Patents

Literature

499results about How to "Guaranteed bonding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

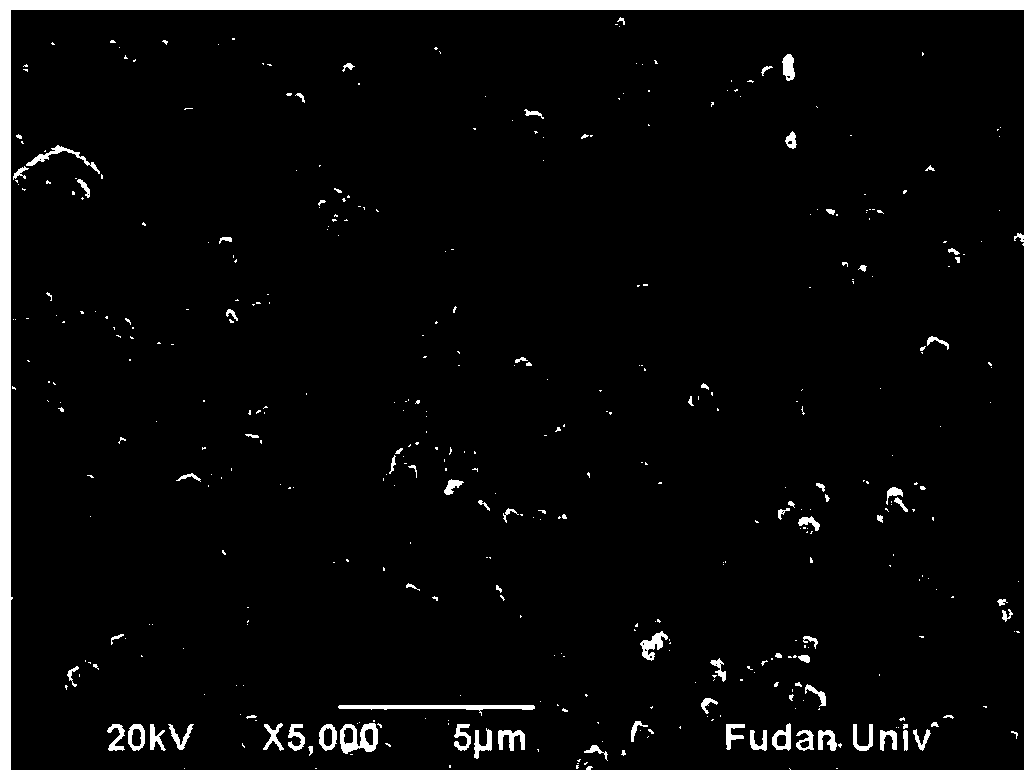

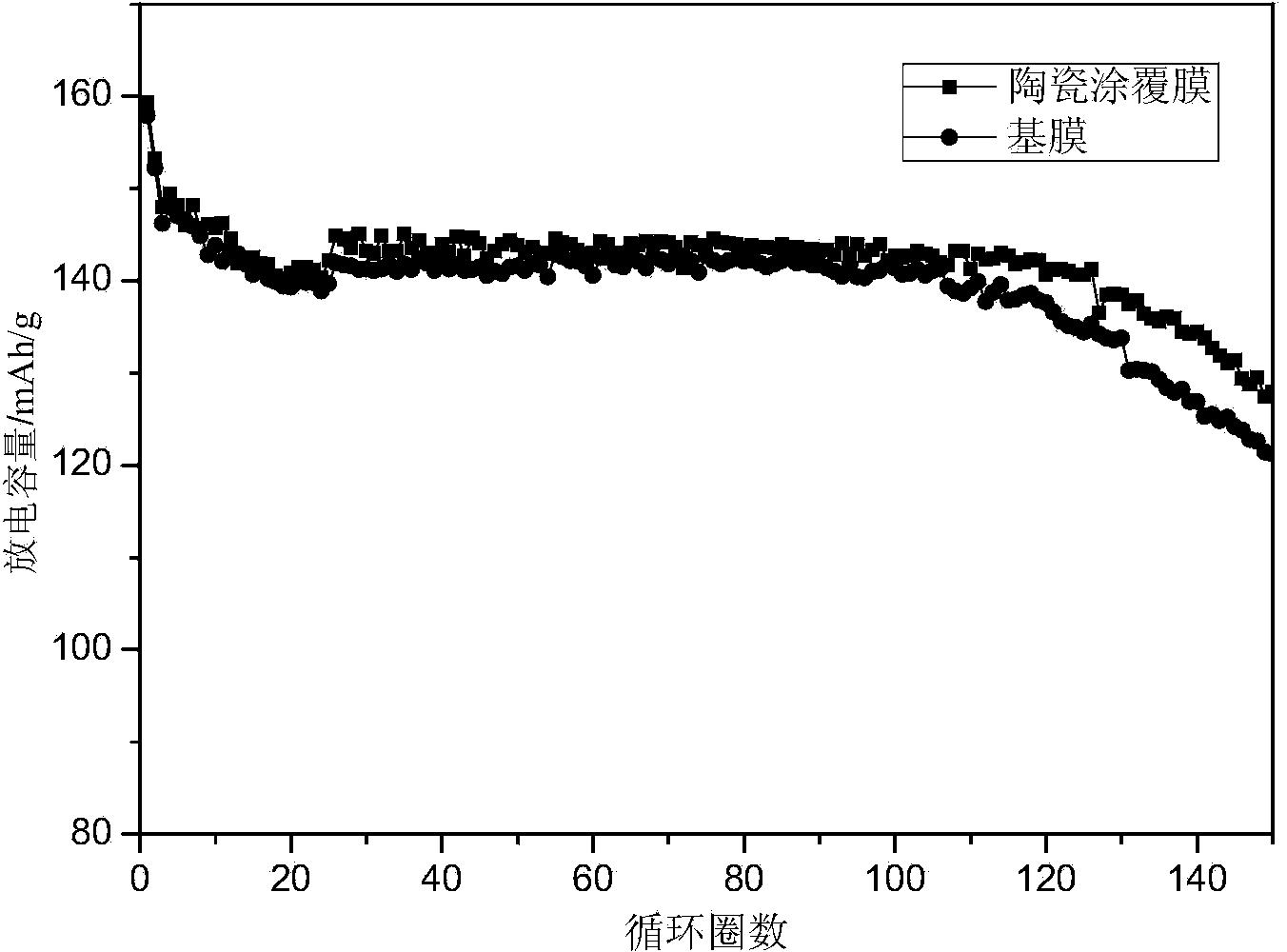

Ceramic coating diaphragm for lithium battery and preparation method of ceramic coating diaphragm

InactiveCN104269509AGood air permeabilityImprove peel forceCell component detailsCeramic coatingDiameter ratio

The invention discloses a ceramic coating diaphragm for a lithium battery and a preparation method of the ceramic coating diaphragm, and belongs to the technical field of batteries. The ceramic coating diaphragm comprises a ceramic coating and a substrate diaphragm, wherein the ceramic coating is prepared by uniformly coating the substrate diaphragm with water-based ceramic coating slurry; the ceramic coating slurry comprises components in percentage by weight as follows: 10%-30% of aluminum oxide, 0.5%-3% of a bonding agent, 0.2%-1.0% of an additive and 0.01%-0.1% of an auxiliary; and the aluminum oxide is nanometer aluminum oxide powder with the grain diameter ratio D1 / D2 of 0.10-0.20. According to the technical scheme, the safety of the ceramic coating diaphragm is improved, the wetting ability of electrolyte is improved, and the cycle life of the battery can be prolonged when the ceramic coating diaphragm is applied to the lithium battery.

Owner:SHANGHAI ELECTRICGROUP CORP

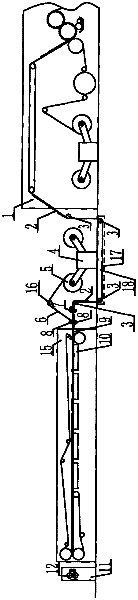

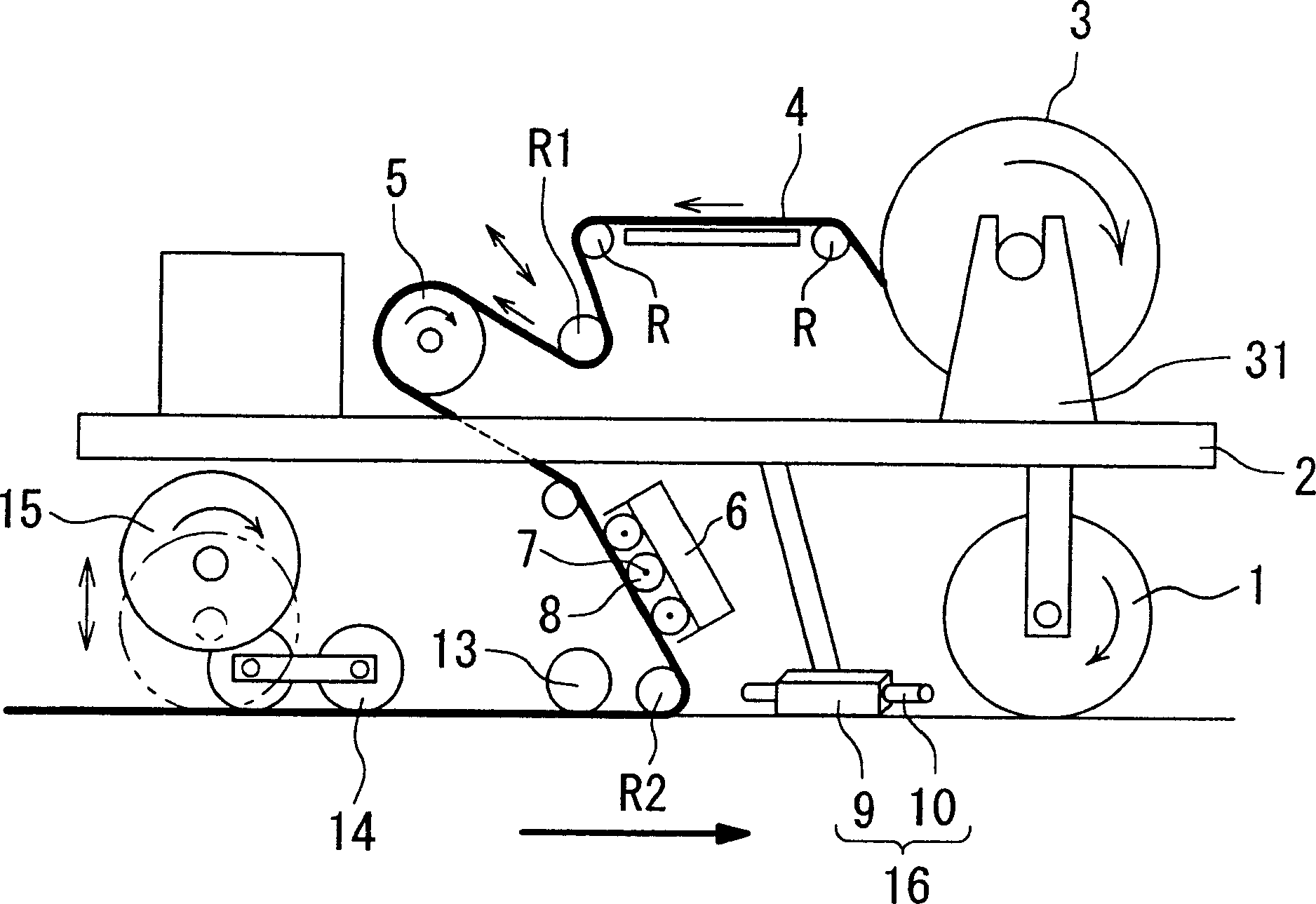

Production method and production line for pre-printed surface paper corrugated paperboards

ActiveCN102173162AAvoid direct contactAvoid damageMechanical working/deformationPaper/cardboard layered productsProduction lineColor printing

The invention provides a production method and production line for pre-printed surface paper corrugated paperboards, and the production method and production line provided by the invention can be used for solving the problem that the existing corrugated paperboard production line and process can not adapt to the production of pre-printed colorful corrugated paperboards. In the invention, because the bonding mode that surface paper is arranged on a single-sided corrugated paperboard is adopted, the direct contact between color-printing paper and a high temperature hot plate at a drying part can be avoided, thereby effectively preventing the damages on the materials, patterns, gloss oil and plastic films of the color-printing paper. The corrugated paperboard production method and corrugated paperboard production line disclosed by the invention can effectively adapt to the application requirements of pre-printed colorful paper on the premise of not increasing the cost.

