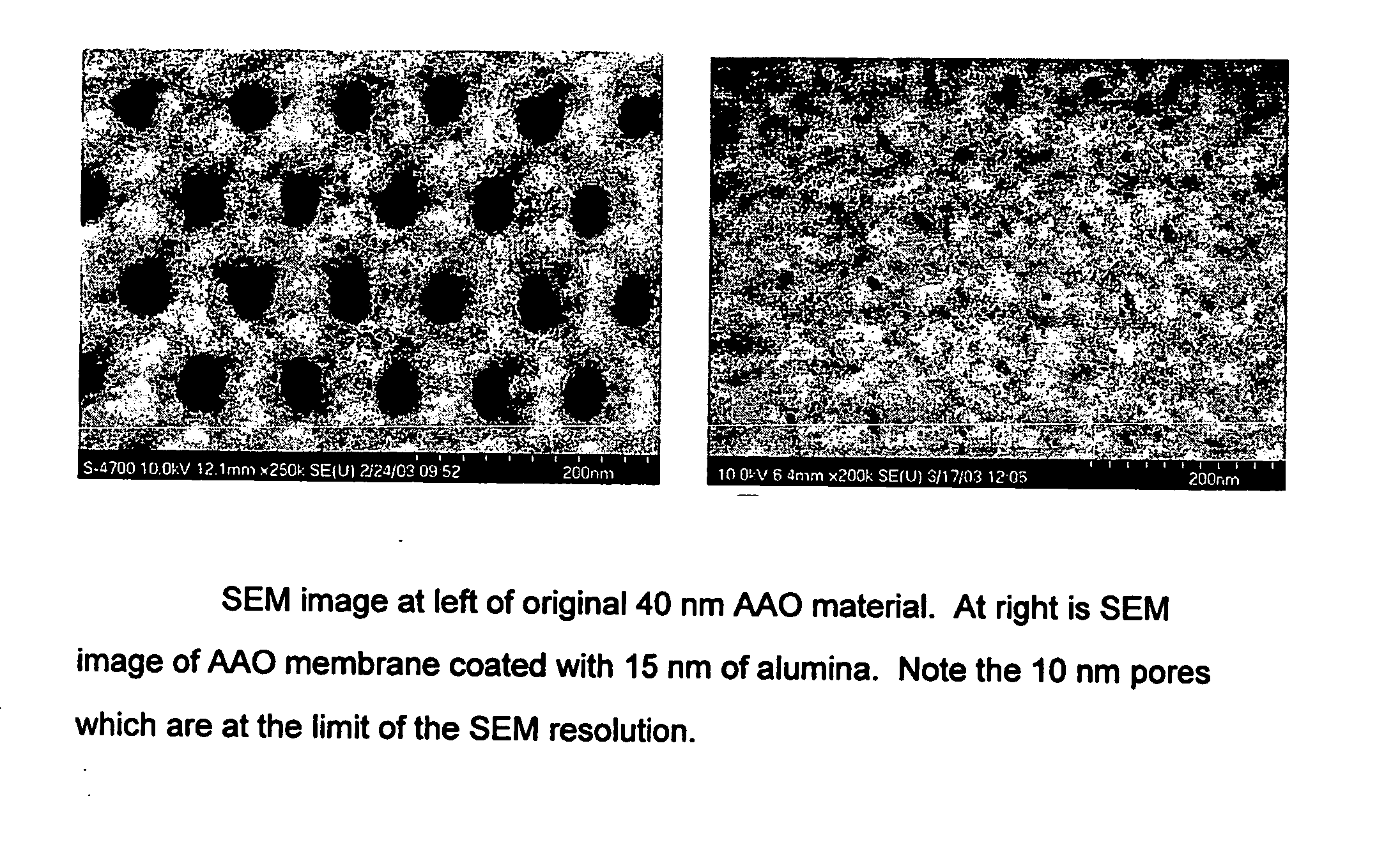

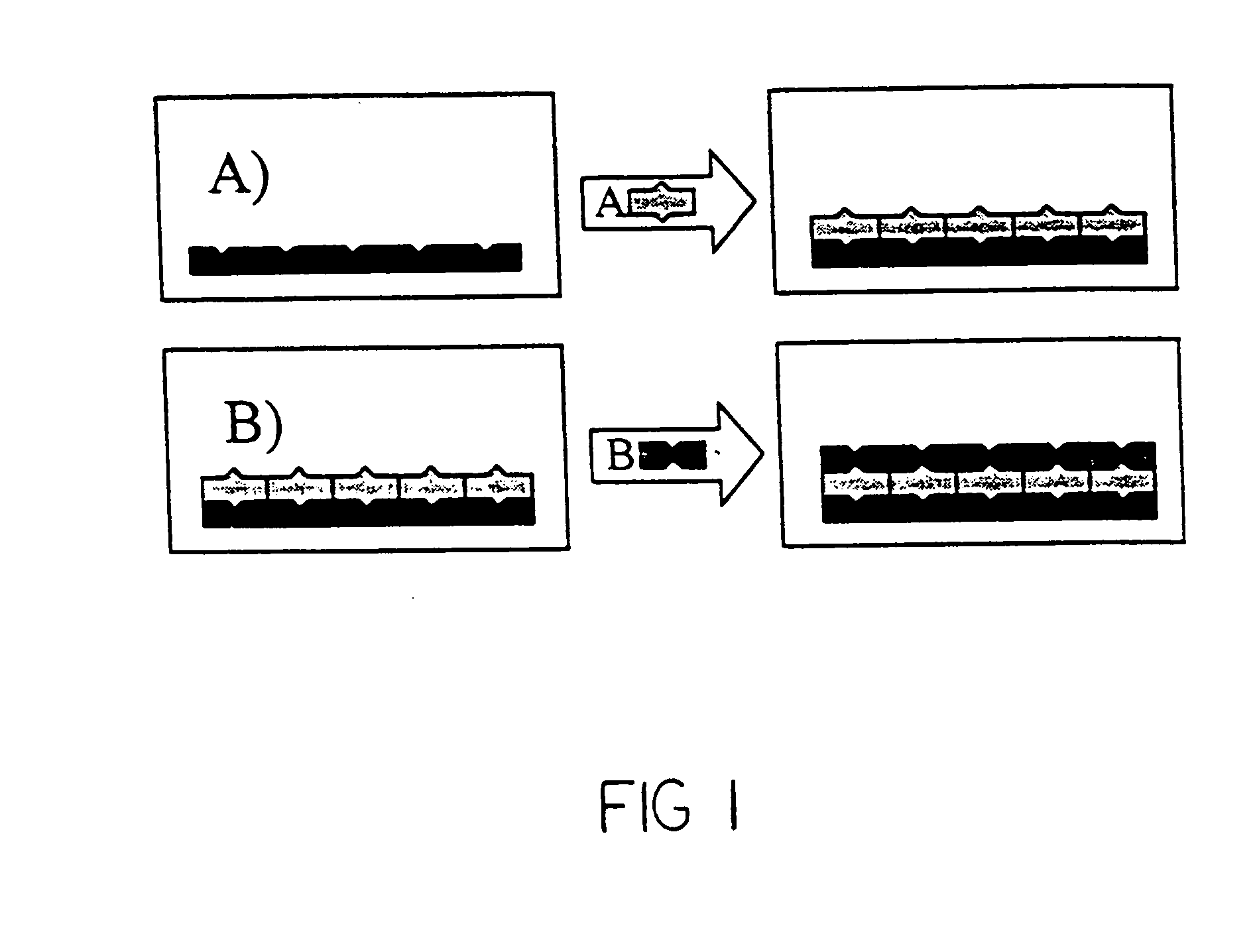

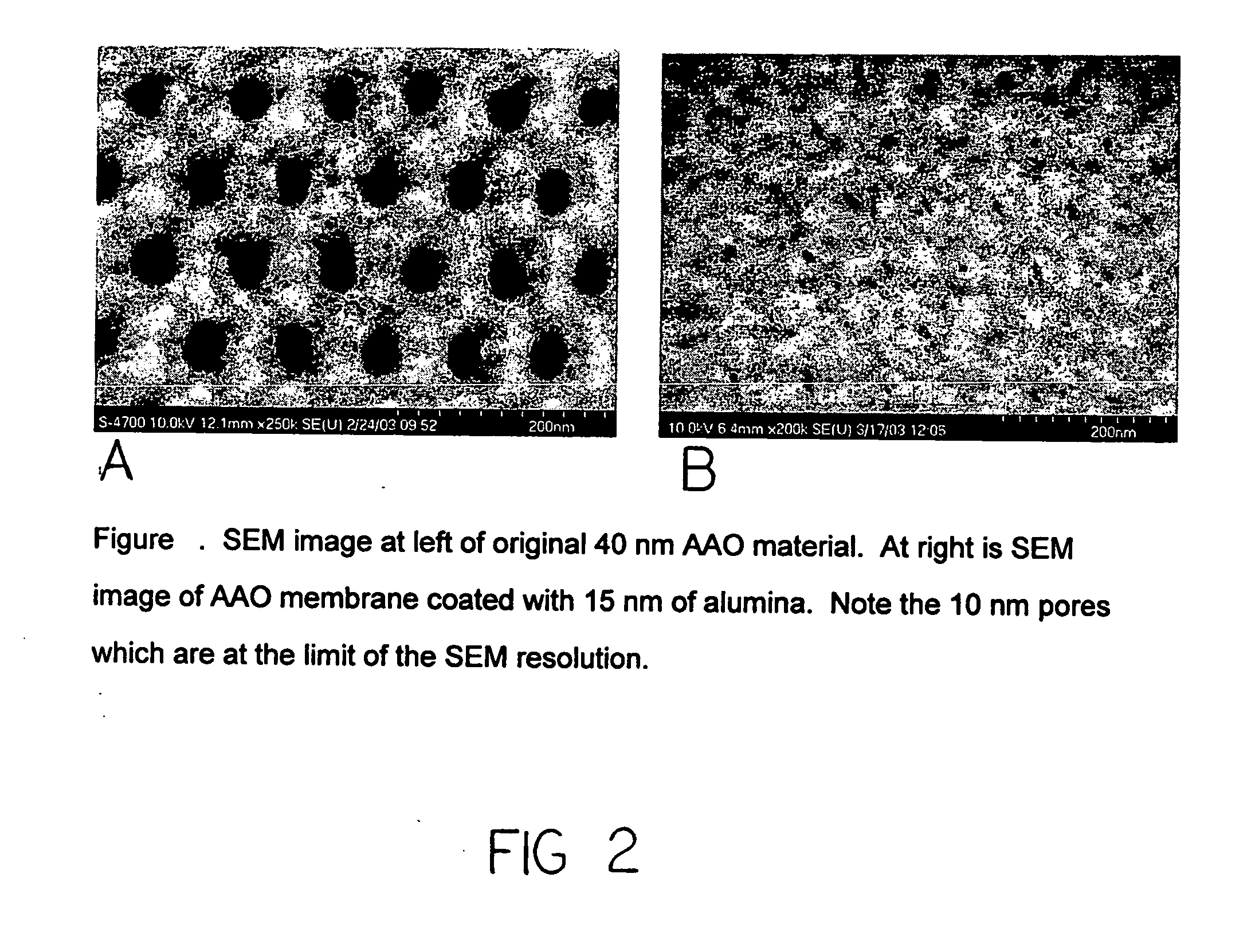

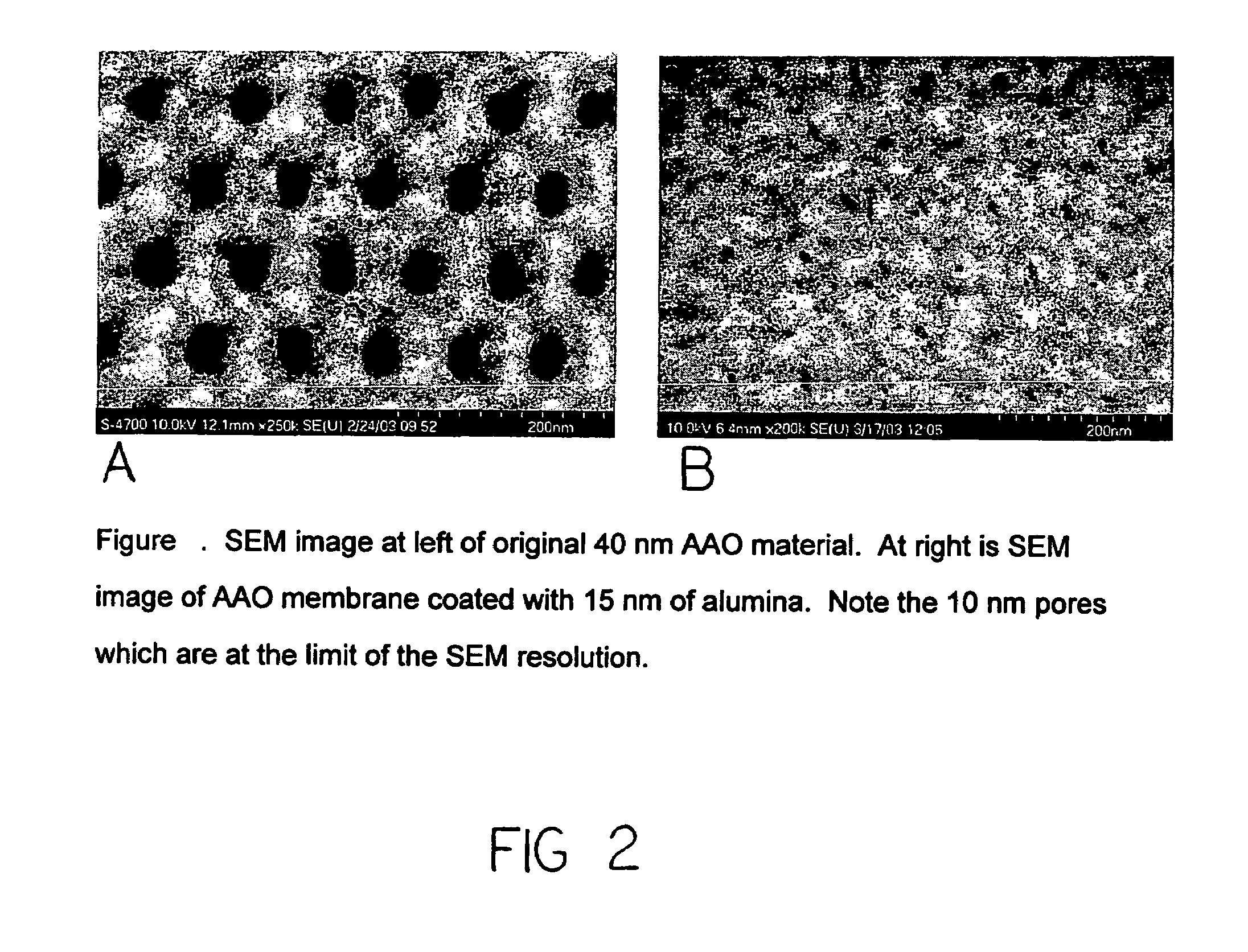

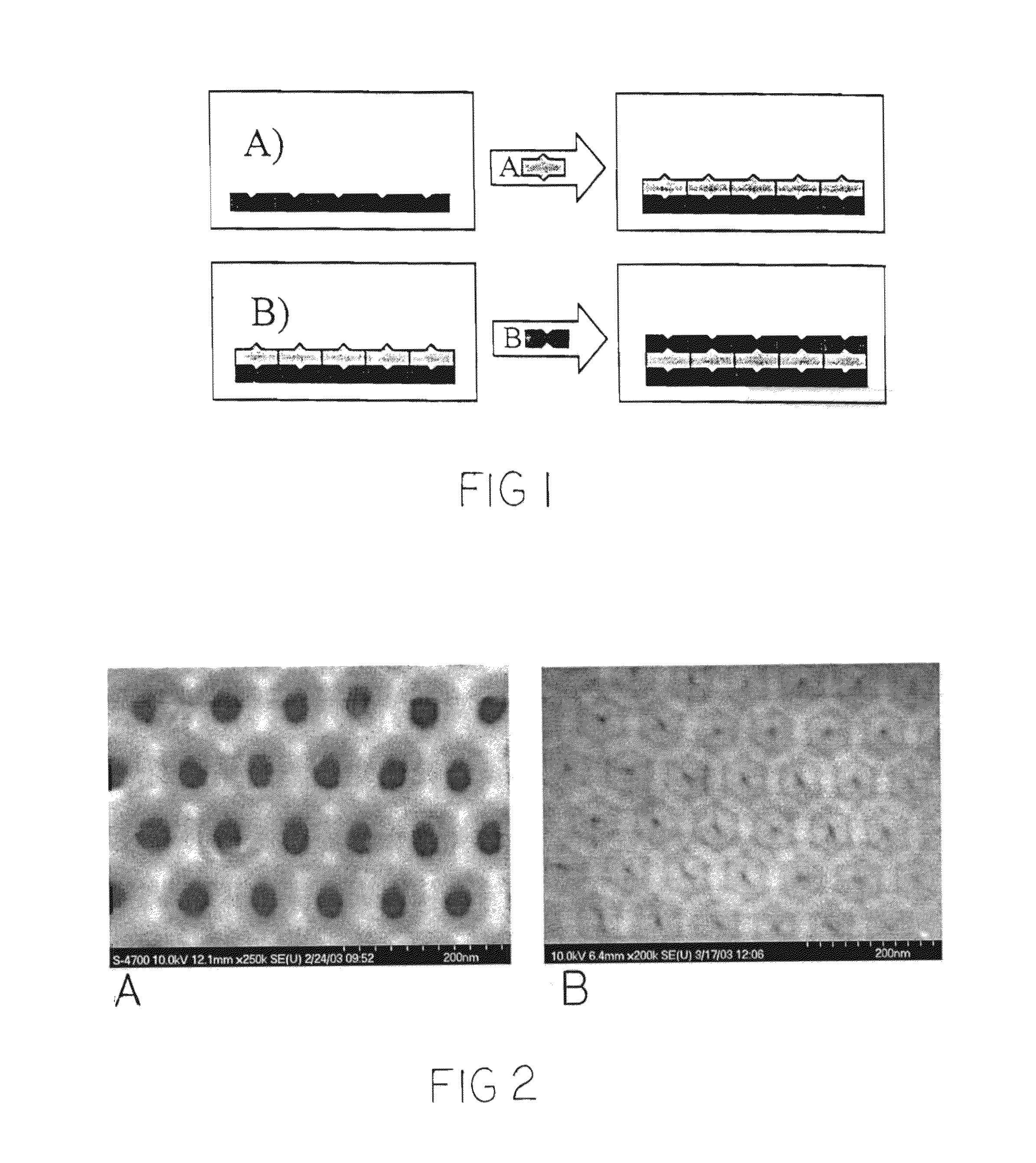

Catalytic nanoporous membranes

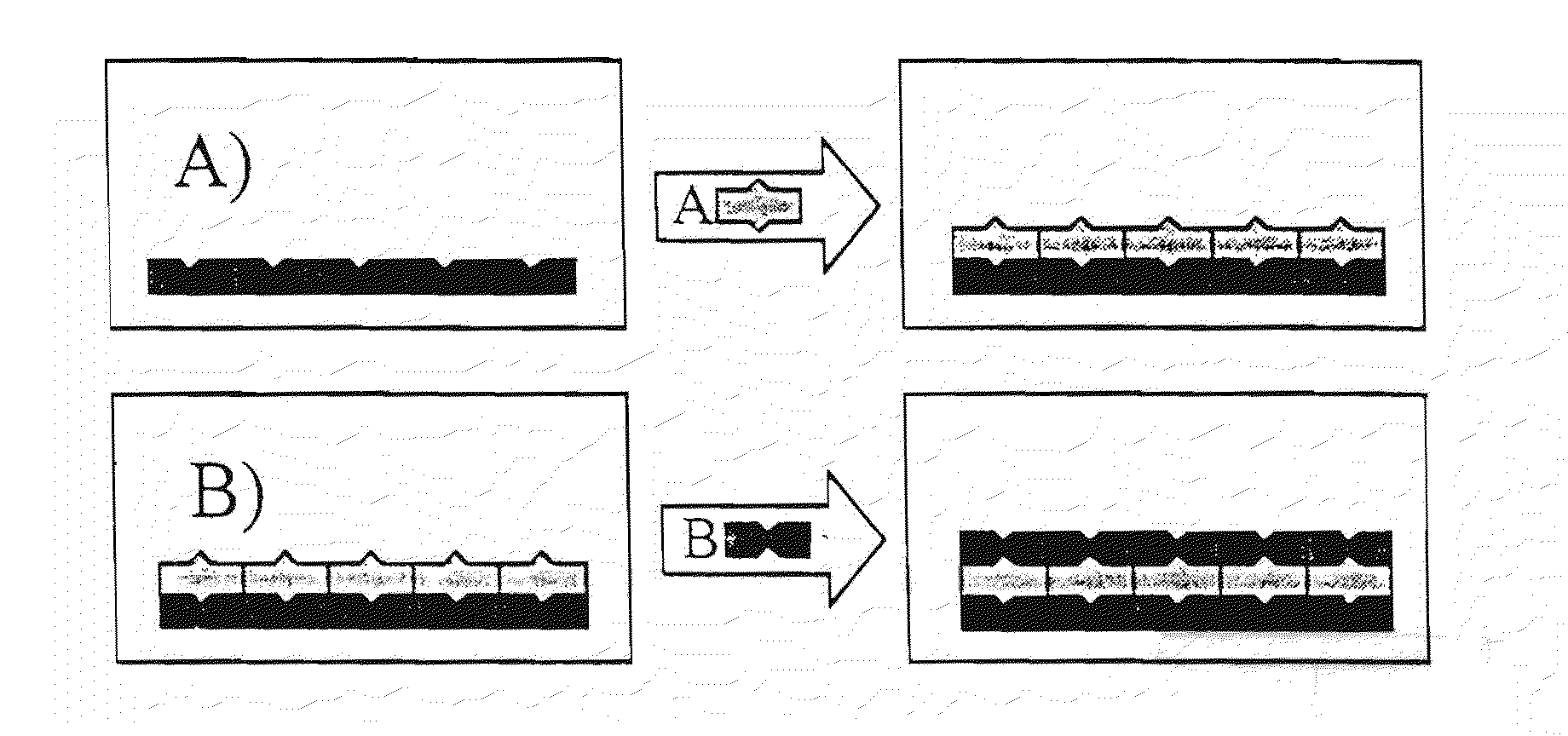

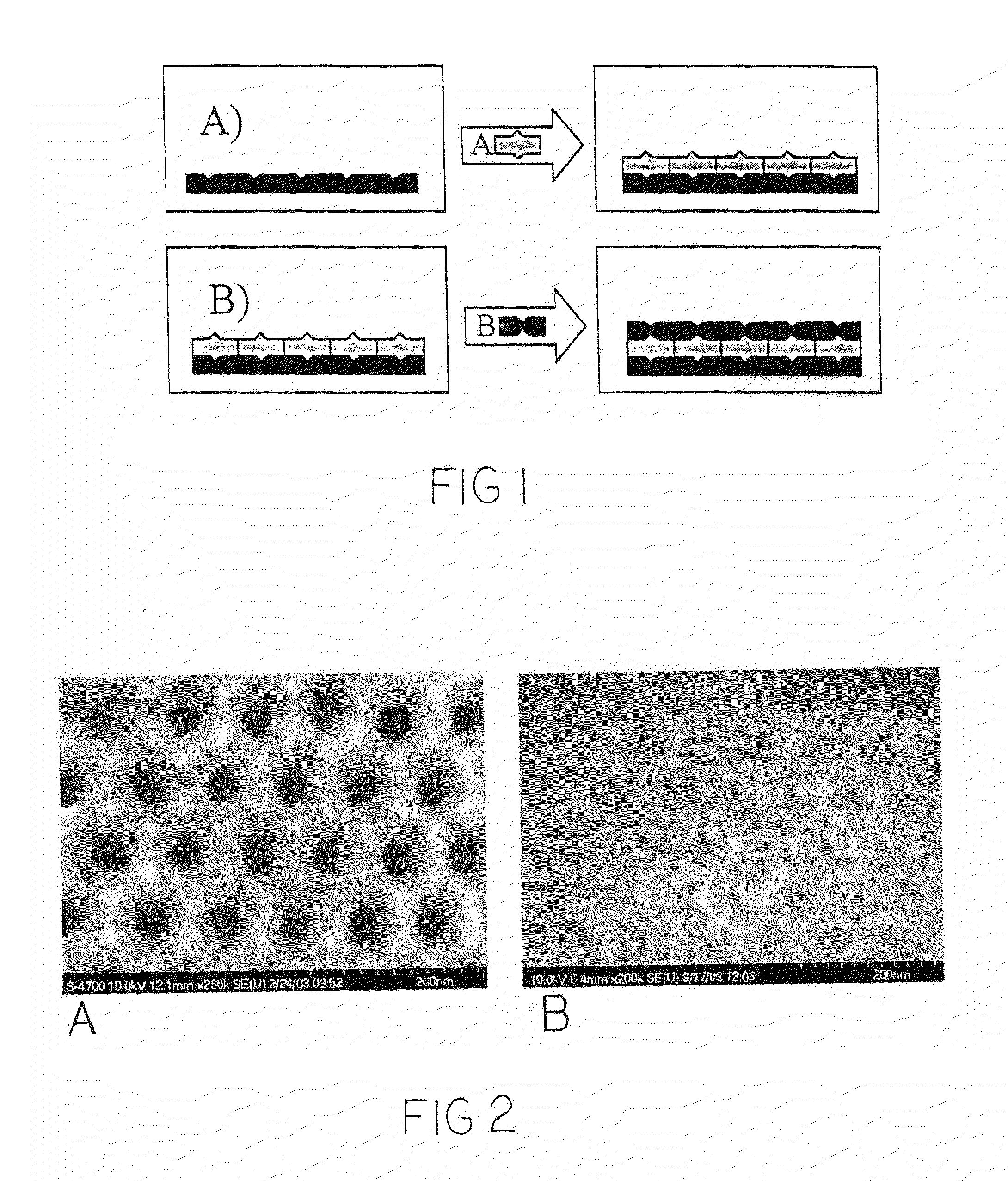

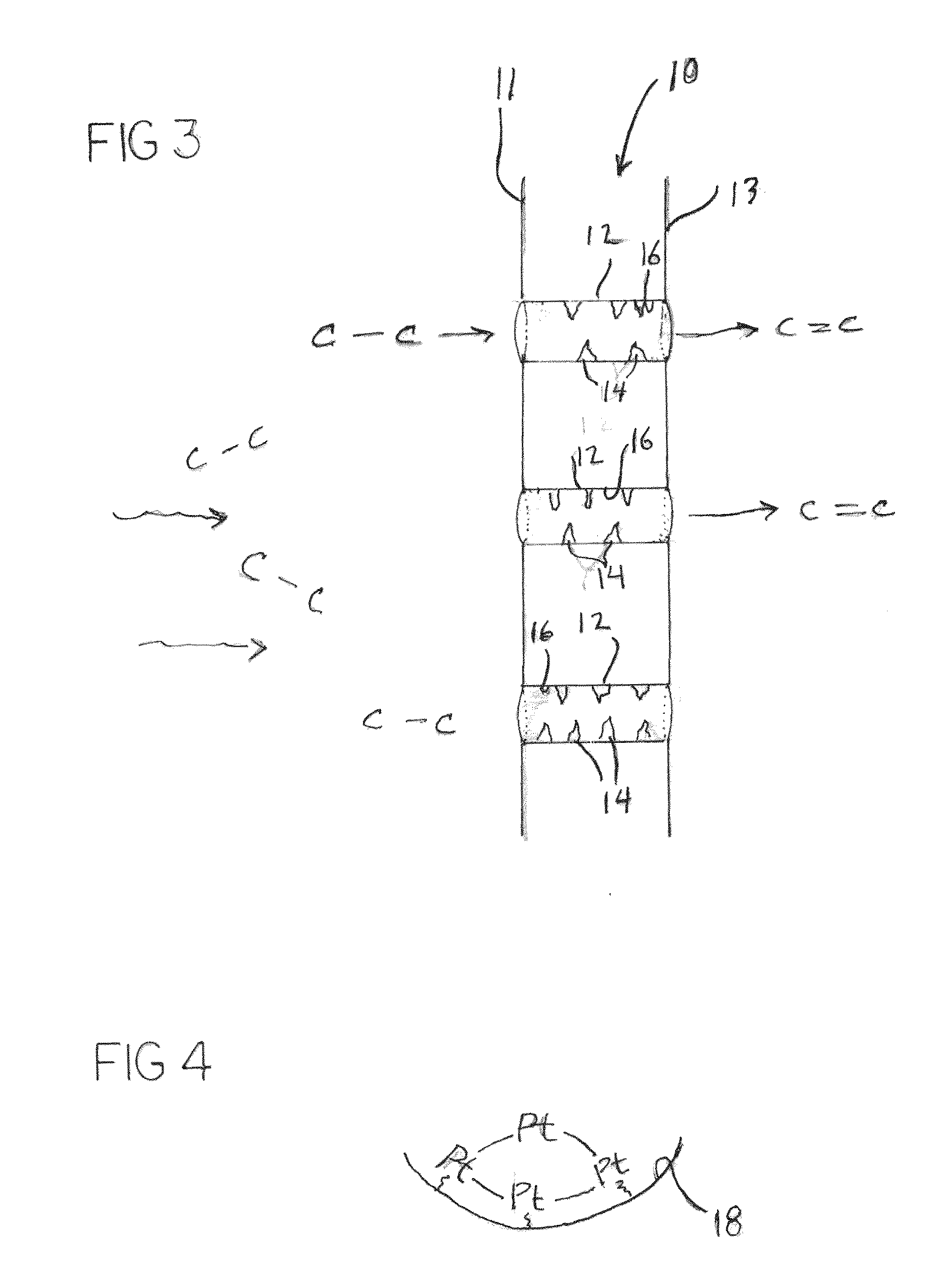

InactiveUS20050065028A1Unique catalyst environmentUniform coatingNanotechOther chemical processesPartial oxidationNanoporous membrane

A nanoporous catalytic membrane which displays several unique features including pores which can go through the entire thickness of the membrane. The membrane has a higher catalytic and product selectivity than conventional catalysts. Anodic aluminum oxide (AAO) membranes serve as the catalyst substrate. This substrate is then subjected to Atomic Layer Deposition (ALD), which allows the controlled narrowing of the pores from 40 nm to 10 nm in the substrate by deposition of a preparatory material. Subsequent deposition of a catalytic layer on the inner surfaces of the pores reduces pore sizes to less than 10 nm and allows for a higher degree of reaction selectivity. The small pore sizes allow control over which molecules enter the pores, and the flow-through feature can allow for partial oxidation of reactant species as opposed to complete oxidation. A nanoporous separation membrane, produced by ALD is also provided for use in gaseous and liquid separations. The membrane has a high flow rate of material with 100% selectivity.

Owner:UCHICAGO ARGONNE LLC

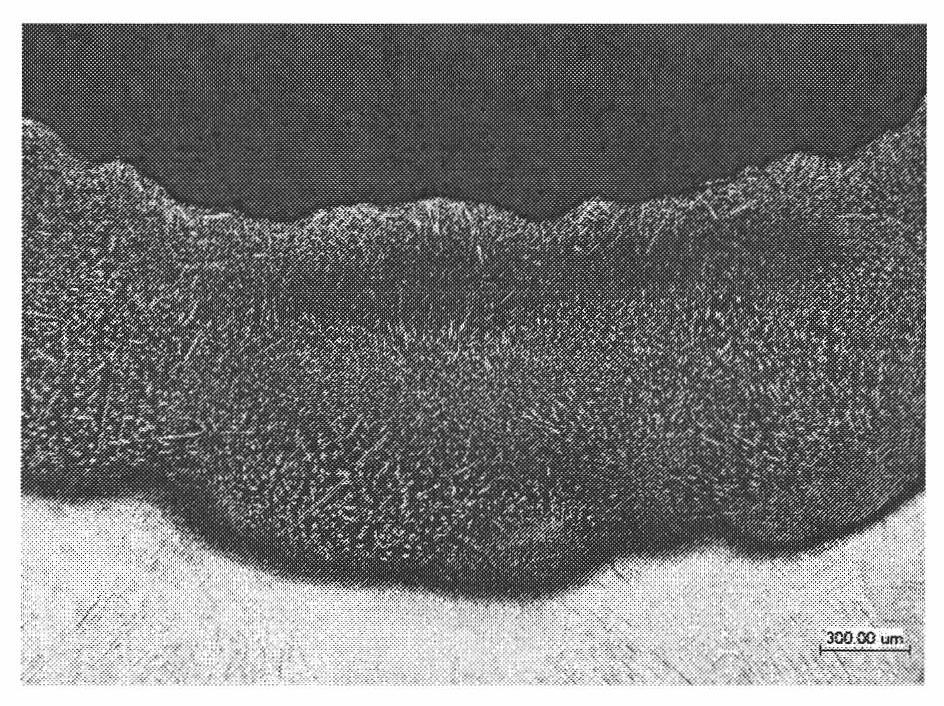

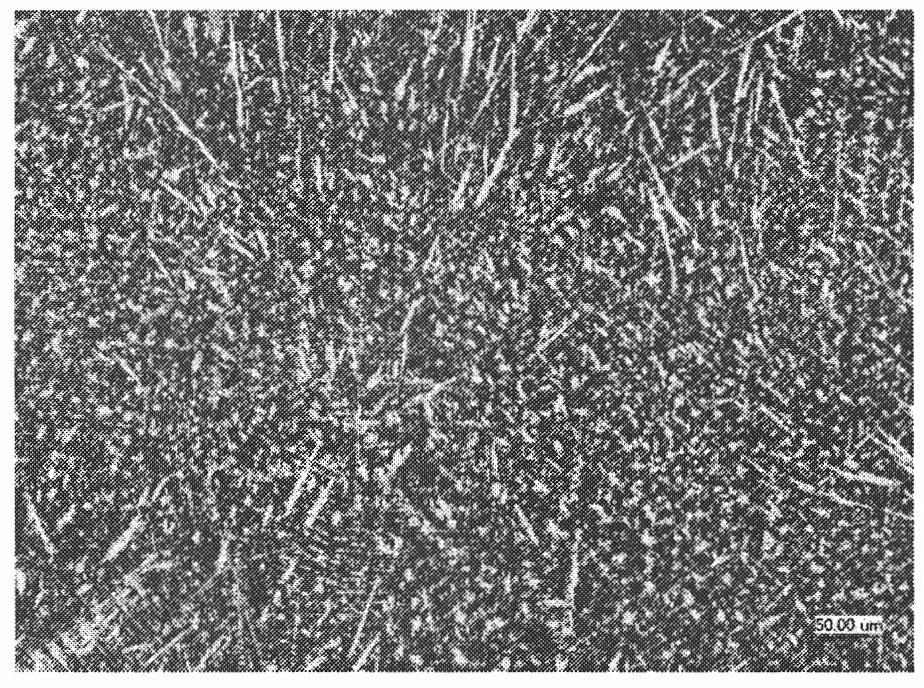

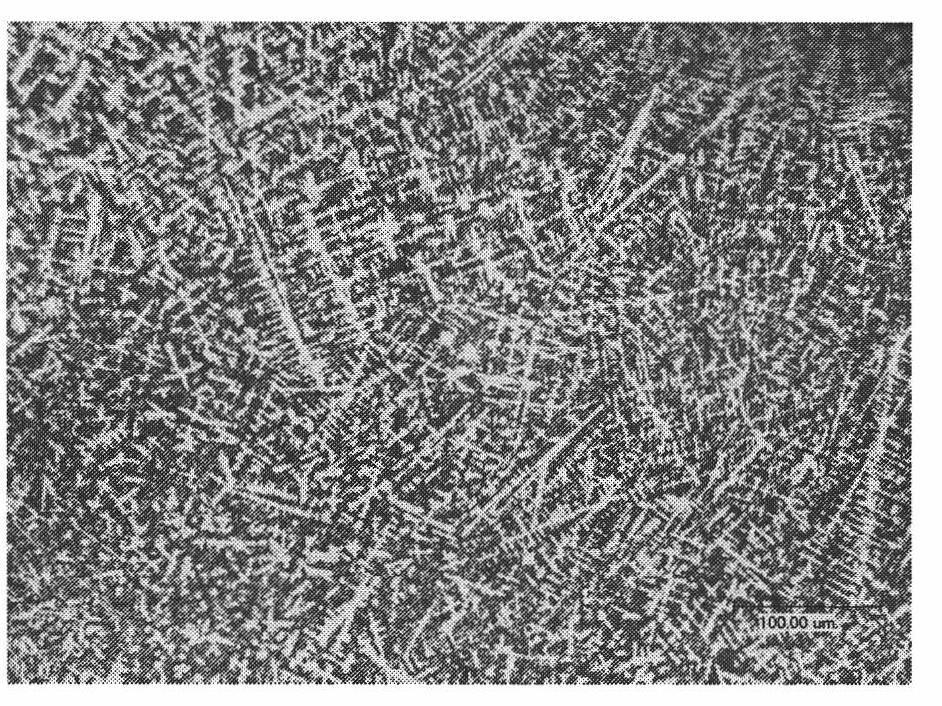

Large-area TiB-TiC reinforced titanium-based composite coating and preparation method thereof

The invention discloses a large-area TiB-TiC reinforced titanium-based composite coating prepared from the following components in percentage by weight: 83-88 percent of Ti, 5-7 percent of B4C, 2-4 percent of Al, 1-3 percent of nano TiC and 3-5 percent of rare-earth oxide. The invention adopts a new method for preparing a pre-coating layer which has the advantages of smooth surface, controllable thickness, less adhesive and relatively simple process. In addition, the invention optimally selects the proportioning of a cladding material system so that the coating after cladding has reinforcing phases of TiB and TiC; in addition, since a base body and a base body material Ti6Al4V are both titanium alloy, the coating and the base body have favorable physical compatibility. The invention also remarkably lowers the intensity degree of reaction for generating TiB and TiC by adding a little amount of thinner nanoTiC.

Owner:SHANGHAI UNIV OF ENG SCI

Catalytic nanoporous membranes

