Patents

Literature

3626 results about "Structure support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A support can refer to a variety of structures in architecture that includes arches, beams, columns, balconies, and stretchers.

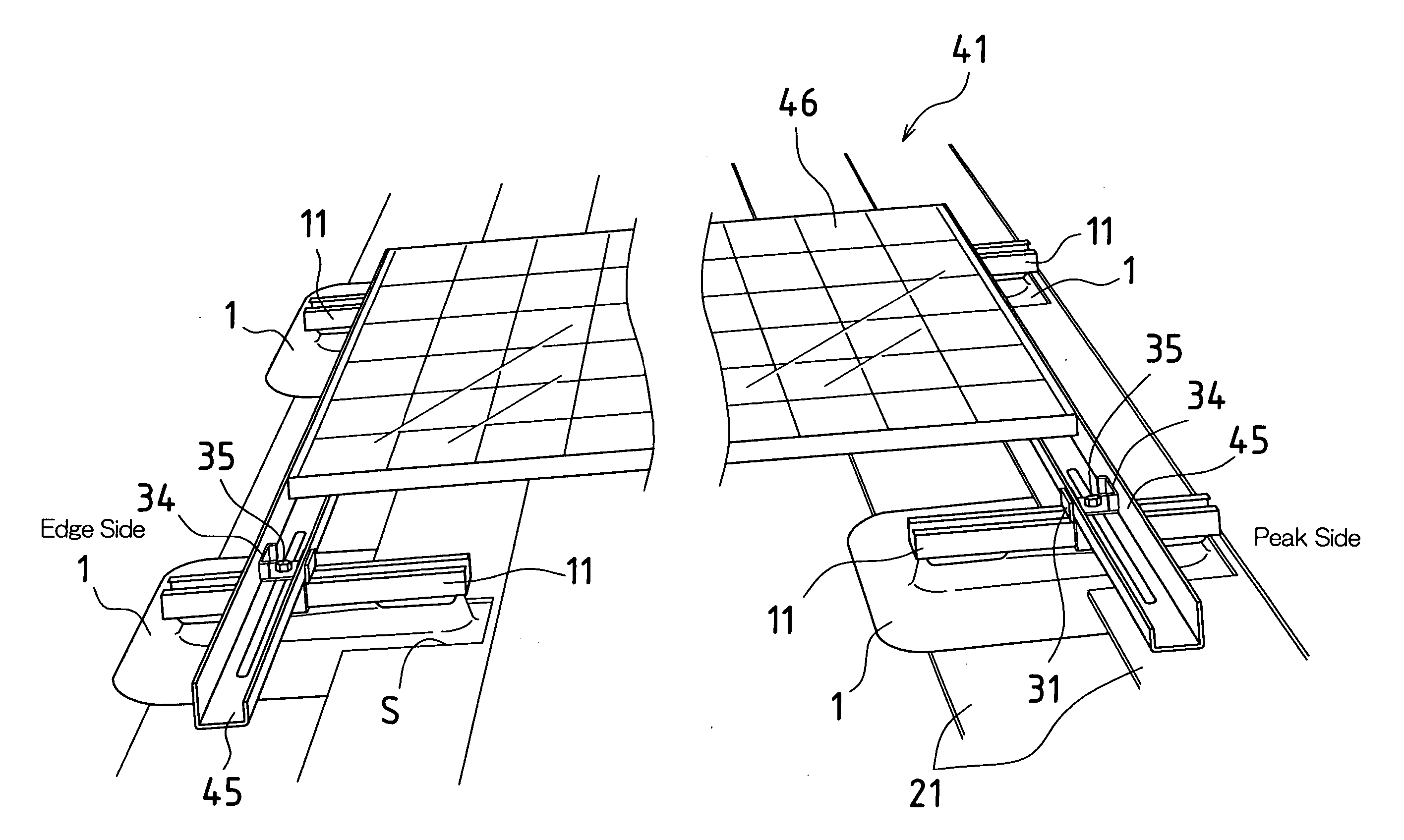

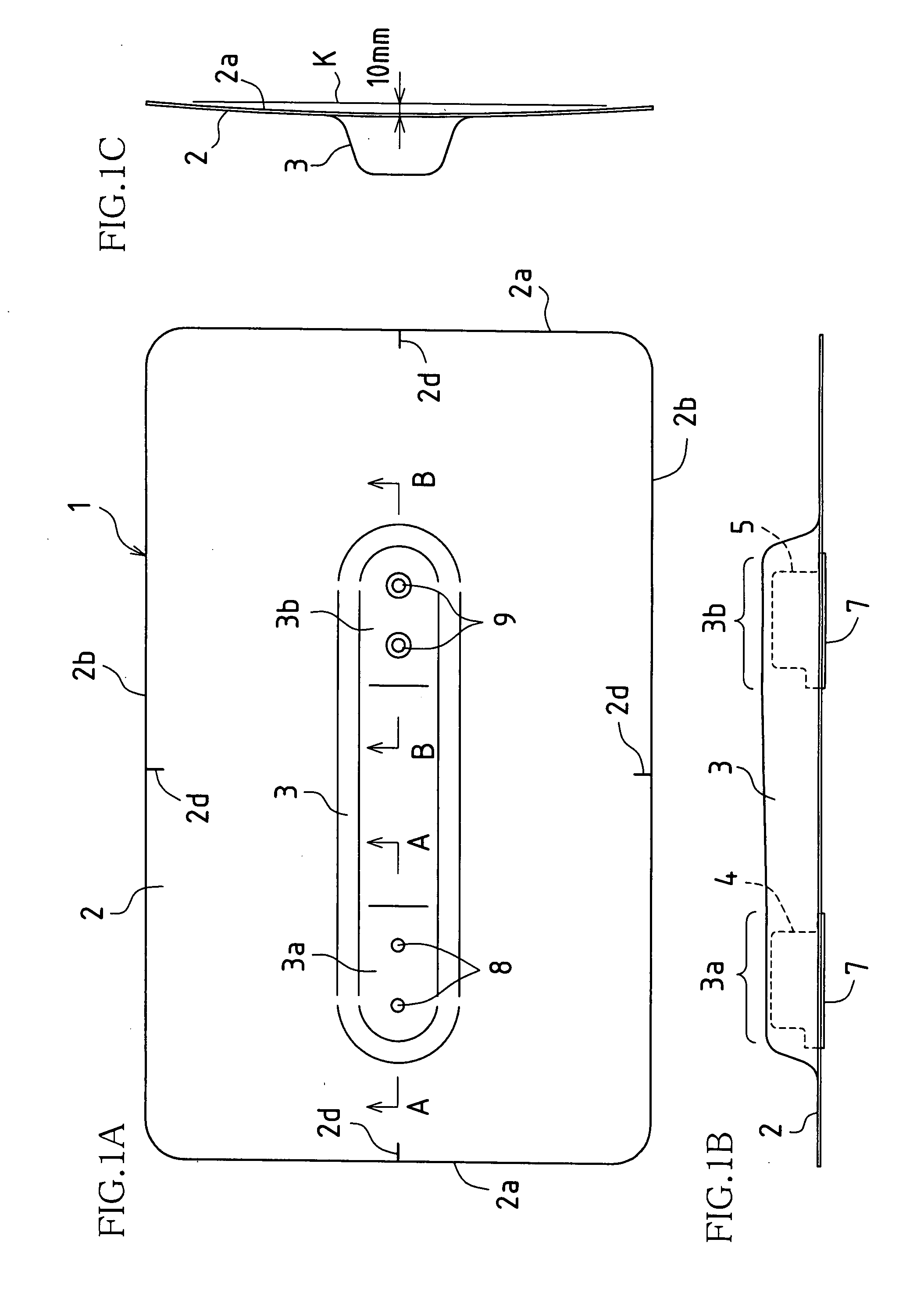

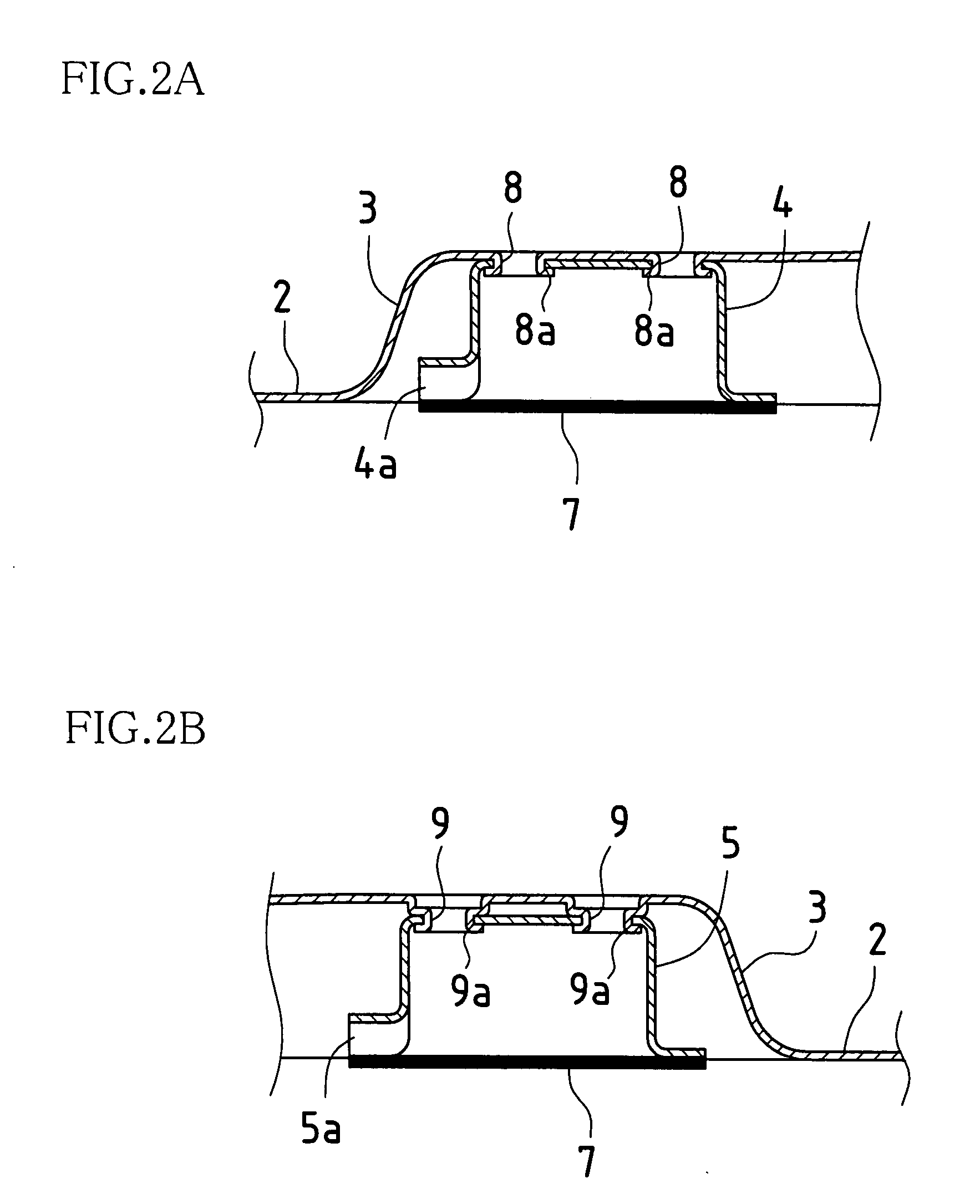

Structure support apparatus and structure installation method

InactiveUS20080053008A1High strengthIncreased durabilityPhotovoltaic supportsSolar heating energyConvex sideEngineering

According to an embodiment of the present invention, a structure support apparatus for anchoring and supporting a structure upon a roof comprises a bowed plate having a dome-shaped convex portion formed in the center of the bowed plate projecting from the concave side toward the convex side of the bowed plate. A screw hole is formed in the dome-shaped convex portion, penetrating the center of the bowed plate, and the structure is supported by the apex of the dome-shaped convex portion.

Owner:SHARP KK

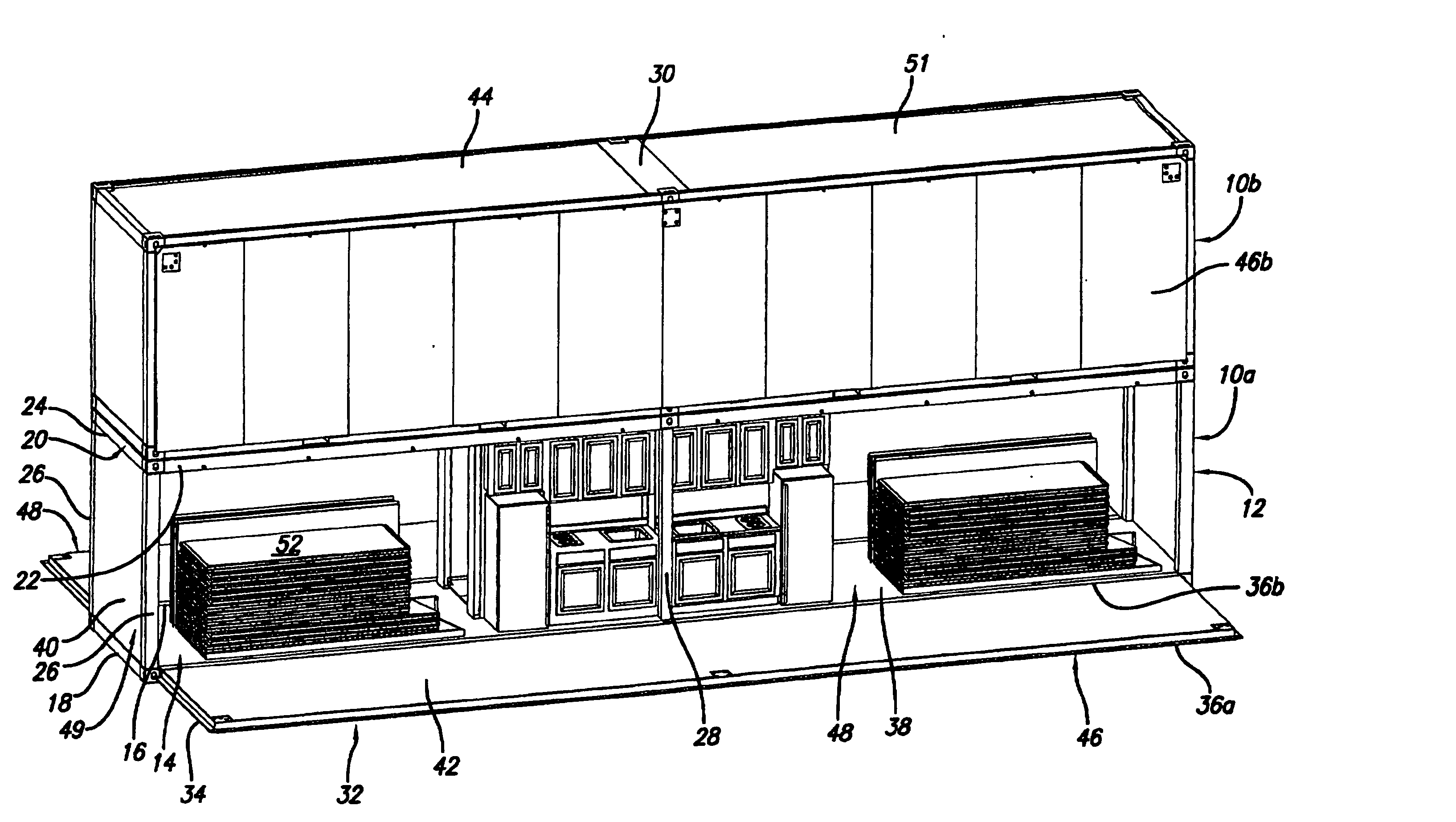

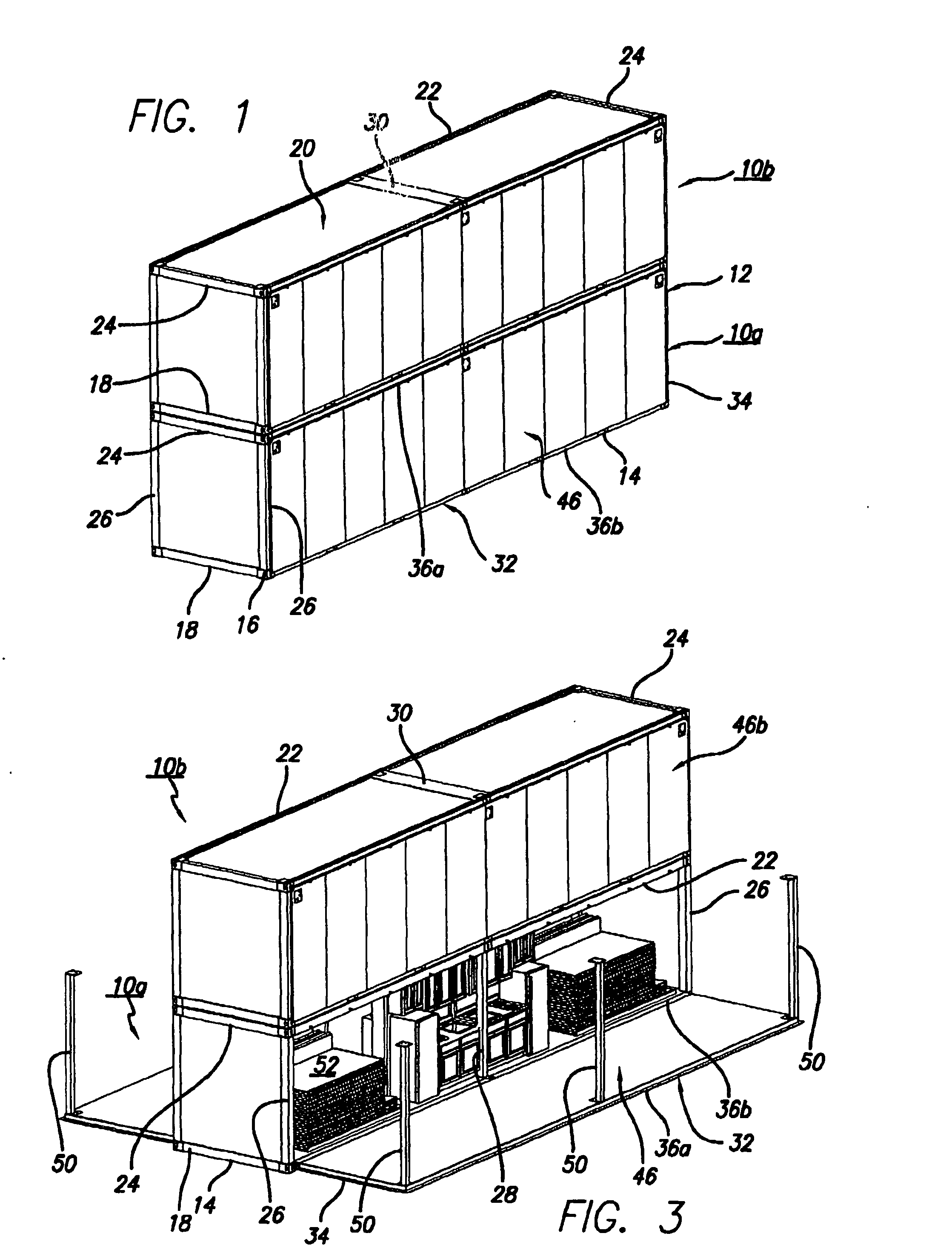

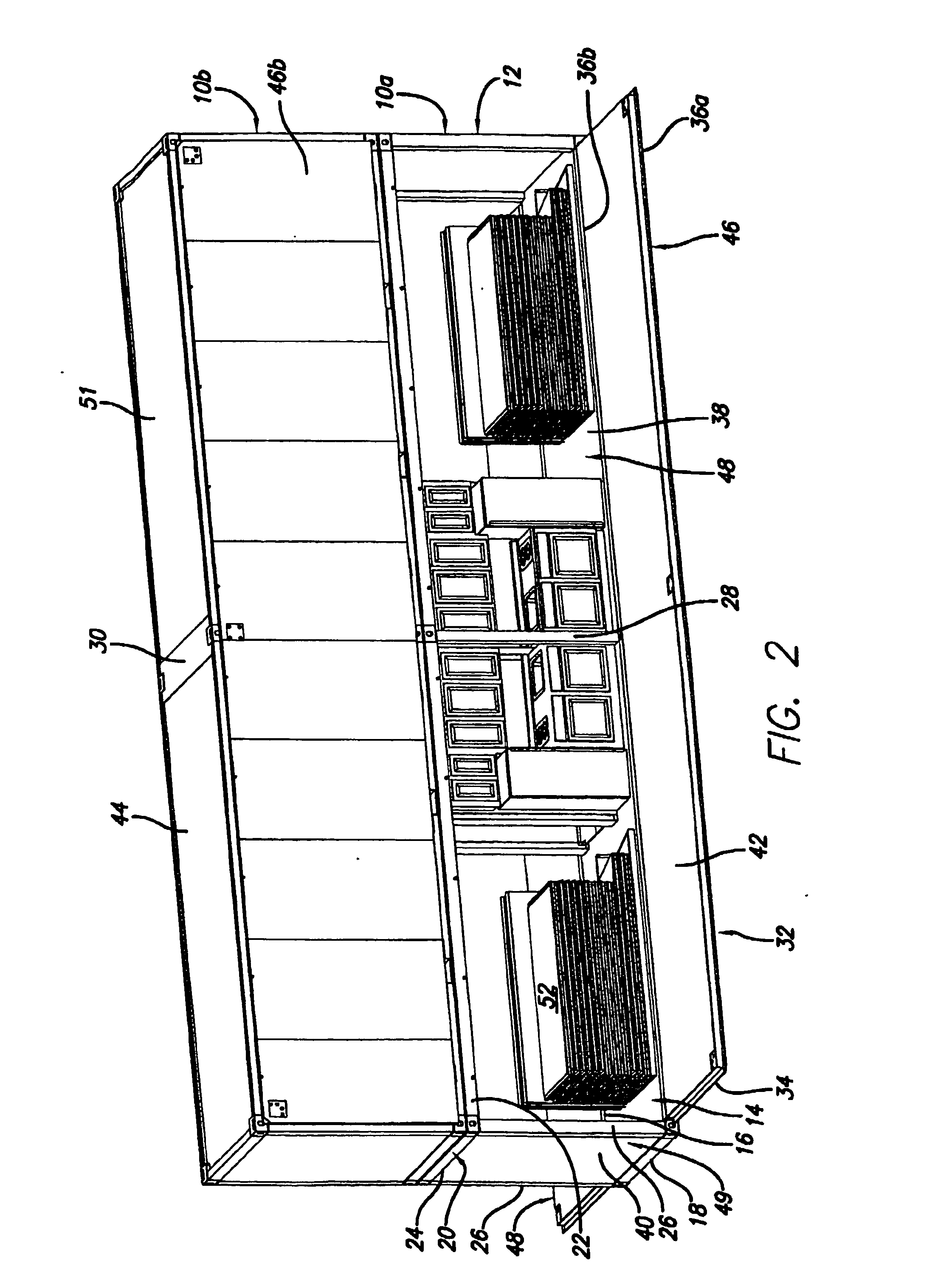

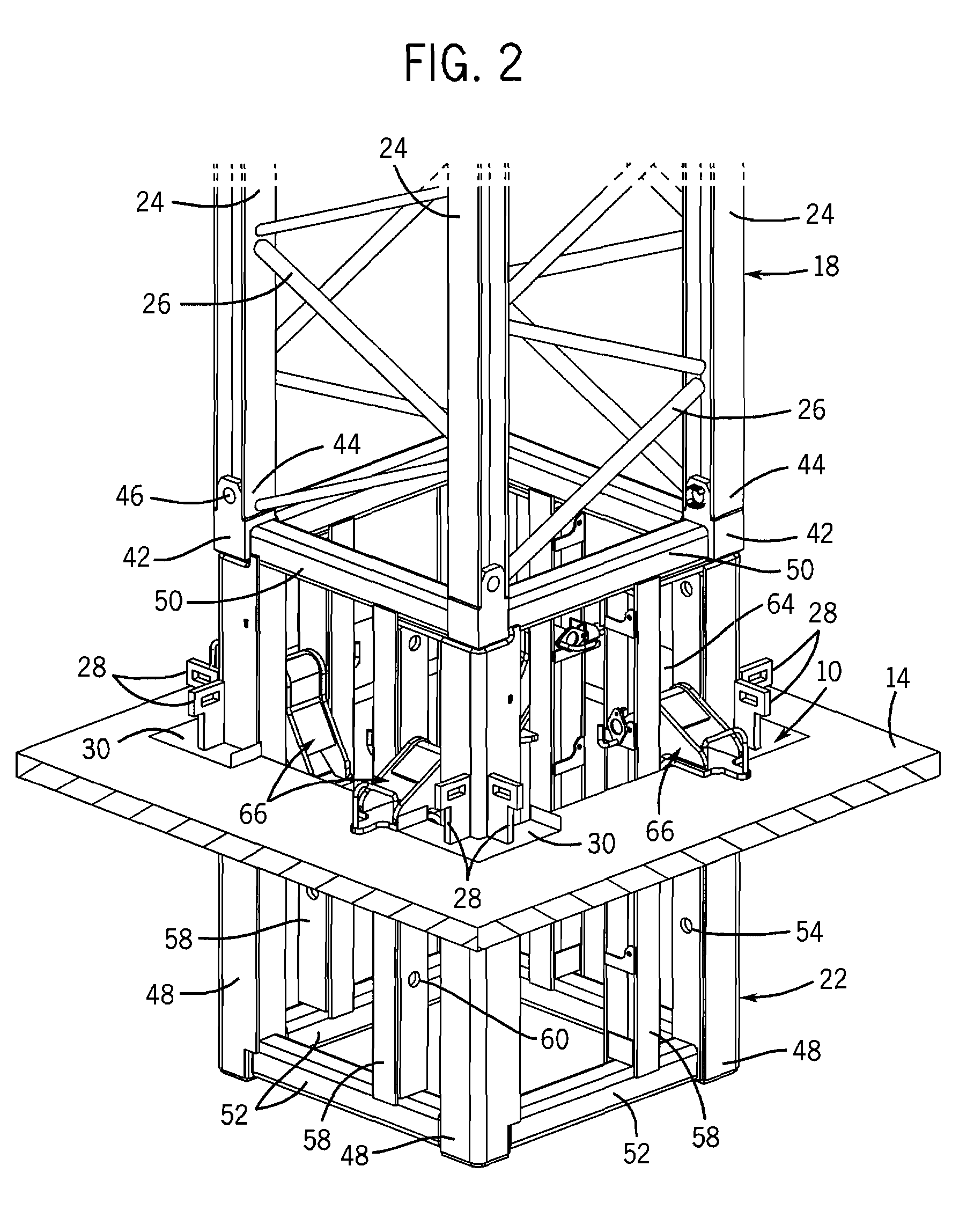

Containerized transportable building structure and method of assembly

Method and apparatus for transforming a plurality of standard-size shipping containers into a finished multi-level building structure of a scale to accommodate humans. Each of the illustrated shipping containers has an open generally rectangular center structural frame which supports panels to provide exterior base, end and top walls. A pair of movable side walls, each having a structural frame and wall panel, are connected to the center frame to complete the enclosure. The containers hold wall and roof sections. Initially the containers are stacked atop one another with their base walls at the bottom. Then, starting at the lowermost container, the side walls, which are hingedly connected along their bottom edges to the center frame, are opened by being pivoted outwardly, downwardly to provide extended floor portions that are in general horizontal alignment with the associated base wall. Then support structures or members are secured to that extended floor portions to provide support for the extended floor portions of the next higher level. Next, the moveable side walls of the next higher container are similarly opened and secured to the support members so as to generally vertically align with the extended floor portions below them. This continues until all the stacked containers have been opened. Finally, wall and roof panels stored in the containers are removed and installed.