Owner:QINGDAO MEIDA INTELLIGENT TECH CO LTD

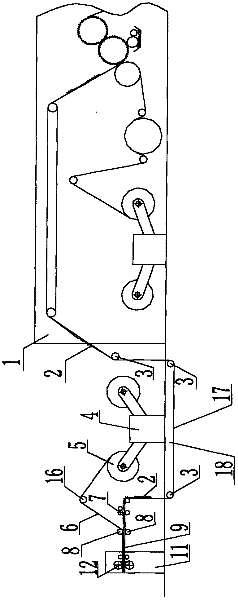

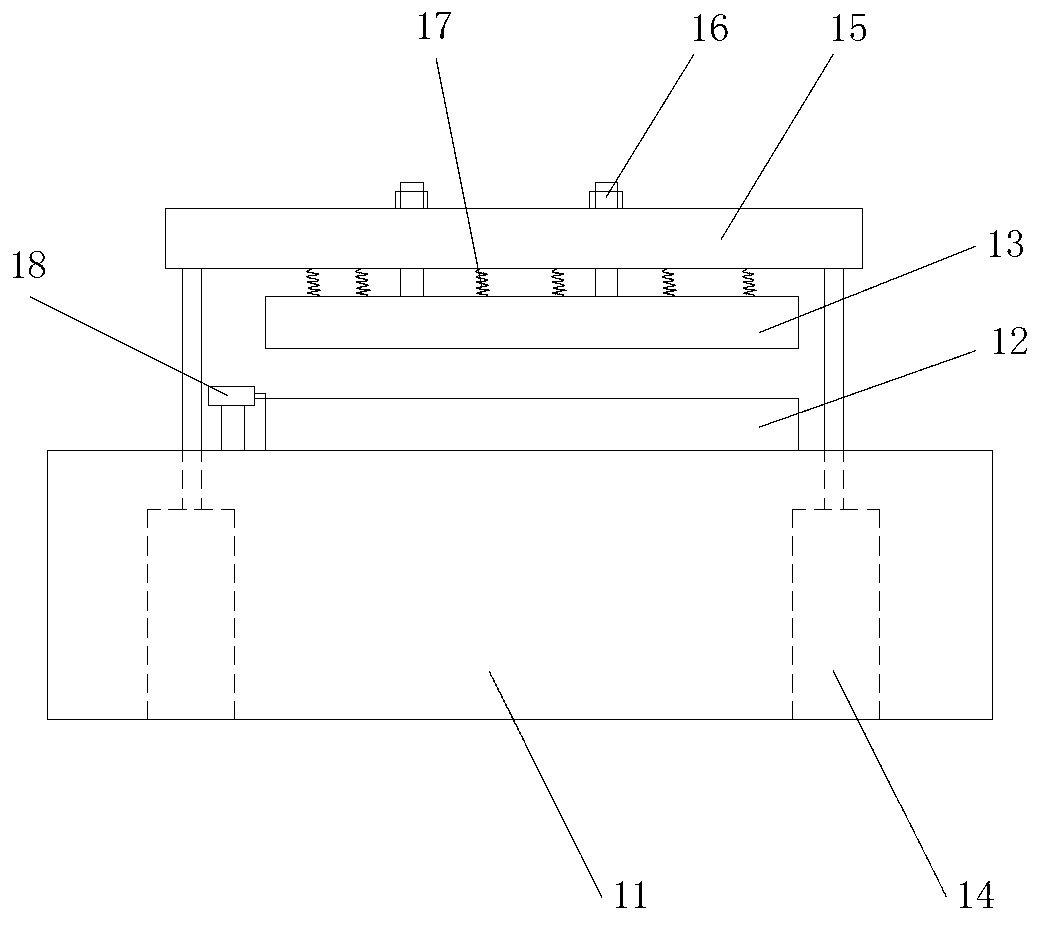

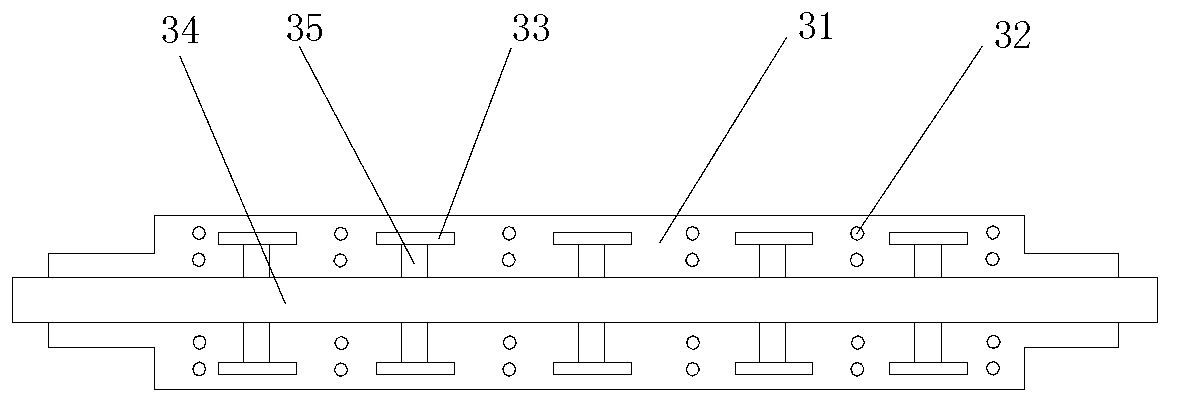

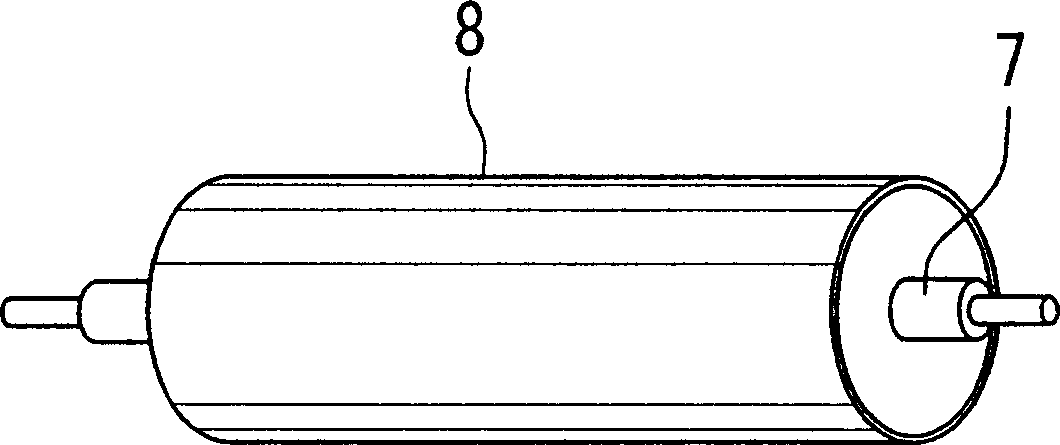

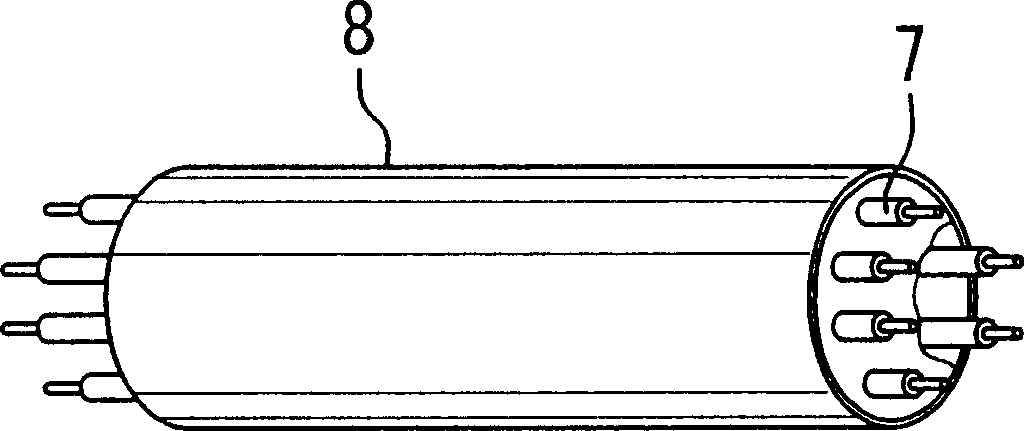

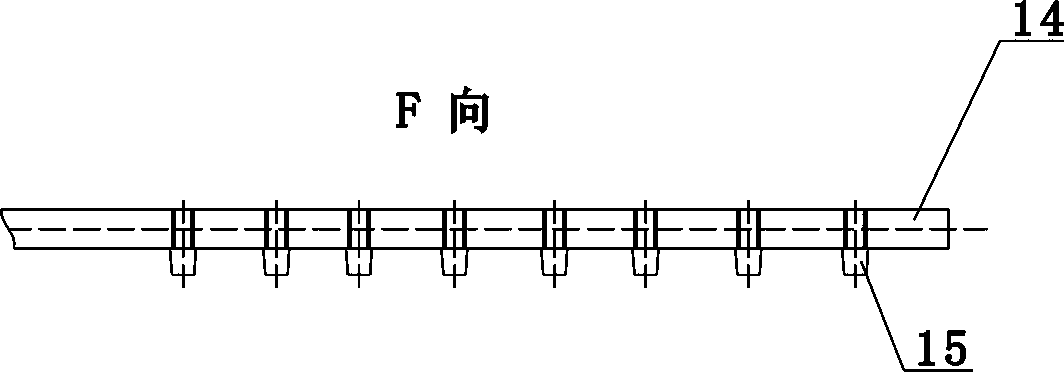

Double-point coating production line for hot-melt adhesive padding cloth

InactiveCN102697213APrevent flutteringAvoid wrinklesInspecting textilesGarmentsProduction linePulp and paper industry

The invention provides a double-point coating production line for hot-melt adhesive padding cloth, and the double-point coating production line comprises a cloth reception device, a wind shielding screen, a size discharging roller, a holt-melt rubber powder blowing / sucking device, a drying oven, a cooling device, an ultraviolet lamp perching device and a rolling device which are arranged in sequence from front to back, wherein the cloth reception device comprises a cloth reception underframe, a lower pressing mould which is arranged on the cloth reception underframe and an upper pressing mould which is arranged on the cloth reception underframe and matched with the lower pressing mould in a lifting manner to crimp padding cloth; the wind shielding screen comprises a screen underframe and a screen plate which is arranged on the screen underframe; the size discharging roller comprises a discharging roller main body and a discharging hole which is formed in the discharging roller main body; and a scraper is arranged in the discharging roller main body. According to the double-point coating production line for hot-melt adhesive padding cloth, the unrolling speed of the padding cloth is increased, the continuous production is realized, the work efficiency is improved, the production cost is reduced and the quality of the padding cloth is improved.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

Waterproof sheet in-situ application machine

Owner:AOI TECH SERVICE KK

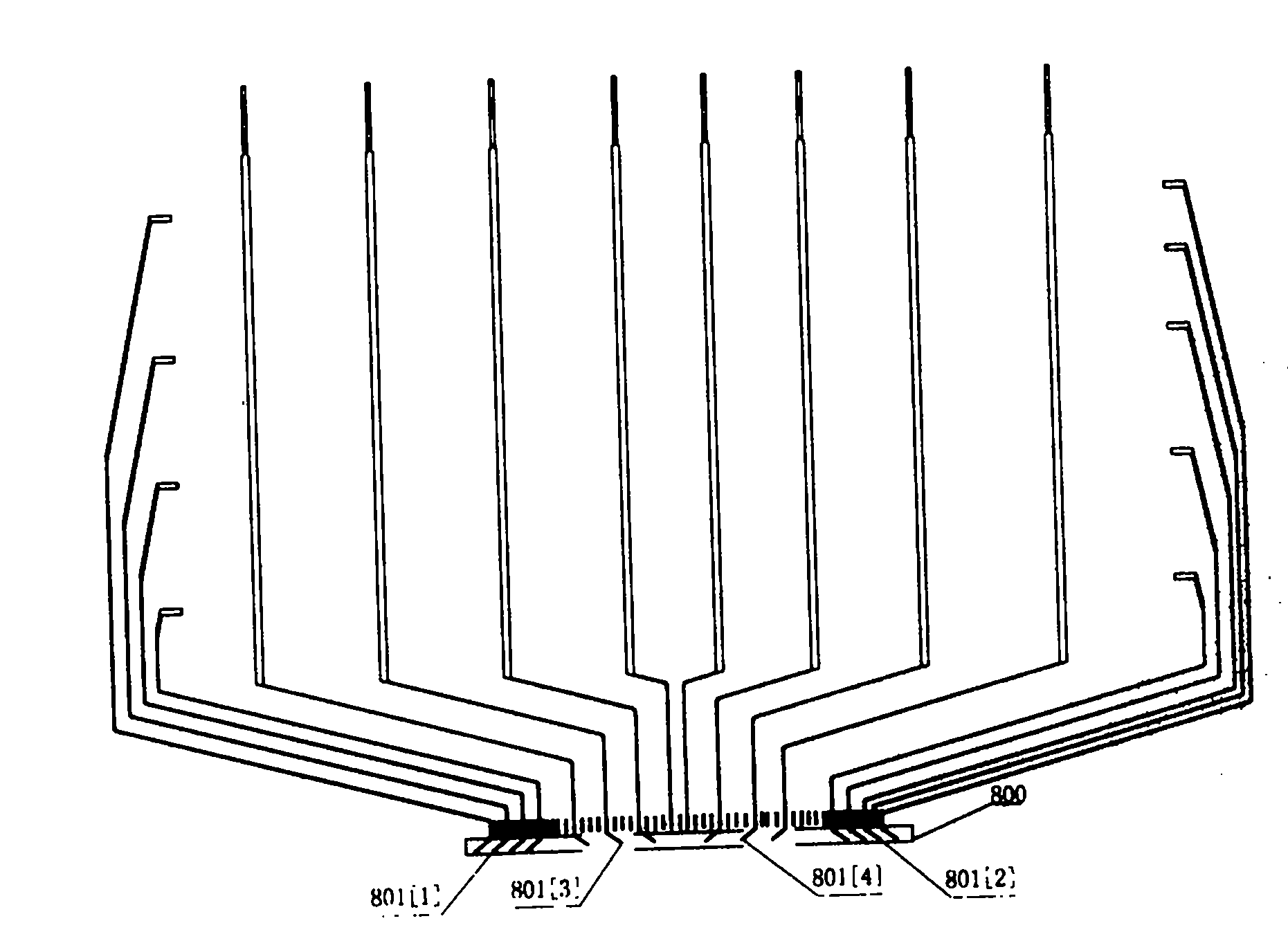

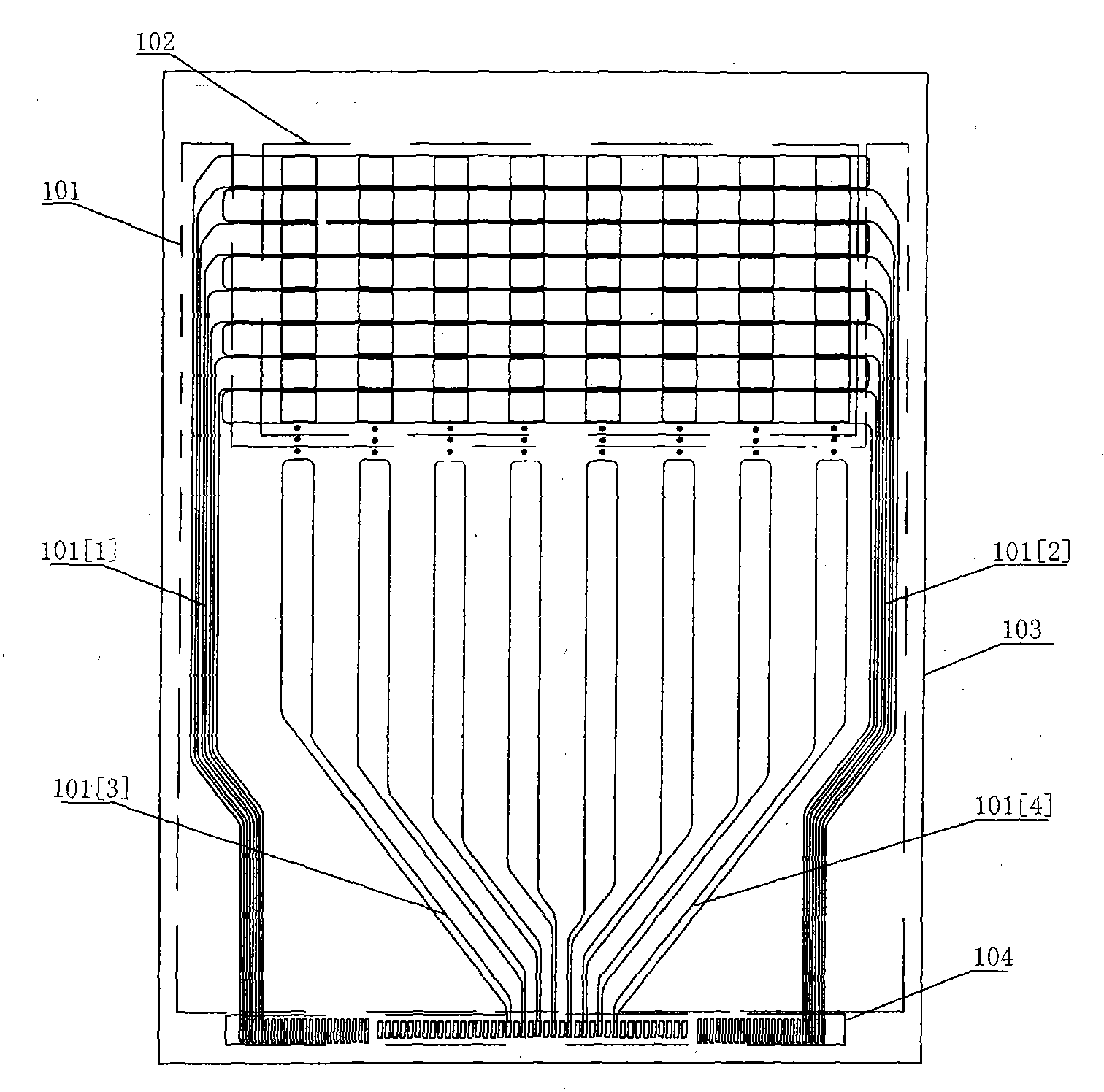

Organic electroluminescence device and test method thereof

ActiveCN101800238AAvoid short circuitIncrease the extension lengthSemiconductor/solid-state device detailsSolid-state devicesTest phaseOrganic electroluminescence

The invention discloses an organic electroluminescence device and a test method thereof. The organic electroluminescence device comprises a luminescent area, a lead wire area and a bonding area. The luminescent area comprises an anode, a organic functional layer and a cathode; the lead wire area consists of a lead wire connecting the anode and the cathode with a driving chip or a circuit board; the bonding area is an area in which the lead wire is connected with the driving chip or the circuit board, wherein a lead wire elongation area is comprised, the end of the lead wire is located in the lead wire elongation area, and the lead wire in the lead wire elongation area and the lead wire in the lead wire area are in parallel or form a certain angel. The invention changes the lead wire arrangement of the OLED. Therefore the conductive adhesive tape can be more easily and accurately in compression connection with the lead wire, and simultaneously prevent the procession lead wire from short circuit during the test phase of the screen body.

