Patents

Literature

30results about How to "Won't lose powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic coating diaphragm for lithium battery and preparation method of ceramic coating diaphragm

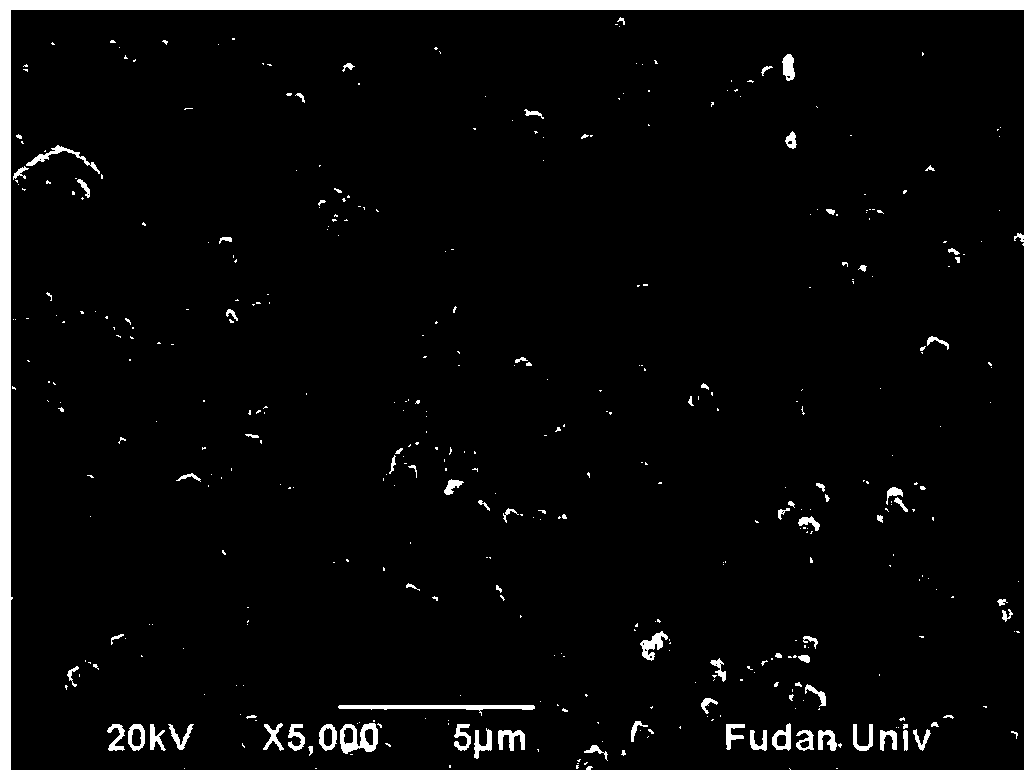

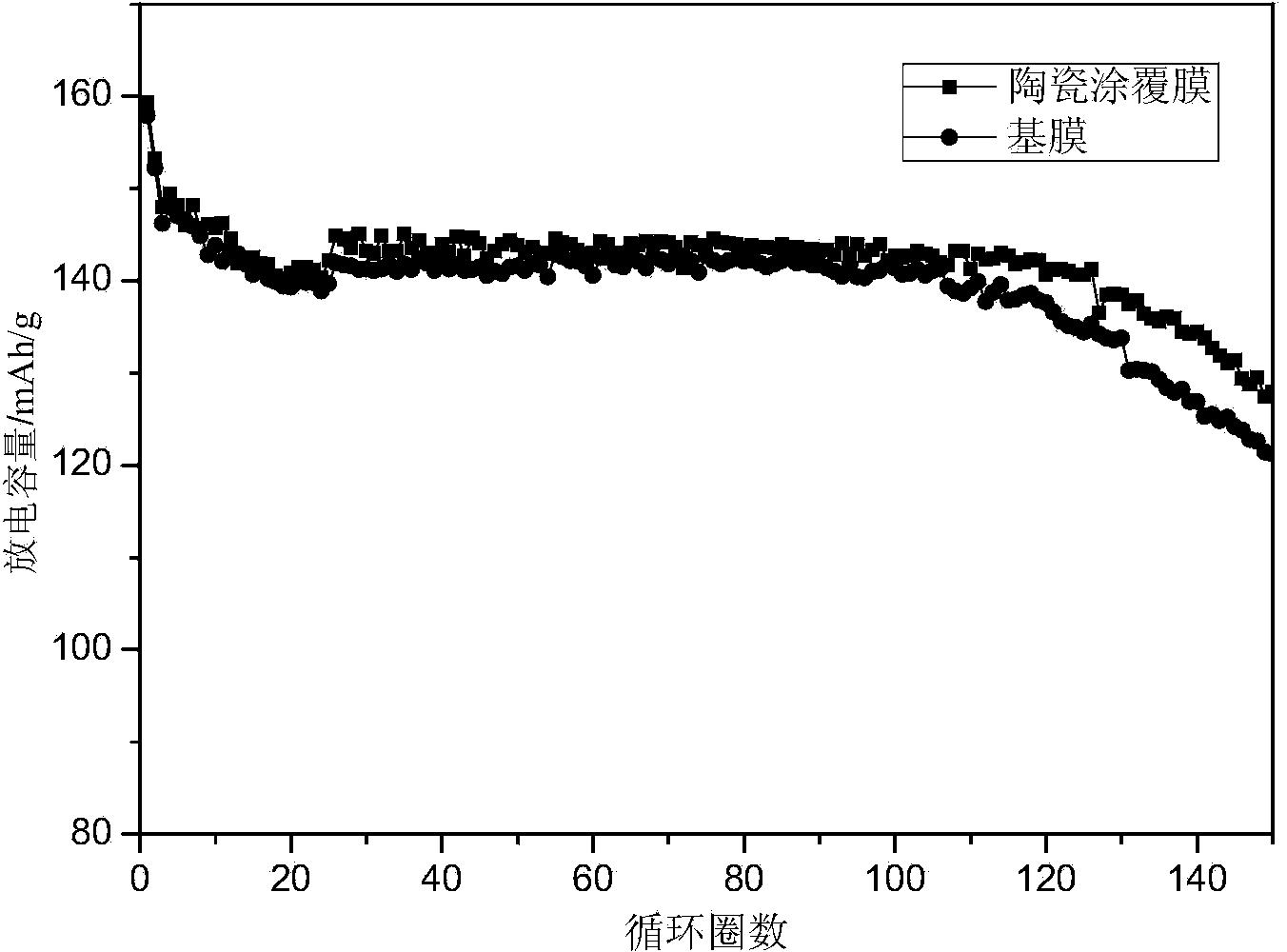

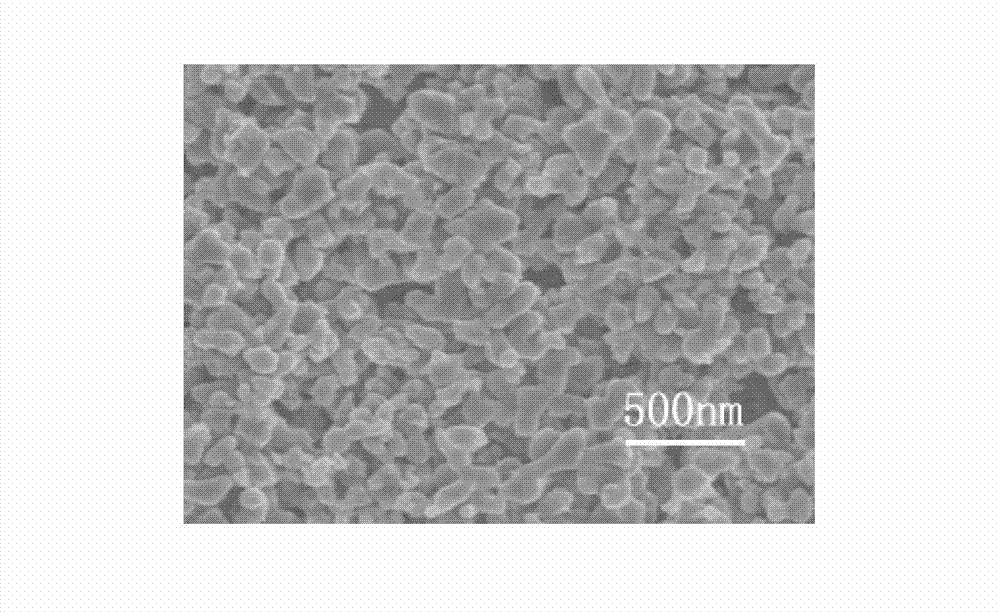

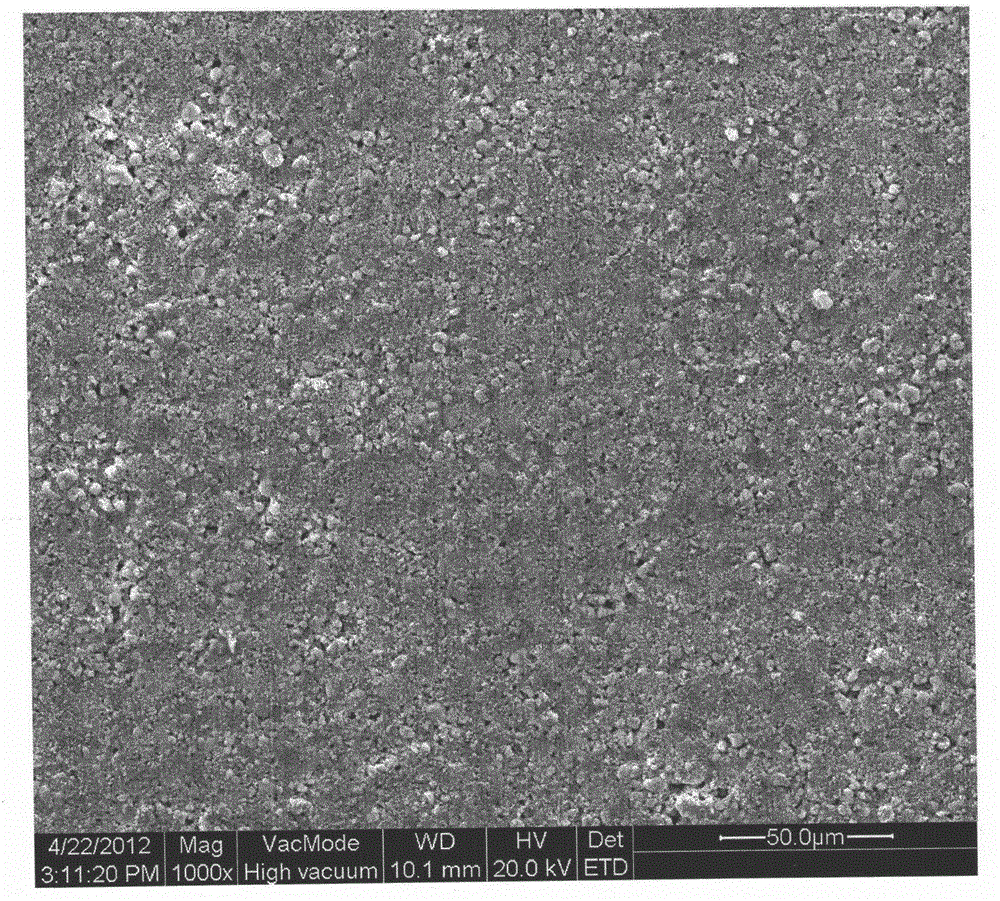

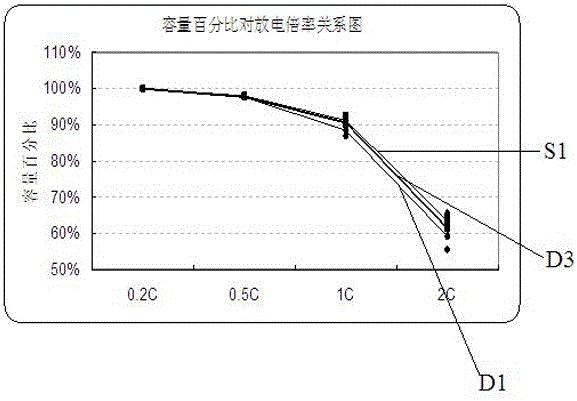

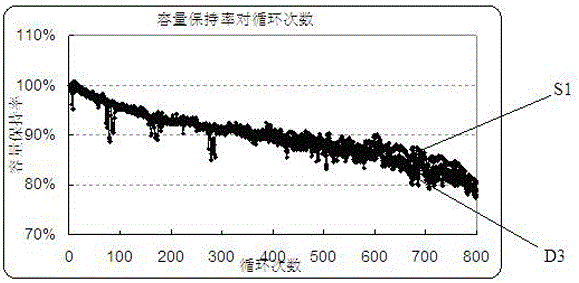

InactiveCN104269509AGood air permeabilityImprove peel forceCell component detailsCeramic coatingDiameter ratio

The invention discloses a ceramic coating diaphragm for a lithium battery and a preparation method of the ceramic coating diaphragm, and belongs to the technical field of batteries. The ceramic coating diaphragm comprises a ceramic coating and a substrate diaphragm, wherein the ceramic coating is prepared by uniformly coating the substrate diaphragm with water-based ceramic coating slurry; the ceramic coating slurry comprises components in percentage by weight as follows: 10%-30% of aluminum oxide, 0.5%-3% of a bonding agent, 0.2%-1.0% of an additive and 0.01%-0.1% of an auxiliary; and the aluminum oxide is nanometer aluminum oxide powder with the grain diameter ratio D1 / D2 of 0.10-0.20. According to the technical scheme, the safety of the ceramic coating diaphragm is improved, the wetting ability of electrolyte is improved, and the cycle life of the battery can be prolonged when the ceramic coating diaphragm is applied to the lithium battery.

Owner:SHANGHAI ELECTRICGROUP CORP

Non-woven ceramic membrane with excellent closed-pore performance for lithium ion battery and technology

ActiveCN103199209AReduce the temperatureSlow down the degree of electrochemical reactionCell component detailsCeramic coatingPore diameter

The invention provides a non-woven ceramic membrane with excellent closed-pore performance for a lithium ion battery. The non-woven ceramic membrane comprises a non-woven base material and coatings with the closed-pore performance. The non-woven ceramic membrane is characterized in that the coatings with the closed-pore performance are uniformly coated on the two surfaces of the non-woven base material, the thickness of the non-woven ceramic membrane for the lithium ion battery is 30-50mu m, the porosity of the non-woven ceramic membrane is 40-60%, the average pore diameter of the non-woven ceramic membrane is 0.1-0.5mu m, the closed-pore temperature of the non-woven ceramic membrane is 120-130 DEG C, and the membrane rupture temperature of the non-woven ceramic membrane is 300-500 DEG C. The invention also provides a preparation technology of the non-woven ceramic membrane with the excellent closed-pore performance for the lithium ion battery. The non-woven ceramic membrane has the advantage that the disintegration or explosion of the battery is not easy cause; the adhesive power between the ceramic coating and the base material is increased, and no powder falls off the surface of the membrane under the conditions of bending, rubbing and the like; the consistency of the membrane thickness is substantially improved; and the non-woven ceramic membrane has good high temperature resistance performance, high ion penetrability, low resistance and stable electrochemical property.

