Patents

Literature

129results about How to "Gap stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

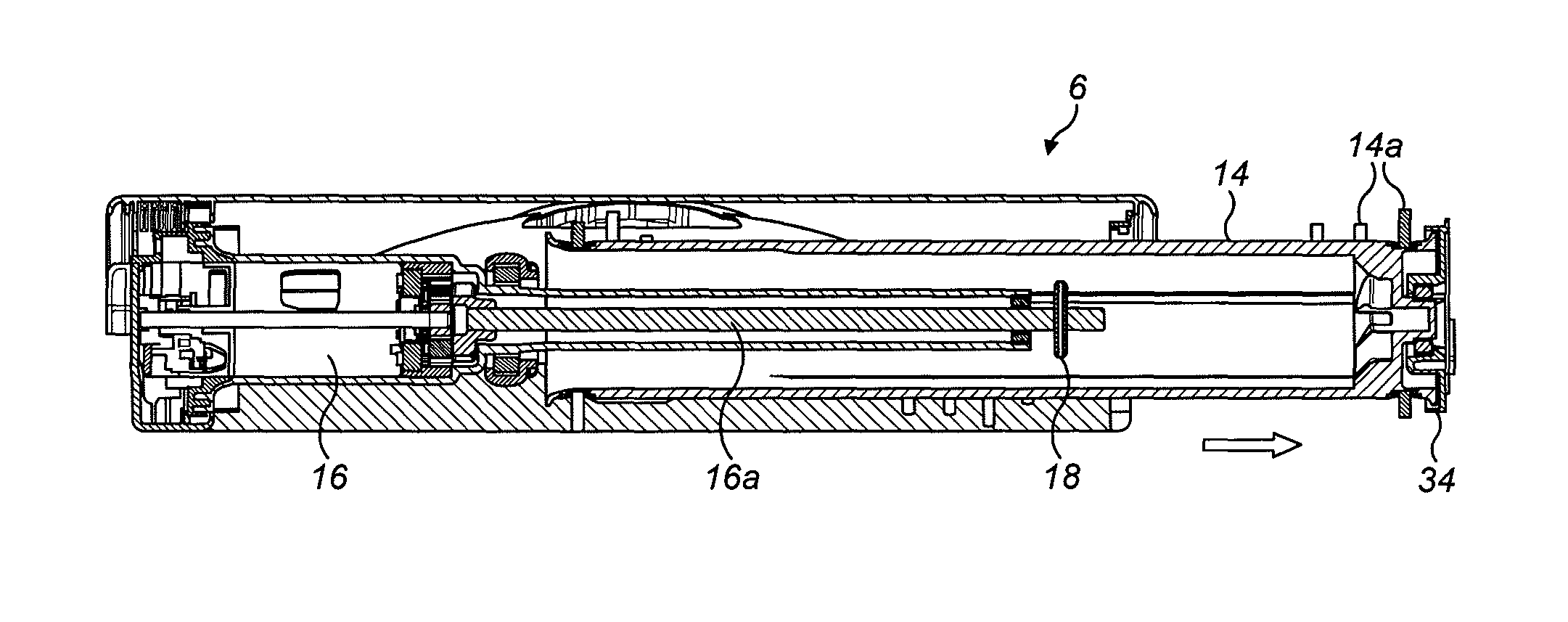

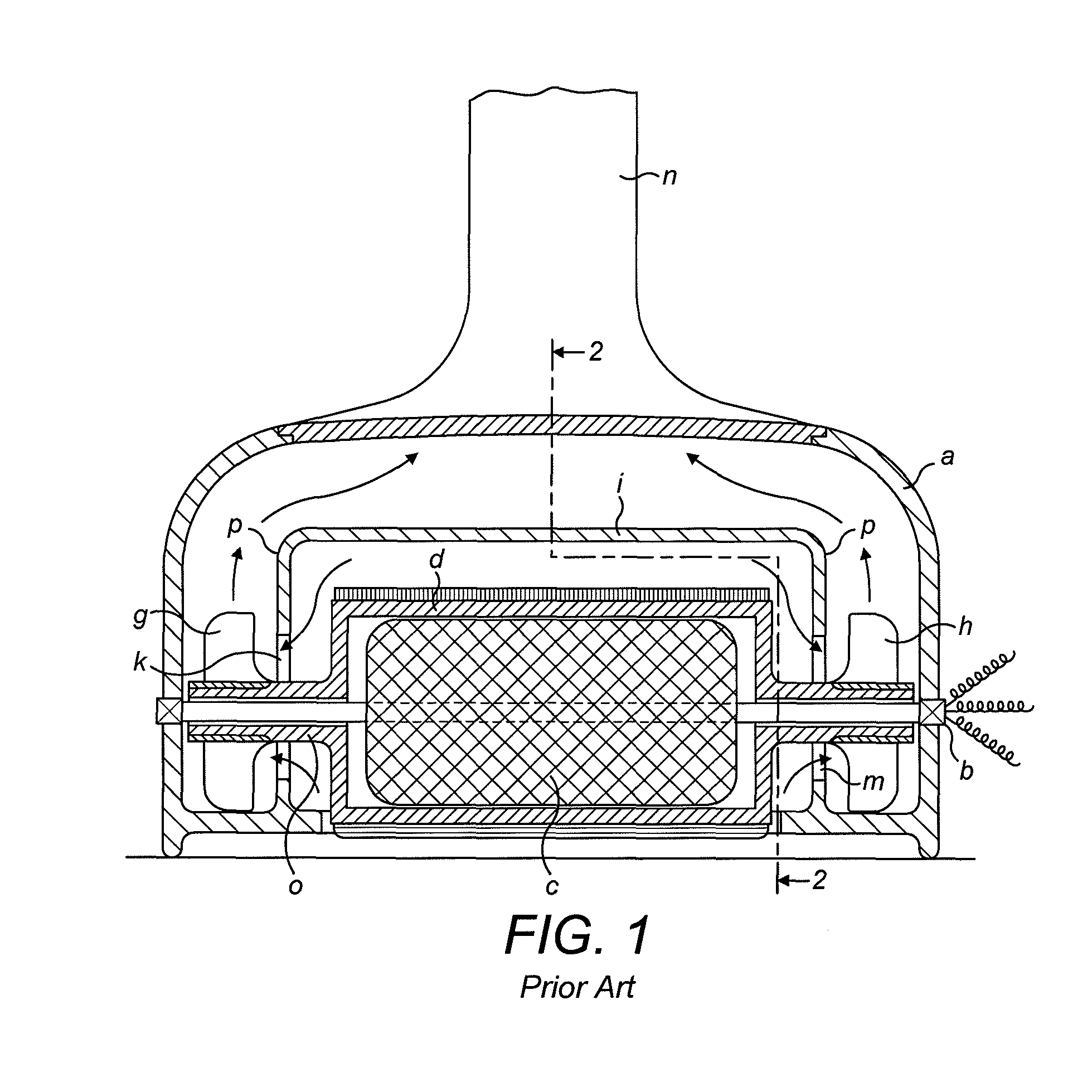

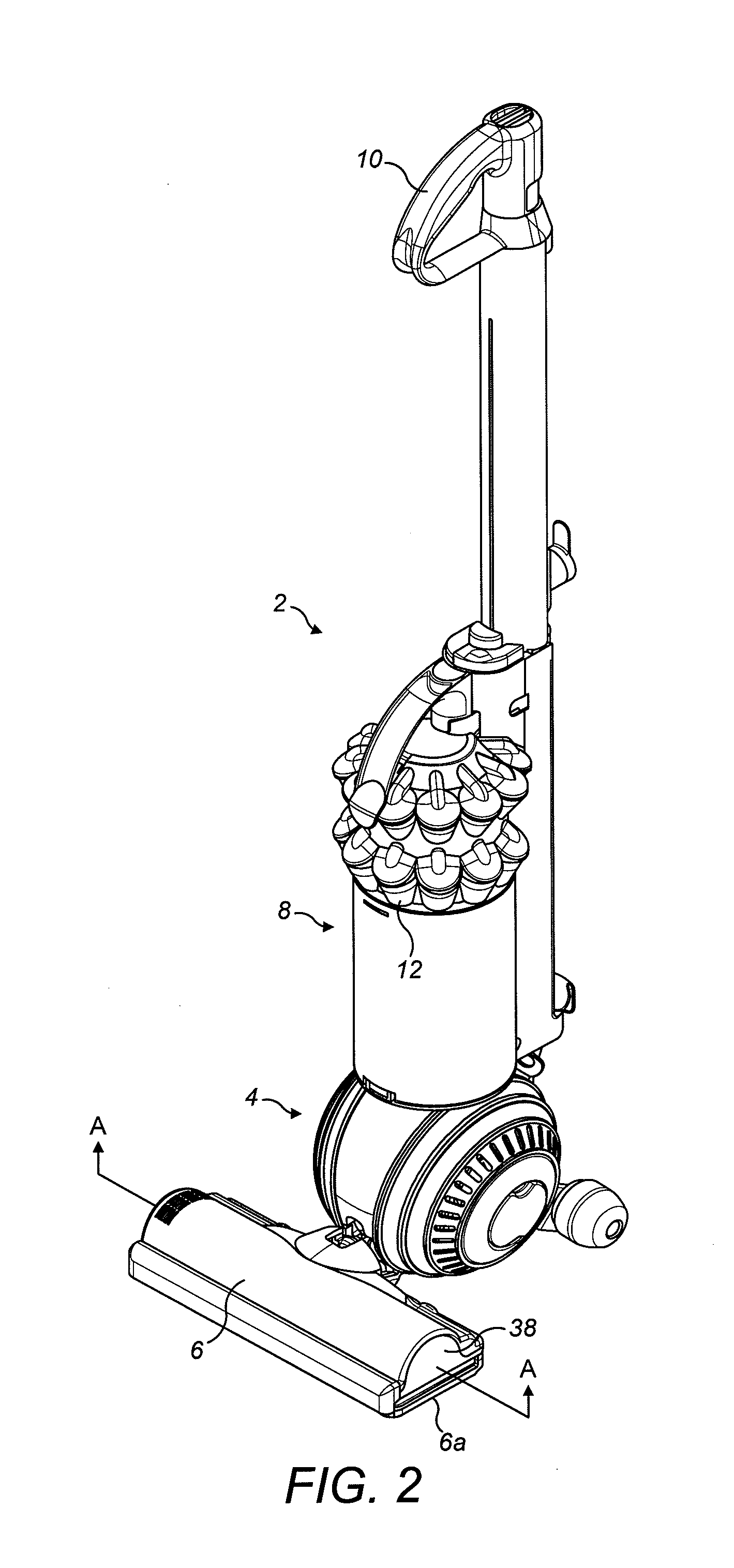

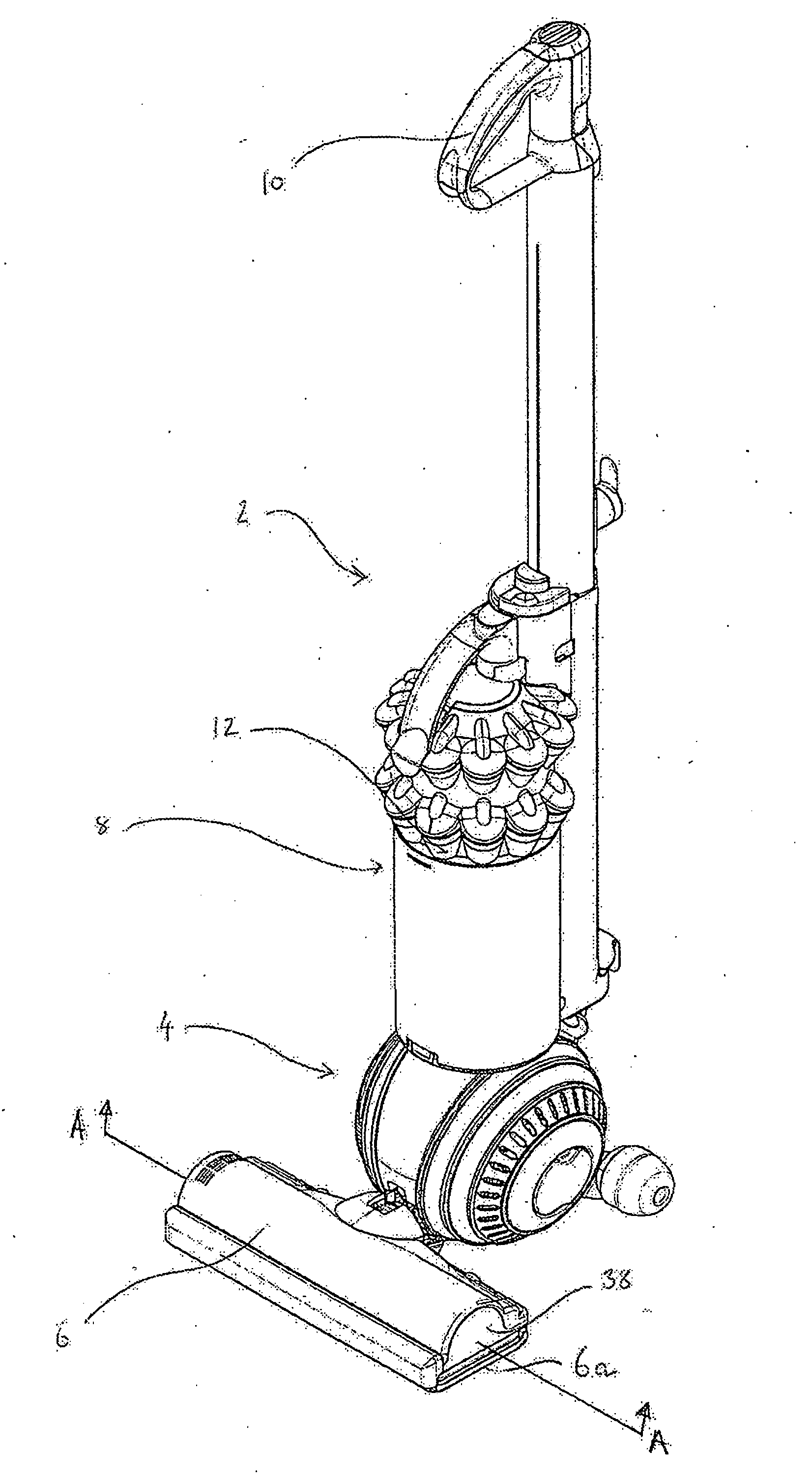

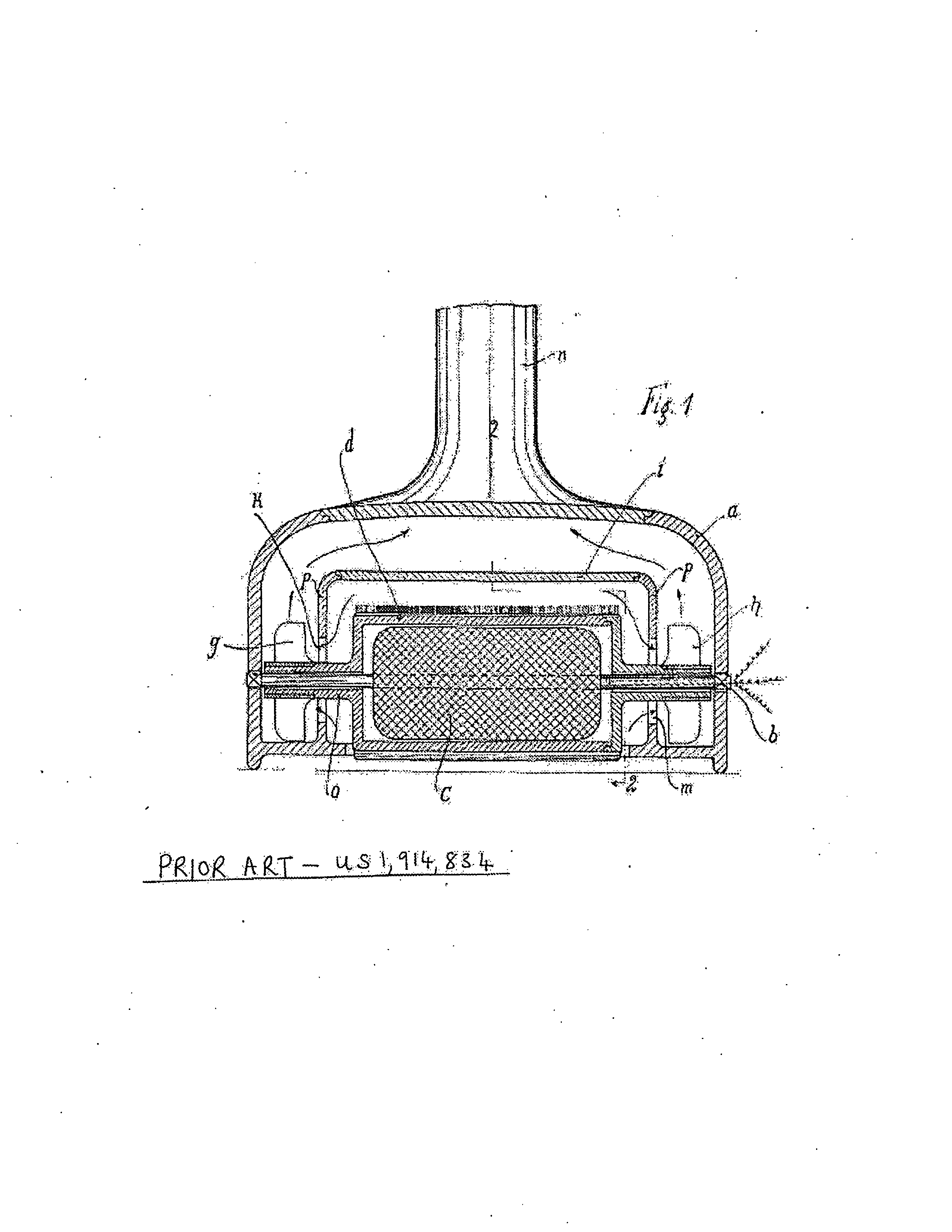

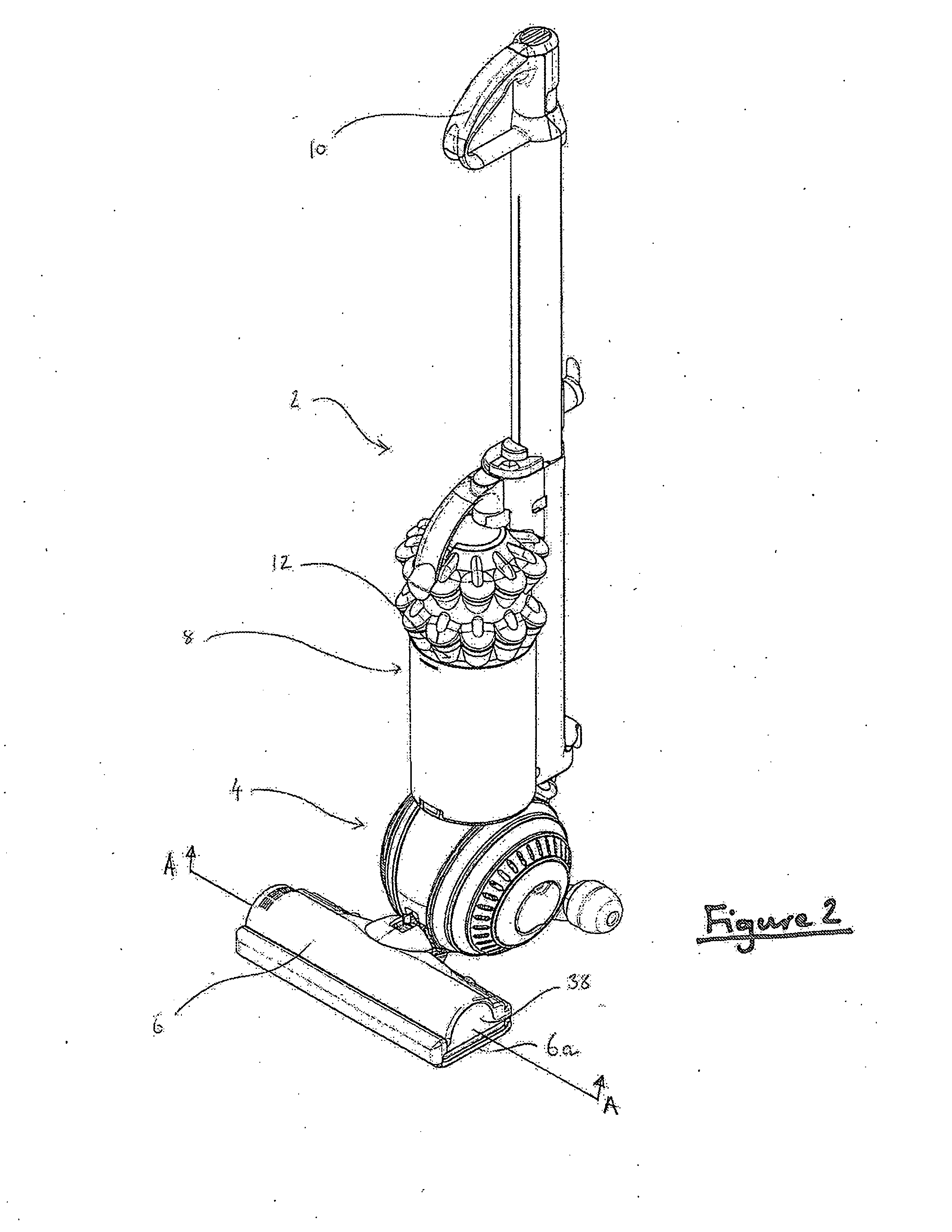

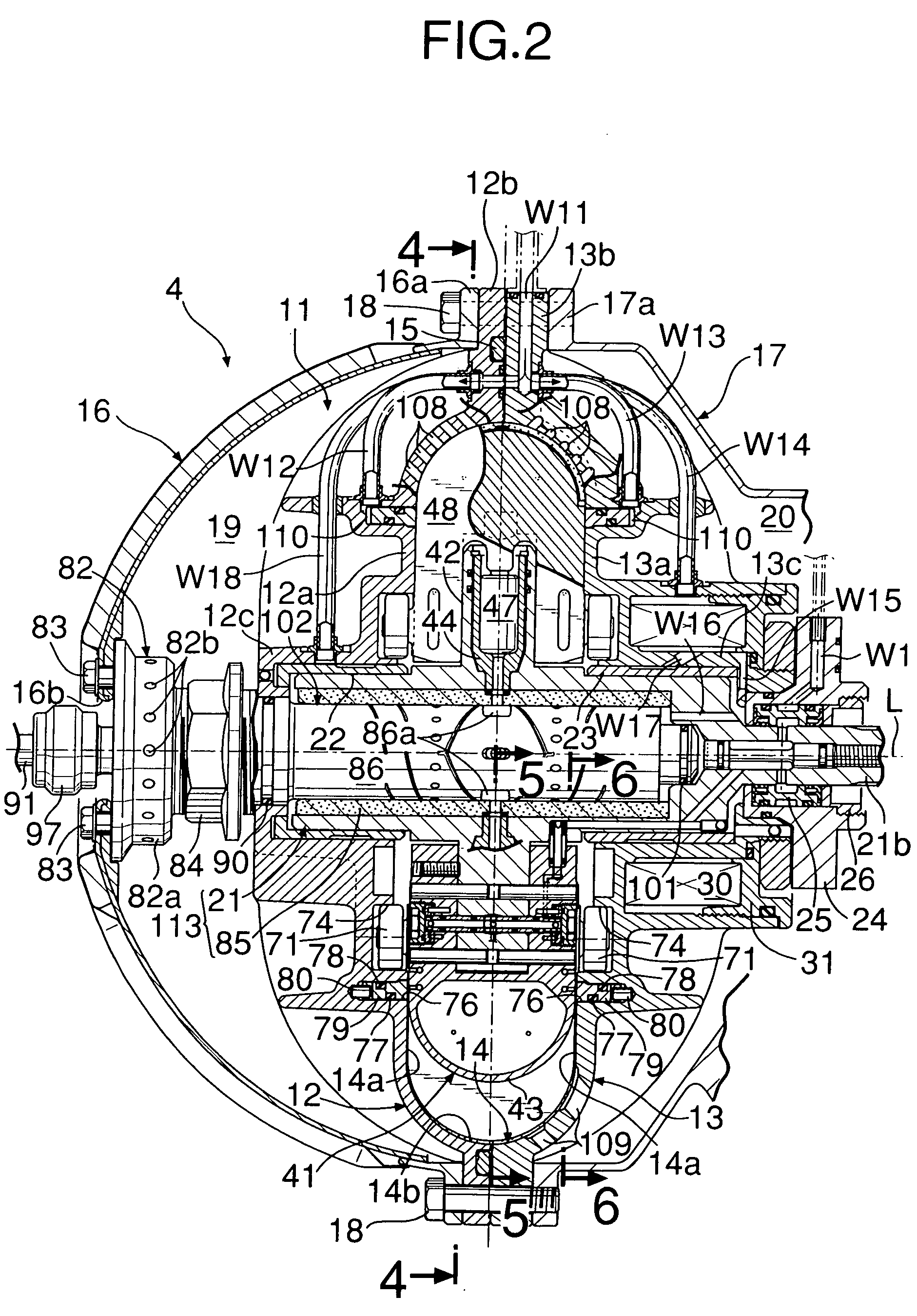

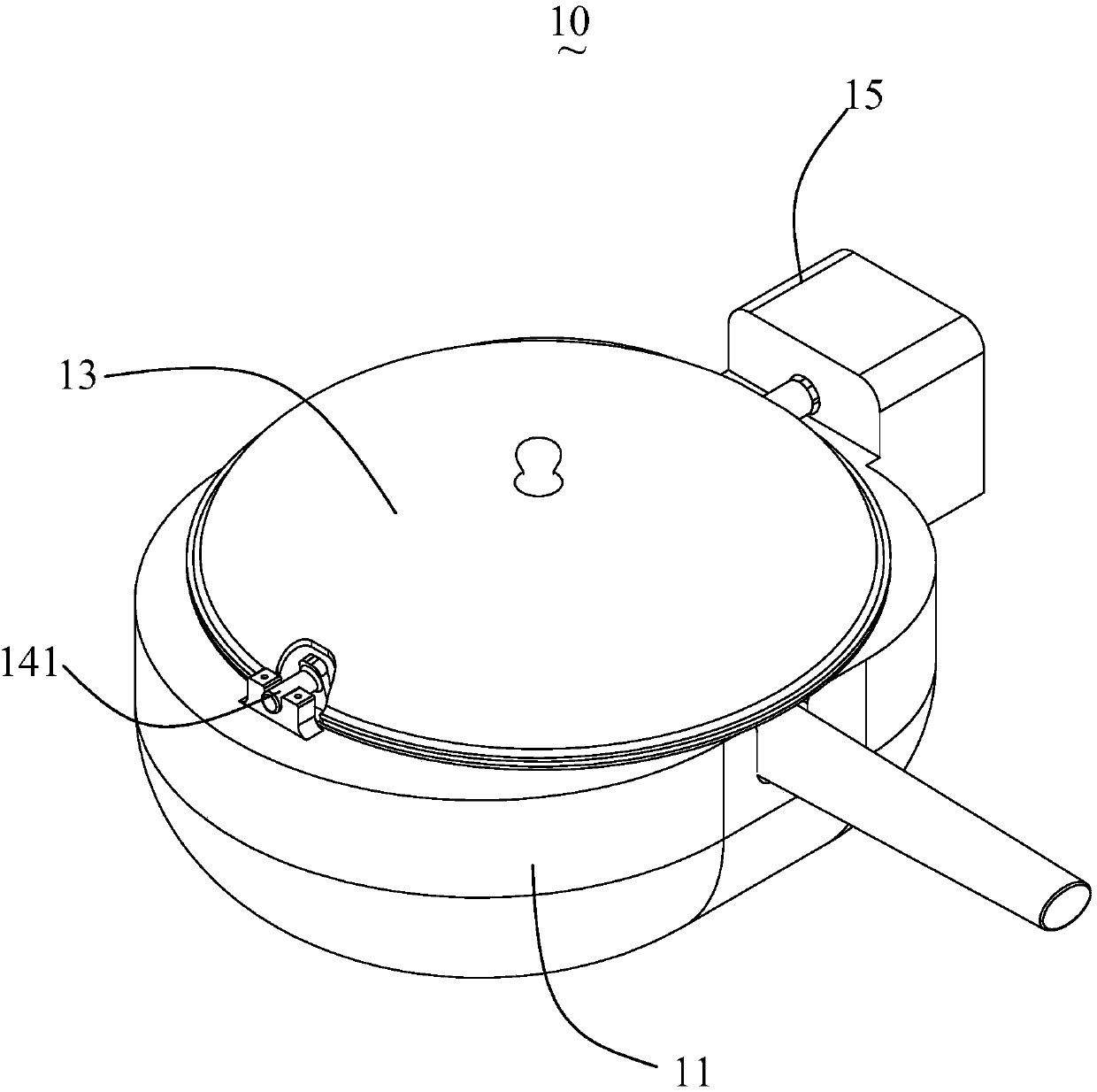

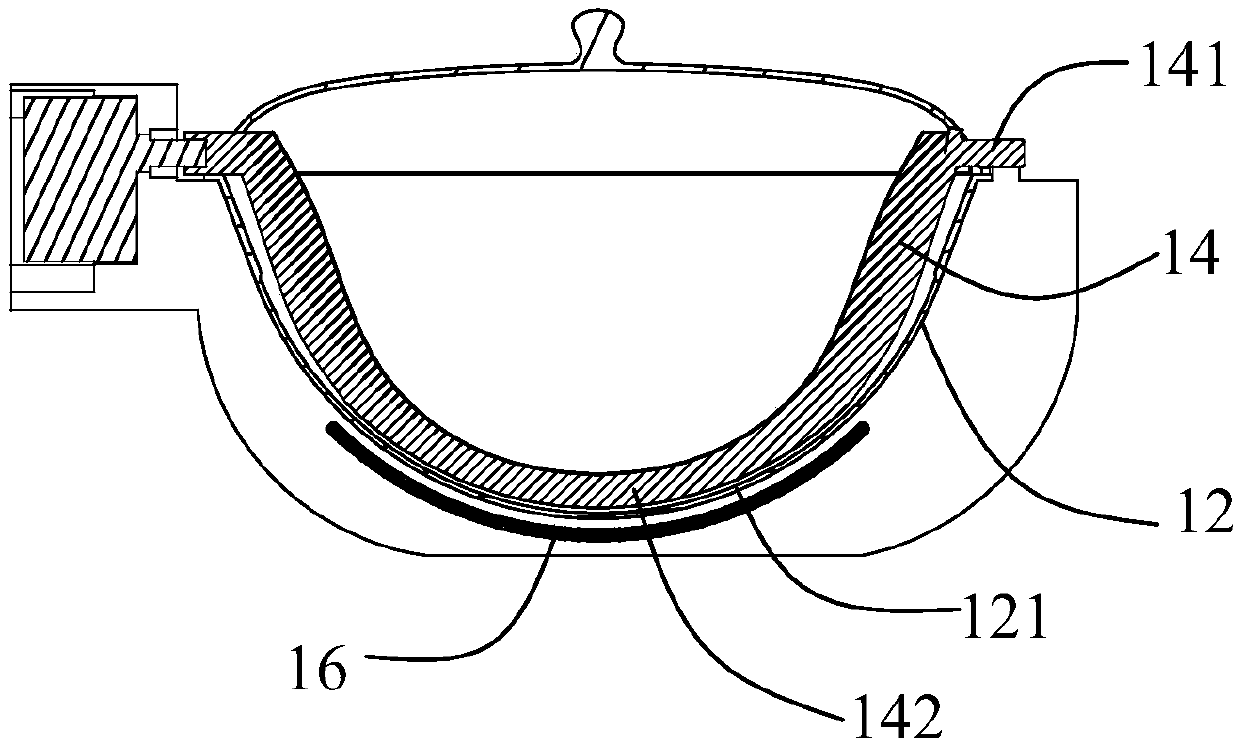

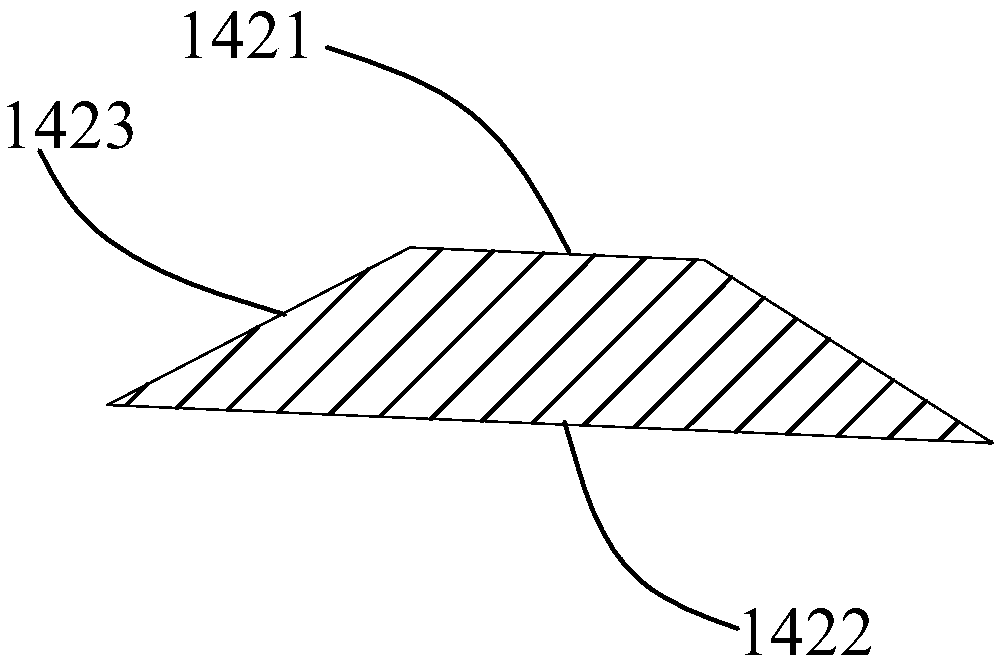

Cleaner head for a vacuum cleaner

ActiveUS8776311B2Straightforwardly and conveniently removedGap stabilitySuction nozzlesEngineeringMechanical engineering

A cleaner head for a vacuum cleaner houses a hollow brush bar mounted for rotation about an axis. This brush bar is driven by a motor housed inside the hollow brush bar, the motor forming part of a drive assembly supported at one end of the cleaner head. The brush bar is arranged for removal from the cleaner head by sliding the brush bar along the axis and out through an opening at the opposite end of the cleaner head and the brush bar is rotatably supported in clearance around the drive assembly by a first bearing, which bearing engages the brush bar in a corresponding axial-sliding fit to allow said sliding removal of the brush bar.