InactiveUS20100075827A1Unique catalyst environmentUniform coatingOther chemical processesCatalyst activation/preparationPartial oxidationGas phase

A nanoporous catalytic membrane which displays several unique features Including pores which can go through the entire thickness of the membrane. The membrane has a higher catalytic and product selectivity than conventional catalysts. Anodic aluminum oxide (AAO) membranes serve as the catalyst substrate. This substrate is then subjected to Atomic Layer Deposition (ALD), which allows the controlled narrowing of the pores from 40 nm to 10 nm in the substrate by deposition of a preparatory material. Subsequent deposition of a catalytic layer on the inner surfaces of the pores reduces pore sizes to less than 10 nm and allows for a higher degree of reaction selectivity. The small pore sizes allow control over which molecules enter the pores, and the flow-through feature can allow for partial oxidation of reactant species as opposed to complete oxidation. A nanoporous separation membrane, produced by ALD is also provided for use in gaseous and liquid separations. The membrane has a high flow rate of material with 100% selectivity. Also provided is a method for producing a catalytic membrane having flow-through pores and discreet catalytic clusters adhering to the inside surfaces of the pores.

Owner:UCHICAGO ARGONNE LLC

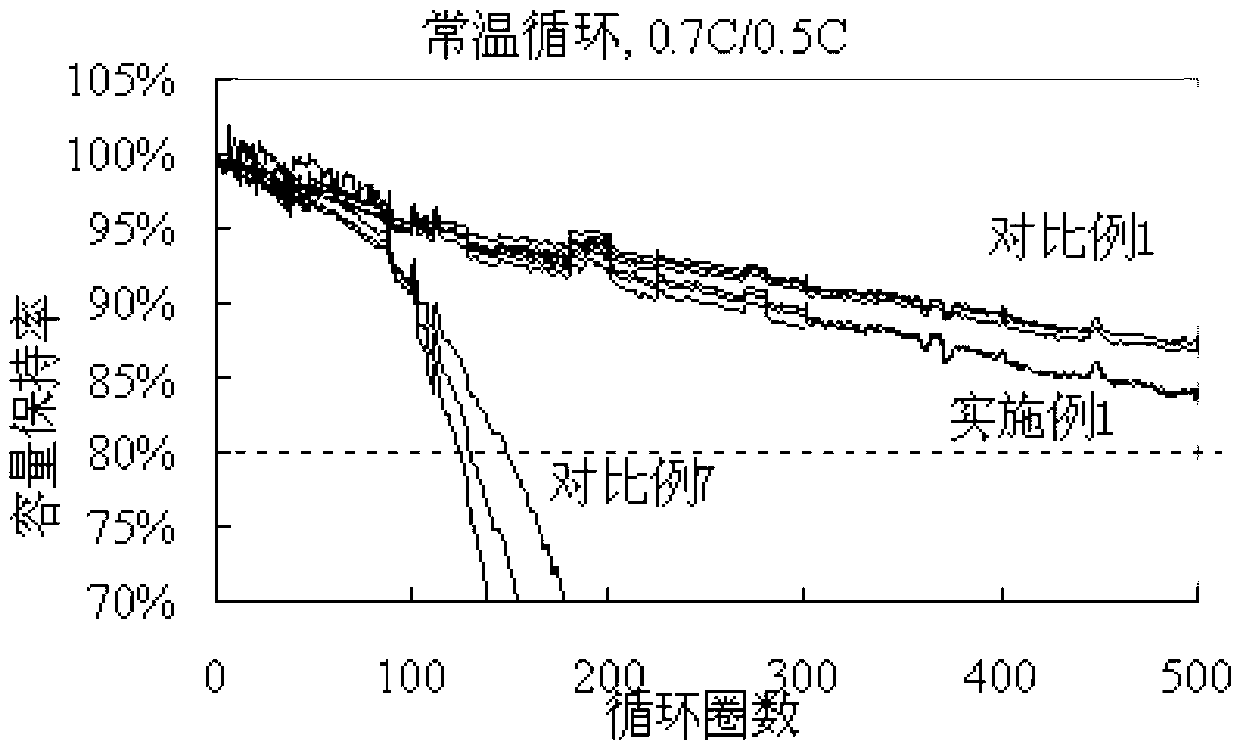

Lithium ion battery and electrolyte thereof

ActiveCN103346349APrevent oxidationProtected cathodeSecondary cellsHigh temperature storageLithium-ion battery

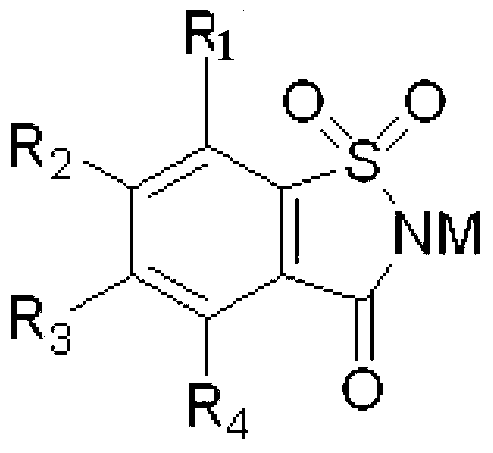

The invention discloses electrolyte of a lithium ion battery. The electrolyte comprises lithium salt, an anhydrous organic solvent and an adding agent, wherein the adding agent contains fluoroethylene carbonate being 0.5-9 percent of the total mass of the electrolyte, nitrile compounds being 1-8 percent of the total mass of the electrolyte and o-benzoyl sulfonyl imide salt being 0.3-5 percent of the total mass of the electrolyte, and the o-benzoyl sulfonyl imide salt has a structural formula as shown in the specification, wherein M is alkali metal, and R1, R2, R3 and R4 are respectively hydrogen or alkyl group or alkyl halide group. In the electrolyte of the lithium ion battery, the o-benzoyl sulfonyl imide salt can overcome a destructive effect of FEC anodic film by-products on cathode; the nitrile compounds are combined with the cathode in a coordination mode, the degree of reaction of the o-benzoyl sulfonyl imide salt and a cathode material is reduced, the o-benzoyl sulfonyl imide salt forms a film at cathode to protect cathode, and the impedance on the cathode is seldom increased; the high-temperature storage performance is improved, and meanwhile the multiplying power and the cycle performance can be kept at an acceptable level.

