Patents

Literature

221results about How to "Meet assembly needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal-plastic composite mobile phone shell and forming method thereof

InactiveCN103722668AUniform wall thicknessBeautiful surfaceDomestic articlesCoatingsConvex structureUltimate tensile strength

The invention provides a metal-plastic composite mobile phone shell and a forming method thereof. The provided mobile phone shell has a metal surface and a plastic structure feature, wherein the external surface of the mobile phone shell is made of a sheet metal and is small in wall thickness, high in strength and beautiful in appearance; a convex structure feature of the internal surface of the mobile phone shell is made of plastics, so that the formation of a complex installation structure is facilitated, and the functional requirements on assembling and shock absorption and the like are satisfied. According to the forming method, structure features of the sheet metal and the plastic are firmly combined together and form an integral structure. Meanwhile, according to the forming method, the combination strength of plastics and metals is high, so that the mobile phone shell satisfies the assembling and application requirements of mobile phones, and also can be applied to the shell production fields of household appliances, computers and other industrial products.

Owner:ZHEJIANG NORMAL UNIVERSITY

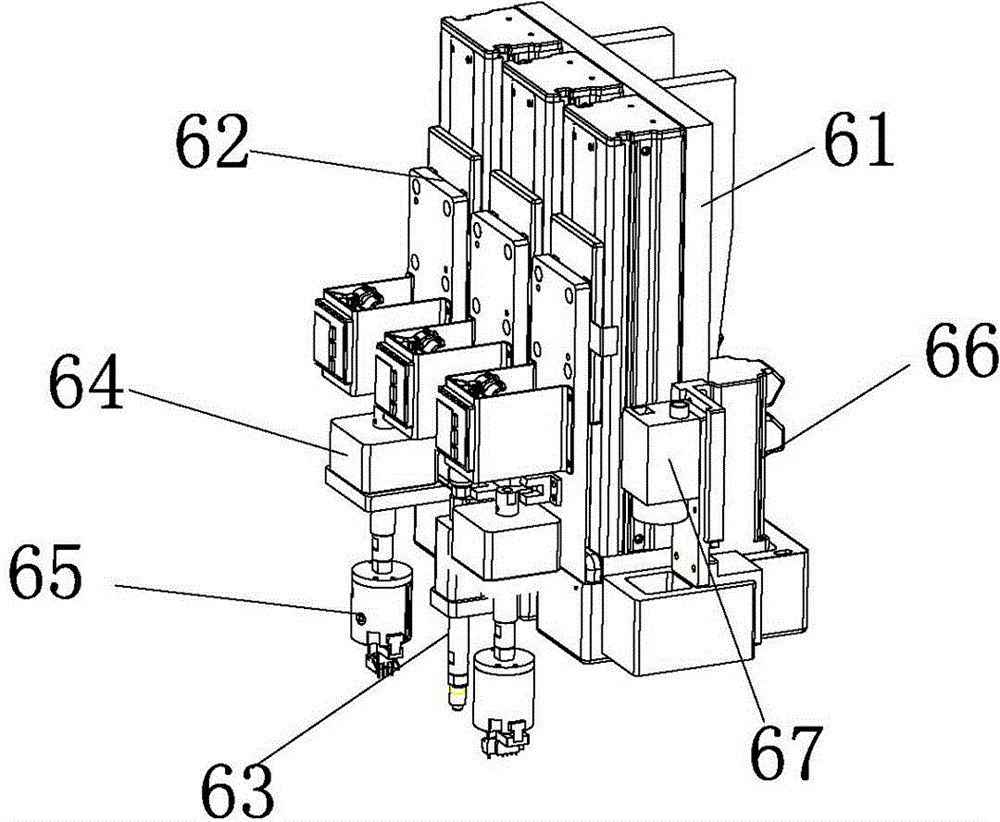

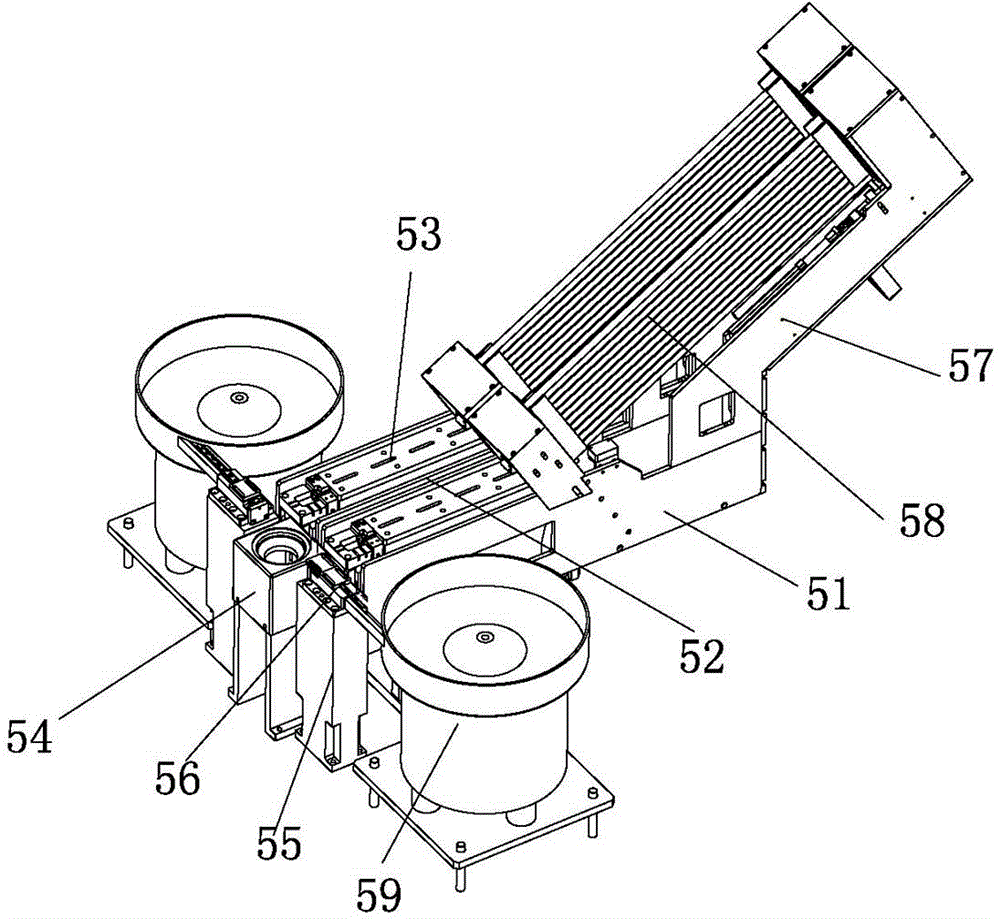

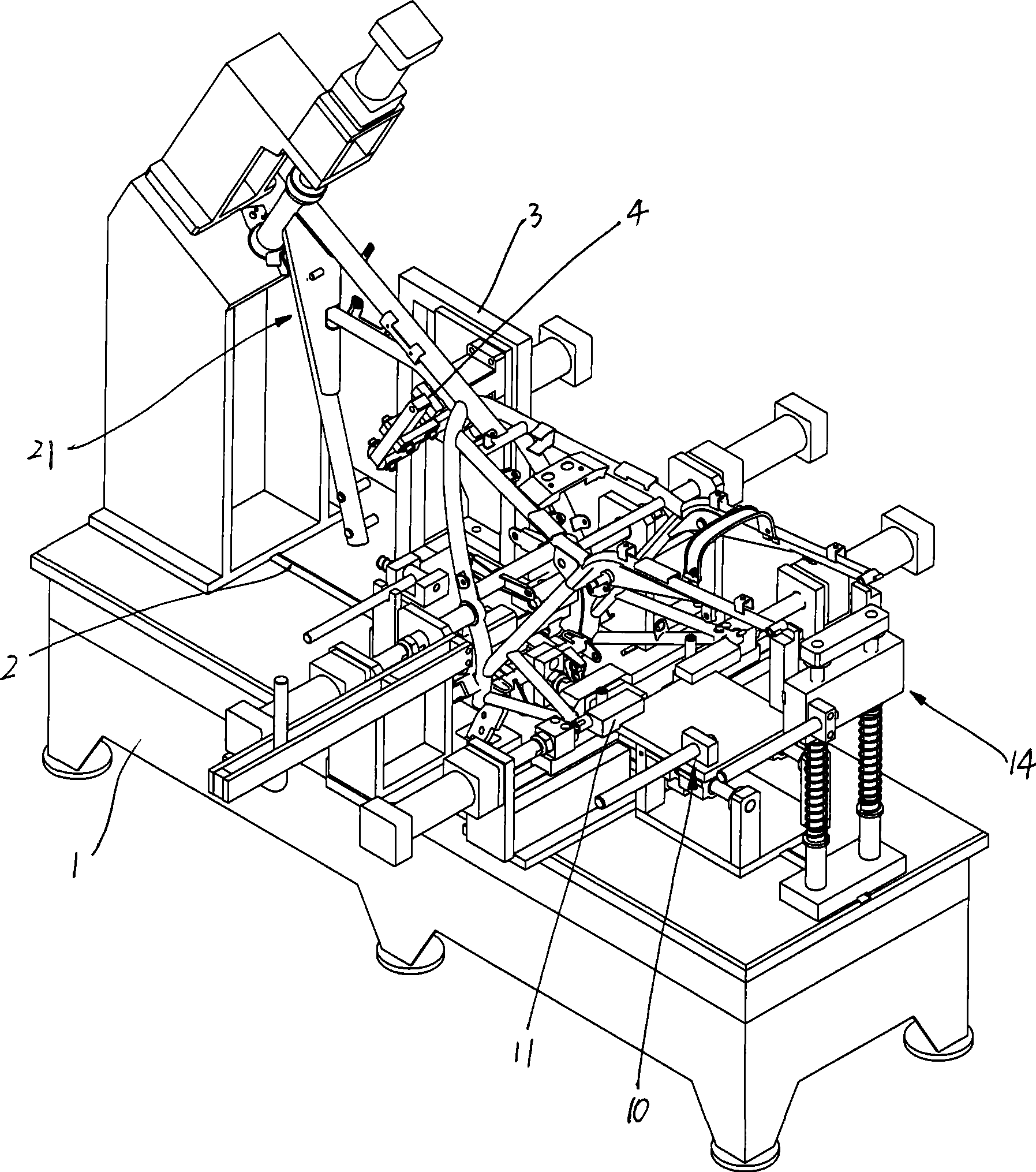

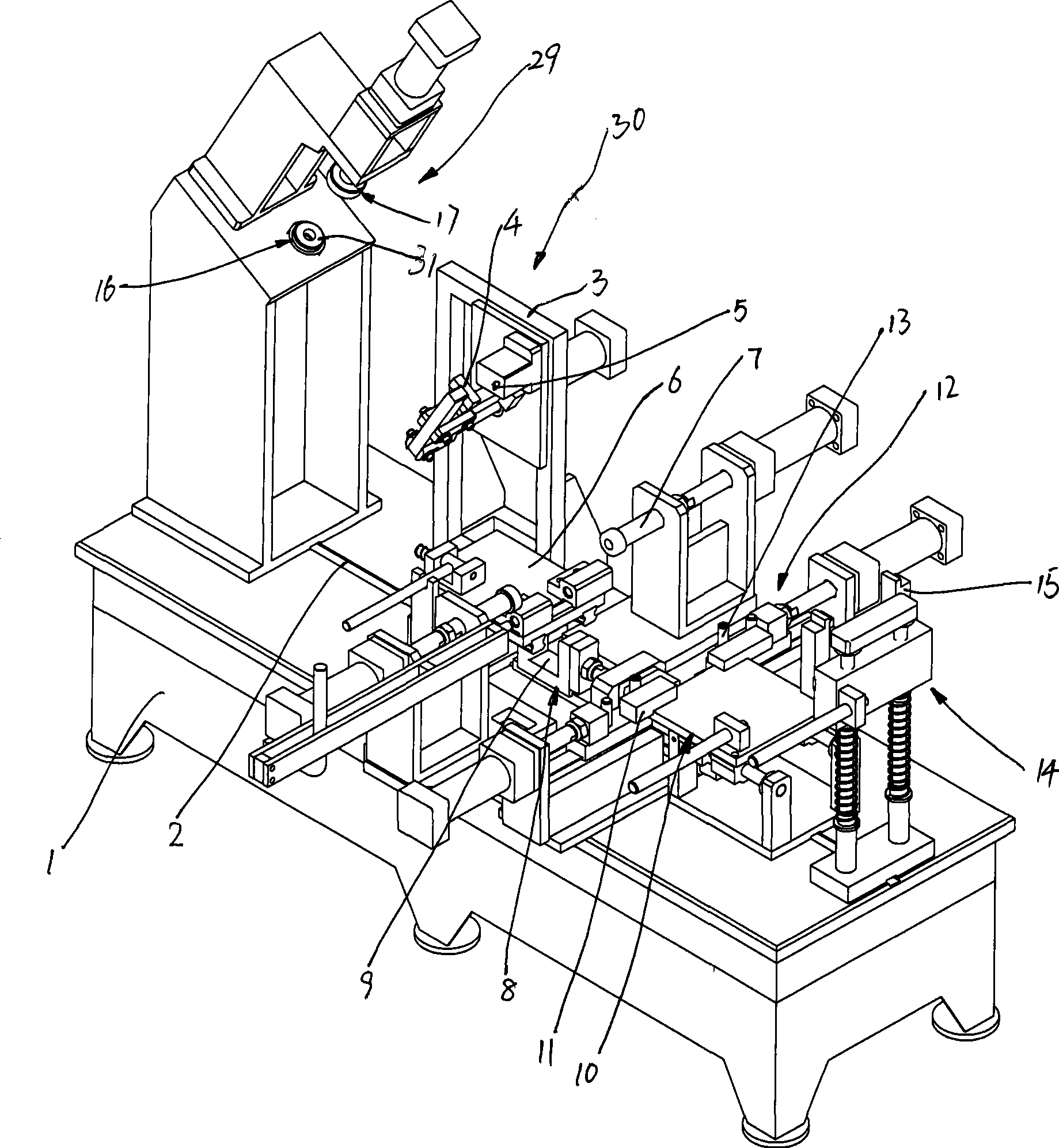

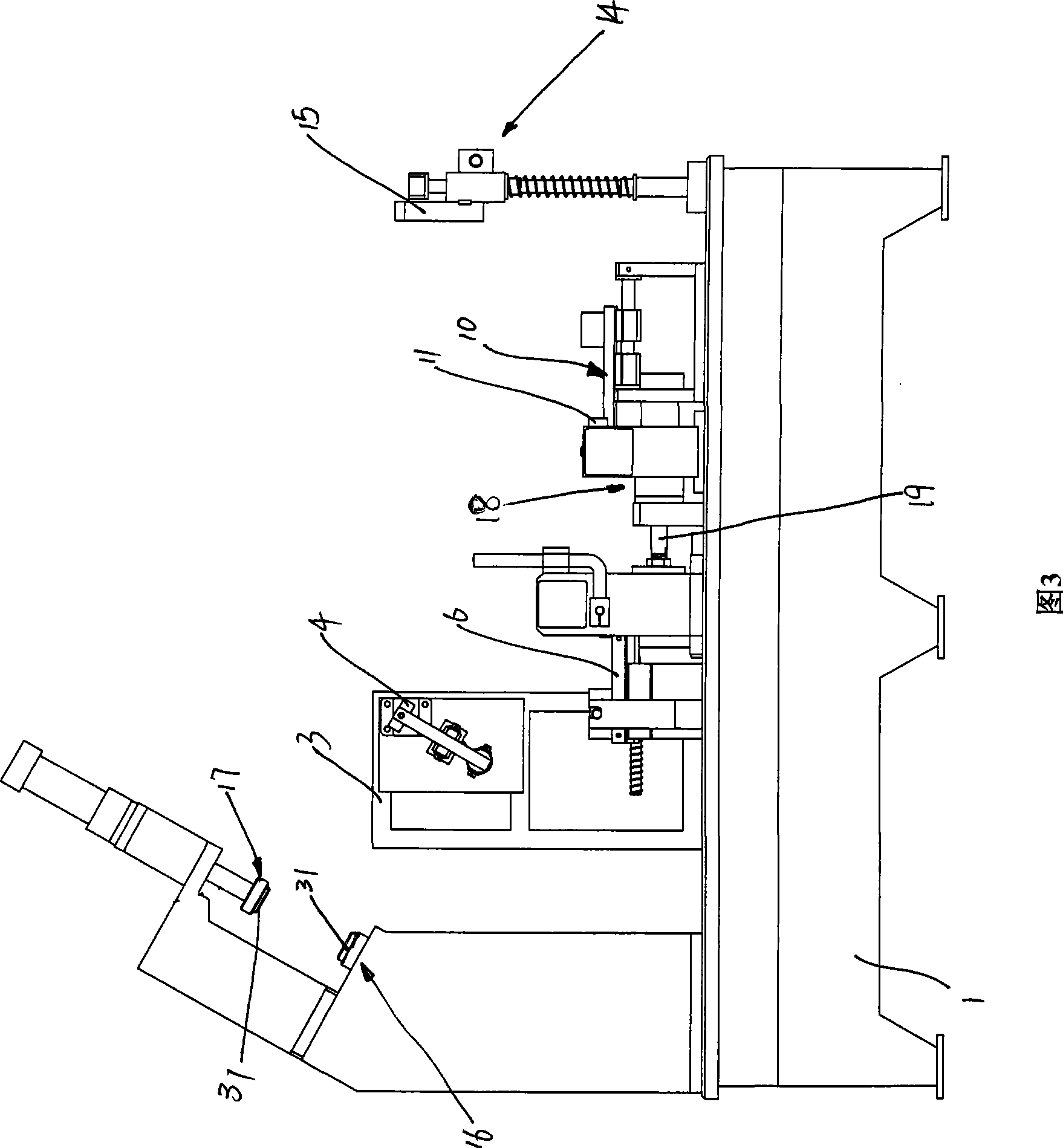

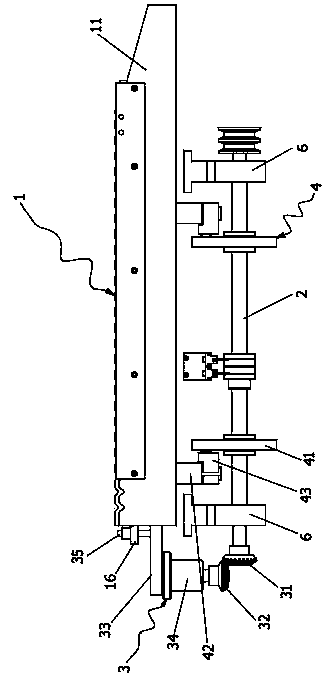

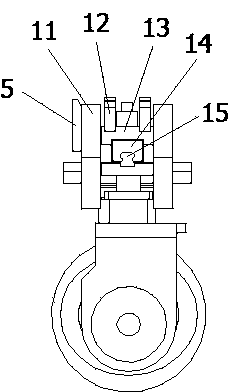

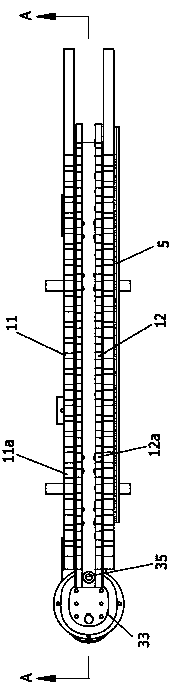

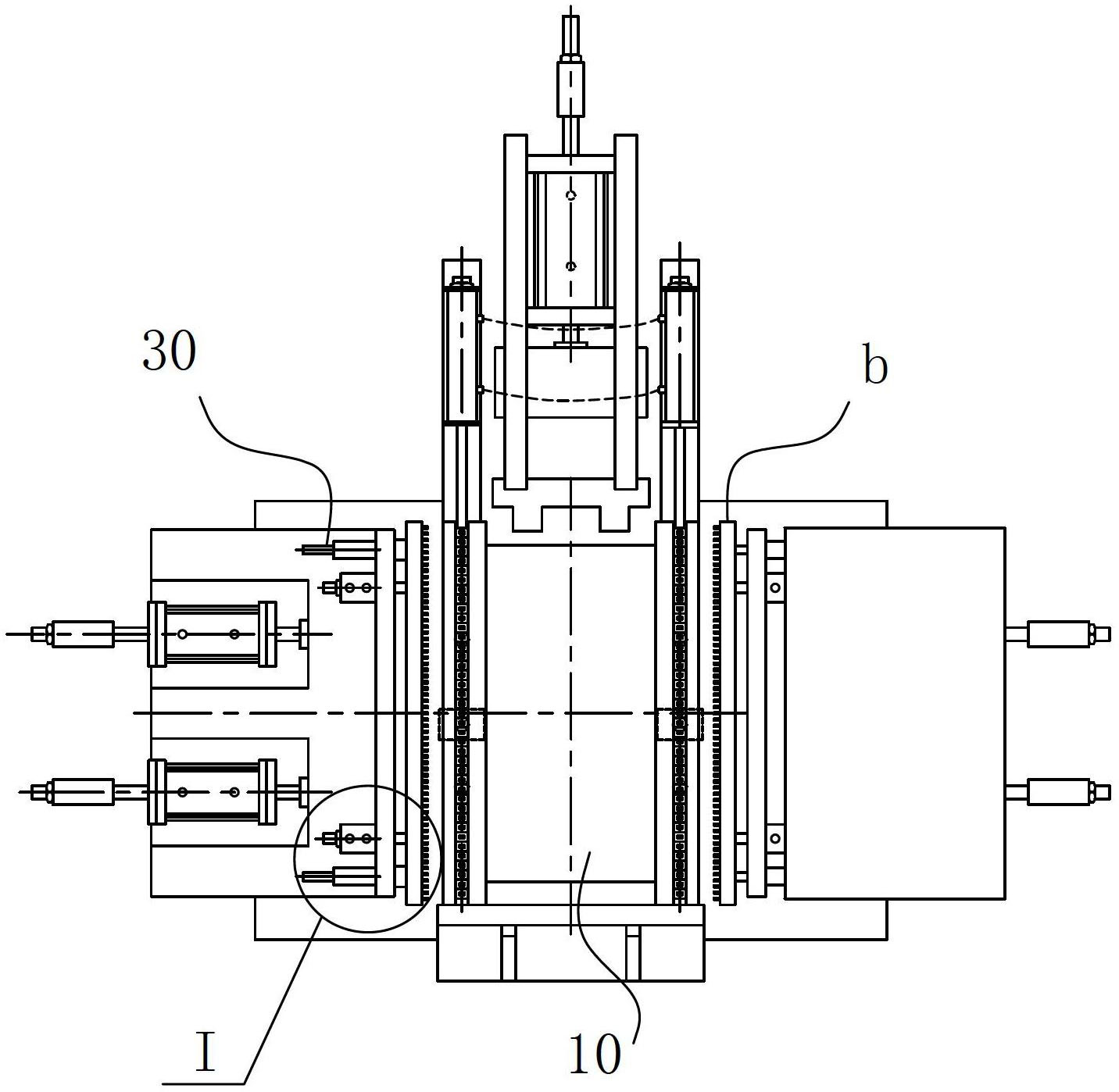

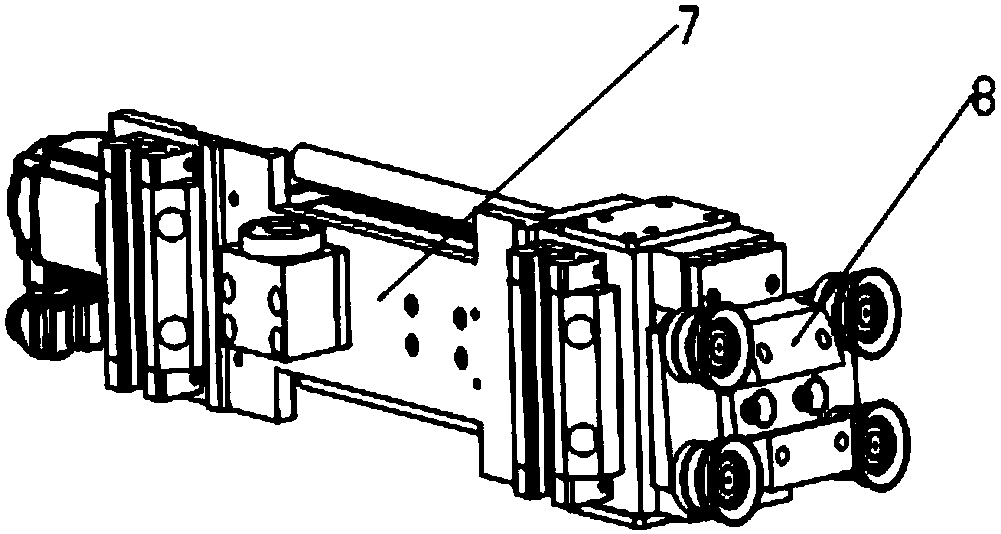

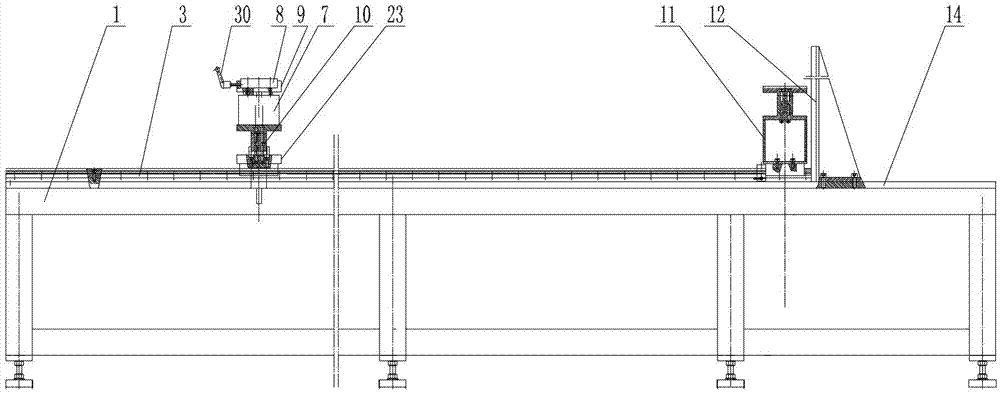

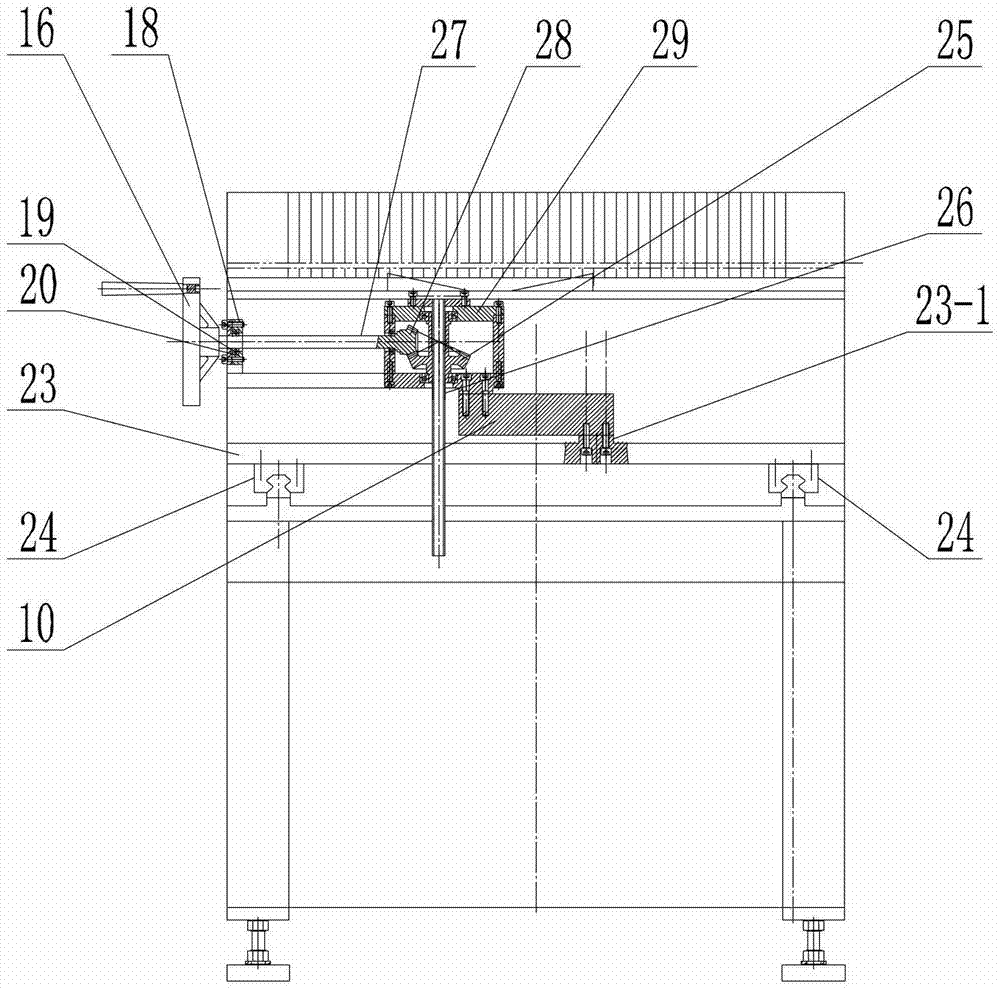

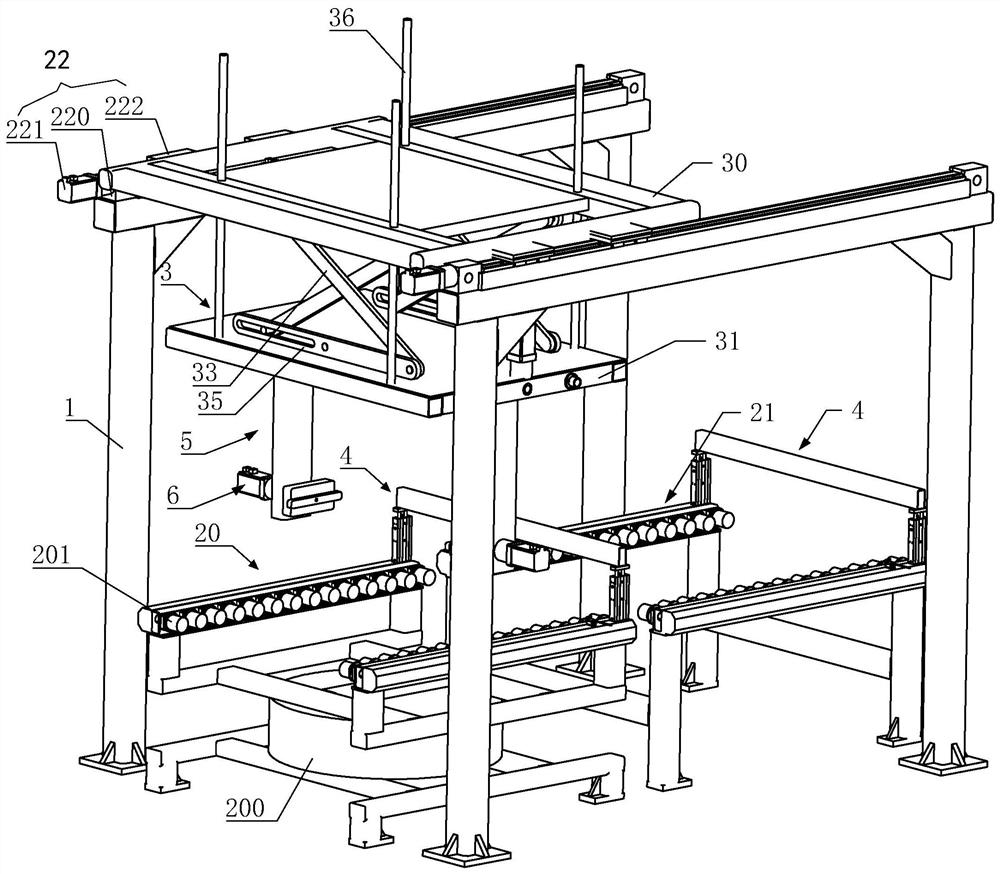

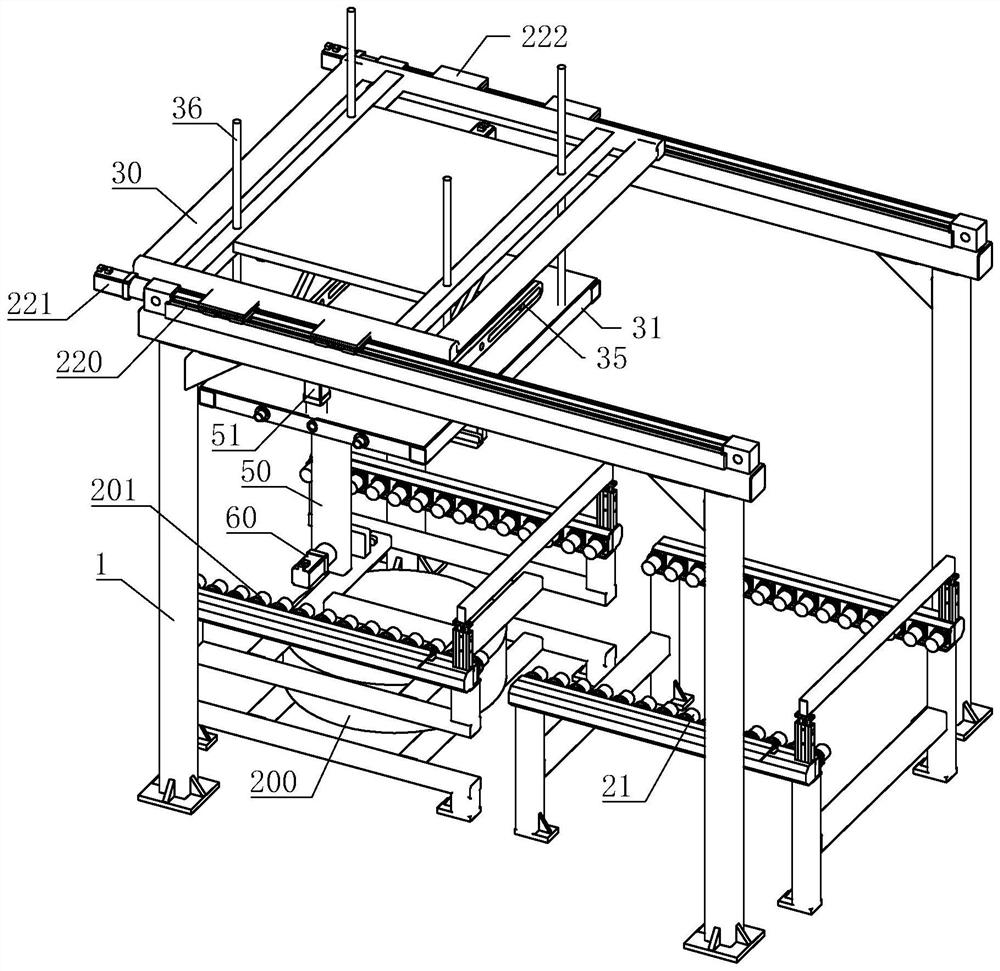

Double-work-head special-shaped insertion machine

PendingCN104582303AFetching is cheapSave round trip timePrinted circuit assemblingElectrical componentsEngineeringElectronic assemblies

The invention discloses a double-work-head special-shaped insertion machine which comprises a machine frame. The machine frame is provided with a transport support used for installation of a transport device with multiple work heads. A PCB conveyance locating device is arranged in the middle of the upper end of the machine frame, and the two sides of the upper end of the machine frame are each provided with a feeding device used for conveying electronic elements to the PCB conveyance locating device. The transport device transports and inserts the electronic elements conveyed by the two feeding devices into PCBs conveyed by the PCB transport locating device. Two work heads are adopted to take materials and insert the materials alternatively, so that the back-and-forth material taking time (about 1 second) of the work heads is saved, the insertion machine is in a working state to insert elements all the time, and therefore the inserting speed of the insertion machine is greatly increased (theoretically, the inserting speed is 1 time higher than that of an insertion machine with a single head). According to the insertion machine, each work head is provided with multiple insertion mechanical arms, the insertion machine is compatible with different special-shaped elements, and the assembly requirement for special-shaped elements of an electronic assembly market can be met.

Owner:KELI ELECTRONICS EQUIP

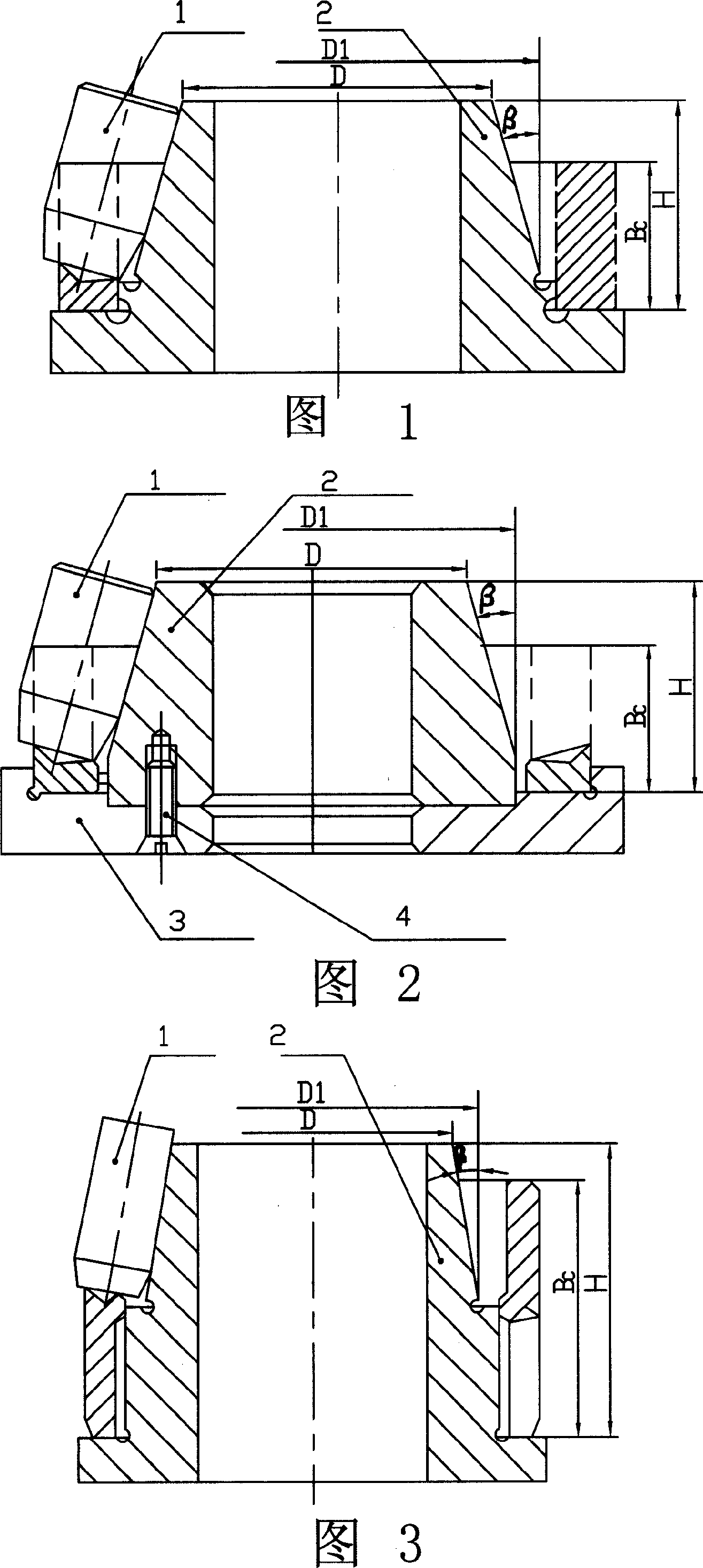

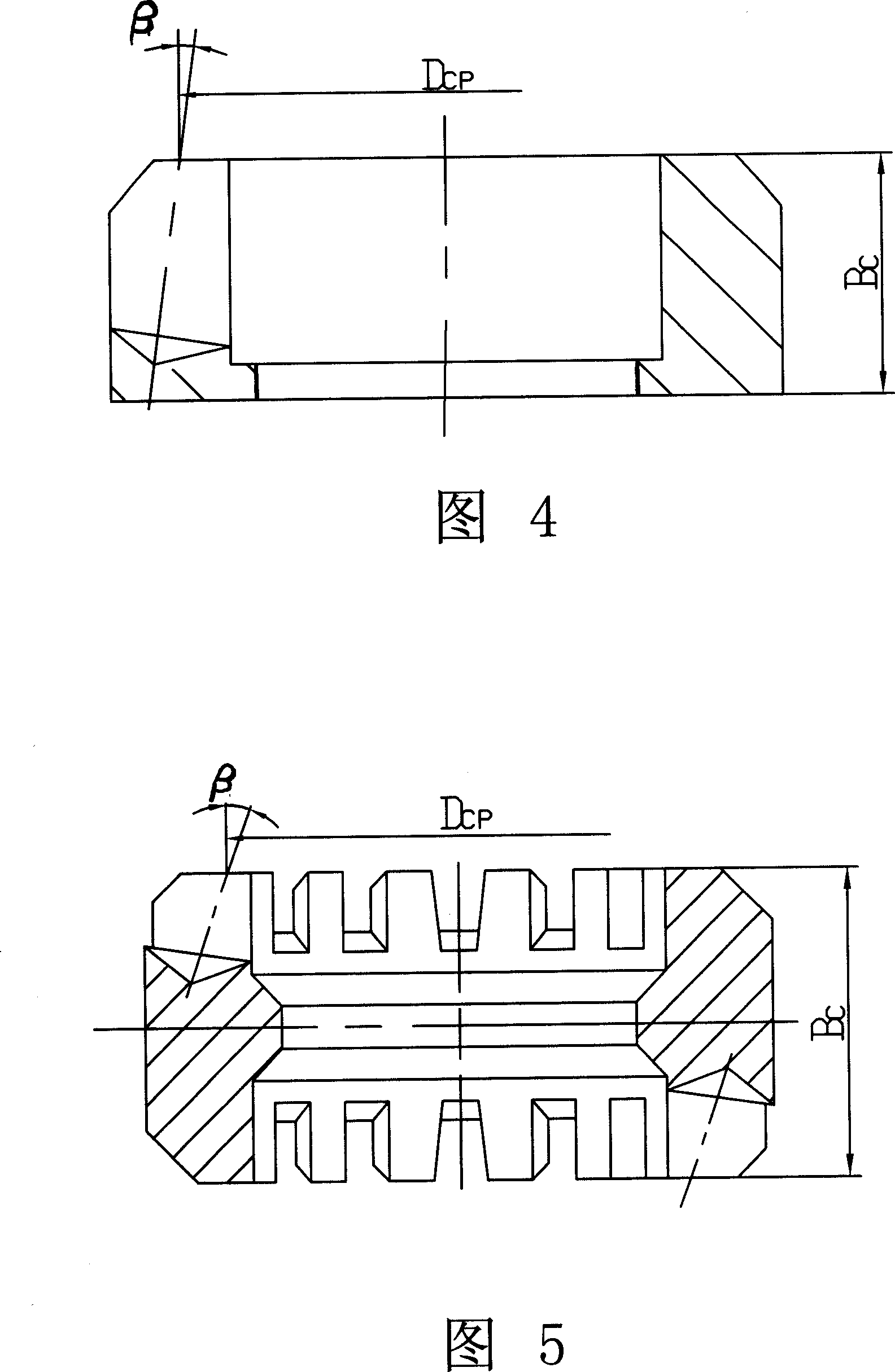

Spherical roller bearing solid cage center-diameter and angle measuring method

InactiveCN101071056AEasy to measureThe measurement method is feasibleAngles/taper measurementsMechanical diameter measurementsCircular coneEngineering