Owner:ABLER LAWRENCE J

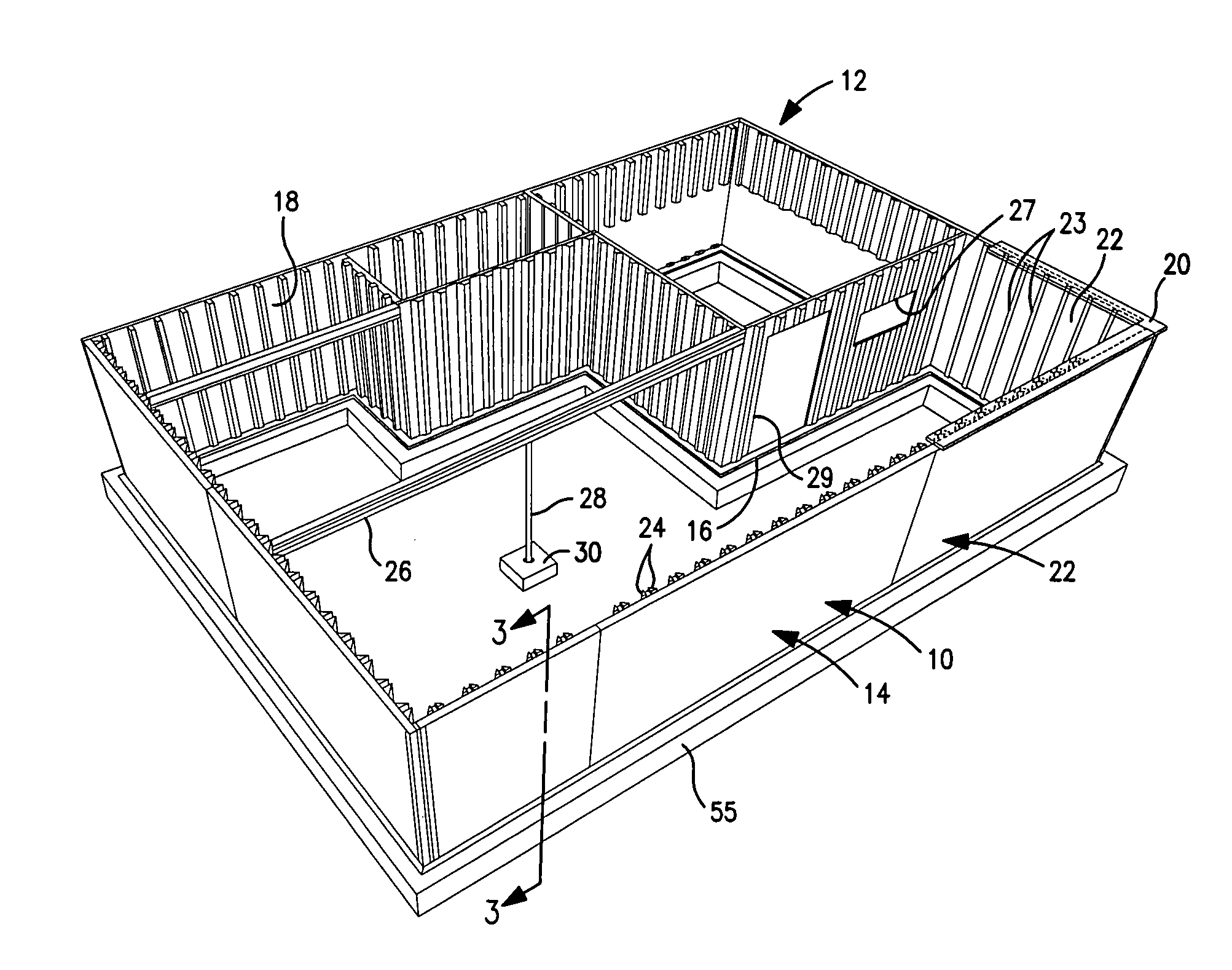

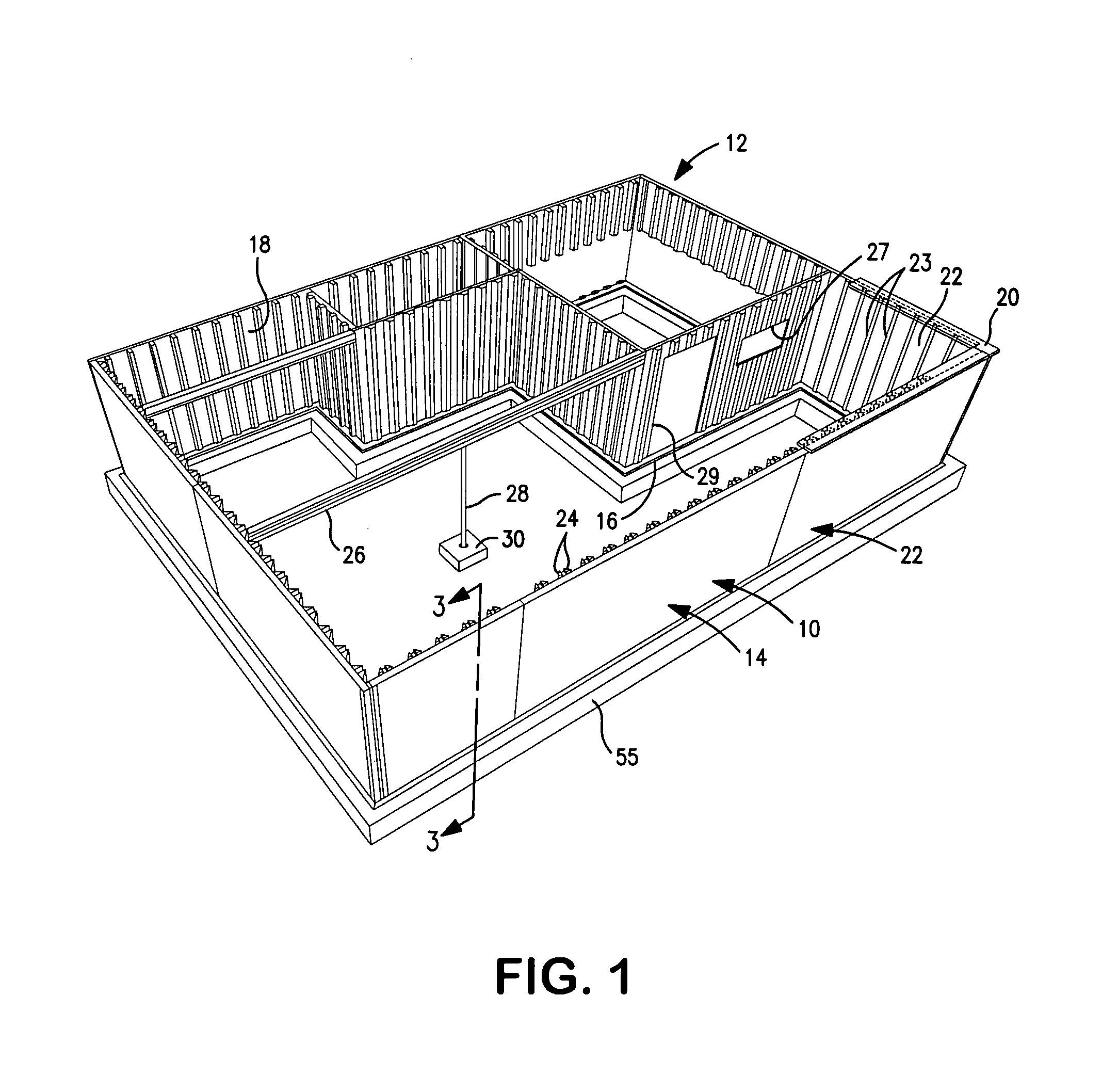

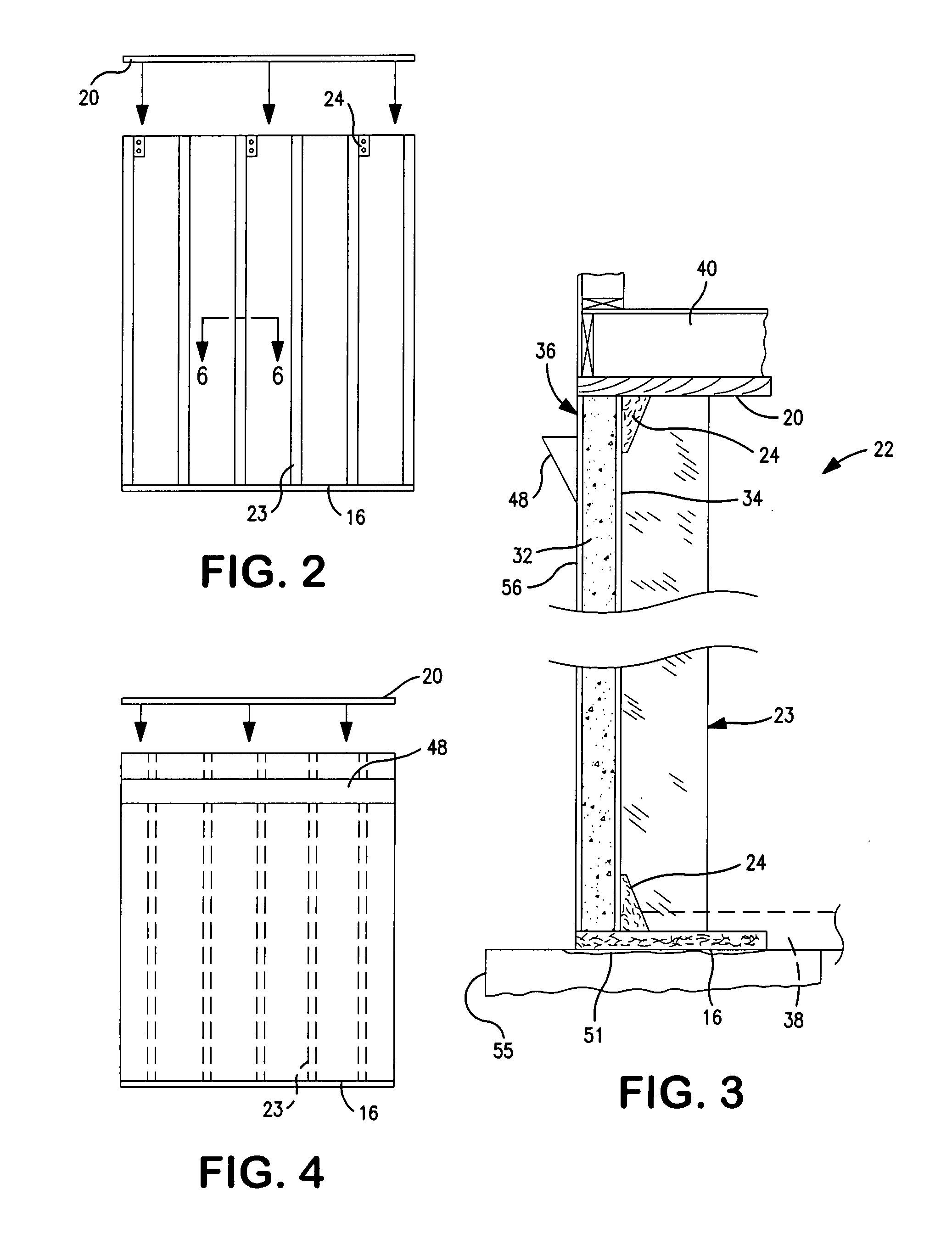

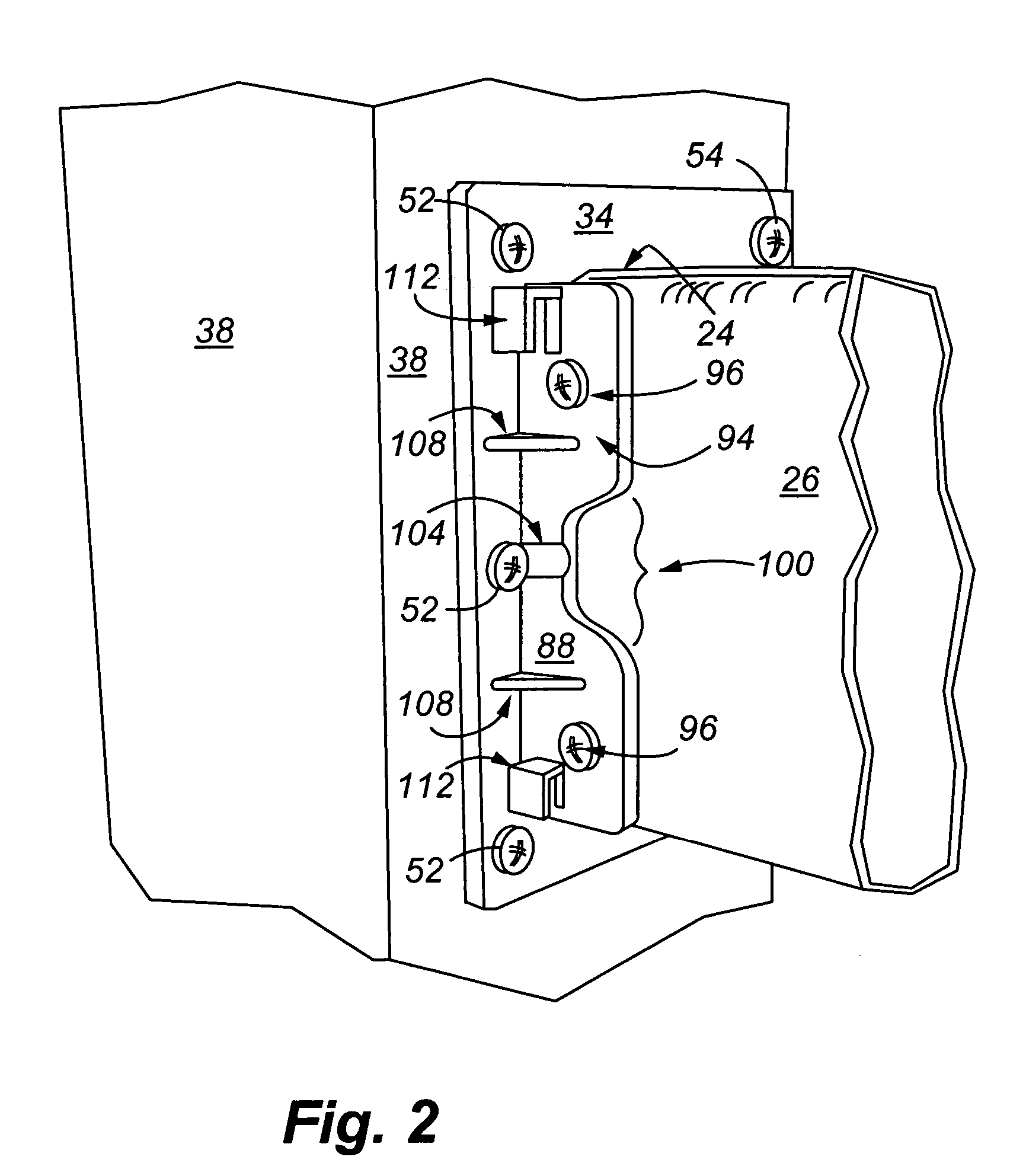

Support pads and support brackets, and structures supported thereby

A tough building system and buildings and associated accessories which make such structures more versatile. Support accessories can include a fiber-reinforced polymeric composite support bracket, adapted to be mounted to a top of a foundation wall, and to support an edge of a slab of concrete adjacent the top of the foundation wall, or to support brick fascia, or to support ends of floor joists adjacent an inner surface of said foundation wall. Support accessories can also include a load-bearing, and load distributing support pad, adapted to be used as an interface support / footer between an underlying natural base and an overlying constructed structure. The support pad has a plurality of fiber-reinforced polymeric layers, optionally stacked one on top of the other. The pad has a load bearing capacity of at least 1000 pounds per square foot. The support pad may be a pultruded product.

Owner:COMPOSITE PANEL SYST

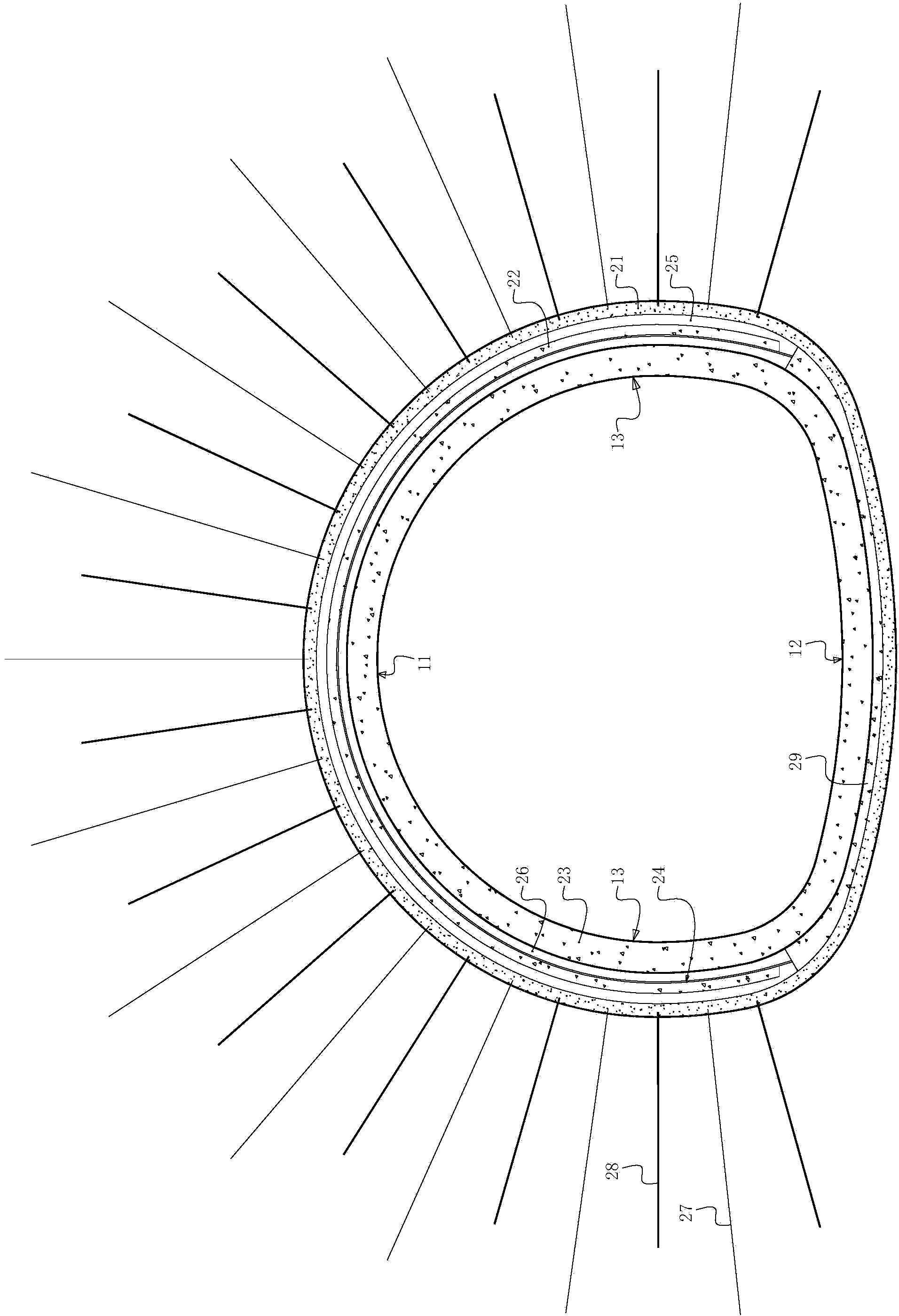

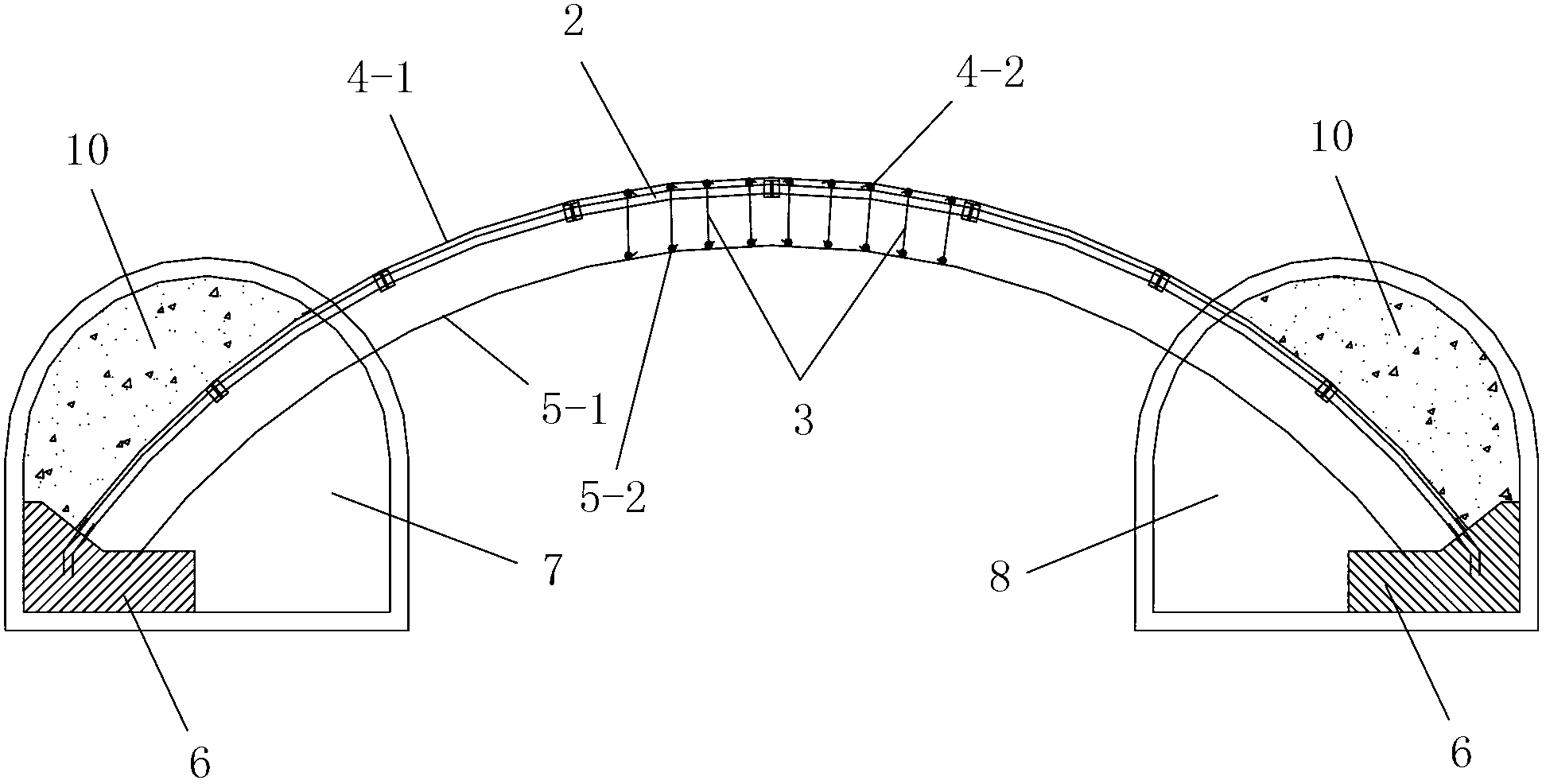

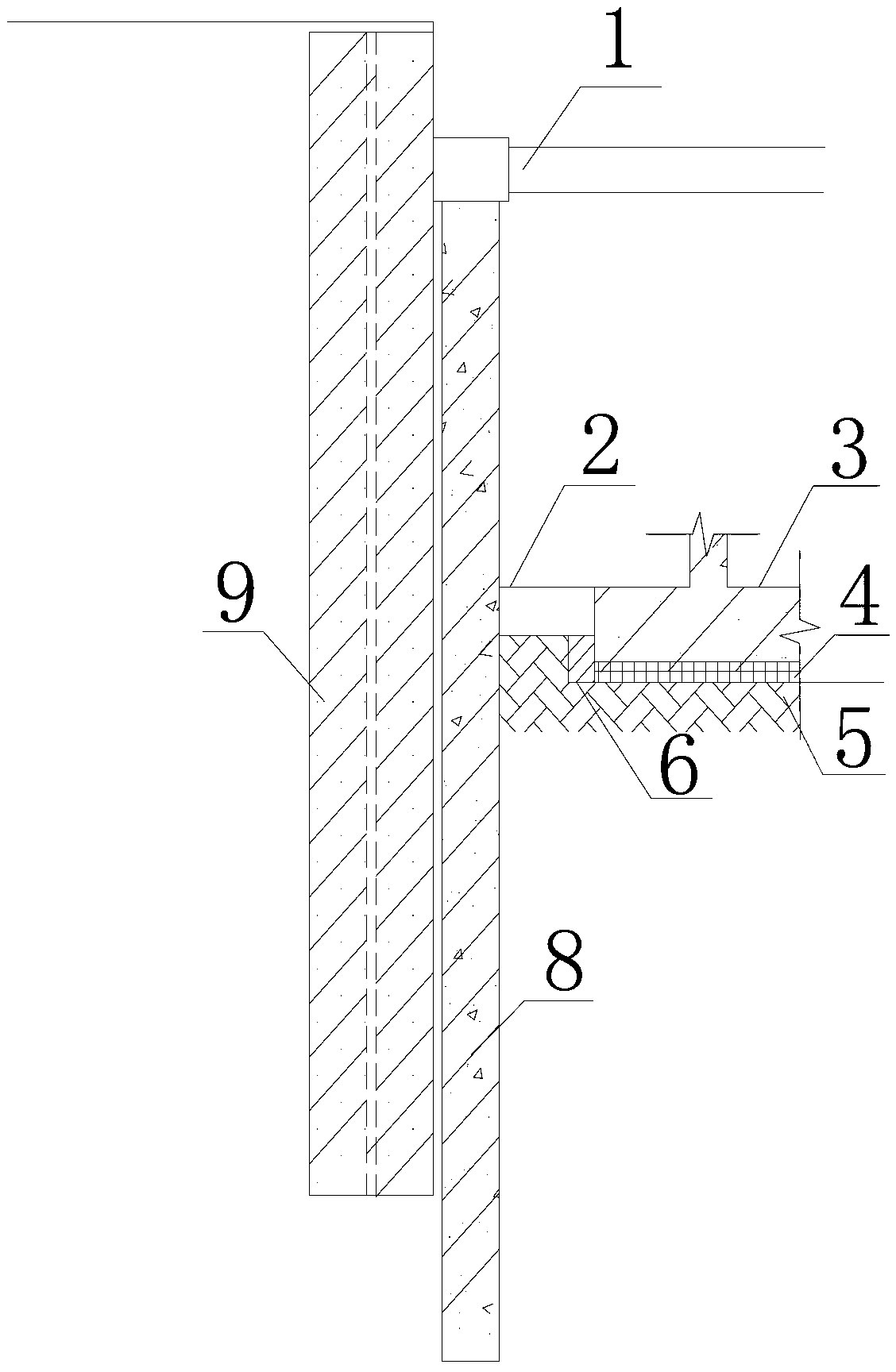

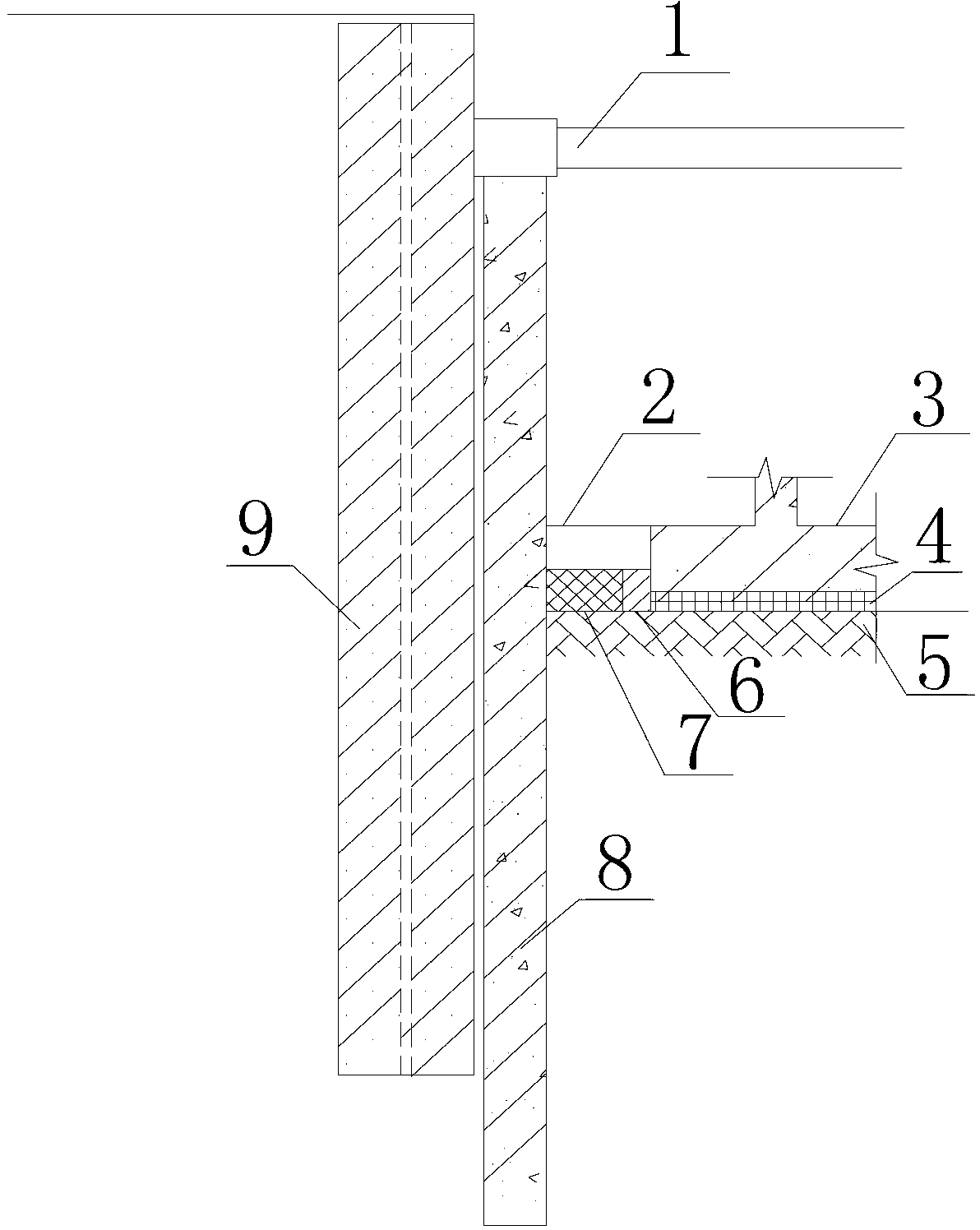

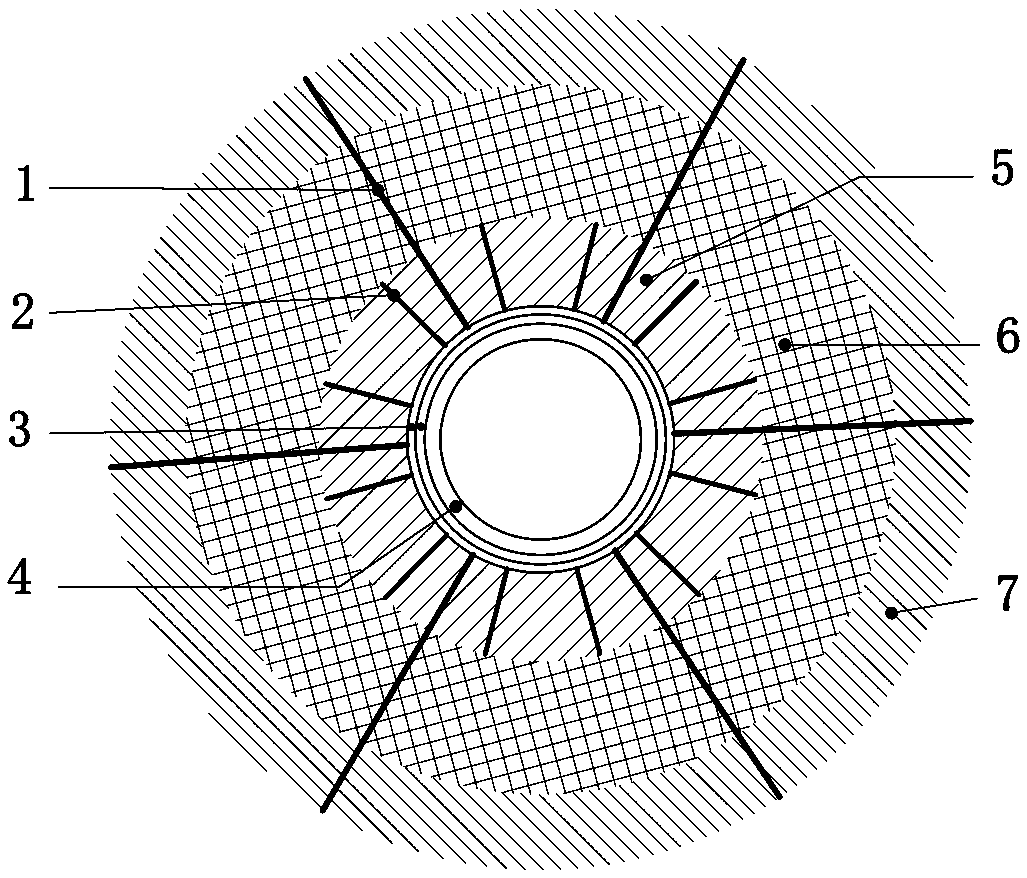

Tunnel supporting structure used for large deformation stratum and construction method of tunnel supporting structure

ActiveCN103527219ASolve support problemsGuaranteed stabilityUnderground chambersTunnel liningArchitectural engineeringLarge deformation

The invention relates to a tunnel supporting structure and a construction method of the tunnel supporting structure, and provides a tunnel supporting structure used for a large deformation stratum. An inner-layer primary support is arranged between a primary support and a secondary lining of the tunnel supporting structure. The construction method includes the steps that when deformation of the primary support reaches variable deformation, the inner-layer primary support is constructed, otherwise, the inner-layer primary support is not constructed, and the secondary lining is constructed according to the practical inner outline of the primary support or the inner-layer primary support. The primary support and the inner-layer primary support are matched, supporting to surrounding rock is initially flexible and then rigid and is initially released and then resisted, active adaptation to deformation of the surrounding rock is achieved, permanent supporting to the surrounding rock is achieved through a strong support formed by the primary support, the inner-layer primary support and the secondary lining, accordingly, the aim of supporting the large deformation stratum can be effectively achieved, and the stability and the safety performance during the running period of a tunnel can be guaranteed.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

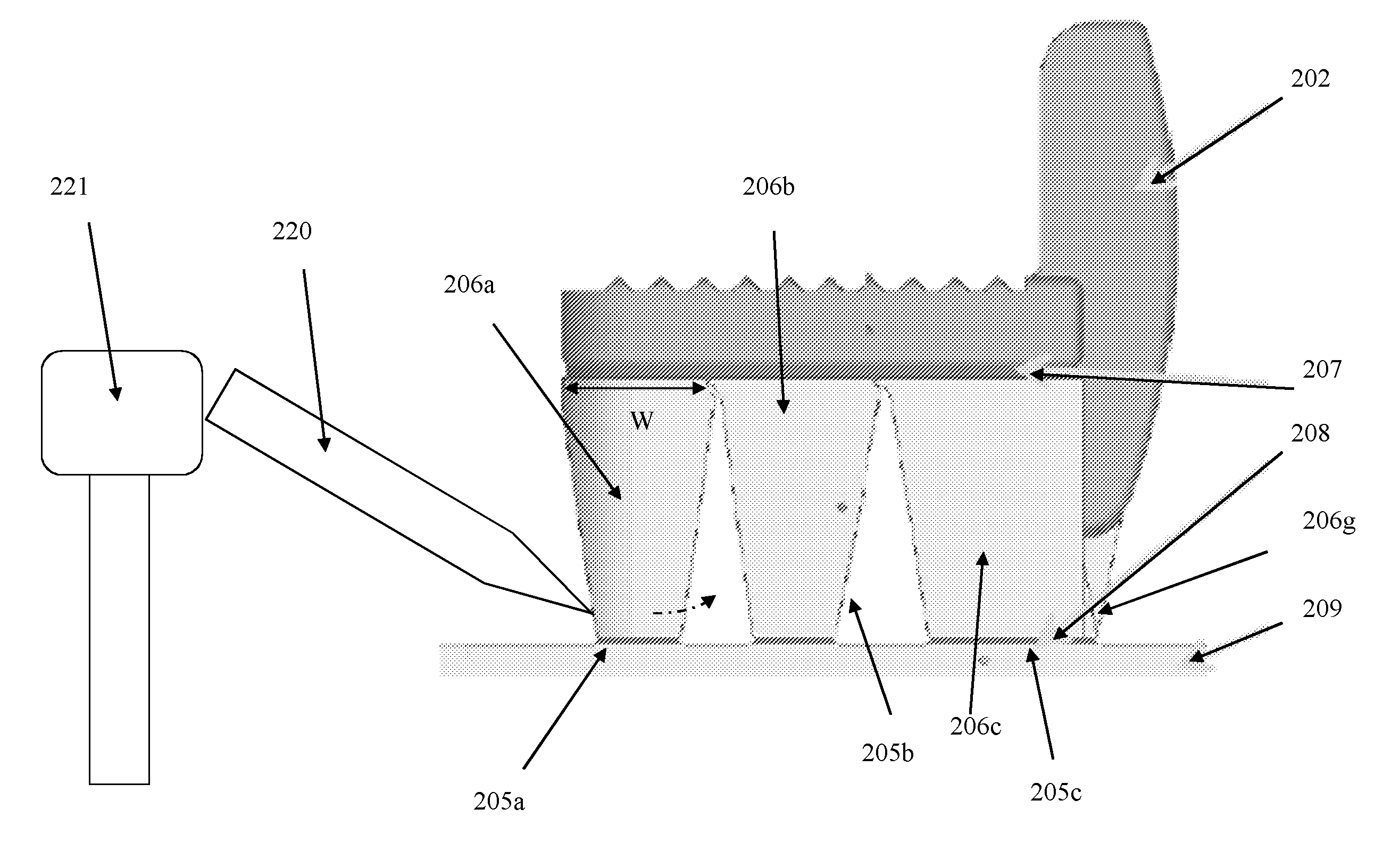

Additive manufacturing method and apparatus

InactiveUS20160175932A1Easy to disassembleEasily brokenAdditive manufacturing apparatusWelding/cutting auxillary devicesEngineeringAdditive layer manufacturing

Owner:RENISHAW PLC

Long pile and short pile combined single-row pile and horizontal internal support pile supporting structure and construction method thereof

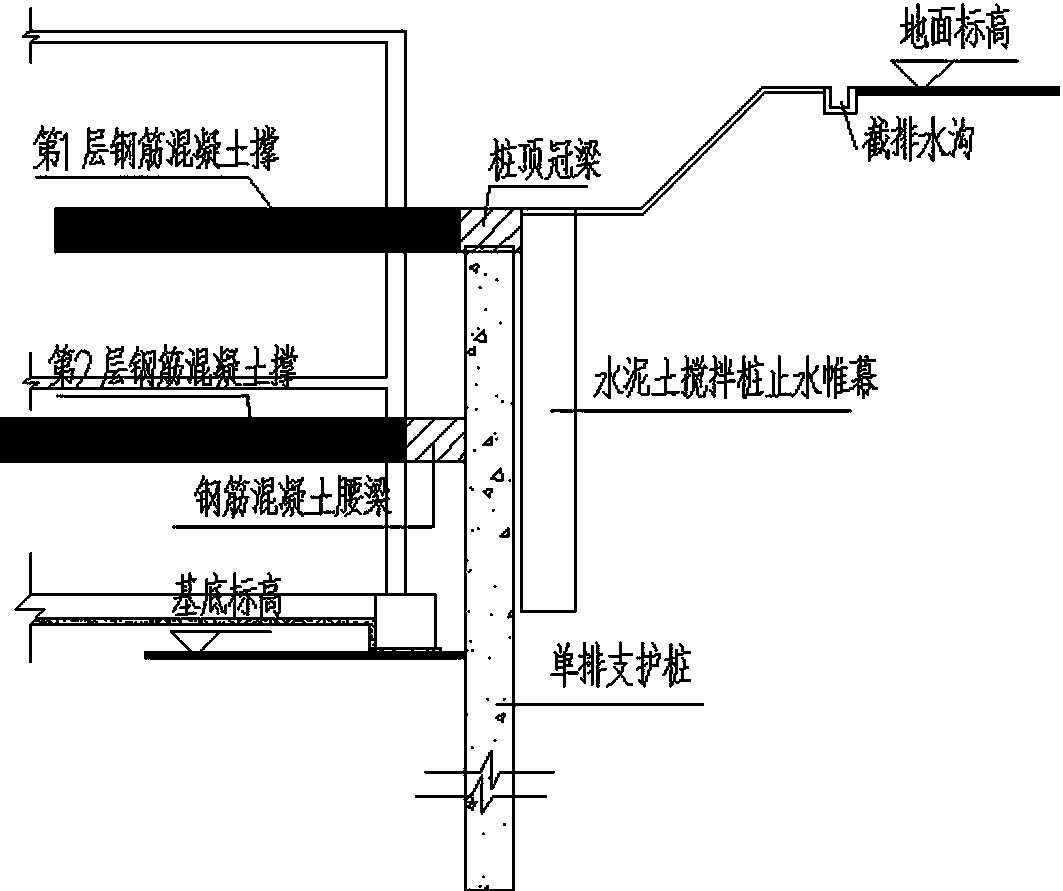

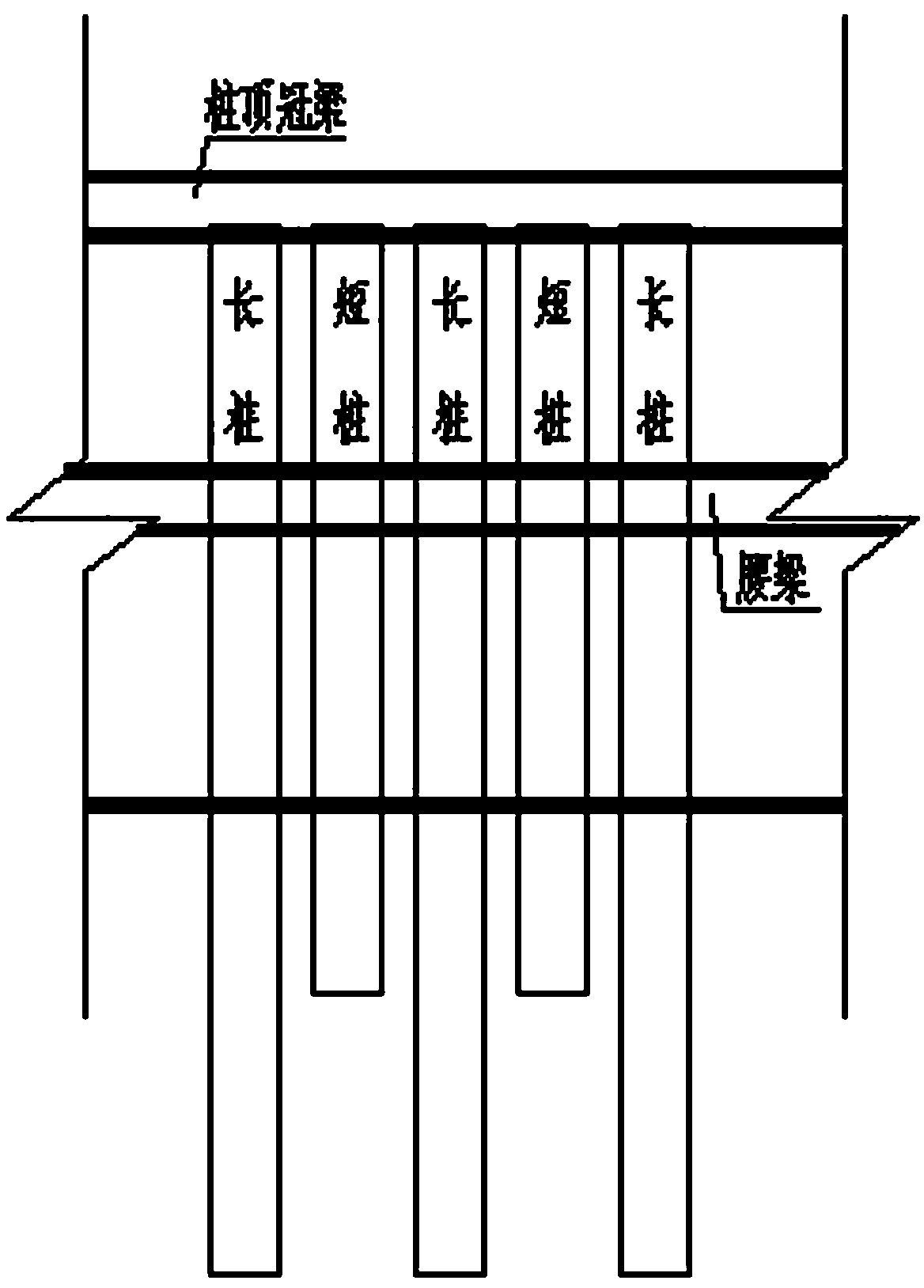

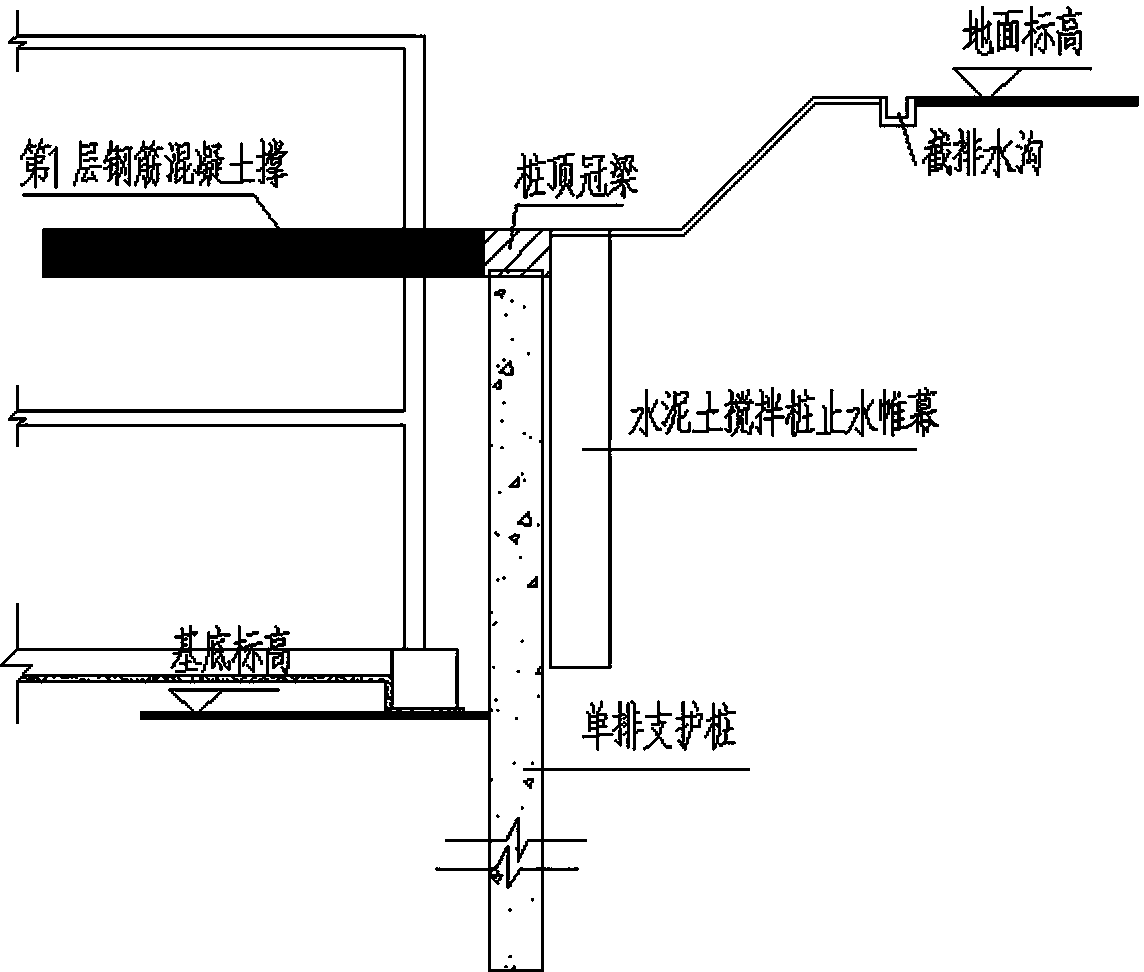

The invention discloses a long pile and short pile combined single-row pile and horizontal internal support pile supporting structure and a construction method thereof. The structure is characterized in that long piles and short piles are arranged in a staggering way at equal intervals in a single row of pile; the clear spacing between two adjacent piles is 200 to 400mm; two rows of concrete deep stirring piles are arranged behind a support pile to serve as a waterproof curtain; the layer number of internal supports is 1 to 3; the first layer of horizontal internal supports is generally arranged on the top of the support pile; the distance between the adjacent internal supports which are arranged up and down is 4 to 6m. When the supporting structure is designed, in all the rows of piles, parameters of the short piles are calculated to make sure that the requirements on the horizontal displacement, the bending capacity and the overturning resistance of the short piles are met and then parameters of the long piles are calculated to make sure that the requirement on the deep slide stability of the long piles is met. The construction method comprises the following main construction steps of constructing the long piles, constructing the short piles, constructing the concrete deep stirring pile curtain, hardening the ground before excavating a foundation pit, constructing a drainage facility, excavating the first layer of earth, constructing a pile top beam and the horizontal internal supports, excavating the second layer of earth, and performing the other steps until the earth is excavated to the bottom of the foundation pit.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