Owner:SUZHOU QUINGYUE OPTOELECTRONICS TECH CO LTD +1

Vertical cotton breathable bra cup pad with silica gel net and preparation method thereof

The invention relates to the technical field of bra cup pad, and specifically relates to a vertical cotton breathable bra cup pad with a silica gel net and a preparation method thereof. The vertical cotton breathable bra cup pad comprises a vertical cotton outer layer and a vertical cotton inner layer; a vertical cotton interlayer is arranged between the vertical cotton outer layer and the vertical cotton inner layer; an adhesive layer is arranged between the vertical cotton interlayer and the vertical cotton inner layer; and a silica gel net layer is arranged between the vertical cotton outer layer and the vertical cotton interlayer. The vertical cotton breathable bra cup pad is prepared by a combined technology of hot pressing and cold pressing. The pad is made of vertical cotton, and is light, comfortable, and breathable. A silica gel layer is arranged between vertical cotton layers, the performance of the pad on resisting water washing is enhanced, the anti-collapse effect is good, three-dimensional effect of the cup pad is long-lasting and stable, and the deformation is difficult to happen.

Owner:HONGJI UNDERWEAR CO LTD

Flame-retardant polyurethane sealant and preparation method thereof

ActiveCN102504751AHigh flame retardant efficiencyGuaranteed flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention relates to flame-retardant polyurethane sealant and a preparation method thereof. The polyurethane sealant comprises the components as follows: polyurethane prepolymer 10 to 45 percent, phosphonate flame-retardant plasticizing agent 0 to 25cent, flame-retardant synergist 0 to 10 percent, plasticizing agent 0 to 25 percent, thixotropic agent 1 to 10 percent, filling material 5 to 30 percent, photo-stabilizer 0.1 to 0.5 percent, antioxygen 0.1 to 0.5 percent, catalyst A 0.001 to 0.05 percent, silane adhesive attraction accelerant 0.5 to 3 percent, and dehumidizer 0.1 to 1.5 percent. Compared with the prior art, the invention has the advantages that the polyurethane prepolymer can play a flame-retardant effect, the phosphonate flame-retardant plasticizing agent with flame-retardant and plasticization effects can be adopted for flame retardancy for the polyurethane sealant, and the flame-retardant synergist can also be adopted for matching for synergy, so that the flame-retardant polyurethane sealant is endowed with a favorable flame retardant property while the physical and mechanical properties and the adhesive property of the polyurethane sealant are guaranteed.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

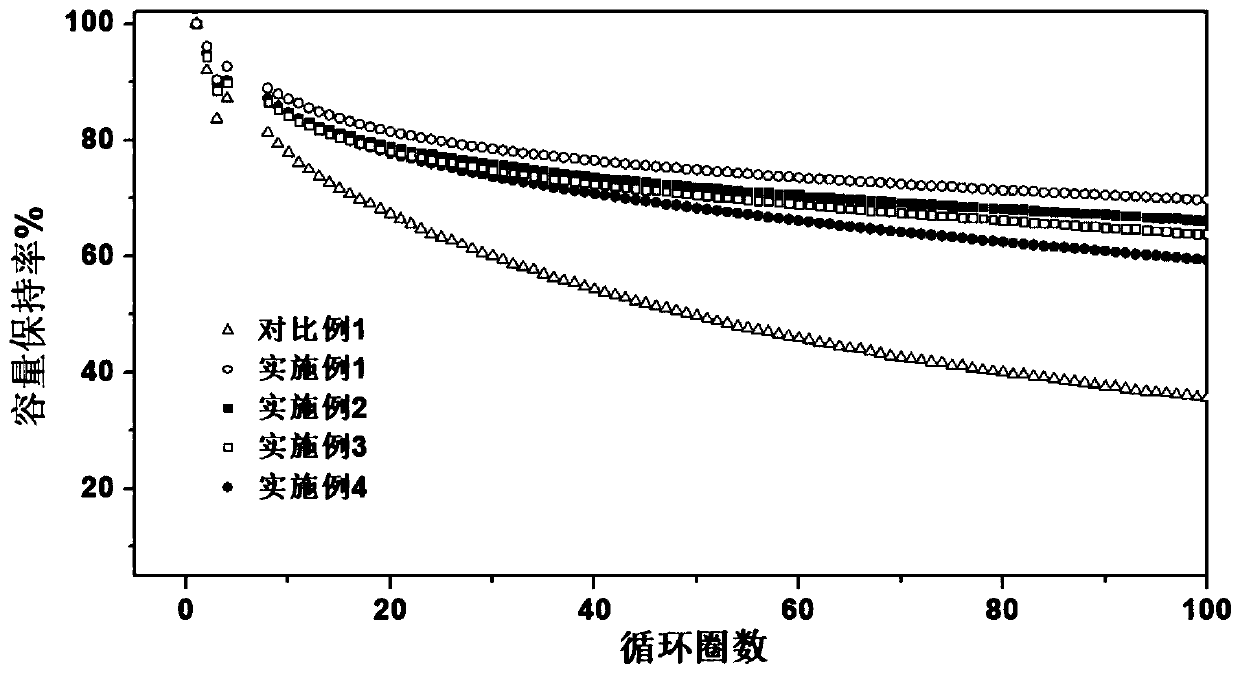

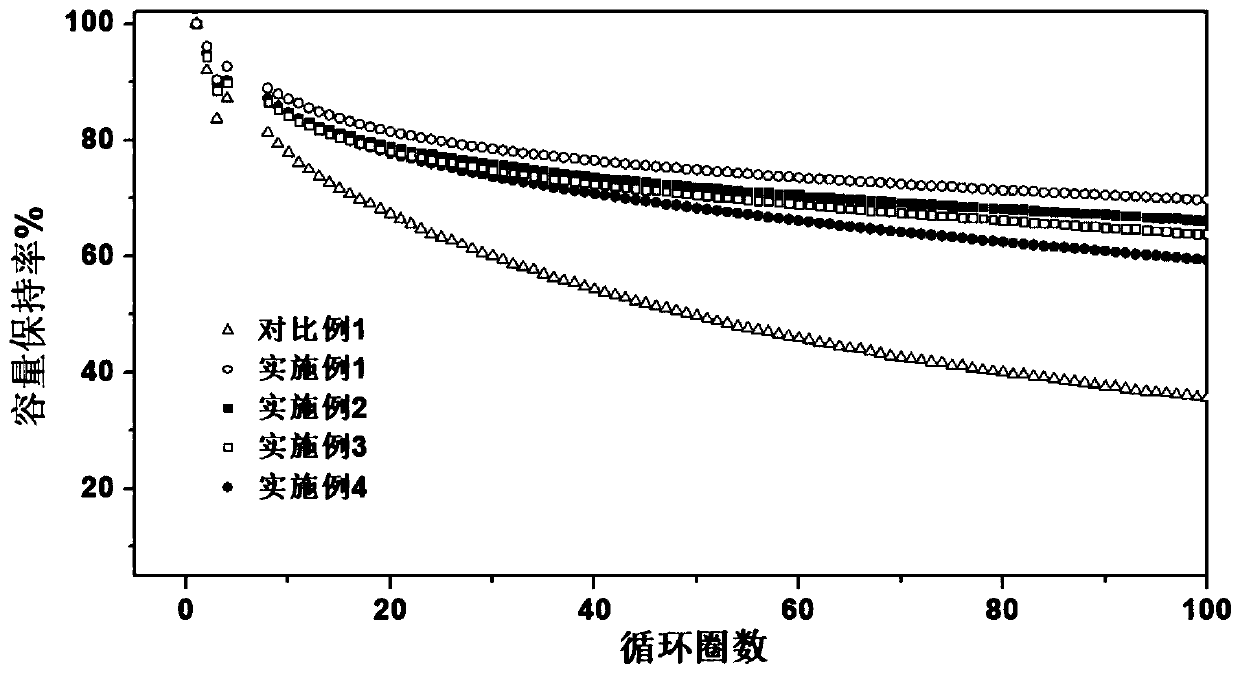

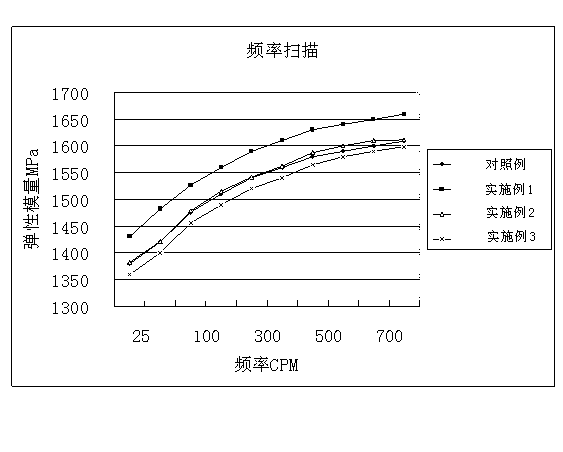

Three-dimensional network water-based composite binder and application thereof in lithium ion battery

ActiveCN111180733AGuaranteed bonding effectGuaranteed cycle performanceNegative electrodesSecondary cellsElectrical batteryCross linker

The invention provides a three-dimensional network water-based composite binder, which is prepared from the following components in percentage by weight: 5 to 50 percent of water-based polymer emulsion, 94.5 to 50 percent of water-soluble polymer and 0.5 to 10 percent of cross-linking agent. The three-dimensional network water-based composite binder is prepared by crosslinking the water-based polymer emulsion and the water-soluble polymer by a crosslinking agent to form a three-dimensional network molecular structure, wherein the water-based polymer emulsion is a water-based polyurethane emulsion or a vinyl acetate water-based copolymer emulsion. The invention also provides a negative electrode prepared from the three-dimensional network water-based composite binder and a lithium ion battery containing the negative electrode. The water-soluble polymer has relatively strong bonding force on the negative electrode material; the water-based polymer emulsion endows the polymer binder witha certain elasticity, and the cross-linking agent endows the binder with a three-dimensional molecular network structure, so that the toughness of the binder is enhanced, the damage of the volume change of active substances to an electrode plate structure in the charging and discharging process of the battery can be buffered, and the cycling stability of the lithium ion battery is maintained.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

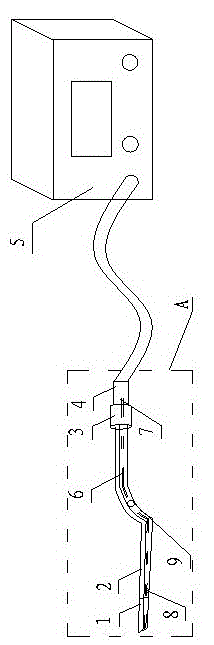

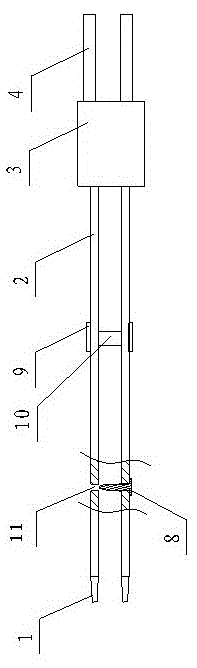

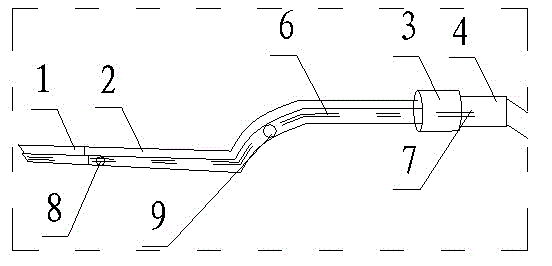

Electric coagulation forcep system with forcep point cleaning function

InactiveCN102743222AGuaranteed bonding effectEasy to operateEnemata/irrigatorsDiagnosticsMicrocontrollerMegasonic cleaning

The invention discloses an electric coagulation forcep system with a forcep point cleaning function, which comprises a forcep body and a host for providing a power source to the forcep body, wherein the forcep body comprises forcep points and forcep rods. The electric coagulation forcep system is characterized in that a temperature detecting device is arranged on the forcep points, the temperature detecting device feedbacks the detected temperature to a chip in the host; and the chip compares the temperature with the preset temperature and then adjusts the power output by the forcep points to adjust the temperature of the forcep points. The system further comprises an electric coagulation forcep supporting seat, wherein the electric coagulation forcep supporting seat comprises a base, grooves matched with two forcep rods of the electric coagulation forcep is formed in the base, the lower parts of the grooves are provided with a hollow cavity capable of holding forcep points; an ultrasound cleaner is arranged in the hollow cavity, a singlechip and a position sensing device for judging whether the forcep rods are arranged in the grooves are further arranged on the base; and a finish detecting device used for detecting the finish of the insides of the forcep points is arranged in the hollow cavity. The electric coagulation forcep system with the forcep point cleaning function is simple in structure; and by using the electric coagulation forcep system, the temperature of the forcep points are automatically detected and adjusted, and the forcep points are automatically cleaned.

Owner:CHONGQING RUNZE PHARM CO LTD

Intermediate-high temperature acid-corrosion-resisting glass fiber treating compound and preparation method thereof

InactiveCN103964708AImprove temperature and weather resistanceGood adhesive properties and thermal stabilityPrepolymerEmulsion

The invention relates to an intermediate-high temperature acid-corrosion-resisting glass fiber treating compound and a preparation method thereof. The method comprises the following steps: putting bisphenol-A epoxy resin and benzoyl peroxide into a flask, and carrying out stirring and rising temperature; then dropwise adding methacrylic acid, and preserving heat; cooling the obtained product, adding paraxylene and dibutyltin dilaurate to continue to stir, dropwise adding vinyltriethoxysilane, and preserving heat to obtain a pale yellow modified epoxy resin prepolymer; adding deionized water and emulsifier into the flask, and then carrying out full stirring and heating for dissolving; adding the modified epoxy resin prepolymer slowly, and continuing to stir after dropwise adding; rapidly cooling the obtained film former emulsion to room temperature, then mixing the film former emulsion, a coupling agent, nanosilicon dioxide, a lubricating agent and an antistatic agent so as to obtain the glass fiber treating compound. The method has the benefit that the temperature resistance of a film former is improved. The treating compound can improve the performance retention rate of glass fiber reinforced plastics materials under the intermediate-high temperature acidic condition.

