High-strength column type electric porcelain insulator for high-voltage line and manufacturing process thereof

A high-voltage circuit and manufacturing process technology, applied to insulators, circuits, electrical components, etc., can solve the problem of easy loosening of porcelain bodies and metal accessories, and achieve the effects of reducing loosening, improving strength, and high quick-setting strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

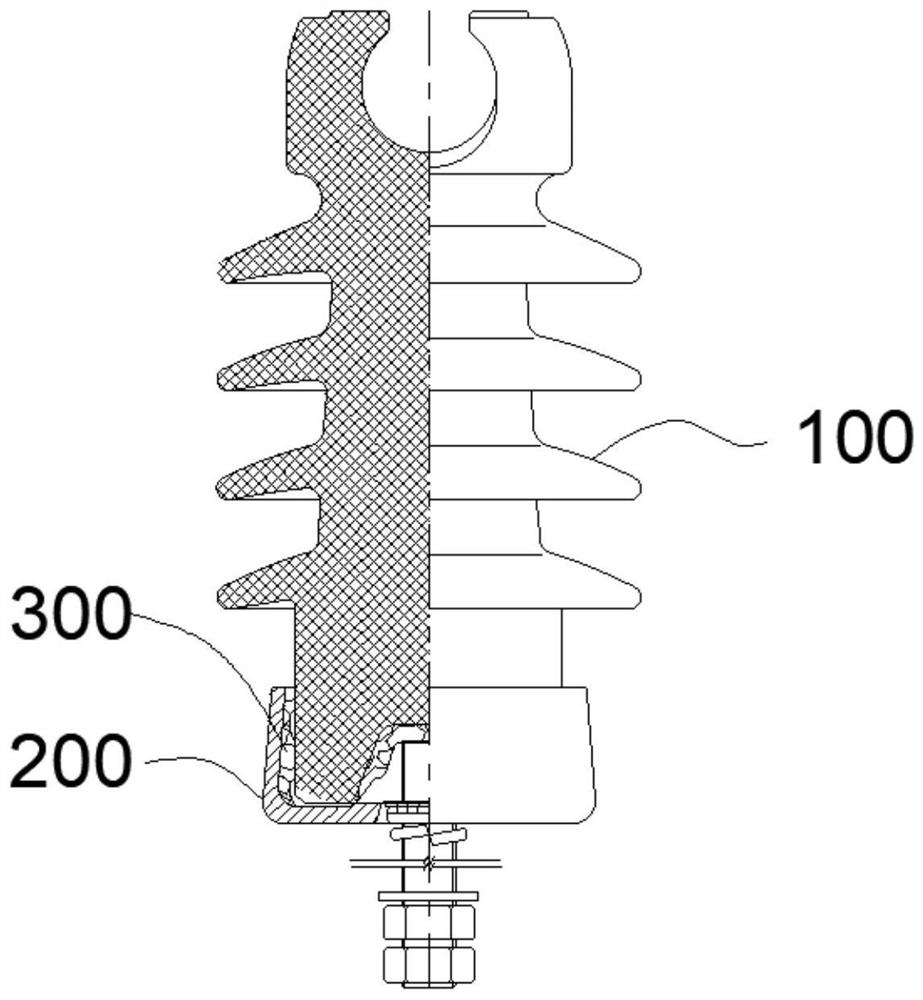

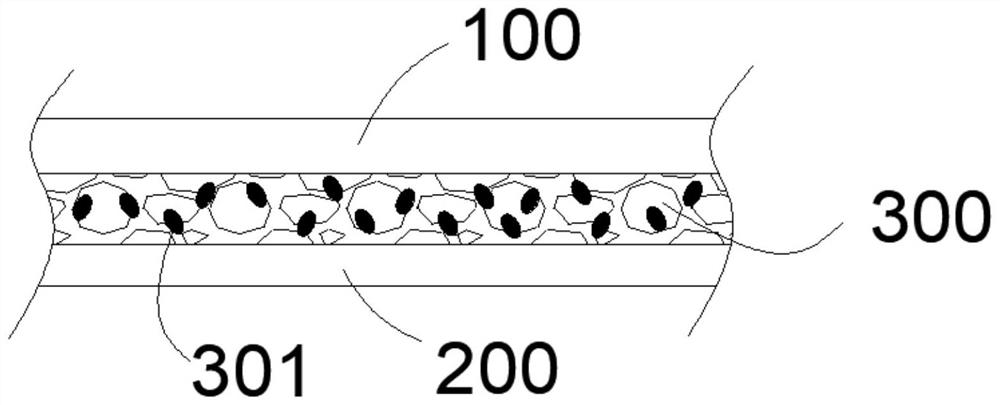

[0050] A high-strength pillar-type electric porcelain insulator for high-voltage lines, including a porcelain body 100 and a metal accessory 200, an adhesive layer 300 is arranged between the metal accessory 200 and the porcelain body 100, and the adhesive layer 300 includes the following raw materials in parts by weight : 90 parts of inorganic gelling material and 15 parts of elastomer 301, wherein the inorganic gelling material contains nano-silica accounting for 1wt%, and the elastomer 301 is porous polyurethane with channels in it. The nano silicon dioxide is adsorbed.

[0051]The inorganic gelling material also includes magnesium oxide, sodium borate, DH-4000 water reducing agent, potassium dihydrogen phosphate, chloride-based early strength agent with a mass ratio of 5:1:0.2:1:0.2:0.15:1.5 , polyvinyl alcohol water-based water-repellent agent and water;

[0052] The particle size of the metal oxide is 0.05mm;

[0053] The particle size of described borate is 0.6mm;

...

Embodiment 2

[0062] A high-strength pillar-type electric porcelain insulator for high-voltage lines, including a porcelain body 100 and a metal accessory 200, an adhesive layer 300 is arranged between the metal accessory 200 and the porcelain body 100, and the adhesive layer 300 includes the following raw materials in parts by weight : 85 parts of inorganic gelling material and 16 parts of elastomer 301, wherein the inorganic gelling material contains nano-silica accounting for 1 wt%, and the elastomer 301 is porous polyurethane with a channel in it, and the channel in the channel is The nano silicon dioxide is adsorbed.

[0063] The inorganic gelling material also includes magnesium oxide, sodium borate, DH-4000 water reducing agent, potassium dihydrogen phosphate, chloride-based early strength agent with a mass ratio of 5:1:0.2:1:0.2:0.15:1.5 , polyvinyl alcohol water-based water-repellent agent and water;

[0064] The particle size of the metal oxide is 0.06mm;

[0065] The particle s...

Embodiment 3

[0074] A high-strength pillar-type electric porcelain insulator for high-voltage lines, including a porcelain body 100 and a metal accessory 200, an adhesive layer 300 is arranged between the metal accessory 200 and the porcelain body 100, and the adhesive layer 300 includes the following raw materials in parts by weight : 68 parts of inorganic gelling material and 8 parts of elastomer 301, wherein the inorganic gelling material contains 1.2wt% of nano-alumina, the elastomer 301 is porous polyurethane, and there are channels in it. The nano silicon dioxide is adsorbed.

[0075] The inorganic gelling material also includes magnesium oxide, sodium borate, DH-4000 water reducer, dihydrogen phosphate, chloride-based early strength agent with a mass ratio of 5:1:0.2:1:0.2:0.15:1.5 , polyvinyl alcohol water-based water-repellent agent and water;

[0076] The particle size of the metal oxide is 0.07mm;

[0077] The particle size of described borate is 0.4mm;

[0078] The particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com