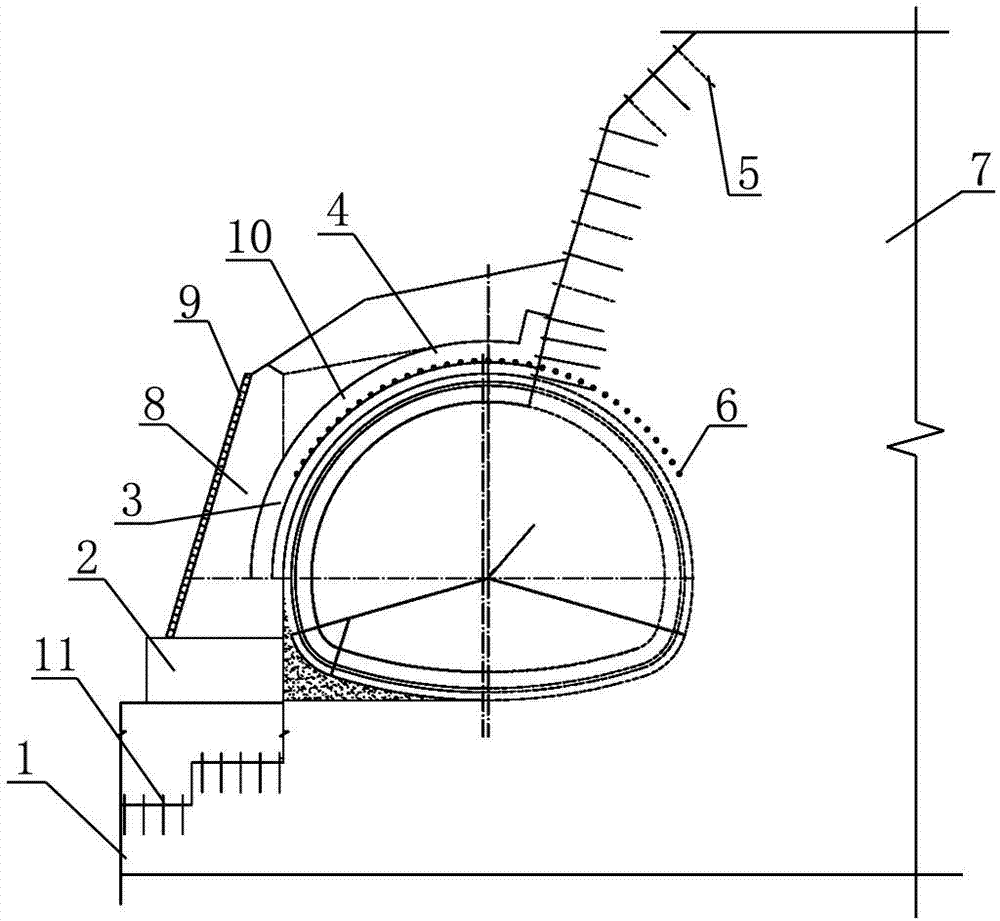

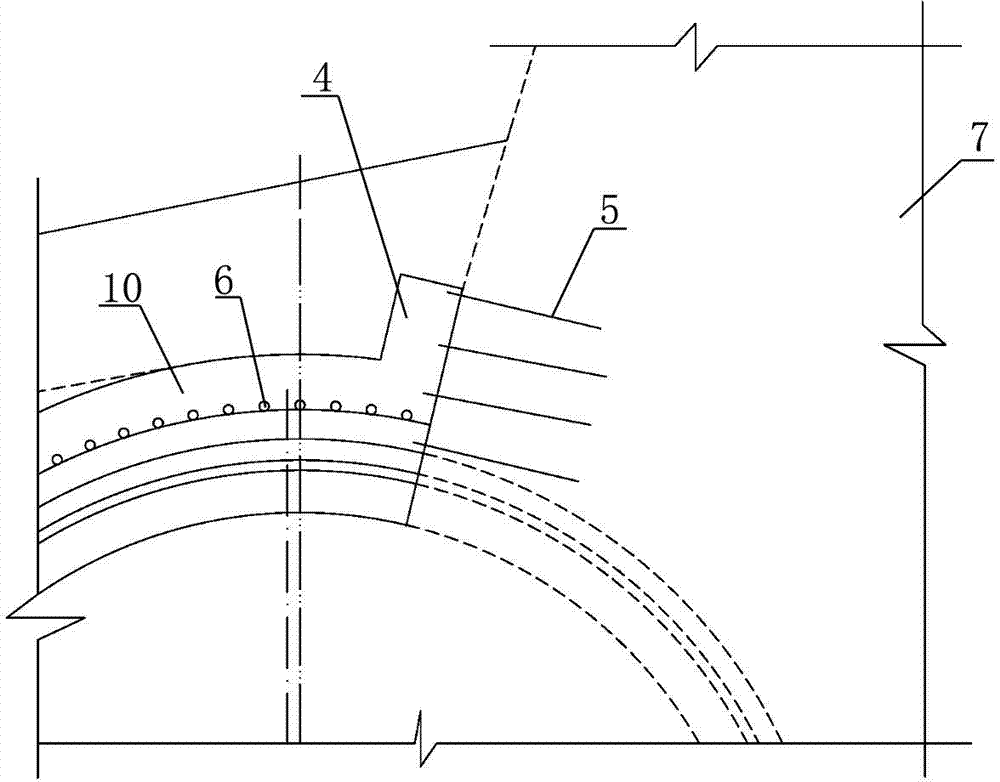

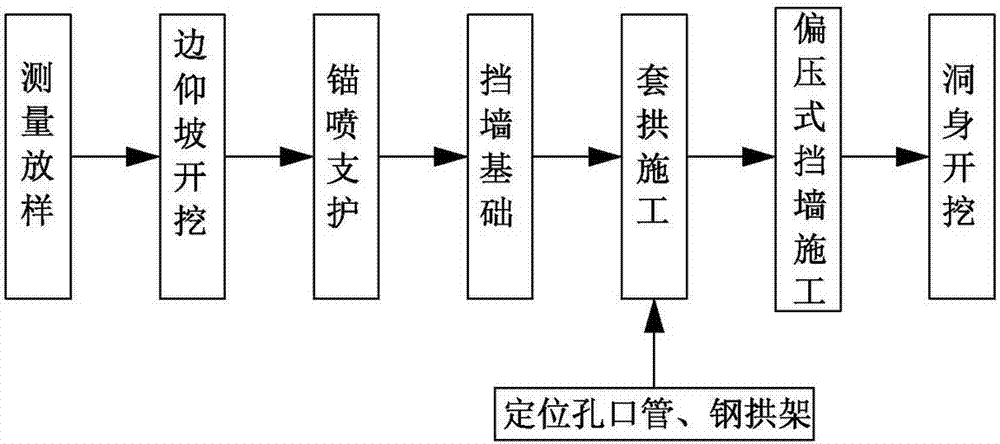

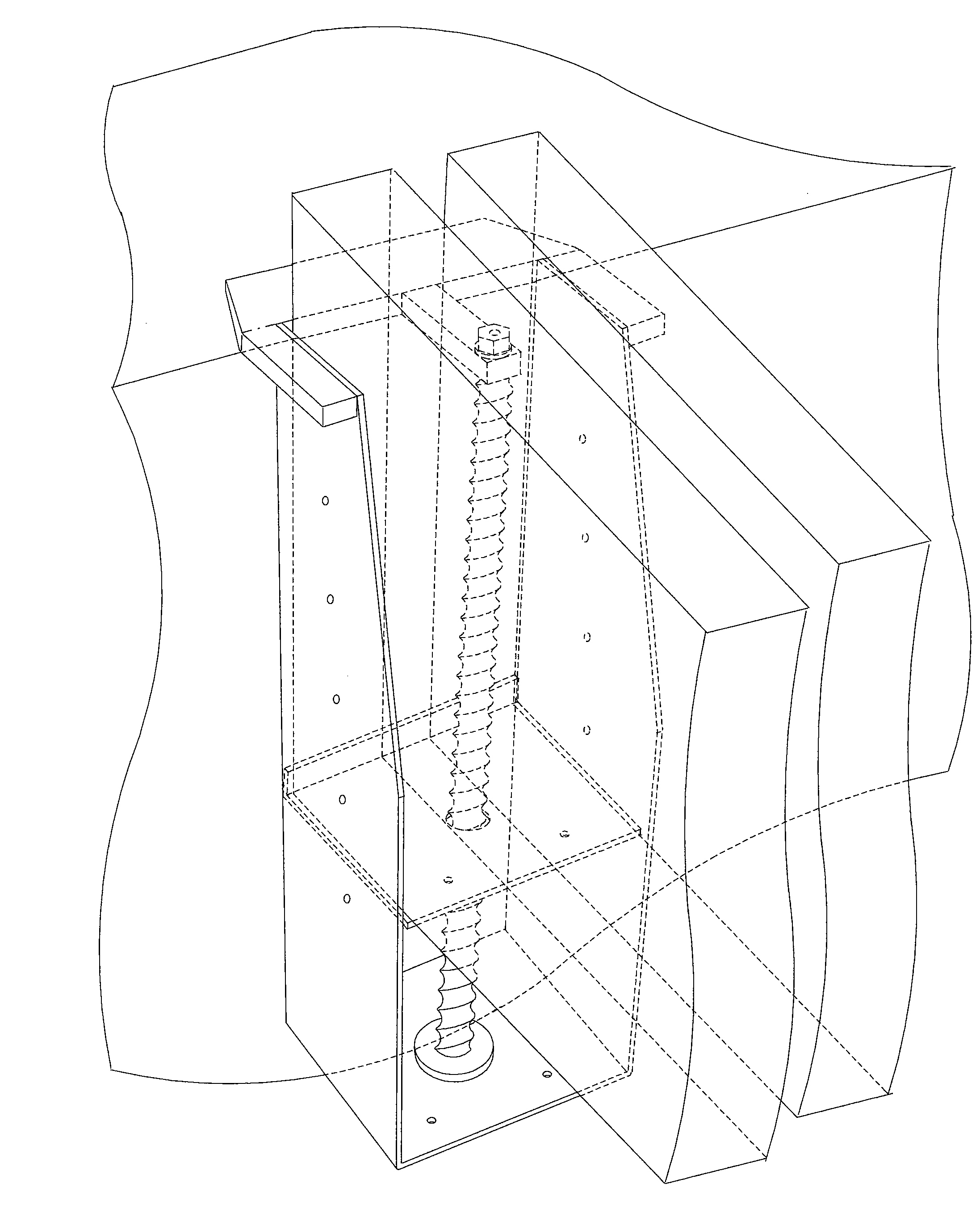

Holed excavation supporting structure for light and dark junction section of tunnel in bias pressure state and construction method

InactiveCN103206219AEnsure structural safetySafe and reliable structureUnderground chambersTunnel liningRetaining wallStructural safety

The invention relates to a holed excavation supporting structure for a light and dark junction section of a tunnel in a bias pressure state and a construction method. In a supporting mode combining a bias pressure earth retaining wall and a cover arch, the unilateral bias pressure of the tunnel is balanced, thus ensuring the safety of a tunnel structure and safe holed excavation of the tunnel. With the adoption of the holed excavation supporting structure and the construction method, a slope is prevented from being destroyed in large area due to open cut tunnel excavation, and original ecological vegetation is protected to keep the slope intact and avoid landslip due to heavy excavation, so that neither engineering construction or environmental protection is neglected, and the engineering cost is also greatly lowered. The holed excavation supporting structure and the construction method can be widely applied to tunnel building in a mountainous hilly area.

Owner:浙江交工宏途交通建设有限公司

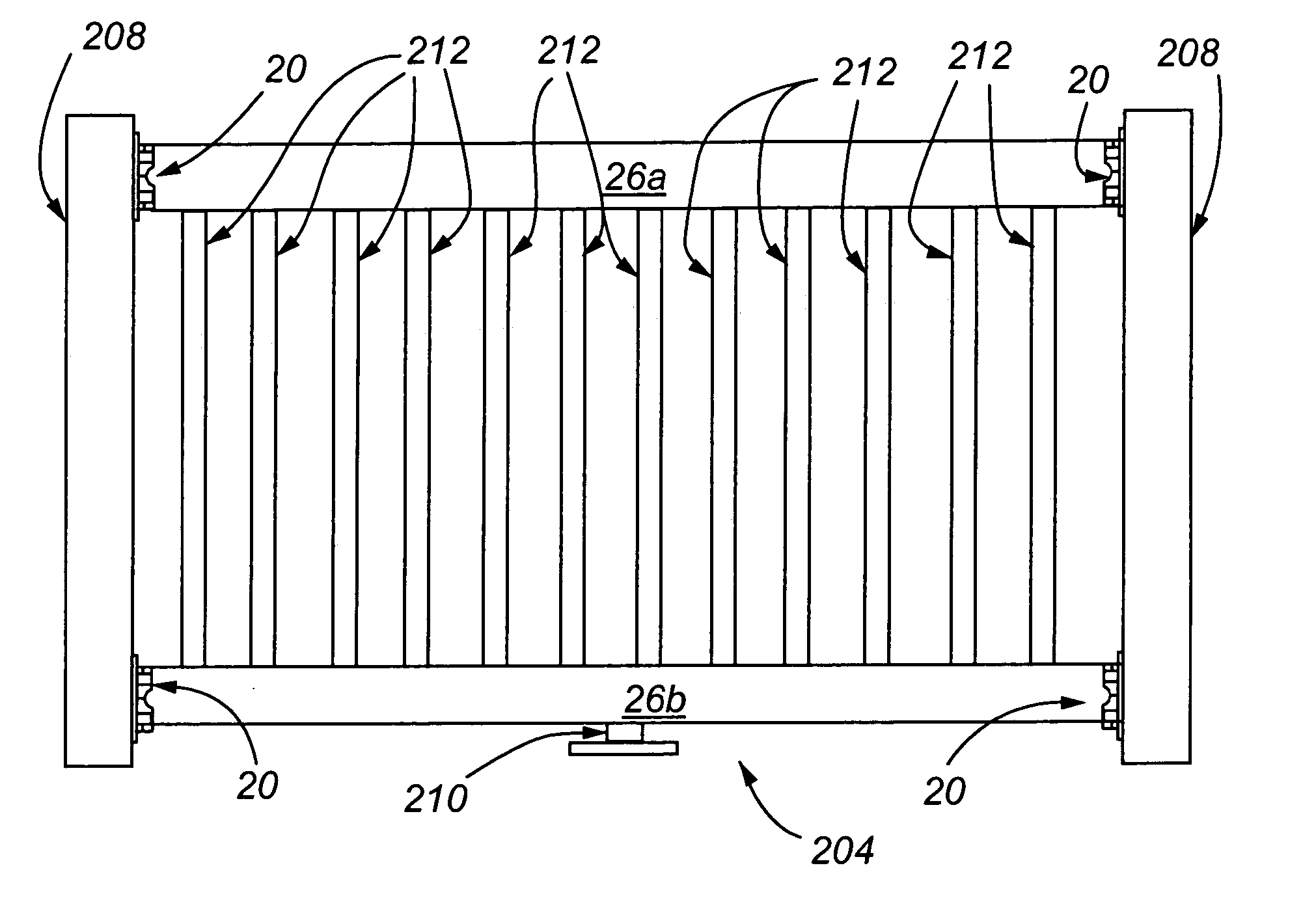

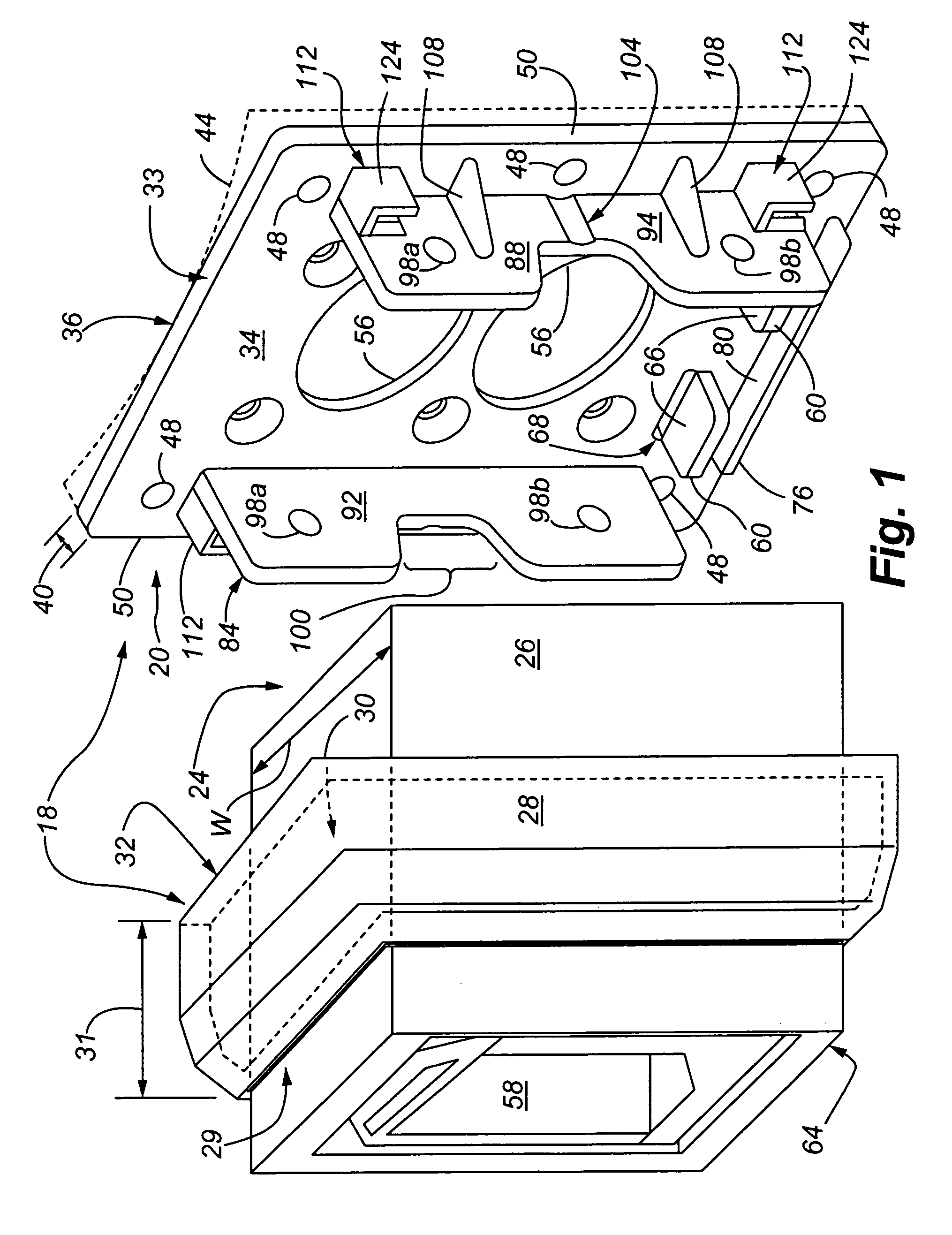

Reusable Adjustable Hanger for Use with Joists and/or Double Wales

A reusable adjustable hanger, including multiple embodiments having varied features and attributes, for general use in forming horizontal concrete structures having permanent vertical support, depending on a supporting structure for horizontal support, vertically adjustable from both top and bottom, capable of receiving and supporting any or all of the following primary spanning ledgers: double walers, single joists, and dual joist structures joined at the middle and having a single joist member at each end, optionally comprising a vertical support structure, optionally comprising an attachable and removable central vertical structure allowing the use of 4× lumber as primary spanning ledgers.

Owner:BORG ADJUSTABLE JOIST HANGER COMPANY

Rail mounting apparatus and method

Owner:LMT MERCER GROUP

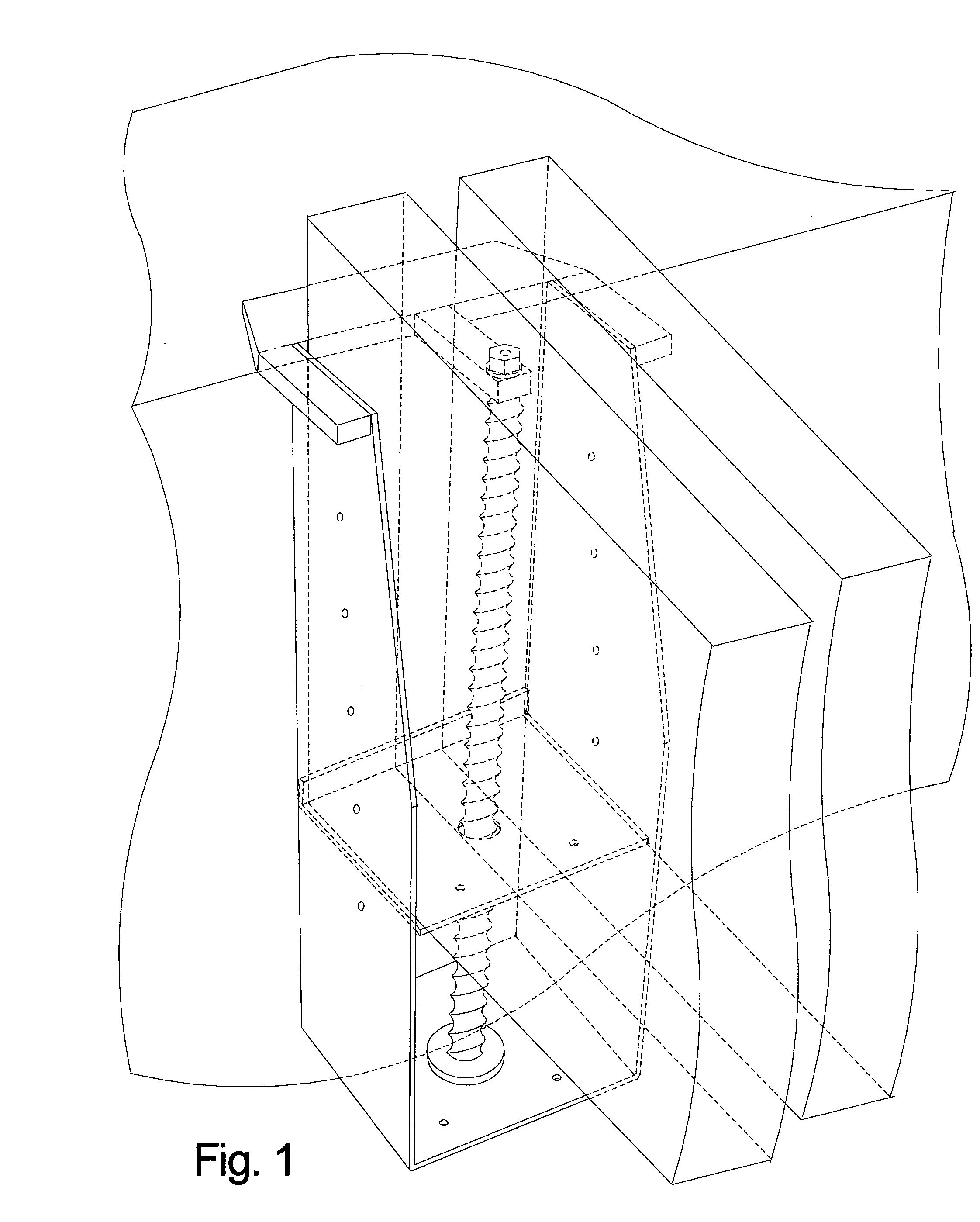

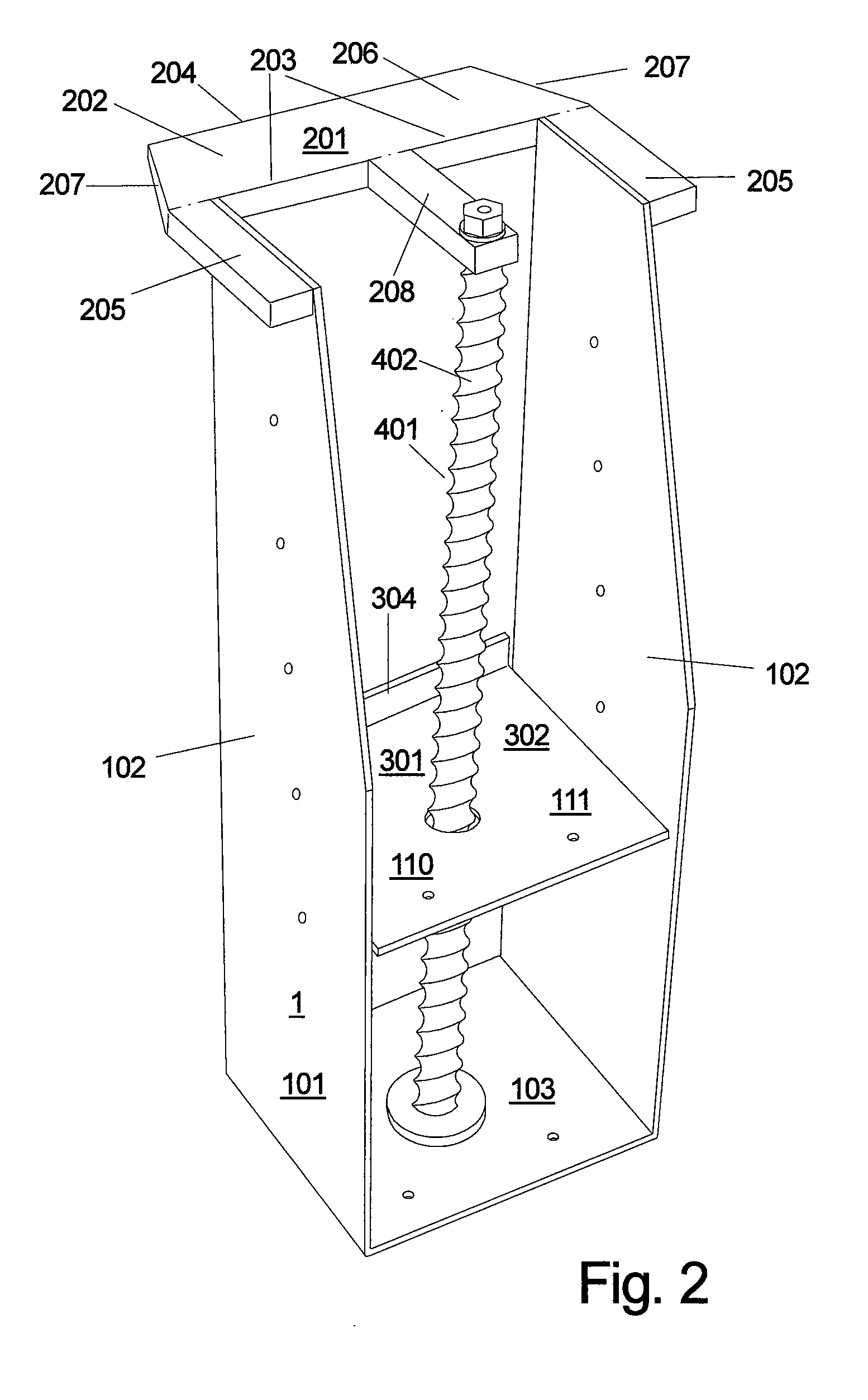

Foundation from bracket and method

InactiveUS20030101670A1Shorten the timeEliminate needFiling appliancesFoundation engineeringEngineeringStructural engineering

A pre-fabricated building foundation form assembly is installed beneath a pre-existing temporarily supported structure in its final position, and a footing dug below the line of the lowest building timber. A rigid sheet form element is positioned along the upper and outside perimeter side portion of the lowest building timber. The brackets are positioned over the lowest timber and against the sheeting at specified intervals and held in place with connectors. Adjustable supports are attached to the brackets and connectors attach brackets to sheeting. J-bolts along with structural steel are installed. A rigid sheet form element is laterally positioned along the inside perimeter of the inner side of the brackets and held with connectors, which completes the suspended enclosure. A flowable and settable foundation material fills the space within the enclosure and extends essentially continuously upwardly from the footing below the site surface to meet the lower surface of the lowest floor timber to support the building thereon once the foundation material has cured. The footing below the rigid sheet form element has a lateral width greater than the space between the portions of the enclosure to form a foundation footing of suitable width.

