Patents

Literature

224results about "Moulding surfaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

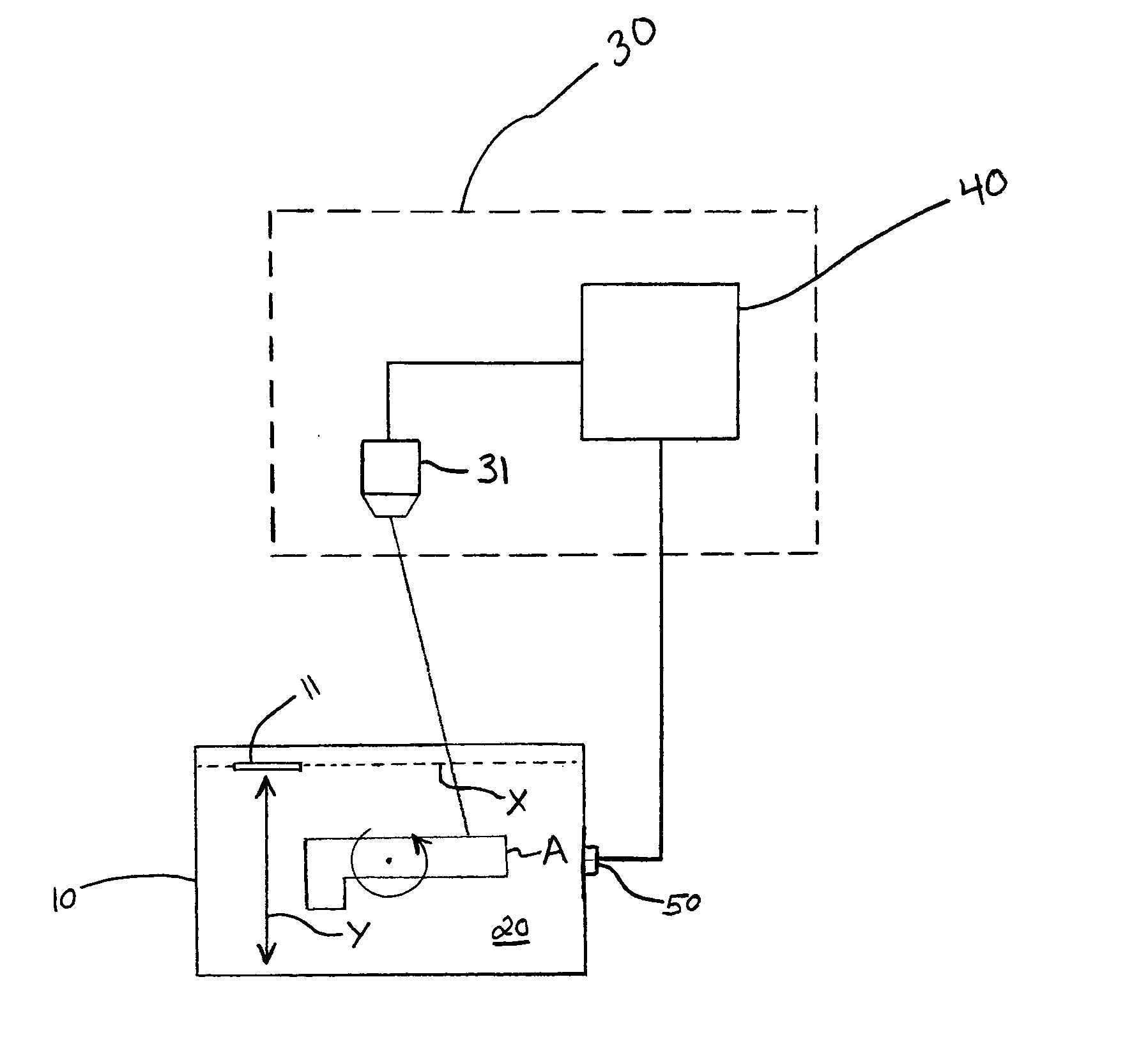

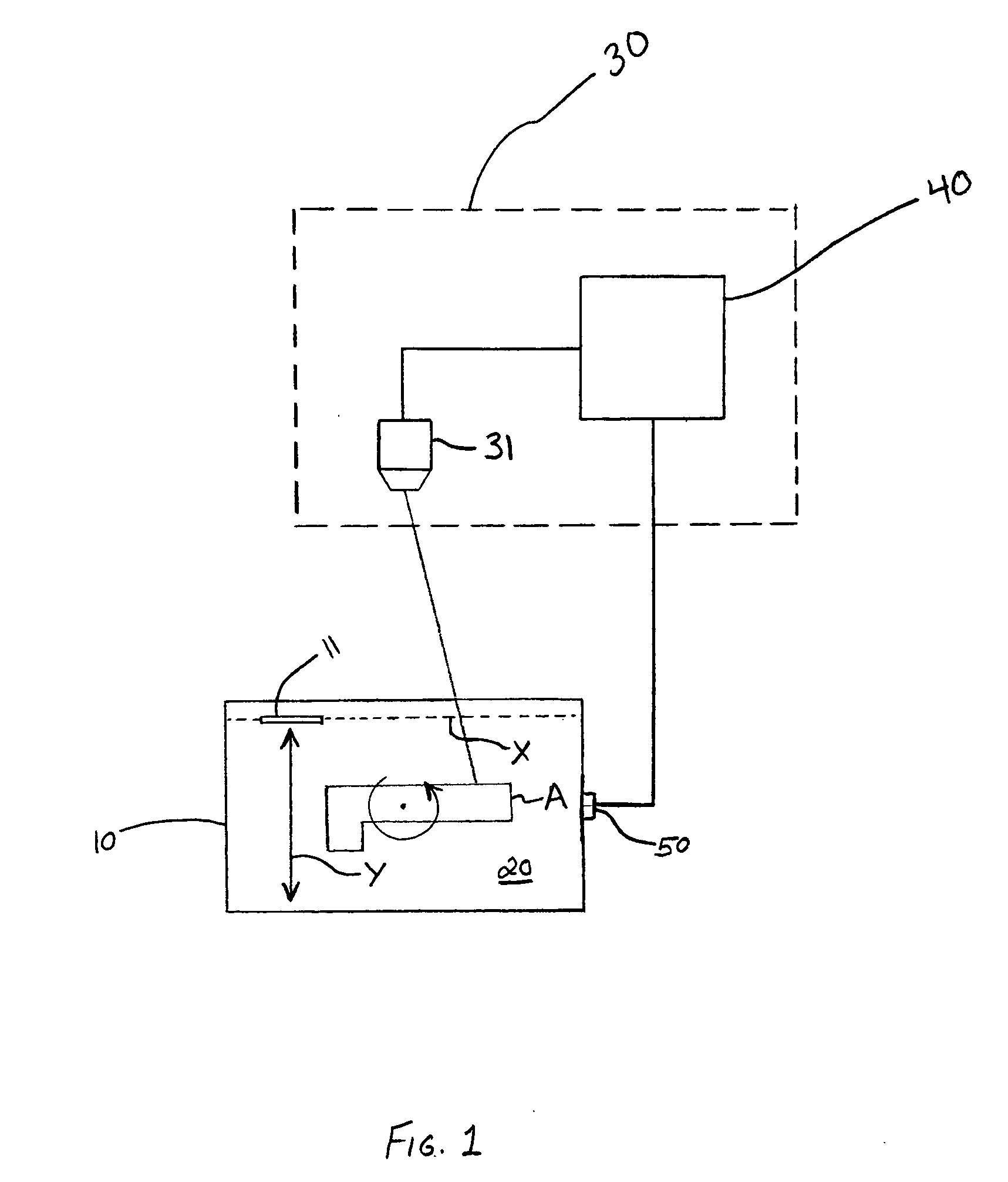

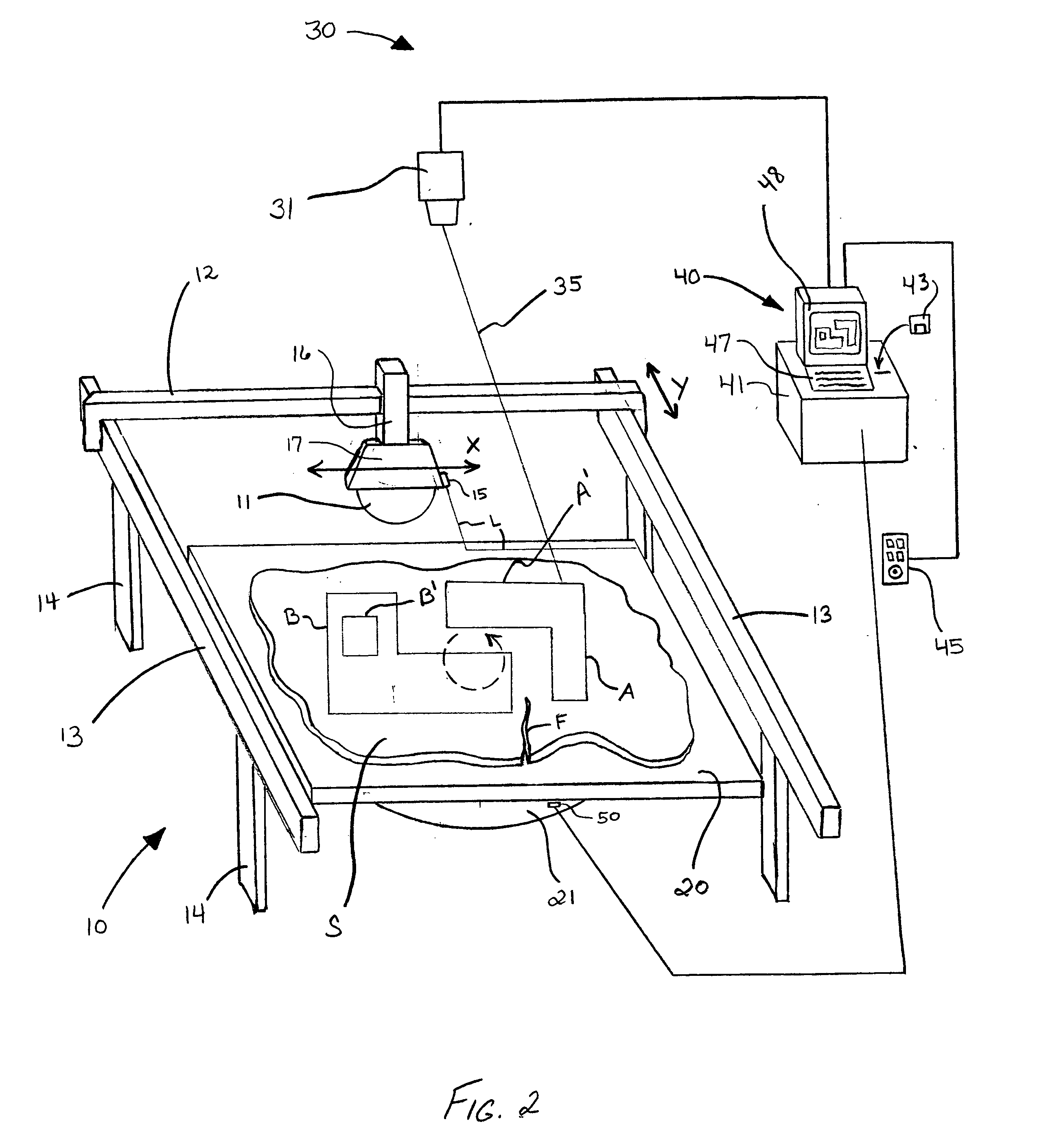

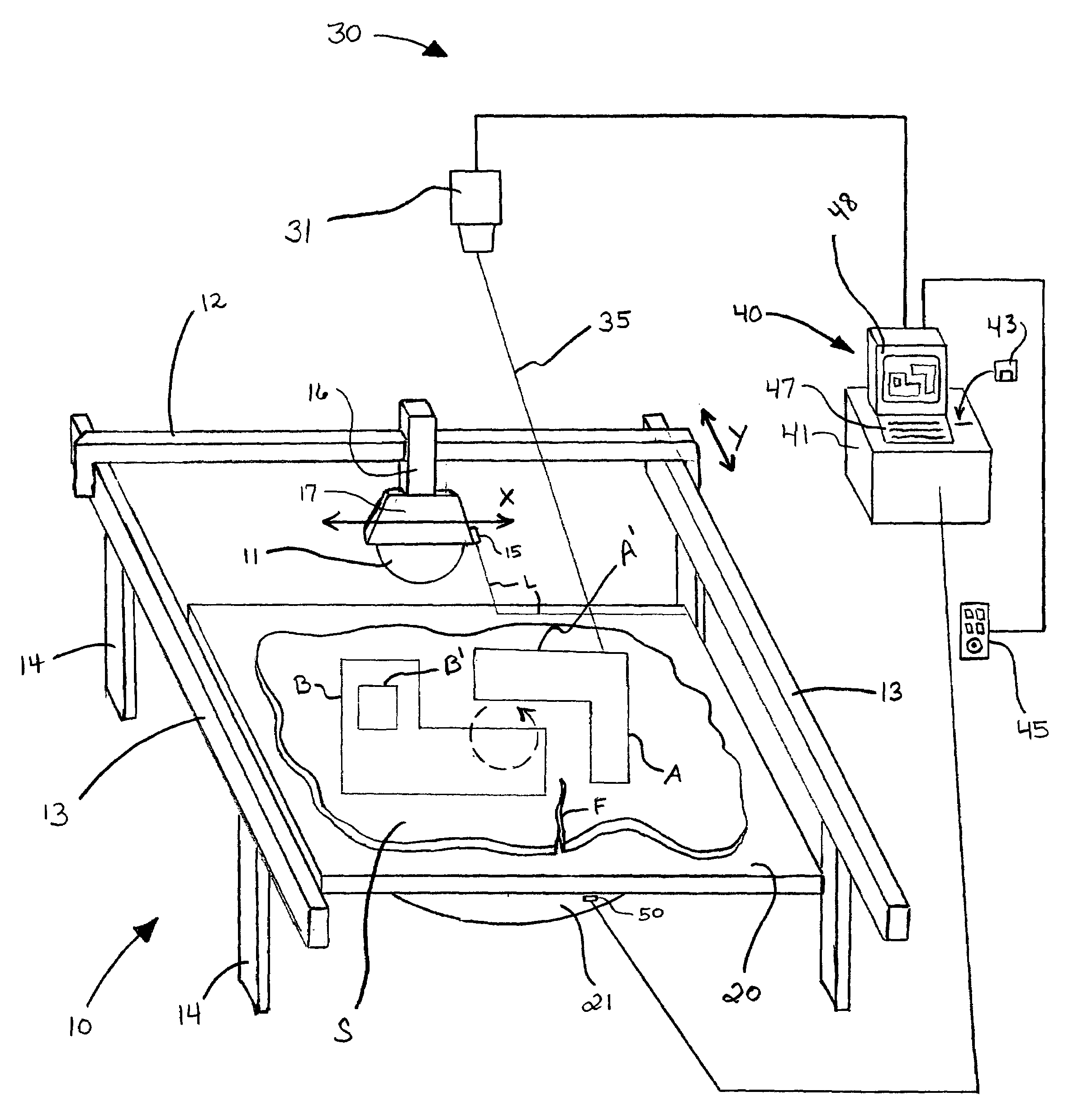

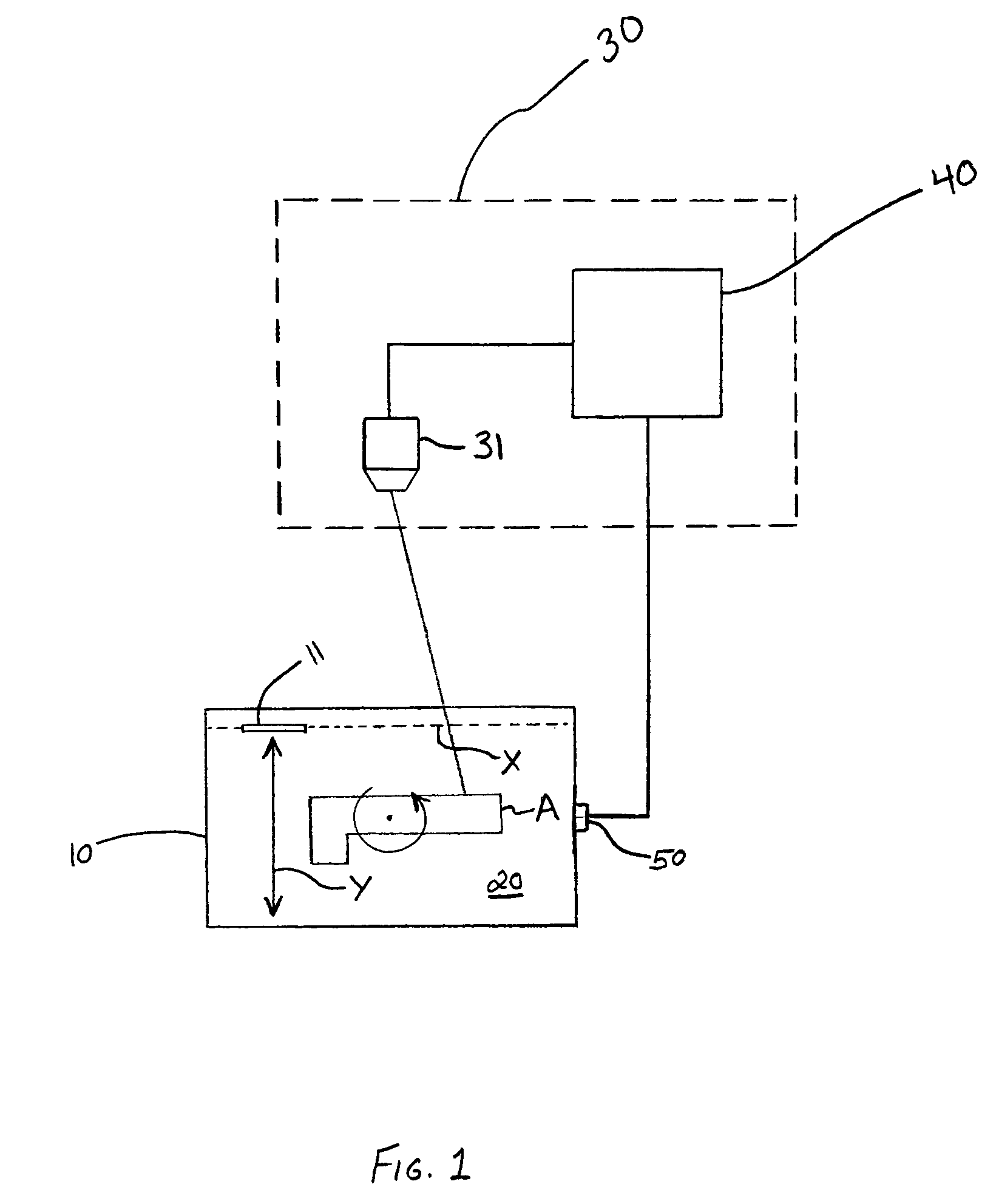

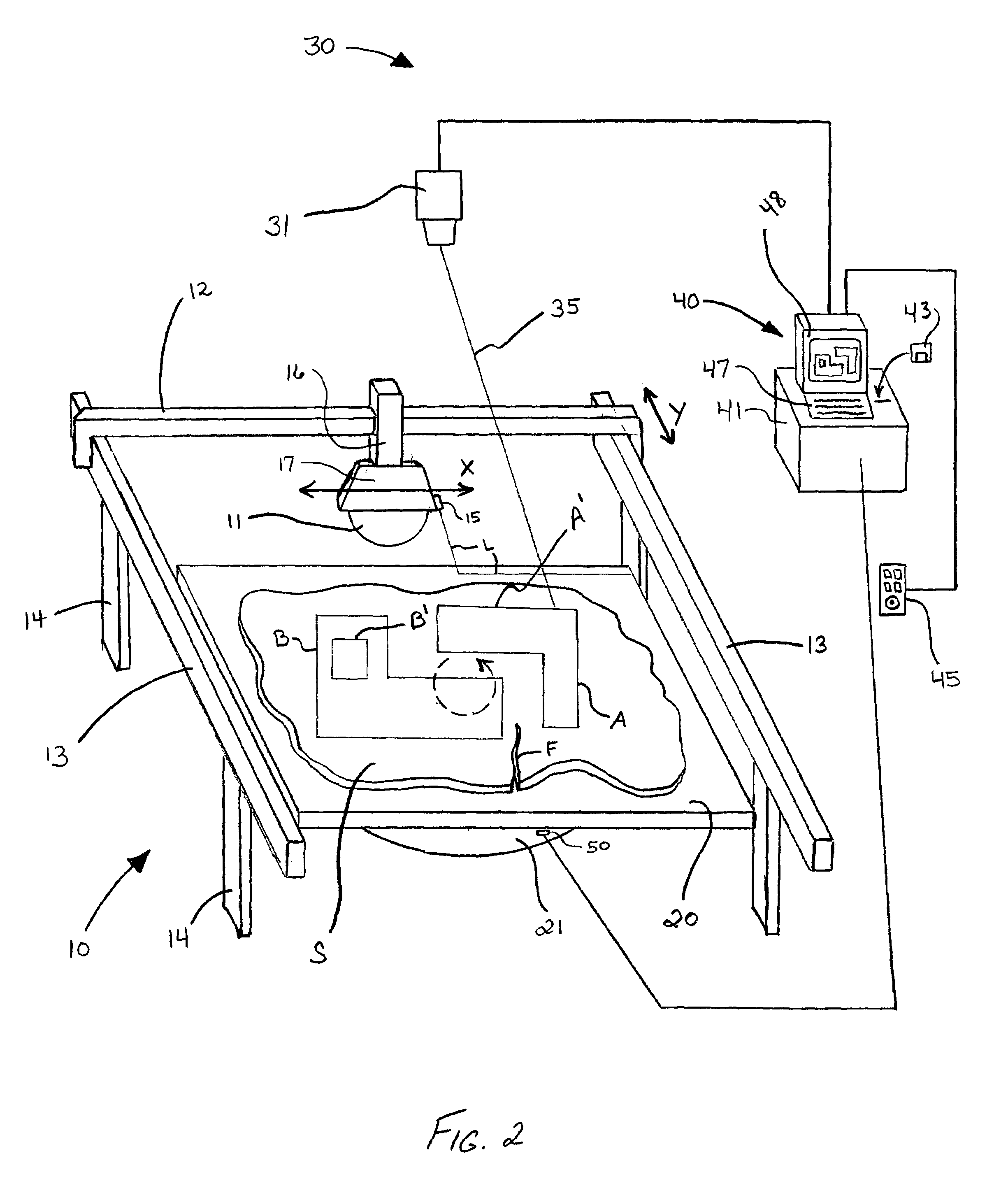

Systems and methods for displaying images and processing work pieces

A method of displaying an image on a work piece positioned on a movable work surface. A method of processing a work piece, as well as a method of displaying an image on a moveable work surface, is also provided. A system for machining a work piece in accordance with one or more images projected onto the work piece is also provided.