The invention relates to a test way of bearing entity holder center drive and angle, particularly relates to the test way of a sphere roller bearing entity holder center drive and the angle. Its characteristic lies in the method including the following steps: first mash and process the center die, the center die is conical die form and roller; then put said three rollers into any three cage ball pockets of tested sphere roller bearing entity. Observing the match condition between said rollers' outside surface and said die form's circular conical surface shows whether the holder center drive and angle of tested sphere roller bearing entity satisfies the designing requirement. The invention's test way is simple, feasible, and test accuracy is high, defective index is low.

Owner:BAOTA IND CO LTD

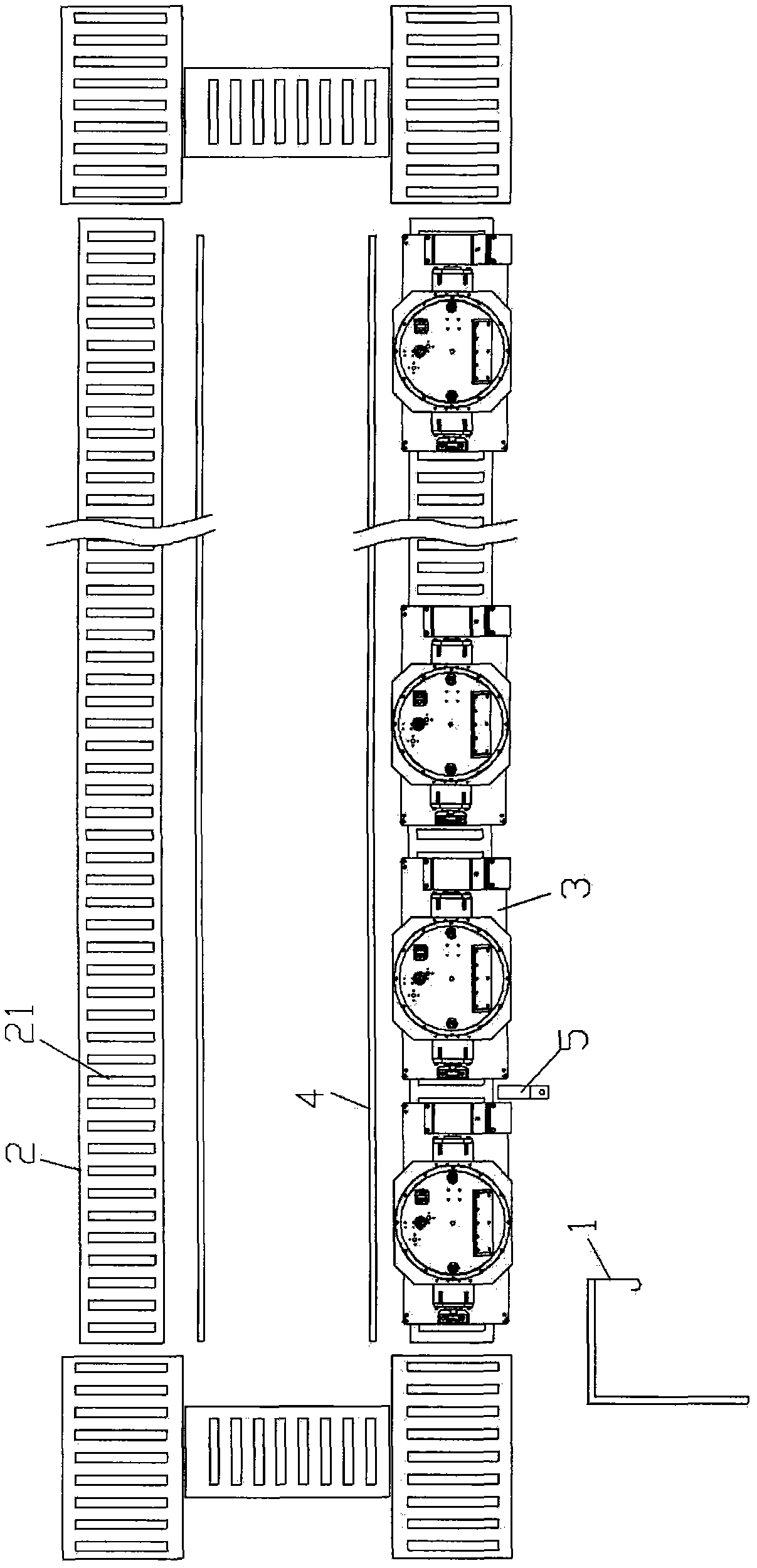

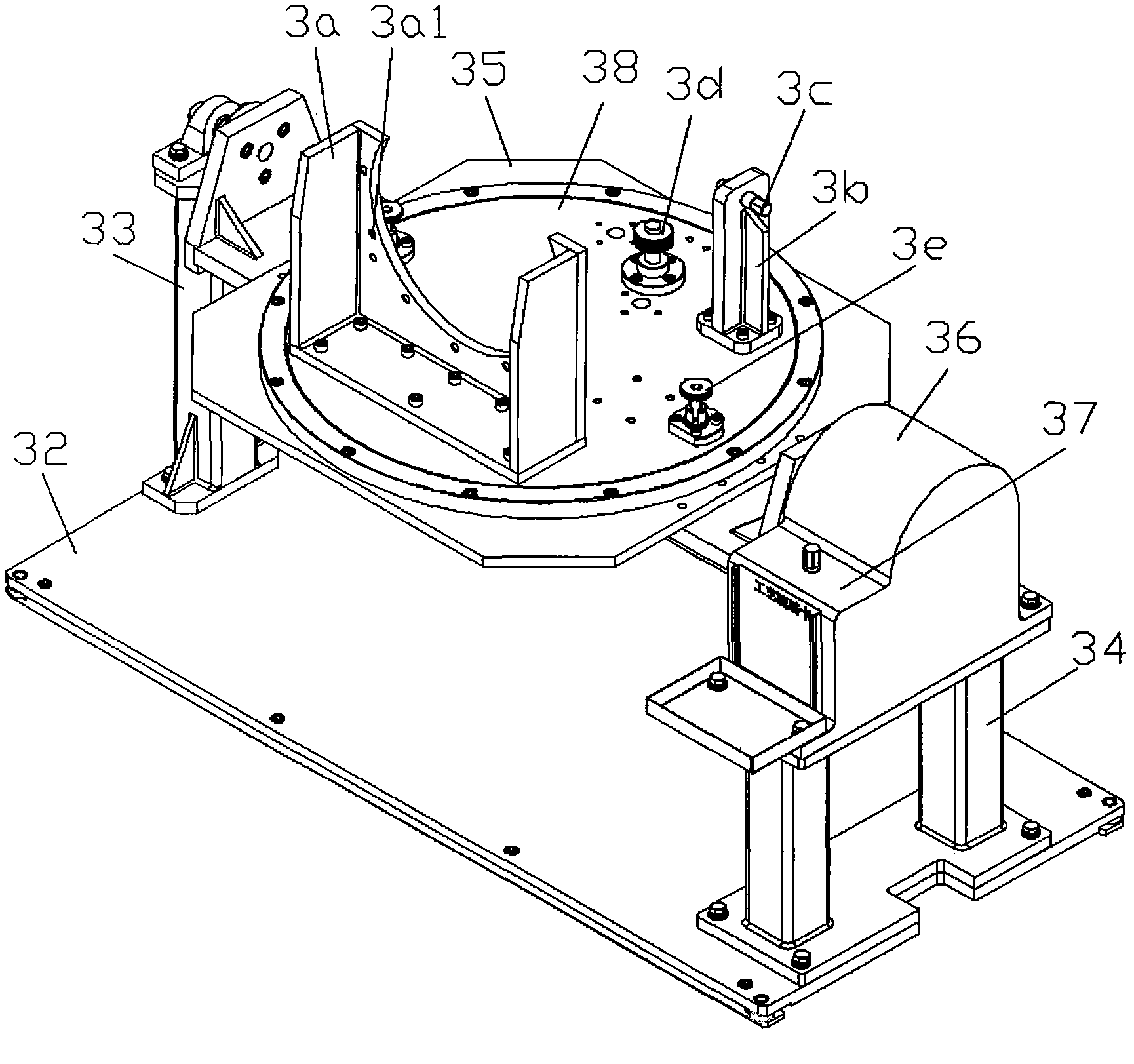

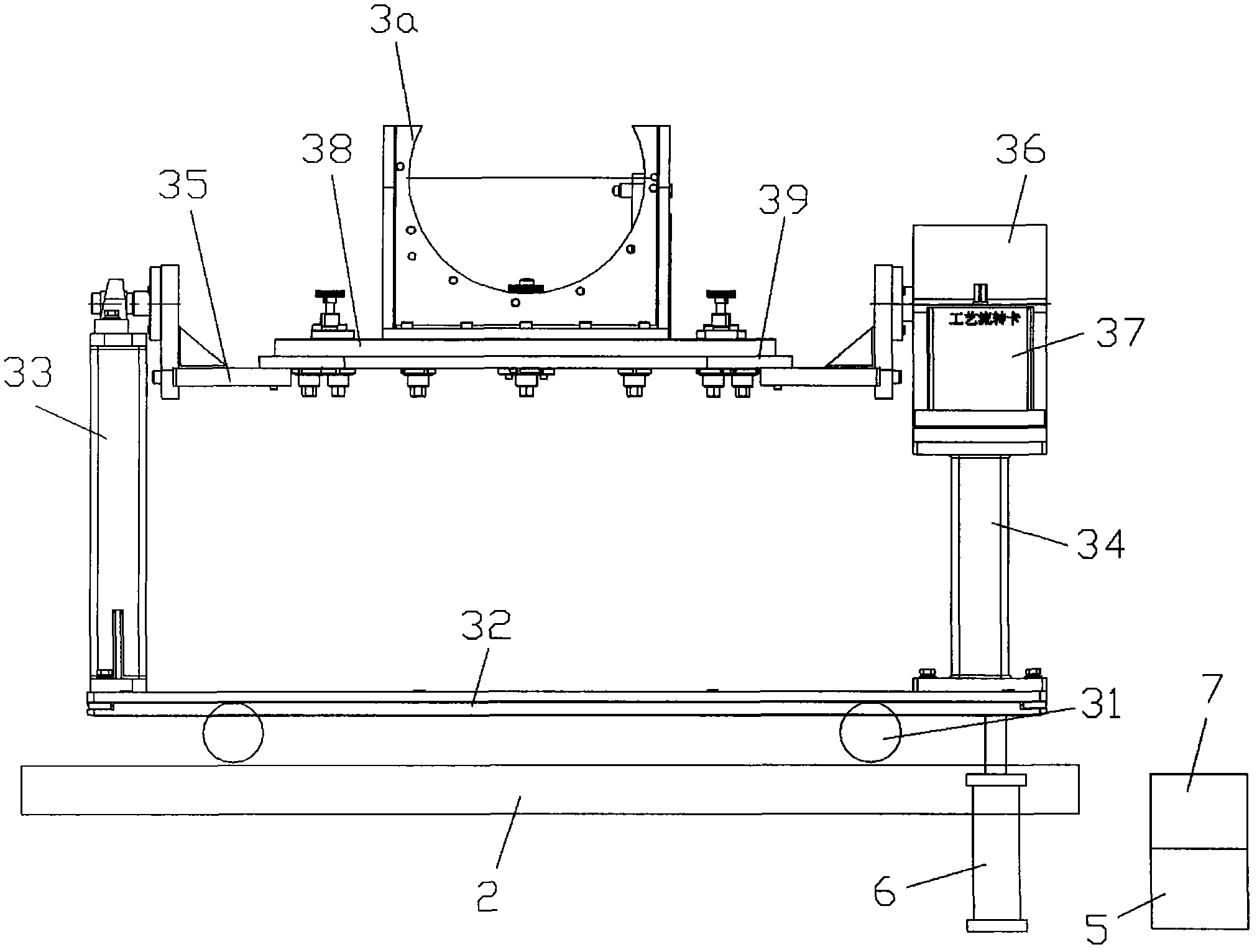

Forklift transmission assembling line

Provided is a forklift transmission assembling line. A suspension arm is disposed on the ground on one side of the periphery of a roller transmission rack in a suspended mode. A traveling wheel of a movable trolley of an assembling line is placed on a roller of the roller transmission rack. Trolley-stop blocking cylinders are fixed on the ground of each station and fixed on the ground on two sides of the roller transmission rack, and a pneumatic switch of the trolley-stop blocking cylinder is disposed on an operating platform of each station. A breast board is placed on the inner-side ground of the roller transmission rack arranged in the shape of a ring, and words for operating steps and precautions are arranged on the breast board. A support platform of the forklift transmission assembling line can rotate 360 degrees, and a workbench of the forklift transmission assembling line can rotate 360 degrees on the surface of the operating platform. During direction changes in assembly, carrying trouble of workers can be removed. The forklift transmission assembling line uses a spring pin for locating after rotation of the workbench so as to avoid rotation of the workbench during assembly. The forklift transmission assembling line is especially suitable for production and assembly of forklift transmissions and low in equipment cost, lowers labor intensity of workers, improves production efficiency, and simultaneously is convenient for management and operation of workers.

Owner:ZHEJIANG ZHONGCHAI MACHINERY

Clamping fixture for correcting vehicle frame

InactiveCN101376208AReduce scrapMeet assembly needsMetal working apparatusMechanical measuring arrangementsVehicle frameEngineering

The invention relates to a correcting fixture for a chassis, which comprises a stander, a fixing device used for fixing the chassis and arranged on the stander, as well as a first detection block, a second detection block and a third detection block which are used for detecting position relationships among components of the chassis. Correcting pressure heads perpendicular to detection surfaces are arranged on both sides of the first detection block and used for correcting the distance of a pair of bent pipes on the chassis; a notch for accommodating a part of chassis is formed on the second detection block, and used for detecting and correcting an angle between a pair of bent pipes and a headstock; and correcting seats can be movably arranged on both sides of the third detection block, and used for correcting the distance of a pair of rear bracing pipes. The correcting fixture can detect and correct the position relationships among the components of the chassis, so as to enable the components to meet the assembly requirements, and enable assembly procedures to be smoothly performed, thereby improving production efficiency, reducing scrapping of parts, saving raw materials and reducing production cost.