Owner:DYSON TECH LTD

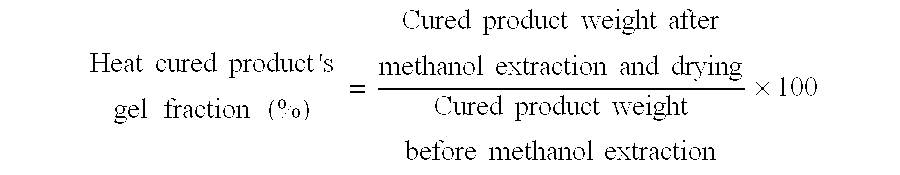

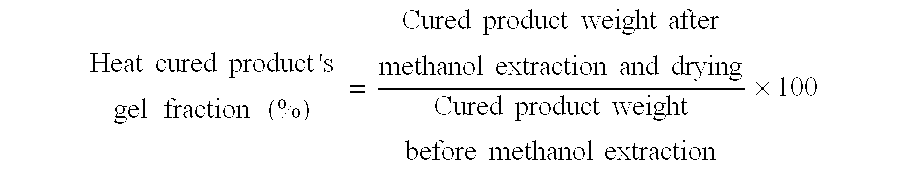

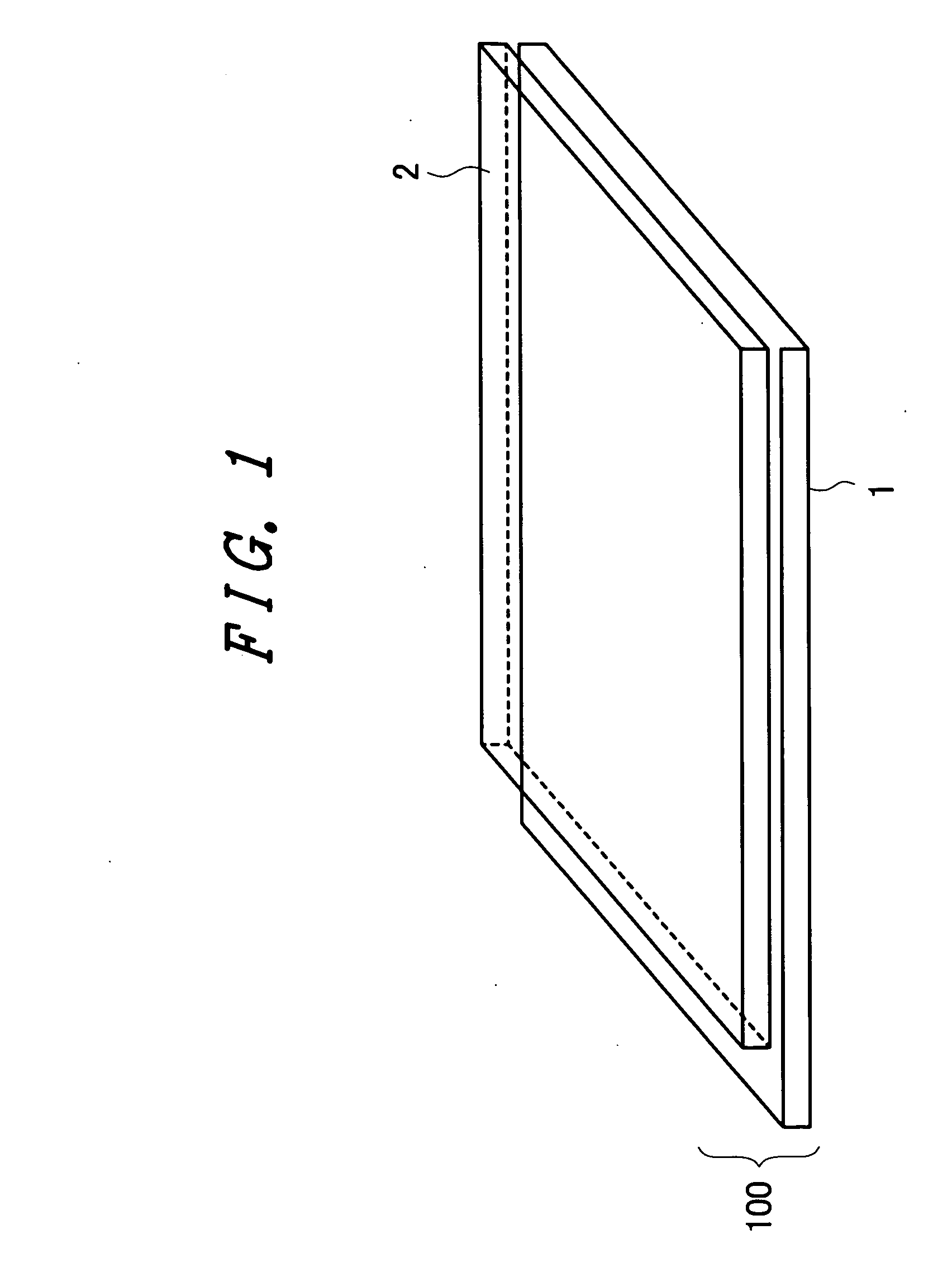

Sealing composition for liquid crystal displays and process for production of liquid crystal display panels

ActiveUS20060009579A1Improve curing effectImprove bond reliabilityLamination ancillary operationsLaminationMethacrylateLiquid crystalline

A liquid crystal sealing agent composition that is a one-component light and heat-curable resin composition containing: (1) a solid epoxy resin having a ring and ball method softening temperature of 40° C. or above; (2) an acrylate monomer and / or a methacrylate monomer, or an oligomer thereof; (3) a thermoplastic polymer having a ring and ball method softening temperature of 50 to 120° C., the thermoplastic polymer being obtained by copolymerizing an acrylate monomer and / or a methacrylate monomer with a monomer copolymerizable therewith; (4) a light-activated radical polymerization initiator; and (5) a latent epoxy curing agent. The light and heat curable liquid crystal sealing agent composition is employable in one drop fill, is excellent in properties of a cured product particularly after first-stage light curing, achieves stable cell gap after cell gap formation, permits prevention of contamination of the liquid crystal in second-stage heat curing, is excellent in curing properties in shaded area, and shows superior bonding reliability.

Owner:MITSUI CHEM INC

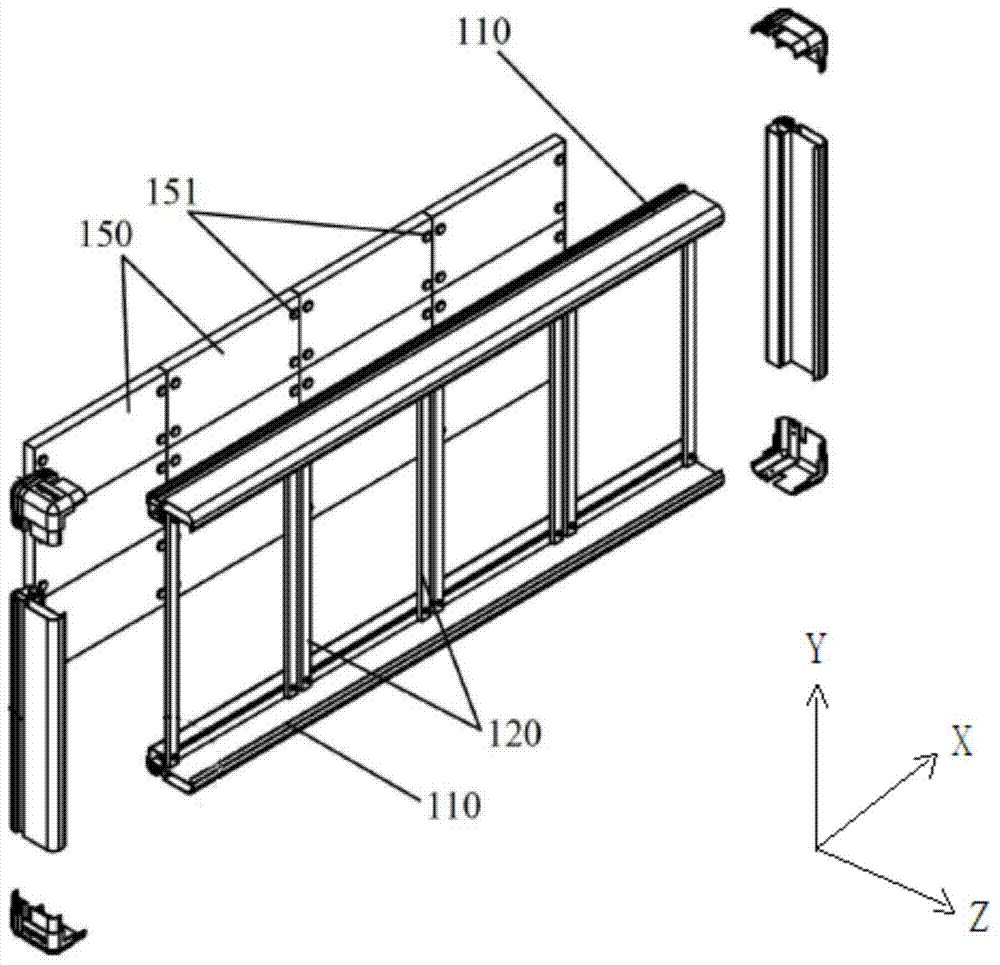

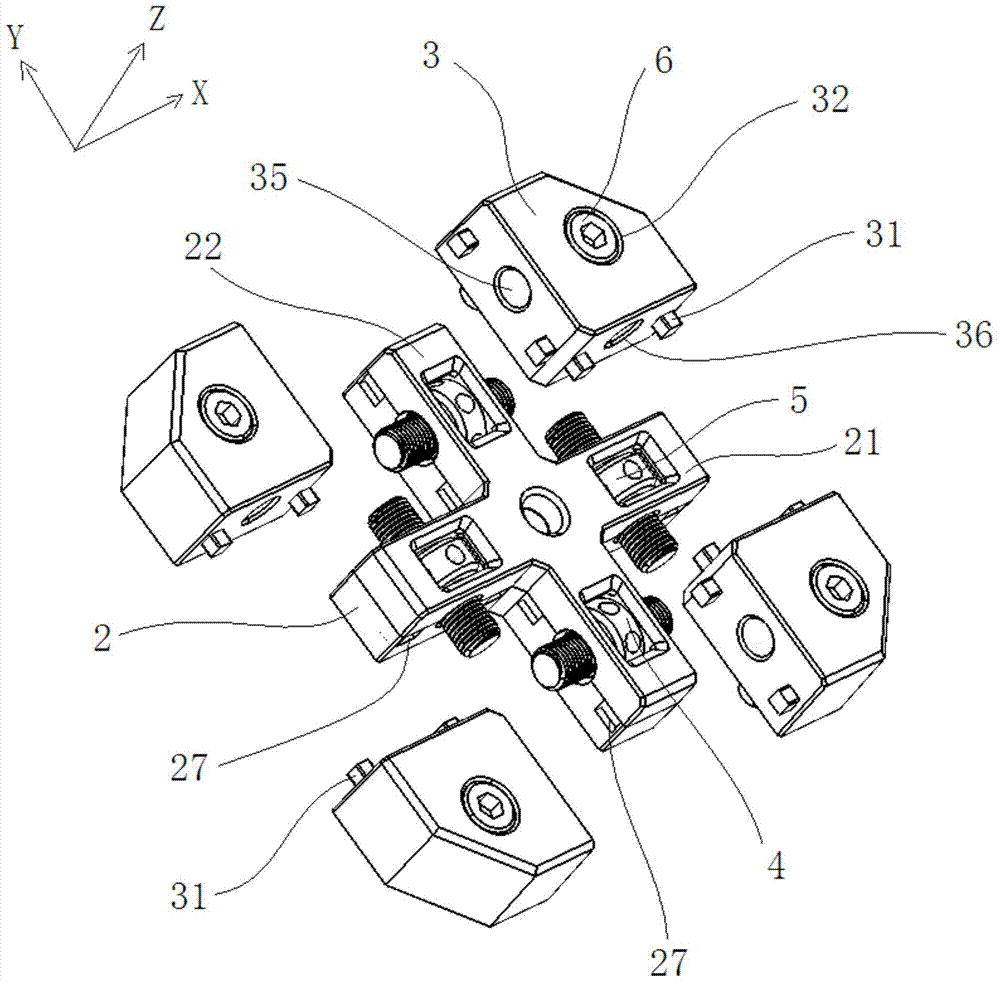

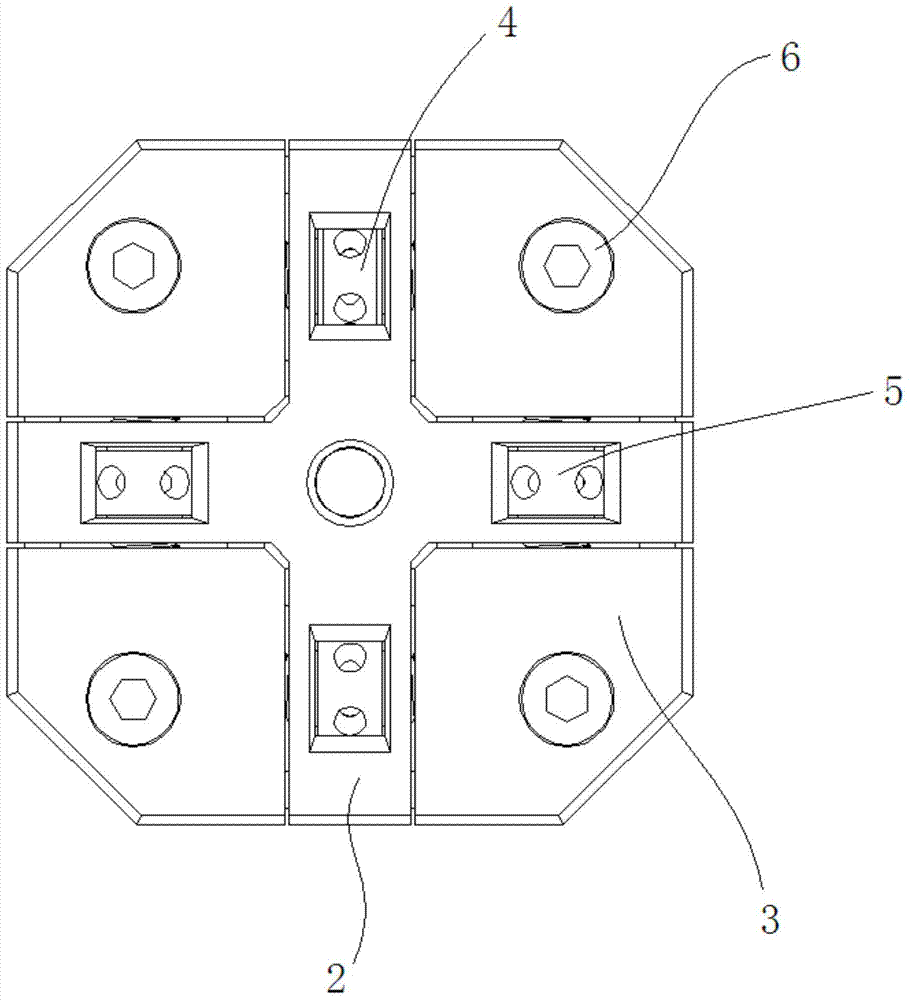

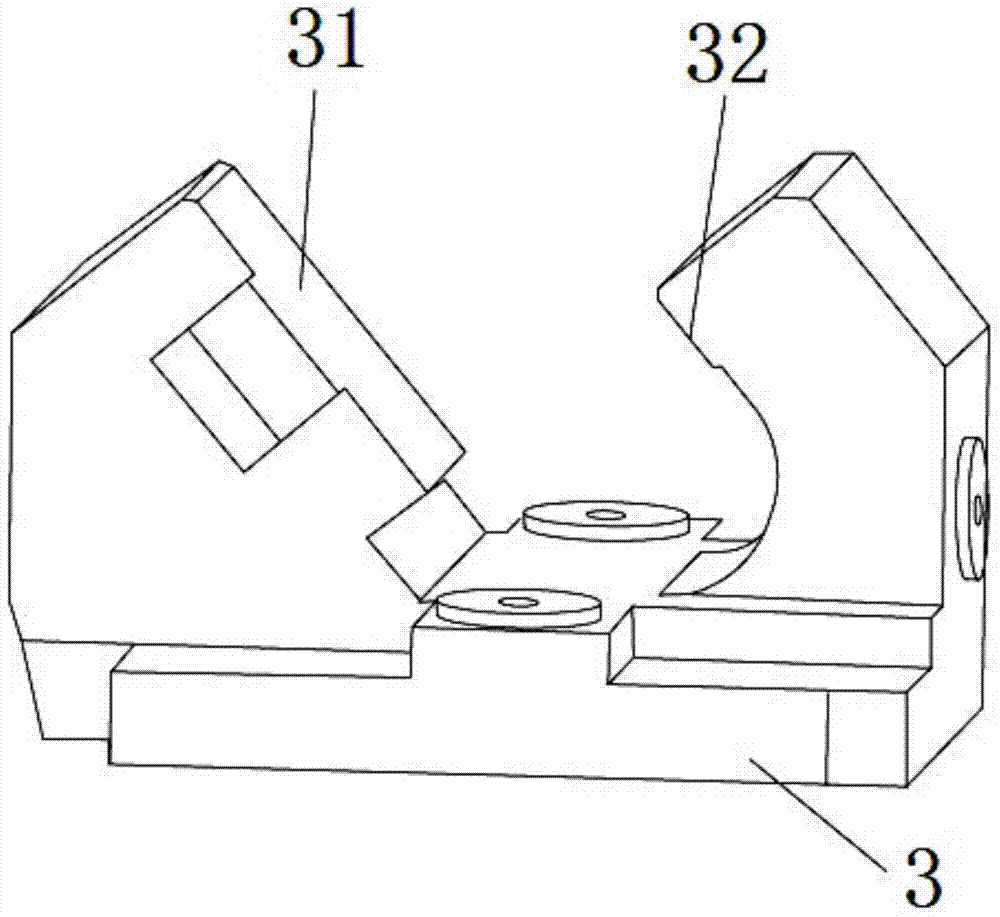

LED module installing mechanism

ActiveCN104723074AEasy to adjustSave adjustment timeCasings/cabinets/drawers detailsPrintingLED displayEngineering

The invention discloses an LED module installing mechanism. The LED module installing mechanism comprises a fixed rack (2), a gap adjusting mechanism on the fixed rack (2), and at least two moving blocks (3) movably connected with the fixed rack (2). LED modules (100) are arranged on the moving blocks (3). The two ends of the gap adjusting mechanism are connected with the moving blocks (3) respectively. By adjusting the moving block (3) on the two sides to move away or get close to each other, a gap between the LED modules (100) arranged on the moving blocks (3) is adjusted. The invention belongs to the technical field of LED modules and LED display screens. According to the LED module installing mechanism, the technical problems in the prior art that the method for adjusting the planar gap between the LED modules is complex and unstable, and the adjustment on the planeness which is perpendicular to the planar direction of the LED modules is unable to achieve are solved. The LED module installing mechanism is particularly applicable to adjusting the planeness perpendicular to the direction of the LED modules and the planar gap between the LED modules, the adjusting operation is simple, and the adjusting effect is stable.

Owner:GLUX VISUAL EFFECTS TECH (SHENZHEN) CO LTD

Austenite stainless steel and a manufacturing technology thereof

ActiveCN104032233AGood dimensional stabilityImprove mechanical propertiesNuclear reactorManufacturing technology

The invention discloses austenite stainless steel comprising, by weight: C <=0.08%, Si 0.20%-0.70%, Mn 0.50%-1.50%, Ni 19.00%-22.00%, Cr 23.00%-25.00%, Mo 2.65%-2.88%, P <0.005%, S <0.005% and Co < 0.01%. The rest is Fe and impurities. The invention also discloses a manufacturing technology of the above-mentioned austenite stainless steel. The stainless steel of this invention has good creeping performance, oxidation performance, corrosion performance and so on. The stainless steel has good neutron economic performance and cost economic performance. The stainless steel has good anti-neutron void swelling performance, can meet the application needs of SCWR fuel canning or reactor internals, and can provide candidate materials for SCWR. In addition, the stainless steel can also meet the needs of constantly enhanced nuclear reactor temperature, safety and economy.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

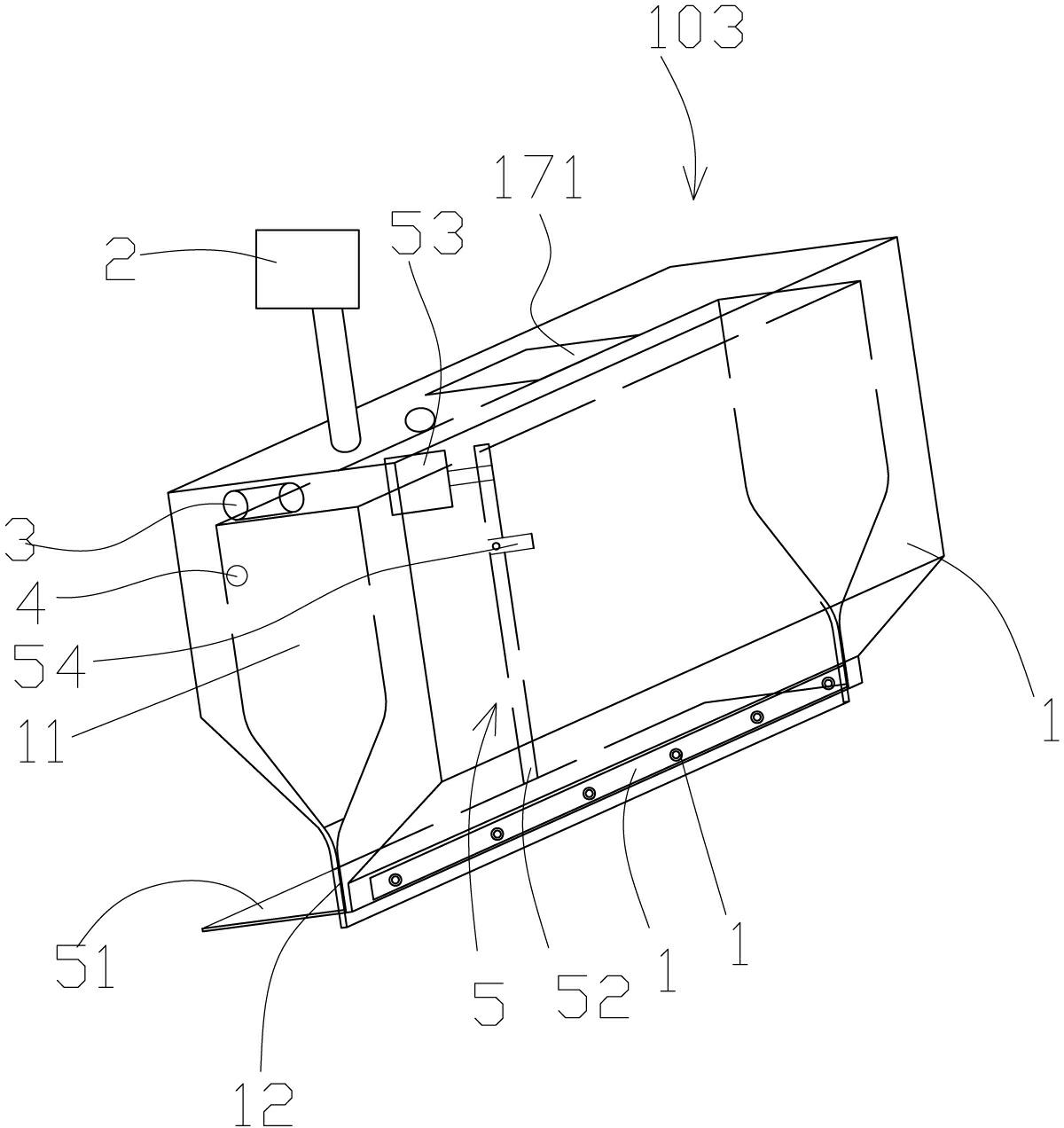

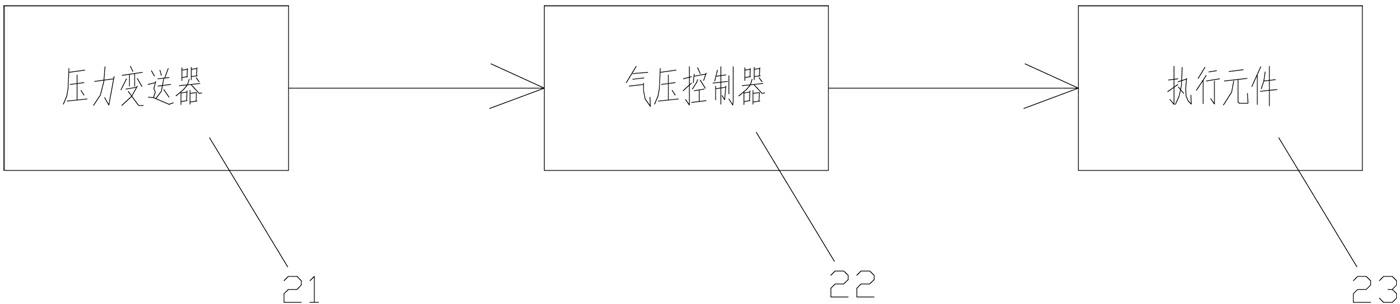

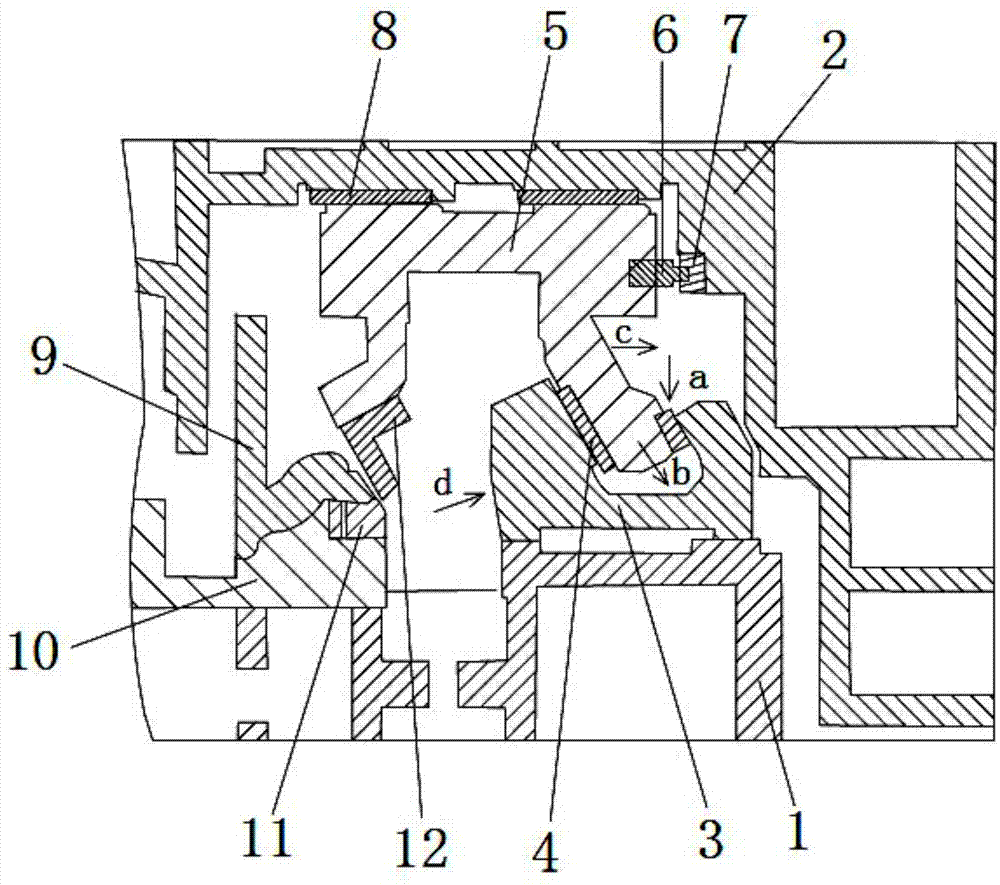

Novel slit type spray head and spray coating machine head

InactiveCN102527578AConstant material pressureQuick responseLiquid surface applicatorsCoatingsSpray nozzleEngineering

The invention discloses a novel slit type spray head, which comprises a spray head main body, a constant-pressure gas supply system, a slurry supply control system and a slit type spray nozzle switch control device, wherein an accommodation cavity and a slit type spray nozzle are formed in the spray head main body; the accommodation cavity is communicated with the slit type spray nozzle; the constant-pressure gas supply system is used for providing constant-pressure gas for the accommodating cavity; the slurry supply control system comprises a slurry supply device and a liquid level control system; the liquid level control system is used for controlling the operating condition of the slurry supply device according to the liquid level of slurry in the accommodation cavity to keep the liquid level of the slurry in the accommodation cavity constant; and the slit type spray nozzle switch control device is used for opening or closing the slit type spray nozzle according to signals of a main control device. By the novel slit type spray head, the problems of thick starting heads and stripe existence of the original spray coating machine are solved, and the stability and the consistency of gaps among coated electrodes can be ensured. In addition, the invention has the advantages that the novel slit type spray head is easy to manufacture and has low cost.

