Patents

Literature

84results about How to "Tightly combined" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet process refractory mortar

The invention relates to wet process refractory mortar which comprises the following raw materials by weight: 25-50 parts of white fused alumina powder with the granularity of not more than 180 meshes, 40-65 parts of the white fused alumina powder with the granularity of not more than 320 meshes, 1-5 parts of phosphate binder, 1-4 parts of plasticizer, 1-3 parts of water retention agent, 0.1-1 part of resin type preservative, 0.05-0.5 part of preservative agent and 0-10 parts of Cr2O3 powder with the granularity of not more than 320 meshes, the wet process refractory mortar is prepared by uniformly stirring the raw materials, adding 12-18 parts of water, continuously uniformly stirring, and then loading into a plastic bag for sealing and preserving, and the preservation period is a year and a half to two years.

Owner:PUYANG REFRACTORIES GRP CO LTD

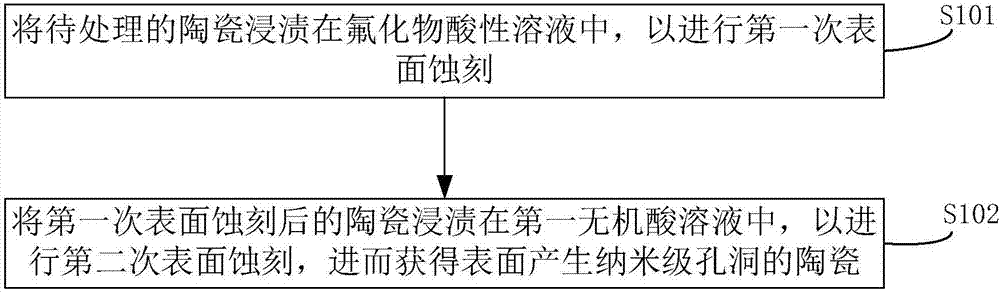

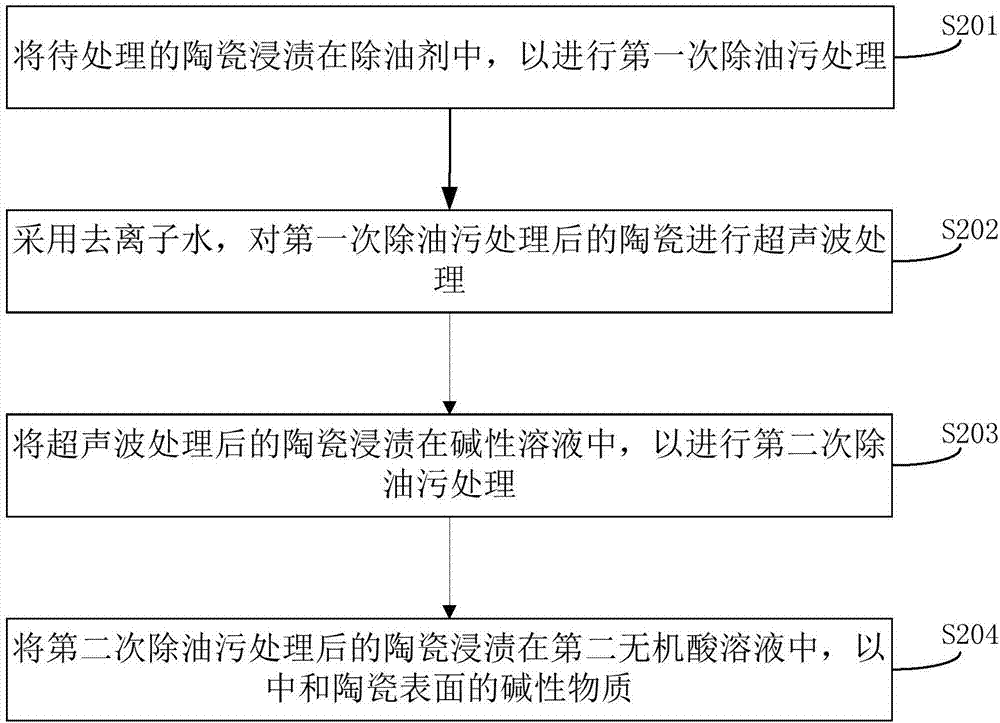

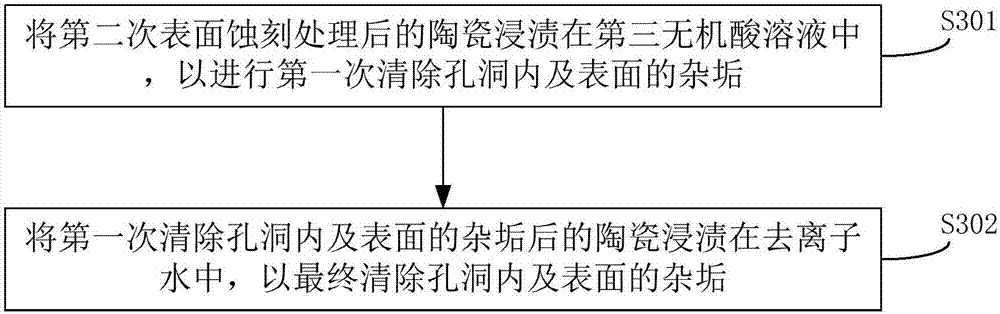

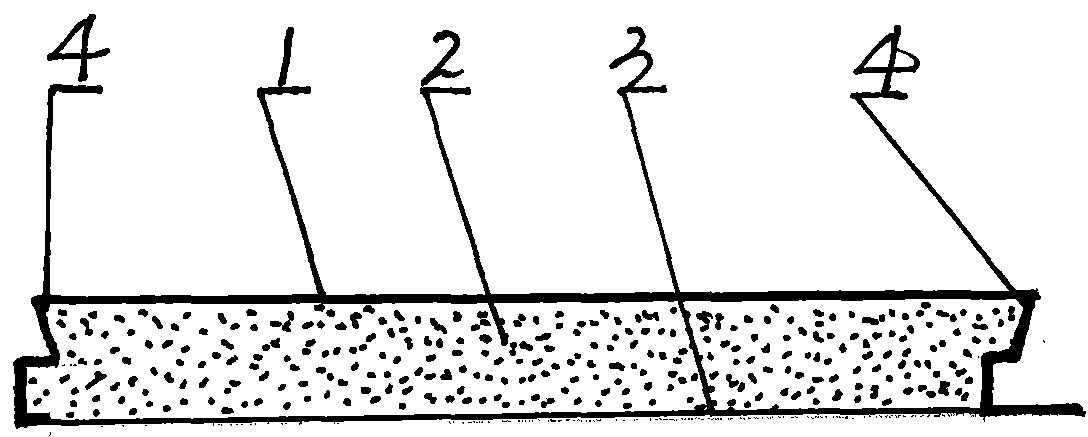

Ceramic surface treatment method, ceramic product and ceramic plastic composite body

ActiveCN107010998AImprove permeabilityPromote infiltrationCoatingsPlastic injection moldingInjection moulding

The invention discloses a ceramic surface treatment method, a ceramic product and a ceramic plastic composite body. The method comprises the following steps of soaking ceramic to be treated into a fluoride acid solution so as to perform primary surface etching; soaking the ceramic subjected to primary surface etching into a first inorganic acid solution so as to perform secondary surface etching; further obtaining the ceramic with nanometer level holes on the surface. By using the mode, the ceramic with the nanometer hole structures can be prepared; after the plastic injection molding forming, the bonding force of the product is high; the combination is very tight.

Owner:GUANGDONG EVERWIN PRECISION TECH

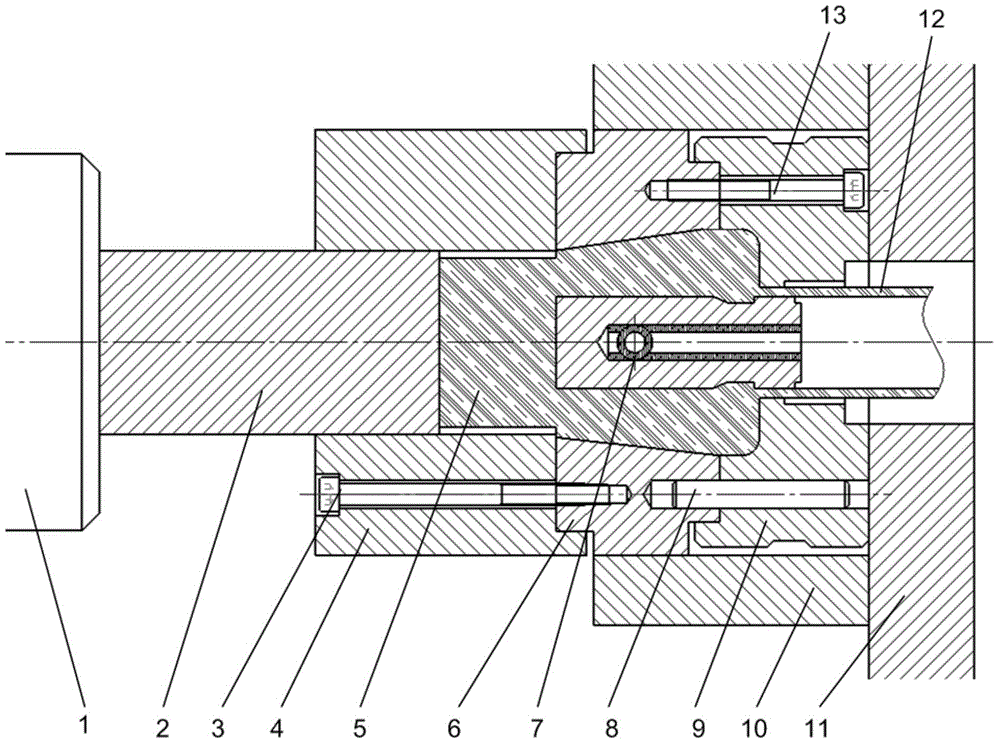

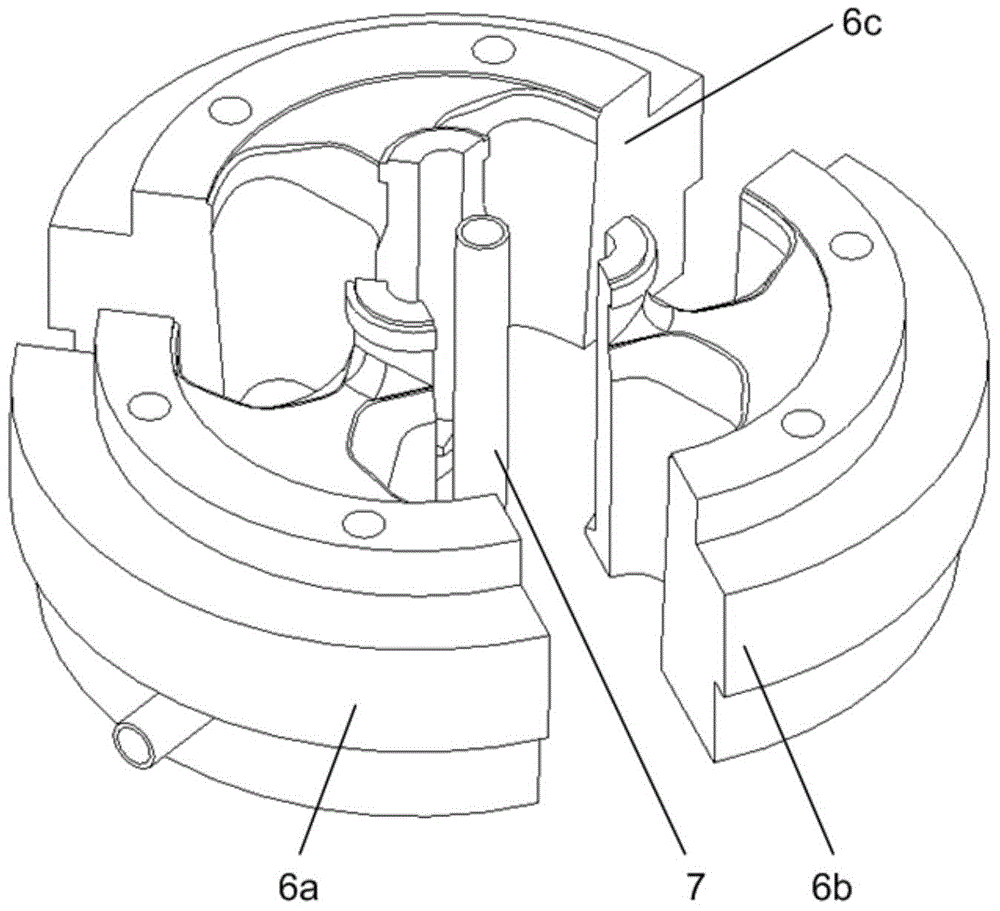

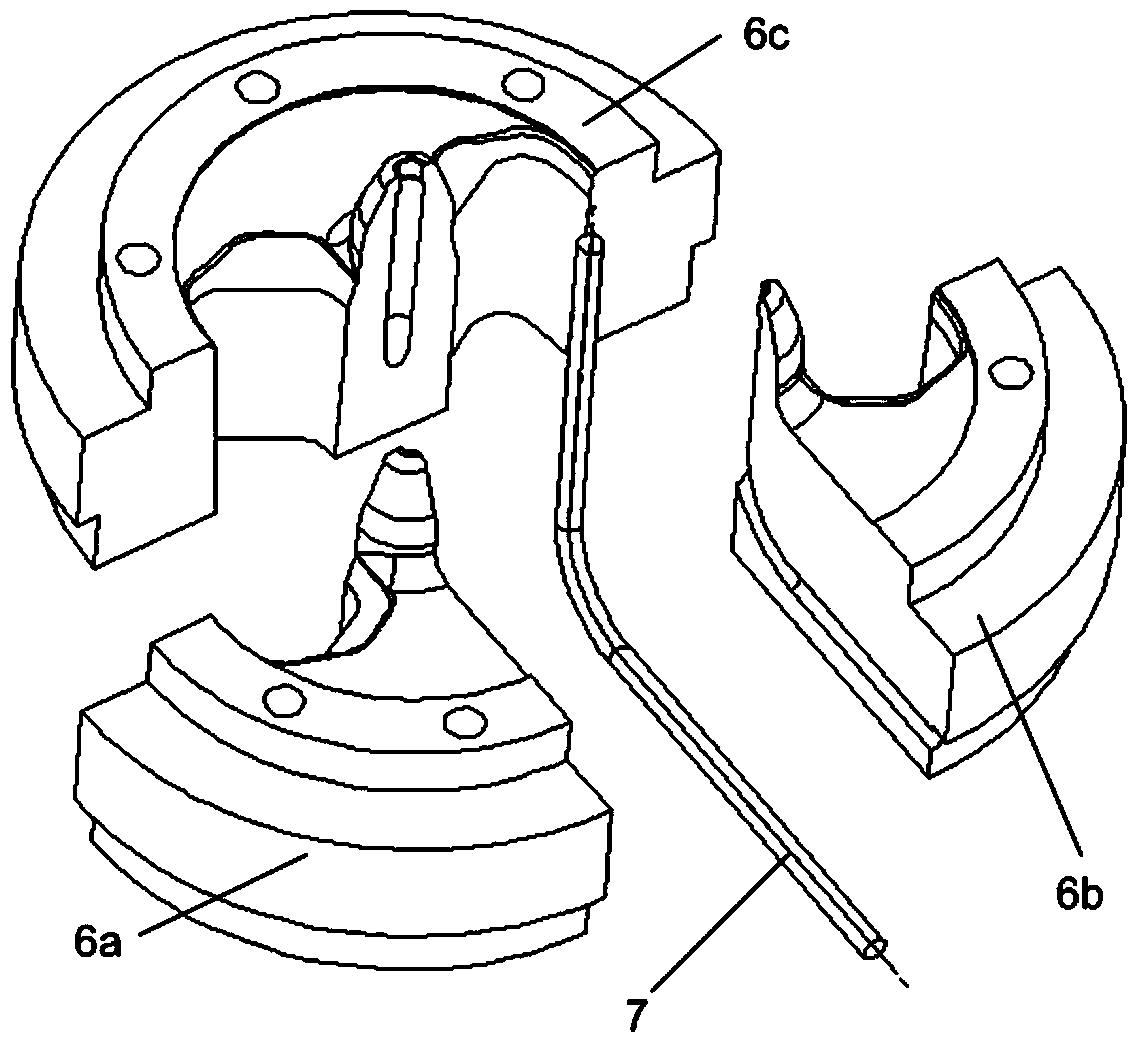

Amorphous alloy round pipe extrusion forming device and technology

ActiveCN104148430AEasy to assemble and disassembleAvoid crystallization and oxidationExtrusion diesExtrusion control devicesScrapBlock structure

The invention relates to an amorphous alloy round pipe extrusion forming device and technology. The device comprises a hydraulic type extrusion structure, an extrusion die and an extrusion tool frame, the extrusion die comprises an extrusion male die, an extrusion cylinder, an extrusion female die and a setting sleeve, the extrusion cylinder, the extrusion female die and the setting sleeve are sequentially and fixedly connected together, a cavity formed in the extrusion mould comprises a blank chamber, a flow dividing chamber, a welding-on chamber and a forming chamber, the extrusion female die is designed to be of a splicing block structure, a splicing line of each splicing block is selectively arranged at the position of the welding-on chamber, the extrusion female die is a cylindrical die body, a mold core is formed on the axis of the die body, the extrusion female die is sleeved with an extrusion female die clamping sleeve, the outer surface of the extrusion female die and the inner surface of the extrusion female die clamping sleeve are combined in a gradually-advancing type conical-face mode, and the extrusion female die clamping sleeve is fixed to the extrusion tool frame. The extrusion forming device is convenient to dismount and mount, and reasonable in structure, the size precision of a formed round pipe is high, the surface quality is good, extrusion wastes are easy to clear, and the production efficiency is high.

