Electric locomotive roof assembly and welding tool

A technology for assembling welding equipment and electric locomotives, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems affecting product quality, parts rework, product scrapping, etc., to ensure the quality of welds, prevent welding bending deformation, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

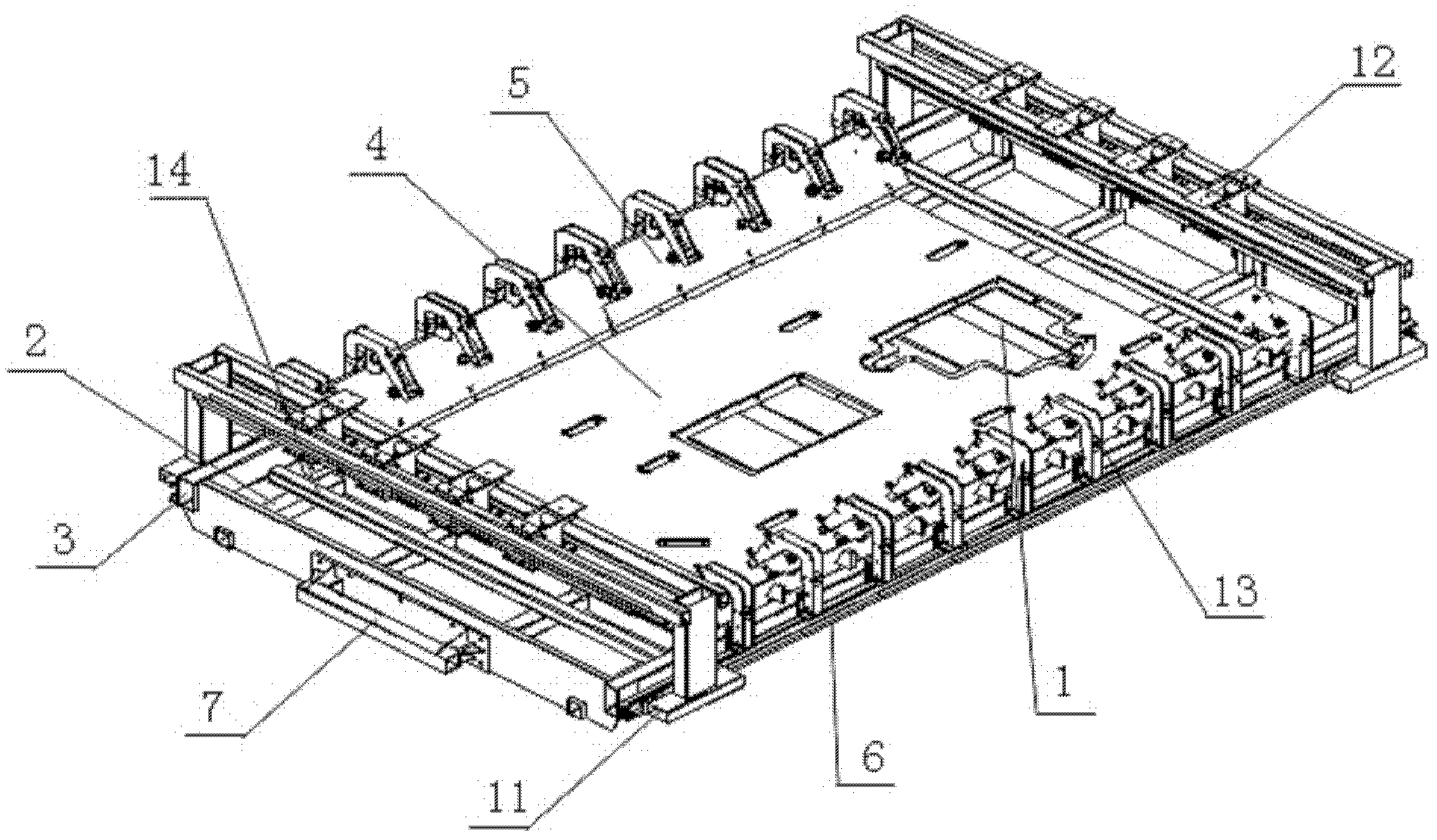

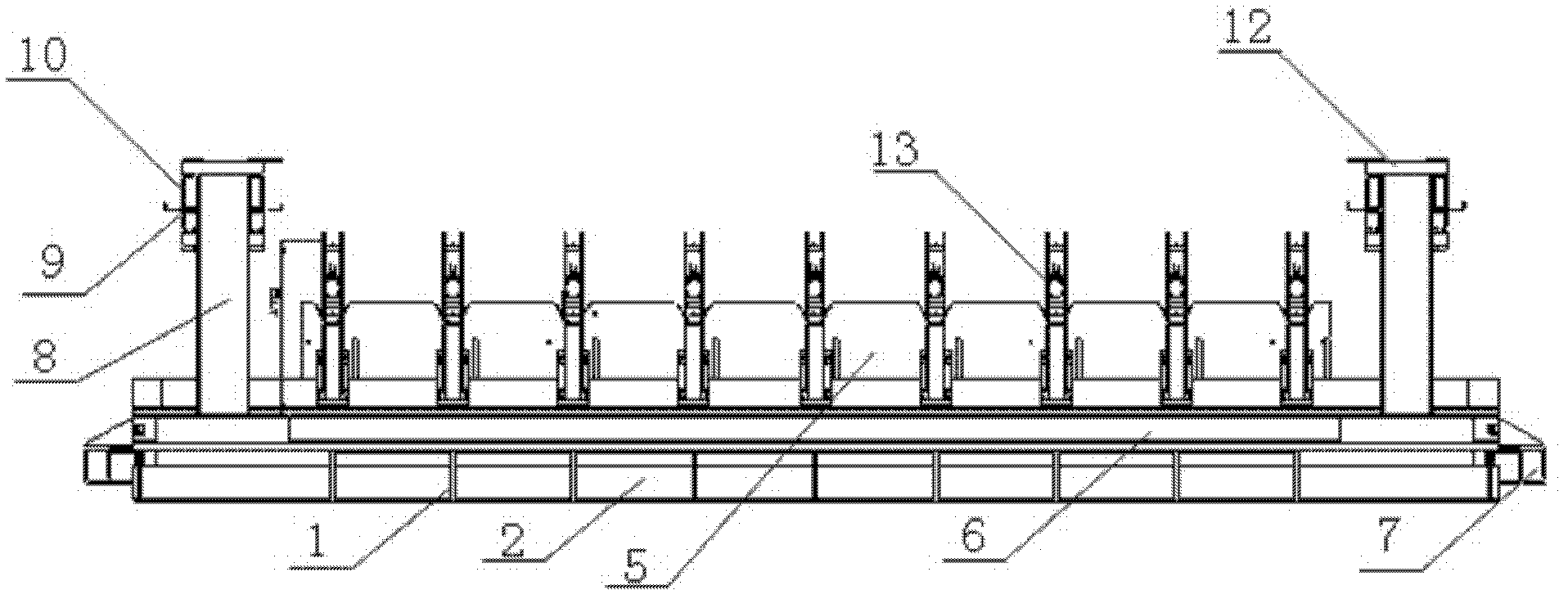

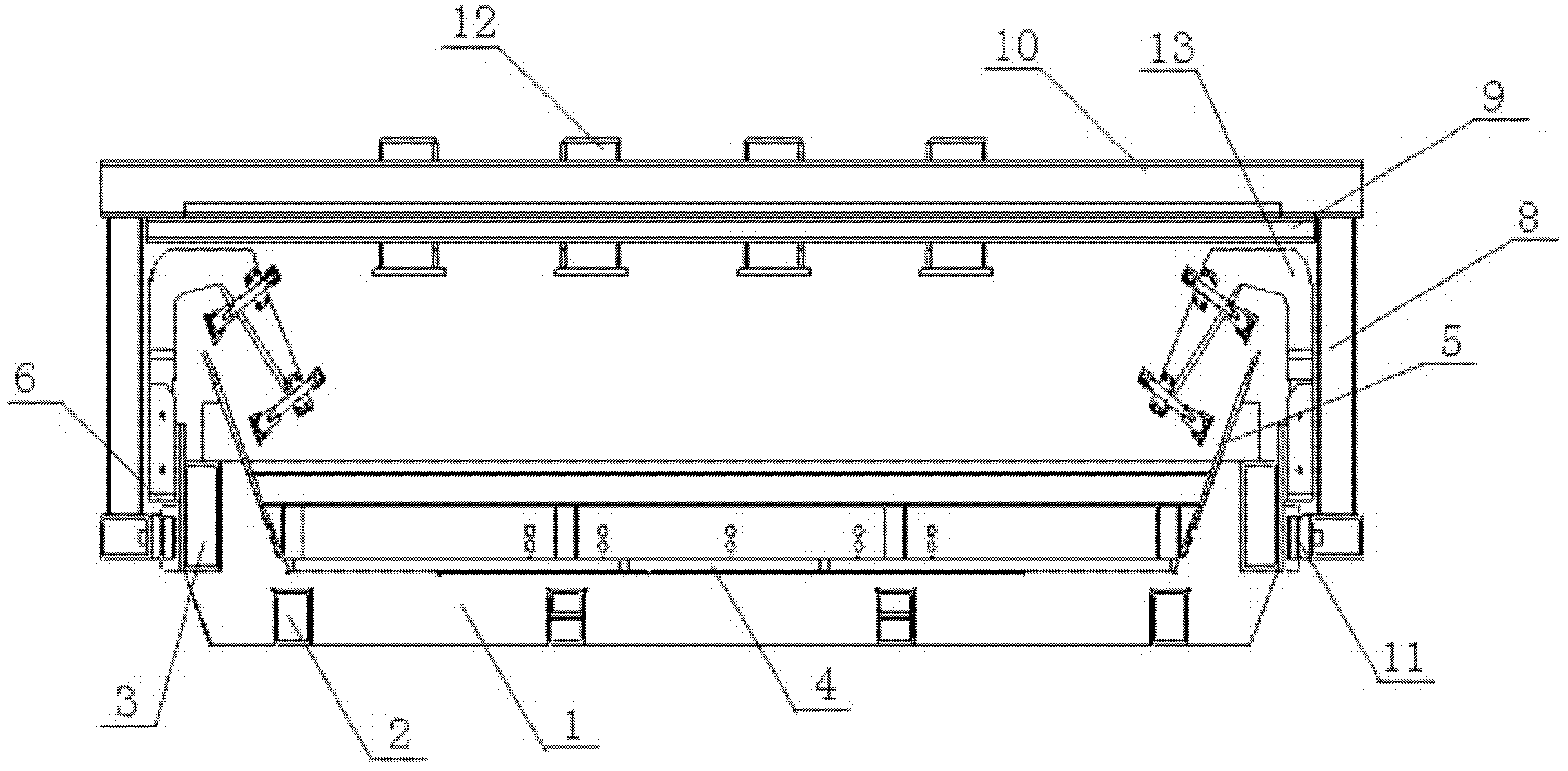

[0015] see figure 1 , figure 2 and image 3 An electric locomotive roof assembly welding tool, including an overall frame, a gantry and a cylinder, the overall frame in the roof assembly welding tool is composed of evenly distributed reinforcing ribs 1, four main beams 2, two square tubes Side beams 3, a bottom plate 4 and two side wall panels 5 form a concave frame structure;

[0016] Four main beams 2 and two cross bars 14 form a well-shaped underframe. Square tube side beams 3 are arranged on both sides of the underframe. A bottom plate 4 is arranged on the underframe. The lower surface of the bottom plate 4 is provided with evenly distributed reinforcing ribs. 1. That is, the bottom plate 4 is a whole steel plate with a thickness of 20 mm, which is placed parallel to the stiffener plate 1 and fixed by spot welding to ensure a flatness of 0.5 mm, and at the same time ensure that the plane cannot be distorted. The whole steel plate is used to ensure the flatness of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com