Owner:CHINA HAISUM ENG

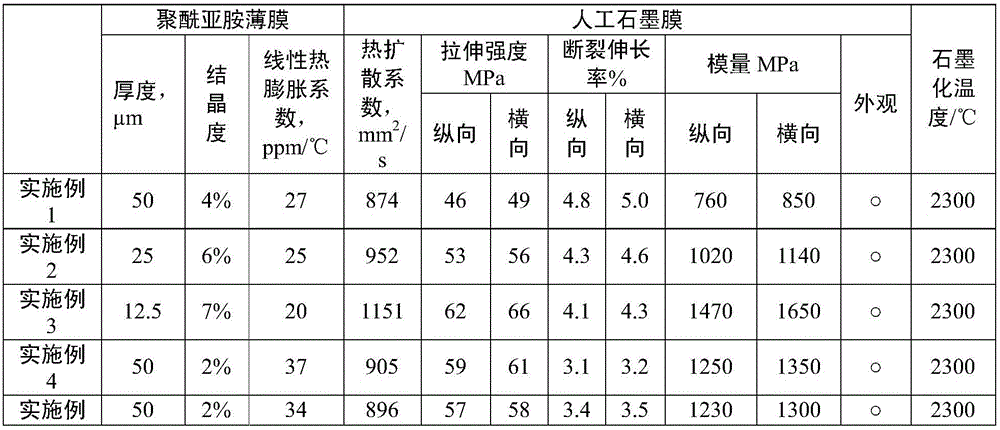

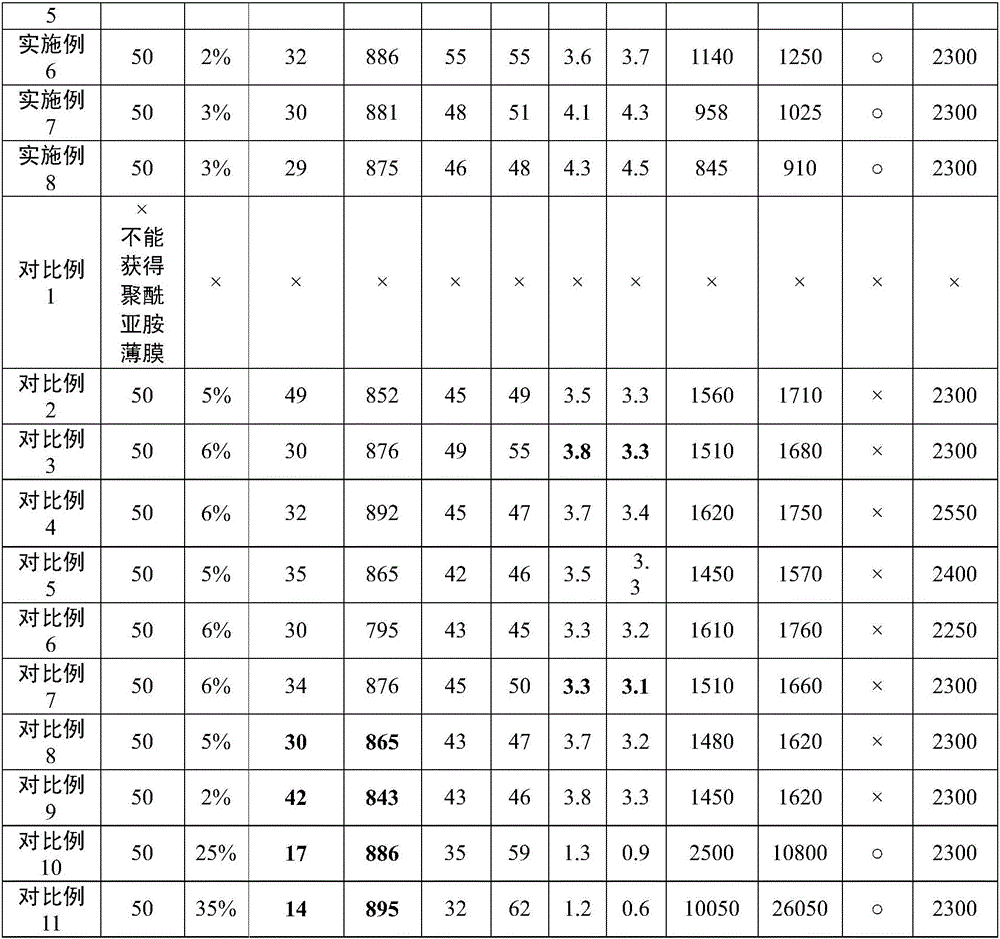

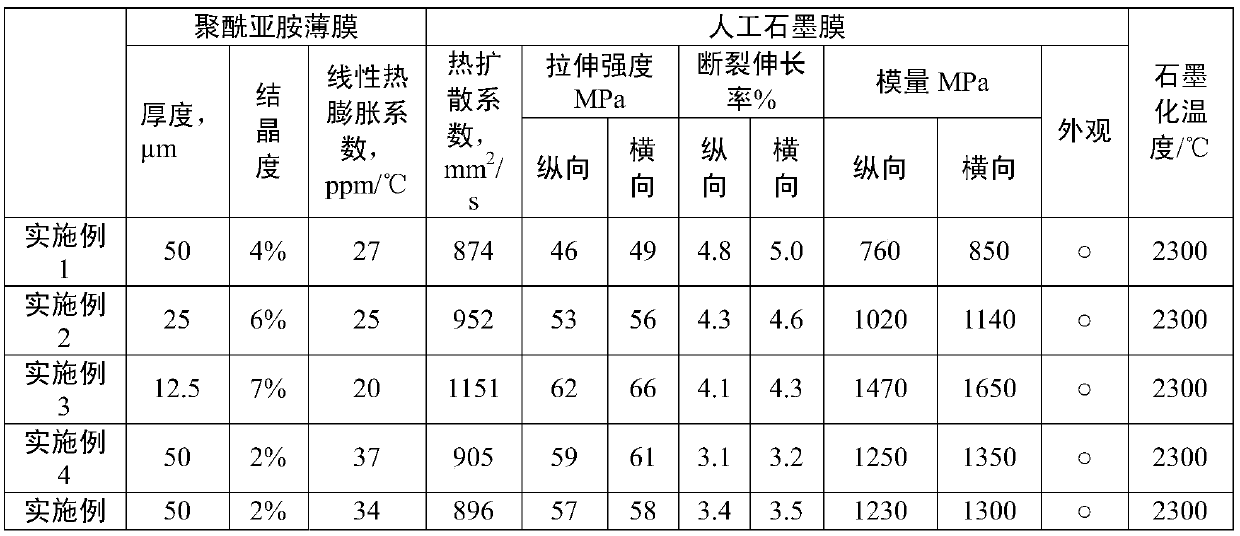

Polyimide thin film for preparing artificial graphite film and preparation method of polyimide thin film

The invention provides a polyimide thin film for preparing an artificial graphite film with excellent mechanical properties and a preparation method of the polyimide thin film. The polyimide thin film is prepared from a raw material diamine monomer which comprises 0 to 75 mol ratio of p-phenylenediamine; the raw material dianhydride monomer, comprises 40 percent to 100 mol ratio of of pyromellitic dianhydride; two types of inorganic fillers, including a calcium-containing compound and transition metal oxide, are uniformly dispersed in the polyimide thin film. The polyimide thin film provided by the invention is applicable to a graphitization process of single-sheet, multilayered stacking and continuous coiled materials and can be used for carrying out graphitization at temperature of 2300 DEG C; the crystallization degree is less than 10 percent. The graphite film prepared from the polyimide thin film has an excellent heat conducting property and has excellent mechanical properties in longitudinal and lateral directions of the thin film; the modulus is less than or equal to 2000MPa, the elongation at break is more than or equal to 3 percent, the tensile strength is more than or equal to 40MPa and the difference of the longitudinal and lateral directions is less than 15 percent.

Owner:RAYITEK HI TECH FILM CO LTD

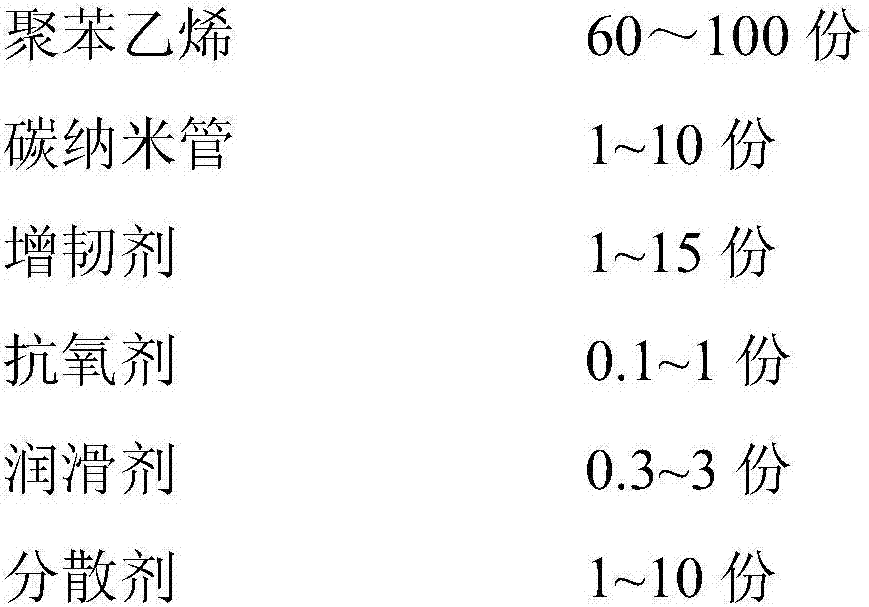

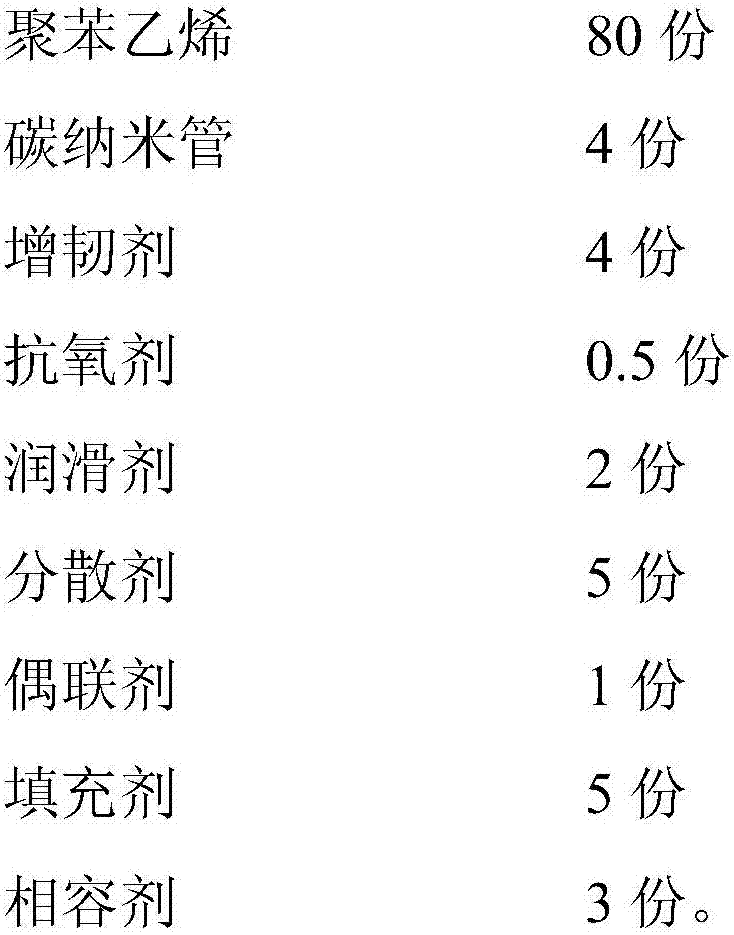

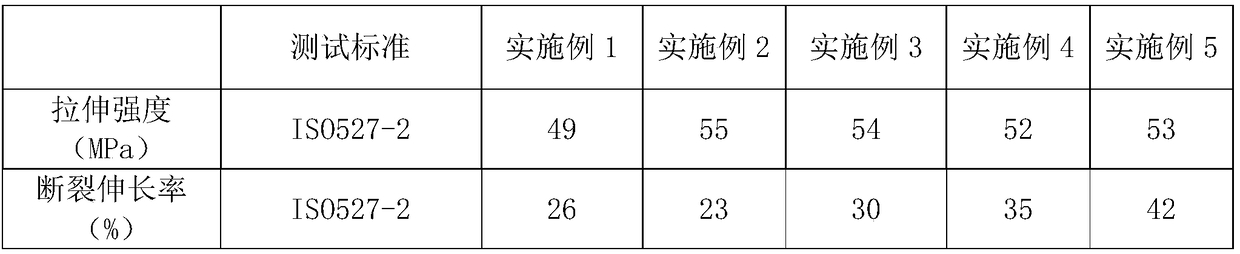

Antistatic polystyrene polymer composite material and preparation method thereof

The invention discloses an antistatic polystyrene polymer composite material which comprises the following components in parts by weight: 60-100 parts of polystyrene, 1-10 parts of carbon nano tubes, 1-15 parts of a flexibilizer, 0.1-1 part of an antioxidant, 0.3-3 parts of a lubricating agent, 1-10 parts of a dispersing agent, 0.1-3 parts off a coupling agent, 0-20 parts of a filling agent and 1-5 parts of a compatilizer. The invention further provides a method for preparing the antistatic polystyrene polymer composite material. The carbon nano tube with the weight fraction of 1-6% is added to serve as an antistatic agent, so that the antistatic polystyrene polymer composite material is high in surface gloss and easy to process and mold and has excellent mechanical property and dimensional stability. Moreover, the material is obvious and uniform in antistatic effect, can achieve the electrical resistivity of 103-108Ohm.m, can achieve a rapid antistatic effect and has permanency. Furthermore, lots of solvents are not used in the process of preparing the polystyrene polymer composite material, the usage amount of the antistatic agent is small, the composite material is convenient for volume production and popularization, and to-be-packaged products and surrounding environments are not polluted.

Owner:SHENZHEN NANOTECH PORT

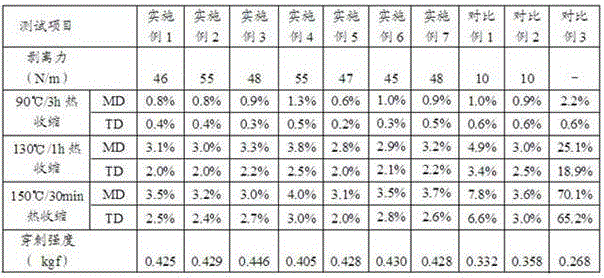

High temperature resistant battery diaphragm containing cellulose fiber substrate and preparation method thereof

InactiveCN107591512AGood wetting propertiesGood liquid absorption and liquid retention capacitySecondary cellsCell component detailsIonEmulsion

The invention discloses a high temperature resistant battery diaphragm containing a cellulose fiber substrate and a preparation method thereof. The high temperature resistant battery diaphragm has a thickness of 20-40micrometer, a porosity of 40-60%, and air permeability of 15-30sec / 100cc. The diaphragm includes a cellulose fiber substrate, a porous adhesive layer and an inorganic coating. The preparation method includes: subjecting an aqueous polyurethane emulsion to mechanical foaming, conveying a foam glue to a foam bath device, immersing the cellulose fiber substrate by traction into foambath for gluing, and letting the foam glue form the porous adhesive layer on the substrate surface; coating the cellulose fiber substrate and the porous adhesive layer with an inorganic paint, conducting compounding to form an inorganic coating; and performing drying. The high temperature resistant battery diaphragm provided by the invention has the advantages of good imbibition and liquid retention ability, no shrinkage, longitudinal and horizontal hot shrinkage both below 2%, high ion penetrability, low resistance, excellent mechanical properties, and stable electrochemical properties, and can prevent battery short circuit and dendrite piercing.