Owner:滕州市产品质量监督检验所

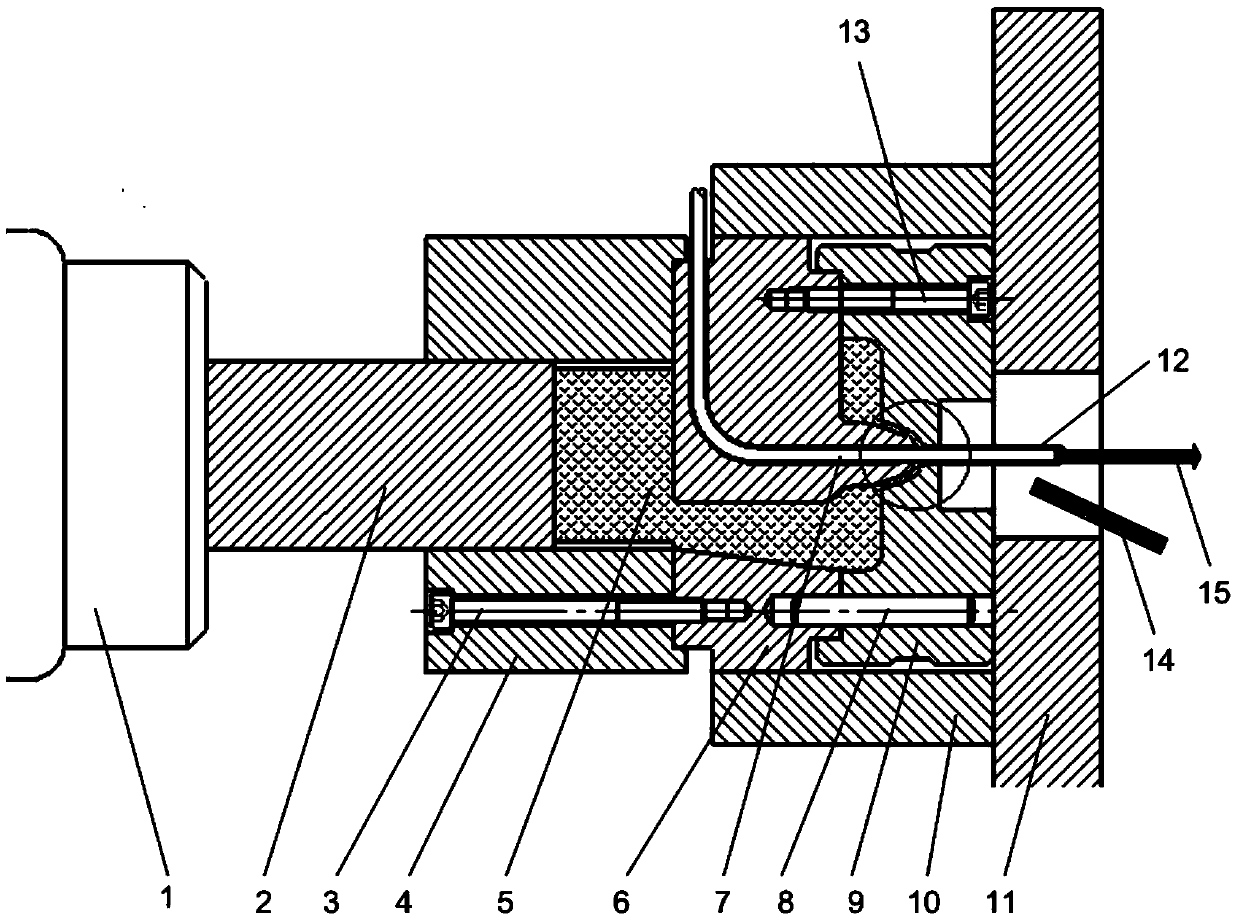

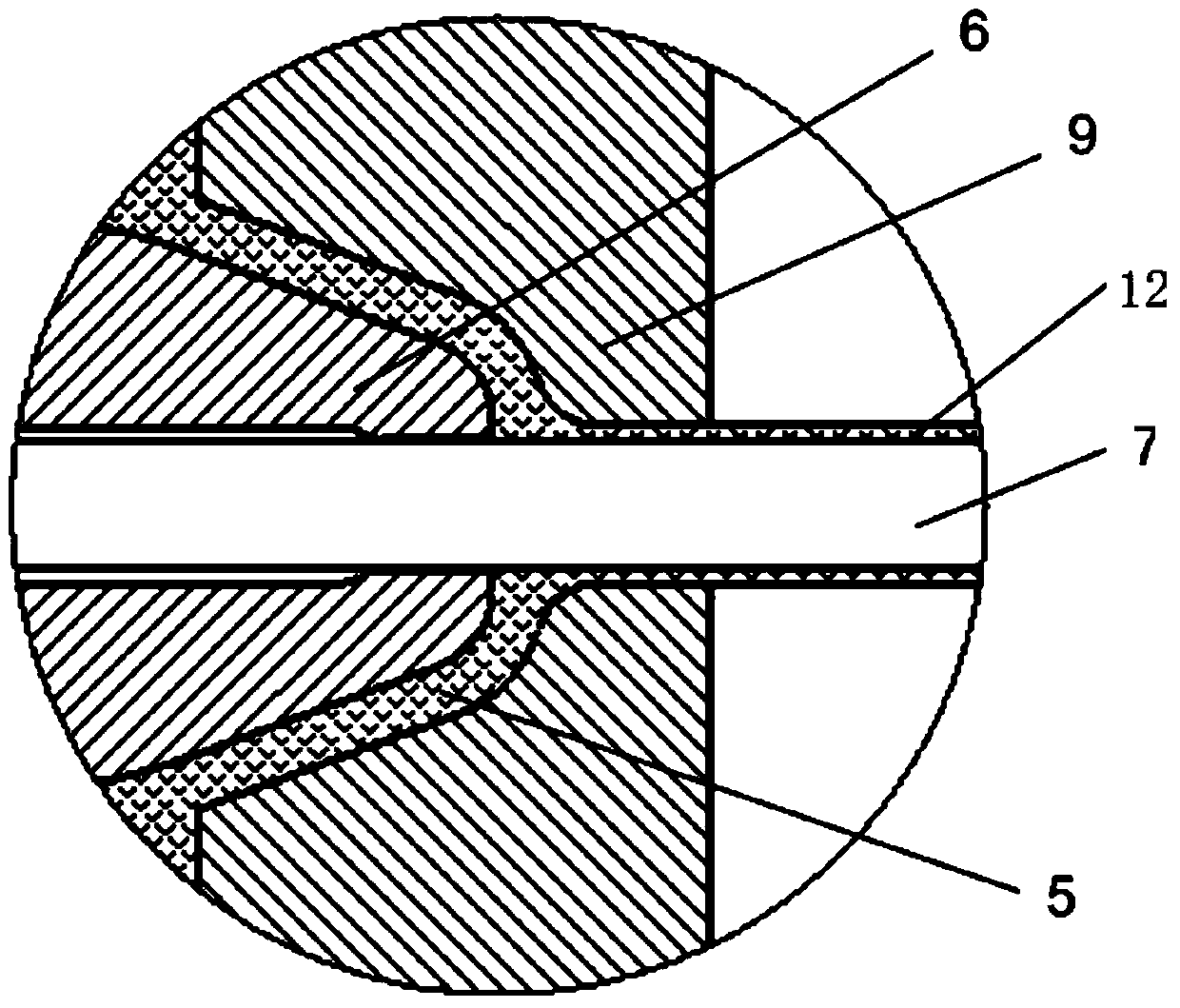

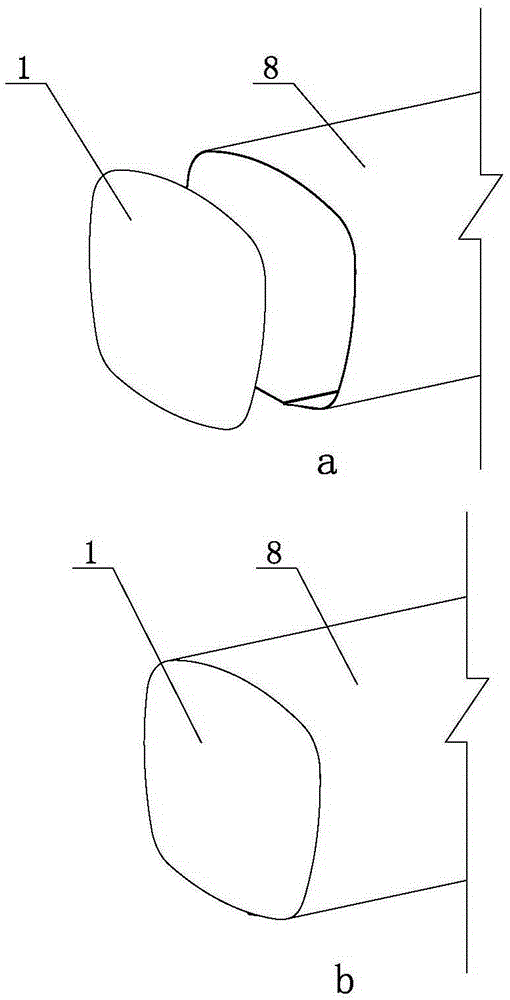

Device and process for realizing amorphous metal continuous wire cladding by virtue of extrusion

ActiveCN104190736AEasy to processEasy to removeExtrusion diesExtrusion mandrelsWear resistanceAmorphous metal

The invention discloses a device and a process for realizing amorphous metal continuous wire cladding by virtue of extrusion. The device comprises a wire traction device, an extrusion convex die, an extrusion cylinder, an extrusion concave die and a setting cover, wherein the size of the extrusion cylinder is matched with that of the extrusion convex die; the extrusion cylinder is fixedly connected with the extrusion concave die; the extrusion concave die is fixedly connected with the setting cover; the extrusion cylinder, the extrusion concave die and the setting cover define an extrusion convex die channel, a blank chamber, a shunt chamber, a welding chamber and a forming chamber; a cooling gas spray pipe is arranged at an outlet of the forming chamber; a wire inlet is formed in the wall of the extrusion concave die; a section of wire channel is formed in each of the die body and the die core; a blank shunt chamber is formed in the periphery of the die core and is communicated with the blank chamber; and blanks and wires are mixed and coated in the welding chamber. According to the device and process disclosed by the invention, the surfaces of the wires are coated with amorphous metals, and the surface quality of the wires is improved, so that the wires have excellent corrosion resistance and wear resistance, the application range of the wires is widened, and the service lives of the wires are prolonged.

Owner:滕州市产品质量监督检验所

Vehicle-mounted aluminum alloy tank production process

The invention discloses a vehicle-mounted aluminum alloy tank production process. The vehicle-mounted aluminum alloy tank production process includes the following steps of firstly, barrel plate machining, secondly, separation plate and end socket machining, thirdly, locating, hoisting and transferring, fourthly, tank wrapping and forming, fifthly, longitudinal seam shaping and longitudinal seam welding, sixthly, inner annular seam welding and seventhly, outer annular seam welding. For the feature of tank body machining, the process is designed into a manufacturing method facilitating mechanical line production, and manufacturing accuracy and efficiency can be improved greatly. Through multiple years of experiment practice and summarization, in the process, the edges of two end sockets of a straight-cylinder tank body are milled into the straight edges so that the edges can be matched with the milled straight edges of the tank body so as to guarantee that the edges of the end sockets is in tight butt joint with the edges of the tank body, and single-face welding and double-face forming are conducted through tig side face welding, so that the pass rate of flaw detection reaches 100%; and the reducing part of the middle portion of the reducing tank body is shaped through a die, the edges are milled so as to be in tight butt joint with the tank body, and the pass rate of flaw detection reaches 100% by conducting single-face welding and double-face forming through tig side face welding.

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

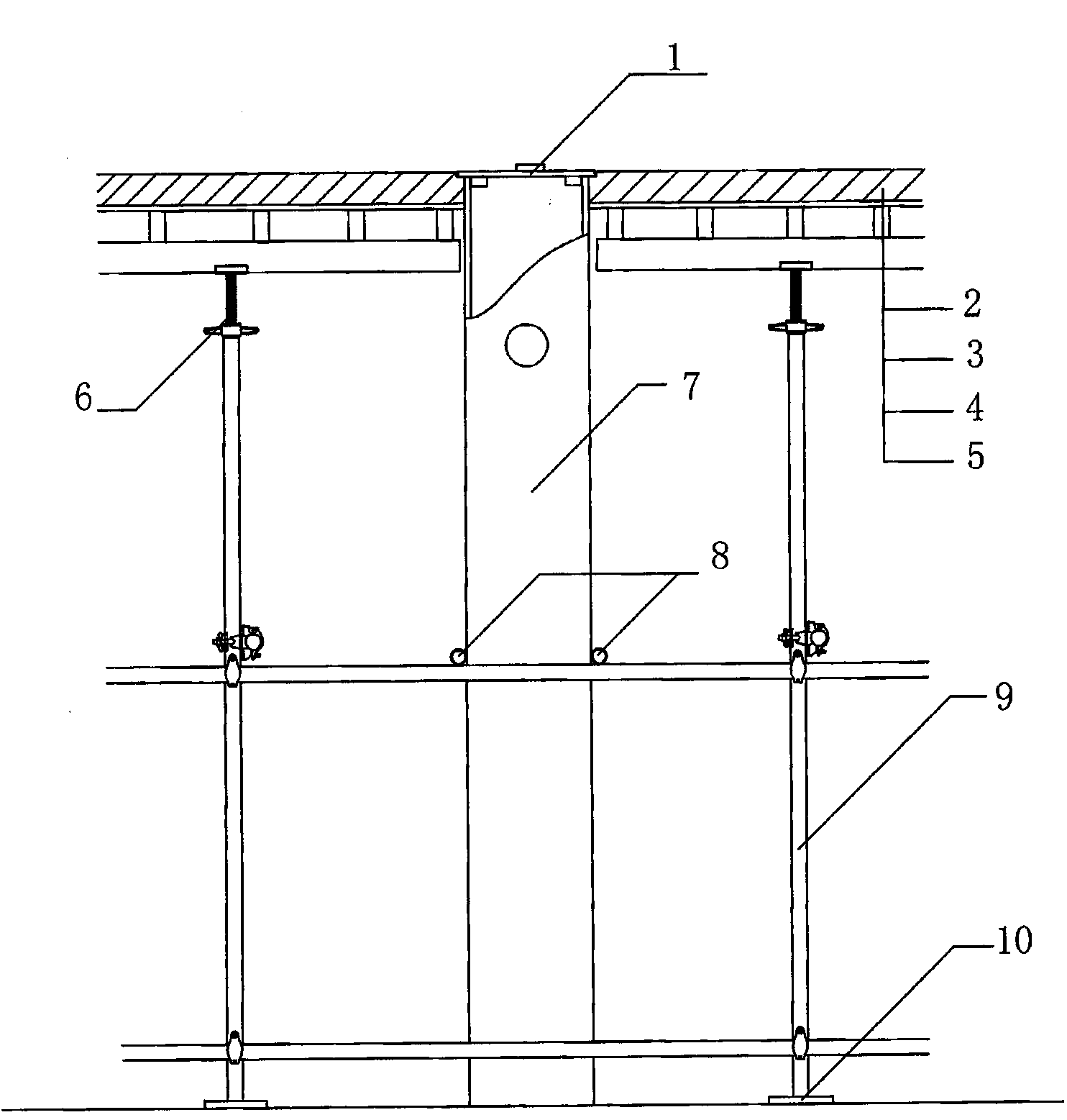

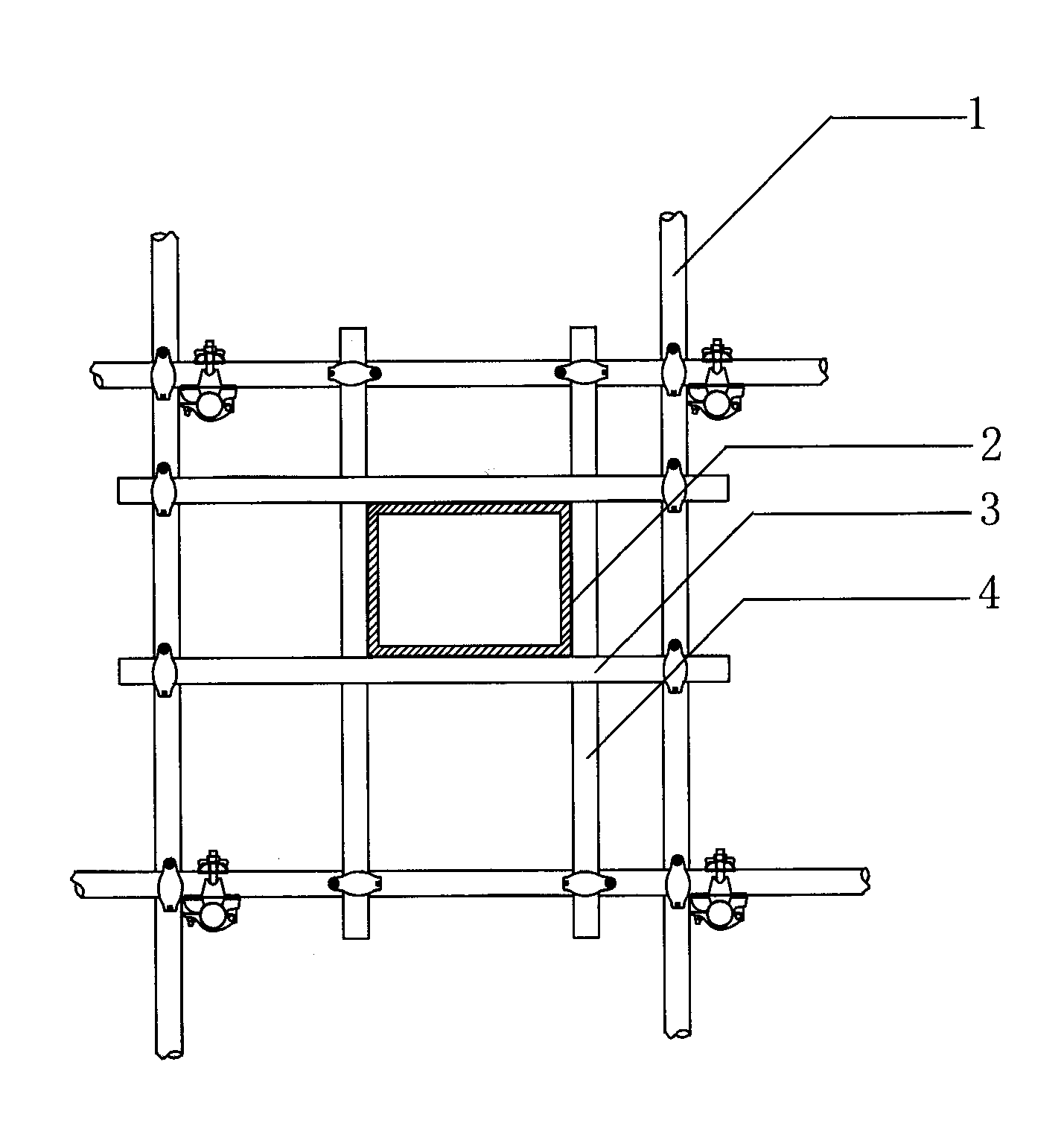

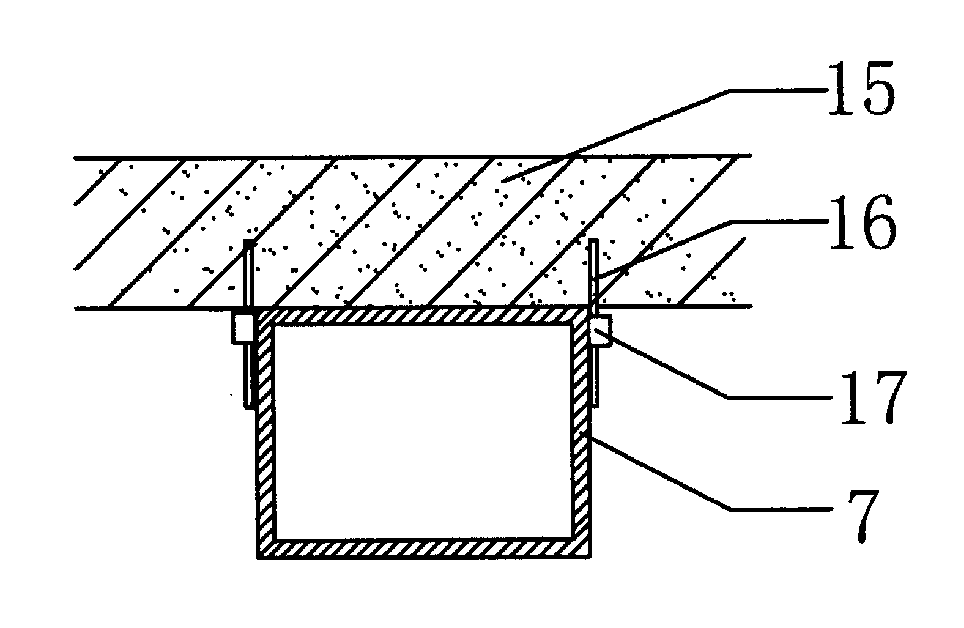

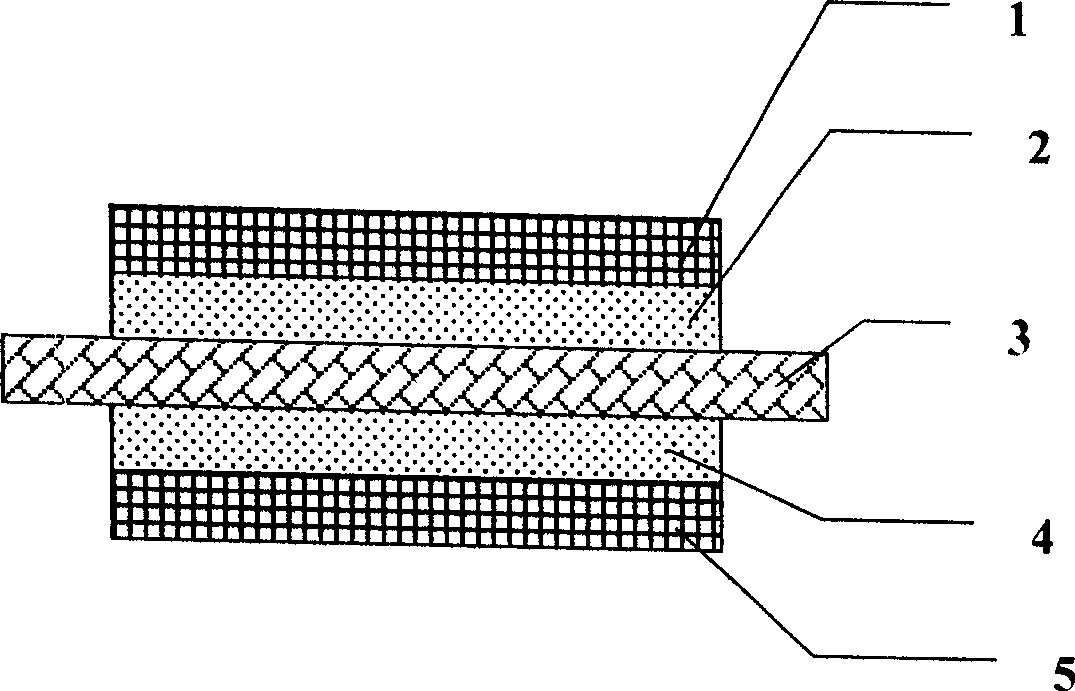

Mounting method of precast air duct during construction stage of construction engineering structure

ActiveCN103572964ATightly combinedRoof waterproof construction progress guaranteeBuilding material handlingVertical ductsArchitectural engineeringEngineering

The invention provides a mounting method of a precast air duct during the construction stage of a construction engineering structure. According to the method, original procedures are changed, the air duct mounting operation is performed after main structure wall construction, and the air duct mounting operation and the top plate template mounting are performed together, each procedure in the existing construction method is omitted, synchronous air duct mounting and main structure construction progress can be achieved on the premise of not increasing construction materials and working hours, and the waterproof construction progress and quality of a roof are better ensured.

Owner:POWERCHINA CONSTR GRP

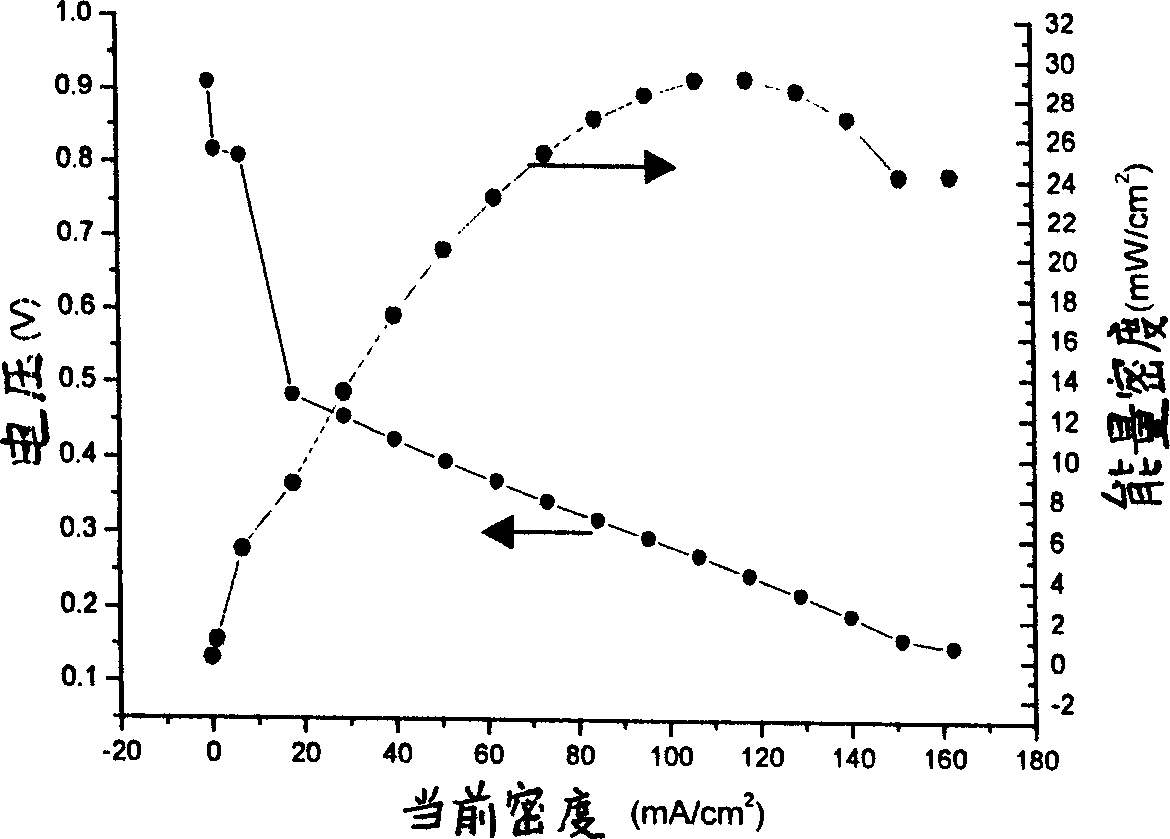

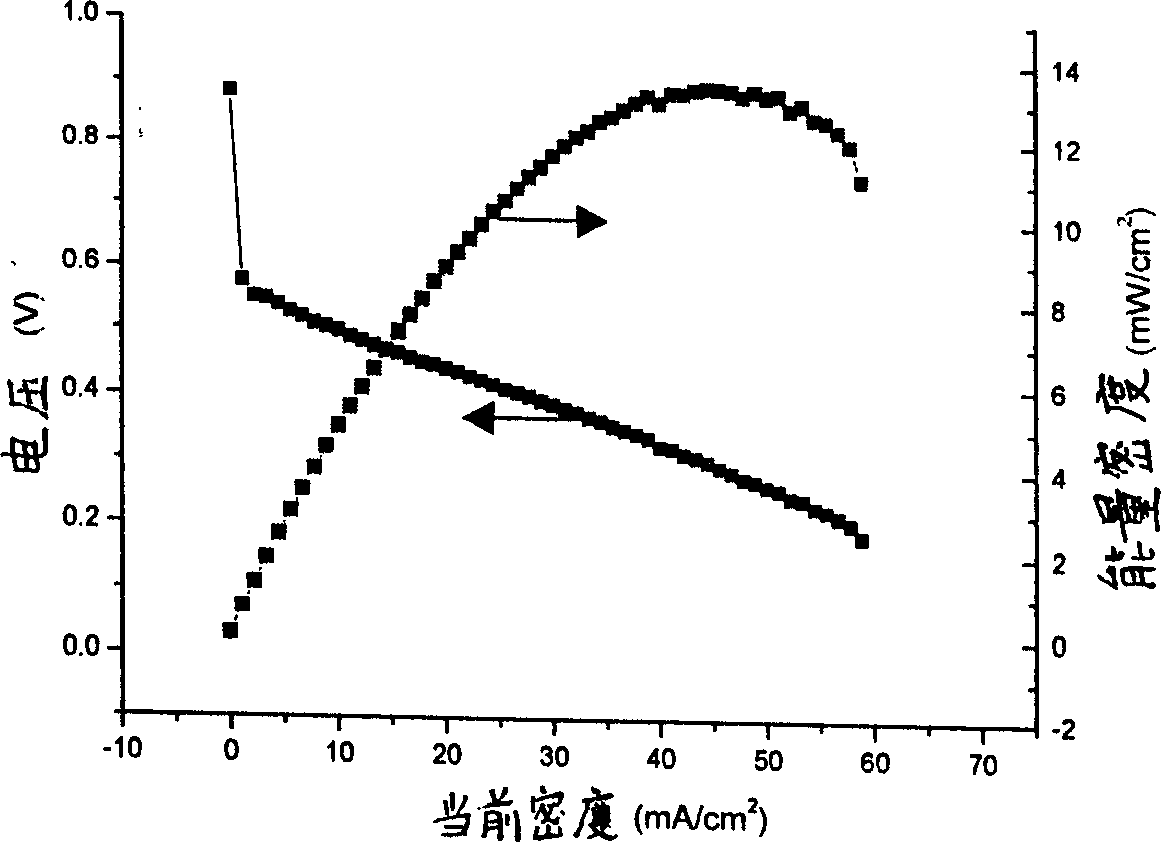

Method for preparing membrane electrode of direct methanol fuel cell

The invention discloses a method for making a membrane electrode of direct methanol fuel battery. The membrane electrode comprises proton exchange membrane, positive electrode of carbon carried platinum-ruthenium catalyst and negative electrode of carbon carried platinum catalyst. The invention is characterized in that it reduces the usage of direct methanol fuel battery catalytic agent noble metal and lowers costs of fuel battery. The direct methanol fuel batteries assembled with the membrane electrode components has the advantages of high output power density, great performance test reproducibility.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