Owner:NINGDE AMPEREX TECH

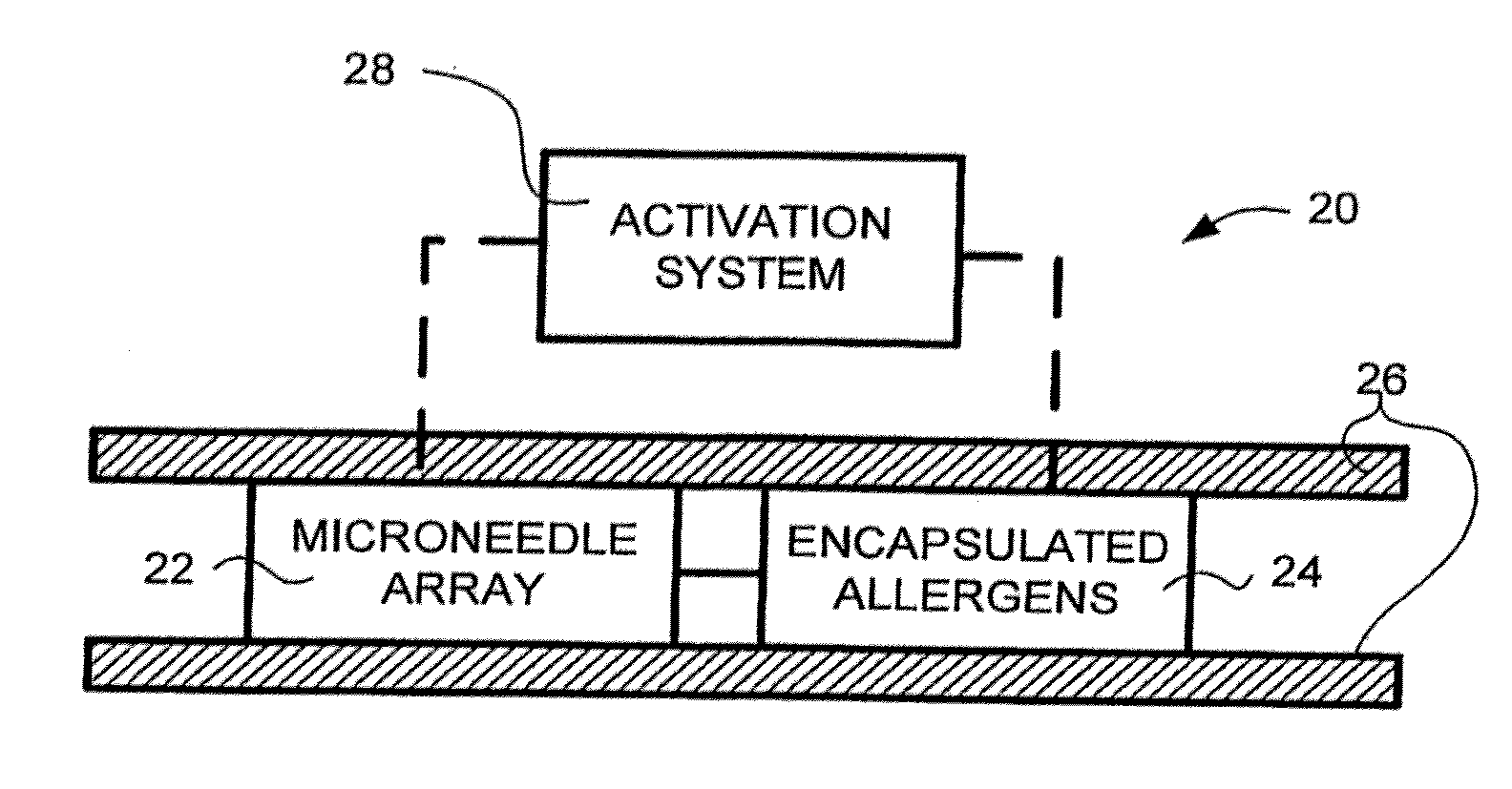

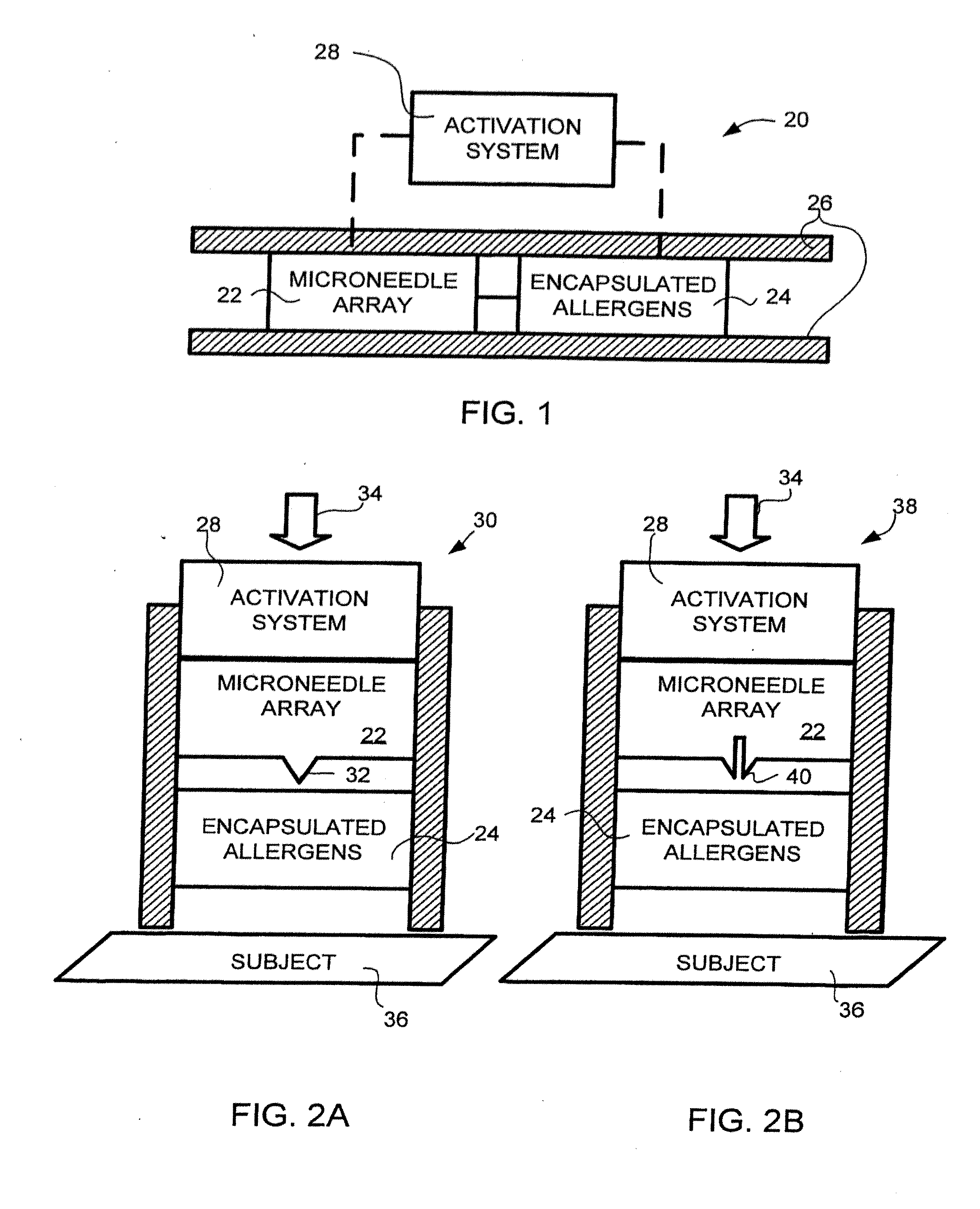

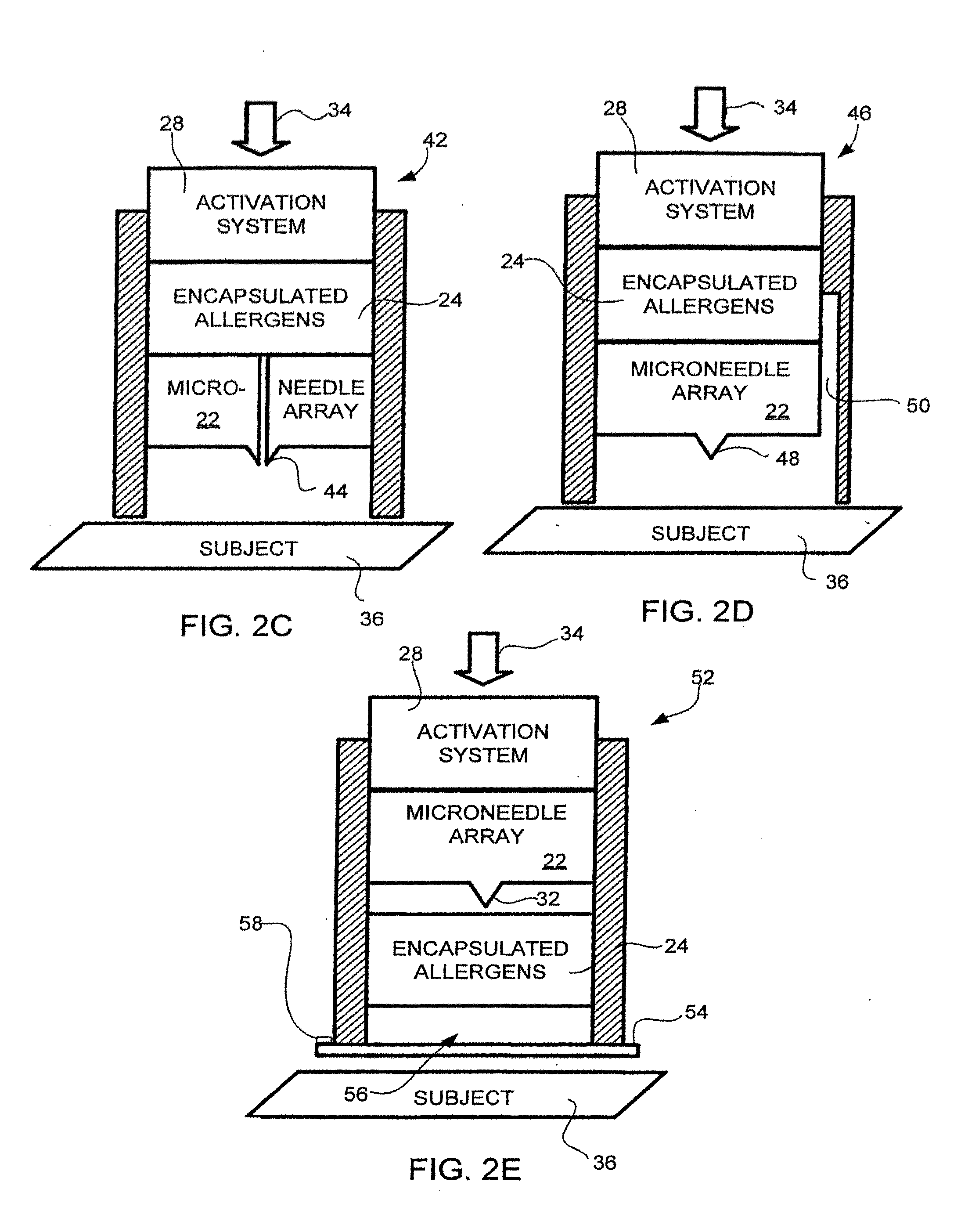

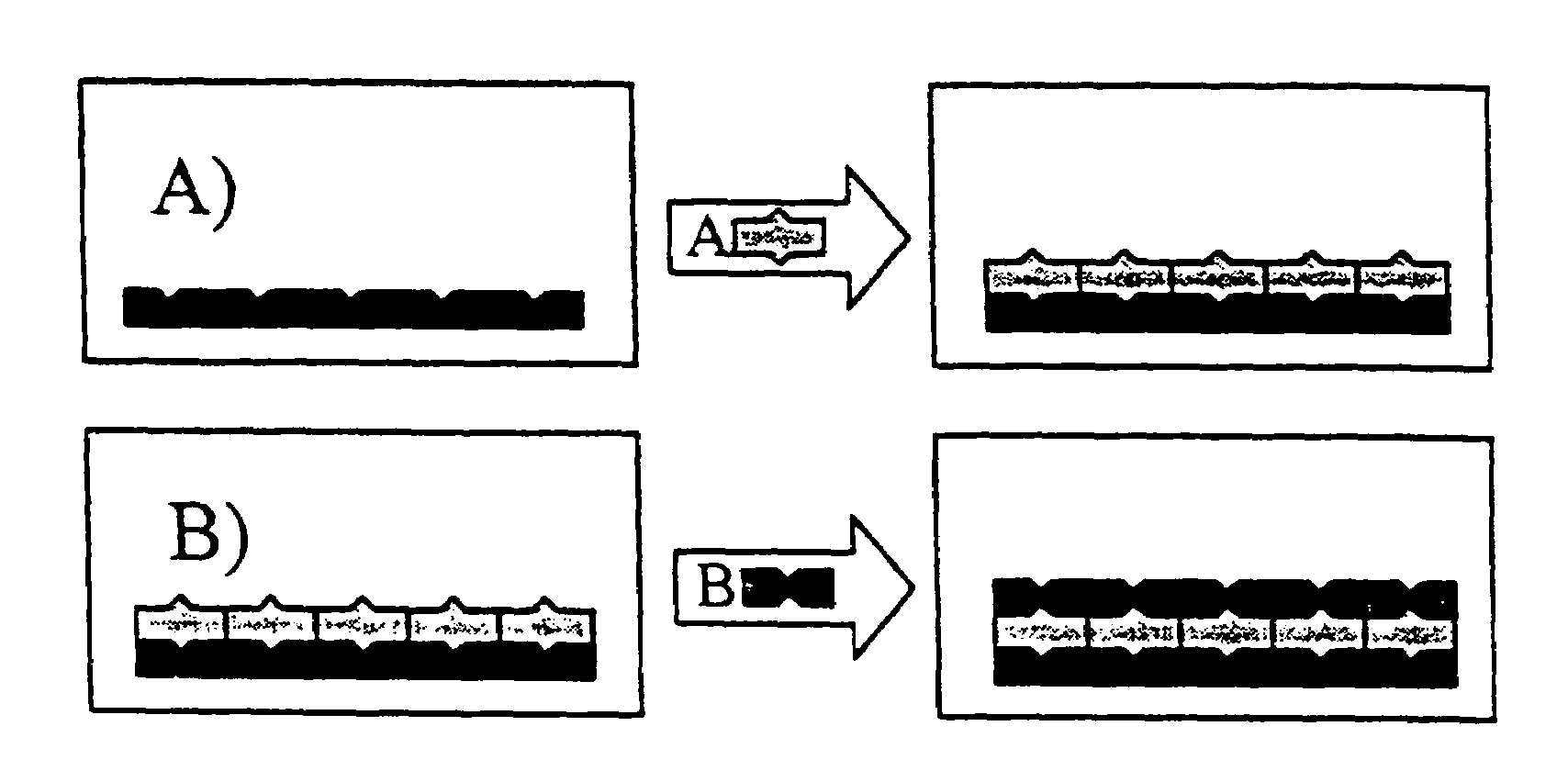

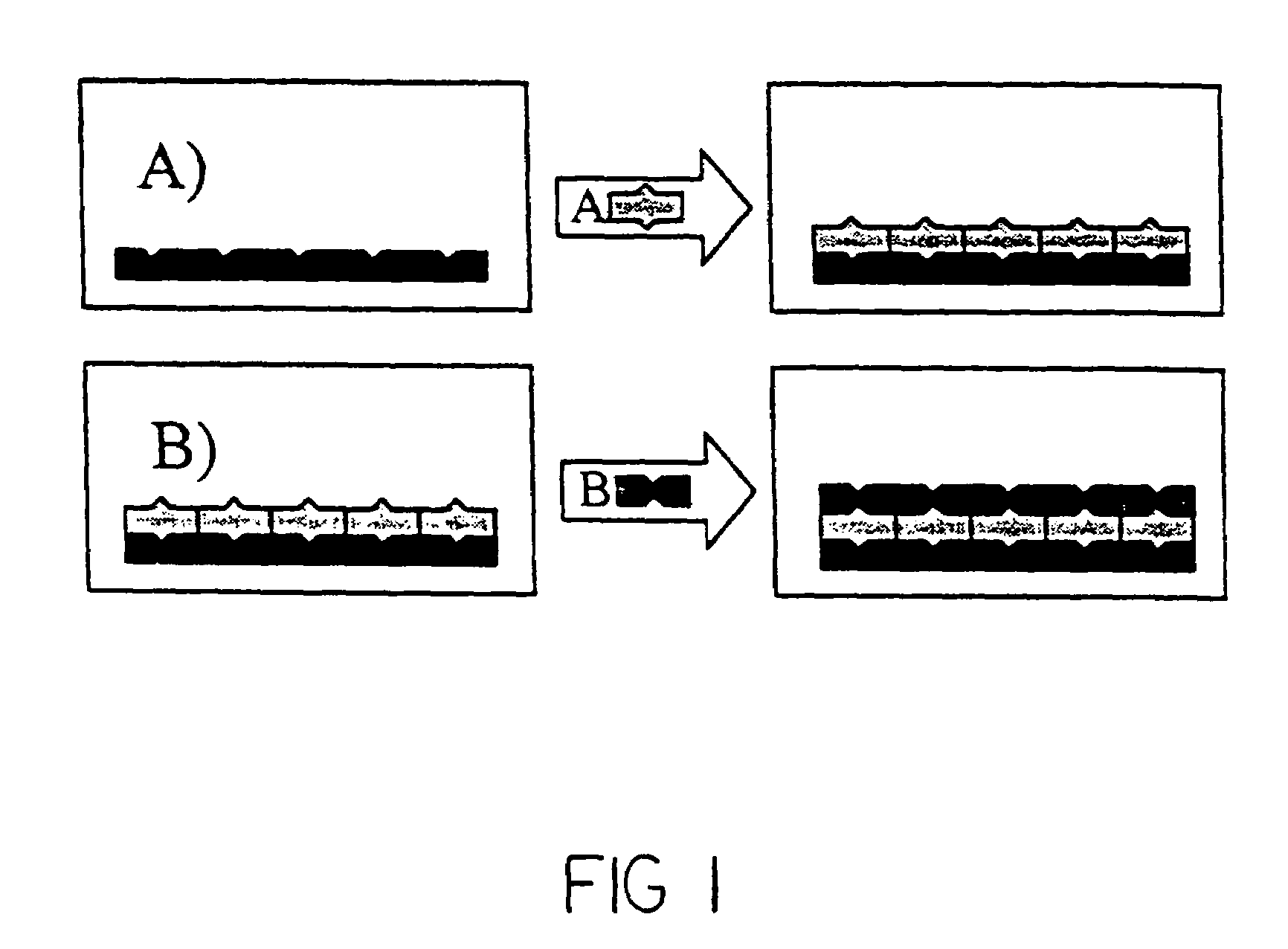

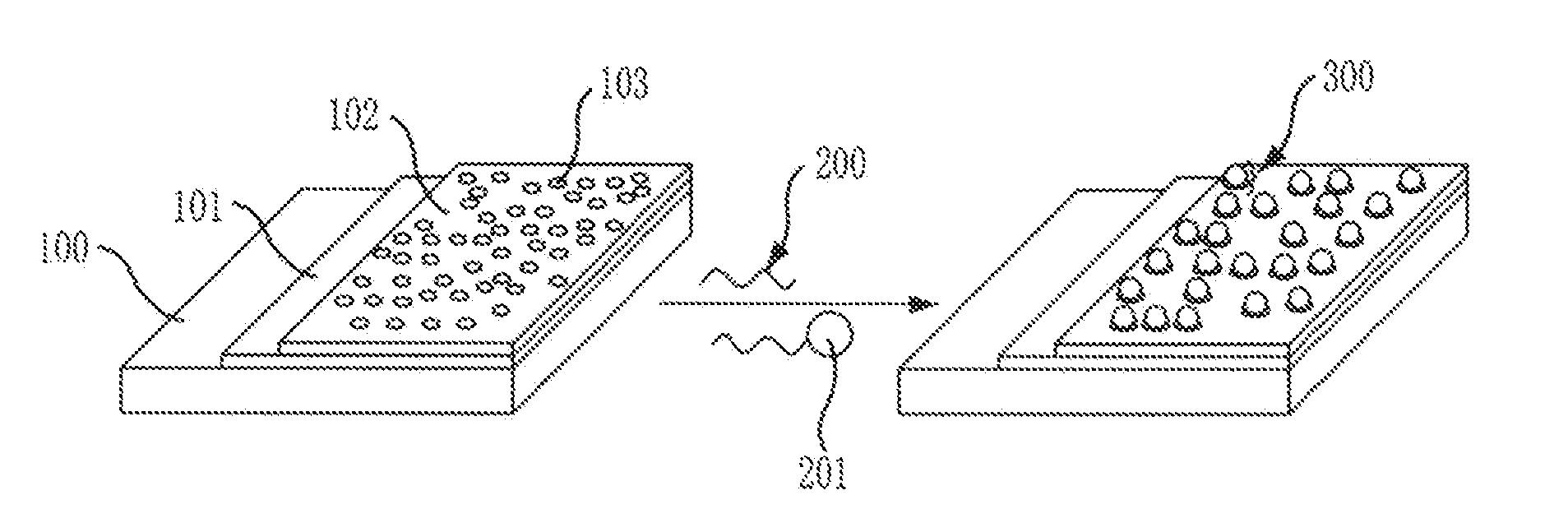

Minimally invasive allergy testing system

InactiveUS20110270122A1Small test area footprintSimplifies and expedites allergy testing processDiagnostics using lightMicroneedlesRest positionHypersensitive response

An allergy testing system includes encapsulated allergens, a microneedle array, and an activation system coupled to the microneedle array and the encapsulated allergens such that the encapsulated allergens are moved into contact with a subject as the microneedle array is moved from a resting position to a penetrating position. A method for determining a degree of reaction to one or more allergens by a patient in a minimally invasive manner is also disclosed. Penetration of one or more microneedles into a skin of the patient is caused. Each of the penetrations into the skin is exposed with an allergen from each of the one or more microneedles. One or more images are captured of each of the penetrations into the skin. Each of the captured images are analyzed to assess the degree of reaction to the specific allergen. Allergic reactivity data is output for at least one of the allergens.

Owner:INFOTONICS TECH CENT

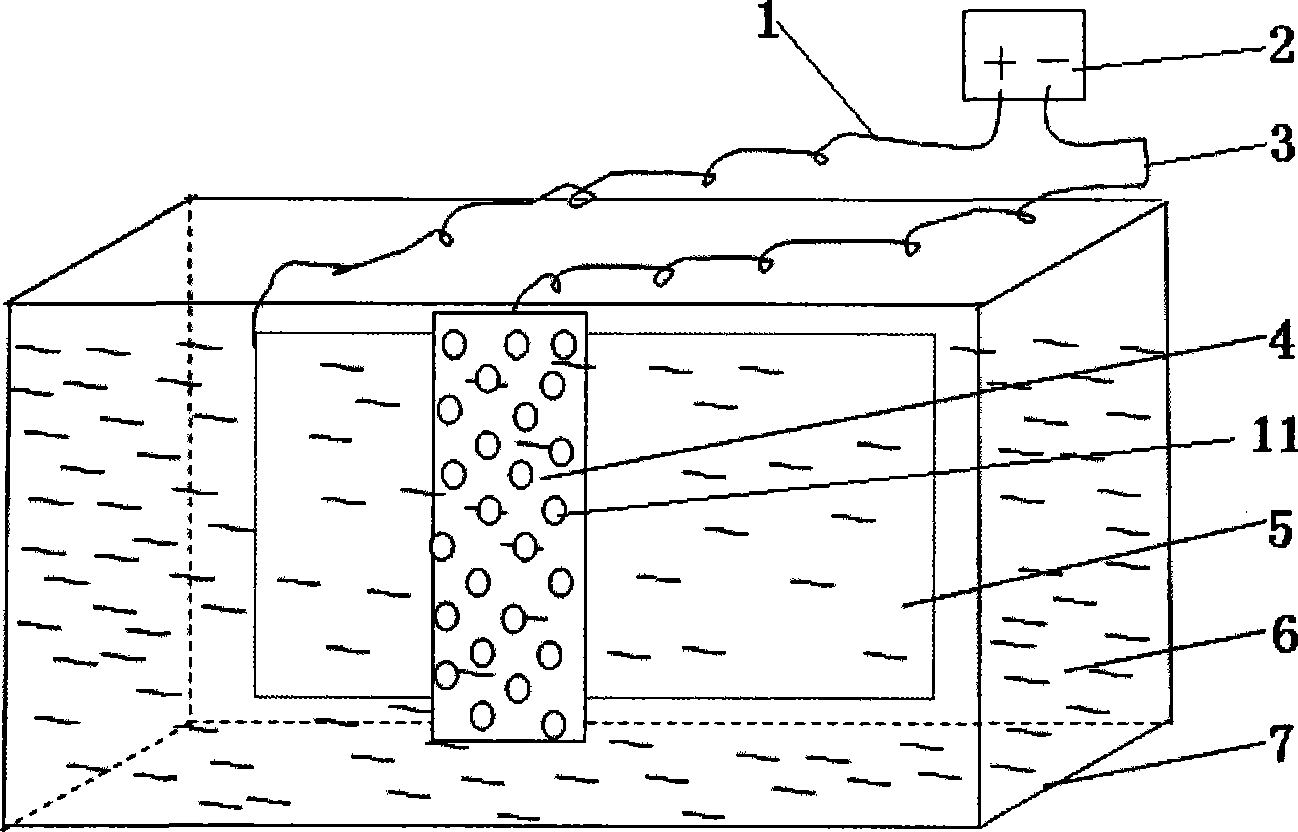

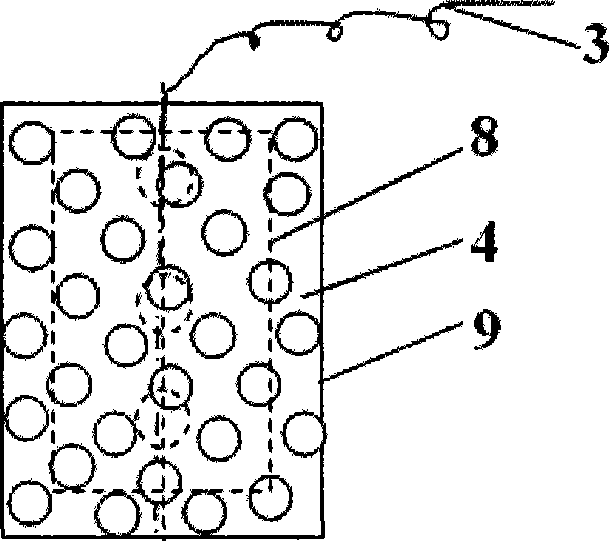

Large area light alloy micro-arc oxidization surface processing method and apparatus

InactiveCN101368286AAchieve continuous micro-arc oxidation treatmentEasy to install and disassembleAnodisationMicro arc oxidationAlloy

The invention discloses a microarc oxidation surface treatment method for treating a large-area light alloy and a corresponding device for implementing the method. The method includes the following steps: arranging a cathodal electrode device with a surface area smaller than the surface area of an anodic workpiece on a local area of a large-area anodic workpiece, so as to process microarc oxidation surface treatment to the local areas of the anodic workpiece; and adjusting the position of the cathodal electrode device relative to the anodic workpiece and gradually enabling the cathodal electrode device to have reaction with all the areas on the surface of the anodic workpiece. All the areas have the same degree of reaction, so the whole surface of the anodic workpiece can be processed with microarc oxidation treatment. The technical proposal is adopted to have the advantage that when processing microarc oxidation surface treatment to different areas of the large-area light alloy, the position of the relative electrode with respect to the anodic workpiece can be adjusted freely. The device is convenient to install and disassemble. The invention has wide application range and can save energy and reduce cost, thus effectively reducing the production cost.

Owner:THIXOMAG TECHNOLOGH WUHU

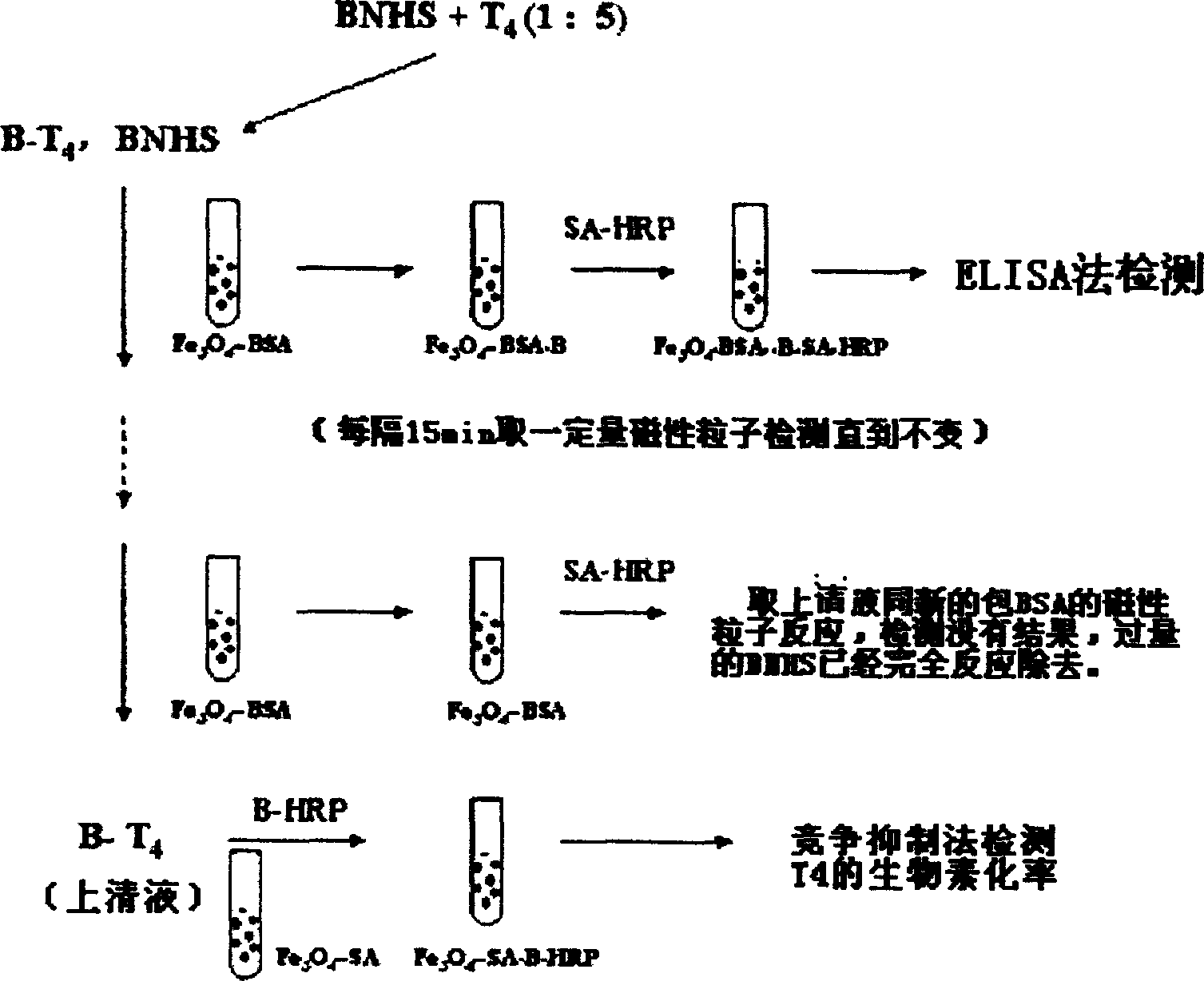

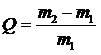

Quick magnetic method for separating and purifying thyroxin marked-by biotin

InactiveCN1540348AHigh purityThe separation effect is the samePeptide preparation methodsMaterial analysisBiotinDegree of reaction

After reaction between bovine serum albumin (bsa) on magnetic particles and biotin label of thyroxin, superfluous biotin reagent in mixed liquor and n-hydroxyl succimide ester generates compound of magnetic particle-bsa-biotin. Under action of external magnetic field, superfluous biotin reagent is removed. Degree of reaction between n-hydroxyl succimide ester and magnetic particles is tested by enzyme immunoassay method. It is determined that final obtained solution is high-purified thyroxin labeled by biotin. Advantages of the invention are simple, quick and high efficiency. The invention is also applicable for separating and purifying biomoleculars of protein, polypeptide, oligonucleotide etc. labeled by biotin.

