Patents

Literature

44results about How to "Reduce stress relaxation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SiGe or SiC layer on STI sidewalls

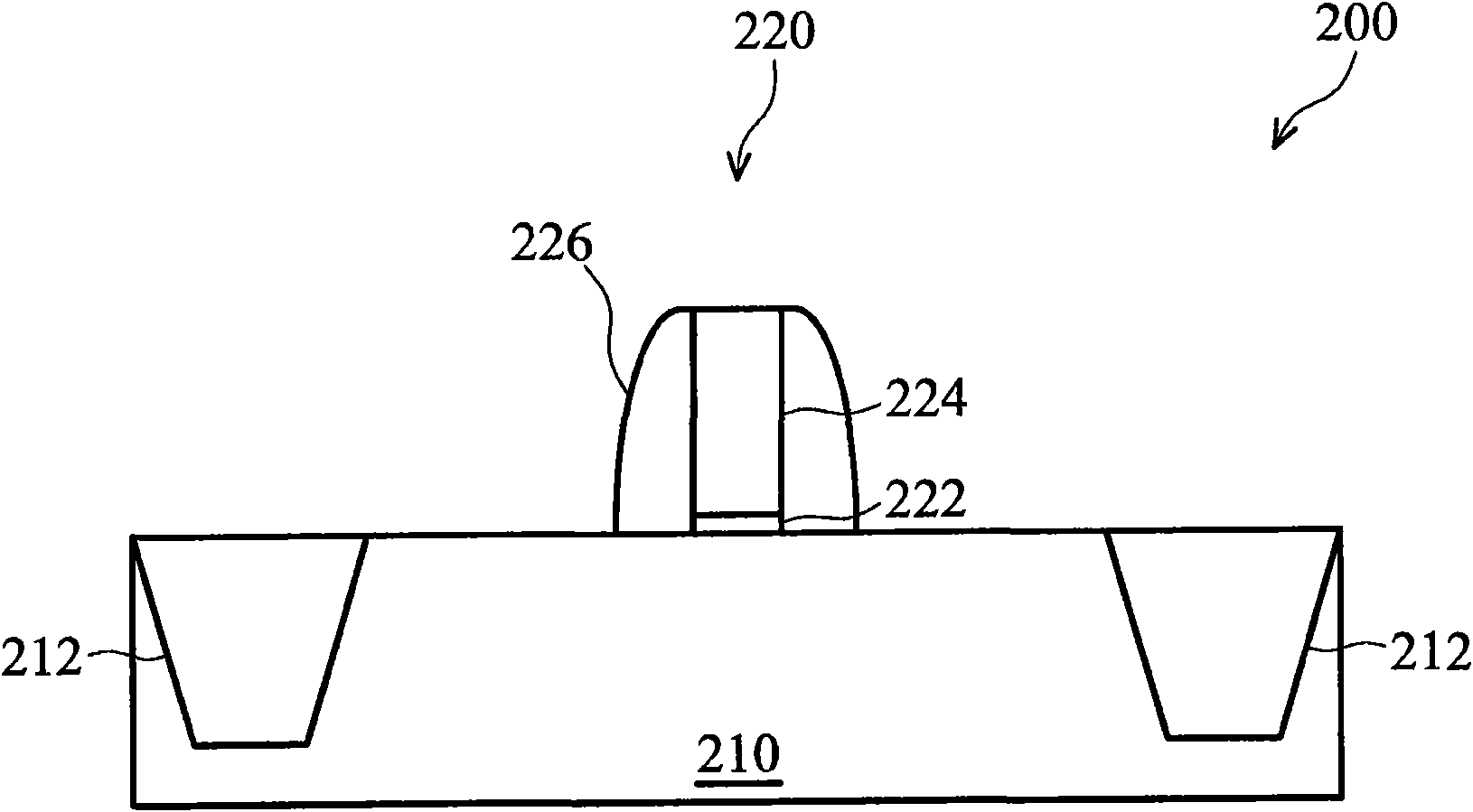

InactiveUS20080290420A1Improve stress conditionReduce stress relaxationTransistorSemiconductor/solid-state device manufacturingSemiconductor structureSemiconductor package

A semiconductor structure includes a semiconductor substrate; an opening in the semiconductor substrate; a semiconductor layer in the opening and covering a bottom and sidewalls of the opening, wherein the semiconductor layer and the semiconductor substrate comprise different materials; and a dielectric material over the semiconductor layer and filling a remaining portion of the opening.

Owner:TAIWAN SEMICON MFG CO LTD

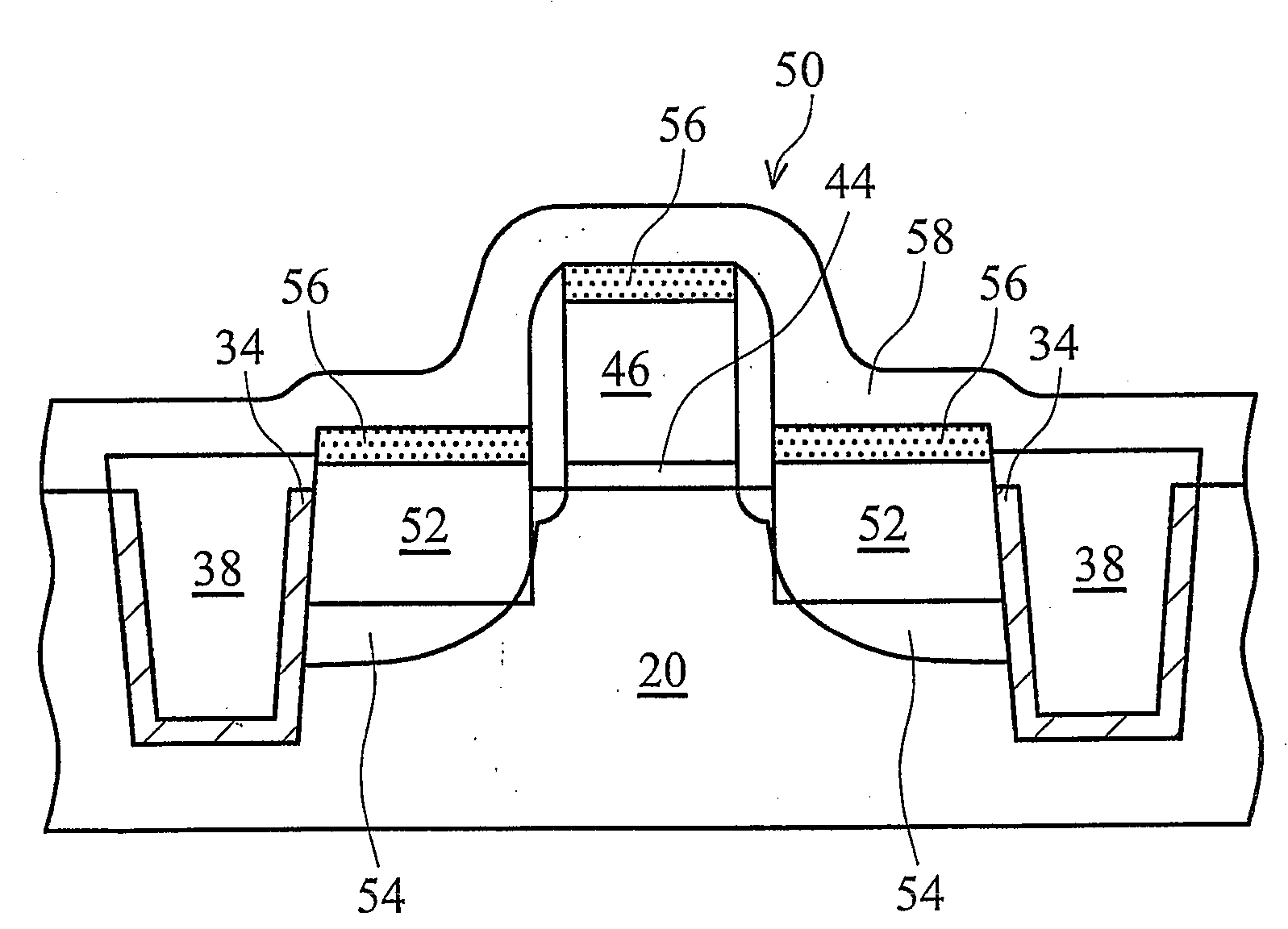

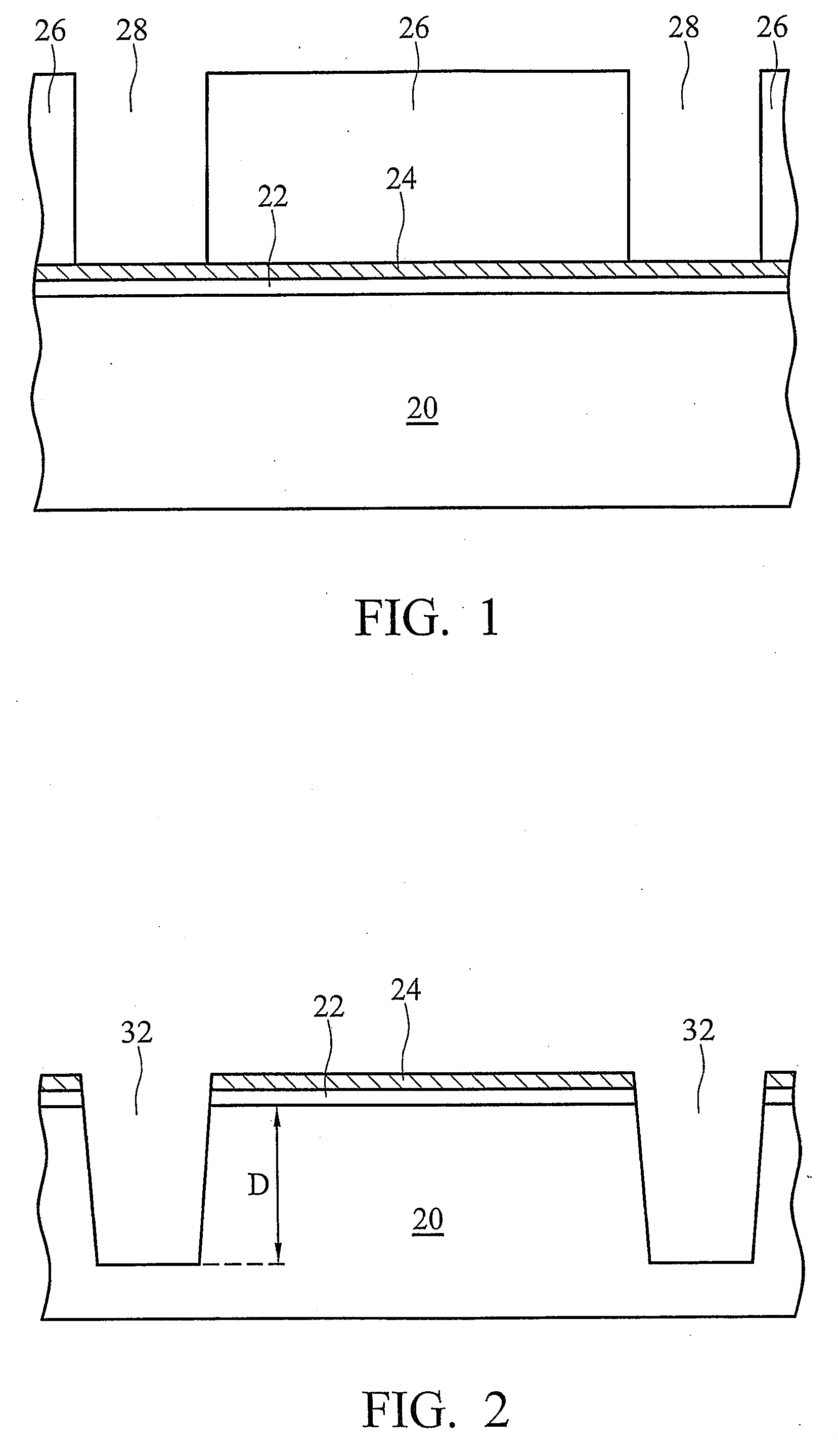

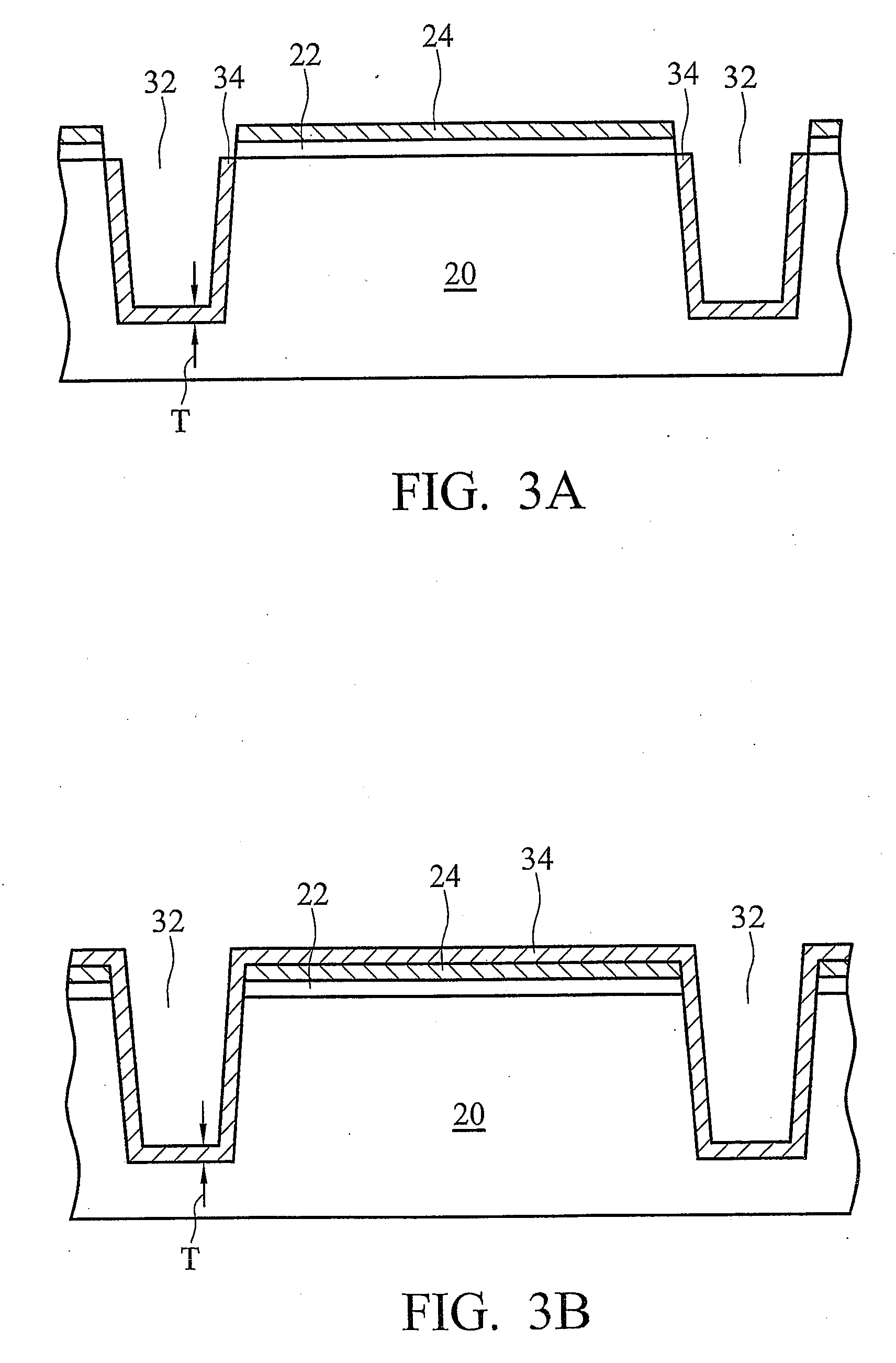

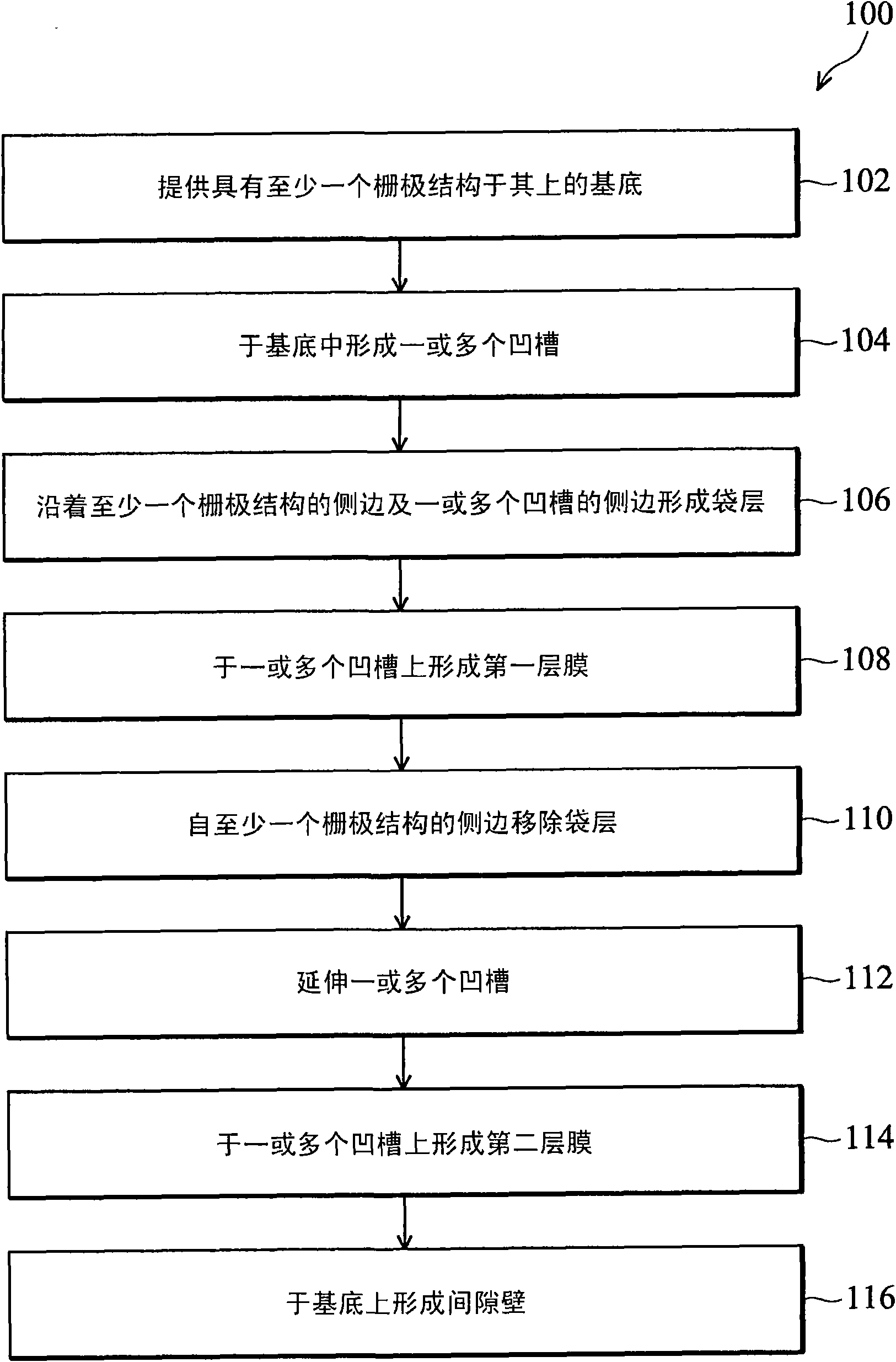

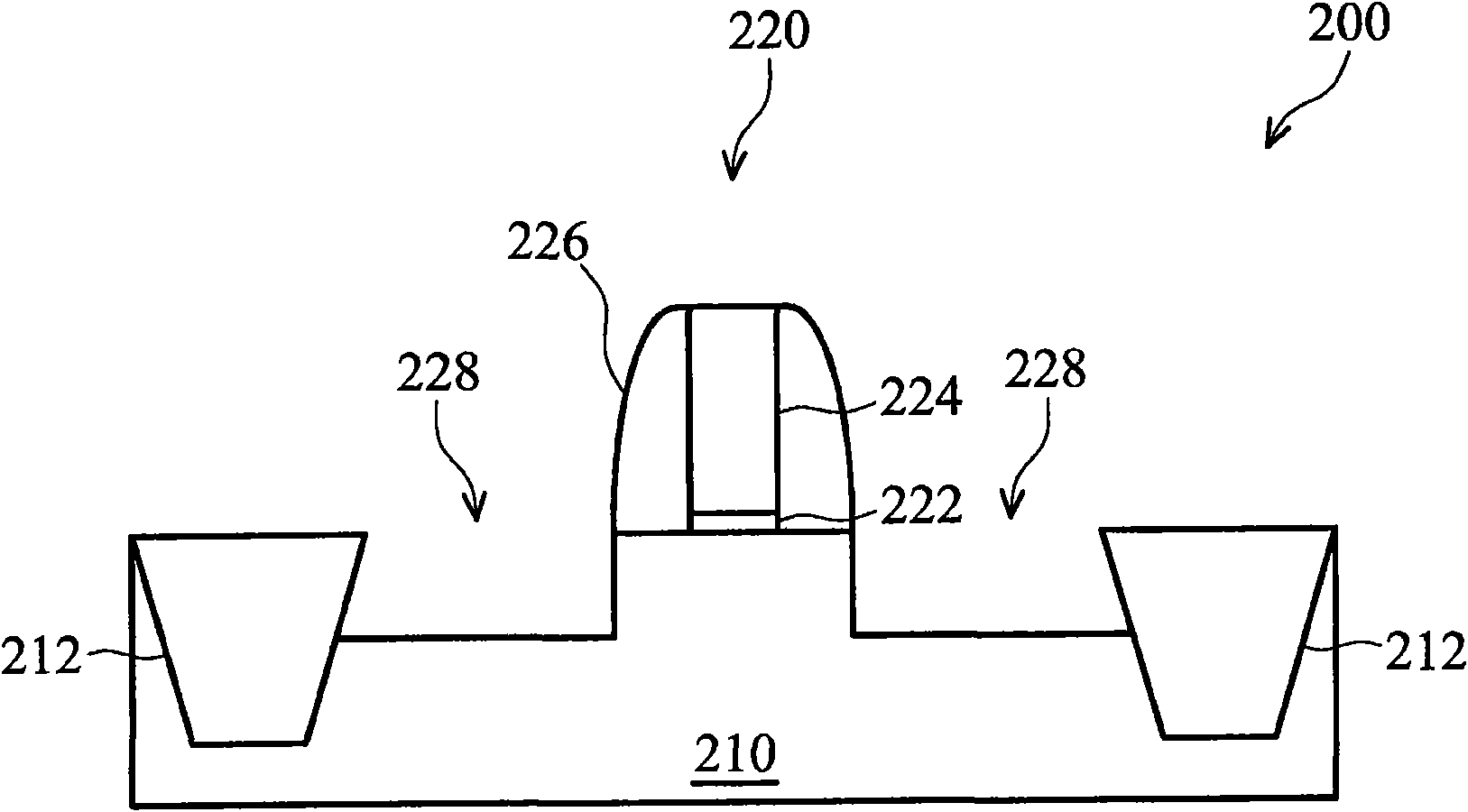

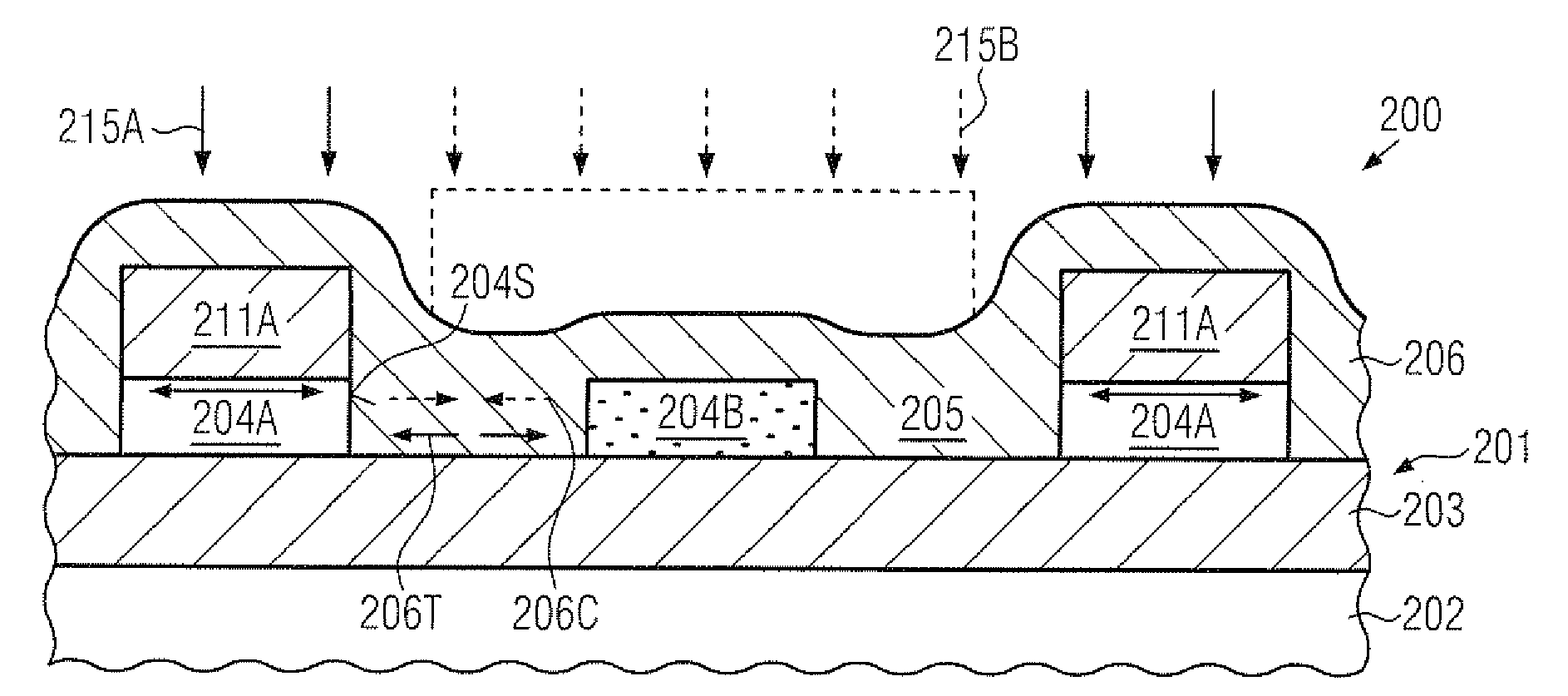

Semiconductor apparatus and method for fabricating the same

ActiveCN101908506AReduce dopingImprove short channel effectTransistorSemiconductor/solid-state device manufacturingElectrical junctionEngineering

The invention provides a semiconductor apparatus and method for fabricating the same. The method comprises providing a substrate comprising a first material; forming at least one gate stack over the substrate; forming one or more recesses in the substrate, wherein the one or more recesses define at least one source region and at least one drain region; and forming a pocket, a first layer comprising a second material, and a second layer comprising a third material in the one or more recesses, the pocket being disposed between the first layer and the substrate. The pockets 234 of the invention,essentially providing an abrupt junction between the source / drain region and substrate interface, may lead to significant improvement in SCEs (short channel effect) and / or reduce current leakage. Improvement in SCEs can allow continual semiconductor device scaling down. Further, in the present embodiment, the method may reduce strain relaxation within the SiGe portions of the source / drain regions, which can improve the performance of semiconductor device. the invention also reduces the channel doping degree.