Owner:庄添财

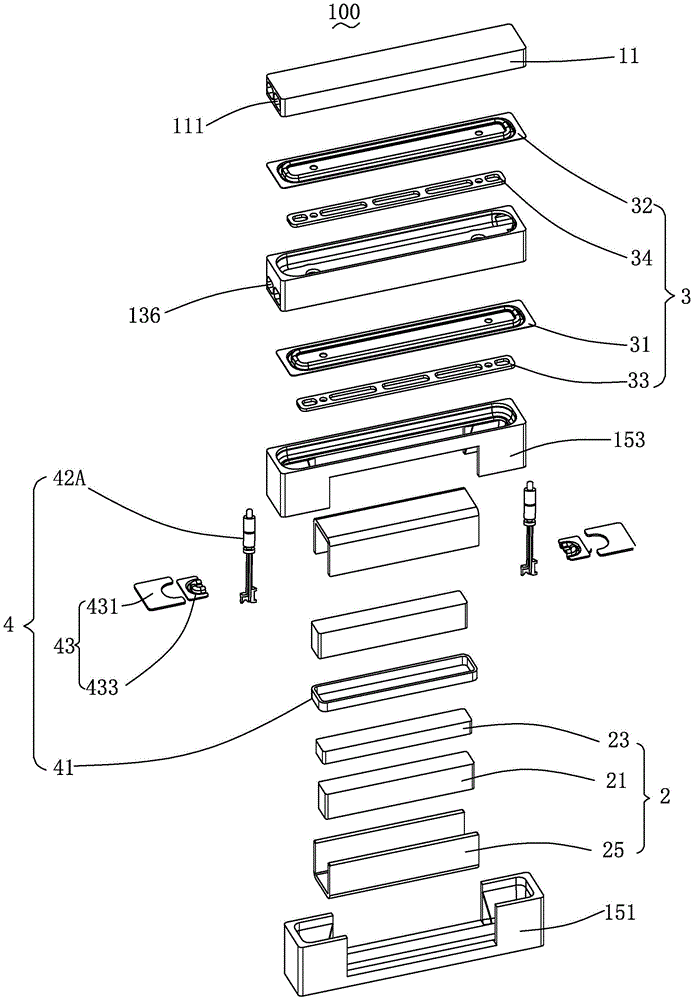

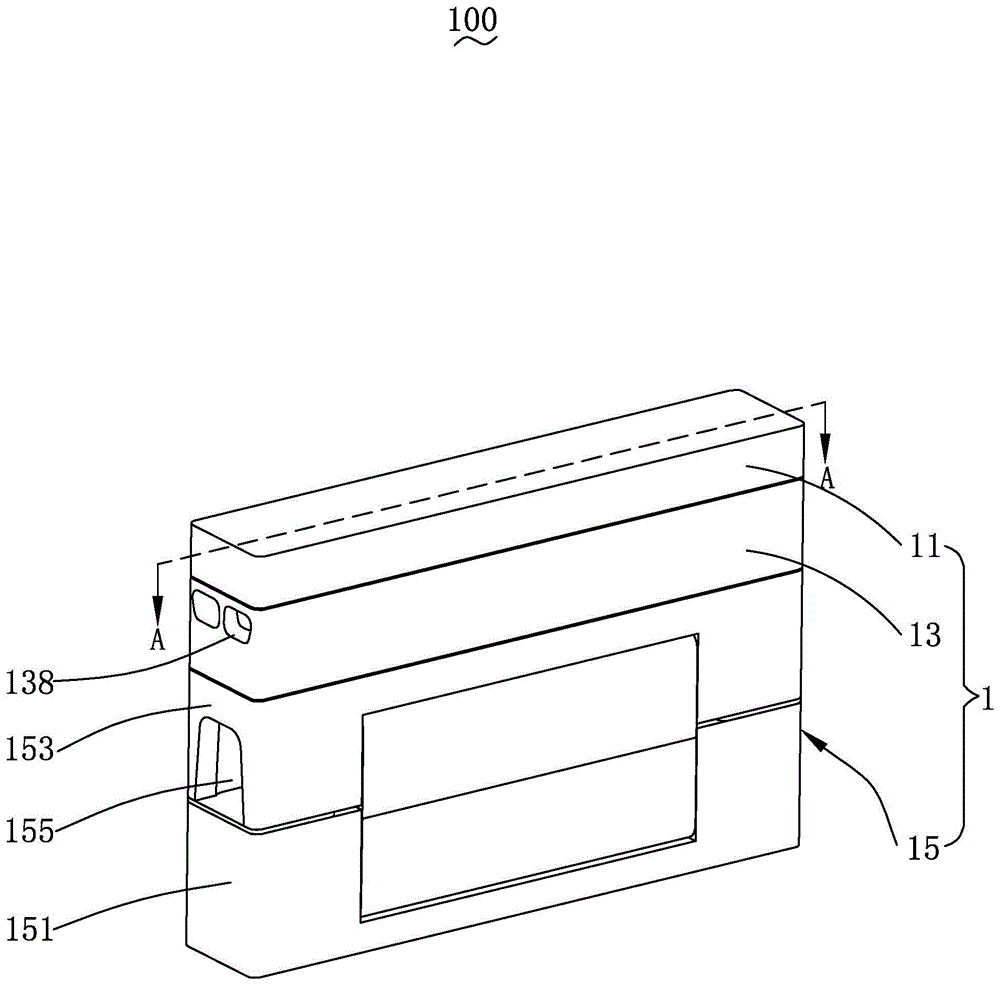

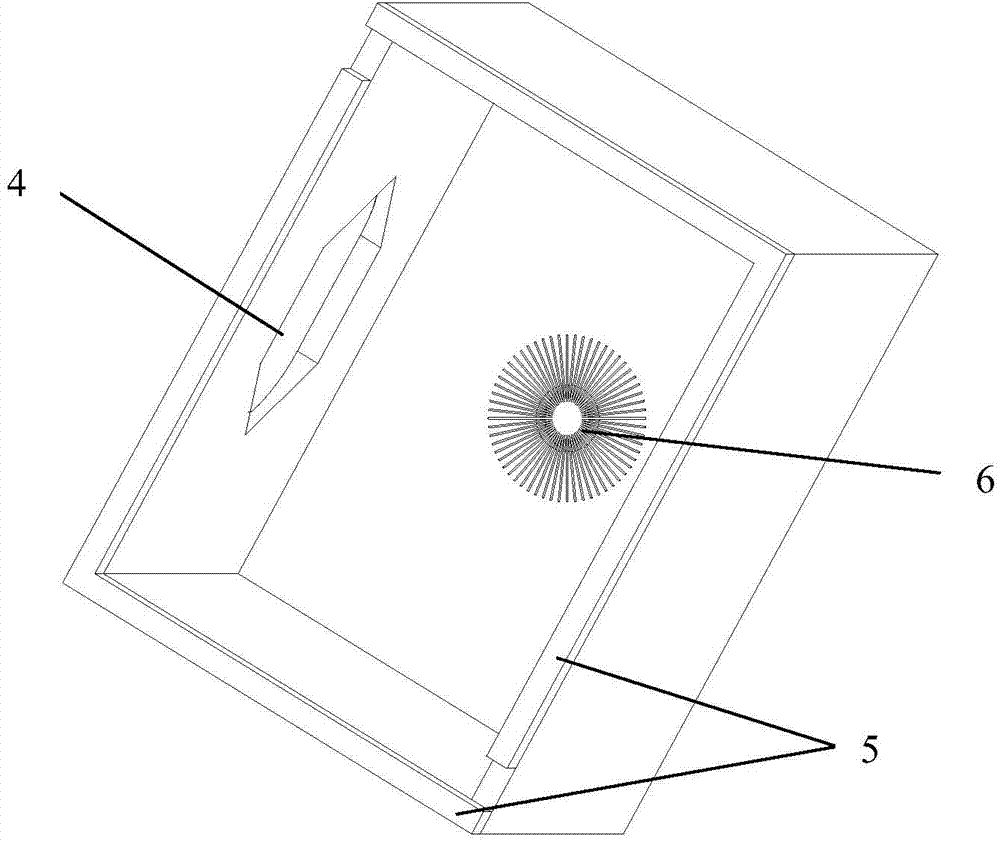

Loudspeaker

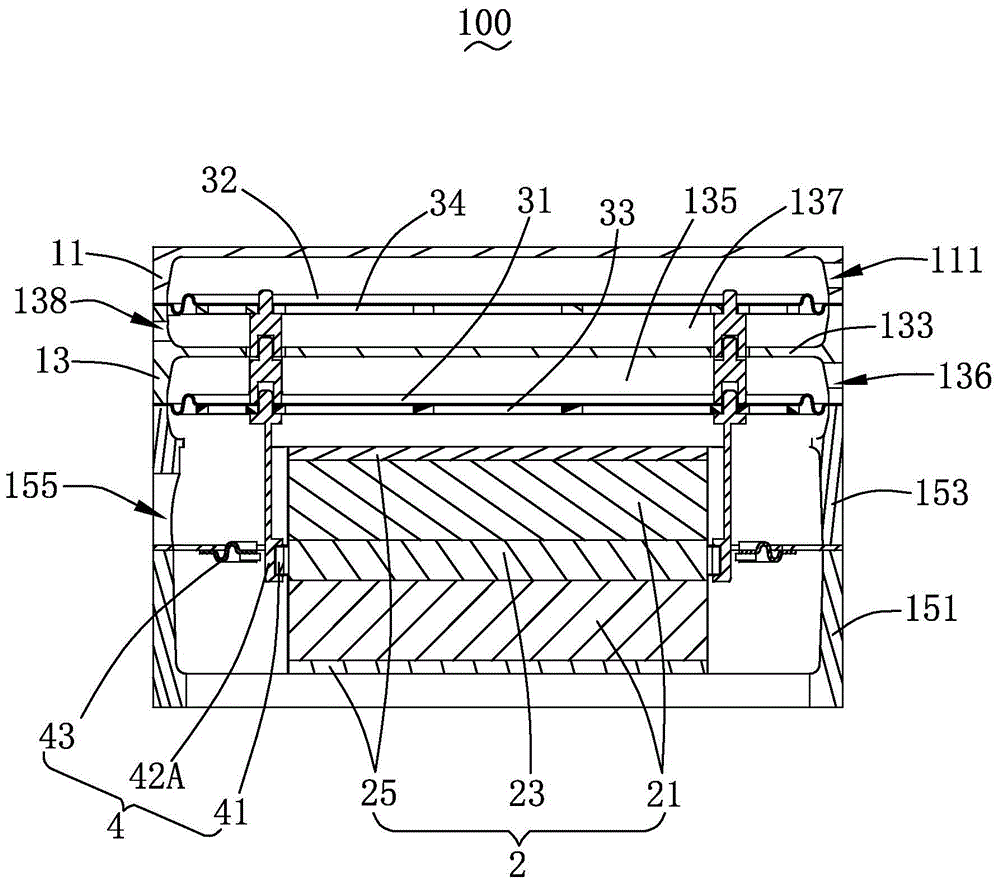

InactiveCN105681984AHigh sensitivityGuaranteed sound effectElectrical transducersEngineeringLoudspeaker

The invention provides a loudspeaker. The loudspeaker includes a casing, a magnetic circuit system accommodated in the casing, a diaphragm system and a driving device, and the diaphragm system includes a plurality of diaphragms arranged perpendicular to the moving direction of the driving device and arranged adjacent to the The diaphragm between the diaphragms is used to hinder the air circulation between the adjacent diaphragms, and the partition divides the space between the adjacent diaphragms into two cavities that are not connected to each other. The magnetic circuit system of the loudspeaker generates driving force, which is transmitted to the transmission member through the voice coil, and the transmission member simultaneously drives a plurality of the diaphragms, and the plurality of diaphragms vibrate at the same time, and the vibration phase same. The loudspeaker of the present invention is conducive to improving the sensitivity of the loudspeaker without increasing the size of the diaphragm.

Owner:AAC MICROTECH CHANGZHOU

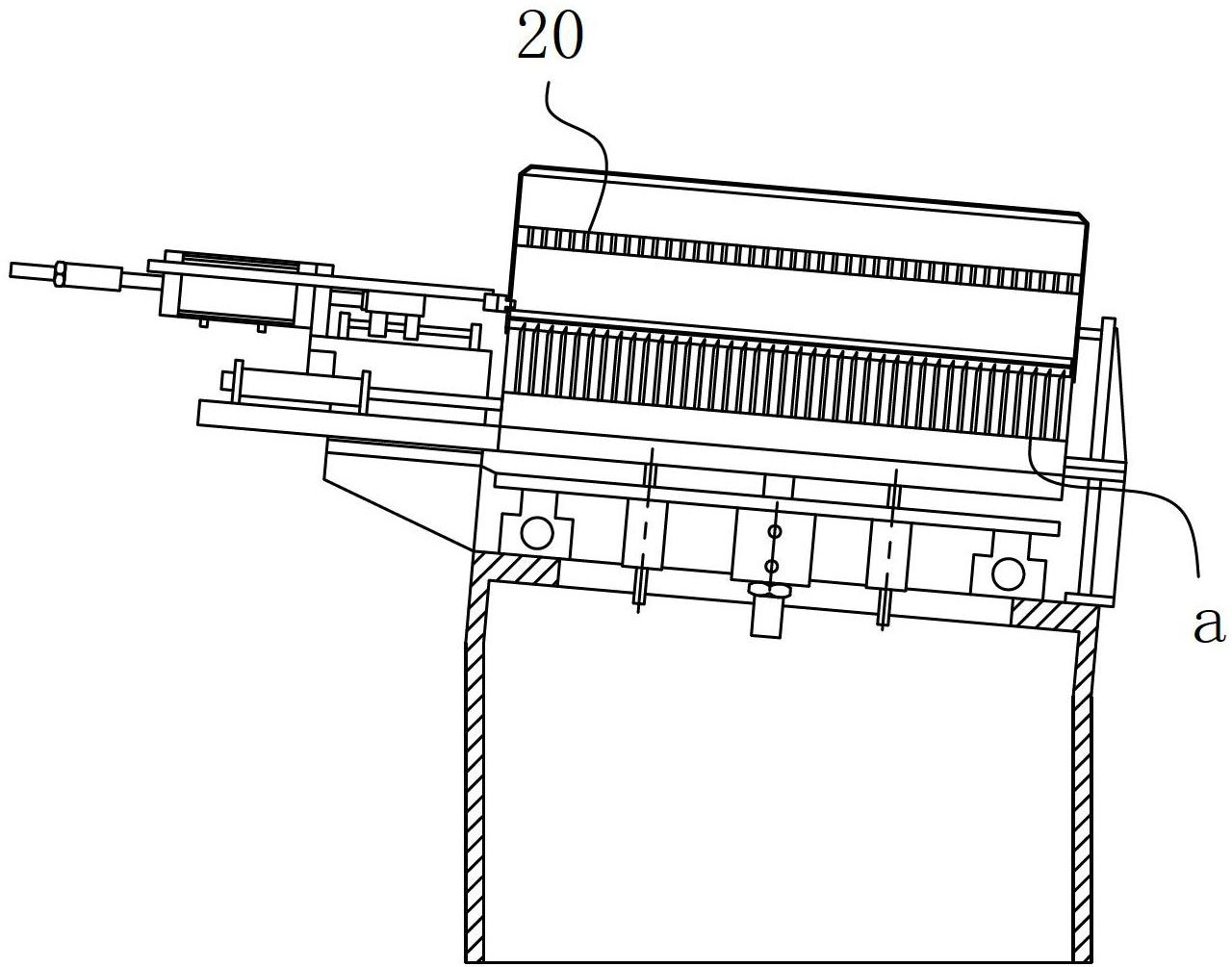

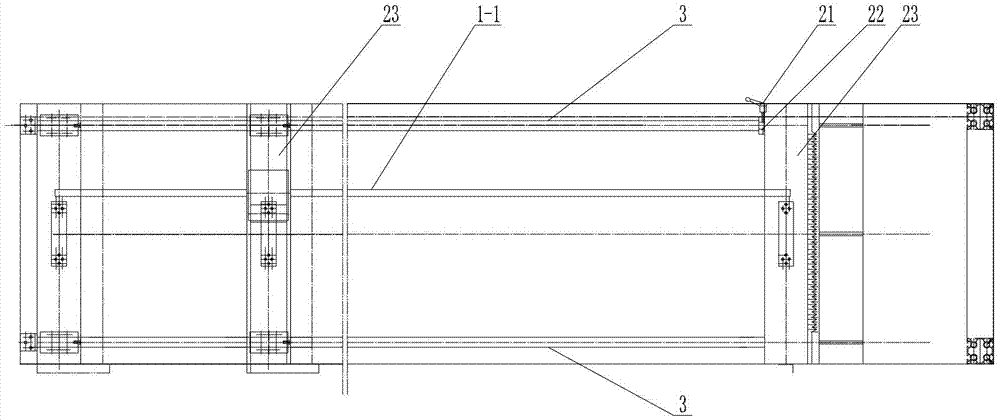

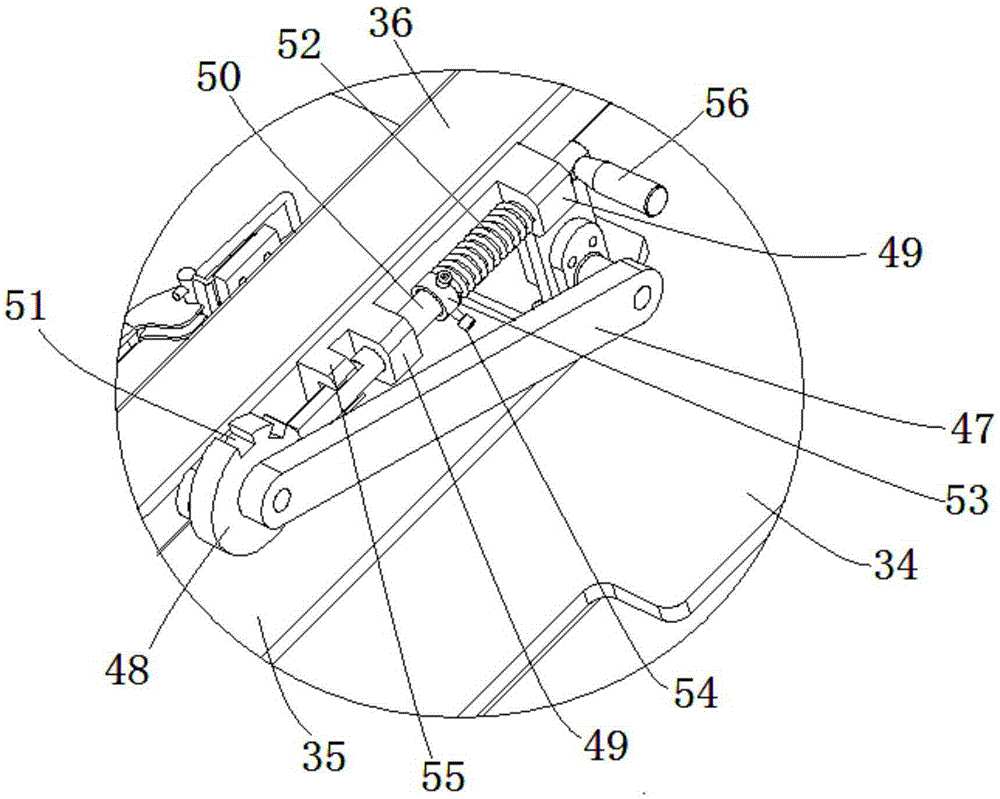

Transmission mechanism for automatic assembly of eyebrow pencils

The invention discloses a transmission mechanism for the automatic assembly of eyebrow pencils. The transmission mechanism comprises a conveying belt which is located on a workbench plate and a main drive camshaft which is located below the workbench plate, wherein the conveying belt consists of two parallel fixed conveying plates, which are fixedly arranged on the workbench plate, and two parallel movable conveying plates which are arranged between the two fixed conveying plates, and groove grids which are arranged at equal intervals and are used for locating and placing the eyebrow pencils are formed in upper plate edges of the fixed conveying plates along the length direction; the main drive camshaft is arranged in a manner of being parallel to the conveying belt and is provided with a reciprocating cam mechanism, which is used for driving the movable conveying plates to do back-and-forth reciprocating movement, and an undulating cam mechanism, which is used for driving the movable conveying plates to do rise-and-fall undulating movement, the movable conveying plates do rise-advancing and fall-retreating combined motion to push the eyebrow pencils in the groove grids of the fixed conveying plates to advance in a grid-by-grid manner, and then, the online transmission for the automatic assembly of the eyebrow pencils is realized. The transmission mechanism is simple in structure and stable in operation and can meet the assembly requirements of the eyebrow pencils for online transmission flow-line production.

Owner:WENZHOU POLYTECHNIC

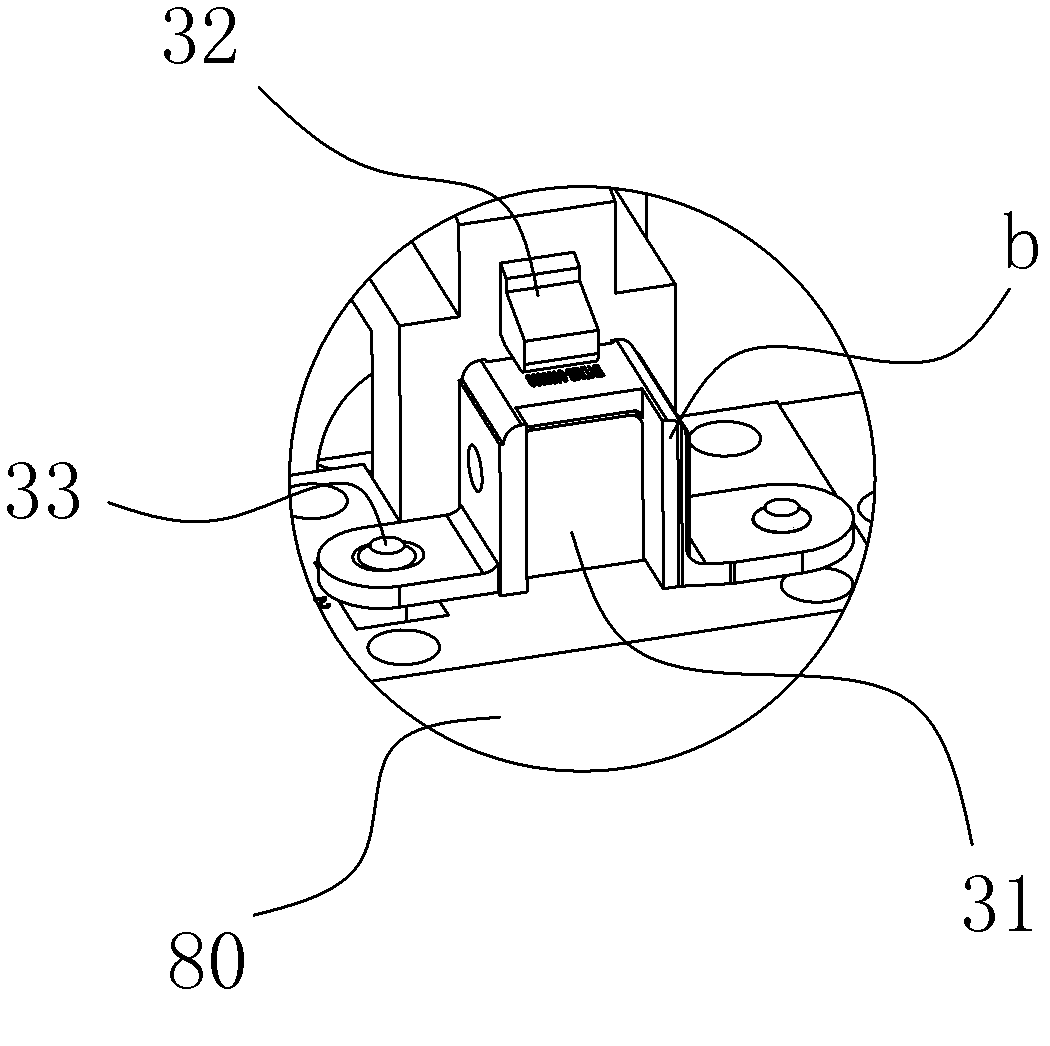

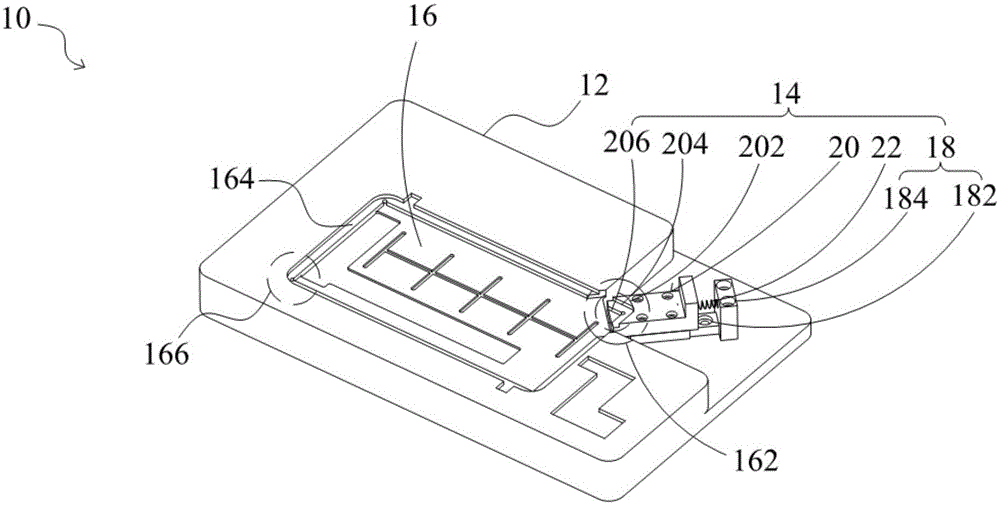

Push type locking and unlocking mechanism

ActiveCN105134730ASolve the problem of self-unlockingShort unlocking strokeSnap-action fastenersEngineeringTorsion spring

The invention discloses a push type locking and unlocking mechanism. The push type locking and unlocking mechanism comprises a shell, a drawer, an unlocking button and an elastic element, wherein a drawer cavity and a drawer opening are formed in the shell; the drawer is arranged in the drawer cavity in a sliding mode and used for carrying a cup rack, or an ashtray or a storage box; the drawer is provided with a first buckling part; the unlocking button is arranged on the shell and can move vertically; the elastic element is arranged between the shell and the drawer. The push type locking and unlocking mechanism further comprises a sliding block and a reset torsion spring, wherein the sliding block is arranged on the shell in a sliding mode and can move leftwards and rightwards under the driving of the unlocking button; a second buckle moving leftwards and rightwards along the sliding block is arranged on the sliding block; when the sliding block is in a locking position, the second buckle and the first buckle are mutually engaged; when unlocking is needed, the sliding block drives the second buckle to retreat from the first buckle, so that unlocking is achieved; the two ends of the reset torsion spring are hooked on the shell and the sliding block respectively. By means of the push type locking and unlocking mechanism, the problem of self-unlocking of the mechanism caused by severe brake action when an accident occurs is solved. The push type locking and unlocking mechanism further has the advantages of being shorter in unlocking stroke, higher in space utilization rate and the like. More assembly requirements can be met.