Owner:SHANGHAI JIAO TONG UNIV

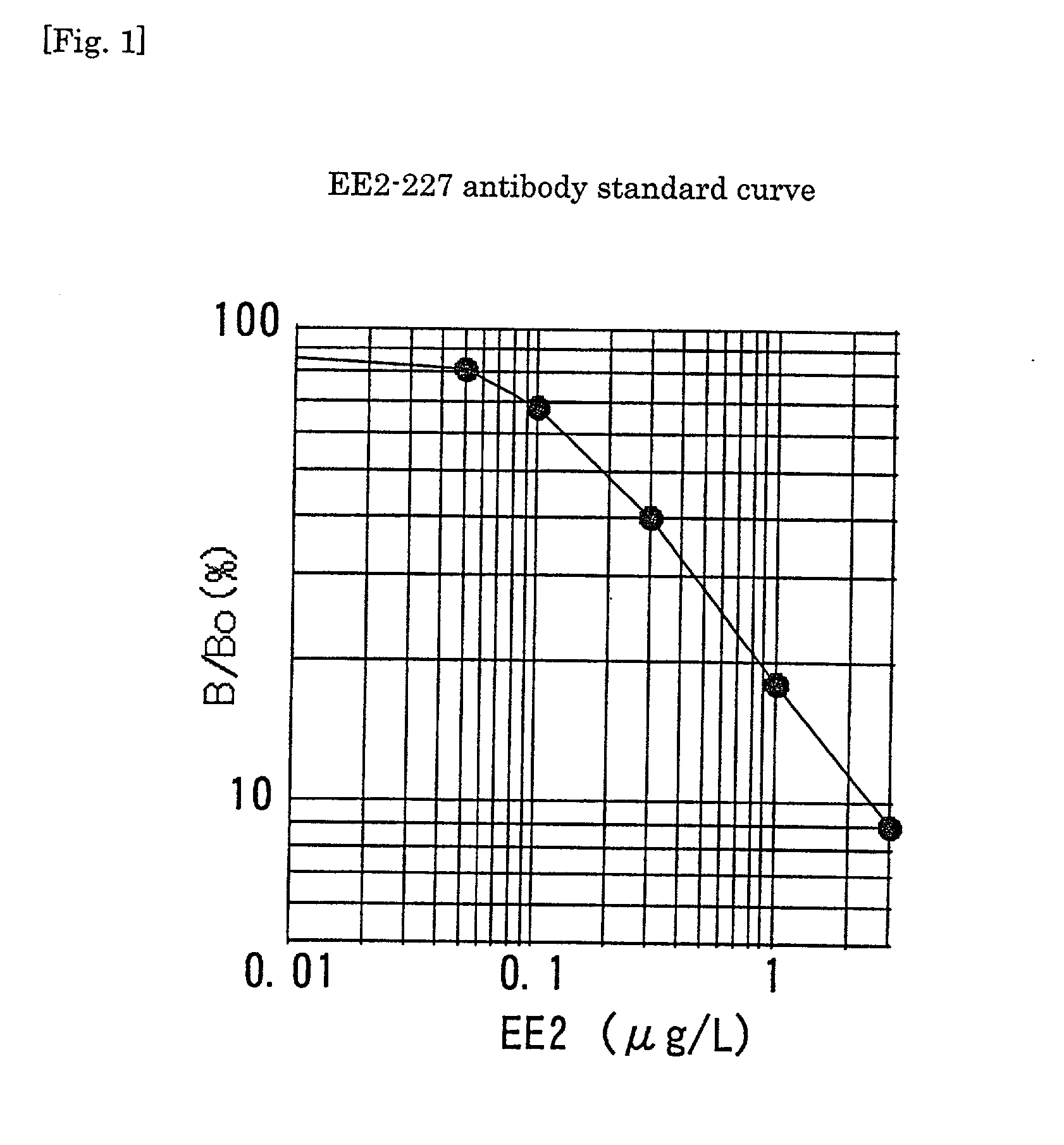

Method of selecting an antibody, a hybridoma, a monoclonal antibody and use thereof

InactiveUS20030064389A1Avoid it happening againAnimal cellsMicrobiological testing/measurementTest sampleMonoclonal antibody

The present invention provides a method of selecting an antibody against a target substance to be measured which comprises selecting the antibody against the target substance by antigen-antibody reaction in the presence of a substance interfering with the antigen-antibody reaction. That is, an antigen and a labeled antigen are reacted with the antibody in the presence of an interfering substance such as an environment pollutant, and on the basis of the degree of reaction thereof, the antibody against the target substance highly resistant to the interfering substance is selected. Thereby, even if a test sample is contaminated with a substance interfering with antigen-antibody reaction, the antibody highly resistant to a substance interfering with antigen-antibody reaction is not influenced by the interfering substance and gives a correct value in the quantification.

Owner:JAPAN ENVIROCHEM

Catalytic nanoporous membranes

InactiveUS7625840B2Shrink poresUnique environmentNanostructure manufactureOther chemical processesPartial oxidationGas phase

A nanoporous catalytic membrane which displays several unique features including pores which can go through the entire thickness of the membrane. The membrane has a higher catalytic and product selectivity than conventional catalysts. Anodic aluminum oxide (AAO) membranes serve as the catalyst substrate. This substrate is then subjected to Atomic Layer Deposition (ALD), which allows the controlled narrowing of the pores from 40 nm to 10 nm in the substrate by deposition of a preparatory material. Subsequent deposition of a catalytic layer on the inner surfaces of the pores reduces pore sizes to less than 10 nm and allows for a higher degree of reaction selectivity. The small pore sizes allow control over which molecules enter the pores, and the flow-through feature can allow for partial oxidation of reactant species as opposed to complete oxidation. A nanoporous separation membrane, produced by ALD is also provided for use in gaseous and liquid separations. The membrane has a high flow rate of material with 100% selectivity.

Owner:UCHICAGO ARGONNE LLC

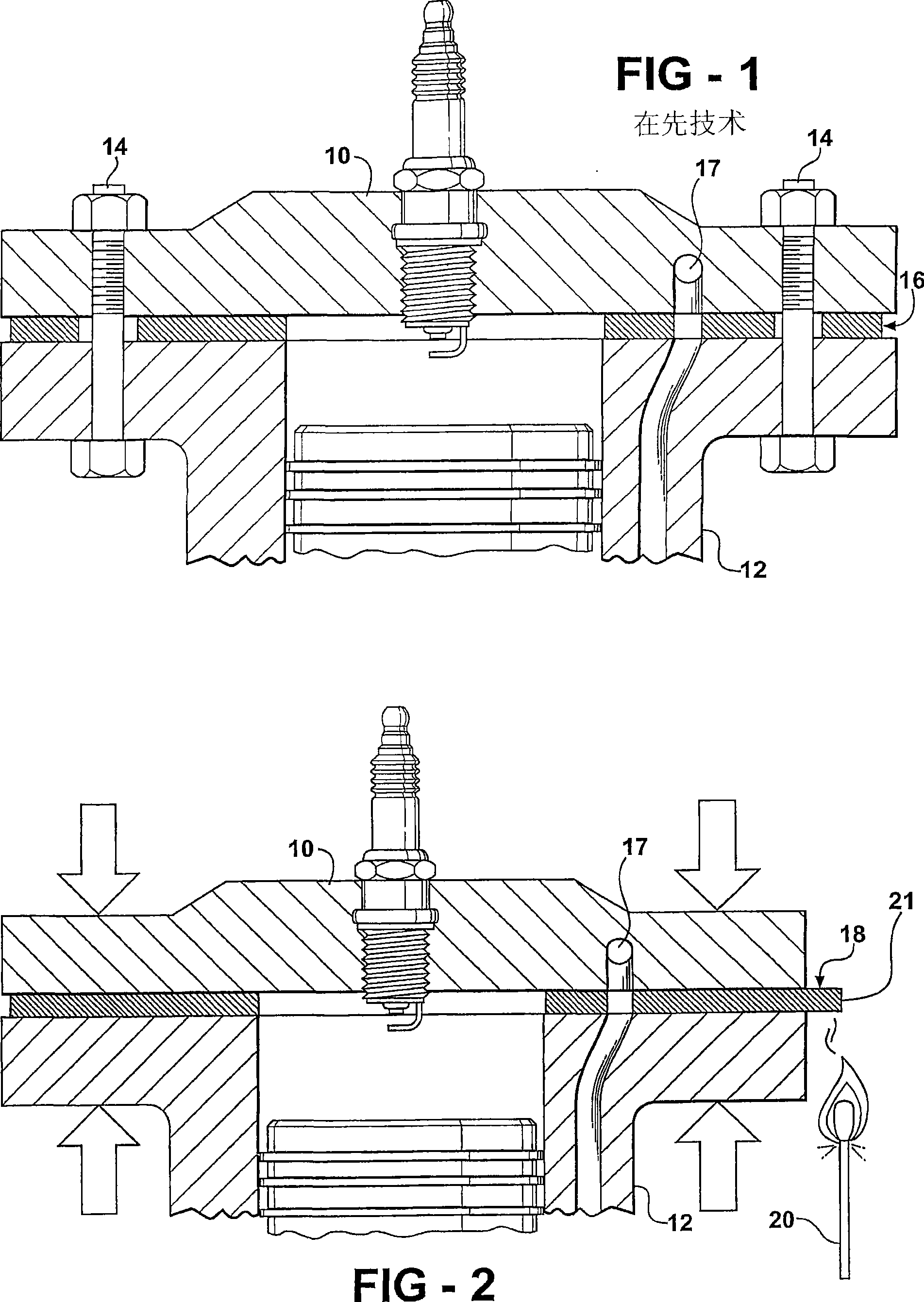

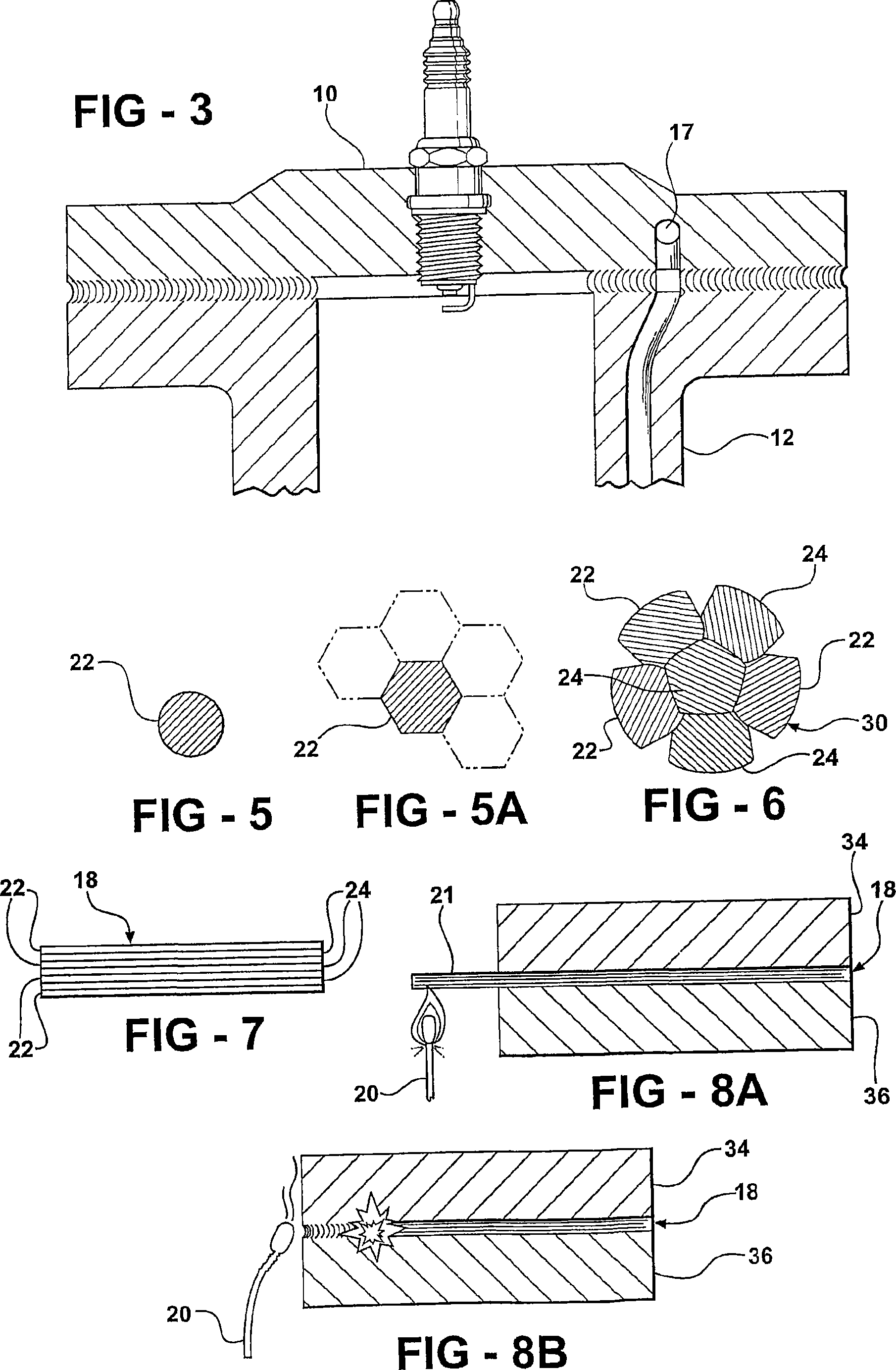

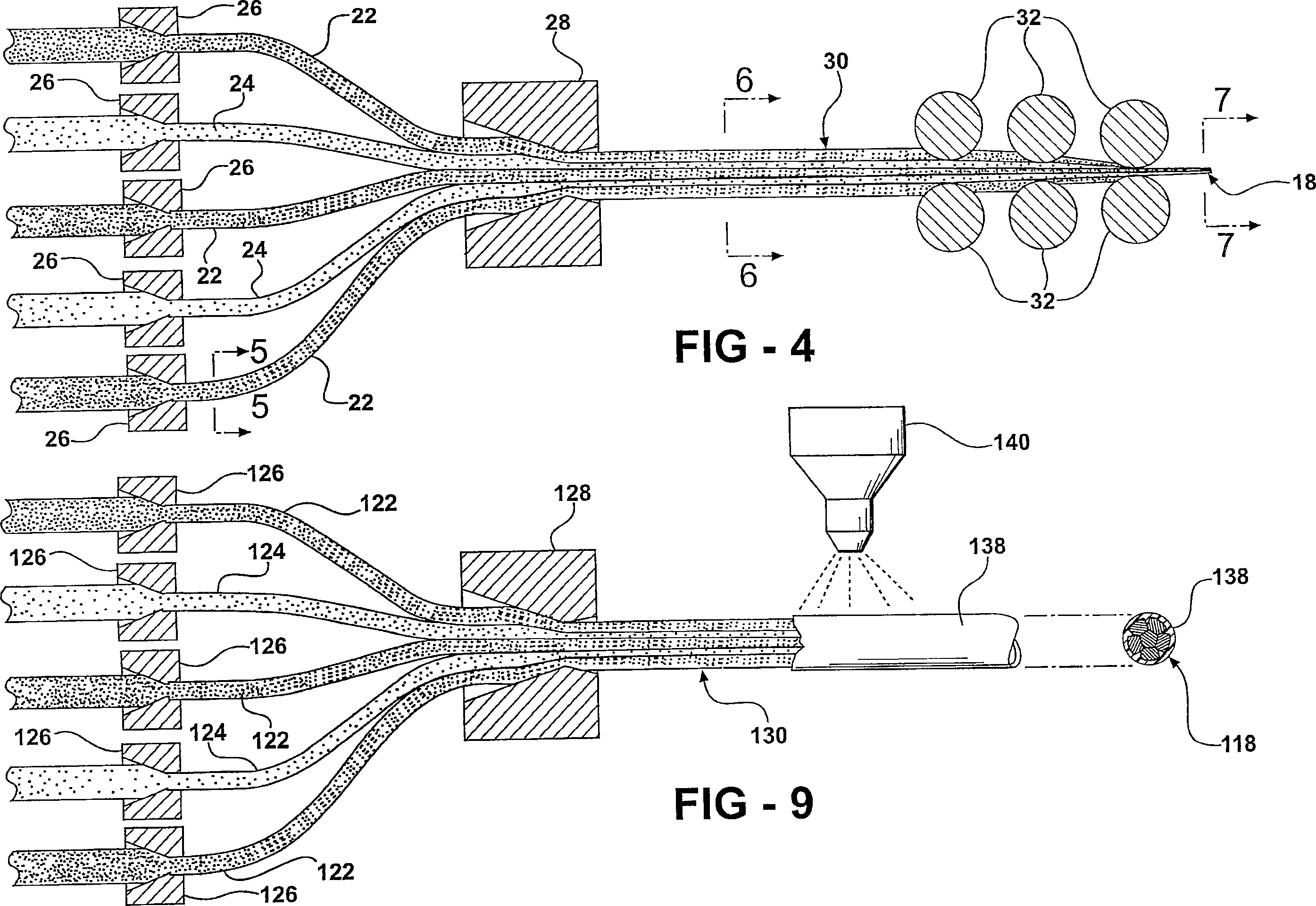

Exothermic wire for bonding substrates

Heating cords, foils or tapes are first manufactured by cold drawing individual round wires of constituent materials in a blanketed gas environment. This cold drawing operation produces a clean surface free of oxides and other contamination. Second, the constituent strands are brought together and twisted, cold drawn, swaged, and / or friction welded to produce an integral rope in which the constituent materials are in intimate contact. The integral rope can then be applied directly or further shaped into a shape and / or thickness. By controlling the dimensional ratios of the component cross-sections, the degree of controllability of the exothermic reaction characteristics can be tuned. Once the integral rope is formed, it can be coated with a layer of brazing and / or molten material to facilitate subsequent operations. Multiple strands may be woven together to form a cloth structure. The heat release device may be used in the field of permanently joining gaskets to opposing surfaces, such as attaching a cylinder head to a cylinder block in the operating position.