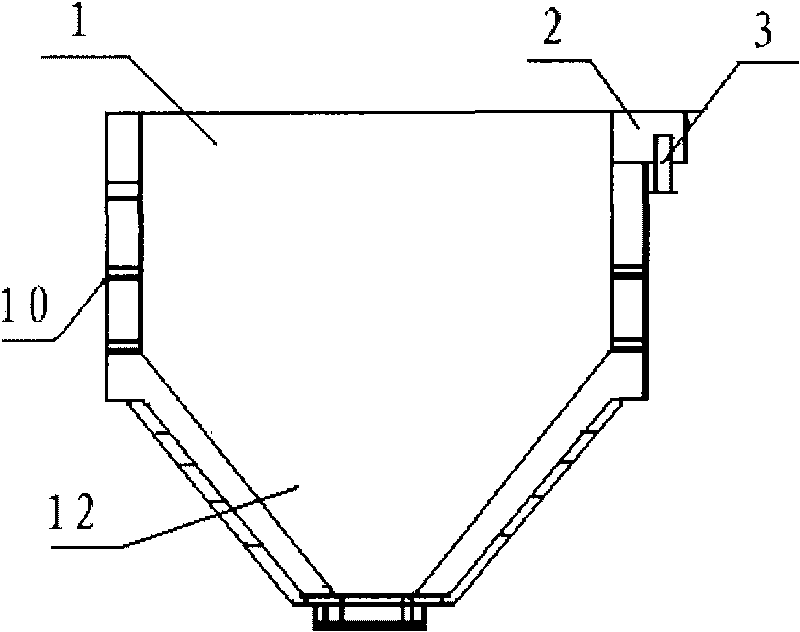

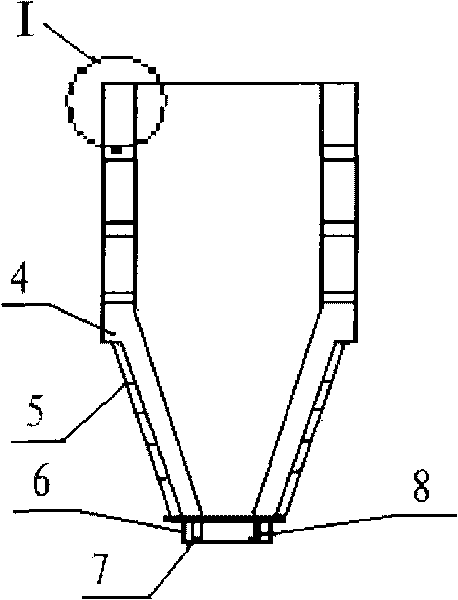

Mechanical molding fiber reinforce plastic (FRP) electrolytic cell and preparation method thereof

The invention discloses a mechanical molding fiber reinforce plastic (FRP) electrolytic cell and a preparation method thereof, belonging to the technical field of the electrolytic cell and the preparation method thereof. The electrolytic cell is formed by four cell wall plates molded by separately mould pressing, the upper part is a rectangular groove, and the lower part is a cone-shaped groove; the rectangular parts of the cell wall plates are provided with grooves when in mould pressing, FRP rectangular tube reinforcing ribs are embedded inside the grooves and fixed with the cell wall plates into a whole, and the cone-shaped parts of the cell wall plates and strap-shaped reinforcing ribs form a whole by being simultaneously processed by mould pressing; the periphery of the connection parts between the rectangular parts and the cone-shaped parts of the cell wall plates is provided with a support groove bearing beam, and FRP is integrated with the electrolytic cell by pouring; and a mould pressing strengthening inner sleeve and a mould pressing strengthening outer sleeve are arranged between the bottom of the cone-shaped groove of the electrolytic cell and the periphery inside a discharge hole. The FRP electrolytic cell has good chemical corrosion resistance, physical property and insulating property. The manufacturing technique is energy-saving and labor-saving, and reduces the loss. Due to all the performances, the electrolytic cell has the service life more than ten years, is not needed to be overhauled by stopping production every year, reduces the maintenance cost, improves the electrolysis yield and saves the cost.

Owner:GRIPM ADVANCED MATERIALS CO LTD +1

Light weight gypsum wall body field one piece constrction method

InactiveCN1556291AImprove sealingSolve the problem of prone to leakageWallsHigh intensityExpansion joint

The method includes following steps: embedding expansion bolts inside frame of wall body in advance; installing prefabricated concrete outline onto the frame through expansion bolts, putting joint strips onto grooves on two sides, and putting stud bolts into transverse through holes; putting several rectangular templates having join edges on side faces of concrete outline, and fastening the templates to concrete outline through assorted head pressures and stud bolts; putting double sticky tape onto join faces, and pouring light weight calcium plaster into cavities of wall body through grout hole on upper part of templates by using slurry pump; after calcium plaster being solidified, unpacking templates and stud bolts, and infilling concrete to bolt holes. Features are simple technique, fast constructing, low cost, saving labor, high intensity and good thermo insulating property.

Owner:李伟文

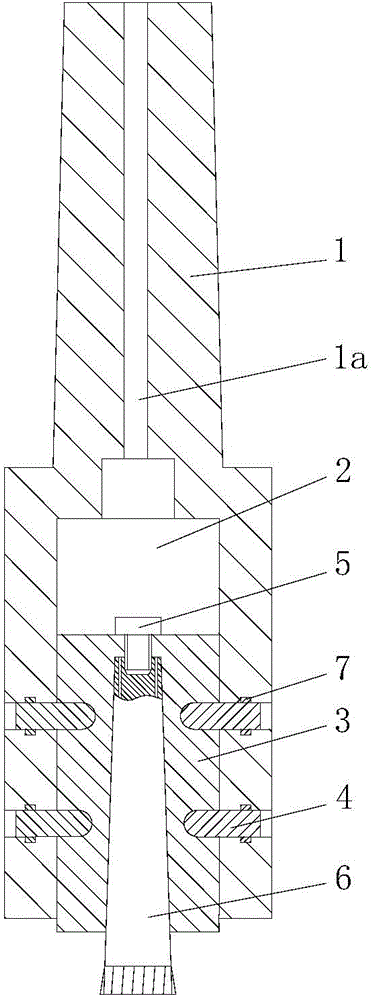

Assembly structure of disc type milling cutter

The invention relates to an assembly structure of a disc type milling cutter. The assembly structure comprises a connecting rod connected with a machine tool, wherein a cavity with open bottom is formed in the lower end of the connecting rod, a transitional joint sleeve is matched in the cavity, a radial hole is formed in the circumferential surface of the connecting rod, fastening screws for fastening the transitional joint sleeve in the cavity of the connecting rod are connected in the radial hole, a tightening screw is arranged at the top of the transitional joint sleeve, a Morse taper hole for mounting the milling cutter is formed inside the tightening screw, one end of the milling cutter is assembled in the Morse taper hole and then fixed by the tightening screw, a spherical mounting hole is formed in the circumferential surface of the transitional joint sleeve, the fastening screws penetrate through the radial hole in the connecting rod and are in threaded connection with the spherical mounting hole in the transitional joint sleeve, and end parts, located in the mounting hole, of the fastening screws are spherical surfaces. The transitional joint sleeve can be fastened reliably and prevented from being thrown out and hurting people.

Owner:常州市海伦工具有限公司

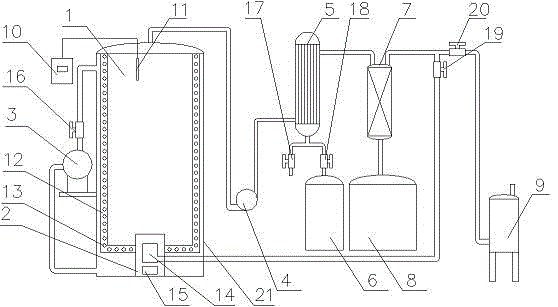

Device for producing wood charcoal and recovering wood vinegar and wood tar

InactiveCN105542815AQuality improvementReduce consumptionDirect heating destructive distillationBiofuelsCombustion chamberHusk

The invention discloses a device for producing wood charcoal and recovering wood vinegar and wood tar, which is composed of a carbonization furnace, an induced fan, a condenser, a low-temperature condenser and a flue gas filter. A retort technique is adopted and comprises the following steps: putting wood, husks and other wood raw materials in the closed carbonization furnace body, adding fuel into the combustion chamber, and igniting to heat the furnace body by using the added fuel so as to heat the raw materials in the carbonization furnace body and perform carbonization; leading out the flue gas byproduct by the induced fan, condensing the flue gas byproduct by the condenser to recover the wood tar, and passing through the low-temperature condenser to recover the wood vinegar, wherein the treated flue gas mainly comprises wood gas; introducing the treated flue gas into the combustion chamber, and combusting, thereby implementing good recovery; and after the carbonization finishes, treating the flue gas through the filter, and discharging the treated flue gas into air.

Owner:XINJI YUAN XIANG GREEN ENERGY TECHOLOGY CO LTD

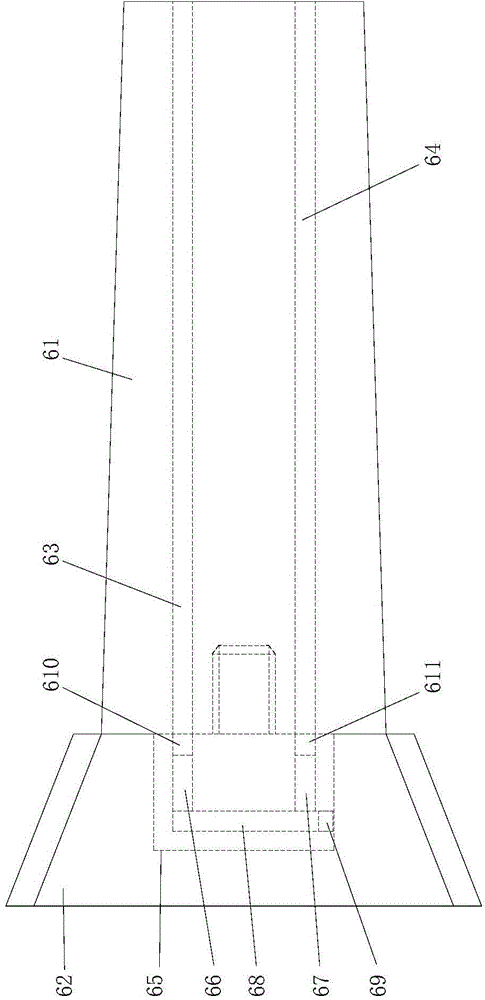

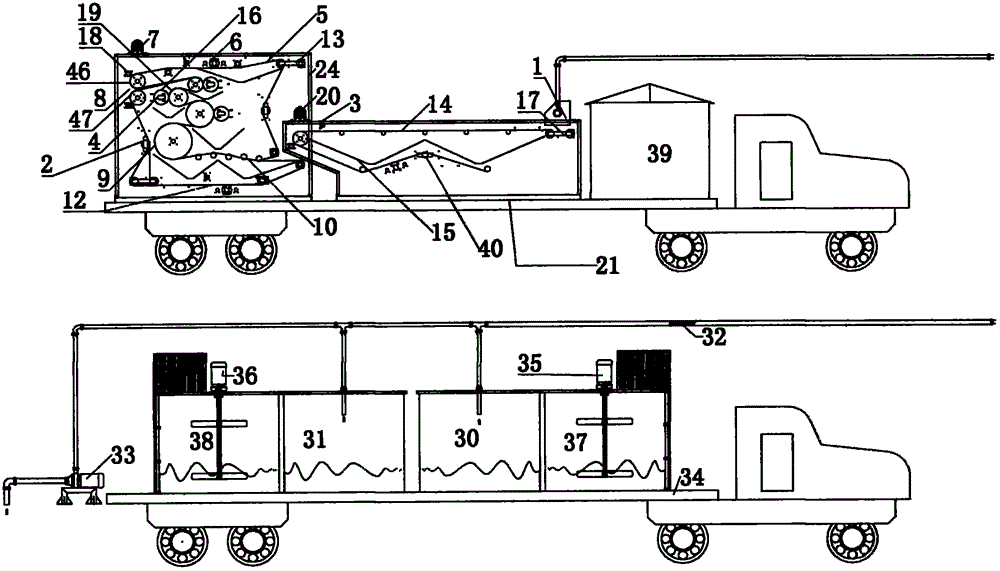

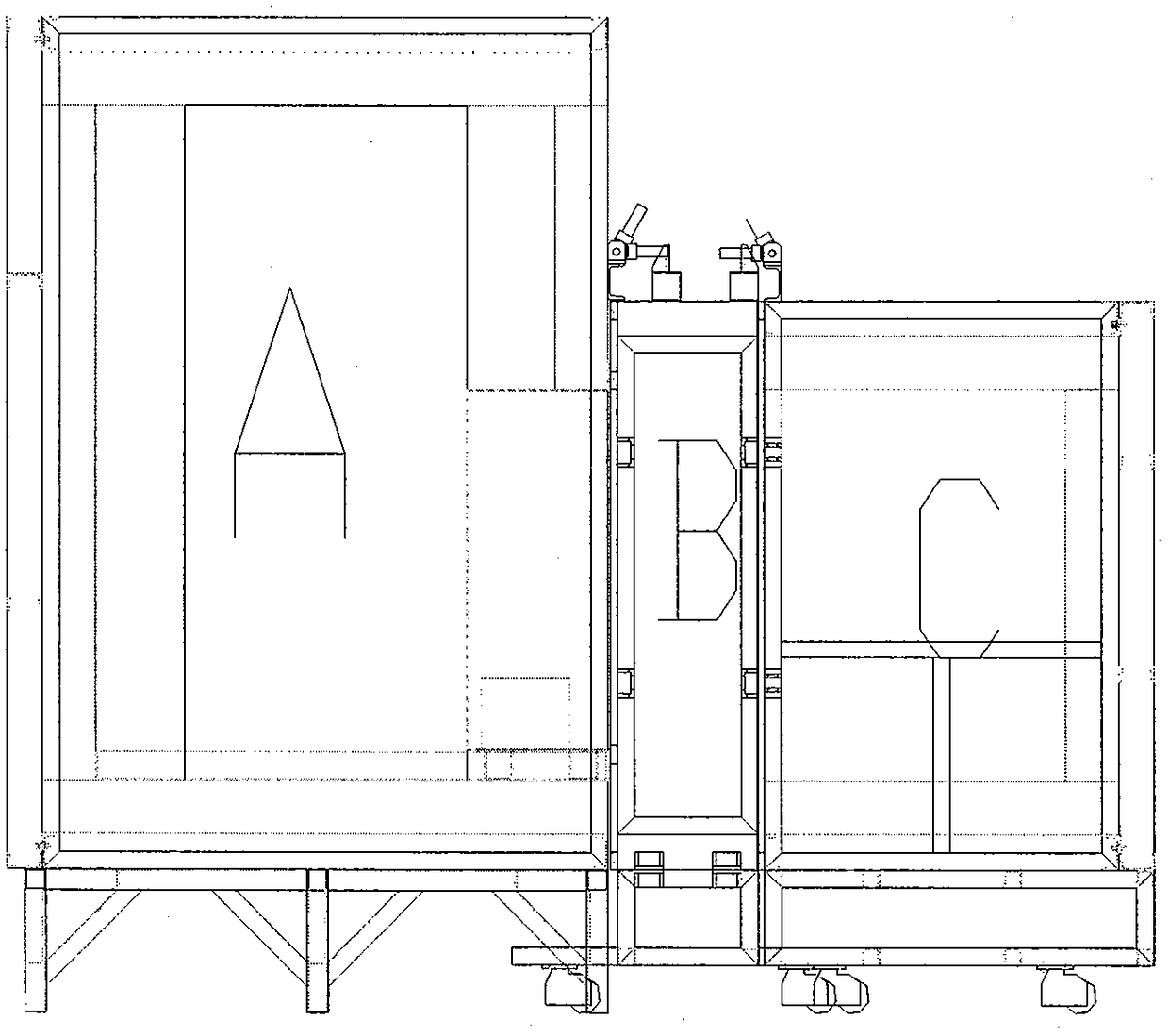

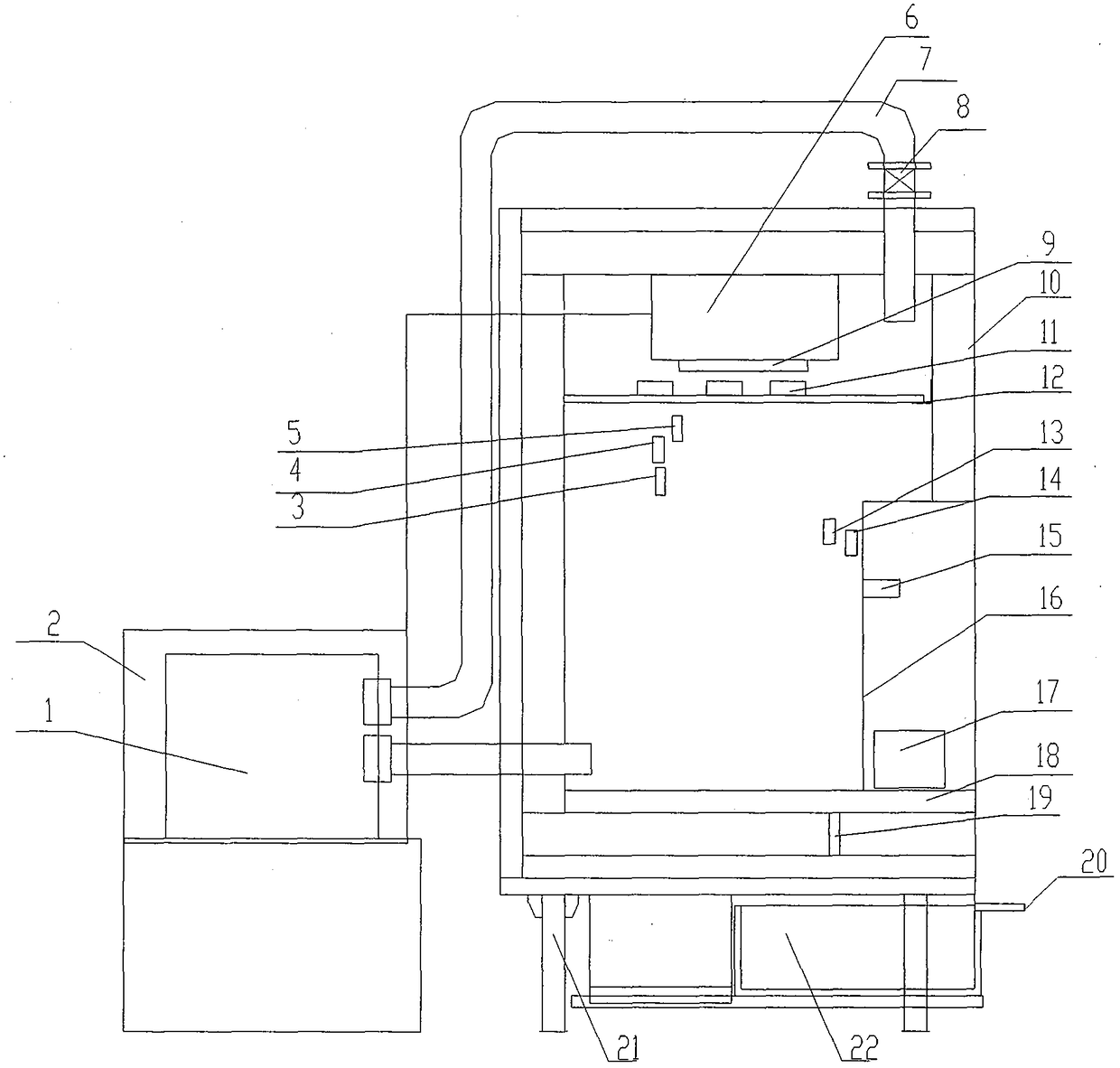

Movable building mud dehydrator

InactiveCN105884168AImprove dehydration effectIncrease solid contentSludge treatment by de-watering/drying/thickeningSludgeEngineering

The invention relates to the technical field of building mud dehydration equipment and in particular discloses a movable building mud dehydrator. The movable building mud dehydrator comprises a main machine, a transmission device, a liquid reagent mixed reaction device, a concentration device, a filtrate collection device and a mud pump, wherein the liquid reagent mixed reaction device is mounted on a vehicle by virtue of a movable chassis B; the main machine, the transmission device, the concentration device and the filtrate collection device are mounted on another vehicle by virtue of a movable chassis A. The advanced liquid reagent mixed reaction device is used, so that the dehydration property of the sludge is improved, the property of filter cakes is improved, and the permeability of water in materials is improved. The movable building mud dehydrator disclosed by the invention is convenient and flexible to use, can be used for various building mud dehydration treatment processes and has the characteristics of high power and high treatment quantity, and the treated mud can be used for improving soil, afforestating city and the like. Moreover, the movable building mud dehydrator is reasonable in structure, high in degree of automation, convenient to move, low in labor intensity and easy to operate.