Owner:WUHAN UNIV OF TECH

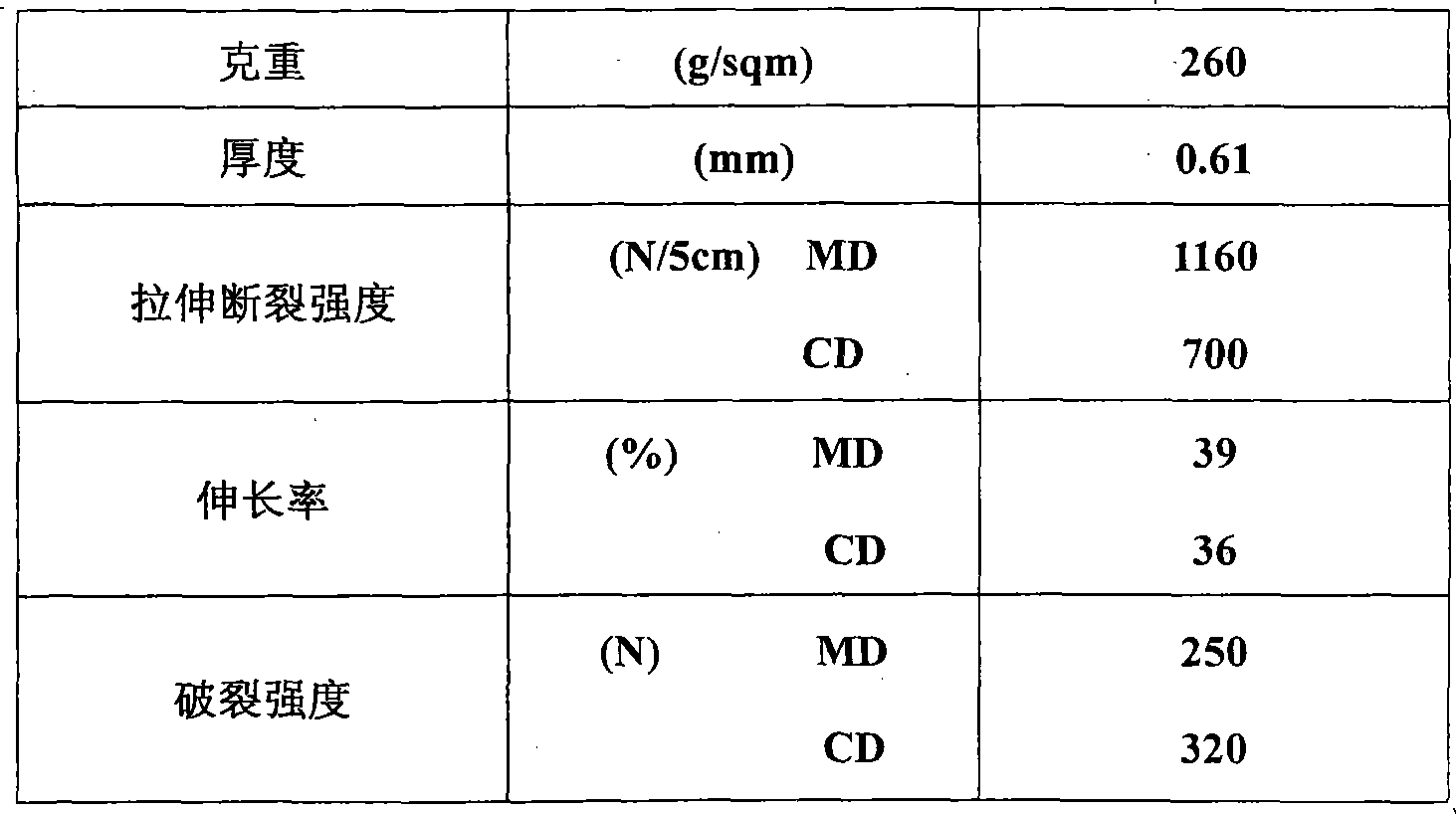

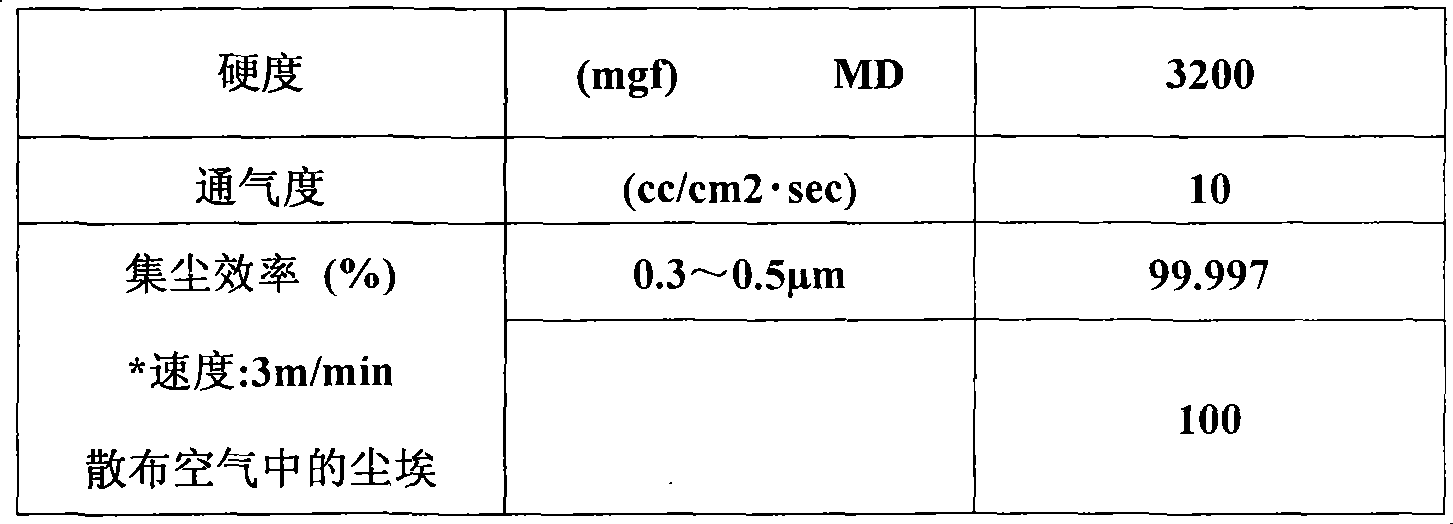

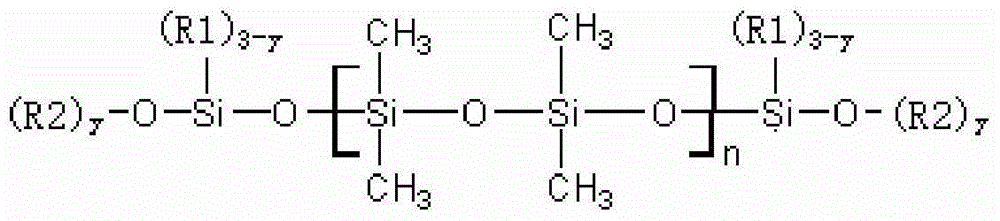

Coated filter material

InactiveCN101362056AImprove capture efficiencyImprove cleanlinessSemi-permeable membranesSynthetic resin layered productsPolymer scienceFilter material

The invention discloses a membrane mulching and filtering material which comprises a spun-bonding nonwoven material and a layer of polymer microporous membrane covered on the surface of the spun-bonding nonwoven. The material has high collection efficiency and excellent mechanical properties and is easy to remove dust.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

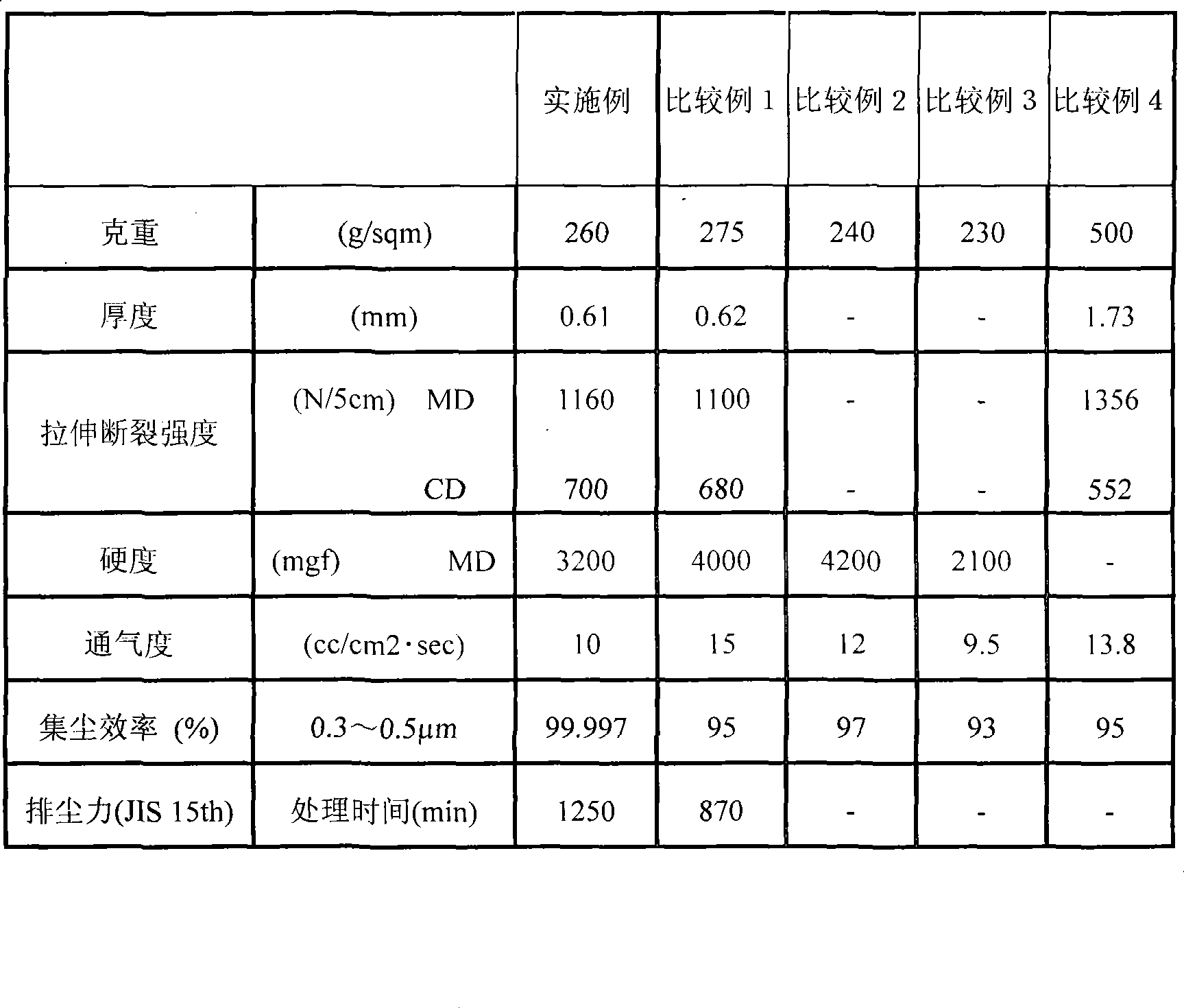

Transparent organic silicon LED light bar pouring sealant and preparation method thereof

ActiveCN104017534AHigh light transmittanceLight transmittance does not affectNon-macromolecular adhesive additivesLED lampDimethyl siloxane

The invention discloses a transparent organic silicon LED light bar pouring sealant and a preparation method thereof. The pouring sealant is prepared from a component (A) and a component (B), wherein the component (A) comprises the following components in parts by weight: 100 parts of polysiloxane base polymer, 0.1-100 parts of alpha, omega-alkoxy capped polydimethylsiloxane, 0-80 parts of reinforcing resin and 0-40 parts of silicone oil; the component (B) comprises the following components by weight: 100 parts of alpha, omega-alkoxy capped polydimethylsiloxane, 0-100 parts of silicone oil, 0-50 parts of reinforcing resin, 0-50 parts of a crosslinking agent, 0.5-15 parts of a thickening agent and 0.001-3 parts of a catalyst. The pouring sealant is a product with high light transmittance and strength, excellent adhesion and yellowing resistance, quick deep solidification and stable storage, can be used for pouring electronic appliances, can fulfill places requiring high light transmittance and high strength. The preparation method is simple, adjustable in solidification time and convenient to operate.