Owner:FEDERAL MOGUL CORP +1

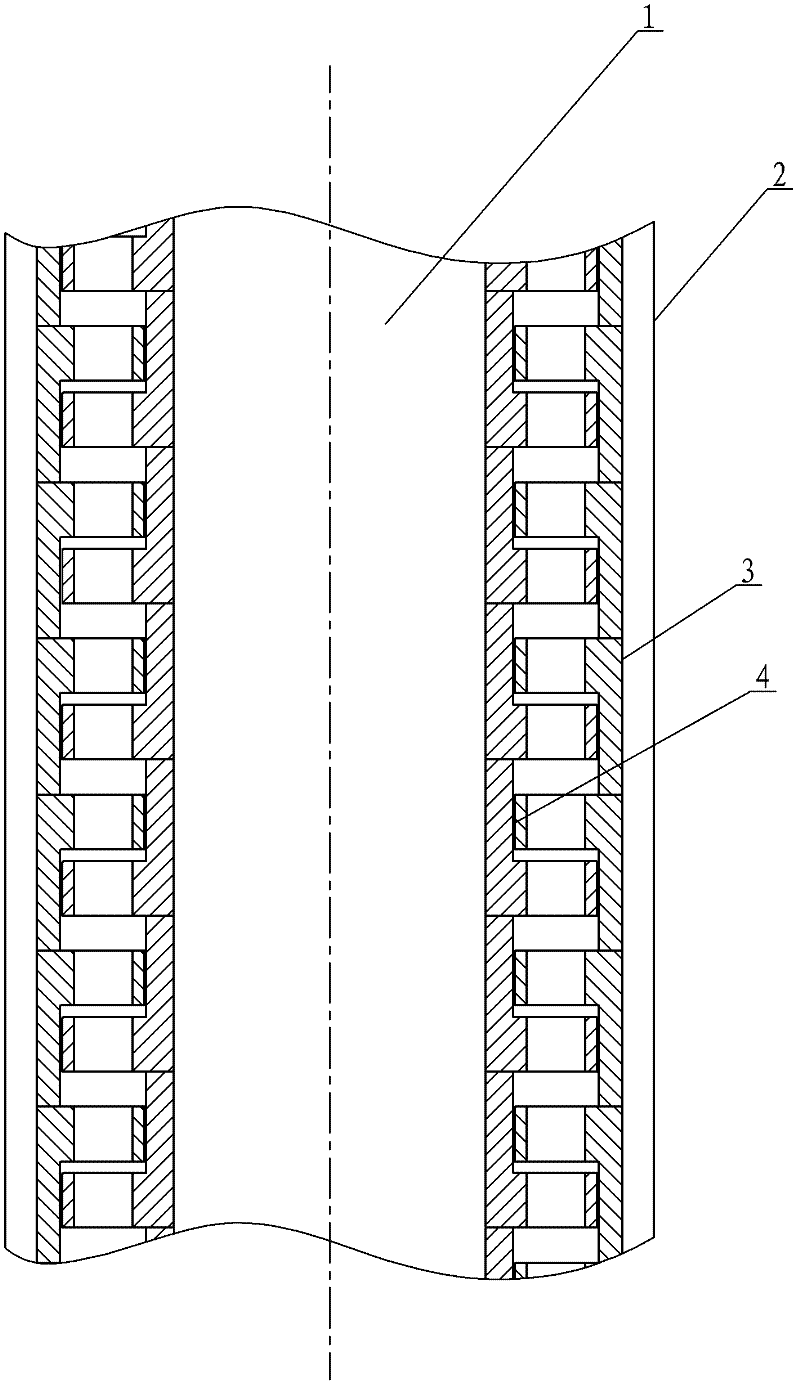

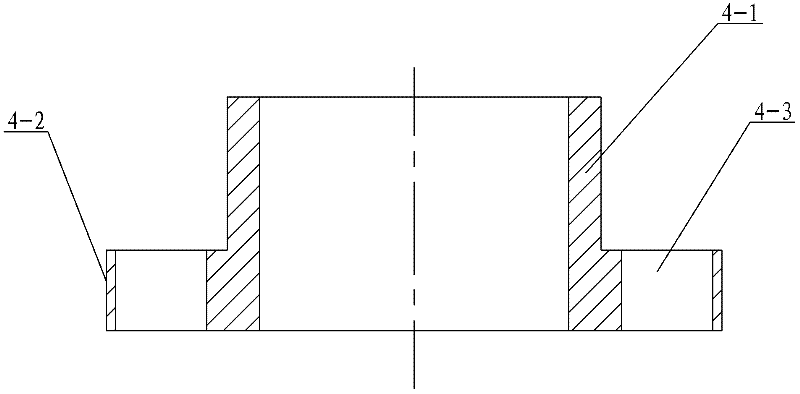

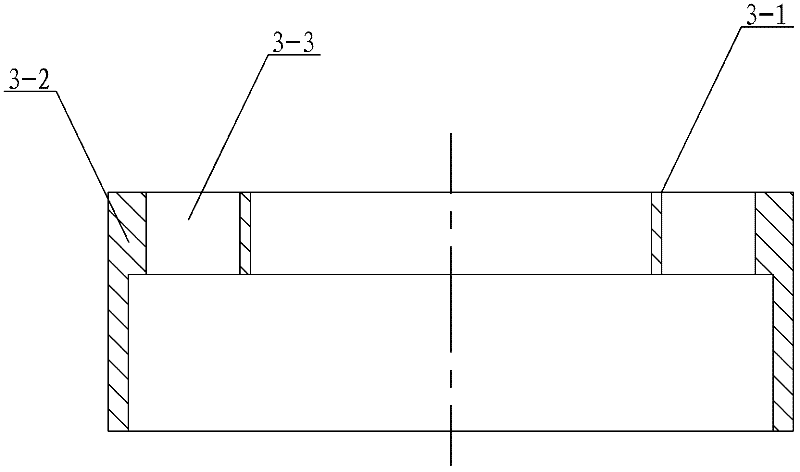

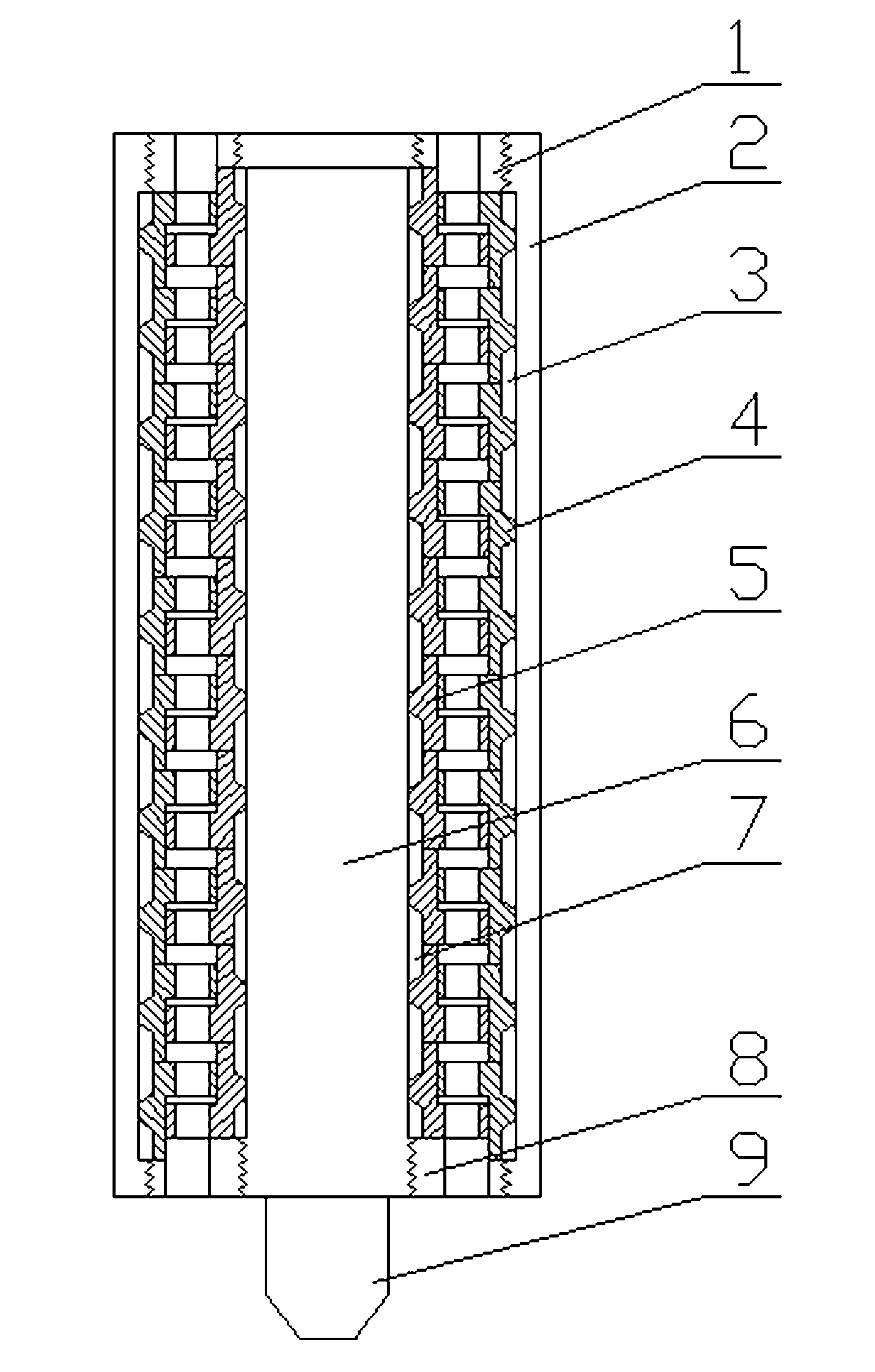

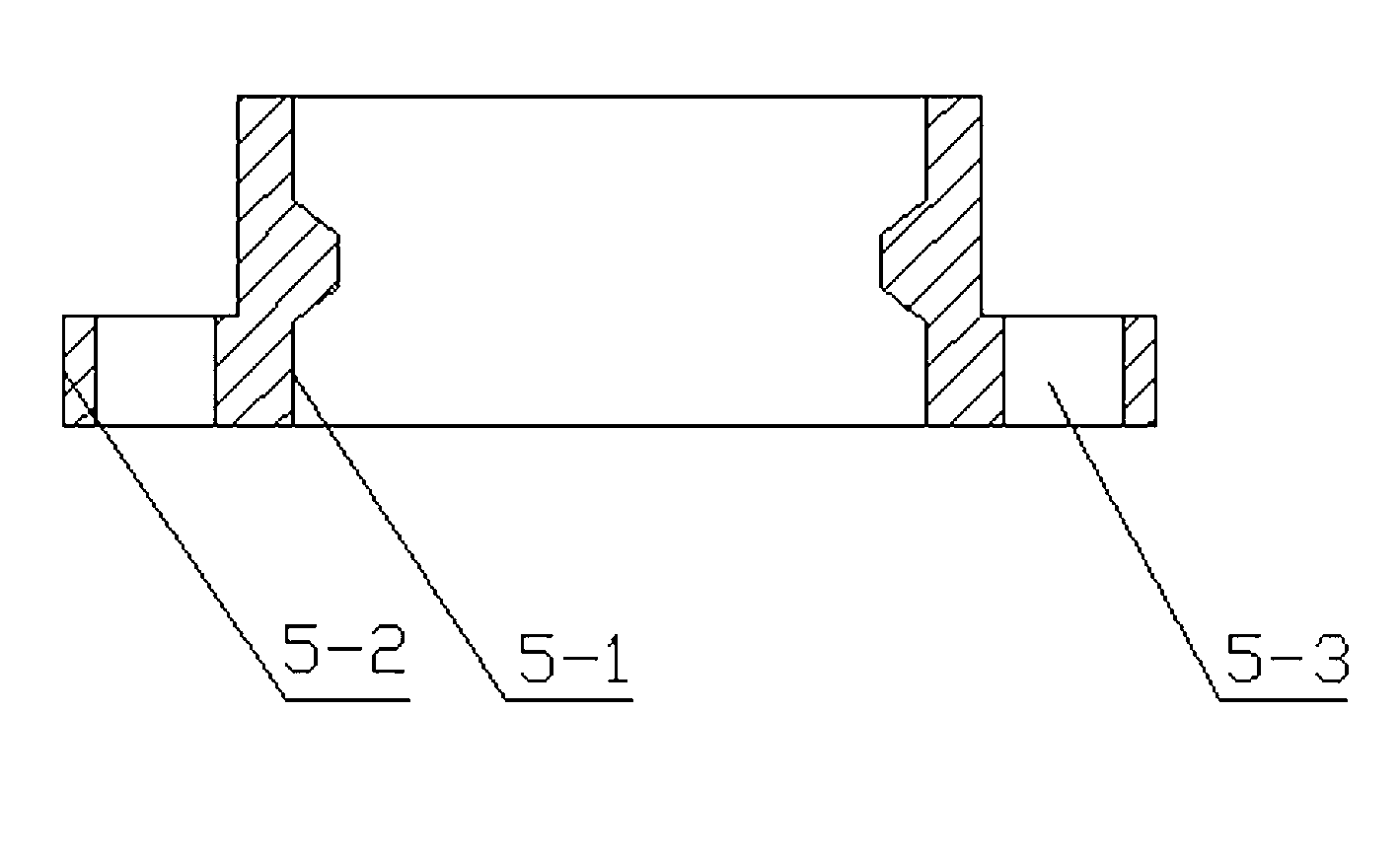

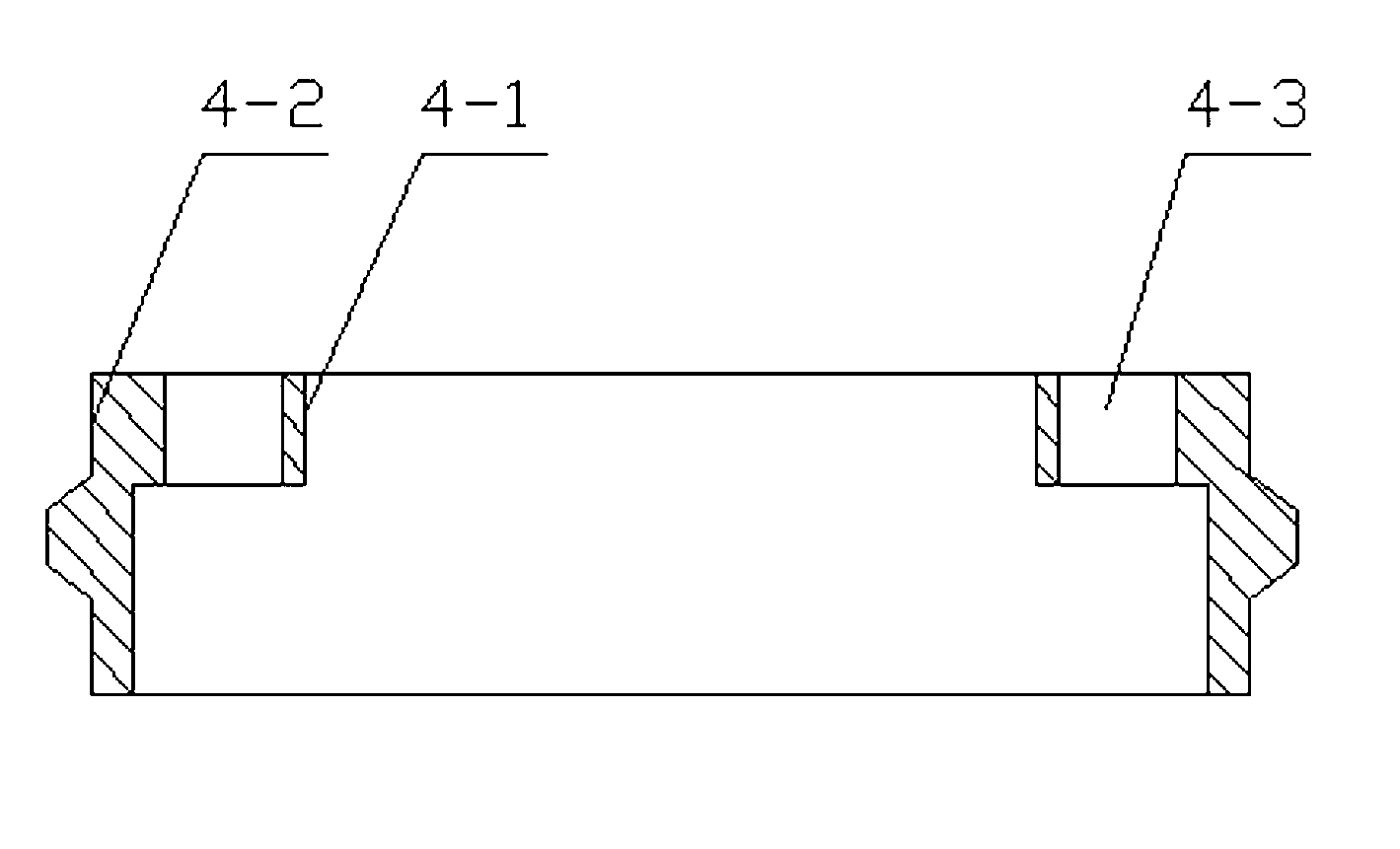

Turbine stator and rotor assembly

InactiveCN102454423AExtended service lifeImprove efficiencyBlade accessoriesStatorsEngineeringDegree of reaction

The invention discloses a turbine stator and rotor assembly, which belongs to petroleum drilling industries and aims to solve the problems of low turbine-stage efficiency and short service life of a turbine drill due to higher viscosity of the conventional drilling fluid. Each rotor blade disc is provided with a stator blade disc, the rotor blade disc and the stator blade disc form a stage, and the reaction degree of the stage is less than 0.5; a plurality of stages are sleeve on a shaft sequentially from top to bottom and are in compression fit with one another through end surfaces; a shell is sleeved on the outer parts of the plurality of stages; molded lines of a rotor blade and a stator blade are constructed a spline curve; the spline curve of the rotor blade has a shape of an arc with a rightward opening; the spline curve of the stator blade has a shape of an arc with a leftward opening; and both the rotor blade and the stator blade are made of ZG20CrMnSiNi2. The turbine stator and rotor assembly is suitable for petroleum drilling.

Owner:中国船舶重工集团公司第七〇三研究所

Preparation method of high-expansion liquid absorption sponge

InactiveCN102585273AUniform pore structureSoft textureAbsorbent padsBandagesForeign matterPolyvinyl alcohol

The invention relates to a preparation method of a high-expansion liquid absorption sponge, which belongs to the field of preparation of biomedical materials. The preparation method comprises the following steps of: mixing two polyvinyl formal reaction solutions with different degrees of reaction, then reacting continuously and performing pouring, curing, demolding, cleaning and other steps for getting a final product. According to the preparation method disclosed by the invention, polyvinyl formal with higher depth of pre-reaction is utilized for making a hole-forming core so as to prepare a sponge material, and the material has the characteristics of regular hole structure, no residue of foreign matters, soft texture, immediate expansion when the material meets with water and the like, and is suitable for surgical hematophagia, liquid absorption and other purposes in the medical field.

Owner:NANCHANG UNIV

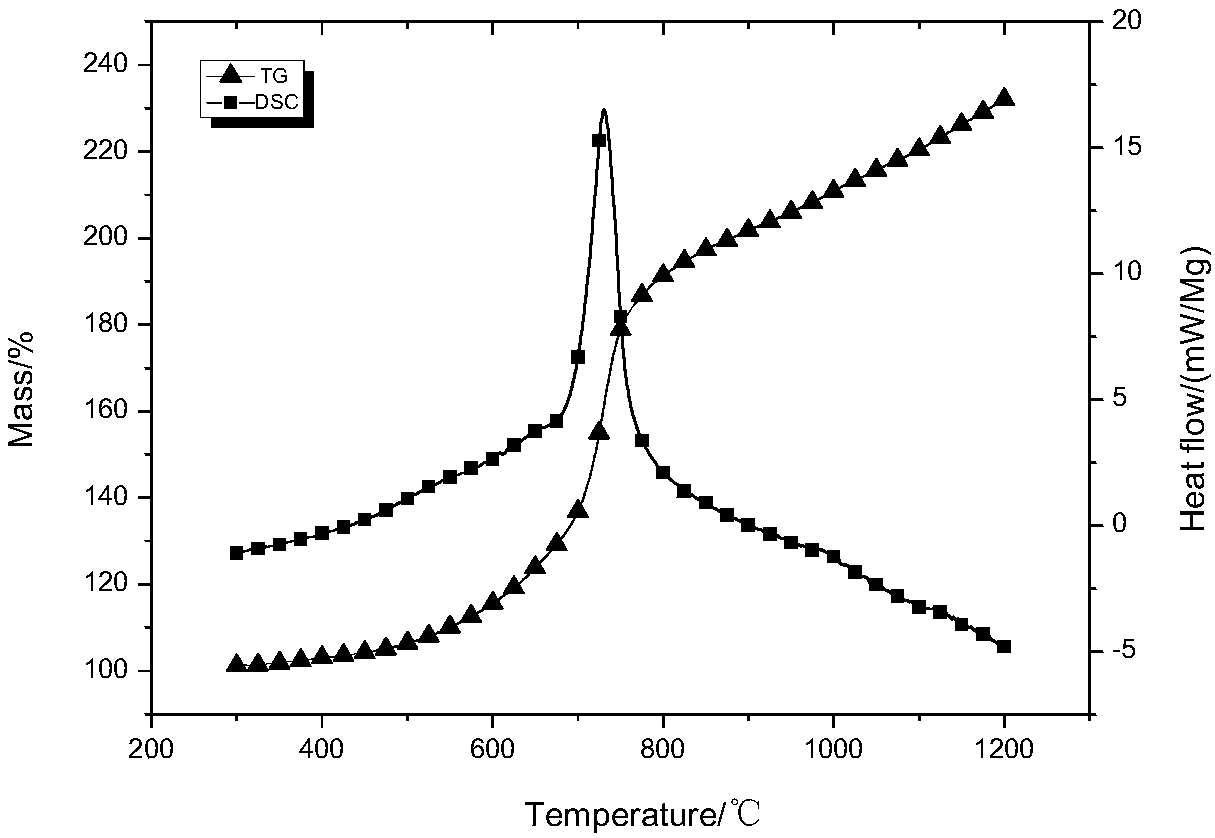

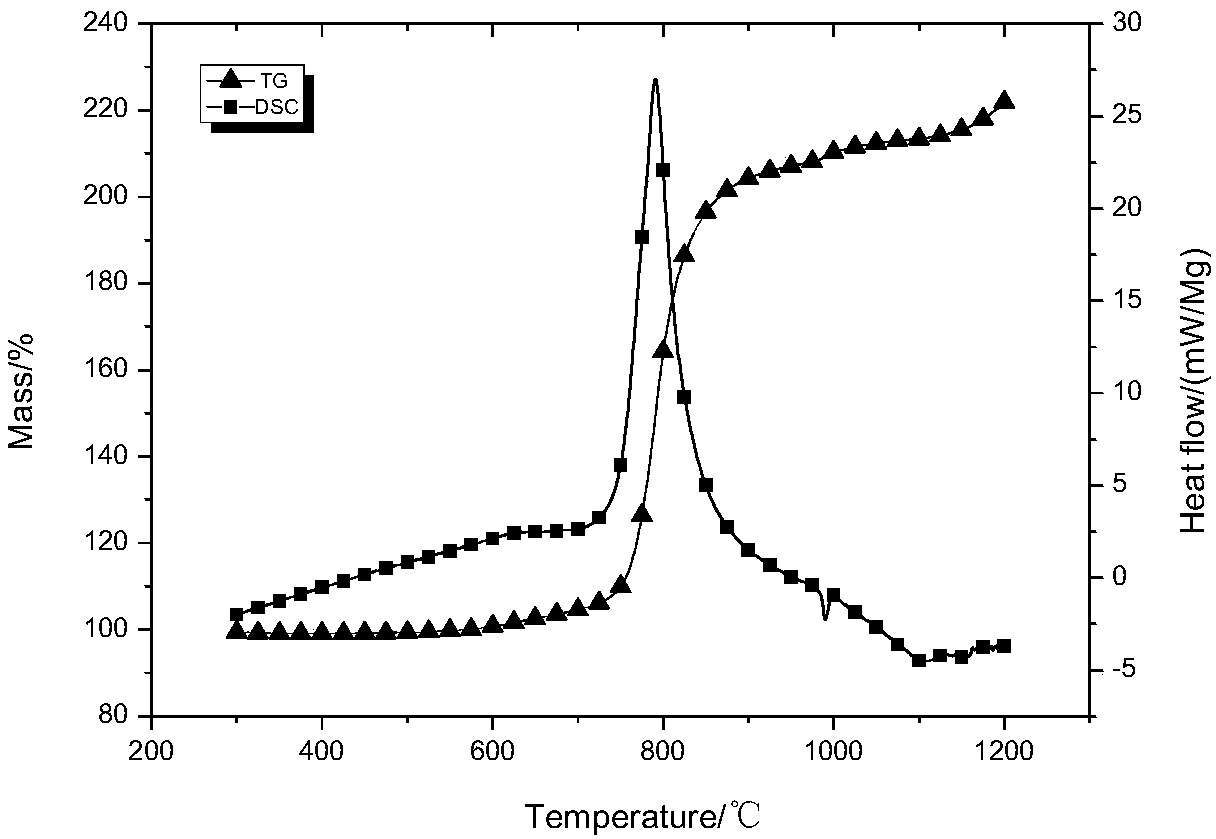

Boron magnesium prealloy powder material, and preparation method thereof

The invention relates to a preparation method of a boron magnesium prealloy powder material, and belongs to the field of metal based combustible matter. The boron magnesium prealloy powder material isof a totally encapsulated type core-shell structure; B is taken as the core; the shell is composed of MgO and MgB2; amorphous form MgO and crystalline state MgB2 are nonuniformly distributed. The preparation method comprises following steps: magnesium powder and boron powder are subjected to pretreatment and mechanical premixing so as to obtain a mixed powder, the mixed powder is subjected to high temperature uniform pre-mixing, is taken out from a furnace, is smashed and grinded under the protection of an inert gas, and then is introduced into the furnace again; vacuuming is carried out, inert gas is introduced, and two-step sintering is carried out; an obtained prealloy powder block is subjected to mechanical smashing grinding under the protection of inert gas so as to obtain the boronmagnesium prealloy powder material. The preparation method is simple; cost is low; reduction of boron oxide in boron powder is realized with magnesium powder in heating process so as to increase the content of effective boron; a part of boron magnesium alloy is formed on interfaces among boron particles, so that boron agglomeration is reduced, heating area of boron particles in oxidation process is enlarged, and the degree of reaction is increased.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Preparation method and polymerization equipment of acrylonitrile base carbon fiber spinning solution

ActiveCN101768239AImprove the mixing effectIncrease the length/diameter ratioFibre chemical featuresPolymer scienceSurface layer

The invention discloses a preparation method and polymerization equipment of acrylonitrile base carbon fiber spinning solution. The preparation method is characterized in that solution polymerization is carried out in the polymerization equipment; the polymerization equipment comprises a reaction kettle and a reactive extruder; and the reaction kettle and the reactive extruder are connected with each other and are respectively provided with a temperature regulating device. The invention has the following benefits: the reaction kettle is connected with the reactive extruder; the screw extrusion structure of the reactive extruder can introduce the reaction media and the chemical reaction in the process of extrusion and has the functions of the synthesis reactors besides the function of mixing materials of the traditional extruders; the reactive extruder can further process high viscosity materials and continuously and quickly generate new and thin material surface layers, thus increasing the surface volume ratio of the materials; and the reaction media are uniformly distributed in the materials and the degree of reaction is improved.

