Patents

Literature

249results about How to "Avoid grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

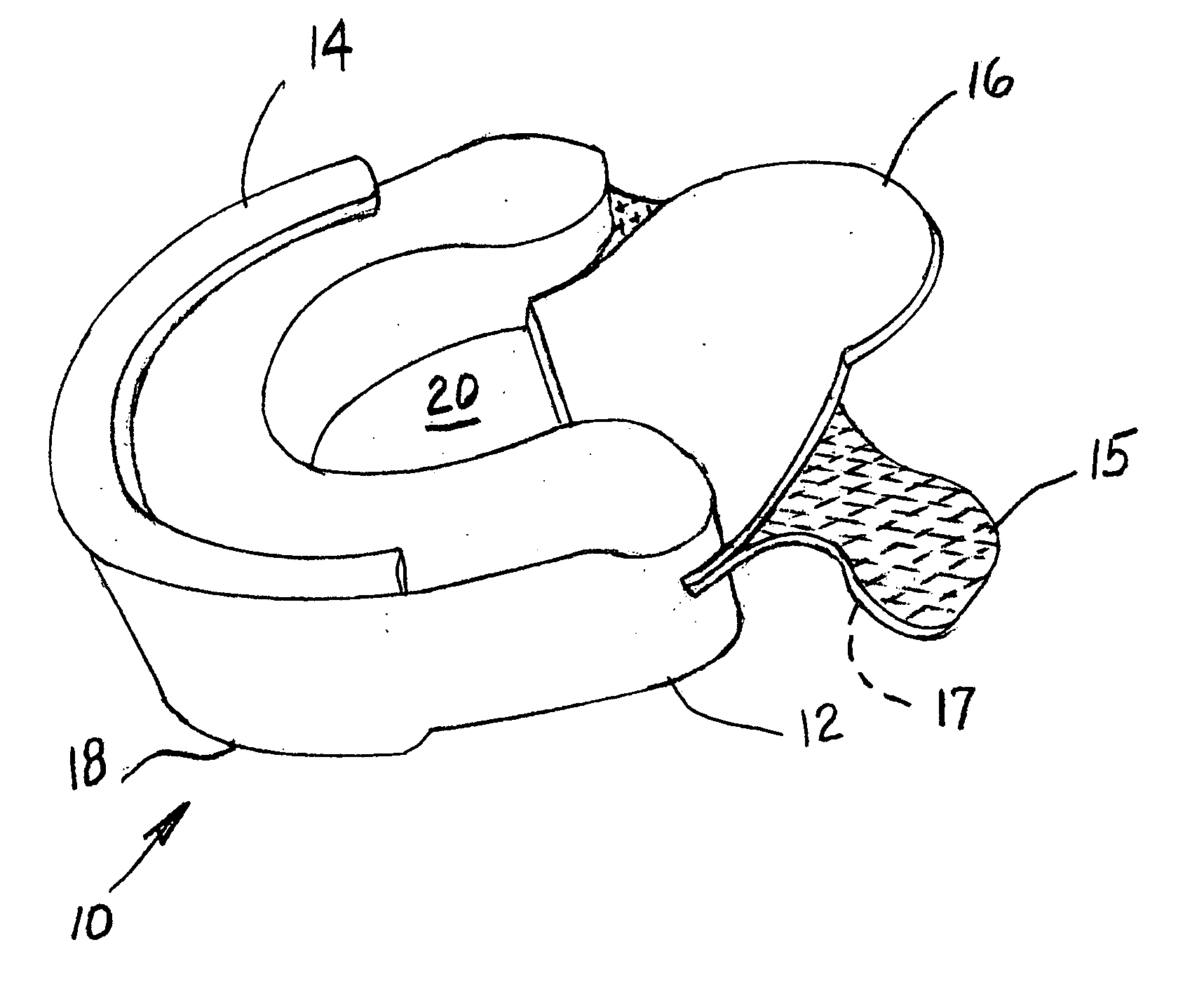

Breathing normalizer apparatus

InactiveUS7137393B2Reduce deliveryPrevent snoringTeeth fillingSnoring preventionOral medicationTeeth grinding

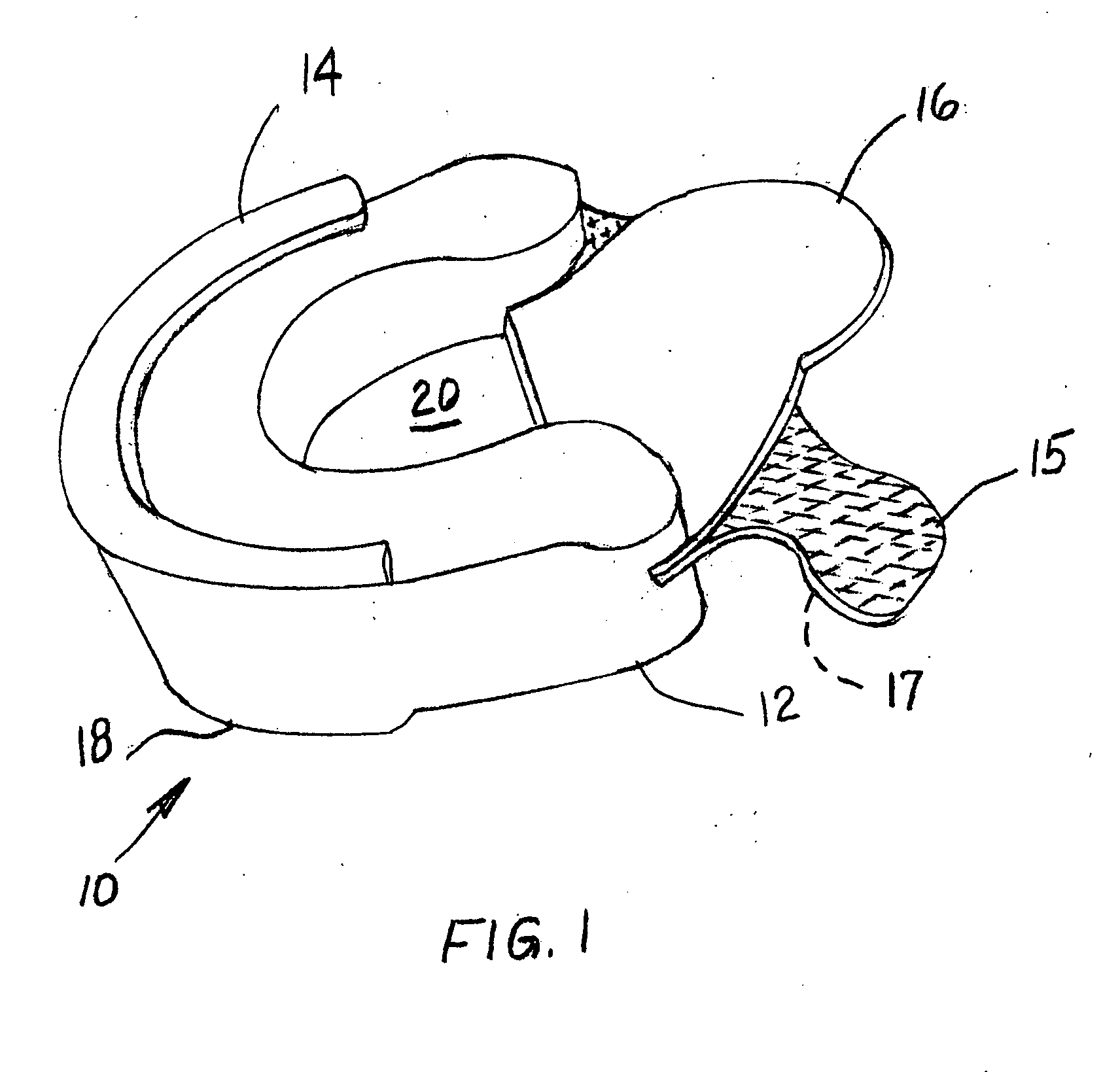

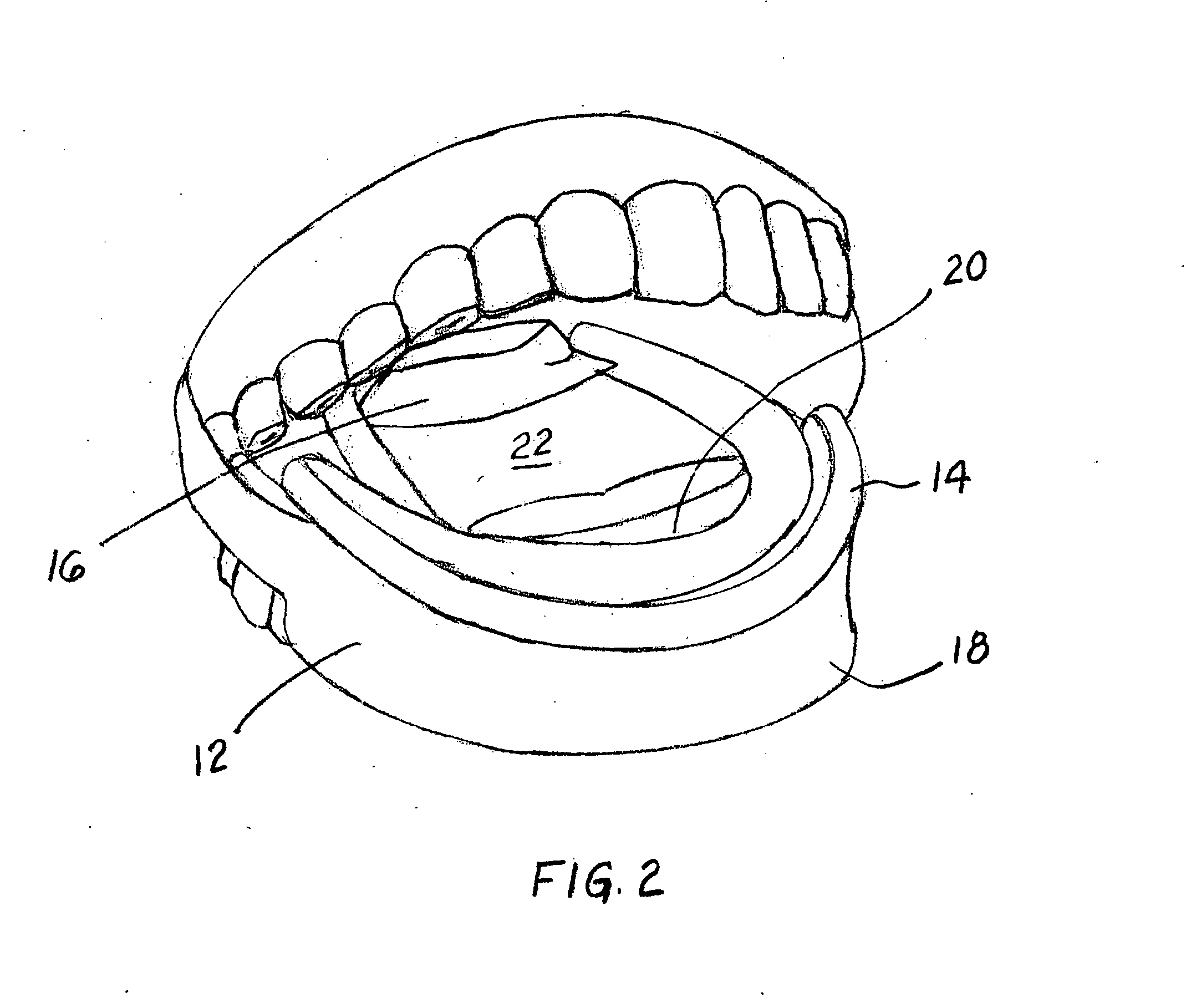

A breathing normalizer for partial insertion within the user's mouth for normalizing breathing patters, prevention of snoring, teeth grinding, and light forms of sleep apnea is disclosed. The device includes an outer plate which is positioned external to the user's mouth when in use, an elongated hollow shaft for connecting the structure to a lip plate adapted to be received between the user's lips and teeth, and a generally C-shaped multi-lobed structure adapted for receiving the user's tongue. The device is positioned within the oral cavity of the user in an operative configuration such that the tongue is retained within the multi-lobed structure, the teeth clamp down upon the connector with the lip plate positioned between the teeth and the inner portions of the upper and lower lips. The outer plate further defines a centrally disposed chamber having an inlet tube in fluid communication with the hollow tubular connector for providing an inlet for breathing air. The inlet tube is adapted for connection to a source of gas, such as oxygen, to assist in delivering the gas to the user through the lungs. In addition, the chamber includes a threaded peripheral edge adapted for threaded engagement with a container of medicine thereby facilitating the delivery of oral medications into the user's oral cavity and preferably the delivery of oral medications below the tongue. A medicine receiving chamber is further provided to allow for medicine received therein to be dispensed and / or evaporated in the user's mouth. As a result of proper application of the apparatus breathing at night is normalized, while snoring, grinding of the teeth, and apena are prevented, and further while medications may be simultaneously delivered orally.

