Turbine blade ordering method relating to turbine thickened blades

A technology for steam turbine blades and thickened blades, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as inability to repair assembly gaps, lack of accurate positioning and sorting methods, concentration or dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

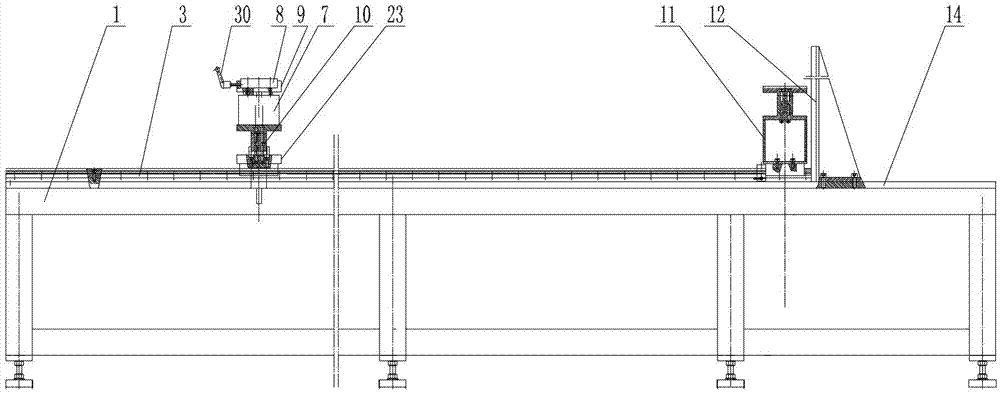

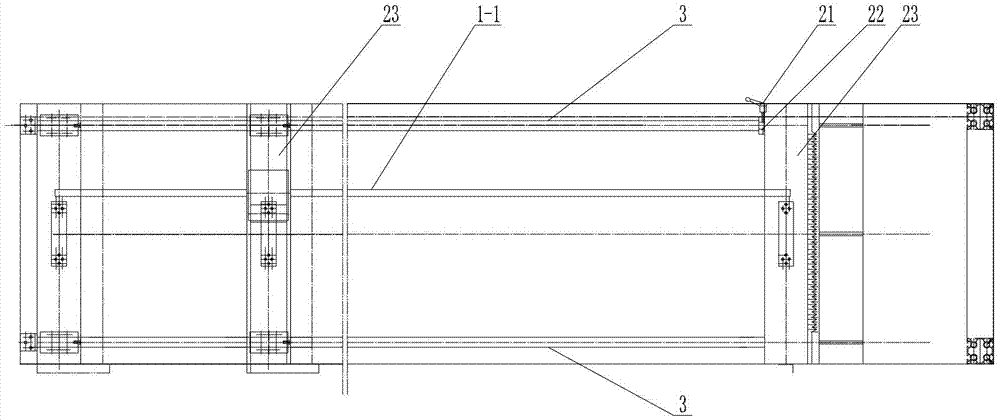

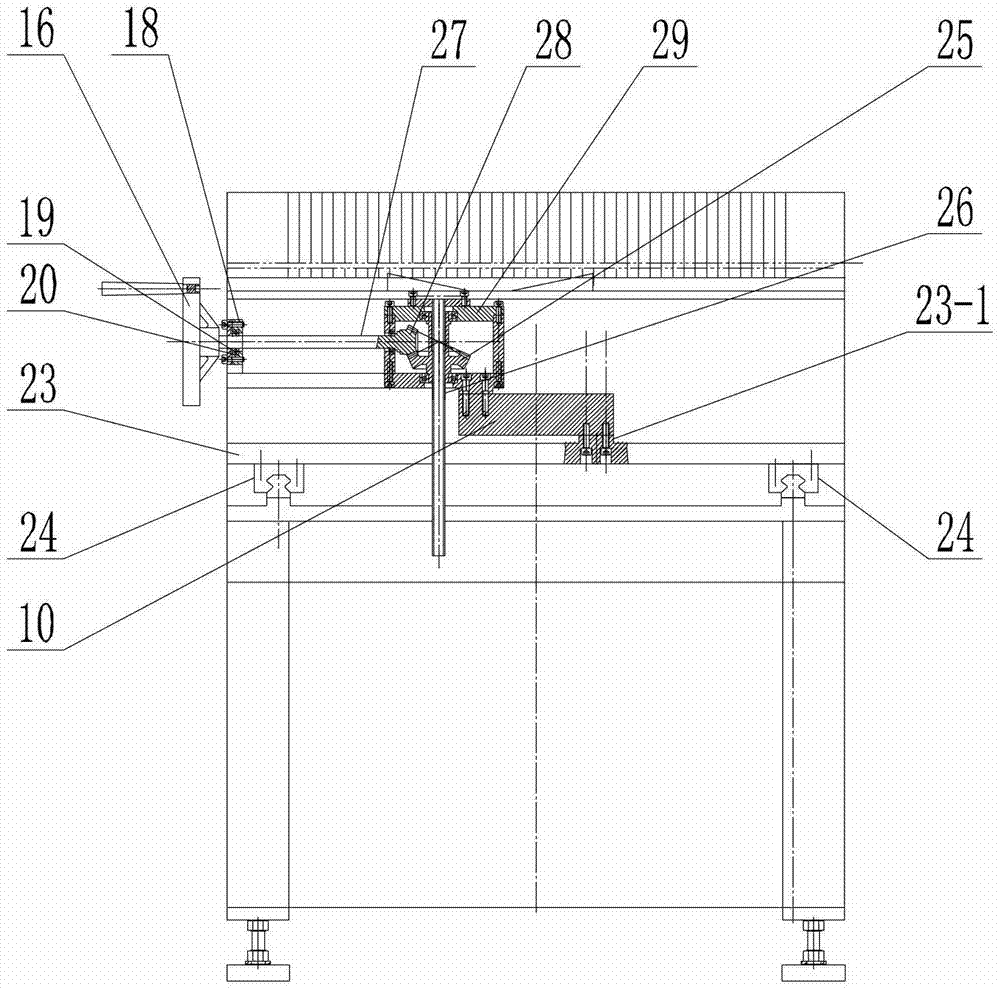

[0105] Embodiment 1: Combining Figure 1-Figure 5 Describing the present embodiment, a steam turbine blade sorting method involving thickened steam turbine blades according to the present embodiment is performed according to the following steps:

[0106] Step 1. According to the product design requirements, determine the ratio of the number of thickened blades involved in the sorting to the total number of blades as A, where the total number of blades of this product is T, and the special blades (first and last blades, locking blades) The number is a; the number of ordinary leaves is b, b=T-n-a;

[0107] Step 2. According to the design requirements of the product, the thickened blades are arranged according to the principle of uniform distribution and the serial number is determined:

[0108] Among them, the number of thickened blades is n, which is obtained from step 1, and the number of thickened blades is n=T×A;

[0109] Then, the installation position numbers of the n th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com