Owner:GUSTIN MORRIS HOUSTON

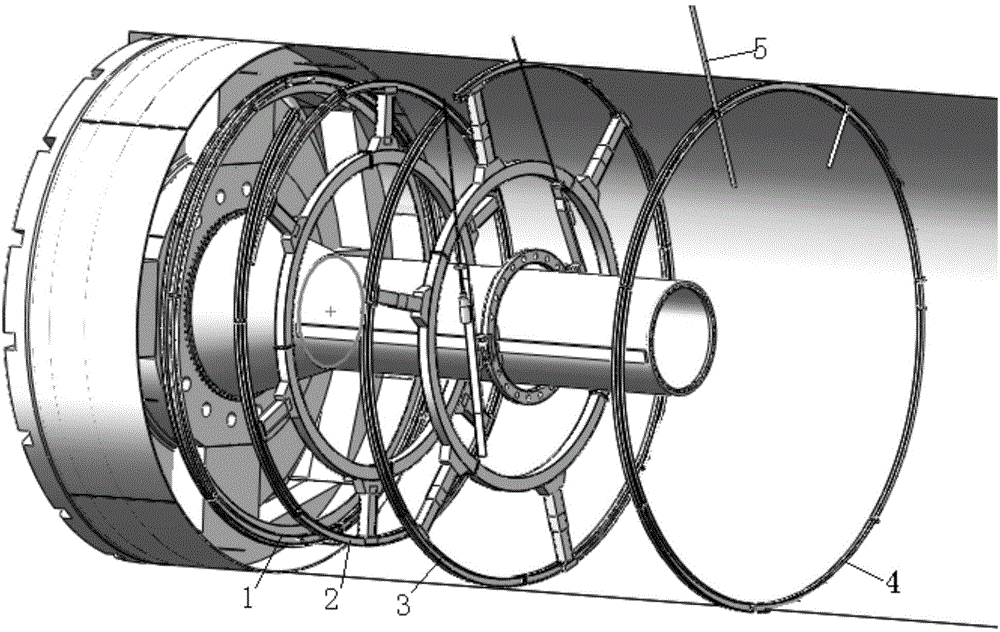

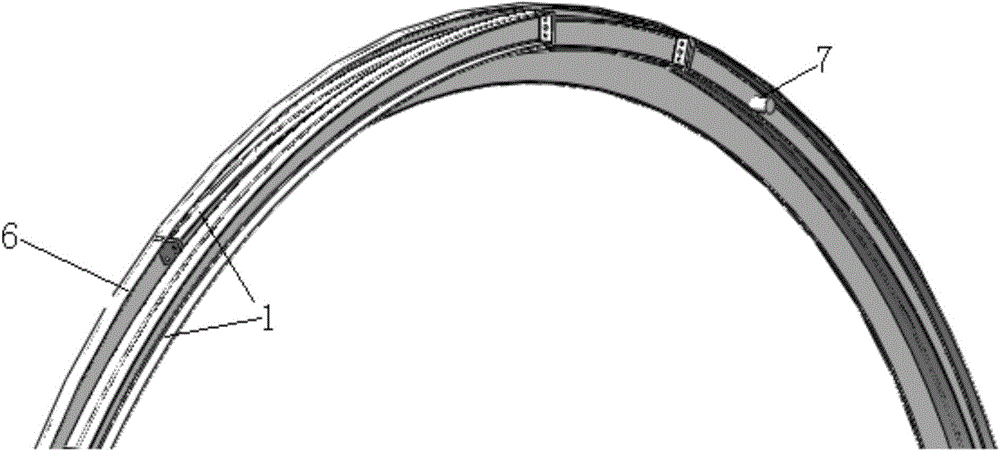

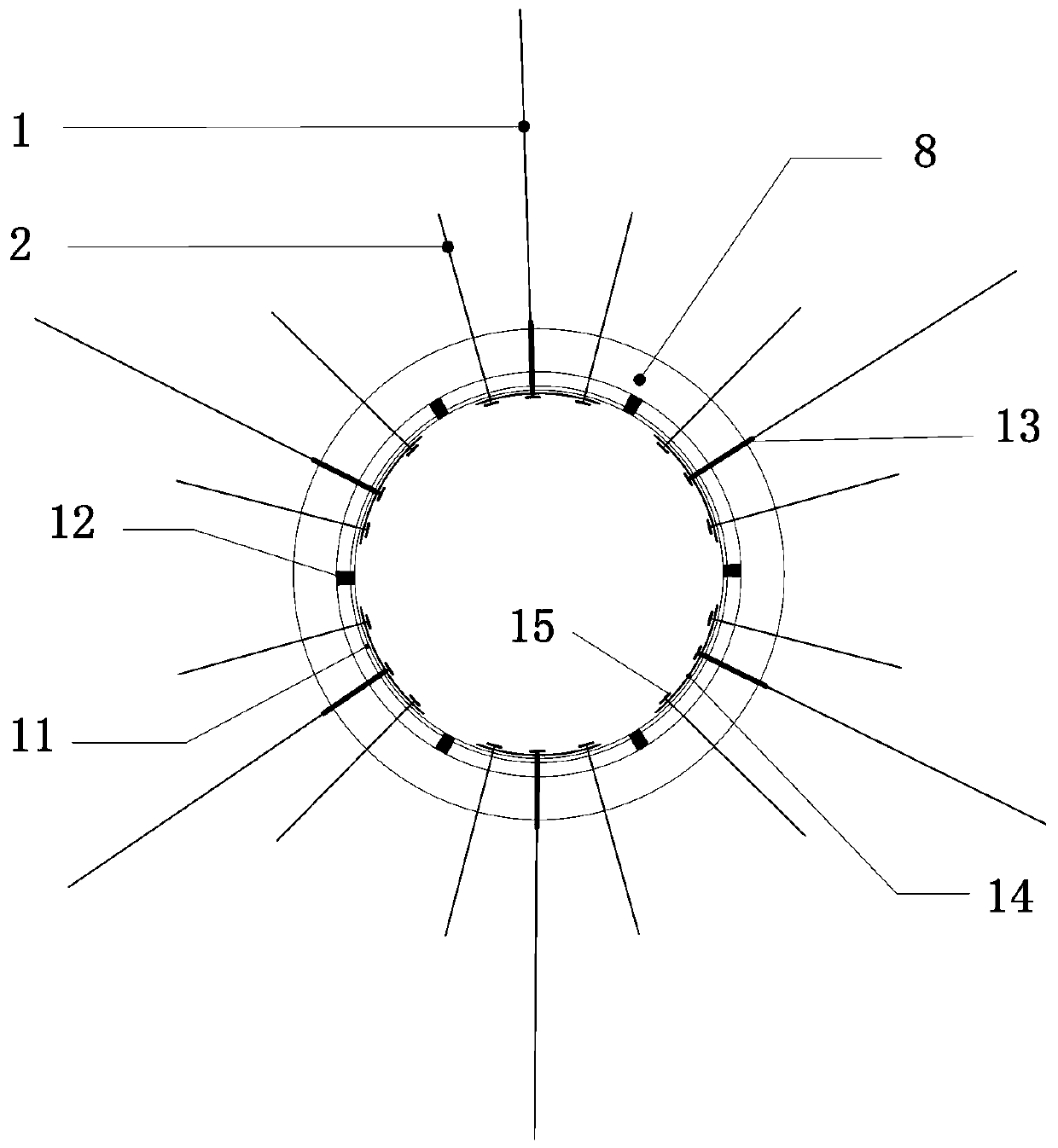

Annular steel structure supporting construction method with open type TBM (tunnel boring machine)

InactiveCN103557013AAvoid manual cleaningReduce dependenceUnderground chambersTunnel liningGratingSlag

An open state is formed behind a shield of an open type TBM (tunnel boring machine), so that bolting and shotcreting with wire mesh and the like can be realized, when unfavorable geological conditions such as crushed zones are encountered, broken surrounding rock collapses and falls, which not only threatens the safety of operating personnel and equipment, but also greatly lowers the construction efficiency. The invention discloses an annular steel structure supporting construction method with the open type TBM. The supporting TBM is provided with a shield which has an annular steel structure installation space. When the unfavorable geological conditions are encountered, the annular steel structure can be fast erected in an assembly line mode under the protection of the shield, the shield is replaced with the annular steel structure for supporting the surrounding rock as the TBM tunnels; under the protection of the annular steel structure, an annular steel grating and a steel mesh hollow structure are used for carrying out the bolting and shotcreting supporting and the like, the previous extensive construction is changed to controllable standardized operation, the original open type unsafe environment is changed to a closed protected operation zone; the construction method disclosed by the invention is different from the passive supporting which is carried out after the surrounding rock collapses and falls; the annular steel structure actively close off the broken surrounding rock, then the surrounding rock becomes a part of the supporting structure, the work amount for backfilling concrete and removing slag is greatly reduced, and thus the method is more efficient and safer, the cost is reduced and the operation is easy to realize.

Owner:王静

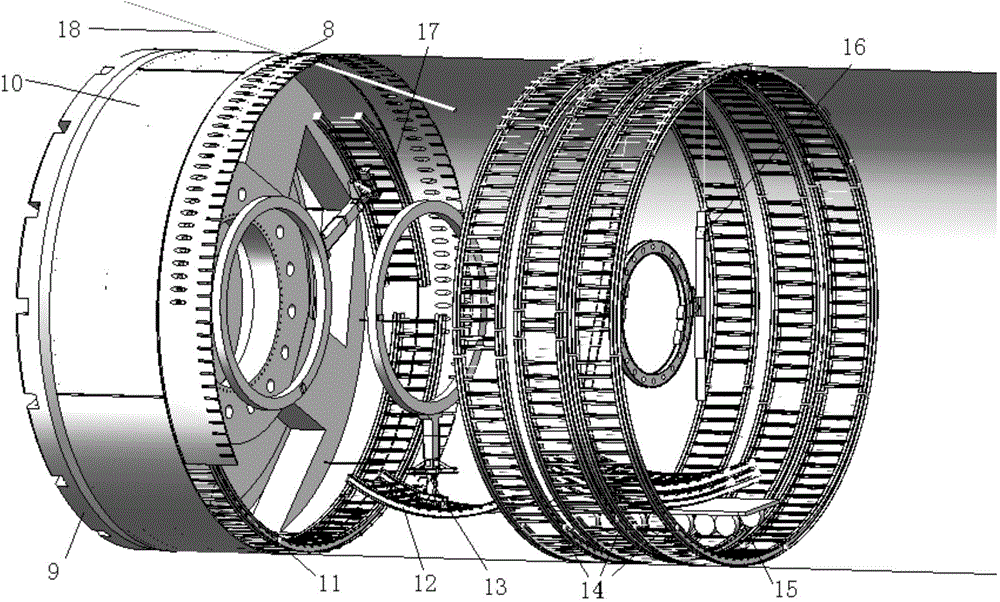

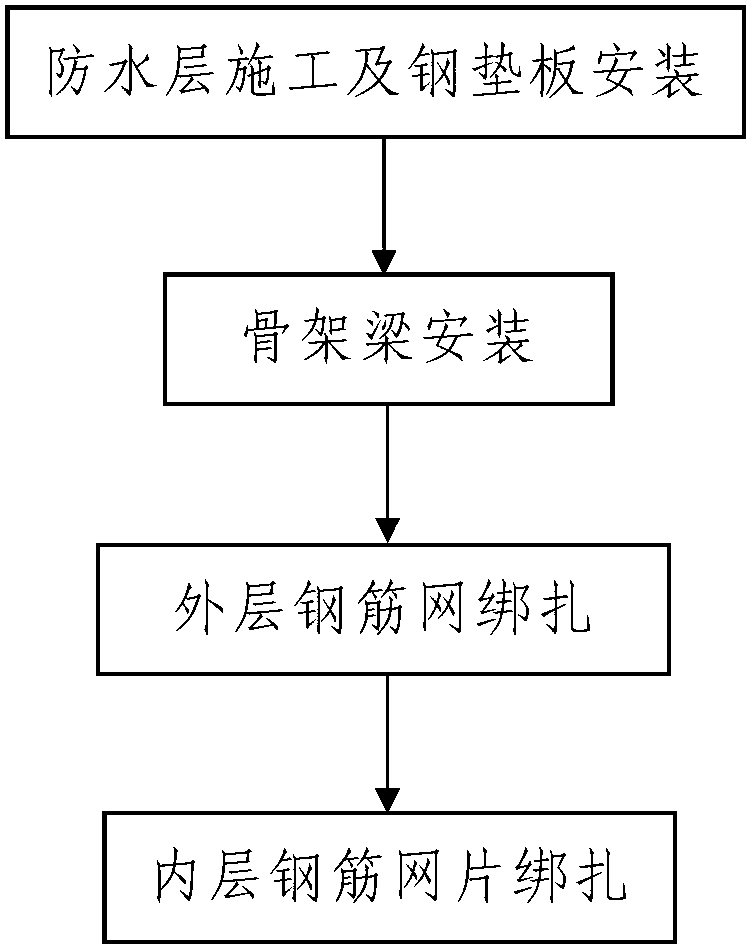

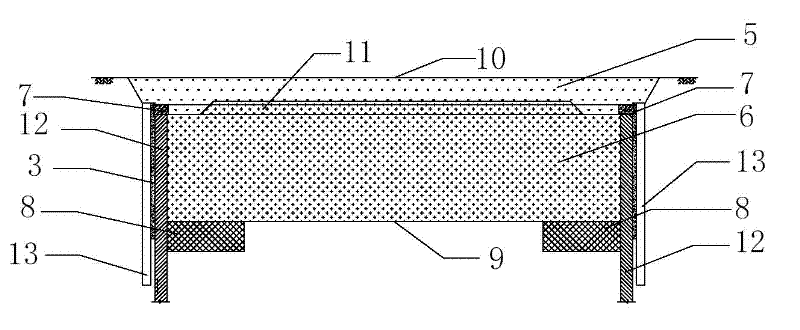

Large-span tunnel arch secondary lining steel bar binding construction method based on skeleton beams

The invention discloses a large-span tunnel arch secondary lining steel bar binding construction method based on skeleton beams. A bound tunnel arch secondary lining steel bar comprises an outer layer reinforcement mat, an inner layer reinforcement mat and a vertical connecting bar for connecting the outer layer reinforcement mat with the inner layer reinforcement mat. The construction method comprises the following steps of: arranging skeleton beam: arranging a plurality of skeleton beams below a tunnel arch primary supporting structure from front to back, wherein the skeleton beams are arch-shaped beams of which the radiuses are the same as that of the outer layer reinforcement mat, and the plurality of skeleton beams construct a load bearing structure of a tunnel arch secondary lining steel bar; and II, binding the tunnel arch secondary lining steel bar: binding the outer layer reinforcement mat on the upper parts of the plurality of skeleton beams, and suspending the inner layer reinforcement mat on the outer layer reinforcement mat through the vertical connecting bar. The method has the advantages of simple construction process, convenience in constructing, good use effect, high practical value, no damage to a paved waterproof structure and easiness and convenience in controlling the deflection of a large-span station arch secondary lining steel bar.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

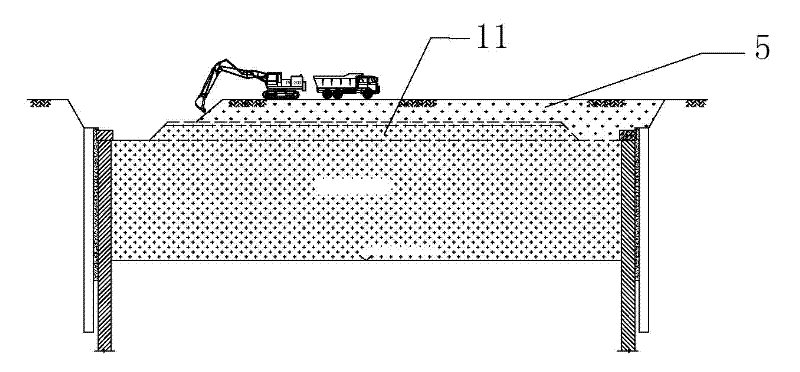

Construction method for deep-foundation pit excavation

ActiveCN102535474AAdvantages of construction methodReasonable designExcavationsEconomic benefitsStructural engineering

The invention relates to a construction method for deep-foundation pit excavation. After foundation pit fender structure construction is finished, an excavation machine is used for excavating and an earthwork vehicle is used for transporting out the earthwork. The construction method is characterized by comprising the following steps of: a. earthwork excavation for the first time: uniformly excavating from every corner of the foundation pit to the center by dividing three regions in a retreating manner; b. fender supporting structure construction and maintenance: pouring the fender supporting structure, and carrying out next-step construction when the supporting concrete strength achieves 80% of the design strength; and c. earthwork excavation for the second time: carrying out earthwork excavation below the fender supporting structure, selecting excavation equipment, excavating, and transporting out the earthwork in the pit in a two-stage overturning and transferring manner to finish excavation. The construction method for deep-foundation pit excavation has the advantages of being reasonable in construction step design, simple to operate and safe and reliable in excavating engineering, lowering engineering construction cost, saving construction period, and being obvious in economic benefit.

Owner:MCC5 GROUP CORP SHANGHAI

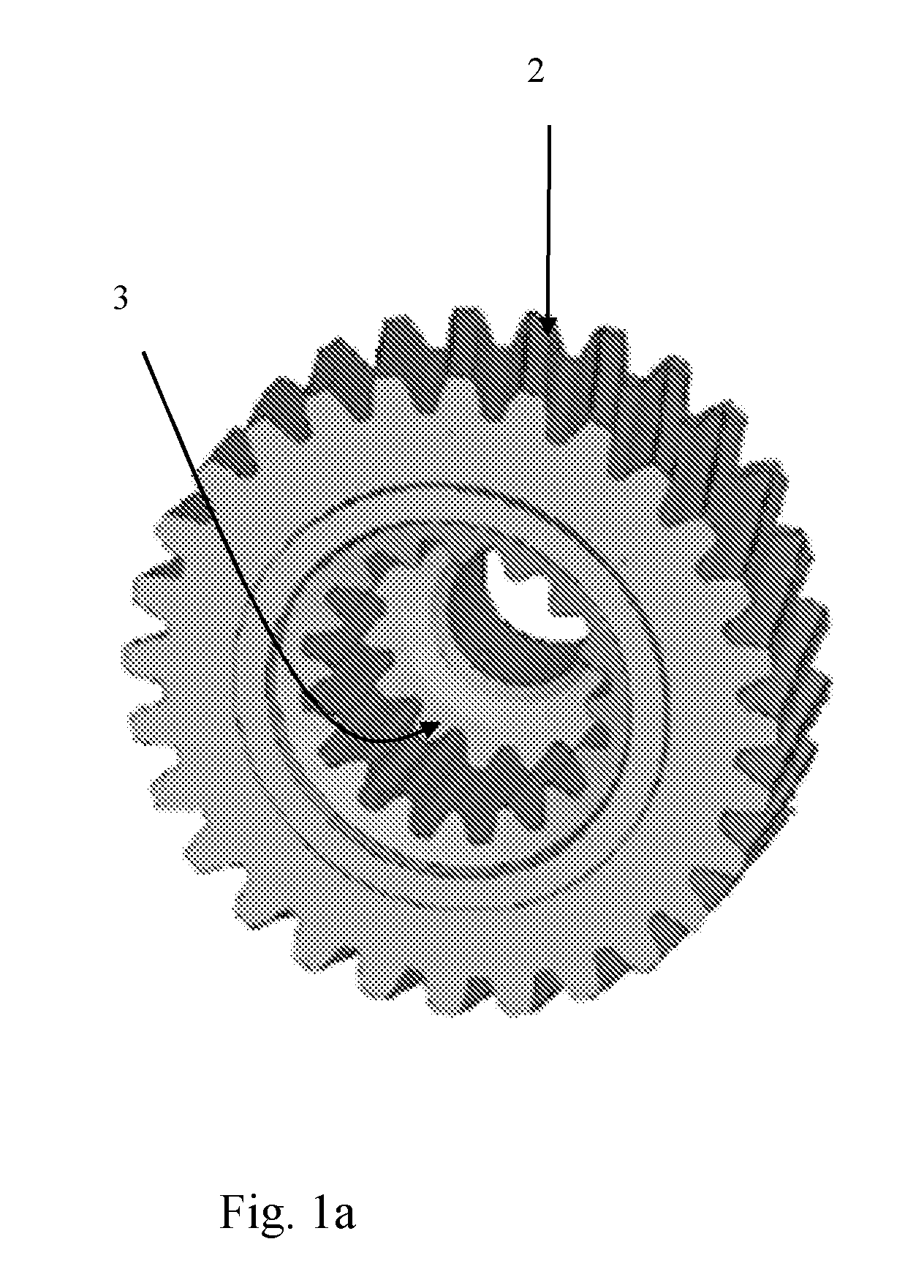

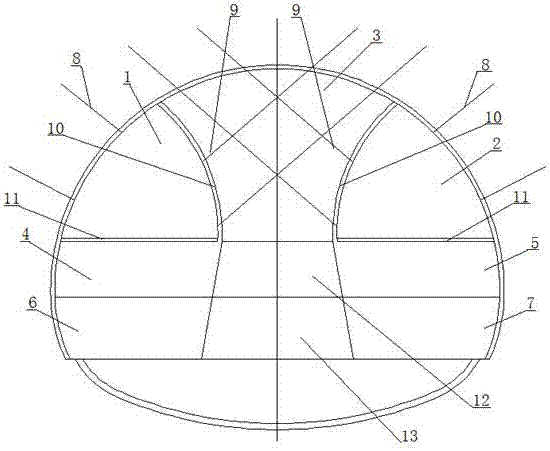

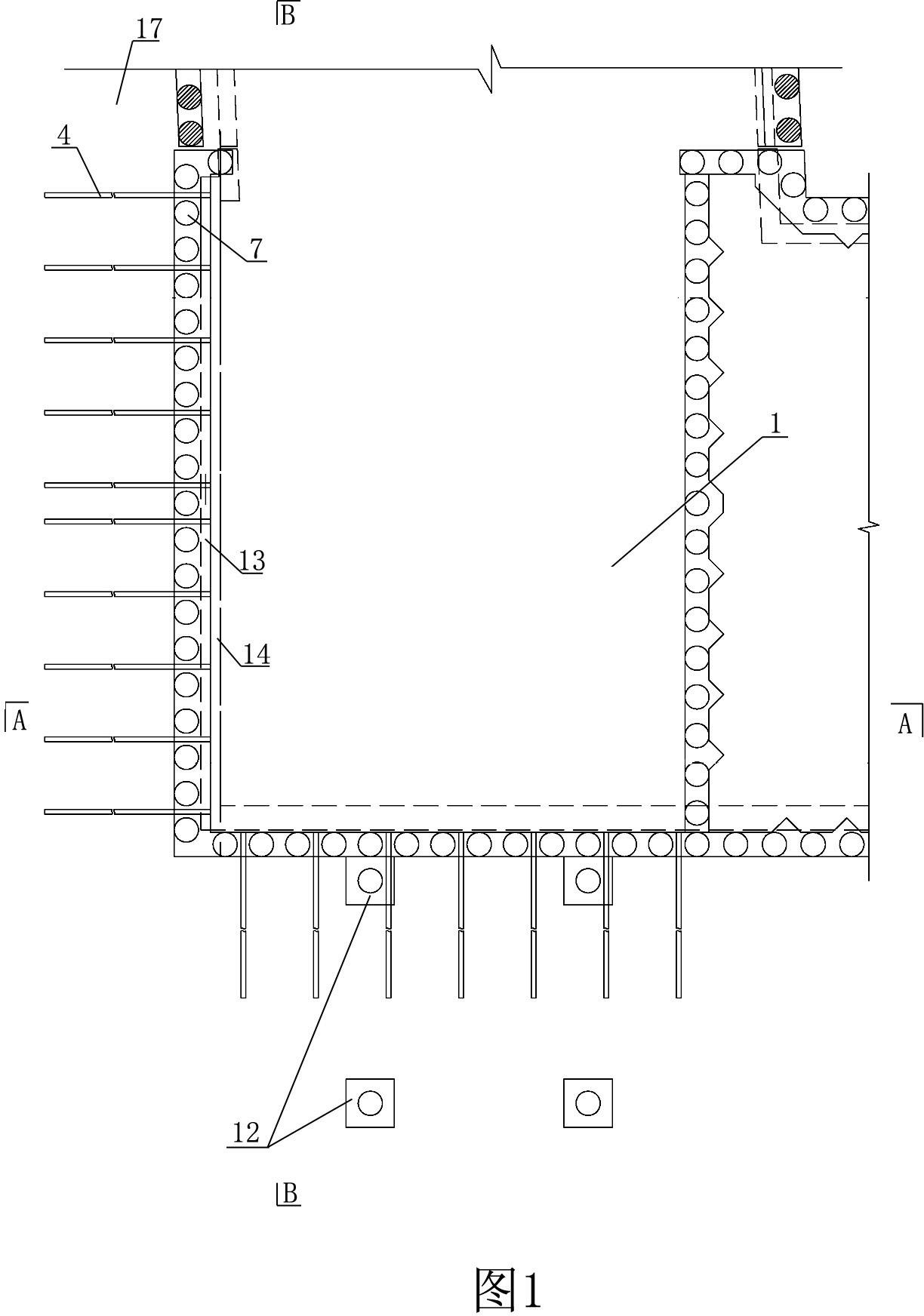

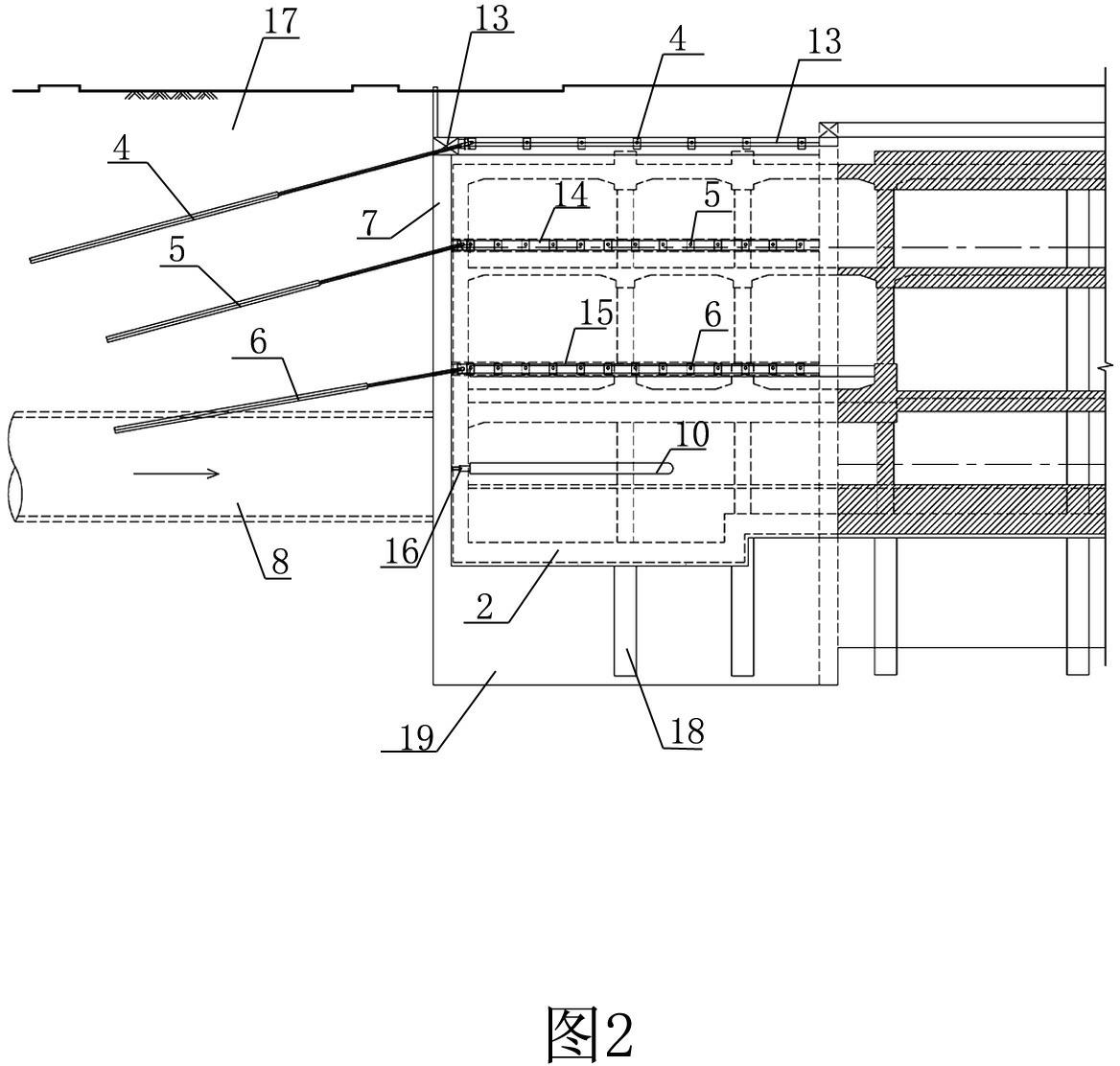

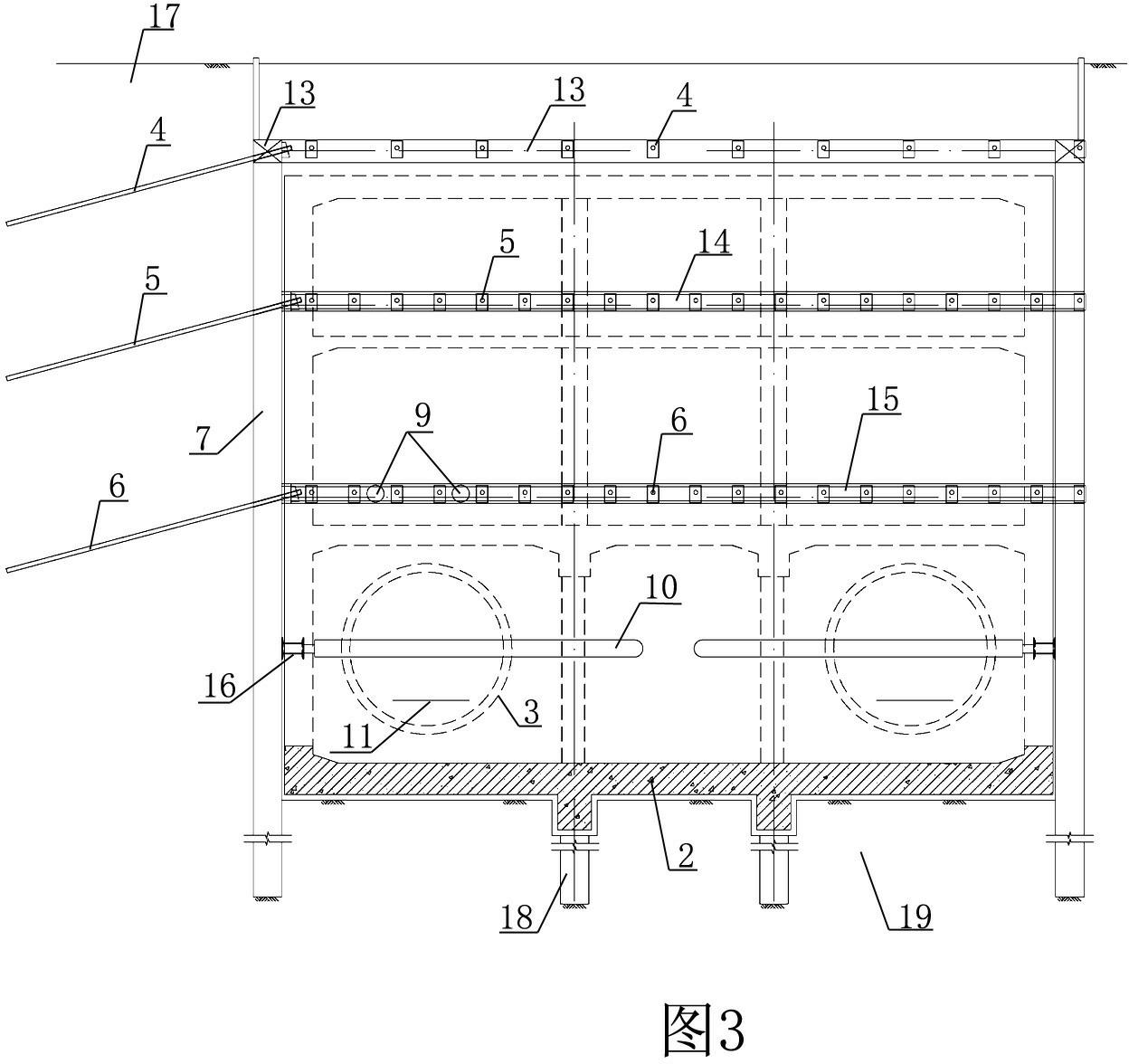

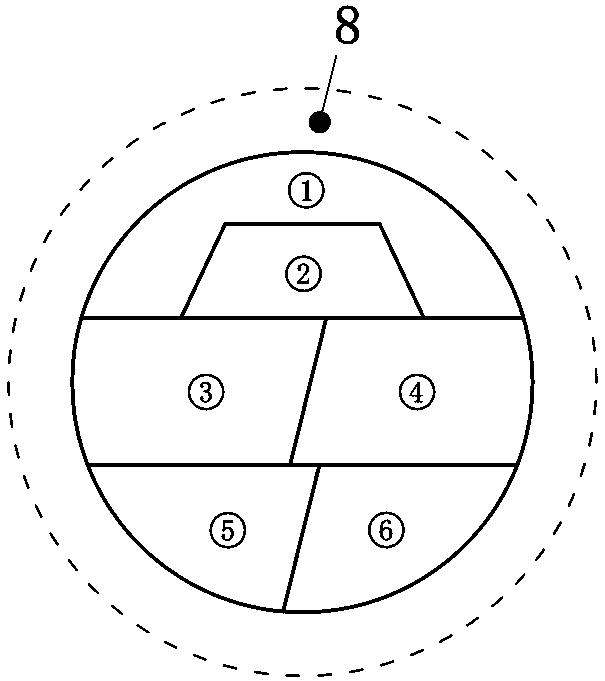

Weak surrounding rock large section tunnel double-side-wall pilot tunnel support structure excavated through three-step method and construction method

ActiveCN107288653AEasy to expandLarge construction spaceUnderground chambersHydro energy generationArchitectural engineeringStructure support

Disclosed are a support structure excavated in a squeezing type weak surrounding rock extra-large section short tunnel and a construction method. The support structure comprises upper supports, middle supports and lower supports from top to bottom; the upper supports comprise the left side wall pilot tunnel support (1), the mid-partition support (3) and the right side wall pilot tunnel support (2); the middle supports comprise the left middle step support (4) and the right middle step support (5); and the lower supports comprise the lower left step support (6) and the lower right step support (7). The construction method comprises the following steps of excavation construction of the left side wall pilot tunnel support (1), excavation construction of the right side wall pilot tunnel support (2), excavation construction of the mid-partition support (3), excavation construction of the middle supports, and excavation construction of the lower supports. Sinking of arch surrounding rock is forcefully resisted, construction safety is guaranteed, meanwhile the construction time of an anchor cable is shortened, and engineering materials are saved.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +1