Owner:LAP LASER

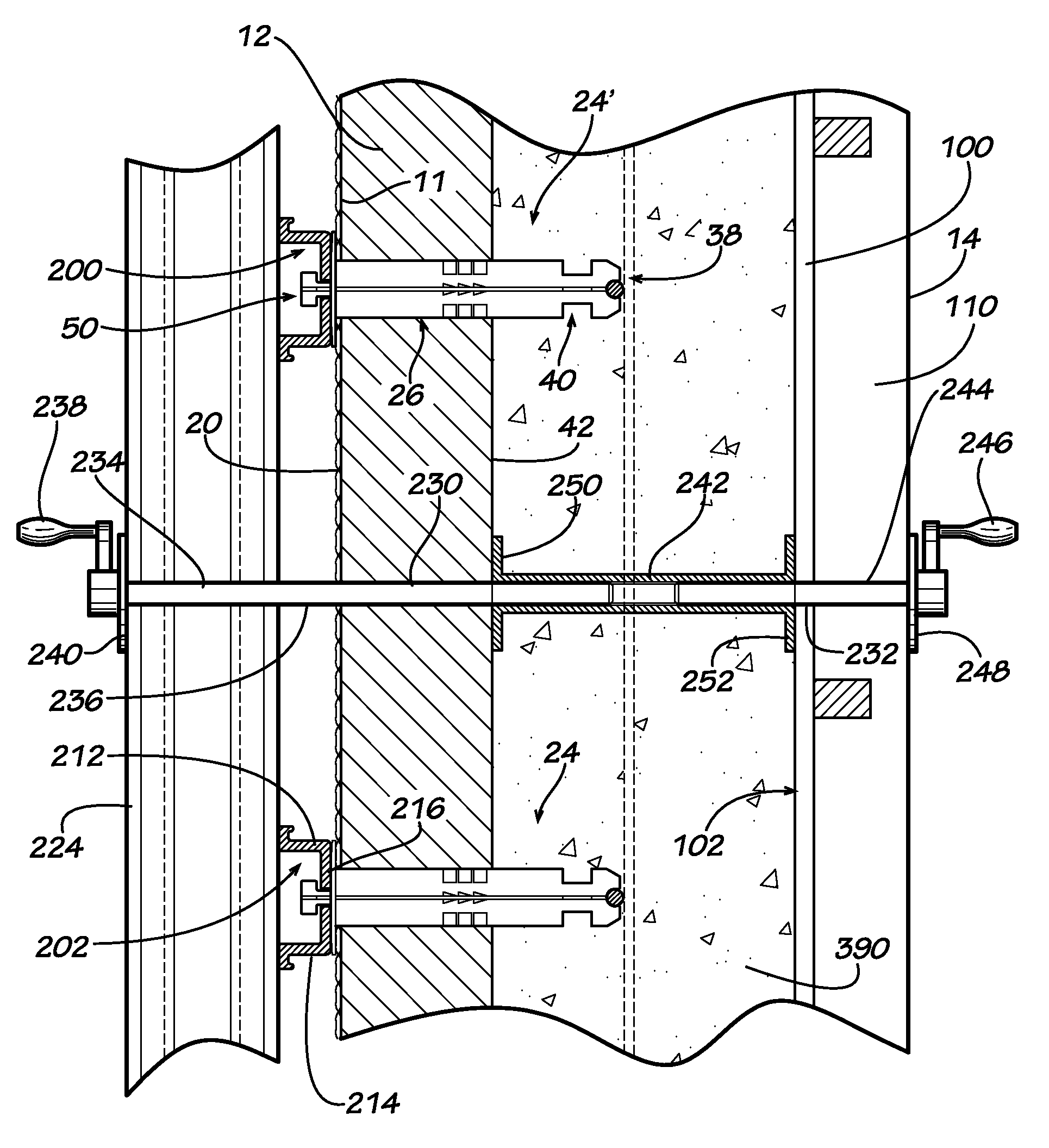

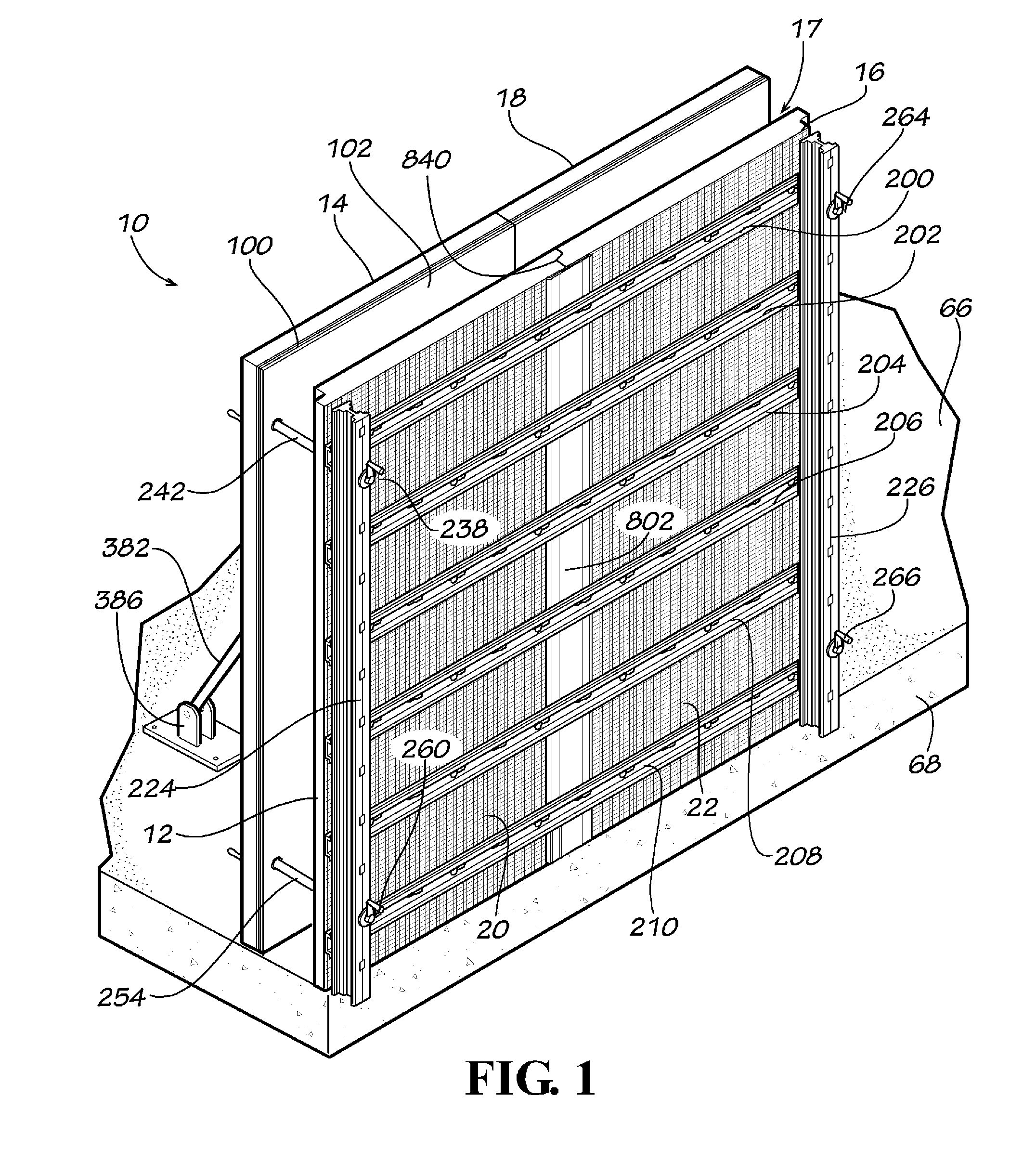

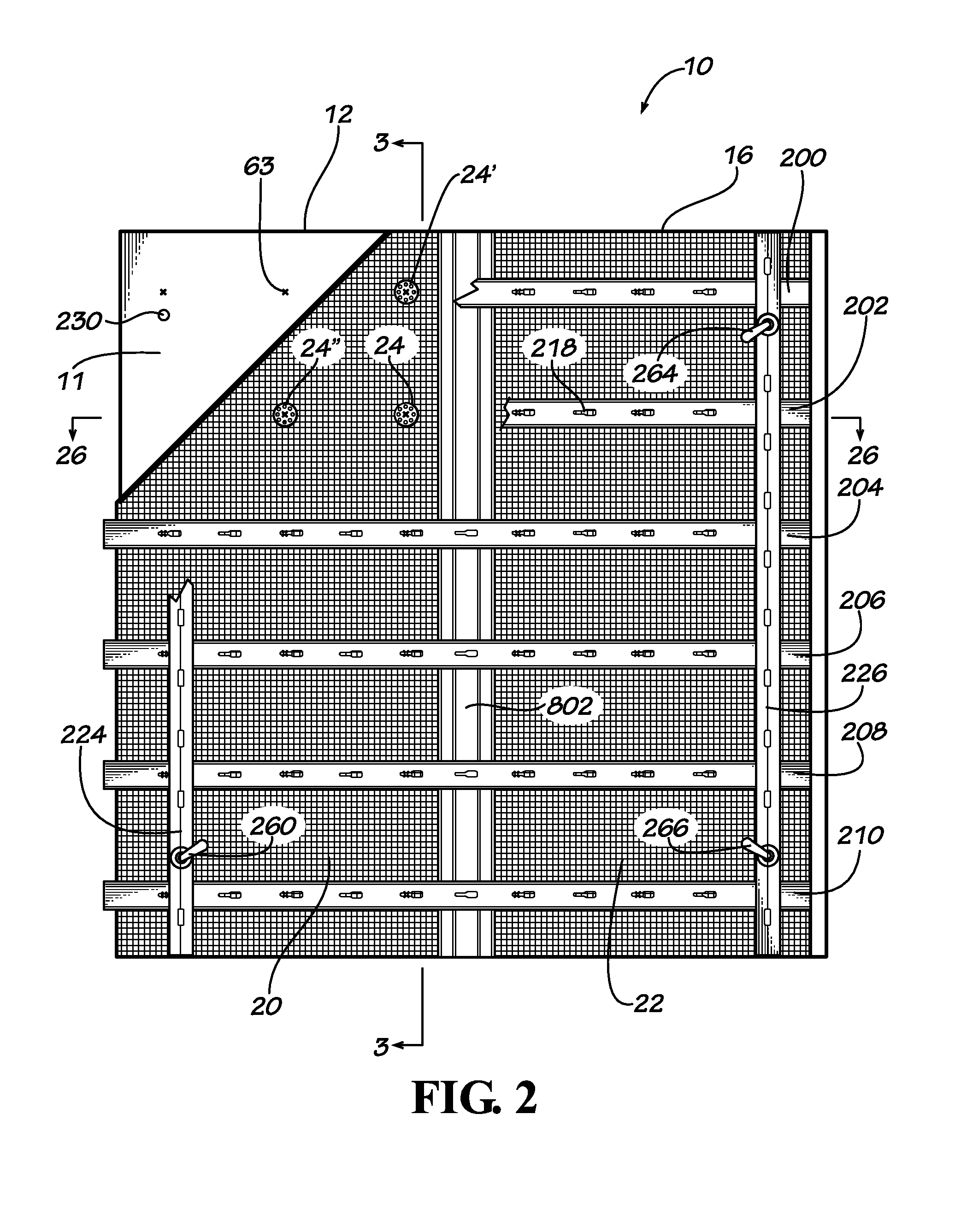

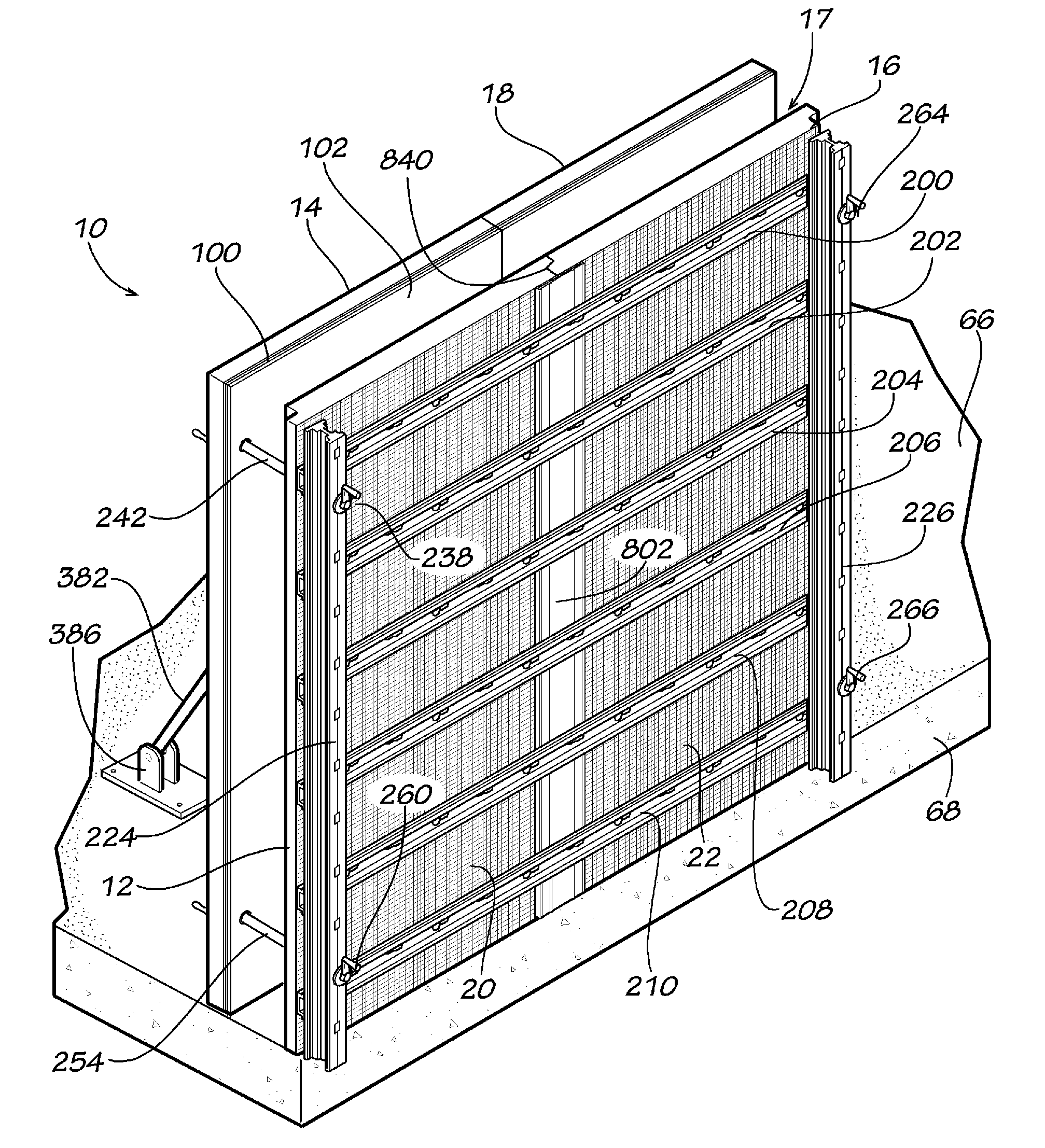

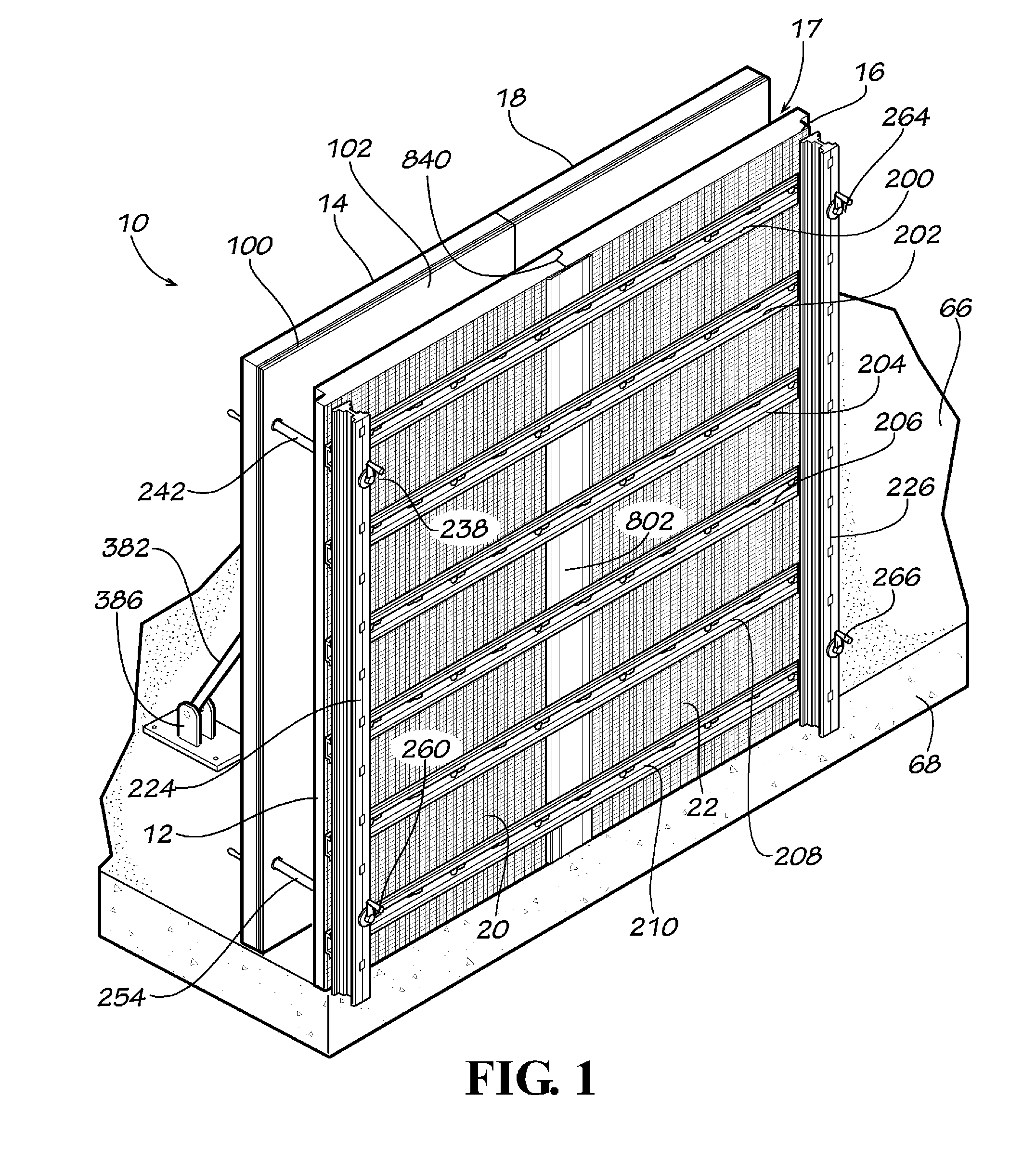

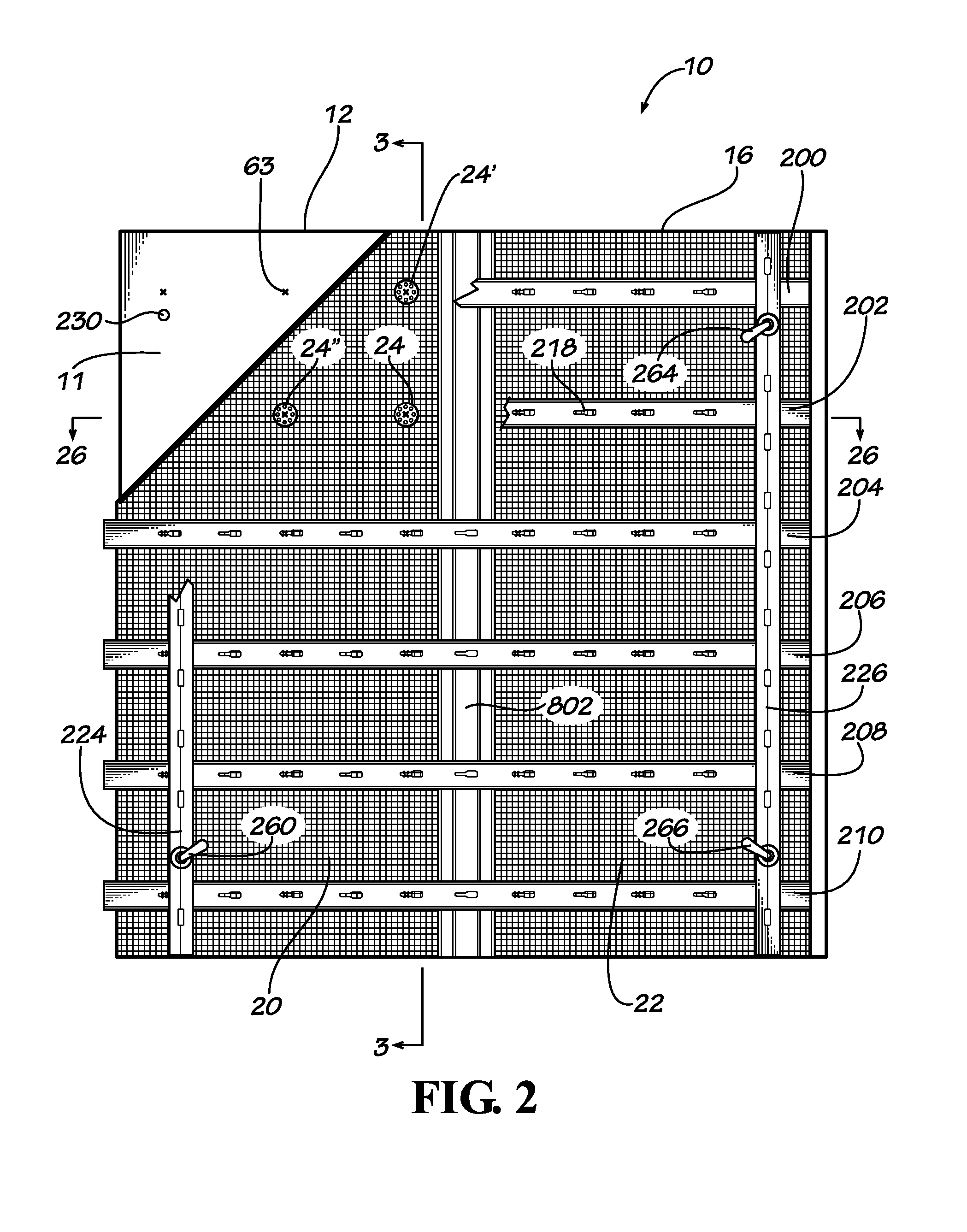

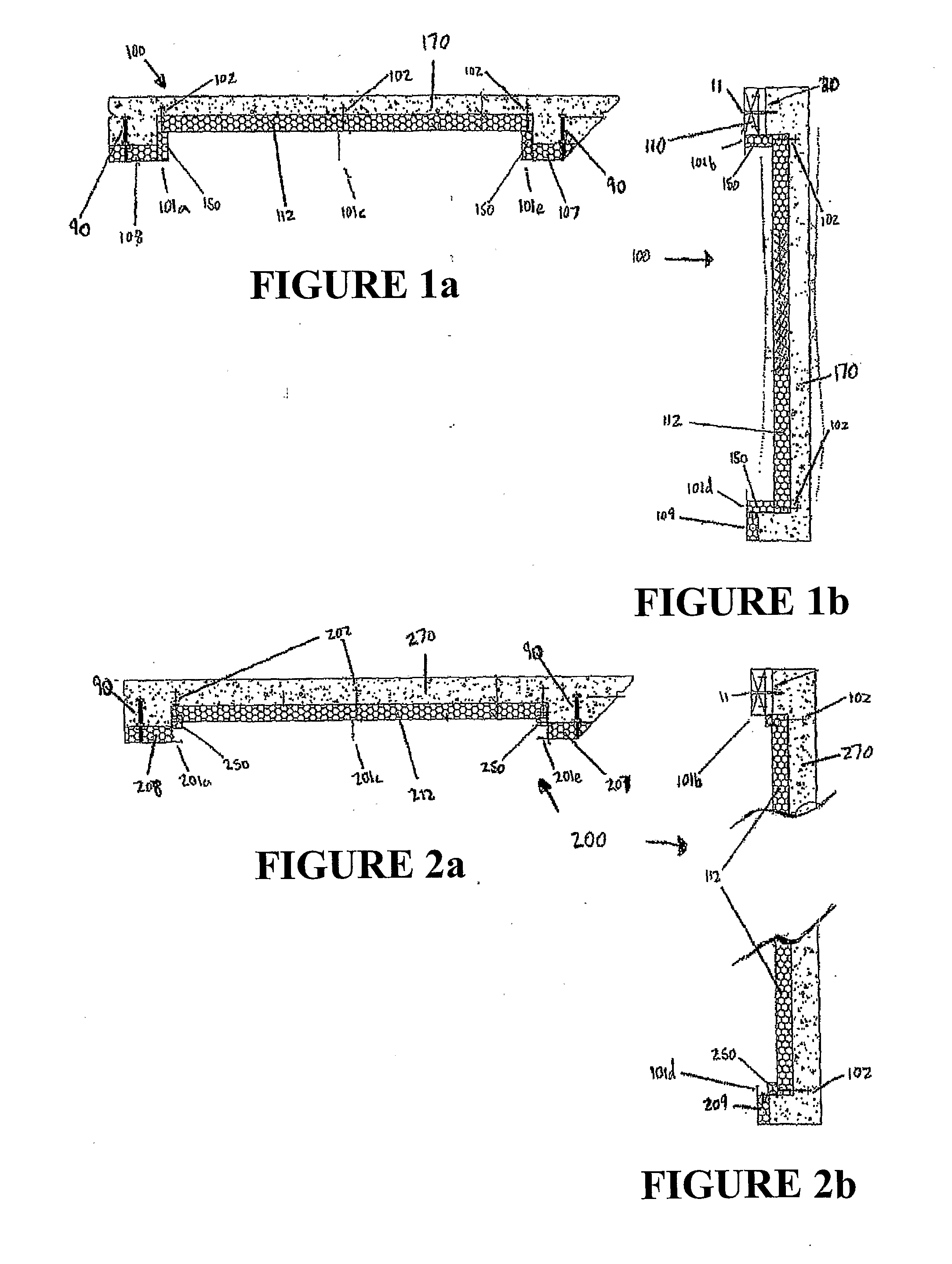

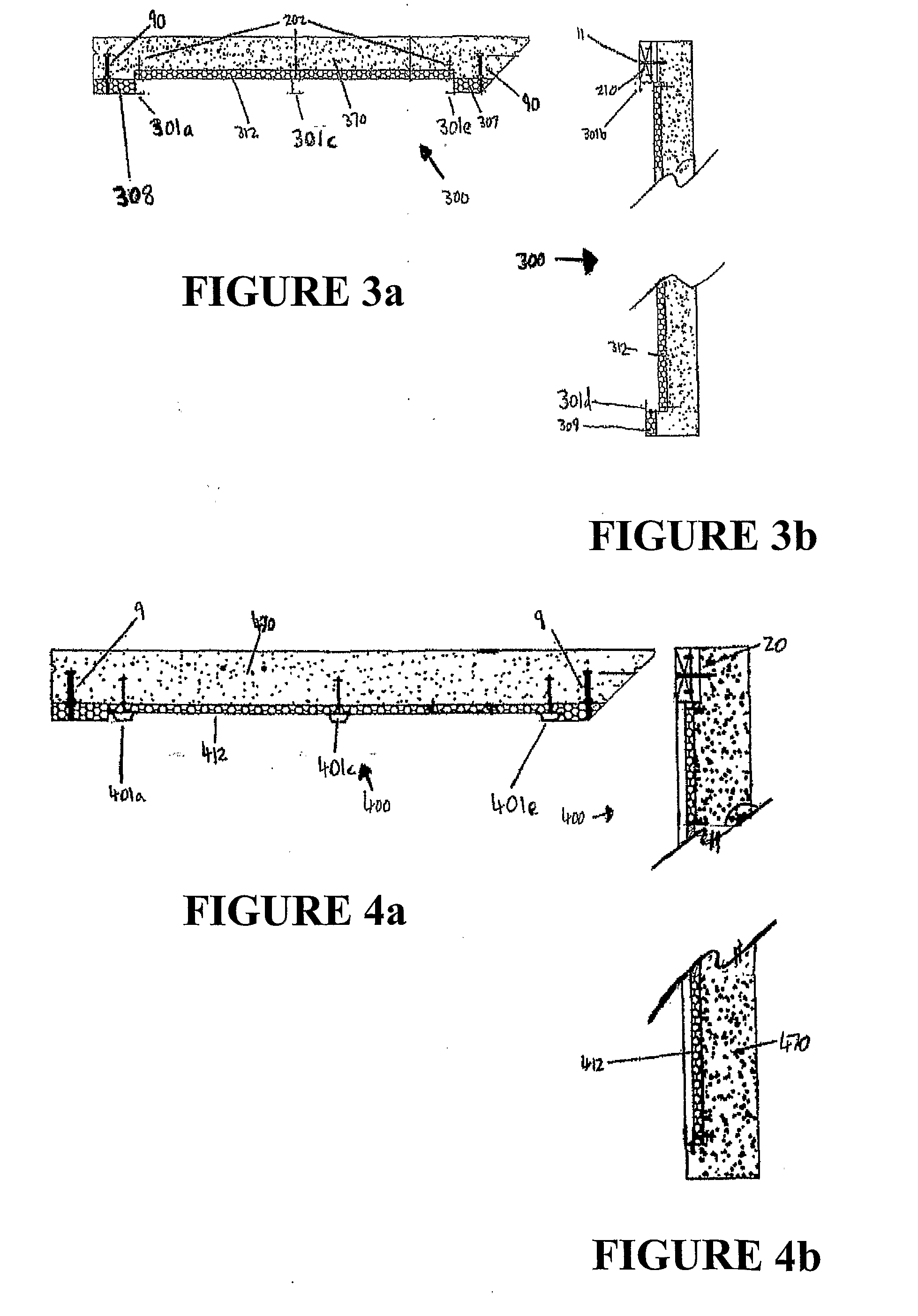

Hybrid insulated concrete form and method of making and using same

The invention comprises a product. The product comprises a foam insulating panel having a first primary surface and an opposite second primary surface. A removable concrete form is spaced from the foam insulating panel and a concrete receiving space is defined between the second primary surface of the foam insulating panel and the removable concrete form. A method of using a hybrid insulated concrete form is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

Hybrid insulated concrete form and method of making and using same

ActiveUS20140263942A1Retain heatEasy and inexpensive attachmentMoulding surfacesWallsInsulating concrete form

The invention comprises a product. The product comprises a foam insulating panel having a first primary surface and an opposite second primary surface. A removable concrete form is spaced from the foam insulating panel and a concrete receiving space is defined between the second primary surface of the foam insulating panel and the removable concrete form. A method of using a hybrid insulated concrete form is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

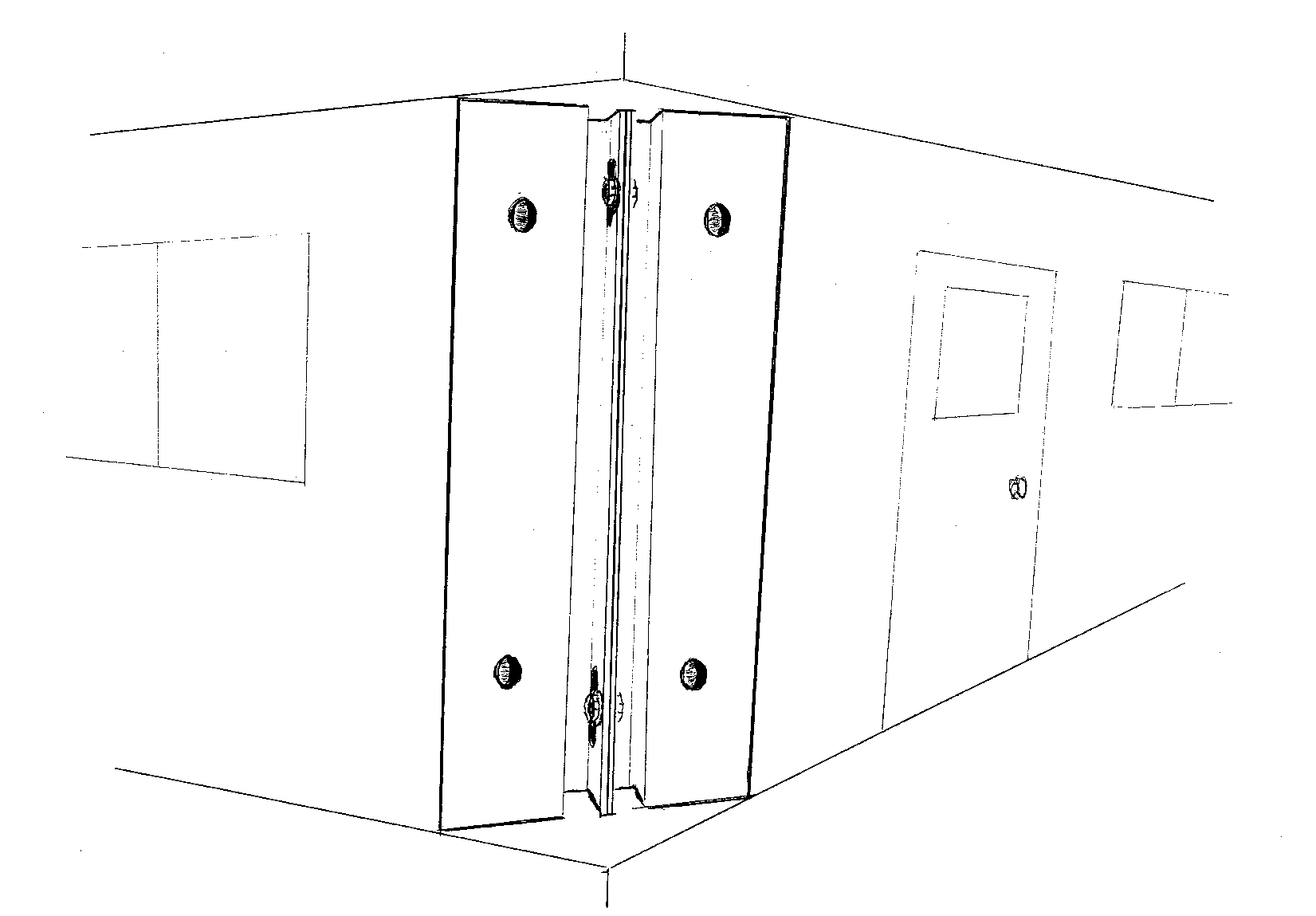

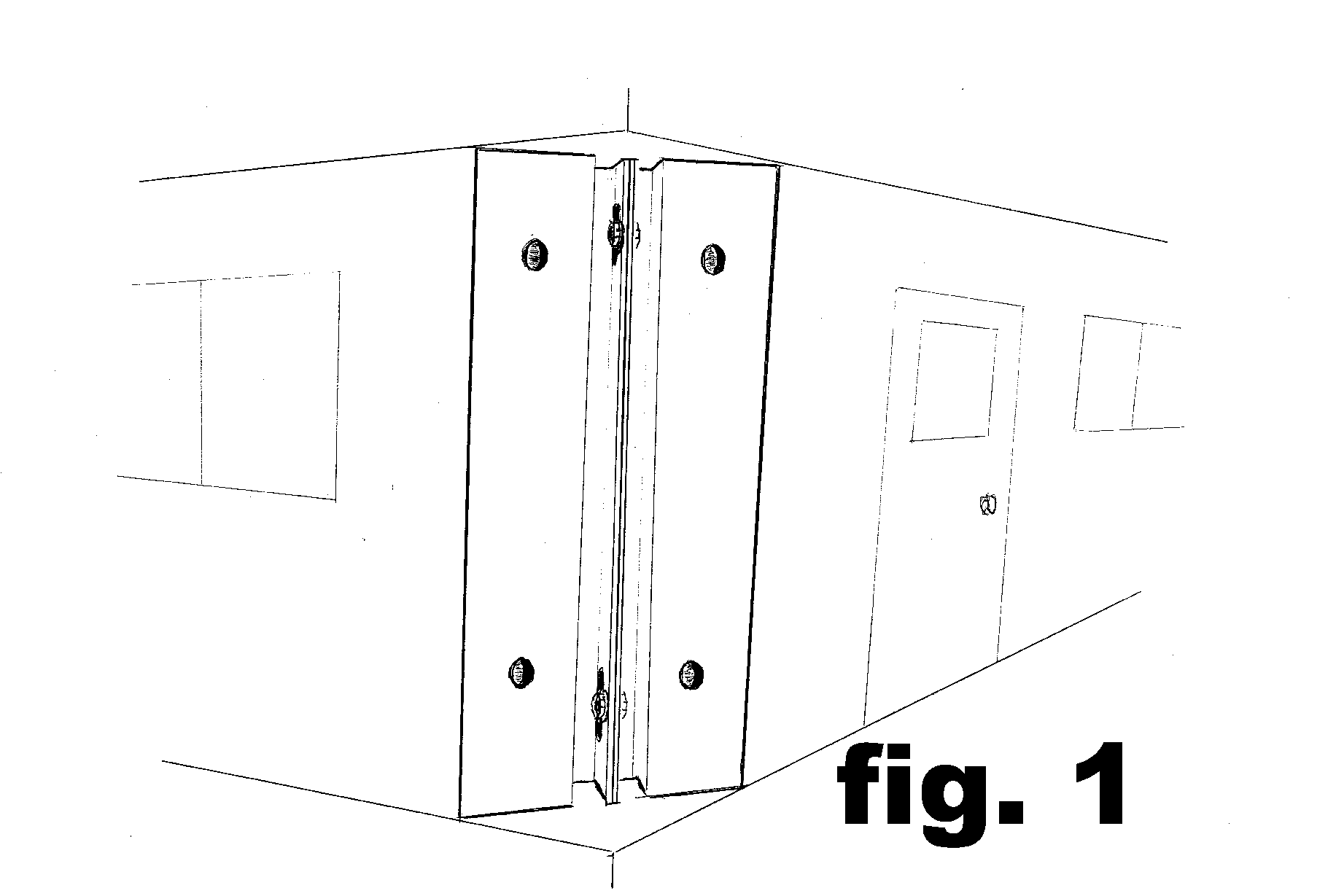

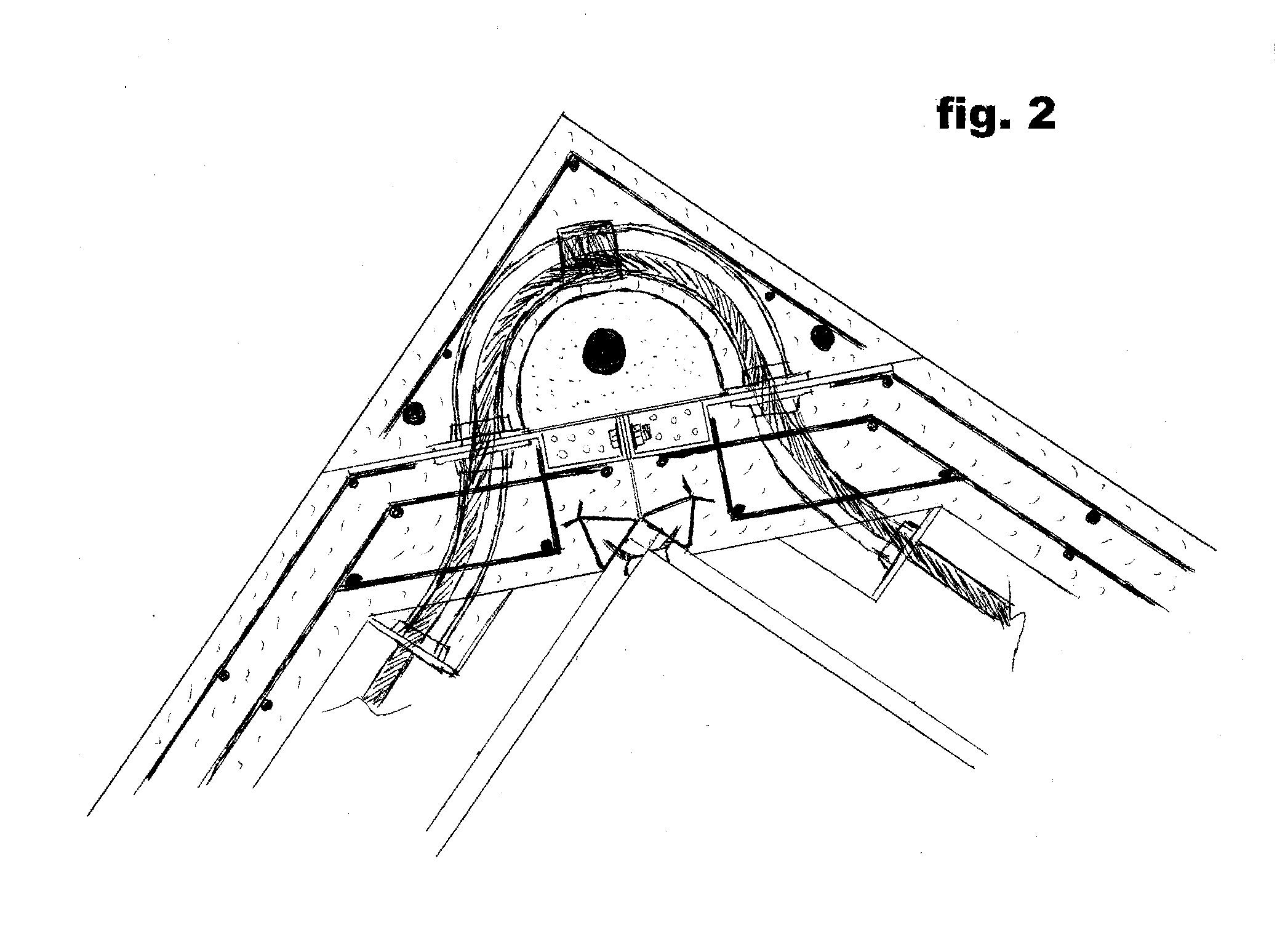

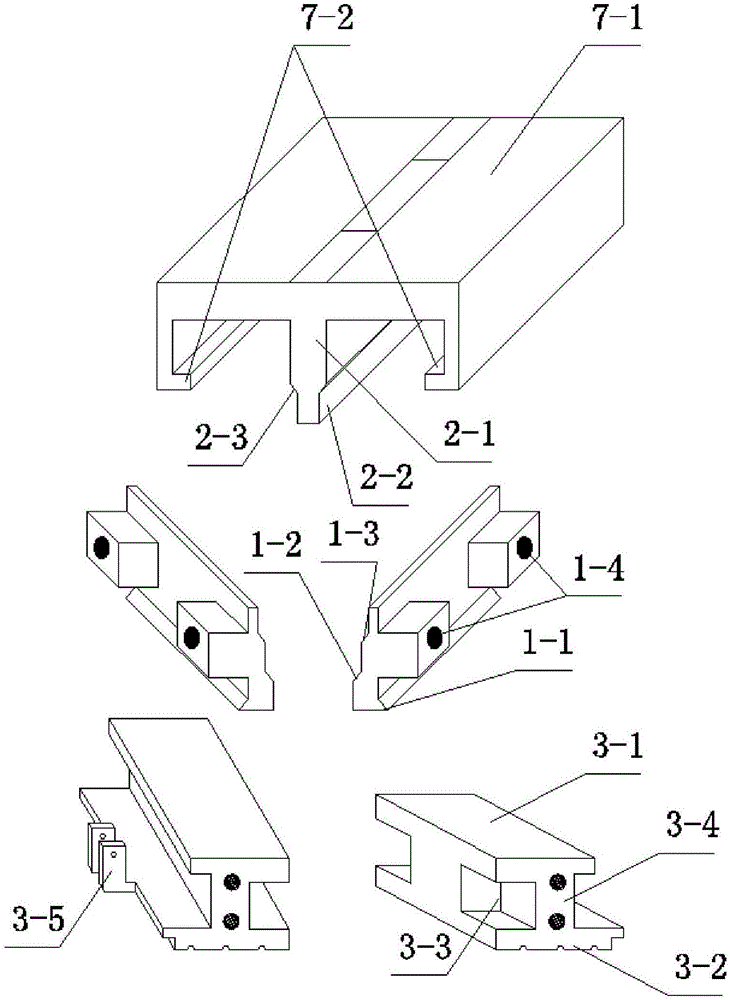

Connectors and Methods of Construction for a Precast Special Concrete Moment Resisting Shear Wall and Precast Special Concrete Moment Resisting Frame Building Panel System

InactiveUS20080098676A1Saving environment protectionThermally efficientMoulding surfacesBuilding roofsComposite constructionInternational Building Code

A precast concrete wall panel molding system for fabricating a wall shell and a plurality of ribs and beams. A precast concrete wall panel molding system with facilities for incorporating door and window frames. A ductile panel end connector for attaching panels one to another whether in parallel or angled as in inside or outside corners. A ductile panel end connector for attaching panels to columns. A wall anchor / shear plate with post-tensioning brace plate. A hybrid precast / cast-in-place special moment resisting shear wall / special moment resisting frame reinforced concrete building system for regions of potential seismic activity. A prescriptive method building system for composite structural building assemblies with conventional wood and light-gauge steel framing, structural steel, and other building code approved and tested building systems, building components, building panel systems, building roofing systems, modular and manufactured buildings, and building electrical, mechanical, and plumbing systems. A precast concrete wall panel system conforming to industry practices and standards as published by the Precast / Prestressed Concrete Institute, (PCI) in it's “PCI Design Handbook” (fifth edition, 1999), the American Concrete Institute “Building Code Requirements for Structural Concrete” (ACI 318-05), The “International Building Code 2006” and the “Uniform Building Code”.

