Patents

Literature

35results about How to "Accurate gap adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

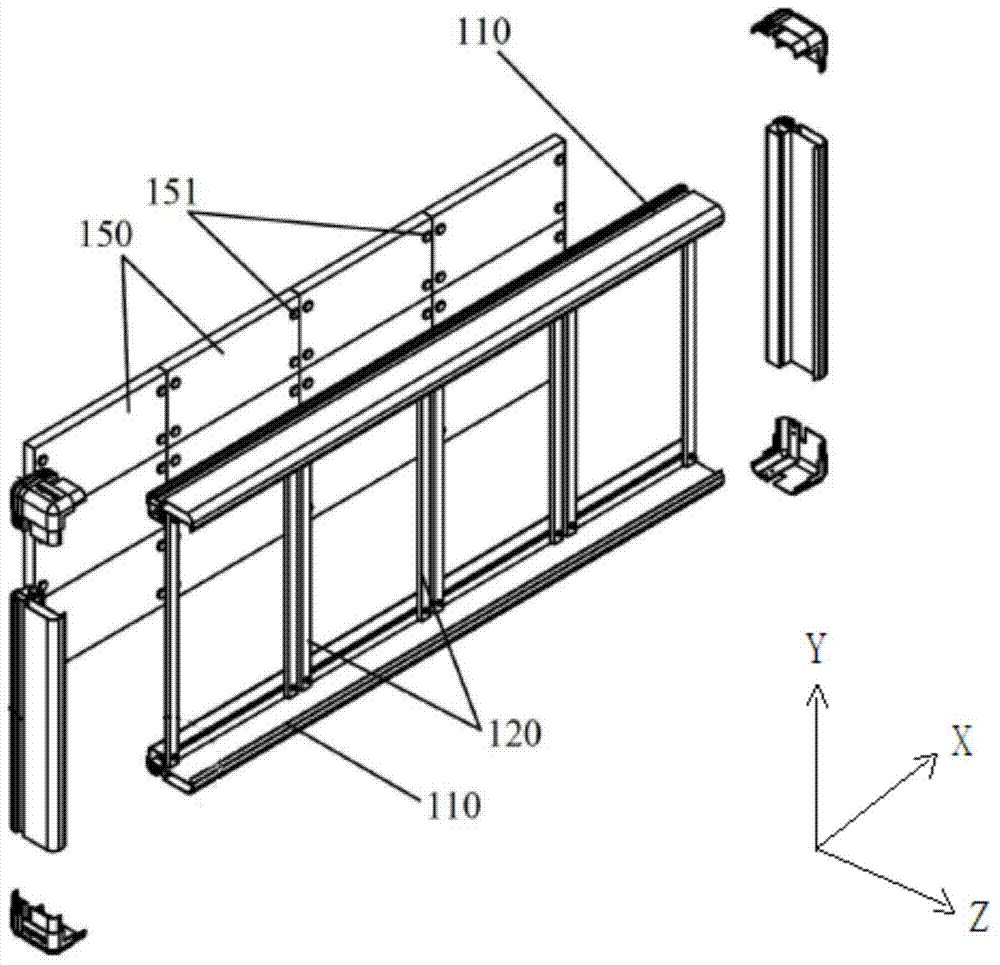

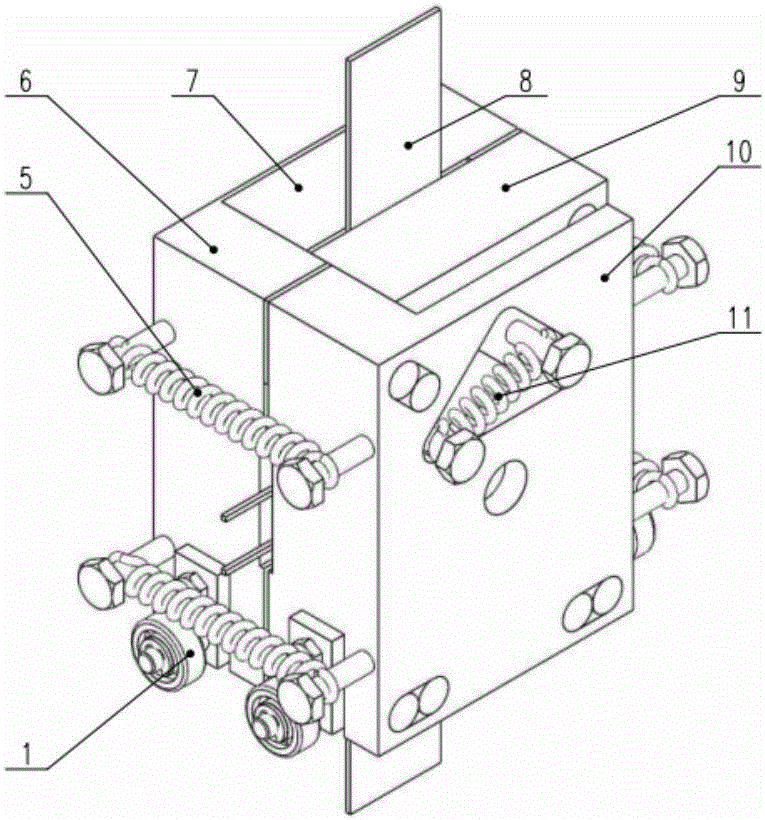

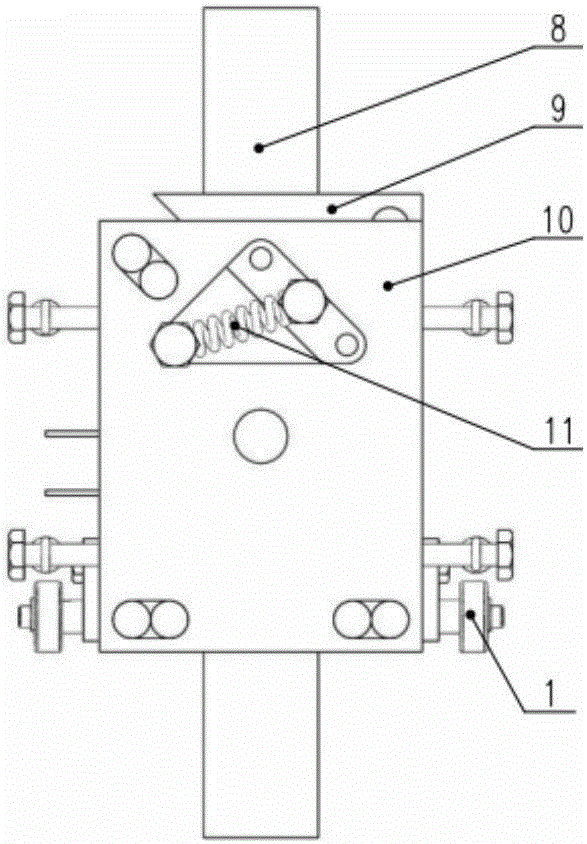

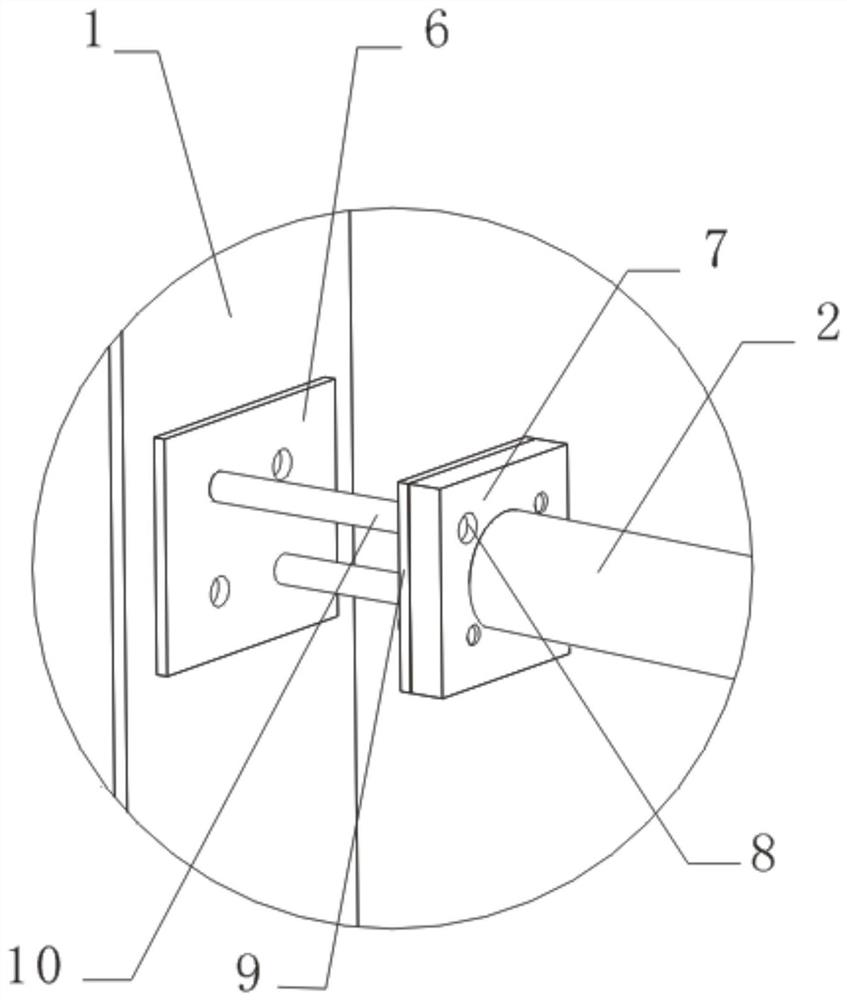

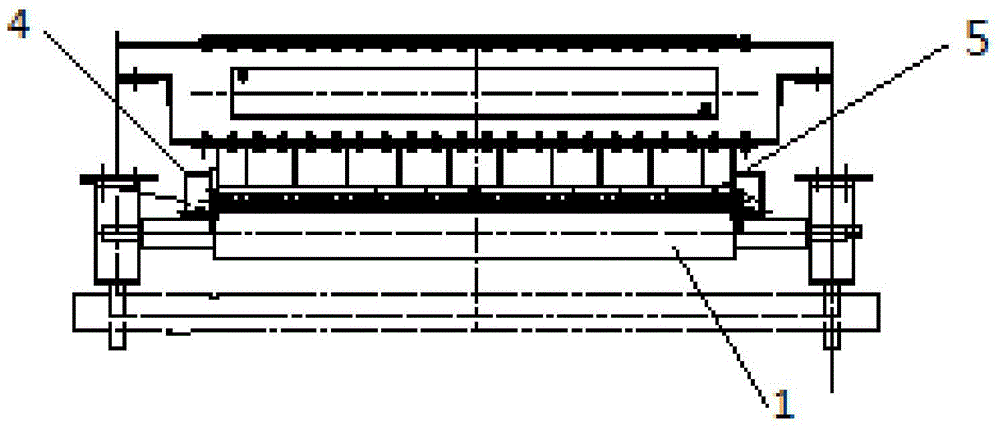

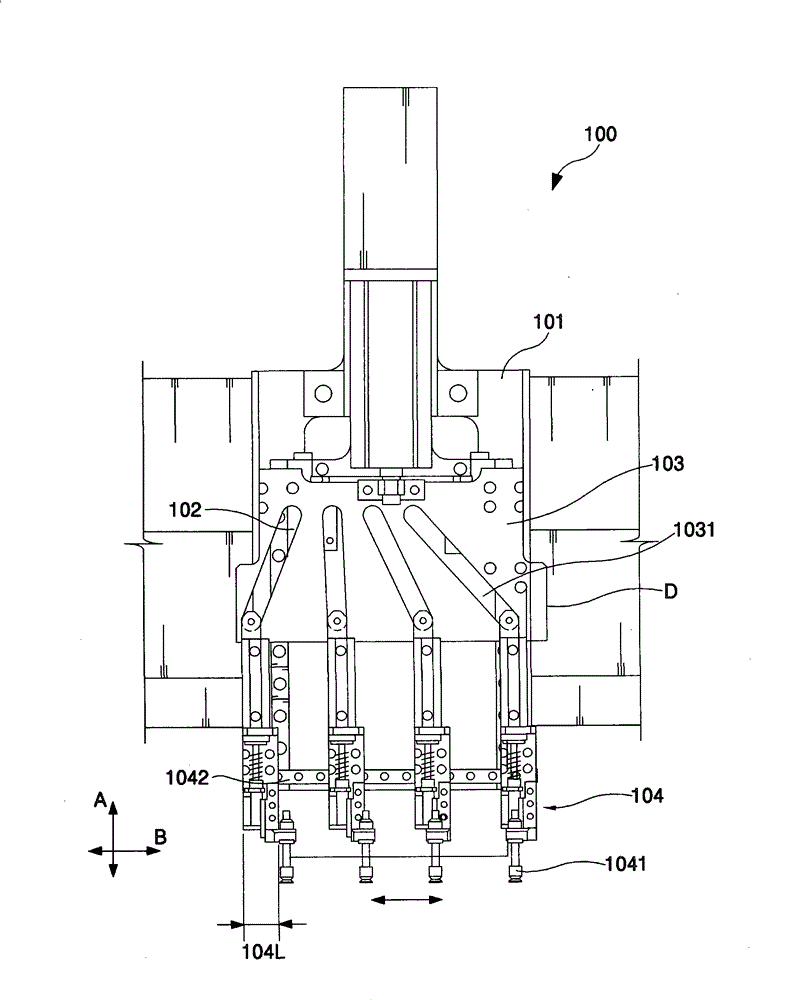

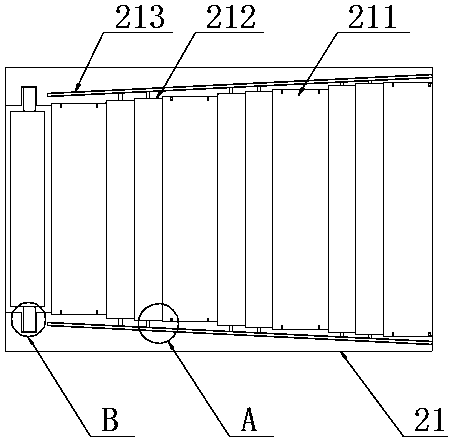

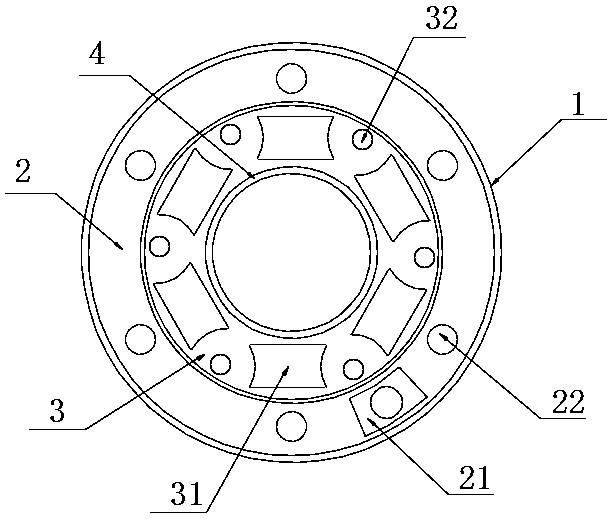

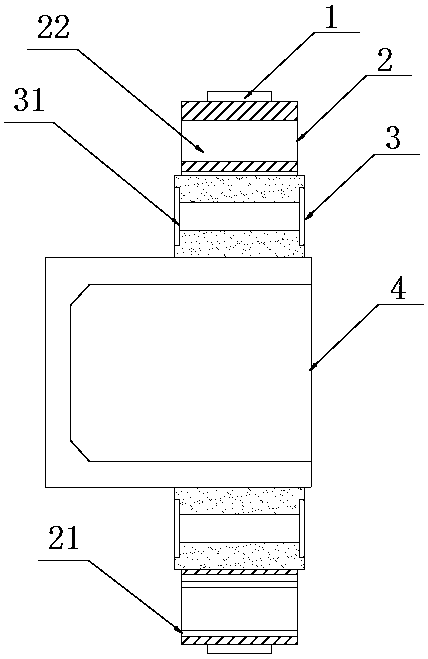

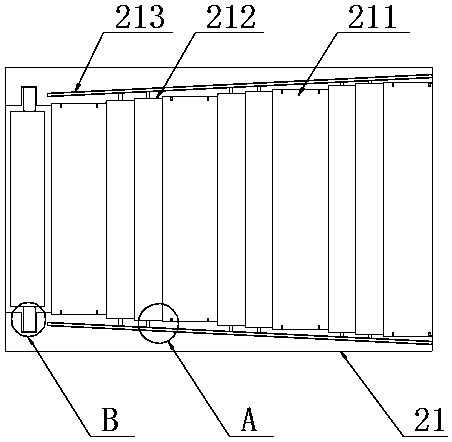

LED module installing mechanism

ActiveCN104723074AEasy to adjustSave adjustment timeCasings/cabinets/drawers detailsPrintingLED displayEngineering

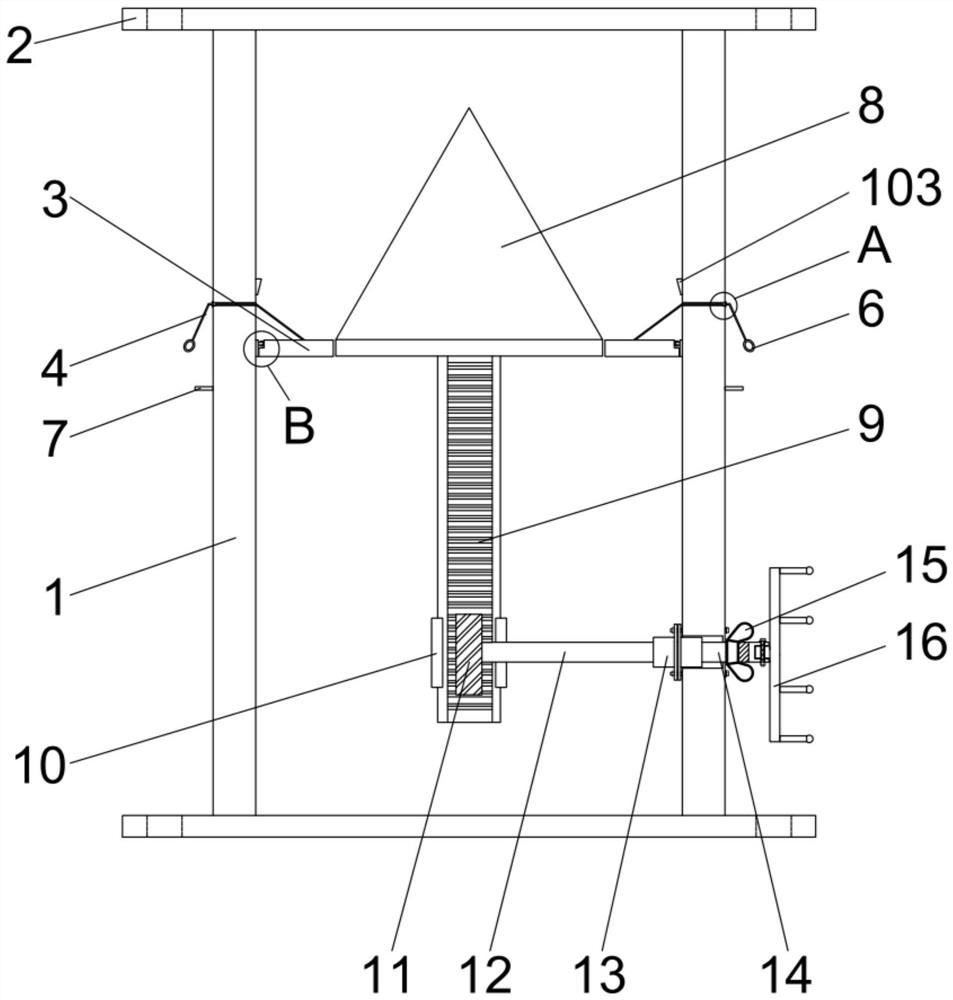

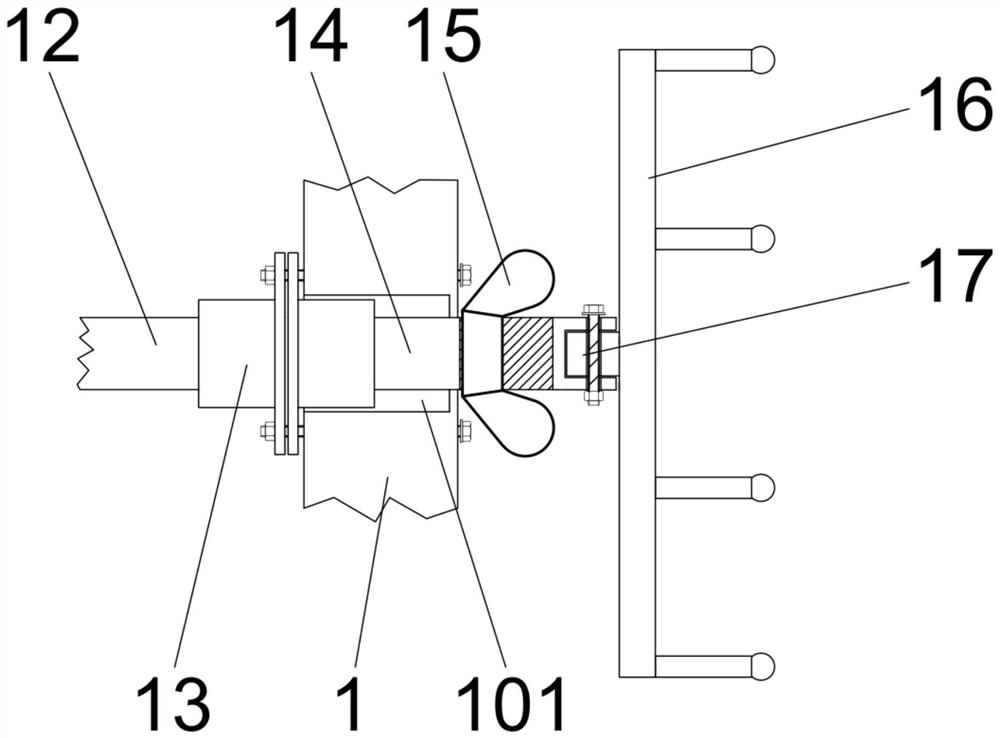

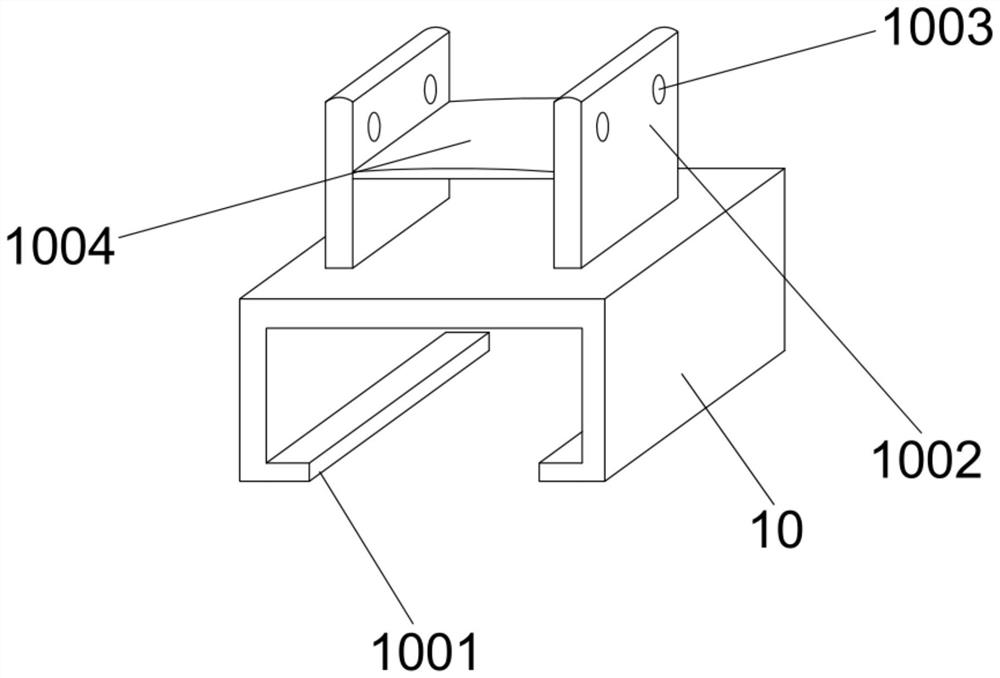

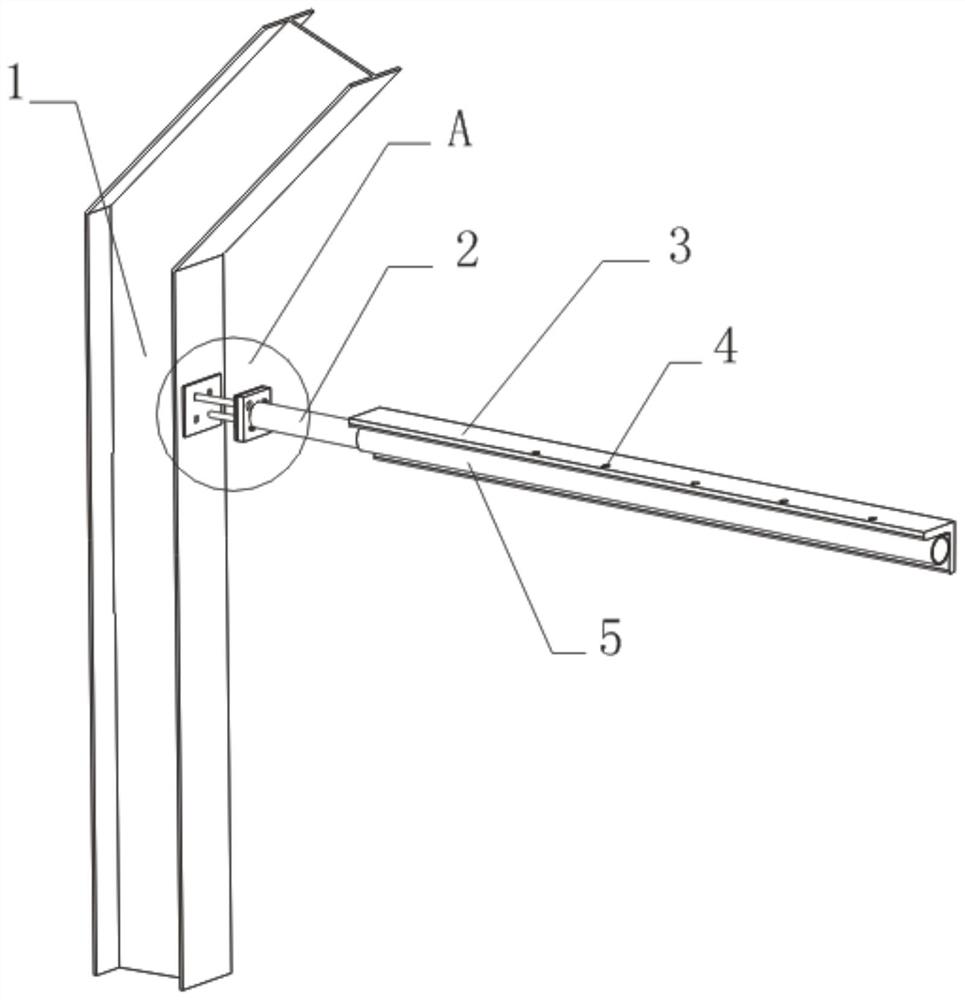

The invention discloses an LED module installing mechanism. The LED module installing mechanism comprises a fixed rack (2), a gap adjusting mechanism on the fixed rack (2), and at least two moving blocks (3) movably connected with the fixed rack (2). LED modules (100) are arranged on the moving blocks (3). The two ends of the gap adjusting mechanism are connected with the moving blocks (3) respectively. By adjusting the moving block (3) on the two sides to move away or get close to each other, a gap between the LED modules (100) arranged on the moving blocks (3) is adjusted. The invention belongs to the technical field of LED modules and LED display screens. According to the LED module installing mechanism, the technical problems in the prior art that the method for adjusting the planar gap between the LED modules is complex and unstable, and the adjustment on the planeness which is perpendicular to the planar direction of the LED modules is unable to achieve are solved. The LED module installing mechanism is particularly applicable to adjusting the planeness perpendicular to the direction of the LED modules and the planar gap between the LED modules, the adjusting operation is simple, and the adjusting effect is stable.

