Formwork support adjustment parts and structural system of light steel support formwork for special-shaped cave construction

A formwork support and adjustment technology, applied in formwork/formwork/work frame, pillar, building structure, etc., can solve the problems of low feasibility, large cross-section change, low reuse rate, etc., to reduce construction difficulty and Project cost, meet the requirements of precision control indicators, and improve the effect of recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention. However, it should be clear that the embodiments described below are only some, not all, embodiments of the present invention. Without departing from the spirit and scope of the present invention defined and determined by the appended claims, all other embodiments obtained by persons of ordinary skill in the art without any creative effort shall fall within the protection scope of the present invention.

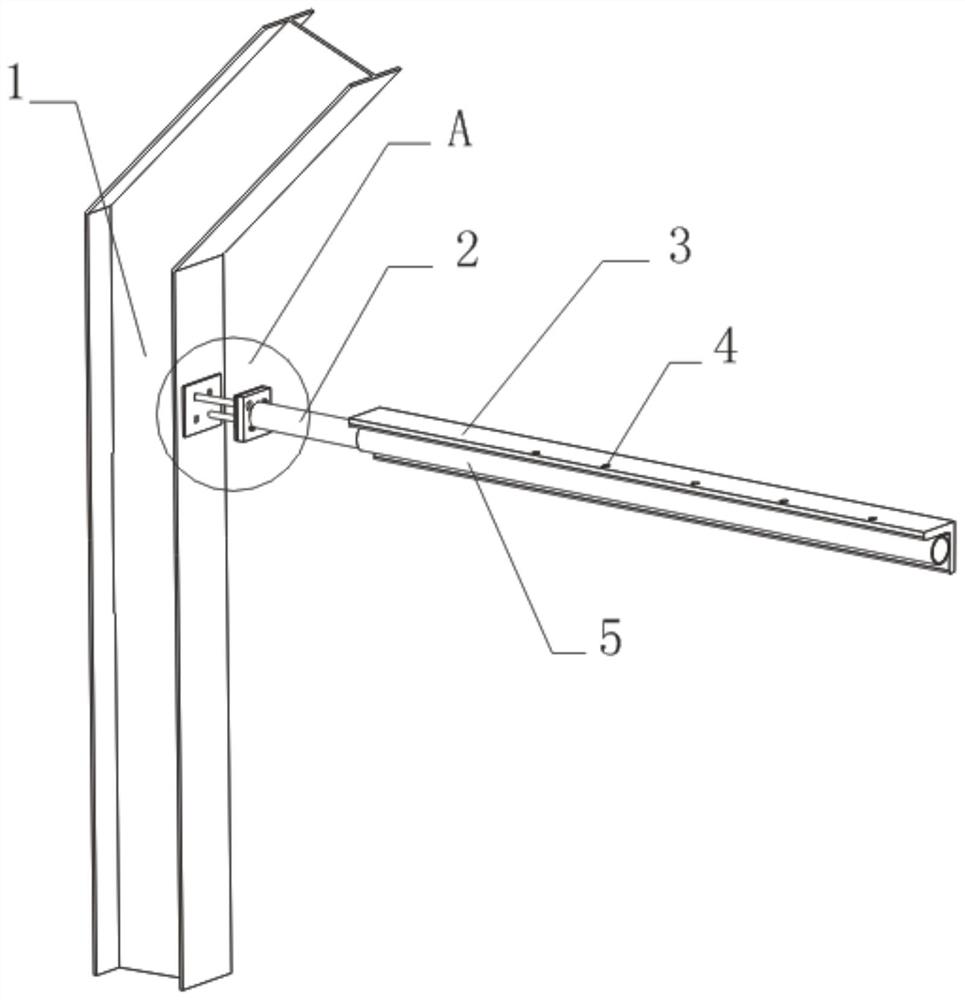

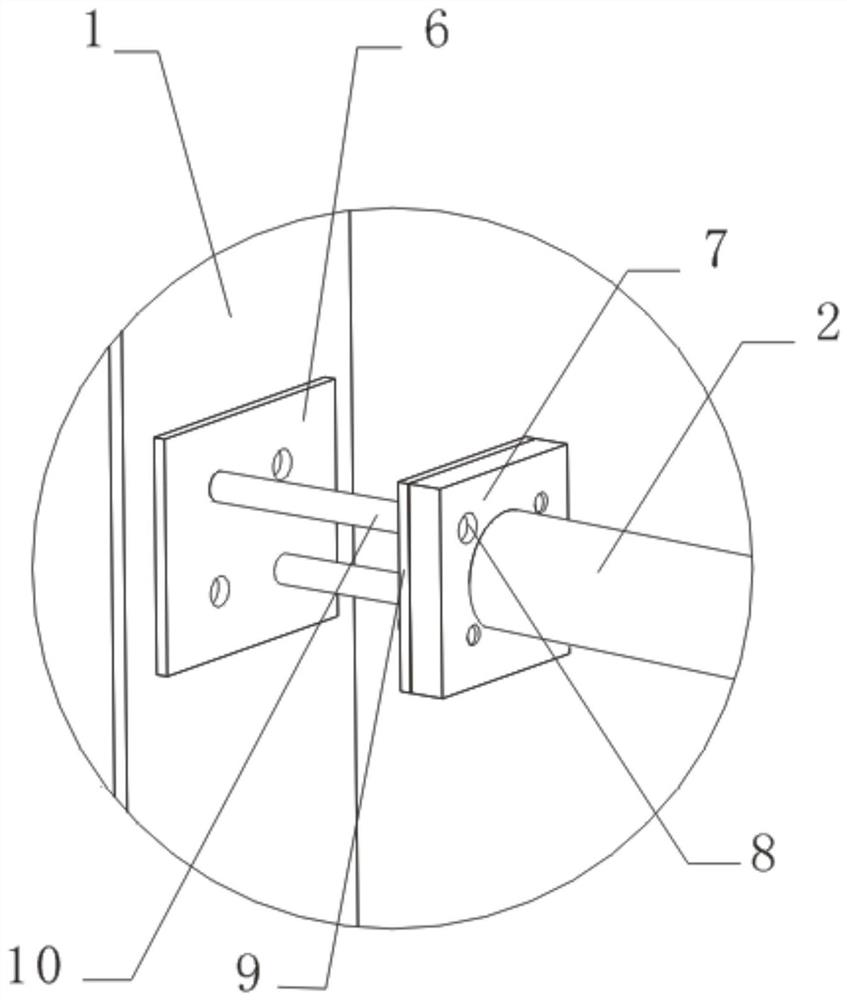

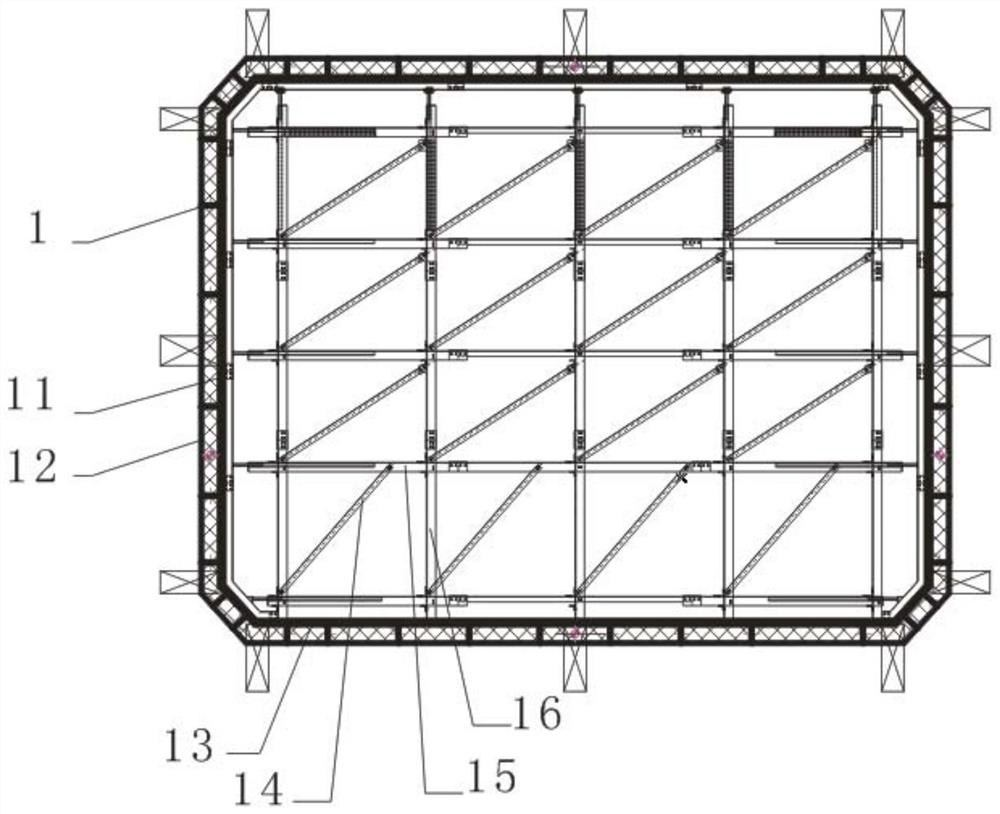

[0023] Such as figure 1 with figure 2 As shown, the formwork support regulator includes a plurality of fixed screws, an outer steel pipe 5 and an angle steel 3 with multiple groups of first bolt holes 4 arranged on both sides; the outer steel pipe 5 is located in the angle steel 3 and is provided with the first bolt hole 4 matched second bolt holes; the inner steel pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com