Owner:TIANJIN YISEN MATERIAL TECH CO LTD

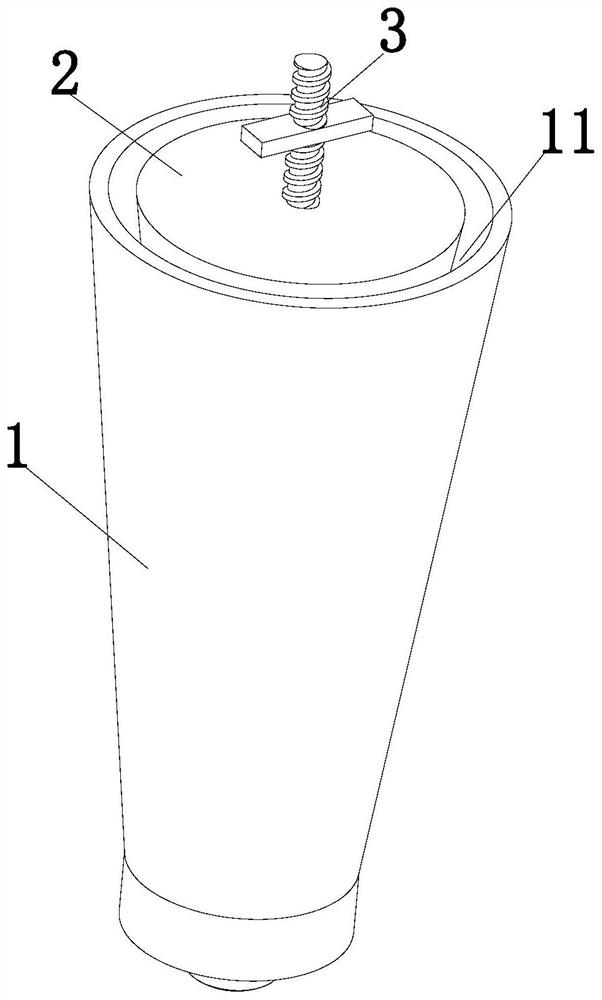

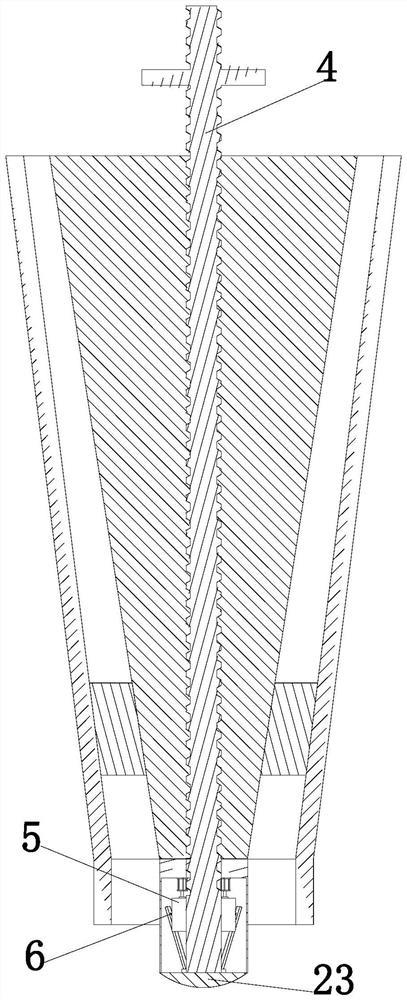

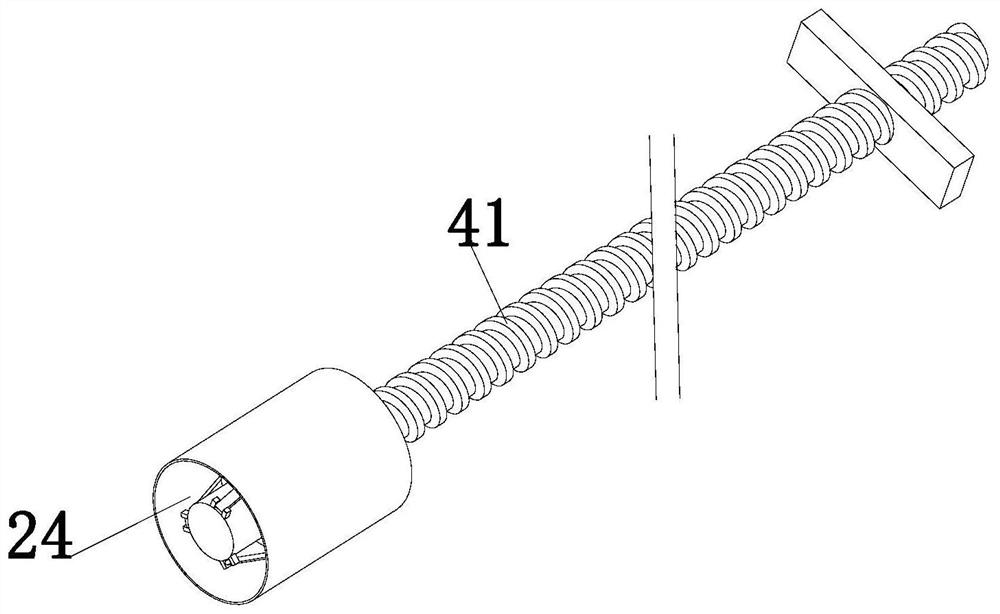

Bone meal conveyor

InactiveCN113349967AAvoid damagePrecise distance controlDental implantsDental instrumentsEngineering

The invention relates to the technical field of dental instruments, in particular to a bone meal conveyor. The bone meal conveyor comprises a bone meal container, a conveying component and a stirring component, the bone meal container is vertically arranged on the horizontal plane and is in an inverted cone shape, a first containing cavity is formed in the bone meal container, the conveying component is arranged in the first containing cavity in the bone meal container, a hollow structure is arranged at the output end of the conveying component, the taper of the conveying component is consistent with that of the bone meal container, the stirring component is arranged in the hollow structure at the output end of the conveying component, the distance entering the maxillary sinus can be accurately controlled by utilizing an outer ring sleeve on the outer side wall of the conveyor, and the maxillary sinus is prevented from being damaged in the conveying process; the bone meal is filled into the maxillary sinus, a funnel-shaped outlet is large, the bone meal can be rapidly and effectively conveyed into the maxillary sinus for filling at a time, the speed is high, powder falling is avoided, operation of medical staff is facilitated, the bone meal filling effect is good, the filling operation time is greatly shortened, and the bone meal in the maxillary sinus can be evenly stirred.

Owner:惠州市了凡口腔医院有限公司

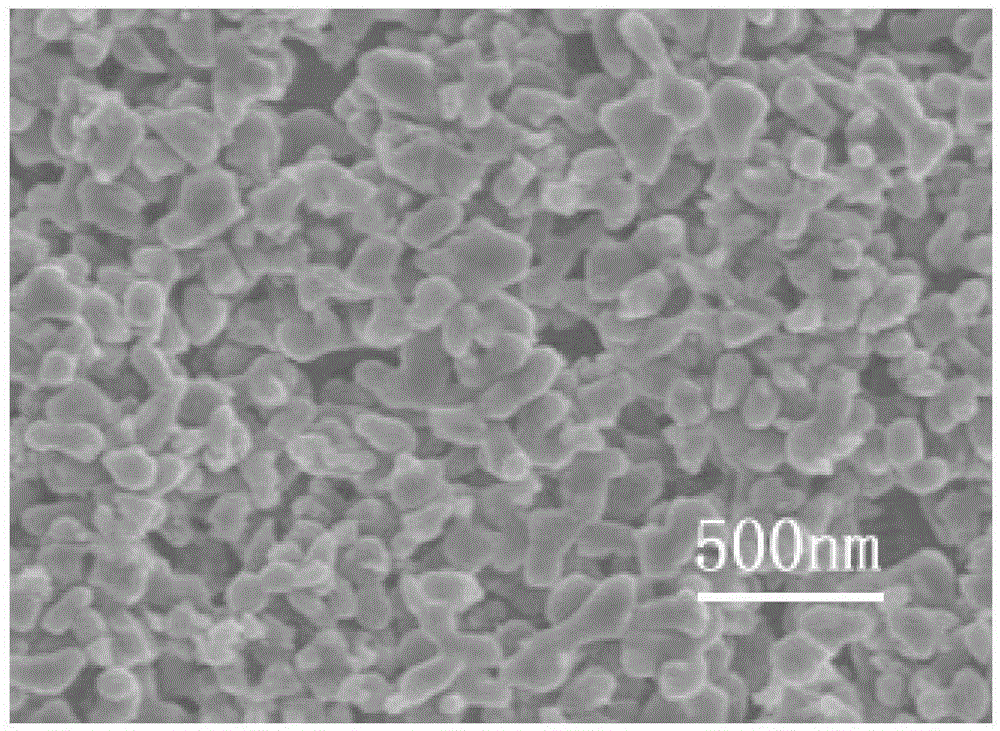

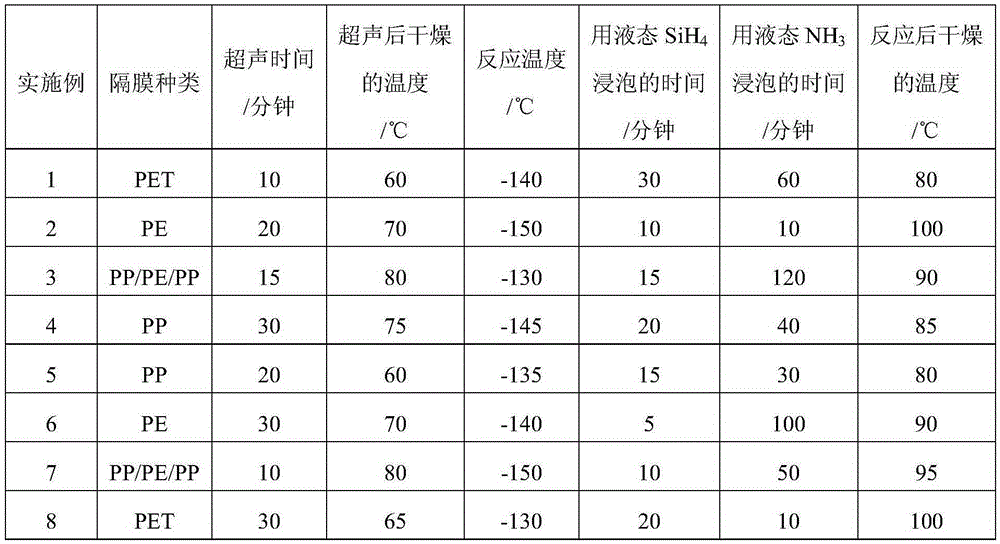

Silicon nitride composite separator and preparation method thereof

The invention relates to a silicon nitride composite separator and a preparation method thereof. The preparation method comprises the following steps: at a temperature of -50 DEG C to -30 DEG C, immersing the separator with liquid monosilane for 5-30 min, then immersing the separator with liquid ammonia for 10-120 min, so as to depositing silicon nitride on the separator surface, and finally performing vacuum drying to obtain the silicon nitride composite separator. By employing the one-step synthetic technology, silicon nitride is effectively uniformly distributed on the separator surface. Because no adhesives are used and a high-temperature sintering process is not used, the silicon nitride composite separator has good heat resistance and is not easy to dust, and thus the safety of a battery is improved. Additionally, the whole preparation process is simple, the raw material cost is low and batch production is easy to realize.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

PC/ABS composite material of metal texture and preparation method thereof

The invention discloses a PC / ABS composite material of a metal texture. The composite material is prepared from the following components in parts by weight: 65-98 parts of resin, 0-2 parts of pearl resin, 0.05-0.1 part of silicone oil, 0.5-5 parts of a metal pigment, 0.5-1.5 parts of an extractant, 0.5-1 part of an adsorbent, 0.2-1 part of a processing heat stabilizer, 0.1-2 parts of a processinglubricant and 0.5-25 part of other functional auxiliary agents. The resin is a mixture of polycarbonate and ABS resin in a proportion of 1: 1. The composite material is high in strength, good in stability, high in processibility, high in metal texture and high in interfacial strength, does not drop powder, and is free of harmful volatile organic compounds, so that the problem of environmental pollution caused by follow-up processing is avoided, and the composite material is more environment-friendly and safe.

Owner:重庆科聚孚新材料有限责任公司 +1

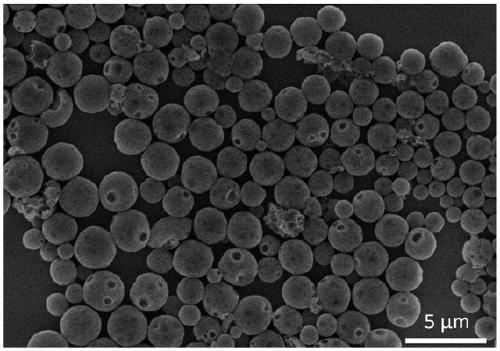

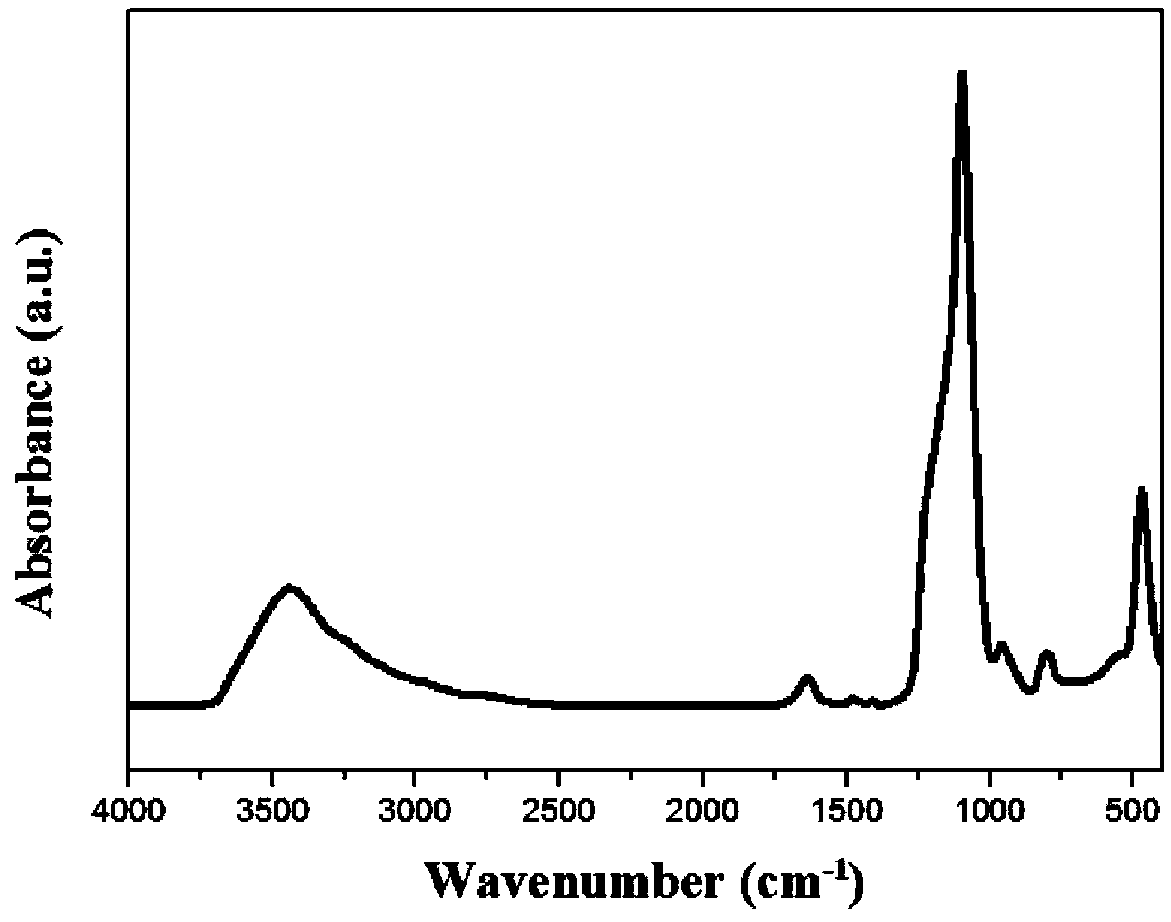

A kind of hydrophilic silicon dioxide airgel microsphere and preparation method thereof

Owner:上海特栎材料科技有限公司

Non-woven ceramic diaphragm and process for lithium-ion batteries with excellent closed-cell performance

ActiveCN103199209BReduce the temperatureSlow down the degree of electrochemical reactionCell component detailsElectrical batteryCeramic coating