Owner:YANFENG ADIENT SEATING CO LTD

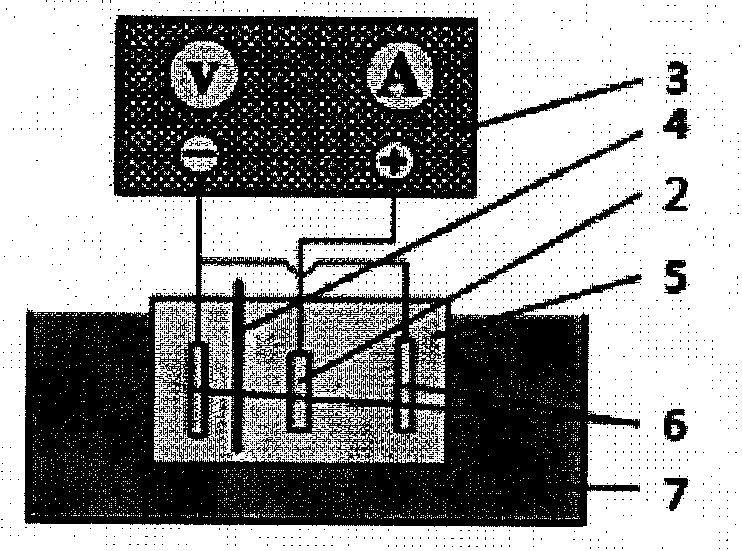

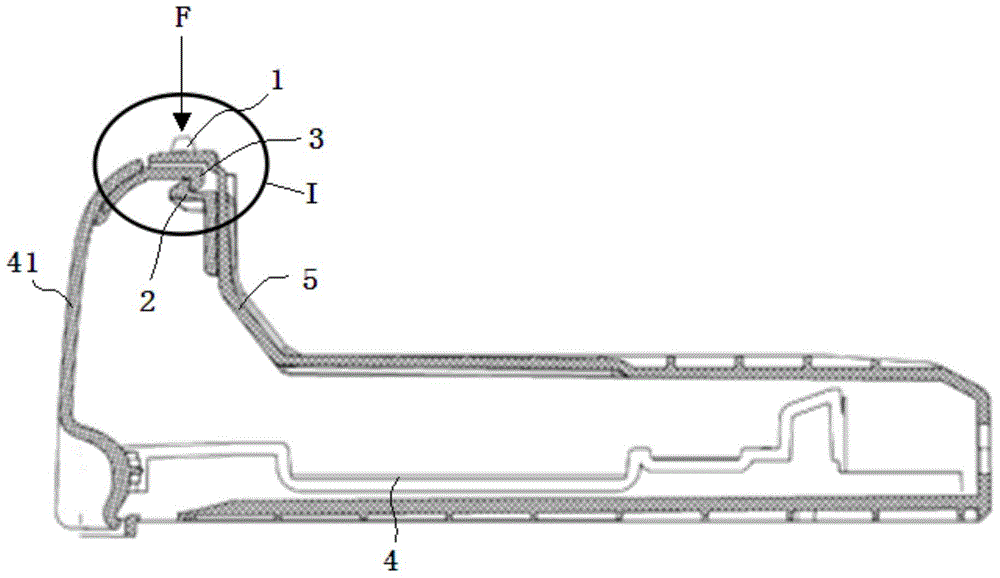

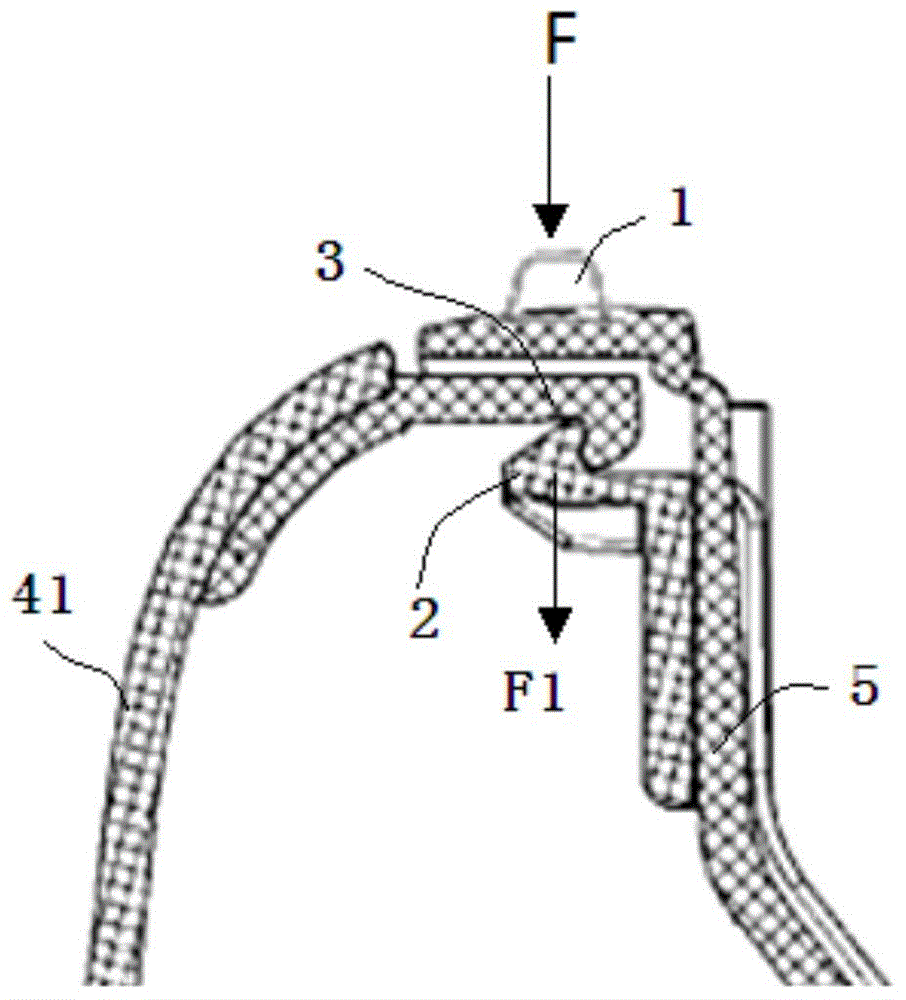

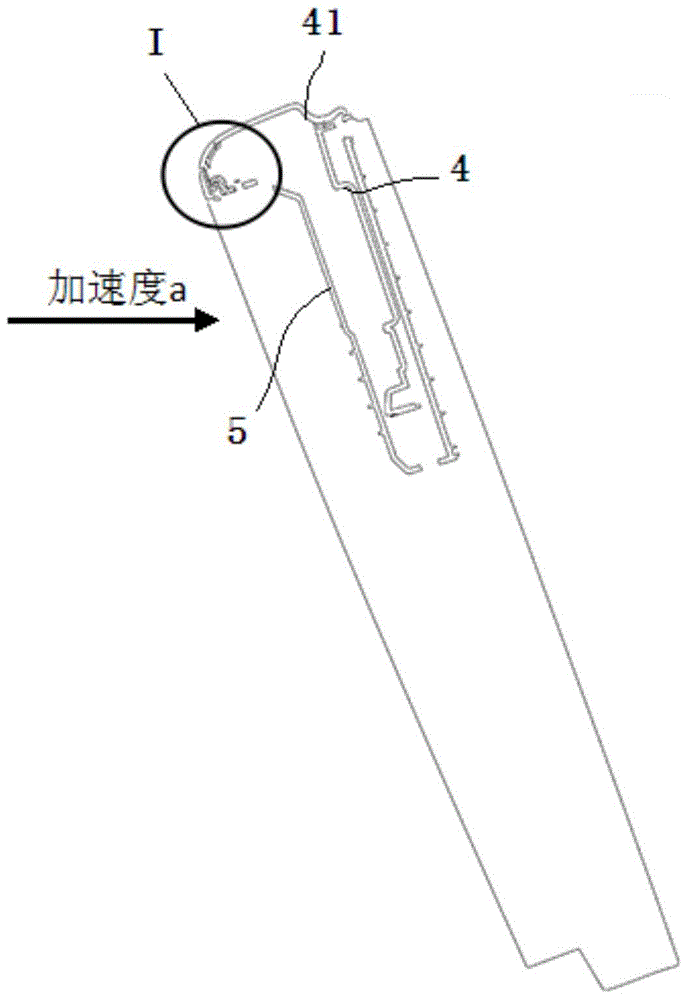

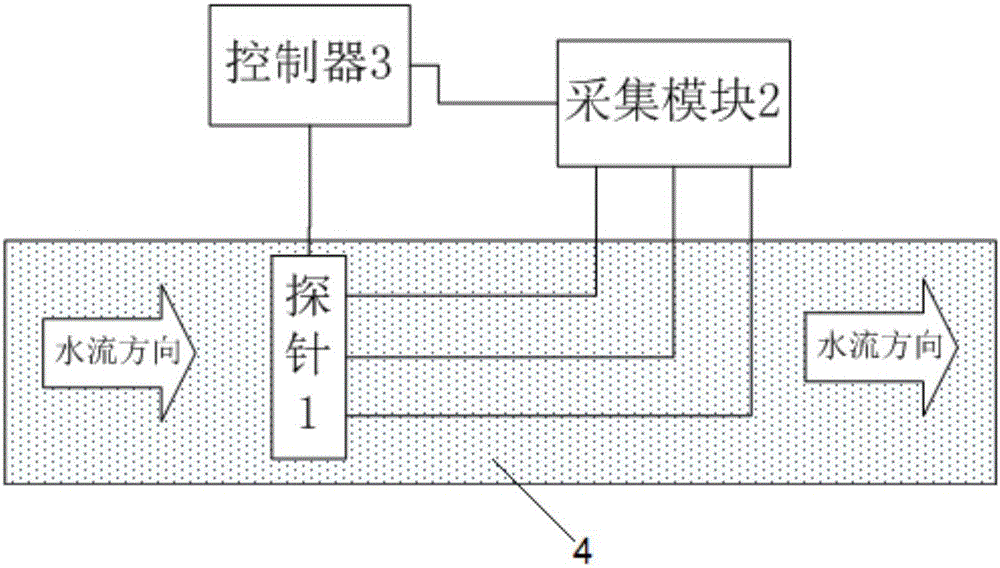

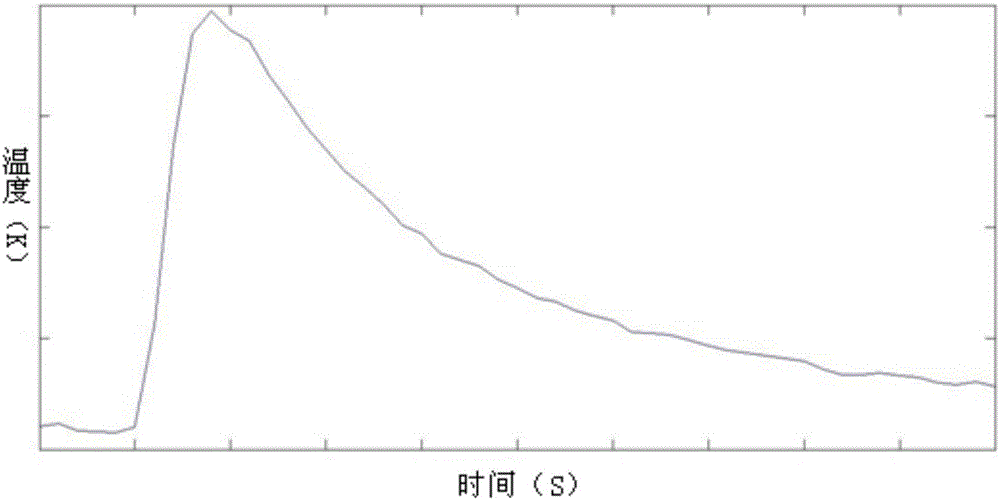

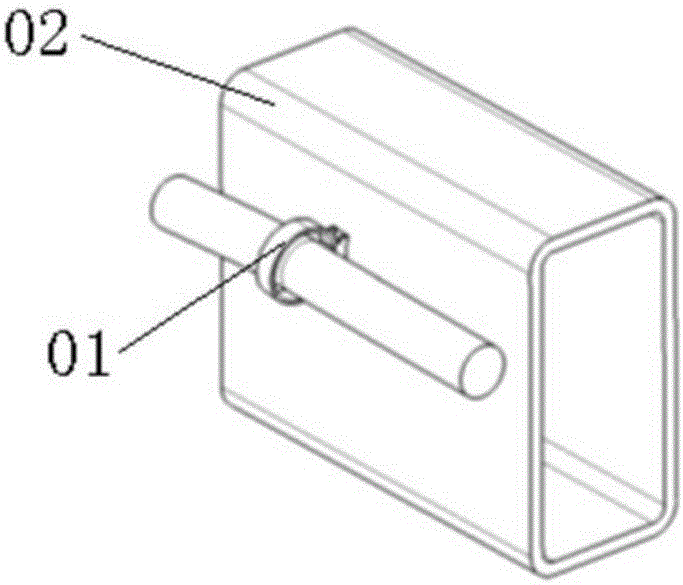

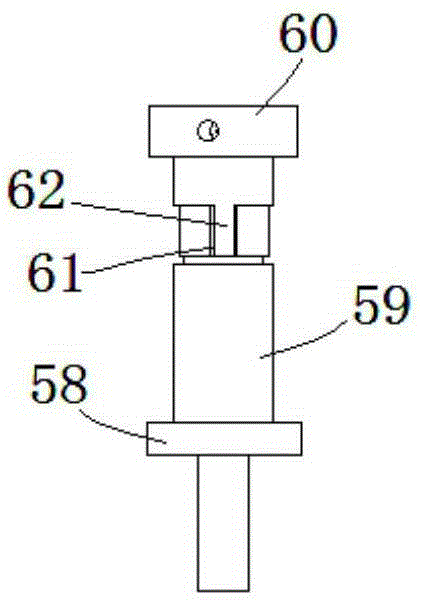

Device and method for measuring soil water flow velocity on basis of thermal pulse method

ActiveCN106199061ANo bendingMeet assembly needsFluid speed measurement using thermal variablesElectrical resistance and conductanceHeating time

The invention relates to a device and method for measuring the soil water flow velocity on the basis of a thermal pulse method. The device comprises a probe, a collection module and a controller; the probe is perpendicularly inserted into soil completely, closely makes contact with the soil and comprises a thermal conducting metal steel shell, a heating resistance wire and thermocouple bare wires, a through hole is formed in the center of the top of the thermal conducting metal steel shell, the heating resistance wire penetrates through the through hole to be fixedly inserted into the probe, the thermocouple bare wires for measuring surface temperature signals of the thermal conducting metal steel shell are uniformly distributed at the periphery of the heating resistance wire, the output ends of the thermocouple bare wires are connected with an input port of the collection module through signal transmission lines separately, and the controller is connected with the heating resistance wire and the collection module separately and used for controlling the heating time of the heating resistance wire to enable heat to be capable of being transmitted into the soil in the mode of an instantaneous pulse and controlling the collection module to conduct data collection. The device and method are precise in measurement and stable in thermal transmission and can be widely applied to soil water flow velocity measurement.

Owner:CHINA AGRI UNIV

Material guiding mechanism based on heat radiator

InactiveCN102672449AMeet assembly needsRealize one-time pipe routing functionMetal working apparatusShortest distanceEngineering

The invention belongs to the field of assembly of heat radiators, and particularly relates to a material guiding mechanism based on heat radiating pipes. The material guiding mechanism comprises a working platform surface, a clamping unit and guiding grooves, wherein the clamping unit is arranged on the working platform surface; the guiding grooves are positioned above the clamping unit; clamping ports of the clamping unit correspond to groove ports of the guiding grooves, and are correspondingly positioned on the guiding paths of the guiding grooves; the distributing direction of the guiding grooves is parallel to or intersected with that of heat radiating pipes; the width of the smallest groove is larger than or equal to the thickness of each heat radiating pipe, and is less than the width of each heat radiating pipe; and the shortest distance between all adjacent guiding grooves is larger than or equal to the width of a heat radiating belt in a flat and straight state. The material guiding mechanism also comprises a power mechanism for driving the guiding grooves to move; the power mechanism has two position states, and when the power mechanism is at the initial position, the guiding grooves are positioned above the clamping unit; and when the guiding action is finished, the power mechanism acts and drives the guiding grooves to separate from the positions above the clamping unit. The material guiding mechanism has the advantages that the whole assembling need of the whole heat radiator can be met by one-time pipe distribution, and the working efficiency is high.

Owner:HUANGSHAN KENENG AUTO RADIATOR

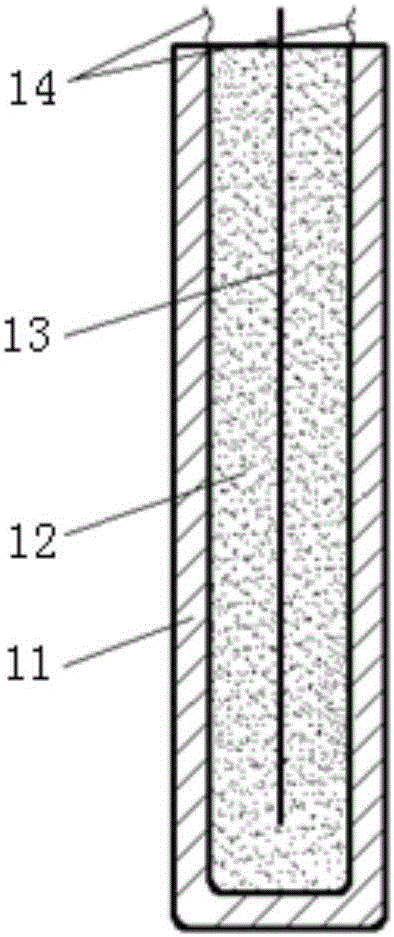

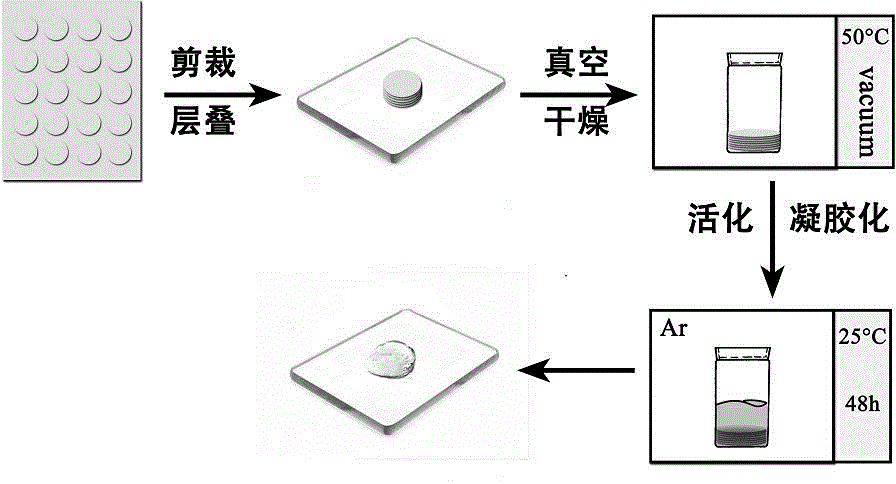

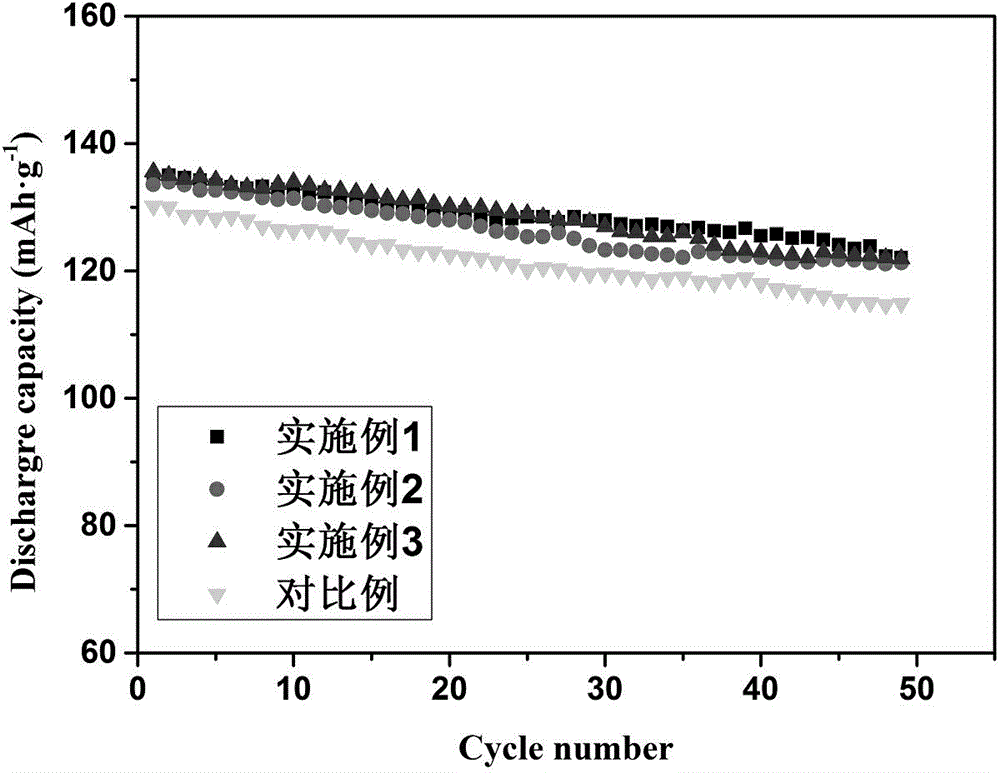

Core/shell structure fiber film-based gel polymer electrolyte and preparation method thereof

InactiveCN104577198AGood compatibilityThe preparation process is simpleSecondary cellsConjugated synthetic polymer artificial filamentsPolymer gelGlovebox

The invention relates to a polymer electrolyte, especially relates to a micropore polymer electrolyte skeletal material prepared by a coaxial electrospinning technology and a method for preparing a gel polymer electrolyte from the skeletal material, and belongs to the field of polymer lithium ion batteries. The preparation method comprises the following steps of 1, preparing core and shell layer electrostatic spinning solutions, 2, preparing a core / shell structure nanometer fiber film by a coaxial electrospinning technology, 3, drying and cutting the nanometer fiber film, and carrying out lamination to obtain a polymer gel electrolyte skeleton, and 4, putting the skeleton into an electrolyte in a glove box and carrying out activation and gelation. The electrolyte skeleton has ultra-strong electrolyte adsorptivity and retentivity. The prepared gel polymer electrolyte has high ion conductivity, a stable electrochemical window, good charging and discharging performances and good interface compatibility with a lithium electrode, satisfies common button cell assembling requirements and can be used for preparation of a secondary lithium ion battery.

Owner:BEIJING UNIV OF CHEM TECH

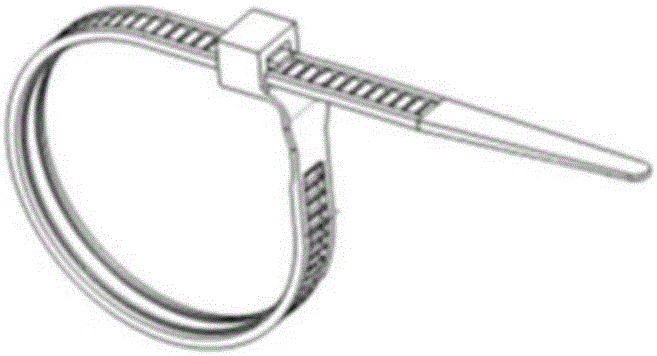

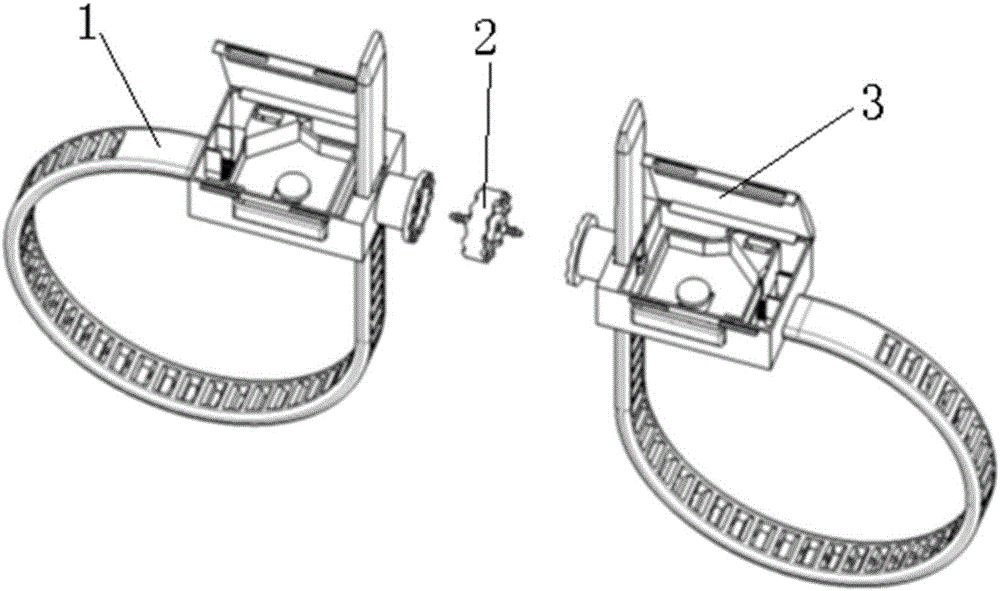

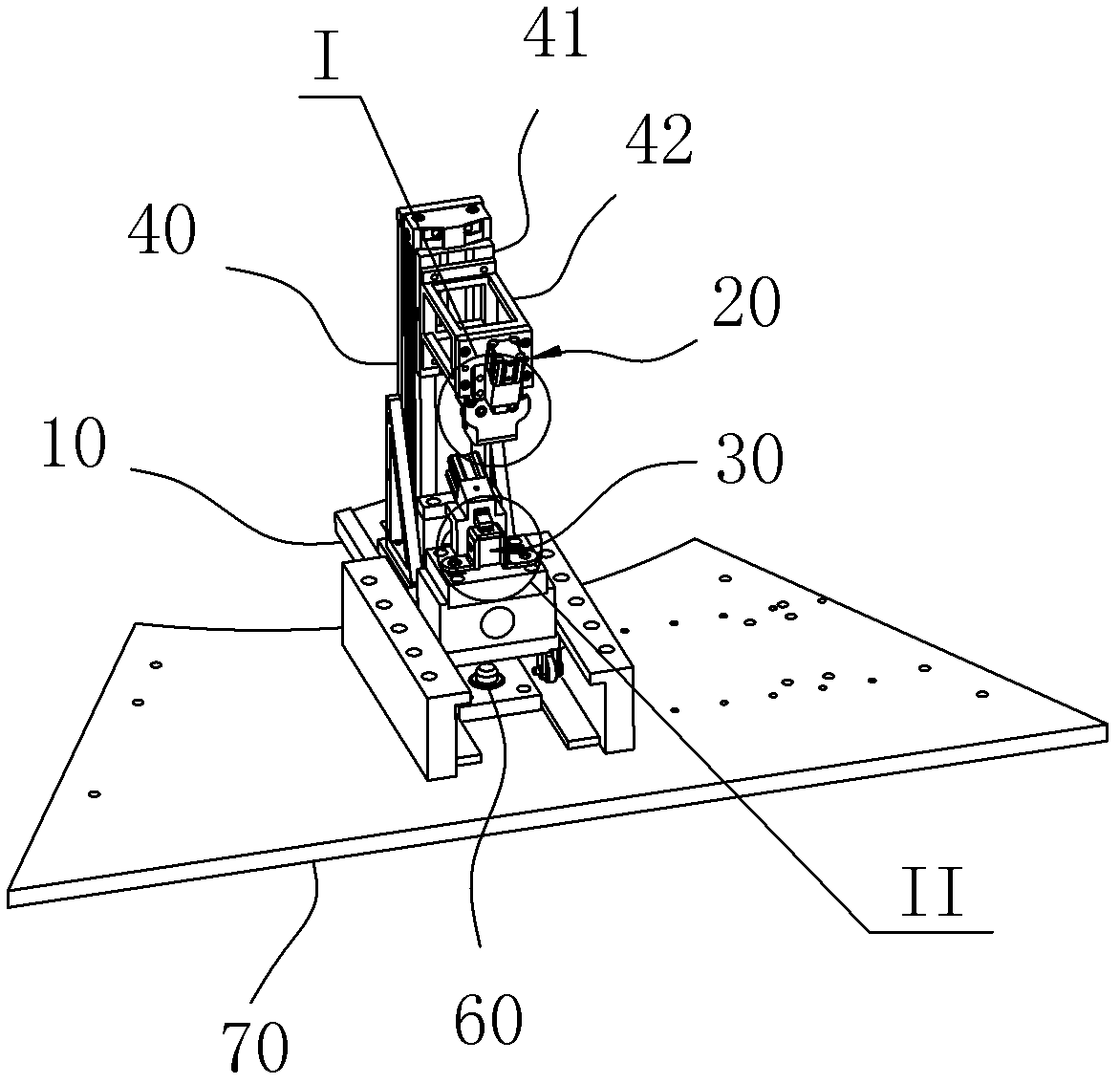

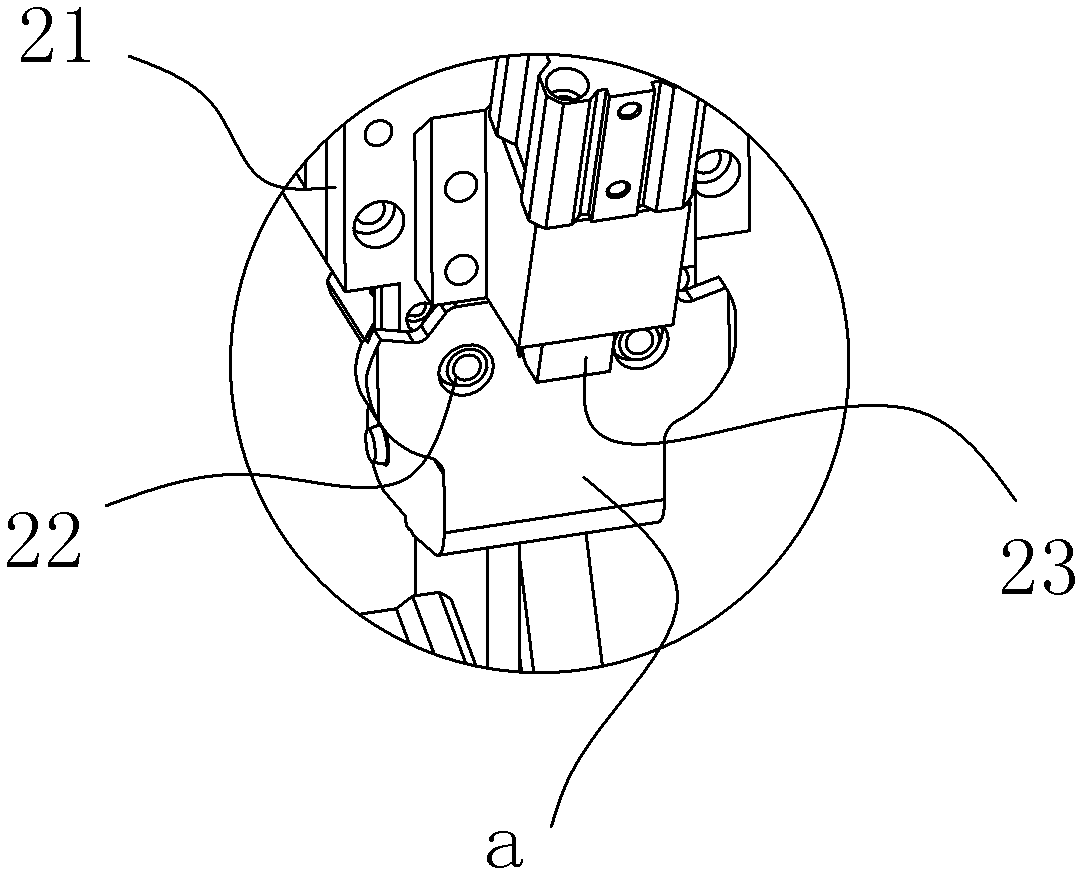

Automobile wire harness band

ActiveCN106394437AMeet assembly needsSolve the problem of breaking freeElectric/fluid circuitIsosceles trapezoidMechanical engineering

