Patents

Literature

88results about How to "Guaranteed flatness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for mounting bottom plates and cylinder of steel lining of nuclear power plant

ActiveCN102061788AShort construction periodShorten the construction periodCovering/liningsArc welding apparatusSupporting systemArchitectural engineering

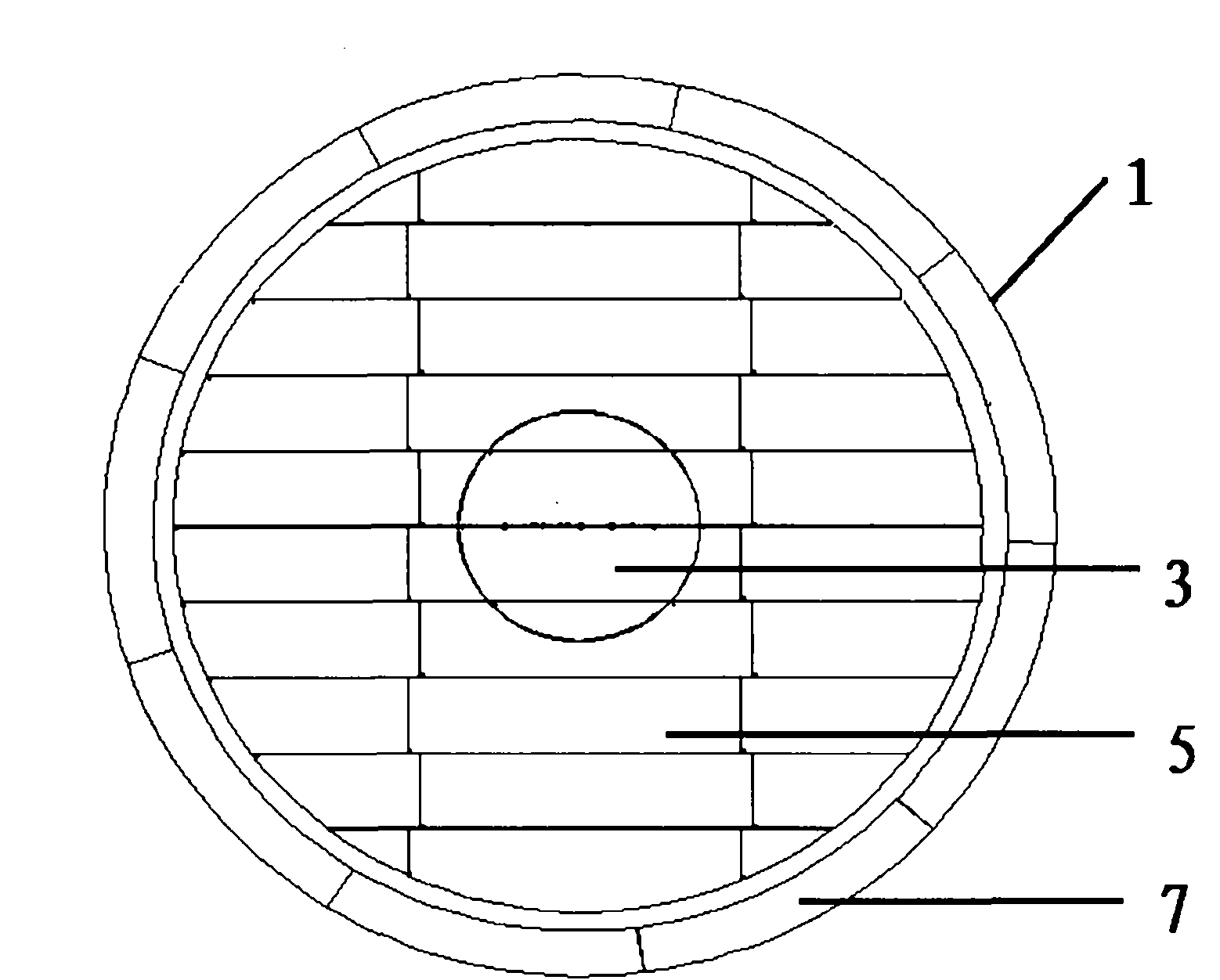

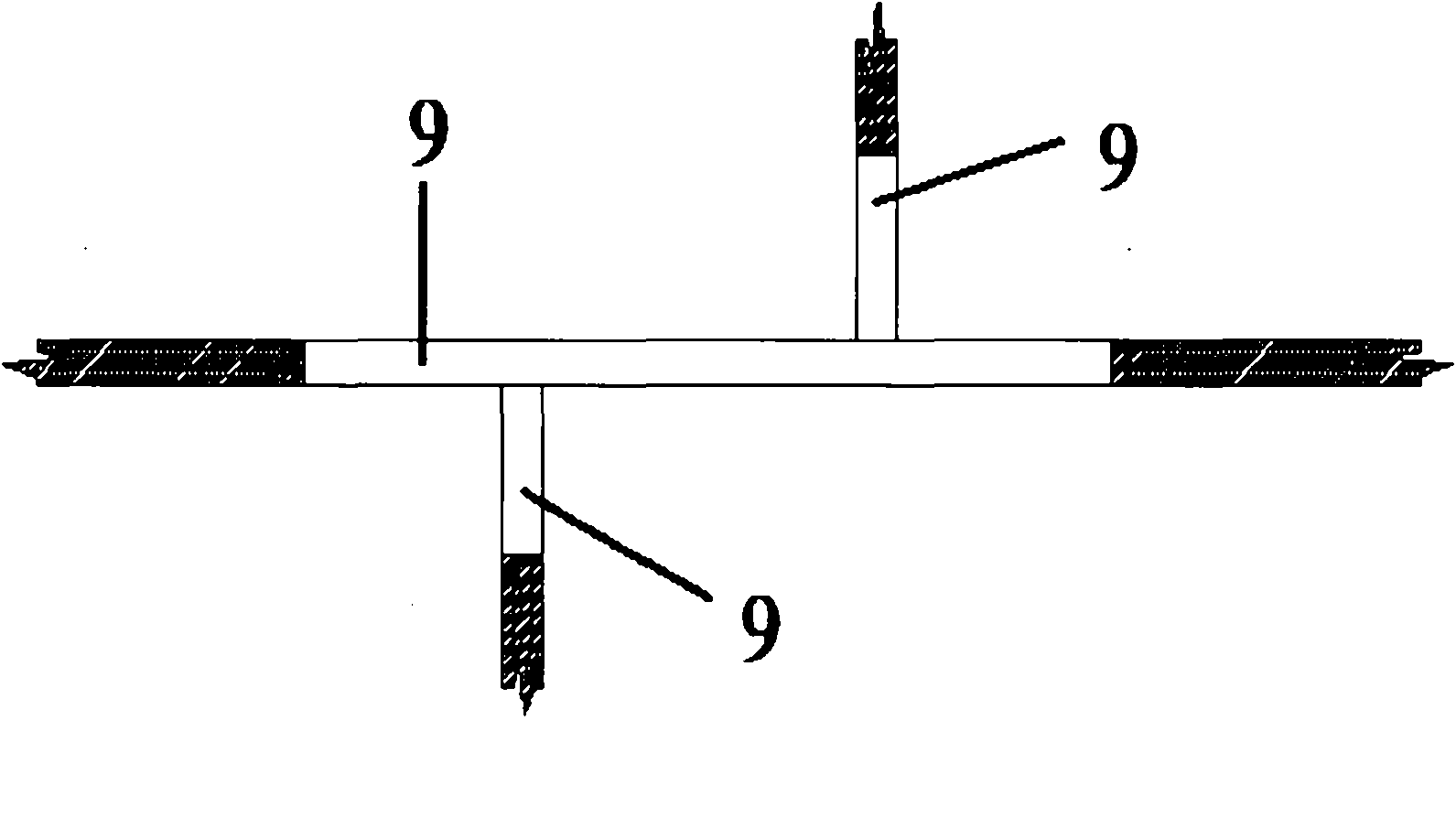

The invention provides a method for mounting bottom plates and a cylinder of a steel lining of a nuclear power plant. The bottom plates are basically circular, and are divided into circular center bosses, annular intermediate annular plates and annular edge plates which consist of a plurality of precast slabs from inside to outside; the cylinder comprises frustums and cylinder wall plates which are formed by splicing the plurality of precast slabs; and the cylinder wall plates are divided into a plurality of layers. The mounting method sequentially comprises the following steps of: mounting a bottom plate support system; putting the bottom plates on the bottom plate support system; putting the frustums; welding the bottom plates and the frustums in pairs; and mounting each layer of cylinder wall plates from bottom to top respectively. By rationally setting a welding process and a construction assembly process, a mounting construction period of the steel lining is effectively shortened, and the sealability of welding seams of the steel lining is ensured.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

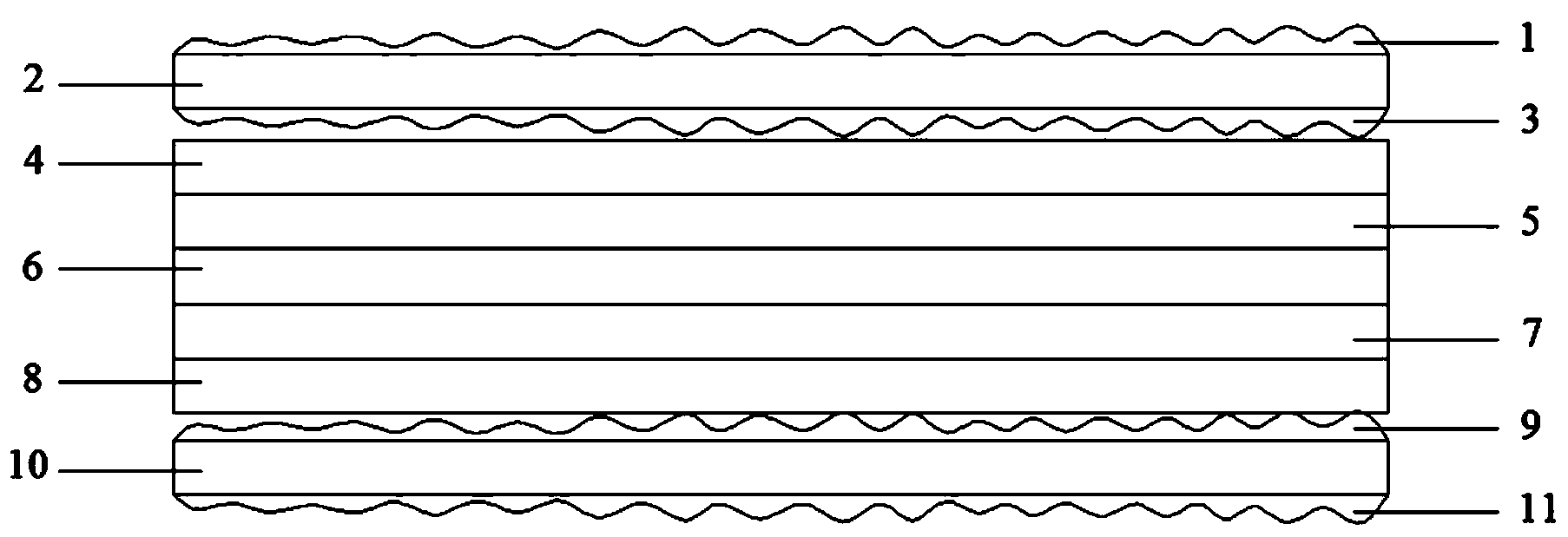

Printed circuit board, design method thereof and terminal product main board

ActiveCN101365291AGuaranteed basic performanceGuaranteed performanceCross-talk/noise/interference reductionPrinted circuit aspectsWire widthSurface layer

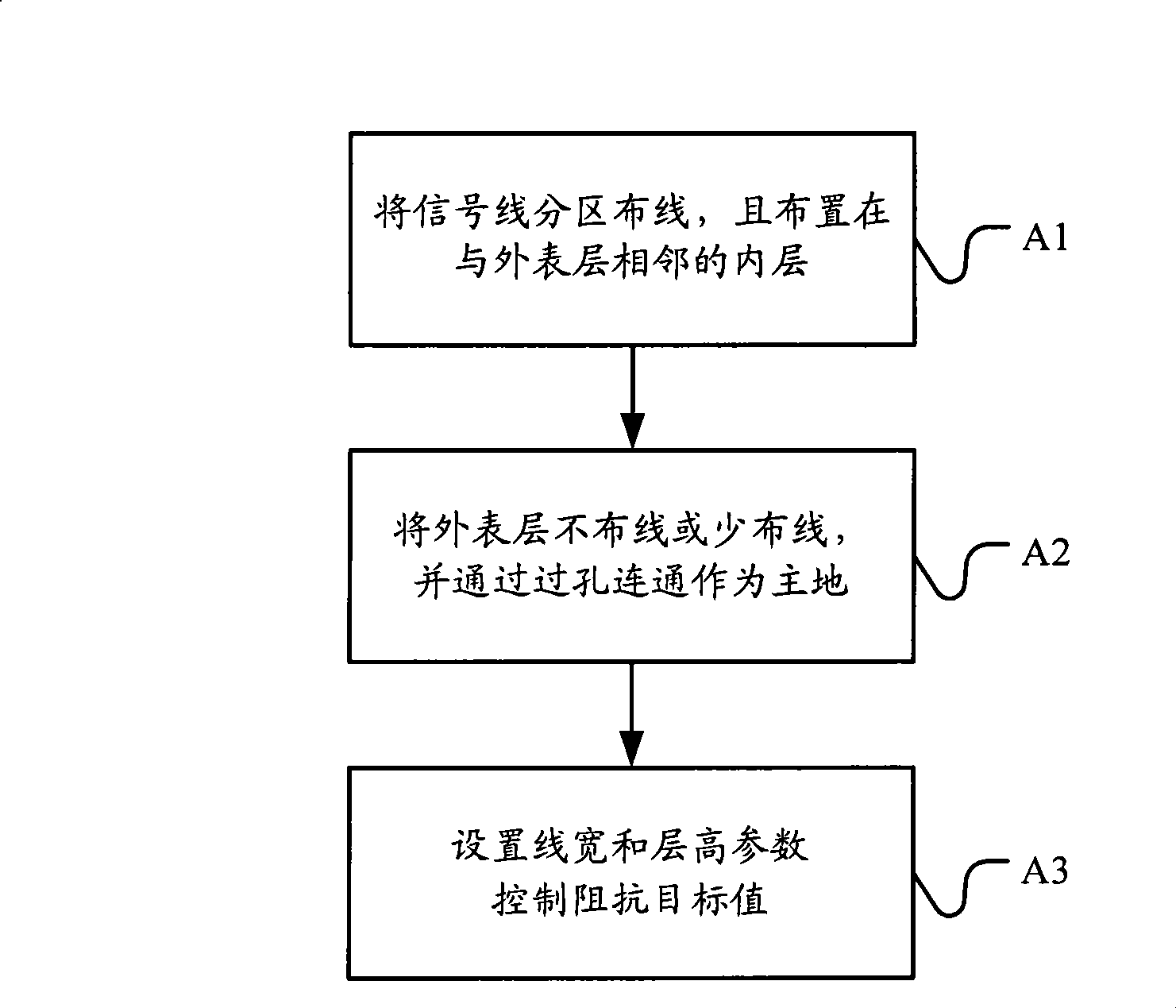

The embodiment of the invention discloses a design method of a printed circuit board. The method comprises the following steps of laying a signal wire on inner layers next to an outer surface layer by zones; not wiring the outer surface layer or laying less wire on the outer surface layer which is used as a main area communicated through a hole; and setting wire width and layer height parameters to control an impedance target value. Correspondingly, the embodiment of the invention provides the printed circuit board, which comprises the out surface layer, and two inner layers positioned between the surface layers. The inner layers next to the out surface layer are used for laying signal wires by zones. Few wires or no wire is laid on the out surface layer and the outer surface layer is used as the main area communicated through the hole. The invention also discloses a terminal product main board using the printed circuit board. The technical proposal provided by the embodiment of the invention can reduce the cost and improve the reliability by layer reduction design under the condition that the basic properties of the original multi-layer printed circuit board is kept.

Owner:HUAWEI TECH CO LTD

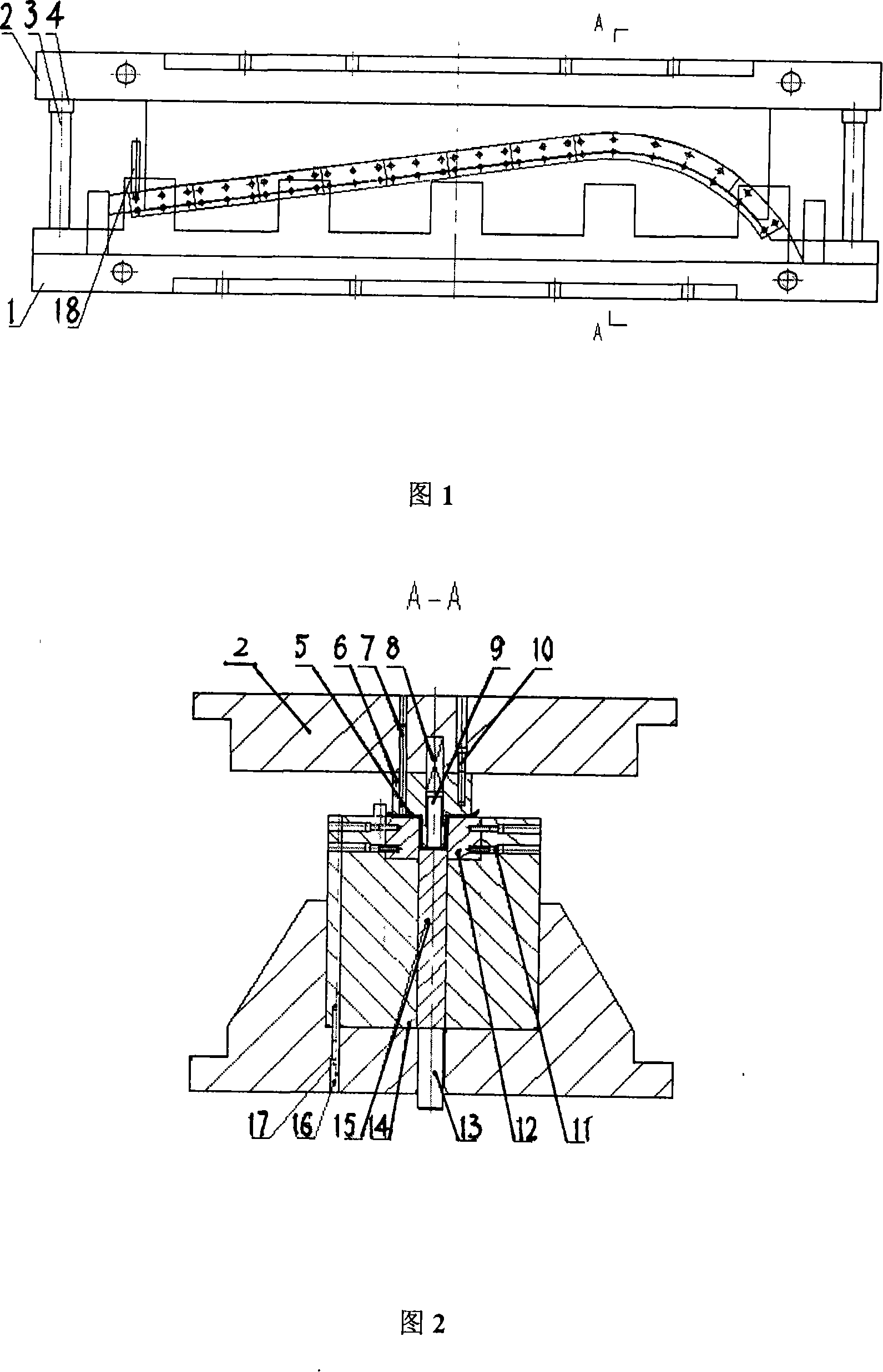

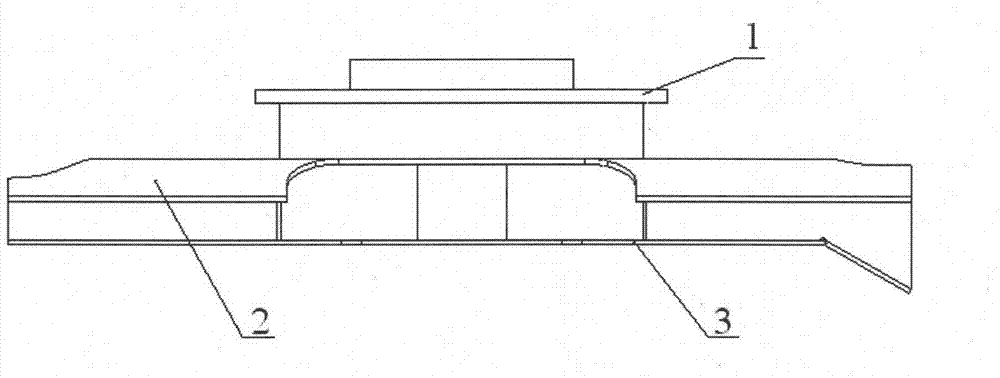

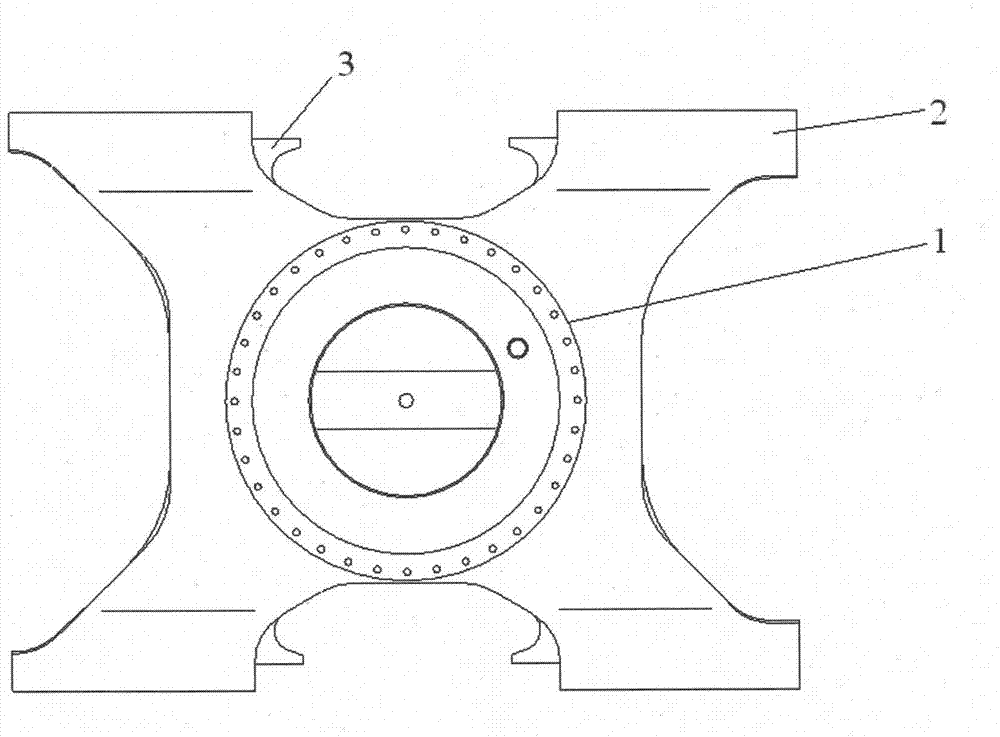

Side pole novel forming technology and mould

InactiveCN101125349AEasy to adjustEasy assembly and maintenanceShaping toolsVehicle componentsMaterials scienceAir cushion

The present invention discloses a novel side post molding art work and relevant mold characterized in that: the mold comprises an upper mold plate and a lower mold plate; the blank is placed on the lower mold plate; the blank is adjusted to a right position, the sliding block of the press moves downward, driving the upper mold to move downward. During the course of downward moving of the upper mold, a male mold firstly goes in contact with a knockout punch, and the panel is firmly clamped; when the male mold moves on downward, the air cushion of the press shrinks synchronously, driving a push off pin and the knockout punch to move downward synchronously, and press the middle panel with a constant pressure together with the knockout punch; at the same time the two side panels go in contact with the embedded blocks of a female mold. Along with the gradual downward motion of the male mold, the panels are pulled deep into a cavity formed by the embedded blocks of the female mold. When the pull process is over, the sliding block goes upward, and the male mold separates from the knockout punch; the knockout punch is pushed by the push off pin to push the working piece out of the cavity formed by the embedded blocks of the female mold, and a working circulation.is finished. Parts produced by adopting the mold and art work regarding the invention have high molding accuracy, stable size, external shape pleasing to the eye ,and ensure the planeness requirement of a side wall.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