Owner:SHENZHEN XINYUREN TECH

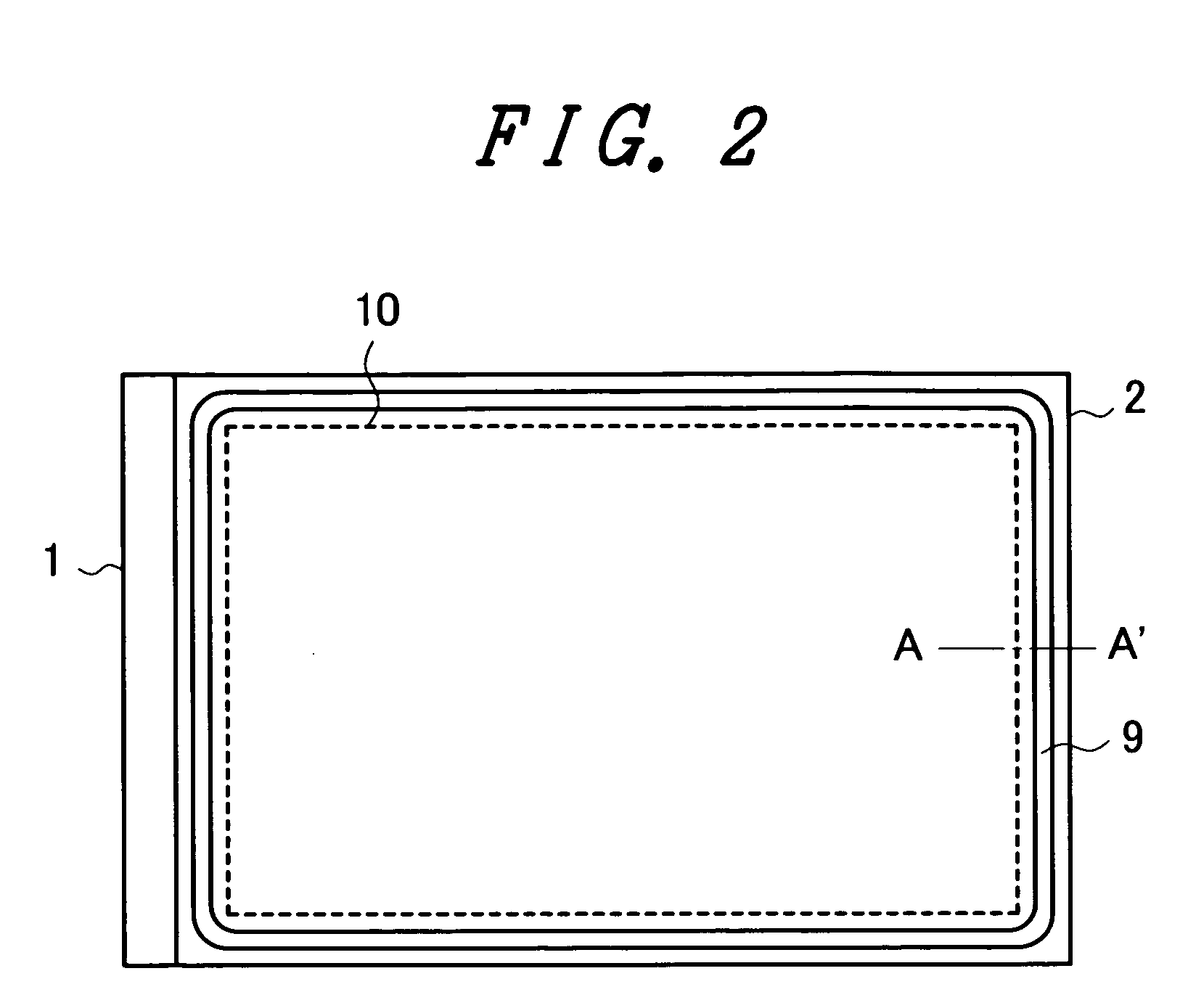

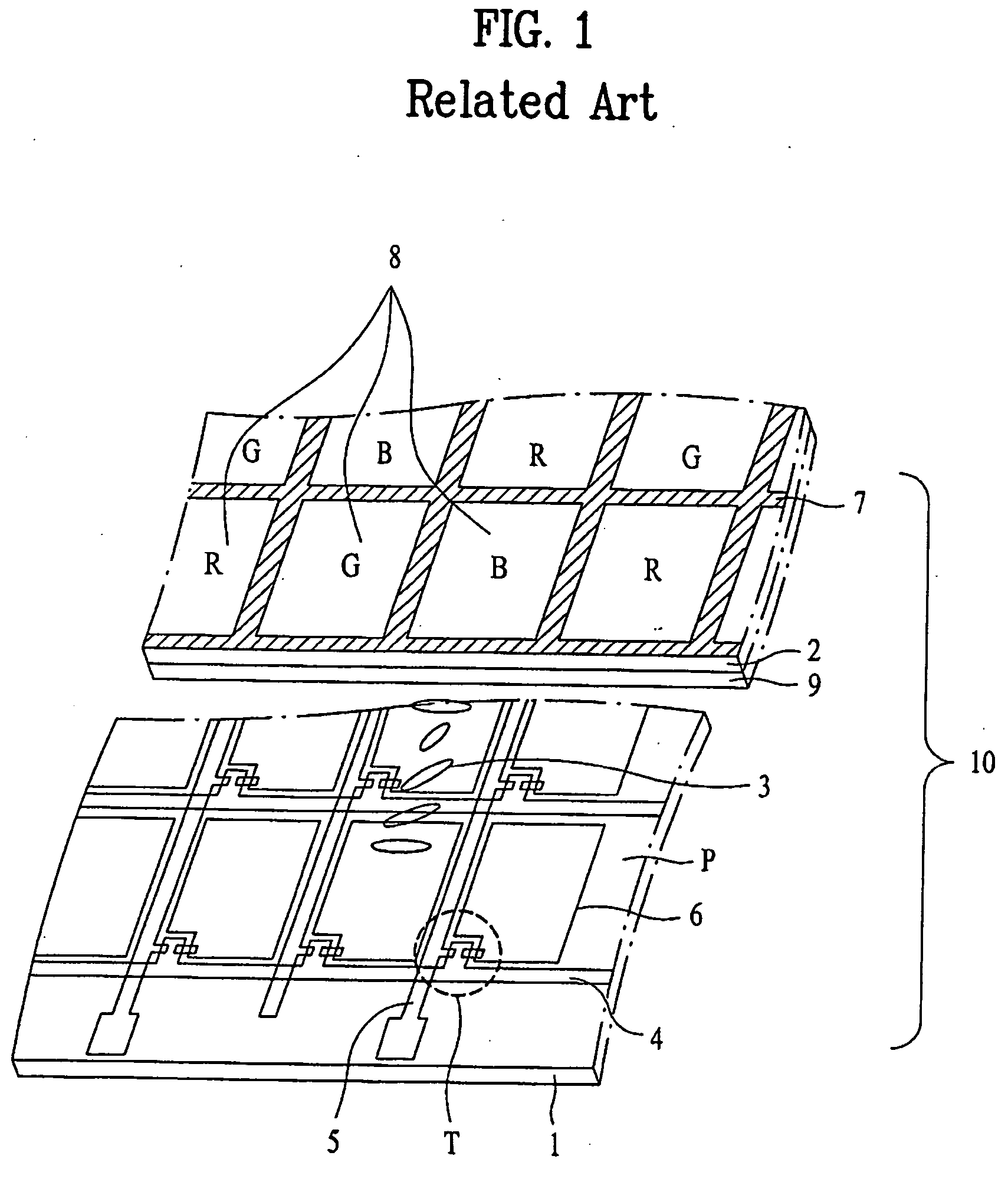

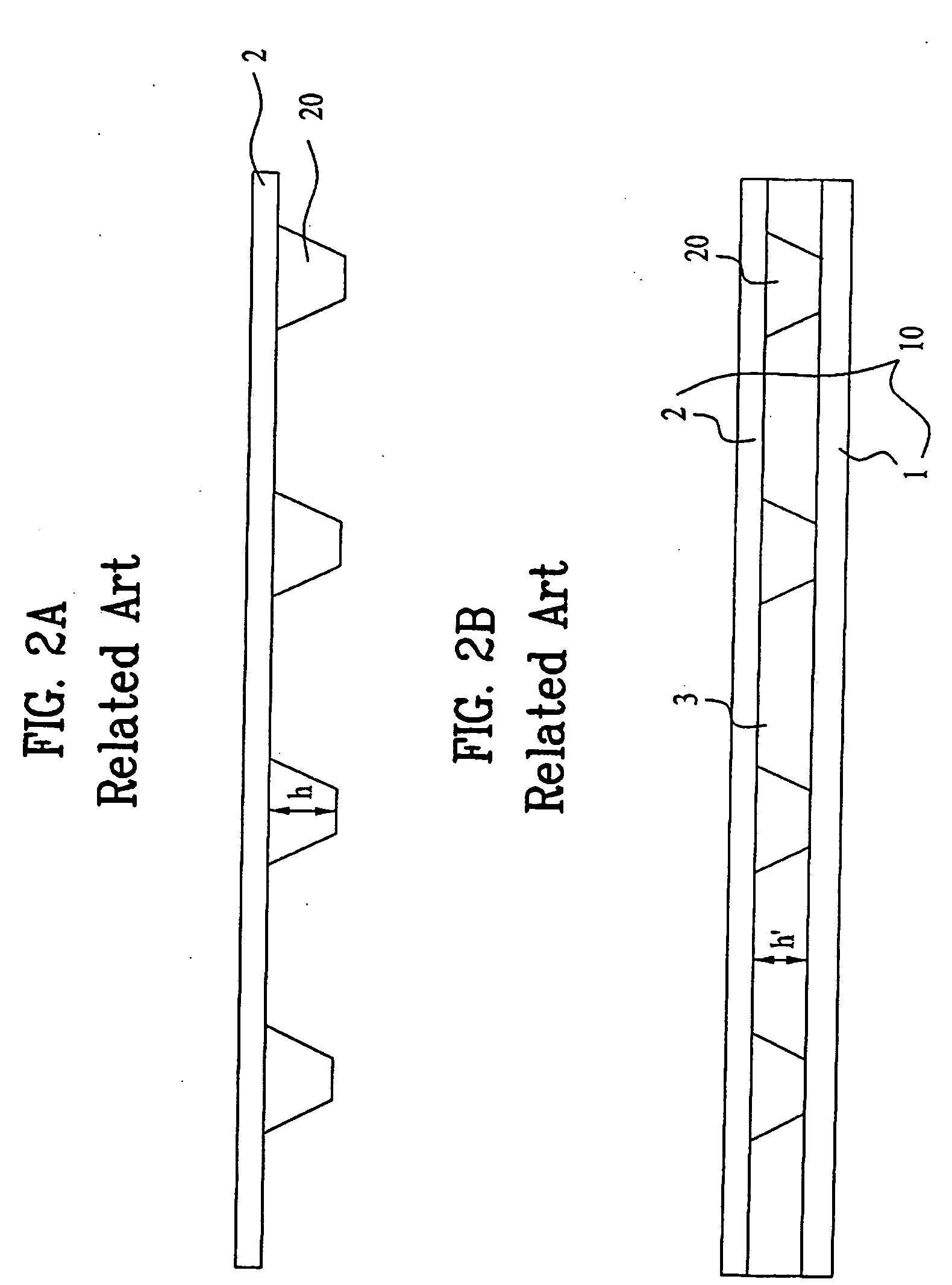

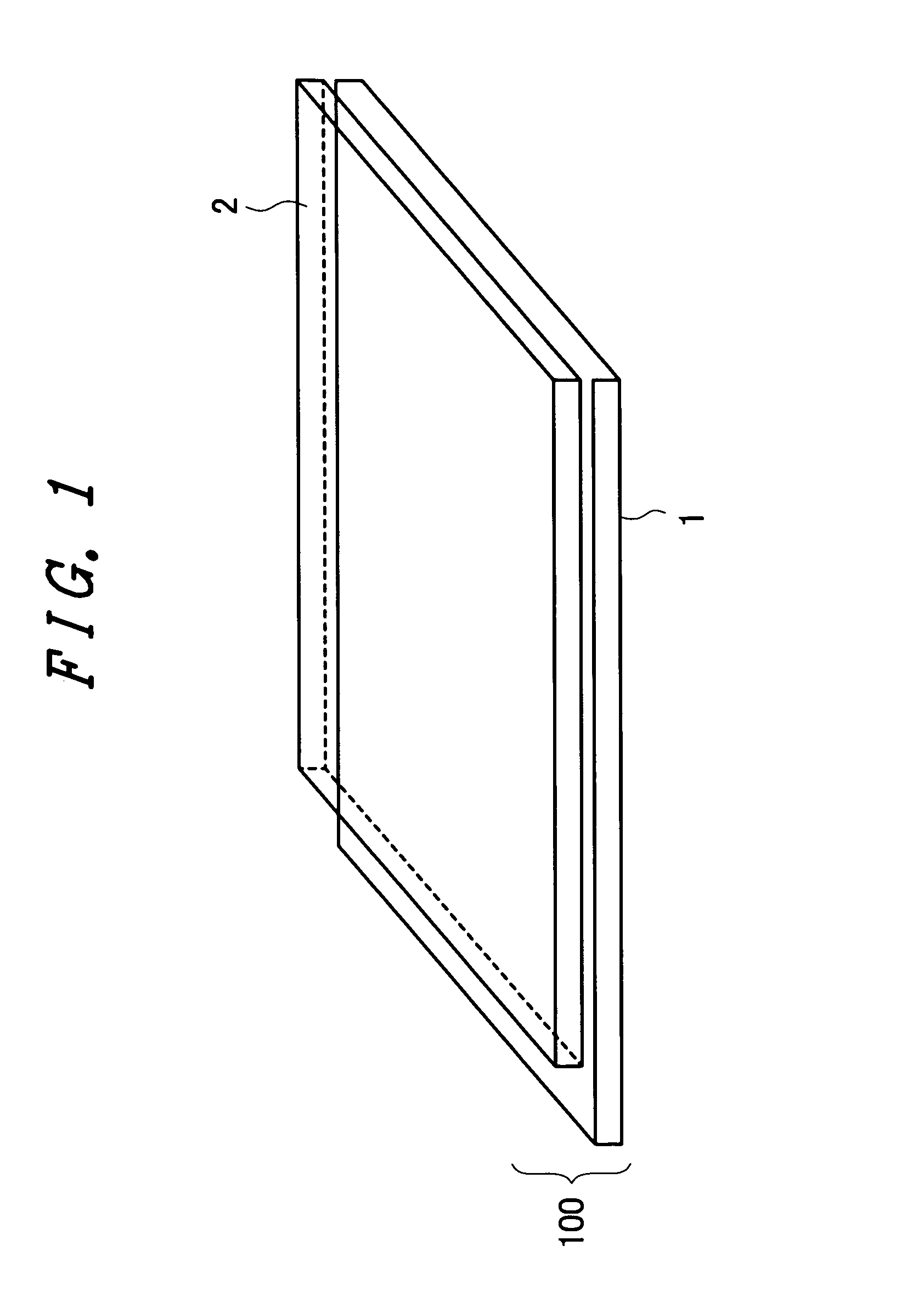

Liquid crystal display device

ActiveUS20080192186A1High bonding strengthQuality improvementNon-linear opticsLiquid-crystal displayEngineering

The present invention provides a liquid crystal display device which can enhance quality and reliability of image display by preventing the generation of bubbles in the inside of a liquid crystal display panel and, at the same time, by suppressing leaking of light from an end of a black matrix film. In the liquid crystal display panel which sandwiches a liquid crystal layer between two glass substrates, the liquid crystal layer is surrounded by a sealing material having a predetermined width. On one glass substrate, a black matrix film and an overcoat film are arranged from one-glass-substrate side such that the black matrix film and the overcoat film overlap the sealing material. The black matrix film is, in the widthwise direction of the sealing material, formed into a planar flat black matrix film until a middle position of the sealing material from a side on which the liquid crystal layer is arranged, and is formed into a slit-shaped slit black matrix film from the middle position. Due to such a constitution, an adhesion area between the glass substrate and the overcoat film under an applied region of the sealing material is enlarged and hence, an adhesion strength is increased thus largely enhancing an adhesion strength.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

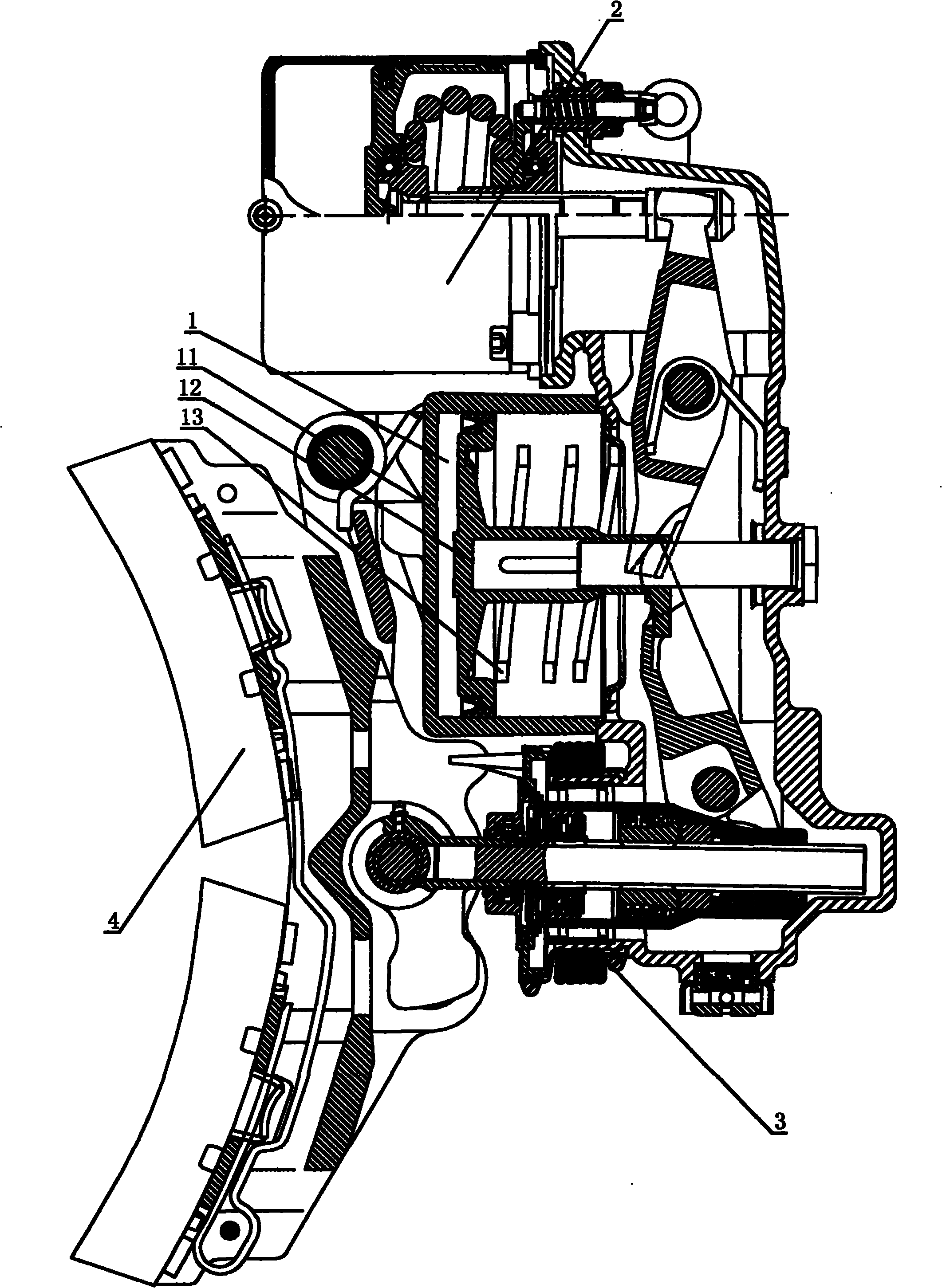

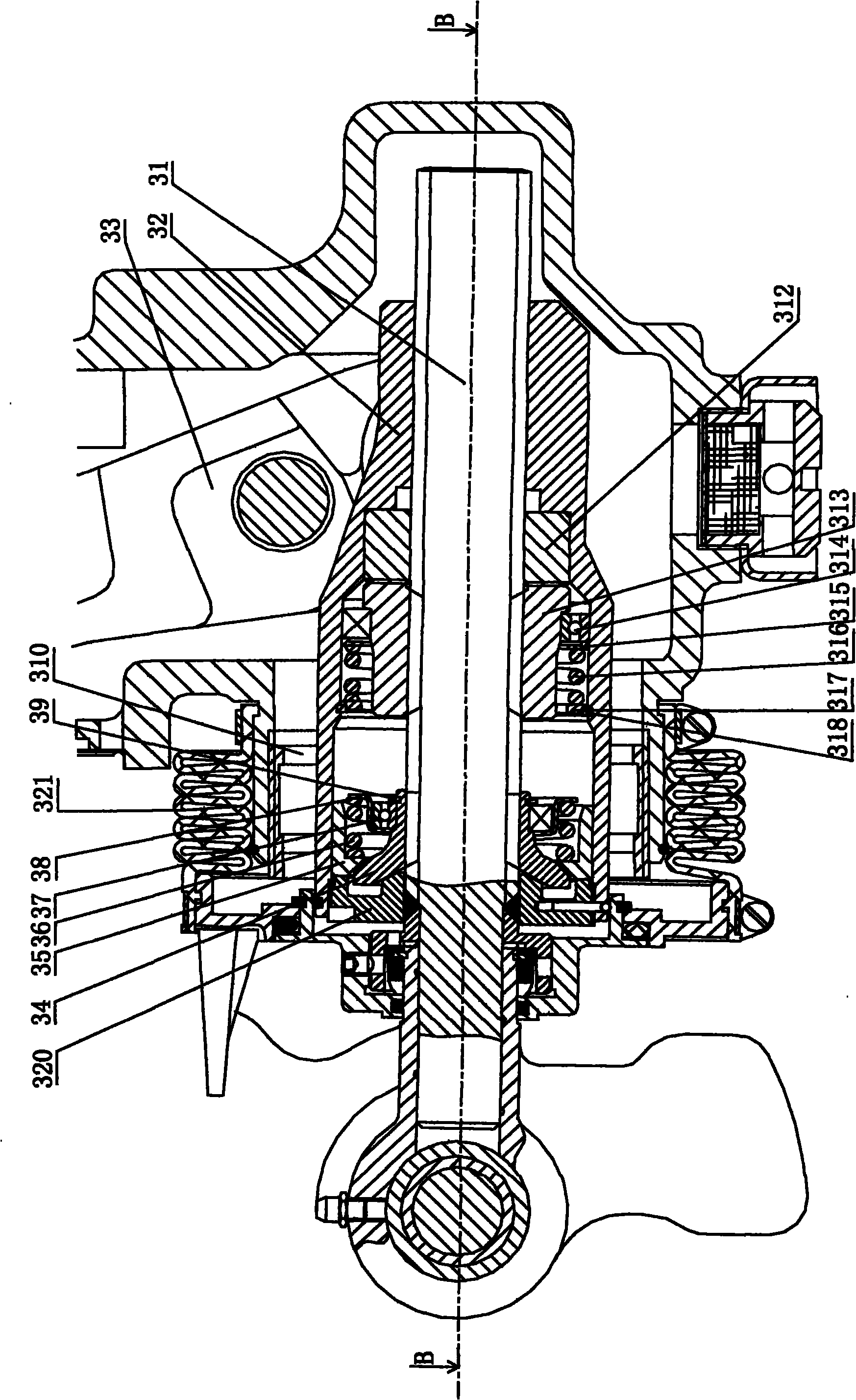

Brake for railway vehicle unit

ActiveCN102060032ATake advantage ofReduce excess spaceBrake wear compensation mechanismRail brake actuationEngineeringStops device

The invention relates to a brake for a railway vehicle unit, which is provided with a brake box body, a brake release device (1) located on the brake box body, a spring stopping device (2) and a brake-shoe abrasion backlash compensation adjuster (3). A brake-shoe assembly (4) is located at the end part of the brake-shoe abrasion backlash compensation adjuster (3). The invention has the advantagesof simple integral structure, reasonable design, space saving, small volume, convenience for installation, uniform force and firm and wearable force propagation path segment. The brake release deviceis used for adjusting the brake-shoe directly via the brake-shoe abrasion backlash compensation adjuster and the spring stopping device can directly control the brake-shoe assembly via a spring stopping lever and the brake-shoe abrasion backlash compensation adjuster.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