The invention relates to an automobile wire harness band. The automobile wire harness band comprises a first strapping band body, a second strapping band body and a clamping part. The first strapping band body comprises a band body part, a band body box and a first rotary disc. Arc structures are uniformly arranged on the surface of a rotary part. The surface between every two adjacent arcs is of a first isosceles trapezoid structure. The clamping part comprises a first cylindrical insert body, a second cylindrical insert part and a second rotary disc. Concave body structures are uniformly arranged on the two surfaces of the second rotary disc. The surface between every two adjacent concave body structures is of a second isosceles trapezoid structure. The concave body structures are matched with the arc structures in a one-to-one correspondence mode. According to the technical scheme, the strapping band bodies can rotate through cooperation of the arc structures and the concave body structures and can also stay at a certain angle stably, automobile assembling requirements are met, and when a wire harness moves relative to other parts, wire harness disengagement caused by stress of the strapping band bodies is avoided.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Automobile door hinge clamp

InactiveCN102248499ASatisfy positioningMeet assembly needsWork holdersEngineeringMechanical engineering

Owner:HEFEI XINGKE PETROCHEM EQUIP TECH

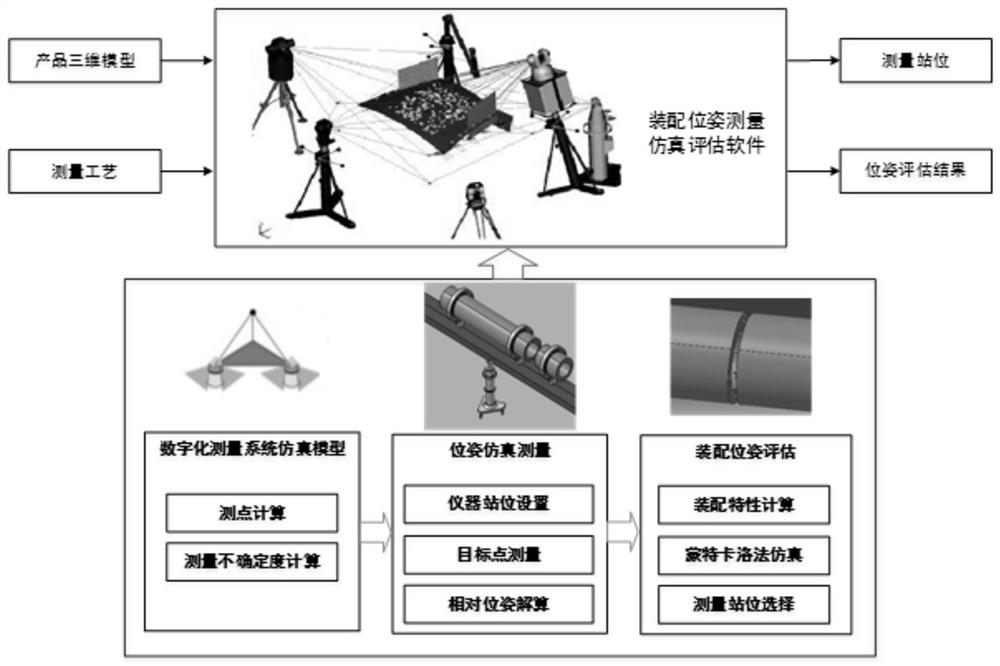

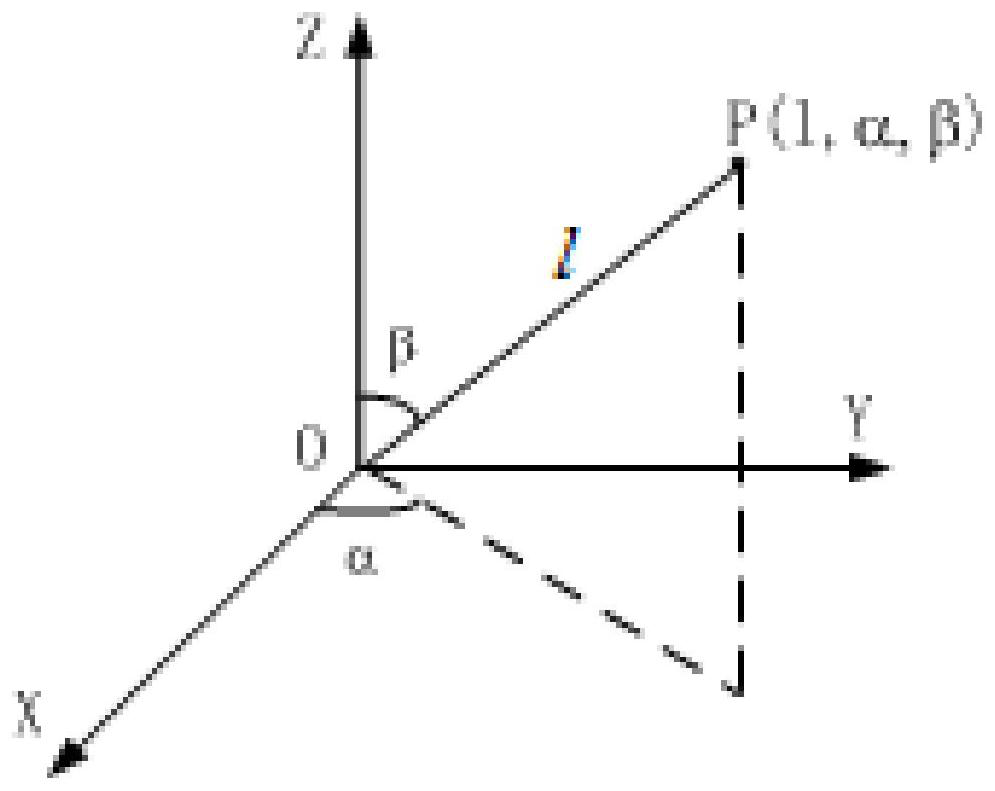

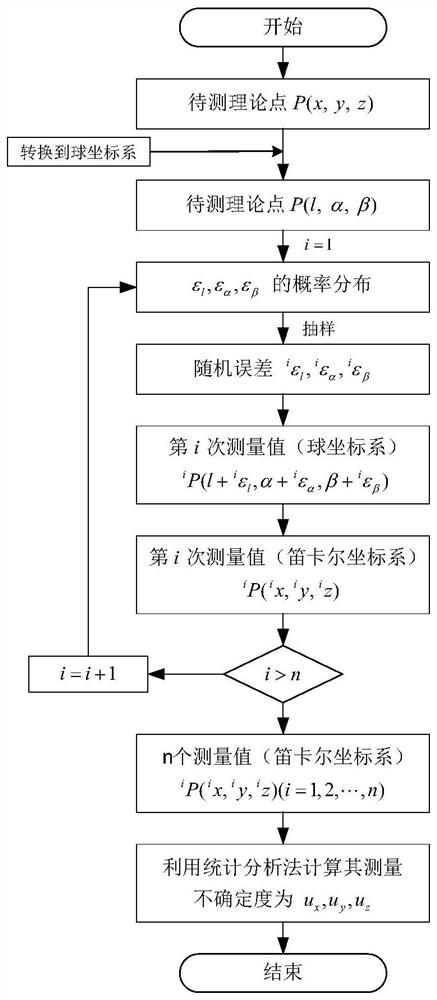

Assembly pose measurement precision pre-evaluation method based on Monte Carlo method

The invention discloses an assembly pose measurement precision pre-evaluation method based on a Monte Carlo method. The method is used to evaluate a fixing device connected with a mobile device in a plugging or butt joint mode, and the measurement of the relative pose of a large component in a simulation environment includes the measurement of a target point, the calculation of a key point, and the calculation of the relative pose. The method comprises the step that 1, a mobile device and a fixing device are placed on the same rail, the mobile device is moved to the position away from the fixing device by a set distance, and a laser tracker is placed on the side face between the mobile device and the fixing device. A distance measuring sensor and two angle measuring sensors are arranged in the laser tracker. In order to solve the problem of pose measurement precision pre-evaluation in large component digital assembly, the invention designs an assembly pose measurement simulation method. The digital measurement process of large component assembly is simulated through a digital measurement system simulation model, pose simulation measurement and assembly pose evaluation to evaluate whether the pose measurement precision meets the assembly requirement or not.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP +1

Automatic riveting device for sealing inner container of water heater

InactiveCN102423783AMeet assembly needsGuaranteed depthMetal-working feeding devicesPositioning devicesEngineeringManipulator

The invention relates to a sealing inner container of a water heater, in particular to an automatic riveting device for the sealing inner container of the water heater, and belongs to the technical field of machining. The device comprises two upright posts, wherein a beam is arranged on the two upright posts; grabbing mechanical hands are fixedly arranged on two sides of the beam; a V-shaped positioning block is arranged on the lower end face of the beam and positioned on a part between two grabbing mechanical hands; corresponding guide grooves are formed on the lower end face of the beam on two sides of the V-shaped positioning block; movable left and right fixing seats are arranged in the guide grooves; end cover positioning blocks are arranged at the corresponding ends of the left and right fixing seats; two symmetrical cylinders are fixedly arranged at the upper end of the beam; and the stretching ends of piston rods of the cylinders are correspondingly connected with the fixing seats. The device has the advantages of compact structure, complete functions, high adaptability and the like, is easy to control, is safe and reliable, and is highly intelligent and high-accuracy special equipment.

Owner:CHUZHOU XINLONG ELECTROMECHANICAL

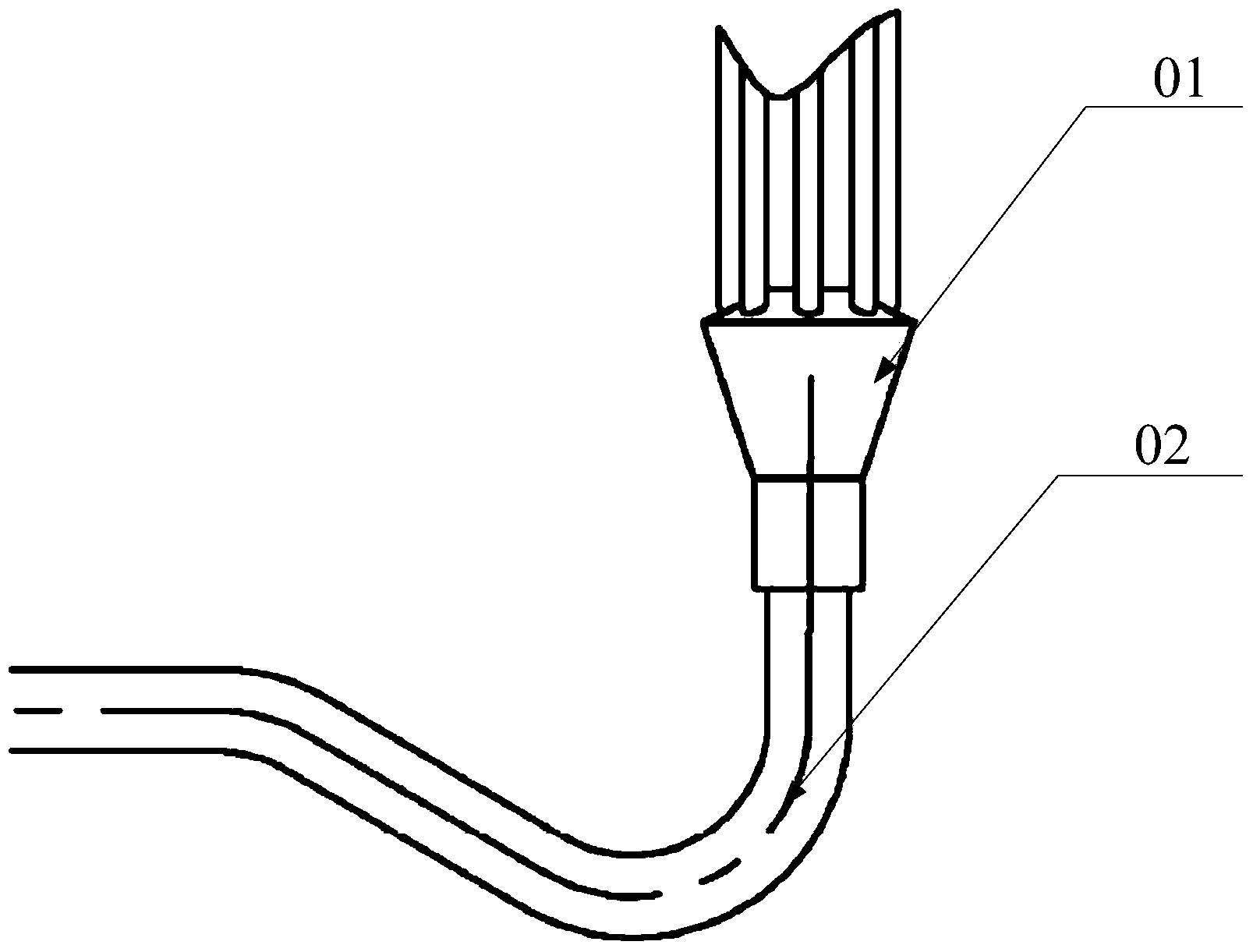

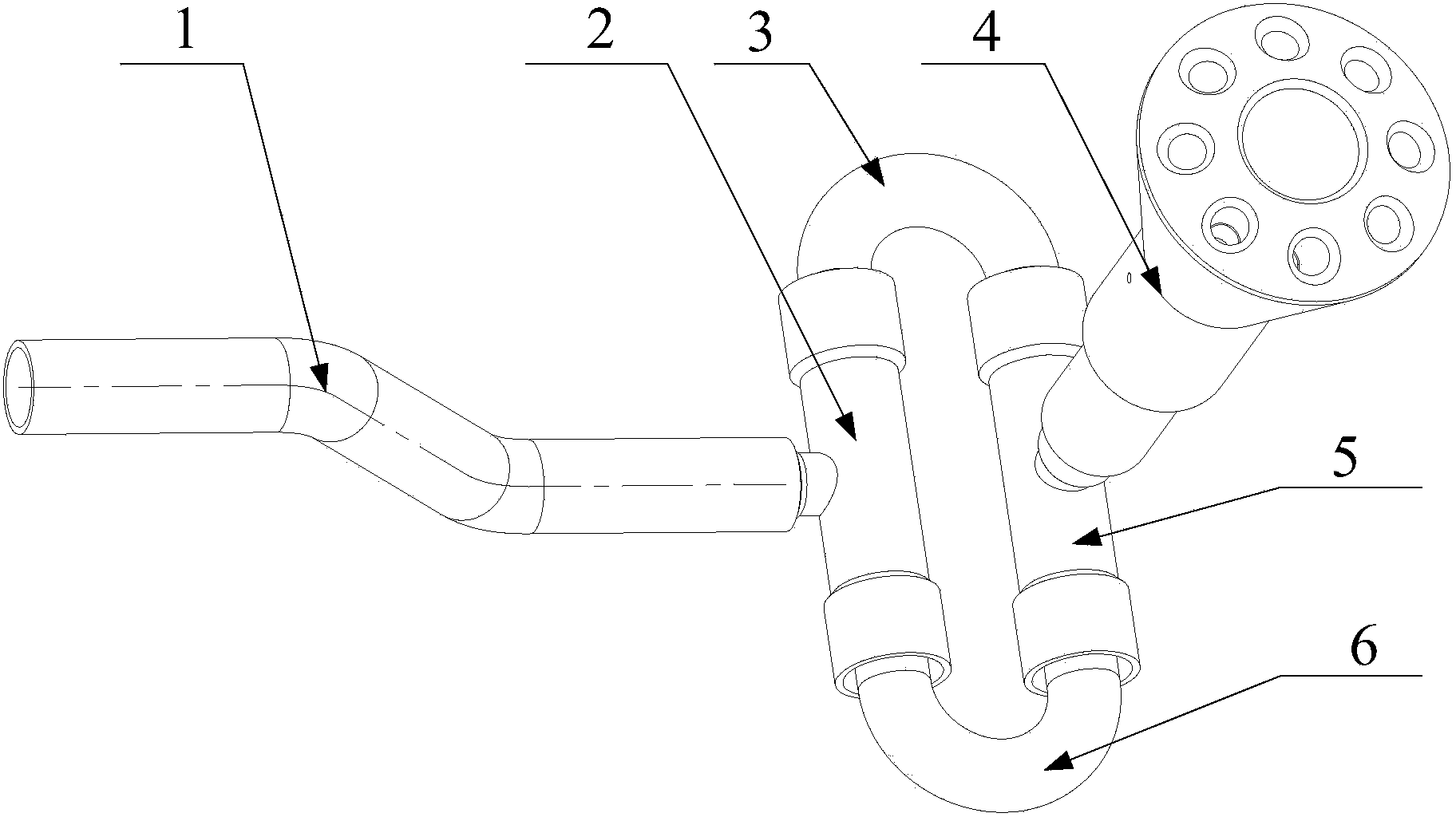

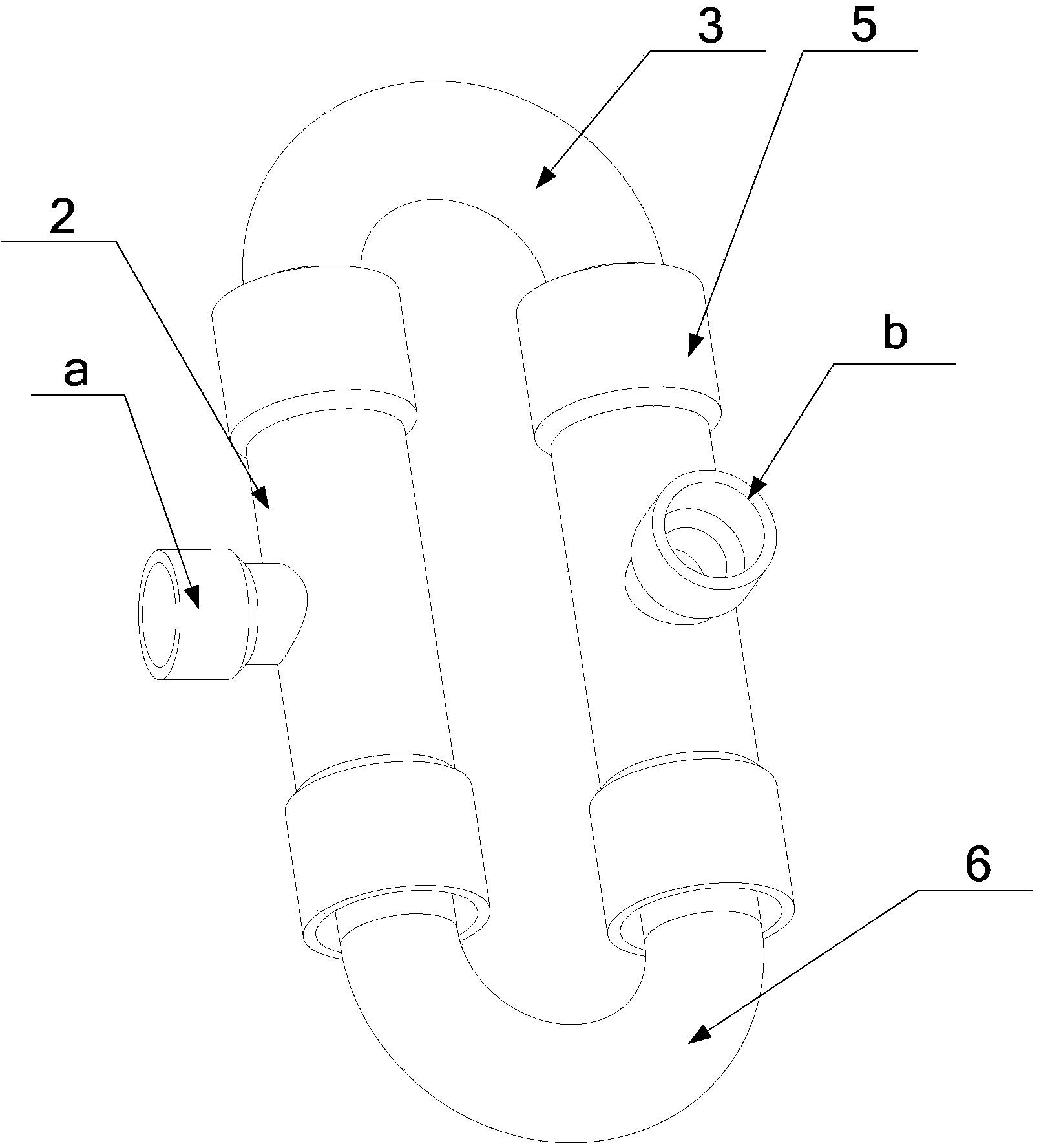

Air conditioner and liquid inlet and flow equalizing device thereof

InactiveCN104034098AMeet assembly needsImprove stabilityFluid circulation arrangementEngineeringFlow diverter

The invention discloses a liquid inlet and flow equalizing device. The liquid inlet and flow equalizing device comprises a flow divider and a liquid inlet pipe, wherein the outlet of the liquid inlet pipe is communicated with the flow divider, the liquid inlet pipe comprises a first elbow and a second elbow, the first elbow and the second elbow are symmetrically arranged, the two ends of the first elbow are communicated with the two ends of the second elbow respectively, and the flow path of fluid flowing in through the inlet of the liquid inlet pipe and flowing through the first elbow to arrive at the outlet of the liquid inlet pipe is equal to the flow path of fluid flowing through the second elbow to arrive at the outlet of the liquid inlet pipe. After gas-liquid mixed refrigerant enters the liquid inlet pipe, one part of the refrigerant flows along the first elbow, the other part of the refrigerant flows along the second elbow, and finally the two parts of gas-liquid mixed refrigerant converge at the outlet of the liquid inlet pipe. Due to the fact that the two parts of gas-liquid mixed refrigerant are opposite in direction at the outlet of the liquid inlet pipe, steady flow is formed by the two parts of gas-liquid mixed refrigerant at the outlet of the liquid inlet pipe, the two parts of gas-liquid mixed refrigerant are evenly mixed and enter the flow divider so that the amounts of liquid refrigerant entering coil pipes are equal, and stability and reliability of the air conditioner are improved.