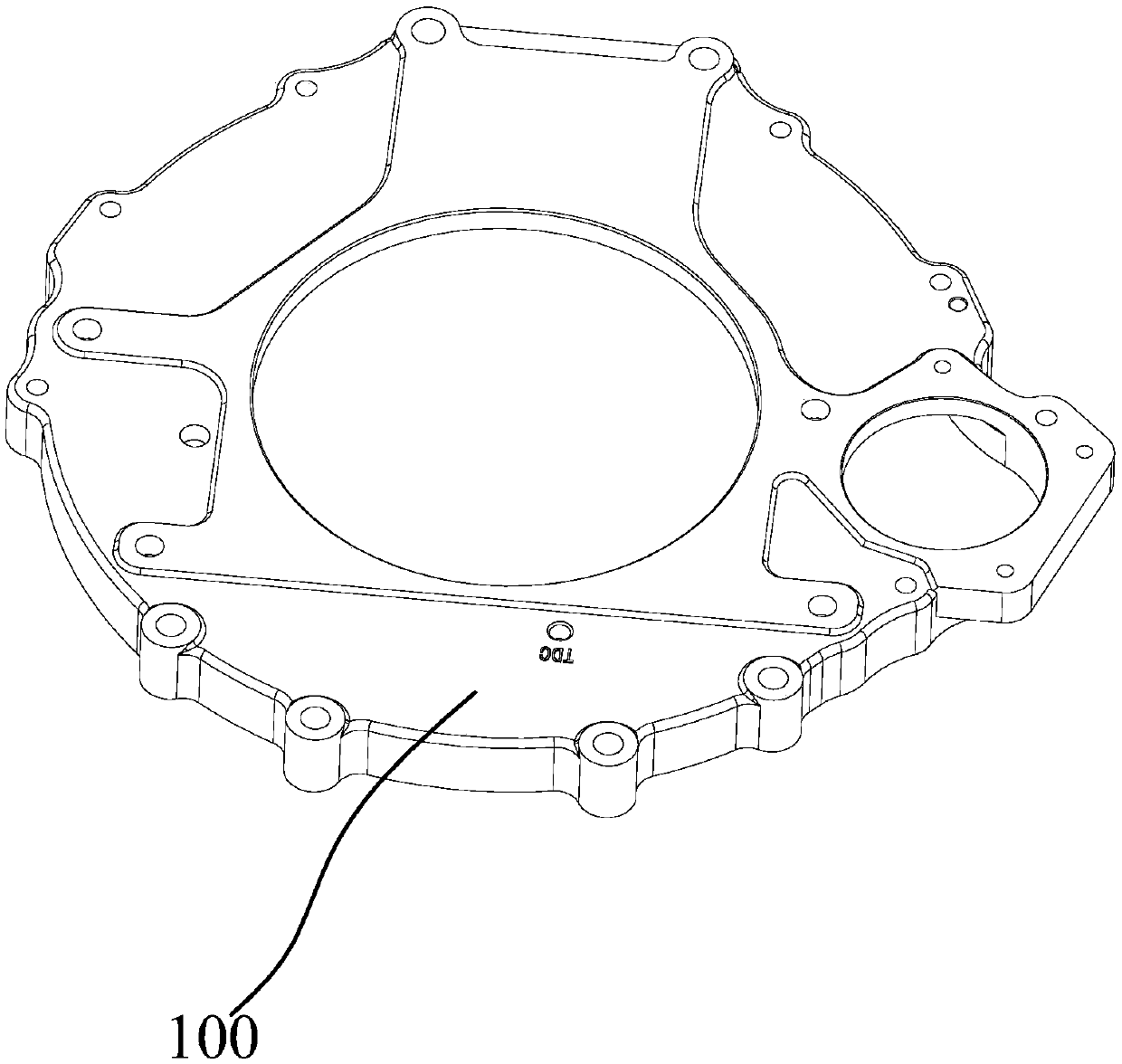

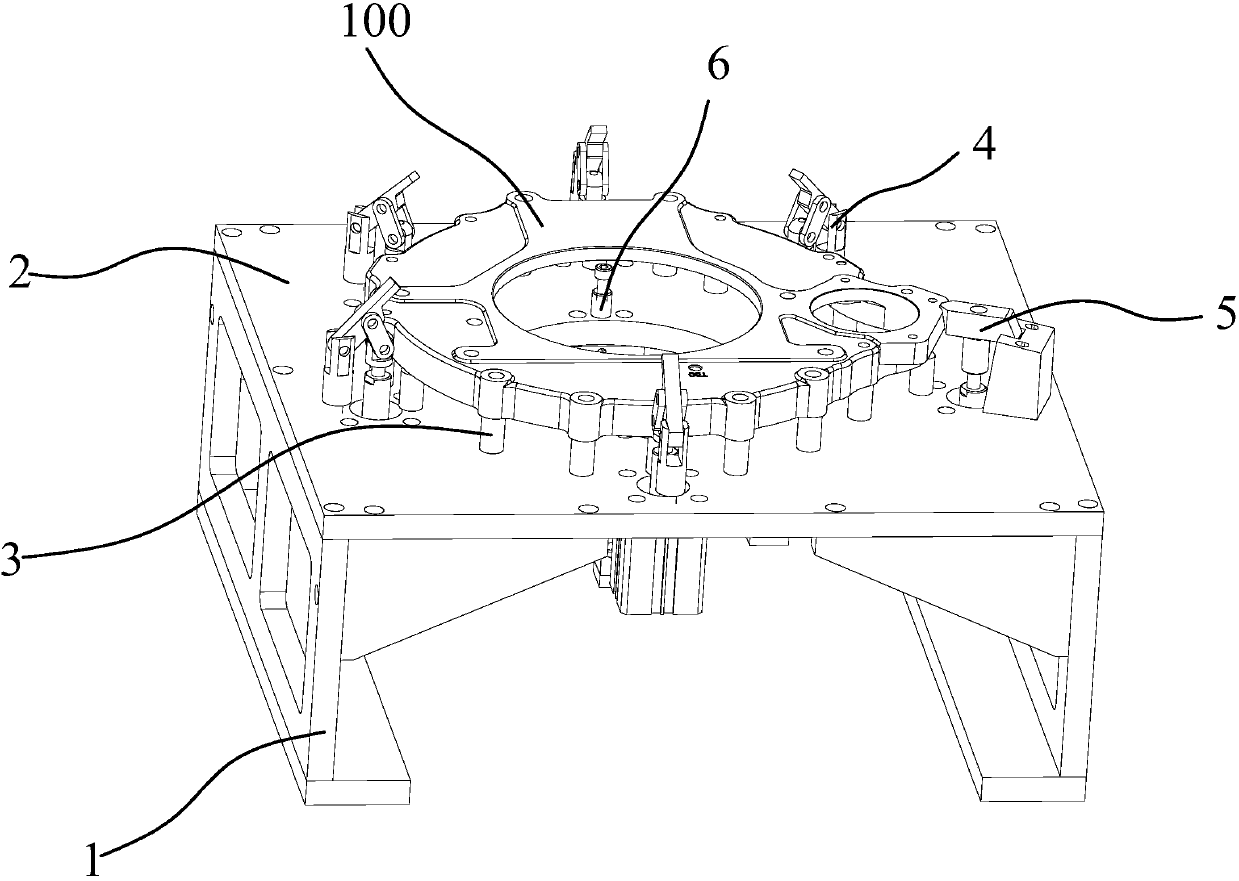

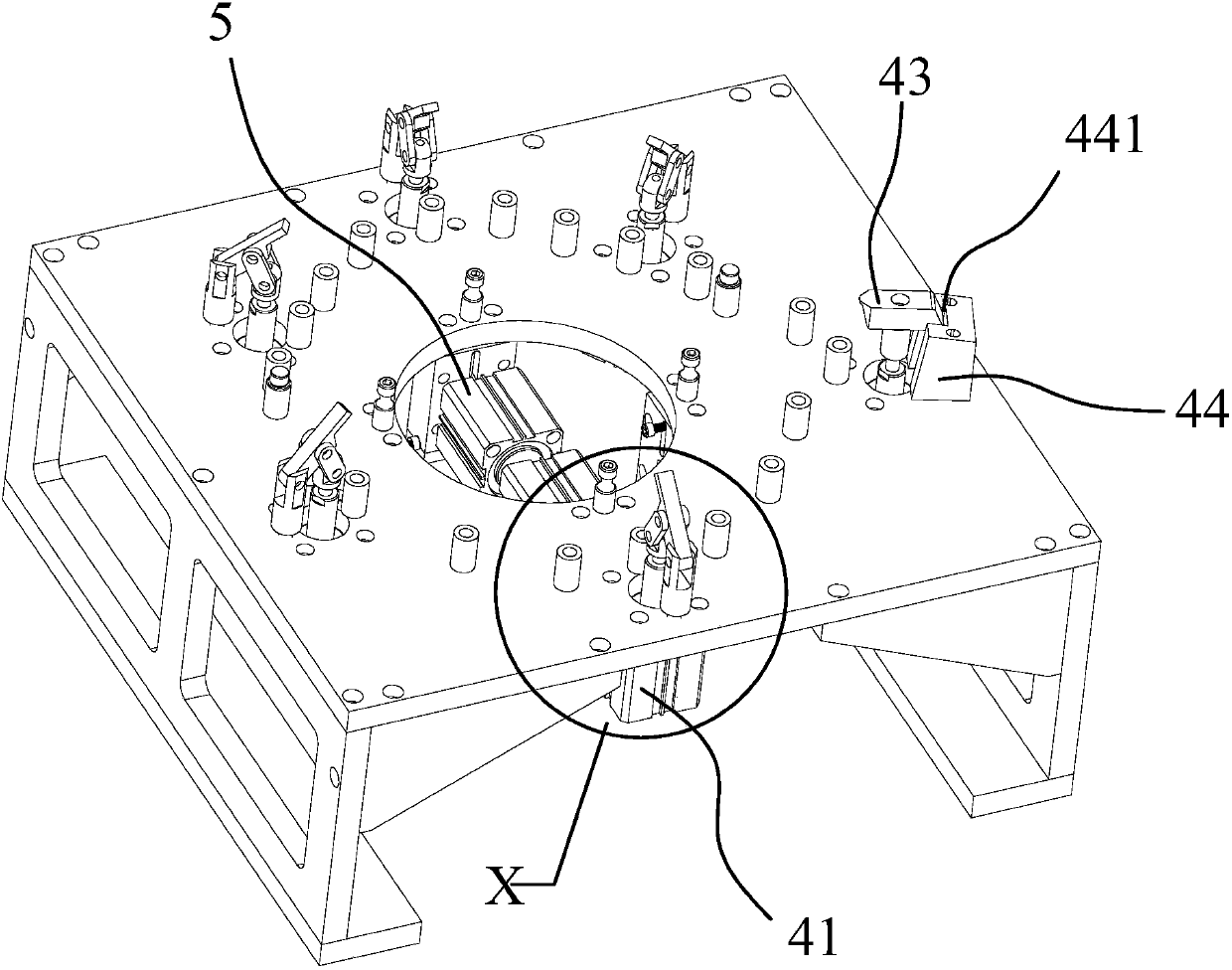

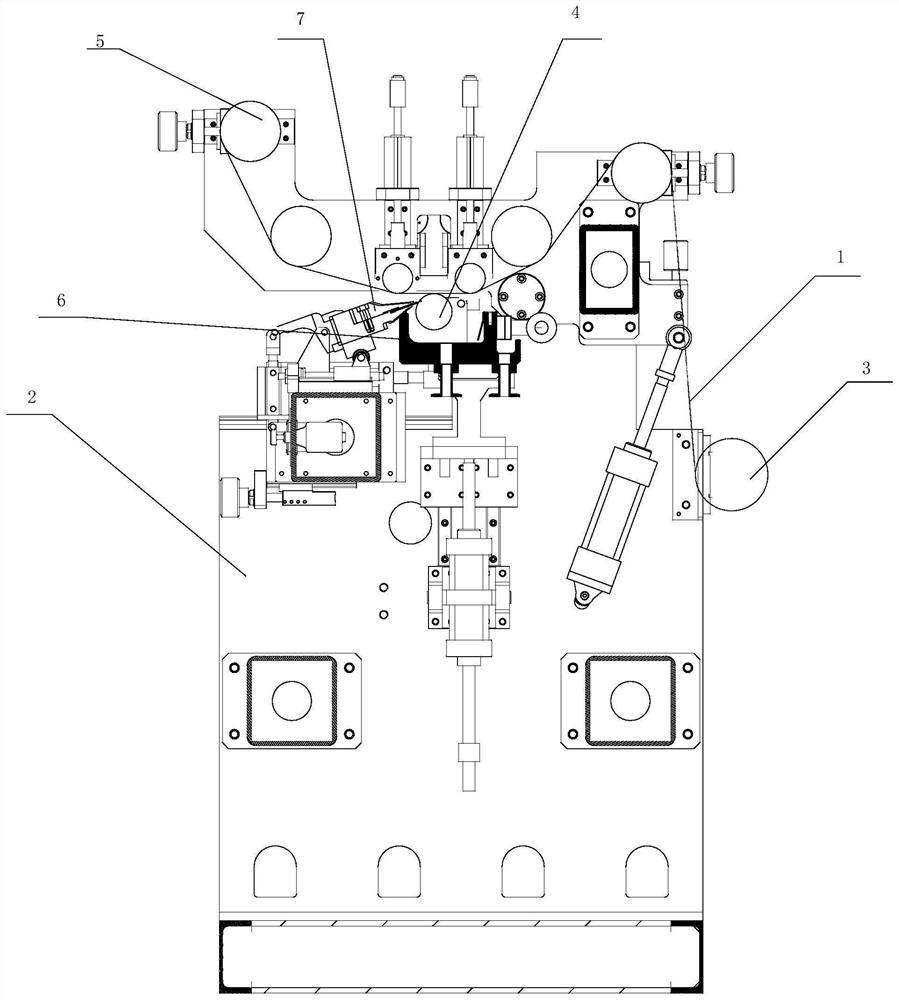

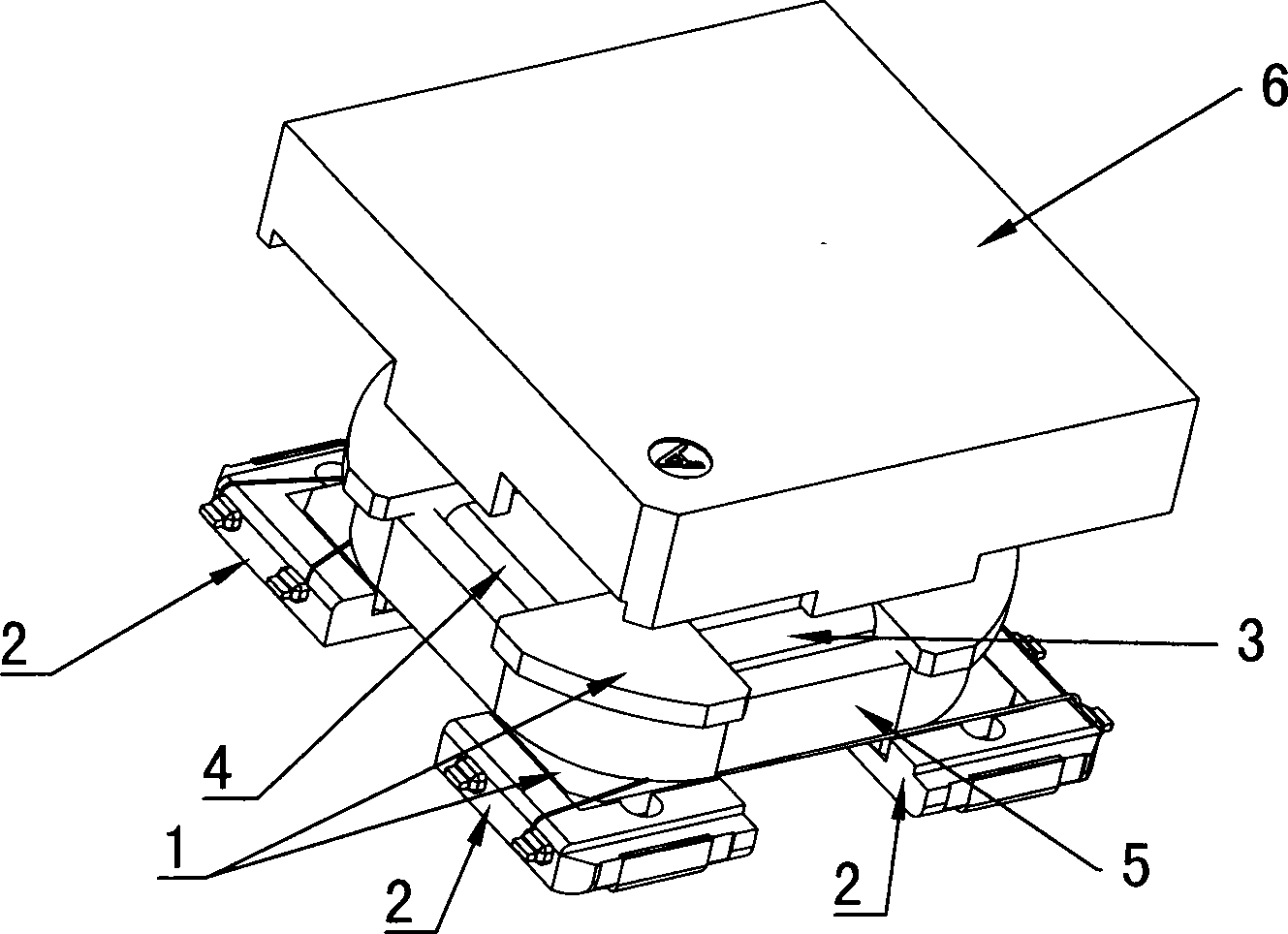

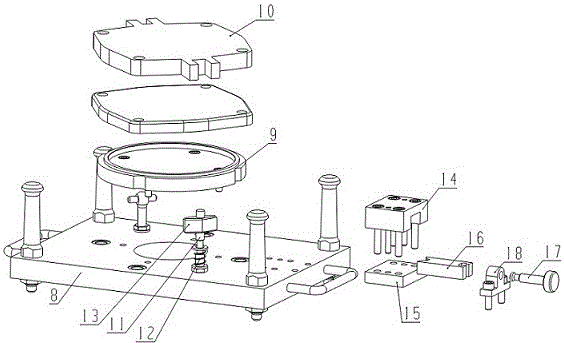

Engine transition connecting plate positioning tool

ActiveCN107738125ASimple structurePrecise positioningWork clamping meansPositioning apparatusEngineeringMechanical engineering

Owner:宁波裕隆汽车制泵有限公司

Double-sided coating equipment and processing technology applying double-sided coating equipment

PendingCN112604911ACorrection high efficiencyBroaden applicationPretreated surfacesCoatingsEngineeringMechanical engineering

The invention relates to double-sided coating equipment. The double-sided coating equipment comprises front-side coating equipment and back-side coating equipment, wherein the back-side coating equipment comprises a second rack, and a first guide roller, a traction roller, a second guide roller and a second coating roller which are sequentially distributed below a base material in the back-side coating direction of the base material are erected on the second rack; and a glue tank used for infiltrating part of the second coating roller is arranged under the second coating roller, the second guide roller is arranged on one side of the second coating roller, a second scraper is fixed to the other side of the second coating roller, the blade point of the second scraper is connected with the outer surface of the second coating roller in an abutting mode, the front-side coating equipment is located below the back-side coating equipment, and a middle roller is positioned between the front-side coating equipment and the back-side coating equipment. According to the high-efficiency double-sided coating equipment and a processing technology applying the double-sided coating equipment, double-sided coating can be achieved on one coating line.

Owner:SUZHOU ACME MACHINERY

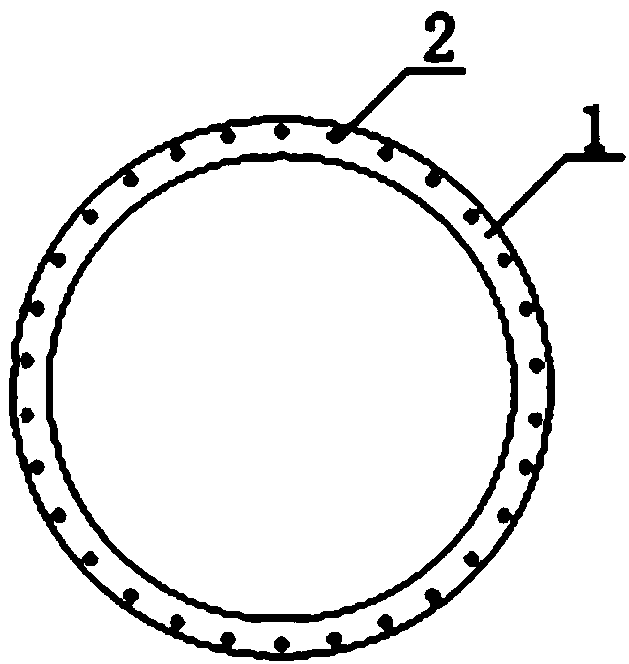

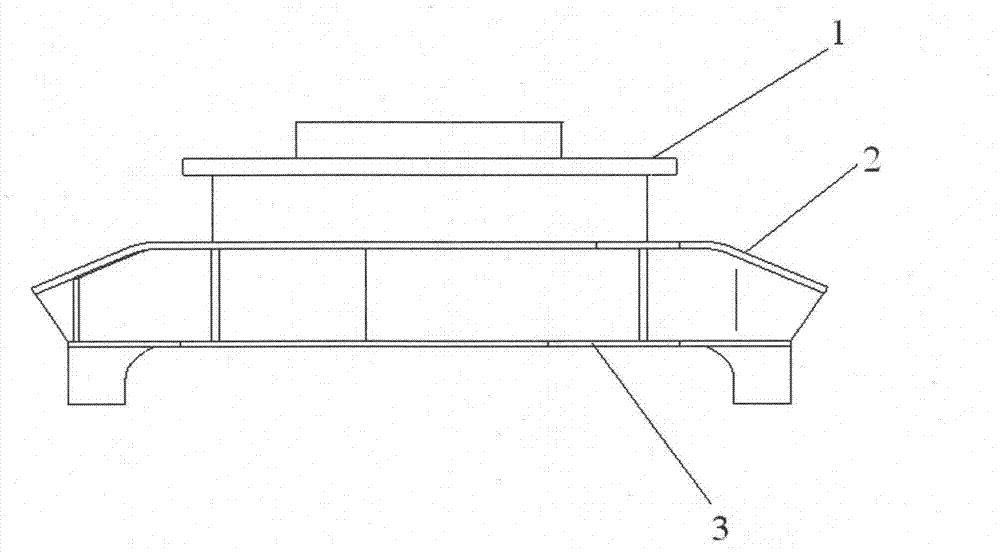

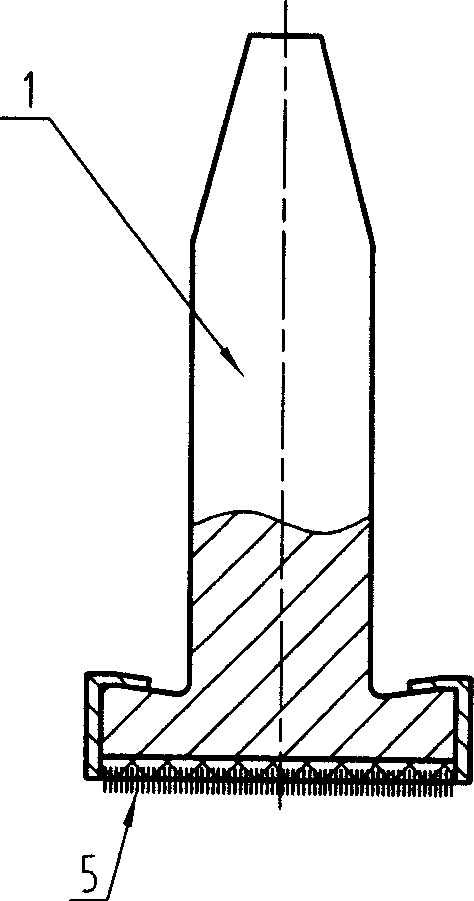

Thin steel ring processing method

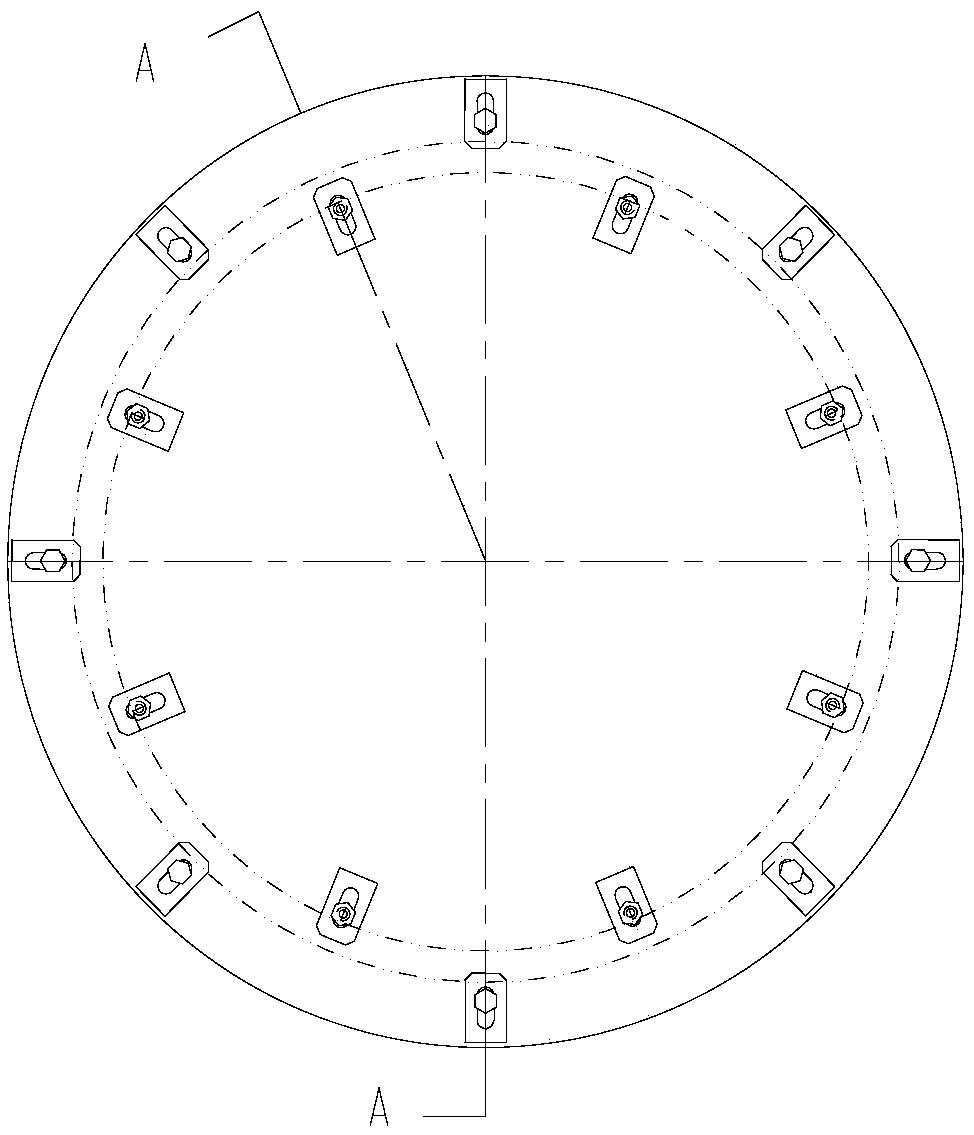

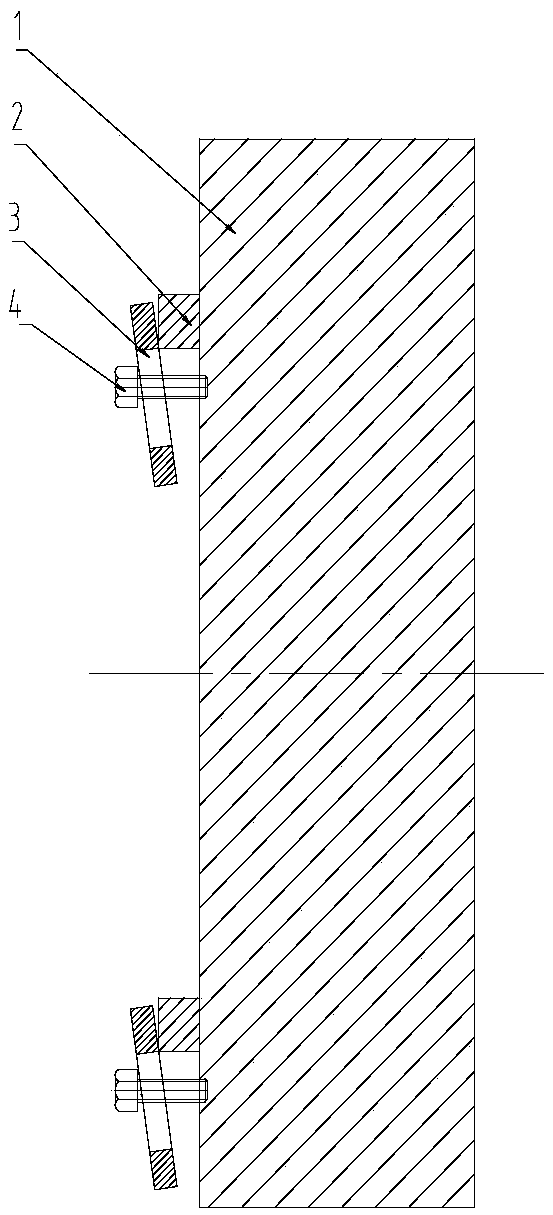

The invention belongs to mechanical processing technology and relates to a thin steel ring processing method. The thin steel ring processing method is characterized by including the following steps of blanking, roughing, drilling, milling of an annular groove, cutting of a skirt edge, clamping of a second blank, finish-milling of inner and outer circles and deburring. By the thin steel ring processing method, requirements on planeness of a thin steel ring 1 are guaranteed.