Owner:季华林

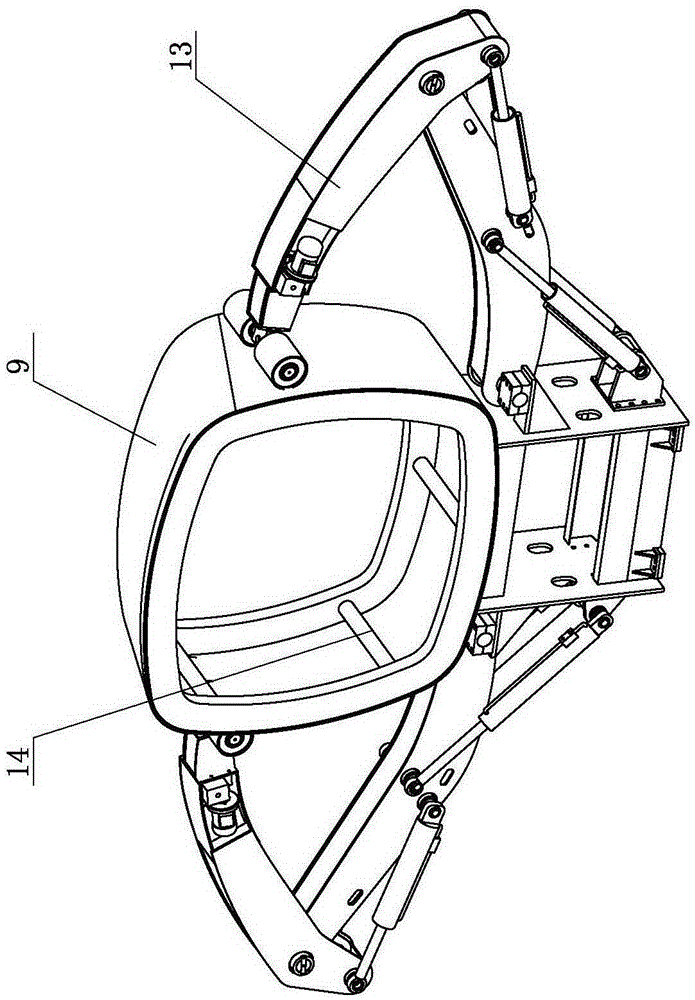

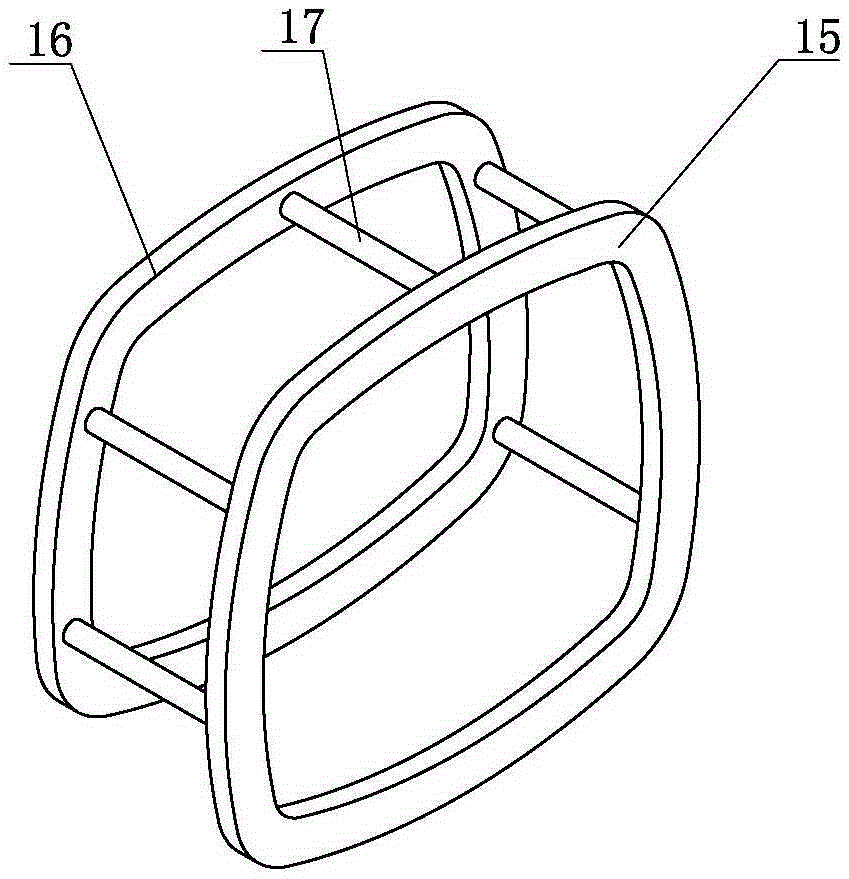

Envelope material durability testing equipment and method

InactiveCN109030330AFully consider energy savingImprove fire performanceWeather/light/corrosion resistanceAutomatic controlData acquisition

The present invention provides envelope material durability testing equipment and a method. The equipment comprises an outdoor environmental box simulation system, an indoor environmental box simulation system, a test piece frame system, a moisture transfer weight acquisition system and an automatic control and data acquisition system. The outdoor environmental box simulation system is connected with one side of the test piece frame system, the other side of the test piece frame system is connected with the indoor environmental box simulation system, and the moisture transfer weight acquisition system is placed at the middle part of the outdoor environmental box simulation system. The test piece frame system comprises a mobile test piece vehicle. The moisture transfer weight acquisition system comprises a moisture content collecting box, a high precision electronic scale, a circulating fan and a temperature and humidity sensor, a moisture content absorption material and a data acquisition and recording system. The equipment can simulate the natural environment factually and perform the repeated aging test and the test piece moisture content variation measurement on the systems of the exterior surfaces of all buildings. The equipment has the advantages of wide application range, simple operation, stable performance and high utilization rate.

Owner:CHINA ACAD OF BUILDING RES

Manufacturing method of recycled plastic composite manhole cover

InactiveCN102888032AImprove impact resistanceGood weather resistanceArtificial islandsUnderwater structuresCompression moldingGlass fiber

The invention relates to an inspection manhole cover of municipal engineering, and particularly relates to a manufacturing method of a recycled plastic composite manhole cover. According to the manufacturing method of a recycled plastic composite manhole cover, raw materials including waste plastics, VT powder, coal ash and processing aids are blended and then subjected to compression molding, injection molding or calendering to obtain the recycled plastic composite manhole cover. According to the invention, the VT powder is produced from the waste circuit board of an electronic product without adding glass fiber, and an effect of enhancing strength and toughness still can be realized; and the cost is greatly lowered.

Owner:GEM CO LTD

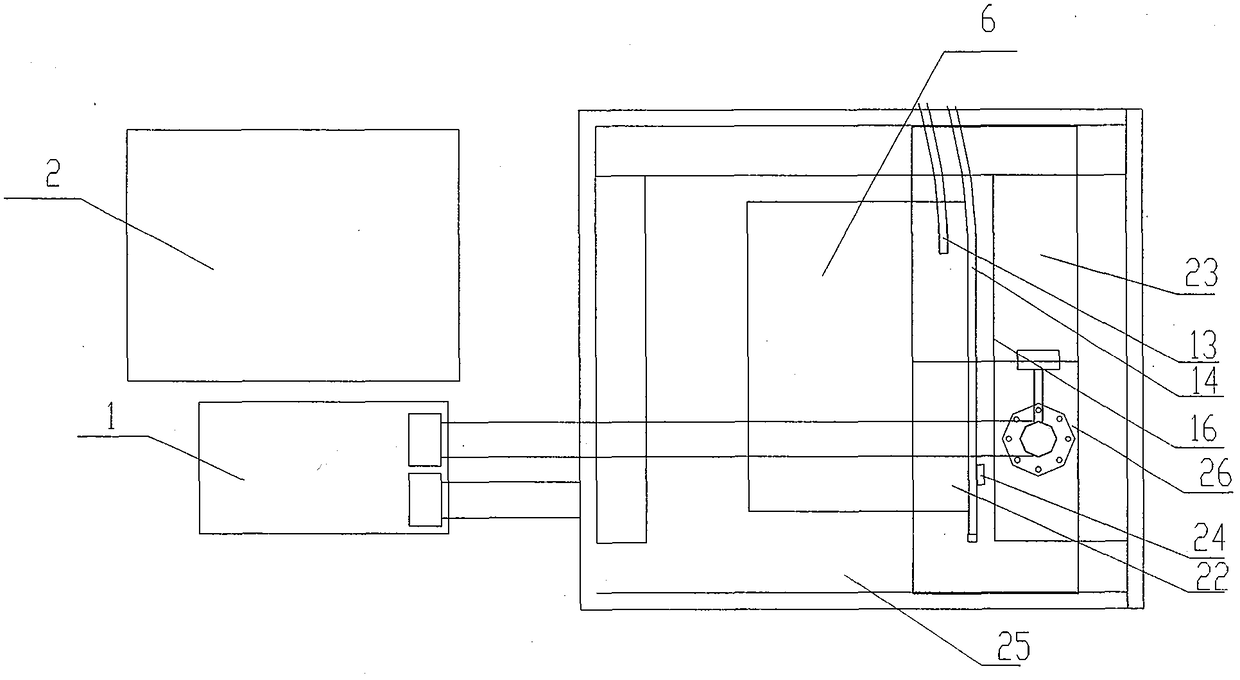

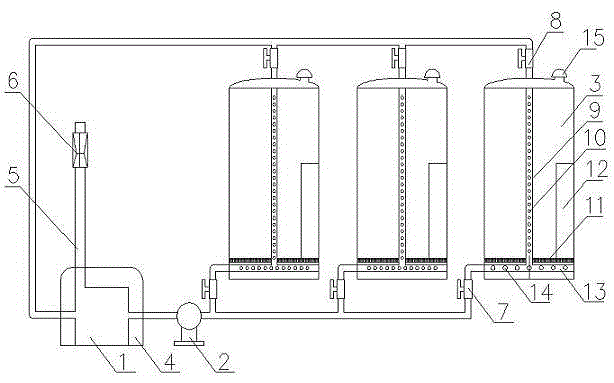

Split type carbonization furnace set

InactiveCN105524629AAvoid environmental pollutionReduce work intensityBiofuelsEnergy inputBiomassProcess engineering

The invention discloses a split type carbonization furnace set. The split type carbonization furnace set comprises a combustion furnace, a hot gas pump and carbonization furnaces, wherein the combustion furnace, the hot gas pump and the carbonization furnaces are sequentially connected through pipelines, the combustion furnace and the carbonization furnaces are separated, and three or more carbonization furnaces are connected in parallel in a process. Wood, fruit peels, straw and other biomass raw materials are put in the closed carbonization furnaces with a dry distillation process, fuel is added to the combustion furnace and combusted to generate hot gas, the hot gas is sent into the carbonization furnaces through the hot gas pump to heat the biomass, accordingly, oxygen-free carbonization is realized, combustible byproducts generated in the carbonization process enter a combustion chamber through the pipelines for combustion, the gas after combustion enters a chimney and is discharged into the air after being treated through a smoke filter, and environment pollution is avoided. The combustion furnace and the carbonization furnaces are separated, multiple carbonization furnaces are connected in parallel, each carbonization furnace can be operated independently, other operation is not affected, semi-continuous production of the carbonization furnaces is realized, the working intensity is reduced, and the equipment production efficiency is improved.

Owner:XINJI YUAN XIANG GREEN ENERGY TECHOLOGY CO LTD

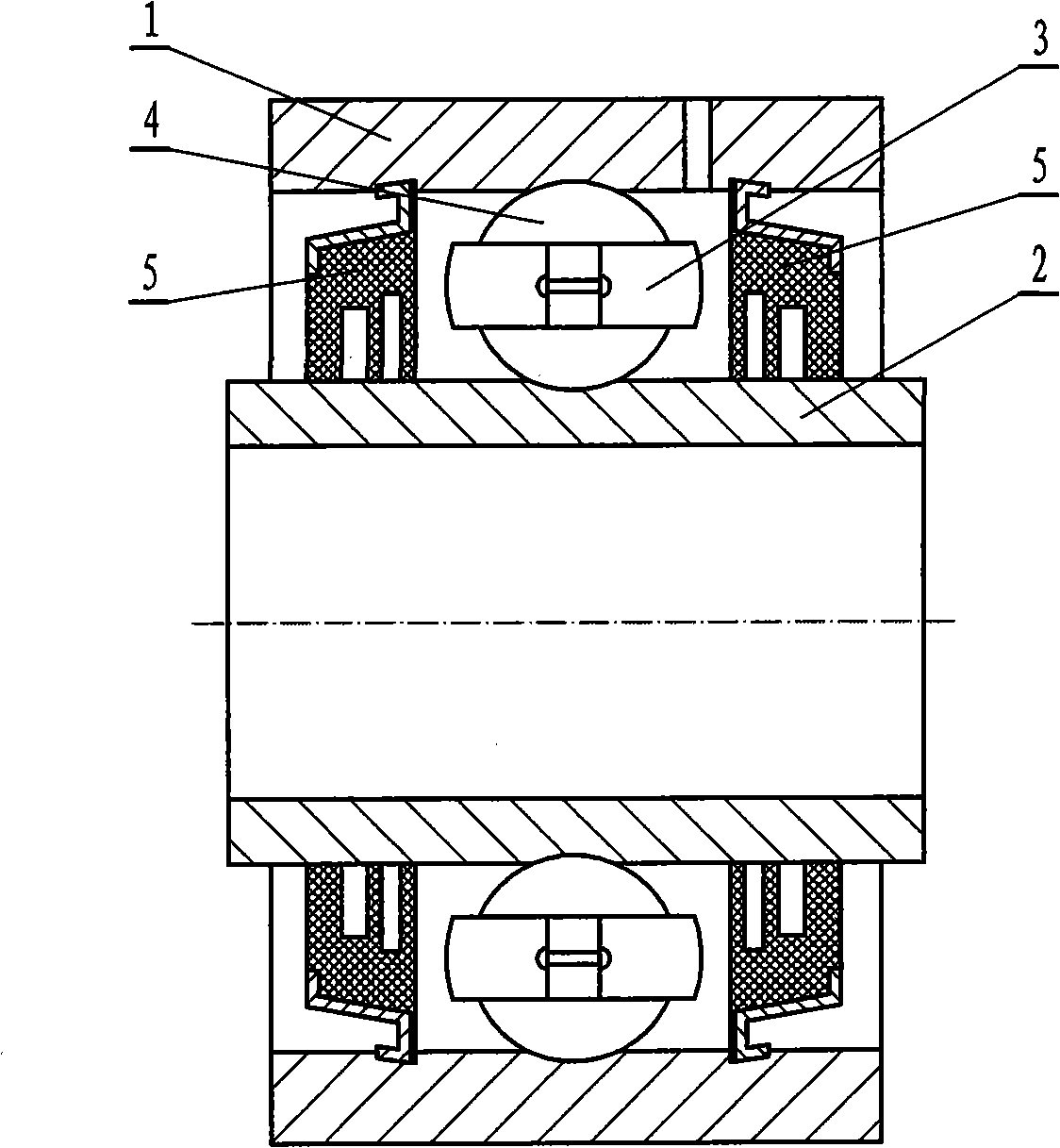

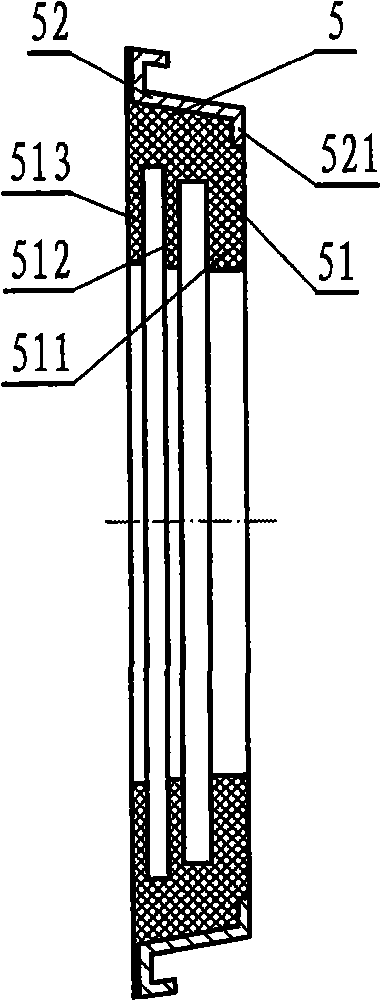

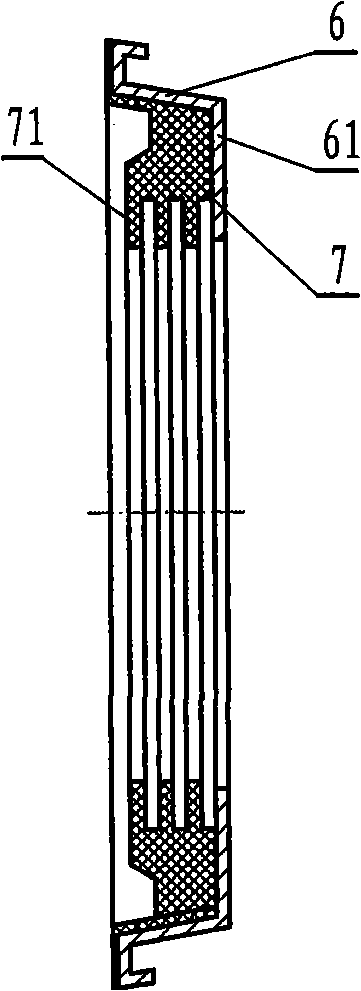

Three lips contact type seal bearing

The invention relates to a three-lip contact-type sealing bearing which comprises a bearing outer ring, a bearing inner race, a retainer, a rolling body and a sealing ring, wherein the sealing ring is provided with a sealing element and a frame; three parallel contacting lips are arranged at the inside circumference of the sealing element and closely contact the external diametric plane of the bearing inner race; the mono-lateral shrink range of the contacting lips and the external diametric plane of the bearing inner race is 1.2mm to 1.8mm; the width of the outermost contacting lip is larger than the width of the other two contacting lips; the external lateral face of the frame is provided with a rib of a positioning sealing element; the closing diameter of the rib is larger than the outer diameter of the bearing outer bring by 8mm to 12mm; the housing washer of the sealing ring is embedded on the inner surface of the bearing outer ring. The sealing bearing has the advantages that good sealing performance is achieved; the entering of external impurity such as dust and mud water into the interior of the bearing and the escape of lubricated lipid in the bearing are avoided; the wear of the bearing is reduced; and the service life of the bearing is prolonged.

Owner:陆连运

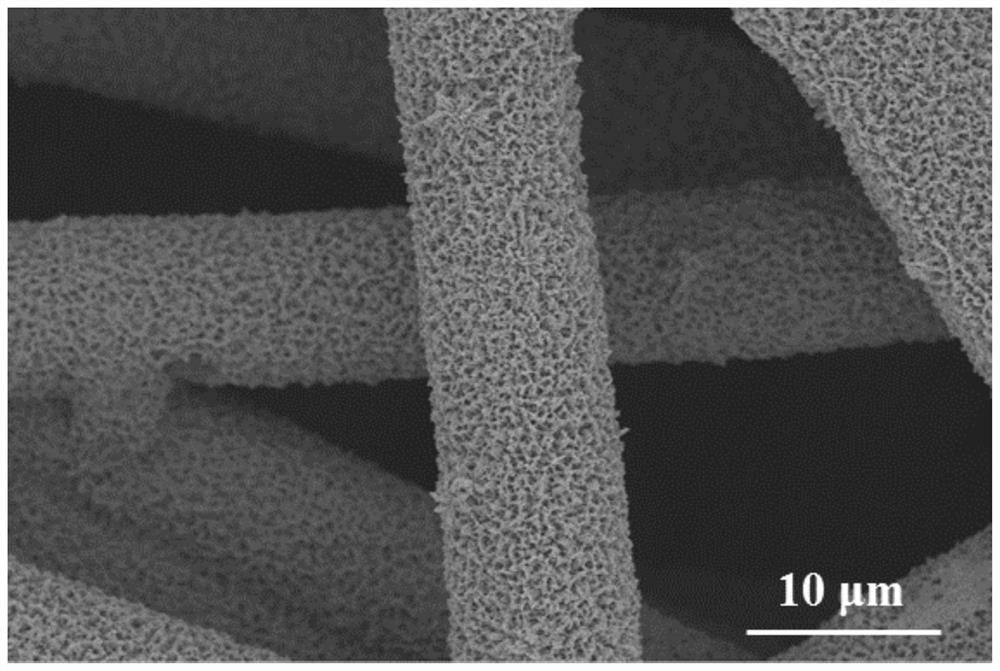

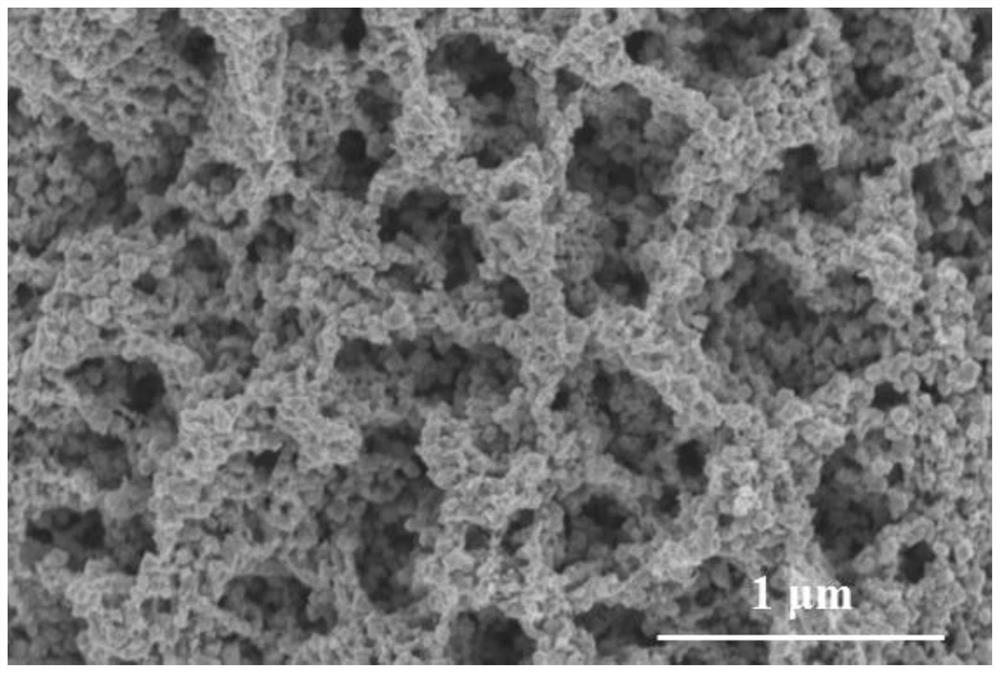

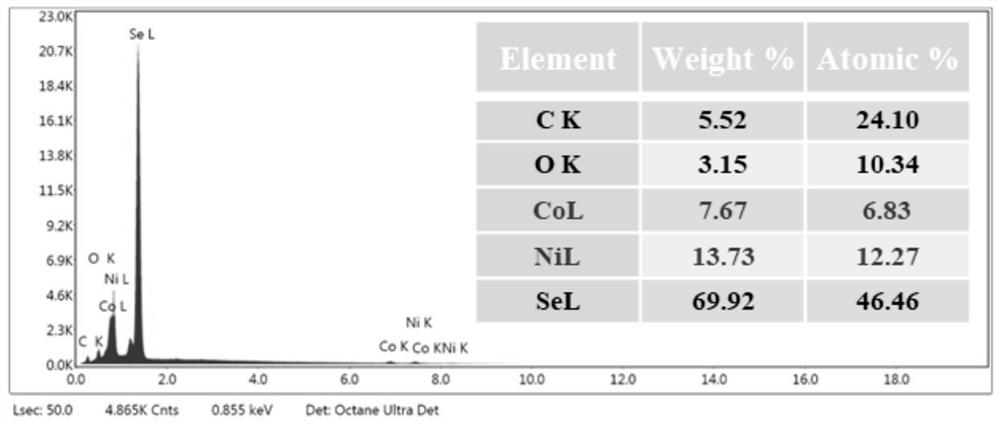

NiSe2-CoSe2/CFs composite material with micro-nano two-stage pores and high structural stability and preparation of NiSe2-CoSe2/CFs composite material

The invention discloses a NiSe2-CoSe2 / CFs composite material with micro-nano two-stage pores and high structural stability and preparation of the NiSe2-CoSe2 / CFs composite material. The composite material comprises a micron-stage porous carbon fiber matrix and a nano foamed NiSe2-CoSe2 material loaded on the carbon fiber matrix, and the atomic ratio of Ni to Co is (1.6-2.5):1. The carbon fiber loaded NiSe2-CoSe2 composite material is prepared by using a hydrothermal method and a chemical vapor deposition method, and is subjected to heat treatment in the atmosphere of H2 and N2. The product provided by the invention has excellent mechanical stability. When the product is directly applied to a cathode electrode for water electrolysis hydrogen production, the destructive effect of gas impact on the structural stability of an active phase of the electrode under the industrial large-current long-time service condition can be relieved, the mechanical stability of the electrode is remarkably improved, and therefore the service life of the electrode is prolonged, and the water electrolysis cost is reduced.

