Panel formwork system

a formwork system and panel technology, applied in the direction of moulding surfaces, building components, mould fastening means, etc., can solve the problems of time-consuming, time-consuming, and the inability to adjust the relative position of the side forms when bolting to the platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be hereinafter described with reference to the accompanying drawings which illustrate two preferred embodiments of the invention. The drawings however are merely illustrative of how the invention might be put into effect, so that the specific form and arrangement of the features shown is not to be understood as limiting on the invention.

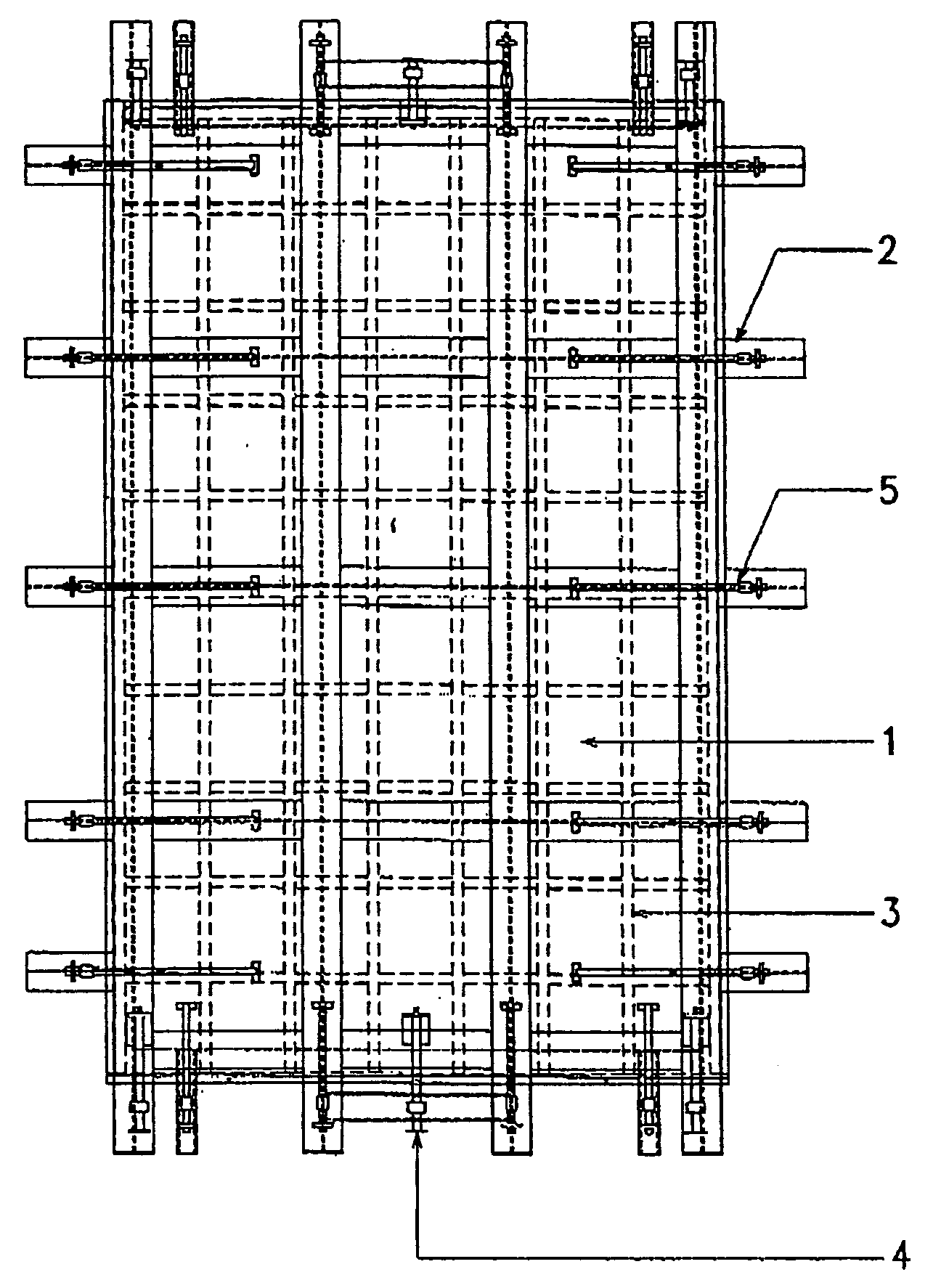

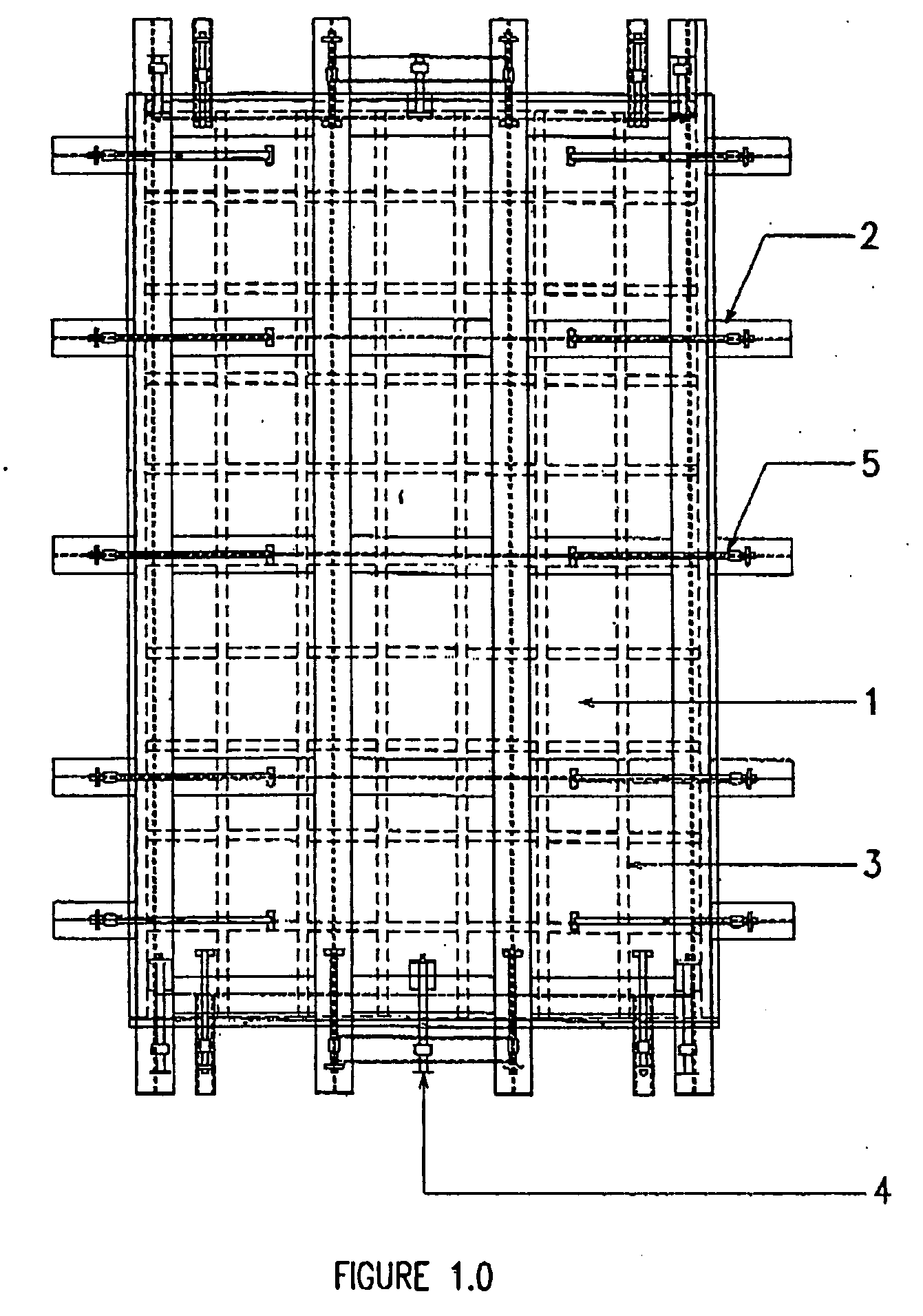

[0016] FIG. 1.0 is a plan view showing the formwork system for casting prefabricated wall panels with retractable bracing according to the invention.