Owner:HARBIN

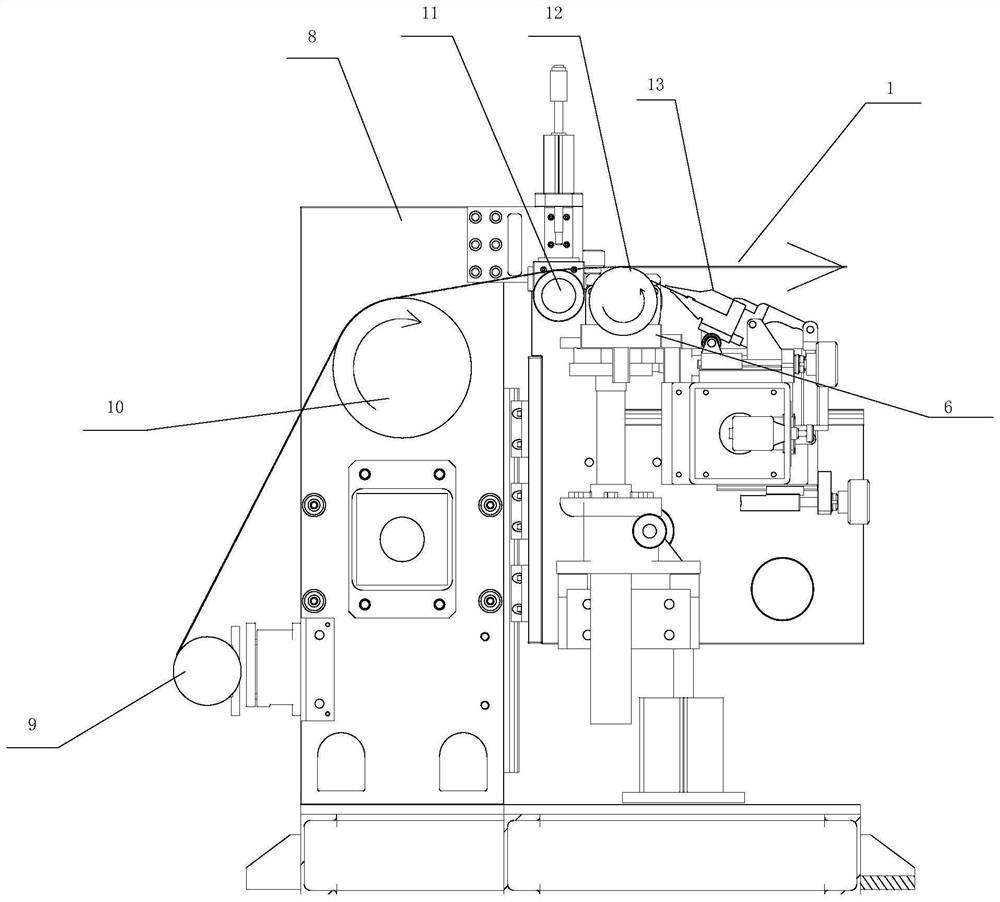

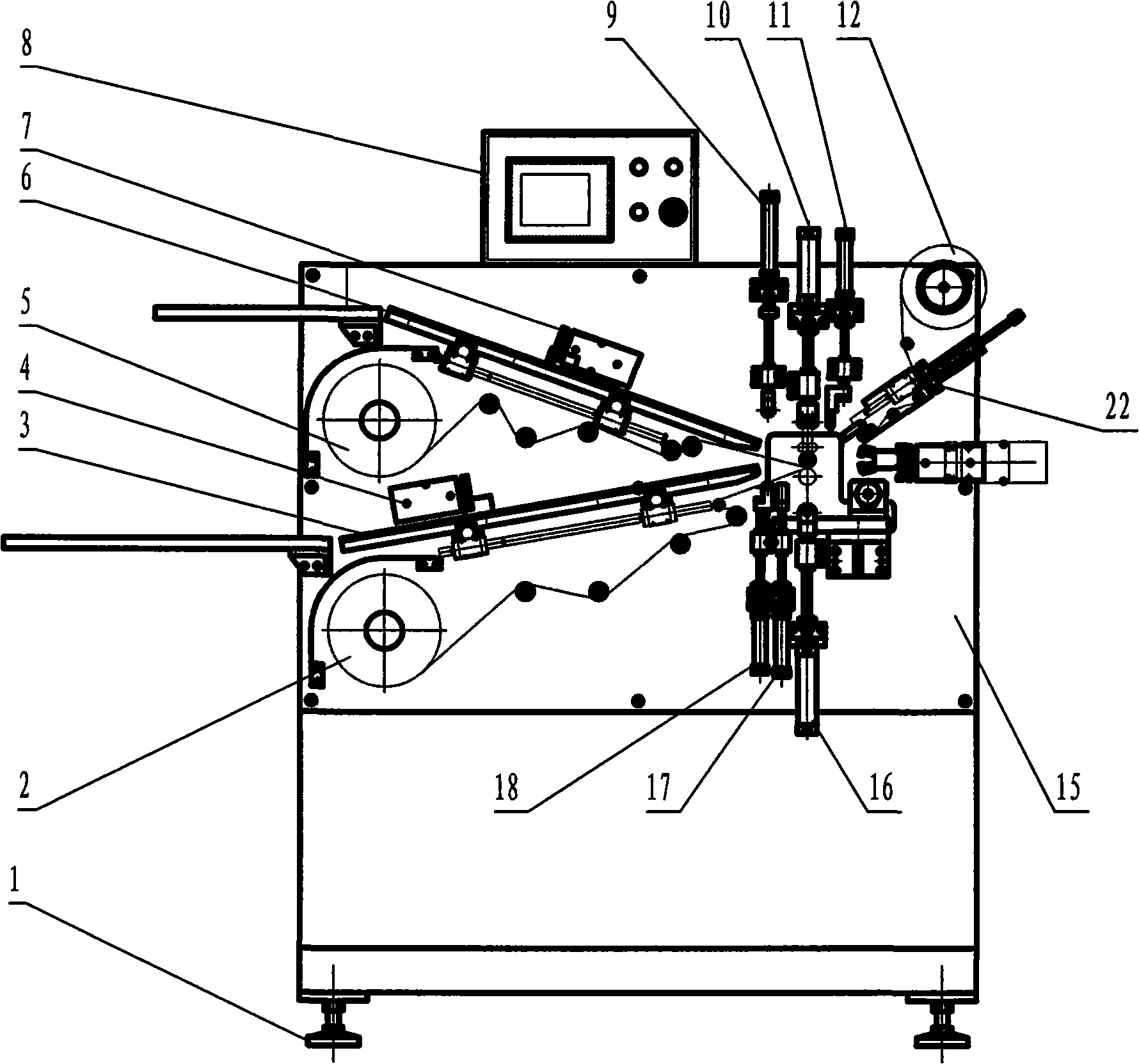

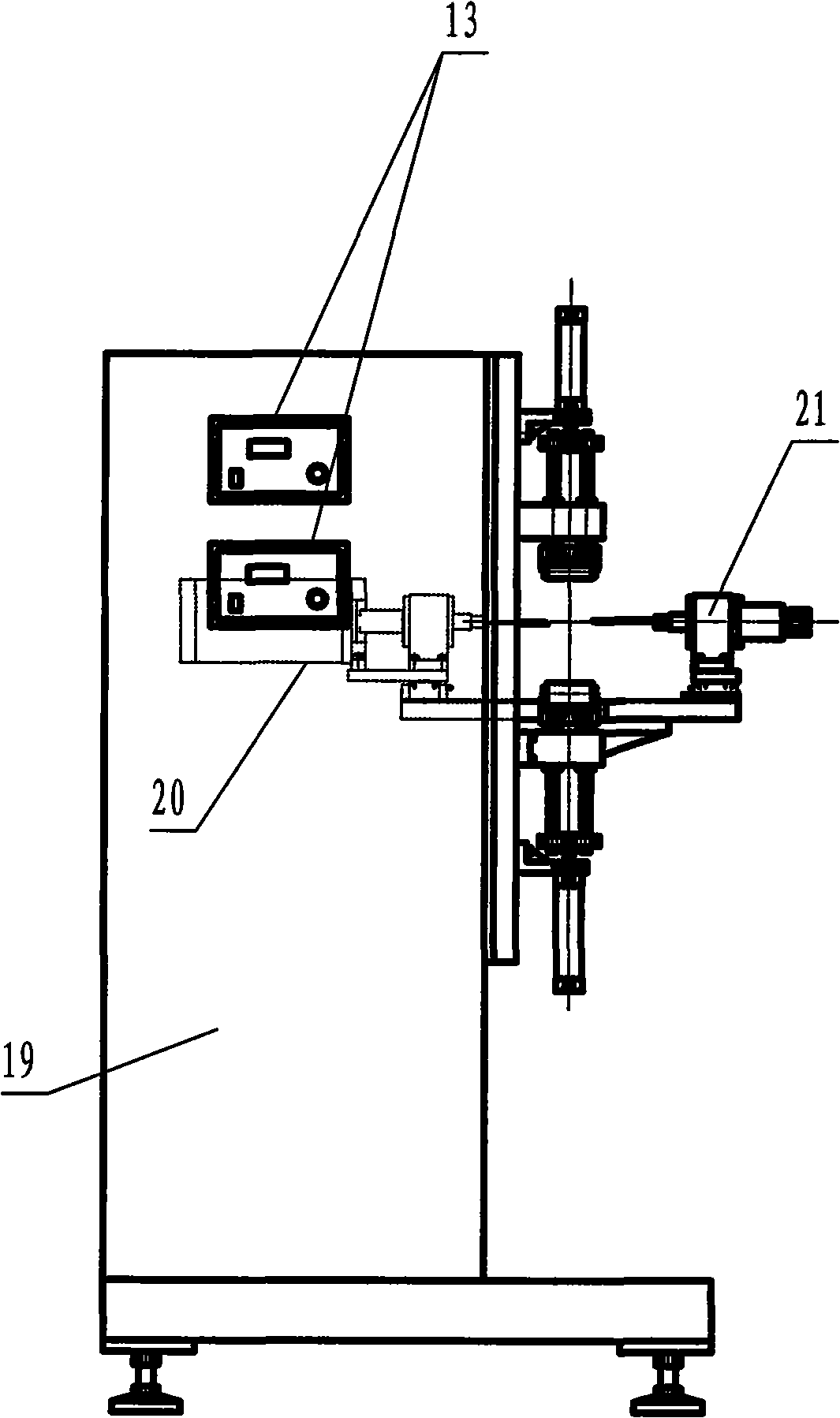

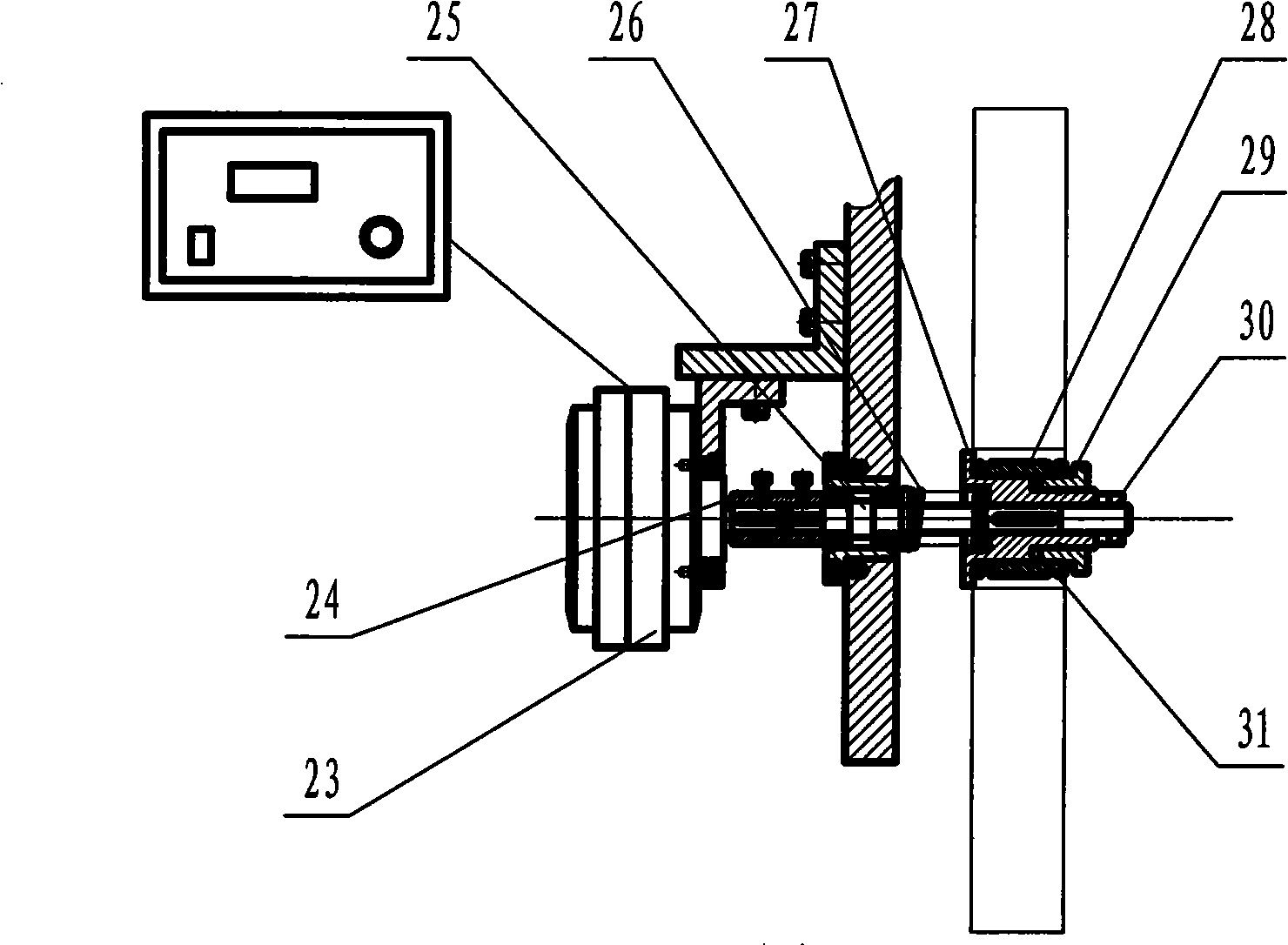

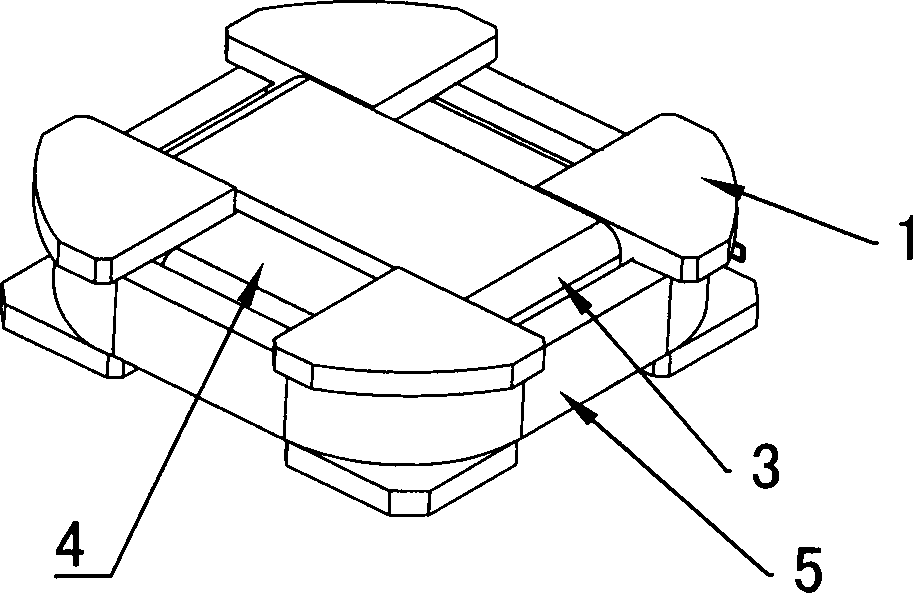

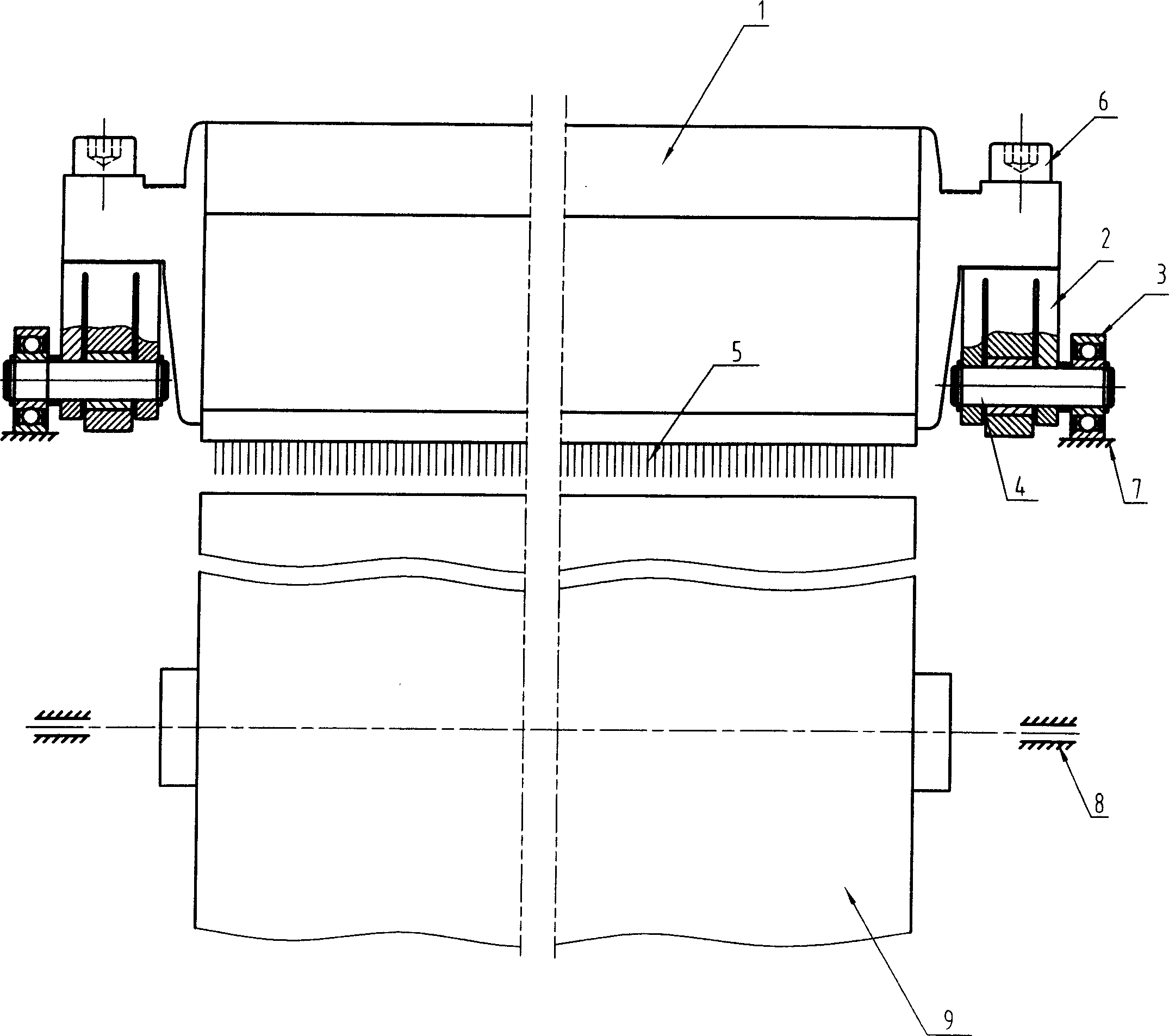

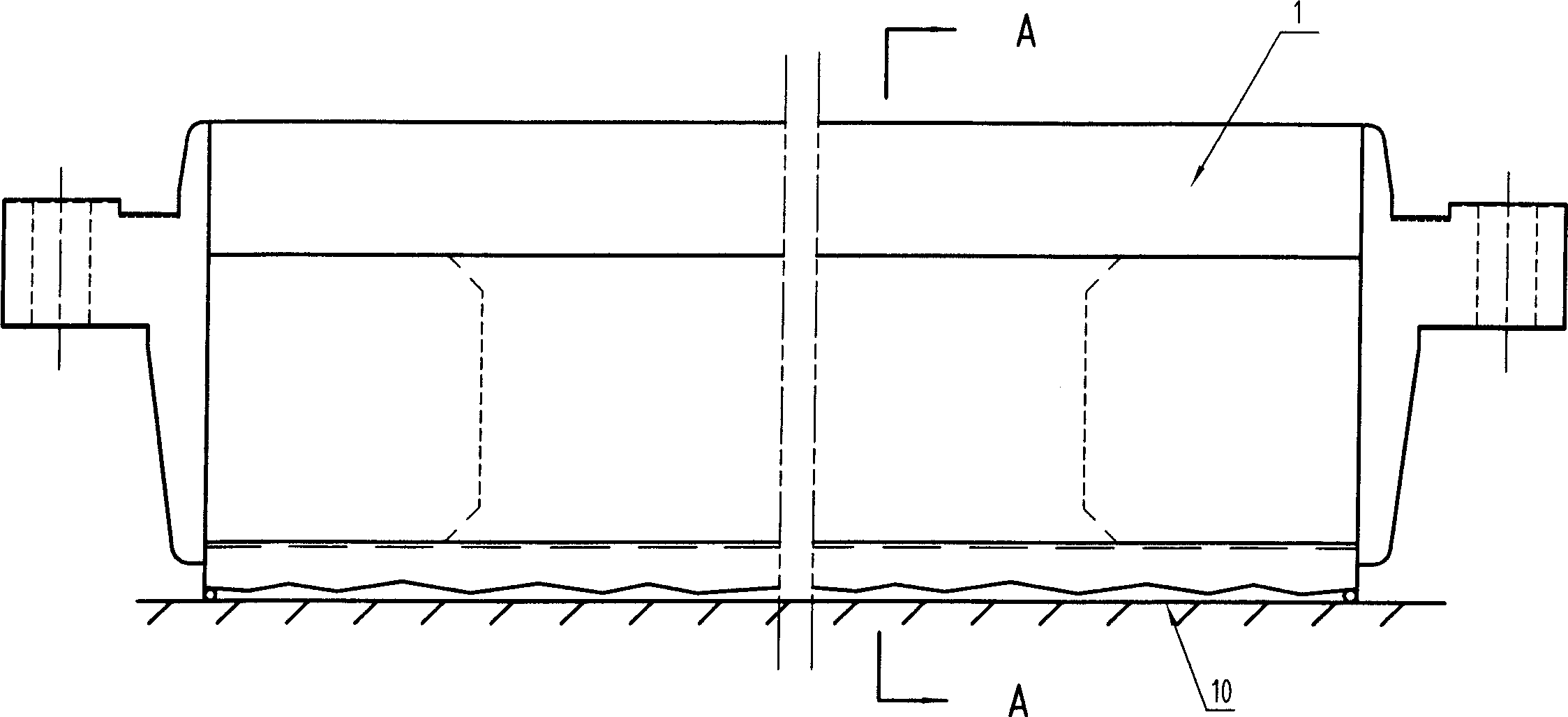

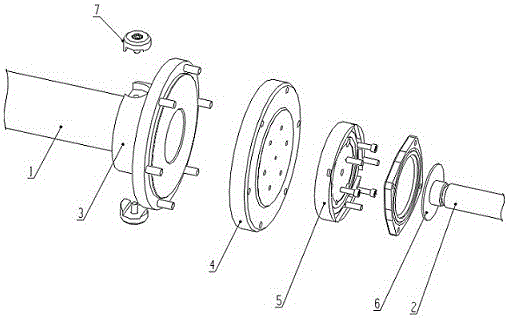

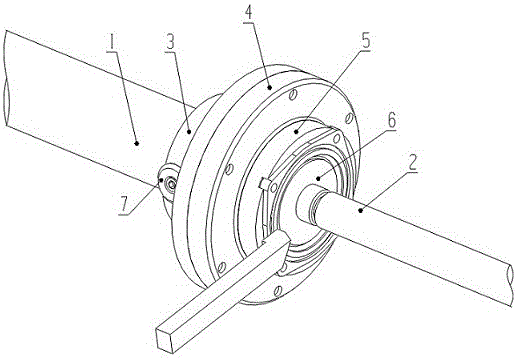

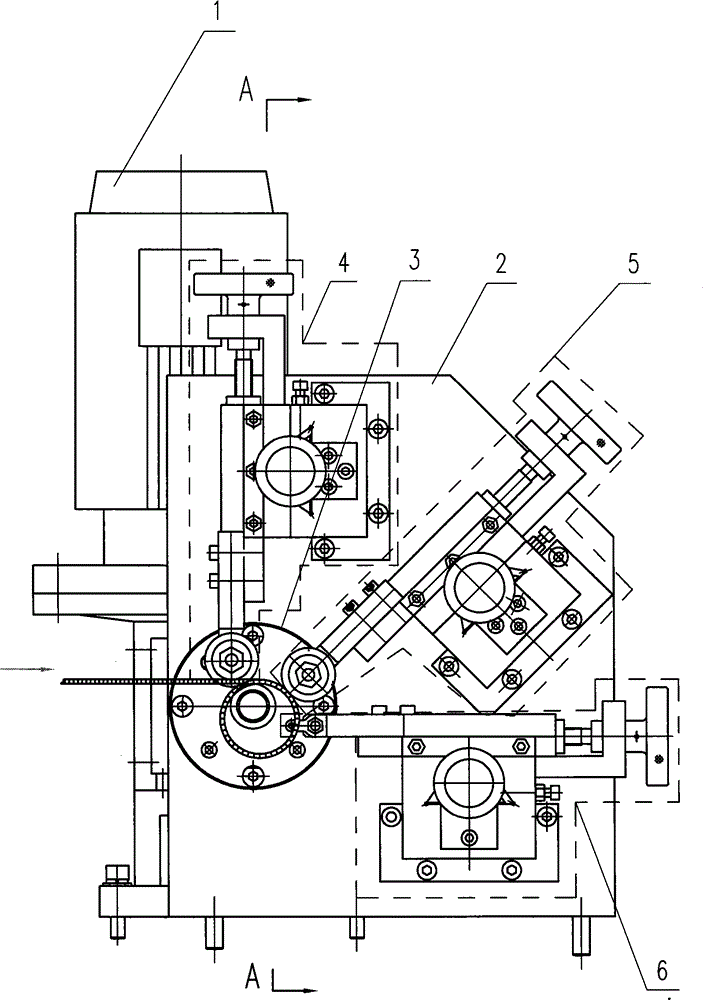

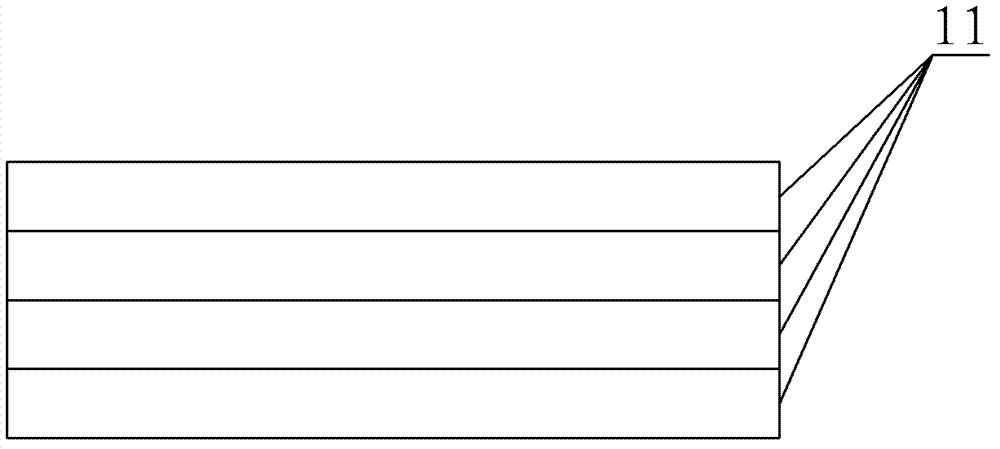

Winding machine for nickel-hydrogen battery

InactiveCN101276930AEnsure correct orientationGuaranteed flatness requirementsFinal product manufactureAlkaline accumulators manufactureMembrane tensionWinding machine

The invention discloses a constant force coiling machine for MH-Ni dynamic cylinder battery coiling, comprising a frame and a device baseplate provided with a battery pole plate base, a membrane base, a pole plate guiding mechanism and a pin mechanism. The device controls a magnetic powder brake by membrane tension to realize membrane constant tension control, controls the coiling compressing mechanism by PLC to realize constant tension coiling and adopts the telescopic pole plate guiding mechanism to ensure flatness of an core end surface of the coiling as well as arranges a membrane grasping mechanism to realize an automatic feed in of a positive and a negative membrane. In the coiling process, under a circumstance that a diameter of the core of the coiling ranges up and down and degrees of tightness of the coiling core in and out are consistent, the constant force coiling machine, is flat at the end surface and low labor intensity in the operation personnel and great in product quality.

Owner:扬州众力电源设备制造有限公司

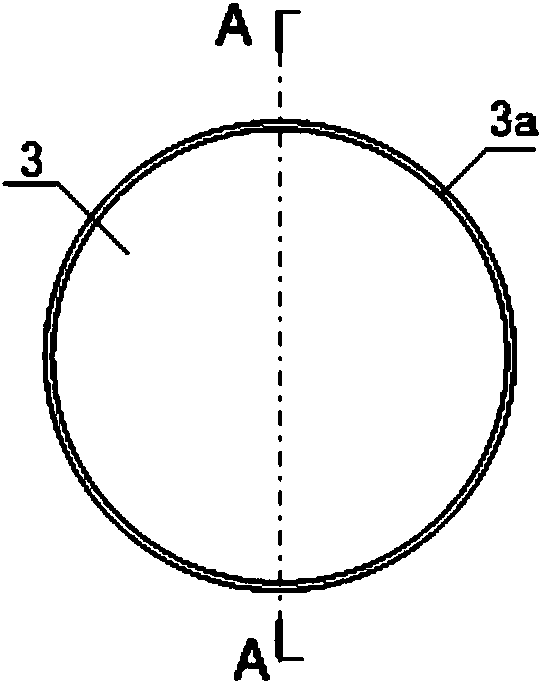

Anti-deformation machining method of medium-pressure air inlet sealing ring of medium-pressure outer cylinder of steam turbine

ActiveCN108620820AGuaranteed drawing size and roughnessGuarantee the quality of product processingCast ironEngineering

The invention discloses an anti-deformation machining method of a medium-pressure air inlet sealing ring of a medium-pressure outer cylinder of a steam turbine, relates to an anti-deformation machining method of a sealing ring, and aims to solve the problem of weak product quality caused by high deformation quantity of the inner circle diameter or the outer circle diameter of the medium-pressure air inlet sealing ring of the medium-pressure outer cylinder of the steam turbine. A blank is roughly turned; the rough-turned blank is naturally aged; the semi-finish turning is performed on the blank; the blank is naturally aged after the semi-finish turning; a cast iron mold is positioned on a lathe worktable for clamping alignment; the upper plane of the cast iron mold is turned; the outer circle and end surface alignment is performed on the blank after the semi-finish turning; the outer circle, the inner circle and the upper and lower rend surfaces of the blank after the semi-finish turning are turned; then, the machined blank after the semi-finish turning is naturally aged; the designed sizes of the outer circle and the inner circle are reached through turning; and the upper and lowerend surfaces are grinded to reach the designed sizes. The diameter deformation quantity of the inner circle and the outer circle of the machine sealing ring is lower than 0.02 mm. The method is suitable for sealing ring machining.