Owner:TAIWAN SEMICON MFG CO LTD

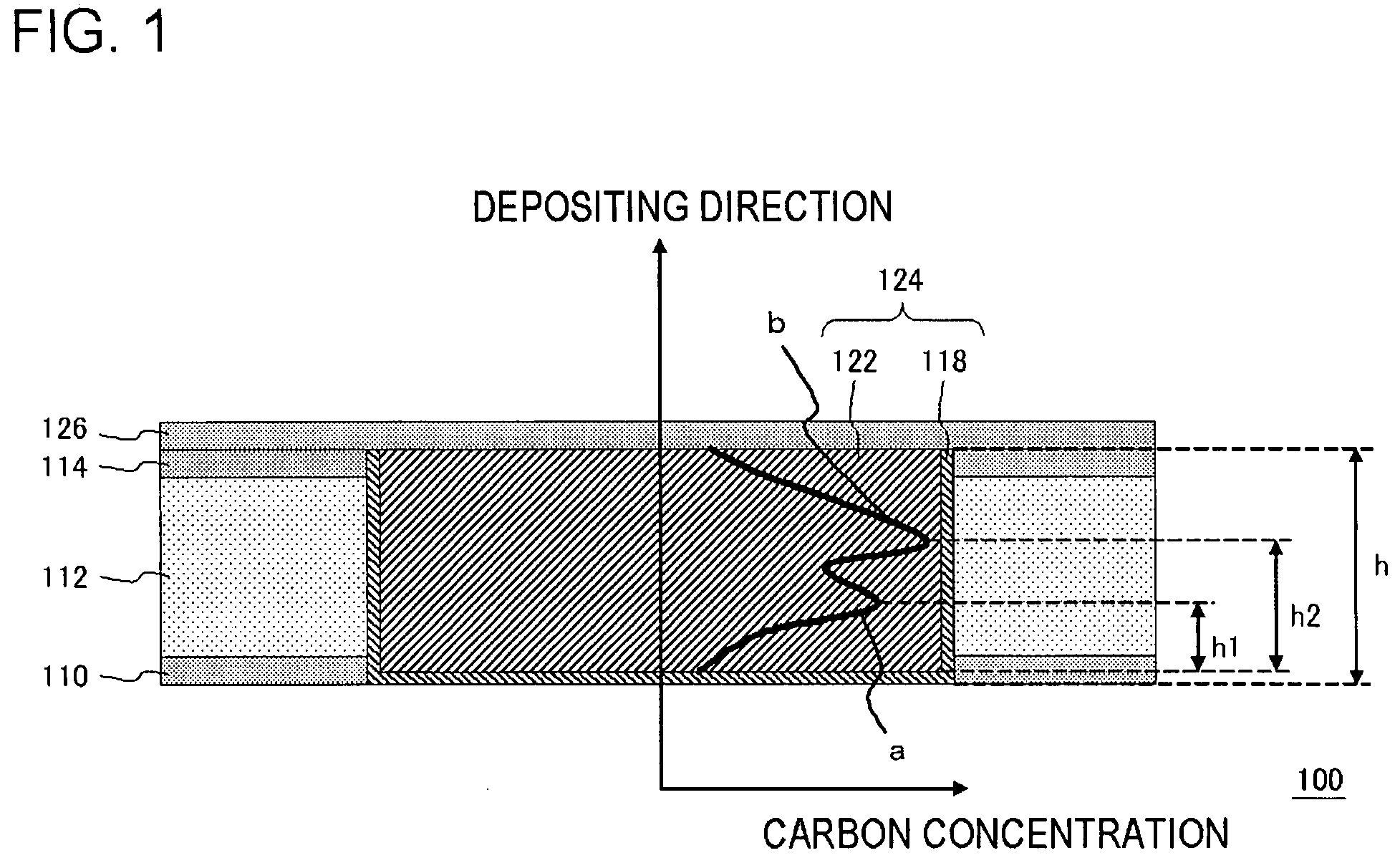

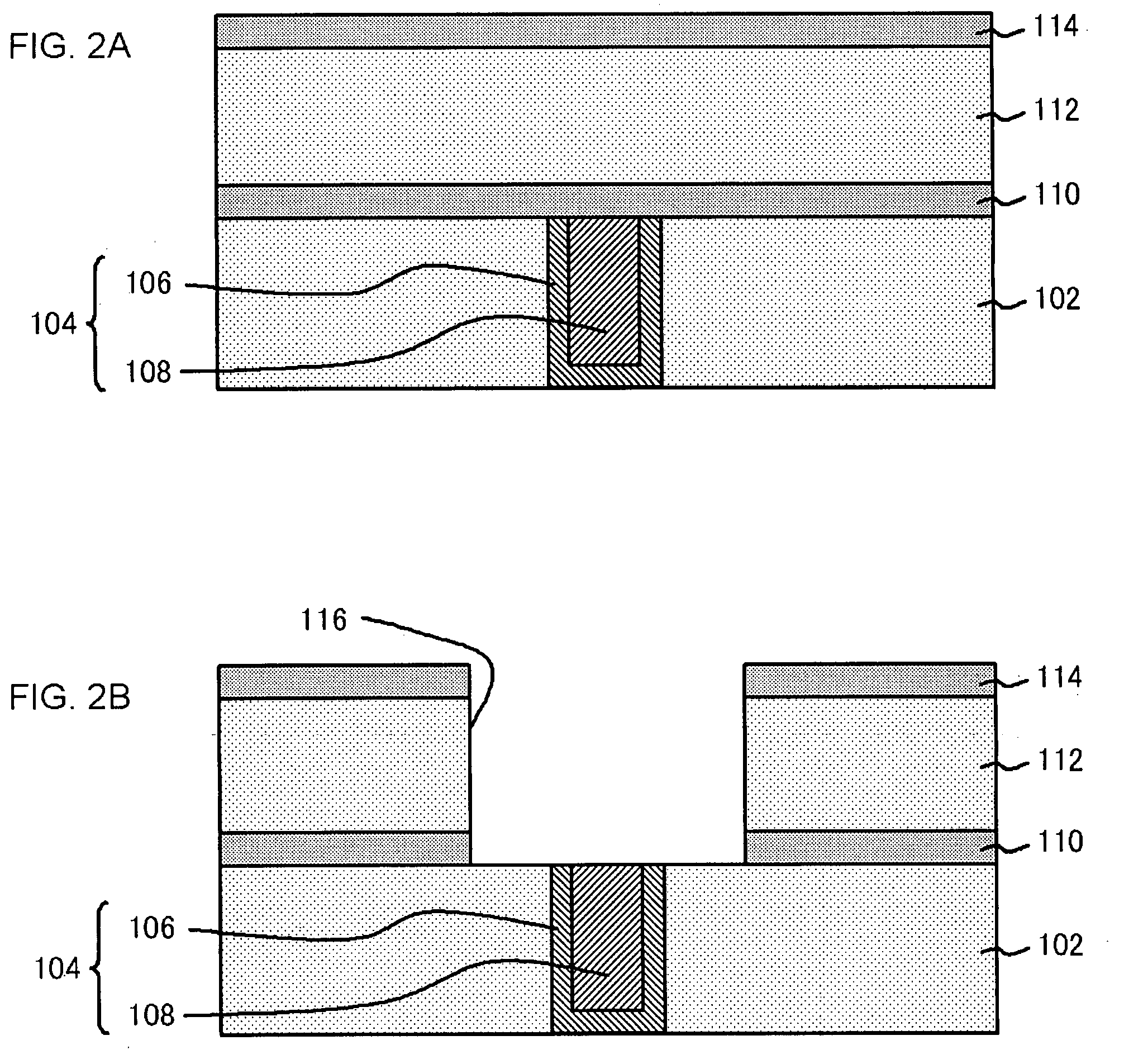

Semiconductor device and method for manufacturing same

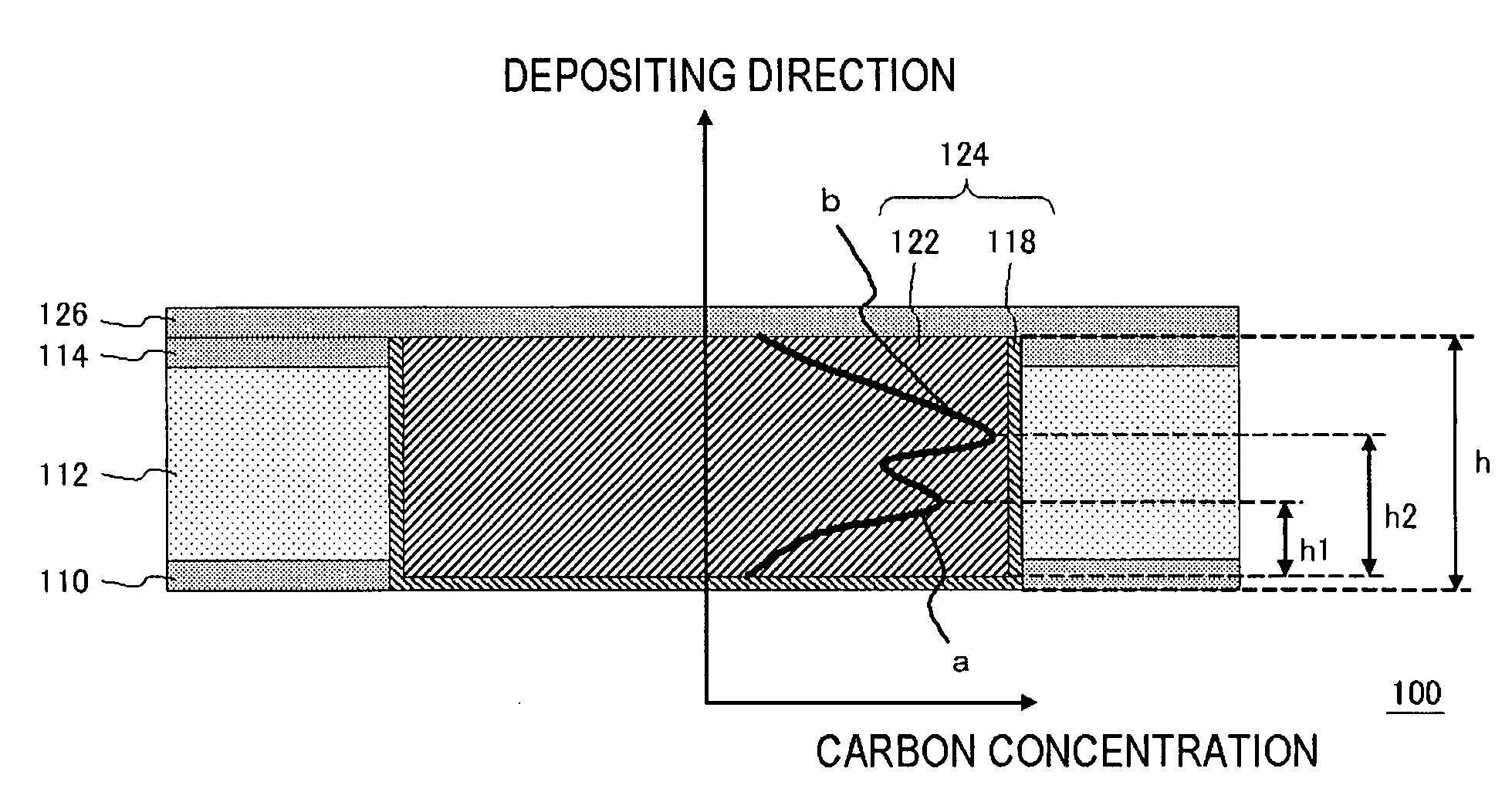

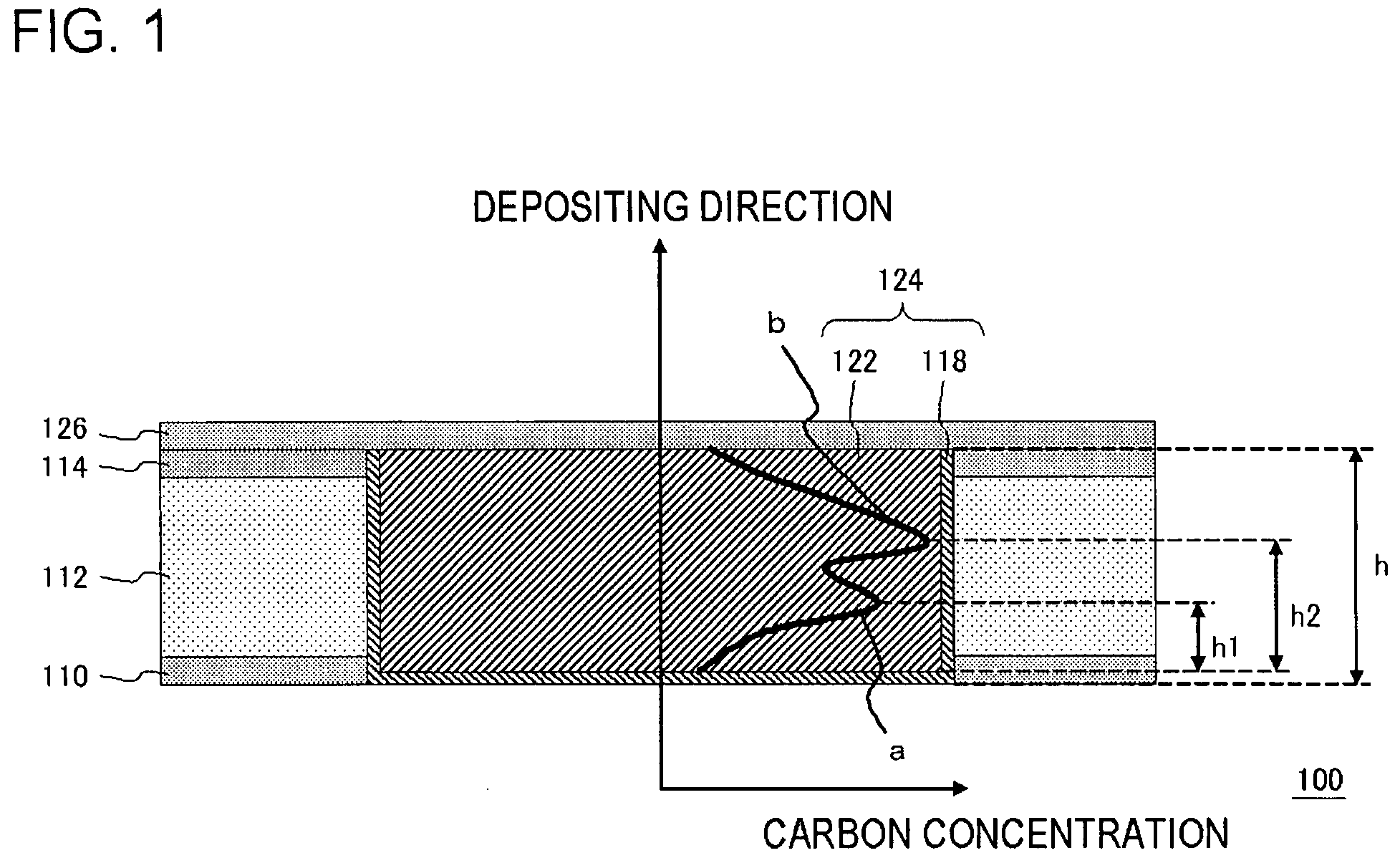

ActiveUS20070190341A1Improved SIV resistanceCarbon concentration can be reducedElectrolytic coatingsSemiconductor/solid-state device detailsElectrical resistance and conductanceCoupling

An improved SIV resistance and an improved EM resistance are achieved in the coupling structure containing copper films. A semiconductor device includes: a semiconductor substrate; a second insulating layer formed on or over the semiconductor substrate; a second barrier metal film, formed on the second insulating film, and being capable of preventing copper from diffusing into the second insulating film; and an electrically conducting film formed on the second barrier metal film so as to be in contact with the second barrier metal film, and containing copper and carbon, wherein a distribution of carbon concentration along a depositing direction in the second electrically conducting film includes a first peak and a second peak.

Owner:RENESAS ELECTRONICS CORP

Method for manufacturing sheet-like gasket

InactiveCN101033386AReduce compounding amountLow tensile strengthEngine sealsOther chemical processesAsbestos sheetFiber

A non-asbestos sheet-like gasket usable at a high temperature, exhibiting only a small decrease in tensile strength and stress relaxation under high temperature conditions is provided. The method for manufacturing the sheet-like gasket comprises a step of obtaining a sheet-forming composition comprising a base fiber other than asbestos, a latex of hydrogenated acrylonitrile-butadiene, a filler, and rubber chemicals and a step of obtaining the sheet-like gasket by molding the composition and vulcanizing the rubber.

Owner:NICHIAS CORP

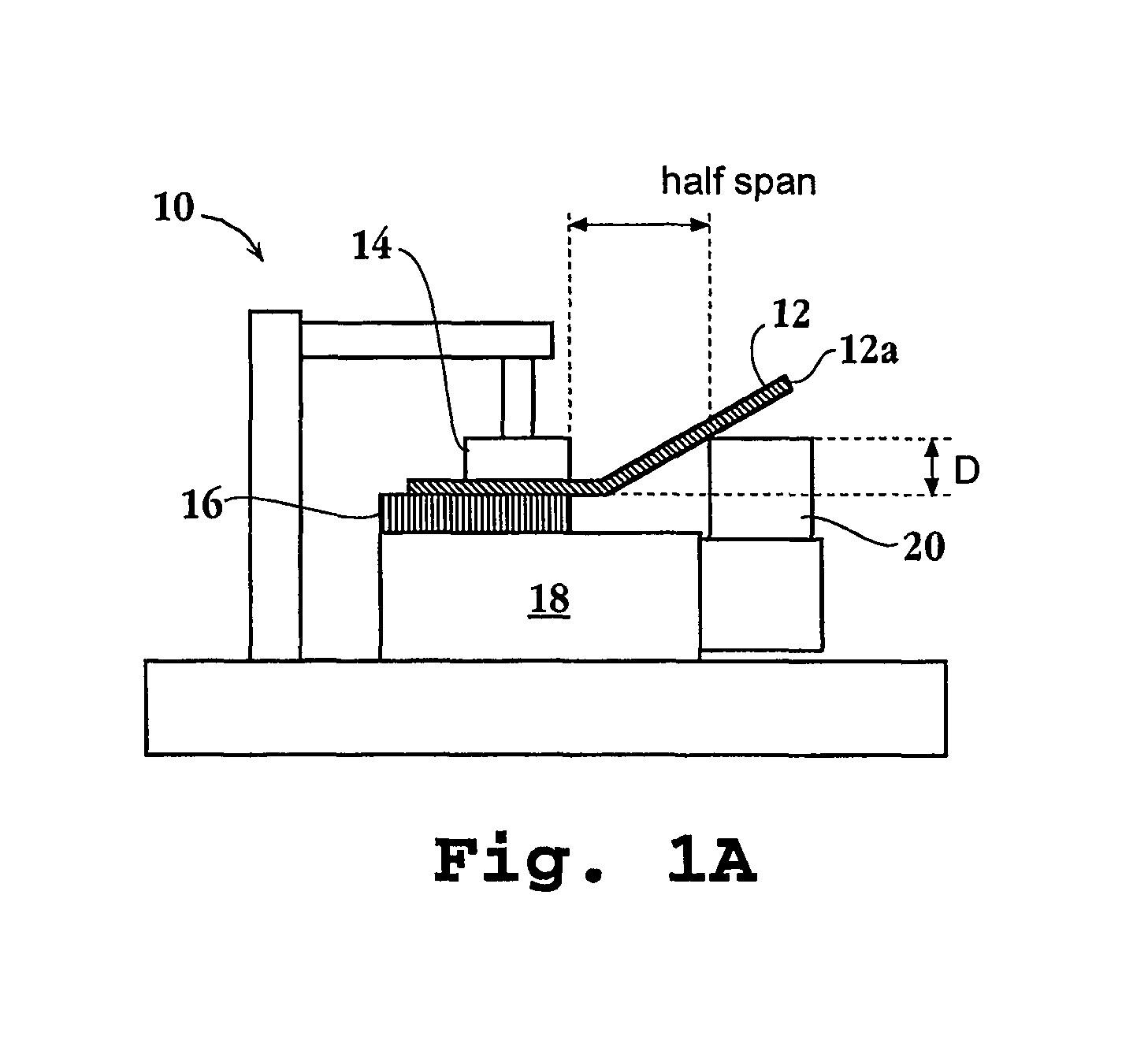

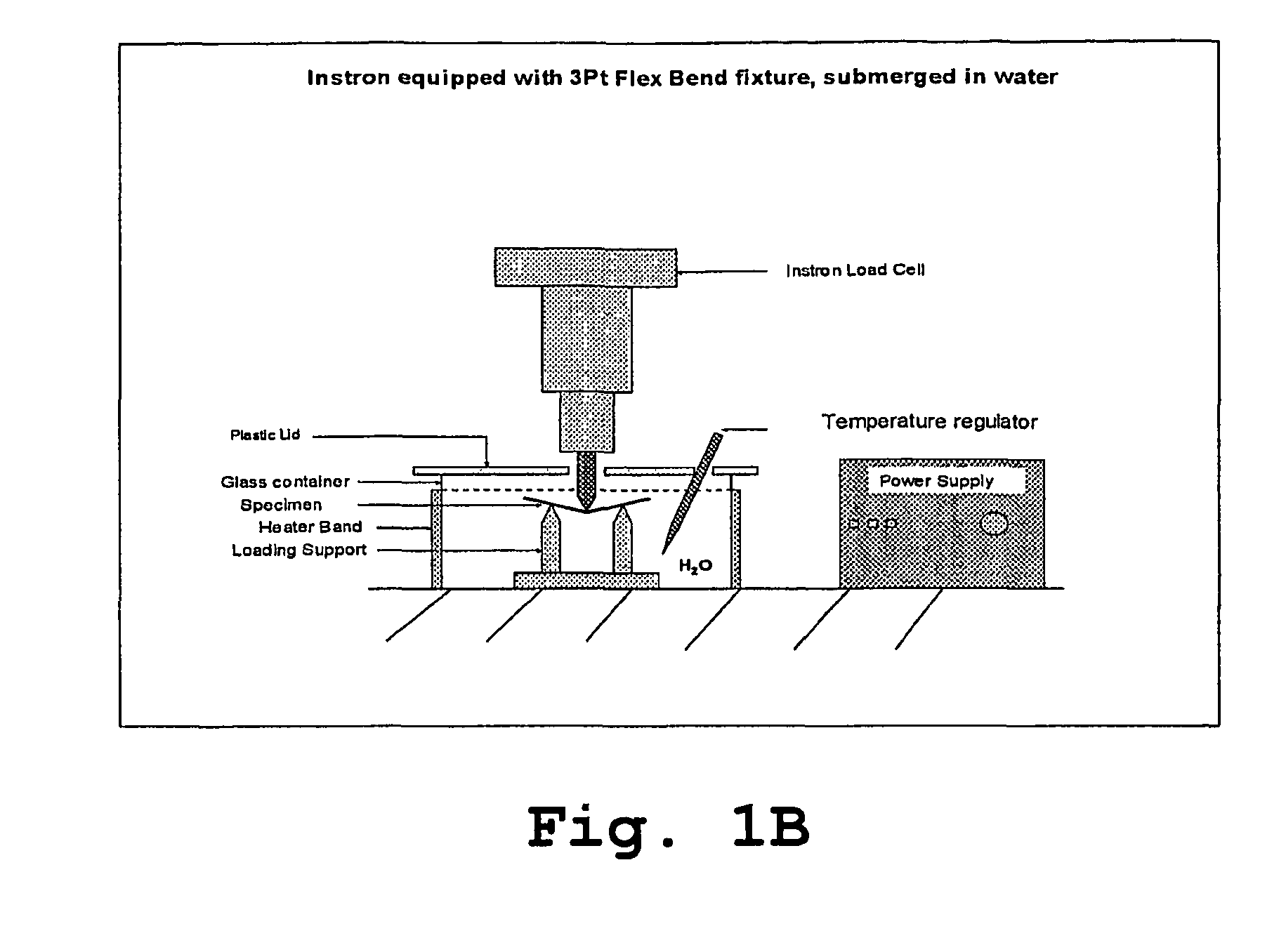

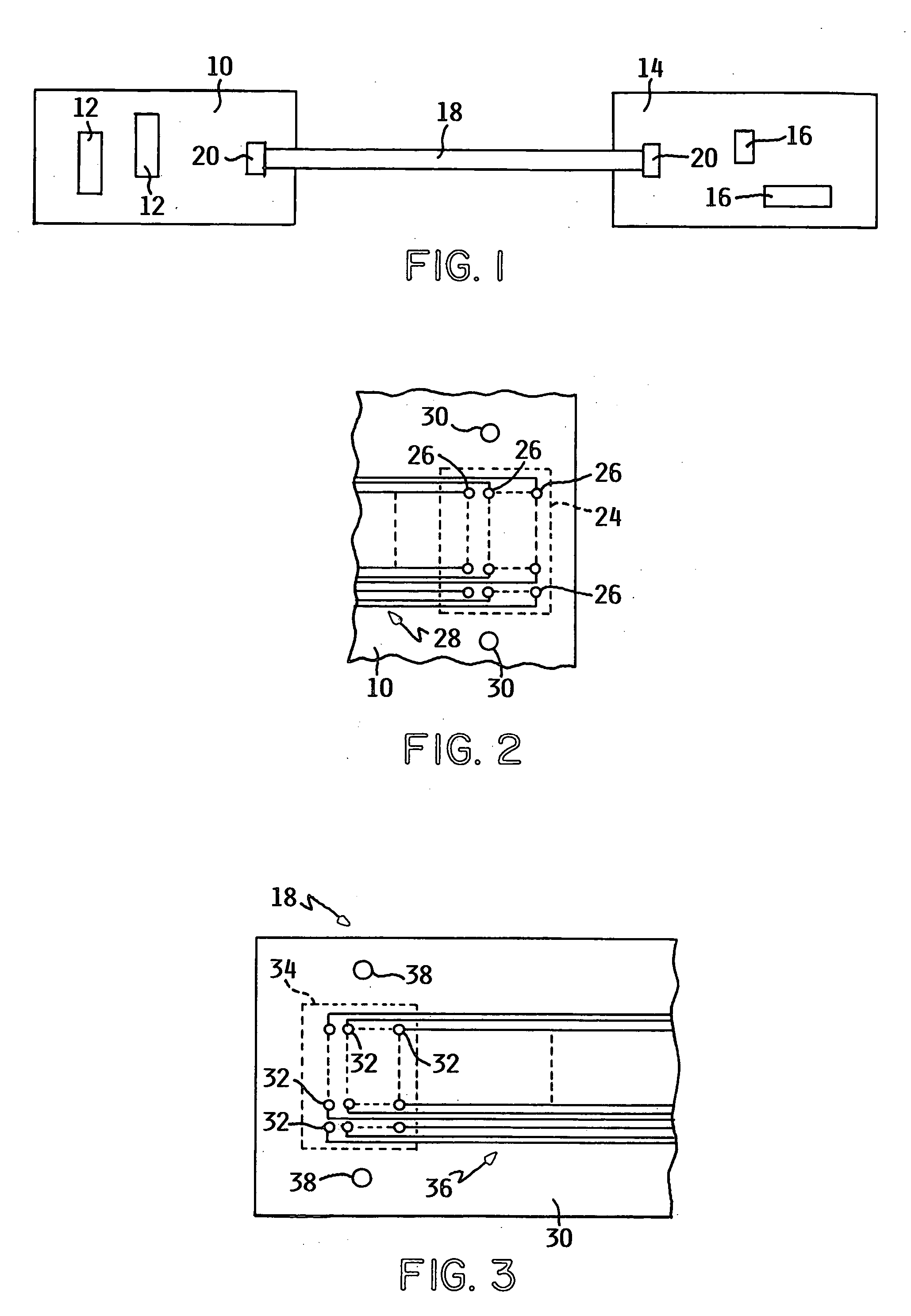

Method of reducing stress relaxation in polymer articles and articles formed thereby

ActiveUS8716425B2Improve mechanical propertiesImprove stabilityCosmetic preparationsImpression capsVitrificationPolymer science

A method of improving the mechanical properties of polymers is described. The method involves heat treating the polymer at a temperature below the glass transition temperature in a wet or in a dry environment. Polymer articles capable of moisture uptake in humid environments, as well as polymer articles less susceptible to moisture uptake, have improved mechanical properties, particularly improved stress relaxation behavior and set properties, when treated in accord with the heat treatment method.