Owner:GLUX VISUAL EFFECTS TECH (SHENZHEN) CO LTD

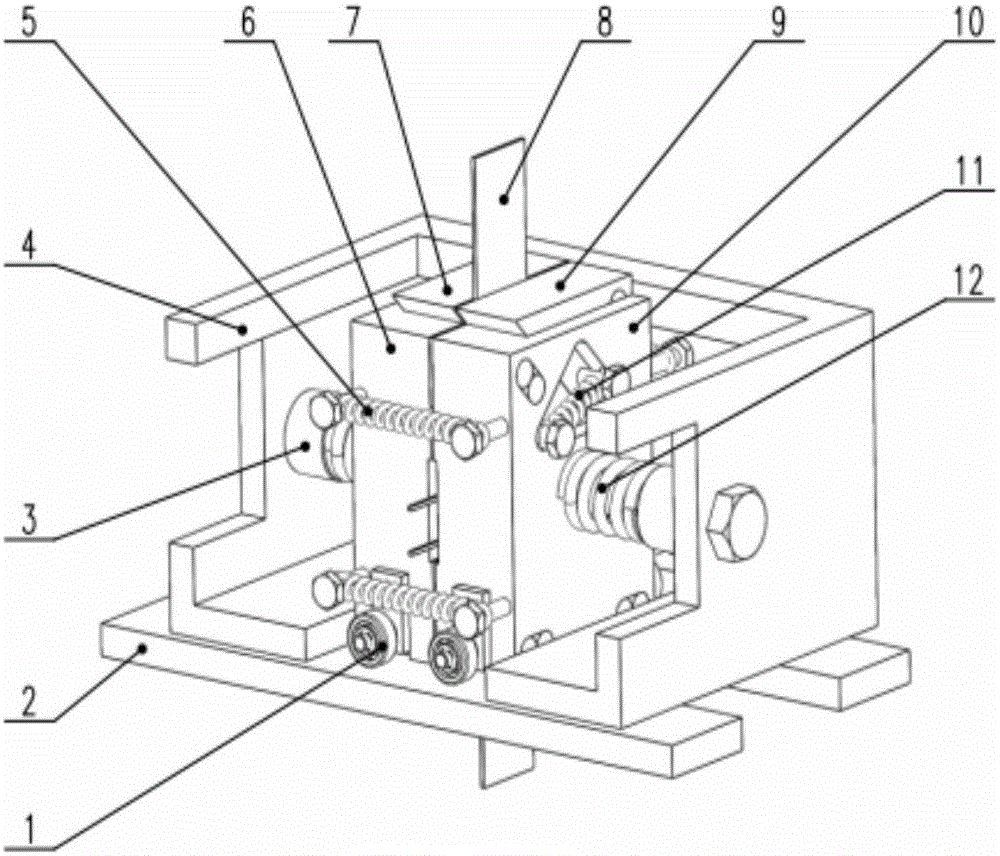

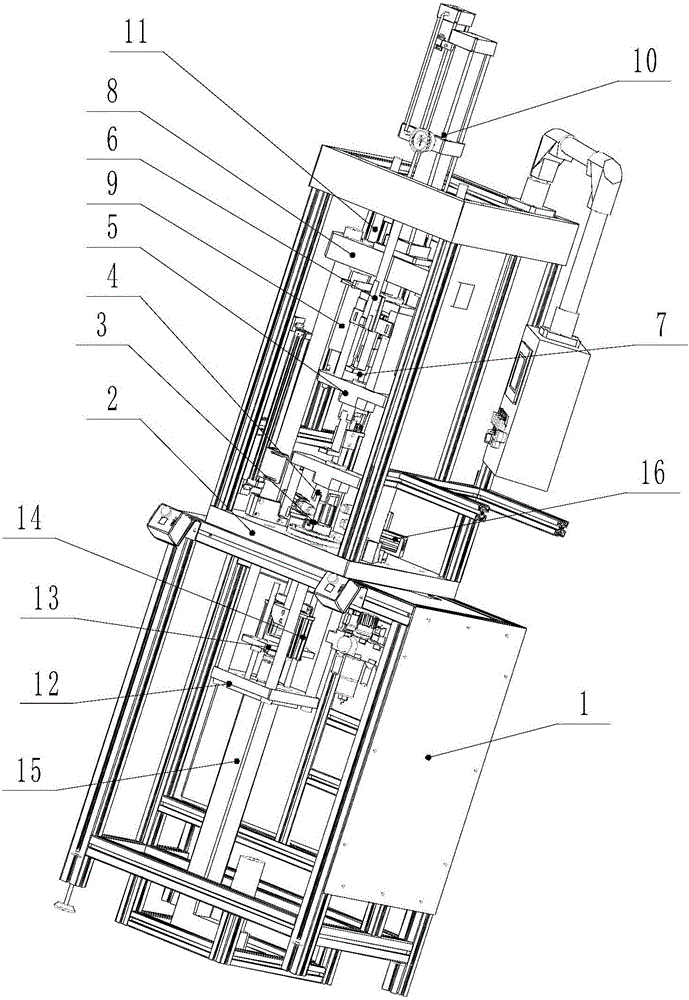

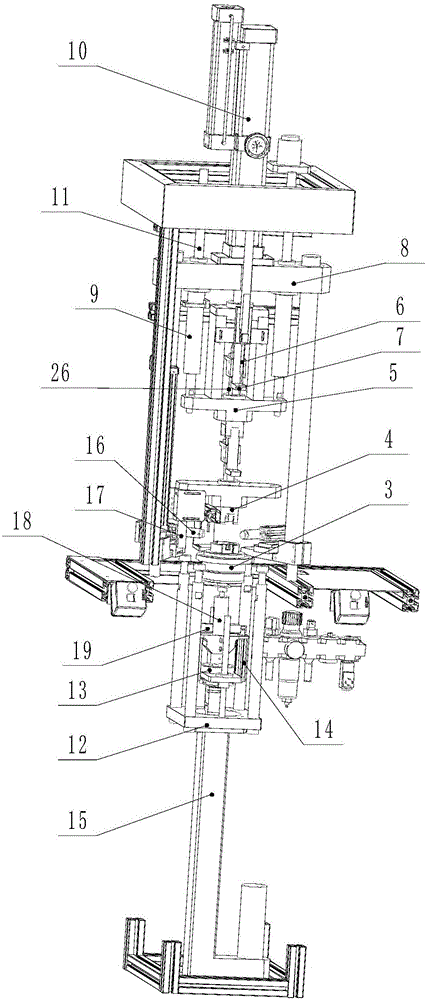

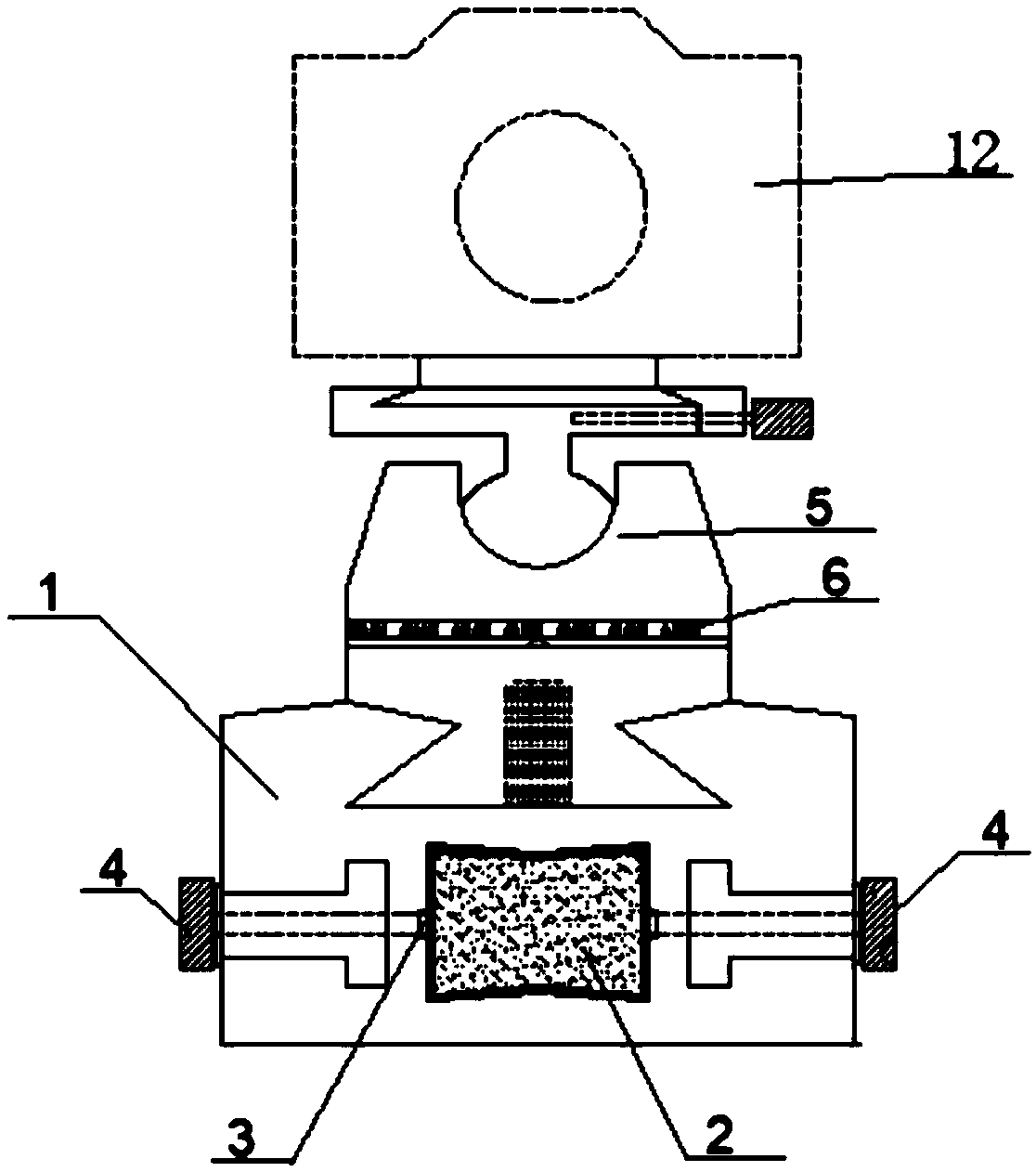

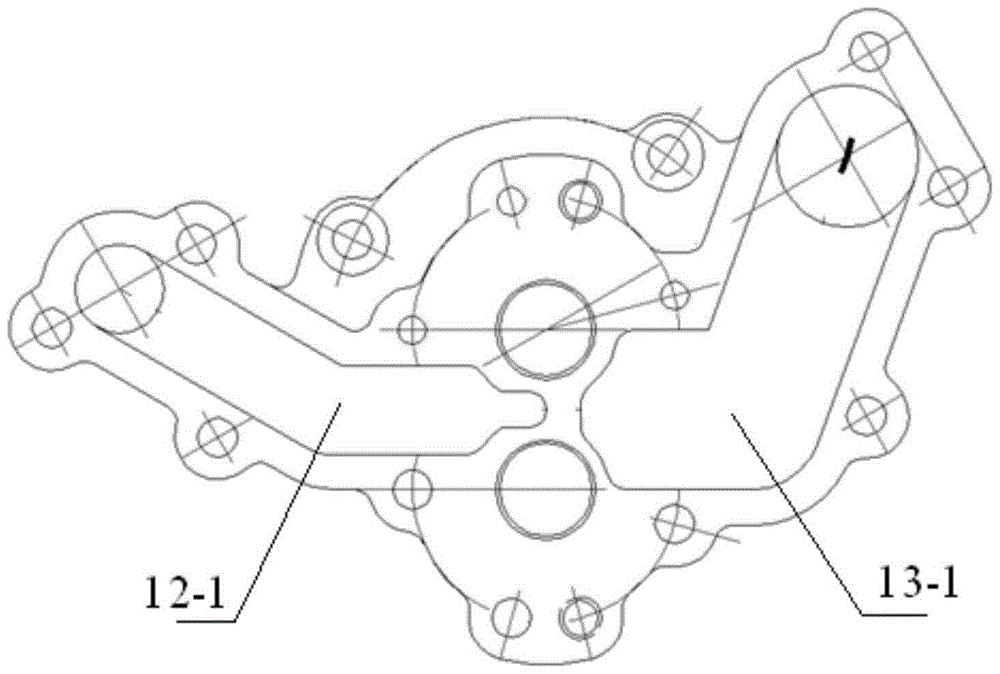

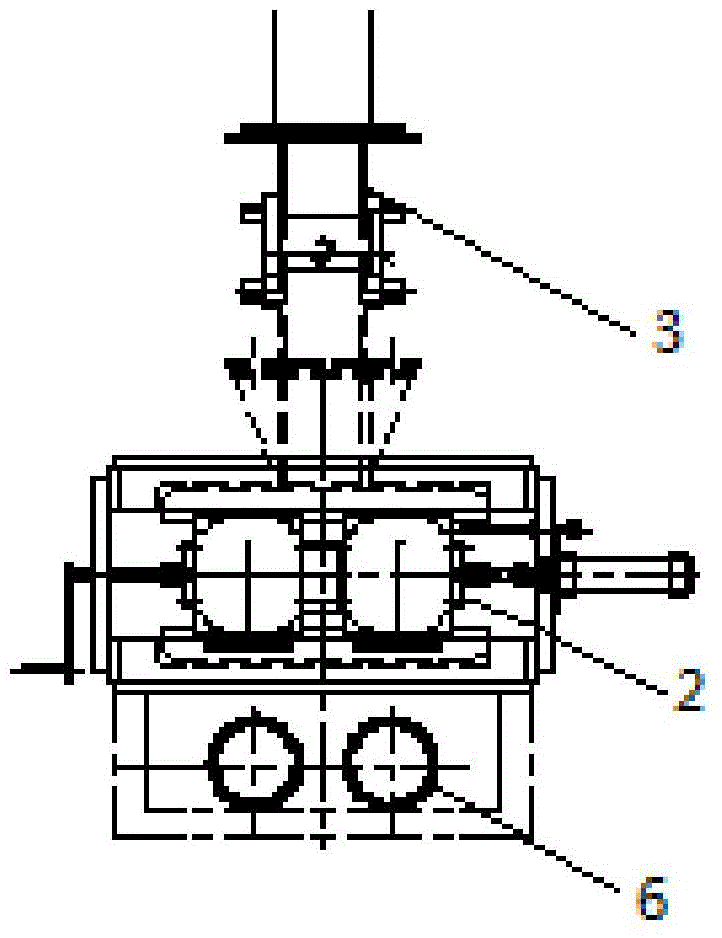

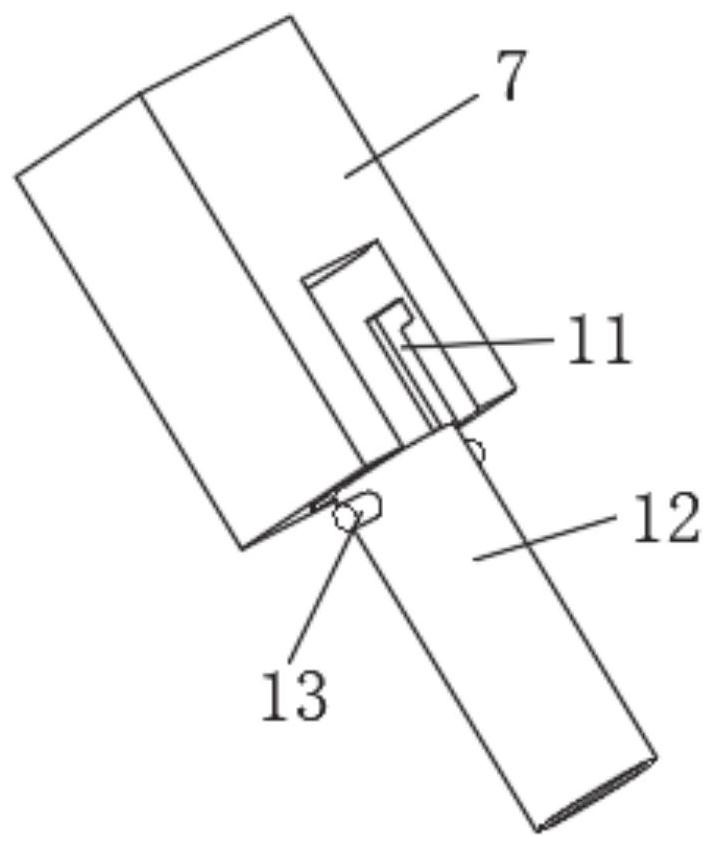

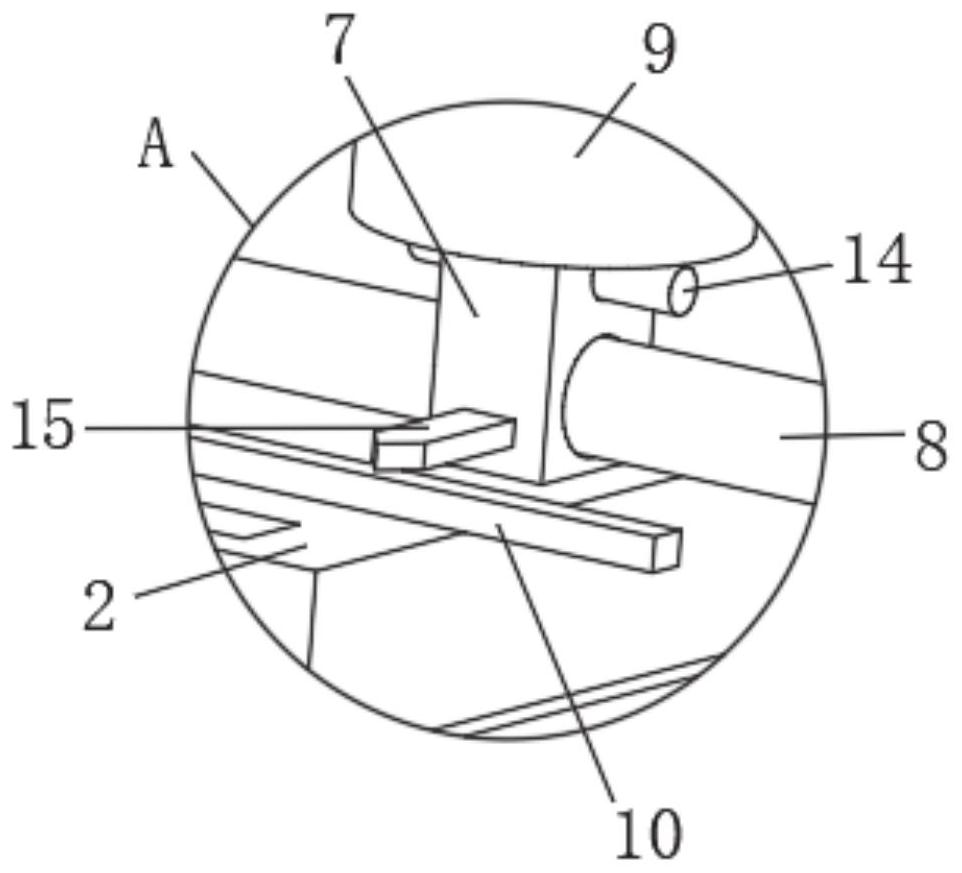

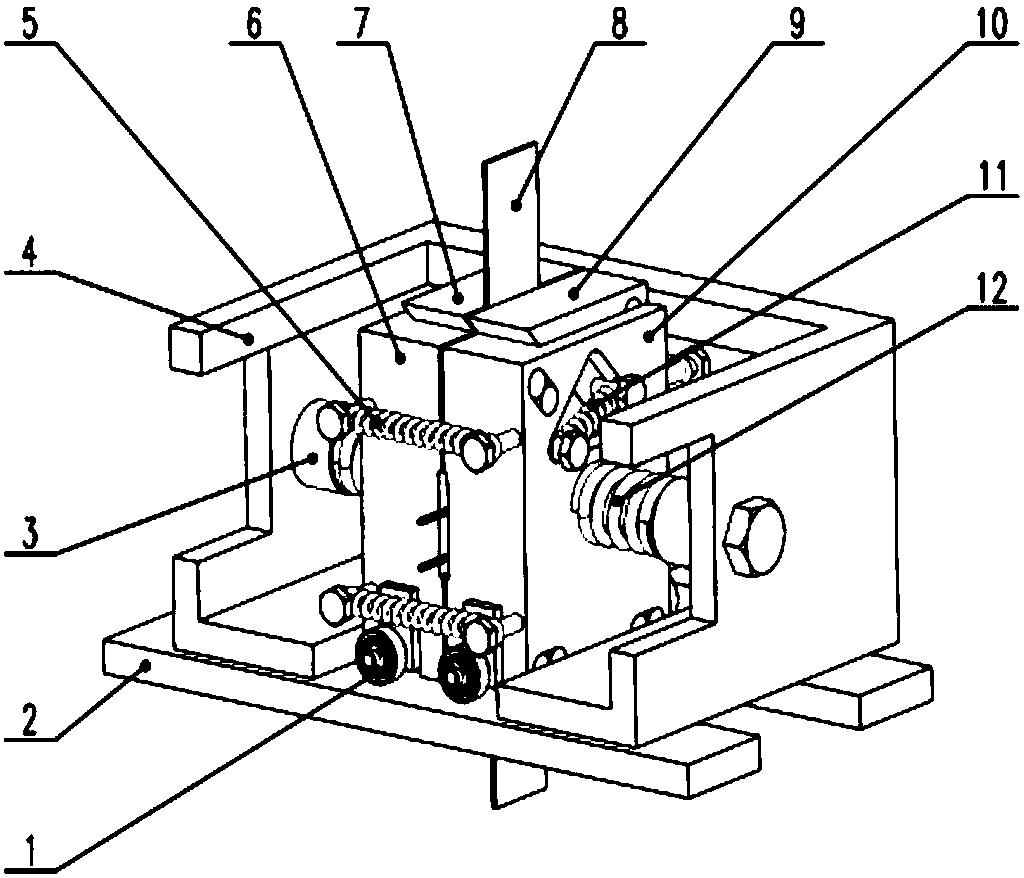

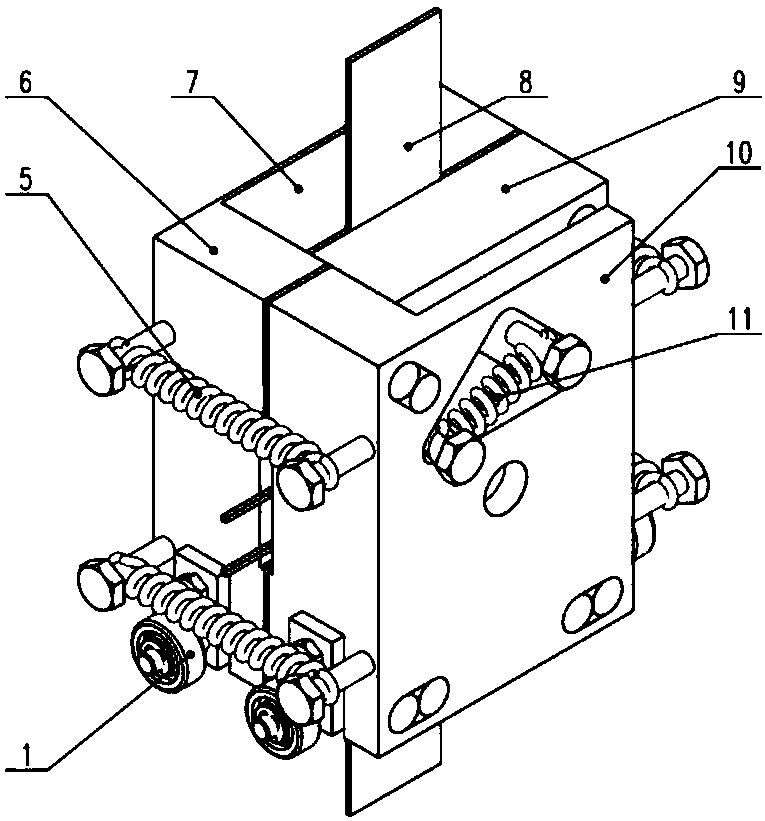

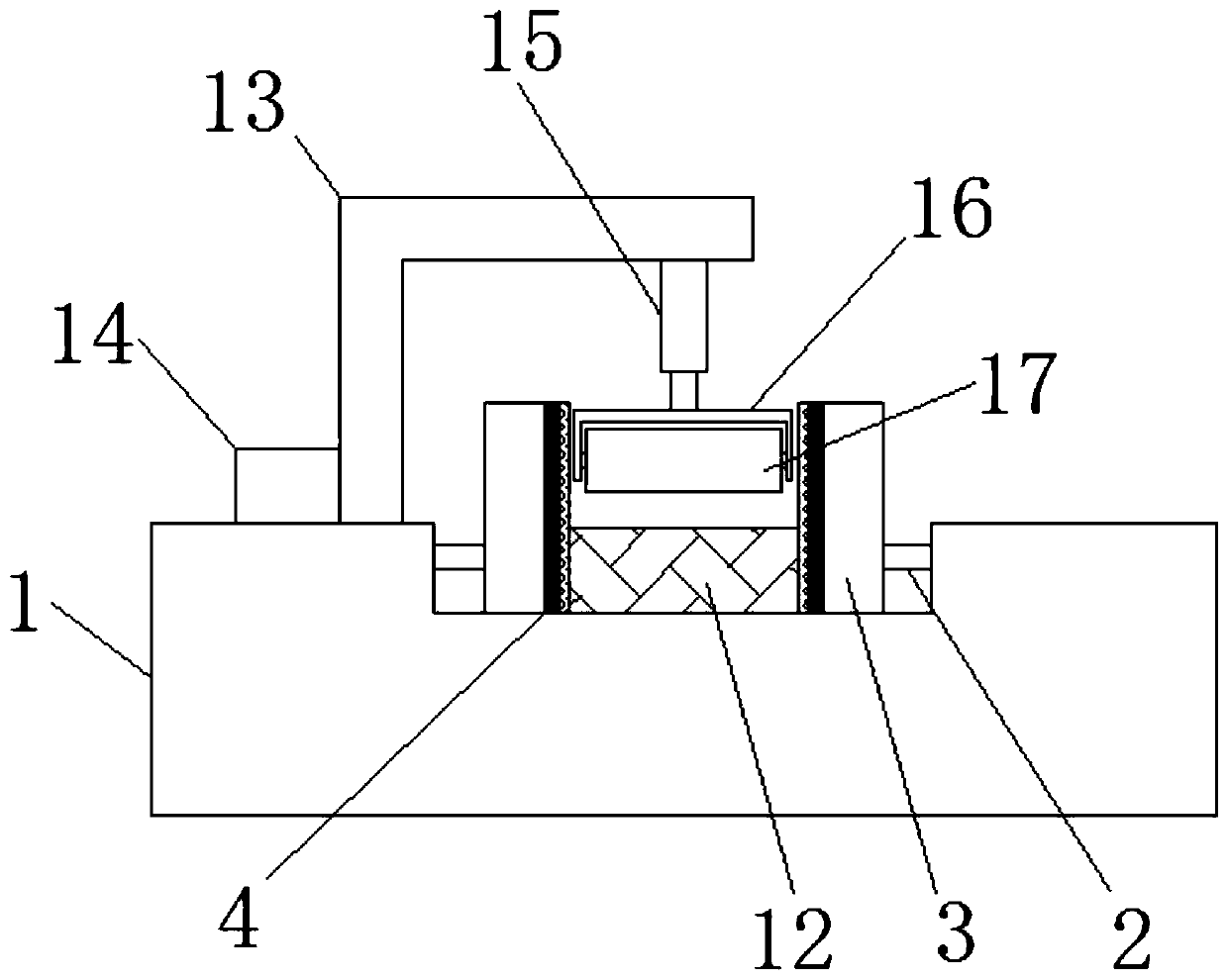

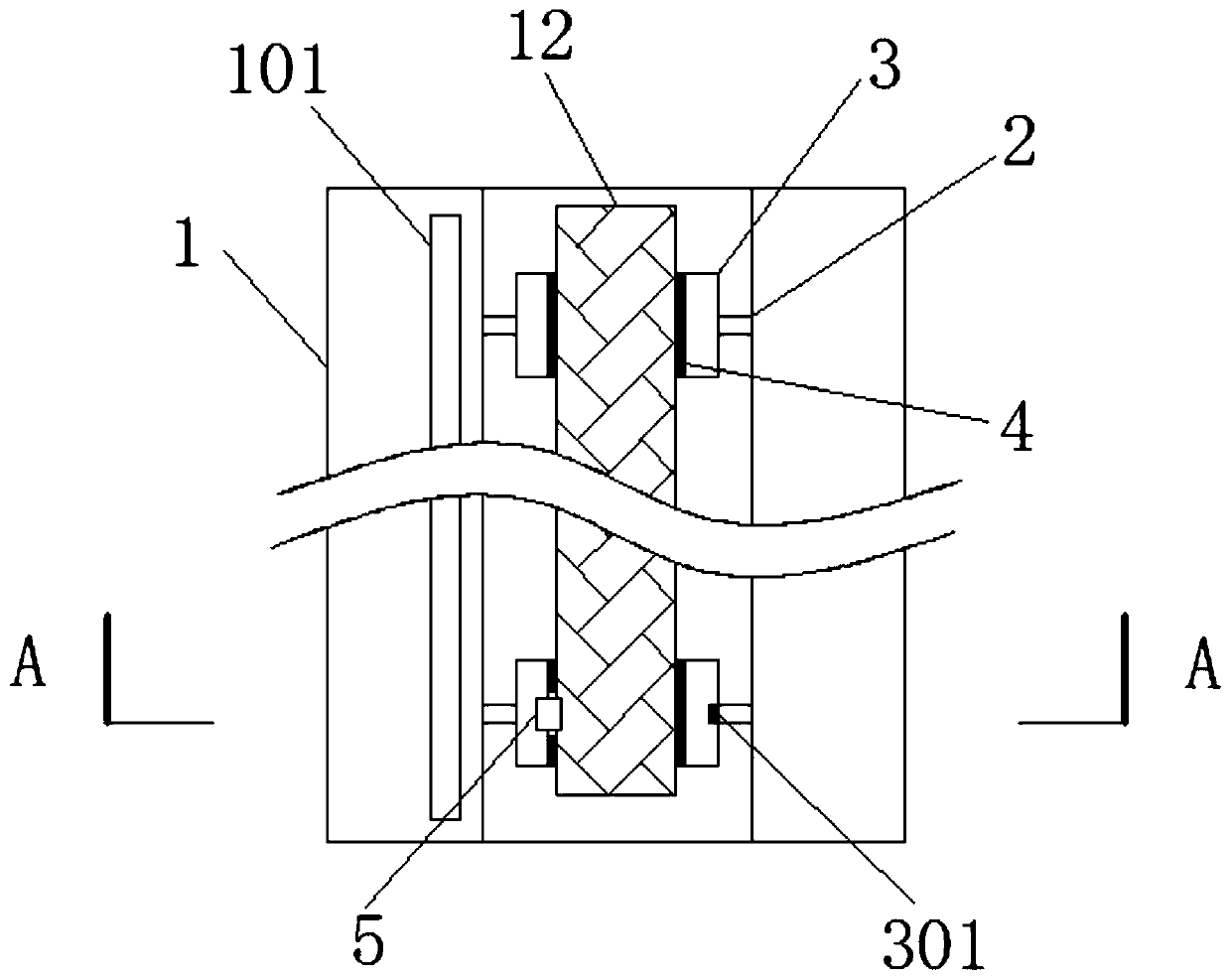

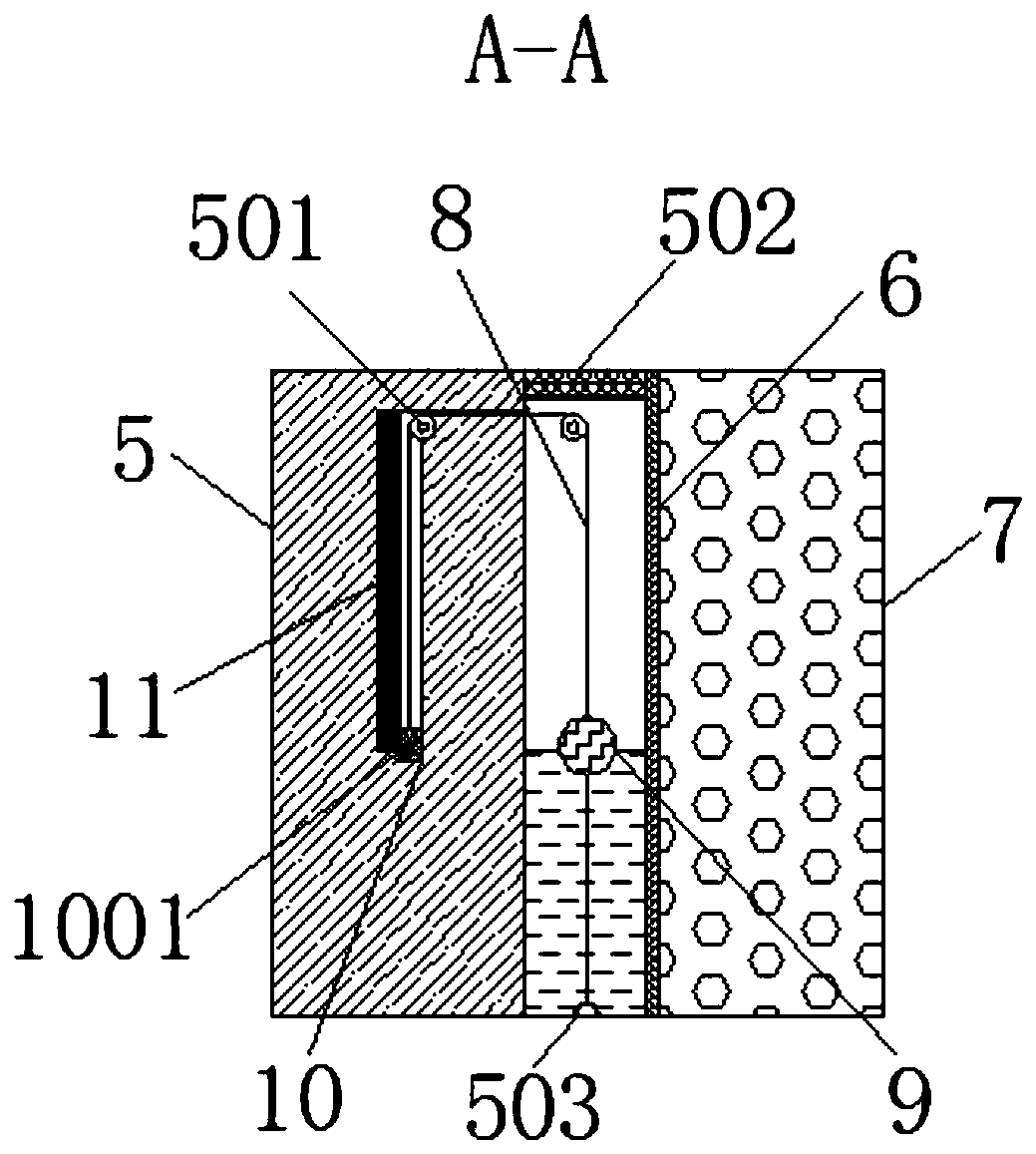

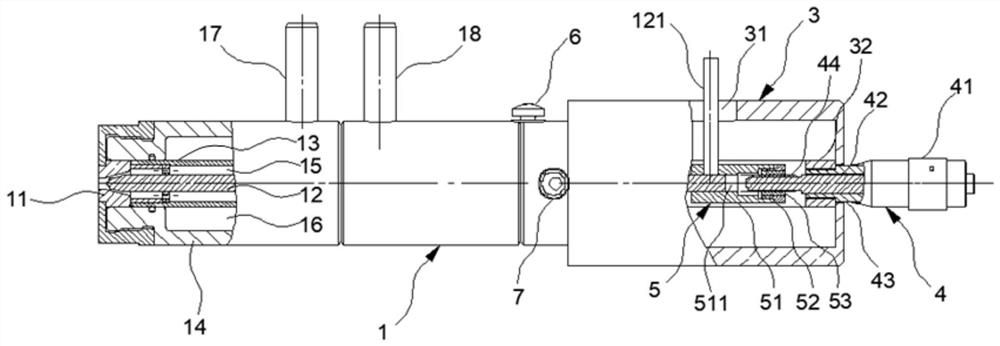

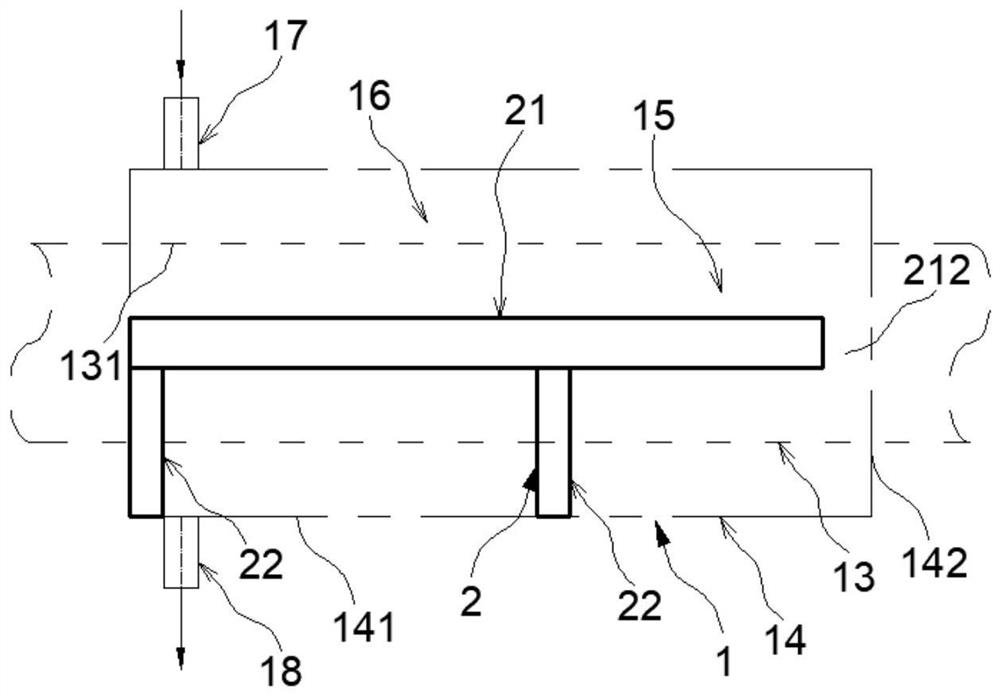

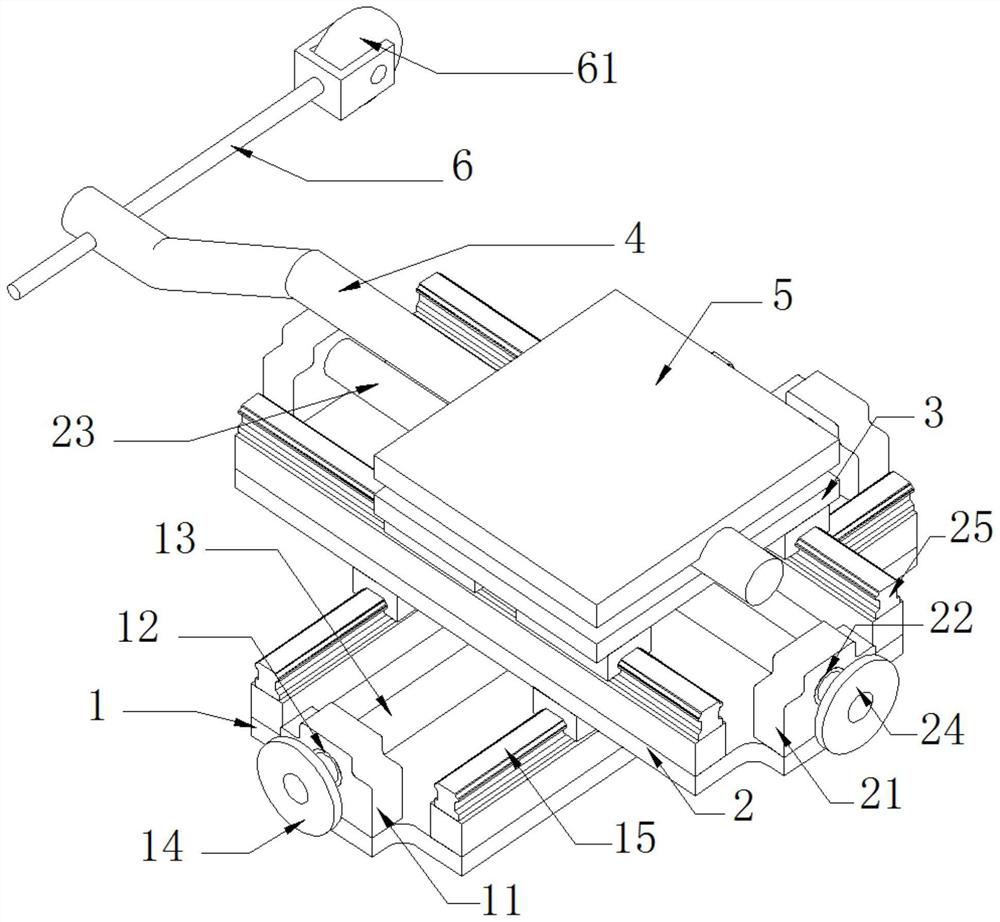

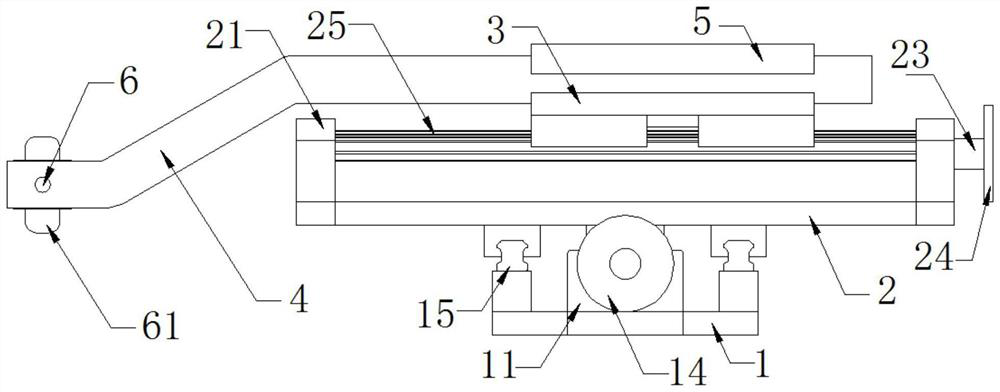

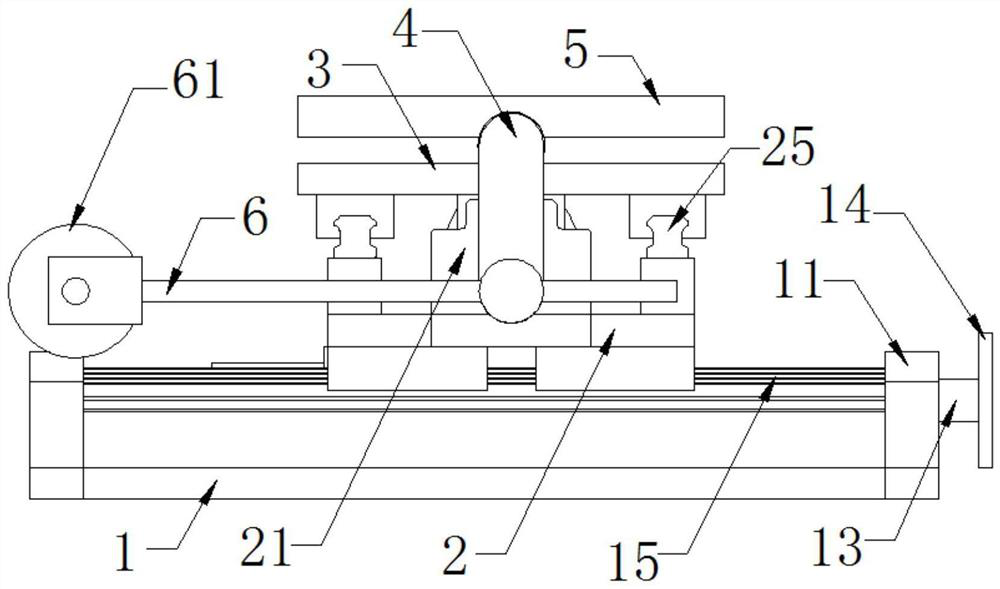

Asymmetric clamping device and experimental method for sheet compressing

ActiveCN106353181AAvoid wrinklesReliable side pressureMaterial strength using tensile/compressive forcesWrinkle skinExperimental methods

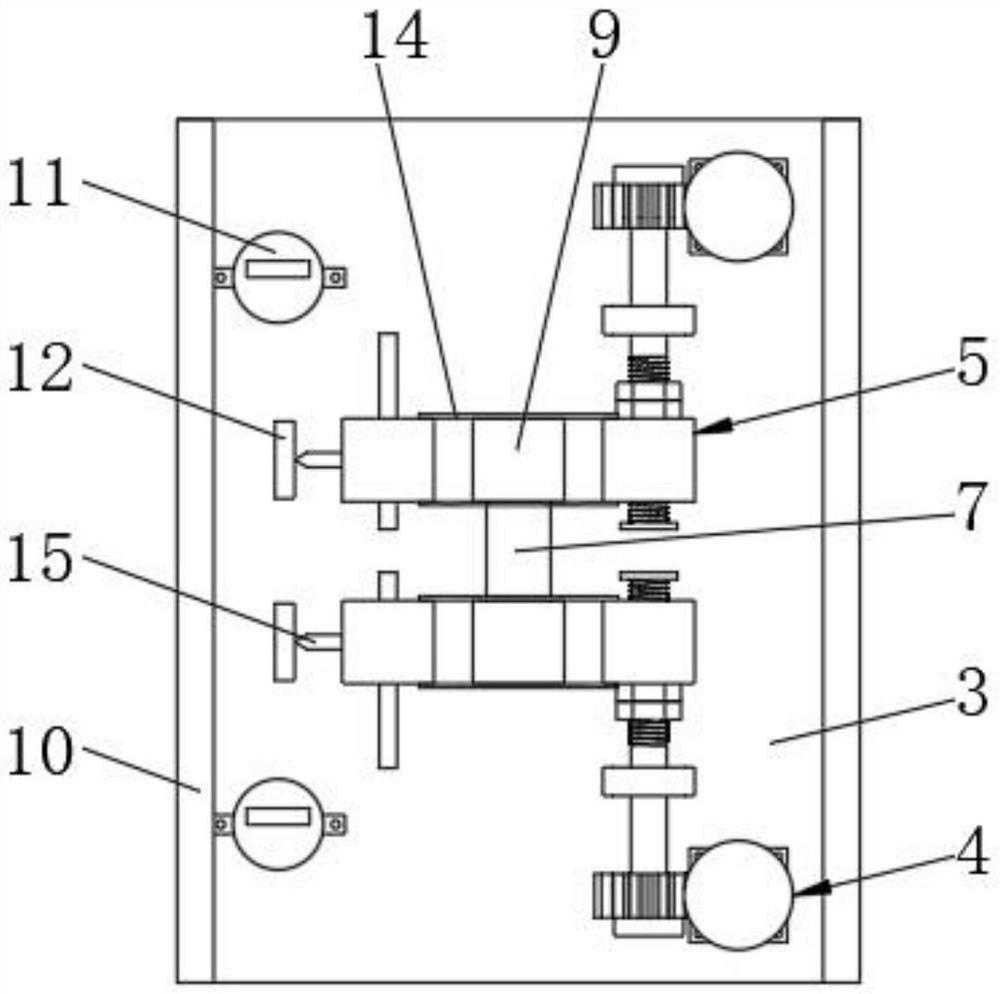

An asymmetric clamping device and experimental method for sheet compressing are provided; two clamp plates of the asymmetric clamping device are positioned in retaining grooves in a center spring support baseplate, lateral pressure is applied to a sheet through the clamp plates and sliders such that the sheet wrinkles in the thickness direction and loses stability in the width direction; two return springs are each fixed between the corresponding clamp plate and slider; tension springs are connected to the lateral sides of the two clamp plates to provide uniform symmetric pressure for the clamp plates; lateral pressure is applied through the springs, a sample is given planar clamping force through the clamping device, the sample is kept moving evenly in the thickness direction, it is guaranteed that a clamping gap may automatically adjust with changes in sheet thickness; a slider movement area is positioned in a sample non-standard distance segment, the transverse frictional force on the sample may not affect a standard distance segment, and the impact of slider movement induced width-directional frictional force upon experimental results is eliminated; the invention provides three travel options, and various sheet tensioning and compressing experimental needs can be met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