Owner:CHINA HAISUM ENG

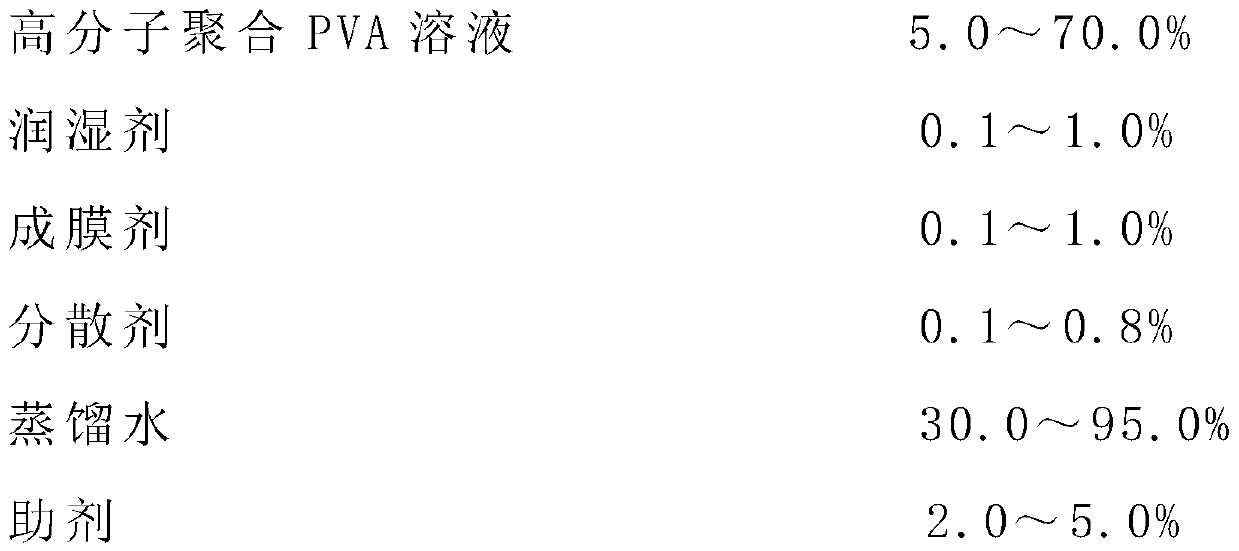

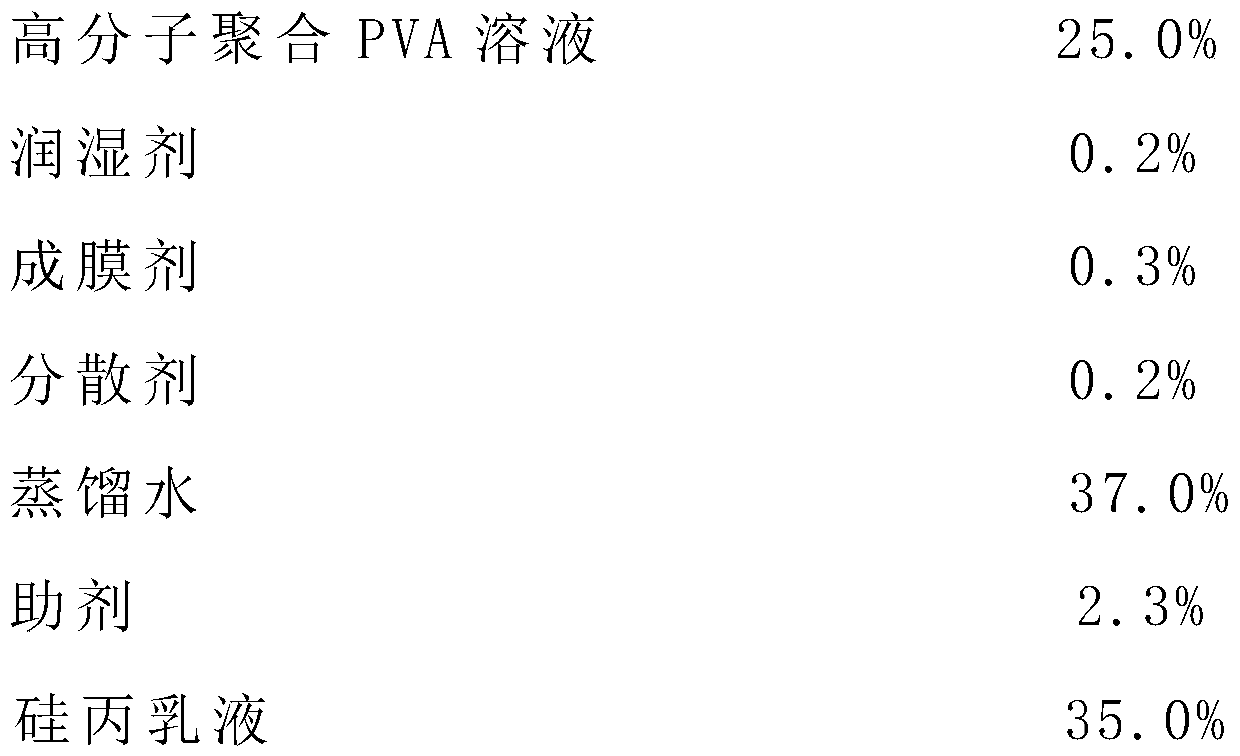

Printing ink connection material

The invention discloses a printing ink connection material which comprises the following components in percentage by weight: 5.0-70.0% of a macromolecular polymerized PVA solution, 0.1-1.0% of a wetting agent, 0.1-1.0% of a film-forming agent, 0.1-0.8% of a dispersant, 30.0-95.0% of distilled water and 2.0-5.0% of an auxiliary agent. The used macromolecular polymerized PVA solution is a safe macromolecular organic matter, does not have toxic or side effect on a human body, has good biocompatibility, and is a common safe film-forming agent in the aspect of paper coating layers. The printing inkconnection material is simple to prepare, common and easily available in materials, low in cost, water-based and environment-friendly and can adapt to large-batch industrial production, and the quality stability of printed matters is ensured; coated paper has digital printing adaptability, can be directly printed by digital printing paper without being coated again, and can be applied to variousoccasions for improving offset printing performance of special paper, enhancing digital printing adaptability and the like.

Owner:李辉

A kind of polyimide film for preparing artificial graphite film and preparation method thereof

Owner:RAYITEK HI TECH FILM CO LTD

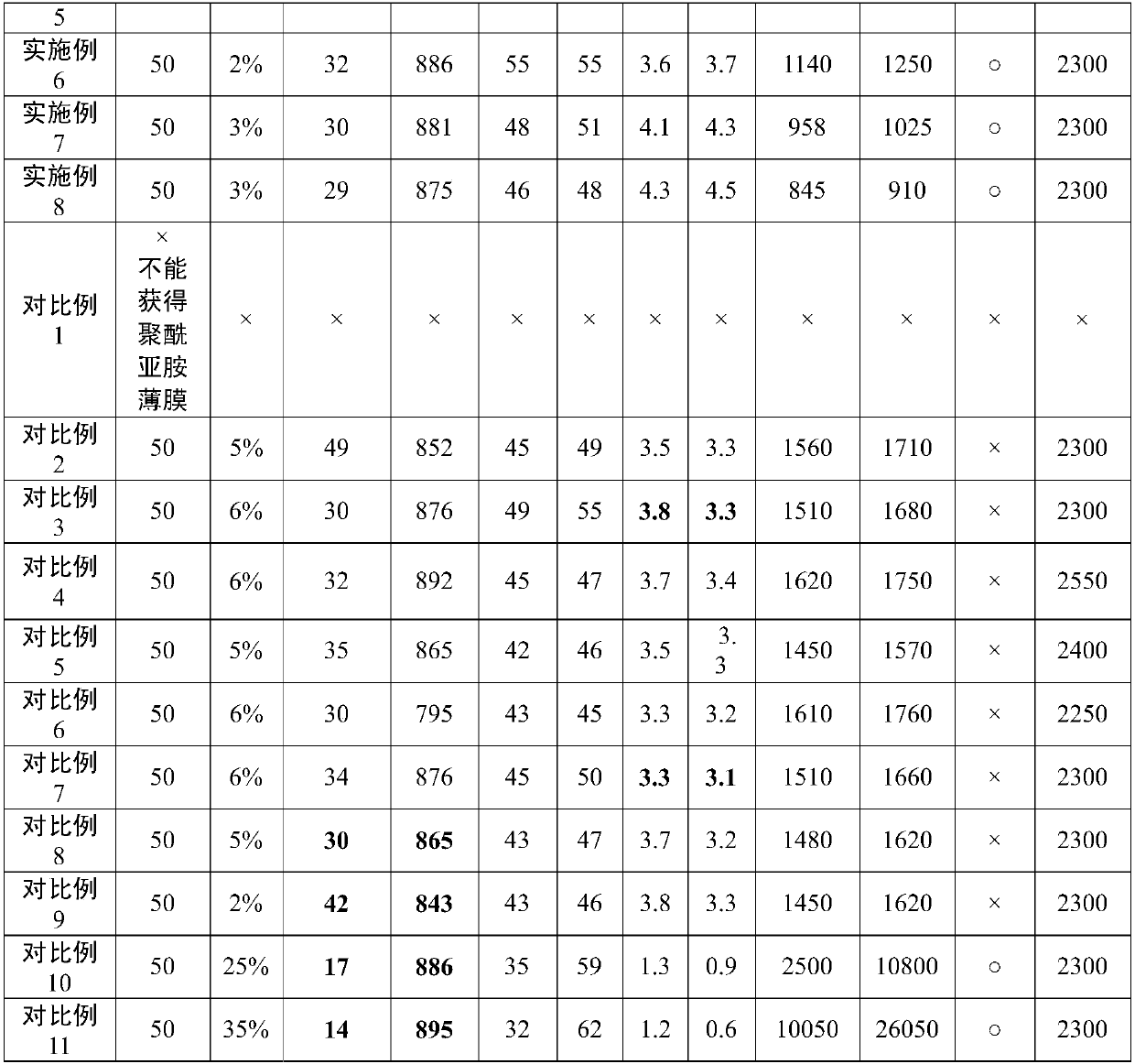

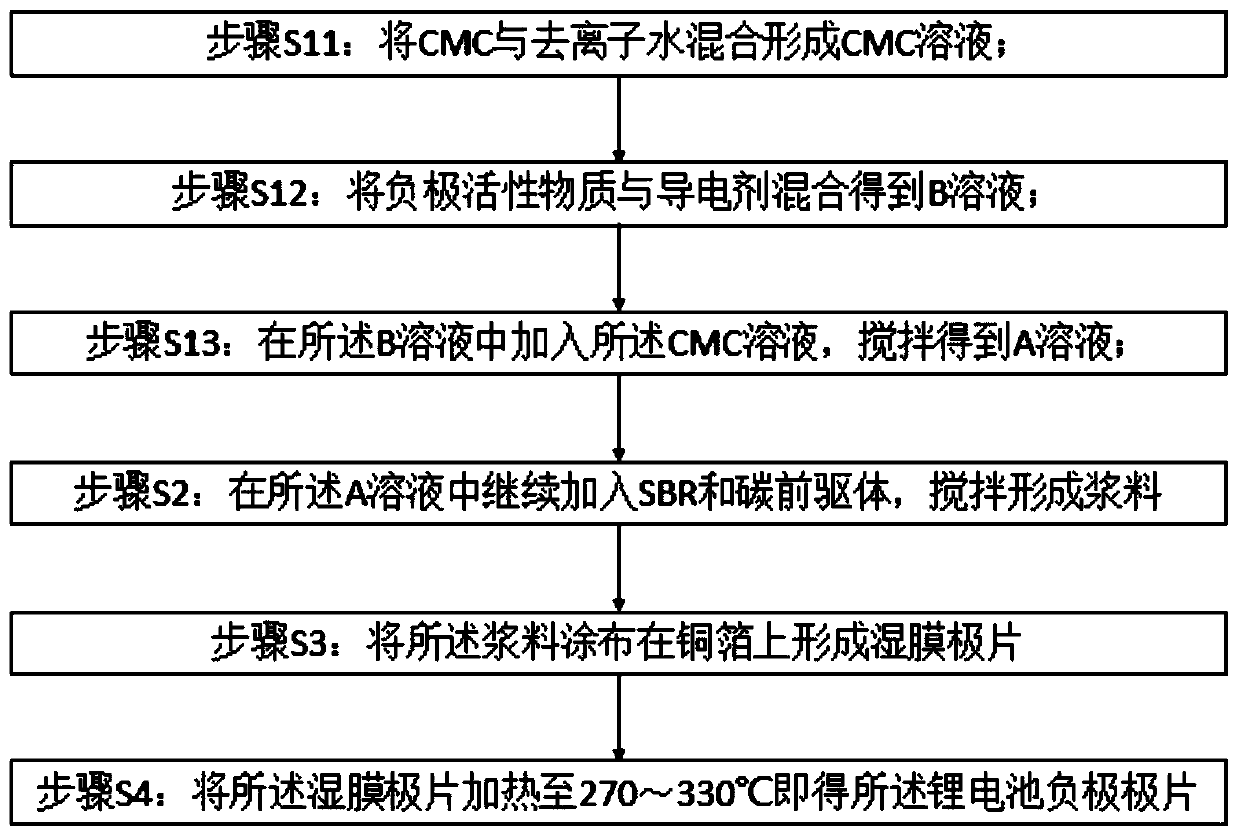

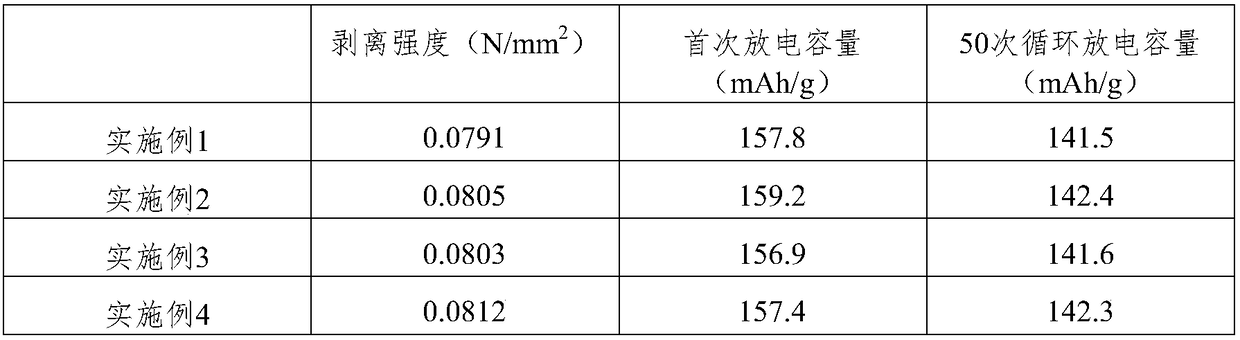

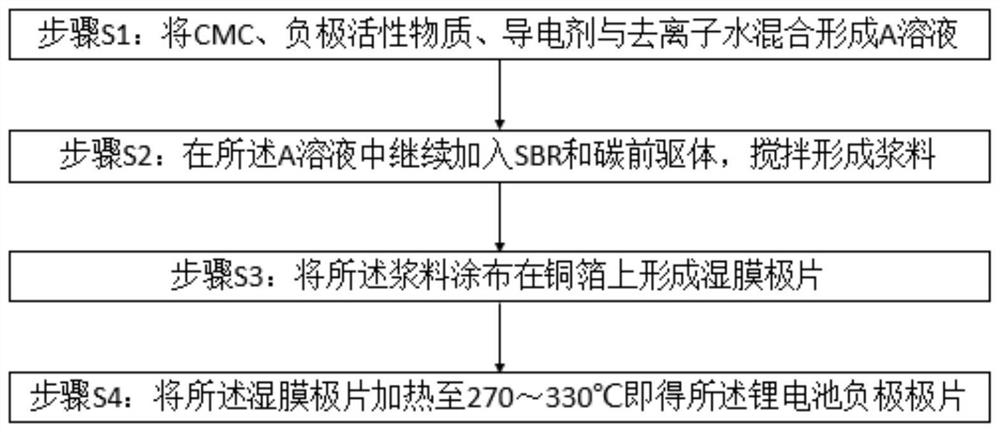

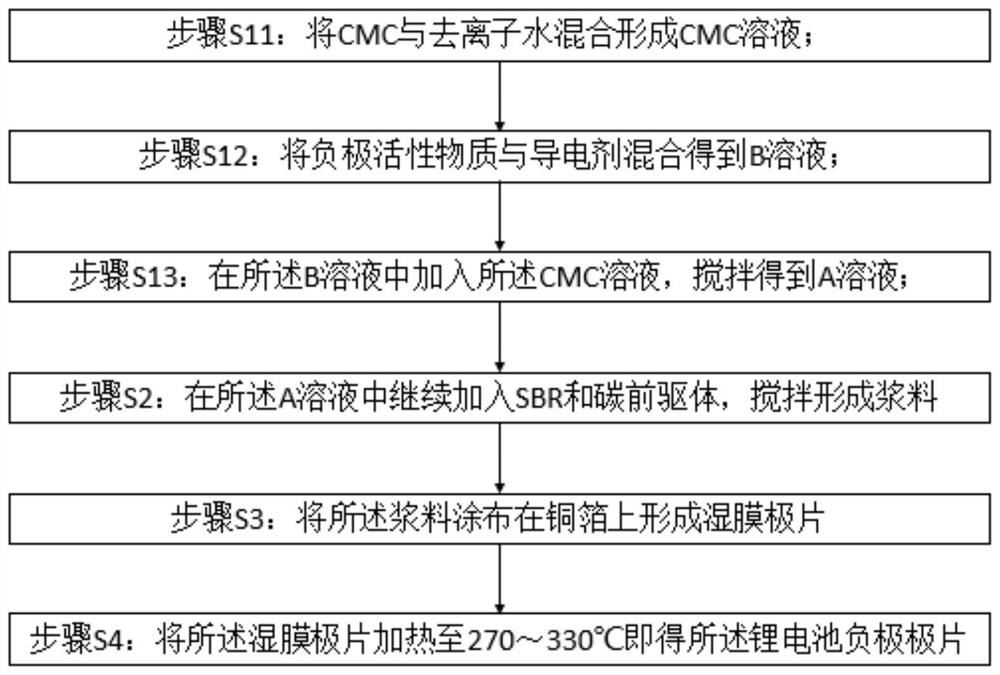

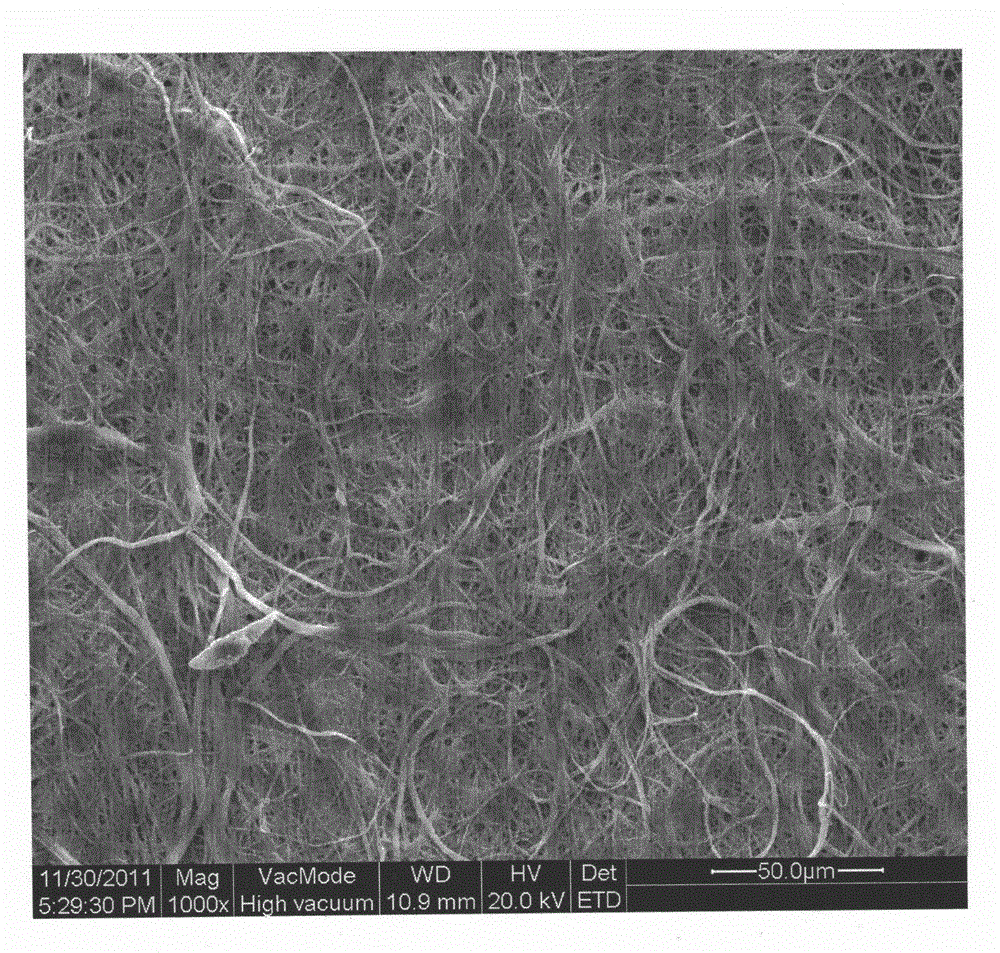

Preparation method of lithium battery negative pole piece

ActiveCN111554873AWide variety of sourcesLow priceSecondary cellsNegative electrodesCopper foilElectrically conductive

The invention discloses a preparation method of a lithium battery negative pole piece. The preparation method comprises the following steps: S1, mixing CMC, a negative active substance, a conductive agent and deionized water to form a solution A; S2, continuously adding SBR and a carbon precursor into the solution A, and performing stirring to form slurry; S3, coating a copper foil with the slurryto form a wet film pole piece; and S4, heating the wet film pole piece to 270-330 DEG C to obtain the lithium battery negative pole piece. According to the preparation method of the negative pole piece provided by the invention, the addition amount of the SBR is reduced, a small amount of carbon precursor is added, and the carbon precursor is heated and decomposed to form a carbon chain with functional groups such as carbonyl and double bonds, so that battery cell expansion caused by SBR swelling is slowed down in the processes of adding electrolyte and charging and discharging, and the polepiece does not drop powder due to reduction of the adding amount of the SBR.