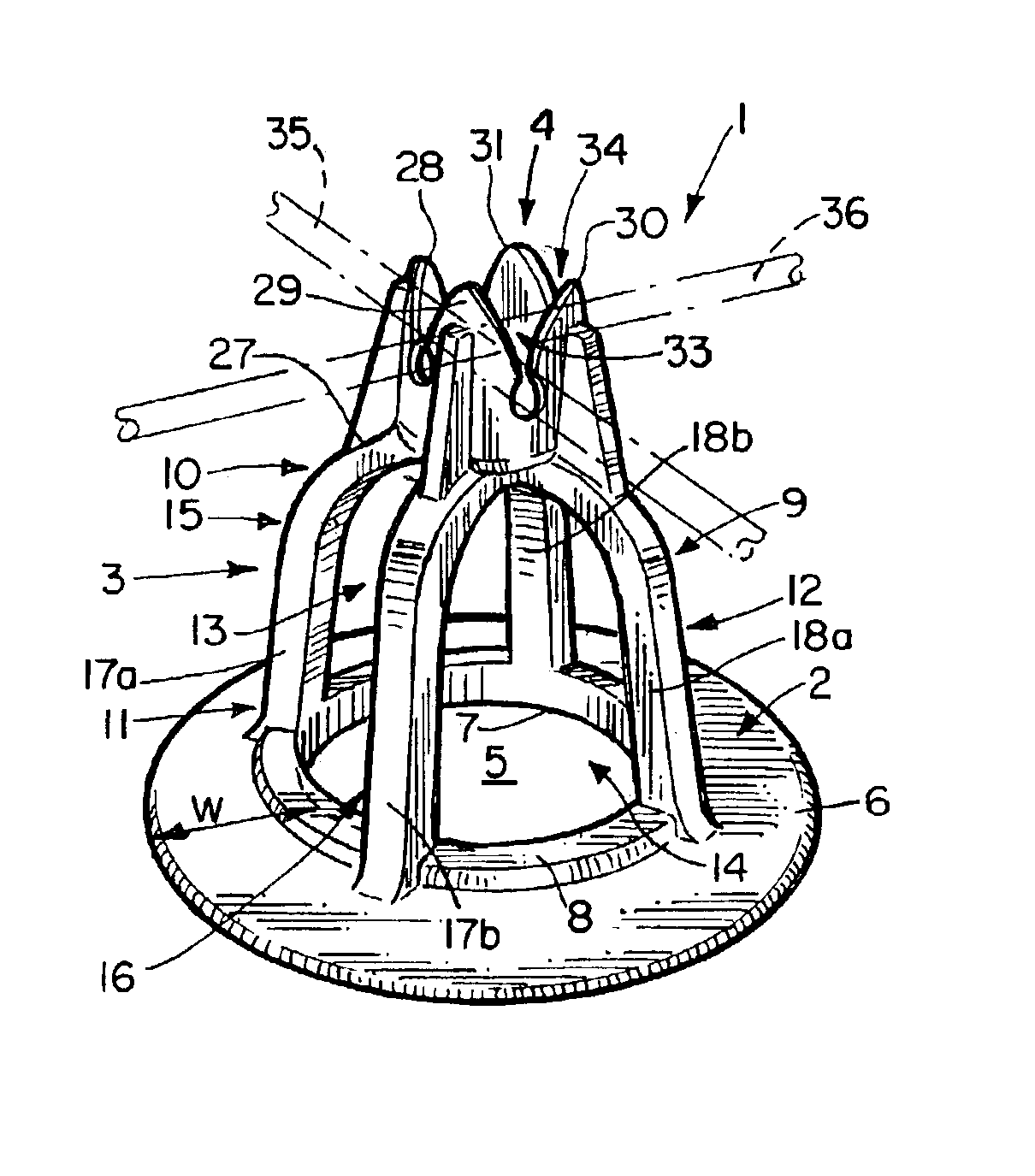

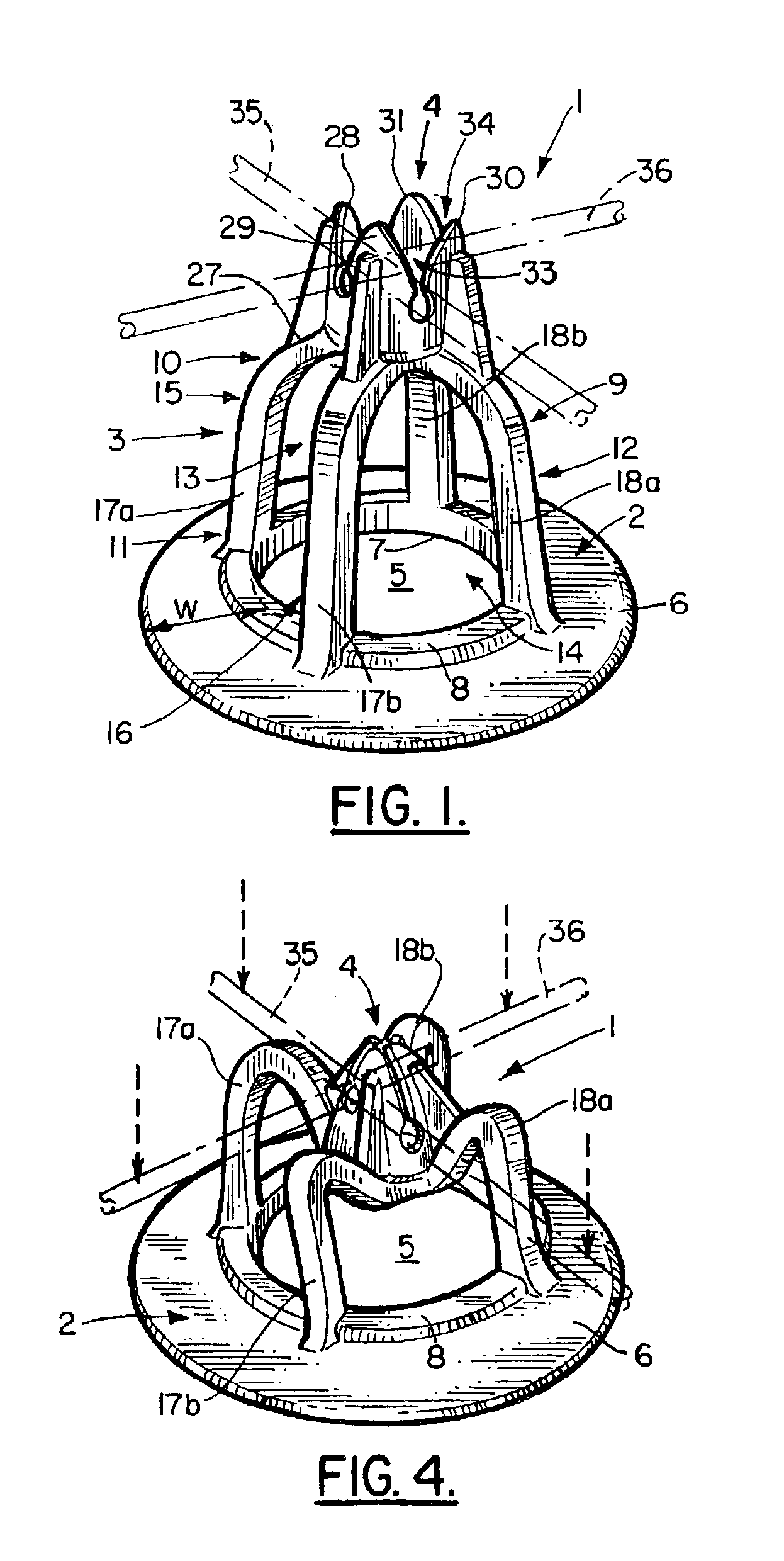

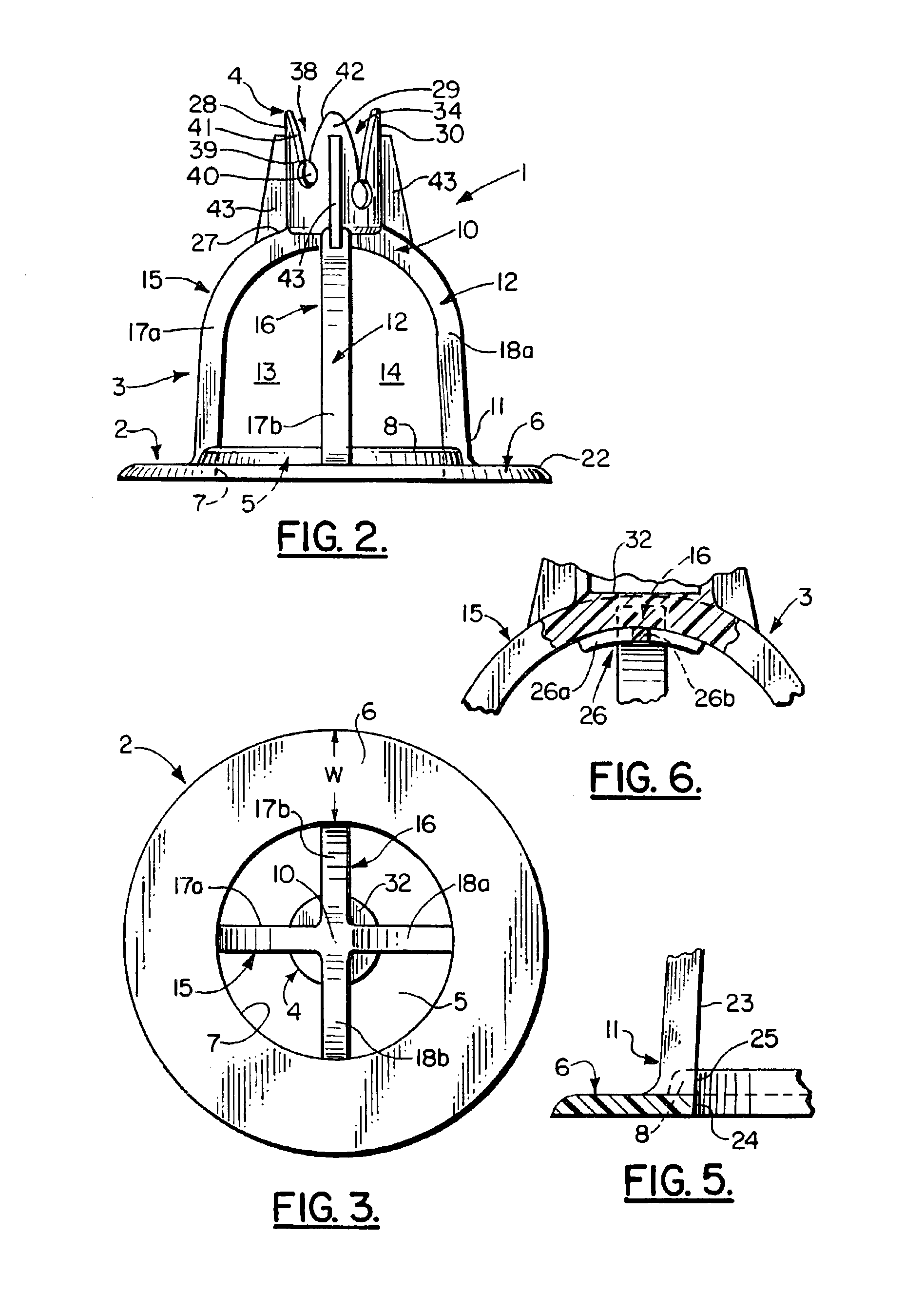

Chair for supporting wire mesh

InactiveUS6962029B2Reduce crackingLess plasticPaving detailsBuilding reinforcementsHigh densityEngineering

An improved chair for supporting intersecting wires forming a wire mesh at a pre-selected elevated position above a bearing surface during formation of a concrete slab is constructed having a base member shaped to rest on the bearing surface, a compressible support structure having a lower section affixed to the base member, a middle section and an upper section affixed to a setting shaped to support the wire mess at the elevated position. The chair is constructed having an improved compressible, generally bell-shape support structure having two pairs of opposing arched-shaped openings in the middle section forming two intersecting arches, each arch having a pair of opposing flexible legs that bow outward when a pre-determined load is applied to the upper section. The support structure further having a strengthening plate affixed on an interior surface of the upper section of the support structure formed by the intersecting arches. The chair constructed from a blend of high density and low density crystalline polymer.

Owner:JOHN L LOWERY & ASSOC

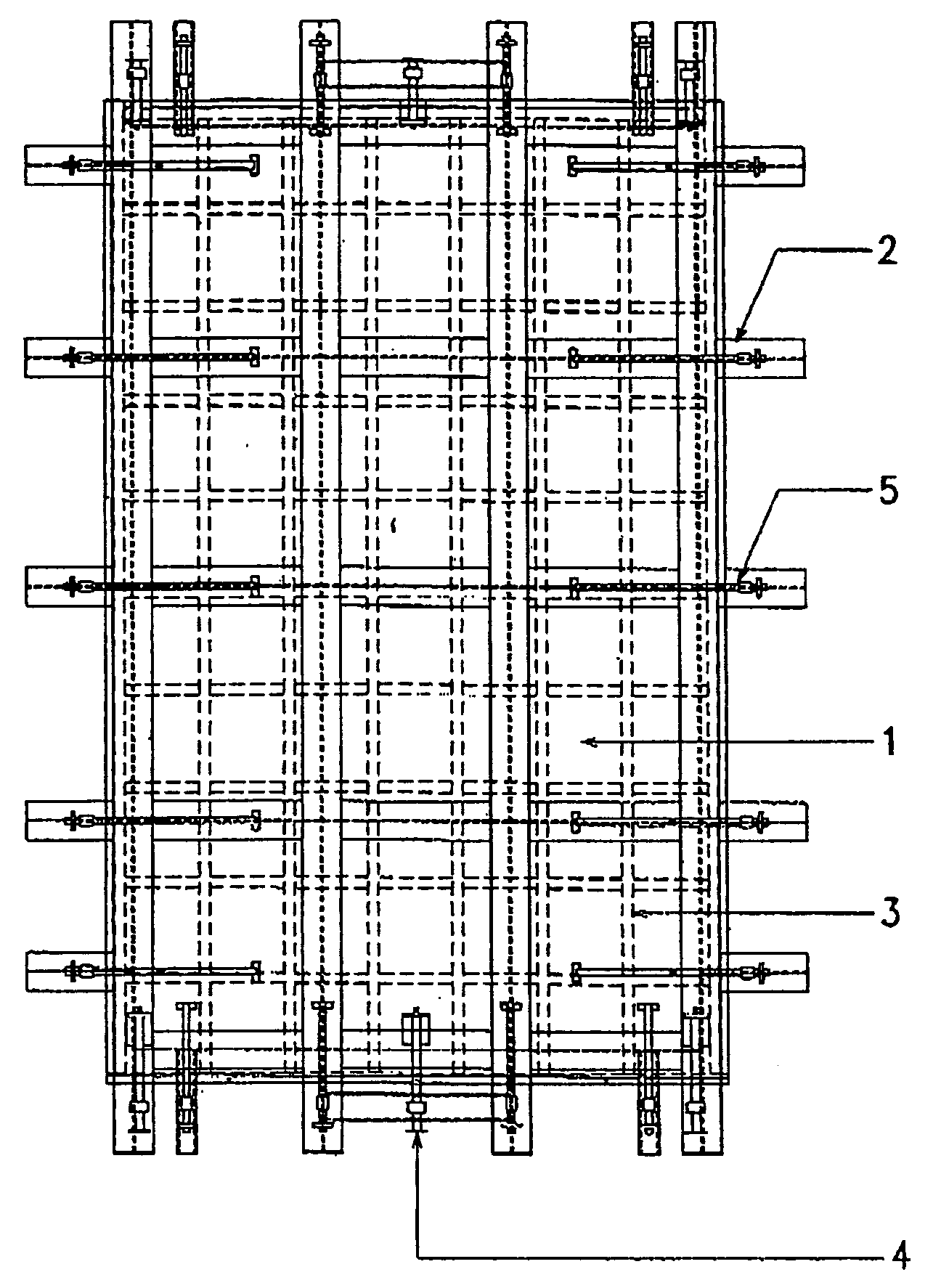

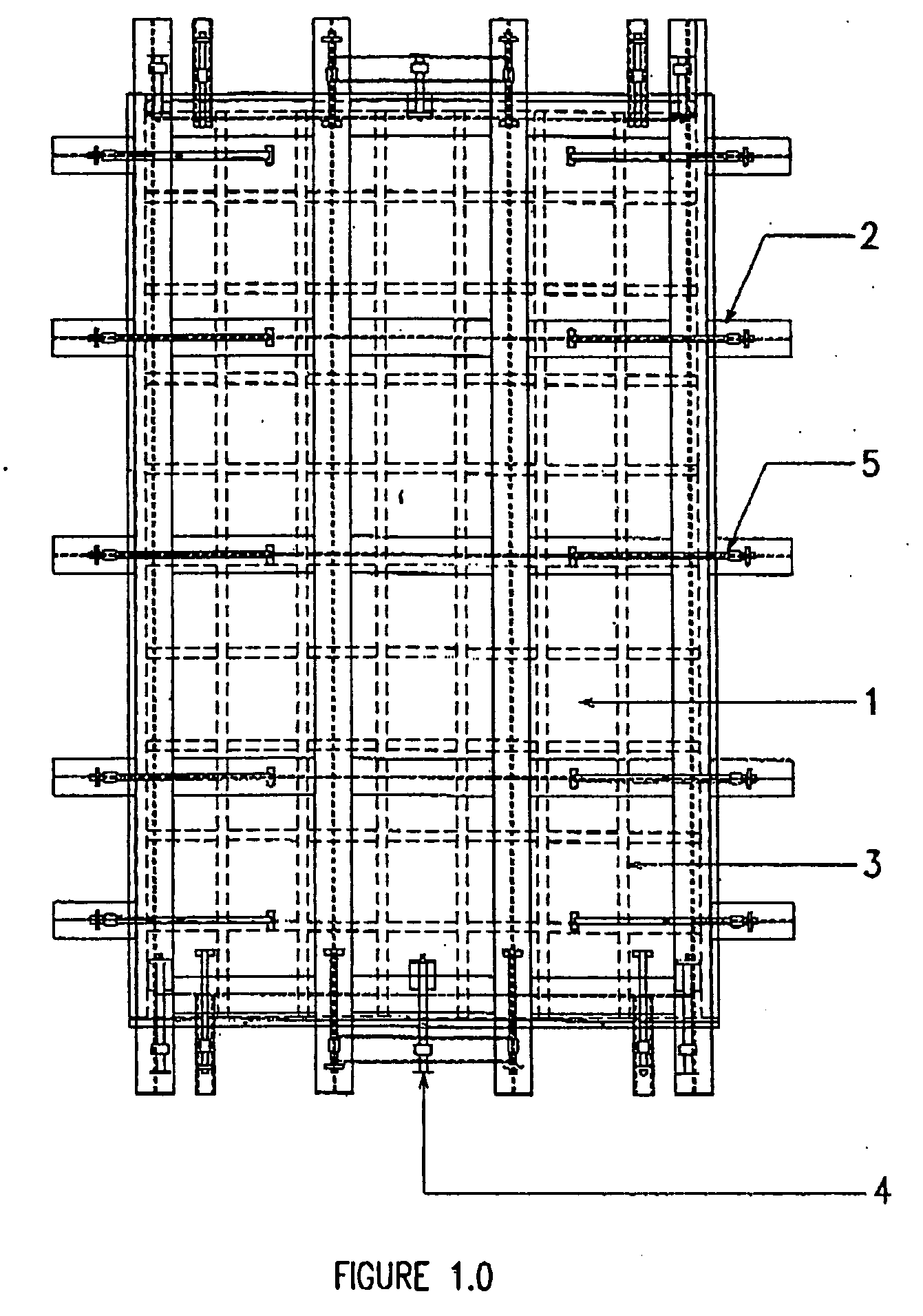

Panel formwork system

Formwork system for the process of casting prefabricated wall and slab panels that is flexible in width and height is provided. This formwork system includes two types of retractable bracing structures that are located on the sides and ends of mould structure. The height and width of panels can be varied by moving the linear retractable bracing structure, while the lever retractable bracing structure holds the side form firmly by clamping down the side form to the platform of the support structure. The thickness of the panel to be cast can be varied by using different modules of side form that are designed to produce a series of modules of various heights. Various patterns on the wall can be designed by incorporating specially designed channels in the mould.

Owner:HC PRECAST SYST

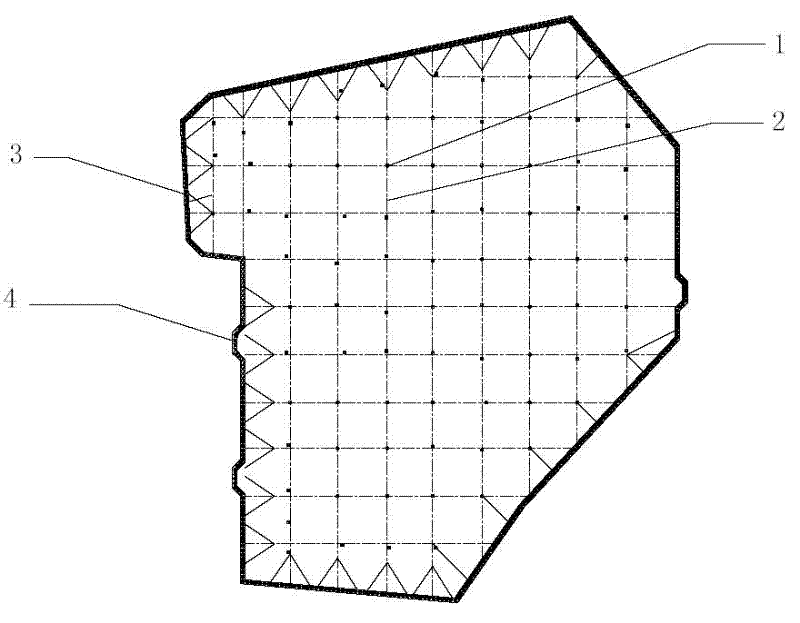

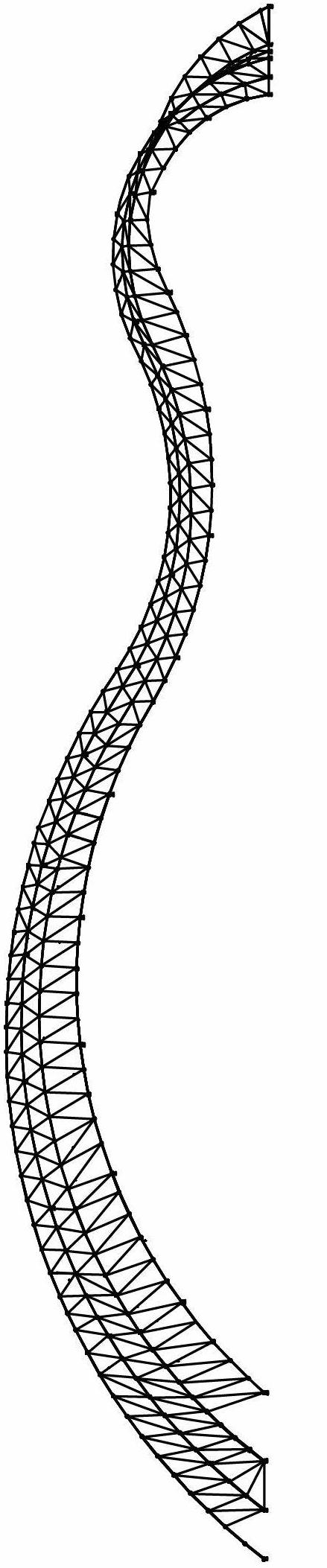

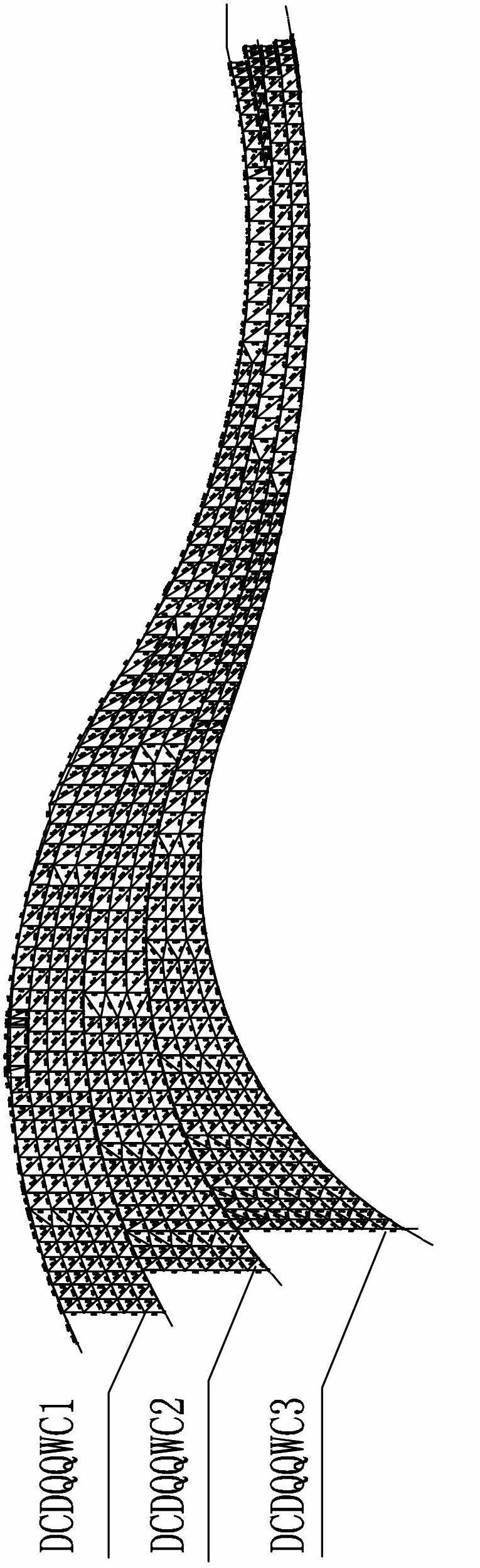

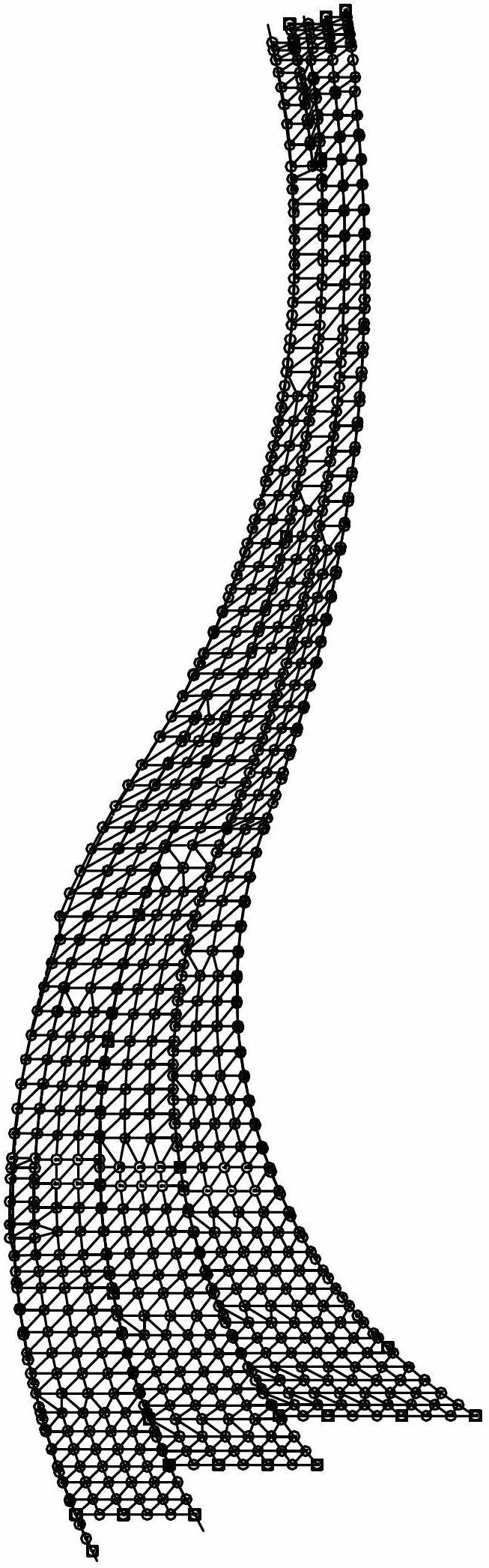

Multilevel multi-curve single-layer welding ball steel structure net rack and construction method thereof

InactiveCN102660996AFair useReasonable designBuilding roofsBuilding material handlingReinforced concreteRebar

Disclosed is a multilevel multi-curve single-layer welding ball steel structure net rack. Each layer of the multilevel multi-curve single-layer welding ball steel structure net rack comprises a structurally separated rod and a hollow ball which are connected into a whole in a welded manner; an elastic support positioned on a reinforced concrete vertical column is connected with each layer of the multilevel multi-curve single-layer welding ball steel structure net rack through a net rack supporting part; the elastic support is capable of inching in a certain direction or an optional direction, and the net rack further comprises a cable-supported structure consisting of a cable-supported structure support, a cable-supported ball, a pull cable and a cable-supported ball supporting rod. The net rack is unique in appearance and suitable for serving as a building steel structure support which has high requirements on the appearance of a building, is unique in appearance and needs to display arc shapes, line shapes, shell shapes and staggered levels, and the construction method of the net rack can be used for effectively controlling space coordinates and positional accuracy of components of the net rack, structural stability and structural appearance diversity of the net rack during installation, so that the requirements of a building structure on high, large, difficult and multidirectional change can be met.

Owner:广西建工第五建筑工程集团有限公司

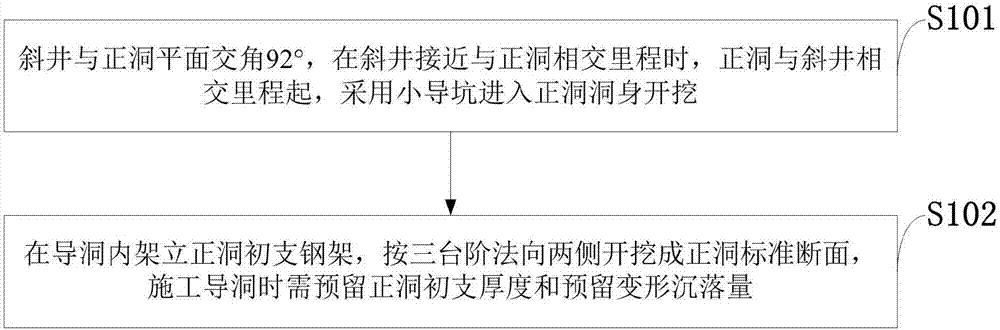

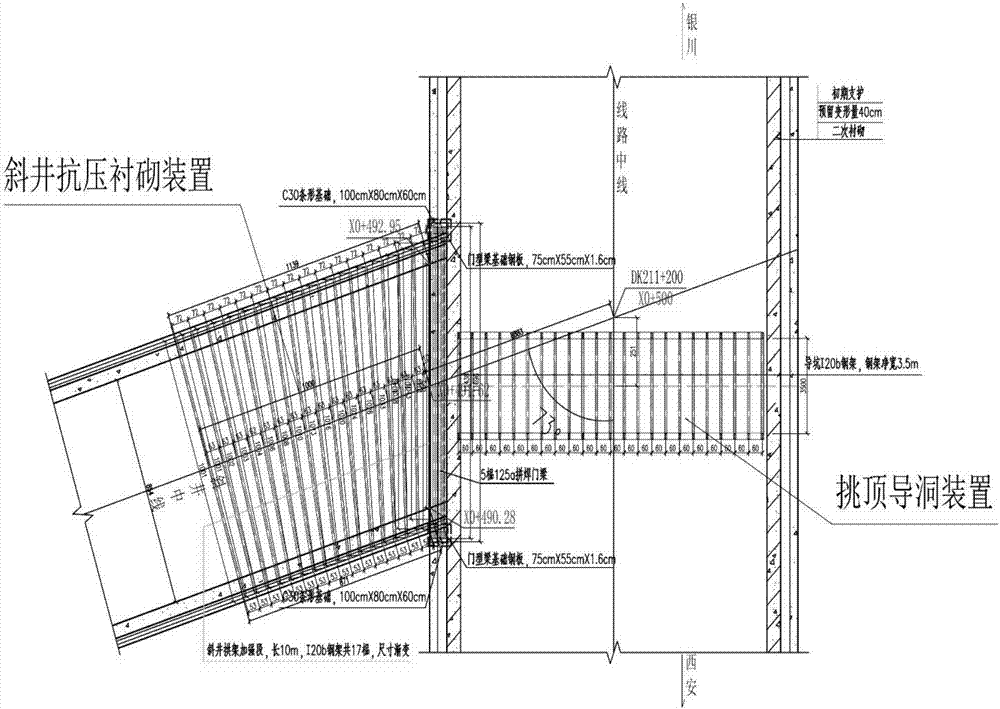

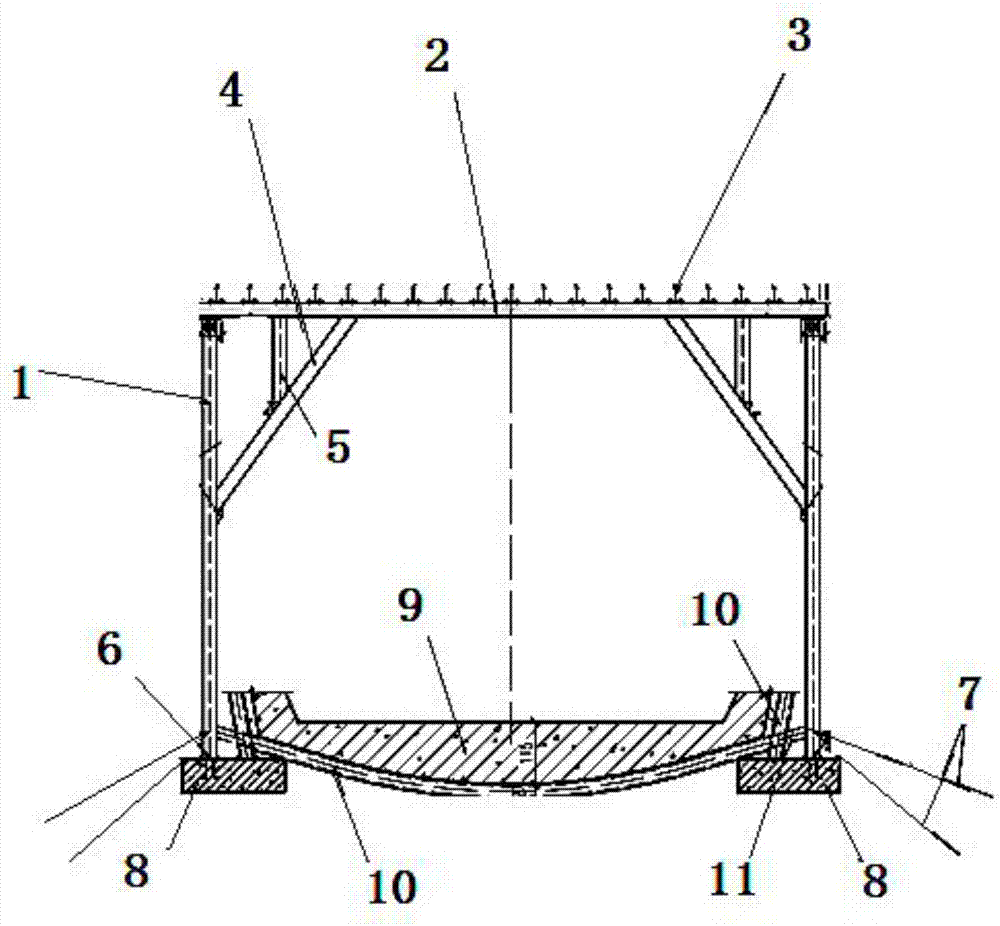

Novel tunnel inclined shaft specific and special construction method

ActiveCN106907161ASimple and fast operationLow costUnderground chambersTunnel liningClosed loopSteel frame

The invention belongs to the technical field of tunnel construction, and discloses a novel tunnel inclined shaft specific and special construction method. A main tunnel section is decomposed into a small cavern in a cross entry mode, then sectional digging is conducted toward the two sides of the small cavern separately, with an auxiliary tunnel composite lining structure being a base point, a primary support structure in the small cavern is supported to form a stable triangular structure, and construction conversion of digging the main tunnel toward the two sides of the main tunnels through a step method is quickly completed; when an inclined shaft is close to a main tunnel cross mileage, from a cross interface, through a method of digging a small pilot tunnel, a main tunnel body is entered to be dug, a main tunnel primary support steel frame is erected in the pilot tunnel, an erection point is acted on the upper part of an inclined shaft five-truss spliced door beam, bolt connection is conducted, a stable system of early closed loop support is completed, then according to a three-step method, digging is conducted toward the two sides of the main tunnel to form a main tunnel standard fracture surface, and a main tunnel primary support thickness and a deformation sunk amount of 40cm need to be reserved during construction of the pilot tunnel. According to the novel tunnel inclined shaft specific and special construction method, the potential safety hazard in the main tunnel specific and special construction process can be lowered to the lowest, and time influence can be reduced to the shortest.

Owner:THE 5TH ENG OF CHINA RAILWAY 22TH BUREAU GROUP +2

Pressure compensation type foundation pit supporting structure and construction method

ActiveCN105155551AControl deformationChange stressExcavationsArchitectural engineeringMechanical engineering

The invention relates to a pressure compensation type foundation pit supporting structure and a construction method. The pressure compensation type foundation pit supporting structure is characterized in that a multi-cavity back-pressure bag composed of a plurality of continuous airtight cavities is arranged on the base foundation supporting side; a bag top beam and a bag bottom beam connected with the bag in an airtight manner are arranged on the top and at the bottom of the multi-cavity back-pressure bag respectively; the bag top beam and the bag bottom beam are connected with a transverse counterforce structure and a vertical counterforce structure respectively; transverse counterforce beams and vertical counterforce beams are arranged at partitions of the airtight cavities; transverse reinforcement bodies are arranged at the crossed parts of the transverse counterforce beams and the vertical counterforce beams; cavity pressurizing pipes and cavity grouting pipes are arranged in the cavities of the multi-cavity back-pressure bag; and a tension steering structure is arranged between the transverse counterforce structure and the side wall of a foundation pit. According to the pressure compensation type foundation pit supporting structure, the change of the stress state of a soil body due to excavation of the foundation pit can be avoided, in addition, an airtight seeping-preventing structure can be formed on the supporting side, and deformation of the soil body on the outer side can be dynamically controlled. The invention further provides the construction method for the pressure compensation type foundation pit supporting structure.