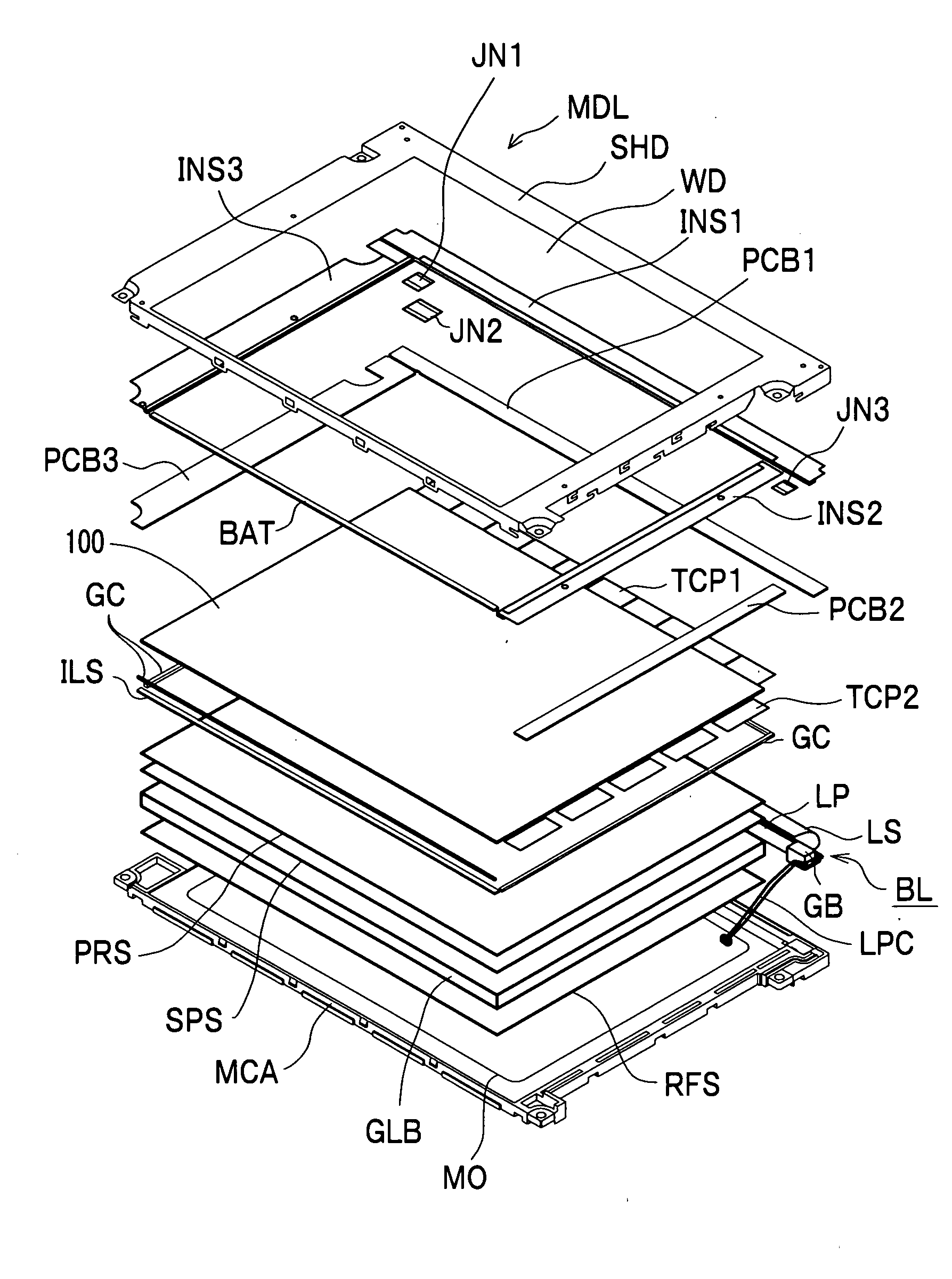

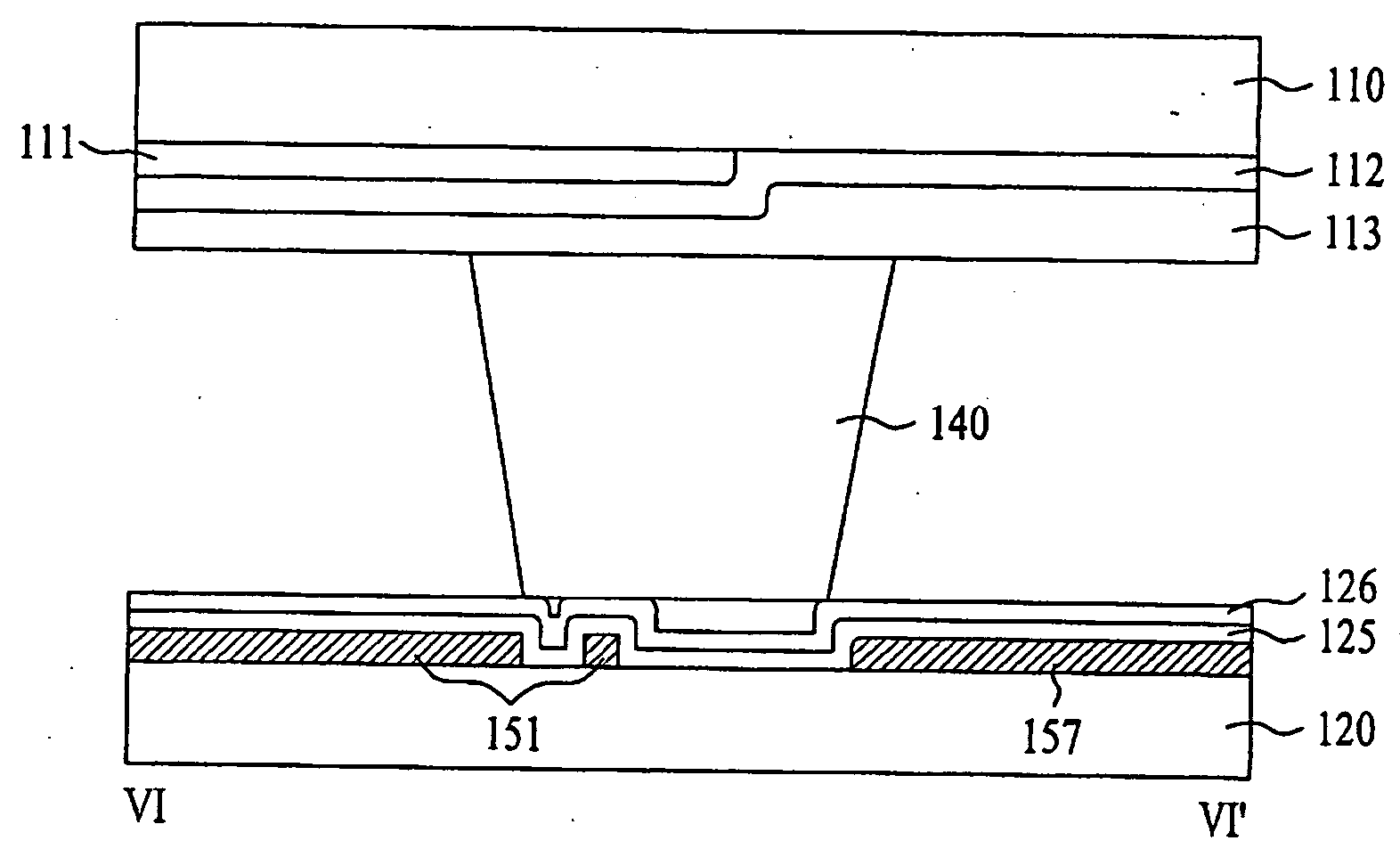

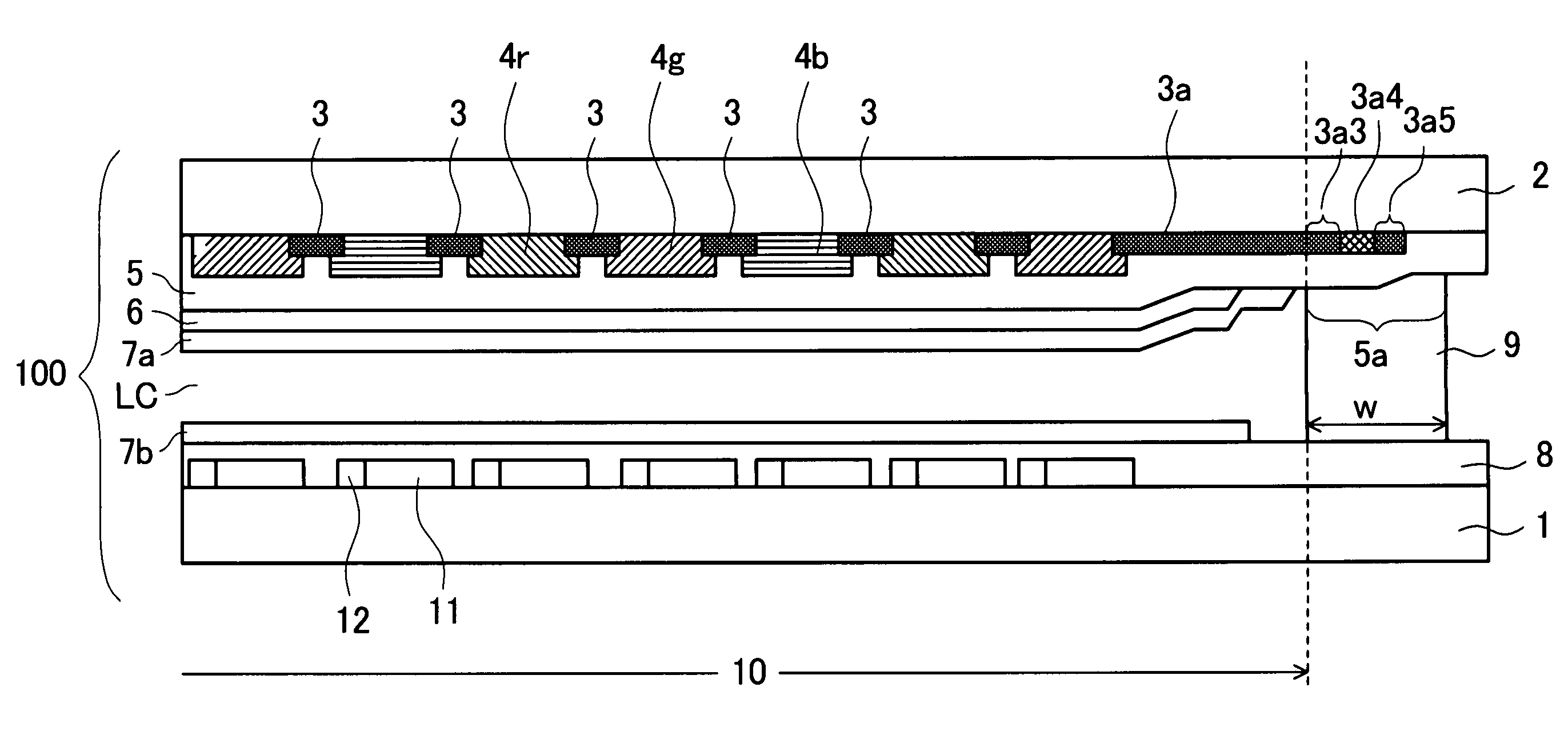

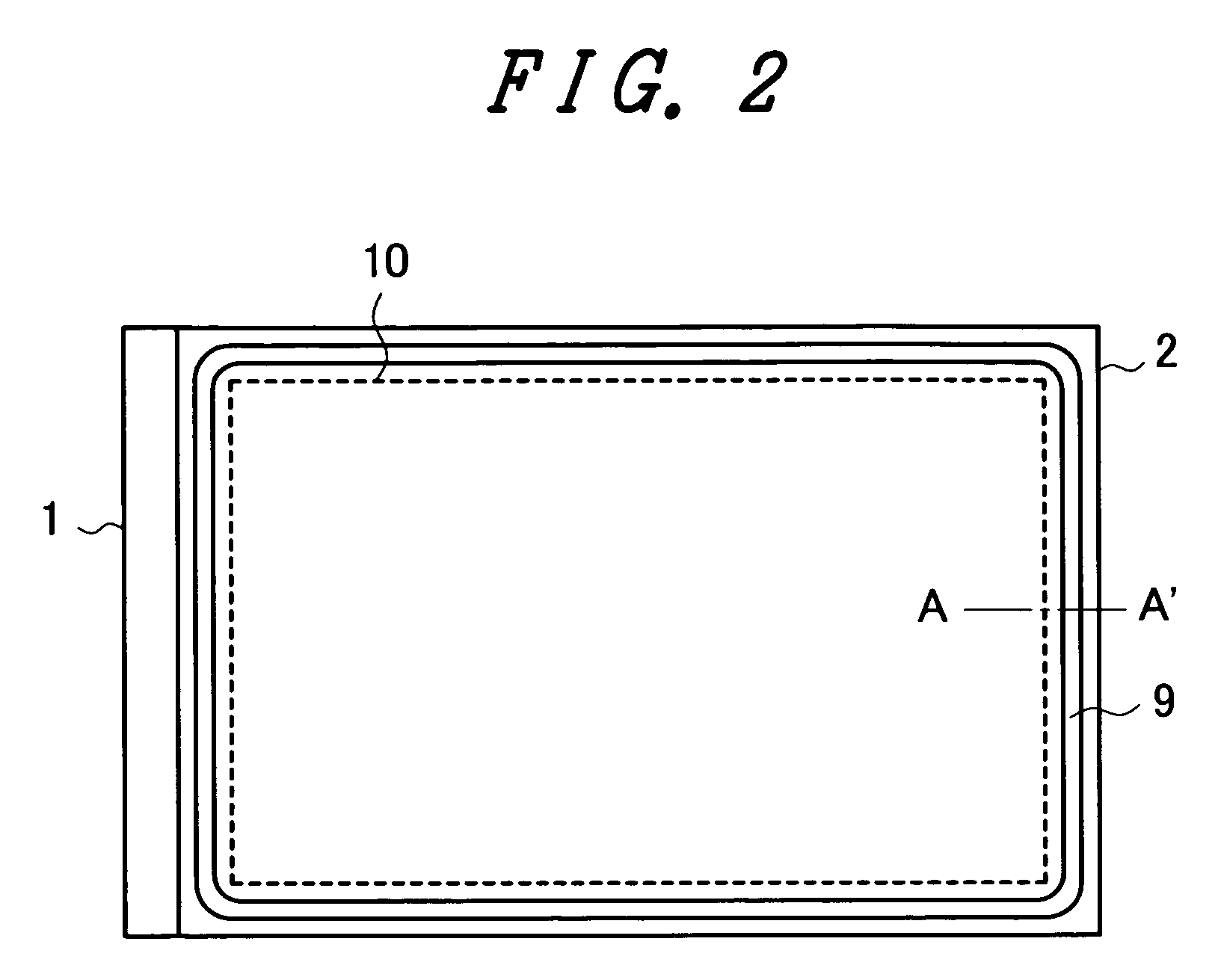

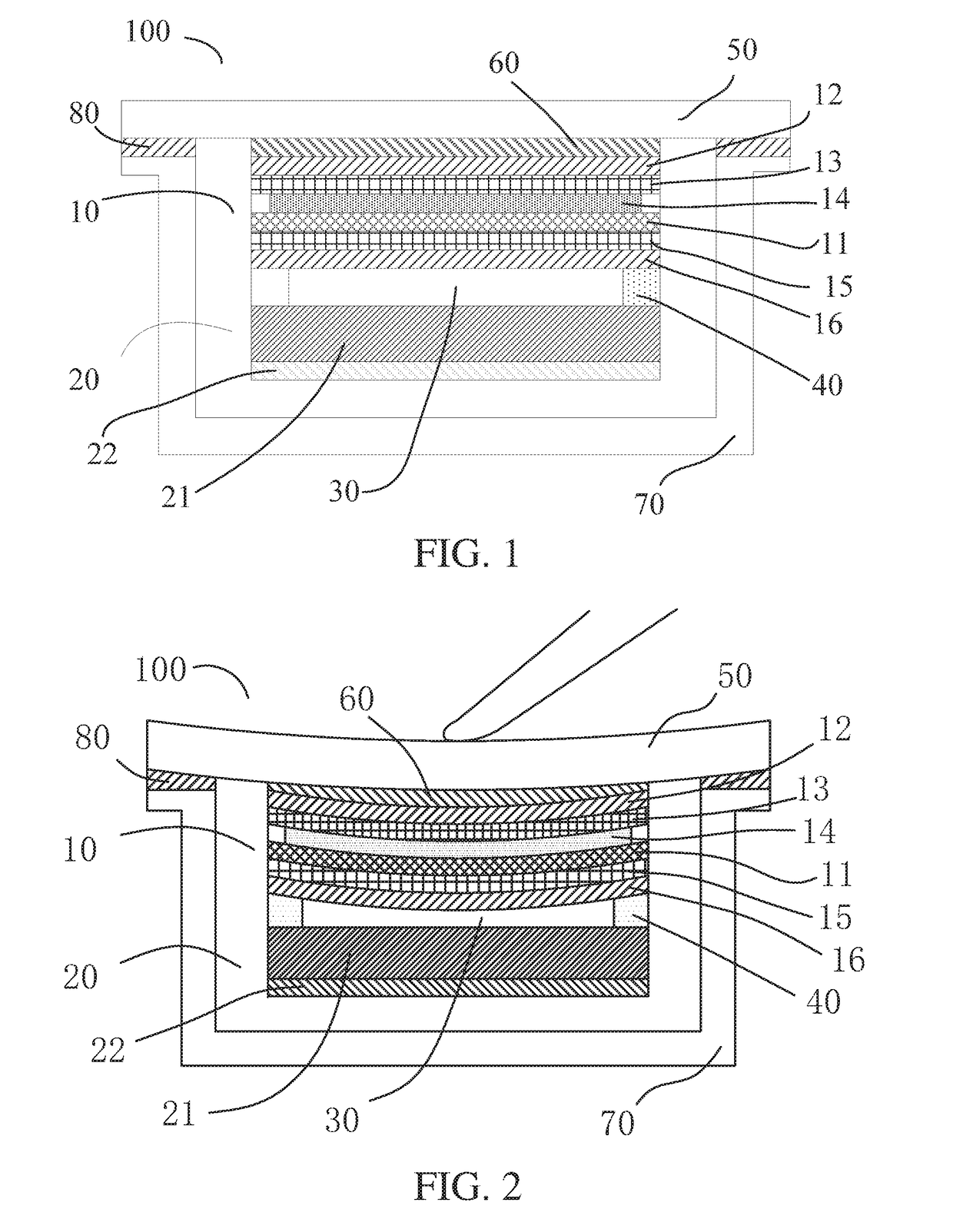

Liquid crystal display device

ActiveUS20060146222A1Reduce contact areaStable cell gapNon-linear opticsLiquid-crystal displayEngineering

An LCD device is disclosed in which column spacers for a cell gap are arranged between gate and common lines to reduce a contact area between the column spacers and an opposing substrate, and a stable cell gap is maintained over the whole panel by reducing variation of a thickness per area of a thin film transistor (TFT) substrate corresponding to the column spacers. The LCD device includes first and second substrates facing each other, gate and data lines formed on the first substrate to cross each other, and pixel regions, a thin film transistor formed in each portion where the gate and data lines cross, common and pixel electrodes alternately formed in the pixel regions, common lines formed adjacent to the gate lines substantially parallel to the gate lines, a first column spacer formed on the second substrate corresponding to a portion between the gate line and the common line, and a liquid crystal layer filled between the first and second substrates.

Owner:LG DISPLAY CO LTD +1

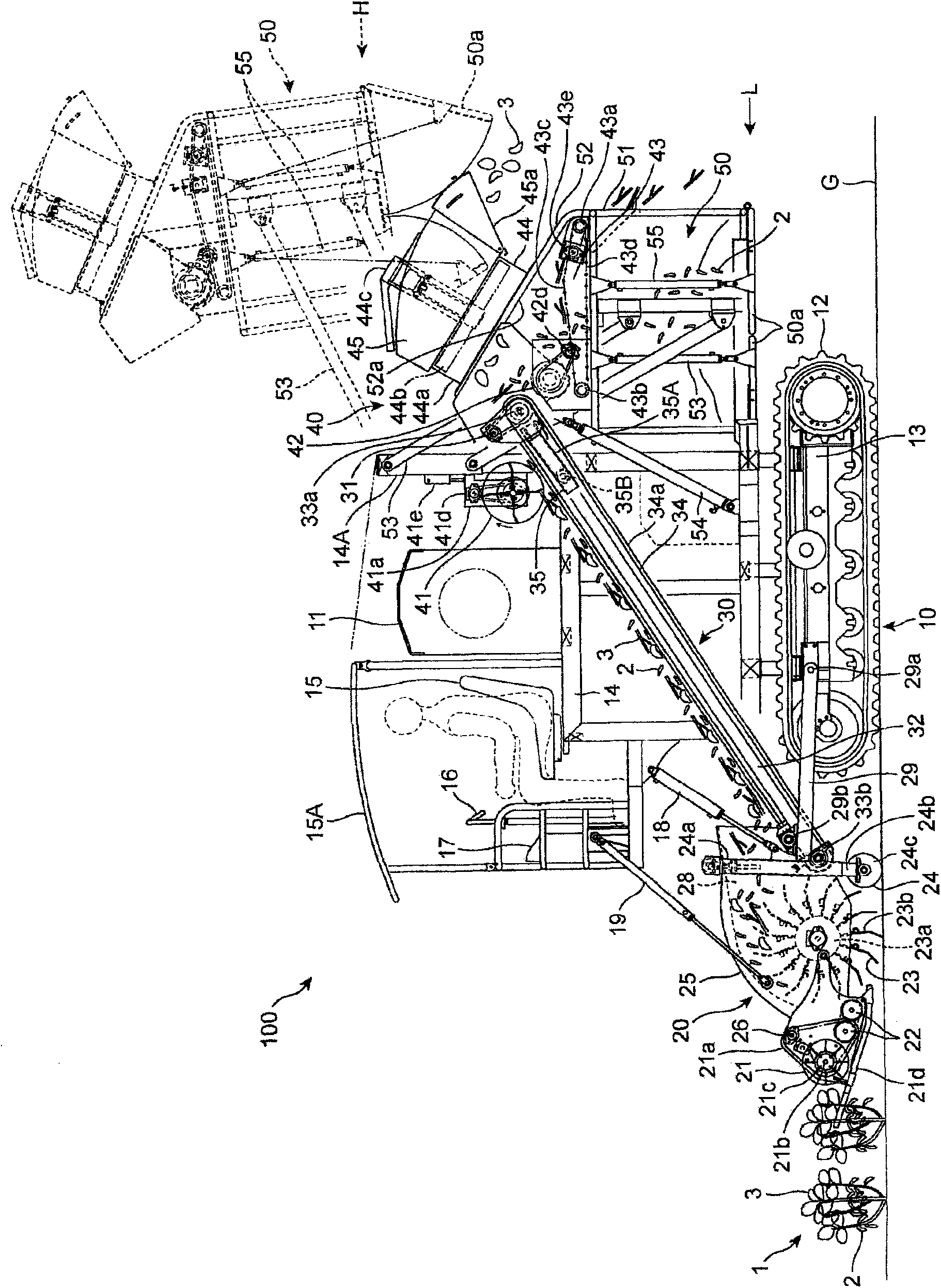

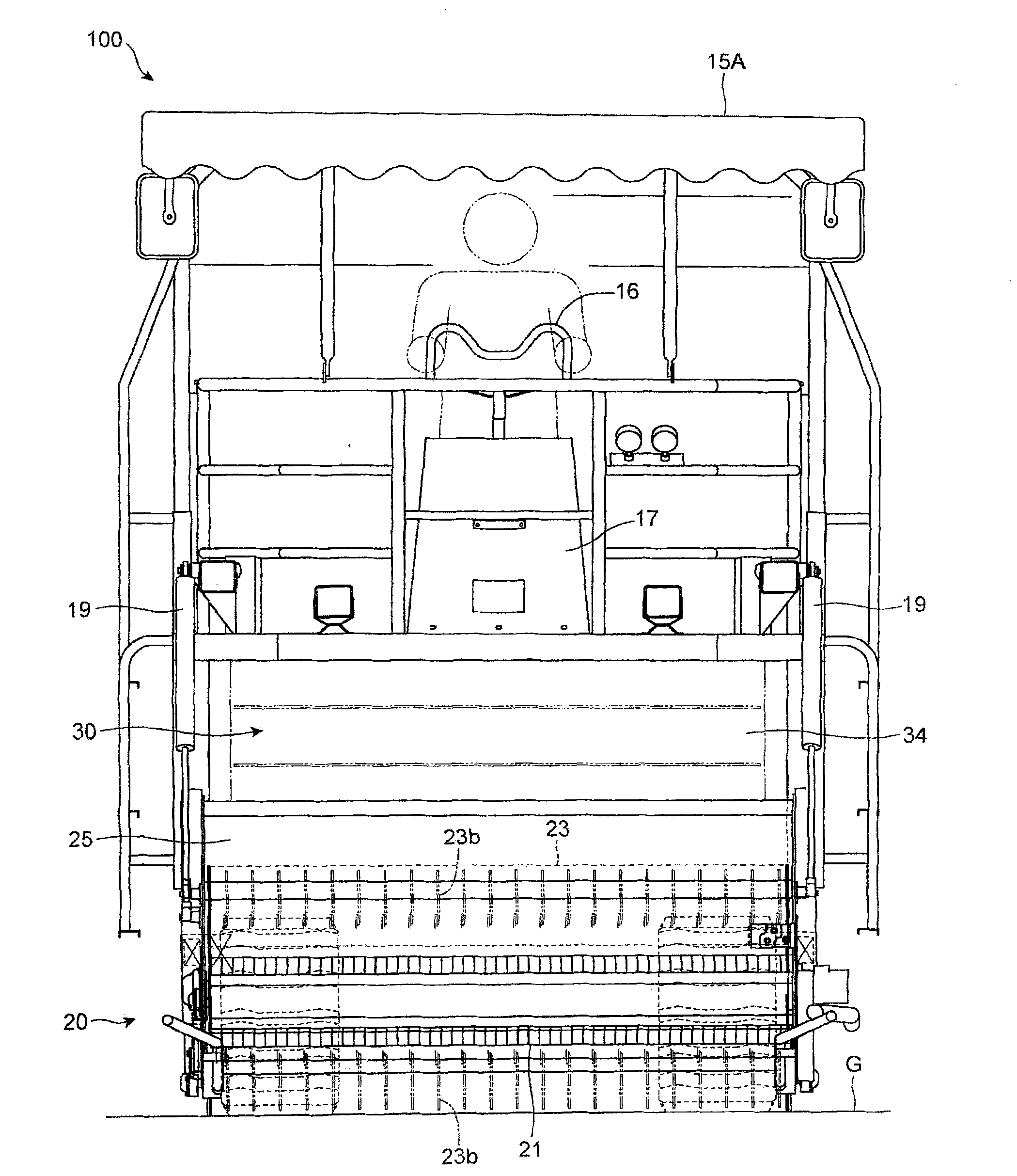

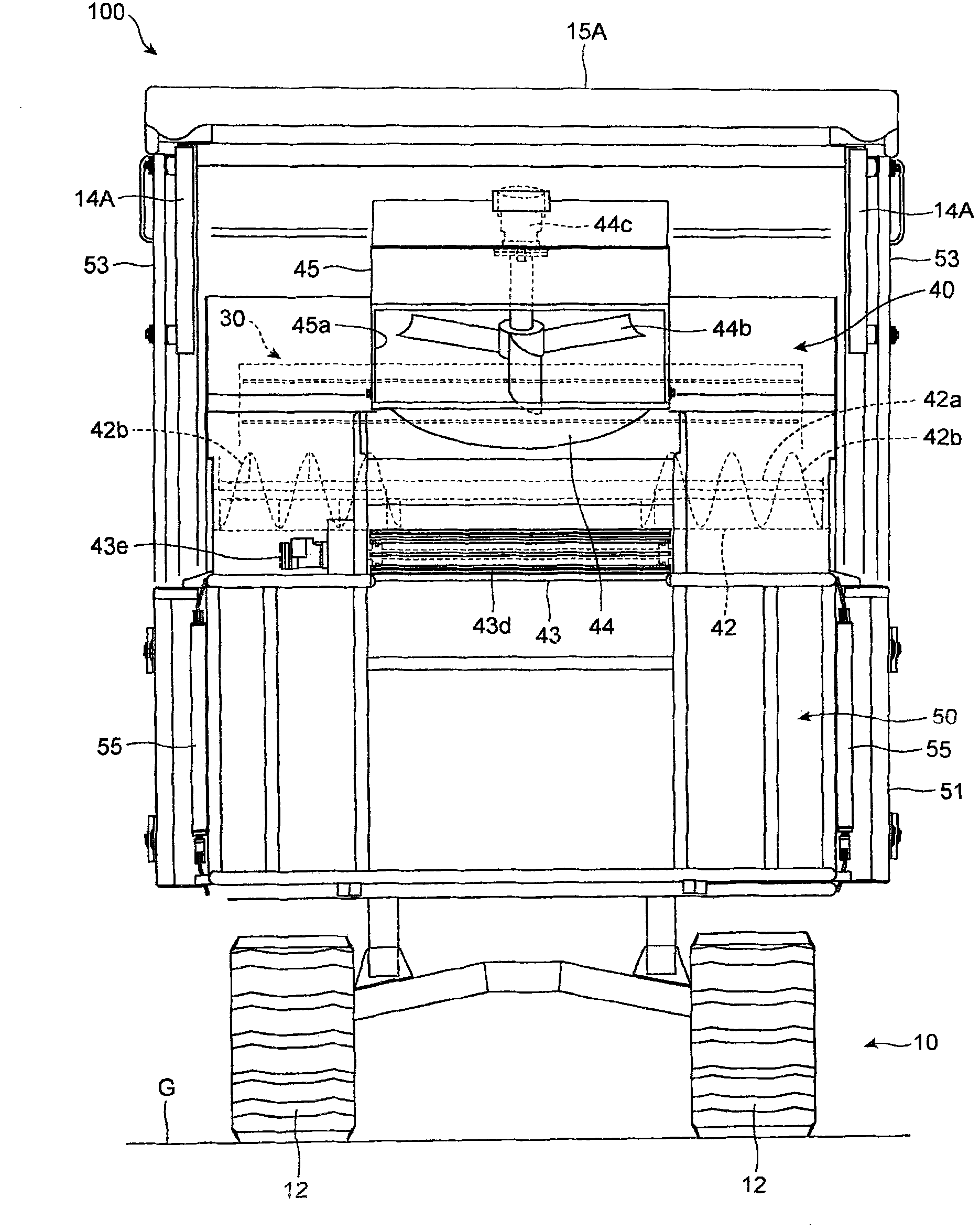

Green soybean harvesting machine

Owner:QINGDAO QINGKAIYUAN ECONOMIC & TECH SERVICE

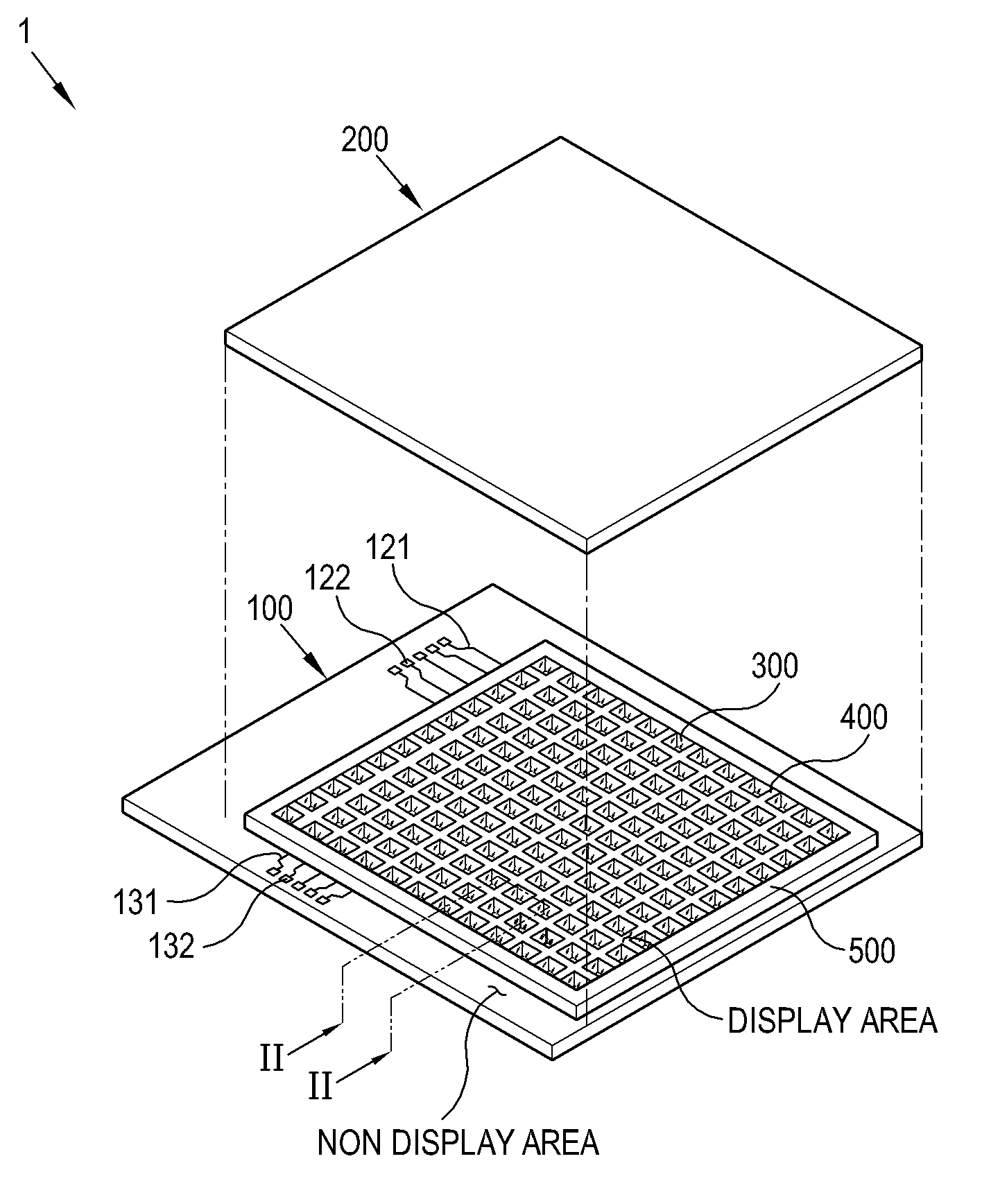

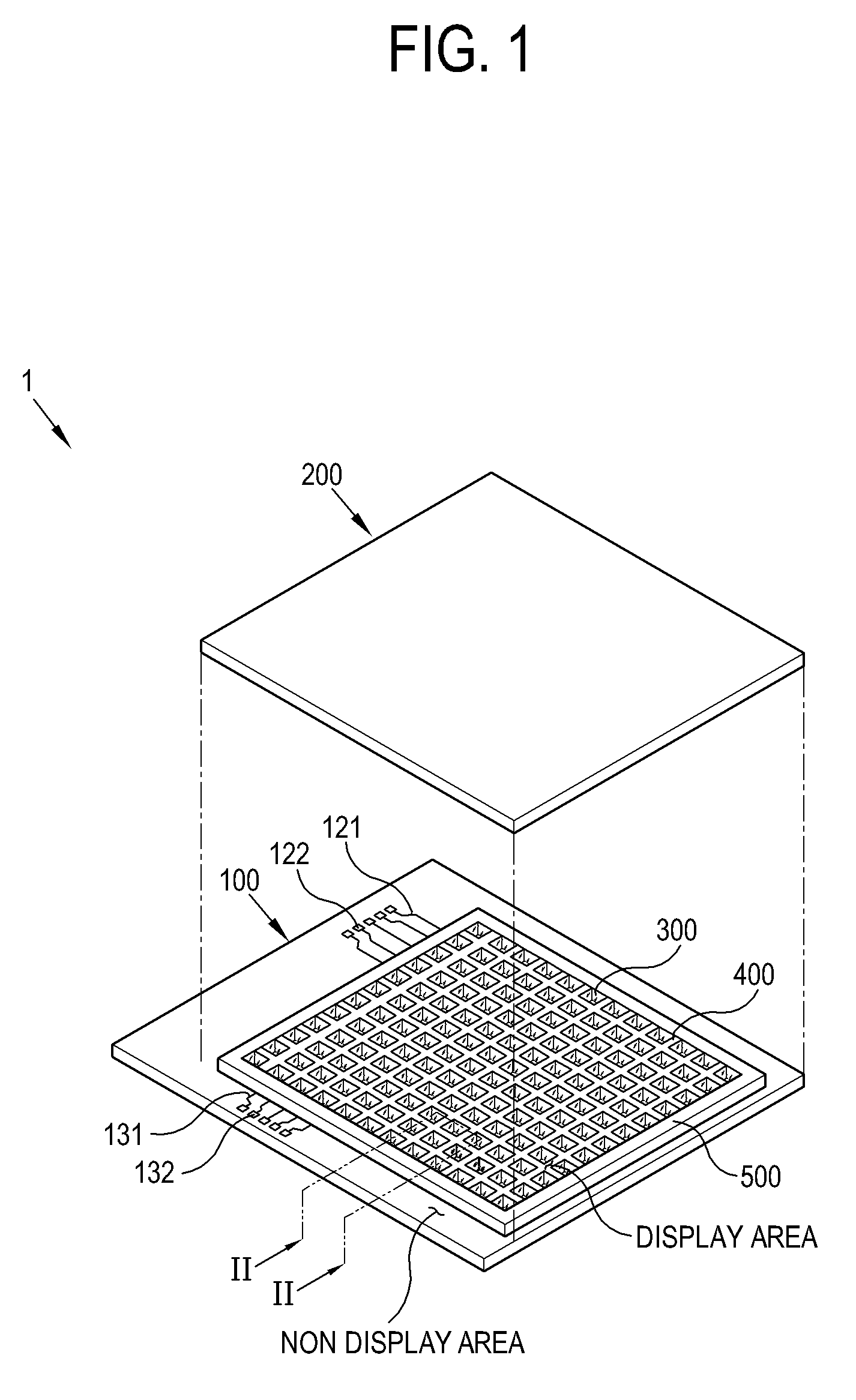

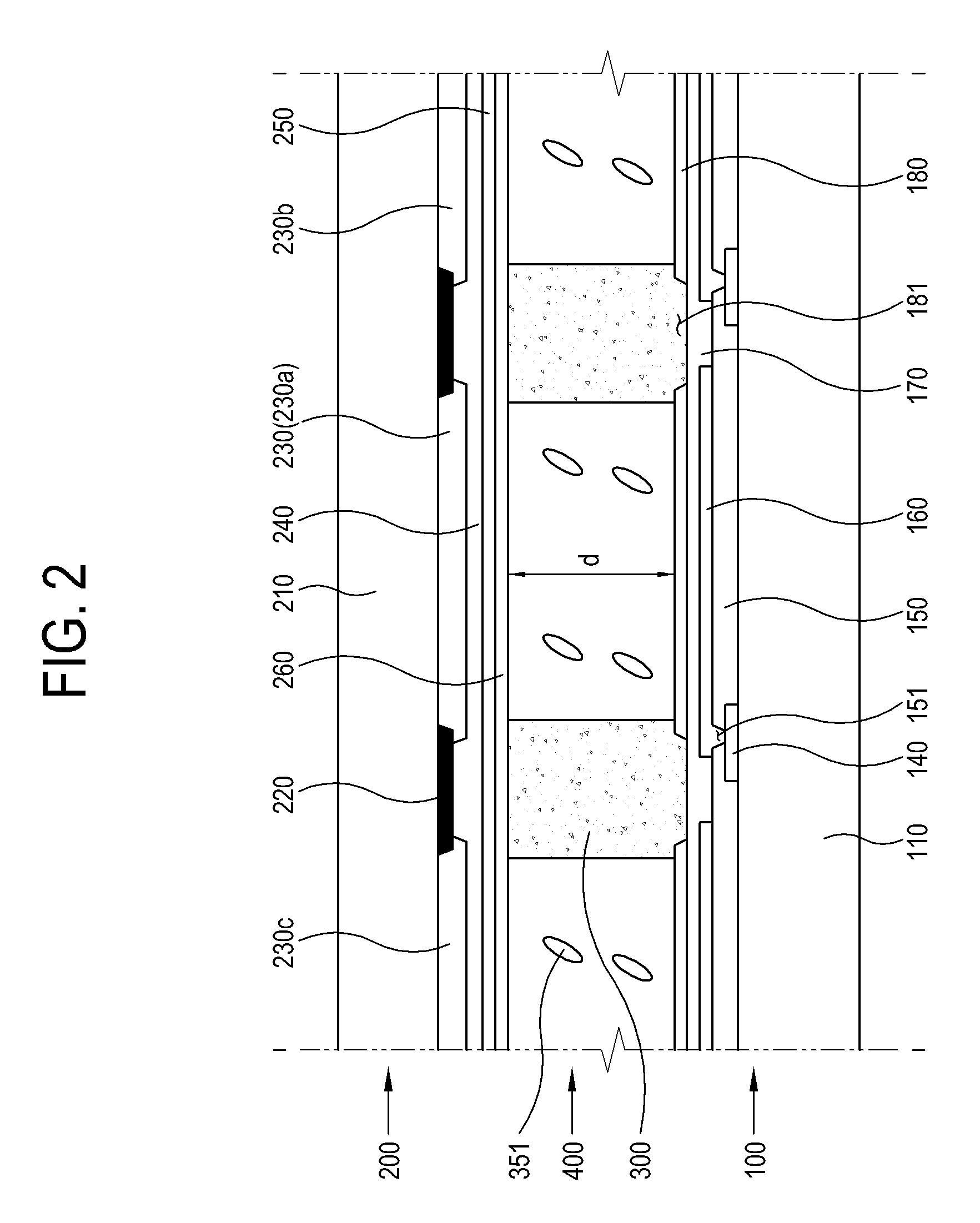

Liquid crystal display device and manufacturing method thereof

A liquid crystal display device, includes a first substrate including a first insulating substrate, a first thin film positioned on the first insulating substrate, and a first alignment layer positioned on the first thin film and including a first exposing area that exposes the first thin film, a second substrate facing the first substrate and including a second insulating substrate, a spacer positioned between the first substrate and the second substrate and including at least a part that corresponds to the first exposing area, and a liquid crystal layer positioned between the first substrate and the second substrate.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV) +1

One component resin composition curable with combination of light and heat and use of the same

A one component resin composition curable with a combination of light and heat, which comprises (1) an epoxy resin, (2) an acrylic ester monomer and / or methacrylic ester monomer, or an oligomer thereof, (3) a latent epoxy curing agent, (4) a photo radical initiator, and (5) a compound having two or more thiol groups per molecule, wherein the ingredient (5) is contained in an amount of 0.001 to 5.0 parts by weight per 100 parts by weight of this resin composition. According to the present invention, a one component resin composition curable with a combination of light and heat, which has excellent curability especially in a light-shielded area can be provided. Also, a liquid crystal sealant composition curable with a combination of light and heat, which is applicable to the one-drop-fill method and has excellent curability in light-shielded areas and adhesion reliability, especially high-temperature and high-humidity adhesion reliability, can be provided.