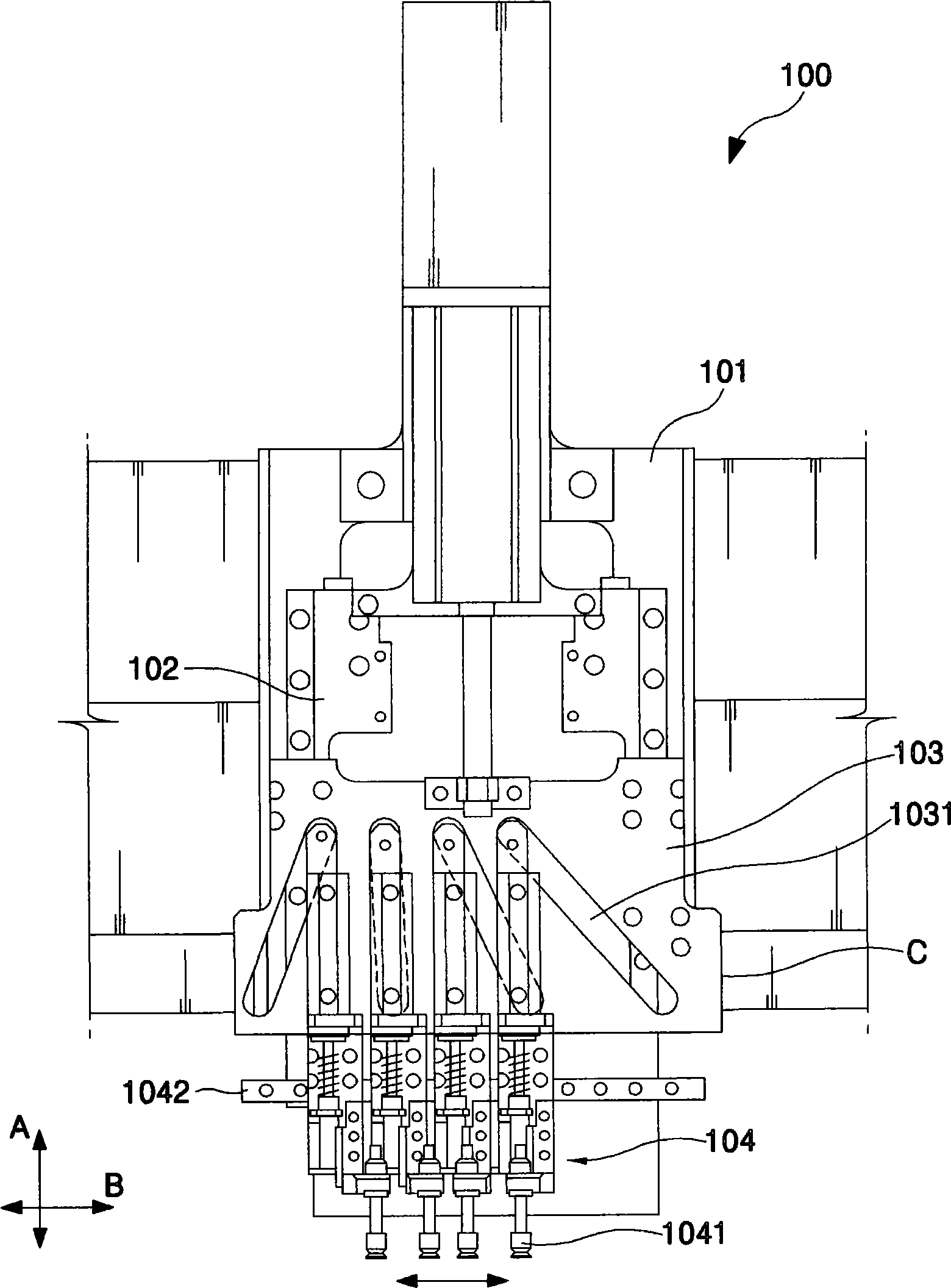

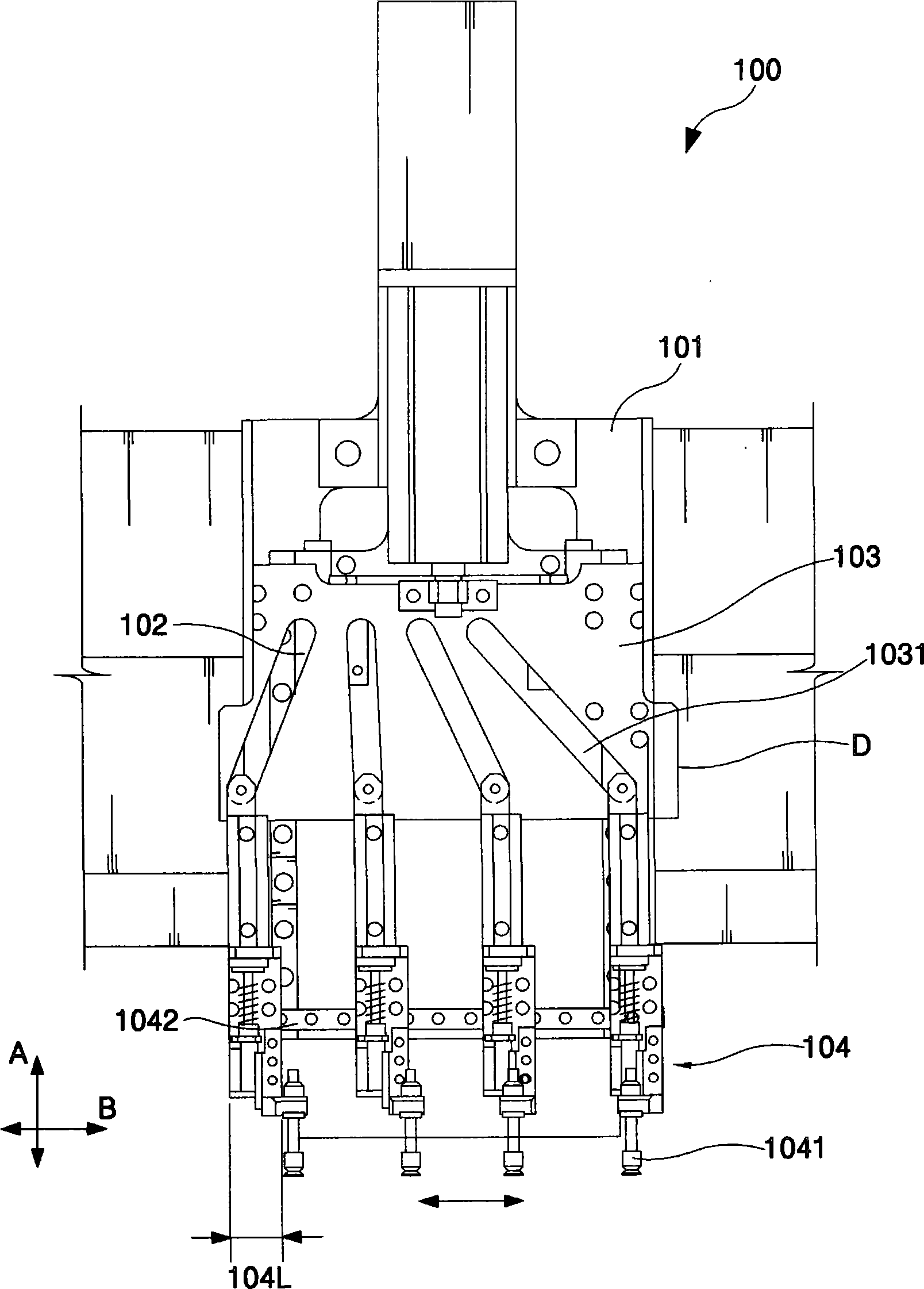

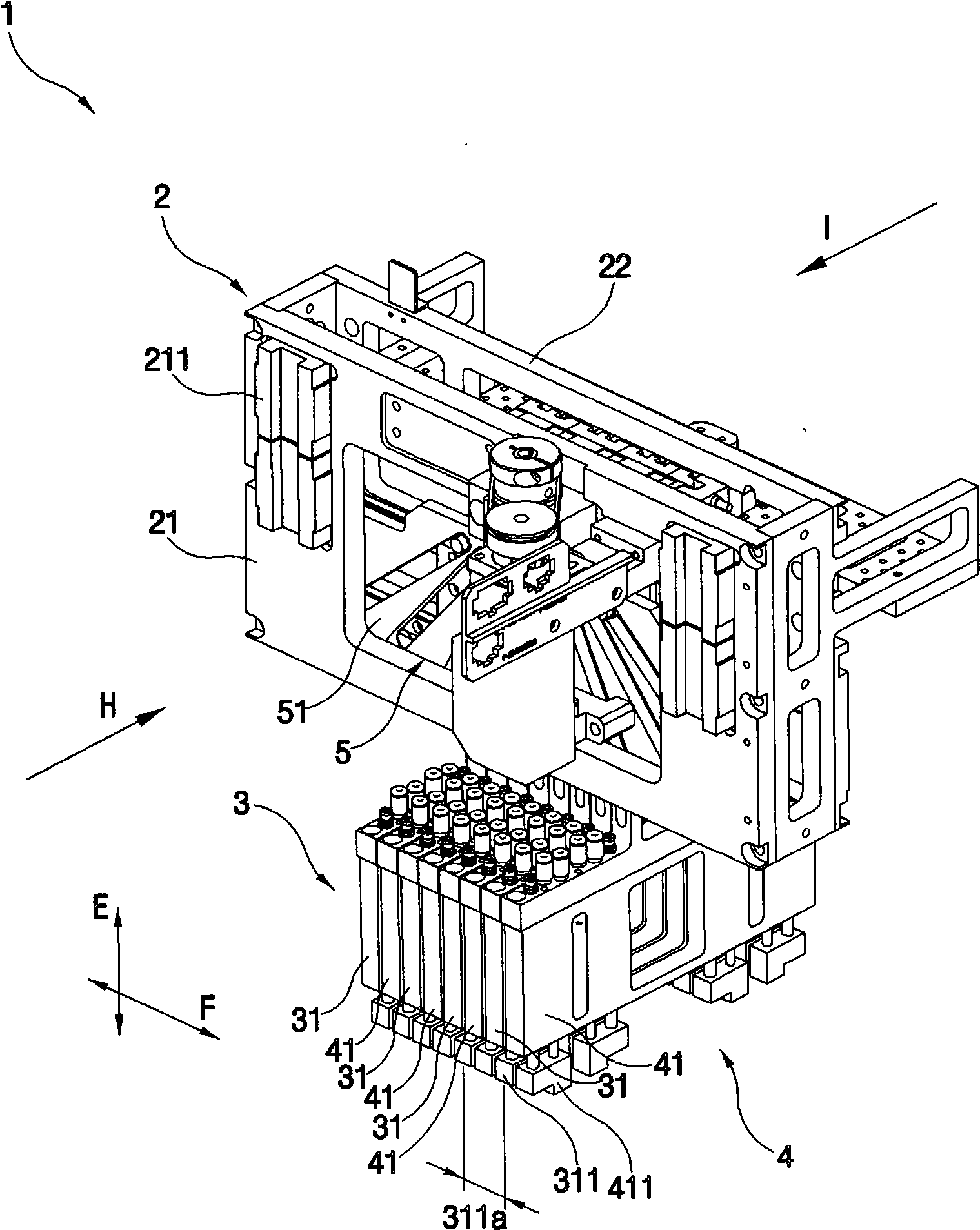

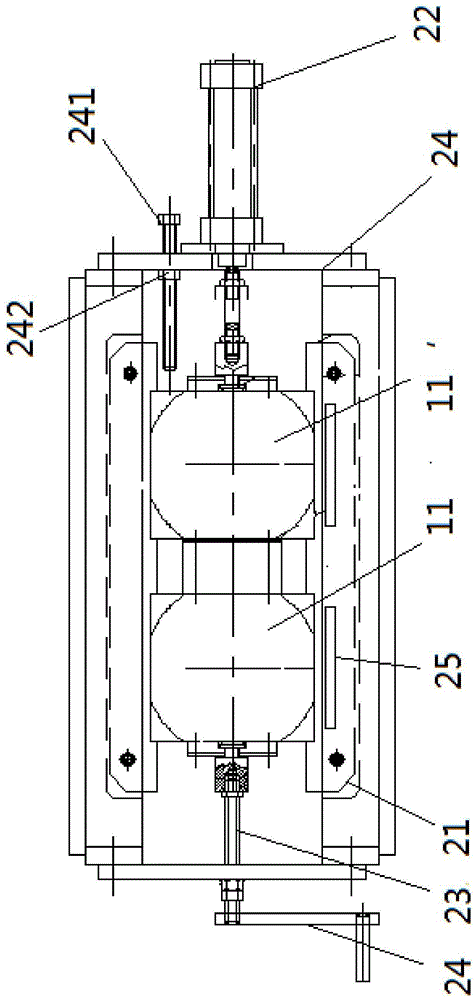

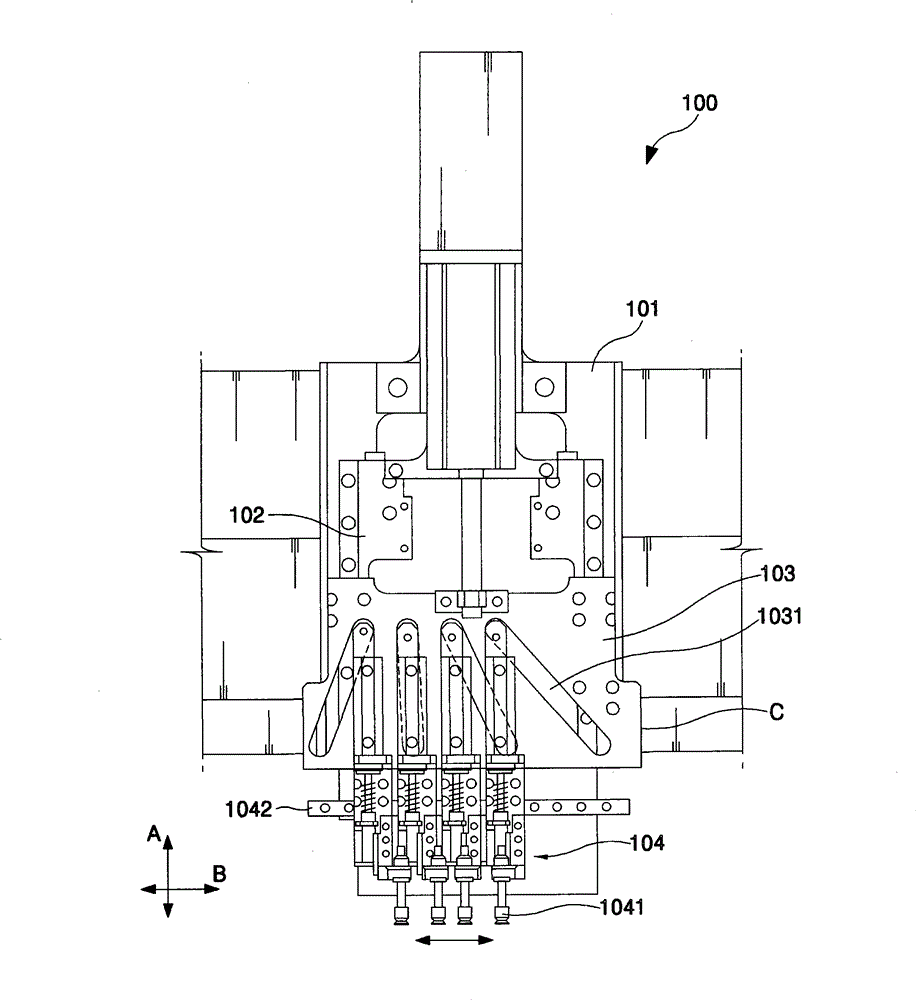

Apparatus for transferring packaged chips, test handler and method for manufacturing packaged chips

ActiveCN101545948AAccurate gap adjustmentSemiconductor/solid-state device testing/measurementElectronic circuit testingMechanical engineeringControl unit

The present invention provides an apparatus for transferring packaged chips, a test handler, and a method for manufacturing packaged chips. The apparatus for transferring packaged chips includes: a main frame having a coupling member coupled to a base plate and a supporting member coupled to the coupling member, a plurality of first pickers coupled to one side of the supporting member so as to be movable in a horizontal direction, a plurality of second pickers coupled to the other side of the supporting member so as to be movable in the horizontal direction, and a control unit to determine distances by which the first pickers and the second pickers move in the horizontal direction. According to the structure, more packaged chips may be transferred each time, and the time for loading and unloading is reduced. The gap between the packaged chips can be accurately controlled, and thereby improving the loading and unloading precision.

Owner:MIRAE CORPORATION

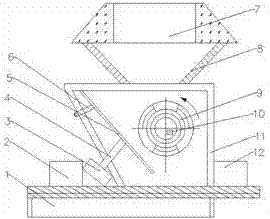

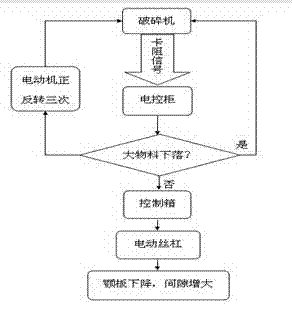

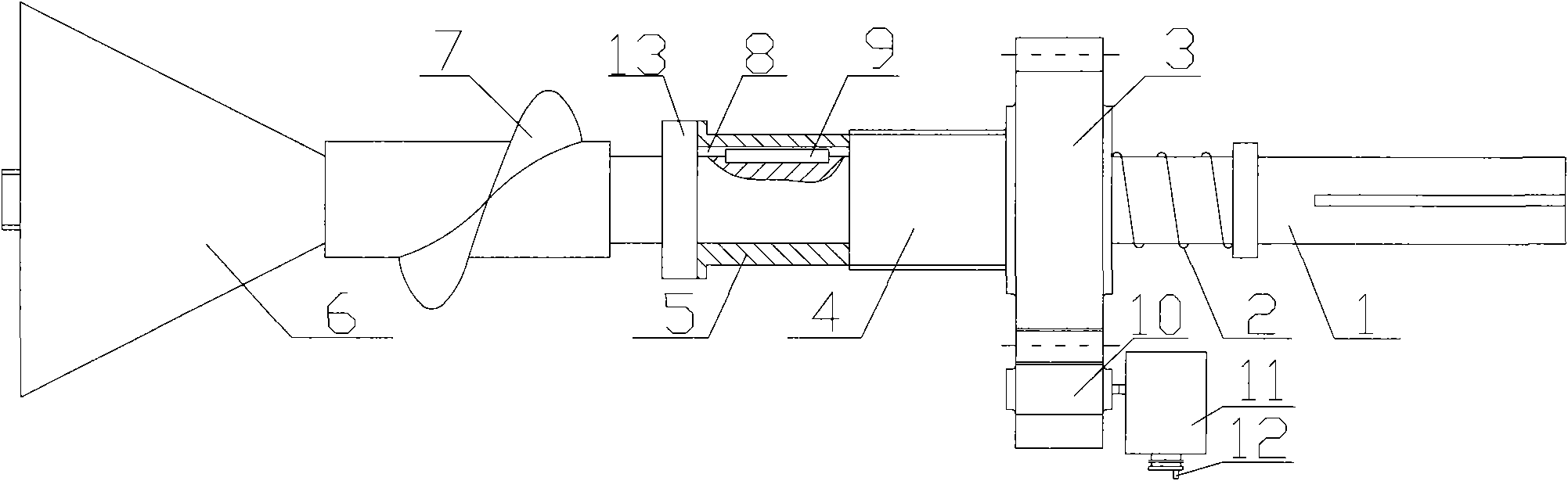

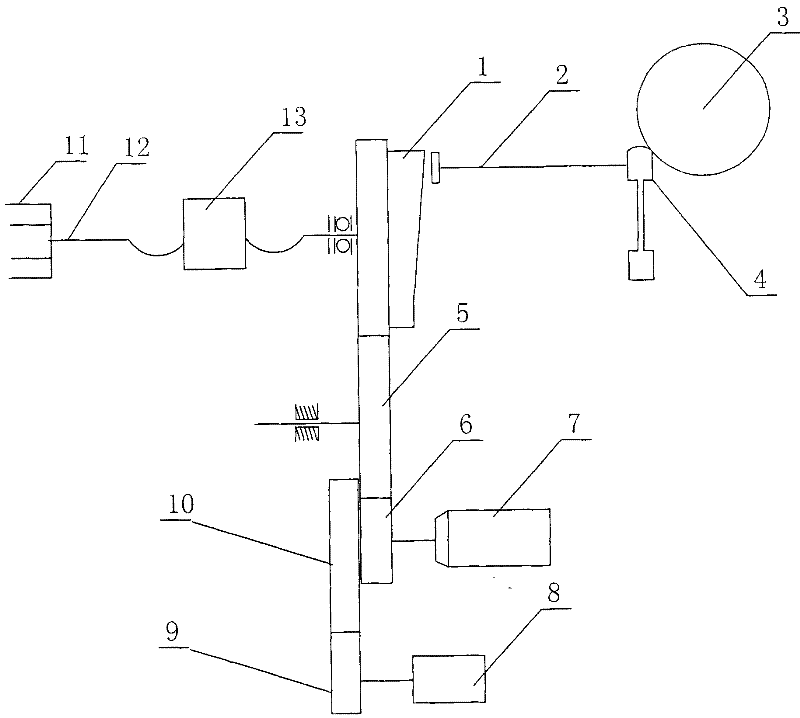

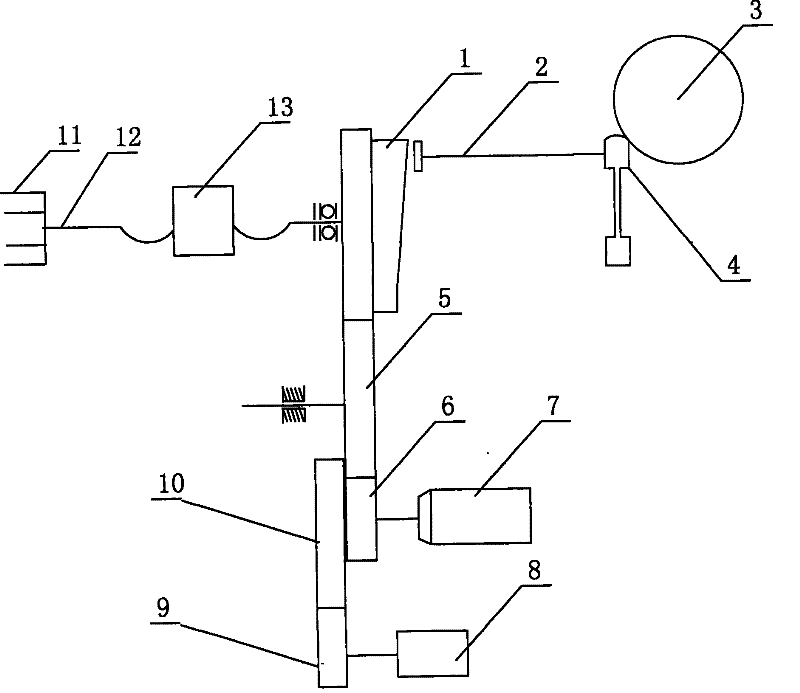

Electric-screw-rod-type clearance adjustment crushing machine and control method thereof

InactiveCN103752371ASave human effortAccurate gap adjustmentGrain treatmentsAutomatic controlProgrammable logic controller

The invention discloses an electric-screw-rod-type clearance adjustment crushing machine and a control method thereof, and belongs to the field of furnace slag treatment. The electric-screw-rod-type clearance adjustment crushing machine comprises a slag bucket, a crushing machine body, a jaw plate, a connection screw rod, a roller shaft and a crushing outlet, and also comprises an electric screw rod, a screw rod jacking bracket, a control box, a jamming inductor and an electric control cabinet, wherein the electric screw rod is arranged at the left lower corner outside the crushing machine body in a tilting manner; the upper top surface of the electric screw rod jacking bracket is in contact with the rear surface of the jaw plate; the electric screw rod is connected with the electric control cabinet through the control box; the upper end of the jaw plate is hinged to the crushing machine body through the connection screw rod; the jamming inductor is arranged on the roller shaft; a roller shaft motor is connected with the electric control cabinet; a PLC (programmable logic controller) control chip is arranged in the electric control cabinet. The electric-screw-rod-type clearance adjustment crushing machine has the advantages that the electric control cabinet realizes automatic control, and labor is saved; due to clearance adjustment by the electric screw rod, the response speed is high, the clearance adjustment is accurate, and the supporting force is high; the electric-screw-rod-type clearance adjustment crushing machine is safe and reliable and has a dual locking prevention function and the like.

Owner:HENAN SHENGSHI ENERGY SAVING ENVIRONMENTAL PROTECTION ENG

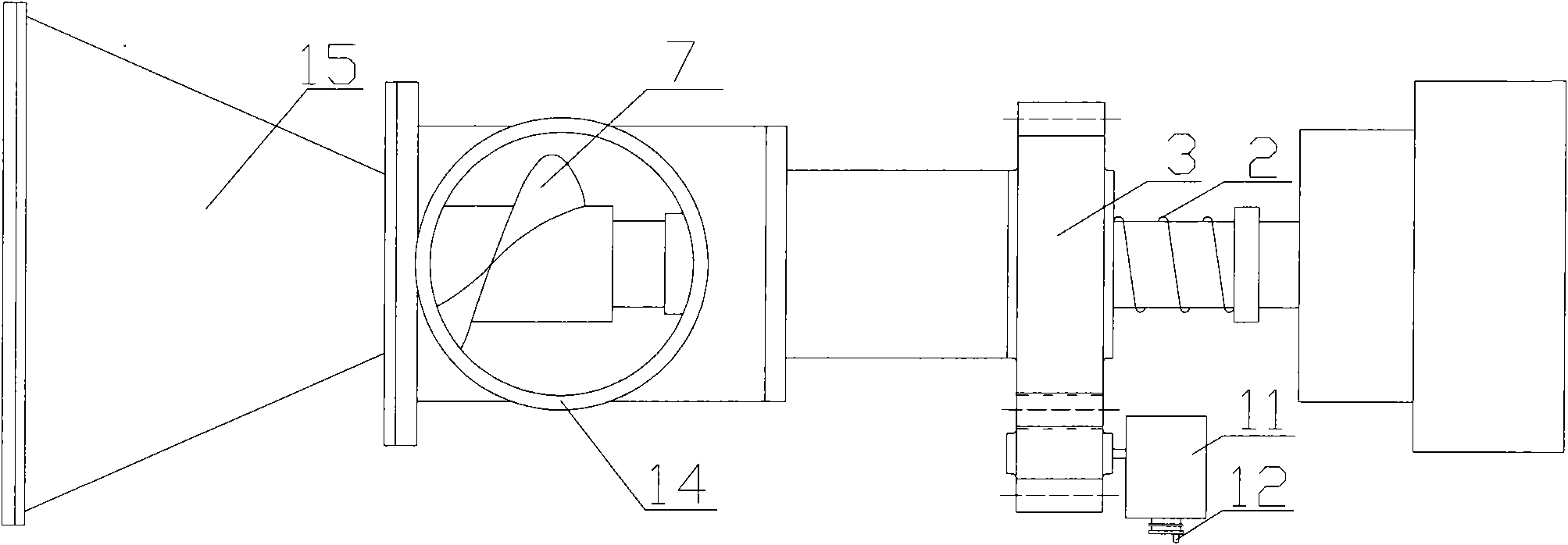

Rotor axial gap adjusting method for auto cooling fan motor

ActiveCN105958746AEasy to operateAutomateManufacturing dynamo-electric machinesComputer fanEngineering

The invention discloses a rotor axial gap adjusting method for an auto cooling fan motor. The gap adjusting method comprises the steps of firstly measuring the axial gap of the rotor of the motor, thus obtaining a real-time measurement result; then jacking the front end cover of a jacking motor by using a jacking block to deform the front end cover, thus generating an axial displacement; measuring after adjustment is completed, and if qualified, completing the adjustment; if not qualified, adjusting in the same way to allow the axial gap to be qualified; and if not qualified either, scraping the motor. Therefore, the gap adjusting method does not need to add the spacer, and is simple to operate, capable of achieving automation, more accurate in gap adjustment, and thus applicable to adjusting the gaps of a large scale of motors, and thereby the axial gap of each motor can be adjusted before leaving the factory, and the whole quality stability of the products is greatly improved.

