Device for detecting breakdown of sulfur hexafluoride gas-insulated electrical equipment

A technology of sulfur hexafluoride gas and electrical equipment, which is applied in the direction of measuring device, sampling device, measuring electricity, etc., can solve the problems of HF instability and interference, improve safety and reliability, and enhance reliability and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

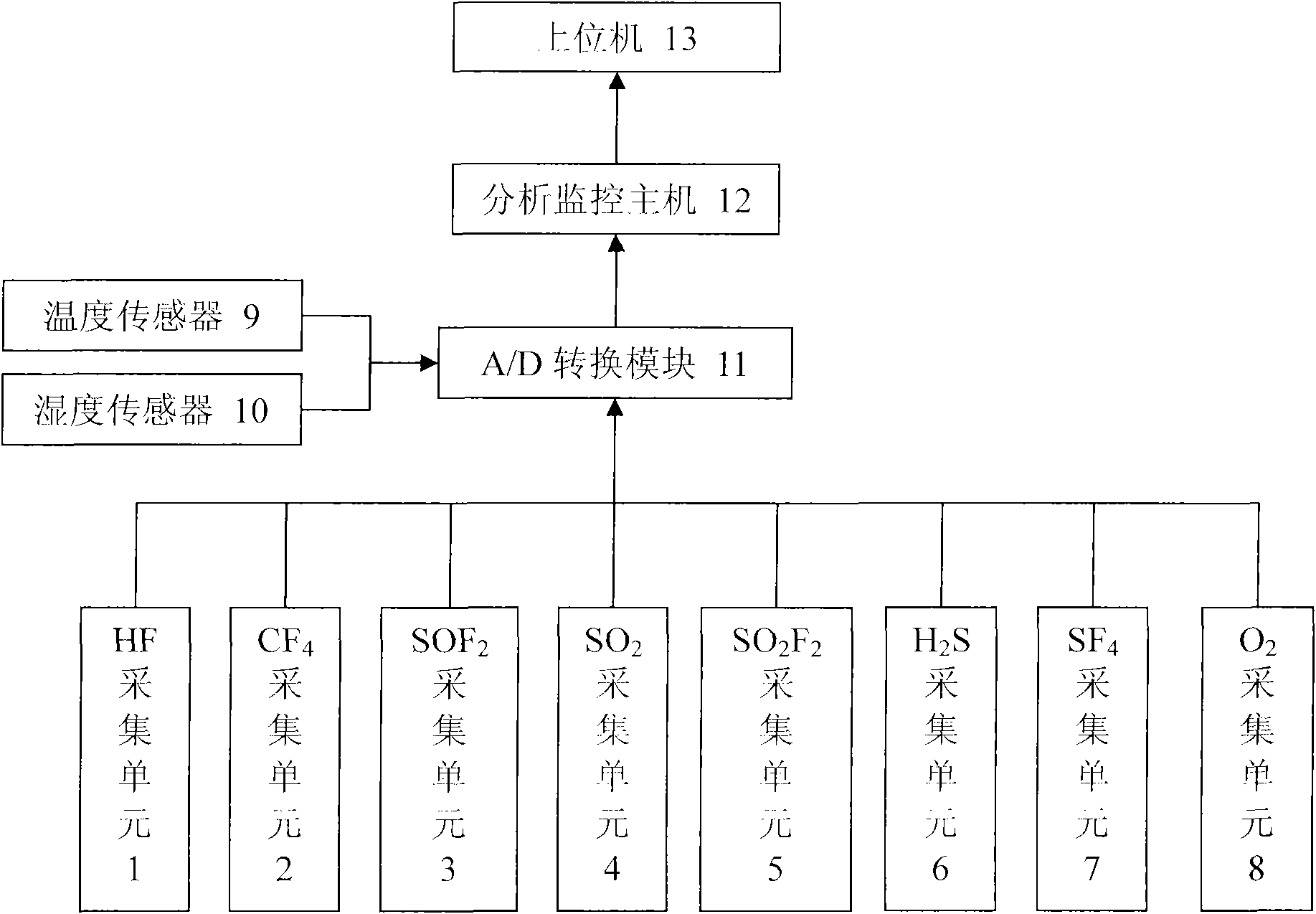

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Analysis of SF under test conditions 6 decomposition gas

