Laminating film for liquid crystal display, and liquid crystal display backlight module

A technology of liquid crystal display and lamination film, applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems of increased material loss, improved rework rate, poor scratch resistance, etc., to promote application promotion, meet scratch resistance, visual The effect of meeting the target

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

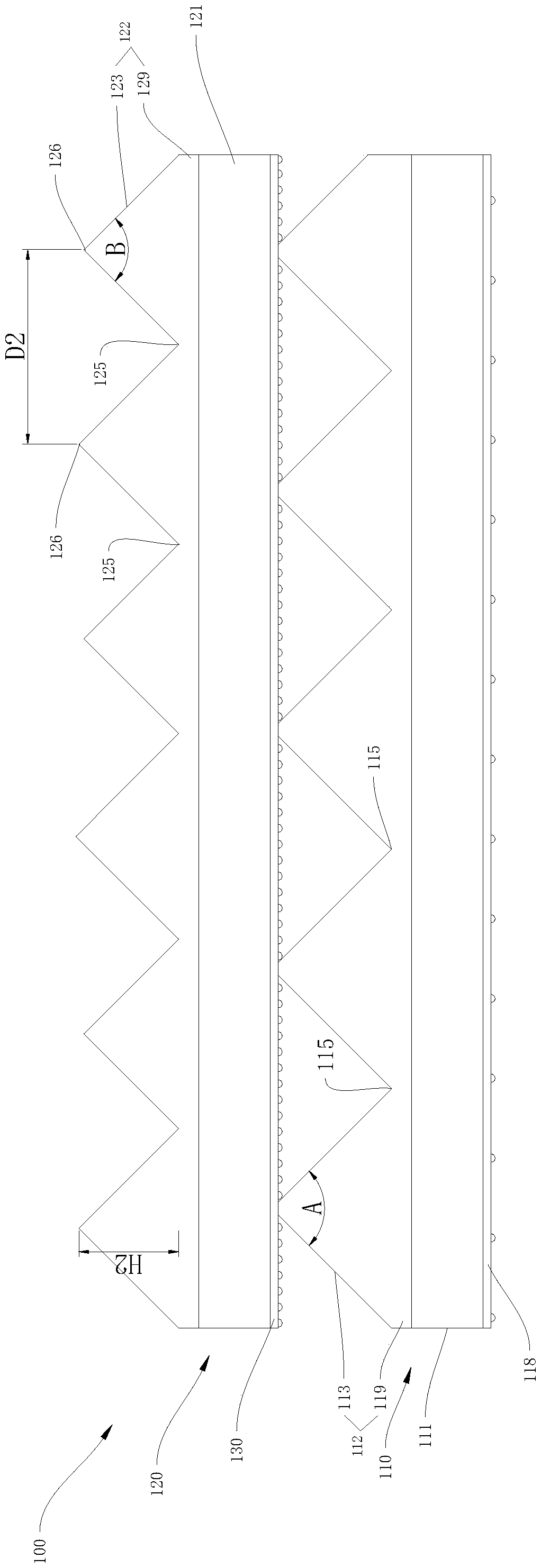

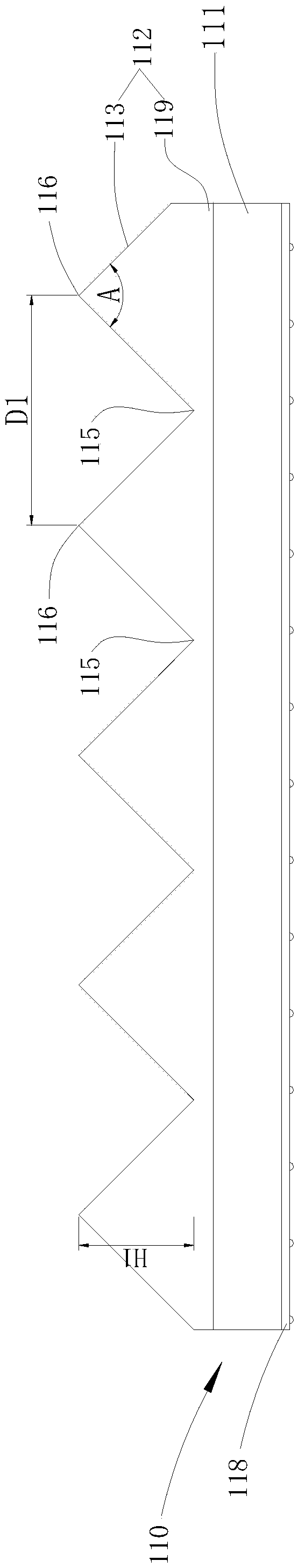

[0061] Such as figure 1 , figure 2 and image 3 As shown, the bonding film 100 for liquid crystal display includes a first structural layer film 110 and a second structural layer film 120 from bottom to top.