Owner:JIANGSU LANGXIN ELECTRIC

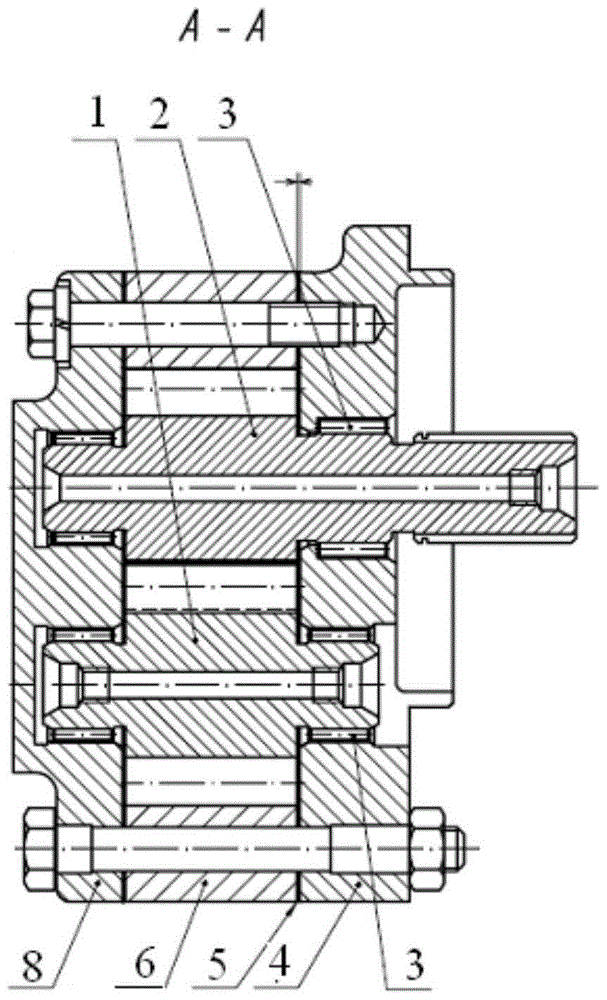

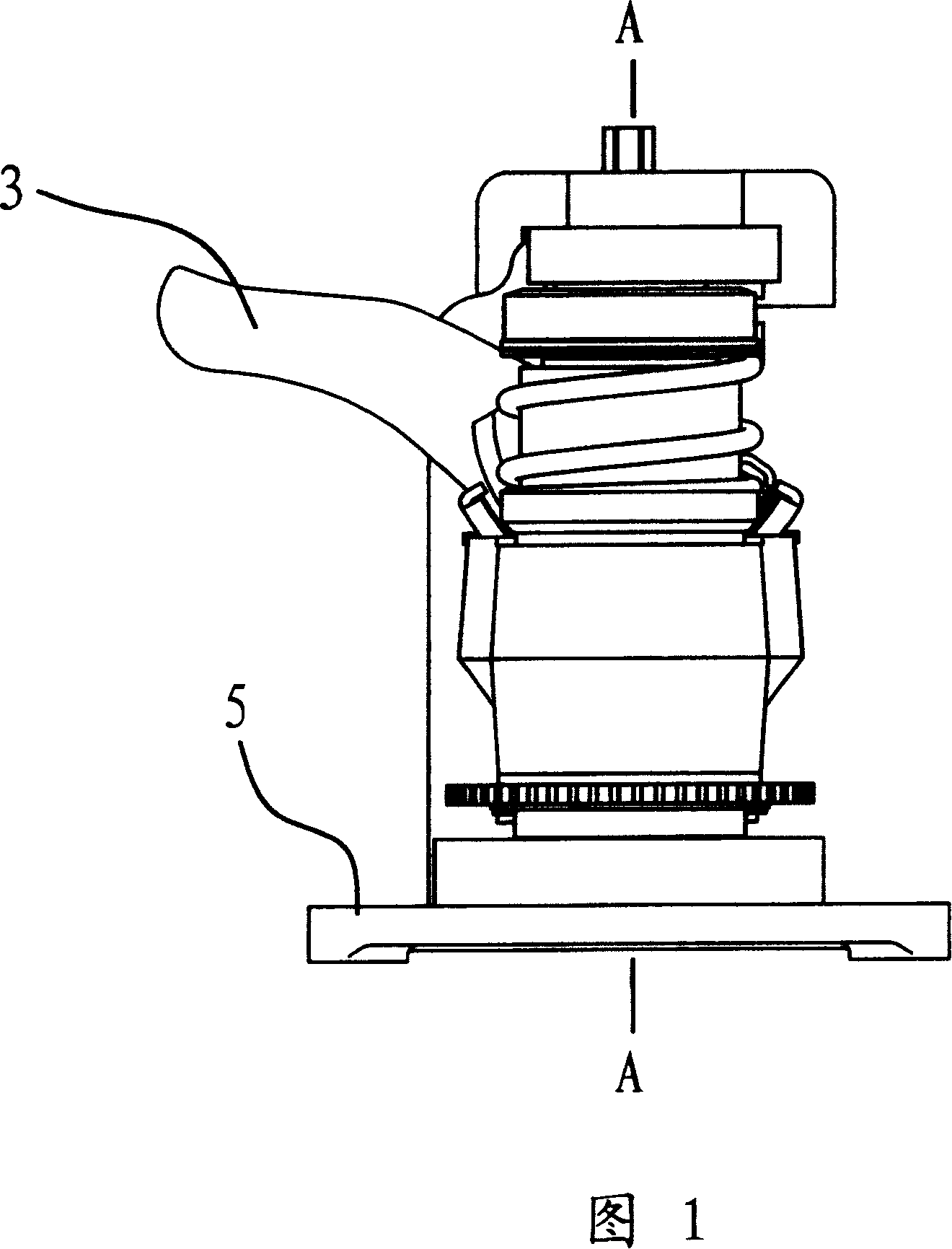

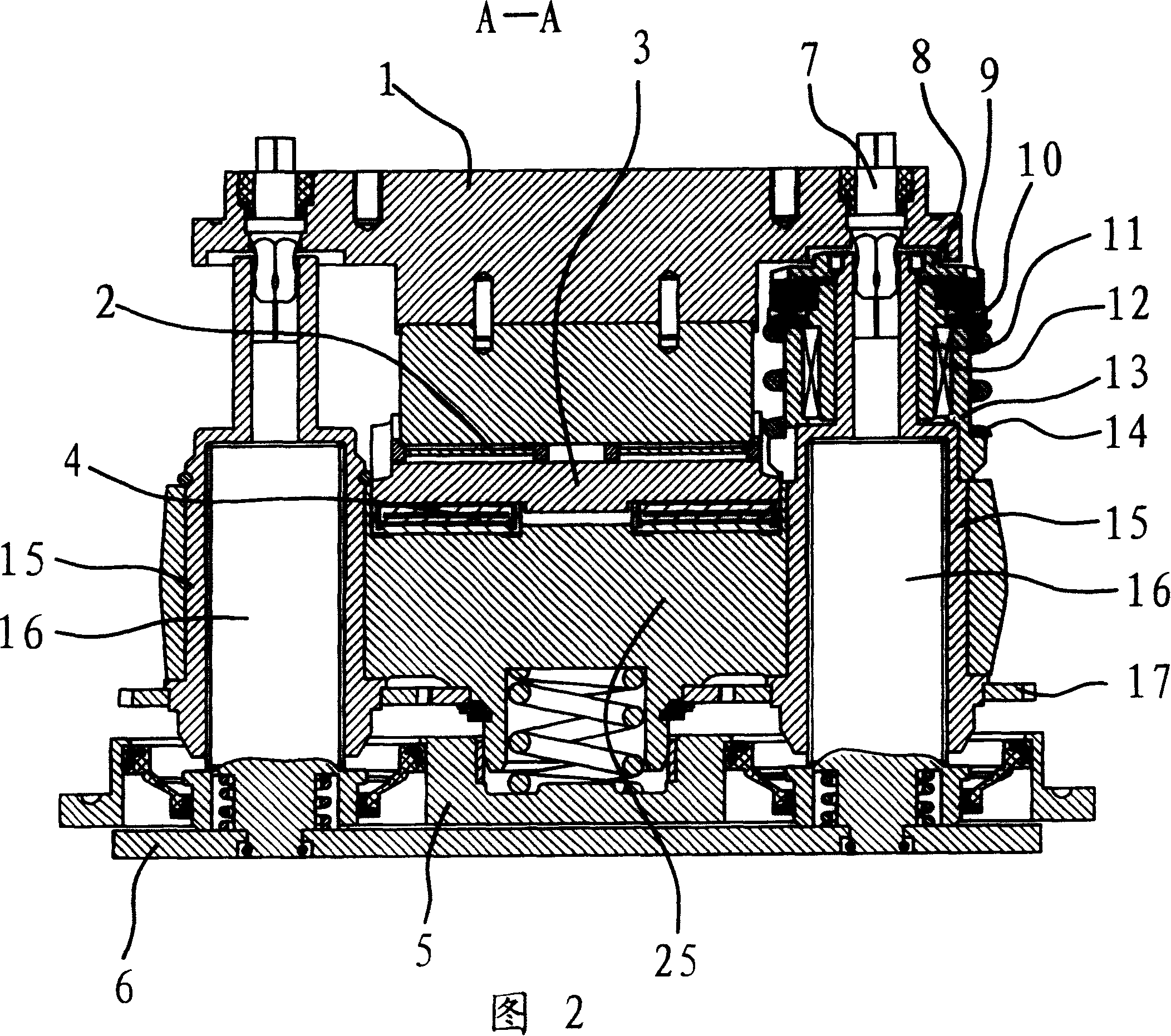

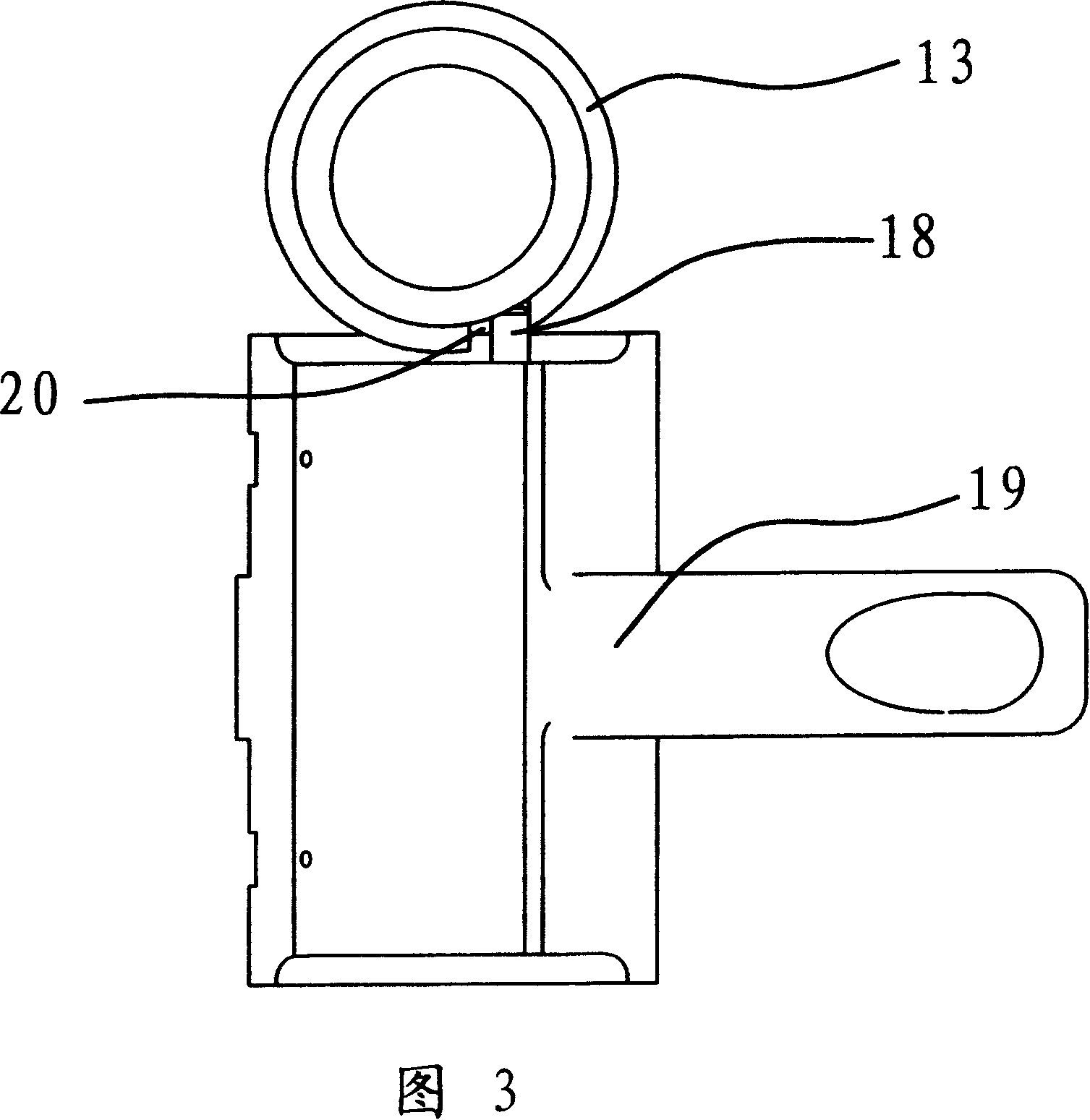

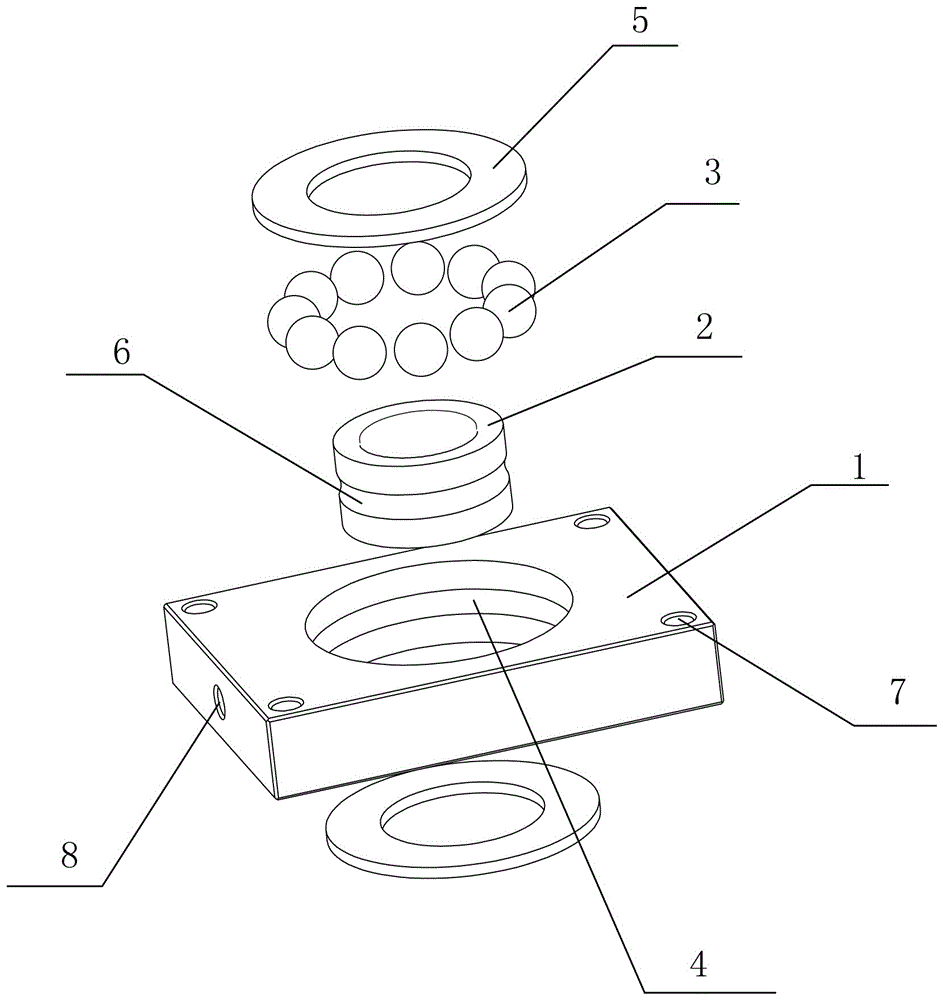

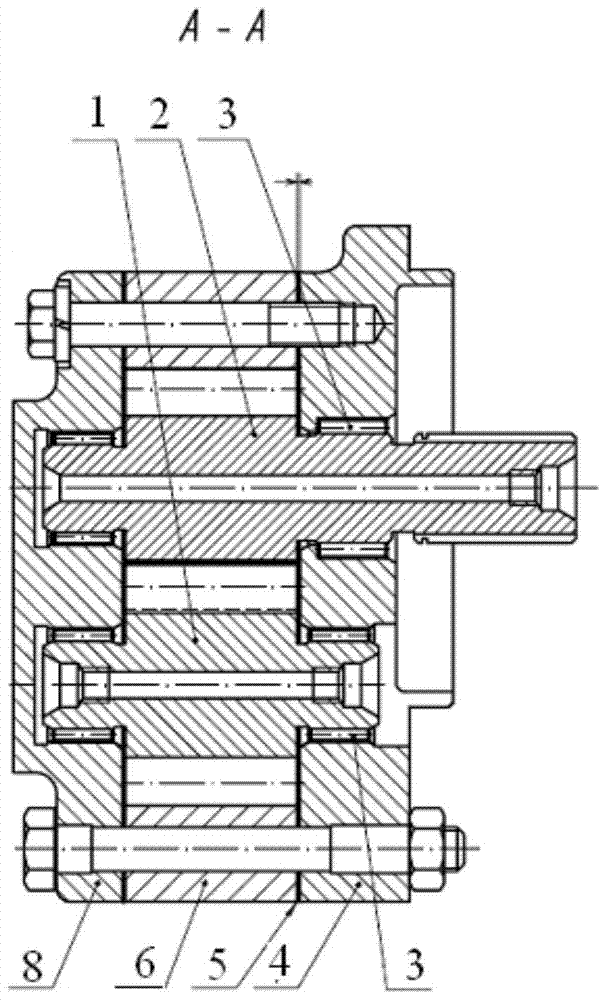

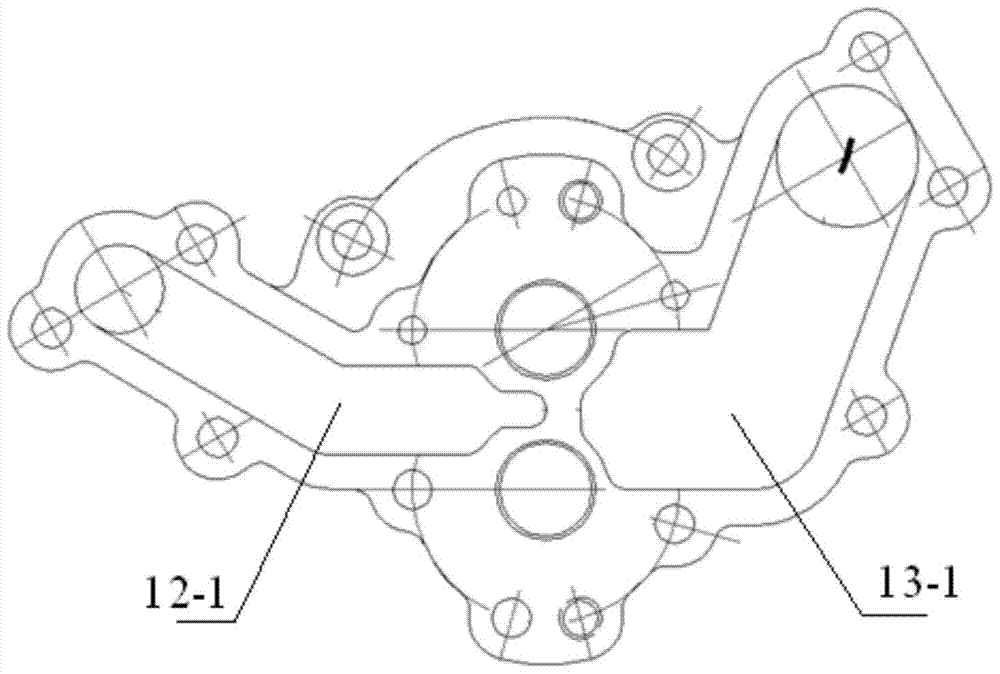

Disk brake slack self-adjusting mechanism

This invention has provided one kind of disc brake gap self-modulation machine structure. In this disc brake gap self-modulation organization, the said brake includes the cam lever, the release forks connected on the lever, adjusting sleeve with a gap inserted with the fork. In the adjustment sleeve is equipped with a cylinder shape unidirectional bearing which is connected tightly with the adjusting sleeve. In the bearing is fitted with an internal sleeve in which is fitted with a screw-tube screw-rod interlinking mechanism. Advantages: accurate gap adjustment and long service life.

