High-precision multifunctional concrete bridge deck slab prefabricated mold and working method thereof

A multi-functional, concrete technology, applied in the direction of manufacturing tools, mold auxiliary parts, forming surfaces, etc., can solve problems such as the inability to guarantee the prefabrication accuracy of concrete prefabricated bridge decks, and achieve overall prefabrication accuracy, assembly accuracy, and positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

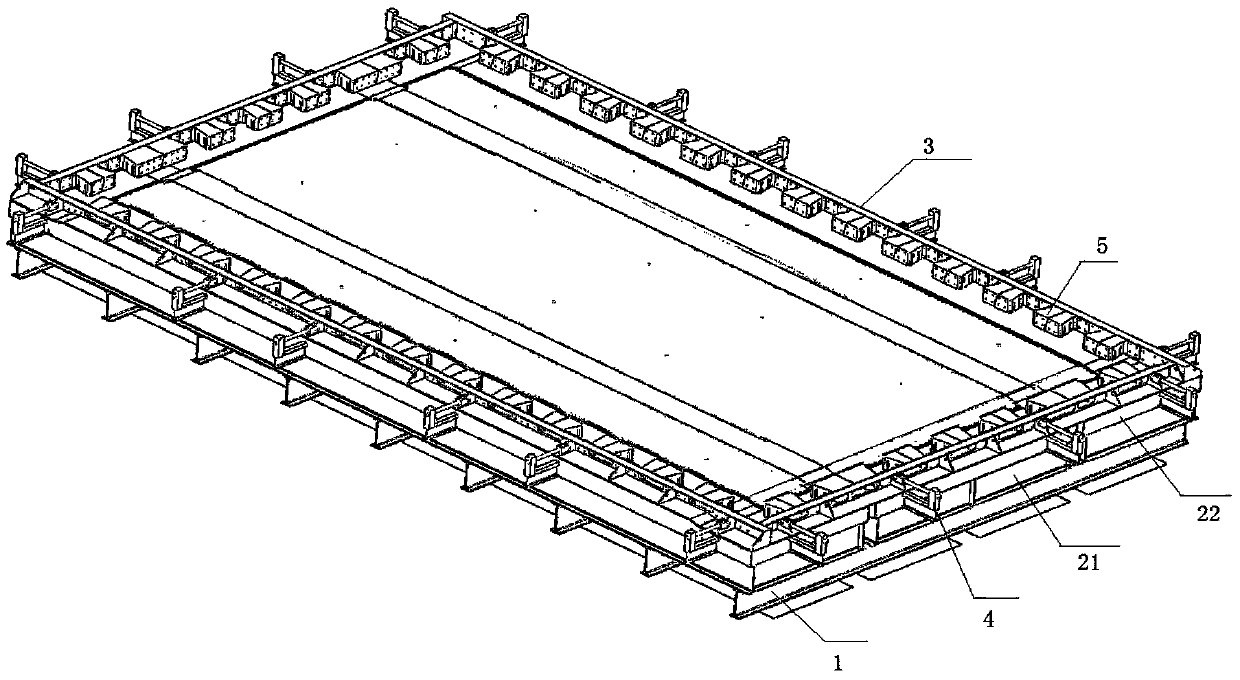

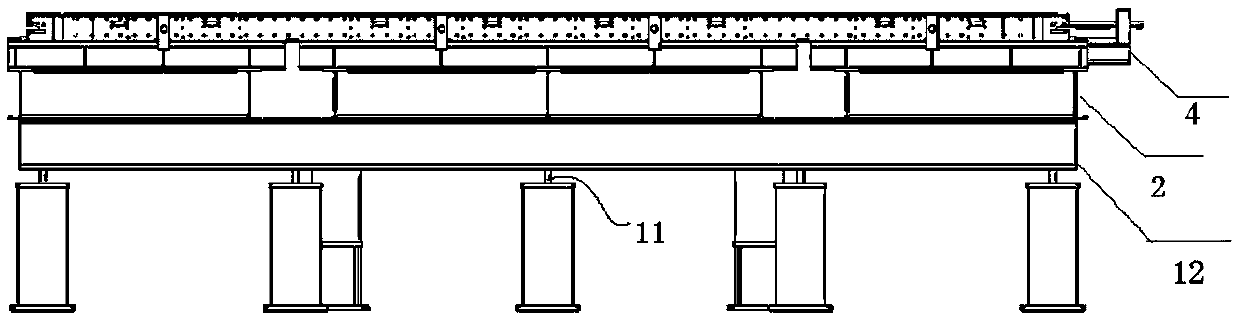

[0030] Embodiment 1: as figure 1 and figure 2 As shown, a high-precision multifunctional concrete bridge deck prefabrication mold according to the present invention includes a base 1, a bottom film 2 positioned on the upper layer of the base 1, a side mold 3 positioned around the bottom film 2, and a demoulding mold positioned outside the side mold. The device 4 and the core film 5 located inside the side mold.