Owner:HUTCHENS JOHN FRANCIS

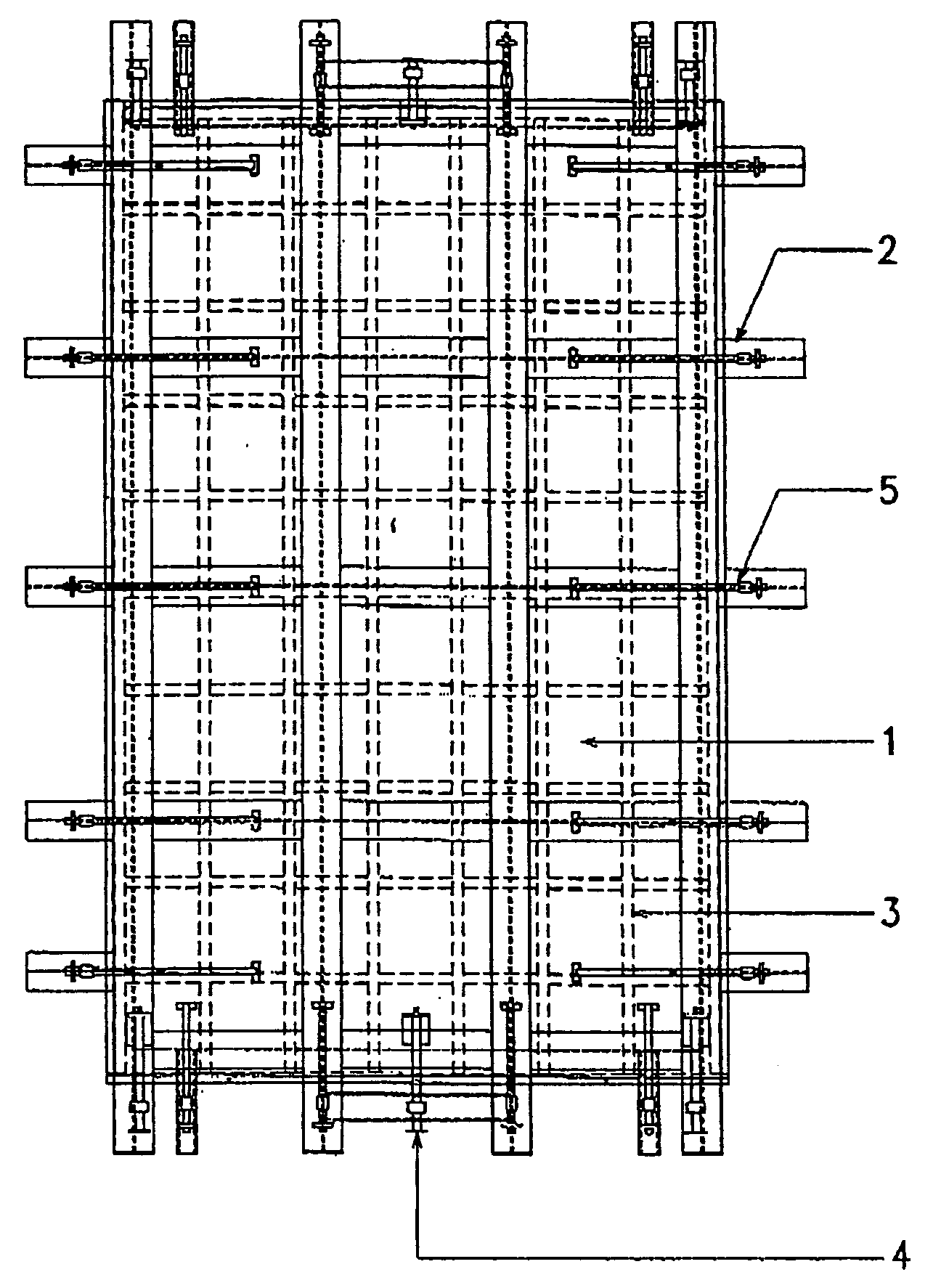

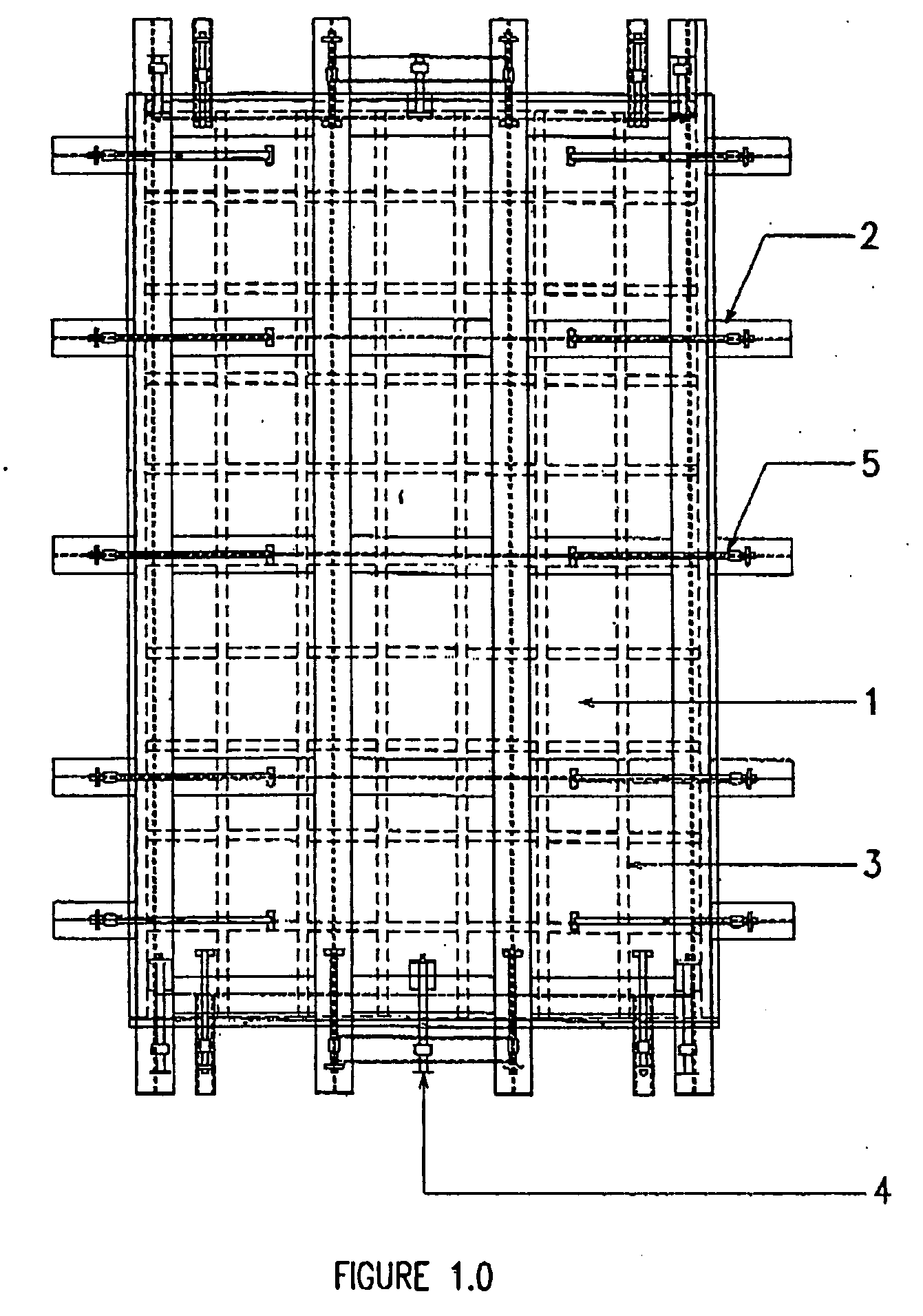

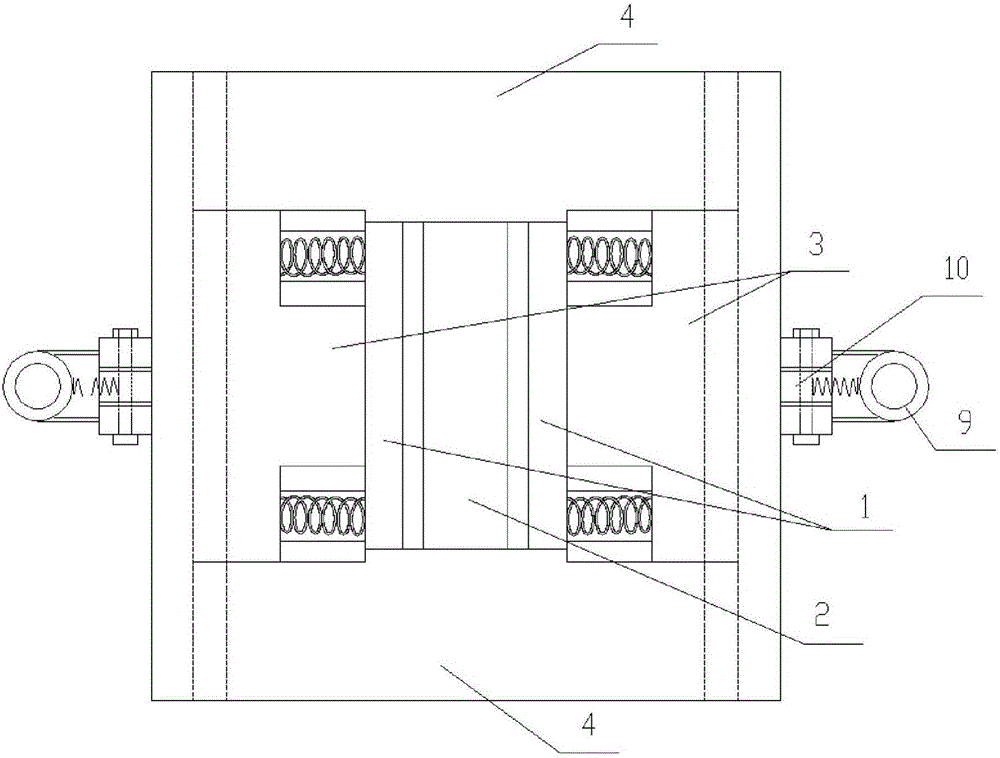

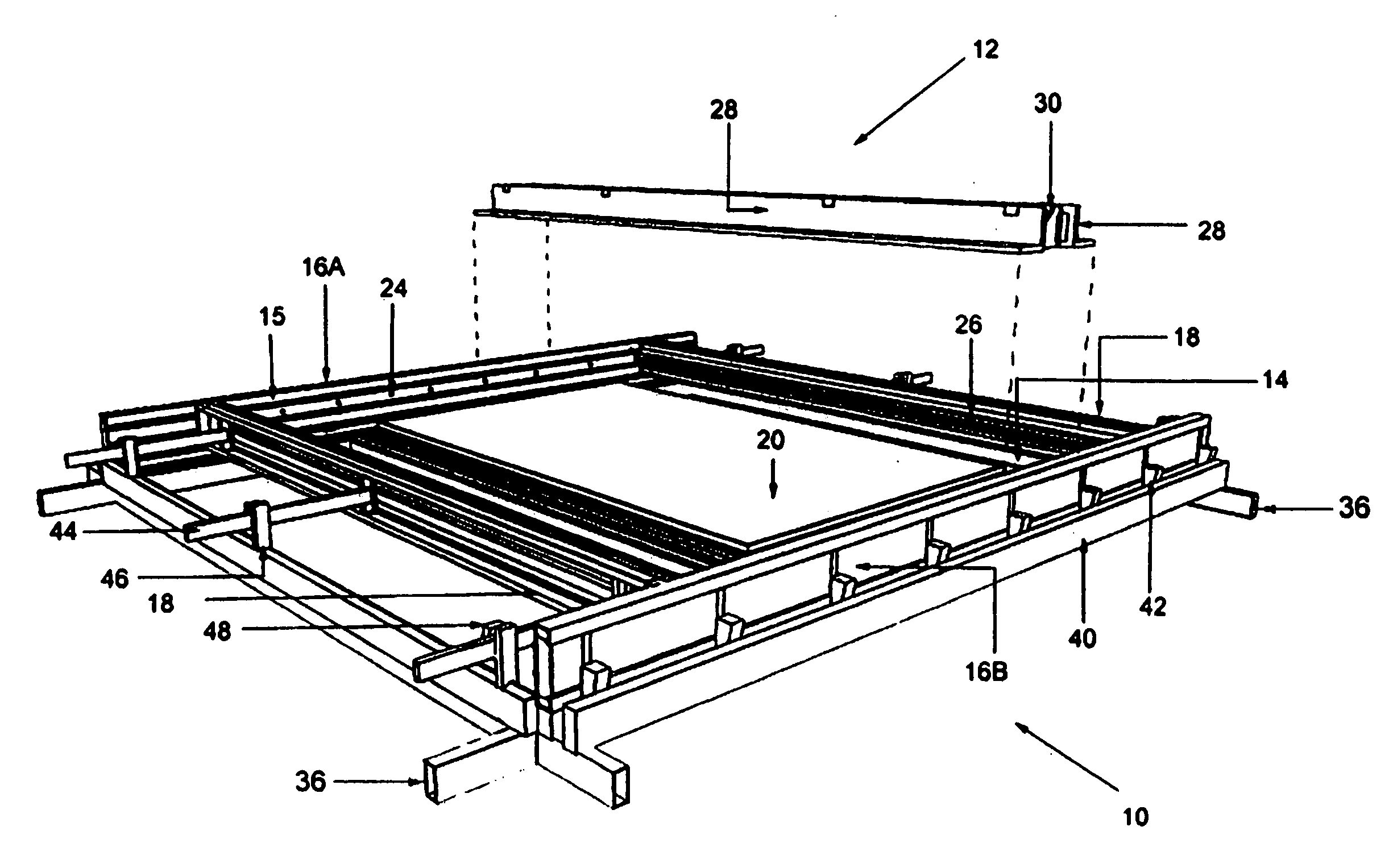

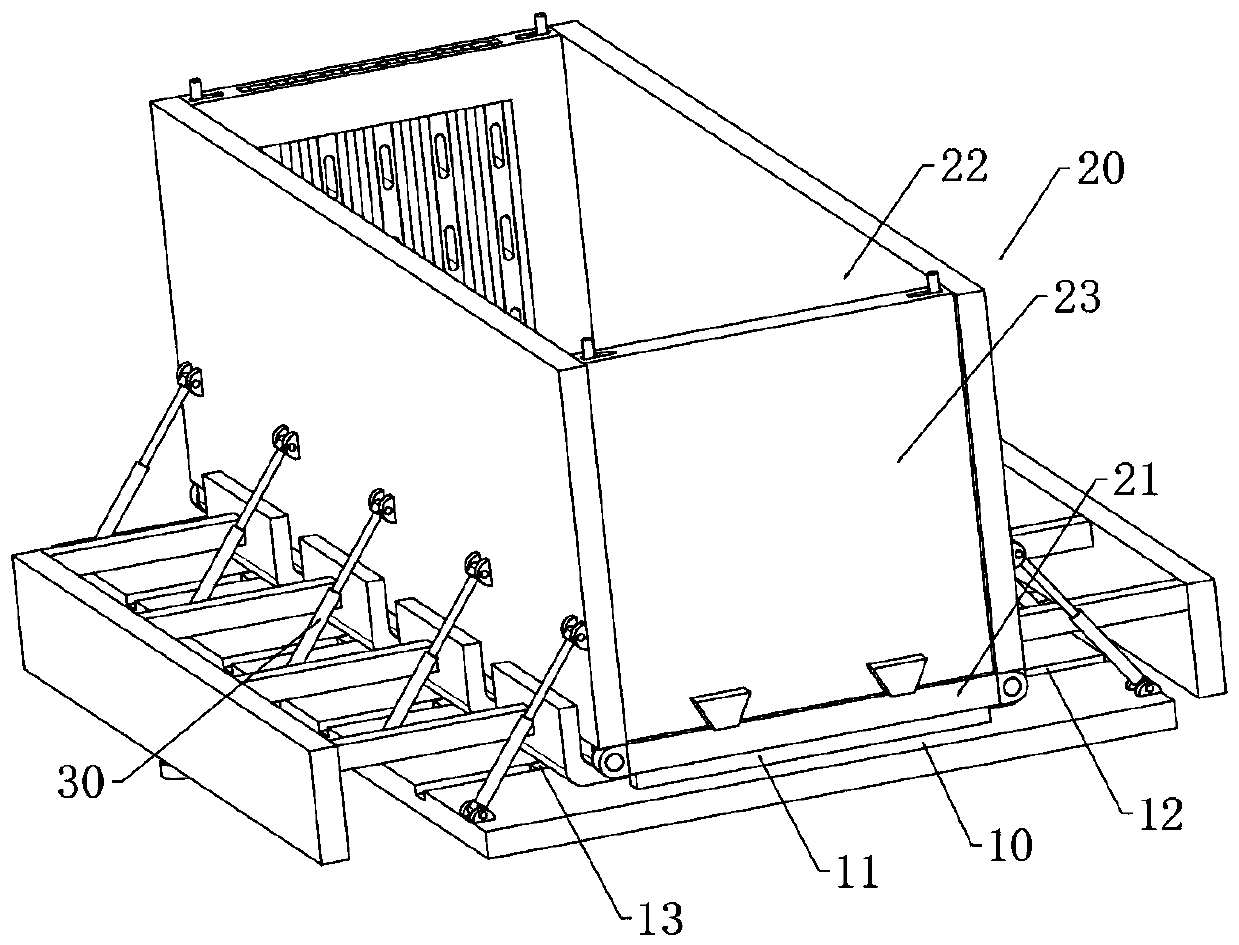

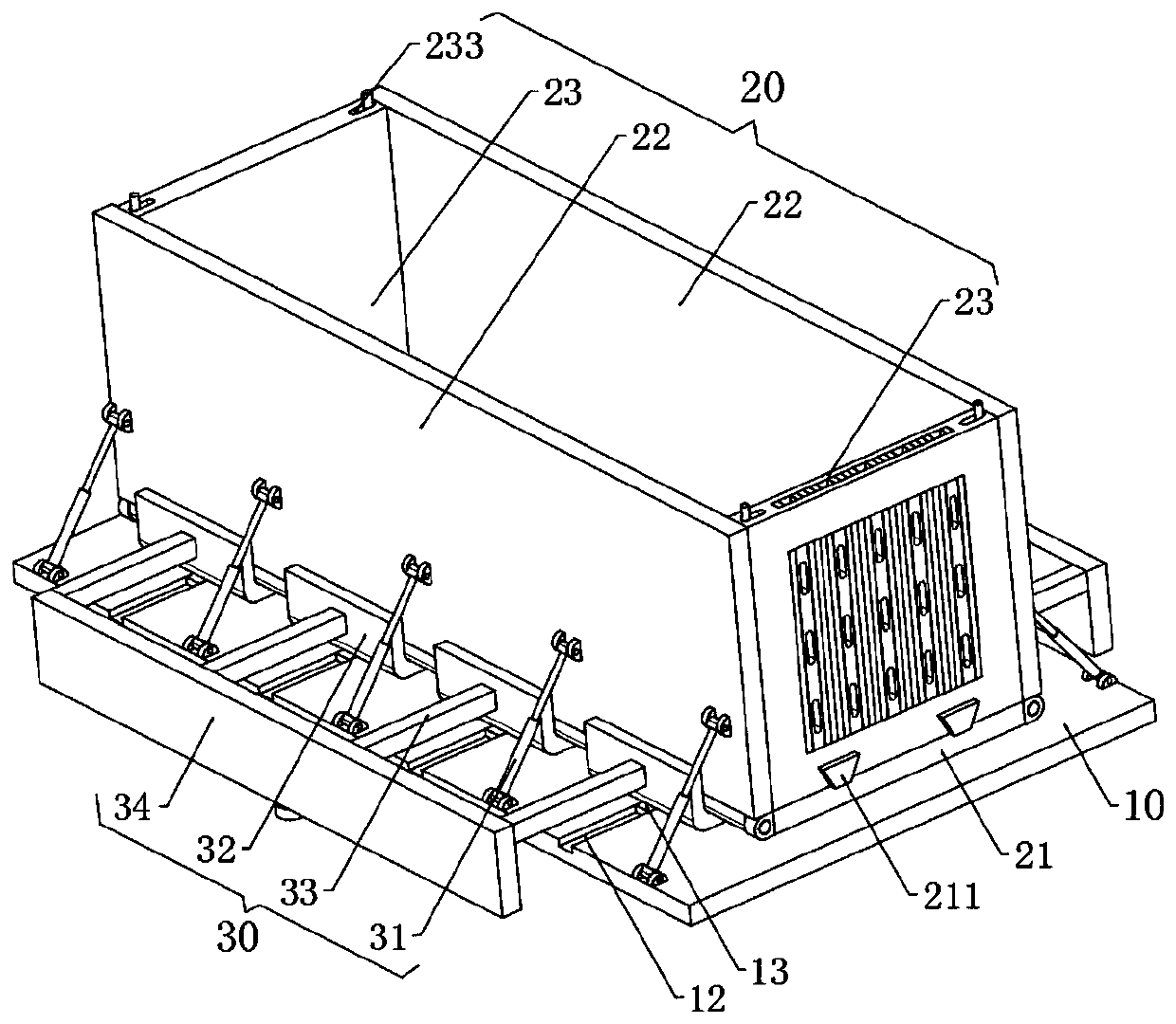

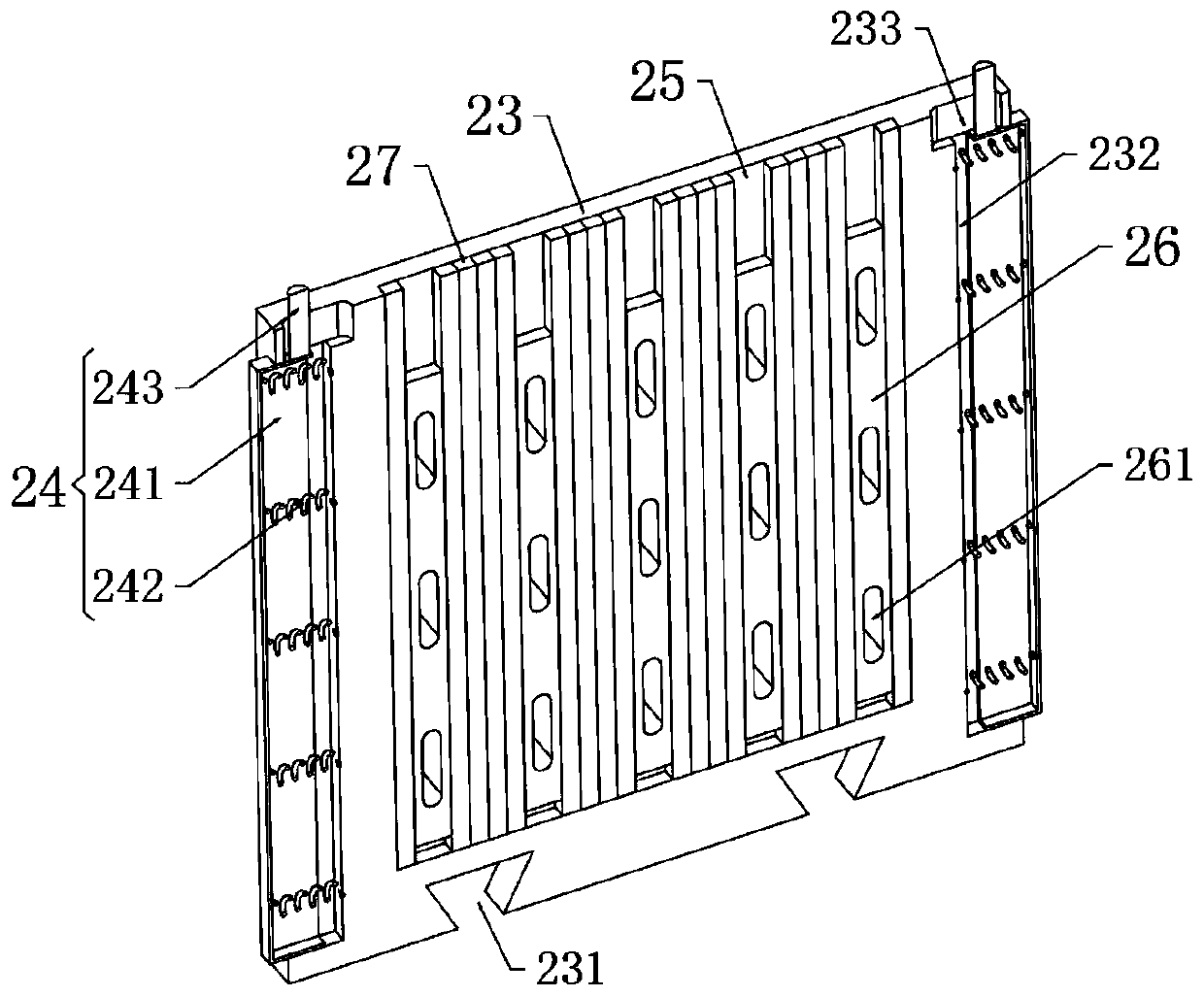

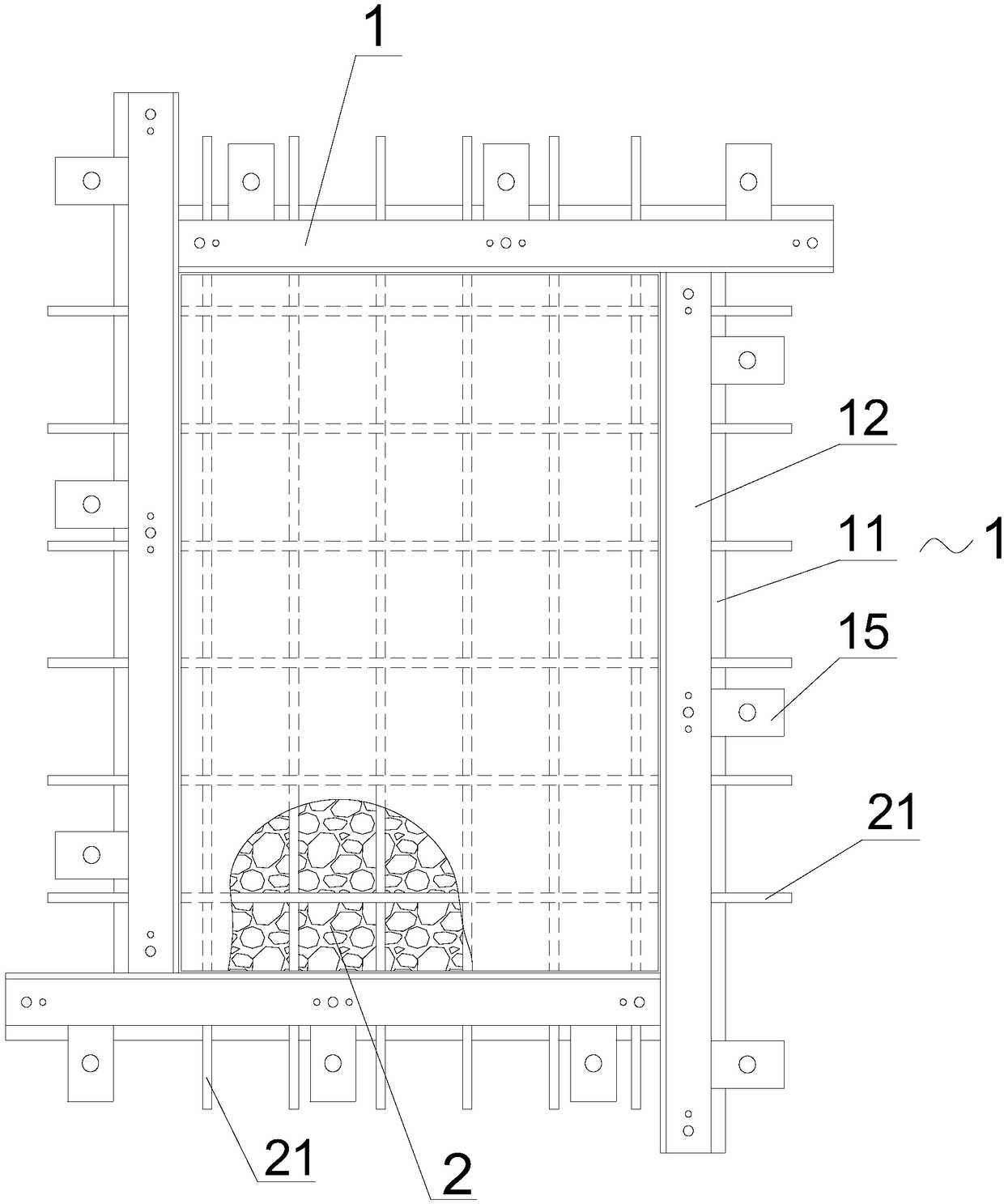

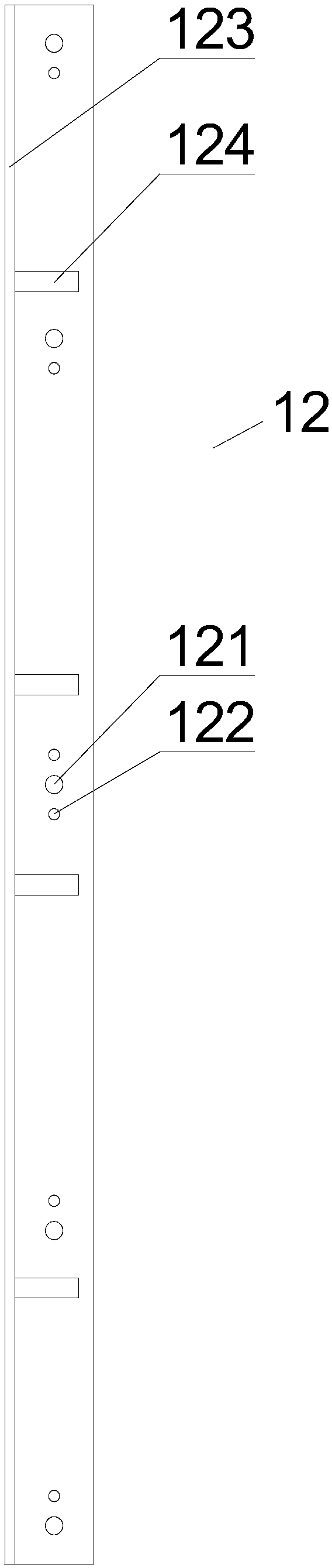

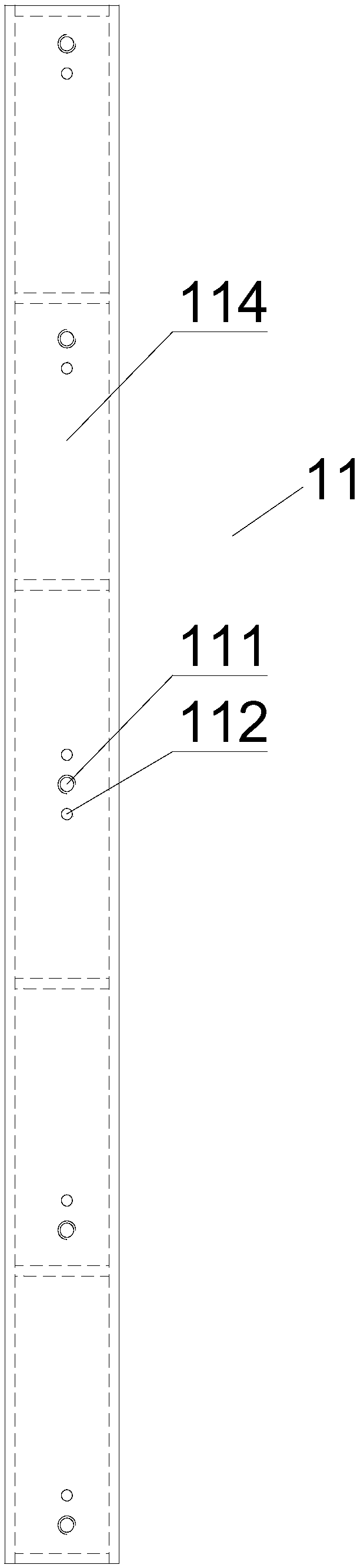

Panel formwork system

Formwork system for the process of casting prefabricated wall and slab panels that is flexible in width and height is provided. This formwork system includes two types of retractable bracing structures that are located on the sides and ends of mould structure. The height and width of panels can be varied by moving the linear retractable bracing structure, while the lever retractable bracing structure holds the side form firmly by clamping down the side form to the platform of the support structure. The thickness of the panel to be cast can be varied by using different modules of side form that are designed to produce a series of modules of various heights. Various patterns on the wall can be designed by incorporating specially designed channels in the mould.

Owner:HC PRECAST SYST

Thermo tech mark ii limited

Owner:THERMO TECH MARK II

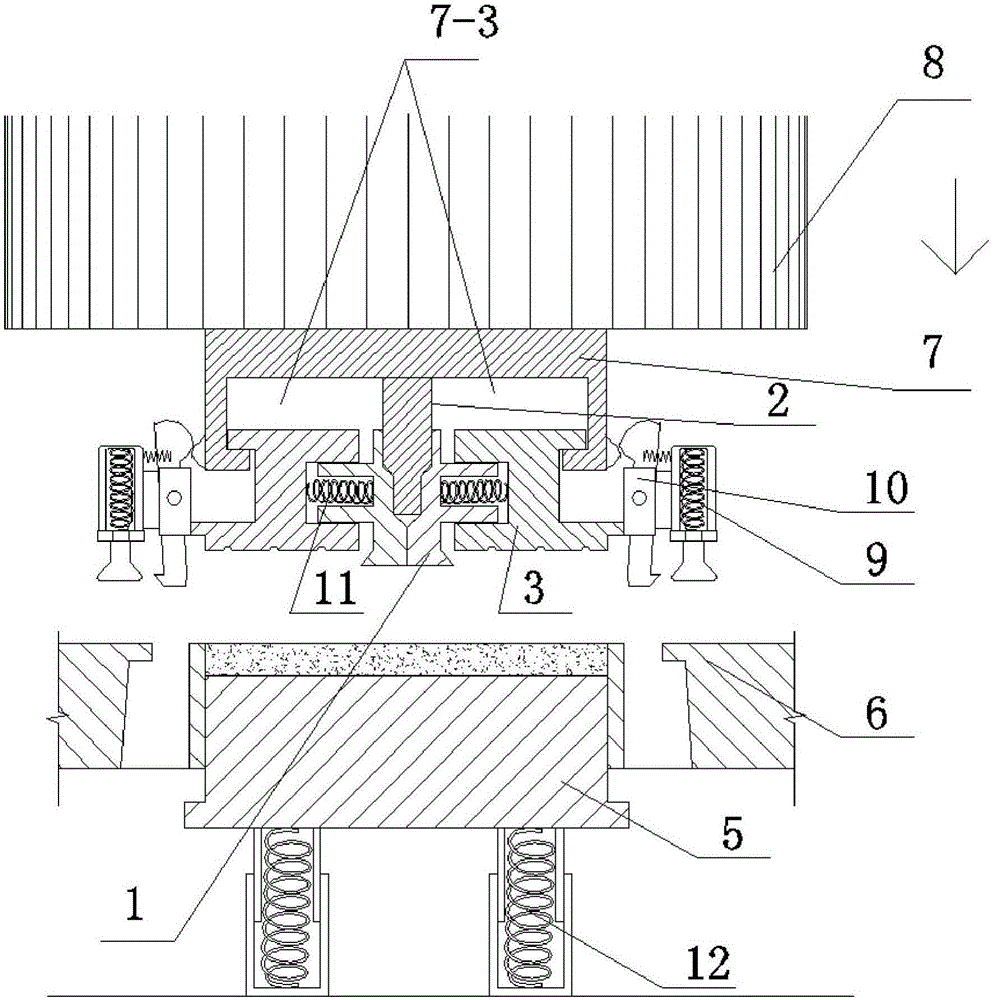

Method and device for manufacturing dovetail groove in back side of ceramic tile

ActiveCN105082332ANo disengagementImprove bindingMoulding surfacesCeramic shaping mandrelsStructural engineeringMechanical engineering

The invention discloses a method and device for manufacturing a dovetail groove in the back side of a ceramic tile. The device comprises a wedge lifting cover (b) and is characterized in that inward stretching lifting arms are arranged on the left side edge and right side edge of the wedge lifting cover respectively, an inner cavity is divided into a left cavity part and a right cavity part by a dovetail combined insert, a wedge body side frame and a half-dovetail component are arranged in each cavity part, and each half-dovetail component can make contact with the dovetail combined insert; an upper ejector plate on each wedge body side frame can move downwards in the corresponding cavity part onto the corresponding lifting arm and be limited by the lifting arm, and a reset spring is arranged between a spring slot formed in the wedge body side frame in each cavity part and a reset spring slot formed in the adjacent half-dovetail component; an insert body of the dovetail combined insert can be combined with two half dovetails located at the two sides of the dovetail combined insert respectively to form a complete dovetail part, and the complete dovetail part is inserted into ceramic tile powder to enable a dovetail groove to be formed in the back side of the ceramic tile; when the dovetail combined insert is pulled upwards in place, the dovetail part which can be pulled out of the dovetail groove and is free of the insert body is formed with width reduced. The method and device have the characteristics that the manufacturing method and device are simple, and operation is convenient.