Owner:XIAN AERONAUTICAL UNIV

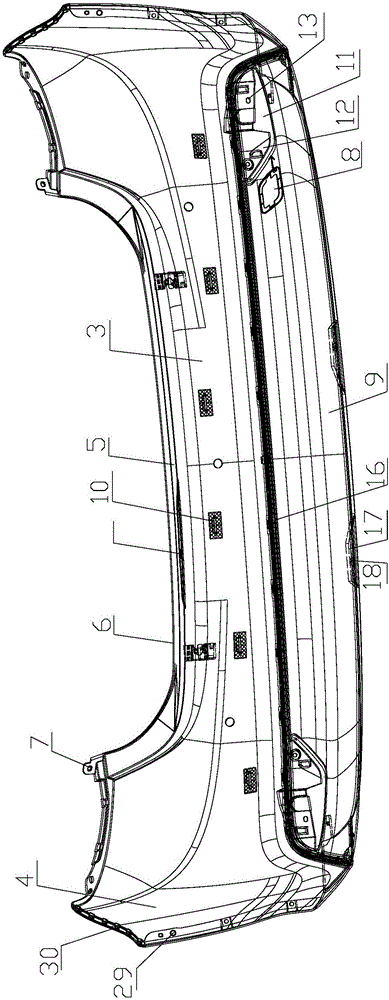

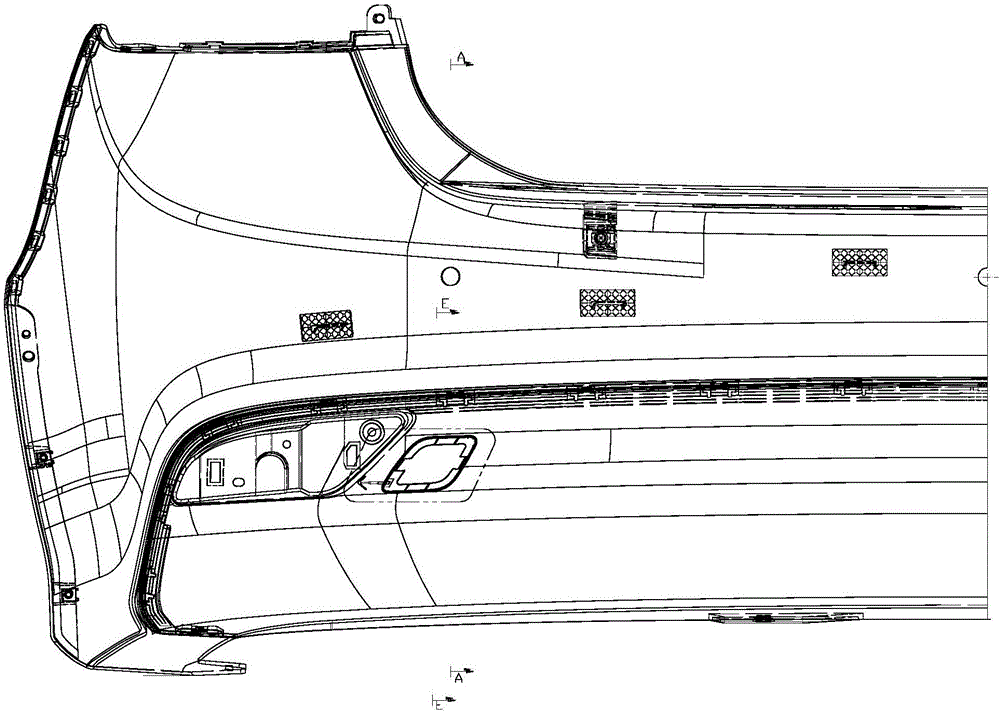

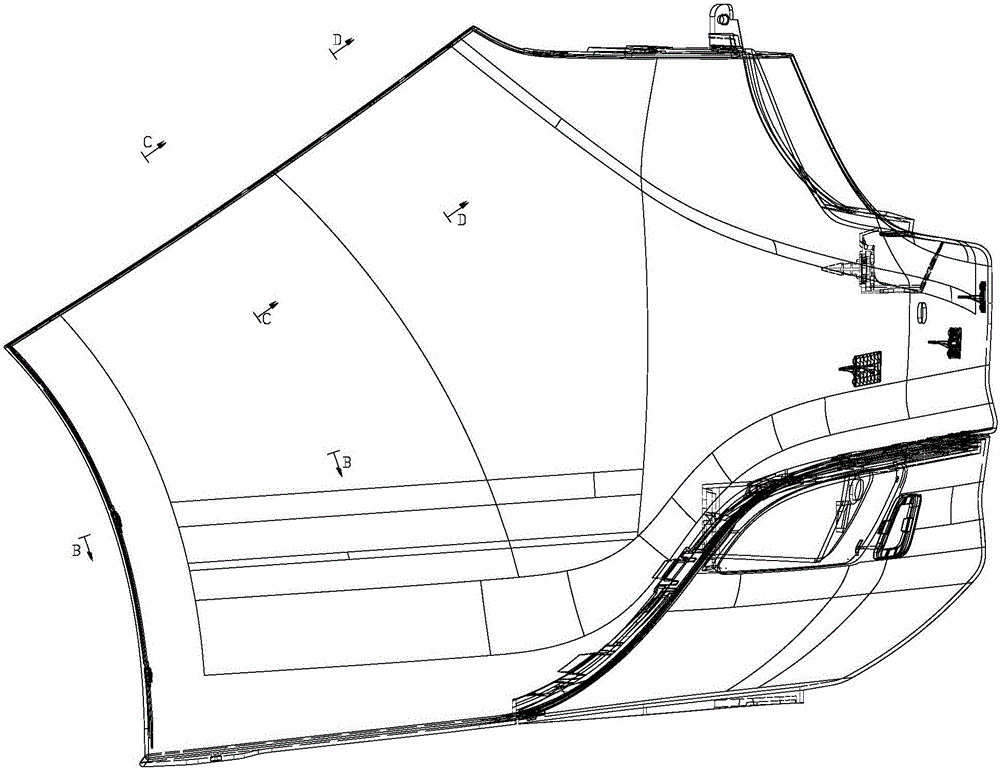

Rear bumper mask assembly

InactiveCN106080463AReduce driving resistanceImprove liquidityBumpersBearing surfaceMechanical engineering

The invention discloses a rear bumper mask assembly. The rear bumper mask assembly is characterized in that the rear bumper mask assembly is fixed on a vehicle through a rear bumper cross beam; the rear bumper mask assembly comprises a side panel and a rear panel; the rear panel extends in a width direction of the vehicle; the rear panel extends in the width direction of the vehicle to be bent towards the two sides of the vehicle so as to form the side panel around the vehicle body; the top of the rear panel is sunken towards the internal side to form a trunk lid bearing surface; and the inner edge of the trunk lid bearing surface is uplifted upwards to form a trunk lid limiting surface.

Owner:TIANJIN HUAXIA LIANSHENG AUTOMO PARTS CO LTD

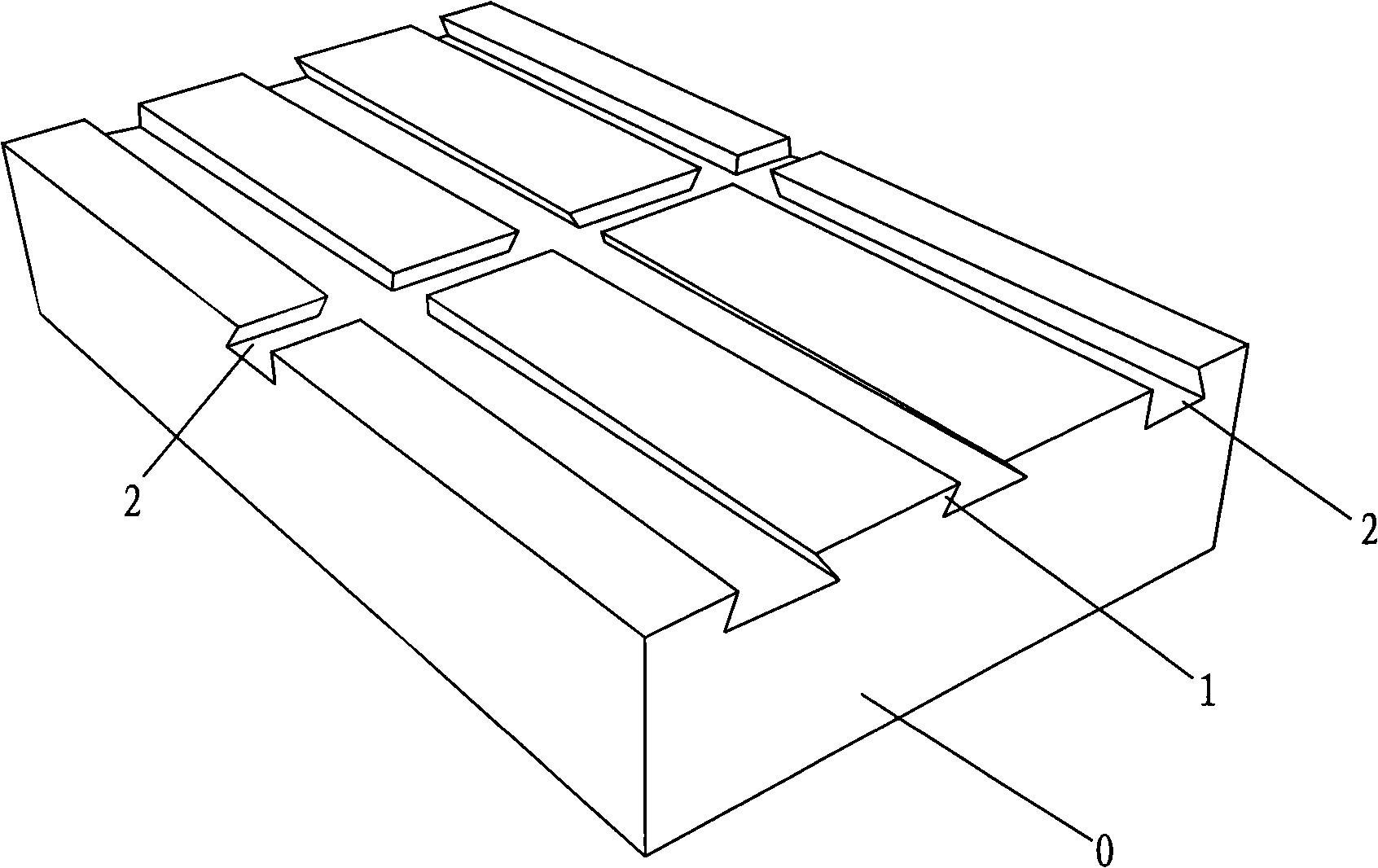

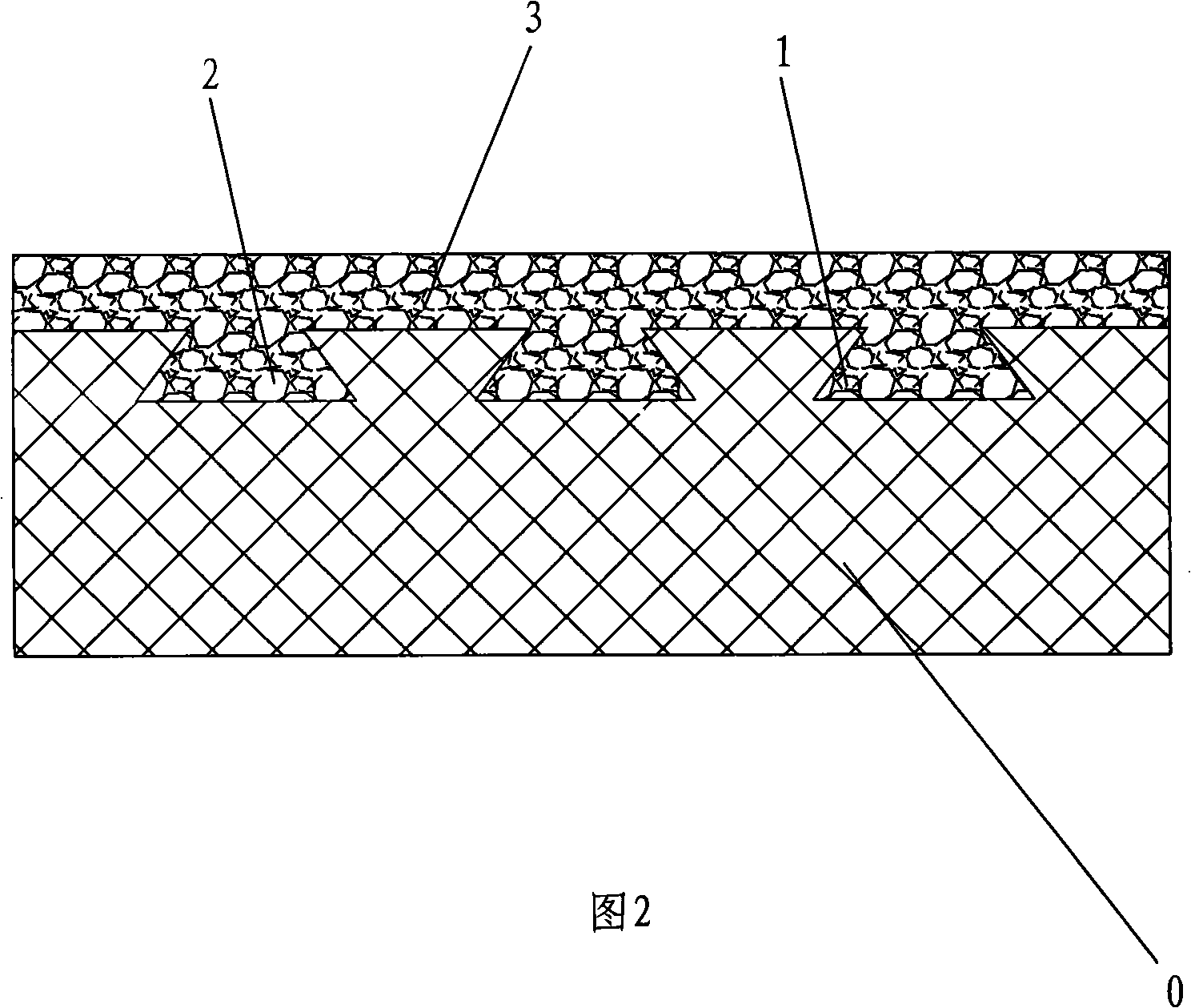

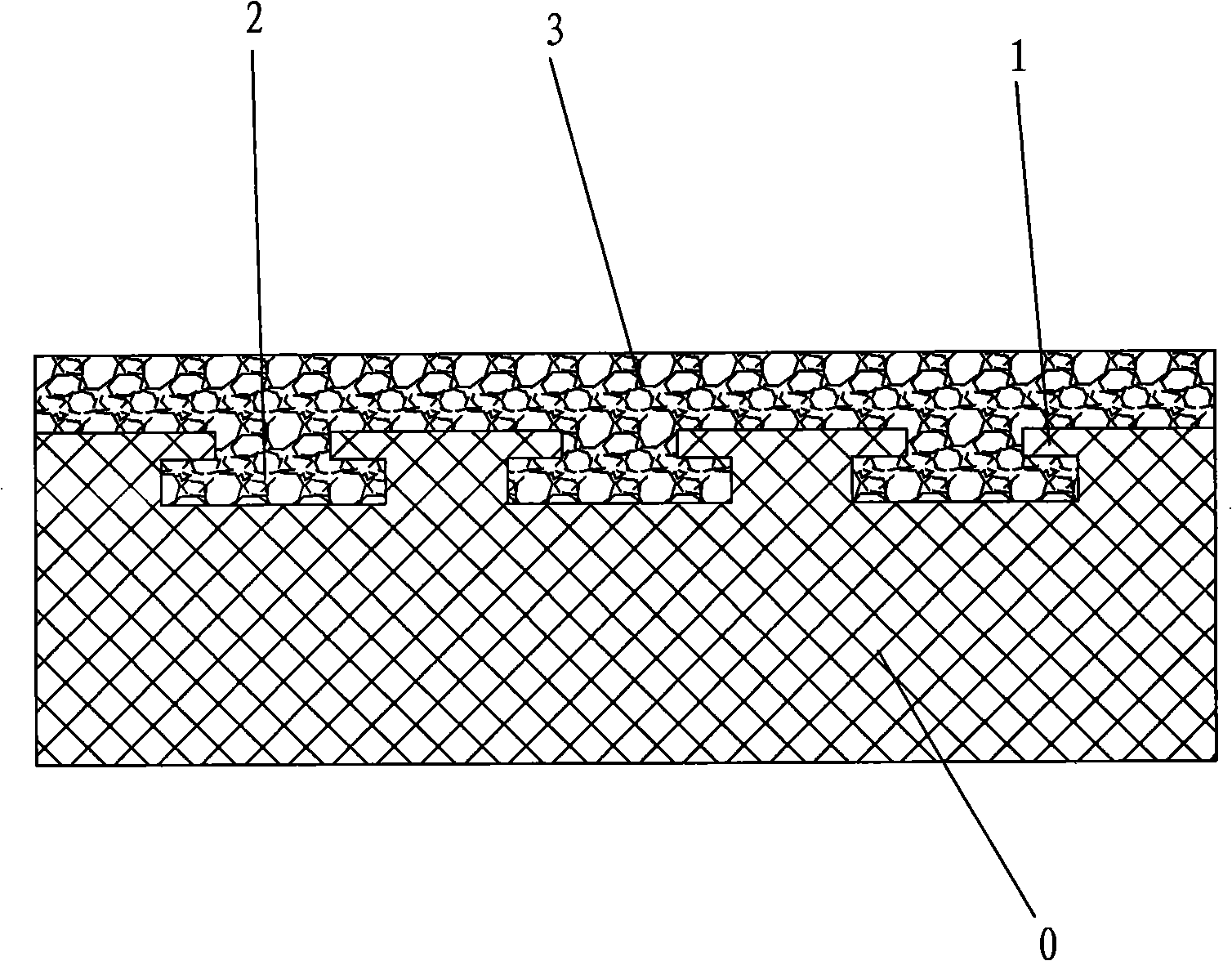

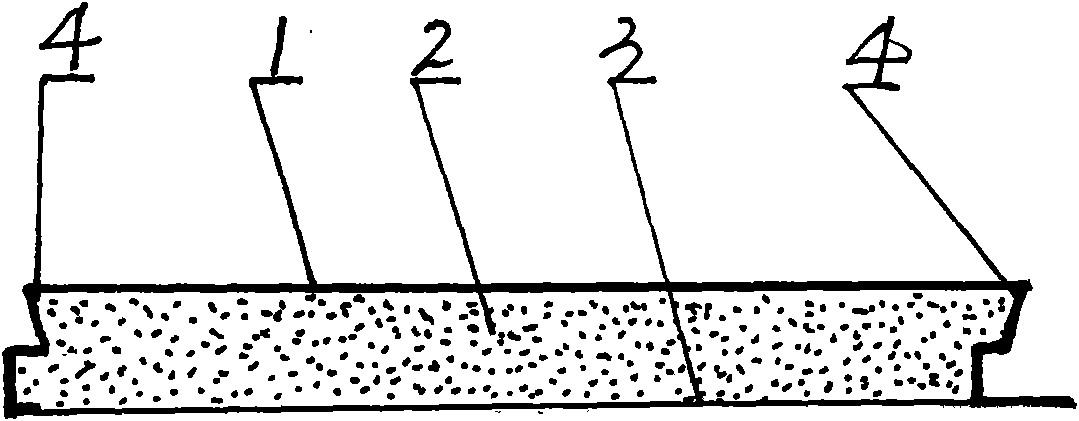

Integrated plate of high strength bonding and thermal insulation facing

InactiveCN101285339AImprove bond strengthHigh bonding strengthCovering/liningsHeat proofingThermal insulationEngineering

The invention relates to the wall body material field, in particular to a high-strength splicing heat-preservation facing integrated plate used in thermal insulation. Compared with the prior art, the integrated plate adopts the following structure that: a surface of a heat-preservation plate glued to a wall body or a decorating plate is provided with a groove with an inverted baffle structure; and the groove is used to increase the contact area between the heat-preservation plate and an adhesion agent. An inverted baffle can effectively combine the adhesion agent and the heat-preservation plate into a whole, thereby greatly reinforcing the adhesion strength of the heat-preservation plate and ensuring that the heat-preservation plate can be closely combined with the wall body or the decorating plate to form an integrated plate.