Owner:BAY MATERIALS

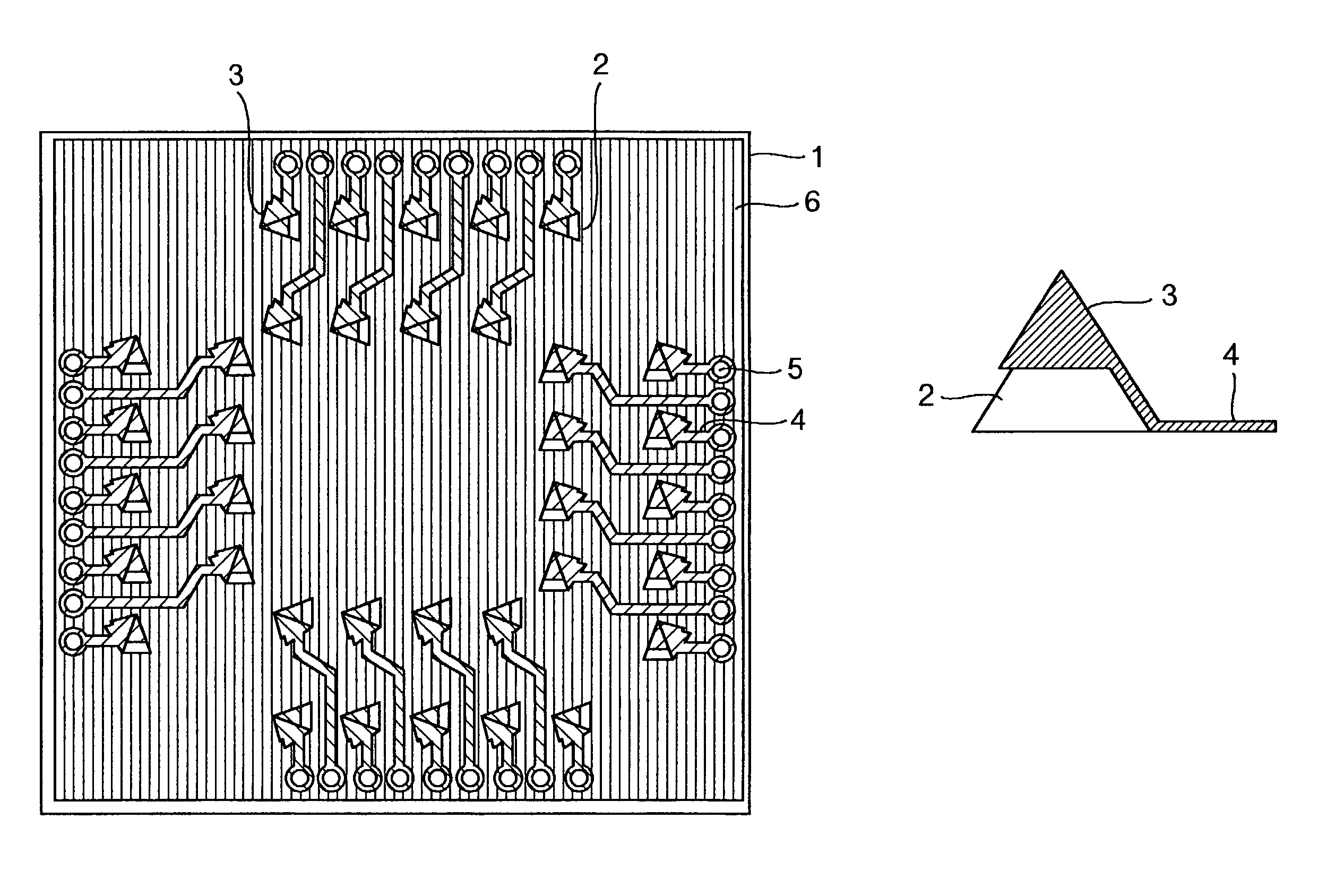

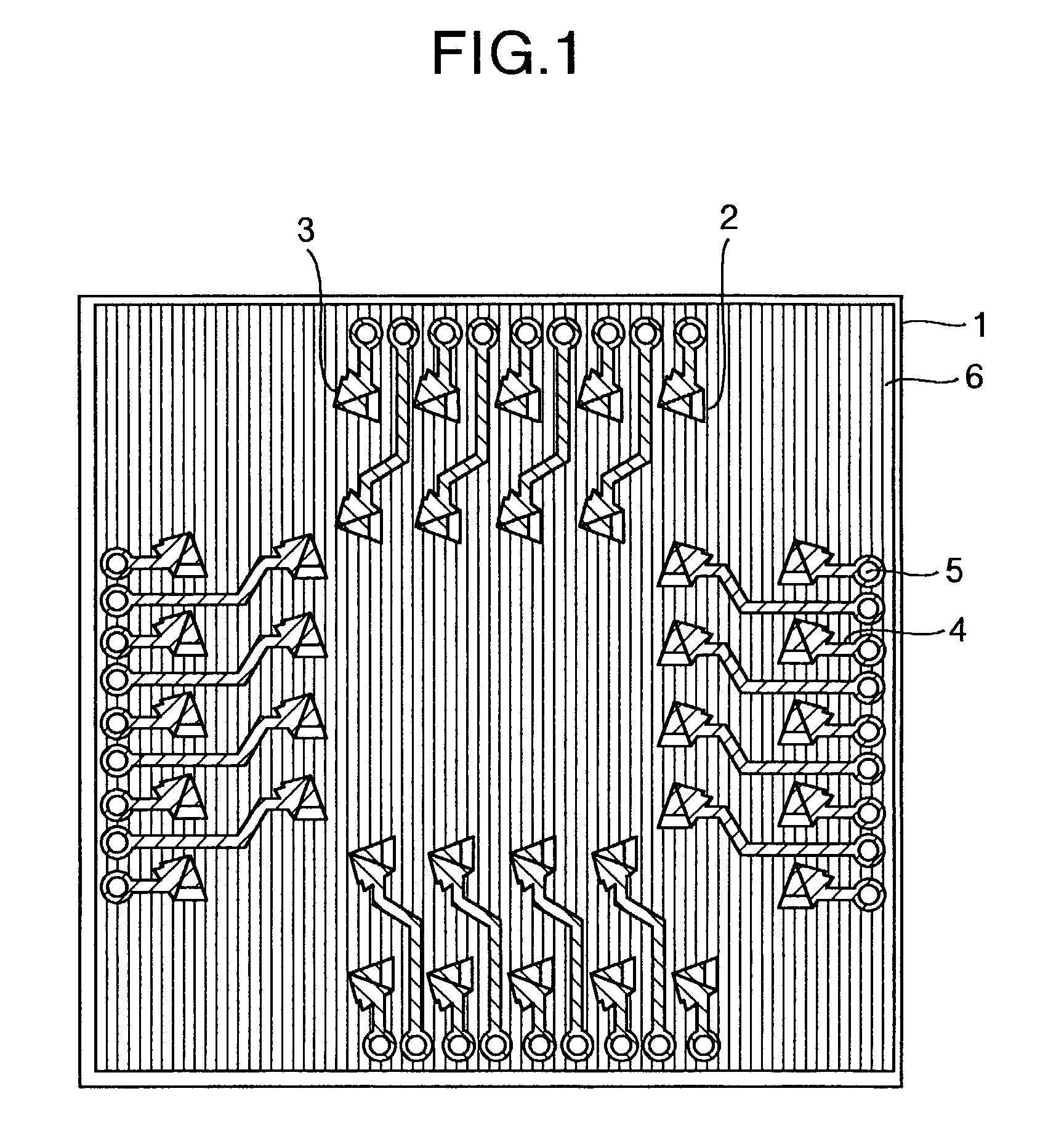

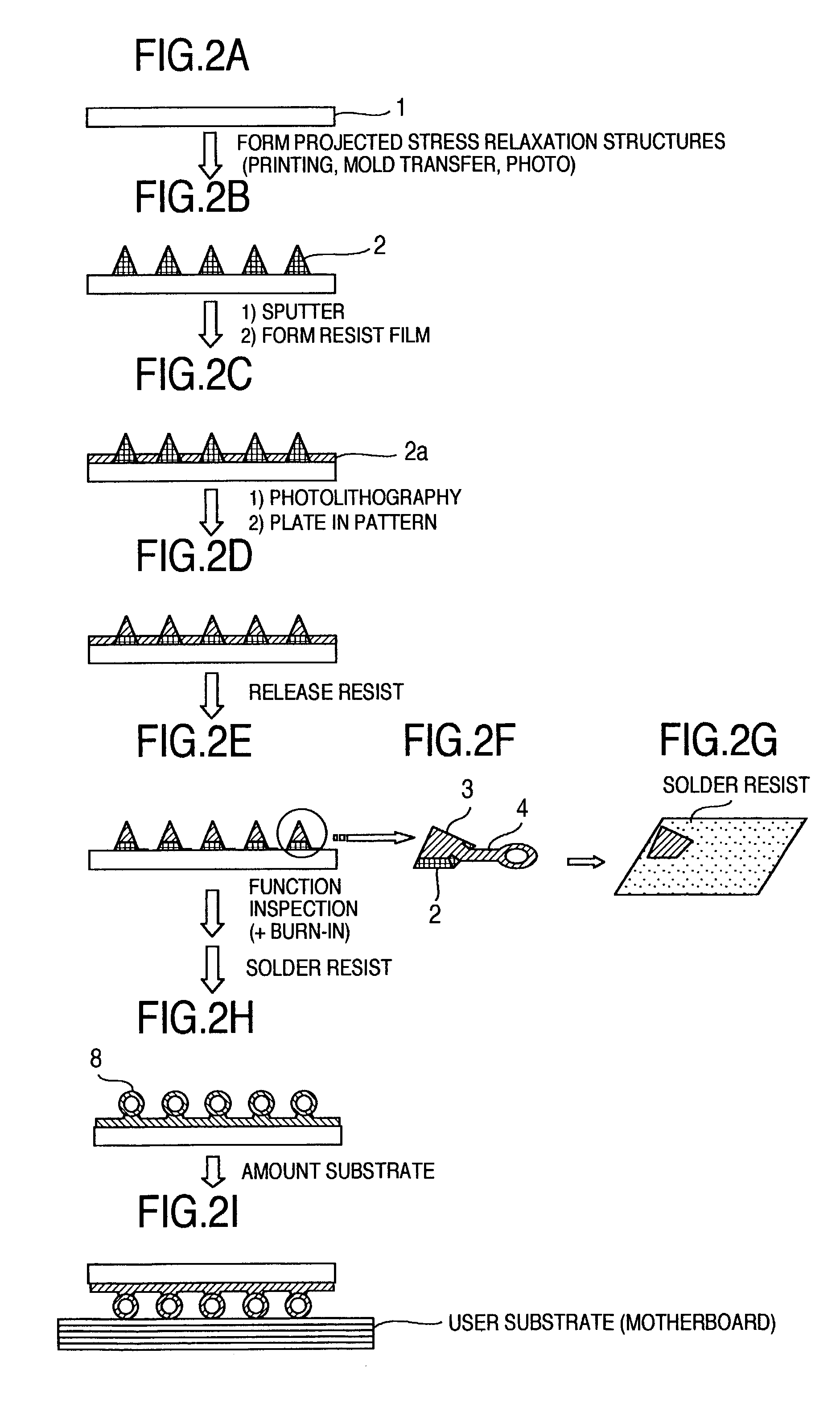

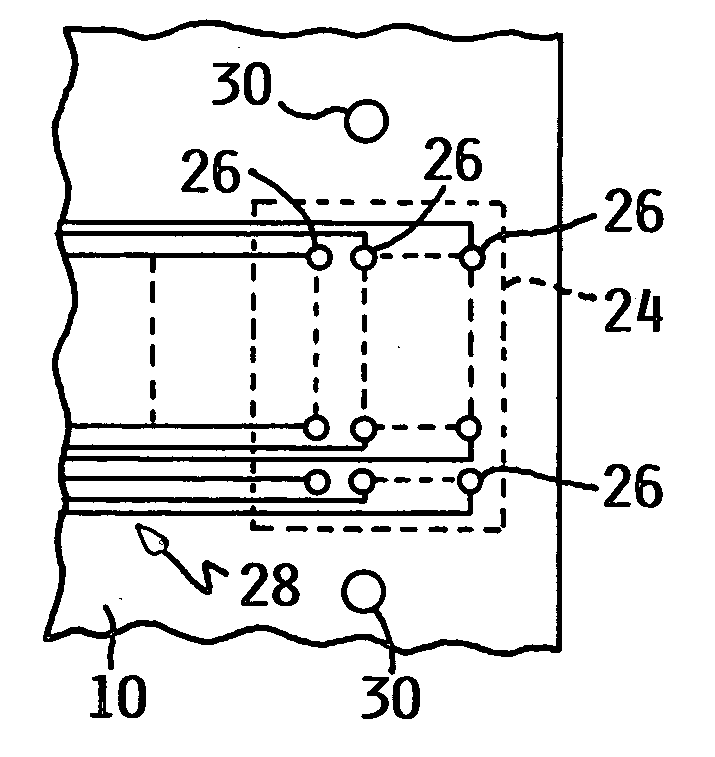

Semiconductor device having projected electrodes and structure for mounting the same

InactiveUS7084498B2Improve connection reliabilityEasy to checkSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductor chipStress relaxation

A semiconductor device which includes a semiconductor chip, an insulating film formed on the semiconductor chip, a plurality of projected stress relaxation materials formed on the insulating film, projected electrodes covering at least tops of the stress relaxation materials, and wiring lines for electrically connecting the projected electrodes and element electrodes of the semiconductor chip.