Owner:PIVOVAROV ALEXANDER R

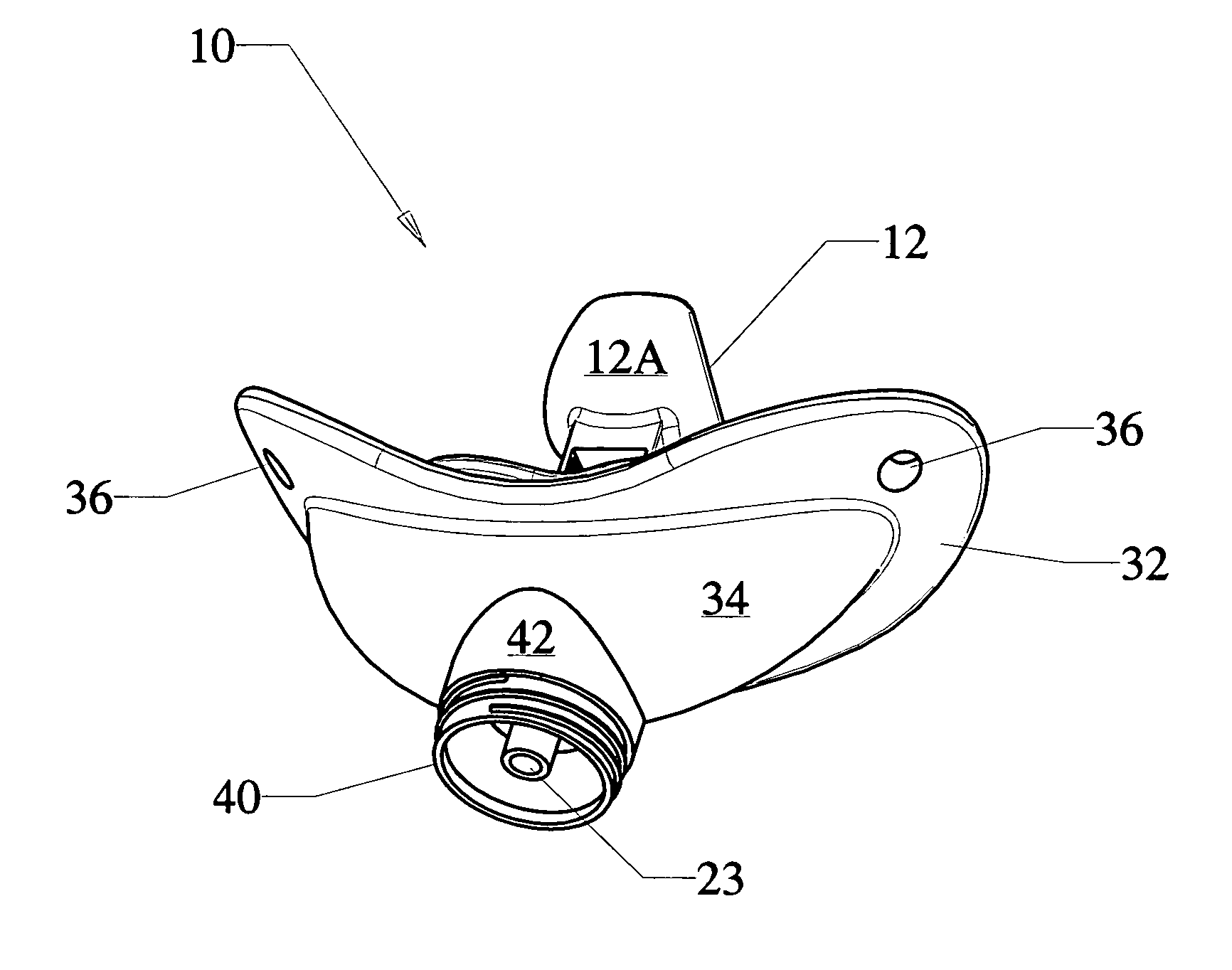

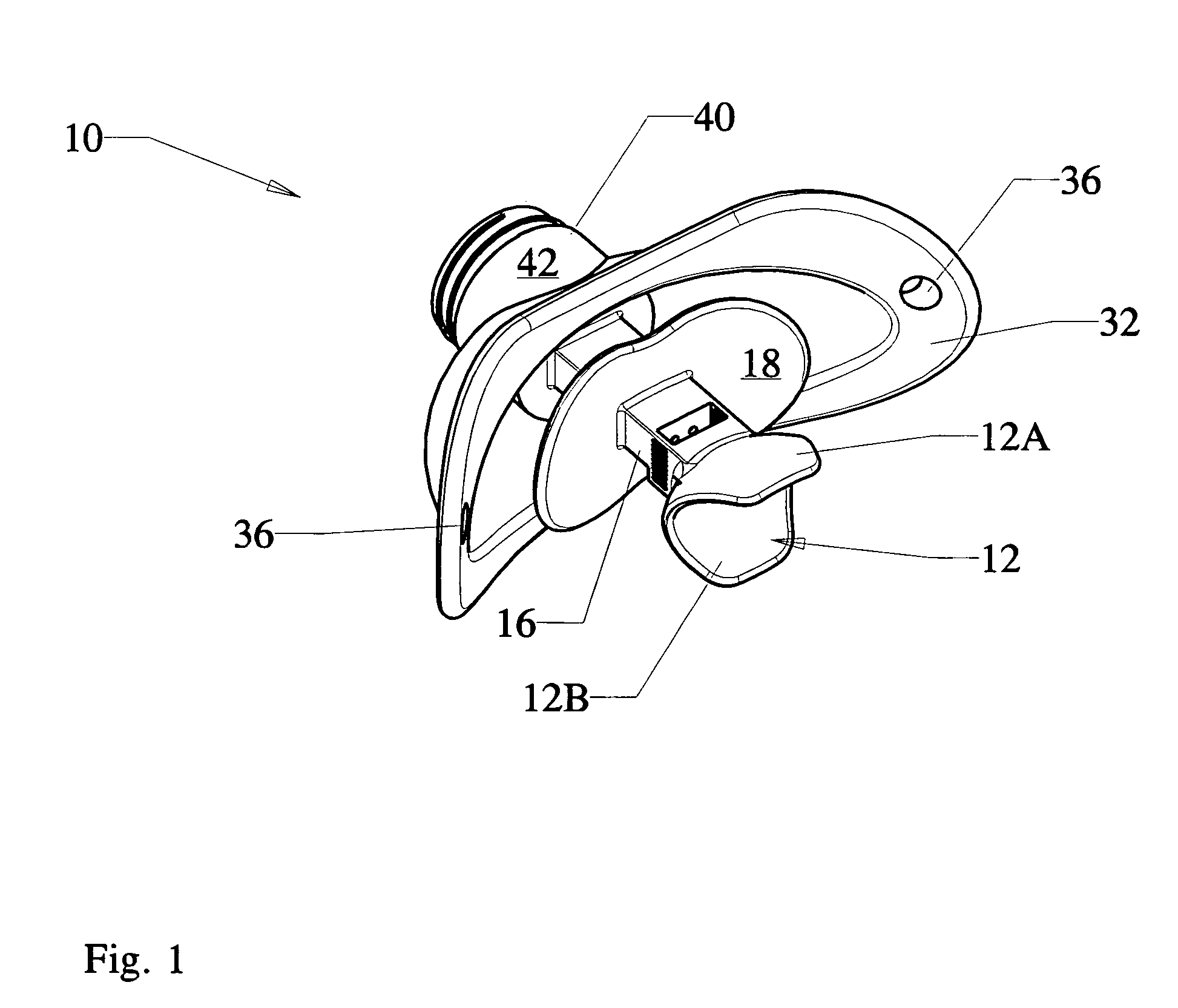

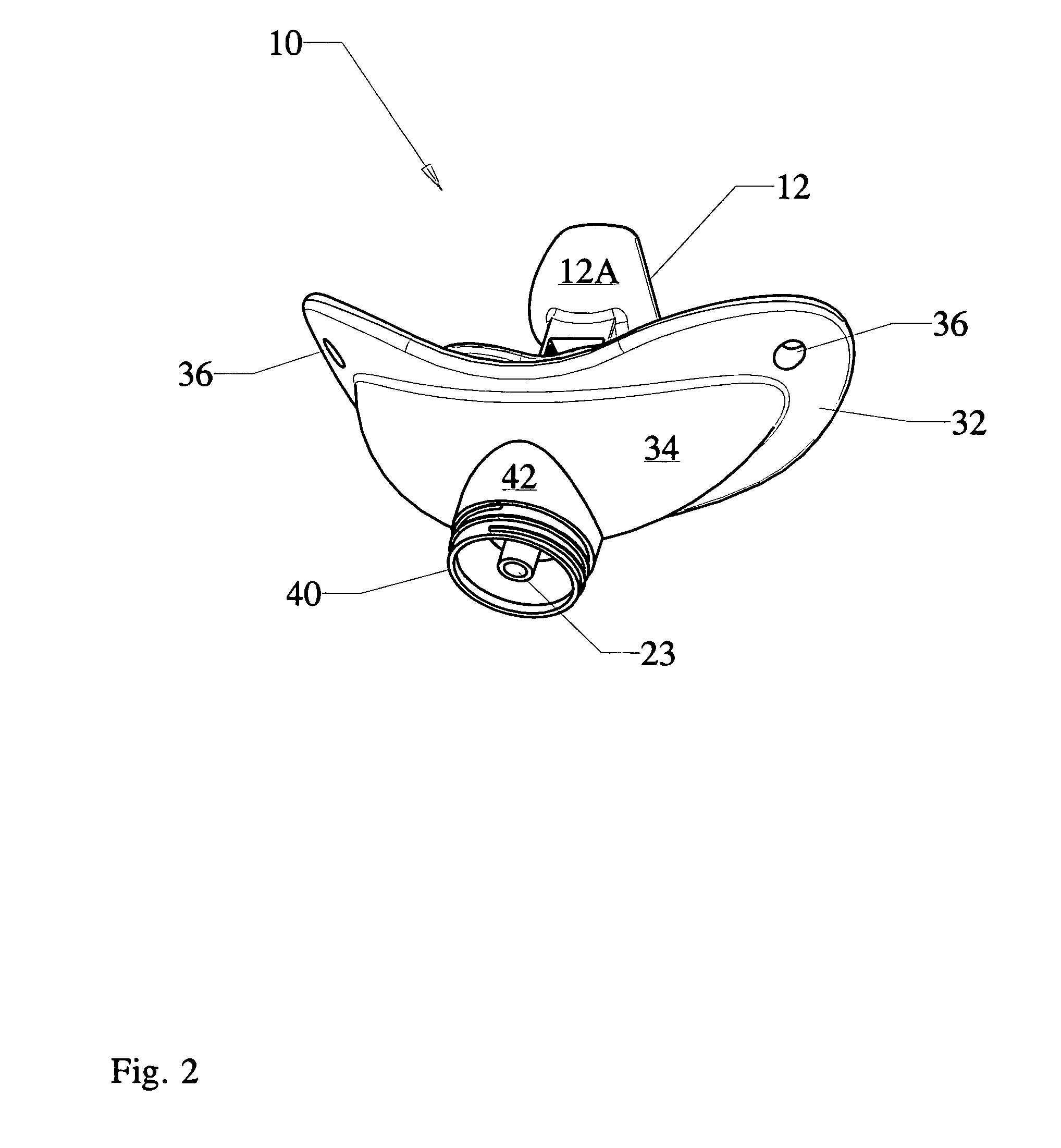

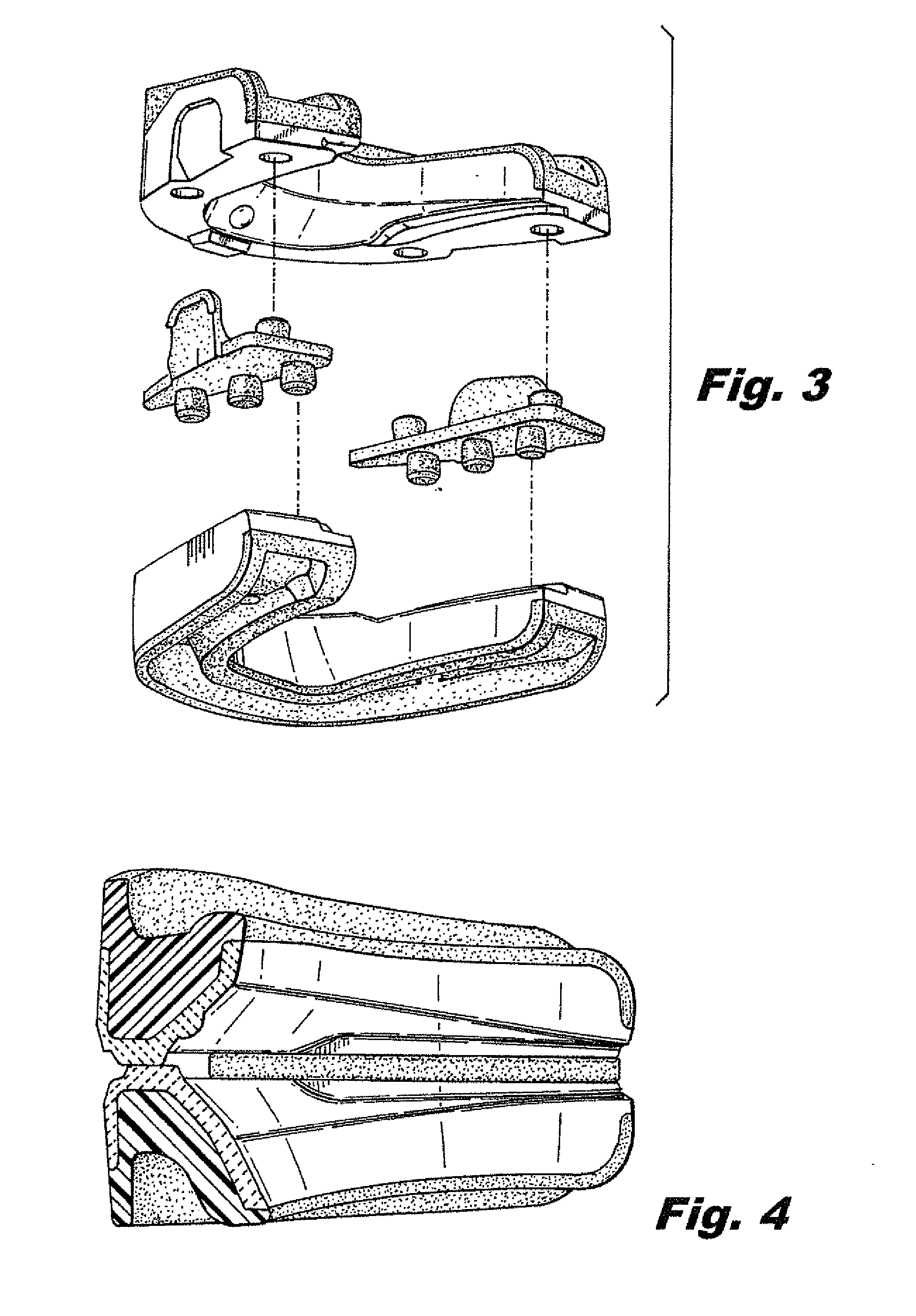

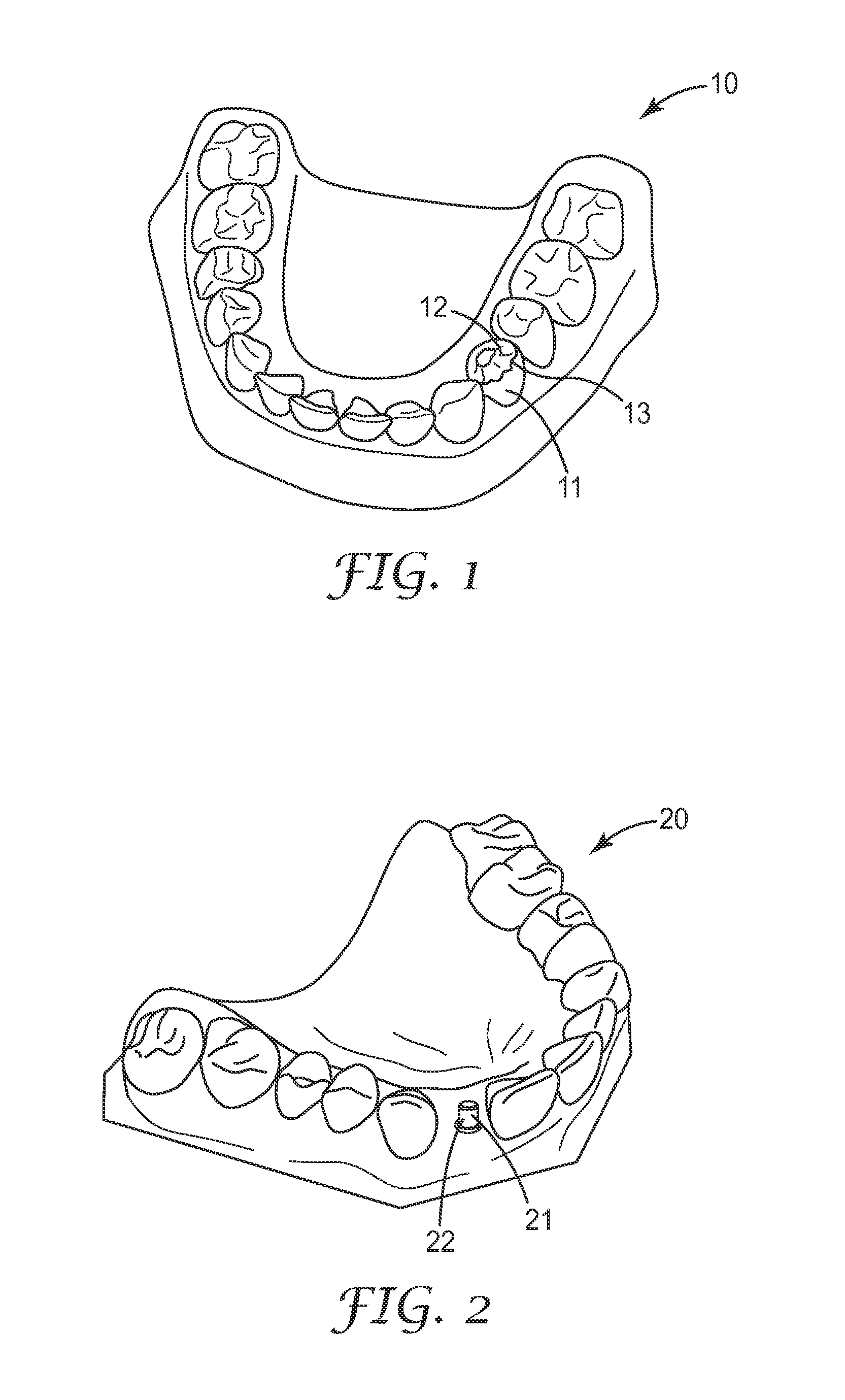

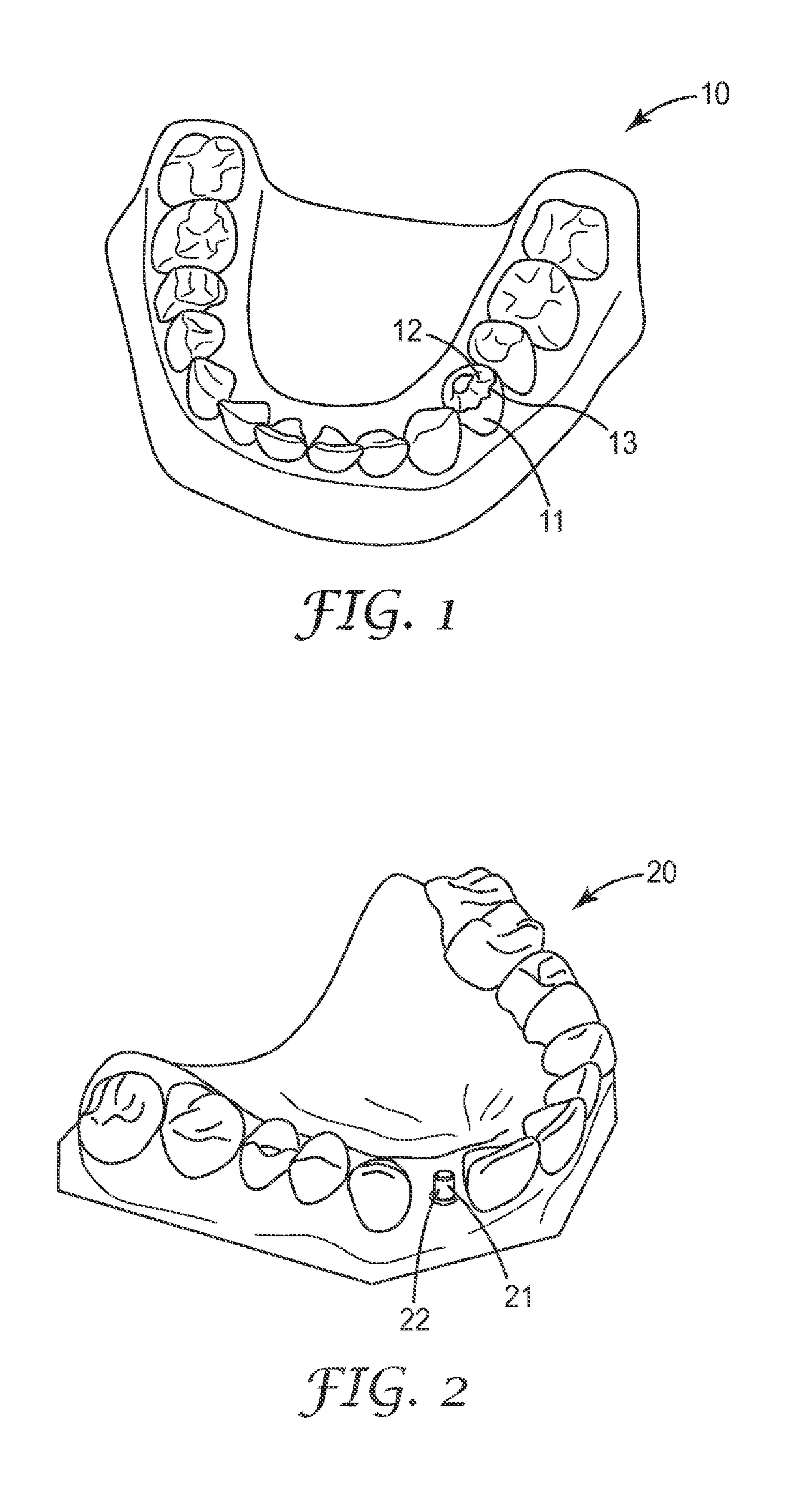

Mouth appliance for mitigating sleep related problems

InactiveUS20080041396A1Avoid grindingPrevent snoringOperating chairsSnoring preventionOral cavityDental arch

An oral nighttime appliance consists of a somewhat resilient U-shaped base substantially complementary with a person's dental arch. At least one integral lip protrudes from anterior edges of the U-shaped base, and a substantially rigid hourglass-shaped flap is connected into and partially spanning the gap between the posterior legs of the U-shaped base, and protrudes rearward and downward. A second flap, nearly semicircular and rigid, extends rearward and upward from the posterior of the base into which one end of the second flap is secured.

Owner:LUCKER DAVID A

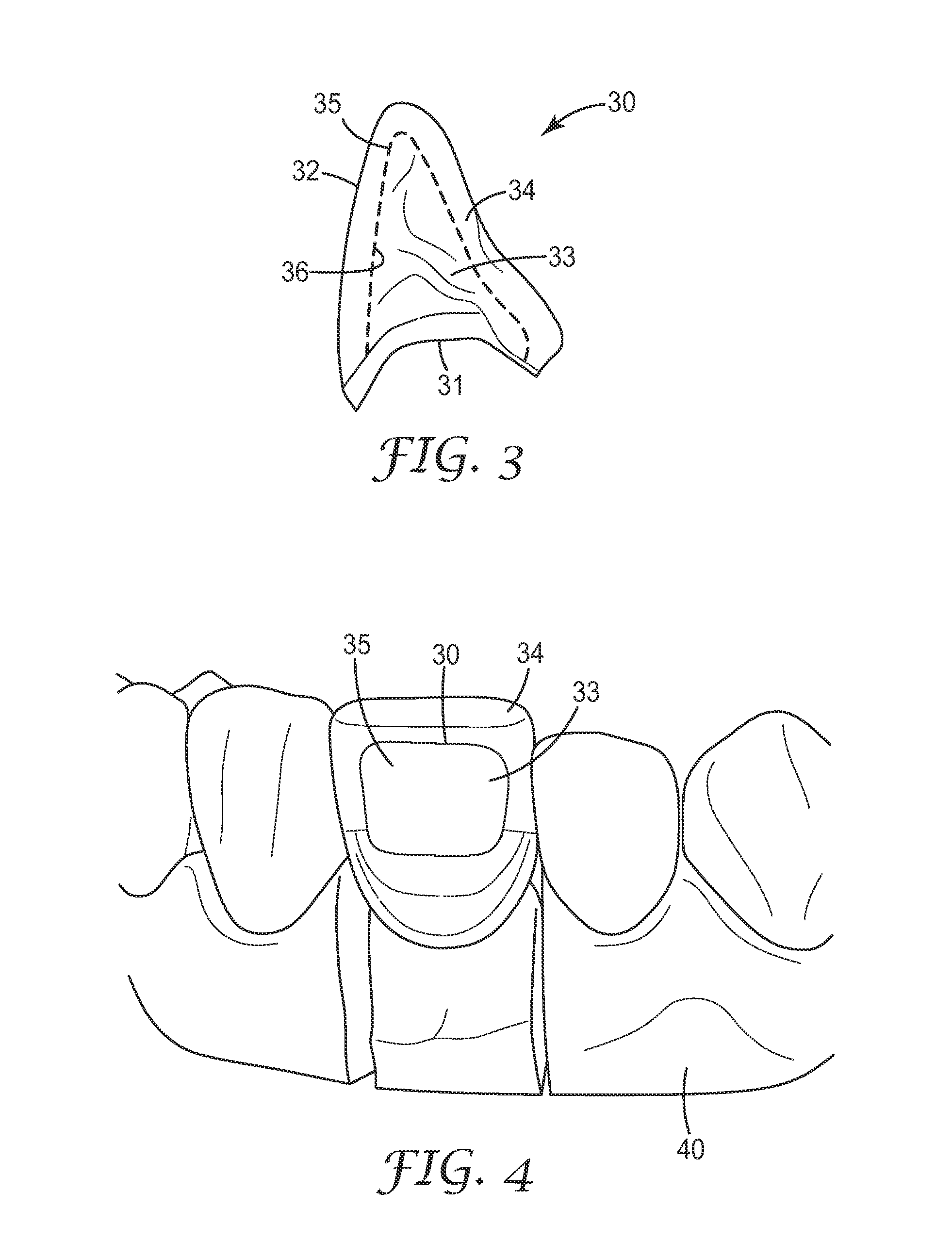

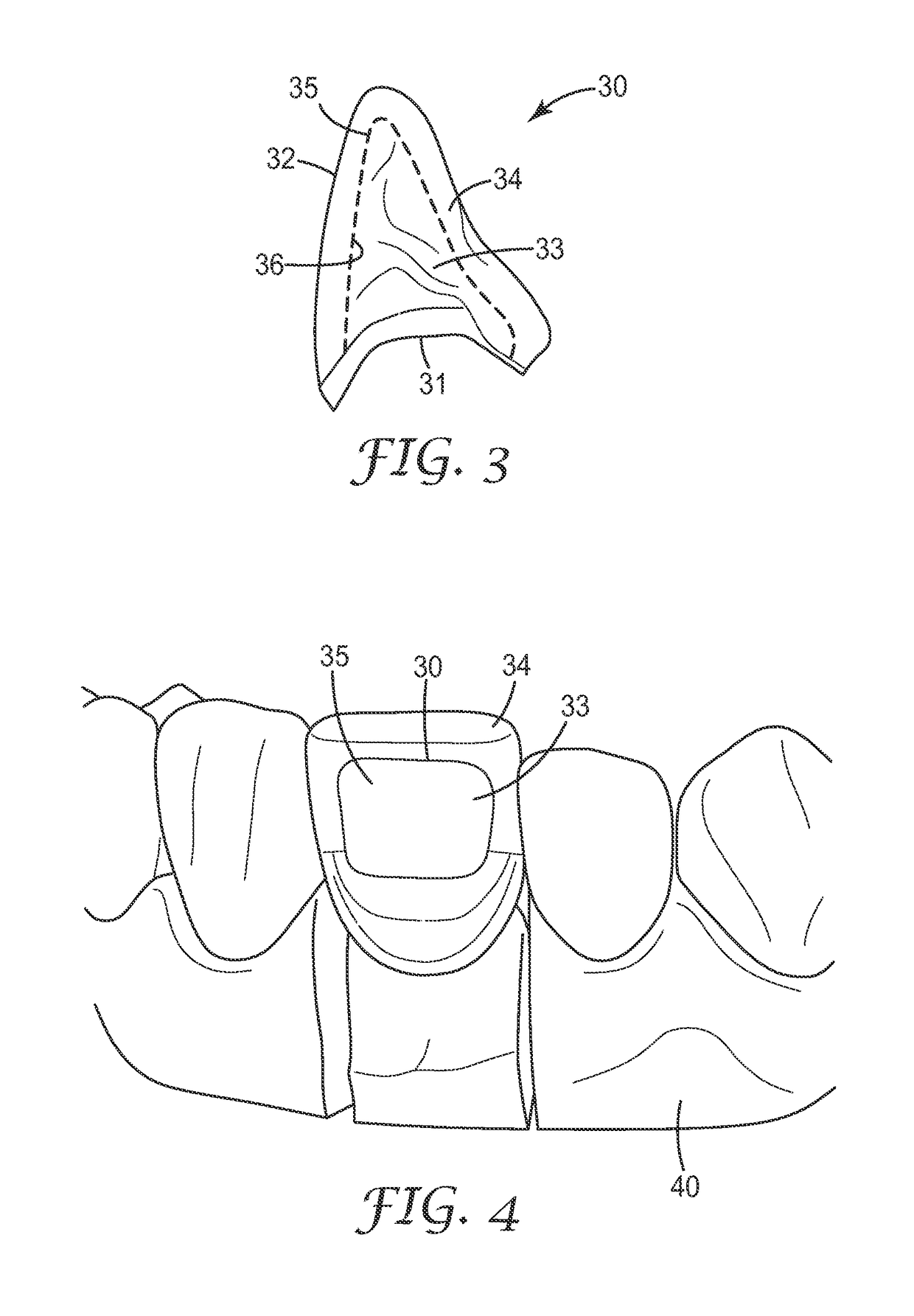

Apparatus and kit for an oral appliance and method for using same

ActiveUS20170000643A1Function increaseSimple structureOthrodonticsSnoring preventionOral applianceDentistry

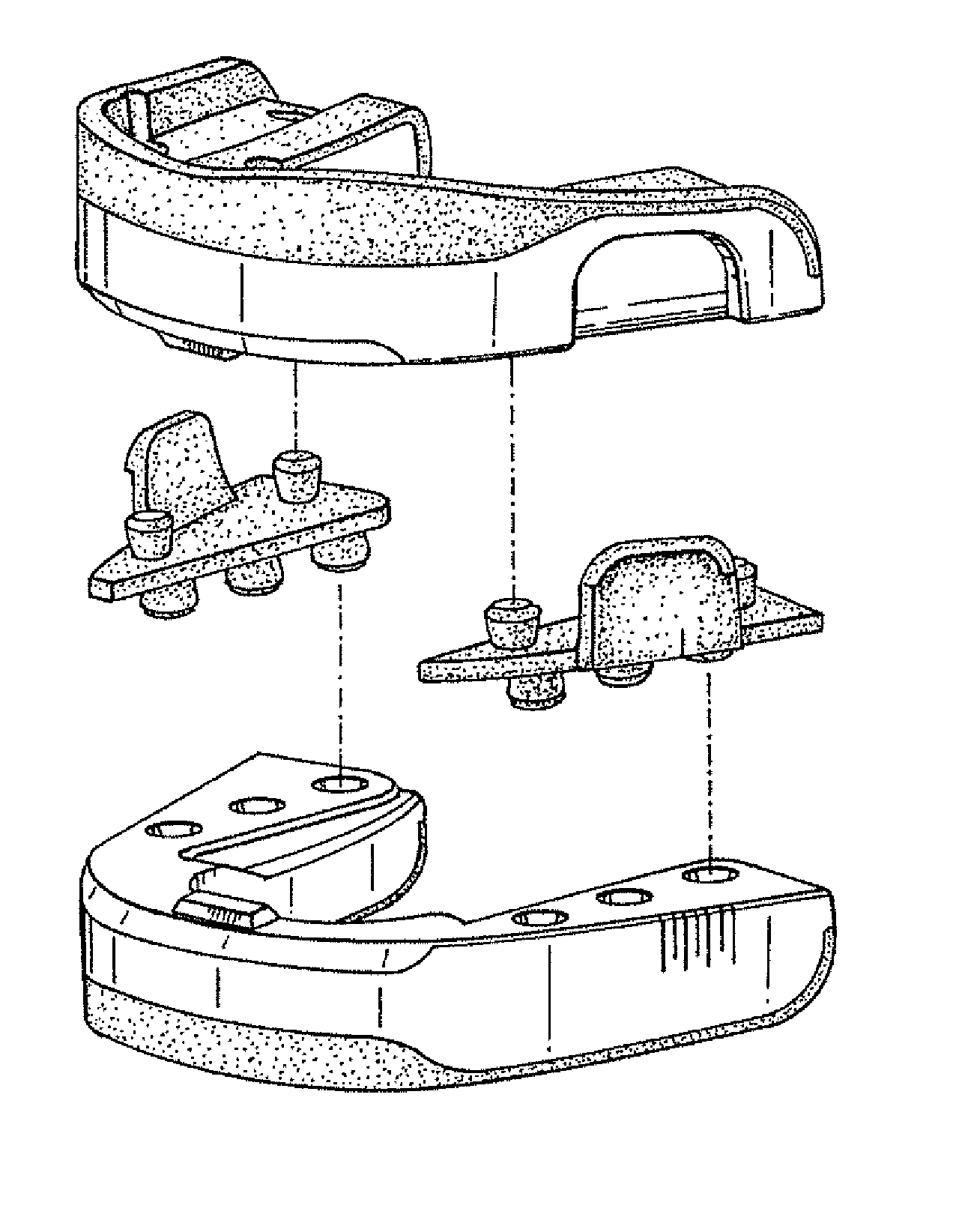

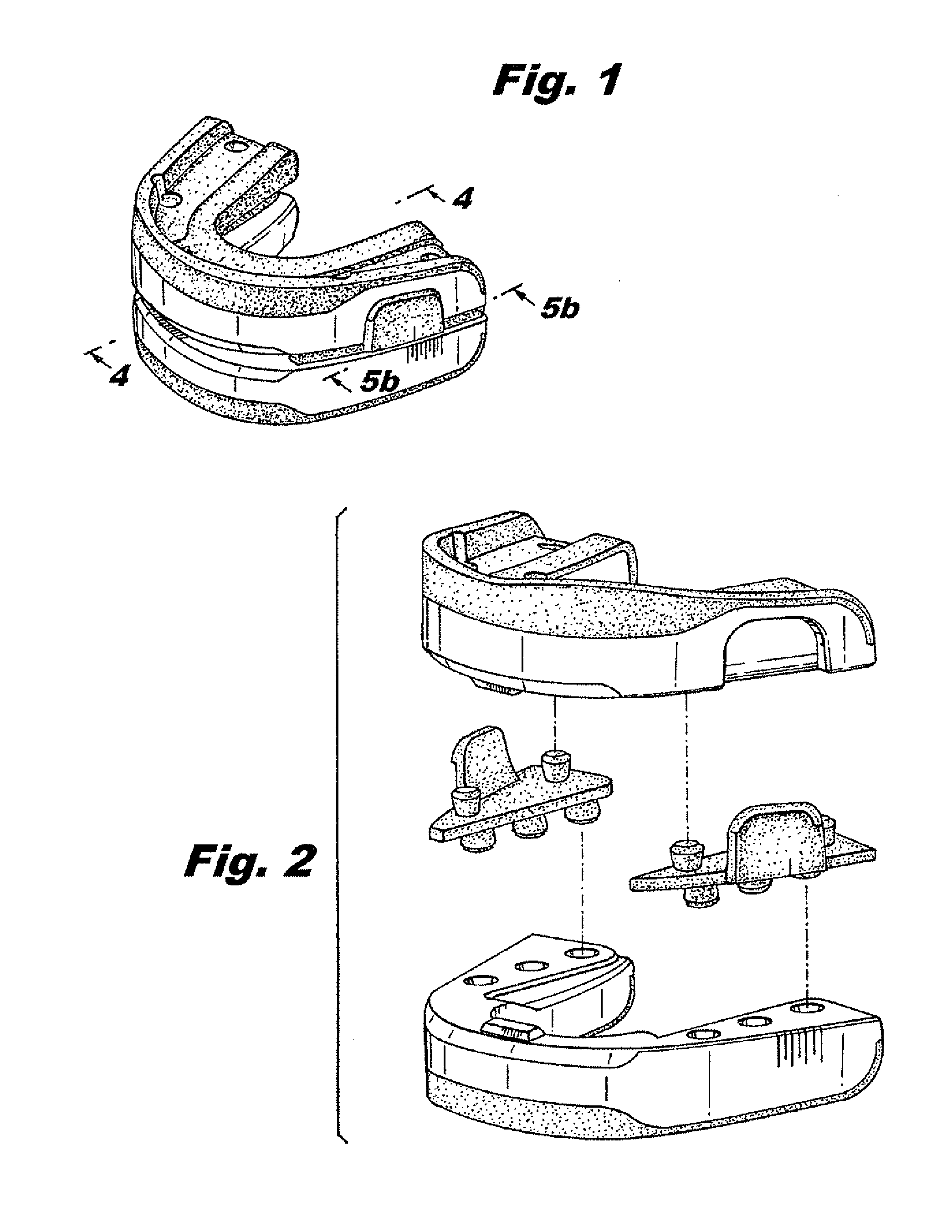

An oral appliance and kit therefor is disclosed. The oral appliance may include generally U-shaped upper and lower body members and a pair of adjustment plates or spacers for removably connecting the upper body member with the lower body member. The generally U-shaped upper and lower body members are adapted to be positioned over at least a portion of first and second arches of teeth, respectively, with the spacers having a system of pins or pegs for adjustably repositioning the upper body member with respect to the lower body member. The upper and lower body members are further configured to provide a lingual-less open space between the upper and lower body members to accommodate a tongue in a relaxed state. The disclosed oral appliance, system and kit therefor is configured for use in correcting the misalignment of a user's jaw.

Owner:GELB MICHAEL +1

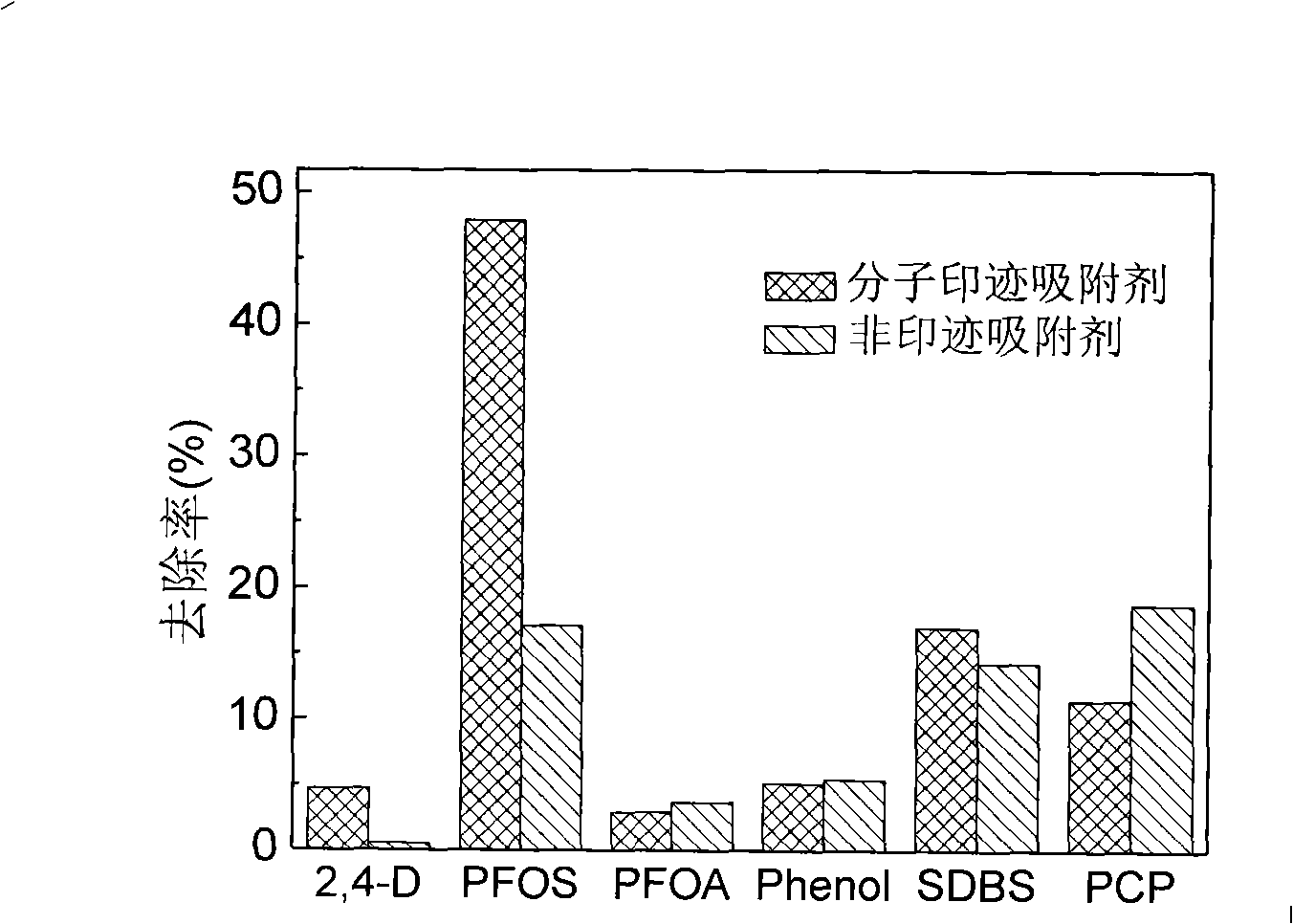

Preparation of chitosan molecular imprinting adsorbing agent

InactiveCN101298039AEasy to prepareAvoid grindingOther chemical processesWater/sewage treatment by sorptionFreeze-dryingSorbent

The invention provides a preparation method for a print adsorbent of chitosan molecules, which relates to a preparation method for an adsorbent that can selectively remove perfluorooctane sulfonate (PFOS) in water. The preparation method adopts a molecular imprinting technique to construct a plurality of specific adsorption sites and the worthy adsorbent has remarkable selectivity adsorption to the PFOS in water. The method takes chitosan as raw material to prepare micro-cross linking chitosan beads; then the chitosan beads are printed with template molecules PFOS for 5 to 24 hours in an acid water solution, a mass ratio between the template molecules and the micro-cross linking chitosan beads is 0.005 to 0.06: 1, and reaction with a cross linker is carried out for 2 to12 hours after printing; the mass ratio between the volume of the cross linker and the micro-cross linking chitosan beads after being printed is 0.0125 to 0.119ml / g; finally, an organic solvent is used for eluting for 1 to 8 hours and the print adsorbent of chitosan molecules is obtained after freeze-drying. The adsorbent is suitable for adsorbing and removing PFOS in complicated water substances and is characterized by strong selectivity and being able to be reused.

