LED module installing mechanism

A technology of LED module and installation mechanism, which is applied to identification devices, lighting devices, components of lighting devices, etc., can solve the problems of inability to achieve adjustment, complicated methods, instability, etc., and achieve convenient operation, precise control, and adjustment methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

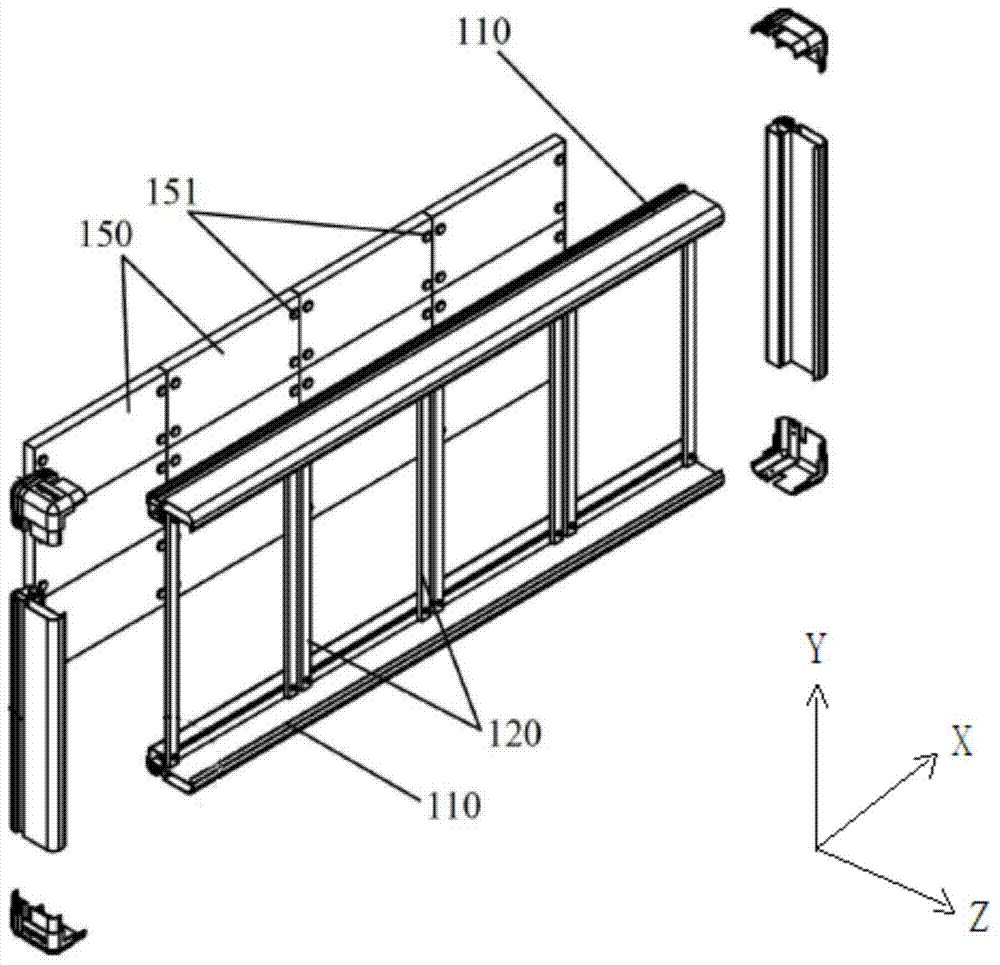

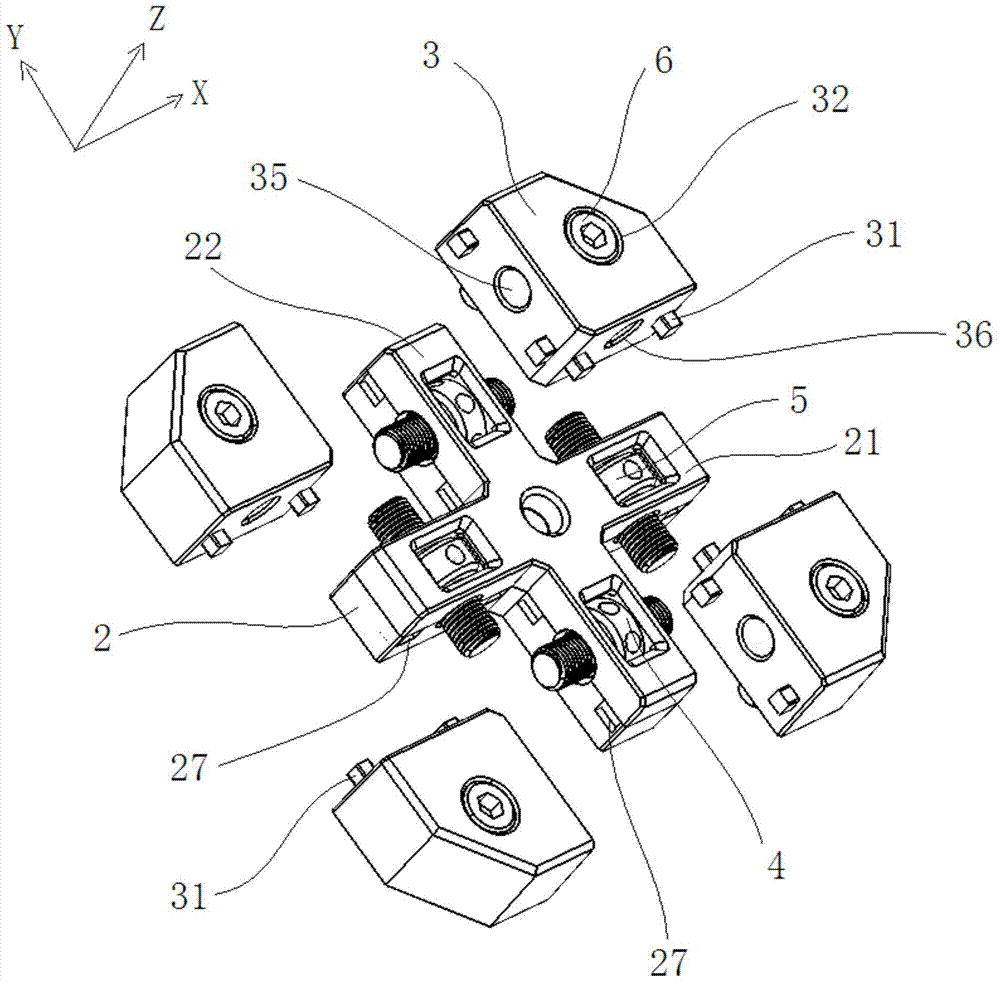

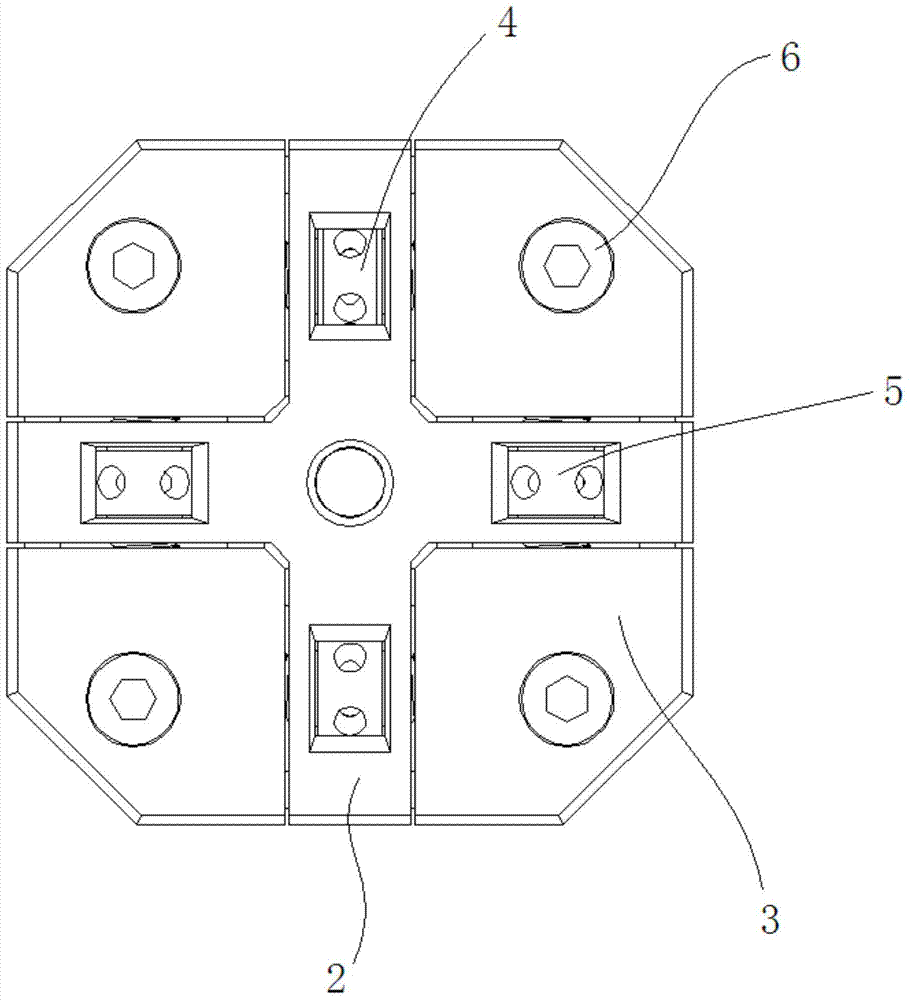

[0048] Refer to Figure 2 ~ Figure 5 , The LED module installation mechanism of the present invention includes a fixed frame 2, at least two movable blocks 3, and a gap adjustment mechanism installed on the fixed frame 2. among them

[0049] The fixing frame 2 can take various shapes. In this embodiment, it is preferably in the shape of a cross and is composed of a horizontal frame 21 and a vertical frame 22. The extension direction of the horizontal frame 21 is defined as the X-axis direction. The extension direction of the vertical frame 22 is the Y-axis direction;

[0050] The movable block 3 is provided with four blocks, which are arranged on both sides of the horizontal frame 21 and the vertical frame 22, and are distributed in a "tian" shape. The movable blocks 3 are arranged on both sides of the horizontal frame 21 It can move along the X-axis direction, the movable blocks 3 arranged on both sides of the vertical frame 22 can move along the Y-axis direction, and each movabl...

Embodiment 2

[0074] The first embodiment of the present invention is basically the same as the first embodiment, and the difference from the first embodiment is that the fixing frame 2 in the second embodiment has a "T" shape, such as Figure 17 with Figure 18 As shown, the vertical frame 22 of the fixed frame 2 is connected to the horizontal frame 21. In this embodiment, it is preferably connected to the middle position of the horizontal frame 21. Two ends of the horizontal frame 21 are respectively provided with The movable block 3 is connected together in the Y-axis direction and the Y-axis adjustment screw 5 is provided on the vertical frame 22 with an X-axis adjustment screw 4 that connects the movable block 3 together in the X-axis direction. The movable block 3 is all installed on the fixed frame 2 through the X-axis and Y-axis adjustment screws, and the LED module 100 installed on the movable block 3 can also pass through a number of this embodiment The LED module installation mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com