Owner:深圳市百丽春粘胶实业有限公司

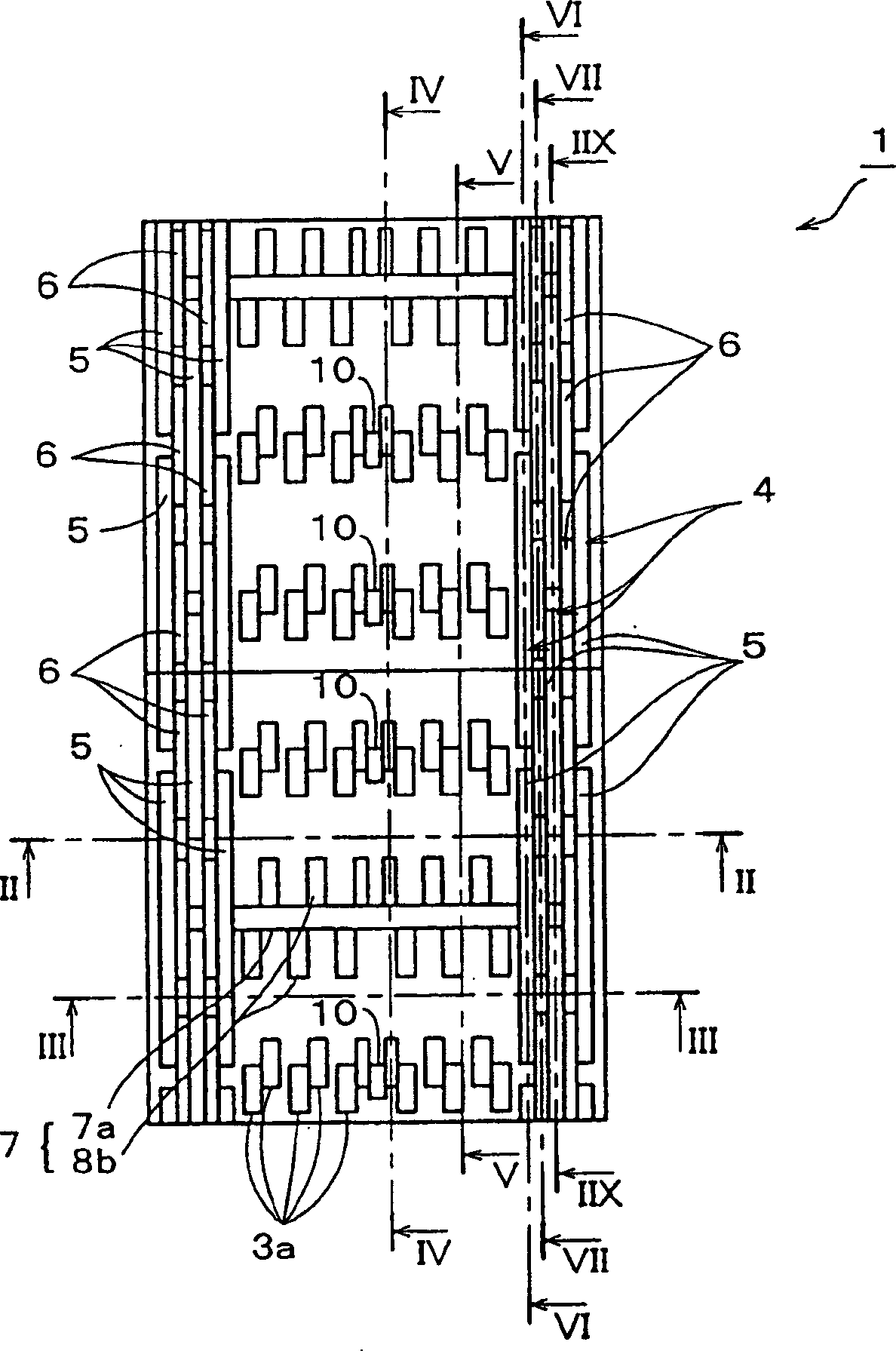

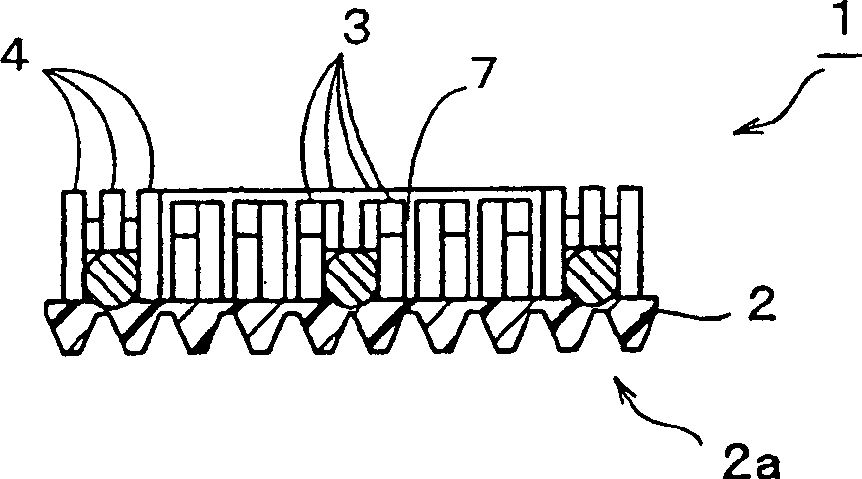

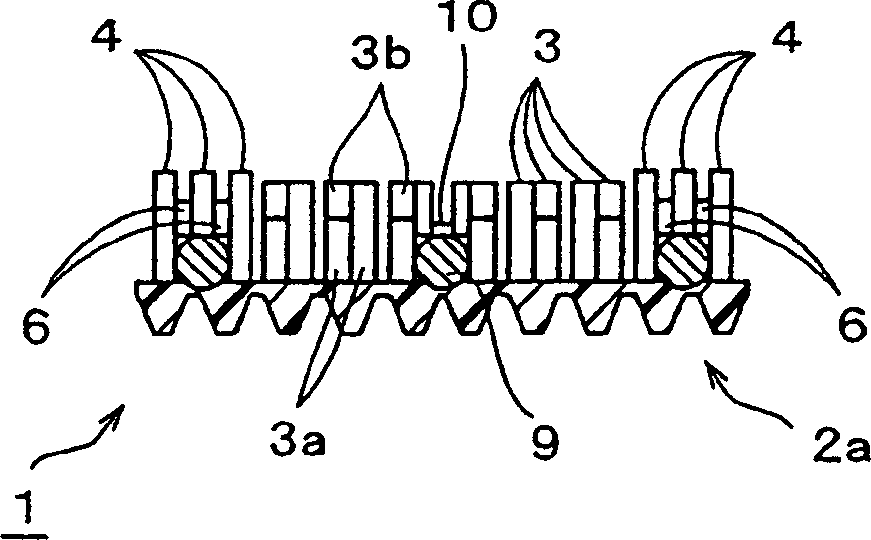

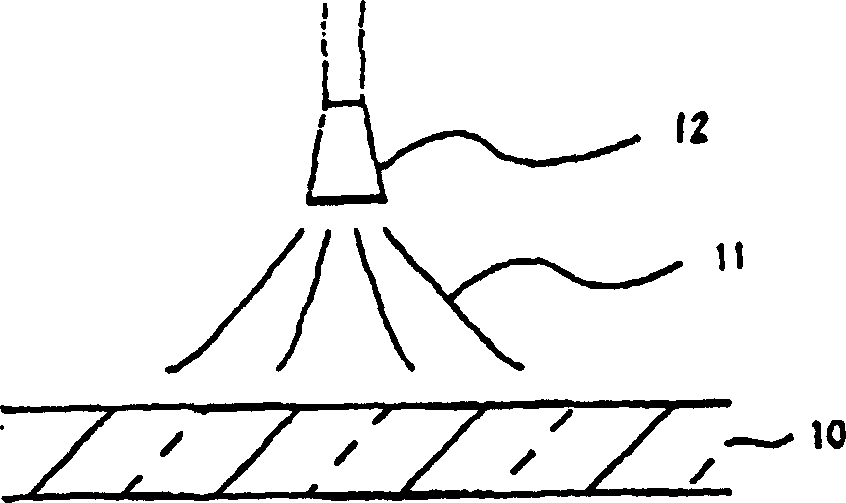

Molded surface fastener and cushion body formed integrally with the molded surface fastener

Owner:YKK CORP

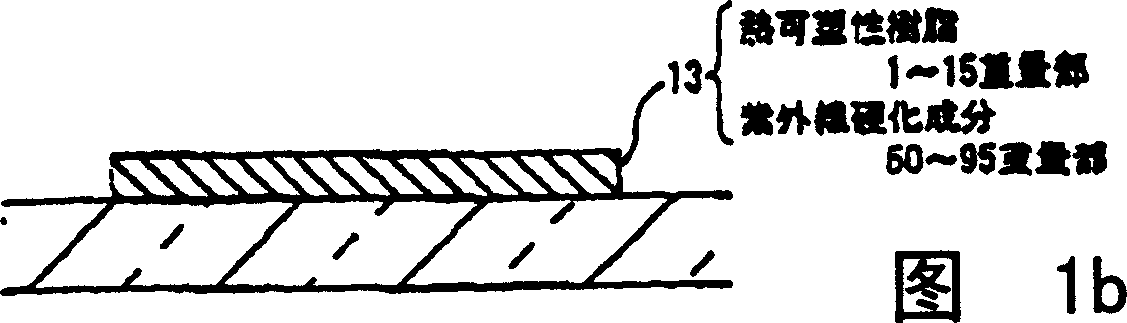

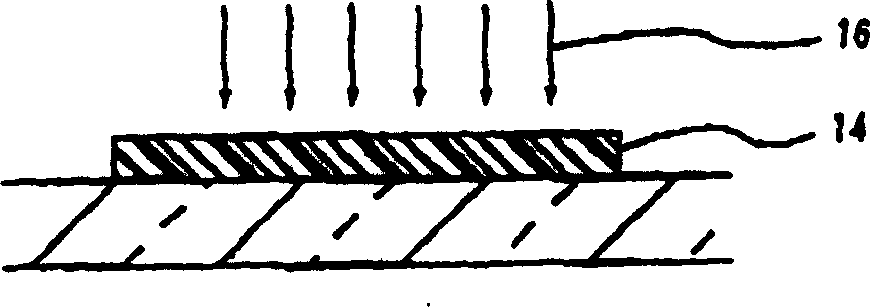

Metal foil scalding and stamping method using ultraviolet curing adhesive

InactiveCN1565856AGuaranteed bond strengthQuality assuranceDuplicating/marking methodsMetal foilBoiling point

The invention provides a metal foil stamping method using ultraviolet-curable binder which can make metal foil and glass container bond closely no matter how much the thermal softening resin content in ultraviolet-curable binder is. The metal foil stamping method is suitable for glass container. The method includes four working procedures: Silicifying flame treatment procedure: using silicon alkyl compound whose boiling point is in the range of 10 to100 DEG as combustion gas, and spraying the glass container surface with the flame generated by the gas combustion; daubing the ultraviolet-curable binder procedure: the ultraviolet-curable binder contains 1-15 parts by weight of thermoplastic resin, 50-95 parts by weight of ultraviolet curing component, and 0.1-10 parts by weight of photo-initiating agent; curing procedure: irradiating the binder daubed on the glass container surface with ultraviolet to cure the binder. Stamping procedure: activating the cured binder and stamping the metal foil onto the glass container surface.

Owner:上海高雅玻璃有限公司

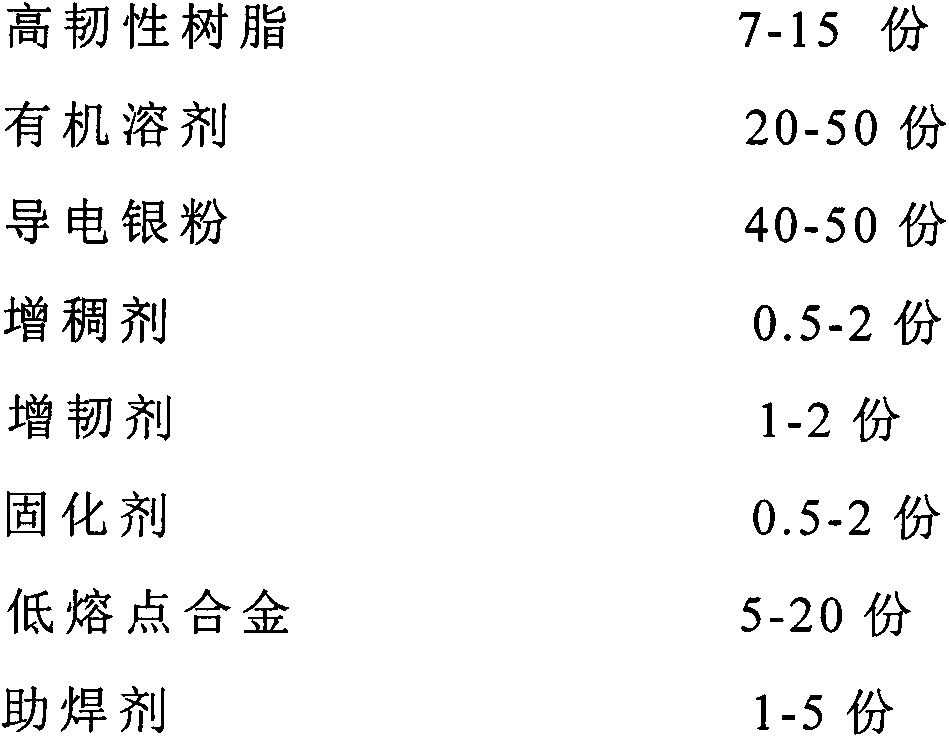

High-conductivity low-temperature sliver paste and preparation method thereof

ActiveCN106297949AUnique designReasonable compositionNon-conductive material with dispersed conductive materialCable/conductor manufactureMembrane switchAlloy

The invention discloses a high-conductivity low-temperature sliver paste and a preparation method thereof. The preparation method comprises the steps of successively mixing a high-toughness resin, a thickening agent, a flexibilizer and an organic solvent; successively adding a low-melting-point alloy, a soldering flux and conductive silver powder, and performing high-speed mixing for obtaining paste; and grinding the paste to the paste with fineness of 5-10 mu m, and obtaining the conductive sliver paste. The conductive silver paste prepared by the invention has advantages of high conductivity and high mechanical property. After the low-melting-point alloy is added, conductivity performance and hardness performance are greatly improved. Through adding appropriate amount of thickening agent and flexibilizer, diffusion performance and bending performance of a sliver strip can be effectively controlled. The low-temperature sliver paste prepared by the invention has advantages of effectively reducing silver content, improving conductivity and mechanical performance and greatly saving cost. The high-conductivity low-temperature sliver paste can be widely applied in the industries of a thin-film switch, a capacitive electrode, a touch screen, etc.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

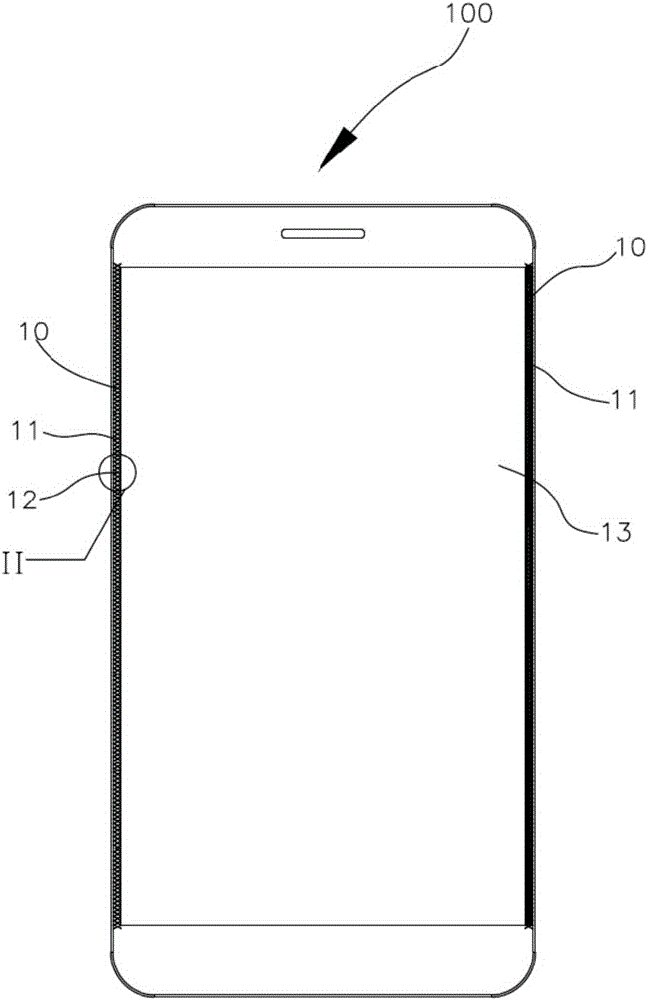

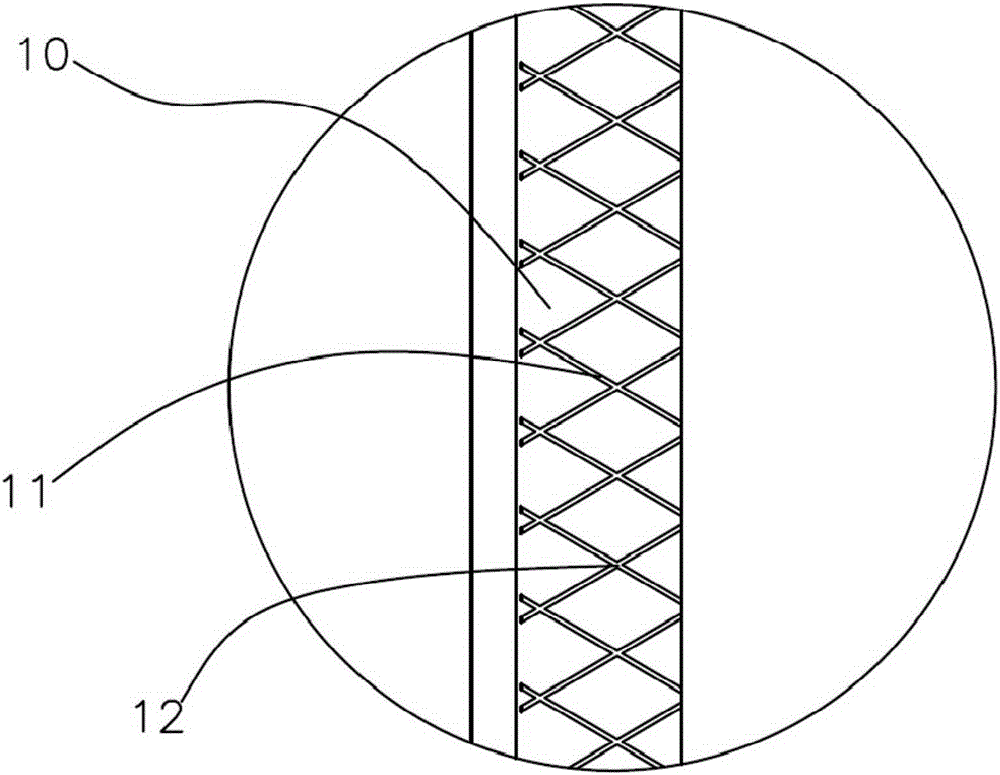

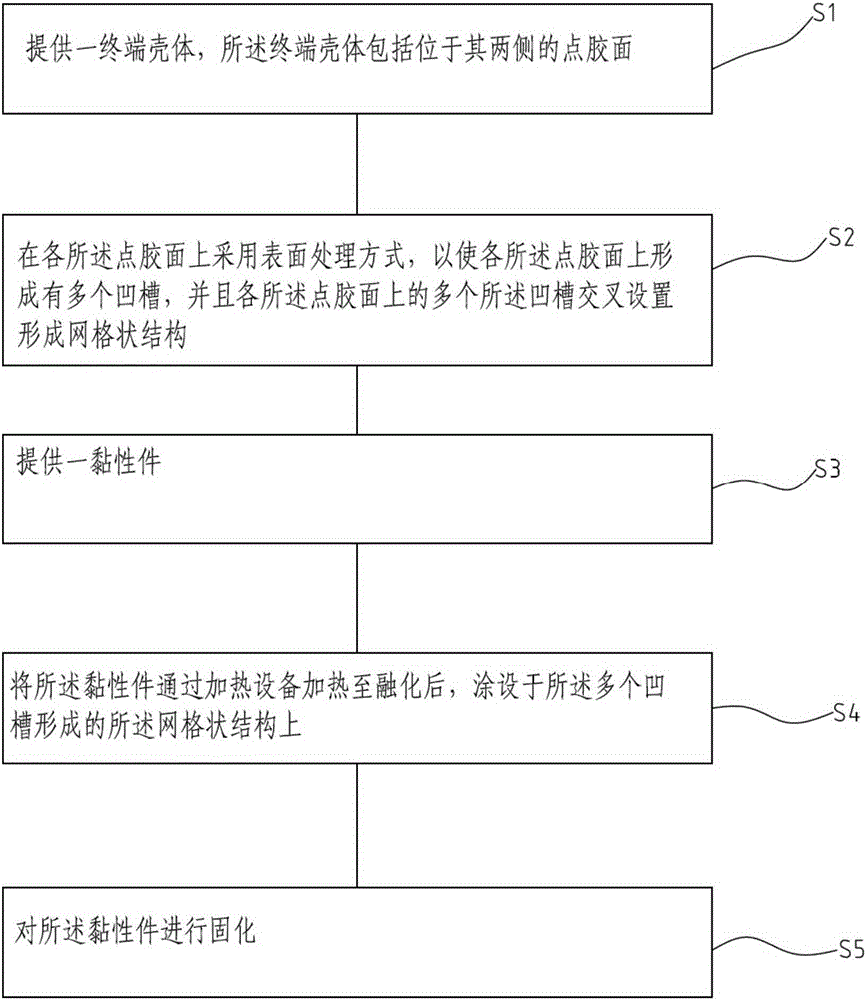

Terminal shell, terminal and treatment method for dispensed surfaces of terminal shell