Owner:HARBIN TURBINE +1

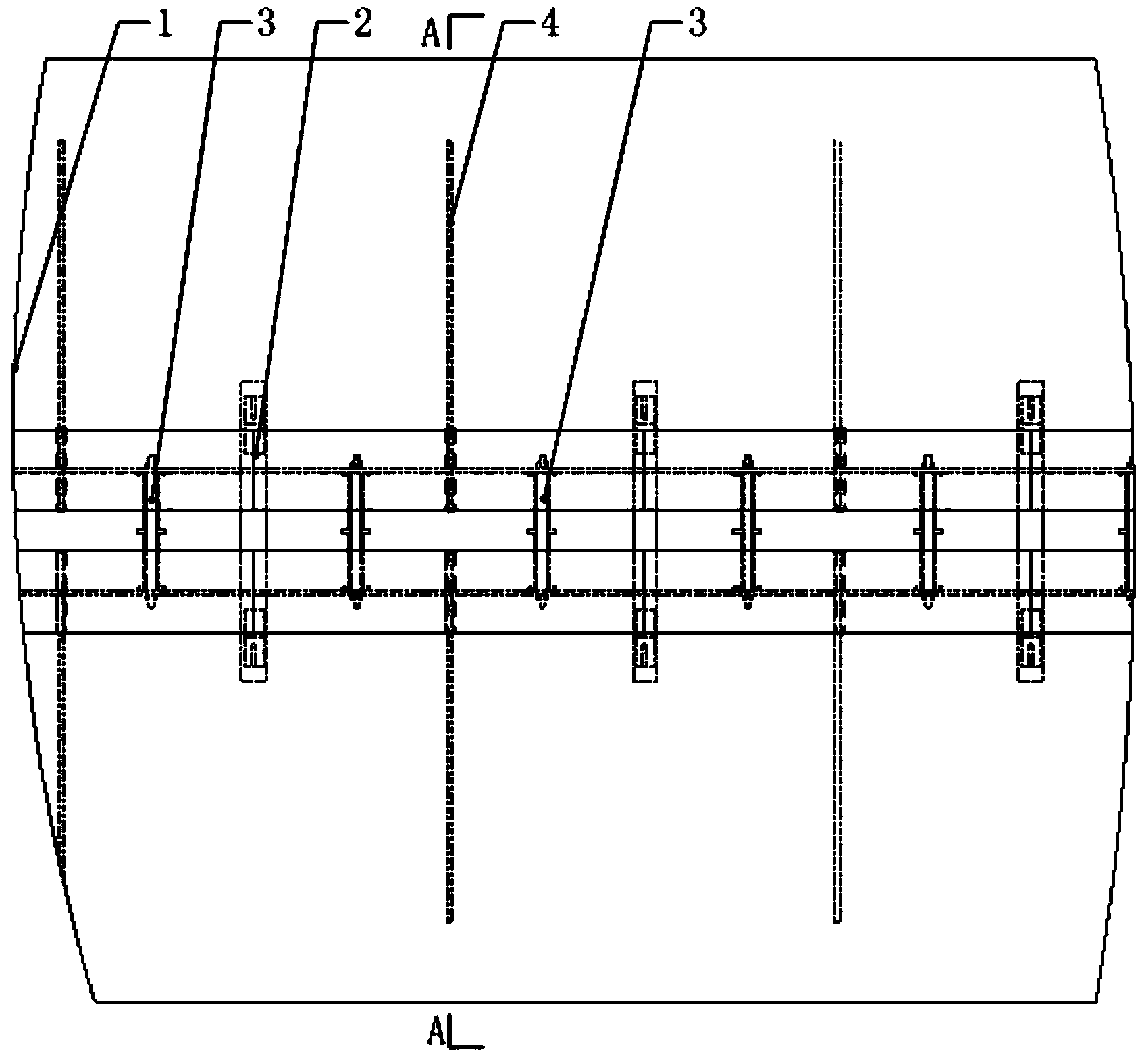

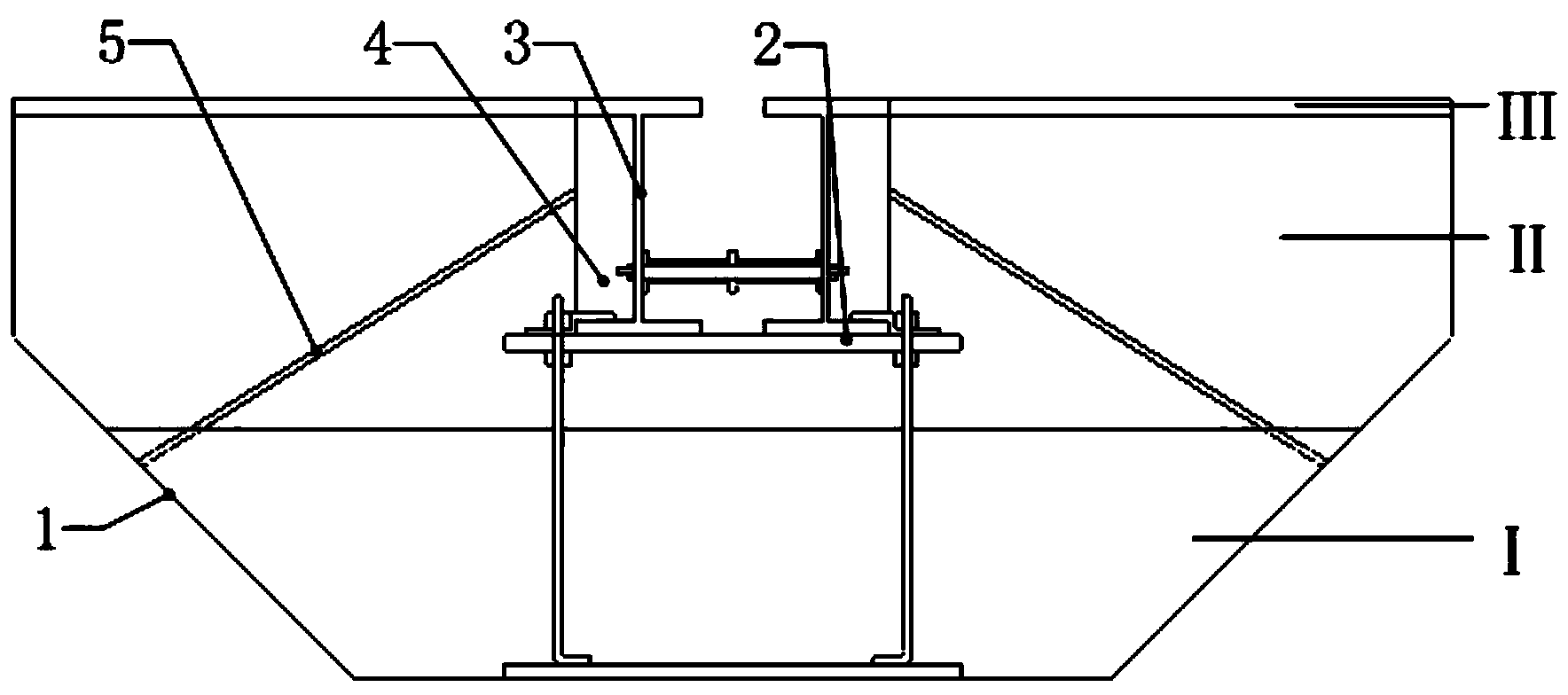

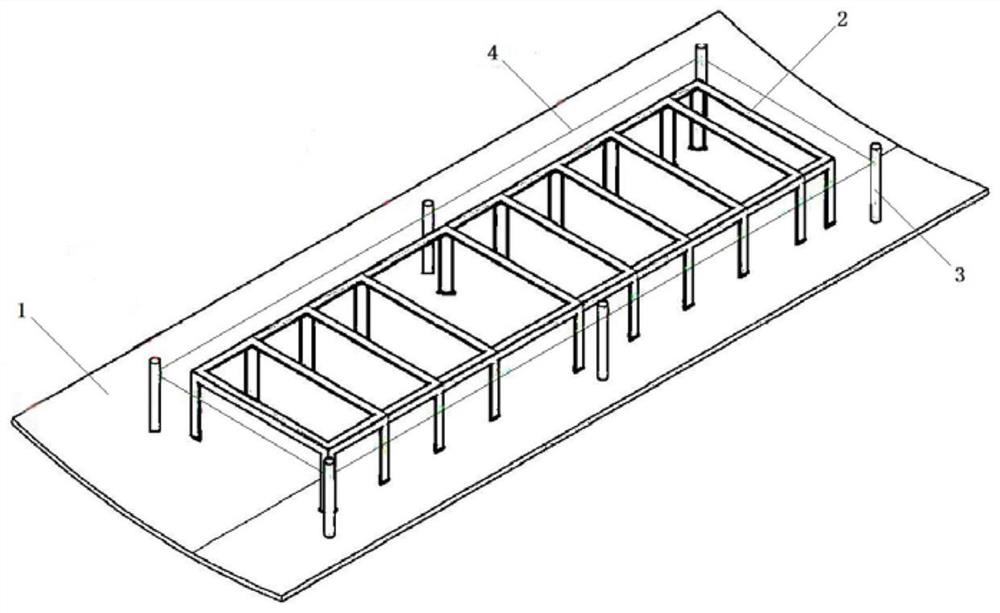

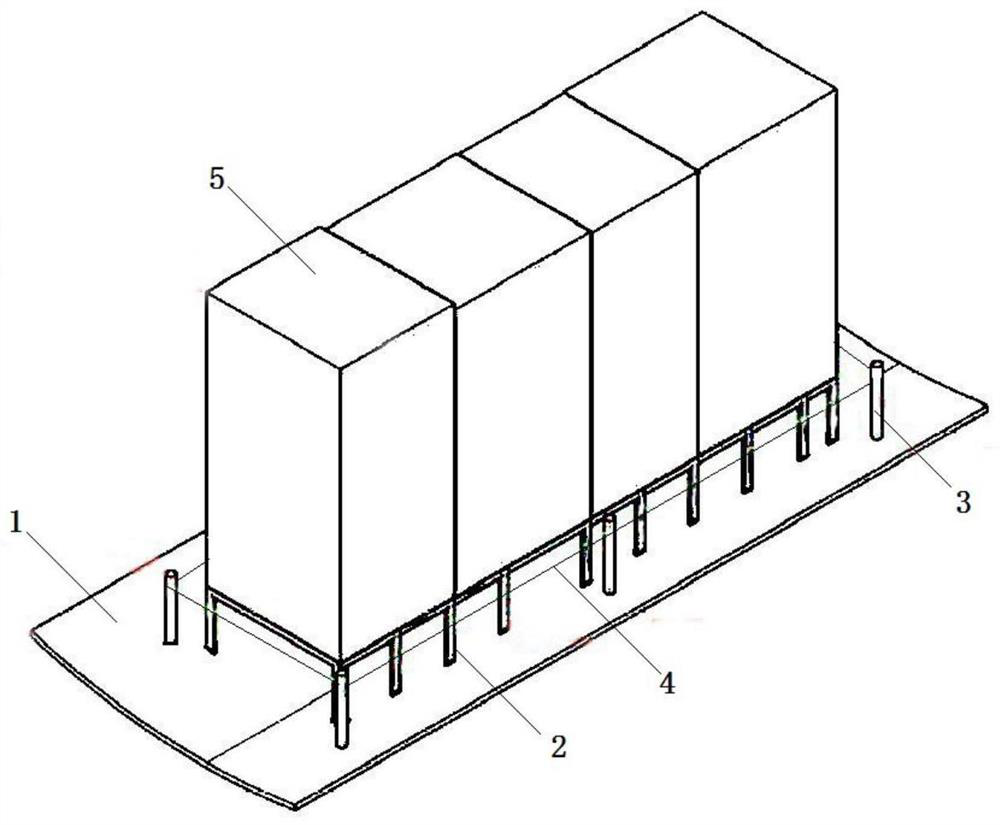

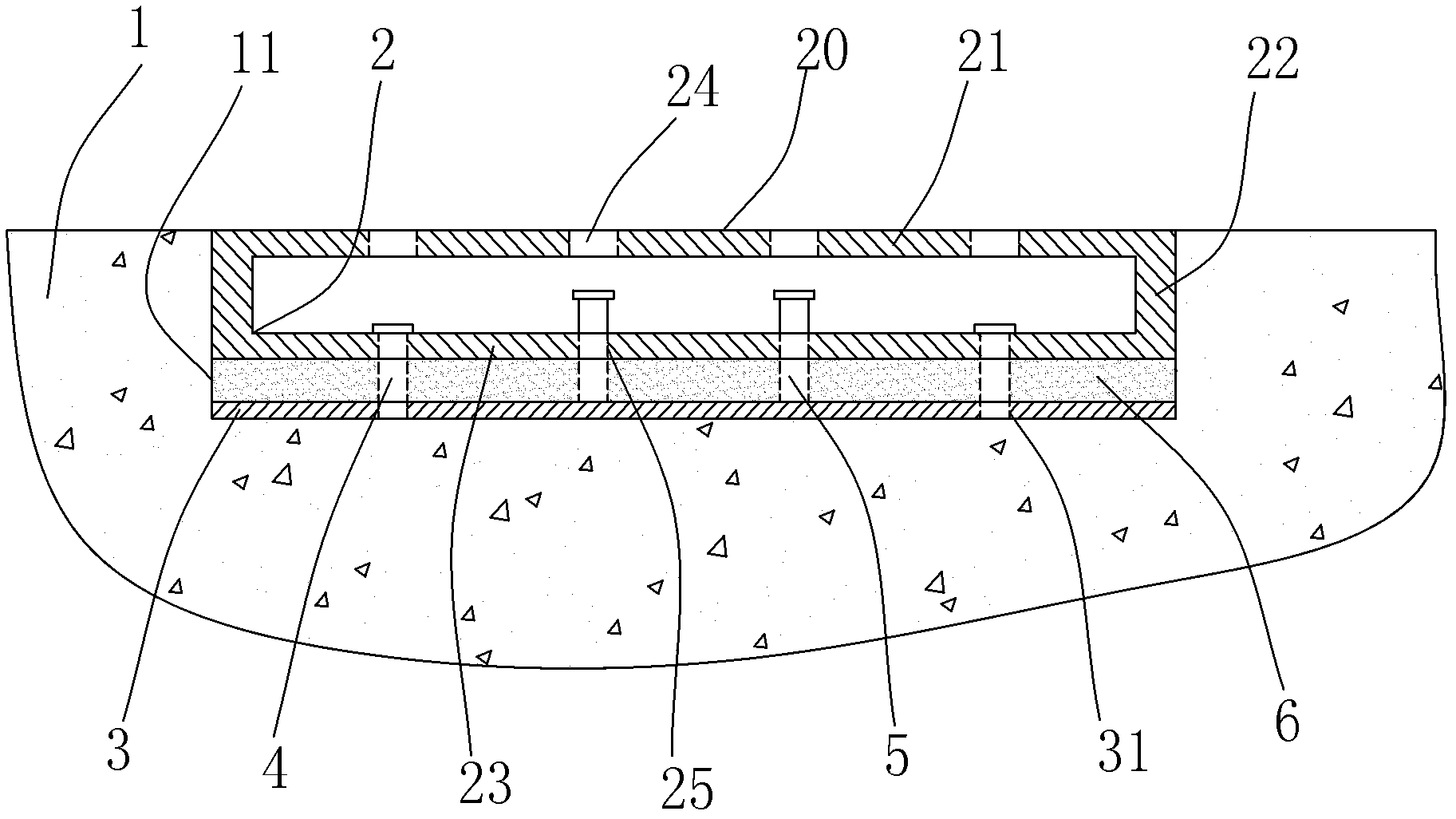

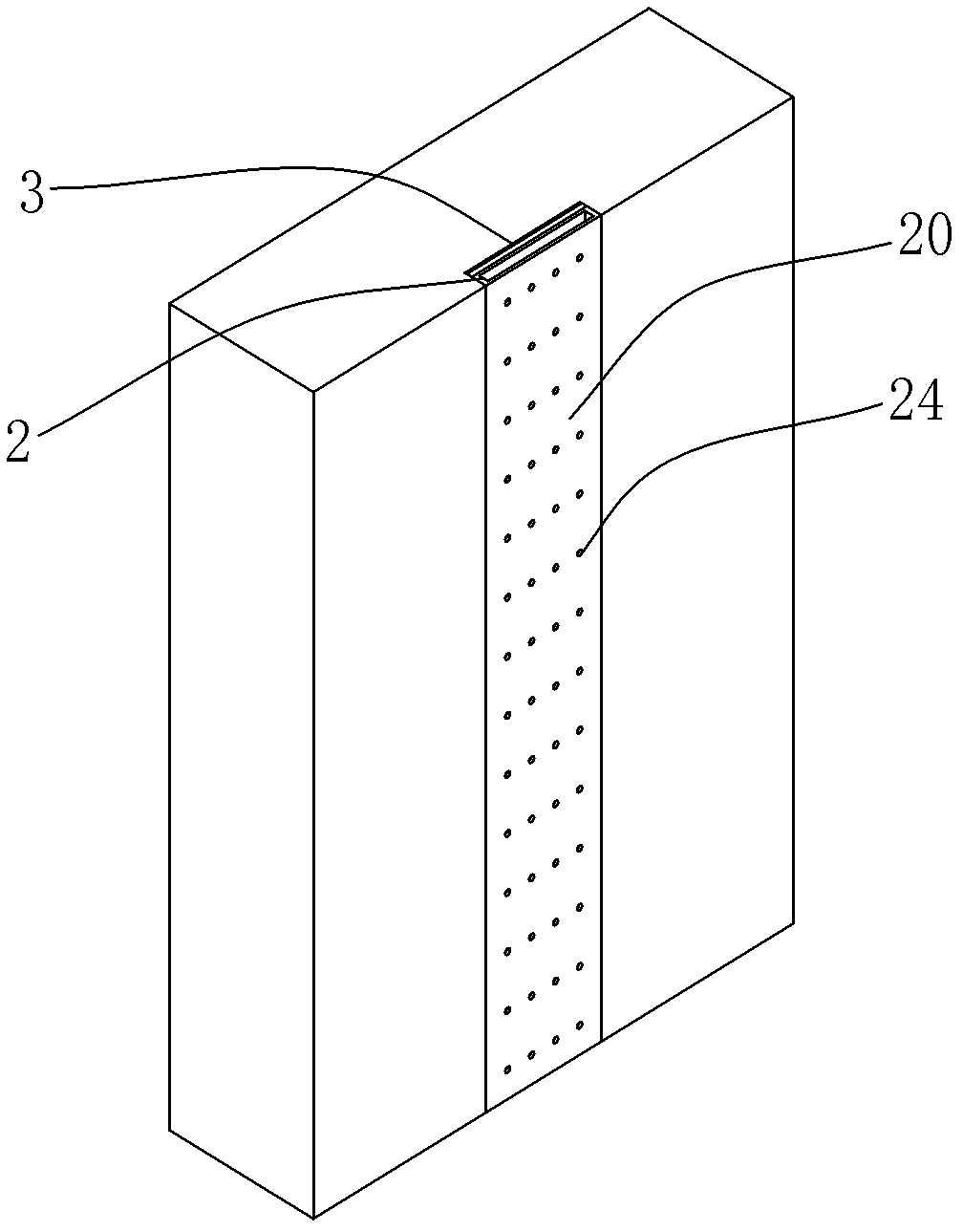

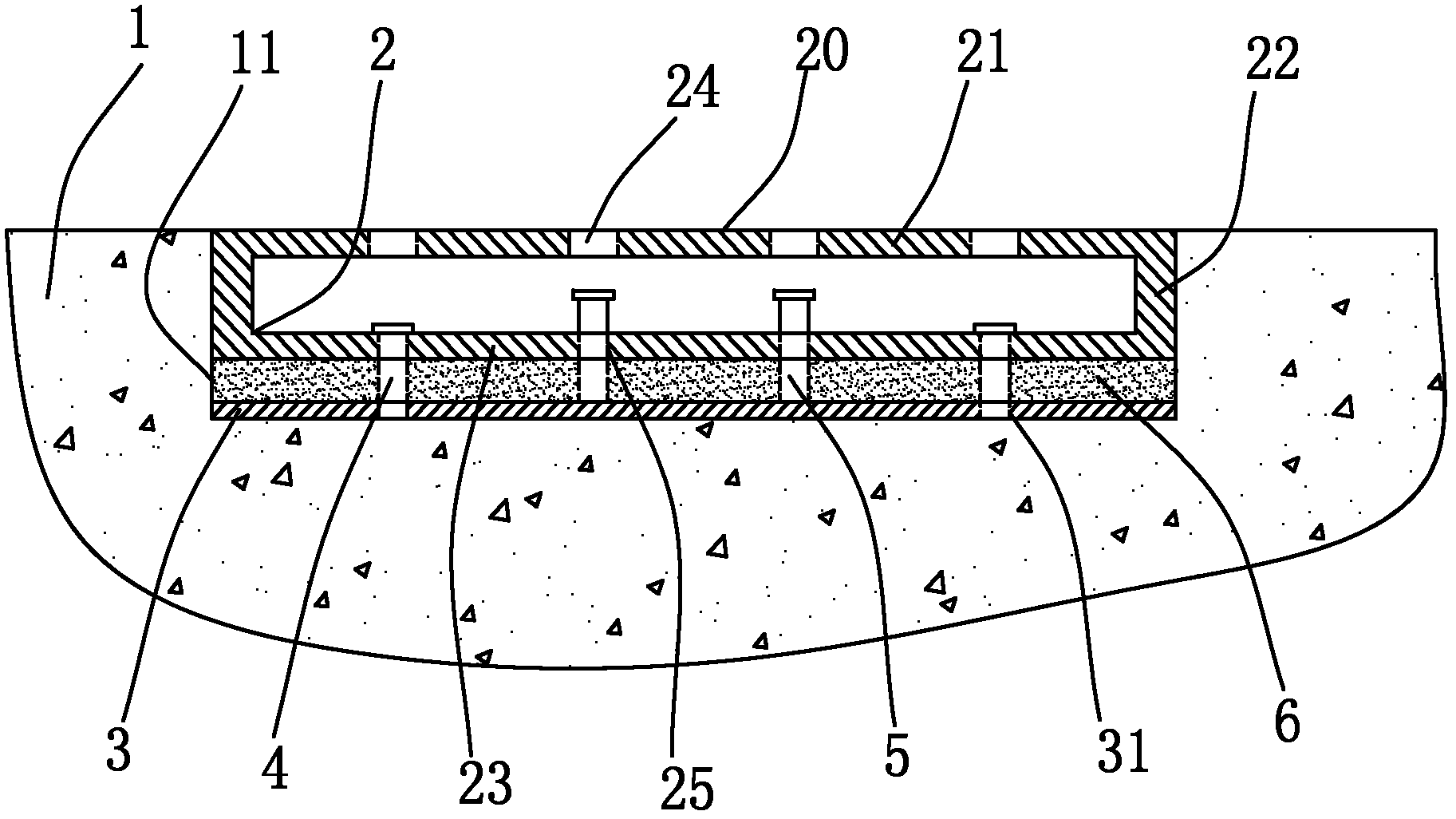

Traction runway for automobile safety crash laboratory and layered construction method of the traction runway

ActiveCN103821061AGuaranteed flatnessReduce riskVehicle testingTemporary pavingsCrash testRoad surface

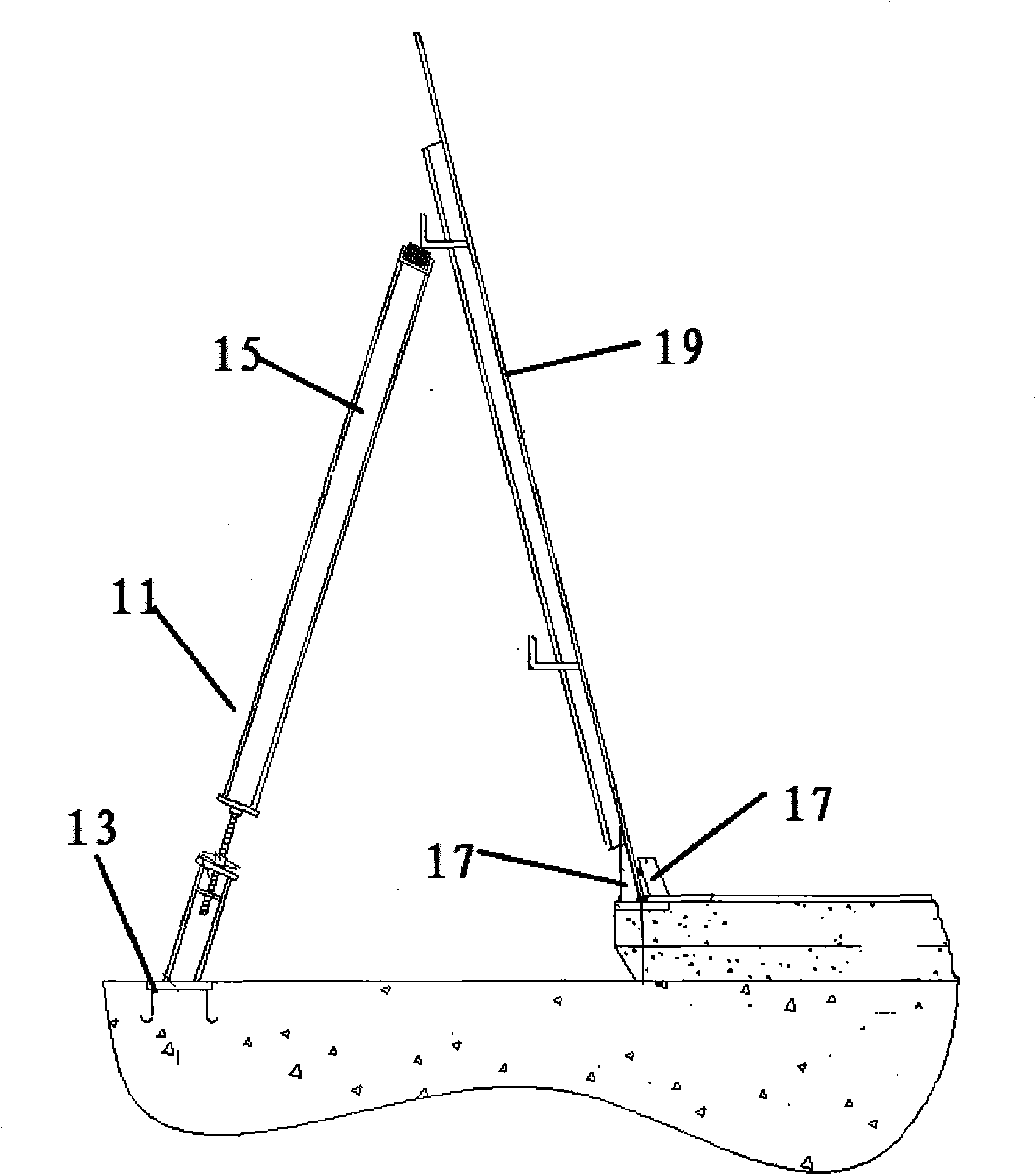

The invention provides a traction runway for an automobile safety crash laboratory. The traction runway comprises a foundation trench, a plurality of groups of supporting devices, a concrete layer and an asphalt layer, wherein the plurality of groups of supporting devices are arranged in the foundation trench and are connected with each other; the concrete layer is poured between the supporting devices and the foundation trench; the asphalt layer is paved on the upper surface of the concrete layer; each supporting device comprises a height adjusting bracket, an H-steel supporting mechanism, a plurality of H-steel reinforcing ribs and restrained steel bars, wherein the height adjusting bracket is arranged on the bottom of the foundation trench, the H-steel supporting mechanism is assembled above the height adjusting bracket, the plurality of H-steel reinforcing ribs are fixedly connected to two sides of the H-steel supporting mechanism, one ends of the restrained steel bars are connected to the H-steel reinforcing ribs, and the other end of the restrained steel bars are obliquely inserted into the restrained steel bars located in the foundation trench; the concrete layer is divided into a bottom concrete layer and a middle concrete layer, wherein the bottom concrete layer is lower than the height adjusting bracket, the middle concrete layer is poured on the bottom concrete layer, and the poured concrete layer is lower than the upper surface of the H-steel supporting mechanism. The traction runway has the beneficial effects that the flatness of the traction runway can be adjusted step by step, and asphalt is paved on the topmost layer, so that a pavement can be repaired at any time, and furthermore, the accuracy of an automobile crash test is ensured.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