Owner:周述文

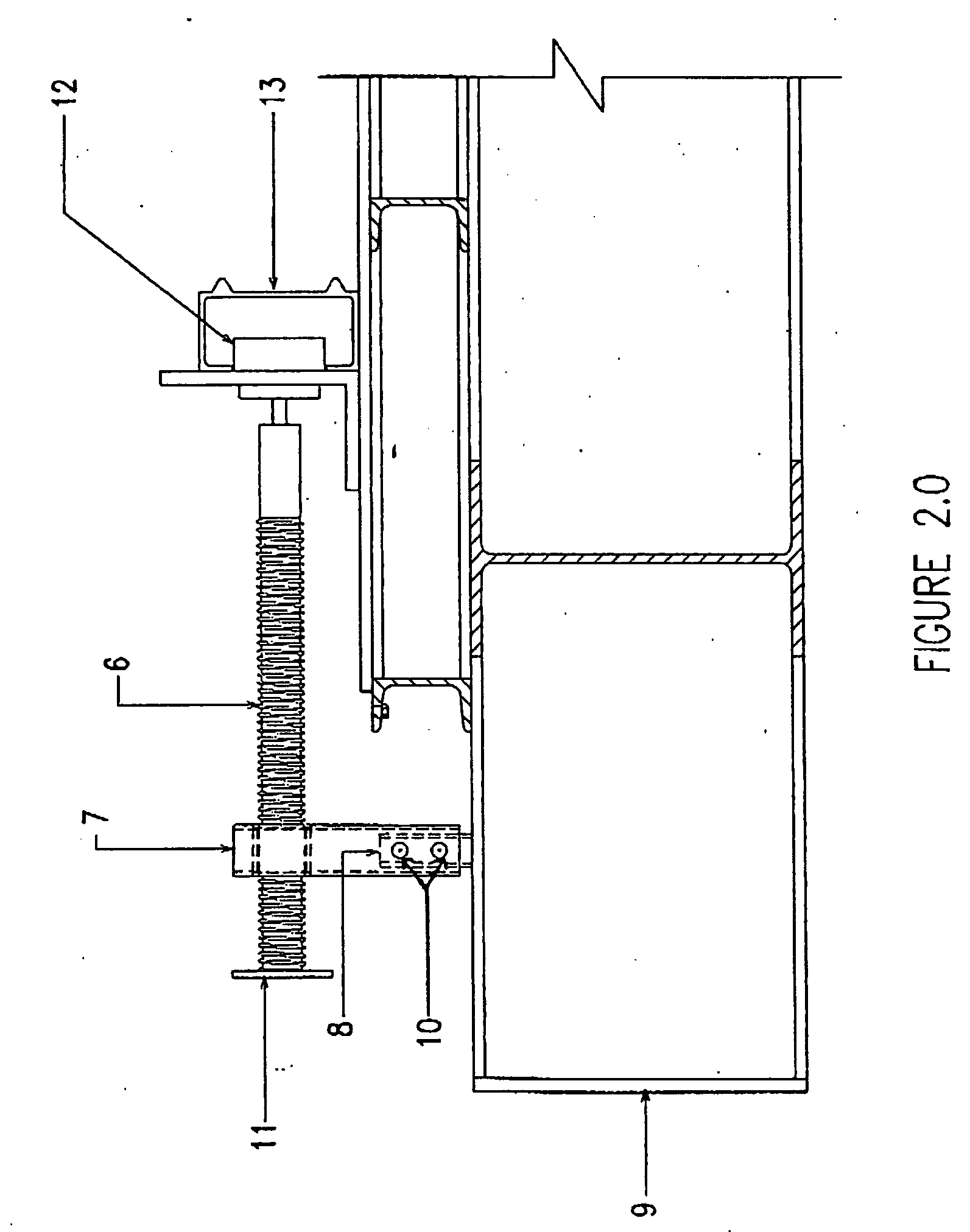

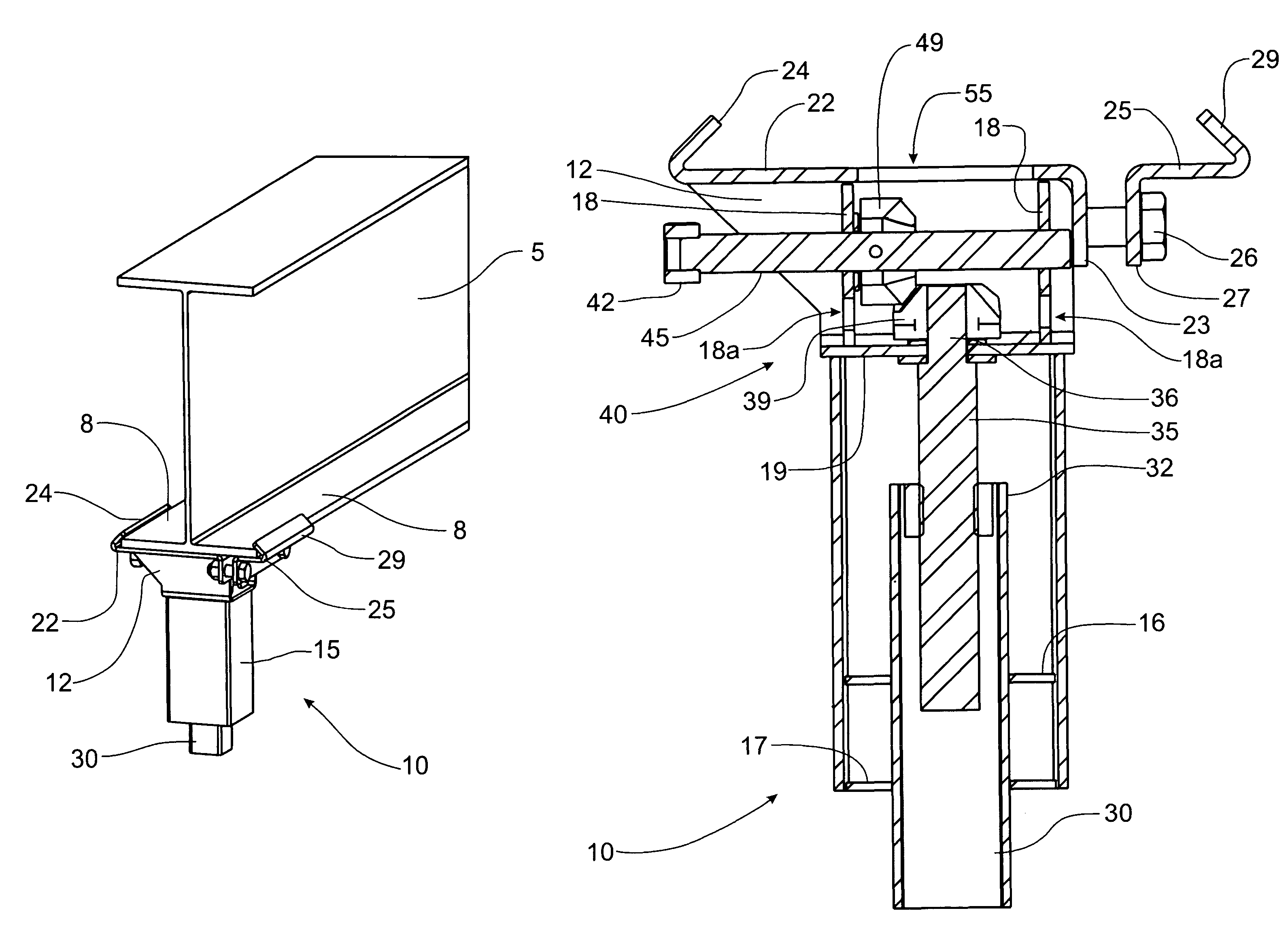

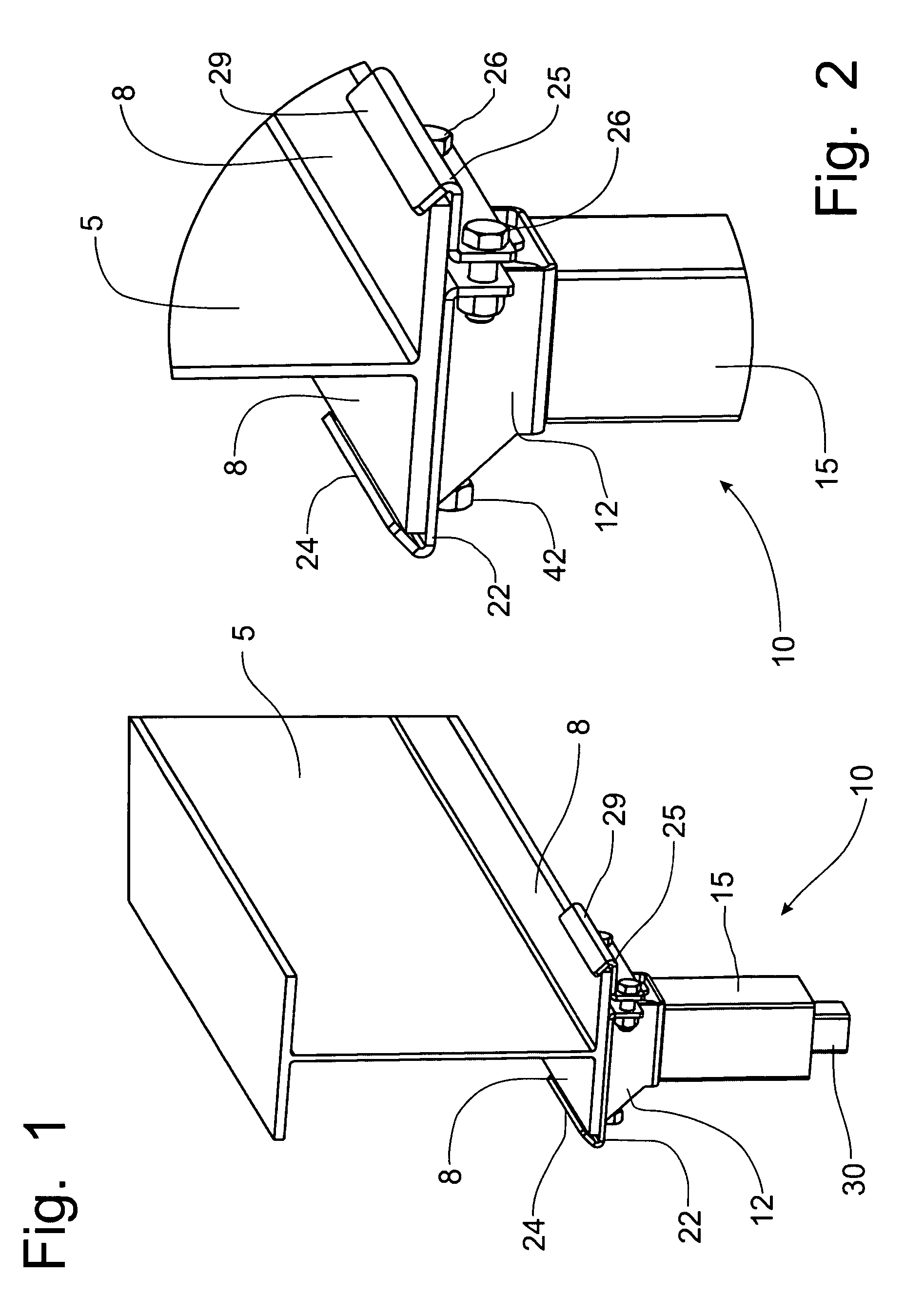

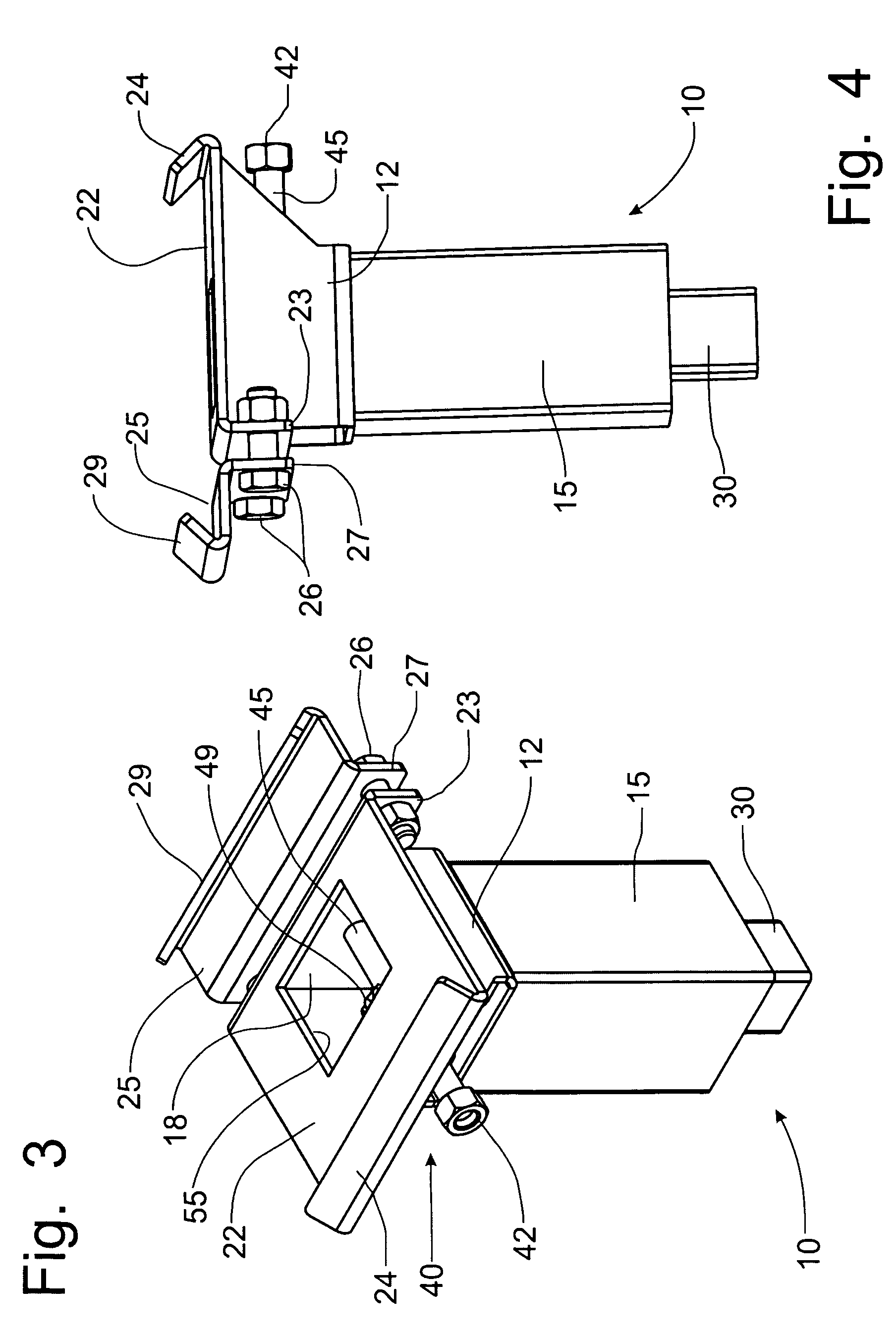

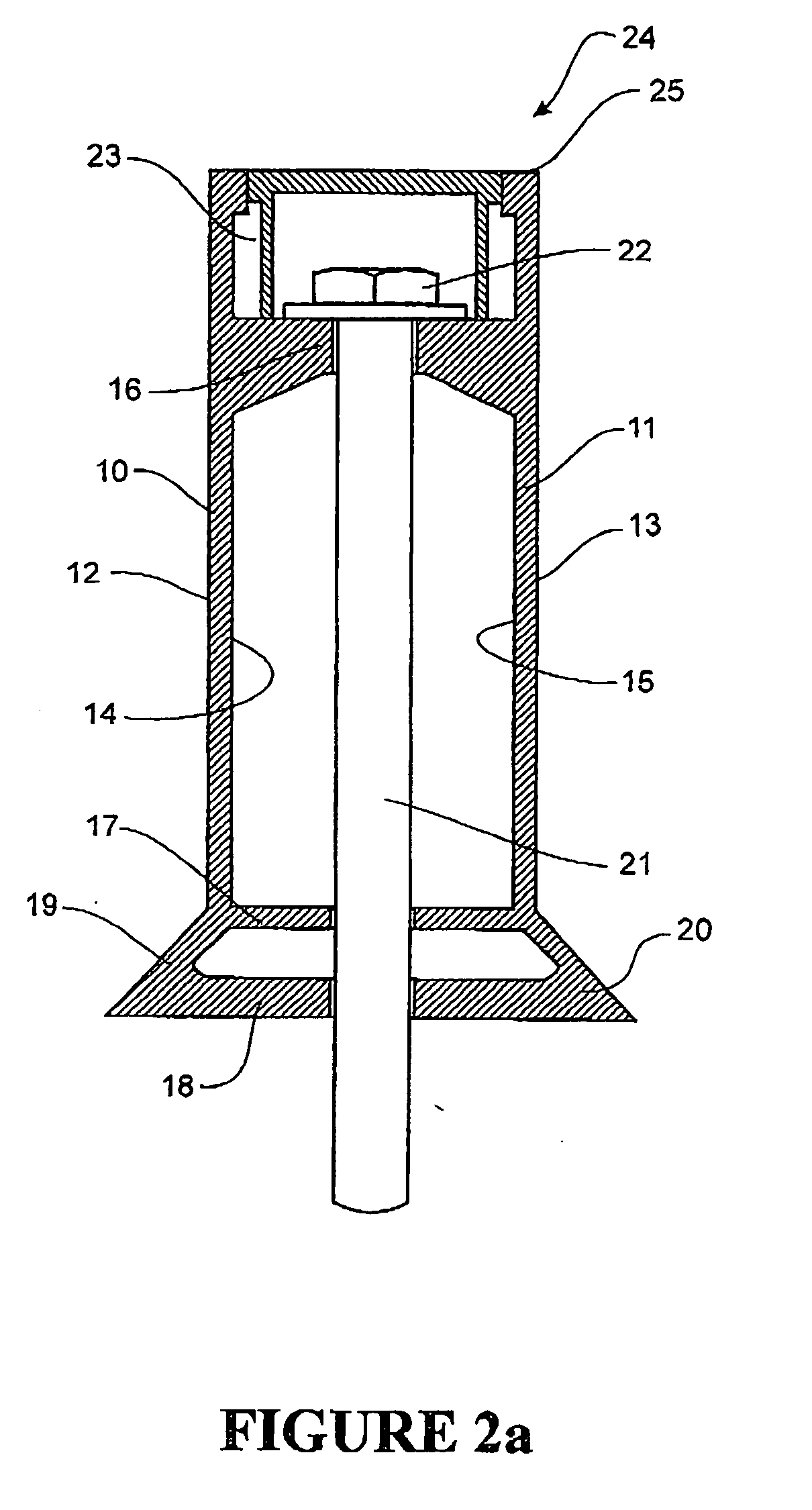

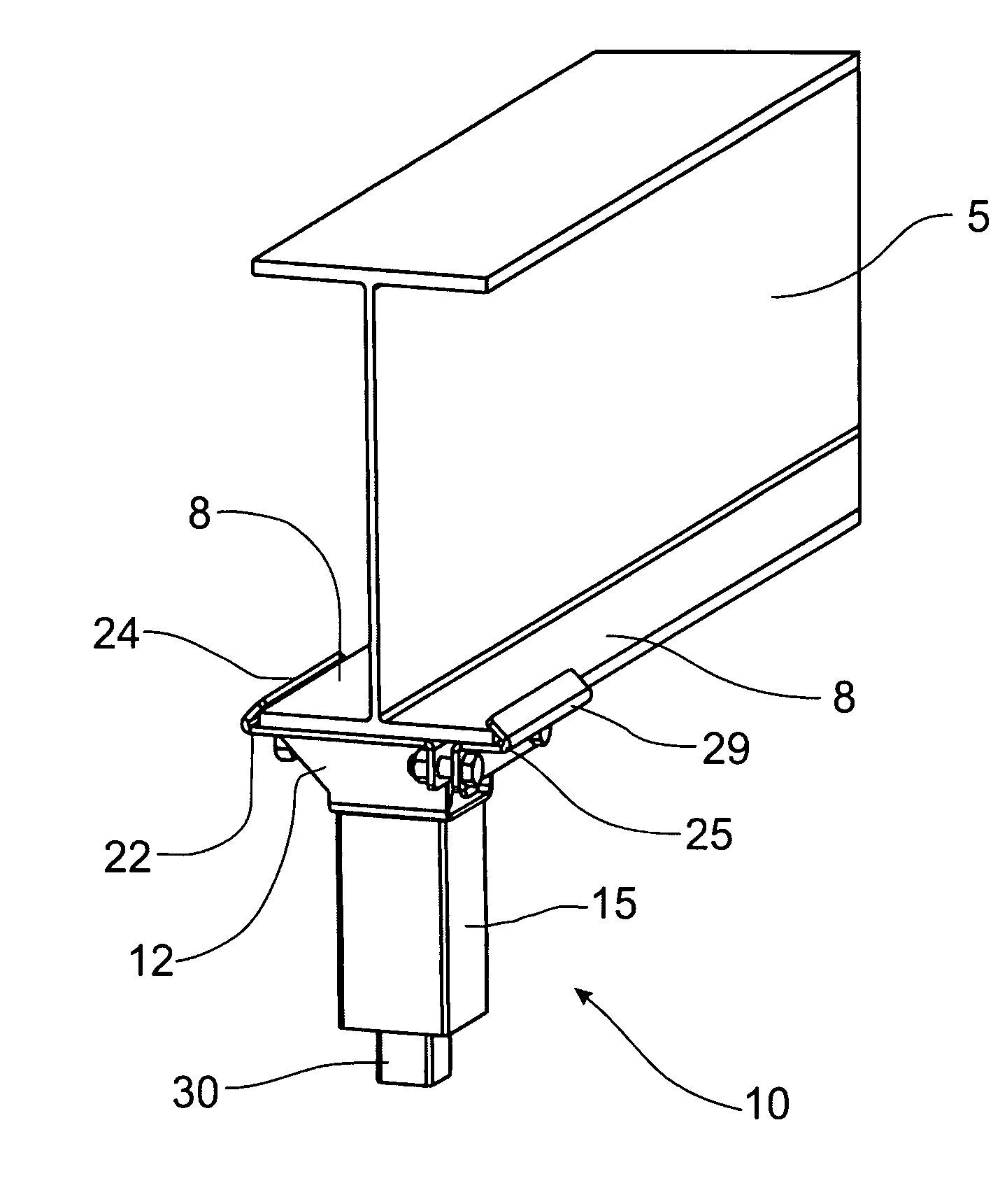

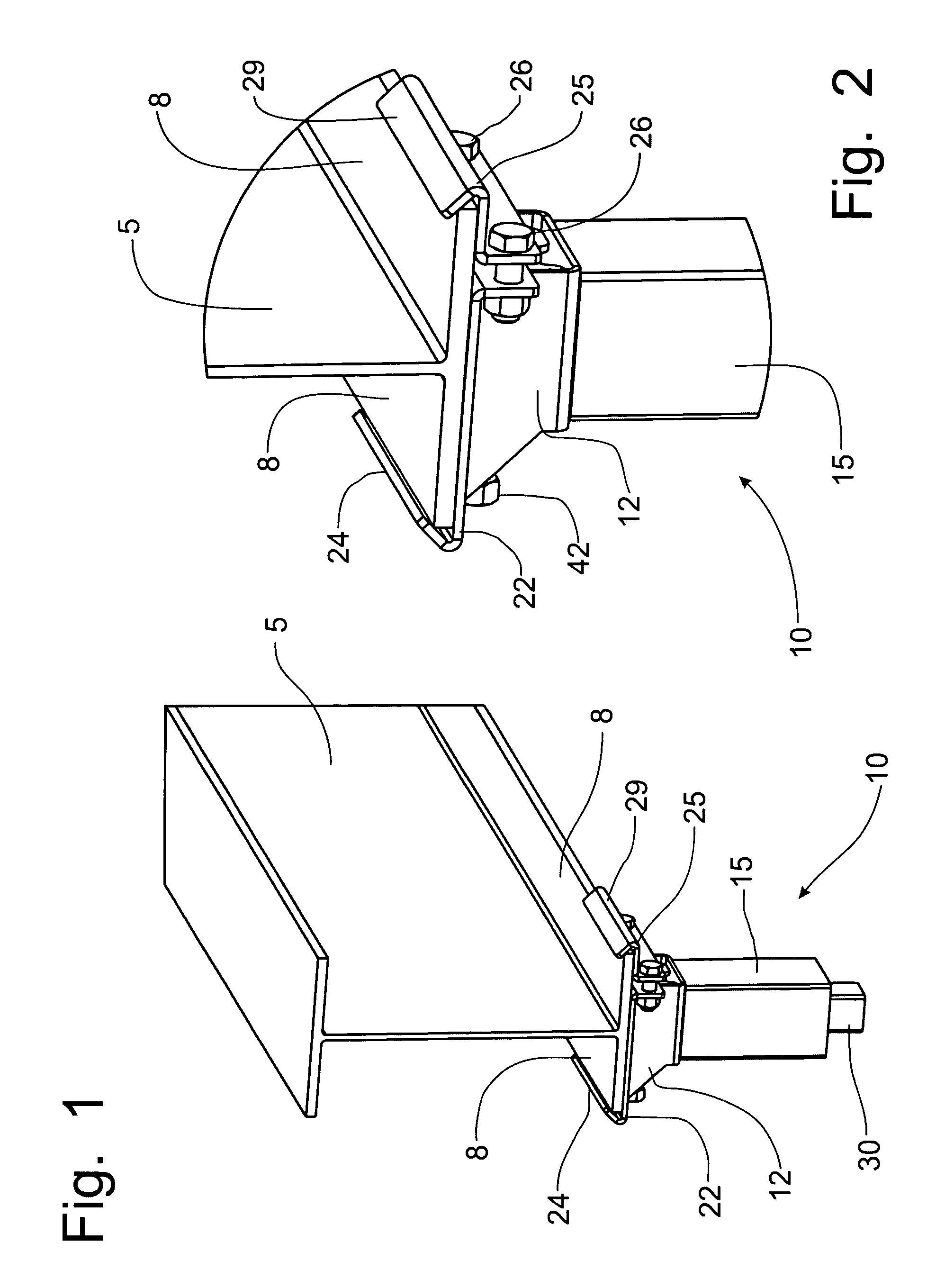

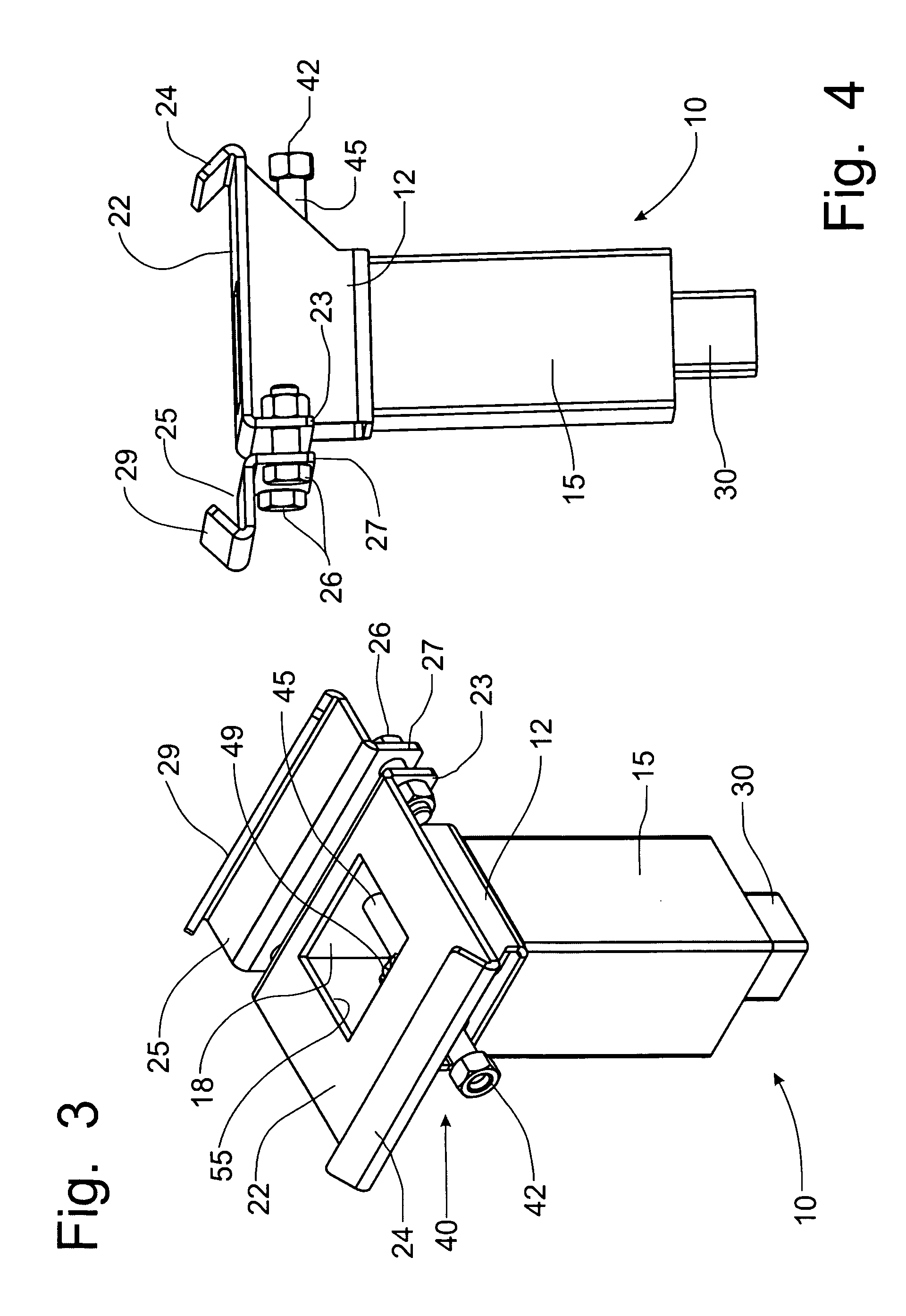

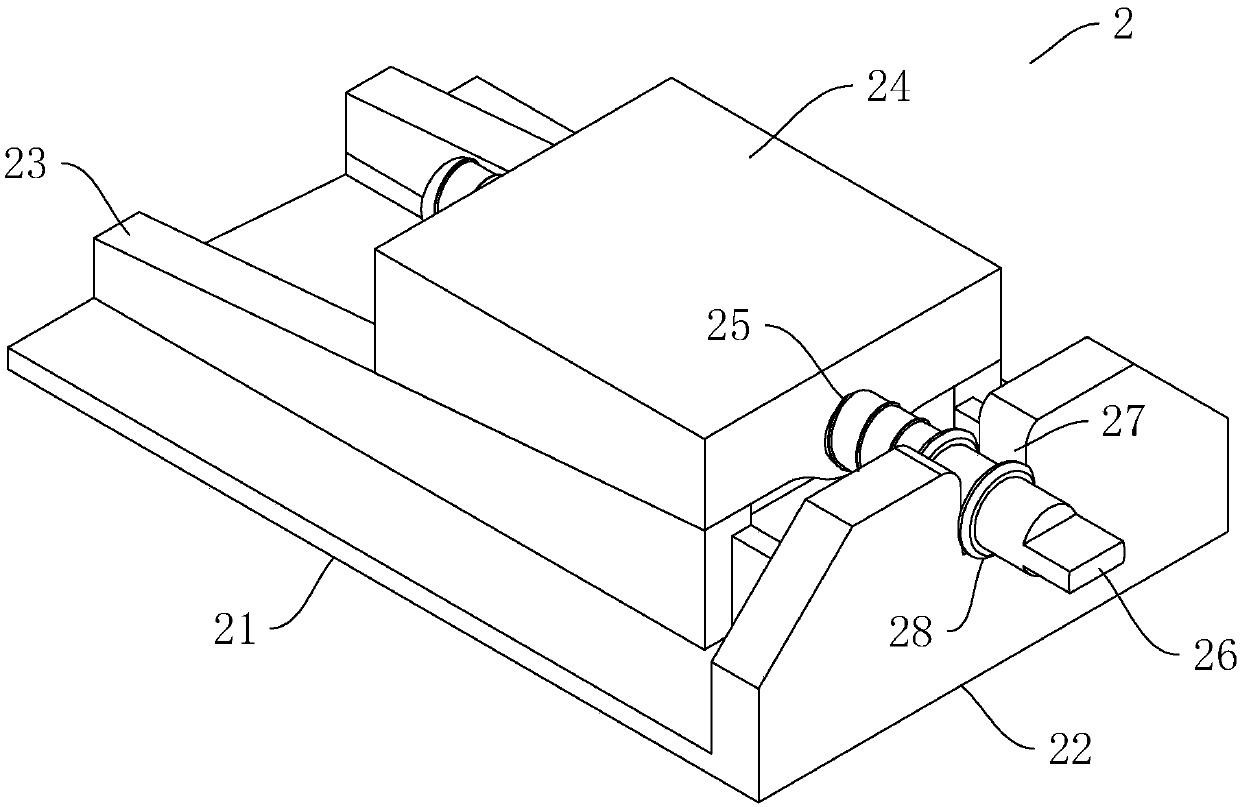

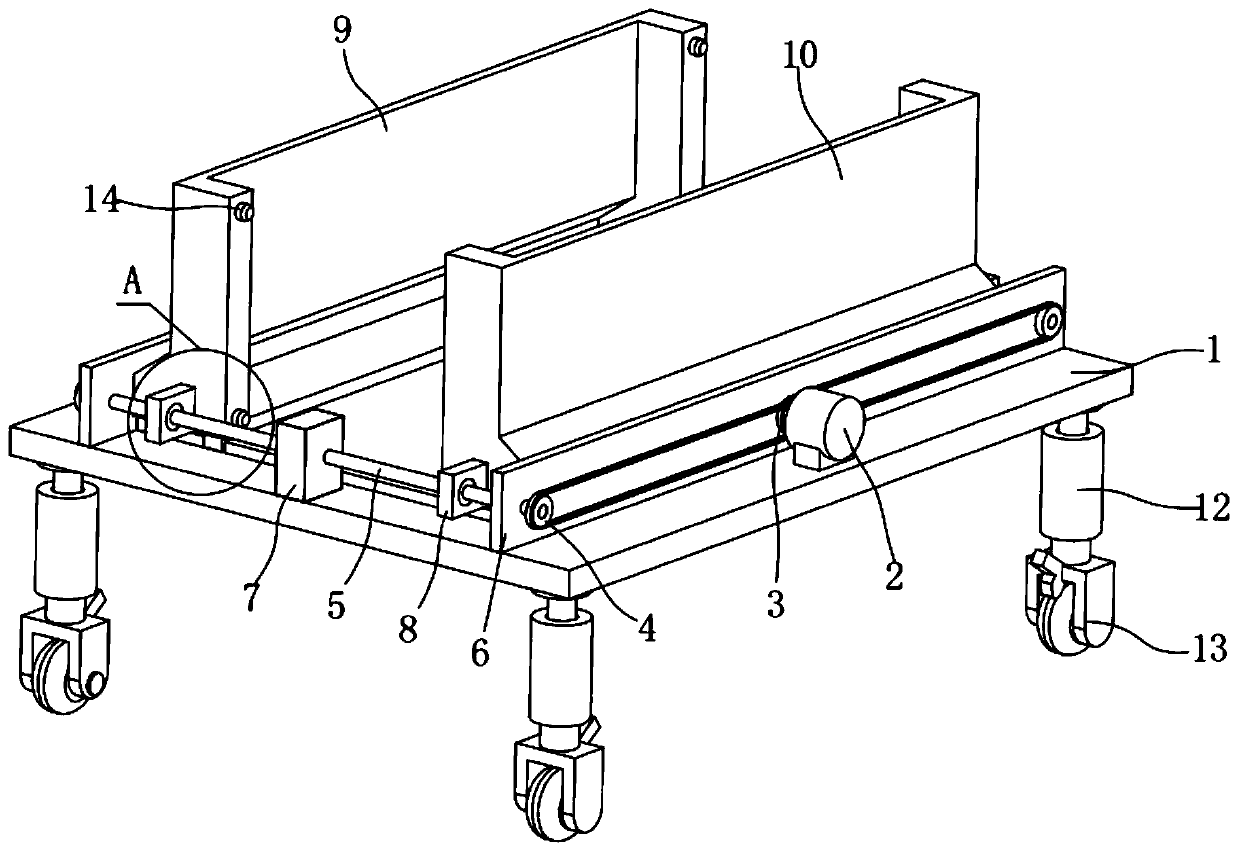

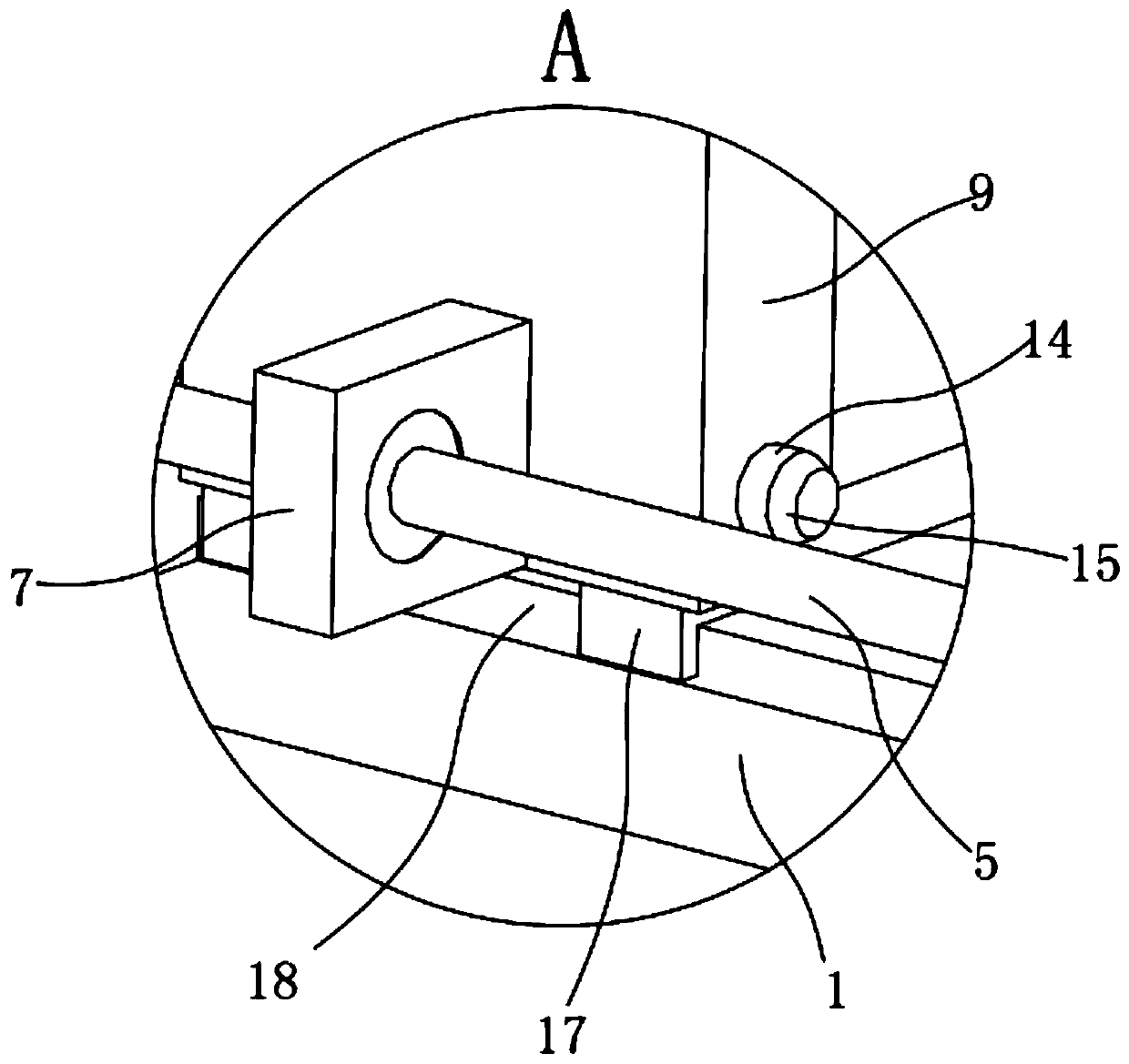

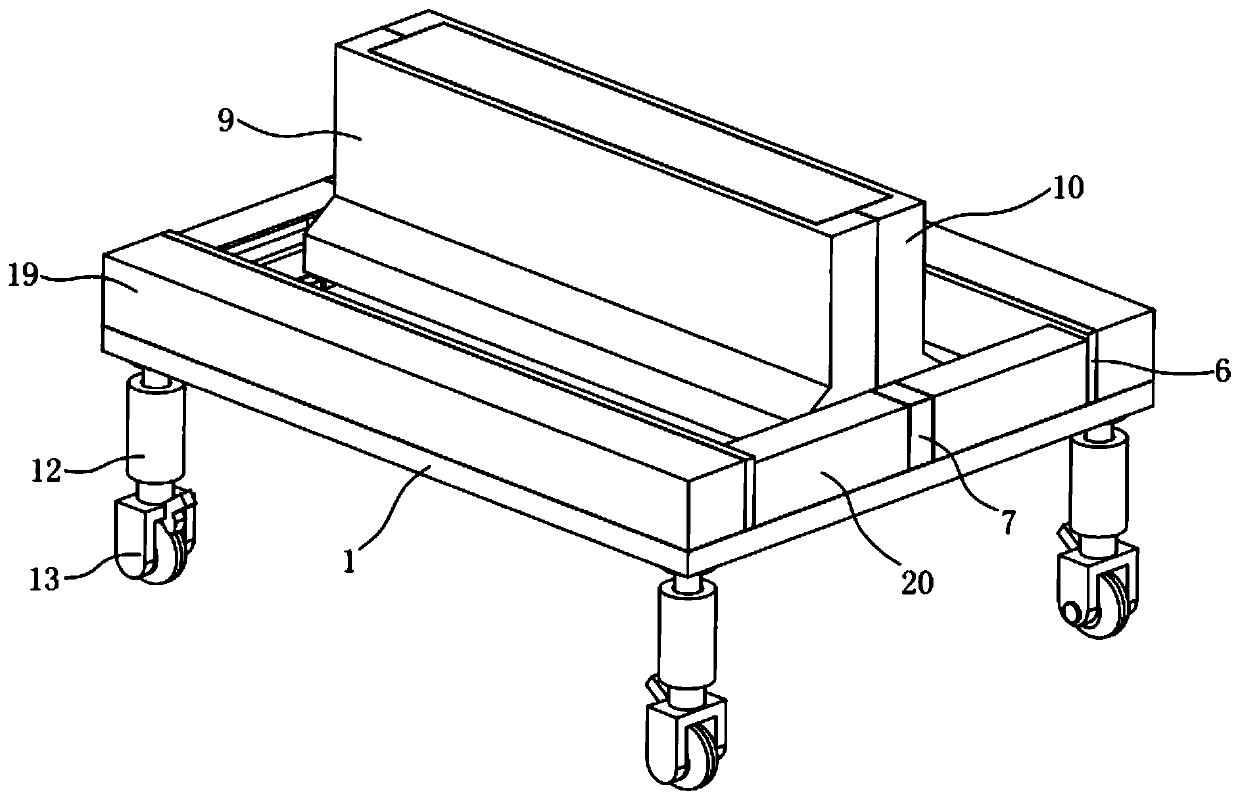

Adjustable support stand for pre-cast concrete wall forms

ActiveUS7922145B2Durable in constructionReduce manufacturing costMoulding surfacesMould separation apparatusDrive shaftEngineering

An adjustable support stand is mounted on a pre-cast concrete wall panel form to facilitate the leveling of the form and the support of the form about the production plant floor. The adjustable support stand includes a frame portion that houses a threaded rod positional fixed for rotation within the frame portion to drive a vertical movement of the leg member in response to rotation of the threaded rod. The adjustable support stand further includes a clamping apparatus that detachably mounts the frame portion to the flanges of a steel beam frame member. The actuator member can be a nut welded to the top of the threaded rod to affect movement of the engaged leg member in response to manipulation with a powered or manually operated hand tool, or a gear set and an orthogonal drive shaft that transfers rotation from a hand tool to the threaded rod.

Owner:SUPERIOR WALLS OF AMERICA

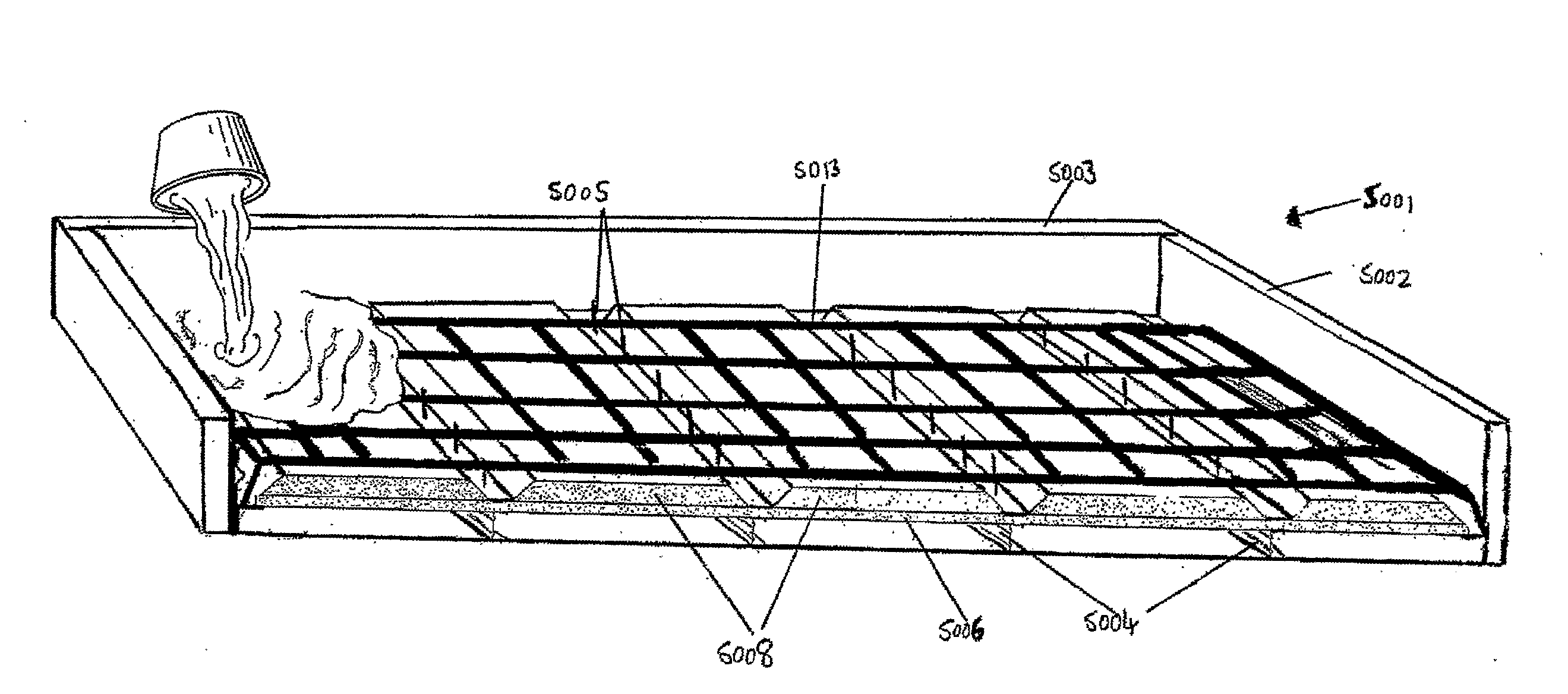

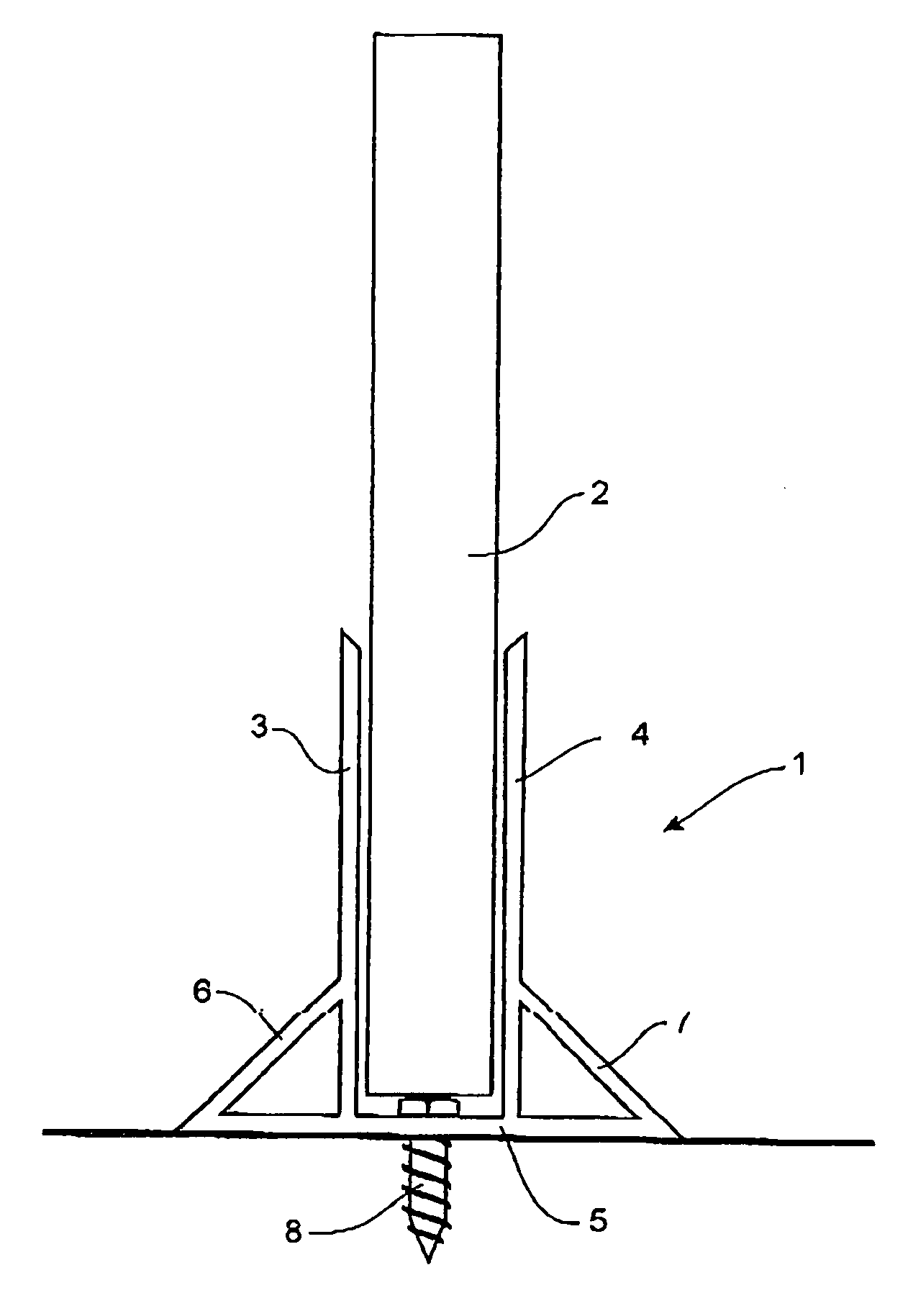

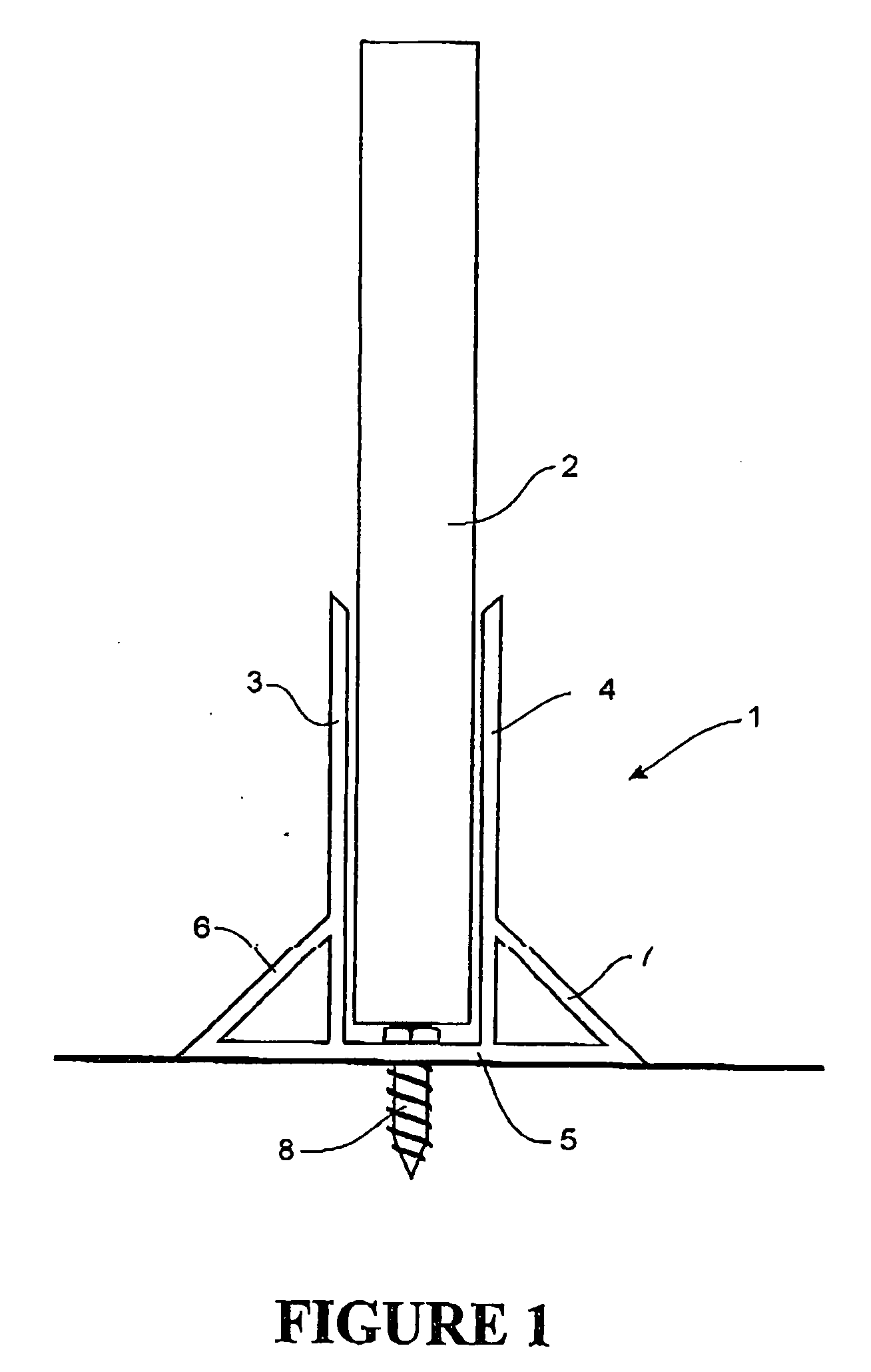

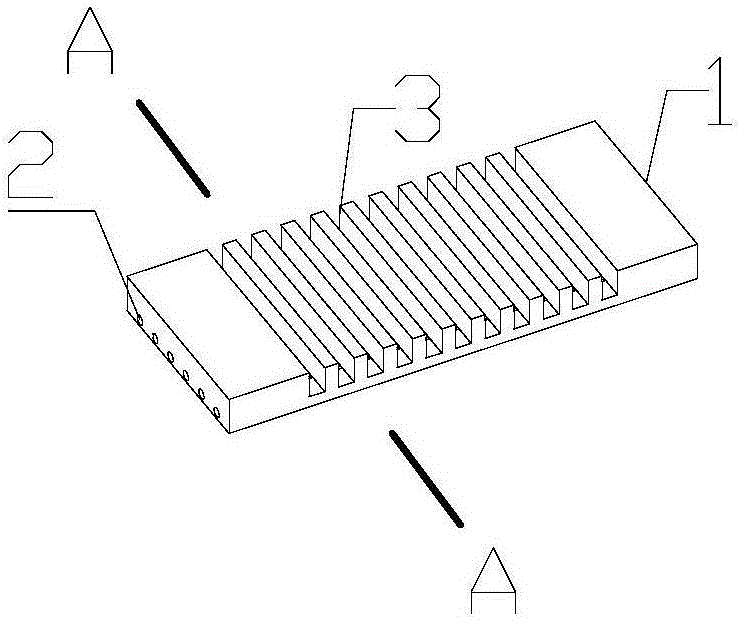

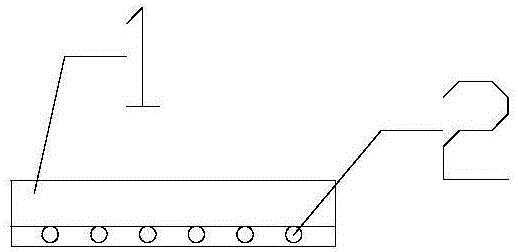

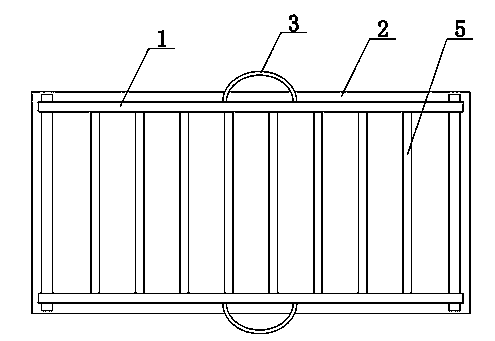

Apparatus and method for forming concrete panels

The invention provides a form member for use in forming concrete panels comprising a pair of upright walls connected by a plurality of ribs. Each of the ribs includes an aperture for allowing a fastener through. The fastener passes through each of the ribs into a casting floor to fix the form member to the floor. A plurality of form members can be