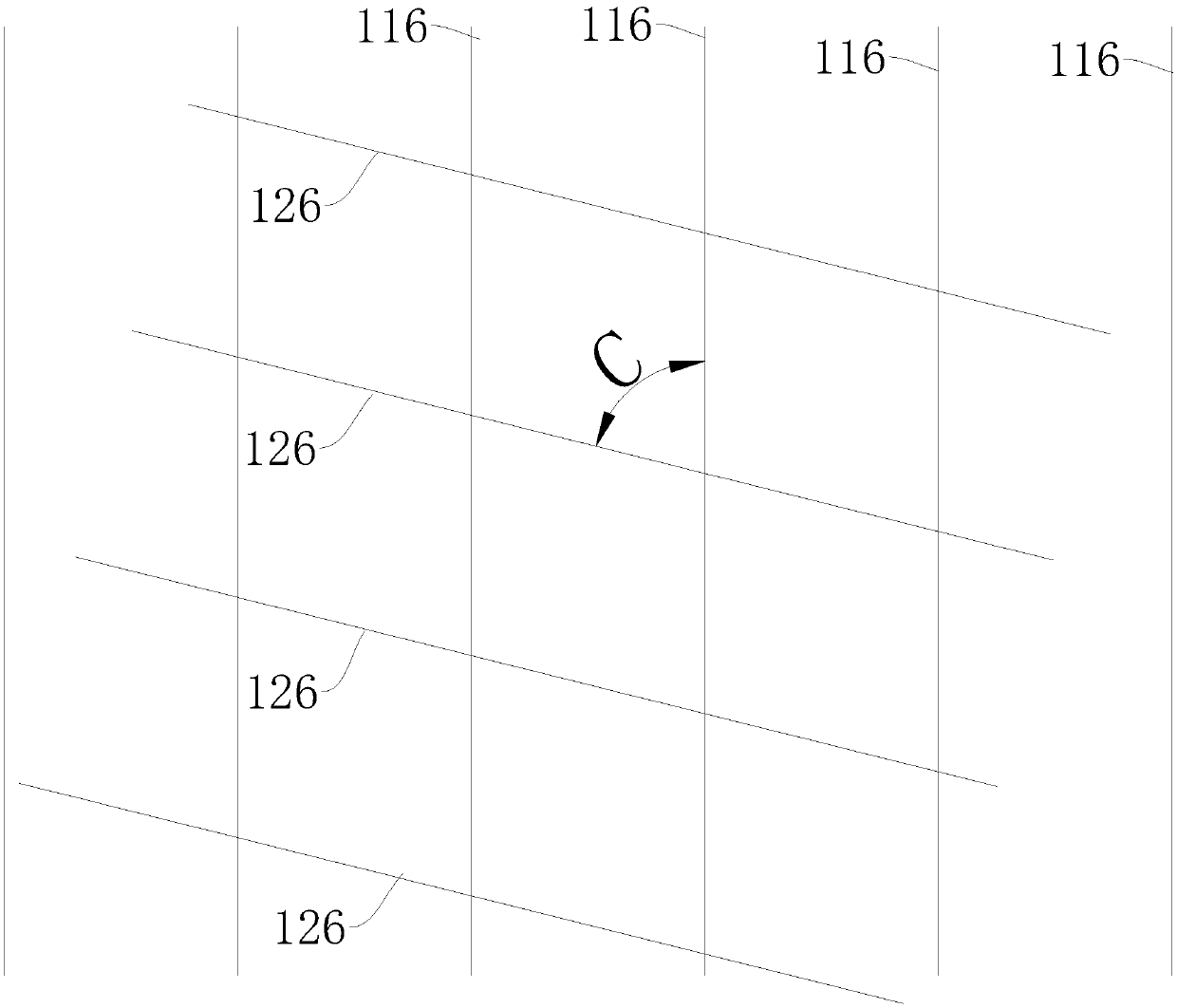

[0062] The first structural layer film 110 includes a first base film 111 and a first prism layer 112 . The first base film 111 is a 125 micron optical grade chemically treated PET film. The first prism layer 112 includes a first prism base 119 and a plurality of first prisms 113 . A plurality of first prisms 113 are arranged continuously without intervals on the first prism base 119 . The section of the first prism 113 is an isosceles triangle, and the apex angle A is a right angle. The first prism 113 has three edges, including two first bottom edges 115 and one first top edge 116 . The two first bottom ribs 115 are disposed on the first prism base 119 . The height H1 of the first top ribs 116 is 30 microns, and the distance D1 between adjacent first top ribs 1...

Embodiment 2

[0076] Such as Figure 4 , figure 2 and image 3 As shown, the bonding film 100 for liquid crystal display includes a first structural layer film 110 and a second structural layer film 120 from bottom to top.

[0077] The first structural layer film 110 includes a first base film 111 and a first prism layer 112 . The first base film 111 is a 125 micron optical grade chemically treated PET film. The first prism layer 112 is disposed on the upper surface of the first base film 111 . The first prism layer 112 includes a first prism base 119 and a plurality of first prisms 113 . A plurality of first prisms 113 are arranged continuously without intervals on the first prism base 119 . The section of the first prism 113 is an isosceles triangle, and the apex angle A is a right angle. The first prism 113 has three edges, including two first bottom edges 115 and one first top edge 116 . The two first bottom ribs 115 are disposed on the first prism base 119 . The height H1 of t...

Embodiment 3

[0091] Such as Figure 5 , figure 2 and image 3 As shown, the bonding film 100 for liquid crystal display includes a first structural layer film 110 and a second structural layer film 120 from bottom to top.

[0092] The first structural layer film 110 includes a first base film 111 and a first prism layer 112 . The first base film 111 is a 125 micron optical grade chemically treated PET film. The first prism layer 112 includes a first prism base 119 and a plurality of first prisms 113 . A plurality of first prisms 113 are arranged continuously without intervals on the first prism base 119 . The section of the first prism 113 is an isosceles triangle, and the apex angle A is a right angle. The first prism 113 has three edges, including two first bottom edges 115 and one first top edge 116 . The two first bottom ribs 115 are disposed on the first prism base 119 . The height H1 of the first apex 116 is 30 or 35 microns, and the first prisms 113 with a first apex height ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com