Owner:SHANGHAI ELECTRICGROUP CORP

Method for improving anode aluminum foil current collector performance

InactiveCN109390550AStir wellImprove toughnessElectrode carriers/collectorsSecondary cellsUltimate tensile strengthAluminum foil

The invention relates to the technical field of anode materials of batteries, and particularly relates to a method for improving an anode aluminum foil current collector performance. The method is characterized in that the surface of an aluminum foil is preprocessed with a preprocessing solution, so that stains on the surface of the aluminum foil can be cleaned, and a metal substrate is completelyexposed; moreover, some acid group anions can be loaded onto the surface of the metal substrate, so that the metal substrate without being washed can be processed in a sodium fluoborate solution, andthus the formation of a microporous film on the surface of the metal substrate can be facilitated; the toughness of the aluminum foil is improved, and the aluminum foil can be closely combined with an adhering agent, the adhering intensity is improved, and the peeling strength is improved.

Owner:遵义源创生产力促进中心有限公司

Production process of flame-retarding polystyrene foam board

InactiveCN109400944AWon't lose powderAchieving Flame RetardancyEnvironmental resistanceFlame resistance

The invention discloses a production process of a flame-retarding polystyrene foam board. The process includes: spraying a flame-retarding agent solution onto the upper or lower surface of a polystyrene foam board; sucking the flame-retarding agent solution, from the corresponding upper or lower surface of the polystyrene foam board, away by using a vacuumizing device; and air-drying the polystyrene foam board. The production process is environment-friendly and the product has good flame-retarding effect.

Owner:ZHEJIANG PENGYUAN NEW MATERIAL TECH GRP CO LTD

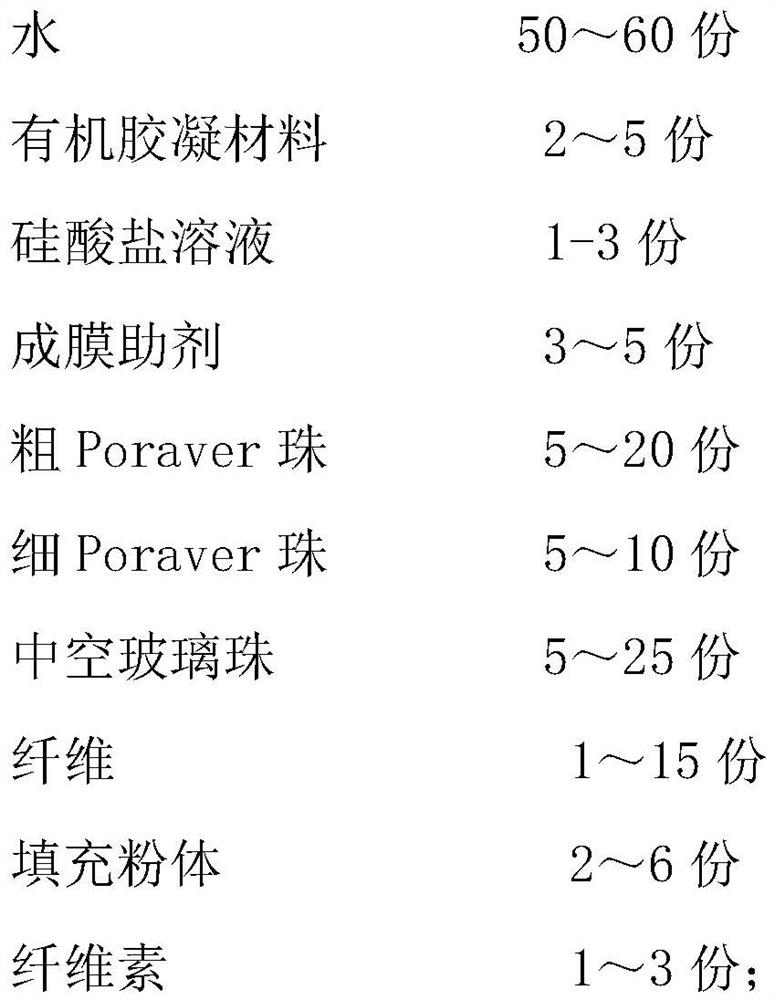

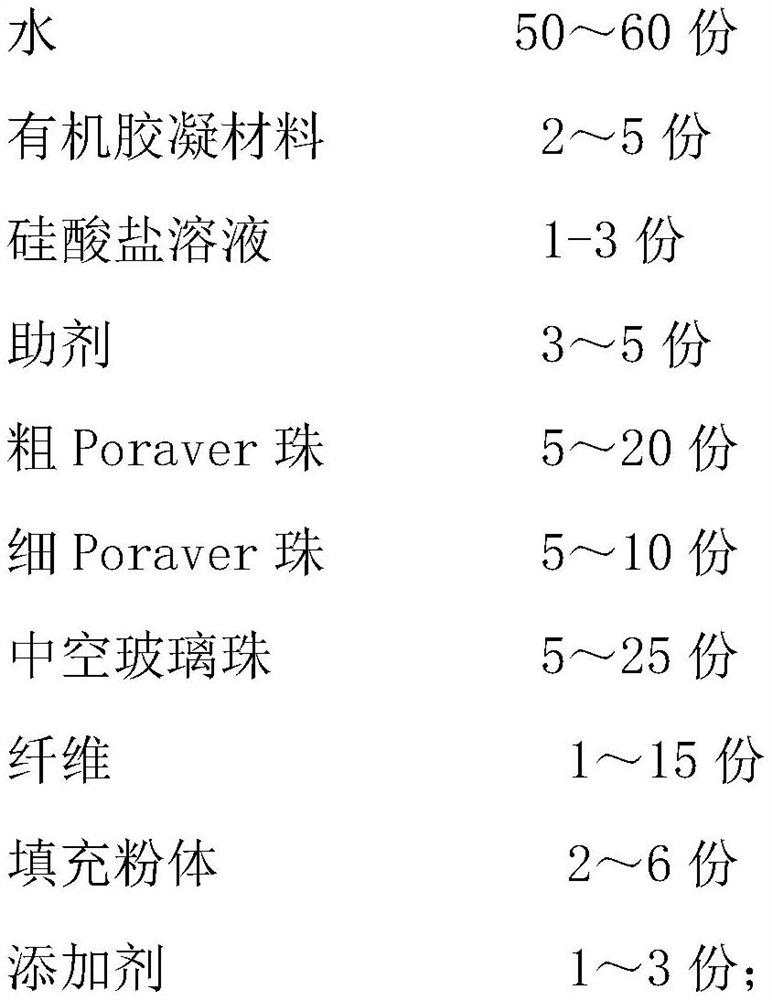

Heat preservation and sound absorption paste for roof and preparation method of heat preservation and sound absorption paste

ActiveCN114196237AImprove the sound absorption coefficientSound absorption frequency bandwidthSolid waste managementMulticolor effect coatingsFiberThermodynamics

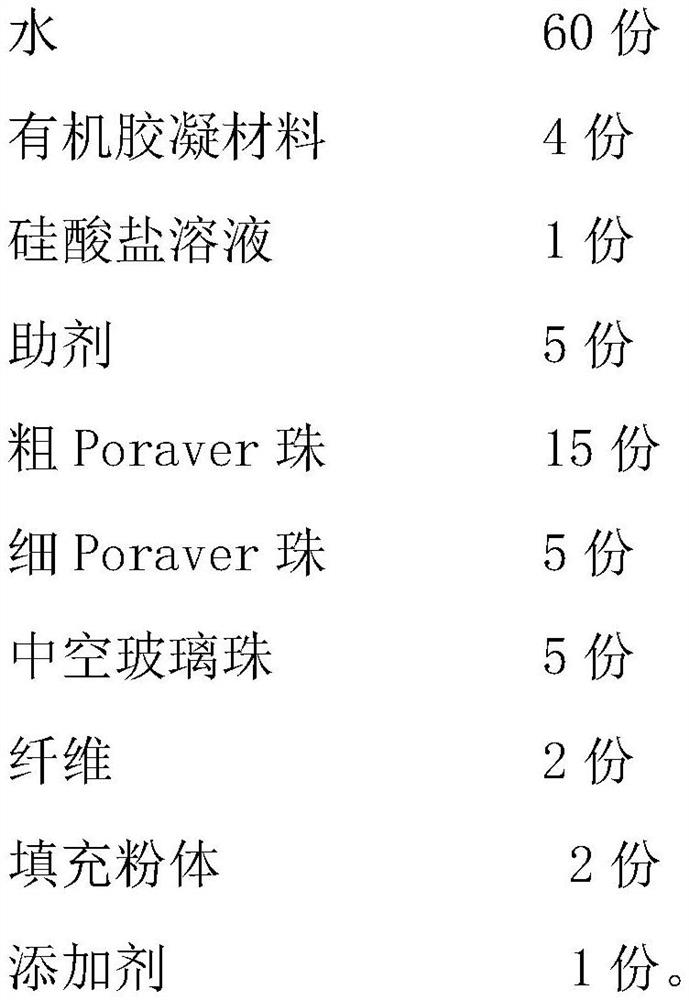

The invention relates to a heat-preservation and sound-absorption paste material for a roof and a preparation method thereof. The heat-preservation and sound-absorption paste material is prepared from the following components in parts by mass: 50-60 parts of water, 2-5 parts of an organic cementing material, 1-3 parts of a silicate solution, 3-5 parts of an auxiliary agent, 5-20 parts of coarse Poraver beads, 5-10 parts of fine Poraver beads, 5-25 parts of hollow glass beads, 1-15 parts of fibers, 2-6 parts of filling powder and 1-3 parts of an additive, the bulk density of the coarse Poraver beads is 110-150kg / m < 3 >, and the particle size D90 of the coarse Poraver beads is less than or equal to 2mm; the bulk density of the fine Poraver beads is 180-220 kg / m < 3 >, and the particle size D90 of the fine Poraver beads is 0.3 mm. The invention has the advantages of high sound absorption coefficient, wide sound absorption frequency band, fast construction, seamless surface, safety, environmental protection and the like.