Owner:TSINGHUA UNIV

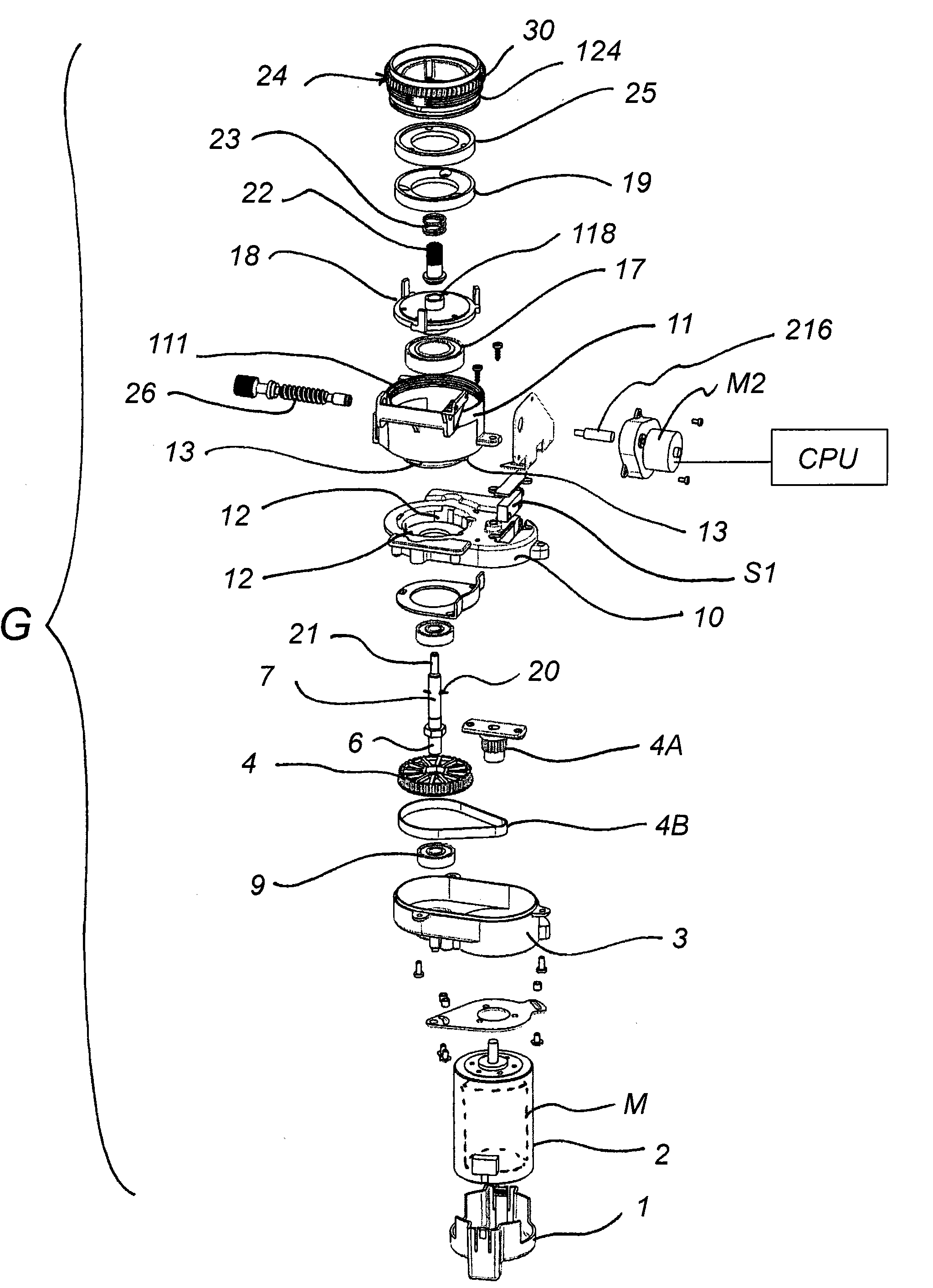

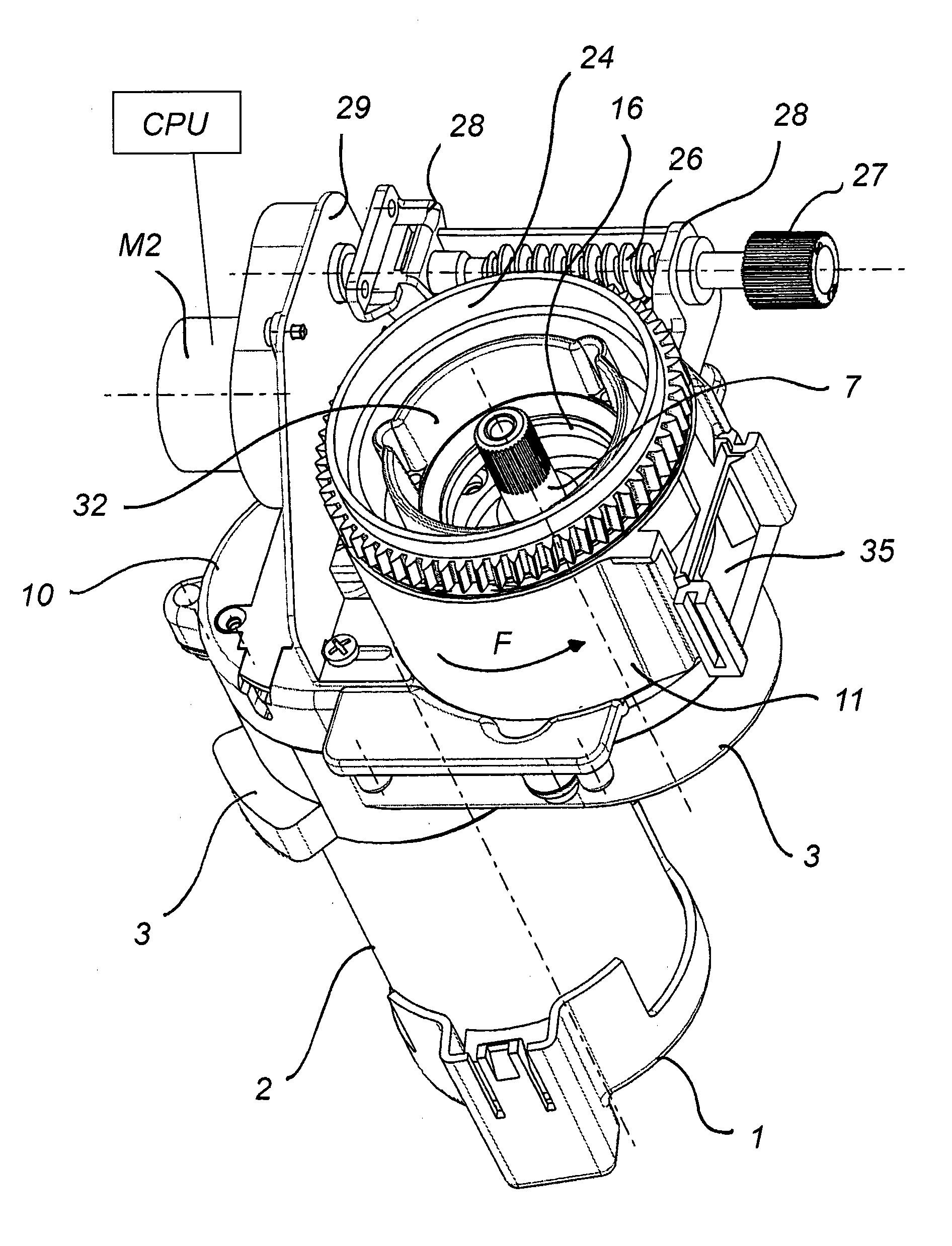

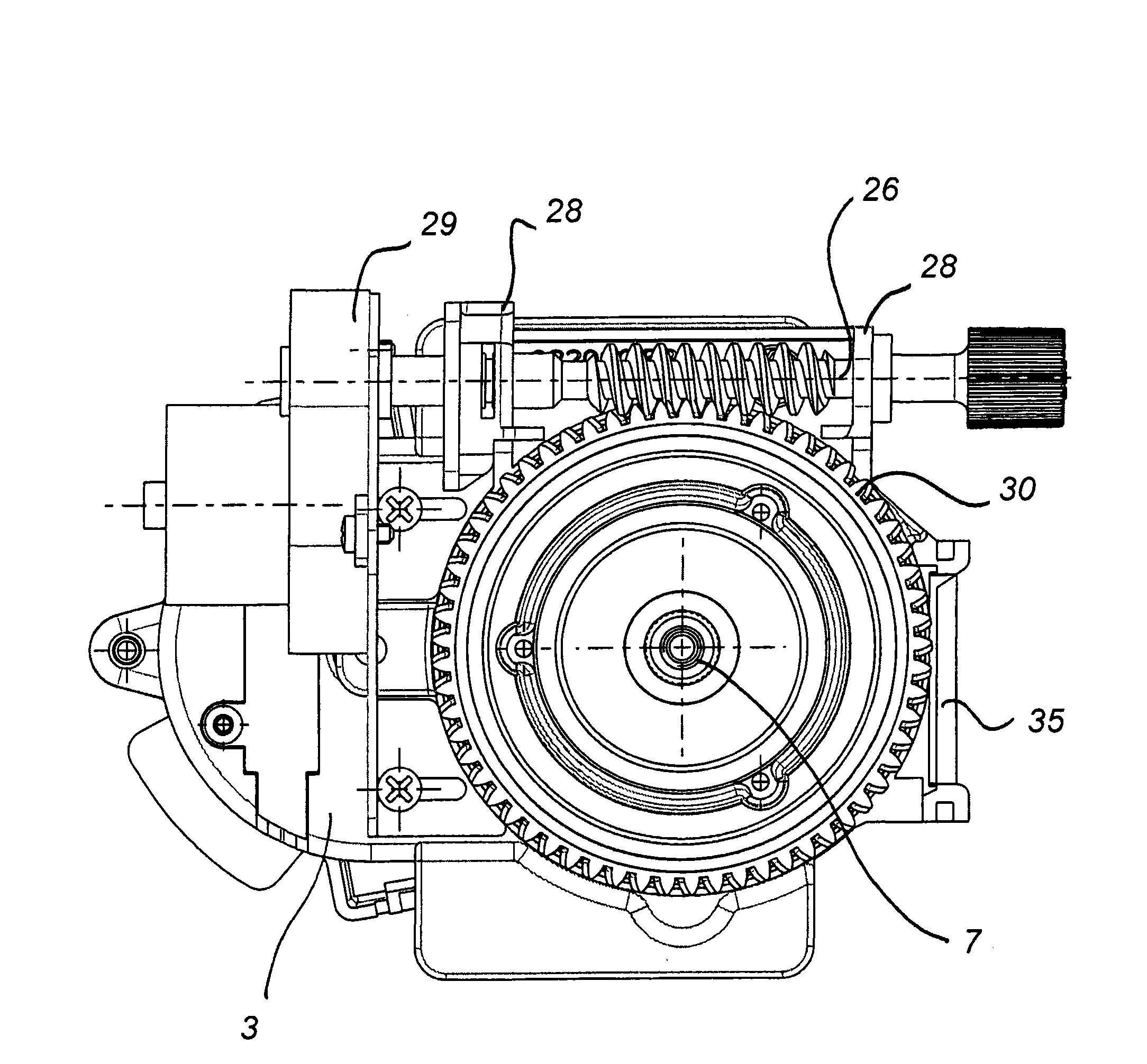

Device for grinding coffee or other alimentary substances

A device for the grinding of coffee, for instance in (semi)automatic machines for the preparation and the dispensing of drinks, comprising a housing (11), inside which are positioned at least two milling heads (19, 25) of which at least one (19) is revolving, means (2) of driving said at least one revolving milling head (19), an inlet (32) for feeding the coffee between the milling heads (19, 25)and an exit (35) for the ground coffee. Advantageously, the housing (11) and the milling heads (19, 25) internal to it are coupled to the means of driving (2) through an insert-and-lock joint (12, 13, 18, 218, 20, 120) that allows their rapid removal and reassembly without the aid of tools. Preferably the device includes means of regulating the relative distance between the milling heads and at least one sensor (S) for the measurement of such distance and / or a sensor (S1) of the speed of rotation of the drive shaft.

Owner:REHVENDORS

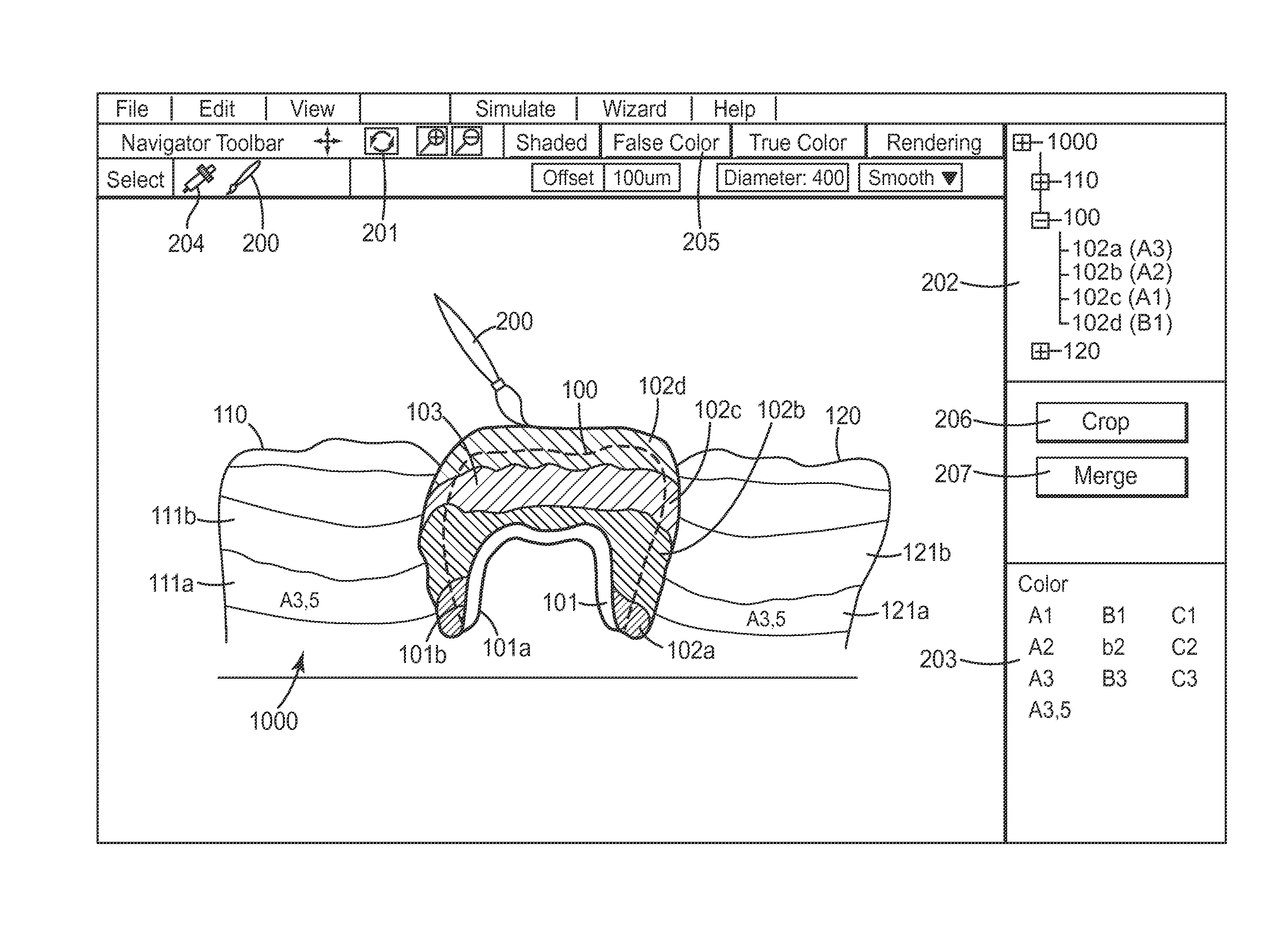

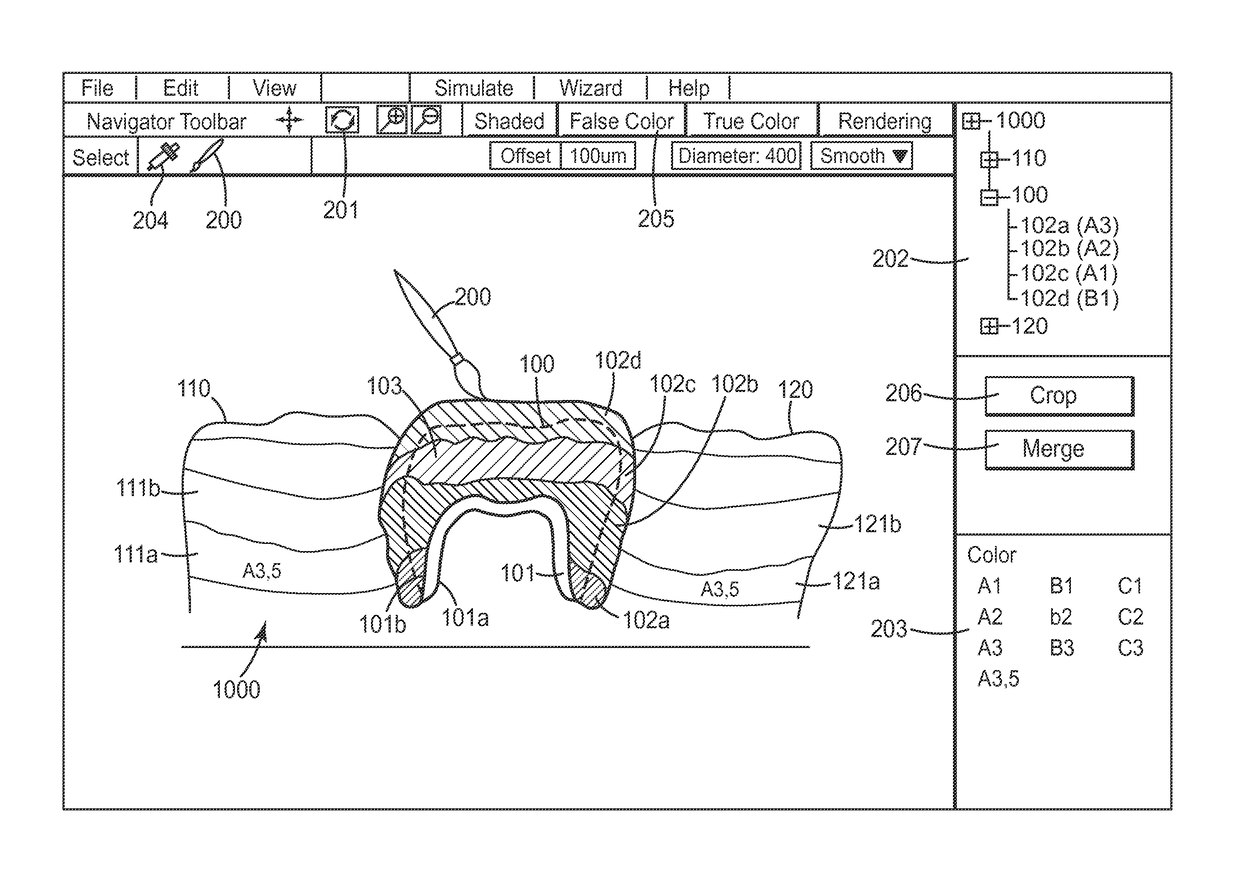

Method and system for making a dental restoration

ActiveUS20140372085A1Easy to manufactureMaximize precisionMechanical/radiation/invasive therapiesArtificial teethDentitionDental restoration

A method and system for making a dental restoration are provided. The method comprises the step of providing a computer model of a three-dimensional reference surface that is based for example on a tooth structure of a tooth to be restored in a patient's dentition. The method further comprises the steps of visualizing the three-dimensional reference surface, providing a user operable virtual material deposition tool, and using the virtual material deposition tool to deposit a plurality of differently colored layers on the reference surface. The system provides functionality to perform the method of the invention. The invention preferably helps maximizing optical and geometrical quality in a dental restoration.