arranged to define enclosures, concrete is then poured into the enclosures to the level of the upright walls, smoothed and allowed to cure to form concrete panels. The form members of the present invention allow a number of panels to be formed at the same time, with some form members common to more than one concrete panel. The invention provides easy of use and savings in space, time and labour.

Owner:SPEEDLINE PANEL FORMERS

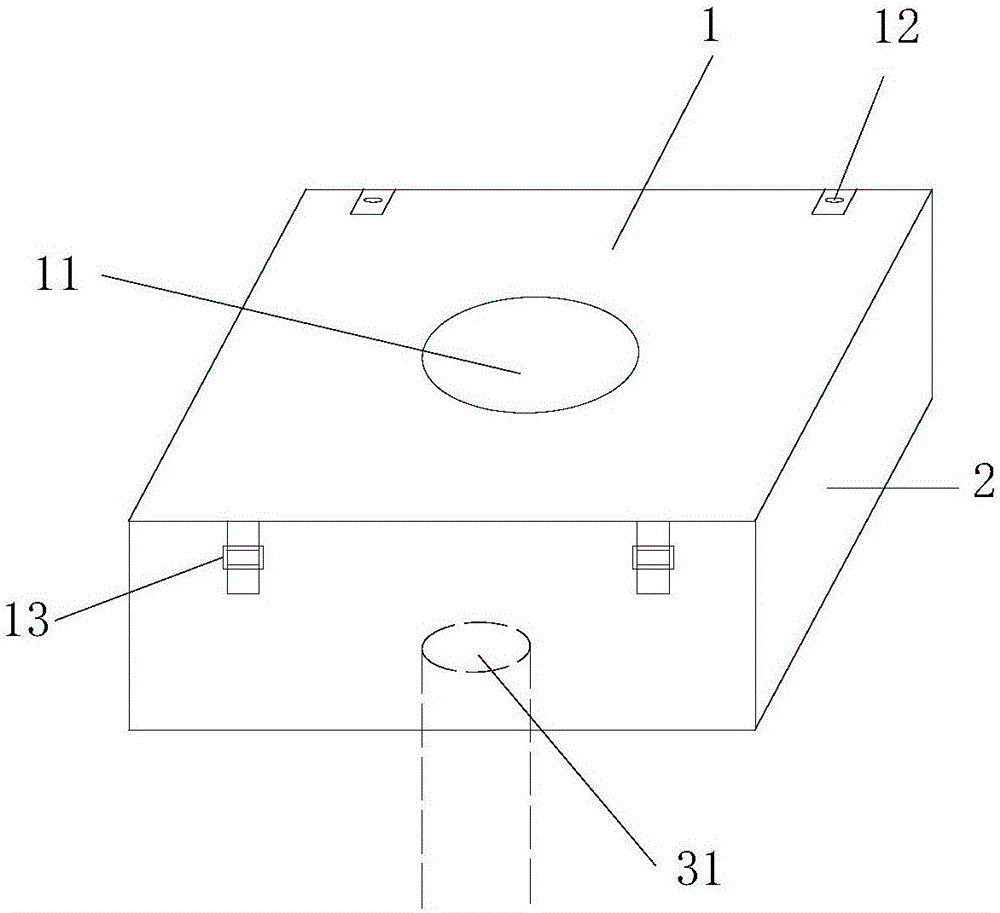

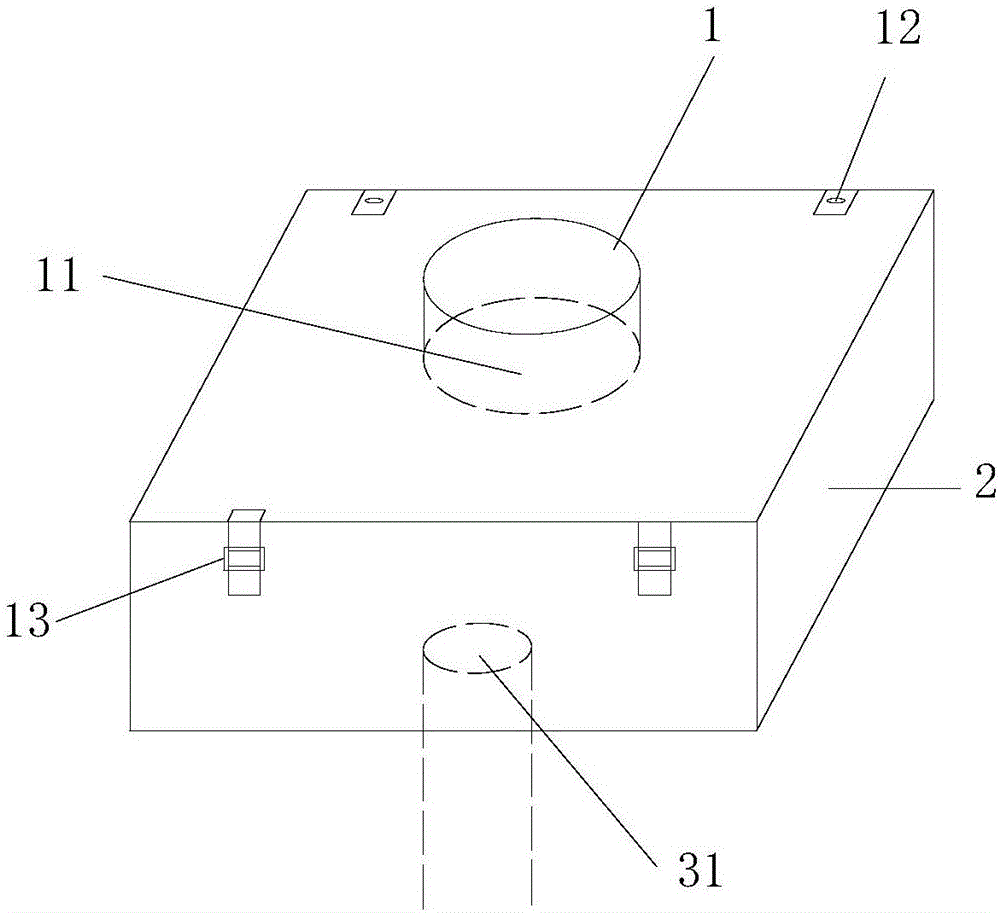

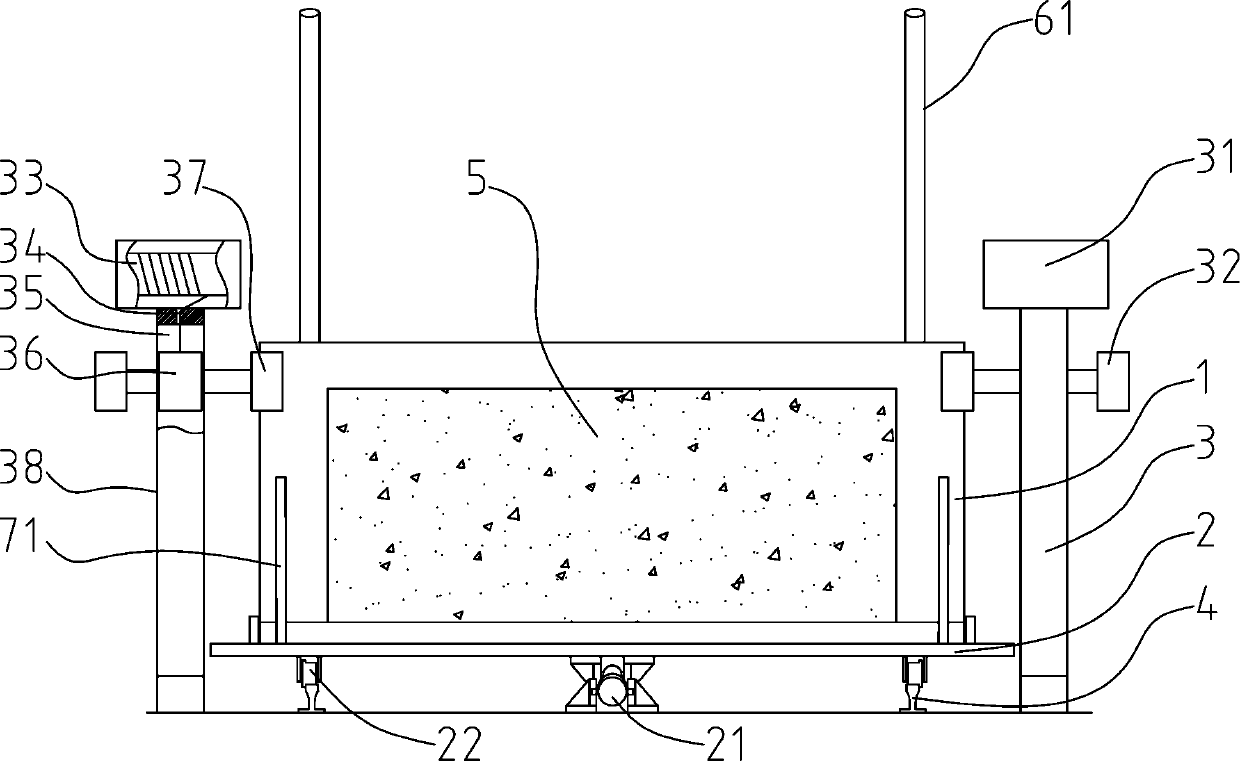

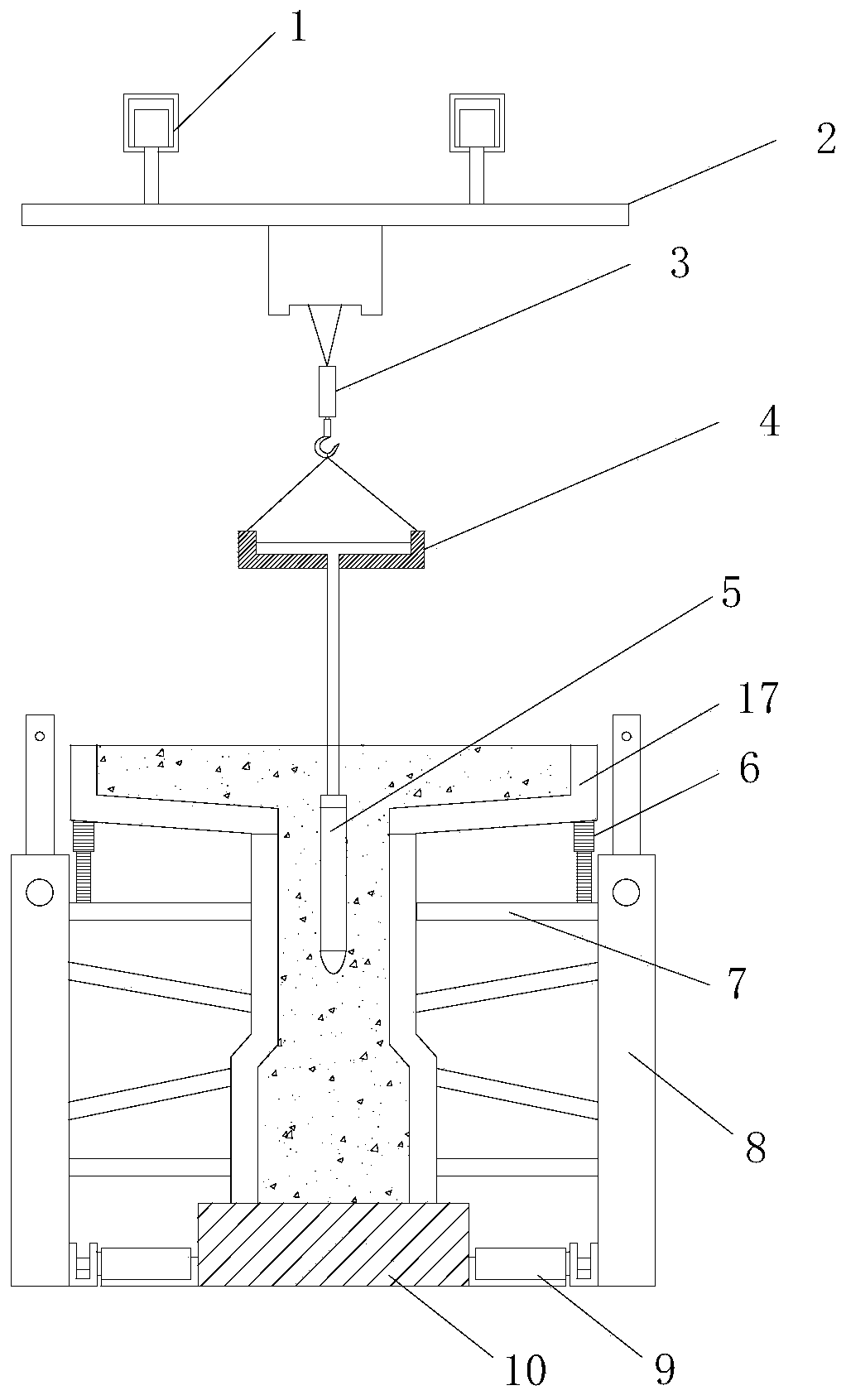

Die and process for producing ceramsite foamed precast concrete

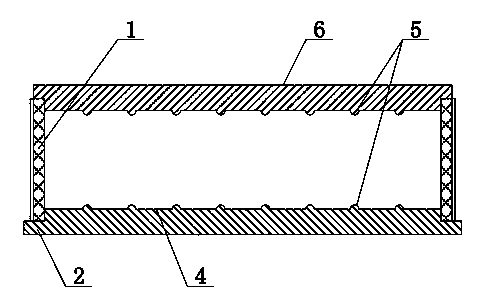

ActiveCN106166788AAvoid floating on the surfaceEvenly distributedMoulding surfacesMould auxillary partsEngineeringPrecast concrete

The invention discloses a die for producing ceramsite foamed precast concrete. The die comprises a top cover, a side template and a base plate which are arranged in the vertical direction in sequence, wherein the side template surrounds the top cover and the base plate and is connected with the top cover and the base plate, the top cover is provided with an overflow hole, and a residual grout pipe is connected to the upper side of the overflow hole; the inner diameter of the overflow hole is 3-5 cm, and the height of the overflow hole is 10-15 cm; a screen net is arranged at the position where the overflow hole is connected with the residual grout pipe, and the aperture of the screen net is smaller than the grain size of ceramsite; a grouting hole is formed in the base plate. The invention further provides a process for producing ceramsite foamed precast concrete. By the adoption of the die and process, a traditional method that mixing is conducted first and then grouting is conducted is replaced, grouting and mixing are conducted at the same time, ceramsite floating is prevented through pre-compacting and the blocking action of the top cover, so that ceramsite is distributed uniformly, ceramsite mixing amount is the largest, the heat insulation property and sound insulation property of the ceramsite foamed precast concrete are improved, and the overall quality of products is improved.