Owner:上海三棵树防水技术有限公司

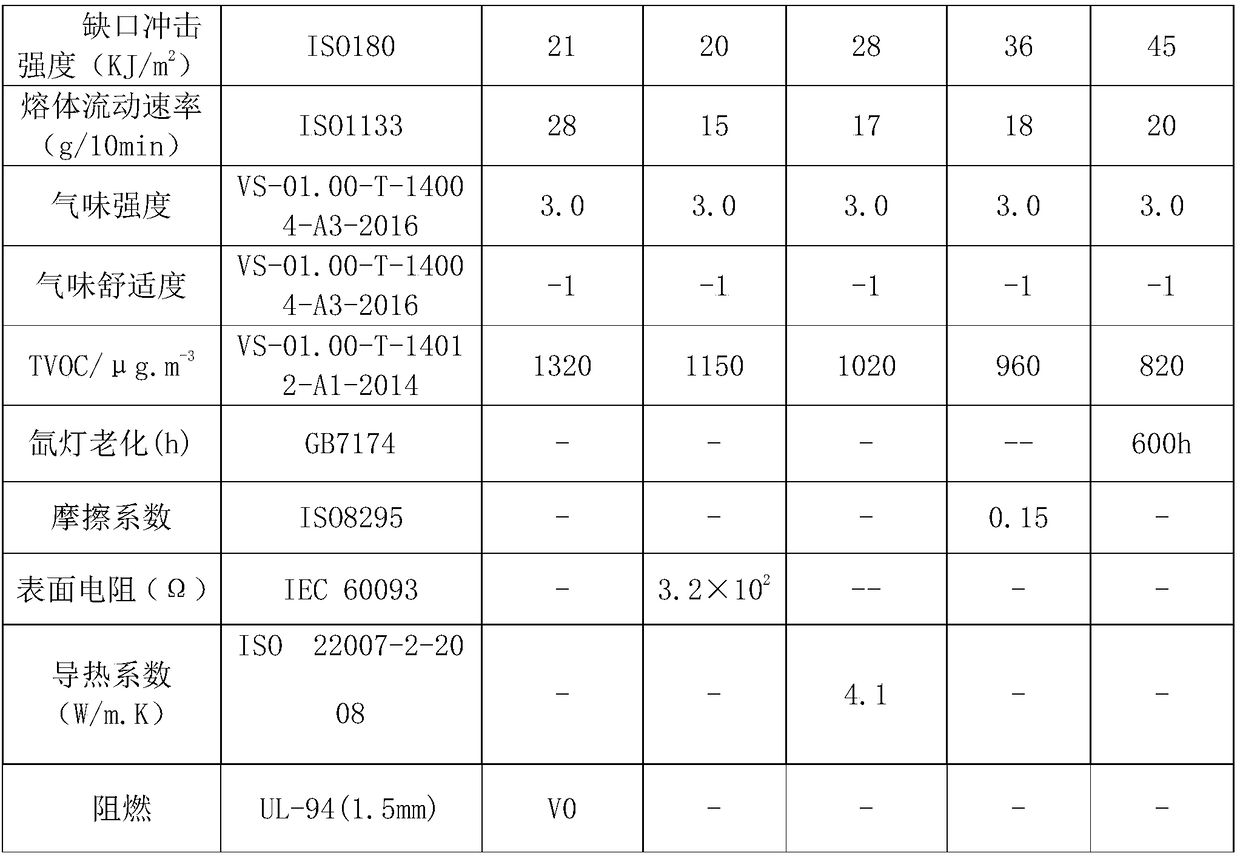

a fuel catalyst

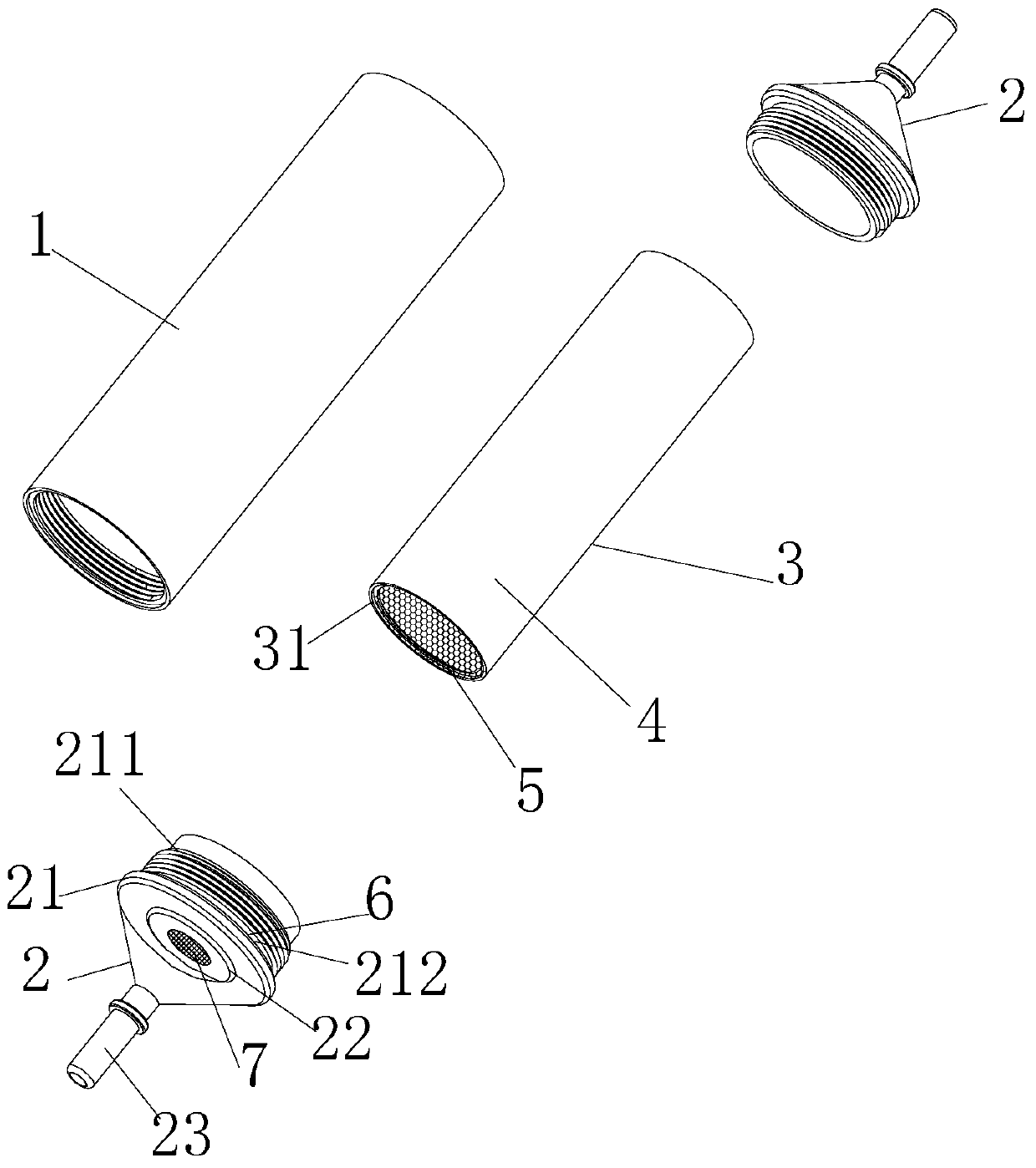

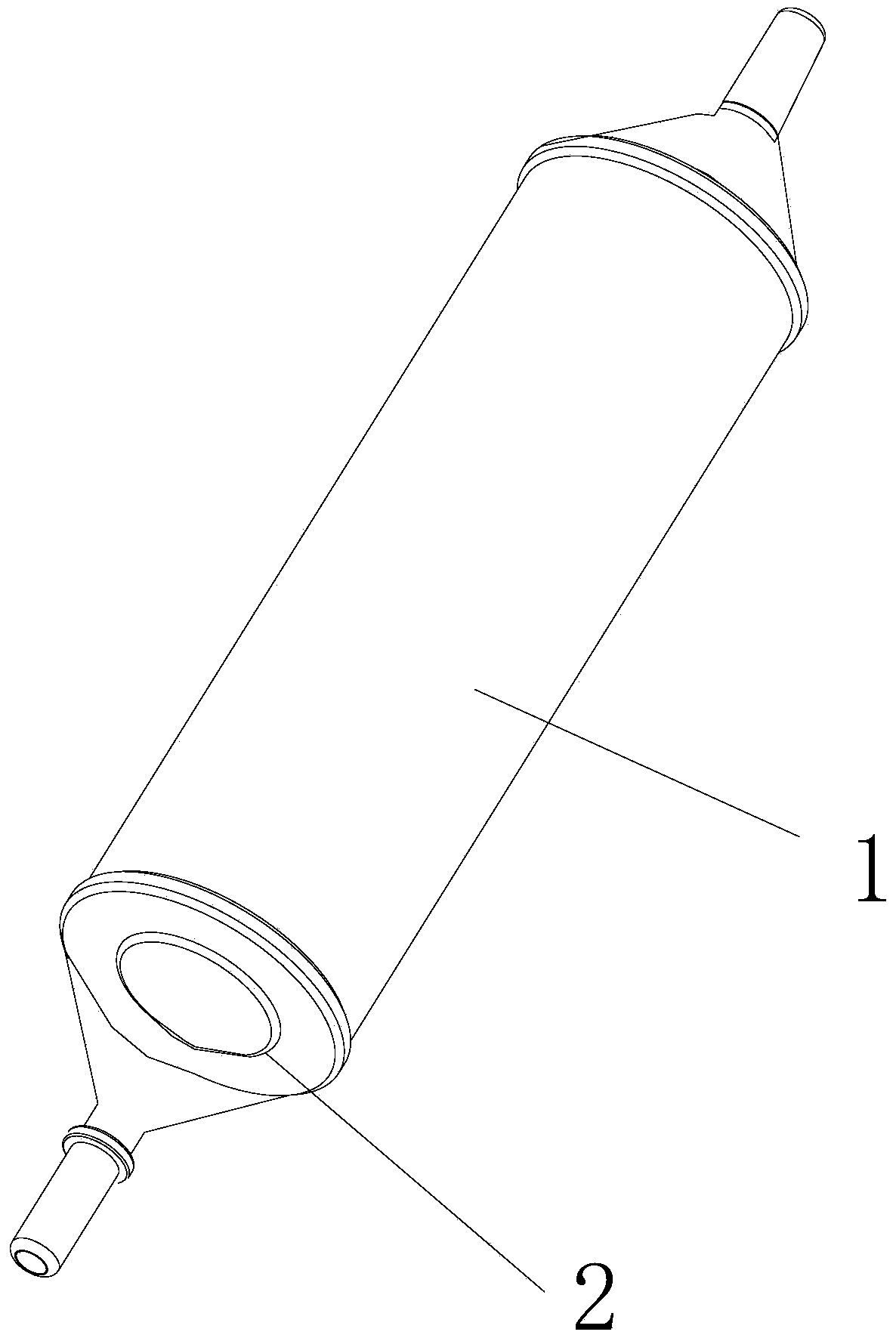

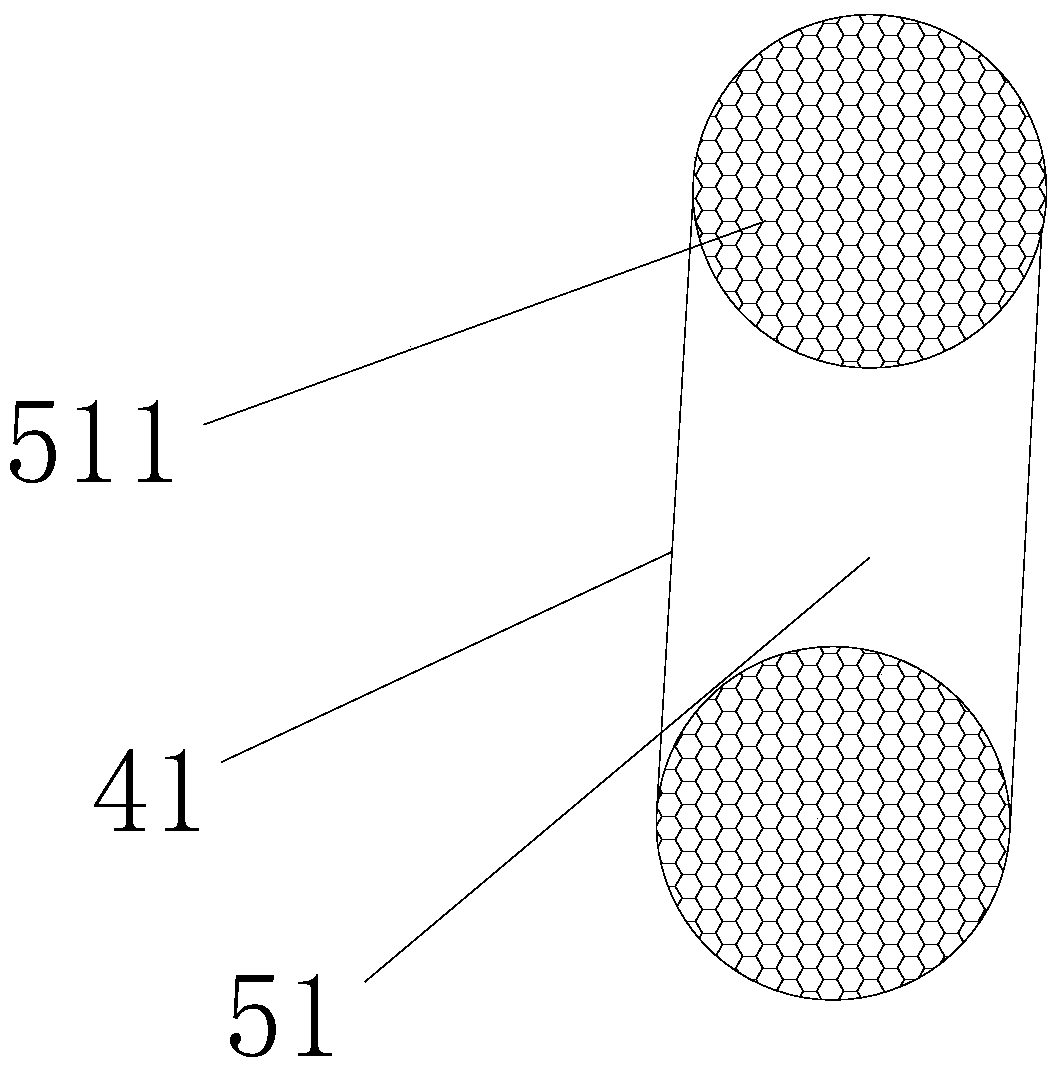

ActiveCN105396543BHigh activityIncrease motivationHeterogenous catalyst chemical elementsFuel re-atomisation/homogenisationFuel oilHoneycomb structure

The invention relates to the technical field of fuel catalytic devices, and in particular to a fuel catalytic converter, which includes a structural main body, which is a hollow columnar structure. Covers are provided at both ends of the structural main body, and oil pipe connection ports are provided on the cover. The structure The main body is equipped with a hollow carrier shell, and the carrier shell is filled with a fuel catalytic core. The fuel catalytic core includes a honeycomb catalyst carrier, and the surface of the honeycomb catalyst carrier is coated with a fuel catalyst. The fuel catalytic core uses a honeycomb catalyst carrier, and the honeycomb structure is regular. The fine pores evenly distribute and catalyze the fuel, and the effect is stable and long-lasting. The honeycomb catalyst carrier is coated with a fuel catalyst, which has a unique structure. The contact area between the fuel and the fuel catalyst is large, reducing fuel consumption by 15-20%, and effectively reducing the original vehicle fuel rate. ; It can increase power by 15-25%, shorten braking distance, and reduce exhaust pollutants by more than 50%. The catalyst will not fall off or be clogged, and fuel can pass smoothly. It has a simple structure and is easy to install.

Owner:GUANGZHOU NANSHU ELECTRONICS TECH CO LTD

Silver-loaded expanded graphite prepared by extra-large flaky graphite and preparation and application thereof

The invention discloses silver-loaded expanded graphite prepared by extra-large flaky graphite and preparation and application thereof. The expanded graphite is loaded with silver nanoparticles, and is prepared by the extra-large flaky graphite. Specific methods comprise an impregnating reducing method, a coating method and a spraying method; the impregnating reducing method adopts a non-toxic reducing agent to simultaneously reduce oxygen-containing functional groups and silver ions of the graphite; the coating method refers to coat a layer of silver nitrate solution onto the expanded graphite; the spraying method refers to spray the silver nitrate solution in a mist state onto the expanded graphite. The silver-loaded expanded graphite prepared by the extra-large flaky graphite through the several methods has the advantages that the bacteria sterilizing and inhibiting properties are excellent, the methods are simple, the operation is easy, the cost is low, and the methods are suitable for being popularized and applied; the silver-loaded expanded graphite prepared by the extra-large flaky graphite is used for wound dressings, the sticking with wounds is avoided in the use process, the pain is relieved, and the healing of the wounds is promoted; the bacteria sterilizing and inhibiting properties are excellent, and the infection of the wounds by bacteria is avoided.

Owner:TSINGHUA UNIV

Hot-melting veiled car line paste and preparation method thereof

The invention relates to a hot-melting veiled car line paste and a preparation method thereof. The car line paste is composed of 100 parts of high-saturated fatty acid, 5 to 10 parts of polyoxyethylene-type nonionic surfactant and 180 to 220 parts of purified water. The preparation method comprises the following steps of: 1) putting the high-saturated fatty acid and the polyoxyethylene-type nonionic surfactant into a container; heating to the temperature of 70 to 80 DEG C and melting, thereby preparing an oil phase; 2) slowly dropwise adding the purified water preheated to the temperature of 70 to 80 DRG C into the oil phase in a stirring manner; after dropwise adding, heating to the temperature of 78 to 85 DRG C; preserving heat and stirring for 30 minutes, thereby obtaining an emulsifying body; and stirring and cooling to the room temperature, thereby obtaining the hot-melting veiled car line paste. By adopting the screen plate printing, a white positioning line formed on the surface of a fabric material is clear, long in retention time and free of blocking a screen plate during the printing process. The positioning line can be automatically molten to disappear after the fabric material is shaped in a processing manner, and cannot generate any residual trace. The raw materials and the product provided by the invention are safe, environment-friendly and free of toxic effect to a human body.

Owner:HUBEI NORMAL UNIV

Silicon nitride composite diaphragm and preparation method thereof

ActiveCN103928647BImprove heat resistanceTightly combinedCell component detailsHeat resistanceBattery cell

The invention relates to a silicon nitride composite diaphragm and a preparation method thereof. The preparation method comprises the following steps: soaking the diaphragm with liquid silane for 5 to 30 minutes at a temperature of -150°C to -130°C, and then using liquid The diaphragm is soaked in ammonia for 10-120 minutes to deposit silicon nitride on the surface of the diaphragm, and finally vacuum-dried to obtain the silicon nitride composite diaphragm. The invention effectively and evenly distributes the silicon nitride on the surface of the diaphragm through a one-step synthesis technique. Because there is no adhesive and high-temperature sintering method, the silicon nitride composite diaphragm of the invention has good heat resistance and is not easy to drop powder, thereby improving the safety of the battery. In addition, the whole preparation process of the present invention is simple, the cost of raw materials is low, and it is easy to realize mass production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