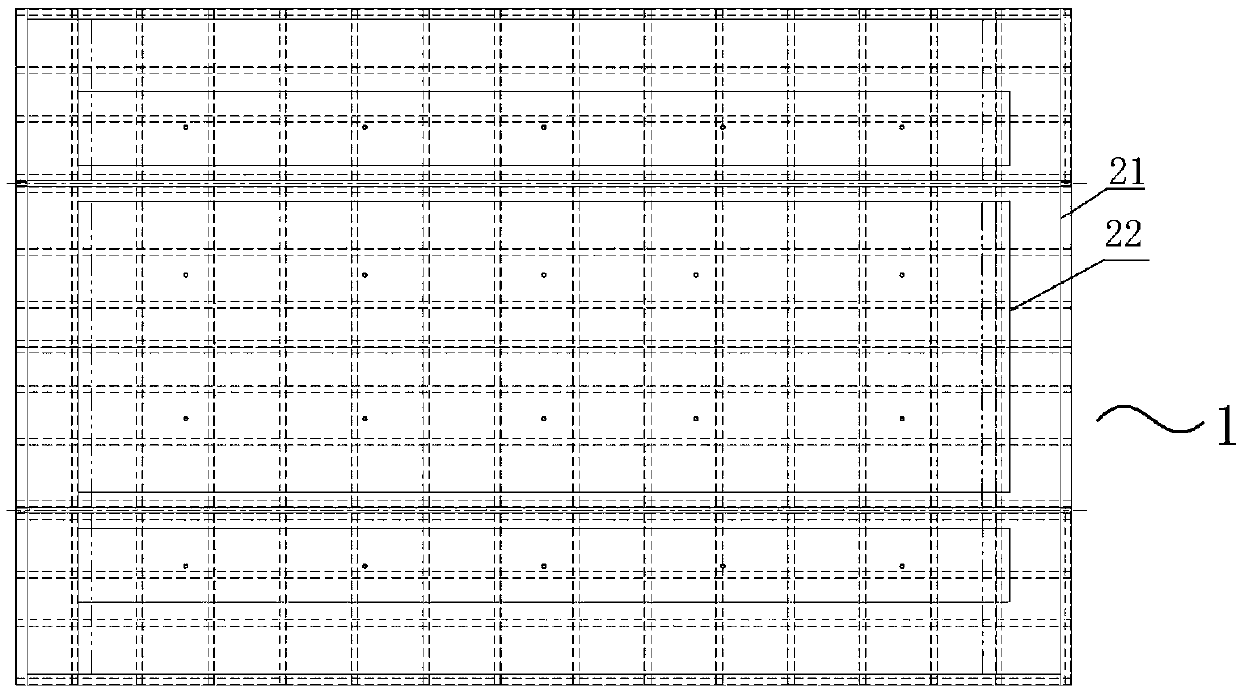

[0031] Such as image 3 and Figure 4 As shown, the base 1 is composed of a number of longitudinal beams parallel to each other and a number of cross beams parallel to each other. The longitudinal beams and the beams are vertically arranged so that the longitudinal beams 11 and the beams 12 are staggered to form a mesh supporting bottom membrane 2; the upper layer of the base 1 is provided with a bottom Die 2, bottom mold 2 is made up of the first bottom mold 21 and the second bottom mold 22 that is positioned at the first bottom mold 21 upper layers, and the firs...

Embodiment 2

[0037] Embodiment 2: based on the structure of embodiment 1, the present invention has made the prefabricated mold of following specification, and concrete preparation method is as follows:

[0038] I-beams and channel steels are used to form a system of beams 12 and longitudinal beams 11, and a foundation pit is set under the base 1 with a height of about 1.2m, which is convenient for screwing bolts. Before the prefabricated mold is assembled, the I-shaped beam of the base 1 is bolted to the embedded plate on the ground, and the overall flatness of the base 1 is adjusted through the bolts.

[0039] In order to facilitate the positioning and assembly of T-shaped embedded components, the connecting part between the base 1 and the bottom mold 2 is divided into three parts, including the middle base and the side bases located on both sides of the middle base, and the base film is also divided into the middle part located above the middle base. The bottom film and the side bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com