Combined piston

A combined piston technology, applied in the direction of pistons, engine components, machines/engines, etc., can solve the problems of increasing ring groove wear, reducing the operating load of the piston connecting rod group, increasing the motion load, etc., to facilitate processing and assembly positioning, Effect of avoiding high temperature heat load and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

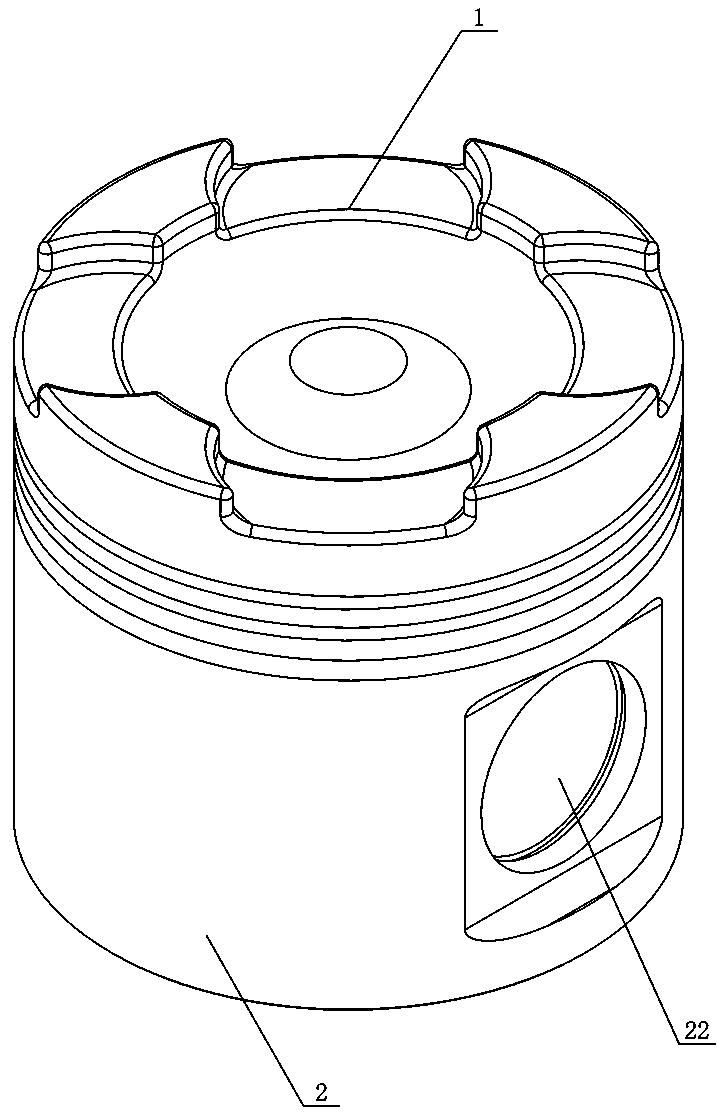

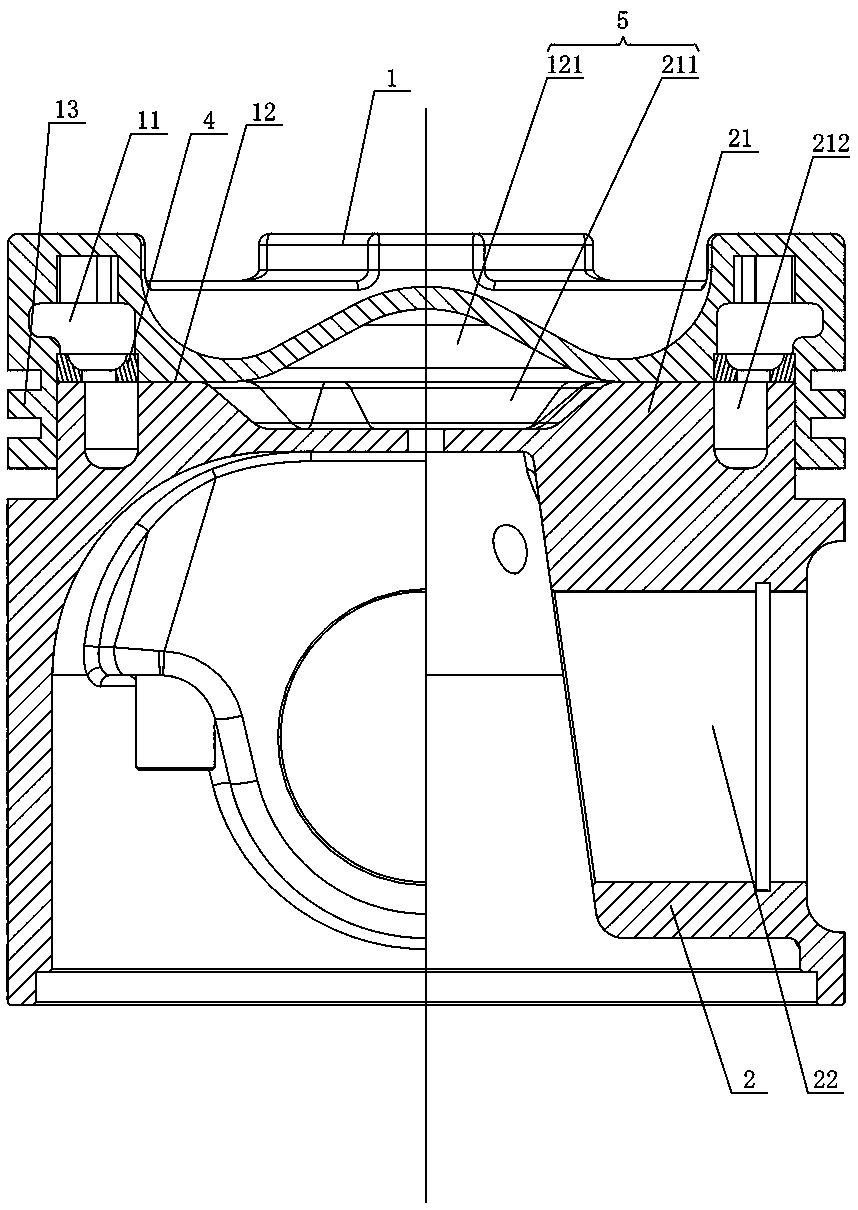

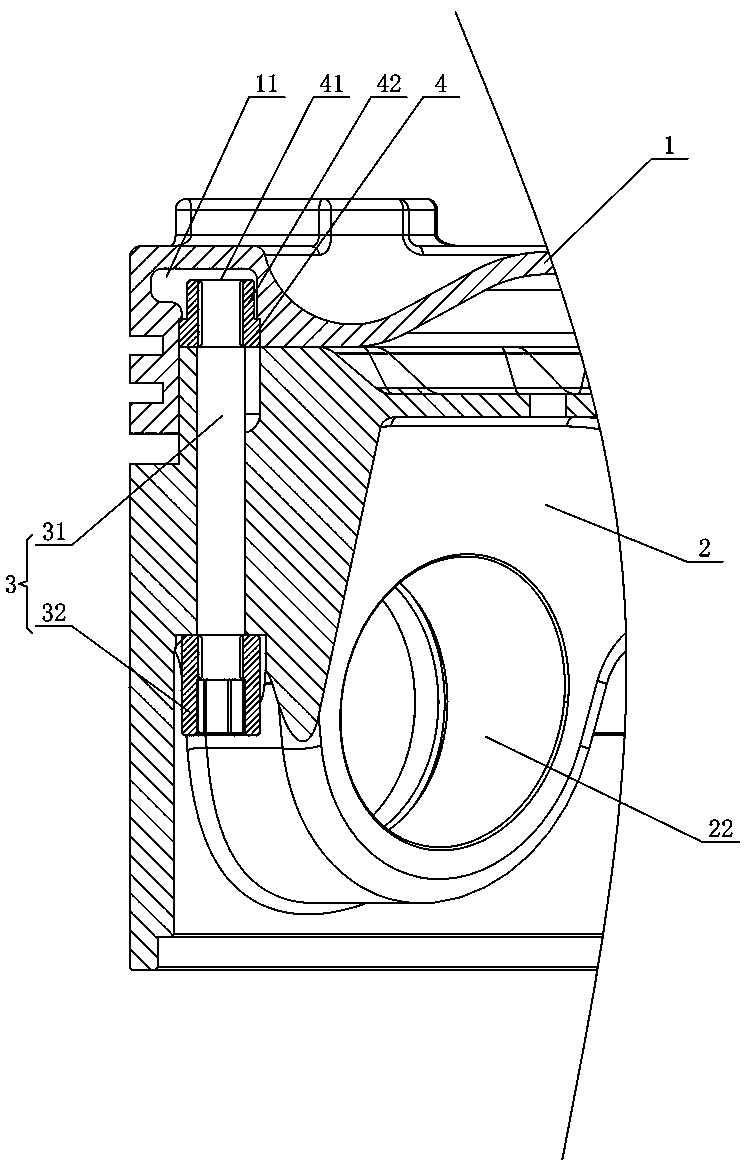

[0034] Figure 1 to Figure 9 Shows the first embodiment of the combined piston of the present invention, including the upper piston 1, the lower piston 2 and the connecting piece 3, the upper piston 1 is provided with an annular internal cooling oil passage 11, and the bottom of the annular internal cooling oil passage 11 is provided There is at least one connecting hole 41 that is symmetrical to the center of the ring, and the piston lower part 2 and the piston upper part 1 are pressed together and tightly connected to the connecting hole 41 through the connecting piece 3 . In this structure, the upper part 1 of the piston and the lower part 2 of the piston are fastened together through the connecting piece 3. Compared with the traditional annular weld, the present invention uses the connecting piece 3 to make the upper part 1 of the piston and the lower part 2 of the piston form a combined Assembled connection, no need for friction welding, no friction flash, that is, there ...

Embodiment 2

[0045] Figure 10 to Figure 12 Shown is the second embodiment of the combined piston of the present invention, the piston is basically the same as Embodiment 1, the only difference is: in this embodiment, the connection table 42 is provided with a pair, that is, the connection structure of two screw rods 31, suitable for volume Smaller piston.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com