Owner:HUAIHAI INST OF TECH

Adjustable Support Stand for Pre-Cast Concrete Wall Forms

ActiveUS20090194665A1Durable in constructionReduce manufacturing costMoulding surfacesMould separation apparatusDrive shaftGear wheel

An adjustable support stand is mounted on a pre-cast concrete wall panel form to facilitate the leveling of the form and the support of the form about the production plant floor. The adjustable support stand includes a frame portion that houses a threaded rod positional fixed for rotation within the frame portion to drive a vertical movement of the leg member in response to rotation of the threaded rod. The adjustable support stand further includes a clamping apparatus that detachably mounts the frame portion to the flanges of a steel beam frame member. The actuator member can be a nut welded to the top of the threaded rod to affect movement of the engaged leg member in response to manipulation with a powered or manually operated hand tool, or a gear set and an orthogonal drive shaft that transfers rotation from a hand tool to the threaded rod.

Owner:SUPERIOR WALLS OF AMERICA

Coated foam form members for concrete structures

A coated foam concrete form member, in one embodiment, includes a core formed from a foamed polymeric material, and a protective layer covering at least a portion of at least one outer surface of the core. The protective layer includes at least one film forming polymeric material.

Owner:GREENSTREAK

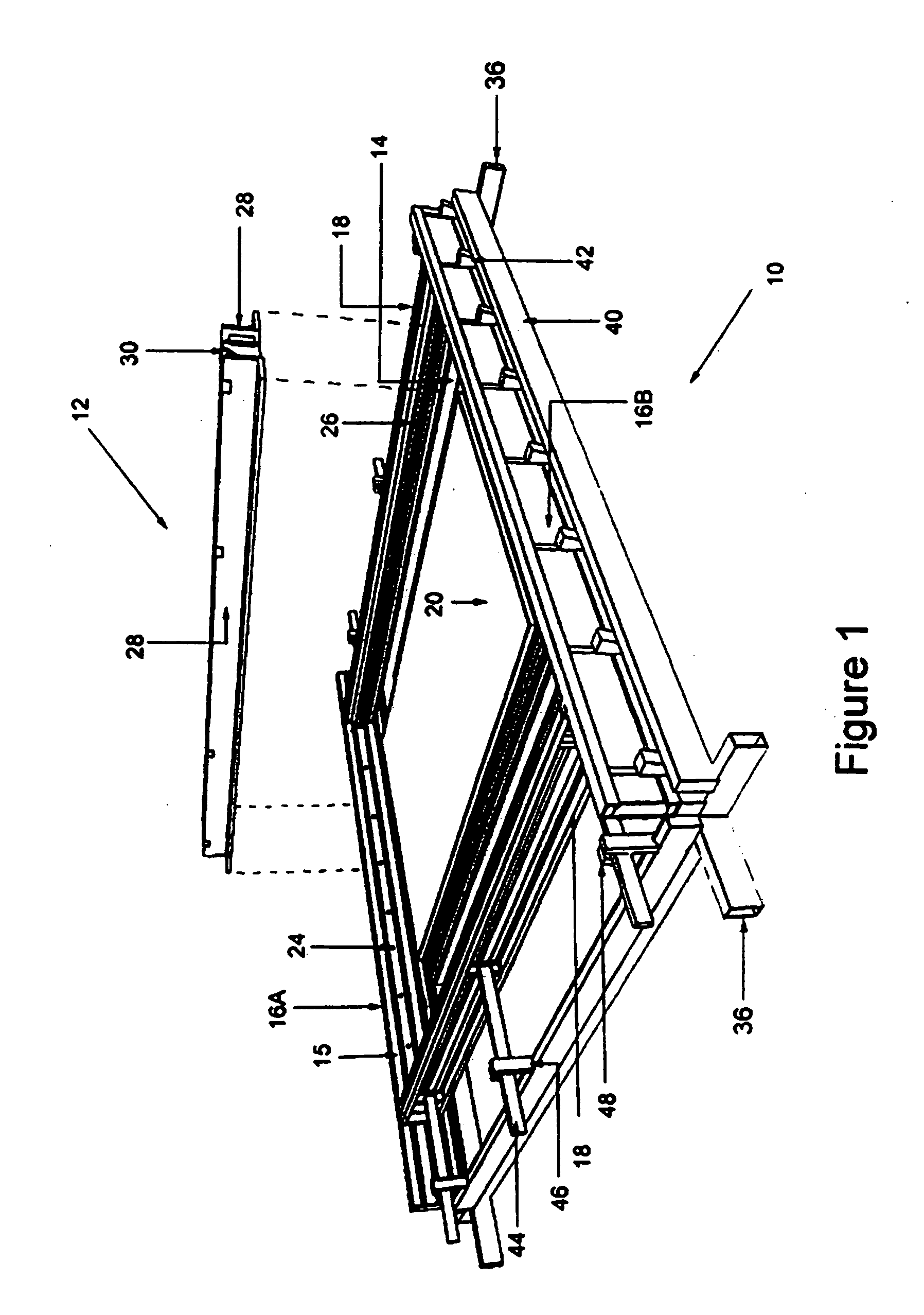

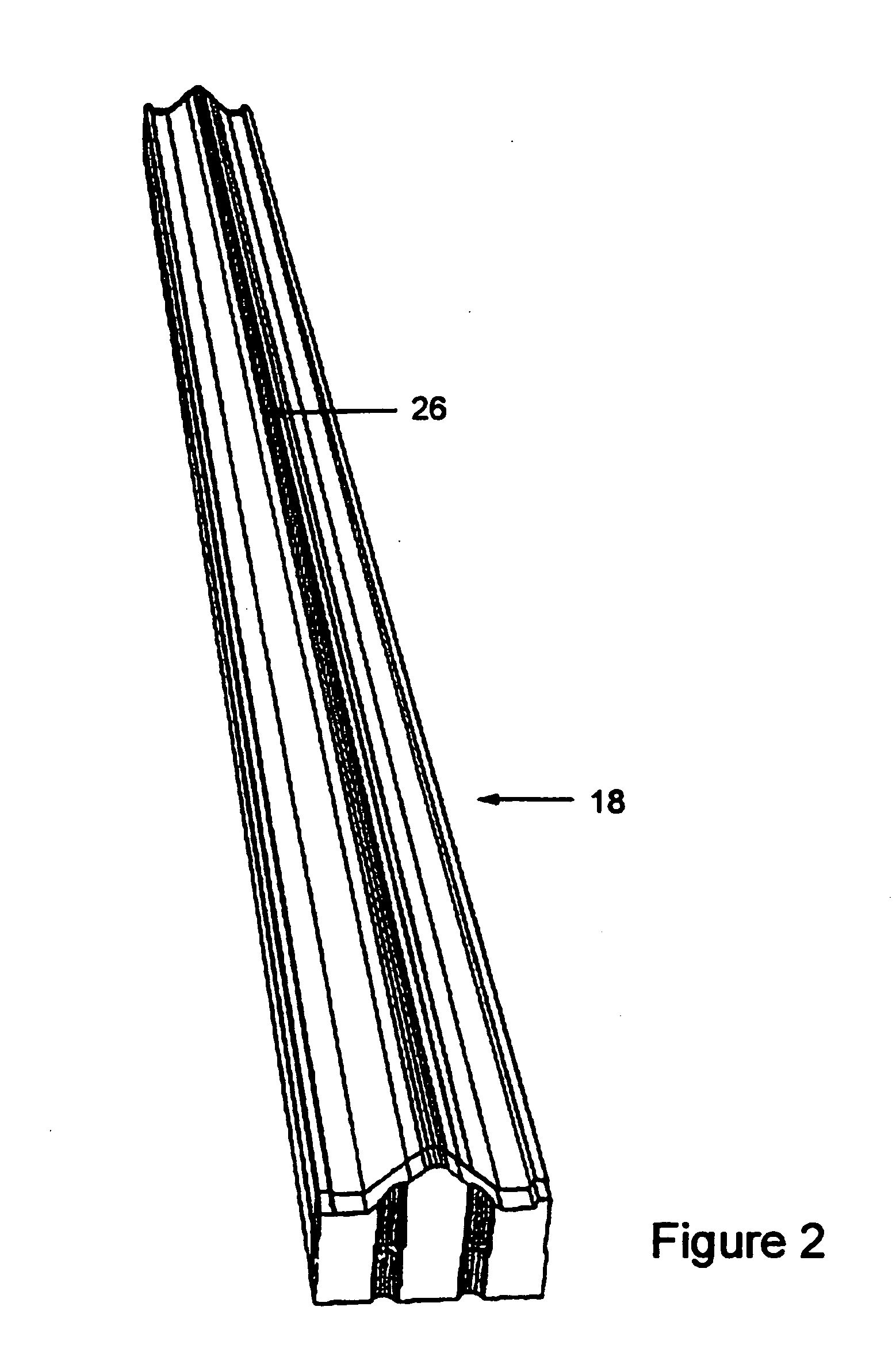

Pre-cast concrete panels for construction of a building

A formwork for precast concrete panel comprises of a quadrangle panel with a base and four side panels. The formwork (10) comprises of a base (14), which is provided with an island region (20) and / or a mound region (22), a pair of parallel fixed spaced apart side panels (16) and a pair of parallel moveable side panels (18). The island region (20) and / or mound region (22) is positioned between the parallel moveable paced apart side panels (18) and wherein said parallel moveable spaced apart side panel (18) are removeably secured to the parallel fixed spaced apart side panels (16) in a tight manner in any desired distance from the center of the island (20) and / or mound (22) region.

Owner:VERCO DECKING +1

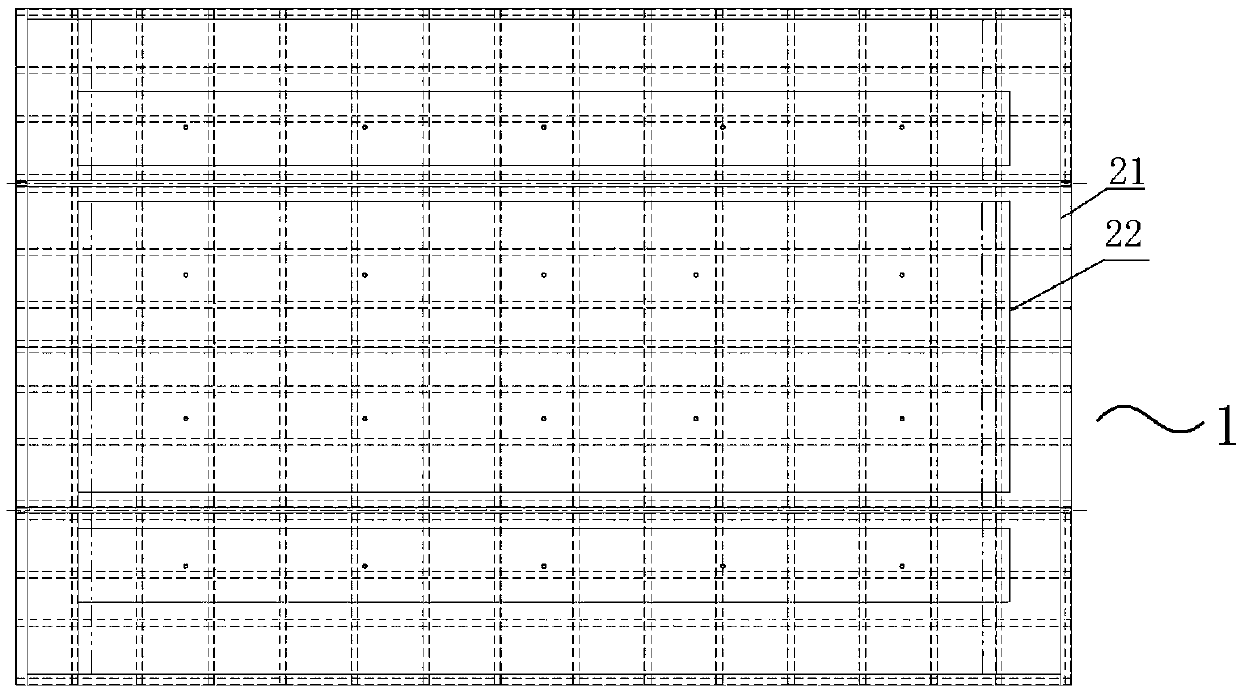

Through bar type concrete composite floor slab structure and manufacturing and assembling method thereof

The invention relates to the field of assembled concrete buildings, in particular to a through bar type concrete composite floor slab structure and a manufacturing and assembling method thereof. The structure comprises prefabricated base plates, longitudinal stressed steel bars, reserved transverse stressed steel bar grooves, hogging moment steel bars, transverse stressed steel bars and the like. Due to the fact that transverse stressed steel bars of the unique prefabricated base plates are continuous, additional connecting measures and additional connecting steel bars are not needed for connection of the prefabricated base plates, construction is simplified, materials are saved, and the integrity of composite slabs is greatly strengthened. The reserved transverse stressed steel bar grooves of the through bar type concrete composite floor slabs reinforce shear resisting and tensile resisting connection of a cast-in-place concrete layer and the prefabricated base plates, and the overall performance of the composite slabs is greatly improved. The transverse stressed steel bars of the through bar type concrete composite floor slab structure are placed in the reserved transverse stressed steel bar grooves formed in the prefabricated base plates, maximum approximating to the prefabricated base plates is achieved, and the anti-bending stress performance of the prefabricated base plates can be same as the performance of cast-in-place slabs.

Owner:SHENYANG SANXIN IND

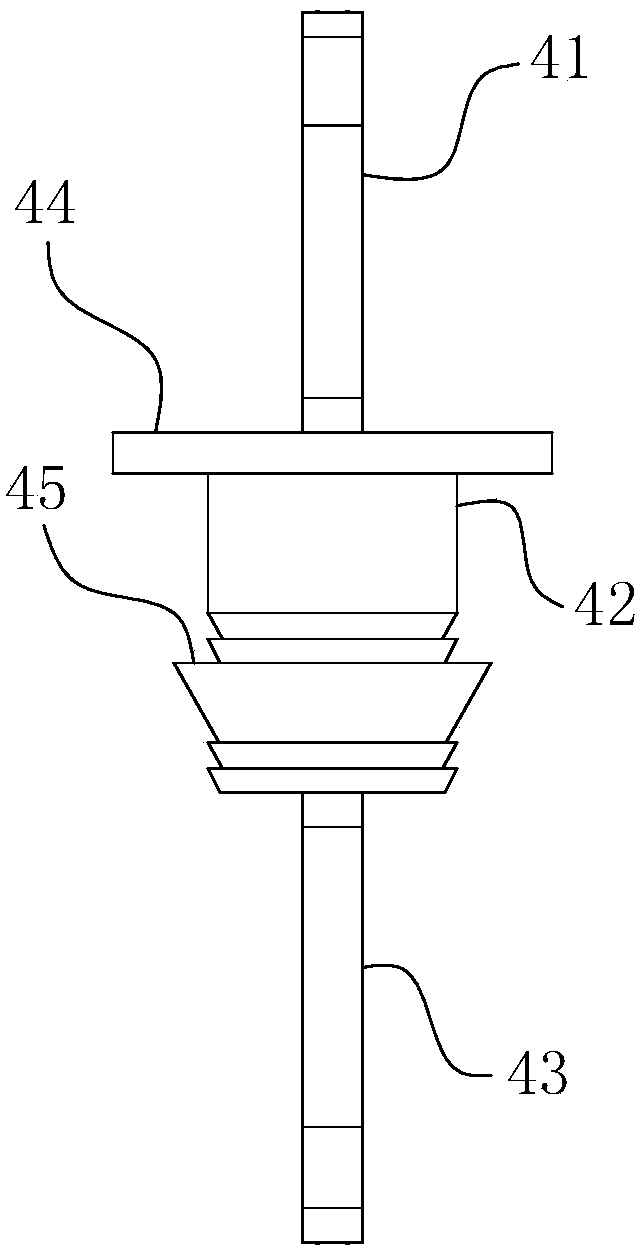

Concrete prefabricated floor slab pouring forming device

The invention discloses a concrete prefabricated floor slab pouring forming device. The concrete prefabricated floor slab pouring forming device comprises a base, fixed side formworks, split side formworks and an adjusting sliding seat, wherein a square bottom plate of a square structure is arranged on the base; the fixed side formworks are rotatably connected to the four edges of the square bottom plate through connecting rotating shafts; the split side formworks are connected into a whole through folding rotating shafts and vertically arranged on the upper surface of the square bottom plate;and a connecting sleeve is arranged in the middle of the adjusting sliding seat, and a hexagonal fixing rod is arranged in the middle of the connecting sleeve in a nested mode. According to the concrete prefabricated floor slab pouring forming device, a prefabricated floor slab pouring formwork is formed through the square bottom plate and the fixed side formworks, the split side formworks arranged on the inner sides of the fixed side formworks are connected into a whole through the folding rotating shafts, the multiple split side formworks are spliced through folding and fixed through the hexagonal fixing rod, thus the sizes of the two side edges of the formwork can be adjusted, the pouring size of a prefabricated floor slab is adjusted accordingly, adjusting is convenient and rapid, andthe applicability and using flexibility of the device are improved advantageously.

Owner:颍上晶宫绿建节能建筑有限责任公司

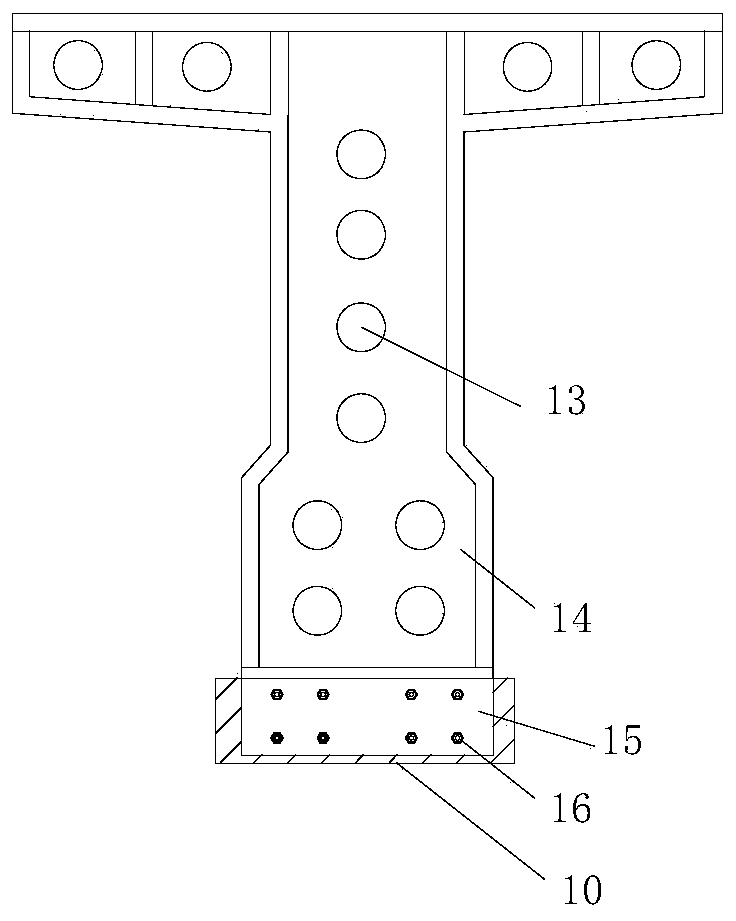

Forming die for manufacturing reinforced concrete prefabricated columns of fabricated building

ActiveCN111546467APlay a supporting roleImprove support strengthMoulding surfacesMould auxillary partsReinforced concreteArchitectural engineering

The invention relates to a forming die for manufacturing reinforced concrete prefabricated columns of a fabricated building. The forming die comprises a workbench and a die arranged above the workbench, wherein the die comprises a bottom plate fixed on the workbench, side plates hinged to the two sides of the bottom plate and end plates slidably arranged at the two ends of the bottom plate, the workbench is fixedly connected with the bottom plate through supporting plates, and supporting devices are arranged at the positions, on the two sides of the bottom plate, of the top of the workbench. According to the forming die, oil cylinders and L-shaped plates which are arranged in a crossed manner are used to jointly support the side plates and the bottom plate, the supporting strength is increased, and meanwhile, the L-shaped plates can be synchronously separated under the driving of electric push rods during demoulding; and first rectangular plates and second rectangular plates are arranged on a group of end plates, the number of groups of second rectangular plates between two adjacent groups of first rectangular plates is increased or reduced to change the spacing between the first rectangular plates, and waist-shaped holes are formed at different heights of the first rectangular plates, so as to adapt to steel bar frameworks in different arrangement manners to pass through.

Owner:扬州通惠系统集成科技有限公司

Fabrication type building cement partition wall plate preparing machining mold

ActiveCN111716496AImprove the quality of workReduce adverse effectsMoulding surfacesDischarging arrangementArchitectural engineeringStructural engineering

The invention relates to a fabrication type building cement partition wall plate preparing machining mold. The mold comprises a work frame, connecting shafts, rotating propelling devices and a mounting bottom plate, the connecting shafts are evenly mounted in the work frame in a sliding fit manner, the left ends and right ends of the connecting shafts are symmetrically provided with the rotating propelling devices, the outer ends of the rotating propelling devices are connected with the mounting bottom plate, the mounting bottom plate is fixed to the ground, and the problems that according toa traditional cement partition wall plate machining mold, after cement forming, a pulling method is directly adopted frequently to pull out a middle mold, the inner surface of a formed cement partition wall board is prone to being worn, in severe cases, the cement partition wall board can be possibly partly broken, the quality of the cement partition wall board is reduced, the traditional cement partition wall board machining mold is generally and directly laid on the ground or partial padding is manually laid, the cement partition wall board and the ground are separated, and in the process, alarge amount of manpower needs to be wasted are solved.

Owner:JIANGSU JIANGZHONG GROUP

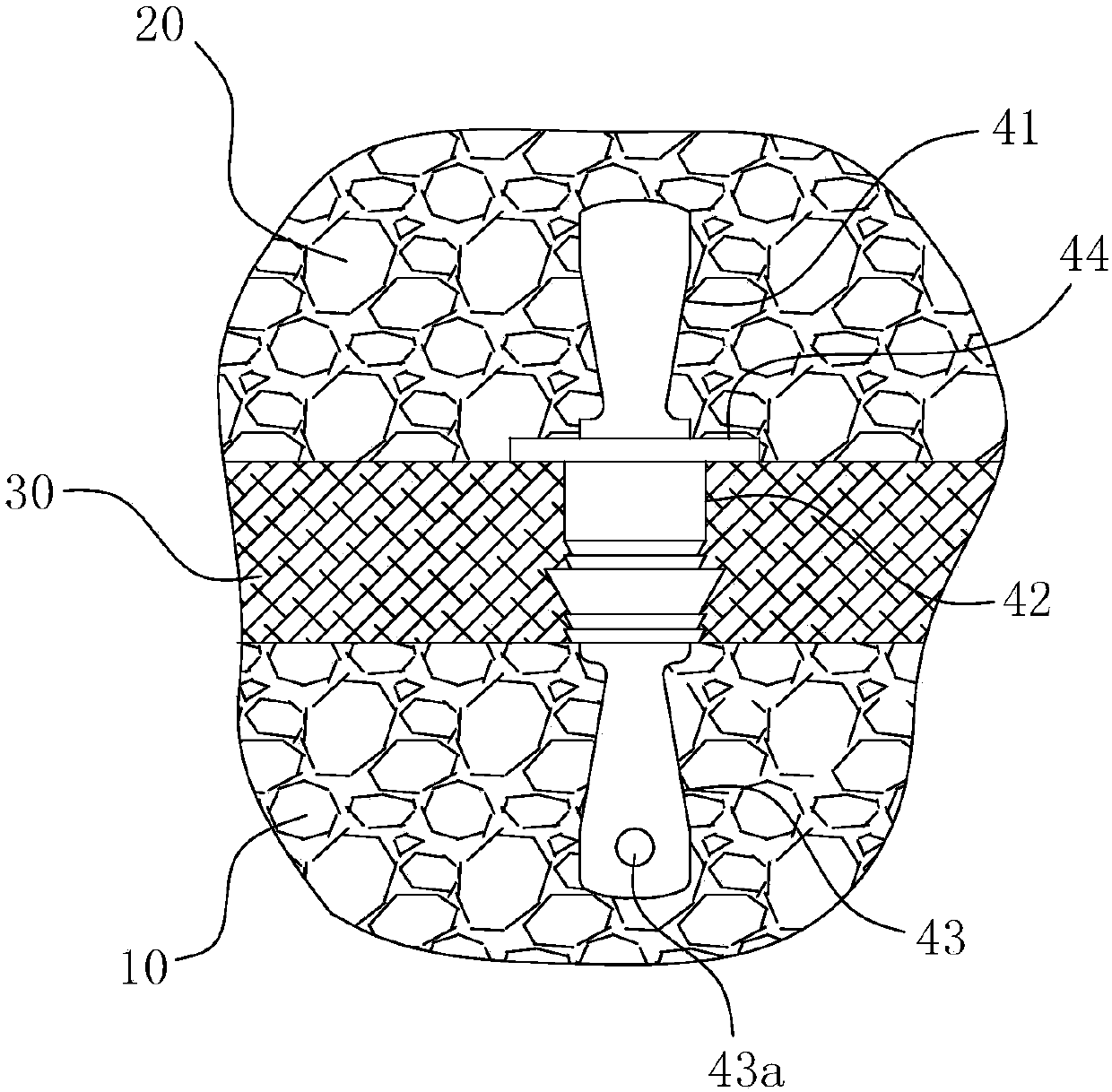

Prefabricated wall plate with heat preservation interlayer and manufacturing method thereof

PendingCN107718241AEasy to fixImprove positional stabilityMoulding surfacesBuilding componentsBuilding productHeat conservation

The invention belongs to the technical field of building products and particularly relates to a prefabricated wall plate with a heat preservation interlayer and a manufacturing method thereof. The prefabricated wall plate comprises an inner wall plate body, an outer wall plate body and a heat preservation plate body and further comprises press buckles used for positioning the outer wall plate body, the heat preservation plate body and the inner wall plate body. The inner wall plate body, the heat preservation plate body and the outer wall plate body which constitute the wall plate are connected tightly and firmly, the integration degree is high, the splicing requirement of a modularized house can be met directly, accordingly heat preservation construction operation of the interlayer does not need to be conducted on site, and the efficiency of the construction progress can be guaranteed while the labor cost is reduced and the engineering quality is guaranteed. The invention further provides a manufacturing method of the prefabricated wall plate. According to the manufacturing method of the prefabricated wall plate, the prefabricated wall plate can be manufactured rapidly and conveniently. The manufacturing method at least comprises the step that cement mortar is poured into the inner wall plate body, the heat preservation plate body is laid, the press buckles pierce the heat preservation plate body, and cement mortar is poured into the outer wall plate body.