Owner:3M INNOVATIVE PROPERTIES CO

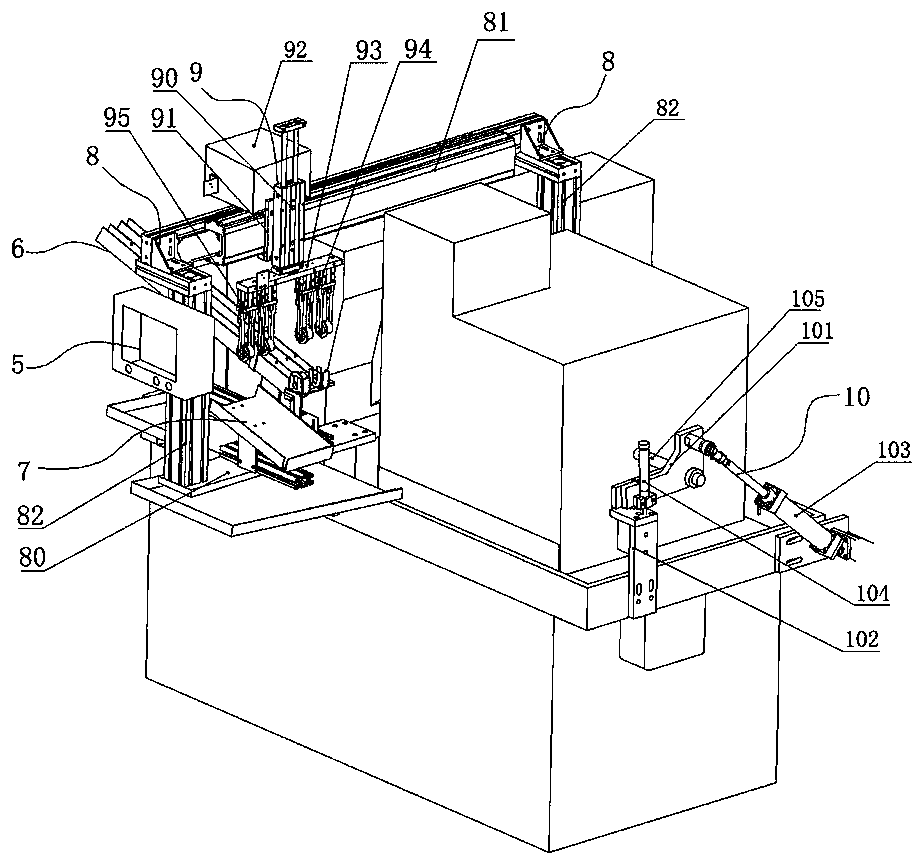

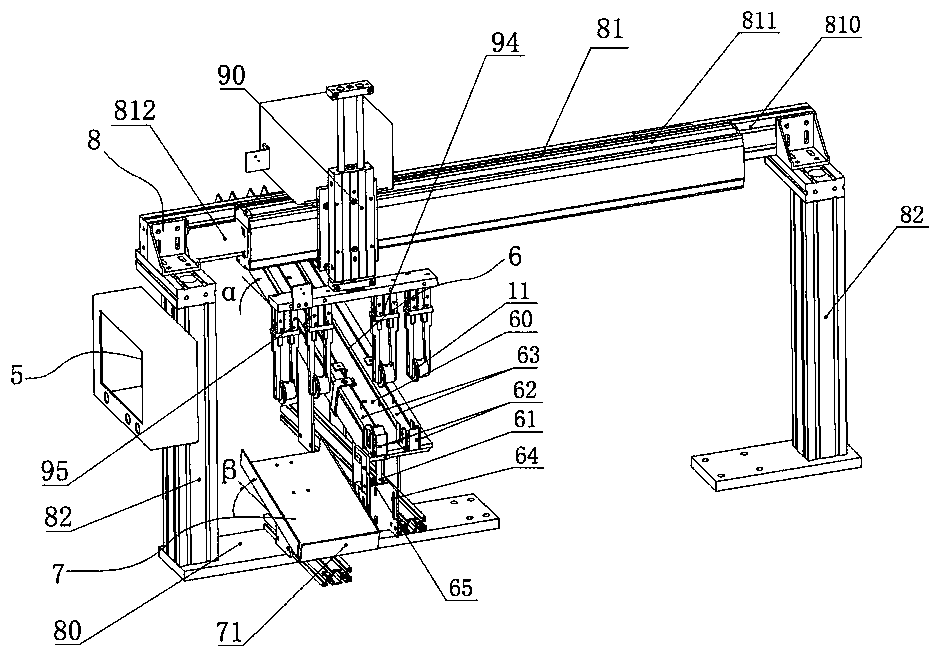

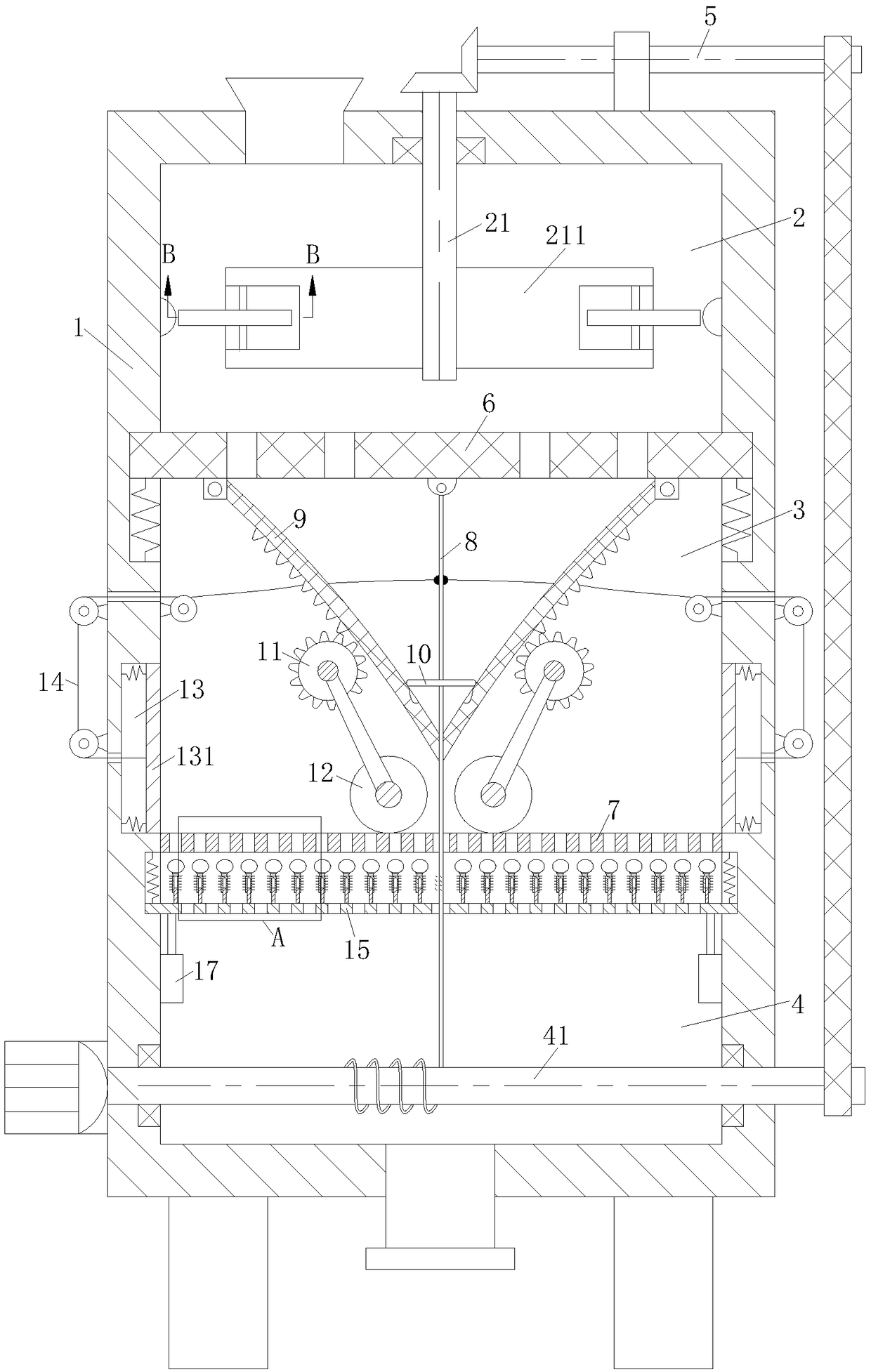

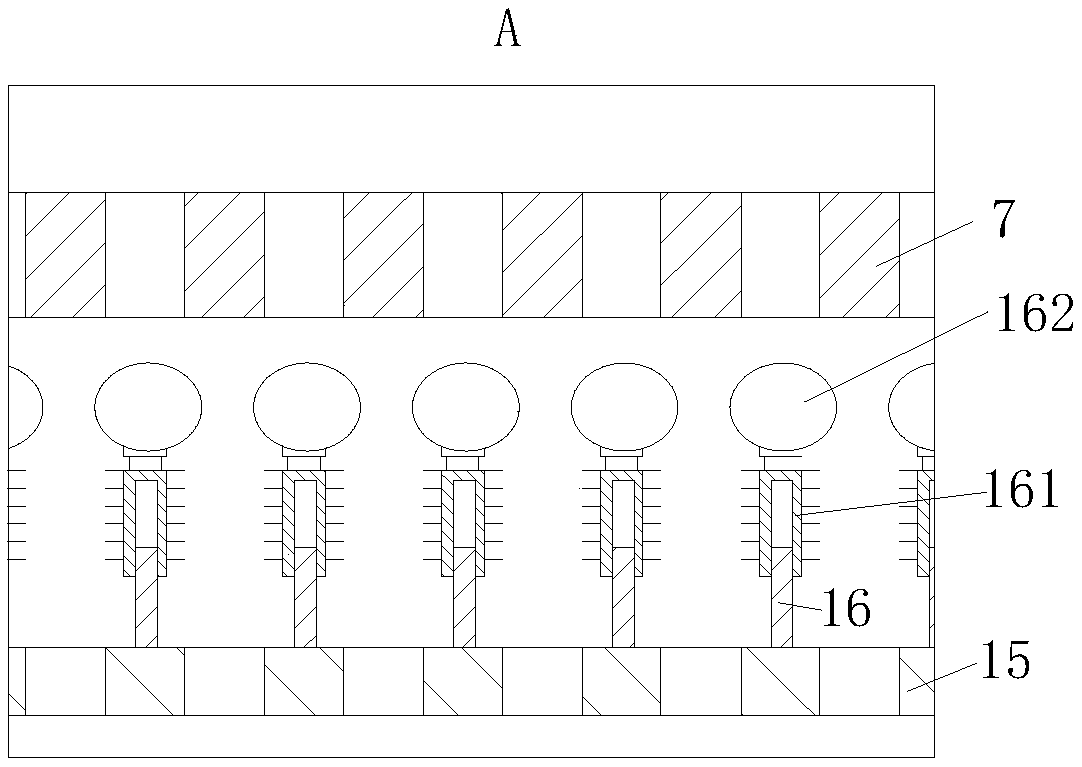

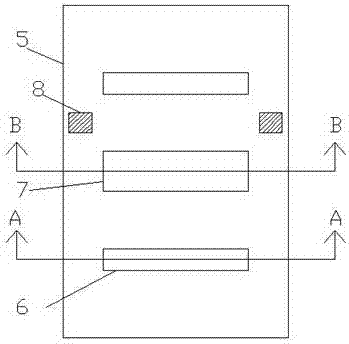

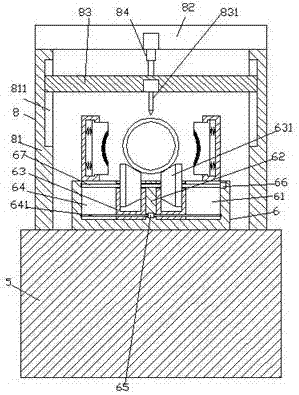

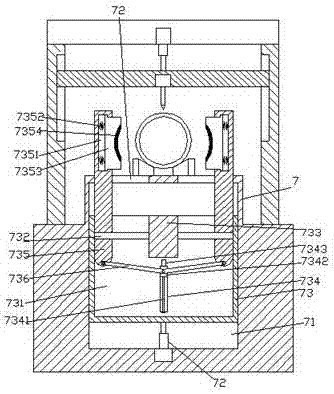

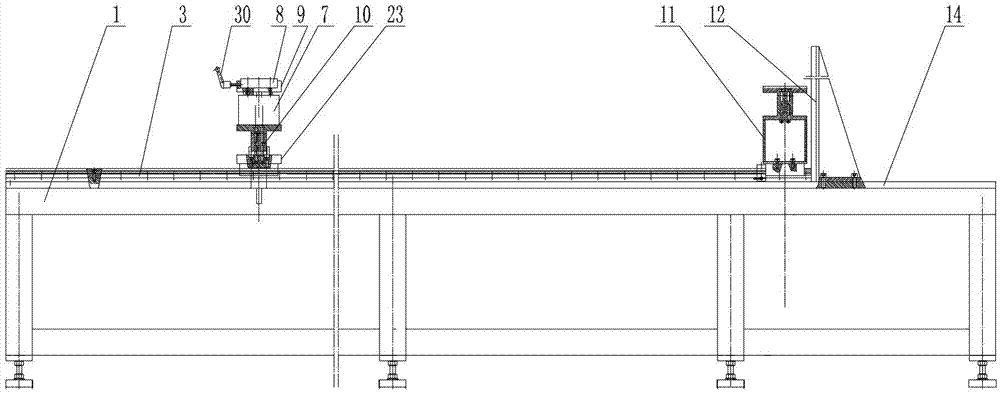

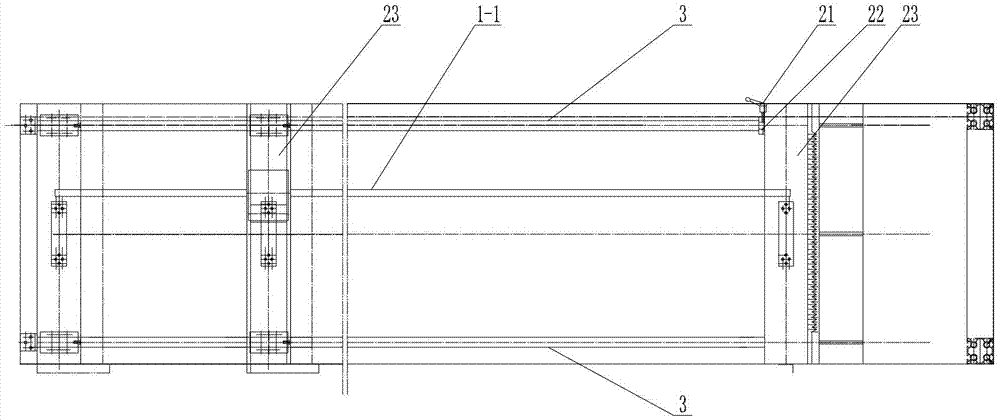

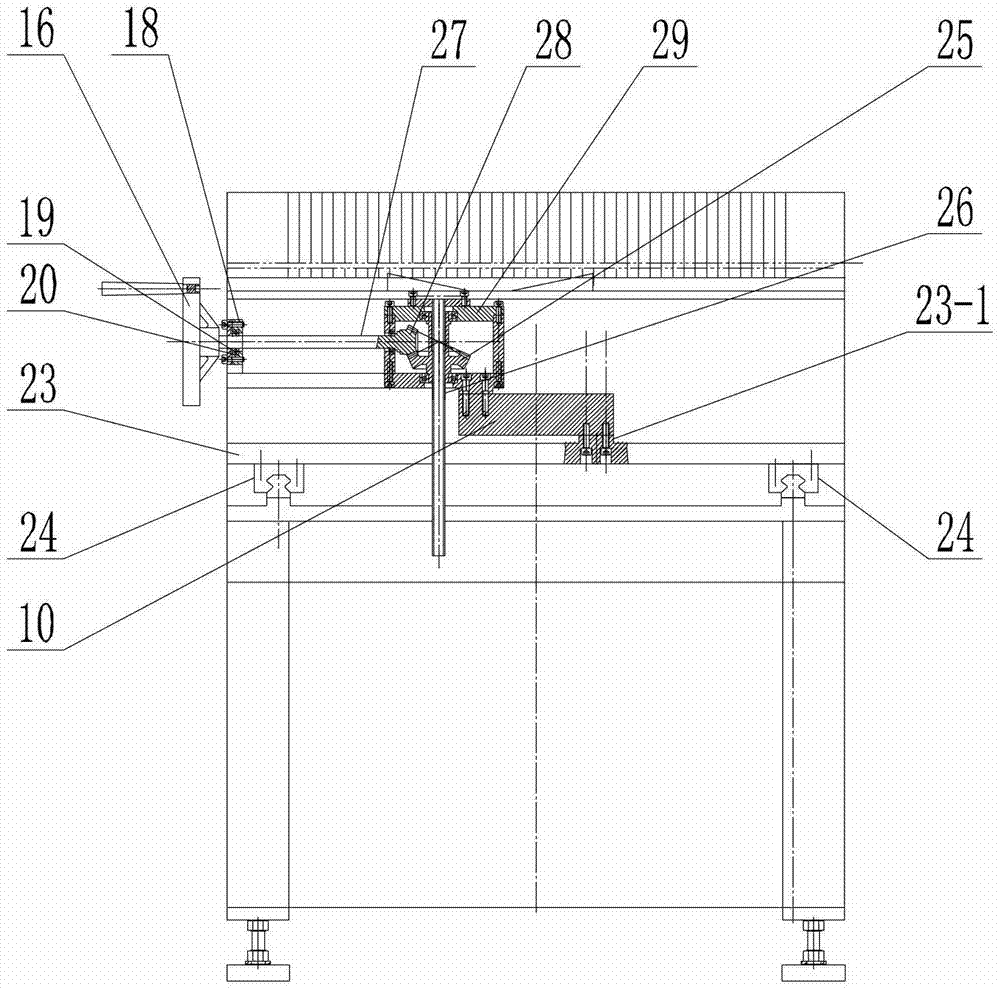

Machining process of loading and unloading conveying device and step shaft sleeves of centerless grinding machine

ActiveCN108436627ASwing neatlyGuarantee processing qualityRevolution surface grinding machinesEngineeringMachining process

The invention relates to the field of machining of centerless grinding machines, in particular to a machining process of a loading and unloading conveying device and step shaft sleeves of a centerlessgrinding machine. The centerless grinding machine comprises a grinding machine base, a grinding wheel, an adjusting wheel and a workpiece bracket; the loading and unloading conveying device comprisesa control cabinet, a feeding mechanism, a discharge bin, a loading and unloading conveying mechanism, a loading and unloading clamping mechanism and a pushing device; the control cabinet is electrically connected with the feeding mechanism, the loading and unloading conveying mechanism and the loading and unloading clamping mechanism; the feeding mechanism takes the charge of tidily placing the step shaft sleeves in sequence; the loading and unloading conveying device is an operating procedure of supporting the loading and unloading clamping mechanism, so that the step shaft sleeves are smoothly loaded and unloaded on the grinding machine, and the manual loading time is saved; through cooperation of the pushing device and the discharge bin, full-automatic grinding is realized, so that thelabor intensity of operators is effectively reduced; and a loading clamping hand and an unloading clamping hand can once clamp at least two step shaft sleeves, so that one half of the machining timeis saved, the labor productivity is improved, and the batch production is achieved.

Owner:CHONGQING ELECTROMECHANICAL VOCATIONAL INST

Processing process of ball bag-shaped stainless steel retainer

InactiveCN101913061AGood benchmarkGood surface qualityTurning toolsBoring/drilling machinesDrill holeEngineering

The invention belongs to the technical field of bearing processing and provides a processing process of a ball bag-shaped stainless steel retainer. The process comprises the following steps of: roughly turning end surfaces, the inner diameter and the outer diameter and cutting off; turning cut-off surfaces; softly grinding the outer diameter; softly grinding the two end surfaces; fine turning the inner diameter; drilling rivet holes and installing rivets; finally turning the outer diameter; finally turning the inner diameter; drilling; and boring. The invention has the advantages of simple process flow, convenient processing, reliable quality, higher efficiency and low cost. The parallel difference of the end surfaces can be guaranteed within 0.015mm by adopting the process, and the roughness is guaranteed within 0.5mum, thus good size and surface precision are obtained.

Owner:LUOYANG LYC BEARING

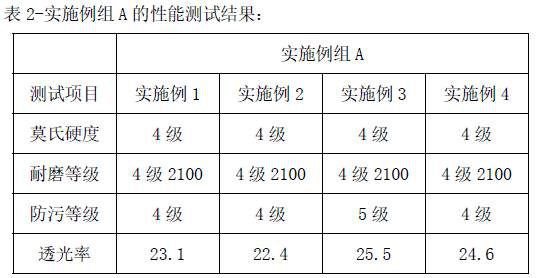

Wear-resistant glaze for glazed bricks, and preparation method thereof

The invention discloses a wear-resistant glaze for glazed bricks, and a preparation method thereof. The wear-resistant glaze is prepared from raw glaze powder, No.1 frit powder and No.2 frit powder, wherein the raw glaze powder comprises, by weight, 8-12% of kaolin, 10-18% of calcined kaolin, 12-20% of quartz, 12-20% of dolomite, 8-15% of calcined talc, 8-15% of nepheline, 5-10% of zinc oxide, 3-6% of barium sulfate and 6-12% of strontium carbonate. The raw materials of the No.1 frit powder comprise zircon sand and barium sulfate, and raw materials of the No.2 frit powder comprise kaolin, calcined talc, fluorite and barium sulfate. The glaze disclosed by the invention contains barium sulfate, so that the color development condition can be improved, the problem of color difference of red and yellow ceramic ink-jet inks during firing of a product is avoided, and the transparency of the wear-resistant glaze is improved under the condition that the hardness and the wear resistance are notinfluenced.

Owner:佛山市东鹏陶瓷发展有限公司 +1

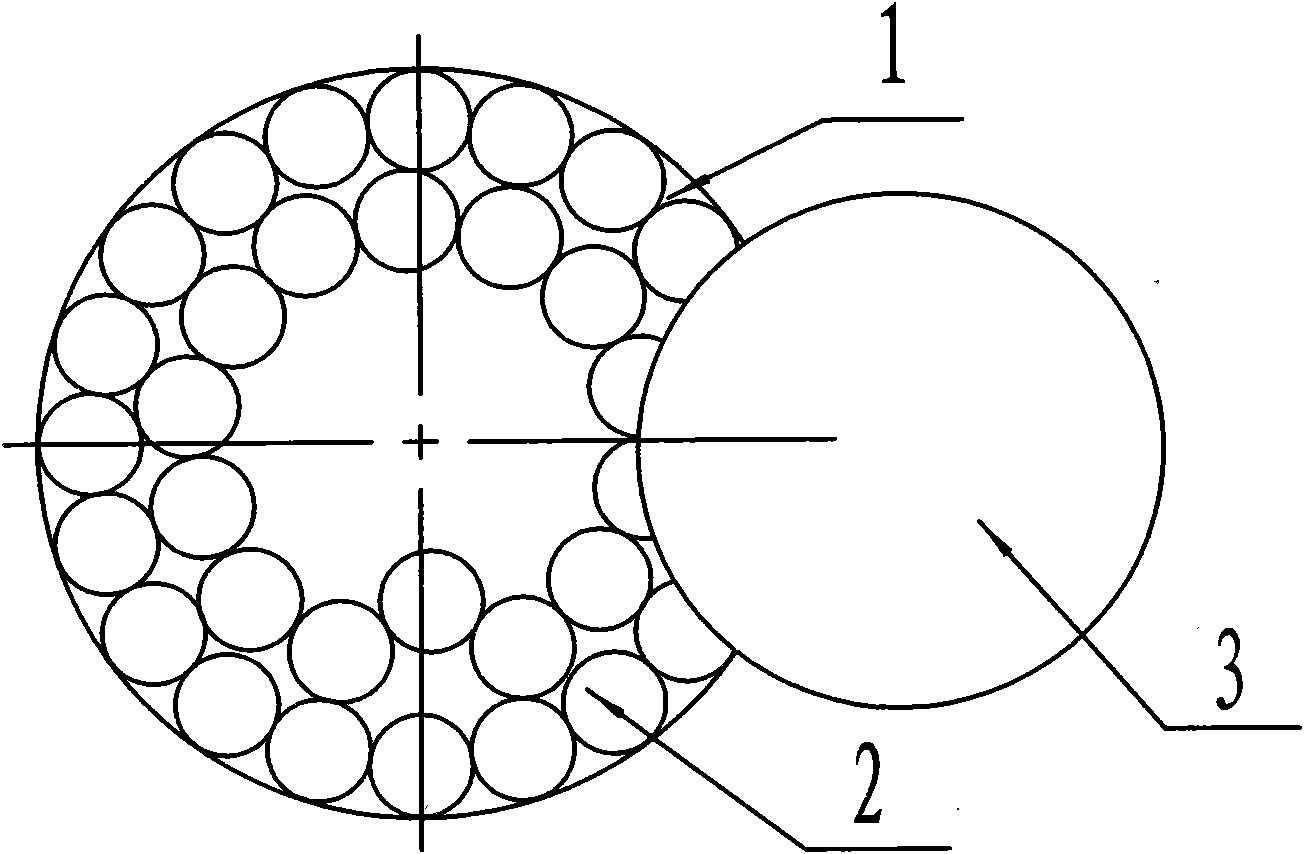

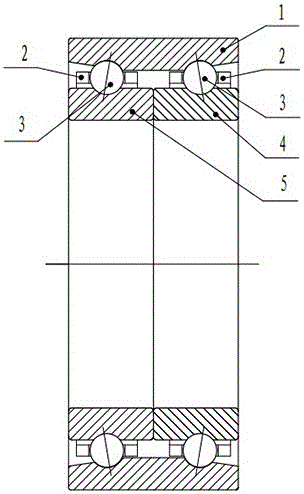

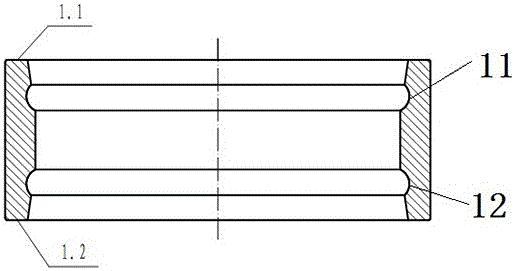

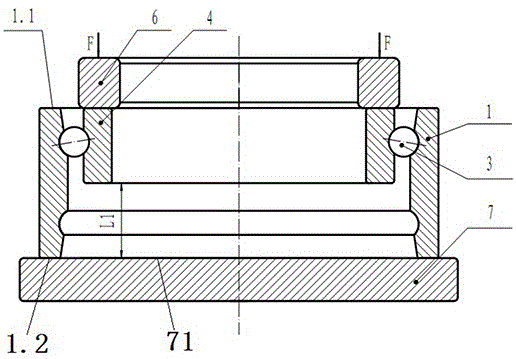

Back-to-back assembly type biserial angular contact ball bearing and assembling method thereof

ActiveCN105041855AIncrease stiffnessSimplify the installation processRolling contact bearingsBearing componentsBall bearingSteel ball

The invention provides a back-to-back assembly type biserial angular contact ball bearing and an assembling method thereof. The back-to-back assembly type biserial angular contact ball bearing comprises an outer ring, wherein a first inner channel and a second inner channel are formed in the inner circumferential surface of the outer ring, a first inner ring and a second inner ring are correspondingly arranged in the outer ring in a sleeved mode, and the two inner rings are arranged in sequence in the front-back direction and are in contact fit in an abutting mode; an outer channel is formed in the outer circumferential surface of each inner ring, steel balls are correspondingly arranged in the outer channels of the two inner rings and the two inner channels of the outer ring, and the hole wall at each of the two ends of the outer ring is of a conical structure which becomes smaller from outside to inside gradually to enable the two axial end faces of the outer ring to be narrow-side end faces arranged backing onto each other. Due to the fact that an inner partition ring and an outer partition ring are omitted, grinding of the inner partition ring and the outer partition ring is avoided, the assembly type biserial angular contact ball bearing pre-tightening force fitting technology is simplified, axial pre-tightening force adjusting time is shortened, and pre-tightening force adjusting efficiency is improved. Due to the adoption of the integral outer ring, the whole back-to-back assembly type biserial angular contact ball bearing can be installed easily and efficiently, complicated adjusting steps are omitted, and installation difficulty is reduced.

Owner:LUOYANG BEARING RES INST CO LTD

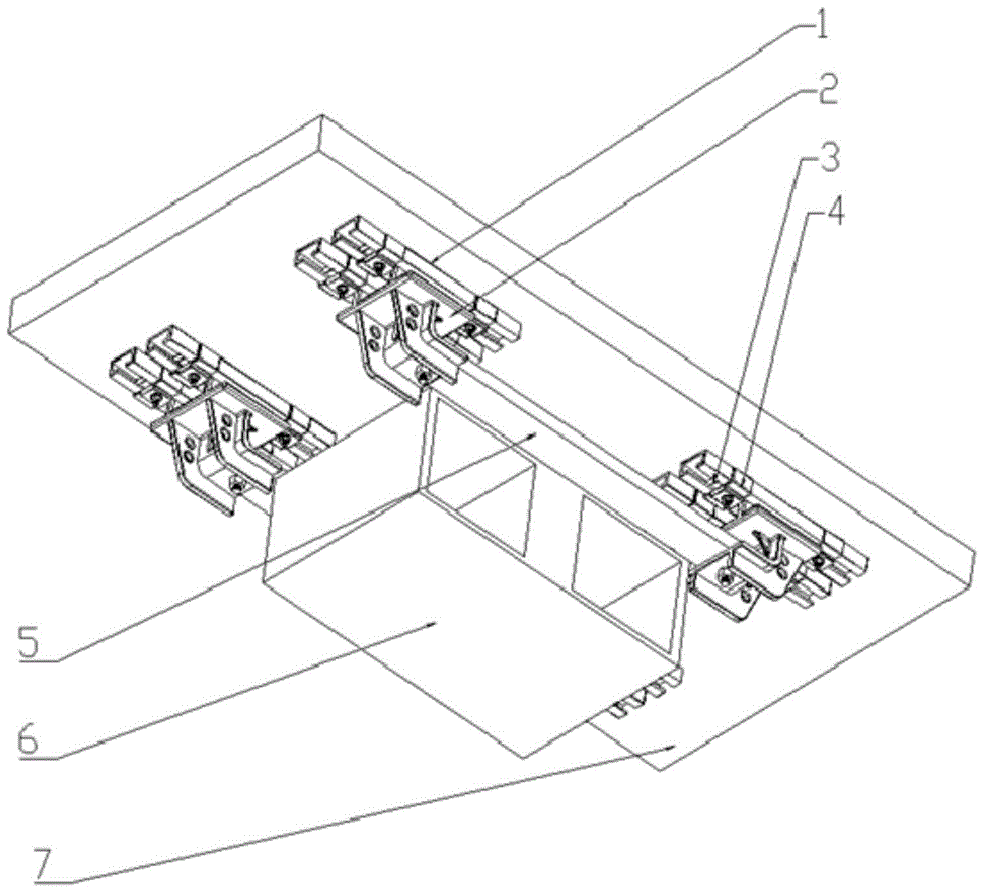

Mounting method and mounting bases for locomotive underframe parts

The invention discloses a mounting method and mounting bases for locomotive underframe parts, and belongs to the technical field of railway locomotives. In order to mount and dismount the parts on a locomotive body underframe conveniently and adjust the positions of the locomotive underframe mounting parts, sliding rails are welded to the locomotive body underframe in advance, mounting beams are welded on one part to be mounted, the mounting bases are arranged at the ends of the mounting beams, then guide rails on the mounting bases are matched with the sliding rails, and the mounting bases are fixed by limiting stopping blocks and positioning stopping blocks. The mounting method is suitable for smoothly mounting most of locomotive underframe parts, the weights of the mounted parts are borne by a locomotive body and the mounting bases, and bolts are prevented from bearing transverse shear force in the locomotive operation process. The sliding rail type mounting structure is used by the locomotive underframe parts, the positions of the locomotive underframe mounting parts can be adjusted easily, the mounted parts can be prevented from abrading pipelines and cables under a locomotive, and therefore the operation safety of the locomotive is improved.