Owner:华泰建设工程有限公司

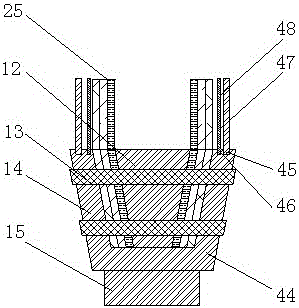

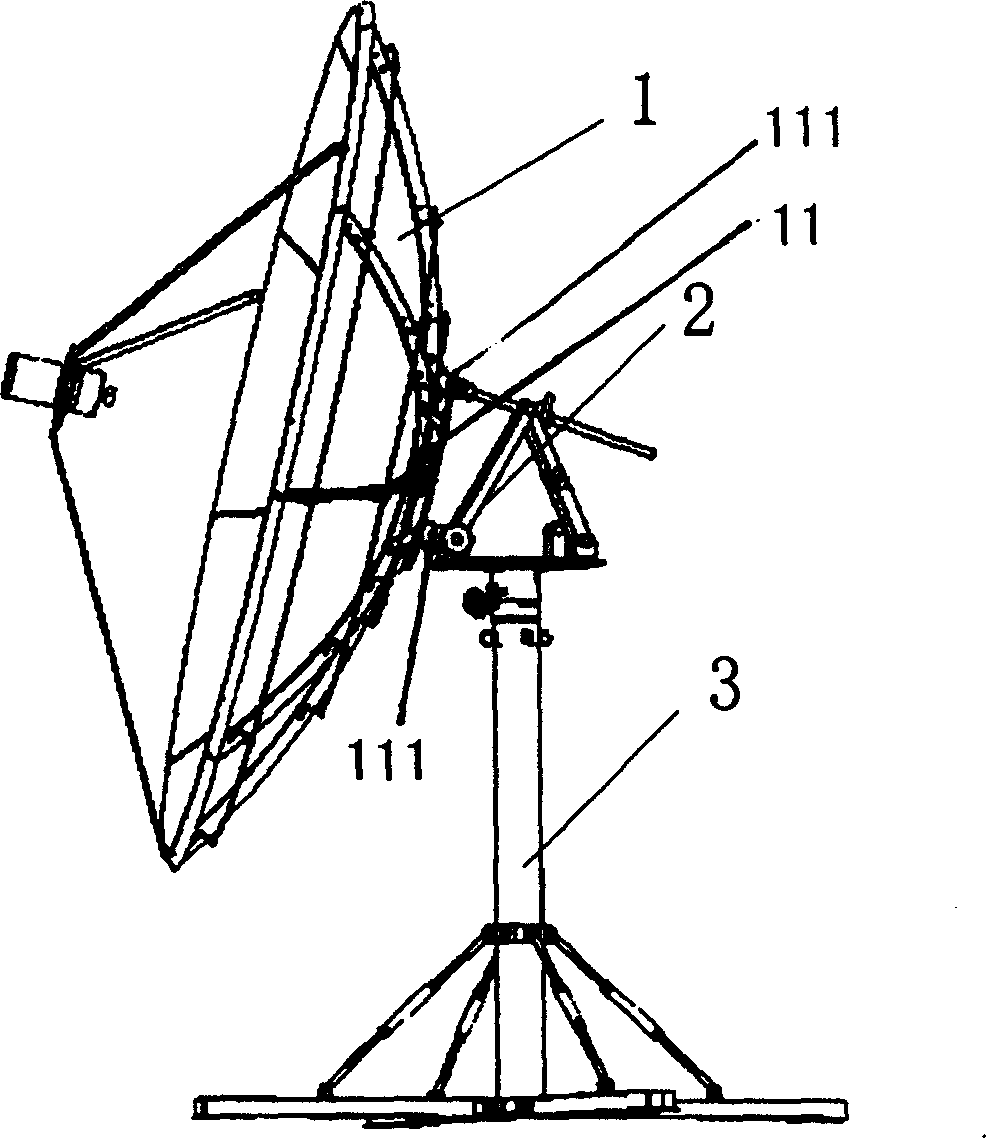

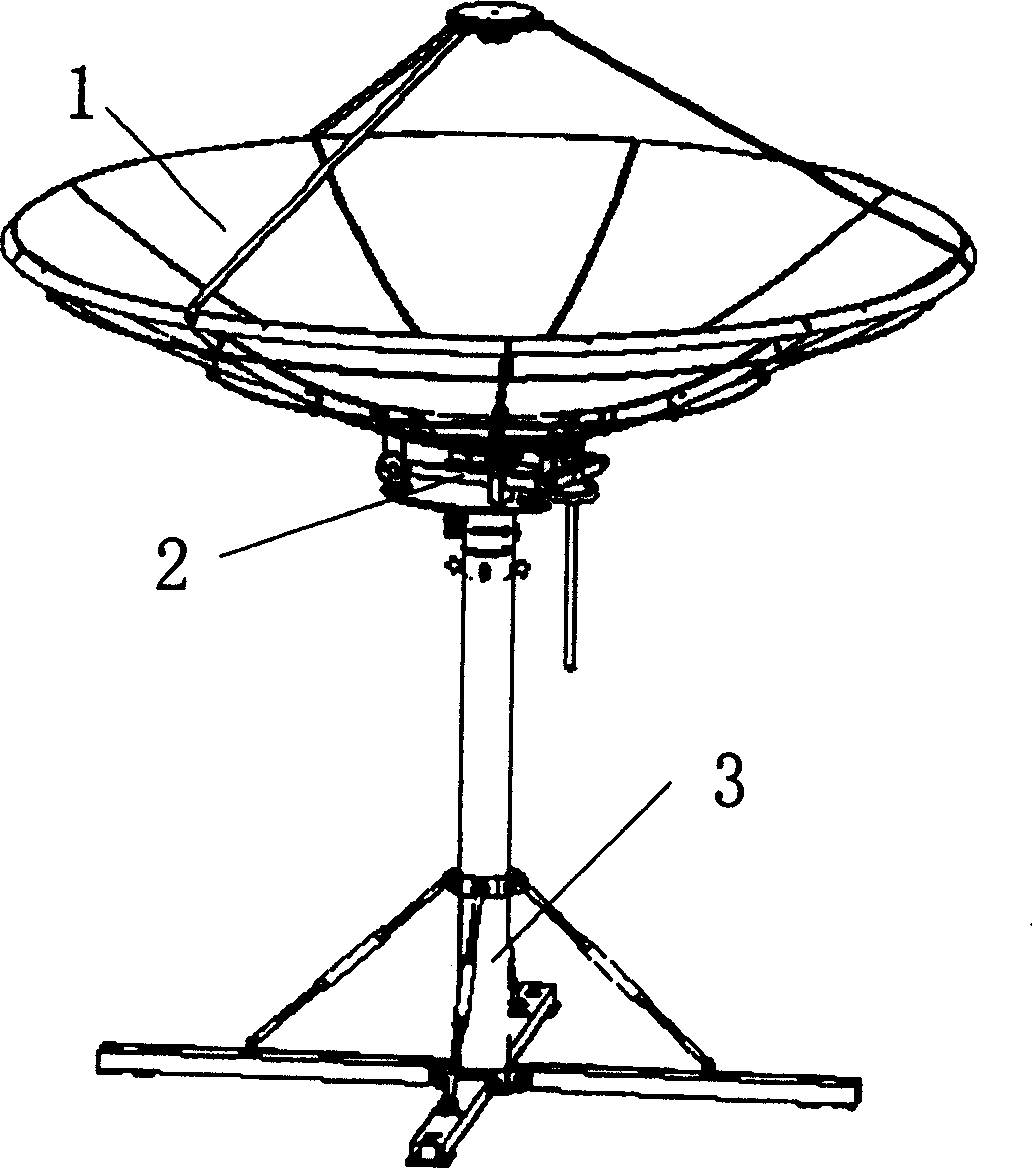

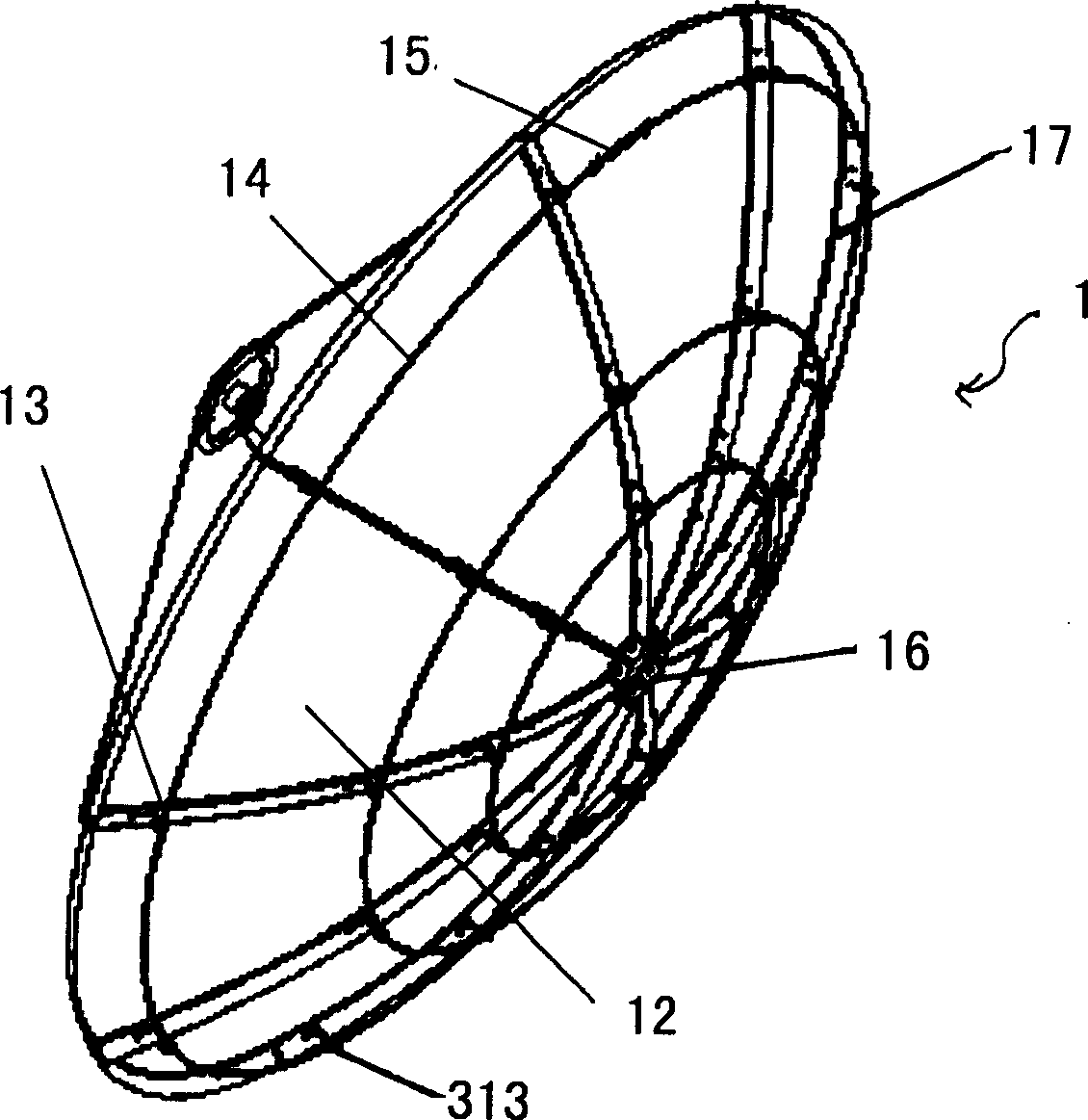

Portable parabolin antenna

InactiveCN1753247AImprove the ability to adapt to the environmentImproved Surface Shape AccuracyAntenna supports/mountingsEngineeringParabolic antenna

The invention relates to a portable paraboloid antenna, comprising a paraboloid reflector spliced rapidly of soft steel ropes, an azimuth / pitching angle adjustment mechanism having arm spindle, able to be rapidly drawn or spread and making screwed finite adjustment, and a crossed adjustable seat frame supporting structure, where the top of the back of the paraboloid reflector is fixed with a fixed seat, there are three stand bars in the proper positions on the seat, the three stand bars are rotatably connected on one side of the azimuth / pitching angle adjustment mechanism; the azimuth / pitching angle adjustment mechanism is fixed on the top end of the seat frame supporting structure; the seat frame supporting structure stands on the ground or corresponding platform. The invention has the characters of simple structure, light weight, good maneuverability, etc, suitable to be used by small group taking part in the field work or on occasion of needing to often move.

Owner:NAT ASTRONOMICAL OBSERVATORIES CHINESE ACAD OF SCI

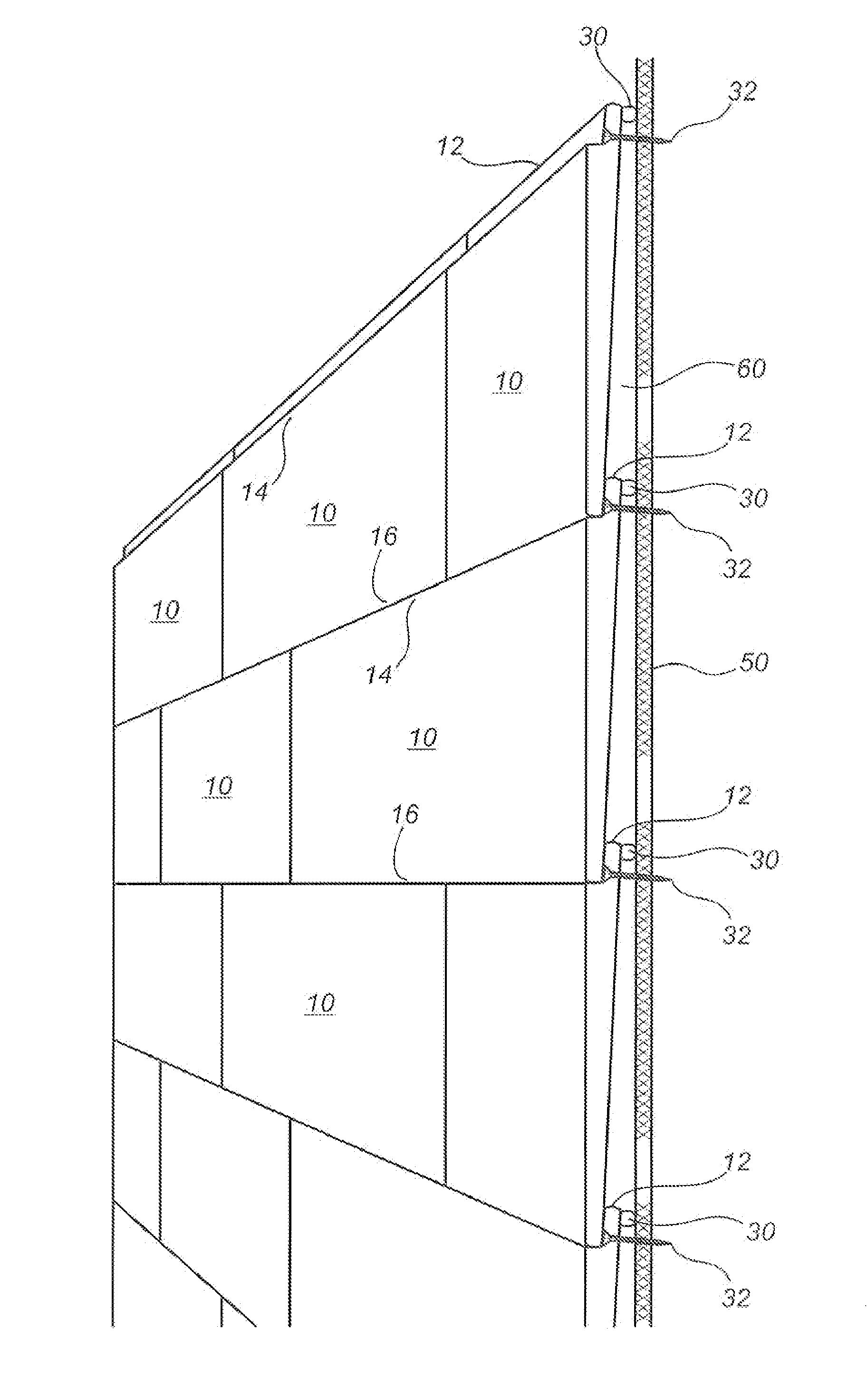

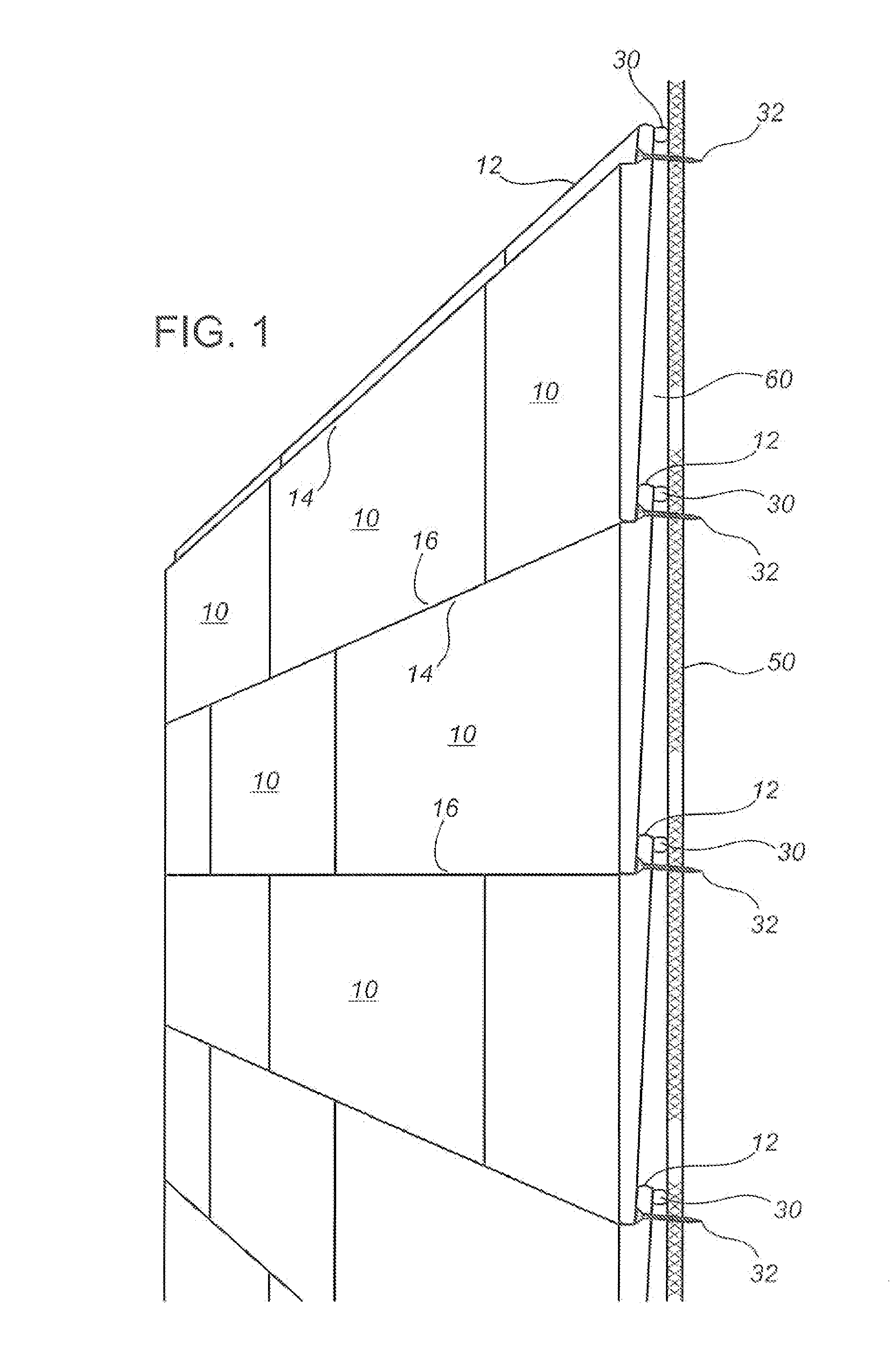

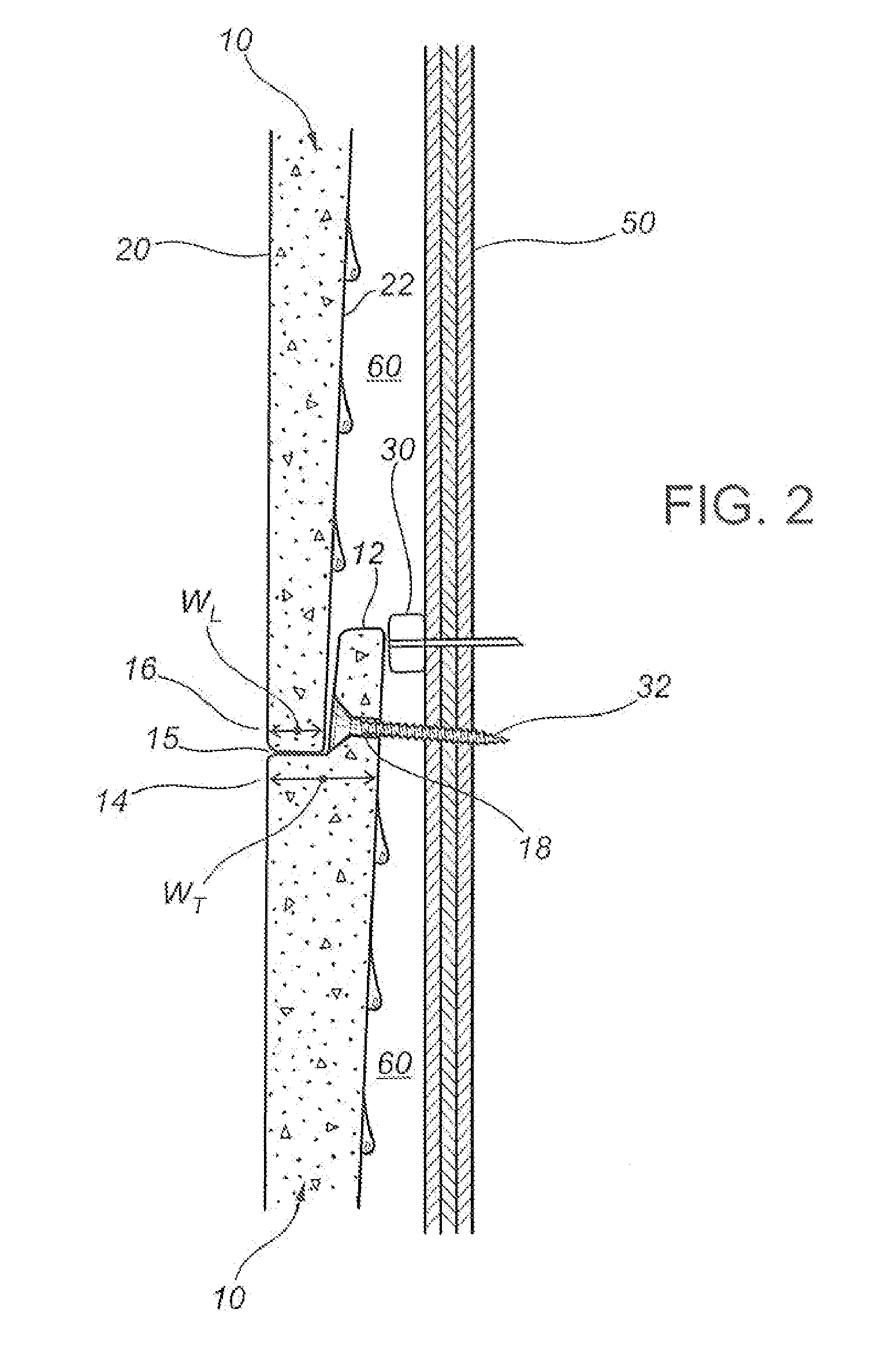

Hangerless precast cladding panel system

InactiveUS20070186501A1Improve drainage efficiencyCeilingsRoof covering using tiles/slatesAir cycleEngineering

In a precast cladding panel system requiring no cast-in mounting hardware, each panel has a continuous notch along its upper edge, forming a ledge adjacent the panel's front face, and an upstand adjacent the panel's rear face. Each panel is mounted to a supporting structure using fasteners installed through openings formed in the upstand. The panels are configured such that their lower edges fit into the notches of underlying panels, with the front faces of all panels being substantially co-planar, aided by spacer means fastened to the supporting structure adjacent to the lowermost panel course. Air circulation behind the installed panel assembly is facilitated by spaced bumpers fastened to the supporting structure so as to space the panel upstands away therefrom. Alternatively, the panels may be mounted with the upstands directly against the supporting structure, with the panels having vertical air channels formed into the upstands and rear panels faces as appropriate.

Owner:KUELKER PETER

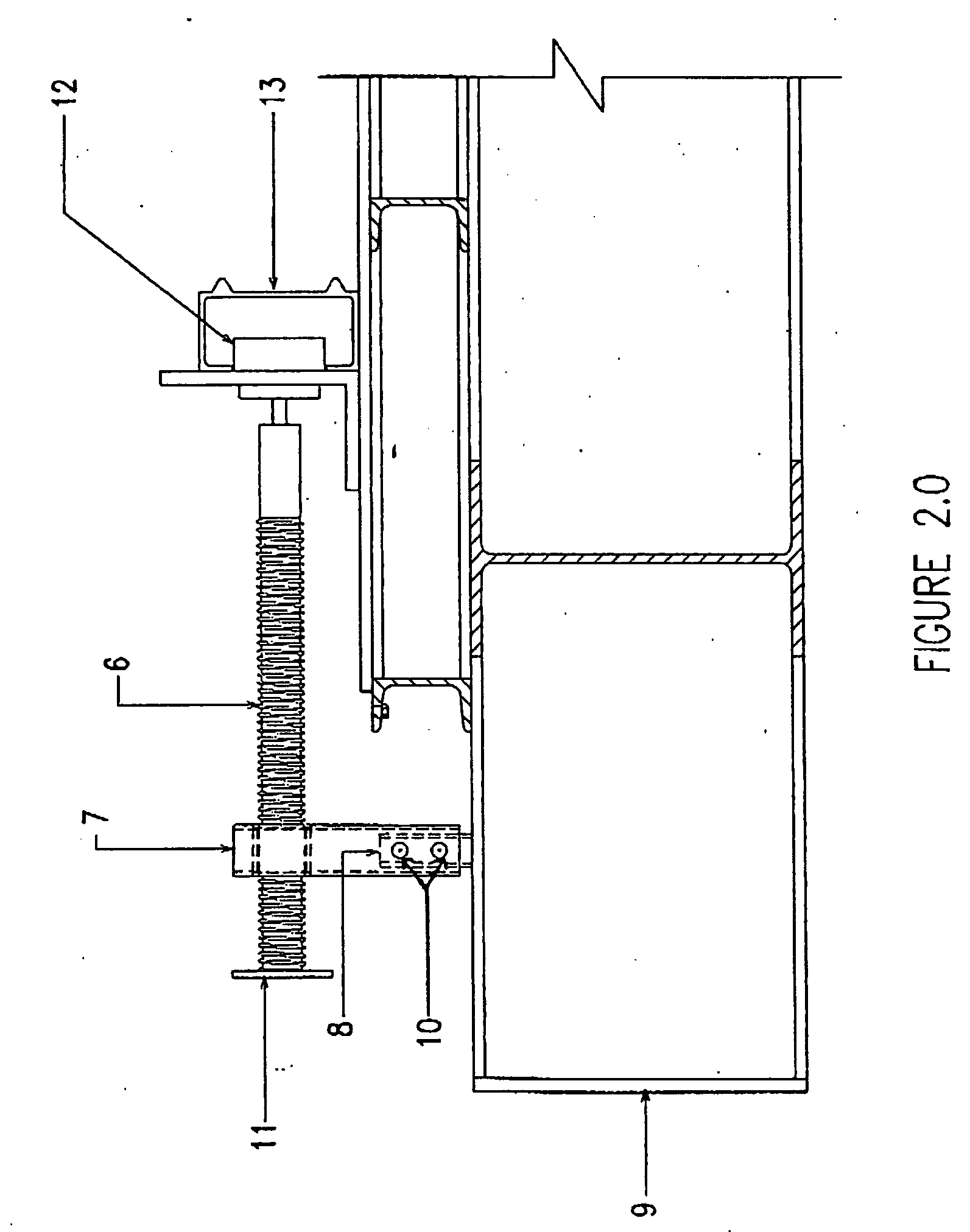

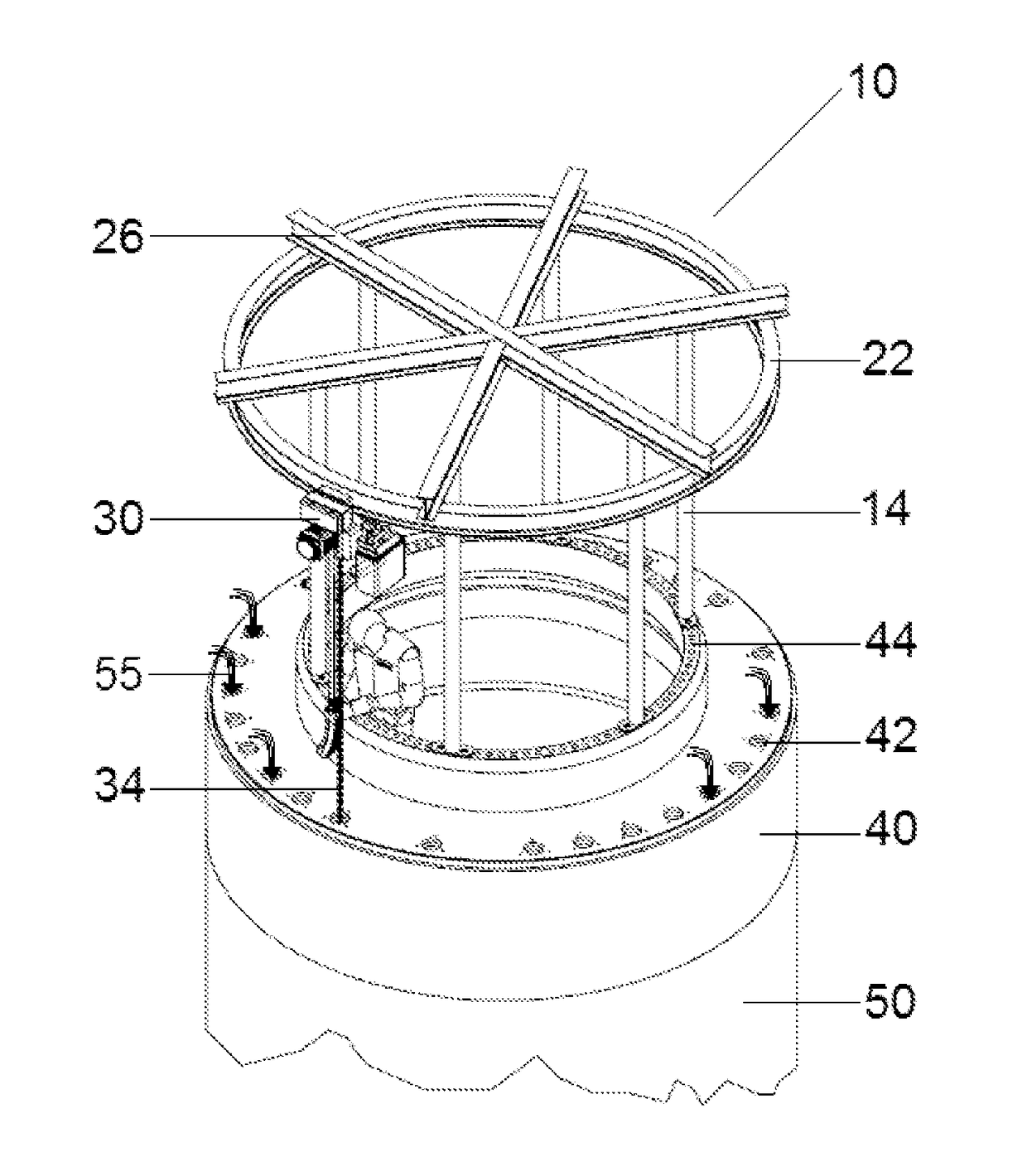

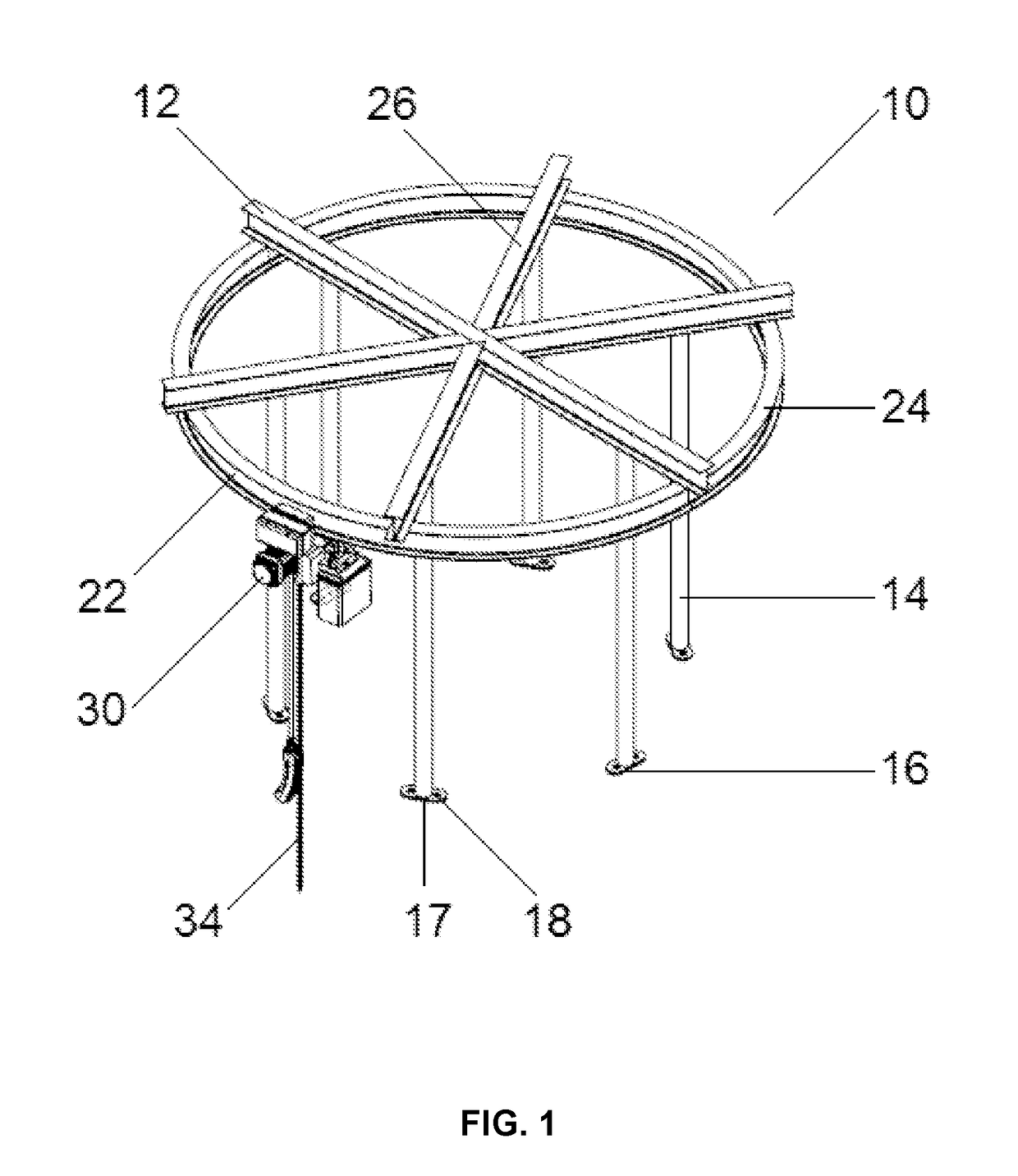

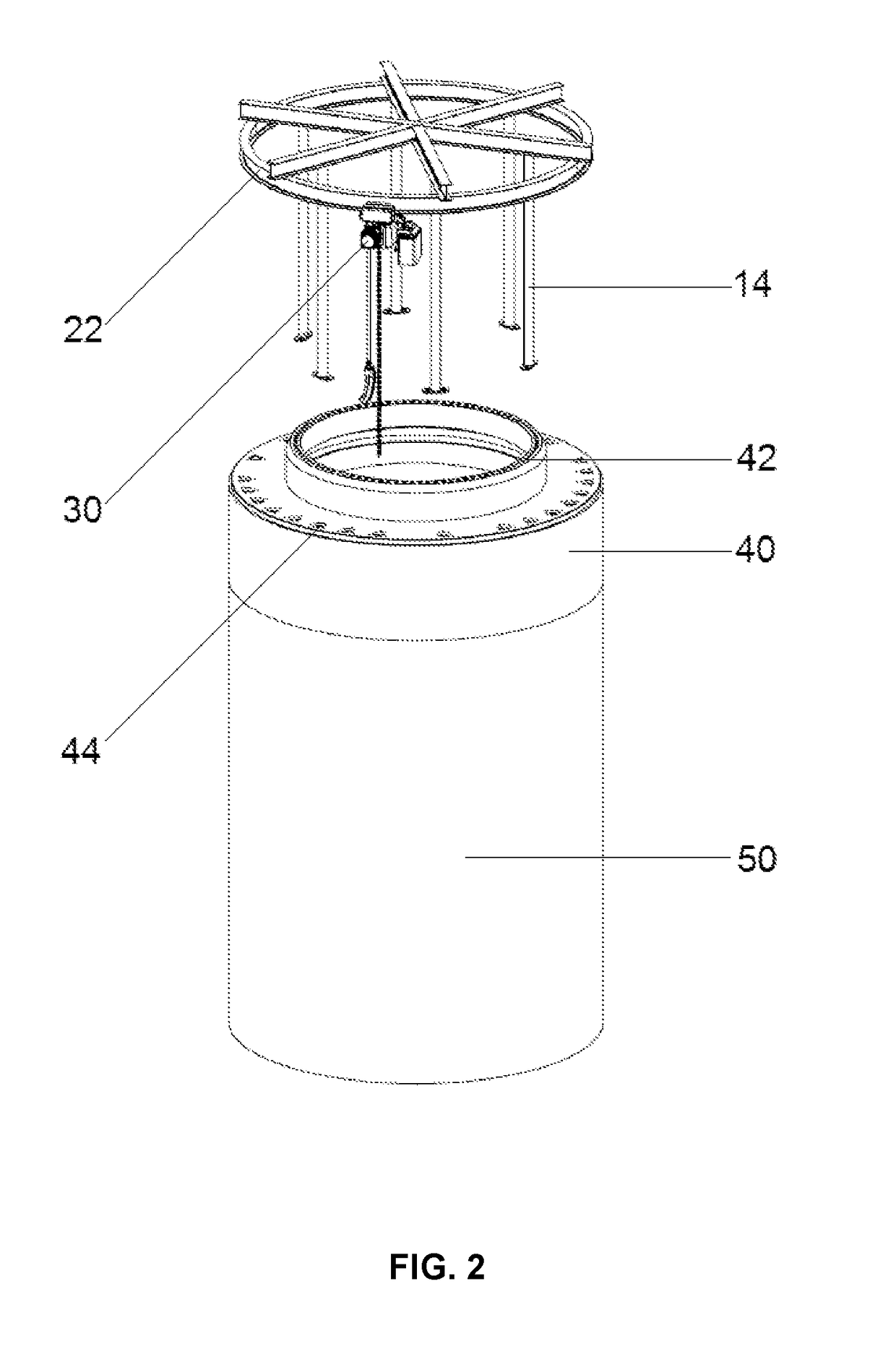

Cables lift system for vertical pre-stresing

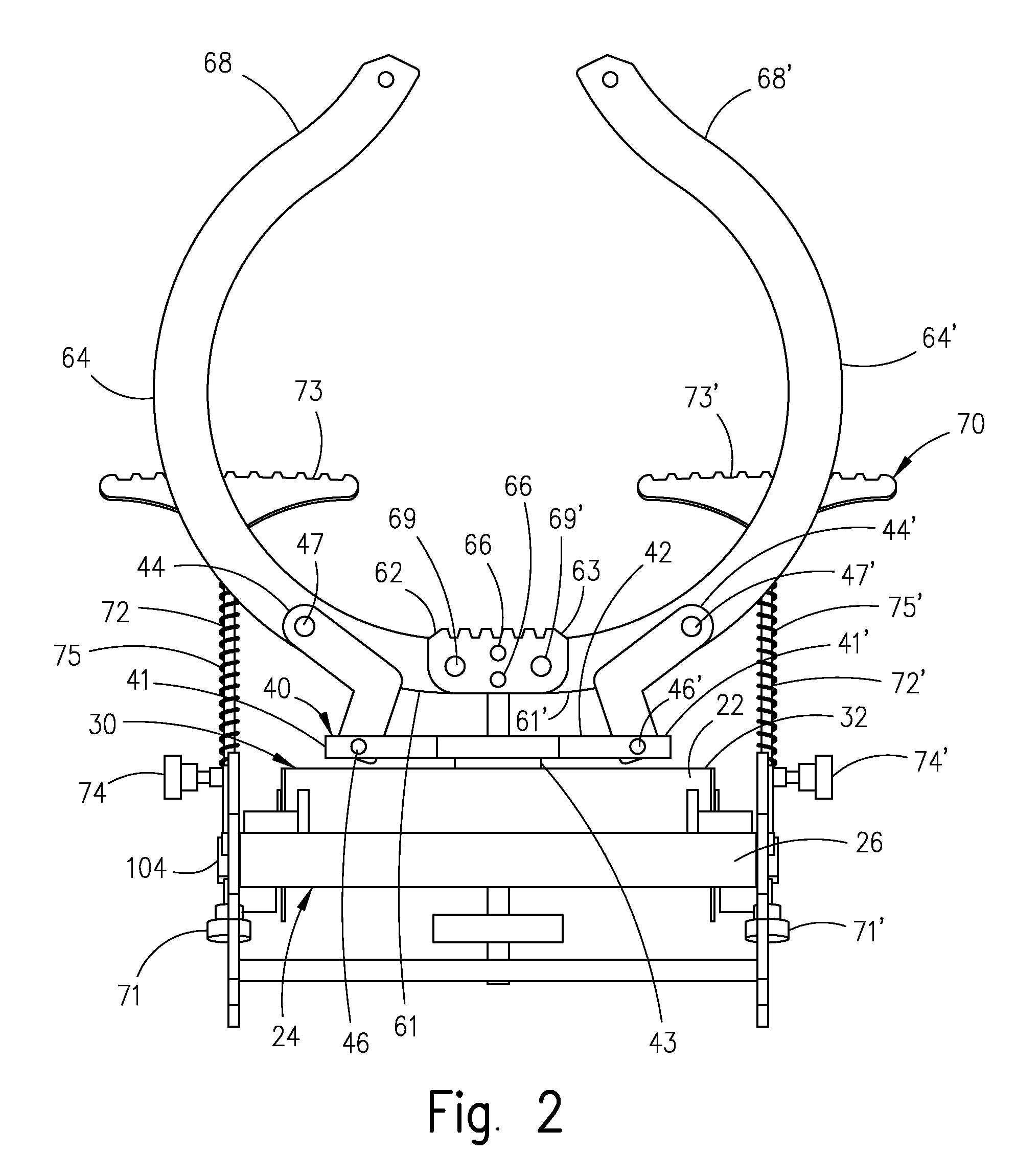

InactiveUS20170183872A1Safe working environmentWind motor supports/mountsTowersPre stressPre stressing

It is described an assembly for lifting pre-stressing cables for a pre-stressed concrete structure having ducts for pre-stressing cables, to be arranged on top of the concrete structure, comprising: (a) a rail 22 on which a hoist or pulley 30 is arranged, which has wheels, which allow hoist 30 to move along the rail 22; (b) a supporting structure 12, attached to rail 22; (c) a plurality of columns 14, which supports the supporting structure 12 of the rail 22, arranged at a certain distance from the rail; and (d) an hoists 30 having a chain 34 which is inserted into the vertical ducts 52 for the pre-stressing cables of the concrete structure, and uploads the wires to the top of the structure.