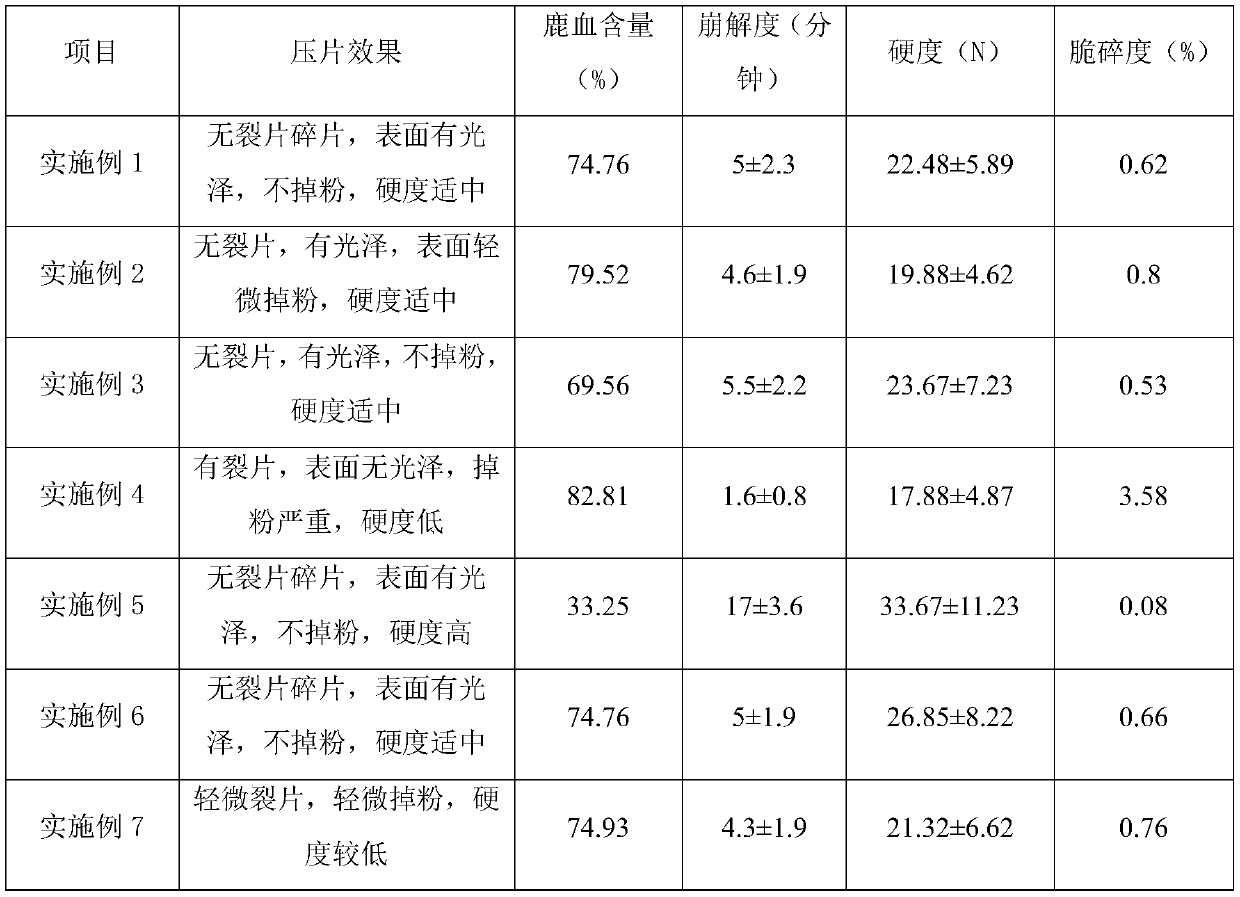

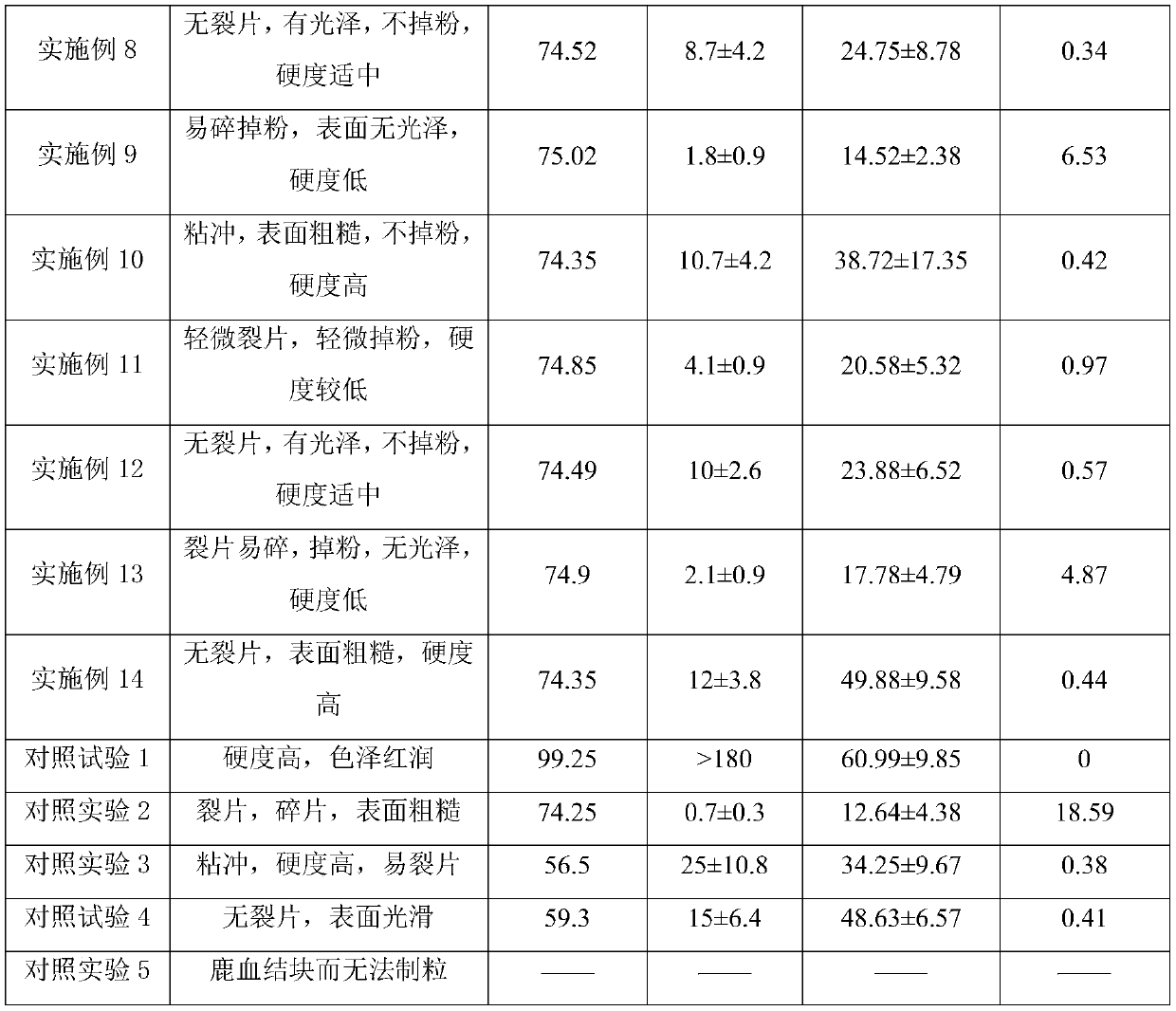

A kind of preparation method of deer blood tablet

InactiveCN108553485BGuaranteed molding effectSolve the problem of easy caking when encountering waterNervous disorderAntinoxious agentsBiotechnologyFood additive

The invention relates to a preparation method of deer blood slices, belonging to the technical field of deer blood deep processing. The method is to dry or freeze-dry deer blood, sterilize, crush, and sieve to obtain spare deer blood powder; dissolve xylitol in ethanol solution to obtain xylitol-ethanol solution; mix spare deer blood powder with xylose Stir the alcohol-ethanol solution to make a soft material, sieve the soft material and granulate to obtain wet granules, dry the wet granules, sieve and granulate to obtain dry deer blood granules; dry deer blood granules and micro The crystalline cellulose was mixed evenly, compressed into tablets and then dried to obtain deer blood tablets. The preparation method of the invention can effectively reduce the content of food additives, promote the preservation of maximum deer blood raw materials, and further improve the health care effect of deer blood powder, and the method is suitable for preparing deer blood tablets.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

Indoor decoration daily use pure kieselguhr process brick and preparation method thereof

The invention provides an indoor decoration daily use pure kieselguhr process brick and a preparation method thereof, and relates to the technical field of decoration materials. The problems that theprocess of the existing kieselguhr water absorption pad product is complicated; the water absorption performance is poor; the powder falling can easily occur; bacteria easily grow are solved. The indoor decoration daily use pure kieselguhr process brick is prepared from the following ingredients in parts by weight:50 to 80 parts of first grade kieselguhr, 20 to 35 parts of binding agents and 15 to30 parts of dispersants. Ingredients possibly harmful to the human body such as plaster, paper pulp fiber and dye are not added in the production process; the process is simple; almost no waste is generated; after the powder body pressing shaping, high-temperature firing is performed; the materials can be used after being taken out and cooled; through the high-temperature firing process, possiblebacteria and organic matters can be removed together; the safety and the sanitation of the products are ensured; after the long-time use, no foreign smell is generated. Only the natural pure kieselguhr is used as raw materials, so that the weight of the finished product is light; meanwhile, the texture is hard and firm; powder falling cannot occur after the wiping and washing by force; the waterabsorption performance is obviously improved.

Owner:吉林省谊美生物科技有限公司

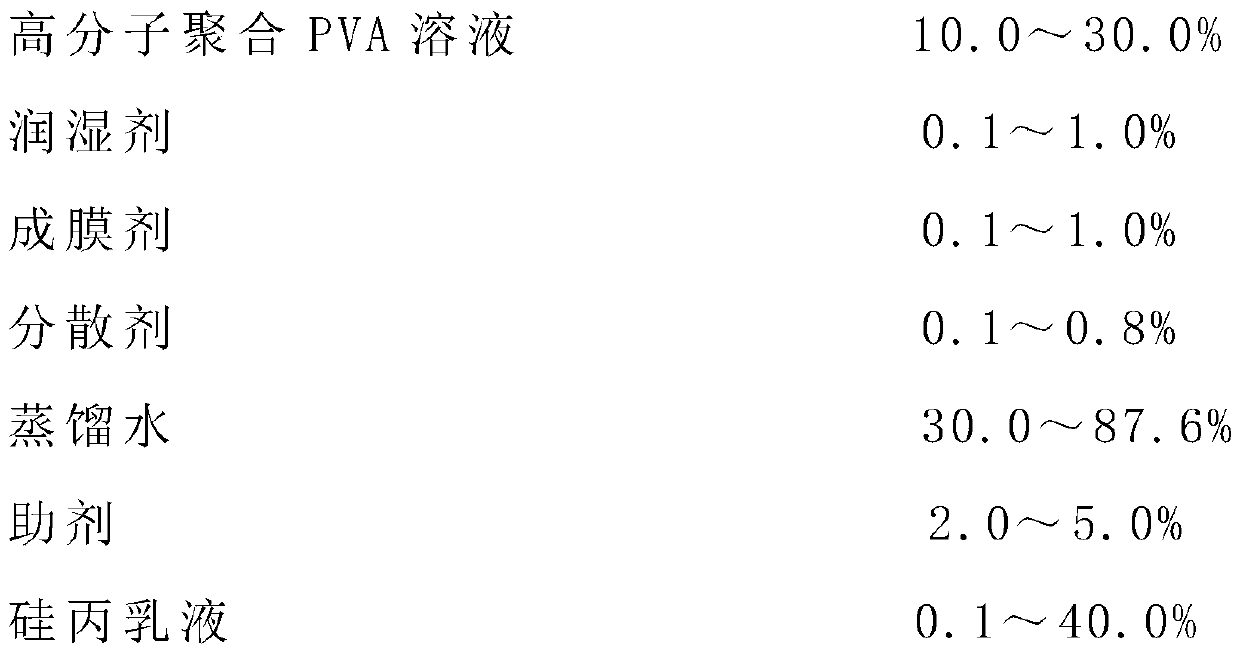

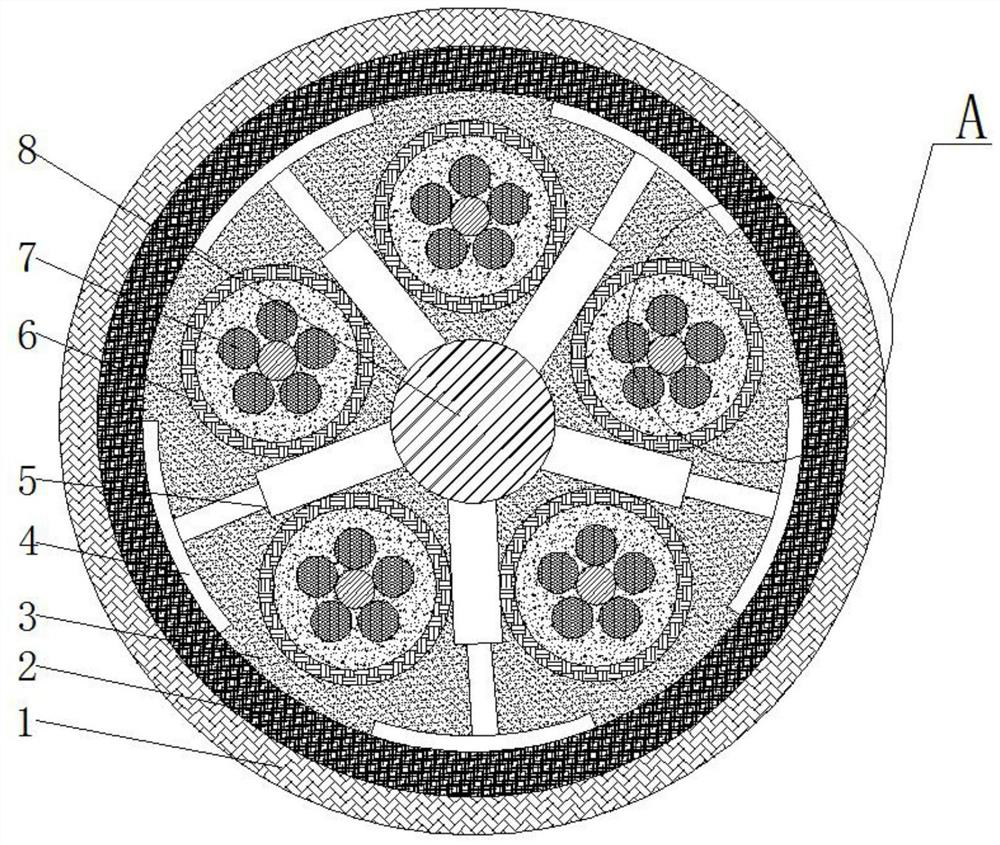

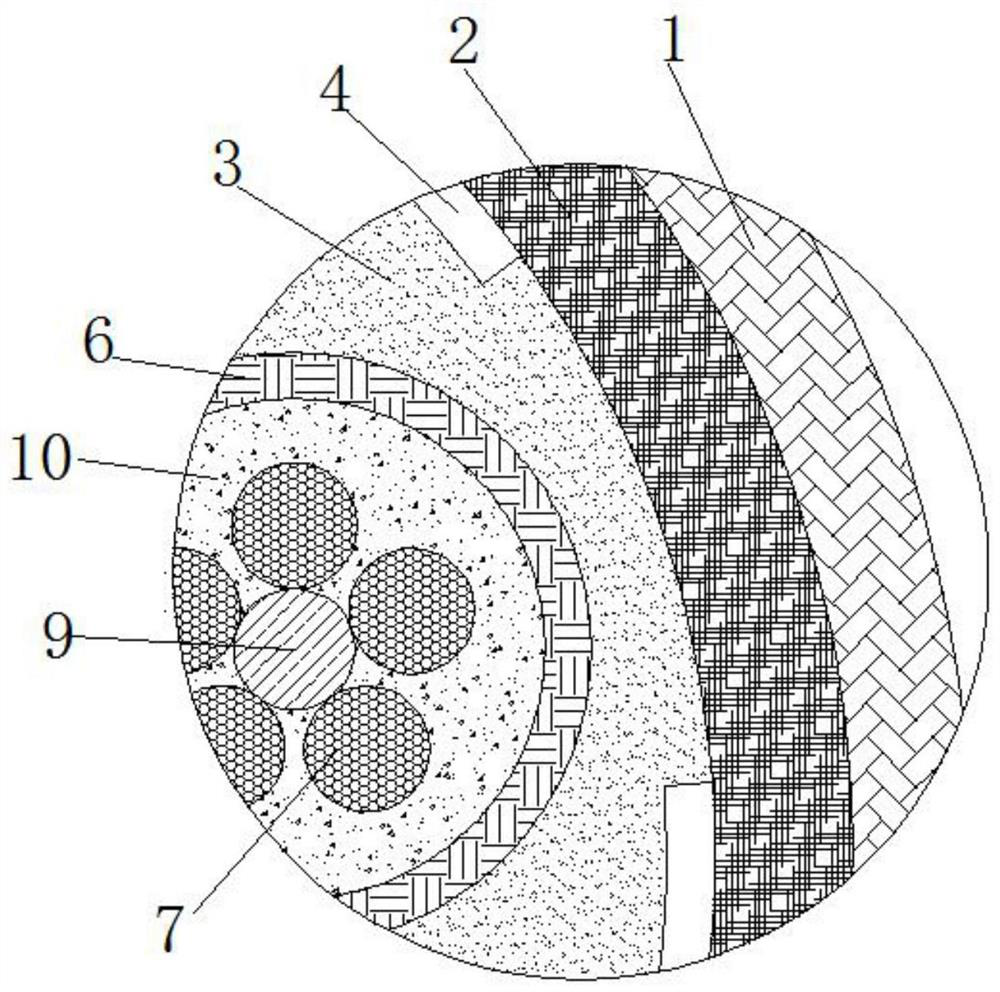

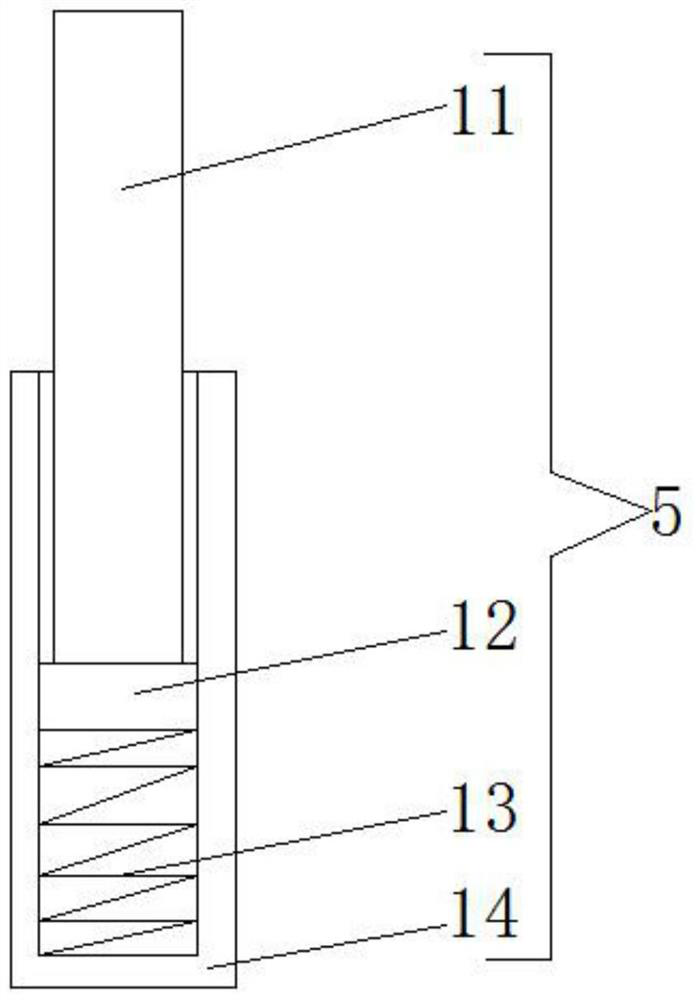

Communication optical cable water-blocking material and preparation method thereof

ActiveCN113311552AWon't lose powderImprove adhesionPolyurea/polyurethane coatingsFibre mechanical structuresEmulsionPolyvinyl alcohol

The invention relates to the technical field of communication optical cables, and discloses a communication optical cable which comprises a plastic film, waterproof cloth is wrapped in the plastic film, non-woven fabric adheres to the outer surface of the waterproof cloth, waterproof paint is smeared on the outer surface of the non-woven fabric, and the space between the waterproof cloth and the plastic film is filled with fireproof asbestos. According to the communication optical cable water-blocking material and the preparation method thereof, the plastic film has a good waterproof effect and is low in cost, the fireproof and flame-retardant properties of optical fibers are improved through the arranged fireproof asbestos, the use safety of the optical fibers is improved, a waterproof coating is arranged on the outer surface of the non-woven fabric, and the polyurethane emulsion is cured after being in contact with moisture in air, a layer of firm and tough seamless integral waterproof film is formed on the surface of the base layer, and the waterproof coating adopts a polyvinyl alcohol adhesive which is prepared by taking a polyvinyl alcohol aqueous solution as an adhesive material, so that the waterproof coating on the non-woven fabric does not fall off and is firmly bonded.