Owner:CRRC DALIAN CO LTD

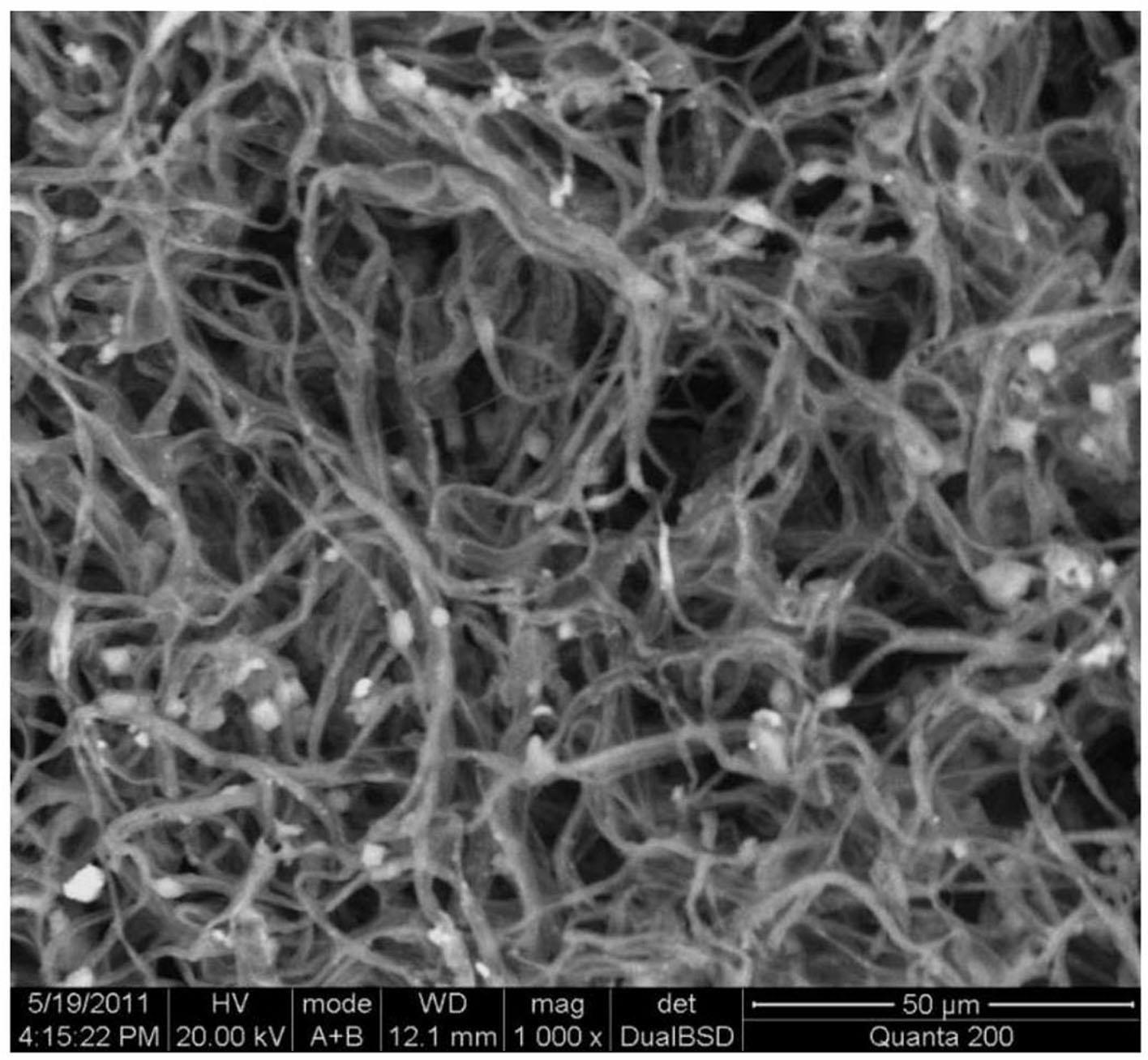

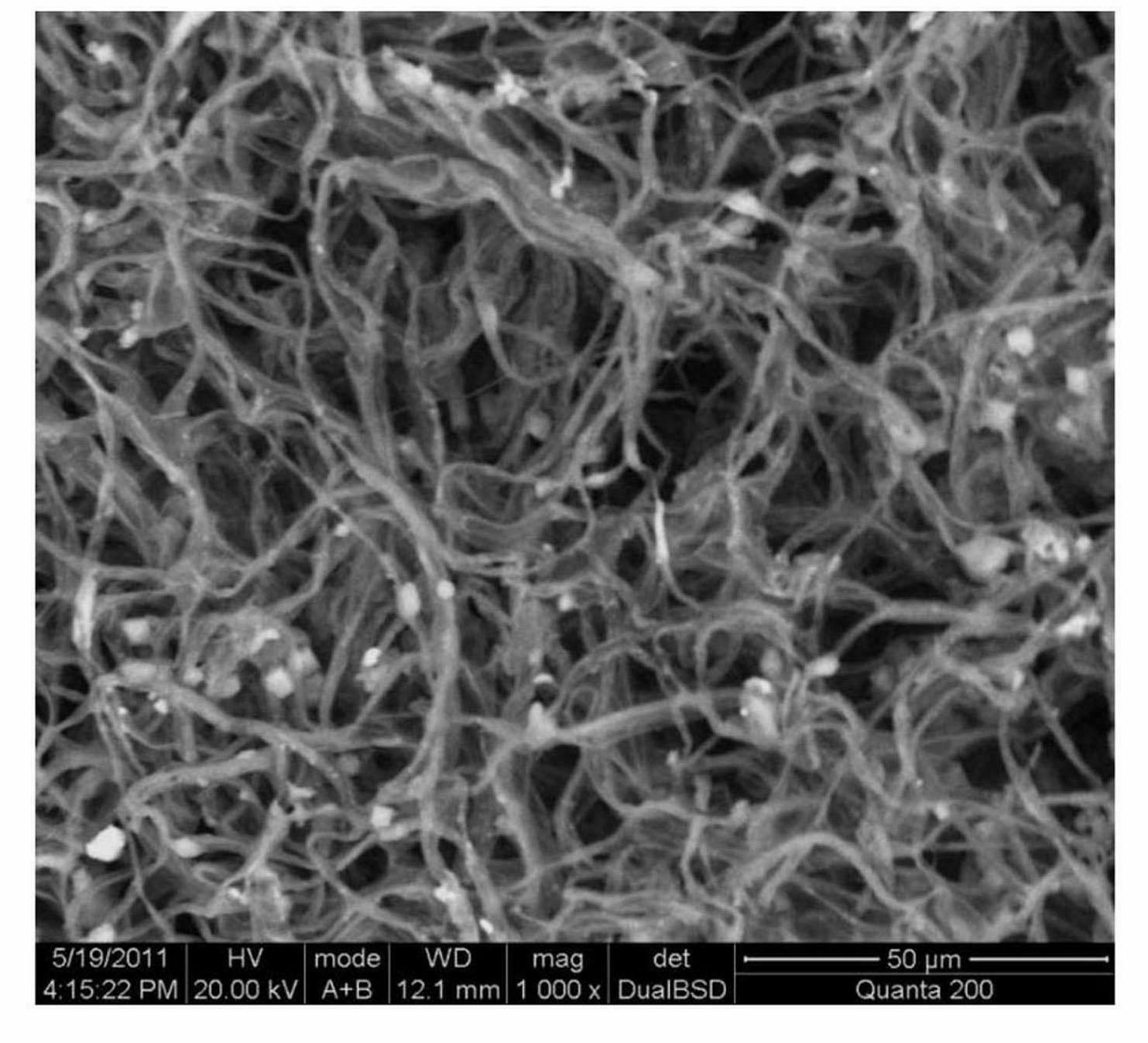

Compound magnetic biological adsorbent and preparation method for same

InactiveCN102614839ASimple manufacturing processEasy to makeOther chemical processesMicroorganism based processesBiotechnologySporeling

The invention discloses a compound magnetic biological adsorbent, which is characterized in that dry mycelia of white rot fungi are used as a carrier, the mycelia are wound to a ball, Fe3O4 nano particles and calcium alginate are embedded into the ball, and the calcium alginate serving as immobilized medium is tightly connected together with the Fe3O4 nano particles. The preparation method for the adsorbent includes the steps: inoculating spore suspension of the white rot fungi into aseptic mixed liquid of the Fe3O4 particles and the calcium alginate under the aseptic condition, mixing uniformly, dropwise adding the mixed liquid of one volume into aseptic CaC12 solution of 4-10 volumes, standing at the room temperature to obtain reaction liquid including Fe3O4-calcium alginate-white-rot fungus microspheres, and performing immobilized culture so as to obtain the compound magnetic biological adsorbent after culture is completed. The compound magnetic biological adsorbent has the advantages of high adsorption capacity, high adsorption speed, high reuse rate, cleanliness, no pollution and the like.

Owner:HUNAN UNIV

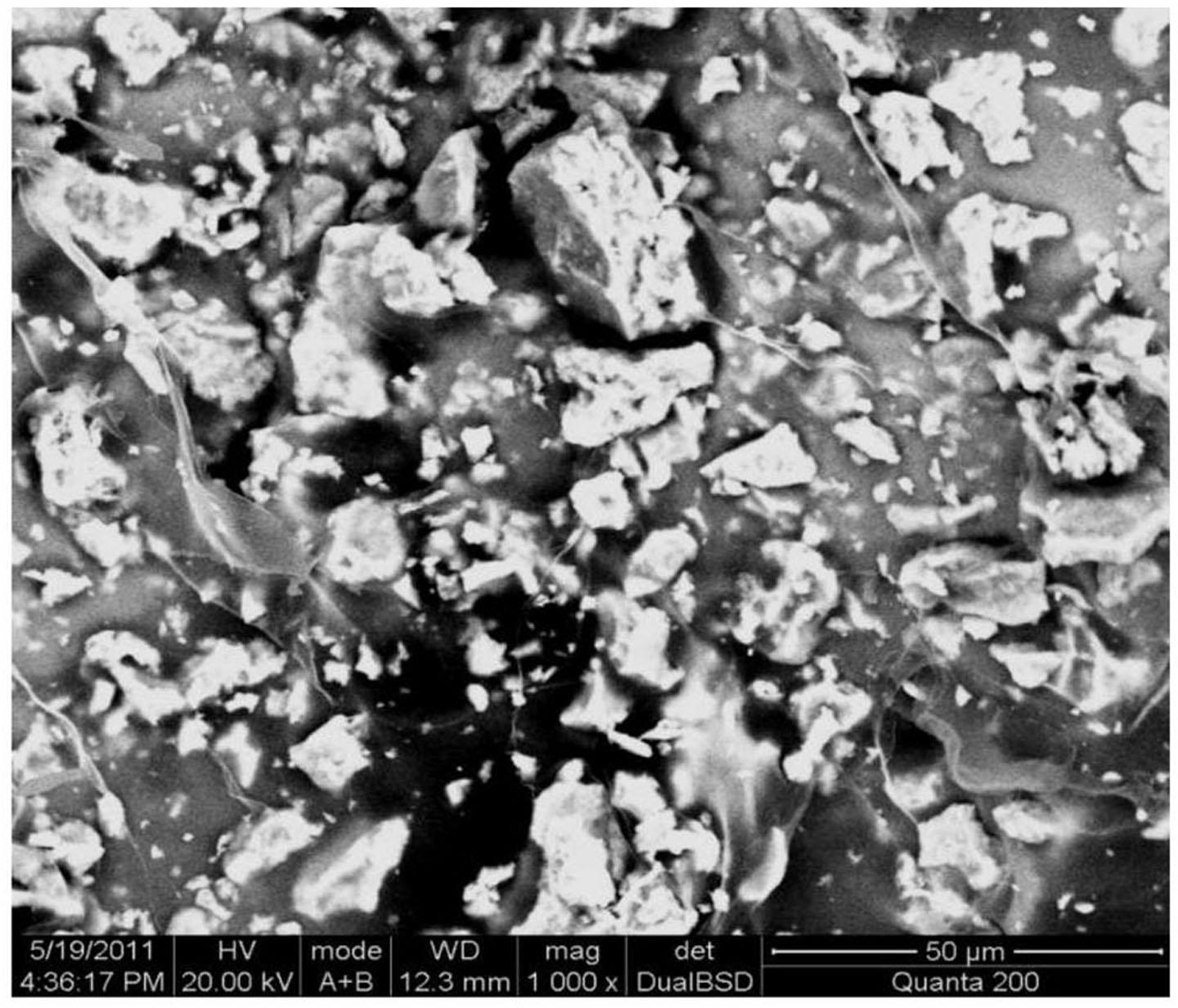

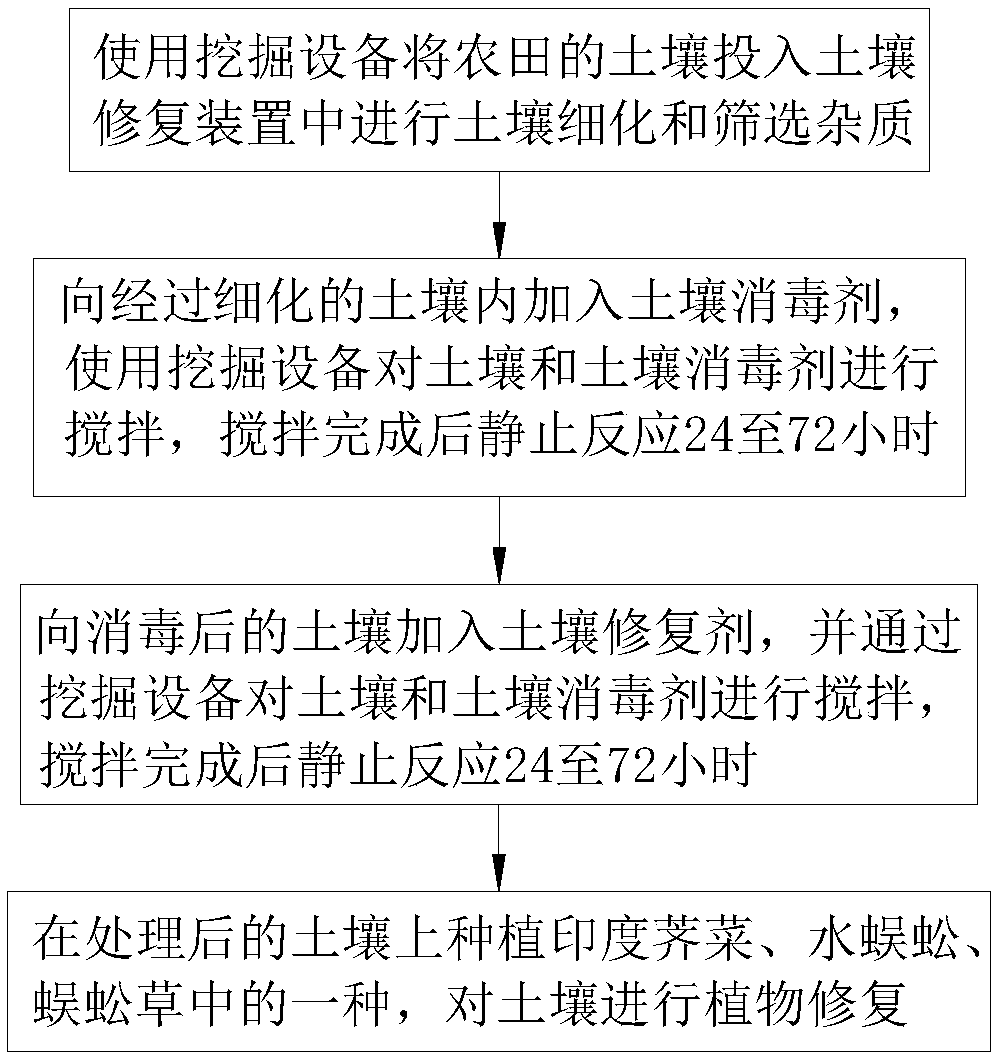

Efficient soil remediation method

ActiveCN109500073AImprove soil qualityReduce heavy metal contentContaminated soil reclamationGrain treatmentsEngineeringLeather belt

The invention belongs to the technical field of soil remediation, and particularly relates to an efficient soil remediation method. A soil remediation device adopted in the efficient soil remediationmethod comprises a box body, a motor and a controller; the box body is internally provided with a crushing cavity, a grinding cavity and a collecting cavity from top to bottom in sequence; a rotary rod is vertically arranged on the middle part of the top wall of the box body, a rotary shaft is horizontally and rotatably installed at the bottom of the box body, a soil inlet is formed in one side atthe top of the box body, and a transmission shaft is arranged on the other side at the top of the box body; crushing plates are symmetrically arranged at the bottom end of the rotary rod, and the topend of the rotary rod extends out of the top wall of the box body and is fixedly connected with a first bevel gear; transmission between the rotary shaft and the transmission shaft is carried out through a belt; a second bevel gear is fixedly connected to the other end of the transmission shaft, and the second bevel gear and the first bevel gear are subjected to transmission in a meshing mode; anelastic separation plate is arranged on the lower parts of the crushing plates; and a baffle is arranged on the lower part of the elastic separation plate. According to the efficient soil remediationmethod, soil is subjected to plant cultivating remediation, so that the heavy metal content in the soil is reduced, and the soil properties of the soil are improved.

Owner:东营市耀城弘丰农业科技有限公司

Nitrided silicon-vanadium-iron alloy and production method thereof

The invention belongs to the technical field of iron alloy, and specifically relates to nitrided silicon-vanadium-iron alloy and a production method thereof. The provided nitrided silicon-vanadium-iron alloy is composed of the following components in percent by weight: 25-55 wt% of vanadium, 11-26 wt% of nitrogen, 8-20 wt% of silicon, and the balance iron and unavoidable impurities. The provided production method for the nitrided silicon-vanadium-iron alloy comprises: crushing the raw material silicon-vanadium-iron alloy, reacting with nitrogen under high temperature, and cooling to obtain the nitrided silicon-vanadium-iron.

Owner:攀枝花市仁通钒业有限公司

Multi-type tap grinding machine

ActiveCN1954965APrevent grindingWill not alter or corrupt effective lengthOther manufacturing equipments/toolsEngineeringGrinding wheel

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

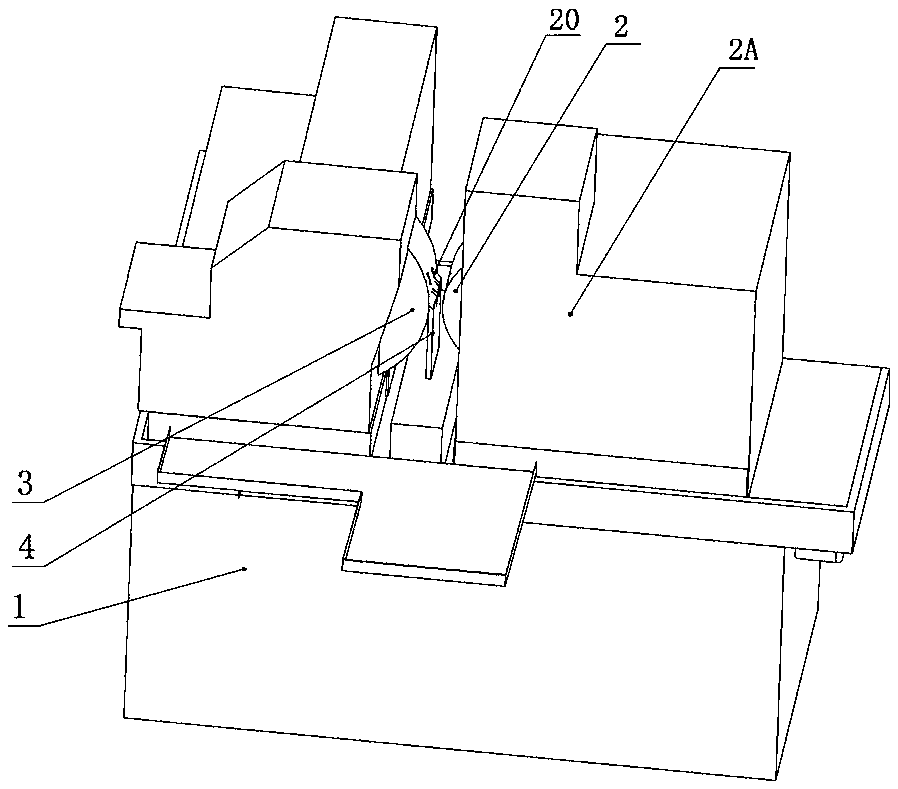

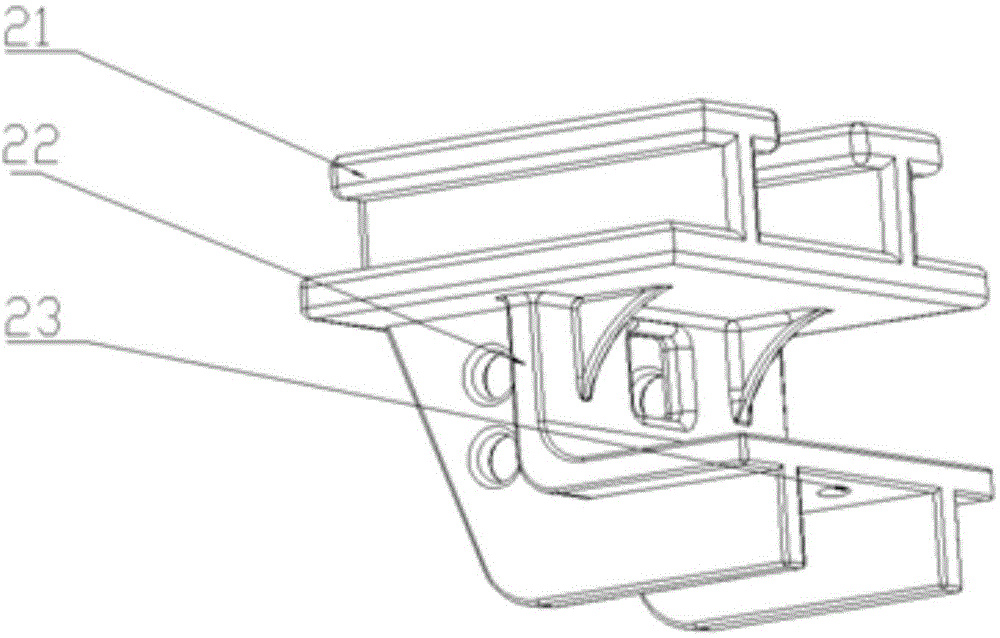

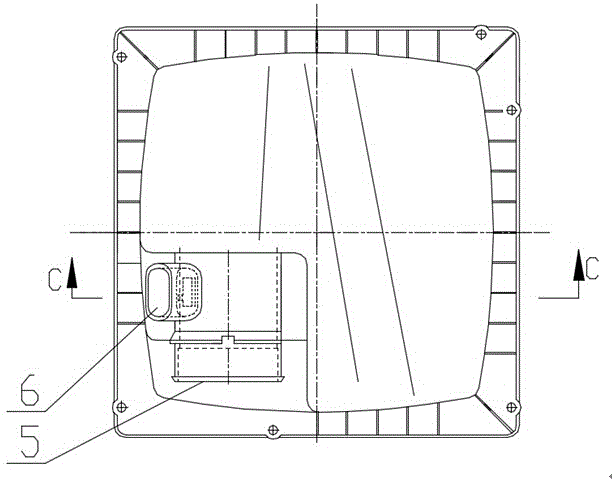

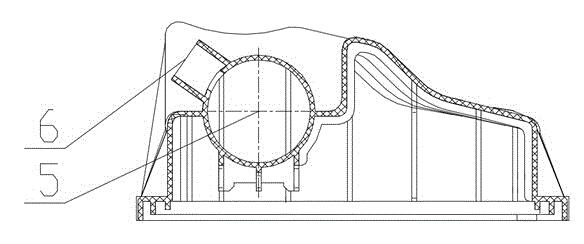

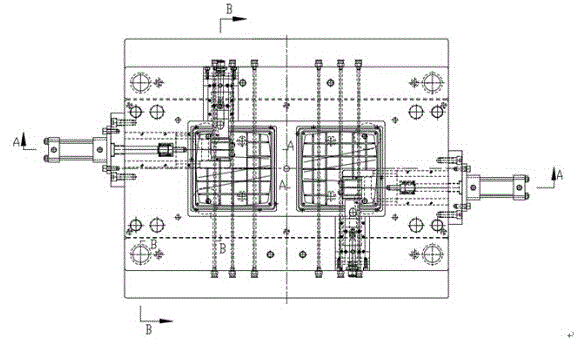

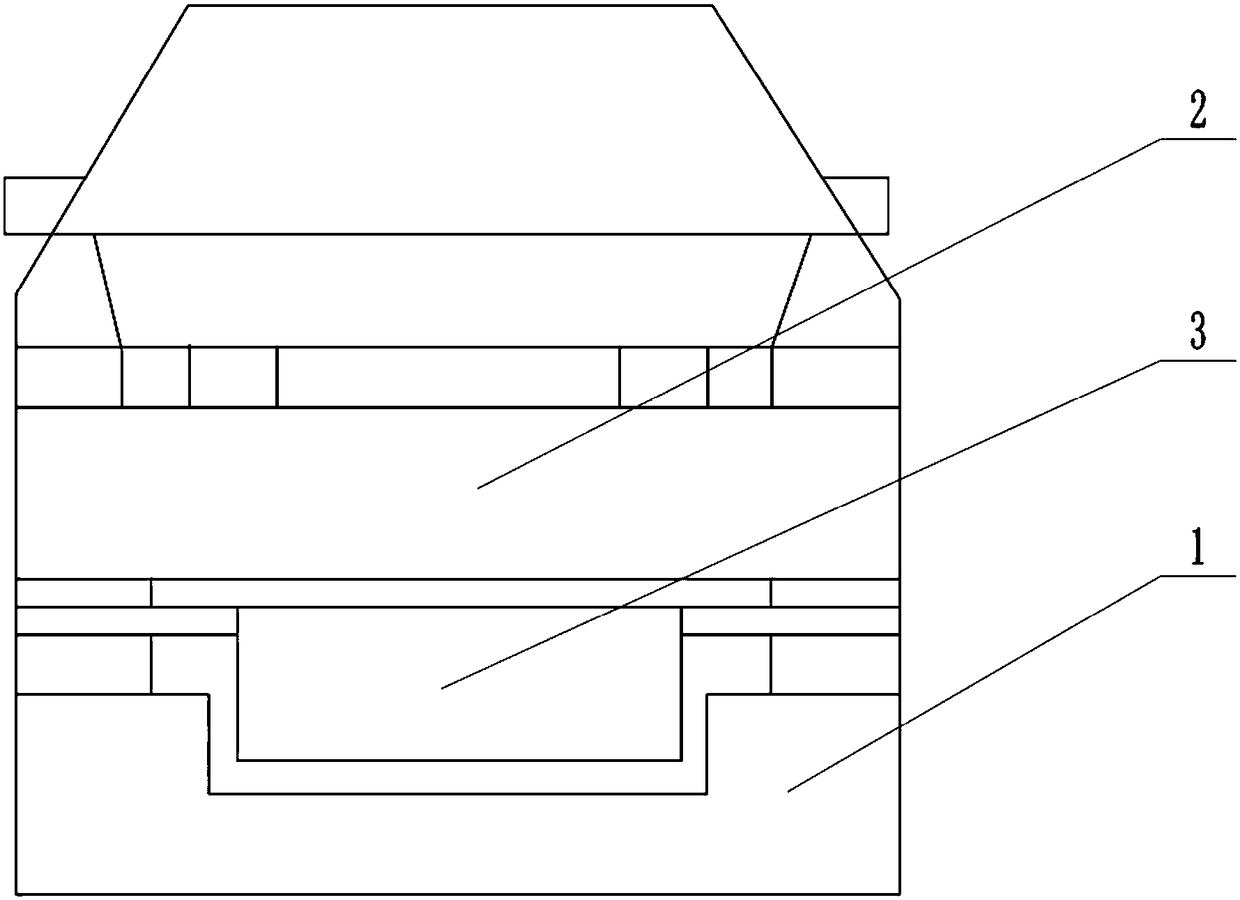

Injection mould for upper housing of car air filter

The invention discloses an injection mould for an upper housing of a car air filter. The injection mould comprises a fixed mould assembly (1), a movable mould assembly (2), a lateral loose core device (3) and an oblique loose core device (4), wherein the fixed mould assembly comprises a fixed mould seat plate (11), a fixed mould plate (12) and a cavity (13); the movable mould assembly comprises a movable mould seat plate (21), a movable mould supporting plate (22), a movable mould plate (23), a cavity (24) and a mould pushing device (25); the lateral loose core device comprises a telescopic push-pull mechanism (31), a mounting plate (32) and a lateral loose core (24); the oblique loose core device comprises a wedge-shaped supporting plate (41), a supporting baffle (42), a traction mechanism (43) and an oblique loose core (44). According to the injection mould, mutually staggered plastic parts along the loose cores can be conveniently manufactured and repaired, easily damaged parts can be conveniently replaced, the service life of the mould can be prolonged, the precision of the plastic parts can be guaranteed, and the maintenance expense of the mould can be reduced.