Owner:RENESAS TECH CORP

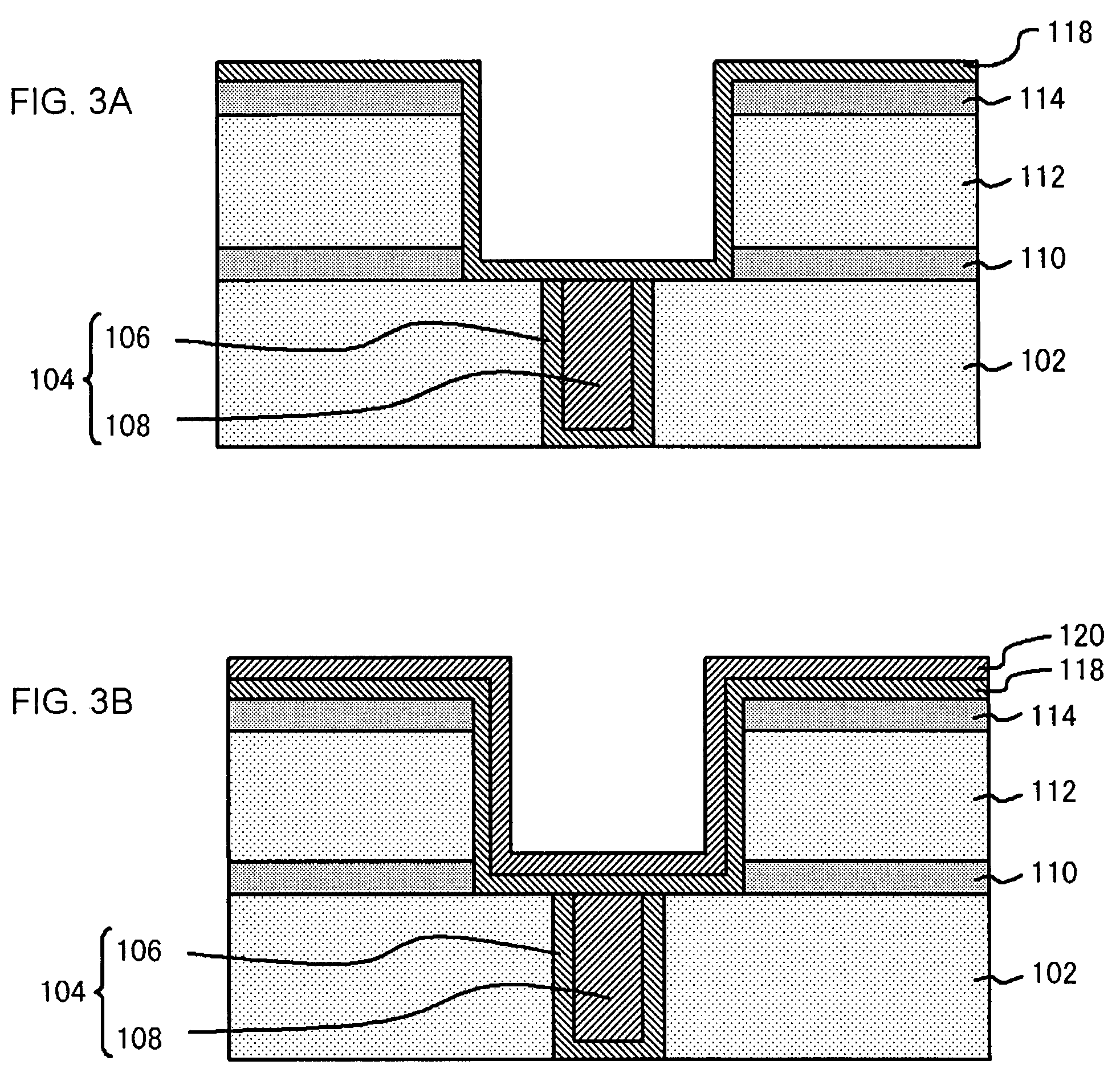

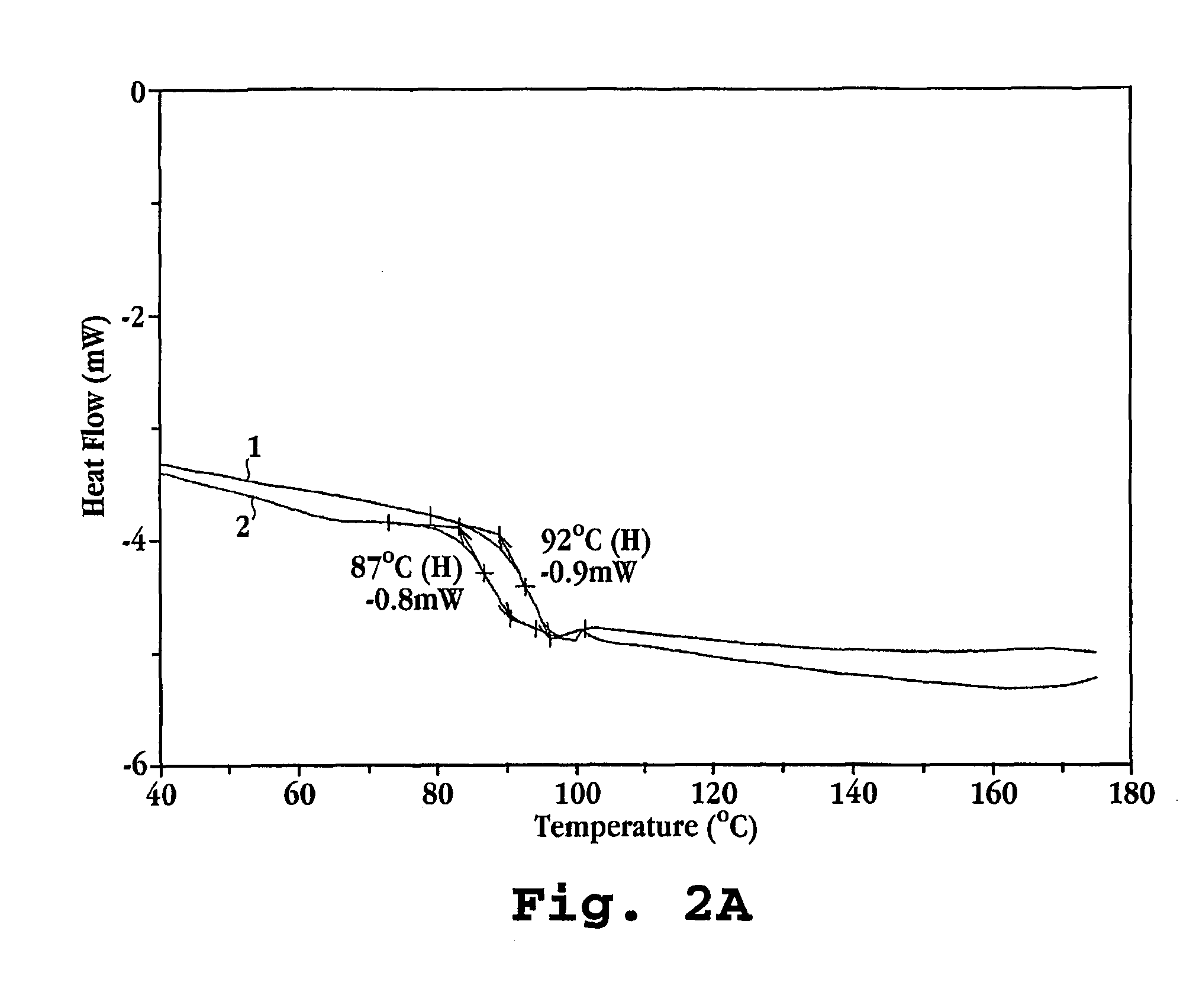

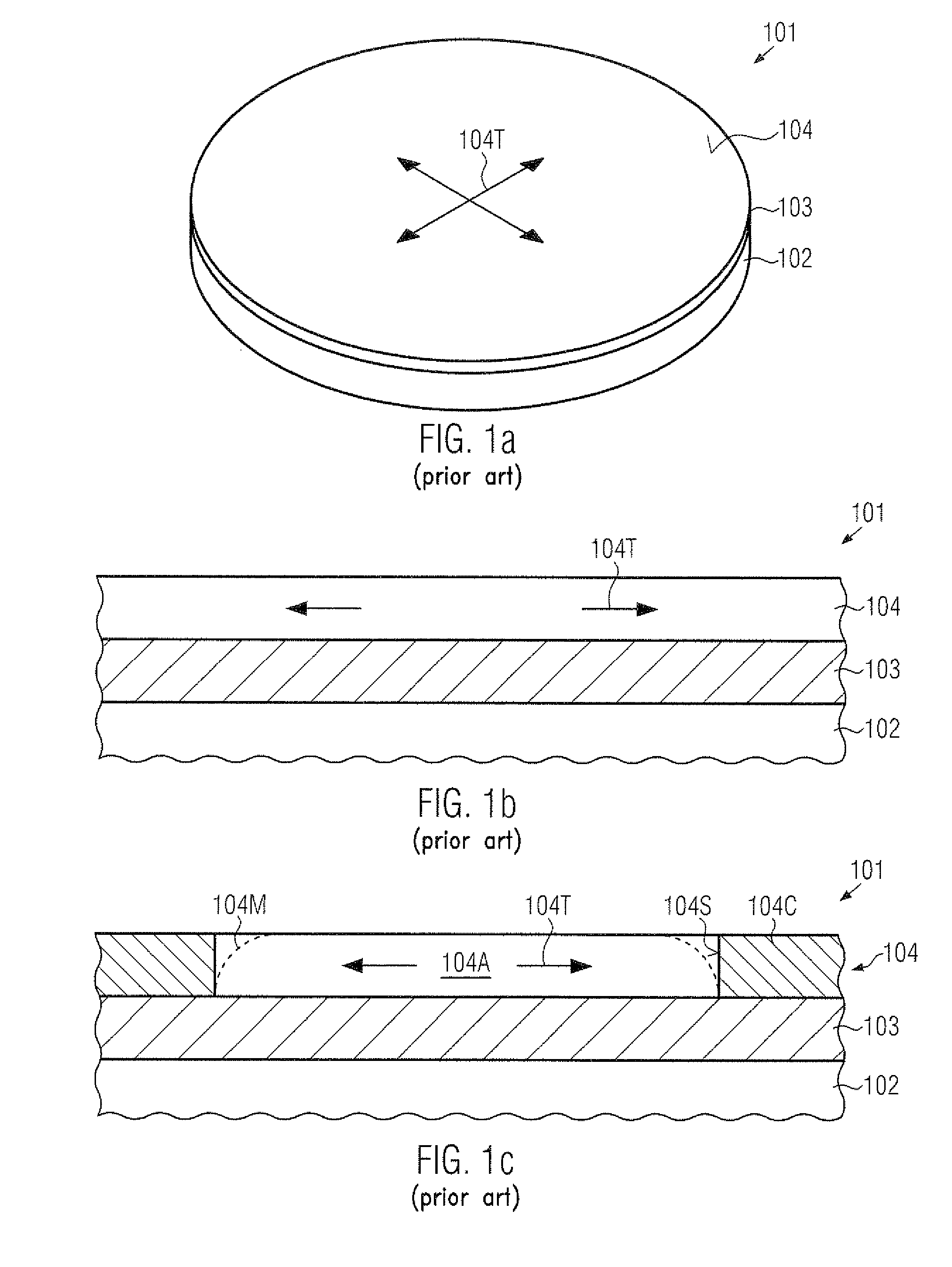

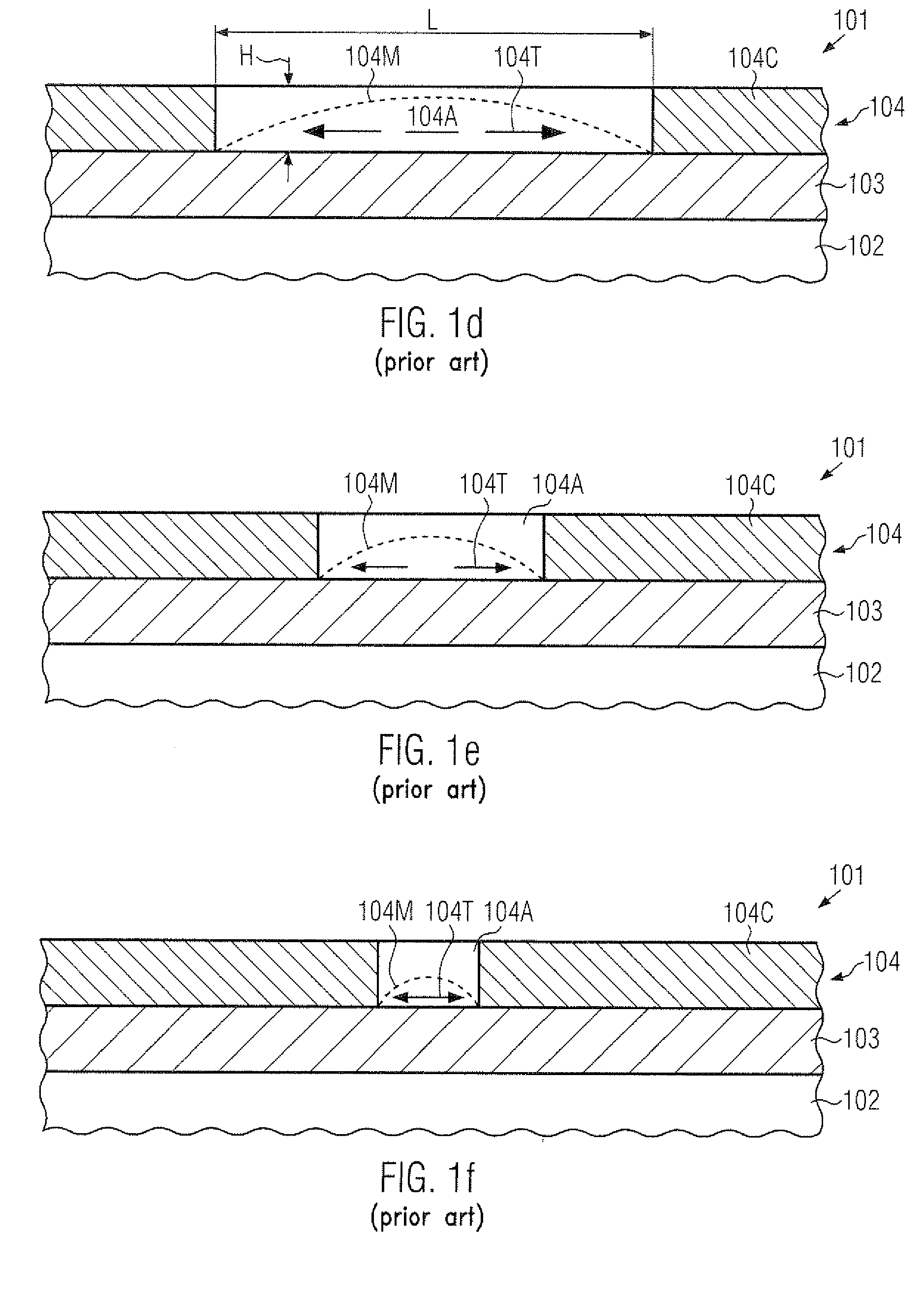

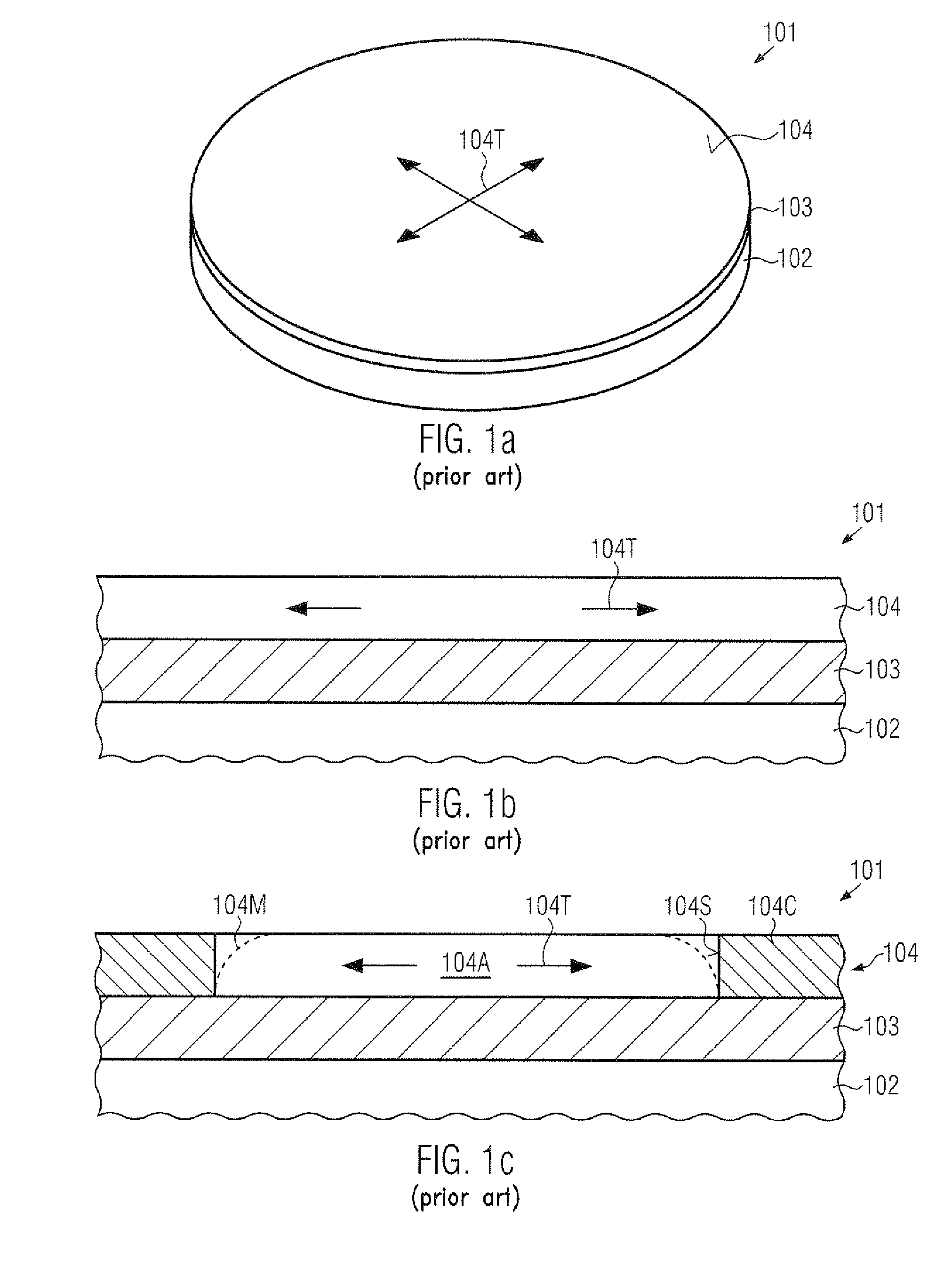

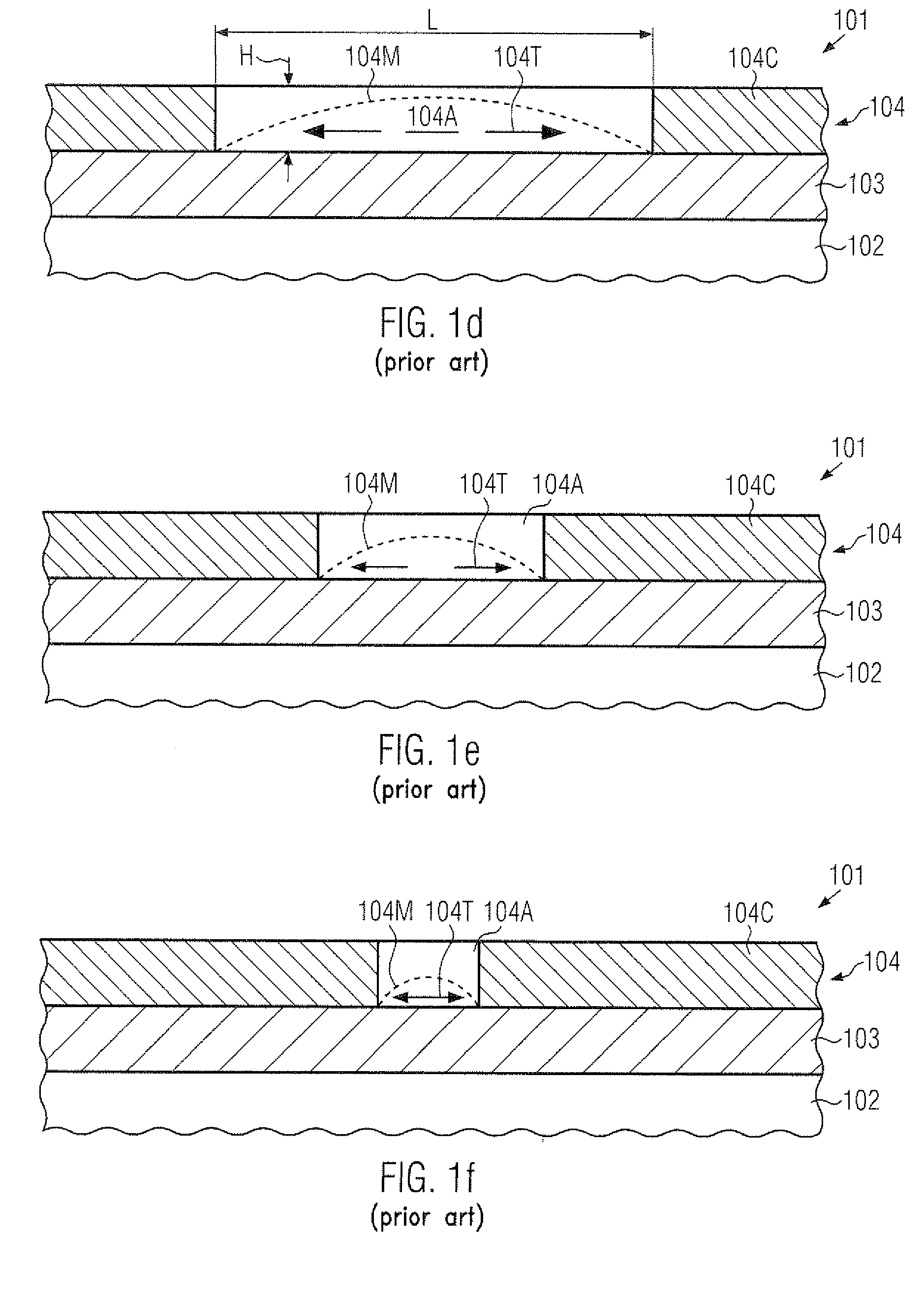

Strain memorization in strained SOI substrates of semiconductor devices

InactiveUS8329531B2Improve mechanical stabilityInhibition is effectiveSolid-state devicesSemiconductor/solid-state device manufacturingSoi substrateEngineering

In sophisticated semiconductor devices, the initial strain component of a globally strained semiconductor layer may be substantially preserved during the formation of shallow trench isolations by using a rigid mask material, which may efficiently avoid or reduce a deformation of the semiconductor islands upon patterning the isolation trenches. Consequently, selected regions with high internal stress levels may be provided, irrespective of the height-to-length aspect ratio, which may limit the application of globally strained semiconductor layers in conventional approaches. Furthermore, in some illustrative embodiments, active regions of substantially relaxed strain state or of inverse strain type may be provided in addition to the highly strained active regions, thereby enabling an efficient process strategy for forming complementary transistors.

Owner:GLOBALFOUNDRIES INC

Preparing method capable of improving strength and toughness of Cu-Ni-Si alloy

The invention belongs to the nonferrous metals processing industry, and particularly relates to a preparing method capable of improving strength and toughness of Cu-Ni-Si alloy. The process comprisesthe steps of semi-continuous casting ingot casting, casting ingot heating, hot rolling, solid-solution treatment (1), face milling, cold rolling (1), side cutting, annealing, cold rolling (2), solid-solution treatment (2), cold rolling (3), solid-solution treatment (3), cold rolling (4), cleaning, aging heat treatment, cleaning, stretching and straightening and slitting. According to the solid-solution treatment (1), the solid-solution temperature ranges from 700 to 850 DEG C, and the cooling strength is larger than 20 DEG C / s; according to annealing, the temperature ranges from 480 to 650 DEGC, and the heat preservation time ranges from four to eight hours; according to solid-solution treatment (2) (3), the solid-solution temperature ranges from 700 to 780 DEG C, the solid-solution timeranges from 90 to 150 s, and the cooling strength is larger than 10 DEG C / s; according to aging heat treatment, the temperature ranges from 400 to 500 DEG C, and the heat preservation time ranges from4 to 8 hours; and according to cold rolling (1) (2) (3) (4), the machining rate ranges from 20 to 85%. The method has the advantages that HV is 225 to 250, Rm is larger than or equal to 690 MPa, Rp0.2 is larger than or equal to 660 MPa, A50 is larger than or equal to 10%, and a strip is bent by 90 degrees and is free of cracking.

Owner:太原晋西春雷铜业有限公司

Strain memorization in strained soi substrates of semiconductor devices

InactiveUS20110210427A1Improve mechanical stabilityReducing strain relaxationSolid-state devicesSemiconductor/solid-state device manufacturingSoi substrateEngineering

In sophisticated semiconductor devices, the initial strain component of a globally strained semiconductor layer may be substantially preserved during the formation of shallow trench isolations by using a rigid mask material, which may efficiently avoid or reduce a deformation of the semiconductor islands upon patterning the isolation trenches. Consequently, selected regions with high internal stress levels may be provided, irrespective of the height-to-length aspect ratio, which may limit the application of globally strained semiconductor layers in conventional approaches. Furthermore, in some illustrative embodiments, active regions of substantially relaxed strain state or of inverse strain type may be provided in addition to the highly strained active regions, thereby enabling an efficient process strategy for forming complementary transistors.

Owner:GLOBALFOUNDRIES INC

High-strength graphene and rare-earth aluminium alloy

The invention discloses a high-strength graphene and rare-earth aluminium alloy. The grapheme and rare-earth aluminium alloy comprises an aluminium alloy matrix and graphene. The composition of the aluminium alloy matrix comprises, by mass, 1.2-1.8% of Cu, 0.18-0.25% of Si, 0.08-0.2% of Cr, 0.6-0.8% of Mg, 0.1-0.2% of Mn, 0.3-0.4% of Fe, 0.3-0.5% of Zn, 0.02-0.06% of Ti, 0.1-0.2% of V, 0.1-0.2% of Ni, 0.04-0.07% of Mo, 0.05-0.12% of Zr, 0.04-0.08% of Nd, 0.04-0.06% of La, 0.03-0.05% of Ce, and the balance Al. The high-strength graphene and rare-earth aluminium alloy has good mechanical properties such as strength, toughness and the like.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

Aircraft engine lip low-half section drawing forming method

InactiveCN107695207AUniform plastic deformation of the sectionUniform plastic deformationShaping toolsButt jointEngineering

The invention relates to an aircraft engine lip low-half section drawing forming method. According to a part theoretical model design drawing forming process model, the process model comprises a convex molded surface and flange edges on the two sides, the upper portion of the convex molded surface is coincident with a part theoretical model, the lower portion of the convex molded surface is an extending supplement face, and the supplement face is composed of a theoretical model tangential extending face and a flange edge vertical extending face; center lines of rolling ribs are designed on theflange edges on the two sides of the process model; a die comprises a female die, edge pressing rings and a male die; the edge pressing rings are matched with the flange edges of the process model, and the upper surfaces of the edge pressing rings are provided with the rolling ribs corresponding to the protruding center lines; the female die is provided with a molding cavity, and a butt joint face of the female die and the edge pressing ring is provided with rolling grooves corresponding to the rolling ribs; and the convex molded surface is the same as a convex molded surface of the process model.

Owner:XIAN AIRCRAFT IND GROUP

Semiconductor device and method for manufacturing same

ActiveUS7800229B2Decrease in dislocation energyIncrease carbon concentrationElectrolytic coatingsSemiconductor/solid-state device detailsElectrical resistance and conductanceCoupling

An improved SIV resistance and an improved EM resistance are achieved in the coupling structure containing copper films. A semiconductor device includes: a semiconductor substrate; a second insulating layer formed on or over the semiconductor substrate; a second barrier metal film, formed on the second insulating film, and being capable of preventing copper from diffusing into the second insulating film; and an electrically conducting film formed on the second barrier metal film so as to be in contact with the second barrier metal film, and containing copper and carbon, wherein a distribution of carbon concentration along a depositing direction in the second electrically conducting film includes a first peak and a second peak.

Owner:RENESAS ELECTRONICS CORP

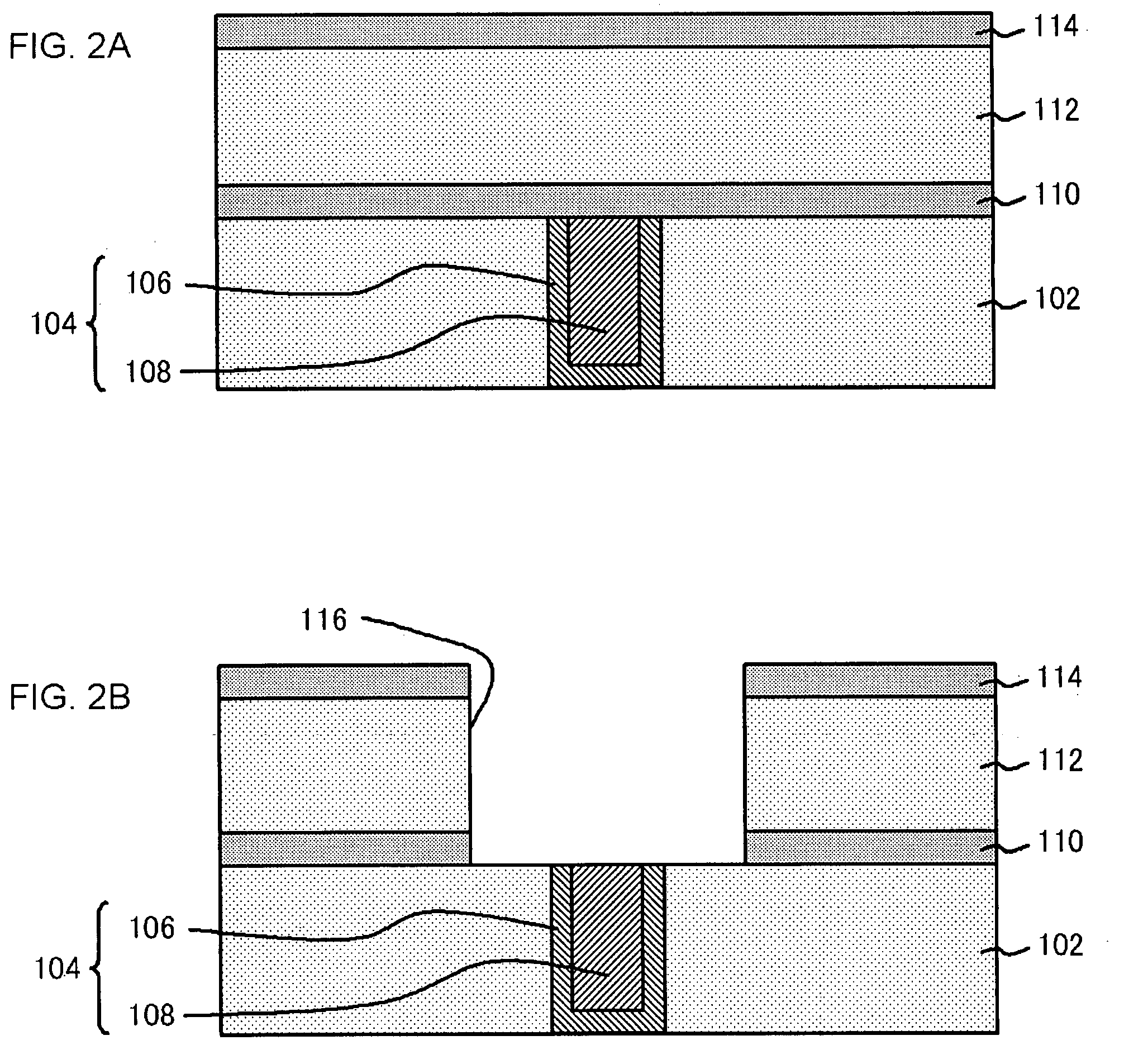

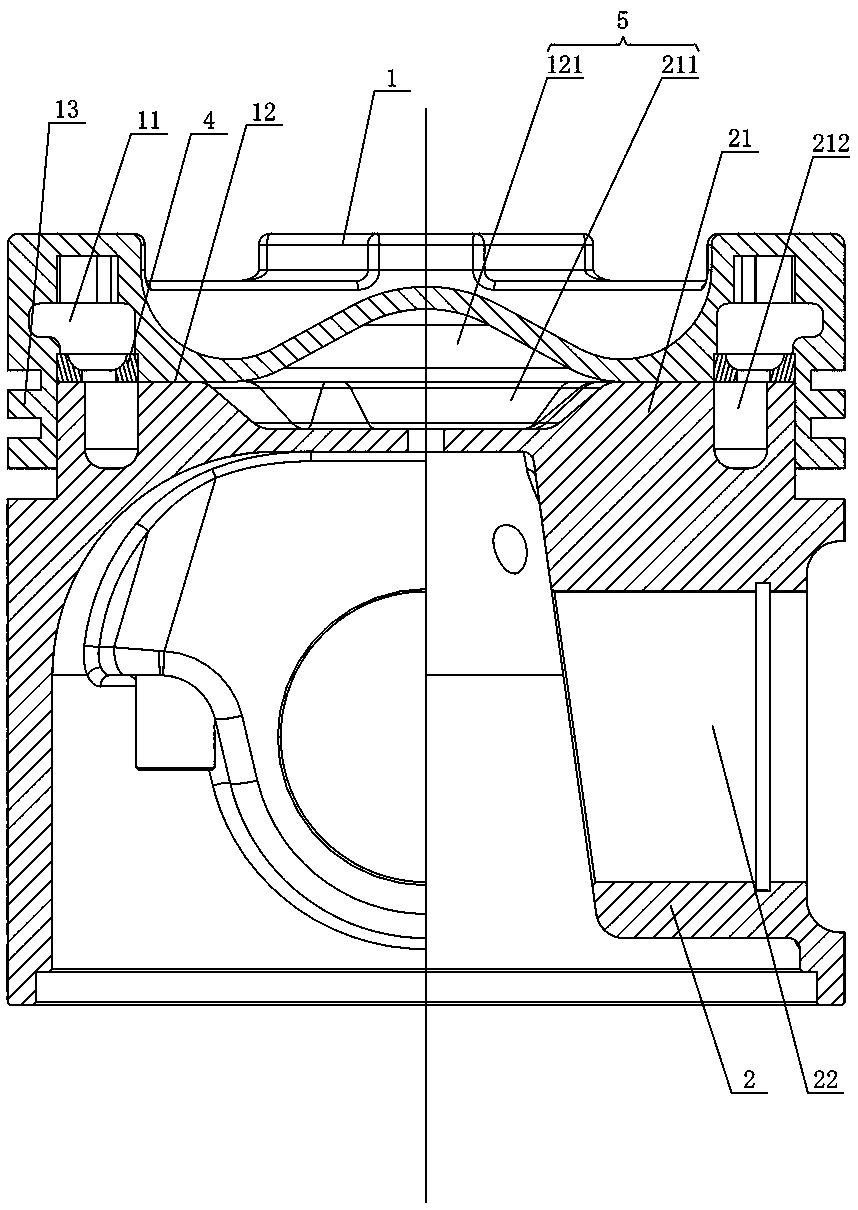

Combined piston

PendingCN110469421AReduce weightReduce stress relaxationMachines/enginesPistonsEngineeringUltimate tensile strength

The invention discloses a combined piston. The combined piston comprises a piston upper part, a piston lower part and a connecting piece; an annular inner cold oil channel is formed in the piston upper part; at least one pair of connecting holes which are centrally symmetrical about a ring center are arranged at the bottom of the annular inner cold oil channel; and the piston lower part and the piston upper part are in fit pressing and are firmly connected with the connecting holes through the connecting piece. The combined piston has the advantages of low manufacturing cost, easiness in formation, high reliability, high connecting strength and capability of reducing weight.

Owner:强莉莉

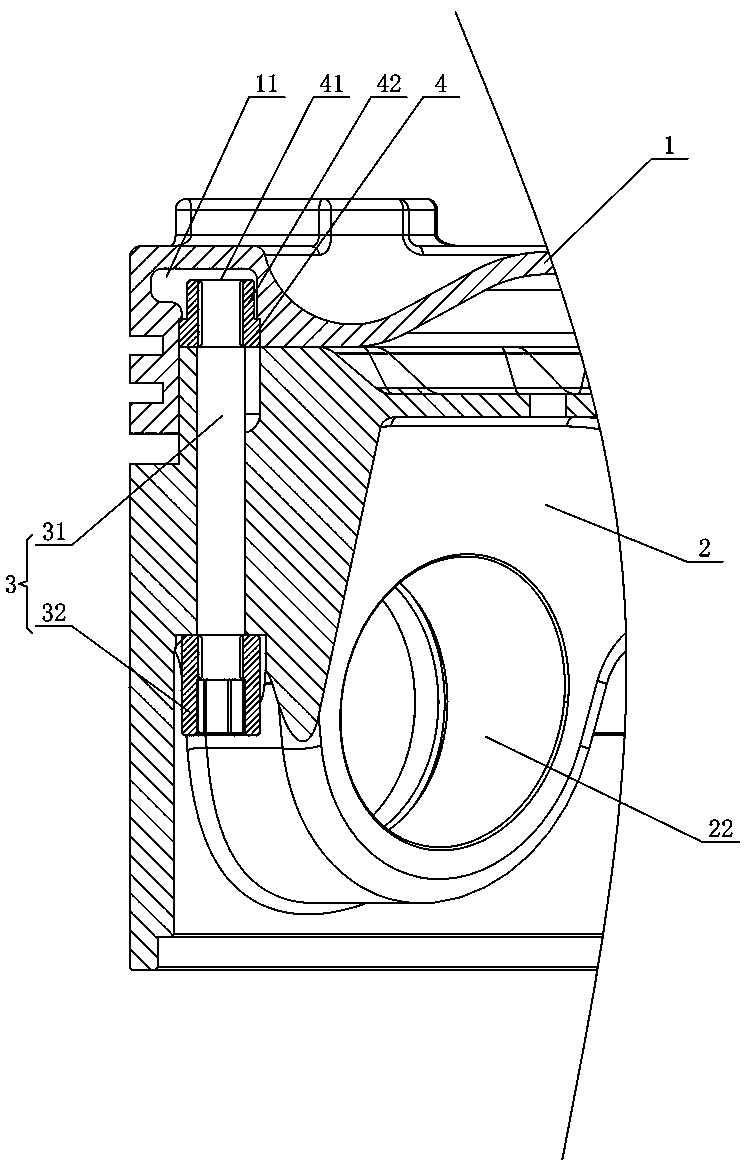

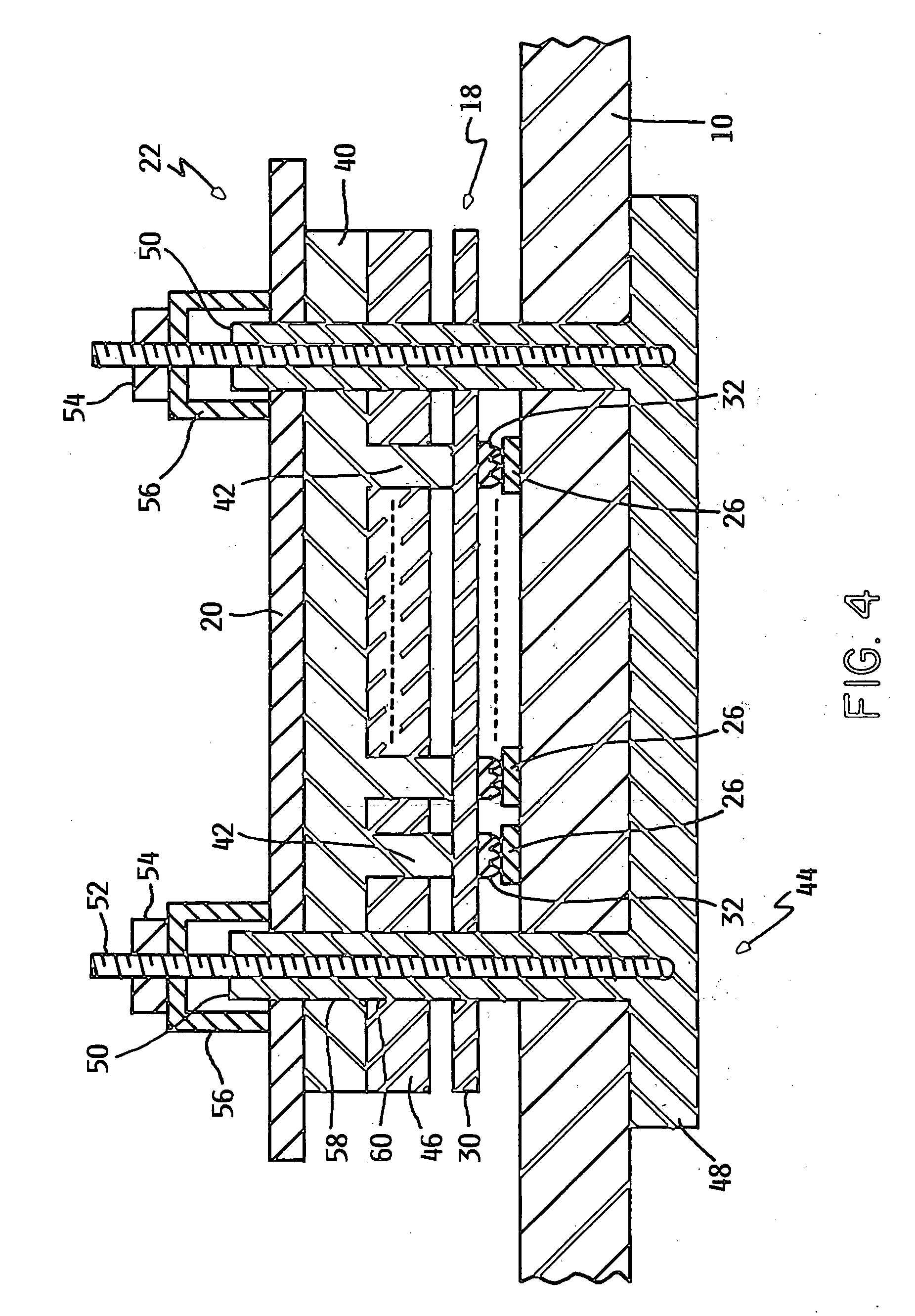

Reduced stress relaxation in elastomeric compression structures adapted for use with electrical components

InactiveUS20070038807A1Reducing stress relaxation issueNegative effectCoupling device detailsElastomeric connecting elements apparatusElastomerMicrosphere

Disclosed are enhanced methods and elastomeric compression structures utilizing embedded gas-filled gas-filled polymeric microspheres that are expanded in predefined conditions that are usable in electrical components for reducing stress relaxation.