Owner:CORDERO ALEJANDRO CORTINA +2

Construction method optimizing deep foundation pit changing supporting construction sequences

InactiveCN103255772AShorten the timeShorten the construction periodExcavationsBrickArchitectural engineering

The invention relates to a construction method optimizing deep foundation pit changing supporting construction sequences. Top-down method sequence construction is adopted, and a supporting structural system of a foundation pit is formed by a drill hole potting supporting pile and a waterproof curtain. When foundation pit grooving is carried out, an original soil layer below a changing supporting structure is reserved, after the foundation pit grooving and construction of foundation brick dies are completed, the changing supporting structure and a cushion layer are poured simultaneously, the changing supporting structure and the foundation brick dies are utilized at the same time to serve as a bottom plate outer die, pouring of a foundation mat is carried out when waterproof construction is finished, and an upper part horizontal supporting structure can be dismantled when both strength of the changing supporting structure and strength of concrete of the foundation mat reach strength when the horizontal supporting structure can be dismantled. The construction method optimizing the deep foundation pit changing supporting construction sequences has the advantages of eliminating cleaning of sundries and back-fill consolidation soil operation construction, shortening a construction period, and reducing risks of the foundation pit.

Owner:TIANJIN SANJIAN CONSTR ENG

Stabilizing mechanism for ladders

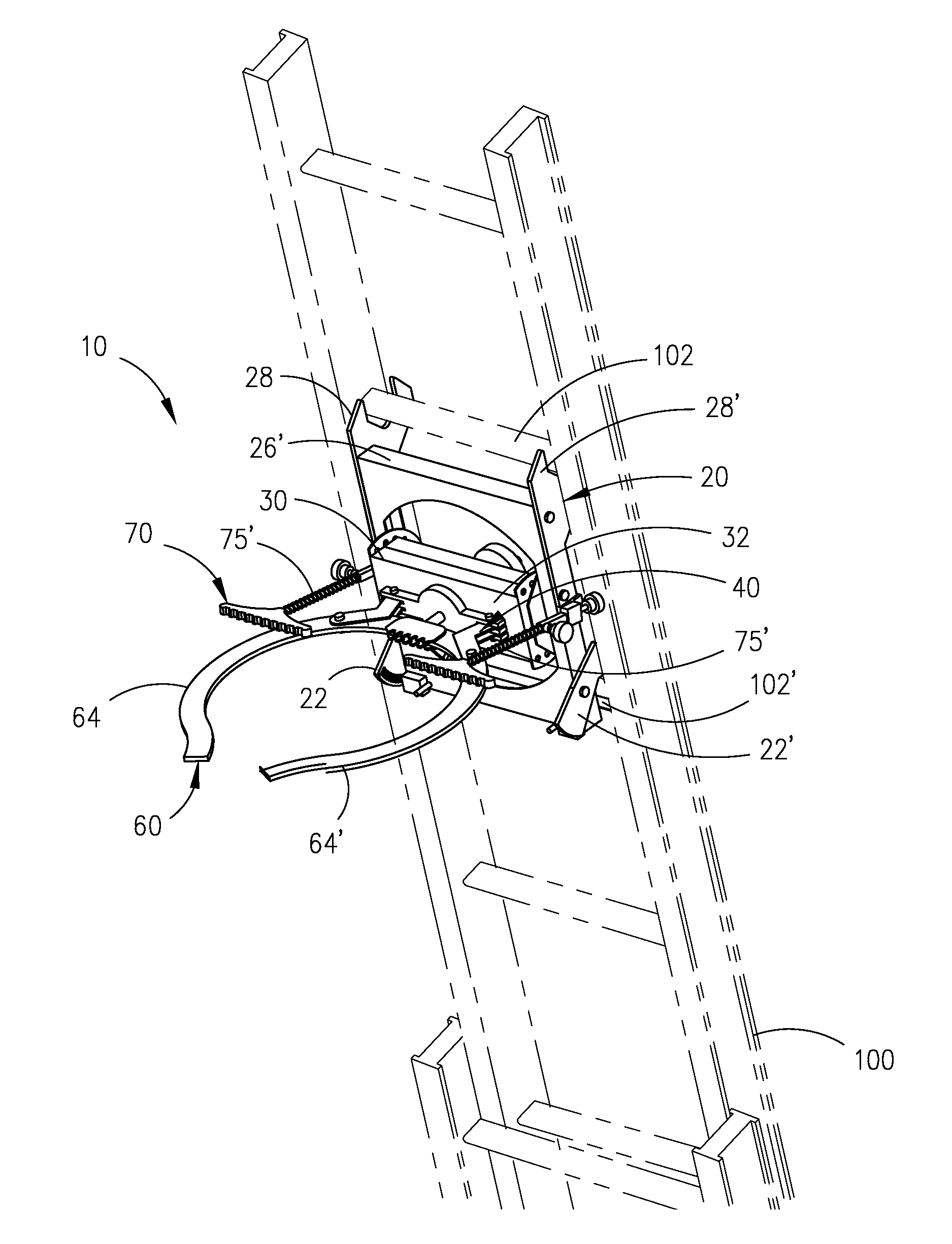

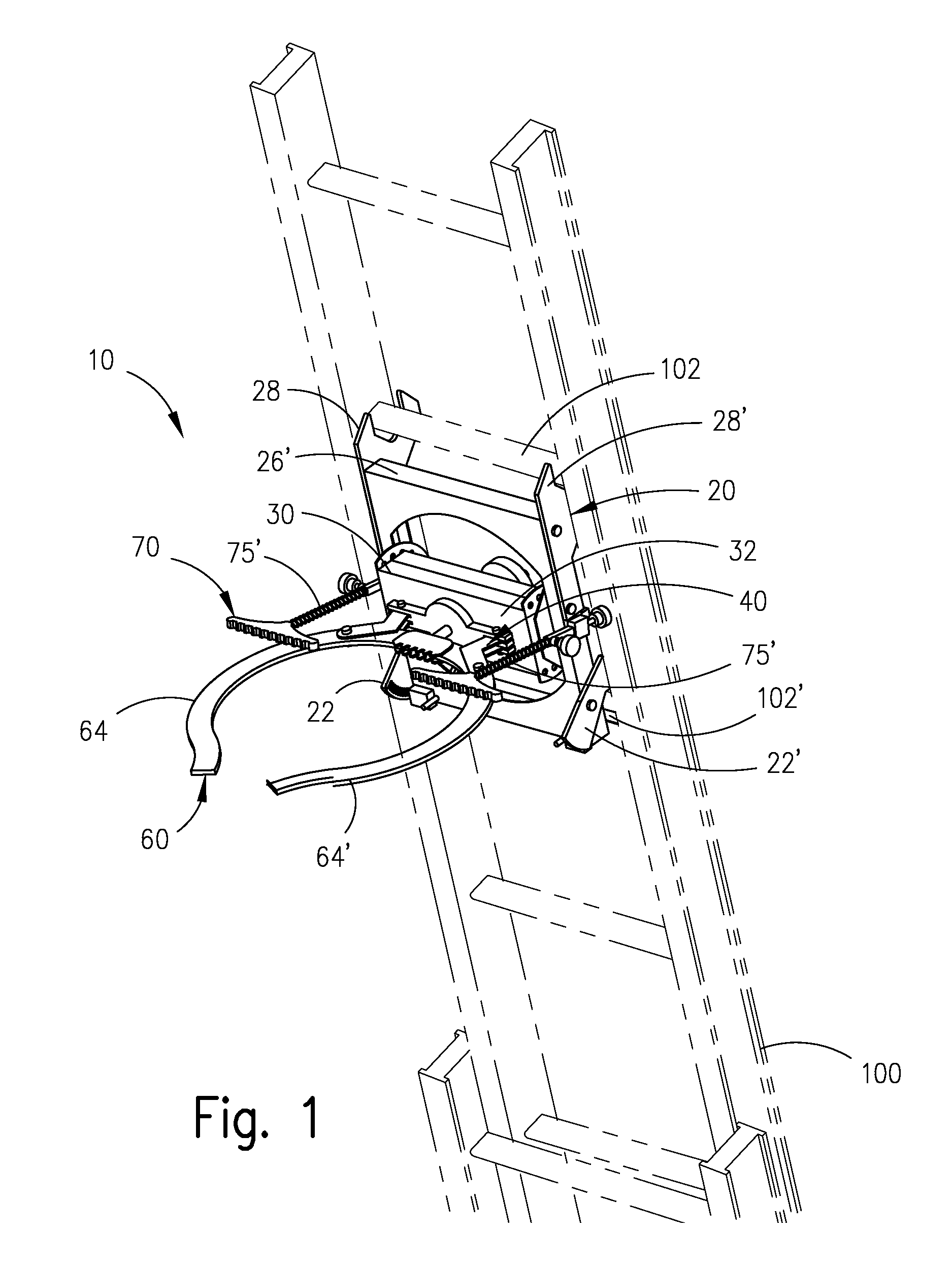

A stabilizing mechanism for rigid fixed and extension ladders that includes an anchorage assembly removably mounted to one of the rungs of a ladder. A linkage assembly is mounted to the anchorage assembly through a transversally and rotably mounted elongated base that permits the setting of linkage assembly in one of several angular positions. Two arched arm members are pivotally mounted to a plate and also, with two linkage arms that are pivotally mounted to a swivel bracket, this two linkage assembly permits the arch members to move coplanarly between two extreme positions. The arm members releasably embrace a support structure thereby providing a firm engagement of the ladder to the support structure. A stabilizing pad assembly includes two pads mounted to adjustable elongate members to engage surrounding surfaces for more stability. A release mechanism remotely disengages the ladder from the support structure after a user descends from the ladder. The engagement is kept by a locking mechanism that includes a pivoting mounted plate with a central opening A shaft rigidly mounted to the rigid plate coacts in the edge of the centered opening to permit the shaft to move in on direction only.

Owner:GUINOVART RUBEN +1

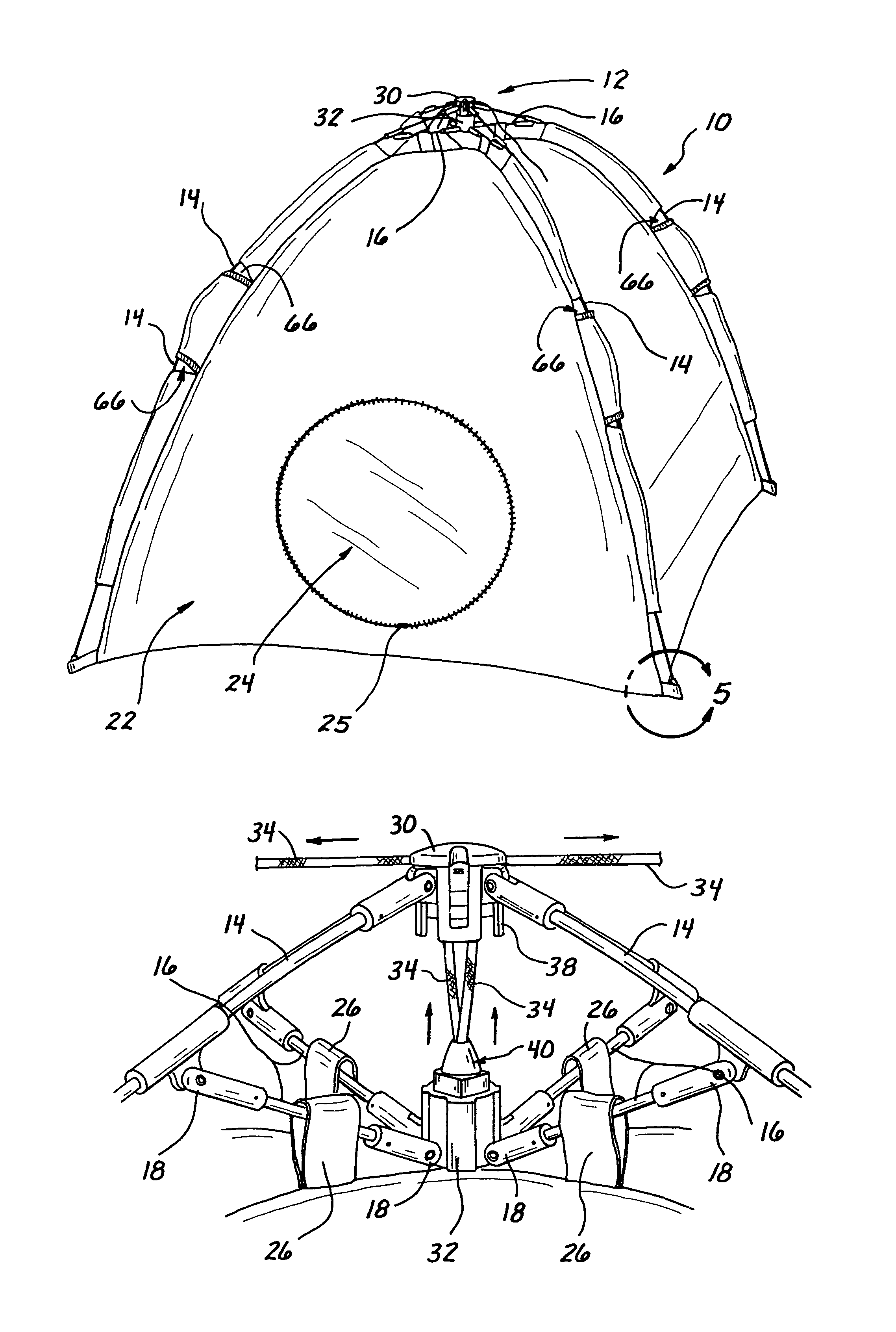

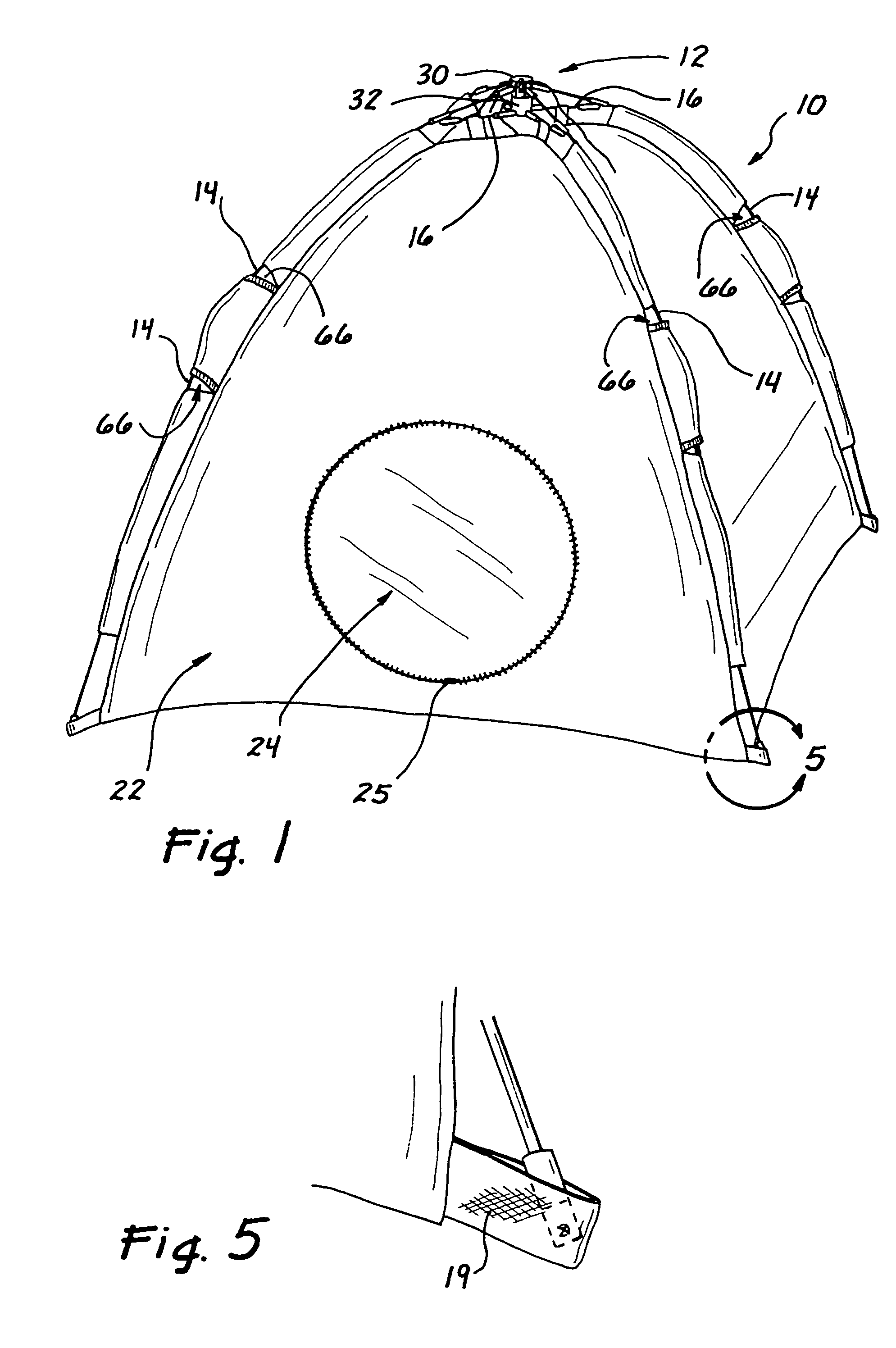

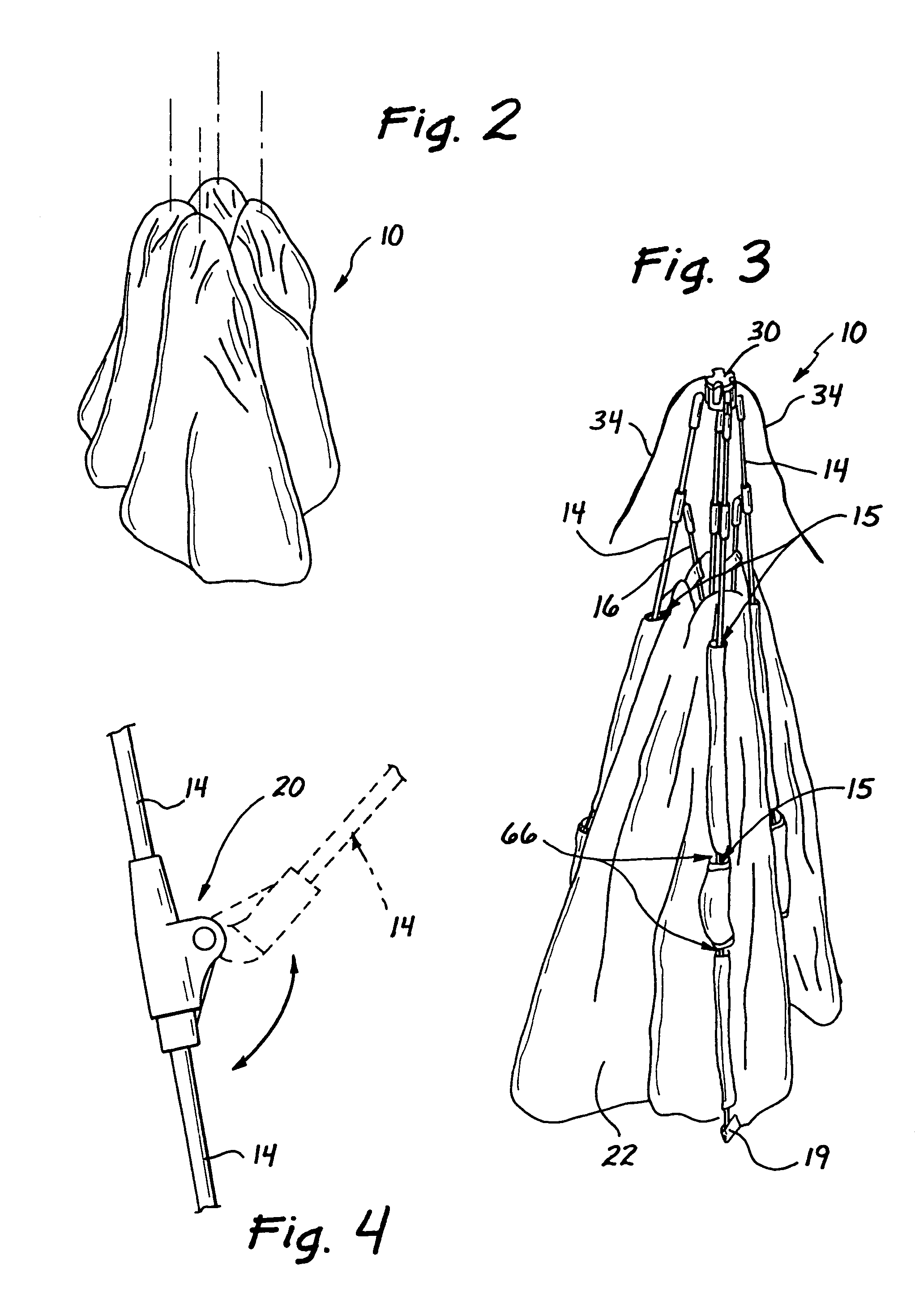

Easily constructable and collapsible portable tents

A collapsible structure comprising a collapsible support structure having a flexible covering disposed thereon. The support structure comprises a plurality of pole members that emanate from an upper assembly. The upper assembly has first and second hub members that, when brought into abutting contact with each other, cause the structure to assume a fully constructed configuration but when separated from each other allow the structure to become collapsed. In many embodiments, the structure can be converted from its constructed configuration to its collapsed configuration substantially with the use of a single hand. In some embodiments, 2 or more of the collapsible structures may be joined together to form a multi-unit structure. These collapsible structures may include decorative markings on the flexible cover, especially in embodiments intended for use by or entertainment of children.