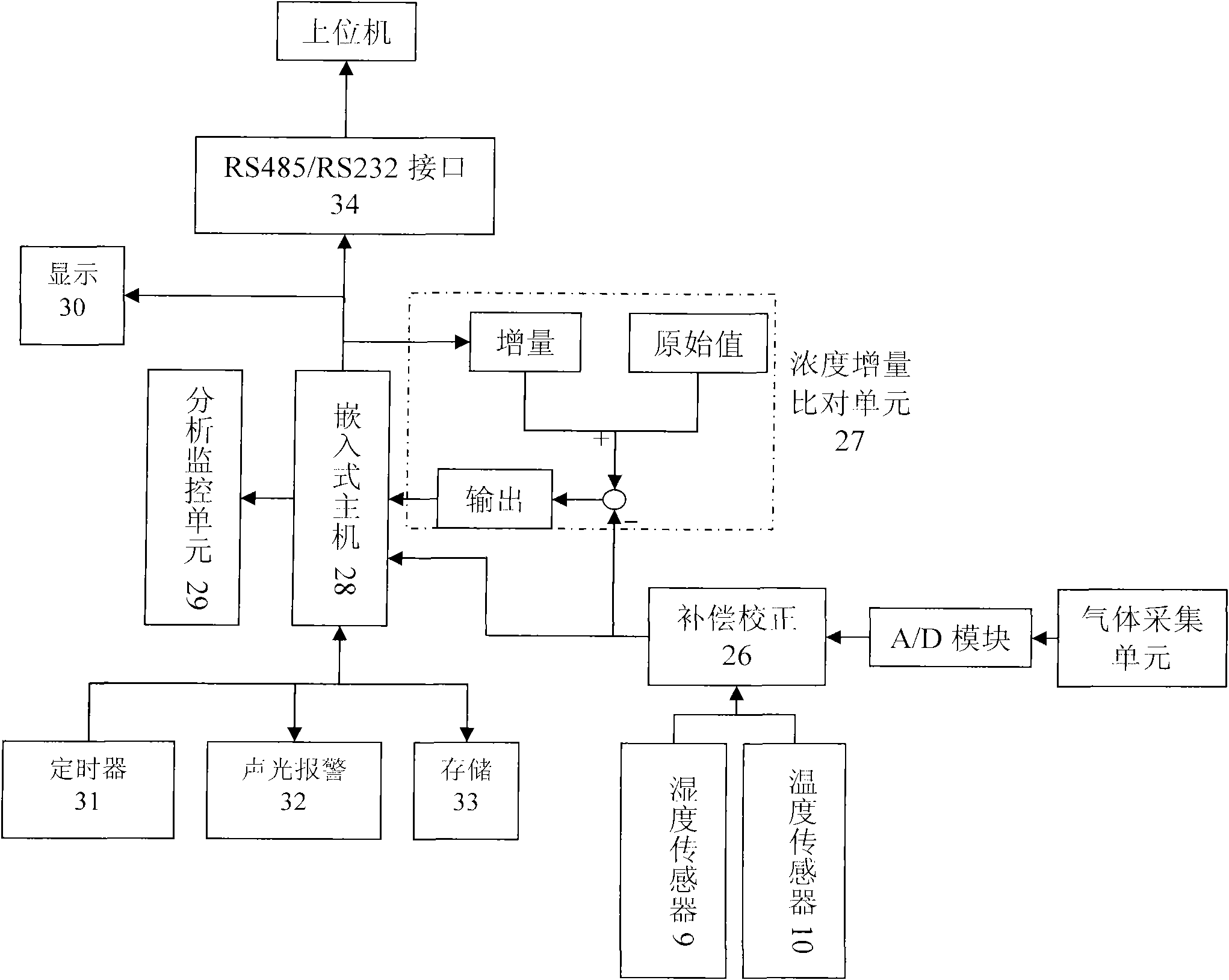

[0029] (1) Before the experiment, first sample an appropriate amount of gas to detect SF in electrical equipment of sulfur hexafluoride 6 For the purity of the gas and other gas impurities contained therein, the gas impurity content is set as a system value and input into the gas concentration increment comparison unit 27 in the analysis monitoring unit 19 .

[0030] (2) Build an experimental platform for partial discharge or other discharges and partial overheating, and conduct partial discharge tests. After the test is completed, the valve on the gas collector is opened, and the gas after the fault is collected by the gas collector.