Owner:LONGZHONG HLDG GRP

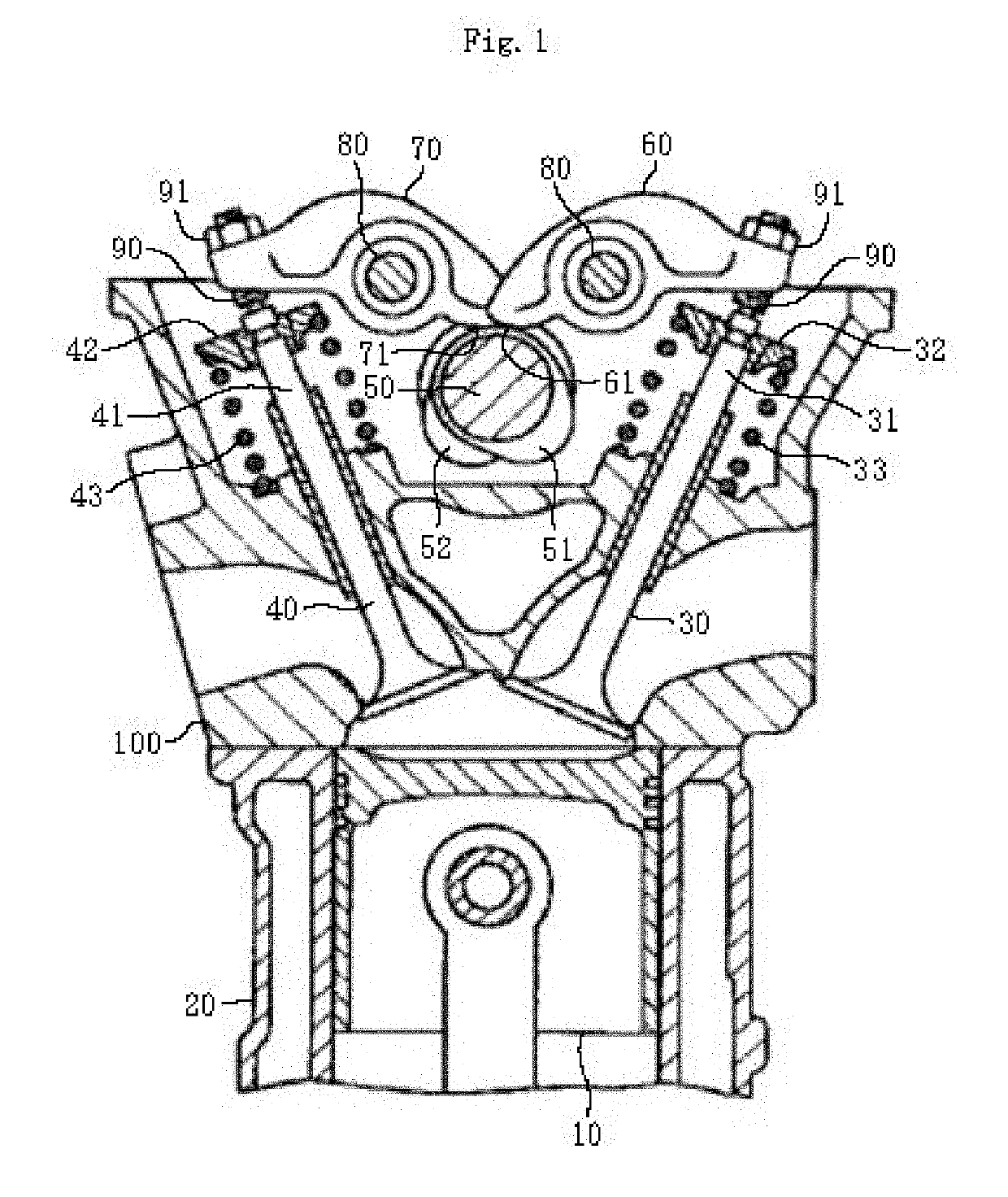

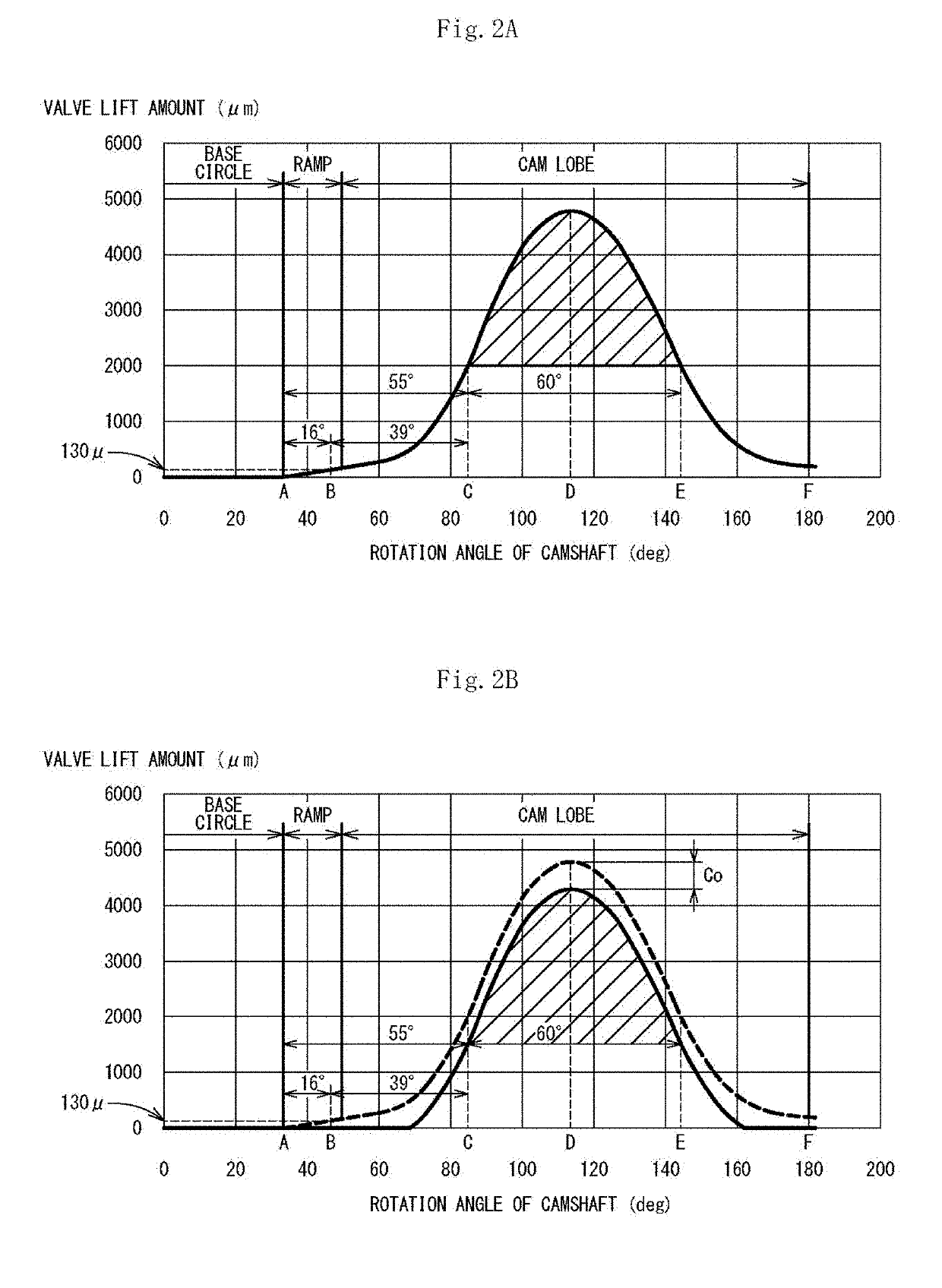

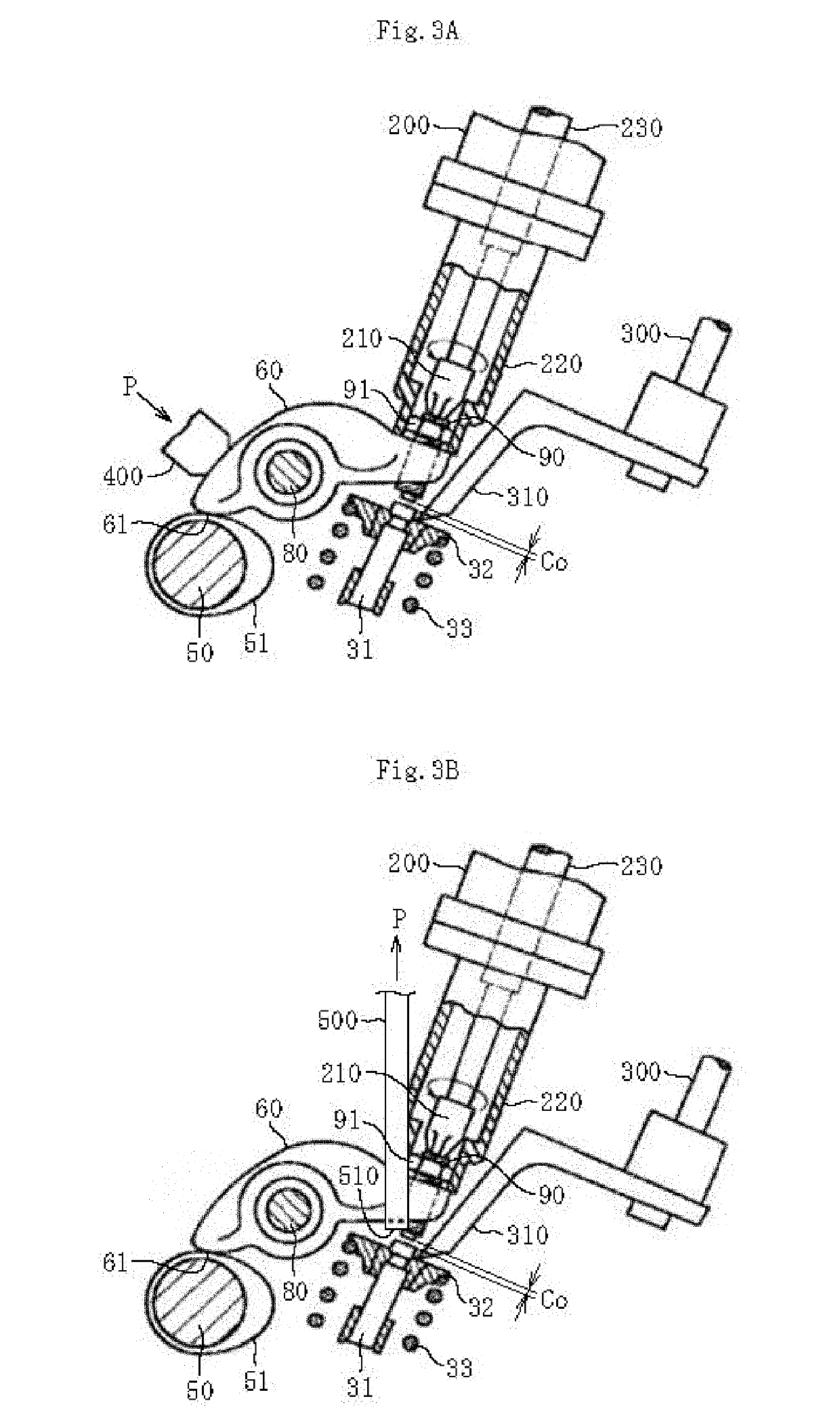

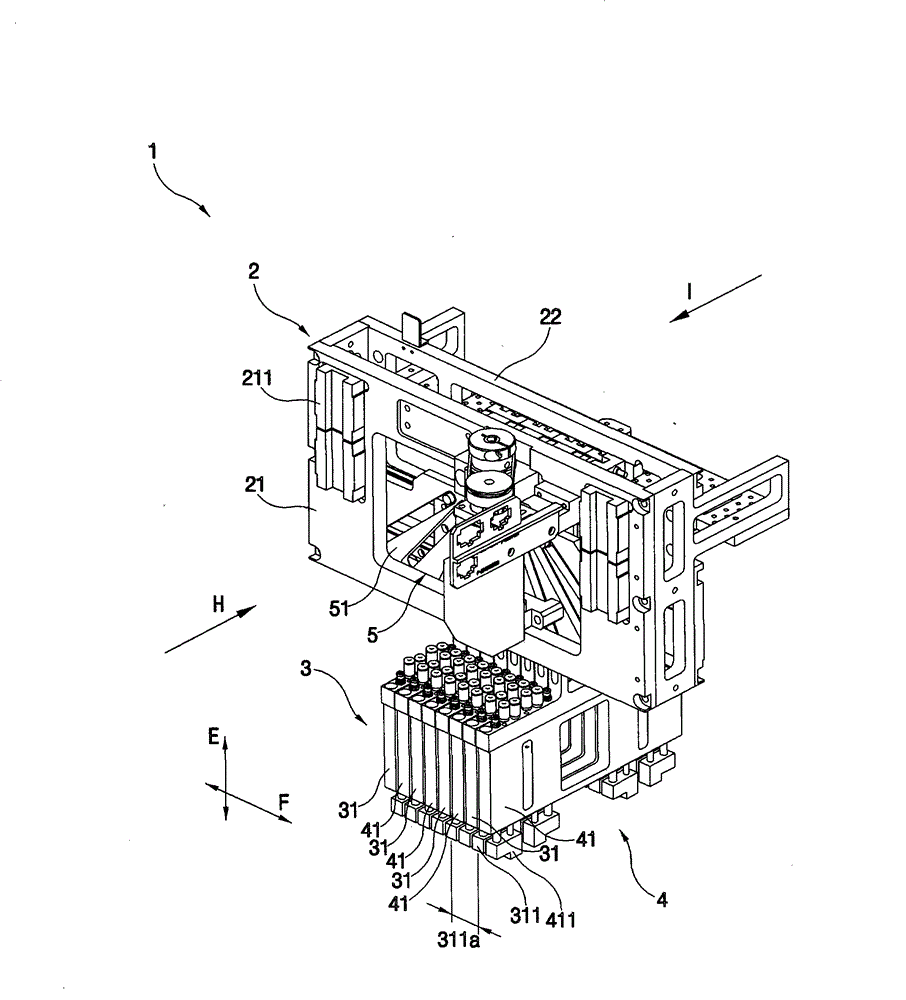

Valve clearance adjusting method

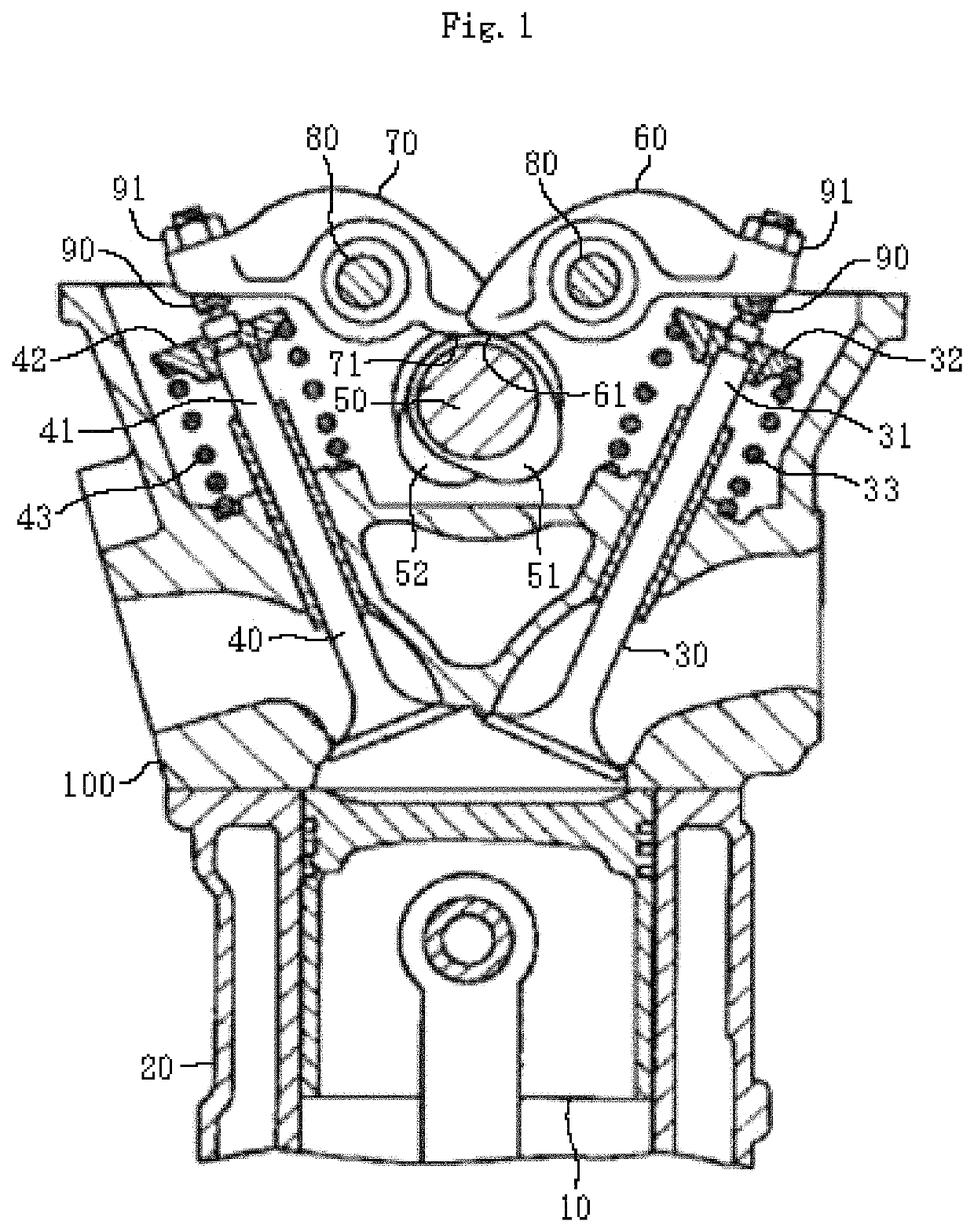

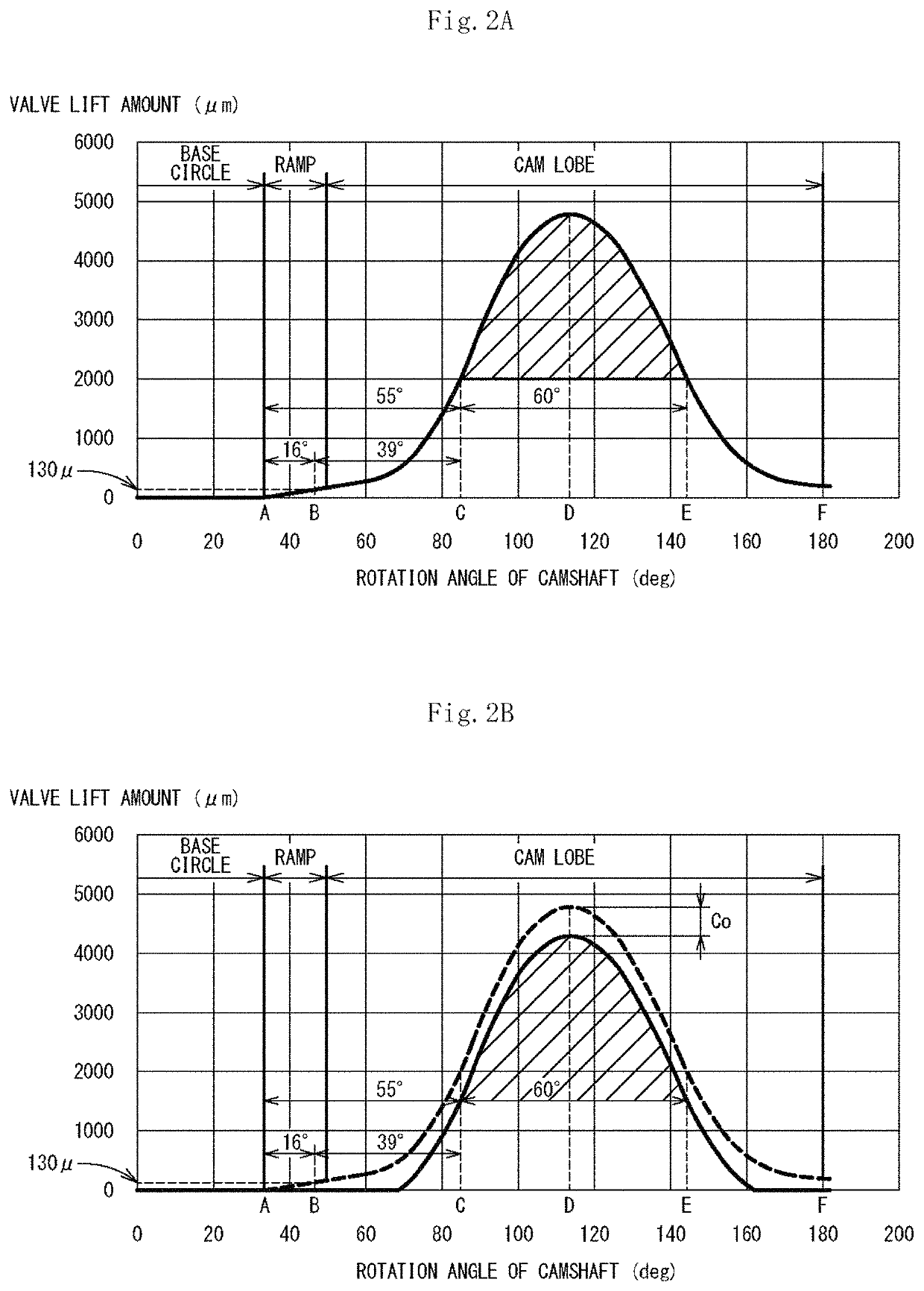

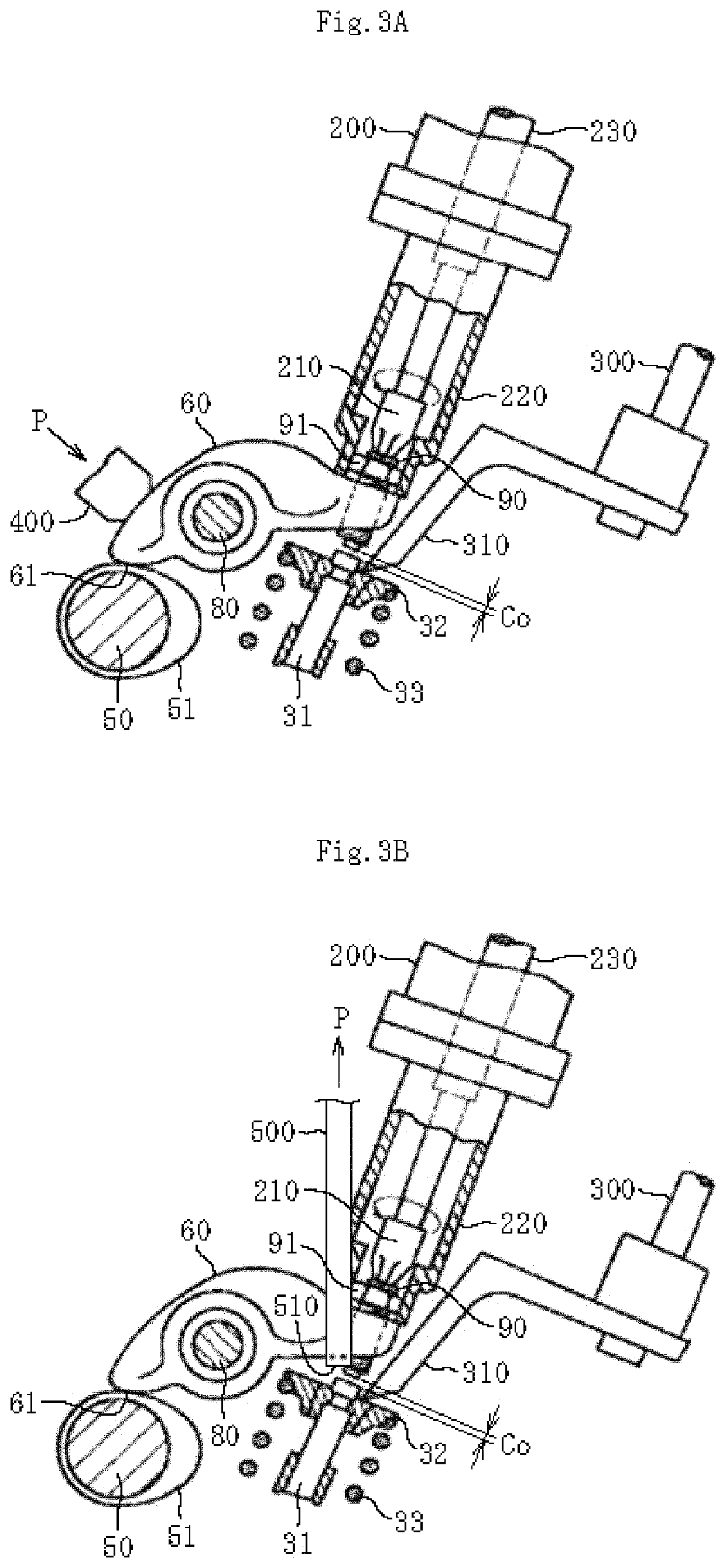

ActiveUS20190101030A1Easy to adjustAccurate gap adjustmentValve arrangementsMachines/enginesCylinder headCam

Provided is a valve clearance adjusting method by which an accurate valve clearance adjustment can be easily performed regardless of the tolerance of pitch dimensions of an adjusting screw. The valve clearance adjusting method including: measuring a cam profile of the camshaft 50 mounted on the cylinder head 100; identifying, on the basis of a measurement result of the cam profile, a predetermined rotation angle θV of the camshaft 50 at which a predetermined lift amount corresponding to a predetermined valve clearance is obtained; rotating the camshaft 50 and allowing a pressed portion 61, 71 of the rocker arm 60, 70 to face a cam surface at the predetermined rotation angle θV; rotating an adjusting screw 90 with the pressed portion faced with the cam surface and setting a valve clearance to zero; and fastening the adjusting screw 90 with a lock nut 91.

Owner:SANYO KIKO KK

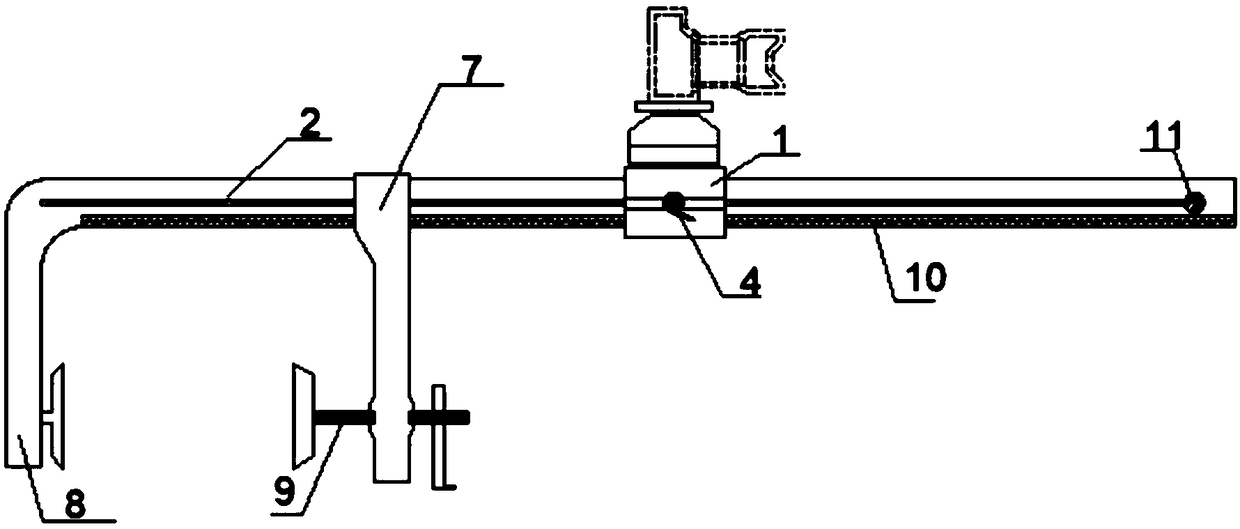

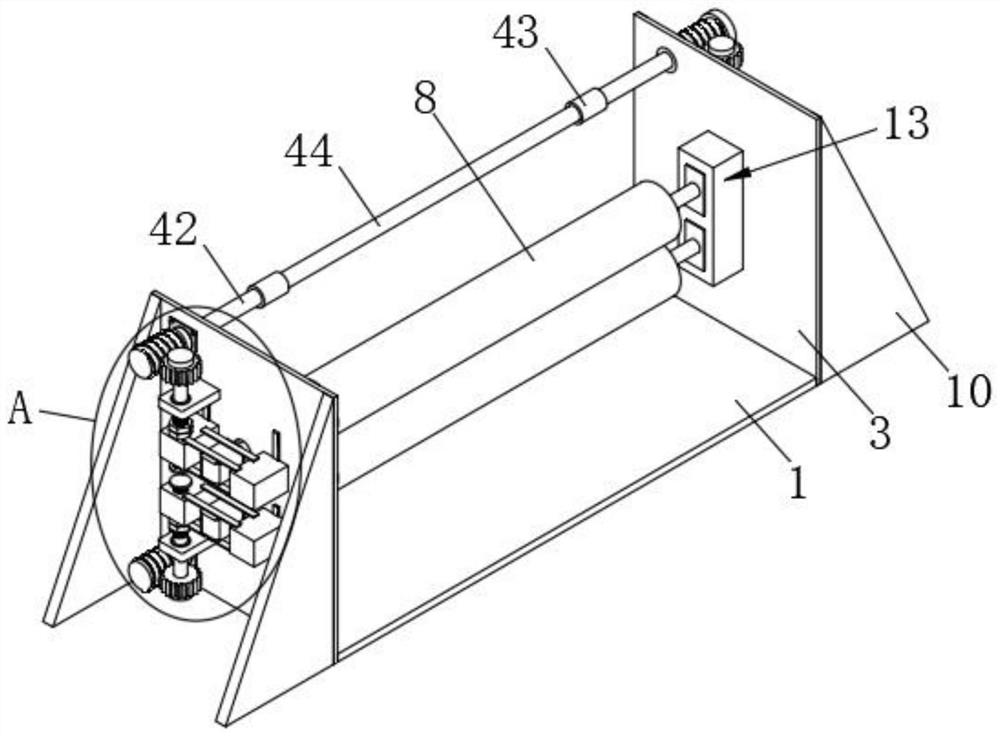

Sponge urban facility monitoring and time-lapse photography camera stabilizing device and application method

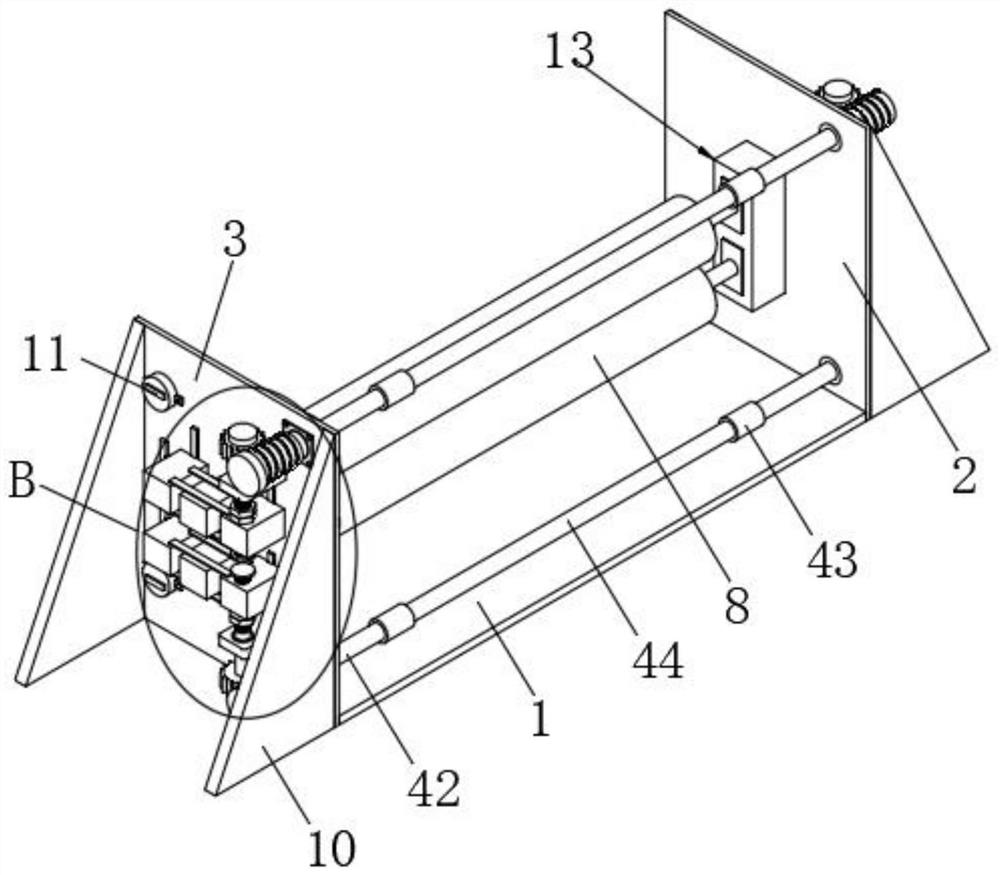

The invention discloses a sponge urban facility monitoring and time-lapse photography camera stabilizing device and an application method. The sponge urban facility monitoring and time-lapse photography camera stabilizing device comprises a transverse rod. A transverse rod ruler is arranged at the bottom end of the transverse rod. One side of the transverse rod is provided with a fixing rod, the transverse rod is further provided with a locking rod, and the shape defined by the transverse rod, the fixing rod and the locking rod is a U-shaped groove. The position, away from the U-shaped groove,of the transverse rod is provided with a sliding stabilization block, the sliding stabilization block is internally provided with a gap locking groove containing the transverse rod, and gap adjustingnuts are arranged on the two side walls of the sliding stabilization block and matched with a screw to fix the sliding stabilization block to the transverse rod. A rotary holder is arranged at the top end of the sliding stabilization block, and an angle ruler is arranged below the holder. According to the sponge urban facility monitoring and time-lapse photography camera stabilizing device and the application method, the position is accurately adjusted and recorded according to the ruler on the transverse rod and the angle ruler on the holder on the sliding stabilization block, and when a camera is erected again, original recorded data are utilized for conducting rapid adjustment to the shooting distance, the pitch angle and the horizontal rotation angle.

Owner:CHINA FIRST METALLURGICAL GROUP

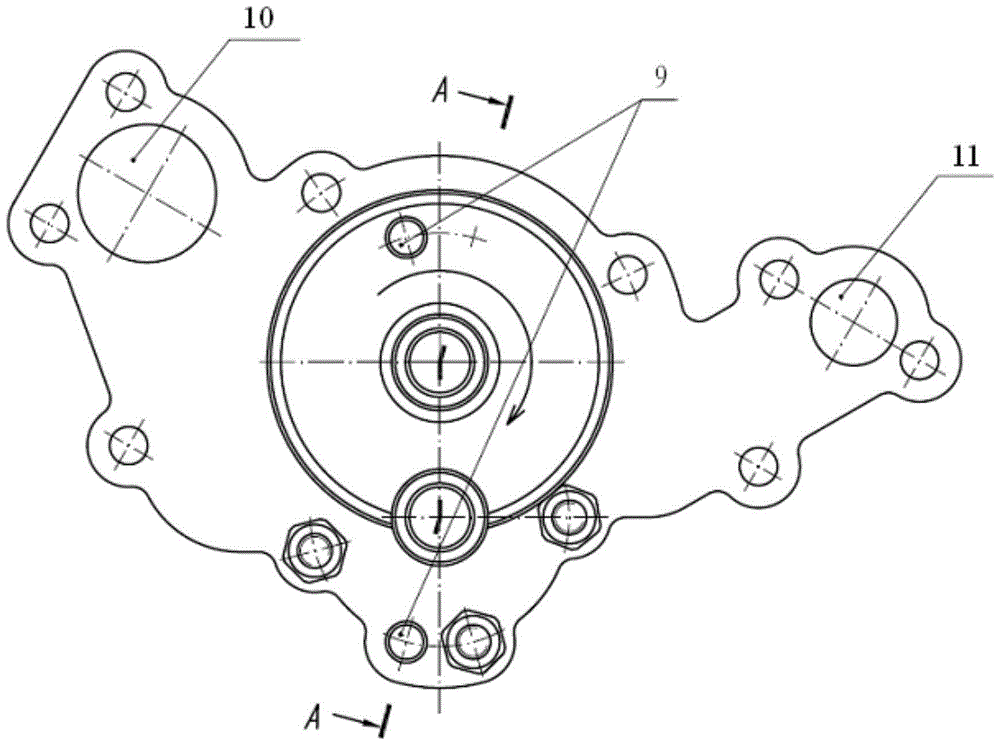

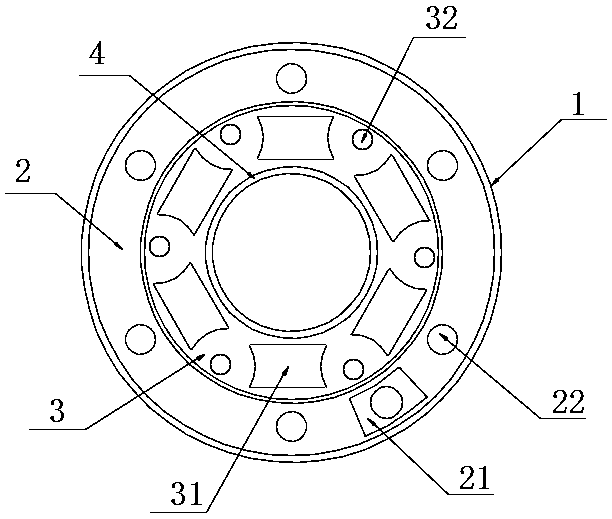

External-meshed gear pump and hydrodynamic transmission hydraulic system

ActiveCN105179229AAccurate gap adjustmentSave spaceRotary piston pumpsRotary piston liquid enginesGear pumpGear wheel

The invention discloses an external-mashed gear pump. The external-mashed gear pump comprises a shell body and a gear mechanism. The gear mechanism is arranged in the shell body and movably connected with the shell body. One end of the gear mechanism is bonded with a hydrodynamic transmission which drives the gear mechanism to rotate in the shell body. The shell body comprises a front shell body, a middle shell body and a rear shell body. A plurality of sealing gaskets are arranged between the front shell body and the middle shell body. A plurality of sealing gaskets are arranged between the middle shell body and the rear shell body. The invention further discloses a hydrodynamic transmission hydraulic system. According to the external-mashed gear pump and the hydrodynamic transmission hydraulic system, the end faces of the shell body are sealed through the sealing gaskets so that the end face gaps of the external-mashed gear pump can be adjusted accurately. Accordingly, the high volume efficiency of the external-mashed gear pump can be obtained, and the using requirement for the service life of the external-mashed gear pump can be met.

Owner:SPECIAL VEHICLE TECH CENT OF HUBEI AEROSPACE TECH RES INST

Disk brake slack self-adjusting mechanism

ActiveCN100371620CSensitivity is not affectedImprove comfortSlack adjustersThrust bearingEngineering

This invention has provided one kind of disc brake gap self-modulation machine structure. In this disc brake gap self-modulation organization, the said brake includes the cam lever, the release forks connected on the lever, adjusting sleeve with a gap inserted with the fork. In the adjustment sleeve is equipped with a cylinder shape unidirectional bearing which is connected tightly with the adjusting sleeve. In the bearing is fitted with an internal sleeve in which is fitted with a screw-tube screw-rod interlinking mechanism. Advantages: accurate gap adjustment and long service life.