ActiveCN105302246AAvoid displacementGuaranteed bonding effectDigital data processing detailsTelephone set constructionsEngineeringMechanical engineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

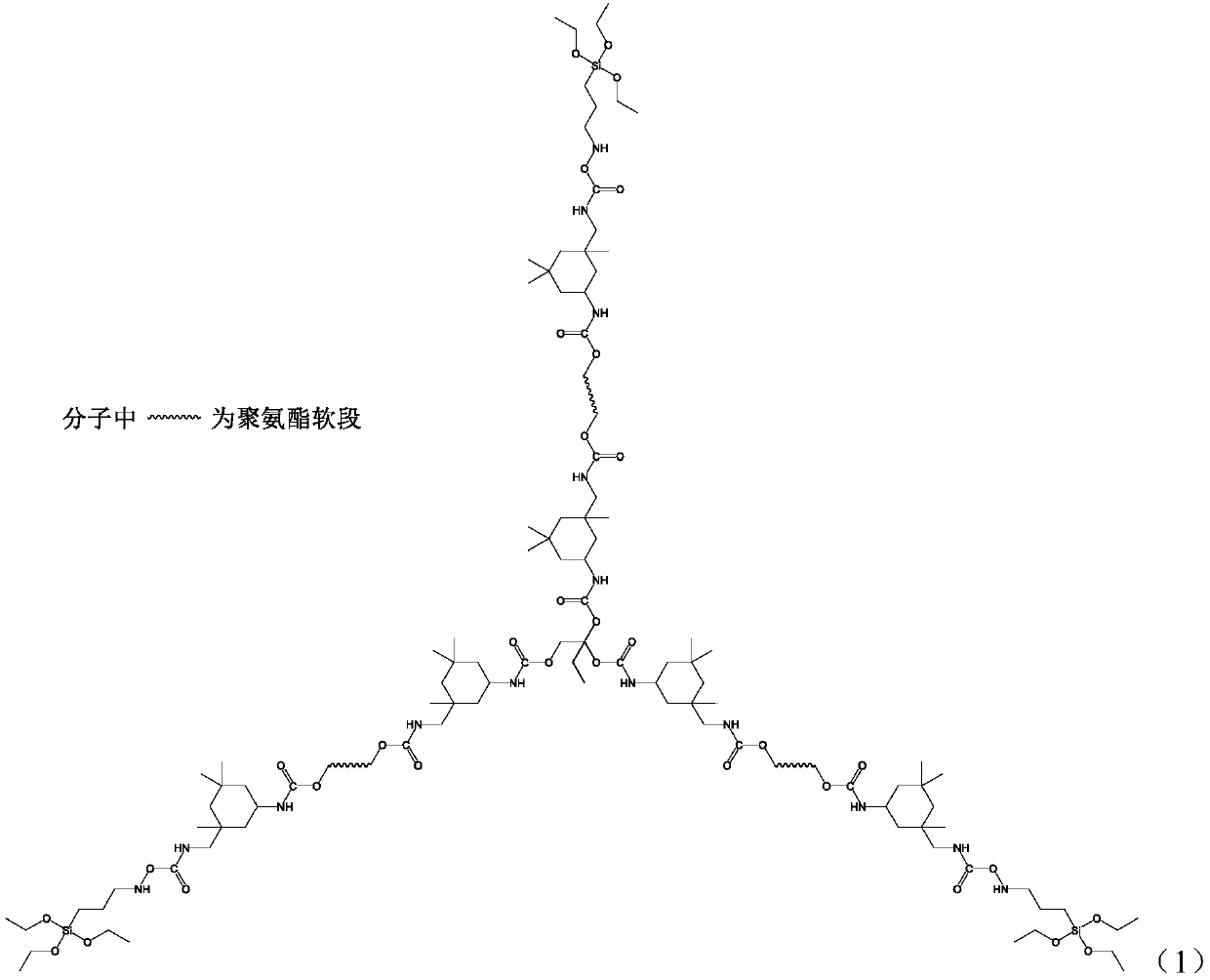

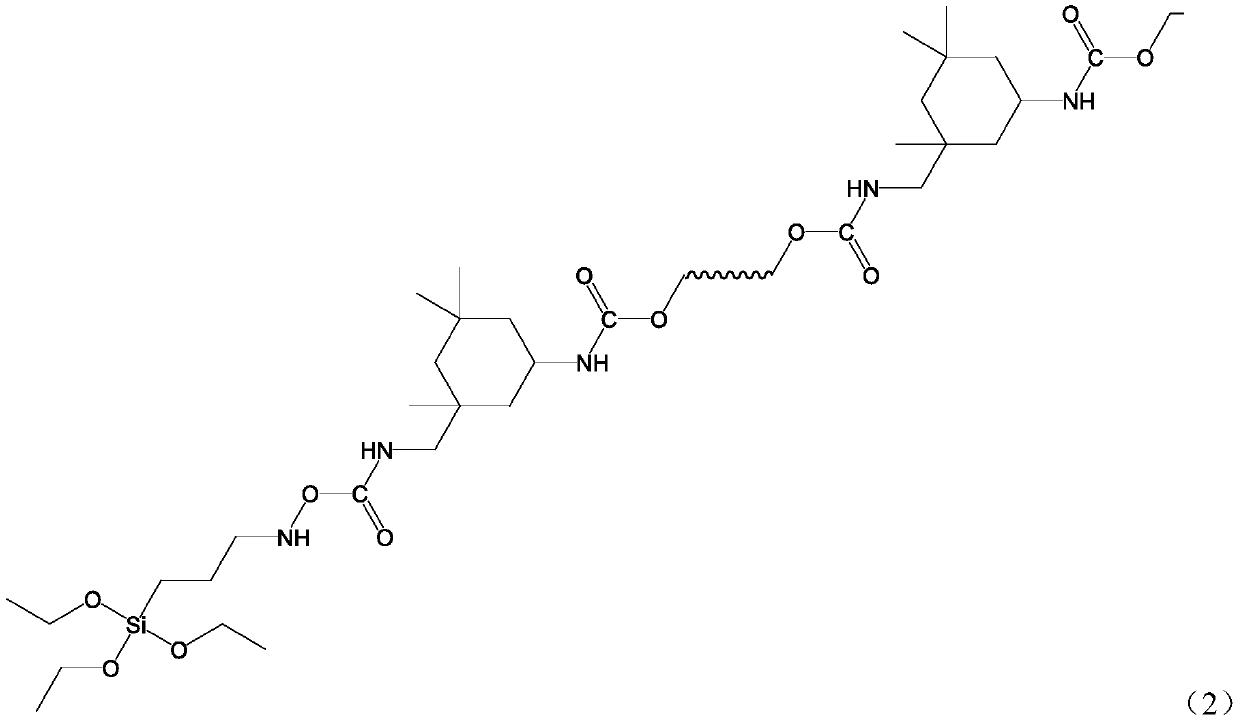

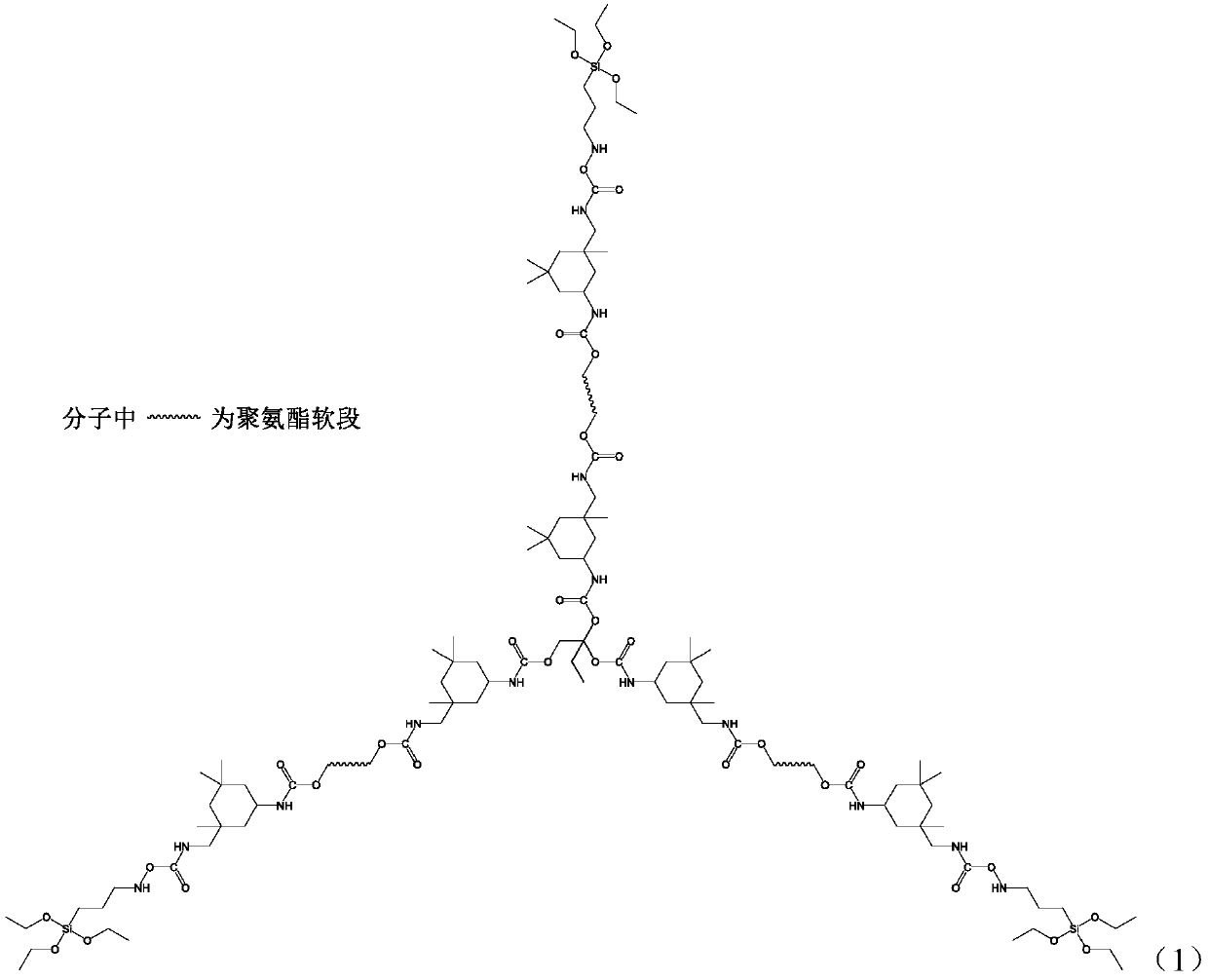

Hyperbranched silane modified polyurethane composite polysiloxane antifouling paint and preparation method thereof

ActiveCN111138974AOvercoming the problem of poor adhesionImprove adhesionAntifouling/underwater paintsPaints with biocidesXylylenePolymer science

The invention relates to a marine antifouling coating technology, and aims to provide a hyperbranched silane modified polyurethane composite polysiloxane antifouling coating and a preparation method thereof. The coating is a three-liquid type product, wherein the main paint is formed by mixing organopolysiloxane containing at least two condensation reactive groups, filler and a xylene solvent; thecross-linking curing agent is formed by mixing hyperbranched silane modified polyurethane, organosilane (which can be subjected to condensation reaction with condensation reactive groups of main paint resin), partial hydrolysate of the organosilane, and a xylene solvent; wherein the curing accelerator is formed by mixing a silane coupling agent, an organic tin catalyst and a xylene solvent. According to the present invention, the adhesion of the polysiloxane low surface energy antifouling finishing coat coating to the epoxy primer can be enhanced, and the low surface energy antifouling finishing coat has advantages of excellent fresh water resistance, salt and alkali corrosion resistance, long-term stable existence at the room temperature, environmental protection requirement meeting, andlow application cost; good rheological performance and film forming performance are achieved, and then good construction performance is achieved; the synthesis method is relatively simple and convenient for industrial production.

Owner:QUZHOU RES INST OF ZHEJIANG UNIV

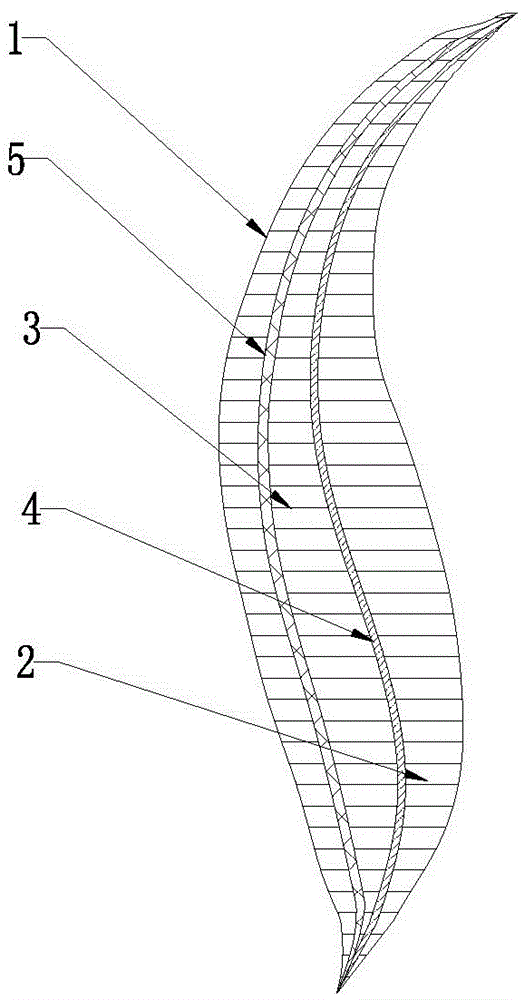

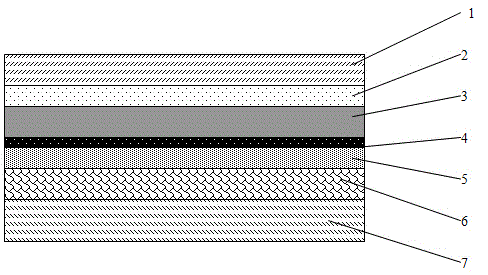

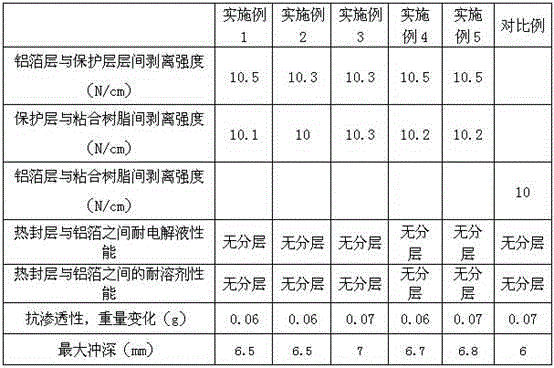

Soft package membrane for lithium battery

ActiveCN104485430AGuaranteed performanceImprove toughnessJackets/cases materialsPolyurethane adhesiveSilsesquioxane

The invention relates to a soft package membrane for a lithium battery. The soft package for the lithium battery membrane is sequentially provided with a nylon layer, a polyurethane adhesive layer, an aluminum foil layer, a preservative treatment layer, a bonding resin layer and a hot sealing layer. The soft package membrane is characterized in that a protective layer is further arranged between the preservative treatment layer and the bonding resin layer; the protective layer contains cage-like silsesquioxane which accounts for 2-8wt% of the total weight; the cage-like silsesquioxane consists of hydroxyl cage-like silsesquioxane and epoxy cage-like silsesquioxane in a weight ratio of 0.1: 1 to 0.3: 1. The soft package membrane for the lithium battery provided by the invention has good scour depth-resisting performance on the premise of satisfying the practical performance.