Owner:江苏科信光电科技有限公司

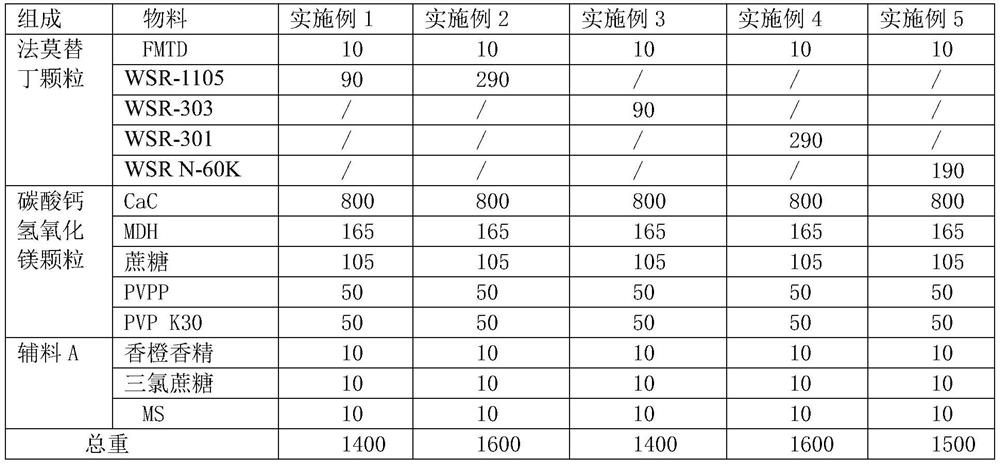

Taste-masking compound famotidine chewable tablet and preparation method thereof

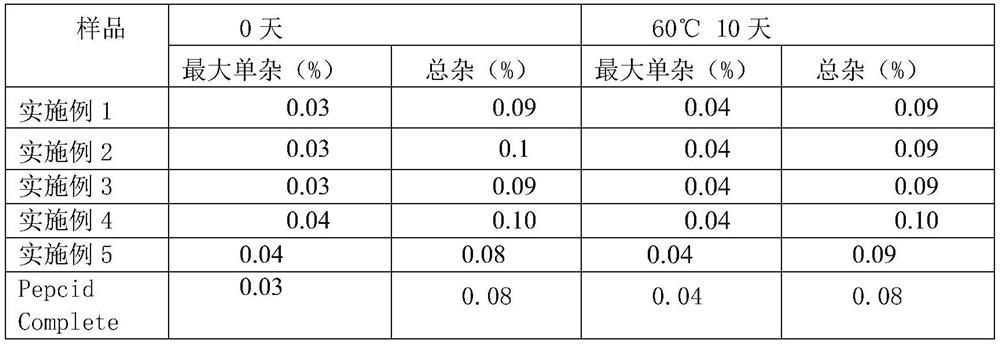

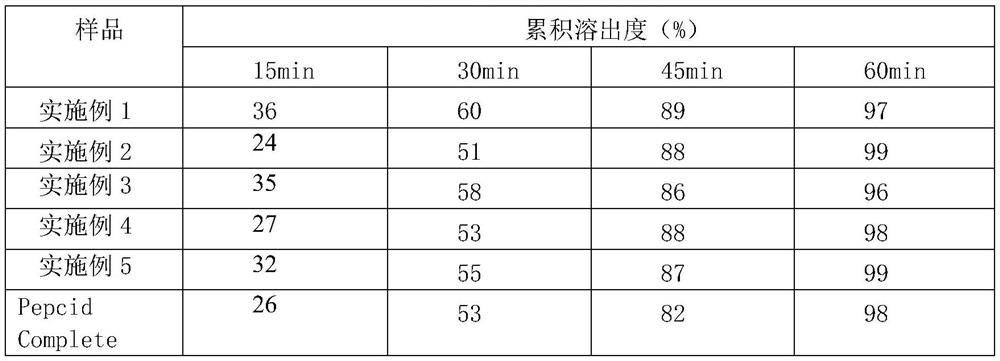

PendingCN113143875ATaste masking effectImprove stabilityOrganic active ingredientsDigestive systemTabletingFamotidine

The invention discloses a taste-masking compound famotidine chewable tablet. The compound famotidine chewable tablet is prepared by the following steps: preparing famotidine granules from famotidine and polyoxyethylene water-soluble resin (PEO), preparing calcium carbonate and magnesium hydroxide granules from calcium carbonate and magnesium hydroxide, uniformly mixing the two granules, adding an additional auxiliary material A, and tabletting to obtain the compound famotidine chewable tablet. The chewable tablet can obtain the friability smaller than or equal to 1.0% under the hardness of 40-100 N, is good in stability and has a taste masking effect.

Owner:河南合智医药科技有限公司

Air purification material and preparation method thereof

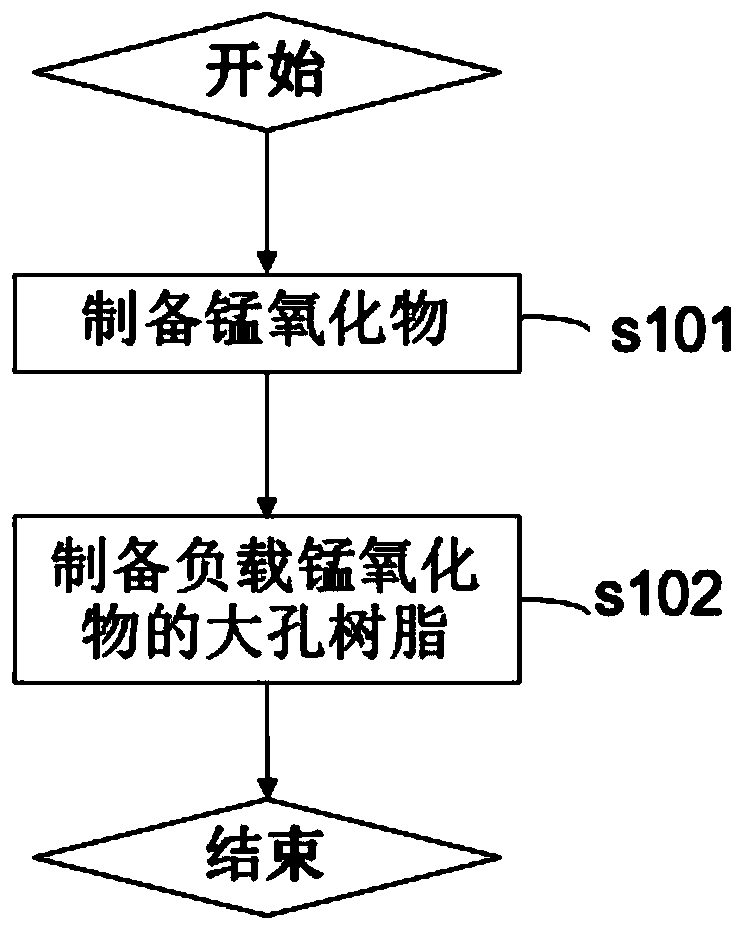

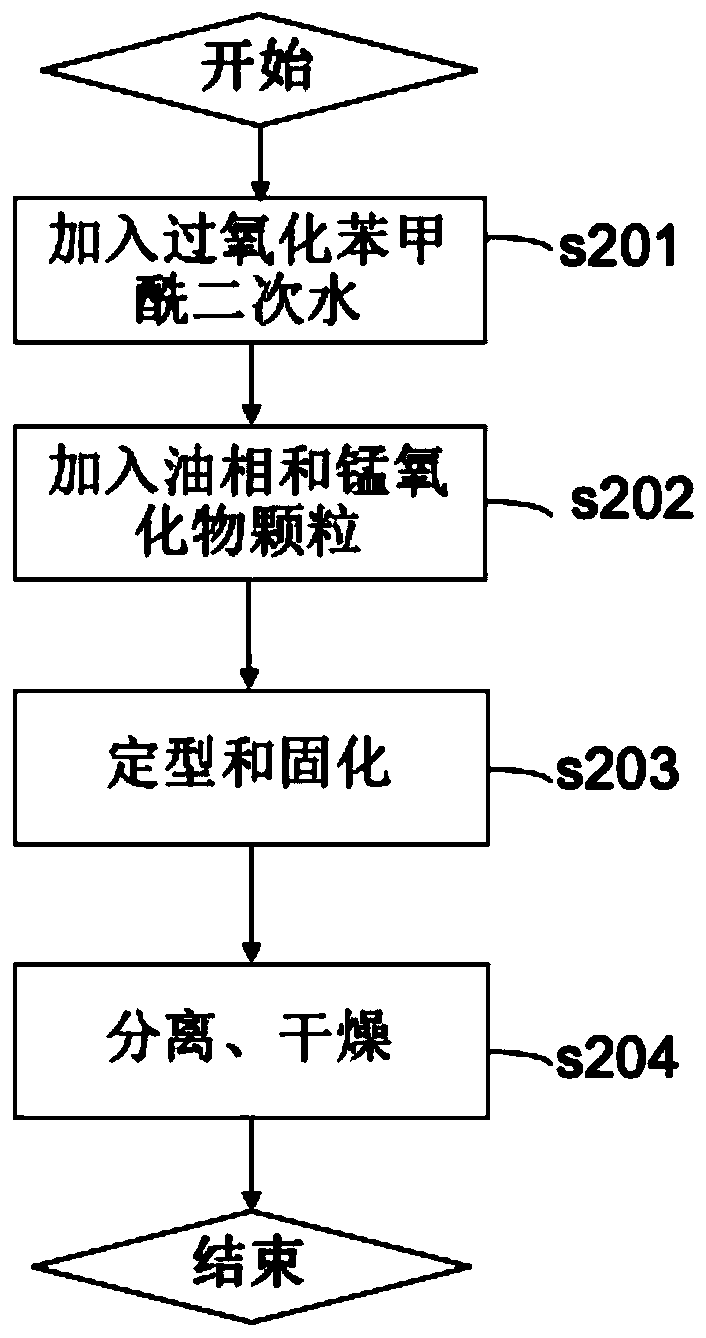

ActiveCN110449027AReduce wind resistanceHigh load rateDispersed particle separationWater bathsCross-link

The invention discloses an air purification material and a preparation method thereof. The method includes: step 1: preparing a material capable of decomposing formaldehyde; step 2: preparing macroporous resin, i.e. preparing an initiator; and adding an oil phase into the initiator, wherein the oil phase is prepared by mixing a monomer, a cross-linking agent, a pore-foaming agent and a dispersantand then subjecting the mixture to ultrasonic dispersion uniformly; step 3: adding the material capable of decomposing formaldehyde into the oil phase, and conducting water bath heating to 75DEG C, and maintaining the state for 5h; and step 4: conducting cooling and constant temperature drying, thus obtaining the air purification material.

Owner:SHENZHEN ZHONGQING TECH CO LTD

High-power-density super-capacitor slurry preparation method

InactiveCN108281301AIncrease coverageGood flexibilityHybrid/EDL manufactureInternal resistancePole piece

The invention discloses a high-power-density super-capacitor slurry preparation method. High-power-density super-capacitor slurry comprises active substances AC, binding agents LA132, conductive agents SP and butadiene styrene rubber SBR, the weight ratio of the active substances AC, the binding agents LA132, the conductive agents SP to the butadiene styrene rubber SBR is 90:5:3:2, active substances are increased by 4% as compared with the previous content in a product, the capacity of a product is increased by 4.5% or more, the energy density of the product is improved, the adhesive force ofan aluminum foil can be increased by the aid of two binding agents, the internal resistance of the product is reduced, the power density of the product is improved, mixing time can be effectively shortened by 2 hours, production efficiency is improved by 20%, flexibility of pole pieces is improved, powder falling in rolling and cutting processes is avoided, and scrap caused by short circuit in rolling-in, flattening and shell entering processes is decreased.

Owner:江苏尊道科技有限公司

A kind of preparation method of negative pole piece of lithium battery

ActiveCN111554873BWide variety of sourcesLow priceSecondary cellsNegative electrodesElectrolytic agentCopper foil

Owner:SHANGHAI ELECTRICGROUP CORP

High temperature-resistant cellulose fiber base material-containing lithium ion battery diaphragm and preparation method of the same

ActiveCN102856522BImprove wettabilityGreat suctionCellulosic plastic layered productsCell component detailsCellulose fiberLithium-ion battery

Owner:CHINA HAISUM ENG

Composite porous membrane and preparation method thereof

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a composite porous diaphragm which comprises an organic layer and an inorganic coating arranged on the surface of the organic layer, wherein the organic layer is a polyolefin porous diaphragm layer; the inorganic coating comprises the following components in percentage by weight: 0.2-2% of water-soluble high molecular thickener, 0.2-5% of waterborne dispersing agent, 1-30% of waterborne latex and 63-98.6% of inorganic particles; and the waterborne latex is a high-molecular polymer of which the solubility parameter is less than or equal to 18(J / cm<3>)1 / 2 and the surface tension is less than or equal to 44 dynes / cm. Compared with the prior art, the composite porous diaphragm provided by the invention has good heat-resistant shrinkage performance; and meanwhile, with better puncture strength, the inorganic coating of the diaphragm effectively reduces the short-circuit risk in a battery, and improves the safety performance of the battery. Moreover, the invention also discloses a preparation method of the diaphragm.

Owner:DONGGUAN AMPEREX TECH

Hot-melting veiled car line paste and preparation method thereof

The invention relates to a hot-melting veiled car line paste and a preparation method thereof. The car line paste is composed of 100 parts of high-saturated fatty acid, 5 to 10 parts of polyoxyethylene-type nonionic surfactant and 180 to 220 parts of purified water. The preparation method comprises the following steps of: 1) putting the high-saturated fatty acid and the polyoxyethylene-type nonionic surfactant into a container; heating to the temperature of 70 to 80 DEG C and melting, thereby preparing an oil phase; 2) slowly dropwise adding the purified water preheated to the temperature of 70 to 80 DRG C into the oil phase in a stirring manner; after dropwise adding, heating to the temperature of 78 to 85 DRG C; preserving heat and stirring for 30 minutes, thereby obtaining an emulsifying body; and stirring and cooling to the room temperature, thereby obtaining the hot-melting veiled car line paste. By adopting the screen plate printing, a white positioning line formed on the surface of a fabric material is clear, long in retention time and free of blocking a screen plate during the printing process. The positioning line can be automatically molten to disappear after the fabric material is shaped in a processing manner, and cannot generate any residual trace. The raw materials and the product provided by the invention are safe, environment-friendly and free of toxic effect to a human body.

Owner:HUBEI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com