Owner:KINGFA SCI & TECH CO LTD +1

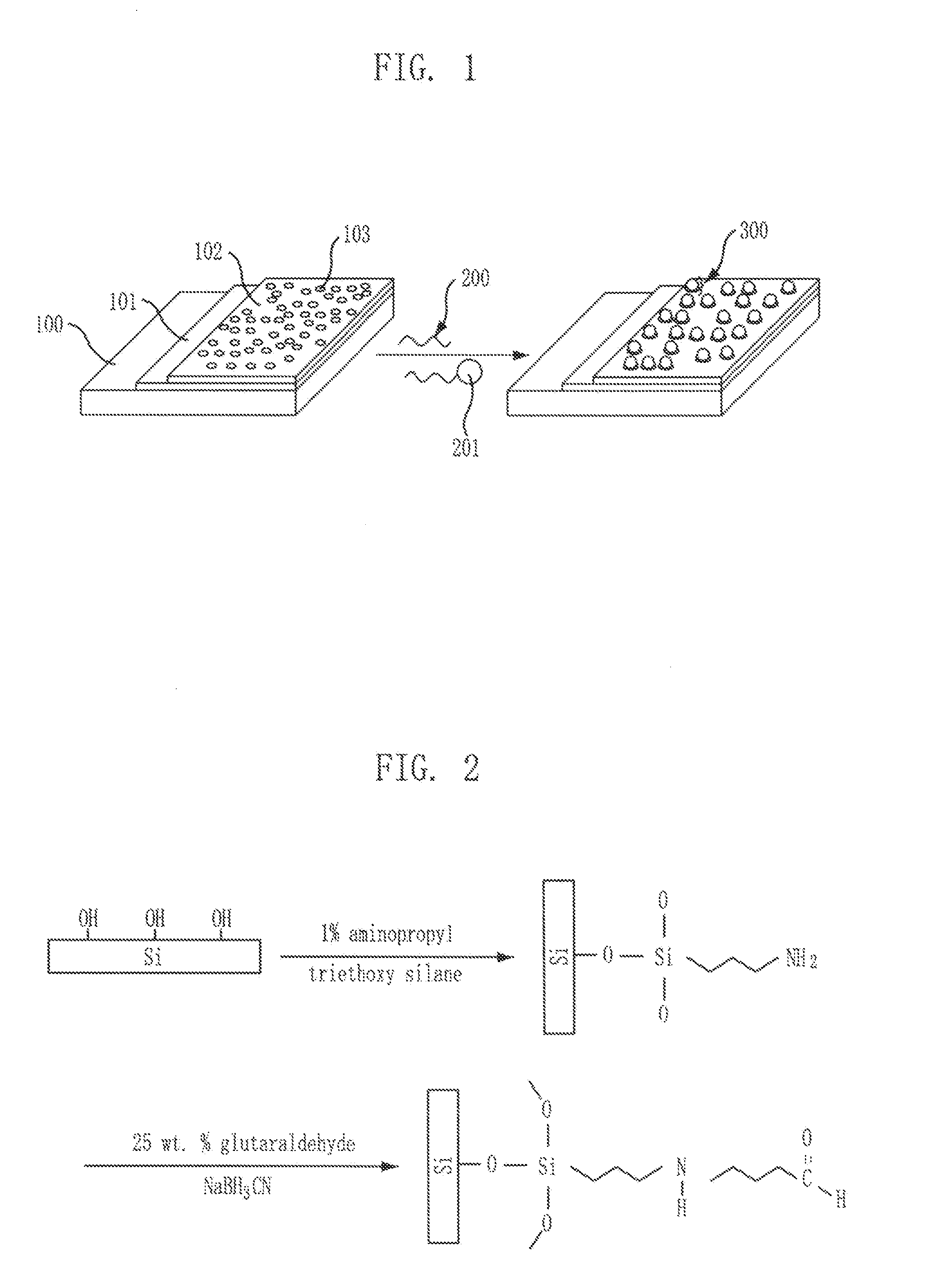

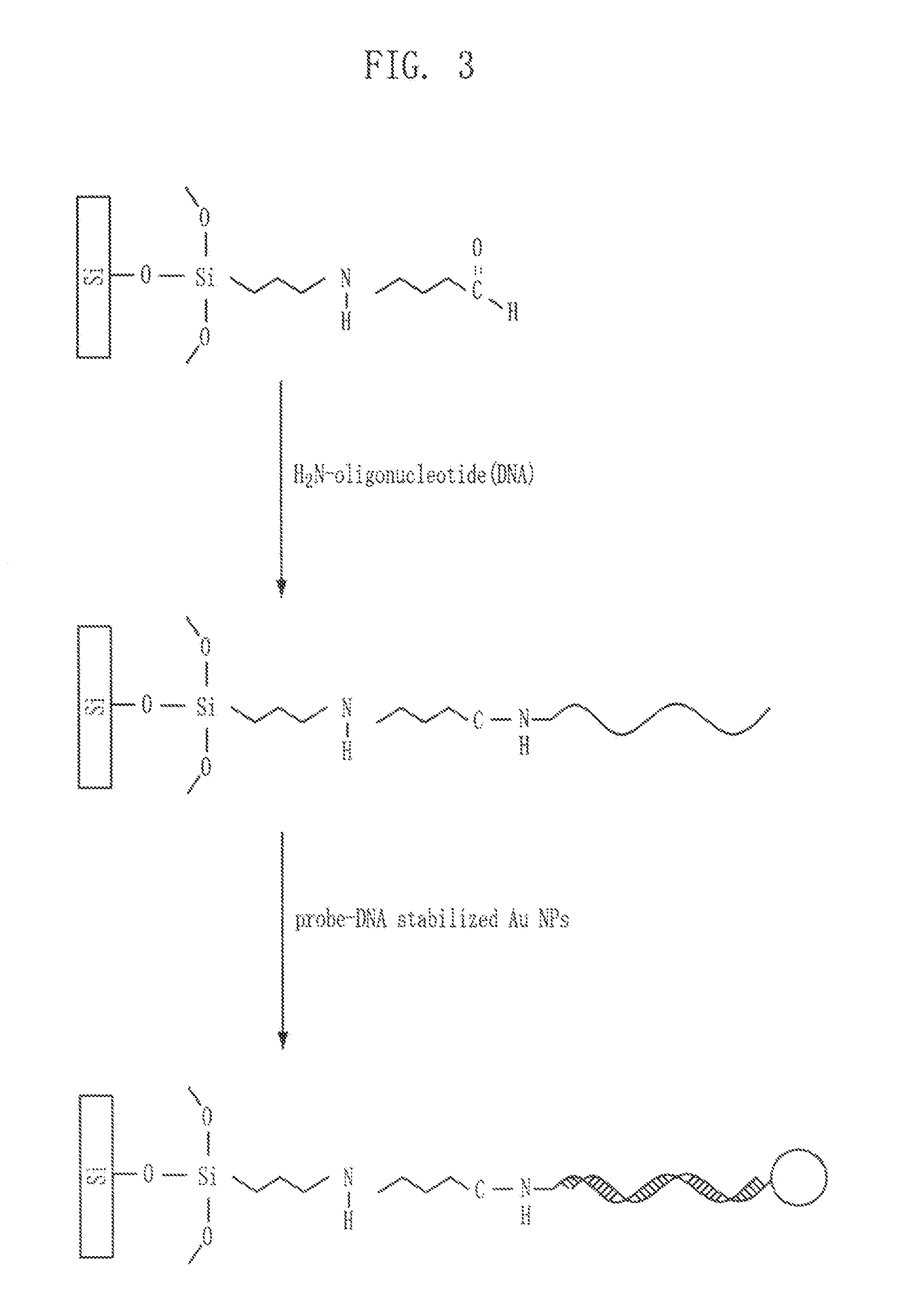

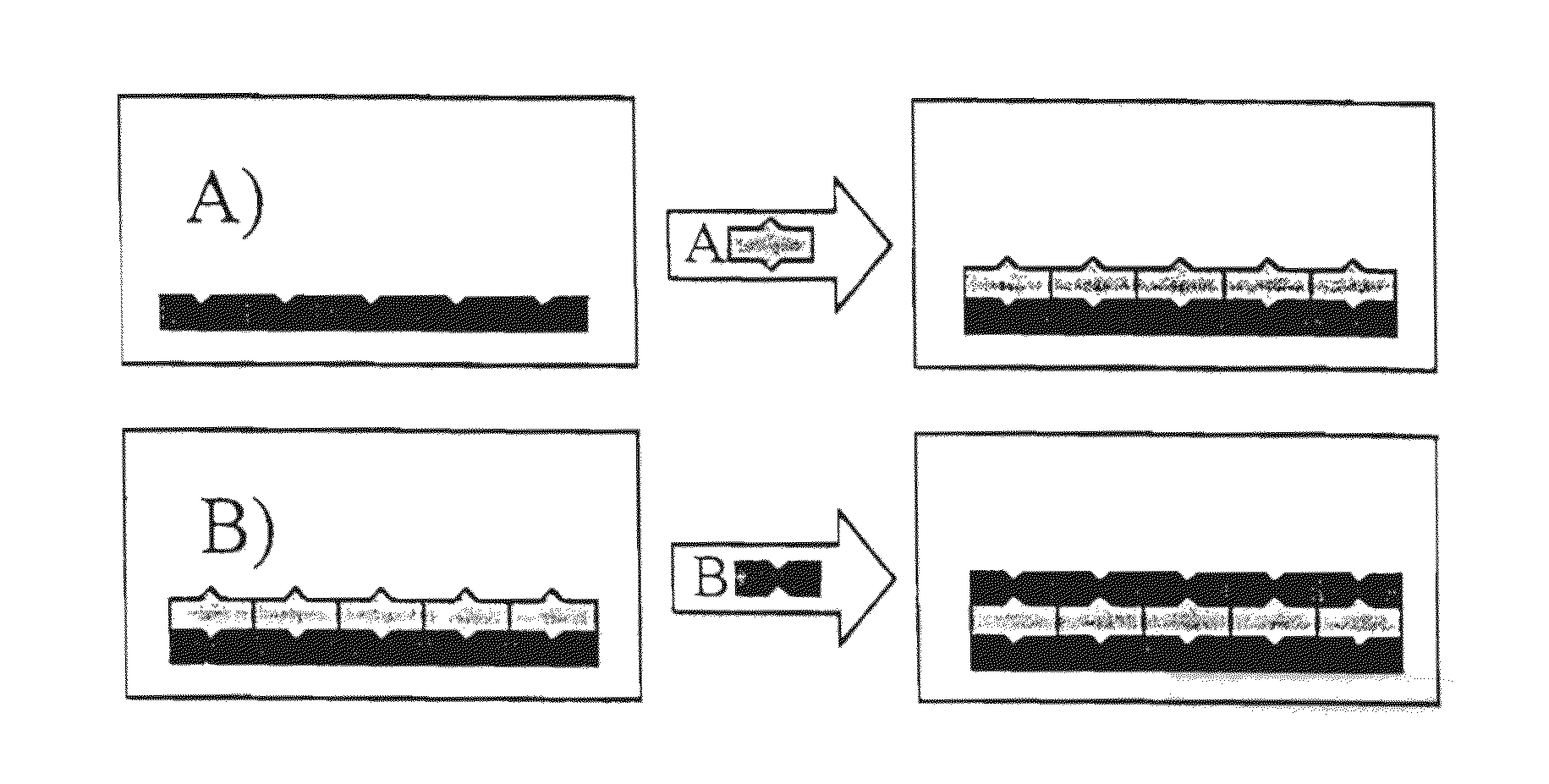

Substrate for analyzing coverage of self-assembled molecules and analyzing method using the same

InactiveUS20100015718A1Efficient measurementMicrobiological testing/measurementNanosensorsNanowireNanoparticle

Provided are a substrate for analyzing the coverage of self-assembled molecules and a method for analyzing the coverage of the self-assembled molecules in nanowire and nanochannel patterned on solid surface, solid surface, or bulk solid surface by using the nanoparticles. According to the method, the presence of specific functional groups of self-assembled molecules and the degree of reaction can be analyzed by introducing nanoparticles to a biomaterial immobilization substrate including self-assembled molecules and measuring the number of gold nanoparticles existing on the surface. The substrate for analyzing the coverage of self-assembled molecules includes: a biomaterial immobilization substrate; a self-assembled molecular layer formed on the substrate and having a functional group capable of reacting with an amine group; a capture DNA molecule having an amine group bounded to the self-assembled molecular layer; and a probe DNA molecule bound to the capture DNA molecule and having nanoparticles attached to on the surface.

Owner:ELECTRONICS & TELECOMM RES INST

Catalytic nanoporous membranes

InactiveUS8518845B2Shrink poresUnique environmentOther chemical processesCatalyst activation/preparationPartial oxidationGas phase

A nanoporous catalytic membrane which displays several unique features Including pores which can go through the entire thickness of the membrane. The membrane has a higher catalytic and product selectivity than conventional catalysts. Anodic aluminum oxide (AAO) membranes serve as the catalyst substrate. This substrate is then subjected to Atomic Layer Deposition (ALD), which allows the controlled narrowing of the pores from 40 nm to 10 nm in the substrate by deposition of a preparatory material. Subsequent deposition of a catalytic layer on the inner surfaces of the pores reduces pore sizes to less than 10 nm and allows for a higher degree of reaction selectivity. The small pore sizes allow control over which molecules enter the pores, and the flow-through feature can allow for partial oxidation of reactant species as opposed to complete oxidation. A nanoporous separation membrane, produced by ALD is also provided for use in gaseous and liquid separations. The membrane has a high flow rate of material with 100% selectivity. Also provided is a method for producing a catalytic membrane having flow-through pores and discreet catalytic clusters adhering to the inside surfaces of the pores.

Owner:UCHICAGO ARGONNE LLC

Production process of granulated mono ammonium phosphate (GMAP)

ActiveCN105084333ALower the targetLow impurity contentPhosphatesAlkali orthophosphate fertiliserHigh concentrationReaction temperature

The invention discloses a production process of high-concentration granulated mono ammonium phosphate (GMAP). The production process comprises the concrete steps of respectively desulfurizing and clarifying dilute phosphoric acid with the mass concentration of 23-25% weighted by P2O5 and concentrated phosphoric acid with the weight concentration of 46-47% weighted by P2O5, and then, mixing and blending the dilute phosphoric acid and the concentrated phosphoric acid according to the weight ratio of (70-75):(25-30) to obtain a phosphoric acid solution; next, adding the phosphoric acid solution and gas ammonia into a tubular reactor, carrying out amino acid neutralization on the gas ammonia and the phosphoric acid solution which are added into the tubular reactor, and controlling the neutralization degree of reaction slurry at 1.02-1.07 and the reaction temperature at 95-105 DEG C; and finally, directly carrying out slurry spraying granulation on the obtained slurry, and drying to obtain the high-concentration GMAP product. Through the processes of desulfurizing, clarifying and acid blending, the content of impurities in phosphoric acid is reduced, the content of nutrients in the high-concentration GMAP product is ensured, and the quality of the product is improved.

Owner:HUBEI CHUXING CHEM

Emergency hydrogen generating device based on nanometer metal powder

InactiveCN103626127AAchieving emergency suppliesNo pollution in the processHydrogen productionEmergency SupplyPhysical chemistry

The invention aims to provide an emergency hydrogen generating device based on nanometer metal powder. The emergency hydrogen generating device comprises a reaction chamber, wherein the reaction chamber is provided with a deionized water inlet, a nanometer metal powder inlet and a hydrogen outlet; a dehumidifier is arranged between the reaction chamber and the hydrogen outlet, the deionized water enters the reaction chamber from the deionized water inlet, the nanometer metal powder enters the reaction chamber from a nanometer metal powder inlet, the nanometer metal powder and the deionized water react to generate hydrogen through reaction, and after being dried, the hydrogen is discharged from the hydrogen outlet. According to the emergency hydrogen generating device provided by the invention, the nanometer metal powder and the deionized water react to generate lots of hydrogen in a short time, the hydrogen is dried and then is supplied to a power device which takes hydrogen as fuel; therefore, the simple structure is utilized to realize the emergency supply of hydrogen and no pollution is generated; the degree of reaction is controlled by regulating the grain size of the nanometer metal powder grains, the reaction safety is guaranteed, and the emergency supply of the hydrogen fuel is rapidly, reliably and safely realized.

Owner:HARBIN ENG UNIV

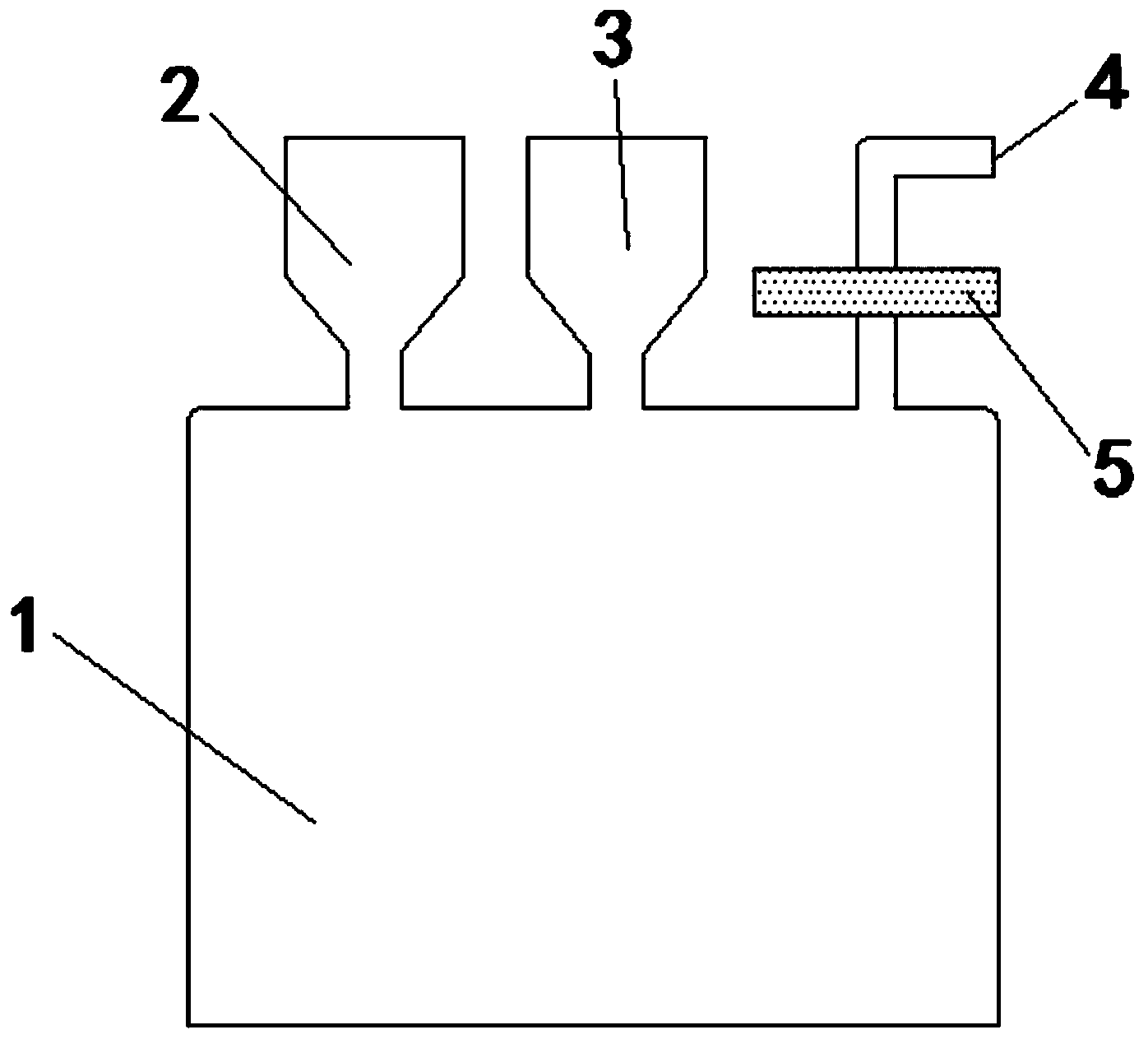

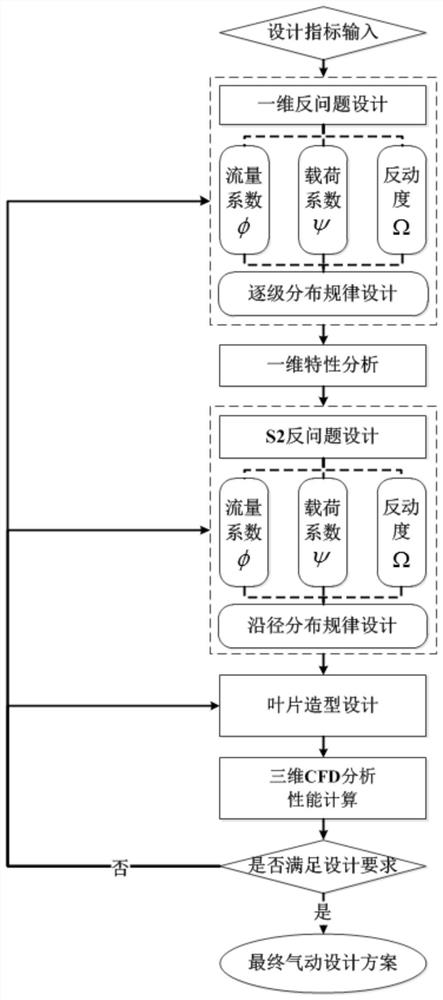

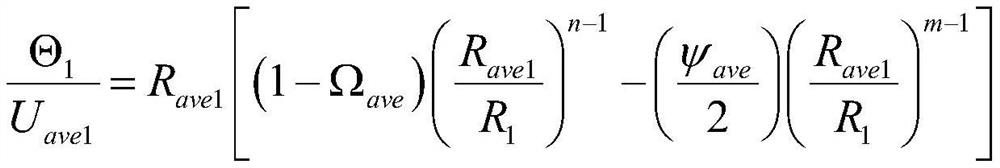

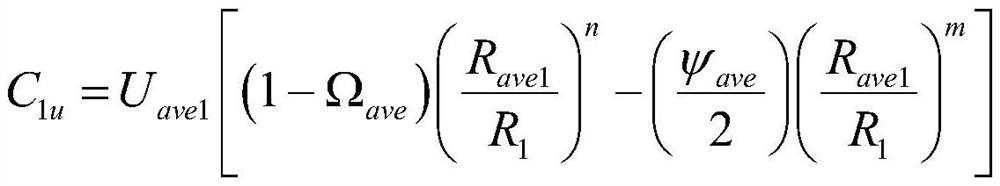

Multistage axial flow compressor aerodynamic design method based on key dimensionless load control parameters

ActiveCN112685851ASolve the space load matching problemImprove aerodynamic performanceGeometric CADDesign optimisation/simulationControl engineeringDegree of reaction

The invention aims to provide a multistage axial flow compressor aerodynamic design method based on key dimensionless load control parameters, which comprises the following steps of: repeatedly iterating links such as one-dimensional inverse problem design and characteristic analysis, S2 inverse problem design, blade modeling design, three-dimensional CFD analysis and the like; and obtaining a multi-stage axial flow compressor aerodynamic design scheme meeting design index requirements. Customized design of the internal load of the multi-stage axial flow compressor is achieved through three dimensionless parameters including the flow coefficient, the load coefficient and the reactivity, and the problem of space load matching between design points and low working conditions in pneumatic design of the multi-stage axial flow compressor is effectively solved; and the pneumatic design of the multistage axial flow compressor achieves the parameterization and refinement degree, the design precision is improved, and the design period is shortened. Meanwhile, the method is not limited to a multi-stage axial flow compressor of a gas turbine, but also suitable for the pneumatic design process of various industrial axial flow compressors and aero-engine axial flow compressors / fans.

Owner:中国船舶重工集团公司第七0三研究所

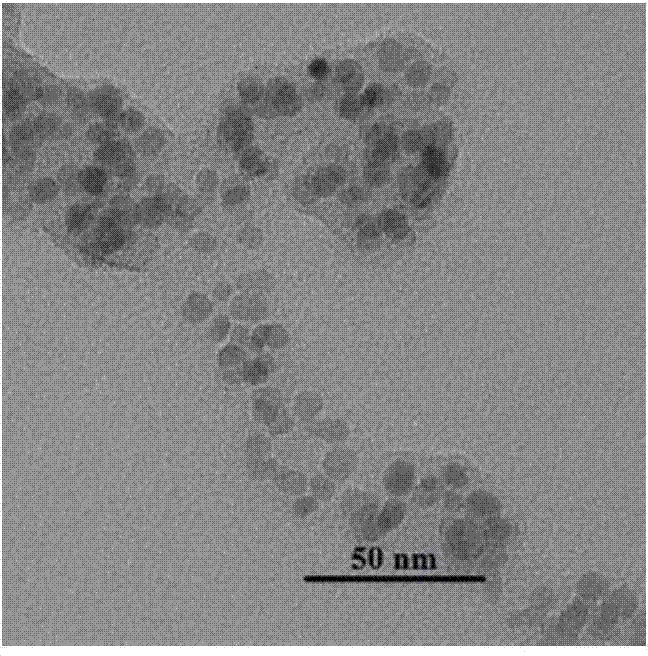

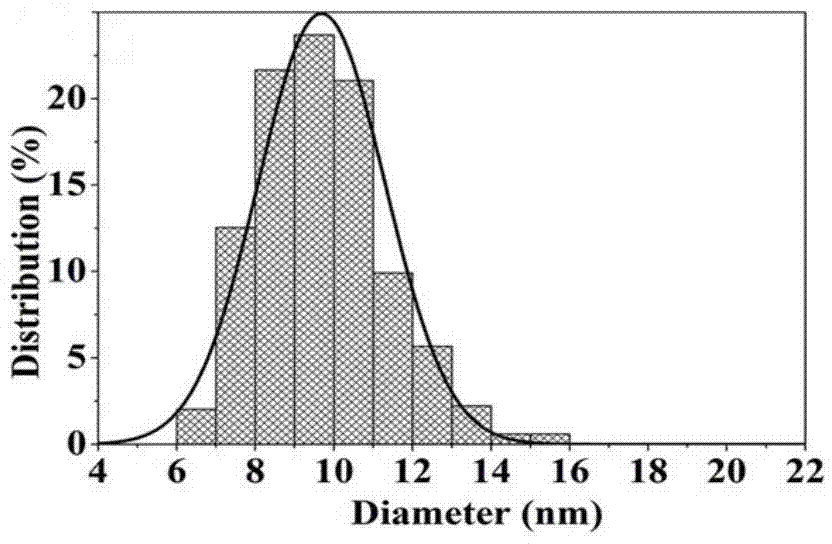

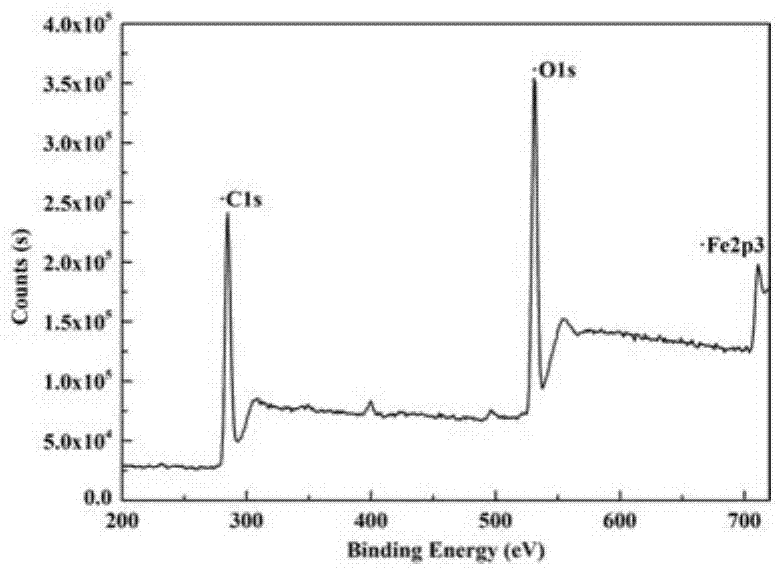

Carbon coated Fe3O4 composite material and preparation method thereof

ActiveCN104760947AGood dispersionShort reaction timeMaterial nanotechnologyFerroso-ferric oxidesSpray pyrolysisDegree of reaction

A method for continuously preparing the carbon coated Fe3O4 composite material by using a micro-reactor coupled spray pyrolysis reactor, Fe3O4 powders are dispersed and coated evenly in the carbon material. Compared with the prior art, the method has the advantages of short reaction time, low cost, high controllable degree of reaction process, simple and convenient to adjust preparation condition, continuous preparation, small particle size of Fe3O4, narrow distribution, and good particle dispersibility.