Owner:ANHUI BAOYE CONSTR ENG GRP CO LTD

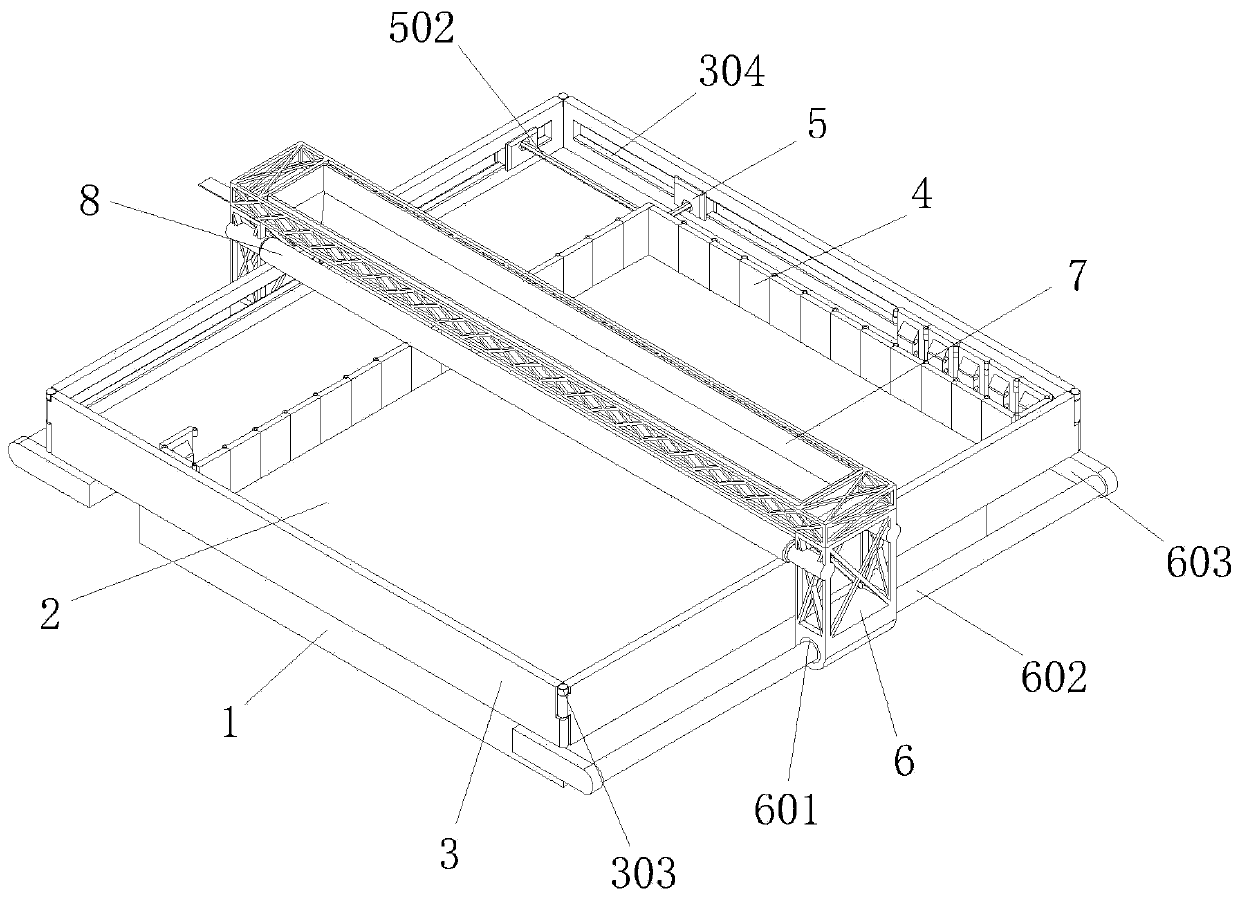

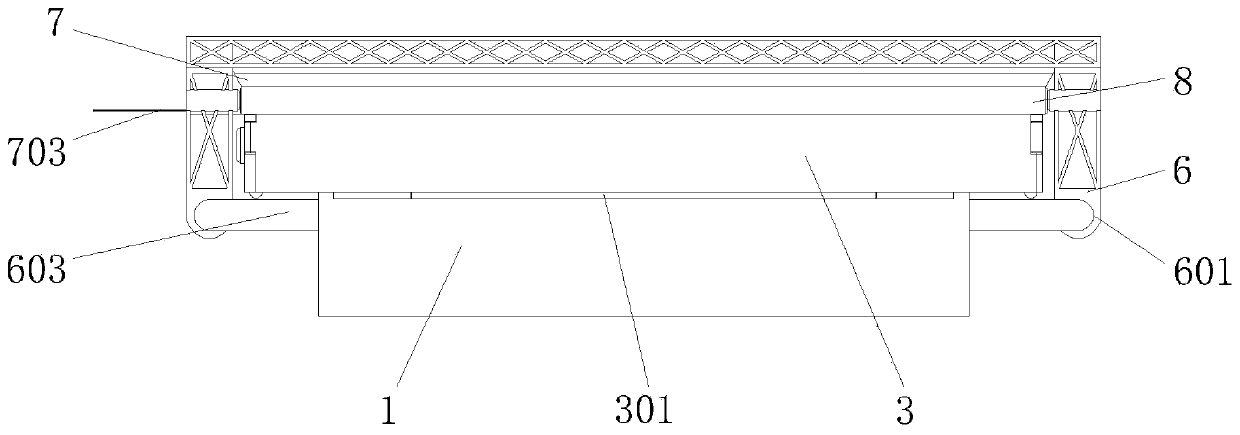

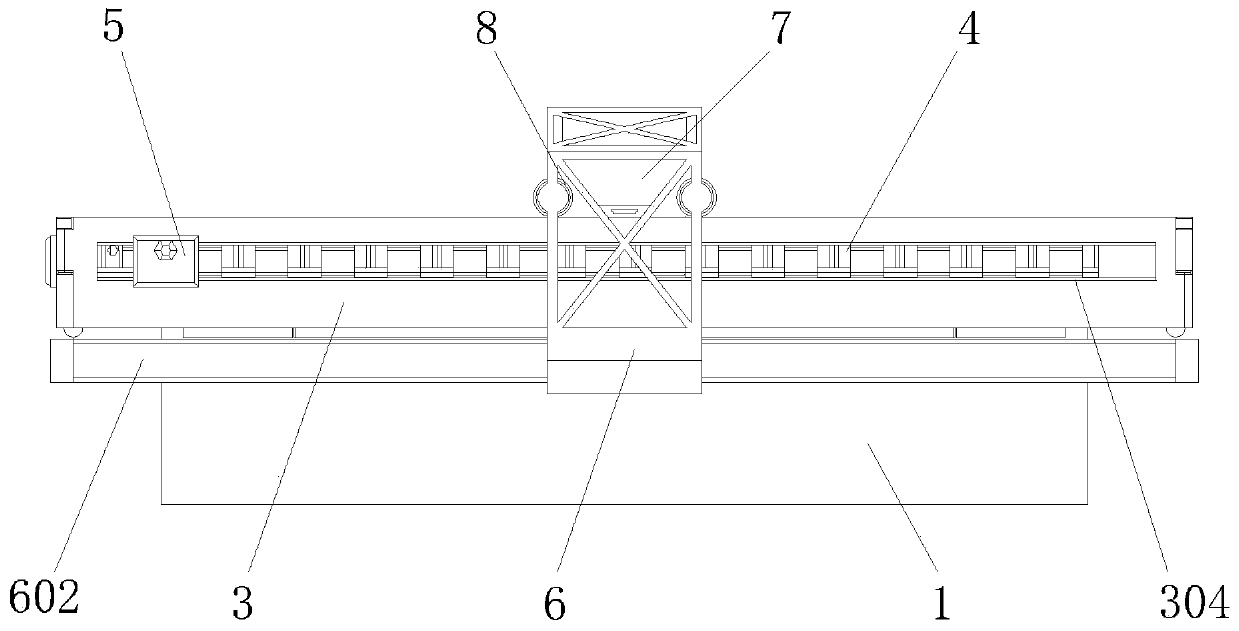

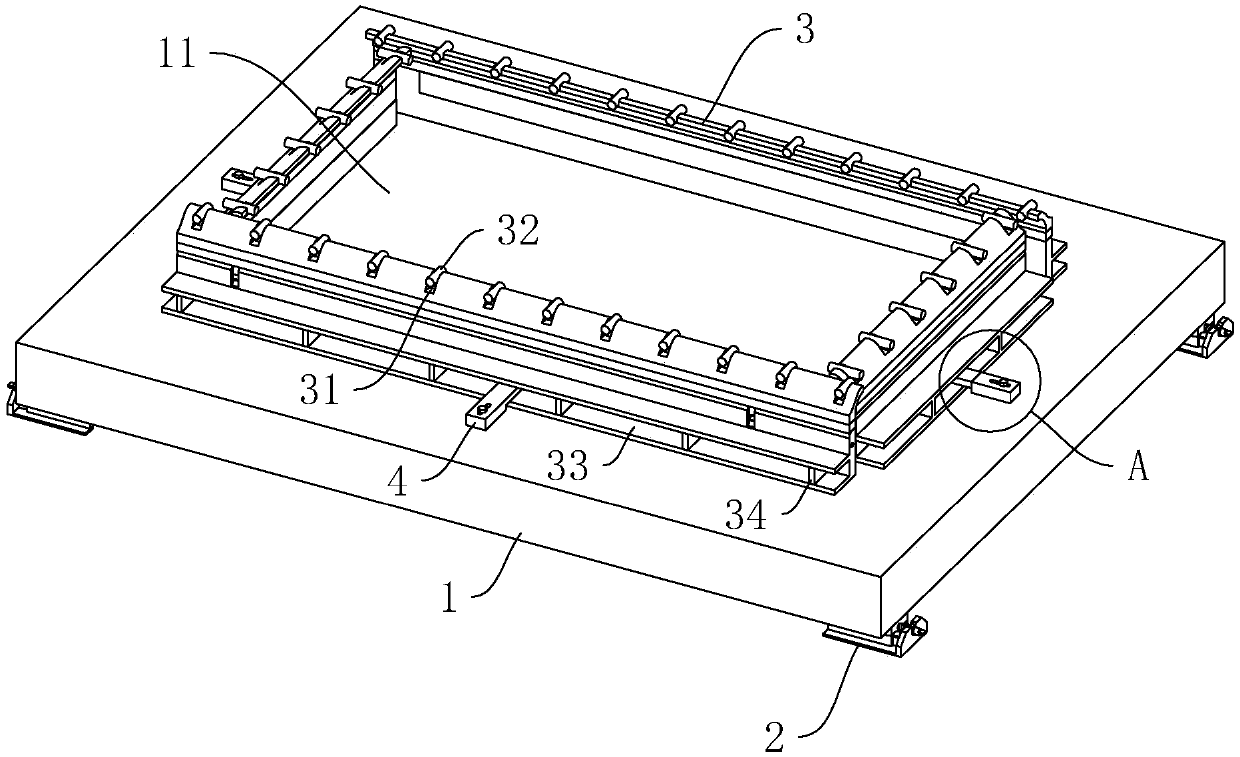

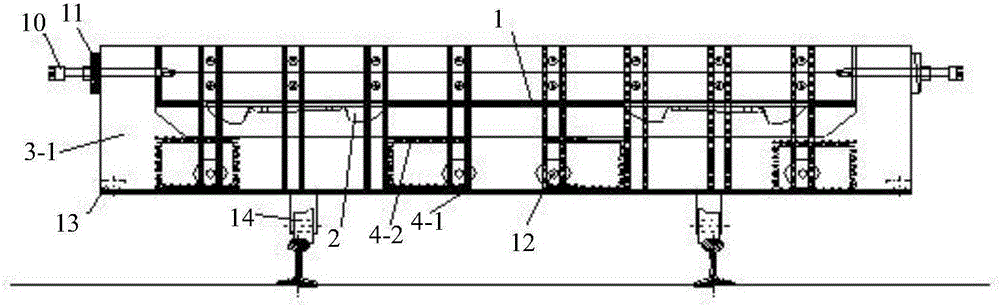

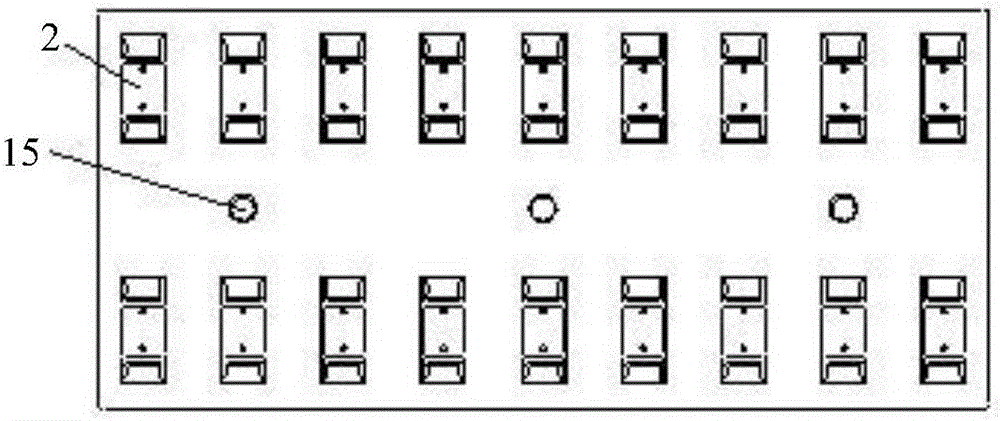

Processing die table of prefabricated panels

ActiveCN109531782APrevent splashReduce wasteMoulding surfacesDischarging arrangementClosed loopEngineering

The invention discloses a processing die table of prefabricated panels, and relates to the field of building operations. The processing die table comprises a base and an operation table which is horizontally arranged on the upper end surface of the base, wherein a plurality of side die strips are arranged on the operation table, and are connected in a head-and-tail manner to form a closed loop; aplurality of mounting grooves which are uniformly distributed in the length direction of the side die strips are formed in the upper end surfaces of the side die strips; each groove is formed in the length direction of the corresponding side die strip is formed in the outer wall of the corresponding side die strip in a penetrating manner; and compacting parts for fixing the side die strips are arranged on the periphery of the operation table, and are compacted to the bottom walls of compacting grooves. The processing die table disclosed by the invention has the following advantages and effectsthat a flat die table is arranged for processing the prefabricated panels, so that the prefabricated panels can be processed and formed in one time, and later-stage polishing is not needed, labor intensity and processing cycle of workers are reduced, and the effect of being convenient for processing the prefabricated panels is achieved; and besides, the side die strips which are convenient to replace and adjust are arranged, so that the die table can perform processing and preparing on the prefabricated panels of different specifications and sizes, and the applicability of the whole die tableis improved.

Owner:曙光装配式建筑科技(浙江)有限公司

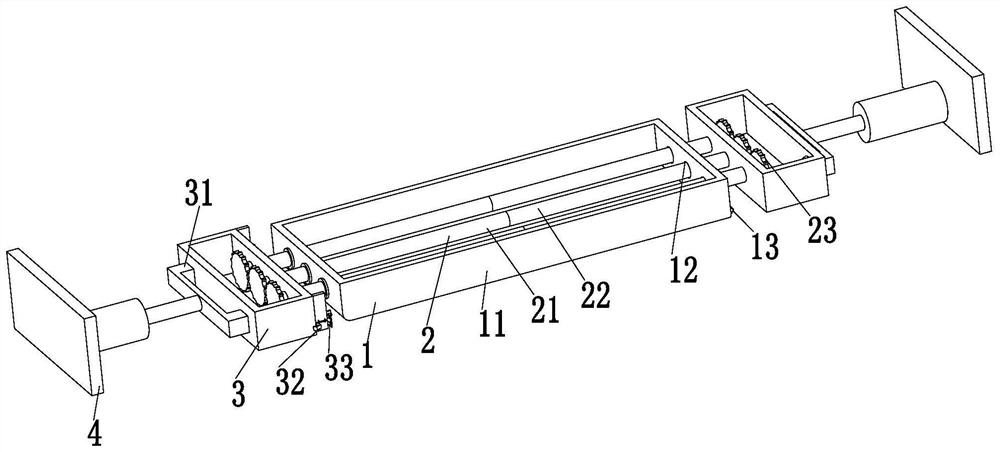

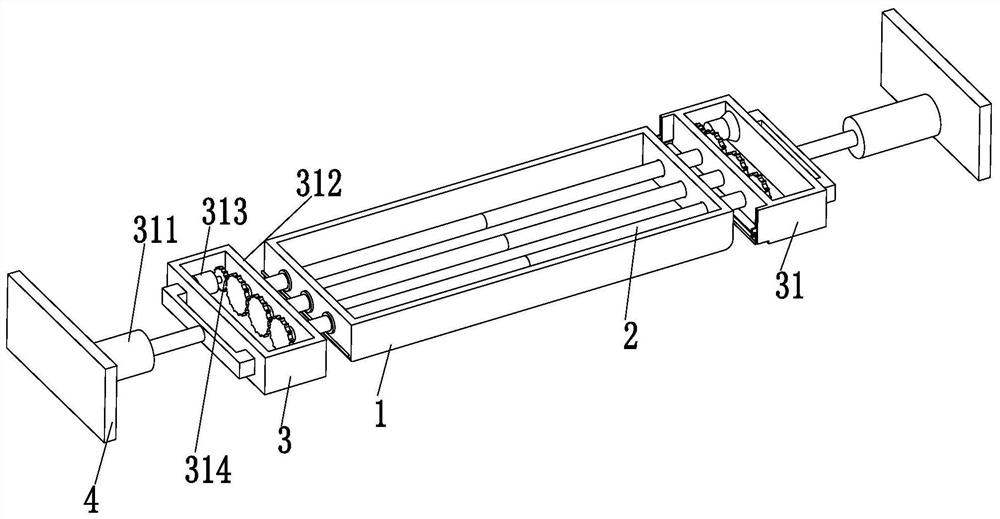

Road construction barrier prefabricating device and prefabricating method

InactiveCN111185994AGuaranteed uptimeImprove work efficiencyMoulding surfacesMouldsElectric machinerySprocket

The invention discloses a road construction barrier prefabricating device. The device comprises a mounting base, wherein servo motors are fixed to the two sides of the upper end face of the mounting base, the ends of output shafts of the two servo motors are in key connection with first chain wheels, the two sides of each first chain wheel are in transmission connection with second chain wheels through chains, lead screws are fixed to the two second chain wheels, the sides, close to the second chain wheels, of the lead screws are rotationally connected with supporting plates through bearings,the supporting plates are fixed to the mounting base, the ends, away from the supporting plates, of the lead screws are rotationally connected with supporting blocks through bearings, the supporting blocks are fixed to the middles of the two sides of the upper end face of the mounting base, the two lead screws are in threaded transmission connection with moving blocks, a first forming die and a second forming die are symmetrically fixed between the two sets of moving blocks, a vibration motor is fixed to the middle of the lower end face of the mounting base through bolts, vibration mechanismsare arranged at the four corners of the lower end face of the mounting base, automatic die assembling and disassembling are achieved, the vibrating function is achieved, and the product quality is improved.

Owner:福建省兴岩建设集团有限公司

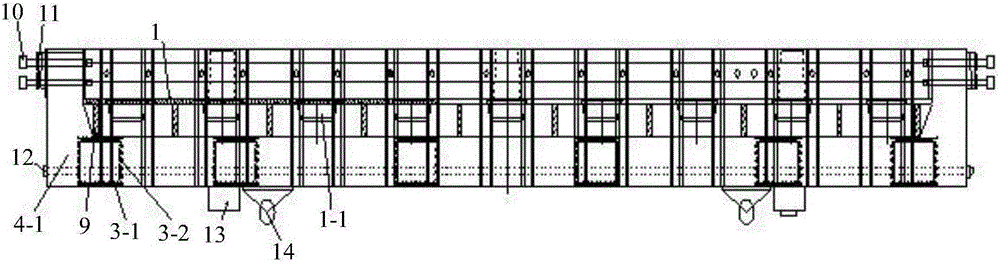

Prestressed concrete rail board die manufactured through bidirectional pre-tensioning method

The invention provides a prestressed concrete rail board die manufactured through a bidirectional pre-tensioning method. The prestressed concrete rail board die is characterized by comprising a rail board bottom die, rail bearing tables, force bearing side dies, force bearing end dies, force plates, prestressed rebar holes, a plurality of tensioning connecting rods, and a plurality of tensioning force locking wedge blocks, wherein rail bearing grooves are uniformly distributed in the rail board bottom die; the rail bearing tables are uniformly distributed and are embedded in the rail bearing grooves; the force bearing side dies are symmetrically arranged on the two sides of the rail board bottom die; the force bearing end dies are symmetrically arranged on the other two sides of the rail board bottom die; the force plates are arranged on the force bearing side dies and the force bearing end dies; the prestressed rebar holes are distributed in the force bearing side dies and the force bearing end dies; the plurality of tensioning connecting rods are inserted on the two sides of the force bearing side dies and the two sides of the force bearing end dies; the plurality of tensioning force locking wedge blocks and the tensioning connecting rods are in one-to-one correspondence; and one of the tensioning force locking wedge blocks is fixed to the force bearing side dies, and the other of the tensioning force locking wedge blocks is inserted into the connecting rods.

Owner:SHANDONG LINQU SLEEPER

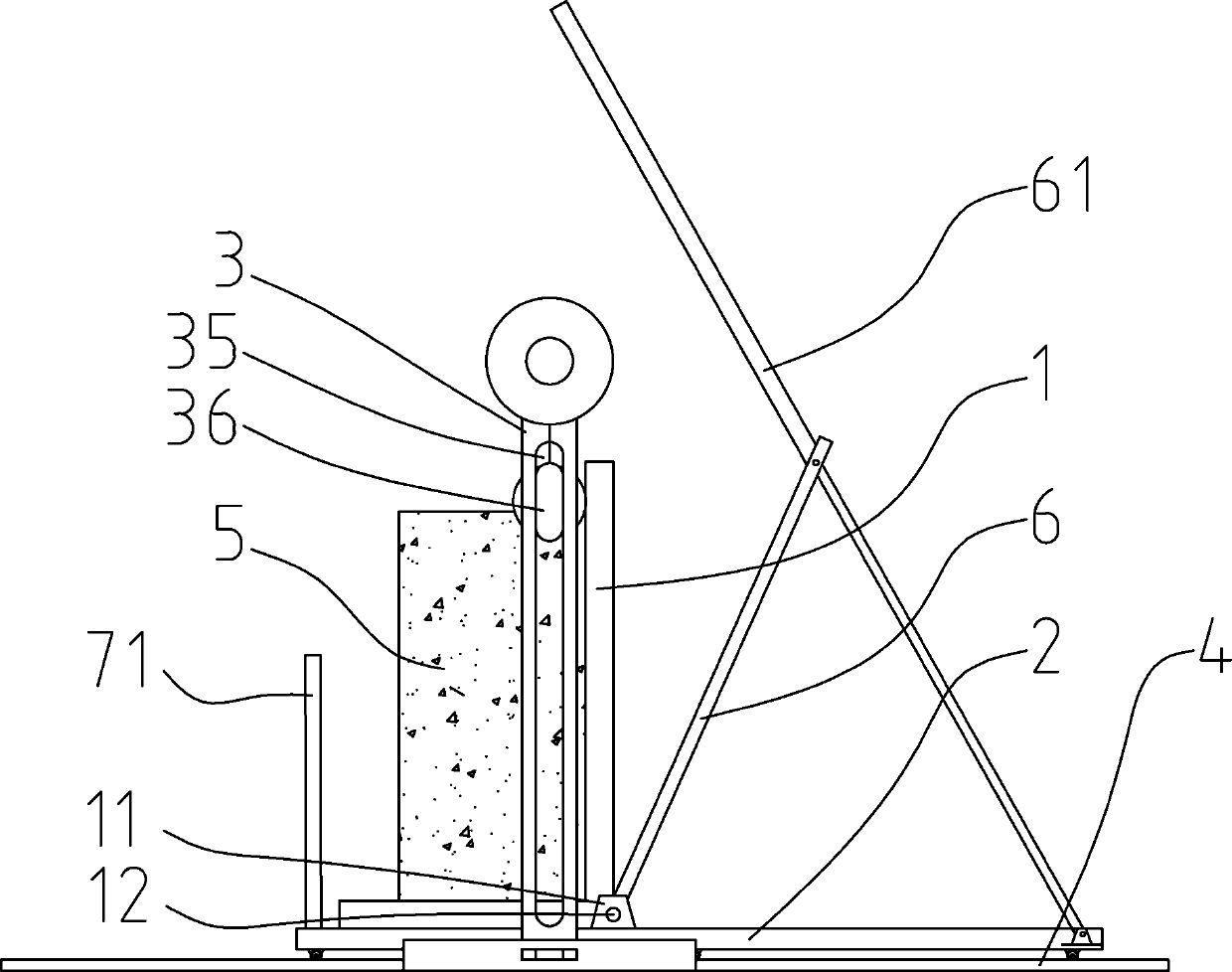

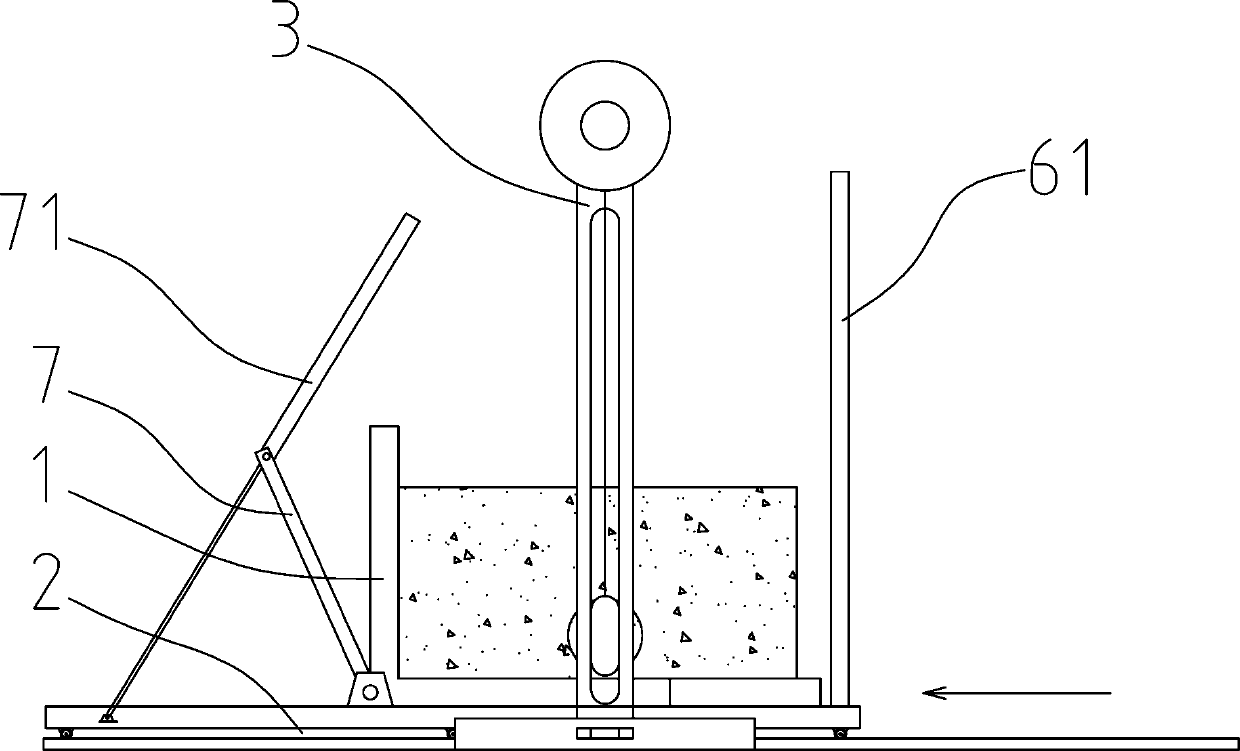

Prefabrication assembly type box culvert prefabrication turnover device and installation method

ActiveCN110528410AReduce frequency of useReduce the chance of damageMoulding surfacesGround-workEngineeringPrefabrication

The invention provides a prefabrication assembly type box culvert prefabrication turnover device and an installation method. The prefabrication assembly type box culvert prefabrication turnover devicecomprises a movable platform, a turnover platform and blocking stand columns, wherein the turnover platform is in an L shape, the turning part of the turnover platform is connected with the movable platform through a rotating seat, the turnover platform is turned over by taking a rotating shaft of the rotating seat as the circle center, the blocking stand columns are fixedly arranged on the bottom surface of at least one side of the movable platform, the blocking stand columns are in contact with the turnover platform through arranged blocking wheels, and when the movable platform moves, theblocking wheels drive the turnover platform to be turned over. In the use process, prefabrication box culvert components are manufactured; the turnover platform is erected; a form is erected on the turnover platform; a reinforcement cage is hoisted in the form; concrete is poured; mold dismounting and maintenance are carried out; and the components are turned over by 90 degrees, and therefore, theusing frequency of hoisting equipment is reduced in the prefabrication installation process of box culverts, the damage probability of the box culverts is reduced, moreover, a pit structure is not required to be arranged on site, and then the movement along with the engineering construction position is also facilitated.

Owner:CCCC SECOND HARBOR ENG

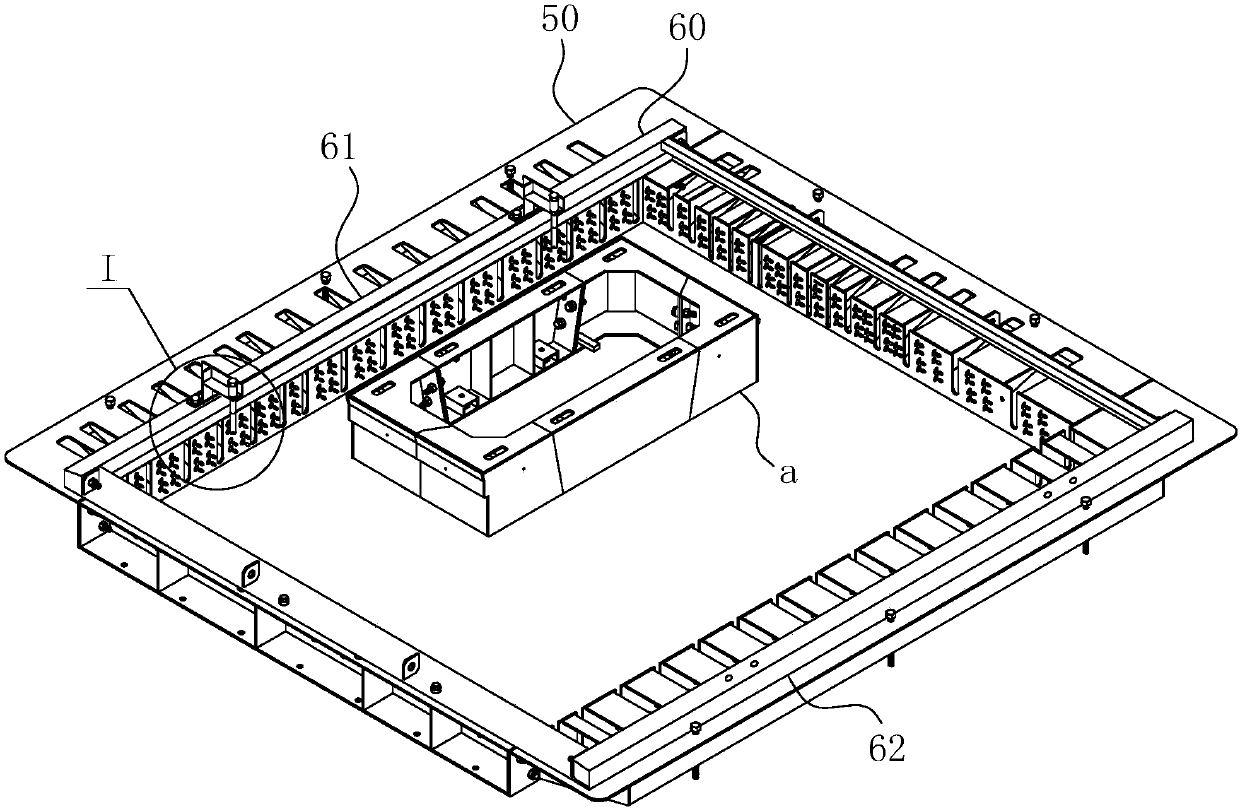

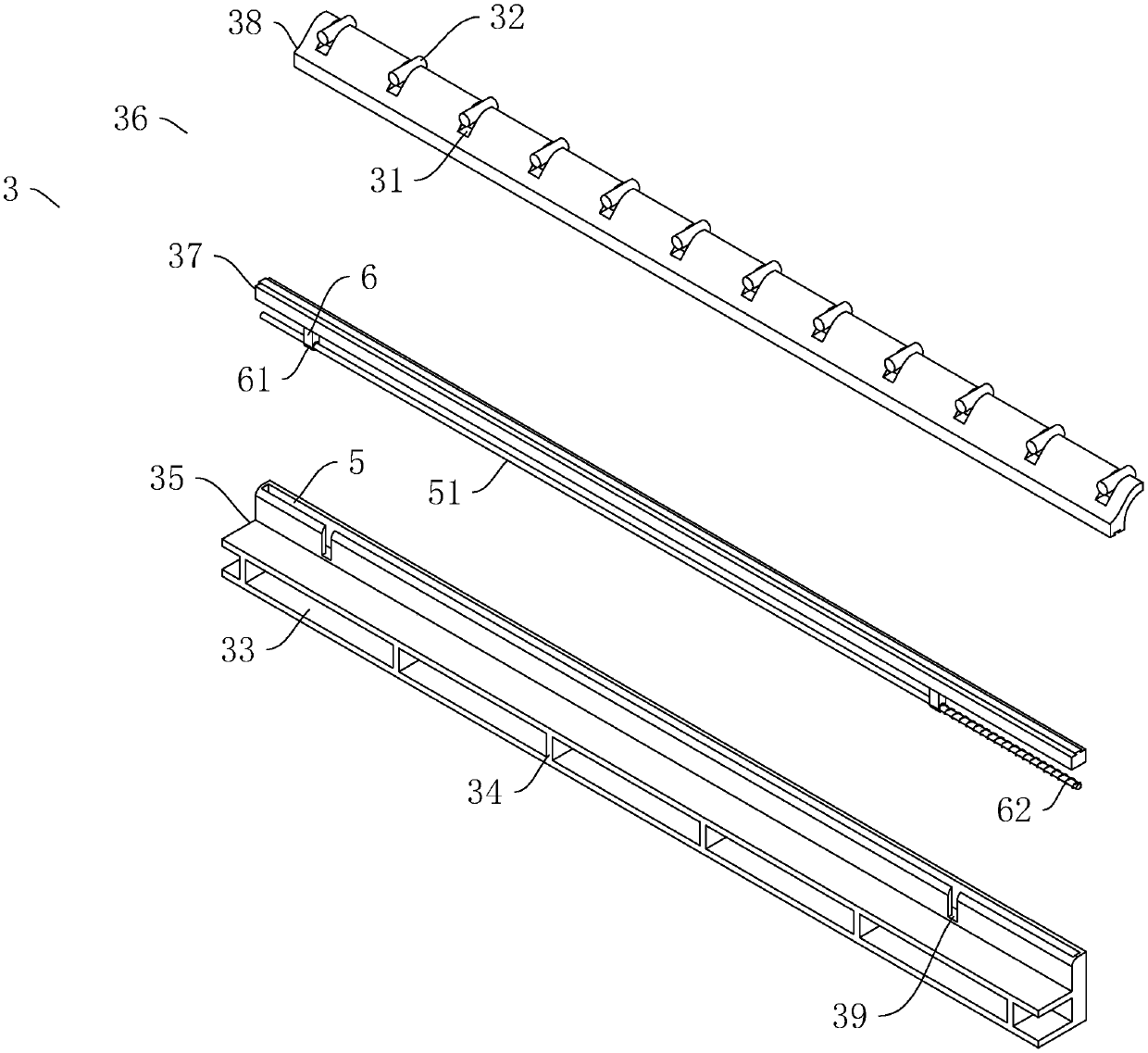

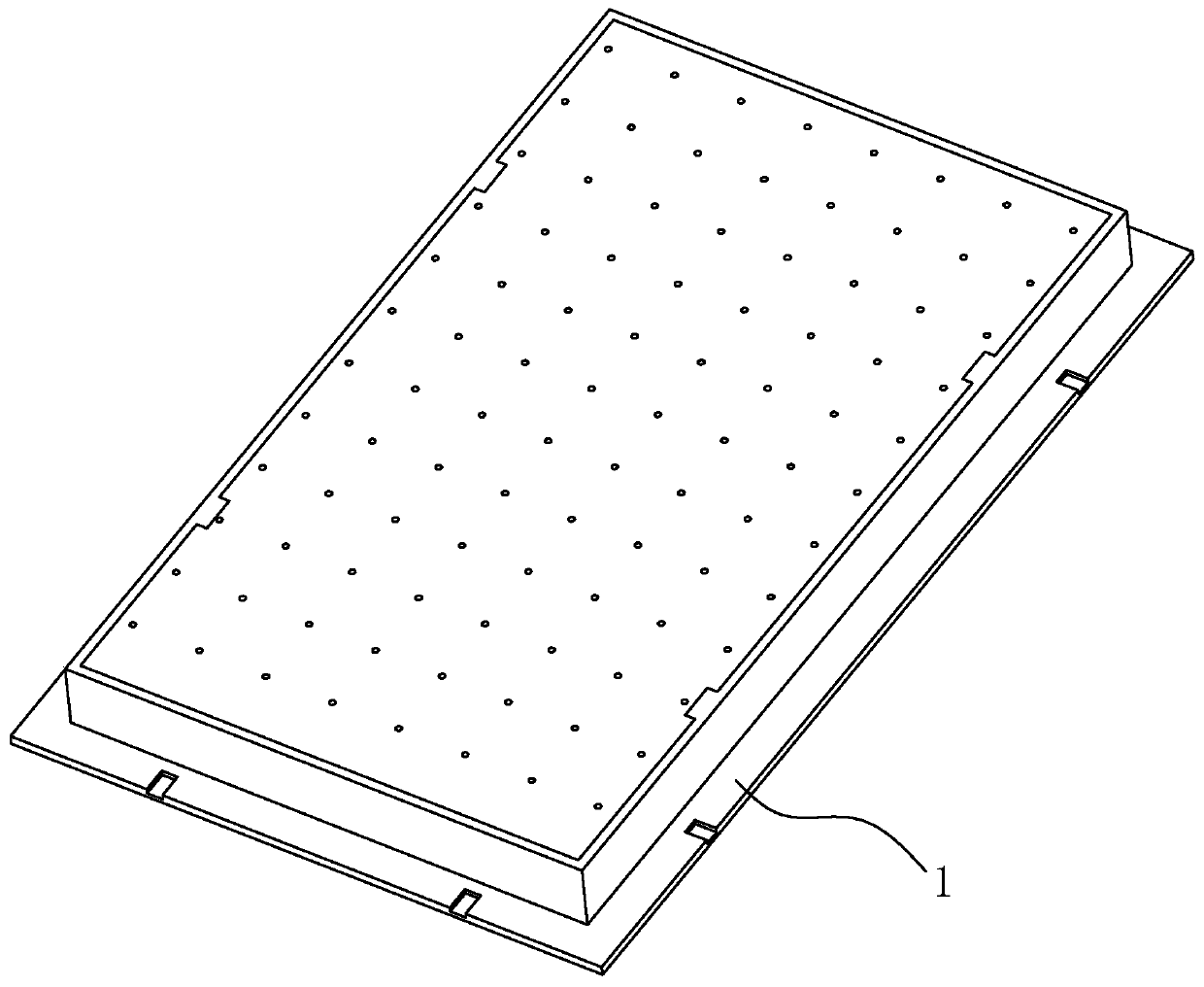

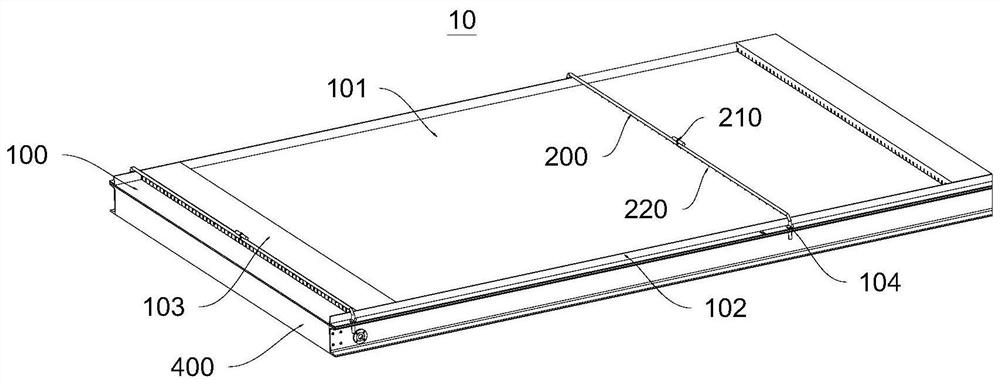

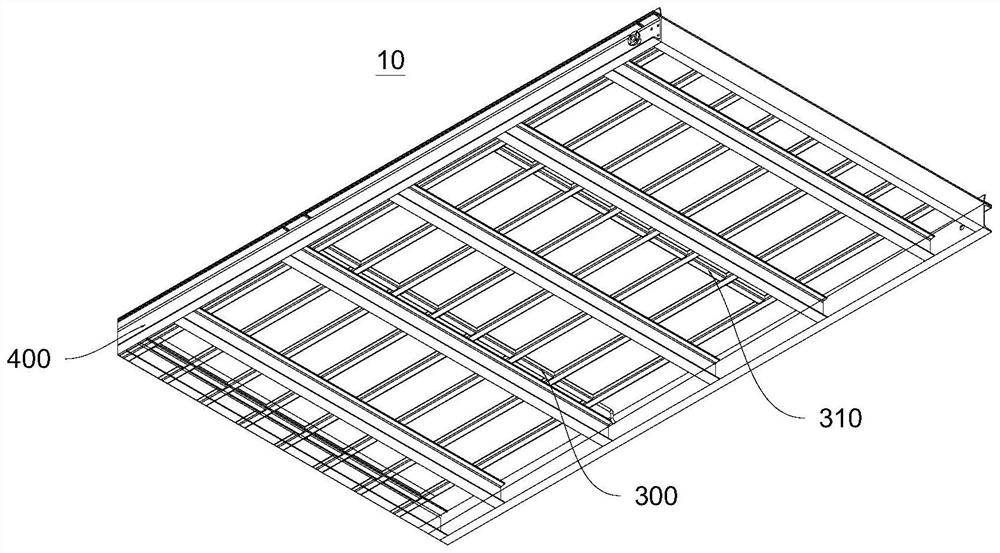

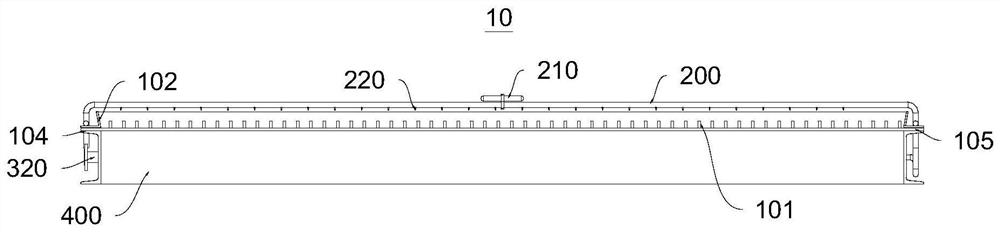

Universal mold for forming of house prefabricated part laminated slab

PendingCN108687939AReduce sizeImprove versatilityMoulding surfacesMould auxillary partsHigh volume manufacturingRebar

