A kind of organopolysiloxane synthetic leather and its preparation method

A technology of polysiloxane and synthetic leather, applied in the field of synthetic leather, can solve the problems of shedding, difficult to control the degree of reaction, poor adhesion of the underlying silicone, and achieve the effect of prolonging the service life, facilitating the degree of reaction and ensuring the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

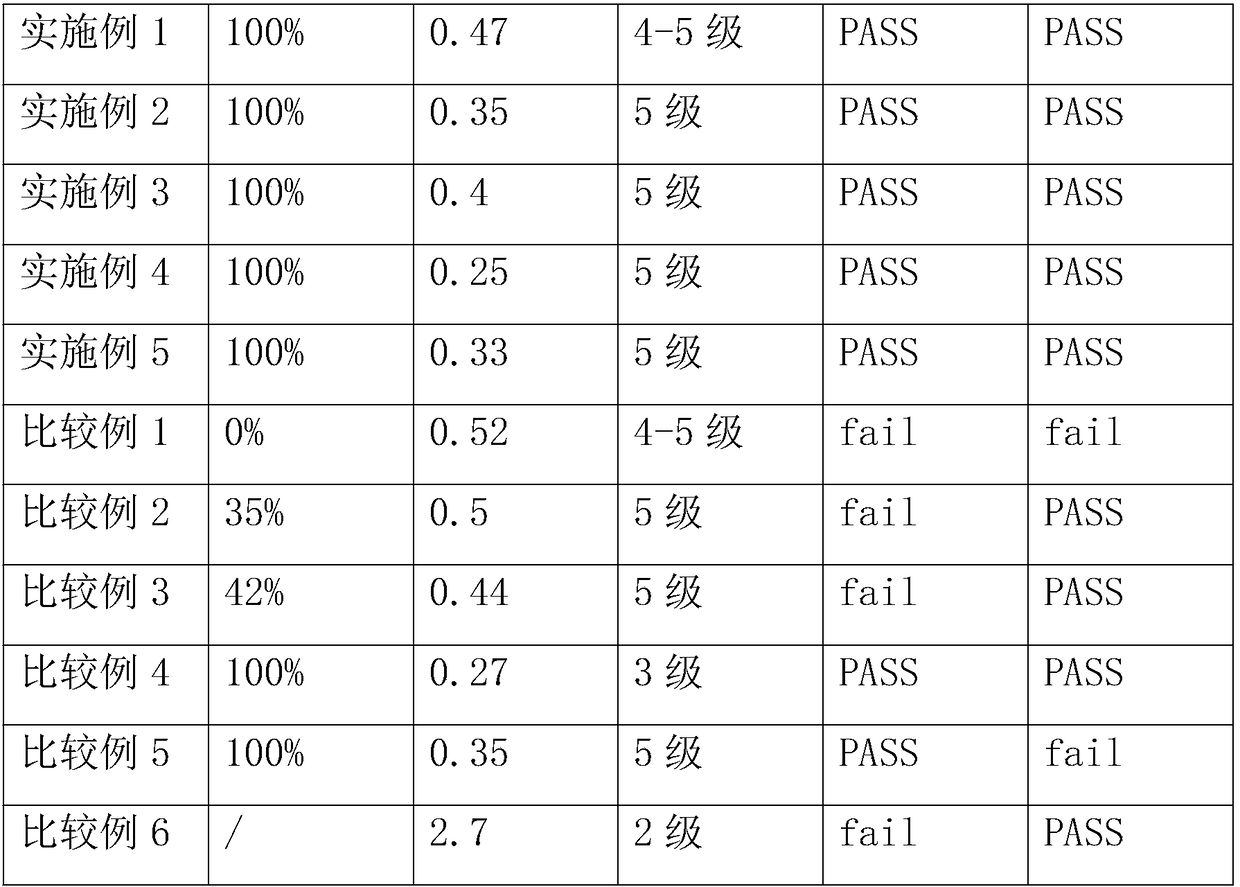

Embodiment 1

[0041] To synthesize photosensitive polysiloxane, add 0.065mol hexamethyldisiloxane, 0.01mol tetramethyldisiloxane, 0.65mol dimethyldiethoxysilane and 0.21mol ethyl orthosilicate into a three-necked flask , Add dropwise 72 grams of concentration in the three-necked flask and be 1% hydrochloric acid aqueous solution, finish dropwise in 1 hour. Then the temperature was raised to reflux temperature and reacted for 4 hours, and then the layers were separated. After removing the upper alcoholic water layer, add trifluoromethanesulfonic acid equivalent to 5 / 10,000 of the total weight of the solution, then raise the temperature to 80°C and maintain vacuum, and separate the generated water with a water separator. After reacting until anhydrous was produced, the temperature was lowered to room temperature, and 1 g of sodium bicarbonate was added to neutralize the product. Finally, add 0.021mol trimethylolpropane triacrylate and a polymerization inhibitor equivalent to five thousandths...

Embodiment 2

[0047] Synthetic photosensitive polysiloxane:

[0048] 0.065mol hexamethyldisiloxane, 0.01mol tetramethyldisiloxane, 0.0275mol tetramethylcyclotetrasiloxane, 2.53mol dimethyldiethoxysilane and 0.21mol ethyl orthosilicate Add a three-necked flask, add 210 grams of 1% hydrochloric acid aqueous solution dropwise, and finish dropping in 1 hour. Then, the temperature was raised to reflux temperature and reacted for 4 hours, and the layers were separated after standing, and the upper alcoholic water layer was removed. Add 5 / 10,000 trifluoromethanesulfonic acid to the total weight of the solution, raise the temperature to 80°C and maintain vacuum, and separate the generated water with a water separator. After reacting until anhydrous was generated, the temperature was lowered to room temperature, and 2 g of sodium bicarbonate was added to neutralize the product. Add 0.15mol trimethylolpropane triacrylate to the above product and a polymerization inhibitor equivalent to 5 / 1000 of th...

Embodiment 3

[0054] To synthesize photosensitive polysiloxane, 0.06mol hexamethyldisiloxane, 0.01mol tetramethyldisiloxane, 0.0075mol tetramethylcyclotetrasiloxane, 0.7mol dimethyldiethoxysilane and 0.2 mol tetraethyl orthosilicate into a three-necked flask, and 85 grams of 1% hydrochloric acid aqueous solution was added dropwise, and the dropwise was completed in 1 hour. Then, the temperature was raised to reflux temperature and reacted for 4 hours. After standing to separate the layers, the upper alcoholic water layer was removed. Add trifluoromethanesulfonic acid equivalent to 5 / 10,000 of the total mass of the solution, raise the temperature to 80°C and maintain vacuum, and separate the generated water with a water separator. After reacting until anhydrous was produced, the temperature was lowered to room temperature, and 1 g of sodium bicarbonate was added to neutralize the product. Add 0.05mol trimethylolpropane triacrylate to the above product and a polymerization inhibitor equivale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com