Owner:BEIJING UNIV OF CHEM TECH

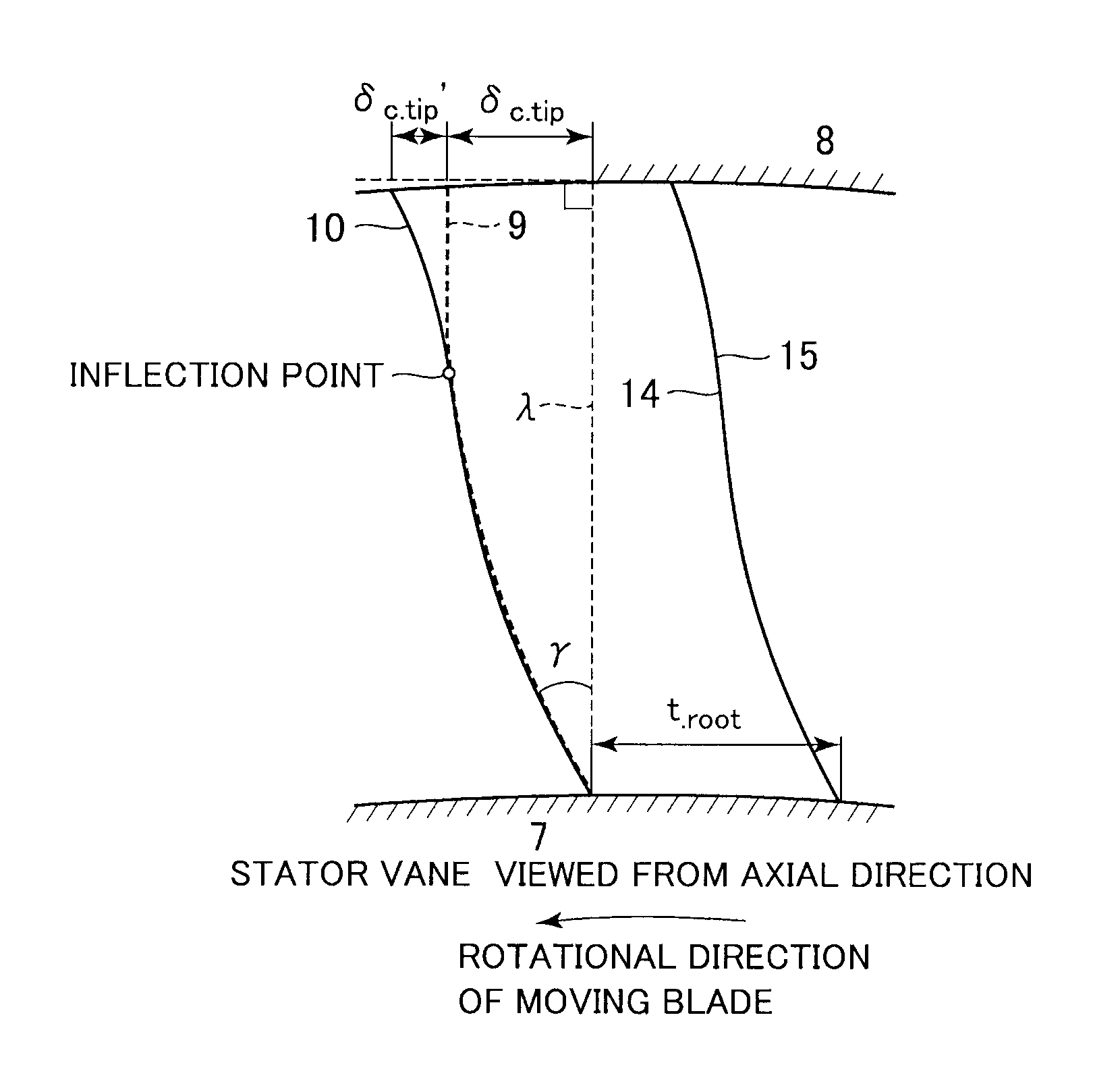

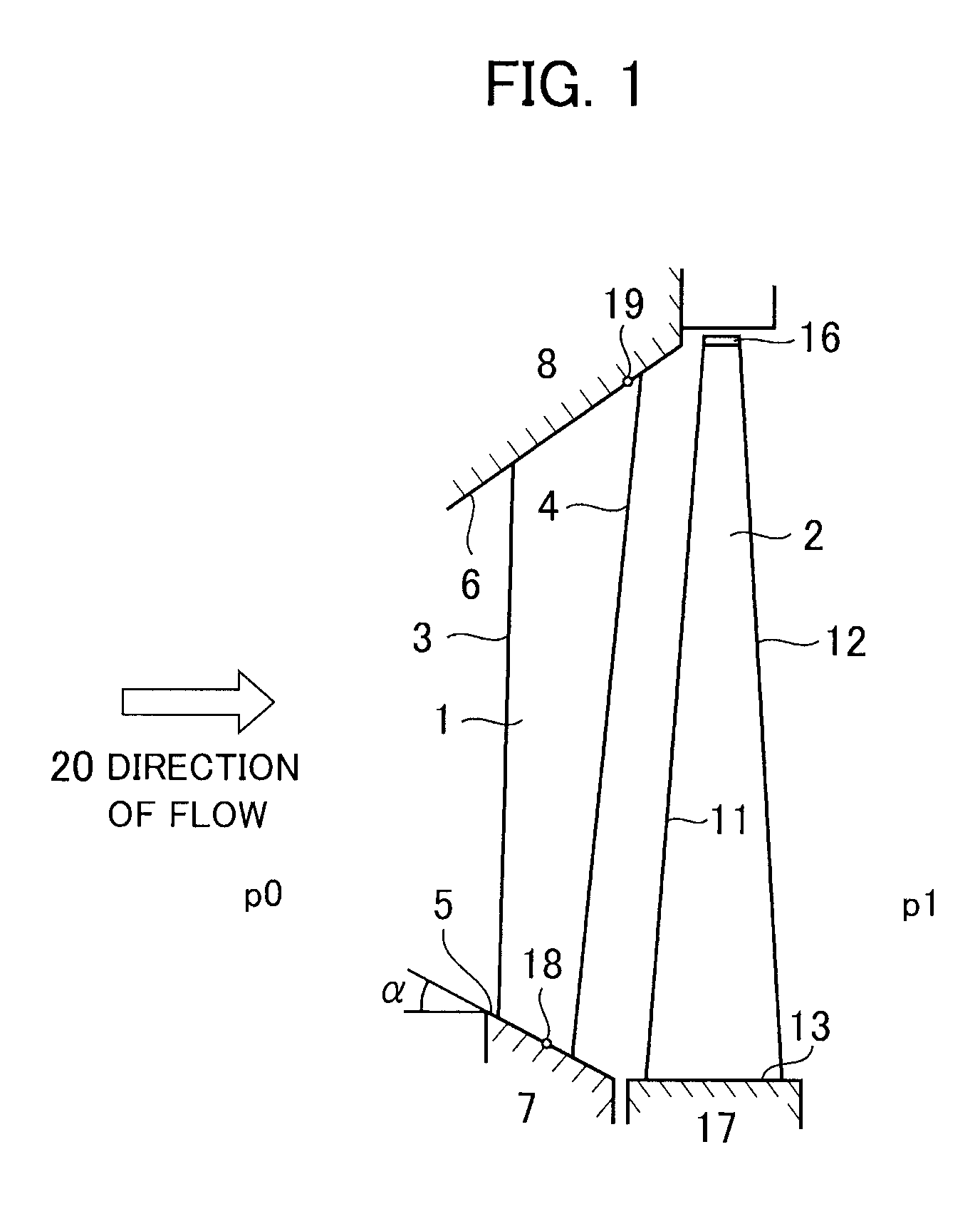

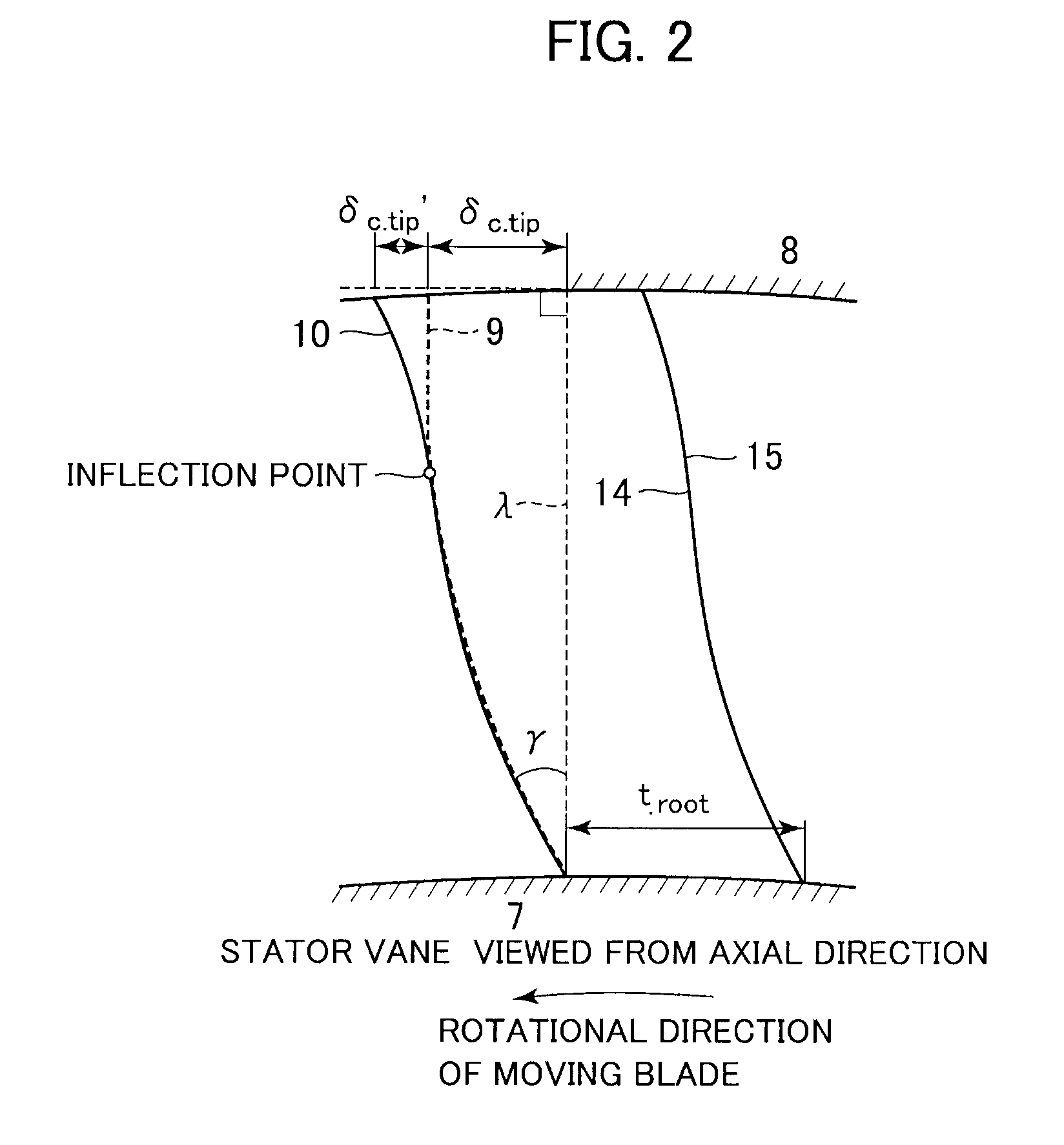

Steam turbine stator vane and steam turbine using the same

InactiveUS9011084B2Increase in profile lossReduce the degree of reactionSupersonic fluid pumpsEngine manufactureDegree of reactionTrailing edge

Suppressing profile loss of a moving blade due to radial flow without an increase in the length of a shaft of a turbine is disclosed. The degree of reaction on an inner circumferential side is set to an appropriate degree, reducing profile loss due to supersonic inflow, and improving turbine efficiency. A steam turbine stator vane has a trailing edge with a curved line when the stator vane is viewed from a downstream side in the axial direction. The curved line has an inflection point located on an outer circumferential side with respect to the center of the stator vane in the height direction of the stator vane. An inner circumferential portion of the curved line is located on the inner circumferential side with respect to the inflection point. An outer circumferential portion of the curved line is located on the outer circumferential side with respect to the inflection point.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

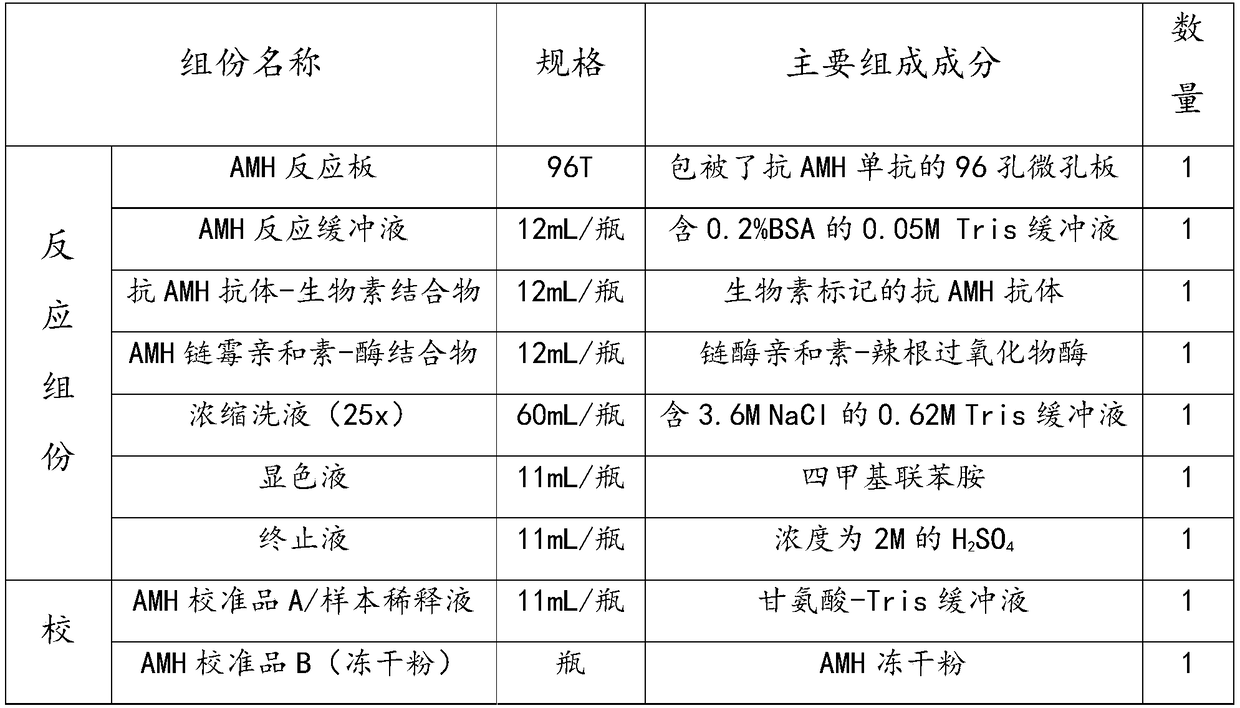

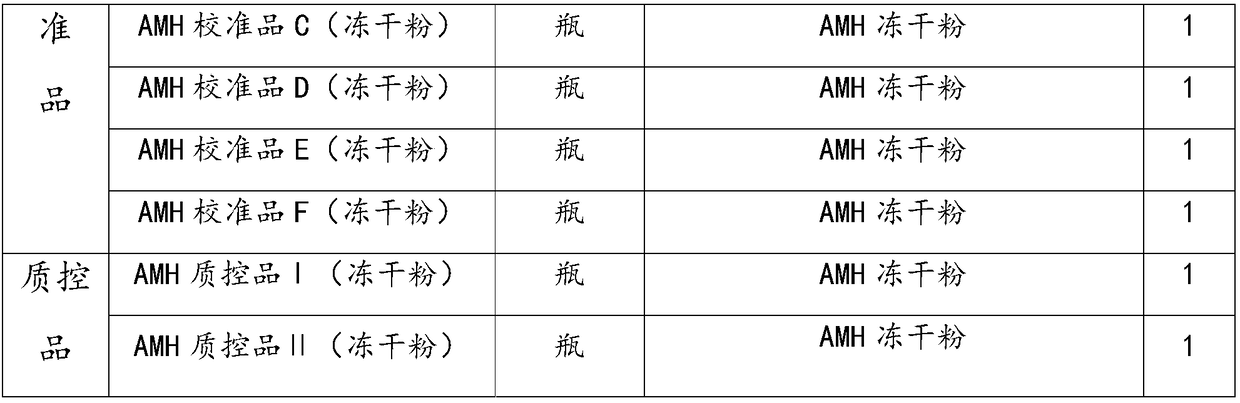

Anti-Mullerian hormone quantitatively detecting method

InactiveCN109490531ASimple stepsEasy to operateBiological testingBiotin-streptavidin complexEnzyme immunoassays

The invention discloses an anti-Mullerian hormone quantitatively detecting method and relates to the technical field of biological detection. The anti-Mullerian hormone quantitatively detecting methodachieves quantitative detection through three-step double-antibody sandwich enzyme immunoassay, and combining biotin-antibodies with solid matrix antibody-antigen compounds and then with streptavidin-horseradish peroxidase conjugates to accordingly combine antibody-antigen-antibody biotin compound-SHRP (streptavidin-horseradish peroxidase) onto micropores for enzyme-substrate chromogenic reaction; measuring the degree of reaction between enzymes and substrate through dual-wavelength chromatography with a main wavelength of 450 nm and a reference wavelength of 620 / 630 nm to obtain absorbance value, and then calculating the concentration of AMH (anti-Mullerian hormone) of a sample to be detected according to a standard curve equation. The anti-Mullerian hormone quantitatively detecting method is concise in process, simple in operation, convenient to use and capable of accurately detecting the AMH concentration and achieving quantitative analysis on detecting results.

Owner:CHANGSHA KINGMED MEDICAL DIAGNOSTICS INST

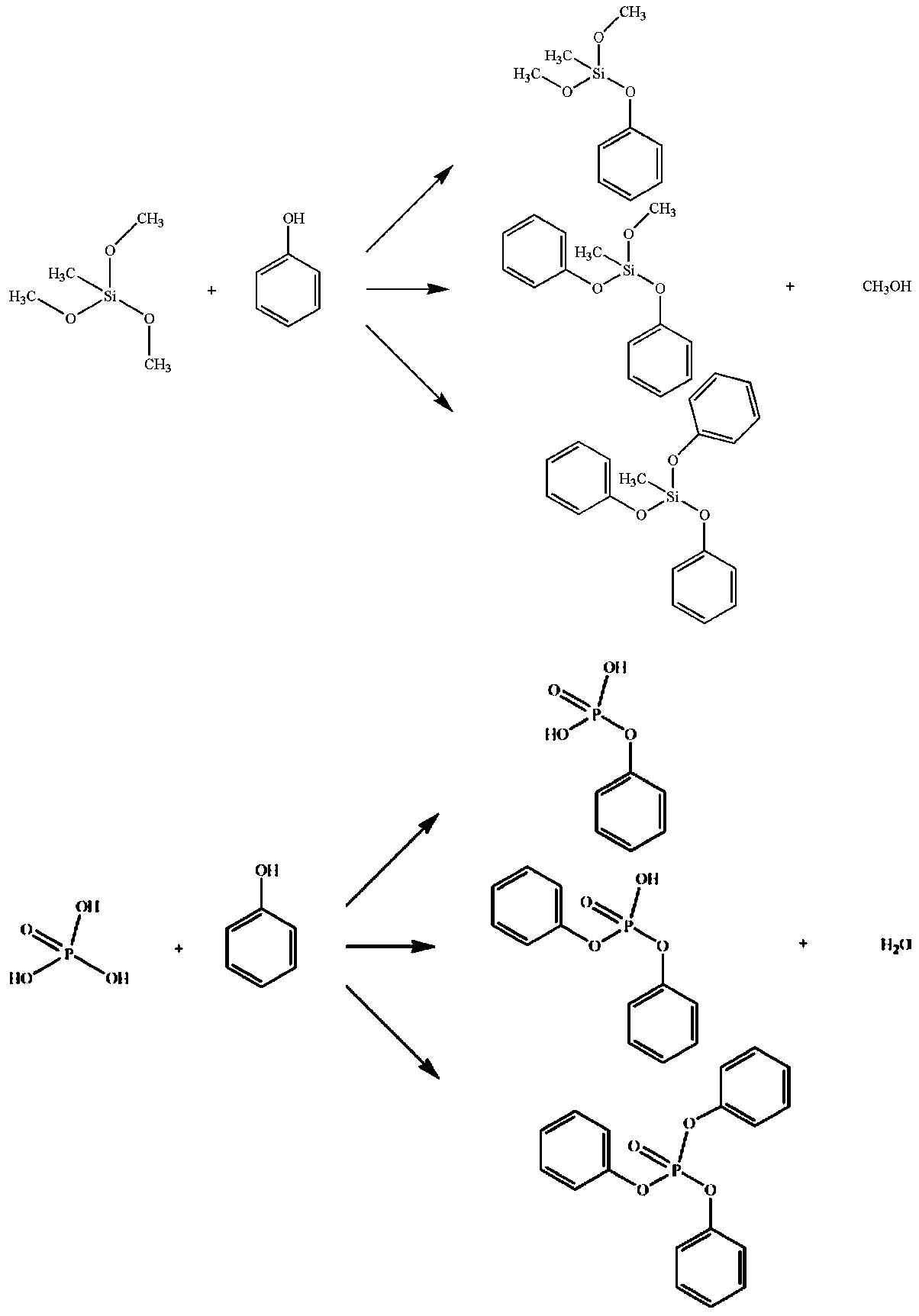

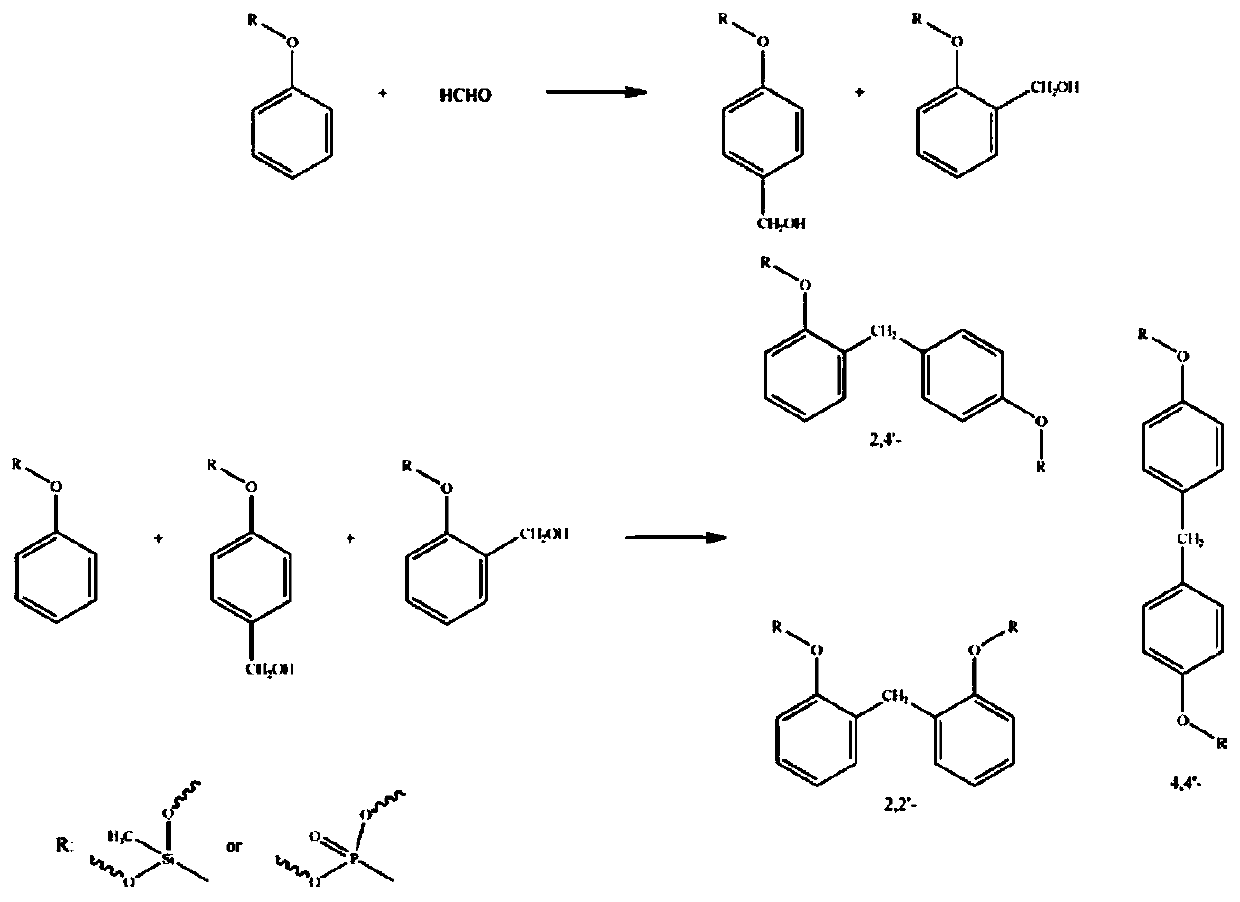

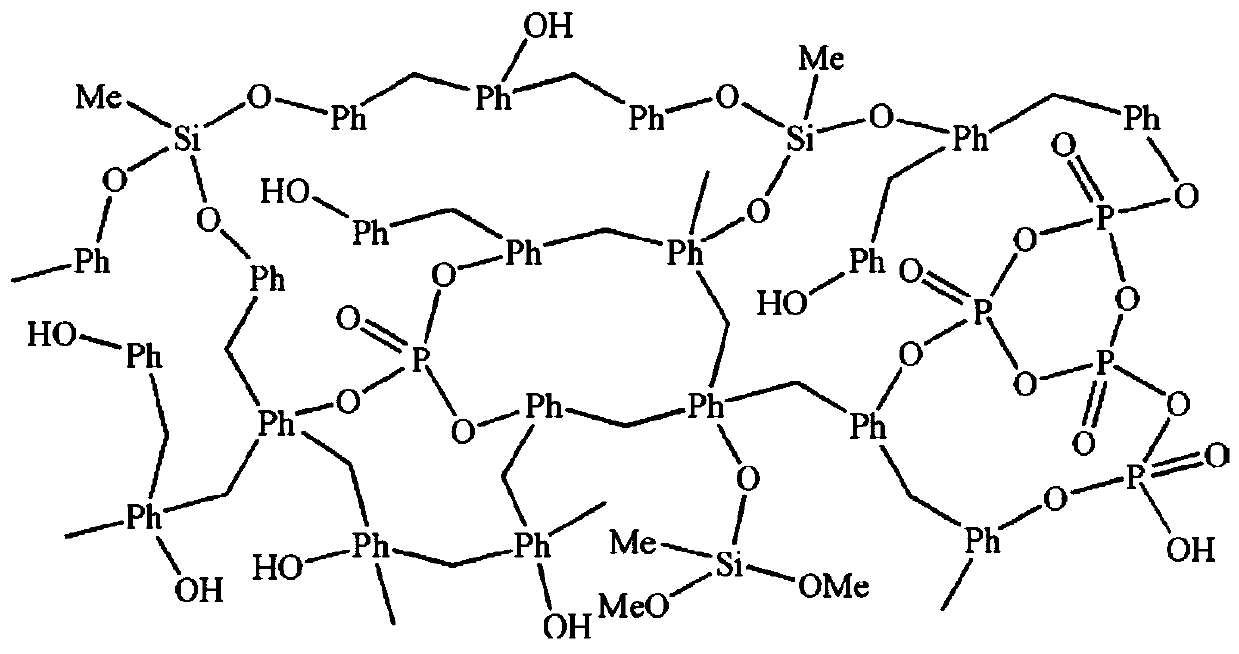

Method for preparing phosphorus-silicon double-modified phenolic resin adhesive

InactiveCN110452642AIncrease crosslink densityImprove heat resistanceAldehyde/ketone condensation polymer adhesivesBond energyPhosphoric acid

The invention discloses a method for preparing a phosphorus-silicon double-modified phenolic resin adhesive. The method mainly comprises the following steps: putting phosphoric acid, a siloxane monomer and a phenolic compound into a reaction kettle, performing uniform stirring, adding an acidic catalyst, performing temperature programming, and performing a reaction at 110-200 DEG C so as to obtainan intermediate with phosphorus atoms or silicon atoms; slowly reducing the temperature, adding a certain amount of an aldehyde compound, and performing a further reaction on the aldehyde compound and the intermediate with the phosphorus atoms or the silicon atoms at 70-95 DEG C, so as to obtain the phosphorus-silicon double-modified phenolic resin adhesive. As a P-O bond (410 kJ / mol) and a Si-Obond (460 kJ / mol) with high bond energy are introduced into a phenolic resin molecule structure, a weak link phenolic hydroxyl group-OH in the structure can be partially blocked, in addition, the average functionality degree of reaction monomers is indirectly increased, the crosslinking density can be increased after the resin is cured, and the thermal resistance of the resin can be improved; andin addition, due to introduction of the phosphorus atoms P in the structure, the flame resistance of the resin can be remarkably improved, and the comprehensive properties of the resin can be improved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

A kind of organopolysiloxane synthetic leather and its preparation method

ActiveCN107675516BExtended service lifeGuaranteed bonding effectCoatingsTextiles and paperSolventSilica gel

Disclosed are a polysiloxane synthetic leather and a manufacturing method therefor, the polysiloxane synthetic leather comprising a polysiloxane surface layer, a silica gel adhesive layer and a substrate layer, which are stacked in sequence from top to bottom, wherein the polysiloxane surface layer is formed by curing a polysiloxane coating liquid, and the silica gel adhesive layer is formed by curing a silica gel coating liquid; the polysiloxane coating liquid contains 25-85 parts of a photosensitive polysiloxane, 0-20 parts of a photosensitive modified filler, 0-20 parts of a filler, 0-70 parts of an environmentally friendly solvent, 0.7-5 parts of a photoinitiator, 0-20 parts of an organosilicone oligomer with photosensitive activity, 0-1 part of a toner and 0-0.1 parts of a platinum catalyst; and the silica gel coating liquid contains 70-90 parts of a liquid addition-type silicone rubber, 0-20 parts of a photosensitive modified filler and 0-20 parts of a colour paste. A photosensitive organopolysiloxane surface coating layer imparts the synthetic leather with smoothness and dust resistance without affecting the texture, which is made by means of a release paper on the surface of the leather, and the rubbing colour fastness thereof, and the degree of reaction can be conveniently controlled, thereby ensuring the adhesion between coating layers, causing the synthetic leather to be more durable and extending the service life of the synthetic leather.