Owner:MITSUI CHEM INC +1

Liquid crystal display device

The present invention provides a liquid crystal display device which can enhance quality and reliability of image display by preventing the generation of bubbles in the inside of a liquid crystal display panel and, at the same time, by suppressing leaking of light from an end of a black matrix film. In the liquid crystal display panel which sandwiches a liquid crystal layer between two glass substrates, the liquid crystal layer is surrounded by a sealing material having a predetermined width. On one glass substrate, a black matrix film and an overcoat film are arranged from one-glass-substrate side such that the black matrix film and the overcoat film overlap the sealing material. The black matrix film is, in the widthwise direction of the sealing material, formed into a planar flat black matrix film until a middle position of the sealing material from a side on which the liquid crystal layer is arranged, and is formed into a slit-shaped slit black matrix film from the middle position. Due to such a constitution, an adhesion area between the glass substrate and the overcoat film under an applied region of the sealing material is enlarged and hence, an adhesion strength is increased thus largely enhancing an adhesion strength.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA +1

Hot press for processing dots on surface of light guide plate

The invention relates to the technical field of plastic product production, and particularly discloses a hot press for processing dots on the surface of a light guide plate. The hot press comprises a rack, a manipulator, a transmission mechanism, a roller set, an output tape, a triaxial mechanism and a transmission supporting frame, wherein a base, a roller supporting frame and a lifting block are arranged in the rack; a hydraulic device is arranged in the roller supporting frame; the bottom of the lifting block is in contact with the top of the hydraulic device; die tapes are arranged on the outer sides of rollers in the roller set, and are made of an inert material with high rigidity, high strength, high thermal conductivity and low expansivity; the using times of the die tapes is maintained to be more than 100,000; the interiors of roller shafts are heated automatically, the temperature monitoring is carried out through a monitoring system, and the technical indexes need maintaining through accurate constant temperature; pressure required in product processing is ensured through adopting the linear scale of the product to finely adjust and set equipment distances, and two-stage adjustment of coarse adjustment and fine adjustment are realized; the technical indexes can be adjusted after the equipment distances are stably maintained.

Owner:苏州亿光源光电科技股份有限公司

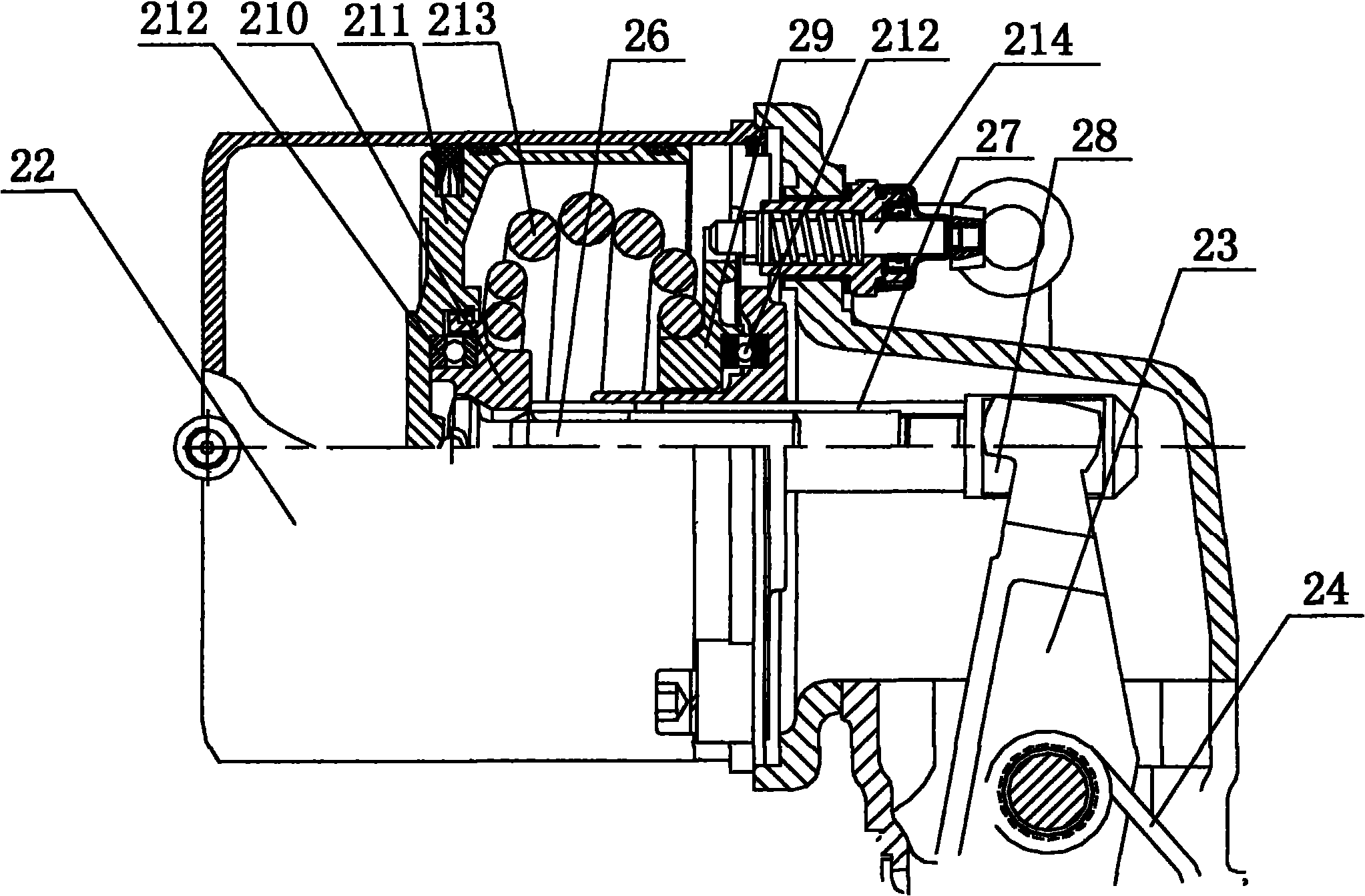

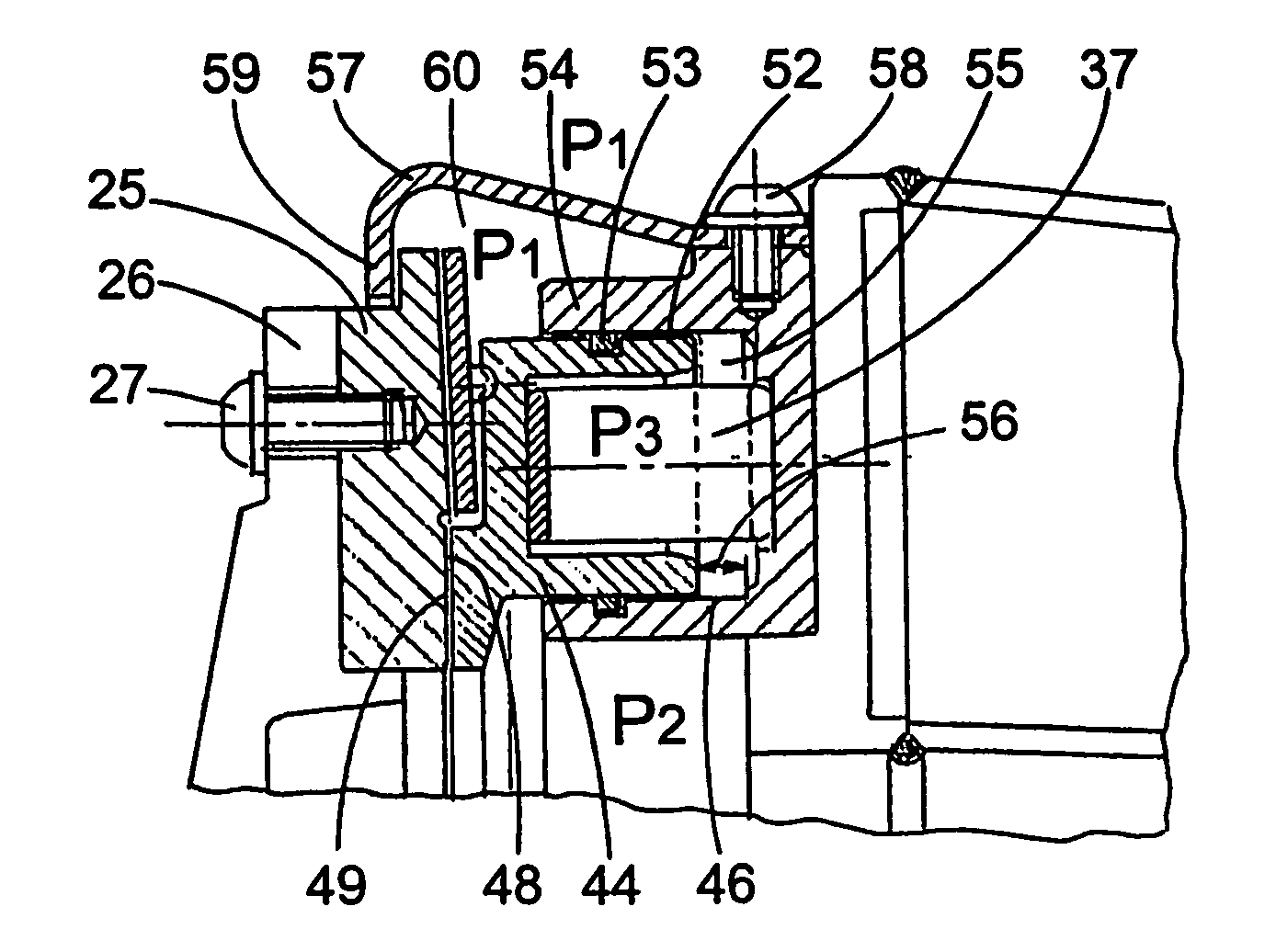

Cleaner head for a vacuum cleaner

ActiveUS20130174373A1Reduce vibrationTaking up assemblySuction nozzlesEngineeringMechanical engineering

A cleaner head for a vacuum cleaner houses a hollow brush bar mounted for rotation about an axis. This brush bar is driven by a motor housed inside the hollow brush bar, the motor forming part of a drive assembly supported at one end of the cleaner head. The brush bar is arranged for removal from the cleaner head by sliding the brush bar along the axis and out through an opening at the opposite end of the cleaner head and the brush bar is rotatably supported in clearance around the drive assembly by a first bearing, which bearing engages the brush bar in a corresponding axial-sliding fit to allow said sliding removal of the brush bar.

Owner:DYSON TECH LTD

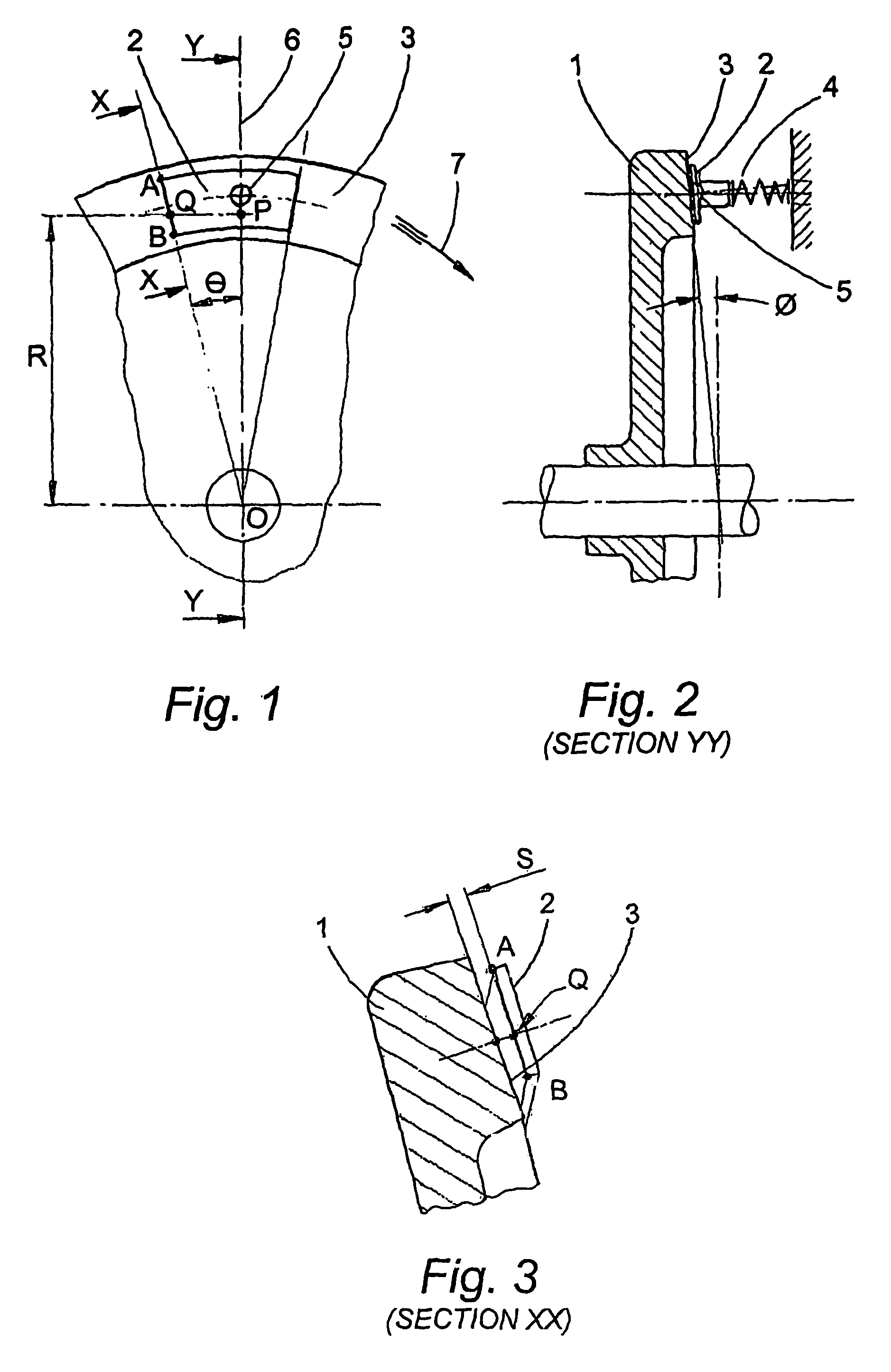

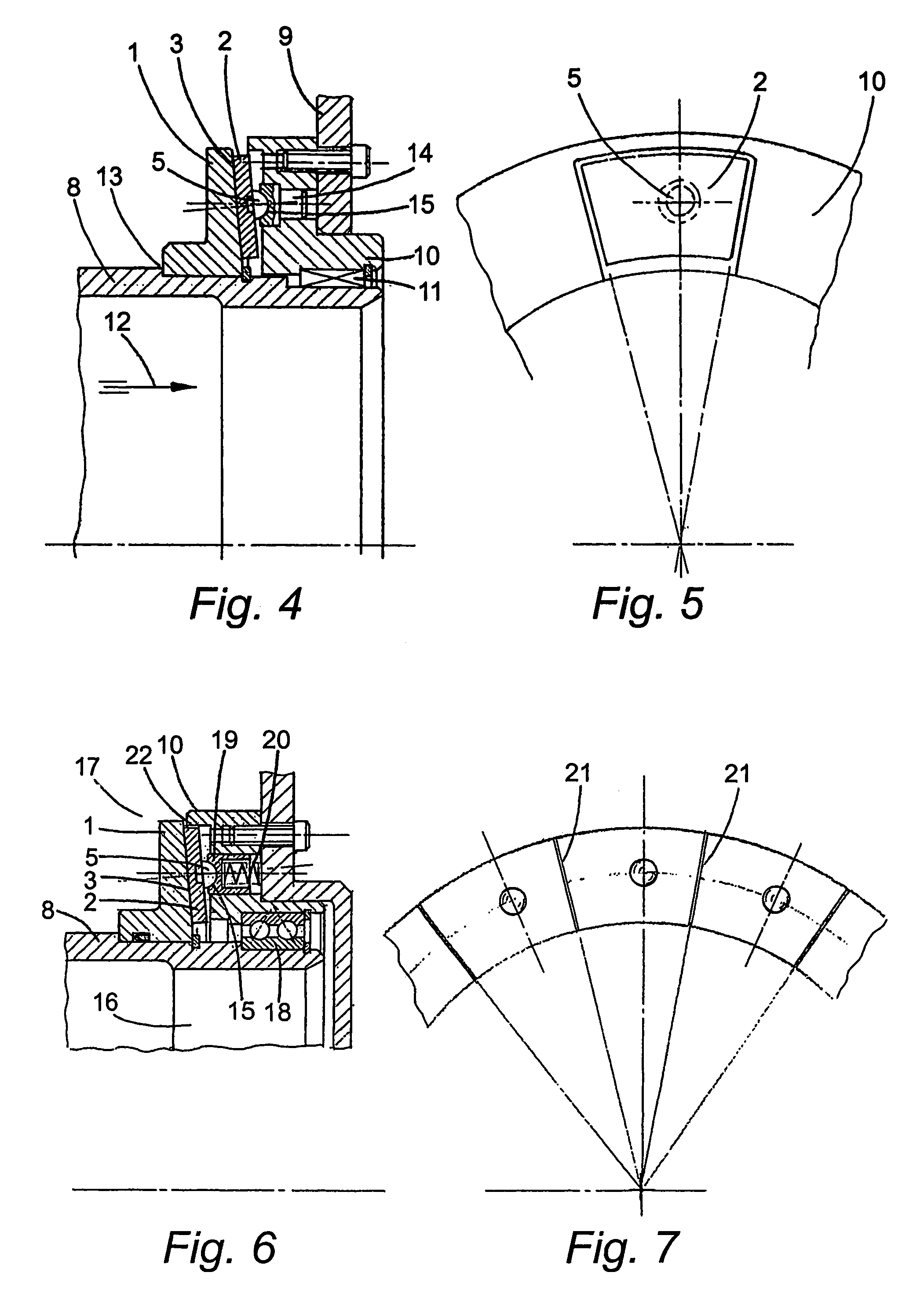

Non-contacting face seals and thrust bearings

InactiveUS7654535B2Improve sealingEliminate additional weightEngine sealsLeakage preventionThrust bearingEngineering

The apparatus, which can be used in aspirating face seals or thrust bearings, spaces two relatively rotatable facing surfaces in use by entraining gas between the surfaces. The apparatus includes a first portion (1) defining a generally frusto-conical surface (3); a second portion (2) defining at least one flat surface disposed adjacent the first portion so that the two surfaces face each other and define at least one point of closest engagement between the surfaces, with diverging gaps extending between the surfaces on either side of a plane which contains the point or points of closest engagement and which extends generally orthogonal to the direction of relative rotation, and a device (4) for biasing the flat surface towards the frusto-conical surface to maintain the gaps within a predetermined dimensional range.

Owner:CROSS MFG

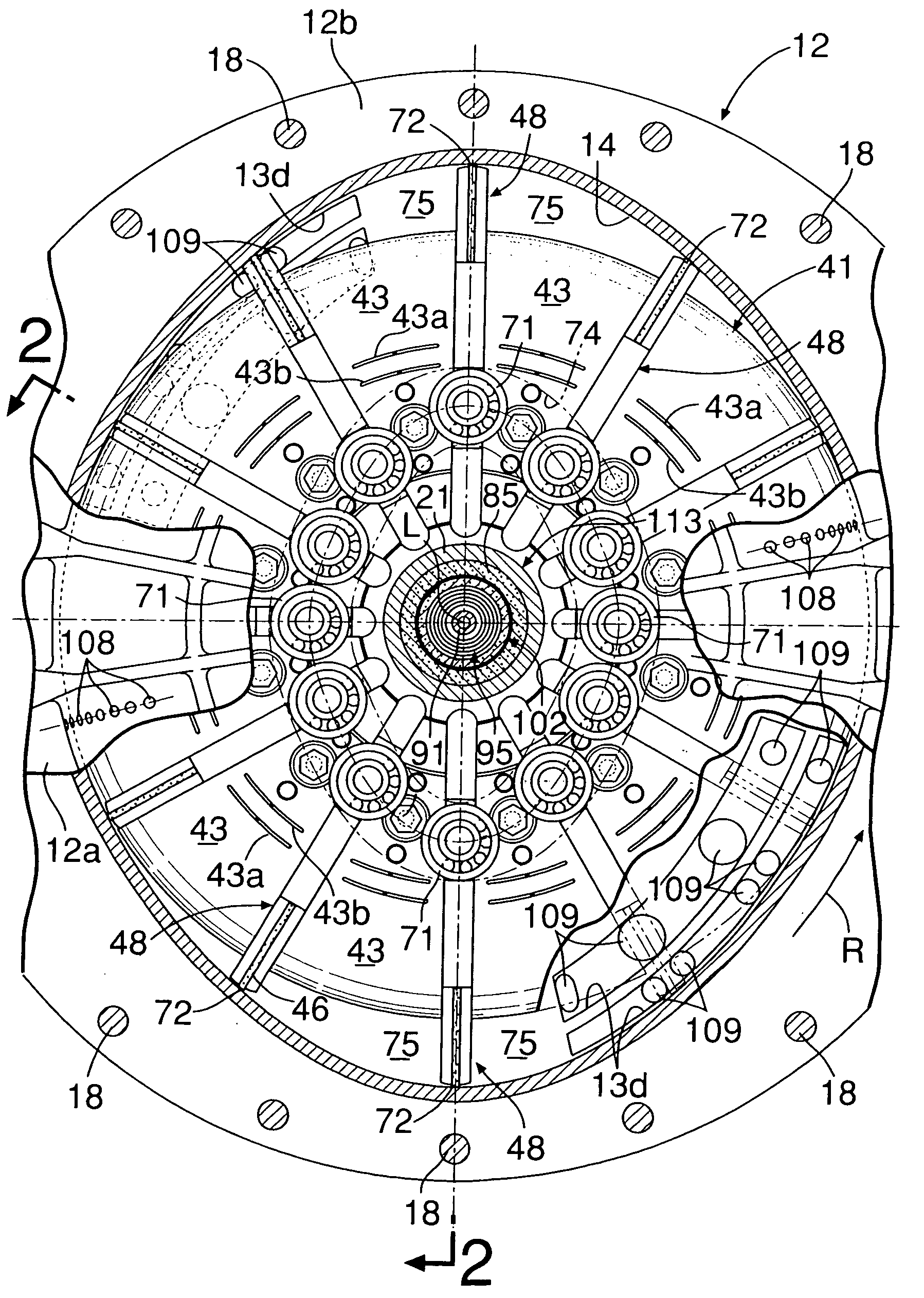

Rotary fluid machine

InactiveUS20050087066A1Increase in leakageIncrease in occurrenceValve arrangementsInternal combustion piston enginesShrink-fittingThermal expansion

A rotary fluid machine is provided that includes a rotor rotatably housed within a casing, a hollow rotating shaft (113) that rotates integrally with the rotor, and a fixed shaft (102) that is relatively rotatably fitted into the inner periphery of the rotating shaft (113); in which the rotating shaft (113) is formed by shrink-fitting an outer sleeve (21) made of metal around the outer periphery of an inner sleeve (85) made of ceramic, etc. having a lower coefficient of thermal expansion than that of metal, and the fixed shaft (102) is formed by shrink-fitting an outer sleeve (88) made of metal around the outer periphery of an inner sleeve (87) made of ceramic, etc. having a lower coefficient of thermal expansion than that of metal. Since thermal expansion of the outer sleeves (21, 88) fitted around the outer peripheries of the inner sleeves (85, 87) is suppressed due to residual tensile stress of the outer sleeves (21, 88), intimate contact between the outer sleeves (21, 88) and the inner sleeves (85, 87) can be maintained.

Owner:HONDA MOTOR CO LTD

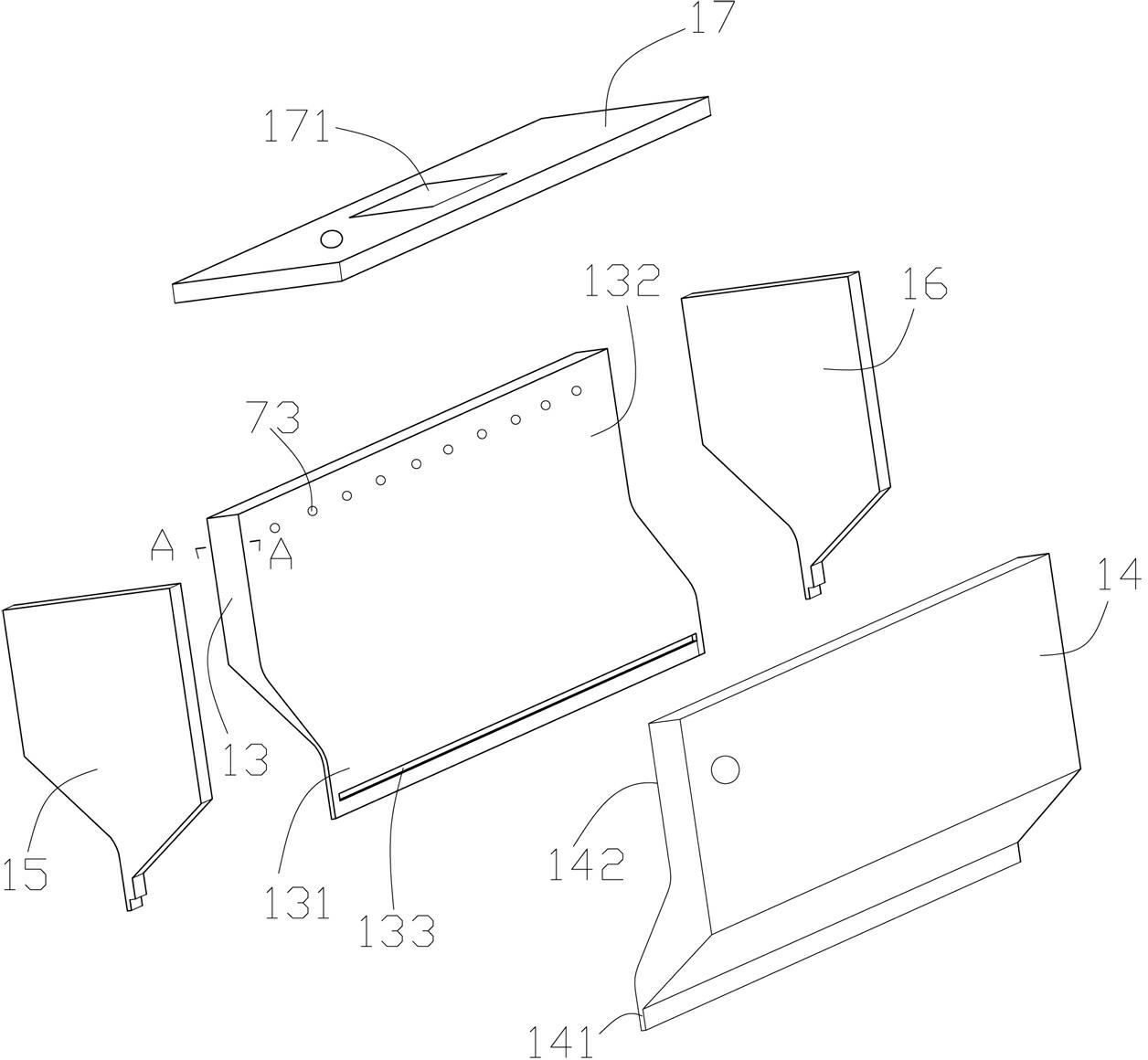

Drawing and trimming die

ActiveCN104289596AExtended service lifeSimple working principleShaping toolsEngineeringMechanical engineering

The invention discloses a drawing and trimming die which comprises a lower die body (1), an upper die body (2), an upper trimming cutter block (12) and a lower trimming cutter block (11). An inclined wedge sliding block (5) is connected with the inside of the upper die body (2), a driving block (3) is arranged on the lower die body (1), and the driving block (3) is provided with two inclined faces. The upper die body (2) moves downwards to drive the inclined wedge sliding block (5) to attach to the two inclined faces of the driving block (3) and slide. An upper trimming cutter block (12) is arranged at one end of the inclined wedge sliding block (5), and the upper trimming cutter block and the inclined wedge sliding block (5) move in a synchronous mode. According to the drawing and trimming die, the working principle is simple, the layout of the parts is compact and reasonable, and the space of the die is not increased. Meanwhile, the inclined wedge sliding block moves stably and smoothly, trimming burrs are avoided, the quality of plate products is ensured, and the service life of the die is prolonged.