Owner:青岛宇信机电科技有限公司

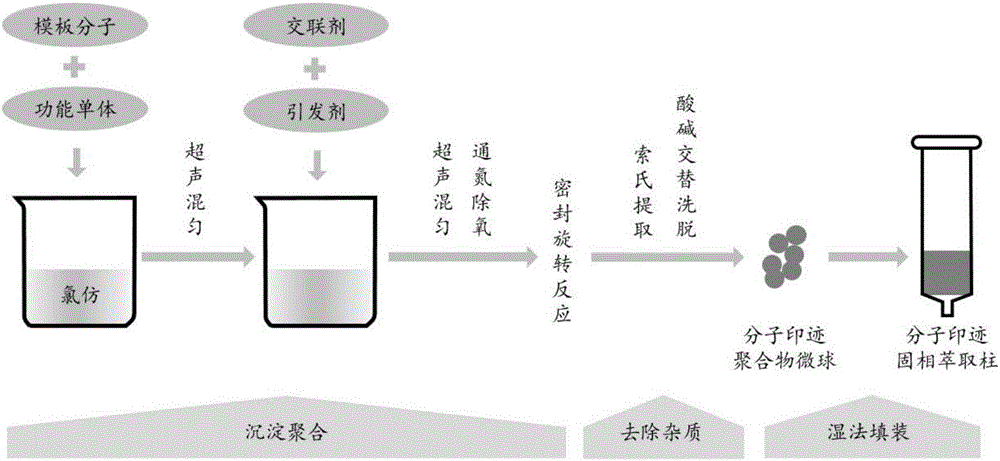

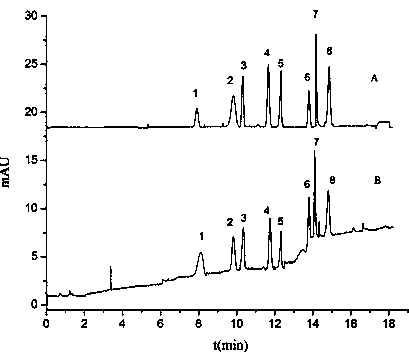

Cinnamate type ultraviolet sun-screening agent molecular engram solid-phase extraction column as well as preparation and application thereof

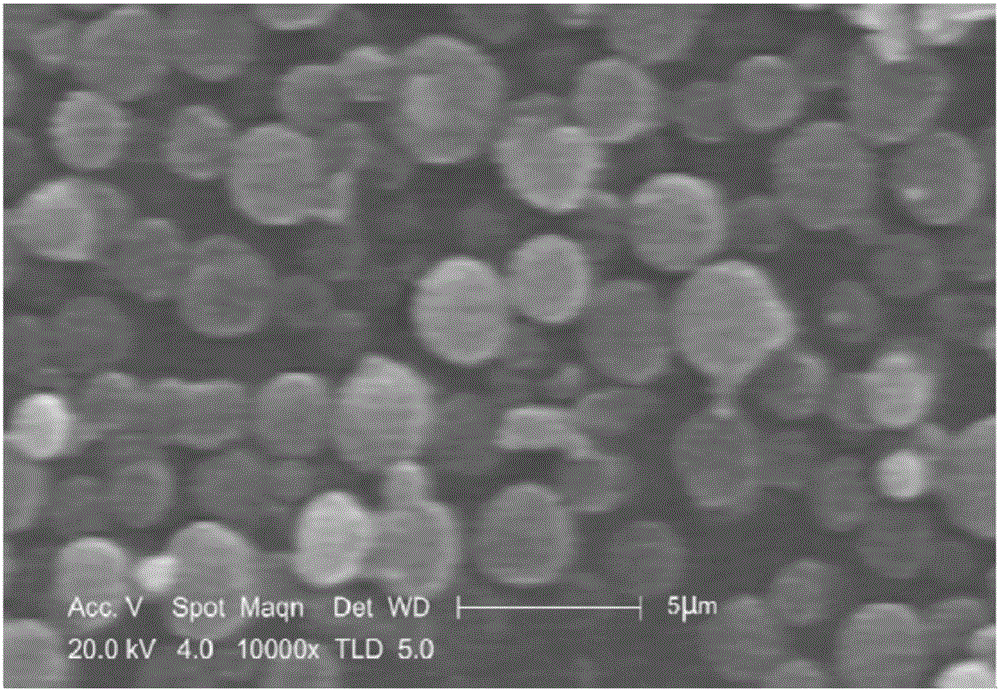

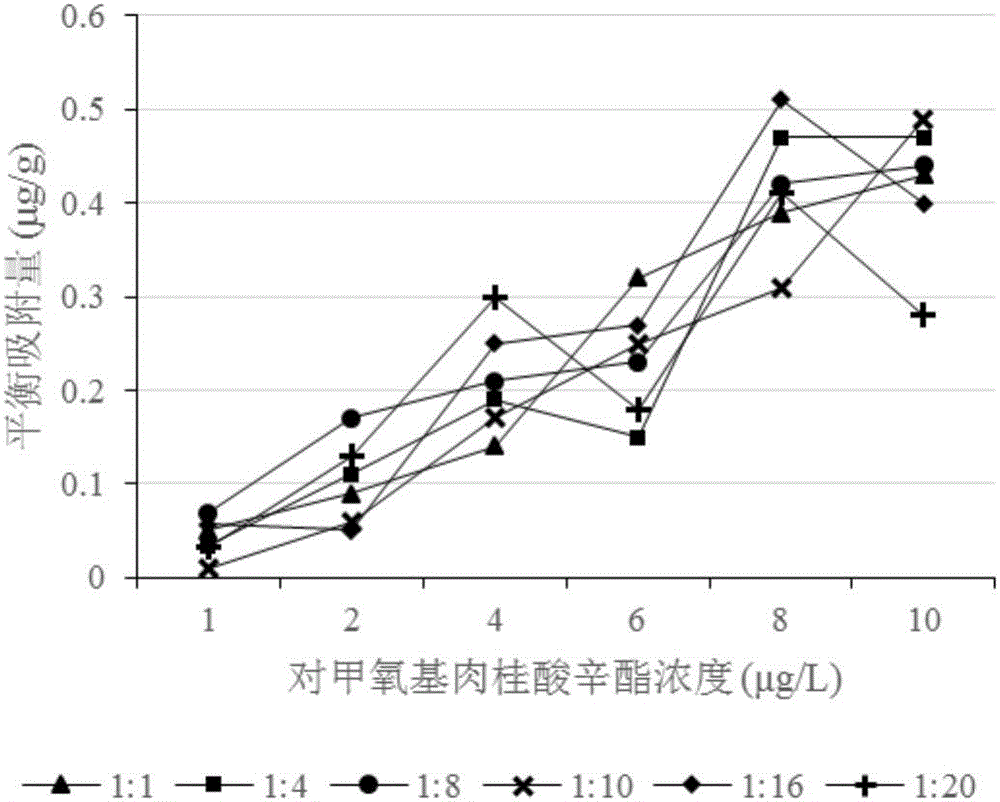

InactiveCN106582066AWith molecular recognition functionPredeterminedOther chemical processesComponent separationFunctional monomerMicrosphere

The invention relates to a cinnamate type ultraviolet sun-screening agent molecular engram solid-phase extraction column as well as preparation and application thereof, and belongs to the technical field of solid-phase extraction of detection analysis. According to the invention, iso-octyl p-methoxycinnamate is adopted as a template molecule, methacrylic acid is adopted as a functional monomer, ethylene glycol dimethyl acrylic ester is adopted as a crosslinking agent, azodiisobutyronitrile is adopted as an initiating agent, cinnamate type ultraviolet sun-screening agent molecular engram polymer microspheres are obtained by virtue of a precipitation polymerization method, and the obtained polymer microspheres are filled into a solid-phase extraction column through a wet method. The molecular engram polymer solid-phase extraction column provided by the invention can selectively adsorb a cinnamate type ultraviolet sun-screening agent, and compared with a conventional solid-phase extraction column, the molecular engram polymer solid-phase extraction column overcomes the defect of poor selectivity of a conventional solid-phase extraction filler, is strong in adsorptivity, high in extraction recovery rate, and achieves efficient selective separation, enrichment and purification of a trace amount of the cinnamate type ultraviolet sun-screening agent in various environments and biological samples.

Owner:SHANGHAI JIAO TONG UNIV

Method and system for making a dental restoration

ActiveUS9827076B2Easy to manufactureMaximize precisionMechanical/radiation/invasive therapiesArtificial teethDentitionDental restoration

Owner:3M INNOVATIVE PROPERTIES CO

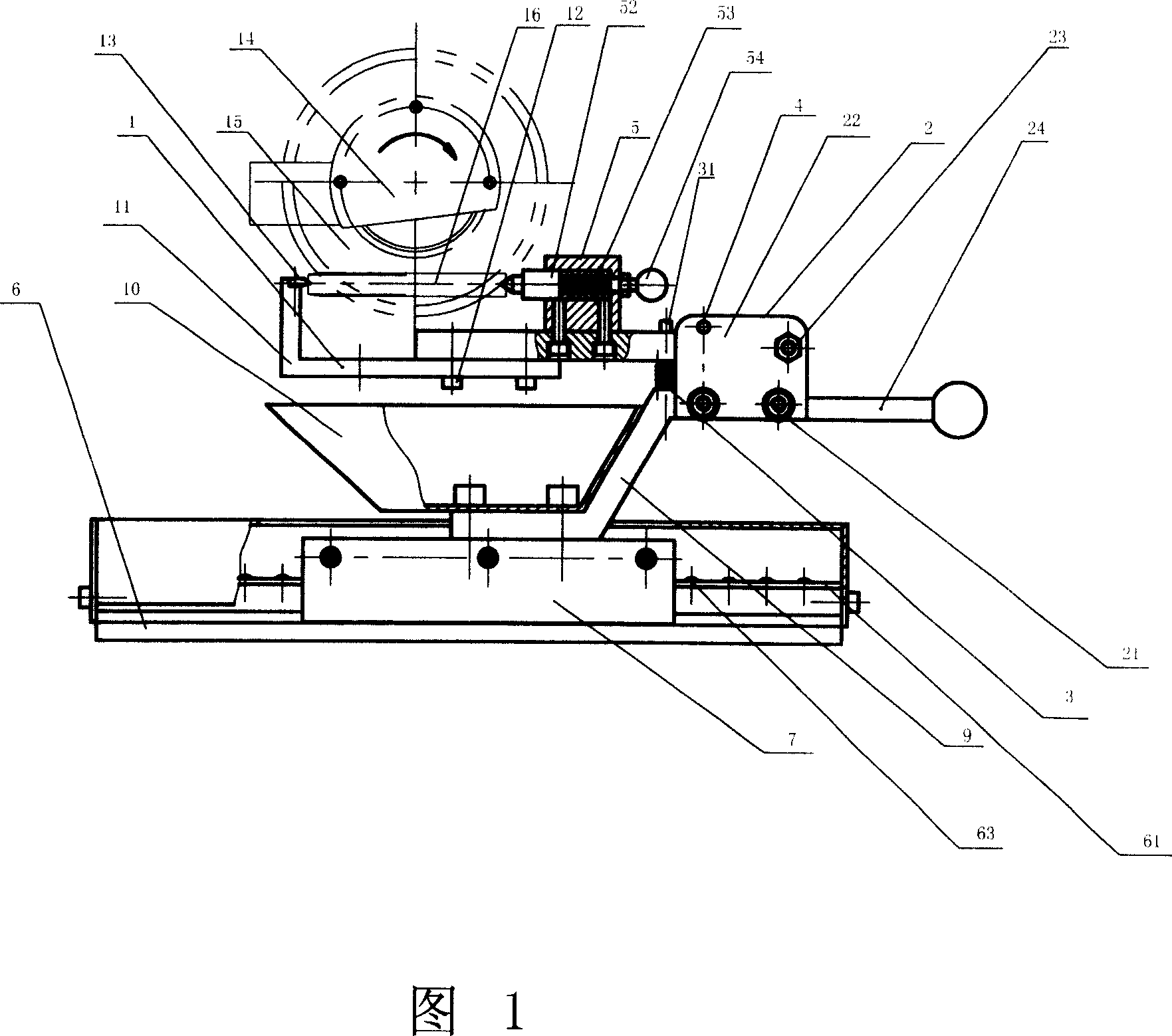

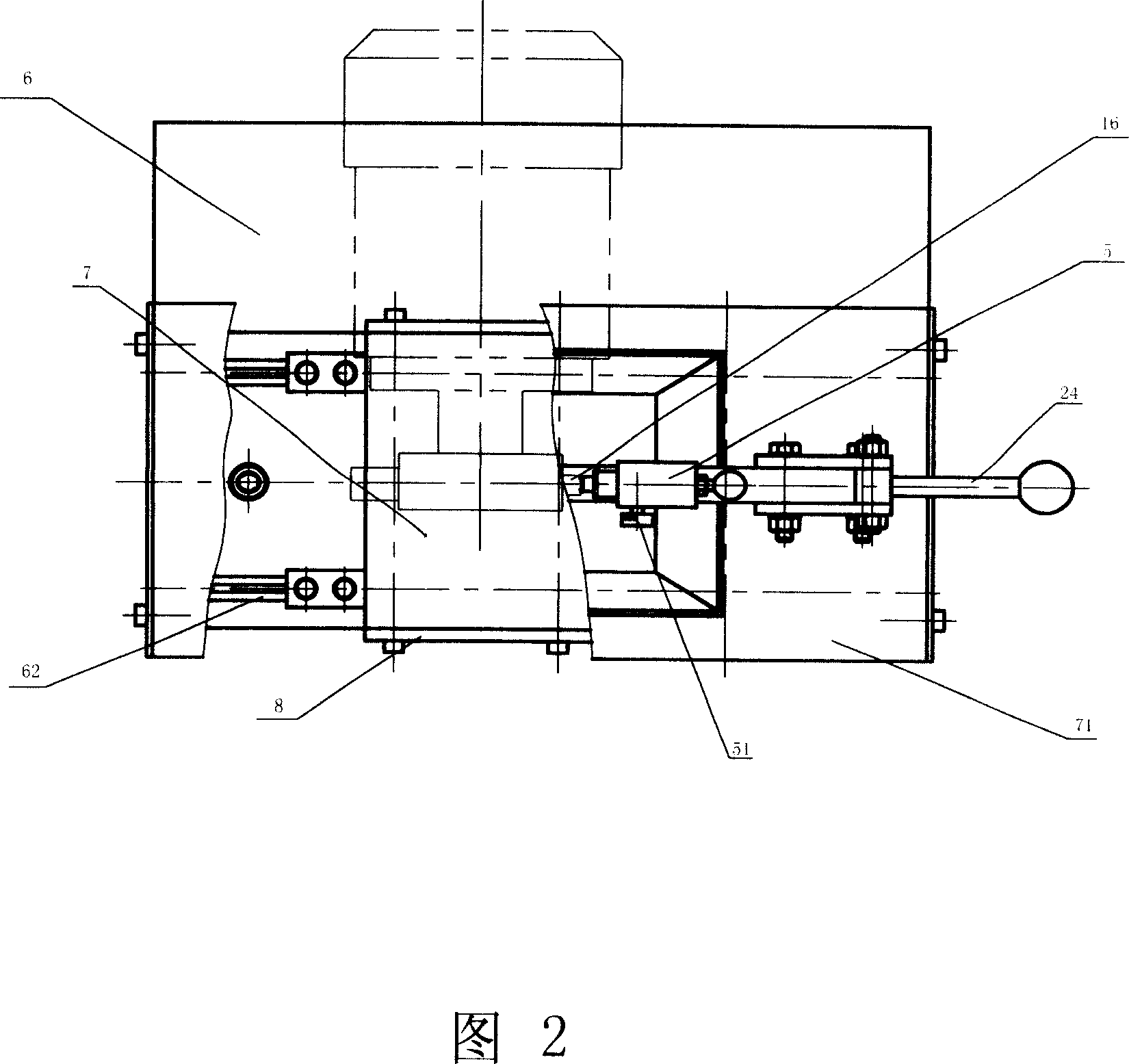

Environment protection device

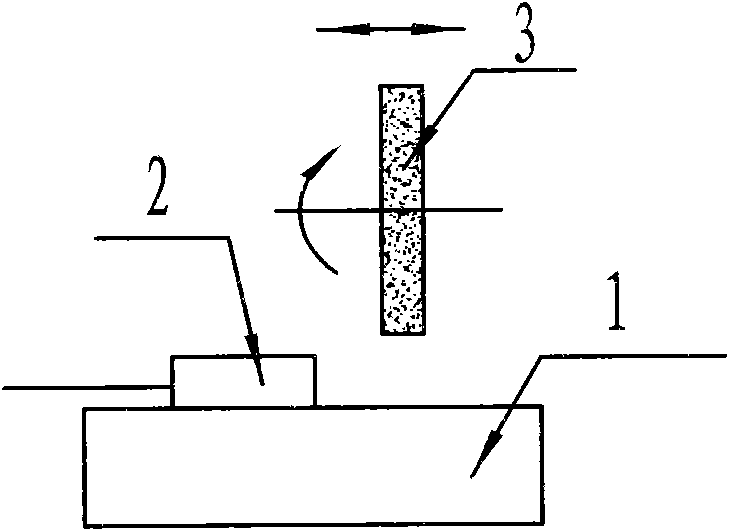

ActiveCN107139026AEasy to adjustConvenient grinding positionGrinding carriagesRevolution surface grinding machinesEngineering

The invention discloses an environment protection device. The environment protection device comprises a main body, wherein a fastening device and aligning devices are arranged at the top of the main body; the aligning devices are symmetrically arranged on the front side and the rear side of the fastening device; a grinding frame is arranged on the main body between the fastening device and the aligning device on the rear side; a first sliding tank and a second sliding tank which are bilaterally symmetrical are arranged in each aligning device; an interlayer is arranged between each first sliding tank and the corresponding second sliding tank; support parts are arranged in the first sliding tanks and the second sliding tanks; conical wheels opposite to each other are arranged in the support parts on the left side and the right side; a first sliding cavity is continuously arranged in the fastening device and the main body at the bottom of the fastening device in a penetrating manner; a sliding part is arranged in the first sliding cavity; horizontal grooves are symmetrically formed in the left side and the right side of the top of the fastening device; a second sliding cavity is formed in the sliding part. The environment protection device is simple in structure and convenient to operate; the grinding accuracy and stability are improved.

Owner:NANTONG AORUN BUILDING MATERIAL TECH

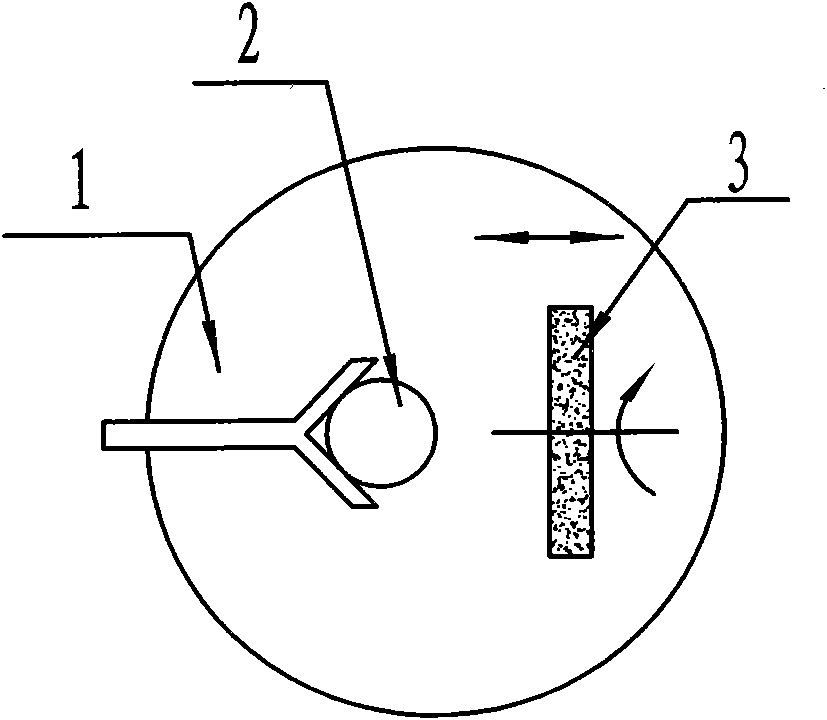

Method for cleaning sic particles

InactiveCN1791497AAvoid grindingGas current separationFine working devicesMetal particleParticle method

Method for cleaning of silicon carbide particles from fine grain particles adhering to said silicon carbide particles, typically in the form of agglomerates of metal particles, subsequent to production (cutting) of silicon wafers and after removal of any present solute or dispersing agent from the particles. The particles (1) of contaminated silicon carbide are firstly exposed to a mechanical treatment in a first step (2) of cleaning in a per se known classifying apparatus where a first coarse fraction (3) of particles, agglomerates, larger than the original silicon carbide particles, are separated out and treated in a process (4) where the agglomerates are broken down to individual grains, without crushing said individual grains, and thereafter recycled (5) to said first step (2) of cleaning. A first fine fraction (6) is discharged from said first step (2) and transferred to a second step (7) of cleaning conducted in a per se known classifying apparatus from which the particles of silicon carbide are discharged in the form of a second coarse fraction (8), while the contaminants separated out in said second step of cleaning, are discharged in the form of a second fine fraction (9).