Owner:郴州赛力珑新材料有限公司

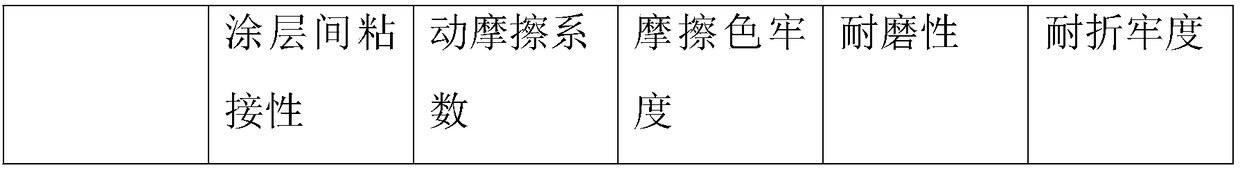

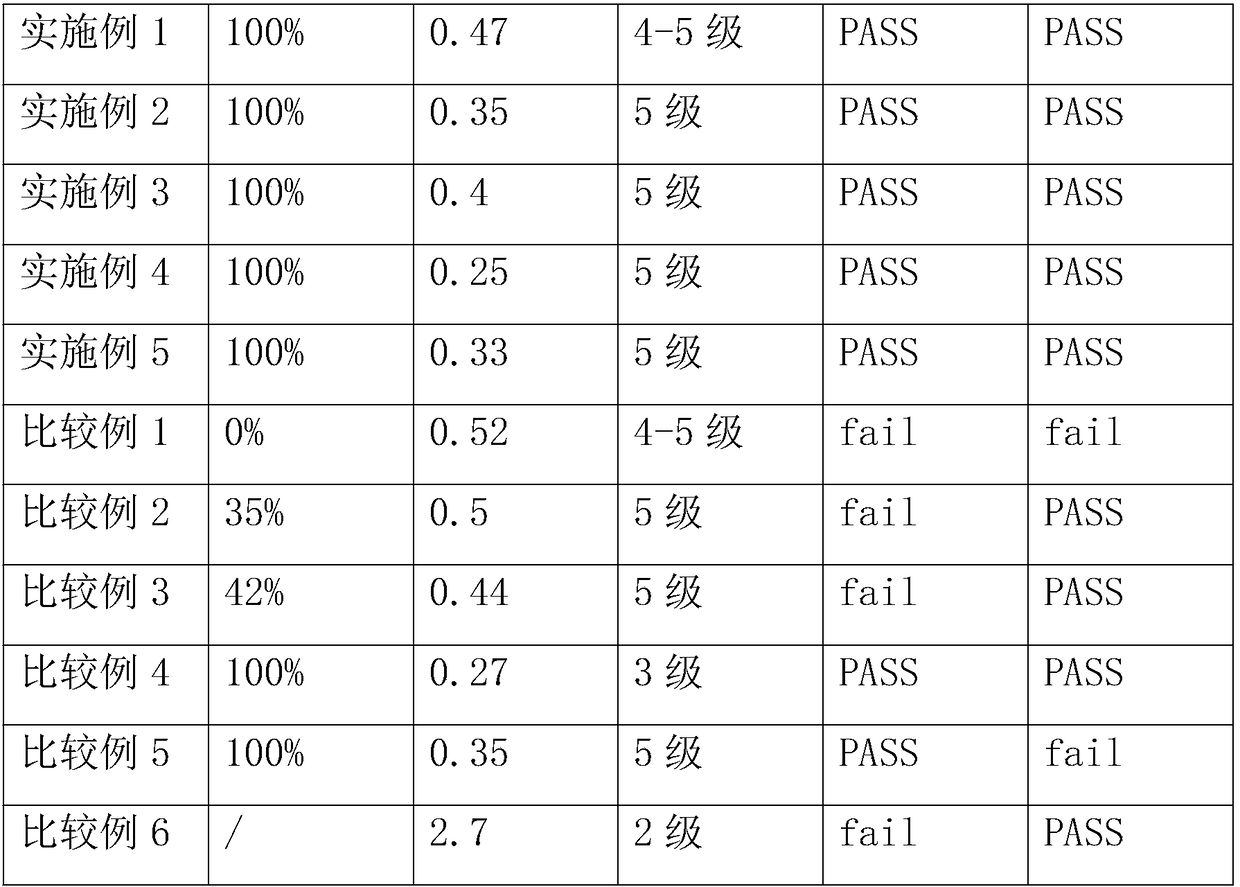

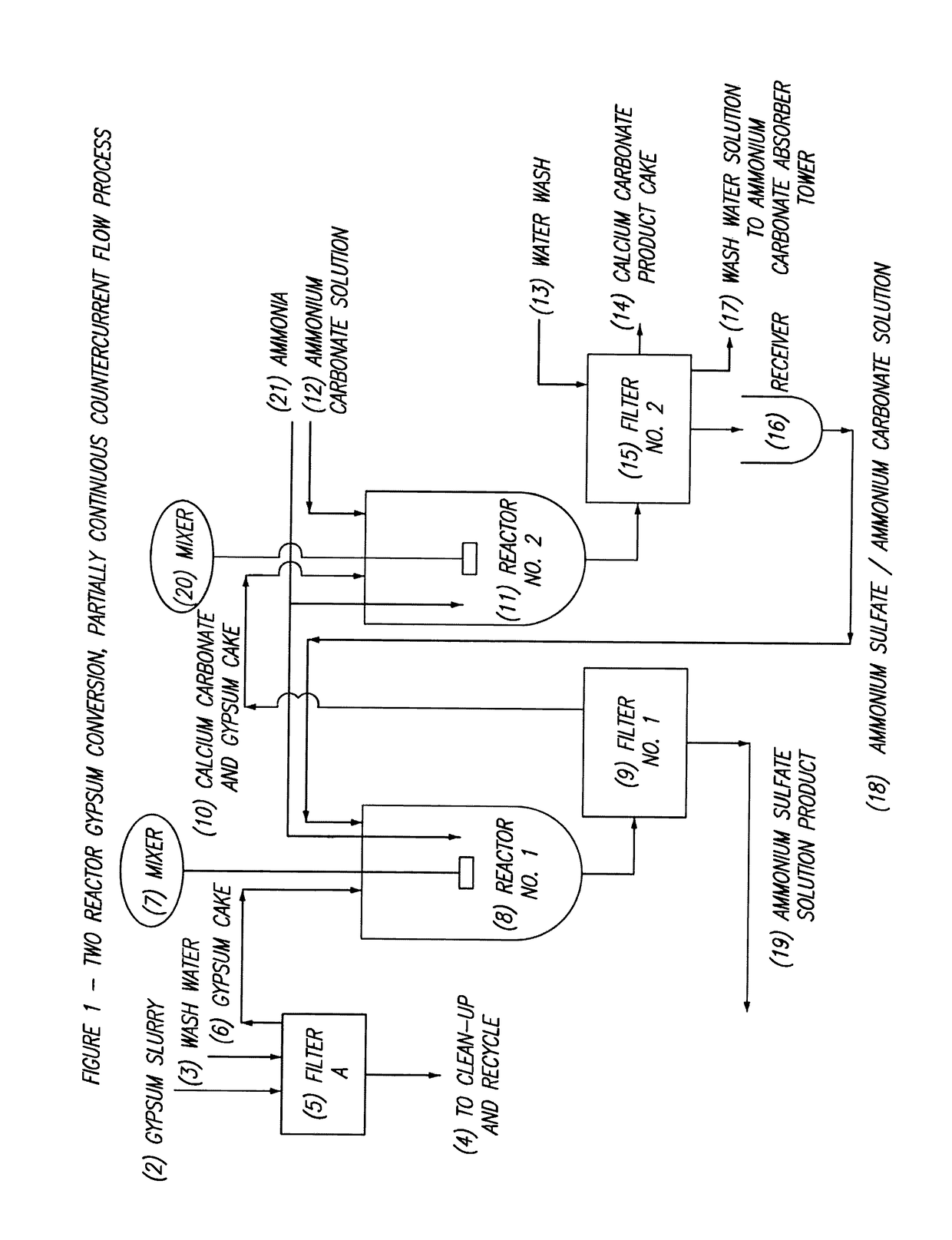

Partially continuous countercurrent process for converting gypsum to ammonium sulfate and calcium carbonate

ActiveUS9682868B2Yield maximizationMaximize purityCalcium/strontium/barium carbonatesPolycrystalline material growthSufficient timeDegree of reaction

The present invention includes a partially continuous countercurrent process for converting gypsum, by reaction with ammonium carbonate, to products of ammonium sulfate and calcium carbonate by introducing the reactants into reactors, mixing the reactants for a predetermined amount of time, employing a novel combination of countercurrent flows coupled with the reactors operated in a batch manner with process recycle of liquids, removing materials from the reactor and separating solids from solutions wherein no reactants are added during the removal process and thus the reactants have sufficient time to react and ensure the desired degree of reaction, yield and purity of product calcium carbonate and ammonium sulfate while minimizing the reaction time.

Owner:SPARSTANE TECH

Stator and rotor assembly for high-power high-speed high-efficiency turbodrills

InactiveCN103015889AHigh speedImprove efficiencyDrill bitsBorehole drivesWell drillingDegree of reaction

A stator and rotor assembly for high-power high-speed high-efficiency turbodrills belongs to the industry of petroleum drilling. The purpose of the invention is to solve the problems of the conventional low-speed turbodrill that: the variety of carried drill bits is limited, the number of stages is excessive, and the efficiency is low. A stator blade disk and a rotor blade disk are formed into a stage, the degree of reaction of the stage is less than 0.5, the ten stages are sleeved on a shaft sequentially from the top down to form a turbodrill power section, the end surfaces of the ten stages are tightly pressed together, a shell is sleeved on the ten stages, splines are adopted to construct the profiles of both the rotor blade and the stator blade, the spline of the rotor blade is shaped like a left-falling stroke, and the spline of the stator blade is shaped like a right-falling stroke.

Owner:中国船舶重工集团公司第七〇三研究所

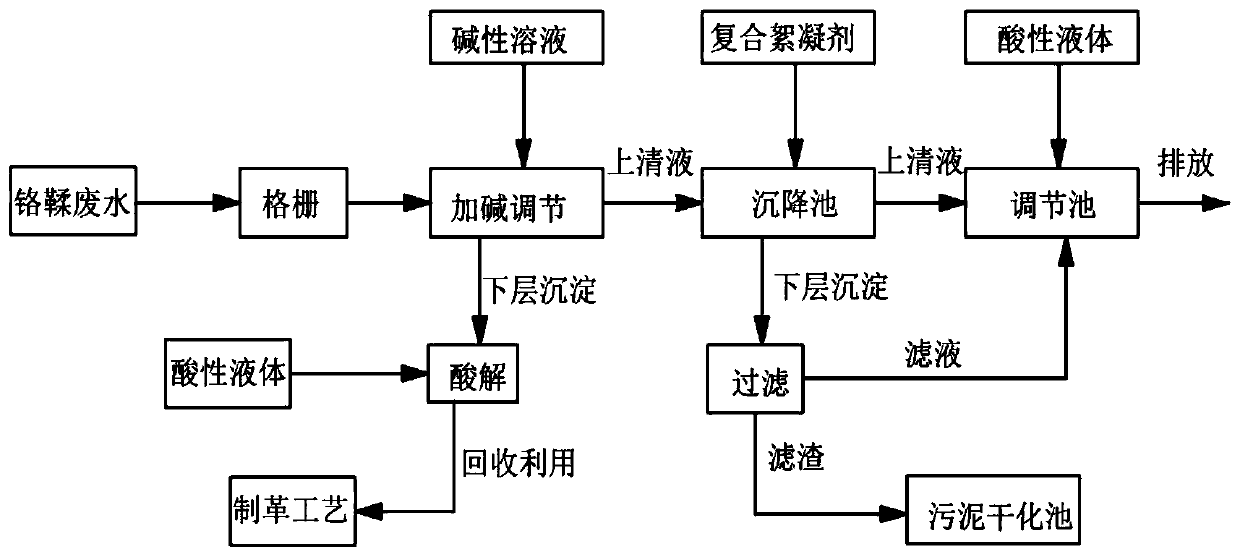

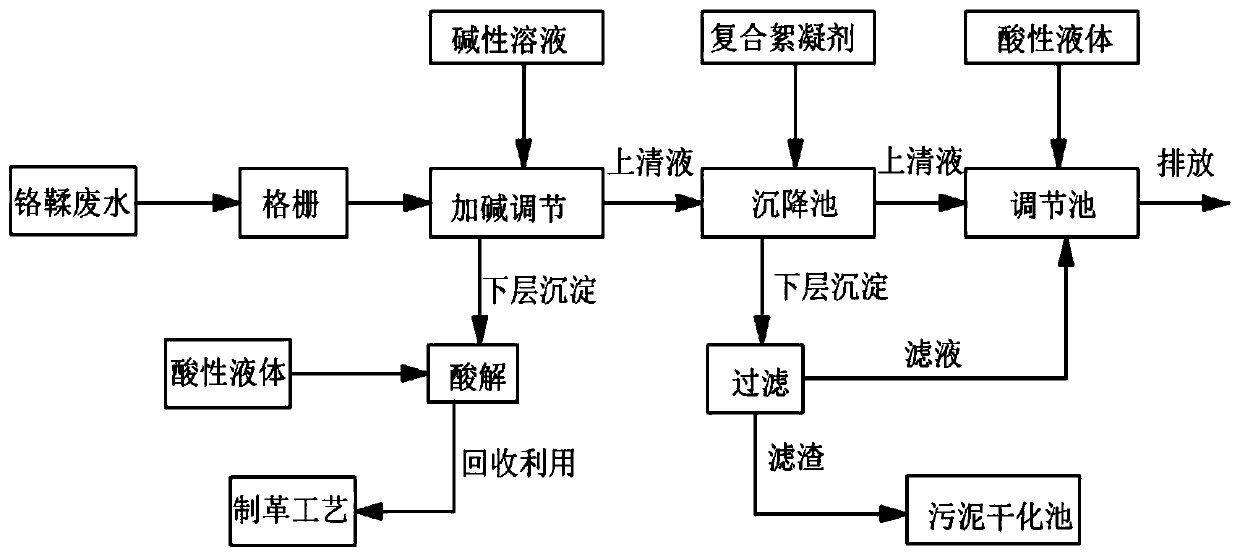

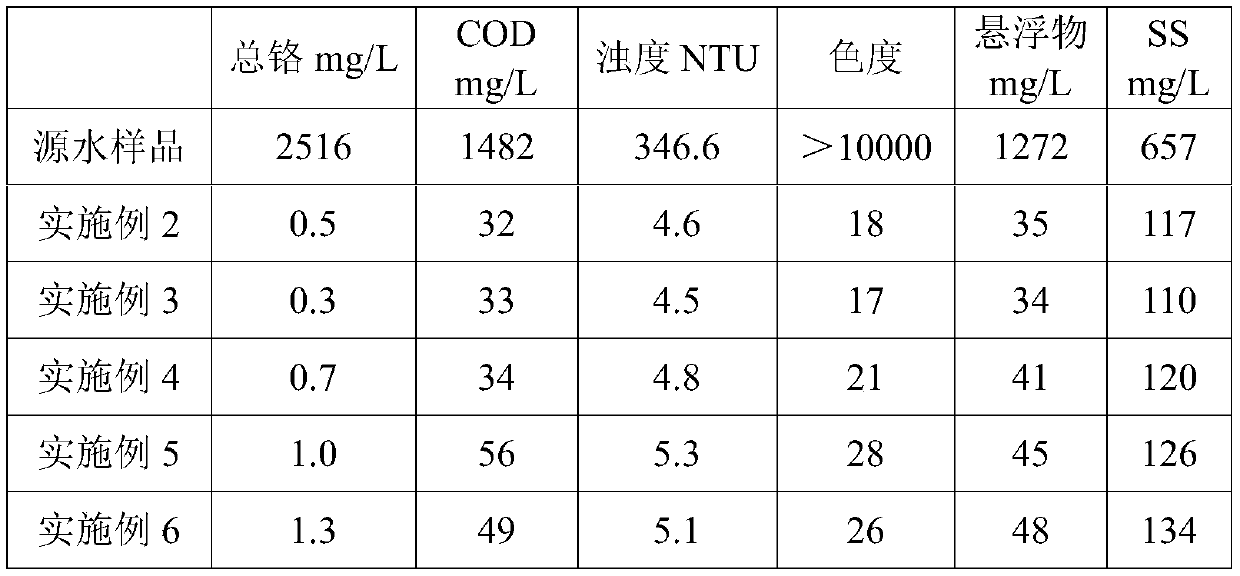

Method for treating chrome tanning wastewater

InactiveCN110002564AHigh cationic degreeHigh intrinsic viscosityOther chemical processesWater contaminantsCross-linkTrapping

The invention provides a method for treating chrome tanning wastewater, and belongs to the technical field of wastewater treatment. The method comprises the steps: performing grid impurity removal, performing adjustment through addition of alkali, performing wastewater sedimentation, and performing adjustment through addition of acid, wherein wastewater sedimentation is performed through a flocculating agent, and the flocculating agent comprises an amphoteric polymer chelating flocculant PDMAMDTC and a chitosan-derived adsorption material; and preparation of the chitosan-derived adsorption material comprises the following steps: dispersing triethylene tetramine and chitosan in an acetic acid solution, then adding a cross-linking agent for a reaction, and then performing washing and drying,and the cross-linking agent contains glutaraldehyde, triethanolamine and 3-mercaptopropionic acid. According to the method for treating the chrome tanning wastewater, a short reaction period of timeis required, the efficiency of decontamination and impurity removal is high, full recycling and utilization of resources are achieved, and the cost of production and treatment is reduced effectively;and the flocculating agent has the advantages of a high degree of reaction completion, low surface energy, high cationic degree, high intrinsic viscosity, large ion adsorption capacity, strong net trapping ability and good performance of flocculation and sedimentation.

Owner:ZHEJIANG OCEAN UNIV

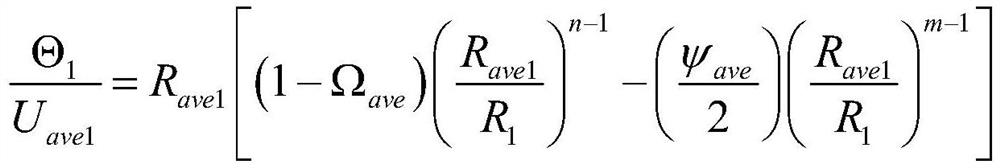

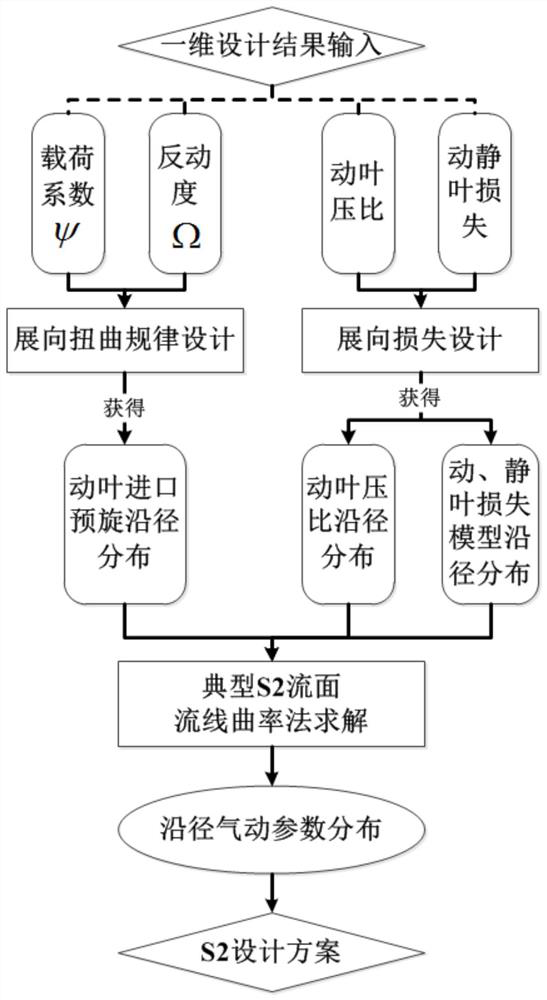

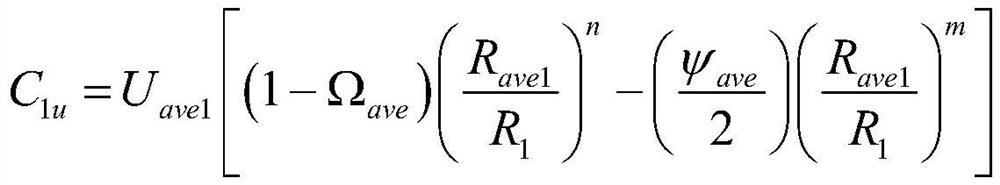

Axial flow compressor S2 inverse problem design method based on dimensionless load control parameters

ActiveCN112699503ASolve the design problem of spatial load extension matchingImprove aerodynamic performanceGeometric CADDesign optimisation/simulationDegree of reactionMechanics

The invention aims to provide an axial flow compressor S2 inverse problem design method based on dimensionless load control parameters. An S2 aerodynamic design scheme of an axial flow compressor is obtained through spanwise distortion rule design, spanwise loss design and typical S2 flow surface streamline curvature method solving. Customized design of prewhirling of all stages of moving blade inlets of the axial flow compressor is conducted through two key dimensionless parameters including the load coefficient and the reaction degree, active control over the space load of the compressor in the S2 design stage is achieved, and the S2 inverse problem through-flow design of the axial flow compressor reaches the parameterization and refinement degree; the pneumatic design precision of the axial flow compressor is effectively improved, the pneumatic performance is improved, and the method is very suitable for engineering design application. Meanwhile, the invention is not limited to a gas turbine axial flow compressor, but also suitable for the pneumatic design process of various industrial axial flow compressors and aero-engine axial flow compressors / fans.

Owner:中国船舶重工集团公司第七0三研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com