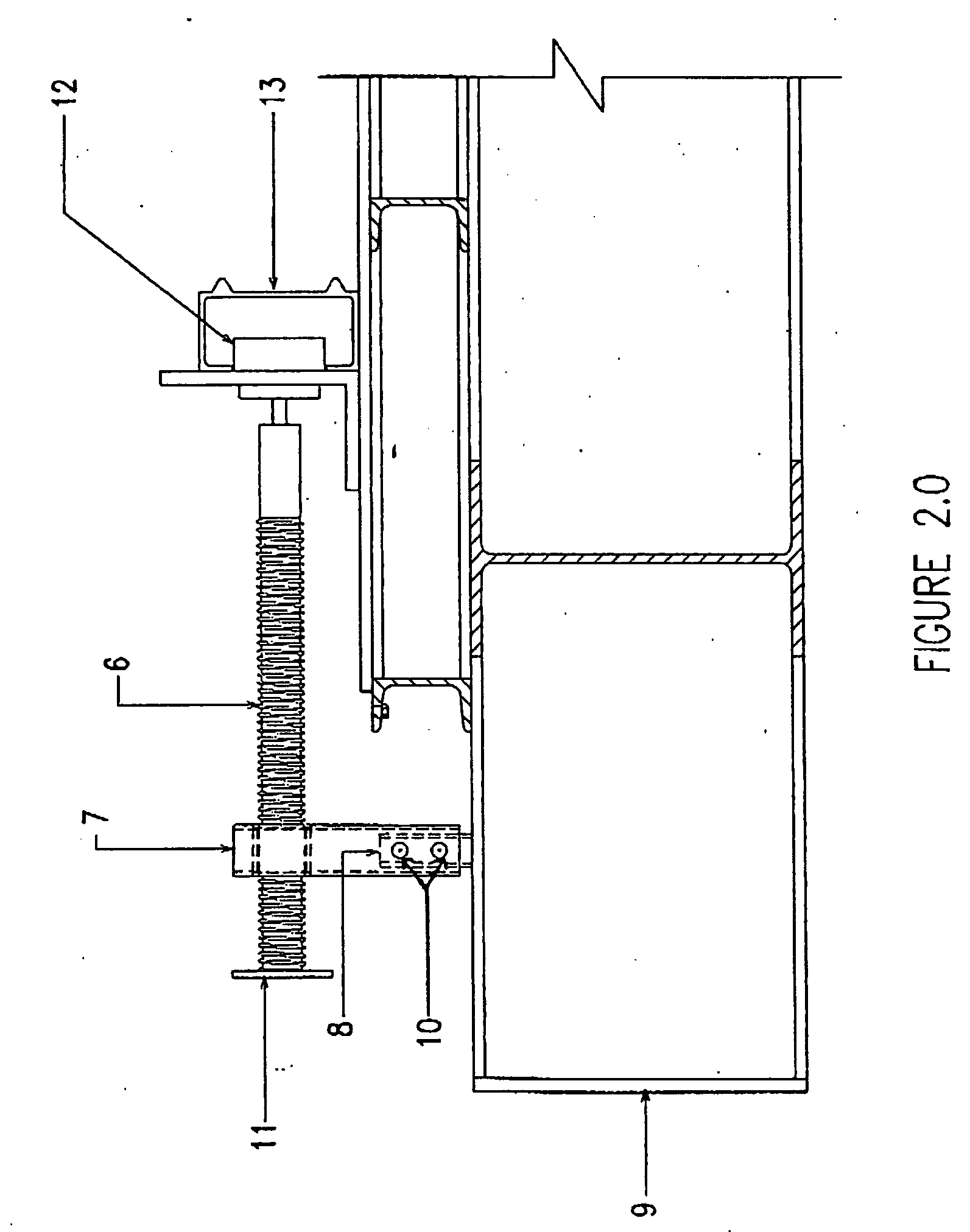

[0017] FIG. 2.0 is a side view of a linear retractable bracing system according to one preferred embodiment of the invention.

[0018] FIG. 3.0 is a side view of a lever retractable bracing system according to another preferred embodiment of the invention.

[0019] FIG. 4.0 is a plan view showing the formwork system for casting prefabricated wall panels with pattern and decorative features.

[0020] FIG. 5.0 is a cross section showing the formwork system for casting prefabricated wall-pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com