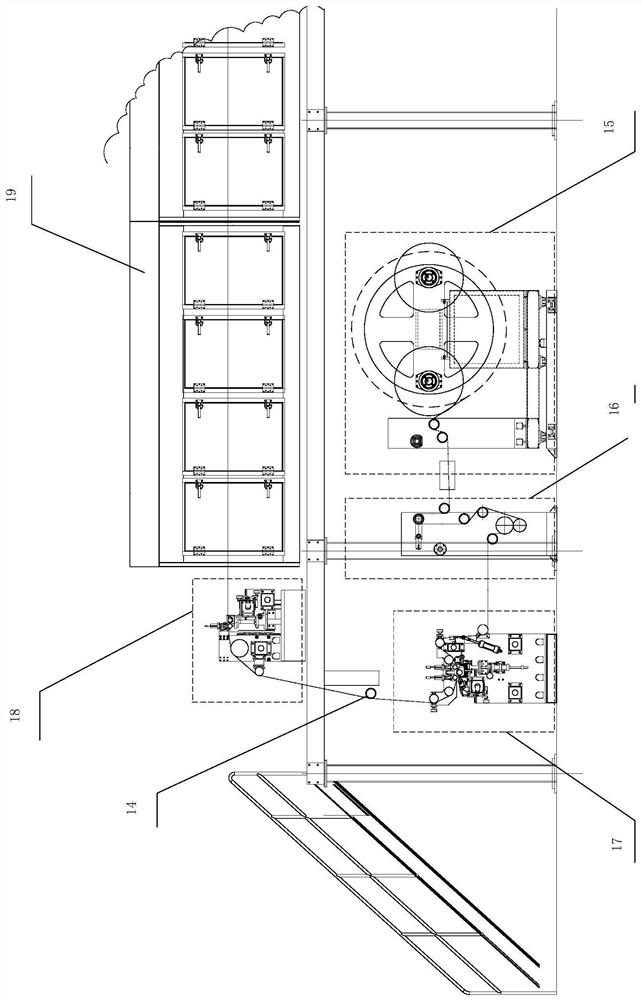

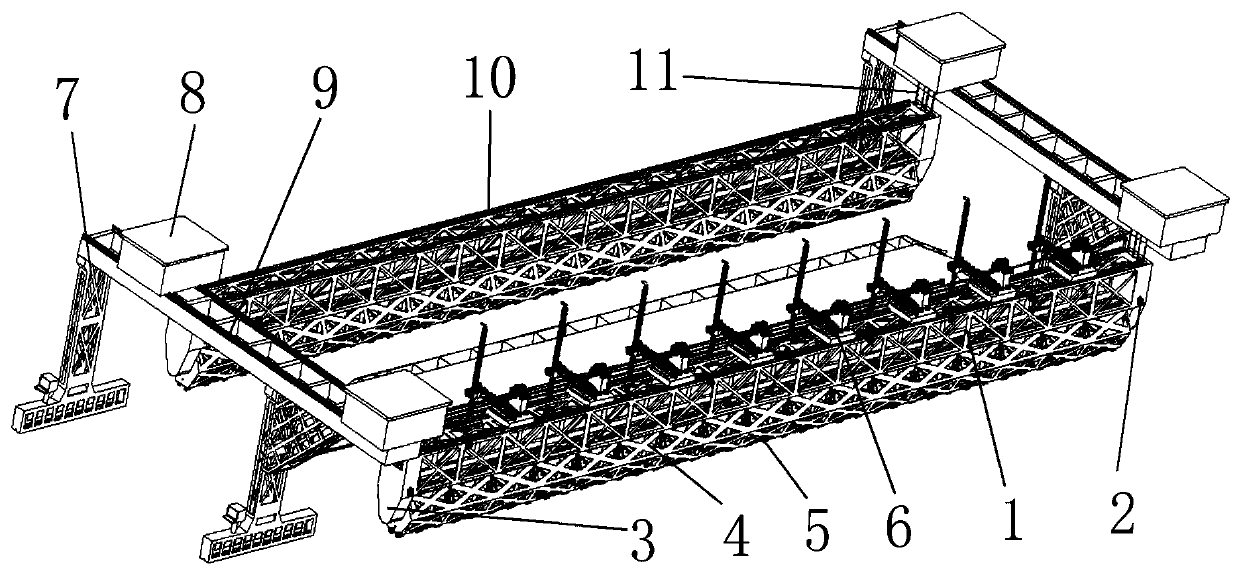

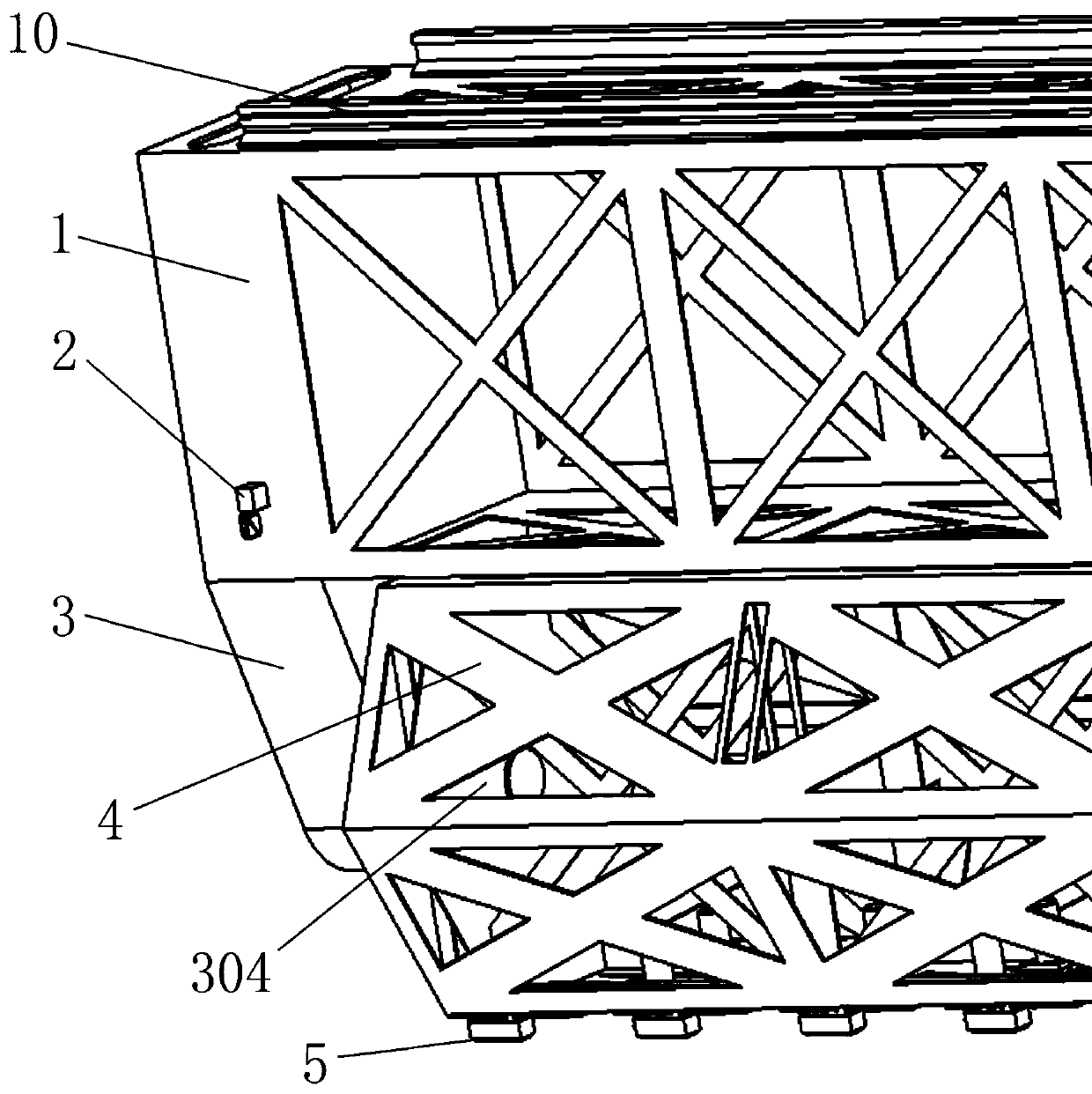

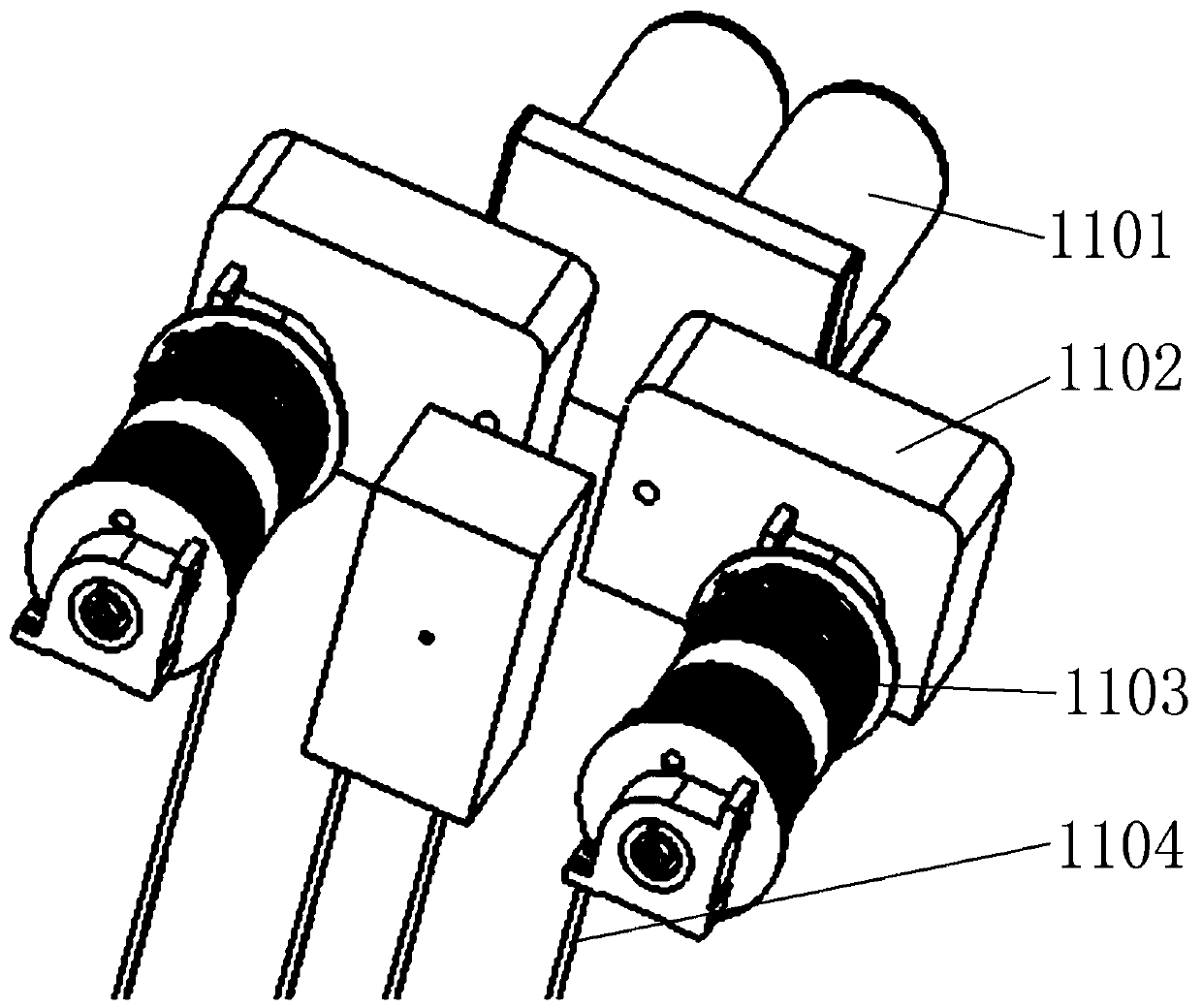

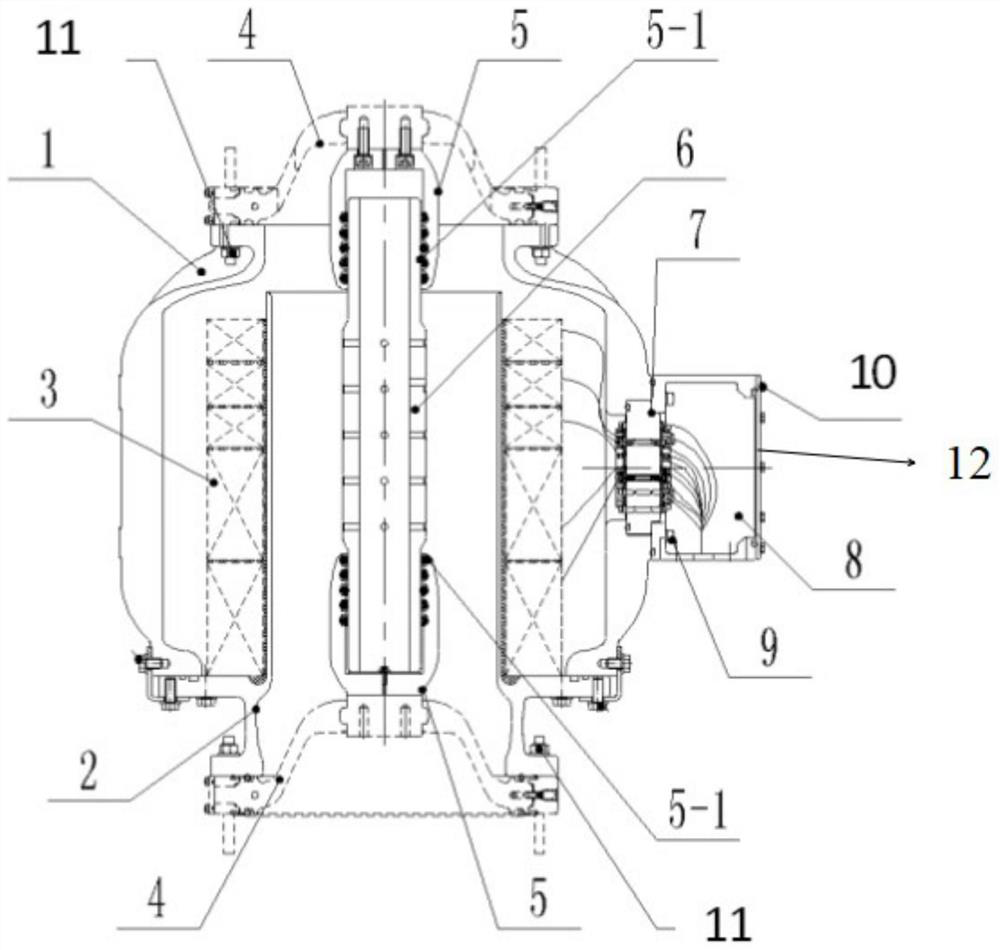

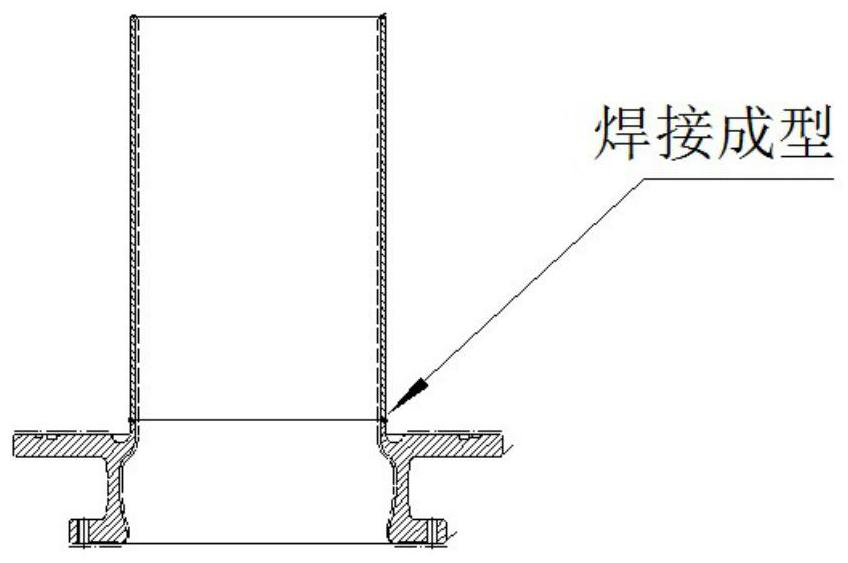

Team-forming welding production system for crane girder webs

ActiveCN111515568AReduce lossHarm reductionWelding/cutting auxillary devicesAuxillary welding devicesMotor homeWeld seam

The invention relates to the field of crane bridge welding and manufacturing, in particular to a team-forming welding production system for crane girder webs. The team-forming welding production system comprises hanging beams, rotating plate frames and two portal frames, wherein the two portal frames comprise top beams, motor home sliding rails are arranged on the upper surfaces of the top beams,house type trolleys are mounted on the motor home sliding rails, and vertical hoisting mechanisms used for synchronously hoisting the hoisting beams are arranged in the two house type trolleys; robotsliding rails are arranged on the upper surfaces of the hanging beams, and assembly welding robots are mounted on the robot sliding rails; and two lifting lug boxes are symmetrically fixed to the twoends of the lower surfaces of the hinging beams, the inner sides of the bottom ends of the two lifting lug boxes are correspondingly and rotationally connected with the two ends of the rotating plateframes, and a plurality of magnetic attraction assemblies used for attracting the webs are evenly arranged on the lower surface of the rotating plate frames in the axial direction of the rotating plate frames. The team-forming welding production system can complete automatic welding of longitudinal welding seams between the webs and cover plates and welding seams between the webs and rib plates inthe vertical direction after the webs are rapidly and accurately hoisted and positioned.