The invention relates to a universal mold for forming of a house prefabricated part laminated slab, and relates to the technical field of house prefabricated part production. An outer frame for forming a prefabricated laminated slab bottom plate is defined by four forming side mold assemblies, a bottom mold and a side mold are arranged in each forming side mold assembly, the bottom molds are fixedto a mold table, the side molds are fixed to the bottom molds, overhead gaskets and sealing strips are arranged between the bottom molds and the side molds, and criss-cross rebar ends in the prefabricated laminated slab bottom plate stretch out of the gaps between the bottom molds and the side molds. Each bottom plate is further provided with two or more fixing pressing plates, one ends of the fixing pressing plates are pressed on the upper surfaces of the bottom molds, and the other ends of the fixing pressing plates are fixed to the mold table through bolts. One forming side mold assembly can adapt to the rebar interval change in different prefabricated laminated slab bottom plates, the universality is good, the specifications of the forming side mold assemblies needed for production are greatly reduced, production and use are convenient, the assembly efficiency of the molds is high, demolding is convenient, and the large-scale production advantages of factories can be fully exerted.

Owner:福建鸿生高科环保科技有限公司

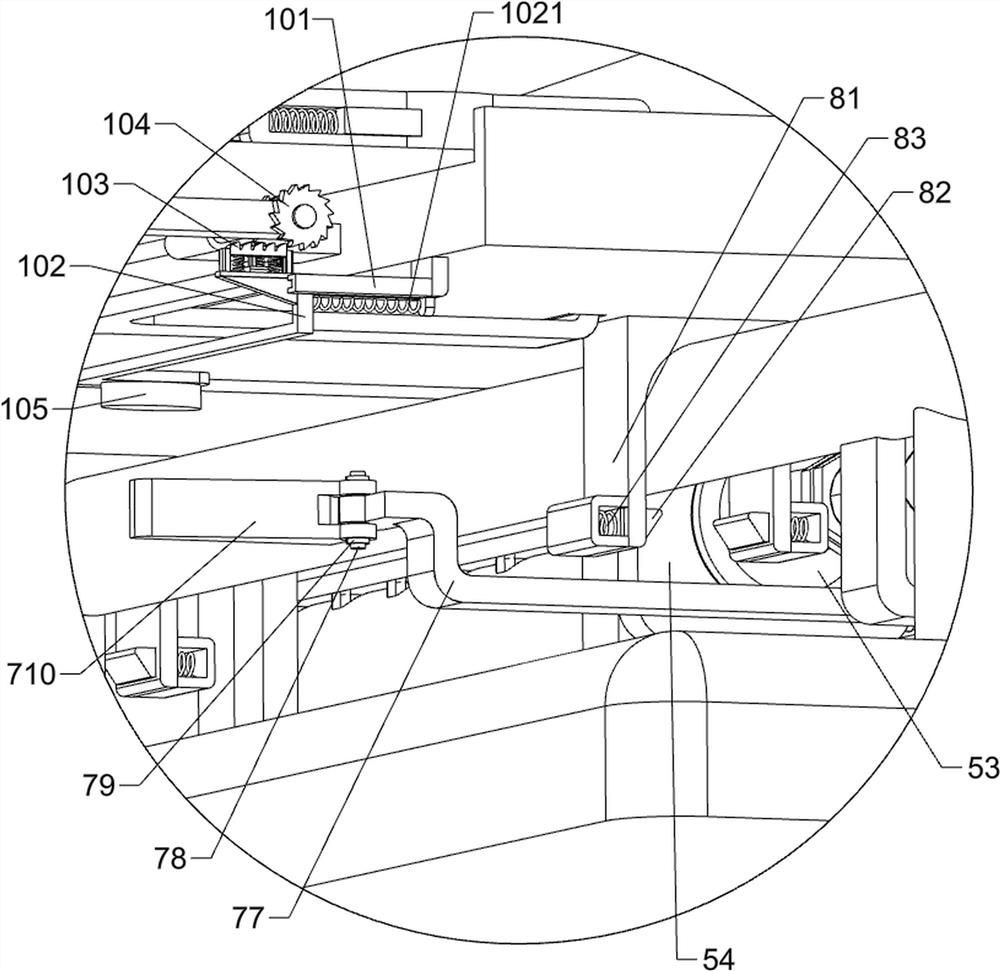

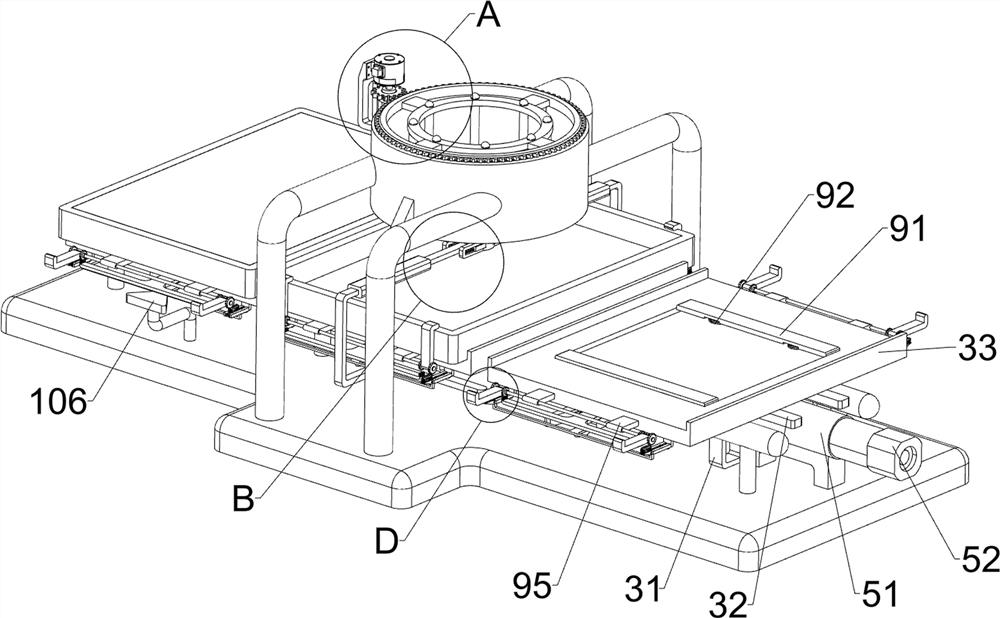

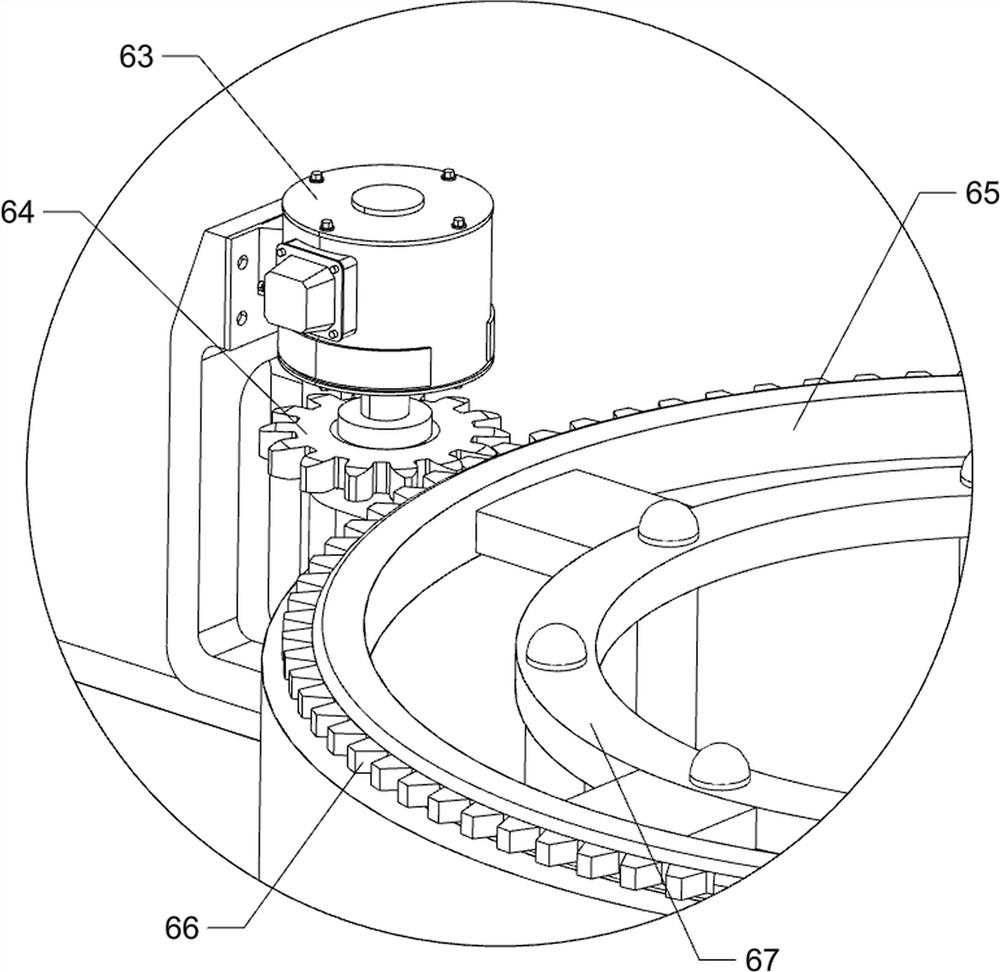

Building prefabricated slab mixing and solidifying equipment for new materials

PendingCN112123549AAchieve placementImplement rightward transferMoulding surfacesFeeding arrangmentsConstruction engineeringNew materials

The invention relates to solidifying equipment, in particular to building prefabricated slab mixing and solidifying equipment for new materials. The building prefabricated slab mixing and solidifyingequipment for the new materials is provided and is diverse in function, easy to operate and high in production efficiency. The building prefabricated slab mixing and solidifying equipment for the newmaterials comprises a bottom plate, wherein supporting frames are symmetrically arranged on the bottom plate; a plate supporting mechanism connected to the supporting frames in a sliding mode, whereina mold is placed on the plate supporting mechanism; and a pushing mechanism arranged on the bottom plate. According to the building prefabricated slab mixing and solidifying equipment for the new materials, the mold is placed through the plate supporting mechanism, and then the mold is conveyed rightwards under cooperation of the pushing mechanism; and through the arrangement of a stirring mechanism, uniform mixing of prefabricated slab materials is achieved.

Owner:广州好未来科技研究有限公司

Concrete civil air defense door and production process thereof

ActiveCN111206857AStrong connectionReduce dosageMoulding surfacesMouldsArchitectural engineeringRebar

The invention discloses a concrete civil air defense door and a production process thereof, and belongs to the technical field of civil air defense door processing. The concrete civil air defense doorcomprises a door frame, wherein two steel bar frameworks with the same structure are sequentially placed in the door frame, and a sandwich mechanism used for separating the two steel bar frameworks is placed on the portion, positioned between the two steel bar frameworks, of the door frame; the sandwich mechanism comprises two steel plates, a cavity is formed between the two steel plates, a discharging cylinder is jointly and fixedly arranged in the middle of the two steel plates, and the discharging cylinder is used for communicating the two steel bar frameworks; and guide plates are symmetrically and fixedly arranged on the two sides of the door frame, and a guide groove is formed in the position, corresponding to the corresponding guide plate, of each steel plate. The civil air defensedoor has the advantages that the weight of the civil air defense door is reduced, and the opening and closing of the civil air defense door are facilitated.

Owner:上海凯斯特民防设备有限公司

High-precision multifunctional concrete bridge deck slab prefabricated mold and working method thereof

PendingCN109571720AGuaranteed stiffnessGuaranteed bearing capacity requirementsMoulding surfacesMould auxillary partsBridge deckRebar

The invention discloses a high-precision multifunctional concrete bridge deck slab prefabricated mold and a working method thereof. The prefabricated mold comprises a base, a bottom mold positioned onthe upper layer of the base, and side molds which are located on the upper layer of the bottom mold and are distributed along the periphery of the edge of the bottom mold, wherein a plurality of first positioning holes used for positioning reinforcing steel bars are formed in each side mold, a plurality of demolding devices distributed at intervals are arranged on the outer sides of the side molds, a plurality of core molds used for positioning the reinforcing steel bars are arranged on the inner sides of the side molds, and a plurality of lifting devices which penetrate through the base andare used for lifting the bottom mold are arranged at the lower layer of the base. By means of the prefabricated mold, the overall prefabricated precision of a concrete prefabricated bridge deck slab can be guaranteed.

Owner:中铁宝桥(扬州)有限公司 +1

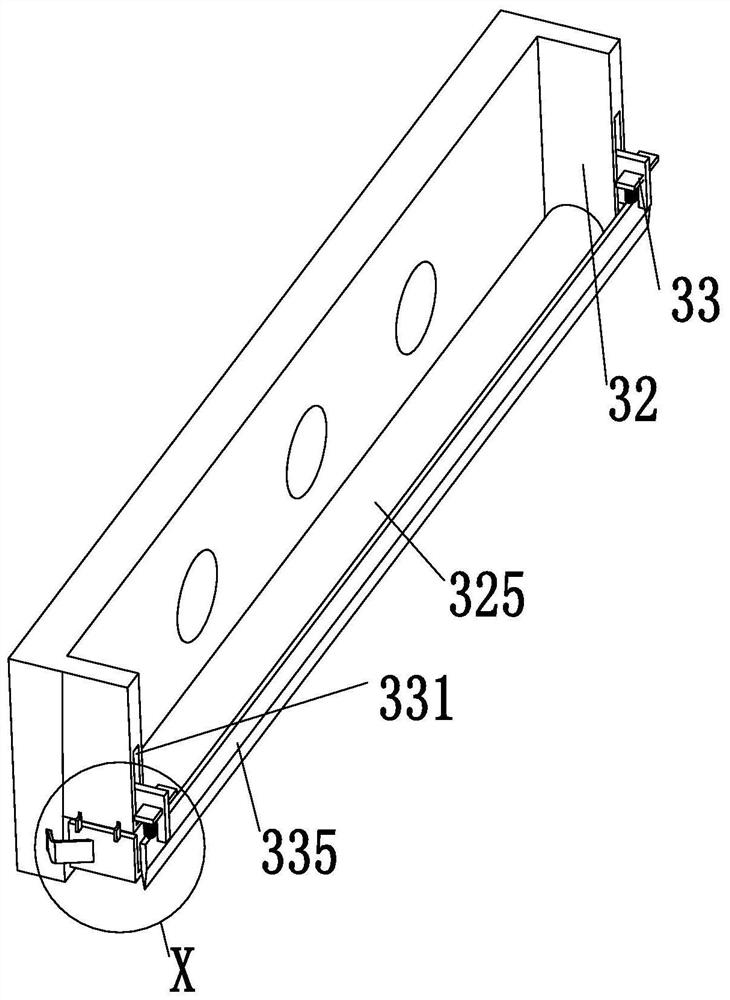

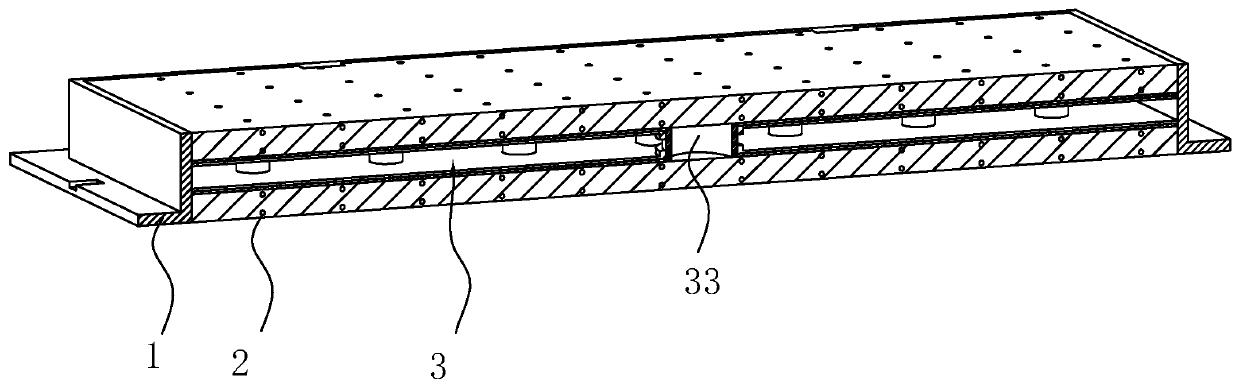

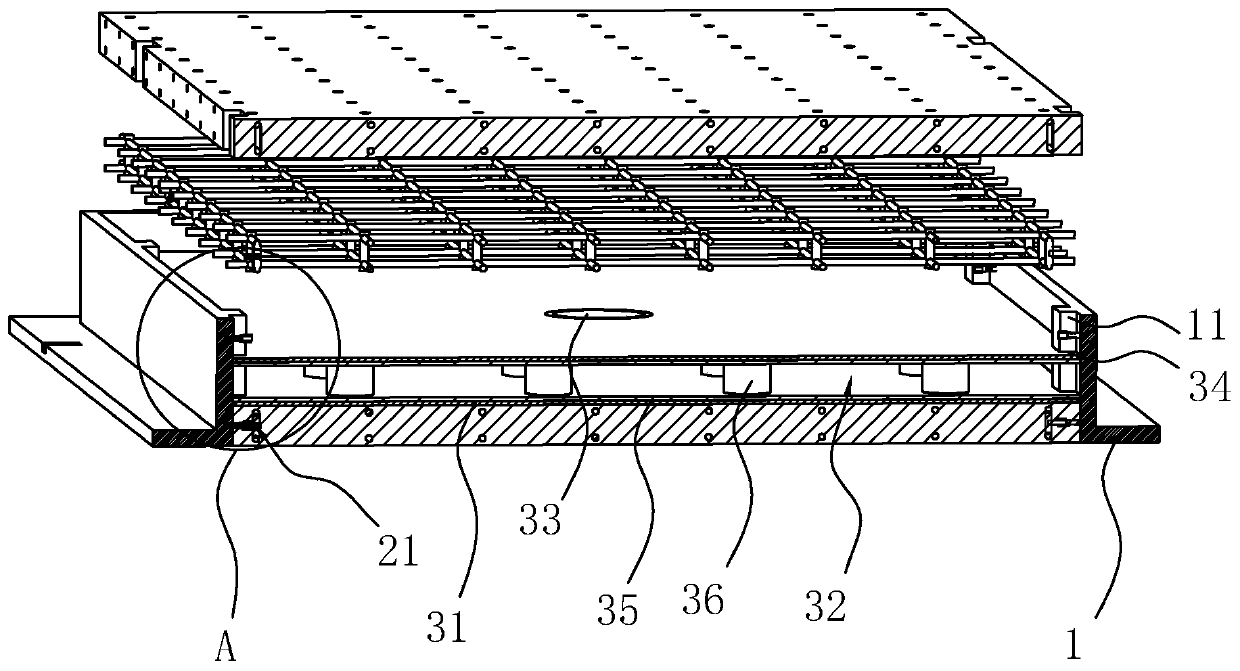

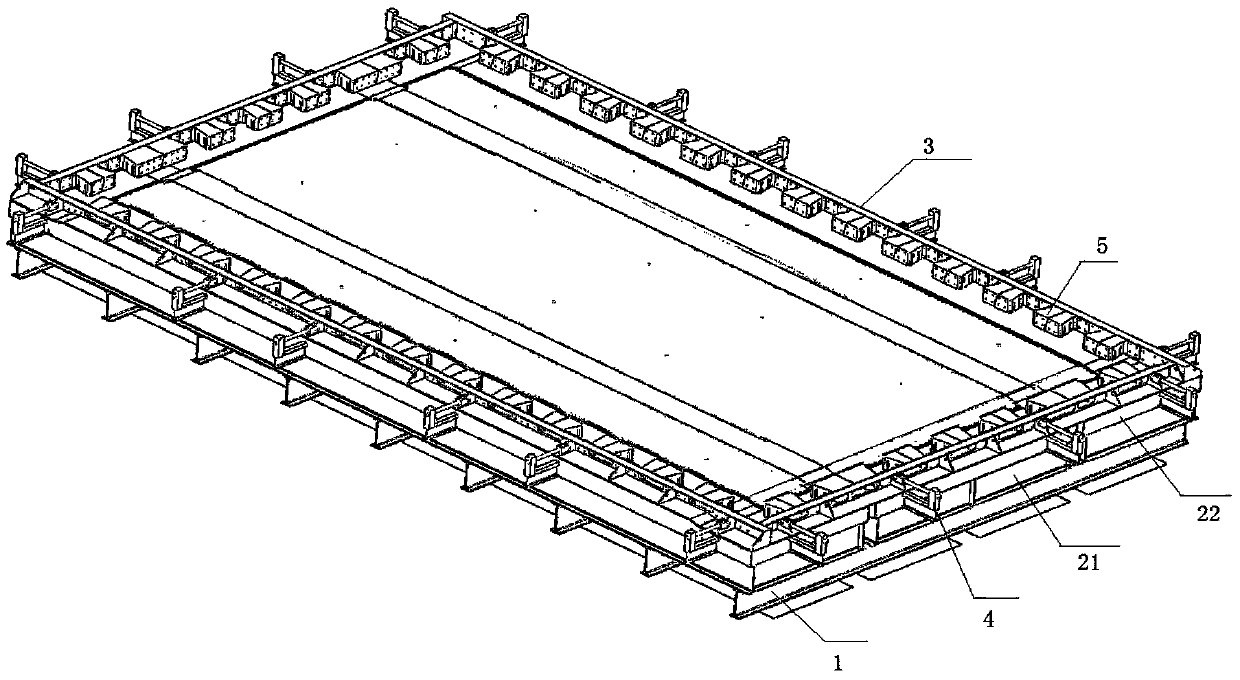

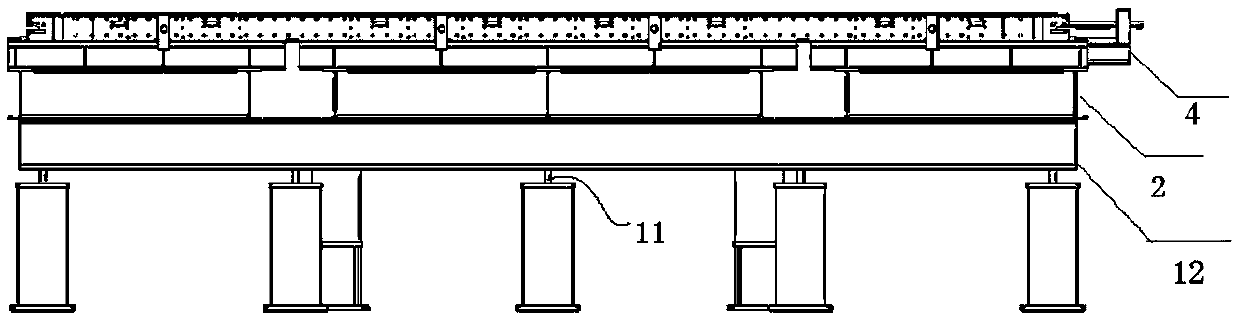

Bench formwork standard section, long formwork bench and laminated slab preparation method

ActiveCN111906900AImprove imprecise technical issuesMoulding surfacesFeeding arrangmentsWater vaporStructural engineering

The invention provides a bench formwork standard section, a long formwork bench and a laminated slab preparation method, and relates to the technical field of fabricated buildings. The bench formworkstandard section comprises a working plate, a plurality of mounting frames and heating mechanisms. A temperature and humidity sensor and a plurality of spray heads are arranged on each mounting frame,and the mounting frames are rotatably mounted on the working plate, so that the temperature and humidity sensors and the spray heads can rotate to the upper side of the working surface of a worktable. The heating mechanisms are distributed at the bottom of the working plate. According to the bench formwork standard section, the temperature and the humidity of a concrete curing environment are directly measured through the temperature and humidity sensors, the temperature and humidity control precision is improved, the humidity and the temperature of the concrete curing environment are directly controlled through water vapor spraying by the multiple spray heads and heating structures, the humidity is always ensured to be 90% or higher, the curing quality is improved, and the curing environment is controlled accurately. According to the laminated slab preparation method, a sectioned curing method is used, the production process can be shortened, and the production benefit can be greatlyimproved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

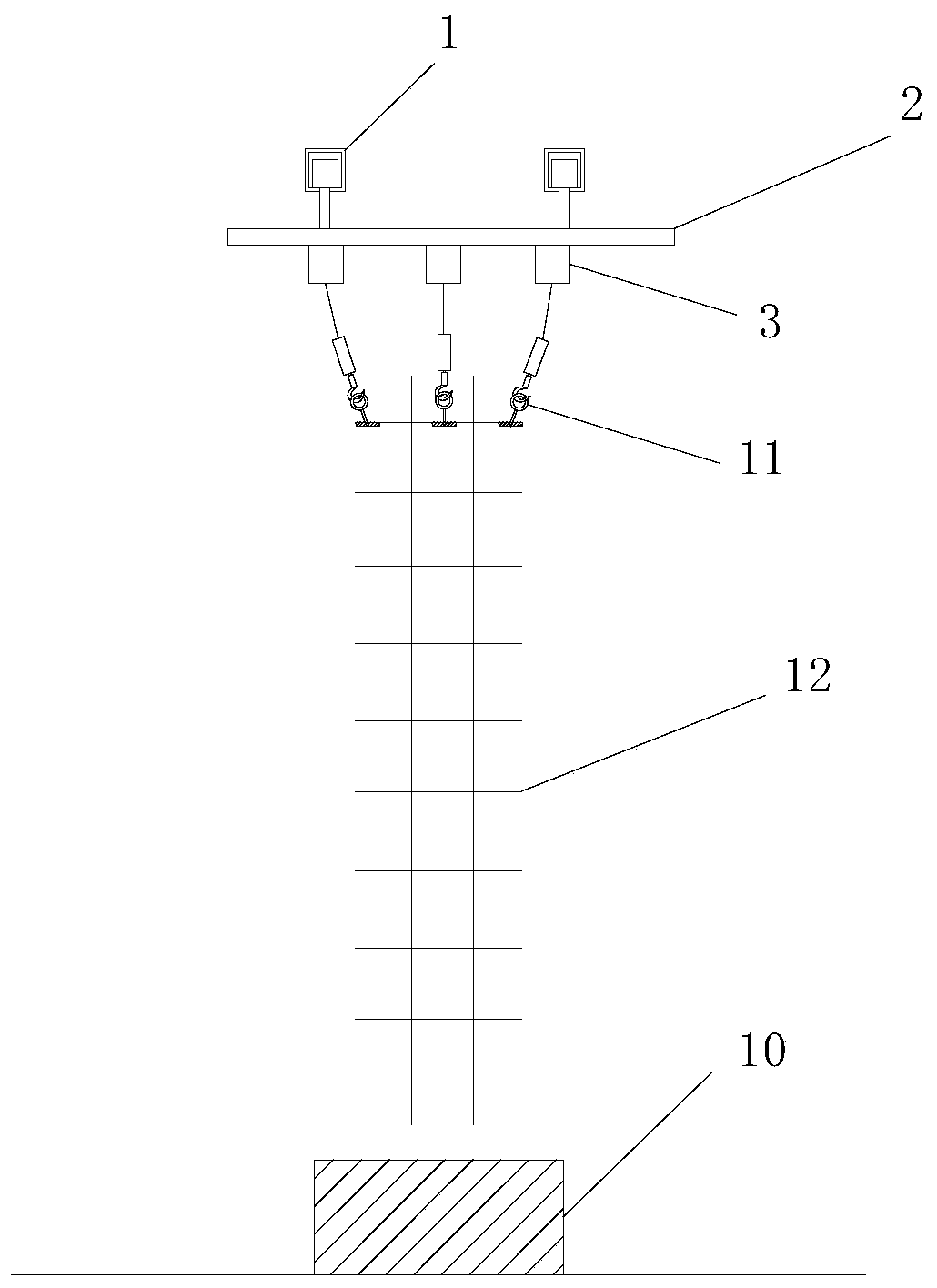

Construction method of spraying prefabricated T beam

ActiveCN111113628AImprove integrityImprove stabilityMoulding surfacesDischarging arrangementT-beamClassical mechanics

The invention relates to a construction method of a spraying prefabricated T beam. The construction method comprises the following steps of 1) preparing a pedestal; 2) binding and mounting reinforcingsteel bars; 3) manufacturing a mod plate; 4) mounting the mold plate; 5) pouring concrete; 6) vibrating the concrete; 7) removing the mold; 8) concrete curing; and 9) wastewater recovery. The construction method has the beneficial effects that horizontal jacks are arranged on the two sides of the T-beam pedestal to serve as jacking demolding devices, end molds are fixedly connected with the pedestal through anchoring bolts, and the integrity and stability of the T-beam formwork can be improved; a top platform and an electric hoist are arranged above the T-beam formwork, so that a reinforcement cage can be temporarily fixed and positioned, a vibrating rod can be driven to vibrate concrete at different parts, and the concrete vibrating quality is improved; and an adjustable rear-mounted movable spraying support is adopted, a swing spray head is mounted at the top, spray support side frames are mounted on the two sides, and a buried spraying head is arranged in the T beam pedestal, so that the T beam can be subjected to omnibearing spray curing.

Owner:湖北省路桥集团有限公司

Brick pressing mold

InactiveCN104015248AEasy to demouldImprove impact resistanceMoulding surfacesMouldsBrickUltimate tensile strength

The invention discloses a brick pressing mold. The brick pressing mold comprises a mold frame, a bottom plate and a top plate, wherein the mold frame which is arranged on the bottom plate is formed into a cuboid-shaped frame body by four rectangular steel plates, the parts, located in the mold frame, of the top plate and the bottom plate, are both higher than the periphery, so that bulges are formed, and protruding ribs are arranged on the surfaces of the bulges. The brick pressing mold provided by the invention is simple in structure and convenient to operate; in the use process, materials move towards the periphery under the action of the bulges of the top plate and the bottom plate, so that the materials are squeezed to corner parts of an unfired brick more easily, the corner parts of the pressed unfired brick are solid, and the quality of bricks is high; and the protruding ribs are formed on the surfaces of the bulges, during construction, grooves of the adjacent bricks can be mutually staggered, so that the impact resistance of a building to a wall is increased, and the firm strength of the wall is improved.

Owner:费林云

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com