Owner:浙江博星化工涂料有限公司

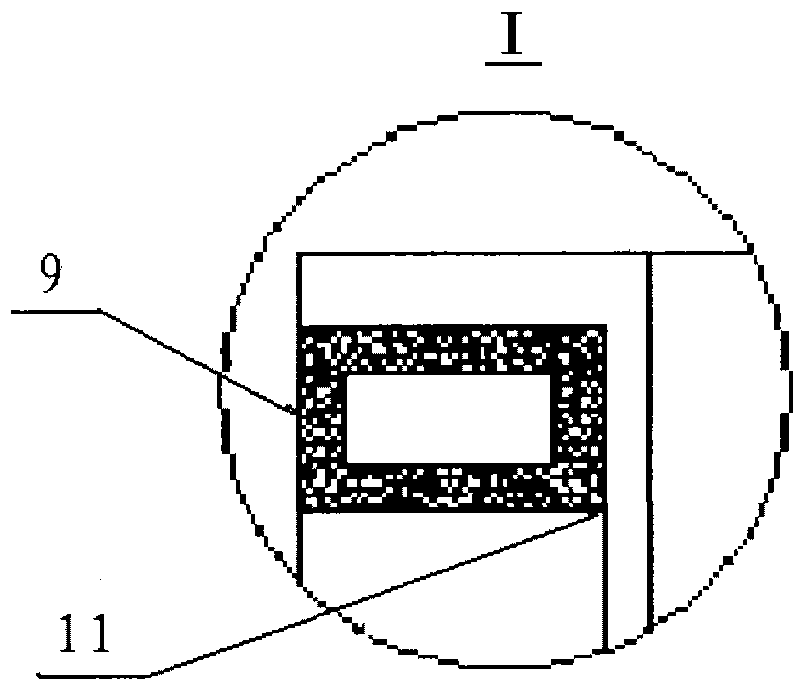

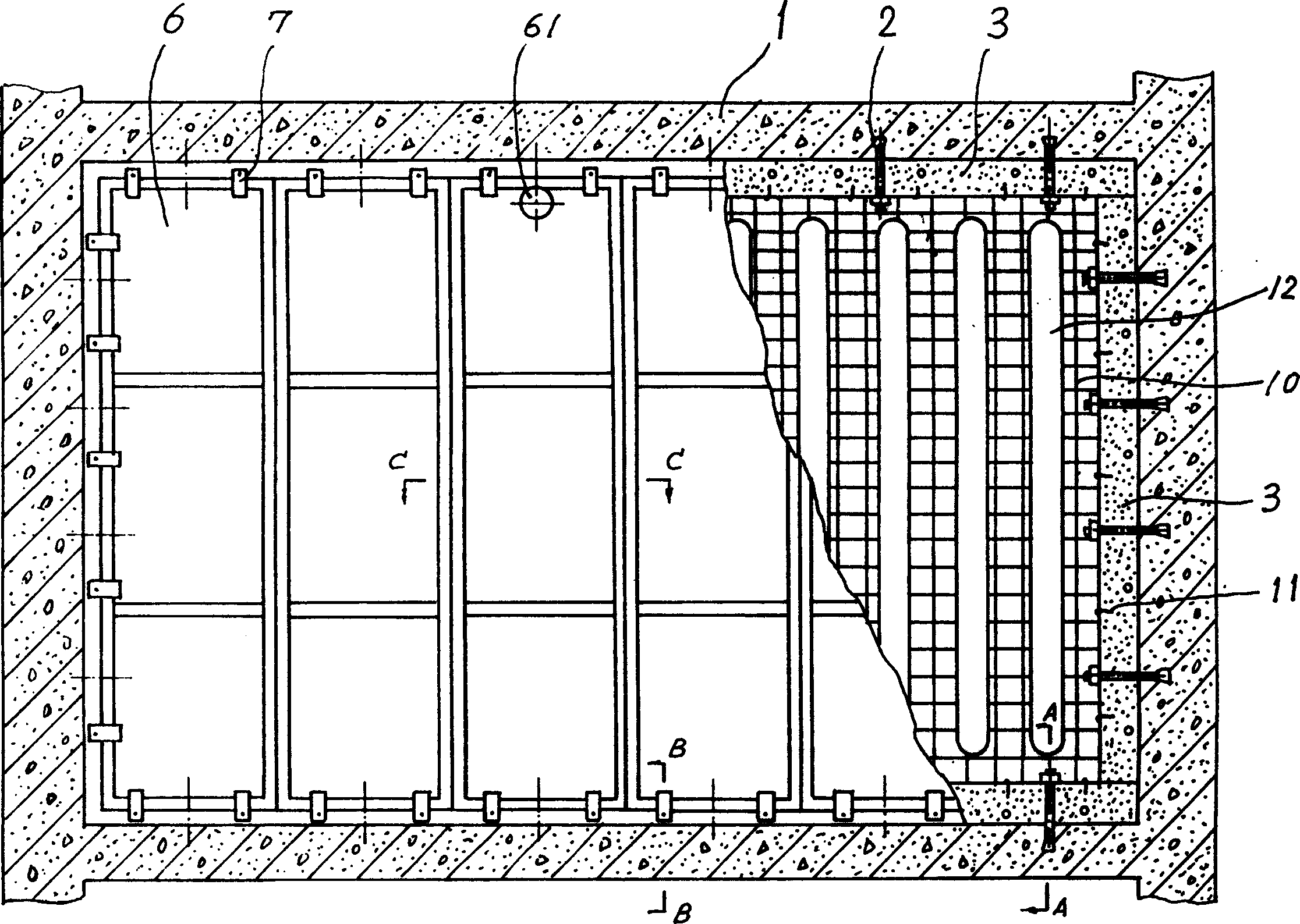

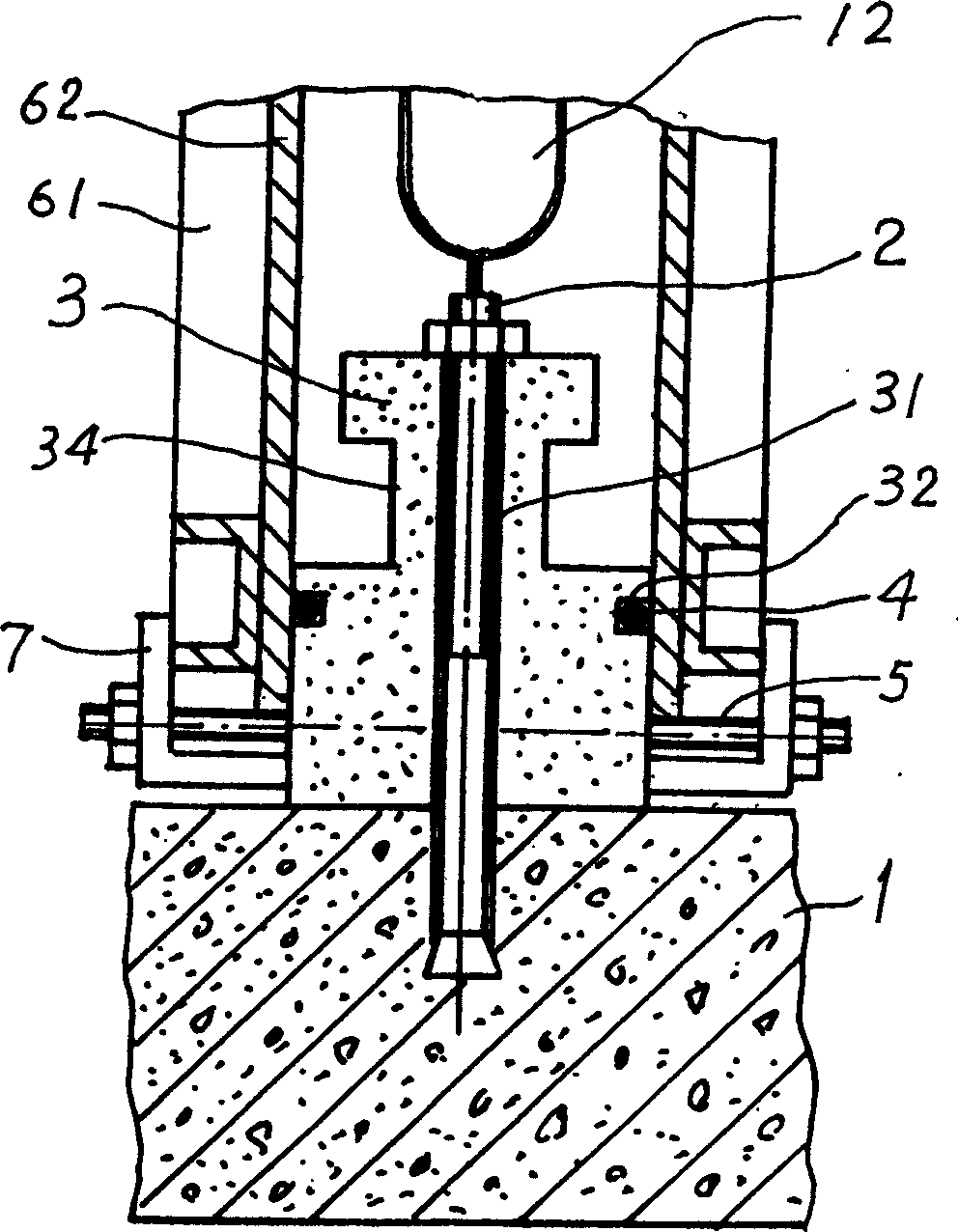

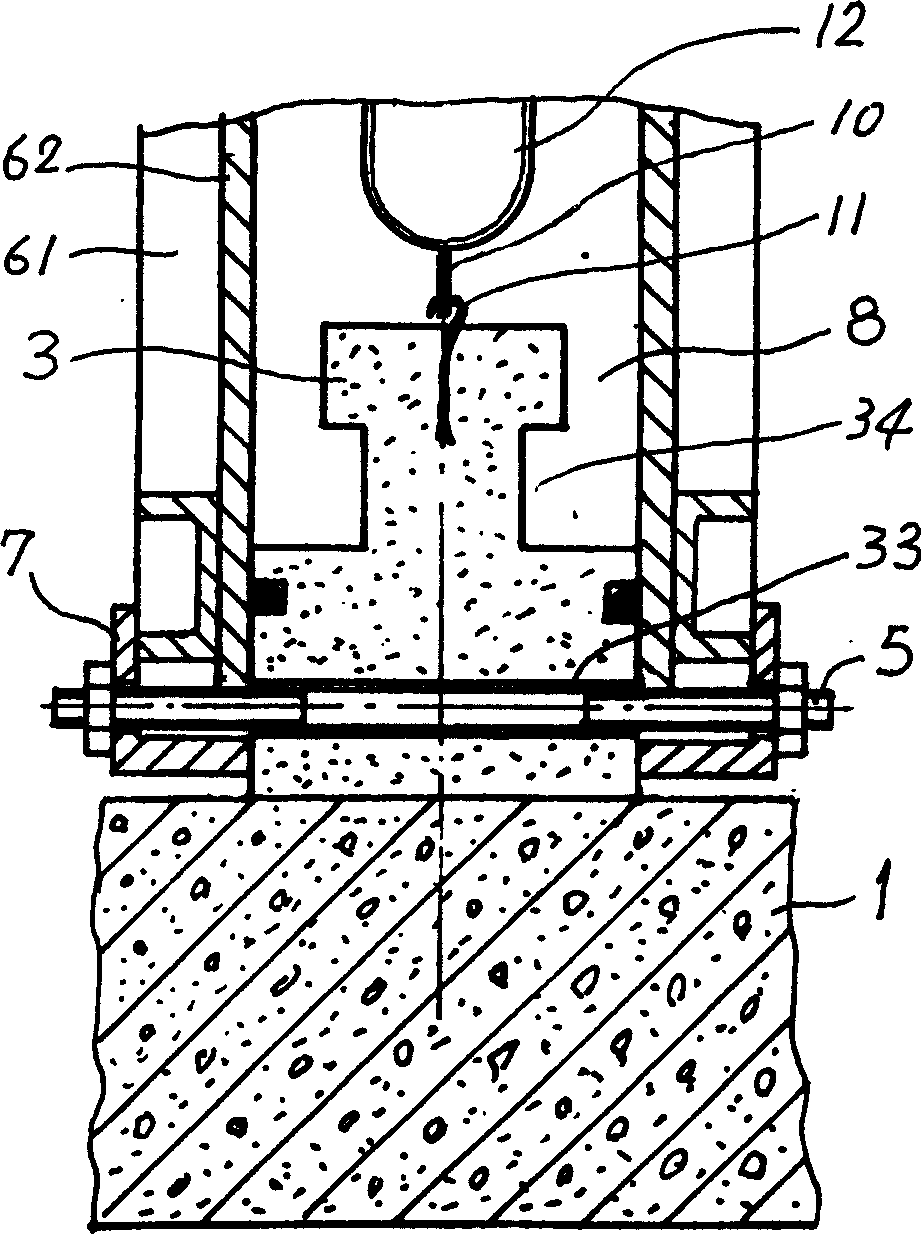

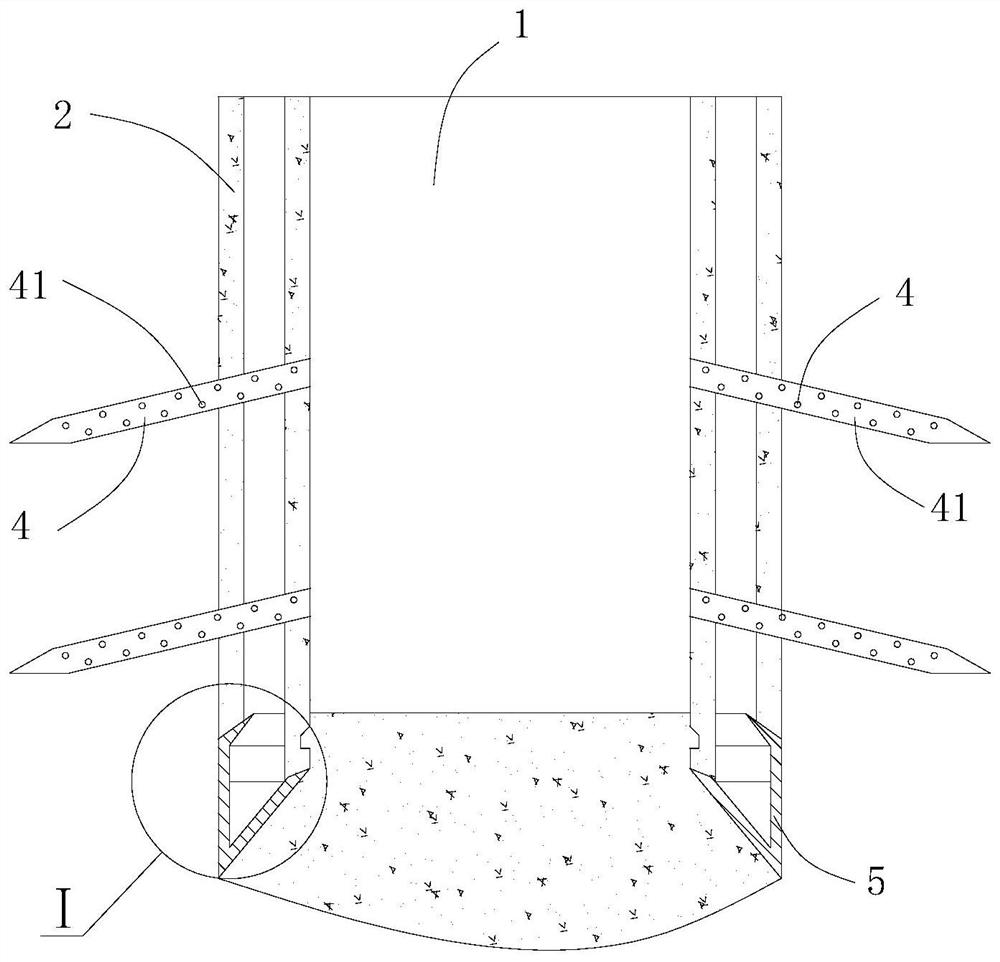

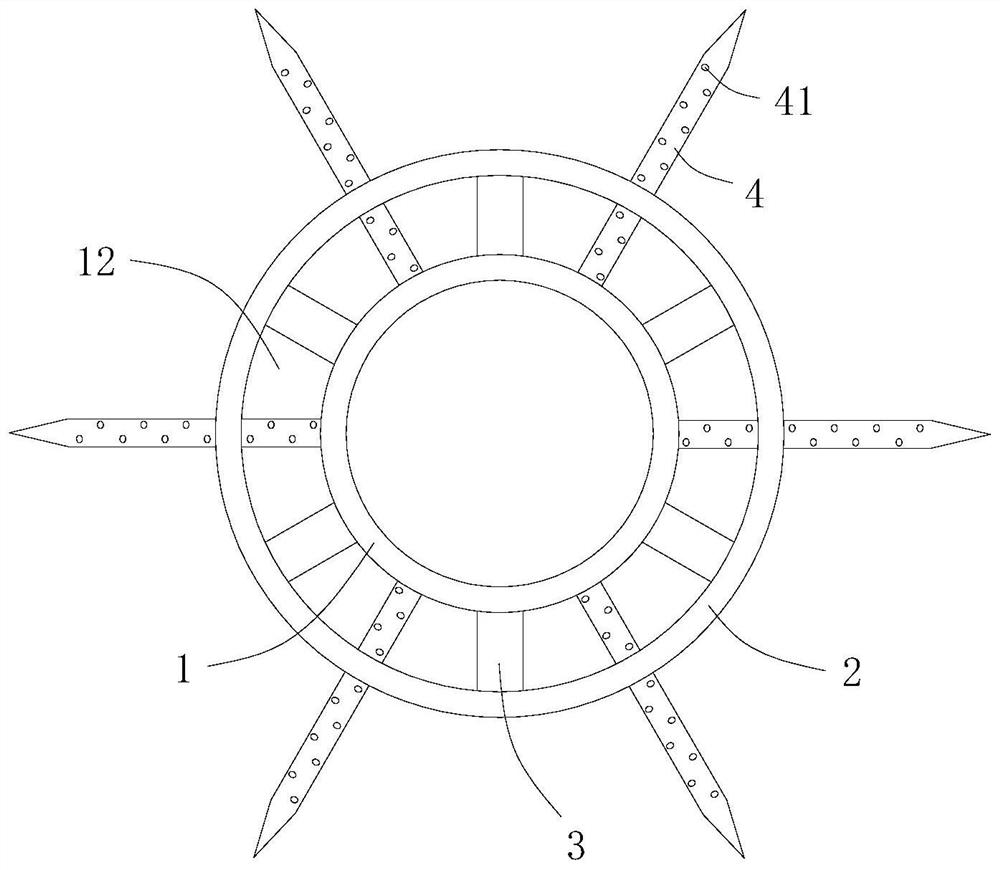

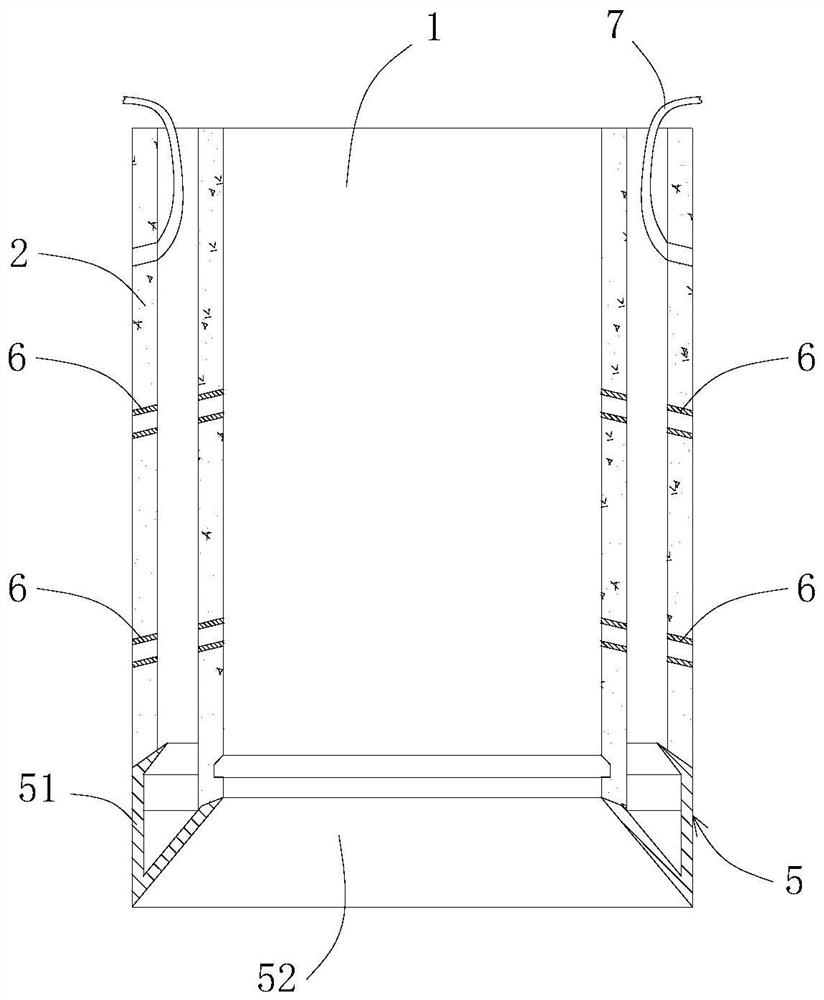

Double-wall concrete open caisson structure and construction method thereof

The invention provides a double-wall concrete open caisson structure and a construction method thereof, and relates to the technical field of concrete open caissons. The double-wall concrete open caisson structure comprises a concrete inner wall, a concrete outer wall, a plurality of concrete partition walls and a plurality of reinforcing anchor rods, and a containing cavity is formed between the concrete outer wall and the concrete inner wall; the concrete partition walls are arranged in the containing cavity; the reinforcing anchor rods penetrate through the concrete inner wall and the concrete outer wall and extend outward in the radial direction of the concrete outer wall; and the lower end of the concrete outer wall is provided with a blade foot assembly, and the blade foot assembly extends towards one side of the concrete inner wall and blocks a lower opening of the containing cavity. According to the double-wall concrete open caisson structure, the concrete inner wall, the concrete outer wall and the concrete partition walls are used for forming a double-wall concrete open caisson, then after the double-wall open caisson sinks underground, the reinforcing anchor rods stretch into a soil layer, mortar is injected into the reinforcing anchor rods, the reinforcing anchor rods are tightly combined with a peripheral soil body, and tight connection between the double-wall open caisson and an external soil layer is improved.