Owner:HENAN WEIHUA HEAVY MACHINE

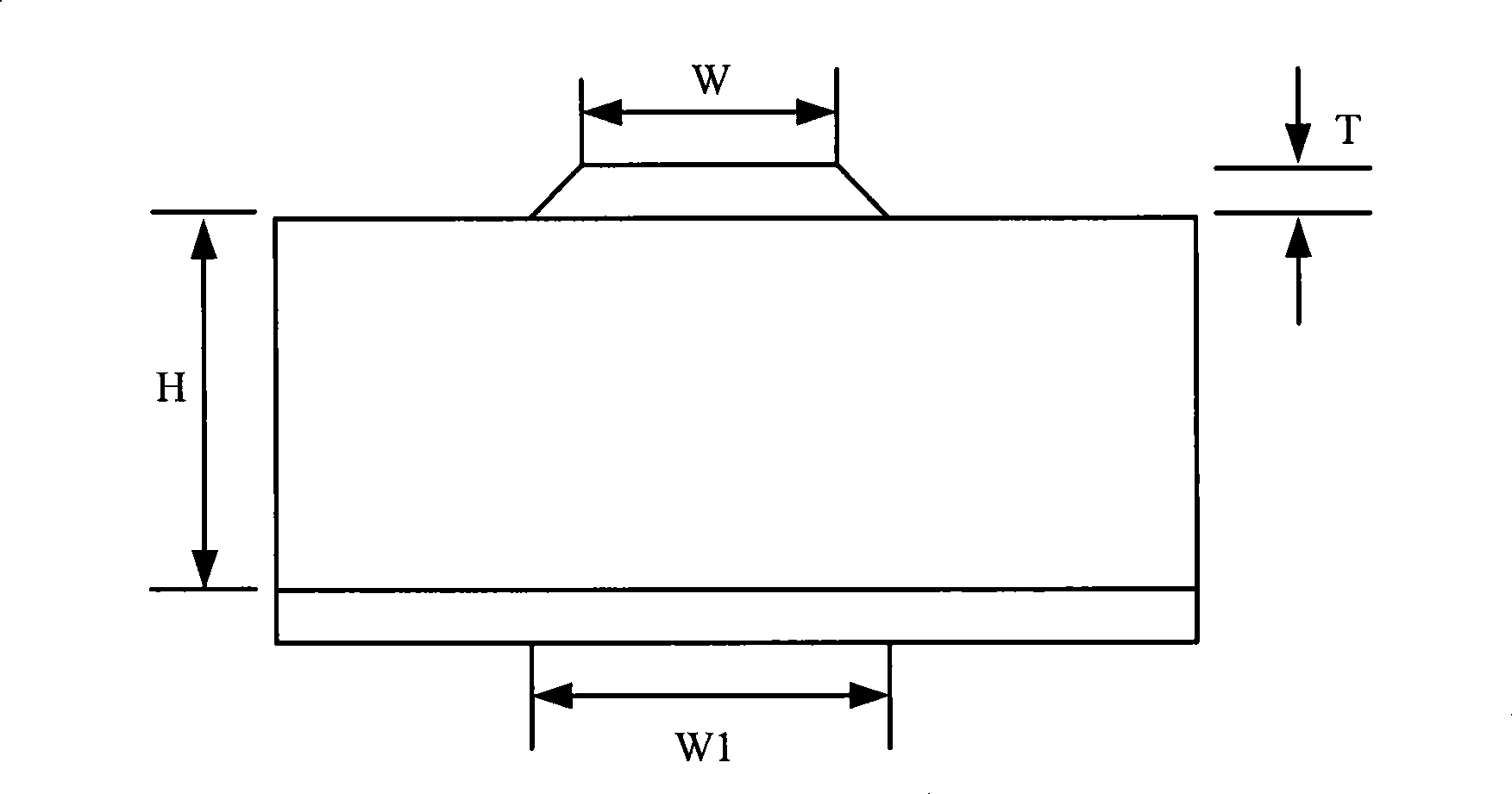

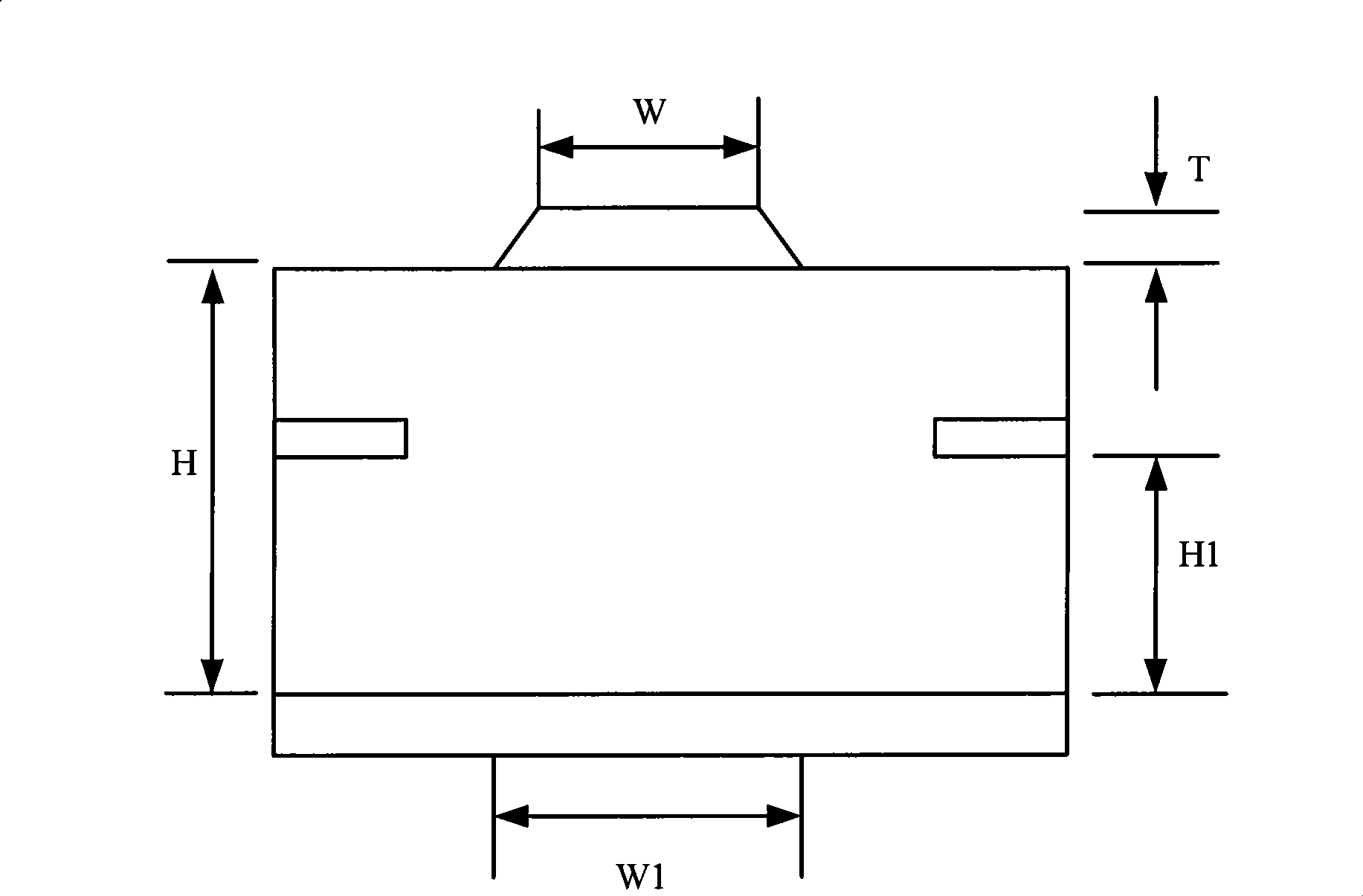

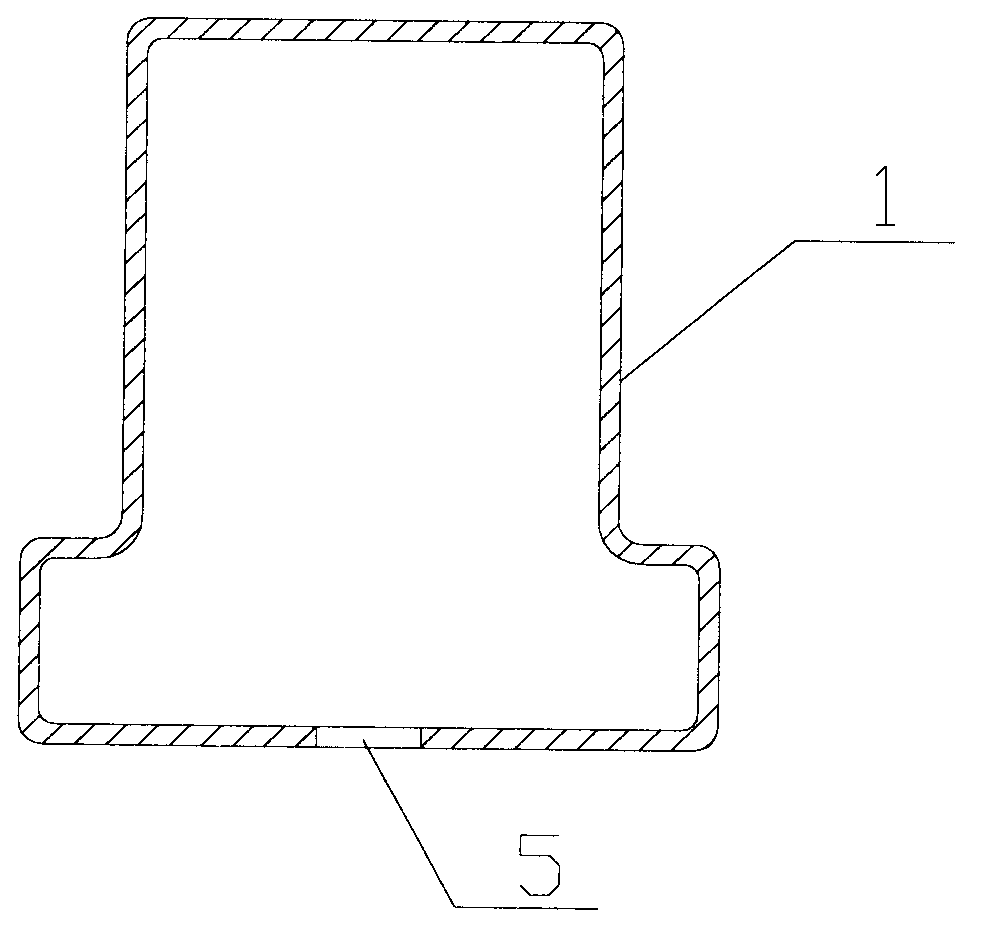

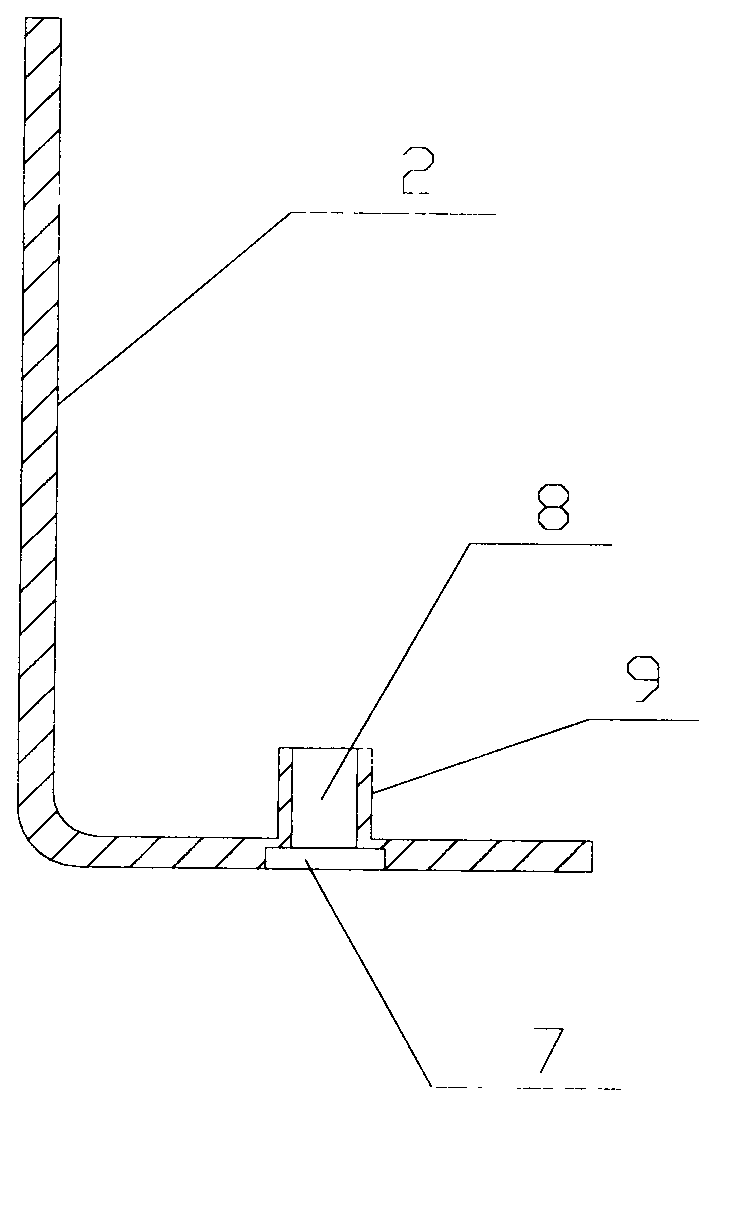

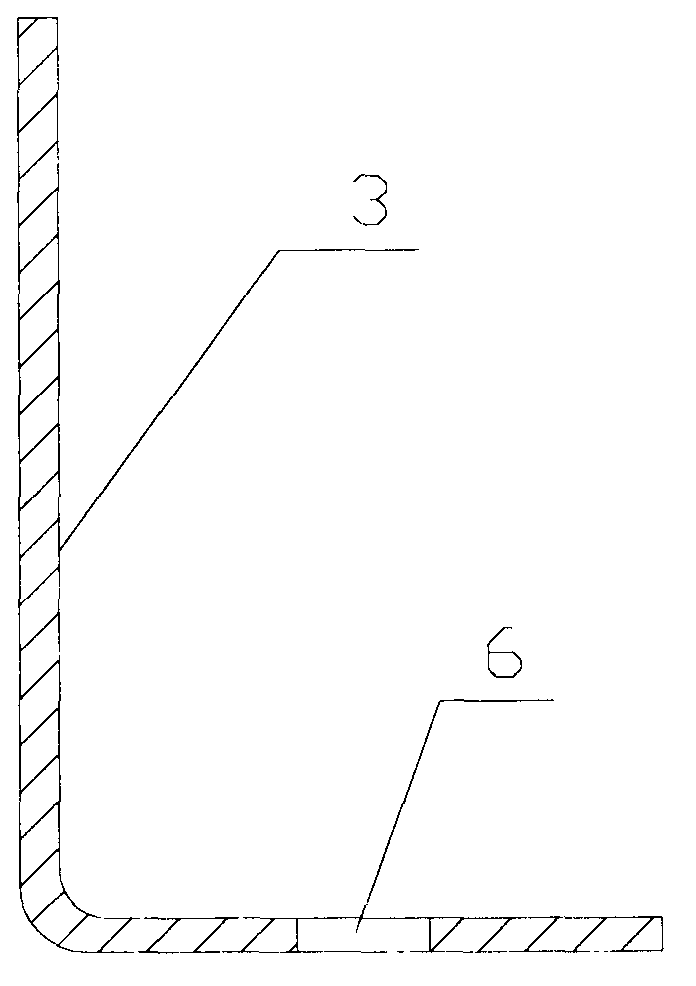

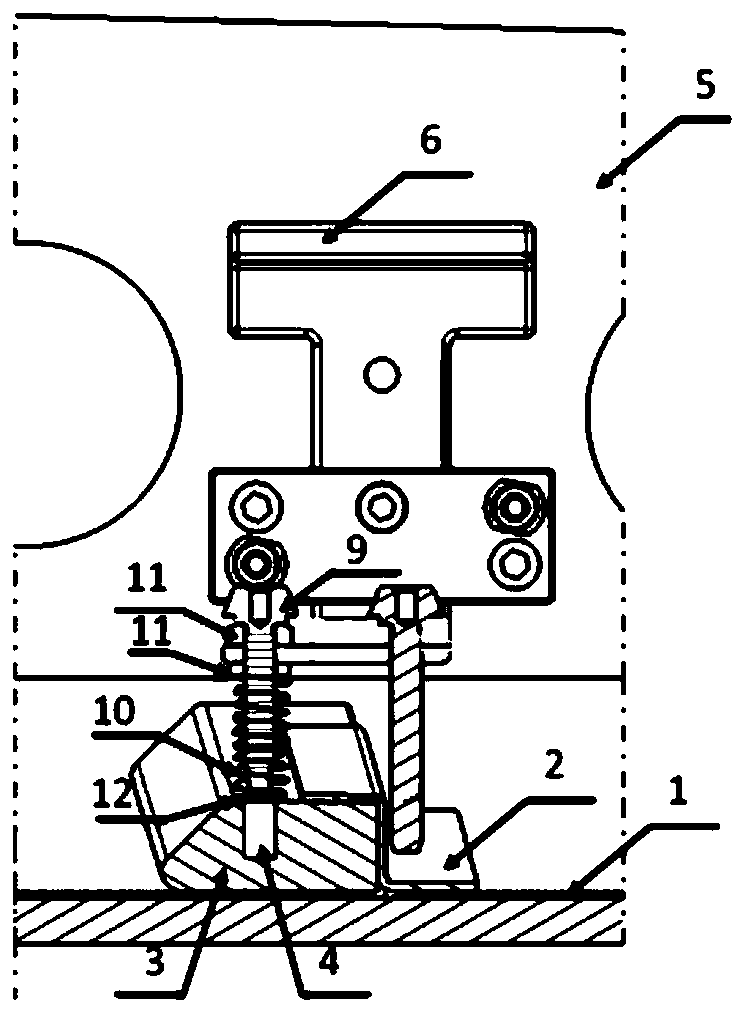

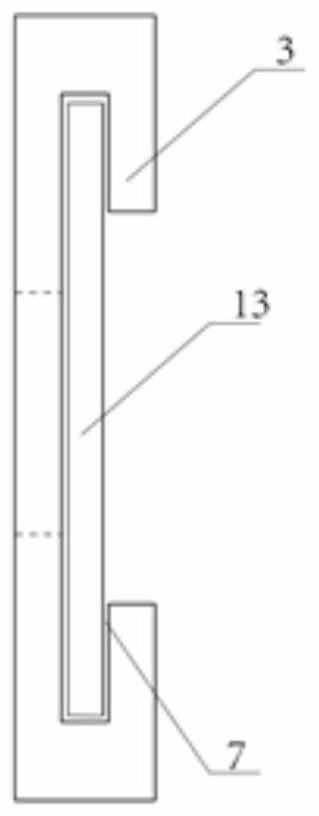

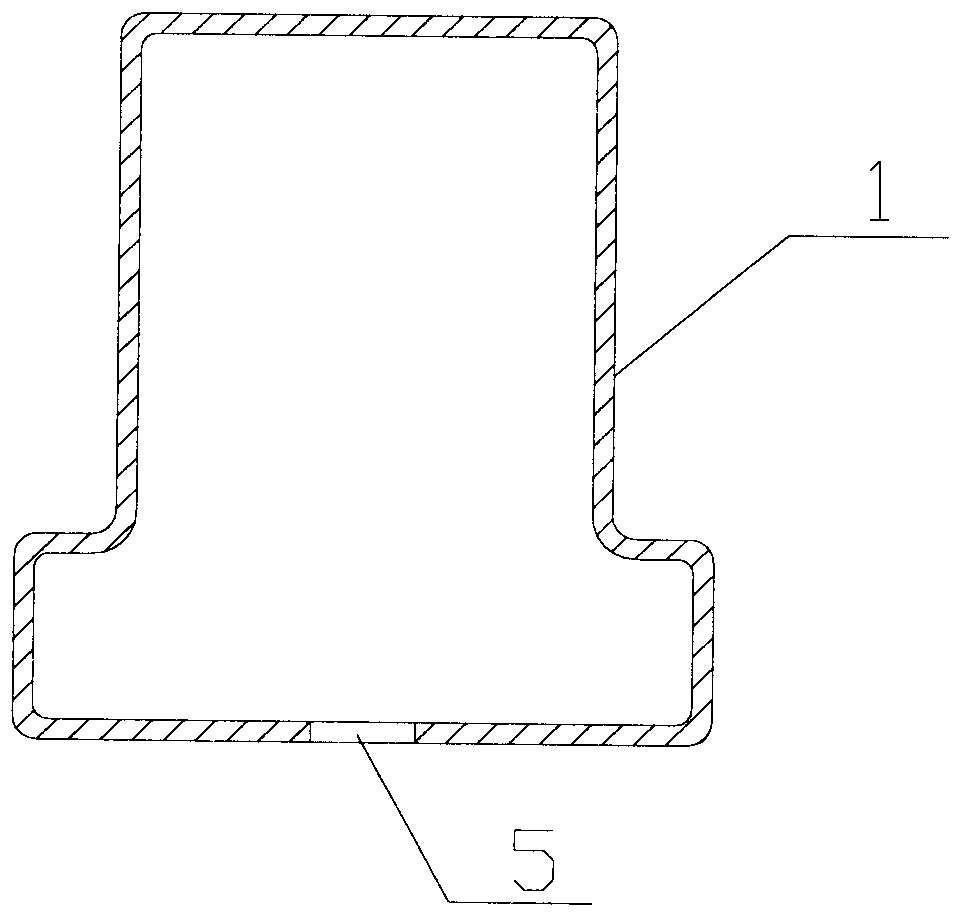

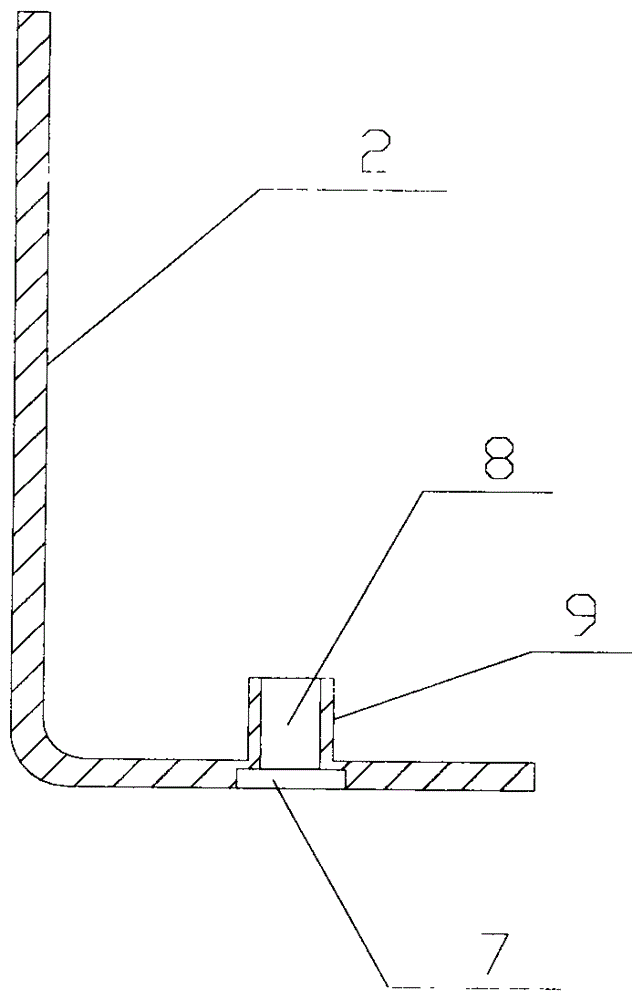

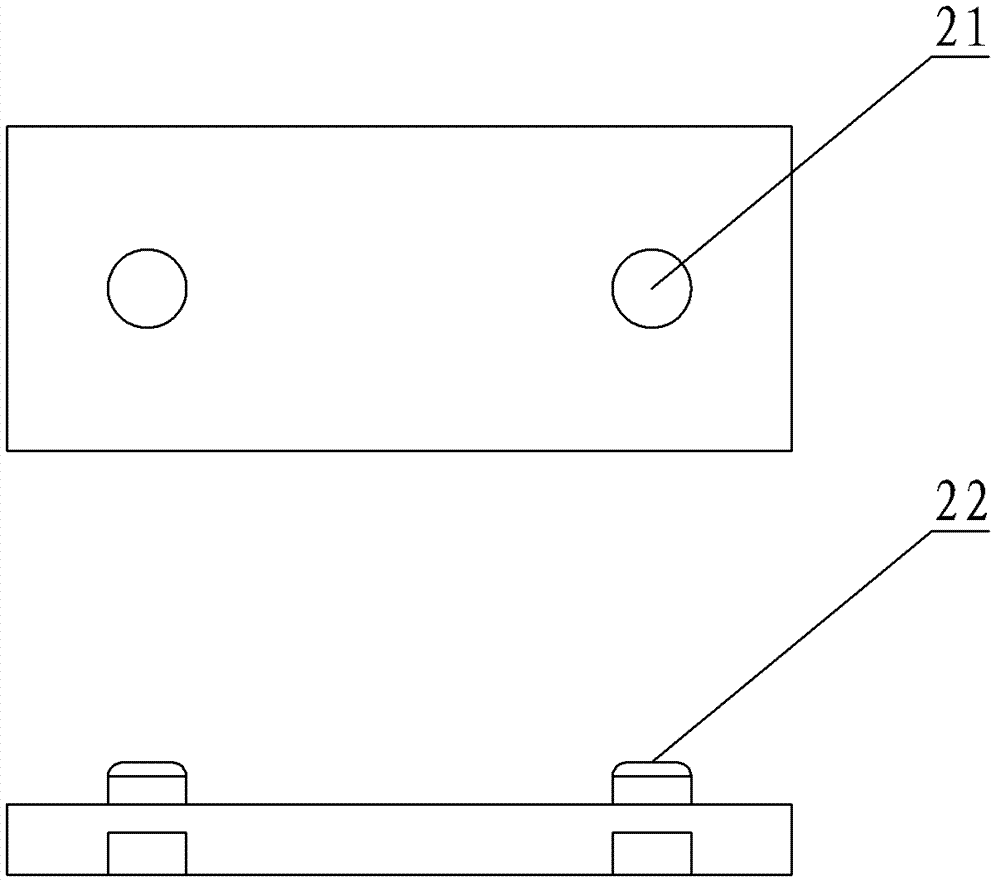

Connection assembly for elevator guide rails and connection fixing method for elevator guide rails

The invention discloses a connection assembly for elevator guide rails and a connection fixing method for the elevator guide rails. By means of the T-shaped seal type hollow guide rails, structural strength is correspondingly increased compared with traditional hollow guide rails. The connection assembly is arranged between two adjacent sections of the guide rails, and the connection assembly is arranged on the inner sides of the guide rails to guarantee glancing flatness between the guide rails. The connection assembly is of a U-shaped structure, compressive strength on two sides of each guide rail is effectively enhanced, deformation of each guide rail is reduced, and service life of each guide rail is prolonged. In addition, the guide rails are formed in a cold roll forming joint automatic oxy-arc welding and water cooling mode, labor intensity of workers is lowered compared with manual electric welding, and production efficiency is improved. Water cooling and automatic shaping are conducted, forming quality of the guide rails is guaranteed, the strength is better than that of common opening seal hollow rails, a galvanized sheet technology is utilized, follow-up galvanization is omitted, and more environment-friendly use of a product is achieved. Compared with the traditional opening type hollow rails, the connection assembly is characterized in that guide surfaces of the guide rails are wider, an elevator operates more stably, and noise is lower.

Owner:苏州塞维拉上吴电梯轨道系统有限公司

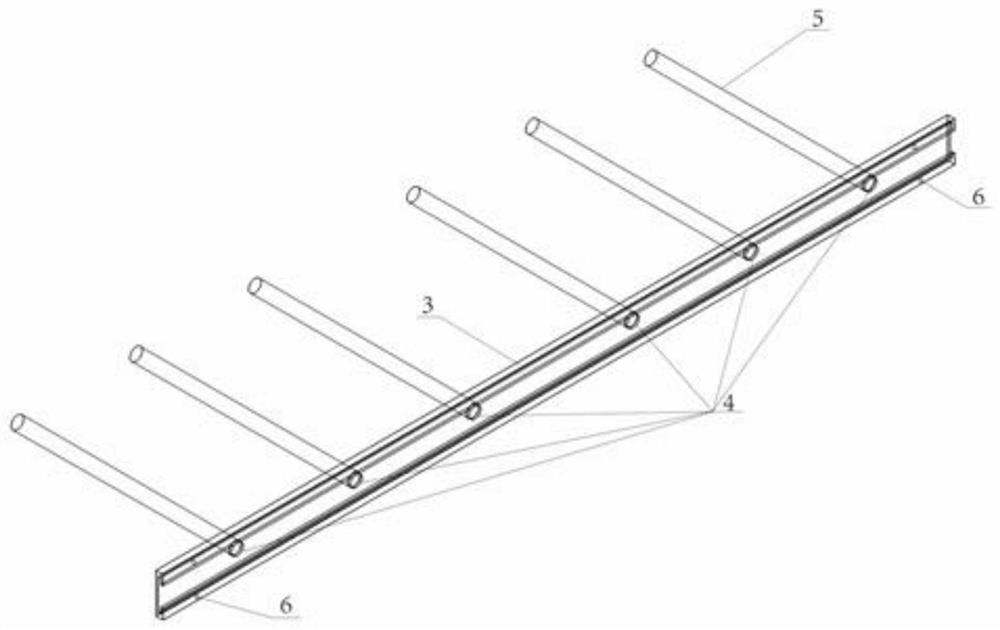

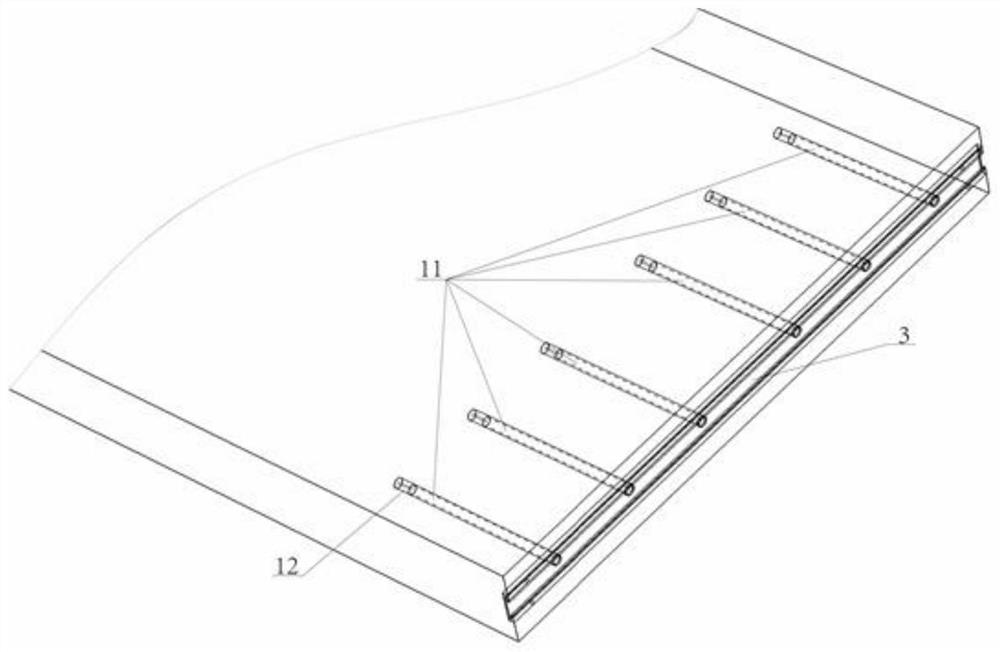

Flexible positioning method for Z-shaped stringer of composite material stiffened wall plate

InactiveCN111590907AGuaranteed positionPrecise positioningDomestic articlesStringerInvestment material

The invention discloses a flexible positioning method for a Z-shaped stringer of a composite material stiffened wall plate. According to the method, a flexible positioning device is used for positioning. The flexible positioning device comprises a positioning angle seat, a specially-made high-temperature-resistant pressure spring, a special pin and a composite material gasket. By using the method,the position degree control requirement of the Z-shaped stringer can be met when a dry-state Z-shaped stringer and a wet-state wall plate skin are jointly glued, the situation that a positioning coremold causes indentations on the surface of the wet-state wall plate skin is avoided, and the surface flatness and thickness requirements of the wall plate skin are ensured. Meanwhile, cutting of avoiding notches in auxiliary materials such as a vacuum bag, a breathable felt and an isolating membrane is not needed during gluing, curing and bag making, the integrity of the vacuum bag is ensured, bag bursting during curing is avoided, and the curing and forming quality of a workpiece is effectively ensured. The bag making process is easy and convenient to operate, and the production efficiency is high.

Owner:XIAN AIRCRAFT IND GROUP

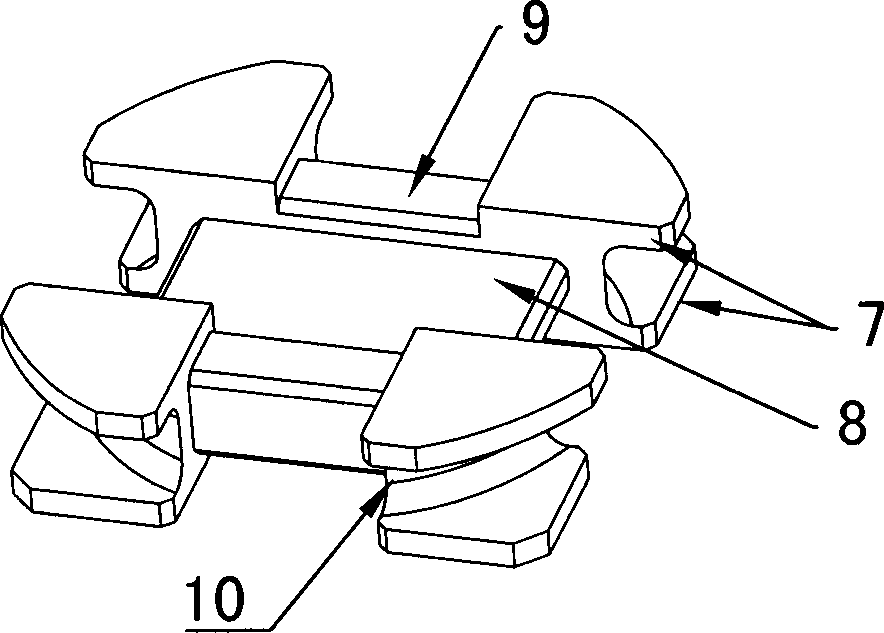

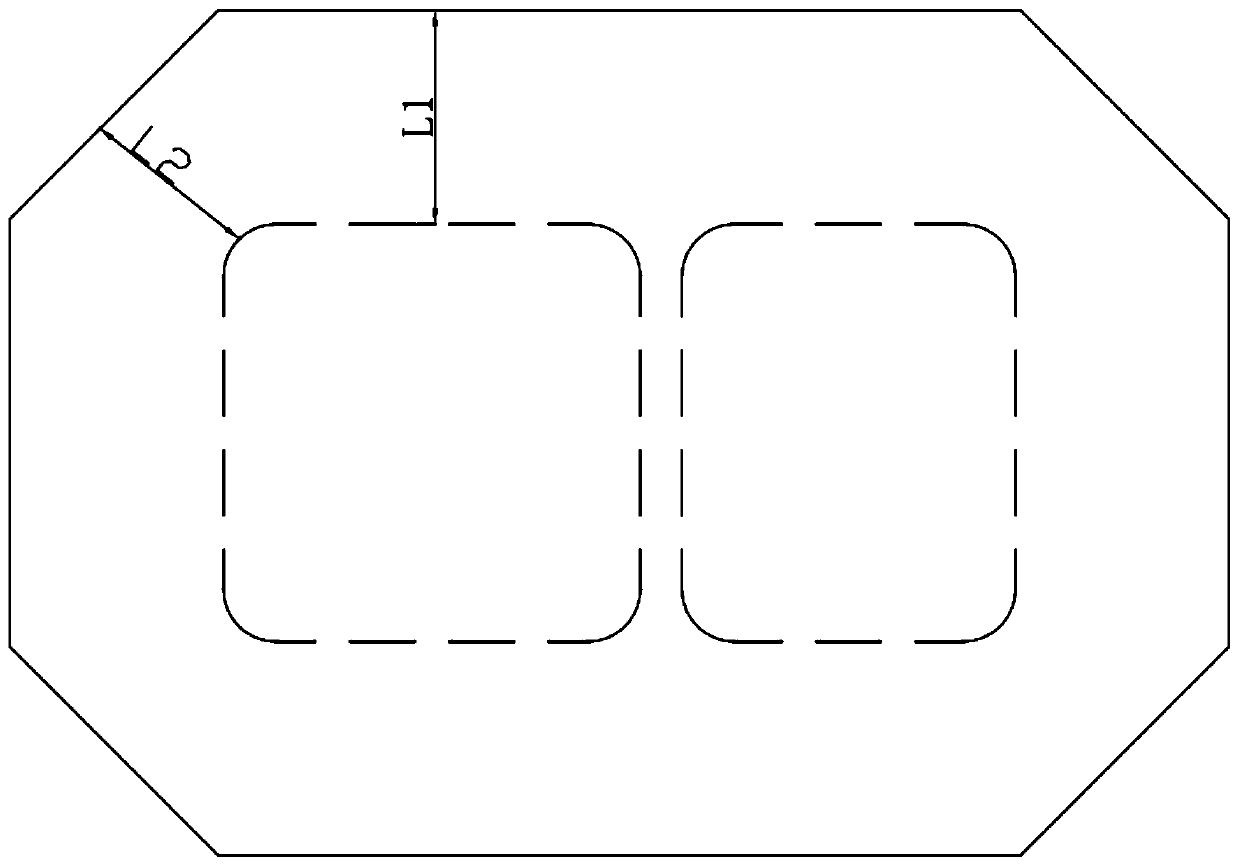

Patch radio-frequency antenna

InactiveCN103022634AAdaptableLow costLoop antennas with ferromagnetic coreAntenna supports/mountingsEngineeringRadio frequency

The invention relates to a patch radio-frequency antenna with distributed bases. The patch radio-frequency antenna comprises H-shaped magnetic cores, each magnetic core is provided with an X-axis coiling groove used for coiling an X-axis coil and a Y-axis coiling groove used for coiling a Y-axis coiling groove, and the coiling directions of the X-axis coil and the Y-axis coil are perpendicularly crossed. Four end corners of the magnetic cores are provided with arc-shaped grooves, a Z-axis coil is coiled in the arc-shaped grooves, and the coiling direction of the Z-axis coil is perpendicular to that of the X-axis coil and the Y-axis coil. The bases are respectively fixed on the four end corners of the magnetic cores and are independent components. The bases are fittingly used with the magnetic cores in different size, so that the patch radio-frequency antenna with the distributed bases can be formed in different size. The patch radio-frequency antenna in different size can be manufactured by designing the magnetic cores in different size to match with the original bases without needs to redesign the bases, so that the patch radio-frequency antenna is high in applicability, and cost and time for development of the patch radio-frequency antenna are reduced and saved.

Owner:邹志荣

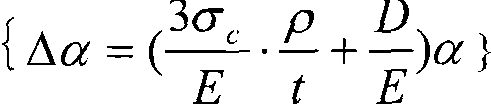

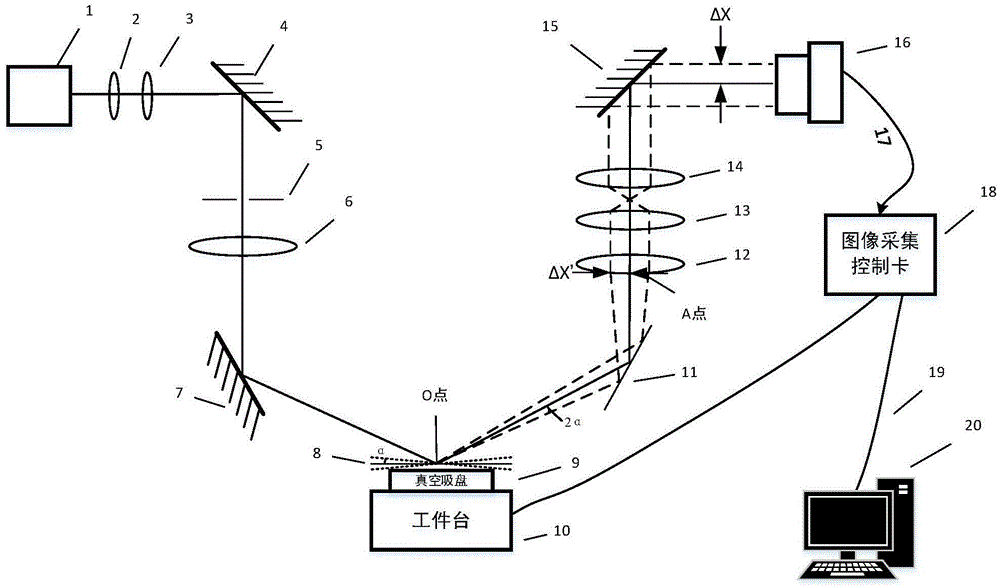

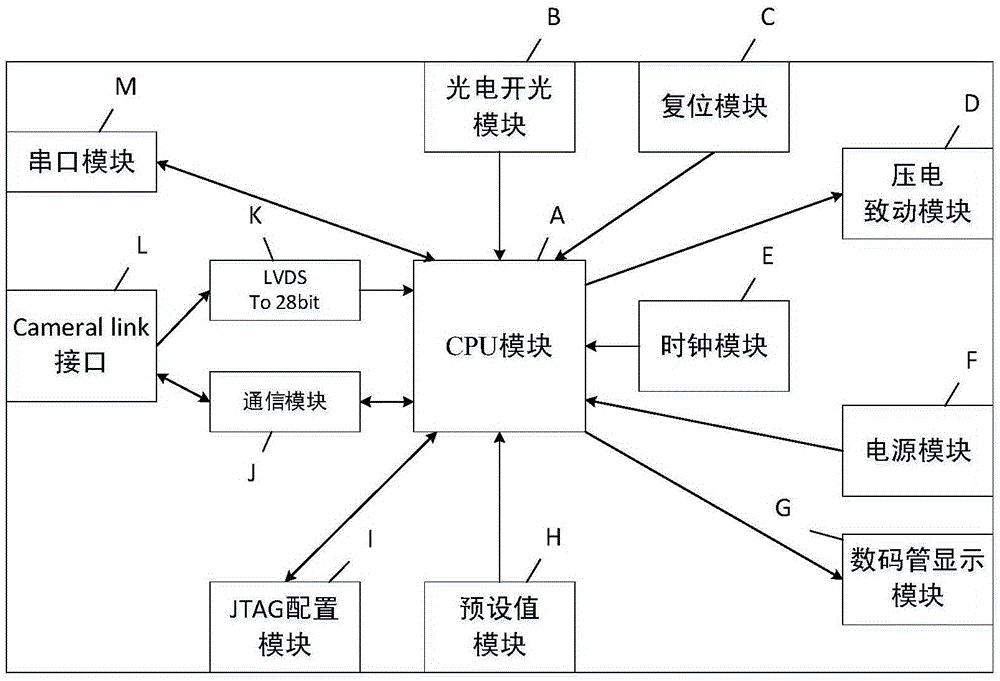

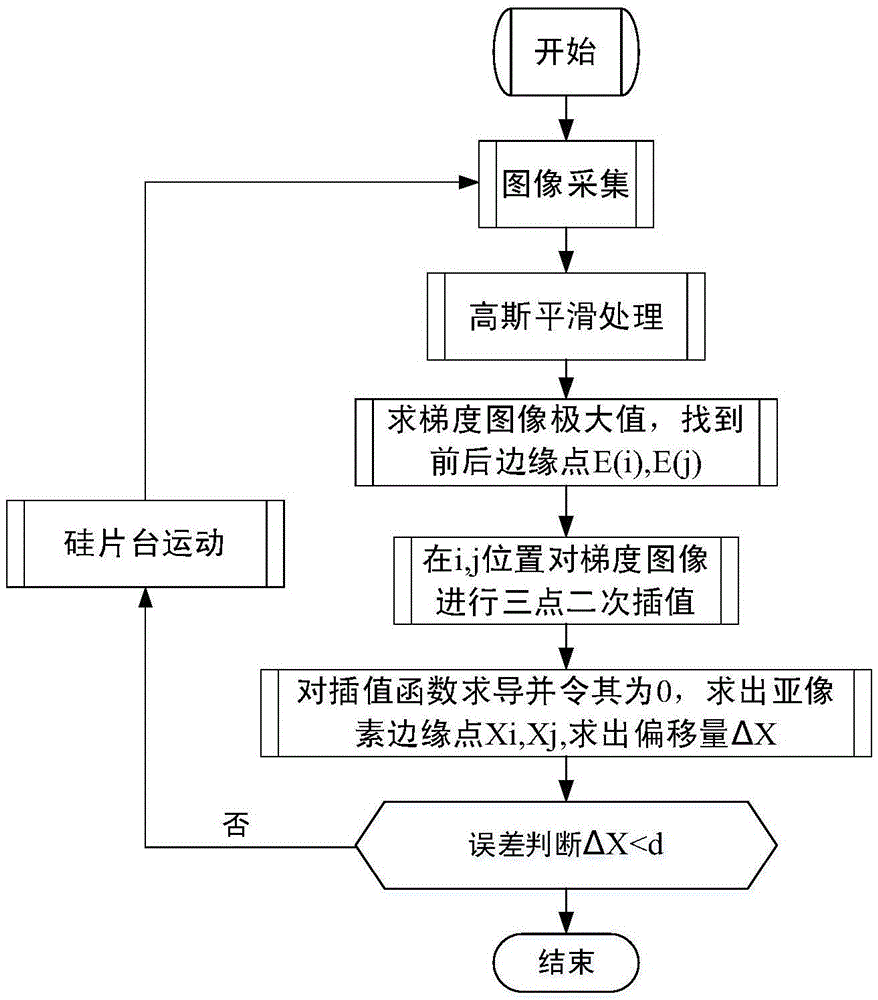

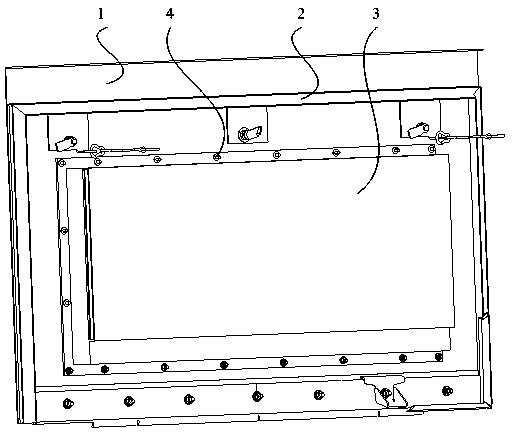

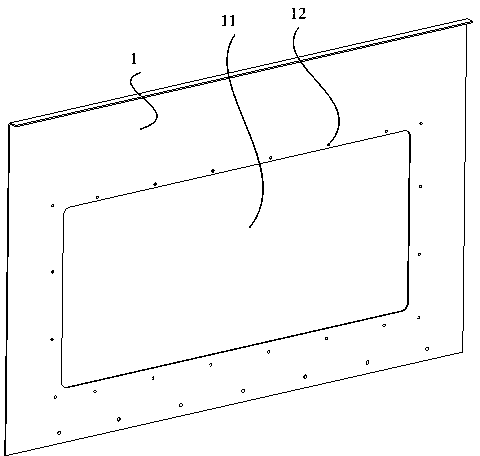

Real-time leveling system suitable for projection photoetching machine and leveling method of real-time leveling system

InactiveCN105607431AReal-time leveling implementationGuaranteed flatness requirementsPhotomechanical exposure apparatusMicrolithography exposure apparatusOptoelectronicsImaging lens

The invention discloses a real-time leveling system suitable for a projection photoetching machine. In the real-time leveling system, a light source forms parallel light beams through a first collimating lens assembly and a second collimating lens assembly to form a slit light beam through a projection diaphragm; the slit light beam is imaged on the surface of a silicon wafer through a first imaging lens assembly; the light beam reflected from the surface of the silicon wafer is imaged on a linear array charge coupled device (CCD) through a second imaging lens assembly, a third imaging lens assembly and a fourth imaging lens assembly; when deflection angle [alpha] exists between the silicon wafer and a workbench, and the reflection light beam reflected from the silicon wafer can deviates by an angle of 2[alpha]; during the deviation, a slit image generates a displacement of Delta X on the linear array CCD; the linear array CCD transmits image information onto an image acquisition control card through a Cameral link transmission line; the image acquisition card is used for sub-pixel processing on the image information to calculate a deviation angle of the silicon wafer; a silicon wafer table is leveled in real time by controlling a piezoelectric actuator below the silicon wafer table, and the flatness requirement of the silicon wafer during exposure is ensured. By the real-time leveling system, the real-time leveling efficiency of the photoetching machine during working is effectively improved, and thus, the working efficiency of the photoetching machine is improved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Aluminum apron board for railway vehicle and machining method thereof

ActiveCN103818397AGuaranteed flatness requirementsImprove ventilationRailway heating/coolingAxle-box lubricationEngineeringSpot welding

The invention provides an aluminum apron board for a railway vehicle and a machining method of the aluminum apron board. The aluminum apron board for the railway vehicle comprises an aluminum plate and an aluminum sectional material frame. The aluminum plate and the aluminum sectional material frame are connected in a spot welding mode. The aluminum apron board further comprises a filter. A vent is formed in the aluminum plate. The periphery of the vent is fixedly provided with riveting studs. The filter is fixed to the riveting studs and shields the vent. The outer surface of the aluminum plate is coated with a paint layer. As the vent is formed in the aluminum plate and the riveting studs are arranged on the periphery of the vent, the filter is installed on the aluminum plate through the riveting studs. Firstly, the riveting studs are directly riveted on the aluminum plate so as to reduce deformation of the aluminum plate and the flatness requirement of the aluminum apron board is met. The outside air can enter the inner side of the aluminum plate through the vent and the filter and the ventilation performance of the aluminum apron board is greatly improved. Under the condition that the appearance flatness is ensured, the ventilation performance of the aluminum apron board for the railway vehicle and the air cleanliness are improved.