Owner:IBM CORP

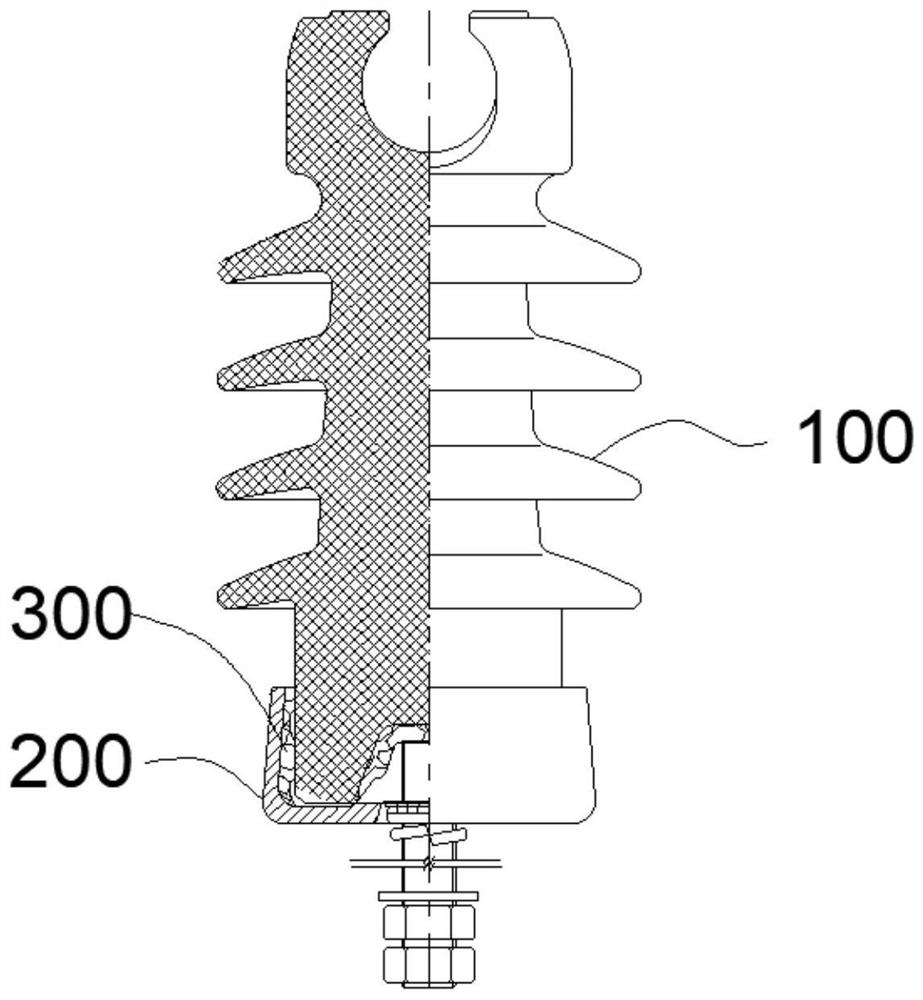

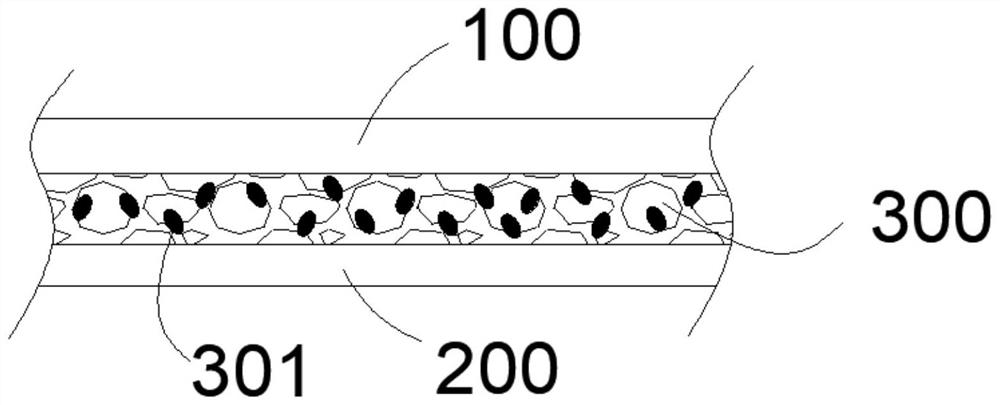

High-strength column type electric porcelain insulator for high-voltage line and manufacturing process thereof

The invention discloses a high-strength column type electric porcelain insulator for a high-voltage line and a manufacturing process of the high-strength column type electric porcelain insulator, and belongs to the field of insulators, the high-strength column type electric porcelain insulator comprises a porcelain body and a metal accessory, an adhesive layer is arranged between the metal accessory and the porcelain body, and the adhesive layer comprises the following raw materials in parts by weight: 50-90 parts of an inorganic cementing material and 1-20 parts of an elastomer, wherein the inorganic cementing material contains a nano oxide, a pore passage is formed in the elastomer, and the nano oxide is adsorbed in the pore passage. According to the invention, the elastomer is added into the inorganic cementing material, so that on one hand, the cementing strength of the inorganic cementing material can be enhanced, cracks are prevented from being generated after use, and the service life is prolonged; on the other hand, due to the excellent elastic performance of the elastomer, stress relaxation generated after the gel layer is used for a long time can be reduced, and the loosening phenomenon of the porcelain body and the metal accessory after long-time use is avoided.

Owner:SUZHOU AIJIAN ELECTRICAL PORCELAIN

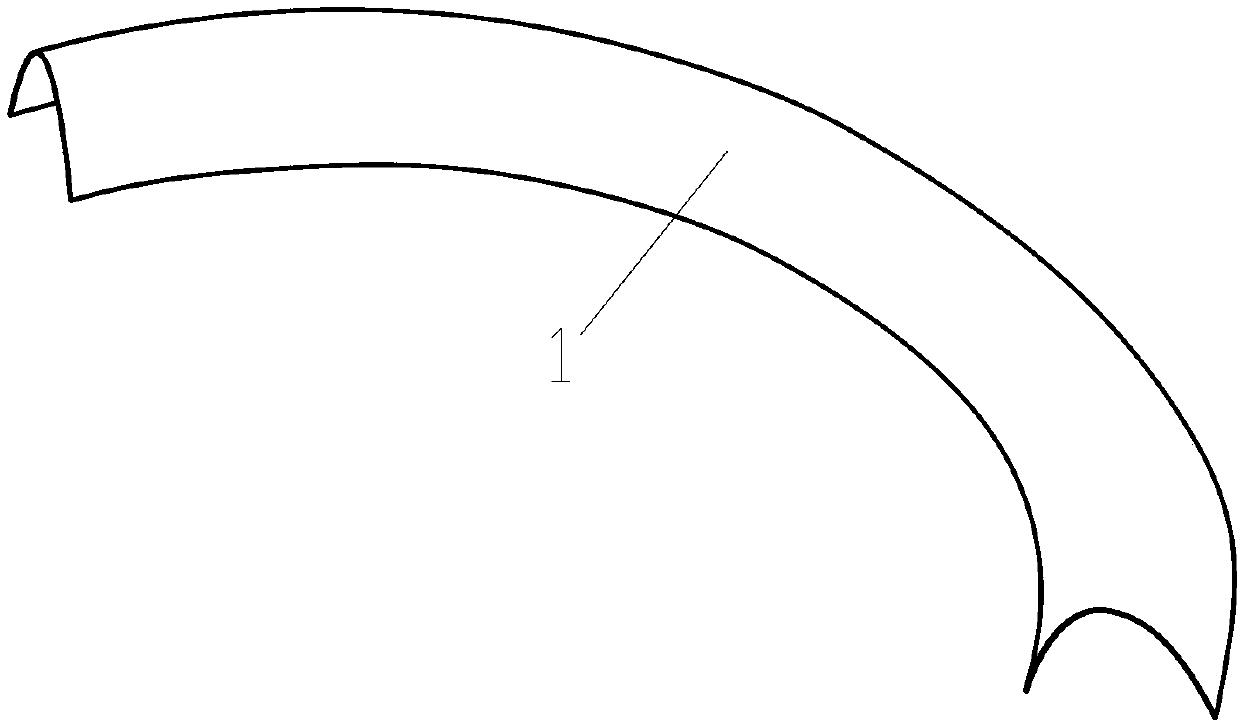

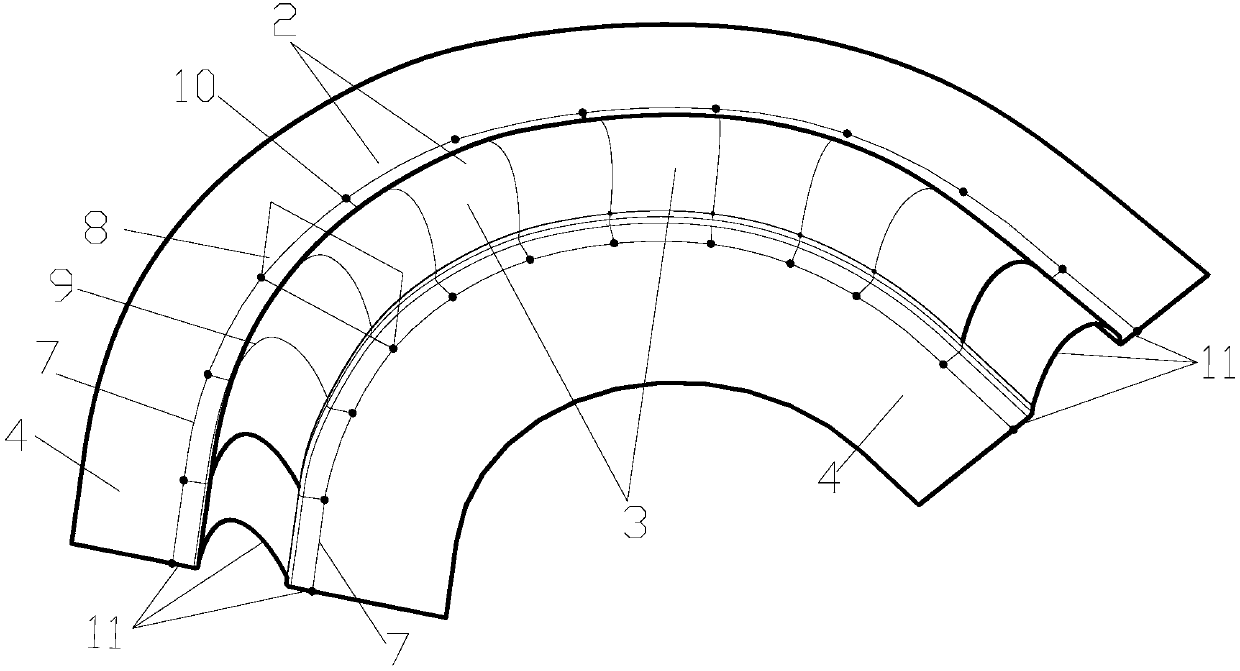

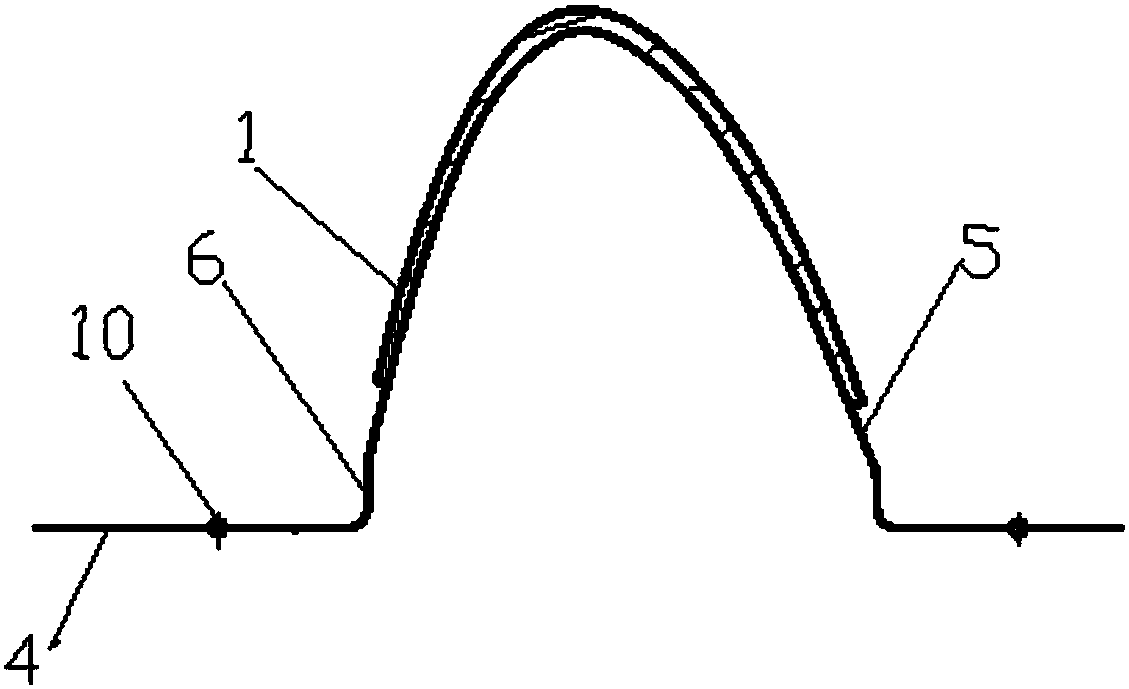

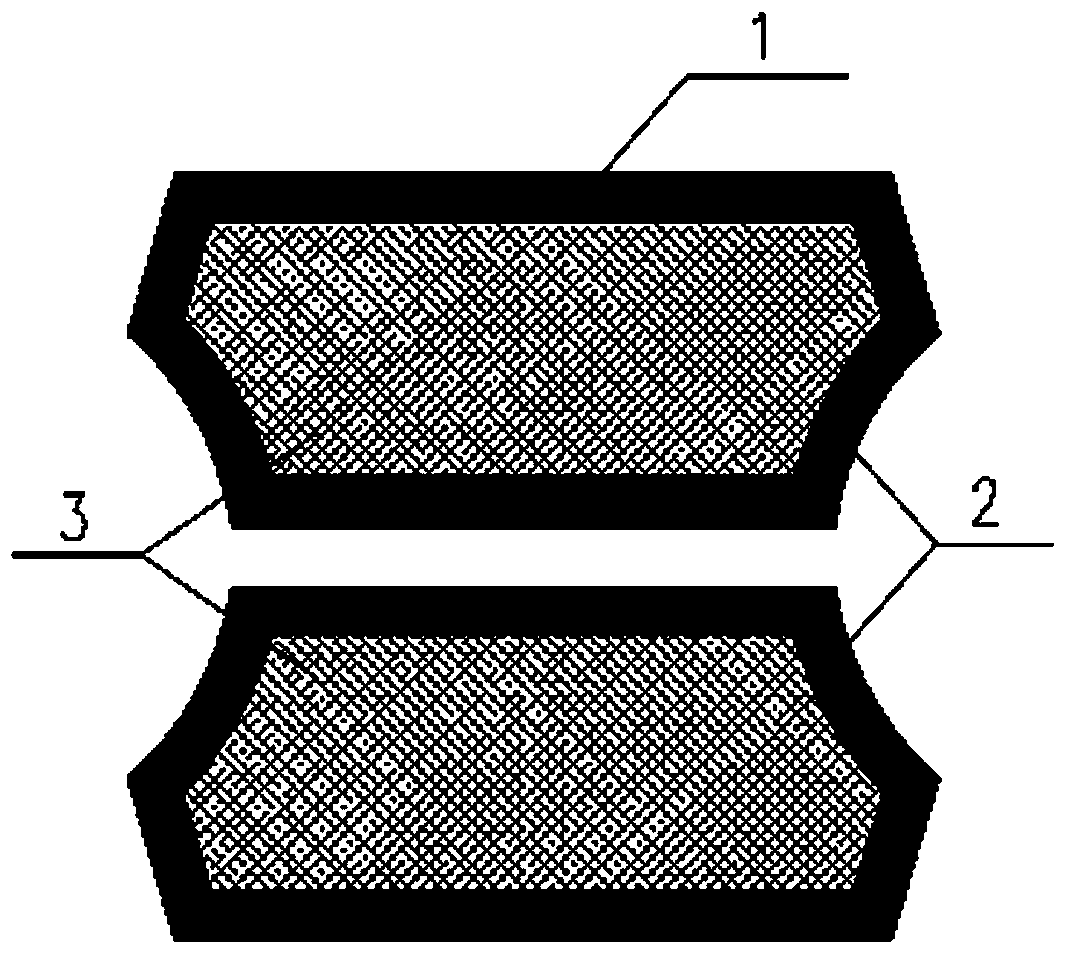

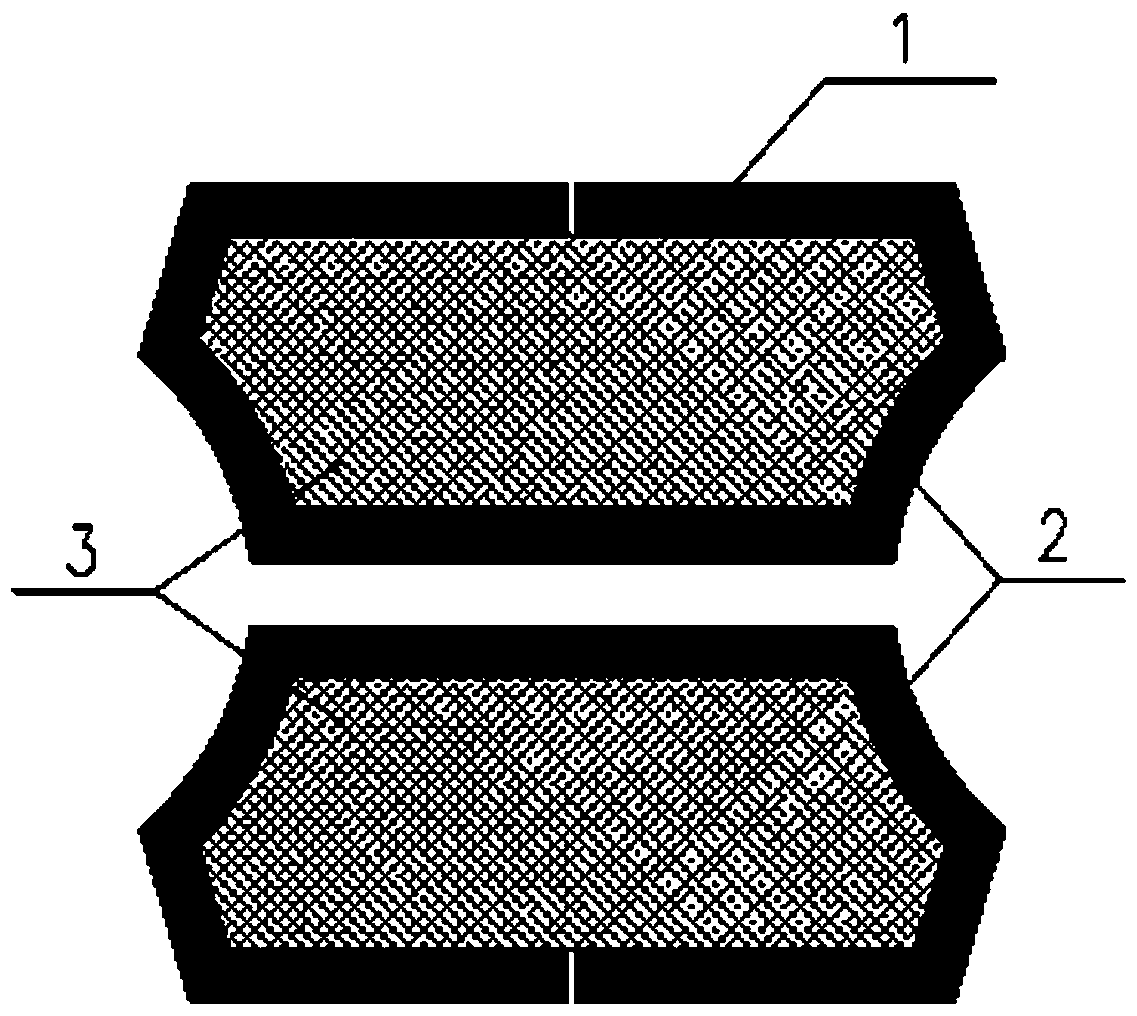

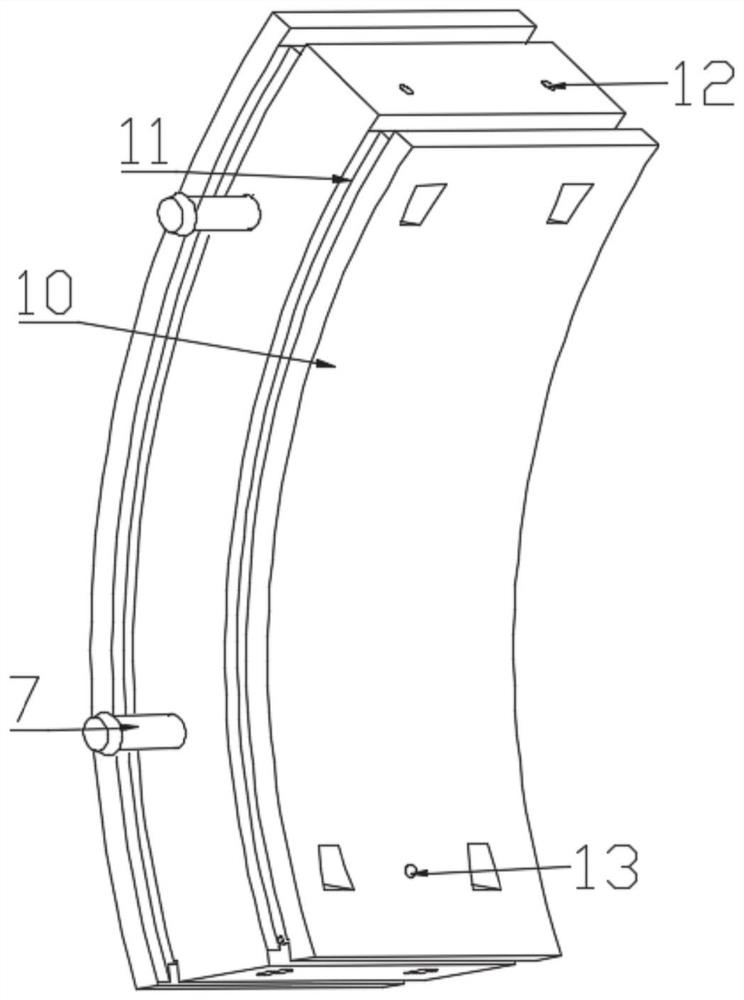

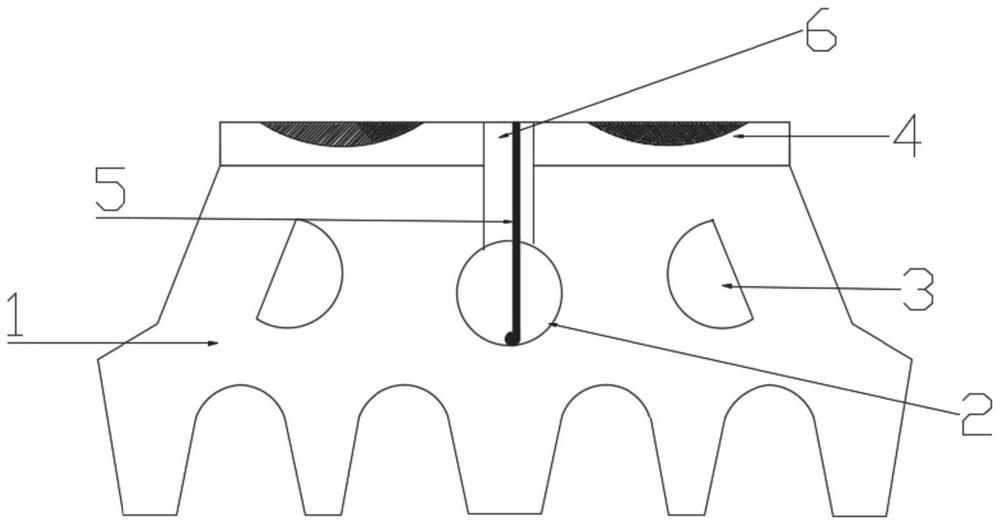

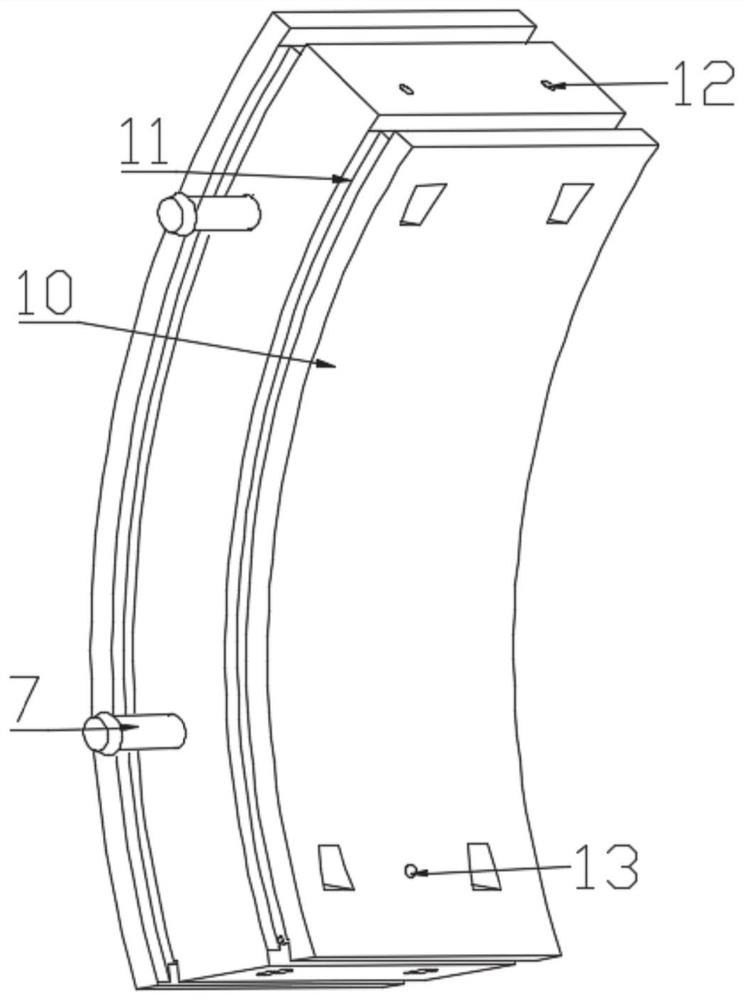

Waterproof elastic sealing gasket for segment joint of shield tunnel

PendingCN108252728AIntegrity guaranteedUniform contact stressUnderground chambersTunnel liningEthylene-propylene-diene-monomerStress relaxation