Owner:LONGZHONG HLDG GRP

Rectangular precise gap adjusting bearing

InactiveCN105952780AExtended service lifeReduce wearRolling contact bearingsBearing componentsEngineering

Owner:辛建辉

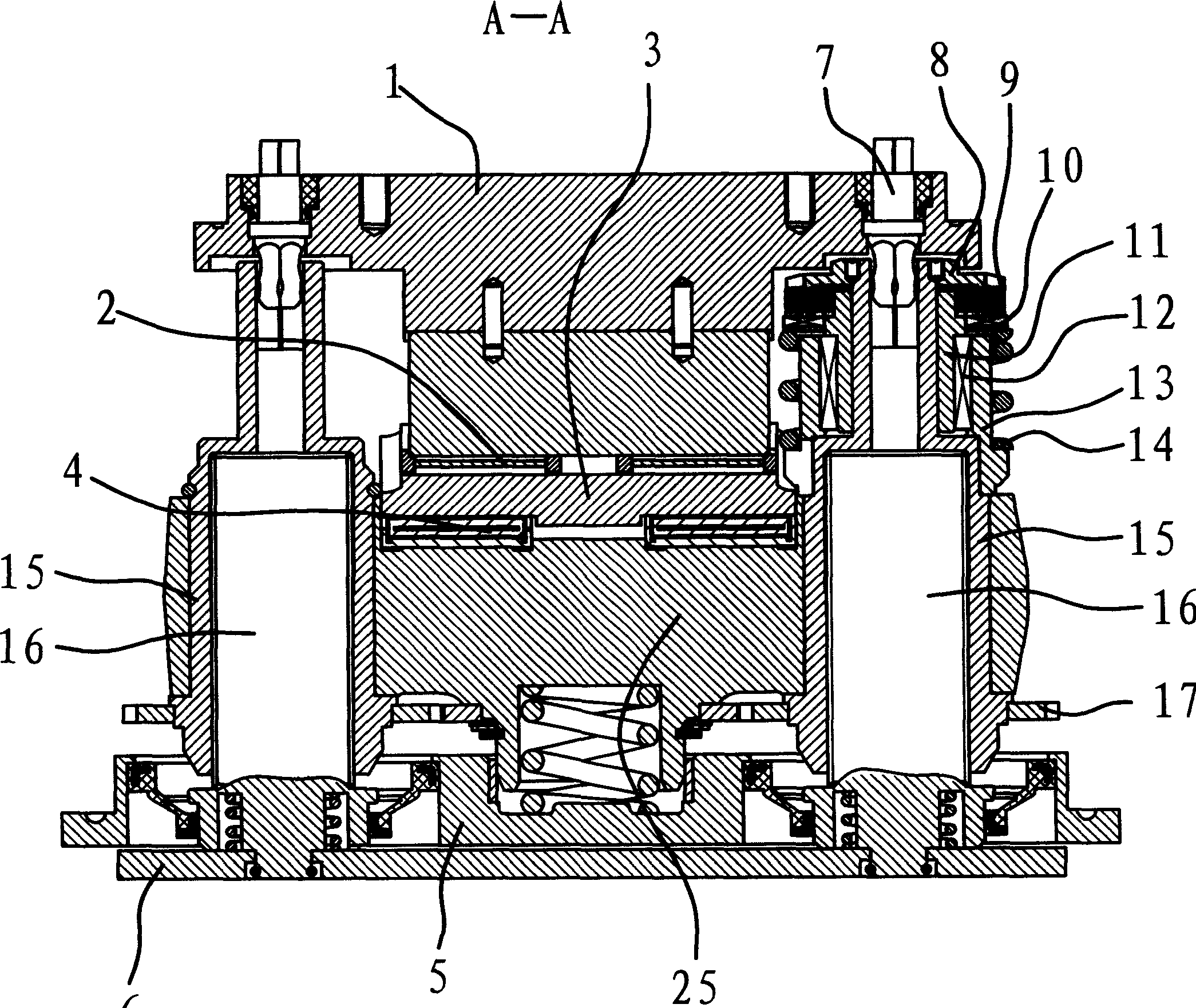

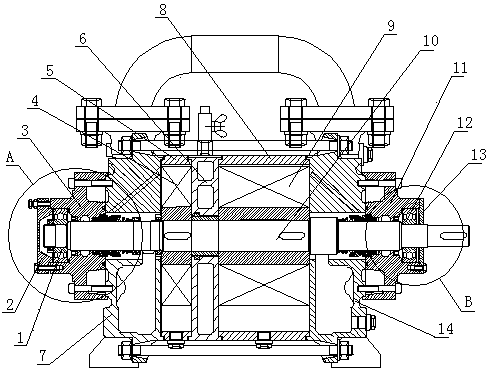

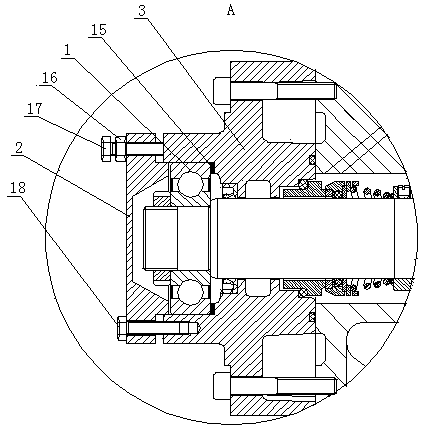

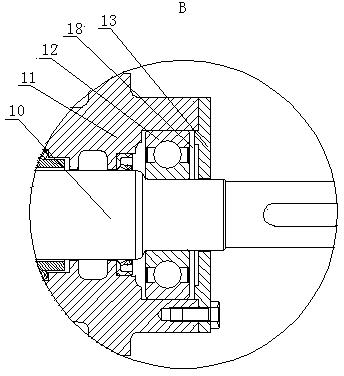

Double stage vacuum pump clearance adjusting device

A double stage vacuum pump clearance adjusting device relates to the technical field of vacuum pump. The double stage vacuum pump comprises a primary pump body, a secondary pump body, an intermediate valve plate, a pump shaft, a primary impeller, a secondary impeller, an absorbing body, a vomiting body and a bearing body. Bearing axial direction sliding space is left between a driving end bearing gland and a driving end bearing at one side of the absorbing body, and a bearing axial at one side of the vomiting body is fixed on the pump shaft. An adjusting screw hole and a fastening hole are arranged on a non-driving end bearing gland at one side of the vomiting body, an adjusting bolt is arranged inside the adjusting screw hole, and a positioning nut is arranged on an adjusting screw bolt between the adjusting bolt head and the non-driving end bearing gland. Fastening screw thread holes are arranged on a bearing body which is at one side of the vomiting body and is opposite to the fastening hole, and a resilient pad is arranged between the inner side of the outer ring of the bearing at one side of the vomiting body and the bearing body. The double stage vacuum pump clearance adjusting device is simple in structure, convenient to adjust, and is capable of accurately adjusting clearance, improving performance of the double stage vacuum pump and elongating service life of the double stage vacuum pump.

Owner:SHANDONG SHUANGLUN EMMECOM PUMPS

Valve clearance adjusting method

ActiveUS10612426B2Accurate gap adjustmentEasy to adjustValve arrangementsMachines/enginesCylinder headEngineering

Provided is a valve clearance adjusting method by which an accurate valve clearance adjustment can be easily performed regardless of the tolerance of pitch dimensions of an adjusting screw. The valve clearance adjusting method including: measuring a cam profile of the camshaft 50 mounted on the cylinder head100; identifying, on the basis of a measurement result of the cam profile, a predetermined rotation angle θV of the camshaft 50 at which a predetermined lift amount corresponding to a predetermined valve clearance is obtained; rotating the camshaft 50 and allowing a pressed portion 61, 71 of the rocker arm 60, 70 to face a cam surface at the predetermined rotation angle θV; rotating an adjusting screw 90 with the pressed portion faced with the cam surface and setting a valve clearance to zero; and fastening the adjusting screw 90 with a lock nut 91.

Owner:SANYO KIKO KK

External gear pump and hydraulic transmission hydraulic system

ActiveCN105179229BAccurate gap adjustmentSave spaceRotary piston pumpsRotary piston liquid enginesGear pumpEngineering

Owner:SPECIAL VEHICLE TECH CENT OF HUBEI AEROSPACE TECH RES INST

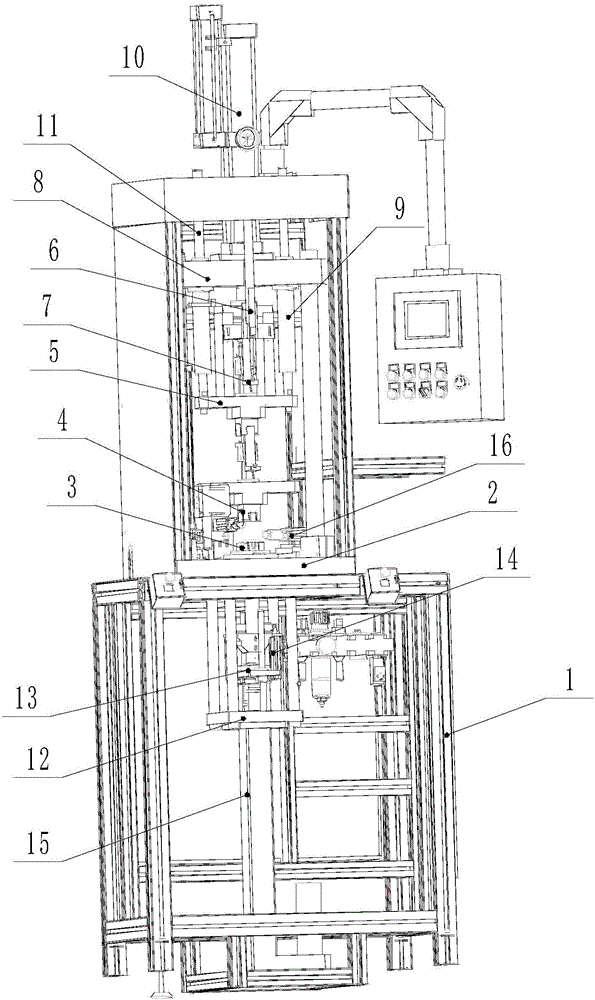

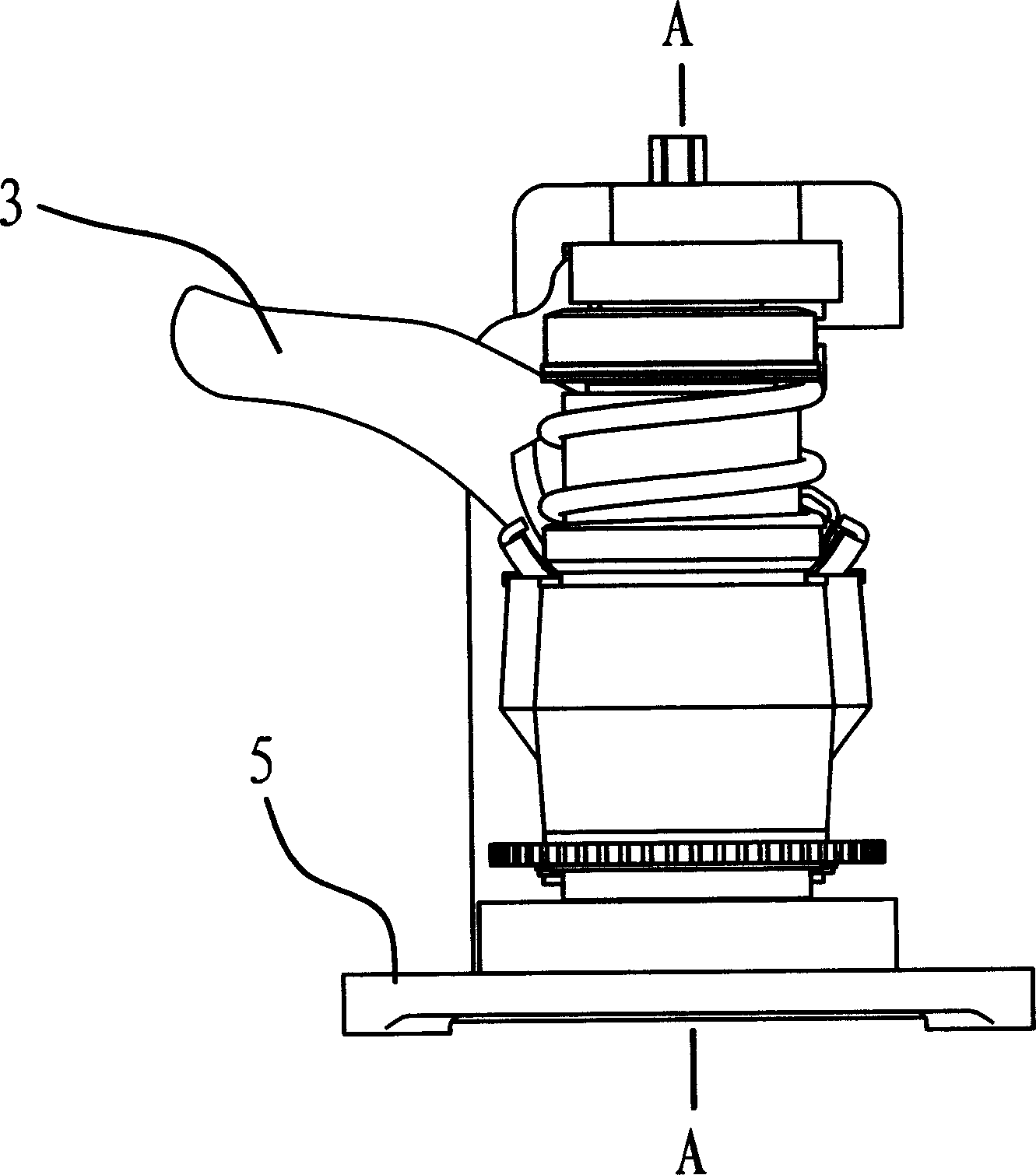

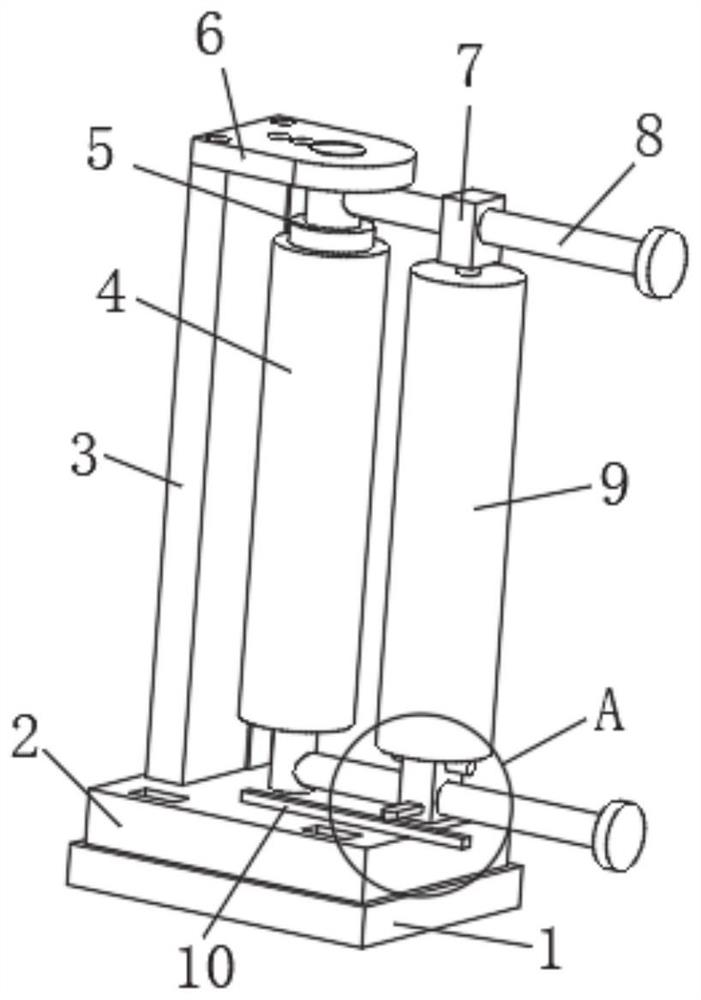

Gap adjusting device used for adjusting grain size of bone cement

ActiveCN101548779ASimple structureEasy to installAnimal feeding stuffGlue/gelatin preparationCrusherAxial transmission

The invention relates to a crusher, in particular to a gap adjusting device used for adjusting grain size of bone cement in a bone cement machine for carrying out processing animal bone. The gap adjusting device overcomes the defects that the manufacture of the gap adjusting device of movable grinding and fine grinding in the existing bone cement machine is difficult, the adjusting procedure is complex and the adjusting precision is low. The invention provides a gap adjusting device used for controlling the grain size of grinded paste of the bone cement, comprising a rotating shaft, an inner cone and an outer cone; wherein the inner cone body is fixed on the rotating shaft; the outer cone is fixed on a shell outside thereof; wherein the central part of the rotating shaft is provided with an axial transmission mechanism; one side of the transmission mechanism is connected with a spring, and the other side thereof is provided with a shaft sleeve with the T-shaped section; one end of the spring is connected with the axial transmission mechanism and the other end thereof is fixed on the rotating shaft; one end with larger diameter in the T-shaped shaft sleeve faces one side of the cone body and supports on the boss of the rotating shaft and the other corresponding end is adjacent to an axial transmission structure. The gap adjusting device has simple structure and convenient installation; when in use, the device has little mechanical friction resistance, precise gas adjustment quantity, convenient and reliable gap adjustment and no need of stopping the machine in the adjustment process.

Owner:青岛市城阳区海天水产加工厂

Drainage pipeline flow limiting adjusting device

ActiveCN112900581AReduce manufacturing costReduce engineering costsSewer pipelinesGear wheelWater flow

The invention provides a drainage pipeline flow limiting adjusting device. The problems that an adjusting valve installed on a large drainage pipeline is complex in structure, consequently, assembling is not easy, and the manufacturing cost is high are solved. The drainage pipeline flow limiting adjusting device comprises a steel pipe; flange plates are fixedly arranged at the upper end and the lower end of the steel pipe; an annular baffle is arranged in the steel pipe and is perpendicular to the inner wall of the steel pipe; a water flowing hole is formed in the middle portion of the annular baffle; a cone capable of moving up and down is arranged in the water flowing hole; the diameter of the bottom of the cone is equal to the inner diameter of the water flowing hole; a vertical tooth plate is arranged at the bottom of the cone; a sliding way component is arranged on the inner wall of the cone; the tooth plate is inserted in a sliding way clamping plate of the sliding way component in a sliding manner; the sliding way clamping plate is of a frame type plate structure with a front opening; a limiting plate preventing the tooth plate from disengaging is arranged at the front portion of the sliding way clamping plate; a gear engaged with the tooth plate is arranged in the steel pipe; the middle portion of the gear is connected with a transversely-arranged shaft rod component; and a shaft hole is formed in the wall body of the lower portion of the steel pipe, and the other end of the shaft rod component penetrates out of the shaft hole to be connected with a hand wheel.

Owner:DALIAN STAR TECH CO LTD

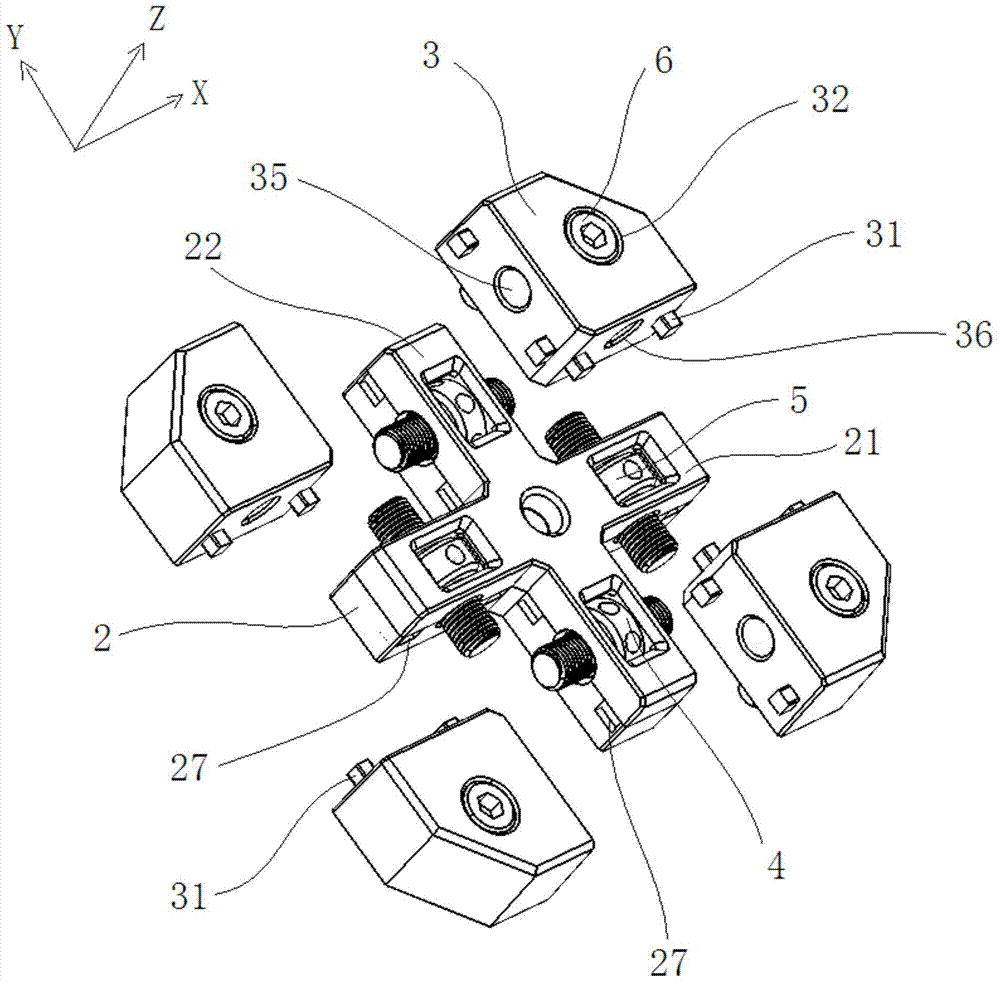

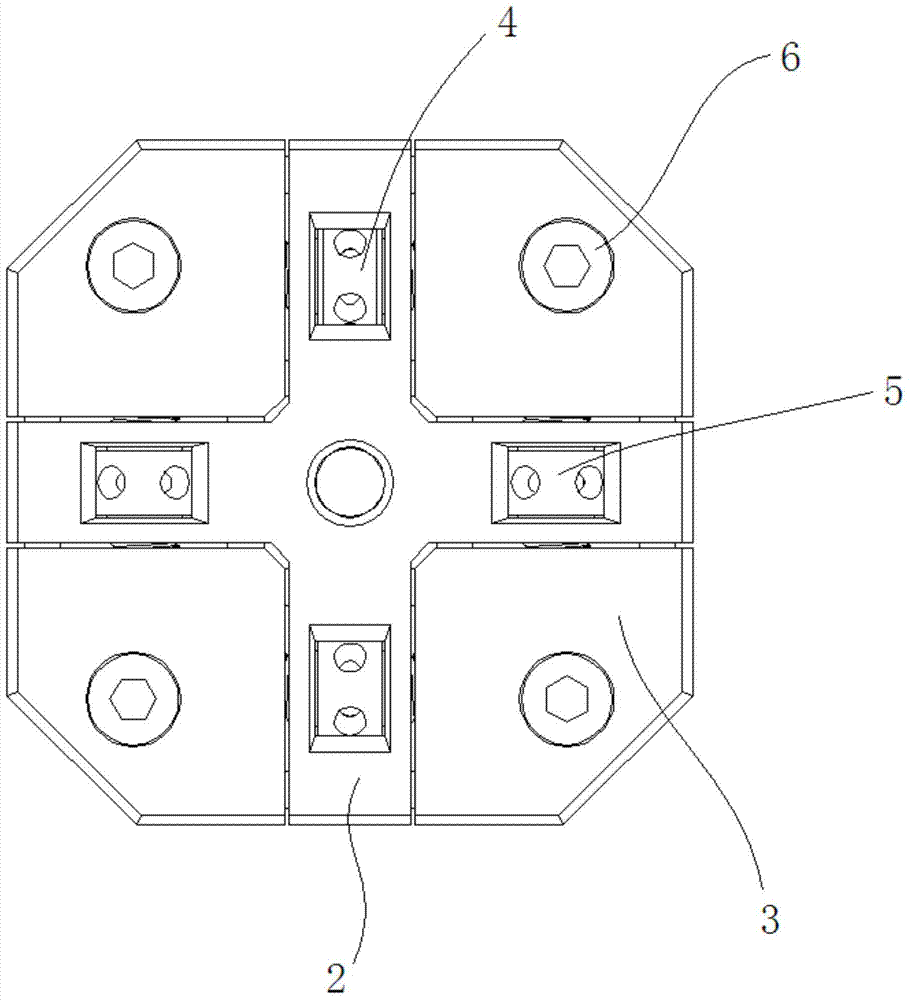

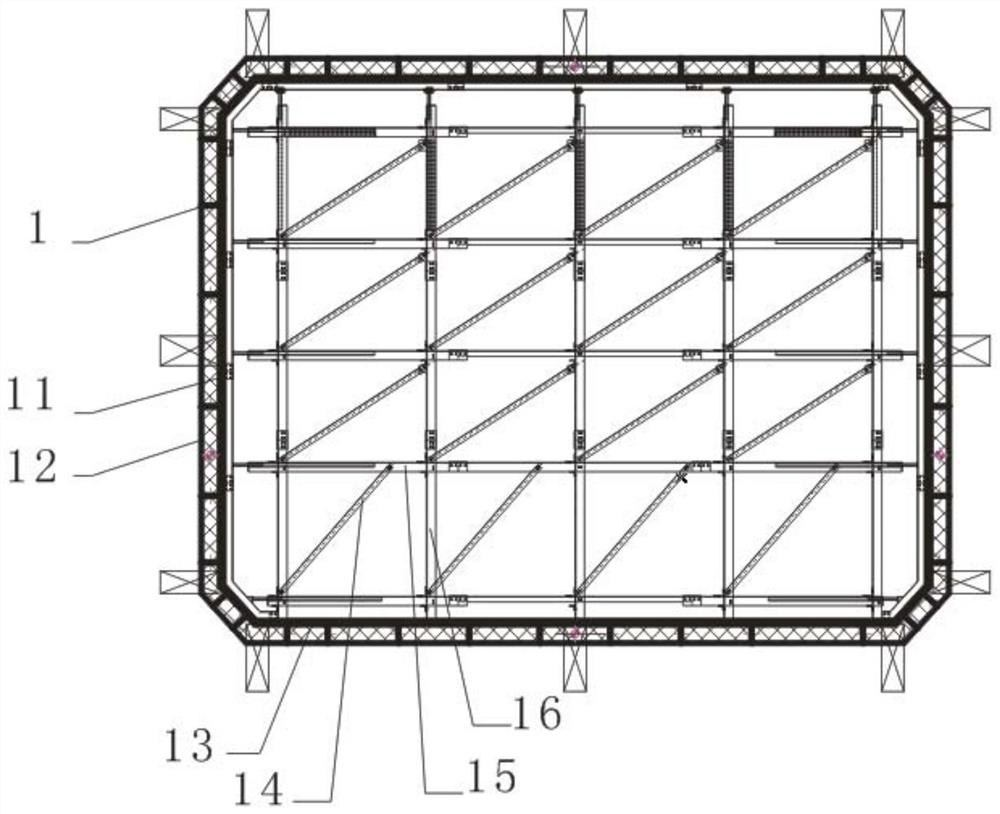

Formwork support adjustment parts and structural system of light steel support formwork for special-shaped cave construction

InactiveCN109339435BAccurate gap adjustmentLow costForms/shuttering/falseworksShoresStructure systemBoard structure

The invention discloses a formwork supporting adjustment part and a special-shaped hole construction light steel supporting formwork structure system, and belongs to the field of architecture. The formwork supporting adjustment part comprises a plurality of fixing screws, an outer steel tube and angle steel provided with a plurality of sets of first bolt holes on both sides; the outer steel tube is located in the angle steel, and second threaded hole matched with first threaded holes are formed in the outer steel tube; the outer steel tube sleeves an inner steel tube, and the inner steel tubeis provided with third bolt holes; the fixing screws sequentially penetrate through the first bolt holes, second bolt holes and the third bolt holes; and an adjustment mechanism with adjustable lengthis arranged at the end, extending out of the outer steel tube, of the inner steel tube, and the adjustment mechanism is connected to profile steel. The special-shaped hole construction light steel supporting formwork structure system comprises a structural skeleton, and the formwork supporting adjustment parts are installed on the left and right sides and the top surface of the structural skeleton. The formwork supporting adjustment parts reduce the construction difficulty of setting up a special-shaped concrete formwork, so that a gap between the structural skeleton and the formwork can be adjusted without changing the length of a structural skeleton beam in real time according to the hole size.

Owner:SOUTHWEAT UNIV OF SCI & TECH

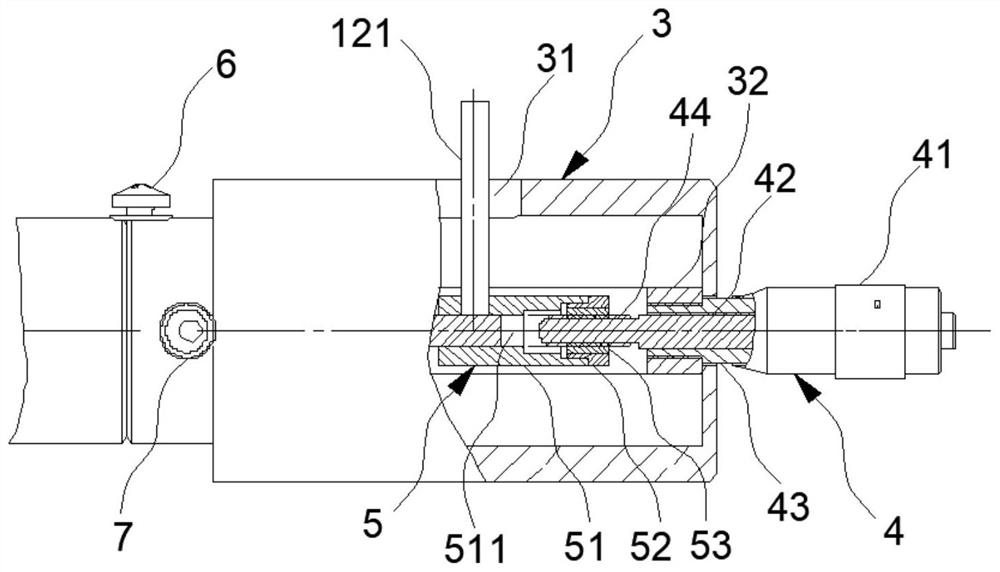

Ink key driving mechanism of printer

InactiveCN101396904BAccurate automatic adjustmentAccurate gap adjustmentPrinting press partsEngineeringCam

The invention discloses an ink key driving device for a printer. The driving device comprises a handspike and a handspike driving device, wherein, the handspike driving device comprises a plane cam and a manual zero adjusting unit or self regulating unit; the end of the handspike is up against the drive surface of the plane cam, and the plane cam is connected with the manual zero adjusting unit and the self regulating unit. The ink key driving device can precisely adjust the gap between an ink key and an ink fountain roller, thereby realizing precise automatic adjustment of the amount of jetted ink, and is completely suitable for being used on printers.