Owner:乐凯胶片股份有限公司

Pet food for inhibiting appetite

InactiveCN101548720APrevent overeatingPrevent chokingAnimal feeding stuffAccessory food factorsAnimal skinAnimal science

The invention discloses a pet food for inhibiting appetite, which comprises dog chews such as leather picker bones or leather rolling bones and the like which are made of animal skin such as cow skin, pig skin and / or sheep skin and the like or the compound of animal skins, and is characterized in that the animal skin or the grains of the animal skin is puffed and then coated, wrapped or blended with galactolipid and / or microencapsulated galactolipid. The dog chews can inhibit the appetite of pets, avoid excessive eating and is beneficial to the health of pets.

Owner:冷博

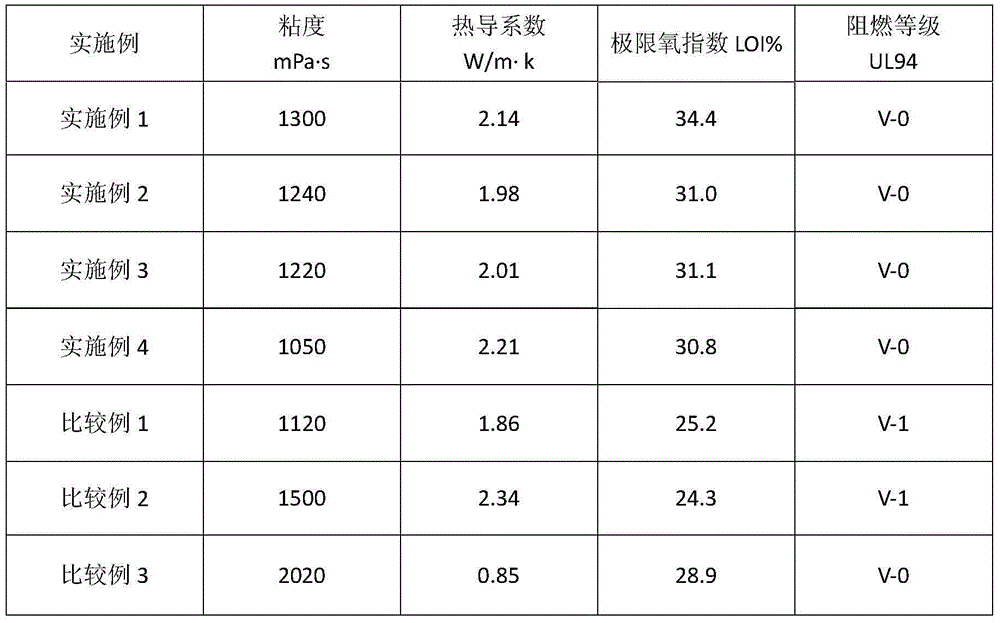

Environment-friendly flame-retardant heat-conducting glue and preparation method thereof

ActiveCN104559890AHigh softening pointImprove flame retardant performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyHeat conducting

The invention discloses environment-friendly flame-retardant heat-conducting glue and a preparation method thereof. The preparation method comprises the following steps: diluting a coupling agent by using absolute ethyl alcohol, regulating the pH value of the diluted solution, adding a heat-conducting filler, and mechanically stirring; centrifuging, washing, and drying, thereby obtaining a component A; uniformly mixing an epoxy resin, a curing agent and a curing accelerator by using a high-speed dispersion machine, thereby obtaining a low-viscosity component B; and uniformly grinding and mixing the component A, the component B, an organic phosphorus flame retardant and aluminum hydroxide, vacuumizing, heating the mixture at the temperature of 80-90 DEG C, and heating at the temperature of 130-150 DEG C, thereby obtaining the environment-friendly flame-retardant heat-conducting glue. The environment-friendly flame-retardant heat-conducting glue is low in viscosity, high in heat conductivity coefficient, good in mechanical property and high in acid-base resistance and corrosion resistance, the flame-retardant level reaches UL94V-0, the heat dissipation problem of a general electronic component can be solved; because the heat-conducting glue has good flame-retardant property, when the heat-conducting glue is applied to high-voltage and high-temperature electrical equipment, the on-fire potential safety hazard of the electronic component is effectively reduced.

Owner:中山沃硅化工科技有限公司

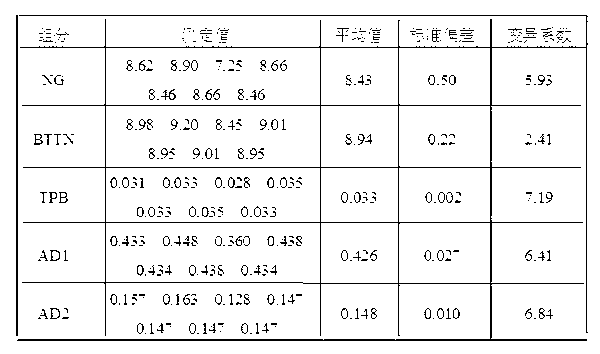

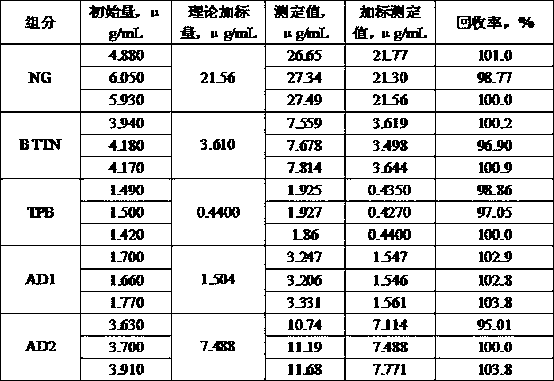

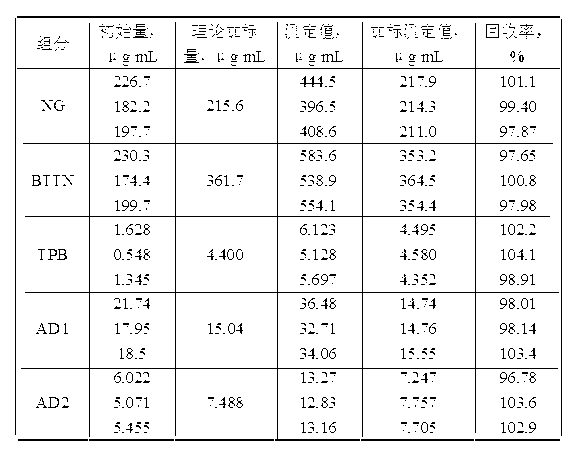

Determination method for migration components in nitrate ester plasticized polyether (NEPE) propellant bonding system

ActiveCN103207243AEnsure the quality of developmentGuaranteed bonding effectComponent separationPtru catalystEngineering

The invention relates to a determination method for migration components in an NEPE propellant bonding system used in the field of aviation fuels. The determination method comprises the following experimental steps: preparation of a to-be-detected sample; determination of detection objects and detection conditions; drafting of an external standard calibration curve; formation of a detection data list; etc. According to the method, a plurality of migration components in the NEPE propellant bonding system are detected, wherein the components comprise a plasticizer nitroglycerine (ND), a plasticizer butanetriol trinitrate (BTTN), an amine stabilizing agent (AD) and a curing catalyst triphenyl bismuth (TPB). The determination method is extensively applicable to qualitative and quantitative detection of a solid rocket and an energetic material used in space and missile technologies and can effectively reduce sample treatment risks, simplify the process of measurement and analysis, reduce data processing errors and save experimental expenses for detection. Moreover, the following advantages are obtained: the determination method is simple and practicable, experimental process is convenient to popularize, repeatability of detection data is good, and data processing is accurate and reliable.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

High-covering black UV silkscreen printing ink

The invention discloses a high-covering black UV silkscreen printing ink. A preparation method for the high-covering black UV silkscreen printing ink comprises the following steps: preheating acrylate and then mixing the preheated acrylate with a part of active monomer; then adding a dispersant and carrying out primary dispersion; then successively adding pigment and a filling material and carrying out secondary dispersion; carrying out grinding to obtain color paste; mixing a phosphine oxide photoinitiator with residual active monomer; and adding the color paste, an organosilicon antifoaming agent and an organosilicon leveling agent and carrying out uniform dispersion so as to obtain the high-covering black UV silkscreen printing ink. The high-covering black UV silkscreen printing ink provided by the invention is reasonable in composition; all the components are in good compatibility; and the prepared printing ink has excellent comprehensive properties and good storage performance, and the viscosity of the printing ink is suitable for silkscreen printing. The printing ink does not need increase in the usage amounts of components like carbon black, prevents unfavorable influence of the components on the appearance and light shading performance of a product, and can meet light shading requirements of the product after only one printing and under the condition of a thickness of 7 to 8 micrometers, so unexpected technical effects are obtained.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

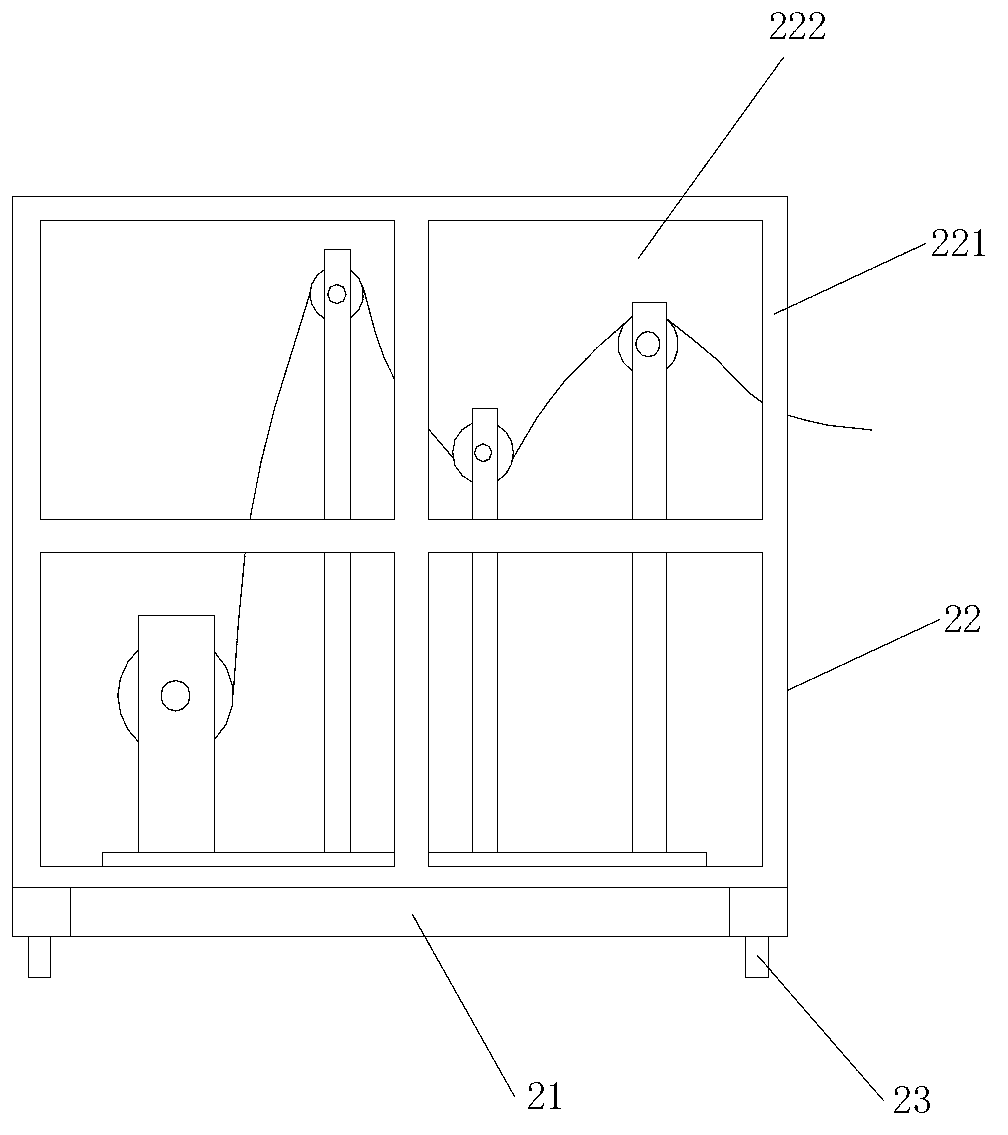

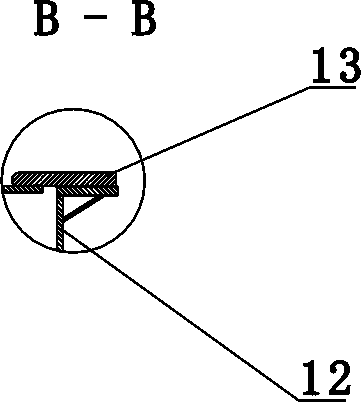

Drum type micro-filtering machine

ActiveCN104190142AReduce energy consumptionReduce laborMoving filtering element filtersControl systemWater level

The invention provides a drum type micro-filtering machine which comprises a housing, a filtering barrel with a filtering net, a backwashing device, a control system and a motor, wherein the filtering barrel is located in the housing, a rotary bracket of the filtering barrel is fixedly connected with the housing, the backwashing device is arranged between the filtering barrel and the housing; the control system comprises a water level sensor arranged in the filtering barrel and a control device assembly arranged outside the housing. By adopting an automatic water level detection function, by virtue of a water level difference, the rotation of the filtering barrel and the starting of backwashing are controlled, the advantages of reducing energy consumption and labor force are achieved; the drum type micro-filtering machine is economic and applicable, simple to operate, and low in production and operation costs.

Owner:杭州启程生态环境工程有限公司

Invisible plant-source fiber antibacterial mask and production method thereof

ActiveCN105146812AGuaranteed antimicrobial propertiesGuaranteed bonding effectNon-woven fabricsProtective garmentPolyesterSurface layer

The invention discloses an invisible plant-source fiber antibacterial mask. The mask comprises a mask body composed of a mask surface layer and a mask inner layer. Mask tying belts facilitating wearing are sewn on the mask body. A middle layer used for filtering out fine dust is arranged between the mask surface layer and the mask inner layer. Both the mask surface layer and the mask inner layer are made of antibacterial fiber layers composed of plant antibacterial fibers and synthetic fibers reinforced with the plant antibacterial fibers. The plant antibacterial fibers are made of plant antibacterial agents and viscose spinning solutions; the synthetic fibers are hot-melt fibers or viscose fibers reinforced with the plant antibacterial fibers in a heat bonding mode, or one or more of cotton fibers, viscose fibers and polyester fibers reinforced with the plant antibacterial fibers in a spunlacing mode. The mask is simple in structure, low in cost and remarkable in antibacterial effect, the antibacterial effect of the mask can be controlled at will, and discriminability between the mask and the face can be reduced to achieve an invisible effect without affecting the antibacterial performance of the mask.