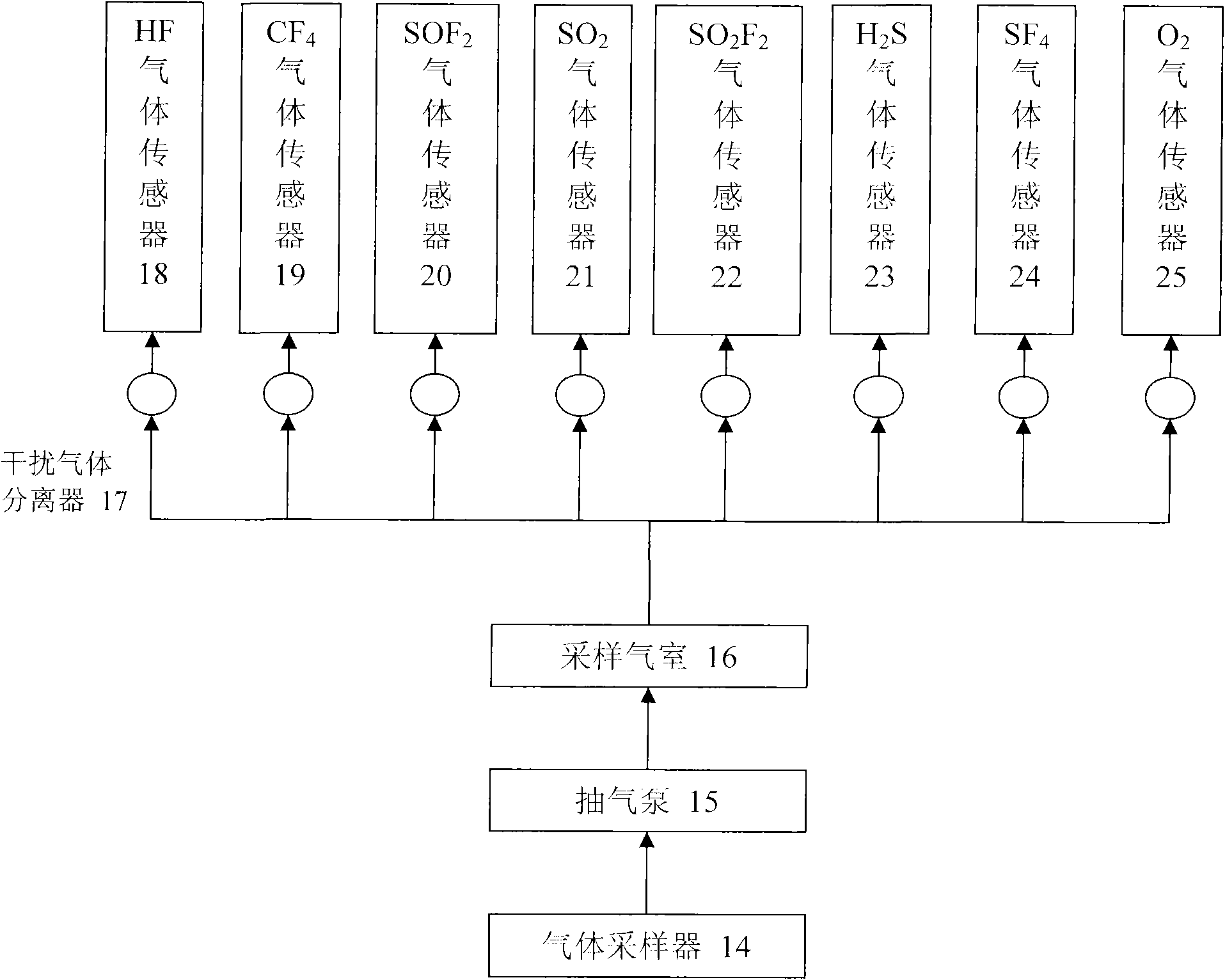

[0031] (3) The interfering gas separator is attached to the electrochemical sensor, and the sampling gas enters the sampling gas chamber 16 through the air pump 15, and is filtered by the interfering gas separator and then sent to the electrochemical gas sensor, and ea...

Embodiment 2

[0036] Example 2: On-line monitoring of sulfur hexafluoride gas-insulated equipment

[0037] (1) System setting: first set the warning value and the original value of the gas impurity content, the setting basis can refer to the gas concentration detected by the specific equipment to be monitored according to the national standard during installation, operation or maintenance; determine the online monitoring Set the timer 31 for the gas sampling time interval.

[0038] (2) The embedded host 28 is connected to the valve of the gas sampler 14, and at regular intervals, the timer 31 will generate instructions to enable the embedded host 28 to start the valve of the gas sampler 14 for gas sampling.

[0039] (3) The gas sampling and processing process is the same as steps (3) and (4) in Example 1.

[0040] (4) An interface of the compensation and correction unit 26 is connected to the embedded host, and the processed detection value is directly input into the embedded host 28 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com