Owner:青岛中车四方轨道车辆有限公司

Machining method for hydraulic excavator walking bar body

InactiveCN102773744AGuaranteed machine sizeVersatilePositioning apparatusMetal-working holdersMachine toolExcavator

The invention provides a machining method for a hydraulic excavator walking bar body, which is characterized by comprising the following steps of: putting a fixture body which is not provided with a movable cross beam onto a machine tool workbench by a special fixture body to enable the fixture body to be parallel with the X axis of the machine tool workbench; then, hoisting the walking bar body onto the fixture body; causing the lower plane of a rotary supporting seat connecting plate to be level with the locating surfaces of a left V-shaped block and a right V-shaped block of the fixture body; regulating a first regulation compression bar and a second regulation compression bar to enable the side edge of the lower cover plate of the walking bar body to be parallel with the X axis of the machine tool workbench; then putting the movable cross beam onto the first supporting seat and the second supporting seat, and locking the second regulation compression bar; meanwhile, locking the first regulation compression bar; and finally, machining the walking bar body according to the art work sheet requirement. According to the method provided by the invention, the deficiency in the prior art is overcome, the machining size, the geometric tolerance and the complete machine performance of the walking bar body can be guaranteed. The machining method for the hydraulic excavator walking bar body has the advantages of strong popularity and simple operation step, the machining efficiency is improved, and meanwhile, the excavator manufacture cost is lowered.

Owner:龙工(上海)挖掘机制造有限公司

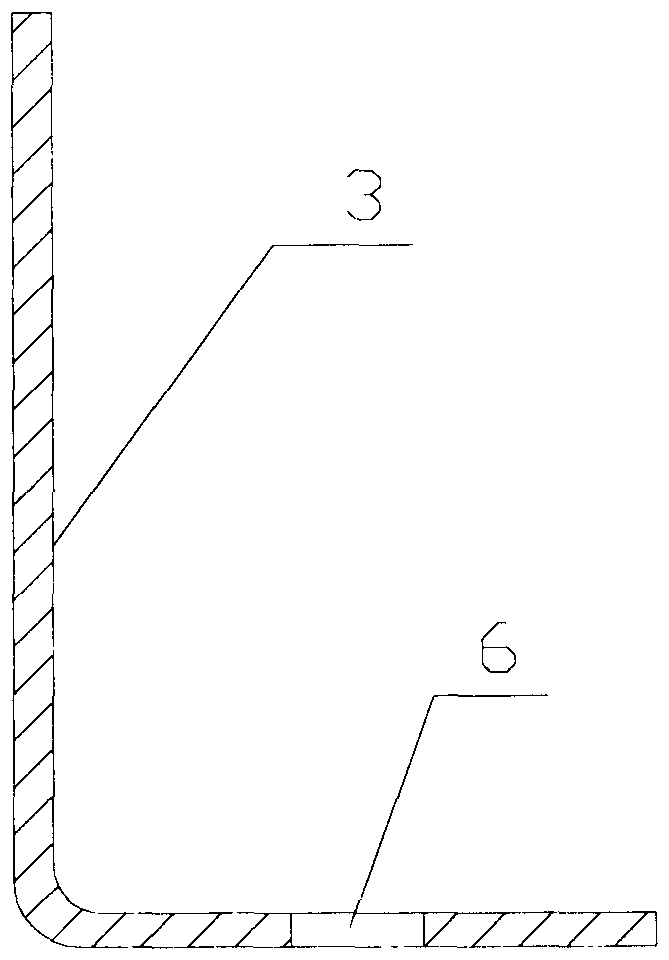

Cover board bar of carding engine cylinder and leveling gum adding method

InactiveCN1884646AGap stabilityGuaranteed straightnessCarding machinesEngineeringMechanical engineering

The invention discloses a mobile lid rod of cotton machine cylinder and extending method, which consists of T-shaped bar-shaped body and bottom plane, wherein the flat glue layer is set on the bottom plane, which is adhered on the bottom plane stickly to improve flatness of bottom. The rod stabilizes gap among cloth and cylinder, which improves carding machine quality cardinally.

Owner:SAURER CHANGZHOU TEXTILE MACHINERY CO LTD

Manufacturing method for cast aluminum type engine blocking cover

The invention discloses a manufacturing method for a cast aluminum type engine blocking cover. The manufacturing method for the cast aluminum type engine blocking cover includes the following steps that firstly, casting is performed, wherein the blocking cover is cast through a metal mold casting method, the bottom face of one side of the blocking cover is a plane, and the other side of the blocking cover is a to-be-machined assembly face; secondly, an end face is turned, wherein the blocking cover is clamped through a turning clamp, the assembly face of the blocking cover is turned, the turning clamp comprises a flange sleeve clamping plate used for ejecting the bottom face of the blocking cover, and a blocking cover top plate used for clamping the assembly face of the blocking cover, and certain machining allowance is reserved for the assembly face of a blank of the blocking cover; and thirdly, hole drilling is performed, wherein the assembly face, machined in the second step, of the blocking cover is placed in a blocking cover installing and clamping device in a whole face attaching manner, the angle and the pressing force of the blocking cover are adjusted by adjusting an angular direction adjusting device and a tight holding force adjusting device, and hole drilling is performed. The invention provides the manufacturing method avoiding sunken deformation of the blocking cover in the end face turning work procedure and thus guaranteeing the planeness of the end face of the blocking cover.

Owner:HEBEI HUABEI DIESEL ENGINE

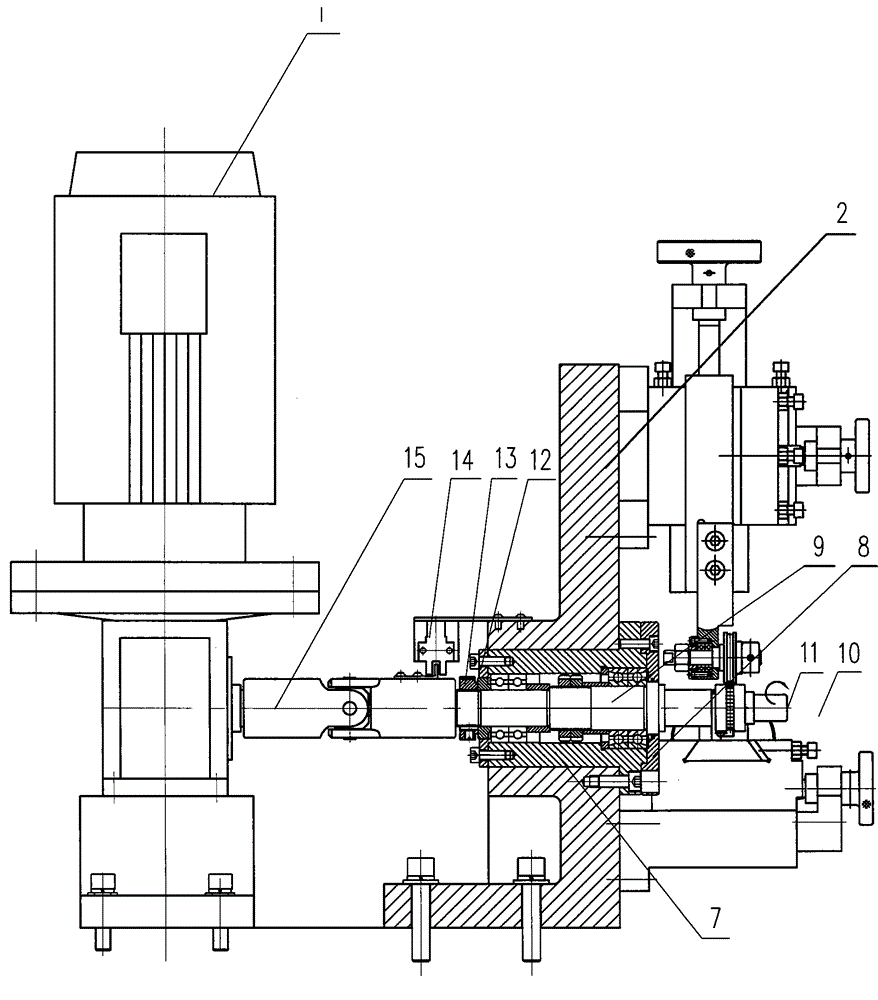

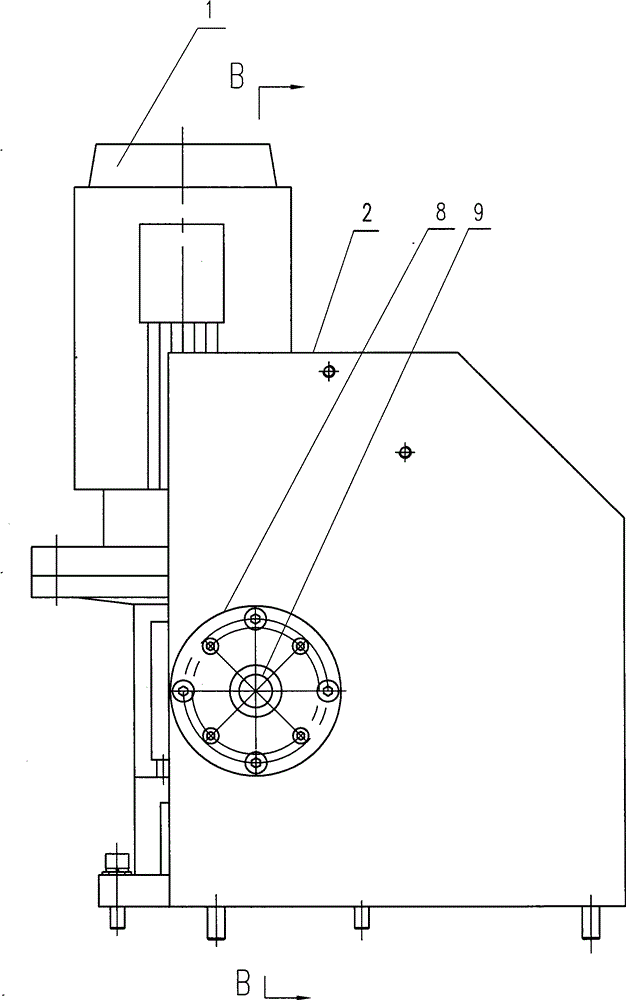

Automatic H-shaped piston bushing ring circulating device

The invention discloses an automatic H-shaped piston bushing ring circulating device. The device is composed of a frequency conversion speed reduction motor, a circulating base plate, an automatic circulating spindle assembly, an automatic circulating vertical tool rest assembly, an automatic circulating inclined tool rest assembly and an automatic circulating horizontal tool rest assembly. The automatic circulating spindle assembly, the automatic circulating vertical tool rest assembly, the automatic circulating inclined tool rest assembly and the automatic circulating horizontal tool rest assembly are installed on the circulating base plate. The automatic circulating vertical tool rest assembly is installed in the vertical direction of the automatic circulating spindle assembly. The automatic circulating inclined tool rest assembly is installed in the inclined direction of the automatic circulating spindle assembly. The automatic circulating horizontal tool rest assembly is installed in the horizontal direction consistent with the direction of the automatic circulating spindle assembly. According to the technical scheme, full automatic production is achieved, the structure is simplified, the adjusting time is shortened, the requirement for the roundness sphericity and the flatness of piston bushing ring circulating is ensured, the production cost is lowered, and the overall productivity is improved.

Owner:安徽金斗机械制造有限责任公司

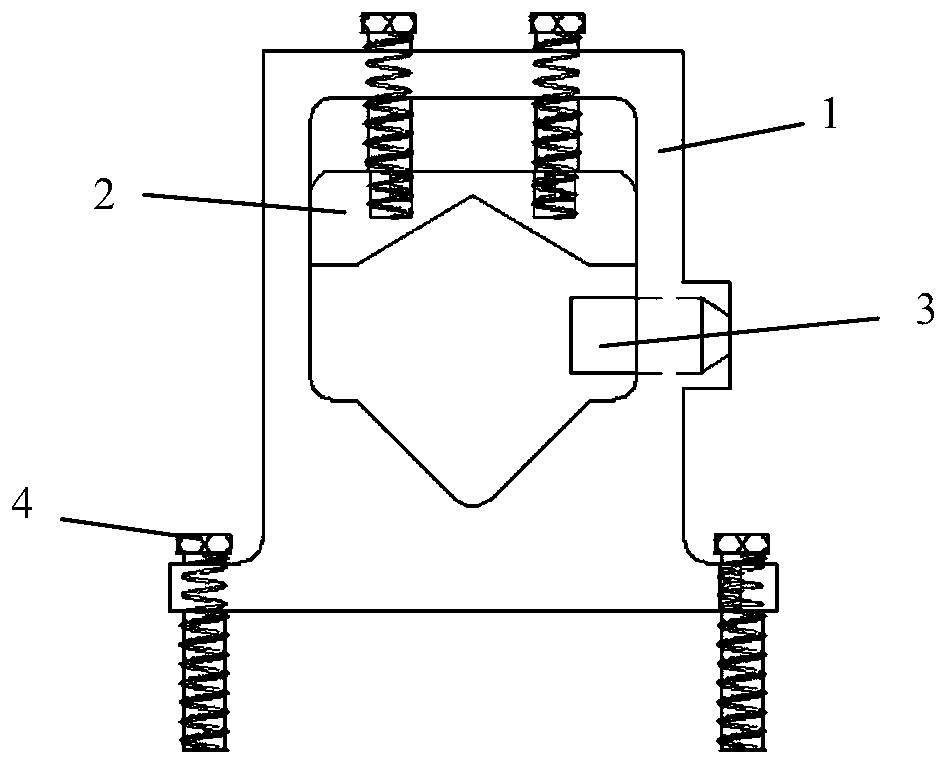

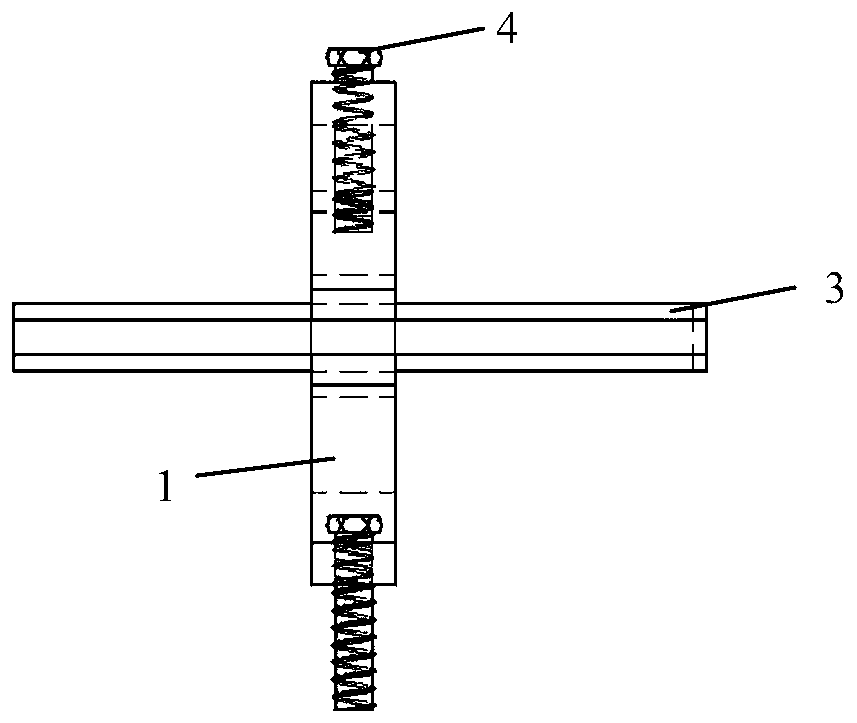

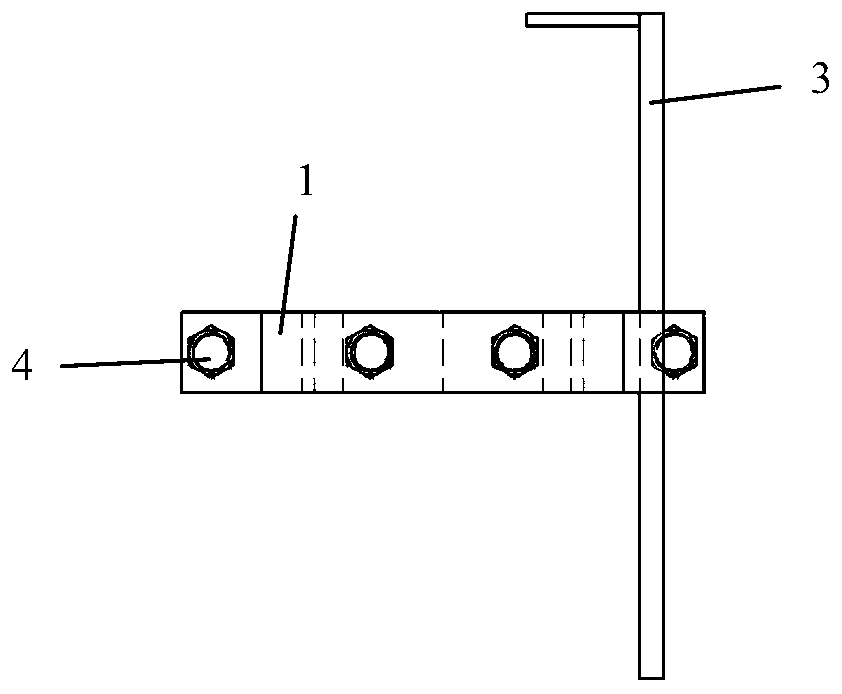

Sample fixture used for rock cutting machine

PendingCN110208057AGuaranteed levelnessGuaranteed flatness requirementsPreparing sample for investigationWorking accessoriesRock cuttingEngineering

The invention relates to a sample fixture used for a rock cutting machine. The sample fixture comprises a positioning frame, a fixing block, an L-shaped graduated scale and bolts, wherein the outer side of the positioning frame is provided with a trapezoidal groove, and the lower side of the inner part is provided with a V-shaped rock clamping groove; the fixing block is arranged in the positioning frame; one side surface of the fixing block is provided with bolt holes which are consistent with the top of the positioning frame and are not penetrated, and the other side surface is provided witha V-shaped clamping groove symmetric with the V-shaped clamping groove in the positioning frame; the graduated part of the L-shaped graduated scale is trapezoidal, an extension part is positioned onthe end part of the graduated part and is vertical to the end part of the graduated part, and the L-shaped graduated scale is arranged in the outer side trapezoidal groove of the positioning frame; the positioning frame and the fixing block are connected through the bolts; and the positioning frame is fixed on a cutting table in a way that the bolts penetrate through the bolt holes on the base. Byuse of the sample fixture, the rock sample is horizontally and firmly fixed on the cutting table, the levelness and flatness requirements of the rock sample as well as the safety of a cutting processare guaranteed, the L-shaped graduated scale can observe the scale while the rock sample is cut, and the cutting accuracy and convenience of the rock sample can be guaranteed.

Owner:TIANJIN UNIV

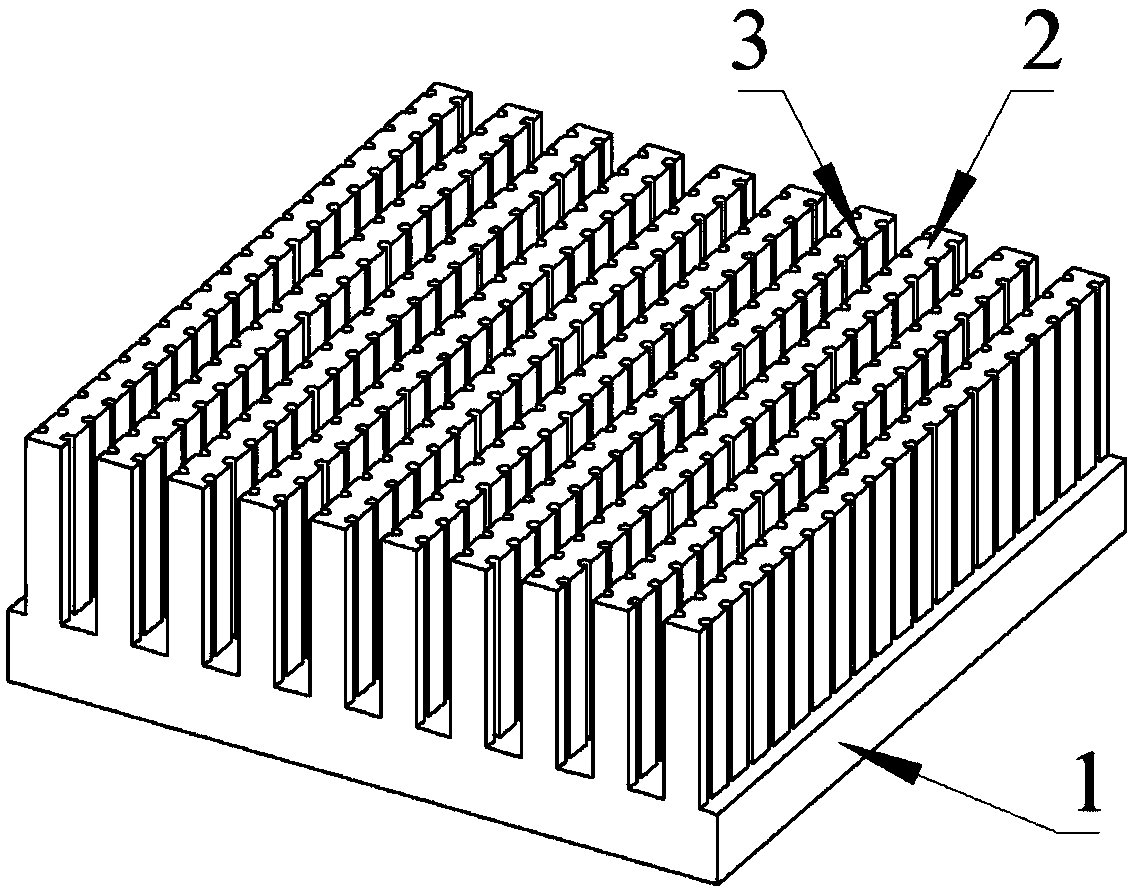

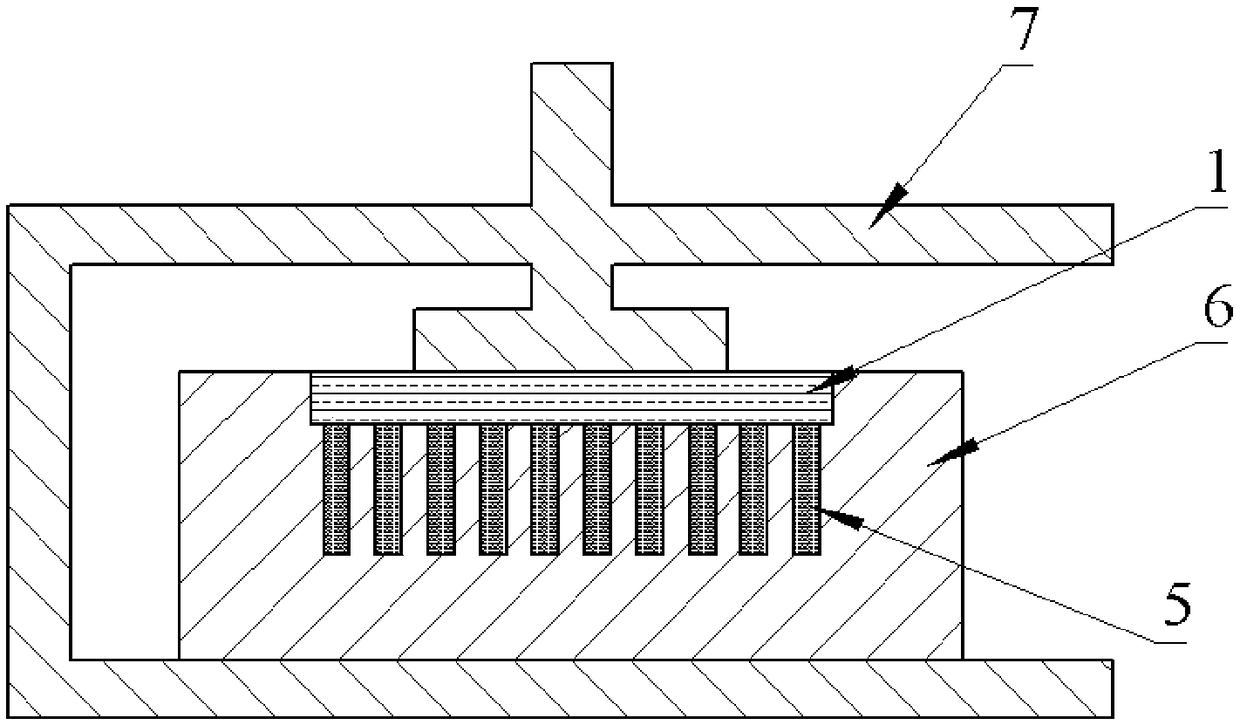

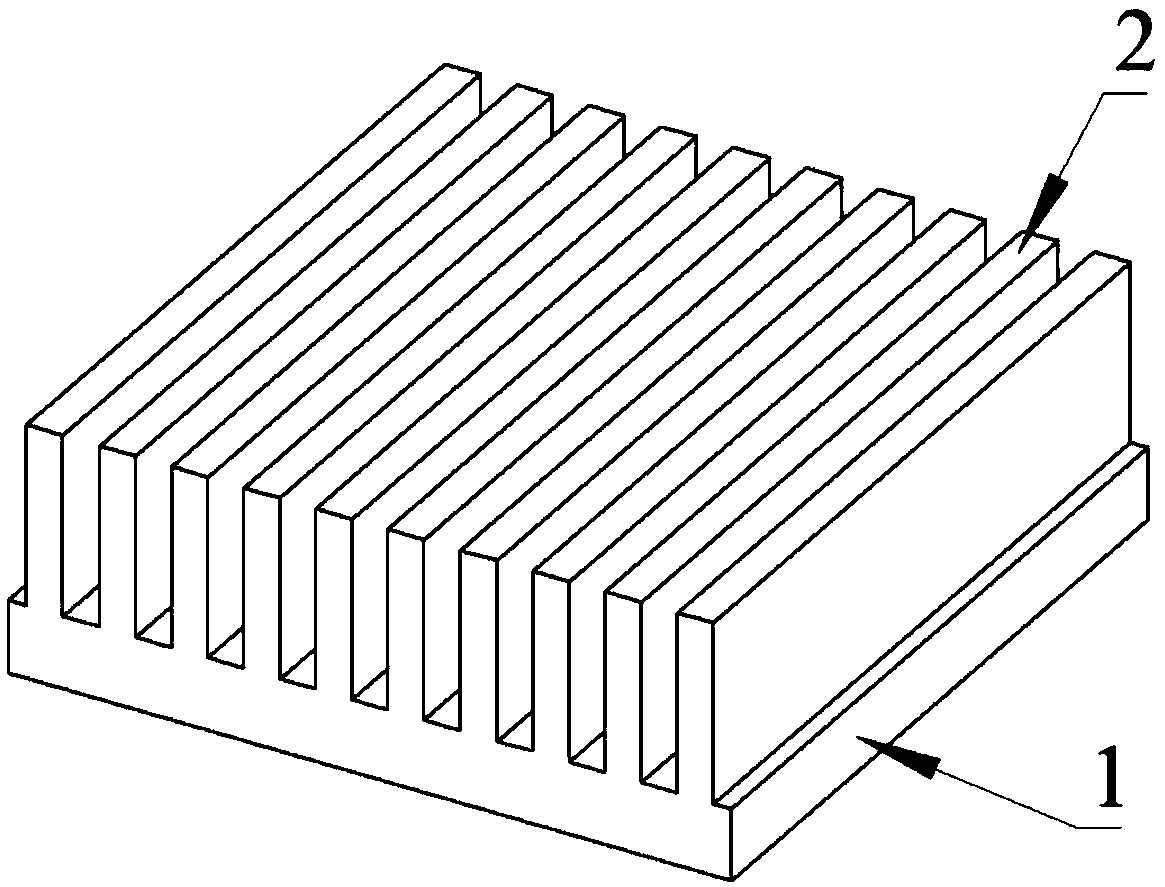

Heat exchange structure and preparation method thereof

PendingCN109411431AControl immersionShorten the motion pathSemiconductor/solid-state device detailsSolid-state devicesNumerical controlMilling cutter

The invention discloses a heat exchange structure. The heat exchange structure comprises a metal substrate and rib plate arrays which are arranged on the substrate in parallel. The invention furthermore discloses a method for preparing the heat exchange structure. The method comprises the steps of: processing the parallel rib plate arrays on the metal substrate; and processing the rib plates downwards from the inner sides of the top edges of the rib plate by using a micro milling cutter through a numerical control milling method, and processing inner grooves on the side surfaces to obtain theheat exchange structure. According to the heat exchange structure and the preparation method, the heat exchange area and nucleate boiling can be effectively increased, a working medium is ensured to form a thin liquid film on the surface of the heat exchange structure, the immersion amount of the heat exchange structure in the working medium is controlled, and the nucleate boiling and thin film evaporation processes are strengthened; and the preparation method is simple, efficient and reliable in principle, and is capable of realizing low-cost and large-scale application in multiple two-phaseradiators.