The invention discloses a waterproof elastic sealing gasket for a segment joint of a shield tunnel. The waterproof elastic sealing gasket is characterized in that the waterproof elastic sealing gasketcomprises a silicon foam inner core and an ethylene-propylene-diene monomer (EPDM) rubber outer tire wrapping the silicon foam inner core. During using, two pieces of elastic sealing gaskets are pasted in waterproof inserting grooves in two adjacent segments in a mirror symmetry mode correspondingly, and the sealing gaskets are extruded after the segments are spliced, so that the silicon foam inner cores contracts and produce contact stress, thus EPDM rubber is mutually fitted and extruded, and a waterproof sealing function is achieved accordingly. Compared with a single-component EPDM through hole rubber sealing gasket commonly used in the existing engineering technology field, the waterproof sealing gasket with the additionally-arranged silicon foam inner core has the advantages of uniform contact stress, close fitting, long-term load maintaining ability, high elasticity recovery ability and the like, the stress relaxation phenomenon of the waterproof sealing gasket under the long-term pressure can be effectively reduced. The waterproof elastic sealing gasket has great value for long-term waterproof performance of the shield tunnel.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

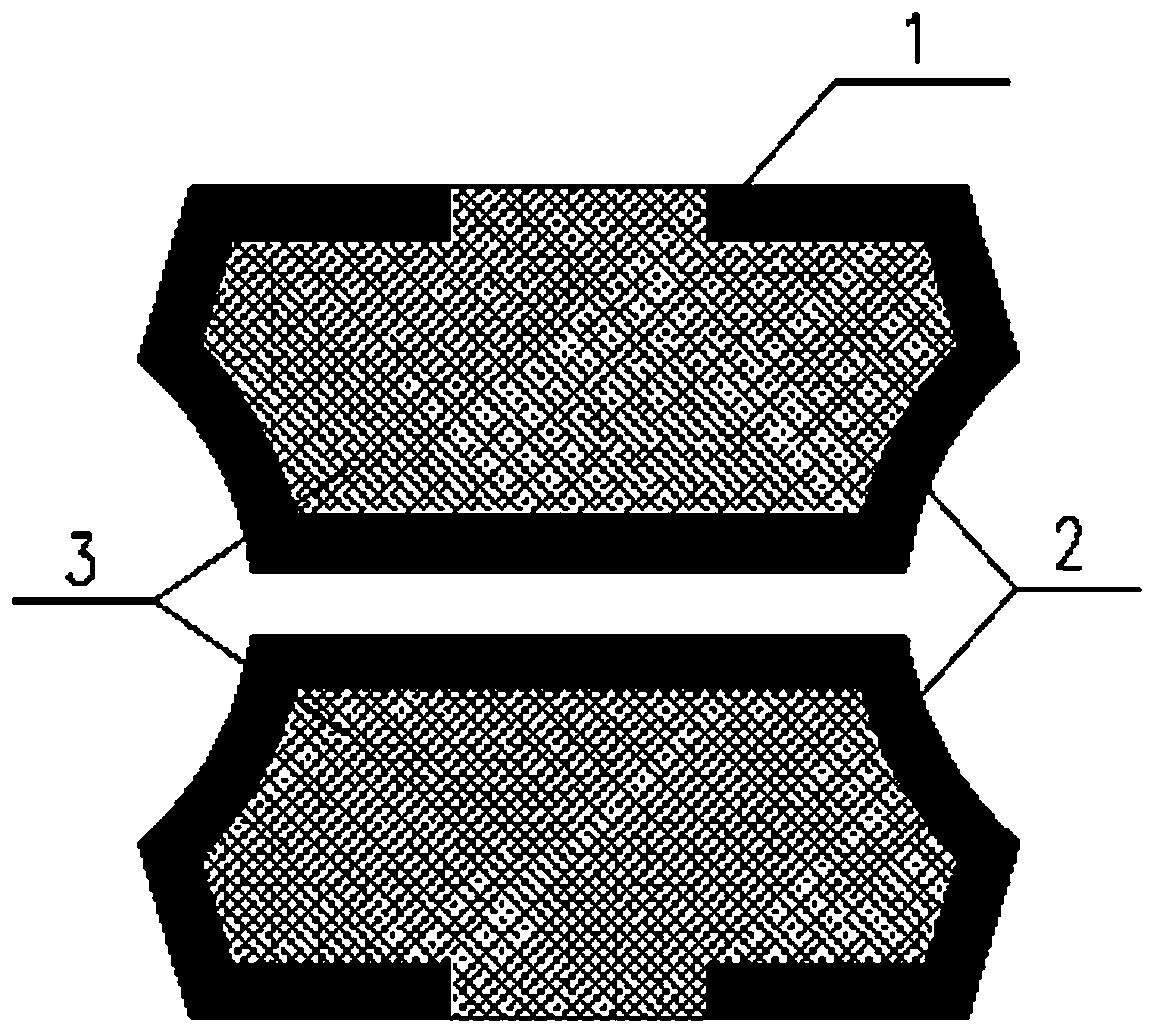

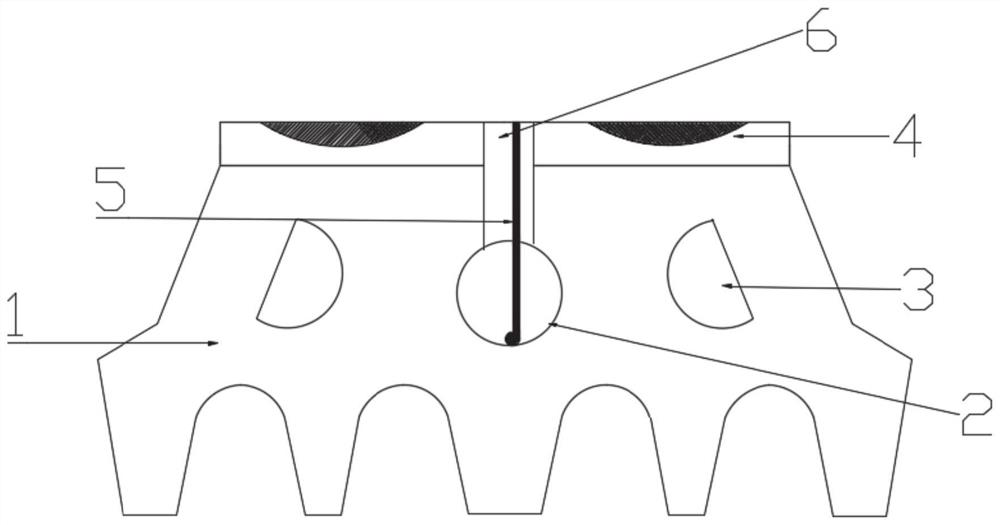

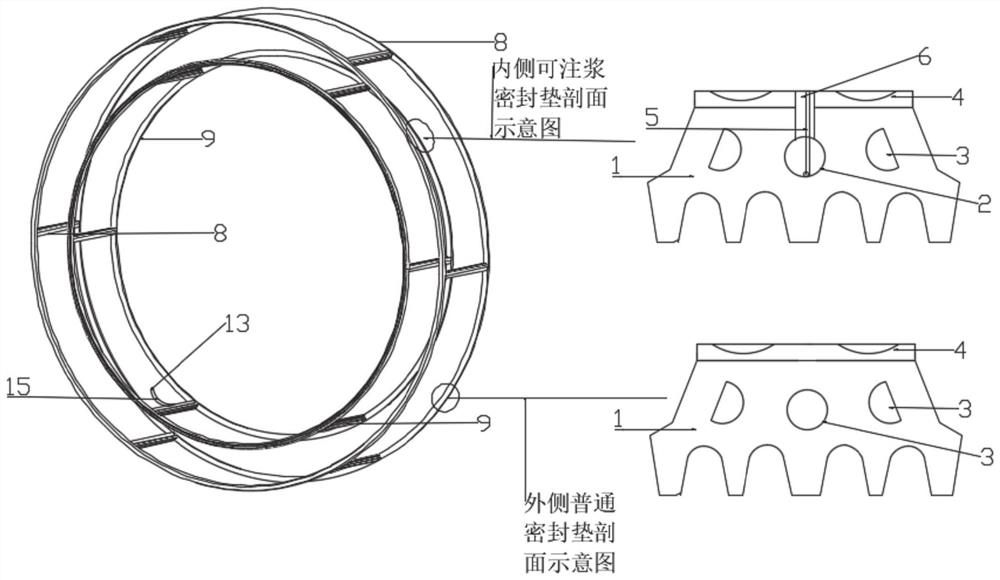

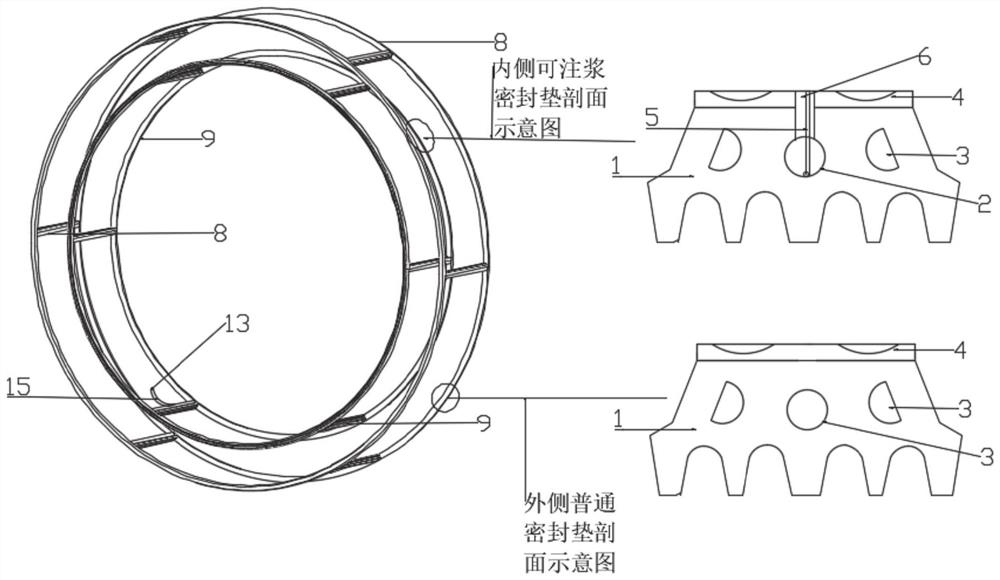

Water-stop sealing gasket capable of being melted and injected with glue for multiple times, duct piece, duct piece ring and construction method

ActiveCN112324476AImprove sealingReduce the loss of manpower and material resourcesUnderground chambersTunnel liningWater leakageEngineering

The invention discloses a water-stop sealing gasket capable of being melted and injected with glue for multiple times, a duct piece, a duct piece ring and a construction method. The sealing gasket capable of being injected with glue comprises a rubber main body, wherein a glue injection hole channel is formed in the rubber main body, a hot melting coil is arranged in the glue injection hole channel, reserved hole channels capable of ensuring that the rubber main body is compressible are reserved in the two sides of the glue injection hole channel, and an expansion water absorption layer is arranged on an outer ring of the rubber main body; and the rubber main body is also provided with a glue outlet hole communicated with the glue injection hole channel. The water-stop sealing gasket capable of being injected with glue is arranged on an inner layer of an annular and longitudinal joint surface of a segment, and a common sealing gasket is normally arranged on an outer layer of the jointsurface. After a segment tunnel operates, if water leakage occurs due to the fact that the water stopping performance of the outer-layer sealing gasket is reduced, an inner-layer sealing gasket glue injection and water stopping program is started. High-temperature water stop glue is injected into a sealing gasket channel and seeps outwards along the glue outlet hole, and when the temperature is reduced to 45 DEG C or below, the liquid glue becomes solid rubber, and the water stop effect is achieved.

Owner:CHINA RAILWAY SHISIJU GROUP CORP +1

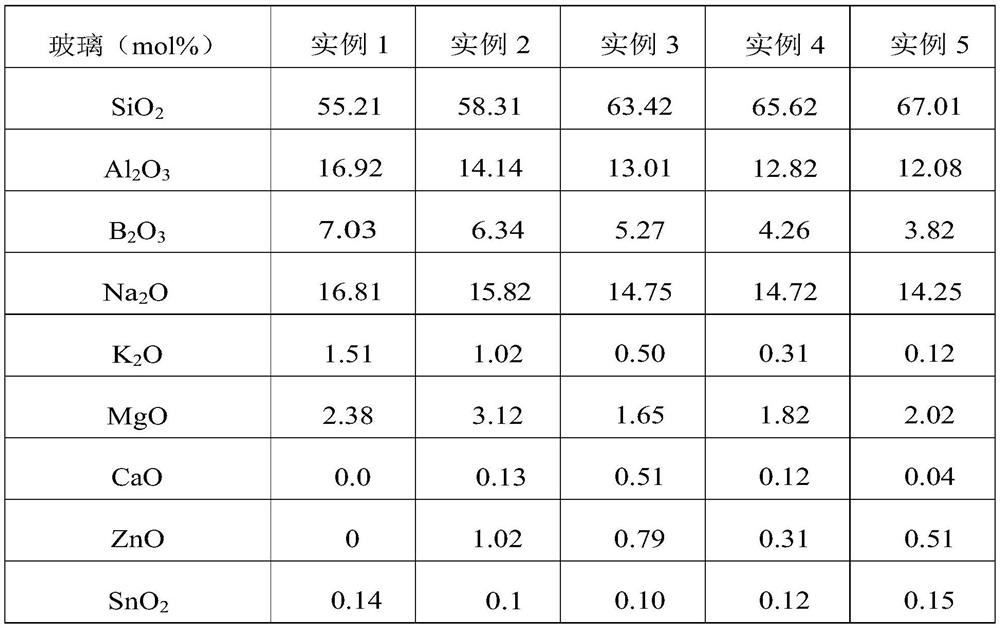

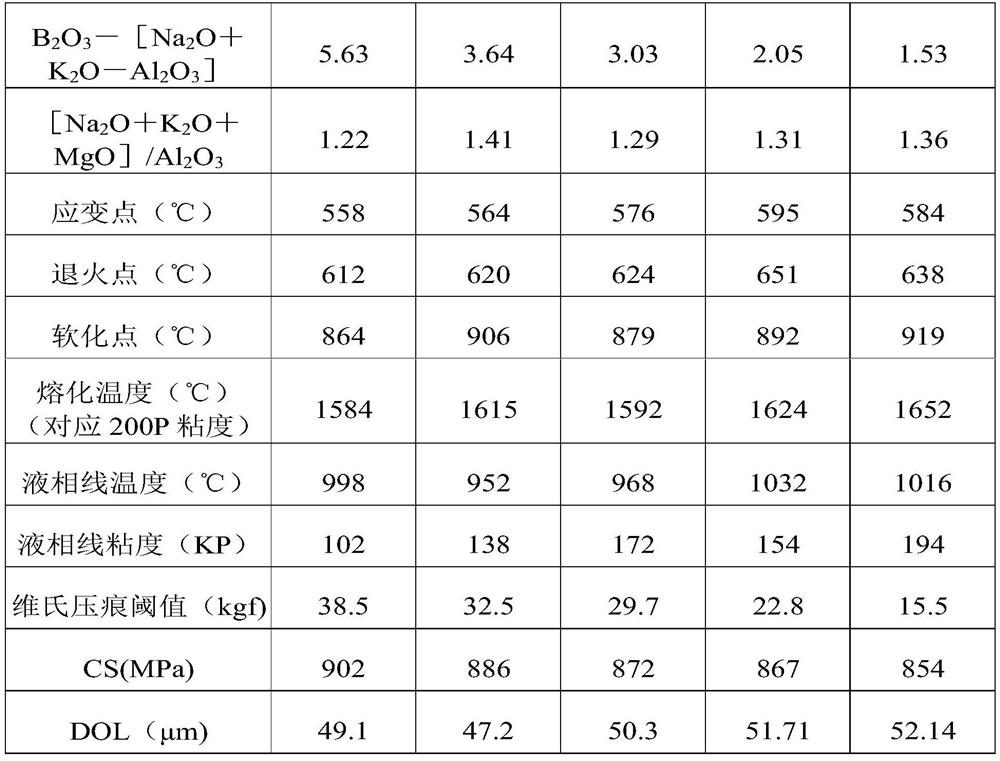

Boron-containing aluminosilicate glass capable of realizing rapid ion exchange

The invention provides boron-containing aluminosilicate glass capable of realizing rapid ion exchange, and the boron-containing aluminosilicate glass not only has high inherent damage resistance, but also has high ion exchange kinetics and rapid exchange capability. The boron-containing aluminosilicate glass comprises the following components in percentage by mole: 54 to 68 percent of SiO2, 12 to 20 percent of Al2O3, 0 to 12 percent of B2O3, 12 to 20 percent of Na2O, 0 to 5 percent of K2O and 0 to 6 percent of RO, the molar percentage of B2O3 is not 0; the RO is one or more of MgO, ZnO and CaO; M(B2O3)-[M (Na2O) + M (K2O)-M (Al2O3)] is greater than 1mol%; [M (Na2O) + M (K2O) + M (MgO)] / M (Al2O3) is greater than 1 and less than 1.4; and M represents the molar percentage of the corresponding component.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