Owner:METAL MFGS LTD

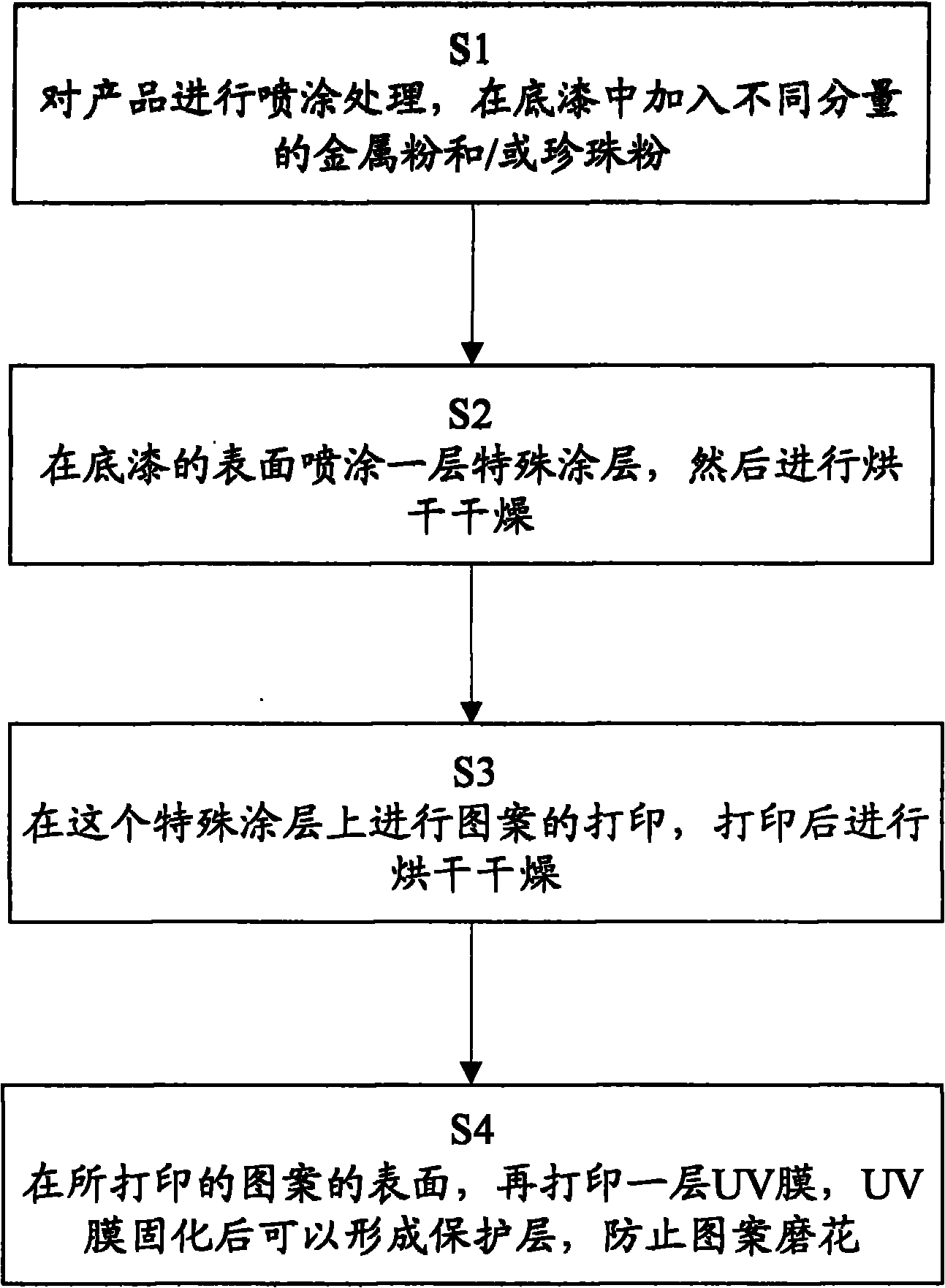

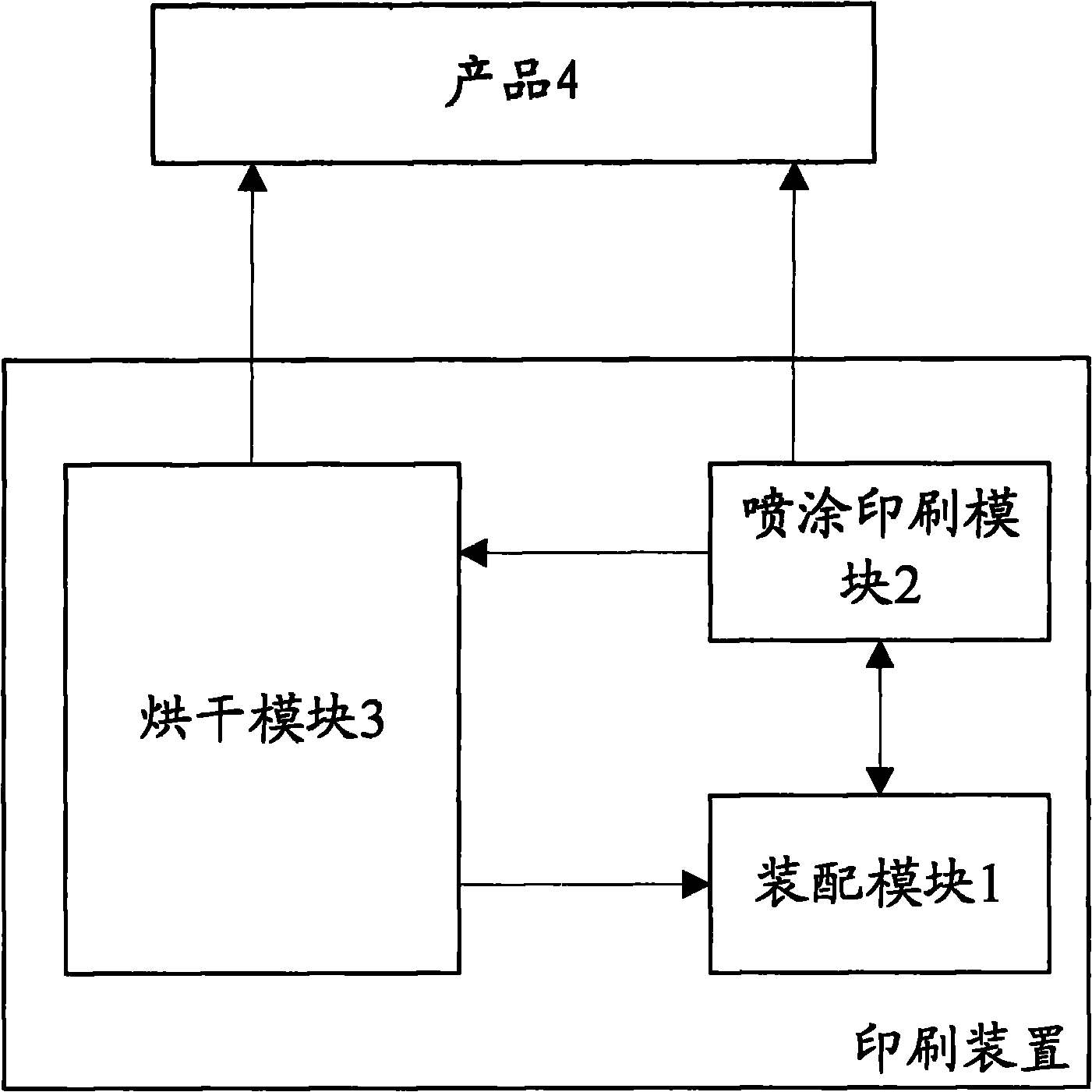

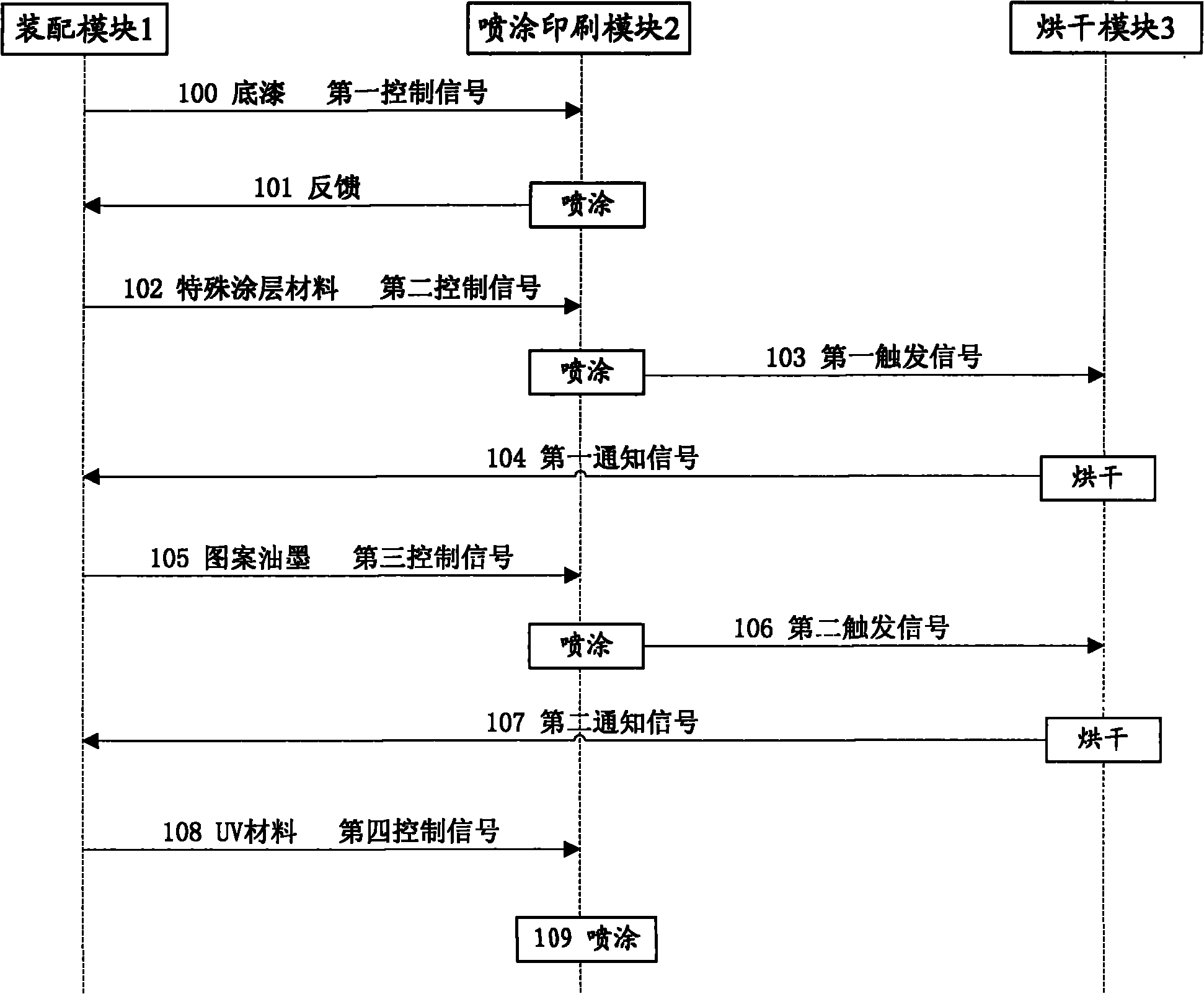

Printing method and device for overlapping printing ink on different bottom colors

ActiveCN101817267AColor stableAvoid grindingOther printing apparatusPrinting press partsPrinting inkUltraviolet

The invention discloses a printing method and a printing device for overlapping printing ink on different bottom colors. The method comprises the following steps of: adding metal powder into a primer with the selected color; spraying the primer on a product; spraying a special coating on the surface of the primer and drying; and according to the color of the primer, printing a pattern on the special coating by selecting the relevant color and drying. In the method and the device, a special metal feeling is generated by performing special treatment on the bottom color and overlapping the bottom color with the color of the printing ink used by the printed pattern; and at the same time, the special coating makes the color more stable and an ultraviolet (UV) film is covered to avoid wear.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

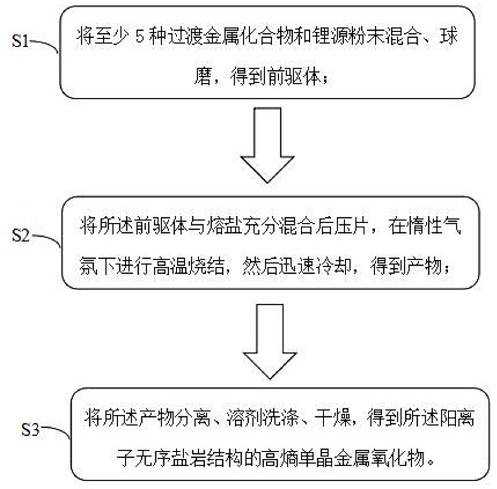

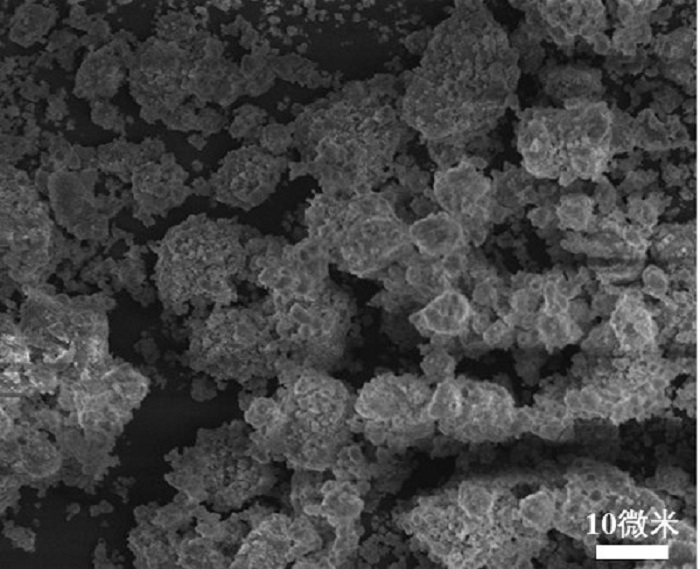

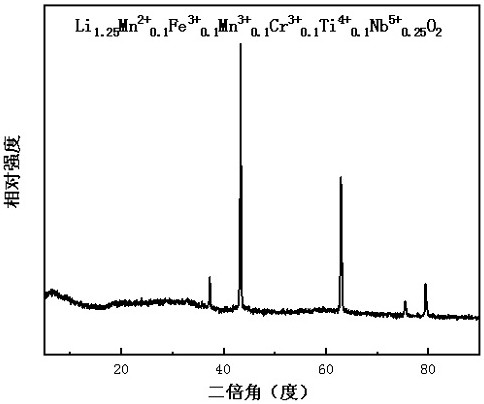

High-entropy single-crystal metal oxide with cation disordered rock salt structure and preparation method and application thereof

ActiveCN113584591AHigh specific capacity and energy densityGood cycle performancePolycrystalline material growthFrom solid stateElectrical batteryCyclic stability

The invention provides a high-entropy single-crystal metal oxide with a cation disordered salt rock structure and a preparation method and application thereof. The preparation method of the metal oxide comprises the following steps of: mixing at least five transition metal compounds and lithium source powder, and carrying out ball milling to obtain a precursor; fully mixing the precursor with fused salt, tabletting, sintering at high temperature in an inert atmosphere, and rapidly cooling to obtain a product; and separating the product, washing the product with a solvent, and drying the product to obtain the high-entropy single-crystal metal oxide with a cation disordered rock salt structure. The transition metal compounds comprise at least one compound selected from Mo < 6 + >, V < 5 + >, Nb < 5 + > and Ti < 4 + >. The metal oxide obtained by the preparation method provided by the invention is a sphere-like single crystal, is of an Fm-3m type structure, is used as a secondary battery positive electrode material, and shows relatively high energy density and good cycling stability.

Owner:CENT SOUTH UNIV

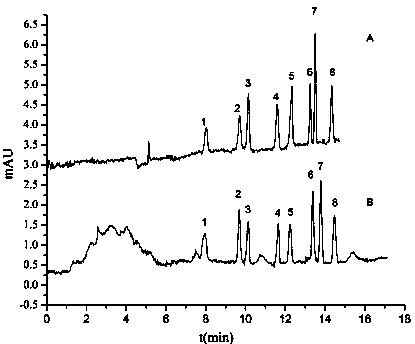

Prometryn molecular imprinting solid phase extraction column and application method thereof

ActiveCN103433009ATake advantage ofHigh yieldOther chemical processesPreparing sample for investigationCross-linkFunctional monomer

The invention relates to the technical field of solid phase extraction, and particularly discloses a prometryn molecular imprinting solid phase extraction column and an application method thereof. With prometryn as a template, methacrylic acid as a functional monomer, glycol dimethyl methacrylate as a cross-linking agent, azodiisobutyronitrile as an initiating agent, dichloromethane as a solvent, a precipitation polymerization method is adopted to prepare prometryn molecular imprintingpolymeric microsphere; microballoons are uniformly filled in the solid phase extraction column, thus obtaining the prometryn molecular imprinting solid phase extraction column; dichloromethane is utilized as, residuals of simazine, atrazine, szimetrin, propazine, ametryn, terbuthylazine, prometryn and terbutryn in a grain sample are simultaneously enriched and purified by taking a sample solvent and dichloromethane-acetonitrile as a leaching solvent and taking methyl alcohol-water as an eluting solvent, when used together with a capillary electrophoresis multiresidue detection method, the prometryn molecular imprinting solid phase extraction column can simultaneously detect the residuals of the eight herbicideds.

Owner:JIANGSU UNIV

Turbine blade ordering method relating to turbine thickened blades

InactiveCN103116689AEasy to GrindProcess balanceSpecial data processing applicationsSorting algorithmSteam turbine blade

The invention provides a turbine blade ordering method relating to turbine thickened blades and relates to a location and sort algorithm of turbine blades. At present, thickened blades in turbine blades are fixed randomly through manual work in an entire circle of blades, no accurate location and ordering method exists, over-concentrated problem or over-dispersive problem exists in assembling, and the problem that grinding of an assembling clearance in assembling is incapable is prone to occur, however, the turbine blade ordering method relating to the turbine thickened blades solves the above problems. The ordering method comprises the main steps: S1, confirming the number of the thickened blades of the products participating in ordering according to product design requirements, S2, arranging the thickened blades through an equally distributed principle and confirming the sequence numbers of the thickened blades, S3, confirming the installation site sequence numbers of numbers of the thickened blades and processing random numbers, S4, weighing the thickened blades, S5, ordering the thickened blades, S6, weighing ordinary blades, and S7, ordering the ordinary blades. The invention relates to turbine blade ordering of the thickened blades.

Owner:HARBIN TURBINE

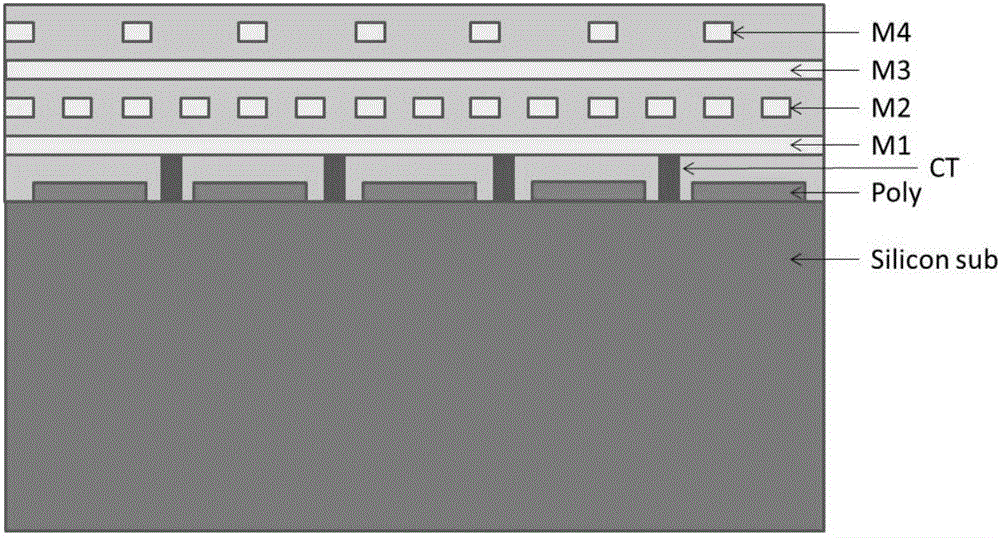

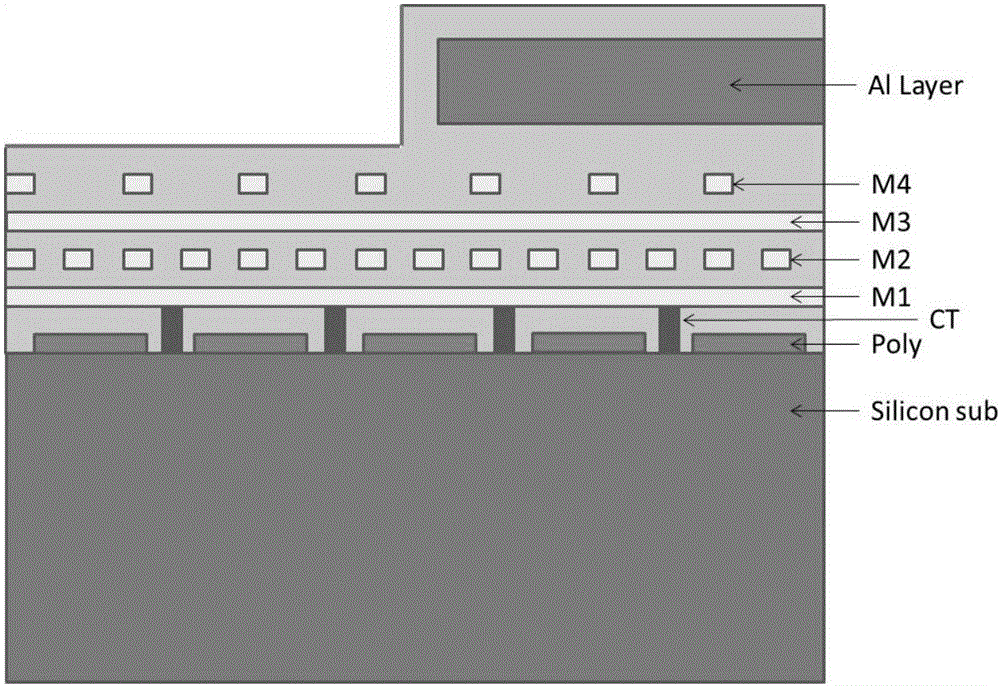

Preparation method for TEM sample

ActiveCN105699698AAvoid processing powerAvoid reactionScanning probe techniquesIon beamCombinatorial chemistry

Disclosed in the invention is a preparation method for a TEM sample. An inclined cutting opening is formed in a chip sample surface by using an ion beam and level removing and TEM sample preparation are carried out on a target area position directly, so that time for TEM sample preparation is substantially shortened; and the position and depth for level removing are controlled precisely, so that the success rate of sample preparation and the quality of the sample are improved. And the chip sample is protected from being damaged.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