Owner:THE 13TH CONSTR CO LTD OF CHINA NAT CHEM ENG

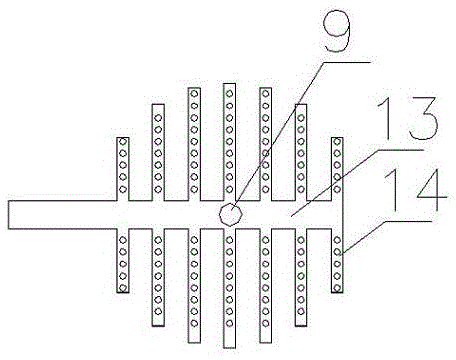

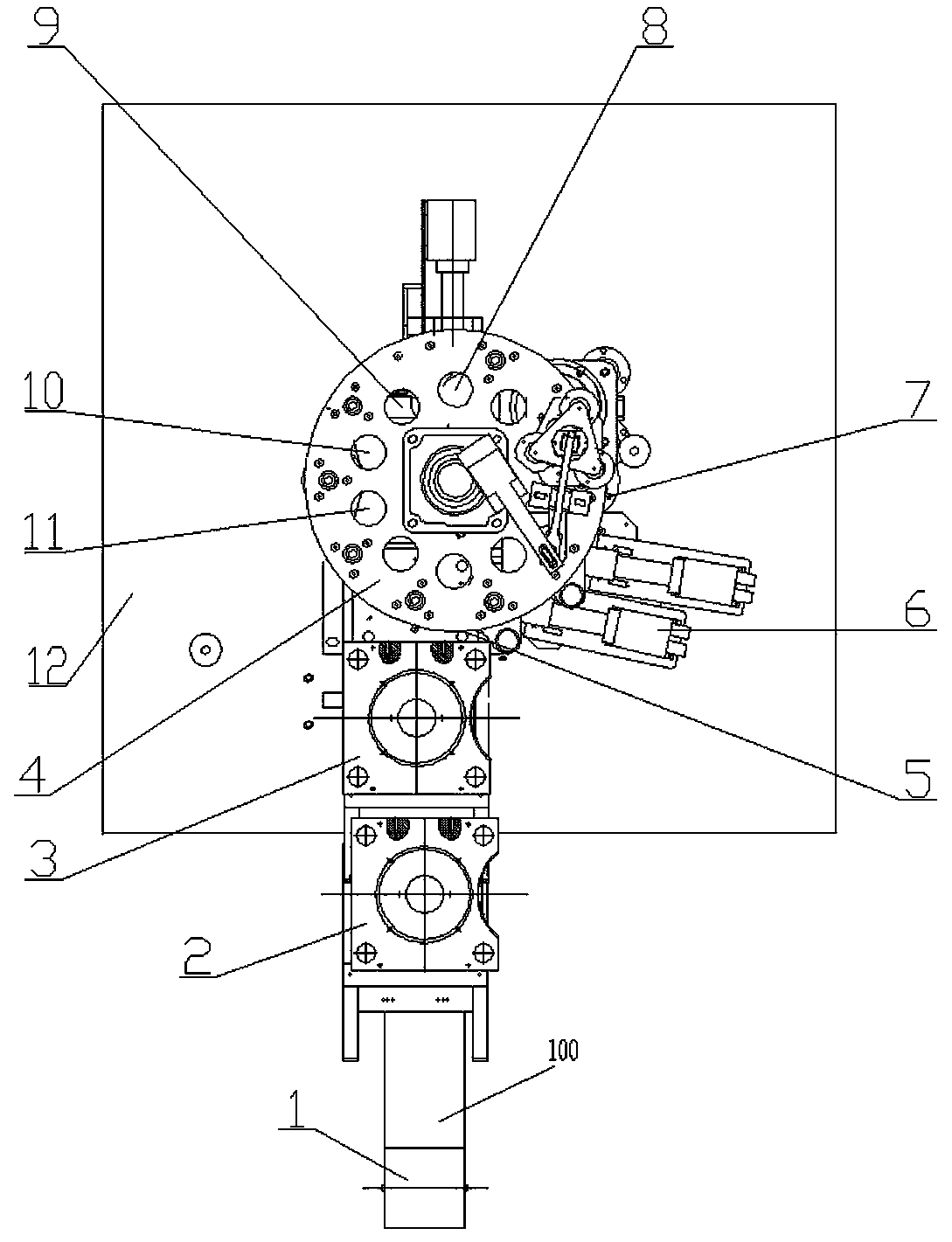

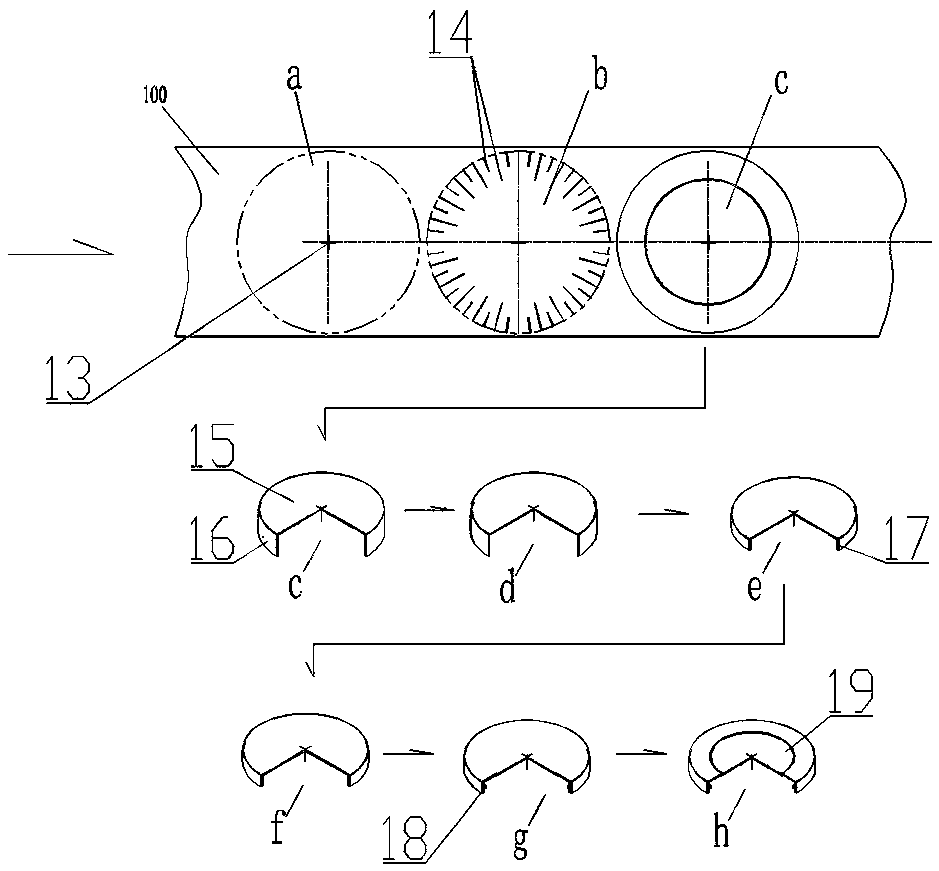

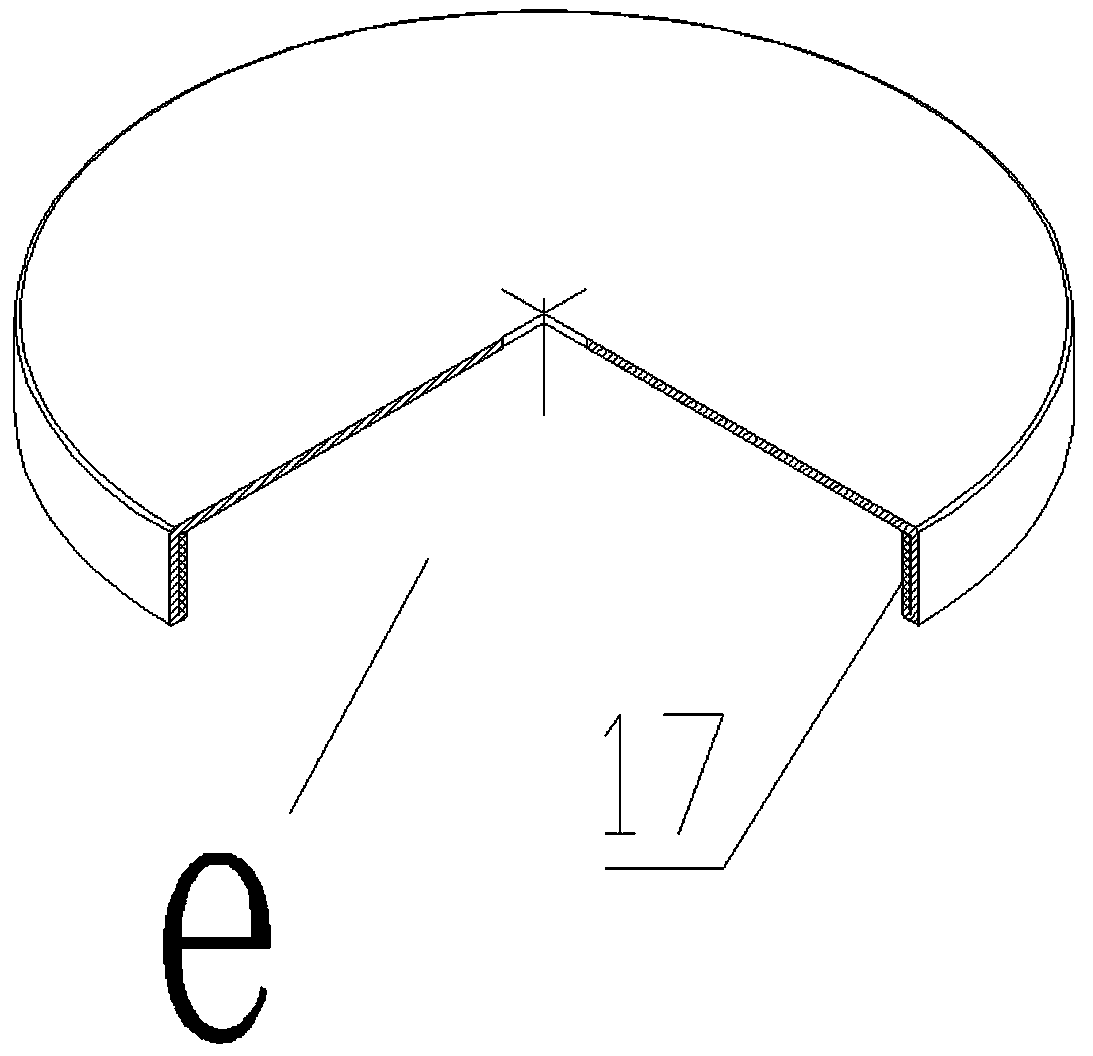

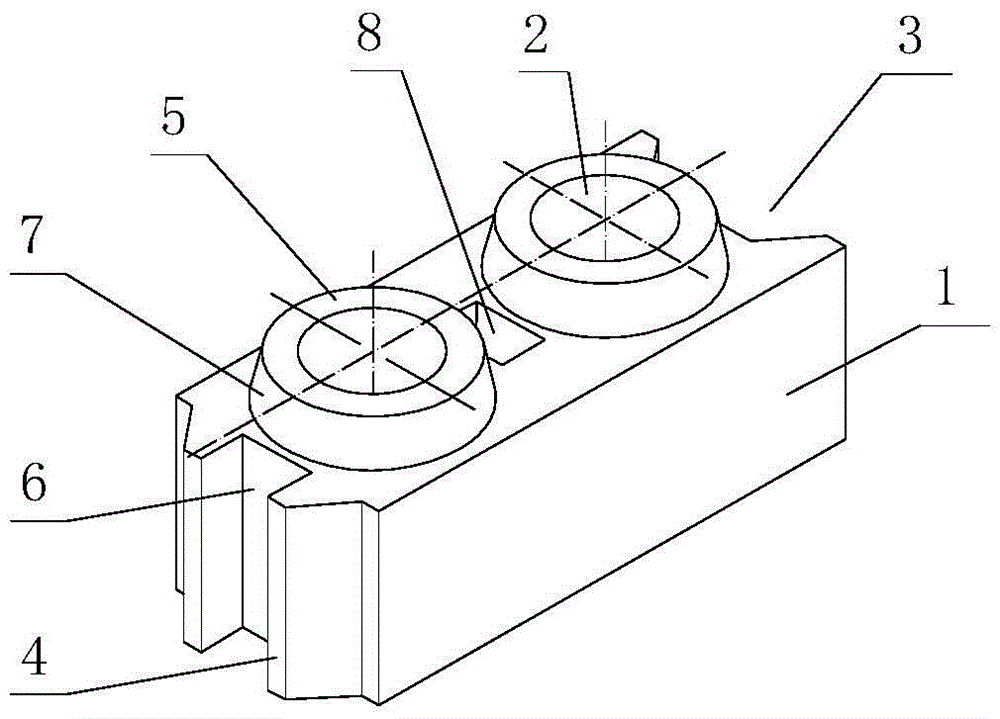

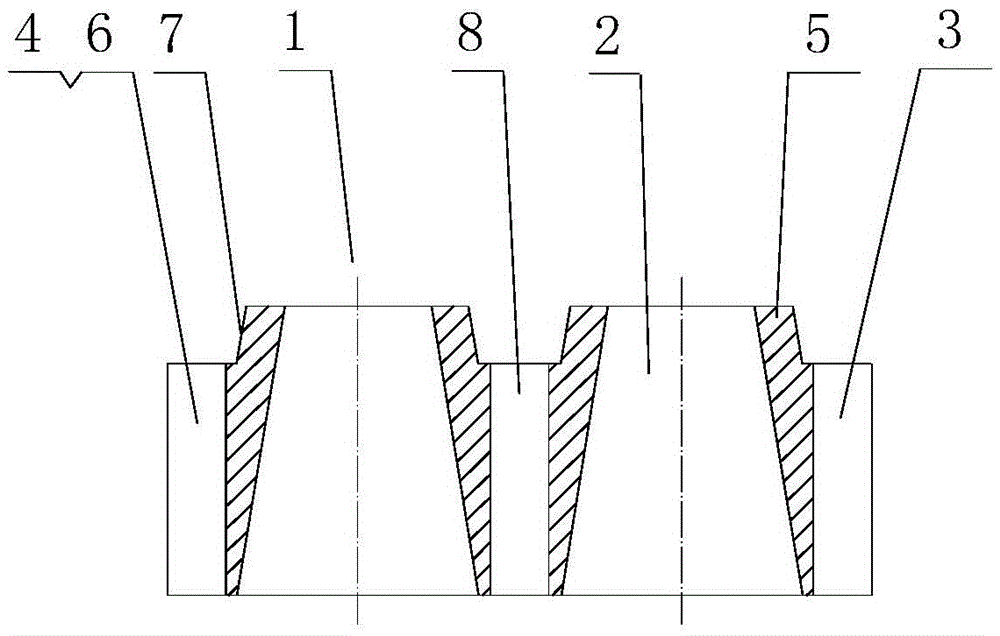

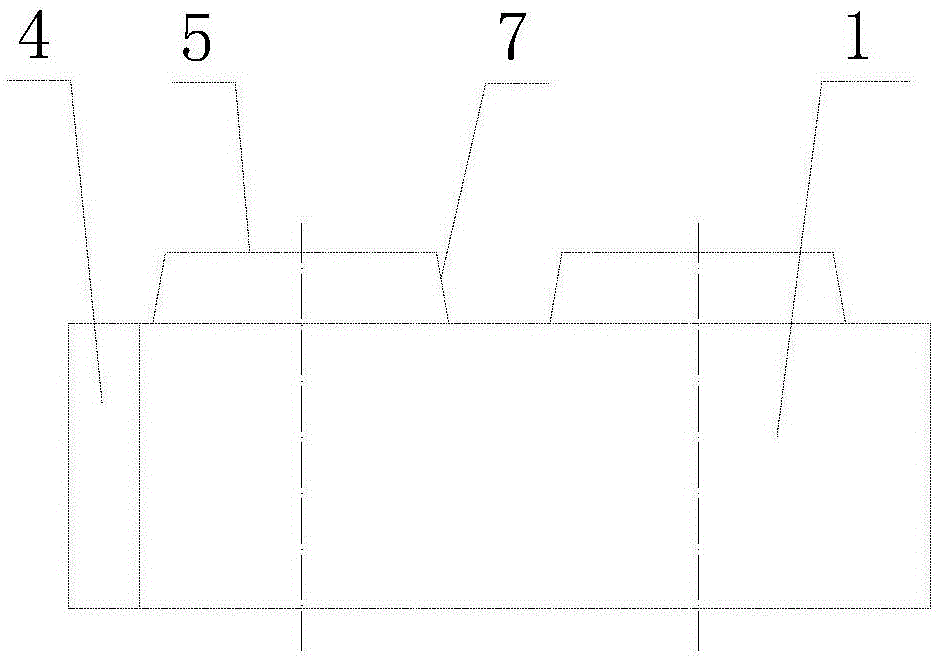

Paper cup cover forming machine station layout structure

ActiveCN110497654AStable performanceIncrease productivityPaper/cardboard articlesFlangingEngineering

The invention discloses a paper cup cover forming machine station layout structure which comprises a workbench. A female die rotating disc is rotationally arranged on the workbench. An unreeling station, a cross stitch punching station and a first indentation station are sequentially arranged on the outer side of the female die rotating disc in the advancing path of raw material paper. A blankingforming station, a first heating forming station, a flanging station, a second heating station, a rolling station, a second indentation station and a cup cover discharging station are sequentially arranged below the female die rotating disc around the rotating center of the female die rotating disc according to the paper cup cover forming process steps. The blanking forming station is connected with the first indentation station, roll paper is directly adopted as raw materials of paper cup covers and is fed according to the takt during production, the structure has the advantages of being stable in performance, high in production efficiency and low in labor cost, and the produced paper cup covers are provided with fastening rings, and are tightly combined with opening edges of cups, and have good anti-disengagement anti-scattering anti-leaking effects.

Owner:RUIAN MINGGUO MACHINERY CO LTD

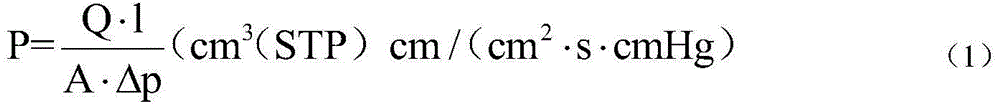

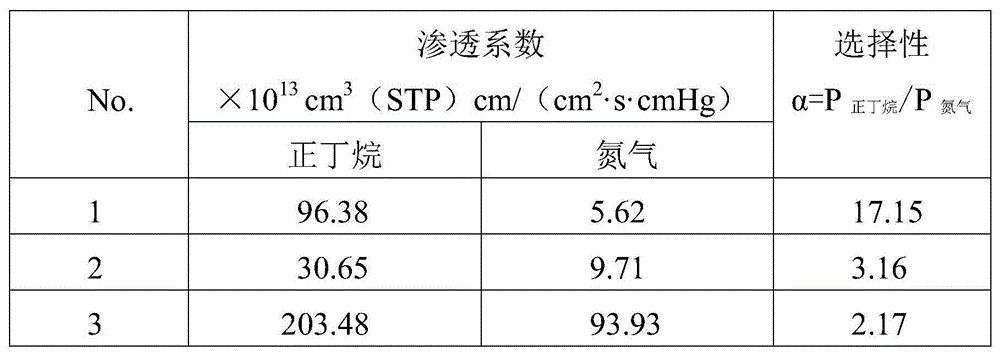

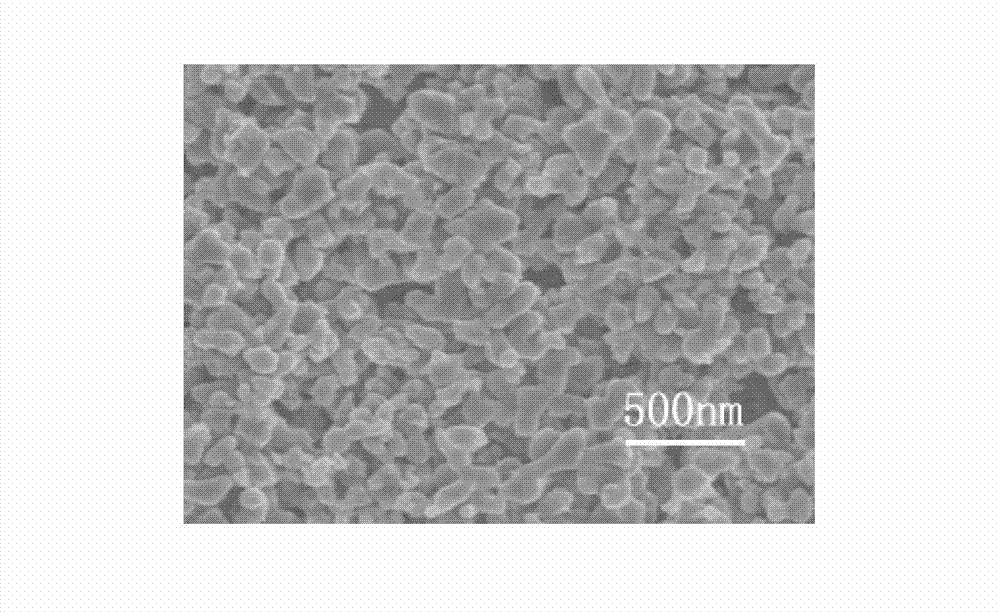

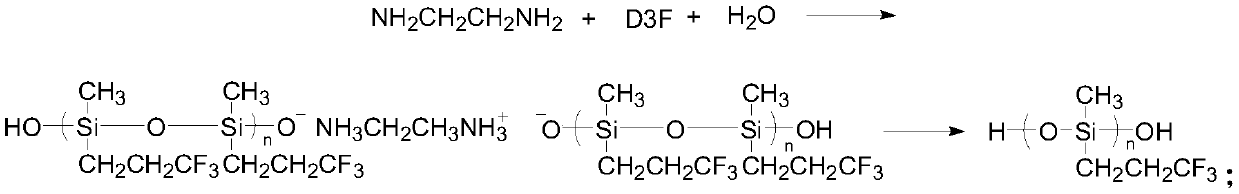

PDMS-KIT-6 composite membrane for separating organic steam and preparation method thereof

ActiveCN104857868AEvenly distributedTightly combinedSemi-permeable membranesDispersed particle separationSeparation factorMass ratio

The invention discloses a PDMS-KIT-6 composite membrane for separating organic steam and a preparation method thereof and belongs to the technical field of membrane separation. The preparation method comprises the following steps of synthesizing a KIT-6 mesoporous material with surface hydrophobicity, carrying out heating pre-treatment on a PVDF base membrane, dissolving a PDMS membrane liquid in n-heptane to obtain a uniform membrane preparation liquid, adding the KIT-6 mesoporous material into the uniform membrane preparation liquid according to different mass ratios, carrying out stirring and ultrasonic defoaming, coating the base membrane with the membrane liquid and carrying out curing at a certain temperature to obtain the PDMS-KIT-6 composite membrane. KIT-6 can be uniformly dispersed in PDMS and the separated layer is compact, has no detects and can be tightly bonded to the PVDF. The PDMS-KIT-6 composite membrane can be respectively used for separating n-butane and nitrogen, propylene and nitrogen, and acetone and nitrogen, has n-butane, propylene and acetone penetration coefficients of 9*10<14>cm<3> (STP) cm / (cm<2>.s.cmHg) or more and has a separation factor of more than 16.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