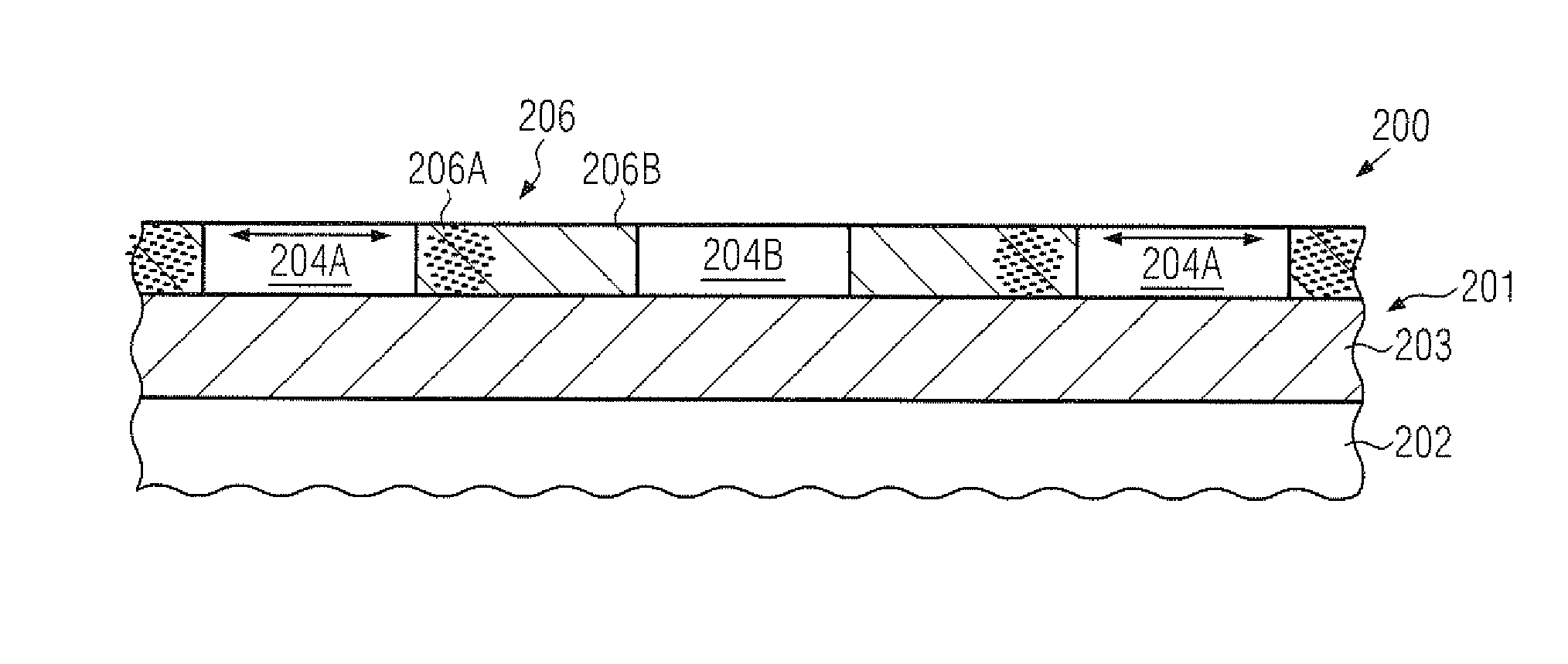

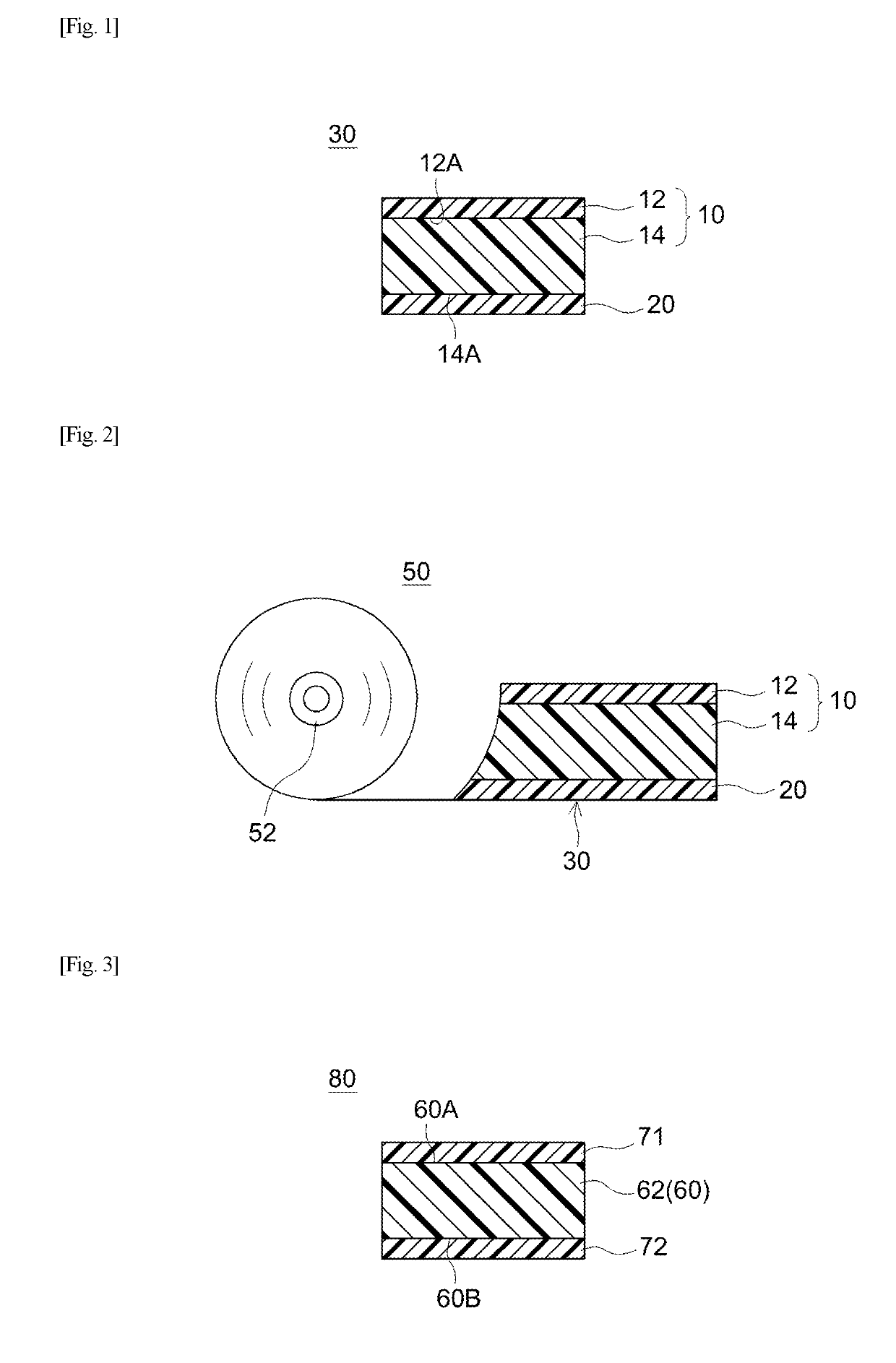

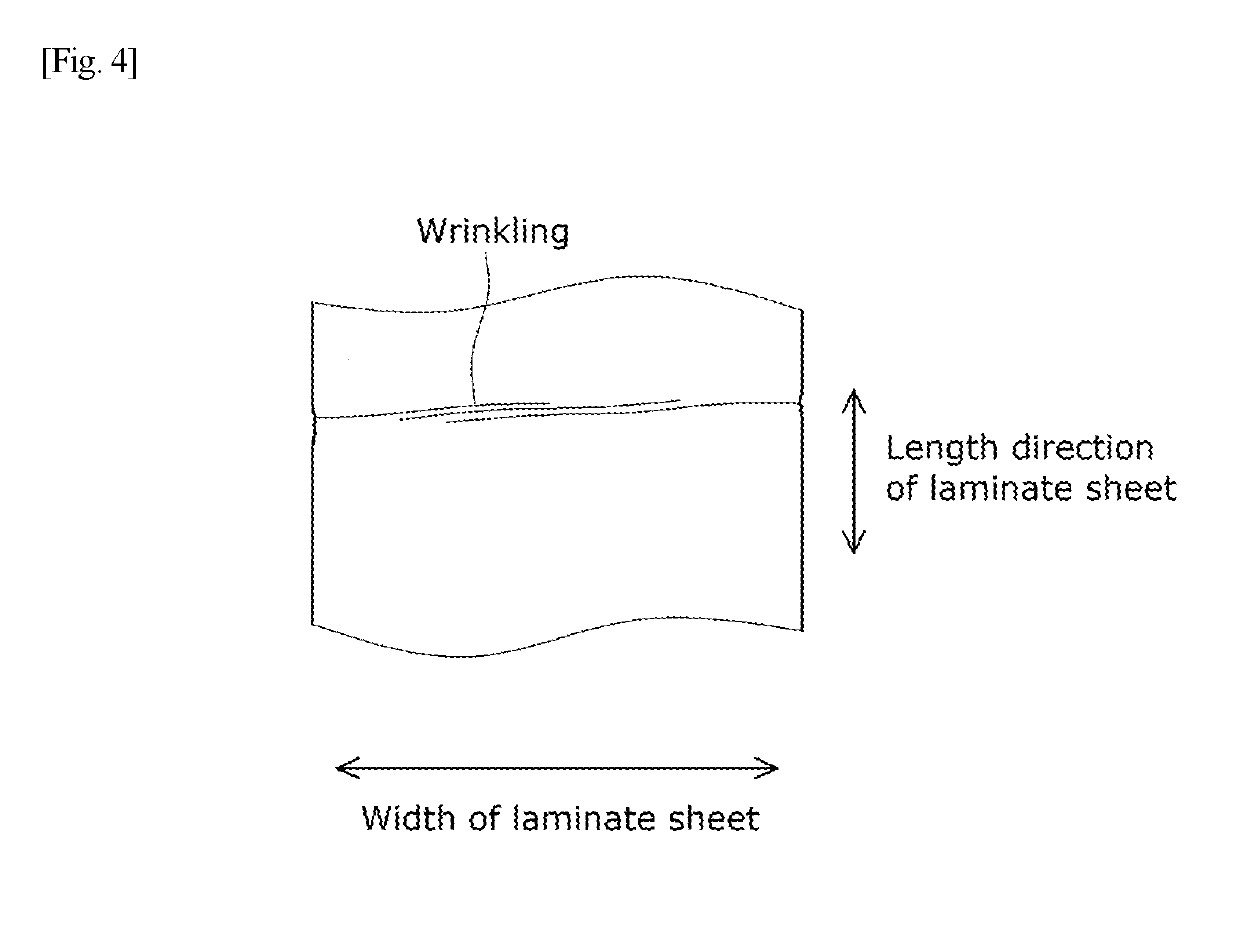

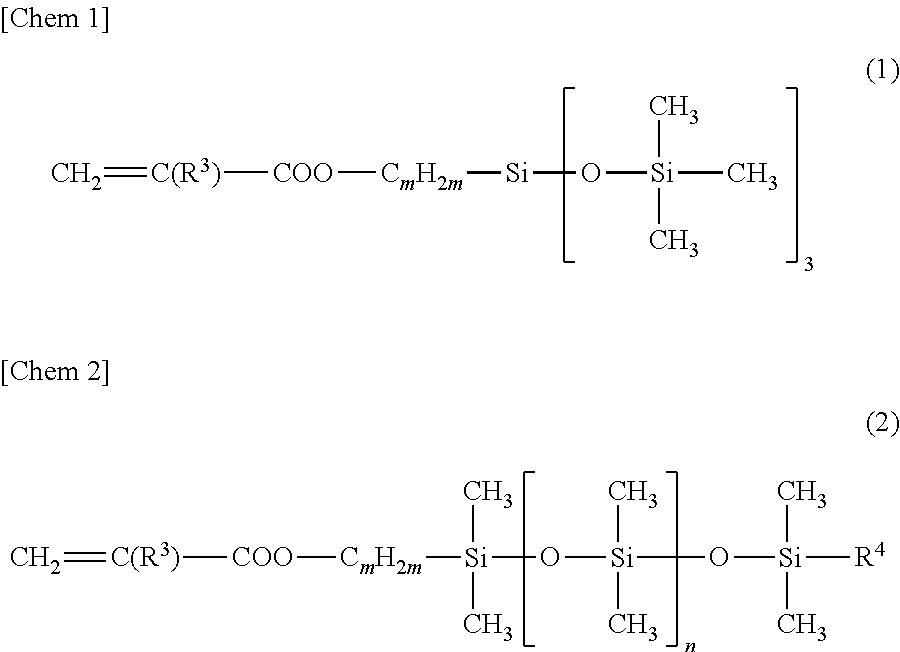

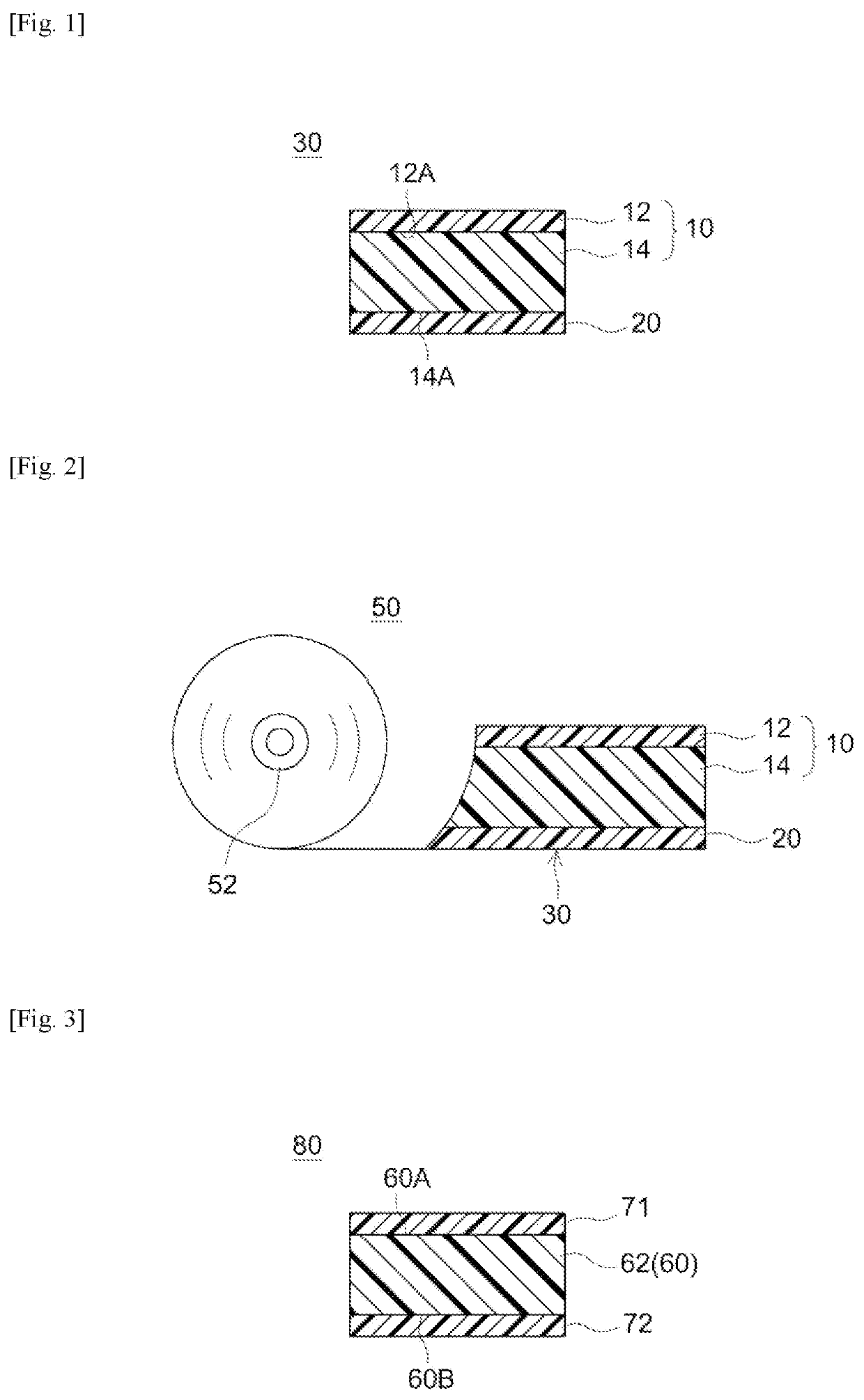

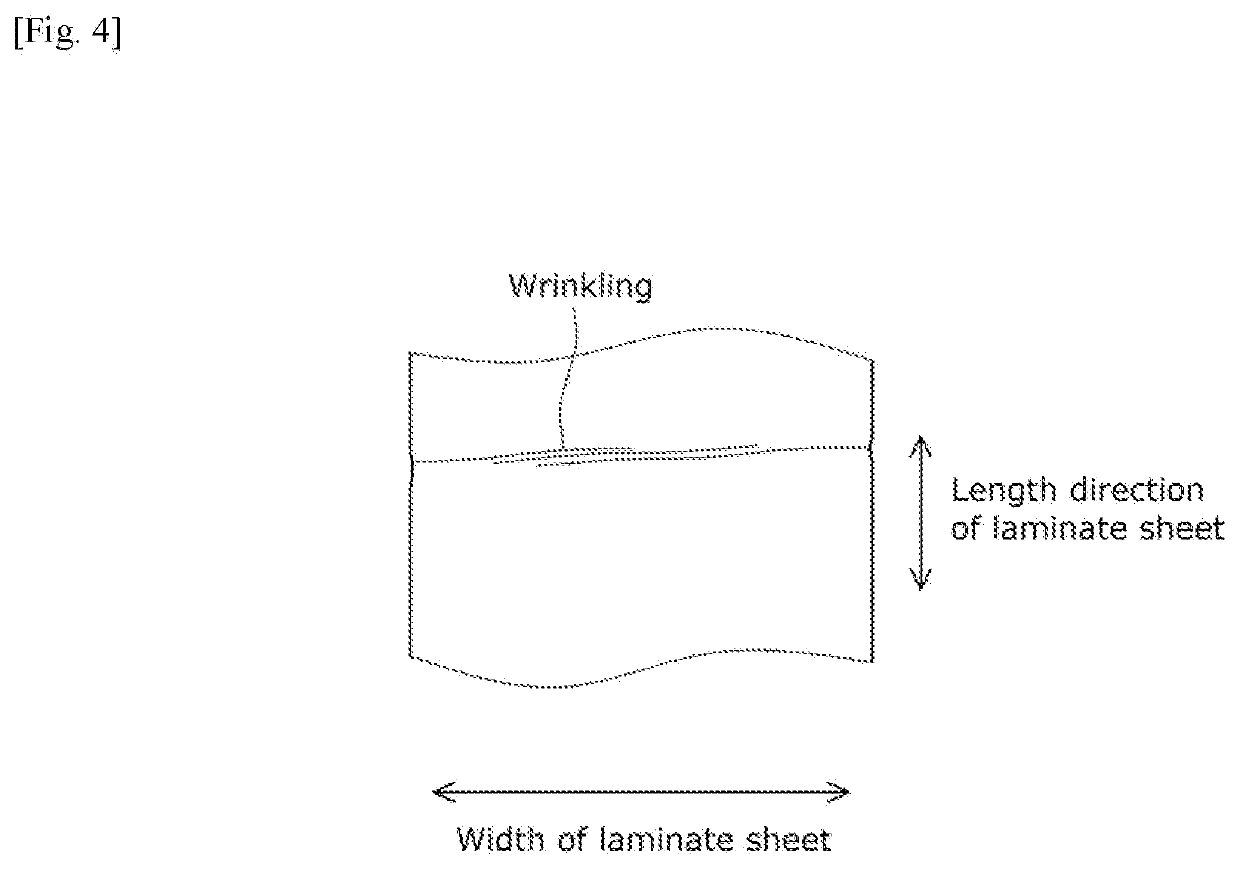

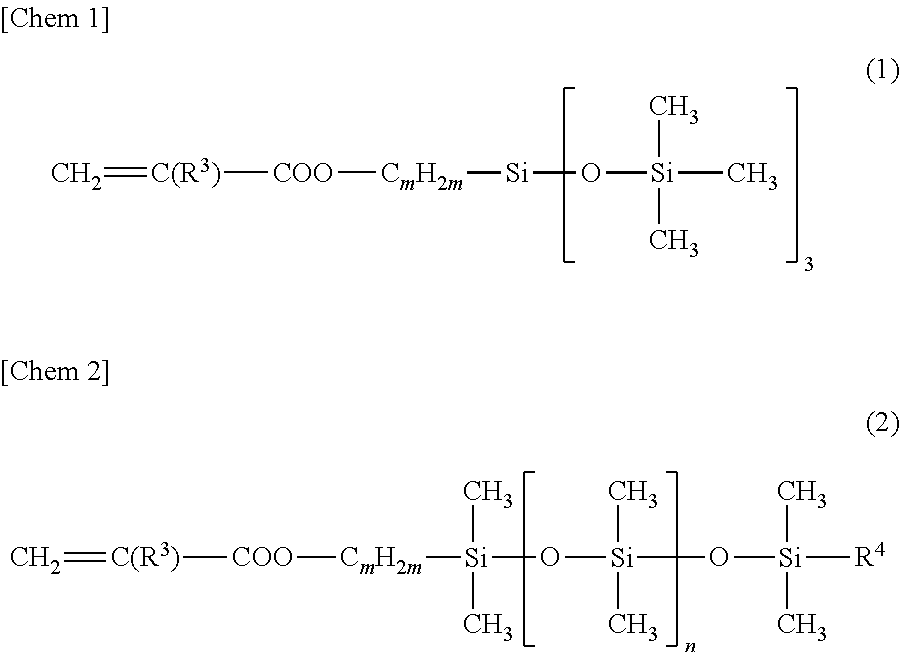

Laminate sheet and roll

ActiveUS20190225838A1Increasing the thicknessReduce the impactLamination ancillary operationsAdhesive articlesEngineeringBiomedical engineering

Provided is a laminate sheet in which a first sheet, a PSA layer and a second sheet are laminated in this order. Of the first and second sheets, at least one is a release liner having a release face on the side facing the PSA layer. The PSA layer has a thickness of 200 μm or greater. The first sheet has a tensile modulus of 1000 MPa or greater and the second sheet has a tensile modulus of 500 MPa or less.

Owner:NITTO DENKO CORP

Waterproof sealing gasket, segment, segment ring and construction method that can be melted and injected multiple times

ActiveCN112324476BImprove sealingImprove the water-stop effectUnderground chambersTunnel liningEngineeringWater effect

The invention discloses a water-tight gasket capable of multiple melting and injection of glue, a segment, a segment ring and a construction method. The gasket that can be injected with glue includes a rubber main body, and a channel for injecting glue is arranged in the rubber main body. A hot-melt coil is provided inside the injection channel, and reserved channels are reserved on both sides of the injection channel to ensure that the rubber body can be compressed, and an expansion water-absorbing layer is arranged on the outer ring of the rubber body; There is a glue outlet connected with the glue injection channel. The glue-injectable water-tight sealing gasket is set on the inner layer of the circumferential and longitudinal joint surfaces of the segment, and the ordinary sealing gasket is normally installed on the outer layer of the joint surface. After the segment tunnel is in operation, if there is water leakage due to the decline in the water-stop performance of the outer gasket, start the glue injection water-stop procedure for the inner gasket. The high-temperature water-stopping glue is injected into the gasket channel and seeps outward along the glue outlet hole. When the temperature drops below 45°C, the liquid glue becomes solid rubber and exerts the water-stopping effect.

Owner:CHINA RAILWAY SHISIJU GROUP CORP +1

Improved anchor rod mortar for high-ground-temperature tunnel support and preparation method of improved anchor rod mortar

InactiveCN106431108AImprove performanceIncrease coefficient of frictionAnchoring boltsGround temperatureFiber

The invention relates to the technical field of underground engineering materials, in particular to improved anchor rod mortar for a high-ground-temperature tunnel support. The improved anchor rod mortar is prepared from 680-730 parts of cement, 150-200 parts of a gel material, 450-500 parts of water, 450-500 parts of lightweight aggregates, 5-10 parts of an additive and 130 parts of jute fiber. The anchor rod mortar provided by the invention is capable of effectively improving the high temperature resistance of the mortar, and effectively reducing the stress relaxation of an anchor rod so as to form effective supporting under a long-time high-temperature condition after being coagulated. The improved anchor rod mortar has the characteristics of high temperature resistance, high tenacity, high anti-compression, anti-pull and anti-bending capabilities and the like. Furthermore, the mortar is favorable in proportion and workability and has less possibility of blocking a pipe during a pumping process, the anchor rod injection efficiency is improved, blockage phenomena during mortar pumping are effectively reduced, and the mortar still has reliable performance under the long-term high-temperature condition; in addition, the improved anchor rod mortar is low in cost, and has favorable economical efficiency; municipal sludge pottery sand, calcium carbonate whiskers and the jute fiber are new green and environment-friendly materials and are free from toxicity and pollution, so that the adverse influence caused by construction material pollution is reduced to a great extent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

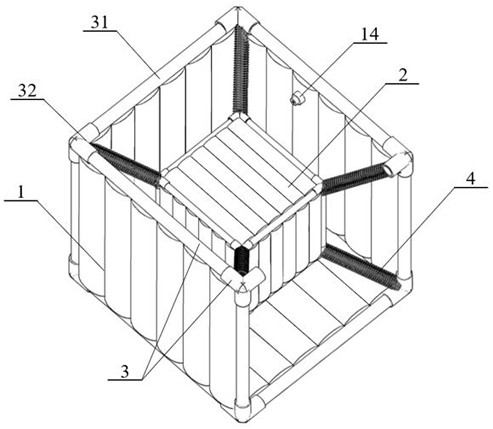

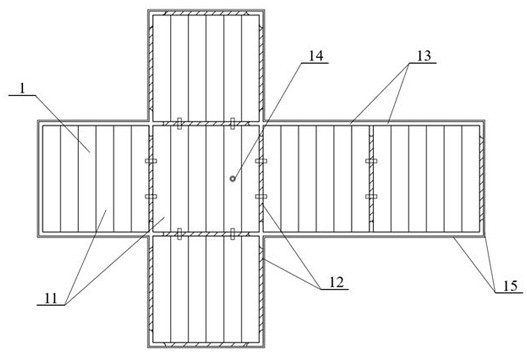

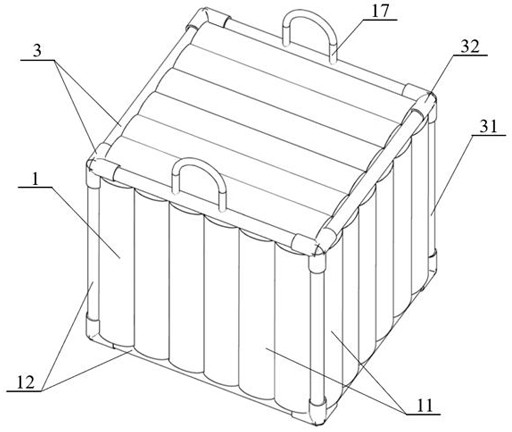

Expandable inflatable membrane structure air-drop device and operation method thereof

ActiveCN112811004AGuaranteed StrengthGuaranteed stiffnessAircraft componentsContainers to prevent mechanical damageClassical mechanicsAirbag

The invention relates to the field of air-drop packaging boxes, in particular to an expandable inflatable membrane structure air-drop device and an operation method thereof. The device comprises an outer airbag type expandable inflatable membrane structure box body, an inner airbag type expandable inflatable membrane structure box body, an outer cable rod framework, an inner cable rod framework and an elastic limiting mechanism. The outer cable rod framework is installed on the edge portion of the outer airbag type expandable inflatable membrane structure box body and connected with the outer airbag type expandable inflatable membrane structure box body. According to the expandable inflatable membrane structure air-drop device, multiple energy dissipation mechanisms of landing impact of an air-drop bag are achieved, and the air delivery time and space of materials are saved through quick inflation and assembly; and the problems that the parachute air-drop hit rate is poor and the landing time is long are solved, the device is suitable for delivering solid and liquid substances in different shapes, work is efficient, the structure is reasonable, cost is low, and industrialization is easy.

Owner:ARMY ENG UNIV OF PLA

Preparation method for reducing hot shrinkage rate of Cu-Ni-Si alloy

PendingCN113249666ALow heat shrinkageHigh strengthFurnace typesMetal rolling arrangementsSilicon alloyStress relaxation

The invention relates to new materials, belongs to the non-ferrous metal processing industry, and particularly relates to a preparation method for reducing the hot shrinkage rate of a Cu-Ni-Si alloy. According to the method, the hot shrinkage rate of the Cu-Ni-Si alloy is reduced so as to meet the requirements for materials applied to high-angle lead frames and image electronic components. The preparation method for reducing the hot shrinkage rate of the Cu-Ni-Si alloy comprises the process steps of semi-continuous ingot casting, ingot heating, hot rolling, first solution treatment, surface milling, first cold rolling, edge cutting, first aging annealing, cleaning, second cold rolling, second solution annealing, third cold rolling, third aging annealing, cleaning, fourth cold rolling, cleaning, withdrawal and straightening and slitting in sequence. According to the method, technical treatment is carried out on the basis of a traditional process, on the premise of ensuring the properties of high strength, high elasticity, medium conductivity, low stress relaxation and the like of the material, different solid solution plus aging heat treatment plus cold rolling plus finishing treatment processes are adopted, the density change in recovery and recrystallization is controlled, and the hot shrinkage rate of the product is reduced.

Owner:TAIYUAN JIN XI CHUNLEI COPPER CO LTD

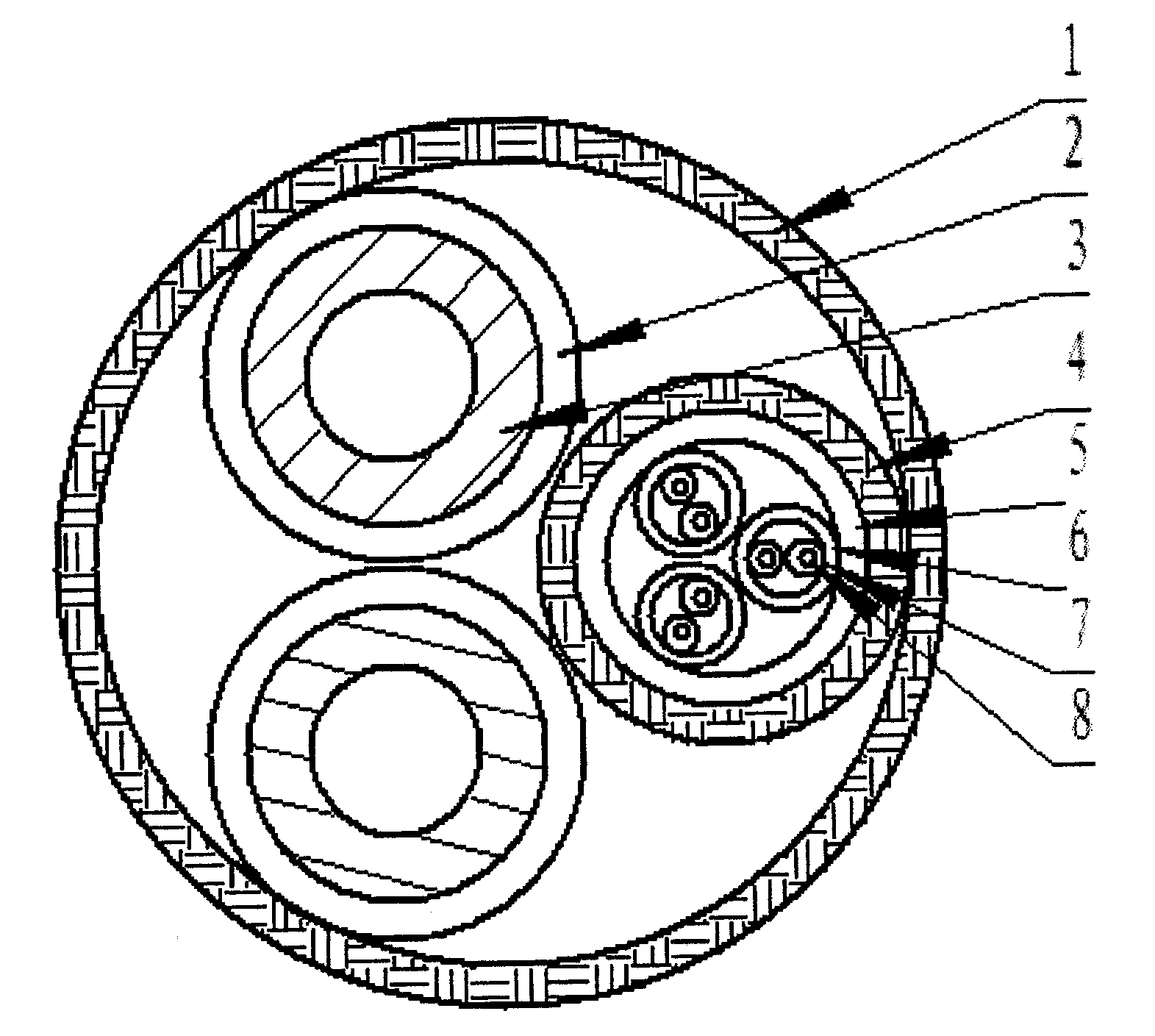

Sunken ship salvage umbilical cable

InactiveCN104332223AGuaranteed reliabilityPerfect water seal protectionSubmarine cablesInsulated conductorsMarine engineeringUmbilical cable

The invention discloses a sunken ship salvage umbilical cable which is suitable for salvage of seaborne large sunken ships and sunken objects. The sunken ship salvage umbilical cable comprises a cable core which is formed by twisting two stainless steel seamless pipes with extruded thermoplastic elastomer protection layers and a digital communication paired cable, and a stainless steel wire braid layer which wraps the exterior of the cable core, wherein the digital communication paired cable comprises a paired cable core, and a digital communication paired cable sheath and another stainless steel wire braid layer which sequentially wrap the exterior of the paired cable core from inside to outside and are used to seal water. The sunken ship salvage umbilical cable is used cooperatively with a deepwater and underwater guiding mud penetrator, and can be practically used for achieving the purpose of salvaging the seaborne large sunken ships and the seaborne large sunken objects.

Owner:ZHENGZHOU CABLE +1

Laminate sheet and roll

ActiveUS10961417B2Increasing the thicknessReduce impactLamination ancillary operationsAdhesive articlesPolymer sciencePolymer chemistry

Provided is a laminate sheet in which a first sheet, a PSA layer and a second sheet are laminated in this order. Of the first and second sheets, at least one is a release liner having a release face on the side facing the PSA layer. The PSA layer has a thickness of 200 μm or greater. The first sheet has a tensile modulus of 1000 MPa or greater and the second sheet has a tensile modulus of 500 MPa or less.