Owner:FUZHEN TECH RES ANHUI

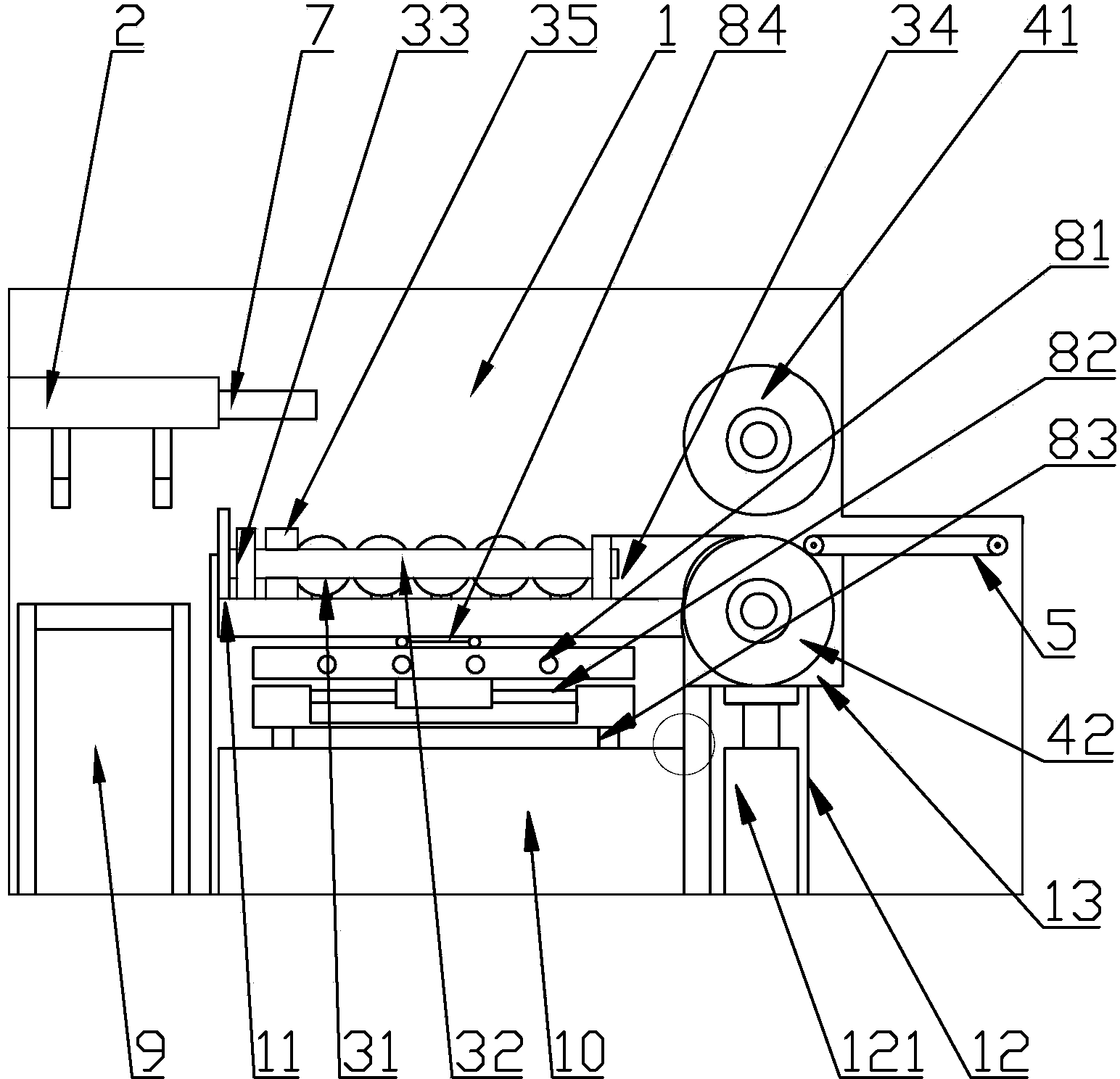

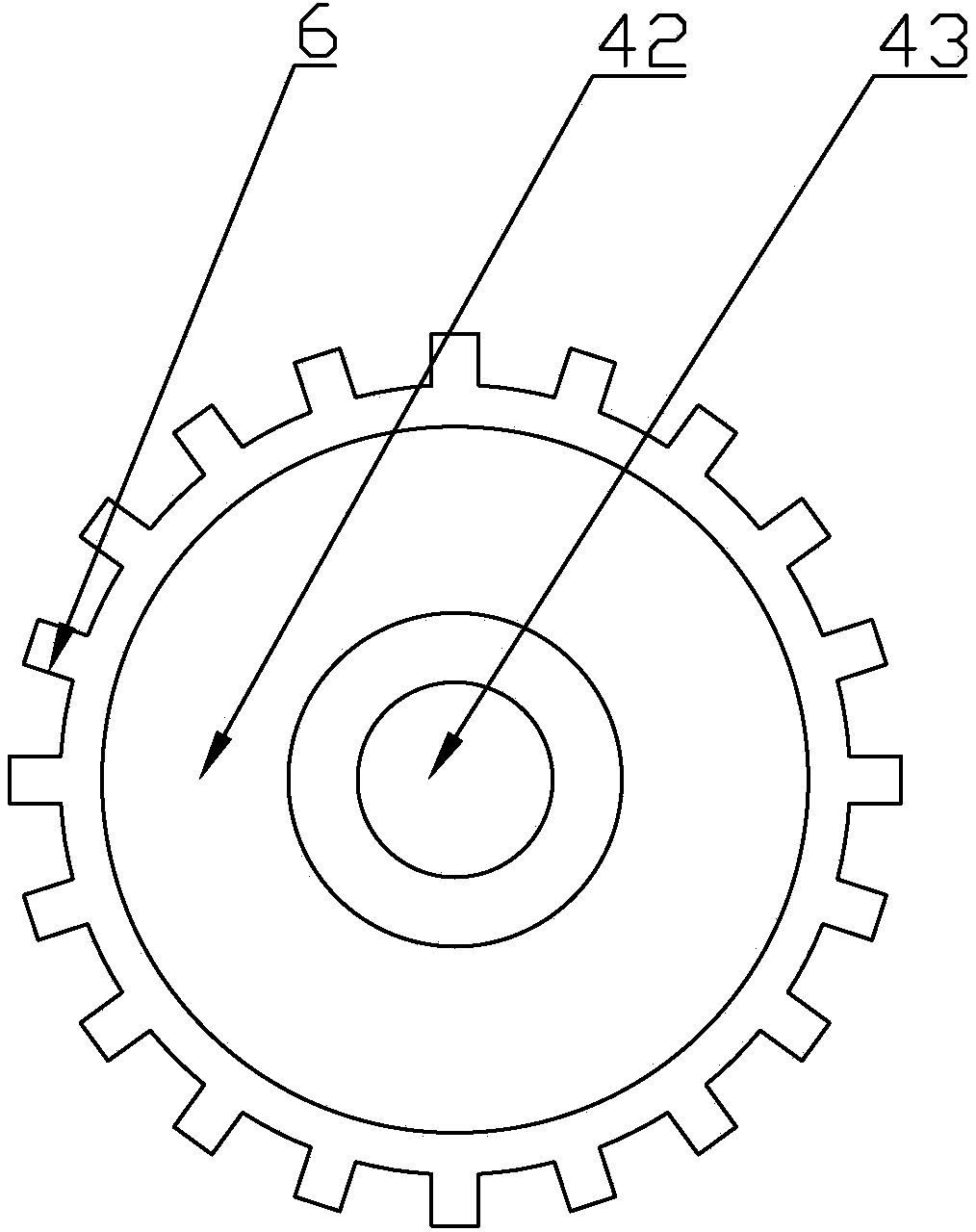

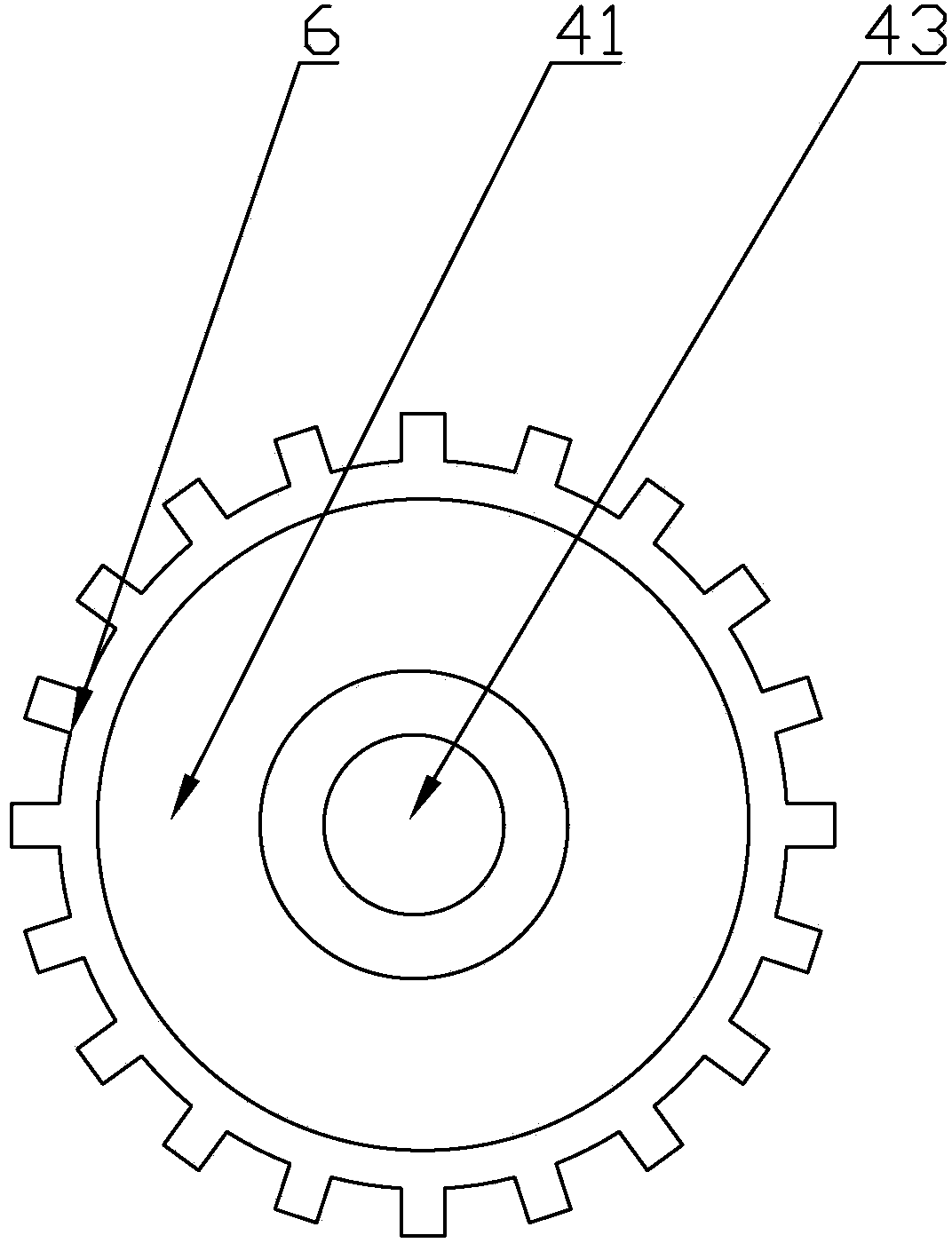

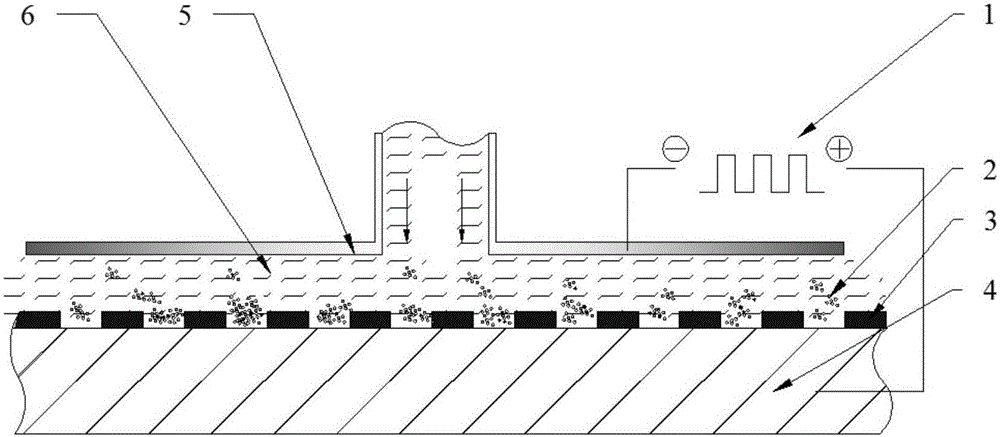

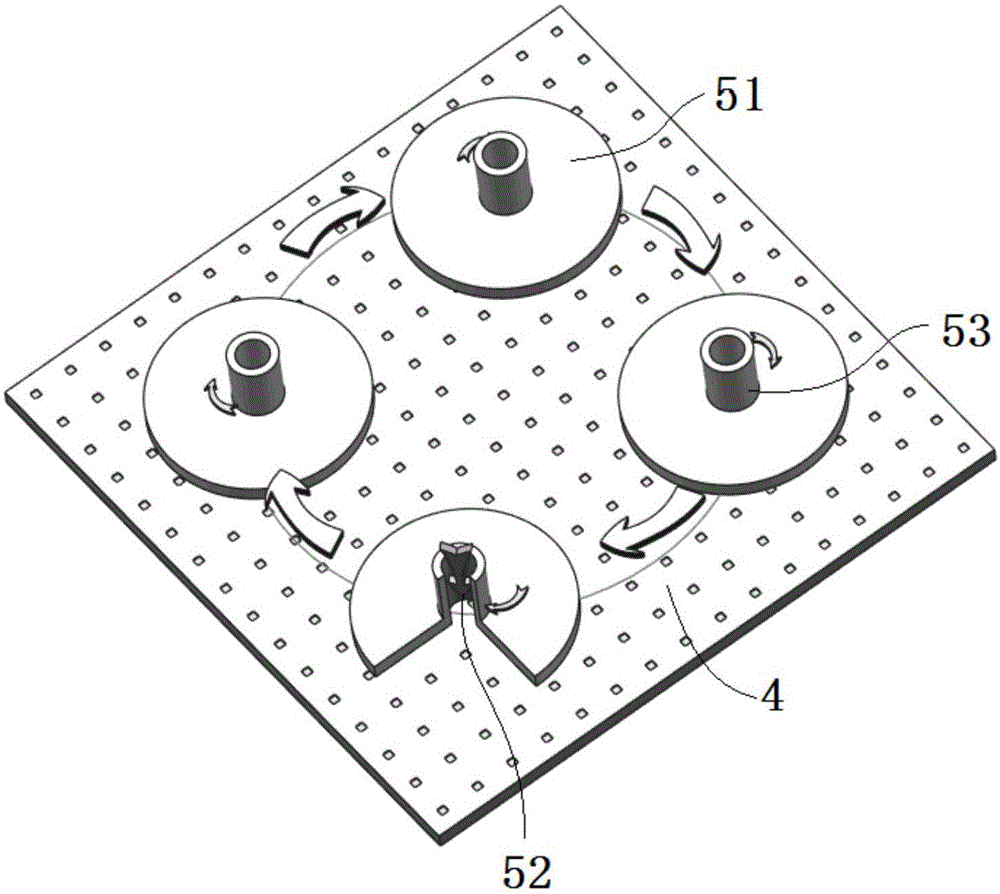

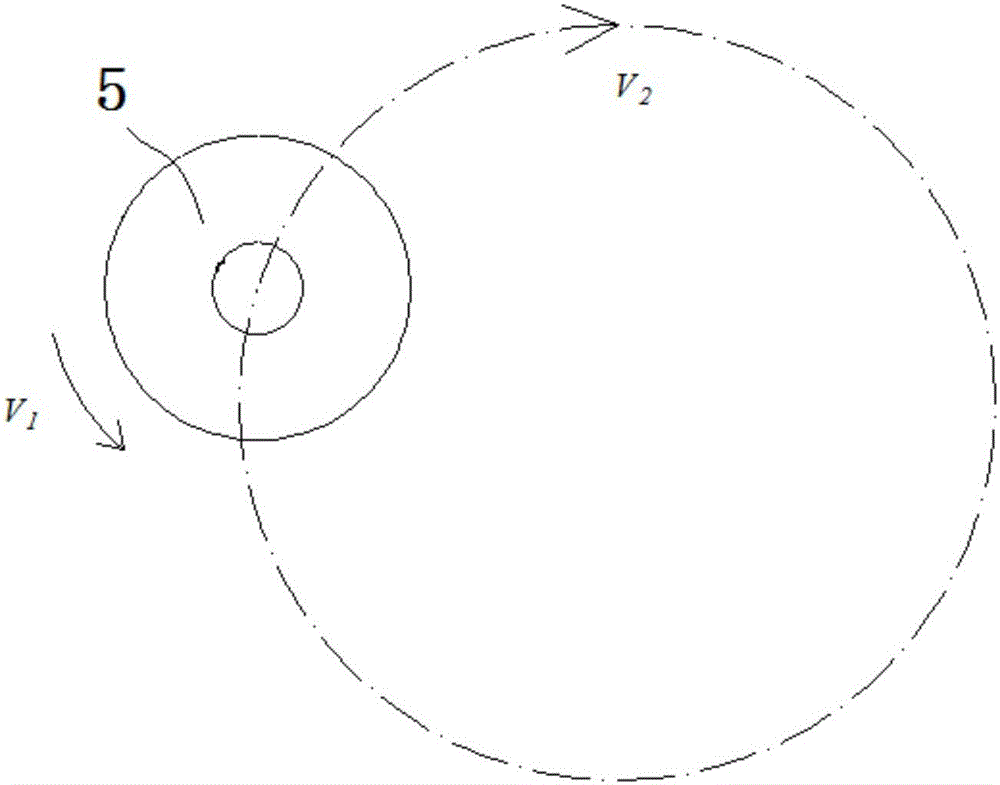

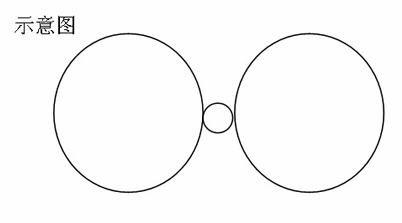

Disc type scanning electrode mask film microelectrolysis electrical discharge machining system and machining method

InactiveCN105127526AAvoid lossGap stabilityElectrical-based auxillary apparatusElectricityWorking fluid

The invention discloses a disc type scanning electrode mask film microelectrolysis electrical discharge machining system. The system comprises a workpiece, a disc type electrode and working fluid, the machining surface of the workpiece is covered with a mask film, machining windows are formed in the mask film, the workpiece is placed in the working fluid, the disc type electrode is located in the part, above the workpiece, of the working fluid, and the workpiece and the disc type electrode are connected with a power source through wires. The machining system and machining method have the advantages that the workpiece is covered with the structurally-insulating mask film, the mask film shape can be precisely copied, the large-scale textured microstructure machining is conducted, the machining is only conducted in areas which are uncovered by the mask film, and the high locality is achieved; the tool electrode which is used is a large-area electrode, and relative movement exists between the tool electrode and the workpiece; losses of all areas of the tool electrode can be made to tend to be balanced by planning a special movement curve, and all machining gaps are made to maintain unified; the electrolysis only serves for the polishing effect, and the main removal form is spark discharge removal; the working fluid is supplied in a mode from top to bottom and sprayed out of the center of the disc type electrode from inside to outside, so that the working fluid renewal is made to be more effective.

Owner:GUANGDONG UNIV OF TECH +1

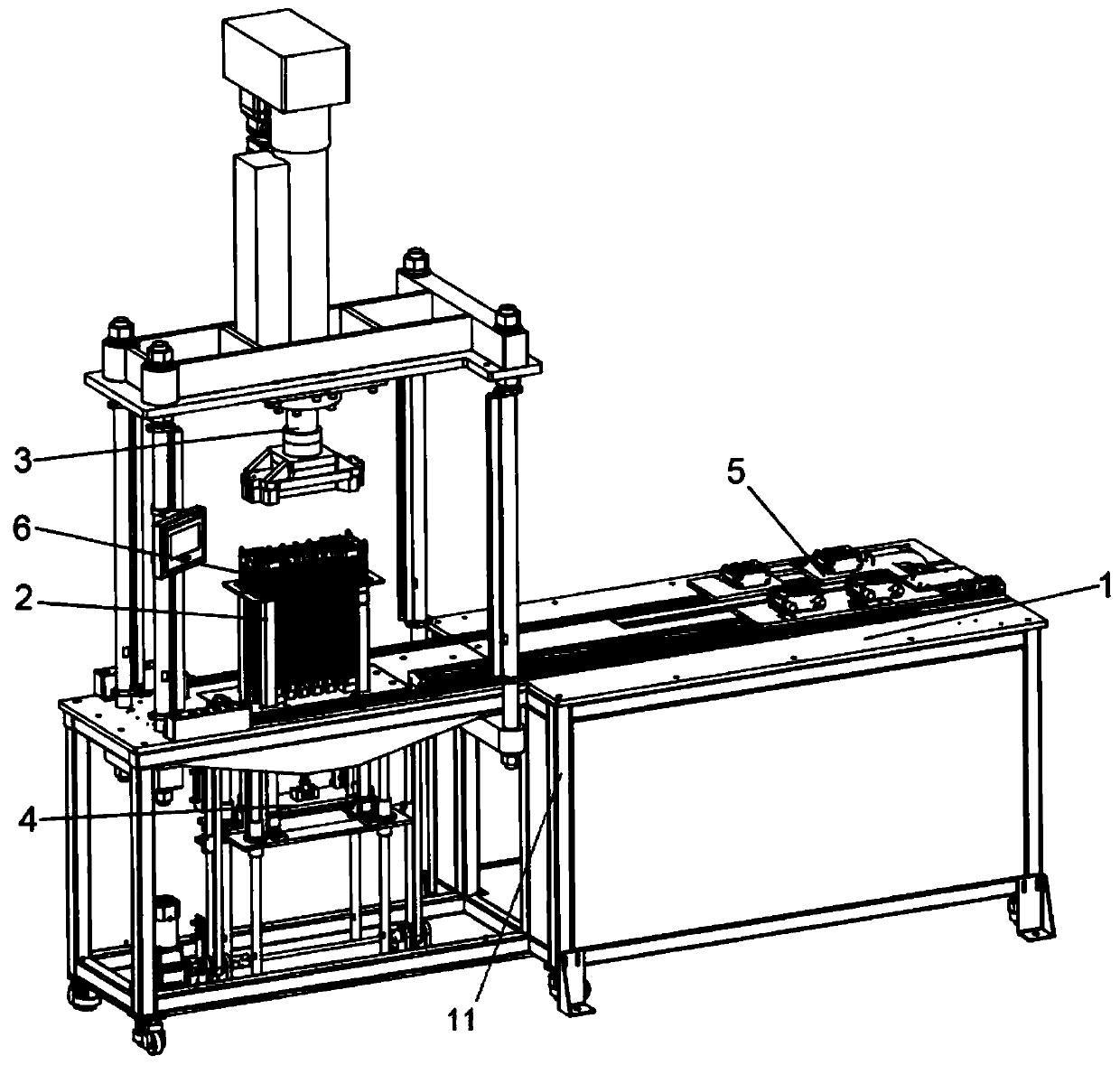

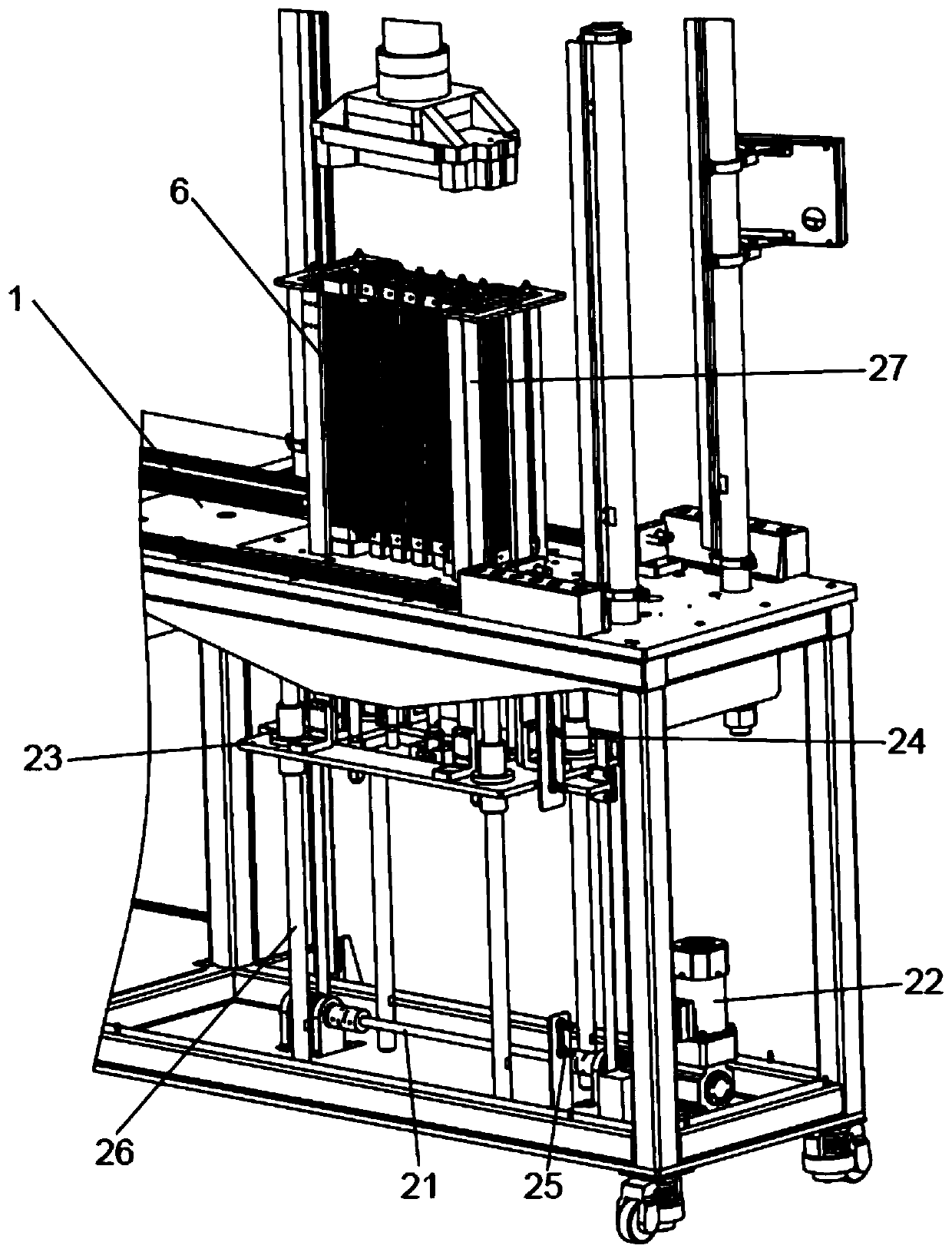

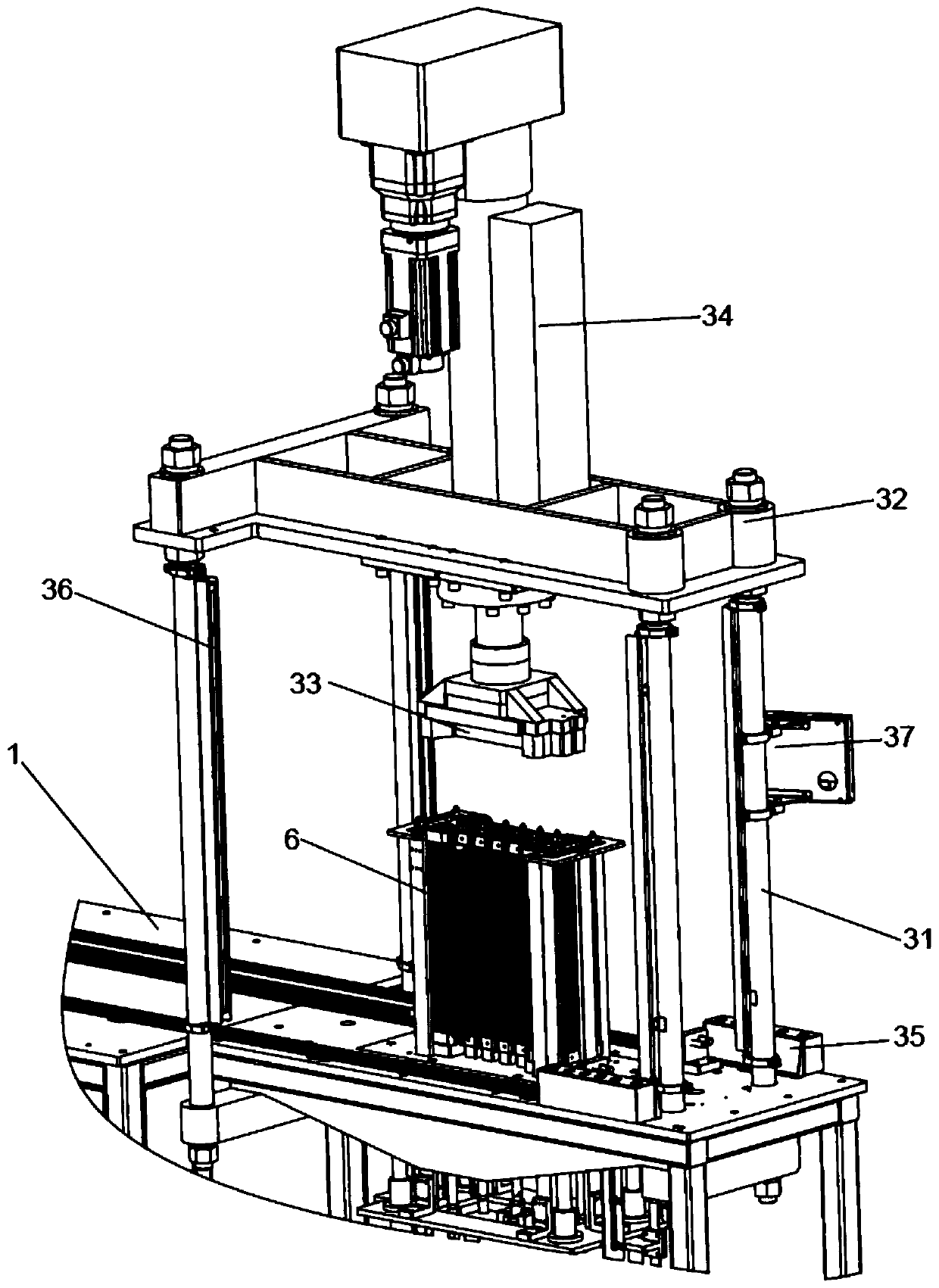

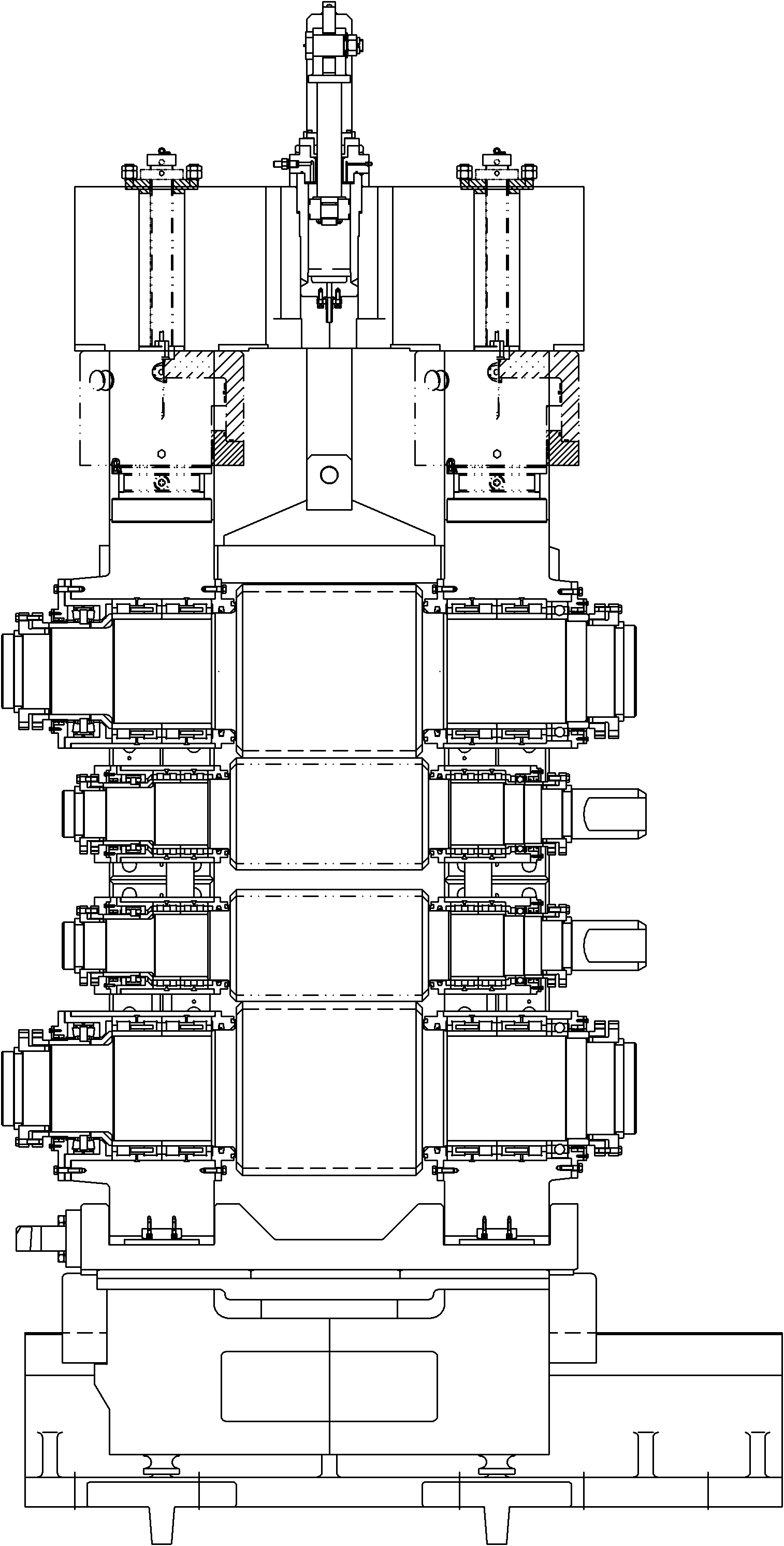

Hydrogen cell packing device and packing method thereof

ActiveCN109841887AThe position is stable during the pressing processGap stabilityFinal product manufactureFuel cellsHydrogen fuel cellPole piece

The invention provides a hydrogen cell packing device which comprises a base, a stack limiting mechanism, a pole piece compaction mechanism, a lifting-up mechanism and transfer mechanism. The invention also provides a hydrogen cell packing method based on the device. Via the stacking limiting mechanism, cell pole pieces can be stacked directly and compacted and packed by the pole piece compactionmechanism, the positions of the cell poles pieces are kept stable in the compaction process, a stable gap is kept among the pole pieces, the packing device integrates the stacking limiting mechanism with the pole piece compaction mechanism, labor force is reduced, and the production efficiency and yield rate of hydrogen fuel cell packing are improved.