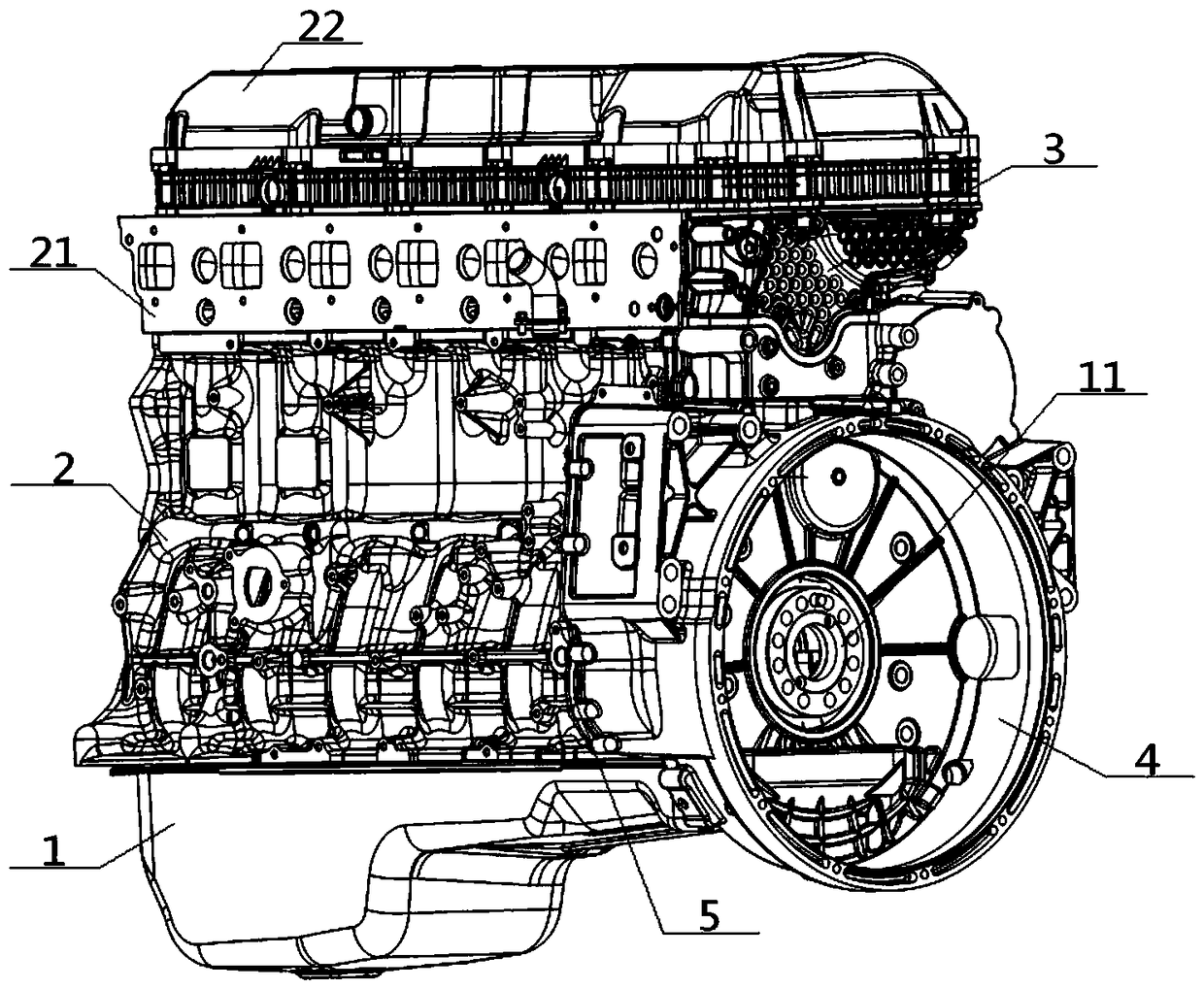

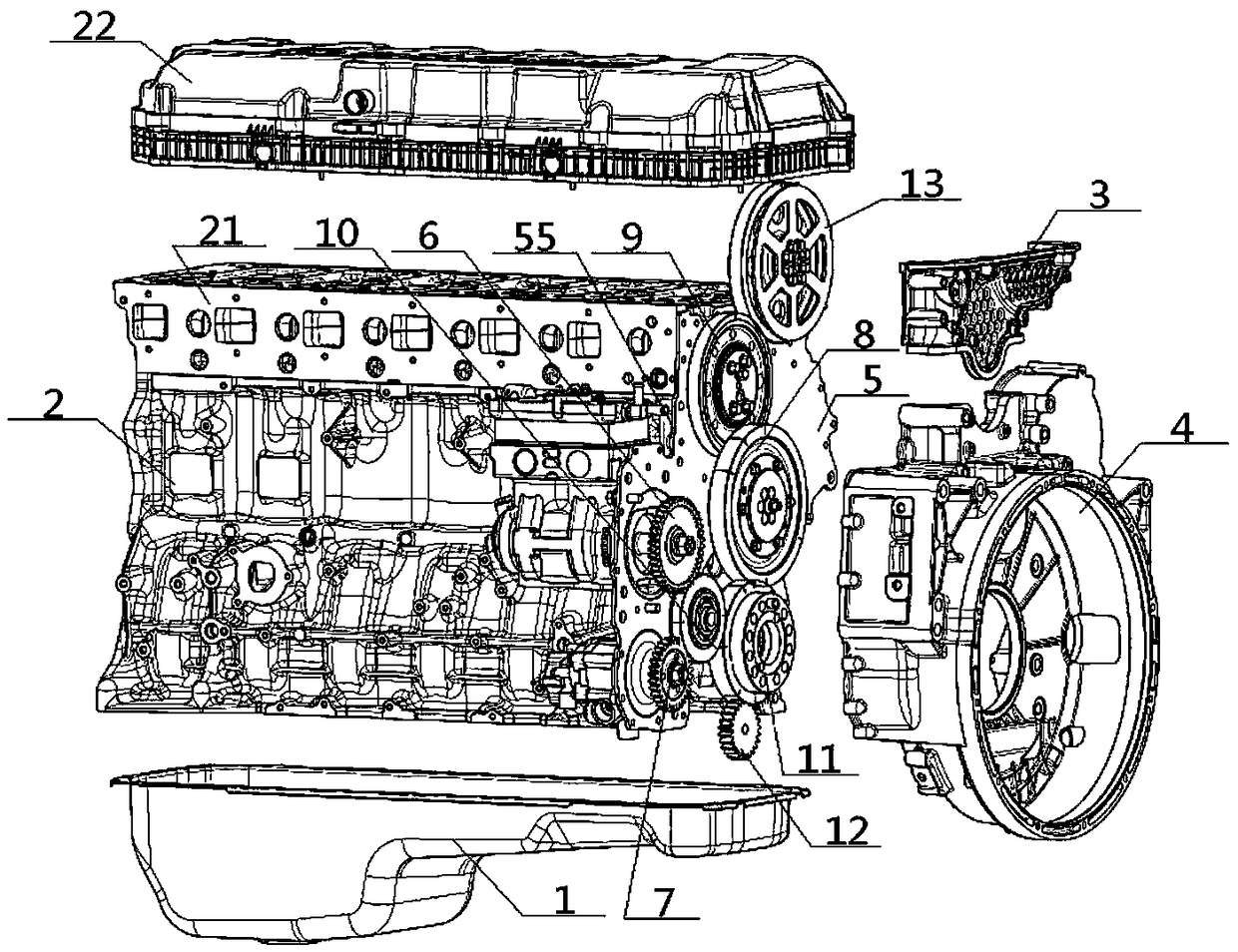

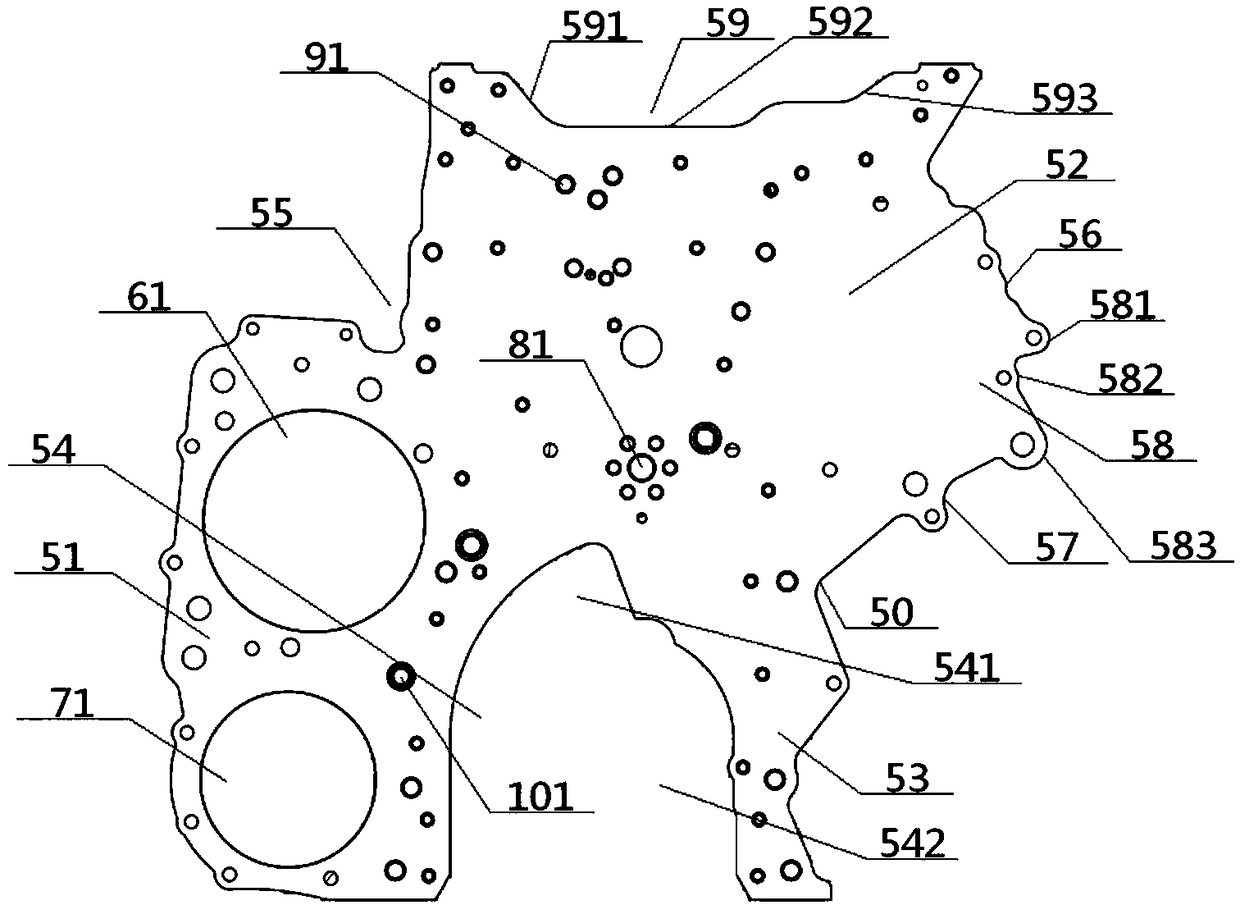

Rear-end gear chamber structure of diesel engine

PendingCN108952993AImprove assembly efficiencyGuaranteed installation spaceCasingsMachines/enginesGear wheelGear system

The invention relates to a rear-end gear chamber structure of a diesel engine. The rear-end gear chamber structure comprises a timing gear chamber cover, a rear-end plate body and a flywheel shell, wherein the middle of a left plate body in the rear-end plate body is connected with an air compressor gear, an oil pump gear and a third idle gear, the middle of an upper plate body is connected with afirst idle gear and a second idle gear, a camshaft gear is arranged on the upper plate body, a crankshaft gear and an oil pump gear are sequentially arranged in the bottom vacancy opening from top tobottom, and the front and back surfaces of the rear-end plate body are connected with a cylinder body / a cylinder cover, the timing gear chamber cover / the flywheel shell respectively; the bottom surface of the cylinder body is connected with an oil pan, the top surface of the cylinder body is connected with the bottom surface of a housing of the cylinder cover through the cylinder cover, the right end of the housing of cylinder cover is connected with the top of the timing gear chamber cover, the bottom of the timing gear chamber cover is in wedge connection with a gear chamber cover matchinggroove formed in the top of the flywheel shell through a cover downward extending end. The rear-end gear chamber structure has the advantages of being convenient in manufacturing, assembling, maintenance and adjustment of gear system, light in weight, high in overall rigidity, and good in noise reduction effect.

Owner:DONGFENG COMML VEHICLE CO LTD

Thermal insulating decorative plate

The invention provides a thermal insulating decorative plate, and belongs to a building decorative material. The thermal insulating decorative plate consists of a metal panel, a thermal insulation packing layer and a protective film, wherein corners formed among the positive surface and two side surfaces of the decorative plate is acute angles of 60 to 80 degrees. The thermal insulating decorative plate has the advantages of simple manufacturing and installation, close combination, capability of effectively preventing rain water from infiltrating and widely suitability for external wall decoration of high-rise buildings.

Owner:刘勋

Silicon nitride composite separator and preparation method thereof

The invention relates to a silicon nitride composite separator and a preparation method thereof. The preparation method comprises the following steps: at a temperature of -50 DEG C to -30 DEG C, immersing the separator with liquid monosilane for 5-30 min, then immersing the separator with liquid ammonia for 10-120 min, so as to depositing silicon nitride on the separator surface, and finally performing vacuum drying to obtain the silicon nitride composite separator. By employing the one-step synthetic technology, silicon nitride is effectively uniformly distributed on the separator surface. Because no adhesives are used and a high-temperature sintering process is not used, the silicon nitride composite separator has good heat resistance and is not easy to dust, and thus the safety of a battery is improved. Additionally, the whole preparation process is simple, the raw material cost is low and batch production is easy to realize.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Nut and dried fruit bar and production process thereof

The invention provides a nut and dried fruit bar and a production process thereof. Compared with the prior art, the nut and dried fruit bar organically combines smashed biscuits, smashed nuts and dried fruits, and the prepared product is rich in nutrient; meanwhile, in the production process, by means of multiple times of water spraying operation by means of a spraying kettle, material surfaces are wetted, the materials can not be added at a time, and it is avoided that the materials are wetted by water too much and the product taste is affected; meanwhile, the adhesiveness of the raw materials is higher, and it is avoided that crumbs are generated to affect the selling appearance and yield of the product. Due to the baking temperature and the time, the product taste is ensured, and nutrients are not lost; then, fire spraying is conducted through a fire spraying gun, the product is fired for 2-3 seconds, the combination of the materials is closer, crumbs can not be easily produced, obvious sugar particles or powder particles on surfaces can be fired and melted, and the product has a better selling appearance.

Owner:ANHUI THREE SQUIRRELS ELECTRONICS BUSINESS

Preparation method of waterproof suit fabric

InactiveCN111300951AWaterproofImprove waterproof performanceJacketsCellulosic plastic layered productsPolymer scienceAdhesive

The invention discloses a preparation method of a waterproof suit fabric, which specifically comprises the following steps: S1, blending wool fibers, cotton fibers and pearl fibers to prepare a surface fabric; S2, uniformly mixing a modified polyurethane emulsion, a thickening agent, ammonia water and a cross-linking agent to prepare a fabric coating agent; S3, uniformly coating the surface fabricwith the fabric coating agent, and drying the fabric coating agent; S4, placing the base cloth in a rubber roller, and coating the surface of the base cloth an adhesive; S5, attaching the waterproofsurface fabric to the base cloth coated with the adhesive, and performing hot pressing on the waterproof surface fabric and the base cloth by using a pressing machine; and S6, cooling, trimming and rolling the hot-pressed fabric to obtain the waterproof suit fabric. The fabric coating agent coats the surface fabric of the suit, and a polyurethane film with stronger adhesive force coats the fabricsurface of the suit fabric, so that the surface fabric of the suit has certain waterproof property and mechanical property.

Owner:安徽弋尚纺织科技有限公司

Mortar-free building block for eliminating energy and reducing shock

A mortar-free block based on energy dissipation and shock absorption, which includes several conical cavities arranged in parallel and with the bottom set as a plane, and a conical boss connected to the center of the top of the conical cavity to form a block body. The side end of the block body is provided with a concave cavity or a protrusion. When the cone at the top of the block body cooperates and superimposes with the cone cavity at the bottom of the other block body, the technical scheme of the hollow cone cavity masonry is formed; it realizes the The rapid and accurate positioning of the block body masonry has opened up the precedent of positioning with a cone surface in this industry; it has better solved the existing building block body with interlocking functions, and there are still few masonry functions, and there are joint gaps between the convex platform and the concave surface Larger, the amount of mortar is more, the positioning error is large, which affects the quality of the masonry, and the gaps and mortar increase the thickness of the masonry and the consumption of raw materials and other unresolved problems; it is suitable for civil and industrial masonry; it is more suitable for earthquake-prone areas earthquake-resistant building materials.

Owner:HUNAN UNIV OF SCI & TECH

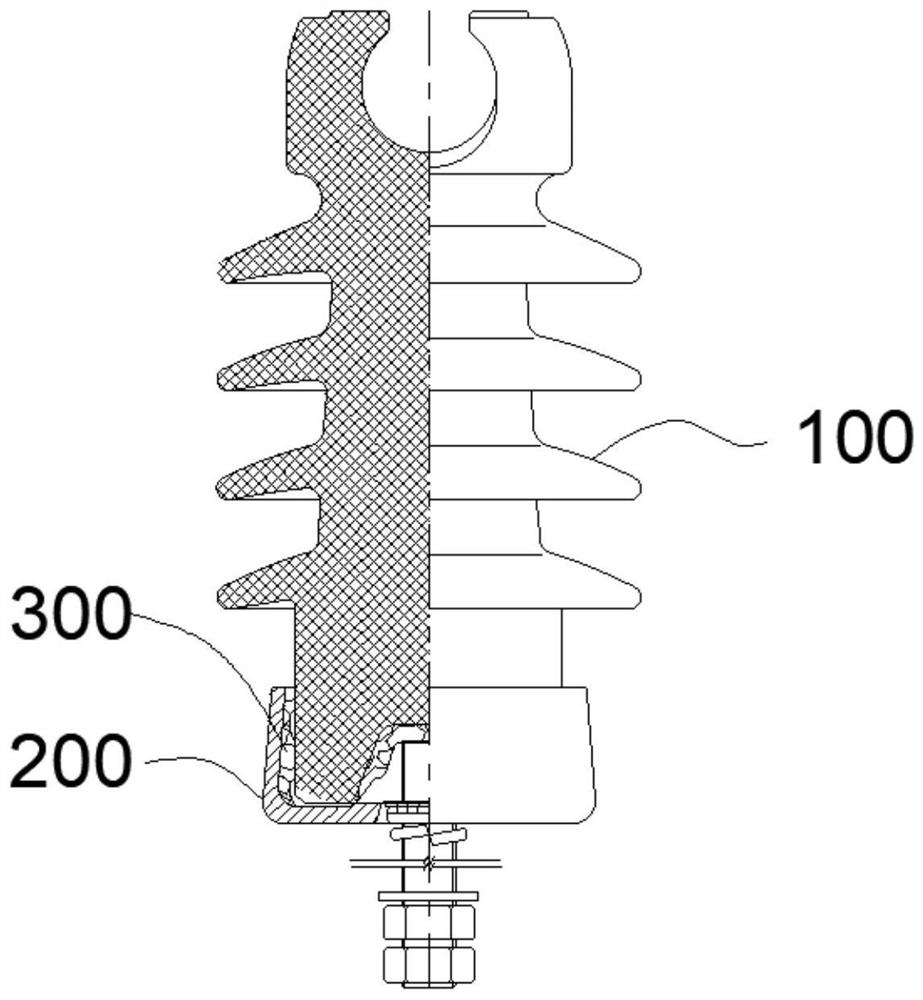

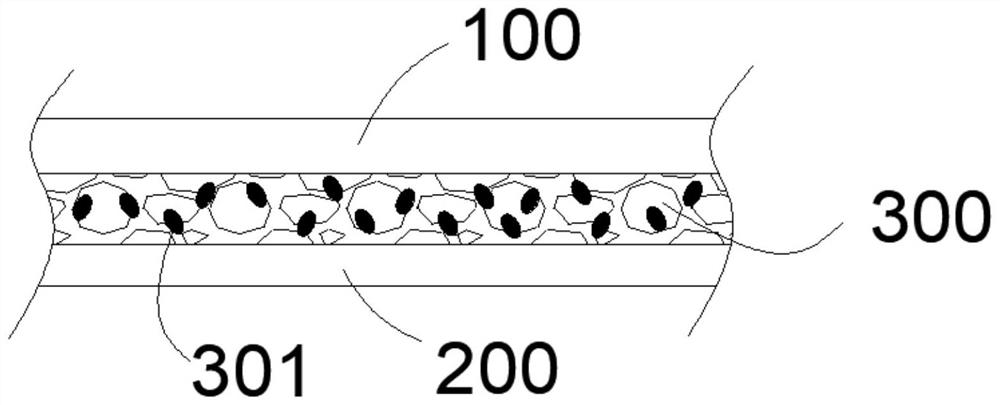

High-strength column type electric porcelain insulator for high-voltage line and manufacturing process thereof

The invention discloses a high-strength column type electric porcelain insulator for a high-voltage line and a manufacturing process of the high-strength column type electric porcelain insulator, and belongs to the field of insulators, the high-strength column type electric porcelain insulator comprises a porcelain body and a metal accessory, an adhesive layer is arranged between the metal accessory and the porcelain body, and the adhesive layer comprises the following raw materials in parts by weight: 50-90 parts of an inorganic cementing material and 1-20 parts of an elastomer, wherein the inorganic cementing material contains a nano oxide, a pore passage is formed in the elastomer, and the nano oxide is adsorbed in the pore passage. According to the invention, the elastomer is added into the inorganic cementing material, so that on one hand, the cementing strength of the inorganic cementing material can be enhanced, cracks are prevented from being generated after use, and the service life is prolonged; on the other hand, due to the excellent elastic performance of the elastomer, stress relaxation generated after the gel layer is used for a long time can be reduced, and the loosening phenomenon of the porcelain body and the metal accessory after long-time use is avoided.

Owner:SUZHOU AIJIAN ELECTRICAL PORCELAIN

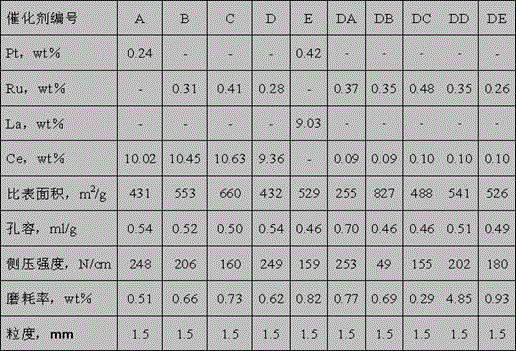

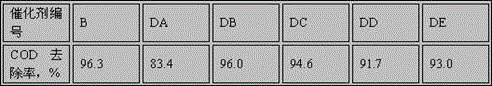

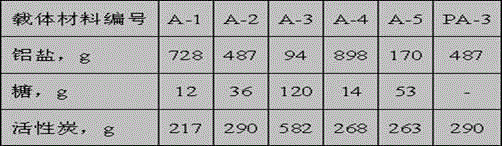

Method for preparing catalytic wet oxidation catalyst

The invention discloses a method for preparing a catalytic wet oxidation catalyst. The catalyst comprises a carrier, an active metal ingredient and an auxiliary, wherein the active ingredient is one or more of Pt, Pd, Rh and Ru, and the auxiliary is rare-earth metal; and the carrier uses activated carbon as a core, and amorphous silica-alumina as a shell. The preparation method comprises the following steps: introducing slurry of saccharide treated activated carbon into the process of gelling amorphous silica-alumina, aging after gelling, and carrying out hydrothermal treatment; filtering, washing and drying to obtain a carrier material; and preparing the carrier, and loading the active metal ingredient and the auxiliary. When being used for a catalytic wet oxidation reaction, the catalyst has relatively high reaction activity and using stability, and the service life of the catalyst can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com