Owner:浙江寿原机械有限公司

An annealing furnace inlet sealing device

ActiveCN104673976BShorten maintenance timeAccurate gap adjustmentFurnace typesHeat treatment furnacesMechanical engineeringWater tanks

Owner:宝钢日铁汽车板有限公司

Water driving wheel device and electroplating processing equipment

The invention discloses a water driving wheel device and electroplating processing equipment. The water driving wheel device comprises a base, a mounting rod, a rotating wheel, water scraping mechanism and two adjusting mechanism, wherein the mounting rod is arranged on the upper surface of the base, and the base is connected with an end cover through a connecting strip; the mounting rod is arranged between the end cover and the base, and the rotating wheel is arranged on the mounting rod; the water scraping mechanism comprises a water scraping wheel arranged on one side of the rotating wheel, and the two ends of the water scraping wheel are connected with connecting blocks through fixing rods; and each adjusting mechanism comprises a threaded rod, and one end of the threaded rod is rotationally arranged on the mounting rod. When the water scraping wheel is damaged, the water scraping wheel can be replaced in time, the practicability of the water driving wheel device is improved; the gap between the water scraping wheel and the rotating wheel can be accurately adjusted through cooperative use of a pointer and a marking ruler; and the precision is high, the flexibility is high, and greater stability is achieved under control of the two threaded rods.

Owner:深圳市兴东辉科技有限公司

Asymmetric clamping device and experimental method for thin plate compression

ActiveCN106353181BAvoid wrinklesReliable side pressureMaterial strength using tensile/compressive forcesWrinkle skinExperimental methods

An asymmetric clamping device and experimental method for sheet compressing are provided; two clamp plates of the asymmetric clamping device are positioned in retaining grooves in a center spring support baseplate, lateral pressure is applied to a sheet through the clamp plates and sliders such that the sheet wrinkles in the thickness direction and loses stability in the width direction; two return springs are each fixed between the corresponding clamp plate and slider; tension springs are connected to the lateral sides of the two clamp plates to provide uniform symmetric pressure for the clamp plates; lateral pressure is applied through the springs, a sample is given planar clamping force through the clamping device, the sample is kept moving evenly in the thickness direction, it is guaranteed that a clamping gap may automatically adjust with changes in sheet thickness; a slider movement area is positioned in a sample non-standard distance segment, the transverse frictional force on the sample may not affect a standard distance segment, and the impact of slider movement induced width-directional frictional force upon experimental results is eliminated; the invention provides three travel options, and various sheet tensioning and compressing experimental needs can be met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

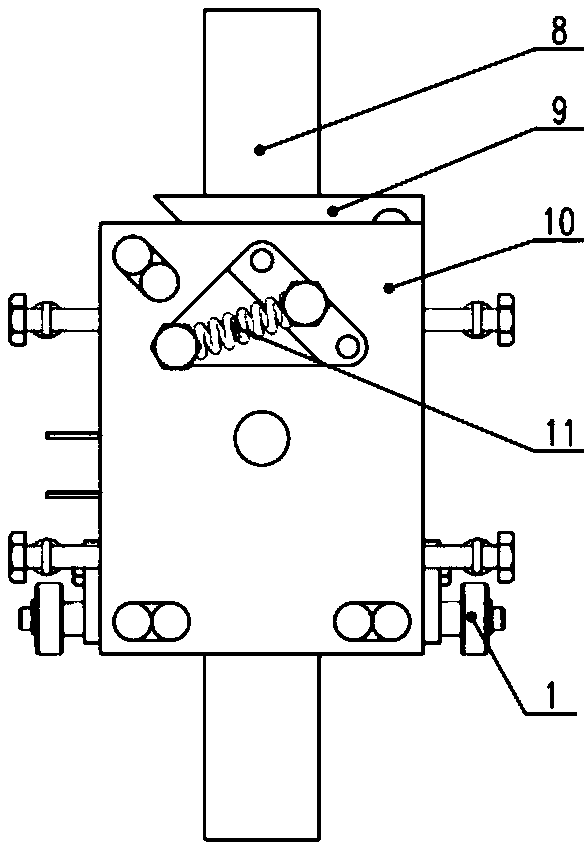

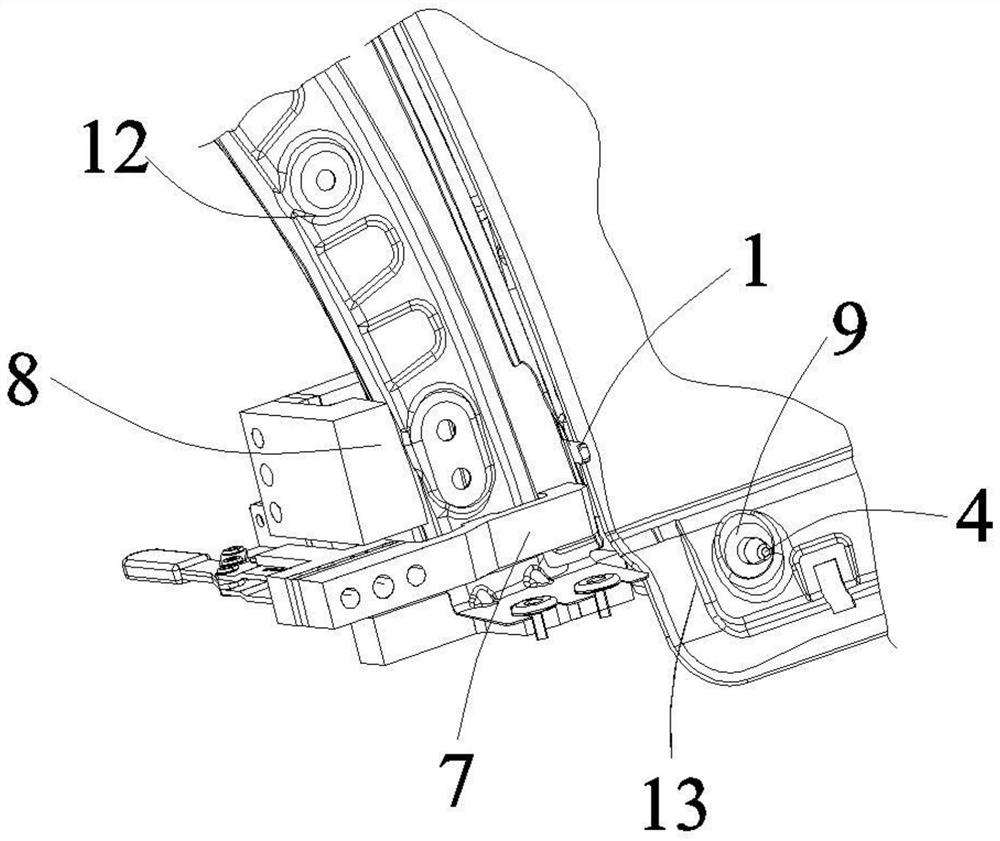

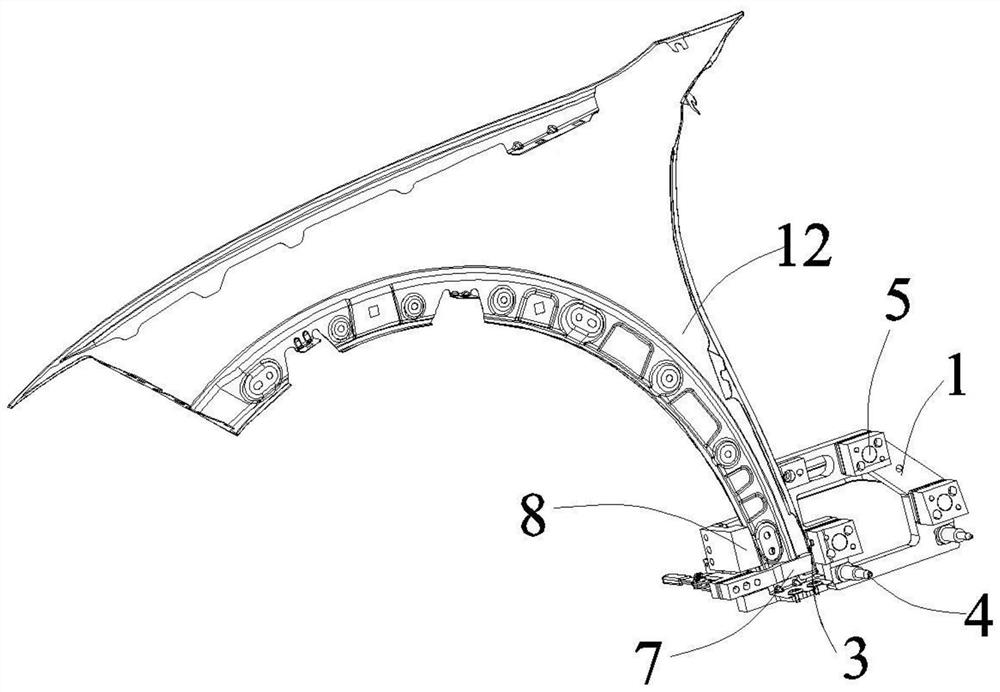

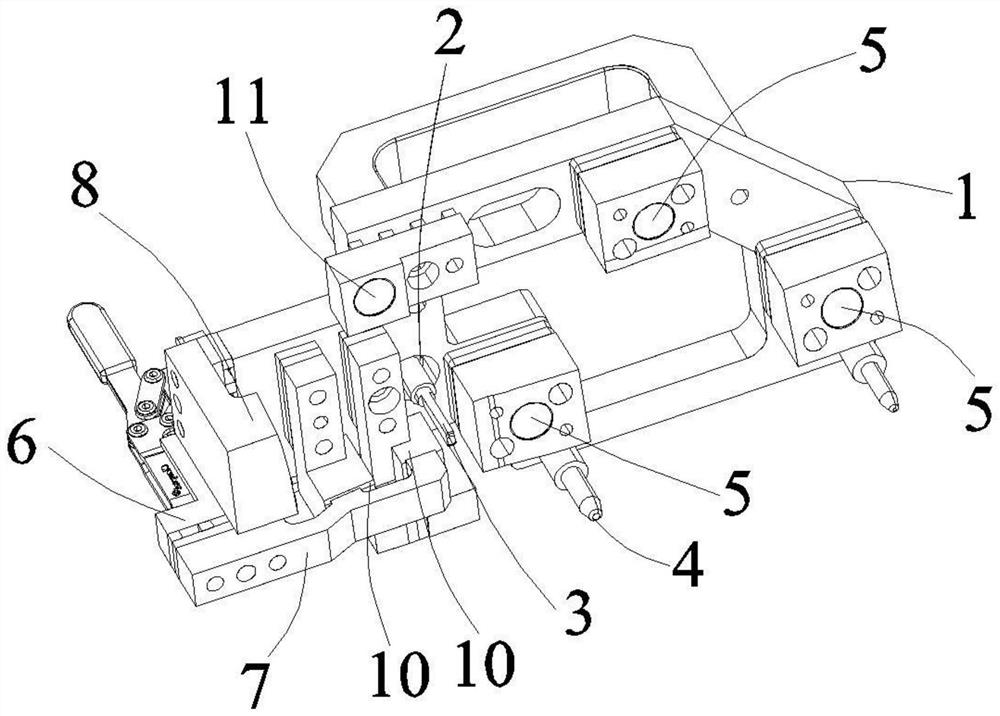

A fender and door assembly tool and assembly method

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

Special film laminating machine convenient for building decoration material film formation

ActiveCN111361258ASolve the problem of incomplete coatingSpray coating is effectiveSpraying apparatusLaminationThin membraneStructural engineering

The invention relates to the technical field of building material processing equipment. The invention discloses a special film laminating machine convenient for building decoration material film formation. The machine comprises a bottom plate, a pressure sensor is arranged between a fixing block at the right front end and a first telescopic rod, the right end of a monitoring device is connected with a thin film layer, the right end of the thin film layer is connected with sponge, the lower end of the right portion of a rope is connected with a floating ball, a metal ball is arranged on the left side of a sliding block, and a variable resistor corresponding to the metal ball is arranged in the monitoring device. The sponge is extruded by a film covering plate to deform, aliquid on the lowerside of the floating ball rises to drive the floating ball to move upwards, the rope drives the metal ball on the sliding block to move on the variable resistor, the current of the circuit where themetal ball and the variable resistor are located changes, a second telescopic rod adjusts the distance between a film covering frame and the film covering plate and the distance between a film covering material and the film covering plate, and the structure solves the problems that an existing film covering machine cannot automatically adjust the gap according to the product thickness, the film covering efficiency is low and film covering is incomplete.

Owner:广东澳美高分子材料有限公司

Brush mechanism for cleaning large Particle on surface of panel

PendingCN114289356ASolve the problem of scratches and insufficient cleaning abilityReduce instabilityFlexible article cleaningCleaning using toolsGear driveCoupling

The brush mechanism for cleaning the large Particle on the surface of the panel comprises a bottom plate, the two sides of the bottom plate are fixedly connected with a driving side plate and an adjusting side plate respectively, and the opposite sides of the driving side plate and the adjusting side plate are each provided with a first adjusting mechanism and a second adjusting mechanism. A hand wheel is rotated to drive a worm to rotate, the worm drives a worm gear meshed with the worm to rotate, the worm gear drives a rotating rod to rotate and drives a threaded block to move up and down through threads on the surface of the rotating rod, and the threaded block and a sliding block are matched with a fixing frame under the action of a linear guide rail to drive a driving motor, a brush and a fixing block to move up and down; a dial indicator, an adjusting scale and a pointer are matched to accurately adjust the gap between the brushes, the transmission of the rotating rod realizes the self-locking capability through an adjusting nut, and the structure instability caused by the increase of the self weight and the load after the brushes absorb water is effectively reduced by matching with a rigid coupling.

Owner:南京华易泰电子科技有限公司

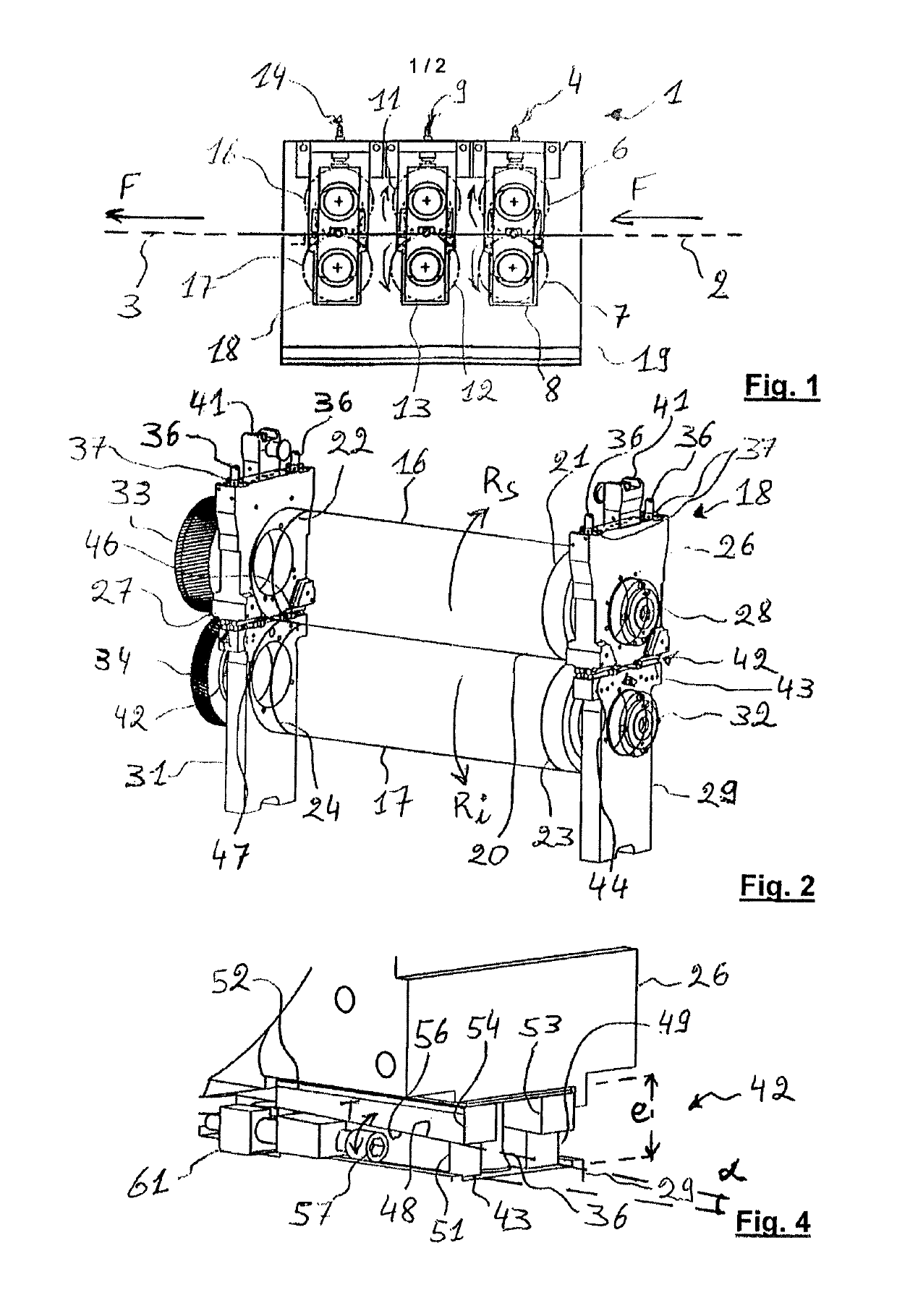

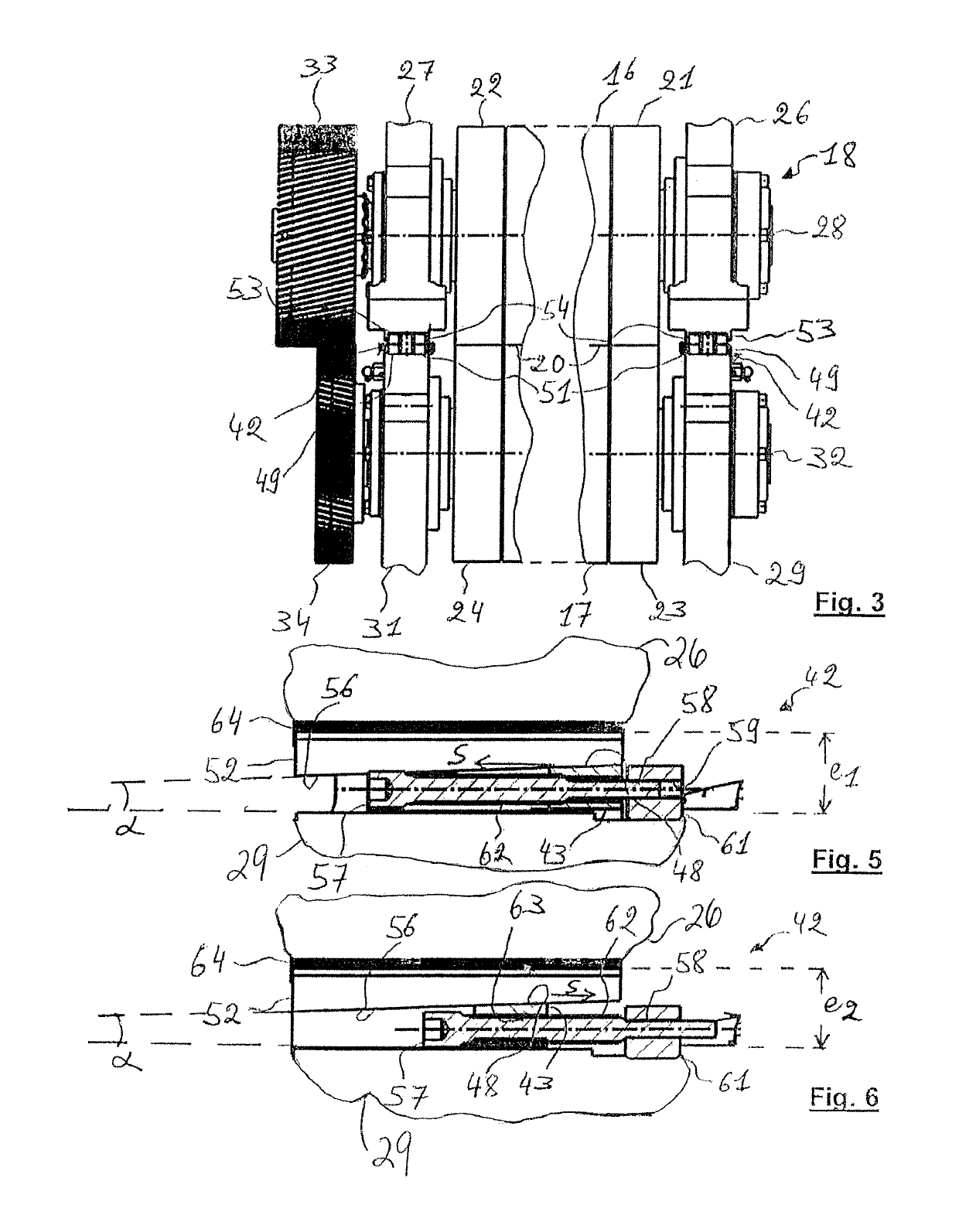

Adjustable converting arrangement for a flat substrate, cassette, unit and machine provided therewith

InactiveUS10391662B2Simpler and more sensitiveAccurate gap adjustmentMechanical working/deformationBox making operationsDifferential screwEngineering

Owner:BOBST MEX SA

Apparatus for transferring packaged chips, test handler and method for manufacturing packaged chips

ActiveCN101545948BAccurate gap adjustmentSemiconductor/solid-state device testing/measurementElectronic circuit testingEngineeringMechanical engineering

Owner:MIRAE CORPORATION

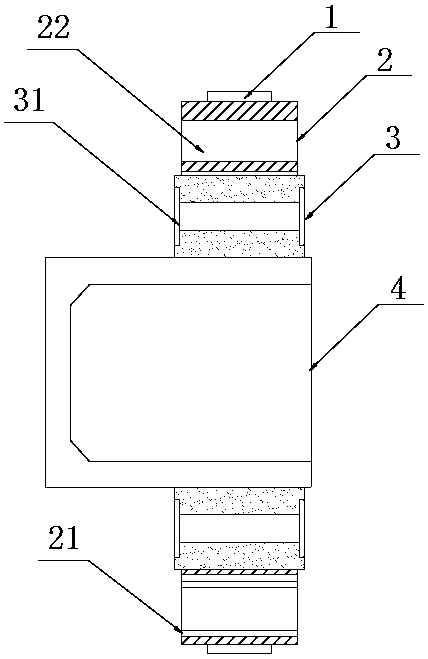

Plasma torch and gap adjusting method thereof

PendingCN113853054AAccurate gap adjustmentDoes not change discharge uniformityPlasma techniqueEngineeringMechanical engineering

The invention relates to the field of mechanical adjustment, in particular to a plasma torch and a gap adjusting method thereof. The plasma torch comprises a plasma torch body, a first insulating sleeve and an adjusting assembly, wherein the plasma torch body comprises a spray head, a tungsten needle, an inner shell and an outer shell, the tungsten needle is connected with a first terminal, the polarity of the spray head is opposite to that of the tungsten needle, the tungsten needle is arranged in the inner shell, the inner shell is arranged in the outer shell, an air cavity is formed between the tungsten needle and the inner shell, and a cooling cavity is formed between the inner shell and the outer shell; the first insulating sleeve is connected with the shell, and the end, away from the nozzle, of the tungsten needle is arranged in the first insulating sleeve; and the adjusting assembly is arranged on the first insulating sleeve and is used for driving the tungsten needle to translate along the axial direction of the plasma torch body so as to change the distance between the tungsten needle and the nozzle. According to the plasma torch provided by the invention, the gap between the tungsten needle and the spray head can be quickly and accurately adjusted, so that the jet flow velocity and jet flow appearance of the plasma beam are changed, and the use requirements of multiple scenes are met.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

Brake disc with adjustable handbrake clearance hole

ActiveCN111336197AAccurate gap adjustmentAvoid grindingBraking discsSlack adjustersBrakeStructural engineering

The invention discloses a brake disc with an adjustable handbrake clearance hole, and particularly relates to the field of brake discs. The brake disc comprises a fixed disc, a connecting disc is fixedly arranged at the center of the fixed disc, a mounting disc is fixedly arranged at the center of the connecting disc in a penetrating mode, a storing disc is fixedly arranged at the center of the mounting disc, a reinforcing disc is fixedly arranged in the connecting disc, a first adjusting groove, a second adjusting groove, an oil groove and a sealing groove are formed in the reinforcing disc,the first adjusting groove, the second adjusting groove and the oil groove are formed in one side of the sealing groove, and the first adjusting groove and the oil groove are formed at interval in thehorizontal direction. According to the brake disc with the adjustable handbrake clearance hole, the handbrake clearance can be adjusted precisely, a elastic sheet makes contact with the inner wall ofthe first adjusting groove so as to remind an operator of the adjusted one-gear distance, a bent elastic sheet makes contact with the inner wall of the second adjusting groove, fine tuning can be conducted on the two-gear distance, and lubricating oil can be added into the oil groove so as to prevent the inner walls of the first adjusting groove and the second adjusting groove from being ground flush due to severe scratching.

Owner:莱州伟辰汽车配件有限公司

Equipment for controlling distance between inductor and raceway in quenching of slewing bearing raceway

PendingCN114717394AAccurate adjustmentQuality assuranceIncreasing energy efficiencyFurnace typesInductorSlewing bearing

The invention relates to the technical field of slewing bearing raceway quenching, and discloses slewing bearing raceway quenching equipment for controlling the distance between an inductor and a raceway, the slewing bearing raceway quenching equipment comprises a longitudinal base, a transverse base and a sliding table, longitudinal limiting blocks are fixedly installed on the front face and the back face of the longitudinal base, and longitudinal through holes are formed in the centers of the longitudinal limiting blocks; a longitudinal adjusting shaft is movably installed on the inner wall of the longitudinal through hole, the longitudinal adjusting shaft is driven to move through a longitudinal adjusting hand wheel arranged on the front face of the longitudinal adjusting shaft, then the coupling gap between the sensor and the gear is adjusted, and the transverse adjusting shaft is driven to move through a transverse adjusting hand wheel arranged on the right side of the transverse adjusting shaft. And the guide wheel arranged on the left side of the guide wheel bracket is put into the track, so that the inductor can stably move along the adjusted gap, and the effects of accurately adjusting the gap between the inductor and the roller path and ensuring the quality of a hardening layer of the slewing bearing roller path are achieved.

Owner:安徽文君自动化科技股份有限公司

A brake disc with an adjustable handbrake clearance hole

The invention discloses a brake disc with an adjustable handbrake gap hole, specifically relates to the field of brake discs, comprising a fixed disc, a connecting disc is fixed in the center of the fixing disc, and a mounting disc is fixed and penetrates through the center of the connecting disc. A placement plate is fixed in the center of the installation plate, and a reinforcement plate is fixed inside the connection plate. There are No. 1 adjustment groove, No. 2 adjustment groove, oil groove and closed groove inside the reinforcement plate, and the No. 1 adjustment groove, Both the No. 2 regulating tank and the oil tank are arranged on one side of the closed tank, and the No. 1 regulating tank and the oil tank are arranged at intervals in the horizontal direction. The invention can precisely adjust the gap of the handbrake. The contact between the elastic piece and the inner wall of the No. 1 adjustment groove can remind the operator that the distance of one tooth has been adjusted, and the contact between the curved elastic piece and the inner wall of the No. 2 adjustment groove can be carried out between two teeth. For fine-tuning, lubricating oil can be added to the inside of the oil tank to prevent the inner walls of the No. 1 adjustment tank and No. 2 adjustment tank from being severely scratched and ground flat.

Owner:莱州伟辰汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com