Owner:SUZHOU JEE INTELLIGENT EQUIP CO LTD

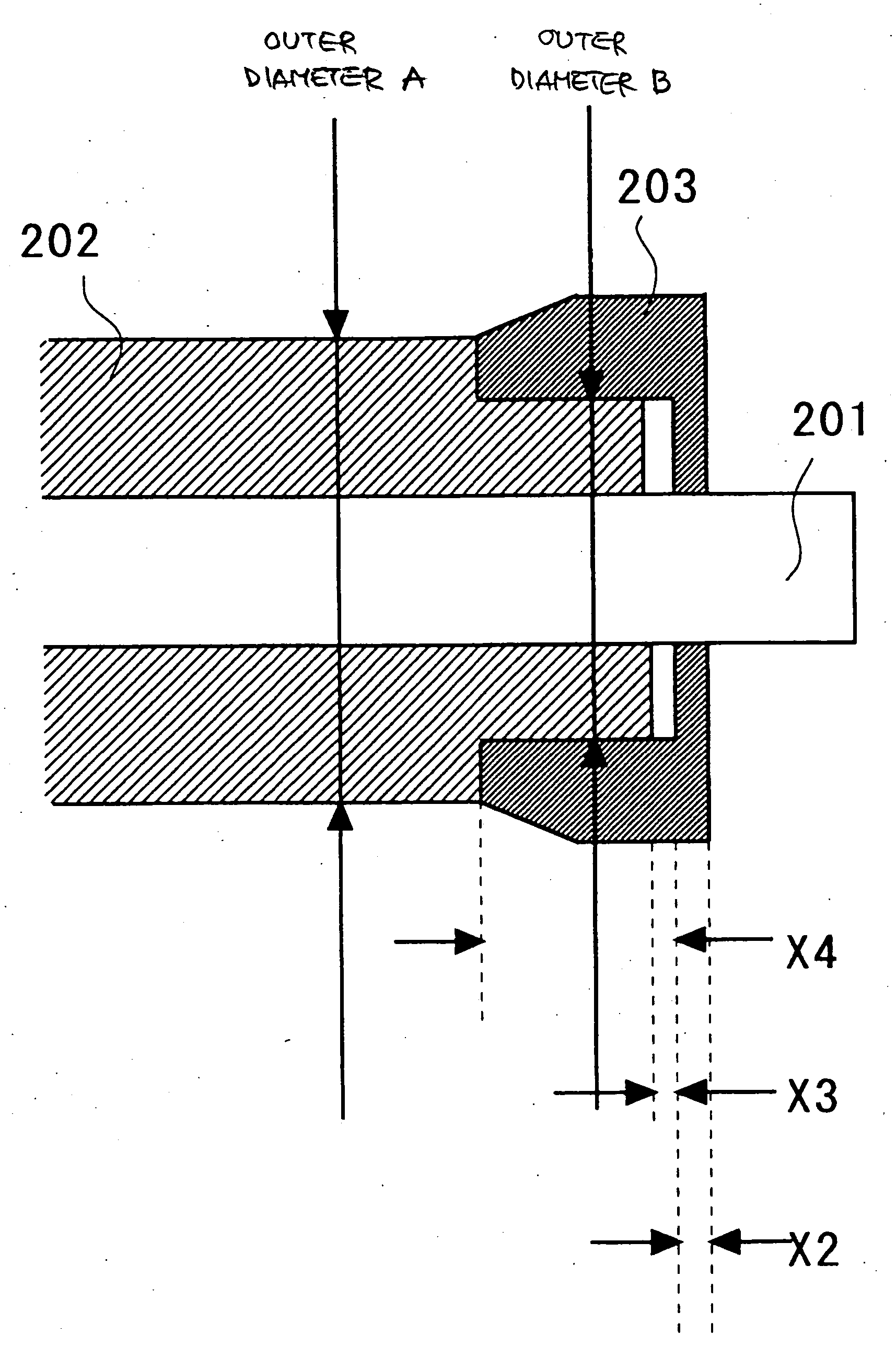

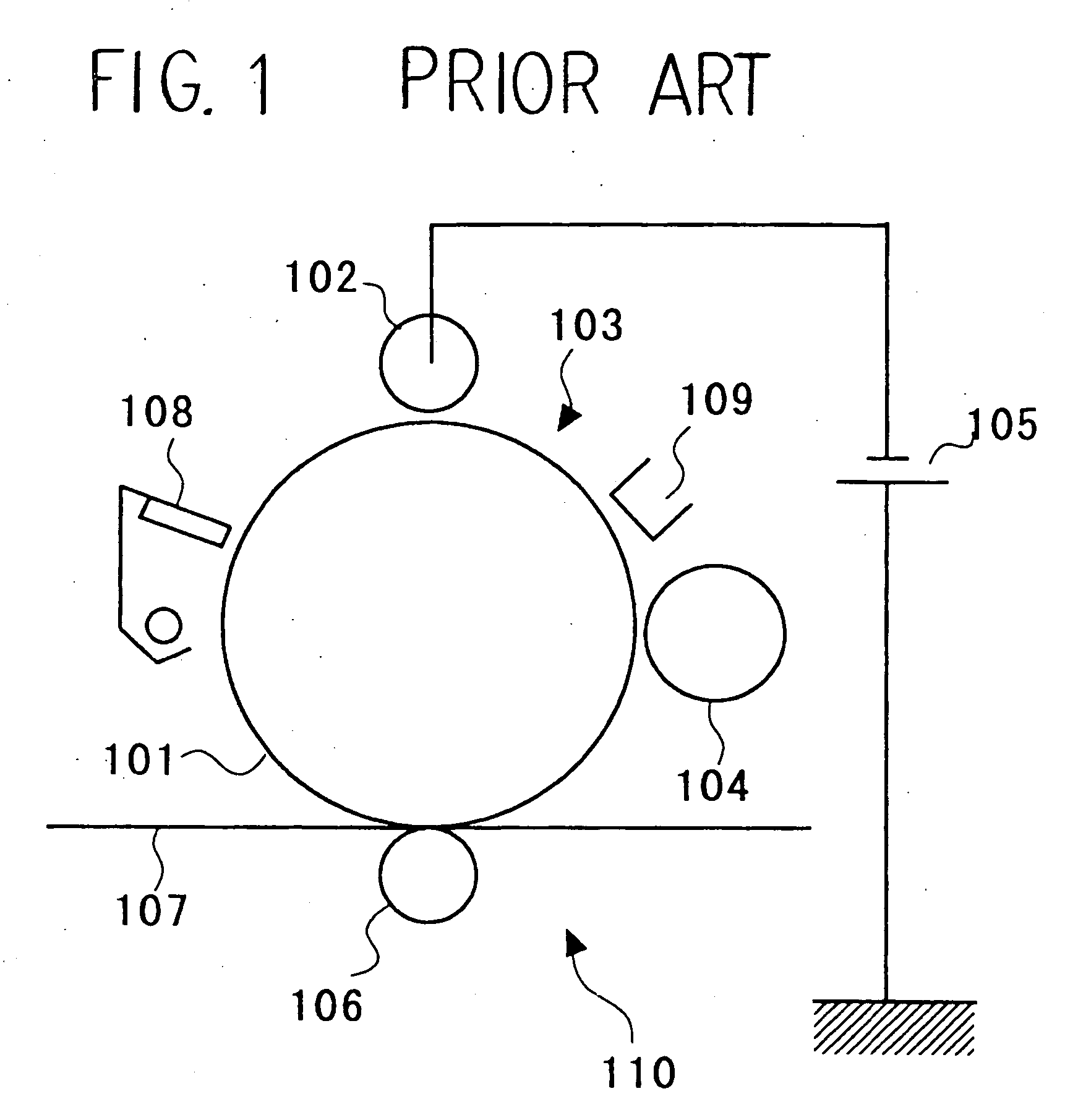

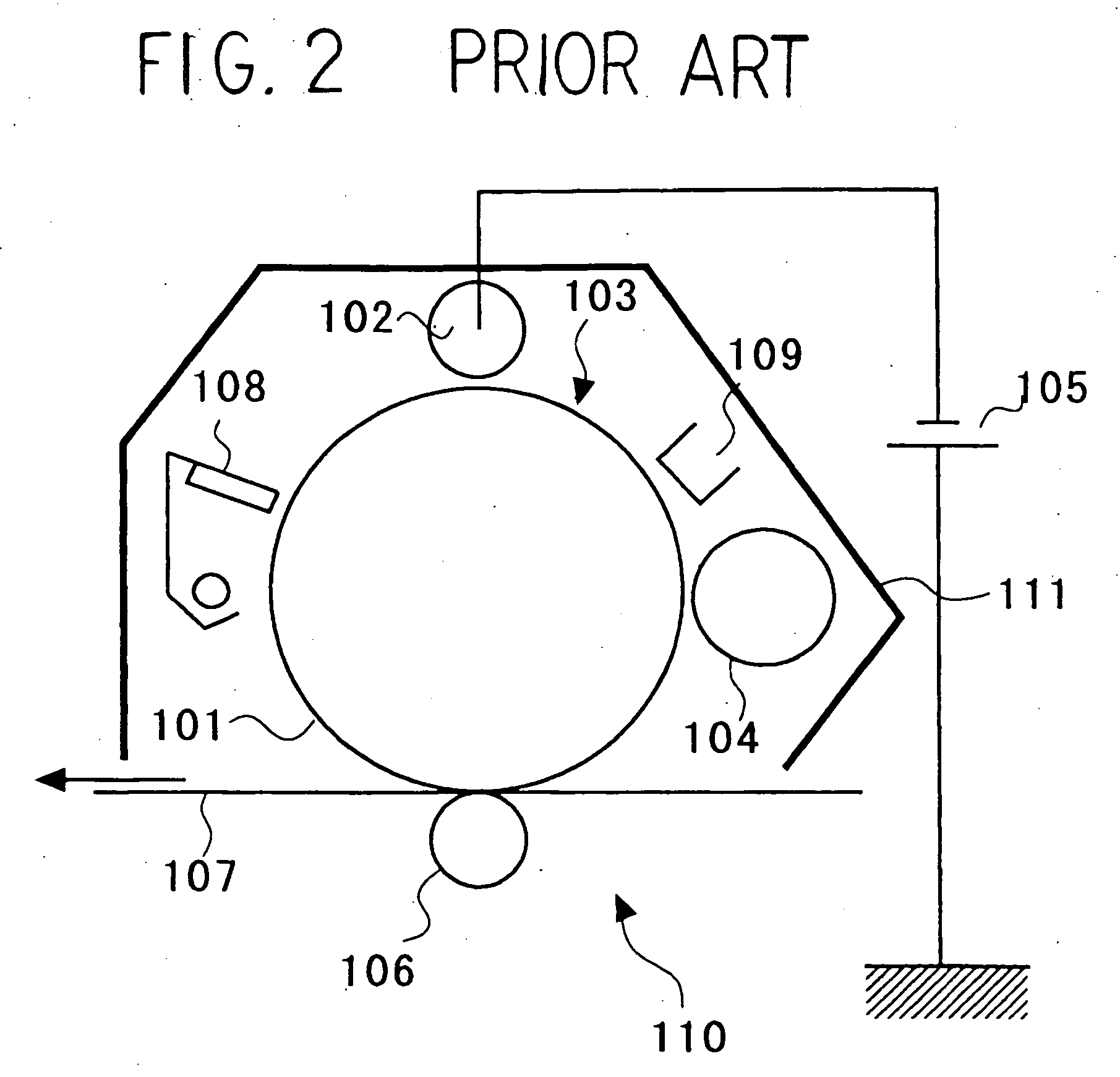

Conductive member, and charging roller, process cartridge and image forming apparatus using same

ActiveUS20070065178A1Highly durableStable gapElectrographic process apparatusCorona dischargeImage formationElectrical resistance and conductance

A conductive member forming a charging roller having high durability which maintains a stable gap with respect to an abutting member, comprising a long conductive supporting body, an electrical resistance adjusting layer, and gap maintaining members, wherein, taking X2 to be the thickness of the portions of the gap maintaining members which oppose the end faces of the electrical resistance adjusting layer, the relationship 1 mm≦X2≦3 mm is satisfied, taking X3 to be the interval between the end faces of the electrical resistance adjusting layer and the gap maintaining members which oppose these end faces, the relationship 0.1≦X3≦1 mm is satisfied, and taking X4 to be the interval from the faces of the gap maintaining members opposing the end faces of the electrical resistance adjusting layer, to the step difference faces of the reduced diameter sections of the electrical resistance adjusting layer, then X4 is 5 mm or greater, and is shorter than the length from the faces of the gap maintaining members which oppose the end faces of the electrical resistance adjusting layer to the positions on the electrical resistance adjusting layer opposing the end sections which correspond to the image forming region of the photosensitive body.

Owner:RICOH KK

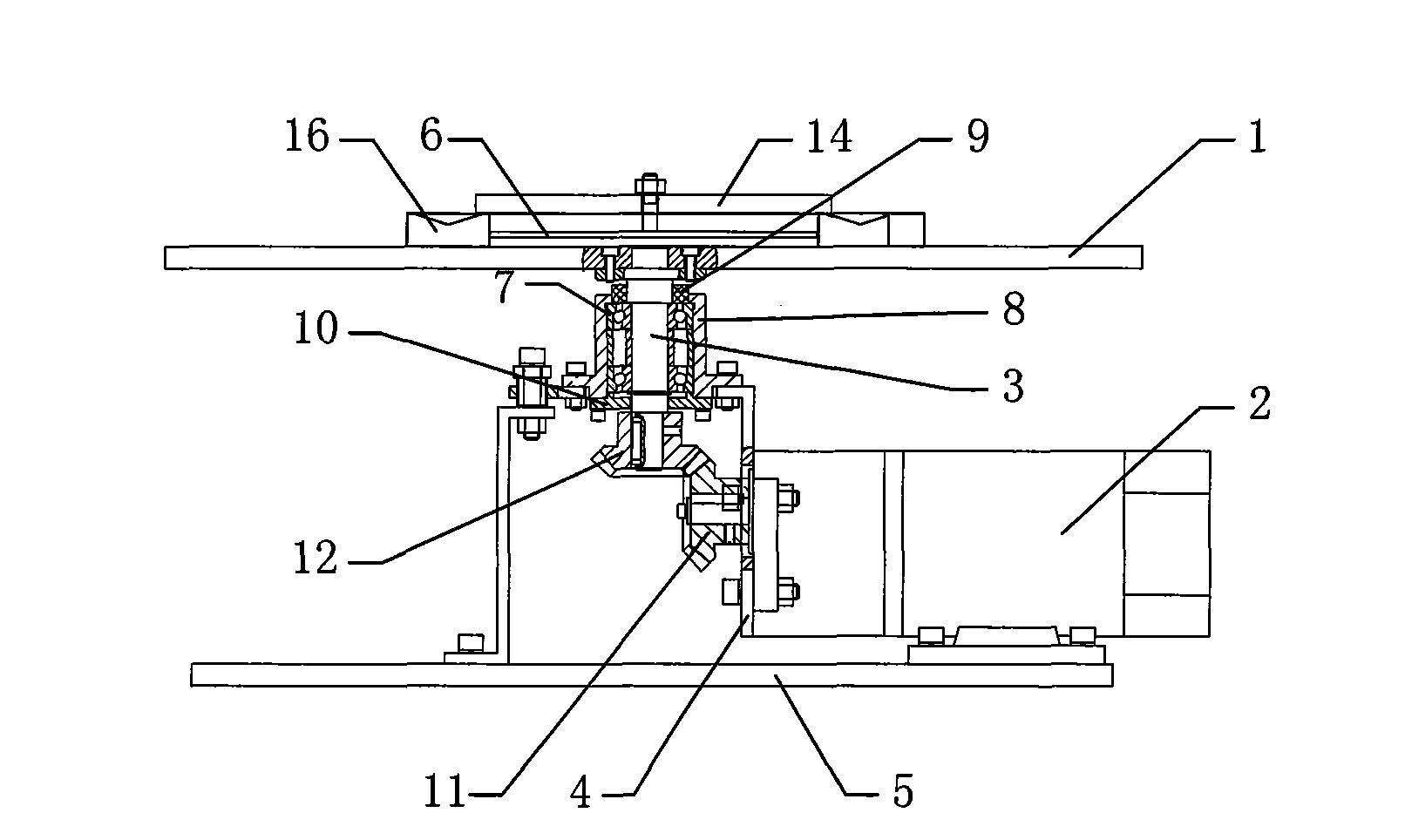

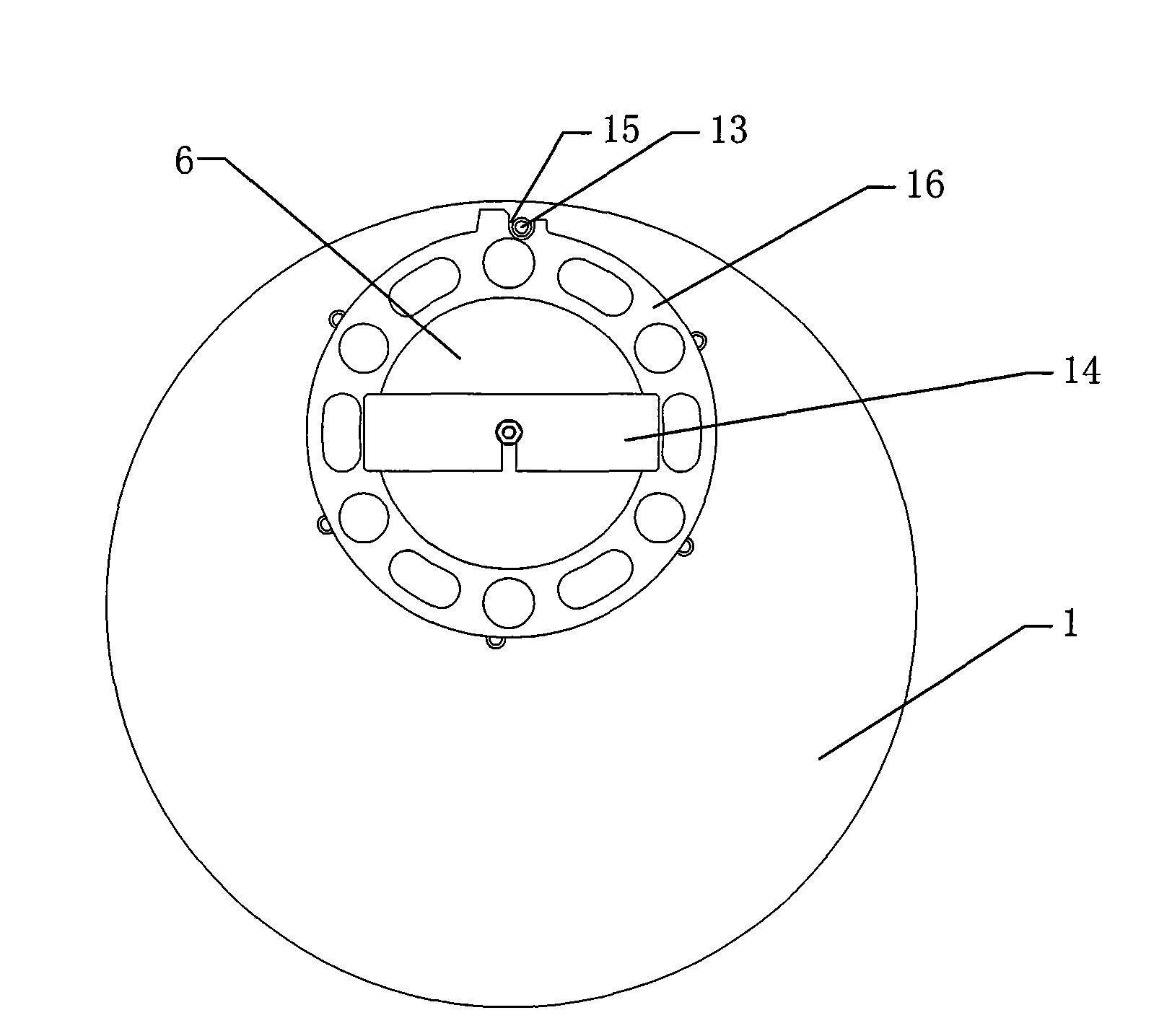

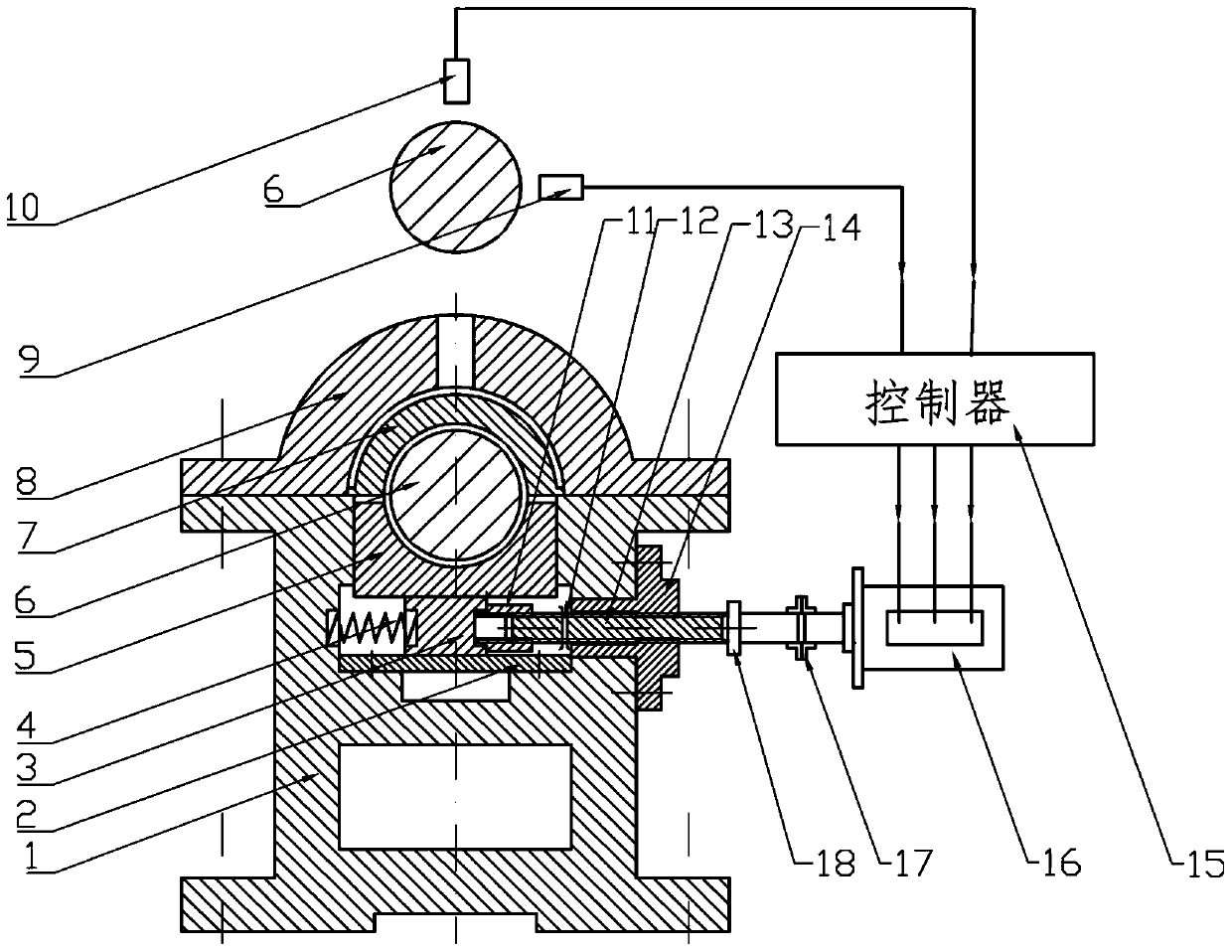

Local centering and rotating device of cone socket

ActiveCN101649382ASolve the stability of hardening depth and hardness differenceGap stabilityFurnace typesIncreasing energy efficiencyQuenchingDrive motor

The invention relates to a local centering and rotating device of a cone socket, which can keep a clearance between a high-frequency induction coil and the cone socket surface according to the requirements of a quenching process stable, thereby solving the problems of effective hardening depth and stable hardness difference. The local centering and rotating device is characterized by comprising arotating disc and a driving motor, wherein the rotating disc is arranged on a rotating shaft which is arranged on a bracket through a bearing, the bracket is arranged on a bottom plate, the rotating shaft is connected with the driving motor by a driving mechanism, and an eccentric positioning disc is arranged on the surface of the rotating disc.

Owner:WUXI POWER ENG

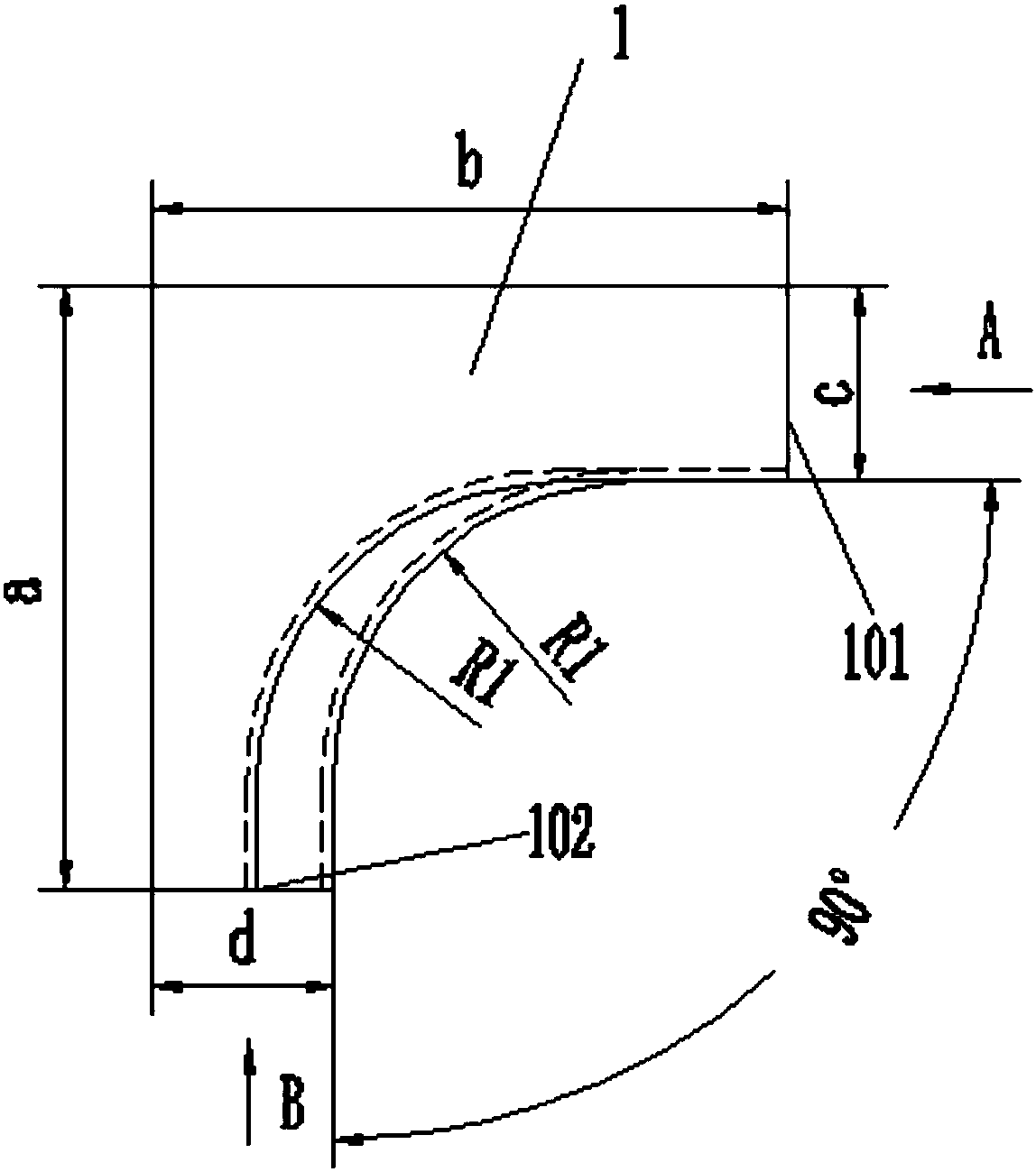

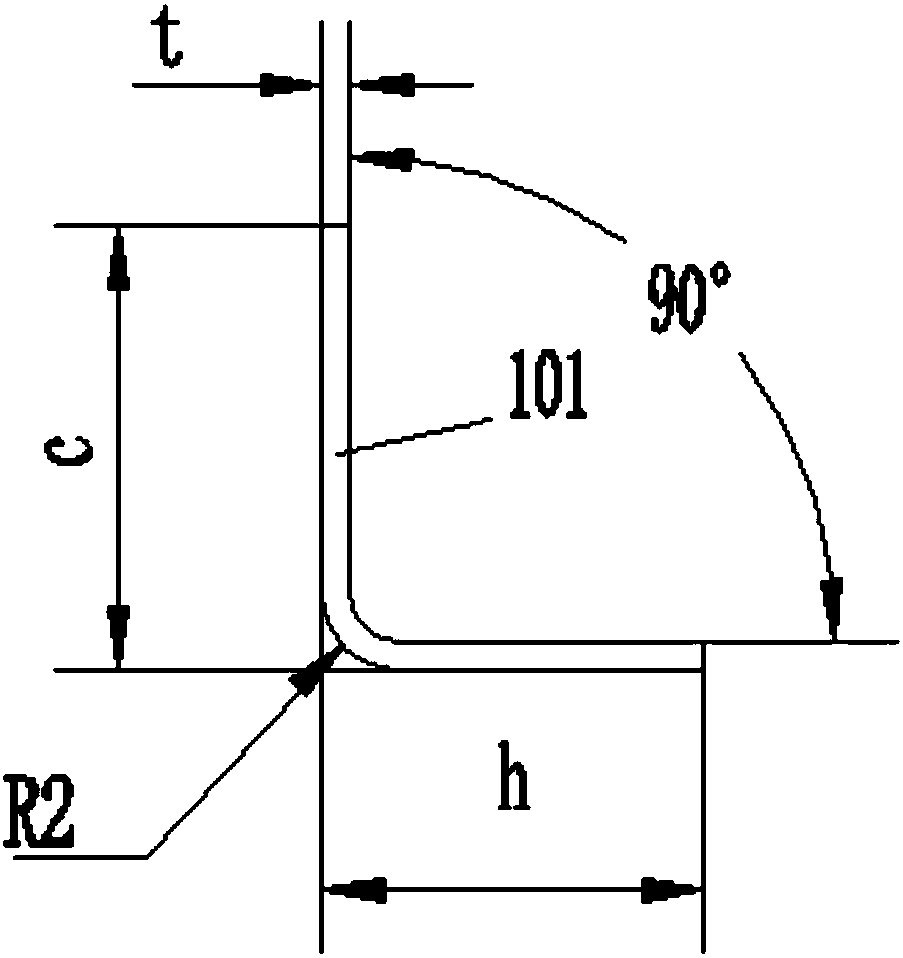

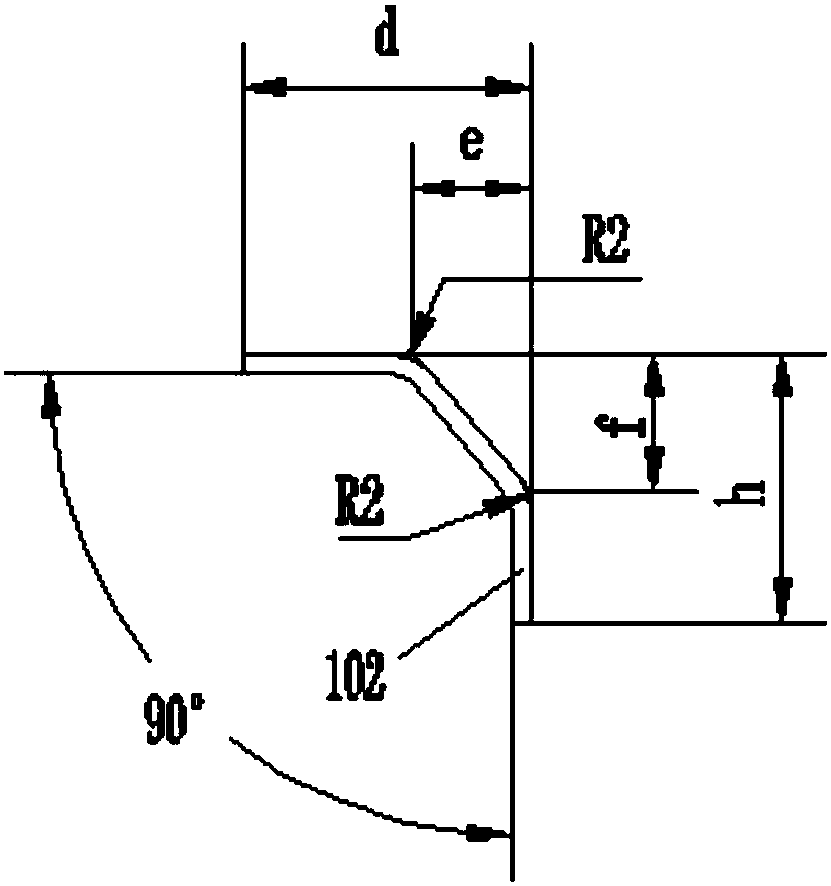

Reshaping die of urban rail vehicle door corner part

InactiveCN108568474AGap stabilityEliminate defects of poor flatnessShaping toolsVehicle componentsEngineeringUrban rail

The invention provides a reshaping die of a door corner part. The reshaping die is used for reshaping an urban rail vehicle door corner part. The reshaping die of the door corner part comprises a lower die plate, an upper die plate, a guide column, a guide sleeve, a convex die, a concave die, a fixed wedge block, a sliding wedge block, a side compressing block and a door corner, wherein a groove is formed in the lower die plate and can reshape the door corner part arranged at a door corner, the plane of the fixed wedge block is in contact with the side compressing block when the door corner part reshaping die is closed and the fixed wedge block goes down, the oblique plane is in contact with the sliding wedge block, and the side compressing block is fixed, so that the fixed wedge block pushes the sliding wedge block to slide towards the concave die and clamp the door corner. Compared with the prior art, the door corner part reshaping die effectively overcomes the two defects of poor planeness and large 90-degree angle resilience occurred in door corner stamping formation, the defect problem which cannot be solved by adopting a traditional door corner reshaping method is eliminated,the product quality and precision of door corners can be effectively improved, and accordingly the forming precision of like members is remarkably improved.