Owner:SOUTH CHINA UNIV OF TECH +1

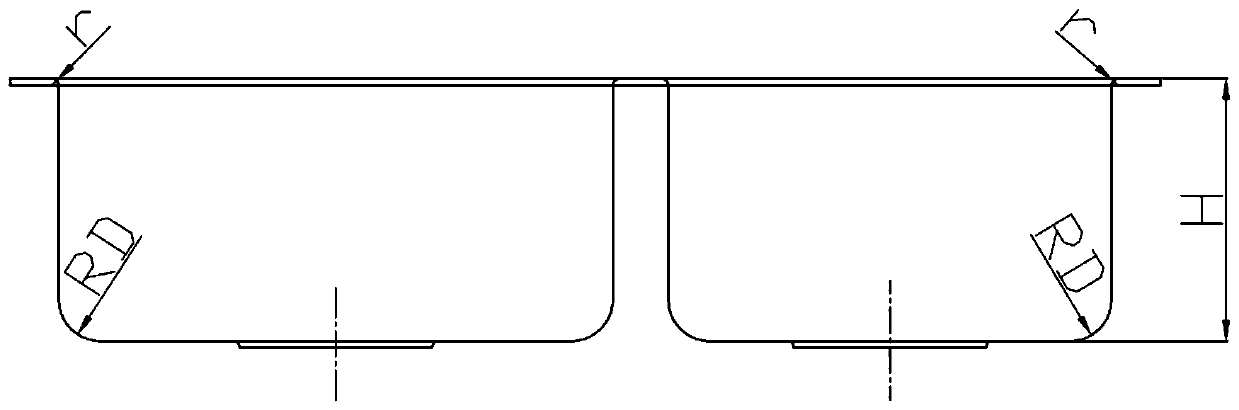

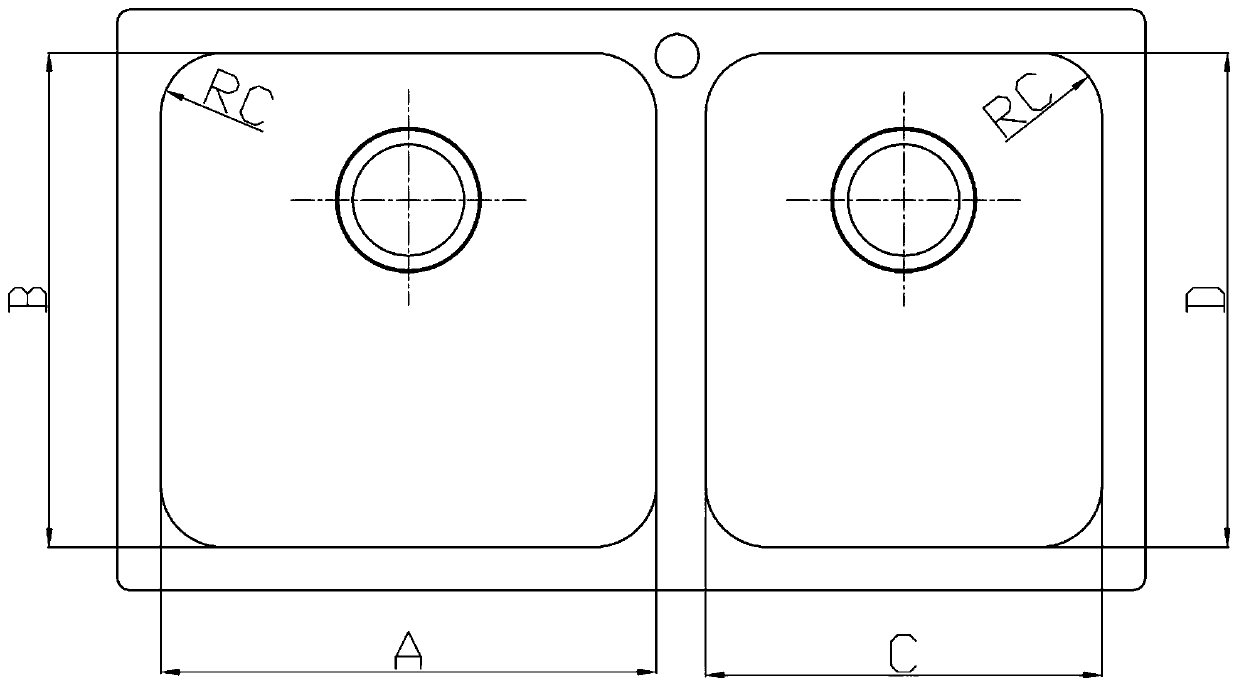

Non-annealing integral forming process of stainless steel water tank

ActiveCN110465602AGuarantee quality requirementsGuaranteed flatness requirementsHollow articlesMetallurgyKitchen utensils

The invention belongs to the field of kitchen utensils, and relates to a non-annealing integral forming process of a stainless steel water tank. The process comprises the following steps of blanking,primary molding, forming of a nano coating, secondary molding, forming of a fluororesin coating, trimming and punching. The integral forming process of the water tank can meet the quality requirementof the water tank without high-temperature annealing, reduces working procedures and improves efficiency. The nano coating and the fluororesin coating are respectively formed on the surface of the water tank through spraying or dipping in the primary forming process and the secondary forming process, and the surface performance of the water tank is greatly improved.

Owner:NINGBO OULIN IND CO LTD

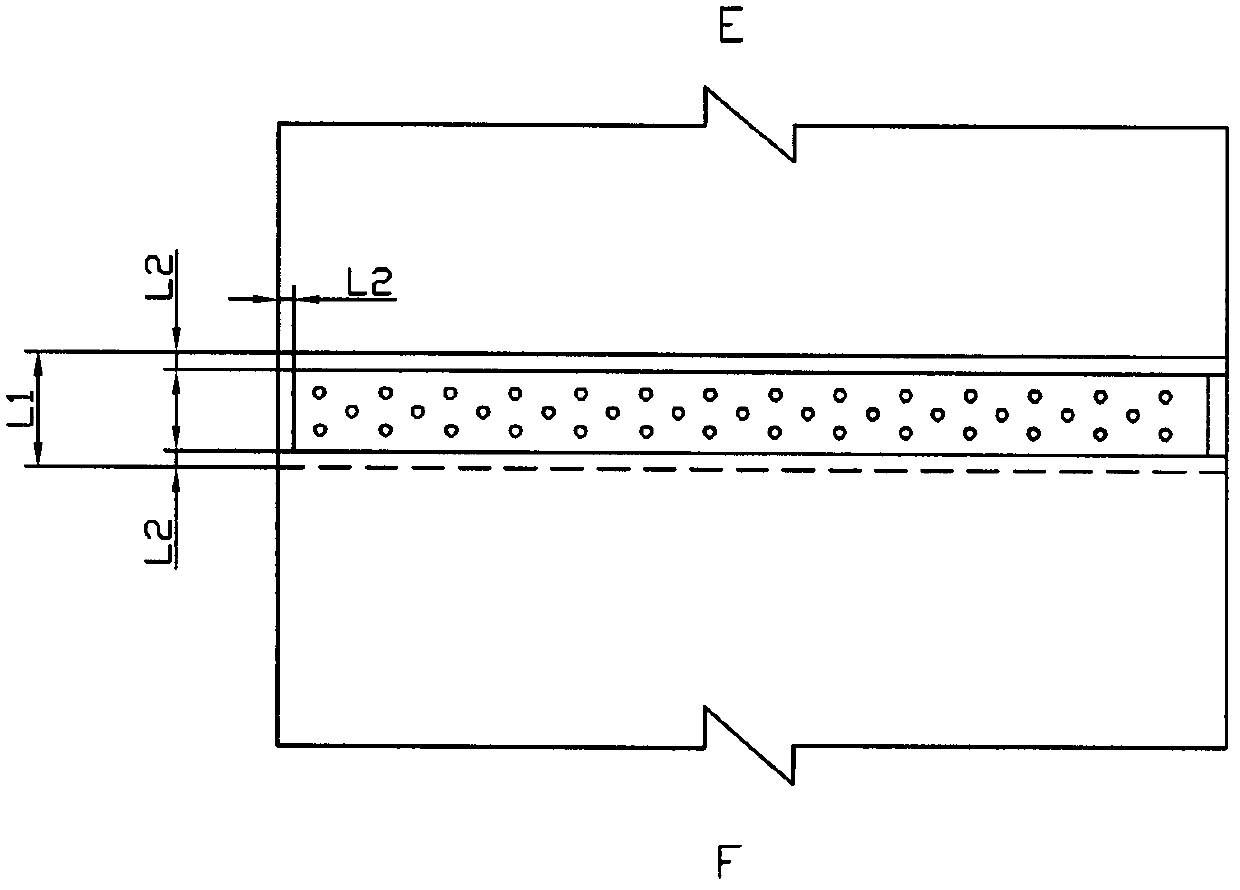

Fabricated cement board force transmission component, cement board and preparation and construction method of cement board

ActiveCN113215898AQuick installationGuaranteed flatnessSingle unit pavingsClimate change adaptationClassical mechanicsCement board

The invention relates to the technical field of assembly type pavements and particularly relates to an assembly type cement board force transmission component, a cement board and a preparation and using method of the cement board. The force transmission component comprises a guide plate and a plurality of launching sleeves perpendicularly and fixedly connected with the guide plate, wherein the guide plate is provided with a plurality of guide holes, the launching sleeves communicate with the guide holes, elastic force transmission rod assemblies are arranged in the launching sleeves, and blocking parts for blocking the elastic force transmission rod assemblies are arranged on the side, away from the launching sleeves, of the guide plate; a targeting sleeve is arranged on the side, away from the launching sleeve, of the blocking part, located on the side, in the moving direction of the elastic dowel bar assembly, and collinear with the launching sleeve. The force transmission component is advantaged in that the elastic dowel bar assembly can be quickly installed on the premise that an upper surface of a prefabricated slab joint is not damaged basically, and overall flatness and attractiveness of a pavement are guaranteed.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

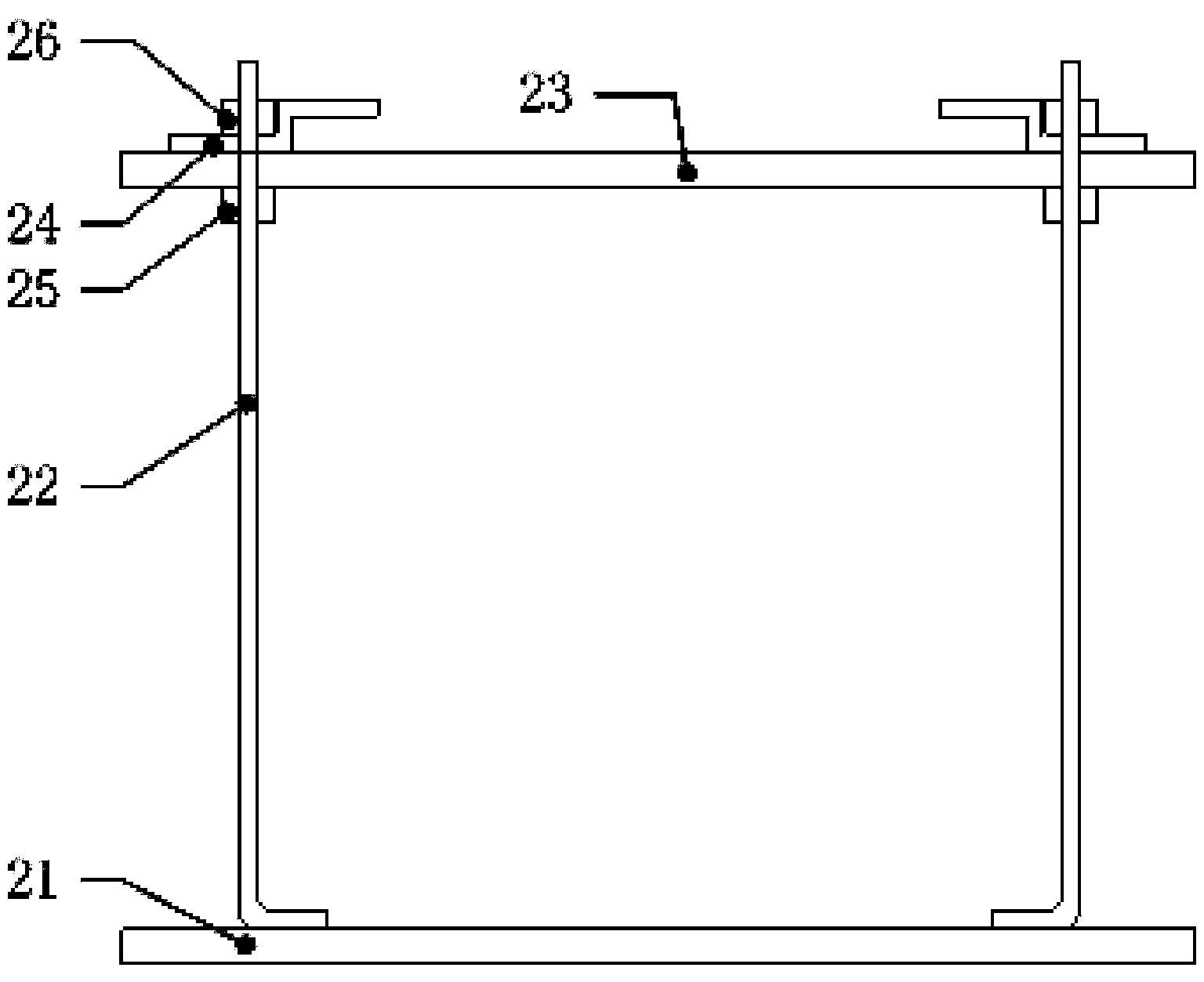

Method for improving installation flatness of ship distribution board

PendingCN114013597AEasy to install and adjustGuarantee quality requirementsWaterborne vesselsSwitchgearMaterial resourcesHull

The invention relates to a method for improving the installation flatness of a ship distribution board. The invention relates to the technical field of ship construction. The system comprises a hull deck and a distribution board, and a base and a plurality of stand columns are arranged on the hull deck. The method specifically comprises the following steps: 1, the flatness of a hull deck in the power distribution room is detected; 2, the base is horizontally adjusted; 3, the base is welded, and after the flatness of the base is adjusted, the base is welded to the deck of the ship body according to the welding requirement; 4, after welding of the base is finished, the distribution boards are hoisted to the base in sequence; 5, the flatness level of the distribution board is inspected, and the flatness of the distribution board is adjusted locally; 6, the distribution board is installed and fixed to the base. According to the invention, the problem that in the prior art, when a distribution board is installed on a deck of a ship body, a large amount of manpower, material resources and financial resources need to be consumed in order to meet the flatness requirement of the distribution board is solved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

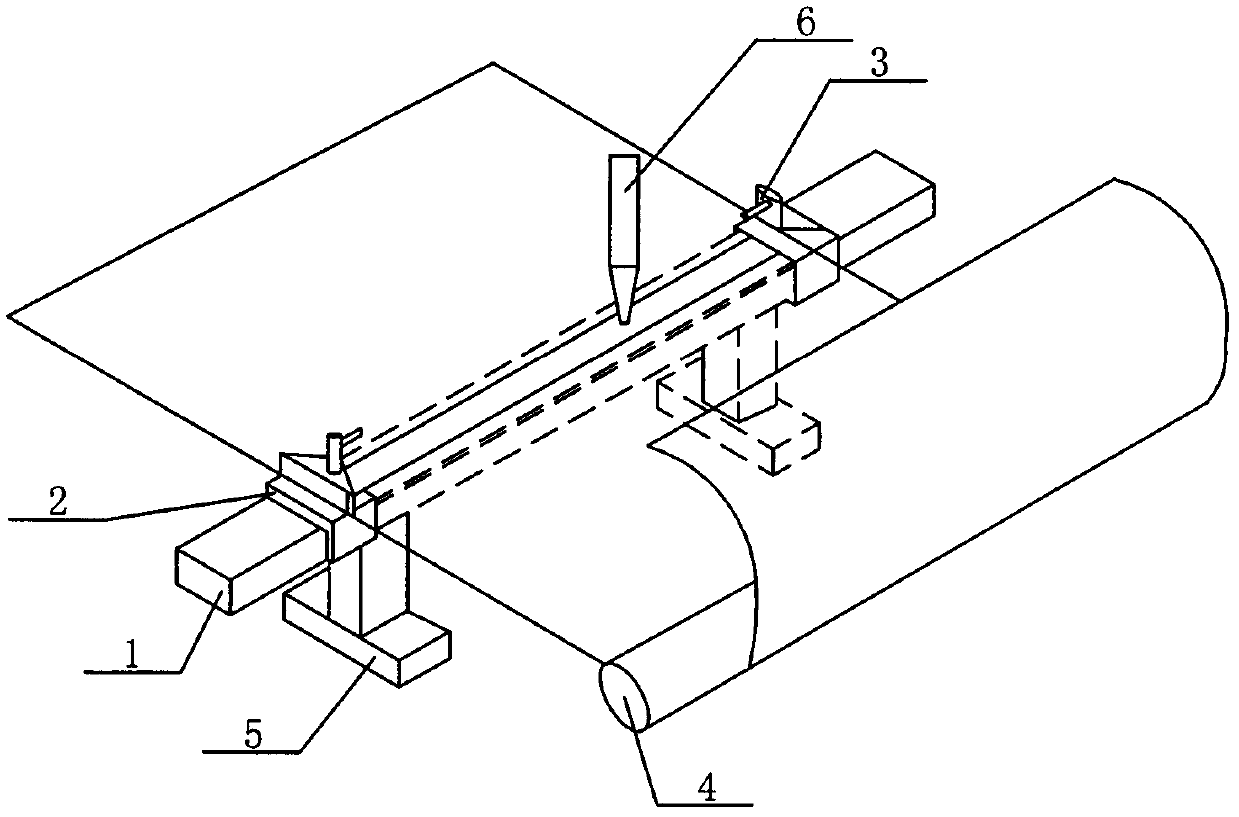

Closed-loop polyester film conveyor belt connecting device of drier and connecting method thereof

InactiveCN103302852AGuaranteed connection strengthGuaranteed tightness requirementsPolyesterDrive shaft

The invention discloses a closed-loop polyester film conveyor belt connecting device of a drier and a connecting method thereof, and relates to the technical field of drying of continuous low temperature films. An adjusting base (2) is slidingly arranged on a welding platform (1), a compressing device (3) is connected on the adjusting base (2) through a thread, a driving shaft (4) is arranged on one side of the welding platform (1), two bases (5) are fixedly arranged on the lower parts at both ends of the welding platform (1), and a high frequency plastic welder (6) is moveably arranged on the upper part of the welding platform (1). With the adoption of the high frequency plastic welder matched with a certain welding method, the connecting strength, the sealing performance and the leveling demand of the conveyer belt are ensured. A conveyer belt welding tool is adopted, so that the linearity of the pulley welded is ensured. Meanwhile, the method can realize field installation, and the structure of equipment is simplified.

Owner:常州朗诣节能技术有限公司

Printable environment-friendly credential card body

ActiveCN103707591AReasonable structureHas hardnessSynthetic resin layered productsEnvironmental resistancePolyethylene terephthalate

The invention discloses a printable environment-friendly credential card body. The printable environment-friendly credential card body is characterized in that the printable environment-friendly credential card body is of a symmetrical composite layer structure, is formed in a hot-pressing way, and sequentially comprises a PET (polyethylene terephthalate) film heat transfer printing processing layer, a PET protective support layer, a PET esterification reaction layer, a PETG (polyethylene terephthalate glycol) connecting layer, a PETG printing layer, a PETG core material layer, a PETG printing layer, a PETG connecting layer, a PET esterification reaction layer, a PET protective support layer and a PET film heat transfer printing processing layer from top to bottom. The printable environment-friendly credential card body is reasonable in structure, easy to operate, environment-friendly, attractive in appearance and high in anti-counterfeiting performance, and credentials can be made and printed on the spot; the card body is high in firmness, high in physical and chemical stability and image accuracy and detail expression, and has good personalized printing effects; after the credentials are synthesized, the credentials have high wear resistance and durability, technical indexes of peeling, torsion, bending and the like completely meet legal credential making standards and requirements, and the potential safety hazard that personal information on the credentials is falsified and replaced is completely eradicated; and the card body has an actually adhesive-free card body structure, and is high in finished product ratio and environment-friendly.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

A method for connecting and fixing elevator guide rails

The invention discloses a connection assembly for elevator guide rails and a connection fixing method for the elevator guide rails. By means of the T-shaped seal type hollow guide rails, structural strength is correspondingly increased compared with traditional hollow guide rails. The connection assembly is arranged between two adjacent sections of the guide rails, and the connection assembly is arranged on the inner sides of the guide rails to guarantee glancing flatness between the guide rails. The connection assembly is of a U-shaped structure, compressive strength on two sides of each guide rail is effectively enhanced, deformation of each guide rail is reduced, and service life of each guide rail is prolonged. In addition, the guide rails are formed in a cold roll forming joint automatic oxy-arc welding and water cooling mode, labor intensity of workers is lowered compared with manual electric welding, and production efficiency is improved. Water cooling and automatic shaping are conducted, forming quality of the guide rails is guaranteed, the strength is better than that of common opening seal hollow rails, a galvanized sheet technology is utilized, follow-up galvanization is omitted, and more environment-friendly use of a product is achieved. Compared with the traditional opening type hollow rails, the connection assembly is characterized in that guide surfaces of the guide rails are wider, an elevator operates more stably, and noise is lower.

Owner:苏州塞维拉上吴电梯轨道系统有限公司

Equipment installation base with convenience for leveling

ActiveCN102620119AEasy to adjustEasy to operateMachine framesSpecial foundation layoutStructural engineeringSteel plates

The invention discloses an equipment installation base with convenience for leveling. The equipment installation base comprises a concrete wall and an installation plane, wherein an installation groove is arranged on the concrete wall; a substrate steel plate is pre-buried at the bottom of the installation groove; the installation groove is further internally provided with a box beam; the box shape of the box beam is enclosed by an upper flat plate, a lower flat plate and two side plates; the lower flat plate is opposite to the substrate steel plate in parallel; a plurality of screw holes are formed in the lower flat plate; a plurality of adjusting screws and a plurality of fastening screws are arranged in the screw holes; the lower ends of the adjusting screws are butted against on the upper surface of the substrate steel plate after penetrating through the screw holes; the lower ends of the fastening screws are fixedly connected with the substrate steel plate after penetrating through the screw holes; operating through holes corresponding to the screw holes are formed in the upper flat plate; and the installation plane is positioned on the upper flat plate. The equipment installation base disclosed by the invention has a good leveling effect, can achieve flatness requirements even for the base with a larger installation plane, and is very convenient to use.

Owner:CCCC SHANGHAI THIRD HARBOR SCI RES INST CO LTD +1

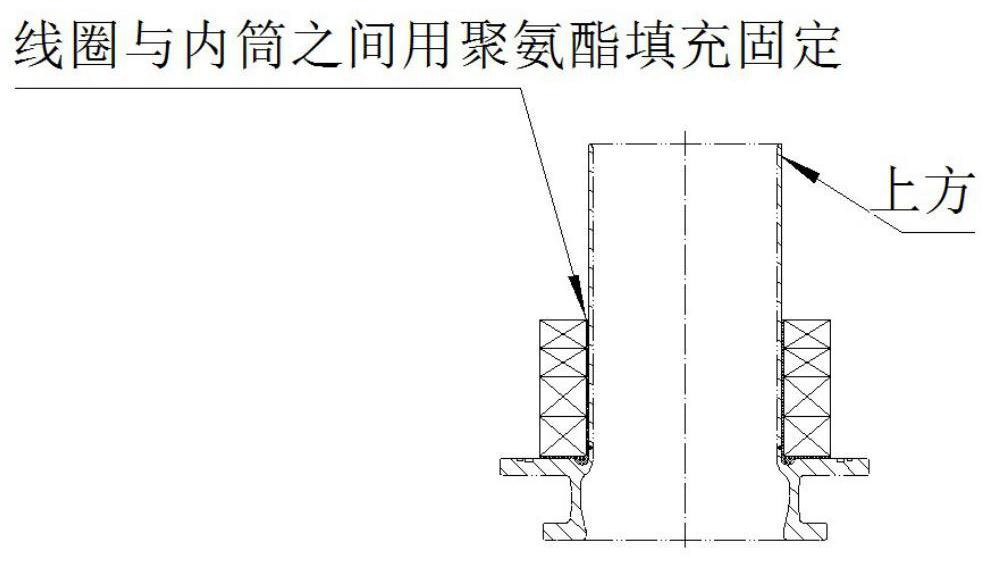

High-capacity high-voltage three-phase common-air-chamber current transformer structure

PendingCN112786298AGuaranteed size requirementsGuaranteed flatness requirementsTransformersTransformers/inductances coils/windings/connectionsElectrical conductorEngineering

The invention provides a large-capacity high-voltage three-phase common-air-chamber current transformer structure which comprises a three-phase common-box shell, a supporting inner cylinder, a current transformer coil, a basin-type insulator, a contact seat, a conductor, a patch board, a protective cover and a first fastener. The supporting inner cylinder is located in the three-phase common-box shell, the current transformer coil is located in the middle of the supporting inner cylinder. The basin-type insulator is located on the inner side of the three-phase common-box shell, the contact seat is located on the inner side of the three-phase common-box shell, the contact seat and the basin-type insulator are connected through a third fastener, and the three-phase common-box shell is connected through a second fastener. According to the high-capacity high-voltage three-phase common-air-chamber current transformer structure, after the current transformer is assembled and formed, only two groups of current transformers need to be assembled into the whole combination switch structure, the operation is very simple and convenient, and the product quality is well guaranteed.

Owner:国电博纳(北京)电力设备有限公司

Riveting process of pieces of sheet metal

InactiveCN103240345AGuaranteed link strengthGuaranteed flatness requirementsEngineeringUltimate tensile strength

The invention discloses a riveting process of pieces of sheet metal. The riveting process of pieces of the sheet metal comprises: punching a piece of the sheet metal; subjecting the rest of the sheet metal to protrusion forming, wherein the positions of protrusions correspond with those of the punched holes; sequentially placing the protrusion-formed sheet metal in an overlapping mode, wherein the protrusions face upwards and the burr stamping directions are the same; enabling the punched holes of the punched sheet metal to be correspond with the protrusions of the protrusion-formed sheet metal, and arranging the punched sheet metal on the top layer of the pieces of the sheet metal; positioning the pieces of the sheet metal placed in an overlapping mode in a mould; and starting the mould to subject the pieces of the sheet metal placed in an overlapping mode to stamping forming to form integral assemblies. The riveting process of pieces of the sheet metal not only guarantees the connection strength among the sheet metal, but also guarantees the flatness requirement of two end faces of products without changing inherent attributes of product materials, and is simple in operation.

Owner:SUZHOU TIANYE MECHANICAL IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com