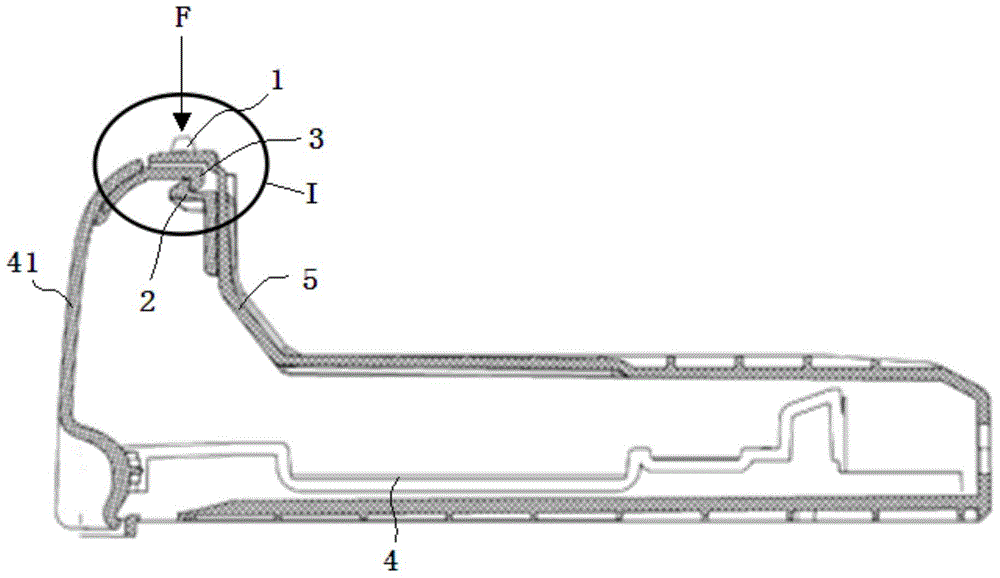

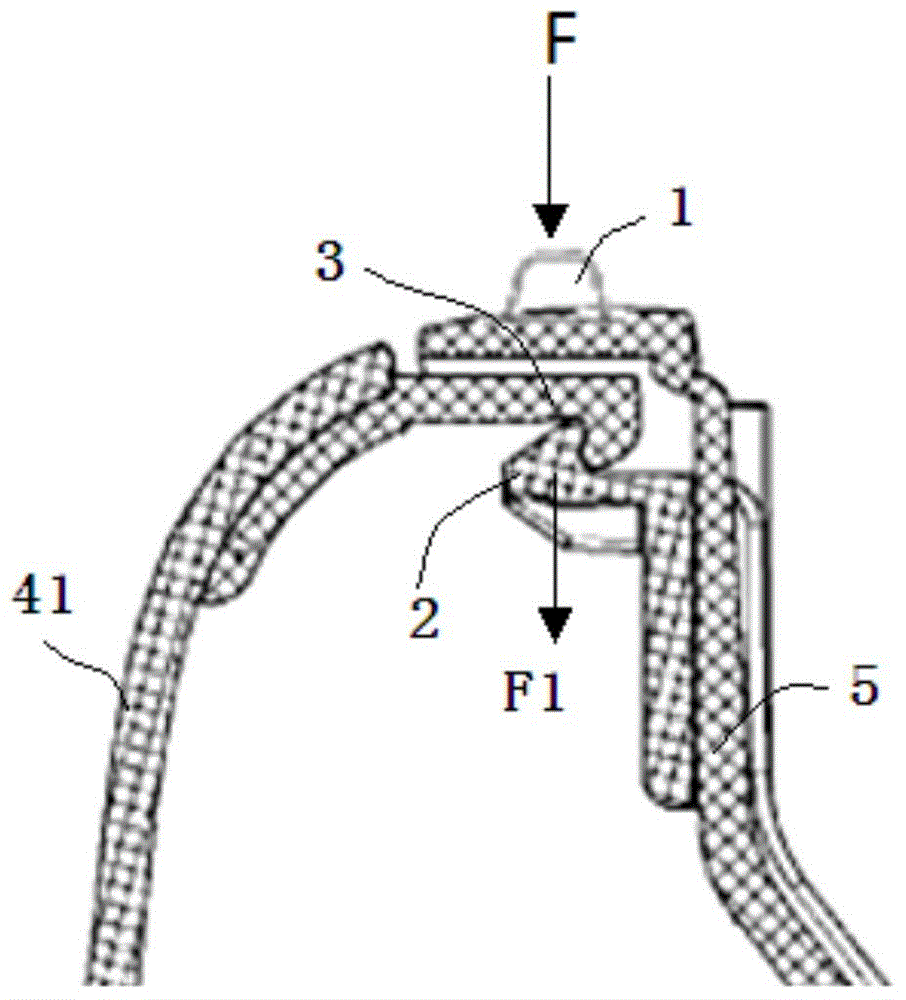

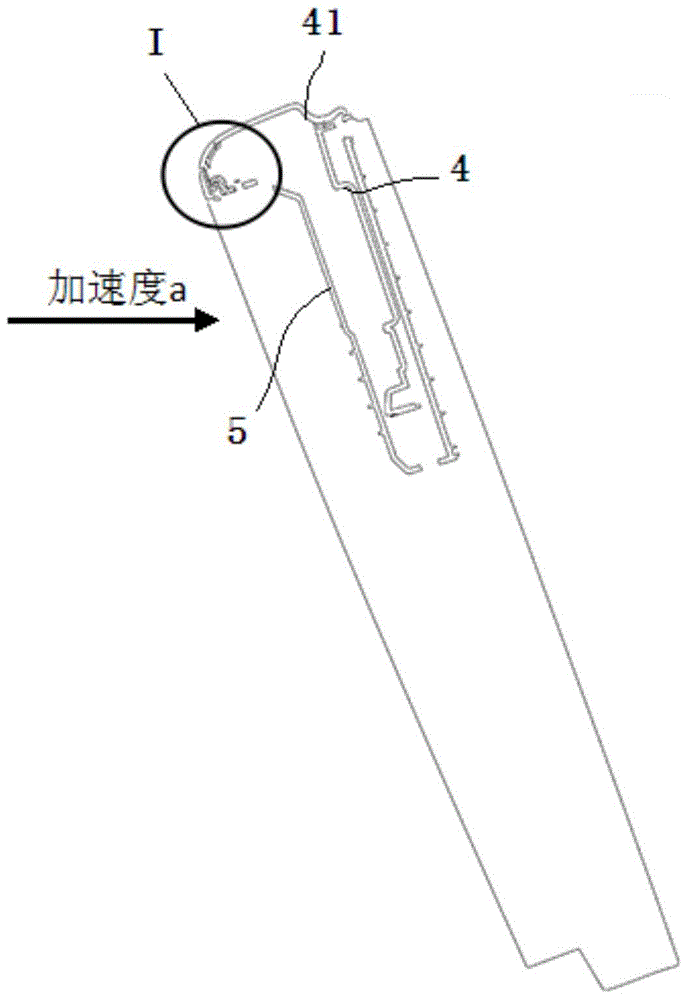

Push type locking and unlocking mechanism

An unlocking mechanism and push-type technology, applied in the direction of quick-action fasteners, etc., can solve the problems of inability to set up a new locking mechanism, unfavorable operation of unlocking button 1, etc., and achieve short unlocking stroke, high space utilization, and multiple assembly requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] see Figure 8a and Figure 8b , the push-type locking and unlocking mechanism given in the figure includes a housing 100 , a drawer 200 , an unlocking button 300 , a slider 400 , a return torsion spring 500 and two coil springs 600 .

[0051] A drawer chamber 110 is disposed inside the housing 100 , and a drawer opening 120 is disposed on one side of the drawer chamber 110 . The drawer mouth 120 is surrounded by upper eaves 130, front eaves 140, left eaves 150, right eaves 160 and bottom eaves 170, wherein the inner edge of the upper eaves 130 is adjacent to the upper edge of the front eaves 140, and the front The lower edge of the cornice 140 is curved and adjacent to the upper cavity wall 111 front edge of the drawer chamber 110, the upper edge of the left cornice 150 and the right cornice 160 are adjacent to the left and right ends of the upper cornice 130, and the left cornice 150. The upper front edge of the right eaves 160 is adjacent to the left and right ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com