Owner:JILIN UNIV

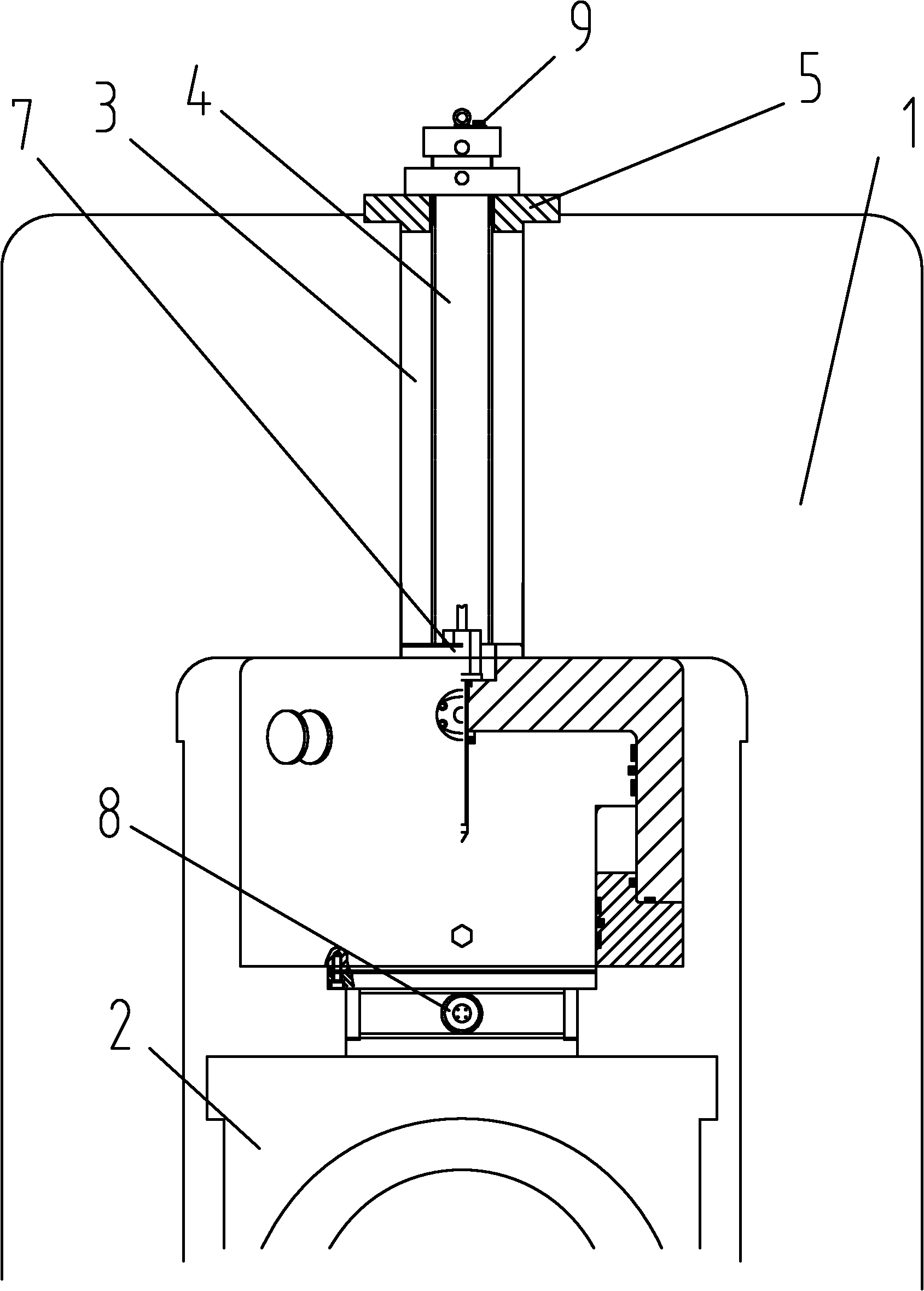

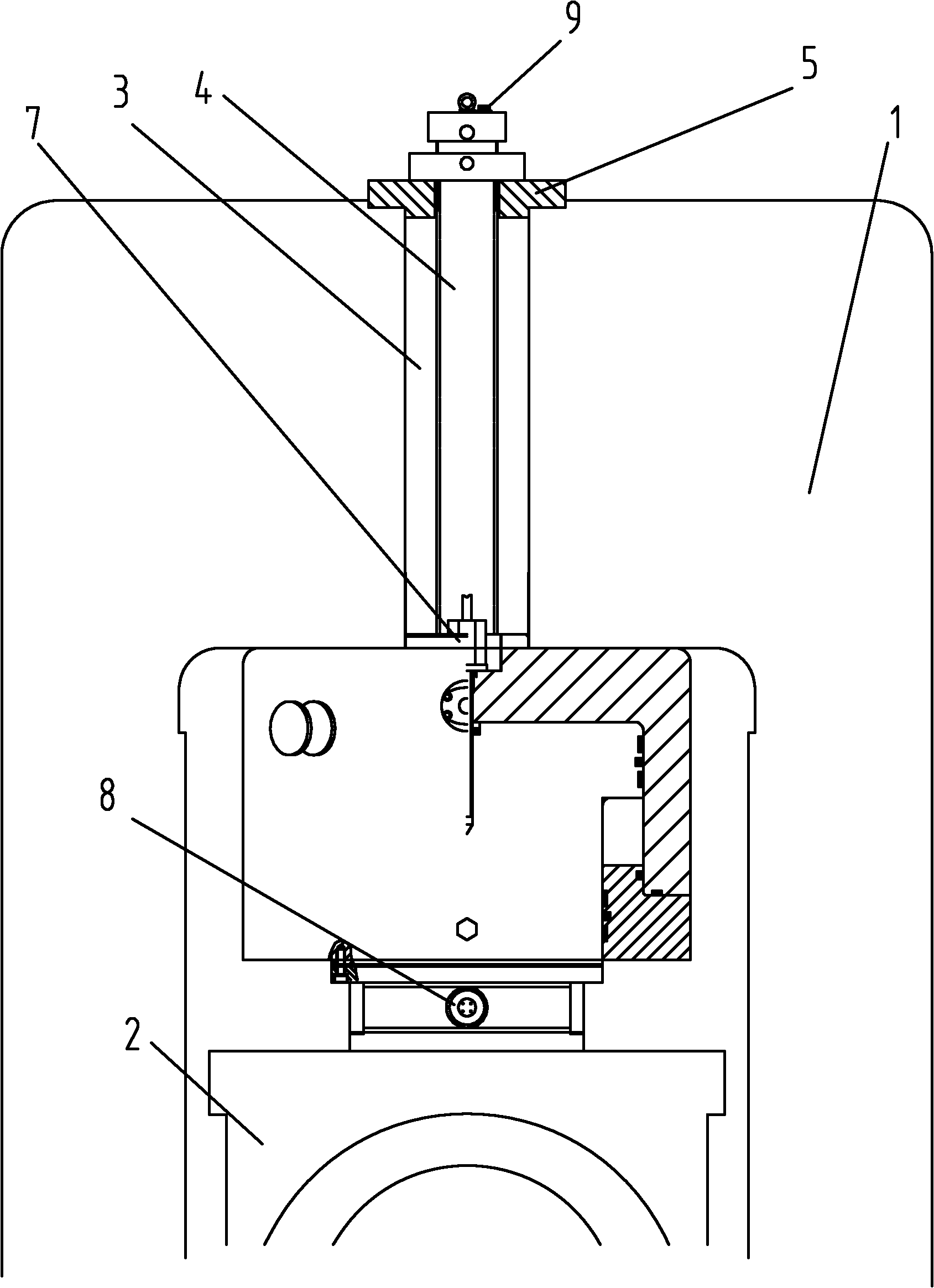

Screw down device of working rolls of four-roll rolling mill

InactiveCN101947556AGap stabilitySave spaceMetal rolling stand detailsMetal rolling arrangementsHydraulic cylinderWork roll

The invention relates to a screw down device of working rolls of a four-roll rolling mill. The device comprises rolling mill memorial archways and bearing blocks arranged between the rolling mill memorial archways of upper supporting rolls. The device is characterized in that the rolling mill memorial archways are respectively provided with a round suspender hole corresponding to the centers of the gearing blocks of the left upper supporting rolls and the right supporting rolls; each round suspender hole is internally provided with a hydraulic cylinder hollow suspender, and the upper end of each hydraulic cylinder hollow suspender passes through a press cover at the top of the round suspender hole and is connected through a nut; the lower end of each hydraulic cylinder hollow suspender is connected with a screw down oil cylinder; and a piston of the screw down oil cylinder is in contact with the upper sides of the bearing blocks of the upper supporting rolls. The invention has the advantages that a hydraulic cylinder is used for replacing a worm gear-worm screw mechanism screw down device, thus not only the space can be saved, but also the gap of the working rolls can be automatically regulated and adjusted by utilizing a sensor to stably maintain the gap of the working rolls.

Owner:TIANJIN JINZHONG HEAVY MACHINE & EQUIP MFG

Intelligent support sliding bearing device with adjustable clearance and clearance adjustment method

ActiveCN111188833AImplementation limitOrientation stabilityShaftsRotary machine partsServoWhole systems

The invention discloses an intelligent support sliding bearing device with adjustable clearance and a clearance adjustment method. The intelligent support sliding bearing device comprises a support sliding bearing, an inclined block is arranged under the support sliding bearing, a guide rail is arranged under the inclined block, the bottom surface of the inclined block is matched with the guide rail in a sliding mode, the inclined block moves in the axial direction of the guide rail, the top surface of the inclined block is an inclined plane with a taper of 1 to 125, a pushing mechanism is arranged at one end of the inclined block, the other end of the inclined block is connected with a reset spring, and a vertical displacement sensor and a horizontal displacement sensor are respectively used for detecting the vertical radial displacement and the horizontal radial displacement of a rotor; the vertical displacement sensor and the horizontal displacement sensor are connected with the input end of a monitoring controller, and the output end of the controller is further connected with the control signal input end of a servo motor; when the rotor vibration is too large, signals collected by the sensors are sent to the controller, the controller controls the servo motor to make a certain action, and the clearance between the bearing and the shaft neck is changed, so that the elliptical bearing play a role, the rotor amplitude is reduced, and the whole system has a good effect of vibration reduction and suppression.

Owner:XI AN JIAOTONG UNIV

Liquid crystal display device

InactiveUS20180356663A1Improve stabilityImprove conductivityOptical light guidesNon-linear opticsCapacitanceLiquid-crystal display

A liquid crystal display device is disclosed in the present disclosure, which includes a liquid crystal display panel and a backlight module, with a gap disposed between the liquid crystal display panel and the backlight module, wherein the liquid crystal display panel includes an array substrate including a touch force sensing electrode disposed thereupon, the backlight module includes a backlight source and a metal backplane disposed on a bottom of the backlight source, and a touch force sensing capacitor of the liquid crystal display device is composed of the touch force sensing electrode and the metal backplane.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

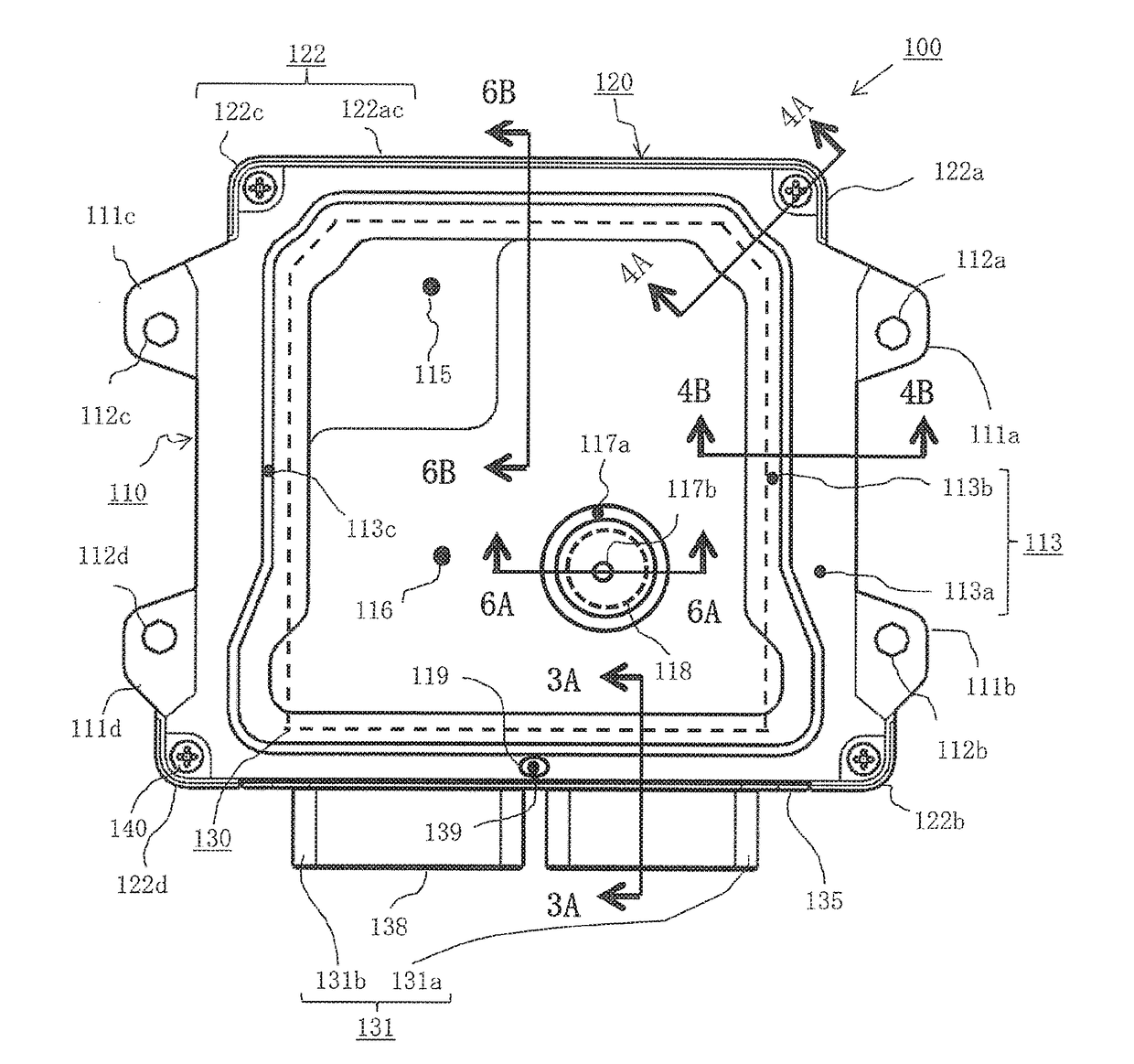

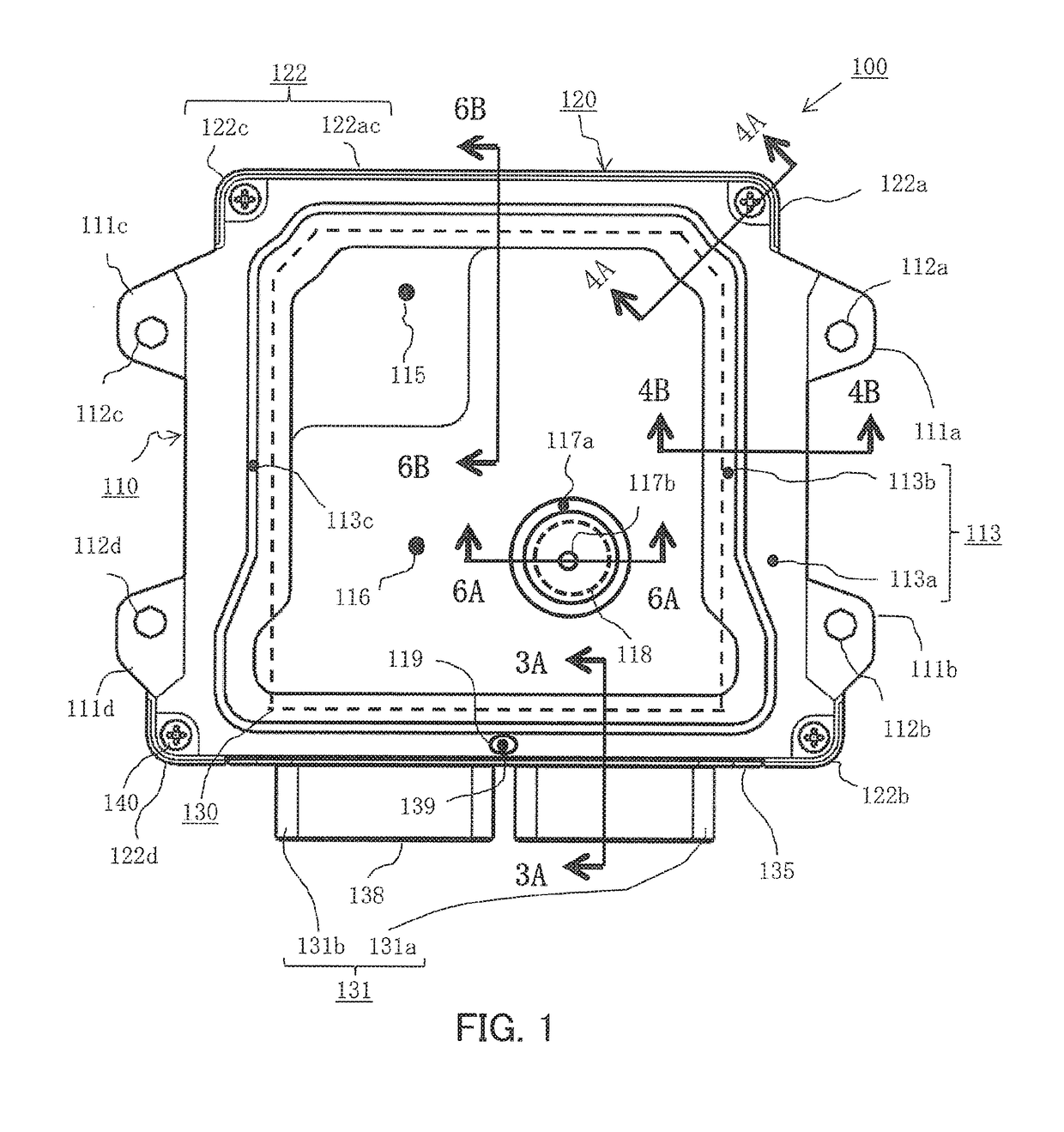

Electronic apparatus unit

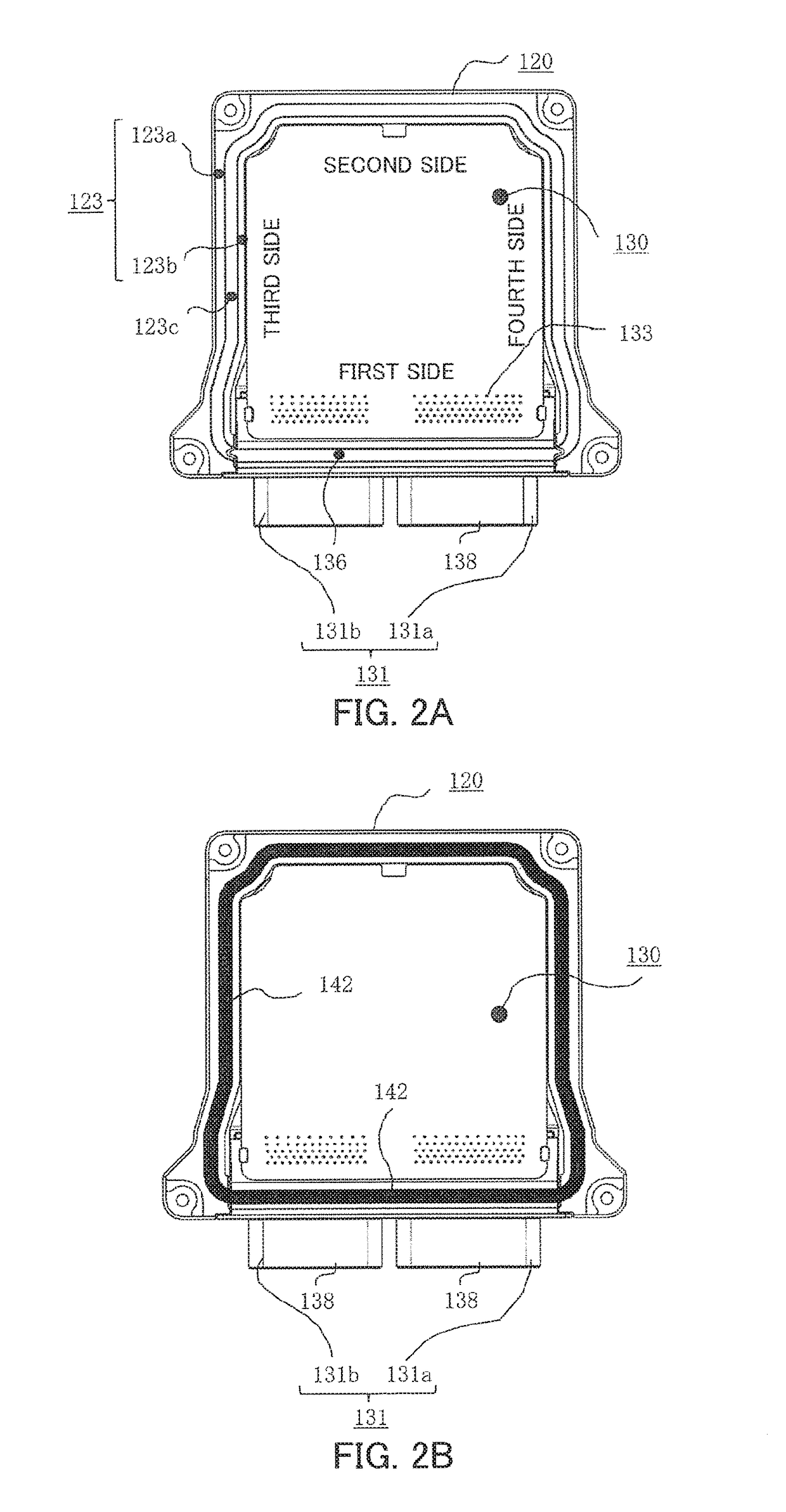

ActiveUS20180213658A1Reduce weightGap stabilityCasings with connectors and PCBClosed casingsFlexural strengthMechanical engineering

A second seal material is coated on an annular seal surface constituted by a partition wall of a connector housing and a three-sided outer peripheral surface of a cover, and is joined with an annular base outer peripheral surface on the base, and the cover and the base are integrated with fastening screws at the four corners, and hold the three sides of a circuit board therebetween. Fastening surfaces of the base are embossed with a first depth so that bending strength is reinforced whereby a stable seal gap is generated, and corner outer walls and a connection outer wall are disposed at four corners and one side of the cover, so as to generate a retention gap to prevent outflow of the second seal material.

Owner:MITSUBISHI ELECTRIC CORP

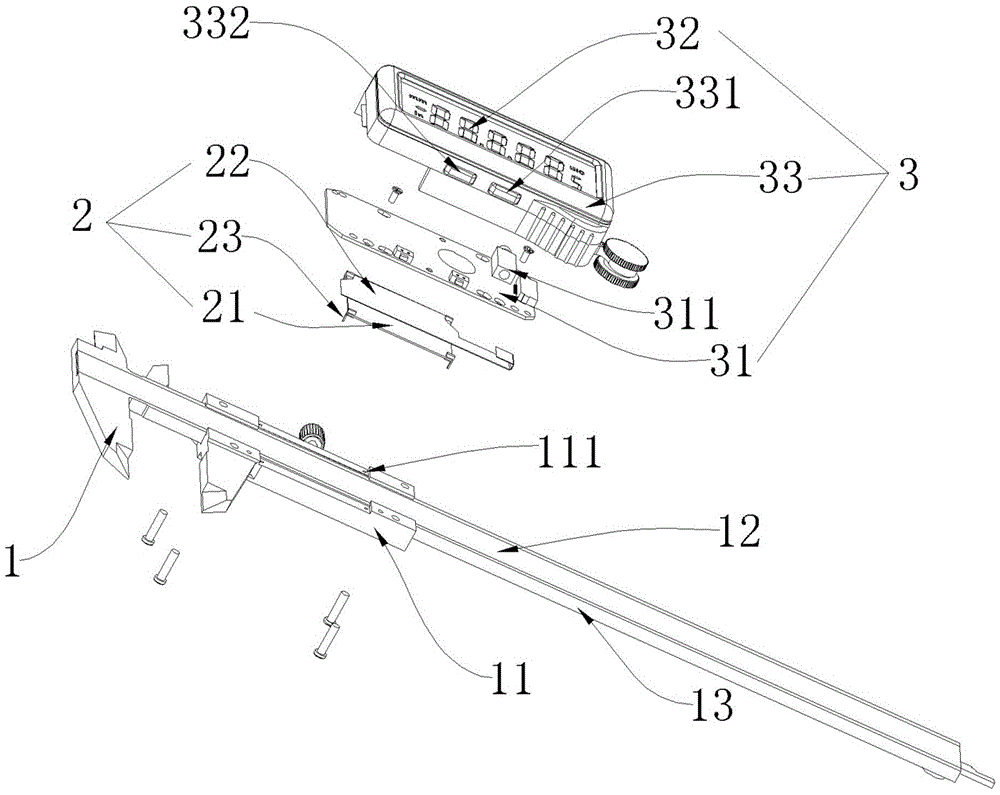

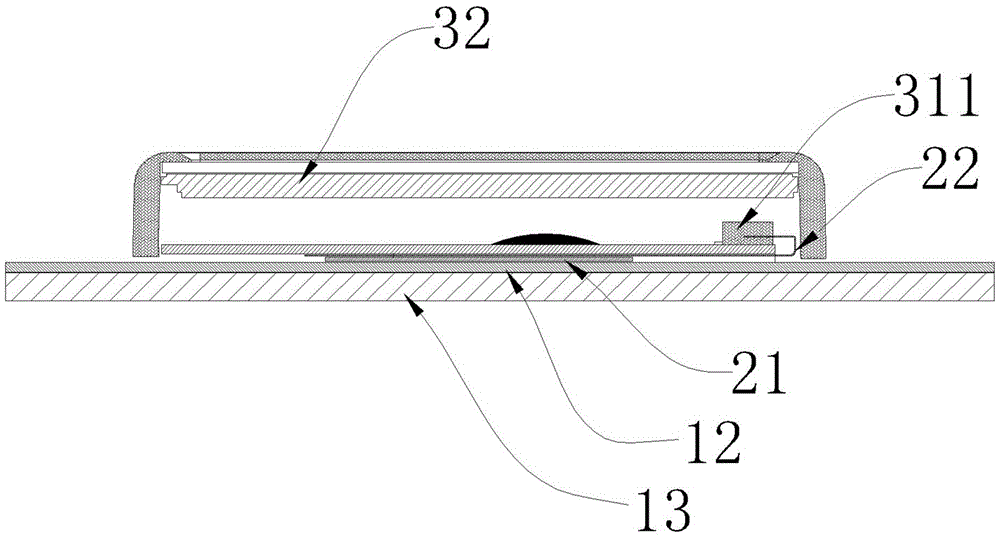

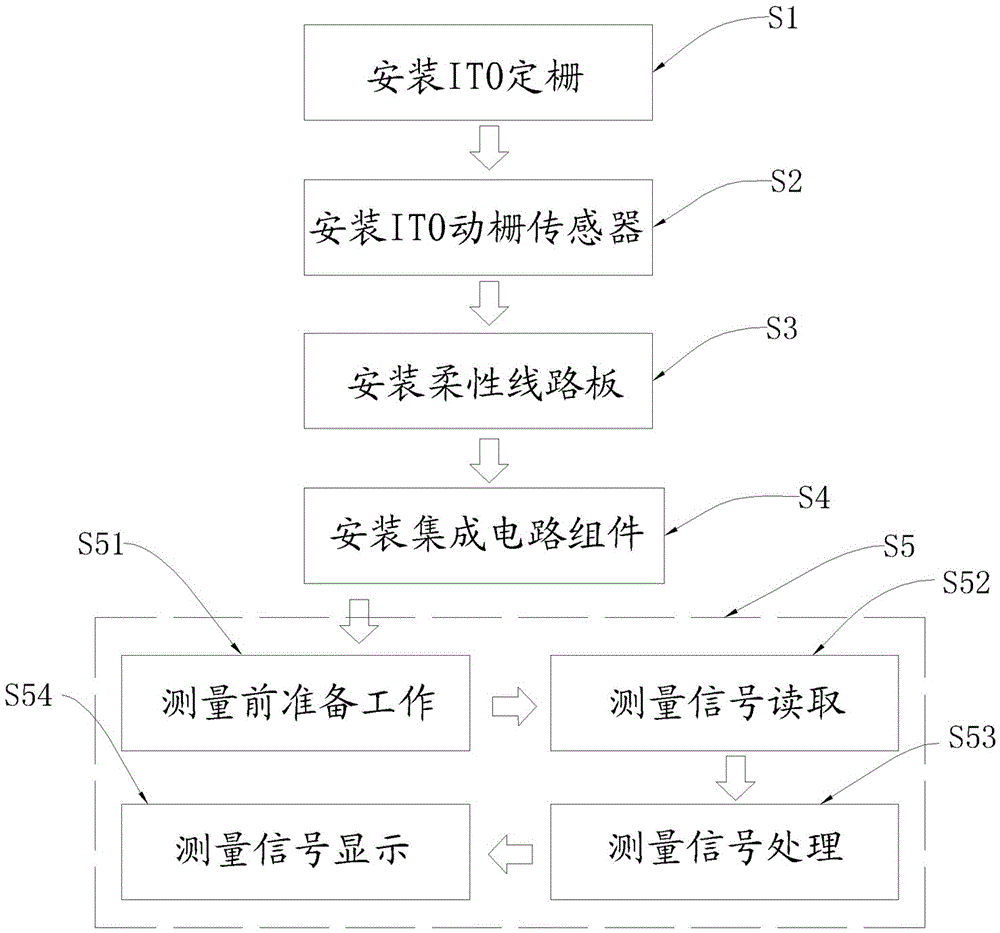

Capacitive grating-type digital caliper with sensor and digital circuit separated and making method thereof

The invention discloses a capacitive grating-type digital caliper with a sensor and a digital circuit separated and a making method thereof. The capacitive grating-type digital caliper comprises a caliper blank, a moving grating assembly and an integrated circuit assembly, wherein the moving grating assembly comprises an ITO moving grating sensor and a flexible circuit board; the caliper blank comprises an ITO static grating and a caliper frame capable of moving on the ITO static grating; the integrated circuit assembly comprises a digital integrated circuit board, a display and a battery; the ITO static grating, the ITO moving grating sensor, the digital integrated circuit board and the display are sequentially and fixedly sleeve the caliper frame; a gap is preserved between the ITO static grating and the ITO moving grating sensor; the battery is electrically connected with the digital integrated circuit board; the ITO moving grating sensor is electrically connected with an input port of the digital integrated circuit board via a flexible circuit board; and the output port of the digital integrated circuit board is electrically connected with the display. After the ITO moving grating sensor collects caliper frame moving signals, the signals are transferred to the digital integrated circuit board, and after processed by the digital integrated circuit board, the signals are displayed via the display.

Owner:UNITED PRECISION MACHINE

Assembling process for automobile differential mechanism assembly

InactiveCN105729108AGap stabilityImprove consistencyAssembly machinesVehicle componentsPlanetProduction line

An automobile differential assembly assembly process, which is characterized in that the oil stains and rust on each assembly part are cleaned first, and then sequential assembly: use a pad selection machine to measure the inner cavity of the differential case and detect the required planetary gears Gaskets, side gear spacers, respectively put the side gears, side gear spacers, planetary gears and planetary gear spacers, and planetary gear shafts into the inner cavity of the differential case, and use a special measuring device to measure and adjust the planetary gears When turning the side gear, there must be no sticking or loosening. Apply thread locking agent to the bolt thread, and the bolt will fasten the driven gear to the differential case until According to the specified torque, special tools are used to press the differential bearings into the two ends of the differential housing, and then the products are rolled off the assembly line. The gap between the planetary gear and the side gear is stable, the product consistency is good, the precision is high, the pass rate is high, the production efficiency is high, the cost is low, the operation is simple, and it has a wide range of popularization and application value.

Owner:HENGYANG FENGSHUN AXLE CO LTD

Cooking utensil

The invention relates to a cooking utensil which comprises a pot, a pot lid, a stirring paddle and a driving mechanism. The stirring paddle can be driven by the driving mechanism to move, and is arranged in the pot in such a manner that the stirring paddle can transversely swing; the stirring paddle at least comprises a cambered section in the length direction, the inner wall of the pot comprisesa cambered surface, the cambered surface adapts to the shape of the cambered section when the cambered section swings, the cambered section comprises a top surface, a bottom surface and side surfaces,the side surfaces are connected with the top surface and the bottom surface, and included angles ranging from 0 degrees to 70 degrees are formed by the bottom surface and the side surfaces. Comparedwith the prior art, the cooking utensil has the advantages that upper and lower layers of food materials can be continuously repositioned to be repeatedly stir-fried, accordingly, the food materials,spices and the like can be uniformly mixed with one another, the cooking degree can be greatly upgraded, and mouth feel can be greatly enhanced.

Owner:JOYOUNG CO LTD

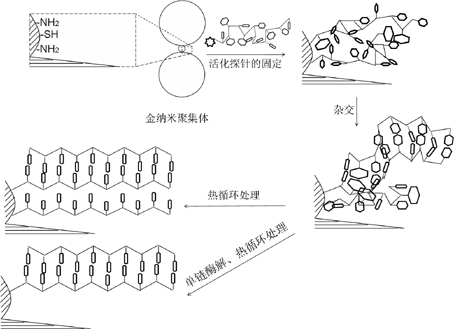

Nano structure for enhancing Raman and fluorescence signals and preparation method thereof

InactiveCN102061164AEnsure the gap is stableEasy for quantitative analysisNanomagnetismLuminescent compositionsFluorescenceClinical diagnosis

The invention discloses a uniform nano aggregate and a preparation method. The nano aggregate comprises a magnetic nano particle modified with sulfydryl, wherein two sides of the magnetic nano particle are respectively connected with a first metal nano particle and a second metal nano particle through the sulfydryl, the first metal nano particle, the magnetic nano particle and the second metal nano particle are arranged in a line, the particle sizes of the first and the second metal nano particles are 20-400nm and the first and the second metal nano particles are same metal nano particles, and the particle size of the magnetic nano particle is 3-20nm. An object to be tested is orientated to a gap between the metal nano particles by using function groups on the surfaces of the nano particles, thus the great enhancement of the Raman and fluorescence signals of a molecular to be tested is realized. The invention can provides a novel rapid and ultra-sensitive detection method for experiment research, clinical diagnosis and large sample screening.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com