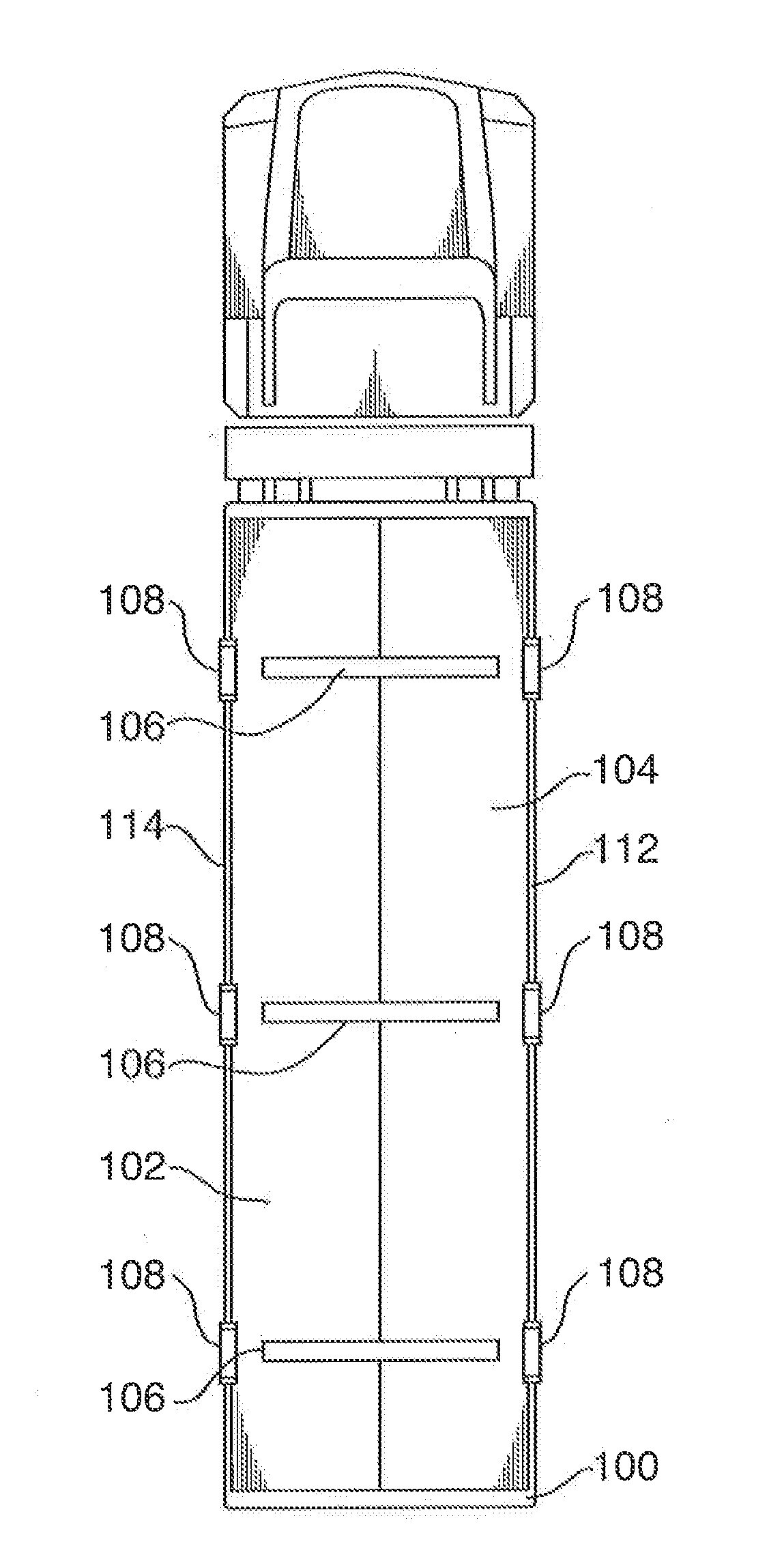

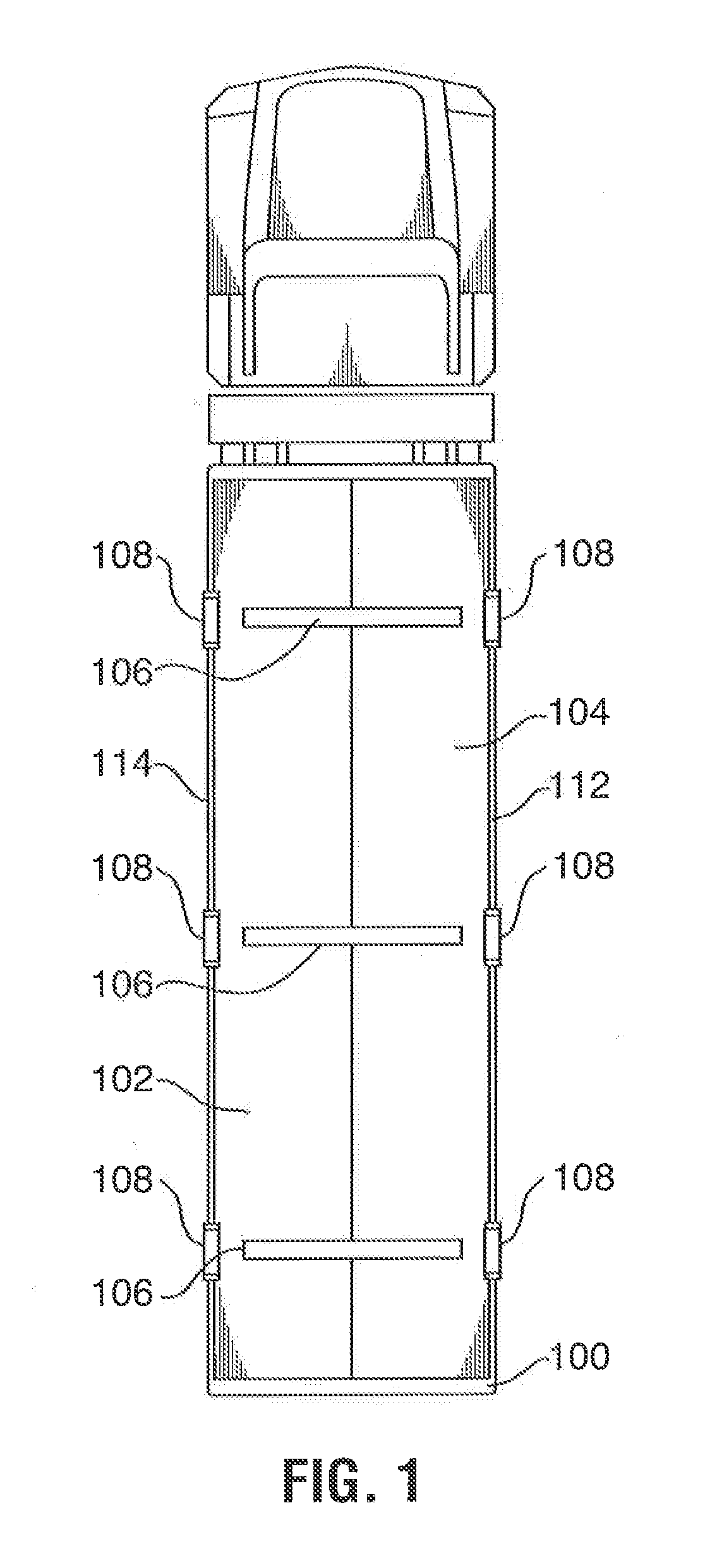

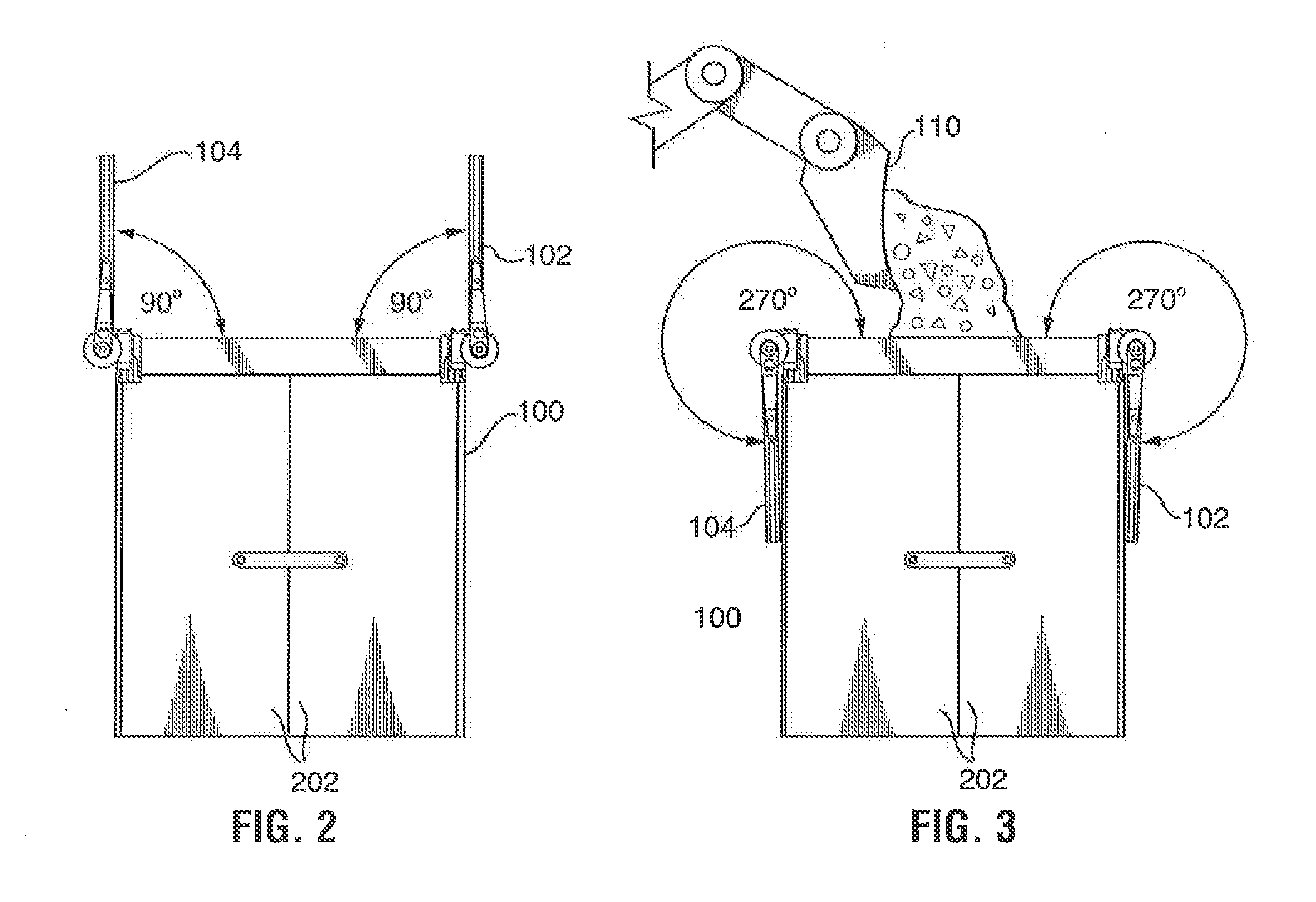

Convertible trailer

ActiveUS20110309590A1Improve structural strengthEasy to moveCarriage/perambulator with multiple axesRailway componentsMaterial transportChassis

Trailers are described that include a chassis, a set of wheels for rollably supporting the chassis on the ground, and a rigid container carried by the chassis. The rigid container comprises a floor, a sidewall, an access door for loading / unloading materials into the container, and a convertible rigid roof. The convertible roof is movable between a closed position which permits waste or other materials to be compressed into the trailer, and an open position which permits the trailer to be loaded with bulk goods from the top. The convertible roof includes movable rigid panels, and a locking bar for holding the panels closed and connecting the opposite sidewalls of the trailer to each other against the expansion pressure exerted by loosely compressed materials transported in the trailer. The panels may be rotating panels hinged to a wall, or may be provided as sliding panels running in tracks.

Owner:TITAN TRAILERS

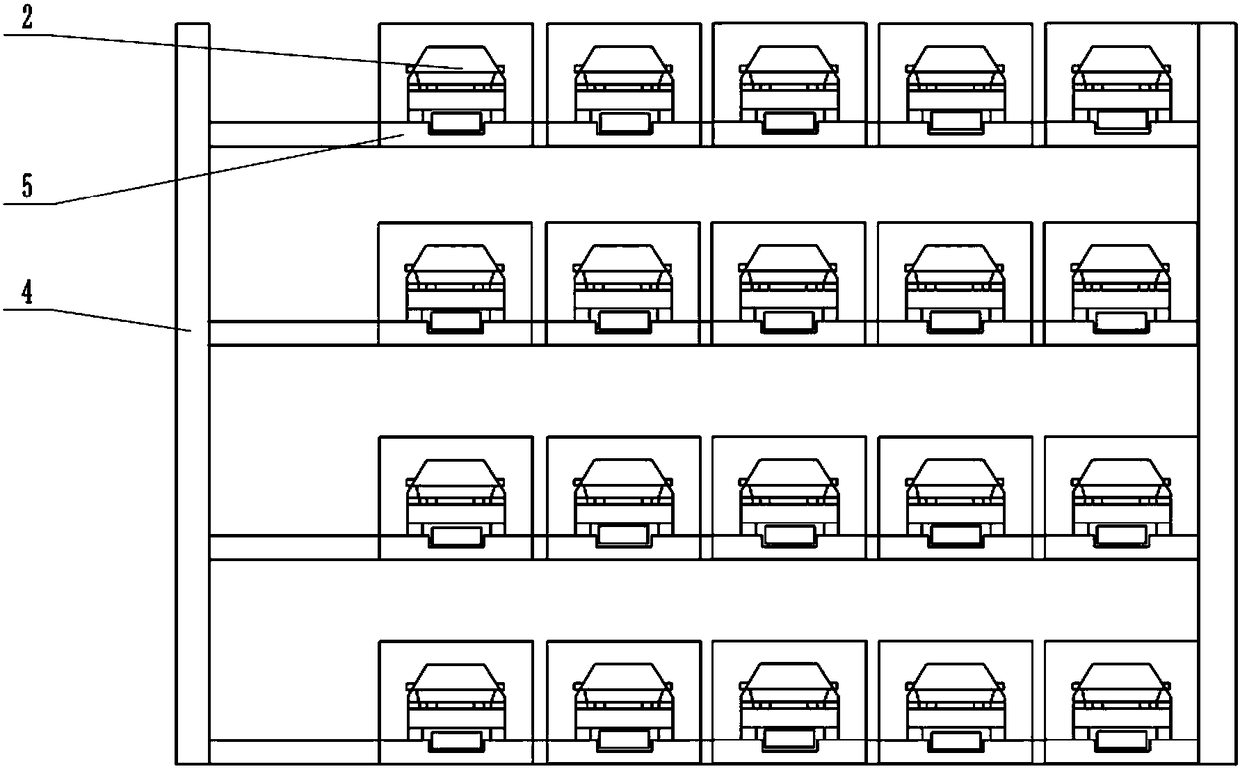

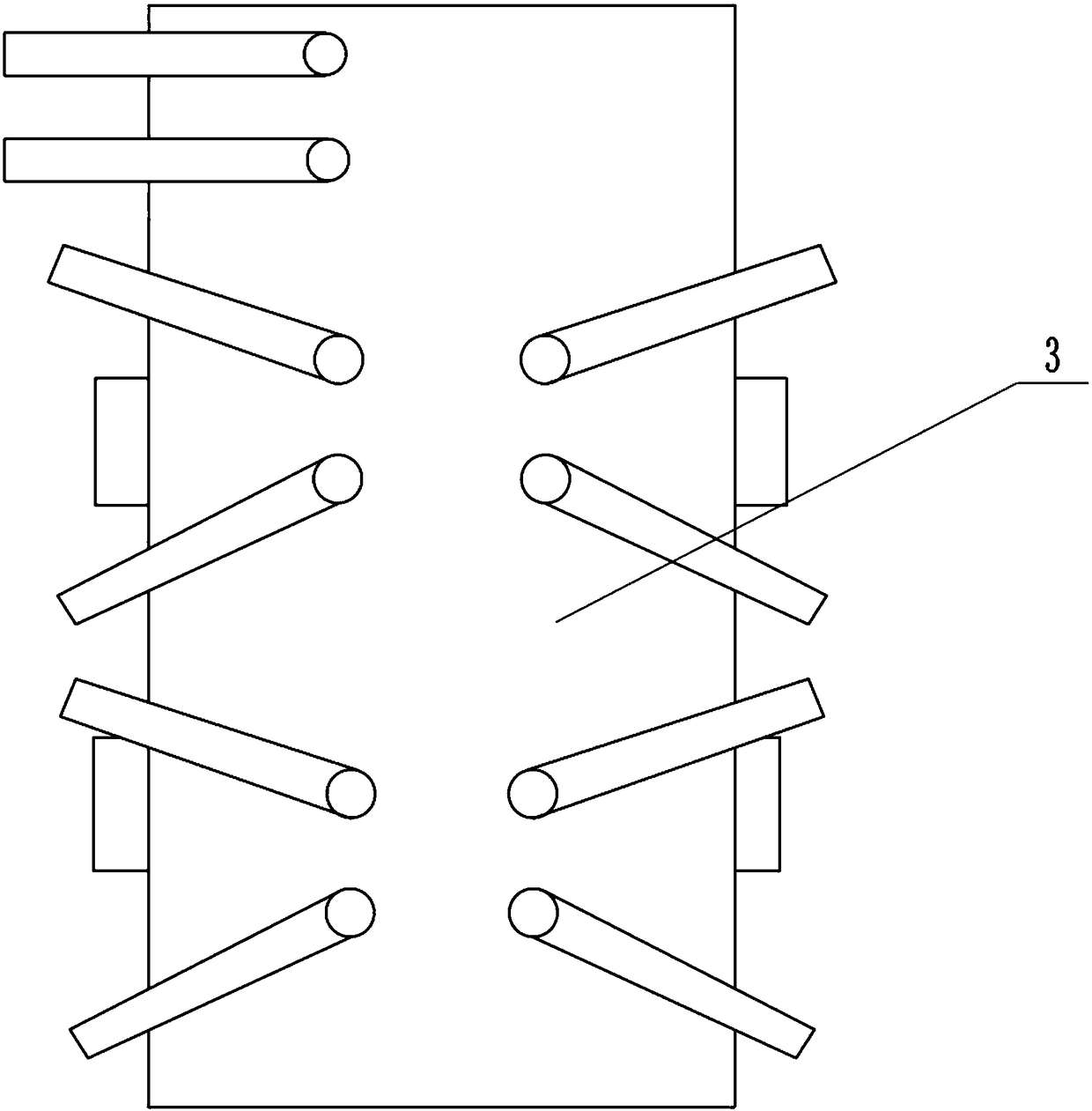

Parking lot electric vehicle automatic charging system

ActiveCN108437826AAvoid entanglementReduce workloadCharging stationsElectric vehicle charging technologyAutomotive engineeringElectric vehicle

The invention relates to the field of parking lot electric vehicle charging and in particular discloses a parking lot electric vehicle automatic charging system. The parking lot electric vehicle automatic charging system comprises an original parking space, where a vehicle owner parks an electric vehicle, a target parking space, where the electric vehicle is conveyed, a connecting device and an adapter device, wherein the connecting device is connected with an electric vehicle charging device on the target parking space, and the adapter device is conveyed together with the electric vehicle when a transferring device automatically conveys the electric vehicle; an electric vehicle charging plug is arranged on the adapter device; and the adapter device can be in automatic communication with the connecting device when being conveyed to the target parking space by the transferring device. Compared with the prior art, the parking lot electric vehicle automatic charging system has the advantage that a purpose of automatically charging the parked electric vehicle needing to be charged after the parked electric vehicle needing to be charged is automatically conveyed to another parking spaceis realized.

Owner:重庆复融科技有限公司

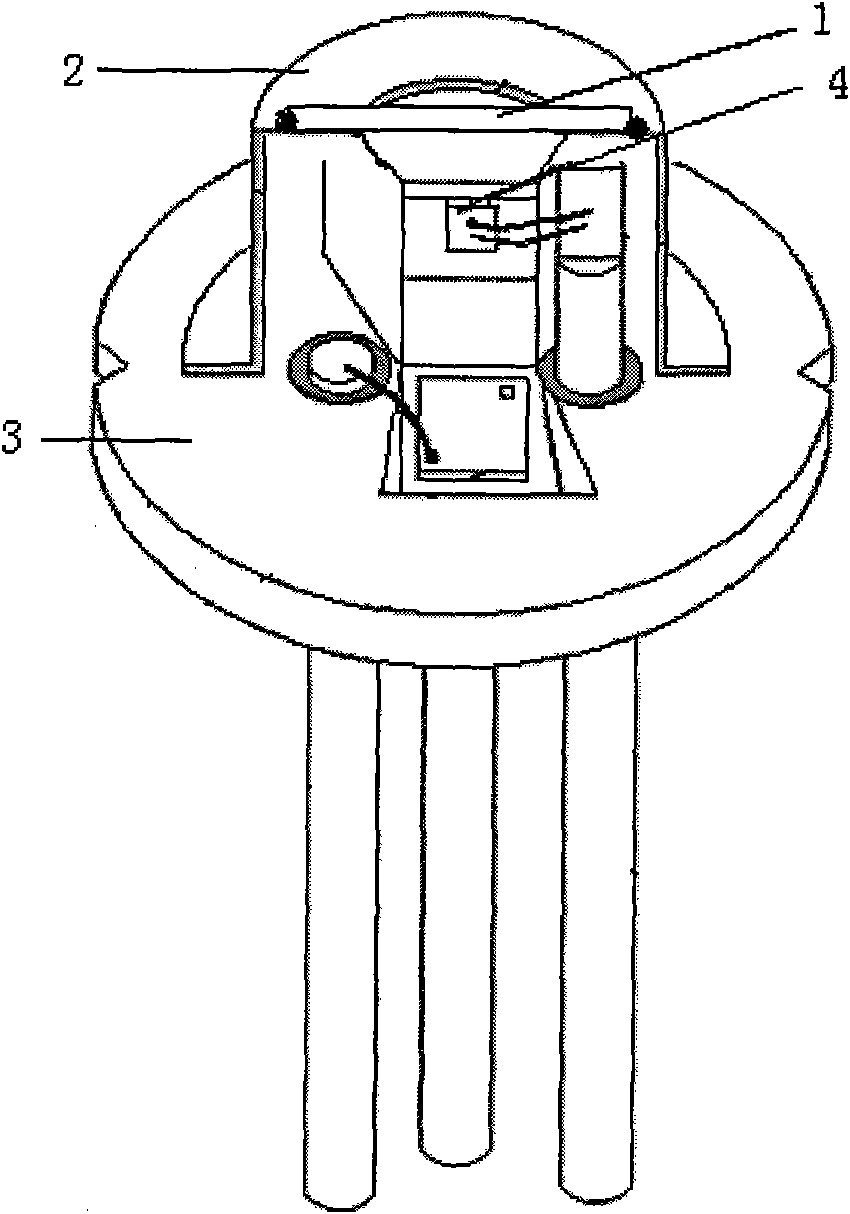

Semiconductor laser TO tube seat packaging beam compression process

InactiveCN101621176AAvoid grindingImproved efficiency of shaping processLaser detailsLaser output parameters controlSemiconductor laser theoryEngineering

The invention provides a semiconductor laser TO tube seat packaging beam compression process which comprises the following steps: (1) evaporating solder on a tube tongue of a TO tube seat on the basis of conventional practice, bonding a tube core of the semiconductor laser in the middle part of the side of the tube tongue, leading the light-emitting cavity surface of the tube core and the upper end surface of the tube tongue to be parallel and level and then carrying out alloy, bonding and photoelectrical test; (2) packaging a tube cap which corresponds to the type of the TO tube seat on the TO tube seat, ensuring that the tube cap is in the middle part of the TO tube seat; (3) bonding a cylindrical lens outside the tube cap by utilizing an optical adjusting bracket, the cylindrical lens is parallel to the cavity surface of the tube core and is in the middle part of the cavity surface relative to the tube core. The invention realizes beam compression by bonding the cylindrical lens outside the tube cap and adjusting the position of the cylindrical lens, changes the realization method of the beam compression by bonding the cylindrical lens inside the tube cap and adjusting the position of the tube cap in the existing beam compression process, avoids carrying out grinding on the tube cap, and leads the shaping process to be improved by 15% to 20%.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

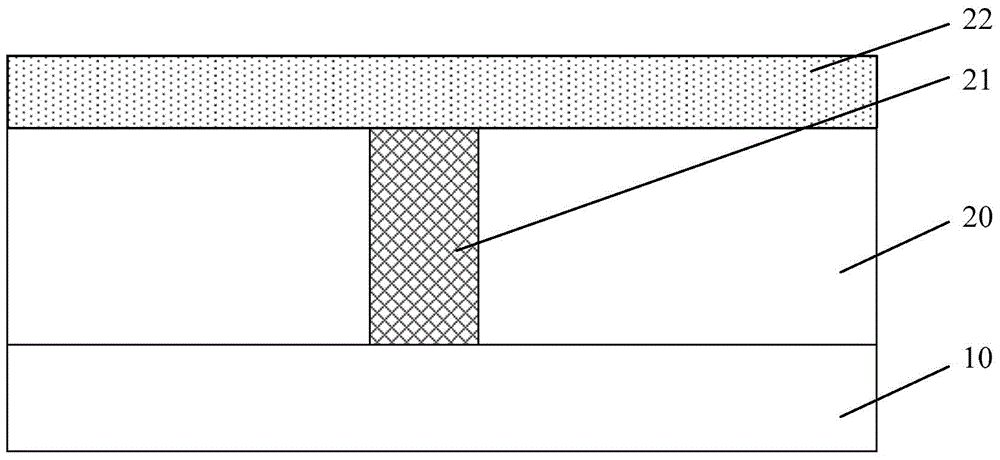

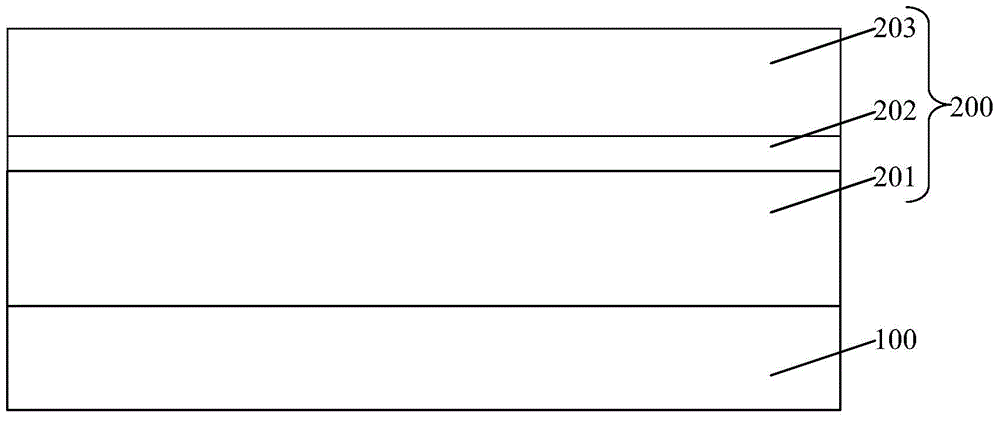

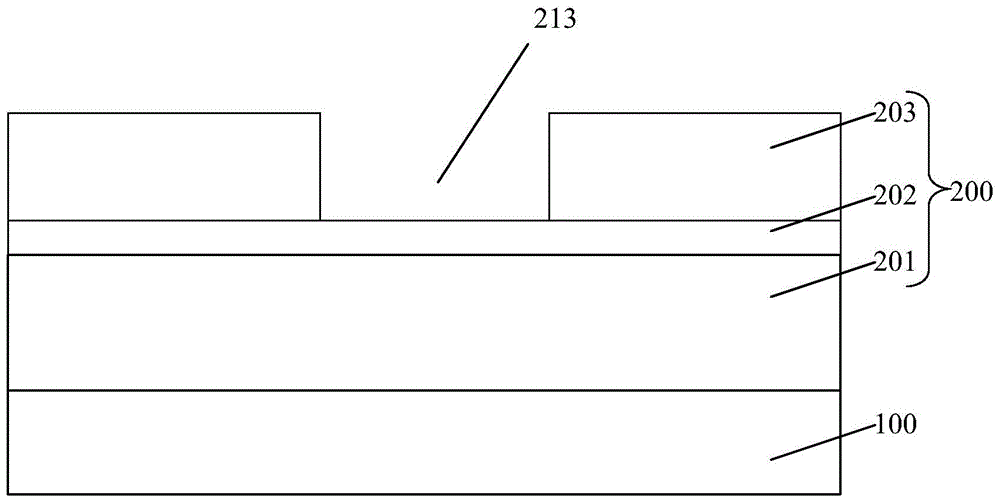

Method of forming phase change random access memory (PCRAM) cell

ActiveCN105449101AAvoid defects such as dentsImprove interface qualityElectrical apparatusPhysicsMetal

A method of forming a phase change random access memory (PCRAM) cell comprises the steps of providing a substrate; forming a dielectric layer on the surface of the substrate; forming a through hole penetrating through the dielectric layer, the through hole comprising a first through hole portion located at the surface of the substrate and a second through hole portion located above the first through hole portion and communicating with the first through hole portion, the first through hole portion having a side wall perpendicular to the surface of the substrate, and the second through hole having an inclined side wall and a larger top width and a smaller bottom width; forming a metal layer on the inner wall surface of the through hole and on the surface of the dielectric layer, the metal layer filling the first through hole portion and covering the side wall of the second through hole portion; forming a sacrificial layer on the surface of the metal layer, the sacrificial layer filling the second through hole portion; carrying out planarization processing, removing the sacrificial layer, a part of the metal layer and a part of the dielectric layer that are over the first through hole portion; and forming a phase change layer on the surface of the remaining dielectric layer and the surface of the metal layer in the first through hole portion. The above method can improve the performance of the formed PCRAM cell.

Owner:SEMICON MFG INT (SHANGHAI) CORP

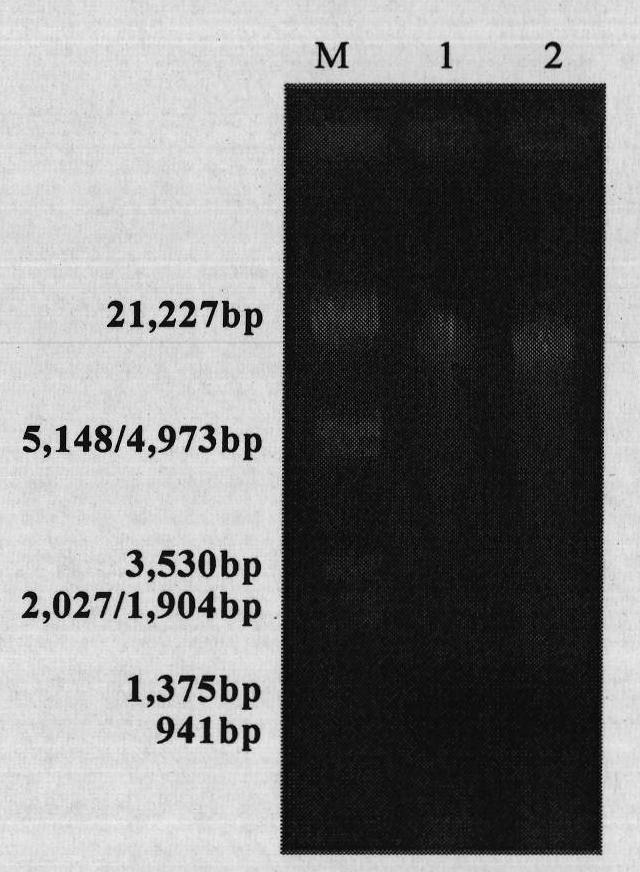

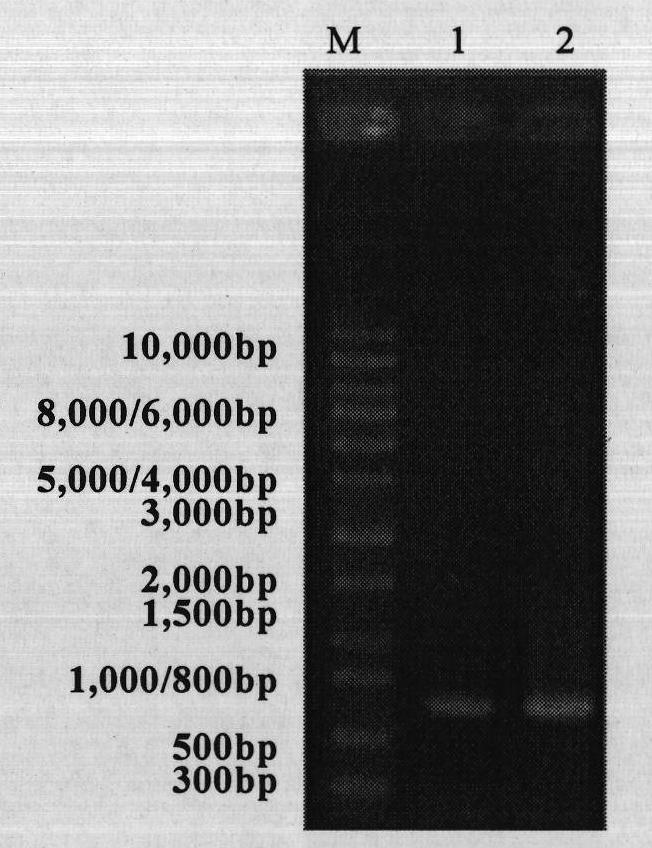

Simple and feasible extract method of edible mushroom genomic DNA

The invention provides a simple and feasible extract method of edible mushroom genomic DNA, which comprises the following steps: selecting materials; grinding; adding buffer solution, and centrifuging after oscillation; standing and depositing; centrifuging; washing and depositing, and air-drying; and dissolving, depositing, preserving and the like. The method for extracting the edible mushroom genomic DNA has short extract time, simple operation, low cost and high extract efficiency.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com