Owner:GREE ELECTRIC APPLIANCES INC

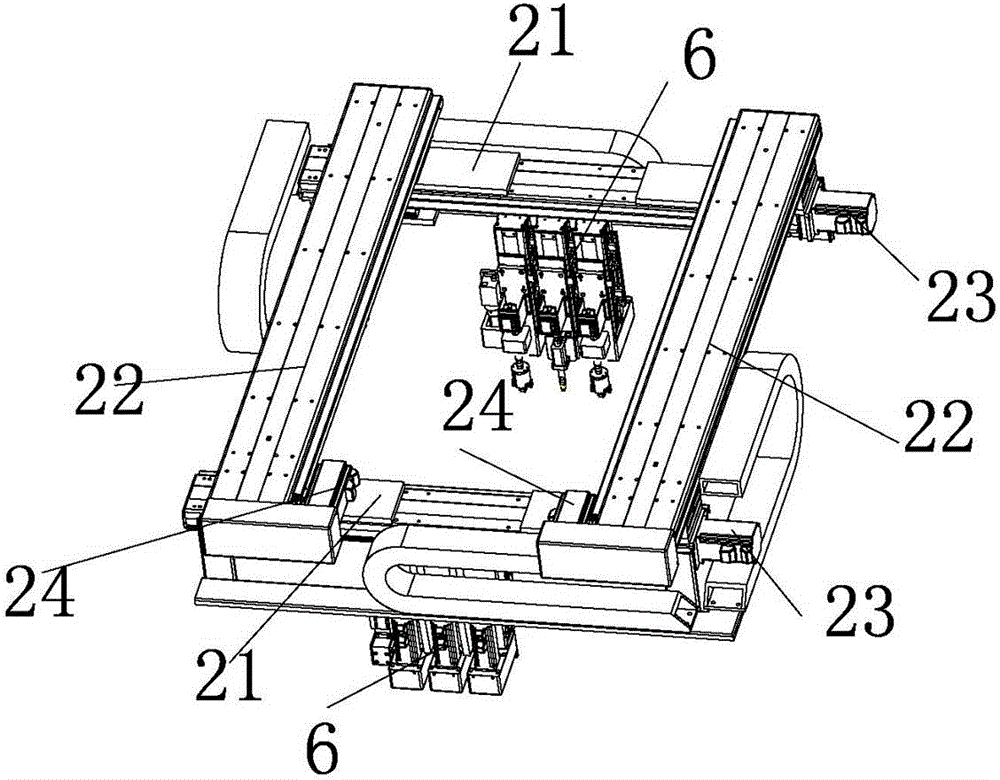

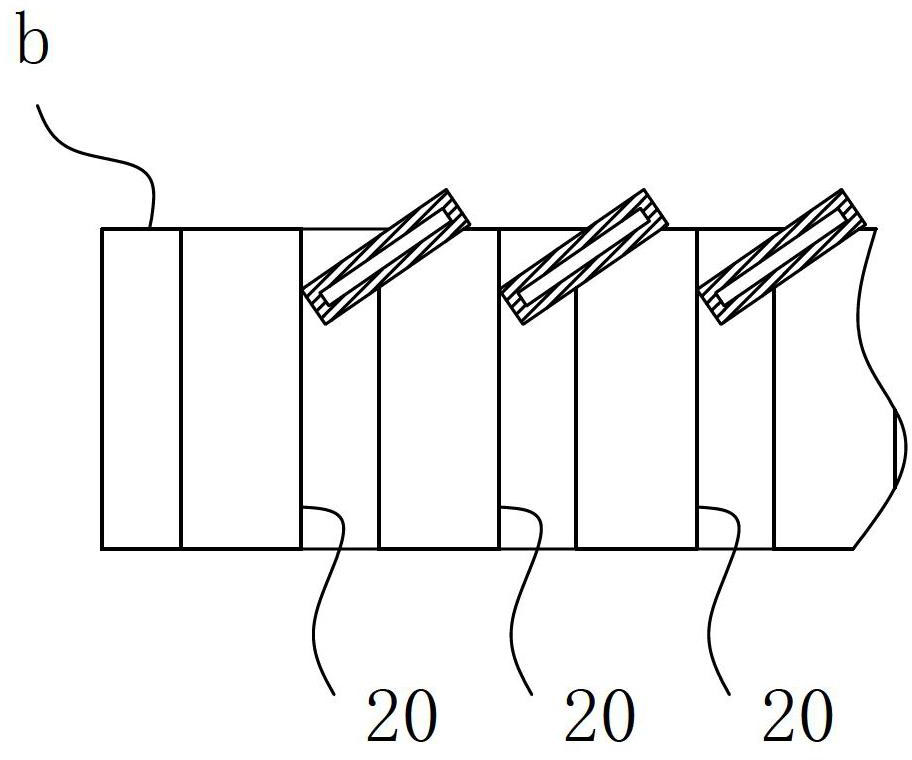

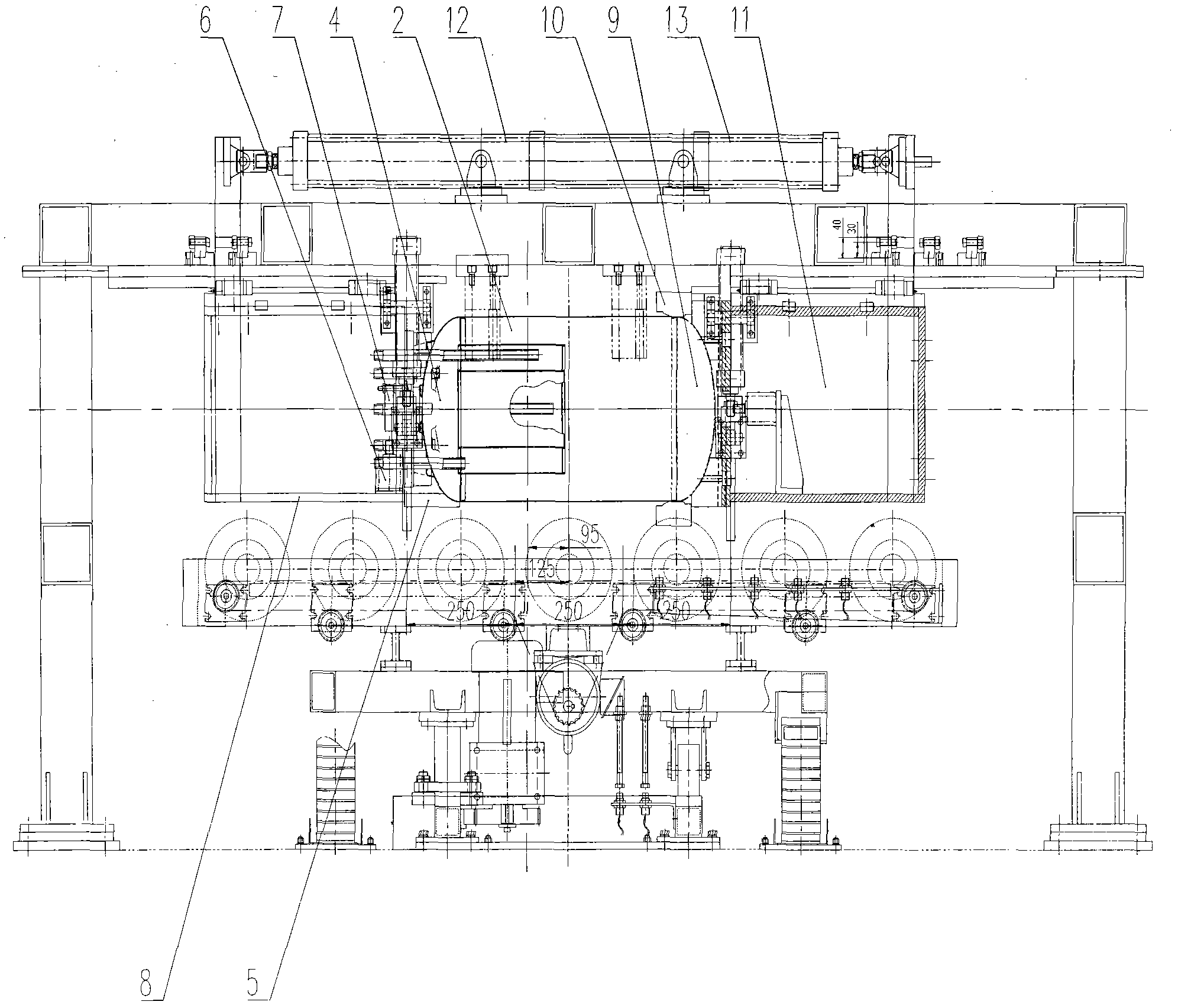

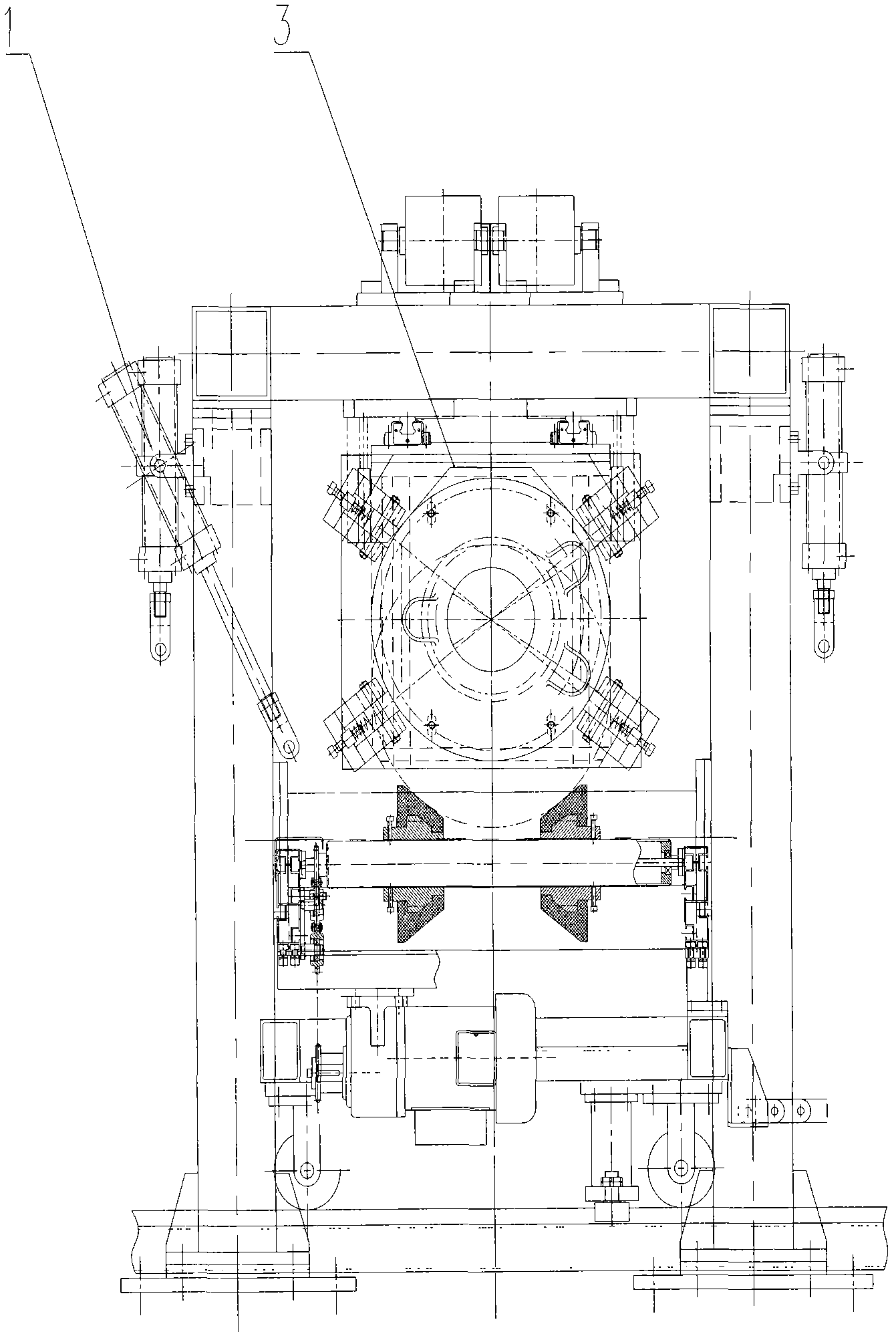

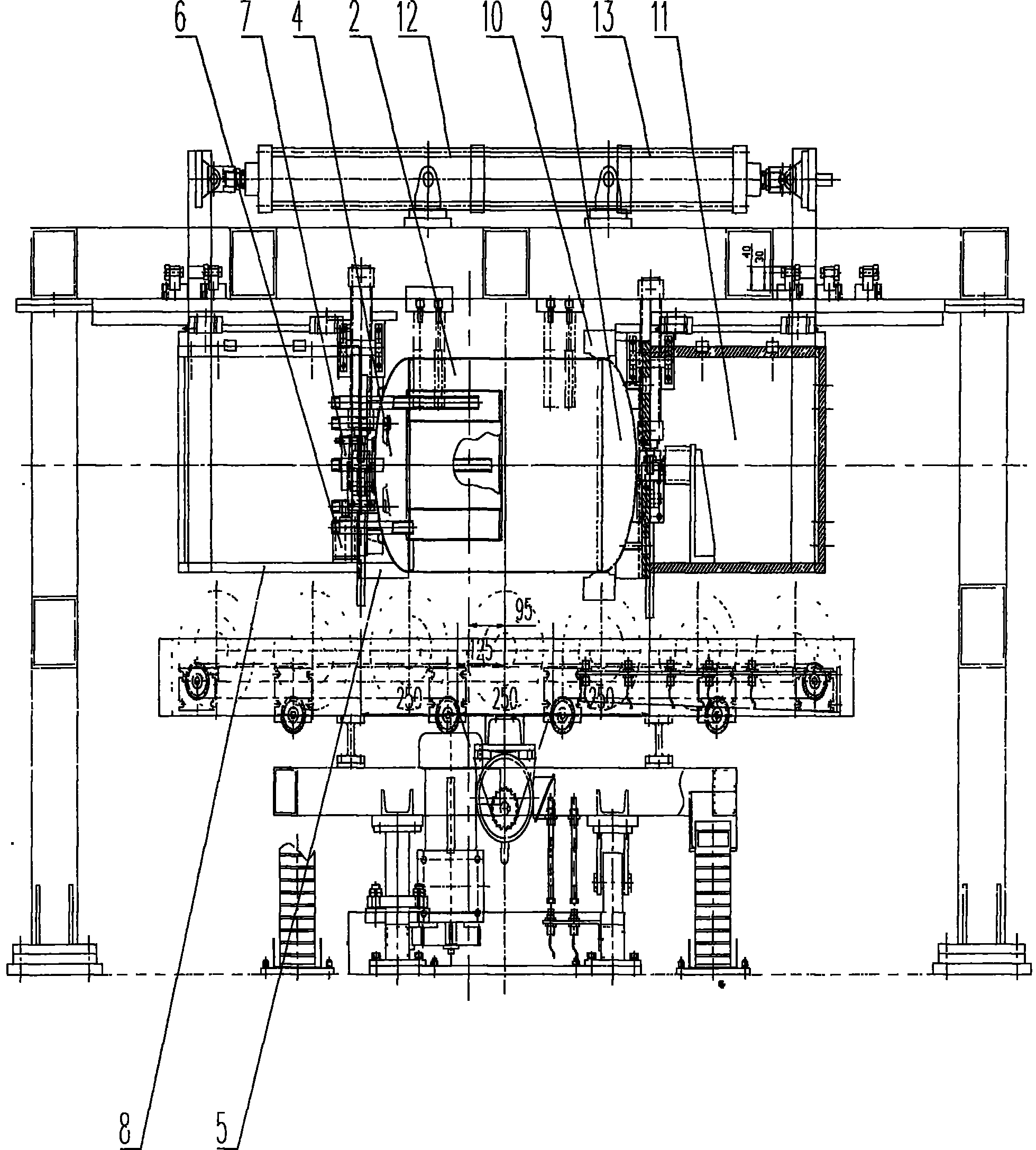

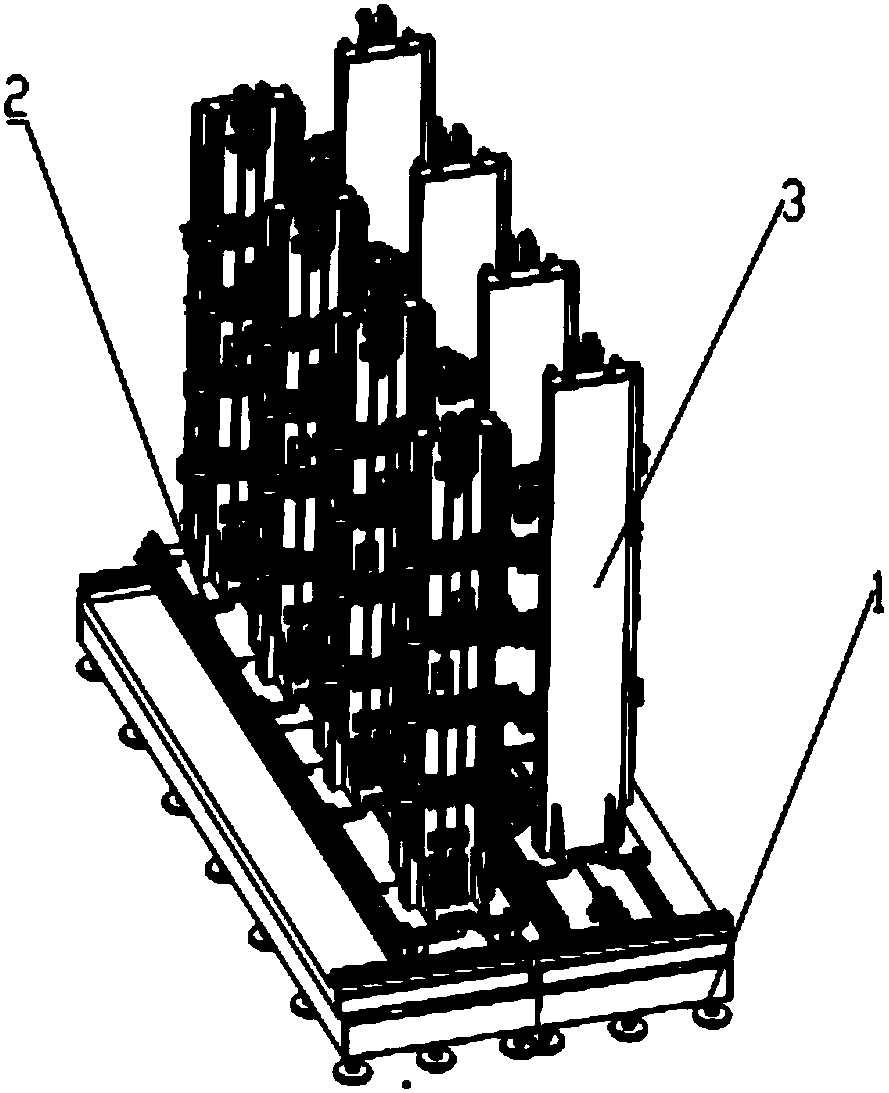

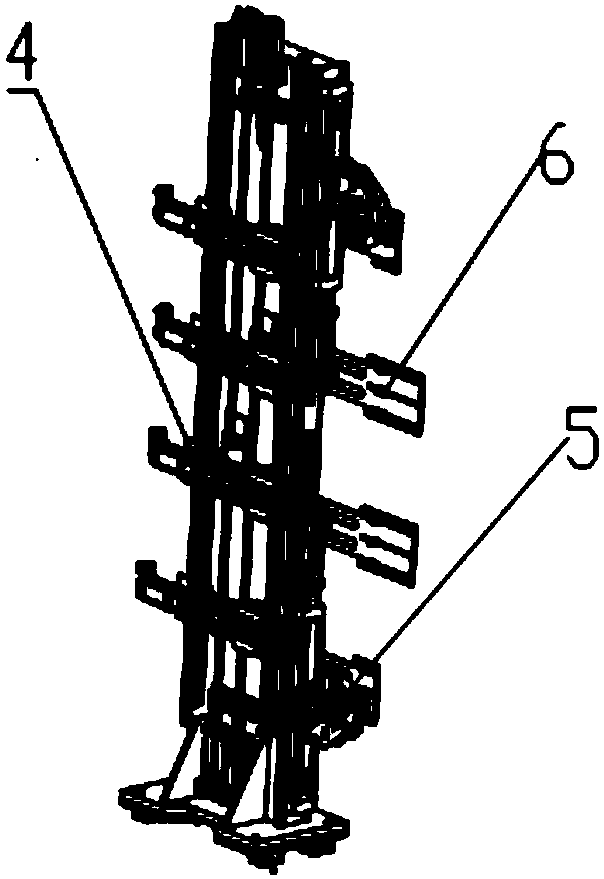

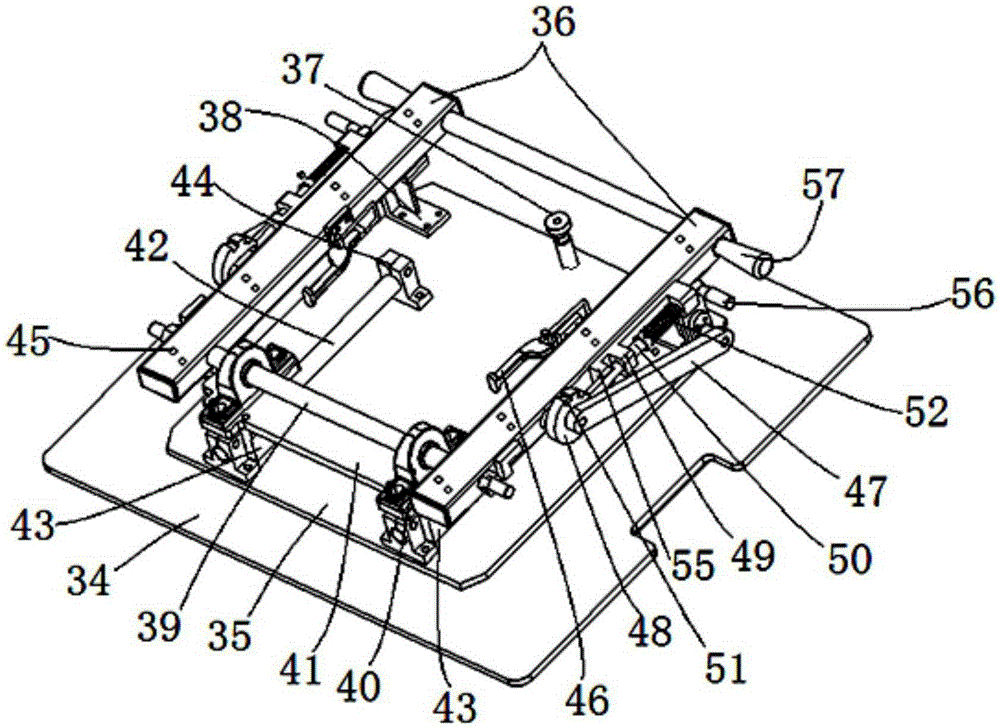

Reconfigurable aircraft panel assembly device

ActiveCN108082531AMeet assembly needsReduce work intensityWork holdersAircraft assemblyReconfigurabilityUltimate tensile strength

The invention discloses a reconfigurable aircraft panel assembly device which is suitable for positioning and mounting of skins and stringers in aircraft panel assembly. No extra auxiliary tool is needed in the positioning process, and the assembly demands of aircraft panels with different sizes and shapes are met. The reconfigurable aircraft panel assembly device is simple in structure, small inoccupied area and high in reconfigurable degree, achieves curved surface positioning point arrangement in assembly of the various different aircraft panels, and accordingly achieves efficient and high-quality assembly of the aircraft panels, the assembly period is greatly shortened, the cost is saved, the demand for personnel in the manufacturing process is reduced, and the work intensity of workers is relived. According to the reconfigurable aircraft panel assembly device, through outer shape adjusting, the positions of inner shape positioning clamping units and outer shape positioning clamping units of the panels can be changed, main positioning face positioning blocks of the positioning clamping units are replaced, the positioning assembly demands of the different aircraft panels are met, and the reconfigurability of the device is guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

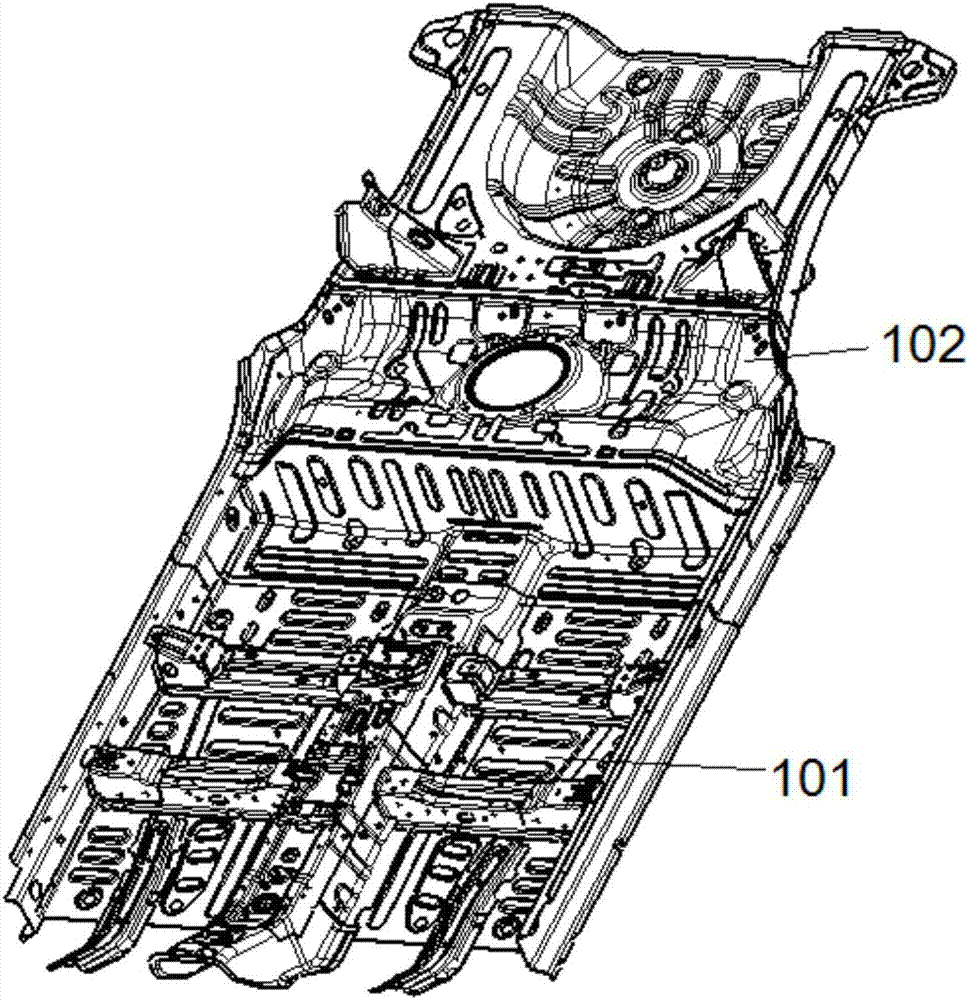

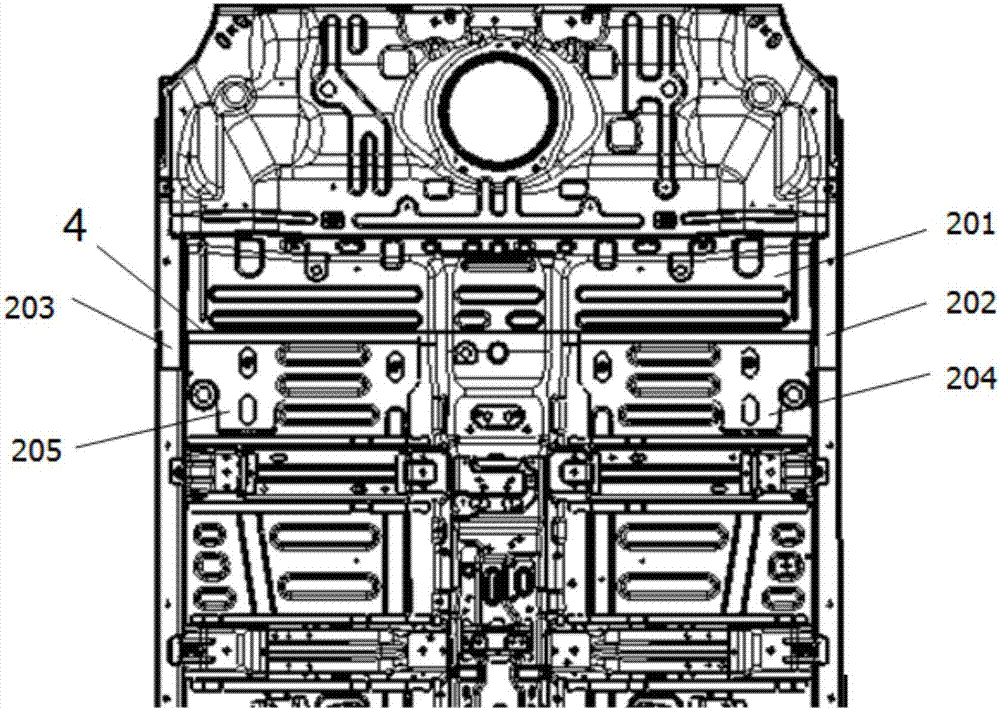

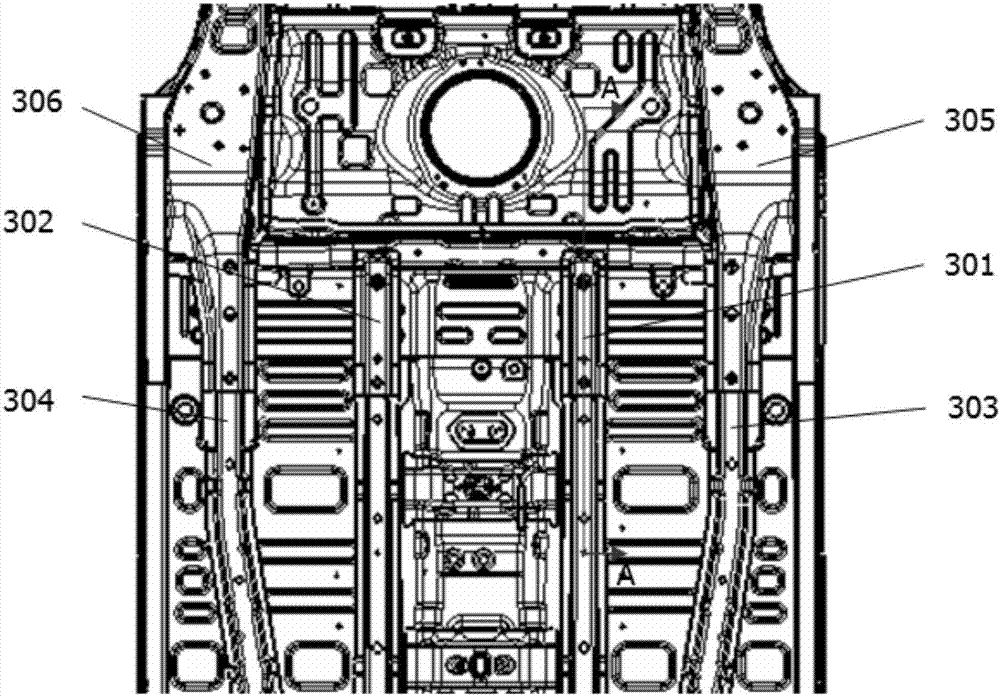

Platformization vehicle body floor structure and assembling method thereof

InactiveCN107226136AMeet assembly needsGuaranteed generalizationSuperstructure subunitsWheelbaseDevelopment period

The invention discloses a platformization vehicle body floor structure. The platformization vehicle body floor structure comprises a front floor assembly and a rear floor assembly, wherein the front floor assembly is connected with the rear floor assembly through a connecting part of which the length is greater than the changing quantity of wheelbase of a lower vehicle body. According to the platformization vehicle body floor structure disclosed by the invention, the change of the wheelbase of the lower vehicle body is realized through changing the length dimension of a part at a joint of the rear floor assembly and the front floor assembly in the first length direction; the connecting position of the front floor assembly and the rear floor assembly can be adjusted to meet the adjusting requirement of the wheelbase of the lower vehicle body, so that the matching requirement of the vehicle body floor for the lower vehicle body with different wheelbases is met; the use rate of generalization parts and components can be increased, the change of the wheelbase of a platformization vehicle can be realized through the minimum change of parts, and the development period and the cost are reduced.