Owner:NITTO DENKO CORP

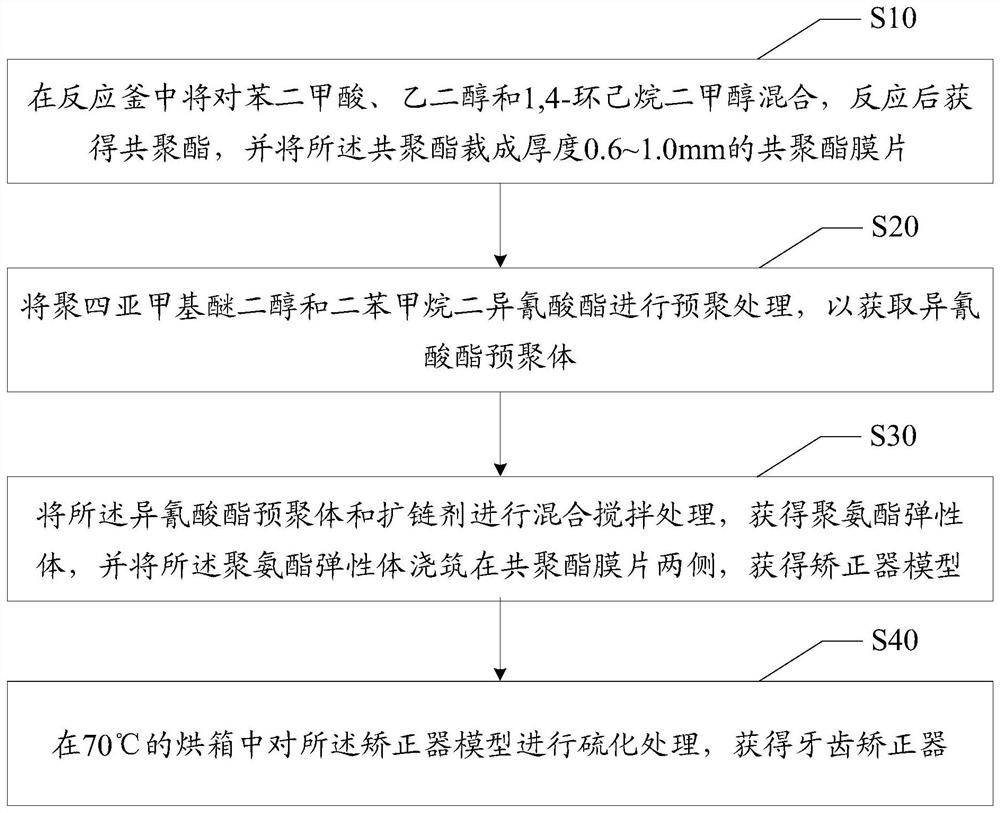

Orthodontic appliance preparation method and orthodontic appliance

ActiveCN111361249BImprove toughnessImprove material toughnessOthrodonticsSynthetic resin layered productsDiphenylmethanePolymer science

The invention discloses a preparation method of a tooth straightener and a tooth straightener. The preparation method of the tooth straightener comprises: mixing terephthalic acid, ethylene glycol and 1,4-cyclohexanedimethanol in a reaction kettle, and reacting Finally, the copolyester is obtained, and the copolyester is cut into a copolyester film with a thickness of 0.6-1.0mm; polytetramethylene ether glycol and diphenylmethane diisocyanate are prepolymerized to obtain isocyanate prepolymer polymer; the isocyanate prepolymer and chain extender are mixed and stirred to obtain polyurethane elastomer, and the polyurethane elastomer is poured on both sides of the copolyester diaphragm to obtain the corrector model; The model of the orthodontic appliance is vulcanized to obtain the orthodontic appliance. The invention improves the toughness and flexibility of the material of the orthodontic appliance, thereby improving the durability of the orthodontic effect.

Owner:深圳艾优泰高分子科技有限公司

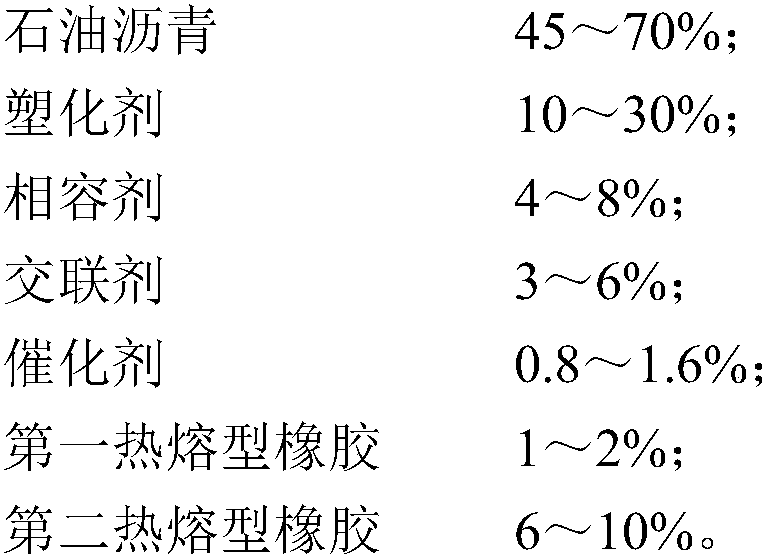

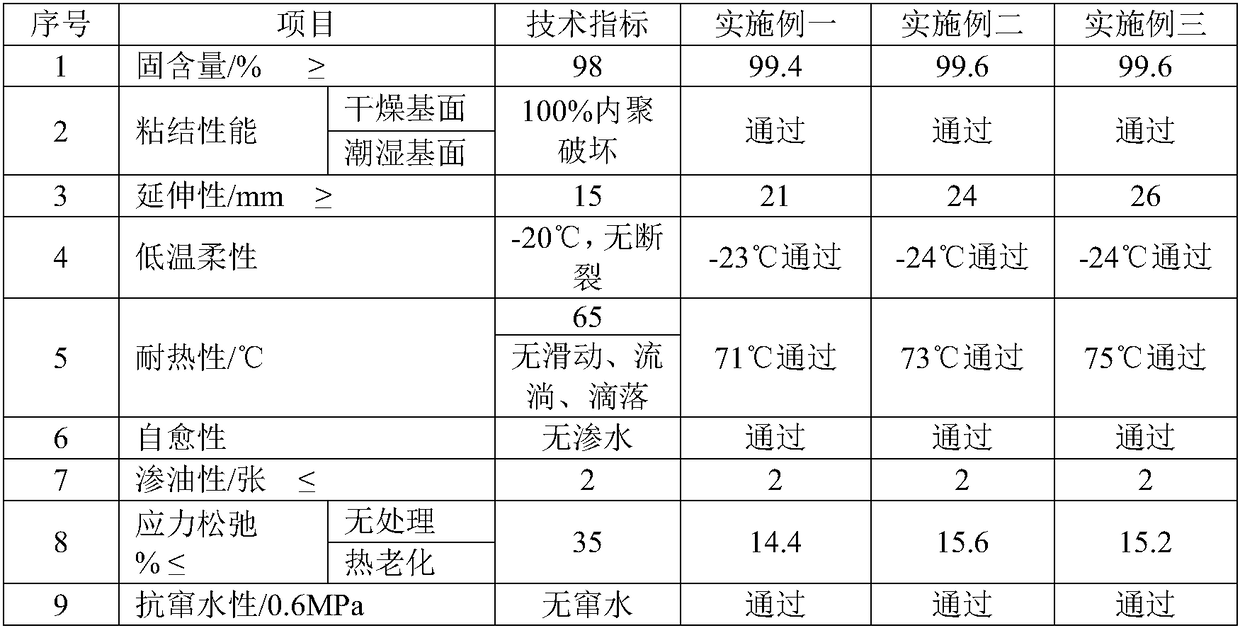

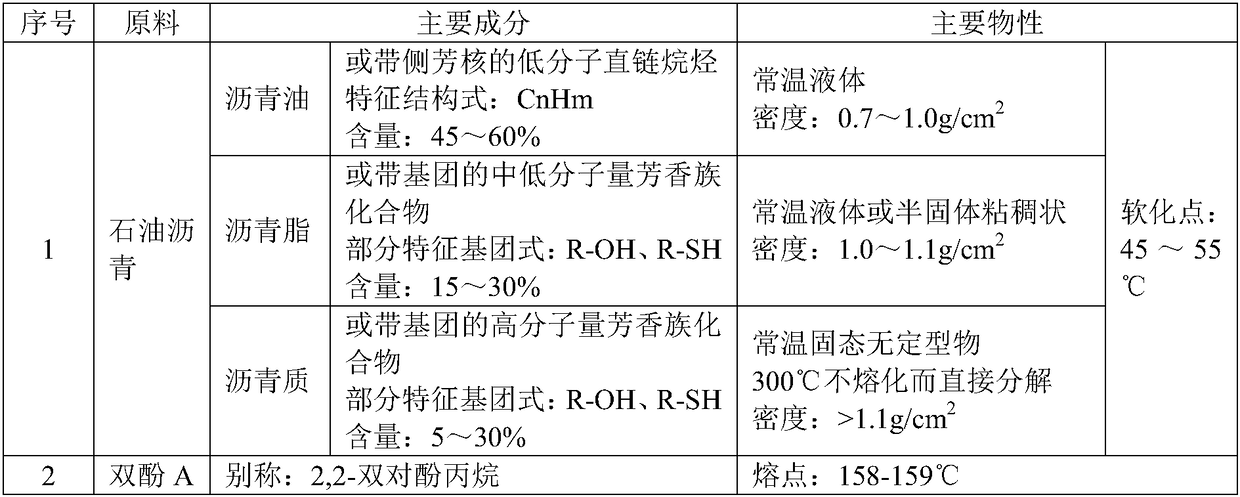

A kind of non-curing rubber asphalt waterproof coating and preparation method thereof

ActiveCN106366923BReduce cohesionLow shear strengthWax coatingsConjugated diene hydrocarbon coatingsPolymer scienceBituminous waterproofing

The invention discloses a non-cured rubber asphalt waterproof coating which is prepared from the following components in percentage by weight: 45 to 70 percent of petroleum asphalt, 10 to 30 percent of a plasticizer, 4 to 8 percent of a compatilizer, 3 to 6 percent of a crosslinking agent, 0.8 to 1.6 percent of a catalyst, 1 to 2 percent of first hot melt type rubber and 6 to 10 percent of second hot melt type rubber. The invention further discloses a preparation method of the non-cured rubber asphalt waterproof coating. By crosslinking modification of the petroleum asphalt by the crosslinking agent and the catalyst, the melting point of the petroleum asphalt is increased, so that adding of SBS (Styrene / Butadiene / Styrene) is reduced, and the effect of improving the high temperature performance of the coating without adding the SBS is achieved; therefore, after being cooled, the coating is sticky and non-cured paste, and is high in creep property and high in self-repairability.

Owner:苏州市姑苏新型建材有限公司

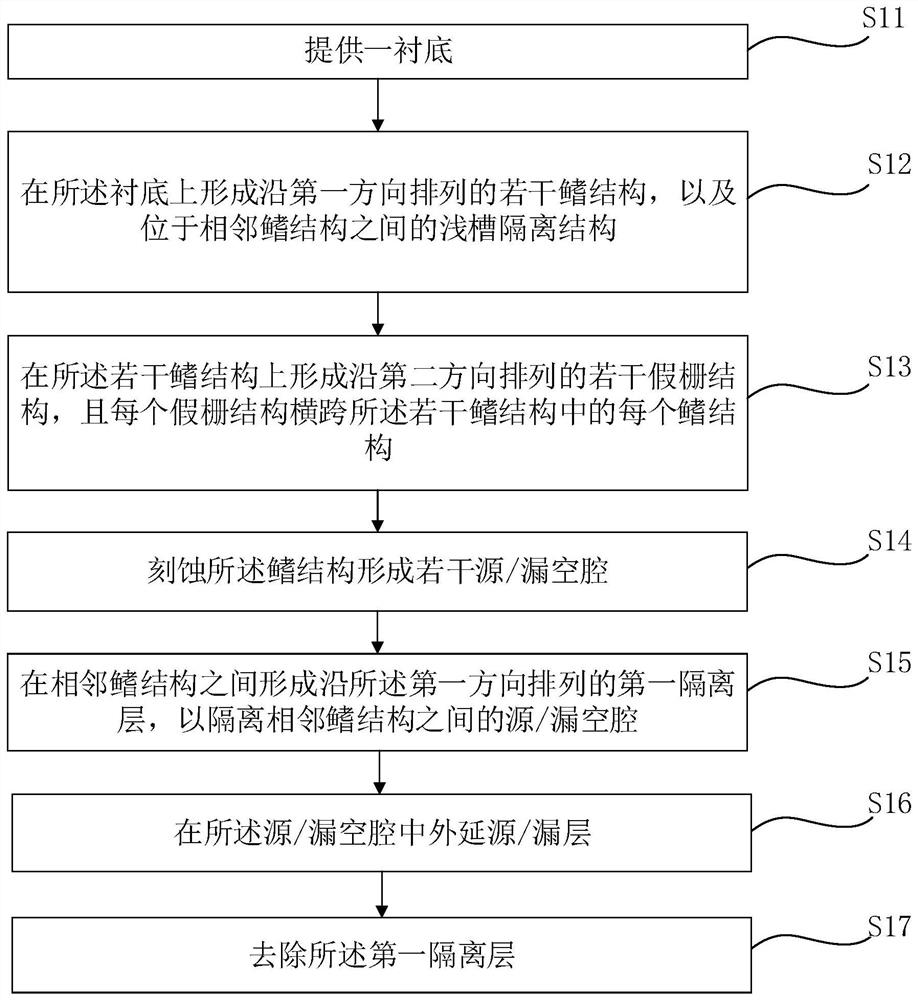

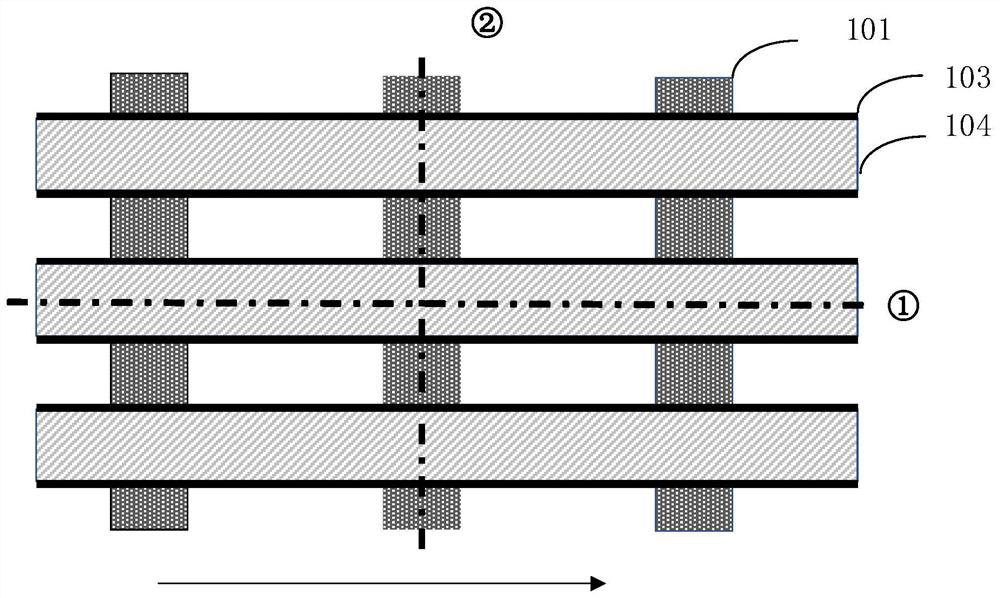

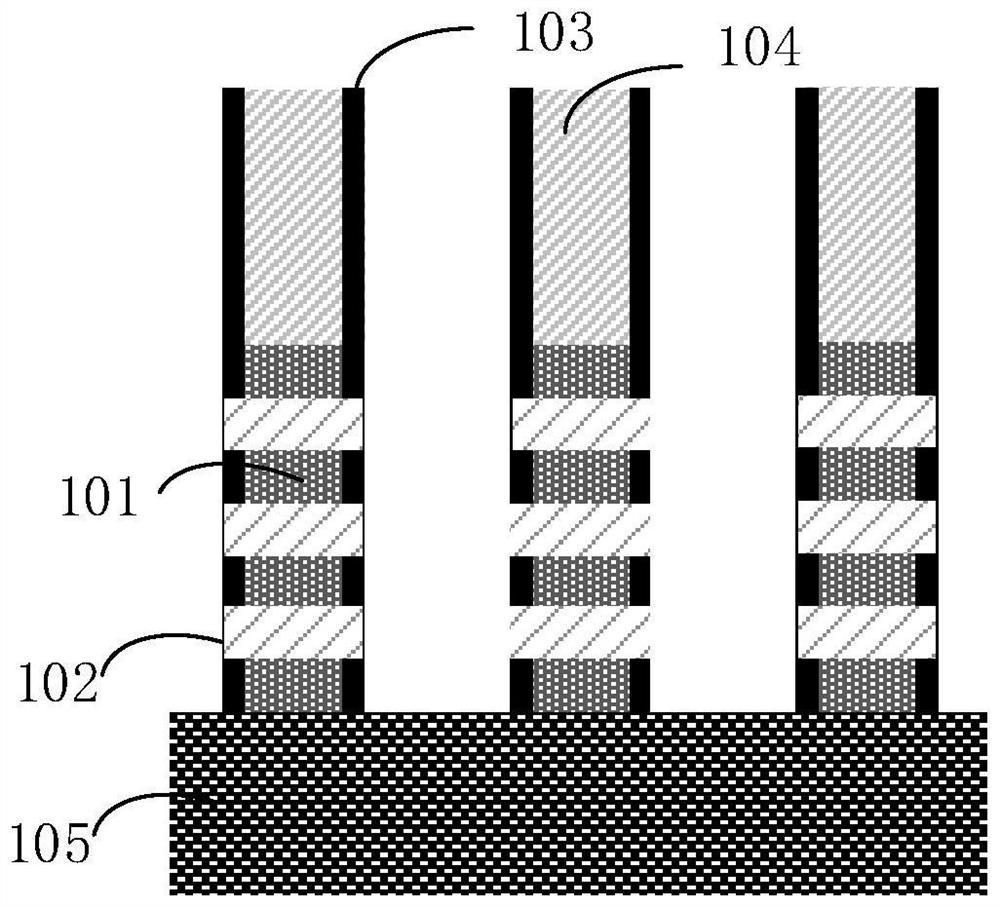

Source-drain limited epitaxy method, device preparation method, device and equipment

PendingCN114783877AMismatch reductionReduce stress relaxationSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringMaterials science

The invention provides a method for controllably limiting epitaxy of a source drain on a gate-all-around device, which comprises the following steps of: forming a plurality of fin structures arranged along a first direction on a substrate, forming a plurality of false gate structures arranged along a second direction on the plurality of fin structures, and enabling each false gate structure to stretch across each fin structure in the plurality of fin structures; etching the fin structure to form a plurality of source / drain cavities; forming a first isolation layer arranged along the first direction between the adjacent fin structures so as to isolate source / drain cavities between the adjacent fin structures; extending a source / drain layer in the source / drain cavity; and removing the first isolation layer. The thickness of the source / drain layer can be limited within the critical thickness of stress release, so that the stress relaxation phenomenon caused by mismatch and dislocation is reduced; certainly, by limiting the thickness of the source / drain layer, the area of the contact surface between the source / drain layer and the grid electrode can be limited, so that the stray capacitance is limited.

Owner:FUDAN UNIV +1

A zero-constrained shrinkage and high corrosion-resistant lightweight resin concrete and its preparation method

ActiveCN110776337BSmall shrinkageReduce early cure shrinkageSolid waste managementCeramicwareFiberEnergy absorption

The invention provides a light resin concrete with zero constraint shrinkage and high corrosion resistance and a preparation method thereof, which is composed of the following components by weight: resin system (including resin, curing agent, accelerator, and an appropriate amount of diluent is added according to the viscosity of the resin) )10.0%~18.0%, lightweight porous coarse aggregate 40.0%~48.0%, sand 15.0%~32.0%, fly ash 4.0%~9.0%, waste rubber particles 2.0%~15.0%, waste rubber powder 0.2%~ 2.0% and chopped fiber 0.1 to 8.0%. The invention mixes waste rubber particles, waste rubber powder and lightweight aggregate, which can reduce the early free shrinkage of resin concrete and shrinkage under restraint conditions; prolong the curing time of resin in resin concrete, increase the stress relaxation of resin concrete, and greatly The amplitude reduces the shrinkage strain of concrete under constraint conditions and eliminates the early non-load cracks of resin concrete, solves the volume instability problem caused by the early curing shrinkage of resin concrete, and also improves the anti-vibration and energy absorption characteristics of resin concrete.

Owner:HARBIN ENG UNIV

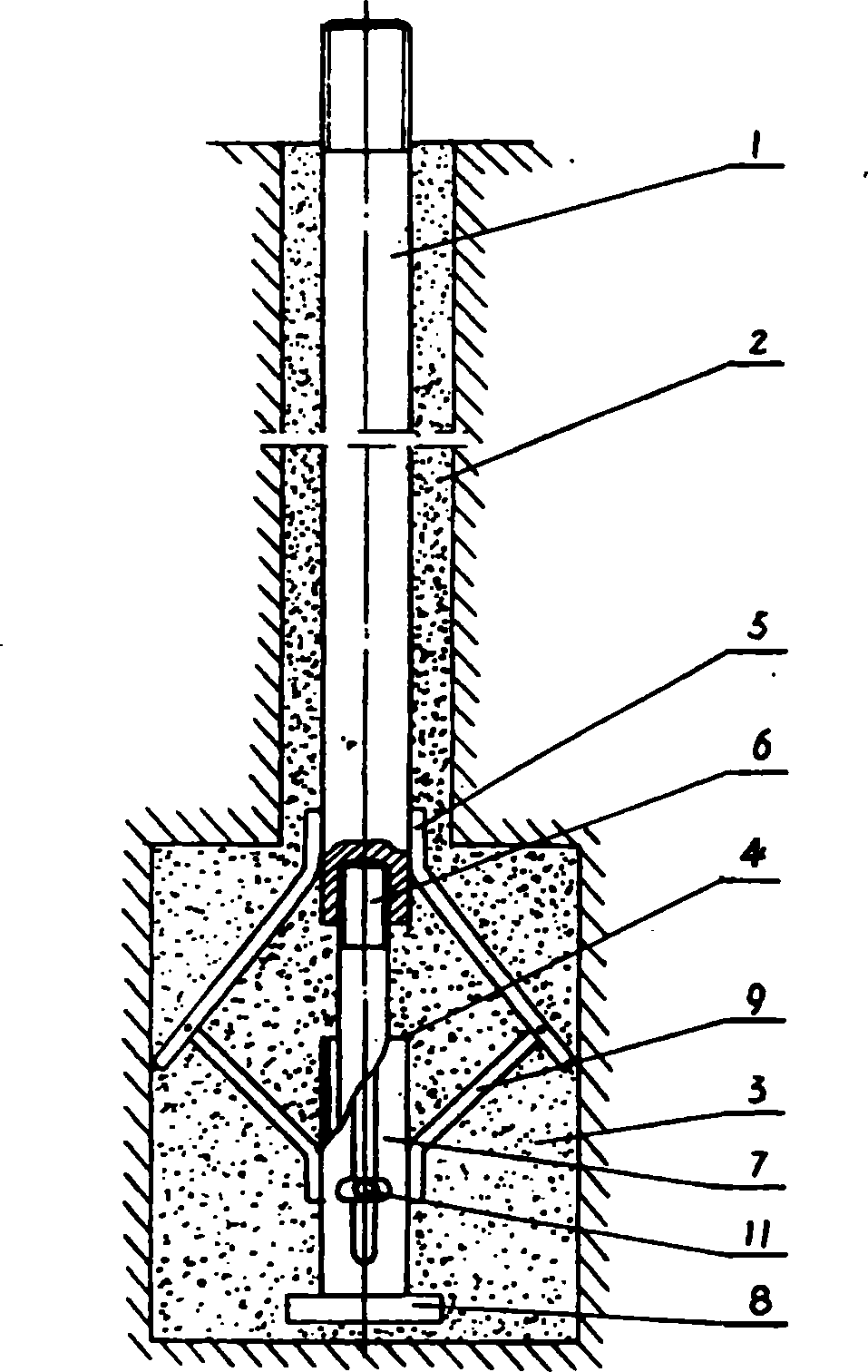

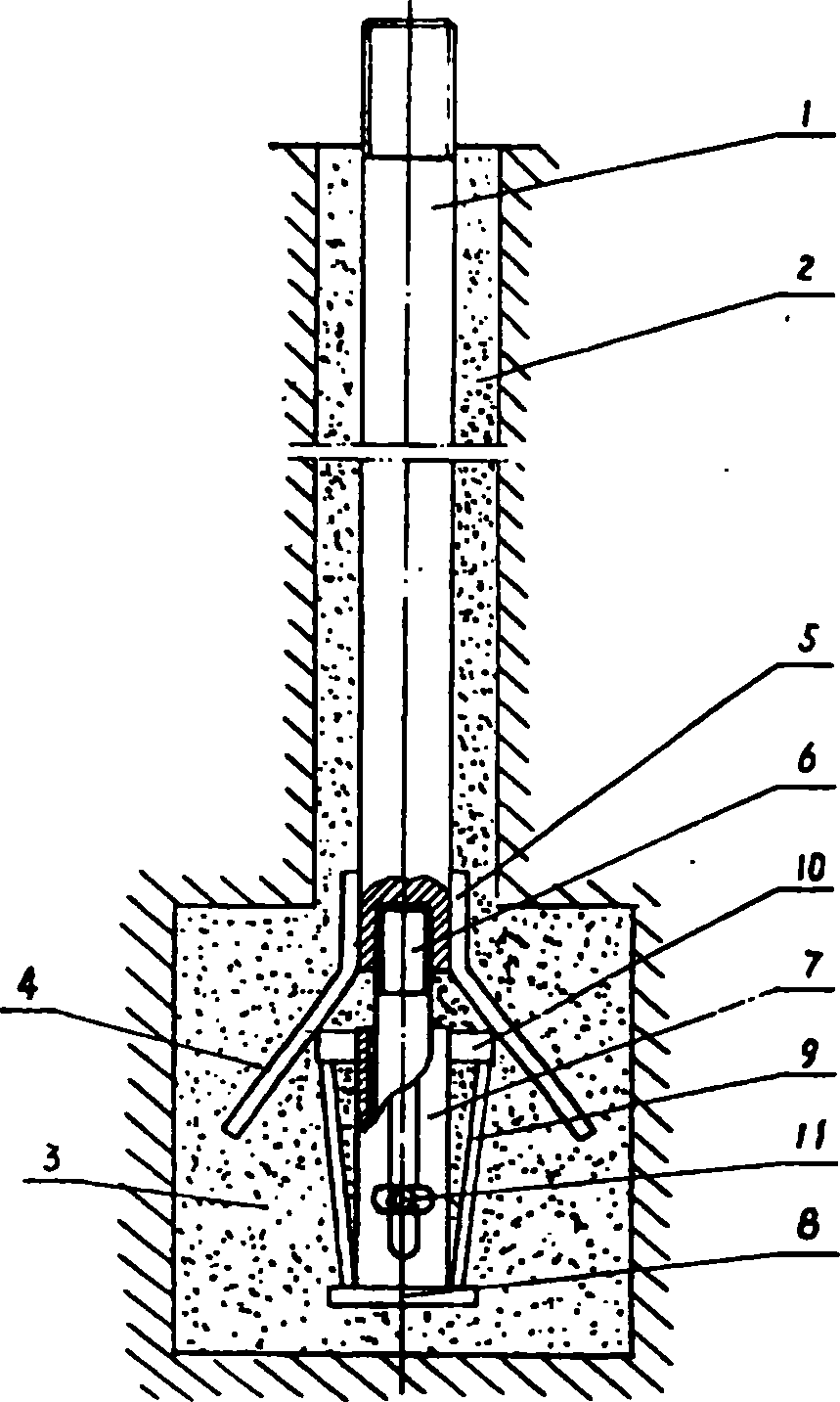

Anchoring method and end-bearing anchor

The present invention relates to an anchoring method, and is characterized by that under the anchor hole in which an anchor bar can be placed an anchor enlarged hole is cut, and in the anchor enlarged hole an anchor head which and rock-soil can produce end resistance between them is placed, and after the anchor head and anchor bar are connected, the concrete can be grouted. Said invention provides the condition required for anchor bar and anchor head structure. Said invented end load-bearing anchor bar includes anchor bar, its lower portion is equipped with lower sliding bar and forced pulling bar which can be opened, and also includes upper sliding bar, lower support bar and supporting plate, etc. It can fully utilize end resistance of rock-soil to greatly raise anchoring force.

Owner:张百全

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com