Owner:上海淳梧新材料科技有限公司

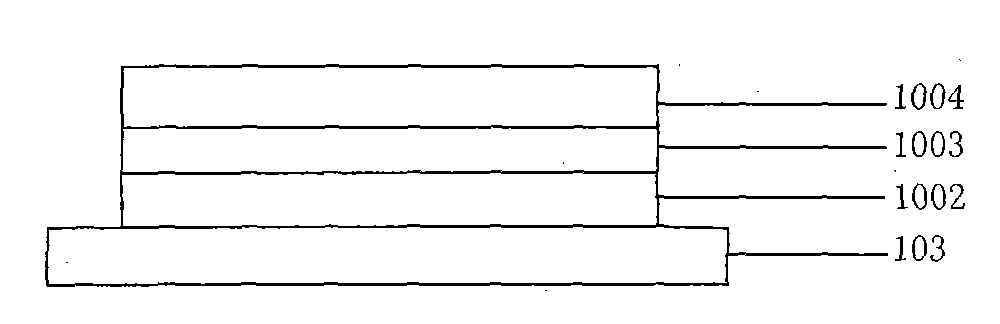

An aqueous ceramic/PVDF mixed coating slurry, a preparation method and an application thereof

ActiveCN109065804AEvenly dispersedReduce crystallinityFinal product manufactureCell component detailsWater basedHexafluoropropylene

A method for prepare an aqueous ceramic / PVDF mixed coat slurry comprises uniformly mixing high-purity water, perfluoroalkyl dispersant, tert-butyl hydrogen peroxide and acetone, continuously introducevinylidene fluoride and hexafluoropropylene gas to obtain aqueous PVDF emulsion; The ceramic material and the first dispersant are dispersed in deionized water, then thickener and adhesive, water-based PVDF emulsion and wetting agent are added, and the slurry is obtained after being uniformly mixed. The water-based ceramic / PVDF mixed coating slurry prepared by the invention is coated on a polyethylene diaphragm to obtain a wet film; A water-based ceramic / PVDF mix coating membrane is obtain by drying. The invention aims at remarkably improving the dispersion uniformity of ceramic / PVDF blend slurry, improving the uniformity of ceramic / PVDF blend coating separator coating, combining the characteristics of ceramic material and PVDF material, and remarkably improving the comprehensive performance of lithium ion battery separator.

Owner:湖南烁普新材料有限公司

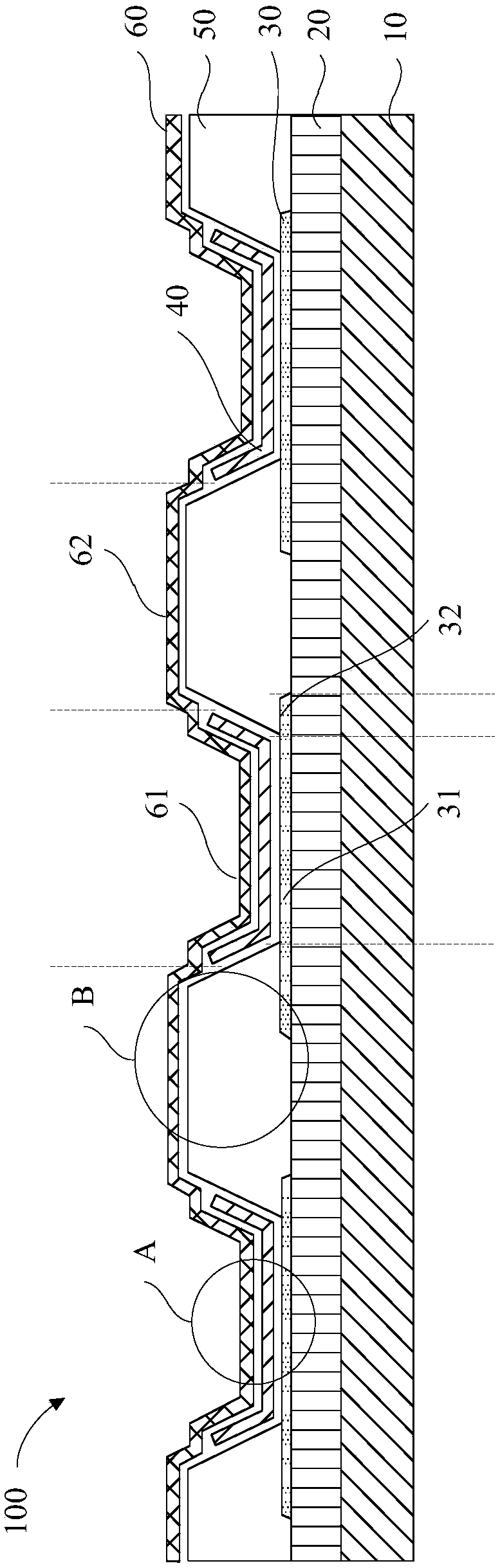

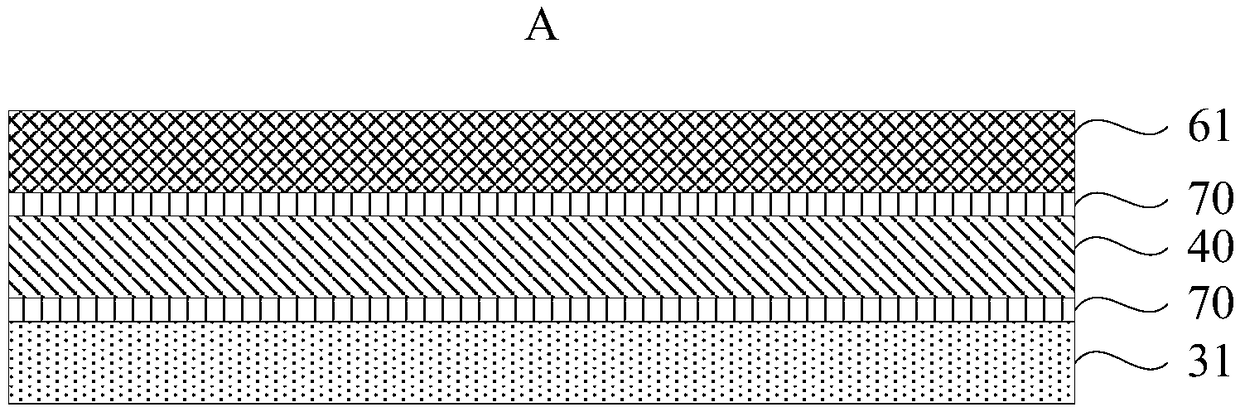

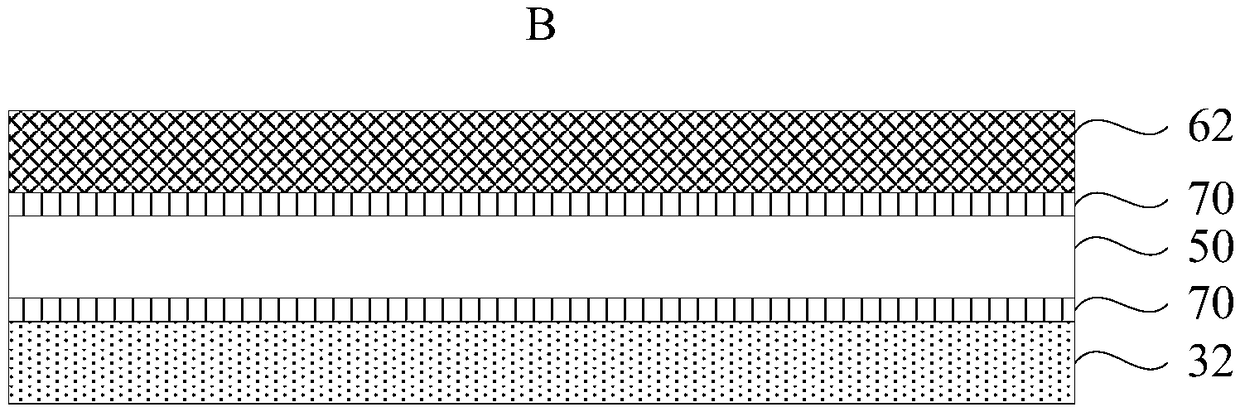

Flexible display panel and flexible display device

ActiveCN109411513AImprove luminous performancePrevent peelingSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayComputer science

The invention provides a flexible display panel and a flexible display device. The flexible display panel comprises a plurality of light emitting units, wherein each light emitting unit comprises a first electrode layer, a pixel layer and a second electrode layer which are stacked in sequence; the flexible display panel further comprises a pixel limiting layer used for separating the pixel layers;and a bonding layer is arranged between at least one of the first electrode layer and the second electrode layer and the pixel layer, wherein the bonding layer is a transparent conductive adhesive layer. According to the flexible display panel, in the bending process of the flexible display device, stripping or separating between a negative electrode layer and a positive electrode layer of a functional membrane layer and an organic light-emitting layer can be effectively avoided, and a breakage or cracking in the interior of the functional membrane layer can be avoided, so that the light-emitting performance of the flexible display device is improved.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

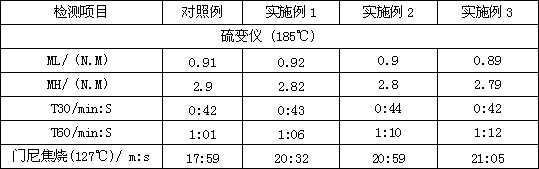

All-steel radial tire belt compound rubber composition and production method thereof

InactiveCN102702586AReduce manufacturing costProtection is goodSpecial tyresRolling resistance optimizationElastomerPolymer science

The invention relates to the technical field of rubber, in particular to an all-steel radial tire belt compound rubber composition, which is characterized by comprising the following materials in parts by weight on the basis of 100 parts by weight of alkadiene elastomer: 30-60 parts of carbon black, 5-15 parts of white carbon black, 3-10 parts of methylene donor, 1-3 parts of environment-friendly resin, 4-10 parts of sulfur, 1-2 parts of cobalt salt and 1-2 parts of accelerant, wherein the environment-friendly resin is obtained from R modified m-phenol diamine, and R mainly represents styrene; and the alkadiene elastomer is selected as one or a mixture of smoke sheet rubber, standard rubber and synthetic polyisoprene rubber. The all-steel radial tire belt compound rubber composition is of great help to reduction of the production cost of the compound; and on the premise of meeting the basic performance such as strength, elongation and resilience of the belt compound, the performances such as an adhesive force between the compound and a steel tire cord and the adhesive force between boundaries of rubber and a steel wire at the later stage of use can be guaranteed.

Owner:TRIANGLE TIRE

Electric coagulation forceps system with supporting seat and function of automatically adjusting temperature of forceps tips

InactiveCN102846372AGuaranteed bonding effectSimple structureCleaning using toolsSurgical instruments for heatingForcepsEngineering

The invention discloses an electric coagulation forceps system with a supporting seat and a function of automatically adjusting a temperature of forceps tips. The electric coagulation forceps system is characterized by comprising an electric coagulation forceps body, a main machine for providing a power supply for the forceps body, and the supporting seat, wherein the forceps body comprises forceps rods and the forceps tips; the electric coagulation forceps system further comprises a current detection device for detecting the current between the forceps tips and a voltage detection device for detecting the voltage between the forceps tips; impedance of a material between the forceps tips is calculated according to a voltage-to-current ratio; output power of electric energy at the forceps tips is gradually reduced by the main machine along with gradual increment of the impedance; the supporting seat comprises a base; grooves matched with the two forceps rods of an electric coagulation forceps are arranged on the base; cavities for receiving the forceps tips are arranged at lower parts of the grooves; a main control chip and a position sensor are also arranged on the base; and a baffle frame is arranged between the two grooves. The electric coagulation forceps system is simple in structure; and the temperature of the forceps tips is controlled to be in a certain range by detecting the impedance between the forceps tips in real time, so that a bonding effect of the electric coagulation forceps is guaranteed and overheat phenomenon is avoided.

Owner:CHONGQING RUNZE PHARM CO LTD

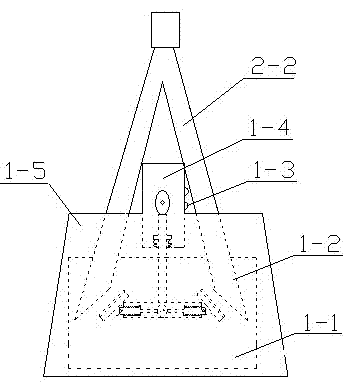

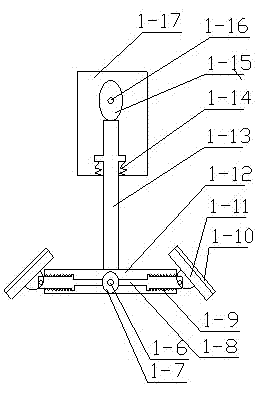

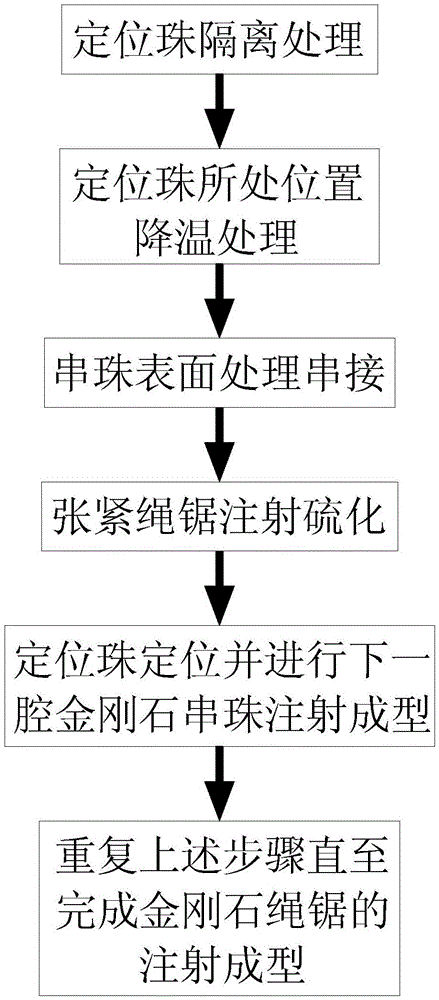

Diamond wire saw rubber injection molding method

The invention discloses a diamond wire saw rubber injection molding method. The diamond wire saw rubber injection molding method includes the following steps that (a) the containing position of a string bead serving as a positioning ball of a to-be-machined diamond rubber rope saw of a next cavity in an injection molding cavity is subject to isolation treatment; (b) the position of the positioning ball is subject to cooling and temperature measurement, and a next working process is executed until the position of the positioning ball reaches the preset temperature; (c) the string bead is sequentially subject to sand blasting, K coating and prepared wire treatment; (d) a prepared wire saw is tensioned, and the string bead is distributed at the corresponding position in the injection molding cavity for waiting for glue injection vulcanization; (e) the to-be-machined diamond rubber wire saw in the injection molding cavity is subject to injection vulcanization, machining of the to-be-machined diamond rubber wire saw in the section is completed; and (f) the string bead in the section of the to-be-machined diamond rubber wire saw serves as the positioning ball of the next section to position the next section of the to-be-machined diamond rubber wire saw in the injection molding cavity, the step d to step e are repeatedly executed, and injection molding of the diamond rubber wire saw is completed and so on. The bonding effect is guaranteed.

Owner:长沙百通新材料科技有限公司

Production method for plastic track

The invention discloses a production method for a plastic track and belongs to the technical field of athletic facility manufacturing. The production method for the plastic track includes the following steps that (1), a track foundation is cleared; (2), a bottom rubber layer is laid in the running direction of the track from a race starting region in a coating mode; (3), a surface rubber layer is laid, and rubber is scraped; (4), anti-slipping rubber particles are scattered before the surface rubber layer is solidified; (5), the redundant anti-slipping rubber particles are recovered; (6), the anti-slipping rubber particles are sprayed with a protection layer; (7), a track line is drawn. Production is easy, construction is easy, the falling rate of the anti-slipping particles is low, and service life is long.

Owner:JIANGSU SULE EDUCATIONAL TOYS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com