Owner:CHERY AUTOMOBILE CO LTD

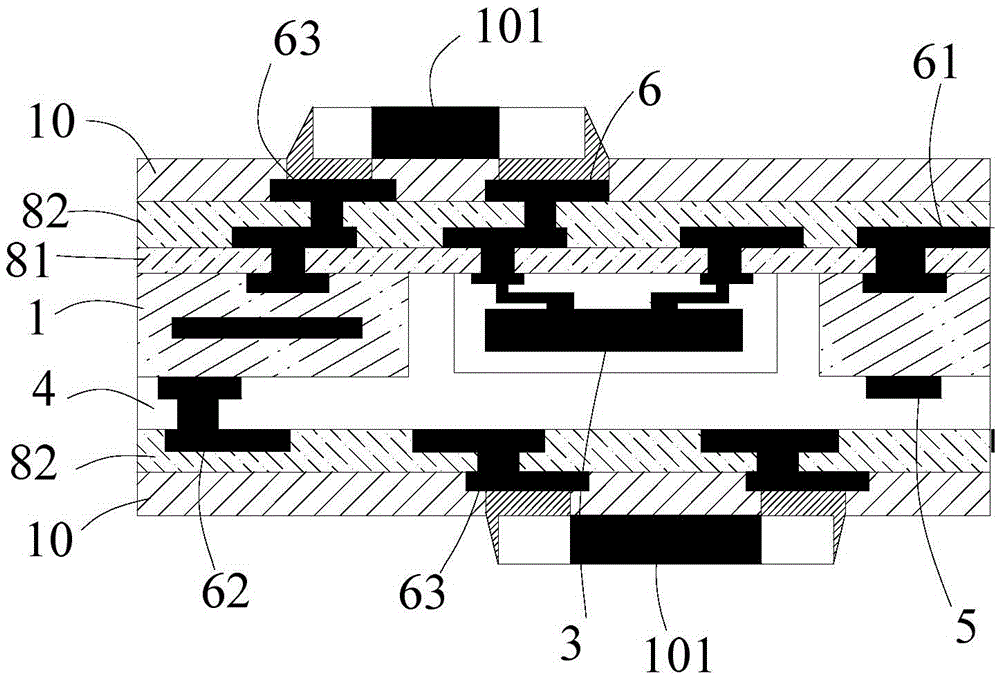

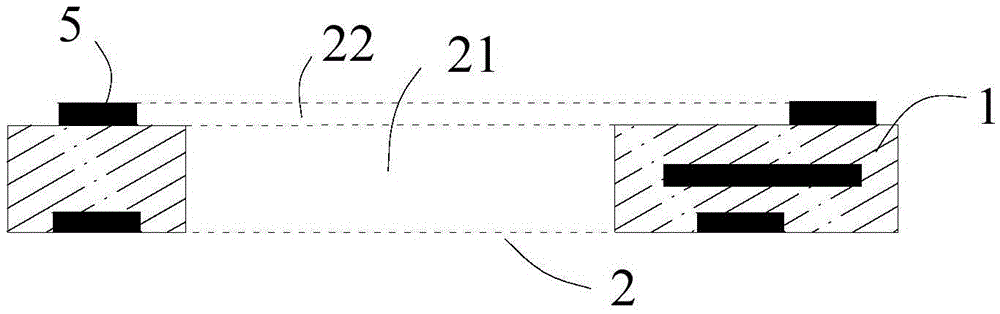

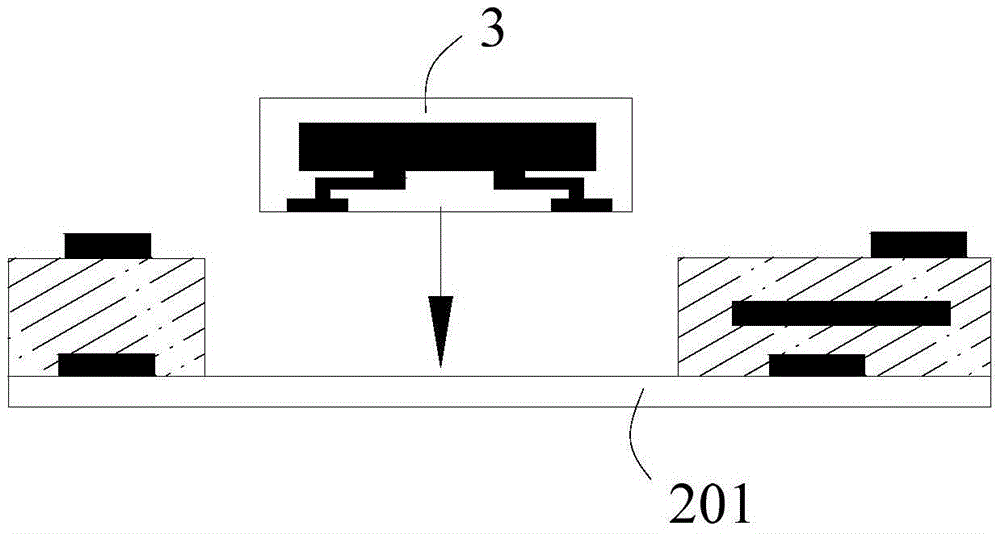

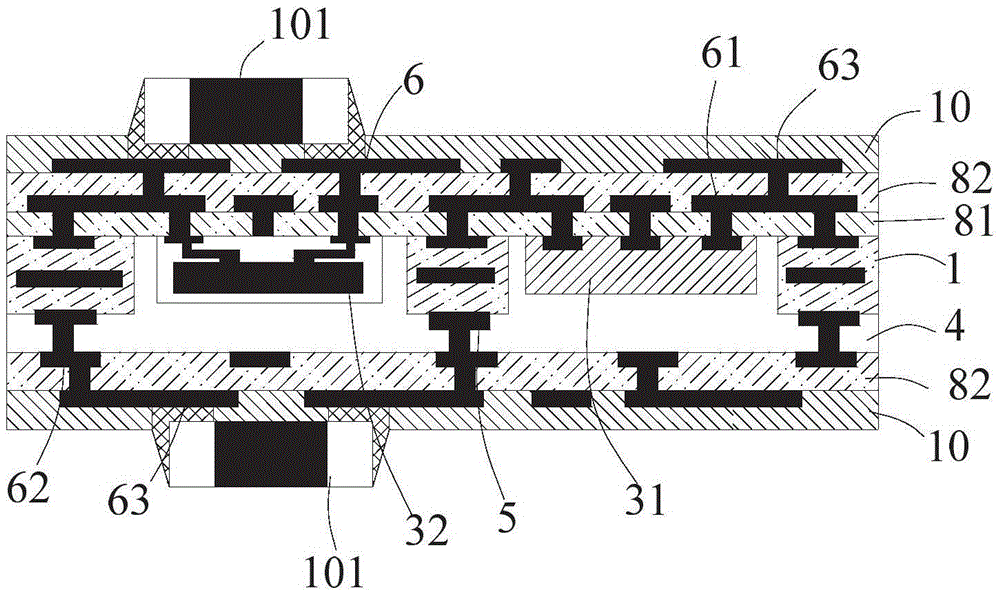

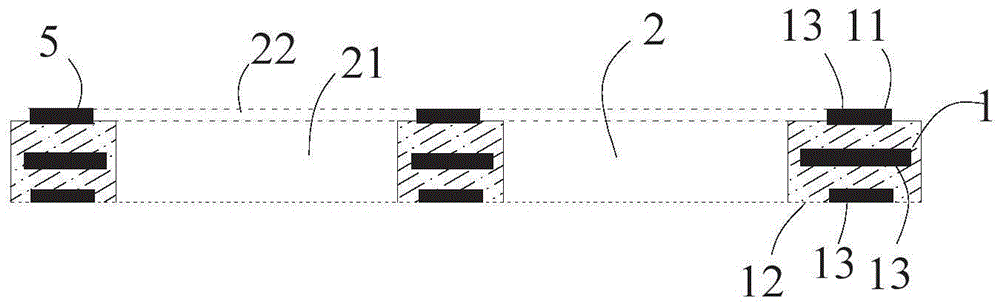

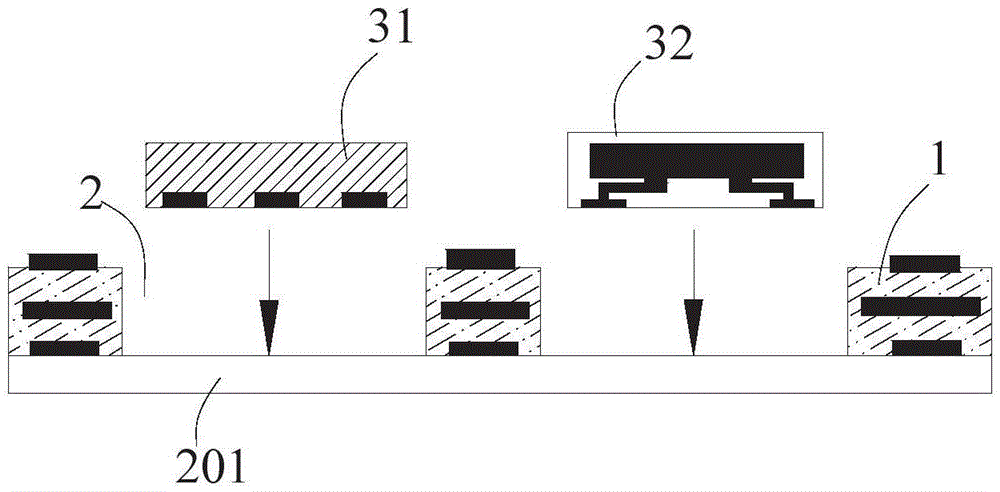

Embedded packaging structure based on semiconductor chip packaging body and packaging method thereof

InactiveCN106653730AProcess stabilityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEmbedded technologySemiconductor chip

The invention discloses an embedded packaging structure based on a semiconductor chip packaging body and a packaging method thereof. The embedded packaging structure comprises a circuit board having a first surface and a second surface which are oppositely arranged, at least one opening or chamber which is arranged in the circuit board and is used for accommodating the semiconductor chip packaging body, the semiconductor chip packaging body arranged in the opening or the chamber, a packaging material at least used for covering the first surface of the circuit board and filling space of the opening or the chamber not being occupied by the semiconductor chip packaging body, and a rewiring layer at least used for electrically connecting the semiconductor chip packaging body and the circuit board. The embedded packaging structure is advantaged in that the semiconductor chip packaging body is assembled through employing the circuit board embedding technology, an assembling technology process of the semiconductor chip packaging body can be simplified, assembling quality and performance can be improved, and an assembling area can be effectively reduced.

Owner:蔡亲佳

Turbine blade ordering method relating to turbine thickened blades

InactiveCN103116689AEasy to GrindProcess balanceSpecial data processing applicationsSorting algorithmSteam turbine blade

The invention provides a turbine blade ordering method relating to turbine thickened blades and relates to a location and sort algorithm of turbine blades. At present, thickened blades in turbine blades are fixed randomly through manual work in an entire circle of blades, no accurate location and ordering method exists, over-concentrated problem or over-dispersive problem exists in assembling, and the problem that grinding of an assembling clearance in assembling is incapable is prone to occur, however, the turbine blade ordering method relating to the turbine thickened blades solves the above problems. The ordering method comprises the main steps: S1, confirming the number of the thickened blades of the products participating in ordering according to product design requirements, S2, arranging the thickened blades through an equally distributed principle and confirming the sequence numbers of the thickened blades, S3, confirming the installation site sequence numbers of numbers of the thickened blades and processing random numbers, S4, weighing the thickened blades, S5, ordering the thickened blades, S6, weighing ordinary blades, and S7, ordering the ordinary blades. The invention relates to turbine blade ordering of the thickened blades.

Owner:HARBIN TURBINE

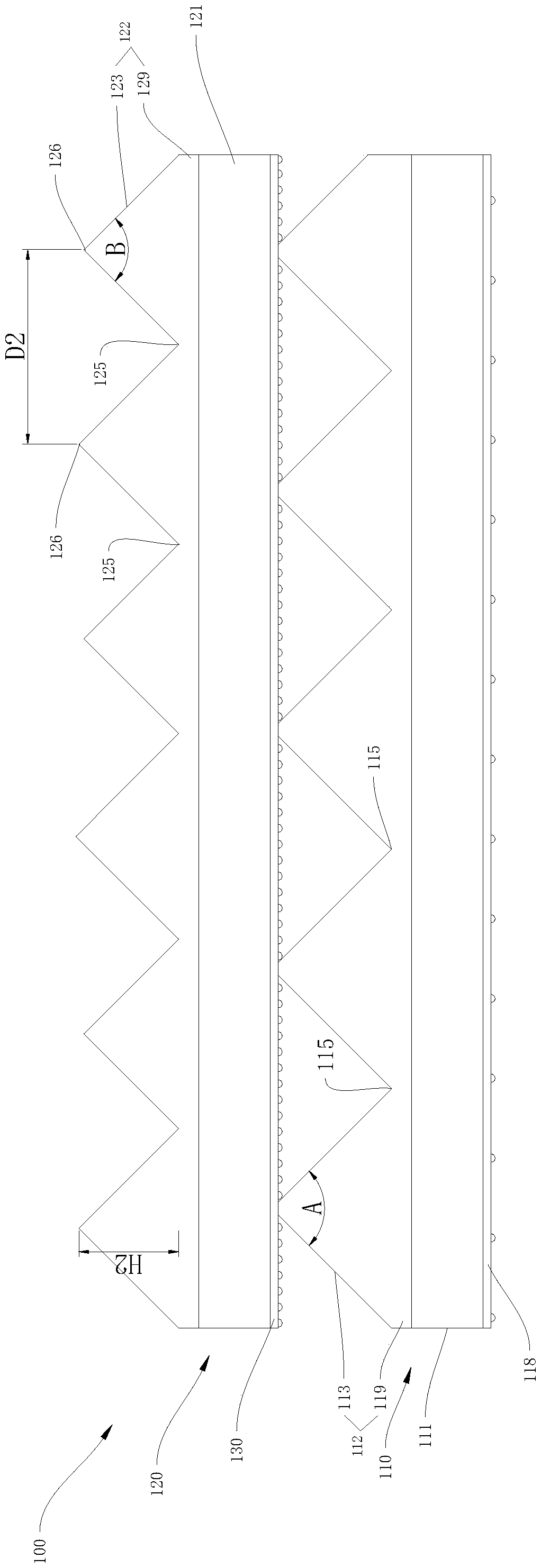

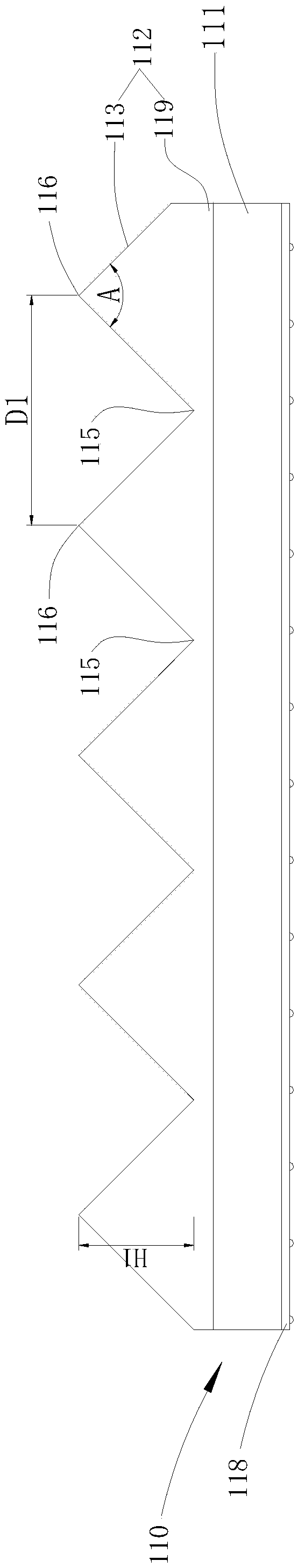

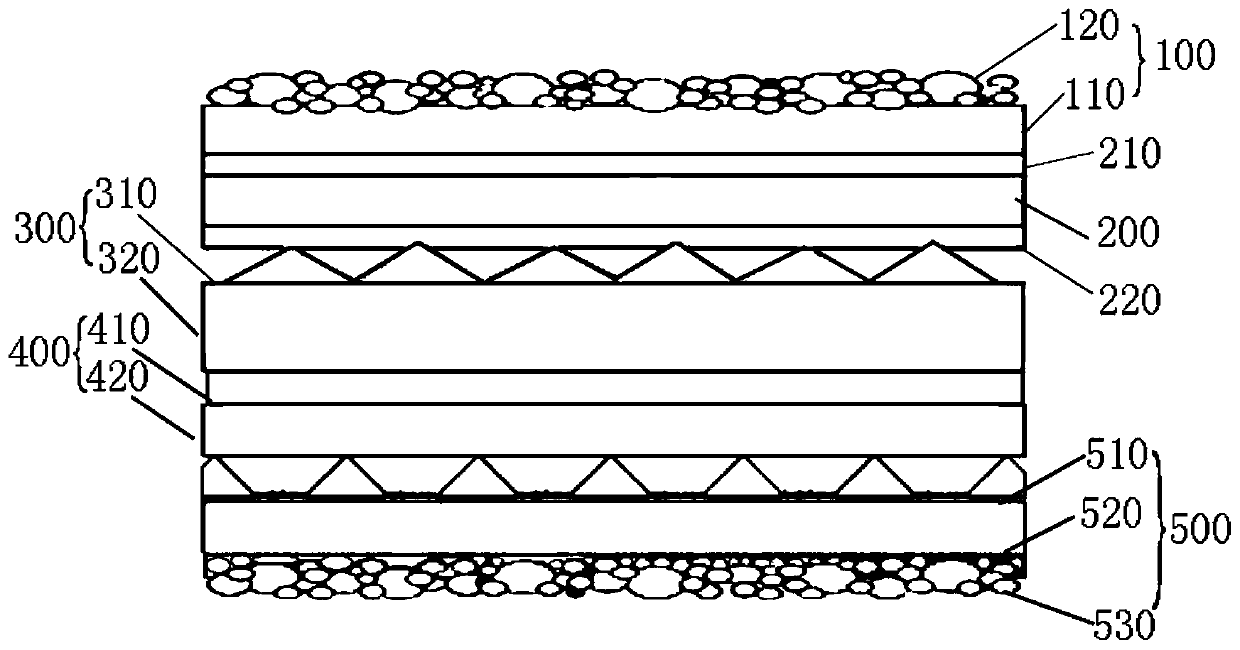

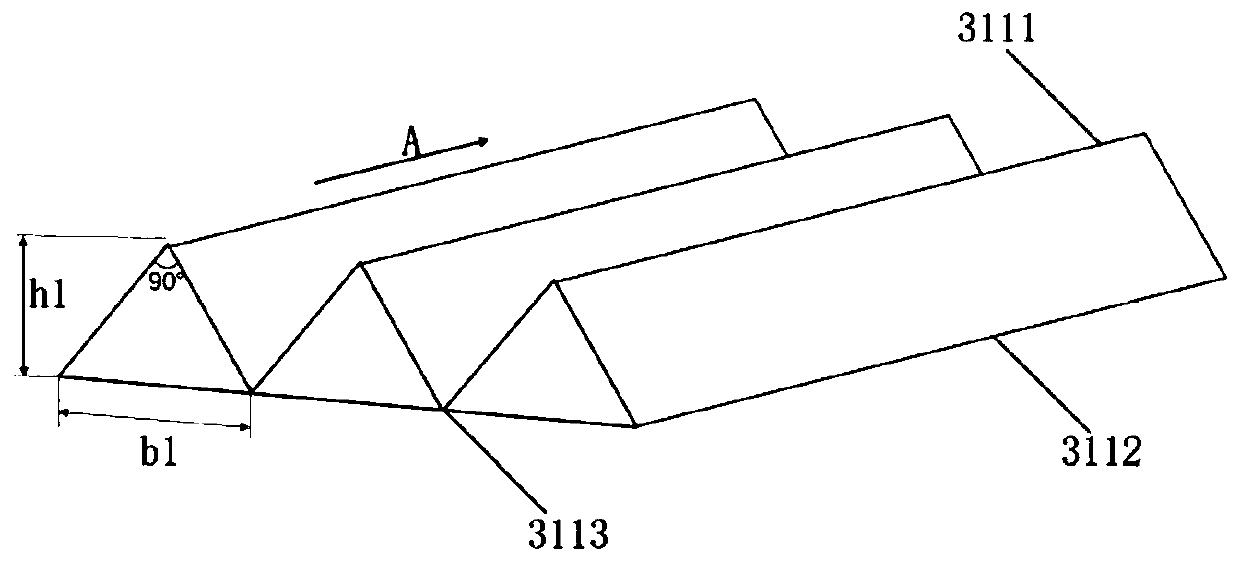

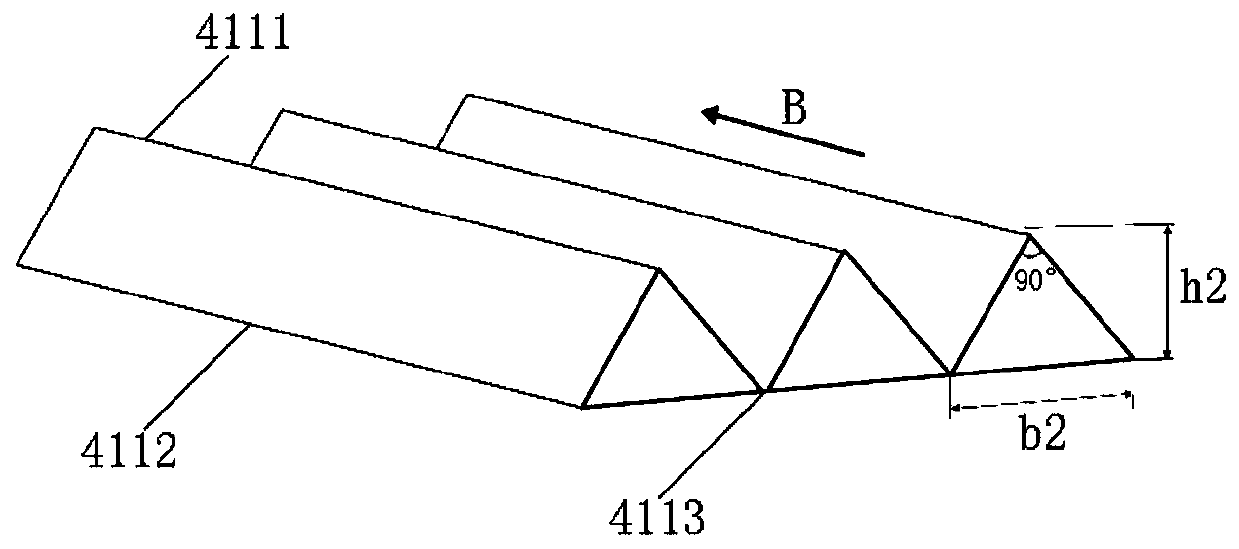

Laminating film for liquid crystal display, and liquid crystal display backlight module

The invention discloses a laminating film for a liquid crystal display (LCD), and a liquid crystal display backlight module. The laminating film for the LCD comprises a first structural layer film, asecond structural layer film, and a composite glue layer; the first structure layer film comprises a first base film, a first prism layer and a back coating; the first prism layer is formed by continuously arranging multiple first prisms, the first prism layer is arranged on an upper surface of the first base layer, and the back coating is arranged at a lower surface of the first base film; the structure layer film comprises a second base film and a second prism layer; the second prism layer is formed by continuously arranging multiple second prisms; the second prism layer is arranged on the upper surface of the second base film; the composite glue layer comprises PBMA or PMMA microspheres; and the first prisms are laminated on the second base film through the composite glue layer. In thepremise of ensuring that the brightness can achieve a liquid crystal display product requirement, the masking can achieve the requirement, thereby ensuring that the interference and the glare are avoided, and the visual effect reaches the standard.