Owner:WINPLUS

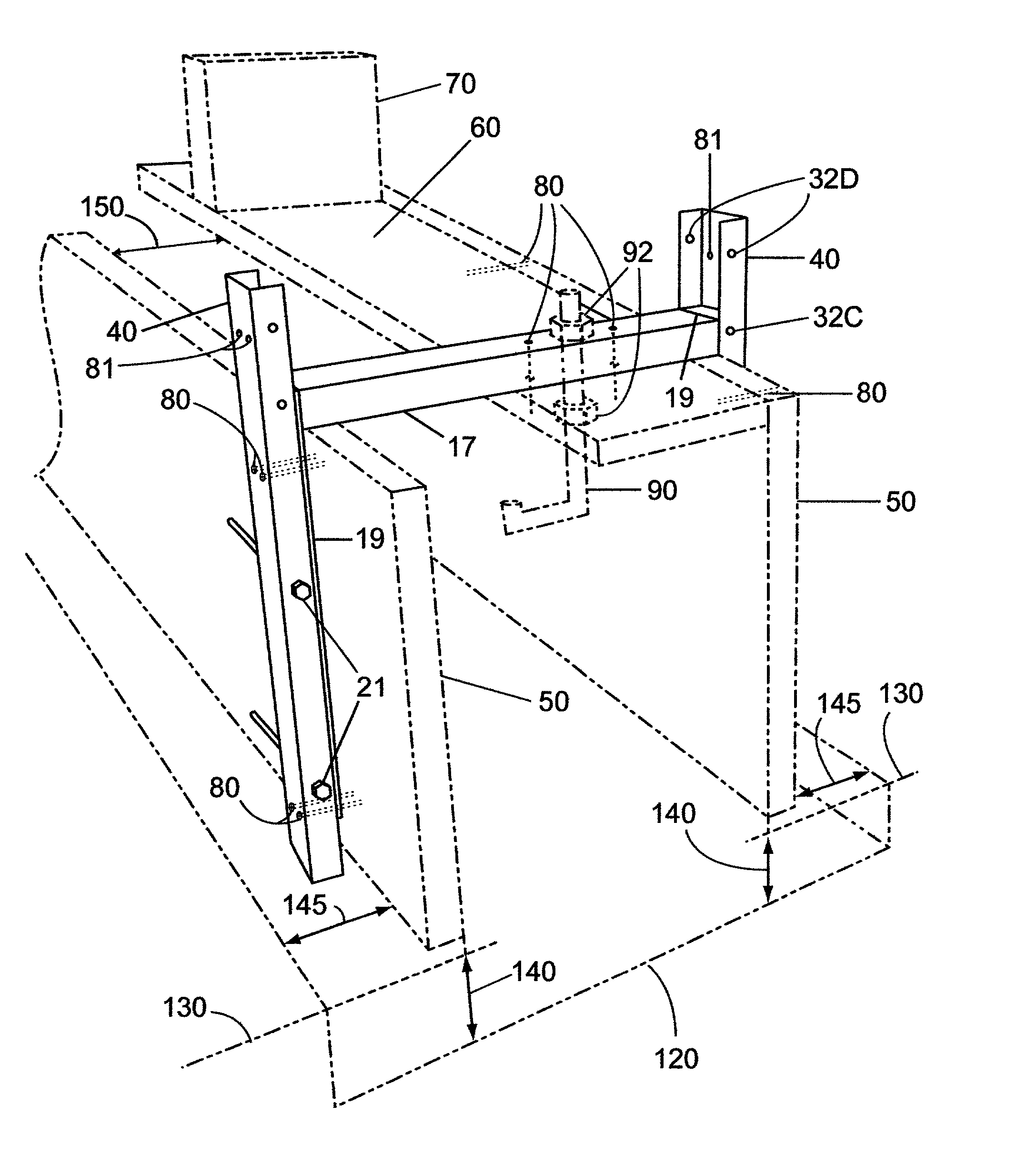

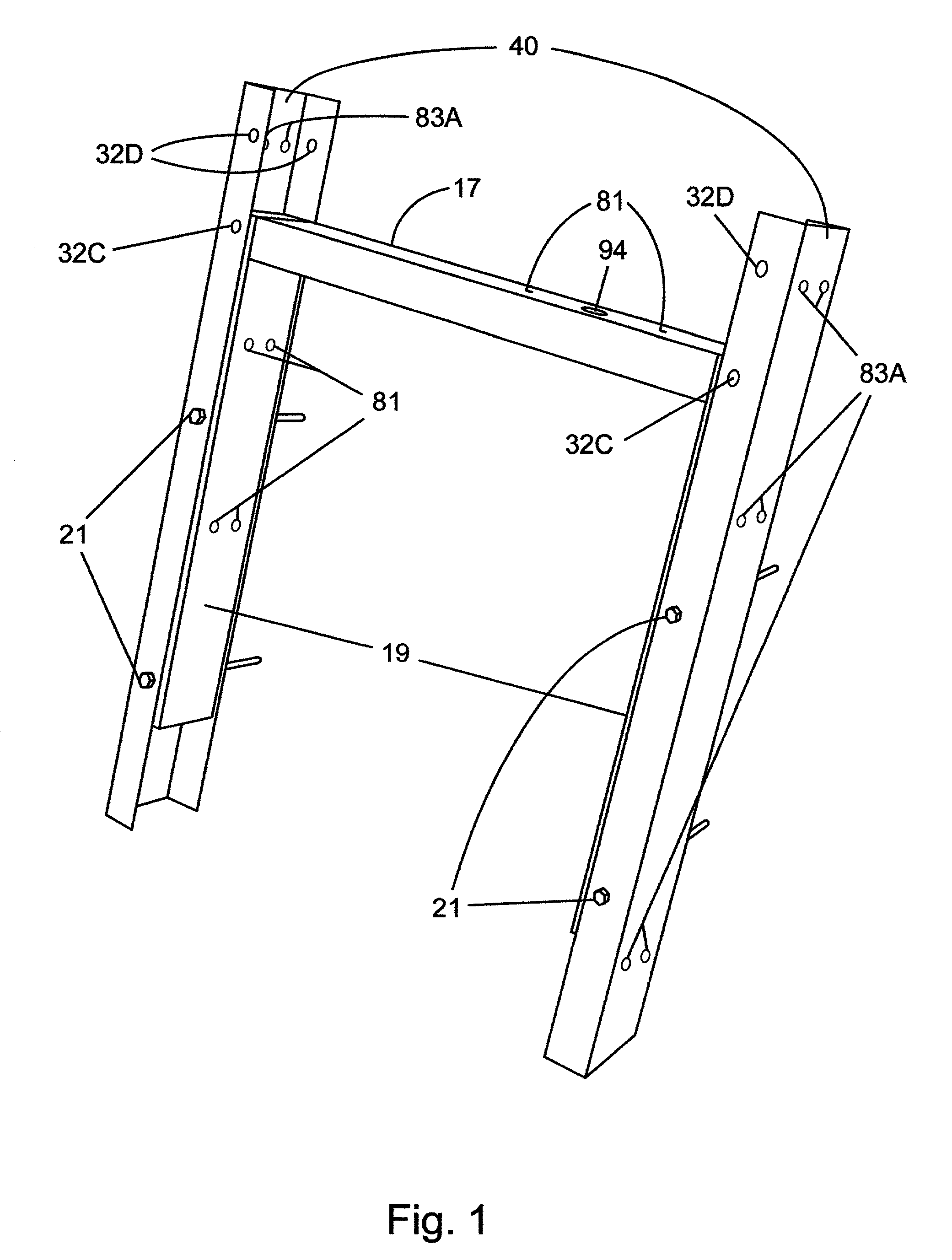

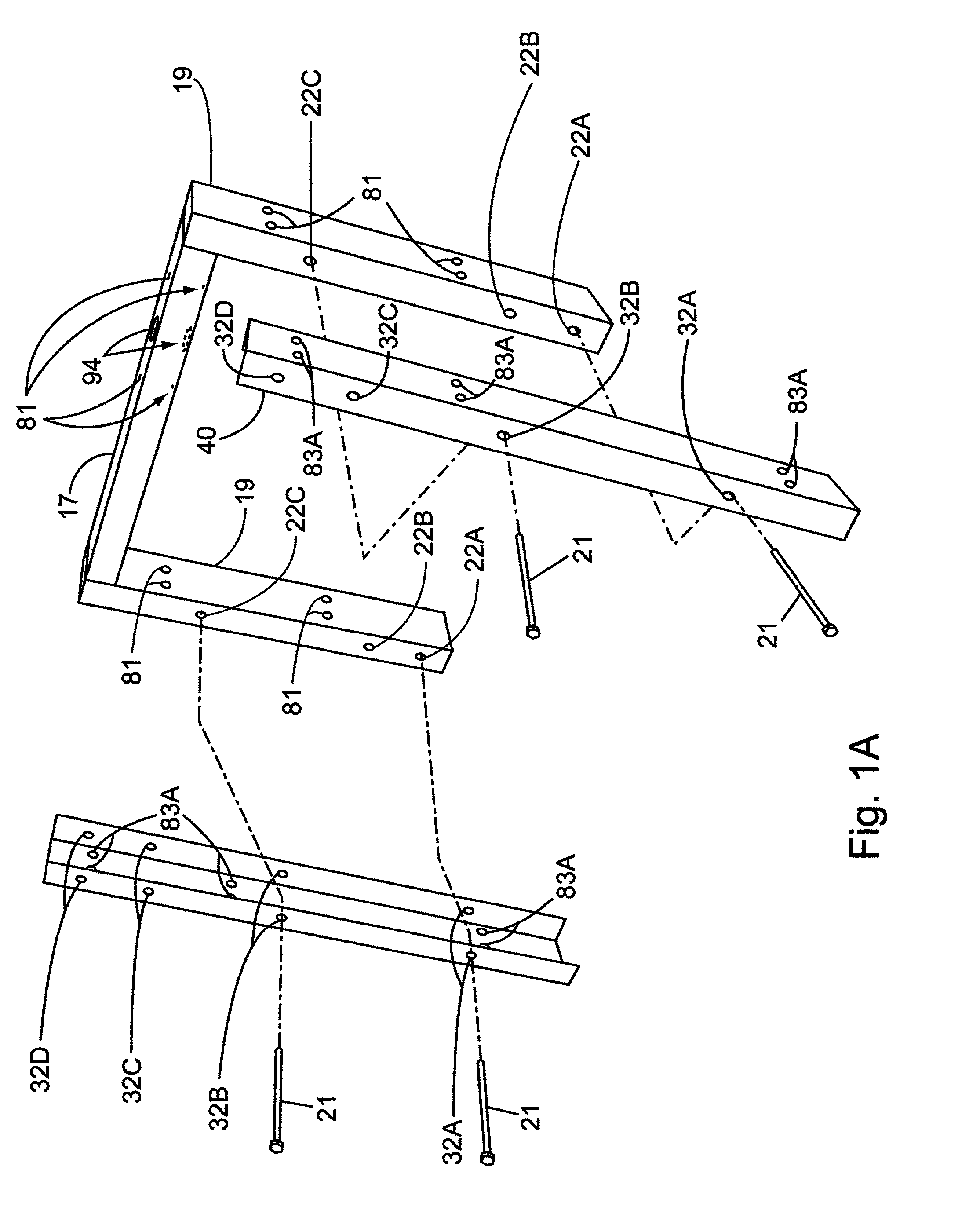

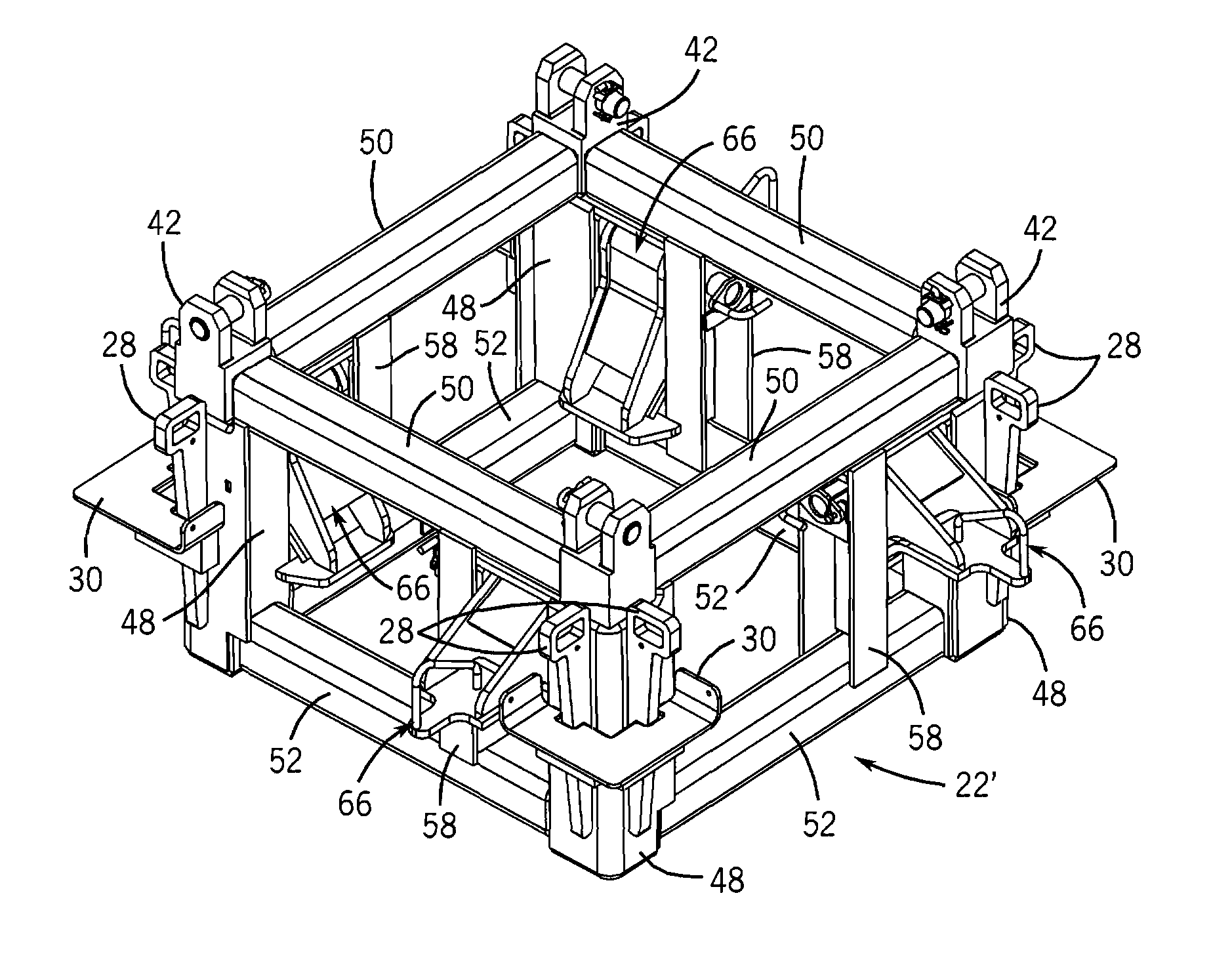

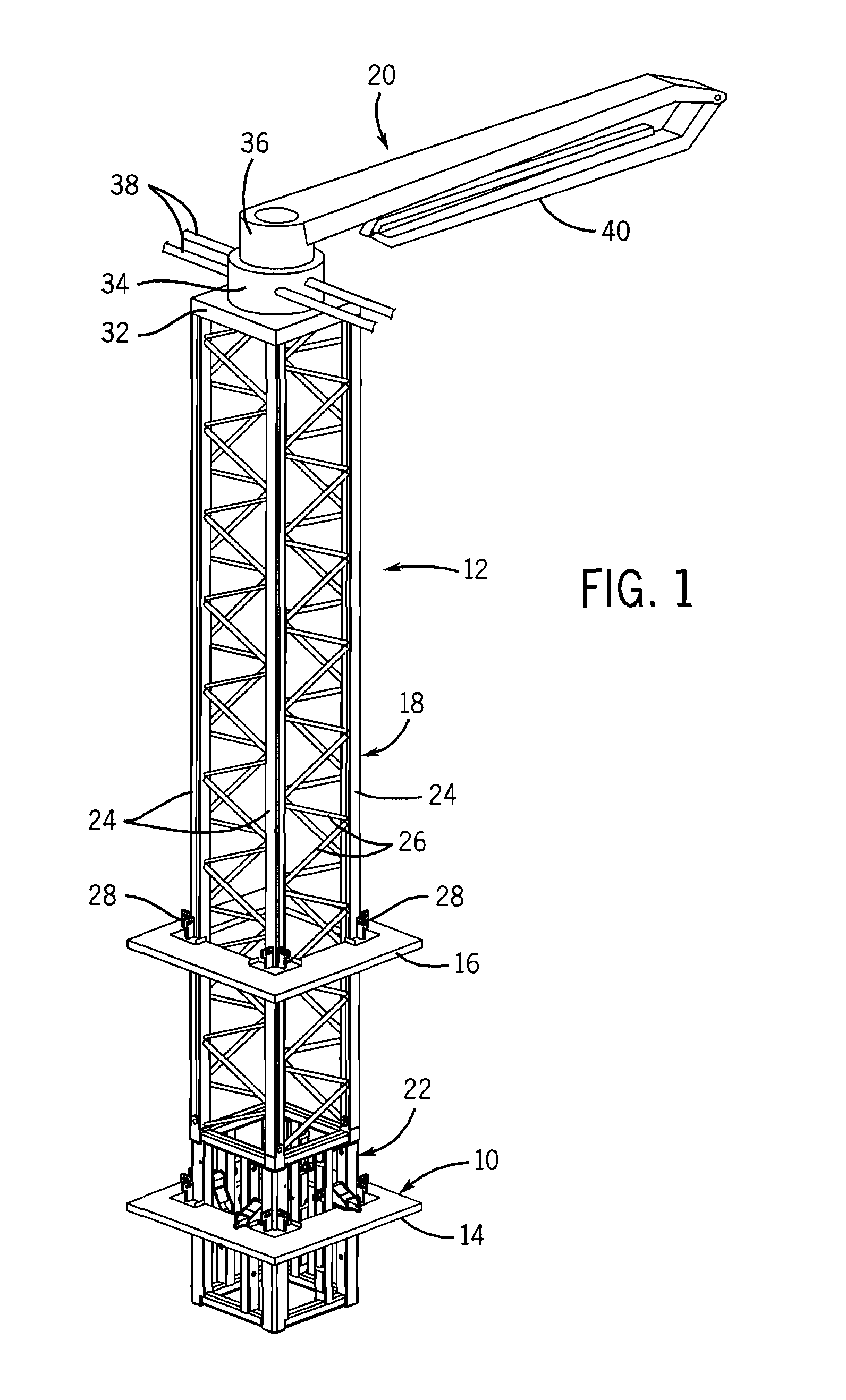

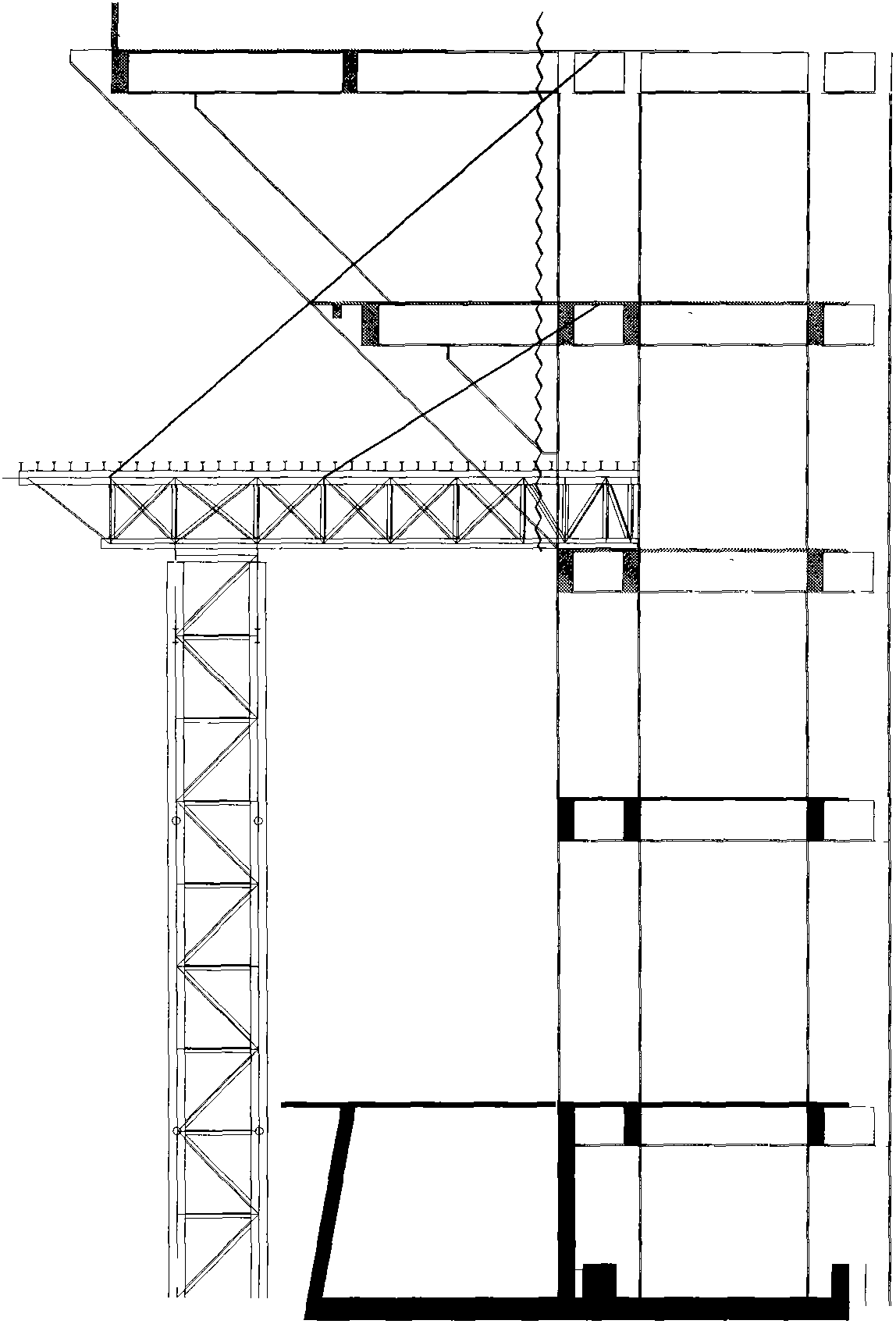

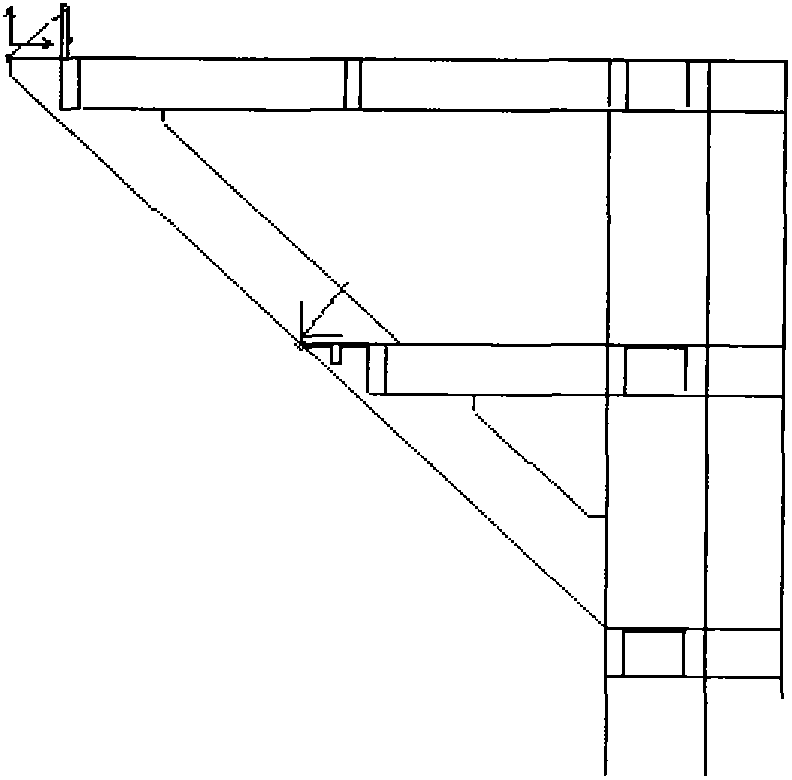

Pumping tower support system and method of use

A support system is provided for supportably securing a vertically movable support structure having a boom attached thereto to a floor structure of a building. The support structure extends through an opening formed in the floor structure. The support system includes a set of support brackets pivotably mounted relative to vertical support members of the support structure. The support brackets are supportably engageable with a portion of the support structure and a first floor structure in a first supporting position. The support brackets are freely swingable and movably engageable with a second floor structure as the support structure is moved relative to the second floor structure enabling the support brackets to be supportably engageable with the portion of the support structure and the second floor structure in a second supporting position.

Owner:PUTZMEISTER AMERICA

Super early receiving supporting structure of shield machine and super early receiving method

ActiveCN102322269AAchieve early receiptReduce construction proceduresTunnelsShield machineBuilding construction

The invention relates to a super early receiving supporting structure of a shield machine and a super early receiving method. The super early receiving supporting structure is characterized by comprising a receiving well foundation pit wall support, a bottom plate support and an outlet hole support, wherein the receiving well foundation pit wall support comprises a foundation pit envelope pile, at least two anchor cables and a steel pipe corner support; the outlet hole support is a temporary horizontal support; and the bottom plate support comprises an anti-pulling pile and a concrete bottom plate paved on a foundation pit bottom soil mass. By the super early receiving supporting structure and the super early receiving method, the construction problem that the shield machine cannot be received in advance when the shield machine arrives at a station in advance is successfully solved, the service life of the shield machine is prolonged, the construction cost of a shield interval is saved, and the construction period is shortened. The structure and the method can be applied to the advanced receiving of the shield machine when a receiving well structure is not completely constructed or finished.

Owner:北京城乡建设集团有限责任公司

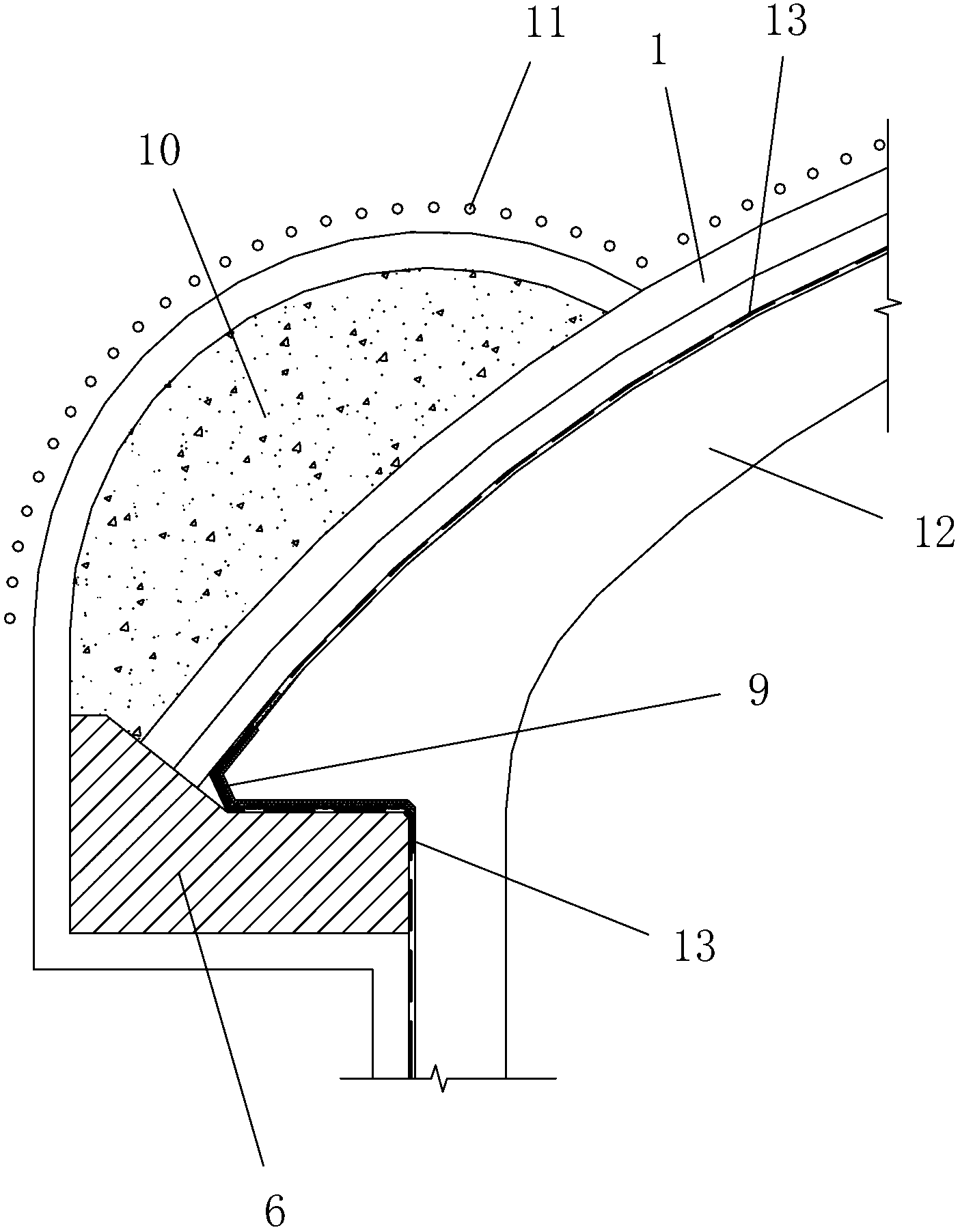

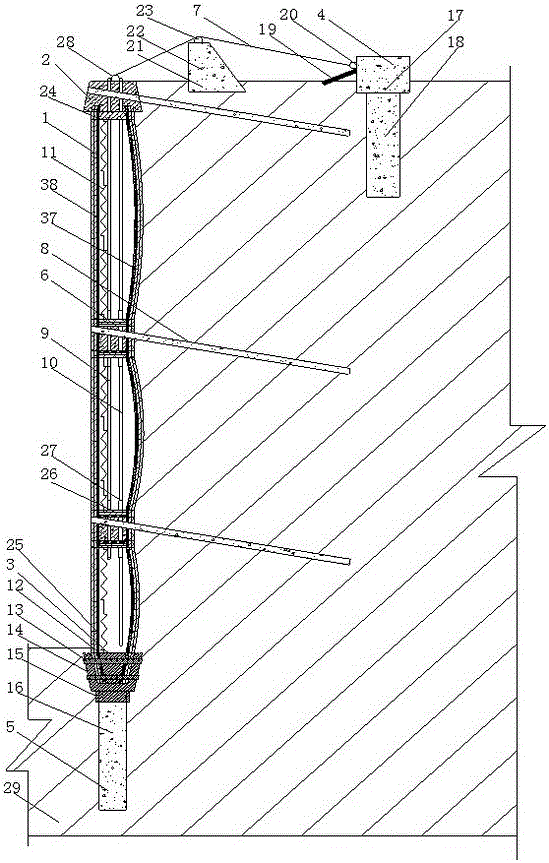

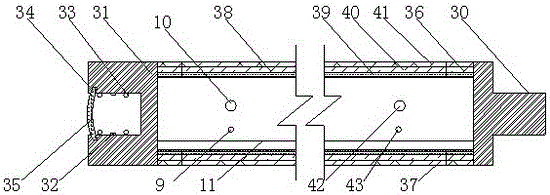

Extremely-high geostress soft rock large-deformation tunnel multistage pressure-yielding and pressure-resisting support structure and construction method thereof

PendingCN110847930AImprove the state of stressThe lining structure is safe and stableUnderground chambersTunnel liningShotcreteReinforced concrete

The invention relates to an extremely-high geostress soft rock large-deformation tunnel multistage pressure-yielding and pressure-resisting support structure and a construction method thereof. The construction method comprises the following steps: excavating a tunnel with a nearly circular section, then driving long anchor cables and short anchor rods into surrounding rock, erecting ring-shaped profile steel frames at tail ends of the long anchor cables and the short anchor rods and spraying concrete, additionally driving reinforcement lengthened or encrypted anchor cables into the surroundingrock, then erecting steel frames and spraying concrete again to form multilayer extension support; constructing a reinforced concrete lining structure on the inner side of the multilayer extension support, and forming the multistage pressure-yielding and pressure-resisting support structure through the long anchor cables, the short anchor rods, multilayer support and the reinforced concrete lining structure. According to the extremely-high geostress soft rock large-deformation tunnel multistage pressure-yielding and pressure-resisting support structure, the pressure is actively released by reserved deformation; the long anchor cables and the short anchor rods are used for anchoring in time with high pre-tightening force, enabling the pressure of the surface surrounding rock to be transferred to the deep part of the surrounding rock and expanding the surrounding rock bearing ring; the pressure-yielding support structure is used for providing high resistance and continuous deformation capacity; the reinforced concrete structure is used for resisting rheomorphism; the deformation of the surrounding rock can be effectively controlled; long-term stability of the structure can be ensured.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

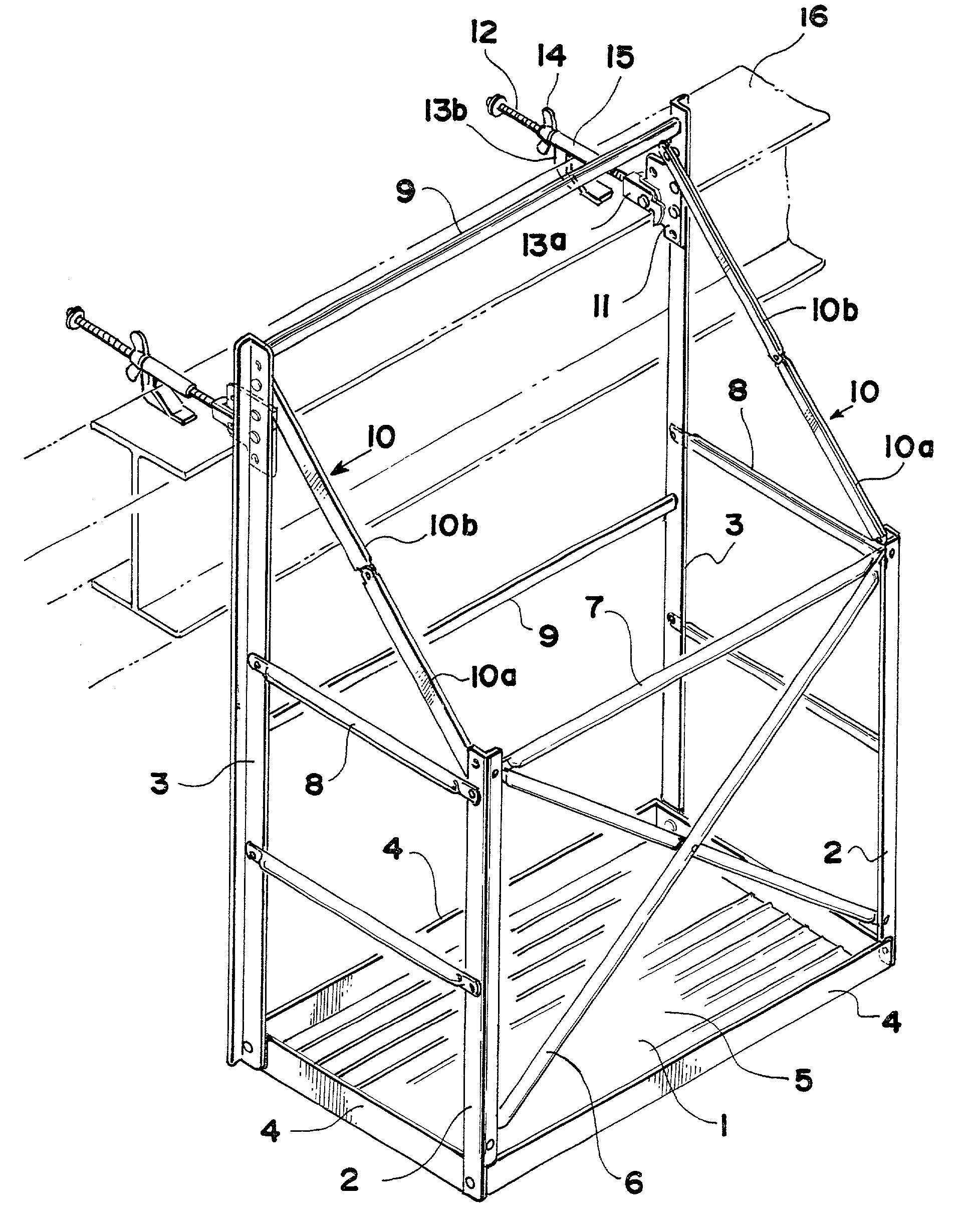

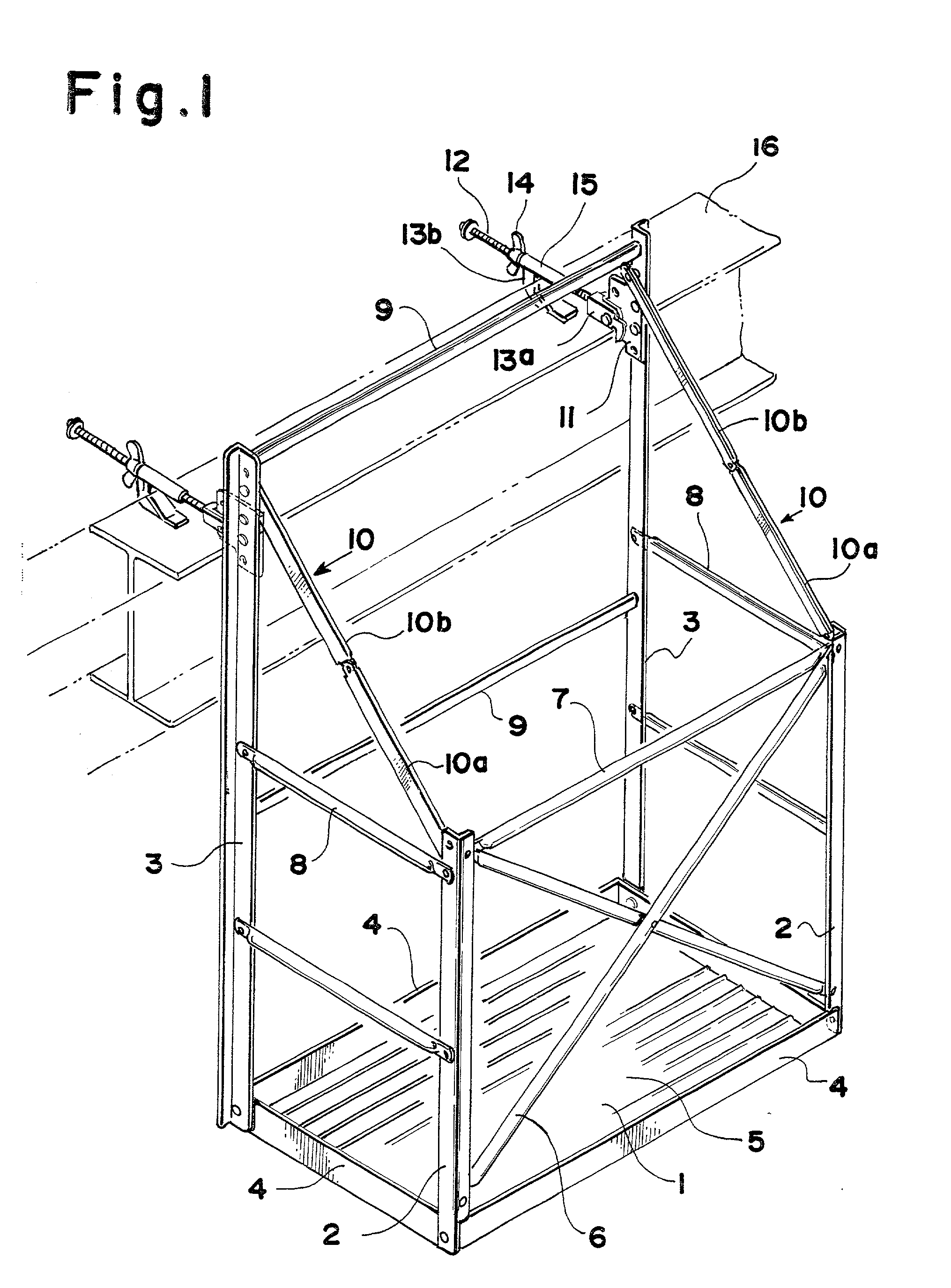

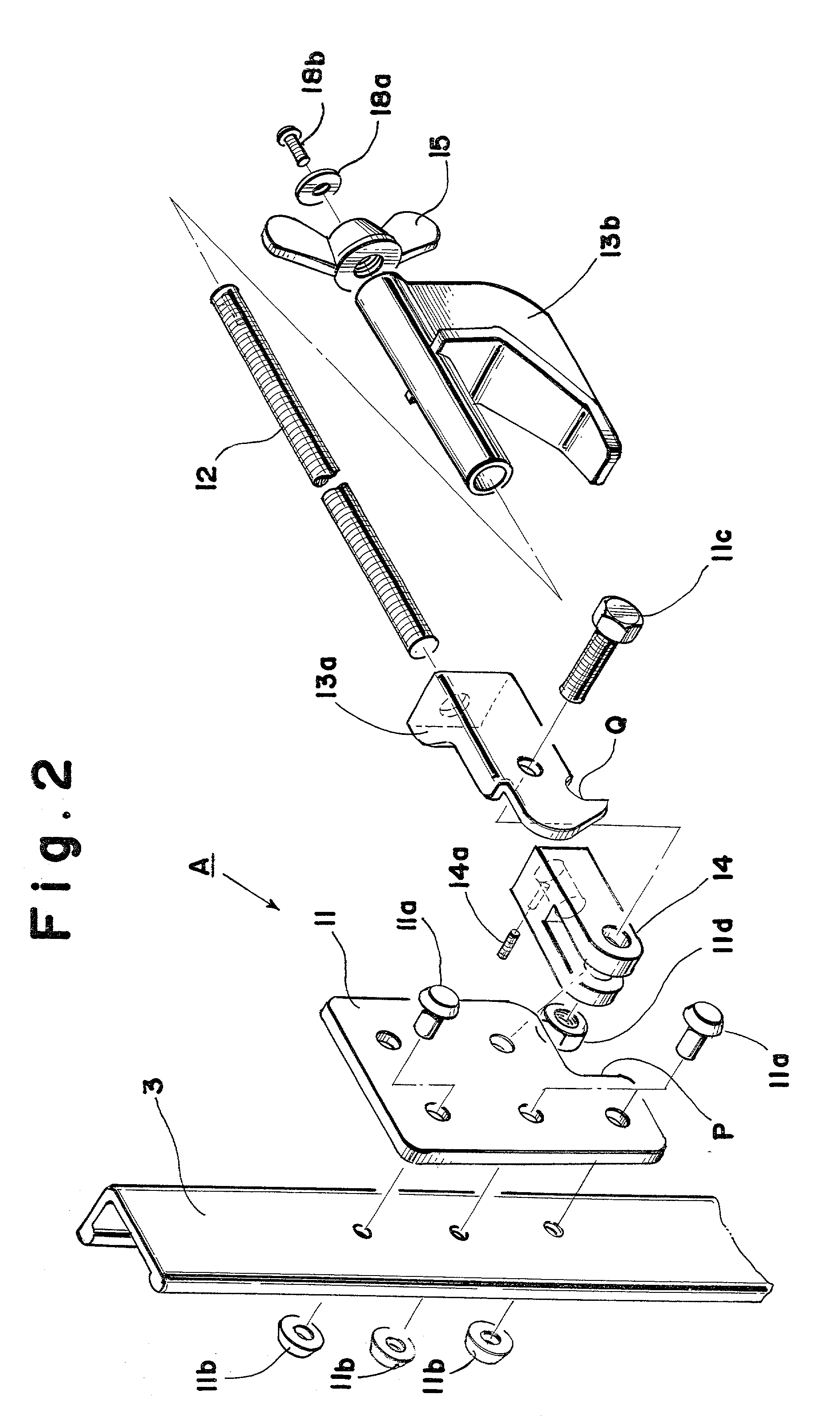

Foldable scaffold device

InactiveUS20020157900A1Scaffold accessoriesBuilding support scaffoldsUniversal jointClassical mechanics

An erectable and transportable scaffold device adapted to be engaged on and supported on a support beam comprises front and rear frame structures which are pivotally interconnected by means of parallel side braces which are connected between the frame structures. A scaffold plate is pivotally connected to the lower ends of each of the front and rear frames. And the front frame is pivotal outwardly from the rear structure to form a cage within the front and rear structures and the side braces having a floor formed by a scaffold plate. The plate has upright bottom edges which fit flush against the insides of an angle member forming the sides of the front frame structure so that it facilitates the holding of the structure in an erected cage forming position. A flexible or foldable member such as a chain or so is connected between the upper ends of each side of the front structure to the upper ends of each side of the rear structure. The rear structure also carries a rotatable hinge or an universal joint connected to a bolt having a front pawl and a rear pawl which is slidable therealong and which may be engaged against a support structure such as an I-beam by threading a wing nut onto the bolt behind said rear pawl to lock it in position.

Owner:ONO TATSUO

Construction method for 45-DEG-inclined long-overhanging reinforced concrete structure project

ActiveCN102322142AReasonable constructionReasonable forceBuilding material handlingFalseworkReinforced concrete

The invention relates to a construction method for a 45-DEG-inclined long-overhanging reinforced concrete structure project. When the project is constructed, a cable-stayed steel tube tower is combined with a scaffold; for a steel-structure support tower, hanging bars are adopted to resist an overturning force; for an upper-part scaffold, inclined braces are adopted to resist an overturning force; for a steel-structure support tower or an inclined-hauled steel truss with a grounded lower part, the upper part of the steel-structure support tower or the upper part of the inclined-hauled steel truss is assisted by a high support formwork with local full fastener steel tubes. The weak links or the dangerous links in a construction process are sufficiently acknowledged, the stress mechanism in the construction process of the 45-DEG-inclined long-overhanging reinforced concrete structure project is disclosed, and the requirements of economy and rationality and safety and reliability are satisfied through technical analysis, so that the construction method for the 45-DEG-inclined long-overhanging reinforced concrete structure project has the advantages of high technological content, stable structure, safety and reliability, explicit force transmission, rational stress, convenience and fastness for construction, shortened construction period for implementation, capability of prefabricating parts in factories and splicing and assembling in field, low cost and good economical efficiency.

Owner:YONGSHENG CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com