Owner:CCS (SHANGHAI) FUNCTIONAL FILMS IND CO LTD

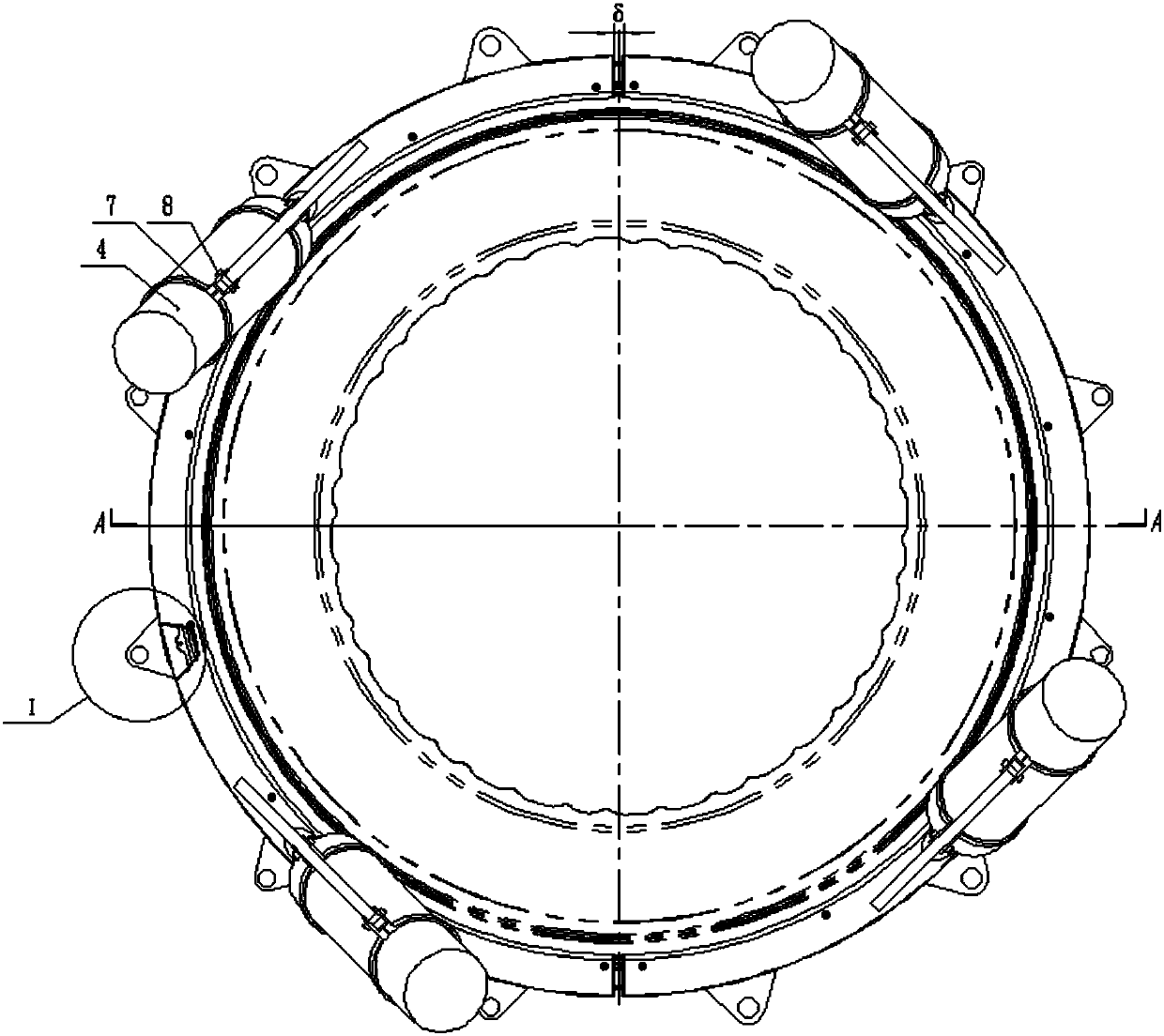

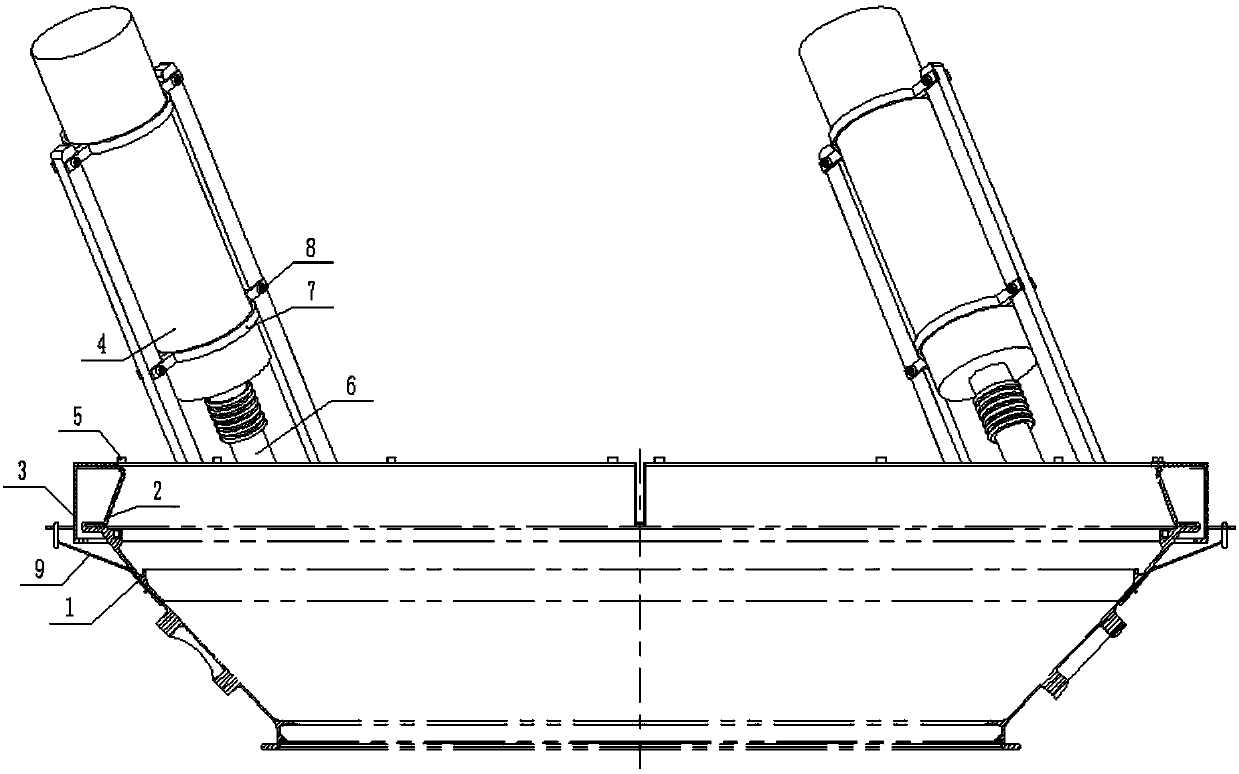

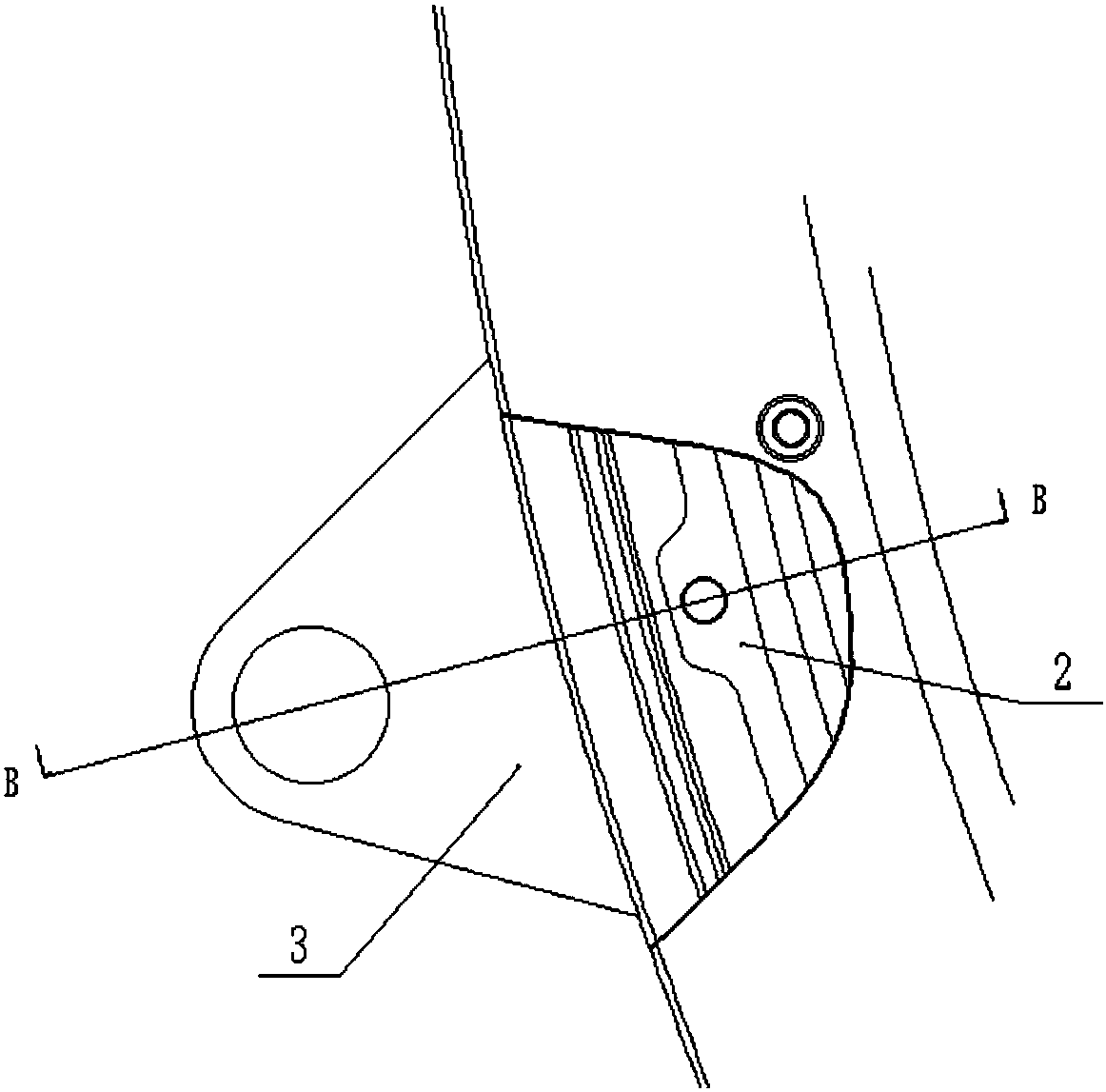

Auxiliary device for aero-engine casing assembling

ActiveCN107931952ALoading and unloadingDecrease productivityMetal working apparatusAviationEngineering

The invention discloses an auxiliary device for aero-engine casing assembling. The auxiliary device comprises an annular channel and 2-6 air heaters arranged on the annular channel, wherein assembly flange spigot sides of to-be-assembled casing segments are surrounded in the annular channel. An outlet of each air heater communicates with the annular channel through an air heating pipe. According to the auxiliary device, the annular channel is designed to be of a halved structure; under the condition that a small distance is reserved between two adjacent casing segments, the two halved parts ofthe annular channel can be fixed to the spigot end faces of the to-be-assembled casing segments, and a spigot is heated; the auxiliary device demounting time and the matched casing assembly adjustingtime are shortened, the pre-assembly work of matched casing segments is advanced to be before spigot heating, and the pre-assembly time is shortened; and the casing assembling requirement is met, andmeanwhile the casing assembling efficiency is greatly improved.

Owner:AECC AERO SCI & TECH CO LTD

Semiconductor embedded mixed packaging structure, and manufacturing method of the same

ActiveCN106816416AReduce circulation and transitSave manpower and material resourcesSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor chip

The invention discloses a semiconductor embedded mixed packaging structure, and a manufacturing method of the same. The embedded mixed packaging structure includes a circuit board, an opening or cavity, a semiconductor chip, a semiconductor chip package, packaging materials, and a rewiring layer, wherein the circuit board is provided with a first surface and a second surface which are arranged oppositely; the opening or cavity is arranged in the circuit board and is at least used for accommodating the semiconductor chip (Bare Die) and the semiconductor chip package (Semiconductor Package); the semiconductor chip is arranged in the opening or cavity; the semiconductor chip package is arranged in the opening or cavity; the packaging materials are at least used for covering the first surface of the circuit board and filling the space, unoccupied by the semiconductor chip and the semiconductor chip package, in the opening or cavity; and the rewiring layer is at least used for electrically connecting the semiconductor chip, the semiconductor chip package and the circuit board. The semiconductor embedded mixed packaging structure, and the manufacturing method of the same utilize the circuit board embedded technical scheme, and can simplify the integration technological process of the semiconductor chip and the semiconductor chip package, can improve the integration quality and performance, and can effectively reduce the integration area.

Owner:浙江熔城半导体有限公司

Assembly base used on automobile seat assembling line

ActiveCN105328454AMeet transportation needsMeet assembly needsAssembly machinesWork holdersSlide plate

The invention discloses an assembly base used on an automobile seat assembling line. The assembly base comprises a base plate arranged on a conveyer chain of the assembling line, a supporting plate which is arranged on the base plate and capable of rotating around the base plate, and a supporting rail, wherein a locking pin matched with a positioning hole in the base plate is arranged on the supporting plate, a supporting base supported by one end of the supporting rail is arranged on the supporting plate, and the other end of the supporting rail is connected with a cross bar; supports in rotary connection with the cross bar are arranged at the two ends of the cross bar, and the cross bar is connected with the supports through bearings installed on the supports; a sliding plate is connected to the bottom end of each support, a sliding block connected with a guide rod arranged on the supporting plate is arranged at the bottom end of each sliding plate, and supporting frames connected with the supporting plate are arranged at the two ends of the guide rod; the supporting base is connected with the supporting rail through an angle adjusting mechanism. The assembly base can meet assembly requirements of different stations, and assembly efficiency can be improved.

Owner:WUHU RUITAI AUTO PARTS

Laminating film for liquid crystal display and backlight module of liquid crystal display

PendingCN110928053AImprove stiffnessSolve the problem of coiling exceptionNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a laminating film for a liquid crystal display. The laminating film comprises an atomization layer film, a base film, a first prism layer film, a second prism layer film and athird prism layer film from top to bottom, and the atomization layer film, the base film, the first prism layer film, the second prism layer film and the third prism layer film are sequentially attached to one another through attaching glue. Moreover, the invention further discloses a backlight module of the liquid crystal display, and the backlight module comprises the laminating film for the liquid crystal display. According to the laminating film for the liquid crystal display, the brightness reaches the effect of two brightness enhancement films and two diffusion films, and the shielding property can also meet the requirements of the liquid crystal display module; and the laminating film can be in direct contact with glass of the liquid crystal display panel, it is guaranteed that interference and glare are avoided, the visual effect reaches the standard, the scratch resistance meets the assembly requirement, and the stiffness of a final product can meet the requirement of a large-size module.

Owner:CCS (SHANGHAI) FUNCTIONAL FILMS IND CO LTD

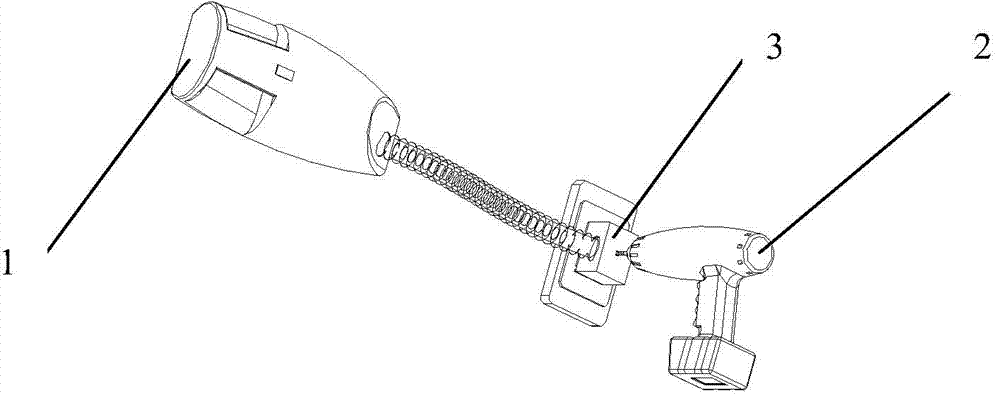

Breaking-in tool for spacecraft ground and on-rack fasteners

InactiveCN104117845ASolve technical problems of demolitionAchieve clean dismantlingPortable power-driven toolsMetal working apparatusConfined spaceOrganic glass

The invention discloses a breaking-in tool for spacecraft ground and on-rack fasteners. The breaking-in tool mainly comprises a dust suction device, a handheld drilling device and a redundancy control box, wherein a dust suction pipe of the dust suction device is communicated with the interior of a box body of the redundancy control box through a connector arranged on the side face of the redundancy control box to ensure that powdered scraps can be effectively sucked into the dust suction device without diffusing; the top of the redundancy control box is provided with a hole so that a drill bit of the handheld drilling device can extend into the redundancy control box to break in and damage the fasteners; the redundancy control box is made of transparent organic glass, and multiple layers of brushes are arranged on the inner side of the box body of the redundancy control box and surrounding the hole in the top to tightly attach to the drill bit of the handheld drilling device and prevent the powdered scraps from diffusing out. The breaking-in tool achieves the technical effect of breaking-in of the fasteners in a confined space and a pollution-sensitive environment, achieves clean dismantling of the fasteners in an abnormal state, and meets the demand for assembly of the spacecraft ground and on-rack fasteners.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

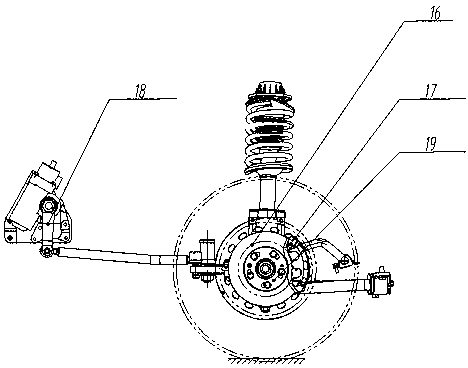

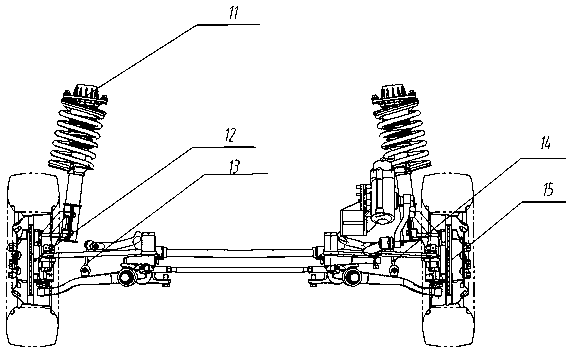

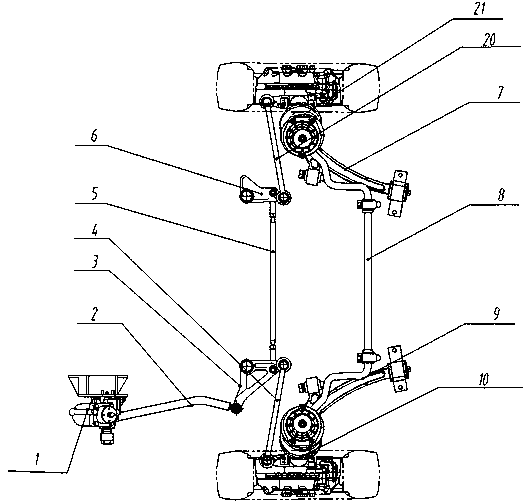

MacPherson independent suspension front axle assembly with circulating ball steering mechanism

InactiveCN104029724AImprove ride comfortIncrease costSteering linkagesInterconnection systemsControllabilityCommercial vehicle

A MacPherson independent suspension front axle assembly with a circulating ball steering mechanism comprises a circulating ball power-assisted steering device, a steering driving mechanism, a MacPherson independent suspension and a hydraulic disc brake system. The circulating ball power-assisted steering device is arranged on a frame and connected with the MacPherson independent suspension through the steering drive mechanism which is a broken type steering trapezium mechanism. The MacPherson independent suspension comprises a transverse stabilization system. The hydraulic disc brake system is provided with an ABS device. The front axle assembly fills in the blank of adopting the MacPherson independent suspension system and the circulating ball power-assisted steering device steering system which are matched for domestic light commercial vehicles, the front steering trapezium is large in steering power assistance, and ride comfort and controllability of vehicles are improved.

Owner:HUNAN YITONG AUTOMOBILE PARTS SCI & TECH DEV

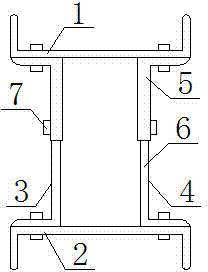

Adjustable bus duct

InactiveCN104269797AMeet assembly needsTotally enclosed bus-bar installationsAgricultural engineering

The invention relates to the technical field of electric transmission and transformation equipment, in particular to an adjustable bus duct. The adjustable bus duct comprises an upper cover plate, a lower cover plate, a left side plate and a right side plate, wherein the upper cover plate and the lower cover plate are connected to the two ends of the left side plate respectively and connected to the two ends of the right side plate respectively, the left side plate and the right side plate are each composed of a main plate and an auxiliary plate, the auxiliary plates are inserted in the main plates and are connected with the main plates in a sliding mode, and the auxiliary plates and the main plates are fixed through nuts. Due to the fact that the left side plate and the right side plate are both designed into the main plate and auxiliary plate combined structures and are fixed through the nuts, the space of the bus duct can be adjusted through relative sliding so that the assembling needs of different specifications of buses can be met, and the application range is greatly expanded.

Owner:常州市武进庙桥南方锻造有限公司

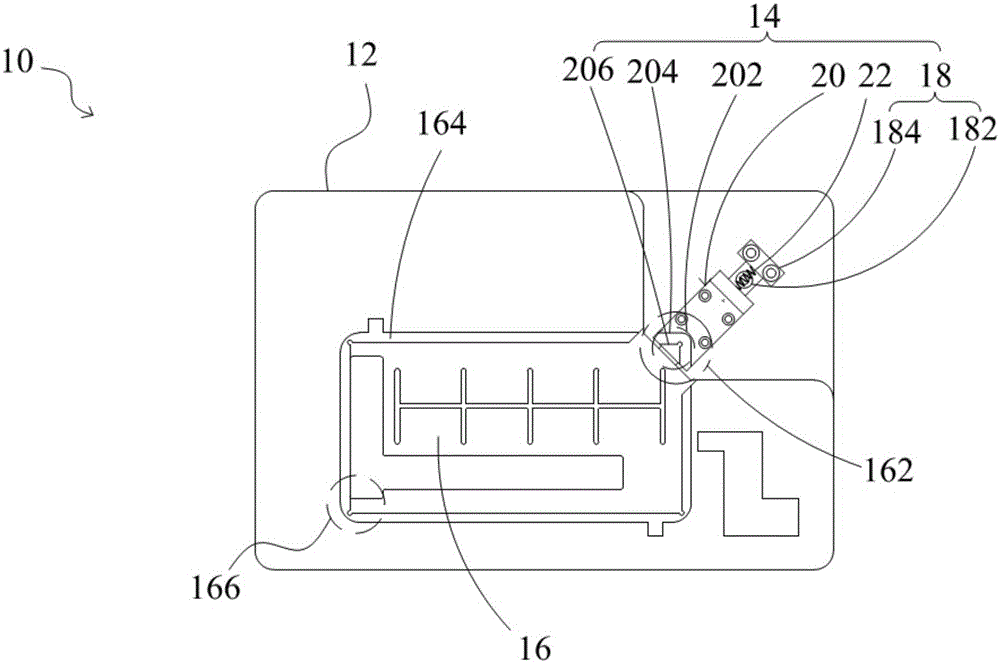

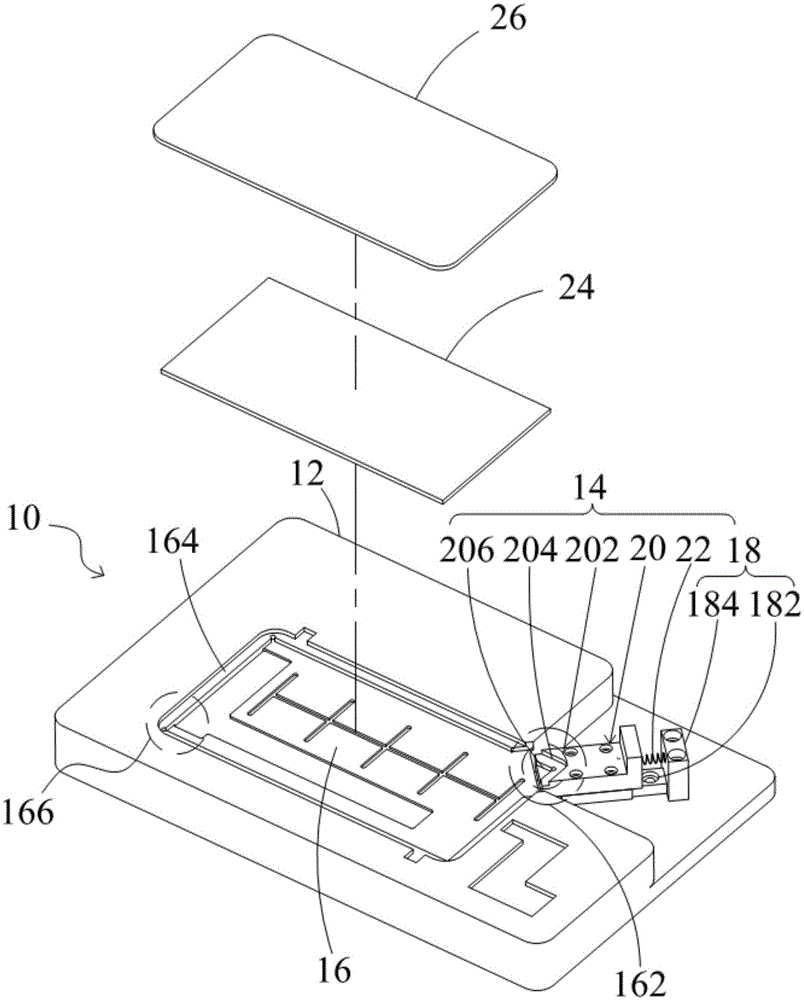

Improved fitting jig of touch liquid crystal module

ActiveCN105117053AAcupoint size reductionReduce machining tolerancesNon-linear opticsInput/output processes for data processingLiquid crystalElectrical and Electronics engineering

The invention discloses an improved fitting jig of a touch liquid crystal module. The improved fitting jig can provide a touch module and a liquid crystal module which are assembled. The improved fitting jig comprises a base with a groove and a positioning apparatus, wherein an opening part is formed in one corner of the groove of the base; the groove can accommodate the touch module and the liquid crystal module; and the positioning apparatus is positioned in the opening part of the base and can fix the touch module and the liquid crystal module in the groove of the base. According to the improved fitting jig, the module-to-module assembly precision of the touch module and the liquid crystal module in the jig can be improved through the positioning apparatus to meet the edge-to-edge 0.2mm assembly tolerance demand of a user on products, and meanwhile, the improved fitting jig of the touch liquid crystal module can greatly reduce the cost of assembly materials to satisfy low-cost manufacturing policies of electronic products nowadays.

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

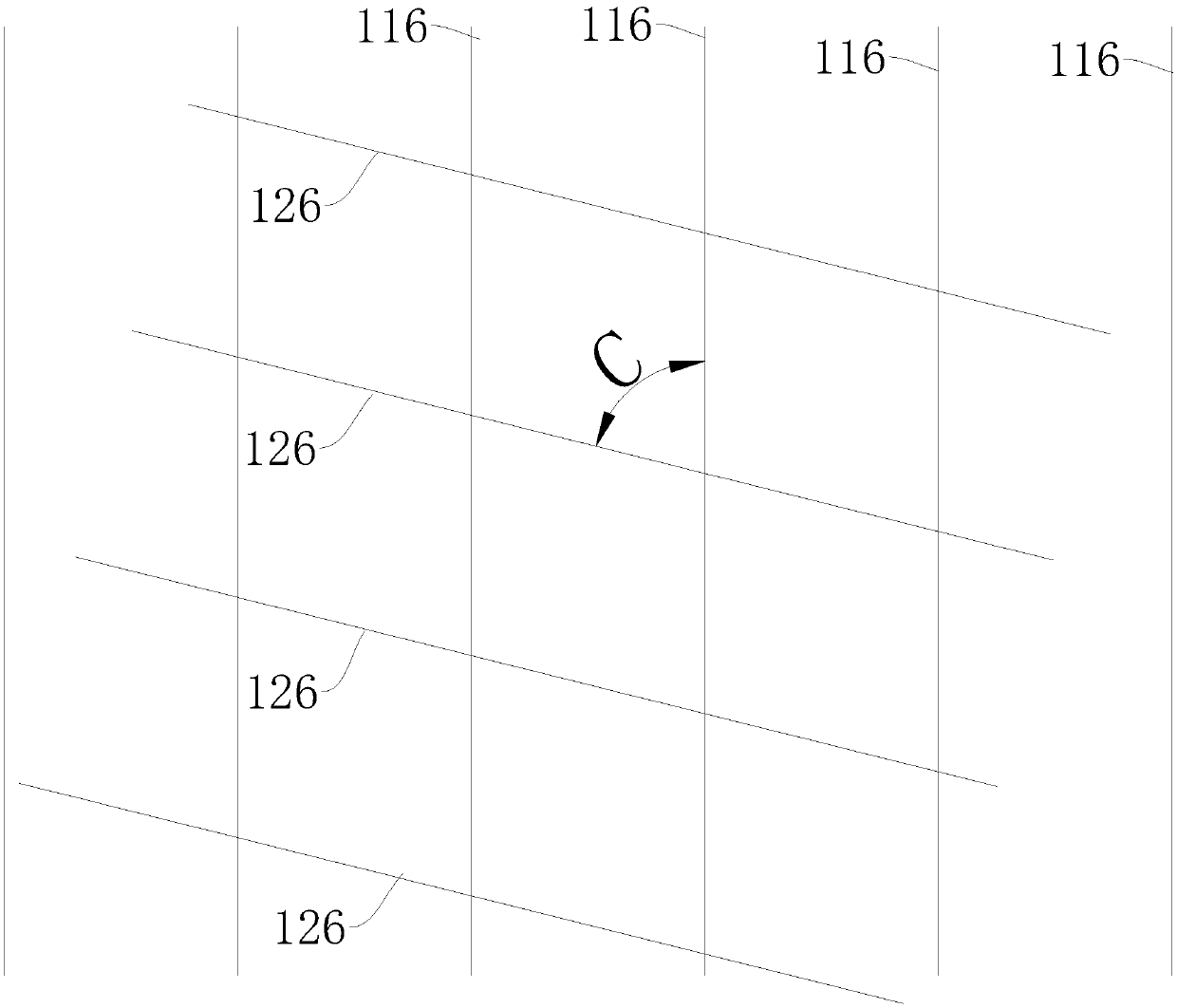

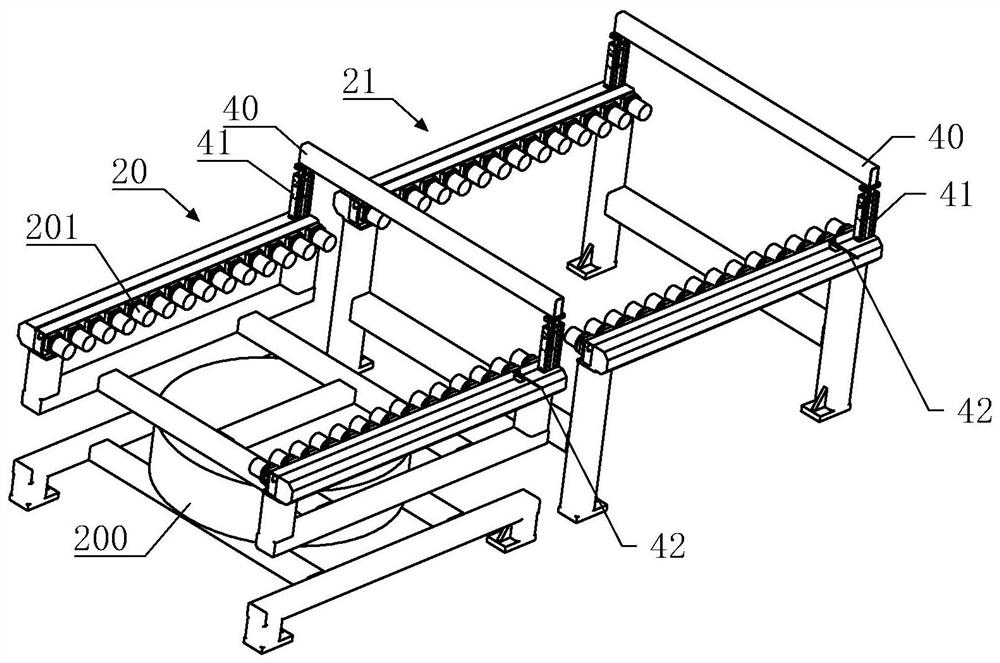

Sand mold assembly workbench suitable for dieless composite forming process

PendingCN113601462ARealize the fixtureAchieve transshipmentWork benchesThermodynamicsProcess engineering

The invention discloses a sand mold assembly workbench suitable for a dieless composite forming process. The sand mold assembly workbench comprises a clamping mechanism, a turnover mechanism, a lifting mechanism and a conveying mechanism, and the clamping mechanism and the turnover mechanism are arranged on the lifting mechanism; the conveying mechanism drives the lifting mechanism, the clamping mechanism and the turnover mechanism to move, and / or drives a sand mold to move; and the lifting mechanism is used for driving the clamping mechanism and the lifting mechanism to ascend and descend. After the sand mold is placed in place, the conveying mechanism drives the lifting mechanism, the clamping mechanism and the turnover mechanism to move to the position above the sand mold, the lifting mechanism drives the clamping mechanism and the turnover mechanism to descend, after the sand mold is placed in place, the clamping mechanism clamps the sand mold, the lifting mechanism ascends again, the conveying mechanism acts to drive the sand mold to move to an assembly station, and the turnover mechanism acts to drive the sand mold to turn over; and after overturning is completed, the lifting mechanism descends, the clamping mechanism loosens the sand mold, and the conveying mechanism can convey the sand mold. Therefore, the sand mold assembly workbench can realize overturning, clamping, transferring, assembling and the like of the sand mold, so that the process time is shortened, and the labor force is saved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com